Drive Technology \ Drive Automation \ System Integration \ Services

Addendum to the

Operating Instructions

MOVIPRO

®

Accessories

Edition 08/2011 19300026 / EN

SEW-EURODRIVE—Driving the world

Contents

Contents

1 General Information ............................................................................................ 4

1.1 Use of this documentation .......................................................................... 4

1.2 Structure of the safety notes ....................................................................... 4

1.3 Rights to claim under limited warranty ........................................................ 5

1.4 Exclusion of liability..................................................................................... 5

1.5 Other applicable documentation ................................................................. 5

1.6 Copyright..................................................................................................... 5

2 PZM2xA-A...-...-00 Power Interface .................................................................... 6

2.1 Type designation......................................................................................... 6

2.2 Nameplate................................................................................................... 6

2.3 Power interface assignment ....................................................................... 7

2.4 Basic unit .................................................................................................... 7

2.5 Scope of functions ...................................................................................... 8

2.6 Maintenance switch .................................................................................... 8

2.7 Power interface – mechanical installation ................................................... 9

2.8 Power interface – electrical installation ..................................................... 11

2.9 Power interfaces – technical data ............................................................. 16

3 Sensor/Actuator Box ........................................................................................ 18

3.1 Sensor/actuator box – electrical installation.............................................. 19

3.2 Technical data of the sensor/actuator box ................................................ 20

4 BW..-0..-0. External Braking Resistors ............................................................ 23

4.1 Braking resistors – mechanical installation ............................................... 24

4.2 Technical data of the external braking resistors ....................................... 28

5 Jumper Plug ...................................................................................................... 33

6 Mounting Accessories...................................................................................... 34

6.1 Handles..................................................................................................... 34

6.2 Mounting brackets..................................................................................... 35

7 Fan Subassembly.............................................................................................. 38

7.1 Mechanische installation of fan subassembly ........................................... 39

Index................................................................................................................... 40

Addendum to the Operating Instructions – MOVIPRO®

3

1

General Information

Use of this documentation

1 General Information

1.1 Use of this documentation

The documentation is an integral part of the product and contains important information

on operation and service. The documentation is written for all employees who assemble,

install, startup, and service this product.

The documentation must be accessible and legible. Make sure that persons responsible

for the system and its operation, as well as persons who work independently on the unit,

have read through the documentation carefully and understood it. If you are unclear

about any of the information in this documentation, or if you require further information,

contact SEW-EURODRIVE.

1.2 Structure of the safety notes

1.2.1 Meaning of the signal words

The following table shows the grading and meaning of the signal words for safety notes,

notes on potential risks of damage to property, and other notes.

Signal word Meaning Consequences if disregarded

DANGER Imminent danger Severe or fatal injuries

WARNIN G Possible dangerous situation Severe or fatal injuries

CAUTION Possible dangerous situation Minor injuries

NOTICE Possible damage to property Damage to the drive system or its envi-

INFORMATION Useful information or tip: Simpli-

fies the handling of the drive

system.

1.2.2 Structure of the section-related safety notes

Section safety notes do not apply to a specific action, but to several actions pertaining

to one subject. The used symbols indicate either a general or a specific hazard.

This is the formal structure of a section safety note:

SIGNAL WORD

Type and source of danger.

Possible consequence(s) if disregarded.

• Measure(s) to prevent the danger.

1.2.3 Structure of the embedded safety notes

Embedded safety notes are directly integrated in the instructions just before the description of the dangerous action.

ronment

This is the formal structure of an embedded safety note:

• SIGNAL WORD Nature and source of hazard.

Possible consequence(s) if disregarded.

– Measure(s) to prevent the danger.

4

Addendum to the Operating Instructions – MOVIPRO®

Rights to claim under limited warranty

1.3 Rights to claim under limited warranty

A requirement of fault-free operation and fulfillment of any rights to claim under limited

warranty is that you adhere to the information in the documentation. Read the documentation before you start working with the unit!

1.4 Exclusion of liability

You must comply with the information contained in this documentation to ensure safe

operation and to achieve the specified product characteristics and performance

features. SEW-EURODRIVE assumes no liability for injury to persons or damage to

equipment or property resulting from non-observance of these operating instructions. In

such cases, any liability for defects is excluded.

1.5 Other applicable documentation

This document supplements the operating instructions and limits the application notes

according to the following information. Use this document only together with the operating instructions.

General Information

1

1.6 Copyright

© 2011 – SEW-EURODRIVE. All rights reserved.

Unauthorized duplication, modification, distribution or any other use of the whole or any

part of this documentation is strictly prohibited.

Addendum to the Operating Instructions – MOVIPRO®

5

2

D-76646 Bruchsal

Made in Germany

MOVIPRO

Feldumrichter

Field-Inverter

Type:

SO#:

Eingang / Input

PZM2xA-A075-D02-00

Ausgang / Output

U =

I =

3 x 380...500 V ± 10%

T =

f =

16 A

50...60 Hz ± 5%

+5...+40 °C

IP 54

7.5 kW

P =

XX.XXXXXXXXXX.XXXX.XX

PZM2xA-A...-...-00 Power Interface

Type designation

2 PZM2xA-A...-...-00 Power Interface

2.1 Type designation

The type designation of the MOVIPRO® PZM2xA-A...-...-00 power interface comprises

the following characteristic data:

PZM2 xA-A ... - ... - 00

MOVIPRO® connection:

D02 = Disconnection switch up to 25 A

D03 = Disconnection switch up to 40 A

M13 = Line and unit protection up to 5 A

M14 = Line and unit protection up to 9 A

M16 = Line and unit protection up to 15 A

Maximum switching capacity:

022=2.2kW

040 = 4.0 kW

075 = 7.5 kW

150 = 15.0 kW

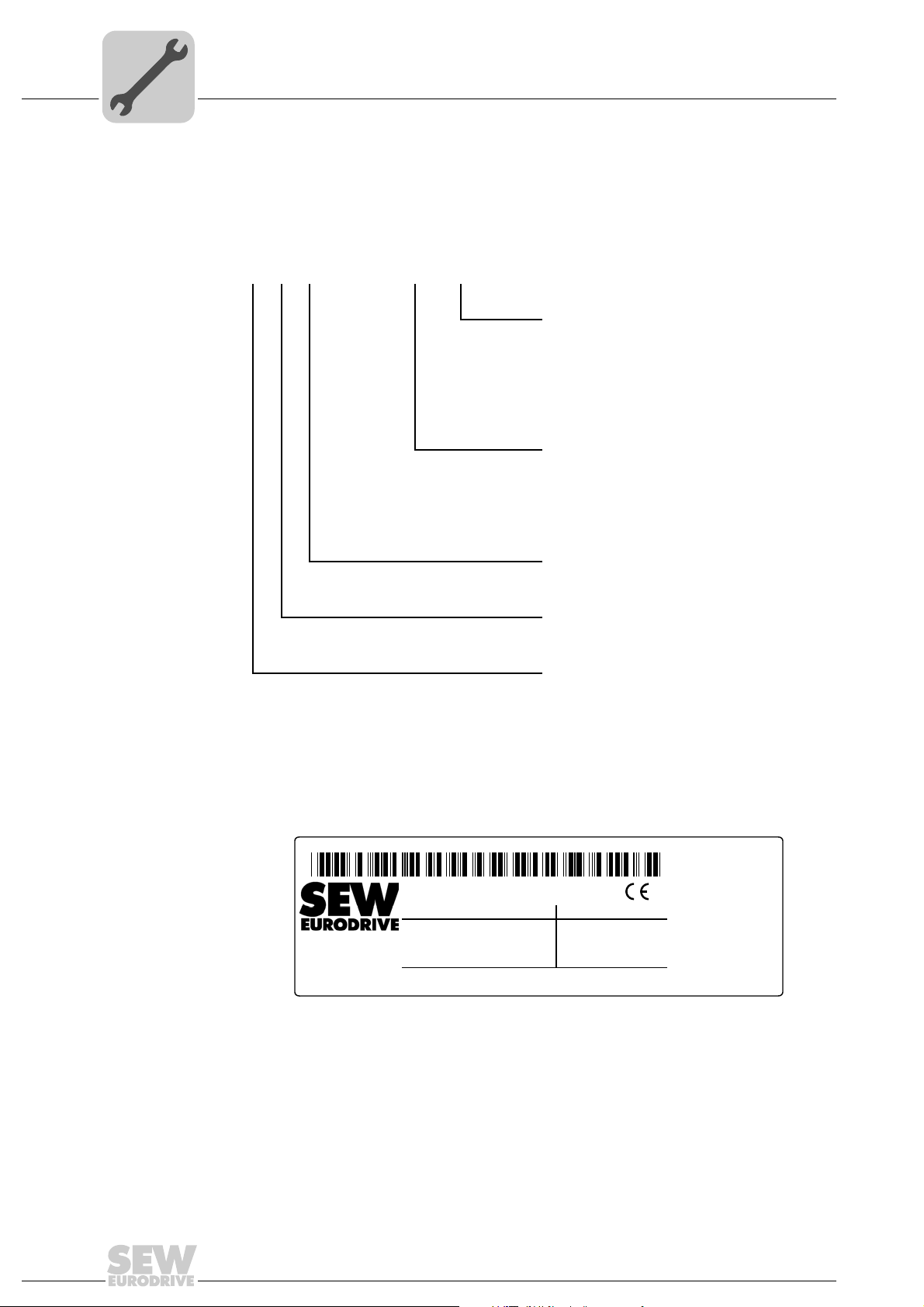

2.2 Nameplate

Housing height:

2 = 110 mm

Typ e:

ZM = Power interface accessories

Product range:

P = MOVIPRO

®

Each unit has a nameplate that provides important information. The following figure

shows an example of a nameplate:

