Page 1

Packing Data

Installation Instructions

PK

English Page 1

Français Page 13

Deutsch Seite 25

Español Página 37

Italiano Pagina 49

Page 2

Packing Data

Installation Instructions

PK

This document describes how to mount a PanelView 1400 terminal in a panel or

enclosure and apply power.

• European Union Directive Compliance

• wiring and safety guidelines

• recommended tools

• enclosures

• mounting dimensions

• clearances

• cutout dimensions

• installing the terminal in a panel

• connecting AC power

For more information on the PanelView 1400 Operator Terminals, refer to

Publication 2711-6.1.

Page 3

PanelView 1400 Terminals2

European Union Directive Compliance

If this product has the CE mark, it is approved for installation within the

European Union and EEA region. It has been designed and tested to meet the

following directives.

EMC Directive

This product is tested to meet Council Directive 89/336/EEC Electromagnetic

Compatibility (EMC) and the following standards, in whole or in part:

• EN 50081-1:1992 EMC – Generic Emission Standard, Part 1 – Residential,

Commercial, and Light Industry

• EN 50082-2:1995 EMC – Generic Immunity Standard, Part 2 – Industrial

Environment

The product described is intended for use in an industrial, light industrial or

commercial environment.

Wiring and Safety Guidelines

Install the PanelV iew 1400 terminal using publication 70E, Electrical Safety

Requirements for Employee Workplaces. In addition to the NFPA general

guidelines, follow these recommendations:

• Connect the PanelView terminal to its own branch circuit

The input power source should be protected by a fuse or circuit breaker rated

at no more than 15 amps.

• Route incoming power to the PanelView 1400 terminal by a separate path

from the communications cable.

• Where power and communication lines must cross, they should cross at right

angles. Communications lines can be installed in the same conduit as low

level DC I/O lines (less than 10 Volts).

• Grounding minimizes noise from Electromagnetic Interference (EMI) and is a

safety measure in electrical installations. T o avoid EMI, shield and ground

cables appropriately.

• A source for grounding recommendations is the National Electrical Code

published by the National Fire Protection Association of Boston.

Page 4

PanelView 1400 Terminals 3

Recommended Tools

In addition to the tools required for the panel cutout, you need the tools

listed below.

For clip mounting:

• socket screw driver (phillips head or slotted)

• 16 inch (406 mm) extension rod (minimum)

• socket driver (in/lb) torque wrench recommended

For stud mounting:

• 7/32 and 3/8 inch socket

• 16 inch (406 mm) extension rod (minimum)

• socket driver (in/lb) torque wrench recommended

Enclosures

The PanelView 1400 terminal must be mounted in an environment that provides

IEC-1131-2 Pollution degree 2 protection.

Mount the terminal in a panel or enclosure to protect the internal circuitry. The

terminal meets NEMA T ype 12/13 and 4X (indoor use) ratings only when

mounted in a panel or enclosure with the equivalent rating.

Allow enough space within the enclosure for adequate ventilation. Consider the

heat produced by other devices in the enclosure. The ambient temperature around

the terminal must be between 0 and 55C (32 and 131F).

Make provisions for accessing the back sides of the terminal. Access is required

for wiring, maintenance, adjusting brightness/contrast, installing a memory card,

and troubleshooting.

