Page 1

Modicon M262 Logic/M otion Controller

EIO0000003651 05/2020

Modicon M262

Logic/Motion Controller

Programming Guide

05/2020

EIO0000003651.04

www.schneider-electric.com

Page 2

The information provided in this documentation contains general descriptions and/or technical

characteristics of the performance of the products contained herein. This documentation is not

intended as a substitute for and is not to be used for determining suitability or reliability of these

products for specific user applications. It is the duty of any such user or integrator to perform the

appropriate and complete risk analysis, evaluation and testing of the products with respect to the

relevant specific application or use thereof. Neither Schneider Electric nor any of its affiliates or

subsidiaries shall be responsible or liable for misuse of the information contained herein. If you

have any suggestions for improvements or amendments or have found errors in this publication,

please notify us.

You agree not to reproduce, other than for your own personal, noncommercial use, all or part of

this document on any medium whatsoever without permission of Schneider Electric, given in

writing. You also agree not to establish any hypertext links to this document or its content.

Schneider Electric does not grant any right or license for the personal and noncommercial use of

the document or its content, except for a non-exclusive license to consult it on an "as is" basis, at

your own risk. All other rights are reserved.

All pertinent state, regional, and local safety regulations must be observed when installing and

using this product. For reasons of safety and to help ensure compliance with documented system

data, only the manufacturer should perform repairs to components.

When devices are used for applications with technical safety requirements, the relevant

instructions must be followed.

Failure to use Schneider Electric software or approved software with our hardware products may

result in injury, harm, or improper operating results.

Failure to observe this information can result in injury or equipment damage.

© 2020 Schneider Electric. All rights reserved.

2 EIO0000003651 05/2020

Page 3

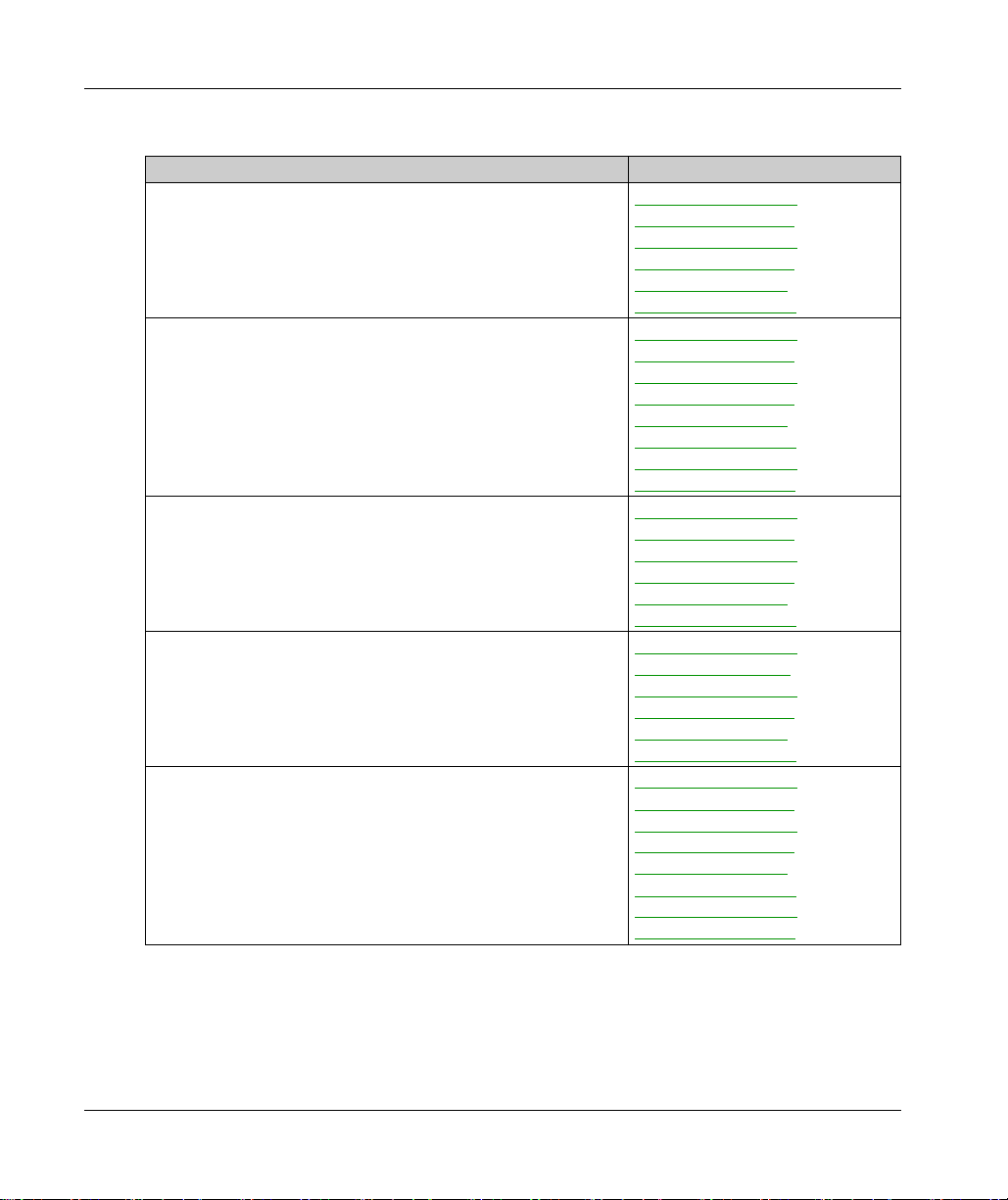

Table of Contents

Safety Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

About the Book . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Chapter 1 About the Modicon M262 Logic/Motion Controller . . . . . 15

M262 Logic/Motion Controller Description. . . . . . . . . . . . . . . . . . . . . .

Chapter 2 Modicon M262 Motion Controller . . . . . . . . . . . . . . . . . . 19

Modicon M262 Motion Controller. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 3 How to Configure the Controller . . . . . . . . . . . . . . . . . . . 21

Configuring the Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 4 Libraries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Libraries. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 5 Supported Standard Data Types . . . . . . . . . . . . . . . . . . 25

Supported Standard Data Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 6 Memory Mapping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Controller Memory Organization . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Flash Memory Organization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RAM Memory Organization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

NVRAM Memory Organization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Relocation Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 7 Tasks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Maximum Number of Tasks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Task Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Task Configuration Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System and Task Watchdogs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Task Priorities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Default Task Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 8 Controller States and Behaviors . . . . . . . . . . . . . . . . . . . 51

8.1 Controller State Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Controller State Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2 Controller States Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Controller States Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3 State Transitions and System Events . . . . . . . . . . . . . . . . . . . . . . . . .

Controller States and Output Behavior . . . . . . . . . . . . . . . . . . . . . . . .

Commanding State Transitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Error Detection, Types, and Management. . . . . . . . . . . . . . . . . . . . . .

Remanent Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15

19

21

23

25

28

30

33

35

36

40

41

45

47

48

50

52

52

56

56

60

61

64

70

71

EIO0000003651 05/2020 3

Page 4

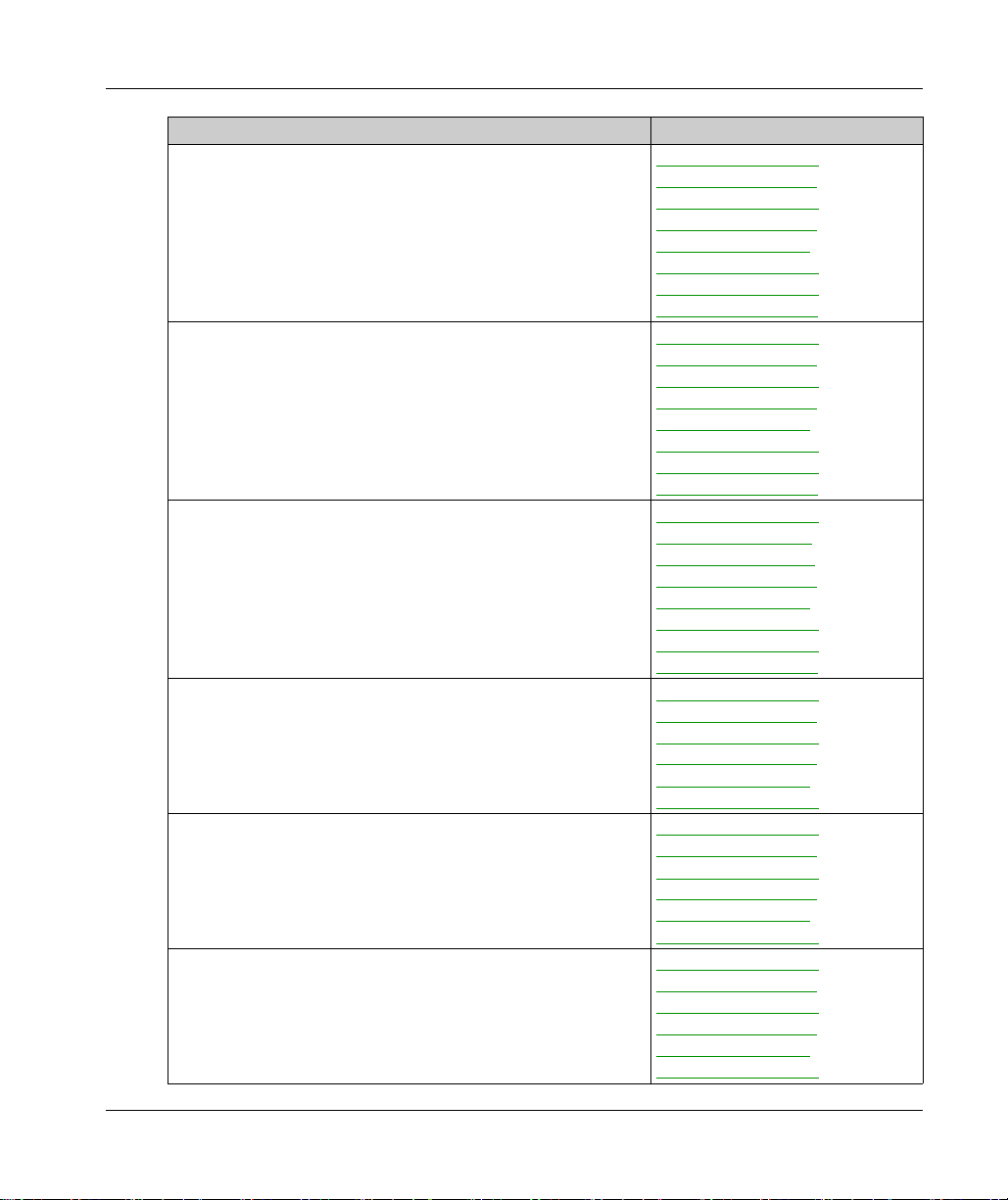

Chapter 9 Controller Device Editor . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Controller Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Communication Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PLC Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Services . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ethernet Services. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Users Rights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

74

76

77

79

81

85

Chapter 10 Embedded Inputs and Outputs Configuration . . . . . . . . . 87

10.1 Configuring the Fast I/Os . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Embedded I/Os Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.2 Hardware Encoder Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hardware Encoder Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Adding an Encoder. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Encoder Motion Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

88

88

94

95

97

100

Chapter 11 Expansion Modules Configuration . . . . . . . . . . . . . . . . . . 101

TM3 I/O Configuration General Description. . . . . . . . . . . . . . . . . . . . .

TM3 I/O Bus Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TMS Expansion Module Configuration. . . . . . . . . . . . . . . . . . . . . . . . .

TM3 Expansion Module Configuration . . . . . . . . . . . . . . . . . . . . . . . . .

Optional I/O Expansion Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

102

106

107

108

109

Chapter 12 Ethernet Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

12.1 Ethernet Services. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Presentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

IP Address Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Modbus TCP Client/Server . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Web Server . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Symbol Configuration Editor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FTP Server. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SNMP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Controller as a Target Device on EtherNet/IP . . . . . . . . . . . . . . . . . . .

Controller as a Slave Device on Modbus TCP. . . . . . . . . . . . . . . . . . .

12.2 Firewall Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dynamic Changes Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Firewall Behavior . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Firewall Script Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

114

115

117

123

125

149

155

156

157

182

187

188

190

191

193

4 EIO0000003651 05/2020

Page 5

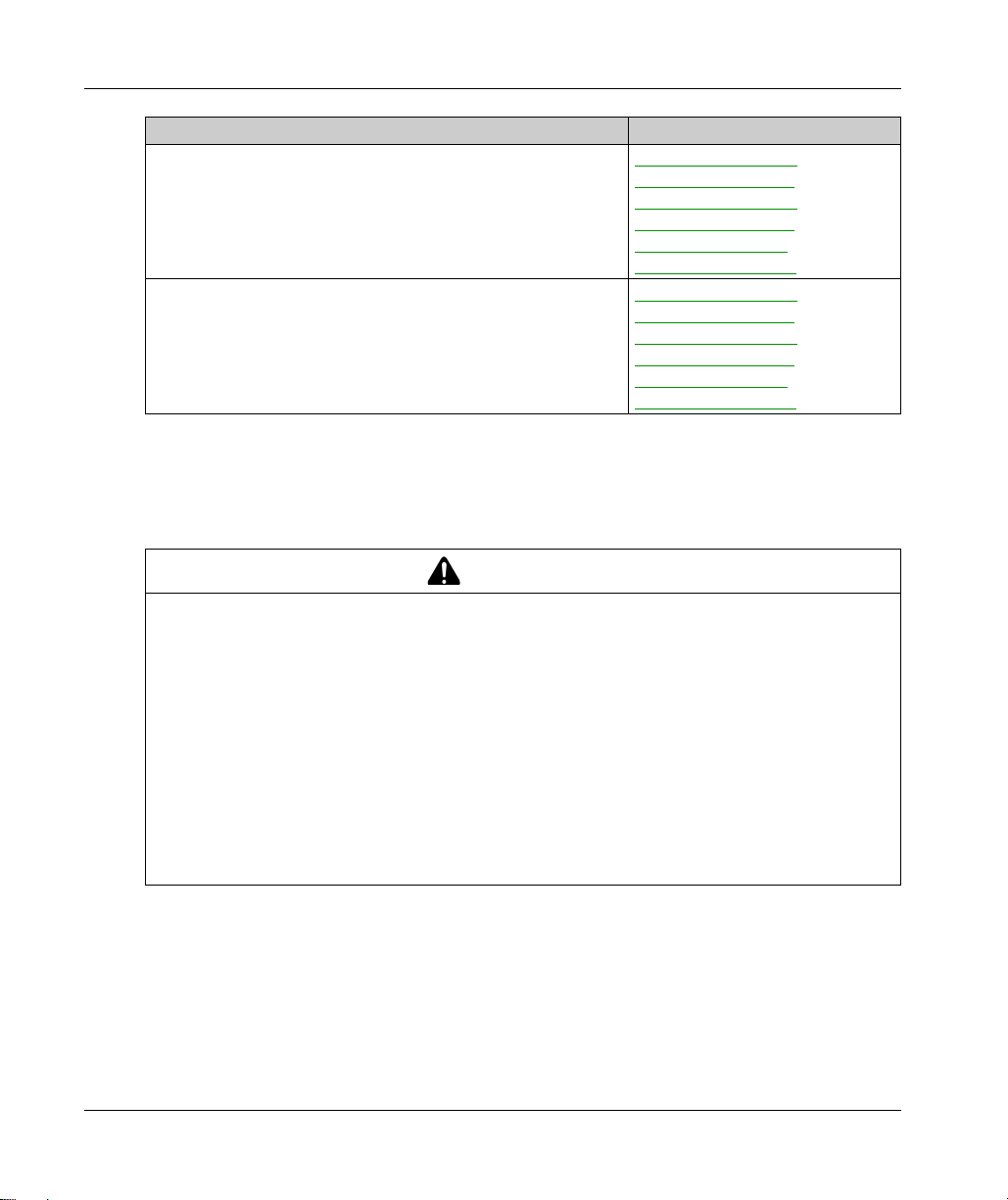

Chapter 13 Industrial Ethernet. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

Industrial Ethernet Presentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DHCP Server. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fast Device Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

202

207

208

Chapter 14 Sercos Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

Overview of the Sercos Standard . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Modicon M262 Logic/Motion Controller Sercos Configuration . . . . . .

