Page 1

q

SERVICE MANUAL

CODE : 00Z

XEA20SUSME

ELECTRONIC

CASH REGISTER

MODEL

CONTENTS

CHAPTER 1. SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

XE-A20S

(U version)

CHAPTER 2. OPTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

CHAPTER 3. MASTER RESET AND PROGRAM RESET. . . . . . . . . 5

CHAPTER 4. HARDWARE DESCRIPTION. . . . . . . . . . . . . . . . . . . . 6

CHAPTER 5. TEST FUNCTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

CHAPTER 8. CIRCUIT DIAGRAM AND PWB LAYOUT . . . . . . . . . 15

Parts mark ed w ith "!" are important for maintaining the safety of the set. Be sure to replace these parts with specified

ones for maintaining the safety and performance of the set.

SHARP CORPORATION

This document has been pub lished to be used

for after sales service only.

The contents are subject to change without notice.

Page 2

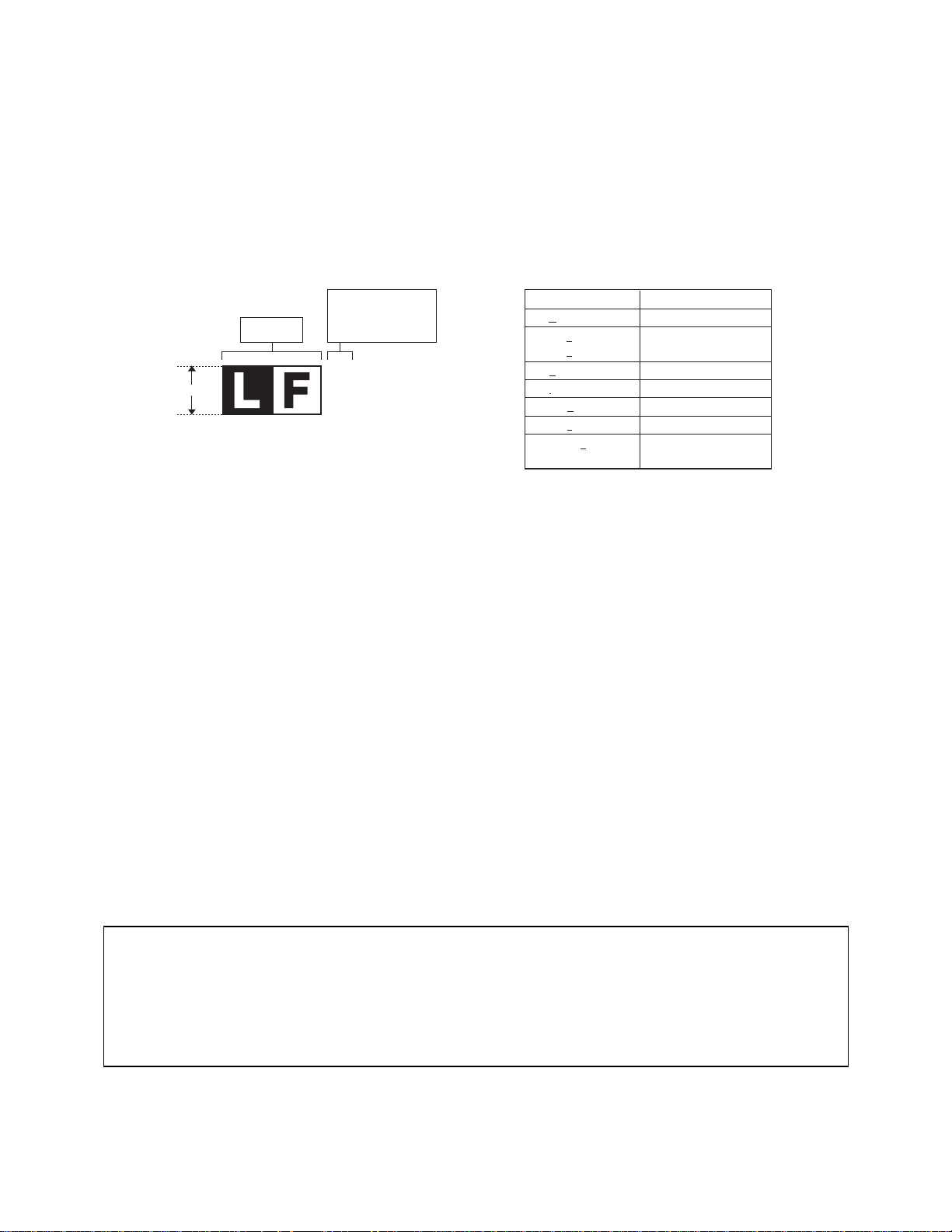

LEAD-FREE SOLDER

The PWB’s of this model employs lead-free solder. The “LF” marks indicated on the PWB’s and the Service Manual mean “Lead-Free” solder.

The alphabet following the LF mark shows the kind of lead-free solder.

Example:

<Solder composition code of lead-free solder>

Solder composition

Sn-Ag-Cu

Sn-Ag-Bi

Sn-Ag-Bi-Cu

Sn-Zn-Bi

Sn-In-Ag-Bi

Sn-Cu-Ni

Sn-Ag-Sb

Bi-Sn-Ag-P

Bi-Sn-Ag

5mm

Lead-Free

Solder composition

code (Refer to the

table at the right.)

a

(1) NOTE FOR THE USE OF LEAD-FREE SOLDER THREAD

When repairing a lead-free solder PWB, use lead-free solder thread. Never use conventional lead solder thread, which may cause a

breakdown or an accident.

Since the melting point of lead-free solder thread is about 40°C higher than that of conventional lead solder thread, the use of the exclusive-use soldering iron is recommendable.

Solder composition code

a

b

z

i

n

s

p

(2) NOTE FOR SOLDERING WORK

Since the melting point of lead-free solder is about 220°C, which is about 40°C higher than that of conventional lead solder, and its soldering capacity is inferior to conventional one, it is apt to keep the soldering iron in contact with the PWB for longer time. This may cause land

separation or may exceed the heat-resistive temperature of components. Use enough care to separate the soldering iron f rom the PWB

when completion of soldering is confirmed.

Since lead-free solder includes a greater quantity of tin, the iron tip may corrode easily. Turn ON/OFF the soldering iron power frequently.

If different-kind solder remains on the soldering iron tip, it is melted together with lead-free solder. To avoid this, clean the soldering iron tip

after completion of soldering work.

If the soldering iron tip is discolored black during soldering work, clean and file the tip with steel wool or a fine filer.

CAUTIONS

THERE IS A RISK OF EXPLOSION IF THE BATTERY

IS REPLACED BY AN INCORRECT TYPE.

PROPERLY DISPOSE OF USED BATTERIES ACCORDING

TO THE INSTRUCTIONS.

XE-A20S LEAD-FREE SOLDER

Page 3

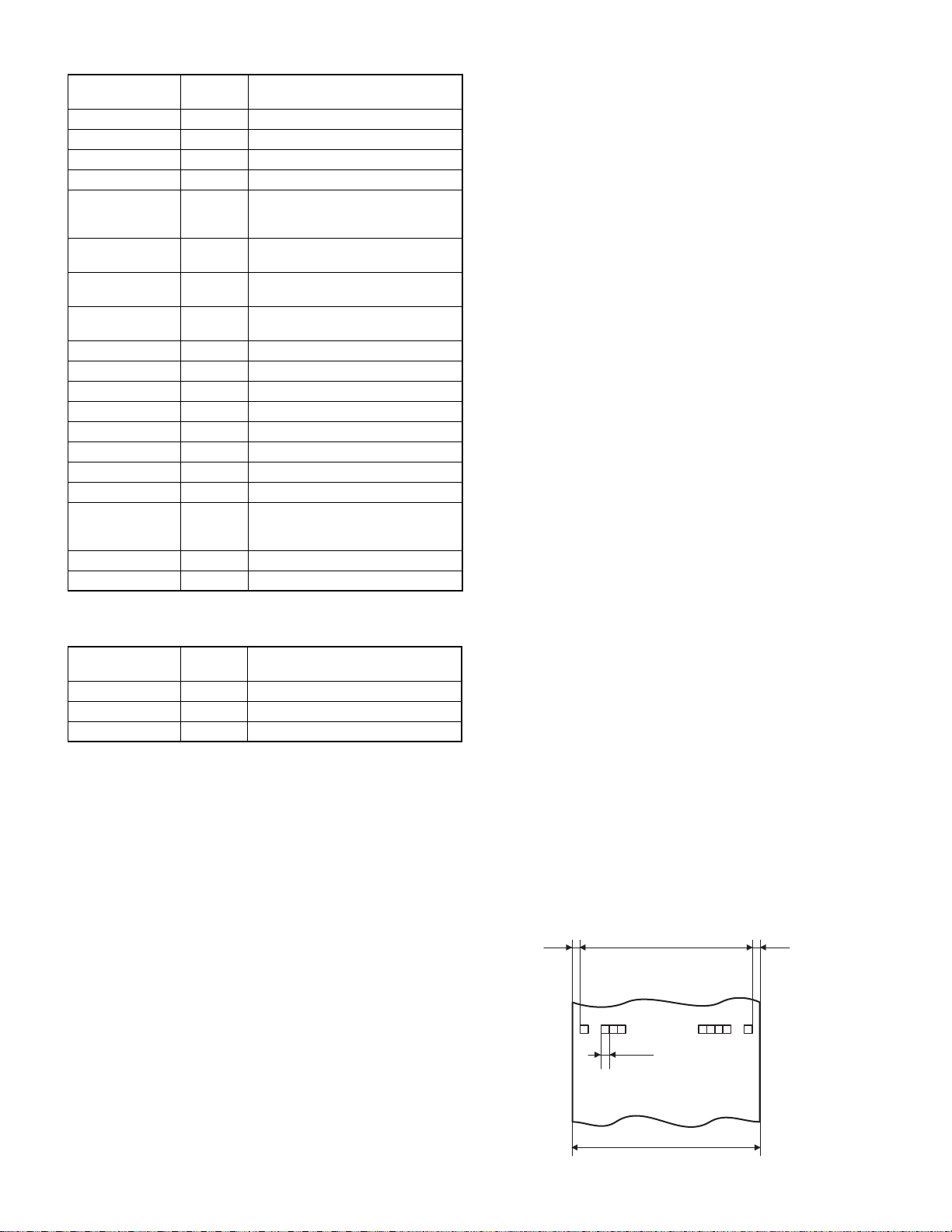

CHAPTER 1. SPECIFICATIONS

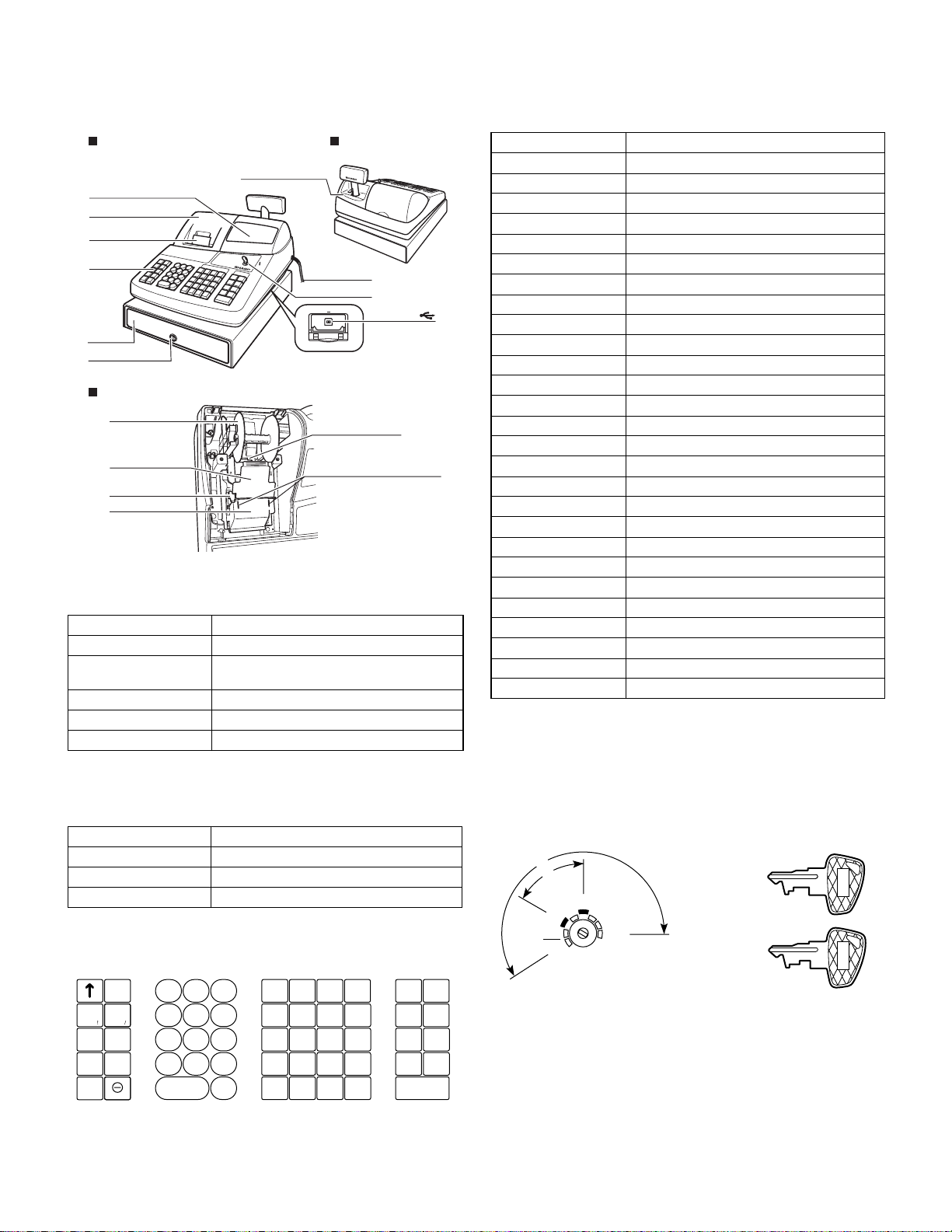

1. APPEARANCE

Front view

Operator display

Printer cover

Receipt paper

Keyboard

Drawer

Drawer lock

Printer

Take-up spool

Print roller arm

Print roller

release rever

Inner cover

Customer display

(Pop-up type)

