Page 1

PanelView 550 Terminals

Catalog Numbers 2711-K5Axx, 2711-B5Axx

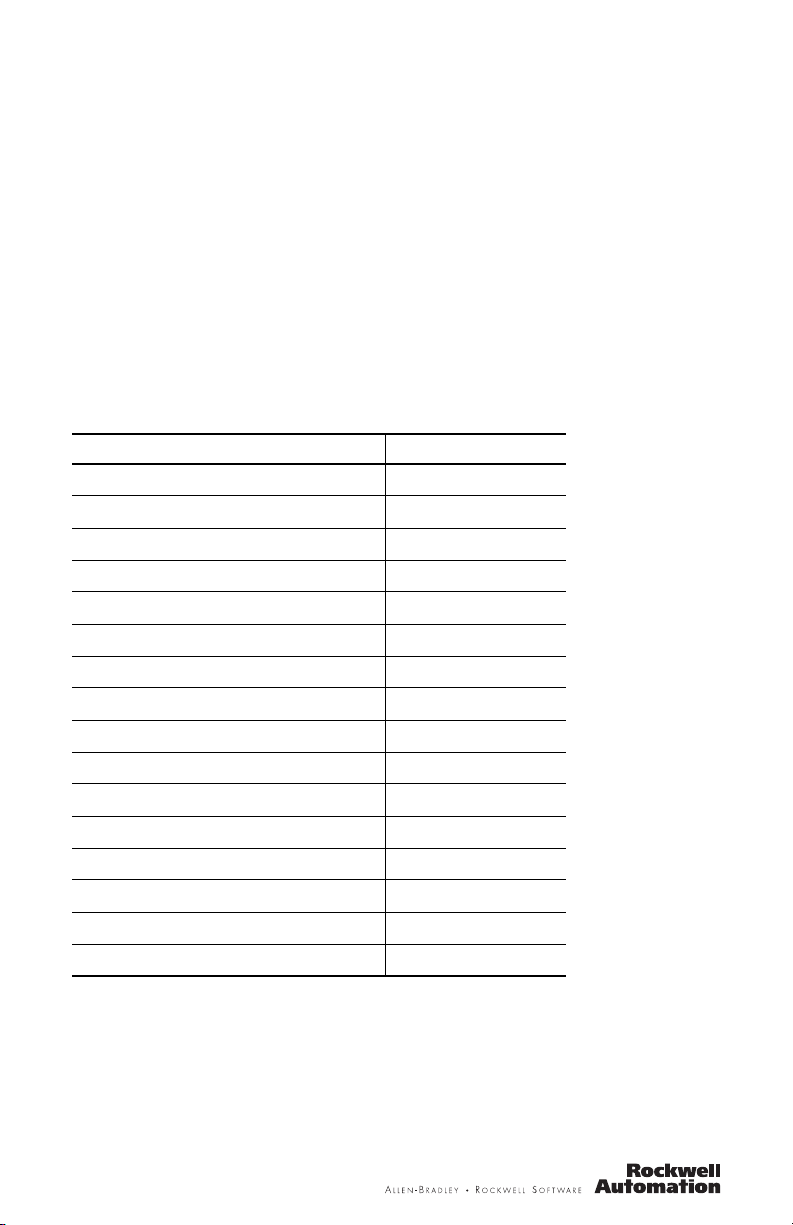

Topic Page

Hazardous Location Considerations 3

European Union Directive Compliance 4

Wiring and Safety Guidelines 5

Enclosures 5

Required Tools 5

Mounting Dimensions 6

Cutout Dimensions 7

Clearances 7

Installing Terminal in a Panel 9

Installing the Memory Card 11

Connecting AC Power 12

Connecting DC Power 13

EtherNet/IP Protocol 15

ControlNet Protocol 15

Battery Removal and Disposal 15

For More Information 17

Installation Instructions

Page 2

2 PanelView 550 Terminals

Important User Information

Solid state equipment has operational characteristics differing from those of electromechanical equipment.

