Page 1

Lexium 62 ILM

EIO0000001351 02/2020

Lexium 62 ILM

Hardware Guide

Original instructions

02/2020

EIO0000001351.07

www.schneider-electric.com

Page 2

The information provided in this documentation contains general descriptions and/or technical

characteristics of the performance of the products contained herein. This documentation is not

intended as a substitute for and is not to be used for determining suitability or reliability of these

products for specific user applications. It is the duty of any such user or integrator to perform the

appropriate and complete risk analysis, evaluation and testing of the products with respect to the

relevant specific application or use thereof. Neither Schneider Electric nor any of its affiliates or

subsidiaries shall be responsible or liable for misuse of the information contained herein. If you

have any suggestions for improvements or amendments or have found errors in this publication,

please notify us.

You agree not to reproduce, other than for your own personal, noncommercial use, all or part of

this document on any medium whatsoever without permission of Schneider Electric, given in

writing. You also agree not to establish any hypertext links to this document or its content.

Schneider Electric does not grant any right or license for the personal and noncommercial use of

the document or its content, except for a non-exclusive license to consult it on an "as is" basis, at

your own risk. All other rights are reserved.

All pertinent state, regional, and local safety regulations must be observed when installing and

using this product. For reasons of safety and to help ensure compliance with documented system

data, only the manufacturer should perform repairs to components.

When devices are used for applications with technical safety requirements, the relevant

instructions must be followed.

Failure to use Schneider Electric software or approved software with our hardware products may

result in injury, harm, or improper operating results.

Failure to observe this information can result in injury or equipment damage.

© 2020 Schneider Electric. All rights reserved.

2 EIO0000001351 02/2020

Page 3

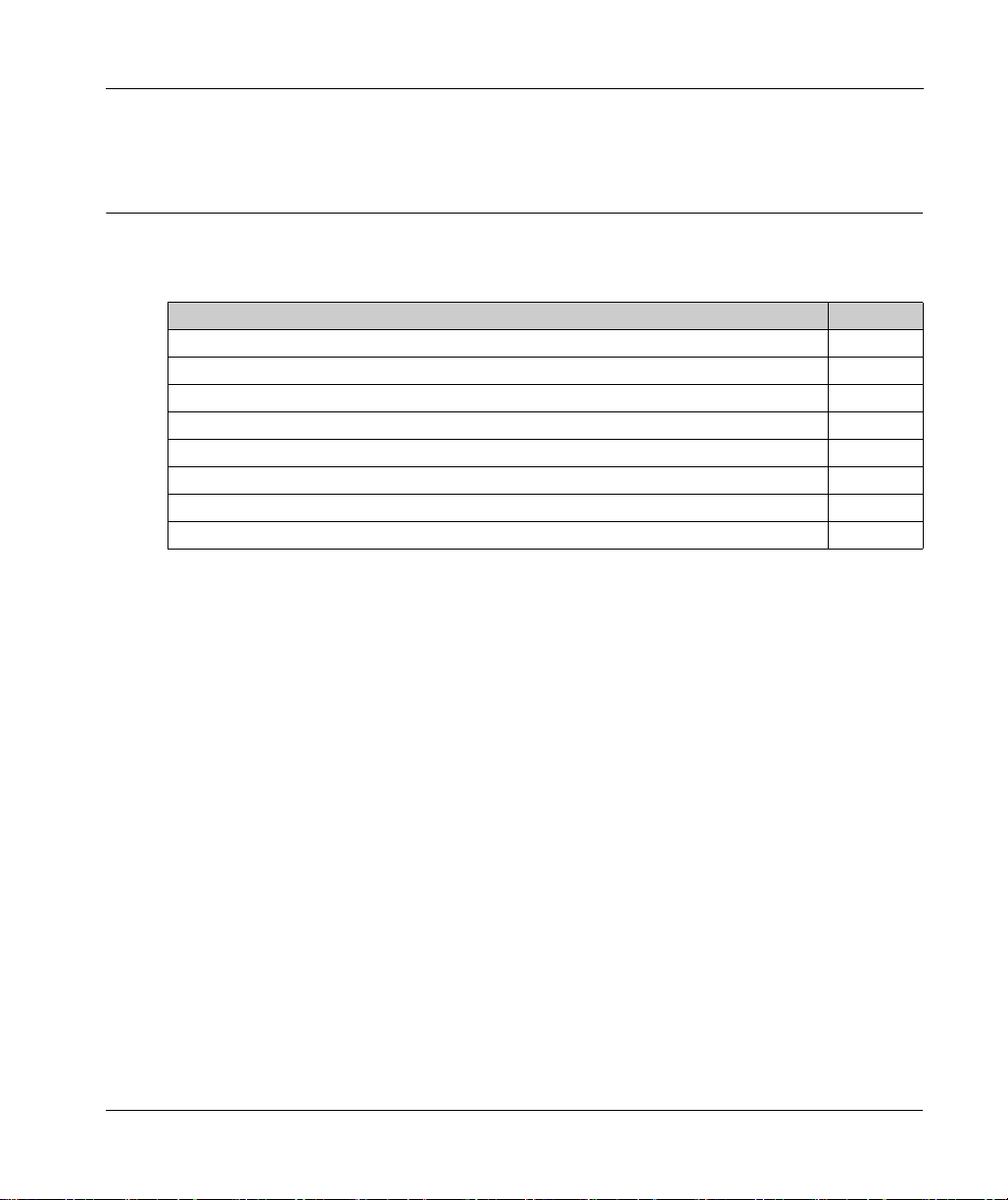

Table of Contents

Safety Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

About the Book . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Chapter 1 Specific Safety Information . . . . . . . . . . . . . . . . . . . . . . . 13

Product Related Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Intended Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Qualification of Personnel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 2 System Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

System Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lexium 62 Power Supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lexium 62 Connection Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lexium 62 Distribution Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lexium 62 ILM Integrated Servo Drive . . . . . . . . . . . . . . . . . . . . . . . .

Lexium 62 ILM Digital I/O Module . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lexium 62 ILM Safety Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ILM Daisy Chain Connector Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 3 Engineering. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

3.1 Electromagnetic Compatibility, EMC . . . . . . . . . . . . . . . . . . . . . . . . . .

Electromagnetic Compatibility, EMC . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 Control Cabinet Planning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Degree of Protection (IP). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mechanical and Climatic Environmental Conditions in the Control

Cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using Cooling Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3 Information about Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General Information about Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cable Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ESD Protection Measures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Conditions for UL / CSA Compliant Use . . . . . . . . . . . . . . . . . . . . . . .

Fusing the Mains Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mains Contactor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mains Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mains Line Reactor (Choke) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connection of the Lexium 62 Power Supply . . . . . . . . . . . . . . . . . . . .

Leakage (Touch) Current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Residual Current Operated Protective Device. . . . . . . . . . . . . . . . . . .

14

18

20

22

24

27

29

31

34

36

38

42

42

46

47

48

49

51

52

53

55

56

58

60

61

62

63

64

65

EIO0000001351 02/2020 3

Page 4

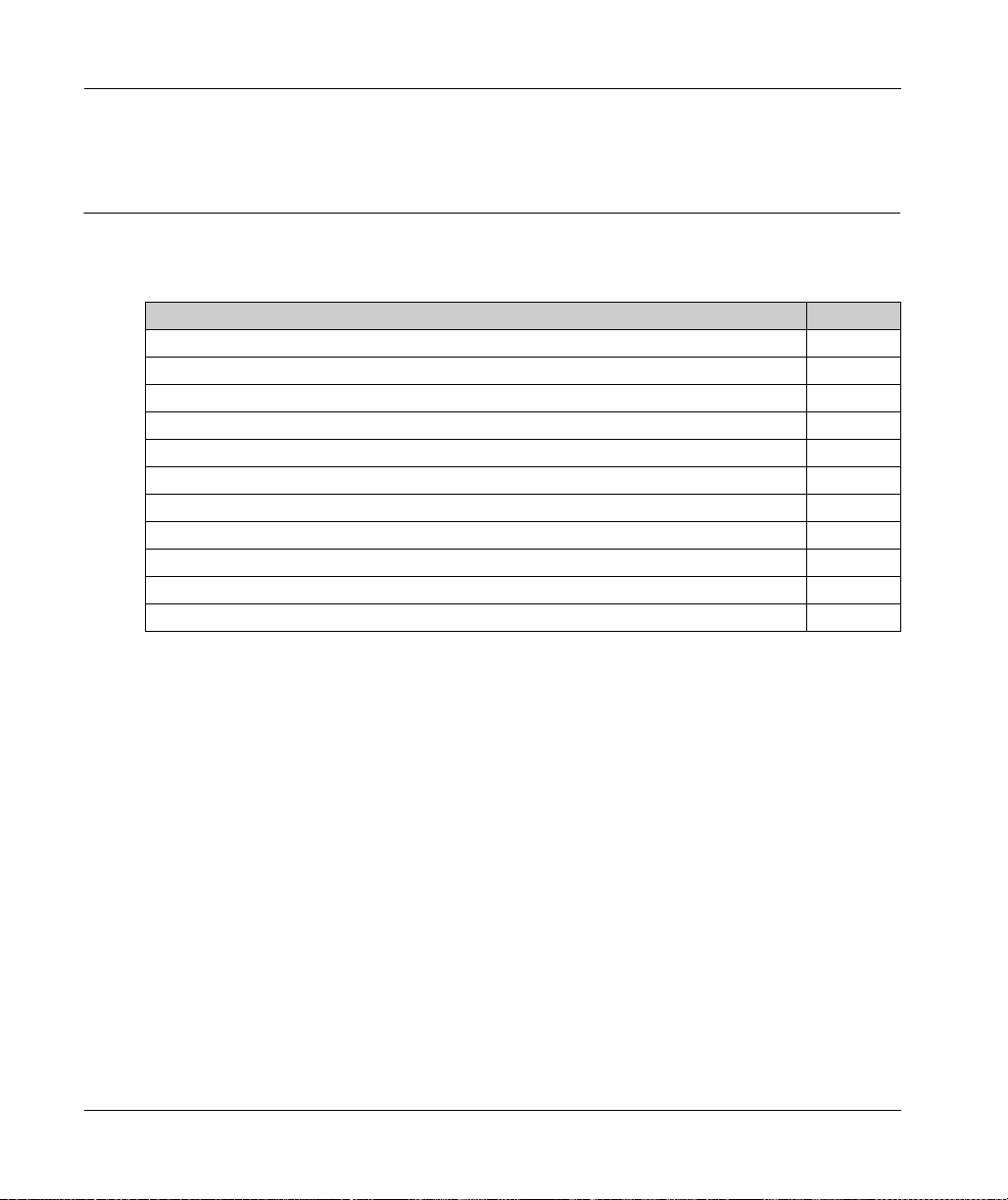

3.4 Functional Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Process Minimizing Risks Associated with the Machine . . . . . . . . . . .

Designated Safety Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setup, Installation and Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . .

Perform Muting with the Optional Modules DIS1 . . . . . . . . . . . . . . . . .

Application Proposals for Hardware-Based Safety Functions . . . . . . .

Application Proposals for Software-Based Safety Functions . . . . . . . .

Commissioning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Best Practices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Physical Environment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5 Special Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Low Air Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

66

67

69

77

79

82

85

86

87

89

90

91

93

93

Chapter 4 Installation and Maintenance . . . . . . . . . . . . . . . . . . . . . . 97

4.1 Prerequisites for Installation and Maintenance . . . . . . . . . . . . . . . . . .

Prerequisites for Maintenance and Installation . . . . . . . . . . . . . . . . . .

4.2 Commissioning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Prerequisites for Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preparing Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Grinding the Holding Brake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preparing the Control Cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Wiring the Lexium 62 Connection Module in Linear or Tree Topologies

Wiring from the Lexium 62 Connection Module in a Daisy Chain

Topology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3 Maintenance, Repair, Cleaning, Replacement Equipment Inventory. .

Prerequisites for Maintenance, Repair, and Cleaning . . . . . . . . . . . . .

Fuse Replacement Lexium 62 Connection Module . . . . . . . . . . . . . . .

Machine Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cleaning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replacement Equipment Inventory . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4 Replacing Components and Cables. . . . . . . . . . . . . . . . . . . . . . . . . . .

Prerequisites for Replacing Components and Cables . . . . . . . . . . . . .

Replacement of the Lexium 62 Connection Module . . . . . . . . . . . . . .

Replacement of the Lexium 62 Distribution Box . . . . . . . . . . . . . . . . .

Replacement of the Lexium 62 ILM Integrated Servo Drive . . . . . . . .

98

98

99

100

101

103

104

108

114

120

124

125

127

131

132

133

134

135

138

141

145

4 EIO0000001351 02/2020

Page 5

Chapter 5 Indicators and Control Elements. . . . . . . . . . . . . . . . . . . 149

Indicators of the Lexium 62 Power Supply . . . . . . . . . . . . . . . . . . . . .

Indicators of the Lexium 62 Connection Module . . . . . . . . . . . . . . . . .

Indicators of the Lexium 62 Distribution Box . . . . . . . . . . . . . . . . . . . .

Indicators of the Lexium 62 ILM Integrated Servo Drive . . . . . . . . . . .

150

153

155

157

Chapter 6 Electrical Power Connections . . . . . . . . . . . . . . . . . . . . . 161

Electrical Connections for the Lexium 62 Power Supply . . . . . . . . . . .

Electrical Connections for the Lexium 62 Connection Module . . . . . .

Electrical Connections for the Lexium 62 Distribution Box . . . . . . . . .

Electrical Connections for the Lexium 62 ILM Integrated Servo Drive

Electrical Connections for the ILM Daisy Chain Connector Box . . . . .

162

168

174

177

179

Chapter 7 Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

Standards and Regulations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ambient Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mechanical and Electrical Data for the Lexium 62 Power Supply . . . .

Mechanical and Electrical Data for the Lexium 62 Connection Module

Mechanical and Electrical Data for the Lexium 62 Distribution Box . .

Mechanical and Electrical Data for the

ILM Daisy Chain Connector Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mechanical and Electrical Data for the Lexium 62 ILM Integrated Servo

Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mechanical and Electrical Data for the ILM070 Servo Motor . . . . . . .

Mechanical and Electrical Data for the ILM100 Servo Motor . . . . . . .

Mechanical and Electrical Data for the ILM140 Servo Motor . . . . . . .

Encoder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Motor Shaft and Bearings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Holding Brake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mounting Arrangement and Degree of Protection. . . . . . . . . . . . . . . .

Torque / Speed Characteristic Curves . . . . . . . . . . . . . . . . . . . . . . . .

186

187

188

191

194

197

202

205

208

211

214

215

217

219

220

Chapter 8 Lexium 62 ILM Digital I/O Module. . . . . . . . . . . . . . . . . . 227

Lexium 62 ILM Digital I/O Module - Description . . . . . . . . . . . . . . . . .

