Page 1

Advantys FTB CANopen

IP67 monobloc input/output

splitter box

User guide

1606218 02 eng 3.0

1606218 02

www.telemecanique.com

Page 2

2

1606218 02 08/2006

Page 3

Table of Contents

Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

About the Book . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Chapter 1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Presentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Presentation of the CANopen Advantys FTB I/O Splitter Box Range . . . . . . . . . 12

Overview of the Accessories Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Chapter 2 Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Presentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Installing the Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Grounding of the Advantys FTB Splitter Box. . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

EMC Compatibility. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Chapter 3 Splitter Box Characteristics and Wiring. . . . . . . . . . . . . . . . . . 27

Presentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Advantys FTB Splitter Box Environment Properties . . . . . . . . . . . . . . . . . . . . . . 28

Electrical Characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Connecting the Actuators and Sensors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Power Supply Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Chapter 4 CANopen Network Interface . . . . . . . . . . . . . . . . . . . . . . . . . . .35

Presentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

4.1 Wiring on the CANopen Bus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Presentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Introduction to Wiring on the CANopen Bus . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Topology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Choice of system cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Connecting the Field Bus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Configuring the Address and Transmission Speed. . . . . . . . . . . . . . . . . . . . . . . 46

4.2 General Principles. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Presentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

About CANopen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

The Device Profile. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

1606218 02 08/2006 3

Page 4

CANopen "Boot-Up". . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Process Data Object (PDO) Transmission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Inhibit Time and Event Timer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Access to Data by Explicit Exchanges (SDO) . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

"Node-Guarding" and "Life-Guarding" Monitoring Protocols. . . . . . . . . . . . . . . . 62

The "Heartbeat" Error Monitoring Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

4.3 Behavior of FTB CANopen Splitter boxes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Presentation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Behavior at Power-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Behavior in the Case of Communication Error. . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Saving / Restoring Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

List of Saved Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Chapter 5 Application-Specific Functions . . . . . . . . . . . . . . . . . . . . . . . . 71

Presentation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

List of Objects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Description of the Discrete Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Description of Discrete Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Description of Configurable Discrete I/Os . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

List of Advantys FTB 1CN08E08SP0 Splitter Box I/O Objects . . . . . . . . . . . . . . 78

List of Advantys FTB 1CN12E04SP0 Splitter Box I/O Objects . . . . . . . . . . . . . . 81

List of Advantys FTB 1CN16EP0 and FTB 1CN16EM0 Splitter Box I/O Objects 85

List of Advantys FTB 1CN16CP0 and FTB 1CN16CM0 Splitter Box I/O Objects 87

List of Advantys FTB 1CN08E08CM0 Splitter Box I/O Objects . . . . . . . . . . . . . . 91

Chapter 6 Software Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Presentation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

6.1 Introduction to Software Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

6.2 Product Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

At A Glance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Characteristics of an EDS File. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Existing EDS File for CANopen Advantys FTB Splitter Box . . . . . . . . . . . . . . . 103

Creating a New EDS and DCF Configuration File . . . . . . . . . . . . . . . . . . . . . . . 104

6.3 Network Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Setting the Network Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

6.4 PLC Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Presentation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Integration and Use under PL7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Examples of SDO Requests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Chapter 7 Diagnostics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Presentation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Power Supply Diagnostics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Field Bus Status Diagnostics LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

LED Status Diagnostics for I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

4 1606218 02 08/2006

Page 5

CANopen Objects Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Behavior in the Event of Short-circuit / Overload / Under-voltage. . . . . . . . . . . 130

Chapter 8 The Object Dictionary. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .131

Presentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

8.1 The Object Dictionary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

The Object Dictionary. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

8.2 Objects of the Communication Profile 1000H to 1FFFH . . . . . . . . . . . . . . . . . 134

At a Glance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

Object 1000H: Device Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Object 1001H: Error Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

Object 1002H: Manufacturer Status Register . . . . . . . . . . . . . . . . . . . . . . . . . . 137

Object 1003H: Pre-defined Error Field . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

Object 1005H: COB-ID SYNC Message. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

Object 1006H: Communication Cycle Period . . . . . . . . . . . . . . . . . . . . . . . . . . 141

Object 1008H: Manufacturer Device Name. . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

Object 100AH: Manufacturer Software Version (MSV). . . . . . . . . . . . . . . . . . . 143

Object 100CH: Guard Time. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

Object 100DH: Life Time Factor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

Object 1010H: Store Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

Object 1011H: Restore Default Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

Object 1014H: COB-ID Emergency Message (EMCY) . . . . . . . . . . . . . . . . . . . 150

Object 1016H: Consumer Heartbeat Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

Object 1017H: Producer Heartbeat Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

Object 1018H: Identity Object . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

Object 1200H: Server SDO Parameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

Object 1400H: 1st Receive PDO Communication Parameter. . . . . . . . . . . . . . 155

Object 1405H: 2nd Receive PDO Communication Parameter . . . . . . . . . . . . . 156

Object 1600H: 1st Receive PDO Mapping Parameter . . . . . . . . . . . . . . . . . . . 157

Object 1605H: 2nd Receive PDO Mapping Parameter. . . . . . . . . . . . . . . . . . . 159

Object 1800H: 1st Transmit PDO Communication Parameter. . . . . . . . . . . . . 161

Object 1805H: 2nd Transmit PDO Communication Parameter . . . . . . . . . . . . 164

Object 1A00H: 1st Transmit PDO Mapping Parameter. . . . . . . . . . . . . . . . . . . 167

Object 1A05H: 2nd Transmit PDO Mapping Parameter . . . . . . . . . . . . . . . . . . 169

8.3 Manufacturer-specific Zone Objects 2000H to 5FFFH . . . . . . . . . . . . . . . . . . . 171

At a Glance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

Object 2000H: Input / Diag Parameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

Object 2001H: Input/Output Parameter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

Object 3000H: Manufacturer Specific Diagnostic . . . . . . . . . . . . . . . . . . . . . . . 174

8.4 Hardware Profile Objects 6000H to 9FFFH . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

At a Glance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

Object 6000H: Read Inputs 8 Bits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

Object 6100H: Read Input 16 Bits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

Object 6102H: Polarity Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 178

Object 6103H: Filter Constant Input 16 Bits . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

Object 6200H: Write Outputs 8 Bits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

1606218 02 08/2006 5

Page 6

Object 6300H: Write Outputs 16 Bits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

Object 6302H: Polarity Outputs 16 Bits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

Object 6306H:Fallback Mode 16 Bits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

Object 6307H: Fallback Value 16 Bits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 184

Object 6308H: Filter Mask Output 16 Bits . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

Appendices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .187

At a Glance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

Appendix A IEC Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

Glossary of Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .191

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 197

6 1606218 02 08/2006

Page 7

Safety Information

§

Important Information

NOTICE Read these instructions carefully, and look at the equipment to become familiar with

the device before trying to install, operate, or maintain it. The following special

messages may appear throughout this documentation or on the equipment to warn

of potential hazards or to call attention to information that clarifies or simplifies a

procedure.

The addition of this symbol to a Danger or Warning safety label indicates

that an electrical hazard exists, which will result in personal injury if the

instructions are not followed.

This is the safety alert symbol. It is used to alert you to potential personal

injury hazards. Obey all safety messages that follow this symbol to avoid

possible injury or death.

DANGER

DANGER indicates an imminently hazardous situation, which, if not avoided,

will result in death or serious injury.

WARNING

WARNING indicates a potentially hazardous situation, which, if not avoided, can

result in death, serious injury, or equipment damage.

CAUTION

CAUTION indicates a potentially hazardous situation, which, if not avoided, can

result in injury or equipment damage.

1606218 02 08/2006 7

Page 8

Safety Information

PLEASE NOTE Electrical equipment should be installed, operated, serviced, and maintained only by

qualified personnel. No responsibility is assumed by Schneider Electric for any

consequences arising out of the use of this material.

© 2006 Schneider Electric. All Rights Reserved.

8

1606218 02 08/2006

Page 9

About the Book

At a Glance

Document Scope This user guide contains the information required to install an Advantys FTB

CANopen monobloc IP67 splitter box.

