Allen-Bradley

Getting Started

with PanelBuilder

Software

User

Manual

Important User Information

Because of the variety of uses for the products described in this

publication, those responsible for the application and use of this

control equipment must satisfy themselves that all necessary steps

have been taken to assure that each application and use meets all

performance and safety requirements, including any applicable laws,

regulations, codes and standards.

The illustrations, charts, sample programs and layout examples

shown in this guide are intended solely for purposes of example.

Since there are many variables and requirements associated with any

particular installation, Allen-Bradley does not assume responsibility

or liability (to include intellectual property liability) for actual use

based upon the examples shown in this publication.

Allen-Bradley publication SGI-1.1, Safety Guidelines for the

Application, Installation, and Maintenance of Solid-State Control

(available from your local Allen-Bradley office), describes some

important differences between solid-state equipment and

electromechanical devices that should be taken into consideration

when applying products such as those described in this publication.

Reproduction of the contents of this copyrighted publication, in

whole or in part, without written permission of Allen-Bradley

Company, Inc., is prohibited.

Throughout this manual we use notes to make you aware of safety

considerations:

ATTENTION: Identifies information about practices

or circumstances that can lead to personal injury or

!

death, property damage or economic loss.

Attention statements help you to:

• identify a hazard

• avoid the hazard

• recognize the consequences

Important: Identifies information that is critical for successful

application and understanding of the product.

PanelBuilder, PanelView 550, PanelView 600, PanelView 900, PanelView 1400, SLC, SLC 500, SLC 5/01, SLC 5/02, SLC

5/03, SLC 5/04, Data Highway Plus are trademarks of Allen-Bradley Company, Inc.

PLC and PLC-5 are registered trademarks of Allen-Bradley Company, Inc.

RSLinx and INTERCHANGE are trademarks of Rockwell Software Inc.

Microsoft, Windows, and MS-DOS are registered trademarks, and Windows NT is a trademark of Microsoft Corporation.