Safety Guidelines for the Application, Installation and Maintenance of Solid State Controls (Publication

available from your local Rockwell Automation sales office or online at

SGI-1.1

http://literature.rockwellautomation.com

equipment and hard-wired electromechanical devices. Because of this difference, and also because of the

wide variety of uses for solid state equipment, all persons responsible for applying this equipment must

satisfy themselves that each intended application of this equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages

resulting from the use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many

variables and requirements associated with any particular installation, Rockwell Automation, Inc. cannot

assume responsibility or liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits,

equipment, or software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell

Automation, Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

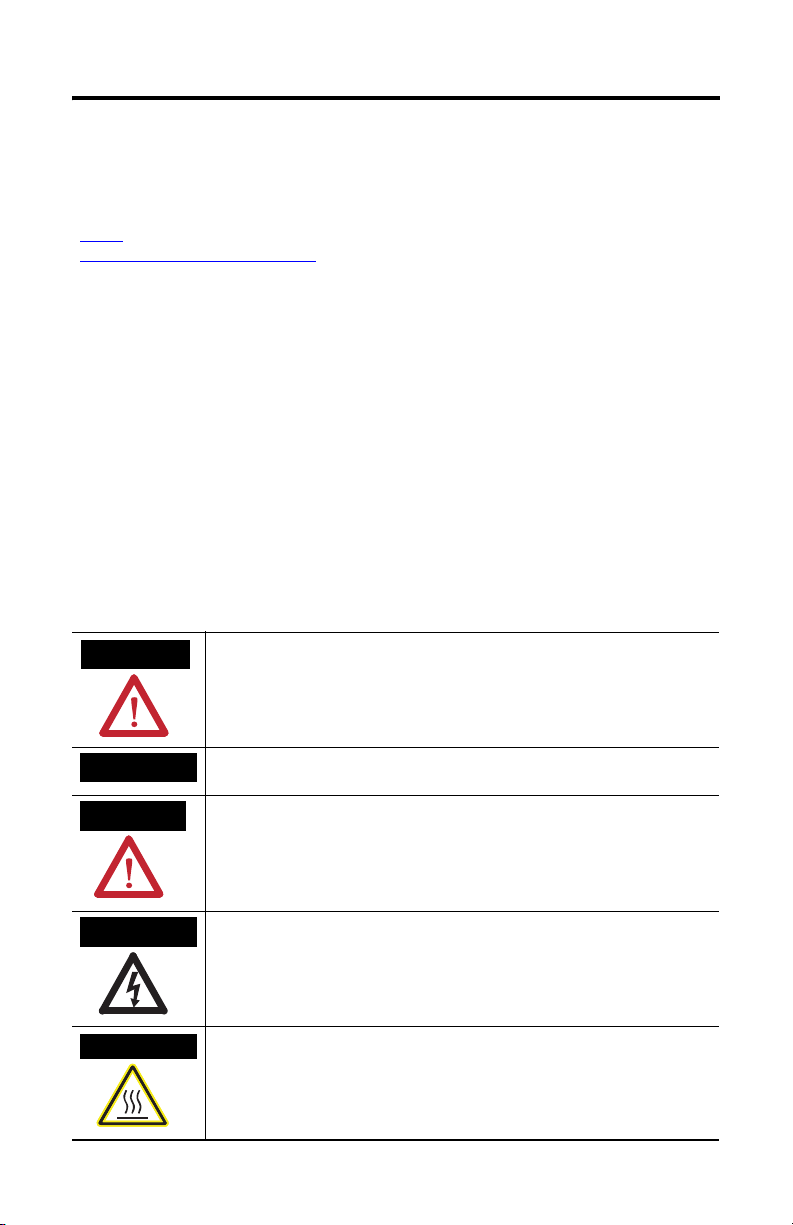

WARNING

Identifies information about practices or circumstances that can cause an explosion in

a hazardous environment, which may lead to personal injury or death, property

damage, or economic loss.

