SEW-Eurodrive MOVIMOT MM07, MOVIMOT MM11, MOVIMOT MM15, MOVIMOT MM22, MOVIMOT MM30 Operating Intstructions

...

Gearmotors \ Industrial Gear Units \ Drive Electronics \ Drive Automation \ Services

MOVIMOT

Edition 05/2007

11641819 / EN

®

for Energy Efficient Motors

O

perating

I

nstructions

SEW-EURODRIVE – Driving the world

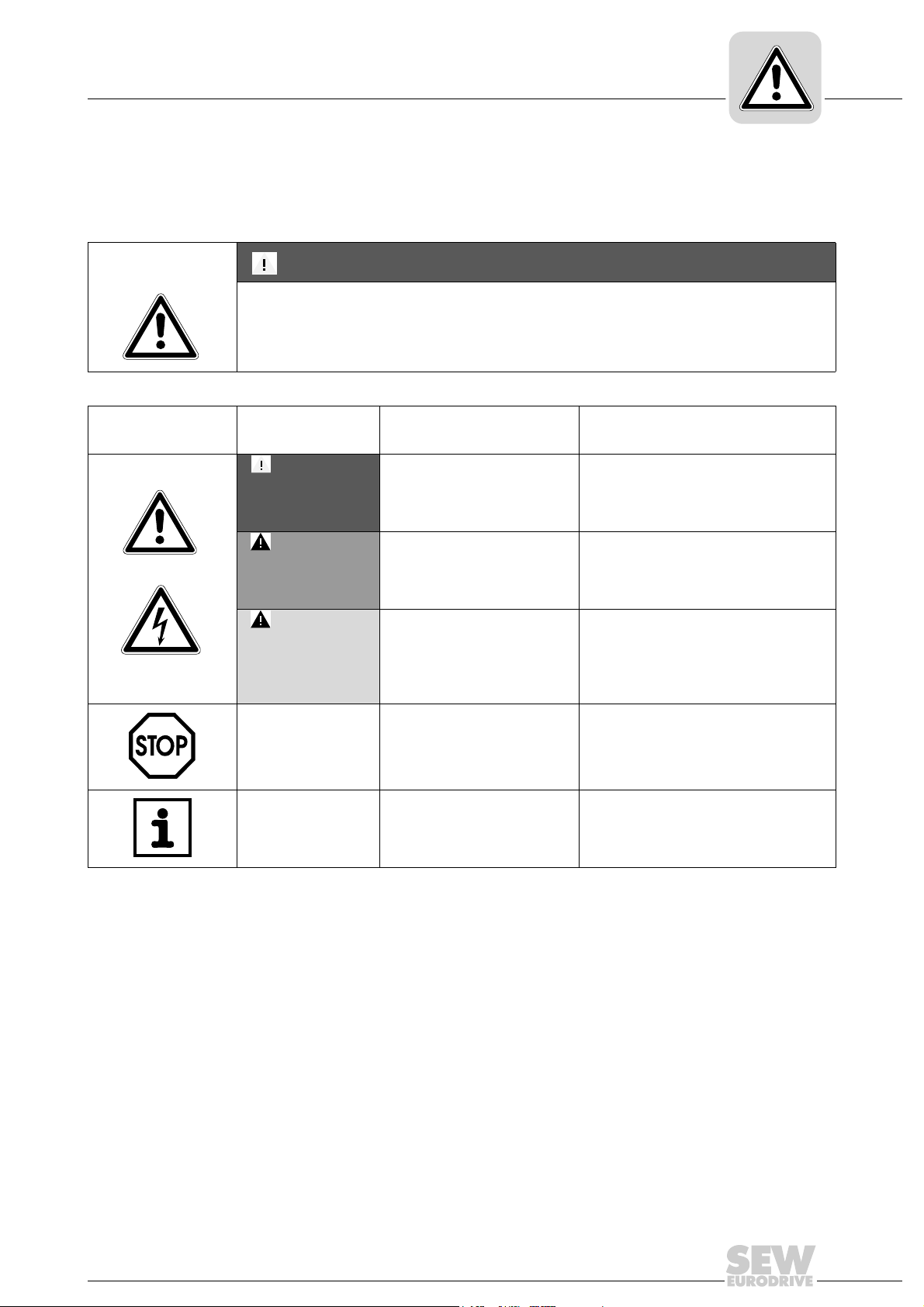

General notes

Structure of the safety notes

1

1 General notes

Addendum to the Operating Instructions

1.1 Structure of the safety notes

The safety notes in these operating instructions are designed as follows:

Pictogram SIGNAL WORD!