Modicon M262 Motion Controller and Safety Controllers with Sercos

Single Wire Architecture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

210

212

213

214

Chapter 15 Serial Line Configuration . . . . . . . . . . . . . . . . . . . . . . . . 217

Serial Line Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Machine Expert Network Manager . . . . . . . . . . . . . . . . . . . . . . . . . . .

Modbus Manager. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ASCII Manager . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Modbus Serial IOScanner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Adding a Device on the Modbus Serial IOScanner . . . . . . . . . . . . . . .

Adding a Modem to a Manager . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

218

220

221

225

227

229

235

Chapter 16 OPC UA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 237

16.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

OPC UA Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

16.2 OPC UA Server Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

OPC UA Server Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

OPC UA Server Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

OPC UA Server Symbols Configuration . . . . . . . . . . . . . . . . . . . . . . .

OPC UA Server Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

16.3 OPC UA Client Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

OPC UA Client Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Programming the OPC UA Client . . . . . . . . . . . . . . . . . . . . . . . . . . . .

238

238

239

240

241

244

246

249

250

251

Chapter 17 Post Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 253

Post Configuration Presentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Post Configuration File Management . . . . . . . . . . . . . . . . . . . . . . . . .

Post Configuration Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

254

255

257

Chapter 18 Connecting a Modicon M262 Logic/Motion Controller to a

PC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 259

Connecting the Controller to a PC . . . . . . . . . . . . . . . . . . . . . . . . . . . .

259

EIO0000003651 05/2020 5

Page 6

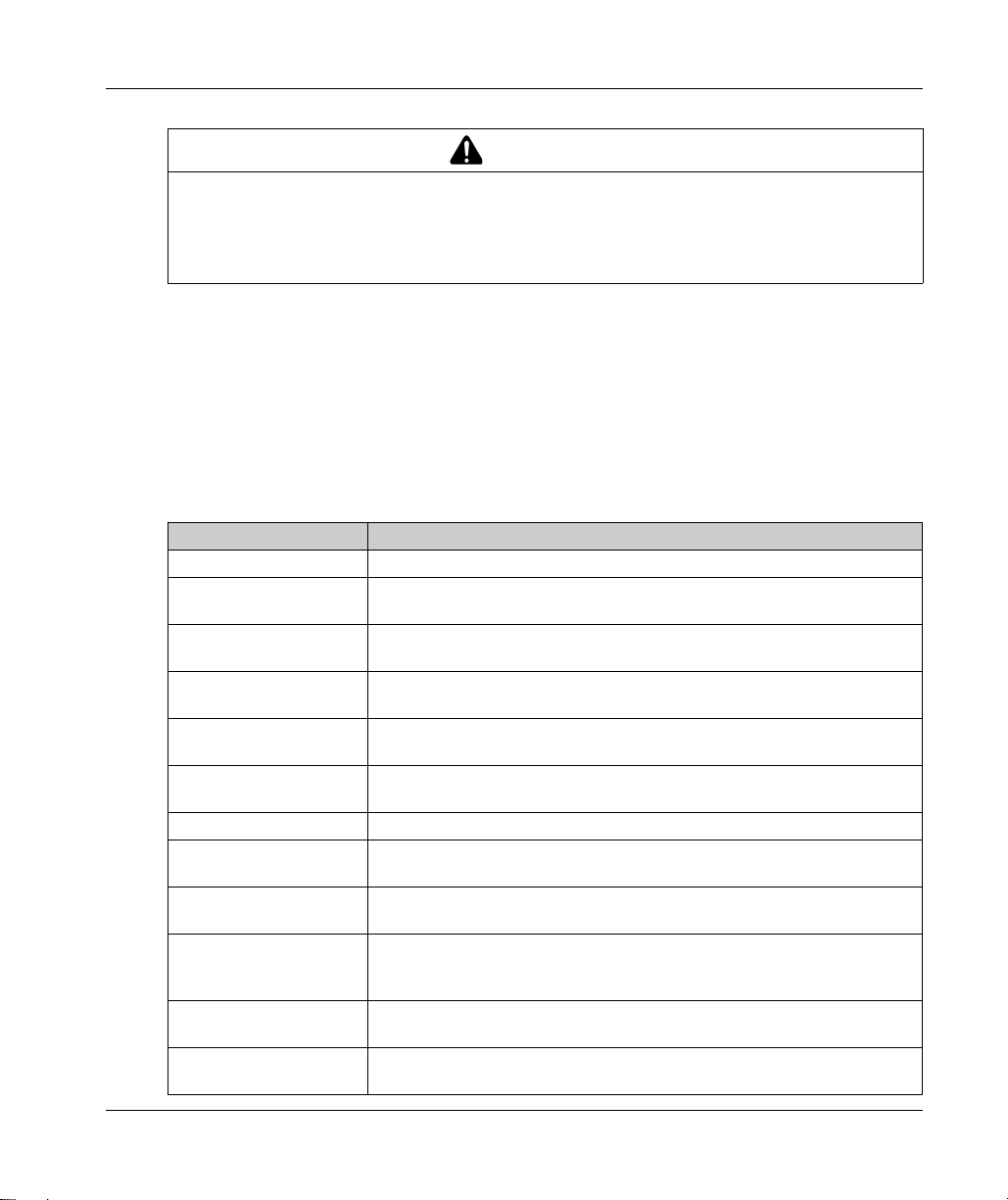

Chapter 19 Updating Firmware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 261

Updating the Controller Firmware by SD Card. . . . . . . . . . . . . . . . . . .

Updating the Controller Firmware by Controller Assistant . . . . . . . . . .

Updating TM3 Expansion Modules Firmware . . . . . . . . . . . . . . . . . . .

Updating TMS Expansion Modules Firmware . . . . . . . . . . . . . . . . . . .

Chapter 20 Managing Script Files. . . . . . . . . . . . . . . . . . . . . . . . . . . . 273

Creating a Script . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Generating Scripts and Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Transferring Scripts and Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 21 Cloning a Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 283

Before Cloning a Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cloning a Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 22 Compatibility. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 289

Software and Firmware Compatibilities . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 23 Industrial Plug and Work . . . . . . . . . . . . . . . . . . . . . . . . . 291

23.1 Accessing the Web Server. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Launching the Web Server. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

23.2 Using the Machine Assistant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Launching the Machine Assistant . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Managing the Network Scan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Managing the Devices Network Settings . . . . . . . . . . . . . . . . . . . . . . .

Backing Up/Restoring Configuration . . . . . . . . . . . . . . . . . . . . . . . . . .

Exporting/Importing .semdt Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix A How to Change the IP Address of the Controller . . . . . . . 303

changeIPAddress: Change the IP address of the controller . . . . . . . .

Appendix B Functions to Get/Set Serial Line Configuration in User

Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 307

GetSerialConf: Get the Serial Line Configuration . . . . . . . . . . . . . . . .

SetSerialConf: Change the Serial Line Configuration . . . . . . . . . . . . .

SERIAL_CONF: Structure of the Serial Line Configuration Data Type

Appendix C Controller Performance . . . . . . . . . . . . . . . . . . . . . . . . . . 313

Processing Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

262

265

268

271

274

279

280

284

286

289

292

292

293

294

295

297

299

300

301

303

308

309

311

313

315

327

6 EIO0000003651 05/2020

Page 7

Safety Information

Important Information

NOTICE

Read these instructions carefully, and look at the equipment to become familiar with the device

before trying to install, operate, service, or maintain it. The following special messages may appear

throughout this documentation or on the equipment to warn of potential hazards or to call attention

to information that clarifies or simplifies a procedure.

EIO0000003651 05/2020 7

Page 8

PLEASE NOTE

Electrical equipment should be installed, operated, serviced, and maintained only by qualified

personnel. No responsibility is assumed by Schneider Electric for any consequences arising out of

the use of this material.

A qualified person is one who has skills and knowledge related to the construction and operation

of electrical equipment and its installation, and has received safety training to recognize and avoid

the hazards involved.

8 EIO0000003651 05/2020

Page 9

About the Book

At a Glance

Document Scope

The purpose of this document is to help you to program and operate your Modicon M262

Logic/Motion Controller with the EcoStruxure Machine Expert software.

NOTE: Read and understand this document and all related documents before installing, operating,

or maintaining your Modicon M262 Logic/Motion Controller.

The Modicon M262 Logic/Motion Controller users should read through the entire document to

understand all features.

Validity Note

This document has been updated for the release of EcoStruxure

The technical characteristics of the devices described in the present document also appear online.

To access the information online, go to the Schneider Electric home page

https://www.se.com/ww/en/download/

The characteristics that are described in the present document should be the same as those

characteristics that appear online. In line with our policy of constant improvement, we may revise

content over time to improve clarity and accuracy. If you see a difference between the document

and online information, use the online information as your reference.

TM

Machine Expert V1.2.3.

.

EIO0000003651 05/2020 9

Page 10

Related Documents

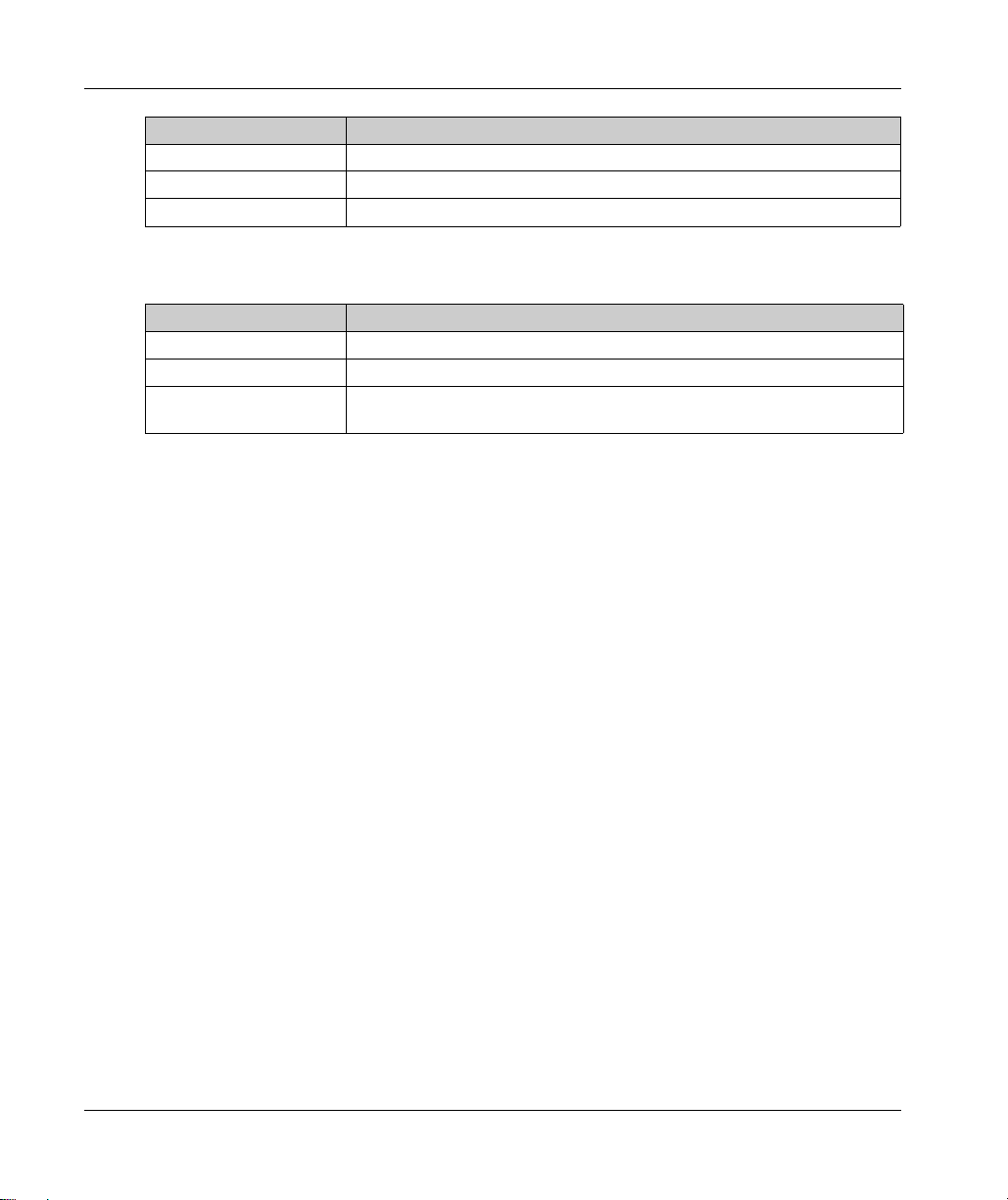

Title of Documentation Reference Number

EcoStruxure Machine Expert - Programming Guide

Modicon M262 Logic/Motion Controller - Hardware Guide

Modicon TM3 Expansion Modules Configuration - Programming

Guide

Modicon TM5 EtherNet/IP Fieldbus Interface - Programming Guide

Modicon TMS Expansion Modules - Programming Guide

EIO0000002854 (ENG)

EIO0000002855 (FRE)

EIO0000002856 (GER)

EIO0000002857 (SPA)

EIO0000002858 (ITA)

EIO0000002859 (CHS)

EIO0000003659 (ENG)

EIO0000003660 (FRE)

EIO0000003661 (GER)

EIO0000003662 (SPA)

EIO0000003663 (ITA)

EIO0000003664 (CHS)

EIO0000003665 (POR)

EIO0000003666 (TUR)

EIO0000001402 (ENG)

EIO0000001403 (FRE)

EIO0000001404 (GER)

EIO0000001405 (SPA)

EIO0000001406 (ITA)

EIO0000001407 (CHS)

EIO0000003707 (ENG)

EIO0000003708(FRE)

EIO0000003709 (GER)

EIO0000003710 (SPA)

EIO0000003711 (ITA)

EIO0000003712 (CHS)

EIO0000003691 (ENG)

EIO0000003692 (FRE)

EIO0000003693 (GER)

EIO0000003694 (SPA)

EIO0000003695 (ITA)

EIO0000003696 (CHS)

EIO0000003697 (POR)

EIO0000003698 (TUR)

10 EIO0000003651 05/2020

Page 11

Title of Documentation Reference Number

Modicon M262 Logic/Motion Controller - System Library Guide

EIO0000003667 (ENG)

EIO0000003668 (FRE)

EIO0000003669 (GER)

EIO0000003670 (SPA)

EIO0000003671 (ITA)

EIO0000003672 (CHS)

EIO0000003673 (POR)

EIO0000003674 (TUR)

Modicon TM3 Expert I/O Modules - HSC Library Guide

EIO0000003683 (ENG)

EIO0000003684 (FRE)

EIO0000003685 (GER)

EIO0000003686 (SPA)

EIO0000003687 (ITA)

EIO0000003688 (CHS)

EIO0000003689 (POR)

EIO0000003690 (TUR)

Modicon M262 Logic/Motion Controller - Encoder Library Guide

EIO0000003675 (ENG)

EIO0000003676(FRE)

EIO0000003677(GER)

EIO0000003678 (SPA)

EIO0000003679 (ITA)

EIO0000003680 (CHS)

EIO0000003681 (POR)

EIO0000003682 (TUR)

M262 Embedded Safety - Integration Guide

EIO0000003921 (ENG)

EIO0000003923 (FRE)

EIO0000003922 (GER)

EIO0000003926 (SPA)

EIO0000003924 (ITA)

EIO0000003925 (CHS)

Sercos for M262 - User Guide

EIO0000003883 (ENG)

EIO0000003885 (FRE)

EIO0000003884 (GER)

EIO0000003888 (SPA)

EIO0000003886 (ITA)

EIO0000003887 (CHS)

Controller Assistant - User Guide

EIO0000001671 (ENG)

EIO0000001672 (FRE)

EIO0000001673 (GER)

EIO0000001675 (SPA)

EIO0000001674 (ITA)

EIO0000001676 (CHS)

EIO0000003651 05/2020 11

Page 12

Title of Documentation Reference Number

EcoStruxure Machine Expert - FtpRemoteFileHandling Library Guide

EcoStruxure Machine Expert - SnmpManager Library Guide

You can download these technical publications and other technical information from our website

at https://www.se.com/ww/en/download/ .

