Page 1

LXM32

Common DC bus

Application note

MNA01M001EN, V1.01, 08.2014

MNA01M001EN, V1.01, 08.2014

www.schneider-electric.com

Page 2

LXM32

The information provided in this documentation contains general

descriptions and/or technical characteristics of the performance of the

products contained herein. This documentation is not intended as a

substitute for and is not to be used for determining suitability or reliability of these products for specific user applications. It is the duty of

any such user or integrator to perform the appropriate and complete

risk analysis, evaluation and testing of the products with respect to the

relevant specific application or use thereof. Neither Schneider Electric

nor any of its affiliates or subsidiaries shall be responsible or liable for

misuse of the information contained herein. If you have any suggestions for improvements or amendments or have found errors in this

publication, please notify us.

No part of this document may be reproduced in any form or by any

means, electronic or mechanical, including photocopying, without

express written permission of Schneider Electric.

All pertinent state, regional, and local safety regulations must be

observed when installing and using this product. For reasons of safety

and to help ensure compliance with documented system data, only

the manufacturer should perform repairs to components.

When devices are used for applications with technical safety requirements, the relevant instructions must be followed.

Failure to use Schneider Electric software or approved software with

our hardware products may result in injury, harm, or improper operating results.

Failure to observe this information can result in injury or equipment

damage.

© 2013 Schneider Electric. All rights reserved.

2 Common DC bus

MNA01M001EN, V1.01, 08.2014

Page 3

LXM32 Table of contents

Table of contents

Table of contents 3

Safety Information 5

Hazard categories 5

Qualification of personnel 6

Intended use 6

Basic information 7

DC bus voltage measurement 9

Standards and terminology 9

About the book 11

1 Introduction 13

1.1 Permissible device types for common DC bus 14

2 Technical Data 15

2.1 Firmware version 15

2.2 DC bus data 16

2.3 Braking resistor 17

2.3.1 External braking resistors (accessories) 19

2.4 Cables for the DC bus 20

3 Engineering 21

3.1 Energy balance 22

3.1.1 Energy balance basics 22

3.2 Electromagnetic compatibility (EMC) 24

3.3 DC bus connection 24

3.4 Fuses 25

3.4.1 DC bus connection of single-phase drives 25

3.4.2 DC bus connection of three-phase drives 27

3.4.3 Supply via the DC bus 29

3.5 Braking resistors 32

3.5.1 Rating the braking resistor 32

3.5.2 Rating information 34

3.6 Mains reactor 36

3.7 Mains filter 38

3.8 Mains reactor and external mains filter 39

4 Installation 41

MNA01M001EN, V1.01, 08.2014

Common DC bus 3

Page 4

Table of contents LXM32

4.1 Assembling cables 42

4.2 Wiring the DC bus 45

4.2.1 Drives with connectors 45

4.2.2 Drives with terminals 47

4.2.3 Connecting the DC bus 48

4.3 Verifying installation 49

5 Commissioning 51

5.1 Commissioning procedure 52

5.1.1 DC bus connection LXM32 to LXM32 52

5.1.2 Supply via the DC bus 53

5.2 LXM32: Setting the braking resistor parameters 54

6 Accessories and spare parts 55

6.1 DC bus accessories 55

6.2 DC fuses 55

6.3 External braking resistors 56

Glossary 57

Units and conversion tables 57

Length 57

Mass 57

Force 57

Power 57

Rotation 58

Torque 58

Moment of inertia 58

Temperature 58

Conductor cross section 58

Terms and Abbreviations 59

Table of figures 61

Index 63

4 Common DC bus

MNA01M001EN, V1.01, 08.2014

Page 5

LXM32

Safety Information

Safety Information

Read these instructions carefully, and look at the equipment to

become familiar with the device before trying to install, operate, or

maintain it. The following special messages may appear throughout

this documentation or on the equipment to warn of potential hazards

or to call attention to information that clarifies or simplifies a procedure.

The addition of this symbol to a Danger safety label indicates that an electrical hazard exists, which will result in

personal injury if the instructions are not followed.

This is the safety alert symbol. It is used to alert you to

potential personal injury hazards. Obey all safety messages

that follow this symbol to avoid possible injury or death.

Hazard categories

Safety instructions to the user are highlighted by safety alert symbols

in the manual. In addition, labels with symbols and/or instructions are

attached to the product that alert you to potential hazards.

Depending on the seriousness of the hazard, the safety instructions

are divided into 4 hazard categories.

DANGER

DANGER indicates an imminently hazardous situation, which, if not

avoided, will result in death or serious injury.

WARNING

WARNING indicates a potentially hazardous situation, which, if not

avoided, can result in death, serious injury, or equipment damage.

CAUTION

CAUTION indicates a potentially hazardous situation, which, if not

avoided, can result in injury or equipment damage.

NOTICE

NOTICE indicates a potentially hazardous situation, which, if not

avoided, can result in equipment damage.

MNA01M001EN, V1.01, 08.2014

Common DC bus 5

Page 6

Safety Information

Qualification of personnel

Intended use

LXM32

Only appropriately trained persons who are familiar with and understand the contents of this manual and all other pertinent product documentation are authorized to work on and with this product. In addition,

these persons must have received safety training to recognize and

avoid hazards involved. These persons must have sufficient technical

training, knowledge and experience and be able to foresee and detect

potential hazards that may be caused by using the product, by changing the settings and by the mechanical, electrical and electronic equipment of the entire system in which the product is used.

All persons working on and with the product must be fully familiar with

all applicable standards, directives, and accident prevention regulations when performing such work.

The functions described in this document are only intended for use for

the products described in this document.

The product may only be used in compliance with all applicable safety

regulations and directives, the specified requirements and the technical data.

Prior to using the product, you must perform a risk assessment in view

of the planned application. Based on the results, the appropriate

safety measures must be implemented.

Since the product is used as a component in an entire system, you

must ensure the safety of persons by means of the design of this

entire system (for example, machine design).

Operate the product only with the specified cables and accessories.

Use only genuine accessories and spare parts.

Any use other than the use explicitly permitted is prohibited and can

result in hazards.

Electrical equipment should be installed, operated, serviced, and

maintained only by qualified personnel.

6 Common DC bus

MNA01M001EN, V1.01, 08.2014

Page 7

LXM32

Safety Information

Basic information

DANGER

HAZARD DUE TO ELECTRIC SHOCK, EXPLOSION OR ARC FLASH

• Only appropriately trained persons who are familiar with and

understand the contents of this manual and all other pertinent

product documentation and who have received safety training to

recognize and avoid hazards involved are authorized to work on

and with this drive system. Installation, adjustment, repair and

maintenance must be performed by qualified personnel.

• The system integrator is responsible for compliance with all local

and national electrical code requirements as well as all other

applicable regulations with respect to grounding of all equipment.

• Many components of the product, including the printed circuit

board, operate with mains voltage. Do not touch. Use only electrically insulated tools.

• Do not touch unshielded components or terminals with voltage

present.

• The motor itself generates voltage when the motor shaft is rotated. Block the motor shaft to prevent rotation prior to performing

any type of work on the drive system.

• AC voltage can couple voltage to unused conductors in the motor

cable. Insulate both ends of unused conductors of the motor

cable.

• Do not short across the DC bus terminals or the DC bus capacitors.

• Before performing work on the drive system:

- Disconnect all power, including external control power that

may be present.

- Place a "Do Not Turn On" label on all power switches.

- Lock all power switches in the open position.

- Wait 15 minutes to allow the DC bus capacitors to discharge.

Measure the voltage on the DC bus as per chapter "DC bus

voltage measurement" and verify the voltage is <42 Vdc. The

DC bus LED is not an indicator of the absence of DC bus voltage.

• Install and close all covers before applying voltage.

Failure to follow these instructions will result in death or serious injury.

MNA01M001EN, V1.01, 08.2014

Common DC bus 7

Page 8

Safety Information

LXM32

WARNING

LOSS OF CONTROL

• The designer of any control scheme must consider the potential

failure modes of control paths and, for certain critical functions,

provide a means to achieve a safe state during and after a path

failure. Examples of critical control functions are emergency stop,

overtravel stop, power outage and restart.

• Separate or redundant control paths must be provided for critical

functions.

• System control paths may include communication links. Consideration must be given to the implication of unanticipated transmission delays or failures of the link.

• Observe all accident prevention regulations and local safety

guidelines.

• Each implementation of the product must be individually and thoroughly tested for proper operation before being placed into service.

Failure to follow these instructions can result in death, serious

injury, or equipment damage.

1)

1) For USA: Additional information, refer to NEMA ICS 1.1 (latest edition), “Safety

Guidelines for the Application, Installation, and Maintenance of Solid State Control”

and to NEMA ICS 7.1 (latest edition), “Safety Standards for Construction and Guide

for Selection, Installation and Operation of Adjustable-Speed Drive Systems”.

8 Common DC bus

MNA01M001EN, V1.01, 08.2014

Page 9

LXM32

Safety Information

DC bus voltage measurement

The DC bus voltage can exceed 800 Vdc. The DC bus LED is not an

indicator of the absence of DC bus voltage.

DANGER

ELECTRIC SHOCK, EXPLOSION OR ARC FLASH

• Disconnect the voltage supply to all connections.

• Wait 15 minutes to allow the DC bus capacitors to discharge.

• Use a properly rated voltage-sensing device for measuring

(>800 Vdc).

• Measure the DC bus voltage between the DC bus terminals (PA/+

and PC/-) to verify that the voltage is less than 42 Vdc.

• Contact your local Schneider Electric representative if the DC bus

capacitors do not discharge to less than 42 Vdc within a period of

15 minutes.

• Do not operate the product if the DC bus capacitors do not discharge properly.

• Do not attempt to repair the product if the DC bus capacitors do

not discharge properly.

Failure to follow these instructions will result in death or serious injury.

Standards and terminology

Technical terms, terminology and the corresponding descriptions in

this manual are intended to use the terms or definitions of the pertinent standards.

In the area of drive systems, this includes, but is not limited to, terms

such as "safety function", "safe state", "fault", "fault reset", "failure",

"error", "error message", "warning", etc.

Among others, these standards include:

• IEC 61800 series: "Adjustable speed electrical power drive systems"

• IEC 61158 series: "Digital data communications for measurement

and control – Fieldbus for use in industrial control systems"

• IEC 61784 series: "Industrial communication networks – Profiles"

• IEC 61508 series: "Functional safety of electrical/electronic/

programmable electronic safety-related systems"

Also see the glossary at the end of this manual.

MNA01M001EN, V1.01, 08.2014

Common DC bus 9

Page 10

Safety Information

LXM32

10 Common DC bus

MNA01M001EN, V1.01, 08.2014

Page 11

LXM32

About the book

Source manuals The latest versions of the manuals can be downloaded from the Inter-

Work steps If work steps must be performed consecutively, this sequence of steps

About the book

This document describes how several Schneider Electric drives type

LXM32 can share a common DC bus.

This application note replaces application note MNA01D001.

The information provided in this document supplements the manuals.