Page 5

PanelView 1400 Terminals4

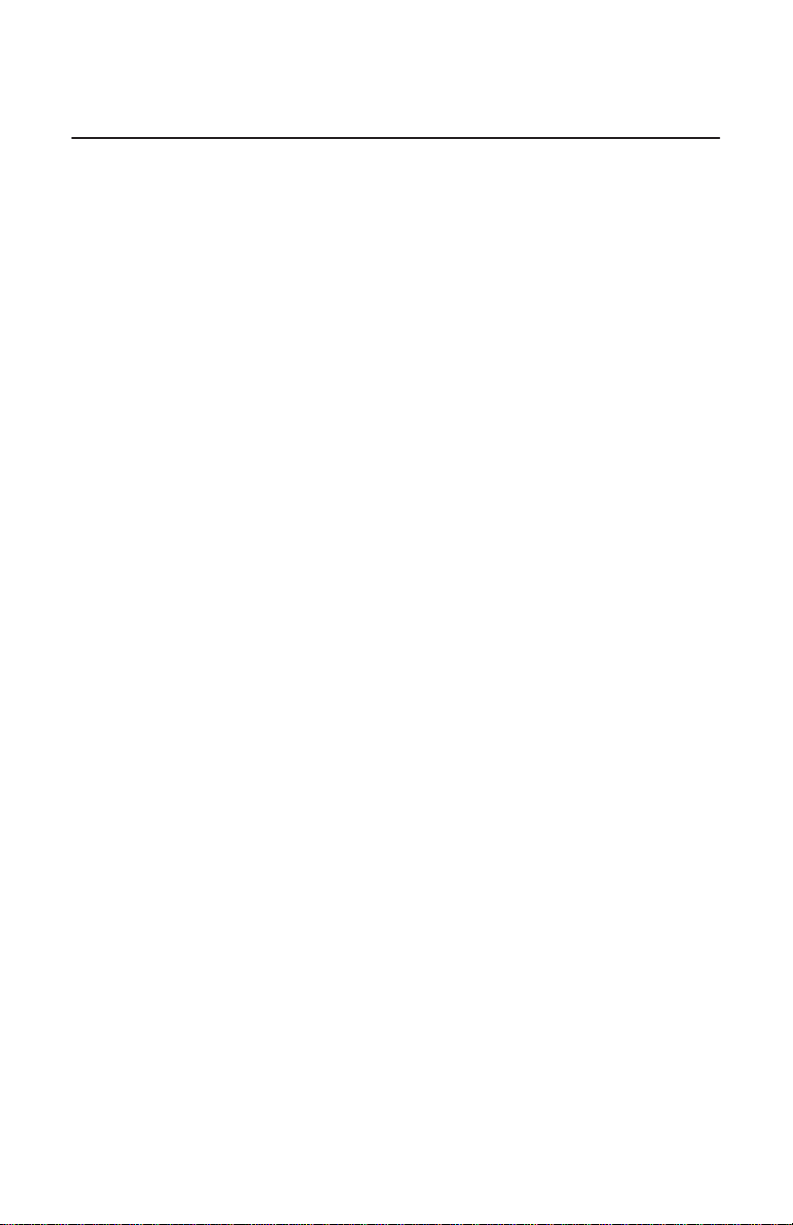

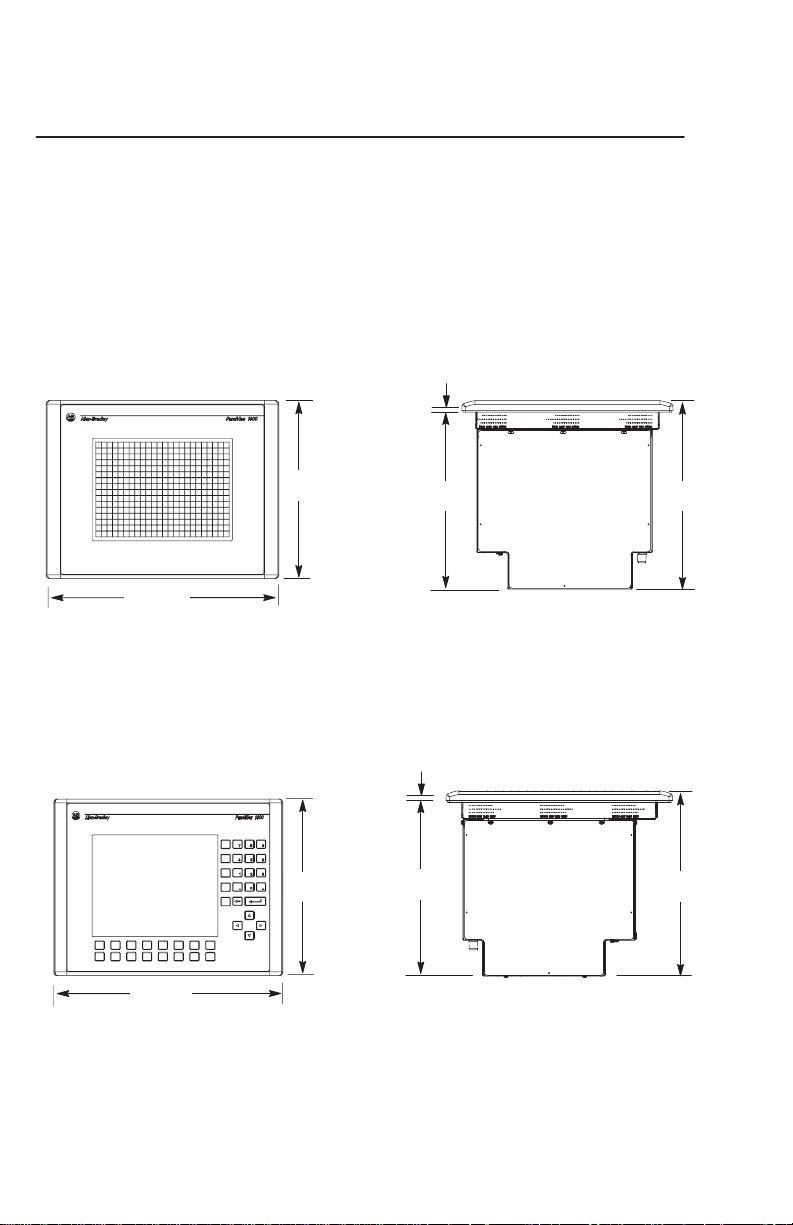

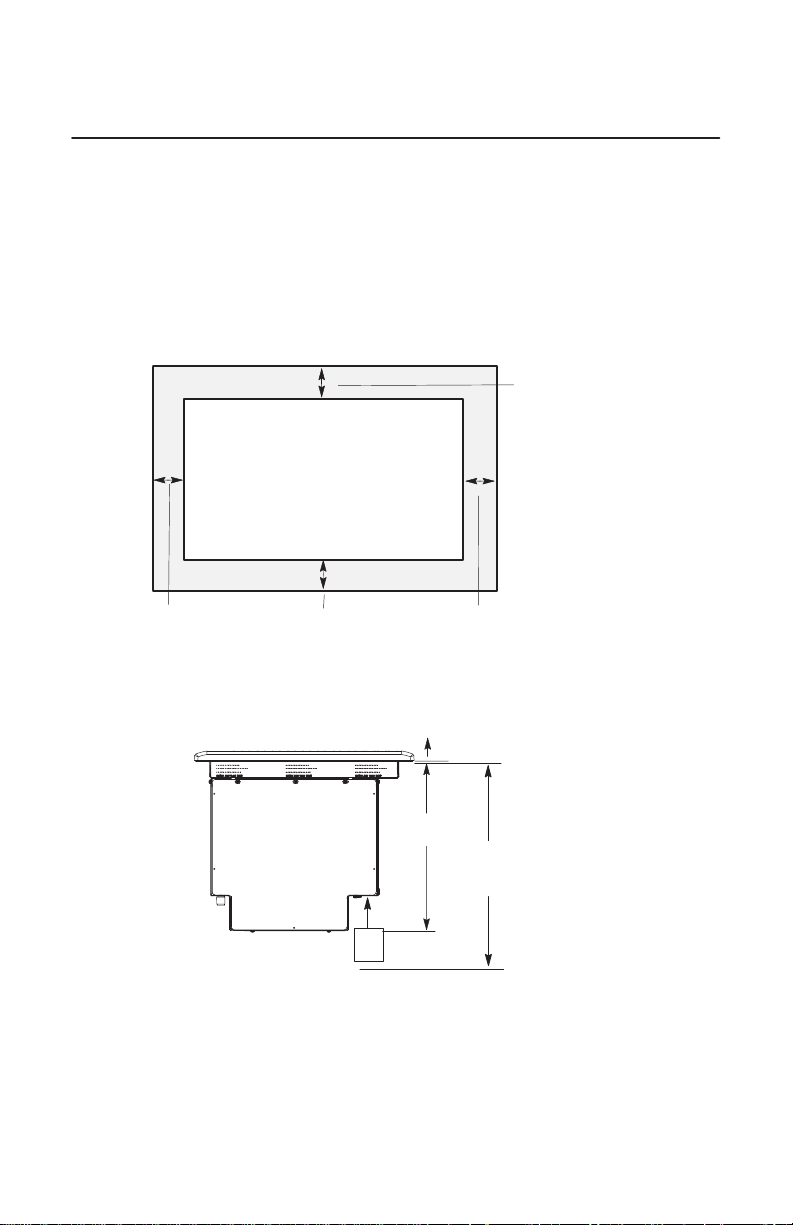

Mounting Dimensions

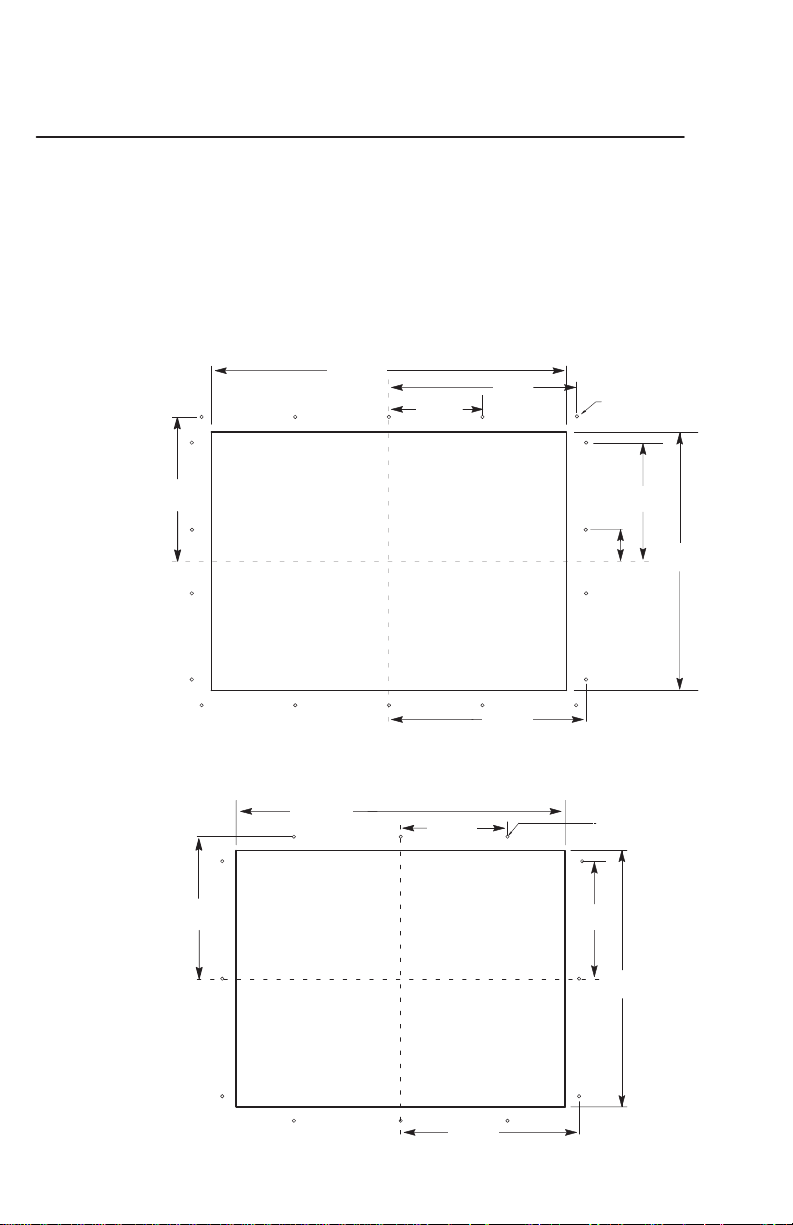

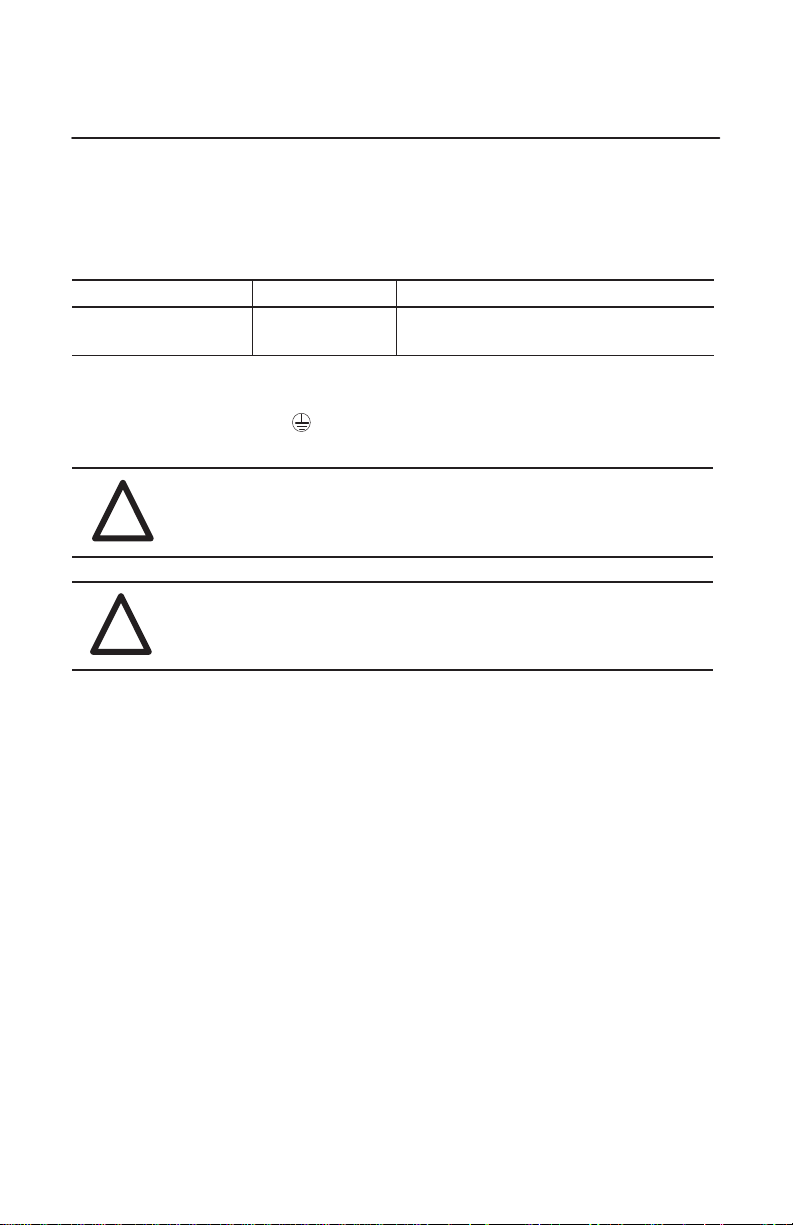

Figures 1 and 2 show mounting dimensions for the PanelV iew 1400 terminals.

Figure 1

Touch Terminal Mounting Dimensions

3.3 mm

(.13 in)

355 mm

(13.97 in)

441 mm

(17.37 in)

Figure 2

Keypad Terminal Mounting Dimensions

355 mm

(13.97 in)

483 mm

(19.0 in)

(14.58 in)

3.3 mm

(.13 in)

370 mm

(14.58 in)

370 mm

394 mm

(15.53 in)

394 mm

(15.53 in)

Page 6

PanelView 1400 Terminals 5

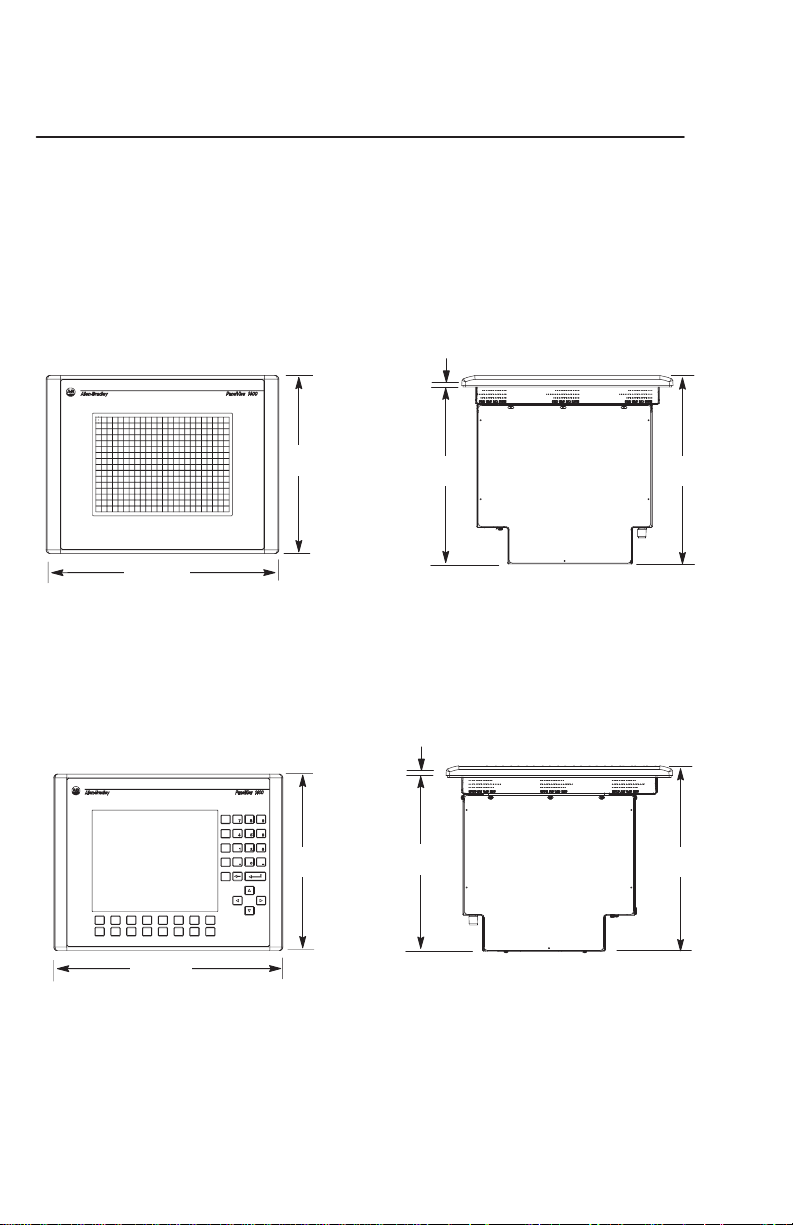

Clearances

Allow adequate space for mounting, air flow , maintenance, and for installing a

memory card and legend inserts.

Figure 3

Mounting Clearances

Side, Top and Bottom Clearances

Leave 51 mm (2 in.)

for Mounting and Air Flow

PANEL CUTOUT

Use Full Size Template

shipped with Terminal Front

View

Leave 51 mm (2 in.)

for Mounting and Air Flow

Leave 51 mm (2 in.)

for Mounting

Back Clearance

Card

Leave 51 mm (2 in)

for Mounting and Air Flow

3.3 mm

(.13 in.)

370 mm

(14.58 in.)

Approximately 400 mm

(15.75 inches) is

required to load a

memory card.