Product Related Information

LOSS OF CONTROL

The designer of any control scheme must consider the potential failure modes of control paths

and, for certain critical control functions, provide a means to achieve a safe state during and

after a path failure. Examples of critical control functions are emergency stop and overtravel

stop, power outage and restart.

Separate or redundant control paths must be provided for critical control functions.

System control paths may include communication links. Consideration must be given to the

implications of unanticipated transmission delays or failures of the link.

Observe all accident prevention regulations and local safety guidelines.

Each implementation of this equipment must be individually and thoroughly tested for proper

operation before being placed into service.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

EIO0000002779 (ENG)

EIO0000002780 (FRE)

EIO0000002781 (GER)

EIO0000002782 (SPA)

EIO0000002783 (ITA)

EIO0000002784 (CHS)

EIO0000002797 (ENG)

EIO0000002798 (FRE)

EIO0000002799 (GER)

EIO0000002800 (SPA)

EIO0000002801 (ITA)

EIO0000002802 (CHS)

WARNING

1

1

For additional information, refer to NEMA ICS 1.1 (latest edition), "Safety Guidelines for the

Application, Installation, and Maintenance of Solid State Control" and to NEMA ICS 7.1 (latest

edition), "Safety Standards for Construction and Guide for Selection, Installation and Operation of

Adjustable-Speed Drive Systems" or their equivalent governing your particular location.

12 EIO0000003651 05/2020

Page 13

UNINTENDED EQUIPMENT OPERATION

Only use software approved by Schneider Electric for use with this equipment.

Update your application program every time you change the physical hardware configuration.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

Terminology Derived from Standards

The technical terms, terminology, symbols and the corresponding descriptions in this manual, or

that appear in or on the products themselves, are generally derived from the terms or definitions

of international standards.

In the area of functional safety systems, drives and general automation, this may include, but is not

limited to, terms such as

safety, safety function, safe state, fault, fault reset, malfunction, failure

error, error message, dangerous

Among others, these standards include:

Standard Description

IEC 61131-2:2007 Programmable controllers, part 2: Equipment requirements and tests.

ISO 13849-1:2015 Safety of machinery: Safety related parts of control systems.

EN 61496-1:2013 Safety of machinery: Electro-sensitive protective equipment.

ISO 12100:2010 Safety of machinery - General principles for design - Risk assessment and risk

EN 60204-1:2006 Safety of machinery - Electrical equipment of machines - Part 1: General

ISO 14119:2013 Safety of machinery - Interlocking devices associated with guards - Principles

ISO 13850:2015 Safety of machinery - Emergency stop - Principles for design

IEC 62061:2015 Safety of machinery - Functional safety of safety-related electrical, electronic,

IEC 61508-1:2010 Functional safety of electrical/electronic/programmable electronic safety-

IEC 61508-2:2010 Functional safety of electrical/electronic/programmable electronic safety-

IEC 61508-3:2010 Functional safety of electrical/electronic/programmable electronic safety-

IEC 61784-3:2016 Industrial communication networks - Profiles - Part 3: Functional safety

General principles for design.

Part 1: General requirements and tests.

reduction

requirements

for design and selection

and electronic programmable control systems

related systems: General requirements.

related systems: Requirements for electrical/electronic/programmable

electronic safety-related systems.

related systems: Software requirements.

fieldbuses - General rules and profile definitions.

WARNING

,

, etc.

EIO0000003651 05/2020 13

Page 14

Standard Description

2006/42/EC Machinery Directive

2014/30/EU Electromagnetic Compatibility Directive

2014/35/EU Low Voltage Directive

In addition, terms used in the present document may tangentially be used as they are derived from

other standards such as:

Standard Description

IEC 60034 series Rotating electrical machines

IEC 61800 series Adjustable speed electrical power drive systems

IEC 61158 series Digital data communications for measurement and control – Fieldbus for use in

industrial control systems

Finally, the term

hazards, and is defined as it is for a

2006/42/EC

(

zone of operation

) and

ISO 12100:2010

may be used in conjunction with the description of specific

hazard zone

or

danger zone

in the

Machinery Directive

.

NOTE: The aforementioned standards may or may not apply to the specific products cited in the

present documentation. For more information concerning the individual standards applicable to the

products described herein, see the characteristics tables for those product references.

14 EIO0000003651 05/2020

Page 15

Modicon M262 Logic/Moti on Controller

About the Modicon M26 2 Logic/Motion Con troller

EIO0000003651 05/2020

About the Modicon M26 2 Logic/Motion Con troller

Chapter 1

About the Modicon M262 Logic/Motion Controller

M262 Logic/Motion Controller Description

Overview

The M262 Logic/Motion Controller has various powerful features and can service a wide range of

applications.

Software configuration, programming, and commissioning are accomplished with the EcoStruxure

Machine Expert software version 1.1 or later, described in detail in the EcoStruxure Machine

Expert Programming Guide as well as the present document.

Programming Languages

The M262 Logic/Motion Controller is configured and programmed with the EcoStruxure Machine

Expert software, which supports the following IEC 61131-3 programming languages:

IL: Instruction List

ST: Structured Text

FBD: Function Block Diagram

SFC: Sequential Function Chart

LD: Ladder Diagram

EcoStruxure Machine Expert software can also be used to program these controllers using CFC

(Continuous Function Chart) language.

Power Supply

The power supply of the M262 Logic/Motion Controller is 24 Vdc

Controller, Hardware Guide)

.

(see Modicon M262 Logic/Motion

Real Time Clock

The M262 Logic/Motion Controller includes a Real Time Clock (RTC) system

Logic/Motion Controller, Hardware Guide)

.

(see Modicon M262

The system time is maintained by capacitors when the power is off. The time is maintained for

1 000 hours when the controller is not supplied.

EIO0000003651 05/2020 15

Page 16

About the Modicon M262 Logic/Motion Controller

Run/Stop

The M262 Logic/Motion Controller can be operated externally by the following:

A hardware Run/Stop switch

A Run/Stop operation by a dedicated digital input, defined in the software configuration. For

(see Modicon M262 Logic/Motion Controller, Hardware Guide)

more information, refer to Configuration of Digital Inputs

An EcoStruxure Machine Expert software command.

The system variable PLC_W in a Relocation Table

The Web server

(see page 125)

Memory

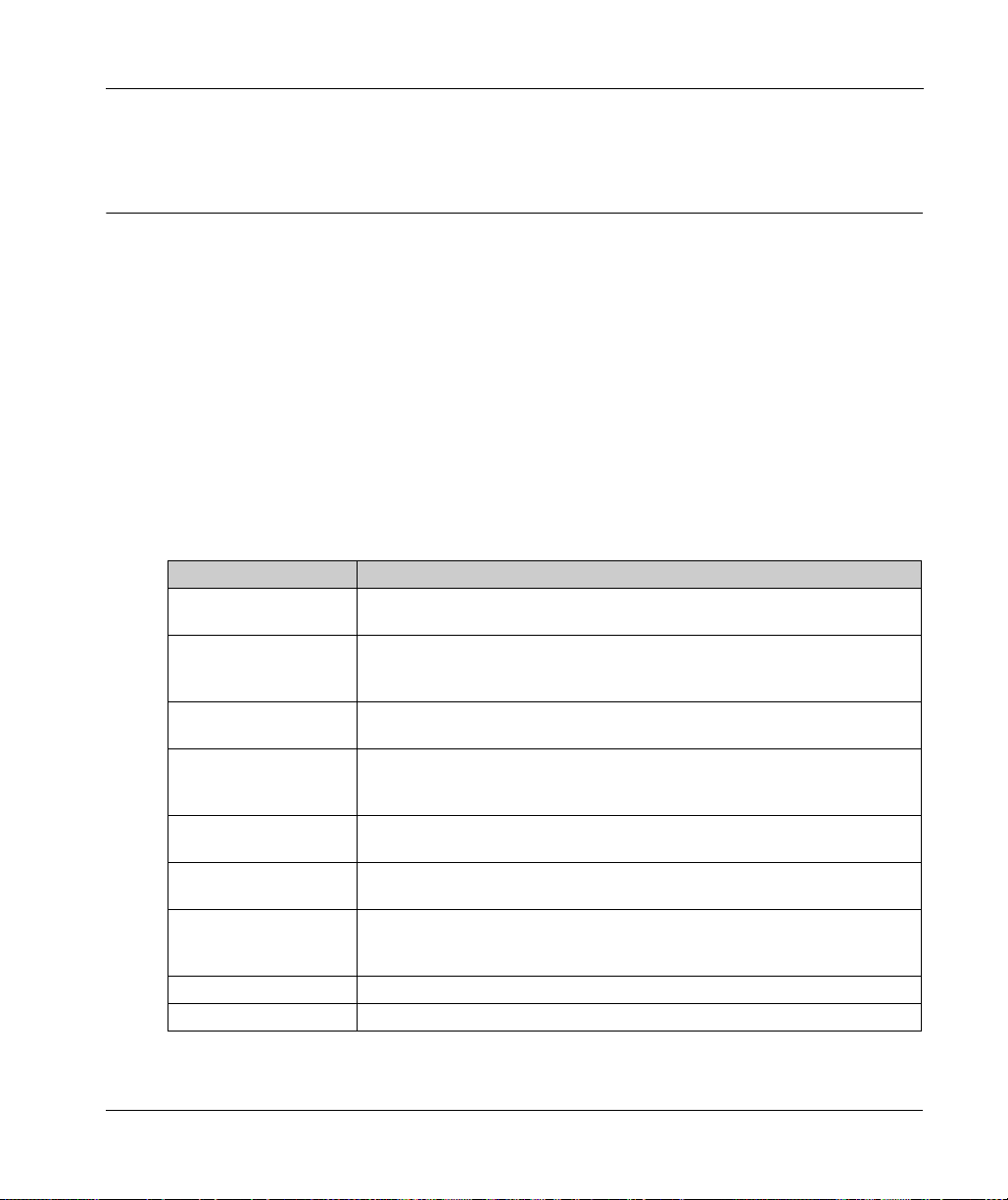

This table describes the different types of memory:

Memory Type Size Use

RAM 256 Mbytes, of which 32 Mbytes are

available for the application

Flash 1 Gbyte Non-volatile memory dedicated to the retention

Non-volatile RAM 512 Kbytes Non-volatile memory dedicated to the retention

Embedded Inputs/Outputs

The following embedded I/O types are available:

Fast inputs

Fast source outputs

.

(see page 89)

(seepage36)

.

.

.

For the execution of the application and the

firmware.

of the program and data in case of a power

interruption.

of the retain-persistent variables, and the

diagnostic files and associated information.

Encoder

The following encoder modes are available:

Incremental mode

SSI mode

Removable Storage

The M262 Logic/Motion Controllers include an integrated SD card slot

Logic/Motion Controller, Hardware Guide)

The main uses of the SD card are:

Initializing the controller with a new application

Updating the controller and expansion module firmware

Applying post configuration files to the controller

Storing recipes files

Receiving data logging files

16

(see Modicon M262

.

(see page 261)

(see page 254)

EIO0000003651 05/2020

Page 17

About the Modicon M262 Logic/Motion Controller

Embedded Communication Features

The following types of communication ports are available:

Ethernet

USB Mini-B

Serial Line

Sercos (Ethernet 1)

(see Modicon M262 Logic/Motion Controller, Hardware Guide)

(see Modicon M262 Logic/Motion Controller, Hardware Guide)

(see Modicon M262 Logic/Motion Controller, Hardware Guide)

Expansion Module and Bus Coupler Compatibility

Refer to the compatibility tables in the EcoStruxure Machine Expert - Compatibility and Migration

User Guide

(see EcoStruxure Machine Expert Compatibility and Migration, User Guide)