) describes some important differences between solid state

IMPORTANT

ATTENTION

SHOCK HAZARD

BURN HAZARD

Identifies information that is critical for successful application and understanding of

the product.

Identifies information about practices or circumstances that can lead to personal injury

or death, property damage, or economic loss. Attentions help you identify a hazard,

avoid a hazard and recognize the consequences.

Labels may be on or inside the equipment, for example, a drive or motor, to alert

people that dangerous voltage may be present.

Labels may be on or inside the equipment, for example, a drive or motor, to alert

people that surfaces may reach dangerous temperatures.

Publication 2711-IN009E-EN-P - February 2009

Page 3

PanelView 550 Terminals 3

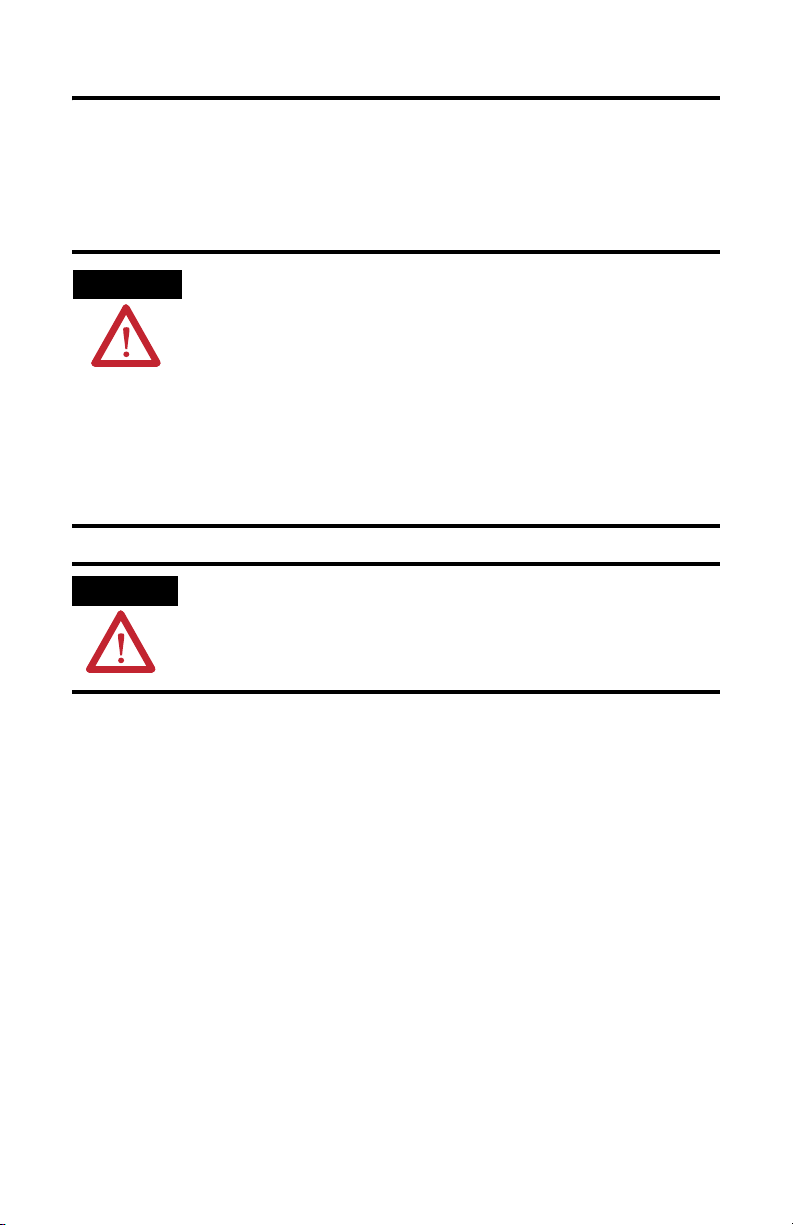

Hazardous Location Considerations

This equipment is suitable for use in Class I, Division 2, Groups A, B, C, D; Class II,

Division 2, Groups F and G; Class III Division 2; or non-hazardous locations only.

