Page 1

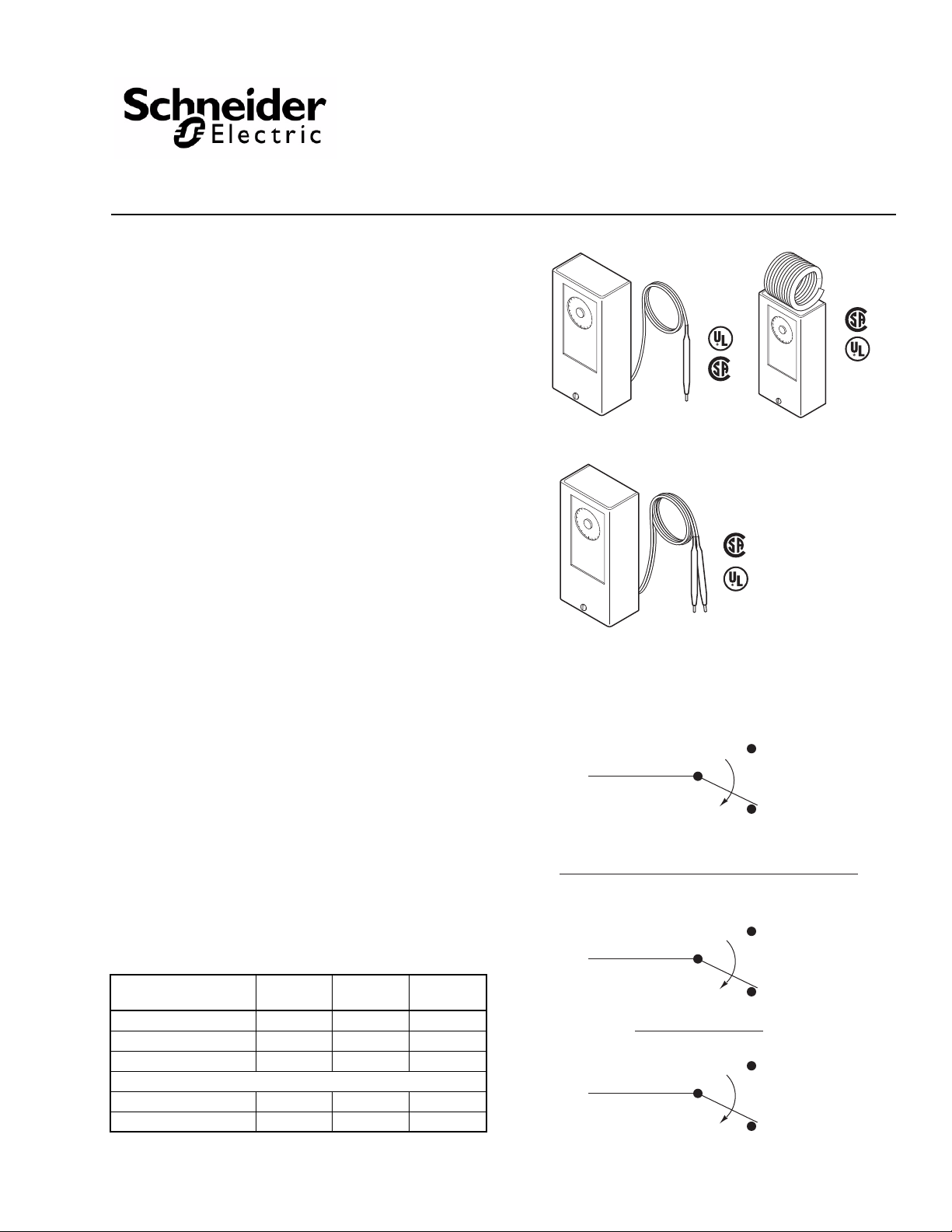

APPLICATION

N.O.

N.C.

Temp. Drop

N.O. makes ON temperature drop

Low (N.O.)

Low (N.C.)

1st stage cool

Temp. Drop

Common

Common

High (N.O.)

1st stage Heat

High (N.C.)

Temp. Drop

Typical Two Stage

Typical Single Stage

Common

Low

High

Typical

Single Bulb

Typical

Dual Bulb

For on-off control of media temperature in ducts, tanks, liqui d

lines, etc.

SPECIFICATIONS

Setpoint Dial Range: Dial plate is marked as °F on one

side and °C on the other. See Table-2 for specific ranges.

