Page 1

Allen-Bradley

DTAM

Programming

Programming

Software

Catalog No. 2707-NP

Manual

Page 2

Important User Information

Solid state equipment has operational characteristics differing from those of

electromechanical equipment. “Safety Guidelines for the Application,

Installation and Maintenance of Solid State Controls” (Publication SGI-1.1)

describes some important differences between solid state equipment and

hard–wired electromechanical devices. Because of this difference, and also

because of the wide variety of uses for solid state equipment, all persons

responsible for applying this equipment must satisfy themselves that each

intended application of this equipment is acceptable.

In no event will the Allen-Bradley Company be responsible or liable for

indirect or consequential damages resulting from the use or application of

this equipment.

The examples and diagrams in this manual are included solely for illustrative

purposes. Because of the many variables and requirements associated with

any particular installation, the Allen-Bradley Company cannot assume

responsibility or liability for actual use based on the examples and diagrams.

No patent liability is assumed by Allen-Bradley Company with respect to use

of information, circuits, equipment, or software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without

written permission of the Allen-Bradley Company is prohibited.

Throughout this manual we use notes to make you aware of safety

considerations.

ATTENTION: Identifies information about practices or

circumstances that can lead to personal injury or death, property

!

damage, or economic loss.

Attentions help you:

• identify a hazard

• avoid the hazard

• recognize the consequences

Important: Identifies information that is especially important for successful

application and understanding of the product.

PLC and PLC–5 are registered trademarks of Allen-Bradley Company, Inc.

SLC, DTAM Plus, and DTAM Micro are trademarks of Allen-Bradley Company, Inc.

IBM is a registered trademark of International Business Machines, Incorporated.

Page 3

Table of Contents

DT AM Programming Software

User Manual

Using this Manual

Installing / Running

DTAM Programming

Software

Chapter 1

Objectives 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Contents 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Intended Audience 1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Conventions 1–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Related Publications 1–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 2

Chapter Objectives 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Introduction to DTAM Programming Software 2–1. . . . . . . . . . . . . . . . . . . . . . . .

Software Requirements 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Firmware Compatibility 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Performing Firmware Upgrade with Older Software Versions 2–2. . . . . . . . . . . . .

System Requirements 2–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Communication Cables 2–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Making a Backup Copy 2–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation Files 2–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing DT AM Programming Software 2–3. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Running DPS 2–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Menu Conventions 2–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Screen Building Conventions 2–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cursor Status Line 2–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Moving Around Screens 2–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Linking Application Screens 2–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Designing DTAM Plus and

DTAM Micro Applications

Creating or Editing an

Application File

Chapter 3

Objectives 3–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DT AM Plus / DTAM Micro Comparison 3–2. . . . . . . . . . . . . . . . . . . . . . . . . . . .

DT AM Plus / DTAM Micro File Types 3–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Screen Types and Data Formats 3–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PLC Data Formats 3–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SLC Data Formats 3–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Data Scaling 3–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Application Example 3–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Example Application Description 3–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Designing an Application 3–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 4

Chapter Objectives 4–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Opening Menu 4–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Edit Application File 4–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Save Application File 4–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

i

Page 4

Table of Contents

DT AM Programming Software

User Manual

Using Screen Builder

Creating Menu and

Sub-Menu Screens

Chapter 5

Chapter Objectives 5–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Screen Builder 5–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Accessing Screen Types 5–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Editing Screen Displays 5–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Copying Screens 5–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Selecting Other Screens 5–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Clearing Screens 5–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inserting the Time or Date 5–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Exiting Screen Builder 5–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 6

Chapter Objectives 6–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Menu Screens 6–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Main Menu Screens 6–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Sub-Menu Screens 6–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Building a Menu 6–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Main Menu and Sub-Menu Screen Builder 6–3. . . . . . . . . . . . . . . . . . . . . . . . . .

Creating a Menu Screen 6–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Creating Data

Display Screens

Creating Data

Entry Screens

Chapter 7

Chapter Objectives 7–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Data Displays 7–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Scaling 7–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Data Display Screen Builder 7–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Creating a Display Screen 7–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Display Register Format Selections 7–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 8

Chapter Objectives 8–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Data Entry Screens 8–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Scaling 8–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Data Entry Screen Builder 8–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Creating a Data Entry Screen 8–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Data Entry Register Format Selections 8–6. . . . . . . . . . . . . . . . . . . . . . . . . . . .

ii

Page 5

Table of Contents

DT AM Programming Software

User Manual

Creating Security Screens

Creating Recipe Screens

Creating Bar

Graph Screens

Chapter 9

Chapter Objectives 9–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Security Screens 9–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Security Screen Builder 9–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Creating a Security Screen 9–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 10

