Page 1

PanelView Standard Operator

Terminals

User Manual

(Catalog Numbers

PV550, PV600, PV900, PV1000, PV1400

PV300 Micro, PV300,

)

Page 2

Important User Information

Solid state equipment has operational characteristics differing from those of electromechanical equipment. Safety Guidelines

for the Application, Installation and Maintenance of Solid State Controls (publication SGI-1.1 available from your local

Rockwell Automation sales office or online at http://literature.rockwellautomation.com

between solid state equipment and hard-wired electromechanical devices. Because of this difference, and also because of the

wide variety of uses for solid state equipment, all persons responsible for applying this equipment must satisfy themselves

that each intended application of this equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the use or

application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or liability

for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or

software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation, Inc., is

prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

) describes some important differences

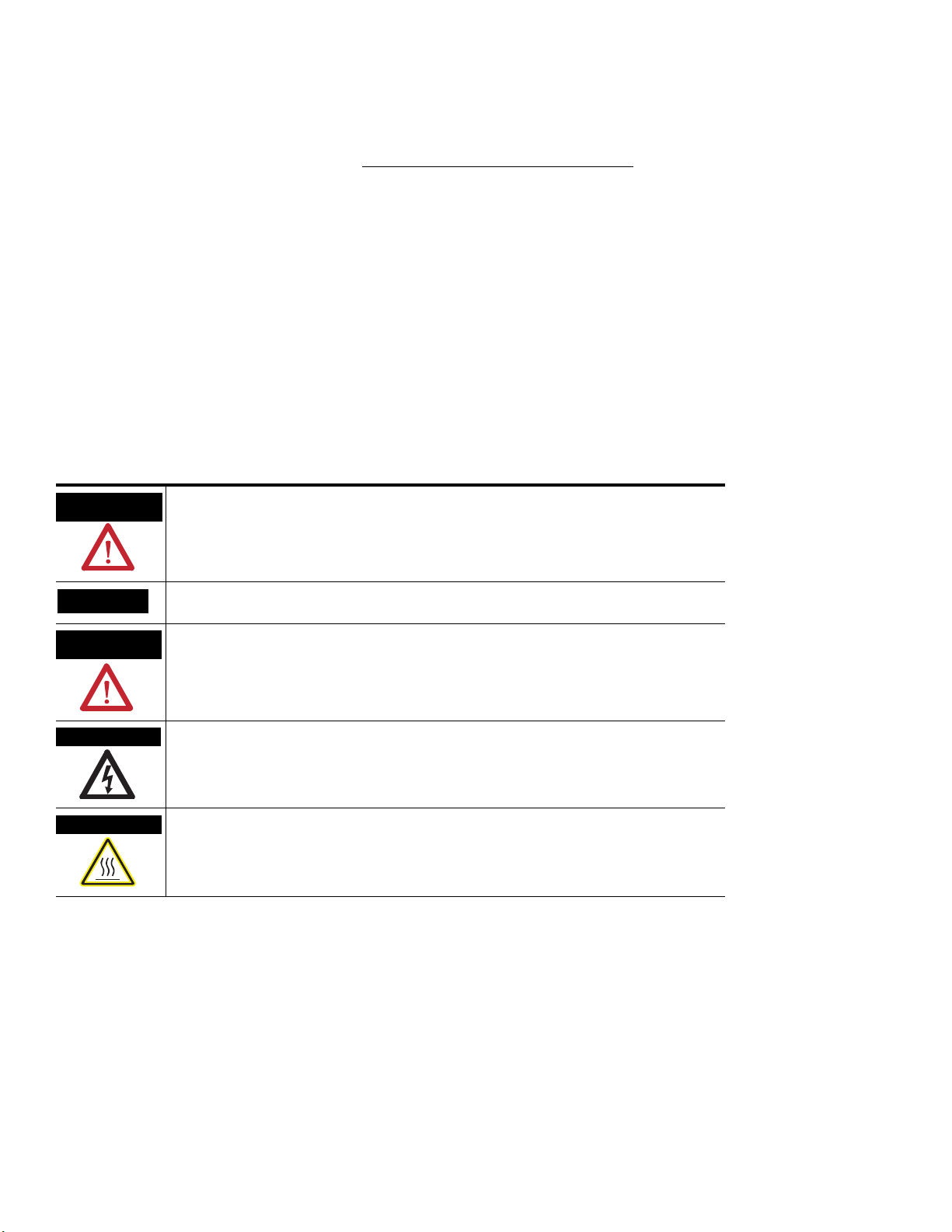

WARNING

Identifies information about practices or circumstances that can cause an explosion in a

hazardous environment, which may lead to personal injury or death, property damage, or

economic loss.

IMPORTANT

ATTENTION

Identifies information that is critical for successful application and understanding of the product.

Identifies information about practices or circumstances that can lead to personal injury or death,

property damage, or economic loss. Attentions help you identify a hazard, avoid a hazard, and

recognize the consequence

SHOCK HAZARD

Labels may be on or inside the equipment, for example, a drive or motor, to alert people that

dangerous voltage may be present.

BURN HAZARD

Labels may be on or inside the equipment, for example, a drive or motor, to alert people that

surfaces may reach dangerous temperatures.

Allen-Bradley, Rockwell Automation, and TechConnect are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Page 3

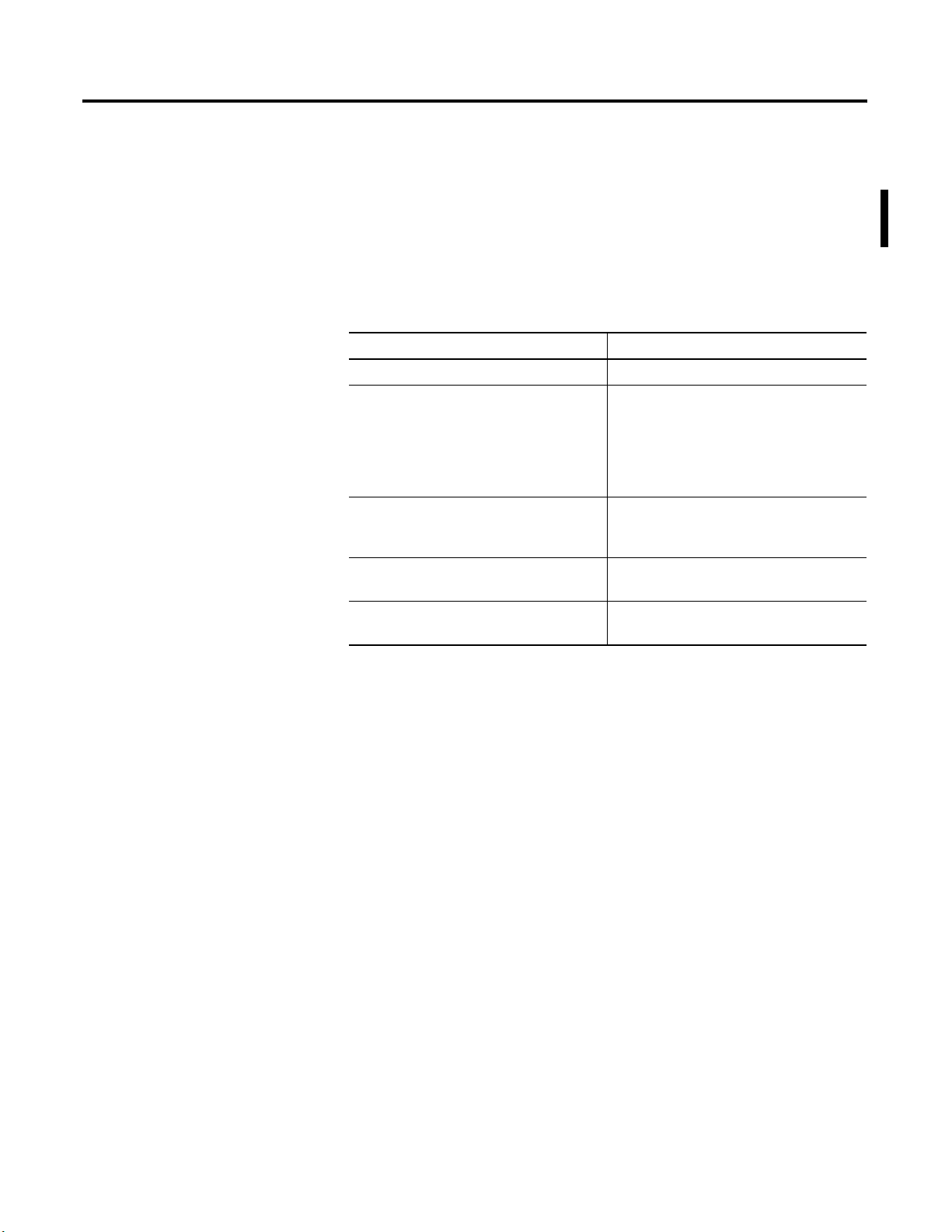

Summary of Changes

The information below summarizes the changes to this manual since

the last publication.

To help you find new and updated information in this release of the

manual, we have included change bars as shown to the right of this

paragraph.

Topic Page

Updated list of supported memory cards. 105

Added information on the proper placement

of the sealing gasket.

Added information on airborne

contaminants for the PanelView 300

terminal.

Added EU Battery Directive to the list of

agency certifications.

Added information on battery replacement

and disposal.

136

143

150

158

167

173

235

248

271

3Publication 2711-UM014G-EN-P - September 2008 3

Page 4

Summary of Changes

4 Publication 2711-UM014G-EN-P - September 2008

Page 5

Table of Contents

Preface

Terminal Overview

Objectives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Terminology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Installing PanelView Terminals . . . . . . . . . . . . . . . . . . . . . . 15

European Union Directive Compliance . . . . . . . . . . . . . . . . 15

Additional Resources. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Technical Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Chapter 1

Chapter Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Intended Uses. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Terminal Types. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Color and Grayscale Terminals . . . . . . . . . . . . . . . . . . . . 18

PanelView 300 Monochrome Terminals . . . . . . . . . . . . . 18

PanelView 300 Micro Monochrome Terminals . . . . . . . . . 18

PanelView 550 Monochrome Terminals . . . . . . . . . . . . . 19

PanelView 600 Color Terminals . . . . . . . . . . . . . . . . . . . 20

PanelView 900 Monochrome Terminals . . . . . . . . . . . . . 21

PanelView 900 Color Terminals . . . . . . . . . . . . . . . . . . . 22

PanelView 1000 Color Terminals . . . . . . . . . . . . . . . . . . 23

PanelView 1000 Grayscale Terminals . . . . . . . . . . . . . . . 24

PanelView 1400 Color Terminals . . . . . . . . . . . . . . . . . . 25

PanelView 300 Micro Terminal Features. . . . . . . . . . . . . . . . 26

PanelView 300 Micro Terminal Features (front) . . . . . . . . 26

PanelView 300 Micro Terminal Features (back) . . . . . . . . 26

PanelView 300 Terminal Features . . . . . . . . . . . . . . . . . . . . 27

PanelView 300 Terminal Features (front). . . . . . . . . . . . . 27

PanelView 300 Terminal Features (back). . . . . . . . . . . . . 28

PanelView 550 Terminal Features . . . . . . . . . . . . . . . . . . . . 29

PanelView 550 Terminal Features (front). . . . . . . . . . . . . 29

PanelView 550 Keypad or Keypad and Touch Screen

Terminals (back) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

PanelView 550 Touch Screen Terminal Features (back) . . 32

PanelView 600 Terminal Features . . . . . . . . . . . . . . . . . . . . 34

PanelView 600 Terminal Features (front). . . . . . . . . . . . . 34

PanelView 600 Keypad or Keypad & Touch Screen

Terminal (back) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

PanelView 600 Touch Screen Terminal Features (back) . . 38

PanelView 900/1000 Terminal Features . . . . . . . . . . . . . . . . 40

PanelView 900/1000 Terminal Features (front) . . . . . . . . 40

PanelView 900/1000 Terminal Features (back) . . . . . . . . 42

PanelView 1400 Terminal Features. . . . . . . . . . . . . . . . . . . . 44

PanelView 1400 Terminal Features (front). . . . . . . . . . . . 44

PanelView 1400 Terminal Features (back and sides) . . . . 46

5Publication 2711-UM014G-EN-P - September 2008 5

Page 6

Table of Contents

Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Touch Screen Operation . . . . . . . . . . . . . . . . . . . . . . . . 49

Keypad Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Configuration Mode Menu. . . . . . . . . . . . . . . . . . . . . . . . . . 50

Terminal Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Printing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Alarm List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Function Key Legend Kits. . . . . . . . . . . . . . . . . . . . . . . . 52

Memory Cards and Retainer . . . . . . . . . . . . . . . . . . . . . 52

Antiglare Overlay. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

DH-485 Operating and Programming Cables . . . . . . . . . . 53

PanelView File Transfer Utility . . . . . . . . . . . . . . . . . . . . 54

Power Supply and Link Couplers . . . . . . . . . . . . . . . . . . 54

RS-232 Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Remote I/O or DH+ Cable . . . . . . . . . . . . . . . . . . . . . . 55

Replacement Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Backlight Lamps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Real Time Clock Modules. . . . . . . . . . . . . . . . . . . . . . . . 56

Panel Mount Clips and Studs . . . . . . . . . . . . . . . . . . . . . 57

Remote I/O Connector. . . . . . . . . . . . . . . . . . . . . . . . . . 57

Power Input Connector . . . . . . . . . . . . . . . . . . . . . . . . . 57

Applying Power and Resetting

Terminal

Configuring the Terminal

Chapter 2

Chapter Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Wiring and Safety Guidelines. . . . . . . . . . . . . . . . . . . . . . . . 59

Hazardous Location Considerations . . . . . . . . . . . . . . . . . . . 60

Connect AC Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Connect dc Power. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Reset the Terminal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Power-up Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

For DH-485 and RS-232 Terminals . . . . . . . . . . . . . . . . . 67

For Remote I/O Terminals . . . . . . . . . . . . . . . . . . . . . . . 68

Chapter 3

Chapter Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Application Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Access the Configuration Mode Menu . . . . . . . . . . . . . . . . . 72

Operations List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Language. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Run Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Reset Video . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Comm and Fault Status Indicators. . . . . . . . . . . . . . . . . . 73

6 Publication 2711-UM014G-EN-P - September 2008

Page 7

Table of Contents

Select a Language . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Language List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Exit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Use a Memory Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Memory Card Listing . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Disconnect Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Applications on Card . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Restore From Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Save to Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Erase/Format Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Exit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Configure Communication. . . . . . . . . . . . . . . . . . . . . . . . . . 75

DH-485 Communication. . . . . . . . . . . . . . . . . . . . . . . . . 75

DH+ Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Remote I/O Communication. . . . . . . . . . . . . . . . . . . . . . 78

ControlNet Communication . . . . . . . . . . . . . . . . . . . . . . 79

DeviceNet Communication. . . . . . . . . . . . . . . . . . . . . . . 82

DF1 Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

EtherNet/IP Communication . . . . . . . . . . . . . . . . . . . . . . 86

Configure Presets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Power-up with Presets or Last States. . . . . . . . . . . . . . . . 88

Restart Unit and Load Values . . . . . . . . . . . . . . . . . . . . . 88

Key Repeat Rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Key Repeat Delay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Exit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Viewing Terminal Information . . . . . . . . . . . . . . . . . . . . . . . 89

