Cleveland Controls

Model

Division of UniControl Inc.

AFS–262

AIR PRESSURE SENSING SWITCH WITH ADJUSTABLE SET POINT RANGE

APPLICATION

Model AFS-262 Air Pressure Sensing Switch

is a general purpose proving switch designed for HVAC and Energy Management

applications. It may be used to sense positive, negative, or differential air pressure.

GENERAL DESCRIPTION &

OPERATION

The plated housing contains a diaphragm, a

calibration spring and a snap-acting SPDT

switch.The sample connections located on

each side of the diaphragm accept ¼" OD

metallic tubing via the integral compression

ferrule and nut.

An enclosure cover guards against accidental contact with the live switch terminal

screws and the set point adjusting screw.

The enclosure cover will accept a ½" conduit

connection.

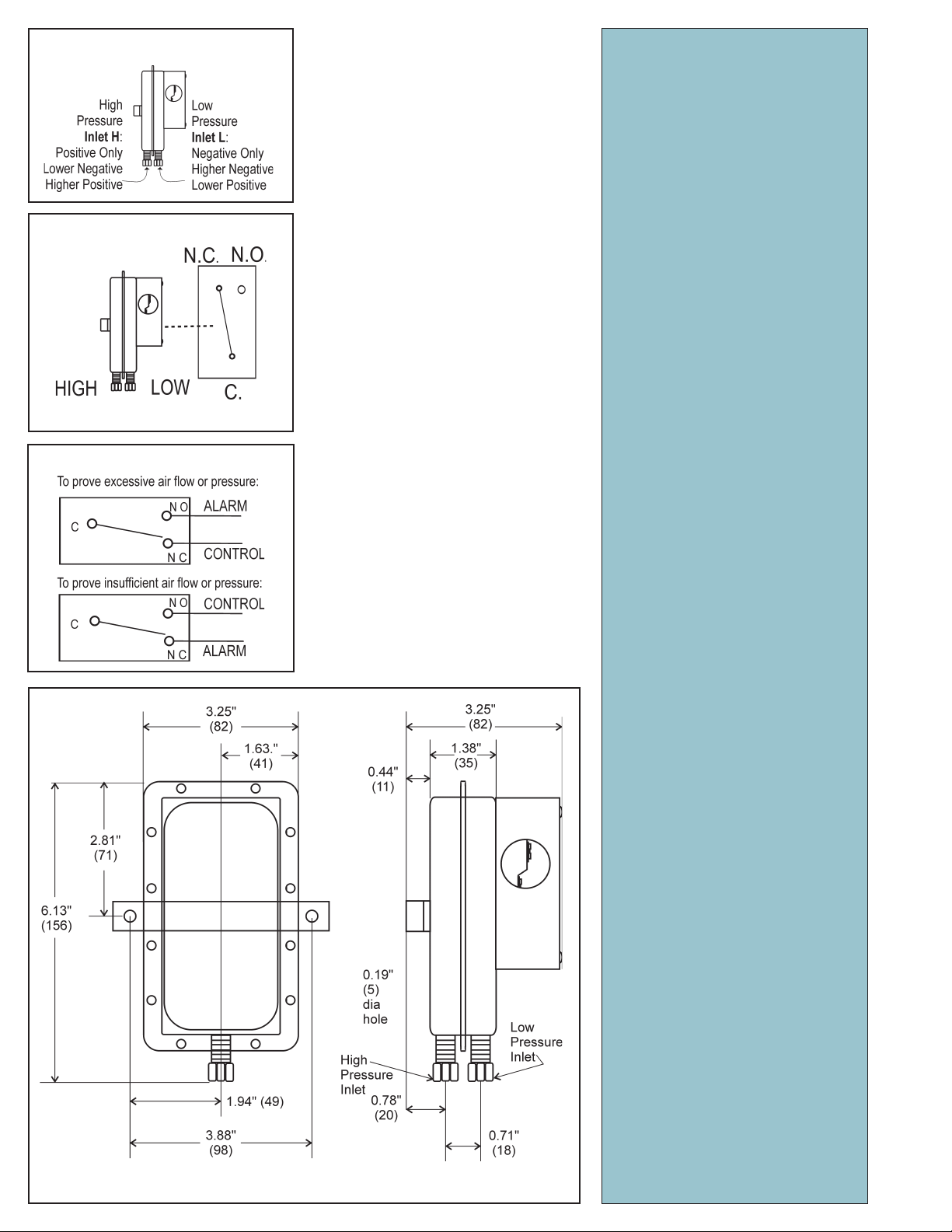

MOUNTING (SEE FIGURE 1)

Select a mounting location which is free from

vibration. The AFS-262 must be mounted

with the diaphragm in any vertical plane in

order to obtain the lowest specified operating

set point. Avoid mounting with the sample

line connections in the "up" position. Surface

mount via the two 3/16" diameter holes in

the integral mounting bracket. The mounting

holes are 3-7/8" apart.

