+

7

Ραπτομηχανή-Overlock

Overlock Sewing Machine SON 90 A1

KOMPERNASS GMBH

BURGSTRASSE 21 · D-44867 BOCHUM

www.kompernass.com

ID-Nr.: SON 90 A1-01/11-V1

IAN: 64780

Overlock Sewing Machine

Operating instructions

R

Maşină de cusut şi surfilat

Instrucţiunile

Ρ

Οδηγίες χρήσης

Šivači stroj

Upute za upotrebu

Оверлог машина

Ръководство за експлоатация

Overlock-Nähmaschine

Bedienungsanleitung

SON 90 A1

i

1

uztr

2

3

o

p

a

s

d

e

w

q

4

f

5

6

7

8

9

0

INDEX PAGE

Intended Usage 3

Safety instructions 3

Items supplied 4

Technical Data 4

Description of the appliance 5

Bringing the upper blade into a rest position 5

Needle Information 5

Upper looper element 5

Opening the front flap 6

Preparation 6

Connecting the foot pedal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Controlling the sewing speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Safety switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Fitting the waste container . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Removing needle(s) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Inserting needle(s) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Operating the handwheel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Adjusting the thread tree . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Threading 8

General instructions for threading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Threading the upper looper thread (red) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Threading the lower looper thread (yellow) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Threading yarn for the right needle (green) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Threading yarn for the left needle (blue) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Trial run . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Changing threads (binding together) 15

Set the stitch length 15

Setting the seam width 15

... by using the right or left needle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

... by turning the seam width adjustment knob . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Setting the seam width adjustment knob . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Adjust sewing foot pressure 16

Differential transport 17

Manner of operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Gathered overlock seam - Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Stretched overlock seam - Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Free arm sewing 18

Read these operating instructions carefully before using the appliance for the first time and preserve this booklet for later reference. Pass this booklet on to

whoever might acquire the appliance at a future date.

- 1 -

Overlock seams 19

Roll hemmings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Binding-off and sample sewing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Recommended tension settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

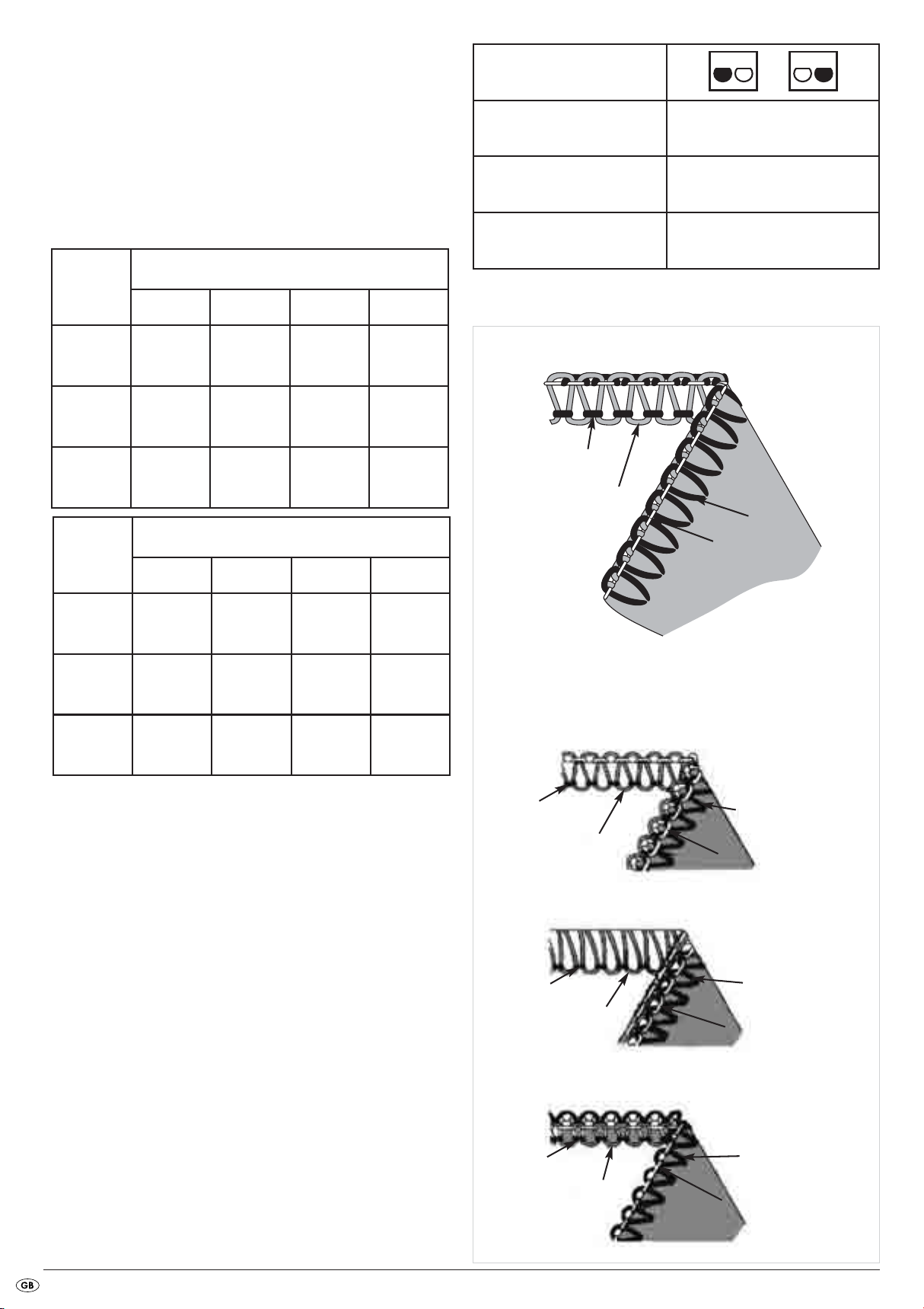

2-thread overcast chain stitch (overlock) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

2-thread-overcast-stitch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

3-thread chain stitch (overlock) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

3-thread - flatlock seam . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

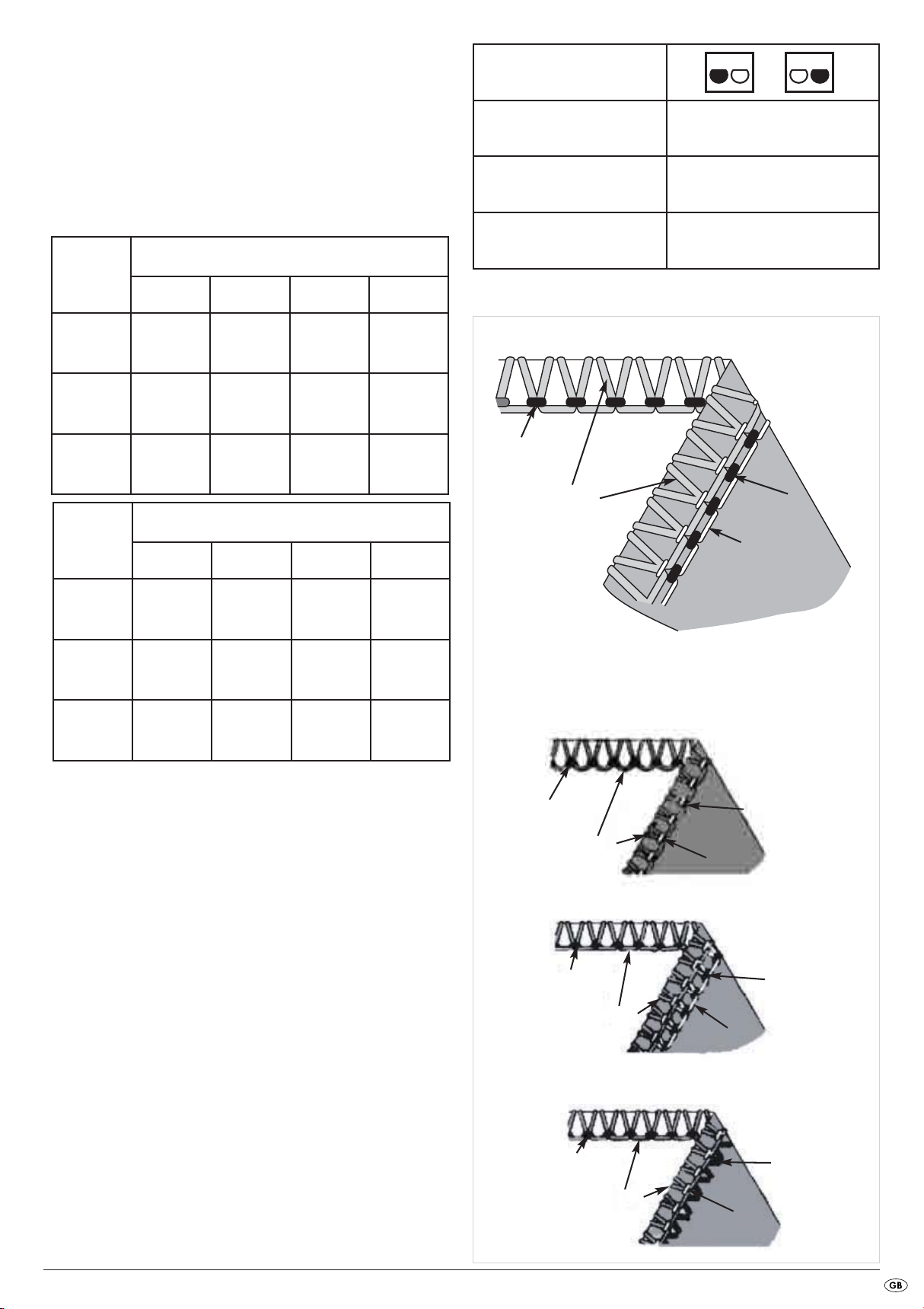

3-thread overcast chain stitch (overlock) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

3-thread safety stitch, highly elastic, imitated . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

4-thread safety stitch, highly elastic, imitated . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

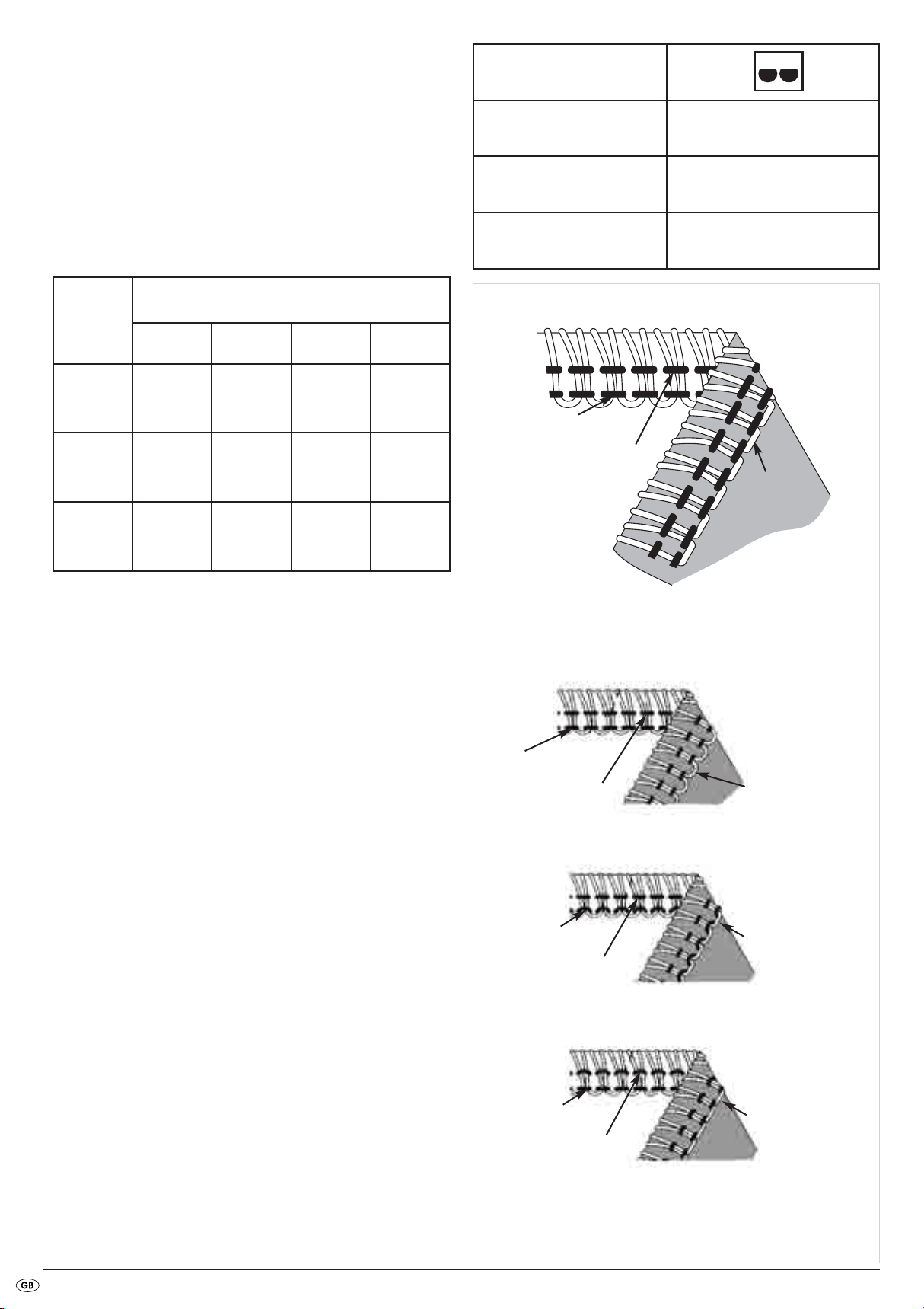

Roll hemmings 28

3-thread rolled hem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

3-thread upper looper overcast rolled hem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

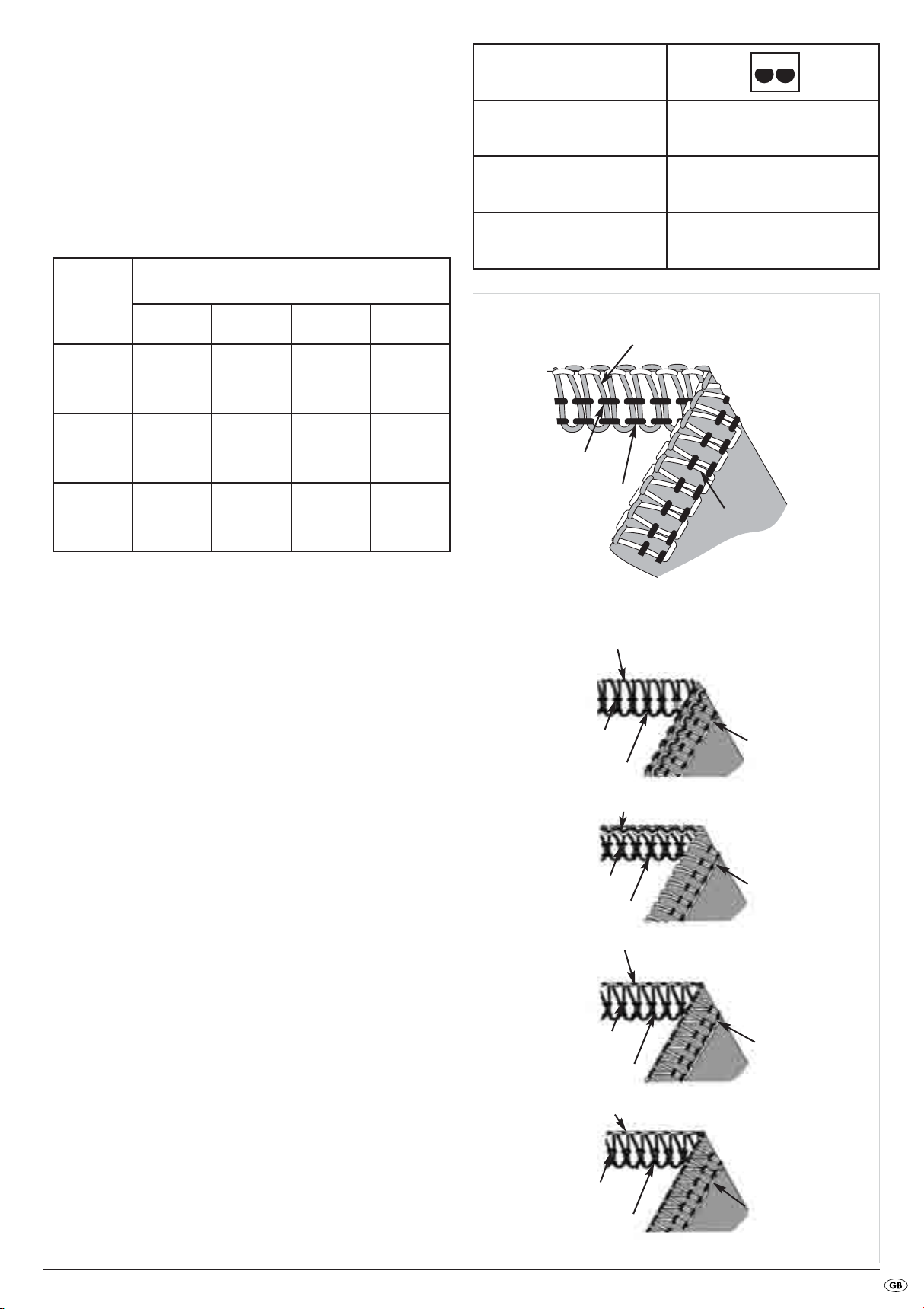

2-thread rolled hem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

2-thread lower looper overcast rolled hem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Flatlock decorative seams 30

Flatlock seam as assembly seam . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Flatlock seam as decorative seam . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Overlock blind hems 31

Pin tucks 31

Sewing corners 32

Outer corners . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Inner corners . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Tips and Tricks 33

Using pins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Secure empty threads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Seam reinforcement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Edging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Maintenance and Cleaning 34

Cleaning and lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

Exchanging the lower blade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

Storage 35

Disposal 35

Warranty and Service 35

Importer 35

Troubleshooting 36

- 2 -

Intended Usage

OVERLOCK SEWING MACHINE

This overlock sewing machine is intended ...