Boot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Firmware. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Filename . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Font File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Exit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Adjust Screen Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . 90

PanelView 300 Micro Terminal Screen Setup. . . . . . . . . . 90

PanelView 300 Terminal Screen Setup . . . . . . . . . . . . . . 91

PanelView 550 Terminal Screen Setup . . . . . . . . . . . . . . 93

PanelView 600/900/1000 Color Terminal Screen Setup . . 94

PanelView 900 Monochrome Terminal Screen Setup . . . . 95

PanelView 1000 Grayscale Terminal Screen Setup . . . . . . 97

PanelView 1400 Color Terminal Screen Setup . . . . . . . . . 98

Set the Time and Date. . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Set the Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Set the Date. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Exit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Publication 2711-UM014G-EN-P - September 2008 7

Page 8

Table of Contents

Using a Memory Card

Running Applications

Set Up the Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Handshaking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Communication Parameters . . . . . . . . . . . . . . . . . . . . . 102

Baud Rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Top of Form . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Port Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Exit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Chapter 4

Chapter Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Supported Memory Cards . . . . . . . . . . . . . . . . . . . . . . . . . 105

Use the Memory Card Retainer . . . . . . . . . . . . . . . . . . . . . 106

Load Application from a Memory Card. . . . . . . . . . . . . . . . 108

Load Application on a Memory Card . . . . . . . . . . . . . . . . . 110

Store Font Files on a Memory Card . . . . . . . . . . . . . . . . . . 111

Remove a Memory Card . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Chapter 5

Chapter Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Application Information. . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Important Information for PanelView 300 Micro Terminal

Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Screen Security . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Push Button Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Control Lists . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Active List Item . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Active Control List . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Cursor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

List Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Cursor-piloted Control Lists . . . . . . . . . . . . . . . . . . . . . 117

Numeric Entry Cursor Point . . . . . . . . . . . . . . . . . . . . . 118

Keypad Enable Button . . . . . . . . . . . . . . . . . . . . . . . . . 118

Scratchpad. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

ASCII Entry Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

ASCII Scratchpad - Keypad or Keypad/Touch Screen

Terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

ASCII Scratchpad - PV300 Micro/300 Terminals . . . . . . . 122

ASCII Scratchpad - PV550/600 Touch Screen Terminals . 123

ASCII Scratchpad - PV900/1000/1400 Touch Screen

Terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

ASCII Scratchpads in Other Languages . . . . . . . . . . . . . 125

Screen Selectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Cursor Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

List Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

List Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

8 Publication 2711-UM014G-EN-P - September 2008

Page 9

Installing the PV300 Micro

Terminal

Table of Contents

Multistate Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Bar Graph Displays. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Analog Gauges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Numeric Data Displays . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Message Displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Time or Date . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

Printing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

Chapter 6

Chapter Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

Hazardous Location Considerations . . . . . . . . . . . . . . . . . . 133

Enclosures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

Required Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

Mounting Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

Cutout Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Clearances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Install Terminal in Panel . . . . . . . . . . . . . . . . . . . . . . . . . . 136

Installing the PV300 Terminal

Installing the PV550 Terminal

Chapter 7

Chapter Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

Hazardous Location Considerations . . . . . . . . . . . . . . . . . . 139

Enclosures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

Required Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

Mounting Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

Cutout Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

Clearances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

Install the PV300 Terminal in a Panel. . . . . . . . . . . . . . . . . 143

Chapter 8

Chapter Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

Hazardous Location Considerations . . . . . . . . . . . . . . . . . . 145

Enclosures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

Required Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

Mounting Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

PV550 Keypad, Keypad & Touch Screen Terminals . . . . 147

PV550 Touch Screen Terminals. . . . . . . . . . . . . . . . . . . 147

Clearances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

Cutout Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

PV550 Keypad, Keypad and Touch Screen Terminals . . 149

PV550 Touch Screen Terminals. . . . . . . . . . . . . . . . . . . 149

Install the PV550 Terminal in a Panel. . . . . . . . . . . . . . . . . 150

Publication 2711-UM014G-EN-P - September 2008 9

Page 10

Table of Contents

Installing the PV600 Terminal

Installing the PV900/1000

Terminals

Chapter 9

Chapter Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

Hazardous Location Considerations . . . . . . . . . . . . . . . . . . 153

Enclosures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

Required Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

Mounting Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

PV600 Keypad, Keypad and Touch Screen Terminals . . 155

PV600 Touch Screen Terminals. . . . . . . . . . . . . . . . . . . 155

Cutout Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

PV600 Keypad, Keypad and Touch Screen Terminals . . 156

PV600 Touch Screen Terminals. . . . . . . . . . . . . . . . . . . 156

Clearances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

PV600 Keypad and Keypad and Touch Screen

Terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

PV600 Touch Screen Terminals. . . . . . . . . . . . . . . . . . . 157

Install the PV600 in a Panel . . . . . . . . . . . . . . . . . . . . . . . . 158

Chapter 10

Chapter Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

Hazardous Location Considerations . . . . . . . . . . . . . . . . . . 161

Enclosures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

Required Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

PV900 Terminals Mounting Dimensions . . . . . . . . . . . . . . . 163

PV900 Touch Terminal Mounting Dimensions . . . . . . . . 163

PV900 Keypad Terminal Mounting Dimensions . . . . . . . 163

PV1000 Terminals Mounting Dimensions . . . . . . . . . . . . . . 164

PV1000 Touch Terminal Mounting Dimensions . . . . . . . 164

PV1000 Keypad Terminal Mounting Dimensions . . . . . . 164

Clearances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

Cutout Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

PV900 Panel Cutout Dimensions. . . . . . . . . . . . . . . . . . 166

PV1000 Panel Cutout Dimensions . . . . . . . . . . . . . . . . . 166

Install the PV900/PV1000 Terminals in a Panel . . . . . . . . . . 167

Chapter 11

Installing the PV1400 Terminal

10 Publication 2711-UM014G-EN-P - September 2008

Chapter Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

Enclosures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

Required Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

Mounting Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

PV1400 Touch Terminal Mounting Dimensions . . . . . . . 170

PV1400 Keypad Terminal Mounting Dimensions . . . . . . 170

Clearances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

Cutout Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

PV1400 Keypad Terminals . . . . . . . . . . . . . . . . . . . . . . 172

PV1400 Touch Screen Terminals. . . . . . . . . . . . . . . . . . 172

Page 11

Terminal Connections

Table of Contents

Install the PV1400 Terminal in a Panel . . . . . . . . . . . . . . . . 173

Mount Terminal with Mounting Studs . . . . . . . . . . . . . . 175

Chapter 12

Chapter Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

Wiring and Safety Guidelines. . . . . . . . . . . . . . . . . . . . . . . 177

Cable Charts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 178

Runtime Communication Cables - to Processors . . . . . . 178

Runtime Communication Cables - to Network Interface

Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

Application File Upload/Download (Direct) Cables . . . . 184

Remote I/O Terminal Connections. . . . . . . . . . . . . . . . . . . 185

Remote I/O Terminal Ports. . . . . . . . . . . . . . . . . . . . . . 185

Supported Controllers . . . . . . . . . . . . . . . . . . . . . . . . . 186

Making Remote I/O Connections . . . . . . . . . . . . . . . . . 187

Remote I/O Pass-through using DH+ . . . . . . . . . . . . . . 188

DH+ Terminal Connections . . . . . . . . . . . . . . . . . . . . . . . . 189

DH+ Terminal Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

Typical DH+ System Configuration . . . . . . . . . . . . . . . . 190

Making DH+ Connections . . . . . . . . . . . . . . . . . . . . . . 191

DH-485 Terminal Connections. . . . . . . . . . . . . . . . . . . . . . 192

DH-485 Terminal Ports (RJ45). . . . . . . . . . . . . . . . . . . . 192

Connecting to a Single SLC Controller (Point-to-point). . 193

Connecting to a DH-485 Network. . . . . . . . . . . . . . . . . 194

Connecting a Computer . . . . . . . . . . . . . . . . . . . . . . . . 196

Connecting a Hand-held Terminal . . . . . . . . . . . . . . . . 198

RS-232 (DH-485) Terminal Connections . . . . . . . . . . . . . . . 199

RS-232 Terminal Ports . . . . . . . . . . . . . . . . . . . . . . . . . 199

Connecting to an SLC, CompactLogix, MicroLogix

Controller (Point-to-point) . . . . . . . . . . . . . . . . . . . . . . 200

Connecting to a MicroLogix Controller through an

AIC+ Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

Connecting a Computer . . . . . . . . . . . . . . . . . . . . . . . . 201

Connecting a DH+ to DH-485 Pass-through Link. . . . . . 202

RS-232 (DF1) Terminal Connections. . . . . . . . . . . . . . . . . . 202

Compatible Controllers. . . . . . . . . . . . . . . . . . . . . . . . . 203

RS-232 (DF1) Terminal Ports. . . . . . . . . . . . . . . . . . . . . 203

RS-232/DF1 Port Connector . . . . . . . . . . . . . . . . . . . . . 204

Connecting to a MicroLogix 1000 Controller . . . . . . . . . 204

Connecting to an SLC, PLC, or MicroLogix 1500LRP

Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 205

Connecting to a CompactLogix or FlexLogix . . . . . . . . . 205

Using a Modem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 206

Connecting to a DeviceNet or EtherNet/IP Network . . . 206

Constructing a Null Modem Cable . . . . . . . . . . . . . . . . 207

Publication 2711-UM014G-EN-P - September 2008 11

Page 12

Table of Contents

ControlNet Connections . . . . . . . . . . . . . . . . . . . . . . . . . . 207

Related Information . . . . . . . . . . . . . . . . . . . . . . . . . . . 207

ControlNet Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . 208

Compatible ControlNet Controllers . . . . . . . . . . . . . . . . 208

ControlNet Terminal Ports . . . . . . . . . . . . . . . . . . . . . . 208

Typical ControlNet Network . . . . . . . . . . . . . . . . . . . . . 209

Making ControlNet Connections . . . . . . . . . . . . . . . . . . 210

NAP and Redundant Cables . . . . . . . . . . . . . . . . . . . . . 211

DeviceNet Network Terminal Connections . . . . . . . . . . . . . 212

DeviceNet Terminal Ports. . . . . . . . . . . . . . . . . . . . . . . 212

Making DeviceNet Connections . . . . . . . . . . . . . . . . . . 213

Typical DeviceNet Network . . . . . . . . . . . . . . . . . . . . . 214

EtherNet/IP Connections . . . . . . . . . . . . . . . . . . . . . . . . . 215

EtherNet/IP Terminal Ports. . . . . . . . . . . . . . . . . . . . . . 215

Ethernet Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . 216

Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 216

Typical EtherNet/IP Configuration . . . . . . . . . . . . . . . . 217

PanelView 300 Micro Terminal Connections. . . . . . . . . . . . 218

RS-232 Communication Port . . . . . . . . . . . . . . . . . . . . . 218

Connecting to a MicroLogix Controller . . . . . . . . . . . . . 218

Connecting to an SLC, PLC-5, ControlLogix, MicroLogix

1500LRP, CompactLogix, or FlexLogix. . . . . . . . . . . . . . 219

Connecting to an Advanced Interface Converter . . . . . . 220

Connecting to a DeviceNet Interface (DNI) . . . . . . . . . . 220

Connecting to a Personal Computer (Application File

Transfers) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 221

Connecting a Computer or Printer to the Terminal . . . . . . . 223

Chapter 13

Troubleshooting and Maintenance

Chapter Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 225

Equipment Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 225

Use the Troubleshooting Chart . . . . . . . . . . . . . . . . . . . . . 225

Interpret Status Indicators . . . . . . . . . . . . . . . . . . . . . . . . . 229

Clean the Display Window . . . . . . . . . . . . . . . . . . . . . . . . 231

Remove Paint and Grease . . . . . . . . . . . . . . . . . . . . . . 231

Equipment Hose-downs . . . . . . . . . . . . . . . . . . . . . . . . 231

Replace the Clock Module. . . . . . . . . . . . . . . . . . . . . . . . . 232

Replace the Backlight . . . . . . . . . . . . . . . . . . . . . . . . . . . . 232

Appendix A

Specifications

12 Publication 2711-UM014G-EN-P - September 2008

PanelView 300 Micro Terminal . . . . . . . . . . . . . . . . . . . . . 233

PanelView 300 Terminal . . . . . . . . . . . . . . . . . . . . . . . . . . 234

PanelView 550 Terminals . . . . . . . . . . . . . . . . . . . . . . . . . 236

PanelView 600 Color Keypad and Touch Terminals . . . . . . 238

PanelView 600 Color Touch Only Terminals . . . . . . . . . . 239

Page 13

Messages, Codes and Self-test

Numbers

Table of Contents

PanelView 900 Monochrome and Color Terminals . . . . . . . 240

PanelView 1000 Color & Grayscale . . . . . . . . . . . . . . . . . . 244

PanelView 1400 Color . . . . . . . . . . . . . . . . . . . . . . . . . . . . 245

Communication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 247

Agency Certifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 248

Appendix B

Types of Terminal Messages . . . . . . . . . . . . . . . . . . . . . . . 249

Status Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 249

Reminder Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . 249

Warning Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . 249

Fault Messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 249

General Terminal Messages . . . . . . . . . . . . . . . . . . . . . . . . 250

DH-485 Terminal Messages . . . . . . . . . . . . . . . . . . . . . 254

ControlNet Terminal Messages . . . . . . . . . . . . . . . . . . . 255

Remote I/O Terminal Messages . . . . . . . . . . . . . . . . . . 256

EtherNet/IP Messages. . . . . . . . . . . . . . . . . . . . . . . . . . 256

DH+ Terminal Messages. . . . . . . . . . . . . . . . . . . . . . . . 257

DF1 Terminal Messages . . . . . . . . . . . . . . . . . . . . . . . . 258

Terminal Codes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 258

DeviceNet Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 258

General Codes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 262

ControlNet Codes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 262

EtherNet/IP Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . 263

Remote I/O Communication Loss. . . . . . . . . . . . . . . . . . . . 267

Self-test Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 267

Appendix C

European Union Directive

Compliance

EMC and Low Voltage Directives . . . . . . . . . . . . . . . . . 269

Intended Use of Product . . . . . . . . . . . . . . . . . . . . . . . 270

Wiring Recommendations. . . . . . . . . . . . . . . . . . . . . . . 270

Declarations of Conformity. . . . . . . . . . . . . . . . . . . . . . 270

Battery Replacement and Disposal . . . . . . . . . . . . . . . . 271

Glossary

Index

Publication 2711-UM014G-EN-P - September 2008 13

Page 14

Table of Contents

14 Publication 2711-UM014G-EN-P - September 2008

Page 15

Preface

Objectives

Intended Audience

Conventions

Read this preface to familiarize yourself with the rest of this manual.

• Intended audience

• Conventions used

• Terminology

• Installing PanelView terminals

• European Union Directive Compliance

• Related publications

• Technical support

No special knowledge is required to understand this manual or

operate the PanelView terminals. Before running an application, you

must know the functions of all screens and screen objects. This

information is available from the application designer.

Equipment installers must be familiar with standard panel installation

techniques.

The manual uses these conventions:

Terminology

Installing PanelView Terminals

European Union Directive Compliance

• For specific PanelView terminals, PanelView is replaced with the

PV abbreviation. For example: PV1000 refers to the PanelView

1000 terminal.