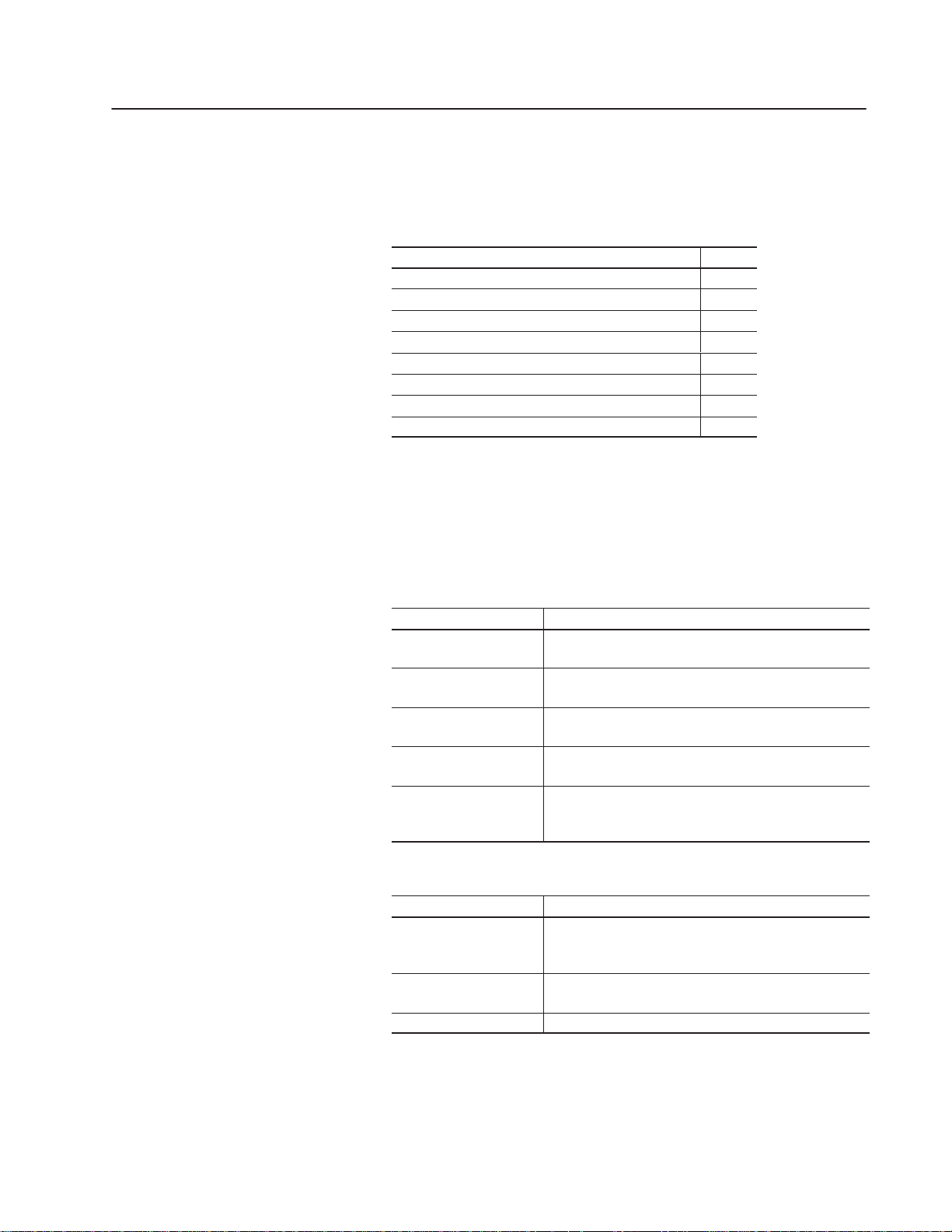

Preface

Contents of this Guide P–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Conventions P–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Related Publications P–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

What You Need P–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PanelBuilder Basics

Initial System Setup

Overview of Sample Application

Chapter 1

Chapter Objectives 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Windows Environment 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PanelBuilder Windows 1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Accessing Objects 1–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Placing Objects 1–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Selecting Objects 1–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Sizing Objects 1–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Moving Objects 1–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Getting Help 1–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 2

Chapter Objectives 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting up System Components 2–1. . . . . . . . . . . . . . . . . . . . . . . . . .

Loading the SLC Ladder Logic Program 2–5. . . . . . . . . . . . . . . . . . . .

Loading the PLC Ladder Logic Program 2–5. . . . . . . . . . . . . . . . . . . .

Chapter 3

Chapter Objectives 3–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Purpose of Application 3–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Application Screens 3–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Motor Status Screen 3–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Motor Speed Screen 3–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Alarm Banner 3–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Application Tags 3–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DH-485 or DH+ Application Tags 3–7. . . . . . . . . . . . . . . . . . . . . . . .

Remote I/O Application Tags 3–8. . . . . . . . . . . . . . . . . . . . . . . . . . .

Publication 2711-6.2

Table of Contentsii

Creating the Sample Application

Chapter 4

Chapter Objectives 4–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Starting PanelBuilder 4–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Opening a New Application File 4–3. . . . . . . . . . . . . . . . . . . . . . . . . .

Creating the Motor Status Screen 4–4. . . . . . . . . . . . . . . . . . . . . . . . .

Opening a New Screen 4–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting Grid Attributes 4–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Creating the Start Motor Push Button 4–6. . . . . . . . . . . . . . . . . . . .

Creating the Stop Motor Push Button 4–8. . . . . . . . . . . . . . . . . . . . .

Creating the Motor Speed Screen Button 4–11. . . . . . . . . . . . . . . . . .

Creating a Goto Config Screen Button 4–12. . . . . . . . . . . . . . . . . . . .

Creating the Select Mode Control List 4–13. . . . . . . . . . . . . . . . . . . .

Creating Control List Keys 4–16. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Creating the Mode Indicator 4–17. . . . . . . . . . . . . . . . . . . . . . . . . . .

Creating the Status Indicator 4–21. . . . . . . . . . . . . . . . . . . . . . . . . .

Closing the Motor Status Screen 4–24. . . . . . . . . . . . . . . . . . . . . . . .

Creating the Motor Speed Screen 4–25. . . . . . . . . . . . . . . . . . . . . . . . .

Opening the Toolbox and Color Palette 4–25. . . . . . . . . . . . . . . . . . .

Opening a New Screen 4–25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Creating the Increase Speed Push Button 4–26. . . . . . . . . . . . . . . . .

Creating the Decrease Speed Push Button 4–28. . . . . . . . . . . . . . . .

Creating the Motor Status Screen Button 4–29. . . . . . . . . . . . . . . . . .

Creating the Speed Bar Graph and Scale 4–31. . . . . . . . . . . . . . . . .

Creating the Speed Numeric Entry Object 4–34. . . . . . . . . . . . . . . . .

Creating the RPM Data Display 4–37. . . . . . . . . . . . . . . . . . . . . . . . .

Closing the Toolbox and Color Palette 4–39. . . . . . . . . . . . . . . . . . . .

Closing the Motor Speed Screen 4–39. . . . . . . . . . . . . . . . . . . . . . . .

Linking the Motor Speed and Motor Status Screens 4–39. . . . . . . . . . . .

Creating Alarms 4–40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Saving the Application 4–43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Summary 4–43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Publication 2711-6.2

Table of Contents iii

PanelView Terminal Setup

Entering the Application Tags

Validating and Downloading the Application

Chapter 5

Chapter Objectives 5–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Defining Remote I/O Communication Settings 5–2. . . . . . . . . . . . . . . .

