Schneider Electric Altivar Process Installation Manual

Altivar Process

Drive Systems

Installation manual

English

10/2020

www.se.com

NHA3711 .039

The information provided in this documentation contains general descriptions and/or technical

characteristics of the performance of the products contained herein. This documentation is not intended

as a substitute for and is not to be used for determining suitability or reliability of these products for

specific user applications. It is the duty of any such user or integrator to perform the appropriate and

complete risk analysis, evaluation and testing of the products with respect to the relevant specific

application or use thereof. Neither Schneider Electric nor any of its affiliates or subsidiaries shall be

responsible or liable for misuse of the information contained herein. If you have any suggestions for

improvements or amendments or have found errors in this publication, please notify us.

You agree not to reproduce, other than for your own personal, noncommercial use, all or part of this

document on any medium whatsoever without permission of Schneider Electric, given in writing. You

also agree not to establish any hypertext links to this document or its content. Schneider Electric does

not grant any right or license for the personal and noncommercial use of the document or its content,

except for a non-exclusive license to consult it on an "as is" basis, at your own risk. All other rights are

reserved.

All pertinent state, regional, and local safety regulations must be observed when installing and using this

product. For reasons of safety and to help ensure compliance with documented system data, only the

manufacturer should perform repairs to components.

When devices are used for applications with technical safety requirements, the relevant instructions

must be followed.

Failure to use Schneider Electric software or approved software with our hardware products may result

in injury, harm, or improper operating results.

Failure to observe this information can result in injury or equipment damage.

© 2020 Schneider Electric. All rights reserved.