• PanelView terminal refers to any one of the PanelView

terminals.

This manual contains some terms that may be unfamiliar.

Use the Glossary on page 273

Each terminal is shipped with installation instructions and a panel

cutout. Please follow these instructions when installing your

PanelView terminal in a panel or enclosure.

Refer to Appendix C for details on installing the PanelView terminals

in industrial environments requiring compliance with European Union

Directives.

of this manual for assistance.

15Publication 2711-UM014G-EN-P - September 2008 15

Page 16

Preface

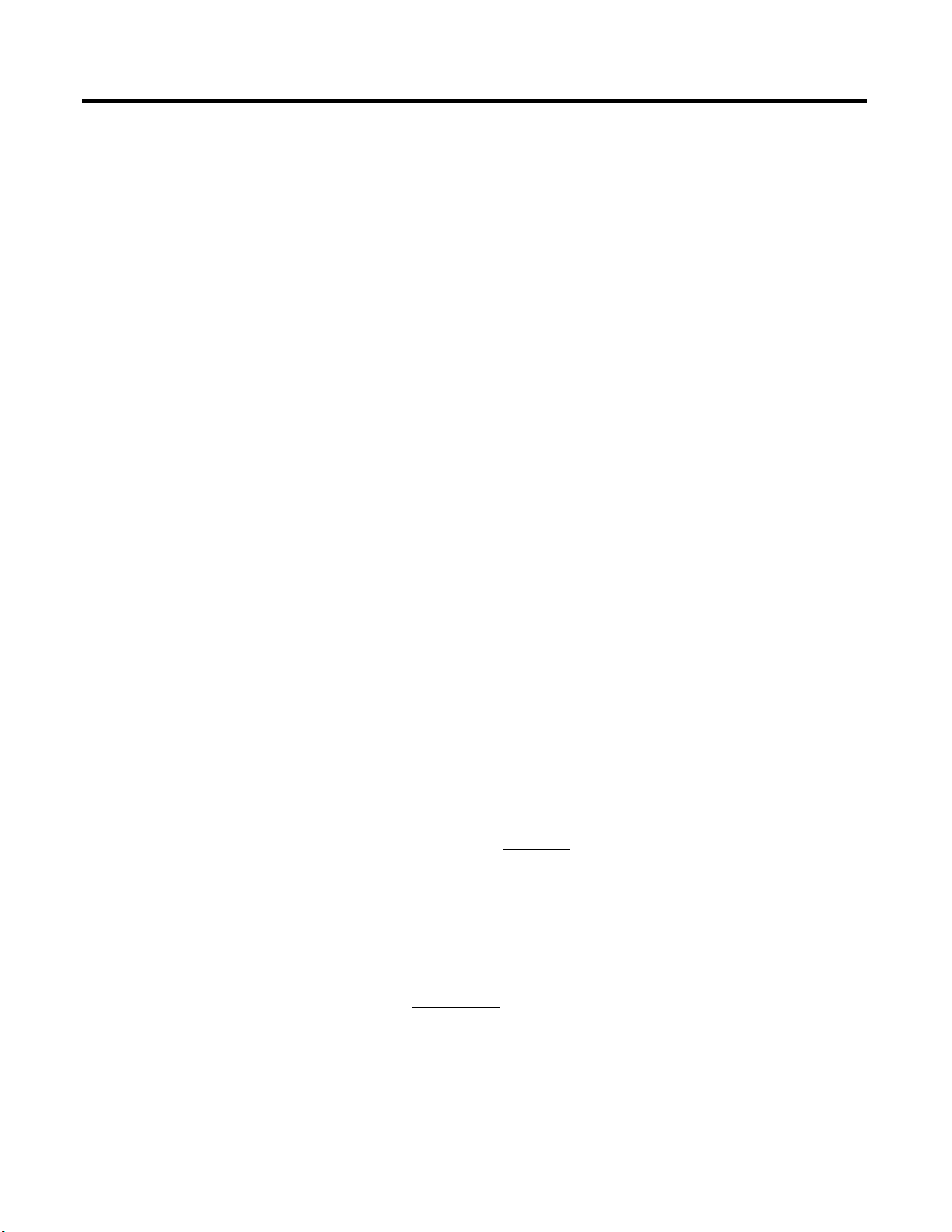

Additional Resources

Refer to the extensive online help for the PanelBuilder32 Software or

the following publications if necessary.

Resource Description

PanelBuilder32 Software Getting Results

Manual, publication 2711-GR003

PanelBuilder32 Quick Start Manual,

publication 2711-QS003

WinPFT File Transfer Utility, publication

2711-TD006

PROFIBUS DP Communication for

PanelView Terminals, publication 2711-6.3

Modbus Communication for PanelView

Terminals, publication 2711-6.9

Programmable Controller Wiring and

Grounding Guidelines, publication 1770-4.1

Data Highway/Data Highway Plus/Data

Highway-485 Cable Installation Manual,

publication 1770-6.2.2

Information about using PanelBuilder32

software

Information about starting PanelBuilder32

software

Information about the WinPFT file transfer

utility

Information about PROFIBUS DP

communication for PanelView terminals

Information about Modbus communication

for PanelView terminals

Information on wiring and grounding

Information about installing Data

Highway/Data Highway Plus/Data

Highway-485 cable

Technical Support

For information relating to your controller, refer to the appropriate

manual.

If you have questions about the PanelView terminals or the

PanelBuilder32 software, please refer to the online manuals or online

help provided with the PanelBuilder32 installation CD. These

publications are also available from the literature library at:

http://literature.rockwellautomation.com

Frequently Asked Questions

Documents on frequently asked questions are available at:

http://www.rockwellautomation.com/knowledgebase

Software and Firmware Upgrades

To receive software updates (software serial number required) and

firmware upgrades for your PanelView terminal:

• locate on PanelBuilder32 installation CD.

• call Rockwell Software at 1-440-646-7700 or fax 1-440-646-7701.

• access www.software.rockwell.com

.

16 Publication 2711-UM014G-EN-P - September 2008

Page 17

Terminal Overview

Chapter

1

Chapter Objectives

Intended Uses

This chapter gives an overview of the PanelView Operator Terminals.

• Intended uses

• Terminal types and features

• Applications

• Configuration mode

• Terminal messages

• Printing

• Accessories and replacement parts

You can use the PanelView operator terminals for a wide variety of

machine control and monitoring applications.

ATTENTION

Do not use a PanelView terminal for emergency stops or other

controls critical to the safety of personnel or equipment. Use

separate hardwired operator interface devices that do not

depend on solid state electronics. See the inside front cover of

this manual for guidelines.

Terminal Types

17Publication 2711-UM014G-EN-P - September 2008 17

PanelView terminals are available in a variety of options.

• Display size and type (monochrome, grayscale, color)

• Operator input (touch screen or keypad)

• Communication port (DH-485, RS-232, remote I/O, DH+,

ControlNet, DeviceNet, Ethernet, EtherNet/IP, DF1)

• RS-232 printer port support

In addition, some terminals are available with:

• AC or DC power (L1 at the end of a catalog number indicates a

DC terminal, for example, 2711-B5A1L1

• stainless steel bezel available on PanelView 550 keypad or

keypad & touch terminals.

Contact your Allen-Bradley representative for availability.

, or -T9C1L1).

Page 18

Chapter 1 Terminal Overview

Color and Grayscale Terminals

Color terminals support a fixed palette of 32 standard EGA colors.

Grayscale terminals support a fixed palette of four colors (shades of

gray). All color in an application is defined when the application is

created. Colors are not selectable at the terminal.