Defining DH-485 Communication Settings 5–4. . . . . . . . . . . . . . . . . . .

Defining DH+ Communication Settings 5–5. . . . . . . . . . . . . . . . . . . . .

Setting Terminal Power-up Options 5–6. . . . . . . . . . . . . . . . . . . . . . . .

Saving the Application 5–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Summary 5–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 6

Chapter Objectives 6–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Opening the Tag Editor 6–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Overview of Tags 6–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Entering the Tags 6–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Exiting the Tag Editor 6–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using the Form View 6–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 7

Chapter Objectives 7–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

V alidating the Application 7–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Downloading the Application 7–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Closing the Application 7–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Running the Application

Chapter 8

Chapter Objectives 8–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Running the Motor in Auto Mode 8–1. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Running the Motor in Manual Mode 8–3. . . . . . . . . . . . . . . . . . . . . . . .

Appendix A SLC Ladder Logic Program

for DH-485/DH+ Application

Appendix B PLC Ladder Logic Program

for Remote I/O Application

Appendix C PLC5 Ladder Logic Program

for DH+ Application

Publication 2711-6.2

Welcome to the PanelBuilder Software. To help you get started,

this guide provides some basics on using the software and a sample

application. It takes you through all the steps that are required to

create, download and run the sample application in a Remote I/O,

DH-485 or DH+ PanelView terminal.

This guide is intended as an introduction. For more information on

software features and how to perform specific tasks refer to the

PanelBuilder Software User Manual.

PanelBuilder runs in the Microsoft Windows environment. You

should be familiar with basic window operations; such as how to use

the mouse, choose commands and work with windows and dialog

boxes.

Contents of this Guide

• Preface

An overview of this guide and what you need to create, download

and run the sample application.

• Chapter 1 – PanelBuilder Basics

Takes a quick look at the PanelBuilder Software.

• Chapter 2 – Initial System Setup

Describes the setup of system components and how to load the

required ladder logic program into a PLC or SLC controller.

• Chapter 3 – Overview of Sample Application

Provides a description of the sample application and its function.

• Chapter 4 – Creating the Sample Application

Provides step-by-step instructions for creating the sample

application.

• Chapter 5 – PanelView Terminal Setup

Shows how to set runtime communication parameters and

power-up options for the PanelView terminal and controller.

• Chapter 6 – Entering the Application Tags

Shows how to use the Tag Editor to enter tags for the application.

• Chapter 7 – Validating and Downloading the Application

Shows how to download the sample application to a PanelView

terminal.

• Chapter 8 – Running the Application

Shows how to run the application in the PanelView terminal.

PrefaceP–2

Conventions

Related Publications

"

The following conventions are used in this guide.

• PanelBuilder refers to the PanelBuilder Configuration Software.

• Terminal refers to a PanelView Operator Terminal.

• Windows refers to Microsoft Windows versions 3.1 (or higher),

or Windows 95.

• Keys on the keyboard appear in small capital letters. For

example, the Ctrl key appears as

ALT, and so on.

CTRL in the text, the Alt key as

• When keys are to be pressed in combination, you’ll see them

connected by a +. For example,

key while you press F4.

ALT+F4 means hold down the ALT

• Bold text precedes all procedures.

To open an application file:

• A solid right cursor in the left margin indicates a tip or hint.

Anchor point is the handle opposite the handle you choose. The

anchor point doesn’t move when sizing objects.

The following table lists other publications related to the

PanelBuilder Software and the PanelView Operator Terminals.

Publication Title Publication No.

PanelBuilder Software User Manual 2711-6.0

PanelView Terminal User Manual 2711-6.1

PanelView File Transfer Utility 2711-805

For information on your PLC or SLC controller, the Advanced

Programming Software, or the 6200 Series Programming Software,

refer to the appropriate manuals.

For information on window operations, refer to your Windows user

guide.

Publication 2711-6.2

Preface P–3

What You Need

This section lists the items needed to create, download and run the

sample application in a PanelView terminal using either:

• Remote I/O communications

• DH-485 communications

• DH+ communications

Personal Computer

The minimum system requirements for installing and running

PanelBuilder Software on a personal computer are:

• Personal computer with a 386 or higher processor

• MS-DOSR operating system version 5.0 or later

• WindowsR 3.1 or later (Windows for Workgroups 3.11 or later),

Windows 95, or Windows NT 4.0.

• 500K free conventional memory

• at least 40 MB available hard disk space

• VGA or other high-resolution display supported by Windows

• Mouse or other Windows pointing device

"

PanelBuilder Software

The PanelBuilder Software (Catalog No. 2711-ND3) is required to

create applications on a computer for PanelView terminals.