Type and source of danger.

Possible consequence(s) if the safety notes are disregarded.

• Measure(s) to prevent the danger.

Pictogram Signal word Meaning Consequences in case of

disregard

Example:

General danger

DANGER! Imminent danger Severe or fatal injuries

WARNING! Possible dangerous situation Severe or fatal injuries

CAUTION! Possible dangerous situation Minor injuries

Specific danger,

e.g. electric shock

STOP! Possible damage to property Damage to the drive system or its environ-

NOTE Useful information or a tip

Simplifies the handling of the

drive system

1.2 Right to claim under warranty

A requirement of fault-free operation and fulfillment of any rights to claim under limited

warranty is that you adhere to the information in the MOVIMOT

sequently, read the operating instructions before you start working with the unit!

Make sure that the operating instructions are available to persons responsible for the

plant and its operation, as well as to person who work independently on the unit. You

must also ensure that the documentation is legible.

ment

®

documentation. Con-

1.3 Exclusion of liability

You must comply with the information contained in the MOVIMOT® documentation to

ensure safe operation of MOVIMOT

tics and performance requirements. SEW-EURODRIVE assumes no liability for injury to

persons or damage to equipment or property resulting from non-observance of these

operating instructions. In such cases, any liability for defects is excluded.

Addendum to the Operating Instructions – MOVIMOT® for Energy Efficient Motors

®

and to achieve the specified product characteris-

3

1

General notes

Other applicable documentation

1.4 Other applicable documentation

• This information does not replace the detailed operating instructions!

• Only electrical specialists are allowed to perform installation and startup observing

applicable accident prevention regulations and the "MOVIMOT

instructions.

®

MM..C" operating

4

Addendum to the Operating Instructions – MOVIMOT® for Energy Efficient Motors

Description of functions

Changes compared to the standard MOVIMOT® MM..C

2 Description of functions

2.1 Changes compared to the standard MOVIMOT® MM..C

• This design is exclusively intended for operation with energy efficient DTE/DVE or

DRE motors (230 V/400 V m/W).

These energy efficient motors meet the requirements of efficiency category .

• Modified MOVIMOT

• Modified DIP switch setting (S2/1), see page 9.

2.2 Sample unit designation

MM 15 C – 503 – 05

®

combinations, see page 6.

Type 0 5

Connection type (3 = 3-phase)

for DTE/DVE motors

for DRE motors (as of firmware status 71)

2

Inverter nameplate (example)

Connection voltage (50 = 380...500 V

Version C

Motor power (15 = 1.5 kW)

MOVIMOT

[1]

71

71 54 C 52 50 -- 10 10 10

MM15C-503-05

1820 462 7

®

series

AC

)

[1] Firmware status

Addendum to the Operating Instructions – MOVIMOT® for Energy Efficient Motors

62024AXX

5

3

Changes compared to the standard MOVIMOT®

MOVIMOT® combinations with energy efficient motors

3 Changes compared to the standard MOVIMOT®

3.1 MOVIMOT® combinations with energy efficient motors

STOP!

All combinations not listed in this document will be rejected with error 9 (slowly flashing

red status LED on MOVIMOT

MOVIMOT® with energy efficient DTE/DVE motors

®

).