Lexium 62 ILM Digital I/O Module - Technical Data . . . . . . . . . . . . . .

Lexium 62 ILM Digital I/O Module - Installation. . . . . . . . . . . . . . . . . .

Lexium 62 ILM Digital I/O Module - Electrical Connections. . . . . . . . .

Lexium 62 ILM Digital I/O Module - Wiring . . . . . . . . . . . . . . . . . . . . .

228

229

231

234

238

Chapter 9 Lexium 62 ILM Safety Module . . . . . . . . . . . . . . . . . . . . 239

Lexium 62 ILM Safety Module - Description . . . . . . . . . . . . . . . . . . . .

Lexium 62 ILM Safety Module - Technical Data . . . . . . . . . . . . . . . . .

Lexium 62 ILM Safety Module - Installation. . . . . . . . . . . . . . . . . . . . .

240

241

243

EIO0000001351 02/2020 5

Page 6

Chapter 10 Hybrid Connector HCN-2 Adapter . . . . . . . . . . . . . . . . . . 247

Hybrid Connector HCN-2 Adapter - Description . . . . . . . . . . . . . . . . .

Hybrid Connector HCN-2 Adapter - Technical Data . . . . . . . . . . . . . .

Hybrid Connector HCN-2 Adapter- Installation . . . . . . . . . . . . . . . . . .

Hybrid Connector HCN-2 Adapter - Electrical Connections. . . . . . . . .

Hybrid Connector HCN-2 Adapter - Dimensions . . . . . . . . . . . . . . . . .

Appendices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix A Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 259

Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

248

249

251

253

255

257

259

261

263

6 EIO0000001351 02/2020

Page 7

Safety Information

Important Information

NOTICE

Read these instructions carefully, and look at the equipment to become familiar with the device

before trying to install, operate, service, or maintain it. The following special messages may appear

throughout this documentation or on the equipment to warn of potential hazards or to call attention

to information that clarifies or simplifies a procedure.

EIO0000001351 02/2020 7

Page 8

PLEASE NOTE

Electrical equipment should be installed, operated, serviced, and maintained only by qualified

personnel. No responsibility is assumed by Schneider Electric for any consequences arising out of

the use of this material.

A qualified person is one who has skills and knowledge related to the construction and operation

of electrical equipment and its installation, and has received safety training to recognize and avoid

the hazards involved.

8 EIO0000001351 02/2020

Page 9

About the Book

At a Glance

Document Scope

Read and understand the material contained in this manual before you work on Lexium 62 ILM

drive for the first time. Take particular note of the chapter

(see page 13)

(see page 20)

A copy of this manual must be available for personnel who work with the Lexium 62 ILM drive.

This manual is to help you use the capabilities of the Lexium 62 ILM drive safely and properly.

Follow the instructions within this manual to help:

Reduce risks

Reduce repair costs and downtime of the Lexium 62 ILM components.

Increase the service life of the Lexium 62 ILM components.

Increase reliability of the Lexium 62 ILM components.

Validity Note

This document has been updated for the release of EcoStruxureTM Machine Expert V1.2.

The technical characteristics of the devices described in the present document also appear online.

To access the information online, go to the Schneider Electric home page

electric.com

Specific Safety Information

. Only those persons who meet the criteria described in

are allowed to work with the Lexium 62 ILM components.

.

Qualification of Personnel

www.schneider-

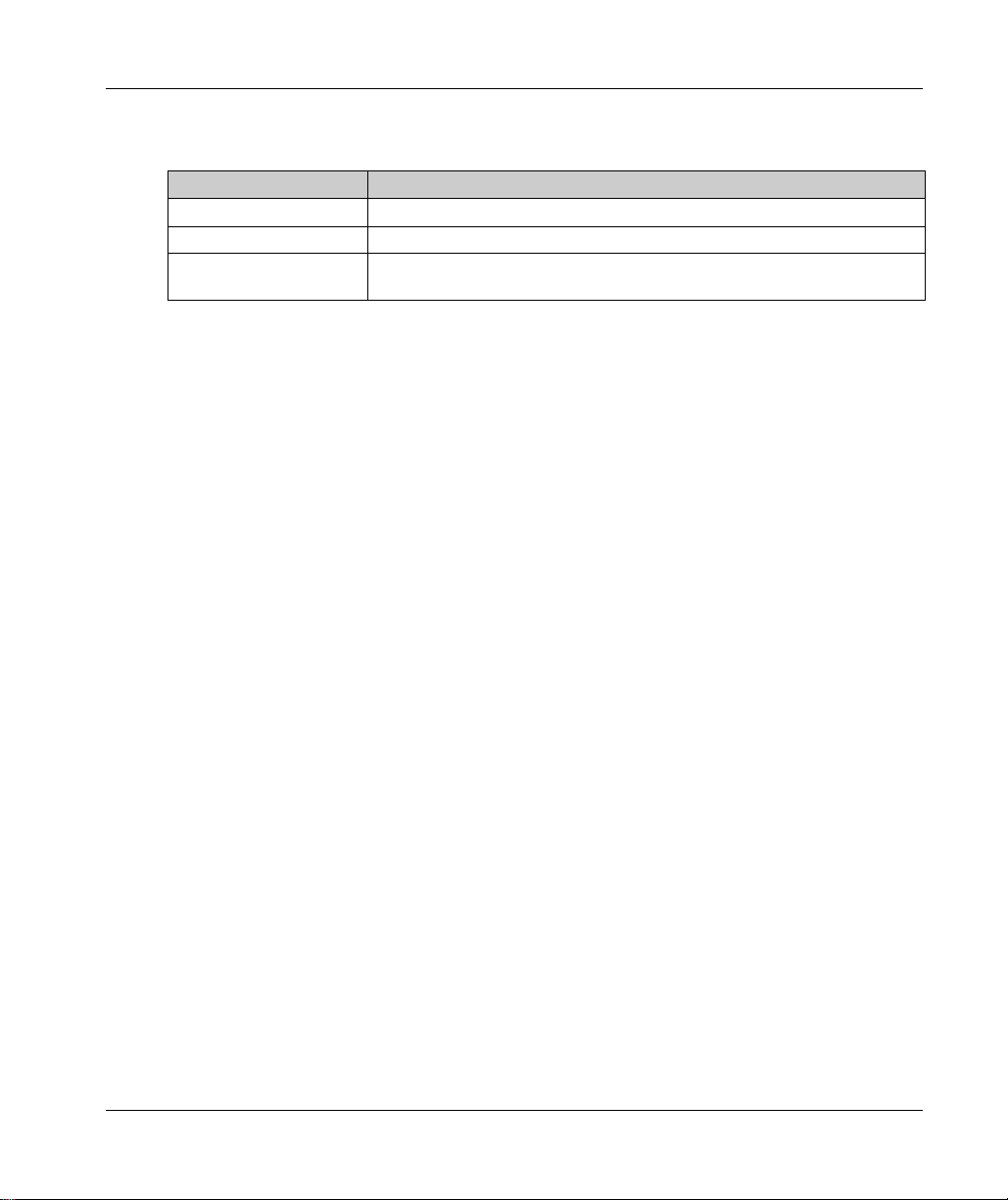

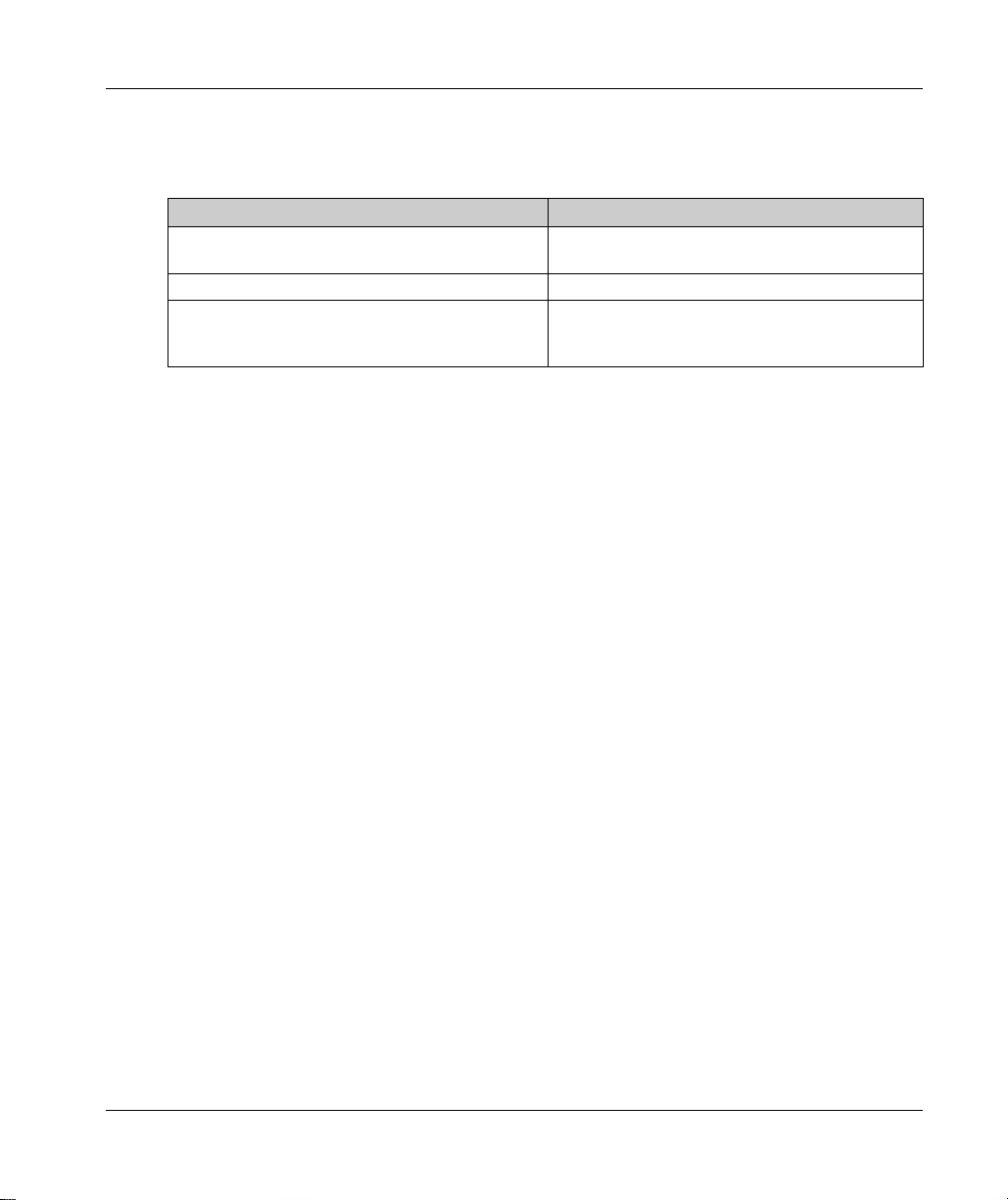

Related Documents

Document title Reference

EcoStruxure Machine Expert Programming Guide

LXM62LT00A01000 Lexium 62 DC Link Terminal,

Instruction Sheet

SH3 Servo Motor - User Guide

EIO0000001351 02/2020 9

EIO0000002854 (ENG)

EIO0000002855 (FRE)

EIO0000002856 (GER)

EIO0000002857 (ITA)

EIO0000002858 (SPA)

EIO0000002859 (CHS)

NVE50846 (ENG)

0198441113987 (ENG)

;

;

Page 10

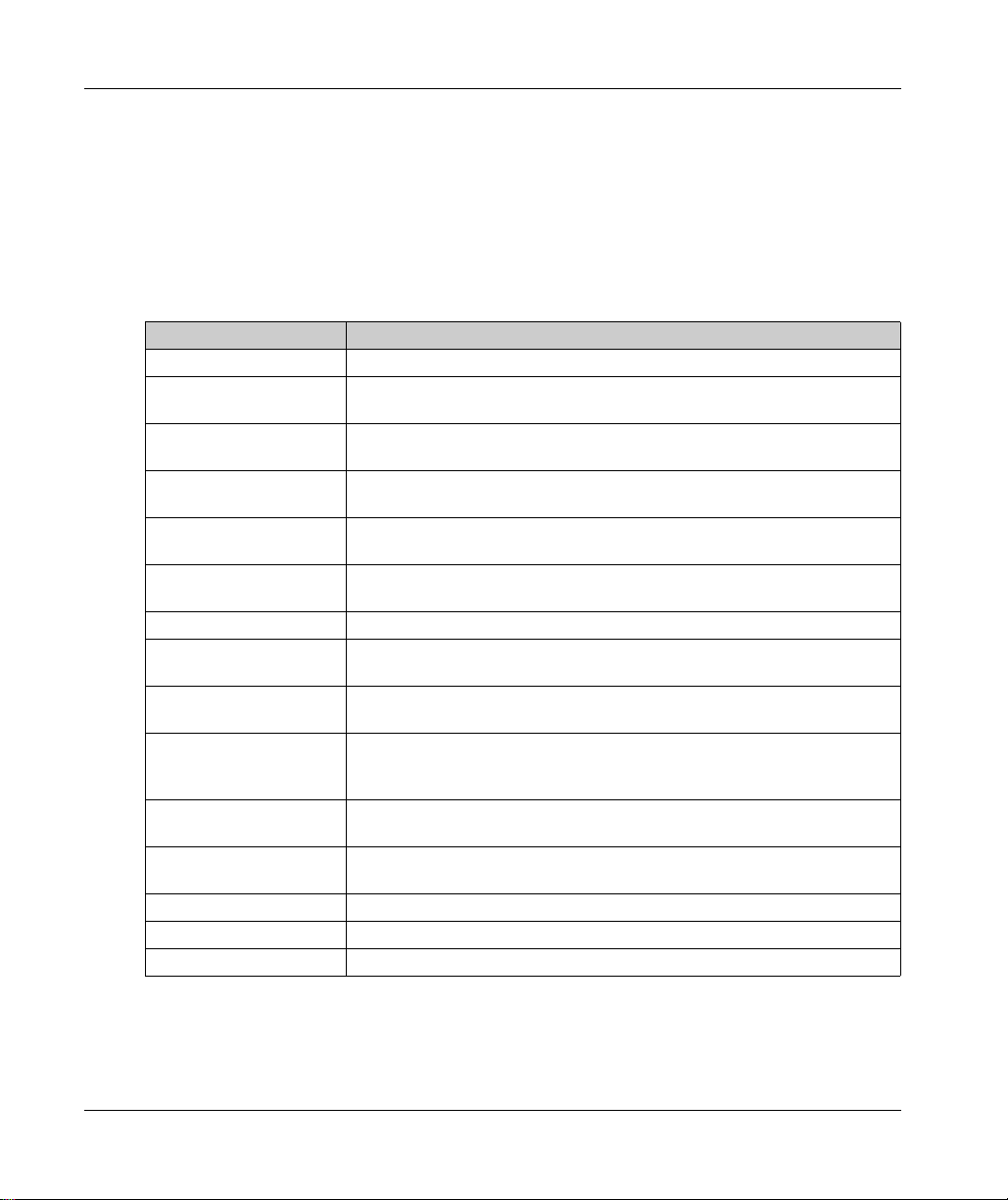

Terminology Derived from Standards

The technical terms, terminology, symbols and the corresponding descriptions in this manual, or

that appear in or on the products themselves, are generally derived from the terms or definitions

of international standards.

