Page 1

Solution Guide

MNB BACnet Support within a

StruxureWare Building Operation

System

Page 2

Disclaimer

This document is not intended to describe the proposed solution in its entirety. Users are solely

responsible for compliance with both national and international safety laws and regulations.

Solution functionality is tied to specific versions of software and hardware, as described within. As

such, solution functionality is subject to change as products are upgraded.

This solution was tested and validated under laboratory conditions. Performance measurements

are provided so that informed design decisions can be made, and are not a guarantee of future

performance.

This document does not replace any specific product documentation.

chneider Electric

S

Document Number: SG-IABACNET-SMARTSTRUXURE-US.BU.N.EN.9.2013.1.00.CC

© 2013 Schneider Electric. All rights reserved.

Schne ider El ectri c Confidential 09/12/13

Page 3

Solution Guide

MNB BACnet Support within a StruxureWare Building Operation System

Table of Contents

Introduction Chapter 1 5

1.1. Who Can Benefit from this Document? 5

1.2. About Solution Guides 5

1.3. Interfacing MNB BACnet Systems with a Building Operation System 6

1.4. Target Applications 7

3

1.5. Applicable Documentation 7

Solution Overview Chapter 2 9

2.1. BACnet with MNB BACnet and Building Operation 9

2.1.1 MNB BACnet 9

2.1.2 Building Operation 9

2.2. Solution Overview 10

Validated System 1Chapter 3 1

3.1. Validated System Architecture 11

3.2. Validated System Components 12

Detailed Solution Steps 1Chapter 4 3

4.1. Define and Configure the MNB BACnet Network 13

4.2. Verify that Each MNB Device Contains the Current Application 16

4.3. Install the Automation Server 16

4.4. Create the BACnet Interface 18

4.5. Discover and Add IP-Level MNB-1000 Devices 20

4.6. Create Remote MS/TP Networks to Represent MS/TP Networks

Connected to the MNB-1000 Devices 23

4.7. Create MS/TP Networks to Represent MS/TP Networks Connected to

Automation Server COM Ports 25

chneider Electric

S

Document Number: SG-IABACNET-SMARTSTRUXUR E-US.BU.N.EN.9.2013.1.0 0.CC

Schne ider El ectri c Confidential 09/12/13

Page 4

Solution Guide

MNB BACnet Support within a StruxureWare Building Operation System

4.8. Discover and Add MNB Devices 29

4.9. Upload MNB Devices to Create BACnet Points 32

Best Practices and Lessons Learned 3Chapter 5 4

5.1. Best Practices 34

5.1.1 Making Changes to Applications of MNB Devices Connected to the Automation

Server 34

5.1.2 Changing the IP Configuration of a Previously Programmed Automation

Server 35

5.1.3 Changing the Automation Server BACnet Instance Number After the BACnet

Interface Is Created 36

5.1.4 Changing the Network Number of an MS/TP Network Previously Added to the

Automation Server 39

5.1.5 Changing the IP Configuration of an MNB‑1000 Previously Added to the

Automation Server 41

5.1.6 Changing the Name of an MNB Device Previously Added to the Automation

Server 42

5.1.7 Changing the Instance Number of an MNB Device Previously Added to the

Automation Server 43

4

5.2. Lessons Learned 44

5.2.1 Deletion of Point or Value Objects within Application Folder of MNB BACnet

Device 44

5.2.2 Troubleshooting Tools 44

5.2.3 BACnet Device Time Sync Recipients 45

5.2.4 MNB BACnet Points Created with Device Upload 45

5.2.5 Menu Support with MNB Systems in Building Operation 49

5.2.6 Working with MNB BACnet Objects and Properties in Building Operation 52

5.2.7 Coexistence of WorkPlace Tech Tool, WorkPlace Commissioning Tool, and

WorkPlace Flow Balance Tool on the Same System 56

5.2.8 Characters Allowed in Names of Created and Uploaded BACnet Objects 57

System Test Results 5Appendix 1 9

chneider Electric

S

Document Number: SG-IABACNET-SMARTSTRUXUR E-US.BU.N.EN.9.2013.1.0 0.CC

© 2013 Schneider Electric. All rights reserved.

Schne ider El ectri c Confidential 09/12/13

Page 5

Solution Guide

MNB BACnet Support within a StruxureWare Building Operation System

Chapter 1

Introduction

This solution allows new and existing I/A Series MicroNet BACnet sites to interface to a Building

Operation system. By implementing this solution, users can take advantage of Building Operation’s

enhanced feature set without replacing existing devices or reengineering I/A Series MicroNet

BACnet points or applications.

Throughout this document, the family of I/A Series BACnet controllers will be referred to as MNB

BACnet devices, as they are in all Building Operation documentation.

Who Can Benefit from this Document?1.1.

5

The goal of this document is to describe how Building Operation supports MNB BACnet systems.

An example of this solution has been tested and validated by Schneider Electric.

This document provides systems integrators and project engineers with the information necessary

to evaluate the feasibility of similar solutions and to make design decisions. The following items are

included:

Example system architecture•

Key component descriptions•

Lab test results•

Best practices•

This document was written as a complement to existing product documentation and provides

references to such documents where appropriate.

Readers possessing a solid understanding of the MNB BACnet product line will benefit the most

from the information provided.

About Solution Guides1.2.

Schneider Electric develops Solution Guides to evaluate proposed architectures that attempt to

solve our customer pain points or give added value as a solution. Schneider Electric tests and

validates these architectures and publishes a document showing what was tested in its labs. Within

the Buildings segment, the end result is a Solution Guide document that describes the solution in

detail, including test results, and best practices for implementation. Each Solution Guide provides

system integrators with the information they need to quickly identify, design, and implement

equivalent solutions with a minimum of risk and uncertainty.