Rear view

Power cord

Mode switch

USB port

Paper roll cradle

Paper positioning guides

2. RATING

XE-A20S

Weight 16.3lb (7.4kg)

Dimensions 13.0 (W) x 16.9 (D) x 11.0 (H) inches

Power source AC 120V (

Power consumption Stand-by 7.7W, Operating 30W (max.)

Working temperature 32°F to 104°F (0°C~40°C)

(330 (W) x 428 (D) x 280 (H) mm)

10%), 60Hz

m

Key names

KEY TOP DESCRIPTION

2

Paper feed key

RA Received-on account key

RCPT/PO Receipt print/Paid-out key

VOID Void key

ESC Escape key

CONV Conversion key

%1, %2 Percent 1and 2 key

RFND Refund key

-

Discount key

@/FOR Multiplication key

• Decimal point key

CL Clear key

0-9,00 Numeric Keys

PLU/SUB PLU/Subdepartment key

DEPT# Department code entry key

DEPT SHIFT Department shift key

CLK# Clerk code entry key

Dept1-32 Department keys

TAX Tax key

Tax 1 SHIFT Tax 1 shift key

Tax 2 SHIFT Tax 2 shift key

AUTO Automatic sequence key

CHK Check key

CH Charge key

MDSE SBTL Merchandise subtotal key

#/TM/SBTL Non-add code/Time display/Subtotal key

CA/AT/NS Total/Amount tender/Non Sale key

4. MODE SWITCH

3. KEYBOARD

1) KEYBOARD LAYOUT

Type Normal keyboard

Key position Std/Max 53keys

Key pitch 19 (W) x 19 (H) mm

Key layout Fixed type

2) KEY LIST

Keyboard layout

PLU

/SUB

4

3

2

1

RCPT

/PO

VOID

DC

ESC

BS

CONV

NUMBER

Ð

RFND

%1RA

%2

SPACE

SHIFT

@/

FOR

CL

¥

789

456

123

0

00

Note: The small characters on the bottom or lower right in each key

indicates functions or characters which can be used for character

entries for text programming.

DEPT

DEPT

A

20

B

8

19

C

7

18

D

6

17

E

5

CLK

#

SHIFT

#

F

24

G

23

H

22

I

21

J

P

K

28

32

L

12

Q

16

27

31

M

11

R

15

26

30

N

10

S

14

25

29

O

9

T

13

AUTO

TAX

X

U

TAX2

TAX1

SHIFT

SHIFT

Y

V

CHK

CH

Z

W

MDSE

#/TM

SBTL

SBTL

CA/AT/NS

XE-A20S SPECIFICATIONS

1) LAYOUT

• Rotary type

MA

OP

REG

OP

MGR

X/Z

X

OFF

VOID

PGM

1/Z1

X2/Z2

The mode switch can be operated by inserting one of the two supplied

mode keys - manager (MA) and operator (OP) keys. These keys can be

inserted or removed only in the “REG” or “OFF” position.

– 1 –

Manager key (MA)

Operator key (OP)

MA

OP

Page 4

The mode switch has these settings:

OFF: This mode locks all register operations. (AC power turns off.)

No change occurs to register data.

OP X/Z: To take individual clerk X or Z reports, and to take flash

reports.

It can be used to toggle receipt state “ON” and “OFF” by

pressing he [RCPT/PO] key.

REG: For entering sales.

PGM: To program various items.

VOID

: Enters into the void mode. This mode allows correction after

finalizing a transaction.

MGR: For manager’s entries. The manager can use this mode for an

override entry.

X1/Z1: To take the X/Z report for various daily totals.

X2/Z2: To take the X/Z report for periodic (weekly or monthly)

consolidation.

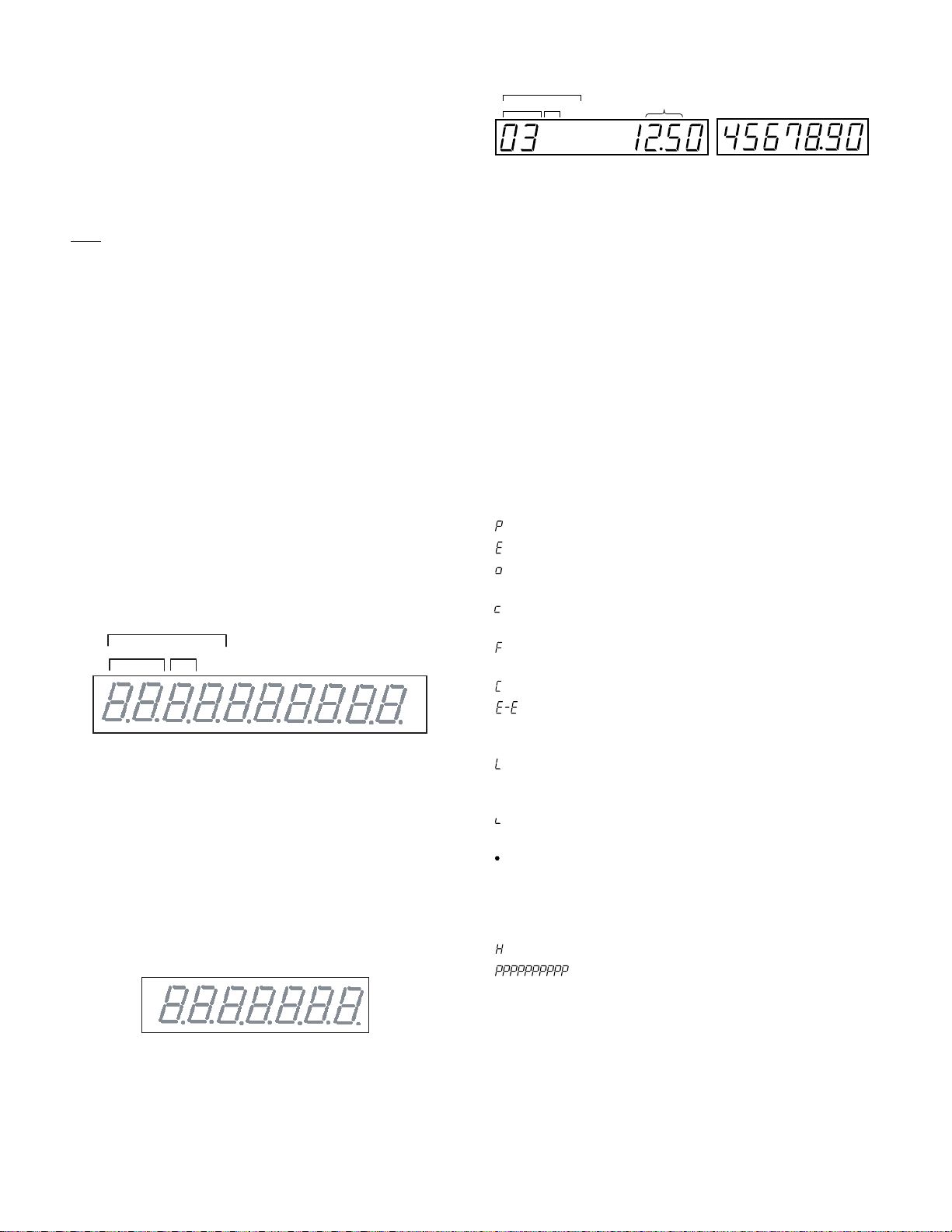

5. DISPLAY

1) OPERATOR DISPLAY

Display device: LED

Number of line: 1 line

Number of positions: 10 digits

Color of display: Yellow / Green

Character form: 7 segment

Character size: Numeric 14 (H) x 8 (W) mm

Layout:

PLU/SUB

REPEAT

DEPT

RCPT

OFF

2) CUSTOMER DISPLAY

Display device: LED

Number of line: 1 line

Number of positions: 7 digits

Color of display: Yellow / Green

Style: Pop up type

Character form: 7 segment

Character size: 14mm (H) x 8mm (W)

Layout:

DC SHIFT NUMBER

Operator display

PLU/SUB

DEPT REPEAT

RCPT

OFF

DC

Clerk code

NUMBERSHIFT

Customer display

(Pop-up type)

Amount: Appears in the far-right eight (max.) positions. When the

amount is negative, the minus symbol “-” appears before the

amount.

Number of repeats for repetitive registrations:

The number of repeats is displayed, starting at “2” and incremental with each repeat. When you have registered ten

times, the display will show “0.” (2

3

3

.....

9 3 0 3 1 3 2

Receipt function status:

The indicator “_” appears in the RCPT OFF position when

the receipt function is in the OFF status.

Time: Appears in the far-right six positions (hour-minute - ”A” or

hour-minute - ”P”) in the OP X/Z, REG, or MGR mode. “A” is

displayed in the morning (AM), and “P” in the afternoon

(PM). In the REG or MGR mode, press the [#/TM/SBTL] key

to display the time.

Machine state symbols

: Appears during program ming.

: Appears when an error is detected.

: Appears when the subtotal is displayed or when the amount

tendered is smaller than the sales amount.

: Appears when the [CONV] key is pressed to calculate a su bto-

tal in foreign currency.

: Appears when a transaction is finalized by pressing the [CA/AT/

NS], [CHK] or [CH] key.

: Appears when the change due amount is displayed.

: May appear in the far-left three positions at the timing of key

entry when the electronic journal (EJ) memory is full. (Depending on programming.)

: Appears when the voltage of the installed batteries is under the

required level. You must replace with new ones within two days

to avoid loss of memory.

:

Appears when the batteries are not installed, or the installed

batteries are dead. You must replace with new ones immediately.

: May appear right below the eighth and ninth places at the timing

of finalization of a transaction when the electronic journal (EJ)

memory is nearly full.

Also appears right below the tenth place when power save

mode is effective.

: Appears when the print roller arm is not locked.

: Appears w hen the paper is not installed or paper is out.

...

)

XE-A20S SPECIFICATIONS

– 2 –

Page 5

Segment

Display

position

Amount 1-8

Minus sign 2-10 -: Floating

Error 8-10 Exx :xx = error code

PGM Mode 10 P

CASH, CHECK,

CHARGE

SUB TOTAL/

short tender

Change 10 C: L i g ht u p w h e n e ve r t h e c hange

Currency

Conversion

Department 9-10 No zero-suppressed

PLU 7-10 No zero-suppressed

Repeat 8 Endless count, starting from 2.

Receipt OFF 9 _

DC _: Double size character entry status

SHIFT _: Shift character entry status

NUMBER _: Number character entry status

Clerk No. 2, 3 -xx-: clerk number

EJ FULL 8-10 E-E: Light up when EJ memory is

Low Battery 10 L:

No Battery 10

10 F: Light up when a registration is

10 o

10 c : Light up whenever the foreign

finalized by depressing CASH,

CHECK, CHARGE key

due amount appears in the display.

amount appears in the display.