MM07 - MM15

MM22 - MM3X

57770AXX

280 – 1400 1/min W 3 x 380 – 500 V (400 V) IEC design

Typ e P

[kW] [Nm] [Nm] [1/min] [A] Preference Alternative [Nm]

DTE90K4/.../MM07 0.75 5.1 1.5 1400 1.8 0.99

DTE90S4/.../MM11 1.1 7.5 1.5 1400 2.4 0.99 20

DTE90L4/.../MM15 1.5 10.2 1.5 1400 3.2 0.99 20

DVE100M4/.../MM22 2.2 15.0 1.5 1400 4.6 0.99

DVE100L4/.../MM30 3.0 20.5 1.5 1400 6.2 0.99 40

M

N

Ma/M

n

n

n

I

n

cosϕ Brake M

n1

BMG2

230 V

BMG4

110 V

BMG2

400 V

BMG4

230 V

290 – 2900 1/min m 3 x 380 – 500 V (400 V) IEC design

Typ e P

[kW] [Nm] [Nm] [1/min] [A] Preference Alternative [Nm]

DTE90K4/.../MM11 1.1 3.62 2.0 2900 3.1 0.99

DTE90S4/.../MM15 1.5 4.95 1.6 2900 4.2 0.99 20

DTE90L4/.../MM22 2.2 7.25 1.6 2900 5.5 0.99

DVE100M4/.../MM30 3.0 9.9 1.6 2900 8.0 0.99

DVE100L4/.../MM3X

1) S1

2) S3, 25 % c.d.f.

3.0

4.0

M

N

1)

9.9 1.6 2900 8.0 0.99

2)

13.2 1.2 2900 10.7 0.99

Ma/M

n

n

n

n

I

cosϕ Brake M

n1

BMG2

230 V

BMG2

110 V

BMG4

110 V

BMG2

400 V

BMG2

230 V

BMG4

230 V

Bmax

20

40

Bmax

20

20

40

40

Thermal classification F as standard

6

Addendum to the Operating Instructions – MOVIMOT® for Energy Efficient Motors

Changes compared to the standard MOVIMOT®

MOVIMOT® combinations with energy efficient motors

MOVIMOT® with energy efficient DTE/DVE motors and increased short-term torque

3

MM11 - MM15

MM22 - MM3X

280 – 1400 1/min W 3 x 380 – 500 V (400 V) IEC design

Typ e P

[kW] [Nm] [Nm] [1/min] [A] Preference Alternative [Nm]

DTE90K4/.../MM11 0.75 5.1 2.1 1400 1.8 0.99

DTE90S4/.../MM15 1.1 7.5 2.1 1400 2.4 0.99 20

DTE90L4/.../MM22 1.5 10.2 2.1 1400 3.2 0.99

DVE100M4/.../MM30 2.2 15.0 2.1 1400 4.6 0.99

DVE100L4/.../MM3X 3.0 20.5 2.0 1400 6.2 0.99 40

M

N

n

Ma/M

1)

n

n

n

I

cosϕ Brake M

n1

BMG2

230 V

BMG2

110 V

BMG4

110 V

BMG2

400 V

BMG2

230 V

BMG4

230 V

290 – 2900 1/min m 3 x 380 – 500 V (400 V) IEC design

Typ e P

[kW] [Nm] [Nm] [1/min] [A] Preference Alternative [Nm]

DTE90K4/.../MM15 1.1 3.62 2.5 2900 3.1 0.99

DTE90S4/.../MM22 1.5 4.95 2.2 2900 4.2 0.99

DTE90L4/.../MM30 2.2 7.25 2.2 2900 5.0 0.99 20

DVE100M4/.../MM3X 3.0 9.9 2.0 2900 8.0 0.99

1) Increased short-term torque in S3 operation, 25 % cdf

M

N

n

Ma/M

1)

n

n

n

I

cosϕ Brake M

n1

BMG2

230 V

BMG2

110 V

BMG4

110 V

BMG2

400 V

BMG2

230 V

BMG4

230 V

57771AXX

Bmax

20

20

40

Bmax

20

20

40

Thermal classification F as standard

Addendum to the Operating Instructions – MOVIMOT® for Energy Efficient Motors

7

3

Changes compared to the standard MOVIMOT®

MOVIMOT® combinations with energy efficient motors

MOVIMOT® with energy efficient DRE motors

MM07 - MM15 MM22 - MM30

62083AXX

280 – 1400 1/min W 3 x 380 – 500 V (400 V) IEC design

Typ e P

[kW] [Nm] [Nm] [1/min] [A] [Nm]

