TAC I/A Series

MNL-V3RVx Controllers

2

Continued from first page.

DIGITAL OUTPUTS

Relay Outputs

SW24H1, SW24H2, and SW24H3 Current

Ratings

24 VA each at 24 Vac, 50/60 Hz. Form A, SinglePole, Single-Throw (SPST), Normally-open. 300K

cycles at 24 Vac, 24 VA (0.4 power factor).

Triac Outputs

Current Ratings

18 VA (0.75 A) each output at 24 Vac. Total of 18 VA

for both outputs.

Typical Load

24 Vac synchronous motor with impedance protected

windings.

DIGITAL INPUT

Dry Contact. Detection of closed switch requires less

than 300 ohm. Detection of open switch requires

more than 100K ohm.

UNIVERSAL INPUT

1K ohm Balco Input

-40 to 250 °F (-40 to 121 °C) range. TSMN-81011,

TS-8000 Series or equivalent.

1K ohm Platinum Input

-40 to 240 °F (-40 to 116 °C) range.

TSMN-58011, TS-5800 Series or equivalent.

1K ohm Resistance

0 to 1.5K ohms.

10K ohm Thermistor with 11K ohm Shunt

Resistor

-40 to 250 °F (-40 to 121 °C) range. TSMN-57011850, TS-5700-850 Series or equivalent.

10K ohm Resistance

0 to 10.5K ohm.

Voltage

0 to 5 Vdc.

Current

0 to 20 mA requires an external 250 ohm shunt

resistor.

Digital Input (Mode Setting for UI)

Dry Contact. Detection of closed switch requires less

than 300 ohm. Detection of open switch requires

more than 1.5K ohm.

ANALOG OUTPUT

Current

0 to 20 mA (output load range from 80 to 550 ohm).

INPUTS FROM MN-Sx TAC I/A SERIES MICRONET SENSOR

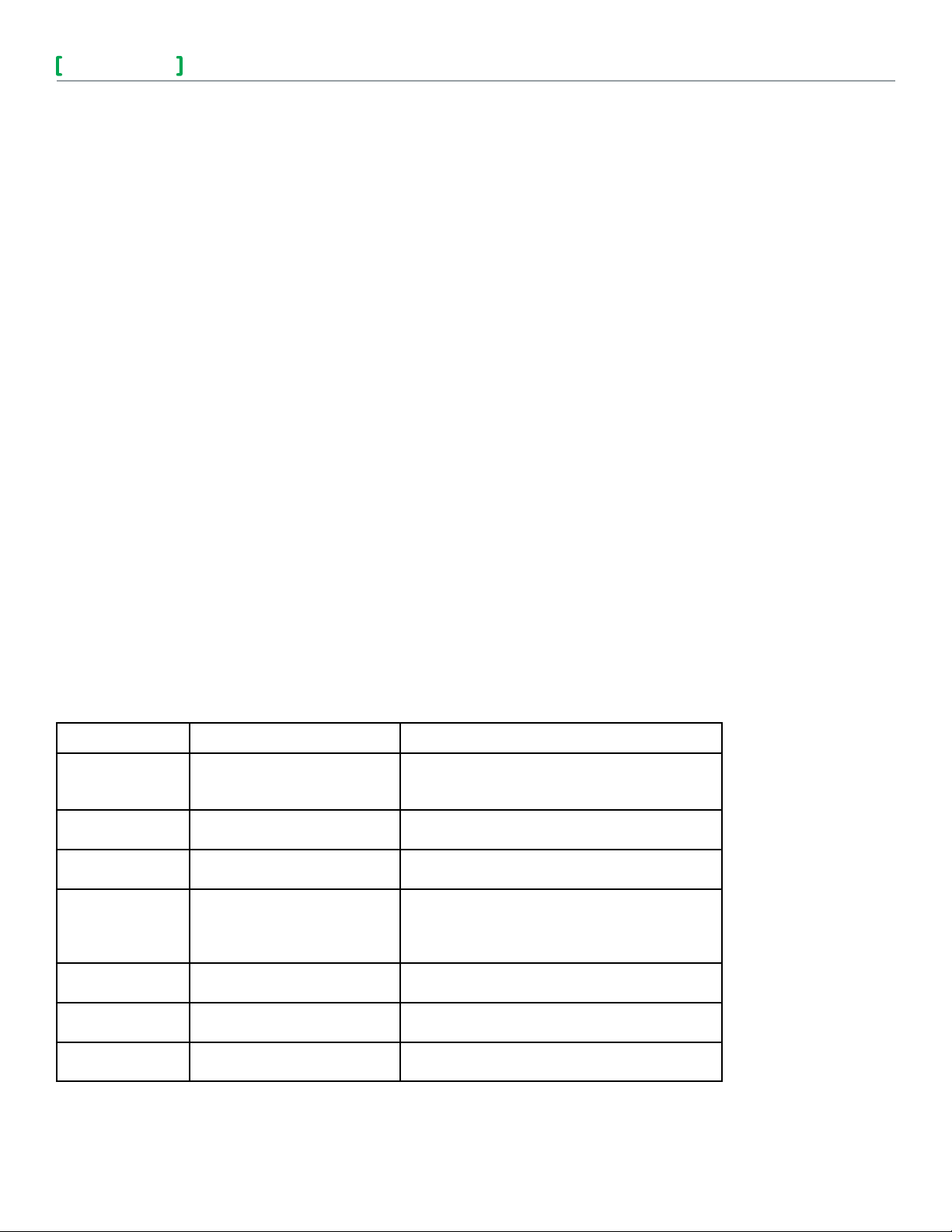

Inputs Description MN-Sx Sensor

Space Temperature 32 to 122 °F (0 to 50 °C) MN-S1, MN-S1HT, MN-S2, MN-S2HT, MN-S3,