chneider Electric

S

Document Number: SG-IABACNET-SMARTSTRUXUR E-US.BU.N.EN.9.2013.1.0 0.CC

Schne ider El ectri c Confidential 09/12/13

Page 6

Solution Guide

MNB BACnet Support within a StruxureWare Building Operation System

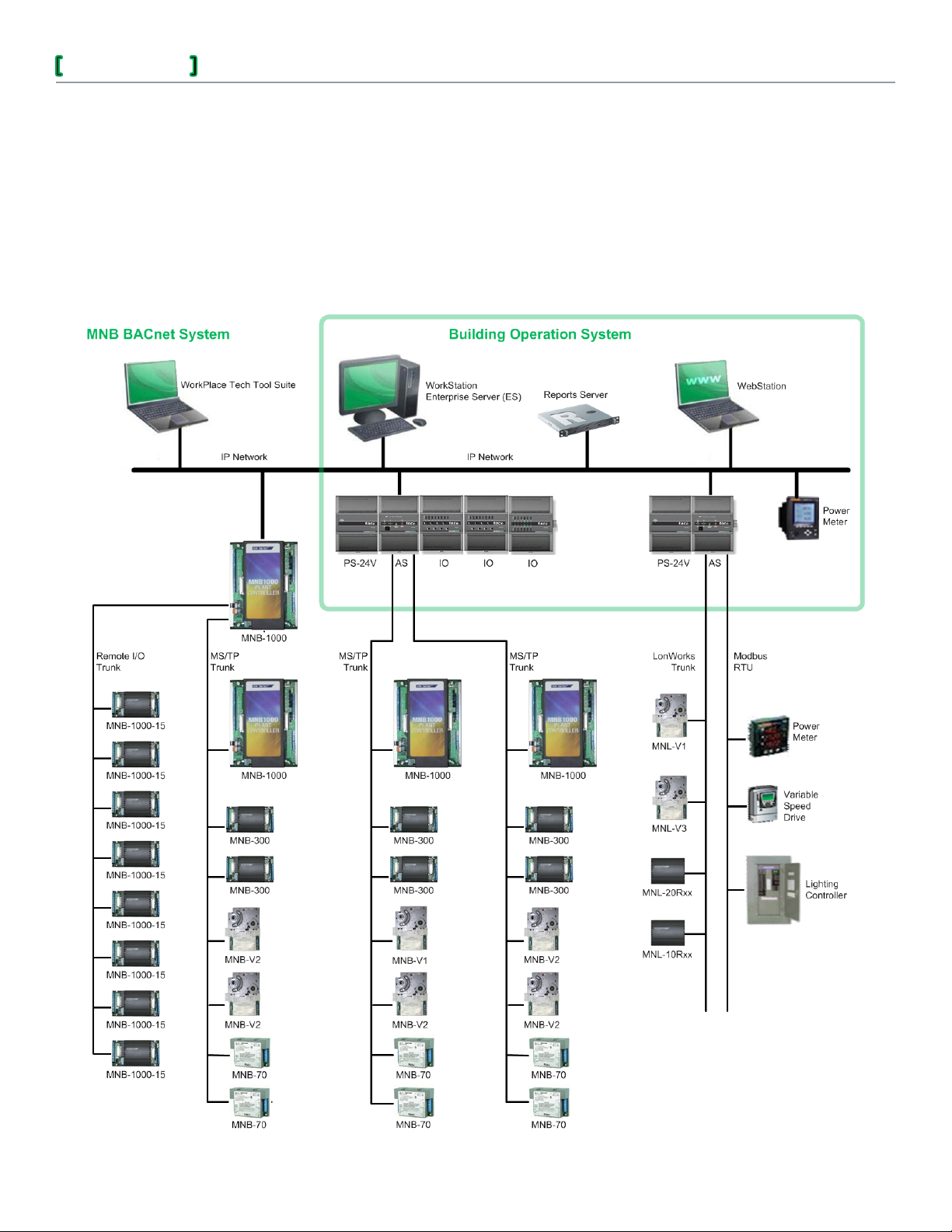

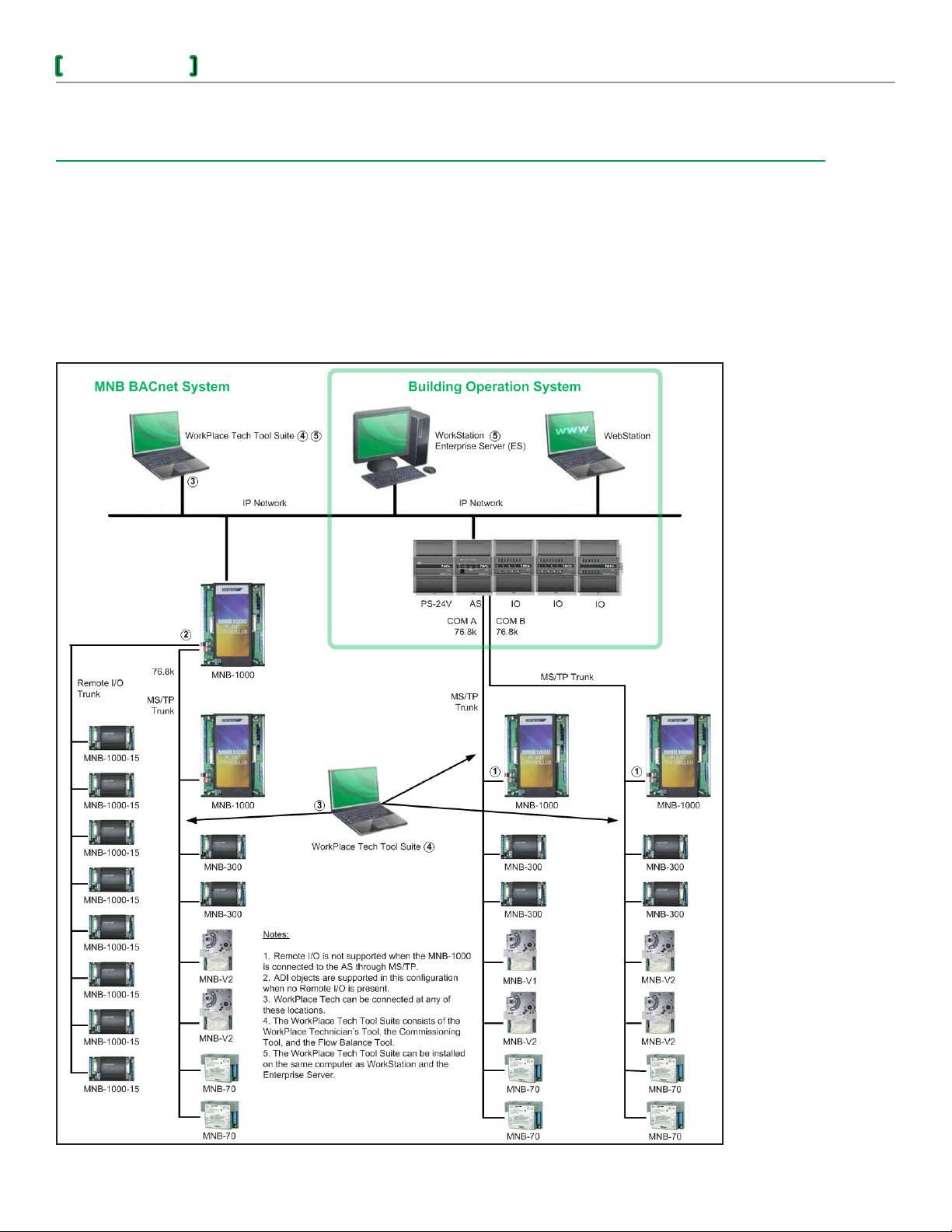

Interfacing MNB BACnet Systems with a Building 1.3.

Operation System

Both MNB BACnet and Building Operation natively support the ASHRAE BACnet® protocol.

Therefore, it is possible to have the MNB devices interoperate with Building Operation devices.

A Building Operation client, be it WorkStation or WebStation, when connected to an Enterprise

Server or Automation Server, can function as a preferred user interface for an MNB system.

6

Figure–1.1 Interfacing an MNB BACnet System with a Building Operation System

chneider Electric

S

Document Number: SG-IABACNET-SMARTSTRUXUR E-US.BU.N.EN.9.2013.1.0 0.CC

Schne ider El ectri c Confidential 09/12/13

© 2013 Schneider Electric. All rights reserved.

Page 7

Solution Guide

The resulting interface experience is as follows:

Any existing MNB BACnet devices will remain, and will not require any updating,•

reconfiguration, or re-programming.

The WorkPlace Tech Tool Suite is required to program and configure MNB BACnet devices.•

The WorkPlace Tech Editor, supplied with Building Operation, is applicable to MNL devices

only.

When used with MNB BACnet devices, Building Operation allows the user to manually perform•

the following tasks:

Discover all network-accessible BACnet devices.•

Create graphics in Building Operation servers. This solution provides the opportunity to•

create improved graphics by leveraging the enhanced graphics capabilities of Building

Operation.

Create trends in the Automation Server to log values from MNB devices.•

Create schedules in the Automation Server to control MNB devices.•

Create alarms in the Automation Server to monitor MNB points.•

Manage BACnet time synchronization.•

MNB BACnet Support within a StruxureWare Building Operation System

7

Building Operation currently cannot:•

View manufacturer-specific properties in MNB devices.•

View or modify schedules residing in the MNB-1000 devices.•

Set up and configure MNB BACnet properties, including setting their names, instances,•

network numbers, and addresses.

Modify application programs residing in the MNB devices.•

Update firmware in MNB devices.•

Link MNB BACnet COV Client objects to BACnet objects in other devices.•

Filter which objects are learned, and which objects are not.•

Target Applications1.4.

This solution is most applicable to customers at new and existing MNB BACnet sites where the

number of objects is within the maximum number supported by Building Operations. For details,

see the Product Announcement for the current shipping version.

Applicable Documentation1.5.

This section lists those documents that contain additional information that may be needed when

supporting an MNB BACnet system within a Building Operation system.

TAC I/A Series WorkPlace Tech Tool BACnet Engineering Guide Supplement, F-27356•

TAC I/A Series WorkPlace Tech Tool Engineering Guide, F-27254 (in conjunction with•

Supplement F-27356, above)

TAC I/A Series WorkPlace Tech Tool Users Guide, F-27255 (in conjunction with Supplement•

F-27356, above)

TAC I/A Series BACnet Wiring, Networking, and Best Practices Guide, F-27360•

chneider Electric

S

Document Number: SG-IABACNET-SMARTSTRUXUR E-US.BU.N.EN.9.2013.1.0 0.CC

© 2013 Schneider Electric. All rights reserved.

Schne ider El ectri c Confidential 09/12/13

Page 8

Solution Guide

MNB BACnet Support within a StruxureWare Building Operation System

TAC I/A Series MicroNet BACnet Commissioning Tool/Flow Balance Tool User’s Guide,•

F-27358

TAC I/A Series MicroNet BACnet MNB-70 Zone Controller Installation Instructions, F-27458•

TAC I/A Series MicroNet BACnet MNB-300 Unitary Controller Installation Instructions, F-27345•

TAC I/A Series MicroNet BACnet MNB-V1, MNB-V2 VAV Controllers Installation Instructions,•

F-27346

TAC I/A Series MicroNet BACnet MNB-1000 Plant Controller Installation Instructions, F-27347•

TAC I/A Series MicroNet MN-Sx Series Sensors General Instructions, F-26277•

TAC I/A Series MicroNet BACnet MNB-70, MNB-300, MNB-V1, MNB-V2 Controllers Protocol•

Implementation Conformance Statement (PICS), F-27365

TAC I/A Series MicroNet BACnet MNB-1000 Plant Controller Protocol Implementation•

Conformance Statement (PICS), F-27461

In Building Operation WebHelp, search for topics on these subjects:•

Compatibility matrix for compatible Web browsers•

Architectural guidelines (contains architectural capabilities, as well as limitations of Building•

Operation)

8

RS-485 biasing and termination•

Automation Server and I/O wiring•

Wiring a Terminal Base•

Setting the date and time in the Automation Server•

BACnet Interface for an Automation Server - Basic tab•

BACnet Interface for an Automation Server - Advanced tab•

Device discovery•

How bindings are manually created•

BACnet time synchronization•

Value Transfer Settings dialog box and the value transfer interval•

chneider Electric

S

Document Number: SG-IABACNET-SMARTSTRUXUR E-US.BU.N.EN.9.2013.1.0 0.CC

© 2013 Schneider Electric. All rights reserved.

Schne ider El ectri c Confidential 09/12/13

Page 9

Solution Guide

MNB BACnet Support within a StruxureWare Building Operation System

Chapter 2

Solution Overview

BACnet with MNB BACnet and Building Operation2.1.

This section contains information on how the ASHRAE BACnet® protocol standard is supported by

MNB BACnet systems and Building Operation systems.

MNB BACnet2.1.1

MNB BACnet is a Schneider Electric building management system that natively supports the

ASHRAE BACnet® protocol standard. The MNB BACnet range of products includes the BACnet

devices listed in the following table.

9

MNB BACnet Product Support for ASHRAE BACnet

MNB-70 Zone Controller BACnet Application Specific Controller (B-ASC)

MNB-300 Unitary Controller BACnet Application Specific Controller (B-ASC)

MNB-V1, MNB-V2 VAV Controllers BACnet Application Specific Controller (B-ASC)

MNB-1000 Plant Controller BACnet Application Specific Controller (B-ASC)

MNB-1000-15 Remote I/O Module n/a (device is only used to expand I/O count of MNB-1000)

For a detailed discussion of an MNB BACnet device’s conformance to the ASHRAE BACnet

standard, refer to the MNB device’s BACnet Protocol Implementation Conformance Statement

(PICS).

Building Operation2.1.2

Building Operation is a Schneider Electric building management system that natively supports

the ASHRAE BACnet® protocol standard. The Building Operation range of products includes the

BACnet devices listed in the following table.

Building Operation BACnet Product Support for ASHRAE BACnet

Automation Server (AS)

Enterprise Server (ES)

a. The Automation Server and the Enterprise Server also have a Web server user interface named WebStation.

b. Requires Building Operation WorkStation client to serve as the user interface.

a

a

BACnet Operator Workstationb (B-OWS)

BACnet Building Controller (B-BC)

BACnet Operator Workstationb (B-OWS)

BACnet Building Controller (B-BC)

All Building Operation BACnet devices are compliant with the ASHRAE BACnet standard and

will therefore interoperate with other Schneider Electric or third-party BACnet-compliant devices.