DRE80M4/.../MM07 0.75 5.1 1.5 1400 1.8 0.99 BE1

DRE90M4/.../MM11 1.1 7.5 1.5 1400 2.4 0.99 BE2

DRE90L4/.../MM15 1.5 10.2 1.5 1400 3.2 0.99 20

DRE100M4/.../MM22 2.2 15.0 1.5 1400 4.6 0.99

DRE100LC4/.../MM30 3.0 20.5 1.5 1400 6.2 0.99 50

M

N

Ma/M

n

n

n

I

n

cosϕ Brake M

n1

230 V

230 V

BE5

120 V

290 – 2900 1/min m 3 x 380 – 500 V (400 V) IEC design

Typ e P

[kW] [Nm] [Nm] [1/min] [A] [Nm]

DRE80M4/.../MM11 1.1 3.62 2.0 2900 3.1 0.99

DRE90M4/.../MM15 1.5 4.95 1.6 2900 4.2 0.99

DRE90L4/.../MM22 2.2 7.25 1.6 2900 5.5 0.99

DRE100M4/.../MM30 3.0 9.9 1.6 2900 8.0 0.99

M

N

Ma/M

n

n

n

I

n

cosϕ Brake M

n1

BE1

230 V

BE2

230 V

BE2

120 V

BE5

120 V

Bmax

10

20

50

Bmax

10

20

20

50

Thermal classification F as standard

8

Addendum to the Operating Instructions – MOVIMOT® for Energy Efficient Motors

Changes compared to the standard MOVIMOT®

3.2 Modified DIP switch setting

The firmware status 70 only supports energy efficient DTE/DVE motors.

The DIP switch S2/1 can be set to ON or OFF.

As of firmware status 71, energy efficient DTE/DVE and DRE motors are supported.

• If the energy efficient DTE/DVE motors are used, the DIP switch S2/1 must be set to

OFF.

• If the energy efficient DRE motors are used, the DIP switch S2/1 must be set to ON.

DIP SWITCH S1:

Modified DIP switch setting

3

S1 1 2 3 4 5

Meaning RS485 address

2021222

ON 1111 Off

OFF 0 0 0 0 On Adjusted 4 kHz Off

3

Motor

protec-

tion

6

Motor power rat-

ing

Motor one stage

smaller

7

PWM fre-

quency

Variable

(16, 8, 4 kHz)

8

No-load

damping

On

DIP SWITCH S2:

S2 1 2 3 4 5 6 7 8

Meaning Motor type Brake released

ON

OFF

1) only possible as of firmware status 71

DRE-1)

Motor

DTE/DVE

motor

without enable

On U/f On

Off VFC Off 0000

Control

mode

Speed moni-

toring

Additional func-

tions

2021222

1111

3

Addendum to the Operating Instructions – MOVIMOT® for Energy Efficient Motors

9

SEW-EURODRIVE – Driving the world

Gearmotors \ Industrial Gear Units \ Drive Electronics \ Drive Automation \ Services

How we’re driving the world

With people who

think fast and

develop the

future with you.

With a global presence

that offers responsive

and reliable solutions.

Anywhere.

With a worldwide

service network that is

always close at hand.

With drives and controls

that automatically

improve your productivity.

With innovative

technology that solves

tomorrow’s problems

today.

With comprehensive

knowledge in virtually

every branch of

industry today.

With online information

and software updates,

via the Internet, available

around the clock.

With uncompromising

quality that reduces the

cost and complexity of

daily operations.

SEW-EURODRIVE

Driving the world

SEW-EURODRIVE GmbH & Co KG

P.O. Box 3023 · D-76642 Bruchsal / Germany

Phone +49 7251 75-0 · Fax +49 7251 75-1970

sew@sew-eurodrive.com

www.sew-eurodrive.com

Loading...

Loading...