Install the PanelBuilder Software as described in Chapter 2 of the

PanelBuilder Software manual.

Publication 2711-6.2

PrefaceP–4

PanelView Operator Terminal

The sample application operates with all of PanelView terminals.

The differences are in the:

• display type (monochrome or color)

• operator input (touch screen or keypad)

• communication ports (Remote I/O, DH-485, RS-232, DH+)

Download Cables

Remote I/O, RS-232 or DH+ Versions of PanelView Terminals

Theses PanelView terminals require one of the following cables to

download applications using an RS-232 connection:

• Catalog No. 2711-NC13

• Catalog No. 2711-NC14

• Catalog No. 2706-NC13

The only difference between the cables is the cable length.

DH-485 Versions of PanelView Terminals

The DH-485 versions of the PanelView terminals require the

following items to download applications:

• Personal Computer Interface Converter (Catalog No. 1747-PIC)

• Communications Cable (Catalog No. 1747-C10, -C11, -C20)

The Personal Computer Interface Converter receives power from an

SLC controller. Downloading an application to the terminal without

an SLC connected requires a power supply (Catalog No. 1747-NP1)

or a powered Link Coupler (Catalog No. 1747-AIC).

Communication Cable

A communication cable is required to connect the PanelView

terminal to a PLC or SLC controller.

Remote I/O Versions of PanelView Terminals

The Remote I/O versions of the PanelView terminals connect to a

PLC controller using Remote I/O cable (Catalog No. 1770-CD),

which is equivalent to the Belden 9463 cable.

Publication 2711-6.2

Preface P–5

DH-485 Versions of PanelView Terminals

The DH-485 versions of the PanelView terminals require one of the

following:

• Catalog No. 1747-C10

• Catalog No. 1747-C11

• Catalog No. 1747-C20

The only difference between the cables is the cable length.

RS-232 Versions of PanelView Terminals

The RS-232 versions of the PanelView terminals use the same cable

for downloading and communications.

• Catalog No. 2711-NC13

• Catalog No. 2711-NC14

• Catalog No. 2706-NC13

DH+ Versions of PanelView Terminals

The DH+ versions of the PanelView terminals connect to a DH+ link

using a Belden 9463 cable (Catalog No. 1770-CD).

PLC or SLC Controller

Remote I/O Versions of PanelView Terminals

The Remote I/O versions of the PanelView terminal operate with a

PLC 5 or SLC controller (with a 1747-SN Scanner). The sample

application uses a PLC 5/25 controller.

DH-485 Versions of PanelView Terminals

The DH-485 versions of the PanelView terminal operate with both

fixed and modular style SLC 500 controllers.

RS-232 Versions of PanelView Terminals

The RS-232 versions of the PanelView terminal require an SLC 5/03

or 5/04 controller.

DH+ Version of PanelView Terminals

The DH+ versions of the PanelView terminal operate with either a

PLC 5 or SLC controller. The sample application uses a PLC 5/25

controller.

Publication 2711-6.2

PrefaceP–6

Application and Ladder Logic Program

The PanelBuilder installation disks contain:

• Getting Started application (.PBA files) for each of the

PanelView terminals.

• Required ladder logic to run the application, including:

– SLC ladder logic files for DH-485/DH+ application

– PLC ladder logic files for Remote I/O application

– PLC ladder logic files for DH+ application

The files are stored on your computer as follows:

DH-485 or DH+ Application C:\AB\PBWIN\GS\5BV2485.PBA

5KV2485.PBA

6BV2485.PBA

6KV2485.PBA

9CKV2485.PBA

9CTV2485.PBA

9MKV2485.PBA

9MTV2485.PBA

10KC_485.PBA

10KG_485.PBA

10TC_485.PBA

10TG_485.PBA

14MKV2485.PBA

14MTV2485.PBA

SLC Ladder Logic Files C:\AB\SLC500\GS\GETSTRTD.AC$

GETSTRTD.ACH

GETSTRTD.B0$

GETSTRTD.B1$

GETSTRTD.B2$

GETSTRTD.IX$

GETSTRTD.LX$

GETSTRTD.NAM

GETSTRTD.OP$

GETSTRTD.PC$

GETSTRTD.XD$

GETSTRTD.XO$

Remote I/O Application C:\AB\PBWIN\GS\5BV2RIO.PBA

5KV2RIO.PBA

6BV2RIO.PBA

6KV2RIO.PBA

9CKV2RIO.PBA

9CTV2RIO.PBA

10KC_RIO.PBA

10KG_RIO.PBA

10TC_RIO.PBA

10TG_485.PBA

9MKV2RIO.PBA

9MTV2RIO.PBA

14MKV2RIO.PBA

14MTV2RIO.PBA

Publication 2711-6.2

Preface P–7

PLC (RIO) Ladder Logic Files C:\AB\PLC5\GS\GSRIO.AC$

GSRIO.AF5

GSRIO.B0$

GSRIO.B1$

GSRIO.D1$

GSRIO.IX$

GSRIO.LX$

GSRIO.OP$

GSRIO.P1$

GSRIO.PC$

GSRIO.TTL

PLC (DH+) Ladder Logic Files C:\AB\PLC5\GS\GSDHP.AC$

GSDHP.AF5

GSDHP.B0$

GSDHP.B1$

GSDHP.D1$

GSDHP.IX$

GSDHP.LX$

GSDHP.OP$

GSDHP.P1$

GSDHP.PC$

Publication 2711-6.2

PanelBuilder Basics

Chapter Objectives

Windows Environment

This chapter covers basics on using PanelBuilder Software.

Section Page

Windows Environment 1–1

PanelBuilder Windows 1–2

Accessing Objects 1–4

Placing Objects 1–5

Selecting Objects 1–7

Sizing Objects 1–8

Moving Objects 1–8

Getting Help 1–9

PanelBuilder runs in the Microsoft Windows environment. You

should be familiar with window operations. That is, you should

know how to use the mouse, choose menu commands, and work with

windows and dialogs.

If you use a mouse, here are the basic terms used:

Term Means

Click Position the mouse pointer on the object, area or field, then

press and release the left mouse button once.

Double-click Position the mouse pointer on the object, area, or field and

then click the left mouse button twice quickly.

Select item or command Click to highlight the item to be affected by the next

command, or click on a dialog box option.

Choose item or command Click on a tool, menu command or an item in a dialog box or

Help window.

Drag Click where to start a selection and hold down the left

mouse button. Move pointer to end of selection and release

the mouse button. Use drag to highlight a text string.

If you prefer to use the keyboard:

Term Means

Choose menu command Press the ALT key and type the underlined letter in the

menu name . Then type the letter underlined in the

command name.

Select item or command Use the arrow keys (or in a dialog, both the TAB and arrow

keys) to move to the item.

Choose item or command Highlight an item, then press the ENTER key.

Publication 2711-6.2

1–2 PanelBuilder Basics

PanelBuilder Windows

Each time you start PanelBuilder, the PanelBuilder window opens.

This is where you create an application. Window elements are

described below.

Menu Bar

Tool Bar

Format Bar *

Border

Mouse Pointer

Status Bar

Control-Menu

Title Bar

Command

Maximize Button

Minimize Button

Close Button

Resizes

⇐⇒

Window

Feature How to use it

Menu Bar Click a name on the menu bar to open a menu and display its

commands.

Or press ALT-X, where X is the underlined letter in the menu name.

Command Click a command to choose it or carry out its action.

Or type the underlined letter in the command name.

Title Bar Drag to move a window.

Tool Bar Click a tool to carry out a frequently used command. The tool bar

toggles on and off from the View menu.

*Format Bar

Click a tool to format an object or text. The format bar doesn’t

appear until you open an application.

Status Bar Shows what PanelBuilder is doing at the moment. The status bar

toggles on and off from the View menu.

Control-Menu Click to open the Control menu. Double-click to close a window.

Minimize button Click to reduce window to an icon.

Maximize button Click to enlarge a window.

Close button Closes the window.

Border Drag to change the size of a window.

Mouse pointer Use to select an item or object.

Publication 2711-6.2

Application File Window

When you open an application, the application file window opens

listing all screens in the application by number and name.

1–3PanelBuilder Basics

Control-menu

Application File Window

Close Button

Maximize Button

Minimize Button

Title Bar

Border

Resizes

⇐⇒

Window

Application Screen Window

Each application screen looks like the PanelView terminal (touch,

keypad, or keypad & touch) for which you are creating the

application. Objects are placed inside the display area. On keypad

terminals, you can also place objects on function keys. Screens are

moved and sized like any other window. Multiple screens can be

open at one time.

Title Bar

Application Screen

Publication 2711-6.2

1–4 PanelBuilder Basics

Accessing Objects

Draw Pointer

Objects are accessed from the Objects menu or the Toolbox.

Toolbox toggles on and

off from the View menu.

After selecting an object and moving the mouse pointer into the

display area, the pointer changes to a crosshair (+). The crosshair

indicates where an object appears when you place it.

If moved to an illegal area of the screen, the crosshair looks like this

.

Publication 2711-6.2

1–5PanelBuilder Basics

Placing Objects

On touch screen terminals, objects are placed in the display area. On

keypad terminals, objects are placed in the display area and assigned

function keys. On terminals that support both keypad and touch

input, you place objects in the display area or on function keys.

To create an object in the display area:

1. Choose an object from the Objects menu.

Or click the appropriate tool in the toolbox.