Before beginning, fully read and understand the manuals of the products used.

net at:

http://www.schneider-electric.com

is represented as follows:

■

Special prerequisites for the following work steps

▶

Step 1

◁

Specific response to this work step

▶

Step 2

If a response to a work step is indicated, this allows you to verify that

the work step has been performed correctly.

Unless otherwise stated, the individual steps must be performed in the

specified sequence.

Making work easier Information on making work easier is highlighted by this symbol:

Sections highlighted this way provide supplementary information on

making work easier.

SI units Technical data are specified in SI units. Converted units are shown in

parentheses behind the SI unit; they may be rounded.

Example:

Minimum conductor cross section: 1.5 mm2 (AWG 14)

Glossary Explanations of special technical terms and abbreviations.

Index List of keywords with references to the corresponding page numbers.

MNA01M001EN, V1.01, 08.2014

Common DC bus 11

Page 12

About the book

LXM32

12 Common DC bus

MNA01M001EN, V1.01, 08.2014

Page 13

LXM32

1 Introduction

Use of electrical energy If an application operates with multiple drive systems, it may be useful

Common DC bus Whether or not a common DC bus makes sense depends on the

1 Introduction

A drive system requires energy for acceleration or constant movement

that must be supplied to the system.

During deceleration, a motor acts as a generator. A considerable portion of the kinetic energy is re-generated as electrical energy.

Since electrical energy can only be stored to a limited extent in a single drive, a drive uses a braking resistor to transform the excess

energy into thermal energy.

to employ a common DC bus. By sharing a common DC bus, the

energy regenerated by one drive can be supplied to another drive.

acceleration and deceleration cycles of the drive systems.

A common DC bus is useful, for example, if one drive systems accelerates while another drive system decelerates.

If the drive systems accelerate and decelerate at the same time, a

common DC bus does not make sense.

MNA01M001EN, V1.01, 08.2014

Common DC bus 13

Page 14

1 Introduction

1.1 Permissible device types for common DC bus

The DC bus of drives with identical numbers of mains phases can be

connected.

Single-phase drives:

• LXM32∙∙∙∙M2 with LXM32∙∙∙∙M2

Three-phase drives:

• LXM32∙∙∙∙N4 with LXM32∙∙∙∙N4

LXM32

14

MNA01M001EN, V1.01, 08.2014

Common DC bus

Page 15

LXM32

2 Technical Data

2.1 Firmware version

2 Technical Data

A common DC bus requires the devices to have at least the specified

firmware versions:

Drive Firmware version

LXM32C, LXM32A V01.04.00

LXM32M V01.02.00

MNA01M001EN, V1.01, 08.2014

Common DC bus

15

Page 16

2 Technical Data

LXM32

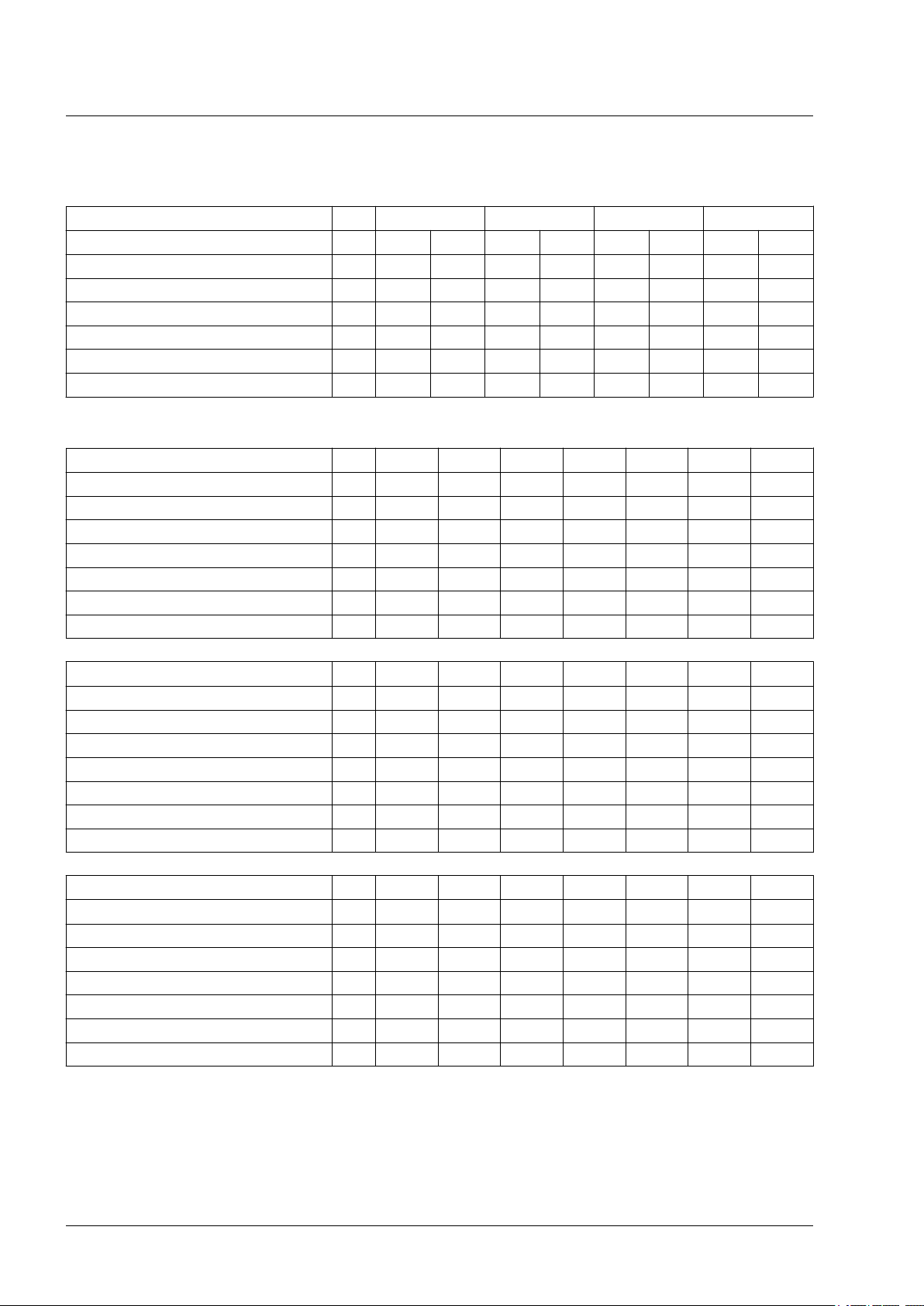

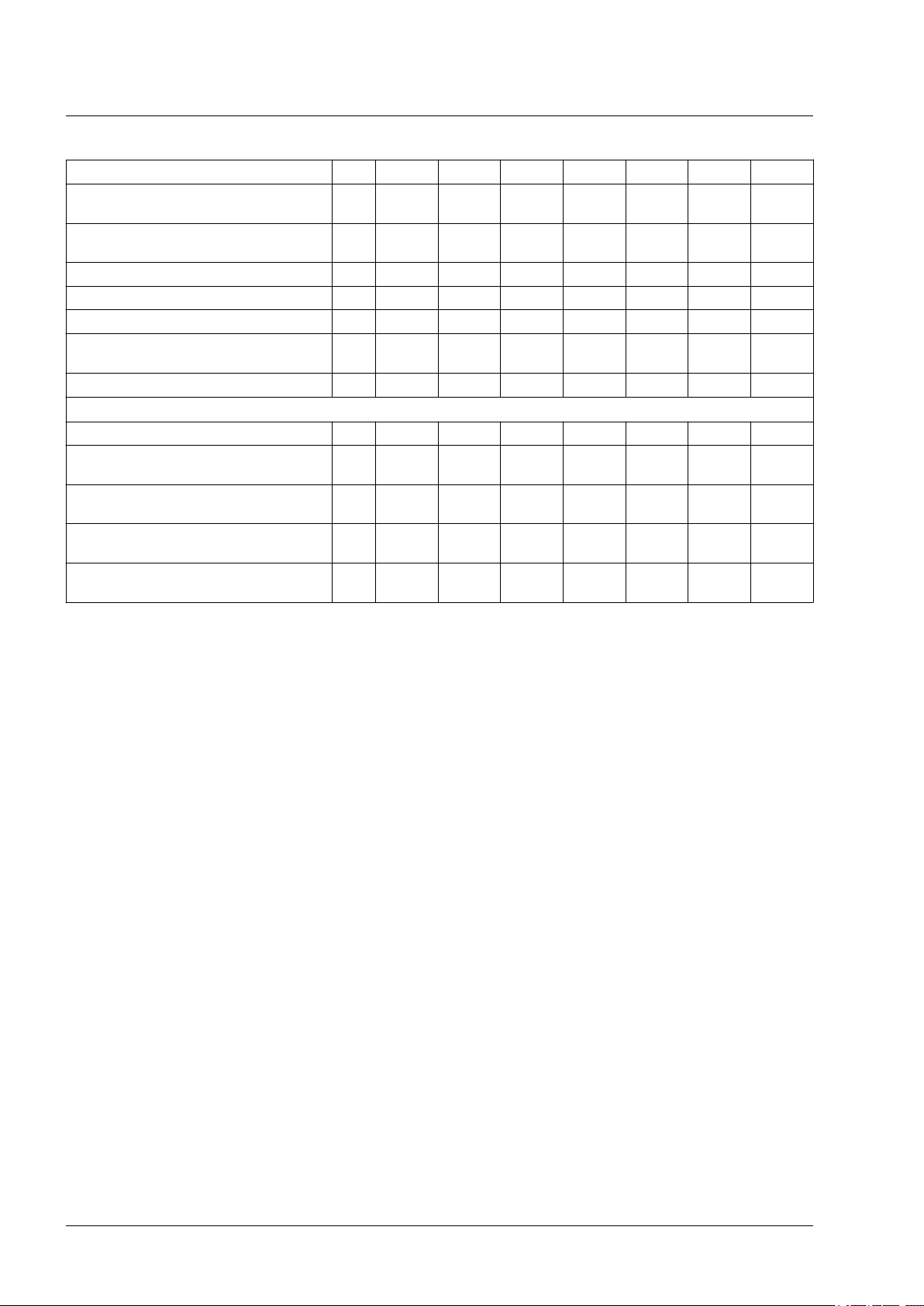

2.2 DC bus data

Single-phase drives

LXM32∙... U45M2 U90M2 D18M2 D30M2

Nominal voltage (1 ∼) V 115 230 115 230 115 230 115 230

Nominal voltage DC bus V 163 325 163 325 163 325 163 325

Undervoltage limit V 55 130 55 130 55 130 55 130

Voltage limit: activation of Quick Stop V 60 140 60 140 60 140 60 140

Overvoltage limit V 450 450 450 450 450 450 450 450

Maximum continuous power via DC bus kW 0.2 0.5 0.4 0.9 0.8 1.6 0.8 2.2

Maximum continuous current via DC bus A 1.5 1.5 3.2 3.2 6.0 6.0 10.0 10.0

Three-phase drives

LXM32∙... U60N4 D12N4 D18N4 D30N4 D72N4 D85N4 C10N4

Nominal voltage (3 ∼) V 208 208 208 208 208 208 208

Nominal voltage DC bus V 294 294 294 294 294 294 294

Undervoltage limit V 150 150 150 150 150 150 150

Voltage limit: activation of Quick Stop V 160 160 160 160 160 160 160

Overvoltage limit V 820 820 820 820 820 820 820

Maximum continuous power via DC bus kW 0.4 0.8 1.7 2.8 6.5 7.0 11.0

Maximum continuous current via DC bus A 1.5 3.2 6.0 10.0 22.0 28.0 40.0

LXM32∙... U60N4 D12N4 D18N4 D30N4 D72N4 D85N4 C10N4

Nominal voltage (3 ∼) V 400 400 400 400 400 400 400

Nominal voltage DC bus V 566 566 566 566 566 566 566

Undervoltage limit V 350 350 350 350 350 350 350

Voltage limit: activation of Quick Stop V 360 360 360 360 360 360 360

Overvoltage limit V 820 820 820 820 820 820 820

Maximum continuous power via DC bus kW 0.8 1.6 3.3 5.6 13.0 15.0 22.0

Maximum continuous current via DC bus A 1.5 3.2 6.0 10.0 22.0 28.0 40.0

LXM32∙... U60N4 D12N4 D18N4 D30N4 D72N4 D85N4 C10N4

Nominal voltage (3 ∼) V 480 480 480 480 480 480 480

Nominal voltage DC bus V 679 679 679 679 679 679 679

Undervoltage limit V 350 350 350 350 350 350 350

Voltage limit: activation of Quick Stop V 360 360 360 360 360 360 360

Overvoltage limit V 820 820 820 820 820 820 820

Maximum continuous power via DC bus kW 0.8 1.6 3.3 5.6 13.0 15.0 22.0

Maximum continuous current via DC bus A 1.5 3.2 6.0 10.0 22.0 28.0 40.0

16

MNA01M001EN, V1.01, 08.2014

Common DC bus

Page 17

LXM32

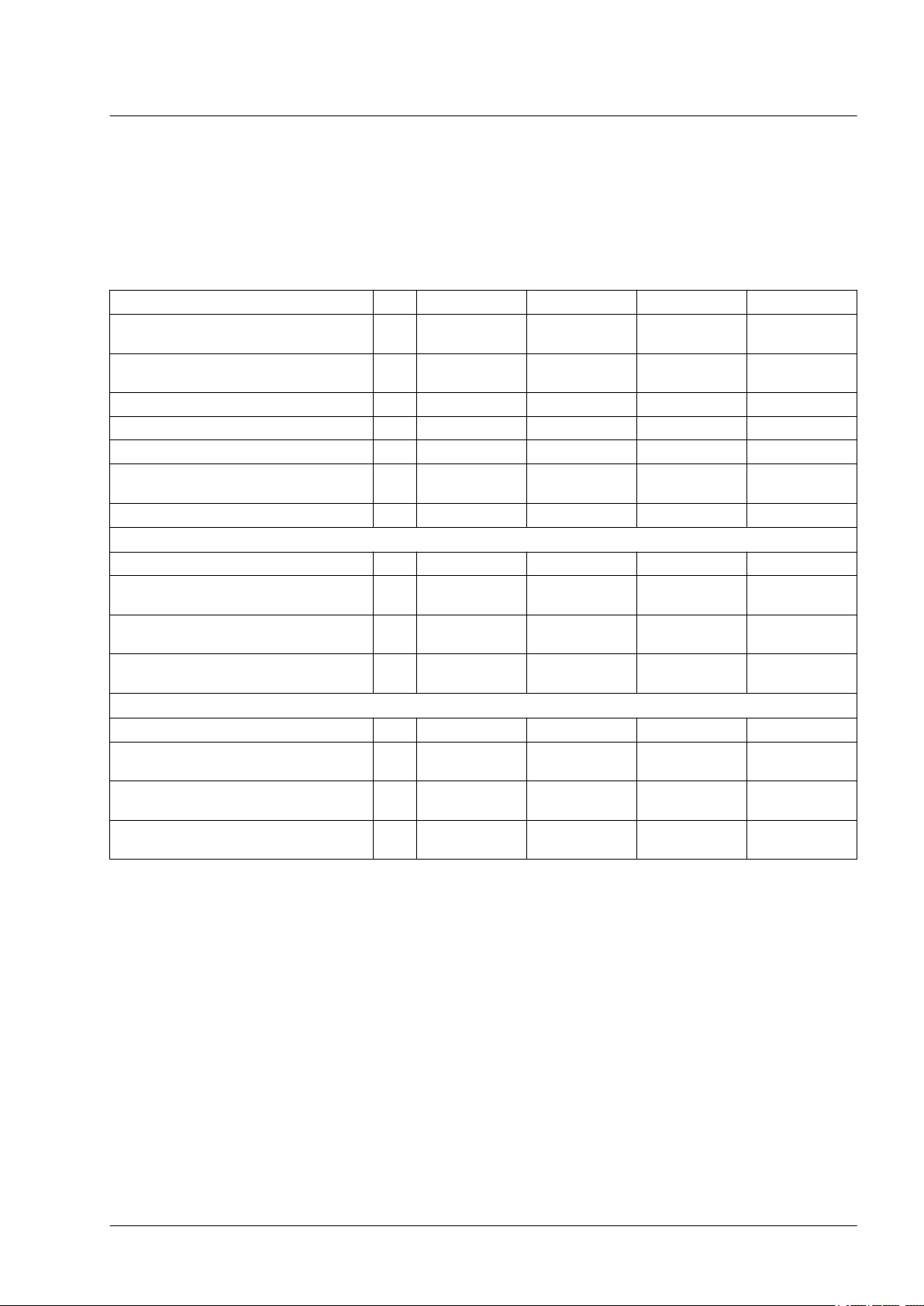

2 Technical Data

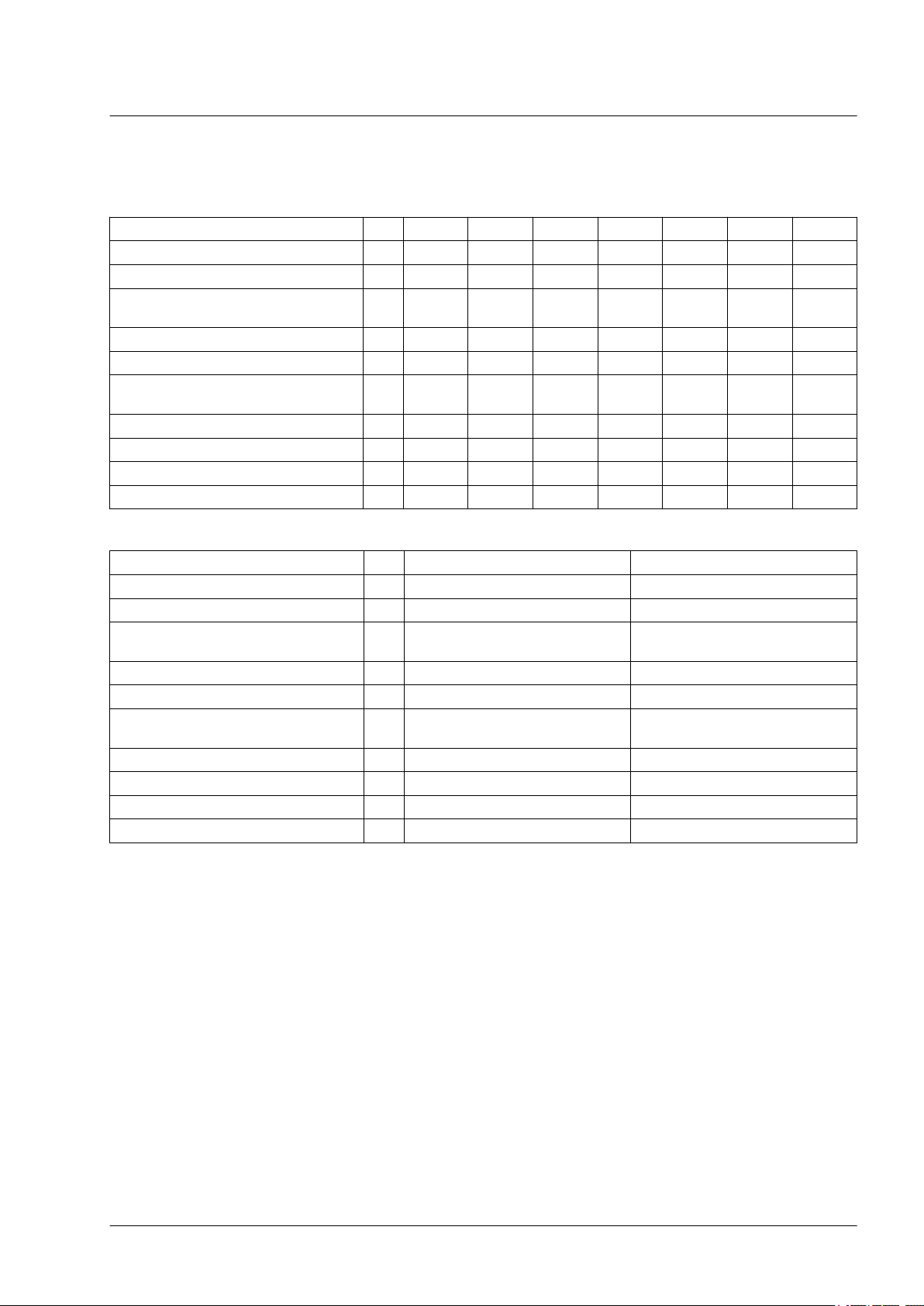

2.3 Braking resistor

LXM32 drives have an internal braking resistor and a connection for

an external braking resistor. If the internal braking resistor is insufficient for the dynamics of the application, one or more external braking

resistors must be connected.

Single-phase drives

LXM32∙... U45M2 U90M2 D18M2 D30M2

Resistance value of internal braking

resistor

Continuous power internal braking resistor P

PR

Peak energy E

CR

External braking resistor minimum

External braking resistor maximum

1)

Maximum continuous power external

braking resistor

Capacitance of internal capacitor μF 390 780 1170 1560

Parameter DCbus_compat = 0 (default value)

Switch-on voltage braking resistor V 430 430 430 430

Energy absorption of internal capacitors

E

at nominal voltage 115 V +10%

var

Energy absorption of internal capacitors

E

at nominal voltage 200 V +10%

var

Energy absorption of internal capacitors

E

at nominal voltage 230 V +10%

var

Parameter DCbus_compat = 1 (reduced switch-on voltage)

Switch-on voltage braking resistor V 395 395 395 395

Energy absorption of internal capacitors

E

at nominal voltage 115 V +10%

var

Energy absorption of internal capacitors

E

at nominal voltage 200 V +10%

var

Energy absorption of internal capacitors

E

at nominal voltage 230 V +10%

var

1) The maximum specified braking resistor can derate the peak power of the device. Depending on the application, it is possible to use

a higher ohm resistor.

