Page 1

Altivar 71

Variable speed drives for synchronous and

asynchronous motors

Programming manual

Specification 383

Software V3.4

12/2009

AAV49426

www.schneider-electric.com

Page 2

Page 3

Contents

Before you begin______________________________________________________________________________________________ 4

Documentation structure________________________________________________________________________________________ 5

Software enhancements ________________________________________________________________________________________ 6

Steps for setting up___________________________________________________________________________________________ 10

Factory configuration _________________________________________________________________________________________ 11

Application functions__________________________________________________________________________________________ 12

Setup - Preliminary recommendations ____________________________________________________________________________ 16

Graphic display terminal_______________________________________________________________________________________ 18

Description of terminal __________________________________________________________________________________ 18

Description of the graphic screen__________________________________________________________________________ 19

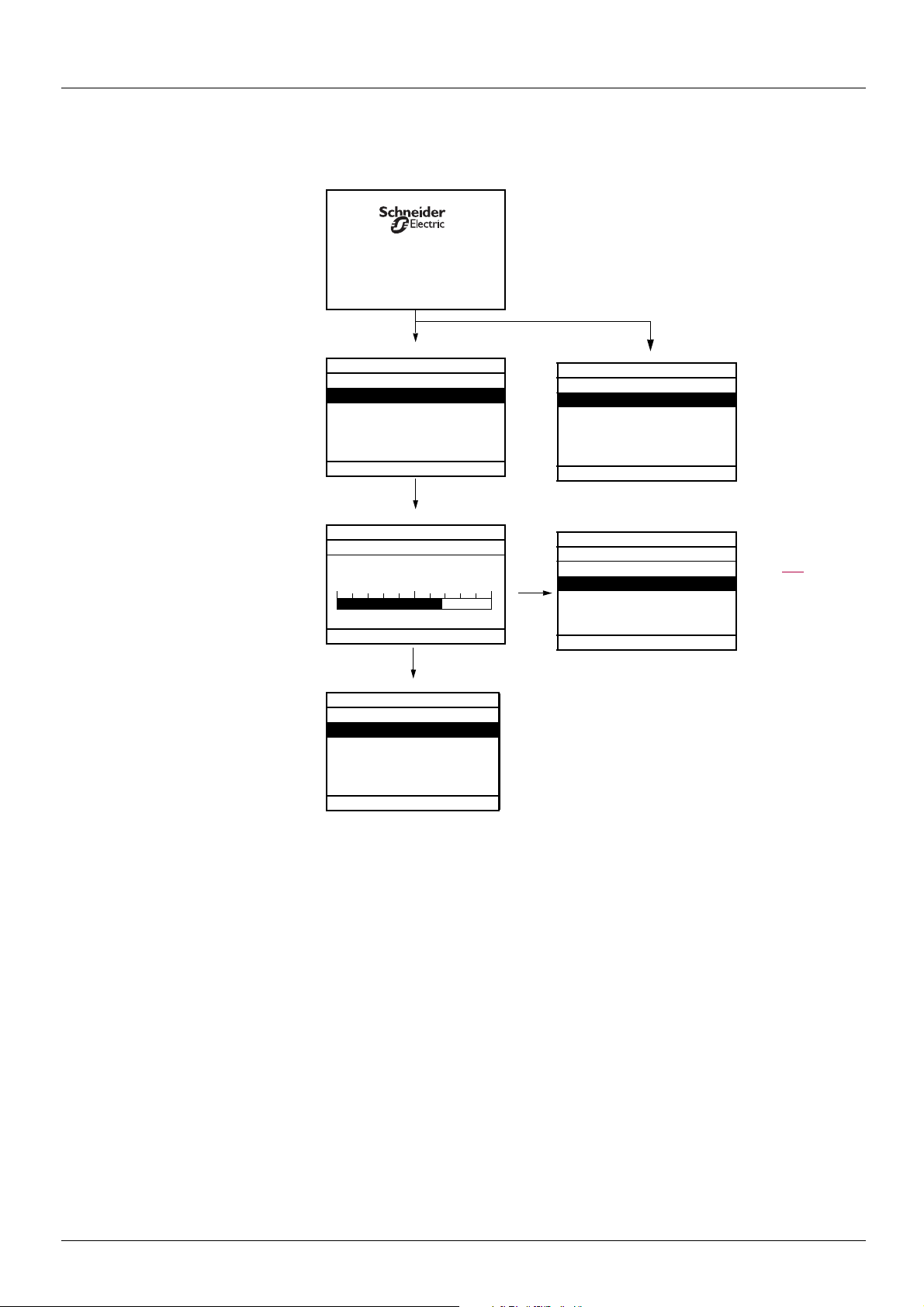

First power-up - [5. LANGUAGE] menu _____________________________________________________________________ 22

Subsequent power ups__________________________________________________________________________________ 23

Programming: Example of accessing a parameter_____________________________________________________________ 24

Quick navigation_______________________________________________________________________________________ 25

Integrated display terminal _______________________________________ ______________________________________________ 28

Functions of the display and the keys_______________________________________________________________________ 28

Accessing menus ______________________________________________________________________________________ 29

Accessing menu parameters _____________________________________________________________________________ 30

[2. ACCESS LEVEL] (LAC-)____________________________________________________________________________________ 31

Structure of parameter tables___________________________________________________________________________________ 34

Interdependence of parameter values ____________________________________________________________________________ 35

Finding a parameter in this document ____________________________________________________________________________ 36

[1.1 SIMPLY START] (SIM-)____________________________________________________________________________________ 37

[1.2 MONITORING] (SUP-) ____________________________________________________________________________________ 45

[1.3 SETTINGS] (SEt-) ________________________________________________________________________________________ 54

[1.4 MOTOR CONTROL] (drC-)_________________________________________________________________________________ 69

[1.5 INPUTS / OUTPUTS CFG] (I-O-) ___________________________________________________________________________ 101

[1.6 COMMAND] (CtL-)_______________________________________________________________________________________ 131

[1.7 APPLICATION FUNCT.] (FUn-) ____________________________________________________________________________ 144

[1.8 FAULT MANAGEMENT] (FLt-) _____________________________________________________________________________ 232

[1.9 COMMUNICATION] (COM-) _______________________________________________________________________________ 257

[1.10 DIAGNOSTICS] ________________________________________________________________________________________ 261

[1.11 IDENTIFICATION]______________________________________________________________________________________ 264

[1.12 FACTORY SETTINGS] (FCS-) ____________________________________________________________________________ 265

[1.13 USER MENU] (USr-)____________________________________________________________________________________ 268

[1.14 PROGRAMMABLE CARD] (PLC-) _________________________________________________________________________ 269

[3. OPEN/SAVE AS]_________________________________________________________________________________________ 270

[4. PASSWORD] (COd-)______________________________________________________________________________________ 272

[6 MONITORING CONFIG.]___________________________________________________________________________________ 274

[7 DISPLAY CONFIG.] _______________________________________________________________________________________ 278

[MULTIPOINT SCREEN] _____________________________________________________________________________________ 283

Maintenance_______________________________________________________________________________________________ 284

Faults - Causes - Remedies_______________________________________________________________ ____________________ 285

User settings tables _________________________________________________________________________________________ 291

Index of functions ___________________________________________________________________________________________ 293

Index of parameter codes_____________________________________________________________________________________ 295

AAV49426 12/2009 3

Page 4

Before you begin

Read and understand these instructions bef ore performing any procedure on this drive.

DANGER

HAZARDOUS VOLTAGE

• Read and understand the Installation Manual before i nstalling or operating the ATV71 drive. Instal lation, adjustment,

repair, and maintenance must be performed by qualified personnel.

• The user is responsible for compliance with all international and national electrical standards in force concerning

protective grounding of all equipment.

• Many parts of this variable speed drive, including the printed circuit boards, operate at the line voltage. DO NOT

TOUCH.

Use only electrically insulated tools.

• DO NOT touch unshielded components or terminal strip screw connections with volta ge present.

• DO NOT short across terminals PA/+ and PC/- or across the DC bus capacitors.

• Install and close all the covers before applying power or starting and stopping the drive.

• Before servicing the variable speed drive

- Disconnect all power.

- Place a “DO NOT TURN ON” label on the variable speed drive disconnect.

- Lock the disconnect in the open position.

• Disconnect all power including external control power that may be present before servicing the drive. WAIT 15

MINUTES to allow the DC bus capacitors to discharge. Then follow the DC bus voltage measurement procedure

given in the Installation Manual to verify that the DC voltage is less than 45 V. The drive LEDs are not accurate

indicators of the absence of DC bus voltage.

Electric shock will result in death or serious injury.

CAUTION

DAMAGED EQUIPMENT

Do not operate or install any drive that appears damaged.

Failure to follow this instruction can result in equipment damage.

4 AAV49426 12/2009

Page 5

Documentation structure

The following Altivar 71 technical documents are available on the Schneider-Electric website (www.schneider-electric.com) as well as on

the CD-ROM supplied with the drive.

Installation Manual

This describes how to assemble and connect the drive.

Programming manual

This describes the functions, parameters and use of the drive terminal (integrated display terminal and graphic display terminal).

The communication functions are not described in this manual, but in the manual for the bus or network used.

Communication Parameters Manual

This manual describes:

• The drive parameters with specific information for use via a bus or communication network.

• The operating modes specific to communication (state chart).

• The interaction between communication and local control.

Manuals for Modbus, CANopen, Ethernet, Profibus, INTERBUS, Uni-Telway, FIPIO

and Modbus Plus, etc.

These manuals describe the assembly, connection to the bus or network, signaling, diagnostics, and configuration of the communicationspecific parameters via the integrated display terminal or the graphic display terminal.

They also describe the communication services of the protocols.

AAV49426 12/2009 5

Page 6

Software enhancements

Since the Altivar ATV 71 was first launched, it has benefited from the addition of several new functions. Software version has now been

updated to V2.8. The new version can be substituted to the previous versions without making any changes.

Although this documentation relates to versi on V2.8, it can st ill be used with previ ous versions, as the update s merely invol ves t he additi on

of new values and parameters. None of the previous versions parameters have been modified or removed.

The software version is indicated on the nameplate attached to the body of the drive.

Enhancements made to version V1.2 in comparison to V1.1

Factory setting

Note 1: In version V1.1, the analog input was 0 ± 10 V. For safety reasons, in the new vers ion this inpu t has been set t o 0 + 10 V.

Note 2: In version V1.1, analog output AO1 was assigned to the motor f requency. In the new version, this output is not assigned

at all.

With the exception of these two parameters, the factory settings of version V1.1 remain the same in the new version. The new functions

are factory-set to disabled.

Motor frequency range

The maximum output frequency has been extended from 1000 to 1600 Hz (depending on the drive rating and control profile).

New parameters and functions

Menu [1.2 MONITORING] (SUP-)

Addition of internal states and values relating to the new functions described below.

Menu [1.3 SETTINGS] (SEt-)

• [High torque thd.] (ttH) page 67.

• [Low torque thd.] (ttL) page 67

• [Pulse warning thd.] (FqL) page 68

• [Freewheel stop Thd.] (FFt) page68

.

.

.

Menu [1.4 MOTOR CONTROL] (drC-)

• [rpm increment] (InSP) page 76.

• Extension of the following configurations to all drive ratings; previously limited to 45 kW (60 HP) for ATV71

(100 HP) for ATV71

[Noise reduction] (nrd) page 95

pppN4:synchronous motor [Sync. mot.] (SYn) page 70, sinus filter [Sinus filter] (OFI) page 72, noise reduction

, braking balance [Braking balance] (bbA) page 98.

Menu [1.5 INPUTS / OUTPUTS CFG] (I-O-)

• Input Al1 can now be configured to 0 +10 V or 0 ± 10 V via [AI1 Type] (AI1t) page 107.

• [AI net. channel] (AIC1) page 111

• New methods of assigning relays and logic outputs page 118

rotation, motor in reverse rotation, measured speed threshold reached, load variation detection.

• Analog output AO1 can now be used as a logic output and assigned to relay functions and logic outputs, page 123

• New method of modifying the scale of analog outputs page 125

max] (ASHx).

• New methods of assigning logic outputs page 126

• New methods of assigning alarm groups page 130

threshold reached, load variation detection.

.

: rope slack, high torque threshold, low torque threshold, motor in forwa rd

using the parameters [Scaling AOx min] (ASLx) and [Scaling AOx

: signed motor torque and measured motor speed.

: rope slack, high torque threshold, low torque threshold, measured speed

pppM3X and to 75 kW

.

6 AAV49426 12/2009

Page 7

Software enhancements

Menu [1.7 APPLICATION FUNCT.] (Fun-)

• The summing, subtraction and multiplication reference fu nctions can now be assigned to virtual input [Network AI] (AIU1) page 151.

• New parameter [Freewheel stop Thd.] (FFt) page 156

or fast stop.

• Brake engage at regulated zero speed [Brake engage at 0] (bECd) page 176

• Weight [Weight sensor ass.] (PES) page 183

• New "rope slack" function page 187

• Use of the ramp [Acceleration 2] (AC2) page 195

• The torque limitation [TORQUE LIMITATION] (tOL-) page 202

increment] (IntP) and assigned to virtual input [Network AI] (AIU1).

• New "stop at distance calculated after deceleratio n limit swi tch" funct ion page 211

linear speed] (nLS) and [Stop corrector] (SFd).

• Positioning by sensors or limit switch [POSITIONING BY SENSORS] (LPO-) page 212

negative logic using [Stop limit config. (SAL) and [Slowdown limit cfg.] (dAL).

• Parameter set switching [PARAM. SET SWITCHING] (MLP-) page 215

[Freq. Th. att.] (FtA) and [Freq. Th. 2 at ta in . ] (F2A).

• New half-floor: [HALF FLOOR] (HFF-) menu page 229

, with the parameters [Rope slack config.] (rSd) and [Rope slack trq level] (rStL).

can now be assigned to virtual input [Network AI] (AIU1).

Menu [1.8 FAULT MANAGEMENT] (FLt)

• Possibility of reinitializing the drive without turning it off, via [Product reset] (rP) page 237.

• Possibility of reinitializing the drive via a logic input without turning it off, using [Product reset assig.] (rPA) page 237

• The possibility of configuring the "output phase loss" fault [Output Phase Loss] (OPL) page 242

extended to all drive ratings (previously limited to45 kW (60 HP) for ATV71

• The external fault [EXTERNAL FAULT] (EtF-) page 245

(LEt).

• New monitoring function based on speed measurement via "Pulse input" page 252

• New function for detecting load variation page 254

• Short-circuit faults on the braking unit can now be configured via [Brake res. fault Mgt] (bUb) page 256

used to set a threshold for switching to freewheel at the end of a stop on ramp

.

when starting and "waking up" the PID function.

can now be configured in whole % or in 0.1% increments using [Torque

, with the parameters [Stop distance] (Std), [Rated

can now be configured in positive logic or

can now be assigned to the frequency thresholds attained

.

.

to [Output cut] (OAC) has been

pppM3X and 75 kW (100HP) for ATV71pppN4).

can now be configured in positive or negat ive logic via [External fault config.]

, via the [FREQUENCY METER] (FqF-) menu.

, via the [DYNAMIC LOAD DETECT] (dLd-) menu.

.

Menu [7 DISPLAY CONFIG.]

In [7.4 KEYPAD PARAMETERS] page 284, the [KEYPAD CONTRAST] and [KEYPAD STAND-BY] parameters to adjust the contrast and

stand-by mode of the graphic display unit.