Chapter Objectives 10–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Recipe Screens 10–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Recipe Screen Builder 10–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Creating a Recipe Screen 10–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 11

Chapter Objectives 1 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

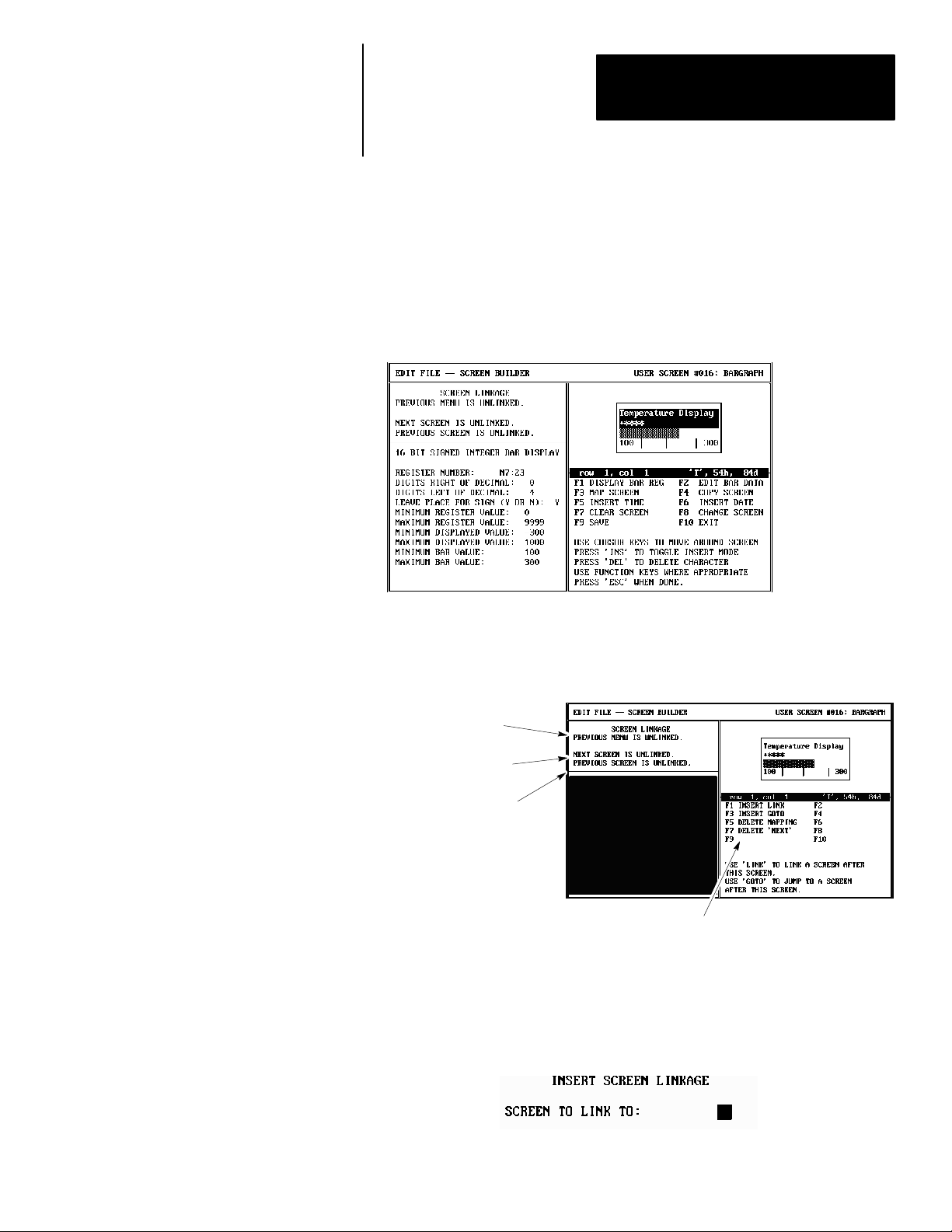

Bar Graph Screens 11–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Bar Graph Screen Builder 11–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Graph Display Range 11–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Creating a Bar Graph Screen 1 1–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Bar Graph Register Format Selections 1 1–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Linking Menu and

Application Screens

Creating Alarm Screens

Chapter 12

Chapter Objectives 12–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Linking Application Screens 12–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Linking Menu Screens 12–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Screen Linking Guidelines 12–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Application Screen Linking Function Keys 12–3. . . . . . . . . . . . . . . . . . . . . . . . . .