Sensing Element: Liquid-filled copper. Differential: See Table-2. Dual Bulb Units: One bulb senses the controlled media;

the second bulb senses the outside air temperature. The

temperature of the controlled media increases as outside air

temperature decreases.

Ambient Temperature Limits:

Case,

Shipping -40 to 160°F (-40 to 71°C). Operating -40 to 150°F (-40 to 65°C): except return

air bulb unit, -40 to 140°F (-40 to 60°C).

Bulb, See Table-2. Electrical Switch: Snap action SPDT, one per stage. Ratings, See Table-1. Connections: Coded screw terminals. Cover: All metal with 1/2" to 3/4" conduit openings. Case Locations: NEMA Type 1 indoor only. Mounting: Case can be mounted in any position. See

ACCESSORIES for bulb mounting kits (order separately).

Dimensions:

Case, 4-5/8" high x 2-1/4" wide x 2" deep (117 mm x 57

mm x 51 mm)

Element and Capillary, See Table-2.

ACCESSORIES

AT-201 Copper bulb well requires AT-209

AT-203 Stainless steel bulb well requires AT-209

AT-206 Copper bulb well

AT-208 Duct mounting kit

AT-209 Bulb mounting kit

AT-210 Concealed adjustment plate

AT-211 Outside bulb shield

Table-1 Maximum Electrical Rating

(All units except TC-4115*)

TC-4100 Series, TC-4200

Series

Bulb Thermostats & Return Air Thermostats

General Instructions

Typical

Return Air Bulb

Switch Rating (50/60

Full Load Amps 9.8 9.8 8.0

Locked Rotor Amps 58.8 58.8 48.0

Pilot Duty VA 60 360 360

Non-Inductive Amps (Resistive)

Single Stage 22 22 22

Two Stage 16 16 8.0

* TC-4115 for TAC System 8000 and applications requiring le ss than one (1)

amp. Electrical Rating: 1.0 amp at 24 Vac; 0.25 amp at 24 Vdc.

Hz)

24V 120V 240V

Figure-1 Switch Action and Terminal Identification.

Printed in U.S.A. 11/09 © Copyright 2009 Schneider Electric All Rights Reserved. F-18895-7