– for use as a portable machine,

– for the trimming of material edges (sewing) of typical household

textiles, and ...

– only for domestic household use.

Safety instructions

Like any other electrical device, a sewing machine can cause serious, even

life-threatening injuries. To avoid these, and to work safely:

• Always disconnect the power supply when leaving the machine unattended.

This will prevent the risk of accidents if the machine is switched on

accidentally.

• Always first disconnect the power plug before carrying out maintenance

work on the machine. This will prevent possibly life-threatening electric

shocks. The LED light is not exchangeable.

• Do not pull the plug out of the wall socket by the lead. When pulling

out the plug, always hold the plug, not the lead.

• Only use the sewing machine in dry rooms.

• Arrange for defective power plugs and/or cables to be replaced at

once by qualified technicians or our Customer Service Department.

• This appliance is not intended for use by individuals (including children) with

restricted physical, physiological or intellectual abilities or deficiences in

experience and/or knowledge unless they are supervised by a person

responsible for their safety or receive from this person instruction in how

the appliance is to be used.

• Children should be supervised to ensure that they do not play with

the appliance.

• Never use the machine when the ventilation apertures are blocked.

Keep the ventilation apertures of the machine and the foot switch free

from fluff, dust and waste material.

• Should the cable connected to the foot pedal become damaged,

to avoid potential risks it must be replaced by the manufacturer, his

customers services or a similarly qualified person.

This overlock sewing machine is not intended ...

– to be installed at a permanent location,

– for the processing of other materials (e.g. leather, canvas, sailcloth

and other heavy materials),

– for commercial or industrial use.

Warning about injuries and material damages:

• Keep your work space tidy. An untidy workplace can lead to accidents.

• Provide adequate lighting when working!

• Do not wear loose clothing or jewellery, as these can be caught in

moving parts. You should also wear a hair net if you have long hair.

• Avoid adopting an unusual posture. Remain steady and in a well-balanced

position at all times.

• If accidents occur as a result of handling the machine with insufficient

care, or failure to follow the safety instructions in this manual, then the

manufacturer cannot accept liability.

• Never cover the ventilation slots! Risk of overheating!

• Keep the sewing machine oil well away from children.

• If swallowed, or should eye contact be made with the sewing machine

oil, consult a doctor immediately.

- 3 -

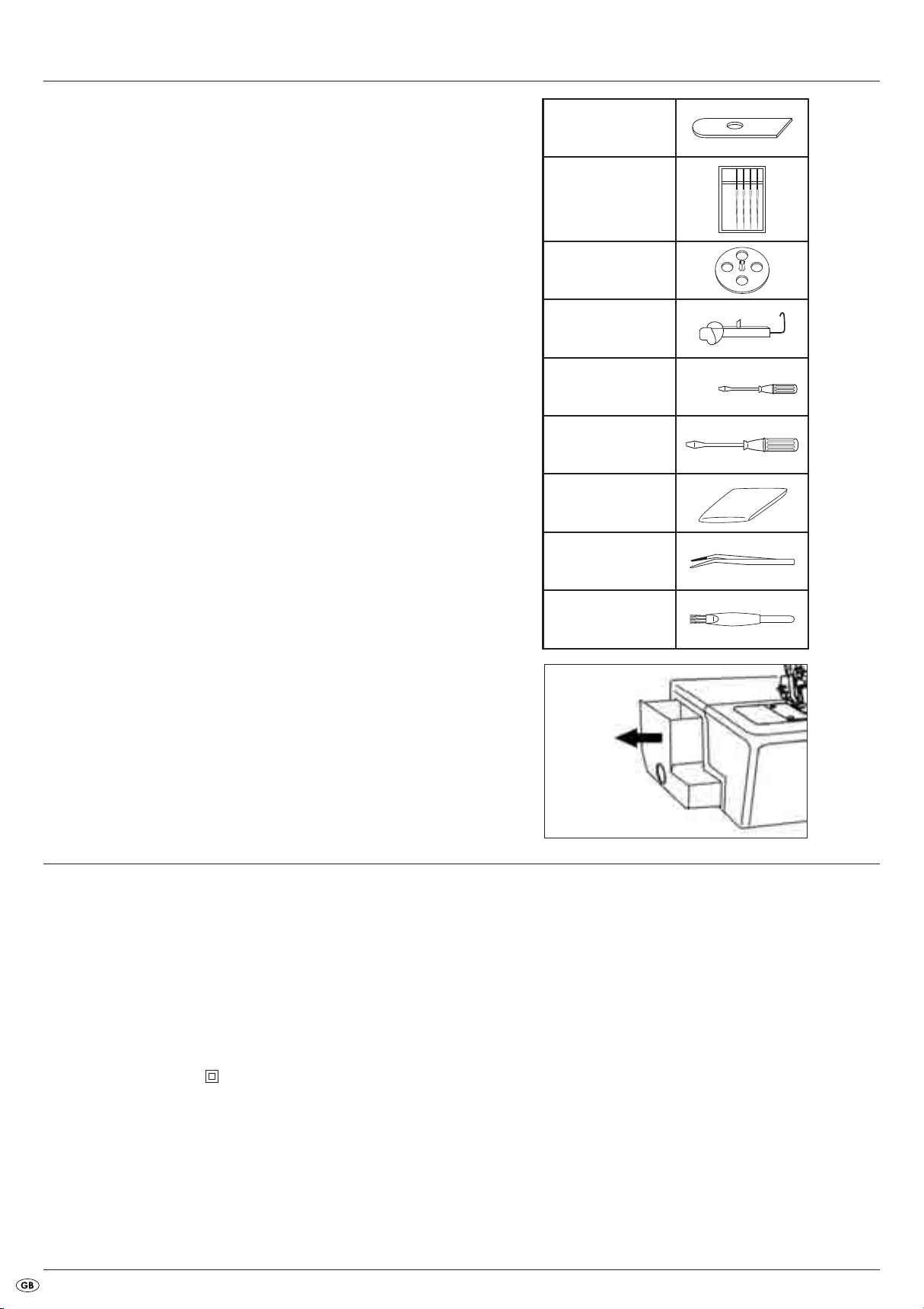

Items supplied

Overlock Sewing Machine

Oil

Waste container

Accessory box

Operating instructions

Replacement blade

(bottom)

2 Needles Nr. 11

4 Needles Nr. 14

(2 in the machine,

pre-installed)

4 Bobbin caps

Upper looper element

Screwdriver small

Screwdriver large

Covering hood

The accessories are to be found in the accessory box on the side

of the machine (Fig.1.).

Technical Data

Number of threads 2, 3 or 4

Number of needles 2 or 1

Sewing speed approx. 1200 rpm

Stitch width

right: 3.0 mm - 4.5 mm

left: 5.2 mm - 6.7 mm

Stitch length 1 – 4 mm

Needles HA x 1 Nr. 11-14 or 130/705 Nr. 75-90

Power consumption : 90 W

Rated voltage: 220 - 240 V ~, 50Hz

Protection class: II

Tweezers

Brush with integrated

unstitcher

Fig. 1

The sound intensity level under normal operating conditions amounts to

78dB(A).

Foot pedal

Use only the foot pedal originally supplied with this sewing machine:

- ELECTRONIC FDM Speed Controller

- Type KD - 2902

- 4 -

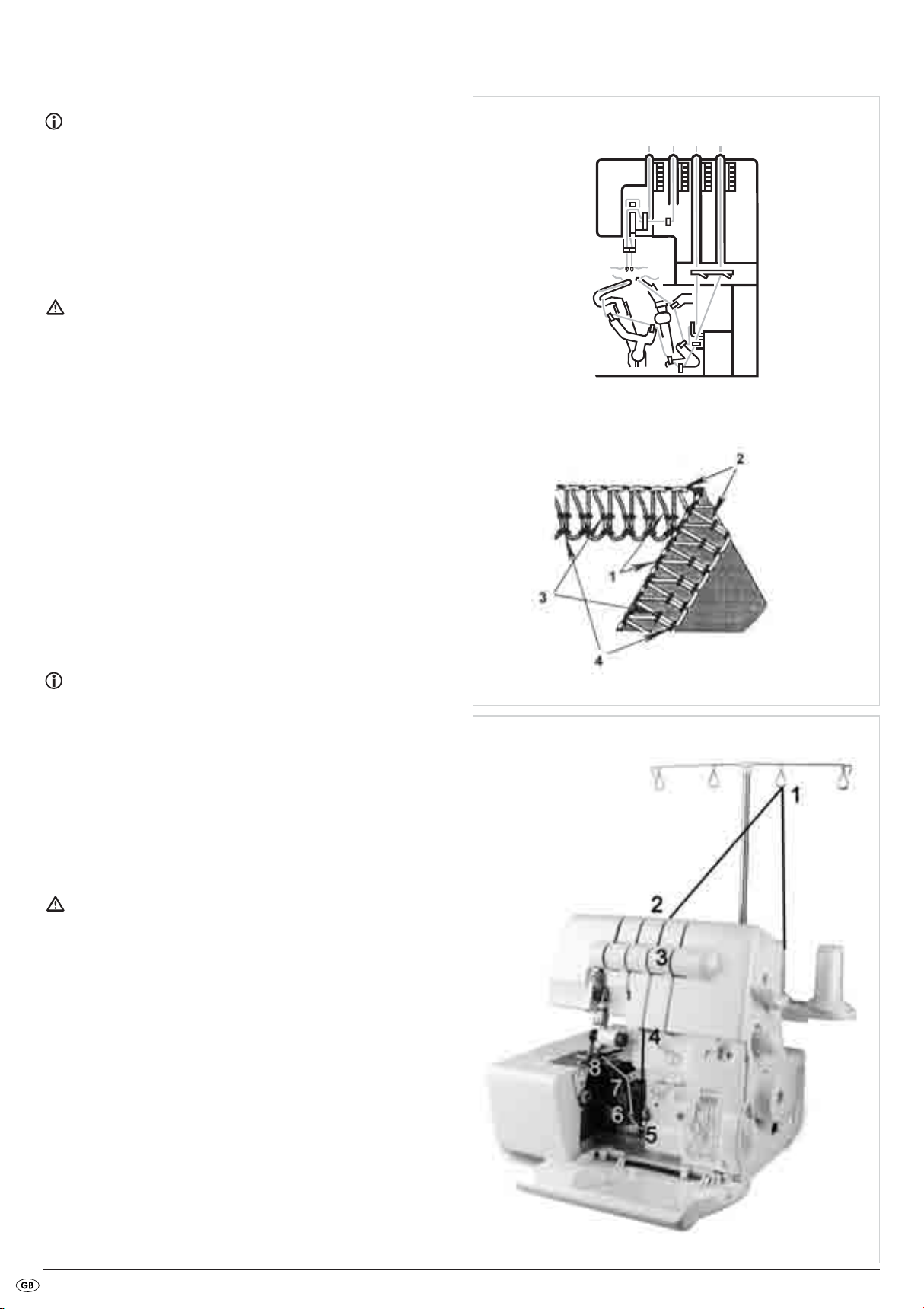

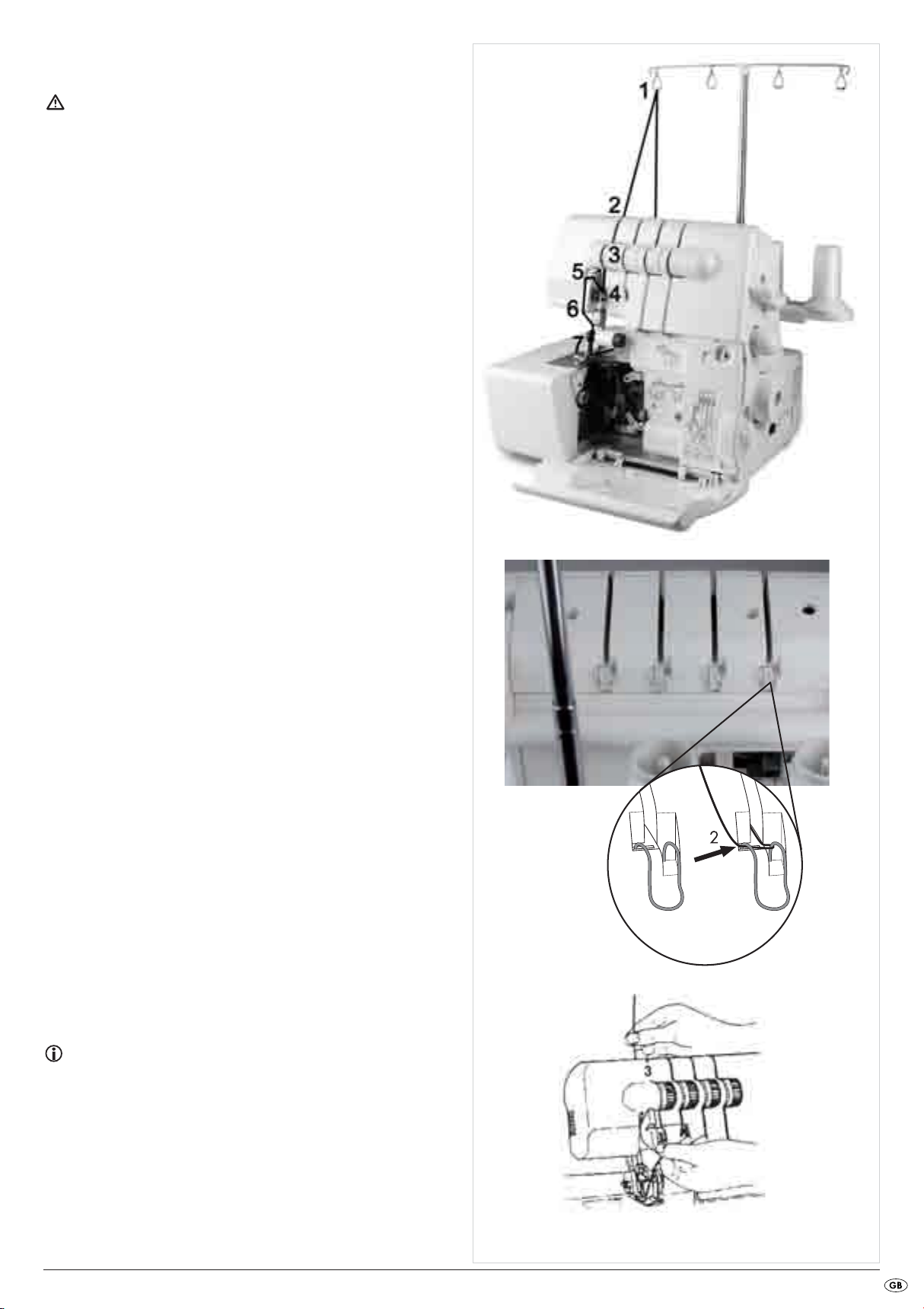

Description of the appliance

On the front fold-out page:

1 Thread tree

2 Spool support

3 Thread roll centerer

4 Sewing foot lever

5 Adjustment wheel for stitch length

6 Handwheel

7 Connection Footpedal/Power supply

8 Power switch (On/Off switch)

9 Differential transport lever

0 Front flap

q Support plate of the seam width finger

w Free arm

e Stitch plate

r Thread tension selector (left needle)

t Thread tension selector (right needle)

z Thread tension selector (upper looper)

u Thread tension selector (lower looper)