Page 7

PanelView 1400 Terminals6

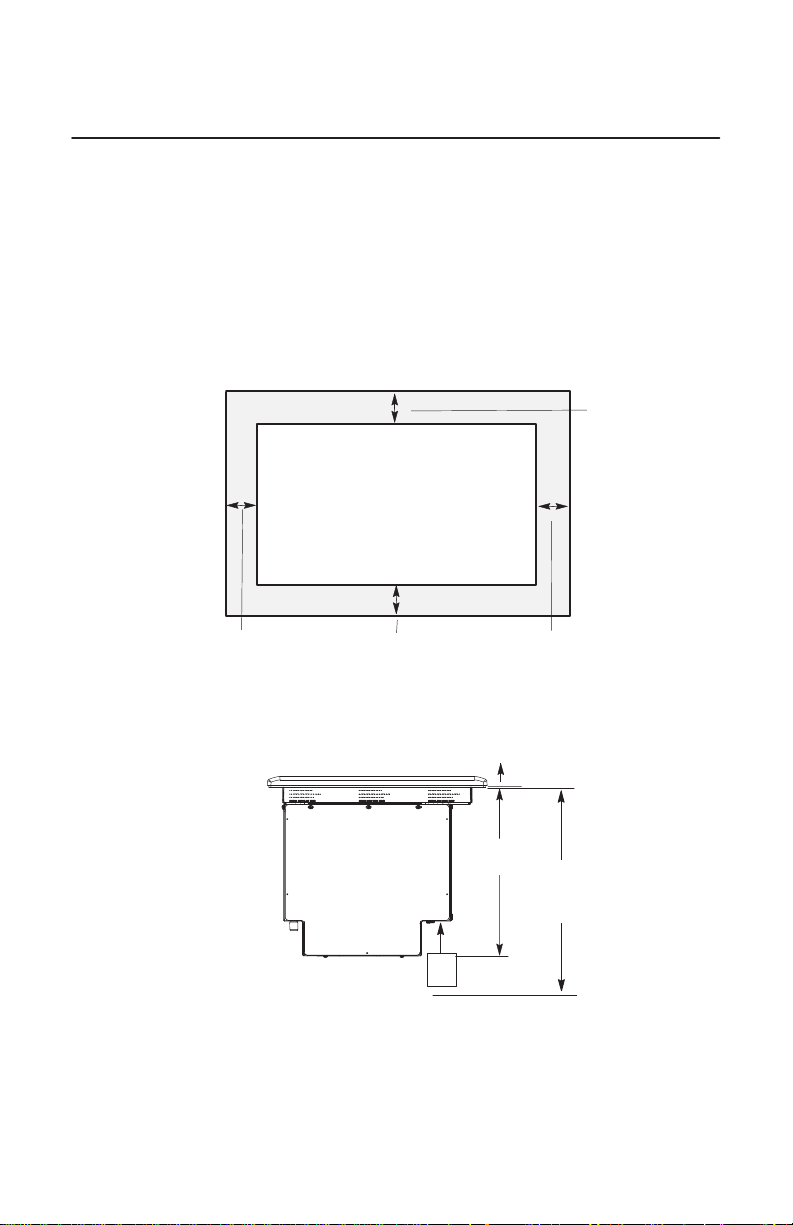

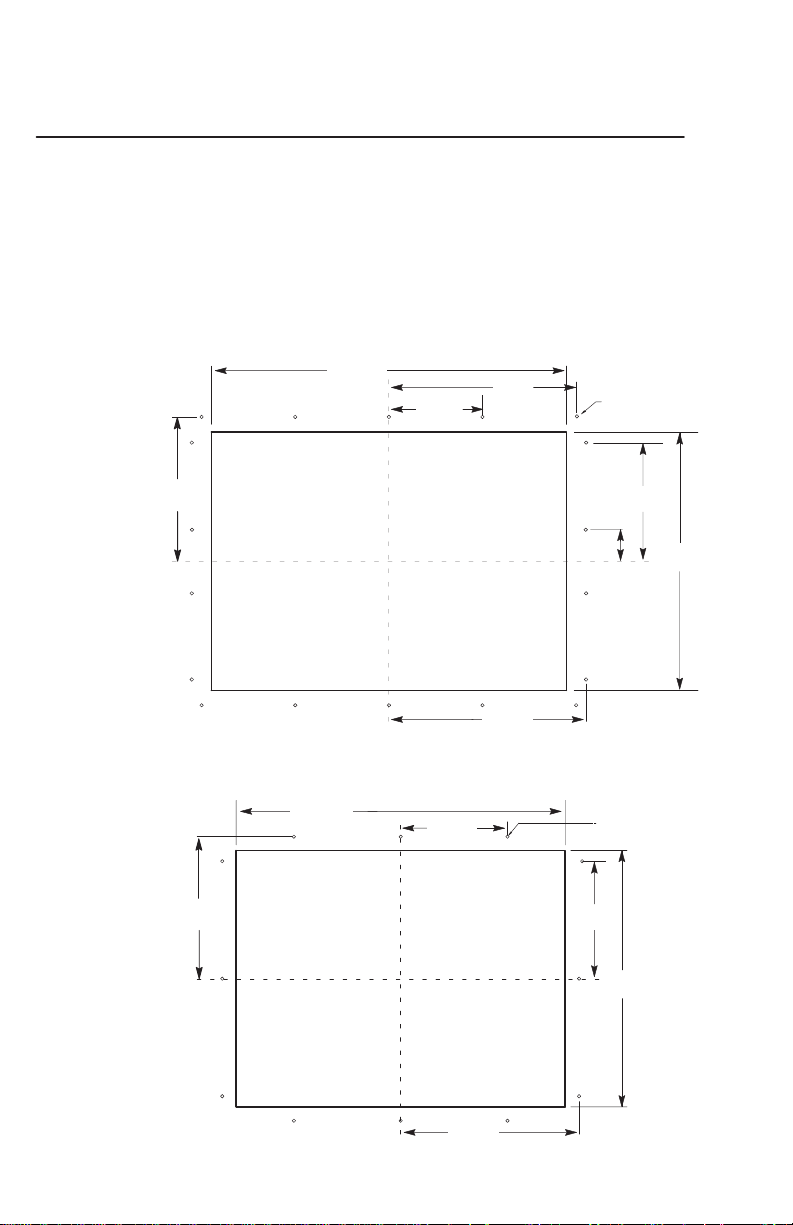

Cutout Dimensions

Use the full size templates shipped with the terminal to mark the cutout

dimensions. Figure 4 shows reduced size cutouts.

Figure 4

PanelView 1400 Cutout Dimensions

PV1400 Keypad Terminals

419 mm

(16.50 in.)

110 mm

(4.35 in.)

221 mm

(8.70 in.)

7/32 in. (5.56 mm) Typical

18 Holes

Ignore stud

holes if mounting terminal using panel clips.

Ignore stud

holes if mounting terminal using panel clips.

170 mm

(6.70 in.)

169 mm

(6.65 in.)

PV1400 Touch Terminals

391 mm

(15.40 in.)

127 mm

(5.0 in.)

233 mm

(9.16 in.)

140 mm

(5.50 in.)

38 mm

(1.50 in.)

7/32 in. (5.56 mm) Typical

12 Holes

140 mm

(5.50 in.)

305 mm

(12.0 in.)

305 mm

(12.0 in.)

212 mm

(8.35 in.)

Page 8

PanelView 1400 Terminals 7

Installing Terminal in a Panel

This section provides procedures for mounting a PV1400 using:

• mounting clips (10 shipped with terminal, 10 required)

• mounting studs (ordered separately, Catalog No. 2711-NP3)

ATTENTION: Disconnect all electrical power from the panel

!

To install the PV1400 terminal in a panel using clips:

1. Cut an opening in the panel using the panel cutout provided with the

terminal. Remove any sharp edges or burrs. Do not drill the mounting stud

holes if you are using clips.

2. Make sure the terminal sealing gasket is properly positioned on the terminal

as shown in Figure 5. This gasket forms a compression type seal. Do not use

sealing compounds.

before making the cutout.

Make sure the area around the panel cutout is clear.

Take precautions so that metal cuttings do not enter any

components that may already be installed in panel.

Failure to follow this warning may result in personal injury or

damage to the panel components.

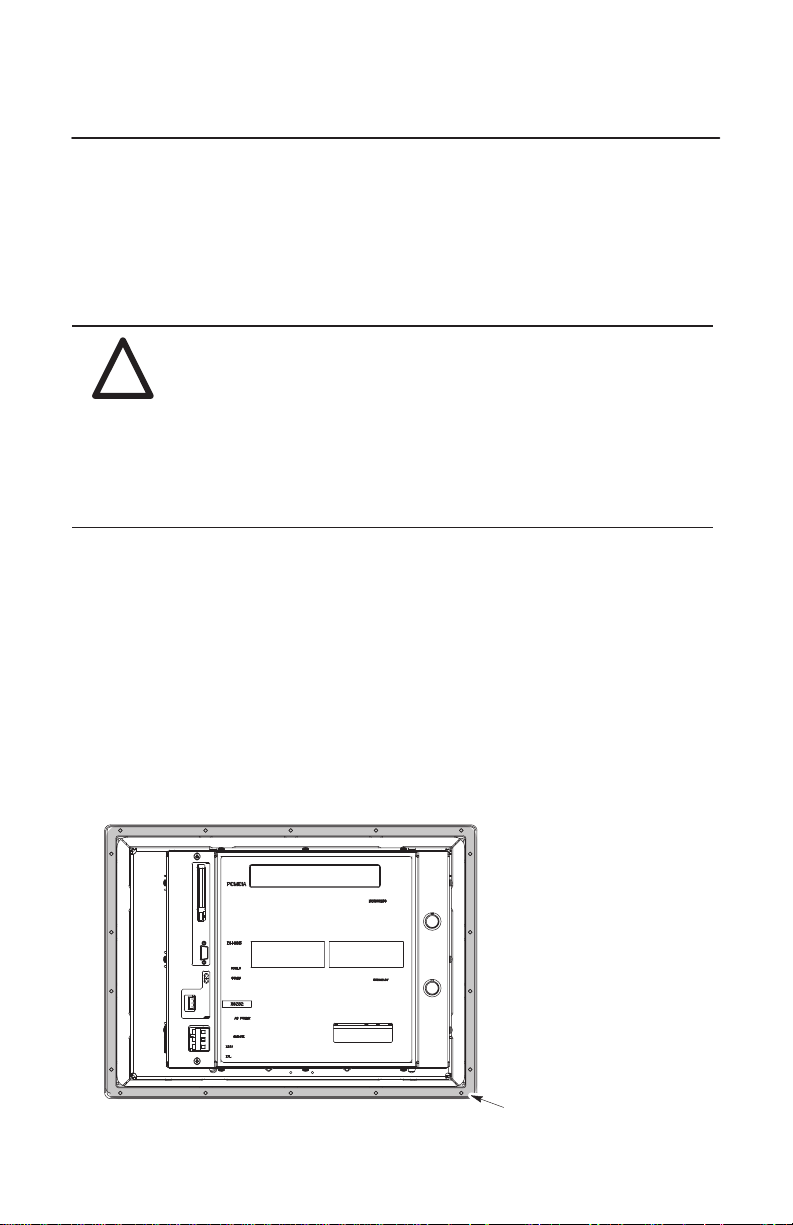

Figure 5

Sealing Gasket

Sealing Gasket

Page 9

PanelView 1400 Terminals8

3. Although the keypad legend strips can be installed at any time, we

recommend that you install them after the terminal is installed.

4. Place the terminal in the panel cutout. The terminal will snap into the panel

as the temporary retaining tabs lock against the panel.

Note: The terminal has 2 metal tabs (on bottom edge) that temporarily lock the

terminal against the panel. These tabs only facilitate installation of the mounting

hardware. The tabs are not designed to provide permanent mounting.

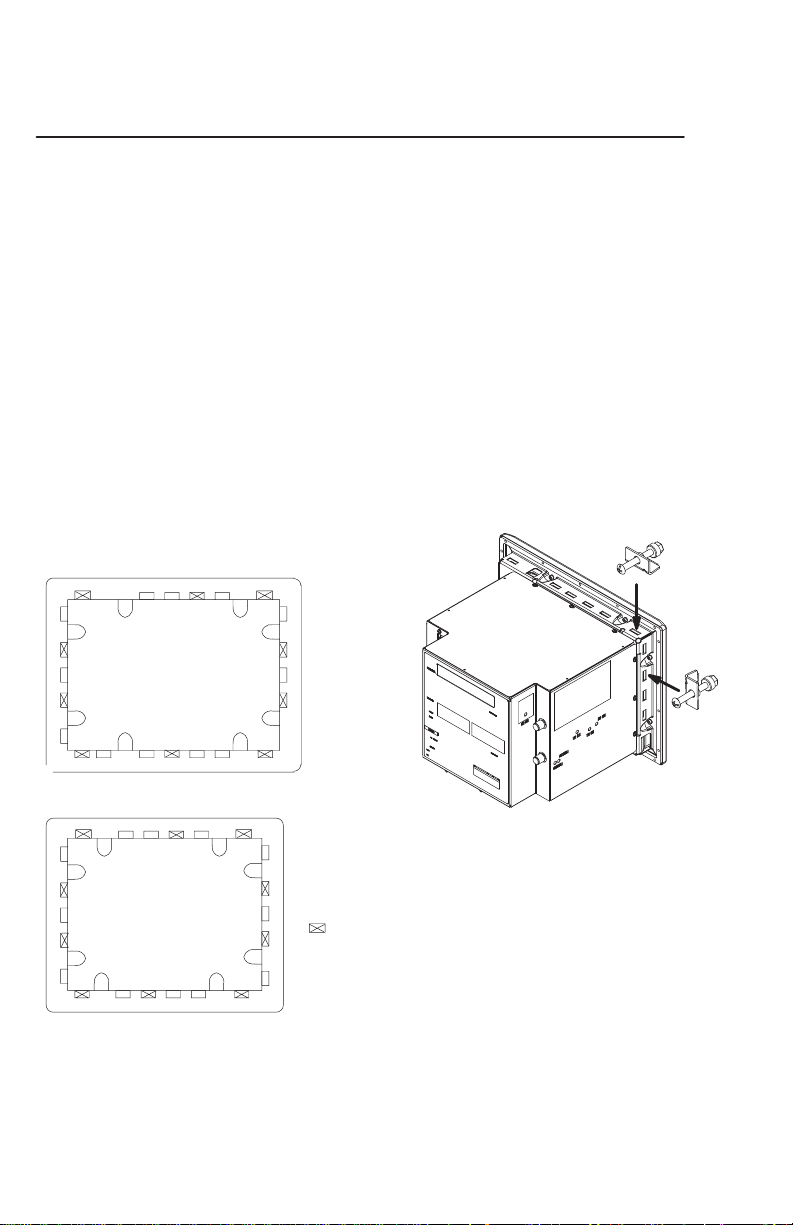

5. Install the 10 mounting clips (3 on top, 3 on bottom, 2 on each side); the ends

of the clips slide into the slots on the terminal. Tighten the clip mounting

screws hand tight.

Figure 6

Mounting Clips

Install 10 Mounting Clips:

Keypad Versions

Touch Screen Versions

= Recommended Placement

of Mounting Clips

Page 10

PanelView 1400 Terminals 9

6. Alternately tighten the mounting clip screws until the terminal is held firmly

against the panel. Tighten mounting screws to a torque of 10 inch-pounds.

Do not over-tighten.

ATTENTION: Tighten mounting clips to a torque of 10

!

inch-pounds (1.1 NSm

potential damage to the terminal. Allen-Bradley assumes no

responsibility for water or chemical damage to the terminal or

other equipment within the enclosure because of improper

installation.