In the area of functional safety systems, drives and general automation, this may include, but is not

limited to, terms such as

safety, safety function, safe state, fault, fault reset, malfunction, failure

error, error message, dangerous

Among others, these standards include:

Standard Description

IEC 61131-2:2007 Programmable controllers, part 2: Equipment requirements and tests.

ISO 13849-1:2015 Safety of machinery: Safety related parts of control systems.

EN 61496-1:2013 Safety of machinery: Electro-sensitive protective equipment.

ISO 12100:2010 Safety of machinery - General principles for design - Risk assessment and risk

EN 60204-1:2006 Safety of machinery - Electrical equipment of machines - Part 1: General

ISO 14119:2013 Safety of machinery - Interlocking devices associated with guards - Principles

ISO 13850:2015 Safety of machinery - Emergency stop - Principles for design

IEC 62061:2015 Safety of machinery - Functional safety of safety-related electrical, electronic,

IEC 61508-1:2010 Functional safety of electrical/electronic/programmable electronic safety-

IEC 61508-2:2010 Functional safety of electrical/electronic/programmable electronic safety-

IEC 61508-3:2010 Functional safety of electrical/electronic/programmable electronic safety-

IEC 61784-3:2016 Industrial communication networks - Profiles - Part 3: Functional safety

2006/42/EC Machinery Directive

2014/30/EU Electromagnetic Compatibility Directive

2014/35/EU Low Voltage Directive

General principles for design.

Part 1: General requirements and tests.

reduction

requirements

for design and selection

and electronic programmable control systems

related systems: General requirements.

related systems: Requirements for electrical/electronic/programmable

electronic safety-related systems.

related systems: Software requirements.

fieldbuses - General rules and profile definitions.

,

, etc.

10 EIO0000001351 02/2020

Page 11

In addition, terms used in the present document may tangentially be used as they are derived from

other standards such as:

Standard Description

IEC 60034 series Rotating electrical machines

IEC 61800 series Adjustable speed electrical power drive systems

IEC 61158 series Digital data communications for measurement and control – Fieldbus for use in

industrial control systems

Finally, the term

hazards, and is defined as it is for a

2006/42/EC

(

zone of operation

) and

ISO 12100:2010

may be used in conjunction with the description of specific

hazard zone

or

danger zone

in the

Machinery Directive

.

NOTE: The aforementioned standards may or may not apply to the specific products cited in the

present documentation. For more information concerning the individual standards applicable to the

products described herein, see the characteristics tables for those product references.

EIO0000001351 02/2020 11

Page 12

12 EIO0000001351 02/2020

Page 13

Lexium 62 ILM

Specific Safety Information

EIO0000001351 02/2020

Specific Safety Information

Chapter 1

Specific Safety Information

Overview

This chapter contains important safety information regarding working with the Lexium 62 ILM.

What Is in This Chapter?

This chapter contains the following topics:

Product Related Information 14

Intended Use 18

Qualification of Personnel 20

Topic Page

EIO0000001351 02/2020 13

Page 14

Specific Safety Information

Product Related Information

Overview

Health and safety risks arising from the Lexium 62 ILM have been reduced. However residual risks

remain, since the Lexium 62 ILM components work with electrical voltage and electrical currents

as well as initiation of movement that may be hazardous depending on your machine design.

If activities involve residual risks, a safety message is made at the appropriate points. This includes

potential hazard(s) that may arise, their possible consequences, and describes preventive

measures to avoid the hazard(s).

Electrical Parts

ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

Disconnect all power from all equipment including connected devices prior to removing any

covers or doors, or installing or removing any accessories, hardware, cables, or wires.

Place a "Do Not Turn On" or equivalent hazard label on all power switches and lock them in

the non-energized position.

Wait 15 minutes to allow the residual energy of the DC bus capacitors to discharge.

Measure the voltage on the DC bus with a properly rated voltage sensing device and verify

that the voltage is less than 42.4 Vdc.

Do not assume that the DC bus is voltage-free when the DC bus LED is off.

Block the motor shaft to prevent rotation prior to performing any type of work on the drive

system.

Do not create a short-circuit across the DC bus terminals or the DC bus capacitors.

Replace and secure all covers, accessories, hardware, cables, and wires and confirm that a

proper ground connection exists before applying power to the unit.

Use only the specified voltage when operating this equipment and any associated products.

Failure to follow these instructions will result in death or serious injury.

DANGER

14

EIO0000001351 02/2020

Page 15

ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

Operate electrical components only with a connected protective ground (earth) cable.

After the installation, verify the secure connection of the protective ground (earth) cable to all

electrical devices to ensure that connection complies with the connection diagram.

Before enabling the device, safely cover the live components to prevent contact.

Do not touch the electrical connection points of the components when the module is

energized.

Provide protection against indirect contact.

Connect and disconnect cables and terminals only after you have verified that the power has

been removed from the system.

Failure to follow these instructions will result in death or serious injury.

Assembly and Handling

This product has a leakage (touch) current greater than 3.5 mA. If the protective ground connection

is interrupted, a hazardous leakage (touch) current may flow if the housing is touched.

INSUFFICIENT GROUNDING

Use a protective ground copper conductor with at least 10 mm

ground copper conductors with the same or larger cross section of the conductors supplying

the power terminals.

Verify compliance with all local and national electrical code requirements as well as all other

applicable regulations with respect to grounding of all equipment.

Failure to follow these instructions will result in death or serious injury.

DANGER

DANGER

Specific Safety Information

2

(AWG 6) or two protective

WARNING

CRUSHING, SHEARING, CUTTING AND HITTING DURING HANDLING

Observe the general construction and safety regulations for handling and assembly.

Use appropriate mounting and transport equipment and use appropriate tools.

Prevent clamping and crushing by taking appropriate precautions.

Cover edges and angles to protect against cutting damage.

Wear appropriate protective clothing (for example, protective goggles, protective boots,

protective gloves).

Failure to follow these instructions can result in death, serious injury, or equipment damage.

EIO0000001351 02/2020 15

Page 16

Specific Safety Information

Hazardous Movements

There can be different sources of hazardous movements:

No, or incorrect, homing of the drive

Wiring or cabling errors

Errors in the application program

Component errors

Error in the measured value and signal transmitter

NOTE: Provide for personal safety by primary equipment monitoring or measures. Do not rely only

on the internal monitoring of the drive components. Adapt the monitoring or other arrangements

and measures to the specific conditions of the installation in accordance with a risk and error

analysis.

UNAVAILABLE OR INADEQUATE PROTECTION DEVICE(S)

Prevent entry to a zone of operation with, for example, protective fencing, mesh guards,

protective coverings, or light barriers.

Dimension the protective devices properly and do not remove them.

Do not make any modifications that can degrade, incapacitate, or in any way invalidate

protection devices.

Before accessing the drives or entering the zone of operation, bring the drives and the motors

they control to a stop.

Protect existing workstations and operating terminals against unauthorized operation.

Position EMERGENCY STOP switches so that they are easily accessible and can be reached

quickly.

Validate the functionality of EMERGENCY STOP equipment before start-up and during

maintenance periods.

Prevent unintentional start-up by disconnecting the power connection of the drive using the

EMERGENCY STOP circuit or using an appropriate lock-out tag-out sequence.

Validate the system and installation before the initial start-up.

Avoid operating high-frequency, remote control, and radio devices close to the system

electronics and their feed lines, and perform, if necessary, an EMC validation of the system.

Failure to follow these instructions will result in death or serious injury.

DANGER

16

EIO0000001351 02/2020

Page 17

Drive systems may perform unanticipated movements because of incorrect wiring, incorrect

settings, incorrect data or other errors.

UNINTENDED MOVEMENT OR MACHINE OPERATION

Carefully install the wiring in accordance with the EMC requirements.

Do not operate the product with undetermined settings and data.

Perform comprehensive commissioning tests that include verification of configuration settings

and data that determine position and movement.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

PELV Circuits

ELECTRIC SHOCK DUE TO INADEQUATE PROTECTIVE SEPARATION

Only connect devices, electrical components, or lines to the signal voltage connectors of these

products that feature a sufficient, protective separation from the connected circuits in accordance

with the standards (IEC 61800-5-1: Adjustable speed electrical power drive systems - safety

requirements).

Failure to follow these instructions will result in death or serious injury.

Specific Safety Information

WARNING

DANGER

EIO0000001351 02/2020 17

Page 18

Specific Safety Information

Intended Use

Installation

Install and operate this equipment in a control cabinet (enclosure) appropriately rated for its

intended environment and secured by a keyed or tooled locking mechanism.

The Lexium 62 ILM and the Lexium 62 Distribution Box are intended for the installation in a

machine.

Provide for Protective Measures

Before installing the device, provide for appropriate protective devices in compliance with local and

national standards. Do not commission components without appropriate protective devices. After

installation, commissioning, or repair, test the protective devices used.

Perform a risk evaluation concerning the specific use before operating the product and take

appropriate safety measures.

UNINTENDED EQUIPMENT OPERATION

Ensure that a risk assessment is conducted and respected according to EN/ISO 12100 during

the design of your machine.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

WARNING

18

If circumstances occur that affect the safety or cause changes to the operating behavior of the

Lexium 62 ILM components, then immediately shut down the Lexium 62 ILM components and

contact your Schneider Electric representative.

EIO0000001351 02/2020

Page 19

Use Original Equipment Only

Use only the accessories and mounting parts specified in the documentation and no third-party

devices or components that have not been expressly approved by Schneider Electric.

There are no user-serviceable parts in the Lexium 62 ILM system. Do not attempt to modify the

Lexium 62 ILM in any way. Refer to Schneider Electric for all repairs and replacements.

UNINTENDED EQUIPMENT OPERATION

Only use software and hardware components approved by Schneider Electric for use with this

equipment.

Do not attempt to service this equipment outside of authorized Schneider Electric service

centers.

Update your application program every time you change the physical hardware configuration.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

Environment Restrictions

The components must not be used in the following environments:

In hazardous (explosive) atmospheres

In mobile, movable, or floating systems

In life support systems

In domestic appliances

Underground

This equipment has been designed to operate outside of any hazardous location. Only install this

equipment in zones known to be free of a hazardous atmosphere.

Specific Safety Information

WARNING

DANGER

POTENTIAL FOR EXPLOSION

Install and use this equipment in non-hazardous locations only.

Failure to follow these instructions will result in death or serious injury.

EIO0000001351 02/2020 19

Page 20

Specific Safety Information

Qualification of Personnel

Target Audience for This Manual

Electrical equipment must be installed, operated, serviced, and maintained only by qualified

personnel. No responsibility is assumed by Schneider Electric for any consequences arising out of

the use of this material.

Qualified Person

A qualified person is one who has skills and knowledge related to the construction and operation

of electrical equipment and the installation, and has received safety training to recognize and avoid

the hazards involved.

The qualified personnel must be able to detect possible hazards that may arise from parameterization, changing parameter values and generally from mechanical, electrical, or electronic

equipment. The qualified personnel must be familiar with the standards, provisions, and

regulations for the prevention of industrial accidents, which they must observe when working on

the drive system.

Designated Safety Functions

Qualified personnel that work with designated safety functions must be trained according to the

complexity of the machines and the requirements of the ISO 13849-1. The training has to include

the production process and the relation between the designated safety function and the machine.

Qualification guidelines are available in the following publication:

Commitment: Competency Guidelines for Safety-Related System Practitioners

IEEE Publications, ISBN 0 85296 787 X, 1999.

Safety, Competency and

.

20

EIO0000001351 02/2020

Page 21

Lexium 62 ILM

System Overview

EIO0000001351 02/2020

System Overview

Chapter 2

System Overview

What Is in This Chapter?

This chapter contains the following topics:

System Overview 22

Lexium 62 Power Supply 24

Lexium 62 Connection Module 27

Lexium 62 Distribution Box 29

Lexium 62 ILM Integrated Servo Drive 31

Lexium 62 ILM Digital I/O Module 34

Lexium 62 ILM Safety Module 36

ILM Daisy Chain Connector Box 38

Topic Page

EIO0000001351 02/2020 21

Page 22

System Overview

System Overview

System Overview

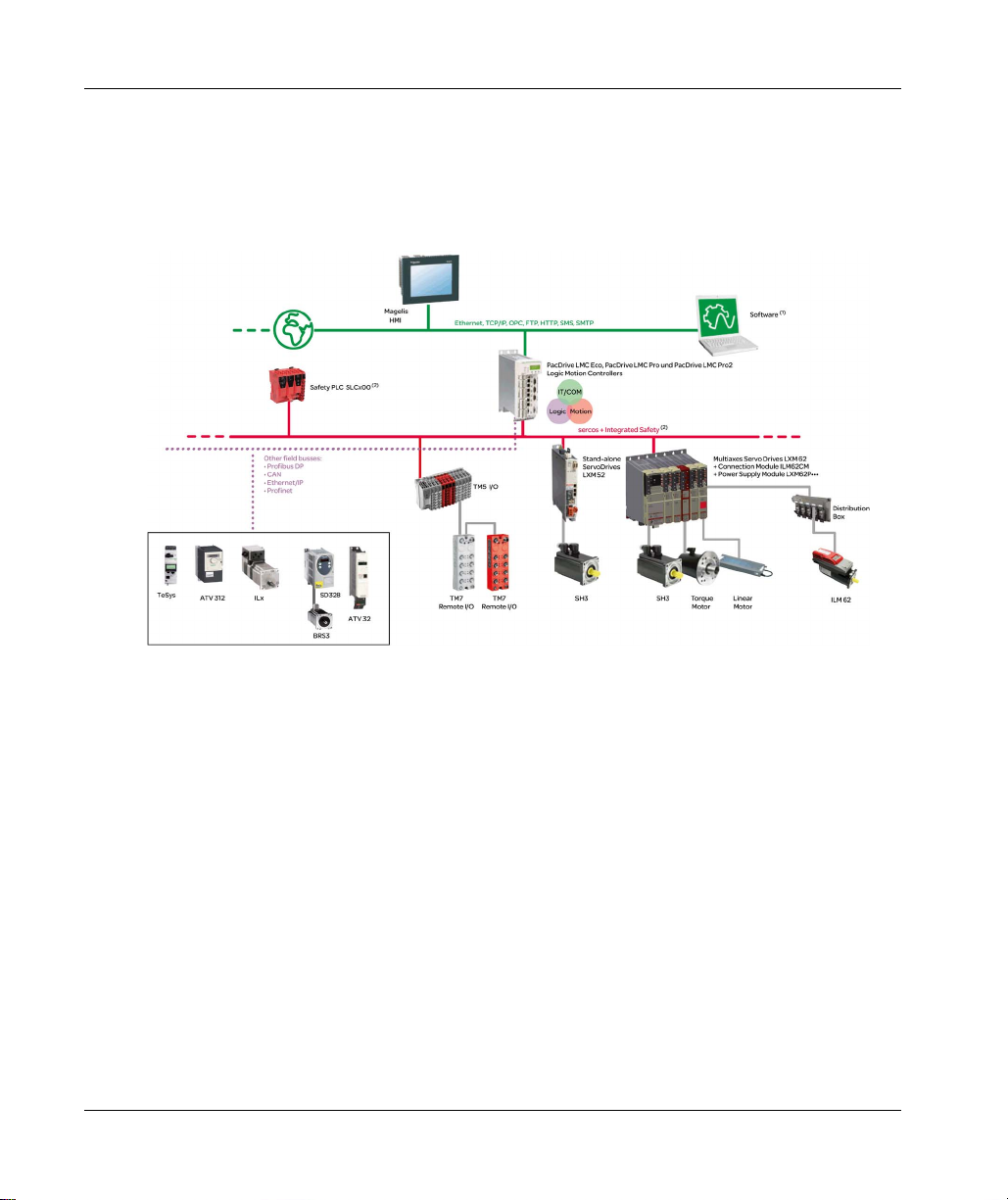

The control system consists of several components, depending on its application.