2. Position the pointer (+) where you want to place the object.

3. Click the left mouse button to place the default size.

Or hold down the left mouse button and drag the pointer to size

the object. Release the mouse when the object is the right size.

The object is automatically selected.

Object

Drag Pointer

to Size Object

4. To place another object of the same type, move the pointer to a

new location and repeat step 3.

5. Click the right mouse button to exit the object mode.

Or click the selection tool in the toolbox.

Or press the

ESC key.

For each object placed on the screen, the status bar shows:

• Object ID number (assigned by PanelBuilder)

• X and Y coordinates of upper left corner of object (in pixels).

Coordinates are referenced from upper left corner of display

(x=0, y=0).

• Width and height of object (in pixels)

• Object type (right element of status bar)

Publication 2711-6.2

1–6 PanelBuilder Basics

To create an object on a function key:

1. Choose an object from the Objects menu.

Or click the appropriate tool in the toolbox.

2. Position the pointer (+) over a function key and click the left

mouse button.

If the function key is already assigned to an object, the pointer

changes to

. Reposition pointer over another key.

Pointer over Function Key

A graphic appears on the function key showing the object type.

An asterisk also appears next to the key number.

*F1

Asterisk

Graphic

3. Click the right mouse button to exit the object mode.

Or click the selection tool in the toolbox.

Publication 2711-6.2

1–7PanelBuilder Basics

electing Objects

S

Before you can move, size or format an object you must first select

the object. A selected object has handles.

To select an object:

Position the mouse pointer anywhere on the object and press the left

mouse button. Handles appear on the object.

A line has one handle at each end. Rectangles and squares have

handles around their edges. Other objects (ellipses and circles) have

handles around an invisible bounding box.

To deselect an object:

• Position pointer outside the object and press the left mouse

button.

• Or select another object.

"

To select multiple objects:

1. Position pointer above and to the left of the objects you want to

group.

2. Press the left mouse button and drag a selection rectangle around

the objects.

Selection Rectangle

3. Release the mouse button.

The other way to select multiple objects is to hold down the

key and click on each object. To add or remove an object from the

selection, hold down the

SHIFT key and click on the object.

SHIFT

To select all objects:

Choose Select All from the Edit menu.

Handles appear on all objects to show that they’re all selected.

Publication 2711-6.2

1–8 PanelBuilder Basics

Sizing Objects

To size an object:

1. Select the object by clicking anywhere on the object.

Handles appear on the object.

Handle

2. Position the pointer over one of the handles.

The pointer changes to show the direction you can size the object.

Size Diagonally

Size Horizontally

Size Vertically

3. Press the left mouse button and drag the handle.

The object stretches from the anchor point to the position of the

pointer, expanding and contracting as you move the mouse.

Moving Objects

"

The anchor point is the handle opposite the handle you choose. It

does not move when objects are sized.

4. Release the mouse button when the object is the right size.

Objects with inner graphics can’t be sized smaller than the graphic.

You might have to move or delete the inner graphic to size the object

appropriately.

To move an object:

1. Move the pointer anywhere inside the object.

2. Hold down the left mouse button and drag the object to its new

location. The pointer changes to show that you are moving the

object. An outline appears as you drag the object.

Old Location

New Location New Location

Publication 2711-6.2

3. Release the mouse button.

1–9PanelBuilder Basics

Getting Help

Help for PanelBuilder is available by choosing a command from the

Help menu or pressing the

F1 key. The following help window opens

when you choose Index from the Help menu.

Help feature How to use it

Contents button Choose to see a list of topics.

Search button Choose to search for topics by keywords.

Back button Choose to view the previous topic. Continue to choose the button

to step back through all the topics.

History button Choose to display a list of topics you have viewed. In the list,

double-click a topic name to view it again.

>> Choose to display the next topic in a series of topics.

<< Choose to display the previous topic in a series of topics.

Publication 2711-6.2

Initial System Setup

Chapter Objectives

Setting up System Components

This chapter contains these sections.

Sections Page

Setting up System Components 2–1

Loading the SLC Ladder Logic Program 2–5

Loading the PLC Ladder Logic Program 2–5

This section shows how to set up the system components that are

required to install, download and run the sample application.

System Components for PanelView with DH-485 Ports

•

DH-485 PanelView Terminal

• Personal Computer with installed:

– PanelBuilder Software

– Advanced Programming Software (APS)

• SLC 500 Controller

• 2 Communication Cables (Catalog No. 1747-C10, -C11 or -C20)

• Personal Computer Interface Converter (Catalog No. 1747-PIC)

Node 0

Personal Computer

PanelBuilder

Serial Port

COM1 or COM2

Make the connections shown below. No other connections are

required.

