Page 1

Attended Workstations

(Catalog Nos. 2708-DH5B2L & -DH5B4L)

(Series B)

User Manual

ALLEN-BRADLEY

Page 2

Disclaimer

Important User Information

Solid state equipment has operational characteristics differing from those of

electromechanical equipment. “Application Considerations for Solid State

Controls” (Publication SGI-1.1) describes some important differences

between solid state equipment and hard–wired electromechanical devices.

Because of this difference, and also because of the wide variety of uses for

solid state equipment, all persons responsible for applying this equipment

must satisfy themselves that each intended application of this equipment is

acceptable.

In no event will the Allen-Bradley Company be responsible or liable for

indirect or consequential damages resulting from the use or application of

this equipment.

The examples and diagrams in this manual are included solely for illustrative

purposes. Because of the many variables and requirements associated with

any particular installation, the Allen-Bradley Company cannot assume

responsibility or liability for actual use based on the examples and diagrams.

No patent liability is assumed by Allen-Bradley Company with respect to use

of information, circuits, equipment, or software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without

written permission of the Allen-Bradley Company is prohibited.

Page 3

Table of Contents

Attended Workstations

User Manual

Introduction

Installing a Network

Chapter Objectives 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Catalog Numbers 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Accessory Items 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Related Publications 1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety Information 1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter Objectives 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Requirements 2–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Simple Network 2–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The RS-485 Network Bus 2–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The Network Connector (Catalog No. 2708-NNC) 2–3. . . . . . . . . . . . .

Cabling a Network Using the Network Connector 2–4. . . . . . . . . . . . .

Cable Wire 2–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preparing the Wire 2–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing the Connector 2–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Master Connection 2–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

NON-MASTER Connection 2–6. . . . . . . . . . . . . . . . . . . . . . . . . . .

Step By Step Installation 2–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The Terminator Switch 2–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Communication Cables 2–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Testing the Network for Data Transmission 2–10. . . . . . . . . . . . . . . . . . . . .

Communication to the Host Computer 2–11. . . . . . . . . . . . . . . . . . . . . . . . .

Description of Large or Complex Network 2–13. . . . . . . . . . . . . . . . . . . . . .

Complex Network 2–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Alternate Communication Links 2–14. . . . . . . . . . . . . . . . . . . . . . . . . . .

Networks Over Telecommunications Lines 2–15. . . . . . . . . . . . . . . . . . .

Barcode Connection

Status Displays

Chapter Objectives 3–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connection 3–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Introduction 4–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Summary Status Display (Status Display 0) 4–2. . . . . . . . . . . . . . . . . . . . .

Network Status (Status Display 1) 4–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reserved Status (Status Display 2) 4–5. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Time Status (Status Display 3) 4–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Reset Status (Status Display 4) 4–5. . . . . . . . . . . . . . . . . . . . . . . . .

A – Error Codes 4–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Network Queue Status (Status Display 5) 4–6. . . . . . . . . . . . . . . . . . . . . . .

Workstation Memory Status (Status Display 6) 4–8. . . . . . . . . . . . . . . . . .

i

Page 4

Table of Contents

Attended Workstations

User Manual

Program Load Status (Status Display 7) 4–9. . . . . . . . . . . . . . . . . . . . . . . .

Program Run Status (Status Display 8) 4–10. . . . . . . . . . . . . . . . . . . . . . . . .

Application Status (Status Display 9) 4–11. . . . . . . . . . . . . . . . . . . . . . . . . .

Configuration Menus

Introduction 5–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using Menus via Workstation Keypad 5–1. . . . . . . . . . . . . . . . . . . . . . . . .

Sub-Menus 5–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Exiting Network Menu 5–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using Menus from

the Comm Port 5–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Menu 1: Network Menu Paramters 5–4. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Workstation 5–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Workstation Type 5–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Menu 2: Comm Port Menu Parameters 5–5. . . . . . . . . . . . . . . . . . . . . . . . .

Comm Port Mode 5–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Comm Baud Rate 5–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Comm Data Bits 5–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Comm Parity 5–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Menu 3: System Menu Parameters 5–8. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Menu 4: Bar Code Menu Parameters 5–8. . . . . . . . . . . . . . . . . . . . . . . . . .

Menu 5: Read Only Menu 5–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Menu 6: Diagnostics Menu Parameters 5–10. . . . . . . . . . . . . . . . . . . . . . . . .

1–Keypad/Laser Test 5–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2–Display Test 5–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3–Destructive RAM Test 5–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4–Continuous RAM Test 5–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5–Comm Transmit Test 5–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6–Comm Receive Test 5–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7–Comm Loop Test 5–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8–Aux Comm Transmit Test 5–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9–Aux Comm Receive Test 5–17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A–Aux Comm Loopback Test 5–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B–RS485 Block Receive 5–19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C–RS485 Block Transmit 5–19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D–RS232 Block Receive 5–20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

E–RS232 Block Transmit 5–21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

F–Lamp Test 5–22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

G–Reset Powerup 5–22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

H–Reset Unit to Factory Defaults 5–22. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ii

Page 5

Table of Contents

Attended Workstations

User Manual

Operating Procedures

Network Design

Host Communications

Chapter Objectives 6–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Verifying Proper Network Operation 6–2. . . . . . . . . . . . . . . . . . . . . . . . . .

Removing a Master 6–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Instituting a New Workstation as Master 6–4. . . . . . . . . . . . . . . . . . . . . . . .

Removing a Workstation from the Network 6–4. . . . . . . . . . . . . . . . . . . . .

Adding a Workstation to the Network 6–5. . . . . . . . . . . . . . . . . . . . . . . . . .

Network Problems 6–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Workstation Status 6–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Networks of 32 Workstations or Less 7–1. . . . . . . . . . . . . . . . . . . . . . . . . .

Network Installation of More than 32 Workstations 7–1. . . . . . . . . . . . . . .

Fault-Tolerant Networks 7–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Extending Networks Over Phone Lines 7–4. . . . . . . . . . . . . . . . . . . . . . . .

Network Status Records 8–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using Retry Counts for Network Diagnosis 8–3. . . . . . . . . . . . . . . . . . . . .

Responses to Network Directives 8–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Network Directives 8–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

< D – Show Unit Display 8–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

< E – Show Last Error Message 8–5. . . . . . . . . . . . . . . . . . . . . . . .

< R – Show Last Reset Message 8–5. . . . . . . . . . . . . . . . . . . . . . .

< S – Show Unit Serial Number 8–6. . . . . . . . . . . . . . . . . . . . . . . .

< T – Show Workstation Date & Time 8–6. . . . . . . . . . . . . . . . . . .

< V – Show Firmware Version 8–6. . . . . . . . . . . . . . . . . . . . . . . . .

> > A – Abort Currently Running A-B VBASIC Program 8–7. . .

> > G – Restart an Aborted BASIC Program 8–7. . . . . . . . . . . . . .

> A – Abort Test 8–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

> C – Send Text Out Comm Port 8–7. . . . . . . . . . . . . . . . . . . . . . .

> c – Send Text Out Aux Comm Port 8–7. . . . . . . . . . . . . . . . . . . .

> D – Display Text on Front Panel 8–7. . . . . . . . . . . . . . . . . . . . . .

> E – Erase the Menu Password 8–8. . . . . . . . . . . . . . . . . . . . . . . .

> F – Reset to Factory Defaults 8–8. . . . . . . . . . . . . . . . . . . . . . . .

> N – Initialize Network 8–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

> R – Reboot Unit 8–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

> T – Set Time 8–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

> Z – Zero Reset Error 8–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

What is BASIC

Introduction 9–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

What is Visual BASIC ? 9–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

What is A-B VBASIC? 9–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

iii

Page 6

Table of Contents

Attended Workstations

User Manual

Developing and Running

An A-B BASIC Program

Step #1 – Planning 10–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The A-B VBASIC Development Procedure 10–1. . . . . . . . . . . . . . . . . . . . .

Step #2 – Coding with the Workstation Application Generator Software . . . .

10–1

Step #3 (Alternate) – Coding with Visual BASIC Editor 10–1. . . . . . . . . . .

Step #4 – Simulation Using Application Library 10–1. . . . . . . . . . . . . . . . .

Step #5 – Compiling the A-B VBASIC Program 10–2. . . . . . . . . . . . . . . . .

Step #6 – Downloading 10–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Loading and Auto-Starting an A-B VBASIC Program 10–3. . . . . . . . . . . . .

Start-up Condition of an A-B VBASIC Program 10–3. . . . . . . . . . . . . . . . .

LCD: 10–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Random numbers: 10–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RAM files: 10–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Variables: 10–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Host device: 10–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Termination of an A-B VBASIC Program 10–4. . . . . . . . . . . . . . . . . . . . . .

A-B VBASIC Run-Time Errors 10–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Format of a BASIC Error Message 10–5. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Failure 10–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The A-B VBASIC

Cross-Compiler

Special Devices in

A-B VBASIC

iv

Overview 11–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Invoking the Compiler 11–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LXB param 1 (,param2) (,param3) (,param4) 11–2. . . . . . . . . . . . .

LXB 11–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LXB Prog1 11–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LXB Prog1,Prog1,Prog1 11–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LXB Prog1,Download,PRN 11–3. . . . . . . . . . . . . . . . . . . . . . . . . . .

LXB Prog1,Startnow,Prog1,Wait 11–3. . . . . . . . . . . . . . . . . . . . . . .