FULL at the timing of key entry

(by PGM selection).

:

L

Description

Decimal Point

Display

position

Decimal point 7-1

TAB 4-1

EJ near full 8, 9 (by PGM selection)

Description

6. PRINTER

1) Printer

• Part number : M-T53II

• No. of station : 1 (Receipt or journal)

• Validation : No.

• Printing system : Line thermal

• No. of dot : 288 dots

• Dot pitch : Horizontal 0.167mm

Vertical 0.167mm

• Font : 10 dots (W) x 24 dots (H)

• Printing capacity : max. 24 characters/Line

• Character size : 1.67mm (W) x 4.00mm (H) at 10 x 24 dots

• Print pitch : Column distance 2.0mm

Row distance 5.21mm

• Print speed : Approximate 60mm/s (Approximate 12 l/s)

• Paper feed speed : Approximate 60mm/s (Approximate 12 l/s)

• (Manual feed) : Approximate 60mm/s (Approximate 12 l/s)

• Reliability : Mechanism LIFE 6 million lines used to

high quality thermal paper

• Paper end sensor : Set up

• Cutter : Manual Cutter

• Near end sensor : No

2) Paper

• Paper roll dimension: 2.25 m 0.02 inch

57.5

0.5mm in width

m

Max. 3.15 inch

Max. 80mm in diameter

• Paper quality: High-quality thermal paper

paper thickness: 0.06 to 0.08mm

Nihon seisi thermal paper TF50KS-E2C

KANZAN thermal paper: KF50

KSP thermal paper: P350

3) Logo stamp

• No

4) Printing area

Number of thermal head heater elements 288 dots

XE-A20S SPECIFICATIONS

– 3 –

(4.75) (4.75)48 (288 dots)

print area

(max.24 characters)

0.167

57.5±0.5

(Paper dimension)

(units : mm)

Page 6

7. DRAWER

8. BATTERY

[OUTLINE]

• Standard equipment: Yes (1)

• Max. number of additional drawers: 0

• The drawer consists of:

1) Drawer box (outer case) and drawer

2) Money case

3) Coin case

4) Lock (attached to the drawer)

[SPECIFICATION]

1) DRAWER BOX AND DRAWER

• Model name of the drawer box : SK-415

• Size : 330 (W) x 418 (D) x 98 (H) mm

• Material : Metal

• Bell :

• Release lever : Standard equipment:

• Drawer open sensor :

• Separation from the main unit :

13 (W) x 16.5 (D) x 3.9 (H) inch

-

locate on the bottom

-

-

2) MONEY CASE

Separation from the drawer Disallowed

Separation of the bill compartments from the

coin compartments

Bill separator

Number of compartments 4B/5C

Layout:

4B/5C

Allowed

-

1) MEMORY BACK UP BATTERY

For memory back up, (3) dry AA batteries are needed.

1. Memory holding time:

Approx. 1 year after NEW dry batteries are installed.

2. Battery replacement method:

When the low battery symbol “L” lights up, replace the batteries (3

AA) by the following method;

1) Power on the ECR.

2) Mode switch turn to “REG” mode.

3) Remove the OLD dry batteries (3 pieces).

4) Insert the NEW dry batteries (3 pieces).

5) Confirm the low battery symbol “L” is off.

2) LOW BATTERY

Low battery indication will appear on the left side of display when the

battery voltage is low.

CASE 1: When machine is sitting idle or after finalization of a transaction.

The machine will always indicate the low battery condition.

CASE 2: During any numeric or item key entry.

Battery condition will not appear.

Except when the power is restored after a power failure, t he low

battery condition will appear on the display only when the battery

is low and the indicator will disapear after any key entry.

[Display sample]

“ 0.00”: Battery is OK.

“L 0.00”: Low battery (You have to change the batteries.)

“

0.00”: No battery (You have to change the batteries immediately.)

L

After finalization

“F 12.34”: Battery is OK.

“L 12.34”: Low battery. (“L” indicate instead of “F”.)

“

12.34”: No battery. (“L” indicate instead of “F”.)

L

Note: “NO BATTERY”: When “NO BATTERY” is displayed, the master

reset is executed upon "POWER ON" after

"POWER OFF" or power failure.

3) LOCK (LOCK KEY : LKGIM7331BHZZ)

Location of the lock: Front

Method of locking and unlocking:

To lock, insert the drawer lock key into the lock

and turn it 90 degrees counter clockwise.

To unlock, insert the drawer lock key and turn it 90

degrees clockwise.

Key No: SK1-1

k

c

o

SK1-1

L

k

c

o

l

n

u

XE-A20S SPECIFICATIONS

– 4 –

Page 7

CHAPTER 2. OPTIONS

1. OPTIONS (NONE)

2. SERVICE TOOL

NO NAME PARTS CODE

1 USB cable For connection between ECR and PC

PRICE

RANK

DESCRIPTION

3. SUPPLIES

NO NAME PARTS CODE

1 Thermal roll paper

TPAPR6656RC05

PRICE

RANK

BA 5 ROLLS/PACK

DESCRIPTION

CHAPTER 3. MASTER RESET AND PROGRAM RESET

1. MASTER RESETTING

Master resetting clears the entire memory and resumes default values.

Master resetting can be accomplished by using the following procedure:

Procedure: 1) Plug in the AC cord to the wall outlet.

2) Set the mode switch to REG position.

3) Remove the 3 AA batteries.

4) Unplug the AC cord from the wall outlet.

5) Wait over 1 minute for discharging.

6) Plug in the AC cord to the wall outlet.

7) Install the 3 AA batteries.

Note: The master reset can also be accomplish ed in the f ollowi ng case.

In case a power failure occurs when the machine has no batteries

installed, the maste r reset ope ration i s automat ically per formed af ter

the power has bee n restored.

When power failure occurs with no batteries installed in the the

machine, all memory is l ost and t he machine does not work pro perly

after power is restored, thus req uir ing the master rese t operat ion. )

2. PROGRAM RESETTING

(INITIALIZATION)

This resetting resumes the initial program without clearing memory.

This resetting can be operated at below sequence in PGM mode.

Procedure: 1) Unplug the AC cord from the wall outlet.

2) W ait over 1 muinite for discharging.

3) S et the mode switch to the PGM position.

4) W hile holding down the FEED key,

plugin the AC cord to the wall outlet.

Note: In case a power failure occurs when the machine has no batter-

ies installed, the master reset operation is automatically performed after the power has been restored.

XE-A20S OPTIONS

– 5 –

Page 8

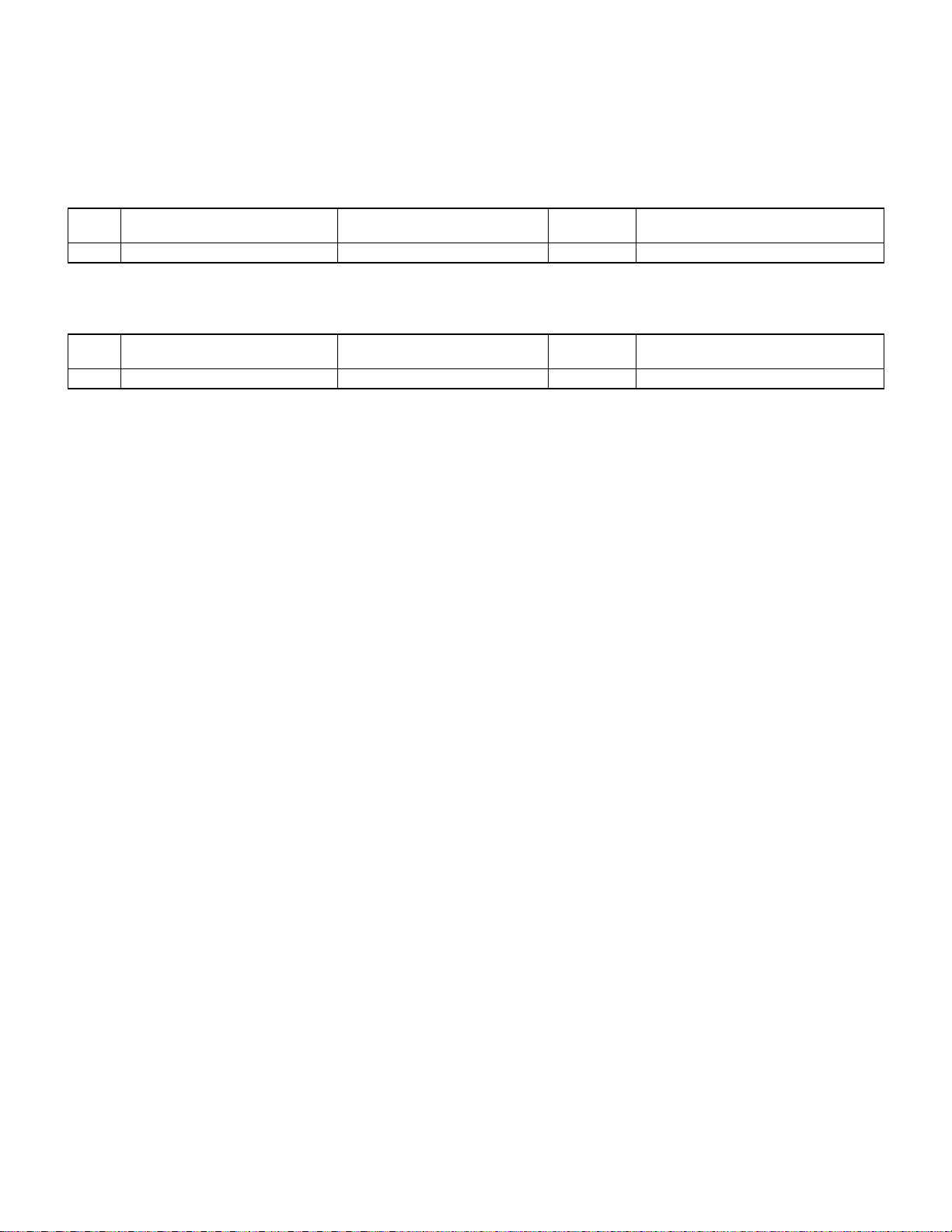

CHAPTER 4. HARDWARE DESCRIPTION

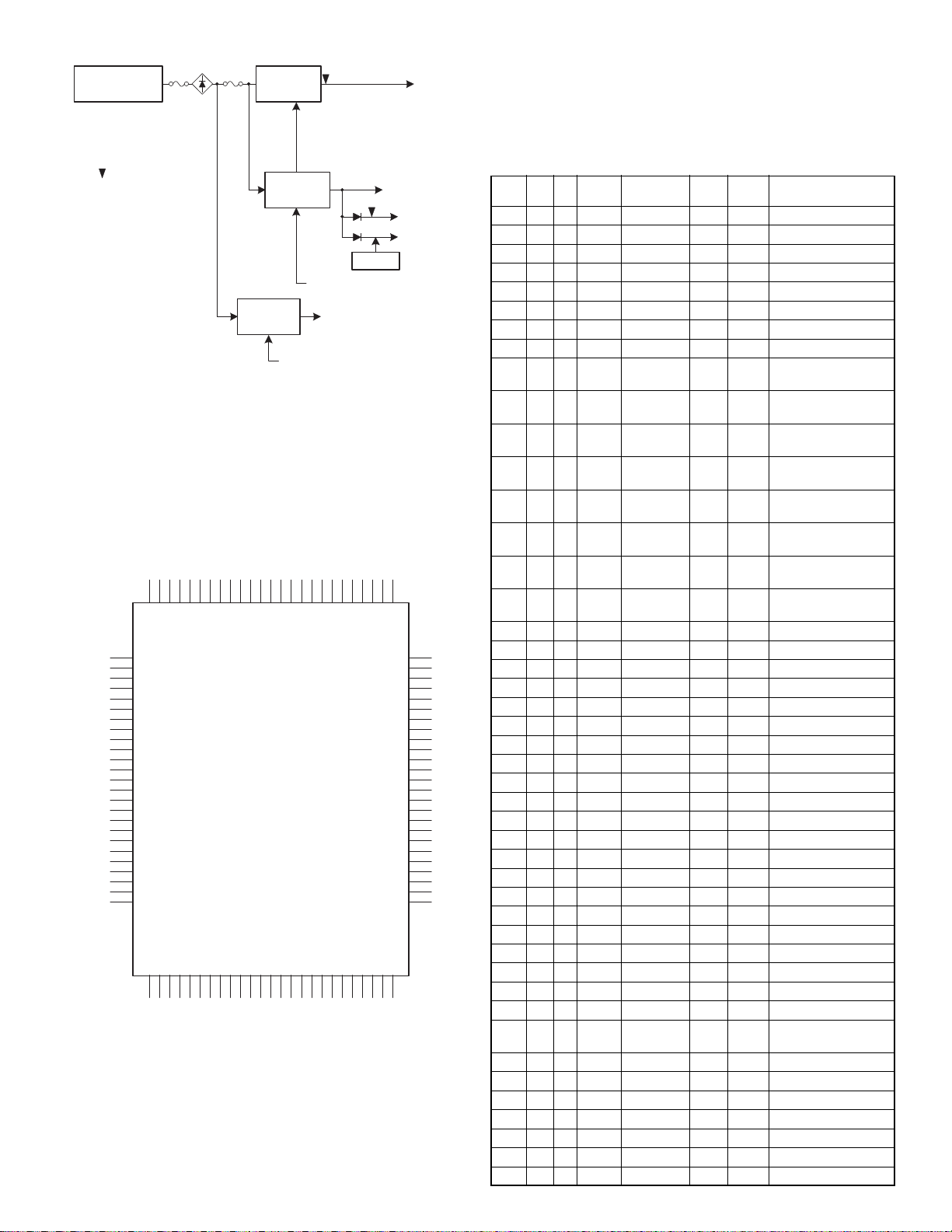

1. HARDWARE BLOCK DIAGRAM

POWER SUPPLY

CPU

Data bus

Address

bus

DRIVER , SENSOR

ROM : 256K Byte

RAM : 20K Byte

STANDARD

DRAWER.