The following WARNING statement applies to use in hazardous locations.

WARNING

See the nameplate on terminal for hazardous locations certifications.

EXPLOSION HAZARD

• Substitution of components may impair suitability for Class I, Class II, Class III

Division 2.

• Do not replace components or disconnect equipment unless power has been

switched off or the area is known to be non-hazardous.

• Do not connect or disconnect components unless power has been switched off

or the area is known to be non-hazardous.

• This product must be installed in an enclosure. All cables connected to the

product must remain in the enclosure or be protected by conduit or other means.

• All wiring must comply with N.E.C. article 501-4(b), 502-4(b), 503-3(b) as

appropriate.

ATTENTION

In Class I, Class II, Class III Division 2 Hazardous locations, the PanelView 550

terminal must be wired per the National Electric Code as it applies to hazardous

locations. Peripheral equipment must also be suitable for the location in which it is

installed.

The following PV550 terminals have an operating temperature code of T2

(maximum operating temperature of 300 °C or 572 °F):

• keypad terminals (series G or earlier)

• keypad and touch screen terminals (series G or earlier)

Do not install these terminals in environments where atmospheric gases have

ignition temperatures less than 300 °C (572 °F).

Publication 2711-IN009E-EN-P - February 2009

Page 4

4 PanelView 550 Terminals

The following PV550 following PV550 terminals have an operating temperature

code of T4 (maximum operating temperature of 135 °C or 275 °F):

• keypad terminals (series H and later)

• keypad and touch screen terminals (series H and later)

Do not install these terminals in environments where atmospheric gases have

ignition temperatures less than 135 °C (275 °F).

European Union Directive Compliance

If a PanelView 550 Operator Terminal is installed within the European Union or

EFTA regions and has a CE mark, the following regulations apply.

EMC and Low Voltage Directives

This apparatus is tested to meet Council Directive 89/336/EEC Electromagnetic

Compatibility (EMC) and amending directives 91/263/EEC, 92/31/EEC, 93/68/EEC;

72/23/EEC Low Voltage Directive, and amending directive 93/68/EEC using the

following standards, in whole or in part:

• EN 50081-2:1993 EMC - Generic Emission Standard, Part 2 - Industrial

Environment

• EN 61000-6-2:1999 EMC - Generic Immunity Standard, Part 2 - Industrial

Environment

• EN 61131-2:1995 EMC - Programmable Controllers - Equipment

Requirements and Tests

• Low Voltage Directive - Safety Sections of EN 61131-2

The product described is intended for use in an industrial environment.

Intended Use of Product

According to these Standards, the factor which determines, for EMC purposes,

whether an apparatus is deemed to be “Industrial” or “Residential, commercial and

light industrial”, is given in Clause 1 of EN50081-2 as follows:

Apparatus covered by this standard is not intended for connection to a

public mains network but is intended to be connected to a power network

supplied from a high- or medium-voltage transformer dedicated for the

supply of an installation feeding a manufacturing or similar plant.

The PanelView 550 terminals are intended for use solely in an industrial

environment as defined above. When installed in Europe, any other application is

in contravention of European Union Directives, and a breach of these laws.

Publication 2711-IN009E-EN-P - February 2009

Page 5

PanelView 550 Terminals 5

Wiring and Safety Guidelines

Install the PanelView 550 terminal using publication 70E, Electrical Safety

Requirements for Employee Workplaces. In addition to the NFPA general

guidelines, follow these recommendations:

• Connect the PanelView terminal to its own branch circuit.

• The input power source should be protected by a fuse or circuit breaker

rated at no more than 15 amps.

• Route incoming power to the PanelView 550 terminal by a separate path

from the communications cable.

• Where power and communication lines must cross, they should cross at

right angles. Communications lines can be installed in the same conduit as

low level DC I/O lines (less than 10 Volts).