Enhancements made to version V1.3 (S383) in comparison to V1.2

New parameters and functions

Menu [1.4 MOTOR CONTROL] (drC-)

New option of operating with Closed-loop synchronous motor page 83

• [Angle auto-test] (ASA) page 84

• [Angle offset value] (ASU) page 85

• [Sync.CL] (FSY) assignment page 71 of parameter [Motor control type] (Ctt)

Menu [1.5 INPUTS / OUTPUTS CFG] (I-O-)

• [Resolver Exct. Freq.] (FrES) and [Resolver poles nbr] (rPPn) page 115

Menu [1.7 APPLICATION FUNCT.] (Fun-)

• New "Inspection" function, page 227, with [Inspection] (ISP) and [Inspection speed] (ISrF) parameters.

AAV49426 12/2009 7

Page 8

Software enhancements

Enhancements made to version V1.7 (S383) in comparison to V1.3 (S383)

New parameters and functions

Menu [1.1 SIMPLY START] (SIM-)

• Addition of a [Lift] (LIFt) macro configuration to the [Macro configuration] (CFG) parameter page 41

Menu [1.3 SETTINGS] (SEt-)

New parameters:

• [Fr.Loop.Stab] (StA) page 56

• [FreqLoopGain] (FLG) page 56

Menu [1.4 MOTOR CONTROL] (drC-)

This menu has been reorganized with parameters now appearing in a different order and some grouped under submenus to simplify

configuration.

The new submenus are as follows:

• [ENCODER FEEDBACK] (EnS-) page 75

• [ASYNC. MOTOR] (ASY-) page 76

• [SYNCHRONOUS MOTOR] (SYn-) page 81

• [ANGLE TEST SETTING] (ASA-) page 84

• [FLUXING BY LI] (FLI-) page 86

• [AUTOMATIC TUNE] (tUn-) page 88

• [SPEED LOOP] (SSL-) page 89

New parameters:

• [Boost] (bOO) page 95

• [Action Boost] (FAb) page 95

• [Increment EMF] (IPHS) page 81

• [Read motor param.] (rEqP) page 82

• [Status motor param] (rEtP) page 82

• [Angle setting type] (ASt) pages 84 and 87

• [Angle auto test] (ASL) page 84

• [Angle setting activ.] (AtA) page 85

• [Angle setting status] (AStS) page 85

• [Speed loop type] (SSL) page 89

• [Inertia Mult. Coef.] (JMUL) page 89

• [Estim. app. inertia] (JESt) page 89

• [Application Inertia] (JAPL) page 90

• [Fr.Loop.Stab] (StA) page 90

• [FreqLoopGain] (FLG) page 90

• [Feed forward] (FFP) page 91

• [Bandwidth feedfor.] (FFU) page 91

Parameters moved from menu [1.7 APPLICATION FUNCT.] (Fun-):

• [Motor fluxing] (FLU) page 86

• [Fluxing assignment] (FLI) page 86

• [Auto-tune assign.] (tUL) page 88

Menu [1.5 INPUTS / OUTPUTS CFG] (I-O-)

New encoder parameters:

• [Encoder protocol] (UECP) page 116

• [Encoder supply volt.] (UECU) page 116

• [Sincos lines count] (UELC) page 116

• [SSI pari t y] (SSCP) page 116

• [SSI frame size] (SSFS) page 116

• [Nbr of revolution] (EnMr) page 116

• [Turn bit resolution] (Entr) page 116

• [SSI code type] (SSCd) page 117

• [Encoder filter activ.] (FFA) page 117

• [Encoder filter value] (FFr) page 117

Menu [1.7 APPLICATION FUNCT.] (Fun-)

Removal of the following parameters (now located in the [1.4 MOTOR CONTROL] (drC-) menu):

• [Motor fluxing] (FLU)

• [Fluxing assignment] (FLI)

• [Auto-tune assign.] (tUL)

8 AAV49426 12/2009

Page 9

Software enhancements

Enhancements made to version V1.9 (S383) in comparison to V1.7 (S383)

New parameters and functions

Menu [1.4 MOTOR CONTROL] (drC-)

• New method of assigning [Angle setting type] (ASt) page 87 : optimised measurement (without motion with memorization).

New parameter :

• [App. Inertia Coef.] (JACO) page 89

Removal from the sub-menu [ASYNC. MOTOR] (ASY-) of the following parameters (now located directly in the

[1.4 MOTOR CONTROL] (drC-) menu):

• [Boost] (bOO) page 95

• [Action Boost] (FAb) page 95

.

Menu [1.5 INPUTS / OUTPUTS CFG] (I-O-)

New encoder parameters:

• [Coder rotation inv.] (EnrI) page 114

• [Clock frequency] (EnSP) page 117

Menu [1.7 APPLICATION FUNCT.] (Fun-)

• New method of assigning for the parameters set switching [2 Parameter sets] (CHA1) page 215 and [3 Parameter sets] (CHA2)

page 215

starting of the ramp (useful for lift application).

: switching during braking sequence. This new assignment allo ws to put higher gain when the brak e is open and before the

.

.

.

.

New sub-menu:

• [TOP Z MANAGEMENT] (tOP-) page 231

and if [Encoder type] (EnS) = [AABB] (AAbb).

New encoder parameter:

• [Stop on top Z] (tOSt) page 231

.

(the parameter can be accessed only if an encoder card VW 3A 411 has been inserted

Enhancements made to version V2.4 (S383) in comparison to V1.9 (S383)

New parameters and function

Menu [1.7 APPLICATION FUNCT.] (Fun-)

New sub-menu:

• [ROLLBACK MGT] (rbM-) page 181

- only for ATV71

-if [Motor control type] (Ctt) page 70

-if [Brake assignment] (bLC) page 175

New parameter of [ROLLBACK MGT] function:

• [Rollback MGT] (rbM) page 181

• [Rbk Compensation] (rbC) page 181

• [Rbk Damping] (rbd) page 181

pppM3X drives up to 45 kW and for ATV71pppN4 drives up to 75 kW,

. Menu can be accessed:

= [Sync.CL] (FSY) or [FVC] (FUC),

is assigned.

.

.

.

Enhancements made to version V2.8 (S383) in comparison to V2.4 (S383)

Menu [1.7 APPLICATION FUNCT.] (FUn-)

• The adjustment range [Time to restart] (ttr) page 177 can now be configured to 0 to 15.00 s.

Menu [7 DISPLAY CONFIG.]

•Addition in [7.4 KEYPAD PARAMETERS] page 284 parameter [Power up menu] to choose the menu displayed on the drive on

power up

.

Enhancements made to version V3.4 (S383) in comparison to V2.8 (S383)

[1.7 APPLICATION FUNCT.] (Fun-) menu

New parameters and functions

• New parameter [REGEN CONNECTION] (AFE) page 232, used to connect an active front end

AAV49426 12/2009 9

Page 10

Steps for setting up

INSTALLATION

v 1 Consult the Installation Manual

PROGRAMMING

Procedure applicable if the factory configuration, page 11, and use of the

[SIMPLY START] (SIM-) menu only are sufficient for the application.

b 2 Power up without run command

v If you are using a separate power

supply for the control section, follow

the instructions on page 16.

b 3 Select the language, if the drive

has a graphic display terminal

b 4 Configure the [SIMPLY START]

(SIM-) menu

v 2-wire or 3-wire control

v Macro configuration

v Motor parameters

) Perform an auto-tuning

operation

v Motor thermal current

v Acceleration and deceleration

ramps

v Speed variation range

Tips:

• Before you start programming, complete

the user setting tables, page 293

.

• Perform an auto-tuning operation to

optimize performance, page 43

.

• If you get lost, return to the factory

settings, page 269

.

Note: Check that the wiring of the

drive is compatible with its configuration.

b 5 Start

10 AAV49426 12/2009

Page 11

Factory configuration

Drive factory settings

The Altivar 71 is factory-set for the most common operating conditions:

• Macro configuration: Start/Stop

• Motor frequency: 50 Hz

• Constant torque application with asynchronous motor and sensorless flux vector control

• Normal stop mode on deceleration ramp

• Stop mode in the event of a fault: freewheel

• Linear, acceleration and deceleration ramps: 3 seconds

• Low speed: 0 Hz

• High speed: 50 Hz

• Motor thermal current = rated drive current

• Standstill injection braking current = 0.7 x rated drive current, for 0.5 seconds

• No automatic starts after a fault

• Switching frequency 2.5 kHz or 4 kHz depending on drive rating

• Logic inputs:

- LI1: forward, LI2: Forward (2 operating direction), 2-wire control on transition

- L13, L14, LI5, LI6: inactive (not assigned)

• Analog inputs:

- AI1: speed reference 0 +10 V

- AI2: 0-20 mA, inactive (not assigned)

• Relay R1: The contact opens in the event of a fault (or drive off).

• Relay R2: Inactive (not assigned)

• Analog output AO1: 0-20 mA, inactive (not assigned)

If the above values are compatible with the application, the drive can be used without changing the settings.

Option card factory settings

The option card inputs/outputs are not factory-set.

AAV49426 12/2009 11

Page 12

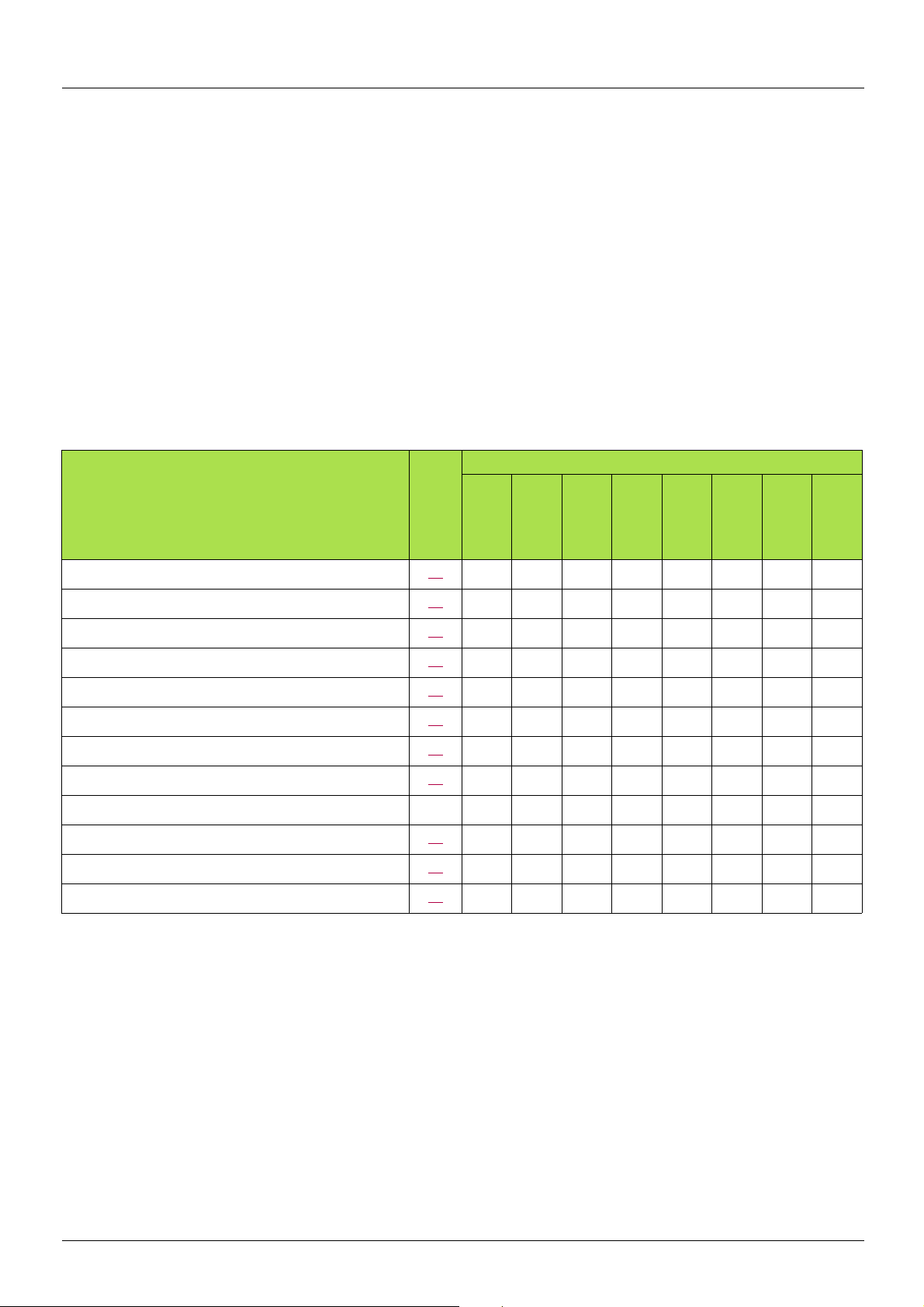

Application functions

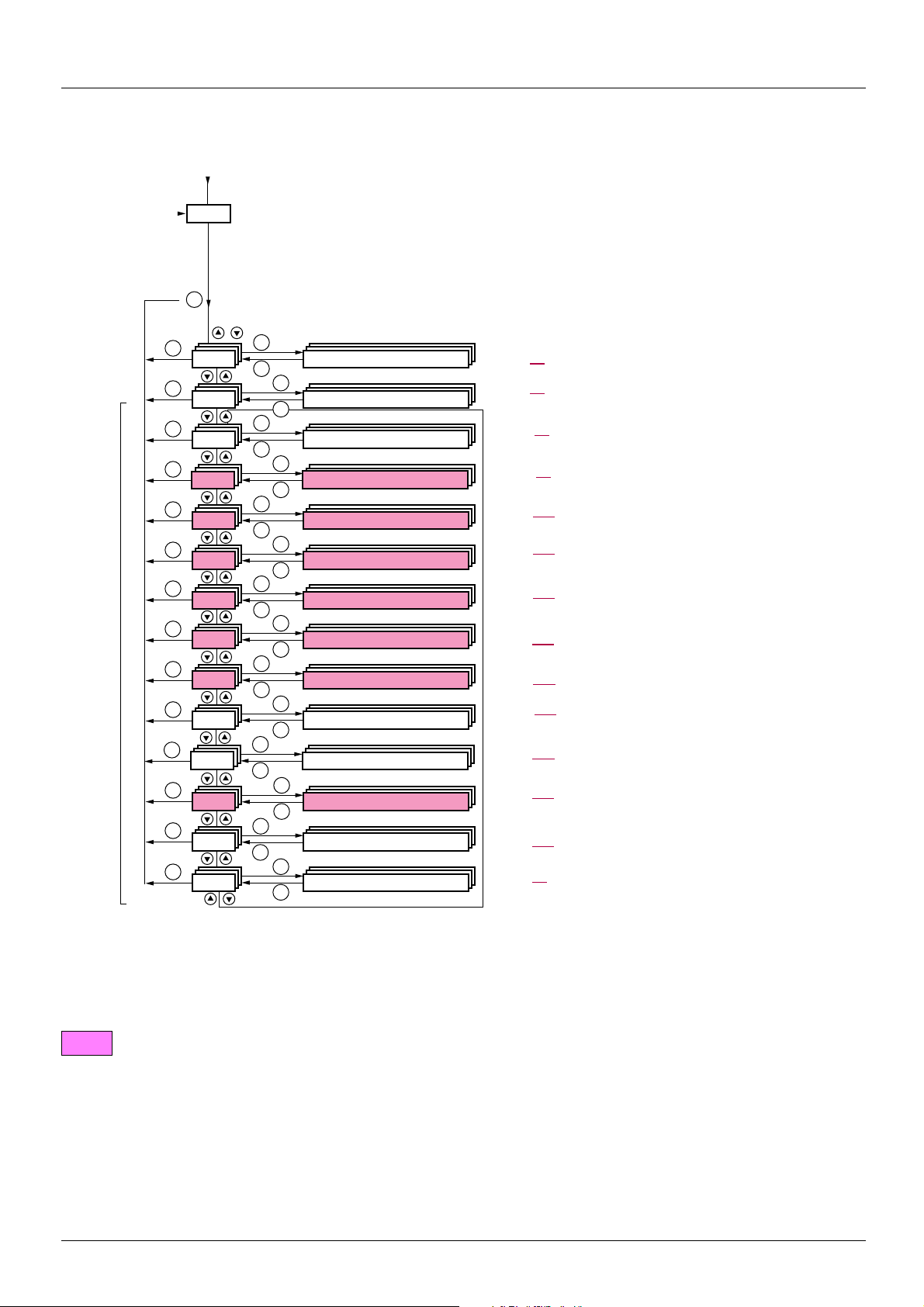

The tables on the following pages show the most common combinations of functions and applications, in order to guide your selection.