The AFS-262 is designed to accept firm-wall

sample lines of ¼" OD tubing by means of

ferrule and nut compression connections.

(Figure 1)

AIR SAMPLING CONNECTION

(SEE FIGURE 2)

For sample lines of up to 10 feet, ¼" OD

tubing is acceptable. For lines up to 20 feet,

use ¼" ID tubing. For lines up to 60 feet, use

½" ID tubing. A ¼" OD adapter, suitable for

slip-on flexible tubing is available: order part

number 18311.

Locate the sampling probe a minimum of

1.5 duct diameters downstream from the air

source. Install the sampling probe

to the center of the airstream as possible.

Refer to Figure 2 to identify the high pressure inlet (H) and the low pressure inlet (L).

Select one of the five application options

listed below, and connect the sample lines

as recommended.

POSITIVE PRESSURE ONLY: Connect the

sample line to inlet H; inlet L remains open

to the atmosphere.

as close

NEGATIVE PRESSURE ONLY: Connect

the sample line to inlet L; inlet H remains

open to the atmosphere.

NEGATIVE SAMPLES: Connect the

TWO

higher negative sample to inlet L. Connect

the lower negative sample to inlet H.

TWO POSITIVE SAMPLES: Connect the

higher positive sample to inlet H. Connect

the lower positive sample to inlet L.

ONE POSITIVE AND ONE NEGATIVE

SAMPLE: Connect the positive sample

to inlet H. Connect the negative sample

to inlet L.

Bulletin AFS-262.06

Cleveland Controls

DIVISION OF UNICONTROL INC.

(Figure 2)

(Figure 3)

(Figure 4)

Nominal Dimensions in Inches (Millimeters)

ELECTRICAL

CONNECTIONS (SEE

FIGURE 3)

Before pressure is applied to the diaphragm,

the switch contacts will be in the normally

closed (NC) position. The snap switch has

screw top terminals with cup washers. Wire

alarm and control applications as shown in

Figure 4.

FIELD ADJUSTMENT

The adjustment range of an AFS-262 Air

Switch is 0.05 ±.02" w.c. to 2.0" w.c. To adjust the set point, t urn the adjusting screw

counterclockwise until motion has stopped.

Next, turn the adjusting screw 4 complete

turns in a clockwise direction to engage

the spring. From this point, the next ten

turns will be used for the actual calibration.

Each full turn represents approximately

0.2" w.c.

Please note: To properly calibrate an air

switch, a digital manometer or other measuring device should be used to confirm the

actual set point.

SPECIFICATIONS

MODEL AFS-262 AIR

PRESSURE SENSING

SWITCH WITH ADJUSTABLE

SET POINT RANGE

Mounting Position:

Mount with the diaphragm in any vertical plane.

Set Point Range:

0.05 ± 0.02" w.c. to 2.0"w.c.

Field Adjustable “Operate Range”:

0.07"w.c. to 2.0" w.c.

Field Adjustable “Release Range”:

0.04"w.c. to 1.9" w.c.

Approximate Switching Differential:

Progressive, increasing from 0.02

± 0.01"w.c. at minimum set point to

approximately 0.1 " w.c. at maximum

set point.

Measured Media:

Air, or combustion by-products that will

not degrade silicone.

Maximum Pressure:

½ psi (0.03 bar).

Operating Temperature Range:

-40F to 180F (-40 to 82C).

Life:

100,000 cycles minimum at 1/2 psi

maximum pressure each cycle and at

maximum rated electrical load.

Electrical Rating:

300 VA pilot duty at 115 to 277 VAC,

15 amps noninductive to 277 VAC,

60Hz.

Contact Arrangement: SPDT.

Electrical Connections:

Screw-type terminals with cup

washers.

Conduit Opening:

7/8" diameter opening accepts ½"

conduit.

Sample Line Connectors:

Male, externally threaded 7/16" 24

UNS 2A thread, complete with nuts

and self-aligning ferrules.

Sample Line Connections:

Connectors will accept ¼" OD rigid or

semi-rigid tubing.

Approvals: UL, FM, CSA.

Shipping Weight: 1.2 lbs.

Accessories:

• P/N 18311 Slip-on ¼" OD Tubing

Adapter, suitable for slipping on flexible

plastic tubing.

• Sample line probes.

• Orifice plugs (pulsation dampers).

Loading...

Loading...