Ω

94 47 20 10

W 10 20 40 60

Ws 82 166 330 550

Ω

68 36 20 10

Ω

110 55 27 16

W 200 400 600 800

Ws 30 60 89 119

Ws 17 34 52 69

Ws 11 22 33 44

Ws 24 48 73 97

Ws 12 23 35 46

Ws 5 11 16 22

MNA01M001EN, V1.01, 08.2014

Common DC bus

17

Page 18

2 Technical Data

LXM32

Three-phase drives

LXM32∙... U60N4 D12N4 D18N4 D30N4 D72N4 D85N4 C10N4

Resistance value of internal braking resistor

Continuous power internal braking resistor P

PR

Peak energy E

CR

External braking resistor minimum

External braking resistor maximum

1)

Maximum continuous power external

braking resistor

Capacitance of internal capacitor μF 110 195 390 560 1120 1230 1230

Parameter DCbus_compat

2)

Switch-on voltage V 780 780 780 780 780 780 780

Energy absorption of internal capacitors

E

at nominal voltage 208 V +10%

var

Energy absorption of internal capacitors

E

at nominal voltage 380 V +10%

var

Energy absorption of internal capacitors

E

at nominal voltage 400 V +10%

var

Energy absorption of internal capacitors

E

at nominal voltage 480 V +10%

var

1) The maximum specified braking resistor can derate the peak power of the device. Depending on the application, it is possible to use

a higher ohm resistor.

2) Parameter DCbus_compat has no effect in the case of three-phase devices

Ω

132 60 30 30 10 10 10

W 20 40 60 100 150 150 150

Ws 200 400 600 1000 2400 2400 2400

Ω

70 47 25 15 8 8 8

Ω

145 73 50 30 12 11 11

W 200 500 800 1500 3000 4500 5500

Ws 28 49 98 141 282 310 310

Ws 14 25 50 73 145 159 159

Ws 12 22 43 62 124 136 136

Ws 3 5 10 14 28 31 31

18

MNA01M001EN, V1.01, 08.2014

Common DC bus

Page 19

LXM32

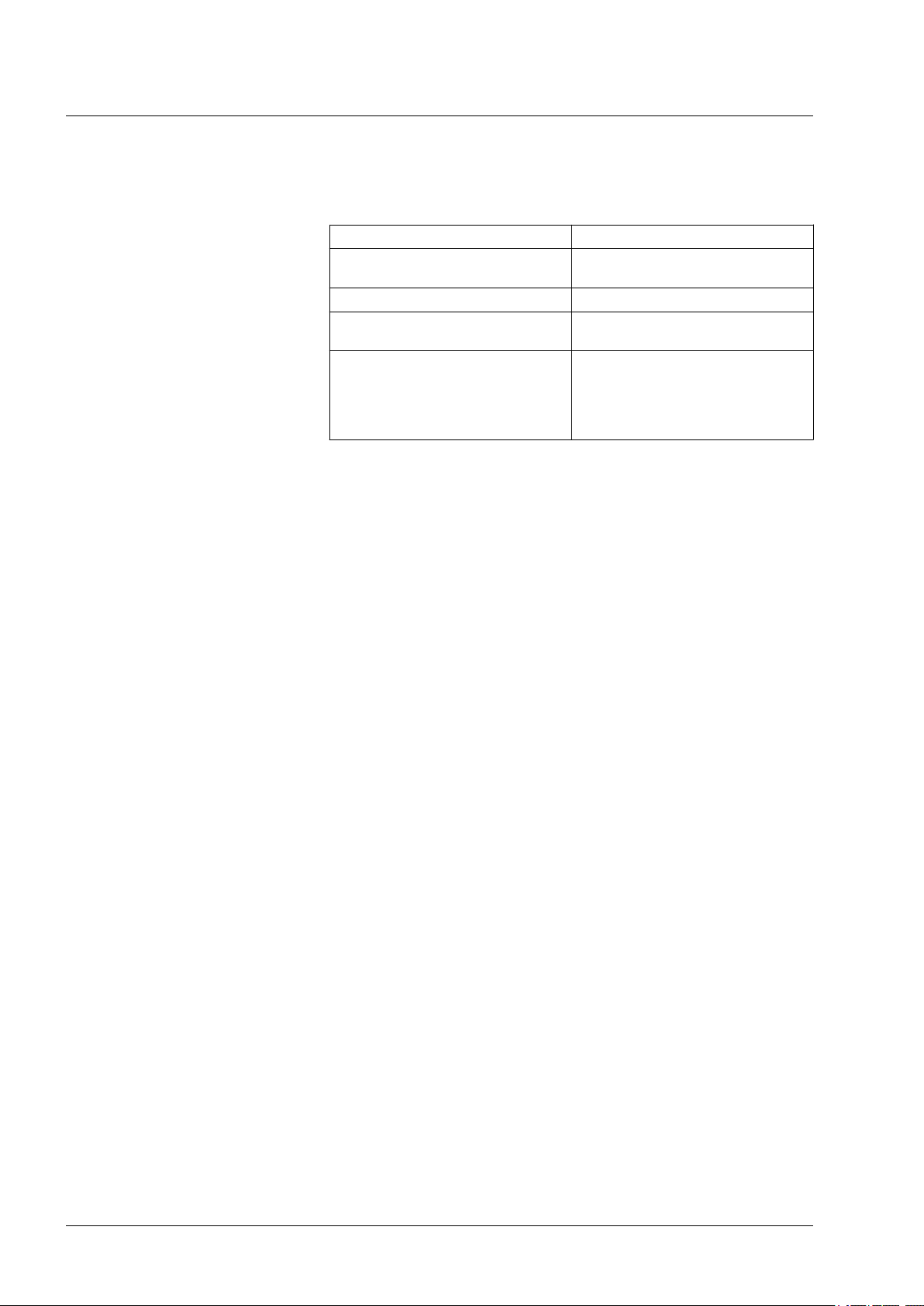

2.3.1 External braking resistors (accessories)

The resistance values for external braking resistors must not be below

the minimum resistance specified for the drives.

2 Technical Data

VW3A760... 1Rxx

Resistance

Continuous power W 400 100 200 400 100 200 400

Maximum time in braking at 115 V /

230 V

Peak power at 115 V / 230 V kW 18.5 6.8 6.8 6.8 2.6 2.6 2.6

Maximum peak energy at 115 V / 230 V Ws 13300 3800 7400 18100 3700 9600 24700

Maximum time in braking at 400 V /

480 V

Peak power at 400 V / 480 V kW 60.8 22.5 22.5 22.5 8.5 8.5 8.5

Maximum peak energy at 400 V / 480 V Ws 7300 1900 4900 11400 2500 6600 16200

Degree of protection IP65 IP65 IP65 IP65 IP65 IP65 IP65

UL approval (file no.) - E233422 E233422 - E233422 E233422 -

1) Resistors with a continuous power of 400 W are not UL/CSA-approved.

VW3A77... 04 05

Resistance

Continuous power W 1000 1000

Maximum time in braking at 115 V /

230 V

Peak power at 115 V / 230 V kW 12.3 18.5

Maximum peak energy at 115 V / 230 V Ws 43100 36500

Maximum time in braking at 400 V /

480 V

Peak power at 400 V / 480 V kW 40.6 60.8

Maximum peak energy at 400 V / 480 V Ws 26500 22500

Degree of protection IP20 IP20

UL approval (file no.) E221095 E221095

Ω

s 0.72 0.552 1.08 2.64 1.44 3.72 9.6

s 0.12 0.084 0.216 0.504 0.3 0.78 1.92

Ω

s 3.5 1.98

s 0.65 0.37

1)

2Rxx 3Rxx 4Rxx

10 27 27 27 72 72 72

15 10

1)

5Rxx 6Rxx 7Rxx

1)

MNA01M001EN, V1.01, 08.2014

Common DC bus

19

Page 20

2 Technical Data

2.4 Cables for the DC bus

Minimum requirement A cable for the common DC bus must meet the following require-

ments.

Shield: Shielded at cable lengths of > 0.2 m

Twisted Pair: Twisted pair at cable lengths of >

Cable: Two wires, shielded

Maximum cable length between 2

drives:

Special characteristics: • Insulation must be rated for the

The connection of the fuses for the DC bus must be rated for the total

maximum continuous current on the DC bus of all drives connected

via the DC bus. Analyze the most critical case in your application (for

example EMERGENCY STOP) and select an appropriate conductor

cross section.

LXM32

0.2 m

3 m

DC bus voltage

• Conductor cross section according to the calculated current, but

at least 2* 6 mm2 (2* AWG 10)

20

MNA01M001EN, V1.01, 08.2014

Common DC bus

Page 21

LXM32

3 Engineering

3 Engineering

This chapter provides engineering information for a common DC bus

for several drives.

Incorrect use of the DC bus may permanently damage the drives

either immediately or over time.

WARNING

DESTRUCTION OF SYSTEM COMPONENTS AND LOSS OF CONTROL

Verify that all requirements for using the DC bus are met.

Failure to follow these instructions can result in death, serious

injury, or equipment damage.

WARNING

DESTRUCTION OF SYSTEM COMPONENTS

• Connect only drives with identical nominal voltages.

• Connect single-phase drives only to single-phase drives. Connect

single-phase drives to the same phase.

• Connect three-phase drives only to three-phase drives.

Failure to follow these instructions can result in death, serious

injury, or equipment damage.

LXM32: See the Engineering chapter in the LXM32 product manual

for vital engineering information concerning the LXM32 drive.

MNA01M001EN, V1.01, 08.2014

Common DC bus

21

Page 22

3 Engineering

3.1 Energy balance

3.1.1 Energy balance basics

LXM32

To be able to estimate the effect of an interconnection of drives via a

common DC bus, create an energy balance of the individual drives

over a movement cycle. A movement cycle typically consists of the following phases: acceleration, continuous movement and deceleration.

The energy generated during deceleration can be used by other

drives connected via a common DC bus. Excess energy can be

absorbed by the braking resistors.

The assessment of the energy balances of the individual drives per

movement cycle and of the cyclic sequence of the movement cycles

allows you to draw a conclusion regarding the efficiency of a common

DC bus.

The energy balance is influenced by the following factors:

Energy absorption of the capaci-

tors E

var

Electrical losses EelThe electrical losses Eel of the drive system can be estimated on the

Mechanical losses E

mech

• Energy absorption of capacitors E

• Electrical losses of the drive system E

• Mechanical losses of the facility and the drive system E

• Braking resistor E

B

in the drive

var

el

mech

The higher the mains voltage, the lower the energy absorption of the

capacitors E

. In your calculation, use the values for the highest

var

mains voltage that is used in your application, see chapter

"2.3 Braking resistor".

The energy absorption of the capacitors E

is the square difference

var

between the voltage prior to the start of the deceleration and the

switch-on voltage of the braking resistor.

basis of the peak power of the drive. The maximum power dissipation

is approximately 10% of the peak power at a typical efficiency of 90%.

If the current during deceleration is lower, the power dissipation is

reduced accordingly.

The mechanical losses result from friction during operation of the system. Mechanical losses are negligible if the time required by the system to coast to a stop without a driving force is considerably longer

than the time required to decelerate the system. The mechanical losses can be calculated from the load torque and the velocity from

which the motor is to stop.