Page 2

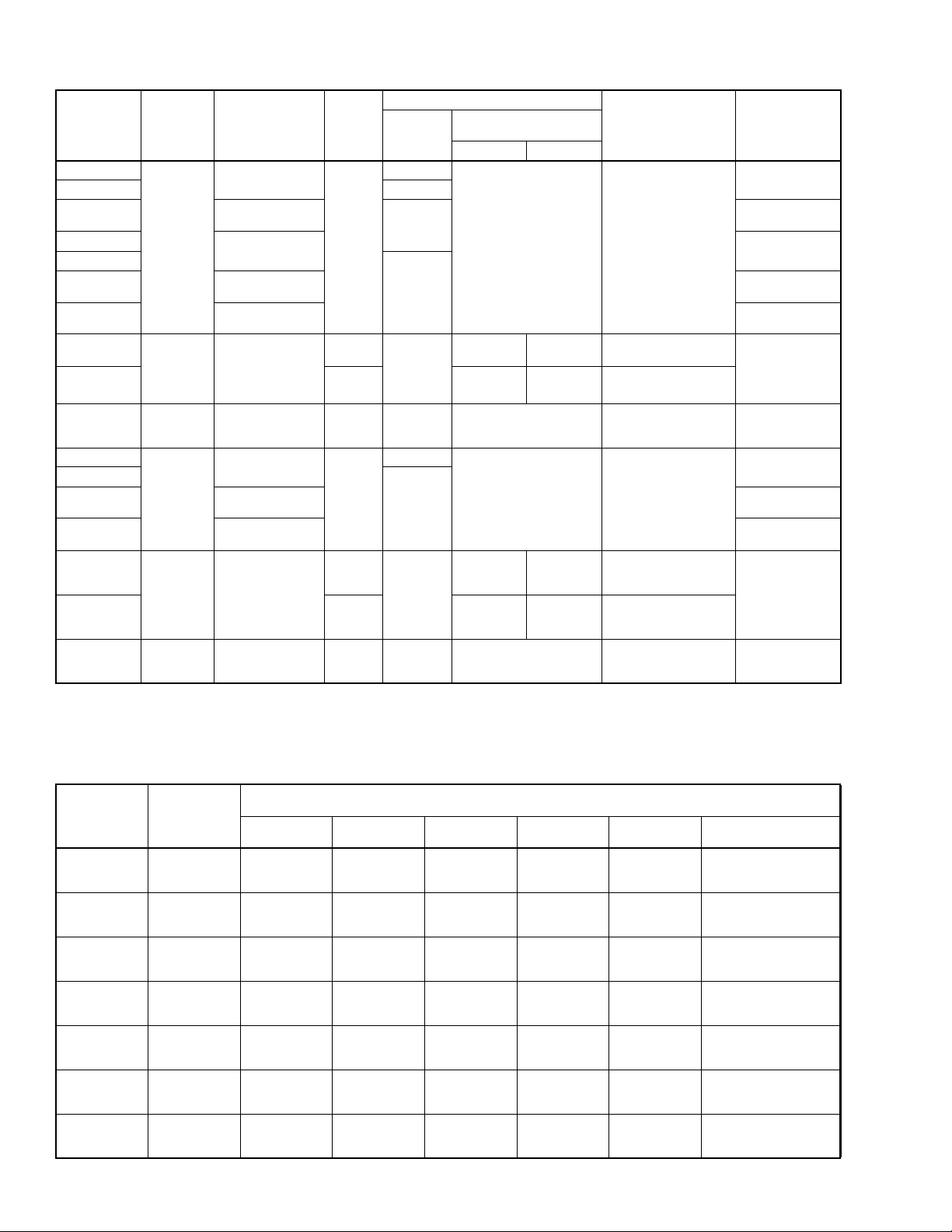

Table-2 Specifications.

Part

Number

Type

TC-4111

TC-4111-020 20 (6)

TC-4112

b

TC-4115

TC-4121

Single Stage

Single Bulb

TC-4122

TC-4123

Setpoint

Adjustment

Range

°F (°C)

-40 to 120

(-40 to 49)

100 to 260

(38 to 127)

-40 to 120

(-40 to 49)

100 to 260

(38 to 127)

190 to 350

(88 to 176)

TC-4151

Single Stage

TC-4152 1:1

Dual Bulb

Single Stage

TC-4166

Return Air

Bulb

TC-4211

TC-4221

TC-4222

Two Stage

Single Bulb

TC-4223

70 to 120

(21 to 49)

50 to 90

(10 to 32)

-40 to 120

(-40 to 49)

100 to 260

(38 to 127)

190 to 350

(88 to 176)

TC-4251

Two Stage

Dual Bulb

70 to 120

(21 to 49)

Dual

Bulb

Ratio

1:1-1/2

1:1-1/2

a

c

c

Capillary

Copper

ft. (m)

6 (1.8)

6 (1.8)

10 (3)

Armored

30 (9)

Each Bulb

None

6 (1.8)

10 (3)

Armored

30 (9)

Each Bulb

TC-4252 1:1

TC-4266

a

First number of reset ratio typically indicates outdoor air temperature change required to increase the setpoint by the second number.

b

See Electrical Rating.

c

For 1-1/2:1 ratio, reverse bulbs and use extra dial supplied with unit.

Return Air

Bulb

Two Stage

50 to 90

(10 to 32)

None

Dimensions

Bulb Copper

in. (mm)

Indoor Outdoor

3/8 x 4

(9.5 x 102)

3/8 x 4

(9.5 x 102)

3/8 x 4

(9.5 x 102)

2-1/2 x 2 (64 x 51)

3/8 x 4

(9.5 x 102)

3/8 x 4

(9.5 x 102)

2-1/2 x 2 (64 x 51)

3/8 x 5-1/2

(9.5 x 140)

(9.5 x 102)

Coiled

3/8 x 4

(9.5 x 102)

3/8 x 5-1/2

(9.5 x 140)

(9.5 x 102)

Coiled

3/8 x 4

3/8 x 4

Differential

°F (°C)

Factory Set 3 (2)

Adj. 3 to 16 (2 to 9)

Factory Set 3 (2)

Adj. 1-1/2 to 10 (1 to 5)

Factory Set 3 (2)

Adj. 3 to 16 (2 to 9)

Fixed 2 (1)

Per Stage Fixed 3 (2)

Between Stages Set 3 (2)