It has been designed to facilitate rapid familiarization with the system, while

optimizing the system's features for the most advanced technology available.

To install Advantys FTB CANopen splitter boxes, the relevant communication

protocol pre-requisites are necessary, and it should only be installed by qualified

personnel. Special points and warnings regarding safety are highlighted in the

different chapters.

The early chapters provide information for designers and installers on installing the

mechanical and electrical elements of the system.

The following chapters, from the section on "network interface", are specific to the

communication protocol. They contain information on specific wiring for the network

interface and all the necessary information for the software application programmer,

and for the end user (diagnostics).

1606218 02 08/2006 9

Page 10

About the Book

Chapter Subject covered

Introduction General presentation of system components

Installation Dimensions

Safe practice for installation

I/O splitter box characteristics

and wiring

CANopen network interface Wiring the splitter box on the network

Application functions Description of application functions (Advantys FTB

Software implementation Software installation help

Diagnostics Performing diagnostics

Object dictionary Description of the objects accessible for communication

Appendices Presentation

Glossary Acronyms

Physical and electrical characteristics

Wiring information

Reminder on the communication protocol

System behavior

CANopen splitter box I/O functions)

Appendix A: List of IEC symbols

Definitions

Related

Documents

Title of Documentation Reference Number

Instruction sheet 1693627

CANopen hardware installation manual 35010859

User Comments We welcome your comments about this document. You can reach us by e-mail at

techpub@schneider-electric.com

10

1606218 02 08/2006

Page 11

Introduction

1

Presentation

Introduction This chapter provides a general overview of Advantys IP 67 FTB CANopen IP67 I/

O splitter boxes.

Advantys FTB CANopen splitter boxes comply with the following specifications:

CiA DS301 V4.02 (CANopen application layer and communication profile)

CiA DS401 V2.1 (CANopen device profile generic I/O modules) (see CANopen

Profiles, p. 50)

Note: The information in this manual is primarily intended for people with some

practical knowledge of the CANopen standard applied to the CANopen field bus.

CANopen equipment installers and users are advised to read the standard

documentation before any equipment installation or handling. All detailed

CANopen specifications may be found at http://www.can-cia.de.

What's in this

Chapter?

1606218 02 08/2006 11

This chapter contains the following topics:

Topic Page

Presentation of the CANopen Advantys FTB I/O Splitter Box Range 12

Overview of the Accessories Range 13

Page 12

Introduction

Presentation of the CANopen Advantys FTB I/O Splitter Box Range

The CANopen

Advantys FTB

Product Range

Configurable

Connectors

Splitter Box

Inputs and

Outputs

The splitter boxes in the CANopen Advantys FTB ranges come in the following

forms:

CANopen plastic unit

CANopen metal unit

Each CANopen Advantys FTB splitter box contains eight connectors used to link the

sensors or actuators.

Each of these connectors supports two channels. Depending on the splitter box

reference, and on its configuration, each channel is either:

an input channel,

an output channel,

a DESINA standard diagnostics channel.

The configuration of the I/O connector channels depends on the splitter box model.

The table below shows the I/O connector channels available for each model:

Distribution of available inputs/outputs Unit type Product reference

8 input / diagnostics channels + 8 output

channels

4 input channels + 4 output channels + 8 input

/ diagnostics channels

8 input channels + 8 input / diagnostics

channels

8 input / output channels + 8 input / output /

diagnostics channels

8 input / output channels + 8 input /

diagnostics channels

Plastic FTB 1CN08E08SP0

Plastic FTB 1CN12E04SP0

Plastic

Metal

Plastic

Metal

Metal FTB 1CN08E08CM0

FTB 1CN16EP0

FTB 1CN16EM0

FTB 1CN16CP0

FTB 1CN16CM0

12

1606218 02 08/2006

Page 13

Overview of the Accessories Range

Introduction

Cables for

Connecting the

Bus to the

Splitter Box

Different cables can be used to connect the splitter box to the field bus. These are

available in different lengths.

4

1

6

8

24 V

3 2

5

FTB 1CN

9

Element Reference Function

1 FTX CN3203

FTX CN3206

FTX CN3210

FTX CN3220

FTX CN3230

FTX CN3250

2 FTX DP2206

FTX DP2210

FTX DP2220

FTX DP2250

3 FTX DP2115

FTX DP2130

FTX DP2150

4 FTXCN12M5

FTXCN12F5

5 FTXCNCT1 Connection T fitted with 2 7/8-type connectors, 5 pins, for power supply cables.

6 FTX CNTL12 Line terminators fitted with 1 M12-type connector.

7 FTX CY1208

FTX CY1212

8 FTX C78B Sealing plug for 7/8 connector.

9 FTX CM12B Sealing plugs for M12-type connectors.

Cables fitted with 2 M12-type elbow connectors, 5 pins, at both ends for connecting the

bus between two splitter boxes.

Cables fitted with 2 7/8-type connectors, 5 pins, at both ends for daisy-chaining 24 VDC

supplies to two splitter boxes.

Cables fitted with 1 7/8-type connector, 5 pins, with one free end and the other for

connecting 24 VDC supplies.

Male and female M12-type connectors, 5 pins, for CANopen bus cables (encoding A).

Distribution Y for connecting 2 M8-type connectors to the M12 connector of the splitter

box.

Distribution Y for connecting 2 M12-type connectors to the M12 connector of the splitter

box.

7

1606218 02 08/2006 13

Page 14

Introduction

14

1606218 02 08/2006

Page 15

Installation

2

Presentation

Introduction This chapter provides all required information for installing an FTB splitter box on a

field bus.

Note: The graphic representations of the splitter boxes in this chapter may not

correspond to those really used. However, the dimensions are exact whatever the

case.

What's in this

Chapter?

1606218 02 08/2006 15

This chapter contains the following topics:

Topic Page

Overview 16

Installing the Unit 17

Grounding of the Advantys FTB Splitter Box 21

EMC Compatibility 23

Page 16

Installation

Overview

Introduction This section gives a detailed technical description of the Advantys FTB CANopen

splitter box.

Description The illustrations below show the plastic units (left) and metal units (right) of the

Advantys FTB CANopen splitter.

1

1

2

2

3

3

4

5

6

9

7

8

1

Element Function

1 Mounting holes

2 M12 connector for the inputs and outputs

3 Label

4 Display elements (diagnostics and status LED)

5 Power supply connectors (PWR IN)

6 Power supply distribution connector (PWR OUT)

7 Bus connector (BUS IN)

8 Bus connector (BUS OUT)

9 Transmission speed and addressing rotary selector switch

4

5

6

9

7

8

1

16

1606218 02 08/2006

Page 17

Installation

Installing the Unit

Introduction This section gives a detailed technical description of Advantys FTB splitter boxes.

Description The Advantys FTB splitter box can be mounted directly onto a wall or a machine.

Two mounting holes have been provided for this purpose inside the splitter box.

Note: When mounting the unit, the support must be flat and smooth so as to

prevent any undue stress on the unit, which may lead to a loss of sealing.

Types of Screws

and Tightening

Torques

Plastic unit

The plastic splitter box is mounted using two 4 mm (0.16 in.) diameter screws and

two washers. The tightening torque is 1.5 Nm (13.3 lb-in).

Metal unit

The metal splitter box is mounted using two 6 mm (0.24 in.) diameter screws and

two washers. The tightening torque is 9 Nm (79.7 lb-in).

Note: For metal units, wire the ground terminal before attaching the splitter box to

its support. See Grounding of the Advantys FTB Splitter Box, p. 21.

1606218 02 08/2006 17

Page 18

Installation

Plastic Unit

Dimensions

The dimensions of the plastic unit (front and side views) are given in the following

illustrations:

18

1606218 02 08/2006

Page 19

Installation

Metal Unit

Dimensions

The dimensions of the metal unit (front and side views) are given in the following

illustrations:

1606218 02 08/2006 19

Page 20

Installation

Method Follow the steps below:

Step Action

1 Position the splitter box on the support.

2 Mount the splitter box using the screws and washers.

RISK OF EQUIPMENT DAMAGE AND NON-COMPLIANCE WITH IP67.