A – Source File Specification 11–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B – Downloaded Executable File 11–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C – Listing File 11–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D – Secondary Download File 11–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Introduction 12–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Device: LCD Display 12–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Device: Keypad 12–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Device: Barcode Scanners 12–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

When reading barcodes: 12–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Device: Host Computer 12–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 7

Table of Contents

Attended Workstations

User Manual

General restrictions and warnings: 12–7. . . . . . . . . . . . . . . . . . . . . .

Details of Specific Statements and Functions 12–8. . . . . . . . . . . . . . . . . . . .

OPEN “HOST” 12–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CLOSE “HOST” 12–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

WRITE # 12–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PUT to HOST 12–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PUT to NET 12–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PUT to QUE 12–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PRINT # 12–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LINE INPUT # for HOST and NET

GET # for HOST and NET (OPEN with RANDOM) 12–10. . . .

LINE INPUT # for QUE

GET # for QUE (OPEN with RANDOM enforced) 12–10. . . . .

EOF for HOST and NET 12–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LOC for HOST and NET 12–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LOF for HOST 12–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LOF for NET 12–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

IOCTL$ (intrinsic function) for HOST and NET 12–11. . . . . . . . . .

IOCTL (statement) for HOST 12–11. . . . . . . . . . . . . . . . . . . . . . . . .

Devices: Communication Ports, Primary and Auxiliary 12–11. . . . . . . . . . . .

A – Output to a Communication Port 12–12. . . . . . . . . . . . . . . . . . . . . . . . . .

B – Input from a Communication Port 12–12. . . . . . . . . . . . . . . . . . . . . . . . .

C – Modem Control Lines 12–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Device: RAM Files 12–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Description: 12–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

File Memory Management 12–14. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Device: Beeper 12–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Device: Front Panel LED’s12–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Device: The #9 User Status Display 12–15. . . . . . . . . . . . . . . . . . . . . . . . . . .

Description: 12–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Device: The Egg Timer 12–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Description: 12–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A-B VBASIC Application

Library

Introduction 13–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using the Library 13–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Writing Programs 13–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using the ENVPC Simulator 13–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A – Predefined Constants 13–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B – Global Variables 13–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C – BASIC Language Development Kit Limitations 13–7. . . . . . . . . . . .

D – PC Simulation Constants and Variables 13–7. . . . . . . . . . . . . . . . . .

Display and Keyboard 13–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Network I/O 13–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

v

Page 8

Table of Contents

Attended Workstations

User Manual

COM and AUX 13–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Status Display 13–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Printing Reports and Forms 13–9. . . . . . . . . . . . . . . . . . . . . . . . . . .

2708-DH5B2L and -DH5B4L

Workstation Specifications

Menu Trigger Keys

Technical Description

Workstation Communication

Pin-Out Diagrams

Distance Limitations

Site Parameter List

Electrical – 2708-NP1 A–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electrical – 2708-NP2 A–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mechanical – 2708-DH5B2L and -DH5B4L A–1. . . . . . . . . . . . . . . . . . . .

Communication Ports A–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Network (RS-485) Cable Length E–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RS-232 (MASTER or HOST) Cable Length E–1. . . . . . . . . . . . . . . . . . . . .

F–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Network Pin-Out Diagrams

for DB9 Connector

Error Messages and Prompts

Time Display Formats

VBASIC Language

Development Kit

Programming Conventions

and Tips

vi

G–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

H–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

I–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Programming Conventions J–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Programming Tips J–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 9

Table of Contents

Attended Workstations

User Manual

A-B VBASIC and

Visual BASIC Tips

Differences Between

A-B VBASIC and

Visual BASIC

Misspellings K–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Strings in TYPEs K–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Variables Beginning with “FN” K–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Accidental Omission of %, &, ! # OR $ K–1. . . . . . . . . . . . . . . . . . . . . . . .

Use of Colons as Statement Separators K–1. . . . . . . . . . . . . . . . . . . . . . . . .

CONSTant Declarations K–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PRINT “text”; : <statement> K–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General Restrictions L–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Supported A-B VBASIC Keywords L–1. . . . . . . . . . . . . . . . . . . . . . . . . . .

ABS(numeric–expression) L–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ASC(string–expression) L–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

BEEP L–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CDBL(numeric–expression) L–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CHAIN filespec L–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CHR$(code) L–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CINT(numeric–expression) L–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CLNG(numeric–expression) L–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CLOSE [ [#]filenumber[,[#]filenumber]...] L–3. . . . . . . . . . . . . . . . . . .

CLS [{ 0 | 1 | 2 }] L–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CONST constname=expression L–4. . . . . . . . . . . . . . . . . . . . . . . . . . . .

CSNG(numeric–expression) L–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CSRLIN L–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CVI, CVS, CVL, (CVD) L–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DATE$ L–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DATE$ = ”yymmddw” L–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DECLARE {FUNCTION | SUB} name(parameters) L–5. . . . . . . . . . .

DEFINT letterrange[,letterrange]... L–5. . . . . . . . . . . . . . . . . . . . . . . . .

DEFSNG letterrange[,letterrange]... L–5. . . . . . . . . . . . . . . . . . . . . . . . .

(DEFDBL letterrange[,letterrange]...) No longer supported L–5. . . . . .

DEFLNG letterrange[,letterrange]... L–5. . . . . . . . . . . . . . . . . . . . . . . .

DEFSTR letterrange[,letterrange]... L–5. . . . . . . . . . . . . . . . . . . . . . . . .

DIM [SHARED] variable[(subscripts)][AS type]... L–6. . . . . . . . . . . . .

DO...LOOP [{WHILE/UNTIL} booleanexpression] L–6. . . . . . . . . . .

END [{FUNCTION/IF/SELECT/SUB/TYPE}] L–6. . . . . . . . . . . . . . .

EOF(filenumber) L–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FIX(x) L–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FOR counter = start TO end [STEP increment]

...

NEXT [counter] L–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

vii

Page 10

Table of Contents

Attended Workstations

User Manual

viii

FRE(numeric expression) L–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FREEFILE L–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FUNCTION name[(parameterlist)][STATIC] L–8. . . . . . . . . . . . . . . . .

GET [#]filenumber[,[recordnumber][,variable]] L–8. . . . . . . . . . . . . . .

GOSUB {linelabel | linenumber}....RETURN L–9. . . . . . . . . . . . . . . . .

GOTO {linelabel/linenumber} L–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

HEX$(expression) L–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

IF...THEN...ELSE L–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

INKEY$ L–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

INPUT$(bytecount[,[#]filenumber]) L–10. . . . . . . . . . . . . . . . . . . . . . . .

INSTR([start,]stringexpression1,stringexpression2) L–10. . . . . . . . . . . .

INT(numeric–expression) L–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

IOCTL$([#]filenumber) L–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

IOCTL[#]filenumber,string L–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

KILL “filespec” L–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LBOUND(array[,dimension]) L–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LCASE$(stringexpression) L–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LEFT$(stringexpression, n) L–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LEN(stringexpression) L–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LEN(variable) L–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LINE INPUT[;][“promptstring”;]stringvariable L–12. . . . . . . . . . . . . . .

LINE INPUT #filenumber,stringvariable L–12. . . . . . . . . . . . . . . . . . . . .

LOC(filenumber) L–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LOCATE[row][,[column][,[cursor]]] L–13. . . . . . . . . . . . . . . . . . . . . . . .

LOF(filenumber) L–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LTRIM$(stringexpression) L–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MID$(stringexpression, start[, length]) L–13. . . . . . . . . . . . . . . . . . . . . .

MKD$, MKI$, MKL$, MKS$ L–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

OCT$(numeric–expression) L–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ON expression GOSUB {line–number–list/line–label–list} L–14. . . . . .

ON expression GOTO {line–number–list/line–label–list} L–14. . . . . . .

OPEN file [FOR mode1][ACCESS] AS[#]filenum [LEN=reclen] L–14.

POS(0) L–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PRINT [expressionlist][{,|;}] L–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PRINT #filenumber,[USING stringexpression;] expressionlist[{,|;}] L–15

PRINT USING formatstring; expressionlist[{,|;}] L–15. . . . . . . . . . . . . .

PUT [#]filenumber[,[recordnumber][,variable]] L–15. . . . . . . . . . . . . . .

RANDOMIZE expression L–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

REM remark

‘ remark L–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RETURN L–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RIGHT$(stringexpression, n) L–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RND L–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RTRIM$(stringexpression) L–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 11

Table of Contents

Attended Workstations

User Manual

SEEK(filenumber) L–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SEEK [#]filenumber,position L–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SELECT CASE text_expression L–17. . . . . . . . . . . . . . . . . . . . . . . . . . .

SGN(numeric–expression) L–17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SHARED variable [AS type] [,variable [AS type]]... L–17. . . . . . . . . . .

SLEEP seconds L–17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SOUND frequency,duration L–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SPACE$(n) L–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

STATIC variablelist L–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

STOP L–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

STR$(numeric–expression) L–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

STRING$(m,n) L–19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

STRING$(m,stringexpression) L–19. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SUB globalname[(parameterlist)][STATIC]

...

...

Application Library

Subroutines

A-B VBASIC Limits

END SUB L–19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SWAP vari1,vari2 L–19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SYSTEM L–19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TIME$ L–20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TIME$ = stringexpression L–20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TIMER L–20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TYPE usertype L–20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

END TYPE L–20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

UBOUND(array[,dimension]) L–21. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

UCASE$(stringexpression) L–21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

VAL(stringexpression) L–21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

WHILE condition L–21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

WEND L–21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

WRITE #filenumber [,expressionlist] L–21. . . . . . . . . . . . . . . . . . . . . . .