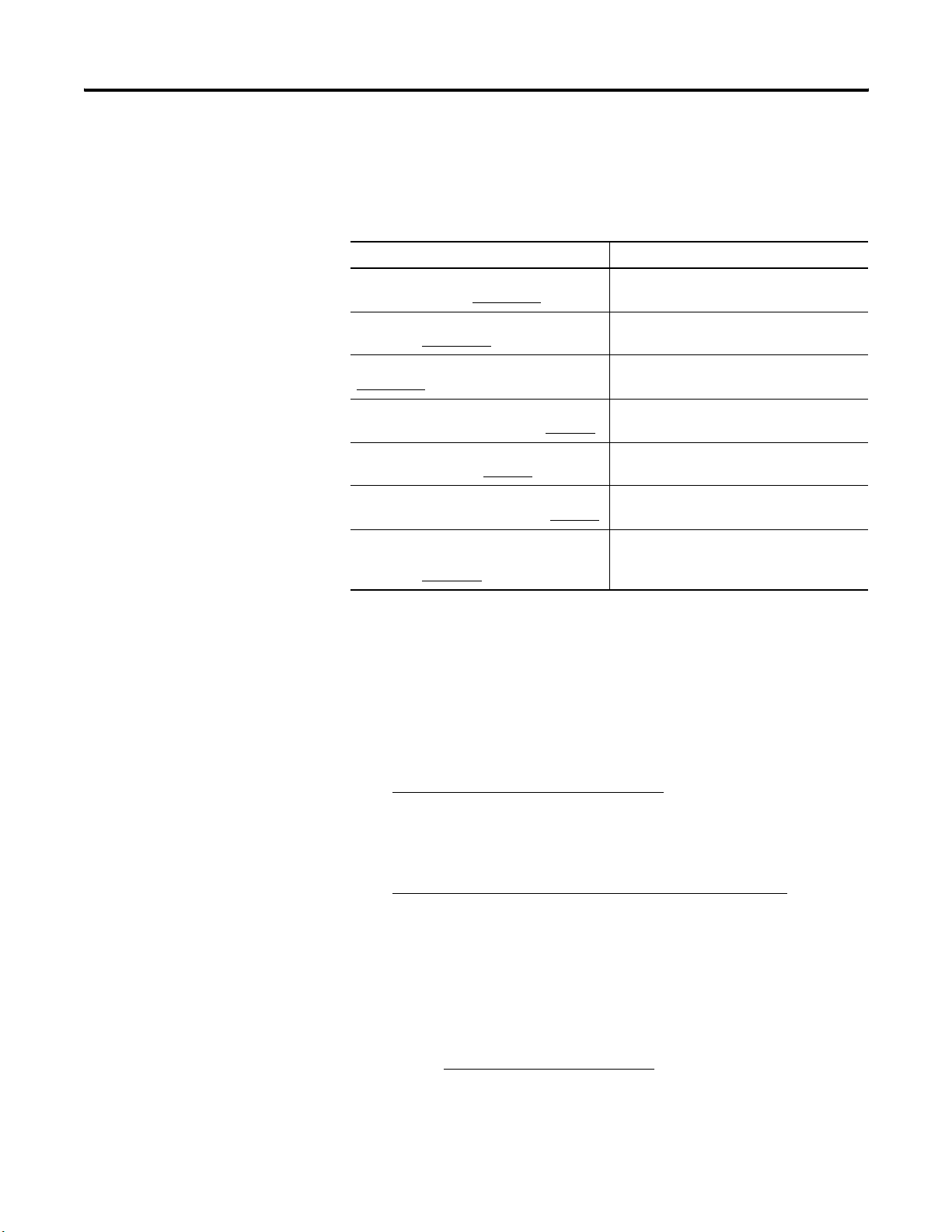

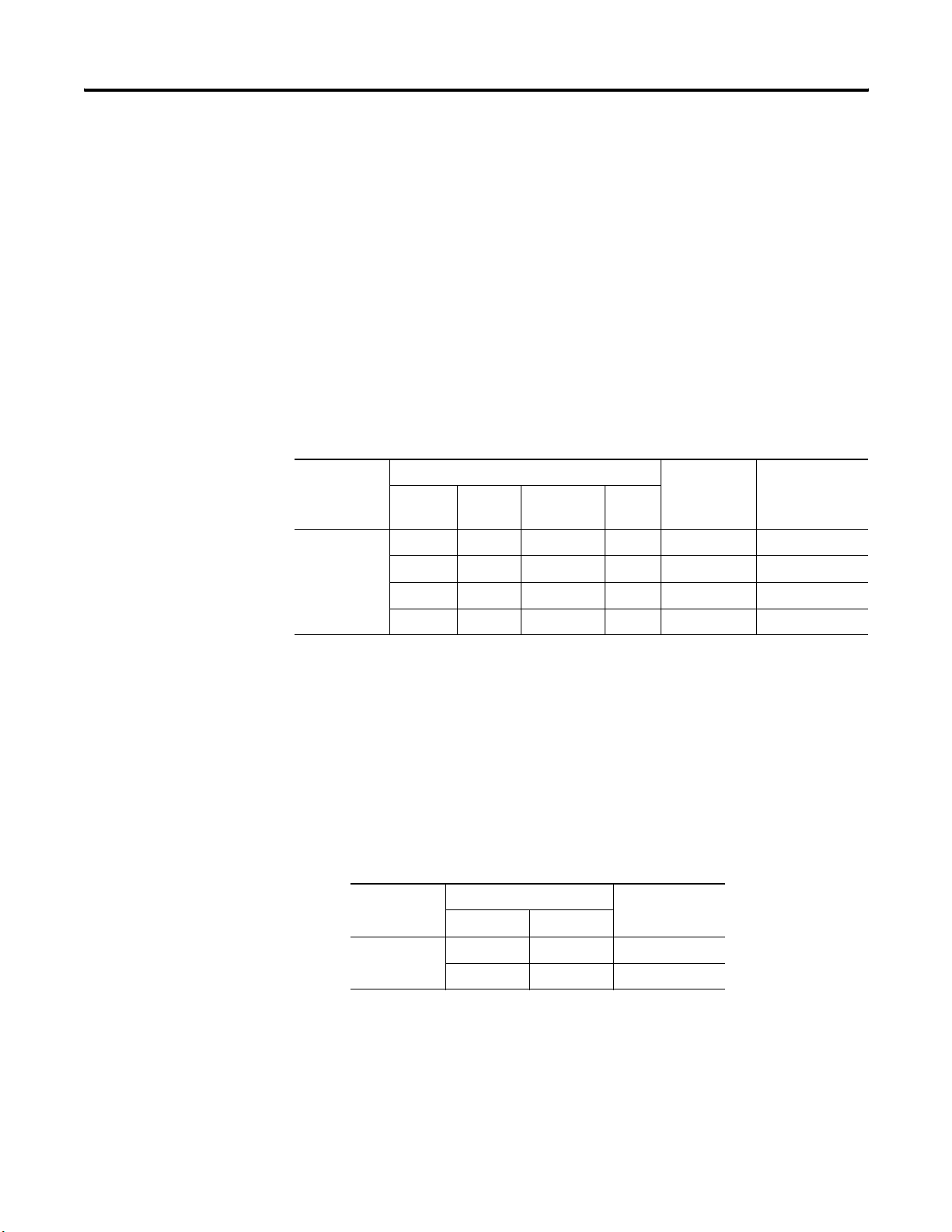

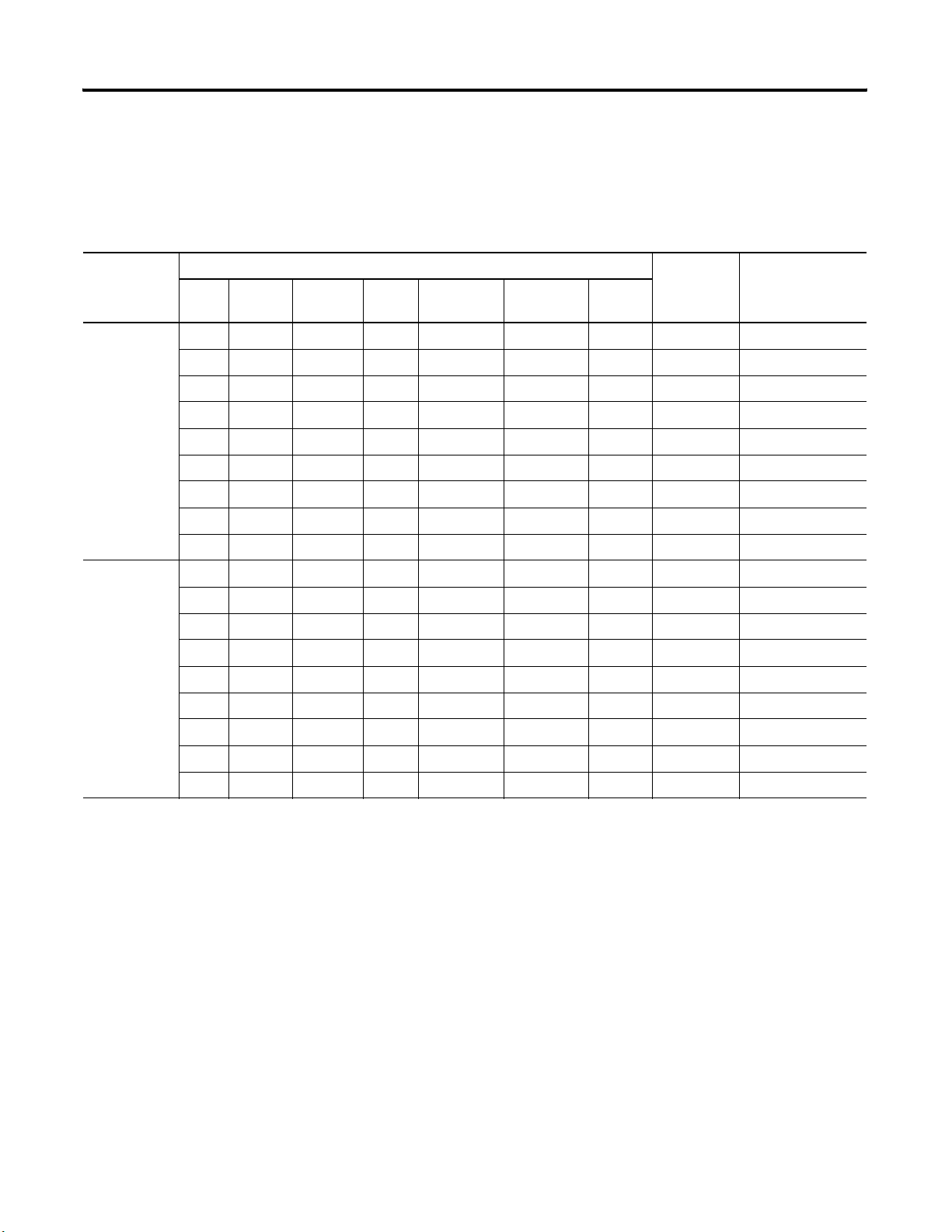

PanelView 300 Monochrome Terminals

The PanelView 300 terminal is only available with 24V DC input

power.

Operator

Input

Keypad x 2711-K3A2L1

Communication Port Printer Port

DH-485 RS-232

(DH-485)

x 2711-K3A5L1

DeviceNet RS-232

(DF1)

x x 2711-K3A10L1

x 2711-K3A17L1

RS-232

Catalog

Number

PanelView 300 Micro Monochrome Terminals

The PanelView 300 Micro terminal is available only with 24V DC input

power and does not have a printer port. The PV300 Micro terminal

contains a single RS-232 communication port which supports either

DF1 or DH485 communication protocols as specified in the table

below.

Operator

Input

Communication Port Catalog

DH-485 DF1

Number

Keypad x 2711-M3A19L1

x 2711-M3A18L1

18 Publication 2711-UM014G-EN-P - September 2008

Page 19

Terminal Overview Chapter 1

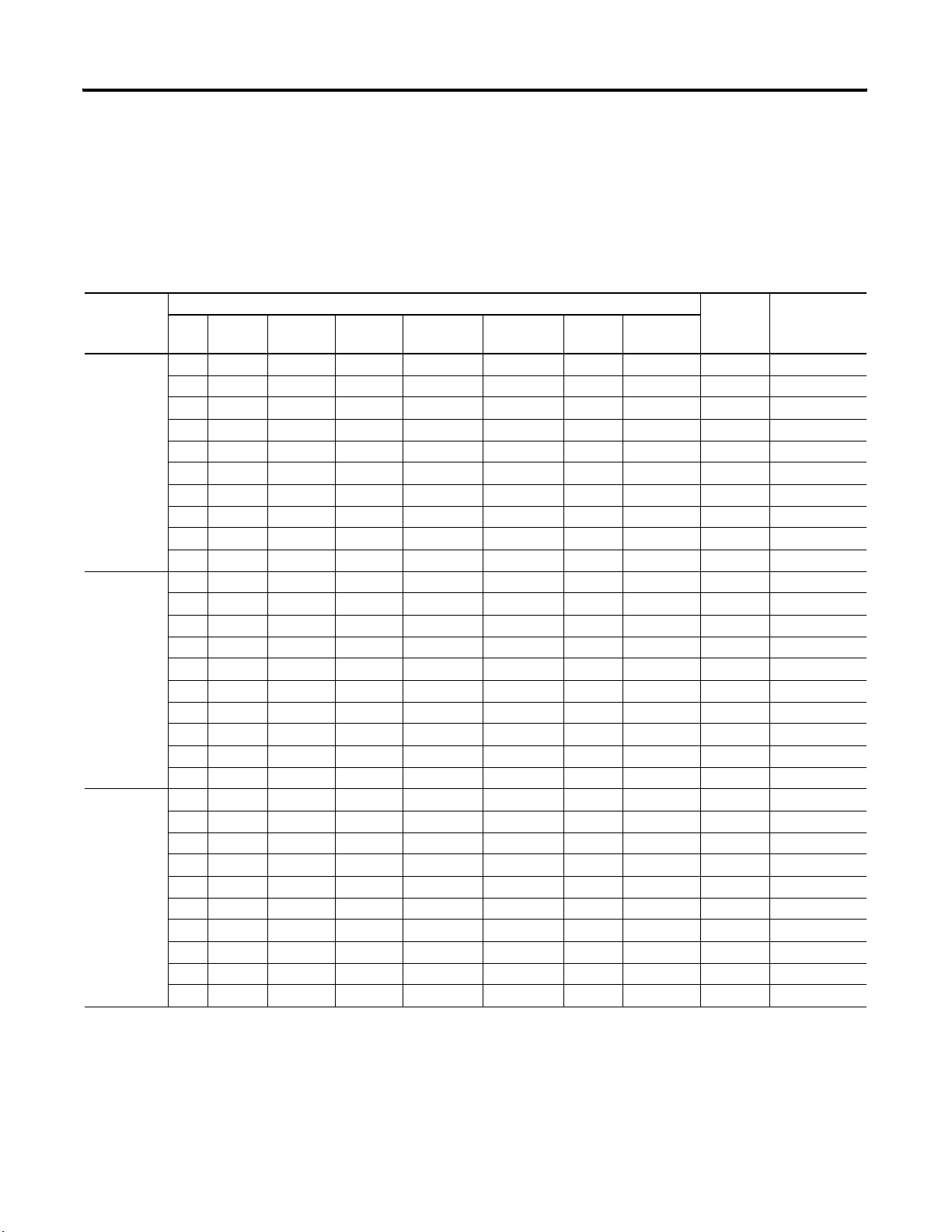

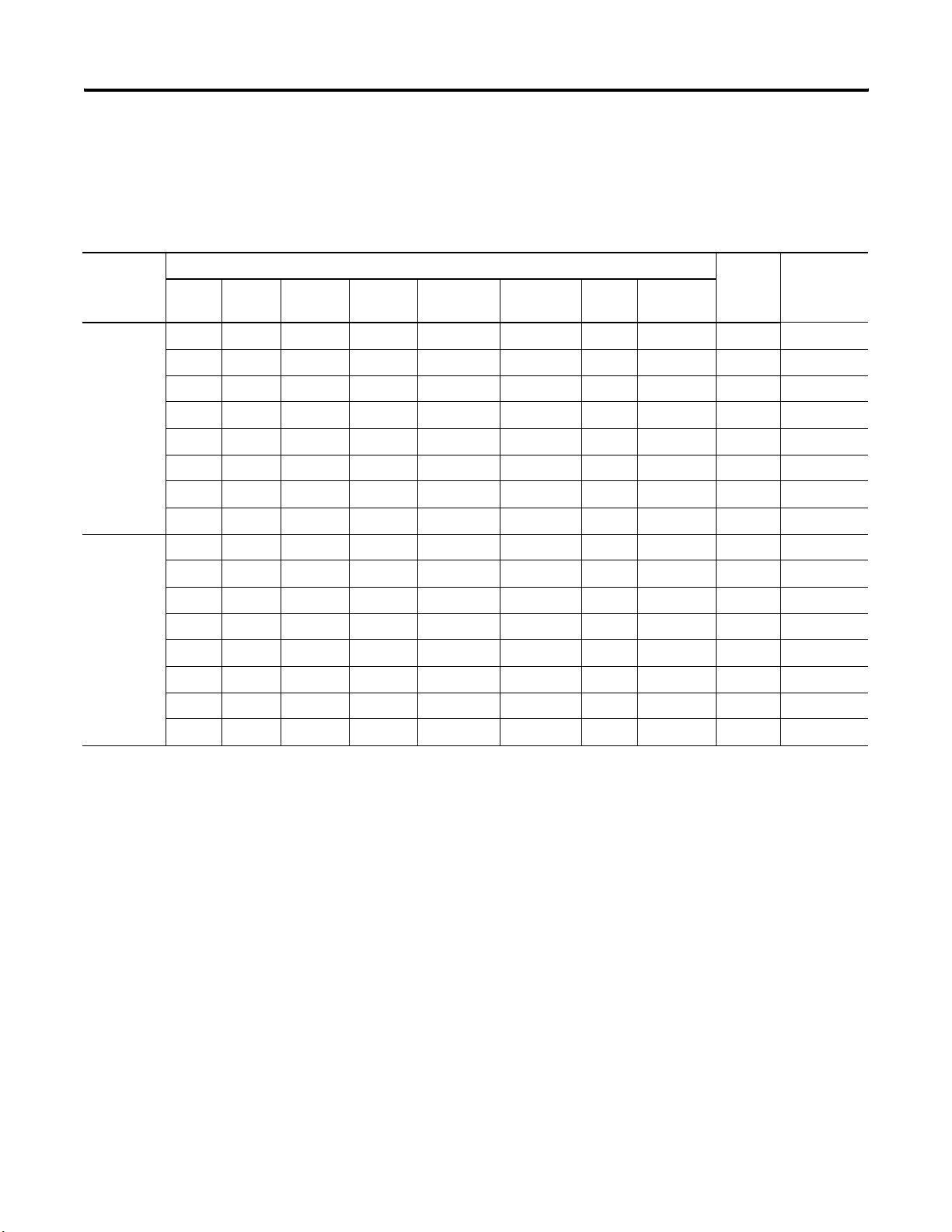

PanelView 550 Monochrome Terminals

The touch screen version of the PanelView 550 terminal is available

only with 24V DC power. The L1 in the catalog number indicates DC

power.

Operator

Input

Touch

Screen and

Keypad

Communication Port Printer

RIO DH-485 RS-232

(DH-485)

DH+ DeviceNet ControlNet RS-232

(DF1)

Ethernet

Port

RS-232

Catalog

Number

x x 2711-B5A1

x 2711-B5A2

x x 2711-B5A3

x 2711-B5A5

x x 2711-B5A8

x x 2711-B5A9

x x 2711-B5A10

x x 2711-B5A15

x x 2711-B5A16

x x 2711-B5A20

Keypad x x 2711-K5A1

x 2711-K5A2

x x 2711-K5A3

x 2711-K5A5

x x 2711-K5A8

x x 2711-K5A9

x x 2711-K5A10

x x 2711-K5A15

x x 2711-K5A16

x x 2711-K5A20

Touch

Screen

(24V DC

only)

x x 2711-T5A1L1

x 2711-T5A2L1

x x 2711-T5A3L1

x 2711-T5A5L1

x x 2711-T5A8L1

x x 2711-T5A9L1

x x 2711-T5A10L1

x x 2711-T5A15L1

x x 2711-T5A16L1

x x 2711-T5A20L1

(1)

Add L1 to the end of the catalog number for 24V DC power.

Add L2 to the end of a catalog number for stainless steel. Not available for the touch screen terminals.

Add L3 to the end of a catalog number for 24V DC power and stainless steel. Stainless steel is not available for the touch screen terminals.

(1)

Publication 2711-UM014G-EN-P - September 2008 19

Page 20

Chapter 1 Terminal Overview

PanelView 600 Color Terminals

Operator

Input

Touch

Screen and

Keypad

Communication Port Printer

RIO DH-485 RS-232

(DH-485)

DH+ DeviceNet ControlNet RS-232

(DF1)

Ethernet

Port

RS-232

Catalog

Number

x x 2711-B6C1

x 2711-B6C2

x x 2711-B6C3

x 2711-B6C5

x x 2711-B6C8

x x 2711-B6C9

x x 2711-B6C10

x x 2711-B6C15

x x 2711-B6C16

x x 2711-B6C20

Keypad x x 2711-K6C1

x 2711-K6C2

x x 2711-K6C3

x 2711-K6C5

x x 2711-K6C8

(1)

x x 2711-K6C9

Touch

Screen

(24V DC

only)

x x 2711-T6C1L1

x 2711-T6C2L1

x x 2711-T6C3L1

x 2711-T6C5L1

x x 2711-T6C9L1

(1)

Add L1 to the end of the catalog number for 24V DC power.