Unused connectors must not be left unprotected. If a connector is not correctly

connected to the end of another connector or to a standard cable, fit a sealing plug

in order to ensure that the product is IP67 standard compliant. To ensure the IP67

protection index, check that the cover is screwed onto the base splitter box and that

all connectors are fitted with cables or sealing plugs.

Failure to follow this instruction can result in injury or equipment damage.

CAUTION

20

1606218 02 08/2006

Page 21

Installation

Grounding of the Advantys FTB Splitter Box

Description The ground connection is connected internally to pin 1 of the M12 connector of the

field bus connector.

WARNING

RISK OF UNINTENDED EQUIPMENT OPERATION

Check that the splitter box is correctly connected to the earth in compliance with

the instructions provided in his section. If the splitter box is not grounded, or if the

ground connection is made with an unsuitable cable, the product will be sensitive

to electromagnetic disturbances. See EMC Compatibility, p. 23.

Failure to follow this instruction can result in death, serious injury, or

equipment damage.

Position of the

Ground

Electrode on the

Plastic Unit

The following figure shows the position of the ground electrode on the plastic boxes.

Note: Use a grounding strip or a conductor with a cross-section of 1 to 1.5 mm2

(AWG18, AWG16) and a length of ≤ 3 m (9.84 ft) long. The maximum

recommended length for the grounding strip is 3 m (9.84 ft).

1606218 02 08/2006 21

Page 22

Installation

Method for

Plastic Units

Position of the

Ground

Electrode on the

Metal Unit

Follow the steps below to connect the ground to the unit:

Step Action

1 Remove the label located above the symbol representing the ground.

2 Insert the end of the grounding strip into the grounding terminal of the splitter

box.

3 Screw in the ground connection screw.

The following figure shows the position of the ground electrode on the metal boxes.

Note: Use a grounding strip or a conductor with a cross-section of 1 to 1.5 mm2

(AWG18, AWG16) and a length of ≤ 3 m (9.84 ft) long. The maximum

recommended length for the grounding strip is 3 m (9.84 ft).

Method for Metal

Units

Mounting the

Metal Unit

22

Follow the steps below to connect the unit to the ground electrode:

Step Action

1 Crimp the lug on the ground cable.

2 Screw in the lug with the ground conductor connection screw (supplied with the

product).

Once these steps have all been completed (see table above), the product can be

mounted on its support.

1606218 02 08/2006

Page 23

EMC Compatibility

Installation

Product

Compliance

This product complies with the European directive 89/336/CEE on "electromagnetic

compatibility".

The products described in this manual meet all the conditions regarding

electromagnetic compatibility and are compliant with the applicable standards.

However, this does not mean that the electromagnetic compatibility of your

installation is assured.

This is why it is strongly recommended to follow all indications concerning an EMC

compliant installation. Only in these conditions and thanks to the exclusive use of

CE approved components, will the devices used be deemed as compliant with the

EMC directives.

When handling the products, ensure that all safety measures related to

electromagnetic compatibility and all conditions for the use of the products are

complied with by all persons concerned. This is especially important when handling

products sensitive to electrostatic discharges.

WARNING

RISK OF ELECTROMAGNETIC INTERFERENCE AND UNINTENDED

EQUIPMENT OPERATION

The products described in this manual contain highly complex semiconductors that

can be damaged or destroyed by electrostatic discharges (ESD). If, for example,

they are used within the vicinity of devices rated as class A or B according to IEC

6100-4-4, the level of electromagnetic interference may be enough to cause the

device to operate unexpectedly, and/or to damage it.

Damage may not necessarily cause a failure or malfunction that is immediately

detectable. It may occur sporadically or in a delayed manner.

If there is a risk of electromagnetic interference, the system designer must

implement the necessary protective measures.

Failure to follow this instruction can result in death, serious injury, or

equipment damage.

1606218 02 08/2006 23

Page 24

Installation

Grounding A low impedance connection with a maximum length of 3 m (9.84 ft) must be

installed between the splitter box's ground electrode and the reference ground in

order to discharge the noise voltages. The inductance of standard grounding cables

(PE) presents a risk of high impedance when high frequency noise voltages are

present. It is therefore advisable to use grounding strips. If this solution is not

possible, use a ground conductor with a large cable cross-section and a ground

connection that is as short as possible.

WARNING

RISK OF UNINTENDED EQUIPMENT OPERATION

If the box is not connected to the ground, or if the ground connection is made using

an inappropriate cable, the product will be sensitive to electromagnetic

disturbances. This may lead to unexpected equipment operation.

Failure to follow this instruction can result in death, serious injury, or

equipment damage.

Cable Routing Make sure that the following basic wiring rules are followed:

Keep the data wire and the power cables apart from one another, in so far as is

possible.

Make sure there is a space of at least 10 cm (3.94 inches) between the data wires

and the power cables.

The data wires and power cables must only cross at a right angle to one another.

It is advisable to route the data wires and power cables through separate shielded

ducts.

When laying the cables, the noise voltage from other devices or wires must be

considered. This particularly applies to frequency converters, motors and other

devices or cables generating high frequency disturbances. High frequency

sources and the cables described in this manual must be as far apart from each

other as possible.

24

WARNING

RISK OF UNINTENDED EQUIPMENT OPERATION

Please read and comply with the cabling rules listed above. Failure to comply with

these wiring rules is a common cause of EMC problems! This may lead to

unexpected equipment operation.

Failure to follow this instruction can result in death, serious injury, or

equipment damage.

1606218 02 08/2006

Page 25

Installation

Control of

Inductive Loads

The outputs of the devices described in this manual are equipped with an integrated

protective system against the high noise voltages that may be generated by

inductive loads.

Integrated protective system against the high noise voltages generated by inductive

loads

Varistor

Inductive load

e.g. electromagnetic

valve

The varistor rapidly discharges the energy accumulated in the magnetic field of the

inductive load.

The high voltages arising from the disconnection of inductive loads create large

fields in the wires that may cause disturbances in nearby circuits or devices. It is

advisable to provide an anti-interference device at the load level. In this way, the

voltage peak generated by the inductive load is short-circuited directly at the point

at which it occurs.

1606218 02 08/2006 25

Page 26

Installation

26

1606218 02 08/2006

Page 27

Splitter Box Characteristics and Wiring

3

Presentation

Introduction This chapter provides an overall description of all Advantys FTB splitter boxes.

Note: The "-" in the tables corresponds to values that are not applicable.

What's in this

Chapter?

This chapter contains the following topics:

Topic Page

Advantys FTB Splitter Box Environment Properties 28

Electrical Characteristics 29

Connecting the Actuators and Sensors 30

Power Supply Connection 32

1606218 02 08/2006 27

Page 28

Splitter Box Characteristics and Wiring

Advantys FTB Splitter Box Environment Properties

Environment

Properties

Characteristic Description Reference standard

Product certification cULus -

Operating temperature -20°C...+60°C (-4°F...+140°F) -

Storage temperature -25°C...+70°C (-13°F...+158°F) -

Degree of protection IP67 According to IEC 60529

Altitude 0m 2,000 m (6,561 ft) -

Vibration withstand capacity

for plastic units

Constant amplitude: 0.35 mm (0.0138 in)

10 Hz≤ f ≤ 57 Hz

Constant acceleration: 5.0 gn

57 Hz≤ f ≤ 150 Hz

Vibration resistance capacity

for metal units

Constant amplitude: 1.5 mm (0.06 in)