The applications in these tables relate to the foll owing machines in particular:

• Hoisting: cranes, overhead cranes, gantries (vertical hoisting, translation, slewing), lifting platforms

• Elevators: elevators in retrofit up to 1.2 m/s

• Handling: palletizers/depalletizers, conveyors, roller tables

• Packing: carton packers, labeling machines

• Textiles: weaving looms, carding frames, washing machines, spinners, drawing frames

• Wood: automatic lathes, saws, milling

• High inertia: centrifuges, mixers, unbalanced machines (beam pumps, presses)

• Process

Each machine has its own special features, and the combinations listed here are neither mandatory nor exhaustive.

Some functions are designed specifically for a particular application. In this case, the application is identified by a tab in the

margin on the relevant programming pages.

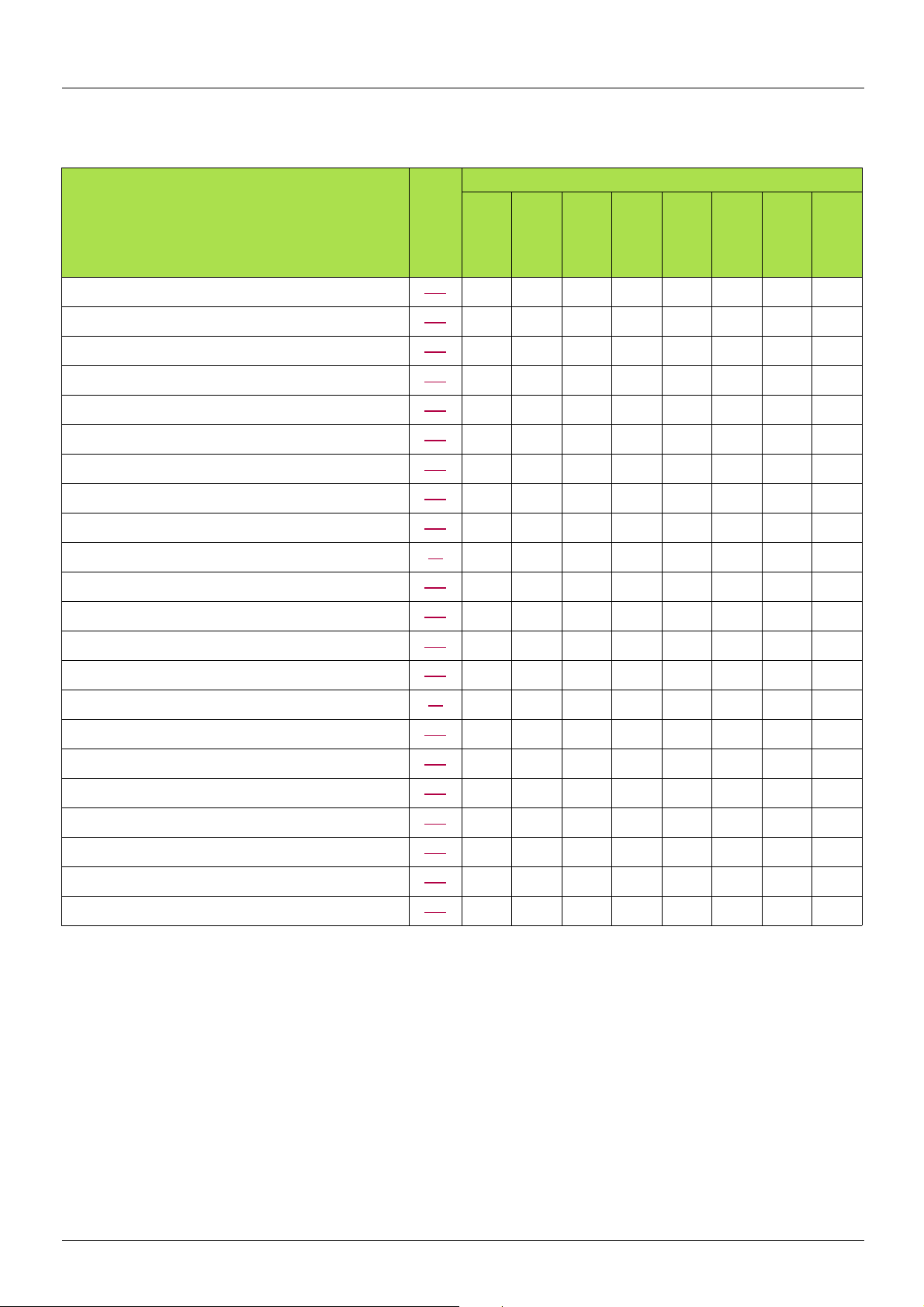

Motor control functions

Applications

Functions Page

V/f ratio

Sensorless flux vector control

Flux vector control with sensor

2-point vector control

Open-loop synchronous motor

Closed-loop synchronous motor

Output frequency of up to 1600 Hz

Motor overvoltage limiting

DC bus connection (see User's Manual)

Motor fluxing using a logic input

Switching frequency of up to 16 kHz

Auto-tuning

70

70

70

70

71

71

76

96

-

86

72

88

Hoisting

Lifts

Handling

Packing

Textiles

Wood

High inertia

Process

bbb

bbbbbbbb

bbbbbbbb

bb

b

bbb

bb

bb

bb

bbb

bbb

bbbbbbbb

12 AAV49426 12/2009

Page 13

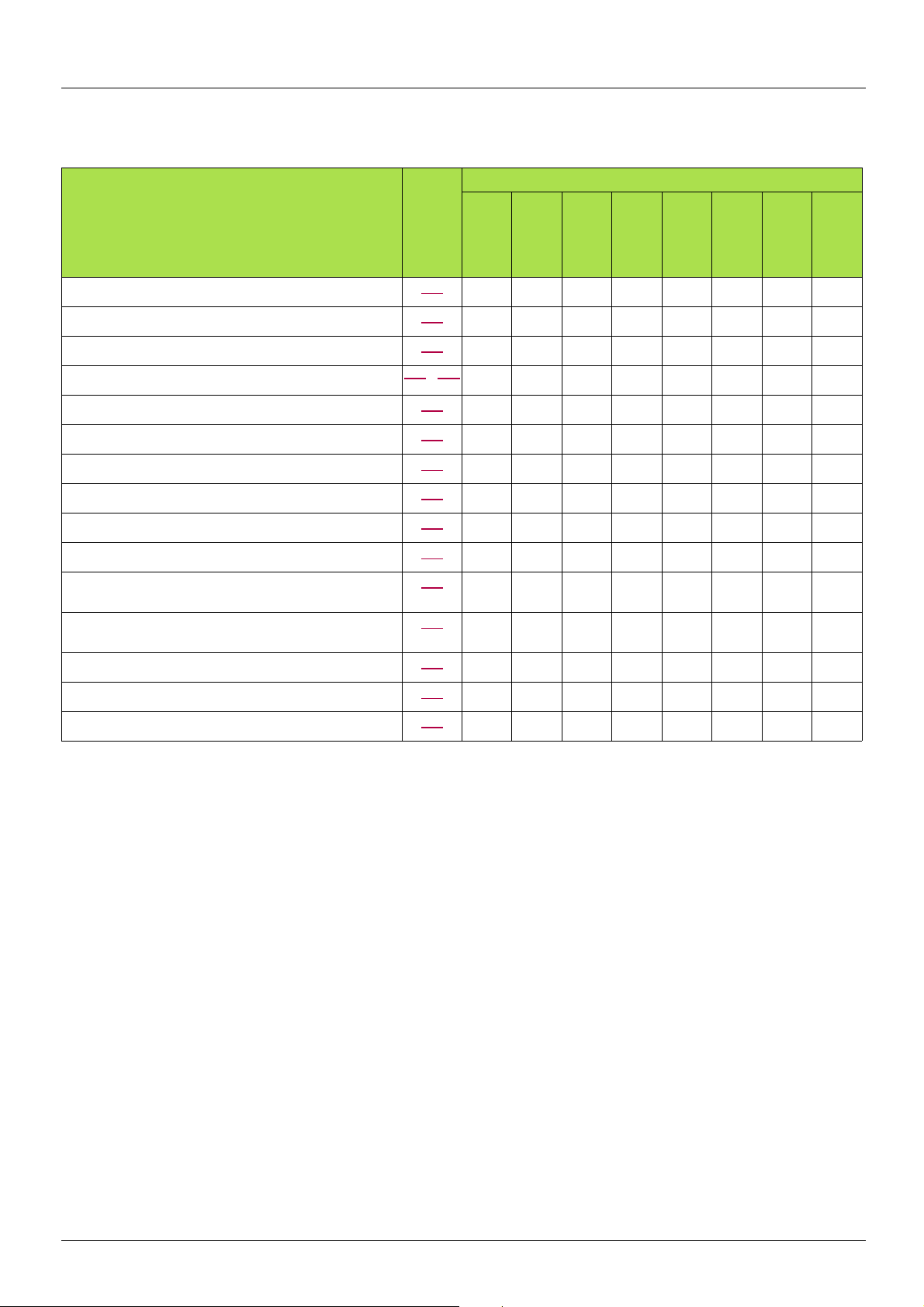

Application functions

Functions on speed references

Functions Page

Applications

Differential bipolar reference 104

Reference delinearization (magnifying glass effect) 106

Frequency control input 140

- 150

Reference switching

Reference summing 149

Reference subtraction 149

Reference multiplication 149

S ramps 152

Jog operation 160

Preset speeds 161

+ speed/- speed using single action pushbuttons

(1 step)

+ speed/- speed using double action pushbuttons

(2 steps)

+/- speed around a reference 166

Save reference 168

Inspection 227

141

164

164

Hoisting

Lifts

Handling

Packing

Textiles

Wood

High inertia

bbb

bb

bb

b

b

b

b

bbb

bb b

bbbb b

b

bb

b

Process

b

b

AAV49426 12/2009 13

Page 14

Application functions

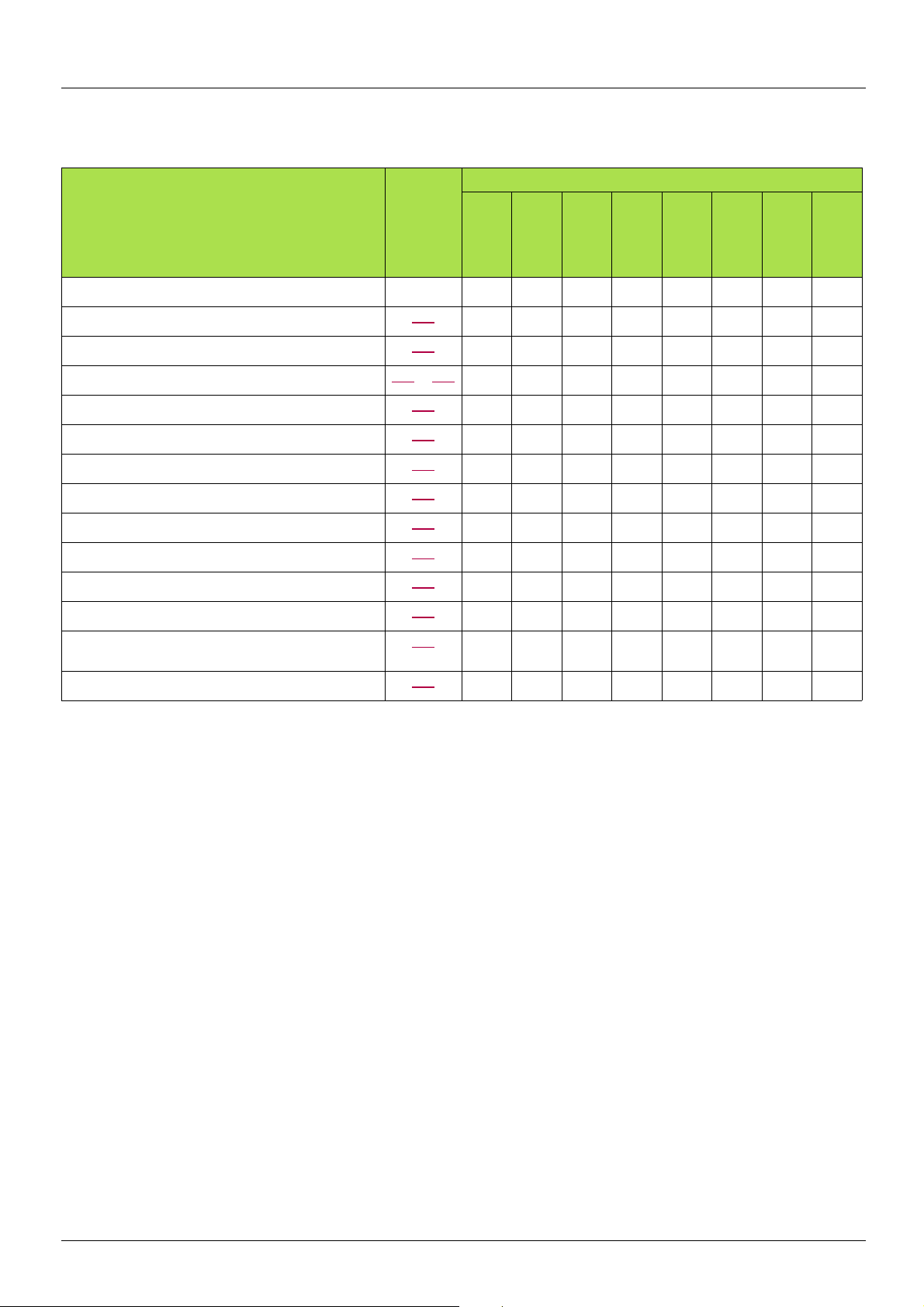

Application-specific functions

Functions Page

Applications

Fast stop 156

Limit switch management 169

Brake control 171

Load measurement 182

High-speed hoisting 184

Rope slack 187

PID regulator 189

Torque monitoring 198

Motor/generator torque limit 201

Load sharing 98

Line contactor control 205

Output contactor control 207

Positioning by limit switches or sensors 209

Stop at distance calculated after deceleration limit switch 211

ENA system (mechanical with unbalanced load) 93

Parameter switching 214

Motor or configuration switching 217

Traverse control 220

Stop configuration 156

Evacuation 229

Half floor 229

Rollback management 181

Hoisting

Lifts

Handling

Packing

Textiles

Wood

High inertia

Process

bb

bbb

bbb

bb

b

b

b

bb b

bbbb

bb

bb b

b

bb

bb

b

bbbbbbbb

bbb

b

bbbb

b

b

b

14 AAV49426 12/2009

Page 15

Application functions

Safety functions/fault management

Functions Page

Applications

Power Removal (safety function, see User's Manual)

Deferred stop on thermal alarm 244

Alarm handling 130

Fault management 235 to 258

IGBT tests 247

Catch a spinning load 239

Braking resistor thermal protection 256

Motor protection with PTC probes 235

Undervoltage management 246

4-20mA loss 248

Uncontrolled output cut (output phase loss) 242

Automatic restart 238

Use of the "Pulse input" input to measure the speed of

rotation of the motor

Load variation detection 254

-

252

Hoisting

Lifts

Handling

Packing

Textiles

Wood

High inertia

Process

bbbbbbbb

b

bbbbbbbb

bbbbbbbb

bbbbbbbb

bbb

bbbb

bbbbbbbb

bbb

bbbbbb

b

b

bbb

b

AAV49426 12/2009 15

Page 16

Setup - Preliminary recommendations

DANGER

UNINTENDED EQUIPMENT OPERATION

• Before turning on and configuring the Altivar 71, check that the PWR (POWER REMOVAL) i nput is deact ivated (at

state 0) in order to prevent unintended operation.