6

Type Type designation SO# Production number

I Max.current carrying capacity P Max. switching capacity

Addendum to the Operating Instructions – MOVIPRO®

2081785611

2.3 Power interface assignment

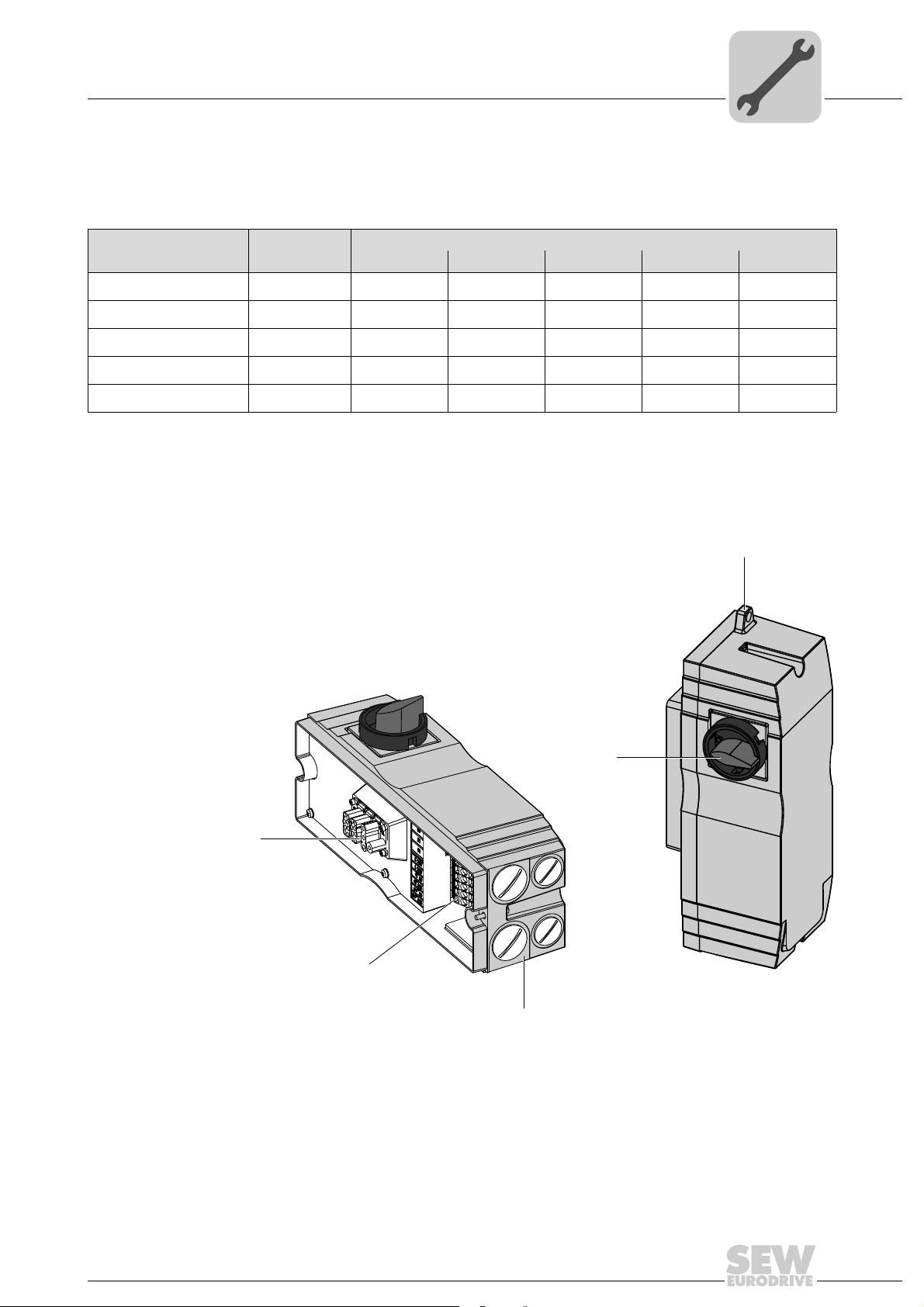

[2]

[3]

[1]

[5]

[4]

PZM2xA-A...-...-00 Power Interface

Power interface assignment

2

The following overview illustrates the assignment of the individual power interfaces to

the respective MOVIPRO

Power interface Part number

PZM2xA-A075-D02-00 1 825 014 9

PZM2xA-A150-D03-00 1 825 015 7

PZM2xA-A022-M13-00 1 825 023 8

PZM2xA-A040-M14-00 1 825 016 5

PZM2xA-A075-M16-00 1 825 017 3

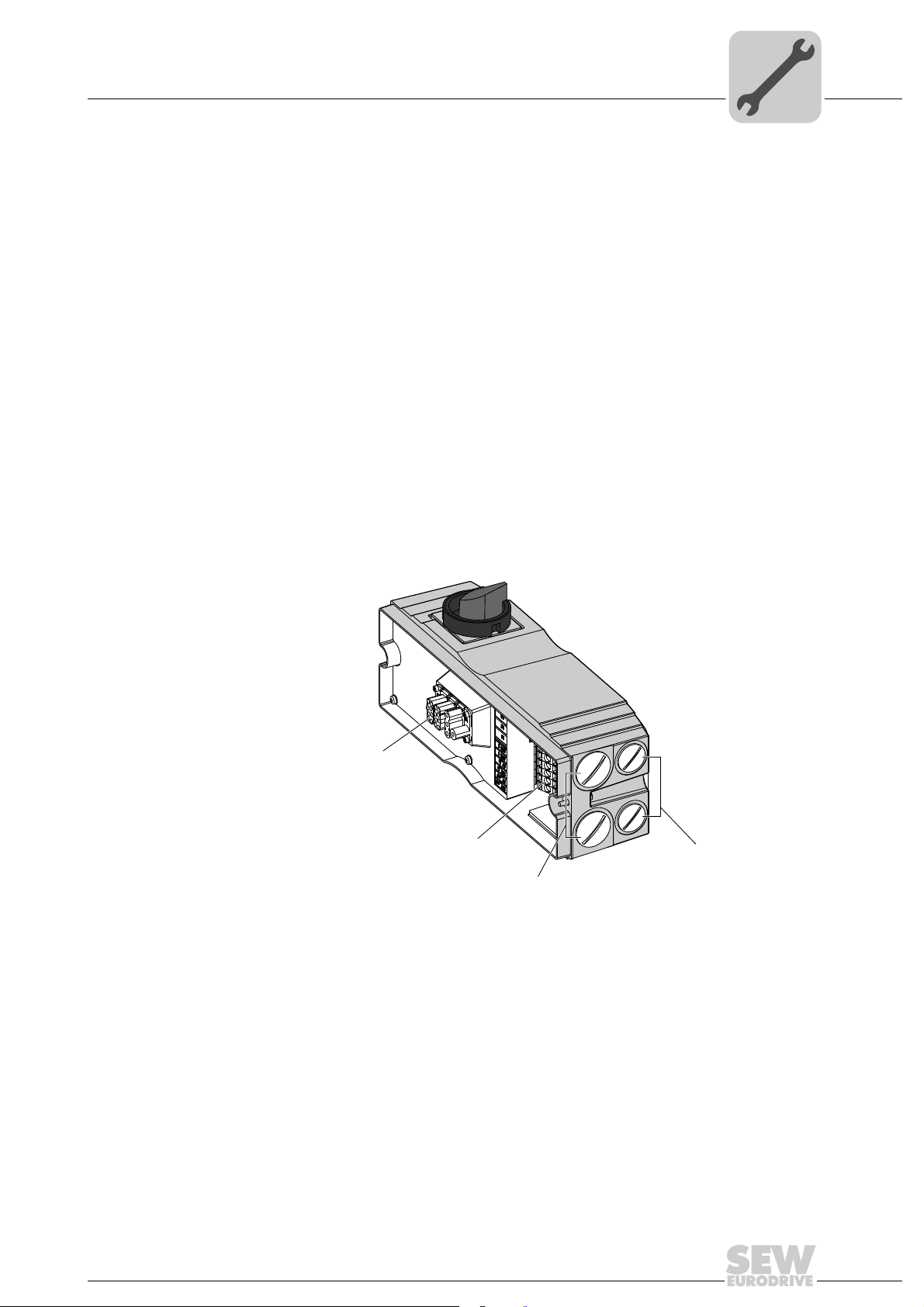

2.4 Basic unit

The following figure shows the power interface:

®

units:

MOVIPRO

up to 2.2 kW up to 4.0 kW up to 7.5 kW up to 11.0 kW up to 15.0 kW

®

•••

•••••

•

•

•

[1] MOVIPRO

[2] Power input terminal strip X1

[3] Front panel connectors

[4] Maintenance switch

Addendum to the Operating Instructions – MOVIPRO®

®

connection (Han® 10 B, female) [5] Suspension device (for storing the power interface

during a MOVIPRO

ple)

2048160523

®

unit replacement, for exam-

7

2

PZM2xA-A...-...-00 Power Interface

Scope of functions

2.5 Scope of functions

2.6 Maintenance switch

The power interface allows for the following functions:

• Connection to the AC 400 V supply system

• Connection to the 24 V backup voltage

• DC 24 V output of the integrated power supply for the MOVIPRO

external DC 24 V cabling (jumper with DC 24 V backup voltage)

• Connected voltages are looped through

• Disconnection of the MOVIPRO

The maintenance switch of the power interface is used to disrupt the AC 400 V power

supply in the power face. The maintenance switch can be secured with 3 locks.

If the maintenance switch is in position "0", the MOVIPRO

AC 400 V voltage supply.

®

unit via the maintenance switch

®

®

self-supply without

is disconnected from the

10 minutes

WARNING

Electric shock due to dangerous voltages present in the power interface.

Severe or fatal injuries.