2 NHA37119.03

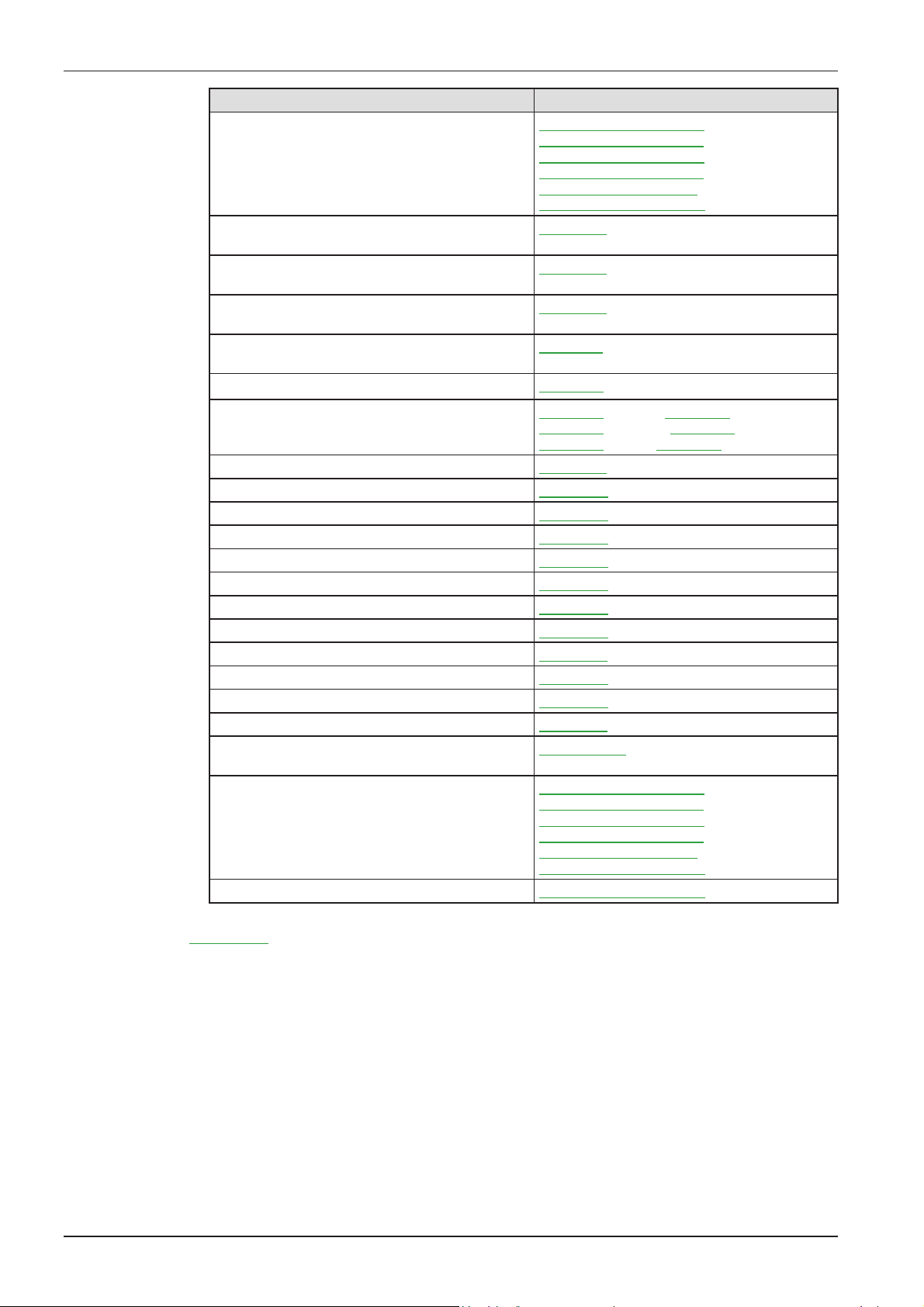

Table of Contents

Safety Information ........................................................................................... 5

About the Book ............................................................................................. 12

Chapter 1 Handling ........................................................................................................ 17

Checking the Scope of Delivery .................................................................................................... 18

Handling Instructions .................................................................................................................... 19

Chapter 2 Mechanical installation ................................................................................. 21

General Mounting Instruction ........................................................................................................ 22

Installation of the Enclosure .......................................................................................................... 23

Chapter 3 Wiring ............................................................................................................. 25

Wiring Instructions ........................................................................................................................ 26

Protective Grounding .................................................................................................................... 26

EMC Grounding ............................................................................................................................ 27

Operation on IT or Corner Grounded Systems ............................................................................. 27

Disconnecting the Built-In EMC Filter ........................................................................................... 27

Shield of the Motor Cable .............................................................................................................. 30

Connection of Power Cables ......................................................................................................... 31

Connection of the Control Cables ................................................................................................. 36

Chapter 4 Commissioning ............................................................................................. 43

Proceeding .................................................................................................................................... 44

Chapter 5 Maintenance .................................................................................................. 49

Scheduled Servicing ..................................................................................................................... 50

Decommissioning .......................................................................................................................... 51

Additional Support ......................................................................................................................... 51

NHA37119.03 3

4 NHA37119.03

Safety Information

Important Information

NOTICE

Read these instructions carefully, and look at the equipment to become familiar with the device before

trying to install, operate, or maintain it. The following special messages may appear throughout this

documentation or on the equipment to warn of potential hazards or to call attention to information that

clarifies or simplifies a procedure.

DANGER indicates a hazardous situation which, if not avoided, will result in death or serious injury.

The addition of this symbol to a "Danger" or "Warning" safety label indicates that an electrical

hazard exists which will result in personal injury if the instructions are not followed.

This is the safety alert symbol. It is used to alert you to potential personal injury hazards. Obey

all safety messages that follow this symbol to avoid possible injury or death.

DANGER

WARNING indicates a hazardous situation which, if not avoided, could result in death or serious

injury.

CAUTION indicates a hazardous situation which, if not avoided, could result in minor or moderate

injury.

NOTICE is used to address practices not related to physical injury.

PLEASE NOTE

Electrical equipment should be installed, operated, serviced, and maintained only by qualified personnel.

No responsibility is assumed to Schneider Electric for any consequences arising out of the use of this

material.

A qualified person is one who has skills and knowledge related to the construction and operation of

electrical equipment and its installation, and has received safety training to recognize and avoid the

hazards involved.

Qualification Of Personnel

Only appropriately trained persons who are familiar with and understand the contents of this manual and

all other pertinent product documentation are authorized to work on and with this product. In addition,

these persons must have received safety training to recognize and avoid hazards involved. These

persons must have sufficient technical training, knowledge and experience and be able to foresee and

detect potential hazards that may be caused by using the product, by changing the settings and by the

mechanical, electrical and electronic equipment of the entire system in which the product is used. All

persons working on and with the product must be fully familiar with all applicable standards, directives,

and accident prevention regulations when performing such work.