In ENV.BAS and ENVPC.BAS M–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

In READ.BAS M–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

In MENU.BAS M–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

In TRIG.BAS M–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

In HYP.BAS M–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

N–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ix

Page 12

Chapter

Chapter Objectives

A–B

1

Introduction

Allen-Bradley workstations are designed to be rugged and very reliable when

installed using the correct voltage and network cabling. An inexpensive

network connector (Catalog No. 2708-NNC) has been designed in order to

simplify the network installation. Although the workstations may be securely

installed without this connector, it is highly recommended that this connector

be used. The time saved and the ease of installation will be significant.

Chapters 2 through 4 describe network installation, host communication, and

the connection of barcode scanners.

Installation of a network includes cabling (both power and network) and

configuration of the workstations. In some instances, it may be necessary to

consult Chapters 5 through 8 for detailed information on the proper ways to

configure the workstations.

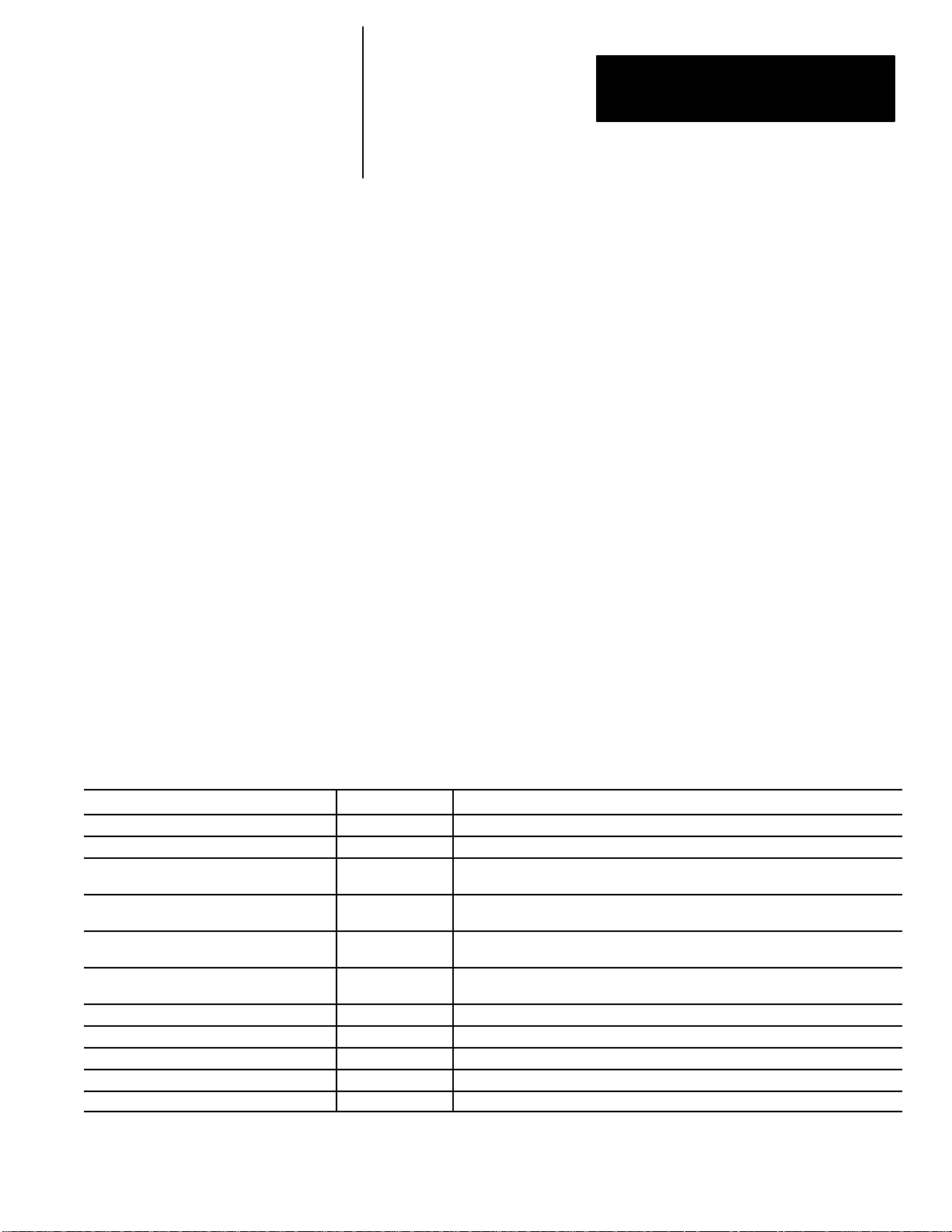

Catalog Numbers

Accessory Items

Item Catalog No. Description

DH5 Power Supply, U.S. 2708-NP1 Accepts 120V AC input power.

DH5 Power Supply, Europe 2708-NP2 Accepts 240V AC input power.

DH5 Network Connector 2708-NNC

Application Generator Software 2708-NAG

Network Manager Software 2708-NNM

Basic Language Development Kit

Software

Hand-Held Scanner 2755-G3, -G6 Visible laser diode, moving beam, hand-held scanner for bar codes.

Bar Code Wand 2755-W1 Visible red light source (high density bar codes).

Bar Code Wand 2755-W2 Visible red light source (low density bar codes).

Bar Code Wand 2755-W5 Infrared light source (high density bar codes).

Slot Scanner 2755-B1, -B2 Slot scanner for bar codes.

The catalog numbers covered by this manual include Attended Workstations

2708-DH5B2L and 2708-DH5B4L.

Accessory items for the 2708-DH5B2L and -DH5B4L workstations are listed

below:

Communications port connector that may be wired for point-to-point or

multidrop applications.

Menu-driven development software package for custom application

programming. Includes Catalog Nos. 2708–NNM and –NBD.

Terminal emulator software utilities package that allows the workstation to

be configured for a variety of network configurations.

2708-NBD

Contains a set of source files that can be used to reduce program

development time.

1–1

Page 13

Chapter 1

Introduction

Related Publications

Publication No. Title Purpose of Publication

2708-801 Application Generator User’s Manual

2708-802 Network Manager User’s Manual

2708-803 Basic Language Kit User’s Manual

2708-2.3

Safety Information

A-B VBASIC vs. Visual BASICt

The following table lists the publications that are available:

Describes how to use Application Generator Software to create

custom application programs.

Describes how to use the Network Manager Software to

configure the workstation for a variety of network configurations.

Describes how to use the Basic Language Kit source files to

reduce program development time.

Describes the differences between standard Visual BASICt

and the Allen-Bradley VBASIC modified for use with the

2708-DH5B_L workstation.

Throughout this manual we use notes to make you aware of safety

considerations.

ATTENTION: Identifies information about practices or

circumstances that can lead to personal injury or death, property

!

damage, or economic loss.

Important: Identifies information that is especially important for successful

application and understanding of the product.

1–2

Page 14

Chapter

Chapter Objectives

A–B

2

Installing a Network

The physical network is based on a twisted pair cabling technique that

follows the Electronic Industrial Association (EIA) RS-485 standard. This

standard specifies the electrical characteristics of the balanced voltage digital

interface circuit. This electrical standard is similar to the more familiar

RS-422 standard. The RS-485 communication drivers are capable of

withstanding greater voltage surges and tolerating more installation errors

than standard RS-422 communications.