• Before turning on the drive, or when exiting the configuration menus, check that the inputs assigned to the run

command are deactivated (at state 0) since they can cause the motor to start immediately.

Failure to follow these instructions will result in death or serious injury.

CAUTION

INCOMPATIBLE LINE VOLTAGE

Before turning on and configuring the drive, ensure that the li ne voltage is compatible with the sup ply voltage range shown

on the drive nameplate. The drive may be damaged if the line voltage is not compatible.

Failure to follow this instruction can result in equipment damage.

CAUTION

• Avoid operating the contactor frequently (premature ageing of the filter capacitors).

• Cycle times < 60 s may result in damage to the pre-charge resistor.

Failure to follow this instruction can result in equipment damage.

DANGER

UNINTENDED EQUIPMENT OPERATION

• Check that changes made to the settings during operation do not present any danger.

• We recommend stopping the drive before making any changes.

Failure to follow these instructions will result in death or serious injury.

Turning on and configuring the drive

Separate control section power supply

When the drive control section is powered independently of the power section (P24 and 0V terminals), whenever an option card is added

or replaced, only the power section must be supplied with power next time the drive is powered up.

By default the new card would not be recogniz ed and it wo uld be impossi ble to confi gure it, th ereby causing the dri ve to lock in fau lt mode.

Power switching via line contactor

User adjustment and extension of functions

• The display unit and buttons can be used to modify the settings and to extend the functions described in the following pages.

• Return to factory settings is made easy by the [1.12 FACTORY SETTINGS] (FCS-) menu, see page 267

• There are three types of parameter:

- Display: Values displayed by the drive

- Adjustment: Can be changed during operation or when stopped

- Configuration: Can only be modified when stopped and no braking is taking place. Can be displayed during operation.

.

16 AAV49426 12/2009

Page 17

Setup - Preliminary recommendations

CAUTION

• Motor thermal protection will not be provided by the drive if th e motor current is less t han 0.2 times the rate d drive

current. Provide an alternative means of thermal protection.

Failure to follow this instruction can result in equipment damage.

CAUTION

• Motor thermal protection is no longer provided b y the drive. Provide an alternative means of thermal protection on

every motor.

Failure to follow this instruction can result in equipment damage.

Starting

Important:

• In factory settings mode, the motor can only be supplied wit h power once the “forward”, “reverse” an d “DC injection st op” commands

have been reset:

- On power-up or a manual fault reset or after a stop command

If they have not been reset, the drive will display "nSt" but will not start.

• If the automatic restart function has been configured ([Automatic restart] (Atr) parameter in the [1.8-FAULT MANAGEMENT] (FLt-)

menu, see page 238

Test on a low power motor or without a motor

• In factory settings mode, [Output Phase Loss] (OPL) detection page 242 is active (OPL = YES). To check the drive in a test or

maintenance environment without having to switch to a moto r with the same rating as the drive (part icularly useful in the case of high

power drives), deactivate [Output Phase Loss] (OPL = no).

• Configure [Motor control type] (Ctt) = [V/F 2pts] (UF2) or [V/F 5pts] (UF5) ([1.4-MOTOR CONTROL] (drC-) menu, see page 70

), these commands are taken into account without a reset being necessary.

)

Using motors in parallel

• Configure [Motor control type] (Ctt) = [V/F 2pts] (UF2) or [V/F 5pts] (UF5) ([1.4-MOTOR CONTROL] (drC-) menu, see page 70)

AAV49426 12/2009 17

Page 18

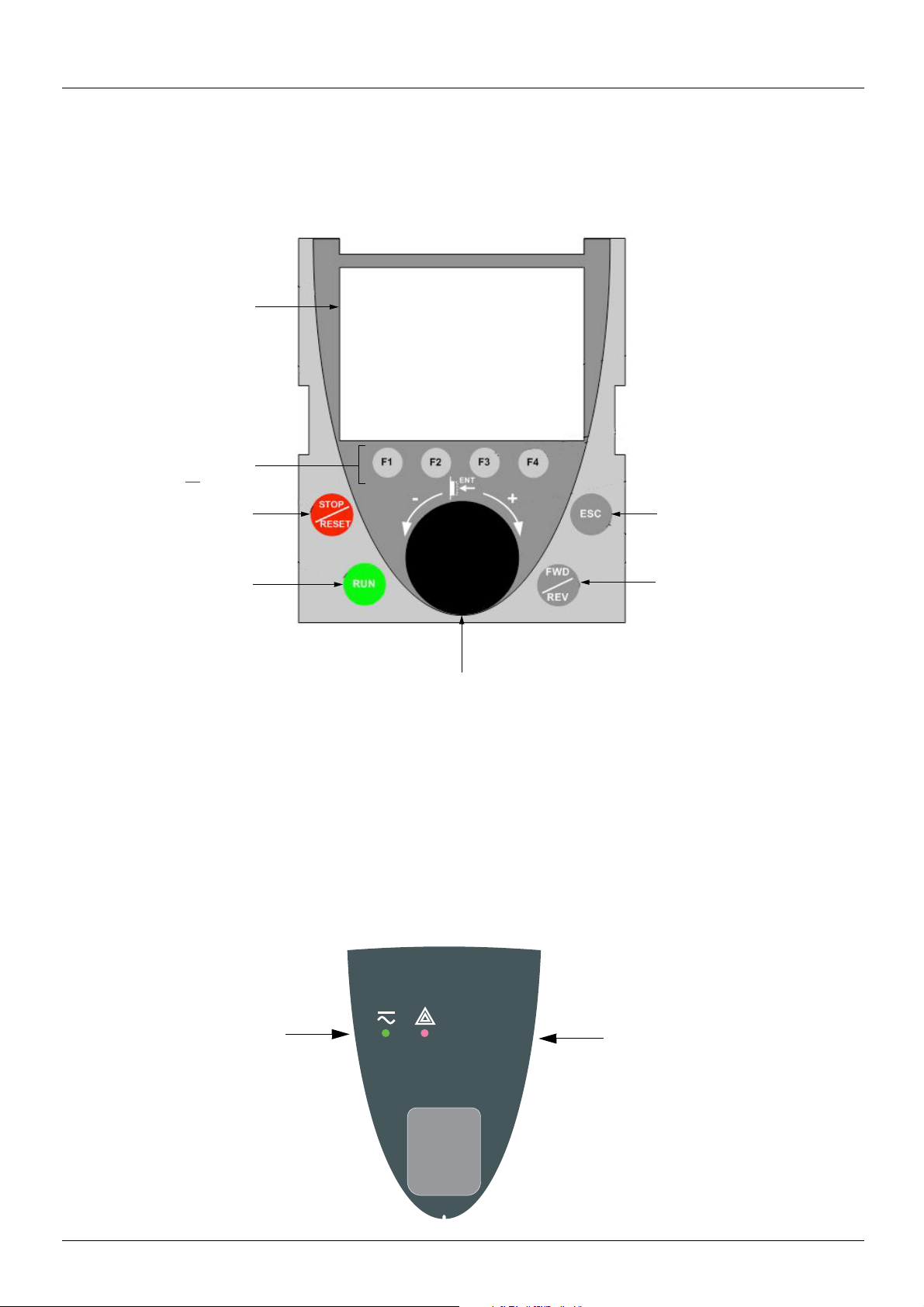

Graphic display terminal

1 Graphic display

2 Function keys

F1, F2, F3, F4,

see page 19

.

3 STOP/RESET

button

4 RUN button

5 Navigation button:

• Press (ENT): - To save the current value

- To enter the selected menu or parameter

• Turn CW/

CCW:

- To increment or decrement a value

- To go to the next or previous line

- To increase or decrease the reference if control via

the terminal is activated

7 ESC key: Aborts a value, a

parameter or a menu to return

to the previous selection

6 Button for reversing the directi on

of rotation of the motor

HMI Modbus

Green LED:

DC bus ON

Red LED:

Fault

Although the graphic display terminal is optional for low-power drives, it is a standard component on high-power drives (see catalog). The

graphic display terminal can be disconnected and connected remotely (on the door of an enclosure for example) using the cables and

accessories available as options (see catalog).

Description of terminal

Note: Buttons 3, 4, 5 and 6 can be used to control the drive directly, if control via the terminal i s ac tivated.

Disconnected terminal

When the terminal is disconnected, 2 LEDs become visible:

18 AAV49426 12/2009

Page 19

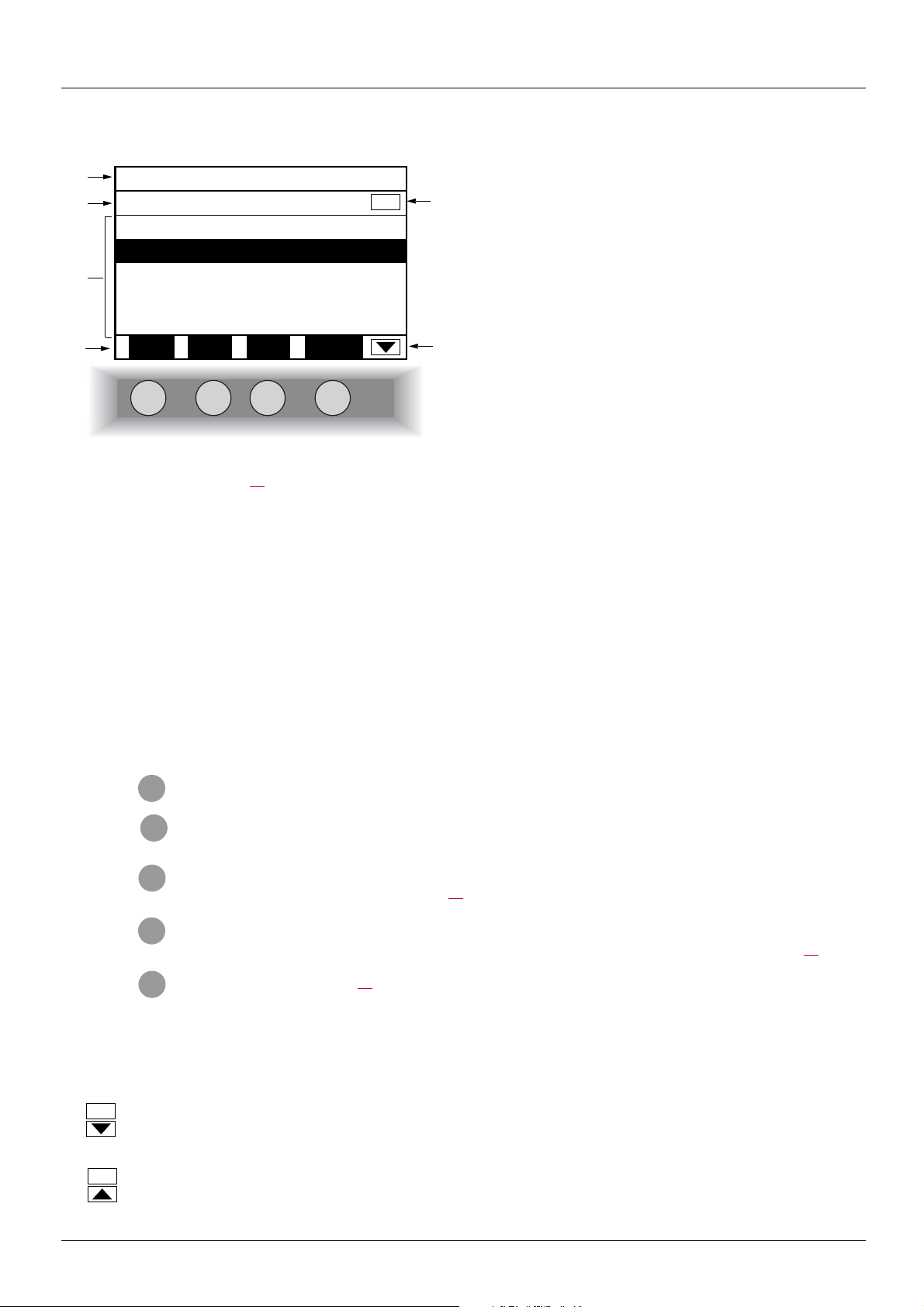

Graphic display terminal

F1 F2 F3 F4

RDY Term +0.00 Hz 0A

1 DRIVE MENU

1.1 SIMPLY START

1.2 MONITORING

1.3 SETTINGS

1.4 MOTOR CONTROL

1.5 INPUTS / OUTPUTS CFG

Code << >> Quick

1

2

3

4

6

5

• Code F1

•HELP F1

• << F2

• >> F3

• Quick F4

Description of the graphic screen

1. Display line. Its content can be configured; the factory settings show:

• The drive state (see page 20

• The active control channel:

- Term: Terminals

- HMI: Graphic display terminal

- MDB: Integrated Modbus

- CAN: Integrated CANopen

- NET: Communication card

- APP: Controller Inside card

• Frequency reference

• Current in the motor

)

2. Menu line. Indicates the name of the current menu or submenu.

3. Menus, submenus, parameters, values, bar charts, etc., are displayed in drop-down window format on a maximum of 5 lines.

The line or value selected by the navigation button is displayed in reverse video.

4. Section displaying the functions assigned to the F1 to F4 keys and aligned with them, for example :

The function keys are dynamic and contextual.

Other functions (application functions) can be assigned to these keys via the [1.6 COMMAND] menu.

If a preset speed is assigned to a function key and i f the f unction he y is pres sed, the mo tor will run at this preset speed u ntil anothe r preset

speed or JOG is pressed, speed reference is changed, or Stop key is pressed.

5. Indicates that there are no more levels below this display window.

Indicates that there are more levels below this display window.

6. Indicates that this display window does not scroll further up.

Indicates that there are more levels above this display window.

: Displays the code of the selected parameter, i.e., the code corresponding to the 7-segment display.

: Contextual help

: Navigate horizontally to the left, or go to previous menu/submenu or, for a val ue, go to the ne xt di git up, di spl ayed

in reverse video (see the example on page 21

: Navigate horizontally to the right or go to next menu/submenu (going to the [2 ACCESS LEVEL] menu in this

example) or, for a value, go to the next digit down, displayed in reverse video (see the example on page 21

: Quick navigation, see page 25.

).

).