RAM

128K Byte

PRINTER

M-T53II

PAPER TAKE

UP MOTOR

4 to 16

DECORDER

KEY SCAN SIGNAL

KEY RETURN SIGNAL

M66291GP

POPUP

Seg. DRIVER

FRONT

LED

Dig. DRIVER

KEYBOARD

MODE SWITCH

USB TYPE B

CPU : RENESAS 30624 (MASK) (ROM 256KB RAM 20KB)

EXTERNAL MEMORY : RAM 128 KB

PRINTER : EPSON M-T53II 1SHEET

USB CONTROLLER : RENESAS M66291FP

XE-A20S HARDWARE DESCRIPTION

– 6 –

Page 9

TRANSFORMER

/

PQ1CG2032

/POFF detect point

PQ1CG2032

ON/OFF Control (MODE SW)

LM2574

+ Tr.

VH, VP (8V)

PRINTER HEAD, MOTOR

PAPER TAKEUP MOTOR

ON/OFF Control (MODE SW,

/POFF, CPU P105)

2. DESCRIPTION OF MAIN LSI’S

2-1. CPU (M30624MGA)

1) Pin configuration

D6

D5D4D3

D2

D1

D0

DTS

LATCH

P105

P104

P103

Vref

P101

GND

TH

VDD

VDD

P97

9998979695949392919089888786858483828180797877

P96

P95

P94

P93

P92

P91

P90

VDD

GND

XCIN

XCOUT

/RESET

XOUT

GND

XIN

VDD

VDD

CTCRL

/FRDY

P-OFF

MOTOR

BUZ1

P77

P76

P75

100

AN4

AN3

AN2

AN1

AN0

SIN4

VREF

AVSS

AVCC

1

SOUT4

2

CLK4

3

TB4IN

4

TB3IN

5

SOUT3

6

SIN3

7

CLK3

8

BYTE

9

CNVss

10

XCIN

11

XCOUT

12

/RESET

13

XOUT

14

Vss

15

XIN

16

Vcc

17

NMI

18

INT2

19

INT1

20

INT0

21

TA4IN/U

22

TA4OUT/U

23

TB3IN

24

TBEOUT

25

TA2INW

TA2OUTW

TA1IN/V

TA1OUT/V

TB5IN

26272829303132333435363738394041424344454647484950

P74

P73

P71

CLK

TB5OUT

TXD1

RXD1

P67

P66

DAT

M30624MGA

CLK1

CLKS1

P64

/FRES

AN5

TXD0

FSD

AN7

AN6

RXD0

CLK0

FRD

FSCK

D0

/RTS0

DR1

D1

/RDY

/RDY

D2

ALE

HOLD

/HOLD

VCC

/HLDA

NC

D6

D5D4D3

CBCLK

/RD

NC

/RD

D7

D7

/BHE

NC

V0 24V

Drawer

VLED 5.7V

VCC 5V

VDD 5V

Battery

PH1

P13

P12

P11

P10

76

D9

D8

D12

D11

D10

/WR

/WR

VSS

VCC

/CS3

/CS3

D13

D14

D15

A10

A11

A12

A13

A14

A15

A16

A17

A18

A19

/CS2

/RAS1

A0

A1

A2

A3

A4

A5

A6

A7

A8

A9

/CS1

BUSY

PH2

75

PH3

74

PH4

73

A0

72

A1

71

A2

70

69

A3

68

A4

67

A5

66

A6

65

A7

64

GND

63

A8

62

VDD

61

A9

A10

60

50

A11

A12

58

A13

57

A14

56

A15

55

A16

54

A17

53

NC

52

NC

51

/CS0

/ROS1

XE-A20S HARDWARE DESCRIPTION

2) Pin description

M16C/62 PORT

MEMORY SPACE : MEMORY PROCE SS O R MO DE

(NORMAL MODE)

PROCESSOR MODE : MEMORY PROCESSOR MODE

It is used by (SEPARATE BUS 8bit Width)

PIN

PORT

No.

P00 88 I/O D0 D0 OUT L

P01 87 I/O D1 D1 OUT L

P02 86 I/O D2 D2 OUT L

P03 85 I/O D3 D3 OUT L

P04 84 I/O D4 D4 OUT L

P05 83 I/O D5 D5 OUT L

P06 82 I/O D6 D6 OUT L

P07 81 I/O D7 D7 OUT L

P10 80 O P10 KST0 L IN KEY DISPLA Y

P11 79 O P11 KST1 L IN KEY DISPLA Y

P12 78 O P12 KST2 L IN KEY DISPLA Y

P13 77 O P13 KST3 L IN KEY DISPLA Y

P14 76 O P14 IN1 L OUT L PAPER FEED

P15 75 O P15 IN2 L OUT L PAPER FEED

P16 74 O P16 ENA1 L OUT L PAPER FEED

P17 73 O P17 ENA2 L OUT L PAPER FEED

P20 72 O A0 A0 OUT L

P21 71 O A1 A1 OUT L

P22 70 O A2 A2 OUT L

P23 69 O A3 A3 OUT L

P24 68 O A4 A4 OUT L

P25 67 O A5 A5 OUT L

P26 66 O A6 A6 OUT L

P27 65 O A7 A7 OUT L

P30 63 O A8 A8 OUT L

P31 61 O A9 A9 OUT L

P32 60 O A10 A10 OUT L

P33 59 O A11 A11 OUT L

P34 58 O A12 A12 OUT L

P35 57 O A13 A13 OUT L

P36 56 O A14 A14 OUT L

P37 55 O A15 A15 OUT L

P40 54 O A16 A16 OUT L

P41 53 O A17 A17 OUT L

P42 52 O A18 A18 OUT L

P43 51 O A19 A19 OUT L

P44 50 O /CS0 (NU) L OUT L

P45 49 O /CS1 /CS1 OUT L USB

P46 48 O /CS2 /CS2 OUT L SRAM

P47 47 O /CS3 /CS3 OUT L SEGMENT LATCH

P50 46 O /WR /WR OUT L

P51 45 O /BHE (NU) OUT L

P52 44 O / RD /RD OUT L

P53 43 O BCLK BCLK OUT L

P54 42 O /HLDA (NU) OUT L

– 7 –

I/O

Pin

name

Signal

name

Initial

value

OFF

MODE

(4 to 16)

(4 to 16)

(4 to 16)

(4 to 16)

MOTOR

MOTOR

MOTOR

MOTOR

CONTROLLER

Function

Page 10

PORT

PIN

No.

I/O

Pin

name

Signal

name

Initial

value

OFF

MODE

Function

P55 41 I /HOLD /EPM IN

P5640O ALE (NU) OUT L

P57 39 I /RDY /RDY IN

P60 38 O P60 DR1 L OUT L DRAWER 1

DRIVE SIGNAL

P6137O P61 (NU) L OUT L

P6236O P62 (NU) L OUT L

P63 35 O P63 /USBRST L OUT L USB CONTR O LLER

RESET

P64 34 O P64 /BUSY L O UT L BOOT BUSY

P65 33 I P65 SCLK IN BOOT SCLK

P66 32 I P66 RXD IN BOOT RXD

P6731O P67 TXD L OUT LBOOT TXD

P70 30 O TX D2 DAT H OUT L PRINTER DATA OUT

P7123O P71 (NU) L OUT L

P72 28 O CLK2 CLK L OUT L PRINTER CLOCK

P7327O P73 DR2 L OUT LDRAWER

2 DRIVE SIGNAL

P7426O P74 (NU) L OUT L

P7525O P75 (NU) L OUT L

P7624O P76 (NU) L OUT L

P7723O P77

/EPM CTRL

HOUT L

P80 22 O P80 BUZZER L OUT L BUZZER

P81 21 O P81 MOTOR L OUT L PAPER TAKE UP

MOTOR

P82 20 I /INT0 POFF IN

P83 19 I /INT1

/DREQUSB

POWER INTERRUPT

IN USB DMA REQUEST

P84 18 I /INT2 /INTUSB IN USB INTERRUPT

P85 17 I /NMI (NU) IN

P8611O

XCOUT

XCOUT 32.768kHz

P87 10 I XCIN XCIN 32.768kHz

P90 7 I P90 P90 IN KEY IN

P91 6 I P91 P91 IN KEY IN

P92 5 I P92 P92 IN KEY IN

P93 4 I P93 P93 IN KEY IN

P94 3 I P94 P94 IN KEY IN

P95 2 I P95 P95 IN KEY IN

P96 1 I P96 P96 IN KEY IN

100

P97

P100

I P97 P97 IN KEY IN

97 I AN0 P100 I N HEAD TEMPERA-

TURE MONITOR

P101

95 I AN1 P101 IN HEAD VOLTAGE

MONITOR

P102

94 O P102 /STB2 H OUT L PRINTER/STB2

P103

93 I AN3 VBAT IN BATTE R Y VO LTAG E

P104

92 O P104 (NU) L O UT L

P105

91 O P105 VPON L OUT L PRINTER HEAD

POWER

P106

90 O P106 /LAT H OUT L PRINTER DATA

LATCH

P107

89 O P107 /STB1 H OUT L PRINTER /STB1

<Power supply/CONTROL pins>

PORT

PIN

No.

BYTE 8 I BYTE Connected to VDD

CNVss 9 I CNVss NORMAL: L

/RESET 12 I /RESET

Xout 13 O X out OPEN

Vss 14 Vss Connected to GND

Xin 15 I Xin Connected to Spectram diffusion IC

Vcc 16 Vcc Connected to VDD

Vcc 62 Vcc Connected to VDD

Vss 64 Vss Connected to GND

AVss 96 AVss Connected to GND

Vref 98 Vref Connected to VDD

AVcc 99 AVcc Connected to VDD

I/O

Signal

name

Function

Launch BOOT: H

3. CLOCK GENERATOR

1) CPU

15

XIN

13

XOUT

CPU

XCOUT

XCIN

Two oscillators are connected to the CPU.

The basic clock X2 is supplied from a 12MHz oscillator.

If the CPU was not operating properly, the signal does not appear on

this line in most cases.

The sub-clock X1 generates 32.768KHz which is primarily used to

update the internal RTC (real time clock).

During the standby mode, it keeps oscillating to update the clock and

monitoring the power recovery.

12MHz

R62

11

10

C41

18P

330

X2

32.768KHz

C42

27P

4. RESET CIRCUIT

VDD

IC

R

C

12

CPU

/RESET

MODE SWITCH

SRV' position

R

VDD

R

C

S-80928ANMP

(1) When the mode switch is placed in the “SRV” position, the reset

signal is sent to the CPU to reset the hardware.

(2) When VDD

(S-80928ANMP)

XE-A20S HARDWARE DESCRIPTION

– 8 –

2.8V, a reset signal is sent from the reset IC.

t

Page 11

5. P-OFF CIRCUIT

I/O

R92

2.7K

C14

1uF/50V

ZD3

MTZJ5.1B

R93

9.1KG

R103

3.9K

R17

0

BA10393

3

2

IC12A

The P-OFF signal detects two signals by two comparators and sent to

the CPU.

V0 (24V) signal: If the power voltage V0 (24V) falls bellow the specified

level, the P-OFF signal is driver to LOW by the comparator IC12A.