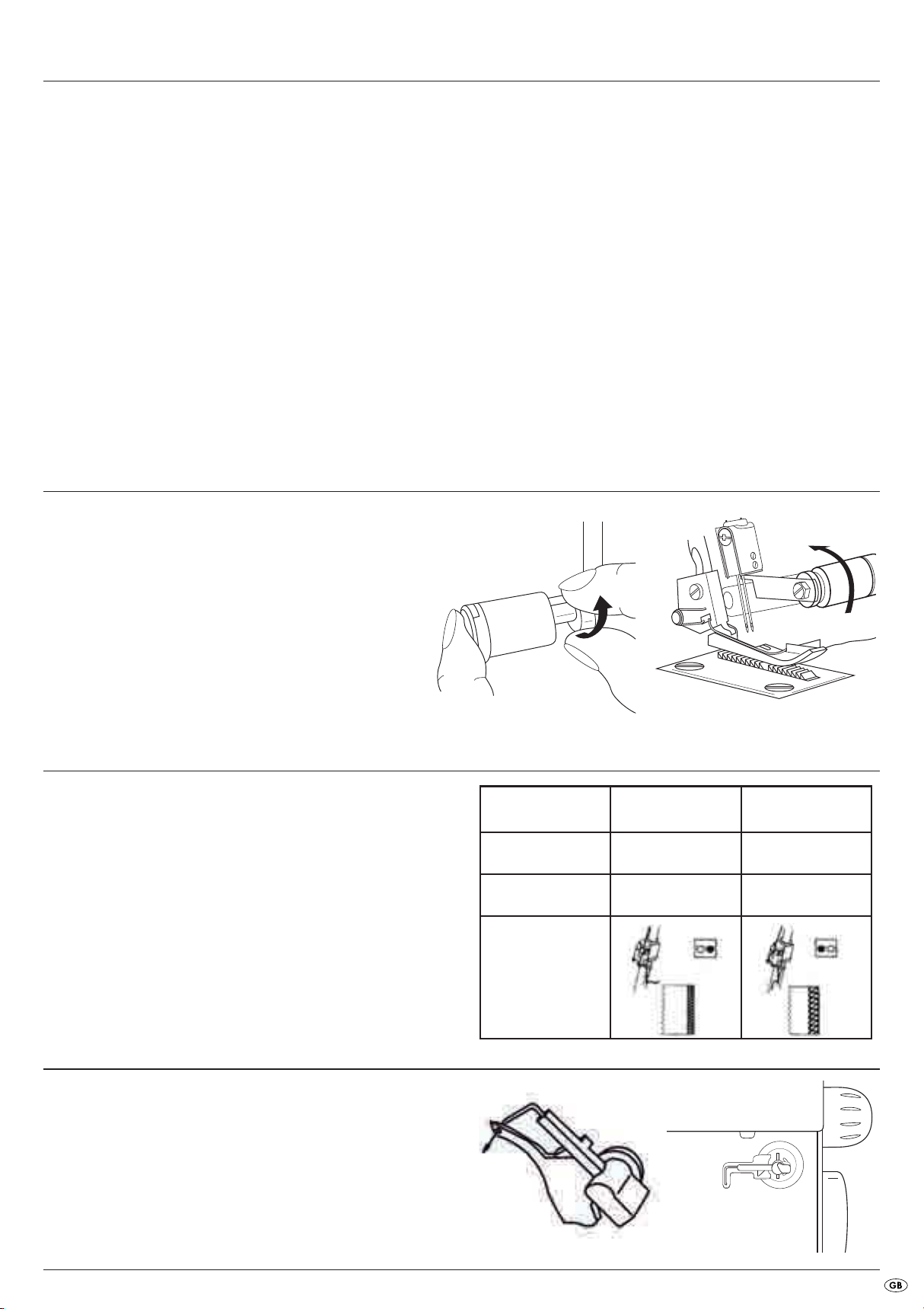

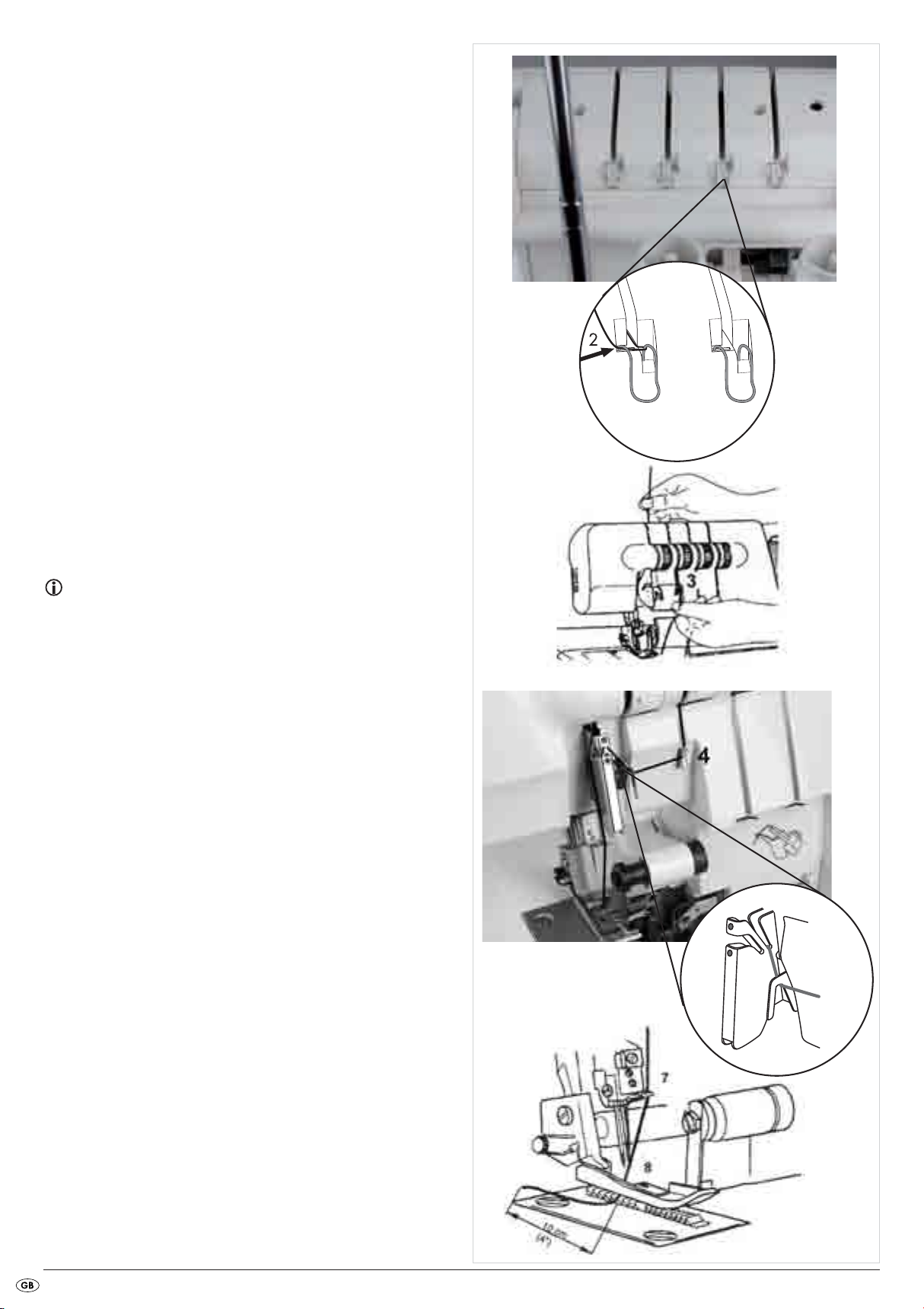

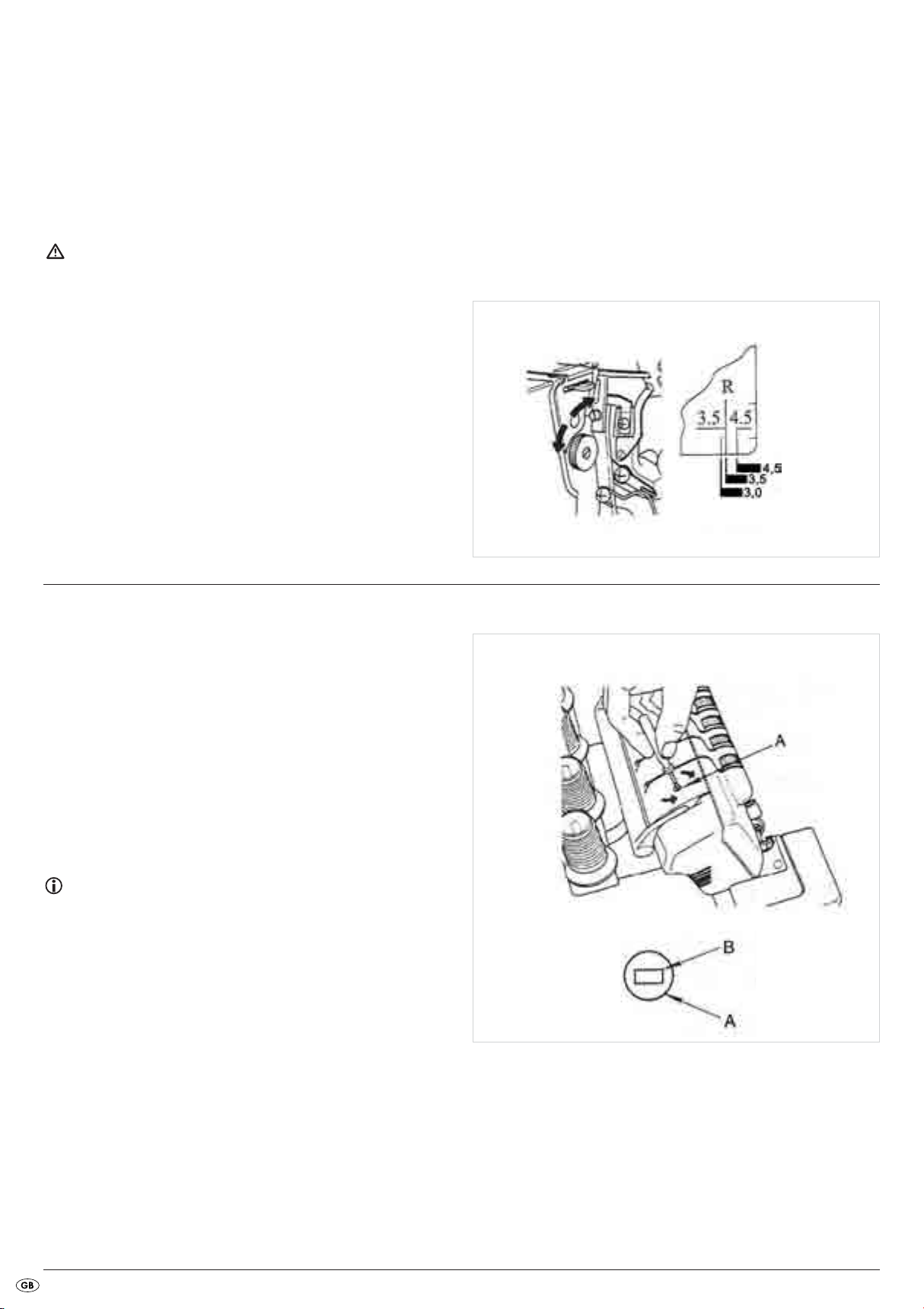

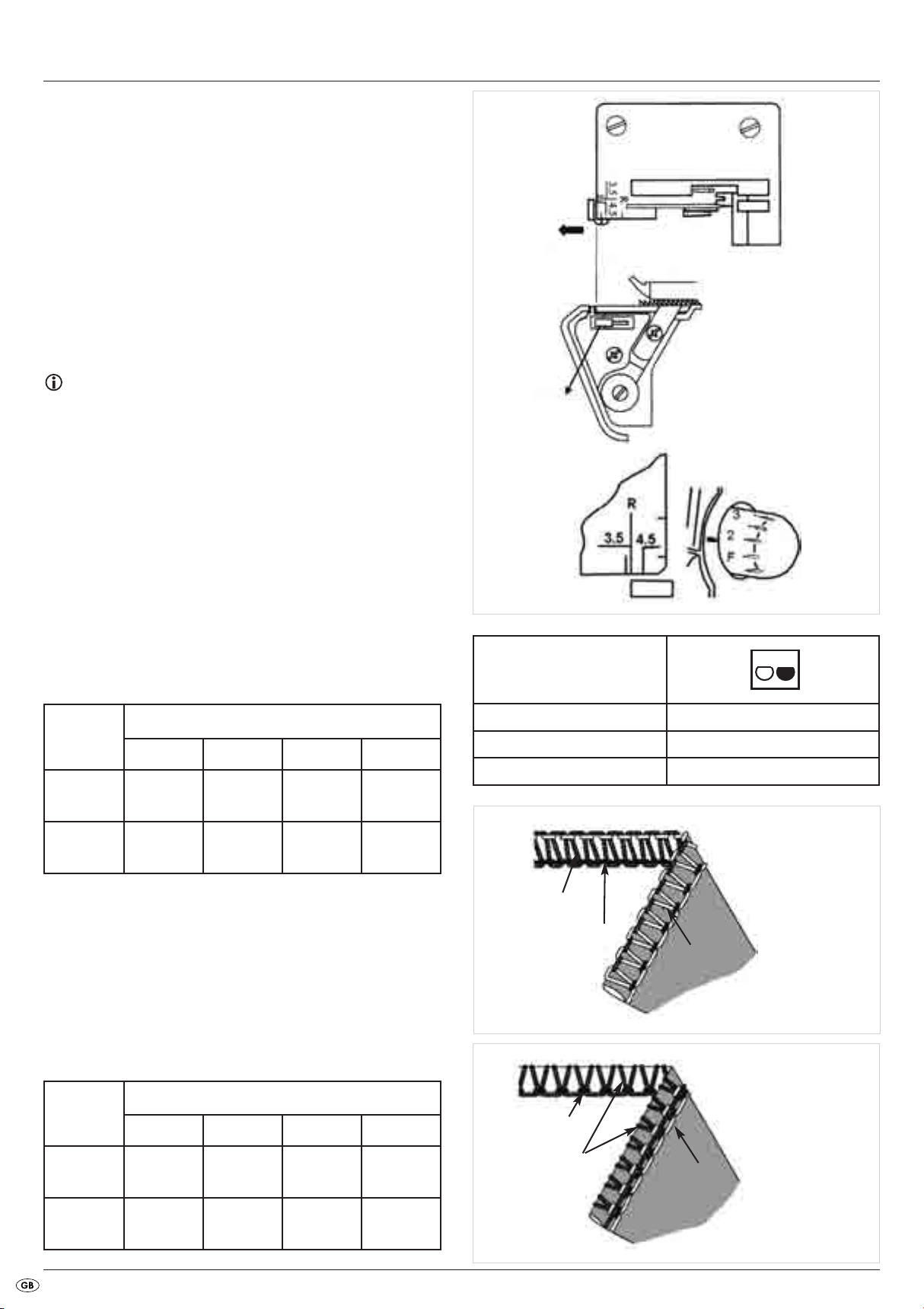

Bringing the upper blade into a rest position

To make certain types of seam, or to more easily operate the adjustment wheel for cutting width f, you must bring the upper blade i into

a rest position.

For this, press the upper blade i to the right and rotate it a little, so

that it is firmly seated (Fig. 2 and 3).

On the rear fold-out page:

i movable upper blade (Upper blade)

o Upper looper

p Lower looper

a Sewing foot

s Fixed lower blade

d Seam width switch

f Seam width adjustment knob

Fig. 2

Needle Information

This machine uses standard commercial flat-shaft needles for sewing machines.

These prevent the incorrect insertion of the needle. You can purchase these

needles in any specialist shop.

You can use needles of the sizes 11 and 14 in this machine.

The adjoining table gives you a brief overview of the differences when using a

needle (for detailed information, see "Setting the seam width).