AAV49426 12/2009 19

Page 20

Graphic display terminal

Drive state codes:

- ACC: Acceleration

- CLI: Current limit

- CTL: Controlled stop on input phase loss

- DCB: DC injection braking in progress

-DEC: Deceleration

- FLU: Motor fluxing in progress

-FST: Fast stop

- NLP: No line power (no line supply on L1, L2, L3)

- NST: Freewheel stop

- OBR: Auto-adapted deceleration

- PRA: Power Removal function active (drive locked)

- RDY: Drive ready

- RUN: Drive running

- SOC: Controlled output cut in progress

- TUN: Auto-tuning in progress

- USA: Undervoltage alarm

- ASA: Measurement of the phase-shift angle in progress

- ICC: Configuration encoder incorrect

20 AAV49426 12/2009

Page 21

Graphic display terminal

RDY Term +0.00Hz 0A

5 LANGUAGE

English

Français

Deutsch

Español

Italiano

<< >> Quick

Chinese

Turkish

Russian

PARAMETER SELECTION

1.3 SETTINGS

Ramp increment

Acceleration

Deceleration

Acceleration 2

Deceleration 2

Edit

RDY Term +0.00Hz 0A

Acceleration

9.51 s

Min = 0.01 Max = 99.99

<< >> Quick

>>

RDY Term +0.00Hz 0A

Acceleration

951 s

Min = 0.01 Max = 99.99

<< >> Quick

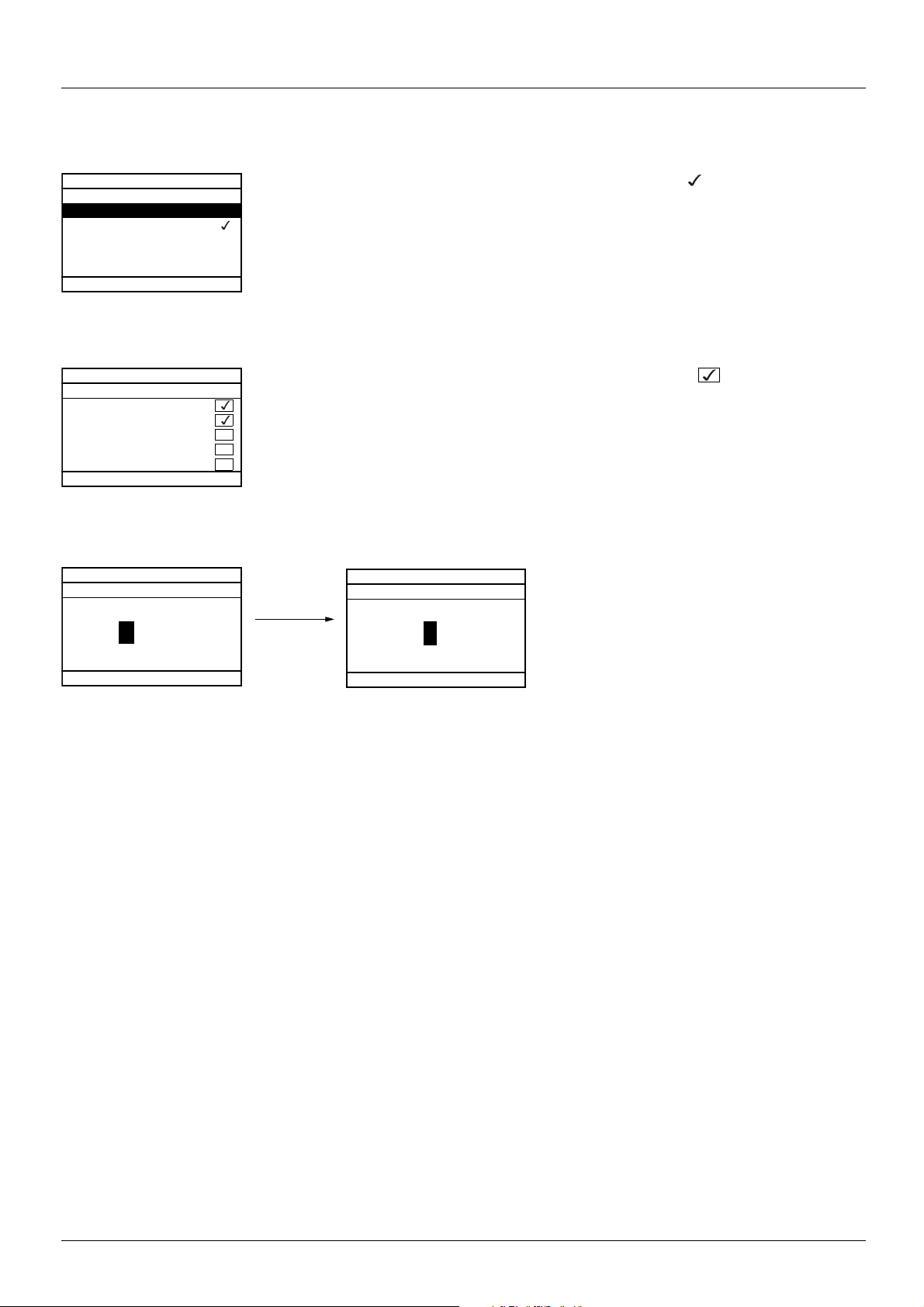

Example configuration windows:

When only one selection is possible, the selection made is indicated by

Example: Only one language can be chosen.

When multiple selection is possible, the selections made are indi cated by

Example: A number of parameters can be chosen to form the [USER MENU].

Example configuration window for one value:

The << and >> arrows (keys F2 and F3) are used to select the digit to be modified, and the navigation button is rotated to increase or

decrease this number.

AAV49426 12/2009 21

Page 22

Graphic display terminal

ATV31HU22N4383

2.2kW/3HP 380/480V

Config. n°1

5 LANGUAGE

English

Français

Deutsch

Español

Italiano

Chinese

RDY Term +0.00Hz 0.0A

2 ACCESS LEVEL

Basic

Standard

Advanced

Expert

RDY Term +0.00Hz 0.0A

1 DRIVE MENU

1.1 SIMPLY START

1.2. MONITORING

1.3. SETTINGS

1.4. MOTOR CONTROL

1.5. INPUTS / OUTPUTS CFG

Code << >> Quick

RDY Term +0.00Hz 0.0A

MAIN MENU

1 DRIVE MENU

2 ACCESS LEVEL

3 OPEN / SAVE AS

4 PASSWORD

5 LANGUAGE

Code Quick

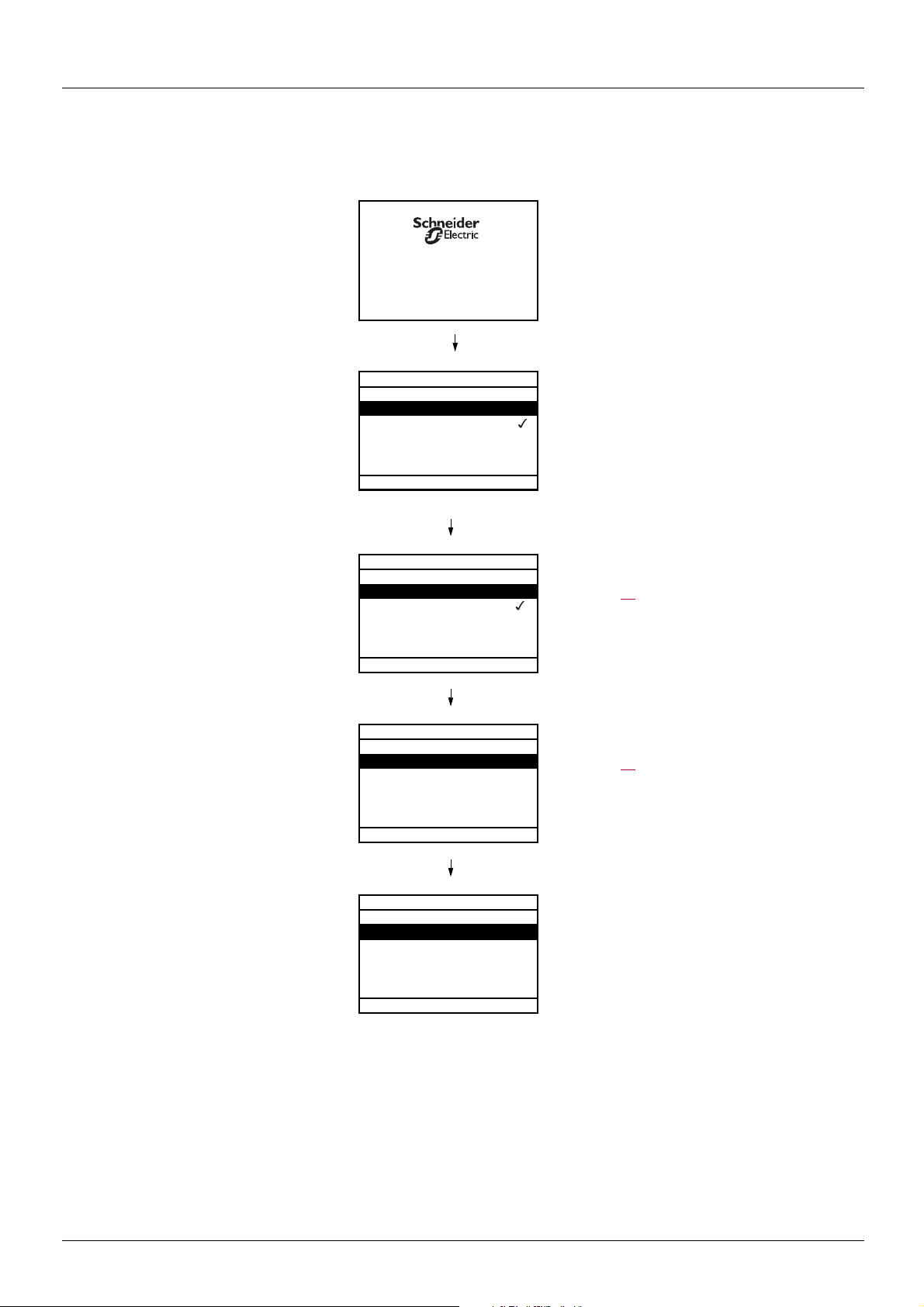

First power-up - [5. LANGUAGE] menu

The first time the drive is powered up, the user will automatically be guided through the menus as far as [1. DRIVE MENU].

The parameters in the [1.1 SIMPLY START] submenu must be configured and auto-tuning performed before the motor is started up.

Display for 3 seconds following power-up

3 seconds

Automatically switches to [5 LANGUAGE]

menu 3 seconds later.

Select the language and press ENT.

ESC

Switches to [2 ACCESS LEVEL] menu

(see page 31

)

Select the access level and press ENT.

Switches to [1 DRIVE MENU]

(see page 27

)

Press ESC to return to [MAIN MENU]

22 AAV49426 12/2009

Page 23

Graphic display terminal

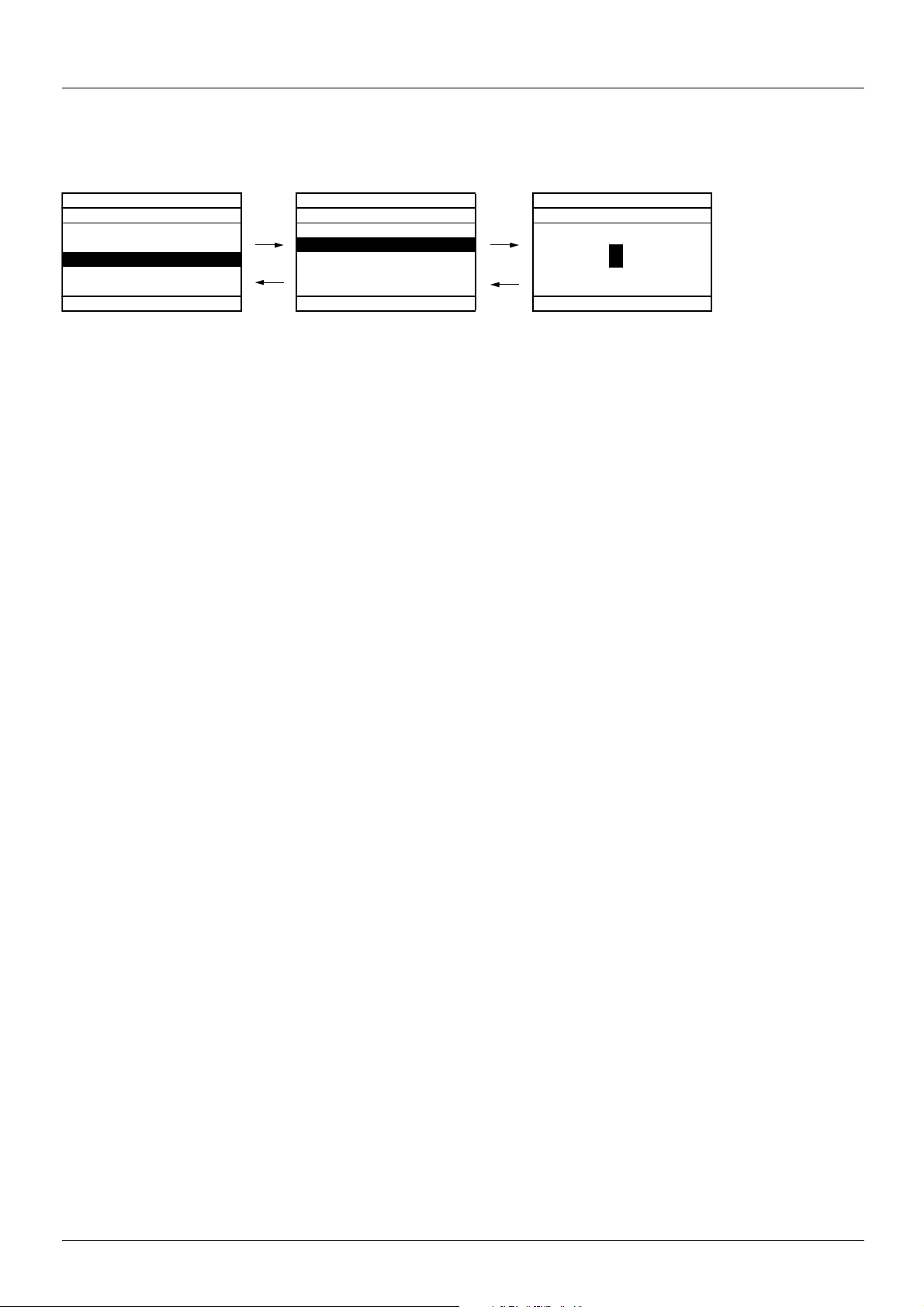

3 seconds later, switches to

[1. DRIVE MENU] or to

[1.14 PROGRAMMABLE CARD].

If no operator inputs are made,

switches to "Display" automatically

10 seconds later (the display will

vary depending on the selected

configuration).

Users can return to [MAIN MENU]

by pressing ENT or ESC.

3 seconds

10 seconds

ESC or ESC

ATV71HU22N4383

2.2kW/3HP 380/480V

Config. n°1

RDY Term +38Hz 0A

1. DRIVE MENU

1.1 SIMPLY START

1.2 MONITORING

1.3 SETTINGS

1.4 MOTOR CONTROL

1.5 INPUTS / OUTPUTS CFG

Code << >> Quick

RDY Term +38Hz 0A

Frequency ref.

Min=0 Max=60

Quick

RDY Term +38Hz 0A

MAIN MENU

1 DRIVE MENU

2 ACCESS LEVEL

3 OPEN / SAVE AS

4 PASSWORD

5 LANGUAGE

Code Quick

38 Hz

RDY Term +0.00Hz 0A

1.14 PROGRAMMABLE CARD

Modbus add Prg C. :17

DATE/TIME SETTINGS

<< >> Quick

RDY Term +0.00Hz 0A

1.3 SETTINGS

Ramp increment: 01

Acceleration 9.51 s

Deceleration: 9.67 s

Acceleration 2: 12.58 s

Deceleration 2: 13.45 s

Code << >> Quick

Menu selected in

[Power up menu]

page 284

ENT

or, if the Controller Inside card is present

Subsequent power ups

AAV49426 12/2009 23

Page 24

Graphic display terminal

RDY Term +0.00Hz 0A

1 DRIVE MENU

1.1 SIMPLY START

1.2 MONITORING

1.3 SETTINGS

1.4 MOTOR CONTROL

1.5 INPUTS / OUTPUTS CFG

Code << >> Quick

ENT

ESC

RDY Term +0.00Hz 0A

1.3 SETTINGS

Ramp increment: 01

Acceleration 9.51 s

Deceleration: 9.67 s

Acceleration 2: 12.58 s

Deceleration 2: 13.45 s

Code << >> Quick

ENT

ENT or

ESC

RDY Term +0.00Hz 0A

Acceleration

9.51 s

Min = 0.01 Max = 99.99

<< >> Quick

Programming: Example of accessing a parameter

Accessing the acceleration ramp

Note:

• To select a parameter:

- Turn the navigation button to scroll vertically.