x x 2711-K6C10

x x 2711-K6C15

x x 2711-K6C16

x x 2711-K6C20

x x 2711-T6C8L1

x x 2711-T6C10L1

x x 2711-T6C15L1

x x 2711-T6C16L1

x x 2711-T6C20L1

20 Publication 2711-UM014G-EN-P - September 2008

Page 21

Terminal Overview Chapter 1

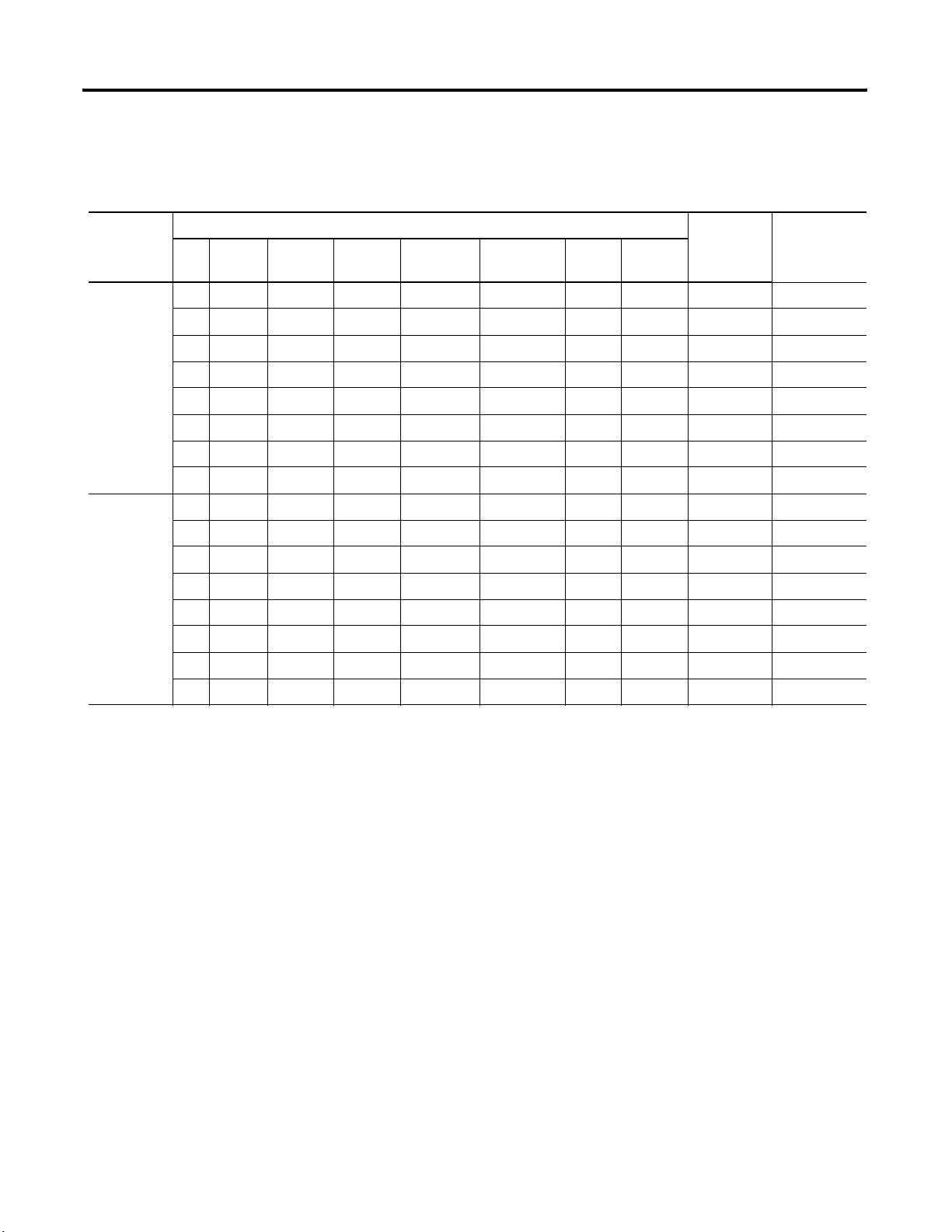

PanelView 900 Monochrome Terminals

These terminals are no longer available for purchase.

Operator

Input

Communication Port Printer Port

RIO DH-485 RS-232

(DH-485)

DH+ DeviceNet ControlNet RS-232

(DF1)

RS-232

Catalog Number

Touch Screen x x 2711-T9A1

x 2711-T9A2

x x 2711-T9A3

x 2711-T9A5

x x 2711-T9A8

x x 2711-T9A9

x x 2711-T9A10

x x 2711-T9A15

x x 2711-T9A16

Keypad x x 2711-K9A1

x 2711-K9A2

x x 2711-K9A3

x 2711-K9A5

x x 2711-K9A8

x x 2711-K9A9

x x 2711-K9A10

x x 2711-K9A15

(1)

x x 2711-K9A16

(1)

Add L1 to the end of the catalog number for 24V DC power.

Publication 2711-UM014G-EN-P - September 2008 21

Page 22

Chapter 1 Terminal Overview

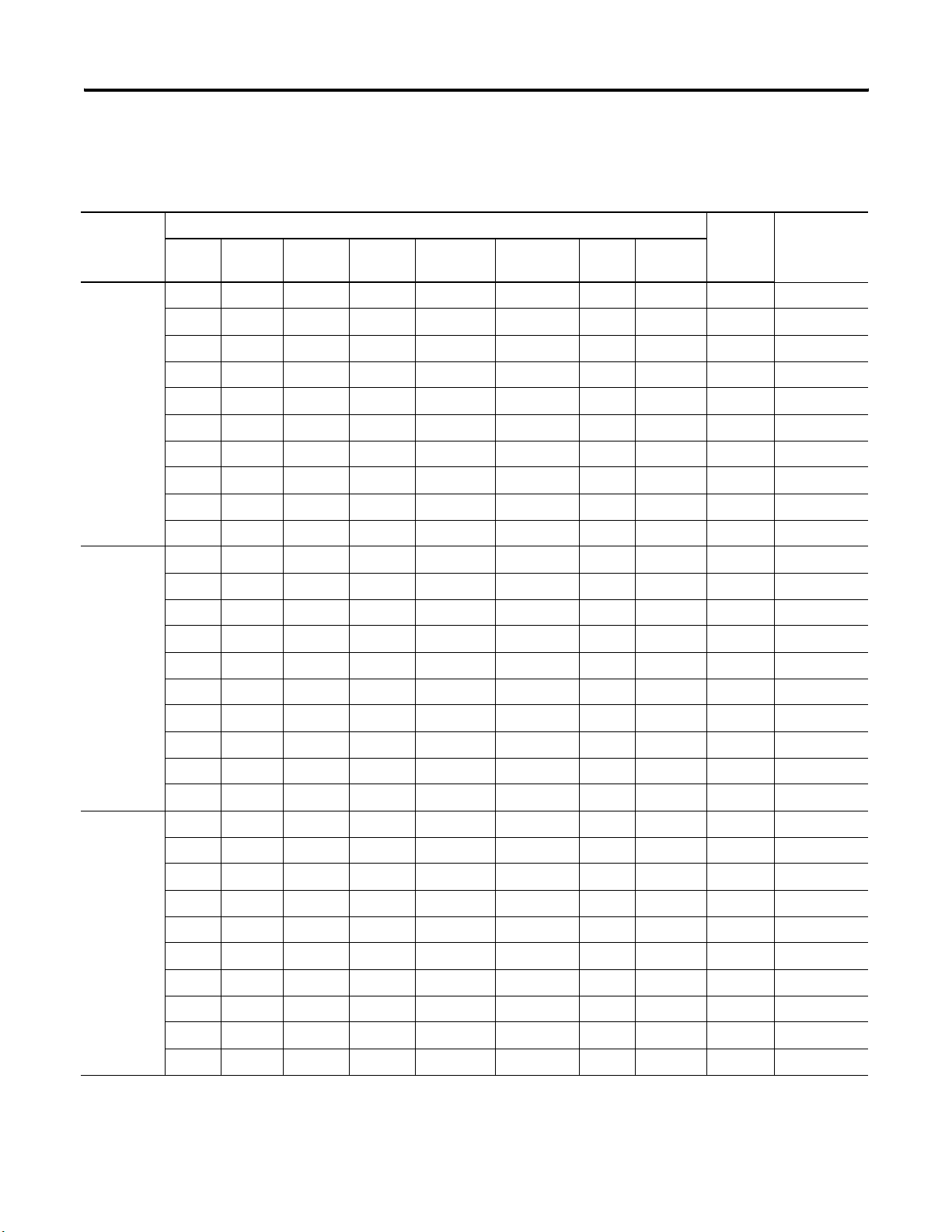

PanelView 900 Color Terminals

These terminals are no longer available for purchase.

Operator

Input

Touch

Screen

Communication Port Printer

RIO DH-485 RS-232

(DH-485)

DH+ DeviceNet ControlNet RS-232

(DF1)

Ethernet

Port

RS-232

Catalog

Number

x x 2711-T9C1

x x 2711-T9C3

x x 2711-T9C8

x x 2711-T9C9

x x 2711-T9C10

x x 2711-T9C15

x x 2711-T9C16

x x 2711-T9C20

Keypad x x 2711-K9C1

x x 2711-K9C3

x x 2711-K9C8

x x 2711-K9C9

x x 2711-K9C10

x x 2711-K9C15

x x 2711-K9C16

x x 2711-K9C20

(1)

Add L1 to the end of the catalog number for 24V DC power.

(1)

22 Publication 2711-UM014G-EN-P - September 2008

Page 23

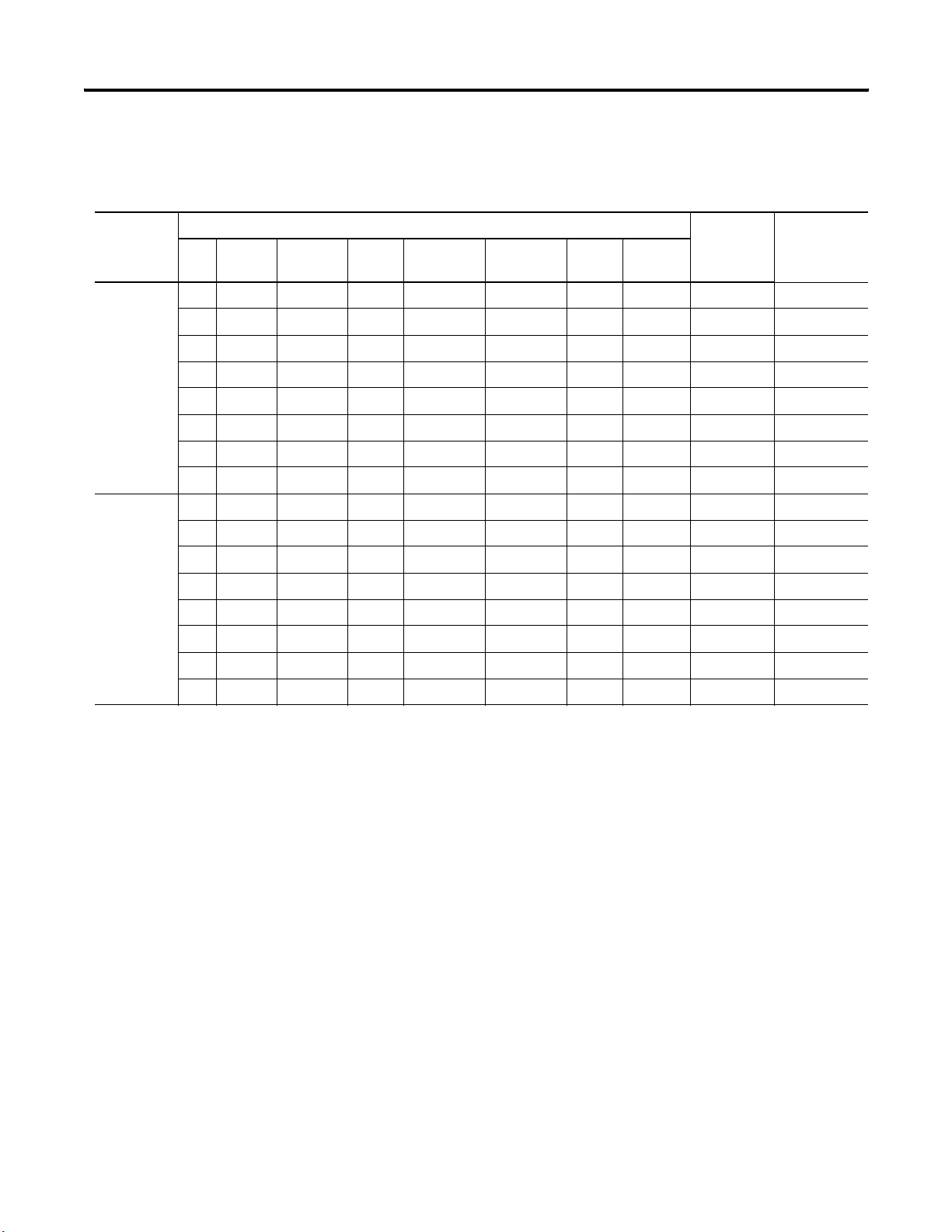

PanelView 1000 Color Terminals

Terminal Overview Chapter 1

Operator

Input

Touch

Screen

Communication Port Printer

RIO DH-485 RS-232

(DH-485)

DH+ DeviceNet ControlNet RS-232

(DF1)

Ethernet

Port

RS-232

Catalog

Number

(1)

x x 2711-T10C1

xx2711-T10C3

xx2711-T10C8

xx2711-T10C9

xx2711-T10C10

xx2711-T10C15

xx2711-T10C16

xx 2711-T10C20

Keypad x x 2711-K10C1

xx2711-K10C3

xx2711-K10C8

xx2711-K10C9

xx2711-K10C10

xx2711-K10C15

xx2711-K10C16

(1)

Add L1 to the end of the catalog number for 24V DC power.

xx 2711-K10C20

Publication 2711-UM014G-EN-P - September 2008 23

Page 24

Chapter 1 Terminal Overview

PanelView 1000 Grayscale Terminals

Operator

Input

Touch

Screen

Communication Port Printer

RIO DH-485 RS-232

(DH-485)

DH+ DeviceNet ControlNet RS-232

(DF1)

Ethernet

Port

RS-232

Catalog

Number

(1)

x x 2711-T10G1

xx2711-T10G3

xx2711-T10G8

xx2711-T10G9

xx2711-T10G10

xx2711-T10G15

xx2711-T10G16

xx 2711-T10G20

Keypad x x 2711-K10G1

xx2711-K10G3

xx2711-K10G8

xx2711-K10G9

xx2711-K10G10

xx2711-K10G15

xx2711-K10G16

(1)

Add L1 to the end of the catalog number for 24V DC power.

xx 2711-K10G20

24 Publication 2711-UM014G-EN-P - September 2008

Page 25

Terminal Overview Chapter 1

PanelView 1400 Color Terminals

These terminals are no longer available for purchase.

