Page 1

EcoStruxure™ Building

IP-IO

SmartX IP Controller

| 1

Introduction

SmartX IP Controller – IP-IO module provides I/O

expansion to your HVAC application over BACnet/IP.

The module can share its I/O resources across

applications running in SmartX servers, SmartX IP

controllers, or third-party systems. With the support of

local alarms and local trend logs, the IP-IO module

avoids unnecessary traffic over the network while being

able to log important information locally. The IP-IO

module can be installed near facilities in the field, away

from the SmartX server or the SmartX IP controller. All

IP-IO models support an optional display that provides

insight and control of the inputs and outputs.

The IP-IO module has the following features:

• IP enabled with dual-port Ethernet switch

• Versatile onboard I/O point mix

• Highly reliable

• Mobile commissioning application

• Full EcoStruxure Building Operation software

support, providing efficient engineering tools

IP connectivity and flexible network topologies

The IP-IO module is based on open protocols that

simplify interoperability, IP configuration, and device

management:

• BACnet/IP communications

• DHCP for easy network configuration

The IP-IO module has a dual-port Ethernet switch,

which enables flexible network topologies:

• Star

• Daisy chain

• Rapid Spanning Tree Protocol (RSTP) ring

In a star topology, the IP-IO module and the parent

EcoStruxure BMS server are individually connected to

an Ethernet switch. You can reduce the installation time

and cost by daisy-chaining multiple IP-IO modules

together. You can use an RSTP ring topology when you

want failures of a single IP-IO module to be detected

and recovered quickly and efficiently.

Models with a versatile mix of I/O points

The IP-IO module comes in three models with different

I/O point count and a versatile mix of I/O point types

that match a wide variety of applications. The universal

inputs/outputs are highly flexible and can be

configured as either inputs or outputs.

• IP addressing

03-20014-01-en, February 2019

© 2019 Schneider Electric. Allrights reserved. Trademarks and registered trademarks are the property of their respective owners.

Page 2

EcoStruxure™ Building

IP-IO

SmartX IP Controller

I/O Point Types by IP-IO Models

II//OO PPooiinntt TTyyppeess IIPP--IIOO--DDII1100 IIPP--IIOO--UUIIOO1100 IIPP--IIOO--UUIIOO55DDOOFFAA44

Digital inputs 10 - Universal I/O

Type Ub

Relay outputs

Form A

High power relay outputs

Form A

Configurations by I/O Point Types

- 10 5

- - 3

- - 1

| 2

CCoonnffiigguurraattiioonnss DDiiggiittaall IInnppuuttss UUnniivveerrssaall II//OO

TTyyppee UUbb

RReellaayy OOuuttppuuttss

FFoorrmm AA

HHiigghh PPoowweerr RReellaayy

OOuuttppuuttss

FFoorrmm AA

Digital inputs yes yes - Counter inputs yes yes - Supervised inputs - yes - Voltage inputs

(0 to 10 VDC)

Current inputs

(0 to 20 mA)

Temperature inputs - yes - Resistive inputs - yes - 2-wire RTD temperature

inputs

Voltage outputs

(0 to 10 VDC)

Digital outputs - - yes yes

Digital pulsed outputs - - yes yes

PWM outputs - - yes yes

Tristate outputs - - yes Tristate pulsed outputs - - yes -

- yes - -

- yes - -

- yes - -

- yes - -

Digital inputs

The digital inputs can be used for cost effective

sensing of multiple dry contact digital inputs in

applications, such as equipment status monitoring or

Universal inputs/outputs

The universal inputs/outputs are ideal for any mix of

temperature, pressure, flow, status points, and similar

point types in a building control system.

alarm point monitoring. As counter inputs, digital inputs

are commonly used in energy metering applications.

03-20014-01-en, February 2019

© 2019 Schneider Electric. All rights reserved. Trademarks and registered trademarks are the property of their respective owners.

Page 3

EcoStruxure™ Building

IP-IO

SmartX IP Controller

As counter inputs, the universal inputs/outputs are

commonly used in energy metering applications. As

RTD inputs, they are ideal for temperature points in a

building control system. As supervised inputs, they are

used for security applications where it is critical to know

whether or not a wire has been cut or shorted. These

events provide a separate indication of alarms and

trouble conditions to the system.

For all analog inputs, maximum and minimum levels

can be defined to automatically detect over-range and

under-range values.

The universal inputs/outputs can also be used as

voltage outputs, without the need for external bias

resistors. Therefore, the universal inputs/outputs

support a wide range of devices, such as actuators.

Relay outputs

The relay outputs support digital Form A point types.

The Form A relays are designed for direct load

applications.