WARNING

CAUTION

NOTICE

NHA37119.03 5

Intended Use

This product is a drive for three-phase synchronous and asynchronous motors and intended for

industrial use according to the specifications and instructions in this manual. The product may only be

used in compliance with all applicable safety regulations and directives, the specified requirements and

the technical data. Prior to using the product, you must perform a risk assessment in view of the planned

application. Based on the results, the appropriate safety measures must be implemented. Since the

product is used as a component in an entire system, you must ensure the safety of persons by means of

the design of this entire system (for example, machine design). Any use other than the use explicitly

permitted is prohibited and can result in hazards.

Product Related Information

Read and understand these instructions before performing any procedure with this drive.

HAZARD OF ELECTRIC SHOCK, EXPLOSION OR ARC FLASH

z Only appropriately trained persons who are familiar with and fully understand the contents of the

present manual and all other pertinent product documentation and who have received all necessary

training to recognize and avoid hazards involved are authorized to work on and with this drive

system.

z Installation, adjustment, repair and maintenance must be performed by qualified personnel.

z Verify compliance with all local and national electrical code requirements as well as all other

applicable regulations with respect to grounding of all equipment.

z Only use properly rated, electrically insulated tools and measuring equipment.

z Do not touch unshielded components or terminals with voltage present.

z Prior to performing any type of work on the drive system, block the motor shaft to prevent rotation.

z Insulate both ends of unused conductors of the motor cable.

z Do not short across the DC bus terminals or the DC bus capacitors or the braking resistor terminals.

Failure to follow these instructions will result in death or serious injury.

DANGER

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION OR ARC FLASH

Before performing work on the drive system:

z Disconnect all power, including external control power that may be present. Take into account that

the circuit breaker or main switch does not de-energize all circuits.

z Place a "Do Not Turn On" label on all power switches related to the drive system.

z Lock all power switches in the open position.

z Wait 15 minutes to allow the DC bus capacitors to discharge.

z Verify the absence of voltage.

Before applying voltage to the drive system:

z Verify that the work has been completed and that the entire installation cannot cause hazards.

z If the mains input terminals and the motor output terminals have been grounded and short-circuited,

remove the ground and the short circuits on the mains input terminals and the motor output

terminals.

z Verify proper grounding of all equipment.

z Verify that all protective equipment such as covers, doors, grids is installed and/or closed.

Failure to follow these instructions will result in death or serious injury.

(1) See chapter "Verifying the Absence of Voltage", page 10.

(1)

6 NHA37119.03

This equipment has been designed to operate outside of any hazardous location. Only install this

equipment in zones known to be free of hazardous atmosphere.

DANGER

POTENTIAL FOR EXPLOSION

Install and use this equipment in non-hazardous locations only.

Failure to follow these instructions will result in death or serious injury.

Your application consists of a whole range of different interrelated mechanical, electrical, and electronic

components, the drive being just one part of the application. The drive by itself is neither intended to nor

capable of providing the entire functionality to meet all safety-related requirements that apply to your

application. Depending on the application and the corresponding risk assessment to be conducted by

you, a whole variety of additional equipment is required such as, but not limited to, external encoders,

external brakes, external monitoring devices, guards, etc.

As a designer/manufacturer of machines, you must be familiar with and observe all standards that apply

to your machine. You must conduct a risk assessment and determine the appropriate Performance

Level (PL) and/or Safety Integrity Level (SIL) and design and build your machine in compliance with all

applicable standards. In doing so, you must consider the interrelation of all components of the machine.

In addition, you must provide instructions for use that enable the user of your machine to perform any

type of work on and with the machine such as operation and maintenance in a safe manner.

The present document assumes that you are fully aware of all normative standards and requirements

that apply to your application. Since the drive cannot provide all safety-related functionality for your

entire application, you must ensure that the required Performance Level and/or Safety Integrity Level is

reached by installing all necessary additional equipment.