VLED signal: If the LED/Logic power voltage VLED falls below the

specified level, the P-OFF signal is driven to LOW by

the comparator IC12B.

R19

56K

8

1

4

P-OFF

VCC VLED

R95

2.7K

BA10393

5

6

IC12B

8

7

C75

0.1uF

/POFF

4

6. MEMORY CIRCUIT

1) Address map

00000h

00400h

05400h

06000h

08000h

28000h

40000h

C0000h

2) RAM control

CPU internal RAM

20kbytes

Segment latch address

External S-RAM : 128kbytes

(128kbytes area)

CPU internal ROM

256kbytes

Power supply circuit

or

Dry battery

/CS3 area

06000h - 07FFFh

/CS2 area

08000h - 27FFFh

/CS1 area

28000h - 3FFFFh

7. PRINTER CONTROL CIRCUIT

1) Paper feed motor circuit

CPU

P14

P15

P16

P17

VCC

IC7

LB1838M

Stepping motor control

The 2-phase, bi-polar stepping motor is driven at a constant voltage by

LB1838M (made by SANYO).

1 step: 0.087mm

1 dot: 2 steps

CPU port

No. CPU port Signal used

76 P14 IN1

75 P15 IN2

74 P16 ENA1

73 P17 ENA2

Drive step

Driver IC input

(CPU output)

STEP

IN1 IN2 ENA1 ENA2

1LLH H H H L L

2HLHHLHHL

3HHH H L L H H

4LHH H H L L H

2) Print circuit

Thermal head configura tion

Figure on next page shows the circuit of the thermal head consists of

heating elements and head drivers which drives and controls the heating elements.

The serial print data input through the DATA IN (DAT) is transferred to

the shift register synchronizing with the CLOCK (CLK) and stored in the

latch register by the LATCH (LAT) signal.

The head conduction signals (print commands 1 ~ 6) turn the gate on to

conduct the heating element corresponding to the print data.

VP

10uF/50V

A

/A

B

/B

MOTOR

Motor drive signal

A

(OUT1)B(OUT3)/A(OUT2)/B(OUT4)

CPU

A0-A16

D0-7

/CS2

/RD

/WR

VDD

VCC

VCC

10K

10K

A0-A16

D0-7

10K

/CS2

150pF

/WR

/RD

CS2

A0-A16

I/O0-7

/CS1

/OE

/WE

VCC

S-RAM

128K byte

IC

VDD

0.1M

11

XE-A20S HARDWARE DESCRIPTION

– 9 –

Page 12

Thermal head block diagram

3

0

Dot #1Dot #288

5,6,18,19

9,10,14,15

11

13

Latch register

Shift register

7

16

17

12

Connector

Thermal head strobe terminals

STB No. Dot No. Number of dots

1 1 ~ 144 144

2 145 ~ 288 144

VP

GND

STB1

STB2

LAT

CLK

DAT

VCC

9. DRAWER DRIVE CIRCUIT

CN

VO

F6

250V

A C

D6

1SS133

VDR

R77

1.8K

T500mA/

C59

DR1

1

+

10uF/50V

C66673

B

FB1

C

Q4

2SD2212

E

C58

0.1uF

C

1N4002

A

D1A1

FB2

C66673

5045-

When the DR1 signal from the CPU is HIGH, Q4 is turned on to operate

the solenoid.

10. BUZZER DRIVE CIRCUIT

3

2

1

8. PAPER TAKE UP MOTOR DRIVE CIRCUIT

VH

CPU

TA4IN/U

MOTOR

(21pin)

R76

C51

CN2

Q1

1K

2SD2212

M

MOTOR

When the MOTOR signal from the CPU is HIGH, Q1 is turned on to

operate the motor.

11. KEYBOARD CIRCUIT

P10-13

P10-13

P10-13

HC138

HC138

/S0-7

/S8-9

/S0-9

Key

Matrix

/S0-7

Mode

Switch

CPU

TA4OUT/U

22pin

1.5k

R58

BZ

BZ

When the pulse signal (about 4KHz) is generated from the CPU, the

buzzer sounds.

/S0-9

/S1

Paper

feed key

/S3 /S4

Head up

sensor

Paper end

sensor

/S9

RS232

signal

/CI

/S0 - 9

P92-97

P91

74HC374

a,b,c,d,e,f,g,dp

A',B',C',D',E',F',G',DP'

CPU

P90

P91

D0-7

/CS3

P92-97

D0-7

/CS3

Four P10-13 signals from the CPU are converted into 16 strobe signals by two 74HC138 for use in various functions.

XE-A20S HARDWARE DESCRIPTION

– 10 –

Front

display

G1',G2',

G3'G4',G5',

G6',G7

Pop-up

display

Page 13

1) Keyboard

r

Scan signal: 10 /S0-9 signals

Return signal: 6 P92-97 signals

The keys are read by the key matrix following the above signals.

2) Mode switch

Scan signal: 8 /S0-7 signals

Return signal: 1 P90 signal

The positions are read by the above signals.

Scan

signal

Mode

switch

position

/S0 /S1 /S2 /S3 /S4 /S5 /S6 /S7

SRV PGM (OFF) TIME REG MGR X1/Z1 X2/Z2

3) Paper feed key

Scan signal: 1 /S1 signal

Return signal: 1 P91 signal

The paper feed key is read by the above signals.

4) Head up sensor

Scan signal: 1 /S3 signal

Return signal: 1 P91 signal

The Head up sensor state is read by the above signals.

Head up sensor Head up detected Head up not detected

P91 Low High

12. USB I/F

The XE-A20S is equipped with 1 USB port (slave) as a standard provision. By use of the USB general-purp ose ASS P device M6629 1,

it sends and receives USB data. The M66291 is mapped to the /CS1

space (28000H~3FFFFFH). The CPU and the M66291 are connected

as shown in the figure below.

Vcc

A1~A6

D0~D7

CS1

RD

WRL

WRH

INT2

INT1

5V

IOVcc

CoreVcc

A0

7

8

D15/AD0

AD1~AD6

D0~D7

CS

RD

LWR

HWR/BYTE

INT0

Dreq0

Xin

24MHz

M16C/62 M66291

<CPU PORT>

No. CPU PORT SIGNAL Application

19 P83 (INT1) /DREQUSE USB DMA CHANNEL 0 DMA

18 P84 (INT2) /INTUSB USB Interrupt 0 Request signal

Request signal

Vbus

TrON

Xout

D+

D-

3.3V

1.5kΩ

1.0{F

27Ω

27Ω

1

Vbus

3

D+

2

D-

4

GND

USB Connecto

5) Paper end sensor

Scan signal: 1 /S4 signal

Return signal: 1 P91 signal

The paper end sensor state is read by the above signals.

Receipt near end sensor End detected End not detected

P91 Low High

6) Display

Scan signal: 10 /S0-9 signals

The above 10 scan signals are used as the following digit signals.

Digit signal:

Scan signal /S0 /S1 /S2 /S3 /S4 /S5 /S6 /S7 /S8 /S9

Digit signal:

Front

Digit signal:

Pop-up

Segment signal : Segment signals: a, b, c, d, e, f, g, and DP are output

G1’ G2’ G3’ G4’ G5’ G6’ G7’ G8’ G9’ G10

’

G1’ G2’ G3’ G4’ G5’ G6’ G7’

by the IC:74HC374, using the data bus signal:D0-7

from the CPU as an input signal and the chip select

signal:/CS3 as a latch signal.

XE-A20S HARDWARE DESCRIPTION

– 11 –

Page 14

CHAPTER 5. TEST FUNCTION

1. TEST ITEMS

The test items are as follows:

NO. Code Description

1 100 Display buzzer test

2 101 Key code

3 102 Printer test

4 104 Keyboard test

5 105 mode switch test

6 106 Printer sensor test

7 107 Clock display test

8 110 Drawer 1 open & sensor test

9 120 External RAM test

10 121 CPU internal RAM test

11 140 CPU internal ROM test

12 160 AD conversion port test

13 520 USB TEST

14 550 Sleep mode test

Starting DIAG.

*

Mode switch : PGM

Key operation : Above code + "CH" key

2) KEY CODE

Key operation

1

RCPT/PO101

Test procedure

2

Display

KEY CODE

Check that:

3

KEY code: Every time a key is pressed, the code of that key is displayed as a decimal number.

When a key is pressed twice or pressed in an incorrect manner, --will be displayed.

End of testing

4

You can exit the test mode by turning the mode s witch to a pos ition

other than the SRV mode. The printer prints as follows:

101

3) PRINTER TEST

Key operation

1

RCPT/PO102

2. DESCRIPTION OF EACH DIAGNOSTIC

PROGRAM

1) DISPLAY BUZZER TEST

1

Key operation

RCPT/PO100

2

Test procedure

Display at operator side 1.2.3.4.5.6.7.8.9.0.

Display at front side 4.5.6.7.8.9.0.

The decimal point will shift in steps of 1 digit from the lower digit to

the upper (every 200 m sec).

After that, all segments turn on (about 1 sec)

Display at operator side 8.8.8.8.8.8.8.8.8.8.

Display at front side 8.8.8.8.8.8.8.

This mode is repeated.

At the same time, the buzzer sounds continuously.

3

Check that:

A) Each position is correctly displayed.

B) The brightness of each number is uniform.

C) The buzzer sound is normal.

4

End of testing

You can exit the test mode by pressing any key. The following is

printed.

100

Test procedure

2

Display 1234567890

ZZZZZZ ----------------ZZZZZ

ZZZZZZ ----------------ZZZZZ

ZZZZZZ ----------------ZZZZZ

3 lines of 24 Z's are printed.

Check that:

3

The print is free from contamination, blur, and uneven density.

End of testing

4

The test will end automatically.

4) KEYBOARD TEST

Key operation

1

RCPT/PO104

Test procedure

2

The keyboard is checked using the check sum data of the key code.

Display 104

KEY CODE

Check:

3

A) The content of completion print

XE-A20S TEST FUNCTION

– 12 –

Page 15

4

End of testing

When the test ends normally 104

When an error occurs E- ~ - 104

Note: Calculation of key check sum data

The hard code (hexadecimal number) at the position (excluding

feed key) where there is input data, the hard code is added.

However, the end key (CA/AT/NS) is not added.

This data to which hard codes have been added is converted into

a decimal number value, which will become the check sum data

that will be entered when the Diag is started.

3

Check that:

“-” blinks and the clock counts up.

4

End of testing

When any key is pressed, the date and time are printed and the test

mode will terminated.

Display 1 0 7 XXXXXX -XXXXXX

year month day hour min sec

5) MODE SWITCH TEST

1

Key operation

RCPT/PO105

2

Test procedure

Display 105 X

MODE:

x :

3

4

_PGM_VOID_OFF_OP X/Z_REG_MGR_X1/Z1_X2/Z2____PGM

12934567 1

The above x must be read in the correct order.

(If the contact is open, 9 will be displayed.)

Check:

The display during testing and the content of the completion print.

End of testing

When the test ends normally: 105

When an error occurs: E- ~ - 105

6) PRINTER SENSOR TEST

1

Key operation

RCPT/PO106

2

Test procedure

Check the status of paper end sensor and head up sensor.

7-segment display: 106 XY

3

Check the following:

X:1 - Paper present Y:1 - Head DOWN

O - Out of paper O - Head UP

4

End of testing

You can exit the test mode by pressing any key and the printer prints

the following:

106

7) CLOCK TEST

1

Key operation

RCPT/PO107

2

Test procedure

Displayed digit:

7-segment display:

8 7 6 5 4 3 2 1

hour min sec

Blinks at an interval of 0.5 sec.

8) DRAWER 1 OPEN AND SENSOR TEST

1

Key operation

RCPT/PO110

2

Test procedure

Display 110 X

O = DRAWER OPEN

X:

C = DRAWER CLOSED

3

Check that:

A) The drawer opens normally.

B) The sensor correctly indicates the status of the drawer 1.

On the XE-A202, “C” (CLOSED) is always displayed.

*

4

End of testing

You can exit the test mode by pressing any key. The printer prints

the following.

110

9) EXTERNAL RAM TEST

1

Key operation

RCPT/PO120

2

Test procedure

The standard 128 Kbyte RAM is checked.

The contents of the memory are lost after this test.

RAM(08000H ~ 27FFFH area) is tested in the following procedure:

a) Data in the test area is stored.

b) Write “00H”

c) Read and compare “00H” and then write”55H”

d) Read and compare “55H” and then write”AAH”

e) Read and compare “AAH”

f) Restore stored data.

If an error occurs at a step, the error is printed.

If an error does not occur, the following addresses are checked.