High power relay output

The high power relay output is ideal for switching loads

of up to 12 A, such as electrical heating elements.

Highly reliable

The IP-IO module supports local trends and alarms,

enabling local operation when the IP-IO module is

offline.

The battery-free power backup of the memory and realtime clock prevents data loss and ensures seamless

and quick recovery after a power failure.

| 3

Display module

In WorkStation, you update the firmware of multiple IP-

IO modules at the same time and with minimum down

time. The EcoStruxure BMS server keeps track of the

installed firmware to support backup, restore, and

replacement of the IP-IO modules. The server can host

IP-IO modules of different firmware versions.

Mobile commissioning application

The eCommission SmartX Controllers mobile

application is designed for local configuration, field

deployment, and commissioning of IP-IO modules. The

mobile application reduces the commissioning time,

allows flexibility in project execution, and eliminates

dependencies on network infrastructure.

The mobile application is designed for use with

Android, Apple (iOS), and Microsoft Windows 10

devices. For more information, see the eCommission

SmartX Controllers Specification Sheet.

All IP-IO models can be equipped with a display addon module (same module as used for the MP-C), which

features an LCD display and five keys. With this

module, you can manually override analog and digital

outputs for testing, commissioning, and maintenance of

equipment connected to the outputs. The display

module's dedicated processing power ensures reliable

override for maintenance applications. The override

status can be viewed in EcoStruxure Building

Operation WorkStation and WebStation, enabling

precise monitoring and reliable control.

eCommission SmartX Controllers mobile app

03-20014-01-en, February 2019

© 2019 Schneider Electric. All rights reserved. Trademarks and registered trademarks are the property of their respective owners.

Page 4

EcoStruxure™ Building

IP-IO

SmartX IP Controller

| 4

Using the eCommission SmartX Controllers mobile

application, you can connect to IP-IO modules and MP

Series controllers over the network. Using a wireless

access point or a network switch, you can connect to a

network of IP-IO modules and MP Series controllers on

the local IP network.

Device configuration

With the eCommission SmartX Controllers mobile

application, you can easily discover IP-IO modules and

MP Series controllers on the IP network. You can

change the configuration of each module and

controller, including the BACnet and IP network

settings, location, and parent server. To save

engineering time, you can save common device

settings and then reuse them for devices of the same

type and model.

Field deployment and I/O checkout

The eCommission SmartX Controllers mobile

application does not require an EcoStruxure BMS

server or a network infrastructure to be in place. You

can use the mobile application to load the IP-IO

application directly into the local IP-IO module and

deploy the IP-IO module. The IP-IO application can be

created offline using Project Configuration Tool or

WorkStation while preserving all external bindings to

server and controller applications using the IP-IO

module's I/O points. You can also perform an I/O

checkout to ensure that the IP-IO module's I/O points

are configured, wired, and operating correctly.

Full EcoStruxure Building Operation software

support

The power of the IP-IO module is fully realized when it is

part of an EcoStruxure BMS, which provides the

following benefits:

• WorkStation/WebStation interface

• Device discovery

• Engineering efficiency

WorkStation/WebStation interface

WorkStation and WebStation provide a consistent user

experience regardless of which EcoStruxure BMS

server the user is logged on to. The user can log on to

the parent EcoStruxure BMS server to engineer,

commission, supervise, and monitor IP-IO modules and

MP Series controllers. For more information, see the

WorkStation and WebStation specification sheets.

Device discovery

The enhanced Device Discovery in WorkStation

enables you to easily identify IP-IO modules on a

BACnet network and to associate the IP-IO modules

with their parent server.

Engineering efficiency

The engineering and maintenance of IP-IO modules

can be done very efficiently using the EcoStruxure

Building Operation reusability features. With these

features, you can create library items (Custom Types)

for a complete IP-IO application that contains I/O point

configurations and all necessary objects such as

trends and alarms. The IP-IO application in the Custom

Types library is reusable across all IP-IO modules of the

same model. You can use the IP-IO application as a

base for creating new IP-IO modules intended for

similar applications. You can then edit the IP-IO

application, and the changes are automatically

replicated to all IP-IO modules, while each IP-IO

module keeps its local values.

WorkStation supports both online and offline

engineering of IP-IO modules. You can make the

configuration changes online or use database mode to

make the changes offline. In database mode, the

changes are saved to the EcoStruxure Building

Operation database so that you can apply the changes

to the IP-IO modules later.

Project Configuration Tool enables you to perform all

the engineering off site, without the need for physical

hardware, which minimizes the time you need to spend

on site. You can run the EcoStruxure BMS servers

virtually and engineer the MP Series controllers and IP-

IO modules before you deploy your server, controller,

and IP-IO applications to the servers, controllers, and

IP-IO modules on site. For more information, see the

Project Configuration Tool specification sheet.