• Disconnect the power interface from the power supply before you perform any work

on the unit.

• Observe a minimum switch-off time of 10 minutes after disconnecting the power

supply.

INFORMATION

When there is a valid enable signal pending for the MOVIPRO®, the motor is supplied

with current as soon as the maintenance switch is set to 1.

NOTICE

Increased wear of the switch contacts.

Damage of the switch contacts.

• Do not operate the maintenance switch under load.

Depending on the respective type, the power interfaces are equipped with different

maintenance switches:

• D.. disconnection switch

• M.. line and unit protection

8

Addendum to the Operating Instructions – MOVIPRO®

PZM2xA-A...-...-00 Power Interface

Power interface – mechanical installation

2.6.1 D.. disconnection switch

The following disconnection switches are possible depending on the unit's power rating:

Power Short designation Description

up to 7.5 kW D02 Disconnection switch up to 25 A

up to 15.0 kW D03 Disconnection switch up to 40 A

2.6.2 M.. line and unit protection

The following line and unit protection is possible depending on the power:

Power Short designation Description

up to 2.2 kW M13 line and unit protection up to 5 A

up to 4.0 kW M14 line and unit protection up to 9 A

up to 7.5 kW M16 line and unit protection up to 15 A

2.7 Power interface – mechanical installation

2

2.7.1 General information

Observe the following notes on mechanical installation:

• Observe the general safety notes.

• Strictly observe all instructions as to the technical data and the permissible conditions regarding the place of installation.

• Do only use provided attachment options when mounting the unit.

2.7.2 Minimum clearance

Observe the required minimum clearance for:

• the connection of the cables and plug connectors

• the operation of the respective devices such as the maintenance switches.

For the dimensions of the required minimum clearances, refer to chapter "Technical

data (page 17)".

Addendum to the Operating Instructions – MOVIPRO®

9

2

[1]

[2]

[4]

[3]

PZM2xA-A...-...-00 Power Interface

Power interface – mechanical installation

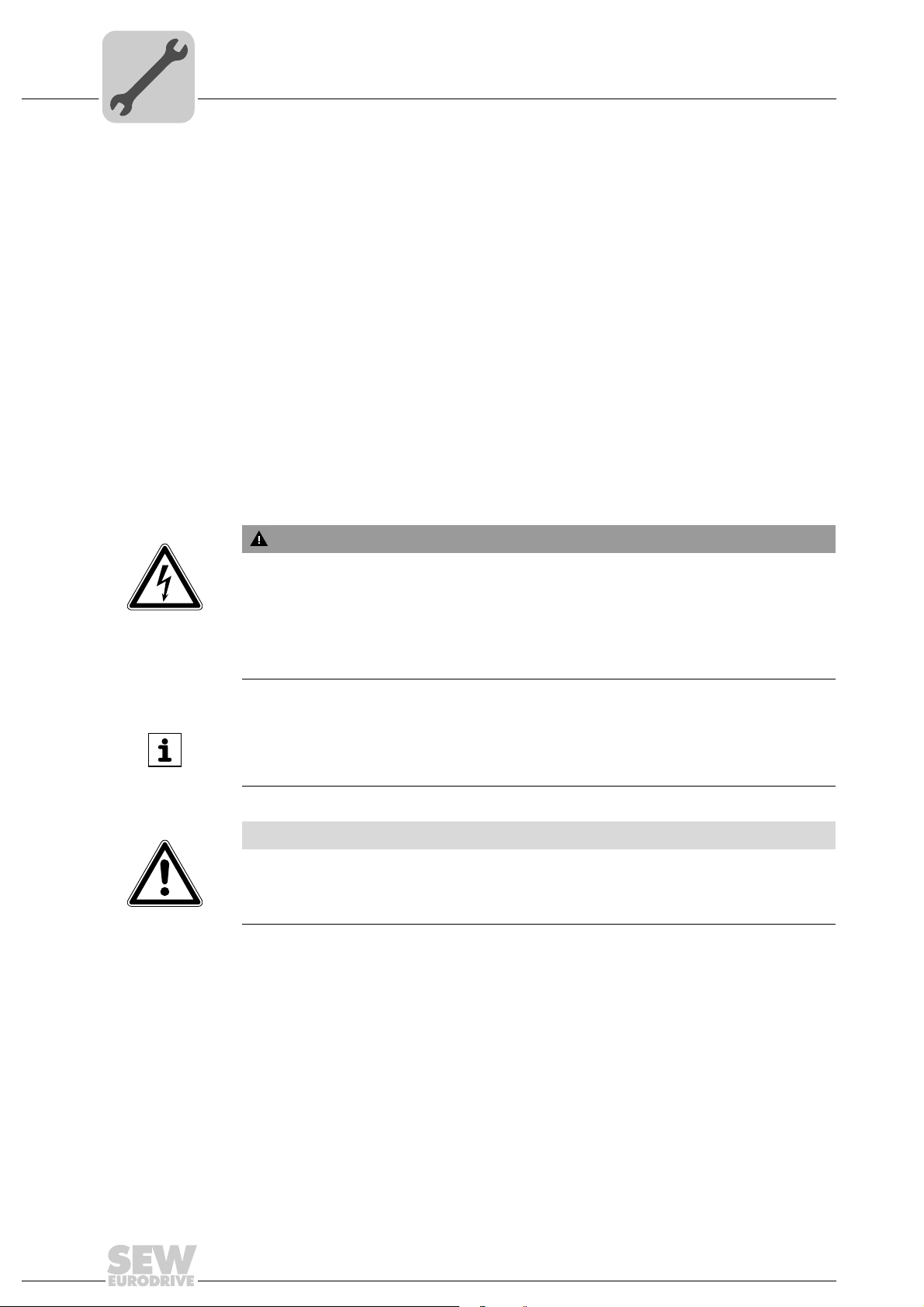

2.7.3 Mounting the power interface

Use the following enclosed parts for assembly:

• 2 × M5 × 30 SW8 screws

Mount the power interface on the right side of the MOVIPRO

unit front).

Proceed as follows to mount the unit:

1. Make the required connections at the connection panel of the power interface, e.g.

AC 400 V supply cable and DC 24 V backup voltage.

®

unit (as viewed onto the

10

[1] MOVIPRO

[2] Power interface flange [4] M5 × 30 SW8 screws

2. Connect the plug connector of the power interface to the plug connector of the

MOVIPRO

®

®

.

3. Attach the power interface to the MOVIPRO

screws with 1.6 Nm – 1.8 Nm (14 in-lb – 16 in-lb).

Addendum to the Operating Instructions – MOVIPRO®

[3] Power interface

®

by tightening the two M5 × 30 SW8

2062166283

PZM2xA-A...-...-00 Power Interface

[1]

[2]

[3]

[4]

Power interface – electrical installation

2.8 Power interface – electrical installation

2.8.1 General Information

Observe the following notes on electrical installation:

• Observe the general safety notes.

• Strictly observe all instructions as to the technical data and the permissible conditions regarding the place of installation.

2.8.2 Cable routing

Comply with the following points when installing the cables:

• Use suitable cables to connect the power supply and the communication.

• Route power cables and signal cables in separate cable ducts.

• Maintain the greatest possible distance between power cables and signal cables.

• Avoid using long cables running parallel to one another.