5 Hz ≤ f ≤ 70 Hz

Constant acceleration: 15 gn

70 Hz ≤ f ≤ 500 Hz

Shock resistance capacity for

30 gn, duration: 11 ms According to IEC 68-2-27, Fc

plastic units

Shock withstand capacity for

50 gn, duration: 11 ms -

metal units

Resistance capacity for

electrostatic discharges

Withstand capacity for

Contact: +/- 4 kV

Air: +/- 8kV

10 V/m (3.05 V/ft) According to IEC 61000-4-3

radiated fields

Withstand capacity for fast

transients

Withstand capacity for surge

Withstand capacity for duct

Power supply: +/- 2 kV

Signal: +/- 2 kV

Power supply:

symmetrical: +/-500VDC

asymmetrical: +/-1,000 VDC

Signals:

symmetrical: +/-500VDC

asymmetrical: +/-1,000 VDC

Ground : +/-500VDC

10 Vrms According to IEC 61000-4-6

fields

Withstand capacity for 50 Hz

30 A/m (9.15 A/ft) According to IEC 61000-4-8

magnetic fields

Mounting In all positions -

According to IEC 68-2-6, Fc

test

According to IEC 68-2-6, Fc

test

test

According to IEC 61000-4-2

According to IEC 61000-4-4

According to IEC 61000-4-5

28

1606218 02 08/2006

Page 29

Electrical Characteristics

Splitter Box Characteristics and Wiring

Splitter Box

Characteristics

Input

Characteristics

Output

characteristics

Characteristic Description

Splitter box's internal consumption 120 mA

Splitter power supply voltage 18...30VDC

Splitter and sensor supply current ≤ 8 A

Actuator supply current ≤ 8 A

Under-voltage detection yes

Characteristic Description

Compliance with IEC 1131-2 Type 2

Compliance with 2-wire/3-wire sensor Yes

Rated power voltage 24 VDC

Maximum current 200 mA (for 2 diagnostics input channels)

Logic Positive PNP Sink

Filtering input 1 ms

Protection against reverse polarity and shortcircuit in sensor power supply

Overload and over-voltage protection Yes

Characteristic Description

Output type Transistors

Output voltage 24 VDC

Output current 1.6 A

Over-voltage protection Yes (transient diode)

Maximum switching cycle 20 Hz

Maximum lamp load 10 W

Connection for outputs / cable lengths

Protection against short-circuits yes

Yes

0.75mm2: 10 m maximum (AWG 19 / 32.8 ft)

0.34 mm2: 5 m maximum (AWG 23 / 16.4 ft)

1606218 02 08/2006 29

Page 30

Splitter Box Characteristics and Wiring

Connecting the Actuators and Sensors

Description The actuators and sensors are connected to the FTB splitter box using M12-type

connectors.

Characteristics

of the

Connections

Assignment of

M12 Connector

Pins

The maximum admissible load for the FTB splitter boxes is limited to:

1.6 A per output (actuator current),

200 mA for both inputs (sensor current).

WARNING

RISK OF EQUIPMENT DAMAGE AND NON-COMPLIANCE WITH IP67

Unused M12 connectors must not be left unprotected. If an M12 connector is not

correctly connected to the end of another connector or standard cable, fit a sealing

plug in order to ensure that the product is IP67 standard compliant. To ensure the

IP67 protection index, check that the cover is screwed onto the base splitter box

and that all connectors are fitted with cables or sealing plugs.

Failure to follow this instruction can result in death, serious injury, or

equipment damage.

The following diagram shows the front view of a 5-pin M12 connector and the

convention for numbering the pins:

Pin Assignment

1 +24 VDC

2 Channel 10 to 17: diagnostics input or functional input or output

30 VDC

4 Channel 00 to 07: functional input or output

5 Ground

30

1606218 02 08/2006

Page 31

Splitter Box Characteristics and Wiring

Allocation of the

M12 Connectors

to the I/Os

The following table shows the assignment of the M12 connector pins to the marking

of the splitter box's Inputs, Outputs and diagnostics:

Connector

number

0 Channel 00 Channel 10

1 Channel 01 Channel 11

2 Channel 02 Channel 12

3 Channel 03 Channel 13

4 Channel 04 Channel 14

5 Channel 05 Channel 15

6 Channel 06 Channel 16

7 Channel 07 Channel 17

Pin 4 Pin 2

1606218 02 08/2006 31

Page 32

Splitter Box Characteristics and Wiring

Power Supply Connection

Description For the FTB splitter boxes, the power supply is linked using a Mini-Style 7/8" 5-pole

connector.

The FTB splitter boxes require a 24 VDC power supply.

Calculation of

the Power

Supply Cable

Cross-Section

Assembling the

Power Supply

Cable

Calculations to find cable cross-sections are made according to the system's own

configuration data and remain the full responsibility of the user.

CAUTION

RISK OF EQUIPMENT DAMAGE

There are two kinds of risk of damage to equipment:

The 7/8" connector is sized for a maximum current of 8 A per pin. The pins of

the 7/8" connector must be provided with adequate protection to prevent an

overload of more than 8 A.

Reversed polarity connections in the power supply may damage the FTB splitter

box.

Failure to follow this instruction can result in injury or equipment damage.

The following diagram gives a view of the shape and size of the connection cable

connector:

32

1606218 02 08/2006

Page 33

Splitter Box Characteristics and Wiring

Pin Assignment The following diagram shows a front view of the PWR IN and PWR OUT connectors:

Pin Assignment

10 VDC

20 VDC

3Ground

4 Splitter box sensor and power supply

5 Actuator power supply

Recommendations for the

Power Supply to

the Sensors,

Actuators and

We recommend the use of 2 independent power supplies so as to separate the

power supply to the splitter boxes / sensors from the power supply to the actuators.

This configuration provides maximum protection against any disturbance on the

outputs (short circuits).

Splitter Boxes

Emergency Stop Separating the splitter box/sensor (pin 4) power supplies means that the emergency

stop can be connected to the actuator power supply (pin 5 of the 7/8" connector).

WARNING

RISK OF UNINTENDED EQUIPMENT OPERATION

Do not connect pin 4 of the power supply connector to the emergency stop circuit

of the system. Interrupting the power supply to this pin, will deactivate the I/O

channels of the splitter box, which can result in an unintended equipment

operation.

Failure to follow this instruction can result in death, serious injury, or

equipment damage.

1606218 02 08/2006 33

Page 34

Splitter Box Characteristics and Wiring

Method Follow the steps below:

Step Action

1 Disconnect all power to the system.

2 On the PWR IN connector:

If the splitter box is the first in the chain, connect a cable with a female

connector and free wires.

If the splitter box is the last in the chain, connect a connection cable.

3 On the PWR OUT connector:

If the splitter box is in the middle of the chain, connect a power supply

connection cable.

If the splitter box is at the end of the chain, fit a sealing plug.

Phaseo Power

Supply

A switch mode power supply such as Phaseo (ABL 7•••) is particularly well-suited to

supply automation systems. It is therefore highly recommended for use with

Advantys FTB splitter boxes.

34

1606218 02 08/2006

Page 35

CANopen Network Interface

4

Presentation

Introduction This section describes how to connect the Advantys FTB CANopen splitter box to

the CANopen network.

What's in this

Chapter?

This chapter contains the following sections:

Section Topic Page

4.1 Wiring on the CANopen Bus 37

4.2 General Principles 48

4.3 Behavior of FTB CANopen Splitter boxes 66

1606218 02 08/2006 35

Page 36

CANopen Network Interface

36

1606218 02 08/2006

Page 37

CANopen Network Interface

4.1 Wiring on the CANopen Bus

Presentation

Introduction The following section describes wiring on the CANopen bus.

What's in this

Section?

This section contains the following topics:

Topic Page

Introduction to Wiring on the CANopen Bus 38

Topology 39

Choice of system cables 42

Connecting the Field Bus 44

Configuring the Address and Transmission Speed 46

1606218 02 08/2006 37

Page 38

CANopen Network Interface

Introduction to Wiring on the CANopen Bus

Introduction The physical characteristics necessary for CANopen bus operation are given in the

following illustration (plastic units on the left and metal units on the right):

1

2

3

4

5

6

Description Function See

1 7/8" connector Power supply connection (PWR IN) Power Supply

2 7/8" connector Power supply connection (PWR OUT)

3 Rotary switch Selecting transmission speed Configuring the

4 Rotary switches Selecting the splitter box address

5 M12 Connector CANopen bus connector (Bus OUT) Connecting the

6 M12 Connector CANopen bus connector (Bus IN)

1

2

3

4

5

6

Connection, p. 32

Address and

Transmission

Speed, p. 46

Field Bus, p. 44

38

1606218 02 08/2006

Page 39

CANopen Network Interface

Topology

Architecture The CANopen network architecture must comply with the following limitations:

bus length / transmission speed (See Transmission Speed, p. 42),

number of connected devices (See Number of Connected Devices, p. 41),

length of the taps and the space between two taps (See Tap Length, p. 40),

line terminator (See Line Terminator Resistance, p. 43).