WARNING

INSUFFICIENT PERFORMANCE LEVEL/SAFETY INTEGRITY LEVEL AND/OR UNINTENDED

EQUIPMENT OPERATION

z Conduct a risk assessment according to EN ISO 12100 and all other standards that apply to your

application.

z Use redundant components and/or control paths for all critical control functions identified in your risk

assessment.

z If moving loads can result in hazards, for example, slipping or falling loads, operate the drive in

closed loop mode.

z Verify that the service life of all individual components used in your application is sufficient for the

intended service life of your overall application.

z Perform extensive commissioning tests for all potential error situations to verify the effectiveness of

the safety-related functions and monitoring functions implemented, for example, but not limited to,

speed monitoring by means of encoders, short circuit monitoring for all connected equipment,

correct operation of brakes and guards.

z Perform extensive commissioning tests for all potential error situations to verify that the load can be

brought to a safe stop under all conditions.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

A specific application note NHA80973 is available on hoisting machines and can be downloaded on

se.com.

NHA37119.03 7

Power Drive Systems (PDS) can generate strong local electrical and magnetic fields. This can cause

interference in electromagnetically sensitive devices.

WARNING

ELECTROMAGNETIC FIELDS

z Keep persons with electronic medical implants, such as pacemakers, away from the equipment.

z Do not place electromagnetically sensitive devices in the vicinity of the equipment.

Failure to follow these instructions can result in death, serious injury or equipment damage.

Drive systems may perform unexpected movements because of incorrect wiring, incorrect settings,

incorrect data or other errors.

WARNING

UNANTICIPATED EQUIPMENT OPERATION

z Carefully install the wiring in accordance with the EMC requirements.

z Do not operate the product with unknown or unsuitable settings or data.

z Perform a comprehensive commissioning test.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

WARNING

LOSS OF CONTROL

z The designer of any control scheme must consider the potential failure modes of control paths and,

for critical control functions, provide a means to achieve a safe state during and after a path failure.

Examples of critical control functions are emergency stop, overtravel stop, power outage and

restart.

z Separate or redundant control paths must be provided for critical control functions.

z System control paths may include communication links. Consideration must be given to the

implications of unanticipated transmission delays or failures of the link.

z Observe all accident prevention regulations and local safety guidelines.

z Each implementation of the product must be individually and thoroughly tested for proper operation

before being placed into service.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

Fans may continue to run for a certain period of time even after power to the product has been

disconnected.

CAUTION

RUNNING FANS

Verify that fans have come to a complete standstill before handling them.

Failure to follow these instructions can result in injury or equipment damage.

8 NHA37119.03

The temperature of the products described in this manual may exceed 100 °C (212 °F) during operation.

WARNING

HOT SURFACES

z Ensure that any contact with hot surfaces is avoided.

z Do not allow flammable or heat-sensitive parts in the immediate vicinity of hot surfaces.

z Verify that the product has sufficiently cooled down before handling it.

z Verify that the heat dissipation is sufficient by performing a test run under maximum load conditions.

Failure to follow these instructions can result in death, serious injury or equipment damage.

NHA37119.03 9

Verifying the Absence of Voltage

The DC bus voltage level is determined by measuring the voltage between the DC bus terminals PA/+

and PC/-.

HAZARD OF ELECTRIC SHOCK, EXPLOSION OR ARC FLASH

Before performing work on the drive system:

z Disconnect all power, including external control power that may be present. Take into account that

the circuit breaker or main switch does not de-energize all circuits.

z Place a "Do Not Turn On" label on all power switches related to the drive system.

z Lock all power switches in the open position.

z Wait 15 minutes to allow the DC bus capacitors to discharge.

z Verify the absence of voltage.

Before applying voltage to the drive system:

z Verify that the work has been completed and that the entire installation cannot cause hazards.

z If the mains input terminals and the motor output terminals have been grounded and short-circuited,

remove the ground and the short circuits on the mains input terminals and the motor output

terminals.

z Verify proper grounding of all equipment.

z Verify that all protective equipment such as covers, doors, grids is installed and/or closed.

Failure to follow these instructions will result in death or serious injury.

(1) See chapter "Verifying the Absence of Voltage", page 10.