• Grounding minimizes noise from Electromagnetic Interference (EMI) and is

a safety measure in electrical installations. To avoid EMI, shield and ground

cables appropriately.

• A source for grounding recommendations is the National Electrical Code

published by the National Fire Protection Association of Boston.

Enclosures

Mount the PanelView 550 terminal in a panel or enclosure to protect the internal

circuitry. The terminal meets NEMA Type 12/13 and 4X (indoor use) ratings only

when properly mounted in a panel or enclosure with the equivalent rating.

Allow enough space within the enclosure for adequate ventilation. Consider heat

produced by other devices in the enclosure. The ambient temperature around the

terminal must be between 0…55 °C (32…131 °F).

Make provisions for accessing the back panel of the terminal for wiring,

maintenance, installing a memory card, and troubleshooting.

Required Tools

Other than the tools required to make the panel cutout, the tools required for

installation are:

• 7mm (M4) deep well socket wrench or nut driver.

• small slotted screwdriver.

• torque wrench (N•m, lb•in).

Publication 2711-IN009E-EN-P - February 2009

Page 6

6 PanelView 550 Terminals

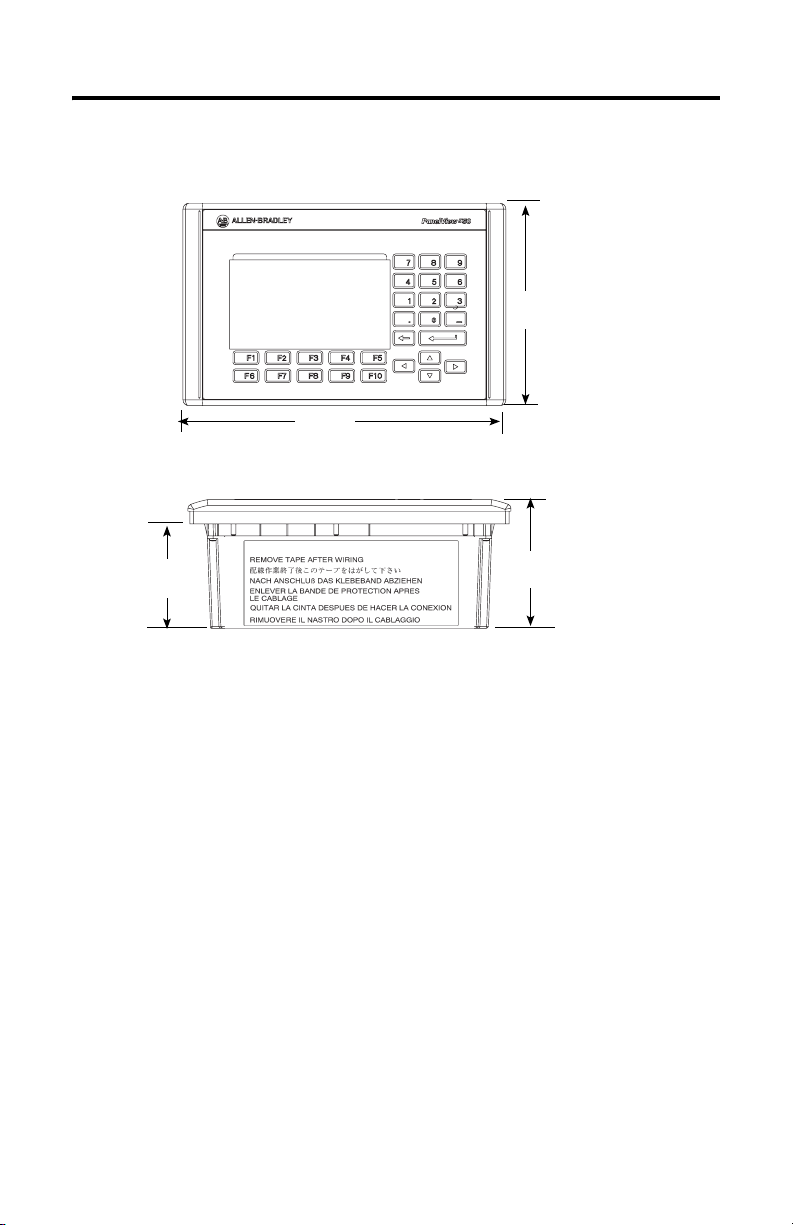

Mounting Dimensions

266 mm

(10.47 in.)