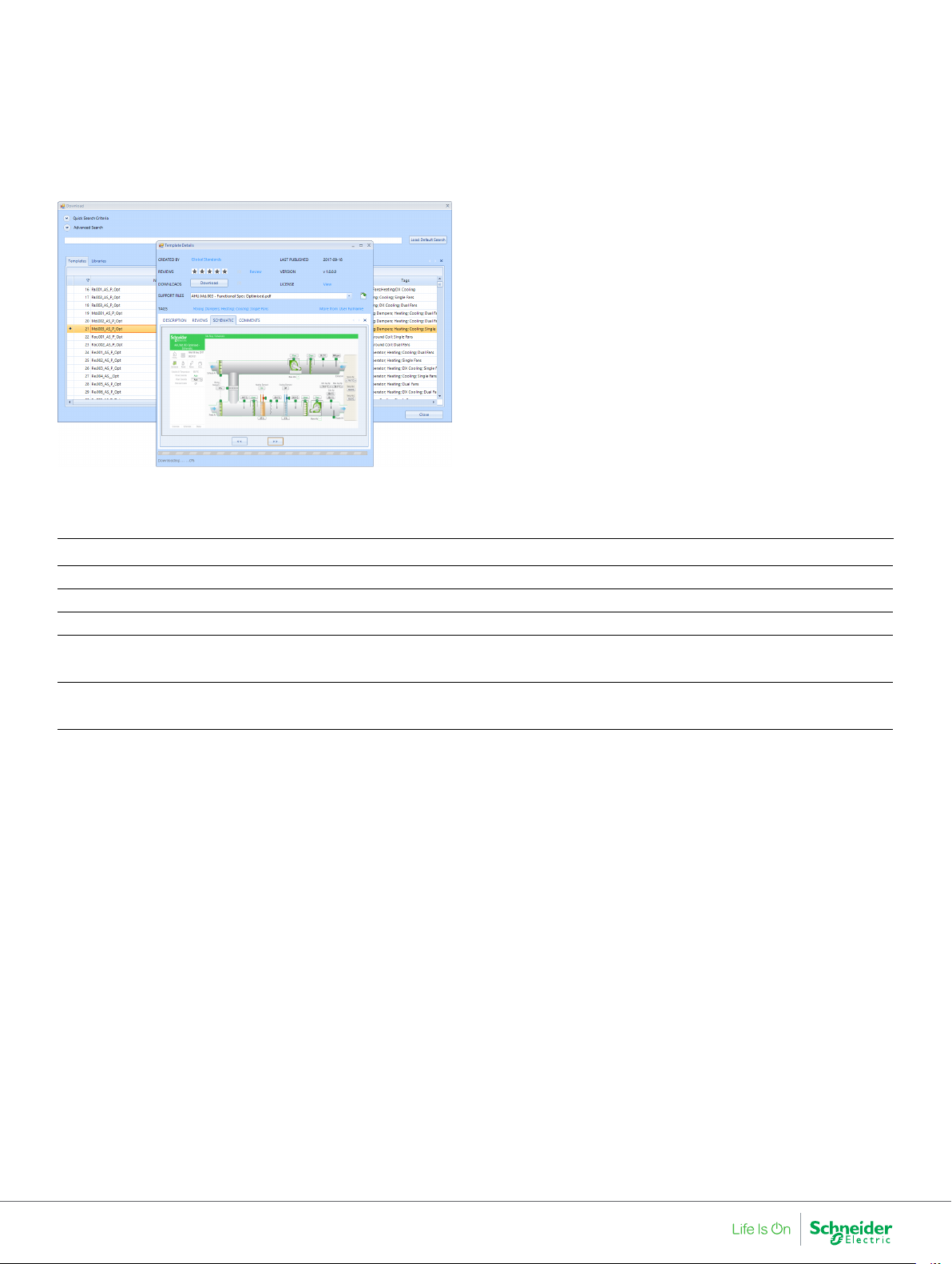

In addition, you can use Automated Engineering Tool to

facilitate your engineering process when using IP-IO

modules. This tool provides access to a library of

standard IP-IO applications that can be quickly

configured and customized using the wizards and

mass edit functions provided in the tool. You can then

load these customized applications into your target

server. The tool also enables the quick creation of your

own templates based on IP-IO applications that you

have developed. These templates facilitate a standard

approach and easy reuse and duplication of common

IP-IO applications. For more information, see the

Automated Engineering Tool specification sheet.