Menu and Sub-Menu Linkage Display 12–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Linking a Menu 12–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Linking Example 12–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 13

Chapter Objectives 13–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Alarm Screens 13–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Alarm Screen Builder 13–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Creating an Alarm Screen 13–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

iii

Page 6

Table of Contents

DT AM Programming Software

User Manual

Entering DTAM

Configuration Data

Chapter 14

Chapter Objectives 14–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuration Parameters 14–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Accessing Configuration Data 14–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Update Interval 14–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DT AM Advisor 14–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Advisor Operation 14–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Time Synchronization 14–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting Master Security Code 14–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Special Security Screen 14–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Printer Port Parameters 14–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SLC Hardware Parameters 14–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SLC Com Port Setup 14–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SLC 500 Slot Configuration 14–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Max Node Address 14–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SLC 500 Node Address 14–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DT AM Node Address 14–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Advisor Update Rate 14–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PLC Hardware Parameters 14–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PLC Com Port Setup 14–17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RIO port Setup with Remote I/O Operating System 14–18. . . . . . . . . . . . . . . . . .

Com Port Setup with DevieNet Operating System 14–19. . . . . . . . . . . . . . . . . . .

Advisor Update Rate 14–20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DTAM Plus

Background Monitor

DTAM Micro

Function Key Builder

Chapter 15

Chapter Objectives 15-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Background Monitor 15-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Background Monitor Screen 15-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Creating a Background Monitor 15-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Background Monitor Register Selections 15-5. . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 16

Chapter Objectives 16–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Function Key Options 16–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Bit Write Mode 16–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Function Key Builder 16–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Linking Screens to Function Keys 16–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Assigning Bit Write Functions 16–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

iv

Page 7

Table of Contents

DT AM Programming Software

User Manual

DTAM Plus

Print Form Builder

DTAM Plus ASCII

Bar Code Input

Transferring / Printing

Application Files

Chapter 17

Chapter Objectives 17–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Printer Form Builder 17–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Printer Control 17–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Print Form Builder Function Keys 17–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Creating a Printer Form 17–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Print Forms 16 Bit Binary Data 17–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 18

Chapter Objectives 18–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ASCII Input 18–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Allen-Bradley Bar Code Message Formats 18–1. . . . . . . . . . . . . . . . . . . . . . . . . .

Creating an ASCII Entry Display 18–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Entering Data with a Bar Code Scanner 18–3. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 19

Chapter Objectives 19–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Upload / Download DIP Switch Settings 19–1. . . . . . . . . . . . . . . . . . . . . . . . . . .

Communication Cables 19–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Computer Setup 19–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Printer Setup 19–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Downloading an Application 19–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Uploading an Application 19–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Printing Application Files 19–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Upgrading the

Operating System

ASCII Character Set

Application and

Screen Worksheets

PLC-5 Mnemonics in DPS

Chapter 20

Chapter Objectives 20–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Upgrading the Operating System 20–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix A

ASCII Table A–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

How to Program Supported ASCII Characters A–1. . . . . . . . . . . . . . . . . . . . . . .

Appendix B

Application and Screen Worksheets B–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix C

v

Page 8

Table of Contents

DT AM Programming Software

User Manual

Data Formats

Appendix D

Data Formats D–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Bit Format D–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

16 Bit Signed Integer D–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

16 Bit Unsigned Integer D–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

16 Bit BCD D–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

16 Bit HEX (Hexadecimal) D–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

32 Bit Unsigned Integer D–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

32 Bit BCD (Binary Coded Decimal) D–4. . . . . . . . . . . . . . . . . . . . . . . . . . . .

32 Bit HEX (Hexadecimal) D–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

32 Bit Floating Point (PLC Controllers Only) D–5. . . . . . . . . . . . . . . . . . . . . . .

DT AM Micro Floating Point Numbers D–5. . . . . . . . . . . . . . . . . . . . . . . . . . . .

ASCII D–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

vi

Page 9

Chapter

Objectives

Contents

A–B

1

Using this Manual

Read this chapter to familiarize yourself with the rest of the manual.

You will learn about:

• Contents of this manual

• Intended audience

• Conventions

• Related publications

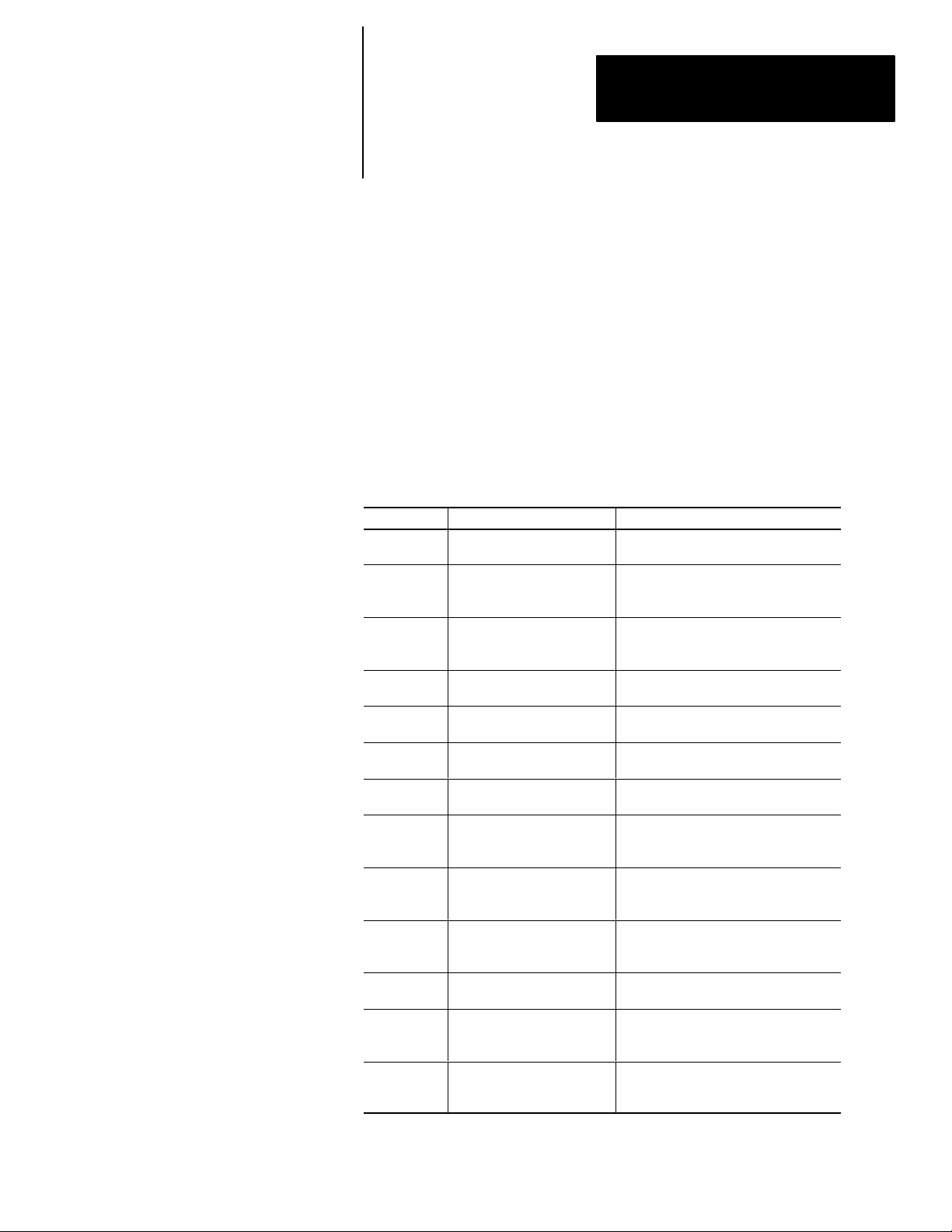

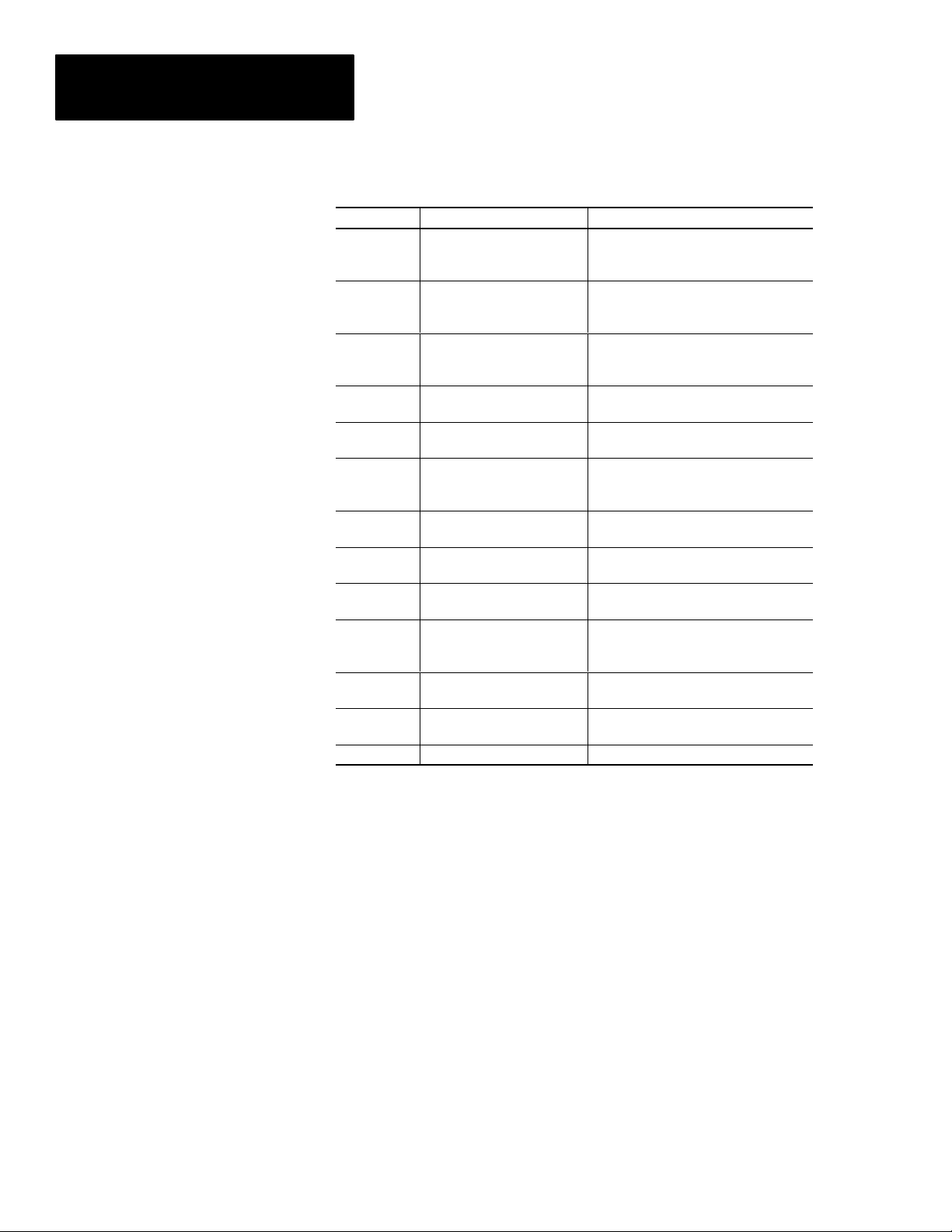

The following table lists the contents of each chapter:

Chapter Title Purpose

1 Using this Manual

2

3

4

5 Using Screen Builder

6

7

8 Creating Data Entry Screens

9 Creating Security Screens

10 Creating Recipe Screens

11 Creating Bar Graph Screens

12

13 Creating Alarm Screens

Installing/Running DTAM

Programming Software

Designing DTAM Plus and

DTAM Micro Applications

Creating and Editing

an Application File

Creating Menu and

Sub-Menu Screens

Creating Data

Display Screens

Linking Menu and Application

Screens

Provides a brief overview of the manual

structure, intended use, and conventions.

Describes how to install DPS on your

computer. Basic software operating

functions are described.

Describes the differences and similarities

between DTAM Micro and DTAM Plus

applications.

Describes how to open, edit, and save

new or existing application files.

Describes how to use Screen Builder to

create application screens.

Describes how to create menu and

sub-menu displays.

Describes how to display the actual or

scaled contents of a controller address.

Describes how to create a screen that

allows an operator to write data to a

controller address.

Describes how to create screens that

restrict operator access to parts of an

application.

Describes how to create screens that

write data to multiple controller

addresses from a single screen.

Describes how to create a data display

using a bar graph.

Describes how to link all of the

application screens into a logical

sequence.

Describes how to create screens that

warn an operator of abnormal operating