) to provide a proper seal and to prevent

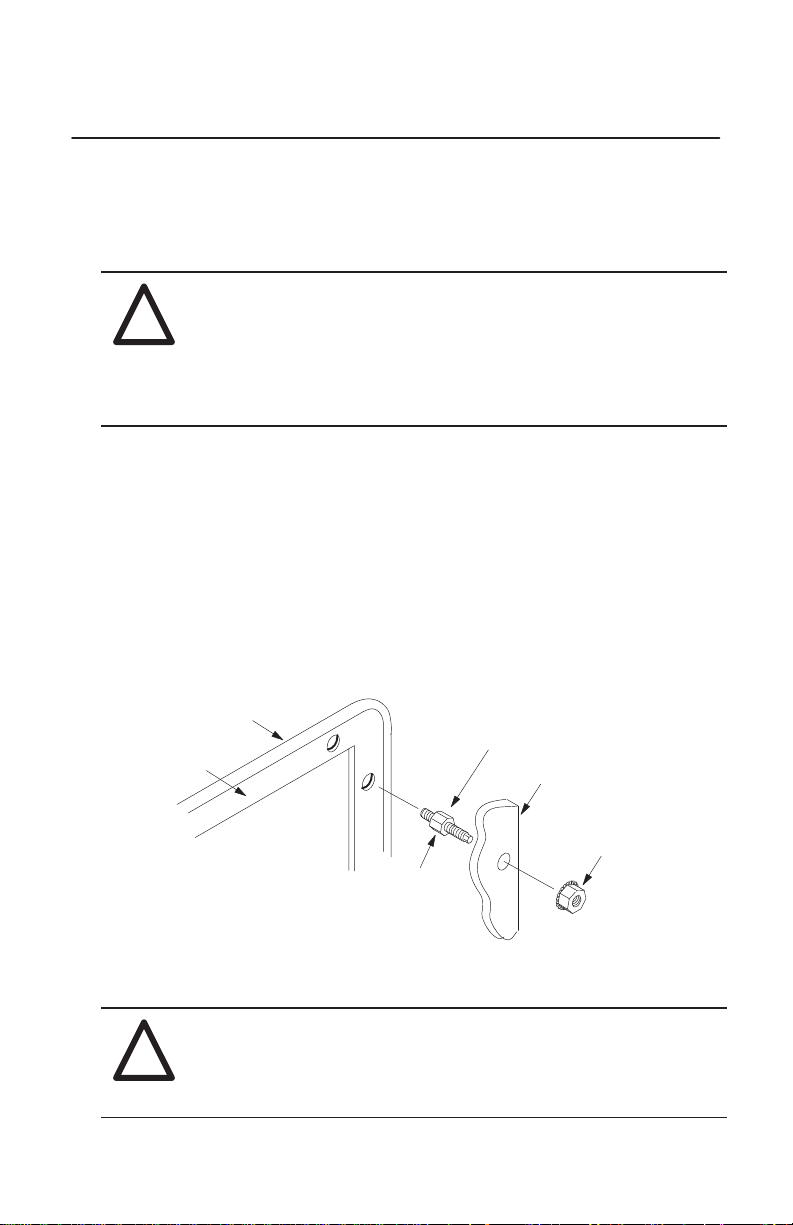

To install the PV1400 terminal in a panel using mounting studs:

1. Cut an opening in the panel using the panel cutout shipped with the terminal.

Carefully drill 5.6 mm (7/32 inch) holes for studs as indicated.

2. Install the mounting studs (Catalog No. 2711-NP3) using a 7/32 inch socket

on the end of the stud. Turn stud clockwise to tighten approximately 10

inch-pounds (1.1 NSm).

Mounting Studs

Bezel

Gasket

(Qty 18 for Keypad

Qty 12 for Touch)

Panel or Enclosure

Self-Locking Nuts

Spacer

ATTENTION: Be careful not to damage the sealing gasket

!

when installing or removing the studs. A damaged seal may

result in damage to the terminal and other panel components due

to a leaking seal.

Page 11

PanelView 1400 Terminals10

3. Make sure the sealing gasket is properly positioned on the terminal. This

gasket forms a compression type seal (NEMA T ype 4). Do not use sealing

compounds.

4. Place the terminal in the panel cutout aligning the studs with the mounting

holes.

5. Install the self-locking nuts hand-tight.

ATTENTION: Tighten mounting nuts to a torque of 10

!

inch-pounds (1.1 NSm) to provide a proper seal and prevent

damage to the terminal. Allen-Bradley assumes no responsibility

for water or chemical damage to the terminal or other equipment

within the enclosure because of improper installation.

6. Alternately tighten the self-locking nuts (use 3/8 inch socket) until the

terminal is held firmly against the panel. (The recommended tightening

sequence is shown below.)

The studs have an integral spacer that prevents the gasket from being

over-compressed. The amount of torque required increases significantly as the

gasket reaches the proper compression. Tighten nuts to a torque 10 inch-pounds

(1.1

NSm).

9

18

Recommended

T orque Sequence

for Keypad T erminals

78

10

17

Note that sequence starts at center studs and continues to the corner studs.

5

1

2

13

1516

34

1112

6

14

43

9

1

Recommended

T orque Sequence

for Touch Terminals

10

2

5

87

1112

6

Page 12

PanelView 1400 Terminals 11

Connecting AC Power

The electrical rating for the PanelView 1400 terminal is shown below.

Terminal Type Supply Voltage Power Consumption

PV1400

The PanelView 1400 terminal is an IEC 1131-2 Equipment Class I device and

requires you to connect the (Protective Earth) terminal to an earth conductor.

ATTENTION: The PanelView 1400 terminal is designed for

!

!

safe use when installed in a suitably rated NEMA Type 12, 13, 4X

(indoor use only), IP54 or IP65 enclosure.

ATTENTION: Do not apply power to the terminal until all

wiring connections have been made. Failure to do so may result in

electrical shock.

85 to 264V ac,

47 to 63 Hz

200 VA maximum

Page 13

PanelView 1400 Terminals12

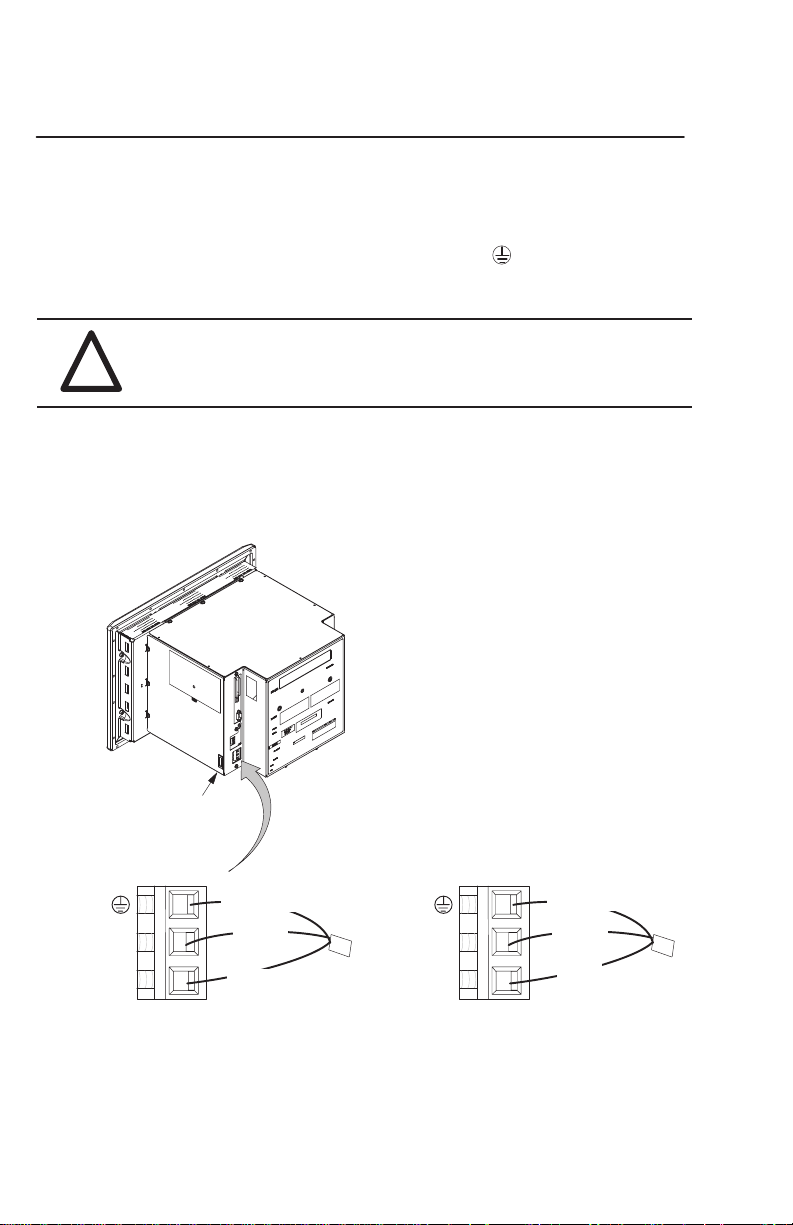

To connect AC power to the PanelView 1400 terminal:

1. Secure the AC power wires to the L1 and L2N screws on the terminal block.

2. Secure the Earth Ground/Protective Earth wire to the

block.

ATTENTION: Improper wiring of the power terminals may result

!

in voltage at the communication connector shells. Refer to Figure 7

when wiring.

3. Apply power to the terminal.

Figure 7

AC Power Connections

Screwdriver slot

120/240V ac, 3 Wire,

120/240V ac, 3 Wire,

U.S. Color Code

L2/N

L1/L

Green

(Earth Ground)

White

(Neutral)

Black

(Line)

European Harmonized

Color Code

L2/N

L1/L

screw on the terminal

Green/Yellow

(Protective Earth)

Blue

(Neutral)

Brown

(Line)

Page 14

Packing Data

Notice d’installation

PK

Ce document explique comment monter un terminal PanelV iew 1400 dans un

panneau ou une armoire et comment le mettre sous tension.

• conformité aux Directives de l’Union européenne

• conseils de câblage et de sécurité

• outillage recommandé

• armoires

• dimensions de montage

• dégagements

• dimensions de découpe

• installation du terminal dans un panneau

• connexion de l’alimentation c.a.

Pour plus d’informations sur les terminaux opérateurs PanelView 1400, se

reporter à la Publication 2711-6.1FR.

Page 15

Terminaux PanelView 140014

Conformité aux Directives de l’Union européenne

Si ce produit a la marque CE, il est homologué pour une installation au sein de

l’Union européenne et de l’Espace économique européen (EEE). Il a été conçu et

testé pour satisfaire aux directives suivantes.

Directive CEM

Cet appareil a été testé pour répondre aux Directives 89/336/EEC du Comité en

matière de compatibilité électromagnétique (CEM) et aux normes suivantes, en

totalité ou en partie:

• EN 50081-1:1992 CEM – Norme générique émission,

Partie 1 – Environnement résidentiel, commercial, industrie légère

• EN 50082-2:1995 CEM – Norme générique immunité,

Partie 2 – Environnement industriel

Le produit décrit est destiné à être utilisé dans un environnement industriel,

industriel léger ou commercial.

Conseils de câblage et de sécurité

Pour installer le terminal PanelView 1400, utiliser la publication NFPA 70E,

“Electrical Safety Requirements for Employee Workplaces”. Suivre en outre les

conseils généraux suivants:

• connecter le terminal PanelView à sa propre ligne secteur.

La source d’alimentation devrait être protégée par un fusible ou un disjoncteur

pour 15 A max.

• faire passer les fils de l’alimentation secteur du terminal par un chemin

différent de celui du câble de communication.

• là où les lignes d’alimentation et de communication doivent se croiser,

qu’elles le fassent perpendiculairement. Les lignes de communication peuvent

être installées dans le même tube que les lignes d’E/S c.c. basse tension

(inférieur à 10 volts).

• la mise à la masse minimise les effets parasites des interférences

électromagnétiques (EMI) et est une mesure de sécurité pour toute installation

électrique. Pour éviter les problèmes causés par les EMI, tous les câbles

doivent être blindés et mis à la masse à une extrémité.

• une source intéressante de conseils pour la mise à la masse est le “National

Electrical Code” publié par la “National Fire Protection Association” de

Boston, Massachusetts (USA).

Page 16

Terminaux PanelView 1400 15

Outils recommandés

A part ceux nécessaires pour la découpe du panneau, les outils dont on aura

besoin pour l’installation sont :

Pour le montage par attaches :

• tournevis à douilles (têtes à fente ou cruciformes)

• un tube allonge de 40 cm (minimum)

• une clé dynamométrique (m.kgf) est conseillée

Pour le montage par goujons :

• douilles de 6 mm (7/32) et 10 mm (3/8)

• un tube allonge de 40 cm (minimum)

• une clé dynamométrique (m.kgf) est conseillée

Armoires

Le terminal PanelView 1400 doit être monté dans un environnement respectant

les normes CEI-1131-2 de protection de degré 2 contre la Pollution.

Monter le terminal sur un panneau ou dans une armoire pour protéger les circuits

internes. Le terminal ne répond aux normes NEMA T ype 12/13 et Type 4X

(utilisation en intérieur) que s’il est monté sur un panneau ou dans une armoire

aux normes équivalentes.

Dans une armoire, laisser assez d’espace pour que la ventilation soit suffisante.

Pour certaines applications, on peut avoir à considérer la chaleur dégagée par les

autres appareils sur le panneau. La température ambiante, autour du terminal, doit

être maintenue entre 0 et 55C.

S’assurer qu’une place suffisante est laissée pour l’accès à la face arrière du

terminal pour le câblage, l’entretien de routine, les réglages de contraste/intensité,

l’insertion d’une carte mémoire et le dépannage.

Page 17

Terminaux PanelView 140016

Dimensions de montage

Les figures ci-dessous indiquent les dimensions de montage pour les terminaux

PanelV iew 1400.

Figure 1

Dimensions de montage du terminal à écran tactile

3,3 mm

(.13 in)

355 mm

(13.97 in)

441 mm

(17.37 in)

Figure 2

Dimensions de montage du terminal à touches

355 mm

(13.97 in)

483 mm

(19.0 in)

(14.58 in)

3,3 mm

(.13 in)

370 mm

(14.58 in)

370 mm

394 mm

(15.53 in)

394 mm

(15.53 in)

Page 18

Terminaux PanelView 1400 17

Dégagements

Laisser une place suffisante pour le montage, la ventilation, et l’insertion de la

carte mémoire et des légendes.