2

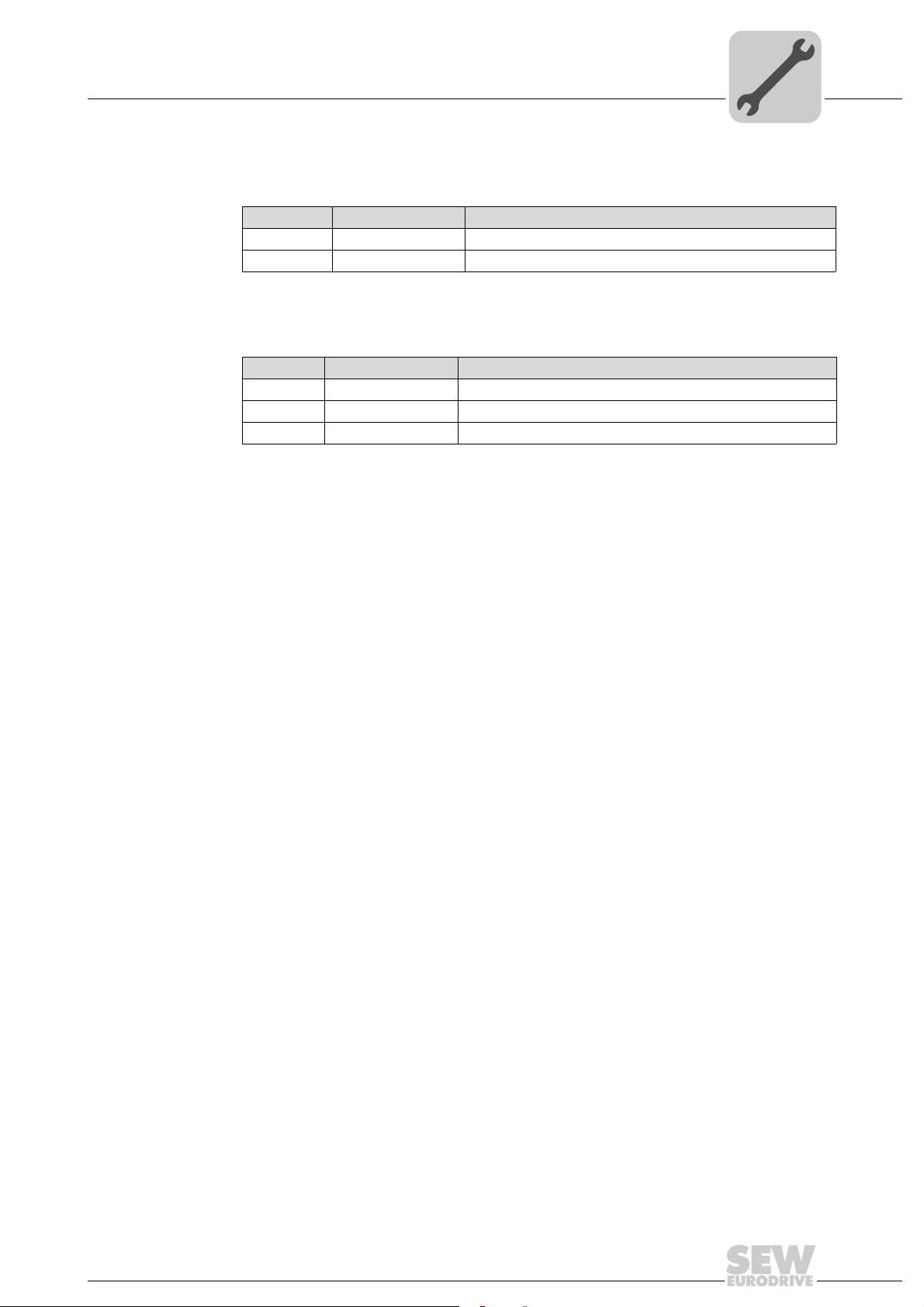

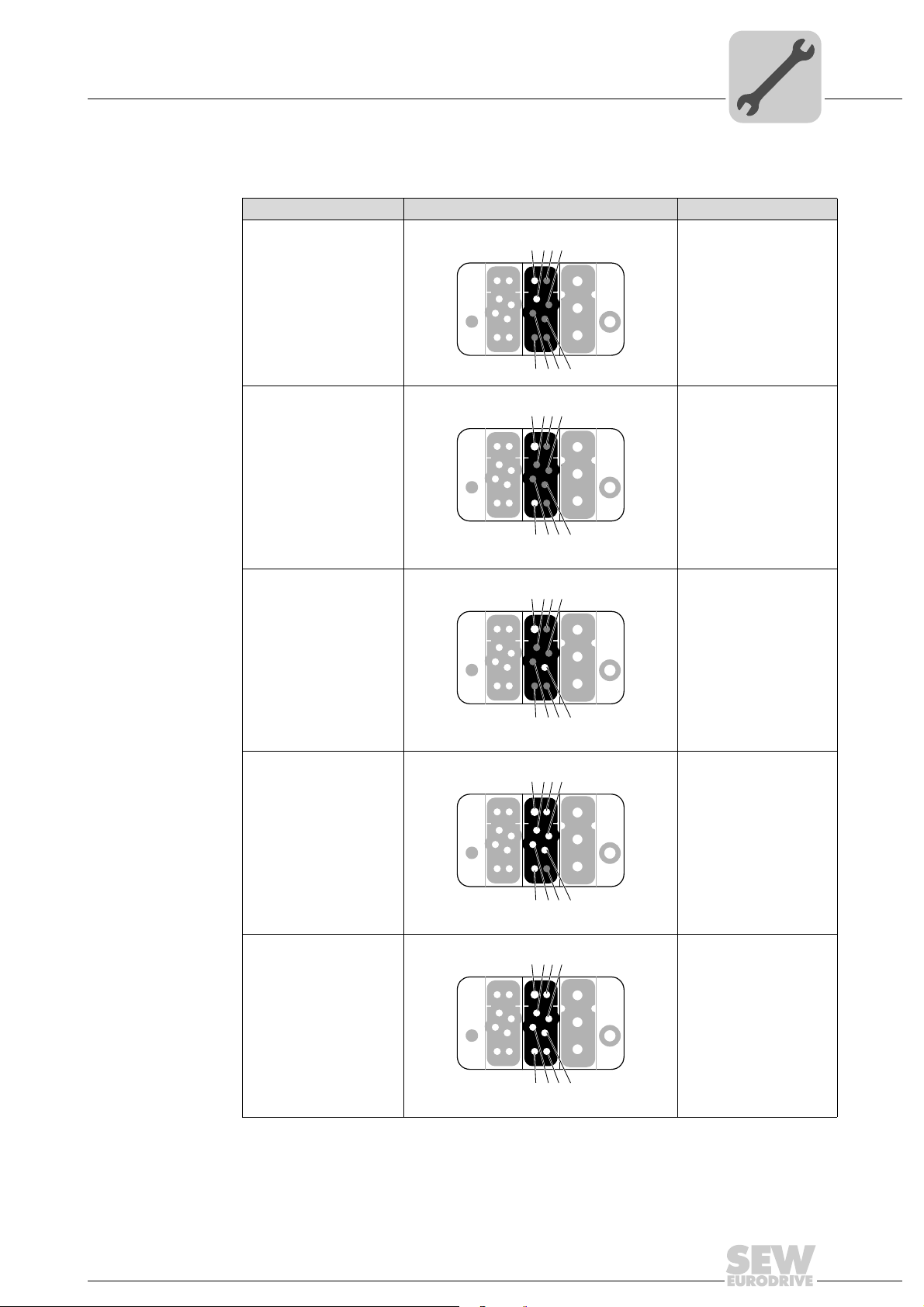

2.8.3 Power interface connections

The following table shows the connections of the power interface:

[1] MOVIPRO

[2] Power input terminal strip X1

[3] Gland (M32 ×1.5)

[4] Gland (M25 ×1.5)

®

connection (Han-Modular® 10 B, female)

1954903947

Addendum to the Operating Instructions – MOVIPRO®

11

2

CA

8

12

1

562

1

562

4

7

3

8

4

7

3

3

PZM2xA-A...-...-00 Power Interface

Power interface – electrical installation

Connection to

MOVIPRO

®

The following table provides information about this connection:

Function

• AC 400 V input to supply units up to

15.0 kW

• DC 24 V output and input

Connection type

Han-Modular® 10 B, female

Wiring diagram

Assignment

No. Name Function

[a] Han®C module, male

1 L1 Supply system phase 1

2 L2 Supply system phase 2

3 L3 Supply system phase 3

[b] Han®EE module, male

Coding of the unit power, see section coding (page 13)

[c] Han®EE module, male

1 +24V_C DC 24 V input – backup voltage

2 SC Signal contact for maintenance switch (external)

3 VO24 DC 24 V output

4 n.c. Not connected

5 0V24_C 0V24 reference potential – backup voltage

6 n.c. Not connected

7 GND Reference potential

8 n.c. Not connected

Hinged frame

PE PE PE connection

• With signal contact for external maintenance switch

• For connecting a power interface (PZM)

2365614987

12

Addendum to the Operating Instructions – MOVIPRO®

PZM2xA-A...-...-00 Power Interface

CA

1562

8374

Power interface – electrical installation

2

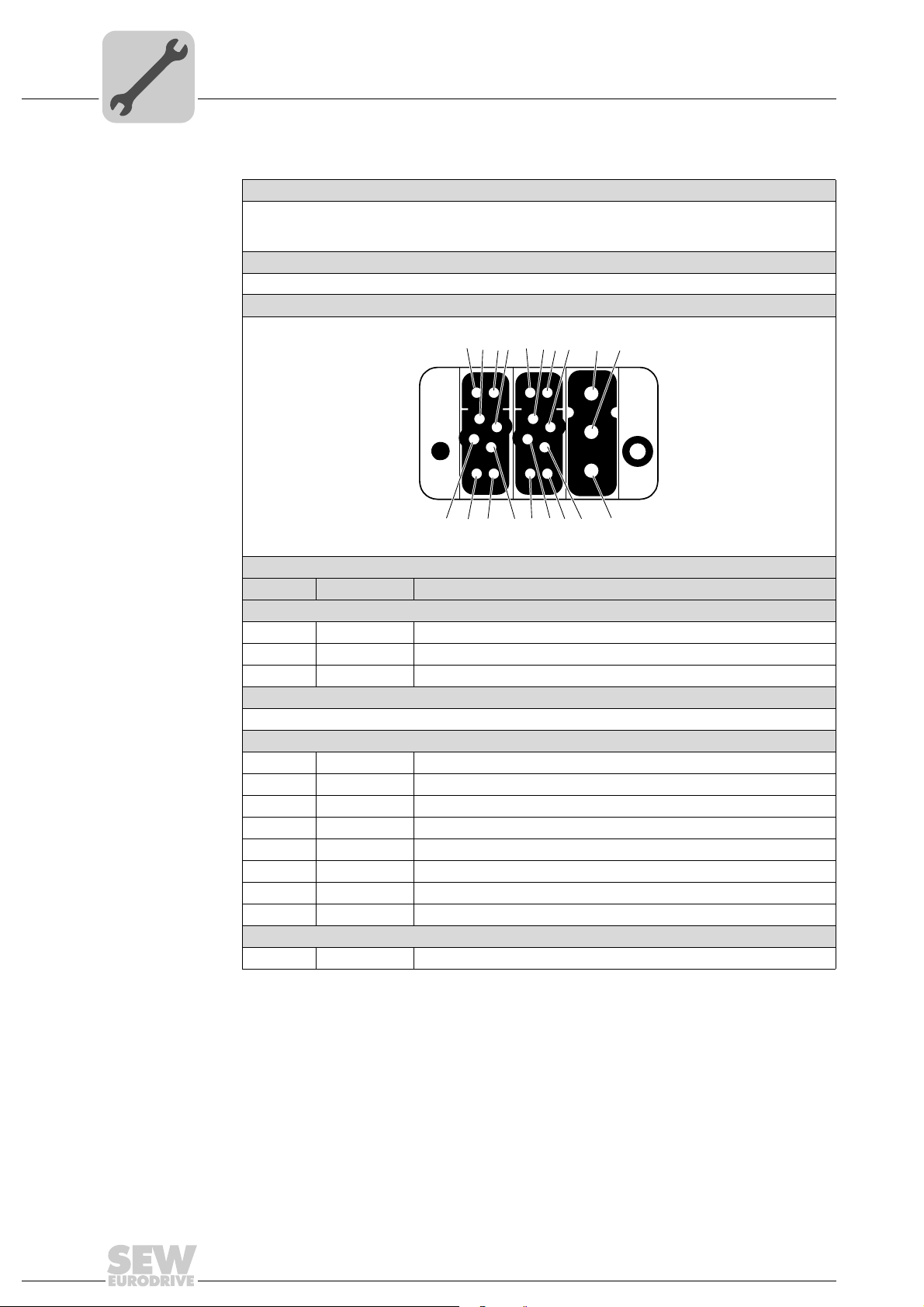

Coding The following table shows the assignment of the different coding to the respective power