Both the Automation Server and the Enterprise Server support two BACnet client user interfaces,

WorkStation and WebStation.

chneider Electric

S

Document Number: SG-IABACNET-SMARTSTRUXUR E-US.BU.N.EN.9.2013.1.0 0.CC

Schne ider El ectri c Confidential 09/12/13

Page 10

Solution Guide

MNB BACnet Support within a StruxureWare Building Operation System

Solution Overview2.2.

The outline, below, contains the major steps in the solution for integrating an MNB BACnet system

into Building Operation. These steps are contained in Chapter 4, Detailed Solution Steps.

Define and Configure the MNB BACnet Network

Verify that Each MNB Device Contains the Current Application

Install the Automation Server

Create the BACnet Interface

Discover and Add IP-Level MNB-1000 Devices

Create Remote MS/TP Networks to Represent MS/TP Networks Connected to the

MNB-1000 Devices

Create MS/TP Networks to Represent MS/TP Networks Connected to Automation Server

COM Ports

Discover and Add MNB Devices

Upload MNB Devices to Create BACnet Points

10

chneider Electric

S

Document Number: SG-IABACNET-SMARTSTRUXUR E-US.BU.N.EN.9.2013.1.0 0.CC

© 2013 Schneider Electric. All rights reserved.

Schne ider El ectri c Confidential 09/12/13

Page 11

Solution Guide

MNB BACnet Support within a StruxureWare Building Operation System

Chapter 3

Validated System

3.1. Validated System Architecture

11

chneider Electric

S

Document Number: SG-IABACNET-SMARTSTRUXUR E-US.BU.N.EN.9.2013.1.0 0.CC

Schne ider El ectri c Confidential 09/12/13

Page 12

Solution Guide

MNB BACnet Support within a StruxureWare Building Operation System

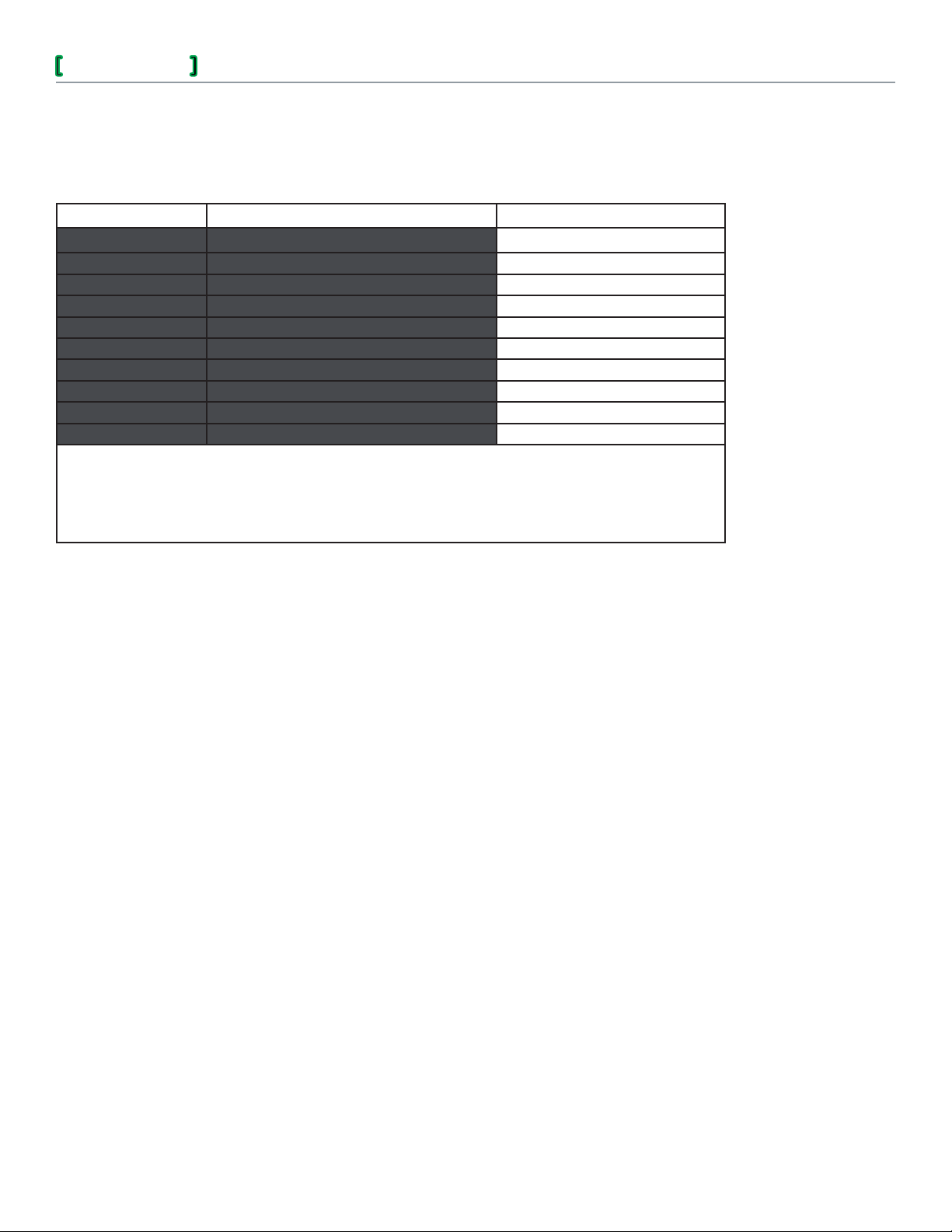

Validated System Components3.2.

The following table lists the components used to test this solution.

Part Number Product Name Firmware Revision

MNB-1000 BACnet Plant Controller P01:01.513, L01:01.421

MNB-1000-15 BACnet Plant Controller Remote IO R01:01.50

MNB-300 BACnet Unitary Controller U01:01.424

MNB-V1, MNB-V2 BACnet VAV Controllers V01.01.424, V02:01.424

MNB-70 BACnet Zone Controller U70:01.424

WP-TECH-58 WorkPlace Tech Tool

— WorkStation PC Windows 7, 64 bit

— StruxureWare Building Operation Enterprise Server V1.4.0.818

— StruxureWare Building Operation WorkStation V1.4.0.818

— StruxureWare Building Operation WebStation V1.4.0.818

a. The WorkPlace Tech Tool includes the following tools:

WorkPlace Technician’s Tool

WorkPlace Commissioning Tool

WorkPlace Flow Balance Tool

b. For the most current system requirements, refer to Building Operation WebHelp topics describing system upgrade software require-

ments.

a

V5.8.5

b

12

12

chneider Electric

S

Document Number: SG-IABACNET-SMARTSTRUXUR E-US.BU.N.EN.9.2013.1.0 0.CC

© 2013 Schneider Electric. All rights reserved.

Schne ider El ectri c Confidential 09/12/13

Page 13

Solution Guide

MNB BACnet Support within a StruxureWare Building Operation System

Chapter 4

Detailed Solution Steps

This chapter contains detailed, step-by-step procedures for implementing the solution to integrate

an MNB BACnet system into Building Operation.

4.1. Define and Configure the MNB BACnet Network

Define and configure the MNB BACnet network before integrating the MNB system into the

Building Operation Automation Server.

Using the WorkPlace Commissioning Tool, upgrade all MNB device firmware to the following 1.

revisions:

13

MNB-1000 P01:01.513, L01:01.421, and R01:01.50 (or later for any of these)

MNB-300 U01:01.424 or later

MNB-V1 V01.01.424 or later

MNB-V2 V02:01.424 or later

MNB-70 U70:01.424 or later

Define and document the topology of the MNB system so that it can be accurately integrated2.

into the Automation Servers.

Identify which MNB devices will be on the MS/TP trunks directly connected to thea.

Automation Servers’ RS-485 ports.

For each Automation Server, determine whether one or two BACnet MS/TP ports will beb.

used.

For each Automation Server, determine whether any additional MNB devices will be addedc.

though the IP connection.

For each MNB-1000 device connected through IP, determine how many MS/TP devicesd.

will be present on its MS/TP trunks.

For each MNB-1000 device connected through IP, determine how many MNB-1000-15e.

Remote I/O Modules will be connected.

The use of MNB-1000-15 Remote I/O Modules is not supported when anNote:

MNB-1000 device is connected to the BACnet internetwork through an MS/TP

trunk. However, use of the MNB-1000-15 is supported when the MNB-1000 is

connected through an IP connection.

Identify whether any BBMDs will be required for connecting the IP subnets.f.

Identify whether any Ethernet devices will be attached, and whether a router needs to beg.

configured.

Referring to the system topology you documented, verify that the items listed below do not3.

exceed the published guidelines. If they have been exceeded, reconfigure the system as

chneider Electric

S

Document Number: SG-IABACNET-SMARTSTRUXUR E-US.BU.N.EN.9.2013.1.0 0.CC

Schne ider El ectri c Confidential 09/12/13

Page 14

Solution Guide

MNB BACnet Support within a StruxureWare Building Operation System

required so that the system fits within the guidelines. Refer to the Building Operation WebHelp

topic discussing architectural guidelines.

The total number of MS/TP devices directly connected to the RS-485 ports of the•

Automation Server. These devices can be distributed between the two ports as needed.

The total number of BACnet IP devices linked to each Automation Server. This includes•

any MS/TP devices directly connected to the BACnet IP devices. Remember that MS/TP

devices that are accessed through IP will also be considered IP devices.

The total number of BACnet objects in the system.•

Any additional interfaces and their connected devices. These must comply with the•

published limits. Refer to the Building Operation WebHelp topic discussing architectural

guidelines.

Once the system topology has been finalized, install any end-of-line and pull-apart terminators4.

required by the MS/TP trunk, as specified in the published documentation. Be sure to follow

any other wiring and installation requirements. Refer to the following documentation for

guidance:

TAC I/A Series BACnet Wiring, Networking, and Best Practices Guide• , F-27360

14

See Appendix A for diagram showing a typical system architecturre, including theNote:

locations of terminations.