Figure 3

Dégagements pour le montage

Dégagements du côté, du dessus et du dessous

Laisser 5 cm (2 in.)

pour le montage et la ventilation

Découpe du terminal

Utiliser le modèle grandeur

nature

livré avec le terminal

Vue de face

Laisser 5 cm (2 in.)

pour le montage et la ventilation

Laisser 5 cm (2 in.)

pour le montage et l’insertion des légendes

Dégagement arrière

Carte

Laisser 5 cm (2 in.)

pour le montage et la ventilation

3,3 mm

(.13 in.)

370 mm

(14.58 in.)

Il faut environ 40 cm

pour insérer une

carte mémoire

Page 19

Terminaux PanelView 140018

Dimensions de découpe

Utiliser le gabarit de découpe grandeur nature livré avec le terminal pour marquer

les dimensions de la découpe. La figure ci-dessous en est un modèle réduit.

Figure 4

Dimensions de découpe du PanelView 1400

Terminaux PV1400 à touches

419 mm

(16.50 in.)

110 mm

(4.35 in.)

221 mm

(8.70 in.)

Diam. 6 mm (7/32 in.)

18 Trous

(6.70 in.)

Ne pas tenir

compte du perçage

pour les goujons

en cas de montage

par attaches.

Ne pas tenir

compte du perçage

pour les goujons

en cas de montage

par attaches.

170 mm

(6.65 in.)

169 mm

Terminaux PV1400 tactiles

391 mm

(15.40 in.)

127 mm

(5.0 in.)

233 mm

(9.16 in.)

140 mm

(5.50 in.)

38 mm

(1.50 in.)

Diam. 6 mm (7/32 in)

12 Trous

140 mm

(5.50 in.)

305 mm

(12.0 in.)

305 mm

(12.0 in.)

212 mm

(8.35 in.)

Page 20

Terminaux PanelView 1400 19

Installation du terminal sur un panneau

Cette section donne les procédures à suivre pour le montage d’un terminal

PV1400 à l’aide de:

• attaches de fixation (10 livrées avec le terminal, 10 utilisées)

• goujons de fixation (commandés séparément, référence 2711-NP3)

ATTENTION: Débrancher toute alimentation électrique du panneau

!

Pour installer le terminal PV1400 sur un panneau à l’aide des attaches:

1. Découper une ouverture dans le panneau à l’aide de la découpe livrée avec le

terminal. Supprimer tous les bords ou barbes coupants. Ne pas percer de

trous pour les goujons si l’on utilise les attaches.

avant de faire la découpe.

S’assurer que la zone autour de la découpe du panneau est dégagée.

Prendre les précautions nécessaires pour qu’aucun copeau métallique

n’entre dans un composant pouvant déjà être installé sur le panneau.

Ne pas respecter cette mise en garde pourrait être cause de blessure

pour le personnel ou de dommages pour les composants du panneau.

2. Vérifier que le joint d’étanchéité du terminal est convenablement positionné

sur celui-ci comme indiqué sur la figure ci-dessous. Ce joint donne une

étanchéité par compression. N’utiliser aucun autre produit pour l’étanchéité.

Figure 5

Joint d’étanchéité

Joint d’étanchéité

Page 21

Terminaux PanelView 140020

3. Bien que l’on puisse installer les légendes des touches à tout moment, il est

conseillé de le faire une fois le terminal installé.

4. Placer le terminal dans la découpe du panneau. Il va se bloquer sur le panneau

grâce aux pattes de maintien temporaires.

Remarque: Le terminal est muni de 2 pattes métalliques (sur le bas) qui

bloquent provisoirement le terminal sur le panneau. Elles ne sont là que pour

faciliter l’installation du matériel et ne sont pas conçues pour être utilisées de

façon durable.

5. Installer les dix attaches de fixation (3 en haut, 3 en bas, 2 de chaque côté);

les extrémités des attaches glissent dans des encoches sur le terminal. Serrer

les vis des attaches de fixation à la main.

Figure 6

Attaches de fixation

Installer 10 attaches de fixation :

Modèles à touches

Modèles à écran tactile

= Positions conseillées pour

les attaches de fixation

Page 22

Terminaux PanelView 1400 21

6. Serrer alternativement les vis des attaches de fixation jusqu’à ce que le

terminal soit fermement maintenu contre le panneau. Serrer les vis avec un

couple de 0,116 mSkgf. Ne pas trop les serrer.

ATTENTION: Les attaches de fixation doivent être serrées

!

avec un couple de 0,116 mSkgf pour que le joint soit

correctement comprimé et que le terminal ne risque pas d’être

endommagé. Allen-Bradley ne serait être en aucune façon

responsable de dommages causés par de l’eau ou des produits

chimiques, au terminal ou à tout autre équipement du boîtier, par

suite d’une installation incorrecte.

Pour installer le terminal PV1400 sur un panneau à l’aide de goujons:

1. Découper une ouverture dans le panneau à l’aide de la découpe livrée avec le

terminal. Percer avec précaution les trous de 6 mm (7/32) pour les goujons.

2. Installer les goujons de fixation (référence 2711-NP3) à l’aide d’une douille

de 6 mm (7/32). T ourner dans le sens des aiguilles d’une montre jusqu’à

obtenir un couple approximatif de 0,116 mSkgf.

Goujons de fixation

Encadrement

Joint

d’espacement

(18 pour PV à touches;

12 pour PV tactiles)

Panneau ou armoire

Ecrou auto-bloquant

Cale

ATTENTION: Prendre soin de ne pas abîmer le joint

!

d’étanchéité en installant ou en retirant les goujons. Un joint

défectueux peut être cause de dommages pour le terminal ou

pour d’autres éléments du panneau.

Page 23

Terminaux PanelView 140022

3. Vérifier que le joint d’étanchéité est correctement positionné sur le terminal.

Il s’agit d’un joint de type compressif (NEMA T ype 4). N’utiliser aucun autre

produit pour l’étanchéité.

4. Placer le terminal dans la découpe du panneau en alignant les goujons sur les

trous de la découpe.

5. Installer les écrous auto-bloquants et les serrer à la main.

ATTENTION: Les écrous auto-bloquants doivent être serrés

!

avec un couple de 0,116 mSkgf pour que le joint soit

correctement comprimé et que le terminal ne risque pas d’être

endommagé. Allen-Bradley ne serait être en aucune façon

responsable de dommages causés par de l’eau ou des produits

chimiques, au terminal ou à tout autre équipement du boîtier, par

suite d’une installation incorrecte.

6. Serrer alternativement les écrous auto-bloquants (avec une douille de 10)

jusqu’à ce que le terminal soit fermement maintenu contre le panneau. (Il est

conseillé de serrer les écrous dans l’ordre indiqué ci-dessous).

Les goujons sont munis d’une cale d’espacement qui empêche une

sur-compression du joint. Le couple de serrage nécessaire augmente de façon

significative quand on approche de la compression correcte. Serrer les écrous

jusqu’à un couple de 0,116 m

Skgf.

9

18

Ordre de serrage

conseillé pour les

terminaux à touches

78

10

17

Remarquer que le serrage commence par les goujons du centre et se termine avec ceux des

coins.

5

1

2

13

1516

34

1112

6

14

43

9

1

Ordre de serrage

conseillé pour les

terminaux tactiles

10

2

5

87

1112

6

Page 24

Terminaux PanelView 1400 23

Connexion de l’alimentation c.a.

Le tableau ci-dessous indique les spécifications électriques pour les terminaux

PanelV iew 1400.

Type de terminal Tension Consommation

PV1400

Le terminal PanelView 1400 répond aux normes CEI 1131-2 Equipement Classe I

et exige que la borne (terre de protection) soit connectée à une masse terre.

ATTENTION: Le terminal PanelView 1400 est conçu pour une

!

!

utilisation sûre quand il est installé dans une armoire aux normes NEMA

Type 12, 13, 4X (en intérieur uniquement), IP54 ou IP65.

ATTENTION: Ne pas appliquer de tension au terminal tant que toutes

les connexions n’ont pas été câblées. Procéder différemment pourrait

entraîner des décharges électriques.

85 à 264 V c.a.,

47 à 63 Hz

200 VA maximum

Page 25

Terminaux PanelView 140024

Pour connecter l’alimentation c.a. au terminal PanelView 1400:

1. Fixer les fils de l’alimentation c.a. dans les bornes L1 et L2N du bornier.

2. Fixer le fil de T erre/Terre de protection dans la borne

ATTENTION: Un câblage incorrect des bornes d’alimentation

!

pourrait donner une tension potentielle aux cosses des connecteurs de

communication. Se référer à la figure ci-dessous lors du câblage.

3. Mettre le terminal sous tension.

Figure 7

Connexions de l’alimentation c.a.

Encoche du tournevis

120/240 V c.a., 3 fils,

120/240 V c.a., 3 fils,

Code de couleurs U.S.

L2/N

L1/L

(Terre)

Blanc

(Neutre)

Noir

(Ligne)

Vert

Code de couleurs

européen

L2/N

L1/L

.

Vert/Jaune

(Terre de protection)

Bleu

(Neutre)

Marron

(Ligne)

Page 26

Packing Data

Installationsanweisungen

PK

Dieses Dokument beschreibt den Einbau eines PanelView 1400 Terminals in eine

Schalttafel oder ein Gehäuse und den Anschluß an die Stromversorgung.

• EU Richtlinien

• Verdrahtungs– und Sicherheitsrichtlinien

• Benötigte W erkzeuge

• Gehäuse

• Einbauabmessungen

• Abstände

• Ausschnittsmaße

• Installation des T erminals in eine Schalttafel

• Anschluß der AC–Versorgung

Für weitere Informationen über die PanelView 1400 Bedienerterminals sollten

Sie sich die Publikation 2711-6.1DE ansehen.

EU Richtlinien

Wenn dieses Produkt das CE–Zeichen hat, dann ist es für die Installation

innerhalb der Europäischen Union und EEA Region zugelassen. Es wurde

entworfen und getestet, um die folgenden Richtlinien zu erfüllen.

Page 27

PanelView 1400 Terminals26

EMV–Richtlinien

Dieses Produkt wurde auf Einhaltung der grundlegenden Anforderungen der

EU–Richtlinie 89/336/EEC Elektromagnetische Verträglichkeit (EMV) überprüft.

Dies geschah mit Hilfe einer technischen Dokumentation entsprechend Artikel 10

(2) der Richtlinie unter vollständiger oder teilweiser Anwendung der folgenden

Normen:

• EN 50081-1:1992 EMV – Fachgrundnorm Störaussendung,

T eil 1 – Privat, gewerblich und leicht industriell

• EN 50082-2:1995 EMV – Fachgrundnorm Störfestigkeit,

T eil 2 – Industriebereich

Das beschriebene Produkt soll nur in einer industriellen, leicht industriellen oder

gewerblichen Umgebung verwendet werden.

Verdrahtungs– und Sicherheitsrichtlinien

Installieren Sie das PV1400 Terminal mit Berücksichtigung der entsprechenden

elektrischen DIN- und VDE-Normen ( USA: Pub.NFPA 70E, Electrical Safety

Requirements for Employee Workplaces). Zuzüglich zu den allgemeinen Richt–

linien (USA: NFPA) haben wir einige spezifische Empfehlungen hinzugefügt:

• Das PanelV iew Terminal sollte zu seiner eigenen Abzweigung verbunden

werden.

Die Eingangsstromquelle sollte durch eine Sicherung oder einen

Trennschalter, der nicht mit mehr als 15A eingestuft ist, geschützt werden.

• Verlegen Sie ankommende Spannungsversorgungskabel zum PanelView 1400

T erminal getrennt vom Kommunikationskabel.

• Wenn sich Spannungsversorgungs– und Kommunikationskabel kreuzen

müssen, sollten sich diese im rechten Winkel kreuzen. Kommunikationskabel

können im gleichen Kabelkanal mit DC E/A– Niederspannungskabel

(weniger als 10 Volt) installiert werden.

• Die korrekte Erdung begrenzt die Wirkung von Störungen durch

Elektromagnetische Interferenz (EMI). Um Probleme zu vermeiden, die durch

EMI verursacht werden, müssen entsprechende Kabel abgeschirmt und

geerdet werden.

• Eine Beschreibung der maßgeblichen Erdungsanforderungen ist in dem

National Electrical Code enthalten, der vom National Fire Protection

Association in Boston, Massachusetts veröffentlicht wurde.

Page 28

PanelView 1400 Terminals 27

Benötigte Werkzeuge

Die folgenden Werkzeuge werden für den Einbau des PV1400 in einen

Schalttafelausschnitt benötigt:

Für die Klammermontage:

• Schraubenzieher–Aufsatz (Schlitz– oder Kreuzschraubenkopf)

• Verlängerung mindestens 406 mm (16 Zoll) lang

• Drehmomentschlüssel (Nm) empfohlen

Für die Gewindebolzenmontage:

• 6 mm (7/32 Zoll) und 10 mm (3/8 Zoll) Nuß (Steckschlüssel)

• Verlängerung mindestens 406 mm (16 Zoll) lang

• Drehmomentschlüssel (Nm) empfohlen

Gehäuse

Das PanelV iew 1400 Terminal muß in einer Umgebung eingebaut werden, die

dem Schutz nach ”IEC-1131-2 Pollution degree 2 protection” entspricht.

Zum Schutz des inneren Schaltkreises muß das T erminal in eine Schalttafel oder

ein Gehäuse eingebaut werden. Das T erminal entspricht den NEMA Typen 12/13

und 4X (Innenräume), wenn es in einer Schalttafel oder einem Gehäuse mit der

gleichen Bewertung eingebaut ist.