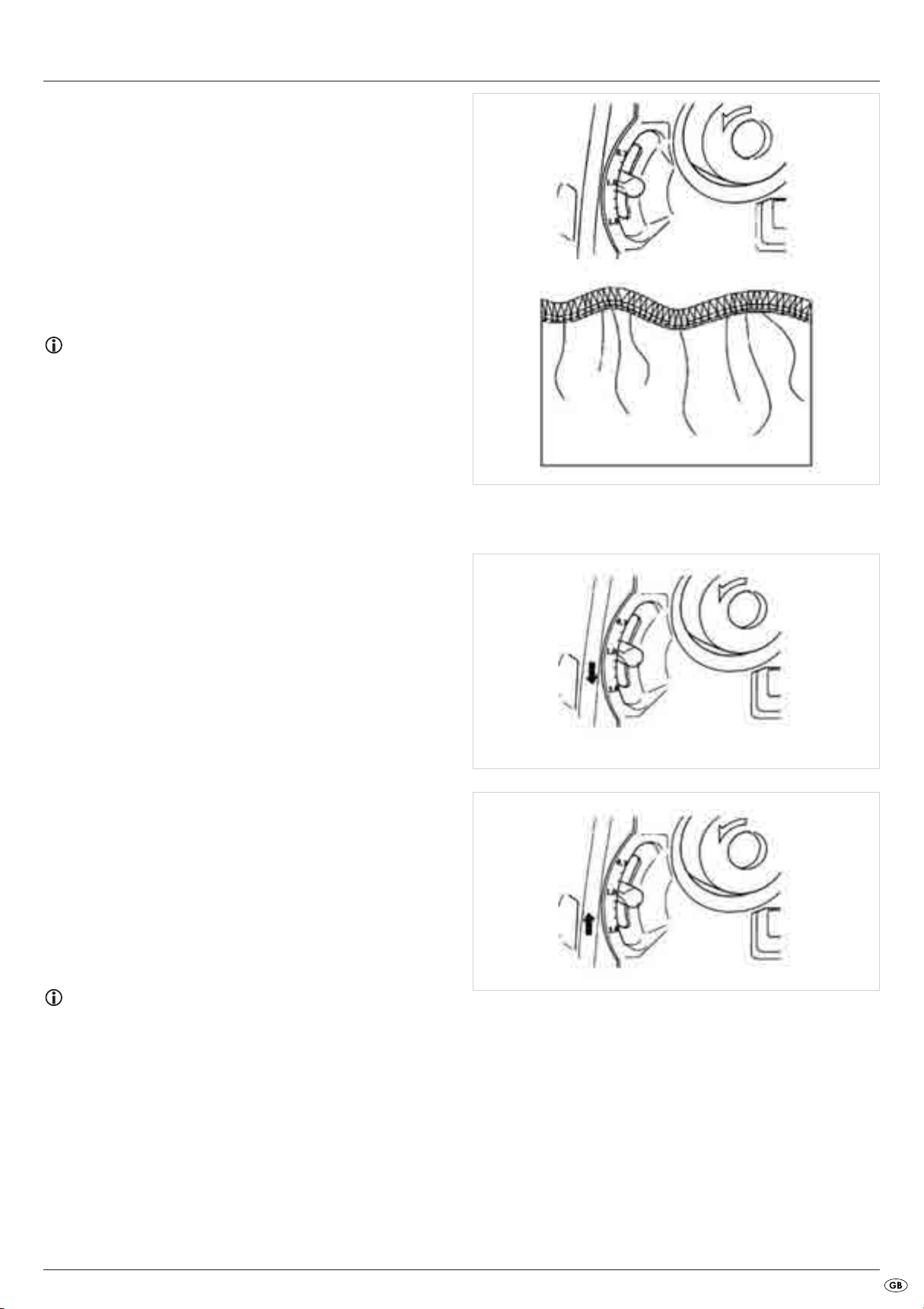

Upper looper element

For some kinds of stitches you will need to use the upper looper element.

When you need to insert it is described in the individual stitches.

Insert the small wire from behind in the eyelet of the upper looper o and

the plastic bolt, on the other end and from the front, in the hole in the upper

looper o (Fig. 4a).

You can store the upper looper ready for use in the slot behind the front

flap 0 (Fig. 4b).

Fig. 3

Seam width 3.5 mm 5.7 mm

Employed needle right needle left needle

Thread tension selector green blue

- 5 -

Fig.4a

Fig.4b

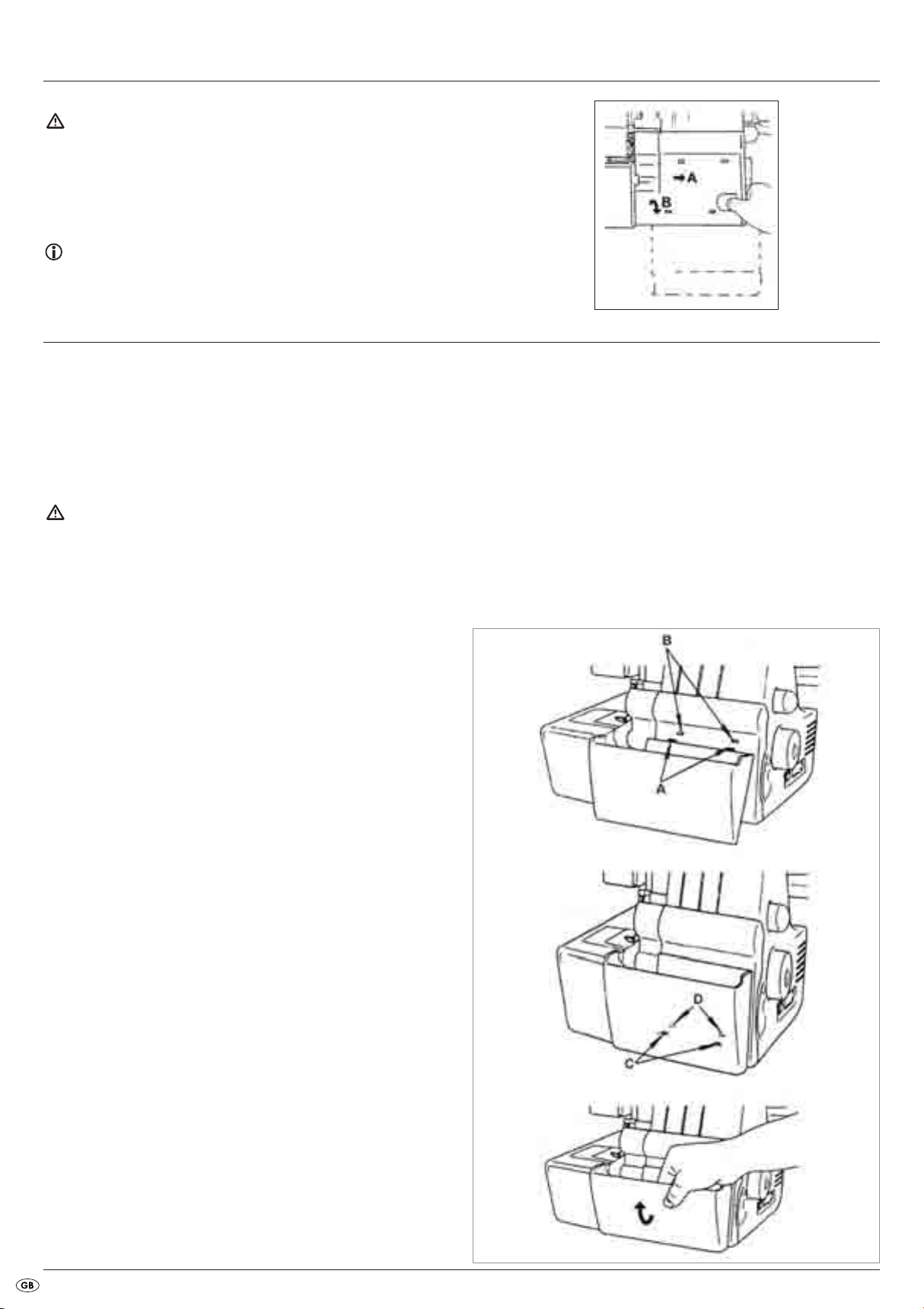

Opening the front flap

Attention!

Always switch the machine off with the power switch 8 when you open

the front flap 0. Risk of Injury!

• Slide the front flap 0 to the right (A) and then pull it towards you (B)

(Fig. 5).You will see the upper looper behind the front flap 0.

Note:

While sewing, the front flap 0 must be kept closed!

Preparation

Place the overlock sewing machine on a stable and level surface.

Ensure there is sufficient illumination at your workplace.

Connecting the foot pedal

• Insert the plug of the foot pedal into the socket for the foot pedal 7.

• Insert the plug into a power socket.

To switch the machine on, press the power switch 8.

Fig. 5

Attention!

During absences from the machine or when doing maintenance work,

always remove the plug from the mains power socket. Risk of Injury!

Controlling the sewing speed

The sewing speed is controlled by means of the footpedal. The sewing

speed is changed by applying more or less pressure to the footpedal.

Safety switch

This machine is fitted with a micro safety switch. You cannot start the machine

if the front flap 0 is open. Close the front flap 0 before you start to sew.

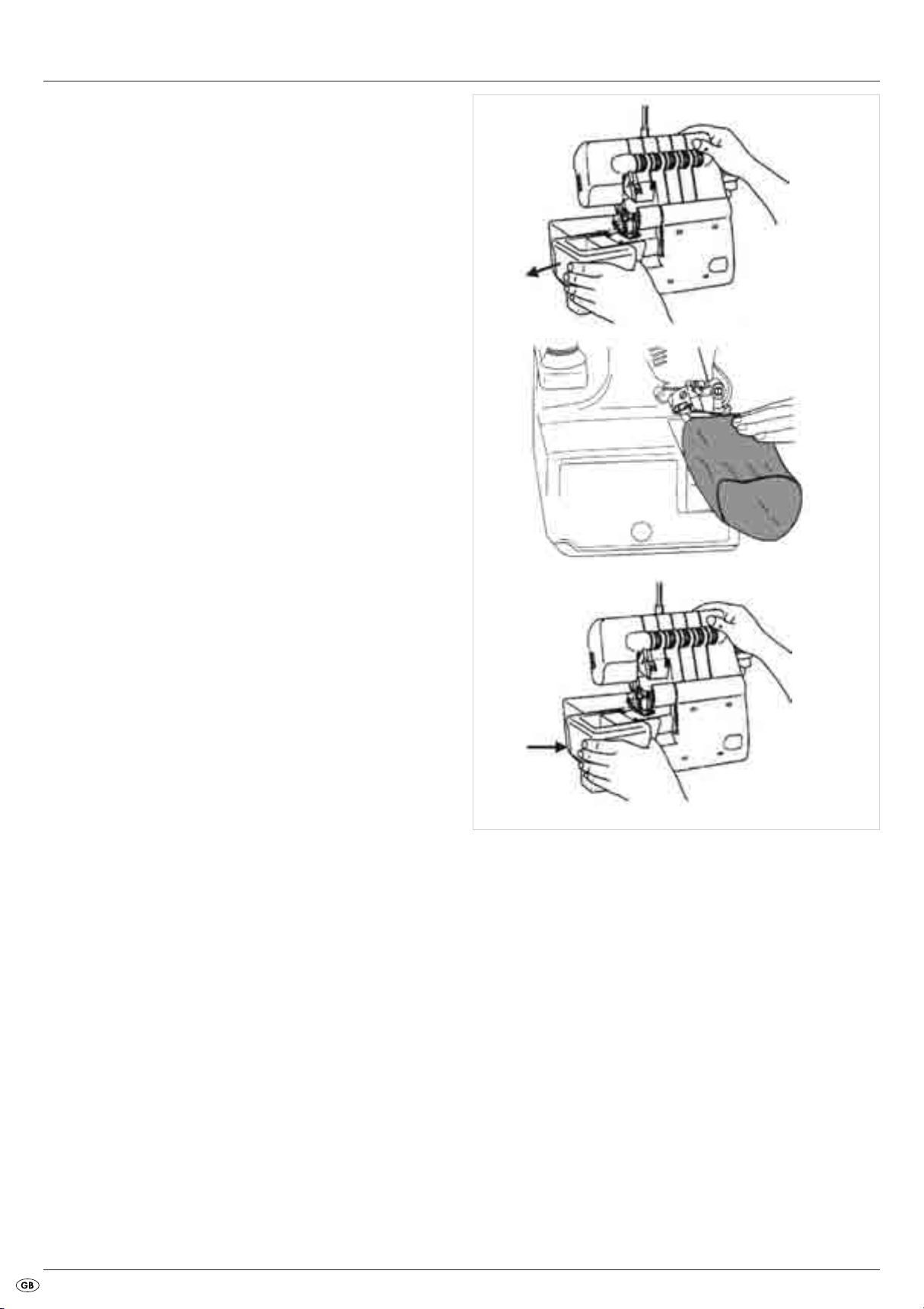

Fitting the waste container

The waste container collects remnants during sewing, so that your workplace

stays tidy.

• First push the two restraints (A) into the receiving holes (B) (Fig. 6).

• Then guide the two restraints (C) into the receiving holes (D) (Fig. 7).

Fig. 6

• To remove the waste container, pull it forward and then tilt it slightly

(Fig. 8).

Fig. 7

Fig. 8

- 6 -

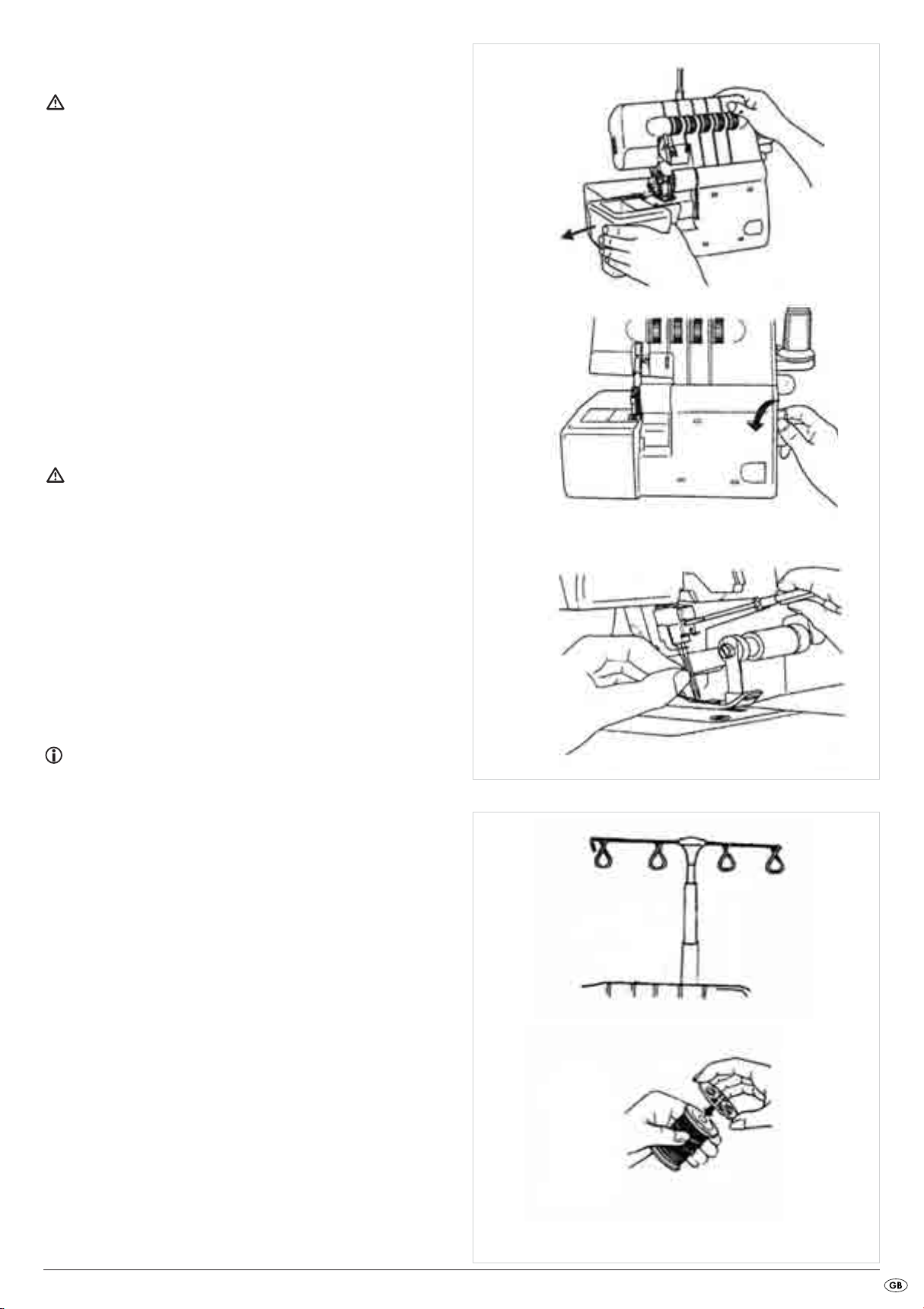

Removing needle(s)

Tip!

Attention!

Before exchanging the needles, remove the power plug. This prevents an

unintended starting of the machine. If you do not, you run a risk of serious

injury!

T

An exchange of the needles is easier if you first remove the free arm cover

(Fig. 9a)!

1. Turn the handwheel 6 towards yourself until the needles are in the

highest position (Fig. 9b)

2. Loosen the needle retaining screws with the small screwdriver until the

needles are free (Fig. 10).

3. Remove the needles.

Inserting needle(s)

Attention!

Before exchanging the needles, remove the power plug. This prevents an

unintended starting of the machine. If you do not, you run a risk of serious

injury!

1. Hold the needle with the flattened side to the rear.

2. Push the needle as far as it will go into the needle holder.

3. Firmly tighten the needle screws with the small screwdriver (Fig. 10).

Fig.9a

Fig.9b

Operating the handwheel

Note:

Always turn the handwheel 6 only towards yourself (Fig. 9b).