Addresses to be checked:

10000H , 10001H , 10002H , 10004H , 10008H

10010H , 10020H , 10040H , 10080H ,

10100H , 10200H , 10400H , 10800H ,

11000H , 12000H , 14000H , 18000H ,

20000H

Display 120

3

Check:

A) The completion print.

XE-A20S TEST FUNCTION

– 13 –

Page 16

End of testing

4

The program ends after printing.

When the test ends normally. 120

When the test ends abnormally. Ex- ~ - 120

x = 1: Data error

x = 2: Address error

When an error occurs, the printer outputs t he error message and

then the address where the error has occurred in the area ****.

*****

10) CPU internal RAM test

Key operation

1

RCPT/PO121

Test procedure

2

The test program checks internal RAM of the CPU.

The contents of the memory are lost after this test.

RAM (00400H - 053FFH area) is tested in the following procedure.

a) Data in the test area is stored.

b) Write “00H”

c) Read and compare “00H” and then write “55H”

d) Read and compare “55H” and then read “AAH”

e) Read and compare “AAH”

f) Stored data is restored.

If an error occurs at a step, the error is printed.

If an error does not occur, the following addresses are checked.

Addresses to be checked:

01000H , 01001H , 01002H , 01004H , 01008H

01010H , 01020H , 01040H , 01080H ,

01100H , 01200H , 01400H , 01800H ,

02000H , 04000H

Display 121

Check:

3

The completion print.

End of testing.

4

The test program ends after printing.

When the test ends normally. 121

When the test ends abnormally. Ex- ~ - 121

x = 1: Data error

x = 2: Address error

If an error occurs, the printer outputs the error message and then

the address where the error has occurred in the area ****.

*****

11) CPU internal ROM test

Key operation

1

RCPT/PO140

Test procedure

2

The test program checks that the checksum of the CPU internal

flash ROM (C0000H - FFFFFH) is correct.

The lower two digits of the checksum should be 10H.(pending)

Display 140

Check:

3

The completion print.

End of testing

4

The test will automatically be terminated and the printer prints as follows:

When the test ends normally. 140

When the test ends abnormally. E- ~ - 140

ROM ******** (CPU CODE)

******** (Version)

ROM ******** (CPU CODE)

******** (Version)

12) AD con ver sion port

Key operation

1

RCPT/PO160

Test procedure

2

The test program displays the voltage of each AD port.

1. Head temperature

2. Head voltage

3. Battery voltage

End of testing

3

You can exit the test mode by pressing any key.

The printer prints the follwing.

1601

1602

1603

XXX

XXX

XXXX

160

13) Communication test

Key operation

1

CH520

Note: USB service tool that should be used.

Test procedure

2

The device address assigned by USB REVISION/VENDOR/

PRODUCT ID and the host is printed.

Check:

3

X X X = Device address

Display

520

USB Rev. Ver. XXXX

VENDOR ID 04DD

PRODUCT ID 90B5

DEVICE ADDRESS X XX 1

End of testing

4

After completion of printing, the test is terminated automatically.

Connect to host : 1~127

Unconnection : 0

14) S lee p mode test

Key operation

1

RCPT/PO550

Test procedure

2

The test program checks the syst em in SLEEP MODE (The display

goes off and the Decimal point comes on) and then waits for any

status change (KEY input).

Check that:

3

A) The display goes off (excluding Decimal point)

B) The system turns active when any key is pressed.

End of testing

4

The test program will automatically be terminated and the printer

prints the following.

550

XE-A20S TEST FUNCTION

– 14 –

Page 17

B

B

B

A10

D7D6D5D4D3

A10OEA11

CS1

10111213141516 17

A2A7A1

A3

DAT 2

P962

C37

IC4

R56

3.3K

T/O7

CLK 2

P952

VCC

I/O6

I/O0

D0

P942

OUT CD

R57

BZ1

1000pF

231 5

181920212223242526272829303132

I/O4

I/O5

I/O1

I/O2

+

R58

P922

P932

4

NC

VDD

VSS

820

/RESET2

B

/RD

R59

10K

VSS I/O3

LP621024DM-70MM

B

PIEZO BZ

1.5K

MOTOR 2

/POFF 3

/DREQUSB

/INTUSB

P902

P912

C39

SII

S-80928ANMP

C38

100pF

B

B

B

B

2200pF

/CS2

C40

33pF

D1

CNVss

VDD

1SS133

A C

0

R61

330

R62

X2

R60

47K

VCC

IC5

X1

CST12.0MTW

33pF

R63

C47

10K

CN1

VCC

D3

D4A4A0D5A1

D1D0D6

D7

D2

VCC

VDD

C46

0.1uF

+

C43

10uF/16V,AL

3

2

1

CST12.0MTW

X3

C42

27pF

32.768KHz

C41

18pF

C49

10uF/10V,OS

C48

330pF

91pF

33

R65

C45

+

C44

0.1uF

678

S0

VDD

FSOUT

FS781

XIN

XOUTS1LF VSS

123

4 5

R64

3.3K

3

1

2

d2

e2

f2

g2

dp 2

dp

19

Q7

8

131417

18111

D4D2D1

D7

D3D2D5D1D6

R40

R39

IC2

33pF*8(C14-C21)

VCC

R36

100pF*4(C10-C13)

R35

R34

R33

R32

10K

R31

10K

R30

10K

VCC VCC

R29

10K

C

C

C

C

C22

0.1uF

VCC

VCC:20pin

GND:10pin

VDD

74HC374

CLK

R43

10k

C23

33pF

VCC

/CS3

TP1

/CS2

/RD

/WR

/CS1

R41

47K

10K

10K

50494847464544434241403938373635343332

RD

WR

CS0

CS1

CS2

CS3

BHE

CBCLK

A19

51

A18

52

A17

53

A16

54

A15

55

A14

56

A13

57

A12

58

A11

59

A10

60

A9

61

VCC

62

A8

63

VSS

64

A7

65

A6

66

A5

67

A4

68

A3

69

A2

70

A1

71

A0

72

D15

73

D14

74

D13

75

D12

76

D11

77

D10

78

D9

79

D8

D6D5D4D3D2D1D0

D7

81808283848586878889909192939495969798

M30624

R49 100

R48 100

R47 100

R46 100

R50 100

R45 100

R44 100

R42 100

R38

10K

10K

R37

10K

10K

10K

10K

10K

10K

10K

10K

D0D1D2D3D4D5D6

D7

C

C

C

C

HLDA

AN7

/STB12

C31

C30

C29

C28

C27

C26

C25

C24

HOLD

AN6

/LAT2

ALE

AN5

VPON3

C33

C32

R51

CLKOUT

AN4

+

0.1uF

VCC

VCC

10uF/50V

J1

47K

DR1 2

CLK0

RTS0

TXD0

RXD0

AN3

AN2

AN1

AVSS

P1012

VBAT3

/STB22

100pF*8(C24-C31)

CNVss

CLKS1

AN0

P1002

CLK1

VREF

VCC

VDD

RXD

RXD1

AVCC

99

VDD

/WR

R52

10K

A15

WE

A15

CS2

VCC

IC3

NC

A16

A14

A12A7A6A5A4A3A2A1A0

123456789

A14

A16A0A4

A12

12345

CON5

TXD

VCC

C35

33pF

R53

47K

31

TXD1

TB5OUT

TB5IN

TA1OUT/V

TA1IN/V

TA2OUTW

TA2INW

TBEOUT

TB3IN

TA4OUT/U

TA4IN/U

INT0

INT1

INT2

NMI

VCC

XIN

VSS

XOUT

RESET

XCOUT

XCIN

CNVSS

BYTE

CLK3

SIN3

SOUT3

TB3IN

TB4IN

CLK4

SOUT4

SIN4

100

VDD

P972

C34

4.7UF/16V

+

C36

33pF

A13

A11

A8

A9

A9

A8

A13

A5

A6

R55

10K

30

29

28

27

26

25

24

23

22

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

R54

100K

VDD

D

D

D

D

1/3

12345678

12345678

12345678

12345678

D[0..7]

A16A9A12

A11

A13

A8

A15

A14A2A10

R22

10K

R21

10K

R20

10K

R19

10K

R18

10K

R17

10K

R16

10K

R15

10K

R14

10K

VCC

R13

10K

R12

10K

R11

10K

R10

10K

R9

10K

R8

10K

R7

10K

R6

10K

VCC

R5

10K

R4

10K

R3

10K

R2

10K

R1

10K

A6

A3

A5

A7

A0

A4

A1

IN12

ENA22

ENA12

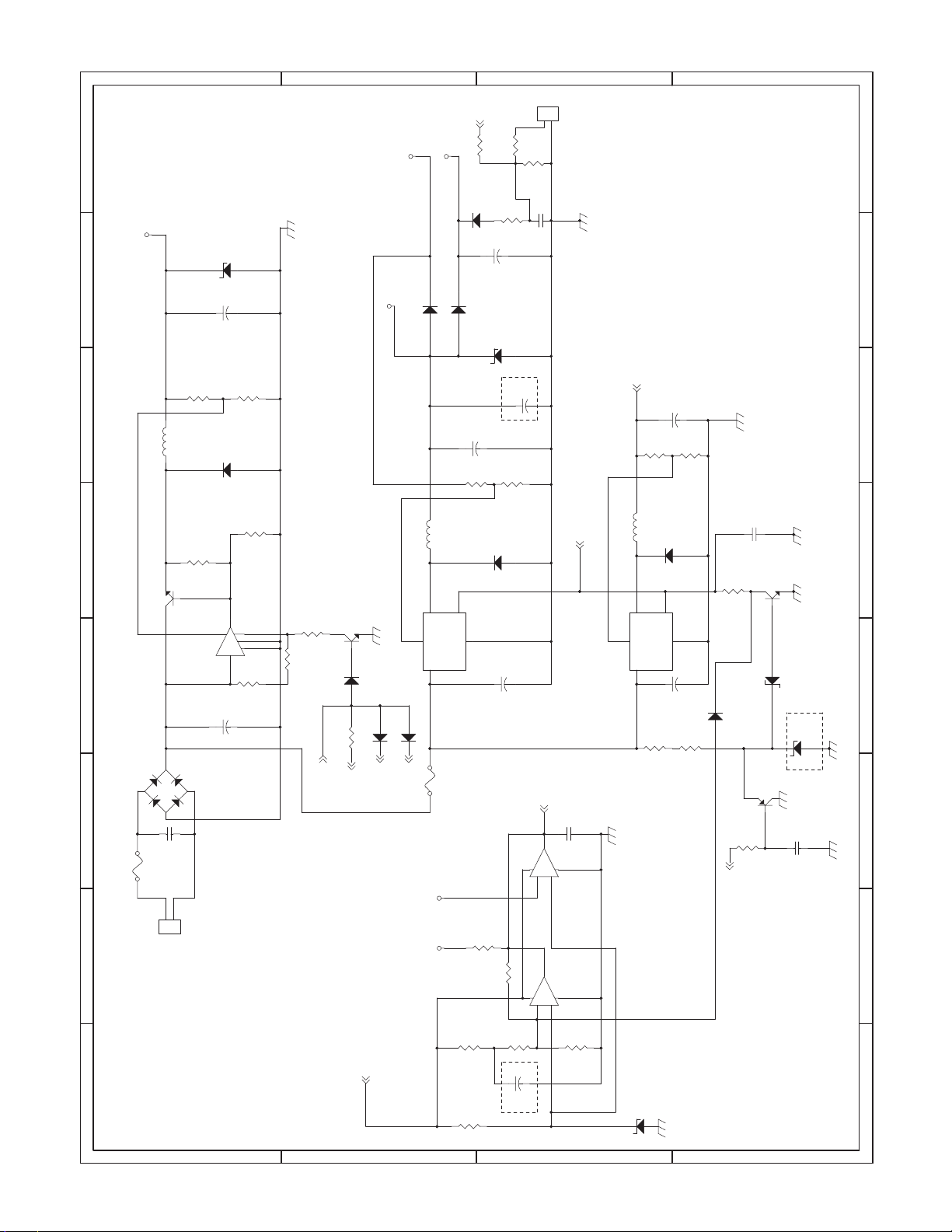

CHAPTER 6. CIRCUIT DIAGRAM AND PWB LAYOUT

1. CIRCUIT DIAGRAM

CPU

D

D

D

D

D[0..7]

IN22

VCC

KST32

A[0..16]

A[0..16]

C9

C8

C7

C6

C5

C4

C3

C2

C1

KST22

KST12

KST02

c2

a2

b2

abcdefg

2569121516

Q0Q1Q2Q3Q4Q5Q6

IC1

D0D1D2D3D4D5D6D7OC

347

D0

R24

10K

R23

10K

33pF*9(C1-C9)