Node 2

SLC Controller

Cable

DH-485 Connector DH-485 Connector

Personal Computer

Interface Converter

Catalog No. 1747-PIC

PanelView 900 DH-485 Terminal Shown

Catalog No. 1747-C10, -C11, -C20

Node 1

Publication 2711-6.2

2–2 Initial System Setup

System Components for PanelView with RS-232 (DH-485) Port

•

RS-232 PanelView Terminal

• Personal Computer with installed:

– PanelBuilder Software

– Advanced Programming Software (APS)

• SLC 5/03 or 5/04 Controller

• One Communication Cable (Catalog No. 2711-NC13,-NC14

or 2706-NC13)

Node 0

Personal Computer

PanelBuilder

PanelView 900 RS-232 Terminal Shown

Node 2

Serial Port

COM1 or COM2

Cable

Catalog No. 2711-NC13,

2711-NC14, 2706-NC13

To Channel 0

Note: The same cable is used for transferring applications to the terminal and

for connecting the terminal to the SLC 5/03 or 5/04 Controller. After downloading

the application, disconnect the cable from the computer and connect to Channel

0 Port of SLC 5/03 or 5/04.

SLC 5/03 or 5/04 Controller

Node 1

Publication 2711-6.2

System Components for PanelView with Remote I/O Port

ode

•

Remote I/O PanelView Terminal

• Personal Computer with installed:

– PanelBuilder Software

– 6200 Series Programming Software

• PLC-5 Controller

• One RIO Communication Cable (Catalog No. 1770-CD),

equivalent to a Belden 9463 cable. Along with two RIO

connectors, one RIO connector is provided with the terminal.

• One RS-232 Communication Cable (Catalog No.

2711-NC13,-NC14 or 2706-NC13)

N

Personal Computer

0

PanelBuilder

2–3Initial System Setup

PanelView 900 Remote I/O Terminal Shown

RS-232 Port

Node 2

Remote I/O Port

3-Pin Terminal Block Connector

Cable

Catalog No. 1770-CD

(Belden 9463)

PLC-5 Controller

PLC RIO Port

Node 1

Serial Port

COM1 or COM2

Cable

Catalog No. 2711-NC13,

2711-NC14, 2706-NC13

Publication 2711-6.2

2–4 Initial System Setup

ode

System Components for PanelView with DH+ Port

•

DH+ PanelView Terminal

• Personal Computer with installed:

– PanelBuilder Software

– 6200 Series Programming Software

• PLC-5 Controller

• One Communication Cable (Catalog No. 1770-CD), equivalent to

a Belden 9463 cable.

• One RS-232 Communication Cable (Catalog No.

2711-NC13,-NC14 or 2706-NC13)

N

Personal Computer

0

PanelBuilder

PanelView 900 DH+ Terminal Shown

RS-232 Port

Node 2

3-Pin Terminal Block Connector

82 or 150

resistor

21

DH+ Port

Node 1

PLC-5 Controller

PLC DH+ Port

2

Blue

SH

Shield

1

Clear

Clear

Shield

Blue

1

SH

2

Serial Port

COM1 or COM2

Cable

Catalog No. 2711-NC13,

2711-NC14, 2706-NC13

Publication 2711-6.2

2–5Initial System Setup

Loading the SLC Ladder Logic Program

For DH-485 or DH+ applications that communicate with an SLC

controller, the required ladder logic program and data files are

supplied on the PanelBuilder installation disks.

The following files are installed in the C:\AB\SLC500\GS directory

during PanelBuilder installation.

SLC Ladder Logic Files

GETSTRTD.AC$

GETSTRTD.ACH

GETSTRTD.B0$

GETSTRTD.B1$

GETSTRTD.B2$

GETSTRTD.IX$

GETSTRTD.LX$

GETSTRTD.NAM

GETSTRTD.OP$

GETSTRTD.PC$

GETSTRTD.XD$

GETSTRTD.XO$

Run the APS software installed on your computer and load the

ladder logic program into the SLC controller. Appendix A contains

the documented ladder logic program.

For details on how to use the Advanced Programming Software refer

to the appropriate manuals.

Loading the PLC Ladder Logic Program

For Remote I/O and DH+ applications that communicate with a

PLC5 controller, the required ladder logic program and data files are

supplied on the PanelBuilder installation disks.

The following files are installed in the C:\AB\PLC5\GS directory

during PanelBuilder installation.

PLC (RIO) Ladder Logic Files PLC (DH+) Ladder Logic Files

GSRIO.AC$

GSRIO.AF5

GSRIO.B0$

GSRIO.B1$

GSRIO.D1$

GSRIO.IX$

GSRIO.LX$

GSRIO.OP$

GSRIO.P1$

GSRIO.PC$

GSRIO.TTL

GSDHP.AF5

GSDHP.AC$

GSDHP.B0$

GSDHP.B1$

GSDHP.D1$

GSDHP.IX$

GSDHP.LX$

GSDHP.OP$

GSDHP.P1$

GSDHP.PC$

Load the ladder logic program into the PLC controller. Appendix B

contains the ladder logic for the Remote I/O application. Appendix C

contains the ladder logic for the DH+ application.