PacDrive 3 system overview:

22

(1) EcoStruxure Machine Expert Software

(2) Safety Logic Controller according to IEC 61508:2010 and EN ISO 13849:2008

EIO0000001351 02/2020

Page 23

Lexium 62 ILM system overview:

1 Lexium 62 Connection Module

2 Lexium 62 Distribution Box

3 Lexium 62 ILM Integrated Servo Drive

4 Lexium 62 ILM with Safety Module

5 Hybrid Cable

System Overview

EIO0000001351 02/2020 23

Page 24

System Overview

Lexium 62 Power Supply

Overview

Product Description

The central Lexium 62 Power Supply, using a

common DC bus, supplies the connected Lexium 62

servo drive(s) with the required power.

For further information, refer to:

Installation and Maintenance (see page 97)

Indicators of the Lexium 62 Power Supply

(see page 150)

Electrical Connections for the Lexium 62 Power

Supply (see page 162)

Mechanical and Electrical Data for the Lexium 62

Power Supply (see page 188)

References

Product Reference

Power supply LXM62PD20A11000

24

LXM62PD84A11000

EIO0000001351 02/2020

Page 25

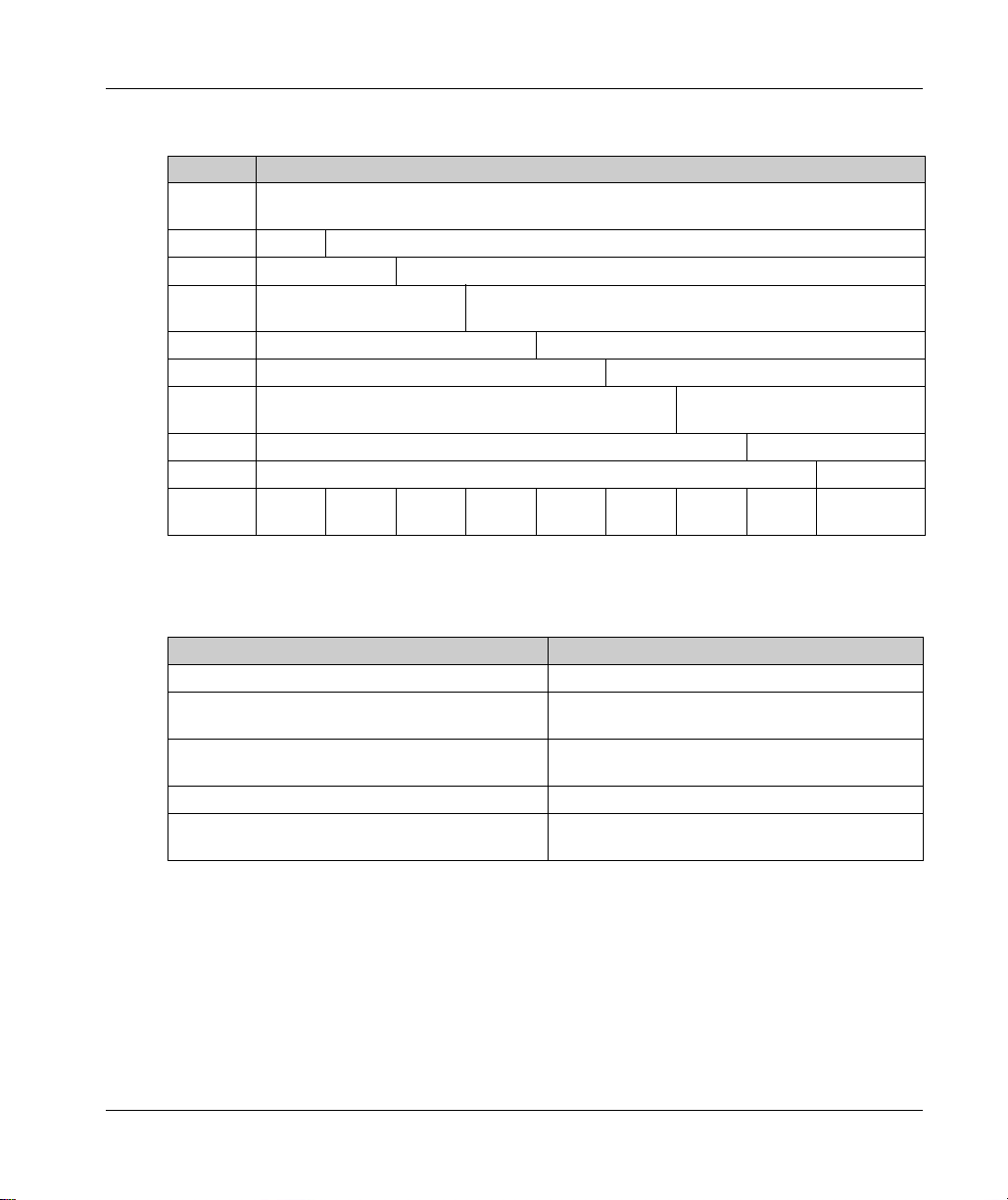

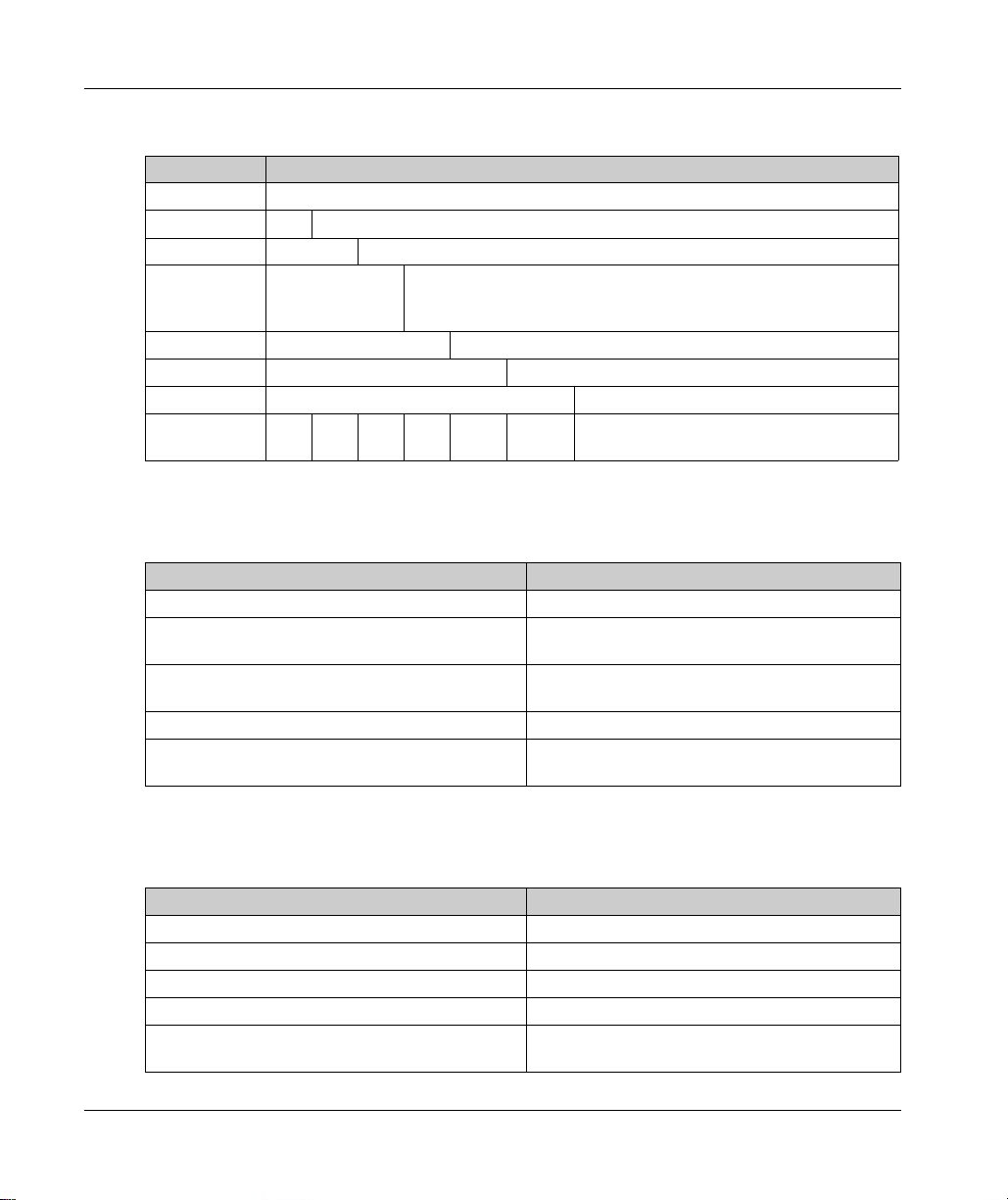

Type Code

Item Meaning

Product

family

Size 62 = Lexium 62

Type P = Power Module

Peak

current

Variants A = Power Supply Module

Options 1 = 1 or 3 Phases x 208...480 Vac

Hardware

release

Internal 0 = Serial production

Customer 00 = Standard

Type code

(example)

Technical Nameplate

The technical nameplate is located laterally on housing.

System Overview

LXM = Lexium

D84 = 84 A

D20 = 20 A

1

LXM 62 P D84 A 1 1 0 00

Label Meaning

LXM62PDxxxxxxx Device type and Unicode

Input ac/dc Input voltage and/or input current (rated- and/or peak

Output dc Output voltage and output current (rated and/or peak

IP20 Degree of protection

Symbols This field displays the symbols of declarations and

EIO0000001351 02/2020 25

value per input)

value per output)

certifications

Page 26

System Overview

Logistic Nameplate

The technical nameplate is located on top of the housing.

Label Meaning

LXM62PDxxxxxxx Device type and Unicode

2528044067 Serial number

RS:01 Hardware revision

DOM Date of manufacture

Symbols This field displays the symbols of declarations and

certifications

26

EIO0000001351 02/2020

Page 27

Lexium 62 Connection Module

Overview

The Lexium 62 Connection Module simplifies the wiring of the devices. With the

Lexium 62 Connection Module you can connect up to 45 servo drives.

Product Description

System Overview

The Lexium 62 Connection Module supplies the

Lexium 62 ILMs with DC voltage from the DC bus via a

hybrid cable or a power cable (daisy chain wiring).

Additionally, the Lexium 62 Connection Module provides the

Inverter Enable and Sercos interface.

For further information, refer to:

Installation and Maintenance (see page 97)

Indicators of the Lexium 62 Connection Module

(see page 153)

Electrical Power Connection of the Lexium 62

Connection Module (see page 168)

Mechanical and Electrical Data for the Lexium 62

Connection Module (see page 191)

References

Product Reference

Lexium 62 Connection Module ILM62CMD20A000

EIO0000001351 02/2020 27

Page 28

System Overview

Type Code

Item Meaning

Product family ILM = Integrated Lexium Servo Module

Size 62 = Lexium 62

Type CM = Connection Module

Power

(cont. DC Bus

current)

Variants A

Internal 0 = Serial production

Customer 00 = Standard

Type code

(example)

Technical Nameplate

The technical nameplate is located laterally on housing.

Label Meaning

ILM62CMxxxxxxx Device type and Unicode

Input dc Input voltage and/or input current (rated- and/or peak

Output ac/dc Output voltage and output current (rated and/or peak

IP20 Degree of protection

Symbols This field displays the symbols of declarations and

D20

ILM 62 CM D20 A 0 00

value per input)

value per output)

certifications

Logistic Nameplate

The technical nameplate is located on top of the housing.

Label Meaning

ILM62xxxxxxxxxx Device type and Unicode

2528044067 Serial number

RS:01 Hardware revision

DOM Date of manufacture

Symbols This field displays the symbols of declarations and

28

certifications

EIO0000001351 02/2020

Page 29

Lexium 62 Distribution Box

Overview

Product Description

The highlights:

1...4 connections for Lexium 62 ILMs or daisy chain lines or further Lexium 62 distribution

boxes.

Pre-assembled hybrid cables or power cables (Daisy Chain wiring).

System Overview

The Lexium 62 Distribution Box is the link between

Lexium 62 Connection Module and Lexium 62 ILM.

Depending on the number of drives, 1 to 4

Lexium 62 ILMs or daisy chain lines can be

connected. When operating more than four drives,

expand the system by using more Lexium 62

distribution boxes.