Top View

167 mm

(6.57 in.)

86 mm

(3.39 in.)

106 mm

(4.17 in.)

Publication 2711-IN009E-EN-P - February 2009

Page 7

PanelView 550 Terminals 7

Cutout Dimensions

Use the full size template shipped with the terminal to mark the cutout dimensions.

The figure below shows a reduced size cutout.

243 mm

(9.55 in.)

4.8 mm dia.

(0.188 in.)

3.3 mm

(0.13 in.)

144 mm

(5.66 in.)

3.3 mm

(0.13 in.)

150 mm

(5.91 in.)

25.9 mm

(1.02 in.)

191 mm

(7.51 in.)

106 mm

(4.19 in.)

85 mm

(3.33 in.)

Recommended Panel

Cutout Dimensions

Clearances

Allow adequate clearances for mounting, air flow, maintenance, and for installing a

memory card and legend inserts.

Publication 2711-IN009E-EN-P - February 2009

Page 8

8 PanelView 550 Terminals

Leave 25 mm (1 in.) for

Mounting and Air Flow

Side, Top and Bottom Clearances

Leave 25 mm (1 in.)

for Mounting and

Air Flow

Terminal Cutout

Use full size template shipped

with terminal.

Front View

Leave 38 mm (1.5 in.) for

Mounting and Legend Inserts

Leave 25 mm (1 in.) for

Mounting and Air Flow

Back Clearance

Approximately

207 mm (8.15 in.) is

required to insert

and remove a

memory card with

the memory card

retainer.

86 mm

(3.39 in.)

card

Memory Card Retainer

Publication 2711-IN009E-EN-P - February 2009

106 mm

(4.17 in.)

Page 9

Installing Terminal in a Panel

To install the PV500 terminal in a panel:

PanelView 550 Terminals 9

ATTENTION

• Disconnect all electrical power from the panel before making the cutout.

• Make sure the area around the panel cutout is clear.

• Take precautions so that metal cuttings do not enter any components that may

already be installed in panel.

• Failure to follow this warning may result in personal injury or damage to the

panel components.

1. Cut an opening in the panel using the panel cutout provided with the

terminal. Remove sharp edges or burrs.

2. Make sure the sealing gasket is properly positioned on the terminal (as

shown below). This gasket forms a compression type seal. Do not use

sealing compounds.

Tape

Sealing GasketLegend Strip Adhesive

3. Verify that the ends of the legend strips are secured with the legend strip

adhesive.

4. Place the terminal in the panel cutout.

5. Make sure the ends of the legend inserts are positioned behind the panel

cutout.

6. Install the six self-locking nuts, hand tight.

Publication 2711-IN009E-EN-P - February 2009

Page 10

10 PanelView 550 Terminals

Mounting Studs

(3 Top/3 Bottom)

Protective Installation Label

Self-locking Nuts

(6 used, 8 provided)

7. Alternately tighten the self-locking nuts until the terminal is held firmly

against the panel. Tighten the nuts to a torque of 1.13 N•m (10 lb•in). Do

not overtighten nuts.

ATTENTION

Mounting nuts must be tightened to a torque of 1.13 N•m (10 lb•in) to

provide a proper seal and to prevent potential damage to the terminal.

Allen-Bradley assumes no responsibility for water or chemical damage to

the terminal or other equipment within the enclosure because of improper

installation.

8. Remove the protective installation label covering the top vents of the

terminal.