M262 Logic/Motion Controller

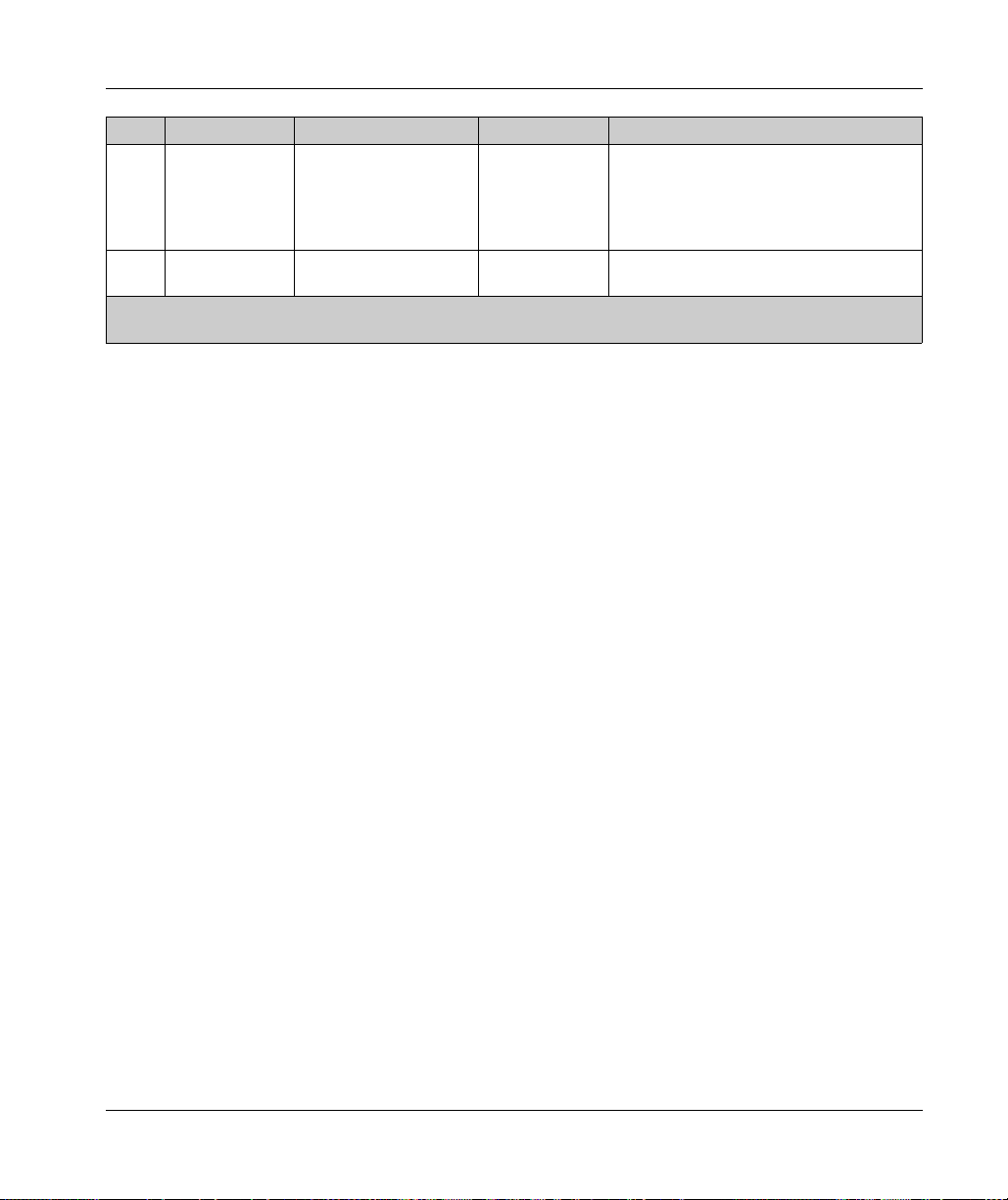

Reference Digital I/O Power supply Communication Ports Terminal Type Encoder

M262 Logic

Controller:

TM262L•

M262 Motion

Controller:

TM262M•

4 fast inputs

Source outputs

4 fast outputs

4 fast inputs

Source outputs

4 fast outputs

24 Vdc 1 serial line port

1 USB programming port

1 Ethernet port

1 dual port Ethernet switch

24 Vdc 1 serial line port

1 USB programming port

1 Ethernet port for fieldbus

with Sercos interface

1 dual port Ethernet switch

Removable

spring

Removable

spring

–

1 Encoder port

NOTE: You can use the fast inputs/outputs as regular inputs/outputs.

.

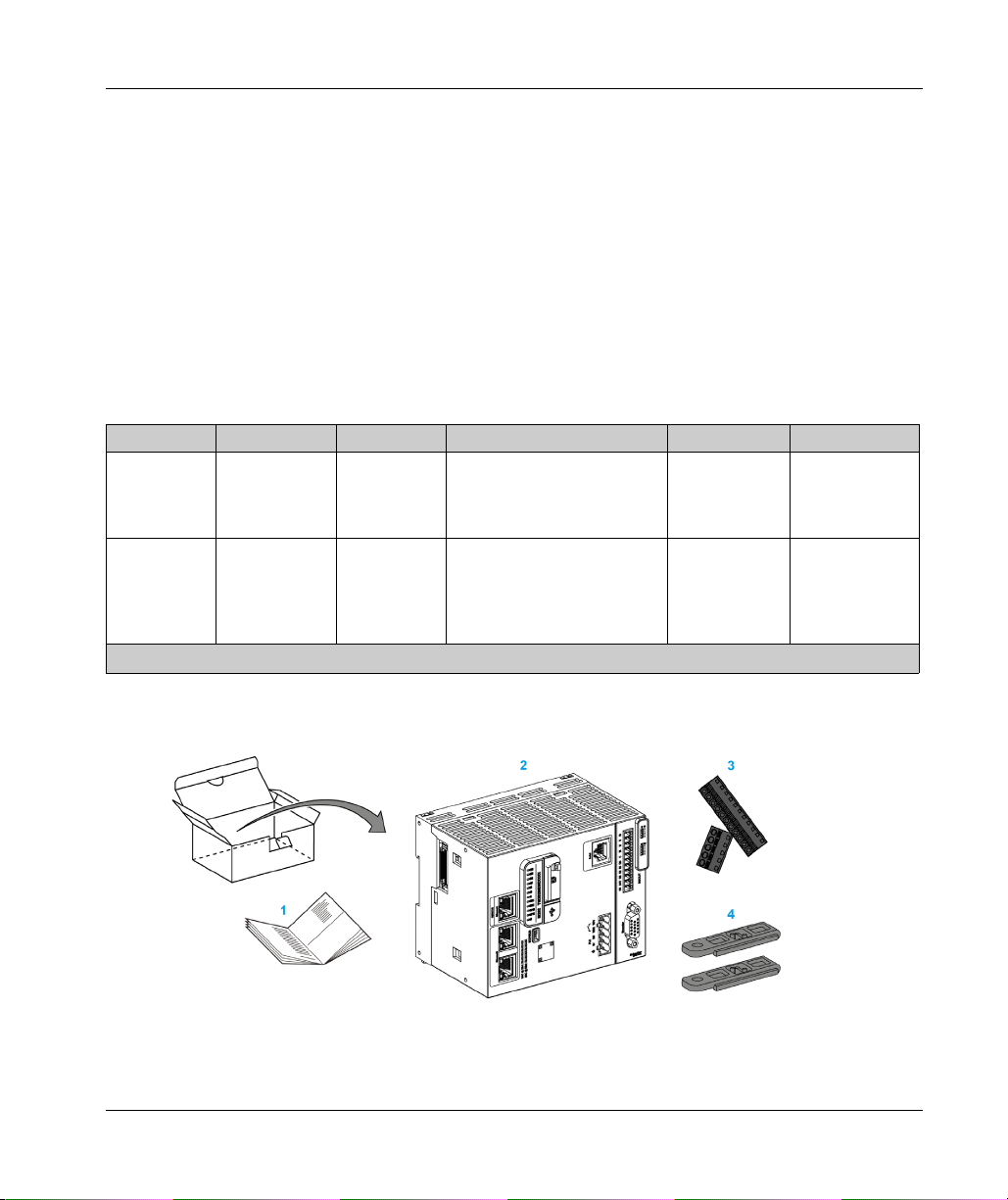

Delivery Content

The following figure presents the content of the delivery for the M262 Logic/Motion Controller:

1 M262 Logic/Motion Controller Instruction Sheet

2 M262 Logic/Motion Controller

3 Removable spring terminal blocks

4 Attachment parts

EIO0000003651 05/2020 17

Page 18

About the Modicon M262 Logic/Motion Controller

18

EIO0000003651 05/2020

Page 19

Modicon M262 Logic/Moti on Controller

M262 Motion Controller

EIO0000003651 05/2020

Modicon M262 Motion Co ntroller

Chapter 2

Modicon M262 Motion Controller

Modicon M262 Motion Controller

Controller Overview

The Schneider Electric Modicon TM262M15MESS8T, TM262M25MESS8T and

TM262M35MESS8T are controllers with various powerful features which can control a wide range

of motion applications.

The Modicon TM262M• Motion Controller centrally implements the Logic Controller functions and

powerful advanced motion functions.

A Modicon TM262M• Motion Controller creates, synchronizes and coordinates the motion

functions of a machine for a maximum of 16 axes, synchronized in 2 ms.

These controllers are designed for axis positioning using the EcoStruxure Machine Expert software

platform.

Performance Overview

The Modicon TM262M• Motion Controller supports all the features normally available in our Logic

Controller, plus it integrates Motion functionalities.

The TM262M• range of Motion controllers is, without additional devices, ready for motion with the

integrated Sercos motion bus. It merges the hard-real-time aspects of the Sercos interface with

Ethernet. It is based upon and conforms to the Ethernet standard IEEE 802.3 and ISO/IEC 88023 to support the real-time application with high performance. Other features supporting motion

functionalities include:

Synchronous axis Sercos devices, managed by PLCopen libraries, are fully synchronous with

the internal Motion task and the Sercos Cycle time, as for example: LMX32S.

Non axis Sercos devices are also synchronized with the internal Motion task, for example,

TM5NS01 islands or safety-related TM5CSLC100/TM5CSLC200 controllers.

External Encoder

External port for Incremental or SSI encoder. The encoder support is fully synchronized with

the Motion application. It can be used like a real axis or a virtual axis.

Fast input

The fast inputs support a touch probe function to capture position. The captured position can

be used in the Motion application.

EIO0000003651 05/2020 19

Page 20

M262 Motion Controller

Motion Kernel is embedded in the TM262M• Motion controller, allowing you to manage the

motion functions:

Synchronous axis in coordinated move in which the Functions blocks are based on the

PLCopen Standard to control easily the position / speed of a single axis.

Gearing mode (Master / Slave Function Block).

Caming mode, based on recipes, with modification on fly. The recipe can be designed thanks

to a cam editor included in EcoStruxure Machine Expert.

Depending the Motion controller and the Sercos Cycle time, you can configure more or less

Synchronous axis and non axis Sercos devices.

A TM5 System island used on Sercos is managed as non axis Sercos device. These islands are

fully configurable. The number of I/O configured increases the load of the Sercos Bus and may lead

to an overflow. If an overflow occurs, and assuming your application tolerates it, increase the

Sercos Cycle time. If increasing the Sercos Cycle time is not compatible with your application, then

optimize the application.