conditions.

1–1

Page 10

Chapter 1

Using this Manual

Chapter

14 Entering Configuration Data

15

16

17

18 ASCII Bar Code Input

19

20

Appendix A ASCII Display Characters

Appendix B

Appendix C

Appendix D PLC-5 Mnemonics in DPS

Appendix E Data Formats

Index

DTAM Plus

Background Monitor

DTAM Micro

Function Key Builder

DTAM Plus

Printer Form Builder

Transferring / Printing

Application Files

Upgrading the Operating

System

Application and Screen

Worksheets

Using a BASIC Module

With An SLC

Title Purpose

Describes how to enter configuration

data that allows the DTAM to

communicate with a controller.

Describes how to monitor controller

addresses for displaying alarm or

generating printouts on the DTAM Plus.

Describes how to assign screen

navigation or bit write functions to the

DTAM Micro function keys.

Describes how to create a DTAM Plus

printer form.

Describes how to input data into a data

entry register using a bar code scanner.

Describes how to transfer applications

between a personal computer and the

DTAM Plus or DTAM Micro.

Describes how to upgrade the DTAM

Micro and DTAM Plus operating systems.

The character set supported by the

DTAM Micro and DTAM Plus.

Worksheets assist in the design of an

application and individual screens.

Describes how to use the SLC BASIC

module with a DTAM Plus AB BASIC

operating system.

Reference section for PLC mnemonic

codes used for addressing.

Description of the data formats used by

SLC and PLC controllers.

Intended Audience

1–2

The DTAM Programming Software does not require special programming

knowledge. It is menu driven and generates a DTAM Plus, DTAM Micro or

MicroView program based on your menu selections and data entries.