The connections to the CANopen bus may be of the chaining or tap type.

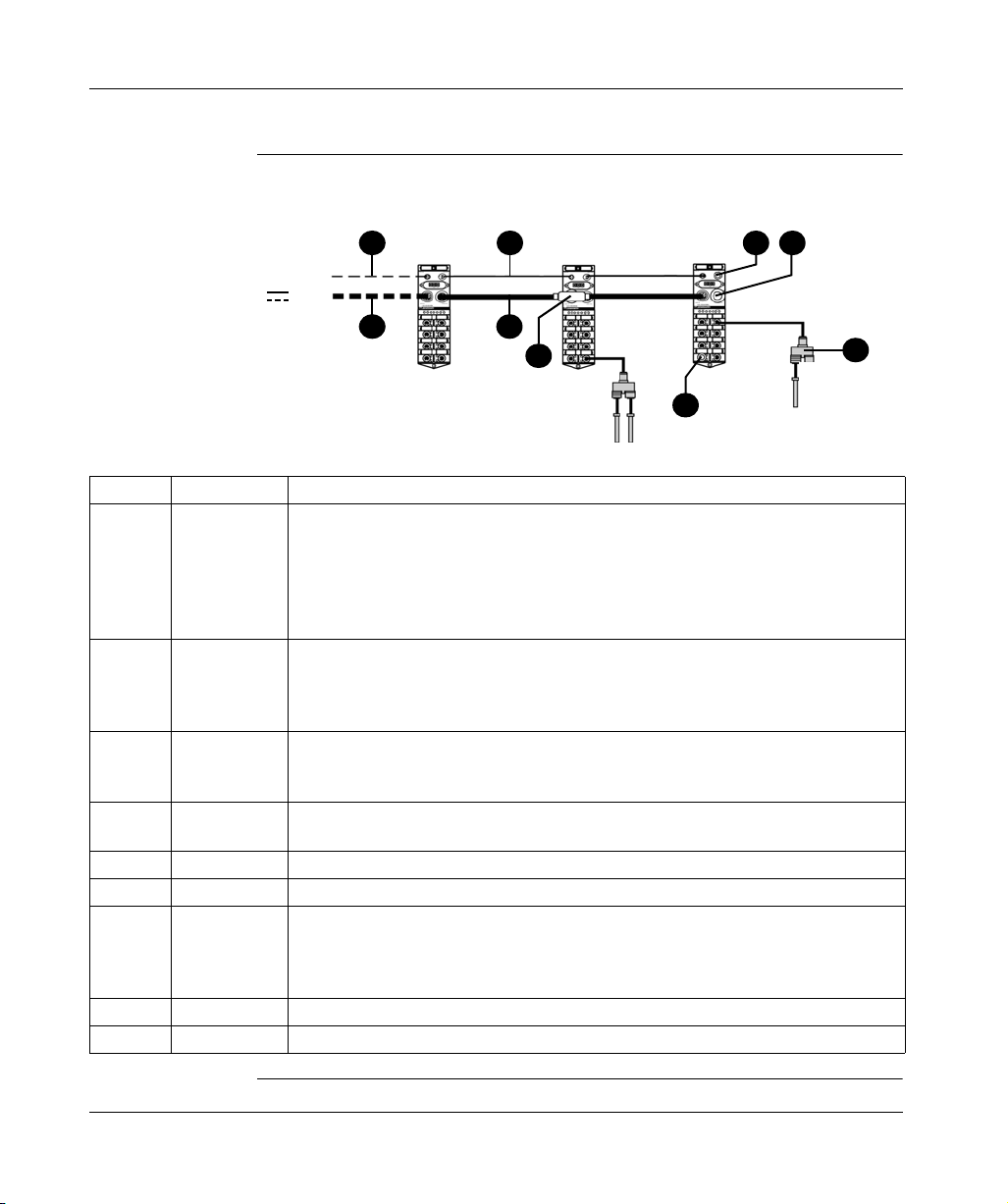

The following is an illustration of a CANopen network architecture:

2

1

7

6

5

6 6

8

The table below describes the components of a CANopen network:

Number Description

1 CANopen devices connected by chaining

2 CANopen devices connected by tap

3 Drop cables (tap junction box / device)

4 Tap junction boxes

5 Chaining cables

6 Line terminator

7 Repeater (identical arbitration on the different bus segments)

or Bridge (different arbitration on the different bus segments)

8 CANopen bus segment

3

Lmax

4 4

Min. interval

8

5

3

6

Note: A single line architecture is recommended to reduce signal reflection. Avoid

using star-type architecture.

1606218 02 08/2006 39

Page 40

CANopen Network Interface

Tap Length A tap creates a signal reflection and thus its length must be limited to the following

parameters:

Lmax is the maximum length of a tap.

ΣLImax is the maximum value of the sum of all taps on the same tap junction box.

Min interval is the minimum distance necessary between two taps.

ΣLGmaxis the maximum value of the sum of all taps on the segment.

The values to use are given in the following table:

Speed Lmax ΣLImax Min. interval

0.6xΣL local

1 Mbits/s 0.3 m (0.98 ft) 0.6 m (1.96 ft) 1.5 m (4.9 ft)

800 Kbits/s 3 m (9.8 ft) 6 m (19.6 ft) 3.6 m (11.8 ft)(*) 15 m (49 ft)

500 Kbits/s 5 m (16.4 ft) 10 m (32.80 ft) 6 m (19.6 ft)(*) 30 m (98.4 ft)

250 Kbits/s 5 m (16.4 ft) 10 m (32.80 ft) 6 m (19.6 ft)(*) 60 m (196.8 ft)

125 Kbits/s 5 m (16.4 ft) 10 m (32.80 ft) 6 m (19.6 ft)(*) 120 m (393.6 ft)

50 Kbits/s 60 m (196.8 ft) 120 m (393.6 ft) 72 m (236 ft)(*) 300 m (984 ft)

20 Kbits/s 150 m (492 ft) 300 m (984 ft) 180 m (590.5 ft)(*) 750 m (2 460.6 ft)

10 Kbits/s 300 m (984 ft) 600 m (1 968.4 ft) 360 m (1 181 ft)(*) 1 500 m (4 921 ft)

Legend:

(*) The minimum cable length between two consecutive tap junction boxes must be greater than 60% of the largest

of the two sums of the lengths of taps on each of the two boxes.

ΣLGmax

40

1606218 02 08/2006

Page 41

CANopen Network Interface

Example The following illustration shows the calculation of the length of a cable located

between two tap junction boxes.

1

Number of

Connected

Devices

2

1 m

(3 ft)

3

1 m

(3 ft)

ΣL=5 m (16 ft)

3 m

(10 ft)

1 m

(3 ft)

3 m

(10 ft)

ΣL=7 m (23 ft)

3 m

(10 ft)

4

Min interval > 0.6 * 7 m (23 ft)

Min interval > 4.2 m (13.8 ft)

The table below describes the components of a CANopen network:

Number Description

1 Connected CANopen devices

2 Drop cables (tap junction box / device)

3 Tap junction boxes

4 Connection cables (tap junction box / tap junction box)

In this example, we have two tap junction boxes and 6 devices. We start by

calculating the sum of the lengths of cables for each tap junction box, and we obtain

5m (16 ft) and 7 m (23 ft). We keep the longest length, i.e. 7 m (23 ft). The minimum

length of the cable between the two tap junction boxes is equal to 60% of 7 m, i.e.

4.2 m (13.8 ft).