For further information, refer to:

Installation and Maintenance (see page 97)

Indicators of the Lexium 62 Distribution Box

(see page 155)

Electrical Connections for the Lexium 62

Distribution Box (see page 174)

Mechanical and Electrical Data for the Lexium 62

Distribution Box (see page 194)

References

Product Reference

Lexium 62 Distribution Box ILM62DB4A000

Sercos bridge plug VW3E6023

EIO0000001351 02/2020 29

Page 30

System Overview

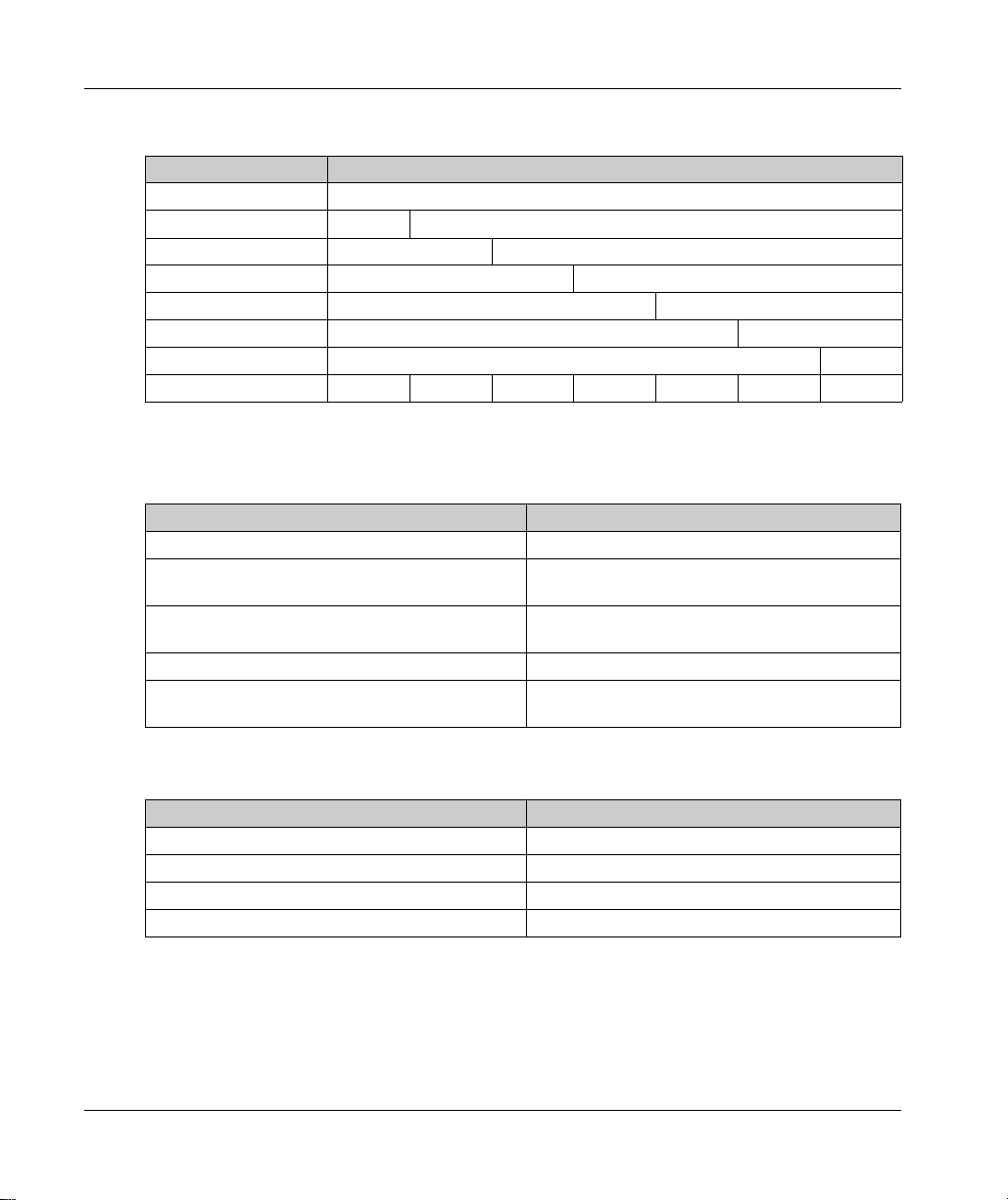

Type Code

Item Meaning

Product family ILM = Integrated Lexium Servo Module

Size 62 = Lexium 62

Type DB = Distribution Box

Hybrid outputs 4

Variants A

Internal 0

Customer 0

Type code (example) ILM 62 DB 4 A000

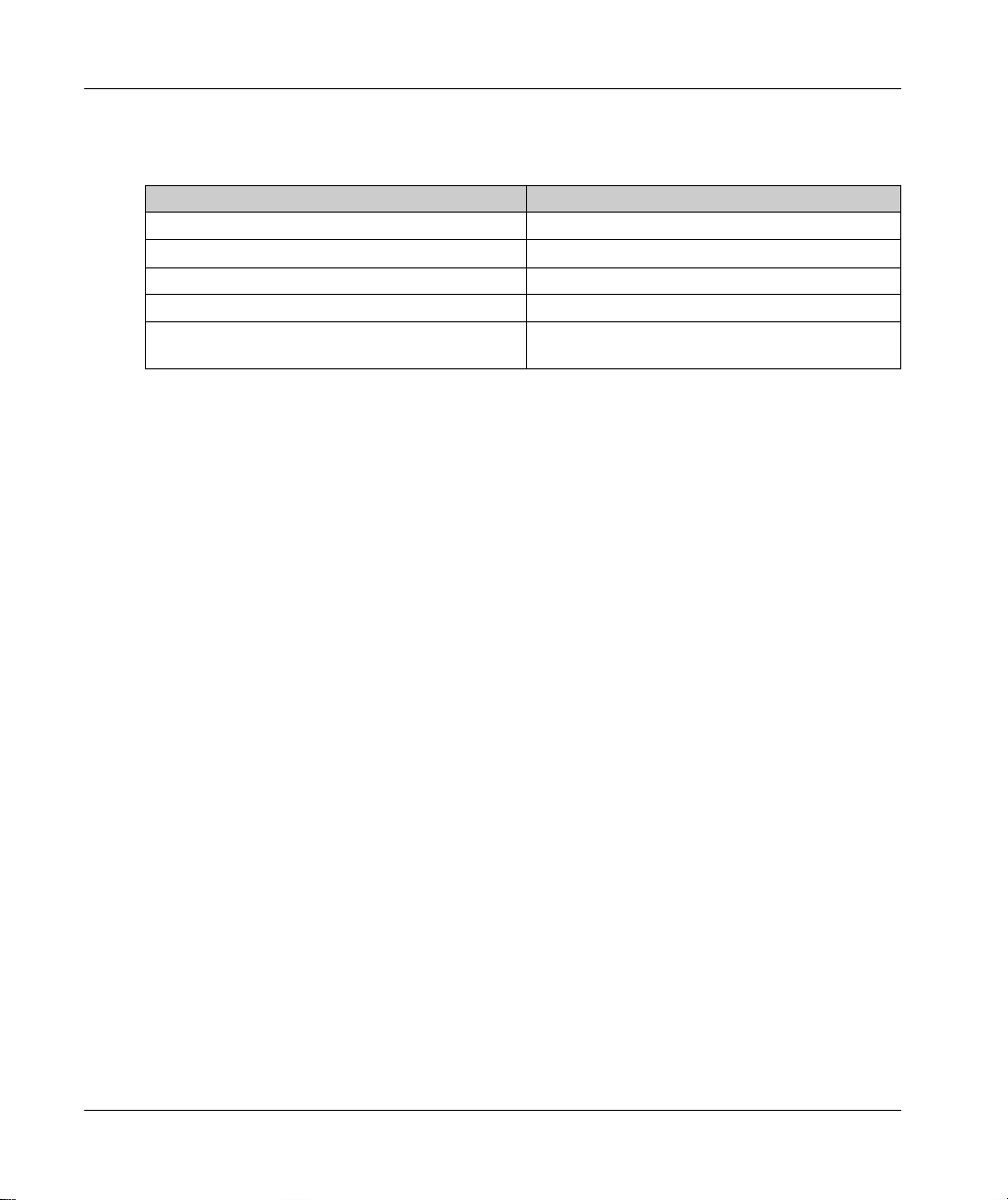

Technical Nameplate

The technical nameplate is located laterally on housing:

Label Meaning

ILM62DBxxxxx Device type and Unicode

Input dc Input voltage and/or input current (rated- and/or peak

Output ac/dc Output voltage and output current (rated and/or peak

IP65 Degree of protection

Symbols This field displays the symbols of declarations and

value per input)

value per output)

certifications

Logistic Nameplate

Label Meaning

ILM62DBxxxxx Device type and Unicode

2328234578 Serial number

RS:01 Hardware revision

DOM Date of manufacture

30

EIO0000001351 02/2020

Page 31

Lexium 62 ILM Integrated Servo Drive

Overview

Product Description

The Lexium 62 ILMs are available in three different flange sizes:

ILM070 (70 mm / 2.76 in.)

ILM100 (100 mm / 3.94 in.)

ILM140 (140 mm / 5.51 in.)

The Lexium 62 ILMs have been derived from the Schneider Electric SH3 family of motors, and

therefore share many characteristics. For instance, when it comes to mounting the motor, the

Lexium 62 ILMs are equivalent.

The highlights:

Compact design

3.5 times peak torque

Integrated Sercos interface

High-resolution single or multi-turn encoder

Degree of protection IP65 (depending on the reference and/or options)

System Overview

The Lexium 62 ILM combines motor, power stage,

and digital servo controller for an axis in a spacesaving housing. Due to its compact design with the

integrated drive, it is suitable for decentralized,

distributed architectures. It is available with singleturn or multi-turn encoders, and simplifies

configuration with the aid of the electronic nameplate

in the Lexium 62 ILM.

For further information, refer to:

Installation and Maintenance (see page 98)

Indicators of the Lexium 62 ILM Integrated Servo

Drive (see page 157)

Electrical Connections for the Lexium 62 ILM

Integrated Servo Drive (see page 177)

Mechanical and Electrical Data for the Lexium 62

ILM Integrated Servo Drive (see page 202)

EIO0000001351 02/2020 31

Page 32

System Overview

References

Device Reference

Lexium 62 ILM Integrated Servo Drive

Type Code

Item Meaning

Product family ILM = Integrated Lexium Servo Module

Flange size 070 = 70 mm / 2.76 in.

Number of

stacks

Winding type P = Standard

Shaft

(see page 215)

Encoder

(see page 214)

Holding brake

(see page 217)

Variants 0

Internal 0 = Standard production

Costumer 00 = Standard

Type code

(example)

ILM0701P

ILM0702P

ILM0703P

ILM1001P

ILM1002P

ILM1003P

ILM1401P

ILM1401M

ILM1402P

100 = 100 mm / 3.94 in.

140 = 140 mm / 5.51 in.

1 = 1 Stack

2 = 2 Stacks

3 = 3 Stacks

M = Optimized in terms of torque (available only with ILM1401)

0 = Smooth shaft, without shaft seal

1 = Parallel key, without shaft seal

2 = Smooth shaft, with shaft seal, IP65

3 = Parallel key, with shaft seal, IP65

1 = Absolute single-turn 128 SinCos periods per

revolution

2 = Absolute multi-turn 128 SinCos periods per revolution

A = Without holding brake

F = With holding brake

ILM 070 1 P 0 1 A 0 0 00

32

EIO0000001351 02/2020

Page 33

Technical/Logistic Nameplate

Label Meaning

ILMxxxxxxxxxxxx Device type, see type code

SN Serial number

Input 1 Rated voltage and rated current of the power supply

Input 2 Rated voltage and rated current of the electronics

Type rating Degree of protection of the housing in accordance with NEMA 250 and

HW Hardware version

SW Software version

IPxx Degree of protection

Th-Cl Insulation material class of the motor

M0 Standstill torque

Mmax Peak torque

nN Nominal speed of rotation

DOM Date of manufacture

Symbols This field displays the symbols of declarations and certifications.

System Overview

UL 50.

EIO0000001351 02/2020 33

Page 34

System Overview

Lexium 62 ILM Digital I/O Module

Overview

Option Module for Lexium 62 ILM Integrated Servo Drive.

Product Description

Reference

Product Reference

Digital I/O Module VW3E702100000

Type Code

Lexium 62 ILM Digital I/O Module with 8 digital inputs

or outputs.

For further information, refer to the chapter

ILM 62 Digital I/O Module (see page 227)

Lexium

.

Item Meaning

Product family VW3 = Integrated Lexium

Size E = PacDrive 3

Type 7 = Option Modules

Drawing reference 021 = I/O Option Module for

Internal 00000

Type code (example) VW3 E 7 021 00000

34

Lexium 62 ILM

022 = Safety Option Module for

Lexium 62 ILM

EIO0000001351 02/2020

Page 35

Technical/Logistic Nameplate Description

Label Meaning

ILM62-iSH-DIO8 I/O module Device type and Unicode

VW3E702100000 Commercial reference

2910229412 Serial number

DOM Date of manufacture

HW Hardware version

FW Firmware version

System Overview

EIO0000001351 02/2020 35

Page 36

System Overview

Lexium 62 ILM Safety Module

Overview

Option module for Lexium 62 ILM integrated servo drive.