22

Braking resistor EBTwo characteristic values determine the energy absorption of a brak-

ing resistor:

• The continuous power PPR is the amount of energy that can be

continuously absorbed without overloading the braking resistor.

• The maximum energy ECR limits the maximum short-term power

that can be absorbed.

MNA01M001EN, V1.01, 08.2014

Common DC bus

Page 23

v

I

t

t

D

i

2π

n

i

2

60

ω

i

2

= Ei =J

t

1

2

J

t

1

2

LXM32

3 Engineering

Rating

Figure 1: Movement cycle: Profile for energy assessment

This profile with velocity (v) and motor current (I) is also used for rating

the motor and the braking resistor. The deceleration segment to be

considered is labeled Di.

Calculation of the energy at constant deceleration:

The total inertia (Jt) must be known.

Jt with:

Jt = Jm + J

c

Jm: Motor inertia with or without holding brake

Jc: Load inertia

The energy for each deceleration segment is calculated as follows:

Units: Ei in Ws (wattseconds), Jt in kgm2, ω in rad and ni in min-1.

See the technical data for the energy absorption E

(without consideration of an internal or external braking resistor).

In the next calculation steps, only consider those segments Di, whose

energy Ei exceeds the energy absorption of the device (see chapter

of the devices

var

"2.2 DC bus data"). These excess energies EDi must be diverted by

means of the braking resistor (internal or external).

MNA01M001EN, V1.01, 08.2014

Common DC bus

EDi is calculated using the following formula:

EDi = Ei - E

(in Ws)

var

The continuous power Pc is calculated for each machine cycle:

23

Page 24

Pc =

Σ

E

Di

Cycletime

3 Engineering

Units: Pc in W, EDi in Ws and cycle time T in s

These calculations allow you to select the required braking resistor.

3.2 Electromagnetic compatibility (EMC)

If drives are to be operated via a common DC bus, the following

aspects must be considered in terms of EMC:

• Keep DC bus cables as short as possible.

• Shielded DC bus cables must be used at a cable length of > 0.2 m.

In the case of shielded DC bus cables, connect the cable shield to

the shield connection (large surface area contact).

3.3 DC bus connection

LXM32

The DC bus is connected by means of a plug and socket connection

or screw terminals.

See the manual of the respective product for tightening torque of the

screw terminals.

Cable specifications See chapter "2.4 Cables for the DC bus", page 20 for the cable speci-

fications. Connector kits and pre-assembled cables can be found in

chapter "6 Accessories and spare parts", page 55.

24

MNA01M001EN, V1.01, 08.2014

Common DC bus

Page 25

PC/- PA/+ PC/- PA/+ PC/- PA/+

DC+

DC

-

N/L2

L1

N/L2 L1 N/L2 L1 N/L2 L1

LXM32

3.4 Fuses

The number of mains fuses depends on the input current of all drives

connected via the common DC bus.

Choose fuse ratings as low as possible according to the power of the

drive as well as the conductor cross section.

See manual of the respective product for more information.

The maximum permissible fuse ratings must not be exceeded.

3.4.1 DC bus connection of single-phase drives

Single mains fuse A single mains fuse is sufficient if the total input current of all drives

connected via the common DC bus is less than the maximum fuse rating shown in the table below.

Single mains fuse Maximum fuse rating

LXM32∙∙∙∙M2 A 25

3 Engineering

MNA01M001EN, V1.01, 08.2014

Common DC bus

Figure 2: Single mains fuse for single-phase drives

25

Page 26

N/L2 L1

N/L2

L1

N/L2 L1N/L2 L1

PC/- PA/+ PC/- PA/+ PC/- PA/+

DC+

DC

-

3 Engineering

Multiple mains fuses Multiple mains fuses are required if the total input current of all drives

LXM32

connected via the common DC bus exceeds the maximum fuse rating

shown in the table below.

Multiple mains fuses Maximum fuse rating

LXM32∙∙∙∙M2 A 25

If multiple mains fuses are required, additional DC bus fuses must be

used upstream of each drive. The DC bus fuses must be suitable for

600 Vdc.

DC bus fuses Maximum fuse rating

LXM32∙∙∙∙M2 A 25

26

Figure 3: Multiple mains fuses for single-phase drives

See chapter "6.2 DC fuses" for fuses for the DC bus.

The use of mains reactors can reduce the input current. Due to the

lower input current, it may be possible to operate the drives with just a

single mains fuse.

MNA01M001EN, V1.01, 08.2014

Common DC bus

Page 27

PC/- PA/+ PC/- PA/+ PC/- PA/+

DC+

DC

-

L3

L2

L1

L2 L1L3 L2 L1L3L2 L1L3

LXM32

3.4.2 DC bus connection of three-phase drives

Single mains fuse A single fuse is sufficient if the total input current of all drives connec-

ted via the common DC bus is less than the maximum fuse rating

shown in the table below.

Single mains fuse Maximum fuse rating

LXM32∙U60N4, LXM32∙D12N4,

LXM32∙D18N4, LXM32∙D30N4,

LXM32∙D72N4

LXM32∙D85N4, LXM32∙C10N4 A 63

3 Engineering

A 32

MNA01M001EN, V1.01, 08.2014

Common DC bus

Figure 4: Single mains fuse for three-phase drives

27

Page 28

PC/- PA/+ PC/- PA/+ PC/- PA/+

L3

L2

L1

L2 L1L3 L2 L1L3L2 L1L3

DC+

DC

-

3 Engineering

Multiple mains fuses Multiple mains fuses are required A single fuse is sufficient if the total

LXM32

input current of all drives connected via the common DC bus is less

than the maximum fuse rating shown in the table below.

Multiple mains fuses Maximum fuse rating

LXM32∙U60N4, LXM32∙D12N4,

LXM32∙D18N4, LXM32∙D30N4,

LXM32∙D72N4

LXM32∙D85N4, LXM32∙C10N4 A 63

If multiple mains fuses are required, additional DC bus fuses must be

used upstream of each drive. The DC bus fuses must be suitable for

600 Vdc.

DC bus fuses Maximum fuse rating

LXM32∙U60N4, LXM32∙D12N4,

LXM32∙D18N4, LXM32∙D30N4,

LXM32∙D72N4

LXM32∙D85N4, LXM32∙C10N4 A 63

A 32

A 32

28

Figure 5: Multiple mains fuses for three-phase drives

See chapter "6.2 DC fuses" for fuses for the DC bus.

The use of mains reactors can reduce the input current. Due to the

lower input current, it may be possible to operate the drives with just a

single mains fuse.

MNA01M001EN, V1.01, 08.2014

Common DC bus

Page 29

LXM32

3.4.3 Supply via the DC bus

3 Engineering

A single or multiple drives can be supplied directly via the DC bus.

The supply is provided by a correspondingly sized drive or by a DC

power supply unit.

In the case of supply via the DC bus, DC bus fuses must be used. The

DC bus fuses must be suitable for 600 Vdc.

The number of DC bus fuses depends on the total maximum continuous current on the DC bus of all drives connected via the common DC

bus.

Single-phase drives

Three-phase drives

DC bus fuses Maximum fuse rating

LXM32∙∙∙∙M2 A 25

DC bus fuses Maximum fuse rating

LXM32∙U60N4, LXM32∙D12N4,

LXM32∙D18N4, LXM32∙D30N4,

LXM32∙D72N4

LXM32∙D85N4, LXM32∙C10N4 A 63

A 32

MNA01M001EN, V1.01, 08.2014

Common DC bus

29

Page 30

L3

L2

L1

L2 L1L3

PC/- PA/+ PC/- PA/+ PC/- PA/+

PC/- PA/+

L2 L1L3 L2 L1L3 L2 L1L3

L2 L1L3 L2 L1L3 L2 L1L3

~

+-

PC/- PA/+ PC/- PA/+ PC/- PA/+

L3

L2

L1

3 Engineering

Single DC bus fuse If the total maximum continuous current on the DC bus of all drives

LXM32

connected via the common DC bus does not exceed the maximum

fuse rating of a drive, a single DC bus fuse is sufficient.

Figure 6: Supply via the DC bus by a drive

Figure 7: Supply via the DC bus by a DC power supply unit

30

MNA01M001EN, V1.01, 08.2014

Common DC bus

Page 31

L2 L1L3 L2 L1L3 L2 L1L3

L3

L2

L1

L2 L1L3

PC/- PA/+ PC/- PA/+ PC/- PA/+

PC/- PA/+

L2 L1L3 L2 L1L3 L2 L1L3

~

+-

PC/- PA/+ PC/- PA/+ PC/- PA/+

L3

L2

L1

LXM32

3 Engineering

Multiple DC bus fuses If the total maximum continuous current on the DC bus of all drives

connected via the common DC bus exceeds the maximum fuse rating

of a drive, DC bus fuses are required at each drive.

Figure 8: Supply via the DC bus by a drive

Figure 9: Supply via the DC bus by a DC power supply unit

MNA01M001EN, V1.01, 08.2014

Common DC bus

31

Page 32

3 Engineering

3.5 Braking resistors

Excess energy in the common DC bus must be absorbed by the braking resistors. Depending on the application, one or more braking resistors can be connected. Consider the internal braking resistors of

LXM32 drives in your calculations.

If drives with a different nominal power are connected via the DC bus,

you must connect braking resistors to the drive with the highest nominal power. See the manual of the respective product for more information.

3.5.1 Rating the braking resistor

An insufficiently rated braking resistor can cause overvoltage on the

DC bus. Overvoltage on the DC bus causes the power stage to be

disabled. The motor is no longer actively decelerated.

MOTOR WITHOUT BRAKING EFFECT

• Verify that the braking resistor has a sufficient rating.

• Verify that the parameter settings for the braking resistor are correct.

• Verify that the I2t value for temperature monitoring does not

exceed 100% by performing a test run under maximum load conditions.

• Verify that the calculations and the test run take into account the

fact that the DC bus capacitors can absorb less braking energy at

higher mains voltages.

LXM32

WARNING

Failure to follow these instructions can result in death, serious

injury, or equipment damage.

The temperature of the braking resistor may exceed 250 °C (482 °F)

during operation.

WARNING

HOT SURFACES

• Ensure that any contact with a hot braking resistor is avoided.

• Do not allow flammable or heat-sensitive parts in the immediate

vicinity of the braking resistor.

• Verify that the heat dissipation is sufficient by performing a test

run under maximum load conditions.

Failure to follow these instructions can result in death, serious

injury, or equipment damage.

Braking resistors are required for dynamic applications. During deceleration, the kinetic energy is transformed into electrical energy in the

motor. The electrical energy increases the DC bus voltage. The braking resistor is activated when the defined threshold value is exceeded.

The braking resistor transforms electrical energy into heat. If highly

dynamic deceleration is required, the braking resistor must be well

adapted to the system.

32

MNA01M001EN, V1.01, 08.2014

Common DC bus

Page 33

R =

P

max

U

2

LXM32

3 Engineering

Further information on the subject Page

Technical data chapter "2.3 Braking resistor" 17

Commissioning chapter

"5.2 LXM32: Setting the braking resistor parameters"

See also chapter "3.1 Energy balance", page 22 for rating information.