03-20014-01-en, February 2019

© 2019 Schneider Electric. All rights reserved. Trademarks and registered trademarks are the property of their respective owners.

Page 5

EcoStruxure™ Building

IP-IO

SmartX IP Controller

Library of standard HVAC applications

Part Numbers

| 5

PPrroodduucctt PPaarrtt nnuummbbeerr

IP-IO-DI10 SXWIPIOAA10001

IP-IO-UIO10 SXWIPIOBA10001

IP-IO-UIO5DOFA4 SXWIPIOCA10001

MP-C DISPLAY

(MP-C override display module)

DIN-RAIL-CLIP, DIN-rail end clip

package of 25 pieces

SXWMPCDSP10001

SXWDINEND10001

Specifications

AC input

Nominal voltage......................................................................................................................................................24 VAC

Operating voltage range........................................................................................................................................+/-20 %

Frequency ............................................................................................................................................................50/60 Hz

Maximum power consumption..................................................................................................................................17 VA

Power input protection................................................................................................MOV suppression and internal fuse

DC input

Nominal voltage.............................................................................................................................................24 to 30 VDC

Operating voltage range ...............................................................................................................................21 to 33 VDC

Maximum power consumption .....................................................................................................................................9 W

Power input protection................................................................................................MOV suppression and internal fuse

Environment

Ambient temperature, operating .................................................................0 to 50 °C (32 to 122 °F) at normal operation

..........................................................-40 to +60 °C (-40 to +140 °F) for rooftop applications, horizontal installation only

03-20014-01-en, February 2019

© 2019 Schneider Electric. All rights reserved. Trademarks and registered trademarks are the property of their respective owners.

a

a

Page 6

EcoStruxure™ Building

| 6

IP-IO

SmartX IP Controller

a) MP-C Display has an operating temperature range of -30 to +60 °C (-22 to +140 °F).

Ambient temperature, storage ............................................................................................-40 to +70 °C (-40 to +158 °F)

Maximum humidity.....................................................................................................................95 % RH non-condensing

Material

Plastic flame rating ...............................................................................................................................................UL94-5V

Ingress protection rating ............................................................................................................................................IP 20

Mechanical

Dimensions...................................................................................... 153 W x 110 H x 64 D mm (6.0 W x 4.3 H x 2.5 D in.)

Weight, IP-IO-DI10

Including terminal blocks .....................................................................................................................0.337 kg (0.742 lb)

Weight, IP-IO-UIO10

Including terminal blocks .....................................................................................................................0.336 kg (0.740 lb)

Weight, IP-IO-UIO5DOFA4

Including terminal blocks..................................................................................................................... 0.357 kg (0.787 lb)

Installation.....................................................................................................DIN rail or other flat surface inside a cabinet

Terminal blocks ................................................................................................................................................Removable

Software compliance

EcoStruxure Building Operation software .............................................................................................version 2.1 or later

Agency compliances

Emission...............................................................RCM; EN 61000-6-3; EN 50491-5-2; FCC Part 15, Sub-part B, Class B

Immunity...............................................................................................................................EN 61000-6-2; EN 50491-5-3

Safety.........................................................................EN 60730-1; EN 60730-2-11; EN 50491-3; UL 916 C-UL US Listed

Real-time clock

Accuracy, at 25 °C (77 °F) ..............................................................................................................+/-1 minute per month

Backup time, at 25 °C (77 °F)...................................................................................................................7 days minimum

03-20014-01-en, February 2019

© 2019 Schneider Electric. All rights reserved. Trademarks and registered trademarks are the property of their respective owners.

Page 7

EcoStruxure™ Building

| 7

IP-IO

SmartX IP Controller

Communication ports

Ethernet................................................................................................................................ Dual 10/100BASE-TX (RJ45)

USB....................................................................................................................................1 USB 2.0 device port (mini-B)

........................................................................................................................1 USB 2.0 host port (type-A), 5 VDC, 2.5 W

Communications

BACnet..........................................................................................................BACnet/IP, port configurable, default 47808

.......................................................................................................BTL B-ASC (BACnet Application Specific Controller)

a) See the BTL Product Catalog for up-to-date details on BTL listed firmware revisions on BACnet International's home

page.

CPU

Frequency ........................................................................................................................................................... 500 MHz

Type...........................................................................................................................................ARM Cortex-A7 dual-core

DDR3 SDRAM ........................................................................................................................................................128 MB

NOR flash memory ...................................................................................................................................................32 MB

Memory backup.......................................................................................................................128 kB, FRAM, non-volatile

a

MP-C Display (Optional)

Removable.....................................................................................................................................................................No

Display size .................................................................................................................36 W x 17 H mm (1.4 W x 0.7 H in.)