For details on how to load the ladder logic program into the PLC

controller, to the appropriate user manuals.

Publication 2711-6.2

Overview of Sample Application

Chapter Objectives

Purpose of Application

This chapter contains these sections.

Sections Page

Purpose of Application 3–1

Application Screens 3–2

Motor Status Screen 3–3

Motor Speed Screen 3–4

Alarm Banner 3–5

Application Tags 3–6

DH-485 or DH+ Application Tags 3–7

Remote I/O Application Tags 3–8

The Getting Started application contains objects to control and

monitor the status of a motor. The PanelView terminal reads/writes

data to either:

• an SLC 500 controller on a DH-485 network

• an SLC 500 controller or PLC 5 controller on a DH+ network

• a PLC 5 controller on a Remote I/O network

Chapter 4 gives procedures for creating the application on a

PanelView 900 monochrome terminal with function keys.

• If creating the application for any of the PanelView touch screen

terminal, touch cell input is automatically enabled.

• If creating the application for a PanelView color terminal, the

procedures reference colors.

For PanelView grayscale terminals, the color palette shows 4

shades of gray. Select the appropriate shades.

• If creating the application for other PanelView terminals, use

appropriate text sizes.

You can open any of the .PBA files stored in AB\PBWIN\GS to view

the getting started application on your computer.

Publication 2711-6.2

3–2 Overview of Sample Application

Application Screens

The application contains 3 screens:

• Motor Status

• Motor Speed

• Alarm Banner (V2.0 or later software only)

The Motor Status and Motor Speed screens each contain a screen

button allowing you to navigate between the two screens.

The Alarm Banner is a global display that pops up over the Motor

Status or Motor Speed screen when an alarm is triggered. Alarms

are supported in PanelBuilder V2.0 (or later) Software.

For touch screen terminals, the application includes a CONFIG

SCREEN button allowing the operator to display the terminal’s

Configuration Mode menu when the application is running.

Publication 2711-6.2

Motor Status Screen

The Motor Status screen is the first screen that appears when you

power on the PanelView terminal. It allows you to:

• start and stop motor

• set motor control to auto or manual mode

• monitor status (start/stop) and mode (auto/manual) of motor

• go to the Motor Speed screen

3–3Overview of Sample Application

Keypad Terminal

Touch Screen Terminal

The following table lists objects on the Motor Status screen and each

object’s function. Object headings are created as background text.

Object Object Type Function

Motor

Speed

F8

Standard Control List

with Background Text

Momentary Push Button

(Normally Open)

Momentary Push Button

(Normally Open)

Goto Screen Button Displays the Motor Speed screen when you

2 Multistate Indicators

with Background Text

Sets the motor to auto or manual mode by

moving the cursor up or down and pressing

the Enter key.

The touch screen terminal requires list keys

to move the cursor through the control list

and select an option.

Starts the motor when you press the F1 key

or touch the screen object.

Stops the motor when you press the F2 key

or touch the screen object.

press the F8 key (F5 on PV550 terminals) or

touch the screen object.

MODE indicator shows whether the motor is

in AUTO or MANUAL mode.

STATUS indicator shows whether the motor

is on (START) or off (STOP).

Publication 2711-6.2

3–4 Overview of Sample Application

Application Screens

Keypad Terminal

Motor Speed Screen

The Motor Speed screen allows you to:

• monitor motor speed

• increase or decrease motor speed

• enter a new motor speed

• go to the Motor Status screen

Touch Screen Terminal

The table below lists objects on the Motor Speed screen and each

object’s function. Object headings are created as background text.

Object Object Type Function

Motor

Status

F8

Numeric Cursor Point

with Background Text

Numeric Data Display Displays the current speed (0 to 1000

Bar Graph and Scale

with Background Text

Momentary Push Button

(Normally Open)

Momentary Push Button

(Normally Open)

Goto Screen Button Displays the Motor Status screen when

Opens the scratchpad for entering a new

motor speed (from 0 to 1000 rpm).

rpm) of the motor.

Displays the current motor speed (0 to

1000 rpm) in a graphic form.

The bar graph scale and tick-mark labels

are created as separate objects.

Increases the speed of the motor when

you press the F1 key or touch the screen

object.

Decreases the speed of the motor when

you press the F2 key or touch the screen

object.

you press the F8 key (F5 on PV550

terminals) or touch the screen object.

Publication 2711-6.2

Loading...

Loading...