Operator

Input

Touch

Screen

Keypad x x x 2711-K14C1

Communication Port Printer

RIO DH-485 RS-232

(DH-485)

x x 2711-T14C1

xx2711-T14C3

xx2711-T14C9

xx2711-K14C3

xx2711-K14C9

DH+ DeviceNet ControlNet RS-232

(DF1)

xx2711-T14C8

xx2711-T14C10

xx2711-T14C15

xx2711-T14C16

xx2711-K14C8

xx2711-K14C10

xx2711-K14C15

xx2711-K14C16

Ethernet

xx2711-K14C20

Port

RS-232

x 2711-T14C20

Catalog

Number

Publication 2711-UM014G-EN-P - September 2008 25

Page 26

Chapter 1 Terminal Overview

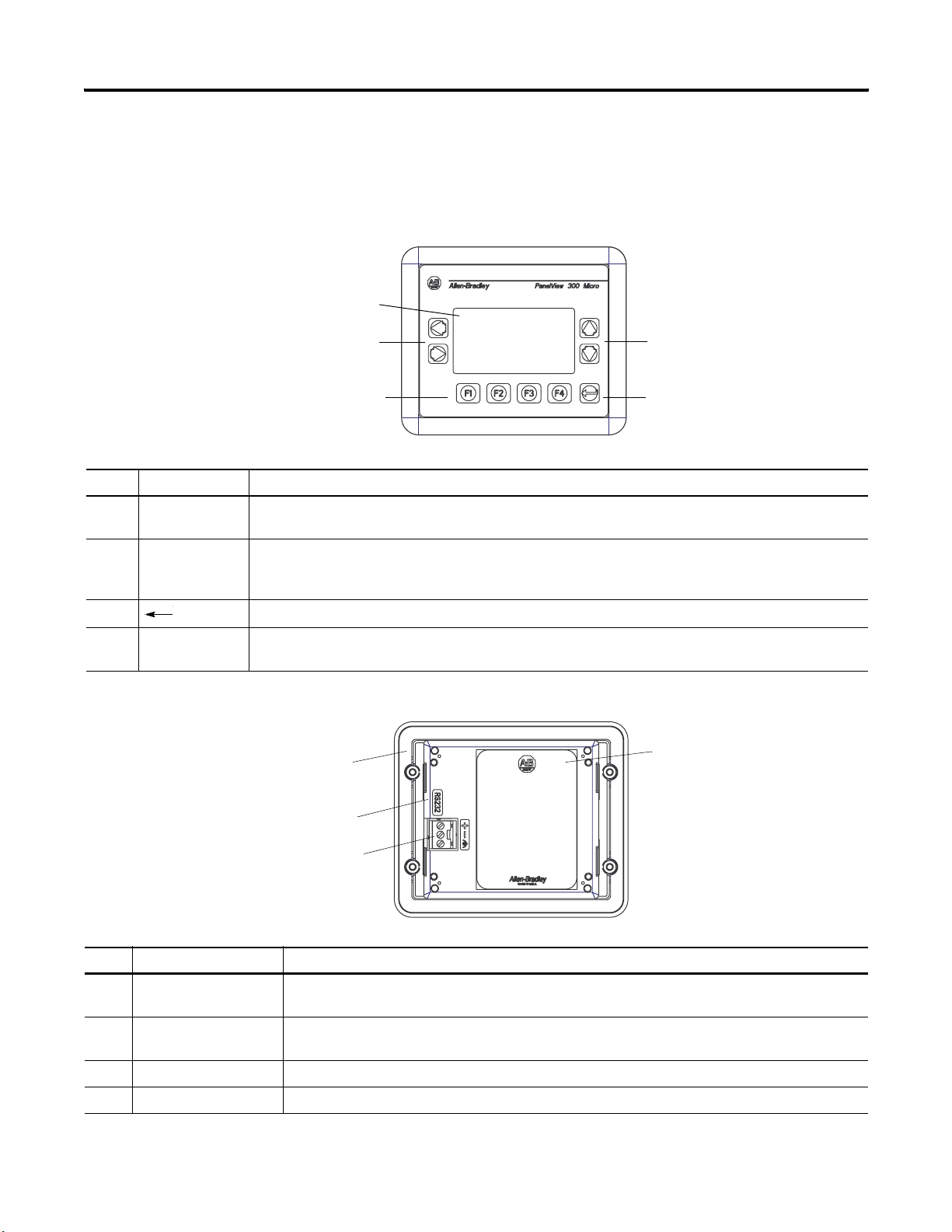

PanelView 300 Micro

This section defines features of the PanelView 300 Micro keypad

terminal.

Terminal Features

PanelView 300 Micro Terminal Features (front)

4

2

13

# Feature Description

1 Function keys

(F1…F4)

2 Cursor keys Use the cursor keys (left, right, up, down) as programmed function keys in addition to the F1…F4 function

3 Stores an entered value.

Use the function keys to initiate functions on the terminal display.

keys or to move the cursor in displayed lists, to select a numeric entry object, to enter configuration mode, or

to enter/modify numeric and ascii data.

2

4 Keypad

terminal display

Liquid crystal display with integral backlight. Displays application text, controls, graphics.

PanelView 300 Micro Terminal Features (back)

3

2

1

# Feature Description

1 Power connection

terminals

2 DF1 or DH-485 (RS232)

communication port

3 Sealing gasket Seals the front of the terminal to an enclosure or panel.

4 Nameplate label Provides product information.

Connects to a 24V DC (11-30V DC) external power source.

Connects to an SLC, PLC, or MicroLogix controller by using an RS-232 connection. Also used for

downloading applications directly from a computer.

4

26 Publication 2711-UM014G-EN-P - September 2008

Page 27

Terminal Overview Chapter 1

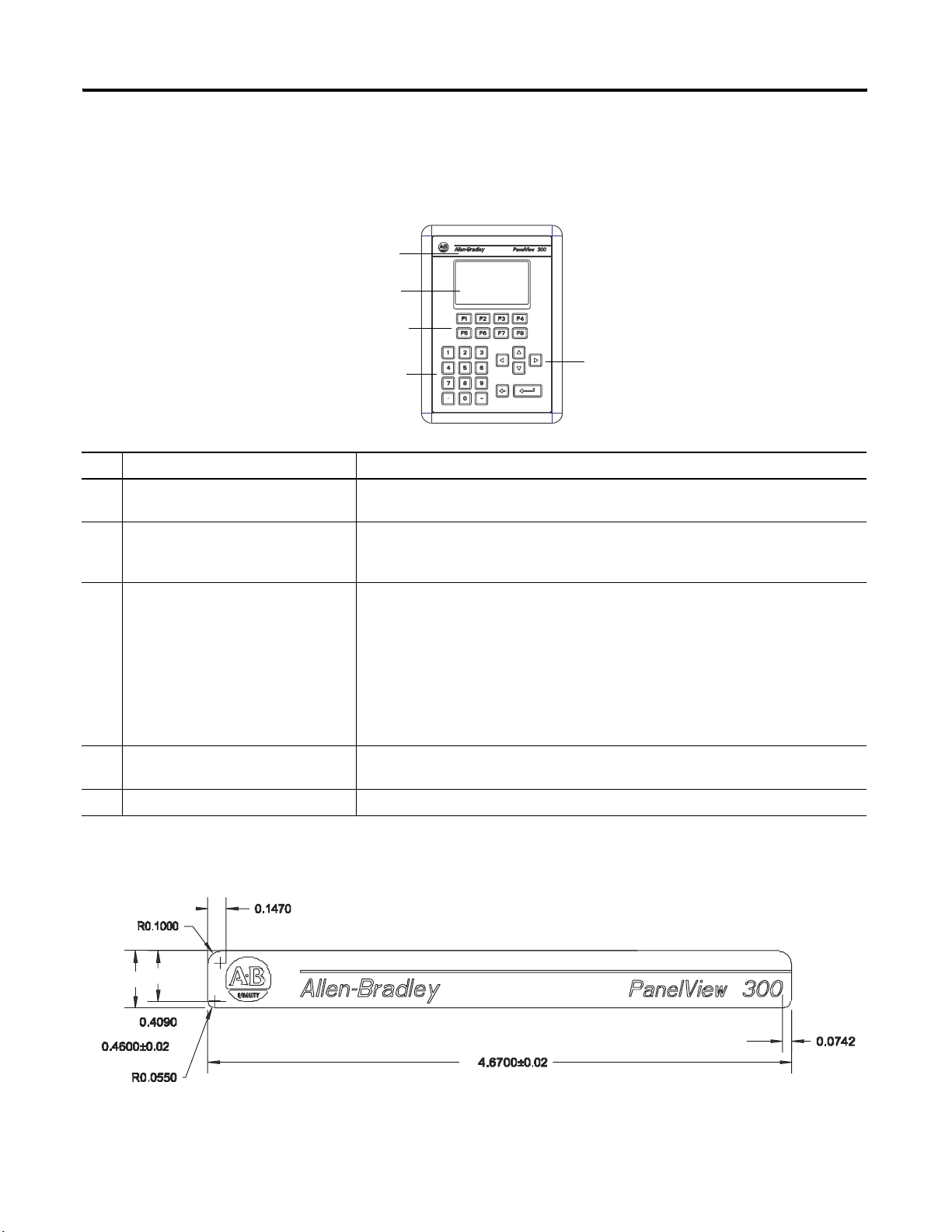

PanelView 300 Terminal Features

This section defines features of the PanelView 300 keypad terminal.

PanelView 300 Terminal Features (front)

5

4

1

3

# Feature Description

1 Function keys (F1…F8) Use the function keys to initiate functions on the terminal display. These keys may have

custom legends.

2 Cursor keys Use the up or down cursor keys to move the cursor up or down in a list or to

increment/decrement values. Use the left or right cursor keys to select an object with an

indicator bar, or to enter configuration mode.

3 Numeric entry keys 0…9 - Enters numeric values.

2

. Enters a decimal point.

- Enters a negative value.

← Clears entered digits or cancels the scratchpad.

↵ Stores an entered value.

4 Keypad terminal display Initiate the function of a displayed object, such as an ON or OFF push button, by pressing

the corresponding function key (F1...F8).

5 OEM label option (series B and later) Contact Rockwell Automation or your authorized distributor for custom label information.

The following illustration shows the dimensions for the OEM label.

Publication 2711-UM014G-EN-P - September 2008 27

Page 28

Chapter 1 Terminal Overview

DeviceNet with additional RS-232 Port

DH-485 without RS-232 Port

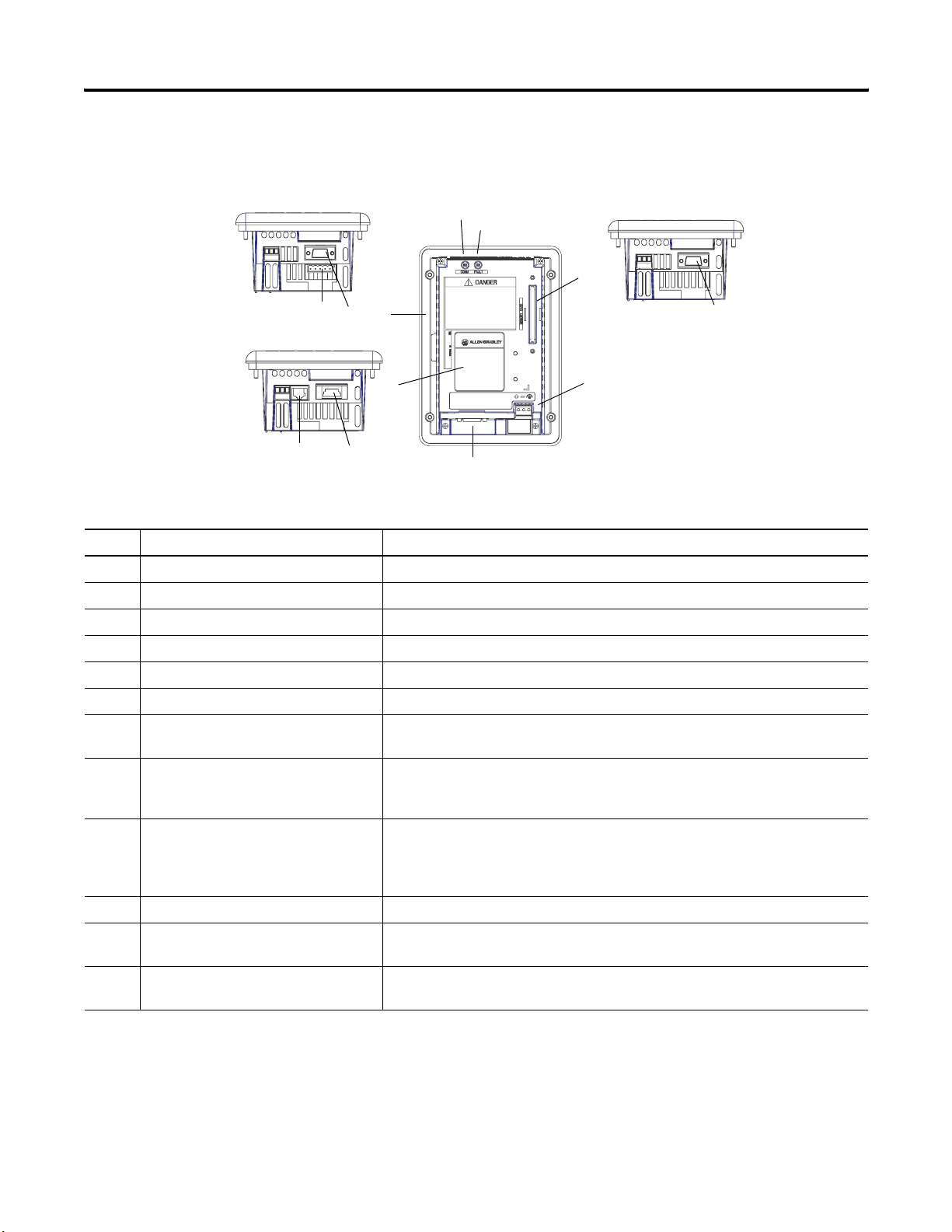

PanelView 300 Terminal Features (back)

3

4

1210 9 or 11

2

RS-232 (DH-485 or DF1) without additional RS-232 Port

5

1

78

7, 8, 9, 10, 11, 12

6

# Feature Description

1 Nameplate label Provides product information.

2 Sealing gasket Seals the front of the terminal to an enclosure or panel.

3 COMM Status indicator (green) Indicates when communication is occurring.

4 FAULT Status indicator (red) Indicates firmware or hardware faults.

5 Memory card slot Accepts a memory card which stores applications.

6 Power connection terminals Connects to an external 24V DC power source (18…32V DC).

7 DH-485 communication port Connects to an SLC or MicroLogix controller, DH-485 network, or Wallmount Power

Supply (Cat. No. 1747-NP1).

8 DH-485 programming connector Connects to a Personal Computer Interface Converter (Cat. No. 1747-PIC) for

transferring applications. Also connects to an SLC programmer, such as the

Hand-held Terminal (Cat. No. 1747-PT1).

9 RS-232 (DH-485) communication port Connects to the Channel 0 port of an SLC 5/03, SLC 5/04, or SLC 5/05 controller for

point-to-point DH-485 communication. Connects to a MicroLogix controller through

an AIC+ Link Coupler. Also connects to the RS-232 serial port of a computer for

transferring applications.

10 DeviceNet connector Connects to a DeviceNet network.

11 RS-232 (DF1) communication port Connects to a PLC, SLC, or MicroLogix controller with a DF1 port. This port also

connects to the RS-232 port of a computer.

12 RS-232 Printer/File transfer port Connects to a printer (K3A10L1 version only). On a DeviceNet terminal, this port also

connects to the RS-232 port of a computer for transferring applications.