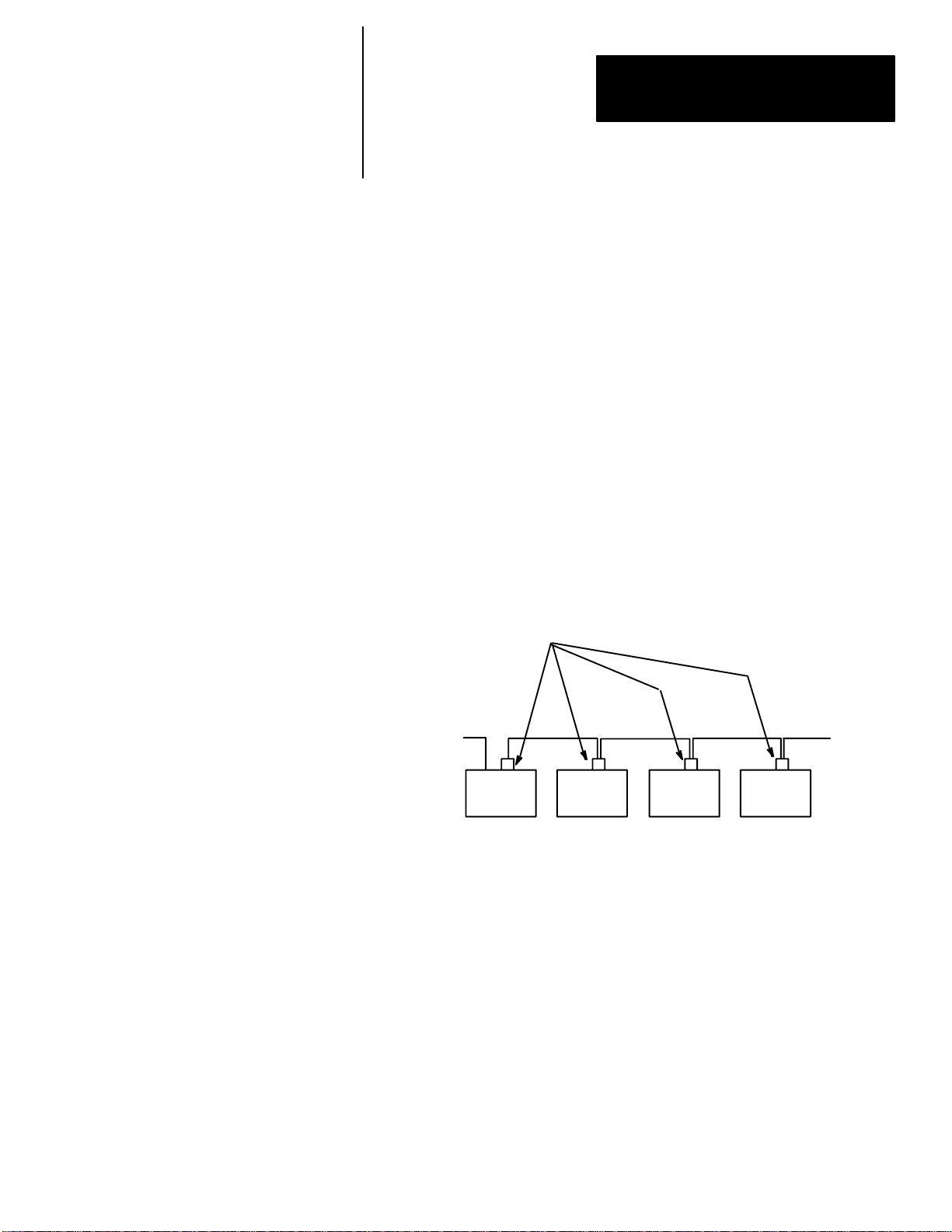

The RS-485 network cabling system used by the workstations is a

daisy-chain (or multidrop) architecture. Each workstation is directly

connected to its neighbor. An example of this multidrop architecture is

shown in Figure 2.1.

Figure 2.1

RS-485 Multidrop Architecture

Network Connector

(Catalog No. 2708-NNC)

RS-232 or RS-422

From Host

Master

Although the workstations in the network may be physically identical, the

network role of an individual workstation may be different from its neighbor.

The seven possible network configurations are:

Normal Standard Workstation

Master Communicates with host computer via COM1

Alternate Backup for the Master

Concentrator Connects Submaster to backbone network

Submaster Connects tributary to Concentrator

Alt Submaster Backup for Submaster

Gateway Master/Concentrator

Normal

RS-485

Normal Normal

To Other

Workstations

These configurations are described in Chapters 5 through 8 along with

workstation set-up instructions. It is necessary to understand the

configuration set-up to be able to wire the network properly.

The network check out may be entirely accomplished by using the diagnostic

tests resident in the workstations.

2–1

Page 15

Chapter 2

Installing a Network

Simple Network

ALLEN-BRADLEY

Power Requirements

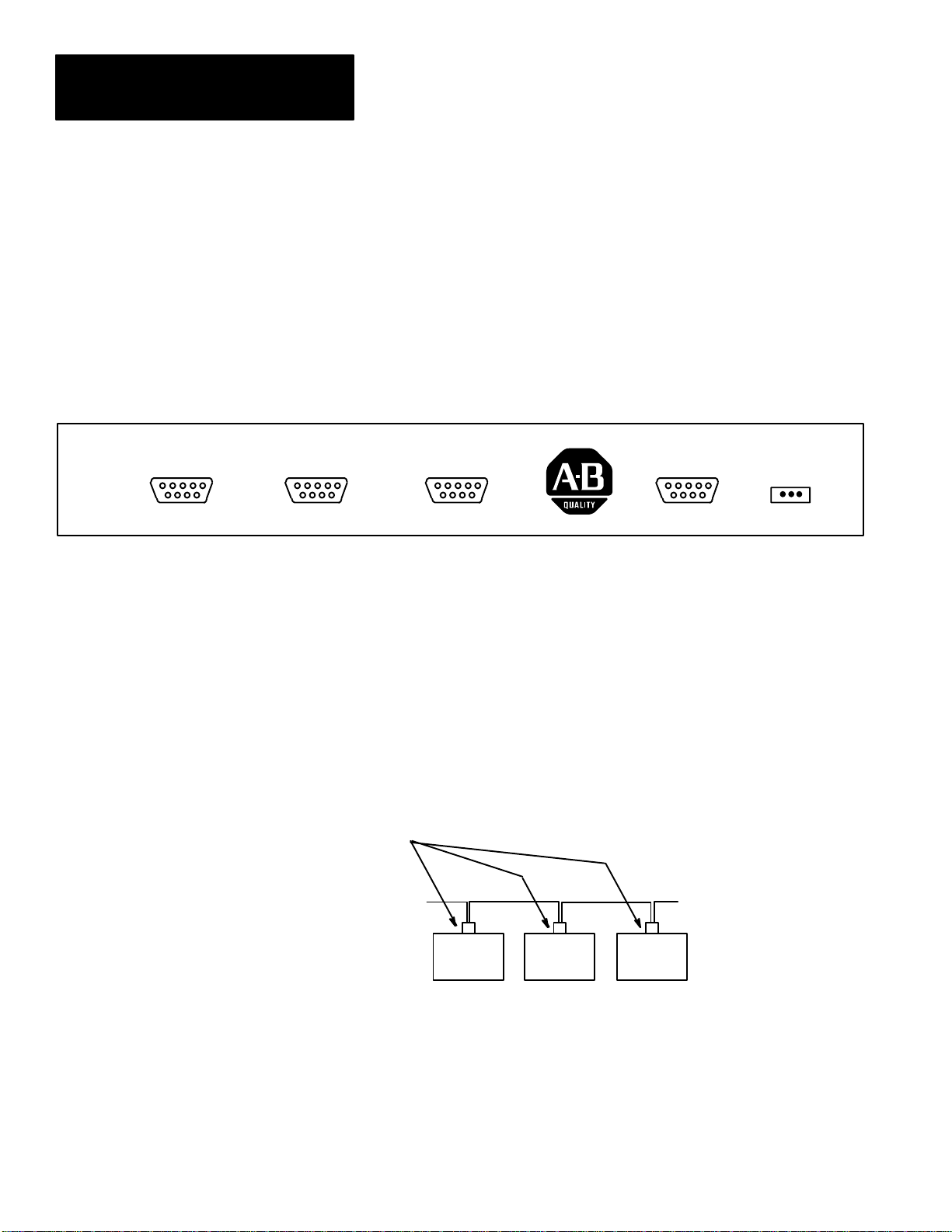

Each workstation must be powered with 28V of AC power. This power is

supplied by the power supply (Catalog No. 2708-NP1, -NP2) which is a

sealed AC adaptor that is plugged into a wall outlet. The power output cable

is plugged into the power connector as shown in Figure 2. A full diagram of

all the connectors is shown in Figure 2.2.

Figure 2.2

Back Plate of the Workstation

MADE IN USA

485 NETCOM1COM2

BARCODE PWR

In a normal installation, each individual workstation is powered by its own

power supply.

The RS-485 Network Bus

It is highly important to recognize that the network should be wired to appear

as a continuous cable or bus and should not be spliced in a manner that

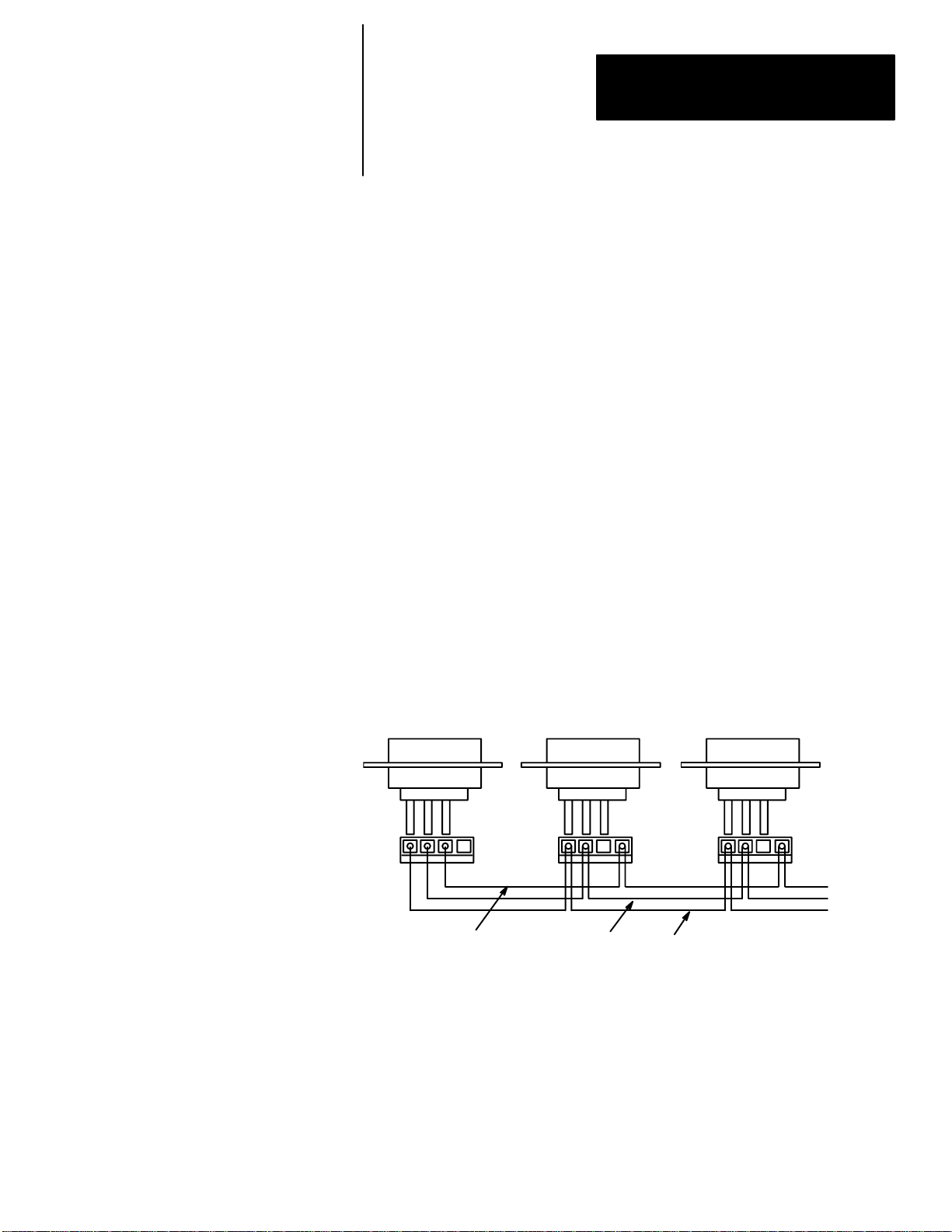

allows the cable to make a 3-way junction. Figure 2.3 shows the right way to

wire a network.