C21

C20

C19

C18

C17

C16

C15

C14

C13

C12

C11

C10

R28

R27

R26

R25

A

21

21

21

21

12345678910111213141516171819202122232425

JST 25FMN-BTK-A

/RD

/CS1

A6

/WR

A3A5A2

/DREQUSB

/INTUSB

3

3

3

R67

10K

R66

/RES

10K

C50

R70

10K

84

3.3k

R69

10K

1000pF

AC

D2

/RESET

1

IC6A

BA10393

+

-

3

2

D3

A C

A A

A A

A A

A

VCC

VO 2,3

R68

VCC

3

1SS133

UDZ4.3B

87654

87654

87654

87654

XE-A20S CIRCUIT DIAGRAM AND PWB LAYOUT

– 15 –

Page 18

B

B

B

D

D

D

D

2/3

12345678

12345678

12345678

12345678

VP

NOT INSTALL

VP

jumper

VCC

MOTOR

1

2

CN2

C51

0.1uF

AS

/ASBS/BS

4113512108

VS1

VS2

OUT1

VCC

ENA1

ENA2

IC7

1

213697

B2B-EH-A

OUT2

OUT3

IN1

OUT4

IN2

Q1

R76

C54

10uF/50V

+

VCONT

GND

GND

14

2SD2212

E C

B

1K

MOTOR1

LB1838M

C

C

C

C

CN3

STRAIGHT CON

DRAWER1

123

5045-03A

D1A1

1N4002

FB1

C66673

JUMPER WIRE(FB1)

VDR

F6

T500mA/250V

VO

C58

FB2

A C

0.1uF

C59

C66673

JUMPER WIRE(FB2)

Q4

2SD2212

E C

B

1.8K

R77

+

10uF/50V

DR11

1SS133

D6

A C

B

FB3

C66673

JUMPER WIRE

C63

0.1uF

R79

22K

R80

4.7K

B

Q5

EC

AC

D7

KRC111S

1SS133

/S6

P91

P911

/S6

NOT INSTALL

A

21

21

21

21

3

3

3

3

VO 1,3

VCC

VP

DRIVER

R71

56KG

TCOFF 3

7

84

+

5

6

R73

30KG

VCC

R72

10KG

C55

10uF/16V

VCC

D4

VCC

/S0

Y0

VCC

ABC

IC8

1234567

KST01

KST11

G

S

AC

1SS133

/S4

+

VCC

/S8

Y0

VCC

ABC

IC9

1234567

HUPS

B

Q3

P911

/S9

D5

C60

G2A

KRC111S

E C

0.1uF

G2BG1Y7

AC

/S3

VCC

DAT 1

R78

10K

VCC

C62

47uF

50V

10111213141516

Y5Y4Y3Y2Y1

74HC138

GND Y6

8 9

1SS133

+

PE

/LA 1

/STB1 1

/STB2 1

AS

BS

VP

123456789

CN5A

C61

0.1uF

VLED

VCC

1

a

abcdefg

CN4

1

cdefg

b

11111

101112

dp 1

dp

/S0

/S0

/S1

/S1

R81

10K

ONLY HOLE

/S2

/S7

/S8

/S2

/S7

/S8

/BS

CN5B

P90 1

/RESET 1

/RESET

P90

P91

CLK 1

/AS

123456789

P91 1

P92 1

P93 1

P94 1

P95 1

P96 1

P97 1

P92

P93

P94

P95

P96

P97

10111213141516171819202122232425262728293031323334

C64

0.1uF

HUPS

C65

TH 1

101112

/S9

/VON 3

/S9

/VON

0.1uF

R83

4.7K

2K

R82

ONLY HOLE

/S3

/S4

/S6

/S5

/S3

/S4

/S5

/S6

123456789

87654

87654

87654

87654

34FE-BT-VK-N

C56

0.1uF

/S6

/S5

/S4

/S3

/S2

/S1

10111213141516

Y5Y4Y3Y2Y1

G2A

74HC138

G2BG1Y7

GND Y6

8 9

/S7

KST21

KST31

PE

C57

0.1uF

2SK2731

D

Q2

P91

P911

ENA11

ENA21

IN11

IN21

IC6B

BA10393

-

R75

5.1KF

C53

330pF

TH1 P10 1

C52

0.1uF

R74

10KG

P1011

B

B

B

D

D

D

D

C

C

C

C

B

A A

A A

A A

A

XE-A20S CIRCUIT DIAGRAM AND PWB LAYOUT

– 16 –

Page 19

B

B

B

D

D

D

D

3/3

12345678

12345678

12345678

12345678

VP

ZD1

PTZ9.1B

A C

C

C

C

C

VCC

VLED +5.8V

VCC +5V

VDD

VBAT1

R96

D15

RB721Q

CN7

100

R101

22K

R102

C74

R99

220

A C

C70

16V

+

330uF

B

1

2

3.3M

B2B-XH-A-E(BLUE)

0.1uF(M)

A

1

2

+

C68

16V

4700uF

VLED

D14

D13

1N4002

1N4002

A C

A C

ZD2

PTZ6.2A

A C

L1

IPEAK>12A :100%

Q6

KTD998

Q1:HEAT SINK

4

D8

F1

3.15A

CN6

R85

17.8KF

63uH

D9

with FUSE

R84

10(FUSE)

EC

B

1

IC10

50V

3300uF

+

C67

1

2

CP301

-+

3

C66

MYLOR

0.033uF

1

2

B2P-VH

H,OPEN:ON

HEAT SINK

L3

4

PQ1CG2032FZ

IC13

P-OFF

VO 1

2

1

VO:23.8V

R105

220uH

R104

C77

1000uF/35V

+

R107

560

10K

C78

0.02uF(M)

RB060L40

D17

A C

R108

10K

Q9

KRC106S

E C

5

3

+

C76

220uF/50V

D18

R106

A C

10K

10K

B

AC

D19

UDZ4.3B

1SS133

EC

R109

33

/VON2

ZD4

MTZJ5.1B

A C

Q8

KRA106S

B

0.1uF

C79

3

3

3

3

NOT

INSTALL

R87

3.3KF

C69

FMB-G24H

A C

R88

18K

L:ON

H:OFF

6,8pin:N.C

LM2574

3

2

4

5 7

R86

24K

R89

22K

Q7

KRC106S

0

R90

E C

B

D10

1SS133

A C

R91

2.2K

D11

TCOFF2

VPON1

L2

180uH

2

5

PQ1CG2032FZ

4

3

1

IC11

HEAT SINK

AC

AC

1SS133

1SS133

D12

F3

1.0A

/VOFF

/POFF1

VCC VLED

C73

+

10uF/10V,OS

NOT

INSTALL

16V

1000uF

+

R98

910F

R94

2.7KF

/VOFF

D16

RB060L40

A C

+

C71

220uF/50V

84

R95

2.7K

R97

56K

84

/VOFF

L:OFF

/POFF 1

0.1uF

C75

7

+

-

5

6

IC12B

BA10393

1

IC12A

BA10393

+

-

3

2

POWER

R100

0

R93

R92

9.1KG

2.7K

NOT

+

C72

INSTALL

VO 1

D

D

D

D

C

C

C

C

1uF/50V

R103

3.9K

87654

87654

87654

87654

ZD3

MTZJ5.1B

A C

B

B

B

B

A A

A A

A A

A

XE-A20S CIRCUIT DIAGRAM AND PWB LAYOUT

– 17 –

Page 20

B

B

B

D

D

D

D

C

C

C

C

B

A

A

1/1

12345678

12345678

12345678

12345678

CN2

12345678910111213141516171819202122232425

VCC

A3

D7

D4D1D5

D2

D3

A2D0A4

A1

A0

D6

A5

A6

/WR

/CS1

/DREQUSB

/INTUSB

/RD

/RST

JST 25FMN-BTK-A

1

2

D5

D4

D7A3D3D6

D2

D1

D0

VCC

A0

GND

IOVcc

D15/A0

HWR#/BYTE#

Dack1#

Dreq1#

D11/P3

D14/P6

D13/P5

D12/P4

TC1#

INT1#/SOF#

IOVcc

Xout

Xin

GNDA1A2A3A4

101112131415171819

D10/P2

CoreVcc

16

R6 10k

D9/P1

D8/P0

3

3

3

3

29

262728

D7

D6

D3D4D5

M66291FP

A5A6D0

D1 D2

20

212223

24 25

Vcore

0.1uF

C9

VCCVCCVcore

3.3V

C3

0.1uF

+

C2

10uF/16V

IC1

/WR

/CS1

/RD

/INTUSB

/RSTA2/DREQUSB

48474645444342414039383736353433323130

CS#

RD#

RST#

INT0#

LWR#

Dreq0#

Dack0#

CoreVcc

GNDD-D+

Vbus

TEST

TrON

123457689

C7

64

VCC

+

8

C8

33uF/10V

0.47uF

87654

87654

87654

87654

R5

C1

0.1uF

R2 27

R1 27

R3 1.5K

L2

2 3

BLM21PG221SN1D

L1

CN1

123

567

1 4

4

8

1M

R4 0

3

1

X1

C4

1uF

D2

A C

D1

A C

C6

22pF

C5

22pF

DLP31SN121SL2

BLM21PG221SN1D

L3

L4

CSTCW24M

2

24MHz

UDZS 6.2B

UDZS 6.2B

BA033F

IC2

A1

A5

A6

A4

■ SUB I/F

USB B Type

BLM21PG221SN1D

B

B

B

D

D

D

D

C

C

C

C

XE-A20S CIRCUIT DIAGRAM AND PWB LAYOUT

B

A

A A

A A

A

– 18 –

Page 21

D

D

D

D

1/1■ PRINTER I/F PWB CIRCUIT

12345678

12345678

12345678

12345678

B

B

B

C

C

C

C

B

A

21

21

21

21

CN31

VCCVP

A/BB/AN.CVPVP

123456789

/LAT

/TH

GND

GND

/STB1

VCC

/STB2

GND

GND

CLK

DATVPVP

N.C

N.C

VCC

LEDPEHUPS

1011121314151617181920212223242526

N.C

27FMN-BTK-A

27

3

3

3

3

C200

0.1uF

C201

0.1uF

123456789

CN4C

D

D

D

D

101112

ONLY HOLE

C

C

C

C

XE-A20S CIRCUIT DIAGRAM AND PWB LAYOUT

123456789

CN4D

B

B

B

B

101112

ONLY HOLE

87654

87654

87654

87654

A A

A A

A A

A

– 19 –

Page 22

B

B

B

D

D

D

D

C

C

C

C

B

A

12345678

12345678

12345678

12345678

1/1■ USB I/F

VCCVCCVcore

3.3V

CN2

12345678910111213141516171819202122232425

VCC

A3

D7

D4D1D5

D2

D3

C3

0.1uF

+

C2

10uF/16V

IC1

/CS1

/RSTA2/DREQUSB

48474645444342414039383736353433323130

CS#

RST#

Dreq0#

Dack0#

CoreVcc

GNDD-D+

123457689

/WR

/RD

LWR#

Vbus

D6

/INTUSB

RD#

INT0#

TEST

TrON

A2D0A4

A1

A0

A5

A6

VCC

A0

GND

IOVcc

D15/A0

D14/P6

D13/P5

D12/P4

HWR#/BYTE#

Dack1#

Dreq1#

TC1#

INT1#/SOF#

IOVcc

Xout

Xin

101112131415171819

/WR

/RD

/CS1

/DREQUSB

/INTUSB

D7A3D3D6

R6 10k

29

D7

D9/P1

D8/P0

D11/P3

D10/P2

GNDA1A2A3A4

CoreVcc

20

16

/RST

D5

D6

D4

A5A6D0

212223

JST 25FMN-BTK-A

D2

D1

D0

262728

D3D4D5

D1 D2

24 25

M66291FP

Vcore

21

21

21

21

3

3

3

3

0.1uF

C9

C7

64

VCC

+

8

C8

33uF/10V

0.47uF

87654

87654

87654

87654

R5

R4 0

C4

1uF

D2

D1

C6

C5

2 3

1 4

DLP31SN121SL2

L3

L4

1M

CSTCW24M

3

2

1

X1

24MHz

A C

UDZS 6.2B

A C

UDZS 6.2B

22pF

22pF

BLM21PG221SN1D

BA033F

IC2

A6

A1

A5

A4

C1

0.1uF

R2 27

R1 27

R3 1.5K

L2

BLM21PG221SN1D

L1

123

4

CN1

567

8

USB B Type

BLM21PG221SN1D

B

B

B

D

D

D

D

C

C

C

C

XE-A20S CIRCUIT DIAGRAM AND PWB LAYOUT

B

A A

A A

A A

A

– 20 –

Page 23

B

B

B

D

D

D

D

C

C

C

C

B

A

1/1

12345678

12345678

12345678

12345678

G1'..G7'