In addition to the length limitations over the whole of the CANopen bus, the following

limitations apply:

Whatever the case, no more than 64 devices may be connected on the same

segment.

1606218 02 08/2006 41

Page 42

CANopen Network Interface

Choice of system cables

Transmission

Speed

Specific

The maximum allowable transmission speeds are given in the following table:

Transmission speed

(kBit/s)

1000 30 m (98 ft)

800 50 m (164 ft)

500 100 m (328 ft)

250 250 m (820 ft)

125 350 m (1 148 ft)

100 500 m (1 640 ft)

50 1 000 m (3 280 ft)

20 2 500 m (8 202 ft)

10 5 000 m (16 404 ft)

Cable length

The specific resistances and AWG cable sections are shown in the following table:

Resistance

Maximum speed Cable length Specific resistance of

cables

Ω

Kbits/s m ft mΩ/m m

1000 for 40 m

(131 ft)

500 for 100 m

(328 ft)

100 for 500 m

(1640 ft)

50 for 1000 m

(3,280 ft)

0 ... 40 0...131 70 21.34 0.25...0.34 AWG24, AWG22

40 ... 300 131...984 < 60 < 18.29 0.34...0.6 AWG22, AWG20

300 ... 600 984...1968 < 40 < 12.19 0.5...0.6 AWG20

600 ... 1000 1968...3280 < 26 < 7.92 0.75...0.8 AWG18

/ft

Cable sections

2

mm

AWG

42

Note: The parameters shown in the above table must be considered for networks

complying with the standard ISO11898-2.

1606218 02 08/2006

Page 43

CANopen Network Interface

Line Terminator

Resistance

What types of

cables can be

used?

To minimize the voltage drop in the connection, it is advisable to use a higher line

terminator resistance for high length cables than that specified by the standard

ISO11898-2. When configuring the system, the connector resistances must also be

taken into consideration. For each connector, 5 mΩ to 20 mΩ must be added to the

terminator resistance.

WARNING

RISK OF UNINTENDED EQUIPMENT OPERATION

The potential difference at the CAN_GND connections of all the CANopen bus

items must not be greater than 2 VDC. The connectors have a standard DC of

5mΩ to 20 mΩ. It is important to connect a 120 Ω line terminator between CAN_H

and CAN_L at the line end (see Physical Layer, p. 49).

Failure to follow this instruction can result in death, serious injury, or

equipment damage.

Pre-assembled cables make installing the system considerably easier. Cabling

errors are avoided and implementation is achieved more rapidly. Schneider Electric

offers a full range of products such as field bus links, power supply cables and

cables for detectors, together with accessories such as line terminators. Connectors

and cables for assembly are also available.

1606218 02 08/2006 43

Page 44

CANopen Network Interface

Connecting the Field Bus

Description The splitter box can either be in the middle of the chain connection or at line end.

The field bus is connected via a 5-pin M12 connector.

Illustration of the

Connection

Cable Connector

Bus Connector

Pin Assignment

The following diagram shows the characteristics of the connection cable connector:

The BUS IN connector is a 5-pin M12 male connector.

The BUS OUT connector is a 5-pin M12 female connector.

The following diagram shows a front view of the bus connectors:

32

BUS

IN

5

14

14

32

5

BUS

OUT

The following table gives the assignments of the bus connector pins:

Pin Signal Meaning

1 (CAN_SHLD) Optional CAN shielding

2 (CAN_V+) NC (not connected)

3 CAN_GND 0 V

4 CAN_H CAN_H bus line

5 CAN_L CAN_L bus line

44

Note: Pin 1 is connected to the ground connection terminal of the splitter box.

1606218 02 08/2006

Page 45

CANopen Network Interface

CAUTION

RISK OF EQUIPMENT DAMAGE AND NON-COMPLIANCE WITH STANDARD

IP67

Unused M12 connectors must not be left unprotected.

If an M12 connector is not fitted with a line terminator or connected to a standard

cable, fit a sealing plug so as to guarantee the product’s IP67 protection.

Failure to follow this instruction can result in injury or equipment damage.

Correspondence

between 9-pin

SUB-D

Connectors and

M12 5-pin

The bus connector on IP20 products is a 9-pin SUB-D connector (e.g. Advantys

OTB CANopen).

The following table shows the correspondence between pins on 9-pin SUB-D

connectors and on 5-pin M12 connectors:

Connectors

9-pin SUB-D

connector

1 - Reserved -

1

6

2

7

3

8

4

9

5

SUB-D

pin

2 CAN_L CAN_L bus line 5

3 CAN_GND 0 V 3

4 - Reserved -

5 (CAN_SHLD) Optional CAN shielding 1

6 (GND) Optional CAN_V- -

7 CAN_H CAN_H bus line 4

8 - Reserved -

9 (CAN_V+) Optional power supply -

Signal Meaning M12 pin 5-pin M12

Method Follow the steps below:

Step Action

1 Connect the connection cable for chaining to the BUS IN connector.

2 If the splitter box is at the end of the line, connect a line terminator resistor to

the BUS OUT connector.

Otherwise, connect a connection cable to the BUS OUT connector.

connector

32

5

14

1606218 02 08/2006 45

Page 46

CANopen Network Interface

Configuring the Address and Transmission Speed

Method Follow the steps below:

Step Action

1 Switch off the power supply to the splitter box.

2 Unscrew both screws on the transparent cover.

3 Set the communication speed.

4 Set the splitter box address.

5 Screw the transparent cover back on.

6 Power up the splitter box.

Illustration of the

Rotary Switches

Assignment of

the Address on

the Network

DATA

NODE ADDRESS

RATE

1

0

9

8

7

6

5

X10 X1

0

1

1

2

8

3

4

9

9

2

8

3

7

7

4

6

6

5

5

2 3

0

1

2

3

4

Element Function

1 Sets the transmission speed

2 Node-ID x 10

3 Node-ID x 1

The CANopen address is configured using two specially designed rotary switches.

Addresses can be configured from 1 to 99. Address zero (0) cannot be used.

Note: When assigning the addresses, ensure that each splitter box is assigned to

a single address.

A configured address is registered at power up. It cannot be changed if you do not

remove the cover.

46

1606218 02 08/2006

Page 47

CANopen Network Interface

Adjustment of

the

Transmission

Speed

The transmission speed is configured using a rotary switch.

The following transmission speeds are possible:

Switch position Transmission speed

0 Automatic recognition

1 10 Kbits/s

2 20 Kbits/s

3 50 Kbits/s

4 100 Kbits/s

5 125 Kbits/s

6 250 Kbits/s

7 500 Kbits/s

8 800 Kbits/s

9 1 Mbits/s

Note: Two different operating modes are possible:

With a set speed of (10 Kbit/s to 1 Mbits/s), the transmission speed of the splitter

box must be the same as that of the other devices on the network.

In automatic recognition mode, at least one of the slaves on the network must

be configured to the speed of the Master.

For each case, if the required condition is not observed, the splitter box will not be

recognized by the network ( it will remain in the "Init" state).

1606218 02 08/2006 47

Page 48

CANopen Network Interface

4.2 General Principles

Presentation

Introduction This section addresses the general principles for operating and using the CANopen

network.

What's in this

Section?

This section contains the following topics:

Topic Page

About CANopen 49

The Device Profile 52

CANopen "Boot-Up" 53

Process Data Object (PDO) Transmission 56

Inhibit Time and Event Timer 60

Access to Data by Explicit Exchanges (SDO) 61

"Node-Guarding" and "Life-Guarding" Monitoring Protocols 62

The "Heartbeat" Error Monitoring Protocol 65

48

1606218 02 08/2006

Page 49

CANopen Network Interface

About CANopen

Introduction CANopen is a standard fieldbus protocol for industrial control systems. It is

particularly well suited to real-time PLCs, as it provides an effective, low-cost

solution for industrial applications.

The CANopen

Protocol

The CANopen protocol was created as a subset of CAL (CAN Application Layer). By

defining profiles, it is able to be even more specifically adapted to use with standard

industrial components. CANopen is a CiA standard (CAN in Automation) that was

very quickly adopted by users when it was put on the market. In Europe, CANopen

is now recognized as the industry standard for industrial systems based on a CAN

design.