Adj. 2 to 10 (1 to 5)

Per Stage Fixed 3 (2)

Between Stages Set 3 (2)

Adj. 1.5 to 6.5 (1 to 4)

Per Stage Fixed 3 (2)

Between Stages Set 3 (2)

Adj. 2 to 10 (1 to 5)

Each Stage Fixed 2 (1)

Between Stages Set 3 (2)

Adj. 1 to 5 (0.5 to 3)

Safe Bulb

Temperature

Range

°F (°C)

-40 to 170

(-40 to 77)

-40 to 310

(-40 to 154)

-40 to 170

(-40 to 77)

-40 to -310

(-40 to 154)

-40 to 400

(-40 to 204)

Total of indoor and

outdoor

temperatures

must not exceed

280 (138)

-40 to 145

(-40 to 63)

-40 to 170

(-40 to 77)

-40 to 310

(-40 to 154)

-40 to 400

(-40 to 204)

Total of indoor and

outdoor

temperatures

must not exceed

280 (138)

-40 to 145

(-40 to 63)

Table-3 Ratio Selection Table.

Outdoor

Temperature

in °F

-30

-20

-10

0

+10

+20

+30

Ratio

1 to 1-1/2

1 to 1

1-1/2 to 1

1 to 1-1/2

1 to 1

1-1/2 to 1

1 to 1-1/2

1 to 1

1-1/2 to 1

1 to 1-1/2

1 to 1

1-1/2 to 1

1 to 1-1/2

1 to 1

1-1/2 to 1

1 to 1-1/2

1 to 1

1-1/2 to 1

1 to 1-1/2

1 to 1

1-1/2 to 1

Dial Set at 70°F Dial Set at 80°F Dial Set at 90°F

70 to 220

70 to 170

70 to 137

70 to 205

70 to 160

70 to 130

70 to 190

70 to 150

70 to 123

70 to 175

70 to 140

70 to 117

70 to 160

70 to 130

70 to 110

70 to 145

70 to 120

70 to 103

70 to 130

70 to 110

70 to 97

80 to 230

80 to 180

80 to 147

80 to 215

80 to 170

80 to 140

80 to 200

80 to 160

80 to 133

80 to 185

80 to 150

80 to 127

80 to 170

80 to 140

80 to 120

80 to 155

80 to 130

80 to 113

80 to 140

80 to 120

80 to 107

Change in Water Temperature for Different Ratios as

Outdoor Temperature Drops from 70°F to Design Temperature

90 to 240

90 to 190

90 to 157

90 to 225

90 to 180

90 to 150

90 to 210

90 to 170

90 to 143

90 to 195

90 to 160

90 to 137

90 to 180

90 to 150

90 to 130

90 to 165

90 to 140

90 to 123

90 to 150

90 to 130

90 to 117

Dial Set at

100°F

100 to 250

100 to 200

100 to 167

100 to 235

100 to 190

100 to 160

100 to 220

100 to 180

100 to 153

100 to 205

100 to 170

100 to 147

100 to 190

100 to 160

100 to 140

100 to 175

100 to 150

100 to 133

100 to 160

100 to 140

100 to 127

Dial Set at

110°F

110 to 260

110 to 210

—

110 to 245

110 to 200

—

110 to 230

110 to 190

—

110 to 215

110 to 180

—

110 to 200

110 to 170

—

110 to 185

110 to 160

—

110 to 170

100 to 150

—

Dial Set at 120°F

120 to 270

120 to 220

—

120 to 255

120 to 210

—

120 to 240

120 to 200

—

120 to 225

120 to 190

—

120 to 210

120 to 180

—

120 to 195

120 to 170

—

120 to 180

120 to 160

—

°C = (°F - 32) 5/9.

2 © Copyright 2009 Schneider Electric All Rights Reserved. F-18895-7

Page 3

DUAL BULB SELECTION

On the dual bulb units, indoor and outdoor bulbs are

determined by the ratio selected (see T able-2). Ratio refers to

the outdoor air temperature change compared to the water

temperature change. The dial setpoint is the water

temperature setpoint when the outdoor temperature is 70°F.

T o select ratio, it is necessary to know only: (1) outdoor design

temperature, (2) maximum water temperature at outdoor

design temperature, and (3) desired water temperature at

70°F outdoors. Use Table-3 to determine the required ratio

based on this information and set the dial per item (3).