1

G1'G2'G3'

G4'G5'G6'

3

LED6

D568GWA

1

4

1

3

LED7

D568GWA

1

4

123456789101112131415

CN31

G1'

G2'

G3'

G4'

G5'

G6'

G7'A'B'C'D'

1

1

0

5681

2

971

1

6

5

1231

1

8

7

41

1

1

0

5681

2

971

1

6

5

1231

1

8

7

41

1

1

0

E'F'G'

52807-1510

DP'

21

21

21

21

A'B'

R1

27

R2

27

C'D'E'

R3

27

3

3

3

3

1

3

LED8

D568GWA

1

4

G7'

38

LED9

S568GWA

REAR DISPLAY PWB CIRCUIT

■

D

D

D

D

5681

2

971

1

6

5

1231

1

8

7

41

912467

0

51

C

C

C

C

R4

27

R5

27

F'G'DP'

R6

27

R7

27

87654

87654

87654

87654

R8

27

B

B

B

B

A A

A A

A A

A

XE-A20S CIRCUIT DIAGRAM AND PWB LAYOUT

– 21 –

Page 24

B

B

B

D

D

D

D

1/1

12345678

12345678

12345678

12345678

G1'

G2'

G3'

G4'

G5'

G6'

G7'

G8'

G9'

G10

C

C

C

C

1

1

0

1

3

LED1

D568GWA

1

4

1

3

LED2

D568GWA

1

4

1

3

LED3

D568GWA

1

4

1

3

LED4

D568GWA

1

4

1

3

LED5

D568GWA

1

4

'

5681

971

1

1231

1

41

1

5681

971

1

1231

1

41

1

5681

971

1

1231

1

41

1

5681

971

1

1231

1

41

1

5681

971

1

1231

1

41

2

6

5

8

7

1

0

2

6

5

8

7

1

0

2

6

5

8

7

1

0

2

6

5

8

7

1

0

2

6

5

8

7

B

A

'

30

R240

B

'

30

R239

C

'

30

R238

D

'

30

R237

E

'

30

R236

F

'

30

R235

G

'

30

R234

DP'

30

R233

A

|LINK

|POPUP.SCH

21

21

21

21

3

3

3

3

DISPLAY PWB CIRCUIT

■

D

D

D

D

C

C

C

C

XE-A20S CIRCUIT DIAGRAM AND PWB LAYOUT

– 22 –

87654

87654

87654

87654

B

B

B

B

A A

A A

A A

A

Page 25

B

B

B

D

D

D

D

C

C

C

C

B

A

11

67 8 910

234 5

1

PF

232221201918

30 31 32 33 34 35

17

29

161514

26 27 28

24 25

12 13

1/1

12345678

12345678

12345678

12345678

OUTPUT

4.7K

COMMON

47K

59

474645444342

21

21

21

21

41

53 54 55 56 57 58

3

3

3

3

3736 403938

48 49 50 51 52

C

COMMON

GND

2

/VO

GND

/S0

/S1

/S2

MOR

/S3

/S4

/S5

/S6

/S7

P97

P96

P95

P94

P93

P92

P91

2

N

2

1

2

0

T

1

9

1

8

1

7

1

6

1

5

1

4

1

3

1

2

1

1

0

1234567891

CN22

1.25mm FPC CN

INPUT

KRA101M, KRA106S

12345678910

E

3003.5K

B

MODE SW

/RESE

2SD2170

OUTPUT

GND

3K

7.2K

49371422625

24 12 1 13 36 48

51521642840

55

57452082133

5947112335

431863042

39 27 3 15 38 50

41 29 5 17 53 54

32 31 7 19 44 56

34 22 9 10 46 58

2.7K

KEY MATRIX PWB CIRCUIT

■

INPUT

D

D

D

D

KID65083

/S0

/S1

/S2

/S3

/S1

1

2

3

CN21

C

C

C

C

XE-A20S CIRCUIT DIAGRAM AND PWB LAYOUT

4

/S4

/S5

5

6

7

8

– 23 –

/S6

/S7

/S8

/S9

9

10

11

12

1.25mm FPC CN

B

B

B

B

A A

A A

A A

A

87654

87654

87654

87654

Page 26

B

B

B

Q38

Q29Q30Q31

Q37Q36Q35Q34

Q33

Q32

KRA101M X 10

or DTA143ESA

B

/S[0..9]

/S[0..9]

G1'

G2'

G3'

G4'

G5'

G6'

G7'

G8'

G9'

G10

IC23H

A

'

1

1

8

IC23G

B

'

1

2

7

IC23F

C

'

1

3

6

IC23E

D

'

1

4

5

IC23D

E

'

1

5

4

IC23C

F

'

1

6

3

IC23B

G

'

1

'

7

2

IC23A

D

P

1

8

'

1

9 PIN :GND

C106

47K * 7EA

100pF

C

C

C

C

VLED

VLED

12K

R217

12K

R216

12K

R215

12K

R214

12K

R213

12K

R212

12K

R211

12K

R210

12K

R209

12K

R208

120

R227

Q28 Q39

120

R226

120

R225

120

R224

120

R223

120

R222

120

R221

120

R220

Q21 Q22 Q23 Q24 Q25 Q26 Q27

120

R219

Q20

KTA1664 KTA1663 KTA1663 KTA1663 KTA1663 KTA1663 KTA1663 KTA1663KTA1664 KTA1664

120

R218

D

D

D

D

1/1

12345678

12345678

12345678

12345678

/VON

/RESET

/RESET

47K

R228

VCC

P90

P90

R204

R205

R207

R201

R202

R203

R206

KEY&MODE SW

2.54mm Pitch

CN22

52044-2245

2

2

2

1

2

0

1

9

1

8

1

7

1

6

1

5

1

4

1

3

1

2

1

1

1

0

123456789

/VON

/S0

/S1

/S2

MDR

/S3

/S4

/S5

/S6

/S7

P97

P96

P95

P94

P93

P92

P91

VCC

A

|LINK

|POPUP.SCH

21

21

21

21

3

3

3

3

g bcdef a

d

p

10PIN : NC

KID65083AP

IRC

KEY INTERFACE PWB C UIT

■

CN21

P[91..97]

FROM MAIN

VLED

VLED

0.1uF

C105

15

G1'

G2'

G1'

G3'

G4'

G5'

G2'

G3'

G4'

POP UP

G6'

G7'A'B'C'D'E'F'G'DP'

G5'

G6'

G7'A'B'C'D'E'F'

A A

A A

A A

A

234567891011121314

52806-1510

G'

DP' 1

87654

87654

87654

87654

C104

100uF/16V

PLACE NEAR CONNECTER

A

B

CDEFGdp/S0

cdefg

a

VCC

b

CN23

/RESET

P90

P91

/S1

/S2

/S7

/S8

dp

P90

P91

/RESET

/S0

/S1

/S2

/S7

/S8

B

B

B

B

/VON

P92

P93

P94

P95

P96

P97

/S9

/S3

/S4

/S5

/S6

P92

P93

P94

P95

P96

P97

/VON

/S3

/S4

/S5

/S6

/S9

10111213141516171819202122232425262728293031323334

123456789

CN24

52044-3445

P[91..97]

1

2

3

4

5

6

7

8

9

10

11

12

1SS133

1SS133

1SS133

1SS133

1SS133

1SS133

D21

D22

D23

D31

/S0

/S1

D

D

D

D

D24

/S1

/S2

/S3

1SS133

1SS133

D25

D26

D27

D28

/S4

/S5

/S6

/S7

1SS133

52045-1245

1SS133

1SS133

D29

D30

/S8

/S9

C

C

C

C

XE-A20S CIRCUIT DIAGRAM AND PWB LAYOUT

– 24 –

Page 27

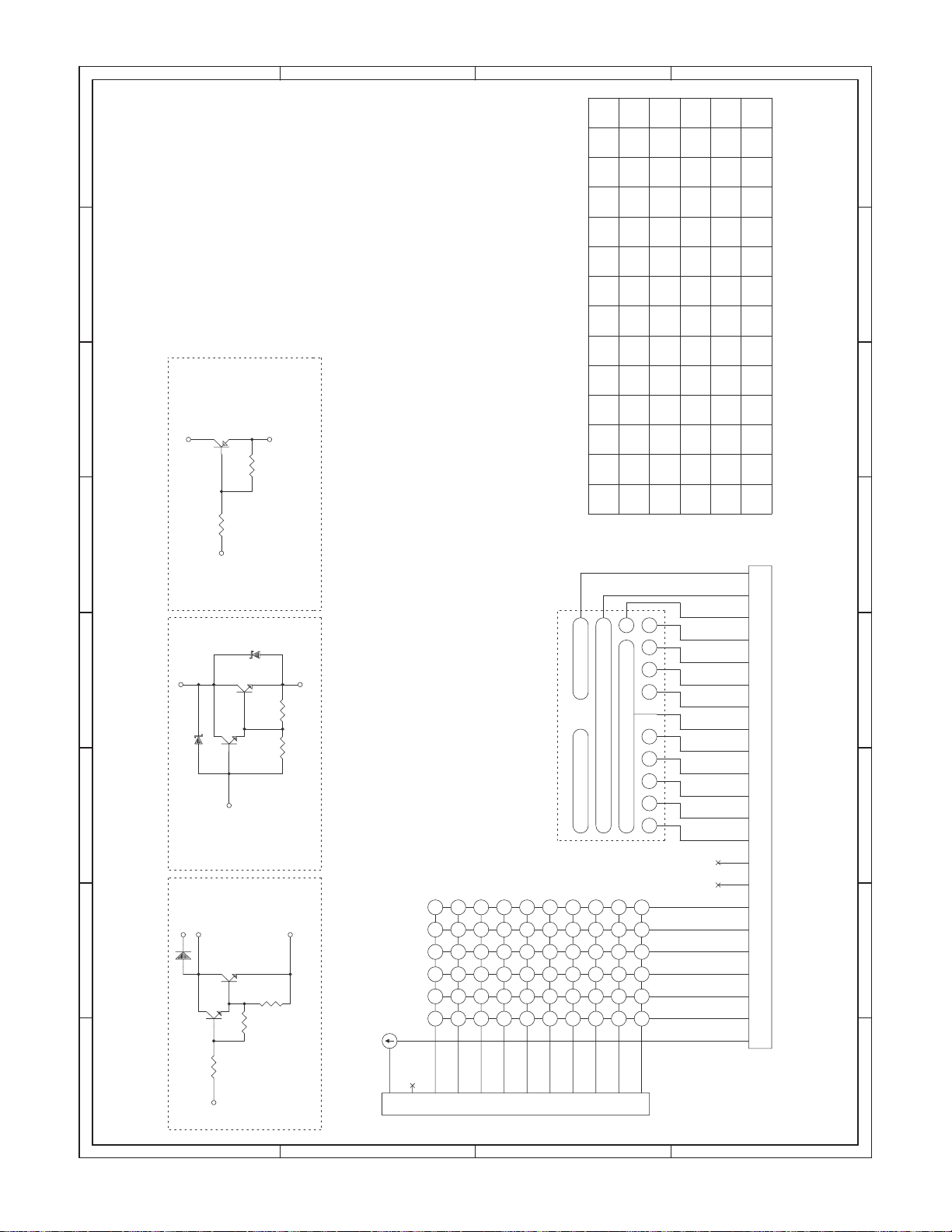

2. PWB LAYOUT

MIAN PWB

A. Side

XE-A20S CIRCUIT DIAGRAM AND PWB LAYOUT

– 25 –

Page 28

B. Side

XE-A20S CIRCUIT DIAGRAM AND PWB LAYOUT

– 26 –

Page 29

Q USB I/F PWB

A. Side

B. Side

XE-A20S CIRCUIT DIAGRAM AND PWB LAYOUT

– 27 –

Page 30

q

COPYRIGHT2005 BY SHARP CORPORATION

All rights reserved.

Printed in Japan.

No part of this publication may be reproduced,

stored in a retrieval system, or transmitted.

In any form or by any means,

electronic, mechanical, photocopying, recording, or otherwise,

without prior written permission of the publisher.

SHARP CORPORATION

Digital Document Systems Group

Products Quality Assurance Department

Yamatokoriyama, Nara 639-1186, Japan

2005 January Printed in Japan

t

Loading...

Loading...