• To modify a parameter:

- Use the << and >> keys (F2 and F3) to scroll horizontally and select the digit to be modified (the selected di git chan ges to white

on a black background).

- Turn the navigation button to modify the digit.

• To cancel the modification:

-Press ESC.

• To save the modification:

- Press the navigation button (ENT).

24 AAV49426 12/2009

Page 25

Graphic display terminal

RDY Term +0.00Hz 0A

1.4 MOTOR CONTROL

Standard mot. freq: 5 0Hz IEC

Rated motor power: 0.37 kW (0.5 HP)

Rated motor volt.: 206 V

Rated mot. current: 1.0 A

Rated motor freq.: 50.0 Hz

Code << >> Quick

ENT

RDY Term +0.00Hz 0A

QUICK NAVIGATION

RETURN TO MAIN MENU

DIRECT ACCESS TO...

10 LAST MODIFICATIONS

GOTO MULTIPOINT SCREEN

Code

See page 285

RDY Term +0.00Hz 0A

MAIN MENU

1 DRIVE MENU

2 ACCESS LEVEL

3 OPEN / SAVE AS

4 PASSWORD

5 LANGUAGE

Code Quick

RDY Term +0.00Hz 0A

DIRECT ACCESS TO...

1.3

SETTINGS

<< >>

ENT

RDY Term +0.00Hz 0A

1.3 SETTINGS

Ramp increment: 01

Acceleration 9.51 s

Deceleration: 9.67 s

Acceleration 2: 12.58 s

Deceleration 2: 13.45 s

Code << >> Quick

RDY Term +0.00Hz 0A

10 LAST MODIFICATIONS

Acceleration: 10 s

ENA prop.gain: 1.2

Rated mot. current: 15 A

Preset speed 4: 20 Hz

Preset speed 5: 30 Hz

Code

ESC

ENT

RDY Term +0.00Hz 0A

Rated mot. current

15.0 A

<< >>

Quick navigation

If the "Quick" function is displayed above the F4 key, you can gain quick access to a parameter from any screen.

Example:

Press F4 to access the Quick screen, which contains

4 selection options.

• [HOME]: Return to [MAIN MENU].

• [DIRECT ACCESS TO...]: Opens the direct access window, which

will contain the text "1". The function keys << and >> (F2 and F3)

can be used to select each of the numbers and the navigation

button to increment or decrement the numbers: 1.3 in the example

below.

• [10 LAST MODIFICATIONS]: Opens a window in which the l ast 10

parameters modified can be accessed directly.

AAV49426 12/2009 25

Page 26

Graphic display terminal

RDY Term +0.00Hz 0A

MAIN MENU

1 DRIVE MENU

2 ACCESS LEVEL

3 OPEN / SAVE AS

4 PASSWORD

5 LANGUAGE

Code Quick

6 MONITORING CONFIG.

7 DISPLAY CONFIG.

RDY Term +0.00Hz 0A

1 DRIVE MENU

1.1 SIMPLY START

1.2 MONITORING

1.3 SETTINGS

1.4 MOTOR CONTROL

1.5 INPUTS / OUTPUTS CFG

Code << >> Quick

1.6 COMMAND

1.7 APPLICATION FUNCT.

1.8 FAULT MANAGEMENT

1.9 COMMUNICATION

1.10 DIAGNOSTICS

1.11 IDENTIFICATION

1.12 FACTORY SETTINGS

1.13 USER MENU

1.14 PROGRAMMABLE CARD

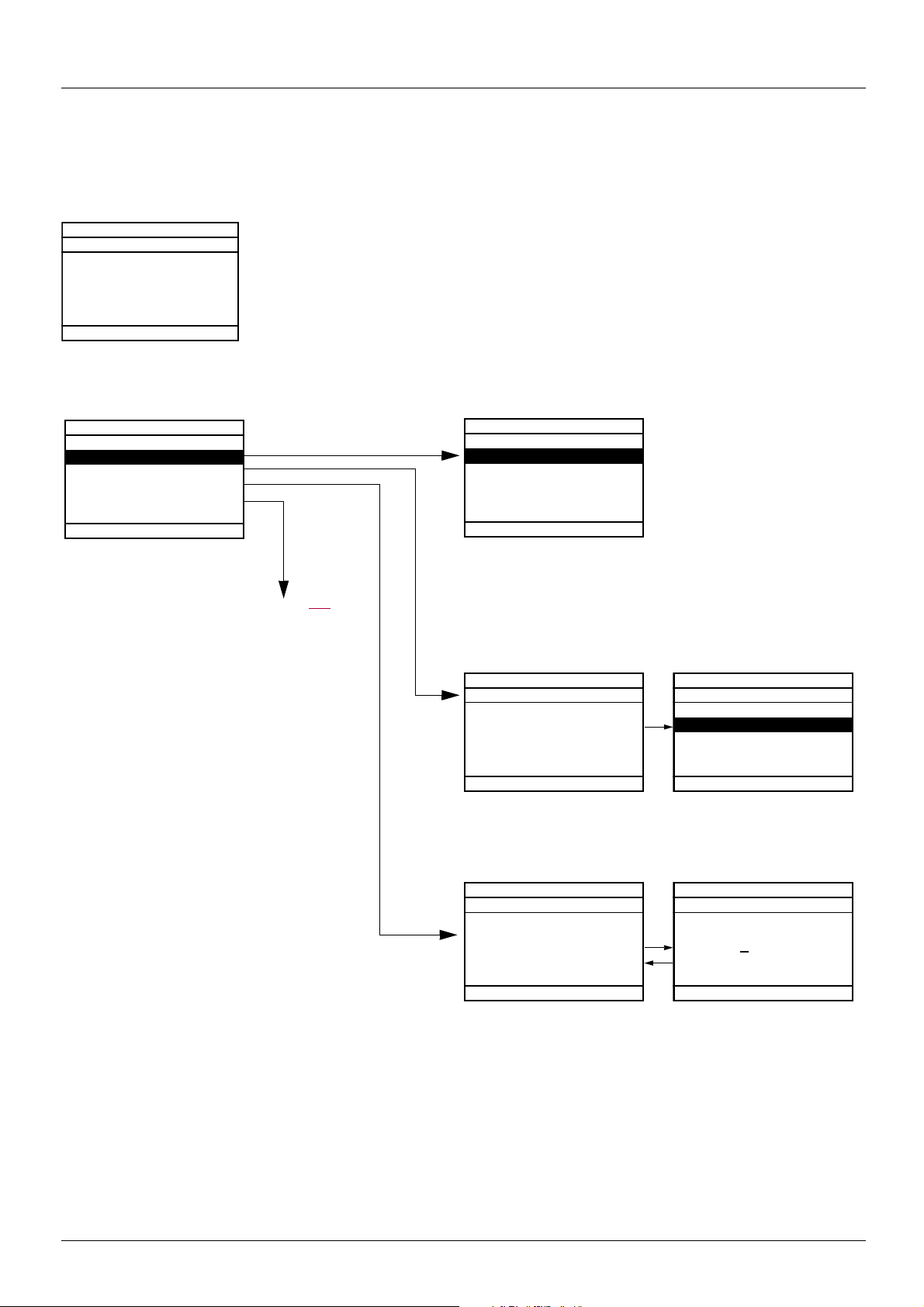

[MAIN MENU] - Menu mapping

Content of [MAIN MENU] menus

[1 DRIVE MENU] See next page

[2 ACCESS LEVEL] Defines which menus can be accessed (level of complexity)

[3 OPEN / SAVE AS] Can be used to save and recover drive configuration files

[4 PASSWORD] Provides password protection for the configuration

[5 LANGUAGE] Language selection

[6 MONITORING CONFIG.] Customization of information displayed on the graphic display terminal during operation

[7 DISPLAY CONFIG.] • Customization of parameters

• Creation of a customized user menu

• Customization of the visibility and protection mechanisms for menus and parameters

26 AAV49426 12/2009

Page 27

Graphic display terminal

[1 DRIVE MENU]

RDY Term +0.00Hz 0A

1.1 SIMPLY START

1.2 MONITORING

1.3 SETTINGS

1.4 MOTOR CONTROL

1.5 INPUTS / OUTPUTS CFG

1.6 COMMAND

1.7 APPLICATION FUNCT.

1.8 FAULT MANAGEMENT

1.9 COMMUNICATION

1.10 DIAGNOSTICS

1.11 IDENTIFICATION

1.12 FACTORY SETTINGS

1.13 USER MENU

1.14 PROGRAMMABLE CARD

1 DRIVE MENU

Code << >> Quick

Content of [1. DRIVE MENU] menus:

[1.1 SIMPLY START]: Simplified menu for a quick start

[1.2 MONITORING]: Visualization of current, motor and input/output values

[1.3 SETTINGS]: Accesses the adjustment parameters, which can be modified during operation

[1.4 MOTOR CONTROL]: Moto r parameters (motor nameplate, auto-tuning, switching frequency, control algorithms, etc.)

[1.5 INPUTS / OUTPUTS CFG]: I/O configuration (scaling, filtering, 2-wire control, 3-wire control, etc.)

[1.6 COMMAND]: Configuration of command and reference channels (graphic displ ay t erminal , t erminals , bu s, e tc.)

[1.7 APPLICATION FUNCT.]: Configuration of application functions (e.g., preset speeds, PID, brake logic con trol, etc.)

[1.8 FAULT MANAGEMENT]: Configuration of fault management

[1.9 COMMUNICATION]: Communication parameters (fieldbus)

[1.10 DIAGNOSTICS]: Motor/drive diagnostics

[1.11 IDENTIFICATION]: Identifies the drive and the internal options

[1.12 FACTORY SETTINGS]: Access to configuration files and return to factory settings

[1.13 USER MENU]: Specific menu set up by t he user in the [7. DISPLAY CONFIG.] menu

[1.14 PROGRAMMABLE CARD]: Configuration of optional Controller Inside card

AAV49426 12/2009 27

Page 28

Integrated display terminal

• Four 7-segment

displays

• Enters a menu or

parameter, or saves the

displayed parameter or

value

• Returns to the previous

menu or parameter, or

increases the

displayed value

• Exits a menu or parameter,

or aborts the displayed

value to return to the

previous value in the

memory

• Goes to the next menu

or parameter, or

decreases the

displayed value

• 2 CANopen status LEDs

• 2 Modbus status LEDs

Note:

Low-power Altivar 71 drives (see catalog) feature an integrated display terminal with a 7-segment 4-digit display. The graphic display

terminal described on the previous pages can also be connected to these drives as an option.

Functions of the display and the keys

• Pressing or does not store the selection.

• Press and hold down (>2 s) or to scroll through the data quickly.

Save and store the selection: ENT

The display flashes when a value is stored.

Normal display, with no fault present and no startup:

- 43.0: Display of the parameter selected in the SUP menu (default selection: motor frequency)

- CLI: Current limit

- CtL: Controlled st op on in pu t phase loss

- dCb: DC injection braking in progress

- FLU: Motor fluxing in progress

- FSt: Fast stop.

- nLP: No line power (no line supply on L1, L2, L3)

- nSt: Freewheel stop

- Obr: Auto-adapted deceleration

- PrA: Power Removal function active (drive locked)

- rdY = Drive ready

- SOC: Controlled output cut in progress

- tUn: Auto-tuning in progress

- USA: Undervoltage alarm

- ASA: Measurement of the phase-shift angle in progress

The display flashes to indicate the presence of a fault.

28 AAV49426 12/2009

Page 29

Integrated display terminal

XXX

CtL-

FUn-

SIM-

I-O-

SEt-

SUP-

ESC

ESC

ESC

ESC

ESC

ESC

ESC

ESC

ENT

ENT

ESC

ENT

ESC

ENT

ESC

ENT

ESC

ENT

ESC

ENT

ESC

ENT

ESC

FCS-

LAC-

CON-

FLt-

ESC

ESC

ESC

ESC

ENT

ESC

ENT

ESC

ENT

ESC

ENT

ESC

ENT

ESC

SPL-

ESC

ENT

ESC

drC-

COd-

USr-

ESC

ENT

ESC

Displays the state of the drive

SETTINGS

APPLICATION FUNCT.

INPUTS / OUTPUTS CFG

FAULT MANAGEMENT

SIMPLY START

Menus

MONITORING

MOTOR CONTROL

COMMAND

Power-up

FACTORY SETTINGS

PASSWORD

ACCESS LEVEL

COMMUNICATION

(page 54) Adjustment parameters, can be modified during

operation

(page 144

)Configuration of application functions (e.g., preset

speeds, PID, brake logic control, etc.)

(page 101

) I/O configuration (scaling, filtering, 2-wire control,

3-wire control, etc.)

(page 234

) Configuration of fault management

(page 37

) Simplified menu for fast startup

(page 45

) Visualization of current, motor and i nput/output values

(page 71

) Motor parameters (motor nameplate, auto-tuning,

switching frequency, control algorithms, etc.)

(page 131

) Configuration of command and reference channels

(graphic display terminal, terminals, bus, etc.)

(page 267

) Access to configuration files and return to factory

settings

(page 274

)

(page 31

)

(page 259

) Communication parameters (fieldbus)

(page 270

) Specific menu, set up by the user using the graphic

display terminal.

USER MENU

PROGRAMMABLE CARD

(page 271

) Menu for the Controller Inside card, if present.

Accessing menus

A dash appears after menu and submenu codes to differentiate them from parameter codes.

Examples: FUn- menu, ACC parameter.

AAV49426 12/2009 29

The grayed-out menus may not be accessible depending on the control access (LAC) configuration.