DANGER

(1)

WARNING

INCORRECT MEASUREMENT VALUES

z Before using measuring equipment and tools, verify that the measuring equipment and tools are in

proper condition.

z Calibrate and maintain all measuring equipment and tools according to the instructions of the

manufacturers of the measuring equipment and tools.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

10 NHA37119.03

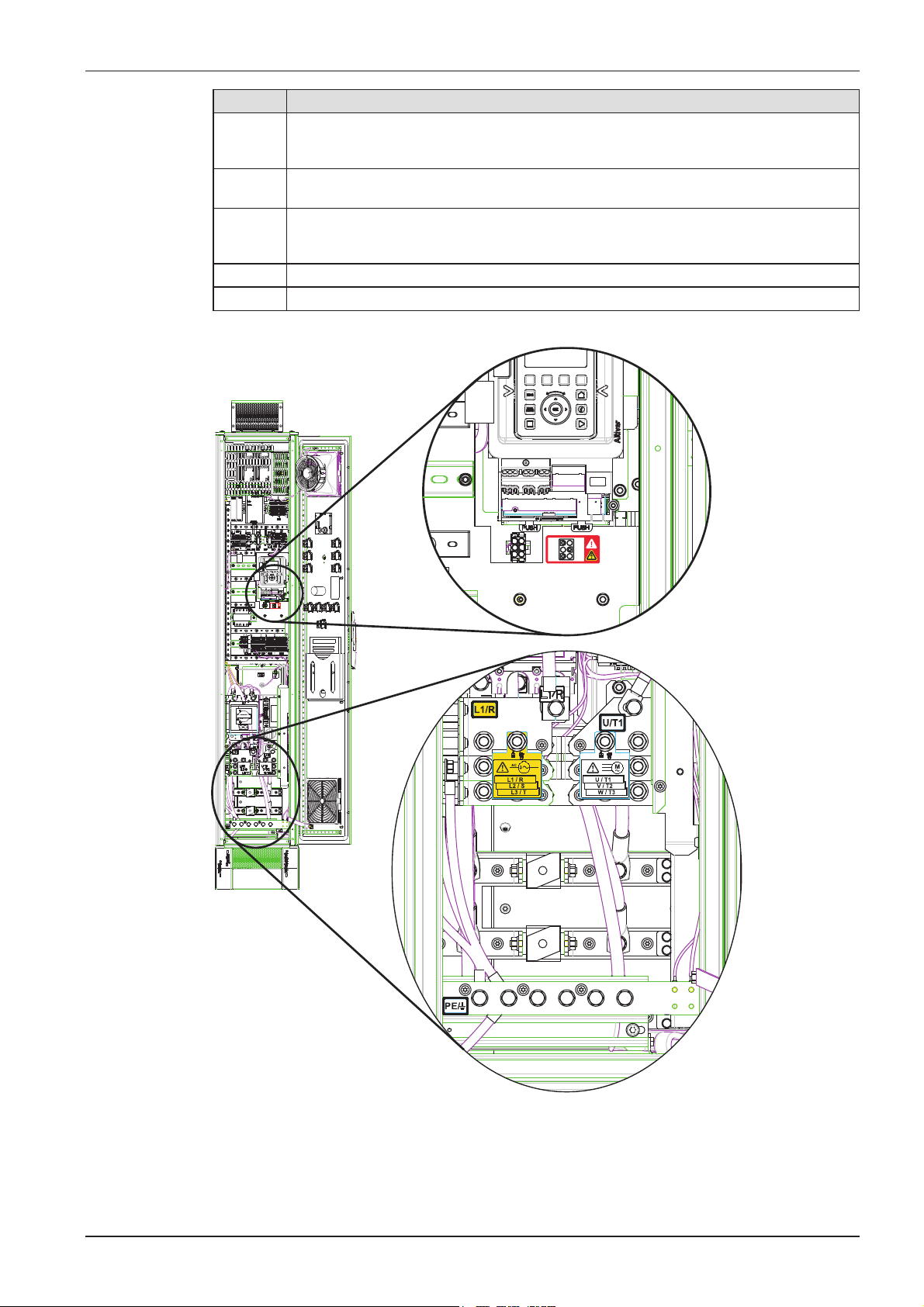

Step Action

1 Measure the voltage (in AC mode and DC mode) on the mains input terminals and the

motor output terminals between the phases and between each phase to ground to verify

that no hazardous voltage is present.

2 Measure the voltage on the DC bus between the DC bus terminals (PA/+ and PC/-) to

verify that the voltage is less than 10 Vdc.

3 If there is still voltage present on the terminals or if the DC bus capacitors do not discharge

properly, contact your local Schneider Electric representative. Do not repair or operate the

product.