Physical Layer CAN uses a differentially driven two-wire bus line (common return). A CAN signal is

the difference between the voltage levels of the CAN_H and CAN_L wires. (See

figure below.)

The following diagram shows the components of the physical layer of a two-wire

CAN bus:

555

1

3

44

2

1 CAN_H wire

2 CAN_L wire

3 Potential difference between CAN-H/CAN-L signals

4 Line terminator 120 Ω

5 Connected devices,

The bus wires can be routed in parallel, twisted or shielded form in accordance with

electromagnetic compatibility requirements.

1606218 02 08/2006 49

Page 50

CANopen Network Interface

CANopen

Profiles

Device

Configuration via

the CAN Bus

General

Specifications

for CANopen

Profiles

The communication profile

The CANopen communication protocol is based on a "communication profile", which

specifies the main communication mechanisms and their description (DS301).

The device profile

The most important types of devices used in industrial automation are described in

the "Device profiles". They also define device functionalities.

Here are some examples of standard devices:

Discrete and analog input/output splitter boxes (DS401)

Motors (DS402)

Control devices (DSP403)

Closed loop controllers (DSP404)

PLCs (DS405)

Encoders (DS406)

The possibility of configuring devices via the CANopen bus is one of the basic

principles of the autonomy required by manufacturers (for each profile family).

CANopen is a set of profiles for CAN systems with the following specifications:

An open bus system

Real-time data exchange without protocol overload

A modular design with the possibility of resizing

Interoperability and interchangeability of devices

Support guaranteed by a large number of international manufacturers

A standardized network configuration

Access to all device parameters

Synchronization and circulation of cyclical process data and/or event-driven data

(possibility of short system response times).

CANopen

Product

Certification

50

All manufacturers offering CANopen-certified products on the market are members

of the CiA (CAN in Automation) industrial consortium. As an active member of the

CiA consortium, Schneider Electric develops its products in compliance with

standard recommendations recognized internationally by the CiA consortium.

1606218 02 08/2006

Page 51

CANopen Network Interface

CAN Standards CANopen specifications are defined by the CiA group and can be accessed (subject

to some restrictions) on the group site at www.can-cia.de. The source codes for

master and slave devices are available from the various suppliers.

Note: To find out more about CANopen standard specifications and mechanisms,

please visit the CiA home page (http//www.can-cia.de).

Communication

on a CANopen

Network

The communication profile is based on CAL (CAN Application Layer) services and

protocols.

It provides the user with access to two types of exchange: SDO and PDO.

On power up, the device enters an initialization phase then goes into "Preoperational" state. At this stage, only SDO communication is authorized. After

receiving a startup command, the device switches to the "Operational" state. PDO

and SDO communications are both authorized when the device is in the

"Operational" state.

1606218 02 08/2006 51

Page 52

CANopen Network Interface

The Device Profile

List of Functions The list of functions supported and their coding are given in the following table:

Function Function code

(binary)

NMT 0000 0 0

SYNC 0001 80 128

EMERGENCY 0001 81 - FF 129 - 255

TPDO (tx) 0011 181- 1FF 385 - 511

RPDO (rx) 0100 201- 27F 513 - 639

TPDO (tx) 0101 281 - 2FF 641 - 767

RPDO (rx) 0110 301 - 37F 769 - 895

TPDO (tx) 0111 381 - 3FF 897 - 1023

RPDO (rx) 1000 401 - 47F 1025 - 1151

TPDO (tx) 1001 481 - 4FF 1153 - 1279

RPDO (rx) 1010 501 - 57F 1281 - 1407

SDO (tx) 1011 581 - 5FF 1409 - 1535

SDO (rx) 1100 601 - 67F 1537 - 1663

Node-Guarding 1110 701 - 77F 1793 - 1919

Resulting COB-ID

(Hex)

Resulting COB-ID

(Dec)

52

1606218 02 08/2006

Page 53

CANopen "Boot-Up"

CANopen Network Interface

Procedure for

"Boot-Up"

The minimum configuration of the equipment specifies a shortened boot procedure.

This procedure is illustrated in the following diagram:

1

Initialisation

Reset Application

Reset Communication

Init

2

7

7

Pre-Operational

433

Operational

5

4

5

Stopped

6

6

6

Legend

Number Description

1 Device power-up

2 After initialization, the device automatically goes into the PRE-OPERATIONAL

state

3 NMT service indication: START REMOTE NODE

4 NMT service indication: ENTER PRE-OPERATIONAL

5 NMT service indication: STOP REMOTE NODE

6 NMT service indication: RESET NODE

7 NMT service indication: RESET COMMUNICATION

NMT : Network Management Telegram

1606218 02 08/2006 53

Page 54

CANopen Network Interface

Active CANopen

Objects

depending on

State Machine

"Reset

Application"

"Reset

Communication"

The crosses in the table below indicate which CANopen objects are active for which

states of the state machine:

Initialisation Pre-Operational Operational Stopped

PDO object: X

SDO object: X X

Emergency X X

Boot-Up X

NMT X X X

The device goes into the "Reset Application" state:

after the device starts up or,

by "RESET NODE" (NMT service,Network Management Telegram).

In this state, the device profile is initialized, and all the device profile information is

reset to default values. When initialization is complete, the device automatically

goes into the state "Reset Communication".

The device goes into the "Reset Communication" state:

after the "Reset Application" state,

by "RESET COMMUNICATION" (NMT service).

In this state, all the parameters (standard value, depending on the device

configuration) of the supported communication objects (1000H - 1FFFH) are saved

in the object directory. The device then automatically goes into the "Init" state.

"Init" The device goes into "Init" mode after being in the "Reset Communication" state.

This state enables you to:

define the required communication objects (SDO, PDO, Sync, Emergency),

install the corresponding CAL services

configure the CAN-Controller.

Initialization of the device is complete and the device automatically goes into the

"Pre-Operational" state and sends a "Boot-Up" message.

54

1606218 02 08/2006

Page 55

CANopen Network Interface

"PreOperational"

The device goes into the "Pre-Operational" state:

after the "Init" state,

on receiving the NMT "ENTER PRE-OPERATIONAL" indication if it was in the

"Operational" or "Stopped" state.

When the device is in this state, its configuration can be modified. However, only

SDOs can be used to read or write device-related data.

When configuration is complete, the device goes into one of the following states on

receiving the corresponding indication:

"Stopped" on receiving the NMT "STOP REMOTE NODE" indication.

"Operational" on receiving the NMT "START REMOTE NODE" indication.

"Stopped" The device goes into the "Stopped" state on receiving the "STOP REMOTE NODE"

indication (NMT service) if it was in "Pre-Operational" or "Operational" state.

In this state, the device cannot be configured. No service is available to read and

write device-related data (SDO). Only the slave monitoring function ("NodeGuarding" or "Heartbeat") remains active.

"Operational" The device goes into the "Operational" state if it was in the "Pre-Operational" or

"Stopped" state on receiving "START REMOTE NODE" indication.

When the CANopen network is started using the NMT "START REMOTE NODE"

services, all device functionalities can be used. Communication can be carried out

via PDOs or SDOs.

WARNING

RISK OF UNINTENDED DEVICE OPERATION

Do not change the device configuration when it is in "Operational" state. Changing

the equipment configuration while it is in the "Operational" state may result in the

device behaving in an unexpected manner and/or in equipment damage or injury

to personnel. If the device needs to be reconfigured, put it in the "Pre-Operational"

state and check that this has been done correctly before proceeding to modify the

configuration.

Failure to follow this instruction can result in death, serious injury, or

equipment damage.

1606218 02 08/2006 55

Page 56

CANopen Network Interface

Process Data Object (PDO) Transmission

Definition of PDO PDOs are objects which provide the communication interface with process data and

enable them to be exchanged in real time. A CANopen device's PDO set describes

the implicit exchanges between this device and its communication partners on the

network.