Product Description

Reference

Product Reference

Safety Module VW3E702200000

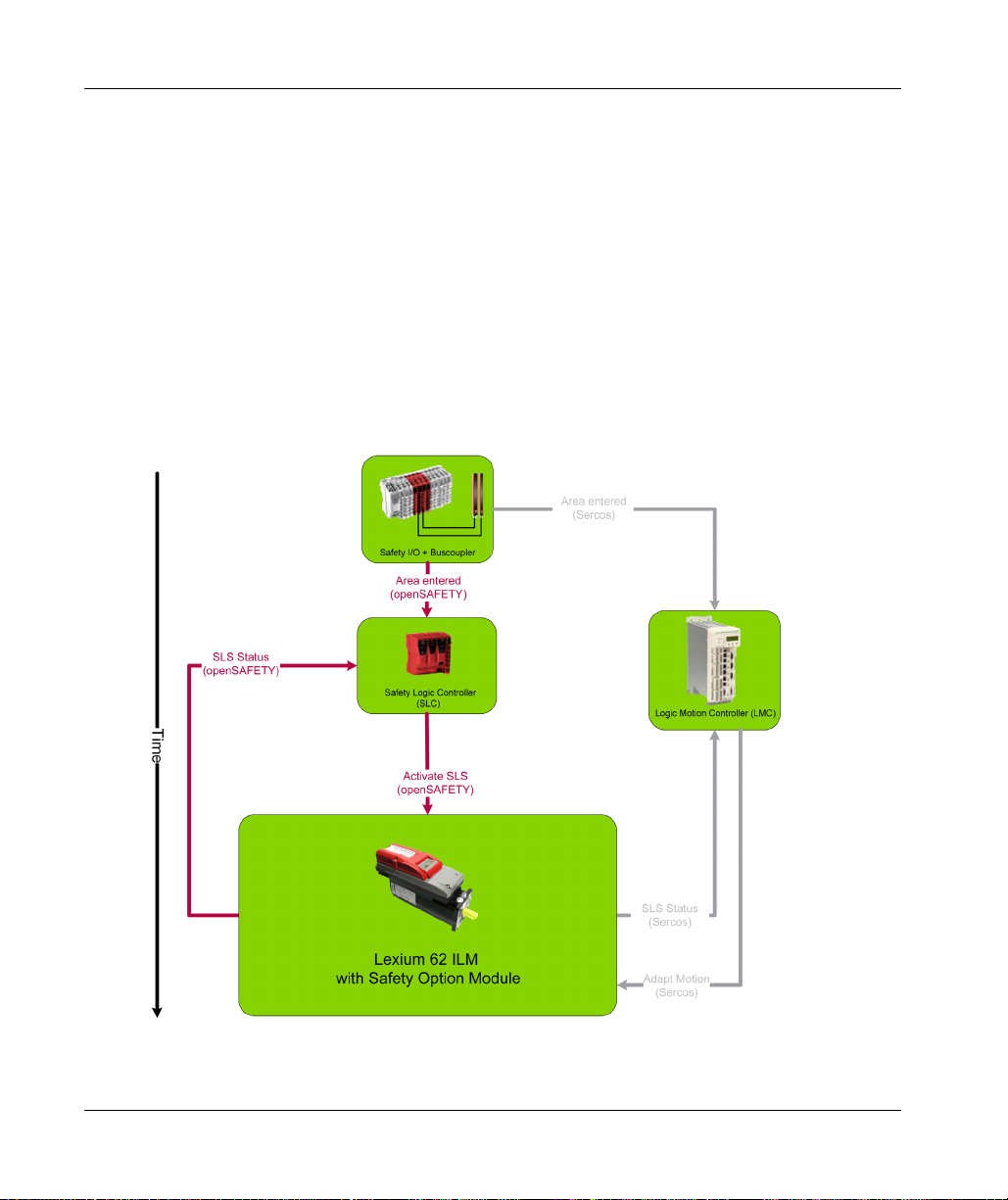

Lexium 62 ILM Safety Module manages the safe

motion functions via Sercos bus.

Safe Torque off (STO)

Safe Stop 1 (SS1)

Safe Operating Stop (SOS)

Safe Stop 2 (SS2)

Safe Maximum Speed (SMS)

Safely-Limited Speed (SLS)

Safe Direction Indication (SDI)

For further information, refer to the chapter

62 ILM Safety Module (see page 239)

Lexium

.

Type Code

Item Meaning

Product family VW3 = Integrated Lexium

Size E = PacDrive 3

Type 7 = Option Modules

Drawing reference 021 = I/O Option Module for

Lexium 62 ILM

022 = Safety Option Module for

Lexium 62 ILM

Internal 00000

Type code (example) VW3 E 7 022 00000

36

EIO0000001351 02/2020

Page 37

Technical/Logistic Nameplate Description

Label Meaning

Lexium 62 ILM safety option module Device type and Unicode

VW3E702200000 Commercial reference

2910171253 Serial number

DOM Date of manufacture

HW Hardware version

FW Firmware version

System Overview

EIO0000001351 02/2020 37

Page 38

System Overview

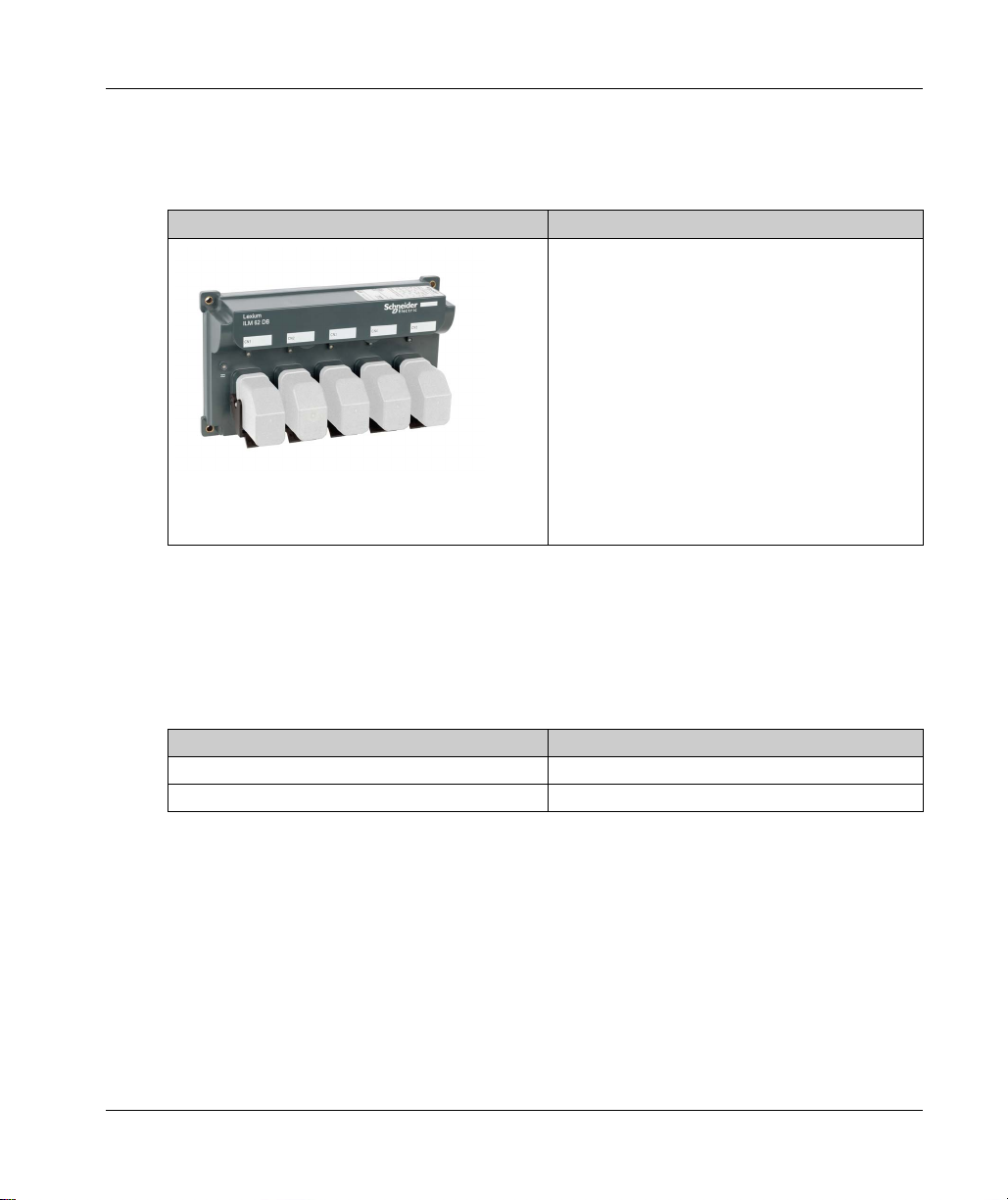

ILM Daisy Chain Connector Box

Overview

Product Description

Type A The ILM Daisy Chain Connector Box is mounted on

Type B Power (DC bus voltage/24 V/Inverter Enable signals)

Type C

a Lexium 62 ILM in order to enable a daisy chain

wiring.

The Lexium 62 ILMs can be either directly connected

to the Lexium 62 Distribution Box or via a

Lexium 62 Connection Module. Refer to

Wiring from

the Lexium 62 Connection Module in a Daisy Chain

Topology (see page 120)

When connecting via a Lexium 62 Distribution Box, a

larger number of drives can be connected.

and Sercos signals are distributed via separate

cables. Each Lexium 62 ILM must be extended by a

Daisy Chain Connector Box (refer to

(see page 108)

Box is used, then up to four daisy chain lines can be

connected to it. If several Lexium 62 distribution

boxes are used, then from the first

Lexium 62 Distribution Box up to and including the

second last Lexium 62 Distribution Box respectively

up to three daisy chain lines and on the last

Lexium 62 Distribution Box up to four daisy chain

lines can be connected. A daisy chain line can

consist of up to nine Lexium 62 ILMs.

). If only one Lexium 62 Distribution

.

Mounting

38

EIO0000001351 02/2020

Page 39

For further information, refer to:

The connection between the Lexium 62 ILMs is established as follows (refer to Wiring from the

Lexium 62 Connection Module in a daisy chain topology

Power cable for power distribution (DC bus voltage/24V/Inverter Enable signals) with an M23

Sercos cable for distribution of the Sercos signals via M12 connector

Reference

Product Reference

ILM Daisy Chain Connector Box

Type Code

Item Meaning

Product

family

Size 62 = Integrated Lexium 62

Type DC = Daisy Chain Connector Box

Series A = Power at back, Sercos at bottom (ILM070, ILM100,

Internal 0 = Serial production

Customer 00 = Standard

Type code

(example)

System Overview

Electrical Connections for the ILM Daisy Chain Connector Box (see page 179)

Mechanical and Electrical Data for the ILM Daisy Chain Connector Box (see page 197)

(see page 120)

):

connector

ILM62DCA000

ILM62DCB000

ILM62DCC000

ILM = Integrated Lexium Servo Module

ILM140)

B = Power at bottom, Sercos at left and right (ILM070)

C = Power at bottom, Sercos at left and right (ILM100)

Z = Protection cap for the last M23 connector

ILM 62 DC A 0 00

EIO0000001351 02/2020 39

Page 40

System Overview

40

EIO0000001351 02/2020

Page 41

Lexium 62 ILM

Engineering

EIO0000001351 02/2020

Engineering

Chapter 3

Engineering

What Is in This Chapter?

This chapter contains the following sections:

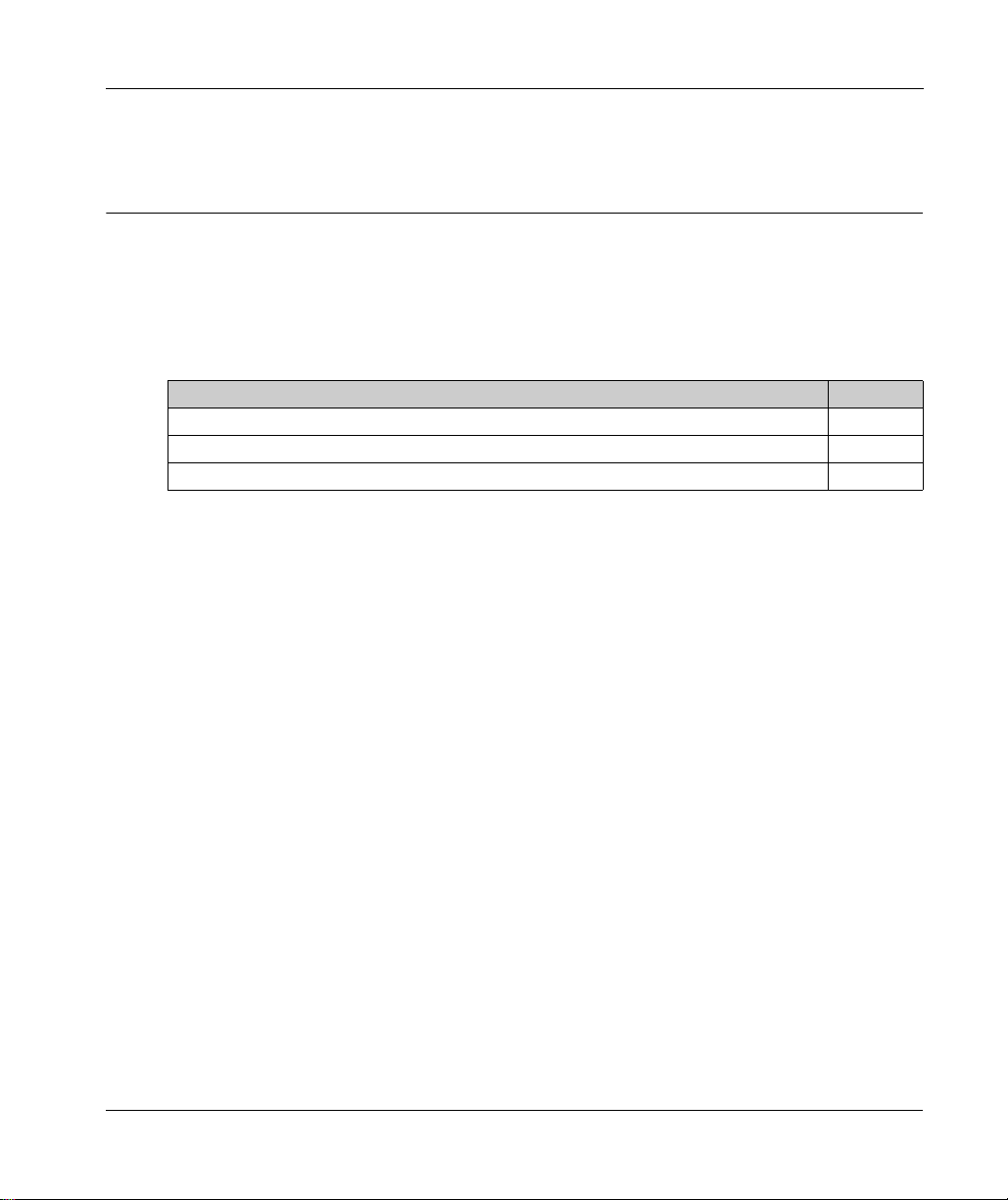

Section Topic Page

3.1 Electromagnetic Compatibility, EMC 42

3.2 Control Cabinet Planning 46

3.3 Information about Wiring 51

3.4 Functional Safety 66

3.5 Special Conditions 93

EIO0000001351 02/2020 41

Page 42

Engineering

Electromagnetic Compatibility, E MC

Section 3.1

Electromagnetic Compatibility, EMC

Electromagnetic Compatibility, EMC

Electromagnetic Disturbances of Signals and Devices

This product meets the EMC requirements according to the standard IEC 61800-3 if the measures

described in this manual are implemented during installation.

Signal interference can cause unexpected responses of the drive and of other equipment in the

vicinity of the drive.

WARNING

SIGNAL AND EQUIPMENT INTERFERENCE

Only operate the drive with the specified external mains filter.

Install the wiring in accordance with the EMC requirements described in the present

document.

Verify compliance with the EMC requirements described in the present document.