ATTENTION

Failure to remove the protective installation label covering the top vents

could result in overheating and damage to the terminal.

Publication 2711-IN009E-EN-P - February 2009

Page 11

PanelView 550 Terminals 11

Installing the Memory Card

The memory card retainer is required for UL508 installations where a memory card

is inserted in the card slot. The retainer protects against electrostatic discharge

(ESD) up to 15 KV and prevents accidental removal of a memory card in high

vibration environments.

To attach the memory card retainer:

Retainer Base

Memory Card

Retainer

Base Mounting Screws

1. Secure the base of the retainer over the existing memory card slot using the

two screws provided. Tighten screws to a torque of 0.7…0.9 N•m

(6…8 lb•in).

2. Insert the memory card and install the retainer until it is properly seated.

3. To remove the retainer, press the tabs on each side and pull.

Publication 2711-IN009E-EN-P - February 2009

Page 12

12 PanelView 550 Terminals

Connecting AC Power

The table below shows the electrical ratings for the AC versions of the terminals.

Terminal Type Supply Voltage Power Consumption

PV550 85…264V AC, 47…63 Hz 45VA maximum

ATTENTION

ATTENTION

• The PanelView 550 terminal is designed for safe use when installed in a suitably

rated NEMA Type 12, 13, 4X (indoor use only), IP54 or IP65 enclosure.

• Do not apply power to the terminal until all wiring connections have been made.

Failure to do so may result in electrical shock.

Explosion Hazard - Do not connect or disconnect equipment while circuit is live

unless area is known to be non-hazardous.

To connect AC power to the PanelView 550 terminals:

1. Secure the AC power wires to the L1 and L2N terminal block screws.

2. Secure the Earth Ground/Protective Earth wire to the GND screw on the

terminal block.

ATTENTION

Improper wiring of the power terminals may result in voltage at the

communication connector shells. Refer to the following figure when wiring.

3. Apply power to the terminal.

Publication 2711-IN009E-EN-P - February 2009

Page 13

PanelView 550 Terminals 13

Power Terminal Block (fixed)

120/240V AC, 3 Wire,

U.S. Color Code

L1

GND GND

L2

Black (line)

White

(neutral)

Green (earth

ground)

To Power Source

120/240V AC, 3 Wire,

European Harmonized Color

Code

L1

L2

Brown (line)

Blue

(neutral)

Green/Yellow

(protective earth)

To Power Source

Connecting DC Power

The L1 and L3 versions (Catalog Number 2711-K5A1L1 or 2711-K5A1L3) of the

PV550 terminals connect to a 24V dc power source.

The table below shows the electrical ratings for the DC versions of the terminals.

Electronic circuitry and an internal fuse protect the terminals from reverse polarity

and over-voltage conditions.

Terminal Type Supply Voltage Power Consumption

PV550 18…30V DC, (24V DC nominal) 12 Watts maximum

(0.5 Amps @ 24V DC)

ATTENTION

• Do not connect the PanelView terminal to an AC power source. Connecting to an

AC power source may damage the terminal.

• The PanelView 550 terminal is designed for safe use when installed in a suitably

rated NEMA Type 12, 13, 4X (indoor use only), IP54 or IP65 enclosure.

Publication 2711-IN009E-EN-P - February 2009

Page 14

14 PanelView 550 Terminals

To connect DC power to the PV550 terminal:

1. Secure the DC power wires to the terminal block screws.

2. Secure the Earth Ground wire to the correct terminal block screw.

ATTENTION

ATTENTION

Explosion Hazard - Do not connect or disconnect equipment while circuit is

live unless area is known to be non-hazardous.

Do not apply power to the terminal until all wiring connections have been

made. Failure to do so may result in electrical shock.