The exchange of PDOs is authorized when the device is in "Operational" mode.

Types of PDO There are two types of PDO:

PDOs transmitted by the device ("Transmit PDO", "TPDO")

PDOs received by the device ("Receive PDO", "RPDO")

PDO Consumer/

Producer

PDOs are based on the "Producer / consumer" model ("Producer" / "Consumer").

The device which sends out a PDO is called the producer, while the device receiving

it is known as the consumer.

PDO

Transmission

Modes

Transfer code Transmission mode Notes

Dec. Hex. Cyclic Acyclic Synchron

0 0 x x Send PDO on first SYNC

1 to 240 1 to F0 x x Send PDO every x SYNC

241 to 251 F1 to FB Reserved -

252 FC x x Receive SYNC message

253 FD x x Update data and send

254 to 255 FE to FF x Send PDO on event

In addition to data to be transported, it is possible to configure the type of exchange

for each PDO.

The PDO transmission mode can be configured as described in the table below.

ous

Asynchro

nous

only RTR

message following an

event

messages

and send PDO on

Remote Request

PDO on Remote Request

(Change of state mode)

56

1606218 02 08/2006

Page 57

CANopen Network Interface

Change of state

Remote Transmission

Request

Synchronous object

(cyclic, acyclic)

Producer

Consumer(s)

Remote frame

Producer

Consumer(s)

Synchronous object

Producer

Consumer(s)

1606218 02 08/2006 57

Page 58

CANopen Network Interface

Synchronous

(mode 0 to 240)

For certain applications, synchronization between scanning of the inputs and

activation of the outputs may be necessary.

For this reason, CANopen provides the "SYNC" object, a high-priority CAN message

without any working data, which, when it is received by the synchronized devices is

used to trigger the reading of inputs or activation of outputs (Trigger).

The following diagram shows the time data for synchronized PDO transmission.

Communication cycle

SYNC SYNC SYNC

Current input data

Set point

Output

Data

Input search in each SYNC

message

Actuation based on outputs

at next SYNC message

Synchronous

window length

Synchronous

RTR (mode 252)

Asynchronous

RTR (mode 253)

58

Aside from polling by request ("timing-related polling"), the slaves can also be polled

by the master by using data request messages ("Remote-Frames", known as RTR

messages).

In mode 252, the device uses the synchronization message to trigger transmission

of the PDO once it has received the RTR message.

In mode 253, the TPDOs are transmitted once the RTR message is received.

1606218 02 08/2006

Page 59

CANopen Network Interface

"Change of

state" (modes

254 and 255)

The asynchronous exchange of PDO in "Change of state" mode enables the rapid

modification of an input value, followed by immediate confirmation of the change of

value. This avoids the need to wait for the master to send a request.

A high priority bus status is assigned to the "Change of state" mode and only the

updated input value is returned, not the image of the full process, thus considerably

reducing traffic on the bus.

"Change of state" corresponds to the modification of the input value (event control).

WARNING

RISK OF UNINTENDED DEVICE OPERATION

The "Change of State" mode must not be used for inputs/outputs whose state

changes continuously (such as analog inputs). The continual modification of I/Os

using the "Change of State" mode may block the transmission of other crucial

commands, resulting in the unintended operation of the device.

Failure to follow this instruction can result in death, serious injury, or

equipment damage.

1606218 02 08/2006 59

Page 60

CANopen Network Interface

Inhibit Time and Event Timer

Inhibit Time In event transmission mode, the Inhibit Time utility is used to define a minimum time

delay before transmission of a new PDO. This avoids overloading the bus where a

significant number of events occur in rapid succession.

The Inhibit Time is expressed in multiple of 100 μs.

Values (hex.) Values (dec.) Actual values (ms)

0000H 0 0000

000AH 10 1

0064H 100 10

03E8H 1000 100

2710H 10 000 1000

FFFFH 65 535 6553.5

Event Timer In event transmission mode, the Event Timer is used to define an expiry time delay

where transmission of a PDO will be forced, even if there has been no change in

status .

The Event Timer is expressed in milliseconds.

Values (hex.) Values (dec.) Actual values (ms)

0000H 0 0 (deactivated)

000AH 10 10

0064H 100 100

01F4H 500 500

03E8H 1000 1000

1388H 5000 5000

2710H 10 000 10 000

60

1606218 02 08/2006

Page 61

CANopen Network Interface

Access to Data by Explicit Exchanges (SDO)

What is an SDO? An SDO allows a device's data to be accessed by using explicit requests.

The SDO service is available when the device is in "Operational" or "PreOperational" state.

Types of SDO There are two types of SDO:

Read SDOs (Download SDO)

Write SDOs (Upload SDO)

The Producer/

Consumer Model

The SDO protocol is based on a 'Producer/Consumer' model.

For a Download SDO

The client sends a request indicating the object to be read.

The server returns the data contained within the object.

For an Upload SDO

The client sends a request indicating the object to be written to and the desired

value.

After the object has been updated, the server returns a confirmation message.

For an unprocessed SDO

In both cases, if an SDO was not able to be processed, the server returns an error

code (abort code).

1606218 02 08/2006 61

Page 62

CANopen Network Interface

"Node-Guarding" and "Life-Guarding" Monitoring Protocols

Introduction Error monitoring protocols are used to detect communication errors on the network.

The default monitoring method, "Node-Guarding", consists in the master controlling

the slaves. It is possible to add "Life-Guarding" control of the master by the slaves.

Note: The simultaneous use of both monitoring methods, "Guarding" and

"Heartbeat", is impossible. Should both methods be activated at once, the

equipment will only use the "Heartbeat" monitoring method.

Definition of

"Life-Time"

Activation of

Monitoring

Reliable

Operation

The "Life-Time" parameter is calculated as follows:

"Life-Time"= "Guard-Time" x "Life-Time-Factor"

The object 100CH contains the ''Guard-Time'' parameter expressed in milliseconds.

The object 100DH contains the ''Life-Time-Factor" parameter.

When one of the two parameters "Life-Time-Factor" or "Guard-Time" is set to "0"

(default configuration), the device does not perform monitoring (no "Life-Guarding").

To activate monitoring over time, you must enter a value (minimum 1) in the object

100DH and specify a time in ms in the object 100CH.

Common typical values for the "Guard-Time" parameter lie between 250 ms and 2 s.

To enable reliable and secure operation, the user must enter a "Life-Time-Factor"

with a minimum value of 2.

When the value 1 is used, should a delay occur due to the processing of high priority

messages or internal processing on the "Node-Guarding" master, the device

switches back to the "Pre-Operational" default state without generating any errors.

WARNING

RISK OF UNINTENDED DEVICE OPERATION

Set the "Life-Time-Factor" (object 100DH) to a minimum value of 2 to prevent any

inadvertent change of state to "Pre-Operational" state. Depending on the I/O

configuration, an inadvertent change of state may result in unintended device

operation.

Failure to follow this instruction can result in death, serious injury, or

equipment damage.

62

1606218 02 08/2006

Page 63

CANopen Network Interface

Importance of

Monitoring

These two monitoring mechanisms are especially important in the CANopen

system. Devices connected to the bus do not regularly indicate their presence in

operating mode, commanded by "Event".

Slave Monitoring Monitoring is performed in the following way:

Phase Description

1 The master sets "Remote-Frames" (or "Remote-Transmit-Request" request

messages) on the "Guarding-CobID" of the slaves to be monitored.

2 The slaves concerned respond by sending the "Guarding" message. This

message contains the "Status-Code" of the slave and the "Toggle-Bit", which

changes after each message.

3 The NMT (Network Management Telegram) master compares the "Status"and

"Toggle-Bit" information:

If they are not in the expected state or if no response is received, the NMT

master considers that an error has occurred on the slave.

1606218 02 08/2006 63

Page 64

CANopen Network Interface

Master

Monitoring

If the master requests "Guarding" messages on a strictly cyclical basis, the slave

can detect a master failure.

If the slave does not receive a request from the master within the defined "Life-Time"

interval ("Guarding" error), it considers that a master failure has occurred

("Watchdog" function).