Erlauben Sie genug Abstand für angemessene Ventilation innerhalb des

Gehäuses. Für einige Anwendungen sollten Sie die Hitze berücksichtigen, die

von anderen Vorrichtungen innerhalb der Schalttafel erzeugt wird. Die

Raumtemperatur um das T erminal muß zwischen 0 and 55C betragen.

Vergewissern Sie sich, daß Vorkehrungen getroffen werden, um den Zugriff auf

die Rückwand des T erminals (für Verdrahtung, alltägliche Wartung, Einstellung

von Helligkeit/Kontrast, Installieren einer Speicherkarte und Fehlersuche) zu

ermöglichen.

Page 29

PanelView 1400 Terminals28

Einbauabmessungen

Abbildung 1 und 2 zeigen die Abmessungen für PanelV iew 1400 Terminals.

Abbildung 1

Touchscreen–Terminal–Abmessungen

3,3 mm

(.13 in)

441 mm

(17.37 in)

Abbildung 2

Tastatur–Terminal–Abmessungen

483 mm

(19.0 in)

355 mm

(13.97 in)

355 mm

(13.97 in)

(14.58 in)

3,3 mm

(.13 in)

370 mm

(14.58 in)

370 mm

394 mm

(15.53 in)

394 mm

(15.53 in)

Page 30

PanelView 1400 Terminals 29

e

Abstände

Erlauben Sie genügend Raum für Einbau, Luftzirklation, Wartung und

Installation der Speicherkarte und der Beschriftungen.

Abbildung 3

Einbauabstände

Seitenabständ

Lassen Sie 51 mm für Einbau

und Luftzirkulation frei.

AUSSCHNITT

Verwenden Sie die

Orginal–Schablone,

die mit dem Terminal

geliefert wird.

VORDERANSICHT

Lassen Sie 51 mm für Einbau

und Luftzirkulation frei.

Lassen Sie 51 mm

für Einbau frei.

Hinterer Abstand

Karte

Lassen Sie 51 mm für Einbau

und Luftzirkulation frei.

3,3 mm

(.13 in.)

370 mm

(14.58 in.)

Es werden ca. 400 mm

benötigt, um eine

Speicherkarte zu laden.

Page 31

PanelView 1400 Terminals30

Ausschnittsmaße

Benutzen Sie die Orginal–Schablone, die mit dem Terminal geliefert wird, um die

Ausschnittmaße aufzuzeichnen. Abbildung 4 zeigt die Ausschnittmaße.

Abbildung 4

PanelView 1400 Ausschnittmaße

PV1400 Tastatur–Terminals

419 mm

(16.50 in.)

110 mm

(4.35 in.)

221 mm

(8.70 in.)

18 Löcher mit einem

5,5 mm Durchmesser

Ignorieren Sie die

Löcher, wenn das

Terminal mit Hilfe

der Paneelklammern eingebaut

wird.

Ignorieren Sie die

Löcher, wenn das

Terminal mit Hilfe

der Paneelklammern eingebaut

wird.

170 mm

(6.70 in.)

169 mm

(6.65 in.)

PV1400 Touch Terminals

391 mm

(15.40 in.)

127 mm

(5.0 in.)

233 mm

(9.16 in.)

38 mm

(1.50 in.)

12 Löcher mit einem

5,5 mm Durchmesser

140 mm

(5.50 in.)

305 mm

(12.0 in.)

140 mm

(5.50 in.)

305 mm

(12.0 in.)

212 mm

(8.35 in.)

Page 32

PanelView 1400 Terminals 31

Installation des Terminals in eine Schalttafel

Dieser Abschnitt beschreibt das Einbauverfahren eines PV1400 mit Verwendung:

• von Montageklammern (10 werden mit dem T erminal geliefert, 10 benötigt)

• von Montagebolzen (können separat bestellt werden, Katalognr. 2711-NP3)

ACHTUNG: Schalten Sie den Strom zur Schalttafel ab, bevor Sie

!

Installation des PV1400 Terminals mit Montageklammern in eine

Schalttafel:

1. Schneiden Sie die Öffnung mit Hilfe der Orginal–Schablone, die mit dem

T erminal geliefert wird, in die Schalttafel ein. Entfernen Sie scharfe Kanten

oder Grate. Bohren Sie nicht die Montagebolzenlöcher, wenn Sie die

Montageklammern verwenden.

den Ausschnitt machen.

Vergewissern Sie sich, daß das Gebiet um den Schalttafelausschnitt

frei ist.

Treffen Sie Vorsichtsmaßnahmen, damit keine Metallspäne in

irgendein vorhandenes Bauteil der Schalttafel eindringen können.

Ein Nichtbeachten dieser Warnung kann die Verletzung von Personen

oder die Beschädigung von Schalttafelbauteilen zur Folge haben.

2. Vergewissern Sie sich, daß sich die T erminaldichtung in der richtigen Position

(siehe Abbildung 5) befindet. Die Abdichtung wird durch die Kompression

hergestellt. Benutzen Sie keine zusätzlichen Dichtungsmittel.

Abbildung 5

Dichtung

Dichtung

Page 33

PanelView 1400 Terminals32

3. Obwohl der Funktionstasten-Beschriftungssatz zu jeder Zeit installiert werden

kann, empfehlen wir die Installation, wenn das T erminal im Gehäuse

eingebaut ist.

4. Fügen Sie das T erminal in den Ausschnitt ein. Das Terminal wird im Paneel

einrasten, wenn die temporären Halterungen es gegen das Paneel

festklemmen.

Hinweis: Das Terminal hat 2 Metallhalterungen (an der unteren Kante), die

temporär das T erminal gegen das Paneel klemmen. Diese Halterungen sollen nur

das Einbauen der Montagehardware erleichtern. Die Halterungen wurden nicht

entworfen, um einen permanenten Einbau herzustellen.

5. Installieren Sie die 10 Montageklammern (3 oben, 3 unten, 2 auf jeder Seite);

die Enden der Klammern werden in die Schlitze des T erminals eingefügt.

Ziehen Sie die Montageklammer-Schrauben erst per Hand an.

Abbildung 6

Montageklammern

Installation der 10 Montageklammern:

Tastatur–Versionen

Touchscreen–Versionen

= Empfohlene Plazierung

der Montageklammern

Page 34

PanelView 1400 Terminals 33

6. Ziehen Sie abwechselnd die Montageklammer-Schrauben an, bis das Terminal

bündig gegen die Schalttafel gehalten wird. Ziehen Sie die Schrauben dann

mit einem Drehmoment von 1,1 Nm fest. Bitte überdrehen Sie die Schrauben

nicht.

ACHTUNG: Um eine korrekte Abdichtung zu erreichen und

!

um potentielle Schäden am Terminal zu verhindern, sollten die

Montageklammern mit einem Drehmoment von 1,1 Nm

festgezogen werden. Allen–Bradley übernimmt keine

Verantwortung für Schäden durch Wasser oder Chemikalien am

Terminal oder anderen Geräten innerhalb des Gehäuses, die

durch unsachgemäße Installation hervorgerufen werden.

Installation des PV1400 Terminals mit Montagebolzen in eine Schalttafel:

1. Schneiden Sie die Öffnung mit Hilfe der Orginal–Schablone, die mit dem

T erminal geliefert wird, in die Schalttafel ein

. Bohren Sie vorsichtig die

5,5 mm (7/32 Zoll) Löcher für die Bolzen, so wie es angezeigt wird.

2. Installieren Sie die Einbaubolzen (Katalognr. 2711-NP3) mit Hilfe einer 6 mm

(7/32 Zoll) Nuß. Ziehen Sie die Bolzen im Uhrzeigersinn mit einem

Drehmoment von 1,1

Nm an.

Dichtung

!

Blende

Bolzen für Touchscreen–Terminals)

Abstandhalter

Montagebolzen

(18 Bolzen für Tastatur– und 12

Paneel oder Gehäuse

Selbstsichernde Mutter

ACHTUNG: Seien Sie vorsichtig, wenn Sie die Bolzen

installieren und entfernen, damit die Dichtung nicht beschädigt

wird. Eine beschädigte Dichtung kann zur Beschädigung des

Terminals und anderer Paneelkomponenten durch eine undichte

Abdichtung führen.

Page 35

PanelView 1400 Terminals34

3. Vergewissern Sie sich, daß sich die Terminaldichtung in der richtigen Position

befindet. Die Abdichtung (NEMA T ype 4) wird durch die Kompression

hergestellt. Benutzen Sie keine zusätzlichen Dichtungsmittel.

4. Plazieren Sie das T erminal im Ausschnitt, richten Sie die Bolzen mit den

Löchern aus.

5. Installieren Sie die selbstsichernden Muttern erst per Hand.

ACHTUNG: Um eine korrekte Abdichtung zu erreichen und

!

um potentielle Schäden am Terminal zu verhindern, sollten die

Montagemuttern mit einem Drehmoment von 1,1 Nm

festgezogen werden. Allen–Bradley übernimmt keine

Verantwortung für Schäden durch Wasser oder Chemikalien am

Terminal oder anderen Geräten innerhalb des Gehäuses, die

durch unsachgemäße Installation hervorgerufen werden.

6. Ziehen Sie abwechselnd die selbstsichernden Muttern mit der 10 mm

(3/8 Zoll) Nuß an, bis das T erminal fest gegen das Paneel gehalten wird. (Die

empfohlen Reihenfolge für das Befestigen wird unten gezeigt.)

Die Bolzen haben integrierte Abstandhalter, die ein zu starkes Zusammendrücken

der Dichtung verhindern. Sie werden eine große Steigerung im Drehmoment

feststellen, wenn Sie die korrekte Kompression erreichen. Befestigen Sie die

Muttern mit einem Drehmoment von 1,1 Nm.

9

18

Empfohlene

Befestigungsfolge für

Tastaturterminals

78

10

17

Beachten Sie bitte, daß die Reihenfolge bei den mittleren Bolzen

startet und dann weiter zu den äußeren Bolzen fortgesetzt wird.

5

1

2

13

1516

34

1112

6

14

78

9

1

5

Empfohlene

Befestigungsfolge für

Touchscreen–Terminals

10

2

6

34

1112

Page 36

PanelView 1400 Terminals 35

Anschluß der AC–Versorgung

Die untere Tabelle zeigt die AC–Bewertung für das PanelView 1400 Terminal.

Terminaltyp

PV1400

Das PanelV iew 1400 Terminal ist ein IEC 1131-2 Equipment Class I

(Geräteklasse 1) Gerät erfordert das Verbinden der

Erdleiter.

ACHTUNG: Das PanelView 1400 Terminal entspricht der NEMA

!

!

12, 13, 4X (nur für Innenräume), IP54 oder IP65, wenn es in einer

Schalttafel oder einem Gehäuse mit der gleichen Bewertung

eingebaut ist.

ACHTUNG: Schalten Sie das Terminal erst ein, nachdem alle

elektrischen Anschlüsse gemacht worden sind. Einer

Nichtbeachtung kann ein elektrischer Schlag folgen.

Versorgungs–

spannung

85 bis 264V AC,

47 bis 63 Hz

Leistungsaufnahme

200 VA Maximum

Klemme (Erdung) zum

Page 37

PanelView 1400 Terminals36

Anschluß des PanelView 1400 Terminals an die AC–Versorgung:

1. Schließen Sie die AC–Stromzuführungen an die

Versorgungsspannungsklemme L1 und L2N an.

2. Schließen Sie den Erdungsdraht an die Erdungsklemme

ACHTUNG: Inkorrekter Stromanschluß kann ein Spannungs–

!

potential am Gehäuse des Kommunikationsanschlusses zur Folge

haben. Bitte beachten Sie Abbildung 7.

3. Legen Sie die Spannung zum T erminal an.

Abbildung 7

Anschluß an die AC–Versorgung

Schraubendreherschlitz

120/240VAC

120/240VAC, 3 Draht

Farbcode U.S.A.

L2/N

L1/L

Grün

(Erdung)

Weiß

(Neutral)

Schwarz

(Netz)

Einheitlicher europäischer

Farbecode (3 Drähte)

L2/N

L1/L

an.

Grün/Gelb

(Erdung)

Blau

(Neutral)

Braun

(Netz)

Page 38

Packing Data

Instrucciones de instalación

PK

Este documento describe cómo montar un terminal PanelView 1400 en un panel o

caja y aplicar energía.

• Adherencia a la Directivas de la Unión Europea

• Recomendaciones de cableado

• Equipo requerido

• Cajas

• Dimensiones de montaje

• Espacios libres

• Dimensiones de recorte

• Instalar el terminal en un panel

• Conexión a energía CA

Refiérase a la Publicación 2711–6.1ES, para más información sobre Terminales

de operador PanelView 1400.

Page 39

Terminales PanelView 140038

Adherencia a la Directiva de la Unión Europea

Si este producto tiene la marca CE, significa que está aprobado dentro de la

Unión Europea o en regiones EEA. Ha sido diseñado y verificado para cumplir

con las siguientes regulaciones.

Directiva EMC

Este producto está verificado para cumplir con el Concilio Directivo 89/336/EEC

de Compatibilidad Electromagnética (EMC) usando las siguientes normas, en

total o en parte:

• EN 50081-1:1992 EMC – Estándar Genérico de la Emisión, Parte 1 –

Residencial, Comercial e Industria ligera

• EN 50082-2:1995 EMC – Estándar Genérico de la Inmudidad, Parte 2 –

Ambiente Industrial

El producto descrito es para uso en un ambiente industrial, industrial ligero o

comercial.