Internal braking resistor A braking resistor to absorb braking energy is integrated in LXM32

drives. The device is shipped with the internal braking resistor active.

If the braking energy of all drives sharing a common DC bus is greater

than the energy the internal braking resistors can absorb, you must

use an external braking resistor. Consider the most extreme case of

your application in calculating the braking energy.

Example: In the case of an EMERGENCY STOP, all drives decelerate

simultaneously; the braking resistors must be able to absorb the entire

braking energy.

External braking resistor An external braking resistor is required in applications in which the

braking energy is greater than the energy that can be absorbed by the

drives sharing a common DC bus. Consider the most extreme case of

your application in calculating the braking energy.

Example: In the case of an EMERGENCY STOP, all drives decelerate

simultaneously; the braking resistors must be able to absorb the entire

braking energy.

54

LXM32: Monitoring LXM32 drives monitor the load on the connected braking resistor. The

Selection of the external braking

resistor

load on the braking resistor can be read out.

The connection of the external braking resistor is short-circuit protected. A ground fault of the braking resistor is not detected.

The rating of an external braking resistor depends on the required

peak power and continuous power with which the braking resistor can

be operated.

The resistance R is derived from the required peak power and the DC

bus voltage.

R = Resistance value in Ω

U = Switch-on voltage braking resistor in V

P

= Required peak power in W

max

If 2 or more braking resistors are connected to one drive, note the following criteria:

• The braking resistors must be connected in parallel or in series so

the required resistance is reached. Only connect resistors with

identical resistance in parallel in order to evenly distribute the load

to all braking resistors.

• The total resistance of all external braking resistors connected to

one drive must not fall below a lower limit.

• The continuous power of the network of connected braking resistors must be calculated. The result must be greater than or equal

to the actually required continuous power.

MNA01M001EN, V1.01, 08.2014

Common DC bus

33

Page 34

3 Engineering

Use only resistors that are specified as braking resistors. See chapter

"2.3 Braking resistor", page 17 for suitable braking resistors.

Connection of braking resistor Braking resistors with degree of protection IP65 may be installed out-

side the control cabinet in an appropriate environment in order to

decrease the temperature in the control cabinet.

The external braking resistors listed in the Accessories chapter are

shipped with an information sheet that provides details on installation.

Further procedure:

• Connect the braking resistors to the drive.

• LXM32: Check the parameter RESint_ext during commissioning.

This parameter allows you to switch between internal and external

braking resistor.

• LXM32: If you have connected an external braking resistor to an

LXM32 drive, you must set the parameters for the external braking

resistor during commissioning.

• During commissioning, test the braking resistors under realistic

conditions, see page 54.

Wire ferrules: If you use wire ferrules, use only wire ferrules with collars for these terminals.

LXM32

3.5.2 Rating information

To rate the braking resistor, calculate the proportion contributing to

absorbing braking energy.

An external braking resistor is required if the kinetic energy that must

be absorbed exceeds the total of the internal proportions, including

the internal braking resistor.

The energy E

the deceleration process and the response threshold.

The voltage prior to the deceleration process depends on the mains

voltage. The energy absorption by the DC bus capacitors is lowest

when the mains voltage is highest. In the calculation, use the values

for the highest mains voltage.

Energy absorption braking resistor Two characteristic values determine the energy absorption of the

braking resistor:

• The continuous power PPR is the amount of energy that can be

continuously absorbed without overloading the braking resistor.

• The maximum energy ECR limits the maximum short-term power

that can be absorbed.

If the continuous power was exceeded for a specific time, the braking

resistor must remain without load for a corresponding period.

is the square difference between the voltage before

var

34

The characteristic values PPR and ECR of the internal braking resistor

can be found in chapter "2 Technical Data".

See page 22 for information on assessing the electrical and mechanical losses.

Example: LXM32 drive Deceleration of a rotary motor with the following data:

MNA01M001EN, V1.01, 08.2014

Common DC bus

Page 35

LXM32

3 Engineering

Selecting an external braking

resistor

• Initial speed of rotation: n = 4000 min

• Rotor inertia: JR = 4 kgcm

• Load inertia: JL = 6 kgcm

2

2

-1

Calculation of the energy to be absorbed:

EB = 1/2 * J * (2*π*n * 1/60)

2

to 88 Ws

Electrical and mechanical losses are ignored.

In this example, the DC bus capacitors absorb 23 Ws (the value

depends on the device type, see chapter "2 Technical Data").

The internal braking resistor must absorb the remaining 65 Ws. It can

absorb a pulse of 80 Ws. If the load is decelerated once, the internal

braking resistor is sufficient.

If the deceleration process is repeated cyclically, the continuous output must be considered. If the cycle time is longer than the ratio of the

energy to be absorbed EB and the continuous power PPR, the internal

braking resistor is sufficient. If the system decelerates more frequently,

the internal braking resistor is not sufficient.

In the example, the ratio EB/PPR is 1.3 s. If the cycle time is shorter, an

external braking resistor is required.

The selection is made in two steps:

• The maximum energy during deceleration must be less than the

peak energy that the internal braking resistor can absorb:

(EDi)<(ECr). In addition, the continuous power of the internal braking

resistor must not be exceeded: (PC)<(PPr). If these conditions are

met, then the internal braking resistor is sufficient.

• If one of the conditions is not met, you must use an external braking resistor. The braking resistor must be rated in such a way that

the conditions are met. The resistance of the braking resistor must

be between the specified minimum and maximum values, since

otherwise the load can no longer be decelerated or the product

might be destroyed.

MNA01M001EN, V1.01, 08.2014

Common DC bus

See chapter "2.3 Braking resistor", page 17 for technical data on the

external braking resistors.

35

Page 36

PC/- PA/+ PC/- PA/+

DC+

DC

-

L3

L2

L1

L2 L1L3 L2 L1L3

S2

S3

S1

E3

E2

E1

3 Engineering

3.6 Mains reactor

LXM32

A mains reactor is required if at least one of the following criteria is

met:

• The output power of the drive is to be increased.

• The short-circuit current rating (SCCR) of the supplying mains is

greater than specified for the drives.

• Current harmonics are to be reduced.

If one drive requires a mains reactor, then all drives connected via the

DC bus must be equipped with mains reactors.

The mains reactor for several drives with a common AC fuse must be

rated in such a way that the nominal current of the mains reactor is

greater than the total of the input current of the drives.

The fuse rating of the fuse upstream of the mains reactor must not be

greater than the nominal current of the mains reactor.

36

Figure 10: Wiring of drives with common AC fuse and a mains reactor, example shows three-phase drives.

MNA01M001EN, V1.01, 08.2014

Common DC bus

Page 37

N/L2

L1

S2

S1

E2

E1

PC/- PA/+

DC+

DC

-

N/L2 L1

S2

S1

E2

E1

PC/- PA/+

N/L2 L1

LXM32

3 Engineering

Figure 11: Wiring of drives with individual AC fuses and mains reactors, example shows singe-phase drives.

See the manual of the respective product for information on mains

reactors.

MNA01M001EN, V1.01, 08.2014

Common DC bus

37

Page 38

PC/- PA/+ PC/- PA/+

DC+

DC

-

L3

L2

L1

L2 L1L3 L2 L1L3

L3

L2

L1

L3'

L2'

L1'

3 Engineering

3.7 Mains filter

LXM32

The emission depends on the length of the motor cables. If the

required limit value is not reached with the internal mains filter, you

must use an external mains filter.

See manual of the respective product for information on mains filters.

The mains filter for several drives with a common AC fuse must be

rated in such a way that the nominal current of the external mains filter

is greater than the total of the input current of the drives.

The fuse rating of the fuse upstream of the external mains filter must

not be greater than the nominal current of the external mains filter.

Mount the external mains filter in such a way that the lines from the

mains filter to the drives are as short as possible. For EMC reasons,

route the cables from the mains filter to the drives separately from the

line to the mains filter.

External three-phase mains filters do not have a neutral conductor

connection; they are only approved for three-phase devices.

38

Figure 12: Wiring of an external mains filter, example shows three-phase

drives.

See the manual of the respective product for information on external

mains filters.

MNA01M001EN, V1.01, 08.2014

Common DC bus

Page 39

PC/- PA/+ PC/- PA/+ PC/- PA/+

DC+

DC

-

L3

L2

L1

L2 L1L3 L2 L1L3

S2

S3

S1

E3

E2

E1

L3

L2

L1

L3'

L2'

L1'

L2 L1L3

LXM32

3.8 Mains reactor and external mains filter

If a mains reactor and an external mains filter are required, the mains

reactor and external mains filter must be arranged according to the

following illustrations for EMC reasons.

3 Engineering

Figure 13: Wiring of drives with common mains fuse, mains reactor and mains filter, example shows three-phase drives.

MNA01M001EN, V1.01, 08.2014

Common DC bus

39

Page 40

3 Engineering

LXM32

40

MNA01M001EN, V1.01, 08.2014

Common DC bus

Page 41

LXM32

4 Installation

4 Installation

An engineering phase is mandatory prior to mechanical and electrical

installation. See chapter "3 EngineeringInstallation", page 21, for basic

information.

Incorrect use of the DC bus may permanently damage the drives

either immediately or over time.

WARNING

DESTRUCTION OF SYSTEM COMPONENTS AND LOSS OF CONTROL

Verify that all requirements for using the DC bus are met.

Failure to follow these instructions can result in death, serious

injury, or equipment damage.

WARNING

DESTRUCTION OF SYSTEM COMPONENTS

• Connect only drives with identical nominal voltages.

• Connect single-phase drives only to single-phase drives. Connect

single-phase drives to the same phase.

• Connect three-phase drives only to three-phase drives.

Failure to follow these instructions can result in death, serious

injury, or equipment damage.

NOTICE

DESTRUCTION DUE TO INCORRECT OPERATION

Verify that the power stage supplies of the drives connected via a

common DC bus are switched on simultaneously.

Failure to follow these instructions can result in equipment

damage.

MNA01M001EN, V1.01, 08.2014

Common DC bus

41

Page 42

L1

N/L2

L1

N/L2

M2

M2

L1

L3

L2

L1

L3

L2

N4

N4

L1

L3

L2

N

L1

L3

L2

N

M2

M2

L1

L3

L2

N

L1

L3

L2

N

N4

M2

4 Installation

LXM32

Figure 14: Specifications for drives with mains supply

4.1 Assembling cables

Pre-assembled cables are available for common DC bus. If the preassembled cables do not have the required length, use cables and

crimp contacts, see chapter "6.1 DC bus accessories", page 55.

Properties of the DC bus cable Note the DC bus cable properties, see chapter

Assembling DC bus cables The following instructions apply to drives with plug connections for the

"2.4 Cables for the DC bus" , page 20.

DC bus.

42

MNA01M001EN, V1.01, 08.2014

Common DC bus

Page 43

4

3

A

1

2

5

C

B

PC/-PA/+

PC/-

PA/+

LXM32

4 Installation

Part Length in mm (inches)

A Cable jacket 130 (5.2)

B Length of shield connection 60 (2.5)

C Stripping length 6 (0.25)

Diameter ring-type cable lug /

fork-type cable lug

For M5 screw

▶

(1) Strip the cable jacket, length A.