Note: If a 1-1/2:1 ratio is selected, the extra di al sup p l ied

with the unit must be used.

Example: Select ratio for an installation with a -10°F design

temperature and estimated supply water temperature of 75°F

at 70°F outdoors and 125°F at -10°F outdoors. From Table-3,

-10°F for 1-1/2:1 ratio, note by interpolation (70°F to 123°F

with dial at 70°F, 80°F to 133°F with dial at 80°F) that water

temperature varies from 75°F to 128°F as outdoor

temperature drops from 70°F to -10°F.

For this application, the 1-1/2:1 ratio should be selected. The

extra dial supplied with the unit would be used, and the dial set

at 75°F.

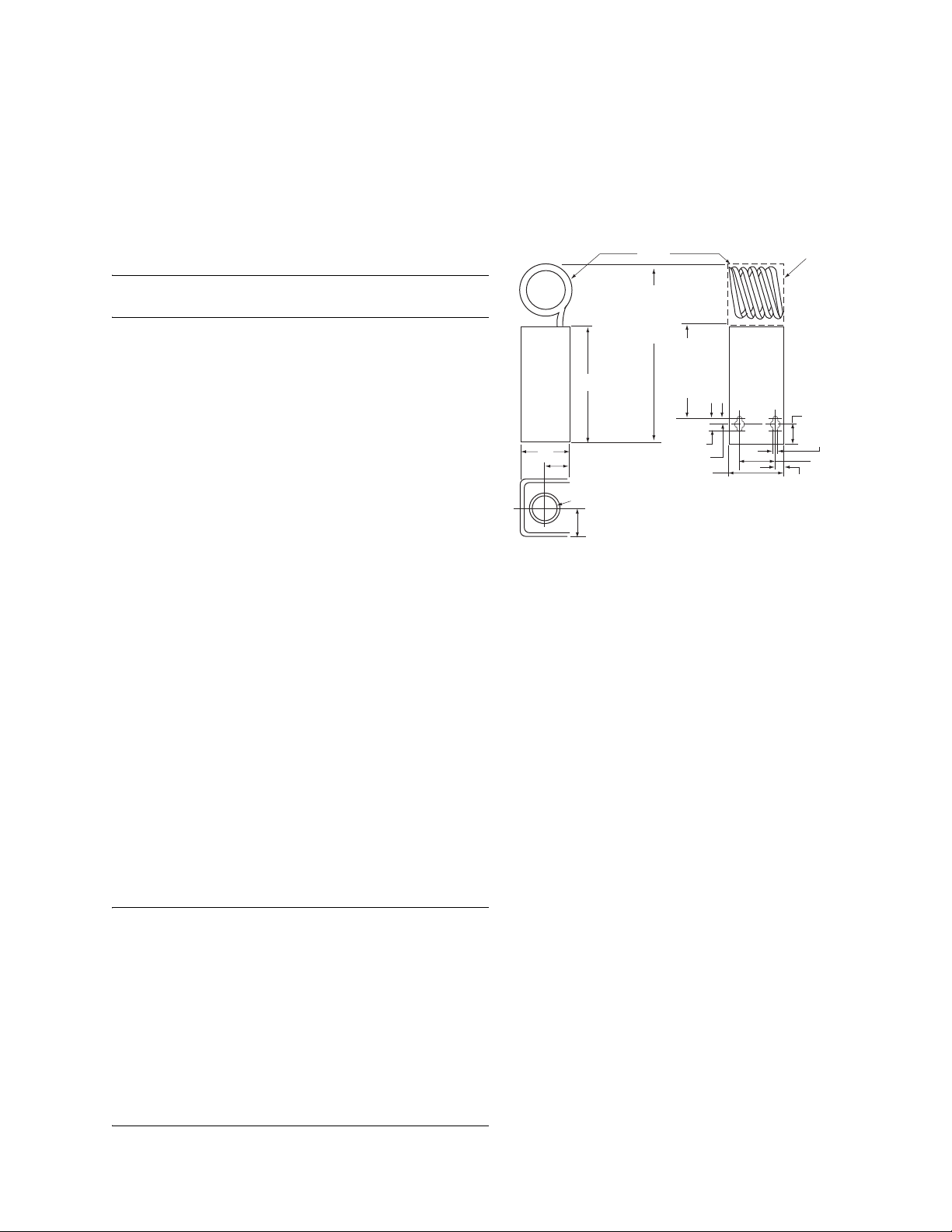

PRE-INSTALLATION

Location

Locate the device allowing proper distance to the bulb

location. The case can be mounted in any position. Refer to

Figure-2 for case dimensions.