28 Publication 2711-UM014G-EN-P - September 2008

Page 29

Terminal Overview Chapter 1

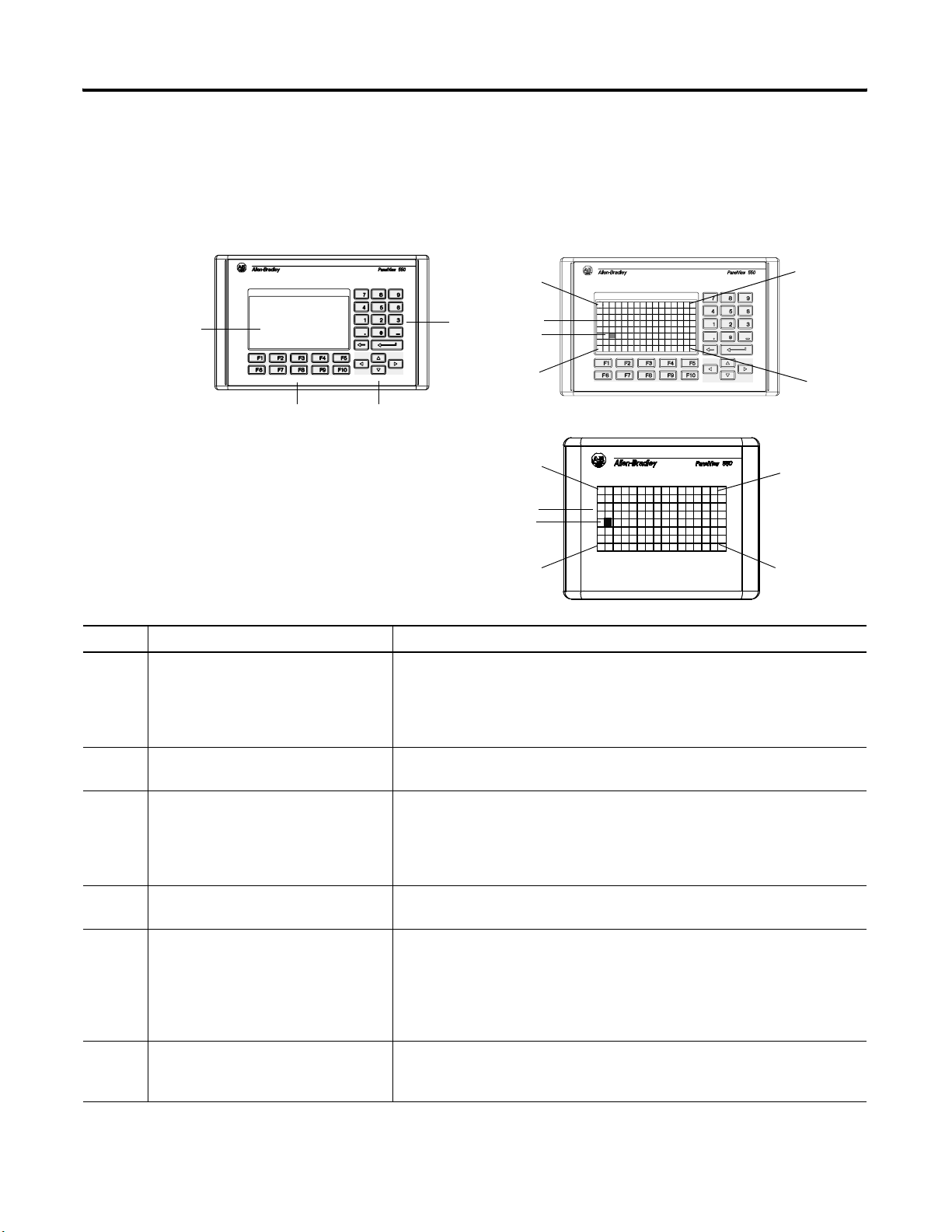

PanelView 550 Terminal Features

Keypad Terminal Keypad & Touch Screen Terminal

43

12

This section defines features of the PanelView 550 terminals.

PanelView 550 Terminal Features (front)

Cell 16

Cell 1

5

6

Cell 113 Cell 128

Touch Screen Terminal

Cell 1

Cell 16

5

6

Cell 113

Cell 128

# Feature Description

1 Function Keys (F1…F10) On keypad terminals, use the function keys to initiate functions on the terminal

display. These keys may have custom legends.

On keypad and touch screen terminals, you can initiate functions by using the

function keys and/or touch screen objects.

2 Cursor Keys Use the cursor keys to move the cursor in displayed lists, to select a numeric entry

object, or to enter configuration mode.

3 Numeric Entry Keys 0…9 - Enters numeric values.

. Enters a decimal point.

- Enters a negative value.

← Clears entered digits or cancels the scratchpad.

↵ Stores an entered value.

4 Keypad Terminal Display On keypad terminals, initiate the function of a displayed object, such as an ON or

OFF push button, by pressing a function key (F1…F10).

5 Touch Screen Terminal Display On touch screen or keypad & touch screen terminals, initiate the function of a

displayed object, such as an ON or OFF push button, by touching the screen object.

Each interactive screen object occupies one or more of 128 cells.

On keypad and touch screen terminals, you can initiate functions by using the

function keys and/or touch screen objects.

6 Touch Cells (Touch Screen terminal) The 128 touch cells (16 columns x 8 rows) let you initiate functions by touching

the screen. Interactive screen objects are aligned with touch cells when the

application is created.

Publication 2711-UM014G-EN-P - September 2008 29

Page 30

Chapter 1 Terminal Overview

PanelView 550 Keypad or Keypad and Touch Screen Terminals

(back)

3

2

1

AC connector shown, DC

connector looks different

DH-485 with additional RS-232 Port

19

RS-232 (DH-485)

without additional RS-232 Port

11 10

DH-485 without additional RS-232 Port

4

5

6

7

11 10

8

9

Backlight lamp behind access cover

Series G and earlier

Remote I/O, DF1, DH+, DeviceNet, ControlNet, Ethernet,

with additional RS-232 Port

12

RS-232 (DH-485)

with additional RS-232 Port

19 12

30 Publication 2711-UM014G-EN-P - September 2008

13, 14, 15, 16, 17, or 18

19

Page 31

Terminal Overview Chapter 1

# Feature Description

1 Power Connection Terminals Connects to external power source.

2 Nameplate Label Provides product information.

3 Sealing Gasket Seals the front of the terminal to an enclosure or panel.

4 COMM Status (Green) Indicator Indicates when communication is occurring.

5 FAULT Status (Red) Indicator Indicates firmware or hardware faults.

6 Memory Card Slot Accepts a memory card which stores applications.

7 Access Cover Provides access to the replaceable backlight lamp.

8 Backlight Lamp Light source for the display backlight. Light transmits through a fiber-optic bundle to

(1)

(1)

9 Spare Bulb Holder

the back of the LCD display.

Stores a spare backlight lamp.

10 DH-485 Communication Port Connects to an SLC or MicroLogix controller, DH-485 network, or Wallmount Power

Supply (Cat. No. 1747-NP1).

11 DH-485 Programming Connector Connects to a Personal Computer Interface Converter (Cat. No. 1747-PIC) for

transferring applications. Also connects to an SLC programmer, such as the

Hand-held Terminal (Cat. No. 1747-PT1).

12 RS-232 (DH-485) Communication Port Connects to the Channel 0 port of an SLC 5/03, SLC 5/04, or SLC 5/05 controller for

point-to-point DH-485 communication. Connects to a MicroLogix controller through

an AIC+ Link Coupler. Also connects to the RS-232 serial port of a computer for

transferring applications.

13 Remote I/O Port Connects to a scanner or sub-scanner on a remote I/O network.

14 DH+ Communication Port Connects to a PLC-5, SLC 5/04, or ControlLogix controller on a DH+ link.

15 DeviceNet Connector Connects to a DeviceNet network.

16 ControlNet Connector Connects to a ControlLogix controller (with 1756-CNB module) or PLC-5 on a

ControlNet network.

17 RS-232 (DF1) Communication Port Connects to a PLC, SLC, or MicroLogix controller with a DF1 port.

18 Ethernet Connector Connects to a PLC-5E or SLC 5/05 controller, or a ControlLogix, MicroLogix, FlexLogix,

or CompactLogix controller (with appropriate bridge module) on an EtherNet/IP

network.

19 RS-232 Printer/ File Transfer Port Connects to a printer.

On remote I/O, DH+, DF1, DeviceNet, EtherNet/IP, or ControlNet terminals, this port

also connects to the RS-232 port of a computer for transferring applications.

The RS-232 port on the DH-485 or RS-232 (DH-485) terminal is used to connect a

printer but not for file transfers.

(1)

Series H and later PanelView 550 Keypad and Keypad Touch Terminals have an integrated LED backlight. This backlight is non-replaceable.

Publication 2711-UM014G-EN-P - September 2008 31

Page 32

Chapter 1 Terminal Overview

PanelView 550 Touch Screen Terminal Features (back)

DH-485 without additional RS-232 Port

5

4

3

2

1

11

DH-485 with RS-232 Port

11

10

19

RS-232 (DH-485) without additional RS-232 Port

12

10

8

9

Backlight lamp behind access cover

Series A only

Remote I/O, DF1, DH+, DeviceNet,

ControlNet, Ethernet, with RS-232 Port

6

7

9

RS-232 (DH-485) with additional RS-232 Port

19

12

19

13, 14, 15, 16, 17, or 18

32 Publication 2711-UM014G-EN-P - September 2008

Page 33

Terminal Overview Chapter 1

# Feature Description

1 Power Connection Terminals Connects to external DC power source.

2 Sealing Gasket Seals the front of the terminal to an enclosure or panel.

3 FAULT Status (Red) Indicator Indicates firmware or hardware faults.

4 COMM Status (Green) Indicator Indicates when communication is occurring.

5 Nameplate Label Provides product information.

6 Memory Card Slot Accepts a memory card which stores applications.

7 Reset Button Resets the terminal.

8 Access Cover

9 Backlight Lamp

Provides access to the replaceable backlight lamp.

Light source for the display backlight.

(1)

(1)

10 DH-485 Communication Port Connects to an SLC or MicroLogix controller, DH-485 network, or Wallmount Power

Supply (Cat. No. 1747-NP1).

11 DH-485 Programming Connector Connects to a Personal Computer Interface Converter (Cat. No. 1747-PIC) for

transferring applications. Also connects to an SLC programmer, such as the

Hand-held Terminal (Cat. No. 1747-PT1).

12 RS-232 (DH-485) Communication Port Connects to the Channel 0 port of an SLC 5/03, 5/04, or 5/05 for point-to-point

DH-485 communication. Connects to a MicroLogix controller through an AIC+ Link

Coupler. Also connects to the RS-232 serial port of a computer for transferring

applications.

13 Remote I/O Port Connects to a scanner or sub-scanner on a remote I/O network.

14 DH+ Communication Port Connects to a PLC-5, SLC 5/04, or ControlLogix controller on a DH+ link.

15 DeviceNet Connector Connects to a DeviceNet network.

16 ControlNet Connector Connects to a ControlLogix controller (with 1756-CNB module) or PLC-5 on a

ControlNet network.

17 RS-232 (DF1) Communication Port Connects to a PLC, SLC, or MicroLogix controller with a DF1 port.

18 Ethernet Connector Connects to a PLC-5E or SLC 5/05 controller, or a ControlLogix, MicroLogix, FlexLogix

or CompactLogix (with appropriate bridge module) on an EtherNet/IP network.

19 RS-232 Printer/File Transfer Port Connects to a printer.

On remote I/O, DH+, DF1, DeviceNet, EtherNet/IP, or ControlNet terminals, this port

also connects to the RS-232 port of a computer for transferring applications.

The RS-232 port on the DH-485 or RS-232 (DH-485) terminal is used to connect a

printer but not for file transfers.

(1)

Series B and later PanelView 550 Touch Terminals have an integrated LED backlight. This backlight is non-replaceable.

Publication 2711-UM014G-EN-P - September 2008 33

Page 34

Chapter 1 Terminal Overview

PanelView 600 Terminal Features

This section defines features of the PanelView 600 terminals.

PanelView 600 Terminal Features (front)

Keypad Terminal

3

4

1

Keypad & Touch Screen Terminal

Cell 1

5

6

Cell 113

2

Cell 16

Cell 128

Cell 1

Cell 113

Touch Screen Terminal

Cell 16

5

6

Cell 128

34 Publication 2711-UM014G-EN-P - September 2008

Page 35

Terminal Overview Chapter 1

# Feature Description

1 Function Keys (F1…F10) Use the function keys on keypad terminals to initiate functions on the terminal

display. These keys may have custom legends.

On the keypad & touch screen terminals, you can initiate functions by using the

function keys and/or touch screen objects.

2 Cursor Keys Use the cursor keys to move the cursor in displayed lists, to select a numeric entry

object, or to enter configuration mode.

3 Numeric Entry Keys 0…9 - Enters numeric values.

. Enters a decimal point.

- Enters a negative value.

← Clears entered digits or cancels the scratchpad.

↵ Stores an entered value.

4 Keypad Terminal Display On keypad terminals, initiate the function of a displayed object, such as an ON or

OFF push button, by pressing a function key (F1...F10).

5 Touch Screen Terminal Display On keypad and touch screen terminals, initiate the function of a displayed object,

such as an ON or OFF push button, by touching the screen object. Each interactive

screen object occupies one or more of 128 cells.

On touch screen and keypad terminals, you can initiate functions, by using the

function keys and/or touch screen objects.

6 Touch Cells (Touch Screen terminal) The 128 touch cells (16 columns x 8 rows) let you initiate functions by touching

the screen. Interactive screen objects are aligned with touch cells when the

application is created.

Publication 2711-UM014G-EN-P - September 2008 35

Page 36

Chapter 1 Terminal Overview

Remote I/O, DF1, DH+, DeviceNet, ControlNet,

or Ethernet with additional RS-232 Port

PanelView 600 Keypad or Keypad & Touch Screen Terminal

(back)

4

10, 11, 12, 13, 14, or 15

16

DH-485 without additional RS-232 Port

7

8

DH-485 with additional RS-232 Port

16

87

RS-232 (DH-485)

without additional RS-232 Port

3

2

1

7, 8, 9, 10

11, 12, 13, 14, 15, 16

RS-232 (DH-485) with additional RS-232 Port

5

6

9

16

9

36 Publication 2711-UM014G-EN-P - September 2008

Page 37

Terminal Overview Chapter 1

# Feature Description

1 Power Connection Terminals Connects to external power source.

2 Nameplate Label Provides product information.

3 Memory Card Slot Accepts a memory card which stores applications.

4 Sealing Gasket Seals the front of the terminal to an enclosure or panel.

5 FAULT Status (Red) Indicator Indicates firmware or hardware faults.

6 COMM Status (Green) Indicator Indicates when communication is occurring.

7 DH-485 Communication Port Connects to an SLC or MicroLogix controller, DH-485 network, or Wallmount Power

Supply (Cat. No. 1747-NP1).

8 DH-485 Programming Connector Connects to a Personal Computer Interface Converter (Cat. No. 1747-PIC) for

transferring applications. Also connects to an SLC programmer, such as the

Hand-held Terminal (Cat. No. 1747-PT1).

9 RS-232 (DH-485) Communication Port Connects to the Channel 0 port of an SLC 5/03, 5/04, or 5/05 for point-to-point

DH-485 communication. Connects to a MicroLogix controller through an AIC+ Link

Coupler. Also connects to the RS-232 serial port of a computer for transferring

applications.

10 Remote I/O Port Connects to a scanner or sub-scanner on a remote I/O network.

11 DH+ Communication Port Connects to a PLC-5, SLC 5/04, or ControlLogix controller on a DH+ link.

12 DeviceNet Connector Connects to a DeviceNet network.

13 ControlNet Connector Connects to a ControlLogix controller (with 1756-CNB module) or PLC-5 on a

ControlNet network.

14 (RS-232) DF1 Communication Port Connects to a PLC, SLC, or MicroLogix controller with a DF1 port.

15 Ethernet Connector Connects to a PLC-5E or SLC 5/05 controller, or a ControlLogix, MicroLogix, FlexLogix,

or CompactLogix (with appropriate bridge module) on an EtherNet/IP network.

16 RS-232 Printer/File Transfer Port Connects to a printer.

On remote I/O, DH+, DF1, DeviceNet, EtherNet/IP, or ControlNet terminals, this port

also connects to the RS-232 port of a computer for transferring applications.