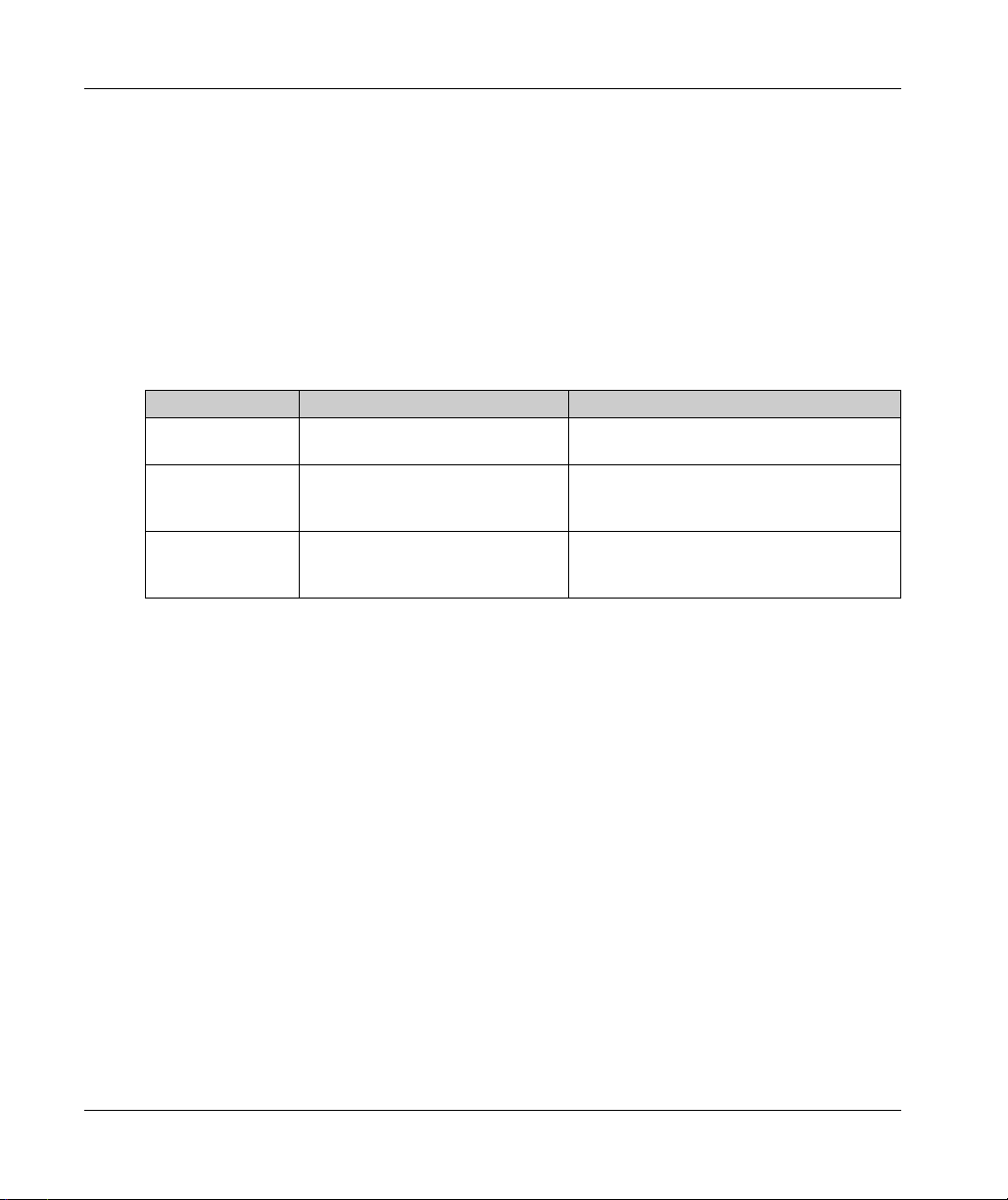

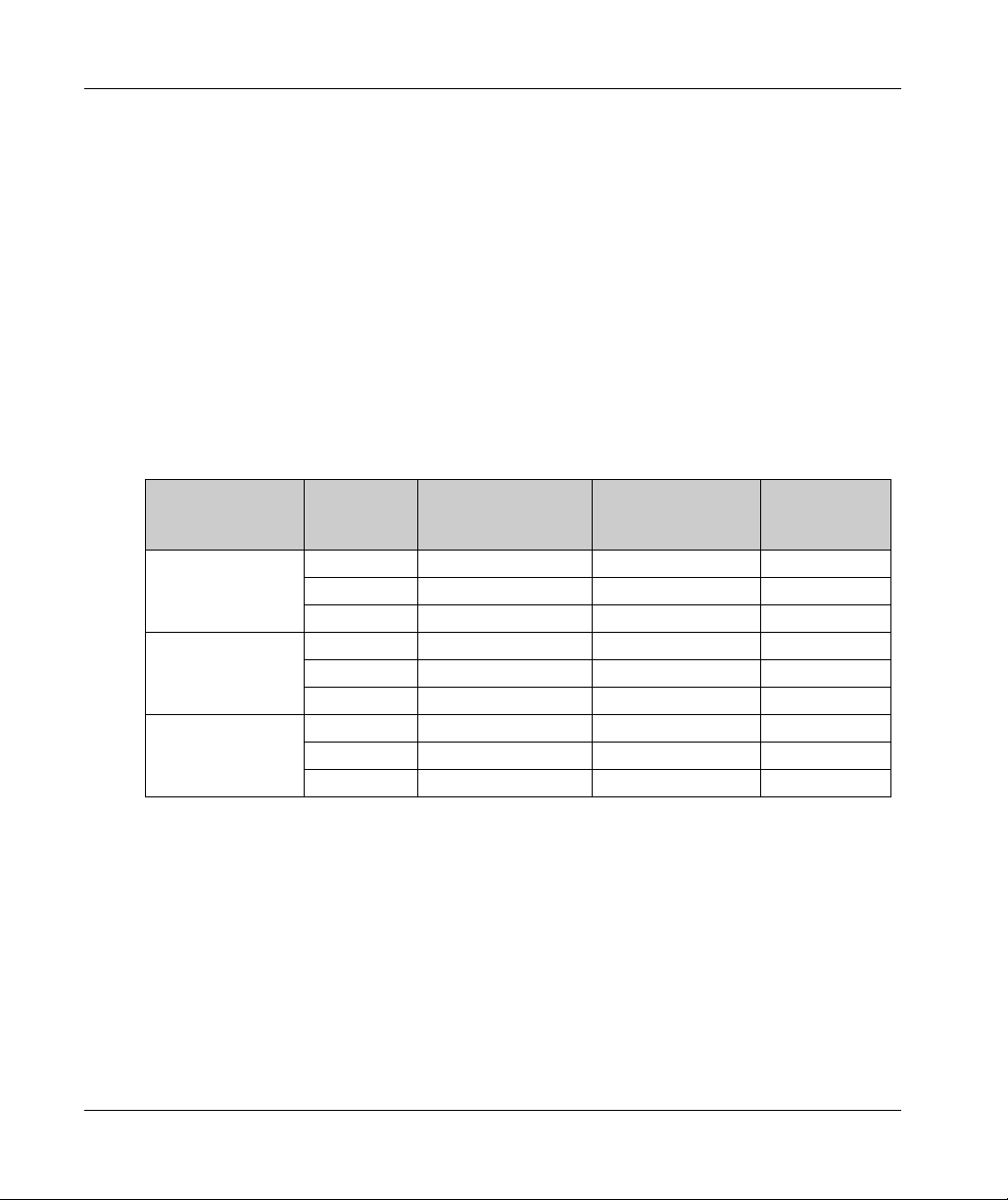

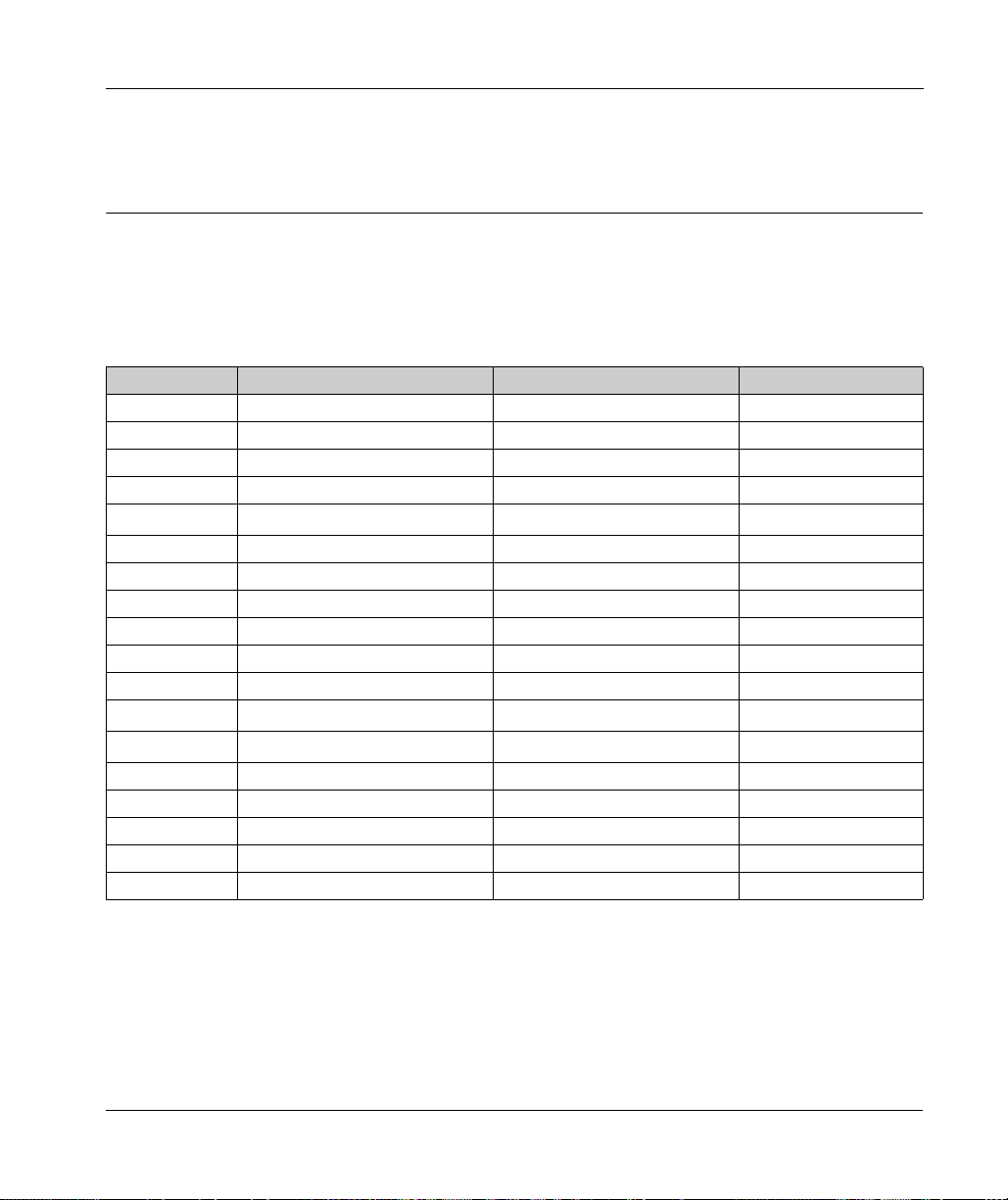

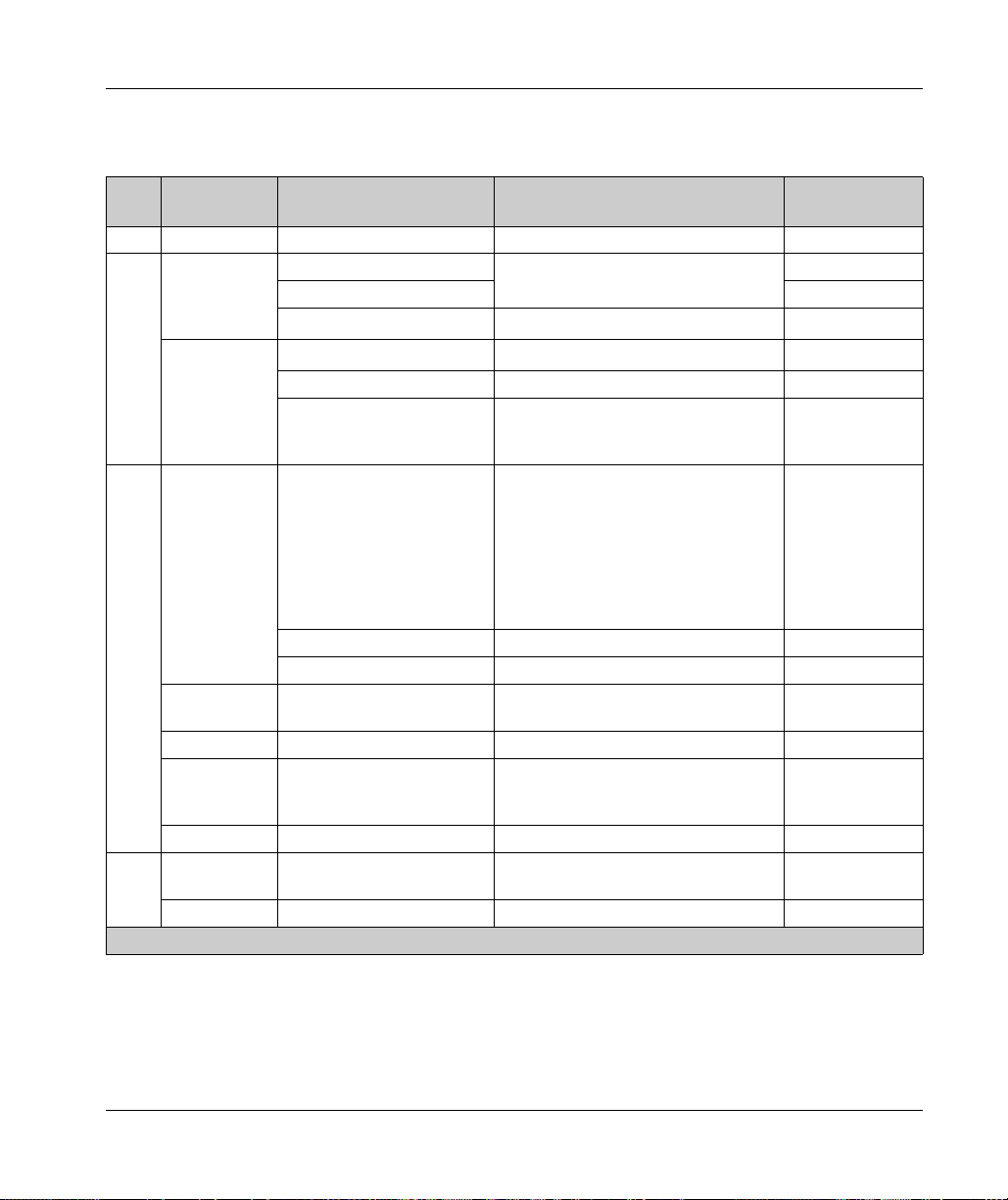

The following table indicates the performance capabilities of the Motion application:

Controller reference Sercos cycle

time

TM262M15MESS8T 1 ms 4 1 4

2ms 4 1 12

4ms 4 1 12

TM262M25MESS8T 1 ms 4 1 8

2ms 8 2 8

4ms 8 2 16

TM262M35MESS8T 1 ms 8 2 8

2ms 16 4 8

4ms 16 4 24

Synchronized axes on

Sercos (activated and

simulated)

Additional virtual axes

FB_ControlledAxis

Additional

Sercos devices

The Motion Sizer is embedded in EcoStruxure Machine Expert to help you define your complete

kinematic architecture. For more information on these features, refer to OneMotionSizer Online

(see Motion Sizer, Online Help)

Help

.

20

EIO0000003651 05/2020

Page 21

Modicon M262 Logic/Moti on Controller

How to Configure the Controller

EIO0000003651 05/2020

How to Configure the Controller

Chapter 3

How to Configure the Controller

Configuring the Controller

Introduction

First, create a new project or open an existing project in the EcoStruxure Machine Expert software.

Refer to the EcoStruxure Machine Expert Programming Guide for information on how to:

Add a controller to your project

Add expansion modules to your controller

Replace an existing controller

Convert a controller to a different but compatible device

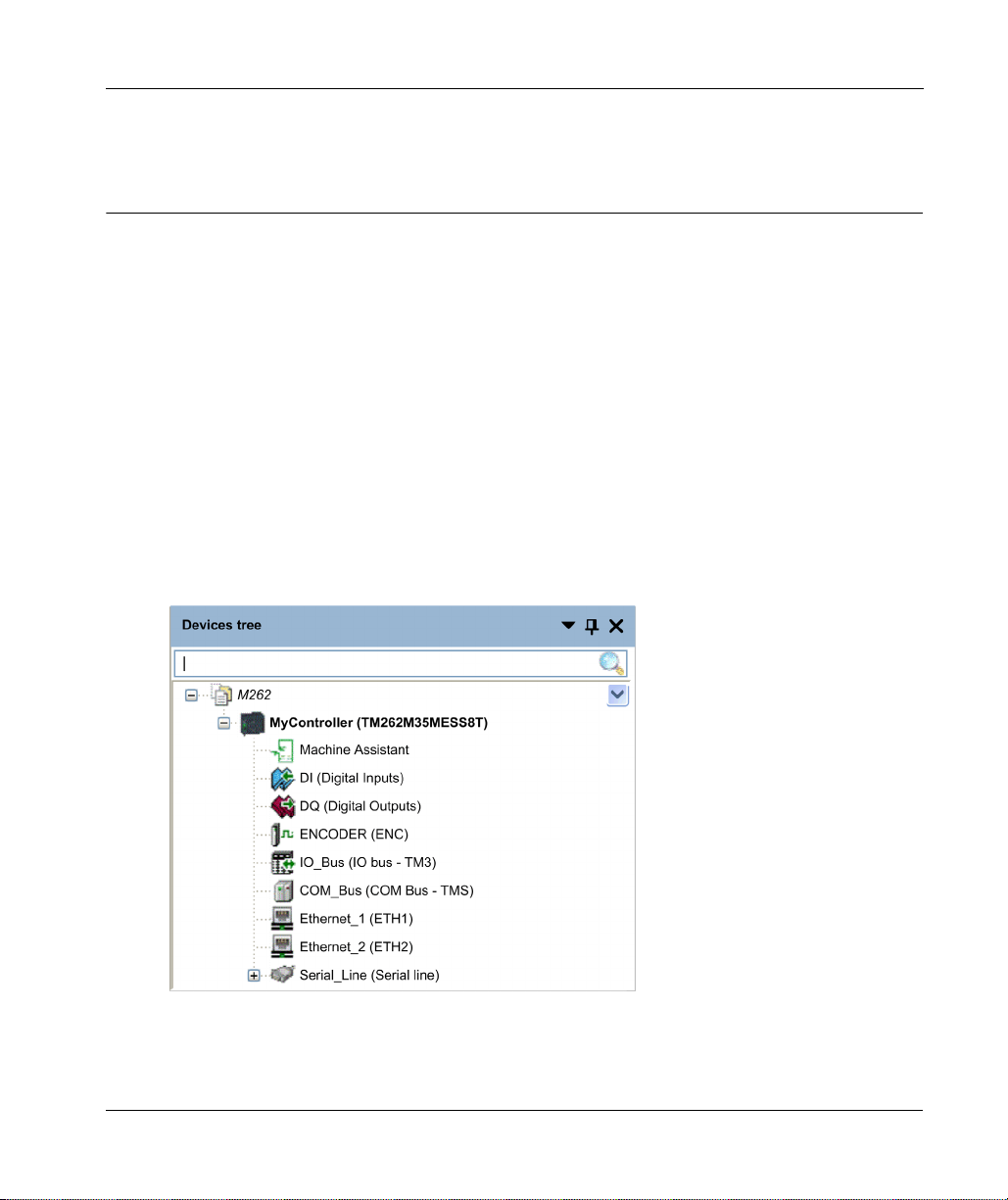

Devices Tree

The Devices tree presents a structured view of the current hardware configuration. When you add

a controller to your project, a number of nodes are added to the Devices tree, depending on the

functions the controller provides.

EIO0000003651 05/2020 21

Page 22

How to Configure the Controller

Item Use to Configure...