TC-4166

TC-4266

Only

Cut Hole in

Duct 2-1/4" W x

2-1/2" H for

Mounting in

Return Air

7/8"

13-64"

1-9/16"

Side

2"

Bottom

TC-4166

TC-4266

Only

7"

TC-4166

TC-4266

Only

3-5/8"

TC-4166

4-5/8"

1"

Hole for 1/2" Conduit

Knockout for 3/4" Conduit

1-5/64"

TC-4266

Only

1/2"

1/4"

2-1/4"

Back

5/16"

Inspection

Visually inspect the carton for damage. If damaged, notify the

appropriate carrier immediately. If undamaged, open the

carton and visually inspect the device for obvious defects.

Return damaged or defective products.

Required Installation Items

• Wiring diagram

• Tools (not provided):

Volt-ohm meter

Room temperature thermometer on °F or °C

Appropriate screwdriver(s) for cover, terminals and

mounting screws

Appropriate drill and drill bit for mounting screws

INSTALLATION

Caution:

1. Installer must be a qualified, experienced technician.

2. Disconnect power supply before installation to prevent electrical shock and equipment damage.

3. Make all connections in accordance with the electrical wiring diagrams, and in compliance with national and local codes. Use copper conductors only.

4. Do not exceed ratings of the device.

5. Avoid locations where excessive moisture, corrosive fumes or vibrations are present.

Figure-2 Case Dimensions.

Procedure for Remote Bulb Mounting

Air Bulb Models — Mounting in Return Air Duct

1. Remove cover and provide two holes for #10 round head screws using the housing as the template or by using the dimensions shown in Figure-2.

2. Partially insert the mounting screws in the screw holes. Fit the housing over the screws, slide housing down on the screws and tighten the screws.

Air Bulb Models —

Mounting Outside of Return Air Duct

1. Prepare duct for mounting by cutting hole and providing mounting screw holes per Figure-2.

2. Fabricate a cover as shown in Figure-3.

3. Carefully roll bulbs toward back of unit and insert through 2-1/4" x 2-1/2" (57 mm x 64 mm) hole.

4. Remove cover and attach unit to duct with #10 screws.

5. Attach cover over 2-1/4" x 2-1/2" (57 mm x 64 mm) hole.

F-18895-7 © Copyright 2009 Schneider Electric All Rights Reserved. 3

Page 4

Figure-3 Field Supplied Duct Hole Cover Plate.

Duct and Outdoor Mounting

Maximum insertion length is 6 inches.

Duct: Install bulb with AT-208 kit as shown in Figure-4.

Figure-7 AT-201 or AT-203 Installation.

AT-201 or AT-203 Installation (see Figures-6 and 7):

1. Install bulb well or adaptor from A T-209 into 3/4" FNPT opening.

2. Place packing nut, washers and packing from AT -209 over bulb support section and insert bulb well or AT-209 adaptor.

3. Push interlocking washers and packing into well or adaptor and tighten packing nut until firmly sealed.

Figure-4 Duct Mounting with AT-208.

Outdoor: Install with AT-211 kit as shown in Figure-5.

1. Mount bulb to outside wall or surface with bulb clip.

2. Place shield over bulb and fasten to mounting surface.

Figure-5 Outdoor Mounting with AT-211.

Bulb Mounting — Liquid Line and Tank

Figure-8 AT-206 Installation.

AT-206 Installation (see Figures-6 and 8):

1. Install AT-206 bulb well into 1/2" FNPT opening.

2. Place packing (included with AT-206) over bulb support section and insert bulb into well.

3. Push packing into nut on well using a screwdriver.

Concealed Setpoint and Lock Cover Screw

Order AT-210 concealed adjustment kit separately.

1. Peel off adhesive film from the concealed adjustment plate and place into the recess of cover.

2. Remove screw from cover.

3. Install lock cover screw provided with AT-210.

Figure-6 Bulb Mounting for Liquid Line and Tank.

4 © Copyright 2009 Schneider Electric All Rights Reserved. F-18895-7

Page 5

Table-4 Bulb Mounting Installation Hardware And Application Limitations.