Recomendaciones de cableado

Instalar los terminales PanelV iew 1400, usando la publicación 70E, los

Requisitos de Seguridad Eléctricos para Fábricas y lugares de Trabajo. Además

de las guías generales del NFPA, siga las siguientes recomendaciones:

• Conectar el terminal PanelView a su propia rama de circuíto.

La entrada de energía debe estar protegida por un fusible o un cortacircuítos

clasificado a no más de 15 amps.

• Enrutar energía entrante al terminal PanelView 1400, separando la ruta del

cable de comunicación.

• Donde la energía y las líneas de comunicación deben cruzar, deben cruzar en

ángulos rectos. Las líneas de comunicación pueden ser instaladas en el mismo

circuíto como líneas de entrada/salida de nivel bajo CC (menos de 10

Voltios).

• Hacer tierra minimiza el ruido de Interferenica Electromagnética (EMI) y es

una medida de seguridad en instalaciones eléctricas. Para evitar EMI, proteja

y haga tierra con los cables, en un extremo.

• Usar el Código de Electricidad Nacional publicado por National Fire

Protection Association of Boston como fuente de tierra.

Page 40

Terminales PanelView 1400 39

Equipo requerido

Además de las herramientas requeridas para hacer el recorte del panel, se

necesitan las siguientes herramientas:

Para montaje con clips:

• destornillador de enchufe (cabeza Phillips o de ranura)

• barra de extensión (mínima) de 406 mm (16 pulg.)

• llave de torsión (pulg. / lbs) recomendada

Para montaje con tornillos:

• enchufe de 5,56mm y 9,53mm (7/32 y 3/8 pulgada)

• barra de extensión (mínima) de 406 mm (16 pulg.)

• llave de torsión (pulg. / lbs) recomendada

Cajas

El terminal The PanelView 1400 debe ser montado en un entorno que

proporciona una protección de grado 2 IEC–1131–2.

Montar el terminal en un panel o caja para proteger la circuitería interna. El

terminal cumple con las clasificaciones NEMA Tipo 12/13 y 4X (uso interior)

sólo cuando es montado en un panel o caja con clasificaciones equivalentes.

Permitir suficiente espacio dentro de la caja para ventilación adecuada.

Considerar el calor que otros productos dentro de la caja producen. La

temperatura ambiente alrededor del terminal debe ser entre 32 y 131F (0 y

55C).

Hacer provisiones para tener acceso a la parte trasera del terminal. Se requiere

acceso para el cableado, ajuste de brillantez/contraste, instalar la tarjeta de

memoria, y localizar averías.

Page 41

Terminales PanelView 140040

Dimensiones de montaje

Las figuras 1 y 2 muestran las dimensiones para los terminales PanelView 1400.

Figure 1

Dimensiones de montaje para terminales táctiles

3,3 mm

(0,13 pulg.)

355 mm

(13,97 pulg.)

441 mm

(17,37 pulg.)

Figure 2

Dimensiones de montaje para terminales de teclado

355 mm

(13,97 pulg.)

483 mm

(19,0 pulg.)

370 mm

(14,58 pulg.)

3,3 mm

(0,13 pulg)

370 mm

(14,58 pulg.)

394 mm

(15,53 pulg.)

394 mm

(15,53 pulg.)

Page 42

Terminales PanelView 1400 41

Esp

uperior

or

Espacios libres

Dejar espacio adecuado, al montar, para flujo de aire, y para insertar la leyenda

del terminal.

Figure 3

Espacios libres

acios libres, en la parte s

Recorte del terminal

Use el recorte de tamaño completo

que recibe con el terminal

Vista frontal

, lateral e interi

Deje 51 mm (2 pulg.) para

montar y para flujo de aire

Deje 51 mm (2 pulg.) para

montar y para flujo de aire

Espacios en la parte trasera

Deje 51 mm (2 pulg.) para montar

3,3 mm

(0,13 pulg.)

Tarjeta

370 mm

(14,58 pulg.)

Se requieren

aproximadamente 400

mm (15,75 pulgadas)

para cargar una tarjeta

de memoria.

Deje 51 mm (2 pulg.) para

montar y para flujo de aire

Page 43

Terminales PanelView 140042

Dimensiones de recorte

Usar el patrón proporcionado con el terminal para marcar las dimensiones del

recorte. La Figura 4 muestra un recorte de tamaño reducido.

Figure 4

Dimensiones de recorte del PanelView 1400

Terminales de teclado PV1400

419 mm

(16,50 pulg.)

110 mm

(4,35 pulg.)

221 mm

(8,70 pulg.)

5,56mm (7/32 pulg.) típico

18 hoyos

Ignorar los hoyos

si está montando

un terminal con

clips de panel.

Ignorar los hoyos

si está montando

un terminal con

clips de panel.

170 mm

(6,70 pulg.)

169 mm

(6,65 pulg.)

Terminales táctiles PV1400

391 mm

(15,40 pulg.)

127 mm

(5,0 pulg.)

233 mm

(9.16 pulg.)

140 mm

(5,50 pulg.)

38 mm

(1,50 pulg.)

5.56mm (7/32 pulg.) típico

12 hoyos

140 mm

(5,50 pulg.)

305 mm

(12,0 pulg.)

305 mm

(12,0 pulg.)

212 mm

(8,35 pulg.)

Page 44

Terminales PanelView 1400 43

Instalar el terminal en un panel

Esta sección proporciona procedimientos para montar un PV1400 usando:

• clips de montaje (10 enviados con el terminal, 10 requeridos)

• tornillos de montaje (ordernados por separado, No. de catálogo 2711-NP3)

ATENCION: Desconectar toda alimentación eléctrica del

!

Para instalar el terminal PV1400 en un panel, usando clips:

1. Poner el terminal en el recorte del panel. El terminal encajará en el panel,

según las lengüetas temporales lo sujetan contra el panel. No taladre los 18

hoyos de montaje si va a usar los clips de montaje.

2. Verificar que la junta selladora del terminal está puesta apropiadamente, tal

como se muestra abajo en la Figura 5. Esta junta forma una compresión de

tipo sellador. No usar mezclas que sellan.

panel antes de hacer el recorte.

Verificar que el área alrededor del recorte de pantalla ha sido

despejada.

T omar las precauciones para que rebabas de metal no entren

en ningún componente que ya esté instalado en el panel.

El no seguir esta advertencia puede resultar en heridas

personales o daño a los componentes del panel.

Figure 5

Junta selladora

Junta selladora

Page 45

Terminales PanelView 140044

3. Aunque las leyendas para el teclado se pueden instalar en cualquier momento,

recomendamos que las instale después de instalar el terminal.

4. Poner el terminal en el recorte del panel. El terminal encajará en el panel,

según las lengüetas temporales lo sujetan contra el panel.

Nota: El terminal tiene dos lengüetas de metal ( en el borde inferior ) que sujetan

el terminal contra el panel temporalmente. Estas lengüetas facilitan la instalación

del hardware de montaje. Las lengüetas no están diseñadas para proporcionar

montaje permanente.

5. Instalar los 10 clips de montaje ( 3 en la parte superior, 3 en la parte inferior y

2 a cada lado ); las puntas de los clips se deslizan en las ranuras del terminal.

Apretar los clips de montaje a mano.

Figure 6

Clips de montaje

Instalar 10 clips de montaje:

Versiones de teclado

Versiones de pantalla táctil

Lugar donde se recomienda

poner los clips de montaje

Page 46

Terminales PanelView 1400 45

6. Apretar los clips de montaje alternamente hasta que el terminal quede sujeto

firmemente contra el panel. Apretar los tornillos a un momento de torsión de

10 pulgada–libras. No apretar demasiado.

ATENCION: Apretar los clips de montaje a un momento

!

Para instalar el terminal PV1400 en un panel usando los tornillos de

montaje:

1. Use el panel enviado con el terminal como guía para cortar una apertura para

el panel. T aladrar con cuidado hoyos de 5,6 mm (7/32 pulg.) para los

tornillos, según es indicado.

2. Instalar los 18 tornillos de montaje ( No. de Catálogo 2711-NP3) usando un

enchufe de 7/32 pulg. al final del tornillo. Apretar a favor del reloj, para

apretarlo aproximadamente a 10 pulgada–libras (1.1

de torsión de 10 libras–pulgada (1.1 NSm) para proporcionar

un sello apropiado y para prevenir daño potencial al

terminal. Allen–Bradley no asume responsabilidad por el

daño causado por agua u otra substancia química o por

daños causados dentro de la caja debido a instalación

impropia.

NSm).

Bezel

Junta

Espaciador

ATENCION: Cuidado de no dañar la junta selladora al instalar

!

o quitar los pernos. Una junta selladora dañada puede resultar en

daños al terminal y a otros compontes del panel.

Tornillos de montaje

(18 para el terminal de teclado

12 para el terminal táctil)

Panel o caja

Tornillos auto–selladores

Page 47

Terminales PanelView 140046

3. Asegurarse que la junta selladora está posicionada correctamente en el

terminal. Esta junta forma un sello de compresión tipo (NEMA Tipo 4) No

usar mezclas que sellan.

4. Poner el terminal en el recorte de panel, alineando los tornillos con los hoyos

de montaje.

5. Instalar los 18 tornillos auto–selladores a mano.

ATENCION: Apretar los clips de montaje a un momento de

!

torsión de 10 libras–pulgada (1.1 NSm) para proporcionar un

sello apropiado y para prevenir daño al terminal. Allen–Bradley

no asume responsabilidad por el daño causado por agua u otra

substancia química o por daños causados dentro de la caja debido

a instalación impropia.

6. Apretar los tornillos auto–selladores alternamente (usar socket de 3/8 pulg.)

hasta que el terminal quede sujeto firmemente contra el panel. (La secuencia

de apretar que se recomienda se muestra abajo)

Los tornillos tienen un espaciador que evita que la junta se comprese demasiado.

La cantidad de torsión requerida aumenta significativamente, según la junta llega

a la compresión apropiada. Apretar los tornillos a una torsión de 10

pulgadas–libra (1.1 NSm).

9

18

Secuencia de torsión re-

comendada para terminales

78

17

de teclado

10

Notar que la secuencia comienza en los tornillos del

centro y continúa a los tornillos de las esquinas.

5

1

2

13

1516

34

1112

6

14

7

4

12

9

Secuencia de torsión re-

comendada para terminales

10

1

táctiles

2

5

8

3

11

6

Page 48

Terminales PanelView 1400 47

Conexión a energía CA

Las clasificaciones eléctricas para los terminales PanelView 1400 se muestran en

la siguiente tabla.

Tipo de terminal

PV1400

El terminal PanelView 1400 es un dispositivo IEC 1131-2 Clase I y requiere que

usted conecte el terminal

ATENCION: El terminal PV1400 está diseñado para uso

!

!

seguro cuando se instala de manera adecuada en una caja de

clasificación NEMA Tipo 12,13, 4X (uso interior solamente)

IP54 ó IP65.

ATENCION: No aplicar energía al terminal hasta que

todas las conexiones del cableado han sido hechas. El no

hacer esto puede resultar en una descarga eléctrica.

Fuente de

voltage

85 a 264V ca,

47 a 63 Hz

(Protective Earth) a un conductor tierra.

200 VA máximo

Consumo de energía

Page 49

Terminales PanelView 140048

Para conectar energía CA a terminales PanelView 1400:

1. Asegurar los cables de energía CA a los tornillos de terminal de bloque L1 y

L2N.

2. Asegure los cables Tierra al tornillo

ATENCION: La conexión impropia de los terminales de

!

energía puede resultar en voltaje en los conectores de

comunicación. Consultar la figura 7 cuando está cableando.

3. Aplicar energía al terminal.

Figura 7

Conexiones a energía CA

Ranura del destornillador

120/240V ca, 3 Cable con

código de color de U.S.A

Verde

(Tierra)

Blanco

L2/N

L1/L

(Neutral)

Negro

(Línea)

en el bloque de terminal screw.

120/240V ca, 3 Cable

con código de color

Europeo

Verde/Amarillo

(protección tierra)

Azul

L2/N

L1/L

(Neutral)

Marrón

(Línea)

Page 50

Packing Data

Guida per l’installazione

PK

Questo documento descrive il montaggio del terminale PanelV iew 1400 in un

pannello o in una custodia e come dare l’alimentazione.

• Rispondenza alle Direttive dell’Unione Europea

• direttive di cablaggio e di sicurezza

• attrezzi necessari

• custodie

• dimensioni di montaggio

• distanze

• dimensioni di taglio

• installazione del terminale in un pannello

• connessione ca

Per ulteriori informazioni sui T erminali Operatori PanelView 1400, consultare la

pubblicazione 2711-6.1IT.

Page 51

Terminali PanelView 140050

Rispondenza alle Direttive dell’Unione Europea

Se il Terminale Operatore PanelView 1400 contiene il marchio della CE, vuol

dire che è stato approvato per l’installazione nell’Unione Europea e nelle regioni

dell’EEA. Il terminale è stato progettato e collaudato con le seguenti regole.

Direttive dell’EMC

Questo impianto è stato collaudato secondo le Direttive del Consiglio

89/336/EEC per la Compatibilità Elettromagnetica (EMC) utilizzando le seguenti

regole completamente o parzialmente:

• EN 50081-1:1992 EMC – Norma generica sull’emissione, Parte 1 – Ambiente

Residenziale, Commerciale, e Industriale Leggero.

