Page 1

Application

Typical of MK-6600 Series

and MK-6800 Series

MK-6911

These valve actuators, with a 50 sq. in. (323 cm2)

effective diaphragm area, are used for propo rt ion al

pneumatic control of hot water or chilled water valves.

• MK-66x1 is used to control 1-1/2 in. to 2 in. VB-7xxx

series valves.

• MK-68x1 is used to control 2-1/2 in. to 4 in.

VB-9xxx series valves

• MK-681 1 is used to control 2- 1/2 in. to 5 in .VB-8xx3

series valves and 2-1/2 in. to 4 in.

VB-9xxx series valves

MK-6600 Series,

MK-6800 Series, and MK-6911

Pneumatic Valve Actuators

General Instructions

• MK-6911 is used to control 6 in. VB-8xxx valves

Features

• Rugged die cast aluminum housing.

• Replaceable beaded molded neoprene diaphragm.

• Built-in spring to retract output shaft.

• Adjustable start point on loss of air pressure.

Applicable Literature

• Pneumatic Products Catalog, F-27383

• Cross-Reference Guide, F-26789

• Reference Manual, F-21683

• Application Manual, F-21335

• AV-430 Linkage General Instructions, F-19072

• AV-495 Linkage General Instructions, F-21665

• AV-497 Linkage General Instructions, F-27253

Printed in U.S.A. 1/10 © Copyright 2010 Schneider Electric All Rights Reserved. F-13895-13

Page 2

SPECIFICATIONS

Construction:

Housing, Die cast aluminum.

Diaphragm, Replaceable beaded molded neoprene.

Stroke: (Table-1).

Effective Area: 50 sq. in. (323 cm2).

Spring: Retracts actuator shaft and raises valve stem on loss of air pressure.

Nominal Spring Range: (Table-1).

Start Point: Adjustable ±2 psi (14 kPa).

Maximum Air Pressure: 30 psig (207 kPa).

Ambient Temperature Limits:

Shipping, -40 to 220 °F (-40 to 104 °C).

Operating, -20 to 220 °F (-29 to 104 °C).

Air Connections: 1/8 in. FNPT.

Valve Linkage: Order separately (Table-2).

Locations: NEMA Type 1 only.

Mounting: In any upright position with actuator head above center line of valve body.

Dimensions: 7-3/4 H x 10-1/2 W x 10-1/2 D in. (199 x 267 x 267 mm).

Table-1 Model Chart.

Model Number

MK-6601 3 to 8 21 to 55

MK-6621 8 to 13 55 to 90 —

MK-6801 3 to 8 21 to 55

MK-6811 5 to 10 34 to 69 2-1/2" to 5"

MK-6821 8 to 13 55 to 90 —

MK-6911 5 to 10 34 to 69 1-3/4 (44) — 6" —

*Nominal no load spring range based on normal stroke

Nominal Spring Range*

psig kPa VB-7xxx VB-8xxx VB-9xxx

Nominal Stroke

in. (mm.)

1-1/2" to 2"

1/2 (13)

1 (25) —

Valve Compatibility

(40 to 50

mm)

—

—

2-1/2" to 4"

(65 to 80

mm)

Table-2 Valve Linkage.

Valve Linkage Valve Body Series

AV-430 VB-7xxx 1-1/2 in. to 2 in. (40 to 50 mm)

AV-495 VB-9xxx 2-1/2 in. to 4 in. (65 to 80 mm)

AV-497 VB-8xxx 2-1/2 in. to 6 in.