If you are creating an application for a DTAM Plus or Micro, you should be

familiar with the user manuals. Refer to related publications on page 1–4.

Page 11

Chapter 1

Using this Manual

Conventions

This manual uses the following conventions:

• Keys that you press on your personal computer keyboard are enclosed in

brackets [ ].

For example: [Esc] refers to the Escape key

• Keys that an operator would press on the DTAM Micro or DTAM Plus

are also enclosed in brackets but are bold [ ].

For example: [F1] refers to the F1 function key on the DTAM Micro.

• [Return] refers to the carriage return key of your computer keyboard.

This key may appear on your keyboard as [Enter] or [

].

• This manual describes how to use the DTAM programming software for

both DTAM Plus and DTAM Micro applications. DTAM Plus screens are

shown for most examples, these illustrations also apply to the DTAM

Micro unless noted.

DTAM Plus shown

but also applies to

DTAM Micro.

• DPS refers to DTAM Programing Software (Catalog No. 2707-NP, Series

J or later)

1–3

Page 12

Chapter 1

Using this Manual

Related Publications

The following publications may be required for additional reference.

DT AM Plus and DTAM Micro Publications

Publication / Catalog

Number

2707-800 DTAM Plus User Manual

2707-803 DTAM Micro User Manual

2707-802 Getting Started With the DTAM Plus

SLC Publications

Publication / Catalog

Number

1747-6.21

1747-6.2

1746-6.1

1746-6.2

1746-6.3

SLC 500 Fixed Hardware Style

Installation and Operation Manual

SLC 500 Modular Hardware Style

Installation and Operation Manual

SLC 500 BASIC Module

Design and Integration Manual

Development Software Programming Manual

Language Reference Manual

Title

Title

SLC 500 BASIC

SLC 500 BASIC

PLC-5 Publications

Publication / Catalog

Number

1785-6.2.1 1785 PLC-5 Programmable Controllers Design Manual

1785-6.1 PLC-5 Instruction Set Reference

1785-6.6.1

1785-7.1 PLC-5 Programmable Controllers Quick Reference

Title

PLC-5 Family Programmable Controllers Hardware

Installation Manual

1–4

Page 13

Chapter

Chapter Objectives

A–B

2

Installing / Running

DTAM Programming Software

This chapter describes how to install the DPS software. Menu and screen

conventions are also provided.

Section Page

Introduction to DTAM Programming Software 2–1

System Requirements 2–2

Communications Cable 2–2

Making a Backup Copy 2–2

Installation Files 2–2

Installing DTAM Programming Software 2–3

Running DPS 2–6

Menu Conventions 2–9

Screen Building Conventions 2–10

Cursor Status Line 2–11

Moving Around Screens 2–11

Linking Application Screens 2–11

Introduction to DTAM Programming Software

Software Requirements

Firmware Compatibility

The DTAM Programming Software (DPS) is a self-prompting, menu driven

package that allows you to create and edit applications for the DTAM Plus or

DTAM Micro operator terminals. DPS does not require any programming

knowledge.

DTAM Plus Series C and later versions require 2707-NP Programming

Software release 7.0 and later.

DTAM Micro Series C and later versions require 2707-NP Programming

Software release 8.0 and later.

Because of the hardware enhancements made to the DTAM Plus and DTAM

Micro products, a minimum level of firmware is required for these products

to operate with the programming software. Previous series of these products

have not been released with the newer firmware required. As a precaution:

You should upgrade the software for the DTAM Micro or DTAM

Plus to Version 9.0 or above.

2–1

Page 14

Chapter 2

Installing / Running

DTAM Programming Software

Performing Firmware Upgrade

with Older Software Versions

System Requirements

Communication Cables

The incompatibility between firmware and hardware causes the screen to go

blank and no communications with the SLC/PLC will occur. You must then

upgrade the firmware to the latest level available before the DTAM will

respond again.

Verify your computer is properly configured with the following:

• IBM PC/AT or 100% compatible

• 640K RAM (minimum)

• One or two diskette drives (720K minimum)

• One fixed (hard) disk drive recommended. Required if only one diskette

drive is present.

• DOS version 3.2 or later

• Serial communications port (COM1 or COM2)

RS-232C or RS-485

• Monochrome or color monitor (color monitor is recommended).

You need an upload/download cable (Catalog No. 2707-NC2) or (Catalog

No. 2707- NC5) to connect the computer to the DTAM Plus or DTAM Micro

communications port. If you have a DTAM Plus Remote I/O version with

only a printer port, you will need to use cable (Catalog No. 2707-NC2) with

a gender adapter. Refer to the DTAM Plus/Micro User Manuals for

download/upload cabling information.