TAC I/A Series MicroNet BACnet MNB‑70 Zone Controller Installation Instructions• ,

F-27458

TAC I/A Series MicroNet BACnet MNB‑300 Unitary Controller Installation Instructions• ,

F-27345

TAC I/A Series MicroNet BACnet MNB‑V1, MNB‑V2 VAV Controllers Installation•

Instructions, F-27346

TAC I/A Series MicroNet BACnet MNB‑1000 Plant Controller Installation Instructions• ,

F-27347

TAC I/A Series MicroNet MN‑Sx Series Sensors General Instructions• , F-26277

Building Operation WebHelp topics discussing:•

RS‑485 biasing and termination

Automation Server and I/O wiring

Wiring a Terminal Base

Once the system topology has been finalized, define and configure the device values, using the5.

WorkPlace Commissioning Tool.

Define and configure unique IP and MS/TP network numbers.a.

When MNB-1000 devices are used as MS/TP devices, connected to a parentNote:

MNB-1000 device, ensure that the MS/TP network number is set to the same value

in each of the child MNB-1000 devices.

For each MNB device, verify that the address switch has been set to the desired, uniqueb.

value for the MS/TP trunk to which it will be connected.

When an MNB-1000 is the parent of an MS/TP network, its address switchesNote:

should all be set to Off, for an address of 0 (zero).

Ensure that a unique name and instance number has been defined for each device. Use anc.

organizational method that avoids duplicates within the BACnet internetwork.

chneider Electric

S

Document Number: SG-IABACNET-SMARTSTRUXUR E-US.BU.N.EN.9.2013.1.0 0.CC

© 2013 Schneider Electric. All rights reserved.

Schne ider El ectri c Confidential 09/12/13

Page 15

Solution Guide

In any installation, a numbering approach that has a predictable pattern is very Note:

helpful to anyone using or supporting the system. Typically, such an approach

incorporates the switch address settings of the MS/TP devices in the instance

numbers.

In the MNB-1000 devices, ensure that the d. Enable Spanning Tree Protocol option has

been disabled.

To access this option, select the MNB-1000 device and then click the Properties1)

button in the toolbar.

In the Properties dialog box, click the Setup tab and then under 2) Communication

status poll interval, check the setting for Enable Spanning Tree Protocol. Disable

this option.

For each MNB-1000 device, open the Device Properties dialog box and then configure thee.

network settings as needed.

MNB BACnet Support within a StruxureWare Building Operation System

If the Note: Enable Spanning Tree Protocol is not present, the firmware of the

MNB-1000 device is an older version. Upgrade the firmware of the device,

using the WorkPlace Commissioning Tool. Refer to the TAC I/A Series MicroNet

BACnet Commissioning Tool/Flow Balance Tool User’s Guide, F-27358.

15

Click the 1) IP tab to configure the IP settings:

Enable IP Port – To disable, clear this check box.

Network Number

IP Address

IP Subnet Mask

Default Gateway

UDP Port

Device Type

Click the 2) Ethernet tab to configure the Ethernet settings:

Enable Ethernet Port – To disable, clear this check box. In most cases, this will be

disabled and not used.

Network Number

Click the 3) MS/TP tab to configure the MS/TP settings:

Enable MSTP Port – To disable, clear this check box.

Network Number

Baud Rate

Max Info Frames – Recommended starting value = 20

Max Master

Click the 4) Advanced tab to configure the APDU settings:

APDU Timeout – Recommended starting value = 10000

The recommended starting value can be adjusted upwards, if necessary, whenNote:

checking the system installation.

To ensure reliable communications, use the same Note: APDU Timeout value in all

intercommunicating devices.

chneider Electric

S

Document Number: SG-IABACNET-SMARTSTRUXUR E-US.BU.N.EN.9.2013.1.0 0.CC

© 2013 Schneider Electric. All rights reserved.

Schne ider El ectri c Confidential 09/12/13

Page 16

Solution Guide

APDU Retries – Recommended starting value = 2

For each of the other MNB MS/TP devices, including MNB-70, MNB-300, MNB-V1 andf.

MNB-V2, open the Device Properties dialog box and then configure the network settings

as needed:

Click the 1) MS/TP tab to configure the MS/TP settings:

Baud Rate – Click Autobaud to open the Autobaud Settings configuration screen.

Max Info Frames – Recommended starting value = 5

Max Master

Click the 2) Advanced tab to configure the APDU settings:

APDU Timeout – Recommended starting value = 10000

APDU Retries – Recommended starting value = 2

MNB BACnet Support within a StruxureWare Building Operation System

The recommended starting value can be adjusted upwards, if necessary, whenNote:

checking the system installation.

To ensure reliable communications, use the same Note: APDU Timeout value in all

intercommunicating devices.

16

For each MNB device, determine whether you want to enable the g. Hide background

BACnet objects option. To enable this option, open the Device Properties dialog box

and then click the Setup tab. For more information on the Setup tab, refer to the Device

Commissioning chapter of the TAC I/A Series MicroNet BACnet Commissioning Tool/Flow

Balance Tool User’s Guide, F-27358.

Perform other configuration tasks as needed. Refer to the Device Commissioning chapterh.

of the TAC I/A Series MicroNet BACnet Commissioning Tool/Flow Balance Tool User’s

Guide, F-27358.

Update the system topology documentation with this configuration information so that you can6.

refer to it later, when configuring the MNB device properties within Building Operation.

4.2. Verify that Each MNB Device Contains the Current Application

Verify that each MNB device has been downloaded with its current application.

For each MNB device that has not yet had its application downloaded, use WorkPlace Tech1.

Tool to download the required application. Refer to the TAC I/A Series WorkPlace Tech Tool

Users Guide, F-27255.

The WorkPlace Tech Tool can be connected directly to the MNB device, to the MS/TPNote:

network under an Automation Server, to the MNB-1000 parent device, or to the IP

network.

4.3. Install the Automation Server

Prepare to integrate the MNB system into the Building Operation system by installing and

configuring the Automation Server.

Start the Device Administrator and then select the Automation Server.1.

chneider Electric

S

Document Number: SG-IABACNET-SMARTSTRUXUR E-US.BU.N.EN.9.2013.1.0 0.CC

Schne ider El ectri c Confidential 09/12/13

© 2013 Schneider Electric. All rights reserved.

Page 17

Solution Guide

MNB BACnet Support within a StruxureWare Building Operation System

Set or change the Automation Server’s network settings.2.

On the a. View menu, click Network Settings and then set or change the Automation

Server’s network settings, including the following:

Static IP address

Host name

Domain

Netmask

DNS

Gateway

DHCP

Verify that the Automation Server has been upgraded to the latest firmware revision.b.

Start WorkStation.c.

Log on to the Automation Server and ensure that its date and time are set to the current date,3.

time zone, and time. You must do this before engineering the Automation Server database.

Refer to Building Operation WebHelp for topics on setting the Automation Server’s date and

time.

17

Be sure to set the Automation Server’s time and date before creating its database .Caution:

If the Automation Server’s clock setting is left at its default setting (“1970”), it will be

possible to create duplicate object ID’s. To correct this error, you will be required to

re-engineer the database.

Refer to the previously documented MNB system topology and connect the MNB devices,4.

either to the network or the appropriate RS-485 ports of the Automation Servers, or a

combination of these methods.

Verify that all end-of-line and pull-apart terminators required by the MS/TP trunk have been5.

installed according to the published guidelines:

TAC I/A Series BACnet Wiring, Networking, and Best Practices Guide• , F-27360

See Appendix A for diagram showing a typical system architecturre, including theNote:

locations of terminations.

Building Operation WebHelp topic: • RS‑485 Biasing and Termination

In WorkStation, create the required BACnet interfaces and networks, according to the6.

procedures in the following sections. Use the same hierarchy previously defined in the system

topology diagram. For example, to produce the Validated System Architecture described in this

solution guide, the following interface and networks were created:

BACnet Interface• – The BACnet device object in the Automation Server, enabling BACnet

communications in Building Operation.

IP Network• – Automatically created when you create the BACnet interface. Represents the

Automation Server as a BACnet IP device.

MSTP Network• – Created beneath the IP MNB-1000 to represent the remote MS/TP

trunk connected to the MNB-1000.

MSTP Network COM A• – The MS/TP trunk connected to the RS-485 COM A port of the

Automation Server.

chneider Electric

S

Document Number: SG-IABACNET-SMARTSTRUXUR E-US.BU.N.EN.9.2013.1.0 0.CC

© 2013 Schneider Electric. All rights reserved.

Schne ider El ectri c Confidential 09/12/13

Page 18

Solution Guide

MNB BACnet Support within a StruxureWare Building Operation System

MSTP Network COM B• – The MS/TP trunk connected to the RS-485 COM B port of the

Automation Server.