—MK-6611 5 to 10 34 to 69 —

ACCESSORIES

AK-42309-500 Positive positioner and linkage

TOOL-75 Spring compression tool

TOOL-95 Pneumatic calibration tool kit

MK-6600 Series

PNV-245-013 3 to 8 psig green spring

PNV-245-015 5 to 10 psig black spring

PNV-245-018 8 to 13 psig blue spring

MK-6700 and MK-6800 Series

PNV-245-103 3 to 8 psig green spring

PNV-245-105 5 to 10 psig black spring

PNV-245-108 8 to 13 psig blue spring

MK-6900 Series

PNV-245-145 5 to 10 psig black spring

PNV-245-148 8 to 13 psig blue spring

All Series

PNV-202 Diaphragm

2 © Copyright 2010 Schneider Electric All Rights Reserved. F-13895-13

Page 3

INSTALLATION

C A U T I O N

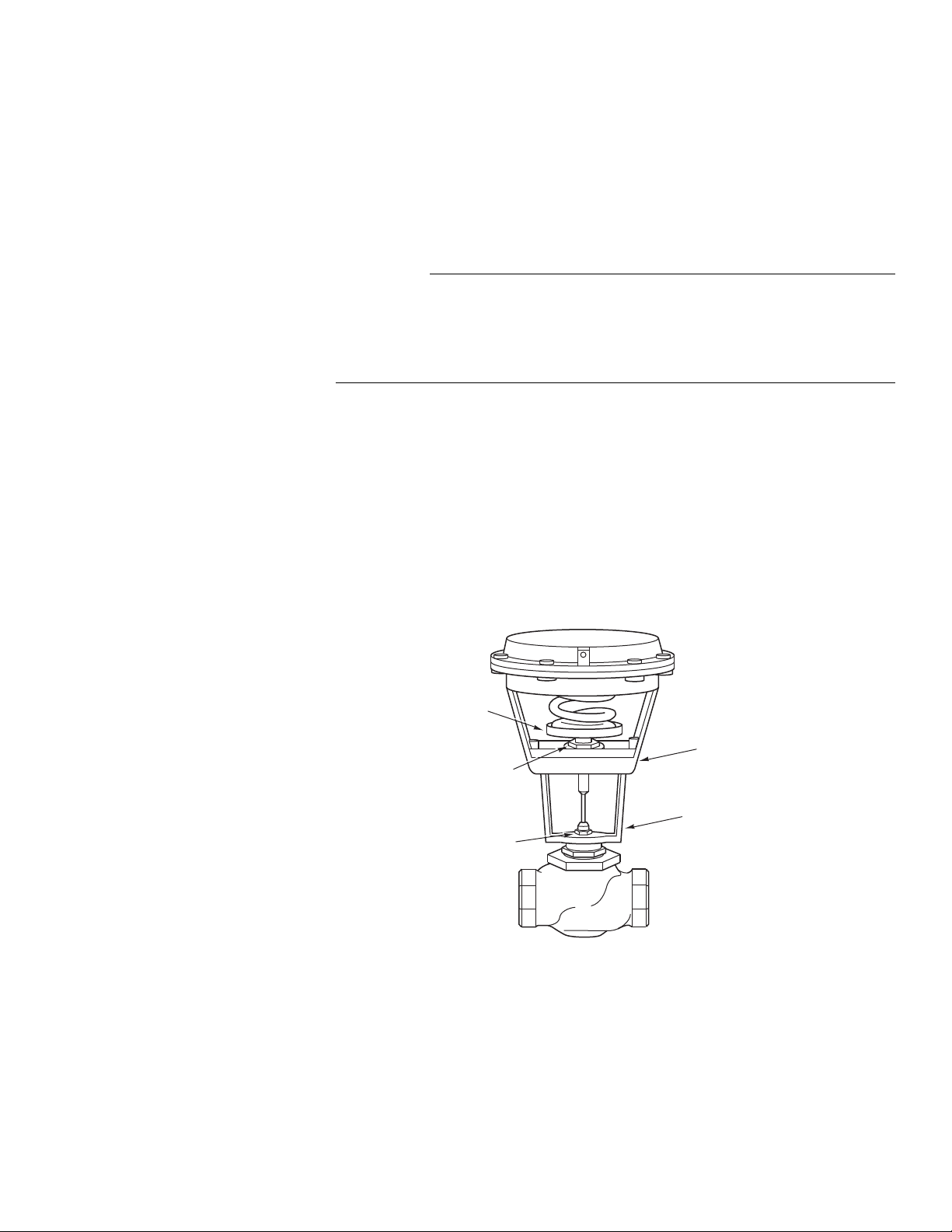

Spring

Retainer

Plate

Brass Hex Nut

for adjusting

start point

Bracket Nut

Actuator to Yoke

Mounting Bolts (2)