4 Verify that no other voltage is present in the drive system.

5 Ground and short-circuit the mains input terminals and the motor output terminals.

PA/+

U

d0

PC/-

PA/+

U

d0

PC/-

NHA37119.03 11

At a Glance

Document Scope

Validity Note

About the Book

Providing mechanical and electrical information about the Altivar Process Drive System and instructions

about mounting, wiring, commissioning and maintenance.

Original instructions and information given in this manual have been written in English (before optional

translation).

This documentation is valid for the Altivar Process Drive Systems.

The technical characteristics of the devices described in this document also appear online. To access

this information online:

Step Action

1 o to the Schneider Electric home page www.schneider-electric.com.

2 In the Search box type the reference of a product or the name of a product range.

z Do not include blank spaces in the reference or product range.

z To get information on grouping similar modules, use asterisks (*).

3 If you entered a reference, go to the Product Datasheets search results and click on the

reference that interests you.

If you entered the name of a product range, go to the Product Ranges search results and

click on the product range that interests you.

4 If more than one reference appears in the Products search results, click on the reference

that interests you.

5 Depending on the size of your screen, you may need to scroll down to see the data sheet.

6 To save or print a data sheet as a .pdf file, click Download XXX product datasheet.

The characteristics that are presented in this manual should be the same as those characteristics that

appear online. In line with our policy of constant improvement, we may revise content over time to

improve clarity and accuracy. If you see a difference between the manual and online information, use

the online information as your reference.