1562

1562

®

units:

8374

®

interfaces and the corresponding MOVIPRO

Power interface Power interface – coding of the connections MOVIPRO

CA

PZM2xA-A022-M13-00 2.2 kW

PZM2xA-A040-M14-00 4.0 kW

CA

PZM2xA-A075-M16-00 7.5 kW

8374

1562

CA

2.2 kW

PZM2xA-A075-D02-00

4.0 kW

7.5 kW

8374

1562

CA

2.2 kW

4.0 kW

PZM2xA-A150-D03-00

7.5 kW

11. 0 k W

15.0 kW

Addendum to the Operating Instructions – MOVIPRO®

8374

13

2

VO24

DGND

+24V_C

0V24_C

HT1

HT2

L3

VO24

DGND

+24V_C

0V24_C

HT1

HT2

L3

PZM2xA-A...-...-00 Power Interface

Power interface – electrical installation

2.8.4 X1 terminal strip of the power interface

The following table shows the connections of the power interface:

[1]

[2]

[3]

[4]

[5]

[6]

[7]

[8]

[9]

0V24_C

HT1

HT2

L1L1L2L2L3

VO24

DGND

+24V_C

VO24

L1L1L2L2L3

DGND

+24V_C

0V24_C

HT1

HT2

[10]

9007201210059403

Terminal strip X1 (power input terminal strip) Terminal

No. Name Function

cross

section

1 VO24 DC 24 V output

2 GND Reference potential / DC 24 V output

3 +24 V_C DC 24 V input

4 0V24_C 0V24 reference potential – input

6mm

2

5 HT1 Auxiliary terminal for additional voltage levels (without internal

function)

6 HT2 Auxiliary terminal for additional voltage levels (without internal

function)

7 L1 Phase L1

8 L2 Phase L2

9 L3 Phase L3

10 mm

2

10 PE Equipotential bonding/protective earth conductor

14

Addendum to the Operating Instructions – MOVIPRO®

PZM2xA-A...-...-00 Power Interface

12 3

4

12 3

4

Power interface – electrical installation

2

DC 24 V supply The MOVIPRO® is equipped with a DC 24 V output that can be used to supply the

MOVIPRO

®

from the DC link.

To use the 24 V supply from the DC link, you must jumper the following terminals:

• 1 with 3

• 2 with 4

The following figure illustrates the wiring for using the 24 V supply from the DC link:

2165934475

To use an external DC 24 V backup voltage, connect it to the following terminals:

•3

•4

In this case, the terminals 1 and 2 must not be used.

The following figure illustrates the wiring for using an external 24 V supply:

2165930891

Addendum to the Operating Instructions – MOVIPRO®

15

2

PZM2xA-A...-...-00 Power Interface

Power interfaces – technical data

2.9 Power interfaces – technical data

2.9.1 Basic unit

The following table lists the technical data for the PZM2xA-A...-...-00 power interfaces:

Power interface

PZM2xA-A022M13-00

Description

Ambient temperature

Derating

Ambient temperature ϑ

Climate class EN 60721-3-3, class 3K3

Storage temperature ϑ

Degree of protection IP20, IP54 (in assembled state)

Weight 2.5 kg (5.5 lb)

Dimensions W × H × D 139 mm × 116 mm × 341 mm (5.47 in × 4.57 in × 13.43 in)

Unit output to MOVIPRO

Max. output current 5 A 9 A 15 A 25 A 40 A

Integrated unit protection 5 A 9 A 15 A – –

Max. switching capacity

(IEC, AC 3)

Max. switching capacity

(UL, DOL rating)

Unit input

Line voltage V

Line frequency f

Supply system terminal

cross section

24 V terminal cross

section

Maximum permitted fuse

(gL characteristics)

1) For UL-compliant installation, also observe the maximum permitted fuse for the connected MOVIPRO®. Always adhere to the smaller

value.

line

line

2.2 kW with line

and unit

protection

U

L

®

2.2 kW 4.0 kW 7.5 kW 7.5 kW 15.0 kW

– – – 7.5 HP 15.0 HP

PZM2xA-A040M14-00

4kW with line

and unit

protection

(non-condensing, no moisture condensation)

2

2.5 mm

– 10 mm2 (flexible with conductor end sleeve)

2

1.5 mm

– 6 mm2 (flexible with conductor end sleeve)

60 A 35 A

PZM2xA-A075M16-00

7.5 kW with line

and unit

protection

+5 – +40°C (+41 – +104 °F)

PN reduction: 3% IN per K

up to 60 °C (140 °F)

−25 –+70 °C (−13 – 158 °F)

3 AC 380 V – 500 V

50 – 60 Hz ± 5%

PZM2xA-A075D02-00

7.5 kW with

disconnection

switch

1)

PZM2xA-A150D03-00

15 kW with

disconnection

switch

50 A

1)

16

Addendum to the Operating Instructions – MOVIPRO®

2.9.2 Power interface – dimension drawings

The dimension drawings show the mechanical dimensions of the power interface

in mm (in):

M32 × 1.5 (2×)

PZM2xA-A...-...-00 Power Interface

Power interfaces – technical data

M25 × 1.5 (2×)

2

SW 8

341 (13.43)

361 (14.21)

44 (1.7)

10 (0.39)

139 (5.47)

Ø 10 (0.39)

122 (4.80)

2.9.3 Additional information

Standards and

certifications

Addendum to the Operating Instructions – MOVIPRO®

The power interface was developed and tested based on the following standards:

• VDE 0100

• EN 50178

152 (5.98)

2052458379

17

3

Sensor/Actuator Box

3 Sensor/Actuator Box

The sensor/actuator box allows for connecting up to 8 sensors/actuators to the

MOVIPRO

The sensor/actuator box provides one connection cable with M23 plug connector and

M12 sockets for the sensors or actuators [1]. The green LED "P" [2] indicates that the

DC 24 V supply voltage is used. Each M12 socket is equipped with a yellow LED for

displaying the status of the inputs/outputs [3].

The following figure shows the sensor/actuator box:

®

unit. It occupies only one connection for digital I/Os of the MOVIPRO® unit.

[3]

[2]

[1]

45035997344566411

[1] M12 socket

[2] Operating display LED

[3] Display status of inputs/outputs

The sensor/actuator box is available with different connection cable lengths.

18

Addendum to the Operating Instructions – MOVIPRO®

Sensor/Actuator Box

Sensor/actuator box – electrical installation

3.1 Sensor/actuator box – electrical installation

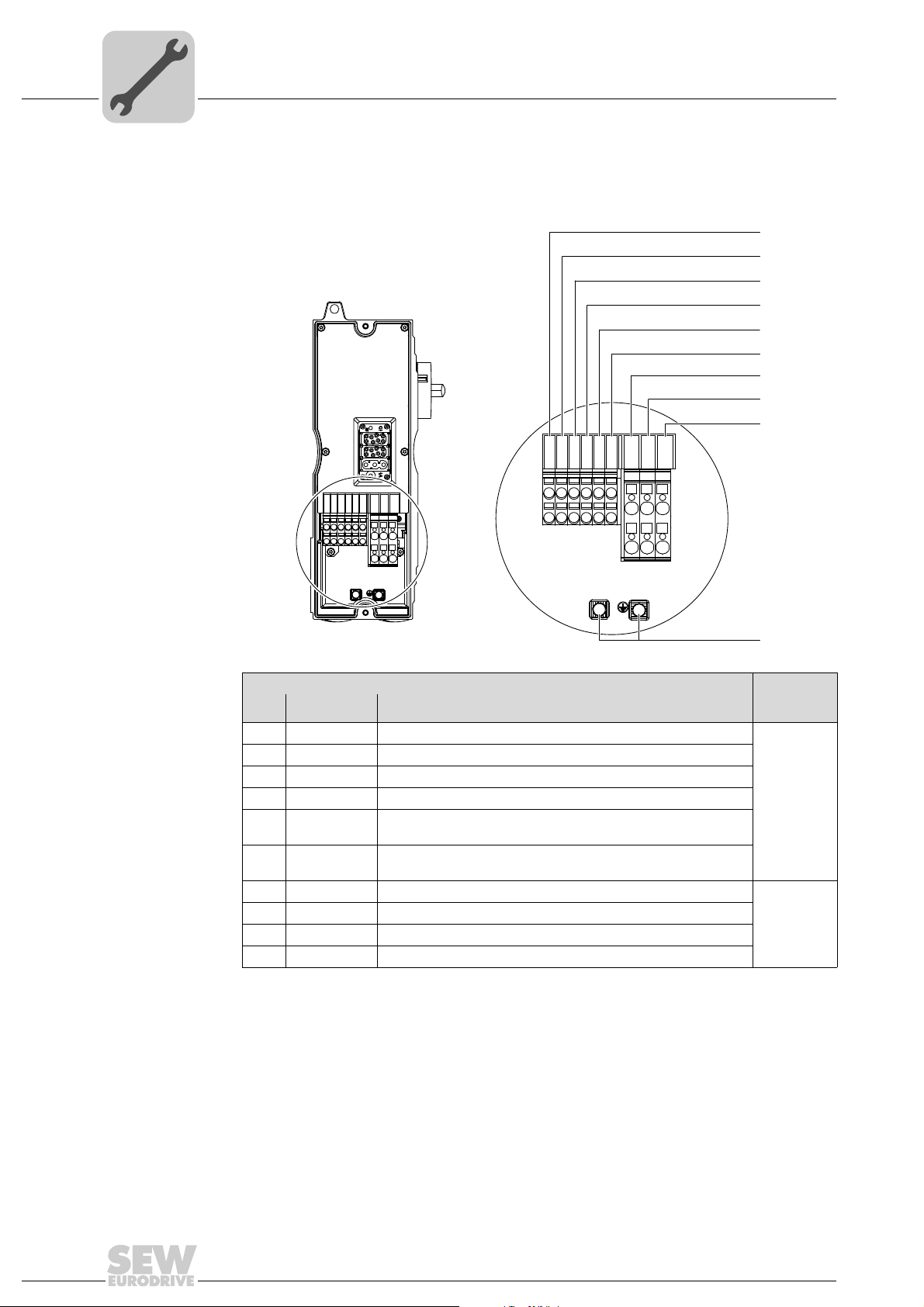

3.1.1 Signals

Connection The following table informs about this connection:

Function

®

Signal transmission to a MOVIPRO

Connection type

M23, P insert 12-pole, female, 0°-coded

Wiring diagram

unit

9

1

10

2

3

8

12

7

3

4

11

Assignment

No. Name Function

1 0 Signal 0

2 1 Signal 1

3 2 Signal 2

4 3 Signal 3

5 4 Signal 4

6 5 Signal 5

7 6 Signal 6

8 7 Signal 7

9 0V24 0V24 reference potential

10 0V24 0V24 reference potential

11 +24V DC 24 V output

12 FE Equipotential bonding/functional ground

6

5

2264822027

Addendum to the Operating Instructions – MOVIPRO®

19

3

Sensor/Actuator Box

Technical data of the sensor/actuator box

Connection cables The following table shows the available cable lengths for the sensor/actuator box:

Connection cable and component

Cable

Length 1 m: Part no. 1 330 926 9

Length 2 m: Part no. 1 330 927 7

Length 3 m: Part no. 1 330 928 5

Length 5 m: Part no. 1 330 929 3

Length 10 m: Part no. 1 330 930 7

Cable design: (3X0.75+8X0.34)

Length/

Installation type

Fixed length

M23, 12-pole, male,

0°-coded

3.2 Technical data of the sensor/actuator box

The following tables show the technical data of the sensor/actuator box:

Nominal voltage V

Maximum operating voltage V

Current carrying capacity

per slot 4 A

in total 8 A

Operating voltage display Green LED

Status display Yellow LED (signal 1)

Operating current display

elements

Degree of protection IP65 (with screwed plug connectors)

[A] = 1 m

Ambient temperature

for fixed routing –30 – +80 °C (–22 – +176 °F)

for cable carrier –5 – +70 °C (–23 – +158 °F)

Cable type Main cable suitable for cable carriers

N

max

Connection cables

(3 ft)

Basic unit

[A] = 2 m

(7 ft)

Sensor/actuator box

(8 M12 slots)

DC 24 V

DC 30 V

≤ 5 mA

[A] = 3 m

(10 ft)

[A] = 5 m

(20 ft)

[A] = 10 m

(33 ft)

20

Addendum to the Operating Instructions – MOVIPRO®

3.2.1 Wiring

Sensor/Actuator Box

Technical data of the sensor/actuator box

The following figure shows the wiring of the sensor/actuator box:

3

0V 1/4

3

5

2/4 6/4 7/4 8/4

4

1

12 678

4

3

1

5

4

3

1

5

4

3

1

5

4

3

5

1

U

h

1214655371

Addendum to the Operating Instructions – MOVIPRO®

21

3

3.2.2 Dimension drawing

Sensor/Actuator Box

Technical data of the sensor/actuator box

The dimension drawing shows the mechanical dimensions of the sensor/actuator box in

mm (in):

[A]

32 (1.3)

50 (2.0)

9 (0.4)

39 (1.5)

17 (0.7)

140 (5.5)

107 (4.2)

73 (2.9)

33 (1.3)

4.5 (0.2)

Ø 4.5 (0.2)

9007200325600523

22

Addendum to the Operating Instructions – MOVIPRO®

BW..-0..-0. External Braking Resistors

4 BW..-0..-0. External Braking Resistors

WARNING

Electric shock due to high DC voltage in the supply lines (about DC 900 V).

Severe or fatal injuries.

• Only use cables provided by SEW-EURODRIVE.

• Install the braking resistor cables according to the regulations.

WARNING

Hot surfaces.

Risk of injuries and fire.

• Select a suitable installation location and observe the minimum clearance.

• Provide for covers to secure hot surfaces.

• Install the protection devices according to the regulations.

• Check the protection devices on a regular basis.

For regenerative operation, the MOVIPRO® is connected to an external braking resistor.

The following figure shows an example of a size 1 braking resistor:

4

INFORMATION

The BW...-0..-0. braking resistors are intrinsically safe. This kind of intrinsic safety

does explicitly not correspond to the kind of intrinsic safety referred to in conjunction

with explosion-protection.

With the BW...-0..-0. braking resistors, intrinsic safety means that the following does

not occur in the event of a continuous overload (e.g. due to a short circuit in the

braking transistor (brake chopper)):

• Short circuit

• Short circuit to frame

•Fire

•Explosion

• Melting of the aluminum housing

Addendum to the Operating Instructions – MOVIPRO®

2084027019

23

4

BW..-0..-0. External Braking Resistors

Braking resistors – mechanical installation

4.1 Braking resistors – mechanical installation

4.1.1 Mounting position

The following table shows the permitted and prohibited mounting positions for the

braking resistors:

Braking resistor Mounting positions

BW100-004-00

BW033-012-01

BW050-008-01

BW017-024-02

4.1.2 Minimum clearance

Calculate the mounting surfaces, the touch guard and the clearance according to the

high surface temperature. However, observe a minimum clearance of 30 mm. For the

dimensions of the required minimum clearances, refer to chapter "Technical data of the

external braking resistors (page 30)".

24

Addendum to the Operating Instructions – MOVIPRO®

4.1.3 Mounting braking resistors

You can mount the braking resistors directly over the retaining plates. Note the following

points during assembly:

• Observe the safety notes.

• Observe the required minimum distances and clearances.

Use the following parts for assembly:

• A mounting plate, for example, to observe the required minimum distances and

clearances

• Suitable mounting and safety elements

Mount the braking resistors as follows:

1. For dimensions of the holes, refer to the dimension sheets in the technical data of the

braking resistors.

2. Drill the holes in the appropriate places.

3. The following figures show how to mount the braking resistors:

Size 0:

BW..-0..-0. External Braking Resistors

Braking resistors – mechanical installation

4

Addendum to the Operating Instructions – MOVIPRO®

2110859403

25

4

1. 2.

BW..-0..-0. External Braking Resistors

Braking resistors – mechanical installation

Sizes 1 and 2:

4. Ground the housing of the braking resistor.

2110862475

26

Addendum to the Operating Instructions – MOVIPRO®

BW..-0..-0. External Braking Resistors

[3]

[1]

[2]

Braking resistors – mechanical installation

4.1.4 Mounting the braking resistors with mounting brackets (only size 1 and 2)

You can use the following mounting brackets to attach the braking resistors:

• BW050-008-01

• BW033-012-01

• BW017-024-02

Note the following points during assembly:

• Observe the safety notes.

• Observe the required minimum distances and clearances.

Use the following parts for assembly:

• The SEW-EURODRIVE "BW bracket mounting set" accessory, part number

1 822 968 9. It contains:

– 4 × mounting brackets

– 8 × M5 × 12 pan head screws

Proceed as follows to attach the mounting brackets:

1. Use the M5 × 12 pan head screws [1] to attach the mounting brackets [3] to the

braking resistor [2] according to the following figure:

4

[1] M5 × 12 pan head screws [2] Braking resistor [3] Mounting brackets

2. Ground the housing of the braking resistor.

INFORMATION

For information on how to attach the brackets to square pipes or bars, refer to chapter

"Mounting accessories (page 36)".