Verify compliance with all EMC regulations and requirements applicable in the country in

which the product is to be operated and with all EMC regulations and requirements applicable

at the installation site.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

42

WARNING

ELECTROMAGNETIC DISTURBANCES OF SIGNALS AND DEVICES

Use proper EMC shielding techniques to help prevent unintended device operation in accordance

with the standard IEC 61800-3.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

EIO0000001351 02/2020

Page 43

These types of devices are not intended to be used on a low-voltage public network which supplies

domestic premises. Radio frequency interference is expected if used in such a network.

RADIO INTERFERENCE

Do not use these products in domestic electrical networks.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

Layout Control Cabinet (Enclosure)

The prerequisite for compliance with the specified limit values is an EMC compatible layout.

Depending on the application, the following measures can improve the EMC-dependent values:

EMC measures Objective

Use galvanized or chromium-plated sub plates, bond

metallic parts across large surface areas, remove

paint layer from contact surfaces.

Ground control cabinet (enclosure), door, and sub

plates by using grounding strips or grounding cables

with a cross-section of 10 mm

Supplement switch devices such as contactors,

relays, or magnetic valves with interference

suppression combinations or spark suppressor

elements (for example, diodes, varistors, RC

elements).

Fit power and control components separately. Reduces mutual interference.

2

(AWG 6).

Engineering

WARNING

Good conductivity by surface area contact.

Reduce emission.

Reduces mutual interference.

Shielded Cables

EMC measures Objective

Connect large surface areas of cable shields, use

cable clamps and ground straps.

Ground shields of digital signal wires at both ends by

connecting them to a large surface area or via

conductive connector housings.

Ground shield of analog signal cables directly on the

device (signal input), insulate the shield at the other

cable end or ground the same through a capacitor,

such as 10 nF.

EIO0000001351 02/2020 43

Reduce emission.

Reduce interference action on signal cables, reduce

emissions.

Reduce grounding loops by low frequency

interferences.

Page 44

Engineering

Cable Installation

EMC measures Objective

Do not route fieldbus cables and signal wires in a

single cable duct together with lines with DC and AC

voltages of more than 60 V. (Fieldbus cables, signal

lines, and analog lines may be in the same cable duct)

Recommendation: Use separate cable ducts at least

20 cm (7.84 in) apart.

Keep cables as short as possible. Do not install

unnecessary cable loops, use short cables from the

central grounding point in the control cabinet to the

external ground connection.

Use equipotential bonding conductors (stranded wire

of equal potential at all grounding locations connected

to an equipotential grounding plane) in the following

cases: wide-area installations, different voltage

supplies, and installation across several buildings.

Use stranded wire potential equalization conductor. Discharging of high frequency interference currents.

If motor and machine are not connected in a

conducting fashion, for example, due to an insulated

flange or a connection not across a full surface, the

motor must be grounded via a grounding cable with a

minimum 4 mm

grounding strip with a length as short as possible.

Use twisted pair for 24 Vdc signals. Reduce interference action on signal cables, reduce

2

(AWG 11) cross-section or a

Reduces mutual interference.

Reduces capacitive and inductive interference.

Reduces current in the cable shield, reduces

emissions.

Reduce emissions, increase interference resistance.

emissions.

Power Supply

EMC measures Objective

Operate product on mains with grounded neutral

point.

Use surge arrester if there is a risk of overvoltage. Reduces the risk of damage caused by overvoltage.

44

Enables effectiveness of mains filter.

EIO0000001351 02/2020

Page 45

Additional Measures for Improving the EMC

Depending on the respective application, the following measures may lead to an EMC compatible

layout:

EMC measures Objective

Upstream connection of mains line reactor (choke) Reduction of the harmonic network oscillations,

Upstream connection of external mains filters Improvement of the EMC limit values.

Special EMC-appropriate layout, for example, within

an enclosed control cabinet complete with 15 dB

attenuation of the interferences emitted

Engineering

extension of the service life of the product.

Improvement of the EMC limit values.

EIO0000001351 02/2020 45

Page 46

Engineering

Control Cabinet Planning

Section 3.2

Control Cabinet Planning

What Is in This Section?

This section contains the following topics:

Degree of Protection (IP) 47

Mechanical and Climatic Environmental Conditions in the Control Cabinet 48

Using Cooling Units 49

Topic Page

46

EIO0000001351 02/2020

Page 47

Degree of Protection (IP)

Overview

Install components such that a degree of protection corresponding to the actual operational

environment is set up.

For more information on the degree of protection of the component, refer to

(see page 187)

The following ambient conditions may damage the components:

Oil

Moisture

Electromagnetic interference

Ambient temperature

Metal dust deposits

UNINTENDED EQUIPMENT OPERATION

Observe and conform to ambient temperatures, storage temperatures and transport

temperatures of the individual components as specified in the operating manuals of the

components.

Prevent the formation of moisture during the operation, storage and transport of individual

components.

Conform to the vibration and shock requirements specified in the operating manuals for the

components when operating, storing and transporting system components.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

.

Engineering

Ambient Conditions

WARNING

EIO0000001351 02/2020 47

Page 48

Engineering

Mechanical and Climatic Environmental Conditions in the Control Cabinet

Overview

Step Action

1 Observe the climatic and mechanical ambient conditions.

For more information on the general climatic and mechanical environmental conditions

according to IEC 60721, refer to

2 Verify the technical data of the device whether the permitted deviations (for example, higher

shock load or higher temperature) are specified.

Ambient Conditions (see page 187)

.

48

EIO0000001351 02/2020

Page 49

Using Cooling Units

Installing a Cooling Unit

How to proceed when installing a cooling unit:

Step Action

1 Position the cooling units so that no condensate drips out of the cooling unit onto electronic

components or is sprayed by the cooling air flow.

2 Provide specially designed control cabinets for cooling units on the top of the control cabinet.

3 Design the control cabinet so that the cooling unit fan cannot spray any accumulated condensate

onto the electronic components when it restarts after a pause.

4 When using cooling units, use only well-sealed control cabinets so that warm, humid outside air,

which causes condensation, does not enter the cabinet.

5 When operating control cabinets with open doors during commissioning or maintenance, ensure

that the electronic components are at no time cooler than the air in the control cabinet after the

doors are shut, in order to avoid any condensation.

6 Continue to operate the cooling unit even when the system is switched off, so that the

temperature of the air in the control cabinet and the air in the electronic components remains the

same.

7 Set cooling unit to a fixed temperature of 40 °C or lower (104 °F).

8 For cooling units with temperature monitoring, set the temperature limit to 40 °C (104 °F) so that

the internal temperature of the control cabinet does not fall below the external air temperature.

Engineering

WARNING

UNINTENDED EQUIPMENT OPERATION

Follow the installation instructions such that the condensation from the cooling unit can not enter

electrical equipment.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

EIO0000001351 02/2020 49

Page 50

Engineering

Installing a cooling unit

50

EIO0000001351 02/2020

Page 51

Information about Wiring

Section 3.3

Information about Wiring

What Is in This Section?

This section contains the following topics:

General Information about Wiring 52

Cable Characteristics 53

ESD Protection Measures 55

Conditions for UL / CSA Compliant Use 56

Fusing the Mains Connection 58

Mains Contactor 60

Mains Filter 61

Mains Line Reactor (Choke) 62

Connection of the Lexium 62 Power Supply 63

Leakage (Touch) Current 64

Residual Current Operated Protective Device 65

Engineering

Topic Page

EIO0000001351 02/2020 51

Page 52

Engineering

General Information about Wiring

Overview

Use only Schneider Electric approved devices in your application, and especially Schneider

Electric pre-fabricated cables, wherever and whenever possible.

For further information, refer to

Use an appropriate torque indication or screwdriver for tightening connections.

Observe and implement the following points when wiring:

1. Observe the minimum cross-sections of the cables necessary for the load carrying capacity of

the equipment being connected.

2. Verify the integrity of cable shields to ensure continuity to ground.

3. Ensure that there is a proper, equipotential connection to ground for all interconnected

equipment.

4. Ensure connection of the motors to the machine ground.

5. Eliminate any ground loops.

6. Do not disconnect cable connection terminals when under power.

7. Ensure that all ground connections have sufficient surface area continuity.

8. Do not interchange motor phases.

9. Do not interchange encoder connections.

10.Connect the hybrid or power cable connections and the Sercos cable connections to the

Lexium 62 Connection Module according to the connection diagram of the machine

manufacturer.

For information on the different cable type refer to

11.Do not interchange the emergency stop circuits. This has to be observed especially when two

different safety-related circuits are used for axis A and axis B of the Lexium 62 Double Drive.

If, for example, two parallel conductors are shown as coming from one point, you may not run just

one conductor and then branch it off at a later point. If it is wired this way, induction loops

(interference emitters and antennas) as well as interfering potential shifts may occur.

Cable Characteristics (see page 53)

Cable Characteristics (see page 53)

.

.

52

DANGER

INCORRECT OR UNAVAILABLE GROUNDING

Remove paint across a large surface at the installation points before installing the devices (bare

metal connection).

Failure to follow these instructions will result in death or serious injury.

EIO0000001351 02/2020

Page 53

Cable Characteristics

Overview

Cable characteristics of the hybrid cable:

Property Value

Hybrid cable voltage isolation 1000 V

Maximum continuous current

Temperature range -40...+80 °C / -40...+176 °F

Cable diameter 14.8 ± 0.3 mm (0.58 ± 0.012 in.)

Bending radius Five x diameter (fixed routing)

Sheath PUR, oil resistant, halogen-free

The hybrid cable (daisy chain wiring) is drag chain capable.

Cable characteristics of the power cable (daisy chain wiring):

Property Value

Voltage isolation 1000 V

Maximum continuous current

Temperature range -40...+80 °C / -40...+176 °F (fixed routing)

Cable diameter 11.7 ± 0.3 mm (0.45 ± 0.012 in.)

Bending radius 5 x diameter (fixed routing)

Sheath PUR, oil resistant, halogen-free, flame-retardant

Engineering

DC Bus: 20 A

24 Vdc: 20 A

10 x diameter (mobile, 5 million bending cycles)

DC Bus: 20 A

24 Vdc: 20 A

-25...+80 °C / -13...+176 °F (mobile)

10 x diameter (mobile, 5 million bending cycles)

The power cable (daisy chain wiring) is drag chain capable.

EIO0000001351 02/2020 53

Page 54

Engineering

Cable characteristics of the Sercos cable (daisy chain wiring):

Property Value

Voltage isolation 300 V

Temperature range -20...+60 °C / -4...+140 °F

Cable diameter 6.7 ± 0.2 mm (0.26 ± 0.008 in.)

Bending radius 5 x diameter (fixed routing)

Sheath PUR, halogen-free, flame-retardant

Cable type and shielding CAT6 with S/FTP (Sercos III)

10 x diameter (mobile, 5 million bending cycles)

54

EIO0000001351 02/2020

Page 55

ESD Protection Measures

General

Observe the following instructions to help avoid damages due to electrostatic discharge:

ELECTROSTATIC DISCHARGE

Do not touch any of the electrical connections or components.

Prevent electrostatic charges, for example, by wearing appropriate clothing.

If you must touch circuit boards, do so only on the edges.

Remove existing static charge by touching a grounded, metallic surface.

Failure to follow these instructions can result in equipment damage.

Engineering

NOTICE

EIO0000001351 02/2020 55

Page 56

Engineering

Conditions for UL / CSA Compliant Use

General

If you use the Lexium 62 ILM system in accordance with UL or CSA standards, you must

additionally, aside from the installation requirements stated in the present document, meet the

following conditions:

Install the “open type equipment” Lexium 62 ILM system at a maximum surrounding air

temperature of 40 °C / 55 °C with derating.

Only connect the power supply to a mains supply with a maximum short circuit current of 22 kA

or, alternatively, take appropriate measures according to UL508A SB4 in the supply circuit of

the control cabinet to limit the short circuit current to 22 kA maximum. This does not apply to

operation in accordance with CSA 22.2 No. 14. Here, it is only permissible to operate the device

for a maximum short circuit current of 5 kA.

Use devices only in connection with a Lexium 62 Power Supply.

To protect the power supply, use a class J fuse according to UL248 with a maximum fuse rating

of 60 A / 600 Vac.

Only use hybrid connection cable approved by Schneider Electric and comply with the

requirements of NFPA 79.

Short-Circuit Current Rating (SCCR)

Only connect the Lexium 62 Drive System to a mains supply network not exceeding the nonoperational case of SCCR (Short Circuit Current Rating) from following table, or take appropriate

measures according to UL 508 A SB4 in the supply (feeder) circuit of the control cabinet to limit the

short circuit current to a value below the least SCCR of those devices you are using from the

following table.

NOTE: The opening of the branch-circuit protective device (fuses in the case of UL conformance,

or any circuit breaker) may be an indication that an invalid condition has been interrupted. To

reduce the risk of fire or electric shock, current-carrying parts and other components of the

controller must be examined and replaced if damaged. If burnout of the current element of an

overload relay occurs, the complete overload relay must be replaced.

56

DANGER

FIRE, ELECTRIC SHOCK OR ARC FLASH

Examine and replace if necessary any current-carrying parts or other controller components in

the case of mains- or branch-circuit protection activation.

Failure to follow these instructions will result in death or serious injury.

According to CSA 22.2 No.14, only a short circuit current rating of 5 kA is permissible.

NOTE: Line reactors according to UL 508 A (SB 4.2.1 Exception No. 1) are not required to have a

short-circuit current rating (SCCR).

EIO0000001351 02/2020

Page 57

Notes on Wiring

For the wiring of the Lexium 62 Power Supply, use at least 60 °C (140 °F) / 75 °C (167 °F)

copper conductors.

Choose the cross-section according to the load of the system and selected overload protection

in your application.

Consider the applicable cross section for the terminal blocks according to following tables:

For Lexium 62 Power Supply

Engineering

Connection Torque [Nm] / [lbf in]

CN1 2.5 / 22 N/A

CN5 N/A 0.5...16 / 20...6

CN6 N/A 0.75...16 / 18...6

CN7 N/A 0.2...6 / 24...10

CN4 N/A 0.5...1.5 / 20...16

(1) To protect the Lexium 62 Power Supply, use a Class J fuse according to UL 248 with a maximum fuse

rating of 60 A / 600 Vac.

DC Bus Coupling

When using the DC bus connection on CN7 of the Lexium 62 Power Supply, ensure that the

current is limited to 35 A via this connection with an appropriate fuse or circuit breaker.

Connection cross section [mm²] / [AWG]

(1)

EIO0000001351 02/2020 57

Page 58

Engineering

Fusing the Mains Connection

General

This data is only valid for fusing the mains connection of each Lexium 62 Power Supply module:

Protect the power supply against any short-circuit and overload using appropriate measures.