Machine Assistant Devices discovery and configuration

DI Embedded digital inputs of the controller

DQ Embedded digital outputs of the controller

ENCODER Incremental or SSI Encoder interface of the controller

IO_Bus Expansion modules connected to the controller

COM_Bus Communication modules connected to the controller

Ethernet_1 Embedded Ethernet dedicated to Motion Bus Sercos on TM262M•, dedicated

Ethernet_2 Embedded Ethernet communication

Serial_Line Serial line communication interface

Applications Tree

The Applications tree allows you to manage project-specific applications as well as global

applications, POUs, and tasks.

Tools Tree

The Tools tree allows you to configure the HMI part of your project and to manage libraries.

The Tools tree allows you to:

Configure the HMI part of your project.

Access to the Library Manager tool.

Access to the Message logger tool

to devices on TM262L•.

(see page 144)

.

22

EIO0000003651 05/2020

Page 23

Modicon M262 Logic/Moti on Controller

Libraries

EIO0000003651 05/2020

Libraries

Chapter 4

Libraries

Libraries

Introduction

Libraries provide functions, function blocks, data types and global variables that can be used to

develop your project.

The Library Manager of EcoStruxure Machine Expert provides information about the libraries

included in your project and allows you to install new ones. For more information on the Library

Manager, refer to the Functions and Libraries User Guide.

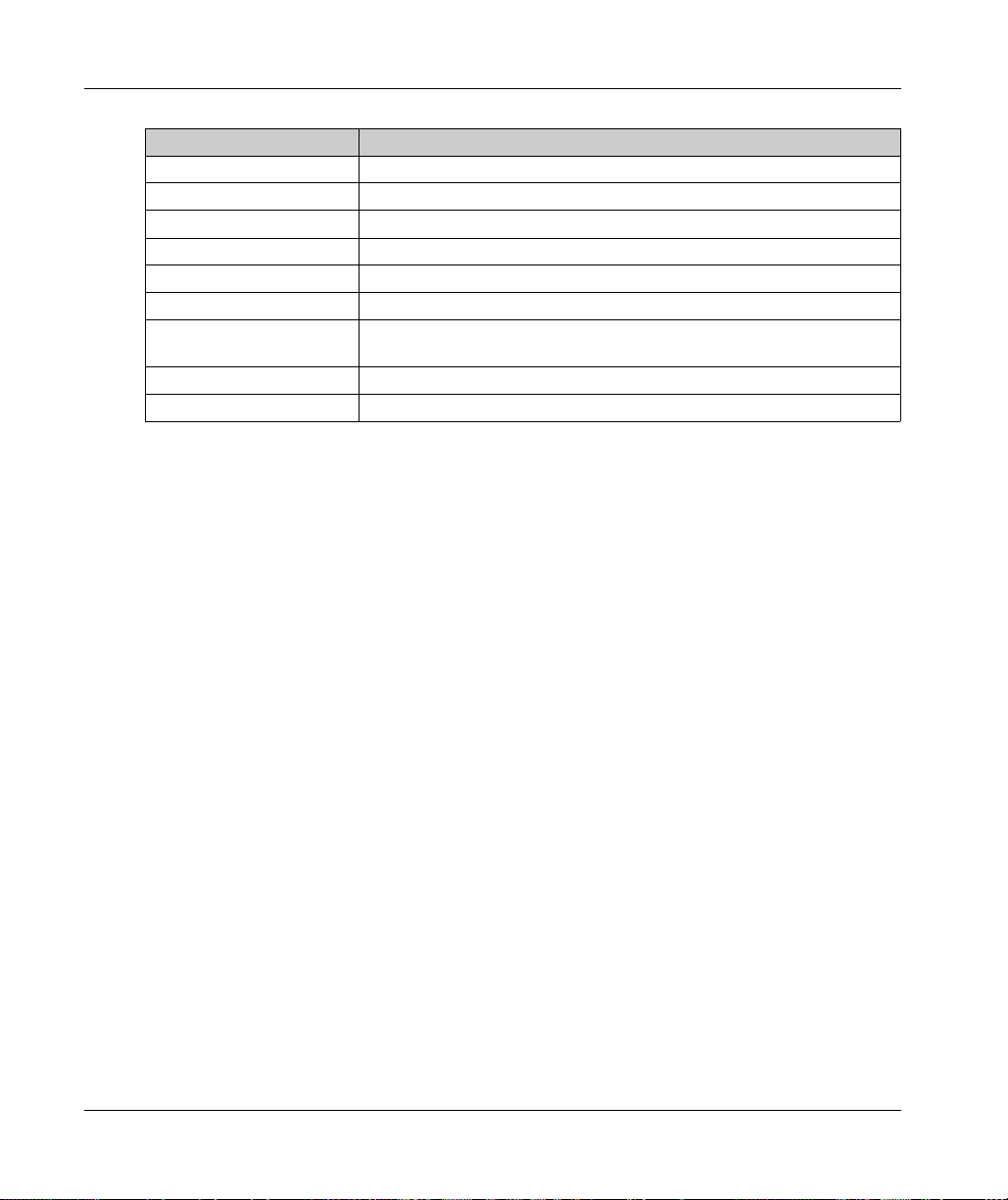

Modicon M262 Logic/Motion Controller

When you select a Modicon M262 Logic/Motion Controller for your application, EcoStruxure

Machine Expert automatically loads the following libraries:

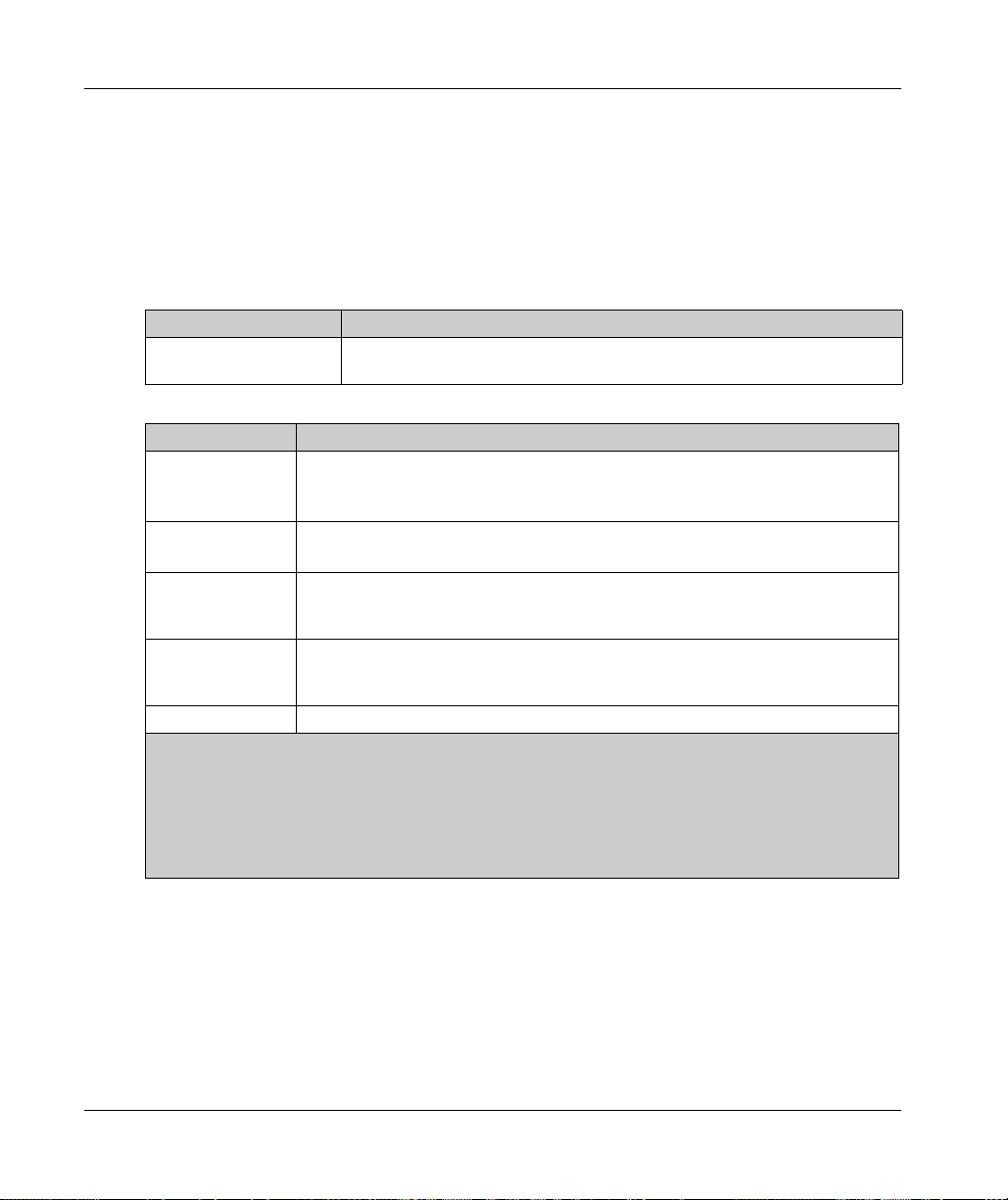

Library name Description

IoStandard Standard library for the IO-configuration. This library provides the basic I/O

interface for every IEC I/O driver.

Standard Contains functions and function blocks which are required matching IEC61131-3

as standard POUs for an IEC programming system. Link the standard POUs to

the project (standard.library).

Util Analog Monitors, BCD Conversions, Bit/Byte Functions, Controller Datatypes,

Function Manipulators, Mathematical Functions, Signals.

SE_PLCCommunication Contains communication functions. Most of them are dedicated to Modbus

exchange. Communication functions are processed asynchronously with regard

to the application task that called the function.

SE_M262 PLCSystem Contains functions and variables to get diagnostic information and send

SE_Relocation Table

(see page 36)

M262 Encoder Contains function blocks and enumerated types for enable, monitor and preset of

TM3System Contains functions and function blocks for TM3 expansion modules.

TMSSystem Contains the function block and enumerated types for TMS expansion modules.

EIO0000003651 05/2020 23

commands to the controller system.

Allows you to optimize exchanges between the Modbus client and the controller,

by regrouping non-contiguous data into a contiguous table of registers.

the encoder, capture of the encoder value in incremental or SSI mode, and read

of the active values of the scaling parameters used to compute the unit value.

Page 24

Libraries

24

EIO0000003651 05/2020

Page 25

Modicon M262 Logic/Moti on Controller

Supported Standard Data Types

EIO0000003651 05/2020

Supported Standard Data Types

Chapter 5

Supported Standard Data Types

Supported Standard Data Types

Supported Standard Data Types

The controller supports the following IEC data types:

Data Type Lower Limit Upper Limit Information Content

BOOL FALSE TRUE 1 Bit

BYTE 0 255 8 Bit

WORD 0 65,535 16 Bit

DWORD 0 4,294,967,295 32 Bit

LWORD 0

64

-1

2

SINT -128 127 8 Bit

USINT 0 255 8 Bit

INT -32,768 32,767 16 Bit

UINT 0 65,535 16 Bit

DINT -2,147,483,648 2,147,483,647 32 Bit

UDINT 0 4,294,967,295 32 Bit

LINT

ULINT 0

63

-2

263-1

64

2

-1

REAL 1.175494351e-38 3.402823466e+38 32 Bit

LREAL 2.2250738585072014e-308 1.7976931348623158e+308 64 Bit

STRING 1 character – 1 character = 1 byte

WSTRING 1 character – 1 character = 1 word

TIME - – 32 Bit

64 Bit

64 Bit

64 Bit

For more information on ARRAY, LTIME, DATE, TIME, DATE_AND_TIME, and TIME_OF_DAY, refer

to the EcoStruxure Machine Expert Programming Guide.

EIO0000003651 05/2020 25

Page 26

Supported Standard Data Types

26

EIO0000003651 05/2020

Page 27

Modicon M262 Logic/Moti on Controller

Memory Mapping

EIO0000003651 05/2020

Memory Mapping

Chapter 6

Memory Mapping

Introduction

This chapter describes the memory maps and sizes of the different memory areas in the Modicon

M262 Logic/Motion Controller. These memory areas are used to store user program logic, data and

the programming libraries.

What Is in This Chapter?

This chapter contains the following topics:

Controller Memory Organization 28

Flash Memory Organization 30

RAM Memory Organization 33

NVRAM Memory Organization 35

Relocation Table 36

Topic Page

EIO0000003651 05/2020 27

Page 28

Memory Mapping

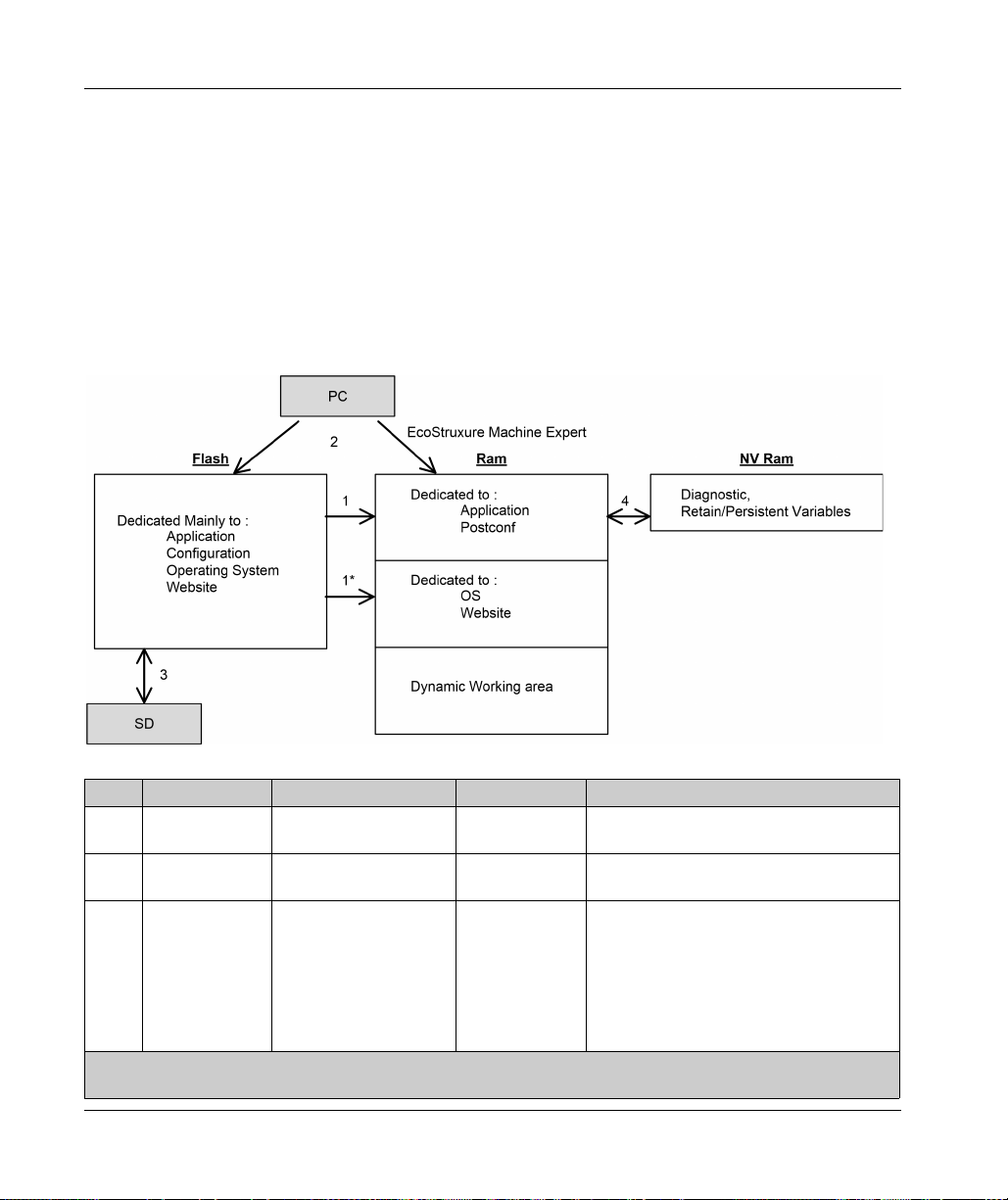

Controller Memory Organization

Introduction

The controller memory is composed of three types of physical memory:

The Flash memory

The Random Access Memory (RAM) is used for application execution.