Figure 2.3

Correct Network Connection

Network

Connector

Workstation

Workstation

Workstation

2–2

Page 16

Chapter 2

Installing a Network

Simple Network (cont’d)

Figure 2.3 shows the correct method of wiring a network. This figure shows

the cable coming into the Network Connector (Catalog No. 2708-NNC) and

making connection with the cable coming out of the connector. If the

workstations are removed from their respective network connectors, it is easy

to determine that a continuous cable or bus has been created.

The network is a signal transmission line and cannot be treated the same as a

power voltage line. The transmission line operates at considerably higher

frequencies and therefore must be properly wired and terminated (resistance

loaded). If this network transmission line is not installed properly, as shown

in Figure 2.3, then voltage standing wave reflections (VSWR) and various

other propagation phenomenon may occur.

This could cause workstations to not come on-line, drop off and on-line, or

have multiple communication retrys in order to make a signal connection.

ATTENTION: It must be emphasized that the network cable be

installed as a transmission line and not as a power voltage line.

!

As discussed in this section, a simple network consists of a single cable to

connect up to 32 workstations. This is called a “backbone” network and is

diagramed on Figure 2.4.

Figure 2.4

Simple Network Configuration

Host M—W—W—W—W—W—W—W—W—W

W Workstation

M Master

Indicates RS-232

Indicates RS-485 backbone

No more than 32 workstations can be connected to the same network cable.

If more than 32 workstations are required, refer to the Complex Networks

section.

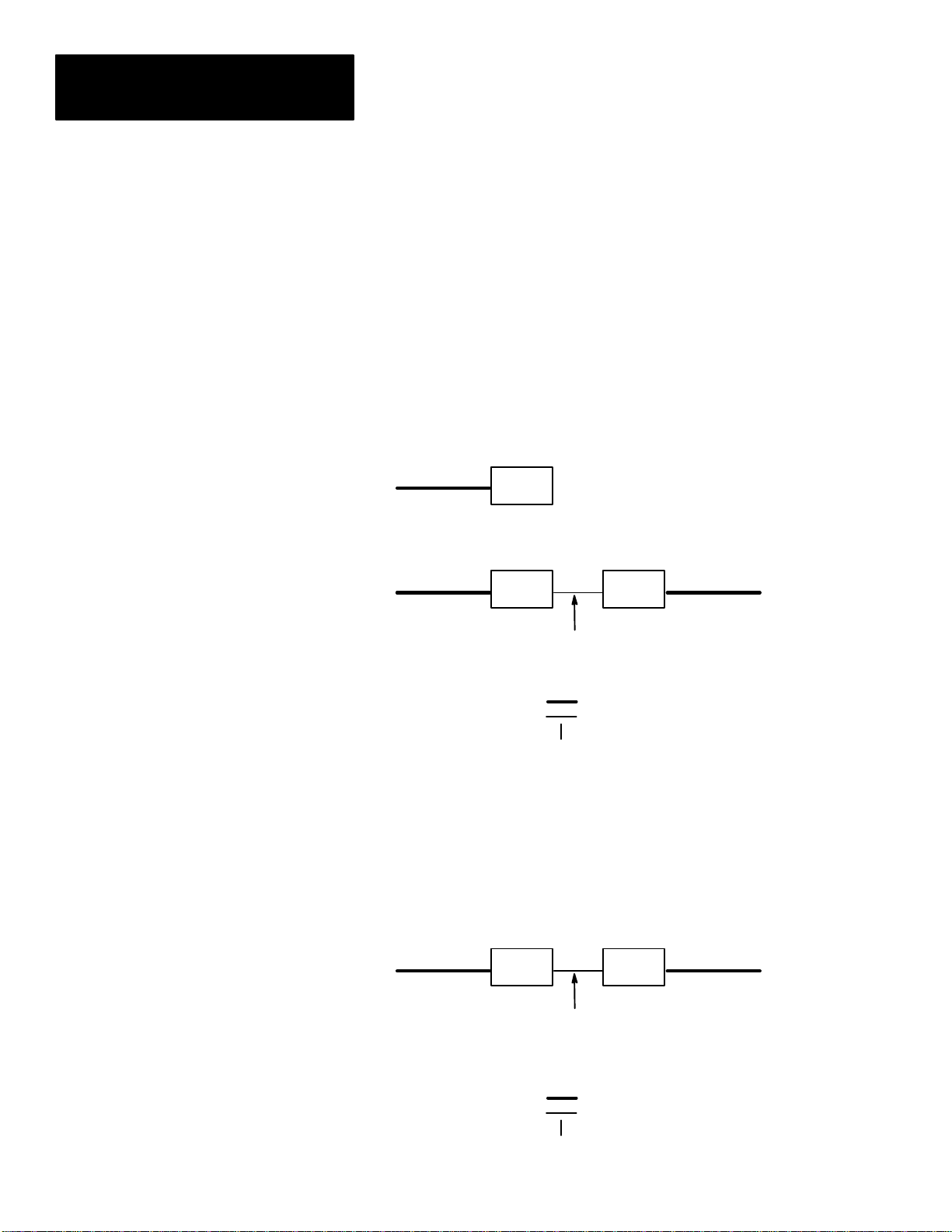

The Network Connector (Catalog No. 2708-NNC)

The Network Connector is made up of three elements. These are (1) the

plastic shroud or hood, (2) the DB-9 connector, and (3) the four screw

terminal block. The terminal block is wired to the back of the DB-9

connector. The black terminal wire is connected to pin 5 of the DB-9

connector and is the network (–) side of the RS-485 network. The red

terminal wire is connected to pin 4 of the DB-9 connector and is the network

(+) side of the RS-485 network. The blue terminal wire is the workstation’s

terminal’s chassis ground, and is connected to pin 8. The last terminal slot is

open and is not connected to the DB-9 connector.

2–3

Page 17

Chapter 2

Installing a Network

Simple Network (cont’d)

Figure 2.5

Network Connector (Catalog No. 2708-NNC)

Cabling a Network Using the Network Connector

Tools Needed — You will need a 3/32” flatblade screwdriver, and a pair of

wire strippers/cutter.

Cable Wire

The recommended cable is a Belden 8723. This cable has 2 pair of

conductors (4 wires) and a common drain wire. Although only one pair of

conductors is necessary for the network, it is desirable to have a back-up or

secondary pair in the event the primary pair has an open wire or some

unforseen malfunction occurs in the primary pair.

The primary cable pair consists of a Red and Black conductor which match

the color of the Network Connector leads. This primary pair will be used in

describing the cable connection.