MN-S3HT, MN-S4, MN-S4HT, MN-S4-FCS, MNS4HT-FCS, MN-S5 and MN-S5HT

Space Humidity 5 to 95% RH, Non-condensing MN-S1HT, MN-S2HT, MN-S3HT, MN-S4HT,

MN-S4HT-FCS, and MN-S5HT

Adjustable Setpoint 40 to 95 °F (4 to 35°C) MN-S3, MN-S3HT, MN-S4, MN-S4HT, MN-S4-

FCS, MN-S4HT-FCS, MN-S5, and MN-S5HT

Override

Pushbutton

For standalone occupancy

control or remote status

monitoring of local status

condition.

Fan Operation and

Speed

Fan mode selection: On, Speed

(Low/Medium/High), or Auto.

System Mode System mode selection: Heat,

Cool, Off, or Auto.

Emergency Heat Emergency heat mode selection:

Enable or Disable

MN-S2, MN-S2HT, MN-S3, MN-S3HT, MN-S4,

MN-S4HT, MN-S5, and MN-S5HT

MN-S4, MN-S4HT, MN-S4-FCS, MN-S4HT-FCS,

MN-S5, and MN-S5HT

MN-S4, MN-S4HT, MN-S5, and MN-S5HT

MN-S5 and MN-S5HT

Schn eide r Elec tric

F-26366- 9 August 2013 tl

© 2013 Schneider Electr ic. All rights reserved.

TAC I/A Series

MNL-V3RVx Controllers

MODELS

Part Number Inputs/Outputs

Box Configuration Reheat Type Other

3 Digital Outputs (DO)

Cooling

Series Fan

Induction

Parallel Fan

MNL-V3RVx

1 Analog Output (AO)

a

2 Triac Outputs (TO)

1 Universal Input (UI)

1 Digital Input (DI)

a V denotes LonMark VAV (Variable Air Volume) profile. “x” denotes profile version.

b Available control strategies depend on controller I/O.

Control Strategies

Staged Electric

Reheat

Floating/Proportional

Hydronic Reheat

Time Proportioned

Occupancy

Satellite

b

3

FEATURES

Designed for new or existing systems, the VAV series

controller may be applied to pressure independent

terminal boxes with, or without, reheat capabilities.

The VAV controller offers the following types of Box

Configuration and Reheat control strategies:

• Cooling.

• Series Fan.

• Parallel Fan.

• Induction.

• Staged Electric Reheat.

• Floating/Proportional Hydronic Reheat.

• Time Proportioned.

• Capability to function in standalone mode or

as part of a LonWorks TP/FT-10 Free Topology

communications network.

• Proportional (P), Proportional Plus Integral (PI),

and Proportional Plus Integral and Derivative (PID)

control for cooling and heating.

• Patented pressure transducer for years of reliable,

accurate air flow readings.

• Air balancing using the TAC I/A Series

MicroNet VAV Flow Balance software.

• Directly compatible with terminal boxes which

contain a synchronous-motor-driven damper

actuator.

• Conforms to the LonMark VAV controller profile.

• Plenum-rated enclosure allows direct mounting in

plenum.

TAC I/A Series VAV FLow Balance Software

Provides flow balancing for networked and

standalone VAV series controllers. Features include:

• Local network control.

• Damper and fan adjustment.

• Setpoint monitoring and adjustment.

• Flow validation and calibration.

• Sequence, calibration, and control setpoint logs.

COMMUNICATIONS

Lon Works Networks

L

onWorks communications network uses an

FTT-10 Free Topology configuration. Controllers on

a L

onWorks network can communicate with each

other in a peer-to-peer fashion. A L

has a communications speed of 78k baud, using

unshielded, twisted-pair cabling, with connections

that are not polarity sensitive.

S-Link

The Sensor Link (S-Link) communications wiring

provides power and a communication interface for an

MN-Sx TAC I/A Series MicroNet sensor. The various

MN-Sx sensors can provide room temperature,

room humidity, setpoint adjustment, and occupancy

override. This connection uses two-wire, unshielded

cable and is not polarity sensitive. Maximum wire

length allowed between a controller and a TAC I/A

Series MicroNet Sensor is 200 ft (61 m).

onWorks network

Software Capabilities

• Conforms to the LonMark guidelines.

• WorkPlace Tech Tool is capable of reconfiguring

and editing application configuration data to

fit a wide range of variable air volume control

requirements.

• HVAC interoperability achieved through use of

LonMark HVAC profiles.

• Air balancing provided by the I/A Series MicroNet

VAV Flow Balance software.

Schn eide r Elec tric

F-26366- 9 August 2013 tl

© 2013 Schneider Electr ic. All rights reserved.

Loading...

Loading...