The Non-Volatile Random Access Memory (NVRAM) is used to save the retain-persistent

variables and diagnostic information.

Files Transfers in Memory

(see page 30)

contains files (application, configuration files, and so on).

Item Controller State File Transfer Events Connection Description

1 – Initiated automatically at

1* – Initiated automatically at

2 All states except

INVALID_OS

Power ON and Reboot

Power ON and Reboot

Initiated by user Ethernet or USB

(1)

Internal Files transfer from Flash memory to RAM.

Internal Operating system files transfer.

programming

port

The content of the RAM is overwritten.

Files can be transferred via:

Web server

FTP server

Controller Assistant

EcoStruxure Machine Expert

(see page 125)

(see page 155)

(see EcoStruxure Machine Expert,

Programming Guide)

(1) If the controller is in the INVALID_OS state, the only accessible memory is the SD card and only for firmware

upgrades.

28

EIO0000003651 05/2020

Page 29

Memory Mapping

Item Controller State File Transfer Events Connection Description

3 All states Initiated automatically by

SD card

Up/download with SD card

(1)

.

script (data transfer) or

by power cycle (cloning)

when an SD card is

inserted

4 All states Initiated by system Internal Save of modified retain-persistent variables

and the context on power OFF.

(1) If the controller is in the INVALID_OS state, the only accessible memory is the SD card and only for firmware

upgrades.

NOTE: The modification of files in Flash memory does not affect a running application. Any

changes to files in Flash memory are taken into account at the next reboot, except for the user files

directly used by the application.

EIO0000003651 05/2020 29

Page 30

Memory Mapping

Flash Memory Organization

Introduction

The Flash memory contains the file system used by the controller.

File Type

The Modicon M262 Logic/Motion Controller manages the following file types:

System function (/sys) Description

Operating System (OS) Controller firmware that can be written to Flash memory. The firmware file is

User functions (/usr) Description

Boot application This file resides in Flash memory and contains the compiled binary code of the

executable application. Each time the controller is rebooted, the executable application

is extracted from the boot application and copied into the controller RAM

Application source Source file that can be uploaded from Flash memory to the PC if the source file is not

available on the PC

Post configuration File that contains Ethernet and serial line parameters.

The parameters specified in the file override the parameters in the executable

application at each reset.

Firewall parameters Settings used to configure the firewall of the M262 Logic/Motion Controller. These

settings restrict access to authorized personnel and protocols only. See Firewall

Configuration

Data logging Files in which the controller logs events as specified by the application.

(1) The creation of a boot application is optional in EcoStruxure Machine Expert, according to application

properties. Default option is to create the boot application on download. When you download an

application from EcoStruxure Machine Expert to the controller, you are transferring only the binary

executable application directly to RAM.

(2) EcoStruxure Machine Expert does not support uploading of either the executable application or the boot

application to a PC for modification. Program modifications must be made to the application source. When

you download your application, you have the option to store the source file to Flash memory.

applied at next reboot of the controller.

(2)

.

(see page 187)

for more information.

(1)

.

30

EIO0000003651 05/2020

Page 31

Memory Mapping

File Organization

This table shows the file organization of the flash memory:

Disk Directory File Content Up/Downloaded

data type

/sys Pkg Temporary file Internal use N/A

/usr App Application.app Boot application Application

Application.crc –

Cfg

/usr Log

Archive.prj

Machine.cfg

CodesysLateConf.cfg Name of application to launch. Configuration

FirewallDefault.cmd Default firewall settings. By default, this

(1)

(1)

UserDefinedLogName_1

Application source –

Post configuration file

file does not exist. It can be added

optionally.

.log All *.log files created using the data

logging functions

(see page 253)

(see EcoStruxure

Configuration

Configuration

log file

Machine Expert, Data Logging

Functions, DataLogging Library Guide)

You must specify the total number of

files created and the names and

contents of each log file using the

datalogging feature.

... – –

UserDefinedLogName_n

pki – Certificate store for M262 secured

Rcp – Main directory for Recipes. –

Syslog

Visu – Used for the Webvisualization feature. –

/sd0 – – SD card. Refer to Managing Script Files

– User files – –

(1) If the files had been created due to specific events or customer requirements.

crash.txt

LoggerFile_xxx.mel

(1)

.log – –

protocols.

Record of detected system errors. For

use by Schneider Electric Technical

Support.

(see page 273)

.

.

–

Log file

–

NOTE: For more information on libraries and available function blocks, refer to Libraries

(see page 23)

EIO0000003651 05/2020 31

.

Page 32

Memory Mapping

Files Redirection

When system, program or certain user activity creates specific file types, the M262 Logic/Motion

Controller examines the file extension and automatically moves the file to a corresponding folder

in flash memory.

The following table lists the file types that are moved in this way and the destination folder in flash

memory:

File extensions Flash memory folder

*.app, *.ap_, *.err, *.crc, *.frc, *.prj /usr/App

*.cfg, *.cf_ /usr/Cfg

*.log /usr/Log

*.rcp, *.rsi /usr/Rcp

Backup Data Logging File

Data logging files can become large to the point of exceeding the space available in the file system.

Therefore, you should develop a method to archive the log data periodically on an SD card. You

could split the log data into several files, for example LogMonth1, LogMonth2, and use the

ExecuteScript command to copy the first file to an SD card. Afterwards, you may remove it from

the internal file system while the second file is accumulating data. If you allow the data logging file

to grow and exceed the limits of the file size, you could lose data.

32

NOTICE

LOSS OF APPLICATION DATA

Backup SD card data regularly.

Do not remove power or reset the controller, and do not insert or remove the SD card while it

is being accessed.

Failure to follow these instructions can result in equipment damage.

EIO0000003651 05/2020

Page 33

RAM Memory Organization

Introduction

This section describes the Random Access Memory (RAM) size for different areas of the Modicon

M262 Logic/Motion Controller.

Memory Mapping

The RAM is composed of two areas:

Dedicated application memory

OS memory

This table describes the dedicated application memory:

Area Element

System area System Area Mappable Addresses

%MW0...%MW59999

System and diagnostic variables

(%MW60000...%MW60199)

This memory is accessible through Modbus requests only.

These must be read-only requests.

Dynamic Memory Area: Read Relocation Table

(%MW60200...%MW61999)

This memory is accessible through Modbus requests only.

These must be read-only requests.

System and diagnostic variables

(%MW62000...%MW62199)

This memory is accessible through Modbus requests only.

These can be read or write requests.

Dynamic Memory Area: Write Relocation Table

(%MW62200...%MW63999)

This memory is accessible through Modbus requests only.

These can be read or write requests.

User area Symbols

Variables

Libraries

Application

(see page 36)

(see page 36)

Memory Mapping

EIO0000003651 05/2020 33

Page 34

Memory Mapping

System and Diagnostic Variables

Variables Description

PLC_R Structure of controller read-only system variables.

PLC_W Structure of controller read/write system variables.

ETH_R Structure of Ethernet read-only system variables (Ethernet counters).

ETH_W Structure of Ethernet read/write system variables. Allows you to reset

SERIAL_R Structure of Serial Line read-only system variables (Serial Line counters).

SERIAL_W Structure of Serial Line read-write system variables. Allows you to reset

TM3_MODULE_R Structure of TM3 modules read-only system variables.

TM3_BUS_W Structure of TM3 modules read-write system variables.

TMS_BUS_DIAG_R Structure of TMS modules read-only system variables (diagnostic).

TMS_MODULE_DIAG_R Structure of TMS modules read-only system variables (diagnostic).

Ethernet counters.

Serial Line counters.

For more information on system and diagnostic variables, refer to the M262 System Library Guide

(see Modicon M262 Logic/Motion Controller, System Functions and Variables, System Library

.

Guide)

34

EIO0000003651 05/2020

Page 35

NVRAM Memory Organization

Introduction

The NVRAM memory contains:

Files saved for the diagnostics

Remanent (retain-persistent) variables

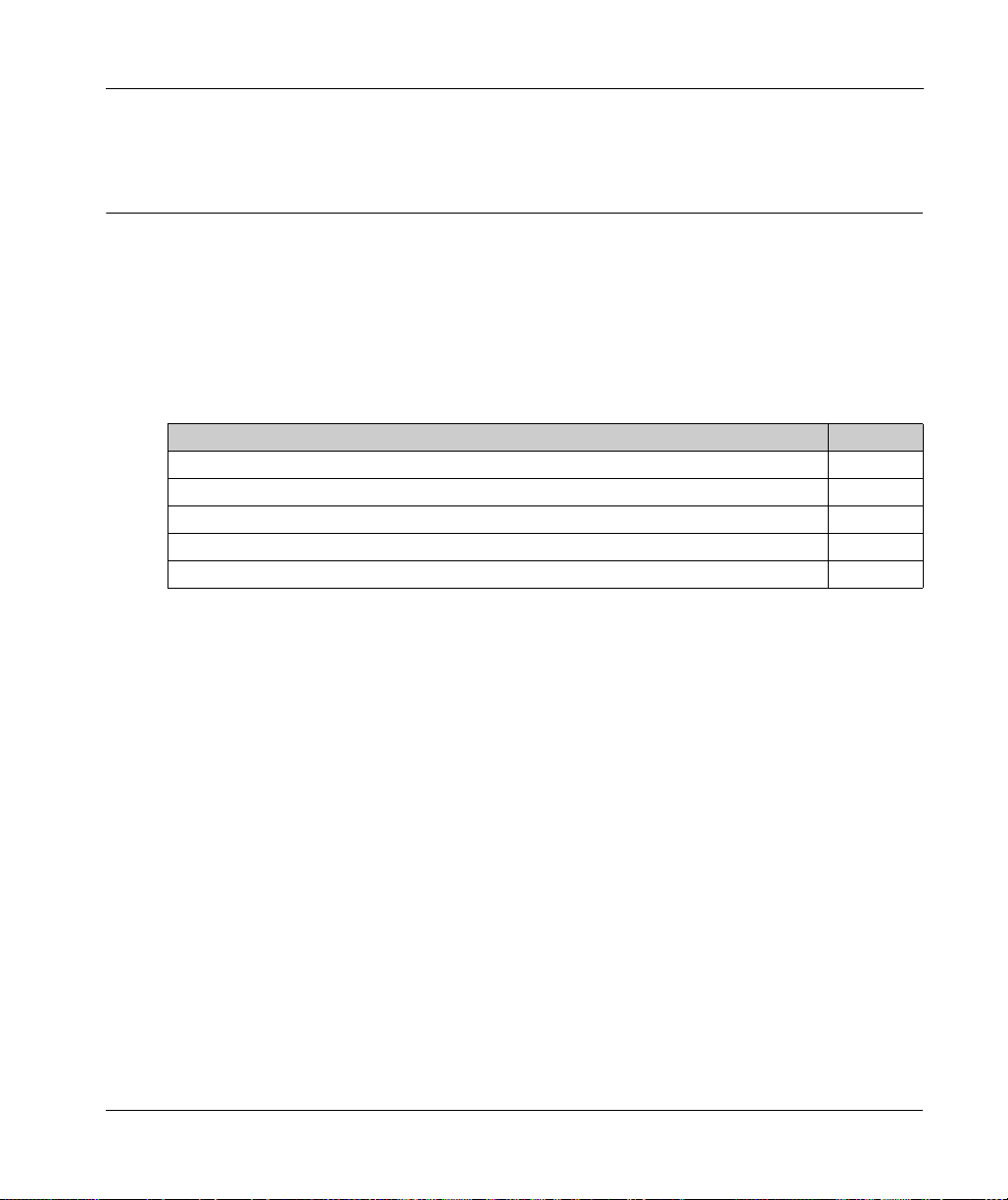

NVRAM size

The following table describes the size of the NVRAM:

User Function Description Size

System diagnostics Contain the controller context saved on power off. 128 Kbytes

Remanent (retain-persistent)

variables

Remanent or retain-persistent variables are saved in the NVRAM. Each subsequent read/write

access to these variables requires a NVRAM access. For more information about remanent

variables, see Remanent Variables

performance, see Processing Performance

NOTE: For an optimum cycle time, only access the retain-persistent variables when necessary. For

frequent (Read) access, copy theses variables to a working memory in the RAM.

Modified and saved in the NVRAM.

Saved after each modification. This action impacts

the cycle time.

(see page 71)

. For more information about the impact on

(seepage313)

.

Memory Mapping

Retain: 64 Kbytes

Persistent: 64 Kbytes

EIO0000003651 05/2020 35

Page 36

Memory Mapping

Relocation Table

Introduction

The Relocation Table allows you to organize data to optimize communication between the

controller and other equipment by regrouping non-contiguous data into a contiguous table of

located registers, accessible through Modbus.

NOTE: A relocation table is considered an object. Only one relocation table object can be added

to a controller.

Relocation Table Description

This table describes the Relocation Table organization:

Register Description

60200...61999 Dynamic Memory Area: Read Relocation Table

62200...63999 Dynamic Memory Area: Write Relocation Table

For further information, refer to M262 System Library Guide.

Adding a Relocation Table

This table describes how to add a Relocation Table to your project:

The %MW registers are read from the variables at each cycle.

The %MW registers are copied to the variables at each cycle.

36

Step Action

1 In the Applications tree tab, select the Application node.

2 Click the right mouse button.

3 Click Objects → Relocation Table....

Result: The Add Relocation Table window is displayed.

4 Click Add.

Result: The new relocation table is created and initialized.

NOTE: As a Relocation Table is unique for a controller, its name is Relocation Table and cannot

be changed.

EIO0000003651 05/2020

Page 37

Relocation Table Editor

The relocation table editor allows you to organize your variables in the relocation table.

To access the relocation table editor, double-click the Relocation Table node in the Tools tree tab:

This picture describes the relocation table editor:

Memory Mapping

EIO0000003651 05/2020 37

Page 38

Memory Mapping

Icon Element Description

- ID Automatic incremental integer (not editable).

- Variable The name or the full path of a variable (editable).

- Address The address of the system area where the variable is stored (not editable).

- Length Variable length in word.

- Validity Indicates if the entered variable is valid (not editable).

New Item Adds an element to the list of system variables.

Move Down Moves down the selected element of the list.

Move Up Moves up the selected element of the list.

Delete Item Removes the selected elements of the list.

Copy Copies the selected elements of the list.

Paste Pastes the elements copied.

Erase Empty Item Removes all the elements of the list for which the "Variable" column is empty.