Display resolution .......................................................................................................................................128 x 64 pixels

Display type......................................................................... FSTN monochrome LCD, white color transflective backlight

Power consumption............................................................................................................. max. 0.15 W (45 mA at 3.3 V)

Ambient temperature, operating .........................................................................................-30 to +60 °C (-22 to +140 °F)

Ambient temperature, storage ............................................................................................-40 to +70 °C (-40 to +158 °F)

Maximum humidity.....................................................................................................................95 % RH non-condensing

Weight ..................................................................................................................................................0.035 kg (0.077 lb)

Compliance with standards ......................................................................................................................EN ISO 16484-2

Digital inputs, DI

Channels, IP-IO-DI10..................................................................................................................................10, DI1 to DI10

Channels, IP-IO-UIO10.....................................................................................................................................................0

Channels, IP-IO-UIO5DOFA4...........................................................................................................................................0

Absolute maximum ratings .......................................................................................................................-0.5 to +24 VDC

Digital input protection........................................................................Transient voltage suppressor on each digital input

Digital inputs

Range.........................Dry contact switch closure or open collector/open drain, 24 VDC, typical wetting current 2.4 mA

Minimum pulse width ..............................................................................................................................................150 ms

Counter inputs

Range.........................Dry contact switch closure or open collector/open drain, 24 VDC, typical wetting current 2.4 mA

Minimum pulse width ................................................................................................................................................20 ms

Maximum frequency..................................................................................................................................................25 Hz

03-20014-01-en, February 2019

© 2019 Schneider Electric. All rights reserved. Trademarks and registered trademarks are the property of their respective owners.

Page 8

EcoStruxure™ Building

| 8

IP-IO

SmartX IP Controller

Universal inputs/outputs, Ub

Channels, IP-IO-DI10........................................................................................................................................................0

Channels, IP-IO-UIO10...................................................................................................................... 10 Ub, Ub1 to Ub10

Channels, IP-IO-UIO5DOFA4.................................................................................................................5 Ub, Ub1 to Ub5

Absolute maximum ratings .......................................................................................................................-0.5 to +24 VDC

A/D converter resolution ..........................................................................................................................................16 bits

Universal input/output protection........................................Transient voltage suppressor on each universal input/output

Digital inputs

Range.........................Dry contact switch closure or open collector/open drain, 24 VDC, typical wetting current 2.4 mA

Minimum pulse width ..............................................................................................................................................150 ms

Counter inputs

Range.........................Dry contact switch closure or open collector/open drain, 24 VDC, typical wetting current 2.4 mA

Minimum pulse width ................................................................................................................................................20 ms

Maximum frequency..................................................................................................................................................25 Hz

Supervised inputs

5 V circuit, 1 or 2 resistors

Monitored switch combinations.............................................................Series only, parallel only, and series and parallel

Resistor range................................................................................................................................................1 to 10 kohm

For a 2-resistor configuration, each resistor must have the same value +/- 5 %

Voltage inputs

Range..............................................................................................................................................................0 to 10 VDC

Accuracy...............................................................................................................................+/-(7 mV + 0.2 % of reading)

Resolution................................................................................................................................................................1.0 mV

Impedance..........................................................................................................................................................100 kohm

Current inputs

Range................................................................................................................................................................0 to 20 mA

Accuracy..........................................................................................................................+/-(0.01 mA + 0.4 % of reading)

Resolution....................................................................................................................................................................1 μA

Impedance .............................................................................................................................................................47 ohm

Resistive inputs

10 ohm to 10 kohm accuracy .......................................................................................................+/-(7 + 4 x 10-3x R) ohm

R = Resistance in ohm

10 kohm to 60 kohm accuracy.....................................................................................+/-(4 x 10-3x R + 7 x 10-8x R2) ohm

R = Resistance in ohm

Temperature inputs (thermistors)

Range................................................................................................................................-50 to +150 °C (-58 to +302 °F)

Supported thermistors

Honeywell .............................................................................................................................................................20 kohm

Type I (Continuum) ...............................................................................................................................................10 kohm

03-20014-01-en, February 2019

© 2019 Schneider Electric. All rights reserved. Trademarks and registered trademarks are the property of their respective owners.