Making a Backup Copy

Installation Files

2–2

Make a backup copy of the DTAM programming software diskette. Insert

the supplied disk into the diskette drive and use either the DISKCOPY or

COPY command of your installed DOS version. Refer to your DOS manual

for information and procedures regarding these commands.

After you have created a duplicate disk, store the original in a safe place and

use the backup disk for normal operations.

The files on the installation disk are compressed and remain compressed

until they are installed. Once installed, the following files are contained in

the subdirectory:

DPS.EXE - DTAM Programming Software

DPS_CFG.EXE - Utility for changing software license information.

DPS_900.SLB - Operating systems for the DTAM Plus or DTAM Micro.

Page 15

Chapter 2

Installing / Running

DTAM Programming Software

Installing DTAM Programming Software

This section shows how to install the software on a personal computer with

at least 1 hard disk drive and 1 floppy disk drive. The software is supplied

1

on 3

/2 inch disks.

1. Turn on your computer. Your computer prompt will display the currently

active drive: A:, B:, or C:

2. Insert the DPS installation disk into the floppy drive.

3. Select the drive containing the disk (A: or B:) and press [Return].

Normally this is the A: drive.

C:> A: [Return]

A:>

4. Type install and press [Return] to start the installation.

A:> install [Return]

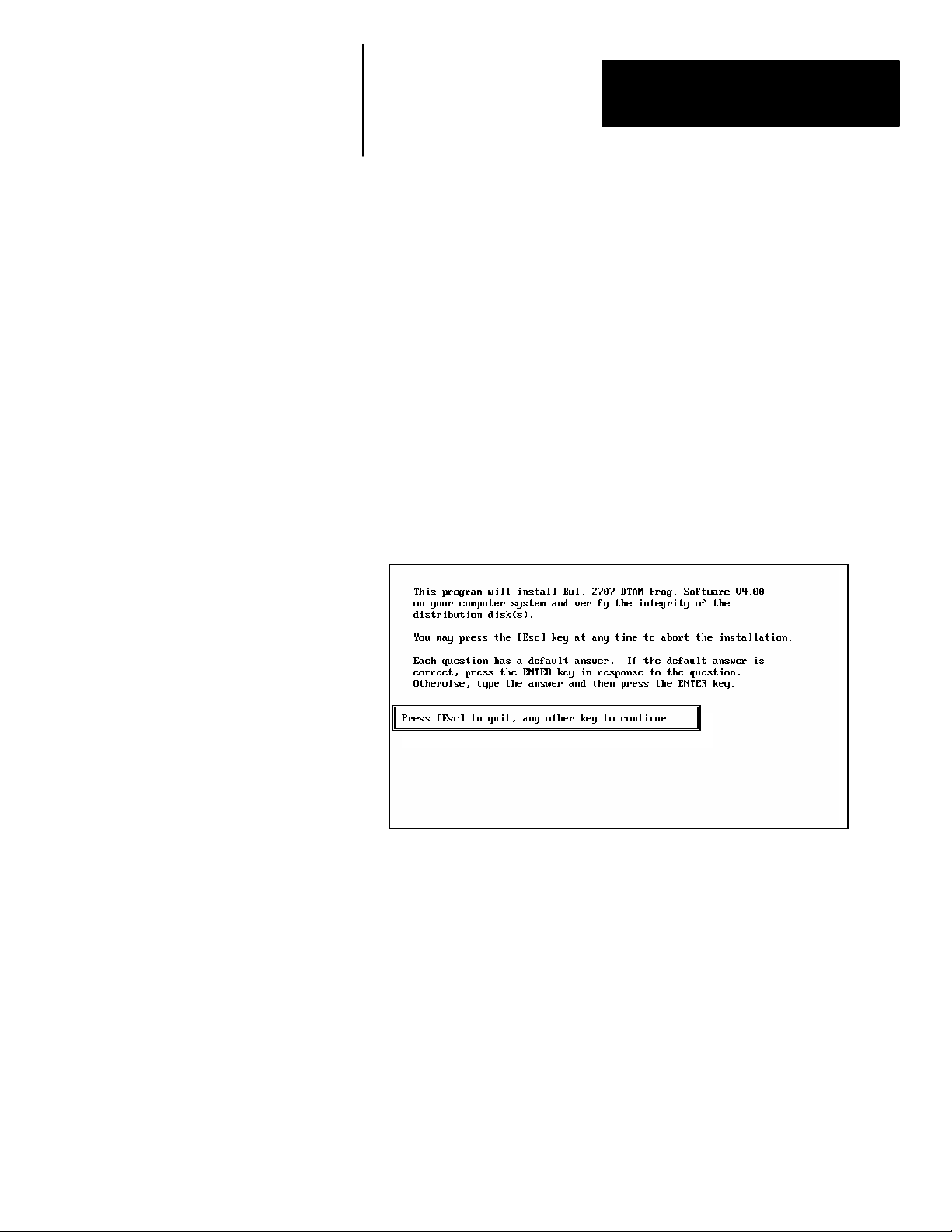

The following screen appears:

2–3

Page 16

Chapter 2

Installing / Running

DTAM Programming Software

Installing DTAM

Programming Software

☞ You cannot install the DPS soft-

ware on the same drive on which

the Install program resides.