38

NOTE: If a variable is undefined after program modifications, the content of the cell is displayed in

red, the related Validity cell is False, and Address is set to -1.

EIO0000003651 05/2020

Page 39

Modicon M262 Logic/Moti on Controller

Tasks

EIO0000003651 05/2020

Tasks

Chapter 7

Tasks

Introduction

The Task Configuration node in the Applications tree allows you to define one or more tasks to

control the execution of your application program.

The task types available are:

Cyclic

Freewheeling

Event

External event

This chapter begins with an explanation of these task types and provides information regarding the

maximum number of tasks, the default task configuration, and task prioritization. In addition, this

chapter introduces the system and task watchdog functions and explains its relationship to task

execution.

What Is in This Chapter?

This chapter contains the following topics:

Topic Page

Maximum Number of Tasks 40

Task Types 41

Task Configuration Screen 45

System and Task Watchdogs 47

Task Priorities 48

Default Task Configuration 50

EIO0000003651 05/2020 39

Page 40

Tasks

Maximum Number of Tasks

Maximum Number of Tasks

The maximum number of tasks you can define for the Modicon M262 Logic/Motion Controller are:

Total number of tasks = 16

Cyclic tasks = 8

Freewheeling tasks = 1

Event tasks = 8

External Event tasks = 8

Special Considerations for Freewheeling

A Freewheeling task

scan starts when the previous scan has been completed and after a period of system processing

(30% of the total duration of the Freewheeling task). If the system processing period is reduced to

less than 15% for more than 3 seconds due to interruptions by other tasks, a system error is

detected. For more information, refer to the System Watchdog

Controller, Programming Guide)

NOTE: You may wish to avoid using a Freewheeling task in a multi-task application when some

high priority and time-consuming tasks are running. Doing so may provoke a task Watchdog

Timeout. You should not assign CANopen to a freewheeling task. CANopen should be assigned

to a cyclic task.

(see page 42)

does not have a fixed duration. In Freewheeling mode, the task

(see Modicon LMC078, Motion

.

40

EIO0000003651 05/2020

Page 41

Task Types

Introduction

The following section describes the various task types available for your program, along with a

description of the task type characteristics.

Cyclic Task

A Cyclic task is assigned a fixed cycle time using the Interval setting in the Type section of

Configuration subtab for that task. Each Cyclic task type executes as follows:

1. Read Inputs: The physical input states are written to the %I input memory variables and other

system operations are executed.

2. Task Processing: The user code (POU, and so on) defined in the task is processed. The %Q

output memory variables are updated according to your application program instructions but not

yet written to the physical outputs during this operation.

3. Write Outputs: The %Q output memory variables are modified with any output forcing that has

been defined; however, the writing of the physical outputs depends upon the type of output and

instructions used.

For more information on defining the bus cycle task, refer to the EcoStruxure Machine Expert

Programming Guide and Modicon M262 Logic/Motion Controller Settings

For more information on I/O behavior, refer to Controller States Detailed Description

(see page 56)

4. Remaining Interval time: The controller firmware carries out system processing and any other

lower priority tasks.

NOTE: If you define too short a period for a cyclic task, it will repeat immediately after the write of

the outputs and without executing other lower priority tasks or any system processing. This will

affect the execution of all tasks and cause the controller to exceed the system watchdog limits,

generating a system watchdog exception.

Tasks

(see page 77)

.

.

EIO0000003651 05/2020 41

Page 42

Tasks

Freewheeling Task

A Freewheeling task does not have a fixed duration. In Freewheeling mode, each task scan begins

when the previous scan has been completed and after a short period of system processing. Each

Freewheeling task type executes as follows:

1. Read Inputs: The physical input states are written to the %I input memory variables and other

system operations are executed.

2. Task Processing: The user code (POU, and so on) defined in the task is processed. The %Q

output memory variables are updated according to your application program instructions but not

yet written to the physical outputs during this operation.

3. Write Outputs: The %Q output memory variables are modified with any output forcing that has

been defined; however, the writing of the physical outputs depends upon the type of output and

instructions used.

For more information on defining the bus cycle task, refer to the EcoStruxure Machine Expert

Programming Guide and Modicon M262 Logic/Motion Controller Settings

For more information on I/O behavior, refer to Controller States Detailed Description

(see page 56)

4. System Processing: The controller firmware carries out system processing and any other lower

priority tasks (for example: HTTP management, Ethernet management, parameters

management).

NOTE: If you want to define the task interval, refer to Cyclic Task

(see page 77)

.

.

(see page 41)

.

42

EIO0000003651 05/2020

Page 43

Event Task

This type of task is event-driven and is initiated by a program variable. It starts at the rising edge

of the boolean variable associated to the trigger event unless pre-empted by a higher priority task.

In that case, the Event task will start as dictated by the task priority assignments.

For example, if you have defined a variable called my_Var and would like to assign it to an Event,

proceed as follows:

Step Action

NOTE: When the event task is triggered with too high a frequency, the controller may detect an

error and transition to the HALT state (Exception). The maximum rate of events is 10 events per

millisecond for TM262L10MESE8T and TM262M15MESS8T, and 16 events per millisecond for

TM262L20MESE8T, TM262M25MESS8T and TM262M35MESS8T. If the event task is triggered

at a higher frequency than this, the message 'ISR Count Exceeded' is logged in the application log

page.

Tasks

1 Double-click the TASK in the Applications tree.

2 Select Event from the Type list in the Configuration tab.

3

Click the Input Assistant button to the right of the Event field.

Result: The Input Assistant window appears.

4 Navigate in the tree of the Input Assistant dialog box to find and assign the my_Var variable.

EIO0000003651 05/2020 43

Page 44

Tasks

External Event Task

This type of task is event-driven and is initiated by the detection of a hardware or hardware-related

function event. It starts when the event occurs unless pre-empted by a higher priority task. In that

case, the External Event task will start as dictated by the task priority assignments.

For example, an External event task could be associated with an HSC Stop event. To associate

the HSC0_STOP event to an External event task, select it from the External event drop-down list

on the Configuration tab.

The external event task can be associated with the CAN Sync event. To associate the

CAN_1_SYNC event to an external event task, select it from the External event dropdown list in

the Configuration tab.

Different types of events can be associated with an External event task:

HSC thresholds

HSC Stop

CAN Sync

HSC Event Periodmeter

Event input

NOTE: CAN Sync is a specific event object, depending on the CANopen manager configuration.

NOTE: When the external event task is triggered with too high a frequency, the controller may

detect an error and transition to the HALT state (Exception). The maximum rate of events is

10 events per millisecond for TM262L10MESE8T and TM262M15MESS8T, and 16 events per

millisecond for TM262L20MESE8T, TM262M25MESS8T and TM262M35MESS8T. If the event

task is triggered at a higher frequency than this, the message 'ISR Count Exceeded' is logged in

the application log page.

(see Modicon TM3 Expert I/O Modules, HSC Library Guide)

44

EIO0000003651 05/2020

Page 45

Task Configuration Screen

Screen Description

This screen allows you to configure the tasks. Double-click the task that you want to configure in

the Applications tree to access this screen.

Each configuration task has its own parameters that are independent of the other tasks.

The Configuration window is composed of four parts:

Tasks

EIO0000003651 05/2020 45

Page 46

Tasks

The table describes the fields of the Configuration screen:

Field Name Definition

Priority Configure the priority of each task with a number from 0 to 31 (0 is the highest priority, 31 is

the lowest).

Only one task at a time can be running. The priority determines when the task runs:

A higher priority task pre-empts a lower priority task

Tasks with same priority run in turn (2 ms time-slice)

NOTE: Do not assign tasks with the same priority. If there are yet other tasks that attempt

to pre-empt tasks with the same priority, the result could be indeterminate and unpredicable.

For important safety information, refer to Task Priorities

(see page 48)

.

Type These task types are available:

Cyclic

Event

External

Freewheeling

Watchdog To configure the watchdog

(see page 41)

(see page 43)

(see page 44)

(see page 42)

(see Modicon LMC078, Motion Controller, Programming Guide)

define these two parameters:

Time: enter the timeout before watchdog execution.

Sensitivity: defines the number of expirations of the watchdog timer before the controller

stops program execution and enters a HALT state.

POUs The list of Programming Organization Units (POUs) controlled by the task is defined in the

task configuration window

To add a POU linked to the task, use the command Add Call and select the POU in the

(see EcoStruxure Machine Expert, Programming Guide)

:

Input Assistant editor.

To remove a POU from the list, use the command Remove Call.

To replace the currently selected POU of the list by another one, use the command

Change Call.

POUs are executed in the order shown in the list. To move the POUs in the list, select a

POU and use the command Move Up or Move Down.

NOTE: You can create as many POUs as you want. An application with several small

POUs, as opposed to one large POU, can improve the refresh time of the variables in online

mode.

,

46

EIO0000003651 05/2020

Page 47

System and Task Watchdogs

Introduction

Two types of watchdog functionality are implemented for the Modicon M262 Logic/Motion

Controller:

System Watchdogs: These watchdogs are managed by the controller firmware. You cannot

configure them.

Task Watchdogs: These watchdogs are optional watchdogs that you can define for each task.

These are configurable in EcoStruxure Machine Expert.

System Watchdogs

Three system watchdogs are defined for the Modicon M262 Logic/Motion Controller. They are

managed by the controller firmware and are therefore sometimes referred to as hardware

watchdogs in the EcoStruxure Machine Expert online help. When one of the system watchdogs

exceeds its threshold conditions, an error is detected.

The threshold conditions for the three system watchdogs are defined as follows:

If all of the tasks require more than 85% of the processor resources for more than 3 seconds, a

system error is detected. The controller enters the HALT state.

If the total execution time of the tasks with priorities between 0 and 24 reaches 100% of

processor resources for more than 1 second, an application error is detected. The controller

responds with an automatic reboot into the EMPTY state.

If the lowest priority task of the system is not executed during an interval of 10 seconds, a

system error is detected. The controller responds with an automatic reboot into the EMPTY

state.

NOTE: You cannot configure the system watchdogs.

Tasks

Task Watchdogs

EcoStruxure Machine Expert allows you to configure an optional task watchdog for every task

defined in your application program. (Task watchdogs are sometimes also referred to as software

watchdogs or control timers in the EcoStruxure Machine Expert online help). When one of your

defined task watchdogs reaches its threshold condition, an application error is detected and the

controller enters the HALT state.

When defining a task watchdog, the following options are available:

Time: This defines the allowable maximum execution time for a task. When a task takes longer

than this, the controller reports a task watchdog exception.

Sensitivity: The sensitivity field defines the number of task watchdog exceptions that must occur

before the controller detects an application error.

To access the configuration of a task watchdog, double-click the Task in the Applications tree.

NOTE: For more information on watchdogs, refer to EcoStruxure Machine Expert Programming

Guide.

EIO0000003651 05/2020 47

Page 48

Tasks

Task Priorities

Task Priority Configuration

You can configure the priority of each task between 0 and 31 (0 is the highest priority, 31 is the

lowest). Each task must have a unique priority. Assigning the same priority to more than one task

leads to a build error.

Task Priority Suggestions

Priority 0 to 24: Controller tasks. Assign these priorities to tasks with a high availability

requirement.

Priority 25 to 31: Background tasks. Assign these priorities to tasks with a low availability

requirement.

Task Priorities of Embedded I/Os

When a task cycle starts, it can interrupt any task with lower priority (task preemption). The

interrupted task resumes when the higher priority task cycle is finished.

48

EIO0000003651 05/2020

Page 49

NOTE: If the same input is used in different tasks the input image may change during the task cycle

of the lower priority task.

To improve the likelihood of proper output behavior during multitasking, a build error message is

displayed if outputs in the same byte are used in different tasks.

UNINTENDED EQUIPMENT OPERATION

Map your inputs so that tasks do not alter the input images in an unexpected manner.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

Task Priorities of TM3 Modules and CANopen I/Os

You can select the task that drives TM3 I/Os and CANopen physical exchanges. In the PLC

settings, select Bus cycle task to define the task for the exchange. By default, the task is set to

MAST. This definition at the controller level can be overridden by the I/O bus configuration

(see page 106)

TM3 and CANopen data is copied into a virtual I/O image during a physical exchanges phase, as

shown in this figure:

Inputs are read from the I/O image table at the beginning of the task cycle. Outputs are written to

the I/O image table at the end of the task.

NOTE: TM3 influence the application execution time. You can configure the Bus cycle options

using I/O mapping tab. Refer to the TM3 Expansion Modules Programming Guide.

. D urin g th e rea d and write phas es, a ll ph ysic al I/O s are ref reshed at the same time.

Tasks

WARNING

EIO0000003651 05/2020 49

Page 50

Tasks

Default Task Configuration

Default Task Configuration

The MAST task can be configured in Freewheeling or Cyclic mode. The MAST task is automatically

created by default in Cyclic mode. Its preset priority is medium (15), its preset interval is 10 ms,

and its task watchdog service is activated with a time of 50 ms and a sensitivity of 1. Refer to Task

Priorities

information on watchdogs.

Designing an efficient application program is important in systems approaching the maximum

number of tasks. In such an application, it can be difficult to keep the resource utilization below the

system watchdog threshold. If priority reassignments alone are not sufficient to remain below the

threshold, some lower priority tasks can be made to use fewer system resources if the

SysTaskWaitSleep function, contained in the SysTask library, is added to those tasks.

NOTE: Do not delete or change the name of the MAST task. Otherwise, EcoStruxure Machine

Expert detects an error when you attempt to build the application, and you are not able to download

it to the controller.

(see page 48)

for more information on priority settings. Refer to Task Watchdogs for more

50

EIO0000003651 05/2020

Page 51

Modicon M262 Logic/Moti on Controller

Controller States and Behaviors

EIO0000003651 05/2020

Controller States and Behaviors

Chapter 8

Controller States and Behaviors

Introduction

This chapter provides you with information on controller states, state transitions, and behaviors in

response to system events. It begins with a detailed controller state diagram and a description of

each state. It then defines the relationship of output states to controller states before explaining the

commands and events that result in state transitions. It concludes with information about

Remanent variables and the effect of EcoStruxure Machine Expert task programming options on

the behavior of your system.

What Is in This Chapter?

This chapter contains the following sections:

Section Topic Page

8.1 Controller State Diagram 52

8.2 Controller States Description 56

8.3 State Transitions and System Events 60

EIO0000003651 05/2020 51

Page 52

Controller States and Behaviors

Controller State Diagram

Section 8.1

Controller State Diagram

Controller State Diagram

Controller State Diagram

This diagram describes the controller operating mode:

52

ALL-CAPS BOLD: Controller states

Bold: User and application commands

Italics

: System events

Normal text: Decisions, decision results, and general information

(1) For details on STOPPED to RUNNING state transition, refer to Run Command

(2) For details on RUNNING to STOPPED state transition, refer to Stop Command

EIO0000003651 05/2020

(see page 64)

(see page 64)

.

.

Page 53

Note 1

Note 2

Note 3

Note 4

Controller States and Behaviors

The alarm relay is open.

The outputs assume their hardware initialization states. The encoder power supply is not enabled.

The voltage is 0. The alarm relay is closed.

In some cases, when a system error is detected, it causes the controller to reboot automatically

into the EMPTY state as if no Boot application were present in the Flash memory. However, the