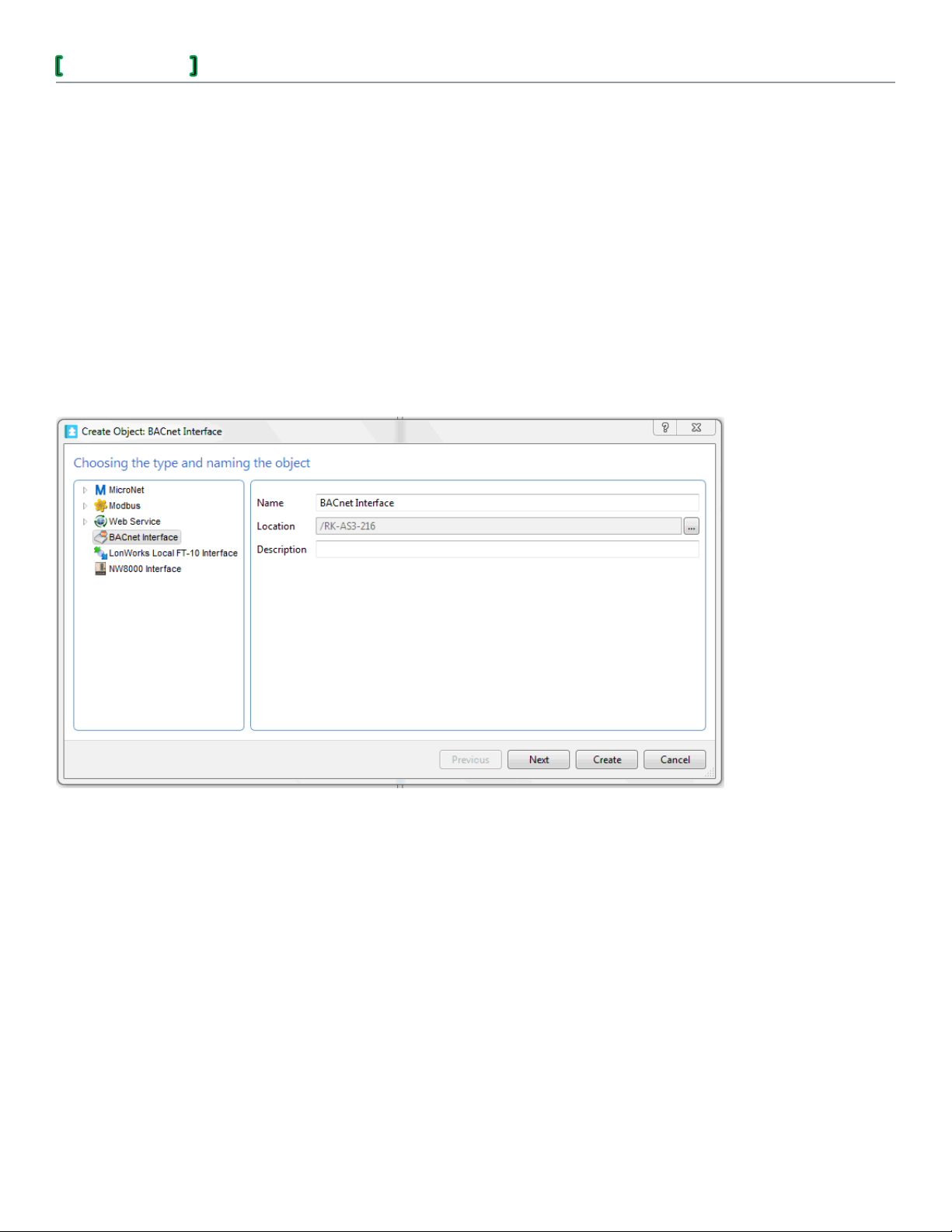

4.4. Create the BACnet Interface

Create the BACnet Interface in the Automation Server database to enable the BACnet

communications port of the Automation Server. The BACnet Interface represents the Automation

Server as a BACnet IP device.

In WorkStation, in the 1. System Tree pane, select the Automation Server.

On the 2. File menu, point to New and then click Interface.

In the object type list, select 3. BACnet Interface.

Accept the default name or type a custom name in the 4. Name box.

18

In the 5. Description box, type a description for the BACnet Interface and then click Next.

Configure the 6. Instance ID, BACnet name, and Network ID, and then click Create.

chneider Electric

S

Document Number: SG-IABACNET-SMARTSTRUXUR E-US.BU.N.EN.9.2013.1.0 0.CC

Schne ider El ectri c Confidential 09/12/13

© 2013 Schneider Electric. All rights reserved.

Page 19

Solution Guide

MNB BACnet Support within a StruxureWare Building Operation System

19

Instance ID – You can choose to let the server automatically generate the ID or you can

manually define the instance ID to match a numbering scheme used in the job site installation.

Be sure to choose an Instance ID that is unique on the internetwork.Note:

BACnet name – Define the name so that it is consistent with the scheme used in the

job site installation. For example, in the Validated System Architecture, RK_Automation

Server3_216_1000 is used, where RK_Automation Server3_216 is the name of the Automation

Server and 1000 is the manually assigned instance number. Alternately, you can allow the

system to automatically assign a name, in which case it will append Automation Server_ with

either an automatically generated ID or the ID you enter.

Network ID – Set to the same network ID (number) currently used for the BACnet IP

internetwork at the job site.

In the 7. System Tree pane, select the BACnet Interface and then click its Properties tab.

Click the a. Basic tab. The Auto-discover sub-networks property’s default setting is Yes

(enabled). To disable this property, change its setting to No.

Click the

b. Advanced tab. This tab allows you to view and configure the advanced

properties of the BACnet Interface, such as BACnet name, APDU segment timeout,

APDU timeout, Number of APDU retries, BBMD IP address, and BBMD port number.

For descriptions of the above properties, refer to Building Operation WebHelp topics: BACnet

Interface for an Automation Server ‑ Basic Tab and BACnet Interface for an Automation Server

‑ Advanced Tab.

When the 8. BACnet Interface is created, an IP Network is automatically created beneath it. If

your installation is using a UDP port other than the default (47808), change the IP port number.

In the a. System Tree pane, select the IP Network and then open its Properties view.

Click the b. Basic tab and then change the IP port number value.

The c. IP address property reflects the IP address assigned to the Automation Server.

Set d. IP broadcast address as specified in the job site plans.

chneider Electric

S

Document Number: SG-IABACNET-SMARTSTRUXUR E-US.BU.N.EN.9.2013.1.0 0.CC

© 2013 Schneider Electric. All rights reserved.

Schne ider El ectri c Confidential 09/12/13

Page 20

Solution Guide

MNB BACnet Support within a StruxureWare Building Operation System

Verify that the e. Online property is set to True.

The f. Network ID property displays the number entered when creating the BACnet

Interface.

When you select the Note: IP Network in the System Tree pane, the right-click menu option,

Download, can be clicked but it is not applicable to the MNB BACnet devices. If you

click this option, the system indicates a successful completion, when in fact it has

rejected the download.

4.5. Discover and Add IP‑Level MNB‑1000 Devices

Using WorkStation, discover and add the IP-level MNB-1000 devices to the Automation Server

system.

If you want Device Discovery to find the BACnet devices on subnetworks, be sure that on the1.

Basic tab of the BACnet Interface, you have set the Auto-discover sub-networks property

to Yes.

In the 2. System Tree pane, select the Automation Server and then open the Device Discovery

view.

20

Choose 3. BACnet devices from the Select device type drop-down list.

The system automatically discovers all accessible BACnet devices that are connected to the4.

Automation Server by IP, direct-connected MS/TP, and routed MS/TP.

chneider Electric

S

Document Number: SG-IABACNET-SMARTSTRUXUR E-US.BU.N.EN.9.2013.1.0 0.CC

© 2013 Schneider Electric. All rights reserved.

Schne ider El ectri c Confidential 09/12/13

Page 21

Solution Guide

MNB BACnet Support within a StruxureWare Building Operation System

21

In most cases, the list contains all BACnet devices that are accessible through the5.

internetwork, not only those that will be added to the particular Automation Server being

programmed. Verify that all the IP-level MNB-1000 devices you intend to add to the

Automation Server appear on this list. Identify any missing or extra devices in this context and

resolve any discrepancies.

Using the list in the Device Discovery view, identify which devices you want to add to the6.

Automation Server.

In the 7. System Tree pane, in the IP Network below the BACnet Interface, create a

corresponding device for each MNB-1000 device on the Device Discovery list.

As an option to the process described in the following steps, you can automaticallyNote:

create MNB devices by dragging the device hardware listed in the Device Discovery

view to the BACnet Interface in the System Tree view. This drag-and-drop method

is enabled for MNB devices beginning with release 1.4 of Building Operation. Refer to

topics in WebHelp describing Device Discovery.

Display the Device Discovery view in the Work Area, so that you can refer to its list ofa.

available BACnet devices and their names.

chneider Electric

S

Document Number: SG-IABACNET-SMARTSTRUXUR E-US.BU.N.EN.9.2013.1.0 0.CC

Schne ider El ectri c Confidential 09/12/13

© 2013 Schneider Electric. All rights reserved.

Page 22

Solution Guide

In the b. System Tree pane, select the IP Network below the BACnet Interface.

On the c. File menu, point to New and then click BACnet device.

In the Create Object dialog box, in the d. Name property, assign a name to the BACnet

device. It is good practice to enter the same name that was assigned to the device through

the WorkPlace Commissioning Tool.

The device name can also be seen in the Device Discovery list.Note:

MNB BACnet Support within a StruxureWare Building Operation System

22

Click e. Next.

On the f. BACnet basic settings page, select Upload from BACnet device and then below

this option, enter the Instance ID that was previously assigned to the BACnet device with

the WorkPlace Commissioning Tool.

© 2013 Schneider Electric. All rights reserved.

chneider Electric

S

Document Number: SG-IABACNET-SMARTSTRUXUR E-US.BU.N.EN.9.2013.1.0 0.CC

Schne ider El ectri c Confidential 09/12/13

Page 23

Solution Guide

MNB BACnet Support within a StruxureWare Building Operation System

23

Click g. Create.

Repeat this process for each additional MNB-1000 device that must be added to the IPh.

network in the Automation Server.

Each time you complete the process of adding an IP BACnet device, the deviceNote:

appears in the System Tree pane with an empty Application object below it.

4.6. Create Remote MS/TP Networks to Represent MS/TP Networks Connected to the MNB‑1000 Devices

For each MS/TP network connected to the IP- or Ethernet-based MNB-1000 devices, create an

MS/TP network in the Automation Server database.

The MNB-1000 device supports BACnet IP to BACnet Ethernet routing. Using an Note:

MNB-1000 as a BACnet router, you can connect BACnet Ethernet devices in Building

Operation. For more information, refer to the TAC I/A Series BACnet Wiring, Networking, and

Best Practices Guide, F-27360.

Create a parent MNB-1000 device that will contain the MS/TP network. Refer to 1. Discover and

Add IP-Level MNB-1000 Devices.

In the 2. System Tree pane, select the MNB-1000 device where the MS/TP network will be

created.

On the 3. File menu, point to New and then click BACnet network.

In the Create Object dialog box, in the 4. Name box, assign the network a name. Although the

default name can be used, it is good practice to use a name that better defines the network, to

aid those who use and support the system. An example is MSTP Network ####, where #### is

the network ID (number).

chneider Electric

S

Document Number: SG-IABACNET-SMARTSTRUXUR E-US.BU.N.EN.9.2013.1.0 0.CC

Schne ider El ectri c Confidential 09/12/13

© 2013 Schneider Electric. All rights reserved.