3. Apply 24V DC power to the terminal.

Power Terminal Block (fixed)

+

Earth Ground

DC Negative

DC Positive

Publication 2711-IN009E-EN-P - February 2009

Page 15

PanelView 550 Terminals 15

EtherNet/IP Protocol

The PanelView terminal is initially set to DHCP with BootP support (Dynamic Host

Configuration Protocol) enabled. If your network has a DHCP/BootP server, you

can connect the PanelView terminal to the EtherNet/IP network and the

DHCP/BootP server will automatically establish an IP address. If your network does

not have a DHCP/BootP server, you need to program an IP address. This is done by

accessing Configuration Mode on the PanelView terminal and selecting

Communication Setup. For details, refer to the PanelView Standard Operator

Terminals Manual, publication 2711-UM014

.

IMPORTANT

If a PanelView is connected to an EtherNet/IP network and has the same IP address as

another device on the network, both devices will drop off the network.

ControlNet Protocol

IMPORTANT

When making ControlNet connections, only use the PanelView Channel B for redundant

communications. Connecting Channel B to a Channel A only ControlNet network will

result in:

• the PanelView not being able to communicate over the network.

• a PanelView communications fault after several minutes.

Battery Removal and Disposal

The terminal contains a lithium battery, which is intended to be replaced during the

life of the product.

ATTENTION

The clock module contains lithium. Do not dispose of the battery in a fire or incinerator, or

the clock module may explode. Follow disposal regulations in your area for lithium

battery disposal.

At the end of its life, the battery contained in this product should be collected separately

from any unsorted municipal waste.

Publication 2711-IN009E-EN-P - February 2009

Page 16

16 PanelView 550 Terminals

Follow these steps to remove or replace the battery (older version).

12

345

678

Publication 2711-IN009E-EN-P - February 2009

Page 17

PanelView 550 Terminals 17

Follow these steps to remove or replace the battery. (newer version)

12

35

4

5

6

7

8

For More Information

For Refer to Refer to

More detailed information on the 550 and the other

Standard PanelView terminals.

Standard PanelView

Terminals User Manual

2711-UM014

If you would like a publication, you can:

• download a free electronic version from the PanelBuilder32 installation CD.

• download free from the internet: http://literature.rockwellautomation.com

Publication 2711-IN009E-EN-P - February 2009

.

Page 18

18 PanelView 550 Terminals

Notes:

Publication 2711-IN009E-EN-P - February 2009

Page 19

Notes:

PanelView 550 Terminals 19

Publication 2711-IN009E-EN-P - February 2009

Page 20

Rockwell Automation Support

Rockwell Automation provides technical information on the Web to assist you in

using its products. At http://support.rockwellautomation.com

technical manuals, a knowledge base of FAQs, technical and application notes,

sample code and links to software service packs, and a MySupport feature that you

can customize to make the best use of these tools.

For an additional level of technical phone support for installation, configuration and

troubleshooting, we offer TechConnect support programs. For more information,

contact your local distributor or Rockwell Automation representative, or visit

http://support.rockwellautomation.com

.

Installation Assistance

If you experience a problem within the first 24 hours of installation, please review

the information that's contained in this manual. You can also contact a special

Customer Support number for initial help in getting your product up and running.

, you can find

United States 1.440.646.3434

Monday – Friday, 8 a.m. – 5 p.m. EST

Outside United

States

Please contact your local Rockwell Automation representative for any

technical support issues.

New Product Satisfaction Return

Rockwell Automation tests all of its products to ensure that they are fully

operational when shipped from the manufacturing facility. However, if your

product is not functioning and needs to be returned, follow these procedures.

United States Contact your distributor. You must provide a Customer Support case number

Outside United

States

PanelView, PanelView 550, PanelBuilder, Allen-Bradley, Rockwell Automation, and TechConnect are trademarks of Rockwell

Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

(call the phone number above to obtain one) to your distributor in order to

complete the return process.

Please contact your local Rockwell Automation representative for the return

procedure.

Publication 2711-IN009E-EN-P - February 2009

Supersedes Publication 2711-IN009D-MU-P - August 2007 Copyright © 2009 Rockwell Automation, Inc. All rights reserved. Printed in the U.S.A.

Loading...

Loading...