Mounting

Bracket

Inspection

Requirements

Mounting

Inspect the package for damage. If damaged, notify the appropriate carrier immediately.

If undamaged, open the package and inspect the device for obvious damage. Return

damaged products.

• Piping diagrams.

• Tools (not provided): Appropriate wrenches for mounting bolts and adjustments.

• Training: Installer must be a qualified, experienced technician or fitter.

• Make all connections in accordance with the piping diagram.

• Avoid locations where excessive moisture, corrosive fumes, or vibration are present.

• The actuator can be mounted in any position above the centerline of the valve body.

When selecting a location, allow sufficient room for accessories and for service of the

product.

The actuator may be shipped assembled to a valve body or as a separate component.

These instructions are intended for use where the actuator is to be installed to a linkage and

valve body, as a replacement unit, or when the actuator must be removed during valve

installation.

Figure-1 Typical Pneumatic Valve Assembly with MK-6xxx Series Actuator.

F-13895-13 © Copyright 2010 Schneider Electric All Rights Reserved. 3

Page 4

Removing Actuator from Valve Body (Figure-1)

N O T E

W A R N I N G

It is not necessary to remove the mounting bracket from the valve body in order to service

the actuator. If removal of the yoke is required, follow step 3.

1. Remove the connecting pin between the actuator piston stem and the valve stem extension. A slight amount of air pressure to the actuator may b e necessary to loosen the pin.

2. Remove the two bolts holding the actuator to the yoke, and lift up the actuator.

3. If it is necessary to remove the mounting bracket: Current style valves (valves that do not require removal of packing nut to mount

the actuator):

a. Remove the bracket nut.

b. Lift the actuator and mounting bracket off the valve body. Obsolete style valves (valves that require removal of packing nut to mount the actuator):

Any 2-1/2 in. to 6 in. VB-9xxx valve body date coded before 8603 (1986, third week) must

have the valve packing nut removed and replaced along with the bracket nut. Before

removing the packing nut, isolate the valve body using shutoff valves or depressurize the

system to zero gauge and drain the piping. System pressure could cause packing parts

to blow out with potential of injury and/or water damage.

a. Remove the packing nut.

b. Remove the bracket nut.

c. Lift the actuator and mounting bracket off the valve body.

Installing Actuator on Valve Body (Figure-1)

If the mounting bracket has been removed, re-install it making certain that the bracket nut is

securely tightened. (On obsolete style valves, which require removal of the packing nut to

mount the actuator, make certain that the packing nut is tight — tightened four turns.)

1. Place the actuator on the mounting bracket and secure with two bolts. Be sure the air connection is in the proper location.

2. Secure the actuator piston stem to the valve stem extension with the connecting pin. It may be necessary to apply a slight amount of air pressure to the actuator to line up the pin holes.

For additional information, refer to AV-430 Linkage General Instructions, F-19072,

AV -495 Linkage General Instructions F-21665, or AV -497 Linkage General Instructions

F-27253.

4 © Copyright 2010 Schneider Electric All Rights Reserved. F-13895-13

Page 5

ADJUSTMENTS

Start Point

Adjustment Nut

Center Stud

Sleeve

Spring

Retainer

Plate

C

T

The start point adjustment is the only actuator adjustment (Figure-1). The start point is the

air pressure which, when applied to the actuator, causes the piston to begin to move

downward under a no load condition.