Page 24

Solution Guide

MNB BACnet Support within a StruxureWare Building Operation System

24

Click 5. Next.

On the 6. BACnet basic settings page, in Network ID, assign a network ID that matches the

network number previously assigned to the MS/TP trunk by the WorkPlace Commissioning

Tool.

Click 7. Create.

In the 8. System Tree pane, the new MS/TP network appears below the MNB-1000 device.

chneider Electric

S

Document Number: SG-IABACNET-SMARTSTRUXUR E-US.BU.N.EN.9.2013.1.0 0.CC

Schne ider El ectri c Confidential 09/12/13

© 2013 Schneider Electric. All rights reserved.

Page 25

Solution Guide

MNB BACnet Support within a StruxureWare Building Operation System

25

In the new MS/TP network, place all the discovered MS/TP devices that belong to this9.

particular MNB-1000 device in the system topology.

By using the approach outlined in the preceding steps, you accurately represent, to the user, Note:

the system topology in the System Tree pane.

This Note: MSTP Network represents an MS/TP trunk that exists below an MNB-1000 device,

and is therefore not associated with any hardware ports on the Automation Server, itself.

This network’s configuration is defined and controlled externally, using the WorkPlace

Commissioning Tool. The presence or absence of this MSTP Network in the System Tree

pane does not affect which devices are listed when Device Discovery is used.

4.7. Create MS/TP Networks to Represent MS/TP Networks Connected to Automation Server COM Ports

For each MS/TP network that is directly connected to the RS-485 COM A or COM B port of the

Automation Server, create an MS/TP network in the Automation Server database.

In the 1. System Tree pane, select the BACnet Interface where the MS/TP network will be

created.

On the 2. File menu, point to New and then click MSTP Network.

In the Create Object dialog box, in the 3. Name box, assign the network a name. Although the

default name can be used, it is good practice to use a name that better defines the network,

to aid those who use and support the system. An example is MSTP Network ####‑COMPort,

where #### is the network ID (number).

chneider Electric

S

Document Number: SG-IABACNET-SMARTSTRUXUR E-US.BU.N.EN.9.2013.1.0 0.CC

© 2013 Schneider Electric. All rights reserved.

Schne ider El ectri c Confidential 09/12/13

Page 26

Solution Guide

MNB BACnet Support within a StruxureWare Building Operation System

26

Click 4. Next.

On the 5. MSTP Network basic settings page, configure the MS/TP network.

Network ID – a. Assign a network ID to the MS/TP trunk of MNB devices that will be

attached to the Automation Server’s RS-485 COM A port. This network ID should match

the network number previously defined in the system topology.

Each MS/TP trunk must have its own unique network number within theNote:

internetwork.

MAC address – b. Keep the default value of 0 (zero). This follows the practice of assigning 0

(zero) as the MAC address when an MNB-1000 hosts an MS/TP network.

chneider Electric

S

Document Number: SG-IABACNET-SMARTSTRUXUR E-US.BU.N.EN.9.2013.1.0 0.CC

© 2013 Schneider Electric. All rights reserved.

Schne ider El ectri c Confidential 09/12/13

Page 27

Solution Guide

MNB BACnet Support within a StruxureWare Building Operation System

RS-485 portc. – Select a serial port: Serial/RS485-COMA or Serial/RS485-COMB.

When MS/TP networks are created, the system will automatically select one of theNote:

RS-485 hardware ports. You can change the port assignment later, if needed.

Click 6. Create.

In the 7. System Tree pane, select the MSTP Network that was created and then open its

Properties view.

The Note: Properties view displays additional properties of the MS/TP network that must be

configured before the network will communicate with the connected BACnet devices.

27

Configure the MS/TP network properties to match the requirements of the installation.8.

Onlinea. – Set to False and then click the Save button. This makes the initial

communications to the trunk more efficient when the initial port configuration is saved.

Network IDb. , RS-485 port, and MAC address – These are already configured, based on

the initial creation of the MSTP Network. Reconfigure any of these properties if needed.

MSTP baud ratec. – In most cases, when MNB BACnet devices are attached to the MS/TP

network, the baud rate of the devices will be set to 38,400 or 76,800. Set this property to

the baud rate previously documented for the system topology.

Enhanced moded. – Set to False. This is the required setting for MNB BACnet devices.

Maximum mastere. – Generally, you can keep the default value of 127 or set it to a value

that is 10% to 20% greater than the maximum number of devices on the MS/TP network.

For more information, refer to the TAC I/A Series BACnet Wiring, Networking, and Best

Practices Guide, F-27360.

Maximum information framesf. – Set this value based on communication traffic needs.

Typically for an MNB BACnet system, select a value in the range of 8 to 20.

Reset the g. Online property to True and then click the Save button.

chneider Electric

S

Document Number: SG-IABACNET-SMARTSTRUXUR E-US.BU.N.EN.9.2013.1.0 0.CC

© 2013 Schneider Electric. All rights reserved.

Schne ider El ectri c Confidential 09/12/13

Page 28

Solution Guide

MNB BACnet Support within a StruxureWare Building Operation System

If you need to connect a second MS/TP network to the Automation Server, repeat the steps9.

used to create the first MS/TP network, with changes as follows:

Namea. – Use a name that distinguishes the second network from the first network. An

example is MSTP Network ####‑COMPort , where #### is the network ID (number).

Onlineb. – Set to False and then click the Save button. This makes the initial

communications to the trunk more efficient when the initial port configuration is saved.

Network ID – c. Assign a network ID to the MS/TP trunk of MNB devices that will be

attached to the Automation Server’s RS-485 COM B port. This network ID should match

the network number previously defined in the system topology.

MAC address – d. Keep the default value of 0 (zero). This follows the practice of assigning 0

(zero) as the MAC address when an MNB-1000 hosts an MS/TP network.

RS-485 porte. – Select the remaining, available serial port: Serial/RS485-COMB.

MSTP baud ratef. – Set this property to the baud rate previously documented for the

system topology.

Enhanced modeg. – Set to False. This is the required setting for MNB BACnet devices.

Maximum masterh. – Generally, you can keep the default value of 127 or set it to a value

that is 10% to 20% greater than the maximum number of devices on the MS/TP network.

For more information, refer to the TAC I/A Series BACnet Wiring, Networking, and Best

Practices Guide, F-27360.

28

Maximum information framesi. – Set this value based on communication traffic needs.

Typically for an MNB BACnet system, select a value in the range of 8 to 20.

Reset the j. Online property to True and then click the Save button.

Once you have created and configured the MS/TP network, verify that all the expected devices10.

are present in the network before proceeding.

In the a. System Tree pane, select the Automation Server and then open the Device

Discovery view.

In the Device Discovery view, you can select BACnet devices and discover additionalb.

BACnet devices that are accessible through the MS/TP network.

chneider Electric

S

Document Number: SG-IABACNET-SMARTSTRUXUR E-US.BU.N.EN.9.2013.1.0 0.CC

© 2013 Schneider Electric. All rights reserved.

Schne ider El ectri c Confidential 09/12/13

Page 29

Solution Guide

Review the list of BACnet devices to verify that all the devices that belong to the MS/TPc.

network are present.

MNB BACnet Support within a StruxureWare Building Operation System

29

When you refer to the MS/TP communication status LED’s on MNB devices, Caution:

remember that the implementation of LED colors in the MNB devices is the opposite

of that found on the Automation Server. More specifically, in MNB devices the

green LED indicates transmit (MSTP XMT) and the amber LED indicates receive

(MSTP RCV). In the Automation Server, the green LED indicates receive (MSTP RCV)

and the amber LED indicates transmit (MSTP XMT).

4.8. Discover and Add MNB Devices

Use WorkStation to discover and add the MNB devices to the Automation Server database.

Set Device Discovery to automatically find BACnet devices on the subnetworks.1.

In the a. System Tree pane, select the BACnet Interface and then open its Properties view.

Click the b. Basic tab and then verify that Auto-discover sub-networks is set to Yes .

chneider Electric

S

Document Number: SG-IABACNET-SMARTSTRUXUR E-US.BU.N.EN.9.2013.1.0 0.CC

Schne ider El ectri c Confidential 09/12/13

© 2013 Schneider Electric. All rights reserved.

Page 30

Solution Guide

MNB BACnet Support within a StruxureWare Building Operation System

In the 2. System Tree pane, select the Automation Server and then open the Device Discovery

view.

Choose 3. BACnet devices from the Select device type drop-down list.

The system automatically discovers all accessible BACnet devices that are connected to the4.

Automation Server by IP, direct-connected MS/TP, and routed MS/TP.

30

In most cases, the list contains all BACnet devices that are accessible through the5.

internetwork, not only those that will be added to the particular Automation Server being

programmed. Verify that all the MS/TP networks and devices you intend to add to the

Automation Server appear on this list. Identify any missing or extra devices in this context and

resolve any discrepancies.

Using the list in the Device Discovery view, identify the devices you want to add to the6.

previously created MS/TP networks in the Automation Server.

The list displays the current name assigned to each BACnet device. Using the WorkPlace7.

Commissioning Tool, or a similar tool, generate a list of the associated device instance

numbers.

chneider Electric

S

Document Number: SG-IABACNET-SMARTSTRUXUR E-US.BU.N.EN.9.2013.1.0 0.CC

Schne ider El ectri c Confidential 09/12/13

© 2013 Schneider Electric. All rights reserved.

Page 31

Solution Guide

MNB BACnet Support within a StruxureWare Building Operation System

For each MNB BACnet device on the Device Discovery list that is to be added to the8.

Automation Server, create a corresponding device in the appropriate BACnet network under

the BACnet Interface.

The steps described here are the same for all three BACnet network types:Note:

IP network-level devices –

MS/TP network-level devices directly connected to the RS-485 ports of the –

Automation Server (COM A and COM B)

MSTP network-level devices remotely connected on a subnetwork (under an –

MNB-1000)

Display the Device Discovery view in the Work Area, so that you can refer to its list ofa.

available BACnet devices and their names.

In the b. System Tree pane, select the appropriate network, below the BACnet Interface.

On the c. File menu, point to New and then click BACnet device.