Set the overload protection depending on the permanent current of the device:

Lexium 62 Power Supply (LXM62PD84A11000) maximum of 40 A (3-phase),

Lexium 62 Power Supply (LXM62PD20A11000) maximum of 10 A (3-phase).

NOTE: The opening of the branch-circuit protective device (fuses in the case of UL conformance,

or any circuit breaker) may be an indication that an abnormal condition has been interrupted. To

reduce the risk of fire or electric shock, current-carrying parts and other components of the system

should be examined and replaced if damaged. If burnout of the current element of an overload

relay occurs, the complete overload relay must be replaced. In any and all cases, determine the

source of the opening of the branch-circuit protection before re-applying power to the system.

FIRE, ELECTRIC SHOCK OR ARC FLASH

Examine and replace if necessary any current-carrying parts or other motor control components

in the case of mains- or branch-circuit protection activation.

Failure to follow these instructions will result in death or serious injury.

DANGER

58

EIO0000001351 02/2020

Page 59

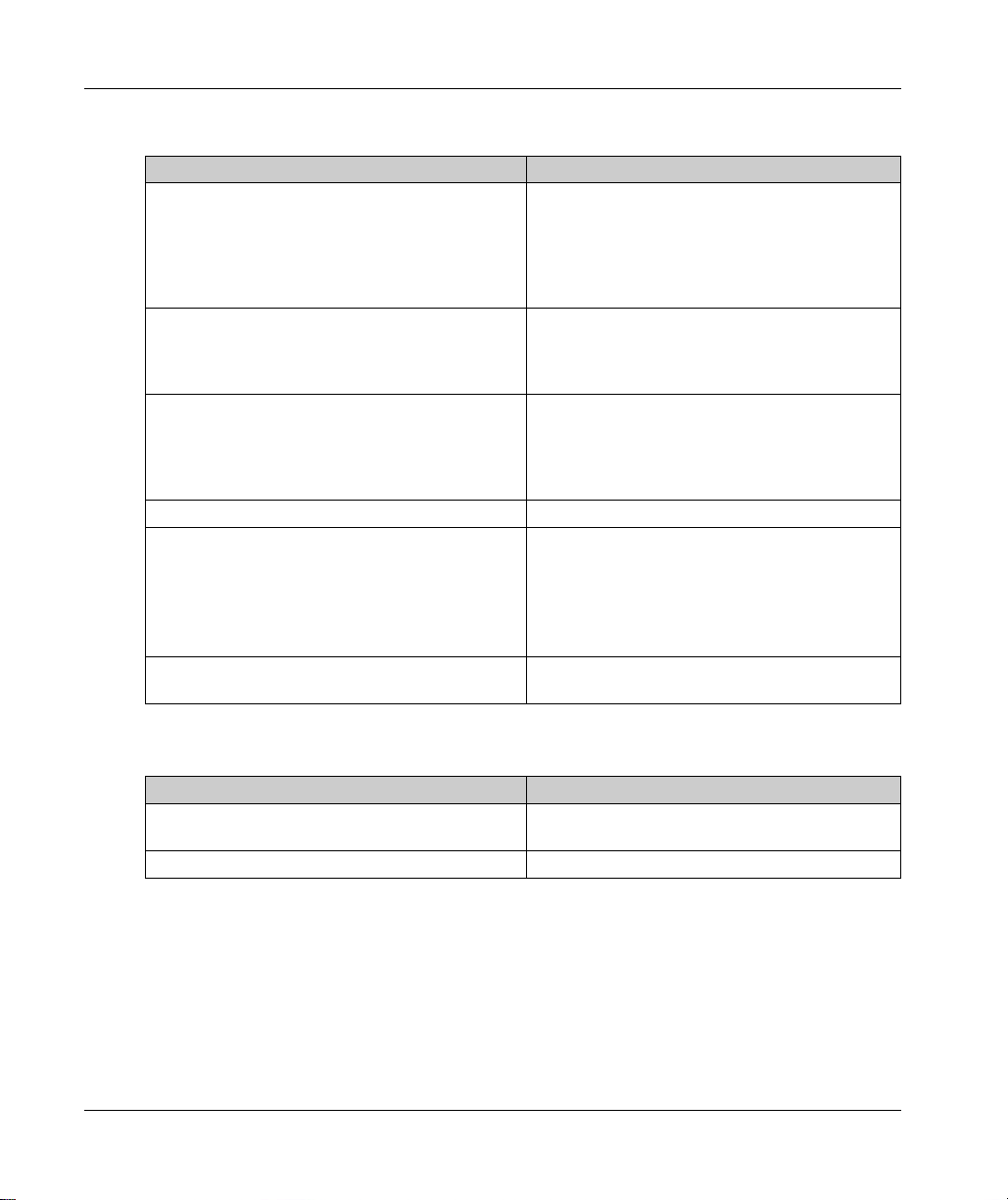

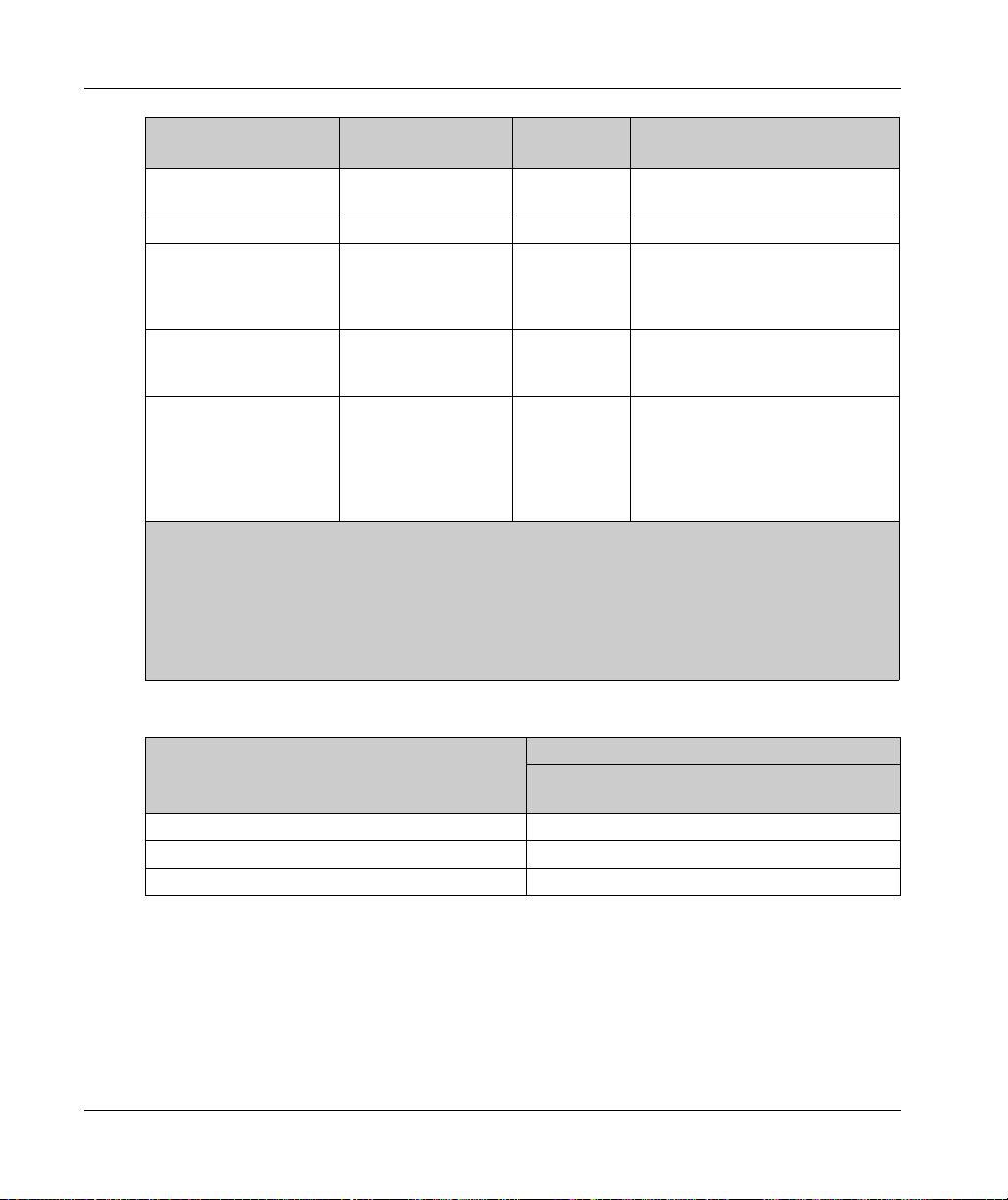

Allowable Combinations

Combine mains contactor and motor protection switch for protection of a Lexium 62 Power Supply

as follows:

Engineering

Mains current DC bus

current (with

mains lines

reactor)

16 A ≤ 8 A 1-phase Circuit breaker iC60N,

20 A ≤10 A 1-phase Circuit breaker iC60N,

9.5 A ≤ 10 A 3-phase TeSys Model U LUB12 with

12 A ≤ 12.5 A 3-phase – TeSys Model U LUB12 with

18 A ≤19 A 3-phase – TeSys Model U LUB32 with

32 A ≤ 33.5 A 3-phase – TeSys Model U LUB32 with

40 A ≤ 42 A 3-phase – Mains contactor

Connection type Protection Lexium 62

Power Supply

(LXM62PD20A11000)

characteristic C, 16 A

characteristic C, 20 A

LUCA12BL

Protection Lexium 62 Power

Supply

(LXM62PD84A11000)

–

–

–

LUCA12BL

LUCA18BL

LUCA32BL

LC1D40ABD motor

protection switch GV3P40

Limit the external 24 Vdc supply to the Lexium 62 Power Supply module with adequate means to

50 A.

EIO0000001351 02/2020 59

Page 60

Engineering

Mains Contactor

General

The selection of the mains contactor must be in accordance with the protection requirements of the

mains line.

60

EIO0000001351 02/2020

Page 61

Mains Filter

Overview

The products described in the present document meet the EMC requirements in accordance with

the standard IEC/EN 61800-3, if the EMC measures described in this manual are complied with

during the installation. The values are based on the reference application specified in the manual.

Refer to Electromagnetic Compatibility, EMC

The connected cable length and the number of connected motors has no significant influence on

the grid-bound emitted interference. Thus, no external mains filter is required when only the

Lexium 62 ILM related components are used.

In the case of a mixed system using the Lexium 62 Servo Drives combined with the Lexium 62 ILM

components, the selection of the external mains filter depends on the devices installed in the

control cabinet and the motor supply cables. The hybrid cable or power cable (with daisy chain

wiring) of the Lexium 62 ILM is not considered as motor supply cables.

NOTE: For additional information on mains filtering, contact your Schneider Electric

representative.

(see page 42)

Engineering

.

EIO0000001351 02/2020 61

Page 62

Engineering

Mains Line Reactor (Choke)

Overview

A mains line reactor (choke) is required for the application. A mains line reactor is necessary to

reduce the harmonics of the mains current. The mains line reactor must have at least 4% voltage

drop at rated load.

With UL/CSA Certification

Mains line reactor with UL / CSA certification:

Schneider Electric: VPM05D100000 for architectures up to 10 A

Schneider Electric: VPM05D250000 for architectures up to 25 A

Schneider Electric: VPM05D500000 for architectures up to 50 A

Schneider Electric: VW3A4551 for architectures up to 4 A

Schneider Electric: VW3A4552 for architectures up to 10 A

Schneider Electric: VW3A4553 for architectures up to 16 A

Schneider Electric: VW3A4554 for architectures up to 30 A

Schneider Electric: VW3A4555 for architectures up to 60 A

A shielded version of the connection cables is not required.

NOTE: Verify that the rated current of the mains line reactor is above preset overload protection of

the protective device.

Correlation Between Mains Current and DC Bus Current (3-Phase Operation)

The mains current is approximately the same as the DC bus current and corresponds to the current

of the mains line reactor. For the design of the mains line reactor, use a dimensioning of the mains

current of 100% to 110% of the DC bus current.

Mains Line Reactor and External Mains Filter

If a mains line reactor and an external mains line reactor are required, the mains line reactor and

external mains filter must be arranged according to the following illustrations for EMC reasons.

62

EIO0000001351 02/2020

Page 63

Connection of the Lexium 62 Power Supply

Overview

Connection of a Lexium 62 Power Supply

Engineering

NOTE: The 24 Vdc supply input current must be limited to 50 A, which can be realized by a 50 A

fuse as shown above. In particular, a 50 A fuse is mandatory if a passive 24 Vdc power supply is

used.

For further information, refer to

EIO0000001351 02/2020 63

Fusing the Mains Connection (see page 58)

.

Page 64

Engineering

Leakage (Touch) Current

Overview

Application Per Lexium 62 Connection

Module

Typical (400V, 50Hz) < 9mA < 18mA ≤141mA

Per Lexium 62 Distribution

Box

Per Lexium 62 Power

Supply

NOTE: If the leakage (touch) current is too high for the respective application, use an isolating

transformer on the mains supply.

This product has a leakage (touch) current greater than 3.5 mA. If the protective ground connection

is interrupted, a hazardous leakage (touch) current may flow if the housing is touched.

DANGER

INSUFFICIENT GROUNDING

Use a protective ground copper conductor with at least 10 mm

ground copper conductors with the same or larger cross section of the conductors supplying

the power terminals.

Verify compliance with all local and national electrical code requirements as well as all other

applicable regulations with respect to grounding of all equipment.

Failure to follow these instructions will result in death or serious injury.

2

(AWG 6) or two protective

64

EIO0000001351 02/2020

Page 65

Residual Current Operated Protective Device

Using Residual Current Protective Devices

When using a residual current protective device in combination with the Lexium 62 Drive System,

certain conditions and restrictions must be considered. As a dc current component in the ground

conductor may result from insulation damage or direct contact, residual current circuit-breakers of

type A or AC may not be triggered and therefore must not be used. Moreover, during system

power-up and also in normal operation the Lexium 62 Drive System can generate a significant

leakage (touch) current

(see page 64)

protective device.

Consequently, observe the following when using residual current protective devices in combination

with the Lexium 62 Drive System:

Only use universal current sensitive residual current circuit-breaker of type B.

Use residual current protective devices with a latent time to prevent unintended triggering at

system power-up.

Consider the leakage (touch) current of the Lexium 62 Drive System in normal operation when

selecting the triggering threshold of the residual current protective device.

If no residual current protective device or only a device with a high current threshold can be

installed, appropriate other measures must be applied to provide protection against electrical

shock and fire hazard

which may lead to unintended triggering of a residual current

Engineering