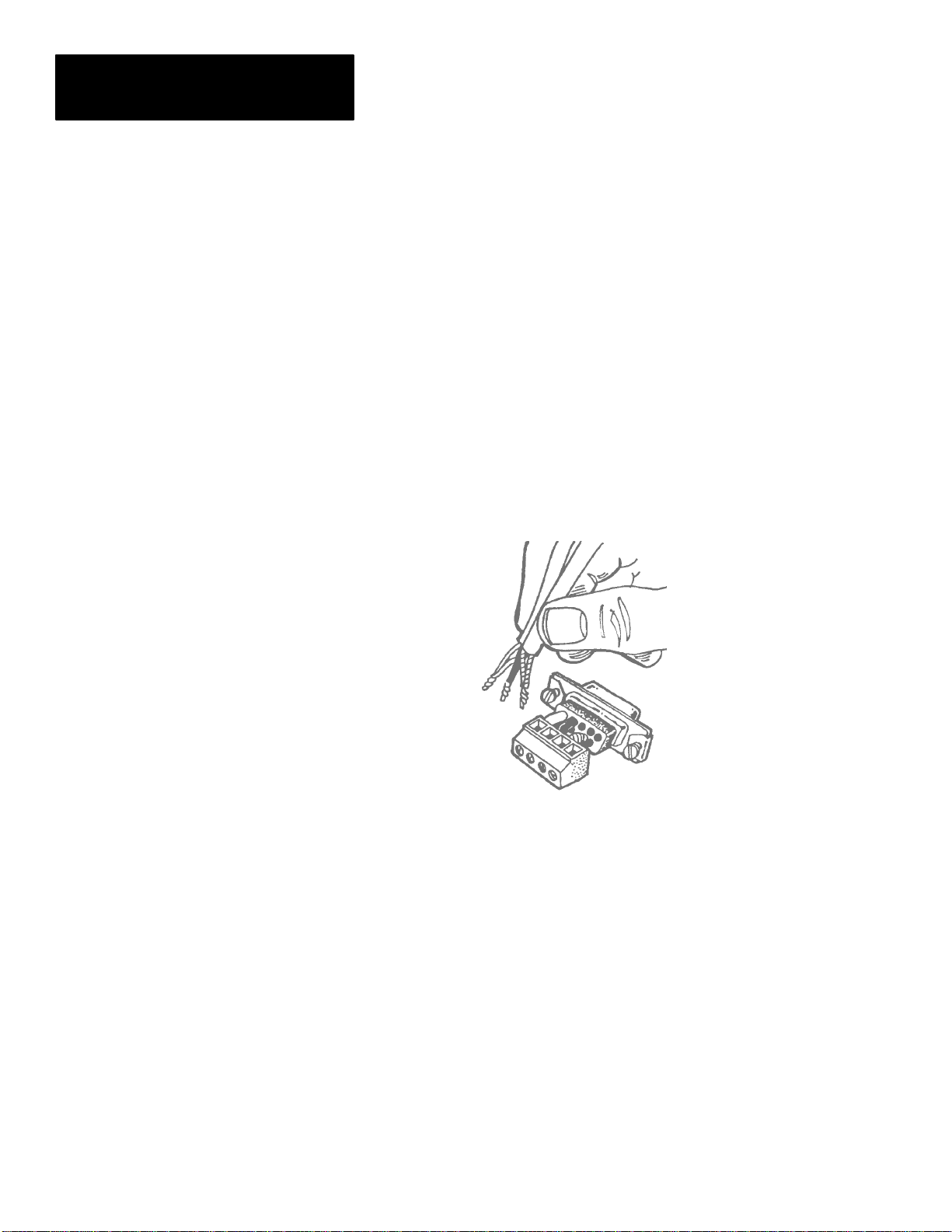

Preparing the Wire

Check that the cable is cut off evenly. (There should be no wire hanging

beyond the cable insulation.) Remove about 3/4” of the insulation from the

end of the cable. Strip about 1/4” of insulation from the end of each wire.

Figure 2.6

Cable Connecting Length

1/4”

3/4”

2–4

Page 18

Chapter 2

Installing a Network

Simple Network (cont’d)

Installing the Connector

There are two types of connections using the Network Connector. These are

a Master connection and a Non-Master connection. These connections are

shown on Figure 2.7. The physical network connector is shown on Figure

2.4. An examination of both figures shows that there are four open sockets in

which to place three wires; the network plus (+), the network (–), and the

shield wires. In the Network Connector, the three wires connecting the

terminal block to the pins in the DB-9 connector are color coded. This is

consistent with all Network Connectors. It is advised the cable be

color-coded to match the Network Connector to avoid confusion.

Master Connection

The network (–) wire is placed in the connector socket for pin 5 of the

network connector. The network (+) wire is placed in the connector socket

for pin 4 of the network connector. The shield or drain wire is placed in the

connector socket for pin 8 and is the ground connection.

The shield wire is placed in the blue connector socket ONLY in a MASTER

or SUB-MASTER connection. This will effectively ground the network

cable at the MASTER only, and eliminate ground loop current problems.

Figure 2.7

Schematic of the RS-485 Network Using the Network Connector

Master Workstation

Shield or

Drain

Wire

Network Connector (Catalog No. 2708-NNC)

Normal Workstation

Net (+) Net (–)

Normal Workstation

To Other

Workstations

2–5

Page 19

Chapter 2

Installing a Network

Simple Network (cont’d)

NON-MASTER Connection

The following connections are NON-MASTER connections:

Normal

Concentrator

Alternate

Alternate Master

Alternate Sub-Master

All Non-Master workstations, with the exception of the last workstation in

the network, will have a cable going into and a cable coming out of the

network connector. This will cause two wires to be installed in each

connector socket. This is shown on Figure 2.8.

Figure 2.8

Two Wires in a Connector Socket

2–6

Twist the network (–) wires (black) together and place them in the black

connector socket and tighten the screw. Next, twist the network (+) wires

(red) together and place them in the red connector socket and tighten the

screw. The only cable leads left should be the drain or shield wires. Twist

these together and place them in the empty socket that has NO wire going to

the DB-9 connector. Tighten the screw and then examine all connections to

make sure they are secure and that no wires are touching any adjacent

connections to cause short circuits.

If the cable was cut and stripped according to instructions, it should be

straightforward to put the shroud on the network connector and complete the

assembly. When possible, it is advantageous to use the cable restraint device

in the connector to avoid pulling connections loose or breaking the wire.

Remember, cabling problems are the number one cause of problems in a

network.

Page 20

Chapter 2

Installing a Network

Step By Step Installation

It is recommended that at least a simple volt/ohm meter along with assorted

screwdrivers be acquired for installation.

Figure 2.9

The Completed Network Connector

Making a good cable installation is one of the keys to having a properly

working network. Cable installation must always alternate between

installation and inspection. The inspector’s job is to play devil’s advocate at

each phase. By inspecting in phases, you avoid having to do the entire job

over again when problems are found too late.

We recommend the following sequence:

1. Obtain tools, select connectors and cable type. Get a sample of the cable

so you can identify the colors.

2. Draw a MAP of where each workstation is to be placed in the building or

area. Trace a general path that the cable will follow in the physical

building. Make multiple copies of this diagram. One good way to do the

map is to get blueprints of the building and draw in the cables and

workstations. Make sure that you note the WORKSTATION NUMBER

which will be in each location, as well as the location of the Host

computer.

3. Make color keyed cable drawings showing which color wires go to the

pins of the connectors. We recommend you make multiple copies of this

drawing, and store one copy with the installation map.

4. Run the cable through the building. Always leave a few extra feet at each

workstation location so that there is room with which to work.

2–7

Page 21

Chapter 2

Installing a Network

Step By Step Installation

(cont’d)

5. Inspect the locations where the cable has been run, using a different

person than the installer. Make sure that the cable:

a. Is not run parallel to AC cables (BUILDING POWER) for more

than a few feet at any time. This will avoid induction of AC onto

your low voltage data network. Whenever the network cable must

cross AC power lines, they should cross perpendicular to each

other.

b. Is not allowed to rest on top of fluorescent lamps in the ceiling. The

ballasts from these lamps are worse than AC power lines.

c. Is never spliced in a manner that allows the cable to make a 3-way

junction. Network cables must be a bus. Only the Master

workstation and the last workstation can have a single network

cable going to them; all others will have two cables.

d. Is not located next to or run over large motors, building

transformers, or very large current areas, such as radiology labs.

e. Is not located where it is easily broken or shifted around.

Note: Make sure that the workstations are not next to building

transformers, or large electric motors. Induced voltage spikes can affect

the operation of the network.

6. Inspect visually every connector. It is recommended that a person, other

than the one who connected the wires, inspects the following:

a. Correct COLORS of wire have been connected.

b. Be sure that ALL of the strands of the conductor are properly

inserted into the connector. It is very easy to nick the wire when

stripping it. This results in the strands breaking.

c. Flex the wire at the connector a few times (this is not the time to

prove your strength, THEY CAN BE BROKEN) to see if the wire

has been badly nicked. It will break if this has occurred.

7. Inspect the pins for proper color in the proper hole.

8. Check continuity of the network cable by:

a. Temporarily short pins 4 and 5 of the MASTER workstation’s

network connector together. You can do this with a clip lead, or use

a female 9 pin solder type connector with pins 4 and 5 soldered

together. (You can get solder type connectors at local electrical

retailers.)

b. Set the voltmeter to the 100 OHM scale (or the nearest available

value).

2–8

Page 22

Chapter 2

Installing a Network

Step By Step Installation

(cont’d)

c. At the next workstation location, place the meter on pins 4 and 5.

You should have almost no resistance. A good rule of thumb is 1

ohm for every 25 feet of network cable. If there is 400 feet of cable

to the Master, then there should be no more than 16 ohms of

resistance.

d. Try each workstation in turn, checking to see that the resistance

does not change drastically. If the resistance is high, you may have

a poorly crimped pin, or a partial break in the cable itself. If the

resistance is infinite (completely open), then there is a break, or a

broken conductor.

e. By going from one station to the next, you can isolate what

segment of the cable has a problem.

f. When the entire cable has been checked, remove the jumper from

the Master’s connector.

9. Install the hoods on the connectors. Attach the connectors to the

workstations.

The Terminator Switch

After the network is installed, it is usually necessary to cancel out signal

reflections inherent in any cable layout. To do this, flip on the terminator

switch underneath the MASTER and SUBMASTER WORKSTATIONS

ONLY. The terminator switch is on the bottom of the workstation. The ON

position is toward the top of the workstation.

Figure 2.10

Terminator Switch

Note: The terminator switch should be OFF on all workstations except the

MASTER and SUBMASTER. If other terminator switches are on,

indeterminate network conditions will occur.

Communication Cables

The cables used to communicate from the Host computer to the Master or

from a Concentrator to a Sub-Master workstation use either RS-232 or

RS-422 signal standards. The connector pin-out diagrams for all of the

possible workstation configurations are shown in Appendix D.