Application Limitations

Part

Number

AT-201

AT-203

AT-206

a

Max. recommended fluid temperature is 350 F (177°C).

b

Requires AT-209.

b

b

Description

Copper

Bulb Well

Stainless Steel

Bulb Well

Copper

Bulb Well

Mounting

Fitting

3/4"

MNPT

1/2"

MNPT

Insertion Size

in. (mm)

1/2 (13) dia. O.D.

9-1/2 (241) long

1/2 (13) dia. O.D.

4-1/2 (114) long

at 250°F (121°C) Fluid Temperature

Max. Recommended

Velocity fps (m/s)

11 (3.3) 250 (1728)

20 (6.1) 500 (3448)

11 (3.3) 250 (1728) 8

WIRING

The thermostat has one 1/2" to 3/4" conduit opening in the

bottom of the housing. Terminal coding and switch action are

shown in Figures-9 and 10.

a

Max. Recommended

Static Press. psig (kPa)

Installation

per Figure

7

Figure-9 Terminal Coding and Switch Action.

Figure-10 Two Stage Switch Sequence.

TYPICAL APPLICATIONS

Figures-11 and 12 show typical heating and cooling

applications for single stage units. Figures-13 and 14 show

typical heating and cooling applications for two stage units.

Figure-11 Typical Heating Application for Single Stage Units.

Figure-12 Typical Cooling Application for Single Stage Units.

Figure-13 Typical Heating Application for Two Stage Units.

F-18895-7 © Copyright 2009 Schneider Electric All Rights Reserved. 5

Page 6

Figure-14 Typical Cooling Application for Two Stage Units.

CHECKOUT

After installing a thermostat, make an initial check of the

switching action. Verify the switch action by listening to the

switch contacts.

1. Turn the setpoint dial to a tempera ture above ambient. This should cause the thermostat to switch, making orange to brown.

2. Turn the setpoint dial setting down gradually. Orange to brown must break, making orange to red.

3. Compare the differential of the device to the differential

shown on the performance charts by turning the dial. The

differential of the device is the difference in dial reading

between the make of orange to brown and the make of

orange to red on single switch units.

ADJUSTMENTS

To adjust interstage differential:

1. Disconnect power to unit.

2. Remove cover.

3. Turn adjustor to approximately desired position.

4. Check out by turning dial and noting dial readings where switch contacts make.

5. After changing interstage differential, recalibrate. See CALIBRATION.

CALIBRATION

1. With all power disconnected, soak bulb(s) for 10 minutes at known temperature (must be 70°F for dual bulb).

2. Turn dial and note where switch contacts make.

3. Turn dial midway between click points.

4. Turn the calibration nut (located under dial) until the temperature of the bulb is indicated on the dial (see Figure-15).

Note: On two stage units follow above procedure. LO switch

is first stage on cooling applications. HI switch is first stage on

heating applications.

MAINTENANCE

Regular maintenance of the total system is needed to assure

sustained optimum performance. Thermostats should be

periodically inspected for dirt or blockage of air over the

elements.

Setpoint

Screwdriver adjustment. Scales dual marked °F on front and

°C on back. To change scale, remove spring retaining ring,

select scale and replace retaining ring.

Differential

The differential is adjustable by turning the adjustor located on

the side of the device (see Figure-15).

Calibration Nut

(Turn with 1/2"

open end wrench)

Incr. Spread

Differential Adjustment

Figure-15 Adjustments.

Single Stage: Each line represents approximately 3°F (2°C)

change.

Two Stage: Each notch represents approximately 2°F (1°C)

change between stages. (Differential per switch is fixed.)

REPAIR

Field repair is not recommended. Replace defective device.

6 © Copyright 2009 Schneider Electric All Rights Reserved. F-18895-7

Page 7

F-18895-7 © Copyright 2009 Schneider Electric All Rights Reserved 7

Page 8

On October 1st, 2009, TAC became the Buildings business of it s parent company Schneide r Electric. This document reflects th e visual identity of Schneider Ele ctric,

however there remains references to T AC as a corporate brand in th e body copy. As each document is updated, the body copy will be changed to reflect ap propriate

corporate brand changes.

Copyright 2009, Schneider Electric

All brand names, trademarks and registered

trademarks are the property of their respective

owners. Information contained within this

document is subject to change without notice.

F-18895-7

Loading...

Loading...