Addendum to the Operating Instructions – MOVIPRO®

2091901579

27

4

BW..-0..-0. External Braking Resistors

Technical data of the external braking resistors

4.2 Technical data of the external braking resistors

4.2.1 Braking resistor assignment

The following table illustrates the assignment of external braking resistors to the respective MOVIPRO

Braking

resistor

BW100-004-00 1 796 218 8 Size 0

BW050-008-01 1 796 224 2 Size 1 6 mm

BW033-012-01 1 796 219 6 Size 1 6 mm

BW017-024-02 1 796 221 8 Size 2 6 mm

Part

number

Size

®

units:

Terminal

cross

section

up to

2.2 kW

up to

4.0 kW

MOVIPRO

7.5 kW

up to

®

up to

11.0 kW

up to

15.0 kW

•••

2

2

2

••••

••••

••

28

Addendum to the Operating Instructions – MOVIPRO®

BW..-0..-0. External Braking Resistors

Technical data of the external braking resistors

4.2.2 Technical data according to IEC

The following tables list the technical data of the external braking resistors according to

IEC:

Braking resistor

BW100-004-00 BW050-008-01 BW033-012-01 BW017-024-02

Function Carrying off of regenerative energy

Degree of protection IP65

Resistance 100 Ω 50 Ω 33.3 Ω 16.7 Ω

Continuous braking

power

Dimensions W × H × D 320 mm × 70 mm × 106 mm 550 mm × 105 mm × 230 mm 550 mm × 158 mm × 330 mm

100% cdf 0.4 kW 0.8 kW 1.2 kW 2.4 kW

50% cdf 0.8 kW 1.6 kW 2.4 kW 4.8 kW

25% cdf 1.5 kW 3.0 kW 4.5 kW 9.0 kW

12% cdf 2.2 kW 4.4 kW 6.6 kW 13.2 kW

6% cdf 3.6 kW 7.2 kW 10.8 kW 21.6 kW

4

4.2.3 Technical data according to UL

The following tables list the technical data of the external braking resistors:according to

UL:

Braking resistor

BW100-004-00 BW050-008-01 BW033-012-01 BW017-024-02

Function Carrying off of regenerative energy

Degree of protection IP65

Resistance 100 Ω 50 Ω 33.3 Ω 16.7 Ω

Continuous braking

power

Dimensions W × H × D

100% cdf 0.24 kW 0.48 kW 0.72 kW 1.44 kW

50% cdf 0.5 kW 1.0 kW 1.5 kW 3.0 kW

25% cdf 1.0 kW 2.0 kW 3.0 kW 6.0 kW

12% cdf 2.2 kW 4.4 kW 6.6 kW 13.2 kW

6% cdf 3.6 kW 7.2 kW 10.8 kW 21.6 kW

320 mm × 70 mm × 106 mm

(12.6 in × 2.8 in × 4.17 in)

550 mm × 105 mm × 230 mm

(21.7 in × 4.13 in × 9.06 in)

550 mm × 158 mm × 330 mm

(21.7 in × 6.22 in × 13.0 in)

Addendum to the Operating Instructions – MOVIPRO®

29

4

86 (3.4)

10 (0.39)

10 (0.39)

Ø 6

(0.2)

10 (0.39)

300 (11.8)

70 (2.8)

ca. 1580 (62.20)

320 (12.6)

106 (4.17)

4.2.4 Braking resistors – dimension drawings

Size 0 braking

resistor

BW..-0..-0. External Braking Resistors

Technical data of the external braking resistors

The dimension drawing shows the mechanical dimensions of the size 0 braking resistor

in mm (in):

2062332427

30

Addendum to the Operating Instructions – MOVIPRO®

BW..-0..-0. External Braking Resistors

Technical data of the external braking resistors

4

Size 1 braking

resistor

Ø 9 (0.4)

(2×)

215 (8.46)

15 (0.59)

12 (0.47)

The dimension drawing shows the mechanical dimensions of the size 1 braking resistor

in mm (in):

230 (9.06)

542 (21.3)

9 (0.4)

105 (4.13)

550 (21.7)

v

M5

15 (0.59)

2062339339

Addendum to the Operating Instructions – MOVIPRO®

31

4

BW..-0..-0. External Braking Resistors

Technical data of the external braking resistors

Size 2 braking

resistors

Ø 9 (0.4)

315 (12.4)

(3×)

165 (6.50)

12 (0.47)

The dimension drawing shows the mechanical dimensions of size 2 braking resistors in

mm (in):

330 (13.0)

15 (0.59)

542 (21.3)

9 (0.4)

158 (6.22)

550 (21.7)

M5

15 (0.59)

2062328587

32

Addendum to the Operating Instructions – MOVIPRO®

5 Jumper Plug

Safe disconnection of the unit is not possible when the jumper plug is used.

Severe or fatal injuries.

• Use the jumper plug only if the unit need not perform any safety functions according

WARNING

to DIN EN ISO 13849-1.

Jumper Plug

5

The jumper plug can be connected to the X5502 terminal of MOVIPRO®. The jumper

plug deactivates the safety functions of the MOVIPRO

The following figure shows the jumper plug, part number 1 174 709 9:

®

.

36028798167876875

Addendum to the Operating Instructions – MOVIPRO®

33

6

[2]

[1]

a

Mounting Accessories

Handles

6 Mounting Accessories

6.1 Handles

You can equip the MOVIPRO® with handles for easier handling:

The handles are available in two lengths depending on the size of MOVIPRO

2049840395

®

:

Handles Part number MOVIPRO® housing height

Handle option 270 1 822 278 1 (2 pieces) 300 mm

Handle option 390 1 822 280 3 (2 pieces) 420 mm

6.1.1 Mounting the handles

Tighten both countersunk screws of each handle with a maximum tightening torque of

3.5 Nm (31 in-lb).

34

1531247243

[1] M8 × 20 countersunk screw (DIN EN ISO 10642) a = Handle option = 270 mm

[2] Handle Handle option = 390 mm

Addendum to the Operating Instructions – MOVIPRO®

6.2 Mounting brackets

You can use mounting brackets to mount the MOVIPRO® safely and easily:

Mounting Accessories

Mounting brackets

6

658542347

Mounting brackets Part number

MOVIPRO

Braking resistors:

BW050-008-01

BW033-012-01

BW017-024-02

®

Mounting bracket kit, large (4 pieces) 1 270 830 5

Mounting bracket kit, BW (4 pieces) 1 822 968 9

For information on how to mount the braking resistors with the mounting brackets, refer

to chapter "Braking resistors – mechanical installation (page 24)".

Addendum to the Operating Instructions – MOVIPRO®

35

6

Mounting Accessories

Mounting brackets

6.2.1 Mounting with mounting brackets

Note the following points during assembly:

• Strictly observe the safety notes contained in this documentation.

• Observe the required minimum distances and clearances.

Use the following parts for assembly:

• The SEW-EURODRIVE "Large bracket mounting set" accessory, part number

1 270 830 5. It contains:

– 4 mounting brackets

– 8 studs M5 × 8 type in accordance with DIN EN ISO 4027

• Suitable mounting and retaining elements to attach the MOVIPRO

fixture:

– e.g. M6 or M8 screws of an appropriate length with washers

Mounting brackets Proceed as follows to attach the mounting brackets to the MOVIPRO

1. Insert the mounting brackets into the T-slots of the MOVIPRO

edge of the bracket is flush with the upper end of the slot.

2. In order to prevent the mounting brackets from slipping out of position in the T-slots,

you can fasten them with M8 × 30 screws in the through bores of the MOVIPRO

®

unit to the

®

unit:

®

unit so that the upper

®

.

Preparing the

fixture

3. Fasten the mounting bracket with the enclosed studs.

Square pipes or bars can be used as a fixture for the MOVIPRO

®

.

INFORMATION

Use only square pipes with an edge length ≤ 35 mm for mounting the MOVIPRO® unit

to avoid mechanical interference.

Proceed as follows to prepare the fixture:

1. Refer to the following table for dimensions of the threaded holes in the holding fixture:

Bore dimension Value

X

2

2. Cut the threads at the appropriate points.

3. For the clearance dimensions of the fixture, refer to the following table:

Distance Value

A Housing dimension Y – 145 mm (5.71 in) (see dimension drawing)

4. Mount the holding fixture within the calculated clearance.

Housing dimension X – 30 mm (1.2 in) (see dimension drawing)

36

Addendum to the Operating Instructions – MOVIPRO®

Mounting Accessories

Mounting brackets

6

Fastening

MOVIPRO

®

1. Use the mounting brackets to hang the MOVIPRO

®

on the fixture.

2. Screw the mounting brackets to the fixture. The following figure illustrates suitable

mounting and locking elements. It shows the main mounting elements and dimensions in mm (in):

[1]

[2]

[4]

[5]

[6]

[5]

[4]

[7]

[8]

Proceed as follows to fasten the unit to the fixture:

86.5 (3.41)

X

X

2

[1] MOVIPRO

[2] Large mounting brackets

[3] Holding fixture, e.g. square pipe or bar

Bore for:

[4] M8 × 30 screw

[5] M5 × 8 stud

[6] M8 screw of an appropriate length with washer

[7] M6 screws with suitable length with washer through bore [7] and [8]

X, Y Housing dimensions

X

2

A Distance

67.5 (2.66) 77.5 (3.05)

A

Y

®

Bore dimension

20 (0.79)

M8

10 (0.39)

(1.59)

15 (0.59)

Ø

6.6 (0.26)

Ø

M6

40.5

66 (2.6)

114.5 (4.508)

M5

M5

20 (0.79)

10 (0.39)

95 (3.7)

115 (4.53)

14.6 (0.575)

20 (0.79)

36028797434827531

[2]

135 (5.31)

Maximum permitted tightening torque: 3.2 Nm (28 in-lb)

Addendum to the Operating Instructions – MOVIPRO®

37

7

[3][2][1]

Fan Subassembly

7 Fan Subassembly

The fan is connected to the MOVIPRO® externally. The axial fans are controlled automatically depending on the temperature. They are encapsulated, and their degree of

protection is IP54.