Page 9

EcoStruxure™ Building

| 9

IP-IO

SmartX IP Controller

Type II (I/NET).......................................................................................................................................................10 kohm

Type III (Satchwell) ...............................................................................................................................................10 kohm

Type IV (FD) ......................................................................................................................................................... 10 kohm

Type V (FD w/ 11k shunt) ....................................................................................................................Linearized 10 kohm

Satchwell D?T......................................................................................................................................Linearized 10 kohm

Johnson Controls .................................................................................................................................................2.2 kohm

Xenta....................................................................................................................................................................1.8 kohm

Balco.......................................................................................................................................................................1 kohm

Measurement accuracy

20 kohm...................................................................................................-50 to -30 °C: +/-1.5 °C (-58 to -22 °F: +/-2.7 °F)

...................................................................................................................-30 to 0 °C: +/-0.5 °C (-22 to +32 °F: +/-0.9 °F)

.................................................................................................................. 0 to 100 °C: +/-0.2 °C (32 to 212 °F: +/-0.4 °F)

.............................................................................................................100 to 150 °C: +/-0.5 °C (212 to 302 °F: +/-0.9 °F)

10 kohm, 2.2 kohm, and 1.8 kohm.......................................................-50 to -30 °C: +/-0.75 °C (-58 to -22 °F: +/-1.35 °F)

..........................................................................................................-30 to +100 °C: +/-0.2 °C (-22 to +212 °F: +/-0.4 °F)

.............................................................................................................100 to 150 °C: +/-0.5 °C (212 to 302 °F: +/-0.9 °F)

Linearized 10 kohm .................................................................................-50 to -30 °C: +/-2.0 °C (-58 to -22 °F: +/-3.6 °F)

...............................................................................................................-30 to 0 °C: +/-0.75 °C (-22 to +32 °F: +/-1.35 °F)

.................................................................................................................. 0 to 100 °C: +/-0.2 °C (32 to 212 °F: +/-0.4 °F)

.............................................................................................................100 to 150 °C: +/-0.5 °C (212 to 302 °F: +/-0.9 °F)

1 kohm ..............................................................................................-50 to +150 °C: +/-1.0 °C (-58 to +302° F: +/-1.8 °F)

RTD temperature inputs

Supported RTDs......................................................................................................................................................Pt1000

Pt1000

Sensor range.....................................................................................................................-50 to +150 °C (-58 to +302 °F)

SSmmaarrttXX IIPP CCoonnttrroolllleerr ddeevviiccee eennvviirroonnmmeenntt SSeennssoorr rraannggee MMeeaassuurreemmeenntt aaccccuurraaccyy

0 to 50 °C (32 to 122 °F) -50 to +70 °C (-58 to +158 °F) +/-0.5 °C (+/-0.9 °F)

0 to 50 °C (32 to 122 °F) 70 to 150 °C (158 to 302 °F) +/-0.7 °C (+/-1.3 °F)

-40 to +60 °C (-40 to +140 °F) -50 to +150 °C (-58 to +302 °F) +/-1.0 °C (+/-1.8 °F)

RTD temperature wiring

Maximum wire resistance.........................................................................................................20 ohm/wire (40 ohm total)

Maximum wire capacitance.......................................................................................................................................60 nF

The wire resistance and capacitance typically corresponds to a 200 m wire.

Voltage outputs

Range..............................................................................................................................................................0 to 10 VDC

Accuracy..............................................................................................................................................................+/-60 mV

Resolution.................................................................................................................................................................10 mV

Minimum load resistance........................................................................................................................................5 kohm

Load range.......................................................................................................................................................-1 to +2 mA

03-20014-01-en, February 2019

© 2019 Schneider Electric. All rights reserved. Trademarks and registered trademarks are the property of their respective owners.

Page 10

EcoStruxure™ Building

| 10

IP-IO

SmartX IP Controller

Relay outputs, DO

Channels, IP-IO-DI10........................................................................................................................................................0

Channels, IP-IO-UIO10.....................................................................................................................................................0

Channels, IP-IO-UIO5DOFA4..................................................................................................................... 3, DO1 to DO3

Contact rating......................................................................................................250 VAC/30 VDC, 2 A, Pilot Duty (C300)

Switch type....................................................................................................................................................Form A Relay

....................................................................................................................................................Single Pole Single Throw

....................................................................................................................................................................Normally Open

Isolation contact to system ground.....................................................................................................................3000 VAC

Cycle life (Resistive load) ..............................................................................................................At least 100,000 cycles

Minimum pulse width ..............................................................................................................................................100 ms

High power relay outputs, DO

Channels, IP-IO-DI10........................................................................................................................................................0

Channels, IP-IO-UIO10.....................................................................................................................................................0

Channels, IP-IO-UIO5DOFA4................................................................................................................................. 1, DO4

Contact rating....................................................................................................250 VAC/24 VDC, 12 A, Pilot Duty (B300)

Switch type....................................................................................................................................................Form A Relay

....................................................................................................................................................Single Pole Single Throw

....................................................................................................................................................................Normally Open

Isolation contact to system ground.....................................................................................................................5000 VAC

Cycle life (Resistive load) ..............................................................................................................At least 100,000 cycles

Minimum pulse width ..............................................................................................................................................100 ms

Terminals

Follow proper installation wiring diagrams and

instructions, including these instructions:

• All IP-IO models have several RET terminals for

connection of I/O returns, so a common

chassis/signal ground rail is optional and may not

be needed.