2–9

Page 23

Chapter 2

Installing a Network

Testing the Network for Data Transmission

1. At the LAST workstation in the network, place the workstations into the

menu setup mode (see Appendix B).

a. Press the left arrow key (<) until the Diagnostic menu statement

appears in the display.

b. Press the ENTER key and then depress the left arrow key (<) until

RS-485 – BLK-Rx is shown on the display.

c. Press the ENTER key and the following should appear:

Rx = 00000 ERRS = 00

000

If the counters are not zero, press EXIT, then press ENTER, and they

should be set to zero.

d. Repeat steps a, b, and c for all workstations, except the Master

workstation.

2. At the Master workstation enter the Diagnostic menu and press the left

arrow key (<) until RS-485 – BLK-Tx is shown on the display.

a. Press ENTER and the display should show the following,

momentarily:

Tx = 00000 ERRS = 00

000

After the counters appear, the Tx counter will begin incrementing to

represent the number of blocks being transmitted over the network to all

workstations.

b. An observation of the display of the workstations placed in receive

will show the Rx counter changing accordingly as the transmitted

network blocks are received.

c. After a reasonable testing interval, press the EXIT key on the

Master workstation, thus suspending the network block test.

d. Examine each workstation to see that the Rx block count is the

same. It should be the same at all workstations (It is possible to be

off by one or two counts.) Also, inspect to see that ERRS count is

zero or less than three. Either a missing block count or high error

count indicates a bad network connection or a faulty workstation.

Exchanging the workstation will determine which is the case.

e. For additional confidence, perform step 1 at the Master workstation

location and step 2 at the last location. Step 1 may be repeated at all

other workstations. The changing of block transmission locations

verifies communications in the opposite direction.

f. Press EXIT three times on each workstation.

2–10

3. Always use retaining screws for all DB-9 connectors. Connect the RS-232

(or RS-422) cable to the host computer.

Page 24

Chapter 2

Installing a Network

Communication to the Host Computer

Connect the WORKSTATION COM1 Port to the Host computer using a

cable wired according to the pin-out diagrams shown in Appendix D. To

communicate to the Host computer, it is necessary to be able to make your

computer send and receive ASCII characters in an asynchronous

communication manner. If a personal computer is used, programs such as

PROCOMM

R

, and KERMIT are ideal for this purpose. Most

ASYNCHRONOUS TERMINAL EMULATION PROGRAMS will work.

The communication set-up parameters must be the same for both the

computer and the workstation terminal. Please see Appendix B, Menu

Trigger Keys, for the procedure to enter the workstation menu mode.

If the program is resident in the workstation, press the menu trigger keys

(Enter and Right Arrow simultaneously), disconnect power, then reconnect

power while holding down the Enter and Right Arrow keys simultanenously

to enter the workstation menu mode.

1. In the menu mode

1—Network

Menu

will appear.

Press ENTER; “Terminal Number” will appear.

Press 1, then ENTER; “Terminal Type” will appear.

Press < – until the terminal type changes to “Master”,

then press ENTER, then press EXIT.

2. Press the < –, until “2-Comm Port Menu” appears. Press ENTER;

“Comm Port Mode” will appear.

Press < – until the mode changes to “XON/XOFF”.

①

Press ENTER; and “Comm Baud Rate” will appear.

3. Press < – until the baud rate is the SAME AS THE BAUD RATE

SELECTED ON THE HOST COMPUTER. 9600 and 1200 are the most

②

common baud rates.

In some cases NO character will show up if the

baud rate is improperly set.

Press ENTER; “Comm Data Bits” will appear.

4. Press < – until the Data Bits are the same as the Host computer. This is

normally 7.

Press ENTER “Comm Parity” will appear.

① For testing the cable connections, use XON/XOFF. If you are using a data collection program such as Network

Manager Software (Catalog No. 2708-NNM), you may have to change this to “POLLED” before using such

programs.

② If the baud rate is incorrectly set, when your computer sends characters to the workstation, unpredictable

characters will show up on the display when you are in “COMM RECEIVE TEST” mode. In some cases NO

character will show up if the baud rate is improperly set.

2–11

Page 25

Chapter 2

Installing a Network

5. Press < – until the parity is the SAME AS THE PARITY SETTING ON

THE HOST COMPUTER. A selection of “EVEN” is commonly used.

③

Press ENTER; “Comm Stop Bits” will appear.

6. Press < – until “One” appears.

④

Press ENTER; “Comm CRLF” will appear.

7. Press < – until “ENABLED” appears.

⑤

Press ENTER; “Comm Echo” will appear.

8. Press < – until “ENABLED” appears.

⑥

Press EXIT; “1-Network Menu” will appear.

9. Press OUT; “Diagnostics” will appear.

Press ENTER; Press < – until “Comm Rx Test” appears.

Press ENTER;

10. The following should appear on the two line display:

DTR: ON CD: ON

Pressing the number 1 and 2 will turn DTR ON and OFF.

⑦

11. Start the communication program on the Host computer. If the program is

an asynchronous terminal emulator program, then characters that are

typed on the computer are sent directly over the communication line.

These characters should appear on the top line of the workstation

display.

⑧

2–12

12. Press EXIT; “Comm Rx Test” will appear.

Press OUT; “Comm Tx Test” will appear.

Press ENTER; The top line will be blank and the second line will show:

DTR: ON CD: ON

The Host computer should be receiving a continuous transmission of

③ If the parity is set incorrectly, the workstation will still RECEIVE characters properly. Your Host computer may not

receive correctly, if at all.

④ If the baud rate is incorrectly set, when your computer sends characters to the workstation, unpredictable

characters will show up on the display when you are in “COMM RECEIVE TEST” mode. In some cases NO

character will show up if the baud rate is improperly set.

⑤ If you find that your computer is receiving double spaced lines from the workstation, then set CRLF to

DISABLED. Also disable when using Network Manager Software (Catalog No. 2708-NNM) or similar software.

⑥ If you find that when you are using your workstation program, you see two characters for each one you type

(such as DDIISSPPLLAAYY//HHEELLOO//) then set Com Echo to DISABLED. Note that when using a data

collection program (such as Network Manager Software (Catalog No. 2708-NNM) you will also DISABLE this

option.

⑦ Your computer may be unwilling to transmit characters unless these RS-232 lines are in the proper state. If you

are having trouble communicating, check your cable diagram against the specifications for your computer’s

RS-232 port. Additionially, the workstation requires CD to be high (or on) for communications.

⑧ Random characters on your computer or the workstation display indicate the baud rate is wrong. If about half of

the characters are wrong or missing, the parity is set incorrectly. If nothing at all happens, the cable is wrong or

something is broken.

Page 26

Chapter 2

Installing a Network

“The quick brown fox jumped over the lazy dog”⑨ type of messages.

Communications can receive at rates that are faster than any terminal

emulation program due to the use of POLLED mode as the COMM

PORT MODE.

13. Press EXIT, three times

14. The AUX port (labeled COM2 on the back of the workstation) can be set

up and checked out in the same manner as the primary COM1 port. The

AUX port, however, is strictly a data transfer port operating with

XON/XOFF flow control. It has transmit, receive, and signal ground

lines. There are no modem control lines on this port.

The installation of the workstation in a simple network is now complete.

Complex Network

Description of Large or Complex Network

Installing a large or complex network of workstations involves connecting

together several smaller networks.

The network which connects all of the smaller or sub-networks together is

called the “backbone” network. Each sub-network is referred to as a

“tributary” network. Up to 31 tributary networks may be attached to the

backbone to form a very large network. Each tributary, in turn, may contain

up to 32 workstations. A maximum of 1024 workstations may be connected

in this fashion. Once the layout of such a network has been determined,

cabling proceeds in the same manner as cabling for a single or backbone

network. Both tributary and backbone networks are wired as previously

described.

The workstation which is attached to the Host is configured as the “Master”.

Each workstation on the backbone network that connects to a tributary

network is configured as “Concentrator”. The workstation on the tributary

which attaches to the Concentrator is configured as the “Sub-Master”.

⑨ After a few seconds or minutes of receiving these messages, your computer starts displaying wrong characters or

only parts of messages, then your computer (or the communications program) is unable to accept records at the

rate they are being sent by the workstation. Try a lower baud rate on your Host and the workstation until you can

receive successfully as quickly as the data is sent. Note that some programs such as Network Manager Software

(Catalog No. 2708-NNM) can receive at rates that are faster than any terminal emulation program due to the use

of POLLED mode as the COMM PORT MODE.

2–13

Page 27

Chapter 2

Installing a Network

Figure 2.11

Large Network Configuration

Host M—W—C—W—C—W—C—W—W—C—C—W

W

|

W

|

W

|

S

|

|

S

|

W

|

W

|

W

|

W

|

S

|

W

|

W

|

W

W

|

W

|

S

|

|

S

|

W

|

W

2–14

Key:

W Workstation

S Submaster

C Concentrator

M Master

Indicates RS-232 or RS-422 connection

Indicates RS-485 backbone

Indicates a tributary

All of the workstations, including Masters, Concentrators and Submasters,

are standard workstations which have been configured for their individual

roles in the network. A configuration parameter is changed to allow any

workstation to adopt a new role in the network. Each workstation is capable

of operating in both a data collection and a data communications mode.

A workstation which is being used as a Master, Concentrator, or

Submaster can perform data collection functions even while serving in

the communication network.

Alternate Communication Links

When installing large networks, you may consider redundant communication

links in order to protect against Host or Master workstation failures. This

involves establishing certain workstations as “Alternate Sub-Masters”.

Configuring a large network with Alternate Masters will allow the alternate

workstation to take over communication operations if the designated Master

becomes inoperable or is removed from the network. An Alternate Host

provides full redundancy for collection in the event of a Host failure.