• EN 50082-2:1995 EMC – Norma generica sull’immunità, Parte 2 – Ambiente

Industriale

L’uso del prodotto descritto è previsto per gli ambienti industriali, industriali

leggeri o commerciali.

Direttive di cablaggio e di sicurezza

Prima di installare il terminale PanelView 1400, consultare la pubblicazione 70E,

Requisiti per la Sicurezza Elettrica in Ambiente Industriale. Oltre ai requisiti

generali dell’NFPA si raccomanda di:

• Connettere il terminale PanelView ad una propria derivazione del circuito

L’ingresso di alimentazione dovrà essere protetto da un fusibile o da un

interruttore automatico non superiore a 15 Ampere.

• Instradare il cavo di alimentazione del terminale PanelView 1400

separatamente dal cavo delle comunicazioni.

• Quando le linee di alimentazione e di comunicazione debbono incrociarsi, ciò

deve essere fatto ad angolo retto. Le linee di comunicazione possono essere

installate nello stesso condotto di linee di I/O a bassa tensione cc (meno di 10

volt).

• La messa a terra riduce i rumori derivati dall’Interferenza Elettromagnetica

(EMI) ed è una direttiva di sicurezza per le installazioni elettriche. Per evitare

l’interferenza elettromagnetica, schermare e fare la messa a terra dei cavi

appropriatamente.

• Si possono trovare le raccomandate indicazioni per la messa a terra sull’NEC

(codice nazionale per il materiale elettrico) pubblicato dall’Associazione

Nazionale Protezione Antincendi di Boston.

Page 52

Terminali PanelView 1400 51

Attrezzi necessari

Oltre agli attrezzi necessari per il taglio del pannello, sarà necessario avere:

Per il montaggio con ganci:

• un cacciavite–chiave con punta a croce o piatta

• una barra di estensione di almeno 406 mm

• una chiave dinamometrica (pollici / libbre)

Per il montaggio con perni:

• una chiave di 7/32 e 3/8 di pollice (6mm e 10mm)

• una barra di estensione di almeno 406 mm

• una chiave dinamometrica (pollici / libbre)

Custodie

Il terminale PanelView 1400 dev essere montato in un ambiente che fornisce una

protezione di grado 2 dai contaminanti secondo IEC-1131-2.

Montare il terminale PanelView 1400 in un pannello o custodia per proteggere la

circuiteria interna. Il terminale è conforme alle classificazioni NEMA 12/13 e 4X

(uso interno) solo quando montato in un pannello o custodia con equivalente

classificazione.

È necessario lasciare sufficiente spazio nella custodia per avere adeguata

ventilazione. Considerare il calore prodotto da altri dispositivi nella custodia. La

temperatura ambiente all’esterno del terminale deve essere tra 0 e 55C

(32 e 131F).

Accertarsi di avere accessibilità al retro del pannello del terminale per il

cablaggio, la manutenzione, la regolazione dell’illuminazione/contrasto,

l’installazione di una scheda di memoria e per l’individuazione dei guasti.

Page 53

Terminali PanelView 140052

Dimensioni di montaggio

Le figure sottostanti mostrano le dimensioni di montaggio per i terminali

PanelV iew 1400.

Dimensioni di montaggio per il terminale tattile

3,3 mm

355 mm

441 mm

Dimensioni di montaggio del terminale a tastiera

355 mm

483 mm

370 mm 394 mm

3,3 mm

370 mm

394 mm

Page 54

Terminali PanelView 1400 53

uperiori e

Distanze

Lasciare adeguato spazio per il montaggio, il flusso d’aria, la manutenzione, e per

l’installazione della scheda di memoria e degli inserti legenda.

Distanze di montaggio

Distanze laterali, s

TAGLIO DEL TERMINALE

Utilizzare la dima a dimensioni

reali fornita con il terminale

Veduta Frontale

d inferiori

Lasciare 51 mm per il

montaggio e il flusso d’aria

Lasciare 51 mm per il

montaggio e il flusso d’aria

Lasciare 51 mm per

il montaggio

Distanza posteriore

montaggio e il flusso d’aria

3,3 mm

370 mm

Scheda

Lasciare 51 mm per il

È necessario avere

400 mm per

caricare una

scheda di memoria

Page 55

Terminali PanelView 140054

Dimensioni del Taglio

Utilizzare la dima di taglio a dimensioni reali fornita con il terminale per marcare

le dimensioni. La figura sottostante fornisce una dima ridotta con le dimensioni.

Dimensioni del taglio per il PanelView 1400

Terminale PV1400 a Tastiera

419 mm

110 mm

221 mm

5,56mm dia. (normale)

18 fori

170 mm

Ignorare i fori per i

perni se si utilizzano

ganci per il montaggio

del terminale

Ignorare i fori

per i perni se si

utilizzano ganci

per il montaggio

del terminale

169 mm

Terminali PV1400 Tattili

391 mm)

127 mm

233 mm

140 mm

38 mm

5,56 mm dia. (normale)

140 mm

305 mm

305 mm

12 fori

212 mm

Page 56

Terminali PanelView 1400 55

Installazione del terminale in un pannello

Questa sezione fornisce le procedure per il montaggio del terminale PV1400

usando:

• ganci di montaggio (10 forniti con il terminale, 10 necessari)

• perni di montaggio (ordinati separatamente, N. Catalogo 2711-NP3)

ATTENZIONE: Disinserire tutta la corrente elettrica dal

!

Per installare il terminale PV1400 in un pannello con l’utilizzo dei ganci:

1. Fare un taglio di apertura nel pannello utilizzando la dima del pannello fornita

con il terminale. Rimuovere bordi taglienti o bavature. Non fare i fori per i

perni di montaggio se vengono utilizzati ganci.

pannello prima di fare il taglio.

Accertarsi che l’area vicino al taglio del pannello sia libera.

Fare in modo che i pezzi di metallo non entrino in qualche

componente precedentemente installato nel pannello.

Procedimenti contrari a queste indicazioni potrebbero causare

infortuni o danni all’apparecchiatura.

2. Accertarsi che la guarnizione di tenuta del terminale sia posizionata

correttamente sul terminale come mostrato sulla figura qui sotto. Questa

guarnizione forma una tenuta a compressione. Non usare sostanze sigillanti.

Guarnizione di tenuta

Guarnizione di tenuta

Page 57

Terminali PanelView 140056

3. Anche se la striscia legenda della tastiera può essere installata in qualsiasi

momento, si raccomanda di installarla dopo aver installato il terminale.

4. Posizionare il terminale nella dima del pannello. Il terminale sarà bloccato nel

pannello a mezzo delle linguette provvisorie di ritenzione.

Nota: Il terminale ha due linguette di metallo (sul bordo inferiore) le quali

bloccano temporaneamente il terminale nel pannello. Queste linguette vengono

usate solo per facilitare l’installazione dell’hardware di montaggio e non sono

state progettate per fornire un montaggio permanente.

5. Installare i 10 ganci di montaggio (3 sopra, 3 sotto, 2 su ciascun lato); le

estremità dei ganci scivolano nei canalini del terminale. Stringere a mano le

viti dei ganci di montaggio.

Ganci di montaggio

Installare i 10 ganci di montaggio:

Versioni per tastiera

Versioni per schermo tattile

= Posizionamento dei

ganci di montaggio

Page 58

Terminali PanelView 1400 57

6. Stringere alternatamente le viti dei ganci di montaggio affinchè il terminale

sia tenuto fermamente contro il pannello. Stringere le viti di montaggio con

coppia di serraggio da 1,13 Nm. Non stringere eccessivamente.

ATTENZIONE: Stringere i ganci di montaggio con coppia di

!

Per installare il terminale PV1400 in un pannello utilizzando perni di

montaggio:

1. Fare un taglio di apertura nel pannello utilizzando la dima del pannello fornita

con il terminale. Fare fori di 5,6 mm (7/32 di pollice) per i perni secondo le

indicazioni.

2. Installare i perni di montaggio (N. Catalogo 2711-NP3) utilizzando una

chiave di 5,6mm sull’estremità del perno. Ruotare in senso orario per

stringere di circa 1,1

serraggio da

prevenire danni al terminale. Allen-Bradley non assume nessuna

responsabilità su danni causati da acqua e altre sostanze chimiche

trovate nella custodia del terminale o in altra apparecchiatura

dovuti all’incorretta installazione del terminale.

1,13 Nm per avere una buona tenuta e per

Nm).

Cornice

Guarnizione di Tenuta

ATTENZIONE: Fare attenzione a non danneggiare la

!

guarnizione di tenuta durante l’installazione o la rimozione

dei perni. Una guarnizione danneggiata può causare danni al

terminale e ad altri componenti del pannello.

Perni di montaggio (18 per Tastiera

12 per Tattile

Pannello o Custodia

Dado autobloccante

Distanziatore

Page 59

Terminali PanelView 140058

3. Accertarsi che la guarnizione di tenuta del terminale sia posizionata

correttamente sul terminale. Questa guarnizione forma una tenuta a

compressione (NEMA Tipo 4). Non usare sostanze sigillanti.

4. Posizionare il terminale nella dima del pannello allineando i perni ai fori di

montaggio.

5. Installare e stringere a mano i dadi autobloccanti.

ATTENZIONE: Stringere i ganci di montaggio con coppia di

!

serraggio da 1,13 Nm per avere una buona tenuta e per

prevenire danni al terminale. Allen-Bradley non assume nessuna

responsabilità su danni causati da acqua e altre sostanze chimiche

trovate nella custodia del terminale o in altra apparecchiatura

dovuti all’incorretta installazione del terminale.

6. Stringere alternatamente i dadi autobloccanti (usando una chiave di 10mm)

affinchè il terminale sia tenuto fermamente contro il pannello. (La sequenza

raccomandata di serraggio viene mostrata qui sotto).

I perni hanno un distanziatore integrale che previene l’eccessiva compressione

della guarnizione. La quantità di serraggio aumenta considerevolmente quando si

raggiunge la compressione appropriata della guarnizione. Stringere i dadi con

coppia di serraggio di (1,1 Nm).

9

18

Sequenza raccomandata

di serraggio per terminali

78

17

Notare che la sequenza inizia sui perni al centro e continua su quelli all’angolo.

a tastiera

10

5

1

2

13

1516

34

1112

6

14

43

9

1

Sequenza raccomandata

di serraggio per terminali

tattili

10

2

5

87

1112

6

Page 60

Terminali PanelView 1400 59

Connessione della ca

La tabella qui sotto mostra le classificazioni elettriche per il terminale PanelView

1400.

Tipo di terminale Voltaggio Assorbimento potenza

PV1400

Il terminale PanelView 1400 è un dispositivo di Classe I Apparecchiatura IEC il

quale richiede la connessione del terminale ad un conduttore di terra (terra di

Sicurezza).

ATTENZIONE: Il terminale PanelView 1400 è stato progettato

!

!

tenendo conto della sicurezza nell’uso se installato in una custodia

con classificazione NEMA Tipo 12, 13, 4X (solo per uso interno),

IP54 oppure IP65.

ATTENZIONE: Non applicare tensione prima che sia stato

completato il cablaggio. Procedimenti contrari a queste indicazioni

potrebbero causare scosse elettriche.

DA 85 a 264V ca,

da 47 a 63 Hz

200 VA massimo

Page 61

Terminali PanelView 140060

Per connettere la ca ai terminali PanelView 1400:

1. Fissare il fili di alimentazione a ca sulle viti L1 e L2N della morsettiera.

2. Fissare i fili di T erra/Sicurezza di terra sulle viti di

ATTENZIONE: L’inappropriato cablaggio dei terminali di

!

alimentazione potrebbe dare tensione allo schermo dei connettori di

comunicazione. Prima di fare il cablaggio vedere la figura qui sotto.

3. Applicare tensione al terminale.

Connessioni ca

Fessura per il cacciavite

120/240V ca, 3 Fili,

120/240V ca, 3 Fili,

Codice Colori USA

L2/N

L1/L

Verde

(Terra)

Bianco

(Neutrale)

Nero

(Linea)

Codice Colori Europeo

L2/N

L1/L

della morsettiera.

Verde/Giallo

(Terra di Sicurezza)

Blu

(Neutrale)

Marrone

(Linea)

Page 62

PanelView and PanelView 1400 are trademarks of Allen-Bradley Company, Inc.

Worldwide representation.

Argentina • Australia • Austria • Bahrain • Belgium • Brazil • Bulgaria • Canada • Chile • China, PRC •

Colombia • Costa Rica • Croatia • Cyprus • Czech Republic • Denmark • Ecuador • Egypt • El Salvador •

Finland • France • Germany • Greece • Guatemala • Honduras • Hong Kong • Hungary • Iceland • India •

Indonesia • Ireland • Israel • Italy • Jamaica • Japan • Jordan • Korea • Kuwait • Lebanon • Malaysia •

Mexico • Netherlands • New Zealand • Norway • Pakistan • Peru • Philippines • Poland • Portugal •

Puerto Rico • Qatar • Romania • Russia–CIS • Saudi Arabia • Singapore • Slovakia • Slovenia • South

Africa, Republic • Spain • Sweden • Switzerland • Taiwan • Thailand • Turkey • United Arab Emirates •

United Kingdom • United States • Uruguay • Venezuela • Yugoslavia

Allen-Bradley Headquarters, 1201 South Second Street, Milwaukee, WI 53204 USA, Tel: (1)

414 382-2000 Fax: (1) 414 382-4444

Copyright 1997 Allen-Bradley Company, Inc. Printed in USA

41061-026-01(A)

Loading...

Loading...