• Individual 24 VDC power sources to the field must

be current limited to maximum 4 A for UL

compliant installations, and maximum 6 A in other

areas.

• For more information on wiring, see Hardware

Reference Guide.

03-20014-01-en, February 2019

© 2019 Schneider Electric. All rights reserved. Trademarks and registered trademarks are the property of their respective owners.

Page 11

EcoStruxure™ Building

IP-IO

SmartX IP Controller

| 11

IP-IO-DI10

IP-IO-UIO10

03-20014-01-en, February 2019

© 2019 Schneider Electric. All rights reserved. Trademarks and registered trademarks are the property of their respective owners.

Page 12

EcoStruxure™ Building

IP-IO

SmartX IP Controller

| 12

IP-IO-UIO5DOFA4

Part Numbers in AMER Region for Network Connectivity Accessories

PPrroodduucctt ddeessccrriippttiioonn

Cat 6 field-term plug, UTP ACTPG6TLU001

Cat 6 pass-through plug, UTP, 100-pack ACTPG6PTU100

Actassi crimping tool ACTTLCPT

Cat 6 cable, UTP, 1000 ft (305 m), CMP, green ACT4P6UCP1ARXGR

Cat 6 patch cord, UTP, 30 ft (9 m), CMP, green ACTPC6UBCP30AGR

Cat 6 patch cord, UTP, 50 ft (15 m), CMP, green ACTPC6UBCP50AGR

Cat 6 patch cord, UTP, 70 ft (21 m), CMP, green ACTPC6UBCP70AGR

Cat 6 patch cord, UTP, 90 ft (27 m), CMP, green ACTPC6UBCP90AGR

Cat 5e pass-through plug, UTP, 100-pack ACTPG5EPTU100

Cat 5e cable, UTP, 1000 ft (305 m), CMP, green ACT4P5EUCP1ARXGR

Cat 5e patch cord, UTP, 30 ft (9 m), CMP, green ACTPC5EUBCP30AGR

Cat 5e patch cord, UTP, 50 ft (15 m), CMP, green ACTPC5EUBCP50AGR

Cat 5e patch cord, UTP, 70 ft (21 m), CMP, green ACTPC5EUBCP70AGR

aa

PPaarrtt nnuummbbeerr ((AAMMEERR rreeggiioonn))

03-20014-01-en, February 2019

© 2019 Schneider Electric. All rights reserved. Trademarks and registered trademarks are the property of their respective owners.

Page 13

EcoStruxure™ Building

IP-IO

SmartX IP Controller

Continued

| 13

PPrroodduucctt ddeessccrriippttiioonn

Cat 5e patch cord, UTP, 90 ft (27 m), CMP, green ACTPC5EUBCP90AGR

a) For more information, see the Product Selection Guide (SmartX IP Controllers - Accessories). Abbreviations: UTP (Unshielded Twisted Pair), CMP (Plenum-rated

cable)

aa

PPaarrtt nnuummbbeerr ((AAMMEERR rreeggiioonn))

Part Numbers in EMEA Region for Network Connectivity Accessories

PPrroodduucctt ddeessccrriippttiioonn

Cat 6 field-term plug, UTP ACTPG6TLU001

Cat 6 pass-through plug, UTP, 100-pack ACTPG6PTU100

Actassi crimping tool ACTTLCPT

Cat 6 cable, UTP, 305 m (1000 ft), Euroclass D, green VDICD116118

Cat 6 patch cord, UTP, 10 m (32 ft), LSZH, green ACTPC6UBLS100GR

Cat 6 patch cord, UTP, 15 m (49 ft), LSZH, green ACTPC6UBLS150GR

Cat 6 patch cord, UTP, 20 m (65 ft), LSZH, green ACTPC6UBLS200GR

Cat 6 patch cord, UTP, 25 m (82 ft), LSZH, green ACTPC6UBLS250GR

Cat 5e pass-through plug, UTP, 100-pack ACTPG5EPTU100

Cat 5e cable, UTP, 1000 ft (305 m), Euroclass D, green VDICD115118

Cat 5e patch cord, UTP, 10 m (32 ft), LSZH, green ACTPC5EUBLS100GR

Cat 5e patch cord, UTP, 15 m (49 ft), LSZH, green ACTPC5EUBLS150GR

Cat 5e patch cord, UTP, 20 m (65 ft), LSZH, green ACTPC5EUBLS200GR

Cat 5e patch cord, UTP, 25 m (82 ft), LSZH, green ACTPC5EUBLS250GR

aa

PPaarrtt nnuummbbeerr ((EEMMEEAA rreeggiioonn))

a) For more information, see the Product Selection Guide (SmartX IP Controllers - Accessories). Abbreviations: UTP (Unshielded Twisted Pair), CMP (Plenum-rated

cable), LSZH (Low Smoke Zero Halogen)