In the Create Object dialog box, in the d. Name property, assign a name to the BACnet

device. It is good practice to enter the same name that was assigned to the device through

the WorkPlace Commissioning Tool.

31

The device name can also be seen in the Device Discovery list.Note:

Click e. Next.

On the f. BACnet basic settings page, select Upload from BACnet device and then below

this option, enter the Instance ID that was previously assigned to the BACnet device with

the WorkPlace Commissioning Tool.

chneider Electric

S

Document Number: SG-IABACNET-SMARTSTRUXUR E-US.BU.N.EN.9.2013.1.0 0.CC

© 2013 Schneider Electric. All rights reserved.

Schne ider El ectri c Confidential 09/12/13

Page 32

Solution Guide

MNB BACnet Support within a StruxureWare Building Operation System

32

Click g. Create.

Repeat the preceding steps for each additional BACnet device you wish to add to theh.

three BACnet network types in the Automation Server.

When completed, each MNB BACnet device appears in the 9. System Tree pane with an empty

Application folder below it.

4.9. Upload MNB Devices to Create BACnet Points

Upload each MNB BACnet device to automatically create its associated BACnet points.

Prior to uploading the MNB devices, determine whether you want to hide or show the BACnet1.

background objects associated with the physical I/O points. Hide or show these objects in

the WorkPlace Commissioning Tool by enabling or disabling the Hide background BACnet

objects option on the Setup tab of the Device Properties dialog box. For more information

on this functionality, refer to the TAC I/A Series MicroNet BACnet Commissioning Tool/Flow

Balance Tool User’s Guide, F-27358, and the TAC I/A Series WorkPlace Tech Tool BACnet

Engineering Guide Supplement, F-27356.

Background BACnet objects are used to configure the I/O points in MNB BACnetNote:

devices from Building Operation.

In the 2. System Tree pane, select one of the BACnet networks you created, so that all the MNB

devices added to that network trunk are displayed in the List View.

Select all the listed MNB devices.3.

On the 4. Actions menu, click Upload. The MNB devices are uploaded, one at a time.

When an MNB device finishes uploading, its 5. Application folder contains all the BACnet objects

exposed by the device.

chneider Electric

S

Document Number: SG-IABACNET-SMARTSTRUXUR E-US.BU.N.EN.9.2013.1.0 0.CC

Schne ider El ectri c Confidential 09/12/13

© 2013 Schneider Electric. All rights reserved.

Page 33

Solution Guide

MNB BACnet Support within a StruxureWare Building Operation System

Repeat the preceding steps for each of the other BACnet network types under the 6. BACnet

Interface (IP, direct-connected MS/TP, and routed MS/TP).

When you upload MNB devices to automatically create associated BACnet points in the Note:

Automation Server database, there are certain results that you should consider. Refer to

MNB BACnet Points Created with Device Upload.

33

33

chneider Electric

S

Document Number: SG-IABACNET-SMARTSTRUXUR E-US.BU.N.EN.9.2013.1.0 0.CC

© 2013 Schneider Electric. All rights reserved.

Schne ider El ectri c Confidential 09/12/13

Page 34

Solution Guide

MNB BACnet Support within a StruxureWare Building Operation System

Chapter 5

Best Practices and Lessons Learned

The task of integrating an MNB BACnet system into Building Operation can be facilitated by the

use of supplemental practices and information. Procedural information can be found in the section

titled Best Practices. Advisory information can be found in the section titled Lessons Learned.

5.1. Best Practices

This section contains supplemental procedures that are helpful when integrating a new or existing

MNB BACnet system into Building Operation.

34

Making Changes to Applications of MNB Devices Connected to the 5.1.1

Automation Server

You can use WorkPlace Tech to download and monitor MNB BACnet applications while the MNB

devices are attached to the Automation Server. Anytime you make a change to an MNB application

that affects any BACnet-related object in any way, you must upload the MNB device to the

Automation Server so that the BACnet objects and properties are synchronized. An upload is not

required if only logic changes are made.

Changing the Names of BACnet Objects5.1 .1 .1

Under certain conditions, when BACnet objects in an MNB application are renamed, the names

of those objects in the System Tree pane can become out of sync with the revised names in the

application.

This can occur when you upload an MNB device to the Automation Server, change the name of a

BACnet object in the associated application, download the revised application to the MNB device,

and then upload the device once again to the Automation Server. The result is that the name of the

BACnet object in the System Tree pane does not update to reflect the name change you made in

the application.

For example, you upload an MNB device to the Automation Server and then in the associated

MNB application, use WorkPlace Tech to change the name of an AO point from “AO Test” to

“SFan_VFD”. You download the revised application to the MNB device and then perform another

upload to the Automation Server. When you view the AO point in the System Tree pane, you see

that its name is still “AO Test”, not the new name you set in the application, “SFan_VFD”. This leads

you to believe that the points were not learned from the MNB device.

To synchronize the name in the System Tree pane with the new name in the application, manually

rename the object in the System Tree pane.

In the 1. System Tree pane, select the renamed BACnet object.

On the 2. Edit menu, click Rename.

In the 3. Object name box, type the new name, matching the name in the BACnet name

property on the Advanced tab.

chneider Electric

S

Document Number: SG-IABACNET-SMARTSTRUXUR E-US.BU.N.EN.9.2013.1.0 0.CC

Schne ider El ectri c Confidential 09/12/13

Page 35

Solution Guide

MNB BACnet Support within a StruxureWare Building Operation System

Adding a Second I/O Point with the Same Original Object Name5.1 .1 . 2

If, under the conditions described above, you add another I/O point having the same original name

as the first point, and then upload the MNB device to the Automation Server, the name of this

second point is appended with an “_1”. This occurs because the system still recognizes the original

name of the first point, not its revised name. To avoid this type of duplication, be sure to update the

name of the first object in the System Tree pane before adding the second point.

Changing the IP Configuration of a Previously Programmed 5.1.2

Automation Server

There are cases when there is a need to change the IP address of an Automation Server after it has

been programmed. For example, an Automation Server is pre-programmed off-site, then brought

to the job site and installed. The Automation Server most likely will have a different IP address and

network settings than those required for the job site.

Perform the following steps to update the system to the new settings so that it can be made fully

operational.

For each Automation Server, use the Device Administrator to change the network settings1.

to those required by the job site. The text in parentheses contains the name of any Network

tab properties as they appear in WorkStation, when they are different from the Device

Administrator.

35

Static IP address• (IP/DNS address)

Host name•

Domain• (Domain name)

Netmask• (Subnet mask)

DNS• (DNS server)

Gateway• (Default gateway)

DHCP•

Use WorkStation to log onto the Automation Server, using the new IP address, and then2.

select the IP network below the BACnet Interface to change the following BACnet-related

properties:

IP address•

IP port number•

Network ID•

IP broadcast address•

Remember that if the IP address changes because the Automation Server has been Note:

moved to a different subnet, you must update the IP broadcast address to the new

subnet.

Using WorkStation, log onto the Enterprise Server.3.

In the 4. System Tree pane, select the Enterprise Server and then click the Communication tab.

Ensure the 5. Show/Hide Communications settings button has been set, so that the

settings are displayed for edit.

Select the Automation Server from the list, update the 6. Address property to the new IP

address, and then click the Save button.

chneider Electric

S

Document Number: SG-IABACNET-SMARTSTRUXUR E-US.BU.N.EN.9.2013.1.0 0.CC

Schne ider El ectri c Confidential 09/12/13

© 2013 Schneider Electric. All rights reserved.

Page 36

Solution Guide

MNB BACnet Support within a StruxureWare Building Operation System

Repeat the preceding steps for each Automation Server whose IP address has been changed.7.

The Automation Servers will re-establish communication with the Enterprise Server after a short8.

period of time. If communication to the Automation Servers is not re-established, even though

everything was reconfigured properly, it may be necessary to repair server communications.

In the a. System Tree pane, select the Enterprise Server.

On the b. Actions menu, point to Advanced and then click Repair server communication.

Changing the Automation Server BACnet Instance Number After 5.1.3

the BACnet Interface Is Created

Once a BACnet Interface has been added to the Automation Server, its BACnet instance number

is fixed and cannot be changed from within the Automation Server. If a new instance number

must be assigned to the BACnet Interface, use the automatic or manual approach to update the

Automation Server database.

These steps can be disruptive to system operation. Take all necessary precautions.Caution:

Approach 1 – Automatic Assignment5.1 . 3 .1

36

Follow these steps to allow the system to automatically assign the new instance number to the

BACnet Interface.

In the 1. System Tree pane, select the BACnet Interface.

On the 2. File menu, click Export. This includes all IP and MS/TP networks and their associated

devices and objects.

In the 3. Export preview dialog box, select Export special and then click Export.

Document all references to or from the MNB devices and objects below the 4. BACnet Interface

that extend outside the context of the exported selections. For example, if only the BACnet

Interface is selected, then you would document all references that extend outside it.

In the 5. System Tree pane, select and then delete the BACnet Interface. Doing so will also

delete everything it contains.

In the 6. Confirm Delete dialog box, select Keep references in other object(s) to the objects

you selected to delete and then click Yes.

Import the 7. BACnet Interface you previously exported, which contains all the original networks

and devices.

The 8. BACnet Interface will automatically assign an instance number to itself, as part of the

import process.

The import process removes all device instances that were previously defined. As a result, you9.

must reassign an instance number to each MNB device.

In the a. System Tree pane, select an MNB device.

On the b. Actions menu, point to Device and then click Associate with device.

In the c. Device ID box, type the original or new instance number.

chneider Electric

S

Document Number: SG-IABACNET-SMARTSTRUXUR E-US.BU.N.EN.9.2013.1.0 0.CC

© 2013 Schneider Electric. All rights reserved.

Schne ider El ectri c Confidential 09/12/13

Page 37

Solution Guide

MNB BACnet Support within a StruxureWare Building Operation System

Upload all the MNB devices to ensure they are synchronized with the Automation Server10.

database.

Manually add all the missing references that you previously documented, back into the11.

Automation Server.

Manual Assignment5.1 . 3 .2

Follow these steps to manually assign the new instance number to the BACnet Interface.

In the 1. System Tree pane, select the BACnet Interface.