Adjusting the thread tree

• Completely remove the thread tree 1 before threading (Fig. 11).

• Turn the thread tree 1 so that the thread guides stand exactly above

the spool supports 2.

• In the correct position, the two jointed parts of the thread tree 1 snap

audibly into position.

• Place the thread rolls on the thread roll centrings.

If you do not use industrial coils, remove the thread roll centrings. Slide

a spool cap onto each of the thread rolls (Fig. 12). This will hold them in

place when sewing.

Fig.10

Fig. 11

- 7 -

Fig. 12

Threading

143 2

Note:

On delivery, all 4 threads are already threaded. You can begin sewing immediately. Should you wish to change the thread, and all 4 threads are still

threaded, then proceed as described in the chapter "Changing threads

(binding together)“.

Should you need to rethread all threads from scratch, then proceed as

described in this chapter, "Threading“.

General instructions for threading

Attention!

Before threading, ALWAYS place the power switch 8 at "O" (Off) and

remove the plug from the mains power socket. This prevents an unintended

starting of the machine. If you do not, you run a risk of serious injury!

Correct threading is important, so that the stitches are not irregular and that

the yarn does not break.

Behind the front flap 0 there is a diagram with instructions for threading.

Additionally, the thread guides are marked in various colours.

In the accessory box you will find tweezers, the use of which helps make

threading easier.

Threading is done in this order (Fig. 13/14):

1. First step: Upper looper (red)

2. Second step: Lower looper (yellow)

3. Third step: Thread for the right needle (green)

4. Fourth step: Thread for the left needle (blue)

Note:

When all threads are threaded, and the lower looper thread loosens itself,

proceed as follows:

• Unthread the two threads of the needles.

• Then thread the lower looper thread.

• First then rethread the threads of the two needles again.

The needles must always be the last to be threaded!

For simplification, the individual steps are numbered on the drawings.

Fig. 13

Fig. 14

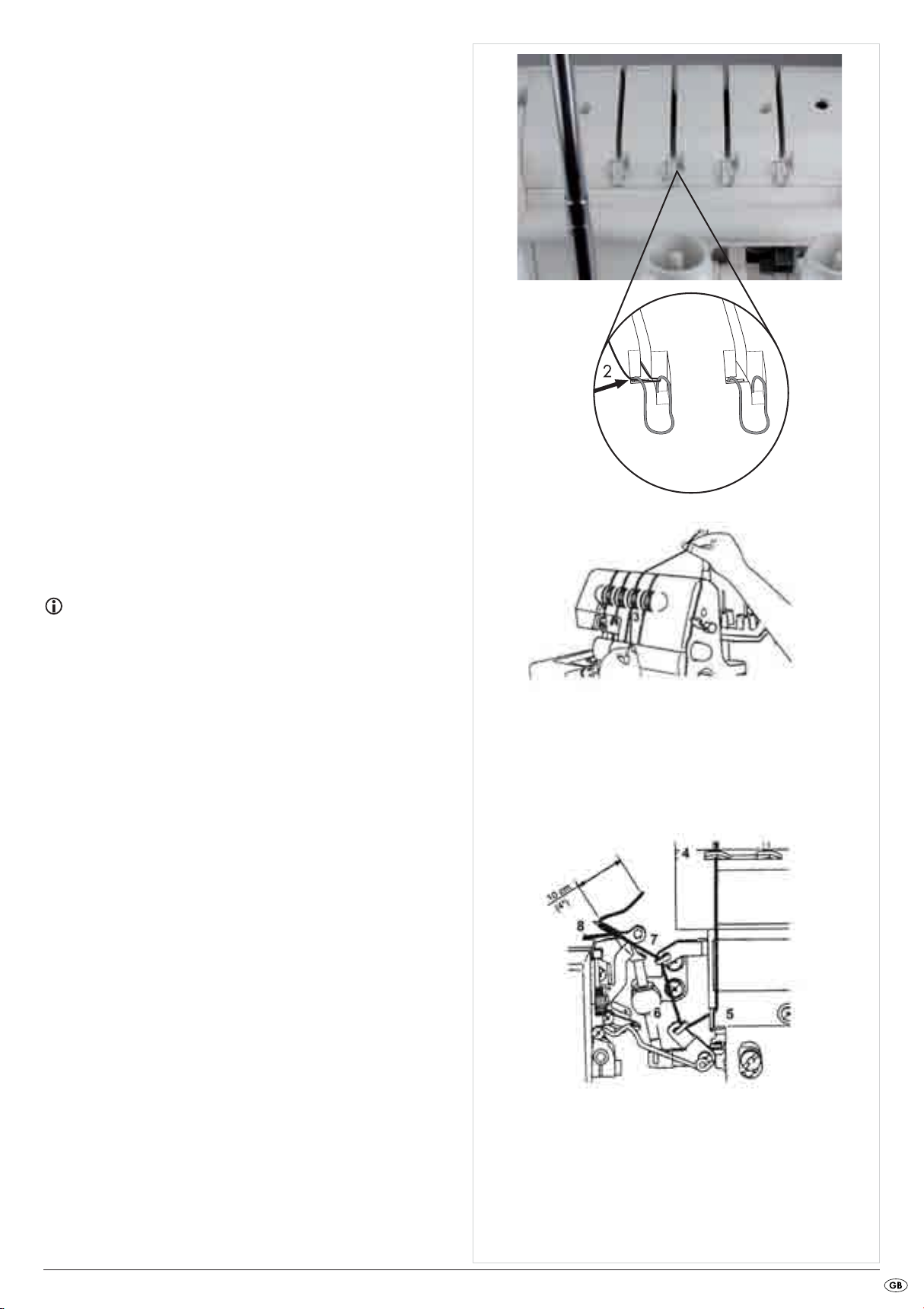

Threading the upper looper thread (red)

Attention!

Before threading, ALWAYS place the power switch 8 at "O" (Off) and

remove the plug from the mains power socket. This prevents an unintended

starting of the machine. If you do not, you run a risk of serious injury!

Always use the accompanying drawings for assistance.

Figure 15 shows the thread path of the upper looper thread. The individual

threading positions are numbered and described in detail in the following.

1. Open the front flap 0.

2. Guide the yarn from back to front through the thread tree 1 (1).

Fig. 15

- 8 -

3. Thread the yarn into the thread guide in that you pull the thread down

until it slips under the thread guide (2) (Fig. 16).

Fig. 16

4. Firmly hold the yarn with your fingers, guide it between and through

the discs of the thread tension selector z and then pull it down (3)

(Fig. 17).

Note:

The yarn must lie correctly between the two discs of the thread tension

selector z.

5. Thread the yarn in the looper area as per the red markings (Fig. 18).

6. Pull the thread from back to front through the upper looper o.

7. Pull around 10 cm of thread through the looper and place it behind

the stitch plate e.

Fig. 17

- 9 -

Fig. 18

Threading the lower looper thread (yellow)

Attention!

Before threading, ALWAYS place the power switch 8 at "O" (Off) and

remove the plug from the mains power socket. This prevents an unintended

starting of the machine. If you do not, you run a risk of serious injury!

Figure 19 shows the thread path of the lower looper thread. The individual

threading positions are numbered and described in detail in the following.

1. Guide the yarn from back to front through the thread tree 1 (1).

2. Thread the yarn into the thread guide in that you pull the thread down

until it slips under the thread guide (2) (Fig. 20).

3. Firmly hold the yarn with your fingers, guide it between and through

the discs of the thread tension selector u and then pull it down (3)

(Fig. 21).

Fig. 19

Fig. 20

Note:

The yarn must lie correctly between the two discs of the thread tension

selector u.

4. Turn the handwheel 6 to yourself until the lower looper p is at the

far right.

Fig. 21

- 10 -

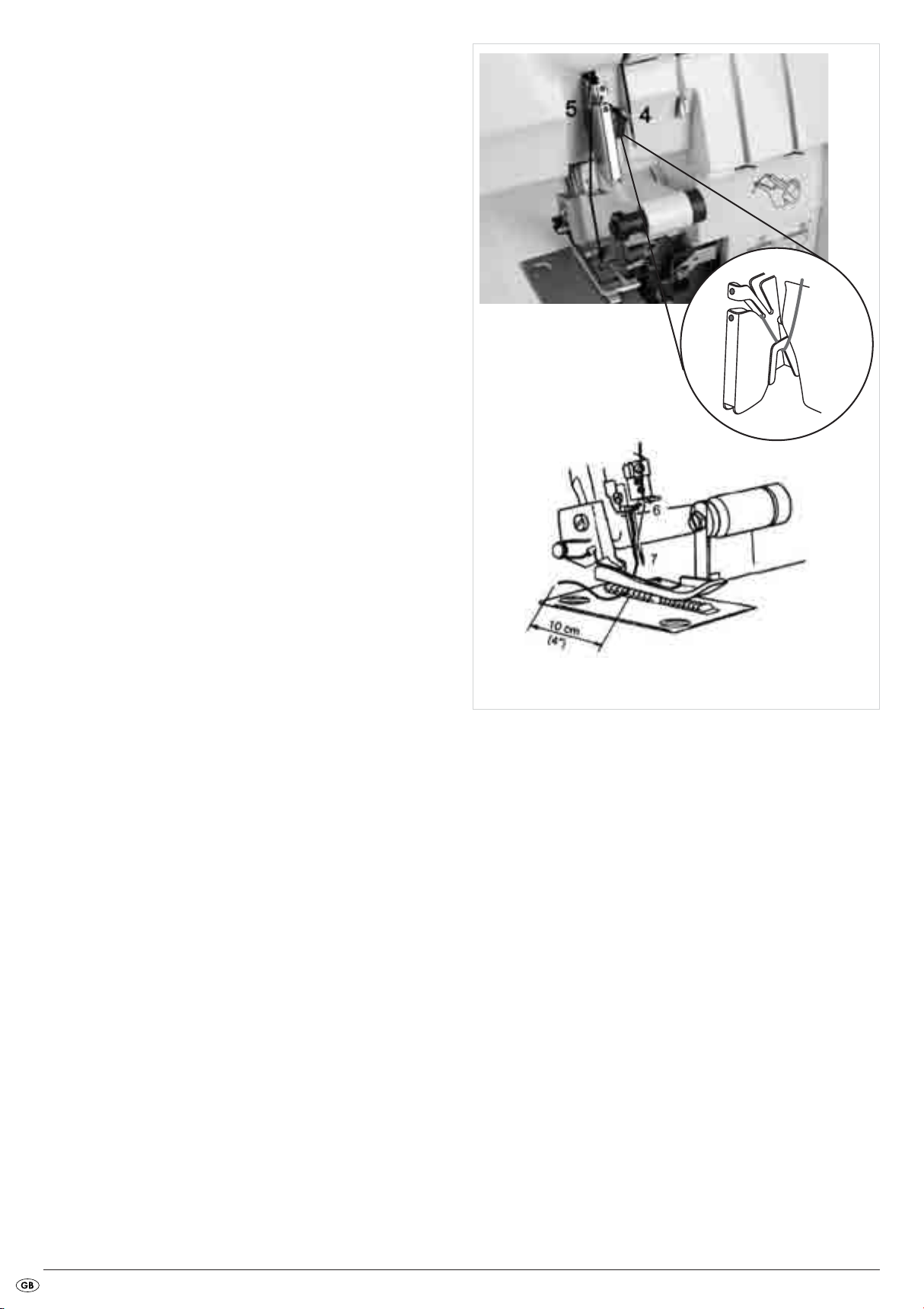

5. Thread the yarn in the looper area as per the yellow markings (4 - 8)

over

(Fig. 22).

6. Firmly hold the yarn with the tweezers about 4 cm from the thread

guide (Fig. 23).

7. Now guide it lightly, from the left and with the tweezers, under the

thread guide.

8. Pull the yarn upwards into the thread guide (9).

Fig. 22

9

9. Lead the yarn to the rear and over the upper end of the lower looper p

(10A) (Fig. 23).

10. Then, carefully pull the yarn down so that it slides into the recess of

the looper (10B) (Fig. 23). For this step also use the drawing which

is attached to the machine!

11. Guide the thread through the looper eyelet (11). The yarn should run

in the groove of the lower looper p (Fig. 23).

12. Draw around 10 cm of yarn through the looper and place it to the

rear

the upper looper o and the stitch plate e.

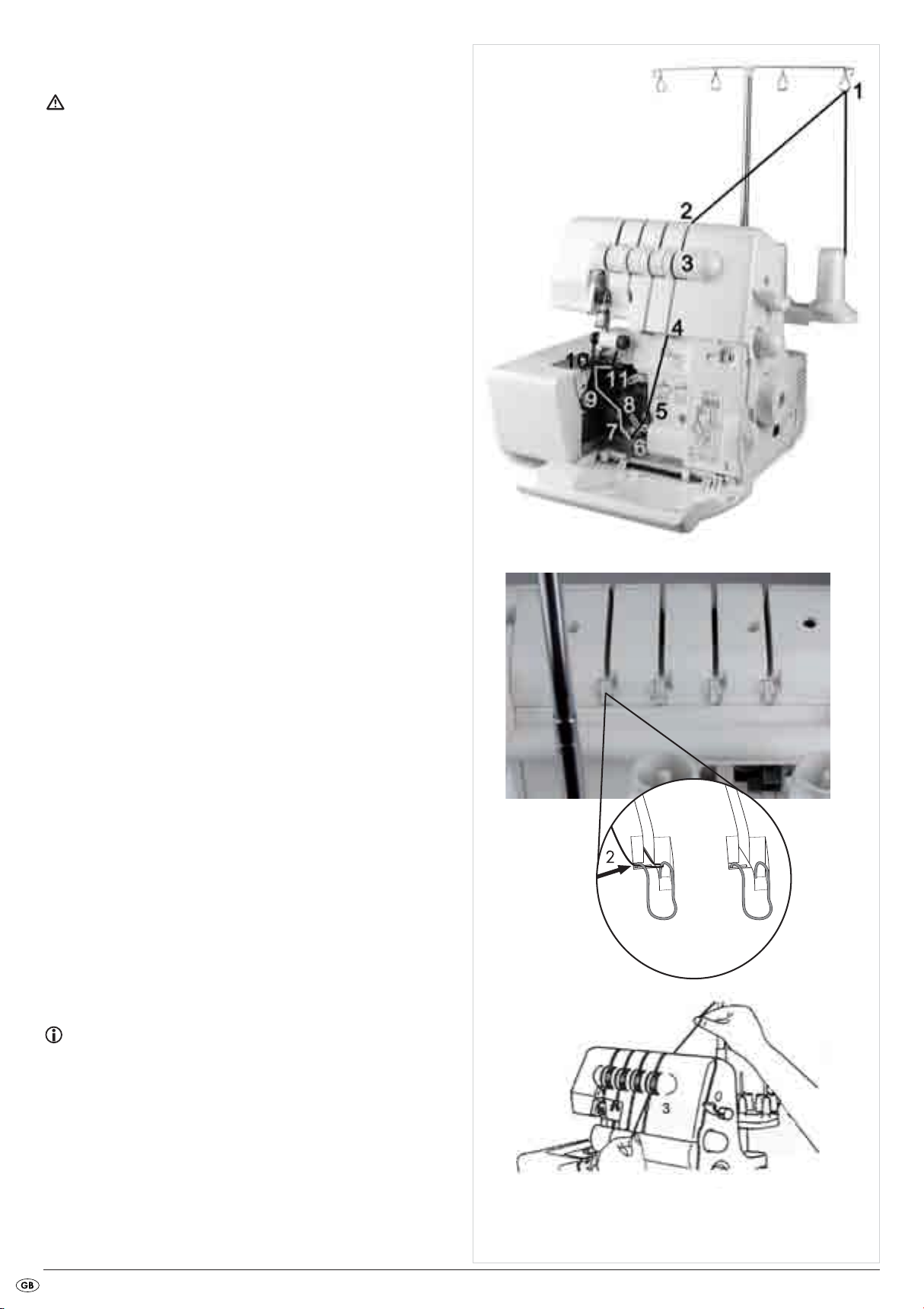

Threading yarn for the right needle (green)

Attention!

Before threading, ALWAYS place the power switch 8 at "O" (Off) and

remove the plug from the mains power socket. This prevents an unintended

starting of the machine. If you do not, you run a risk of serious injury!

Fig. 23

11

8

10

10

Figure 24 shows the thread path of the right needle thread. The individual

threading positions are numbered and described in detail in the following.

1. Guide the yarn from back to front through the thread tree 1 (1).

Fig. 24

- 11 -

2. Thread the yarn into the thread guide in that you pull the thread down

5

6

until it slips under the thread guide (2) (Fig. 25).

Fig. 25

3. Firmly hold the yarn with your fingers, guide it between and through

the discs of the thread tension selector t and then pull it down (3)

(Fig. 26).

Note:

The yarn must lie correctly between the two discs of the thread tension

selector t.