The following figure shows the fan subassembly:

[1] Air baffle

[2] Connection cable

[3] Axial fan

Part number

Fan subassembly 1 270 970 0

36028797698977163

38

Addendum to the Operating Instructions – MOVIPRO®

Mechanical installation of the fan subassembly

[1]

[2]

[4]

[3]

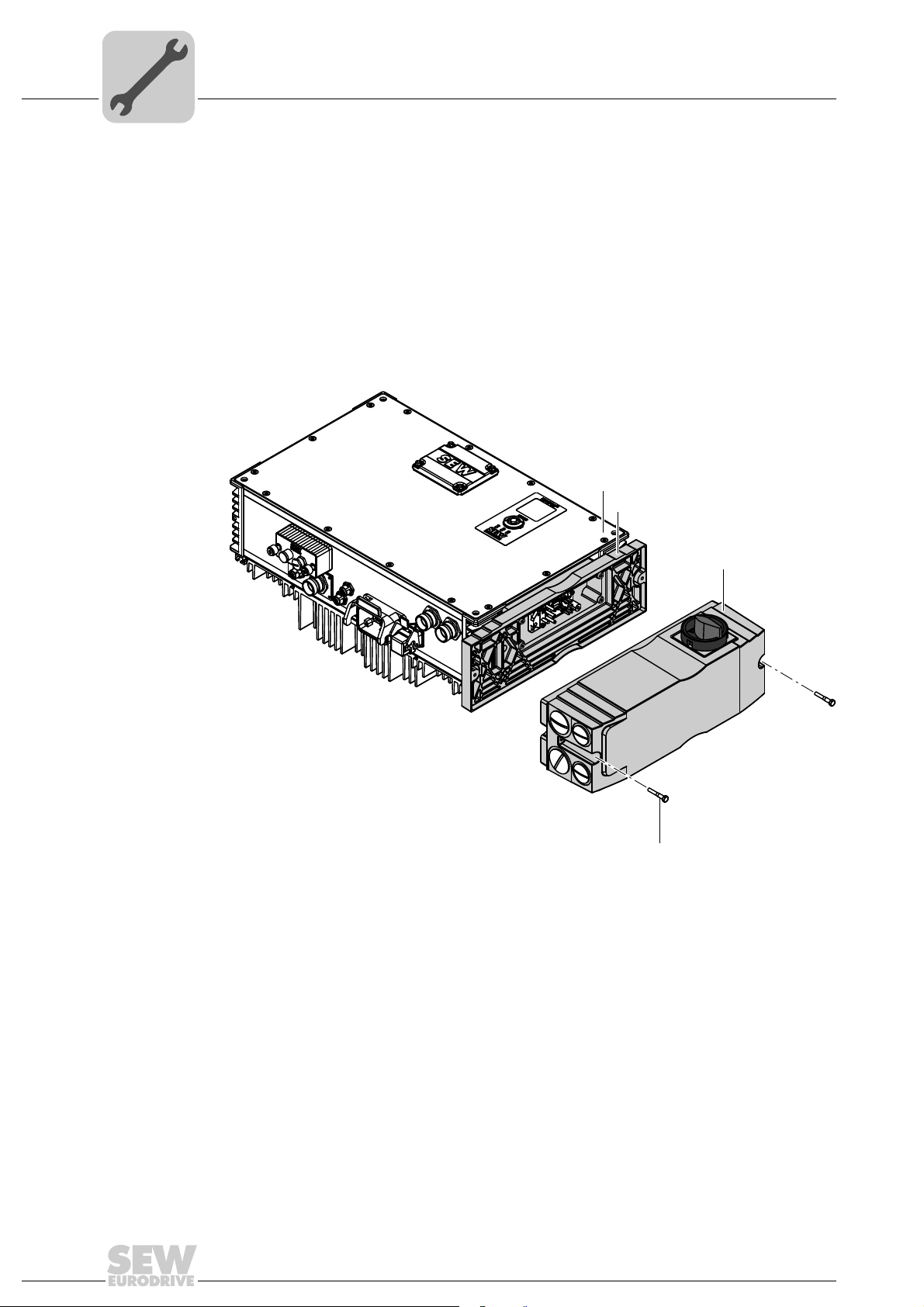

7.1 Mechanical installation of the fan subassembly

Use the following enclosed parts for assembly:

• 6 screws M5 × 75

• 6 serrated lock washers

Proceed as follows to mount the fan subassembly:

1. Use the M5 × 75 screws [4] and the serrated lock washers to mount the fan subassembly [3] according to the following figure:

Fan Subassembly

7

9007201339415307

[1] X5111 connector of MOVIPRO® [3] Fan subassembly

[2] MOVIPRO

2. Plug the connector of the fan cable onto the X5111 connector [1] of MOVIPRO

®

[4] M5 × 75 screws

®

[2].

Addendum to the Operating Instructions – MOVIPRO®

39

Index

Index

A

AC 400 V input

Connection.........................................................12

Assignment

External braking resistors ..................................28

Power interface ....................................................7

B

Basic unit

Power interface ....................................................7

Brackets .................................................................35

Part number .......................................................35

Braking resistors, see external braking resistors ...23

BW017-024-02.......................................................23

BW033-012-01.......................................................23

BW050-008-01.......................................................23

BW100-004-00.......................................................23

C

Cable routing

Power interface ..................................................11

Cables

see connection...................................................20

Certifications

Power interface ..................................................17

Connection

AC 400 V input...................................................12

Digital inputs/outputs..........................................19

Connections ...........................................................14

Power interface ..................................................11

Control unit, see Communication and control unit .19

Copyright..................................................................5

D

Digital inputs/outputs

Connection.........................................................19

Digital I/Os, control unit

Cables................................................................20

Dimension drawings

External braking resistors ..................................30

Power interface ..................................................17

Sensor/actuator box...........................................22

Disconnection switch

D02/D03...............................................................9

Power interface ....................................................9

E

Electrical Installation

Sensor/actuator box........................................... 19

Electrical installation

Power interface.................................................. 11

Embedded safety notes ........................................... 4

Exclusion of liability..................................................5

External Braking resistors

Mounting brackets ............................................. 27

External braking resistors ......................................23

Assignment ........................................................ 28

Dimension drawings .......................................... 30

IEC data............................................................. 29

Mechanical installation....................................... 24

Minimum clearance............................................ 24

Mounting ......................................................25, 27

Mounting position............................................... 24

Part numbers ..................................................... 28

UL data .............................................................. 29

F

Fan subassembly...................................................38

Mechanical installation....................................... 39

Part number .......................................................38

Functions

Power interface.................................................... 8

H

Handle option.........................................................34

Mounting ............................................................ 34

Part numbers ..................................................... 34

Handles..................................................................34

Part numbers ..................................................... 34

I

IEC data

External braking resistors ..................................29

Installation, mechanical ...........................................9

I/O, see Digital inputs/outputs................................ 19

J

Jumper plug ...........................................................33

Part number .......................................................33

40

Addendum to the Operating Instructions – MOVIPRO®

Index

M

Maintenance switch

Power interface ....................................................8

Mechanical Installation.............................................9

Mechanical installation

External braking resistors ..................................24

Fan subassembly...............................................39

Power interface ....................................................9

Minimum clearance

External braking resistance................................24

Power interface ....................................................9

Motor protection switch

M14/D16 ..............................................................9

Power interface ....................................................9

Mounting

External braking resistors ............................25, 27

Handle option.....................................................34

Power interface ..................................................10

Mounting accessories ............................................34

Brackets .............................................................35

Handle option.....................................................34

Handles..............................................................34

Mounting brackets..............................................35

Mounting bracket

Use.....................................................................36

Mounting brackets..................................................35

External braking resistors ..................................27

Part numbers .....................................................35

Mounting position

External braking resistors ..................................24

Mounting with mounting brackets...........................36

N

Nameplate

Power interface ....................................................6

Notes

Designation in the documentation........................4

P

Part number

Jumper plug .......................................................33

Part numbers

Brackets............................................................. 35

External braking resistors ..................................28

Fan subassembly............................................... 38

Handle option..................................................... 34

Handles.............................................................. 34

Mounting brackets ............................................. 35

Sensor/actuator box........................................... 20

Power input, see AC 400 V input...........................12

Power interface

Assignment .......................................................... 7

Basic unit ....................................................... 7, 16

Cable routing ..................................................... 11

Certifications ...................................................... 17

Dimension drawings .......................................... 17

Disconnection switch ........................................... 9

Electrical installation .......................................... 11

Functions ............................................................. 8

Maintenance switch ............................................. 8

Mechanical installation......................................... 9

Minimum clearance.............................................. 9

Motor protection switch........................................9

Mounting ............................................................ 10

Nameplate ...........................................................6

PZM2xA-A022-M13-00 .................................... 6, 7

PZM2xA-A040-M14-00 ..............................6, 7, 16

PZM2xA-A075-D02-00 .............................. 6, 7, 16

PZM2xA-A075-M16-00 ..............................6, 7, 16

PZM2xA-A150-D03-00 .............................. 6, 7, 16

Standards .......................................................... 17

Technical data ................................................... 16

Type designation ................................................. 6

power interface

PZM2xA-A022-M13-00 ...................................... 16

PZM2xA-A022-M13-00 .................................. 6, 7, 16

PZM2xA-A040-M14-00 .................................. 6, 7, 16

PZM2xA-A075-D02-00 .................................. 6, 7, 16

PZM2xA-A075-M16-00 .................................. 6, 7, 16

PZM2xA-A150-D03-00 .................................. 6, 7, 16

R

Rights to claim under limited warranty ..................... 5

Addendum to the Operating Instructions – MOVIPRO®

41

Index

S

Safety notes

Designation in the documentation........................4

Structure of the embedded safety notes ..............4

Structure of the section-related safety notes .......4

Section-related safety notes ....................................4

Sensor/actuator box...............................................18

Dimension drawing ............................................22

Electrical installation ..........................................19

Part numbers .....................................................20

Technical data....................................................20

Wiring.................................................................21

Signal words in the safety notes ..............................4

Standards

Power interface ..................................................17

Supply system, see AC 400 V input.......................12

T

Technical data

Power interface.................................................. 16

Sensor/actuator box........................................... 20

Type designation

Power interface.................................................... 6

U

UL data

external braking resistors...................................29

X

X5001 .................................................................... 19

X5111 .................................................................... 39

X5502 .................................................................... 33

0 ... 9

400 V input, see AC 400 V input............................ 12

42

Addendum to the Operating Instructions – MOVIPRO®

SEW-EURODRIVE—Driving the world

SEW-EURODRIVE

Driving the world

SEW-EURODRIVE GmbH & Co KG

P.O. Box 3023

D-76642 Bruchsal/Germany

Phone +49 7251 75-0

Fax +49 7251 75-1970

sew@sew-eurodrive.com

www.sew-eurodrive.com

Loading...

Loading...