Page 28

Chapter 2

Installing a Network

Figure 2.12

Large Network Configuration with Alternate Masters

Host 1 M—A—C—C—C—W—C—C—W—C—C—C

Host 2

S

AS

W

|

|

S

|

|

W

|

|

W

|

W

W

|

W

|

AS

S

W

|

W

|

|

|

S

|

|

S

|

AS

|

W

Key:

W Workstation

S Submaster

M Master

C Concentrator

A Alternate Master

AS Alternate Submaster

Indicates RS-232 or RS-422 connection

Indicates RS-485 backbone

Indicates a tributary

An Alternate Submaster will allow the communication operations to continue

through a secondary Concentrator if the primary Concentrator becomes

inoperable or is removed from the network.

Networks Over Telecommunications Lines

It is possible to configure a workstation network which spans multiple

buildings, outposts, or sub-stations located at remote sites. Switched or

leased telephone lines can be used with asynchronous modems to provide

communication links for such a network.

Asynchronous short-haul modems may be used to extend the normal RS-232

communication distance from 100 feet to as much as several miles. To use

modems for communications between a Concentrator and Submaster the

workstations MUST have an RS-232 communication port (Workstation

Catalog No. 2708-DH5B2L). A modem cable must be correctly connected to

TXD, RXD, RTS, CTS, DSR, DTR, and GROUND signals (see Appendix

D). The COMM BAUD RATE parameter must be changed to the same baud

rate as the modem.

2–15

Page 29

Chapter 2

Installing a Network

As soon as the modems establish communication between themselves, the

remote system will be ready for use.

Extension of a network across telephone lines consists of placing a modem

on one side of the line to connect with the Concentrator, and placing another

modem on the other side to connect with the Submaster.

Figure 2.13

Extending Network Across Common Carrier

Backbone

Network

W

|

M

|

W

|

W

|

C

|

W

|

W

Key:

W Workstation

S Submaster

C Concentrator

M Master

Figure 2.14

Use of the Gateway Option

Backbone

Network

W

|

W

|

G

|

W

|

W

HOST

modem modem

Telco

Indicates RS-232 connect

Indicates telephone line

Indicates RS-485 backbone

modem modem

Telco

Tributary

Network

W

|

W

|

W

|

S

|

W

Tributary

Network

W

|

S

|

W

2–16

Key:

W Workstation

S Submaster

C Concentrator

M Master

G Gateway

Indicates RS-232 connect

Indicates telephone line

Indicates RS-485 backbone

Page 30

Chapter

Chapter Objectives

A–B

3

Barcode Connection

The barcode connector on the back of the workstation is a 9 pin DB-9

connector for the bar code scanner.

Connection

The pin-out for the BARCODE connector on the back of the workstation is

shown on Figure 3.1.

Figure 3.1

BARCODE Connector

54321

9876

Pin Number Function

1 Start of Scan. . . . . . . . . . . . . . .

2 Data. . . . . . . . . . . . . . .

3 LED light. . . . . . . . . . . . . . .

4 NOT CONNECTED. . . . . . . . . . . . . . .

5 Trigger. . . . . . . . . . . . . . .

6 Laser synchronization. . . . . . . . . . . . . . .

7 GROUND. . . . . . . . . . . . . . .

8 GROUND. . . . . . . . . . . . . . .

9 Power (+5V). . . . . . . . . . . . . . .

Allen-Bradley offers the following barcode scanners for use with the

workstation:

— Catalog Number 2755-G3 or -G6 Hand-Held Scanner

— Catalog Number 2755-W1, -W2, or -W5 Wand

— Catalog Number 2755-B1 or -B2 Slot Scanner

3–1

Page 31

Chapter

Introduction

A–B

4

Status Displays

The status display provides visible and easily available information

concerning the state of the 2708-DH5B2L or -DH5B4L Attended

Workstation. The workstation reports its operational status through ten

informational displays on the front panel LCD Display. The status displays

are automatically shown when the workstation is powered up unless a

BASIC program is running. Each of the status displays is assigned a number

from 0 to 9. To see status display 1, press the “1” key. When any number is

entered, the workstation will present the status display associated with that

number. The ten displays are:

1. Network Status.

2. Reserved Status.

3. Time Status.

4. System Reset Status.

5. Network Que Status.

6. Workstation Memory Status.

7. Program Load Status.

8. Program Run Status.

9. Application Status.

0. Summary Status.

On the workstation’s 2 x 40 display, two separate status displays will be

shown.

Figure 4.1

Example Status Display

N . . . . . . NN . 01–01 <0 2> NETWORK 2

01234556789 MASTR

4–1

Page 32

Chapter 4

Status Displays

Introduction (cont’d)

With the display, the workstation can show two status displays at the same

time. In Figure 4.1, the summary status display is on the left hand side along

with the reserved status on the right hand side. The ‘< 0’(in Figure 4.1) is

associated with the summary status (left hand side), and signifies that the

summary status is status display number zero. The ‘2>’ tells us that the right

hand display is status display number 2.

On the display, as the user selects a new status display, the new status screen

will be displayed on the left hand side, and the display on the right hand side

will be replaced by the one from the left hand side.

Invoking Status Display – Status displays are visible under these

circumstances:

1. After power-up for 15 seconds.

2. When the workstation has a non-zero terminal number, but is without an

A-B VBASIC program.

3. When the A-B VBASIC program terminates.

4. When manually invoked during a power up. This method will present the

status display for 15 seconds after the last keystroke. The A-B VBASIC

program, if loaded, will resume execution after this 15 second status

display.

Summary Status Display (Status Display 0)

The Status Display 0 summarizes the status of the other nine status displays.

The numbers 0-9 on the lower line represent the ten status displays. The

information above each number refers to the number under it, i.e. the ’.’ over

the 3 refers to the status display 3 – the time display.

Figure 4.2

Summary Status Display

N . . . . . . NN . 01–01

01234556789 MASTR

4–2

Page 33

Summary Status Display

(Status Display 0) (cont’d)

Chapter 4

Status Displays

Display No. / Name Code Description

1 Network Status.

2

3

4 System Reset.

5 Network Queue.

6 Workstation Memory .

7 Program Load.

8 Program Run.

9 Application.

0 Summary

Reserved Status.

Time Status.

Online

O

S

•

T

•

R

•

O

•

F

•

N

L

•

E

N

•

Offline

Standalone

Always a period

Time is set

Time is not set

No serious errors

Serious error occurred

Online

Offline

Memory remains

Out of memory

Program loaded

Never loaded

Loading error

No errors

Run error

Never ran

Always a period

To view one of the other nine status displays, simply enter the number key

associated with the status display desired while viewing status.

The ‘01-01’ is the workstation number. The first number is the Master

number (01), the second number is the individual workstation number (01).

In this example the Master number and the workstation number are the same.

In the case of Master number 06 and workstation number 24 the total

workstation I.D. number would be ‘06-24’.

4–3

Page 34

Chapter 4

Status Displays

Network Status (Status Display 1)

The Network Status display shows information about the network. The

information is updated many times a second, to reflect the status as it

changes.

The information displayed appears in the following form:

Figure 4.3

Network Status, Display 1

mm-tt Ready a

mode [type] a

where, moving from left to right on the top line:

mm is the Master ID or Submaster attached to the workstation. If the

workstation is not attached to a network string, no Master ID will

be present.

tt is the workstation or station ID number.

Ready indicates that the application program is capable of performing a

SEND operation. Alternately,

4–4

Full Indicates that there is no memory remaining in which to save data.

a represents the current polling address. The character which

represents the polling address will be a space, while the unit has the

factory configuration and is offline. If the workstation is online and

waiting for a poll, a question mark will appear in this position.

Moving from left to right, the bottom line meanings are:

mode ONLINE The workstation will send records to its Master.

OFFLINE The workstation will not send records.

TERMINAL The workstation is in standalone mode, and sends

each keystroke.

type The role the workstation plays in the network:

[N] Normal

[M[ Master

[A] Alternate Master

[C] Concentrator

[SM] Submaster

[AM] Alternate Submaster

[G] Gateway

Page 35

Chapter 4

Status Displays

Reserved Status (Status Display 2)

Time Status (Status Display 3)

This display (Figure 4.4) currently has no function. Allen-Bradley has

reserved this menu for future enhancements.

Figure 4.4

Reserved Status, Display 2

NETWORK 2

This display shows the time and date.

Figure 4.5

Time Status, Display 3

2:01:25 PM

MON MAY 8, 1990

To change the format of the time and data, simply choose the option CLOCK

MODE on the system menu (menu 3). Refer to Appendix I for a description

of the CLOCK MODE options.

System Reset Status (Status Display 4)

Serious errors encountered by a workstation are known as “system resets”.

To try and correct a problem the workstation will reset itself and in the

process will attempt to identify the error. The error is then logged, and the

number of system resets is incremented.

Figure 4.6

System Reset Status, Display 4

EC ##

AThhmmssnnyymmdd

The EC in Figure 4.6 represents the Error Code. The ## represents the

number of serious errors. The lower lines gives you “at time and date”.

4–5

Page 36

Chapter 4

Status Displays

System Reset Status

(Status Display 4) (cont’d)

A – Error Codes

1 Undetermined reason for failure

8, 10 These error codes could be the result of excessive power

fluctuations or a sign that the workstation is not functioning

properly because of a hardware problem. Technically, the error is a

result of the micro-processor vectoring to the restart vectors. If the

problem continues, contact your A-B representative.

82 Stack overflow

83 Bad transaction memory structure