In the course of meeting system requirements or replacing the diaphragm spring, the start

point may have been changed. T o adjust the start point, proceed as follows (viewing actuator

in position shown in

Figure-1).

1. Apply desired air pressure to the actuator.

2. Rotate the start point adjustment nut until the desired start point is obtained.

To raise the start point, rotate the adjustment nut clockwise (CW).

To lower the start point, rotate the adjustment nut counterclockwise (CCW).

Figure-2 Using Spring Compression Tool.

enter Stud

hreads

Figure-3 TOOL-75 Spring Compression Tool.

F-13895-13 © Copyright 2010 Schneider Electric All Rights Reserved. 5

Page 6

Cover

Spring

Retainer Plate

Piston

Diaphgram

(PNV-202)

Spring

Actuator

Lower

Housing

Adjustment Nut

(See ACCESSORIES

for part numbers)

6 © Copyright 2010 Schneider Electric All Rights Reserved. F-13895-13

Figure-4 Exploded View of Actuator.

Page 7

MAINTENANCE

W A R N I N G

N O T E

W A R N I N G

N O T E

FIELD REPAIR

Regular maintenance of the total system is recommended to assure sustained performance.

Replacing Actuator Diaphragm (Figure-2, Figure-3, and Figure-4)

Strong spring forces are present. Removing the actuator top without securing the spring

can result in violent release of spring energy — perhaps resulting in flying parts. Follow

the procedure below to prevent possible injury and damage to equipment.

1. Remove the actuator from the yoke as explained in the “Installation” section.

2. Place the actuator upside down on the cover top.

3. Thread the center stud of TOOL-75 into the piston stem.

4. Turn the TOOL-75 sleeve down until it rests on the actuator housing.

5. Holding the center stud of TOOL-75 with a small rod or screwdriver to keep it from

turning, turn the sleeve clockwise (CW) to compress the actuator spring. When the

spring and piston rotate freely within the actuator, the spring is sufficiently compressed

to permit removing the actuator cover.

6. Remove the cover screws, cover, and diaphragm.

7. Install the replacement diaphragm and follow the above steps in reverse order.

Be sure that the diaphragm rib fits properly in the actuator cover groove to prevent air

from leaking from the diaphragm.

Replacing Actuator Spring (Figure-2, Figure-3, and Figure-4)

Strong spring forces are present. Removing the actuator top without securing the spring

can result in violent release of spring energy — perhaps resulting in flying parts. Follow

the procedure below to prevent possible injury and damage to equipment.

1. Follow the steps outlined for replacing the diaphragm.

2. Place the actuator upside down on the piston top.

3. Holding the center stud of TOOL-75 with a small rod or screwdriver to keep it from turning, turn the sleeve counterclockwise (CCW) to release the spring tension.

The spring can be replaced with an identical spring without changing the start point

adjustment. To do this, be sure that the brass start point adjustment nut does not rotate

within the spring retainer plate. T o make certain the spring range has not been changed,

refer to the “Adjustments” section.

4. Remove TOOL-75 center stud from the actuator piston stem.

5. Lift the actuator lower housing away from the spring and piston assembly.

6. Lift the adjustment nut and spring retainer plate off the spring.

7. Replace the spring and re-install the parts removed above in the proper order.

F-13895-13 © Copyright 2010 Schneider Electric All Rights Reserved. 7

Page 8

On October 1st, 2009, TAC became the Buildings business of its parent com pany Sc h neider Electr ic . This doc um ent ref lect s the visual identity of Schneider Electric,

ho wever there remains refer ences t o TAC as a cor p orate brand i n the body copy. As eac h document is updated, the body copy wil l be changed to reflec t appropriate

corpo rate bra nd ch a nges.

Copyright 2010, Schneider Electric

All brand names, trademarks and registered

trademarks are the property of their respective

owners. Information contained within this

document is subject to change without notice.

F-13895-13

Loading...

Loading...