4. Thread the yarn as per the green markings (4- 7) (Fig. 27/28).

Fig. 26

5. Thread the yarn through the right needle (8) (Fig. 28).

6. Lay the yarn to the rear under the sewing foot a.

Fig. 27

Fig. 28

- 12 -

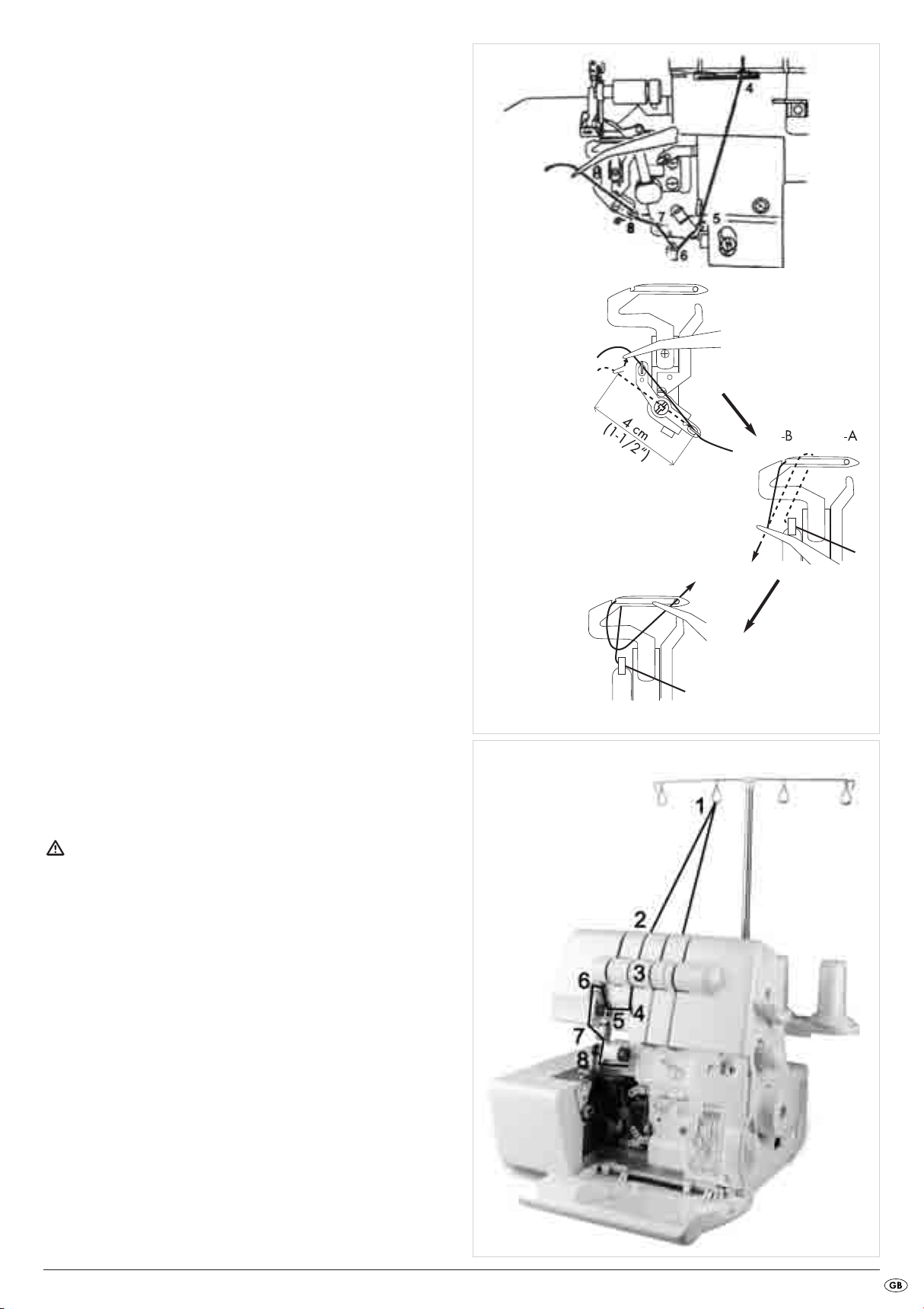

Threading yarn for the left needle (blue)

Attention!

Before threading, ALWAYS place the power switch 8 at "O" (Off) and

remove the plug from the mains power socket. This prevents an unintended

starting of the machine. If you do not, you run a risk of serious injury!

Figure 29 shows the thread path of the left needle thread. The individual

threading positions are numbered and described in detail in the following.

1. Guide the yarn from back to front through the thread tree 1 (1).

2. Thread the yarn into the thread guide in that you pull the thread down

until it slips under the thread guide (2) (Fig. 30).

Fig. 29

Fig. 30

3. Firmly hold the yarn with your fingers, guide it between and through

the discs of the thread tension selector r and then pull it down (3)

(Fig. 31).

Note:

The yarn must lie correctly between the two discs of the thread tension

selector r.

Fig. 31

- 13 -

4. Thread the yarn as per the blue markings (4 - 6) (Fig. 32/33).

4

5

5. Thread the yarn through the left needle (7) (Fig. 33).

6. Lay the yarn to the rear under the sewing foot a.

Fig. 32

Trial run

When yarn has been threaded for the first time, or after a yarn breakage

it must be rethreaded, proceed as follows:

Lift the sewing foot a.

Hold the ends of the threads between the fingertips of your left hand, slowly turn the handwheel 6 two or three times towards yourself and

then check the threads once again.

Lay the material for a trial run under the sewing foot a and slowly start

to sew.

The material will be automatically fed through.

When the task is complete, continue sewing until an approximately

5cm (2") long length of threads has formed at the end of the material.

Cut through the threads with scissors.

Fig. 33

- 14 -

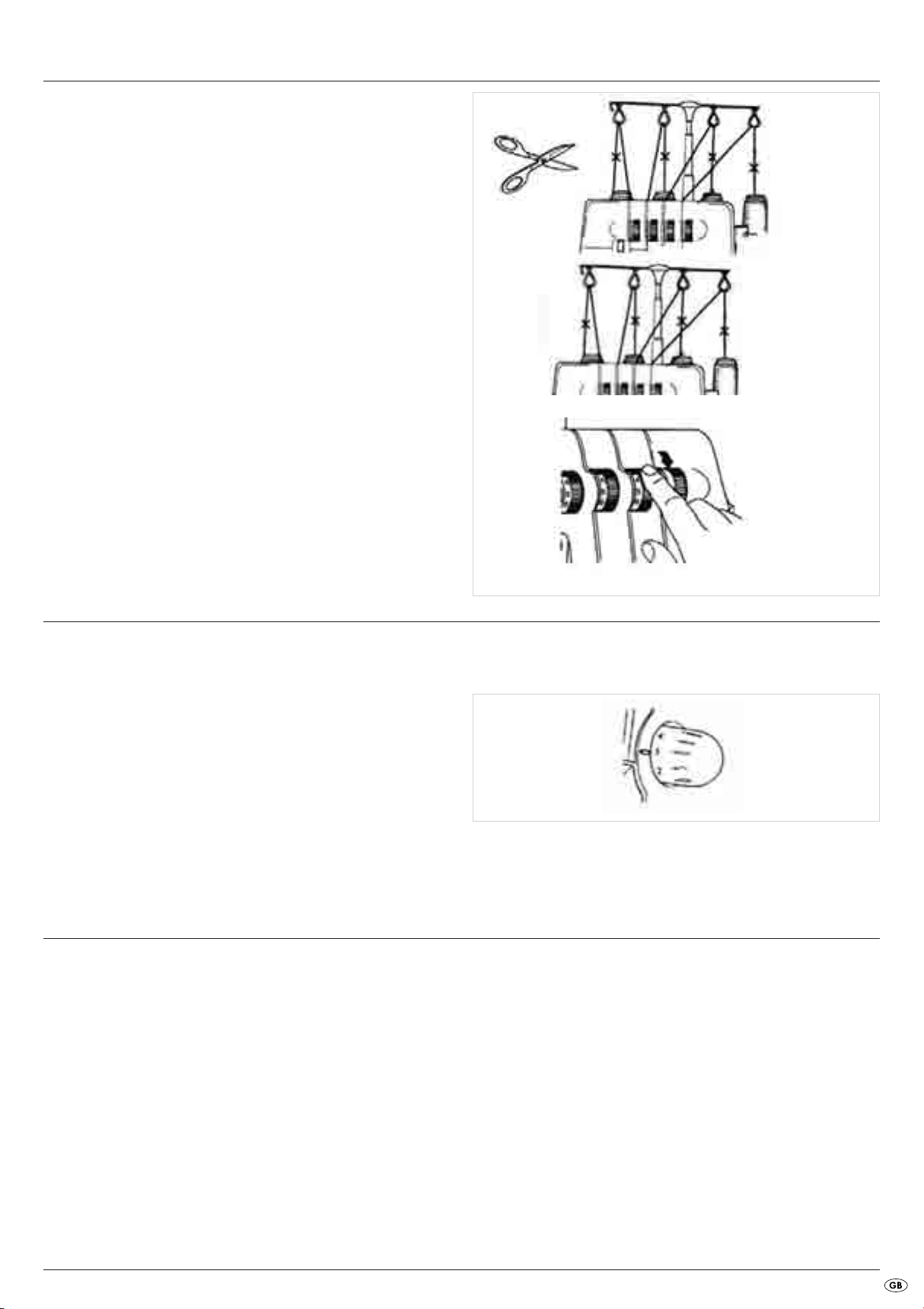

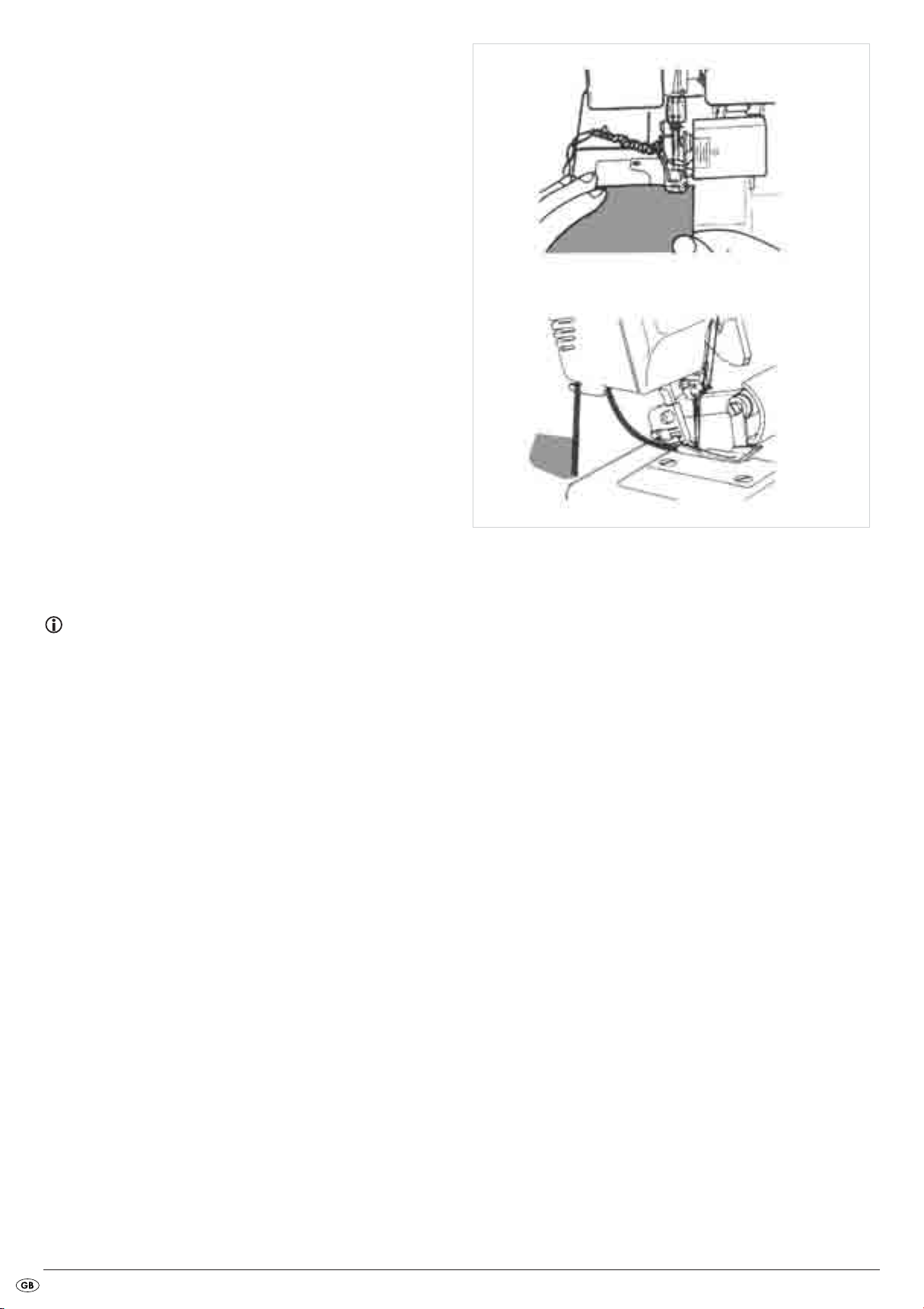

Changing threads (binding together)

Changing threads is quite simple with the following procedure:

1. Cut the yarn above the spool support 2 (Fig. 34) and place the new

roll of thread on the spool support 2.

2. Tie the ends of the new and the old thread together (Fig. 35).

3. Place the thread tension selector r/t/z/u at "0" (Fig. 36) and lift

the sewing foot a.

4. Pull on the other end of the yarn until the knot passes under the sewing

foot a.

5. For threading it in the needle, pull on the other end until the knot is in

the eye of the needle and then cut the yarn to the left and right of the

knot. Then carry out the rethreading.

Fig. 34

Fig. 35

Fig. 36

Set the stitch length

The stitch length can be adjusted from 1.0 to 4.0 mm. Almost all overlock

work is carried out with a stitch length of 2.5 – 3.5 mm.

Turn on the adjustment wheel for stitch length 5 (Fig. 37) to adjust the

stitch length:

• A stitch length of 3 mm is recommended for most sewing.

• For the working of heavy fabrics, a stitch length of 4 mm is to be recommended.

• For the working of light fabrics, a stitch length of 2 mm is to be recommended..

With these settings you will produce respectable seams and the fabric

will not be crimped.

Setting the seam width

The width of seams can be determined both by changing the needle position

and via the seam width adjustment knob f.

... by using the right or left needle

The width of the seam can be determined by using the left or the right

needle.

Fig. 37

• Only the left needle is used: 5.7 mm

• Only the right needle is used: 3.5 mm

- 15 -

... by turning the seam width adjustment knob

By using the seam width adjustment knob f, seam width can be adjusted

within the ranges indicated below.

• Only the left needle is used: 5.2 - 6.7 mm

• Only the right needle is used: 3.0 - 4.5 mm

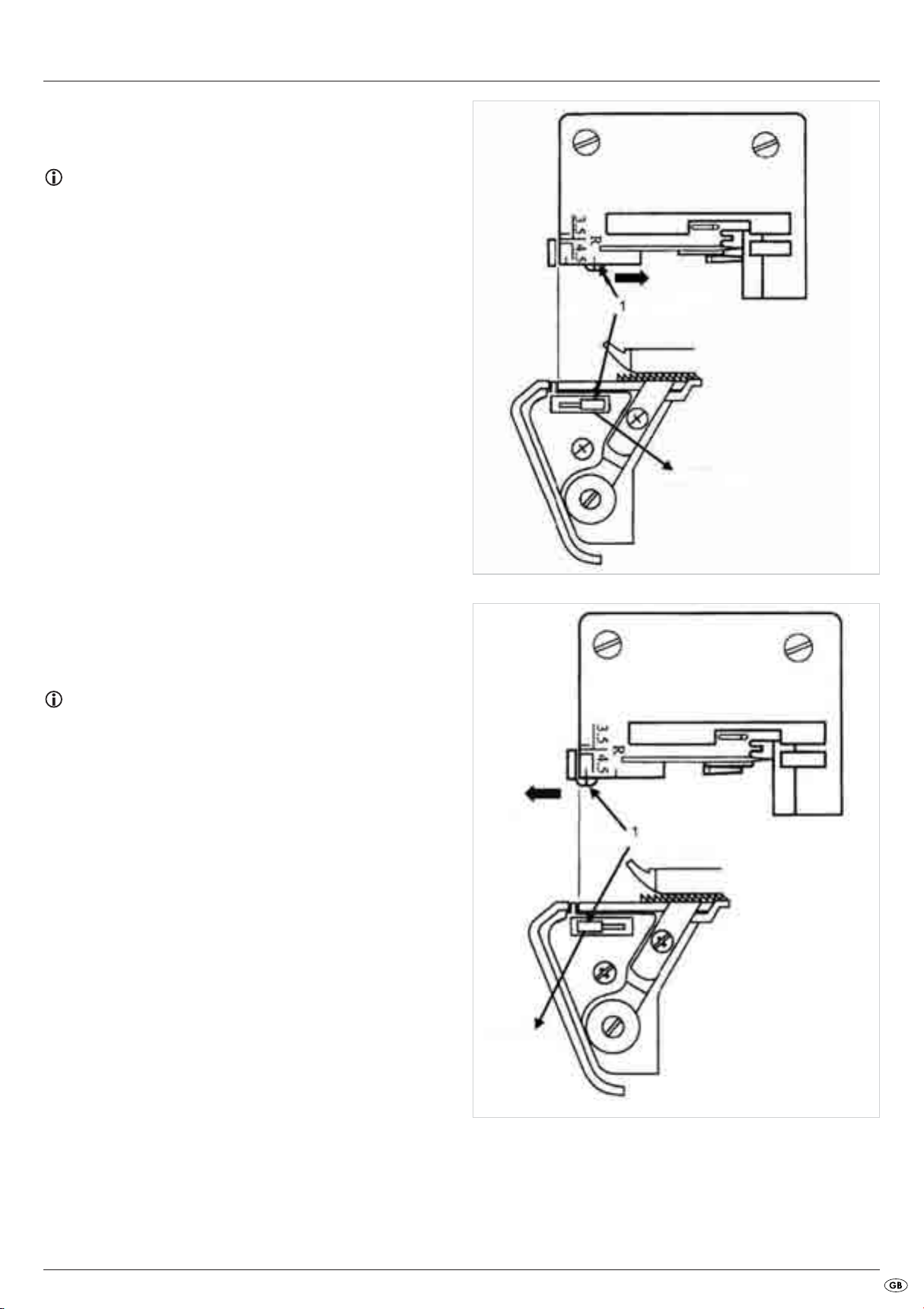

Setting the seam width adjustment knob

Attention!