Page 30

Integrated display terminal

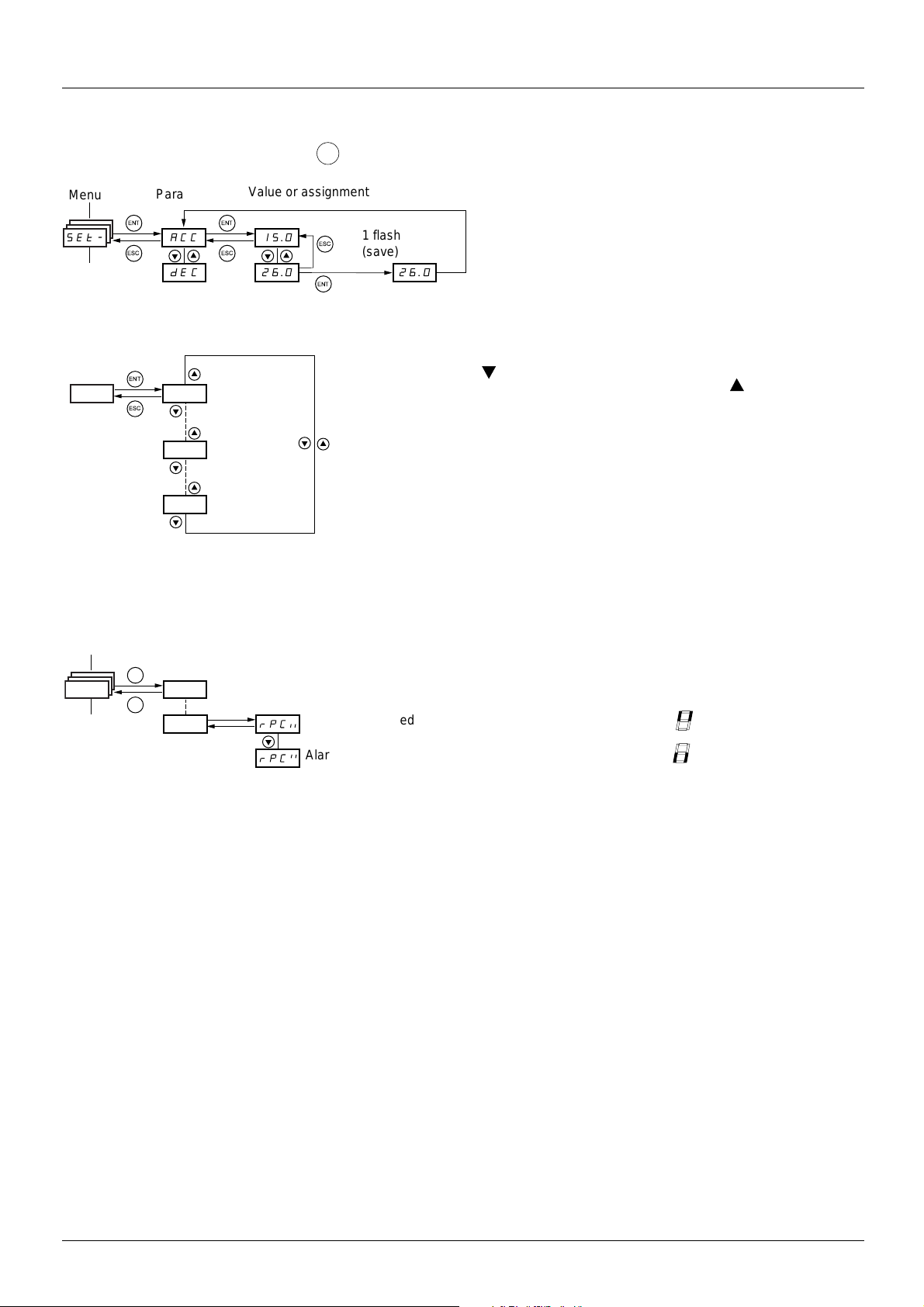

ENT

ACC 15.0

ENT

ESC

ENT

ESC

26.0 26.0

ESC

dEC

ENT

SEt-

Menu

Value or assignment

1 flash

(save)

Parameter

(Next parameter)

ENT

ESC

1

st

n

th

last

Menu

ENT

ESC

I-O-

Alarm not selected

Alarm selected

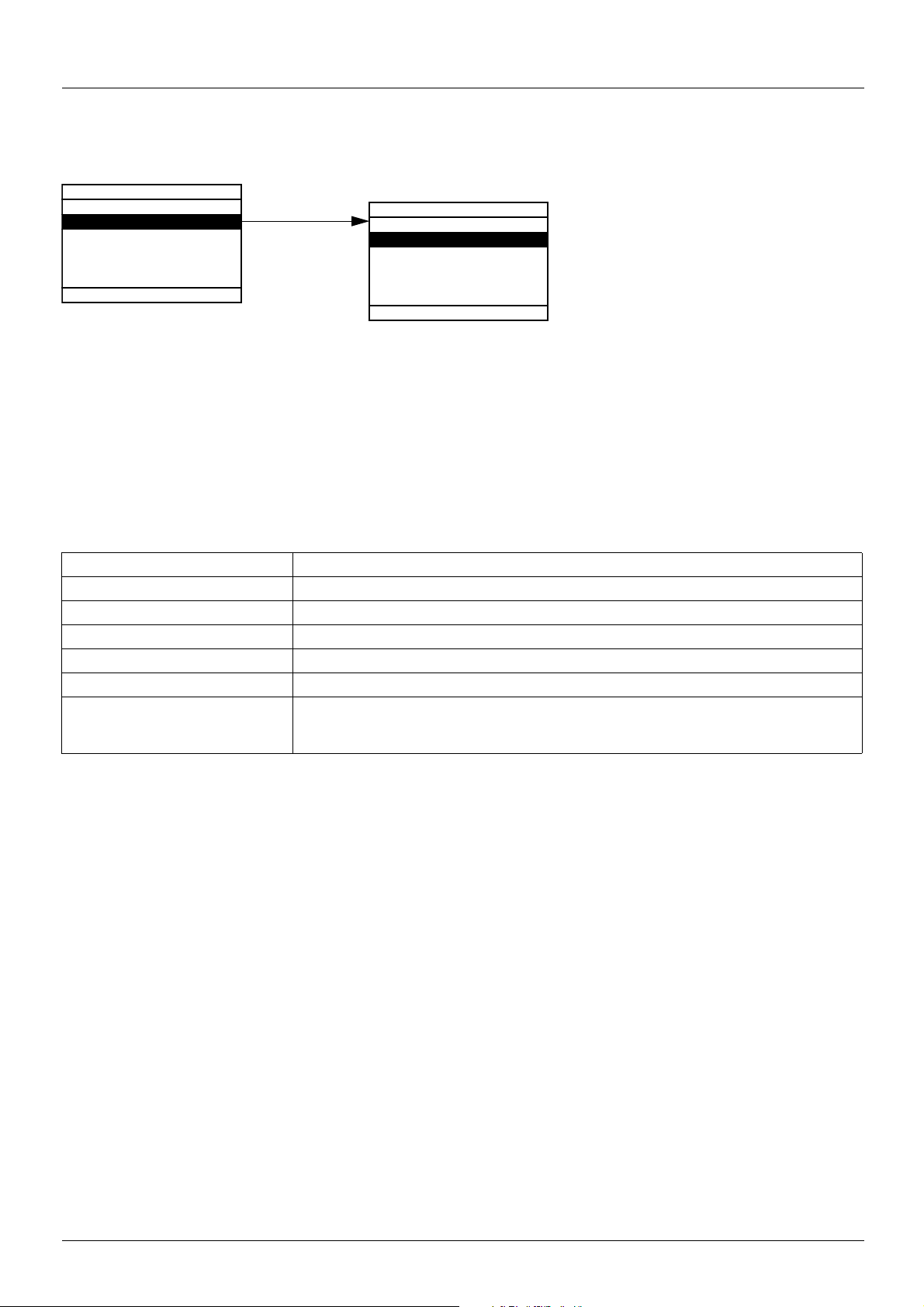

Accessing menu parameters

Save and store the displayed selection :

The display flashes when a value is stored.

All the menus are "drop-down" type menus, which means that after the last pa rameter, if

you continue to press , you will return to the first parameter and, conver sely, you can

switch from the first parameter to the last parameter by pressing .

Selection of multiple assignments for one parameter

Example: List of group 1 alarms in [INPUTS / OUTPUTS CFG]

(I-O-) menu

A number of alarms can be selected by "checking" them as

follows.

The digit on the right indicates: selected

not selected.

The same principle is used for all multiple select ions.

30 AAV49426 12/2009

Page 31

[2. ACCESS LEVEL] (LAC-)

RDY Term +0.00Hz 0A

2 ACCESS LEVEL

Basic

Standard

Advanced

Expert

<< >> Quick

RDY Term +0.00Hz 0A

MAIN MENU

1 DRIVE MENU

2 ACCESS LEVEL

3 OPEN / SAVE AS

4 PASSWORD

5 LANGUAGE

Code << >> Quick

RDY Term +0.00Hz 0A

1. DRIVE MENU

1.1 SIMPLY START

1.2. MONITORING

1.3. SETTINGS

1.11. IDENTIFICATION

1.12. FACTORY SETTINGS

Code << >> Quick

1.13 USER MENU

RDY Term +0.00Hz 0A

MAIN MENU

1 DRIVE MENU

2 ACCESS LEVEL

3 OPEN / SAVE AS

4 PASSWORD

5 LANGUAGE

Code Quick

6 MONITORING CONFIG.

RDY Term +0.00Hz 0A

1 DRIVE MENU

1.1 SIMPLY START

1.2 MONITORING

1.3 SETTINGS

1.4 MOTOR CONTROL

1.5 INPUTS / OUTPUTS CFG

Code << >> Quick

1.6 COMMAND

1.7 APPLICATION FUNCT.

1.8 FAULT MANAGEMENT

1.9 COMMUNICATION

1.10 DIAGNOSTICS

1.11 IDENTIFICATION

1.12 FACTORY SETTINGS

1.13 USER MENU

1.14 PROGRAMMABLE CARD

RDY Term +0.00Hz 0A

MAIN MENU

1 DRIVE MENU

2 ACCESS LEVEL

3 OPEN / SAVE AS

4 PASSWORD

5 LANGUAGE

Code Quick

6 MONITORING CONFIG.

7 DISPLAY CONFIG.

RDY Term +0.00Hz 0A

MAIN MENU

1 DRIVE MENU

2 ACCESS LEVEL

3 OPEN / SAVE AS

4 PASSWORD

5 LANGUAGE

Code Quick

6 MONITORING CONFIG.

7 DISPLAY CONFIG.

With graphic display terminal

Basic

Access to 5 menus only, and access to 6 submenus only in the

[1. DRIVE MENU] menu.

A single function can be assigned to each input.

Standard

This is the factory-set level. Access to 6 menus only, and access to all

submenus in the [1. DRIVE MENU] menu.

A single function can be assigned to each input.

AAV49426 12/2009 31

Advanced

Access to all menus and submenus.

Several functions can be assigned to

each input.

Expert

Access to all menus and submenus as for [Advanced] level, and access to

additional parameters.

Several functions can be assigned to each input.

Page 32

[2. ACCESS LEVEL] (LAC-)

XXX

SIM-

ESC

ESC

ENT

LAC-

ESC

ENT

ESC

COd-

Displays the state of the drive

ACCESS LEVEL

Power-up

With integrated display terminal:

Code Name/Description Factory setting

LAC-

bAS

• bAS: Limited access to SIM, SUP, SEt, FCS, USr, COd and LAC menus. Only one function can be assigned to

Std

each input.

Std

Adu

Epr

• Std: Access to all menus on the integrated display terminal. Only one function can be assigned to each input.

• AdU: Access to all menus on the integrated display terminal. Several functions can be assigned to each input.

• EPr: Access to all menus on the integrated display te rminal and access to additional p arameters. Several functions

can be assigned to each input.

32 AAV49426 12/2009

Page 33

[2. ACCESS LEVEL] (LAC-)

Comparison of the menus that can be accessed on the graphic display terminal/

integrated display terminal

Graphic display terminal Integrated display terminal Access level

[2 ACCESS LEVEL] LAC- (Access level)

[3 OPEN/SAVE AS] [4 PASSWORD] COd- (Password)

[5 LANGUAGE] [1 DRIVE MENU] [1.1 SIMPLY START] SIM- (Simply start)

[1.2 MONITORING] SUP- (Monitoring)

[1.3 SETTINGS] SEt- (Settings)

[1.11 IDENTIFICATION] [1.12 FACTORY SETTINGS] FCS- (Factory settings)

[1.13 USER MENU] USr- (User menu)

A single function can be assigned to each input. A single function can be assigned to

each input.

[1.4 MOTOR CONTROL] drC- (Motor control)

[1.5 INPUTS / OUTPUTS CFG] I-O- (I/O configuration)

[1.6 COMMAND] CtL- (Command)

[1.7 APPLICATION FUNCT.] FUn- (Application functions)

[1.8 FAULT MANAGEMENT] FLt- (Fault management)

[1.9 COMMUNICATION] COM- (Communication)

[1.10 DIAGNOSTICS] [1.14 PROGRAMMABLE CARD] (1) PLC- (Controller Inside card) (1)

[6 MONITORING CONFIG.] -

A single function can be assigned to each input. A single function can be assigned to

each input.

[7 DISPLAY CONFIG.] -

Several functions can be assigned to each input. Several functions can be assigned

to each input.

Expert parameters Expert parameters

Several functions can be assigned to each input. Several functions can be assigned

to each input.

Basic bAS

Advanced AdU

Standard Std(factory setting)

Expert EPr

(1)Can be accessed if the Controller Inside card is present.

AAV49426 12/2009 33

Page 34

Structure of parameter tables

5

2

3

1

4

6

8

7

1. Name of menu on 4-digit 7-segment display.

2. Submenu code on 4-digit 7-segment display.

3. Parameter code on 4-digit 7-segment display.

4. Parameter value on 4-digit 7-segment display.

5. Name of menu on graphic display terminal.

6. Name of submenu on graphic display terminal.

7. Name of parameter on graphic display terminal.

8. Value of parameter on graphic display terminal.

The parameter tables in the descriptio ns of the various menus can be used wit h both the graphi c display terminal an d the integrated display

terminal. They, therefore, contain information for these two terminals in accordance with the description below.

Example:

[1.7 APPLICATION FUNCT.] (FUn-)

Code Name/Description Adju s t ment rang e Factory setting

UPd-

USP

LI1

Note:

• The text in square brackets [ ] indicates what you will see on the graphic display terminal.

• The factory settings correspond to [Macro configuration] (CFG) = [Start/Stop] (StS). This is the macro configuration set at

the factory.

b [+/- SPEED]

Function can be accessed for reference channel [Ref.2 channel] (Fr2) = [+/- speed] (UPdt) ,

see page 141

M [+ speed assignment]

no

v [No] (nO): function inactive

v [LI1] (LI1)

[No] (nO)

34 AAV49426 12/2009

Page 35

Interdependence of parameter values

The configuration of certain parameters modifies the a dju stment ra nge of ot her p aramet ers, in order to redu ce t he risk of error s. This may

result in the modification of a factory setting or a value you have already selected.

Example:

1. [Current Limitation] (CLI) page 62 set to 1.6 In or left at its factory setting, 1.5 In

2. [Switching freq.] (SFr) page 62

3. If [Switching freq.] (SFr) is increased to 4 kHz, [Current limitation] (CLI) is no longer restricted, but remains at 1.36 In. If you require

1.6 In, you must reset [Current Limitation] (CLI).

set to 1 kHz (and confirmed with "ENT") restricts [Current Limitation] (CLI) to 1.36 In

AAV49426 12/2009 35

Page 36

Finding a parameter in this document

F1

RDY Term +0.00Hz 0A

1.3 SETTINGS

Ramp increment: 01

Acceleration 9.51 s

Deceleration: 9.67 s

Acceleration 2: 12.58 s

Deceleration 2: 13.45 s

Code << >> Quick

Code

RDY Term +0.00Hz 0A

1.3 SETTINGS

Ramp increment: 01

ACC 9.51 s

Deceleration: 9.67 s

Acceleration 2: 12.58 s

Deceleration 2: 13.45 s

Code << >> Quick

The following assistance with finding explanations on a parameter is provided:

• With the integrated display terminal: Direct use of the parameter code index, page 297

, to find the page giving details of the

displayed parameter.

• With the graphic display terminal: Select the required p arameter and press : [Code]. The parameter code is displayed instead

of its name while the key is held down.

Example: ACC

Then use the parameter code index, page 297

, to find the page giving details of the displayed parameter.