The RS-232 port on the DH-485 or RS-232 (DH-485) terminal is used to connect a

printer but not for file transfers.

Publication 2711-UM014G-EN-P - September 2008 37

Page 38

Chapter 1 Terminal Overview

Remote I/O, DF1, DH+, DeviceNet, ControlNet,

or Ethernet with additional RS-232 Port

PanelView 600 Touch Screen Terminal Features (back)

5

11, 12, 13, 14, 15, or 16

17

DH-485 without additional RS-232 Port

8

9

DH-485 with additional RS-232 Port

17

8

9

RS-232 (DH-485)

without additional RS-232 Port

4

3

2

1

8, 9, 10, 11

12, 13, 14, 15, 16, 17

RS-232 (DH-485) with additional RS-232 Port

6

7

10

17

10

38 Publication 2711-UM014G-EN-P - September 2008

Page 39

Terminal Overview Chapter 1

# Feature Description

1 Power Connection Terminals Connects to external power source.

2 Nameplate Label Provides product information.

3 Fault Status (Red) Indicates firmware or hardware faults.

4 COMM Status (Green) Indicates when communication is occurring.

5 Sealing Gasket Seals the front of the terminal to an enclosure or panel.

6 Reset Button Resets the terminal.

7 Memory Card Slot Accepts a memory card which stores applications.

8 DH-485 Communication Port Connects to an SLC or MicroLogix controller, DH-485 network, or Wallmount Power

Supply (Cat. No. 1747-NP1).

9 DH-485 Programming Connector Connects to a Personal Computer Interface Converter (Cat. No. 1747-PIC) for

transferring applications. Also connects to an SLC programmer, such as the

Hand-held Terminal (Cat. No. 1747-PT1).

10 RS-232 (DH-485) Communication Port Connects to the Channel 0 port of an SLC 5/03, 5/04, or 5/05 for point-to-point

DH-485 communication. Connects to a MicroLogix controller through an AIC+ Link

Coupler. Also connects to the RS-232 serial port of a computer for transferring

applications.

11 Remote I/O Port Connects to a scanner or sub-scanner on a remote I/O network.

12 DH+ Communication Port Connects to a PLC-5, SLC 5/04, or ControlLogix controller on a DH+ link.

13 DeviceNet Connector Connects to a DeviceNet network.

14 ControlNet Connector Connects to a ControlLogix controller (with 1756-CNB module) or PLC-5 on a

ControlNet network.

15 RS-232 (DF1) Communication Port Connects to a PLC, SLC, or MicroLogix controller with a DF1 port.

16 Ethernet Connector Connects to a PLC-5E or SLC 5/05 controller, or a ControlLogix, MicroLogix, FlexLogix,

or CompactLogix (with appropriate bridge module) on an EtherNet/IP network.

17 RS-232 Printer/File Transfer Port Connects to a printer.

On remote I/O, DH+, DF1, DeviceNet, EtherNet/IP, or ControlNet terminals, this port

also connects to the RS-232 port of a computer for transferring applications.

The RS-232 port on the DH-485 or RS-232 (DH-485) terminal is used to connect a

printer but not for file transfers.

Publication 2711-UM014G-EN-P - September 2008 39

Page 40

Chapter 1 Terminal Overview

PanelView 900/1000 Terminal Features

Keypad Terminal

4

This section defines features of the PanelView 900 and 1000 terminals.

IMPORTANT

PanelView 900 terminals are no longer available. Contact your

local sales office or authorized Rockwell Automation Distributor

for suitable substitutes.

PanelView 900/1000 Terminal Features (front)

Touch Screen Terminal

Cell 1

5

6

3

Cell 361

Cell 24

1

2

Cell 384

40 Publication 2711-UM014G-EN-P - September 2008

Page 41

Terminal Overview Chapter 1

# Feature Description

1 Function Keys (F1…F16) Use the function keys on keypad terminals to initiate functions on the terminal

display. These keys may have custom legends.

2 Cursor Keys Use the cursor keys to move the cursor in displayed lists, to select a numeric entry

object or to enter configuration mode.

3 Numeric Entry Keys 0…9 - Enters numeric values.

. Enters a decimal point.

- Enters a negative value.

← Clears entered digits or cancels the scratchpad.

↵ Stores an entered value.

4 Keypad Terminal Display On keypad terminals, initiate the function of a displayed object, such as an ON or

OFF push button, by pressing a function key (F1…F16).

5 Touch Screen Terminal Display On touch screen terminals, initiate the function of a displayed object, such as an

ON or OFF push button, by touching the screen object. Each interactive screen

object occupies one or more of 384 cells.

6 Touch Cells (Touch Screen terminal) The 384 touch cells (24 columns x 16 rows) let you initiate functions by touching

the screen. Interactive screen objects are aligned with touch cells when the

application is created.

Publication 2711-UM014G-EN-P - September 2008 41

Page 42

Chapter 1 Terminal Overview

Remote I/O, DF1, DH+, DeviceNet, Ethernet,

or ControlNet with additional RS-232 Port

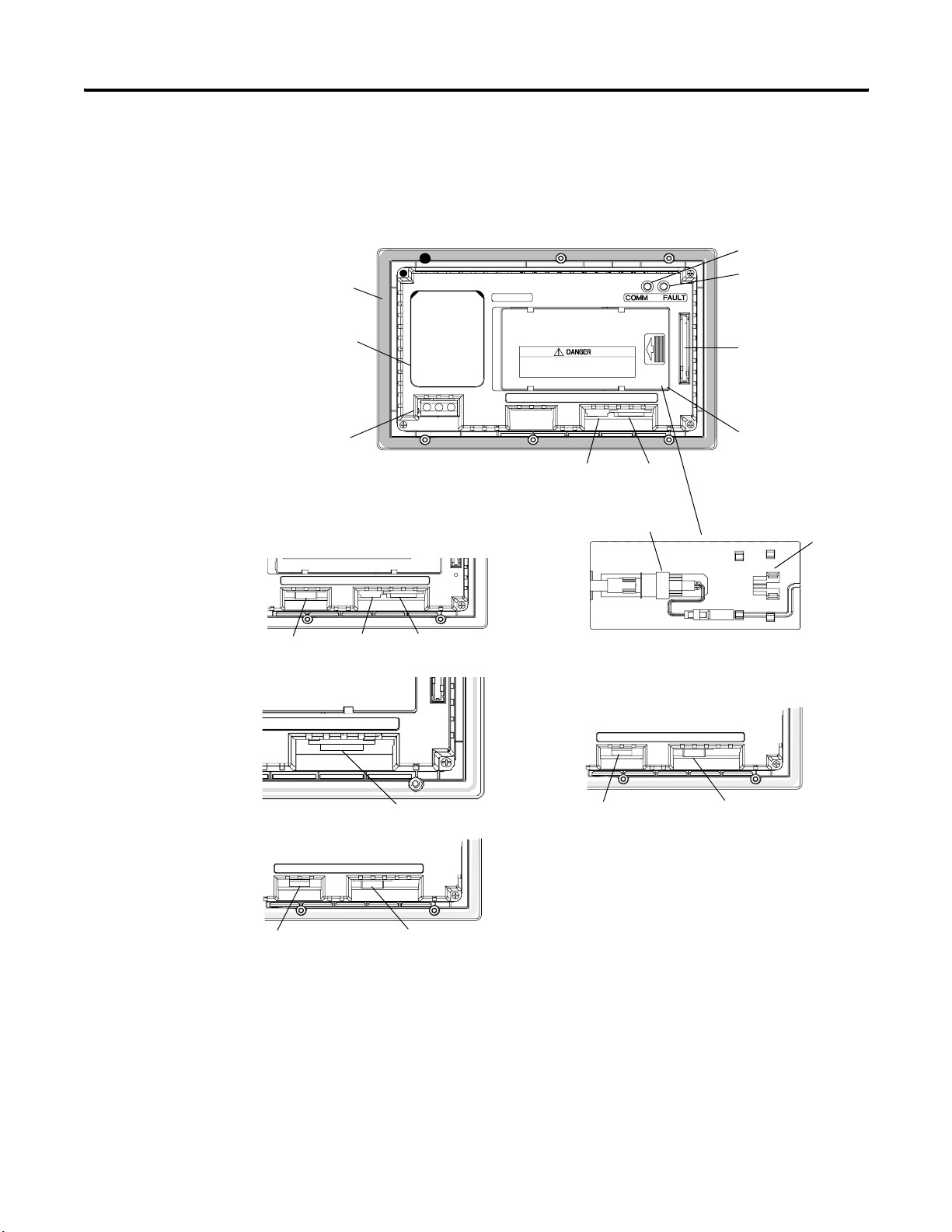

PanelView 900/1000 Terminal Features (back)

4

3

1711, 12, 13, 14, 15, or 16

Back View

Touch Screen Terminal

DH-485 Version without additional RS-232 Port

98

DH-485 with additional RS-232 Port

17

9

8

RS-232 (DH-485) without additional RS-232 Port

10

2

1

8, 9, 10

11, 12, 13, 14, 15, 16, 17

4

3

2

5

6

7

Back View

Keypad Terminal

5

6

1

RS-232 (DH-485) with additional RS-232 Port

17

10

8, 9, 10

11, 12, 13, 14, 15, 16, 17

7

42 Publication 2711-UM014G-EN-P - September 2008

Page 43

Terminal Overview Chapter 1

# Feature Description

1 Power Connection Terminals Connects to external power source.

2 Nameplate Label Provides product information.

3 Reset Button Resets the terminal.

4 Sealing Gasket Seals the front of the terminal to an enclosure or panel.

5 Memory Card Slot Accepts a memory card which stores applications.

6 FAULT Status (Red) Indicator Indicates firmware or hardware faults.

7 COMM Status (Green) Indicator Indicates when communication is occurring.

8 DH-485 Communication Port Connects to an SLC or MicroLogix controller, DH-485 network, or Wallmount Power

Supply (Cat. No. 1747-NP1).

9 DH-485 Programming Connector Connects to a Personal Computer Interface Converter (Cat. No. 1747-PIC) for

transferring applications. Also connects to an SLC programmer, such as the

Hand-held Terminal (Cat. No. 1747-PT1).

10 RS-232 (DH-485) Communication Port Connects to the Channel 0 port of an SLC 5/03, 5/04, or 5/05 for point-to-point

DH-485 communication. Connects to a MicroLogix controller through an AIC+ Link

Coupler. Also connects to the RS-232 serial port of a computer for transferring

applications.

11 Remote I/O Port Connects to a scanner or sub-scanner on a remote I/O network.

12 DH+ Communication Port Connects to a PLC-5, SLC 5/04, or ControlLogix controller on a DH+ link.

13 DeviceNet Connector Connects to a DeviceNet network.

14 ControlNet Connector Connects to a ControlLogix controller (with 1756-CNB module) or PLC-5 on a

ControlNet network.

15 RS-232 (DF1) Communication Port Connects to a PLC, SLC, or MicroLogix controller with a DF1 port.

16 Ethernet Connector Connects to a PLC-5E or SLC 5/05 controller, or a ControlLogix, MicroLogix, FlexLogix,

or CompactLogix (with appropriate bridge module) on an EtherNet/IP network.

17 RS-232 Printer/File Transfer Port Connects to a printer.

On remote I/O, DH+, DF1, DeviceNet, EtherNet/IP, or ControlNet terminals, this port

also connects to the RS-232 port of a computer for transferring applications.

The RS-232 port on the DH-485 or RS-232 (DH-485) terminal is used to connect a

printer but not for file transfers.

Publication 2711-UM014G-EN-P - September 2008 43

Page 44

Chapter 1 Terminal Overview

PanelView 1400 Terminal Features

Keypad Terminal

4

This section defines features of the PanelView 1400 terminals.

IMPORTANT

PanelView 1400 terminals are no longer available. Contact your

local sales office or authorized Rockwell Automation Distributor

for suitable substitutes.

PanelView 1400 Terminal Features (front)

Touch Screen Terminal

Cell 1

5

3

6

Cell 361

Cell 24

Cell 384

1

2

44 Publication 2711-UM014G-EN-P - September 2008

Page 45

Terminal Overview Chapter 1

# Feature Description

1 Function Keys (F1…F21) Use the function keys on keypad terminals to initiate functions on the terminal

display. These keys may have custom legends.

2 Cursor Keys Use the cursor keys to move the cursor in displayed lists, to select a numeric entry

object, or to enter configuration mode.

3 Numeric Entry Keys 0…9 - Enters numeric values.

. Enters a decimal point.

- Enters a negative value.

← Clears entered digits or cancels the scratchpad.

↵ Stores an entered value.

4 Keypad Terminal Display On keypad terminals, initiate the function of a displayed object, such as an ON or

OFF push button, by pressing a function key (F1…F21).

5 Touch Screen Terminal Display On touch screen terminals, initiate the function of a displayed object, such as an

ON or OFF push button, by touching the screen object. Each interactive screen

object occupies one or more of 384 cells.

6 Touch Cells (Touch Screen terminal) The 384 touch cells (24 columns x 16 rows) let you initiate functions by touching

the screen. Interactive screen objects are aligned with touch cells when the

application is created.

Publication 2711-UM014G-EN-P - September 2008 45

Page 46

Chapter 1 Terminal Overview

PanelView 1400 Terminal Features (back and sides)

Remote I/O, DF1, DH+, DeviceNet, ControlNet,

or Ethernet with additional RS-232 Port

16

7, 8, 9

10, 11, 12

13, 14, 15, 16

10, 11, 12, 13, 14, or 15

DH-485 with additional RS-232 Port

7

8

16

19

18

17

6

5

4

3

1

2

Left Side

20

RS-232 (DH-485) with additional RS-232 Port

9

16

Right Side

21

46 Publication 2711-UM014G-EN-P - September 2008

Page 47

Terminal Overview Chapter 1

# Feature Description

1 Brightness Control Adjusts the brightness of the color display.

2 Contrast Control Adjusts the contrast of the color display.

3 Nameplate Label Provides product information.

4 FAULT Status (Red) Indicates firmware or hardware faults.

5 COMM Status (Green) Indicates when communication is occurring.

6 Power Connection Terminals Connects to external power source.

7 DH-485 Communication Port Connects to an SLC or MicroLogix controller, DH-485 network, or Wallmount Power

Supply (Cat. No. 1747-NP1).

8 DH-485 Programming Connector Connects to a Personal Computer Interface Converter (Cat. No. 1747-PIC) for

transferring applications. Also connects to an SLC programmer, such as the

Hand-held Terminal (Cat. No. 1747-PT1).

9 RS-232 (DH-485) Communication Port Connects to the Channel 0 port of an SLC 5/03, 5/04, or 5/05 for point-to-point

DH-485 communication. Connects to a MicroLogix controller through an AIC+ Link

Coupler. Also connects to the RS-232 serial port of a computer for transferring

applications.

10 Remote I/O Port Connects to a scanner or sub-scanner on a remote I/O network.

11 DH+ Communication Port Connects to a PLC-5, SLC 5/04, or ControlLogix controller on a DH+ link.

12 DeviceNet Connector Connects to a DeviceNet network.

13 ControlNet Connector Connects to a ControlLogix controller (with 1756-CNB module) or PLC-5 on a

ControlNet network.