12 NHA37119.03

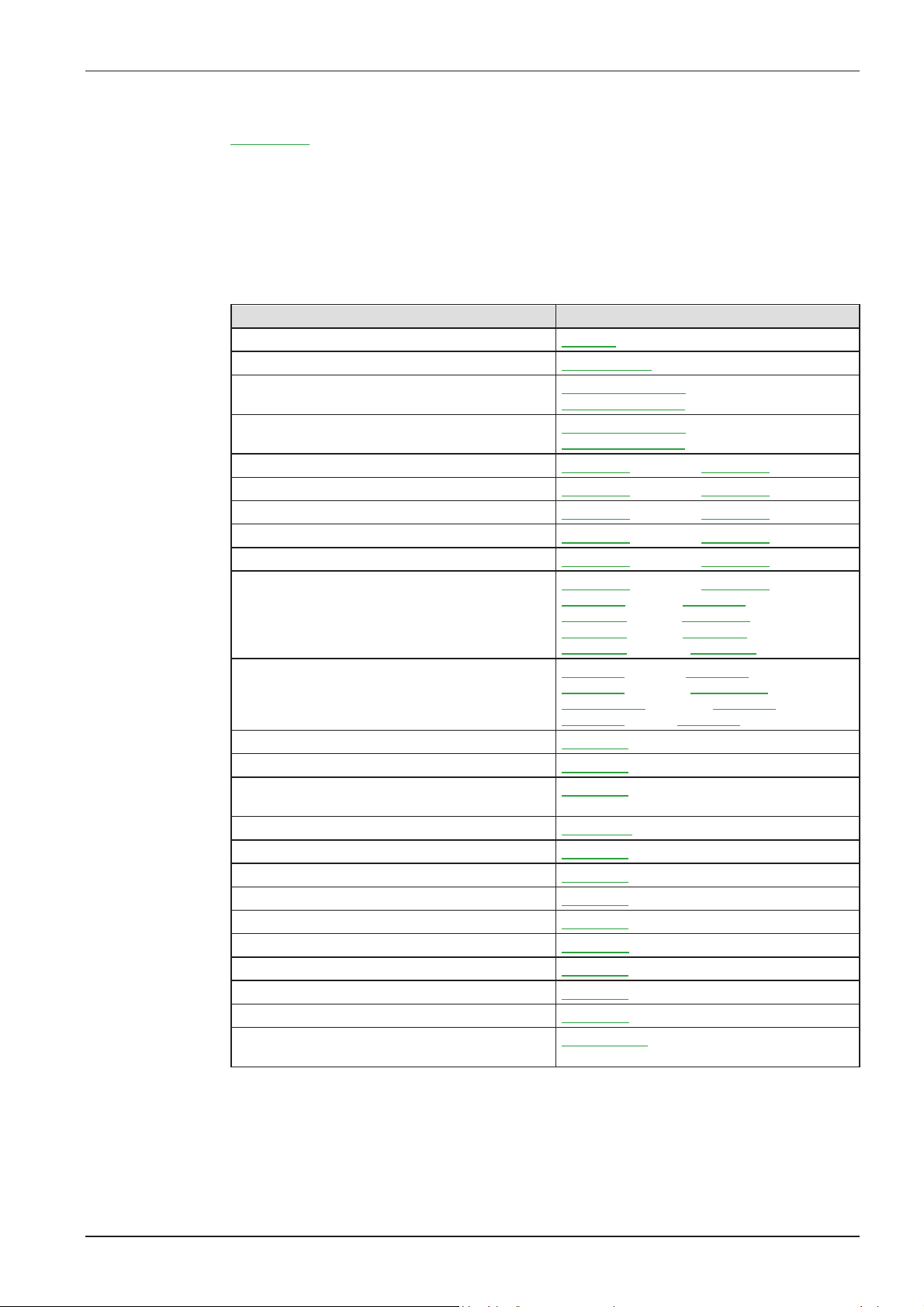

Related Documents

Use your tablet or your PC to quickly access detailed and comprehensive information on all our products

on www.se.com

The internet site provides the information you need for products and solutions:

z The whole catalog for detailed characteristics and selection guides

z The CAD files to help design your installation, available in over 20 different file formats

z Software and firmware to maintain your drive up to date

z A large quantity of White Papers, Environment documents, Application solutions, Specifications... to

z And finally the User Guides related to your drive, listed below:

.

gain a better understanding of our electrical systems and equipment or automation

Title of Documentation Reference number

Digital Catalog for Industrial Automation Digit-Cat

Leaflet: Altivar Process customized drive solutions 998-19696726 (English)

Catalog: Altivar Process ATV600 variable speed

drives

Catalog: Variable speed drives Altivar Process

ATV900

DIA2ED2140502EN (English)

DIA2ED2140502FR (French)

DIA2ED2150601EN (English)

DIA2ED2150601FR (French)

ATV660 Handbook NHA37110 (German), NHA37111 (English)

ATV680 Handbook NHA37112 (German), NHA37113 (English)

ATV960 Handbook NHA37114 (German), NHA37115 (English)

ATV980 Handbook NHA37116 (German), NHA37117 (English)

ATV990 Handbook NHA37143 (German), NHA37145 (English)

Drive Systems – Installation manual NHA37118 (German), NHA37119 (English),

NHA37121 (French), NHA37122 (Spanish),

NHA37123 (Italian), NHA37124 (Dutch),

NHA37126 (Polish), NHA37127 (Portuguese),

NHA37129 (Turkish), NHA37130 (Chinese)

ATV6ƔƔ Programming manual EAV64318 (English), EAV64320 (French),

EAV64321 (German), EAV64318PT (Portuguese),

EAV64318RU (Russian), EAV64322 (Spanish),

EAV64323 (Italian), EAV64324 (Chinese)

ATV6ƔƔ Modbus serial link manual (embedded) EAV64325 (English)

ATV6ƔƔ Ethernet manual (embedded) EAV64327 (English)

ATV6ƔƔ Ethernet IP - Modbus TCP manual

EAV64328 (English)

(VW3A3720, 721)

ATV6ƔƔ BACnet MS/TP manual (VW3A3725) QGH66984 (English)

ATV6ƔƔ PROFIBUS DP Manual (VW3A3607) EAV64329 (English)

ATV6ƔƔ DeviceNet manual (VW3A3609) EAV64330 (English)

ATV6ƔƔ PROFINET manual (VW3A3627) EAV64331 (English)

ATV6ƔƔ CANopen manual (VW3A3608, 618, 628) EAV64333 (English)

ATV6ƔƔ POWERLINK Manual (VW3A3619) PHA99690 (English)

ATV6ƔƔ Communication parameters EAV64332 (English)

ATV6ƔƔ Embedded safety function manual EAV64334 (English)

ATV6ƔƔ$79ƔƔ ATEX manual NVE42416 (English)

SoMove: FDT SoMove_FDT (English, French, German,

Spanish, Italian, Chinese)