36 AAV49426 12/2009

Page 37

[1.1 SIMPLY START] (SIM-)

RDY Term +0.00Hz 0A

MAIN MENU

1 DRIVE MENU

2 ACCESS LEVEL

3 OPEN / SAVE AS

4 PASSWORD

5 LANGUAGE

Code Quick

ENT

RDY Term +0.00Hz 0A

1 DRIVE MENU

1.1 SIMPLY START

1.2 MONITORING

1.3 SETTINGS

1.4 MOTOR CONTROL

1.5 INPUTS / OUTPUTS CFG

Code << >> Quick

ENT

RUN Term +50.00Hz 80A

1.1 SIMPLY START

2/3 wire control

Macro configuration

Customized macro

Standard mot. freq

Input phase loss

Code << >> Quick

XXX

SIM-

SUP-

ESC

ESC

ESC

ENT

ENT

ESC

LAC-

Displays the state of the drive

SIMPLY START

Power-up

With graphic display terminal:

With integrated display terminal:

The [1.1-SIMPLY START] (SIM-) menu can be used for fast startup, which is sufficient for the majority of applications.

The parameters in this menu can only be modified when the d rive is stopped a nd no run command is present, with the f ollowing exceptions:

• Auto-tuning, which causes the motor to start up

• The adjustment parameters on page 44

Note: The parameters of the [1.1 SIMPLY START] (SIM-) menu must be entered in the order in which they appear, as the later

ones are dependent on the first ones.

For example [2/3 wire control] (tCC) must be configured before any other parameters.

The [1.1 SIMPLY START] (SIM-) menu should be configured on its own or before the other drive configuration menus. If a modification

has previously been made to any of them, in particular in [1.4 MOTOR CONTROL] (drC-), some [1.1 SIMPLY START] (SIM-) parameters

may be changed, for example, the motor parameters, if a synchronous motor has been selected. Returning to the [1.1 SIMPLY START]

(SIM-) menu after modifying another drive configuration menu is unneces sary but does not pose any risk. Changes fol lowing modificat ion

of another configuration menu are not described, to avoid unnecessary complication in this section.

Macro configuration

Macro configuration provides a means of speeding up the configuration of functions for a specific field of application.

8 macro configurations are available:

• Start/stop (factory configuration)

• Handling

• General use

•Hoisting

•Lifts

• PID regulator

• Communication bus

•Master/slave

Selecting a macro configuration assigns the parameters in this macro configuration.

Each macro configuration can still be modified in the other menus.

AAV49426 12/2009 37

Page 38

[1.1 SIMPLY START] (SIM-)

Macro configuration parameters

Assignment of the inputs/outputs

Input/

output

AI1 [Ref.1

AI2 [No] [Summing ref. 2][Summing ref. 2][No]

AO1 [No] [No] [No] [No]

R1 [No drive flt] [No drive flt] [No drive flt] [No drive flt]

R2 [No] [No] [No] [Brk control]

LI1 (2-wire) [Forward] [Forward] [Forward] [Forward]

LI2 (2-wire) [Reverse] [Reverse] [Reverse] [Reverse]

LI3 (2-wire) [No] [2 preset

LI4 (2-wire) [No] [4 preset

LI5 (2-wire) [No] [8 preset

LI6 (2-wire) [No] [Fault reset] [No] [No]

LI1 (3-wire) Stop Stop Stop Stop

LI2 (3-wire) [Forward] [Forward] [Forward] [Forward]

LI3 (3-wire) [Reverse] [Reverse] [Reverse] [Reverse]

LI4 (3-wire) [No] [2 preset

LI5 (3-wire) [No] [4 preset

LI6 (3-wire) [No] [8 preset

LI7 to LI14 [No] [No] [No] [No]

LO1 to LO4 [No] [No] [No] [No]

R3/R4 [No] [No] [No] [No]

AI3, AI4 [No] [No] [No] [No]

RP [No] [No] [No] [No]

AO2 [I motor] [I motor] [I motor] [I motor]

AO3 [No] [Sign. torque] [No] [Sign. torque]

F1 key [No] [No] [No] [No]

F2, F3, F4

keys

[Start/Stop] [M. handling] [Gen. Use] [Hoisting]

[Ref.1

channel]

[No] [No] [No] [No]

channel]

speeds]

speeds]

speeds]

speeds]

speeds]

speeds]

[Ref.1

channel]

[Jog] [Fault reset]

[Fault reset] [External fault]

[Torque

limitation]

[Jog] [Fault reset]

[Fault reset] [External fault]

[Torque

limitation]

[Ref.1

channel]

[No]

[No]

Option cards

Graphic display terminal keys

[Lift]

[Ref.1

channel]

[No]

[No]

[No drive flt]

[Brk control]

[Forward]

[Reverse]

[2 preset

speeds]

[4 preset

speeds]

[Fault reset]

[No]

Stop

[Forward]

[Reverse]

[2 preset

speeds]

[4 preset

speeds]

[Fault reset]

[No]

[No]

[No]

[No]

[No]

[I motor]

[Sign. torque]

[No]

[No]

[PID regul.] [Network C.] [Mast./slave]

[Ref.1 channel]

(PID reference)

[PID feedback] [No] [Torque

[No] [No] [No]

[No drive flt] [No drive flt] [No drive flt]

[No] [No] [No]

[Forward] [Forward] [Forward]

[Reverse] [Reverse] [Reverse]

[PID integral

reset]

[2 preset PID

ref.]

[4 preset PID

ref.]

[No] [No] [No]

Stop Stop Stop

[Forward] [Forward] [Forward]

[Reverse] [Reverse] [Reverse]

[PID integral

reset]

[2 preset PID

ref.]

[4 preset PID

ref.]

[No] [No] [No]

[No] [No] [No]

[No] [No] [No]

[No] [No] [No]

[No] [No] [No]

[I motor] [I motor] [I motor]

[PID Output] [No] [Motor freq.]

[No] Control

[No] [No] [No]

[Ref.2 channel]

([Ref.1 channel]

= integrated

Modbus) (1)

[Ref. 2

switching]

[Fault reset] [Fault reset]

[No] [No]

[Ref. 2

switching]

[Fault reset] [Fault reset]

[No] [No]

via graphic

display terminal

[Ref.1

channel]

reference]

[Trq/spd

switching]

[Trq/spd

switching]

[No]

In 3-wire control, the assignment of inputs LI1 to LI6 shifts.

(1) To start up with integrated Modbus, [Modbus Address] (Add) must first be configured, page 261.

Note: These assignments are reinitialized every time the macro configuration changes.

38 AAV49426 12/2009

Page 39

[1.1 SIMPLY START] (SIM-)

Macro configuration parameters

Other configurations and settings

In addition to the assignment of I/O, other parameters are assigned only in the Hoisting, Lift and Mast./slave macro configurations.

Hoisting and lift:

• [Movement type] (bSt) = [Hoisting] (UEr) page 175

• [Brake contact] (bCI) = [No] (nO) page 175

• [Brake impulse] (bIP) = [No] (nO) page 175

• [Brake release I FW] (Ibr) = [Rated mot. current] (nCr) page 175

• [Brake Release time] (brt) = 0.5 s page 176

• [Brake release freq] (bIr) = [Auto] (AUtO) page 176

• [Brake engage freq] (bEn) = [Auto] (AUto) page 176

• [Brake engage time] (bEt) = 0.5 s page 176

• [Engage at reversal] (bEd) = [No] (nO) page 177

• [Jump at reversal] (JdC) = [Auto] (AUtO) page 177

• [Time to restart] (ttr) = 0 s page177

• [Current ramp time] (brr) = 0 s page 179

• [Low speed] (LSP) = Rated motor slip calculated by the drive, page 44

• [Output Phase Loss] (OPL) page 242 = [Yes] (YES), but it is forced to [No] (nO) if [Motor control type] (Ctt) page 70 = [Sync. mot.]

(SYn). No further modifications can be made to this parameter.

• [Catch on the fly] (FLr) = [No] (nO) page 239

Lift:

• [Feed forward] (FFP) = 0 % page 91

. No further modifications can be made to this parameter.

Mast./slave:

• [Motor control type] (Ctt) = [SVC I] (CUC) page 70

Note: These assignments are forced every time the macro configuration changes, except for [Motor control type] (Ctt) for the Mast./slave

macro configuration, if it is configured in [FVC] (FUC).

Return to factory settings:

Returning to factory settings with [Config. Source] (FCSI) = [Macro-Conf] (InI) page 269

configuration. The [Macro configuration] (CFG) parameter does not change, although [Customized macro] (CCFG) disappears.

Note:

• The factory settings that appear in the parameter tables correspond to [Macro con figuration] (CFG) = [Start/Stop] (StS).

This is the macro configuration set at the factory.

will return the drive to the selected macro

AAV49426 12/2009 39

Page 40

[1.1 SIMPLY START] (SIM-)

UWV

L1 L3

ATV71H

KM10

R2A

R2C

L2

M

3

3

2

(1)

AI1

LI1 LI2+24

Electromagnetic brake

Forward

(Ascend)

Reverse

(Descend)

UWV

L1 L3

AI1

L2

M1

3

3

COMA01

LI1 LI2+24

COM AI2 UWV

LI1 +24

AI1

LI2

M2

3

LI3 L1 L3L2

3

ATV 71Hpppp

Slave drive

ATV 71H

pppp

Master drive

TorqueSpeed

ReverseForward

Reverse

Forward

Example diagrams for use with the macro configurations

[Hoisting] (HSt) diagram

(1) A contact on the Preventa module must be inserted in the brake control circuit to engage it safely when the "Power Removal" safety

function is activated (see connection diagrams in the Installation Manual).

[Mast./slave] (MSL) diagram

When the two motors are mechanically connected, the Speed/torque contact closing results in operation in Mast./slave mode. The master

drive regulates the speed and controls the slave drive in torque mode to ensure distribution of the load.

40 AAV49426 12/2009

Page 41

[1.1 SIMPLY START] (SIM-)

+24 LI1 LIx

ATV 71

+24 LI1 LI2 LIx

ATV 71

WARNING

UNINTENDED EQUIPMENT OPERATION

To change the assignment of [2/3 wire control] (tCC) press and hold down the “ENT” key for 2 s.

The following function will be returned to factory settings: [2 wire type] (tCt) page 102

as will all

functions which assign logic inputs.

The macro configuration selected will also be reset it if h as been customized (loss of custom settings).

Check that this change is compatible with the wiring diagram used.

Failure to follow these instructions can result in death or serious injury.

WARNING

UNINTENDED EQUIPMENT OPERATION

To change the assignment of [Macro configuration ] (CFG) press and hold down the “ENT” key for 2 s.

Check that the selected macro configuration is compatible with the wiring diagram used.

Failure to follow these instructions can result in death or serious injury.

Code Name/Description Adjustment range Factory setting

tCC

M [2/3 wire control]

2C

3C

v [2 wire] (2C)

v [3 wire] (3C)

2-wire control: This is the input state (0 or 1) or edge (0 to 1 or 1 to 0), which controls running or stopping.

Example of "source" wiring:

3-wire control (pulse commands): A "forward" or "reverse" pulse is sufficient to command starting, a "stop"

pulse is sufficient to command stopping.

Example of "source" wiring:

[2 wire] (2C)

LI1: forward

LIx: reverse

LI1: stop

LI2: forward

LIx: reverse

AAV49426 12/2009 41

CFG

StS

HdG

HSt

GEn

PId

nEt

MSL

LIFt

CCFG

YES

M [Macro configuration]

v [Start/Stop] (StS): Start/stop

v [M. handling] (HdG): Handling

v [Hoisting] (HSt): Hoisting

v [Gen. Use] (GEn): General use

v [PID regul.] (PId): PID regulation

v [Network C.] (nEt): Communication bus

v [Mast./slave] (MSL): Master/slave

v [Lift] (LIFt): Lifts

M [Customized macro]

Read-only parameter, only visible if at least one macro configuration parameter has been modified.

v [Yes] (YES)

[Start/Stop] (StS)

Page 42

[1.1 SIMPLY START] (SIM-)

100 - slip as a %

100

50 - slip in Hz

50

60 - slip in Hz

60

Code Name/Description Adjustment range Factory setting

bFr

IPL

nPr

UnS

nCr

FrS

nSP

50

60

nO

YES

M [Standard mot. freq]

v [50Hz IEC] (50): IEC

v [60Hz NEMA] (60): NEMA

This parameter modifies the presets of the following parameters:[Rated mo tor volt.] (UnS) below, [High speed]

(HSP) page 44

, [Freq. threshold] (Ftd) page 68, [Rated motor freq.] (FrS ) and [Max frequency] (tFr) .

M [Input phase loss]

v [Ignore] (nO): Fault ignored, to be used when the drive is supplied via a sin gle-phase supply or by the

DC bus.

v [Freewheel] (YES): Fault, with freewheel stop.

If one phase disappears, the drive switches to fault mode [Input phase loss] (IPL), but if 2 or 3 phases

disappear, the drive continues to operate until it trips on an undervoltage fault.

This parameter is only accessible in this menu on ATV71H037M3 to HU75M3 drives (used with a single

phase supply).

M [Rated motor power]

Rated motor power given on the nameplate, in kW if [Standard mot. freq] (bFr) = [50Hz IEC] (50), in HP if

[Standard mot. freq] (bFr) = [60Hz NEMA] (60).

M [Rated motor volt.]

Rated motor voltage given on the nameplate.

ATV71

pppM3: 100 to 240 V

ATV71

pppN4: 200 to 480 V

M [Rated mot. current]

Rated motor current given on the nameplate.

M [Rated motor freq.]

Rated motor frequency given on the nameplate.

The factory setting is 50 Hz, or preset to 60 Hz if [Standard mot. freq] (bFr) is set to 60 Hz.

M [Rated motor speed]

Rated motor speed given on the nameplate.

0 to 9999 rpm then 10.00 to 60.00 krpm on the integrated display terminal.

If, rather than the rated speed, the nameplate indicates the synchronous speed and the slip in Hz or as a %,

calculate the rated speed as follows:

[50Hz IEC] (50)

According to drive

rating

According to drive

rating

According to drive

rating

0.25 to 1.5 In (1) According to drive

10 to 500 Hz 50 Hz

0 to 60000 RPM According to drive

According to drive

rating

According to drive

rating and [Standard

mot. freq] (bFr)

rating and [Standard

mot. freq] (bFr)

rating

• Nominal speed = Synchronous speed x

or

• Nominal speed = Synchronous speed x (50 Hz motors)

or

• Nominal speed = Synchronous speed x (60 Hz motors)

tFr

(1)In corresponds to the rated drive current indicated in the Installation Manual and on the drive nameplate.

42 AAV49426 12/2009

M [Max frequency]

The factory setting is 60 Hz, or preset to 72 Hz if [Standard mot. freq] (bFr) is set to 60 Hz.

The maximum value is limited by the following conditions:

• It must not exceed 10 times the value of [Rated motor freq.] (FrS)

• It must not exceed 500 Hz if the drive rating is higher than ATV71HD37 (values between 500 Hz and 1600Hz

are only possible for powers limite d to 37 kW (50 HP).

10 to 1600 Hz 60 Hz

Page 43

[1.1 SIMPLY START] (SIM-)

Code Name/Description Factory setting

tUn

dOnE

tUS

PEnd

PrOG

FAIL

dOnE

PHr

nO

YES

tAb

AbC

ACb

M [Auto tuning]

[No] (nO)

v [No] (nO): Auto-tuning not performed.

v [Yes] (YES): Auto-tuning is performed as soon as possible, then the parameter automatically changes to [Done]

(dOnE).

v [Done] (dOnE): Use of the values given the last time auto-tuning was performed.

Caution:

• It is essential that all motor parameters ([Rated motor volt.] (UnS), [Rated motor freq.] (FrS), [Rated mot.

current] (nCr), [Rated motor speed] (nSP), [Rated motor power] (nPr)) are configured correctly before

starting auto-tuning.

If at least one of these parameters is modified after auto-t uning has been performed, [Auto tuning] (tUn ) will

return to [No] (nO) and must be repeated.

• Auto-tuning is only performed if no stop command has been activated. If a "freewheel stop" or "fast stop"