▶

(2) Slide back the shield braiding. Open the shield braiding and

twist it to form a shield connection wire.

▶

(3) Shorten the twisted shield connection wire to length B and insulate the shield braiding with heat shrink tube.

Crimp the crimp contacts to the two stripped conductors. The stripping length is C. See chapter "6.1 DC bus accessories", page 55

for information on the crimping tool.

▶

(4) Crimp a fork-type cable lug to the shield connection wire.

Push the crimp contacts into the connector housing. Polarity: the

red wire is PA/+, the black wire is PC/-.

▶

(5) Secure the shield with heat shrink tube.

MNA01M001EN, V1.01, 08.2014

Common DC bus

43

Page 44

3

A

B

1

2

C

4 Installation

LXM32

The following instructions apply to drives with screw terminals for the

DC bus.

LXM32∙... D85, C10

A mm (in) 220 (8.66)

B mm (in) 50 (1.97)

C mm (in) 18 (0.71)

(1) Strip the cable jacket, length A.

(2) Slide the shield braiding back over the cable jacket.

(3) Secure the shield braiding with a heat shrink tube. The

shield must have at least length D. Verify that a large surface

area of the shield braiding is connected to the EMC shield

clamp.

44

MNA01M001EN, V1.01, 08.2014

Common DC bus

Page 45

PA/+

PC/-

LXM32

4.2 Wiring the DC bus

The DC bus is connected by means of a plug and socket connection

or screw terminals.

Cable specifications See chapter "2.4 Cables for the DC bus", page 20 for the cable speci-

fications. Pre-assembled cables and connector kits can be found in

chapter "6 Accessories and spare parts", page 55.

4.2.1 Drives with connectors

Connector coding The connectors are coded. If you do not use pre-assembled cables,

verify that the crimp contacts properly snap into the connector. Verify

that PA/+ is connected to PA/+ and PC/- is connected to PC/-. Incorrect wiring will destroy the devices.

4 Installation

NOTICE

EQUIPMENT DAMAGE CAUSED BY INCORRECT POLARITY

Verify correct polarity during installation.

Failure to follow these instructions can result in equipment

damage.

Connector lock The connector has a snap lock mechanism. Pull the connector hous-

MNA01M001EN, V1.01, 08.2014

Common DC bus

Figure 15: Connector coding

ing to unlock the connector.

Both wires in the connector housing must be able to move independently for unlocking.

If you want to remove the DC bus connection cable, you must open

the connector lock by pulling at the housing.

The connection cable is easier to remove if you remove the motor

connector first.

45

Page 46

PC/-PA/+

PC/-PA/+

4 Installation

LXM32

Figure 16: Unlocking the DC bus connector, step 1: Push cables towards connector.

46

Figure 17: Unlocking the DC bus connector, step 2: Push cables towards connector, at the same time remove the connector with the other hand.

If the two wires cannot move freely, the DC bus connector will not

unlock.

▶

Push the two wires towards the connector (see Figure 16).

▶

While pushing the wires towards the connector, pull the connector

at the connector housing with the other hand.The connector is

unlocked and you can remove the DC bus connection cable (see ).

The connector is unlocked and you can remove the DC bus connection cable (see Figure 17).

Common DC bus

MNA01M001EN, V1.01, 08.2014

Page 47

BR+BR-

L3/TL2/SL1/R

CN9

U/T1 W/T3V/T2PA/+ PC/-PBU/T

1

W/T3

V/T2

PB

LXM32

4.2.2 Drives with terminals

4 Installation

This chapter describes LXM32 drives with screw terminals.

Properties of the connection termi-

nals CN9

Wiring diagram

LXM32∙... D85, C10

Connection cross section mm2

(AWG)

Tightening torque for terminal

screws

Stripping length mm

Nm

(lb.in)

(in)

6 ... 25

(10 ... 4)

3.8

(33.6)

18

(0.71)

The terminals are approved for fine wire conductors and rigid conductors. Observe the maximum permissible connection cross section.

Take into account the fact that wire ferrules increase the conductor

cross section.

Figure 18: Wiring diagram DC bus

Connecting the DC bus

▶

Switch off all supply voltages. Observe the safety instructions concerning electrical installation.

▶

Connect the DC bus to the device. Connect PA/+ to PA/+ (red) and

PC/- to PC/- (black). Note the tightening torque specified for the

terminal screws.

▶

Connect the cable shield with a shield clamp to an EMC rail (large

surface area contact).

Verify that the individual wires are in the individual guides.

▶

Mount the cable guide.

MNA01M001EN, V1.01, 08.2014

Common DC bus

47

Page 48

CN9 DC Bus

PC/- PA/+

ESC

W

V

U

ESC

CN9 DC Bus

PC/- PA/+

W

V

U

4 Installation

4.2.3 Connecting the DC bus

LXM32

Figure 19: DC bus connection, example with connector

▶

Verify that the requirements concerning the DC bus are met, see

chapter "3 EngineeringInstallation".

▶

Use pre-assembled cables whenever possible (page 55) to reduce

the risk of wiring errors.

▶

Only connect the devices with the specified accessories. The connectors are coded. Connect PA/+ to PA/+ (red) and PC/- to PC/(black).

48

MNA01M001EN, V1.01, 08.2014

Common DC bus

Page 49

LXM32

4.3 Verifying installation

▶

▶

▶

▶

▶

4 Installation

Verify that the wiring complies with the specifications as per chapter "3 EngineeringInstallation".

Verify that the fuses used do not exceed the maximum permissible

fuse rating.

Verify that PA/+ is only connected to PA/+ and that PC/- is only

connected to PC/-.

Verify that the shield is connected to a large surface area if you use

shielded DC bus cables.

Verify that the connector locks are properly snapped in.

MNA01M001EN, V1.01, 08.2014

Common DC bus

49

Page 50

4 Installation

LXM32

50

MNA01M001EN, V1.01, 08.2014

Common DC bus

Page 51

LXM32

5 Commissioning

5 Commissioning

For commissioning, follow the commissioning instructions for the individual devices in the manual of the respective product.

Incorrect use of the DC bus may permanently damage the drives

either immediately or over time.

WARNING

DESTRUCTION OF SYSTEM COMPONENTS AND LOSS OF CONTROL

Verify that all requirements for using the DC bus are met.

Failure to follow these instructions can result in death, serious

injury, or equipment damage.

NOTICE

DESTRUCTION DUE TO INCORRECT OPERATION

Verify that the drives connected via a common DC bus are switched

on simultaneously.

Failure to follow these instructions can result in equipment

damage.

MNA01M001EN, V1.01, 08.2014

Common DC bus

51

Page 52

5 Commissioning

5.1 Commissioning procedure

5.1.1 DC bus connection LXM32 to LXM32

Commissioning steps:

▶

Verify proper installation of the drives and the connections for the

common DC bus, see chapter "4.3 Verifying installation", page 49.

▶

Switch on the controller supply for all devices.

▶

Set the parameters for the braking resistors, see chapter

"5.2 LXM32: Setting the braking resistor parameters".

▶

Commission the drives, see the descriptions in the manuals for the

individual products.

LXM32

52

MNA01M001EN, V1.01, 08.2014

Common DC bus

Page 53

LXM32

5.1.2 Supply via the DC bus

5 Commissioning

Commissioning steps:

▶

Verify proper installation of the drives and the connections for the

common DC bus, see chapter "4.3 Verifying installation", page 49.

▶

Switch on the controller supply for all devices.

▶

LXM32: Set the parameter MON_MainsVolt to "DC-Bus Only" for

LXM32.

Parameters Value

MON_MainsVolt

▶

LXM32: Set the parameters for the braking resistors of LXM32

drives, see chapter

"5.2 LXM32: Setting the braking resistor parameters".

▶

Commission the drives, see the descriptions in the manuals for the

individual products.

DC-Bus Only

MNA01M001EN, V1.01, 08.2014

Common DC bus

53

Page 54

5 Commissioning

5.2 LXM32: Setting the braking resistor parameters

An insufficiently rated braking resistor can cause overvoltage on the

DC bus. Overvoltage on the DC bus causes the power stage to be

disabled. The motor is no longer actively decelerated.

WARNING

MOTOR WITHOUT BRAKING EFFECT

• Verify that the braking resistor has a sufficient rating.

• Verify that the parameter settings for the braking resistor are correct.

• Verify that the I2t value for temperature monitoring does not

exceed 100% by performing a test run under maximum load conditions.

• Verify that the calculations and the test run take into account the

fact that the DC bus capacitors can absorb less braking energy at

higher mains voltages.

Failure to follow these instructions can result in death, serious

injury, or equipment damage.

LXM32

The temperature of the braking resistor may exceed 250 °C (482 °F)

during operation.

WARNING

HOT SURFACES

• Ensure that any contact with a hot braking resistor is avoided.

• Do not allow flammable or heat-sensitive parts in the immediate

vicinity of the braking resistor.

• Verify that the heat dissipation is sufficient by performing a test

run under maximum load conditions.

Failure to follow these instructions can result in death, serious

injury, or equipment damage.

▶

Check the parameter RESint_ext. If you have connected an

external braking resistor, you must set the parameter to "external".

▶

If you have connected an external braking resistor, (value of the

parameter RESint_ext is set to "external"), you must assign the

appropriate values to the parameters RESext_P, RESext_R and

RESext_ton. Verify that the selected external braking resistor is

really connected.

▶

Test the function of the braking resistor under realistic, worst case

conditions.

54

If the regenerated power becomes greater than the power that can be

absorbed by the braking resistor, an error message is generated and

the power stage is disabled.

See the product manual for a description of the parameters.

MNA01M001EN, V1.01, 08.2014

Common DC bus

Page 55

LXM32

6 Accessories and spare parts

6 Accessories and spare parts

6.1 DC bus accessories

Description Order no.

DC bus connection cable, 2 * 6 mm2 (2 * AWG 10), pre-assembled, 0.1 m, 5 pieces VW3M7101R01

DC bus connection cable, 2 * 6 mm2 (2 * AWG 10), Twisted Pair, shielded, 15 m VW3M7102R150

DC bus connector kit, connector housing and crimp contacts for 3 ... 6 mm2 (AWG 12 ... 10),

10 pieces

A crimping tool is required for the crimp contacts of the connector kit.

Manufacturer:

Tyco Electronics, Heavy Head Hand Tool, Tool Pt. No 180250

6.2 DC fuses

VW3M2207

The following DC fuses are offered by SIBA.

http://www.siba-fuses.com

Description SIBA order no.

DC fuse, DC 700V 10A 5020106.10

DC fuse, DC 700V 16A 5020106.16

DC fuse, DC 700V 25A 5020106.25

DC fuse, DC 700V 32A 5020106.32

DC fuse, DC 700V 40A 5020106.40

DC fuse, DC 700V 50A 5020106.50

DC fuse, DC 700V 63A 5020106.63

MNA01M001EN, V1.01, 08.2014

Common DC bus

55

Page 56

6 Accessories and spare parts

6.3 External braking resistors

Description Order no.