NHA37119.03 13

Title of Documentation Reference number

Altivar Process ATV6ƔƔ DTM

ATV6xx_DTM_Library_EN

(English),

ATV6xx_DTM_Library_FR (French),

ATV6xx_DTM_Library_DE (German),

ATV6xx_DTM_Library_SP (Spanish),

ATV6xx_DTM_Library_IT (Italian),

ATV6xx_DTM_Library_CN (Chinese),

Application note: ATV600 Multi-drives booster

QGH36060 (English)

control optimized

Application note: ATV600 Multi-masters booster

QGH36061 (English)

control pressure feedback with cervice continuity

Application Note: ATV600 Multi-Drives Standard

QGH36059 (English)

Level Control

Application note: ATV600 Multi-masters with

EAV64367 (English)

optimized level control

Altivar Application Note for Hoisting NHA80973 (English)

ATV9ƔƔ Programming manual NHA80757 (English), NHA80758 (French),

NHA80759 (German), NHA80760 (Spanish),

NHA80761 (Italian), NHA80762 (Chinese)

ATV991, ATV992 Programming manual QGH33275 (English)

ATV9ƔƔ Modbus serial link manual NHA80939 (English)

ATV9ƔƔ Ethernet embedded manual NHA80940 (English)

ATV9ƔƔ PROFIBUS DP manual (VW3A3607) NHA80941 (English)

ATV9ƔƔ DeviceNet manual (VW3A3609) NHA80942 (English)

ATV9ƔƔ PROFINET manual (VW3A3627) NHA80943 (English)

ATV9ƔƔ CANopen manual (VW3A3608, 618, 628) NHA80945 (English)

ATV9ƔƔ EtherCAT manual (VW3A3601) NHA80946 (English)

ATV9ƔƔ POWERLINK manual (VW3A3619) PHA99693 (English)

ATV9ƔƔ Communication parameters addresses NHA80944 (English)

ATV9ƔƔ Embedded safety function manual NHA80947 (English)

ATV6ƔƔ$79ƔƔ ATEX manual NVE42416 (English)

SoMove: FDT SoMove_FDT (English, French, German,

Spanish, Italian, Chinese)

Altivar Process ATV9ƔƔ DTM ATV9xx_DTM_Library_EN (English),

ATV9xx_DTM_Library_FR (French),

ATV9xx_DTM_Library_DE (German),

ATV9xx_DTM_Library_SP (Spanish),

ATV9xx_DTM_Library_IT (Italian),

ATV9xx_DTM_Library_CN (Chinese),

Recommended Cybersecurity Best Practices CS-Best-Practices-2019-340 (English)

You can download these technical publications and other technical information from our website at

www.se.com

14 NHA37119.03

.

Green Premium

Terminology

TM

Information on the environmental impact of products, their resource efficiency, and end-of-life

instructions.

Certificates and relevant product information available at the address: www.se.com/green-premium

You can download RoHS and REACh compliance declarations, Product Environmental Profiles (PEP)

and End-of-Life instructions (EoLi).

The technical terms, terminology and the corresponding descriptions in this manual are inspired by the

terms or definitions in the relevant standards.

In the area of drive systems this includes, but is not limited to, terms such as error, error message,

failure, fault, fault reset, protection, safe state, safety function, warning, warning message and so

on.

Among others, these standards include:

z IEC 61800 series: Adjustable speed electrical power drive systems

z EN 61439 series: Low-voltage switchgear and controlgear assemblies

z IEC 61508, Ed. 2 series: Functional safety of electrical/electronic/programmable electronic safety-

related

z EN 954-1 Safety of machinery – Safety related parts of control systems

z EN ISO 13849-1 and 2 Safety of machinery – Safety related parts of control systems

z IEC 61158 series: Industrial communication networks – Fieldbus specifications

z IEC 61784 series: Industrial communication networks – Profiles

z IEC 60204-1: Safety of machinery – Electrical equipment of machines – Part 1: General requirements

In addition, the term zone of operation is used in conjunction with the description of specific hazards,

and is defined as it is for a hazard zone or danger zone in the EC Machinery Directive (2006/42/EC)

and in ISO 12100-1.

Contact us

Select your country on:

www.schneider-electric.com/contact

Schneider Electric Industries SAS

Head Office

35, rue Joseph Monier

92500 Rueil-Malmaison

France

NHA37119.03 15

16 NHA37119.03

Loading...

Loading...