Before making adjustments with the seam width adjustment knob f

always place the mains switch 8 at the position "O" (Off). This prevents

an accidental start of the appliance and thus the risk of injury!

• Open the front flap 0, this can make the adjustment easier to carry out.

• Turn the seam width adjustment knob f to the desired seam width

(Fig. 38). Orientate yourself on the scale on the stitch plate e

(Fig. 39).

Adjust sewing foot pressure

Upon delivery, the sewing foot pressure is set for medium-weight materials.

If you wish to use heavier or lighter materials, adjust the sewing foot pressure

as follows:

• For lighter fabrics, you need to reduce the pressure.

• For heavier fabrics, you need to increase the pressure.

Insert the small screwdriver into the hole on the upper side of the machine

(Fig. 40). The pressure adjustment screw is located here (A). Ensure that the

screwdriver slips into the slot of the pressure adjustment screw (B) (Fig. 41).

• Turn the screwdriver in the direction "+" if you want to increase the pressure.

• Turn the screwdriver in the direction "-" if you want to reduce the pressure.

Note:

To return to the factory-set default sewing foot pressure, turn the pressure

adjustment screw as far as it will go anti-clockwise (-). Then turn it 6 rotations in

a clockwise (+) direction.

The standard sewing foot pressure is reset.

Fig. 39

Fig. 38

Fig. 40

- 16 -

Fig. 41

Differential transport

Manner of operation

The machine has two sets of toothed rack feeders, one to the front and one

to the rear. Both sets move independant of each other. Through the differential

feed motion both toothed rack sets can move themselves at various speeds.

With this, the fabric is stretched or gathered, depending on which transport

differential has been set between the front and rear rack feeders.

With the aid of the differential transport, interesting effects can be achieved when sewing overlock seams on stretch materials and diagonally cut

fabrics (Fig. 43).

Note:

When the differential transport lever 9 stands at "1.0", that corresponds

to a differential transport ratio of 1:1. Both toothed feed racks move at the

same rate (Fig. 42).

The differential transport lever 9 can be adjusted in a range from 1:0.7

to 1:2.0.

Gathered overlock seam - Settings

The gathered overlock seam is suitable for the ruffling of sleeves, back

upper parts, skirt seams etc.made of elastic materials such as knitwear

and jersey. The individual parts should be brought together before sewing.

• Adjust the differential transport lever 9 to a value higher than 1.0

(Fig. 44). The exact setting depends on the material to be processed

and the desired level of ruffling or gathering.

Therefore always do a sample stitching to test the settings.

Fig. 42

Fig. 43

Stretched overlock seam - Settings

The stretched overlock seam is suitable for the manufacture of ruffles at the

collar, cuffs and skirt edges etc. in soft, stretchy fabric and knitwear.

• Adjust the differential transport lever 9 to a value lower than 1.0 (Fig.

45). The exact setting depends on the material to be processed, and

on the strength of the desired "ruffle effect".

Therefore always do a sample stitching to test the settings.

• Hold the seam down with slight firmness before and behind the sewing

foot a so as to keep the textile under tension.

Note:

If you have set a value of "3" or higher on the adjustment wheel for the

stitch length 5, this setting will automatically return to "3" when you set the

differential transport lever 9 to 2.0.

Fig. 44

Fig. 45

- 17 -

Free arm sewing

To work tubular-shaped fabrics, such as sleeves or trouser legs, you can

remove the free arm cover.

• If appropriate, remove the waste container from the machine.

• Slide the free arm cover to the left and pull it off (Fig. 46)..

• You can now pull the textiles over the free arm w and work them

(Fig. 47).

• To replace the free arm cover, push it onto the free arm w until it clicks

into place and is firmly seated (Fig. 48).

Fig. 46

Fig. 47

Fig. 48

- 18 -

Overlock seams

• Open the front flap 0.

• Slide the seam width switch d to "S", so that the seam width finger is

pushed forward (1) (Fig. 49).

Note:

The seam width switch d must be pushed until it can go no further.

Otherwise, the seams will be untidy.

Standard position

Roll hemmings

• Open the front flap 0.

• Slide the seam width switch d to "R", so that the seam width finger is

pushed backward (1) (Fig. 50).

Note:

The seam width switch d must be pushed until it can go no further,

otherwise the seams will be untidy.

Fig. 49

- 19 -

Roll hem

Fig. 50

Binding-off and sample sewing

• Lay all yarns under the sewing foot a, to the rear, slightly to the left

and over the stitch plate e.

• Firmly hold the yarns under a slight tension.

• Turn the handwheel 6 2 to 3 revolutions onto itself to begin empty

chainstitch formation.

• Lower the sewing foot a with the sewing foot lever 4.

• Hold the empty chainstitch again firmly and carefully activate the foot

pedal until the empty chainstatch is approximately 5 - 7.5 cm long.

• Place the fabric from the front under the sewing foot a and sew a test

seam (Fig. 51). Under no circumstances should you pull on the textile,

otherwise the needle will be bent or could even break off.

• Continue sewing even after the textile is finished for about 15 to 20 cm.

• Cut the empty chainstitch by using the blade at the rear of the machine

(Fig. 52).

Fig. 51

Recommended tension settings

Note:

All information about tension settings for the different kinds of stitches are

purely guiding values. The thread tension itself is always dependant

on the type and thickness of the fabric, as well as needle strength and

the strength, type and material composition of the yarn.

It is therefore absolutely necessary to sew a test seam. It is the only way

you can find out if the tension settings are correct, or if they need to be

changed.

Fig. 52

- 20 -

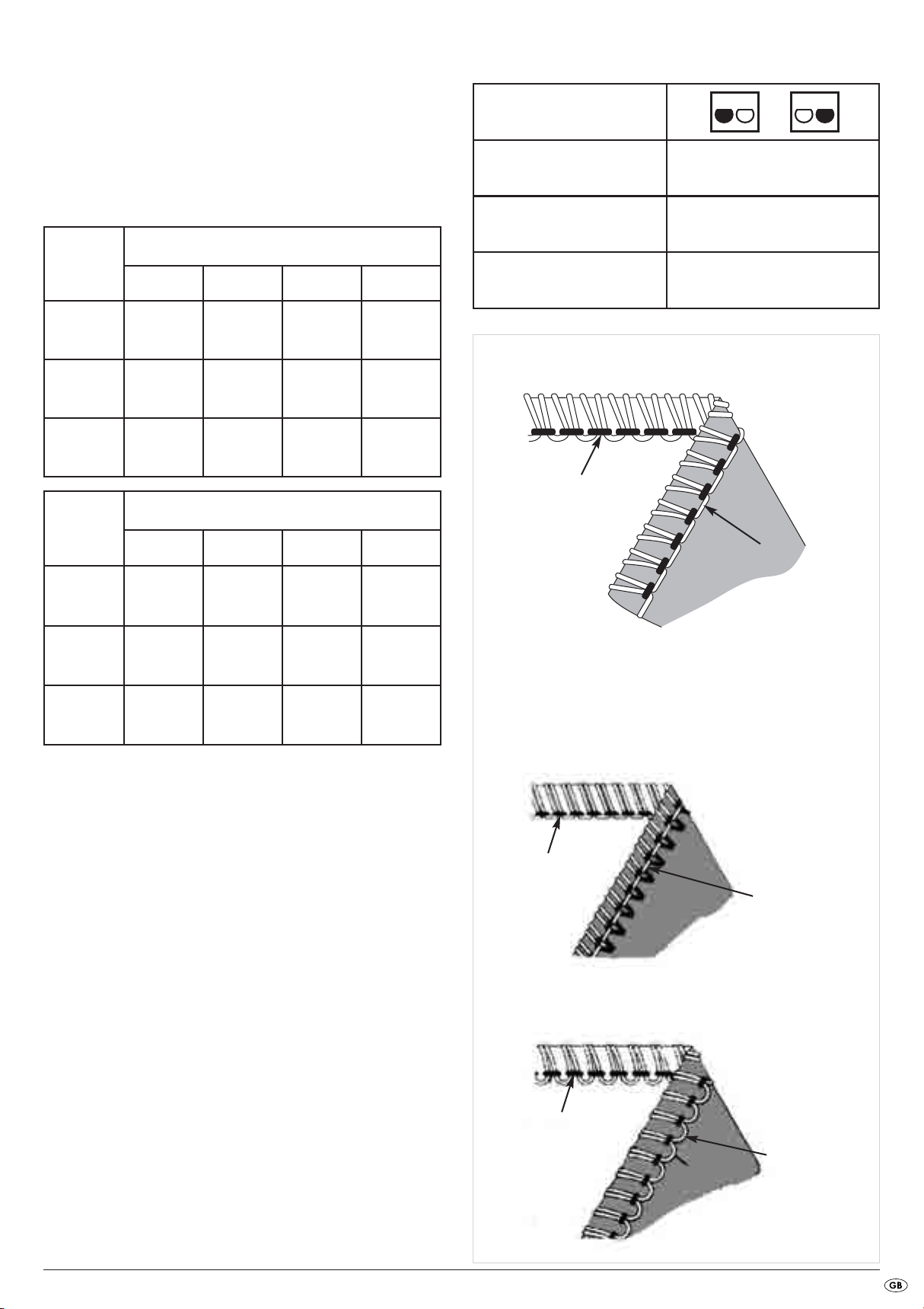

2-thread overcast chain stitch (overlock)

Figure 53 shows you the stitch pattern for this stitch.

This stitch with a needle and 2 threads is used for tidying the edges of

light or stretchy fabrics. By changing the needle position you can obtain a

narrow or a wide overcast seam.

Adjust the thread tension selectors r t z u to the appropriate values

(see table) then sew a test seam on the material being used.

For this type of stitch insert the upper looper element in the upper looper o.

Tensioning the thread

Textiles

blue green red yellow

Needle position

Seam width switch

Stitch length

Upper looper element

S

2 - 4

insert

light

material

medium-

weight

material

heavy

material

Textiles

light material

medium-

weight

material

heavy

material

Inserting the

2.0 -

2.5 -

3.5 -

Tensioning the thread

blue green red yellow

- 1.5

- 1.5

- 3.0

upper looper

element

Inserting the

upper looper

element

Inserting the

upper looper

element

Inserting the

upper looper

element

Inserting the

upper looper

element

Inserting the

upper looper

element

0

0

0.5

0.5

0.5

1.5

needle thread

Top

Correct thread tension

lower looper thread

Underside

Fig. 53

Incorrect thread tension

Should the lower looper yarn appear to be too tight or the needle thread

too loose (Fig. 54) :

• turn the thread tension selector for the lower looper thread u (yellow)

to a lower number, or ...

• turn the thread tension selector for the needle (blue r or green t) to

a higher number.

Should the lower looper yarn appear to be too loose (Fig. 55), turn the

thread tension selector for the lower looper thread u (yellow) to a higher

number.

needle thread

Top

needle thread

Top

lower looper thread

Underside

Fig. 54

Incorrect thread tension

lower looper thread

Underside

Fig. 55

- 21 -

2-thread-overcast-stitch

Figure 56 shows you the stitch pattern for this stitch.

This stitch with a needle and 2 threads is used for tidying normal fabrics

with an overcast stitch. It is also ideal for flat stitch seams (fell or butt seams)

and blind hemming.

By changing the needle position you can obtain a narrow or a wide overcast

seam.

Adjust the thread tension selectors r t z u to the appropriate values

(see table) then sew a test seam on the material being used.

For this type of stitch insert the upper looper element in the upper looper o.

Tensioning the thread

Textiles

blue green red yellow

Needle position

Seam width switch

Stitch length

Upper looper element

Correct thread tension

S

2 - 4

insert

light

material

medium-

weight

material

heavy

material

Textiles

light

material

medium-

weight

material

heavy

material

Inserting the

0.5 -

0.5 -

1.0 -

Tensioning the thread

blue green red yellow

- 1.0

- 1.5

- 1.5

upper looper

element

Inserting the

upper looper

element

Inserting the

upper looper

element

Inserting the

upper looper

element

Inserting the

upper looper

element

Inserting the

upper looper

element

1.0

1.5

1.5

3.0

3.5

3.5

lower looper thread

Top

needle thread

Underside

Fig. 56

Incorrect thread tension

Should the lower looper yarn lie on the underside of the textile (Fig. 57):

• turn the thread tension selector for the lower looper thread u (yellow)

to a higher number, or ...

• turn the thread tension selector for the needle (blue r or green t) to a

lower number.

Should the needle yarn be too loose (Fig. 58):

• turn the thread tension selector for the needle (blue r or green t) to a

higher number.

• turn the thread tension selector for the lower looper thread u (yellow)

to a lower number.

lower looper thread

lower looper thread

- 22 -

Top

Top

Underside

Incorrect thread tension

Underside

needle thread

Fig. 57

needle thread

Fig. 58

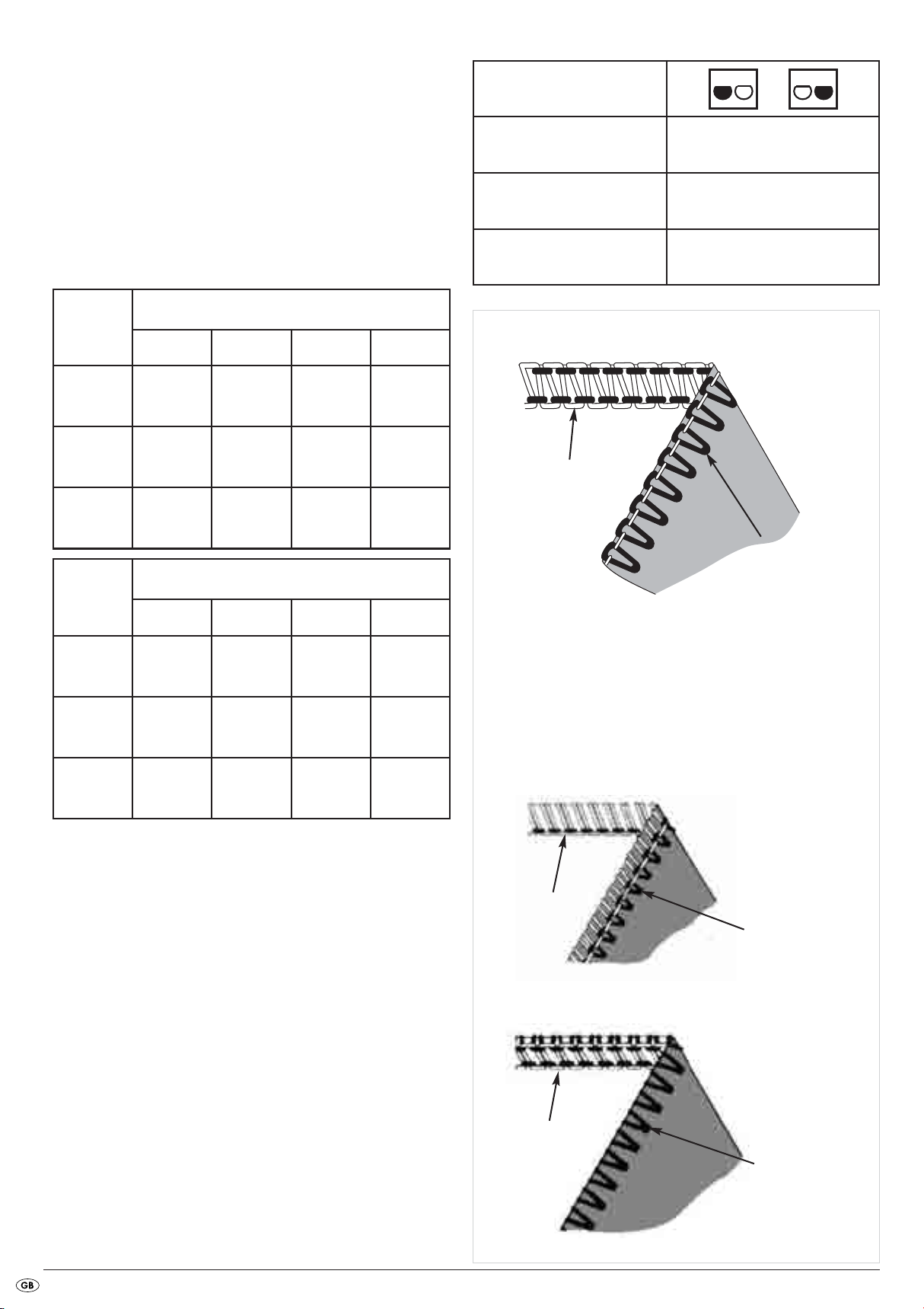

3-thread chain stitch (overlock)

Figure 59 shows you the stitch pattern for this stitch.