Braking resistor IP65; 10 Ω; maximum continuous power 400 W; 0.75 m connection cable

(2.1 mm2), UL

Braking resistor IP65; 10 Ω; maximum continuous power 400 W; 2 m connection cable

(2.1 mm2), UL

Braking resistor IP65; 10 Ω; maximum continuous power 400 W; 3 m connection cable

(2.1 mm2), UL

Braking resistor IP65; 27 Ω; maximum continuous power 100 W; 0.75 m connection cable

(2.1 mm2), UL

Braking resistor IP65; 27 Ω; maximum continuous power 100 W; 2 m connection cable

(2.1 mm2), UL

Braking resistor IP65; 27 Ω; maximum continuous power 100 W; 3 m connection cable

(2.1 mm2), UL

Braking resistor IP65; 27 Ω; maximum continuous power 200 W; 0.75 m connection cable

(2.1 mm2), UL

Braking resistor IP65; 27 Ω; maximum continuous power 200 W; 2 m connection cable

(2.1 mm2), UL

Braking resistor IP65; 27 Ω; maximum continuous power 200 W; 3 m connection cable

(2.1 mm2), UL

Braking resistor IP65; 27 Ω; maximum continuous power 400 W; 0.75 m connection cable

(2.1 mm2), UL

Braking resistor IP65; 27 Ω; maximum continuous power 400 W; 2 m connection cable

(2.1 mm2), UL

Braking resistor IP65; 27 Ω; maximum continuous power 400 W; 3 m connection cable

(2.1 mm2), UL

Braking resistor IP65; 72 Ω; maximum continuous power 100 W; 0.75 m connection cable

(2.1 mm2), UL

Braking resistor IP65; 72 Ω; maximum continuous power 100 W; 2 m connection cable

(2.1 mm2), UL

Braking resistor IP65; 72 Ω; maximum continuous power 100 W; 3 m connection cable

(2.1 mm2), UL

Braking resistor IP65; 72 Ω; maximum continuous power 200 W; 0.75 m connection cable

(2.1 mm2), UL

Braking resistor IP65; 72 Ω; maximum continuous power 200 W; 2 m connection cable

(2.1 mm2), UL

Braking resistor IP65; 72 Ω; maximum continuous power 200 W; 3 m connection cable

(2.1 mm2), UL

Braking resistor IP65; 72 Ω; maximum continuous power 400 W; 0.75 m connection cable VW3A7607R07

Braking resistor IP65; 72 Ω; maximum continuous power 400 W; 2 m connection cable VW3A7607R20

Braking resistor IP65; 72 Ω; maximum continuous power 400 W; 3 m connection cable VW3A7607R30

Braking resistor IP65; 100 Ω; maximum continuous power 100 W; 0.75 m connection cable VW3A7608R07

Braking resistor IP65; 100 Ω; maximum continuous power 100 W; 2 m connection cable VW3A7608R20

Braking resistor IP65; 100 Ω; maximum continuous power 100 W; 3 m connection cable VW3A7608R30

Braking resistor IP20; 15 Ω; maximum continuous power 1000 W; M6 terminals, UL VW3A7704

Braking resistor IP20; 10 Ω; maximum continuous power 1000 W; M6 terminals, UL VW3A7705

VW3A7601R07

VW3A7601R20

VW3A7601R30

VW3A7602R07

VW3A7602R20

VW3A7602R30

VW3A7603R07

VW3A7603R20

VW3A7603R30

VW3A7604R07

VW3A7604R20

VW3A7604R30

VW3A7605R07

VW3A7605R20

VW3A7605R30

VW3A7606R07

VW3A7606R20

VW3A7606R30

LXM32

56

MNA01M001EN, V1.01, 08.2014

Common DC bus

Page 57

LXM32

Glossary

Glossary

Units and conversion tables

The value in the specified unit (left column) is calculated for the

desired unit (top row) with the formula (in the field).

Example: conversion of 5 meters (m) to yards (yd)

5 m / 0.9144 = 5.468 yd

Length

in ft yd m cm mm

in - / 12 / 36 * 0.0254 * 2.54 * 25.4

ft * 12 - / 3 * 0.30479 * 30.479 * 304.79

yd * 36 * 3 - * 0.9144 * 91.44 * 914.4

m / 0.0254 / 0.30479 / 0.9144 - * 100 * 1000

cm / 2.54 / 30.479 / 91.44 / 100 - * 10

mm / 25.4 / 304.79 / 914.4 / 1000 / 10 -

Mass

lb oz slug kg g

lb - * 16 * 0.03108095 * 0.4535924 * 453.5924

oz / 16 - * 1.942559*10

slug / 0.03108095 / 1.942559*10

kg / 0.45359237 / 0.02834952 / 14.5939 - * 1000

g / 453.59237 / 28.34952 / 14593.9 / 1000 -

-3

- * 14.5939 * 14593.9

-3

* 0.02834952 * 28.34952

Force

lb oz p N

lb - * 16 * 453.55358 * 4.448222

oz / 16 - * 28.349524 * 0.27801

p / 453.55358 / 28.349524 - * 9.807*10

N / 4.448222 / 0.27801 / 9.807*10

-3

-

-3

Power

HP W

HP - * 746

W / 746 -

MNA01M001EN, V1.01, 08.2014

Common DC bus

57

Page 58

Glossary

LXM32

Rotation

min-1 (RPM) rad/s deg./s

min-1 (RPM) - * π / 30 * 6

rad/s * 30 / π - * 57.295

deg./s / 6 / 57.295 -

Torque

lb‧in lb‧ft oz‧in Nm kp‧m kp‧cm dyne‧cm

lb‧in - / 12 * 16 * 0.112985 * 0.011521 * 1.1521 * 1.129*10

lb‧ft * 12 - * 192 * 1.355822 * 0.138255 * 13.8255 * 13.558*10

oz‧in / 16 / 192 - * 7.0616*10-3* 720.07*10-6* 72.007*10-3* 70615.5

Nm / 0.112985 / 1.355822 / 7.0616*10-3- * 0.101972 * 10.1972 * 10*10

6

kp‧m / 0.011521 / 0.138255 / 720.07*10-6/ 0.101972 - * 100 * 98.066*10

kp‧cm / 1.1521 / 13.8255 / 72.007*10-3/ 10.1972 / 100 - * 0.9806*10

dyne‧cm / 1.129*106/ 13.558*106/ 70615.5 / 10*10

6

/ 98.066*106/ 0.9806*106-

Moment of inertia

6

6

6

6

2

lb‧in

2

lb‧ft

2

kg‧m

2

kg‧cm

kp‧cm‧s

2

oz‧in

2

lb‧in

- / 144 / 3417.16 / 0.341716 / 335.109 * 16

* 144 - * 0.04214 * 421.4 * 0.429711 * 2304

* 3417.16 / 0.04214 - * 10*10

* 0.341716 / 421.4 / 10*10

2

* 335.109 / 0.429711 / 10.1972 * 980.665 - * 5361.74

/ 16 / 2304 / 54674 / 5.46 / 5361.74 -

lb‧ft

2

kg‧m

2

3

kg‧cm

2

3

kp‧cm‧s

* 10.1972 * 54674

2

oz‧in

- / 980.665 * 5.46

2

Temperature

°F °C K

°F - (°F - 32) * 5/9 (°F - 32) * 5/9 + 273.15

°C °C * 9/5 + 32 - °C + 273.15

K (K - 273.15) * 9/5 + 32 K - 273.15 -

Conductor cross section

AWG 1 2 3 4 5 6 7 8 9 10 11 12 13

2

mm

42.4 33.6 26.7 21.2 16.8 13.3 10.5 8.4 6.6 5.3 4.2 3.3 2.6

AWG 14 15 16 17 18 19 20 21 22 23 24 25 26

2

mm

58

2.1 1.7 1.3 1.0 0.82 0.65 0.52 0.41 0.33 0.26 0.20 0.16 0.13

Common DC bus

MNA01M001EN, V1.01, 08.2014

Page 59

LXM32

Glossary

Terms and Abbreviations

See chapter " Standards and terminology" for information on the pertinent standards on which many terms are based. Some terms and

abbreviations may have specific meanings with regard to the standards.

AC Alternating current

DC Direct current

DC bus Circuit that supplies the power stage with energy (direct voltage).

Drive system System consisting of controller, drive and motor.

EMC Electromagnetic compatibility

Error Discrepancy between a detected (computed, measured or signaled)

value or condition and the specified or theoretically correct value or

condition.

Error class Classification of errors into groups. The different error classes allow

for specific responses to errors, for example by severity.

Factory setting Factory settings when the product is shipped

Fault Fault is an operating state. If the monitoring functions detect an error,

a transition to this operating state is triggered, depending on the error

class. A "Fault Reset" is required to exit this operating state after the

cause of the detected error has been removed. Further information

can be found in the pertinent standards such as IEC 61800-7, ODVA

Common Industrial Protocol (CIP).

Fault Reset A function used to restore the drive to an operational state after a

detected error is cleared by removing the cause of the error so that

the error is no longer active.

Parameter Device data and values that can be read and set (to a certain extent)

by the user.

PELV Protective Extra Low Voltage, low voltage with isolation. For more

information: IEC 60364-4-41

Persistent Indicates whether the value of the parameter remains in the memory

after the device is switched off.

Power stage The power stage controls the motor. The power stage generates cur-

rent for controlling the motor on the basis of the motion signals from

the controller.

Quick Stop The Quick Stop function can be used for fast deceleration of a move-

ment as a response to a detected error or via a command.

Warning If the term is used outside the context of safety instructions, a warning

alerts to a potential problem that was detected by a monitoring function. A warning does not cause a transition of the operating state.

MNA01M001EN, V1.01, 08.2014

Common DC bus

59

Page 60

Glossary

LXM32

60

MNA01M001EN, V1.01, 08.2014

Common DC bus

Page 61

LXM32

Table of figures

Table of figures

1) Movement cycle: Profile for energy assessment 23

2) Single mains fuse for single-phase drives 25

3) Multiple mains fuses for single-phase drives 26

4) Single mains fuse for three-phase drives 27

5) Multiple mains fuses for three-phase drives 28

6) Supply via the DC bus by a drive 30

7) Supply via the DC bus by a DC power supply unit 30

8) Supply via the DC bus by a drive 31

9) Supply via the DC bus by a DC power supply unit 31

10) Wiring of drives with common AC fuse and a mains reactor, example shows three-phase drives. 36

11) Wiring of drives with individual AC fuses and mains reactors, example shows singe-phase drives. 37

12) Wiring of an external mains filter, example shows three-phase drives. 38

13) Wiring of drives with common mains fuse, mains reactor and mains filter, example shows three-phase

drives. 39

14) Specifications for drives with mains supply 42

15) Connector coding 45

16) Unlocking the DC bus connector, step 1: Push cables towards connector. 46

17) Unlocking the DC bus connector, step 2: Push cables towards connector, at the same time remove the

connector with the other hand. 46

18) Wiring diagram DC bus 47

19) DC bus connection, example with connector 48

MNA01M001EN, V1.01, 08.2014

Common DC bus