37

Using the 2. List View, select all the listed MS/TP networks.

On the 3. File menu, click Export. This includes all of the devices and objects associated with the

selected networks.

In the 4. Export preview dialog box, select Export special and then click Export.

In the 5. System Tree pane, select the IP Network below the BACnet Interface.

Using the 6. List View, select all the listed devices and objects.

On the 7. File menu, click Export.

In the 8. Export preview dialog box, select Export special and then click Export.

In the 9. System Tree pane, select the Application folder below the BACnet Interface.

Using the 10. List View, select all the the objects except SXWconfiguration.

On the 11. File menu, click Export.

In the 12. Export preview dialog box, select Export special and then click Export.

Document all references to or from the MNB devices and objects below the 13. BACnet Interface

that extend outside the context of the exported selections. For example, if only the BACnet

Interface is selected, then you would document all references that extend outside it.

In the 14. System Tree pane, select and then delete the BACnet Interface. Doing so will also

delete everything it contains.

In the 15. Confirm Delete dialog box, select Keep references in other object(s) to the objects

you selected to delete and then click Yes.

Select the Automation Server that contained the deleted 16. BACnet Interface.

On the 17. File menu, point to New and then click Interface.

In the object type list, select 18. BACnet Interface.

chneider Electric

S

Document Number: SG-IABACNET-SMARTSTRUXUR E-US.BU.N.EN.9.2013.1.0 0.CC

Schne ider El ectri c Confidential 09/12/13

© 2013 Schneider Electric. All rights reserved.

Page 38

Solution Guide

MNB BACnet Support within a StruxureWare Building Operation System

In the Create Object dialog box, enter the following:19.

In the • Name box, assign the same name as the BACnet Interface you deleted.

Under • Instance ID, manually assign the desired instance number to the BACnet

Interface.

Click 20. Create.

In the 21. System Tree pane, select the Application folder below the BACnet Interface.

On the 22. File menu, click Import.

Using the Import dialog box, select the objects you previously exported and then click 23. Import.

In the 24. System Tree pane, select the IP Network below the BACnet Interface.

On the 25. File menu, click Import.

Using the Import dialog box, select the IP MNB devices and objects you previously exported26.

and then click Import.

In the 27. System Tree pane, select the BACnet Interface.

On the 28. File menu, click Import.

38

Using the Import dialog box, select the MS/TP networks you previously exported and then click29.

Import.

The import process removes all device instances that were previously defined. As a result, you30.

must reassign an instance number to each MNB device.

In the a. System Tree pane, select an MNB device.

On the b. Actions menu, point to Device and then click Associate with device.

In the c. Device ID box, type the original or new instance number.

Upload all the MNB devices to ensure they are synchronized with the Automation Server31.

database.

In the a. System Tree pane, select all the MNB devices in which you reassigned instance

numbers, so that they are displayed in the List View.

Select all the listed MNB devices.b.

On the c. Actions menu, click Upload. The MNB devices are uploaded serially, one at a time.

Manually add all the missing references that you previously documented, back into the32.

Automation Server.

chneider Electric

S

Document Number: SG-IABACNET-SMARTSTRUXUR E-US.BU.N.EN.9.2013.1.0 0.CC

© 2013 Schneider Electric. All rights reserved.

Schne ider El ectri c Confidential 09/12/13

Page 39

Solution Guide

MNB BACnet Support within a StruxureWare Building Operation System

Changing the Network Number of an MS/TP Network Previously 5.1.4

Added to the Automation Server

Once an MSTP Network has been added to the Automation Server to represent an MS/TP

network attached to an MNB-1000, its network number is fixed and cannot be changed from within

the Automation Server. However, sometimes the network number must be changed, for example

to resolve a conflict. If the network number must be changed, then follow one of the approaches

described below to update the Automation Server database.

These steps can be disruptive to system operation. Take all necessary precautions.Caution:

Recommended Method5 .1. 4.1

This approach updates the system to use the new network number and re-establish

communications to the MNB devices on the routed MS/TP network.

While this method is the more expedient of the two options, it does not update the displayed Note:

value for the Network ID property of the routed MS/TP network. It is recommended that you

use the Notes fields in the Properties dialog box, or develop another method, to address

the difference between the displayed network number and the new network number. The

Network ID property is used for display only; it is not used for communications.

39

Using the WorkPlace Commissioning Tool, change the network number of the routed MS/TP1.

network to the new network number.

In the WorkPlace Commissioning Tool, select the MNB-1000 to which the MS/TP networka.

of devices is attached.

Click the b. MS/TP tab and then change the network number of the routed MS/TP network

to the new network number.

If any MNB-1000 devices are attached to the MS/TP trunk, update their MSTP network2.

numbers also.

Exit the WorkPlace Commissioning Tool.3.

The MNB devices on the MS/TP network gradually stop communicating with the parent4.

Automation Server and begin reporting that they are offline, as indicated by their LEDs.

Restart the WorkPlace Commissioning Tool and verify that the affected MNB devices now5.

appear in the discovery list, using the new network number.

Perform a cold reset of the Automation Server, using either of two methods.6.

On the Automation Server, press the • Reset button for 10 seconds.

Perform a cold start in WorkStation.•

In WorkStation, in the 1) System Tree pane, select the Automation Server.

On the 2) Actions menu, point to Device, then Restart, and then click Cold start.

When the Automation Server has finished rebooting, verify device communications and the use7.

of the new network number.

In WorkStation, view the a. System Tree pane to verify that all MNB devices in the

renumbered MS/TP network have resumed communications.

Select the b. BACnet Interface and then open its Properties view.

Click the c. Basic tab and then verify that Auto-discover sub-networks is set to Yes.

In the d. System Tree pane, select the Automation Server and then open the Device

Discovery view.

chneider Electric

S

Document Number: SG-IABACNET-SMARTSTRUXUR E-US.BU.N.EN.9.2013.1.0 0.CC

© 2013 Schneider Electric. All rights reserved.

Schne ider El ectri c Confidential 09/12/13

Page 40

Solution Guide

MNB BACnet Support within a StruxureWare Building Operation System

Choose e. BACnet devices from the Select device type drop-down list.

Verify that the listed MNB devices display the new MS/TP network number.f.

Alternate Method5 .1. 4. 2

This approach updates the system to use the new network number, re-establishes communications

to the MNB devices on the routed MS/TP network, and updates the Network ID property to the

new value.

This method may result in the loss of some of the bindings. As instructed below, be sure Caution:

to document all the bindings to and from the devices under the MS/TP network before

you export and then delete the network.

Back up the Automation Server.1.

In WorkStation, in the a. System Tree pane, select the Automation Server.

On the b. Actions menu, click Backup.

In the c. Backup Options dialog box, select the check box for the Automation Server you

wish to back up.

In the d. Backup content box, select Configuration only or All data for the type of data you

want to back up for this server.

40

In the e. Backup set description box, enter a brief description of up to 255 characters.

Click f. Backup.

Verify that the backup succeeded and then click g. Close.

Document all the bindings to and from the devices below the 2. MSTP BACnet Network.

In the 3. System Tree pane, select the MSTP BACnet Network and then click the List View tab.

Selected all the listed MNB devices and then on the 4. File menu, click Export.

In the 5. Export preview dialog box, select Export special and then click Export.

In the 6. System Tree pane, select the MSTP BACnet Network.

On the 7. Edit menu, click Delete.

In the 8. Confirm Delete dialog box, select Keep references in other object(s) to the objects

you selected to delete.

Click 9. Show references to see a list of the affected references.

In the 10. Confirm Delete dialog box, click Yes.

Recreate the MSTP BACnet Network you previously deleted.11.

In the a. System Tree pane, select the BACnet Interface from where the MS/TP network

was previously deleted.

On the b. File menu, point to New and then click MSTP Network.

In the Create Object dialog box, in the c. Name box, assign the network the same name as

the network you deleted and then click Next.

On the 12. MSTP Network basic settings page, in Network ID, assign a new network number.

Each MS/TP trunk must have its own unique network number within the internetwork.Note:

Click 13. Create.

chneider Electric

S

Document Number: SG-IABACNET-SMARTSTRUXUR E-US.BU.N.EN.9.2013.1.0 0.CC

Schne ider El ectri c Confidential 09/12/13

© 2013 Schneider Electric. All rights reserved.

Page 41

Solution Guide

MNB BACnet Support within a StruxureWare Building Operation System

The system will automatically keep the default Note: MAC address value of 0 (zero) and select

one of the RS-485 hardware ports. You can change the port assignment later, if needed.

In the 14. System Tree pane, select the MSTP Network and then on the File menu, select Import.

In the 15. Open dialog box, select the previously exported file and then click Import.

Reassign an instance number to each imported MNB device.16.

In the a. System Tree pane, select an imported MNB device.

On the b. Actions menu, point to Device and then click Associate with device.

In the c. Device ID box, type the original or new instance number. Once the association is

complete, the device will appear online.

Upload each of the MNB devices to ensure they are synchronized with the Automation Server17.

database.

Manually add all the missing references that you previously documented, back into the18.

Automation Server.

Use Reference Manager to determine if any unresolved references are still present.19.

In WorkStation, on the a. Tools menu, click Control Panel.

41

In the Engineering group, click b. Reference Manager.

In Reference Manager, verify that the list does not contain any unresolved references.c.

Changing the IP Configuration of an MNB‑1000 Previously Added 5.1.5

to the Automation Server

Once an IP-based MNB-1000 device has been added to the Automation Server, its IP address and

port number are fixed and cannot be changed from within the Automation Server. If you use the

WorkPlace Commissioning Tool to change the IP address and UDP port number in the MNB-1000

device, then update the Automation Server database according to the following steps.

These steps can be disruptive to system operation. Take all necessary precautions.Caution:

Note:

It is best to resolve this discrepancy before you add any additional objects, folders, or

bindings to the MNB-1000 device in the Automation Server.

Back up the Automation Server.1.

In WorkStation, in the a. System Tree pane, select the Automation Server.

On the b. Actions menu, click Backup.

In the c. Backup Options dialog box, select the check box for the Automation Server you

wish to back up.

In the d. Backup content box, select Configuration only or All data for the type of data you

want to back up for this server.