This stitch with a needle and 3 threads is used for tidying of normal fabrics

with an overcast stitch.

By changing the needle position you can obtain a narrow or a wide overcast

seam.

Adjust the thread tension selectors r t z u to the appropriate values

(see table) then sew a test seam on the material being used.

Tensioning the thread

Textiles

blue green red yellow

Needle position

Seam width switch

Stitch length

Upper looper element

S

2 - 4

not necessary

light

material

medium-

weight

material

heavy

material

Textiles

light

material

medium-

weight

material

heavy

material

Should the upper looper yarn lie on the underside of the textile (Fig. 60):

• turn the thread tension selector z for the upper looper thread (red) to a

higher number, or ...

• turn the thread tension selector for the lower looper thread u (yellow)

to a lower number.

2.0 - 2.0 1.0

3.0 - 2.0 1.5

3.0 - 3.0 1.5

Tensioning the thread

blue green red yellow

- 2.0 7.0 2.0

- 2.5 6.5 2.5

- 3.5 6.5 2.5

upper looper thread

needle thread

Top

upper looper thread

needle thread

Top

Correct thread tension

lower looper thread

Underside

Fig. 59

Incorrect thread tensions

lower looper thread

Underside

Fig. 60

Should the lower looper yarn lie on the upperside of the textile (Fig. 61):

• turn the thread tension selector for the lower looper thread u (yellow)

to a higher number, or ...

• turn the thread tension selector z for the upper looper thread (red) to a

lower number.

Should the needle thread appear to be too loose (Fig. 62), turn the thread

tension selector for the needle thread (blue r or green t) to a higher

number.

upper looper thread

upper looper thread

- 23 -

needle thread

Top

needle thread

Top

lower looper thread

Underside

Fig. 61

lower looper thread

Underside

Fig. 62

3-thread - flatlock seam

Figure 63 shows you the stitch pattern for this stitch.

This stitch with a needle and 3 threads is used for fell or butt seams and for

ornamental stitches with decorative thread. By changing the needle position

you can obtain a narrow or a wide flatlock seam (flatlock).

Adjust the thread tension selectors r t z u to the appropriate values

(see table) then sew a test seam on the material being used.

Needle position

Seam width switch

Stitch length

S

2 - 4

Textiles

light

material

medium-

weight

material

heavy

material

Textiles

light

material

medium-

weight

material

heavy

material

Tensioning the thread

blue green red yellow

0.5 - 2.5 2.5

0.5 - 2.0 2.0

1.0 - 3.0 3.0

Tensioning the thread

blue green red yellow

- 0 7.0 4.0

- 0.5 7.0 4.0

- 1.0 7.0 4.0

Upper looper element

needle thread

upper looper thread

Top

Incorrect thread tensions

not necessary

Correct thread tension

needle thread

lower looper thread

Underside

Fig. 63

Should the lower looper yarn be too loose (Fig. 64):

• turn the thread tension selector for the lower looper thread u (yellow)

to a higher number, or ...

• turn the thread tension selector for the needle (blue r or green t) to a

lower number.

Should the upper looper yarn be too loose (Fig. 65):

• turn the thread tension selector for the upper looper thread z (red) to a

higher number, or ...

• turn the thread tension selector for the needle (blue r or green t) to a

lower number.

Should the needle yarn be too loose (Fig. 66):

• turn the thread tension selector for the needle (blue r or green t) to a

higher number.

• turn the thread tension selector for the upper looper thread z (red) to a

lower number.

needle thread

upper looper thread

Top

needle thread

upper looper thread

Top

needle thread

upper looper thread

Top

needle thread

lower looper thread

Underside

needle thread

lower looper thread

Underside

needle thread

lower looper thread

Underside

Fig. 64

Fig. 65

Fig. 66

- 24 -

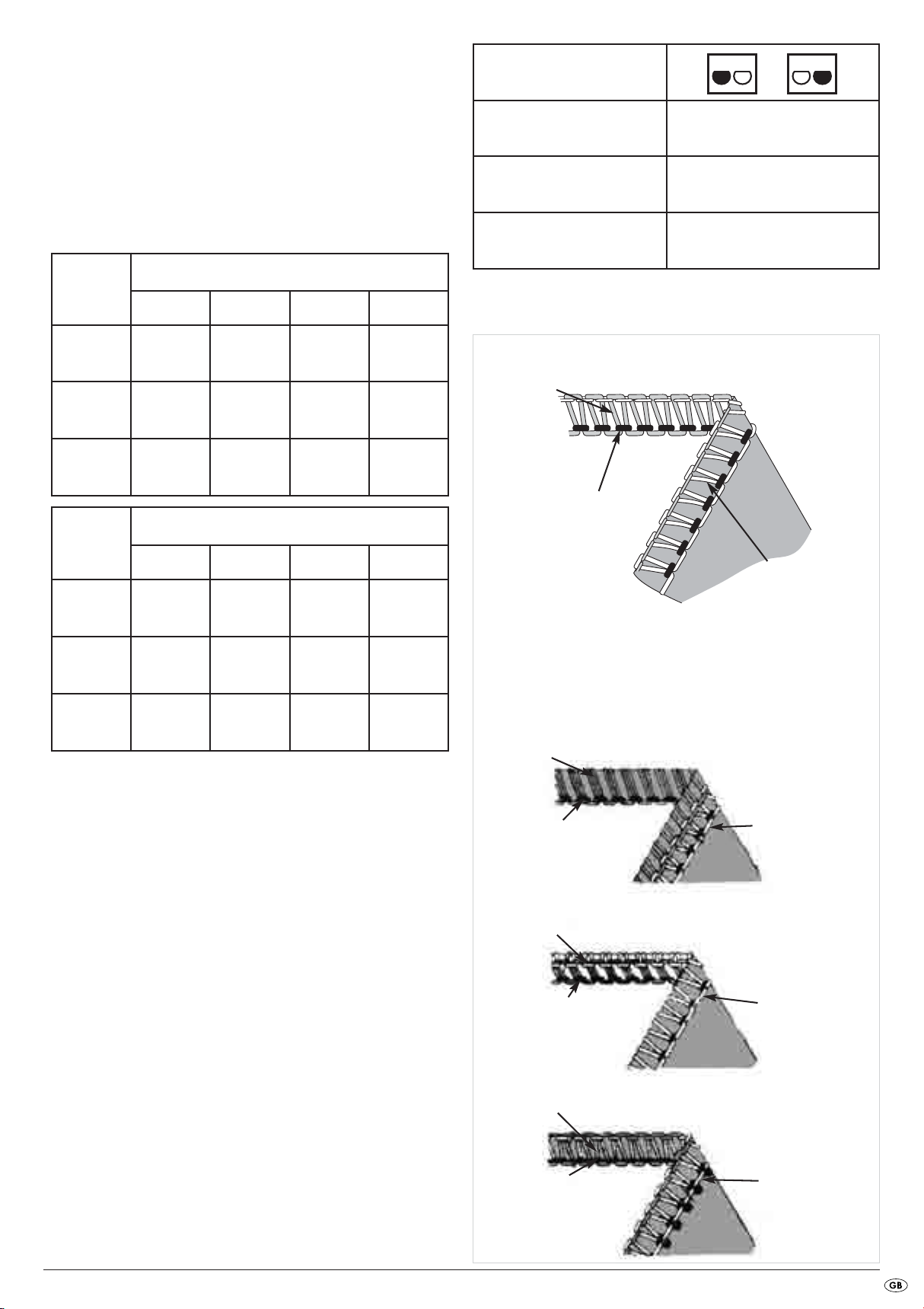

3-thread overcast chain stitch (overlock)

Figure 67 shows you the stitch pattern for this stitch.

This stitch with a needle and 3 threads is used for sewing, for example,

decorative edges.

By changing the needle position you can obtain a narrow or a wide overcast

chain seam.

Adjust the thread tension selectors r t z u to the appropriate values

(see table) then sew a test seam on the material being used.

Needle position

Seam width switch

Stitch length

S

2 - 4

Textiles

light

material

medium-

weight

material

heavy

material

Textiles

light

material

medium-

weight

material

heavy

material

Tensioning the thread

blue green red yellow

2.0 - 0 4.0

3.0 - 0.5 6.5

4.0 - 0.5 7.5

Tensioning the thread

blue green red yellow

- 1.5 0 5.0

- 2.5 1.0 7.0

- 3.0 1.5 8.0

Upper looper element

needle thread

upper looper thread

Top

not necessary

Correct thread tension

needle thread

lower looper thread

Underside

Fig. 67

Incorrect thread tension

Should the upper looper yarn be too loose (Fig. 68):

• turn the thread tension selector for the upper looper thread z (red) to a

higher number.

Should the lower looper yarn be too loose (Fig. 69):

• turn the thread tension selector for the lower looper thread u (yellow)

to a higher number, or ...

• turn the thread tension selector for the upper looper thread z (red) to a

lower number.

Should the needle yarn be too loose (Fig. 70):

• turn the thread tension selector for the needle (blue r or green t) to a

higher number.

• turn the thread tension selector for the upper looper thread z (red) to a

lower number.

needle thread

upper looper thread

Top

needle thread

upper looper thread

Top

needle thread

upper looper thread

Top

Underside

Underside

Underside

needle thread

lower looper thread

Fig. 68

needle thread

lower looper thread

Fig. 69

needle thread

lower looper thread

Fig. 70

- 25 -

3-thread safety stitch, highly elastic, imitated

Figure 71 shows you the stitch pattern for this stitch.

This stitch with 2 needles and 3 threads is ideal for lightweight, extremely

stretchy fabrics such as jersey and spandex.

Adjust the thread tension selectors r t z u to the appropriate values

(see table) then sew a test seam on the material being used.

For this type of stitch insert the upper looper element in the upper looper o.

Needle position

Seam width switch

Stitch length

Upper looper element

S

2 - 4

insert

Tensioning the thread

Textiles

blue green red yellow

light

material

medium-

weight

material

heavy

material

If the lower looper thread is too loose (Fig. 72):

• turn the thread tension selector for the lower looper thread u (yellow)

to a higher number.

2.0 1.5

3.0 2.0

4.0 3.0

Inserting the

upper looper

element

Inserting the

upper looper

element

Inserting the

upper looper

element

0

0.5

1.0

Correct thread tension

Left needle thread

Right needle thread

lower looper thread

Top

Underside

Fig. 71

Incorrect thread tension

Left needle thread

Should the left needle yarn be too loose (Fig. 73):

• turn the thread tension selector for the left needle r (blue) to a higher

number.

Should the right needle yarn be too loose (Fig. 74):

• turn the thread tension selector for the right needle t (green) to a higher

number.

Right needle thread

Top

Left needle thread

Right needle thread

Top

Left needle thread

Right needle thread

Top

lower looper thread

Underside

Fig. 72

lower looper thread

Underside

Fig. 73

lower looper thread

Underside

Fig. 74

- 26 -

4-thread safety stitch, highly elastic, imitated

Figure 75 shows you the stitch pattern for this stitch.

This stitch with 2 needles and 4 threads is ideal for medium to heavy,

stretchy fabrics such as double-knitted materials and swimwear.

It is suitable for combining two materials and neatening the edges at the

same time.

Adjust the thread tension selectors r t z u to the appropriate values

(see table) then sew a test seam on the material being used.

Tensioning the thread

Textiles

blue green red yellow

Needle position

Seam width switch

Stitch length

Upper looper element

upper looper thread

S

2 - 4

not necessary

Correct thread tension

light material

medium-

weight

material

heavy

material

Should the upper looper yarn lie on the underside of the textile (Fig. 76):

• turn the thread tension selector for the upper looper thread z (red) to a

higher number, or ...

• turn the thread tension selector for the lower looper thread u (yellow)

to a lower number.

Should the lower looper yarn lie on the upperside of the textile (Fig. 77):

• turn the thread tension selector for the lower looper thread u (yellow) to a

higher number, or ...

• turn the thread tension selector for the upper looper thread z (red) to

a lower number.

2.5 2.0 2.5 2.0

3.0 2.0 3.0 2.0

4.0 2.5 4.0 2.5

Right needle thread

Left needle thread

Top

upper looper thread

Right needle thread

Left needle thread

upper looper thread

Right needle thread

Left needle thread

upper looper thread

lower looper thread

Underside

Incorrect thread tension

lower looper thread

Top

Top Underside

Underside

lower looper thread

Fig. 75

Fig. 76

Fig. 77

Should the left needle yarn be too loose (Fig. 78):

• turn the thread tension selector for the left needle r (blue) to a higher

number.

Should the right needle yarn be too loose (Fig. 79):

• turn the thread tension selector for the right needle t (green) to a higher

number.

- 27 -

Right needle thread

Left needle thread

Top

upper looper thread

Right needle thread

Left needle thread

Top

lower looper thread

Underside

Fig. 78

lower looper thread

Underside

Fig. 79

Roll hemmings

With this machine you can sew four different roll hemming types. When

sewing roll hemmings, the fabric edge is folded over and provided with an

overlock seam. Lightweight fabrics such as batiste, chiffon, organza and

so on are best for these kinds of seams. Heavy fabrics or stiff materials are

not suitable for roll hemmings.

• Remove the left needle.

• Set the seam width switch d at "R" (Fig. 80).

• Align the support plate of the seam width finger on the marking "R"

on the stitch plate by turning out the seam width adjustment knob f

(Fig. 81).

• Place the dial for the stitch length 5 at "F - 2" (Fig. 82). With this a fine

seam is sewn.

• For roll hemmings use a needle with specification Nr. 14.

Tips:

• For a rolled hem many different combinations of yarn can be used. To

create a particularly beautiful rolled hem (3-thread rolled hem), use a

bushy yarn (bushy polyamid thread/woolly nylon) as the upper looper

yarn and normal yarn for the needle and lower looper. For a 2-thread

rolled hem use bushy yarn for the lower looper thread and normal yarn

for the needle thread.

• At the start of sewing hold the empty thread chain firmly so that they

cannot roll into the seam.

• Subject the material to slight tension in the sewing direction. This will

make the seam more delicate.

• Before cutting the thread chain close to the textile, apply a small drop

of fabric glue to the seam and allow it to dry. Check for colourfastness

on the textile prior to this.

Roll hem

Fig. 81

Fig. 80

Fig. 82

3-thread rolled hem

Figure 83 shows you the stitch pattern for this stitch.

Upper looper

thread

Polyester

Bushy yarn

Adjust the thread tension selectors t z u to the appropriate values

(see table) then sew a test seam on the material being used.

blue green red yellow

- 2.0 7.5 3.0

- 2.0 2.0 2.0

Tensioning the thread

3-thread upper looper overcast rolled hem

Figure 84 shows you the stitch pattern for this stitch. Adjust the thread tension

selectors t z u to the appropriate values (see table) then sew a test

seam on the material being used.

Upper looper

thread

blue green red yellow

Tensioning the thread

Needle position

Seam width switch

Stitch length

Upper looper element

upper looper thread

needle thread

Top

needle thread

R

F - 2

not necessary

lower looper thread

Underside

Fig. 83

Polyester

Bushy yarn

- 2.0 5.5 7.0

- 2.0 0 2.5

upper looper thread

lower looper thread

Top

Underside

Fig. 84

- 28 -

Loading...

Loading...