Part Numbers in Pacific Region for Network Connectivity Accessories

PPrroodduucctt ddeessccrriippttiioonn

Cat 6 field-term plug, UTP ACTPG6TLU001

Cat 6 pass-through plug, UTP, 100-pack ACTPG6PTU100

Actassi crimping tool ACTTLCPT

Cat 6 cable, UTP, 305 m (1000 ft), PVC, green 2D4P6IPV3B-GR

Cat 6 patch lead, UTP, 10 m (32 ft), PVC, green RJ6_100PL-GR

Cat 6 patch lead, UTP, 15 m (49 ft), PVC, green RJ6_150PL-GR

Cat 6 patch lead, UTP, 20 m (65 ft), PVC, green RJ6_200PL-GR

Cat 6 patch lead, UTP, 25 m (82 ft), PVC, green RJ6_250PL-GR

Cat 5e pass-through plug, UTP, 100-pack ACTPG5EPTU100

Cat 5e cable, UTP, 305 m (1000 ft), PVC, green 2D4P5IPV3B-GR

03-20014-01-en, February 2019

© 2019 Schneider Electric. All rights reserved. Trademarks and registered trademarks are the property of their respective owners.

aa

PPaarrtt nnuummbbeerr ((PPaacciiffiicc rreeggiioonn))

Page 14

EcoStruxure™ Building

IP-IO

SmartX IP Controller

Continued

| 14

PPrroodduucctt ddeessccrriippttiioonn

aa

PPaarrtt nnuummbbeerr ((PPaacciiffiicc rreeggiioonn))

Cat 5e patch lead, UTP, 10 m (32 ft), PVC, green RJ5_100PL-GR

Cat 5e patch lead, UTP, 15 m (49 ft), PVC, green RJ5_150PL-GR

Cat 5e patch lead, UTP, 20 m (65 ft), PVC, green RJ5_200PL-GR

Cat 5e patch lead, UTP, 25 m (82 ft), PVC, green RJ5_250PL-GR

a) For more information, see the Product Selection Guide (SmartX IP Controllers - Accessories). Abbreviations: UTP (Unshielded Twisted Pair), PVC (Polyvinyl

chloride)

Regulatory Notices

Federal Communications Commission

FCC Rules and Regulations CFR 47, Part 15, Class B

This device complies with part 15 of the FCC Rules. Operation is subject to the following two

conditions: (1) This device may not cause harmful interference. (2) This device must accept

any interference received, including interference that may cause undesired operation.

Industry Canada

This Class B digital apparatus complies with Canadian ICES-003.

Cet appareil numérique de la classe B est conforme à la norme NMB-003 du Canada.

Regulatory Compliance Mark (RCM) - Australian Communications and Media

Authority (ACMA)

This equipment complies with the requirements of the relevant ACMA standards made under

the Radiocommunications Act 1992 and the Telecommunications Act 1997. These

standards are referenced in notices made under section 182 of the Radiocommunications

Act and 407 of the Telecommunications Act.

CE - Compliance to European Union (EU)

2014/30/EU Electromagnetic Compatibility Directive

2014/35/EU Low Voltage Directive

2011/65/EU Restriction of Hazardous Substances (RoHS) Directive

This equipment complies with the rules, of the Official Journal of the European Union, for

governing the Self Declaration of the CE Marking for the European Union as specified in the

above directive(s) per the provisions of the following standards: EN 60730-1, EN 60730-211, and EN 50491-3 Safety Standards.

WEEE - Directive of the European Union (EU)

This equipment and its packaging carry the waste of electrical and electronic equipment

(WEEE) label, in compliance with European Union (EU) Directive 2012/19/EU, governing the

disposal and recycling of electrical and electronic equipment in the European community.

UL 916 Listed products for the United States and Canada, Open Class Energy

Management Equipment. UL file E80146.

.

03-20014-01-en, February 2019

© 2019 Schneider Electric. All rights reserved. Trademarks and registered trademarks are the property of their respective owners.

Loading...

Loading...