5. Press any key (other than [Esc]) to continue.

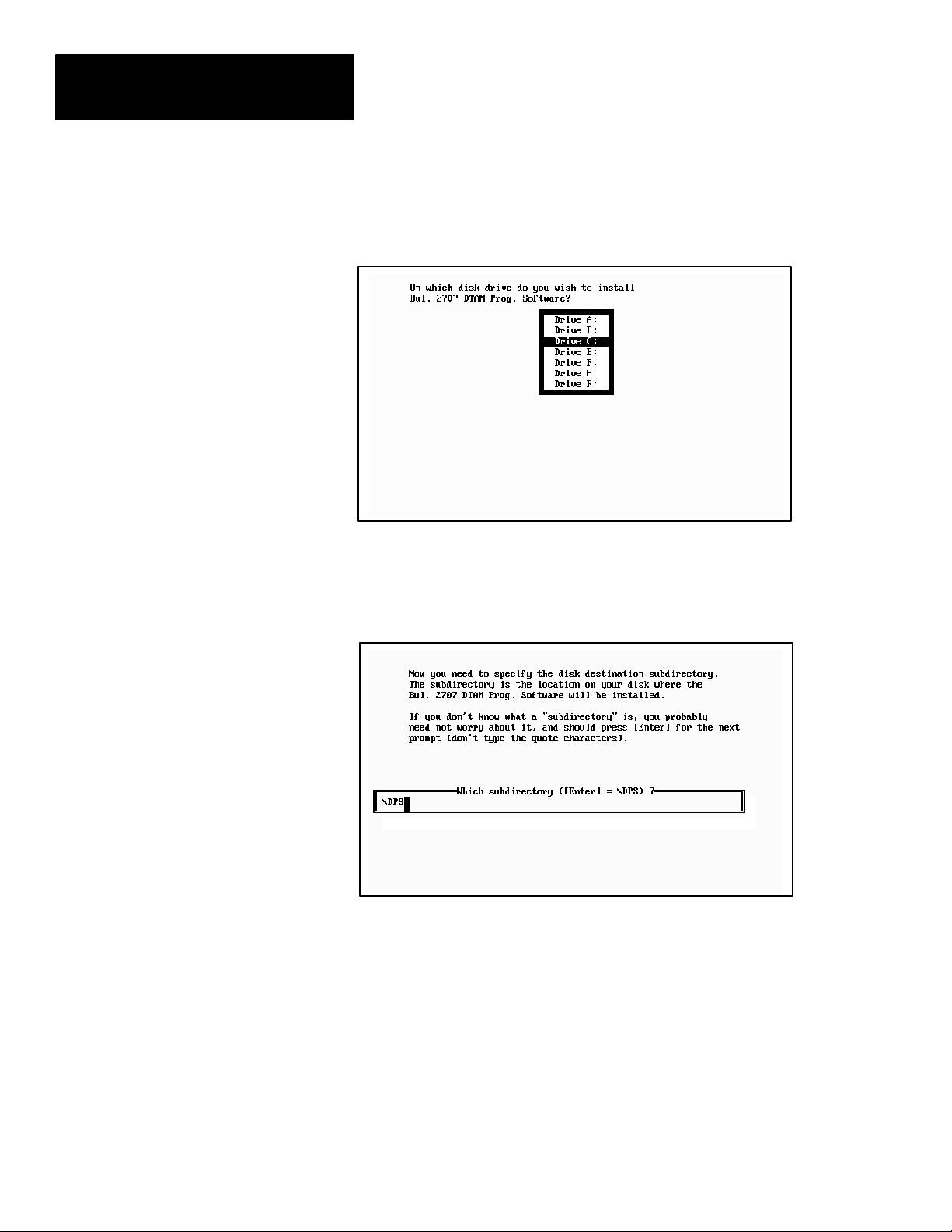

This screen appears.

6. Use the ["][#] arrow keys to highlight the drive on which you want to

install DPS and then press [Return]. The default drive is C:

This screen appears.

2–4

Page 17

Chapter 2

Installing / Running

DTAM Programming Software

☞ You can specify another

directory. The Install program

will create the directory if it

does not exist.

7. Press [Return] to install the DPS software in the \DPS subdirectory. The

Install program creates the subdirectory. If you enter your own

subdirectory name, the entire path name including colons, forward slash,

and name should not exceed 28 characters.

The status of the installation is displayed on the screen.

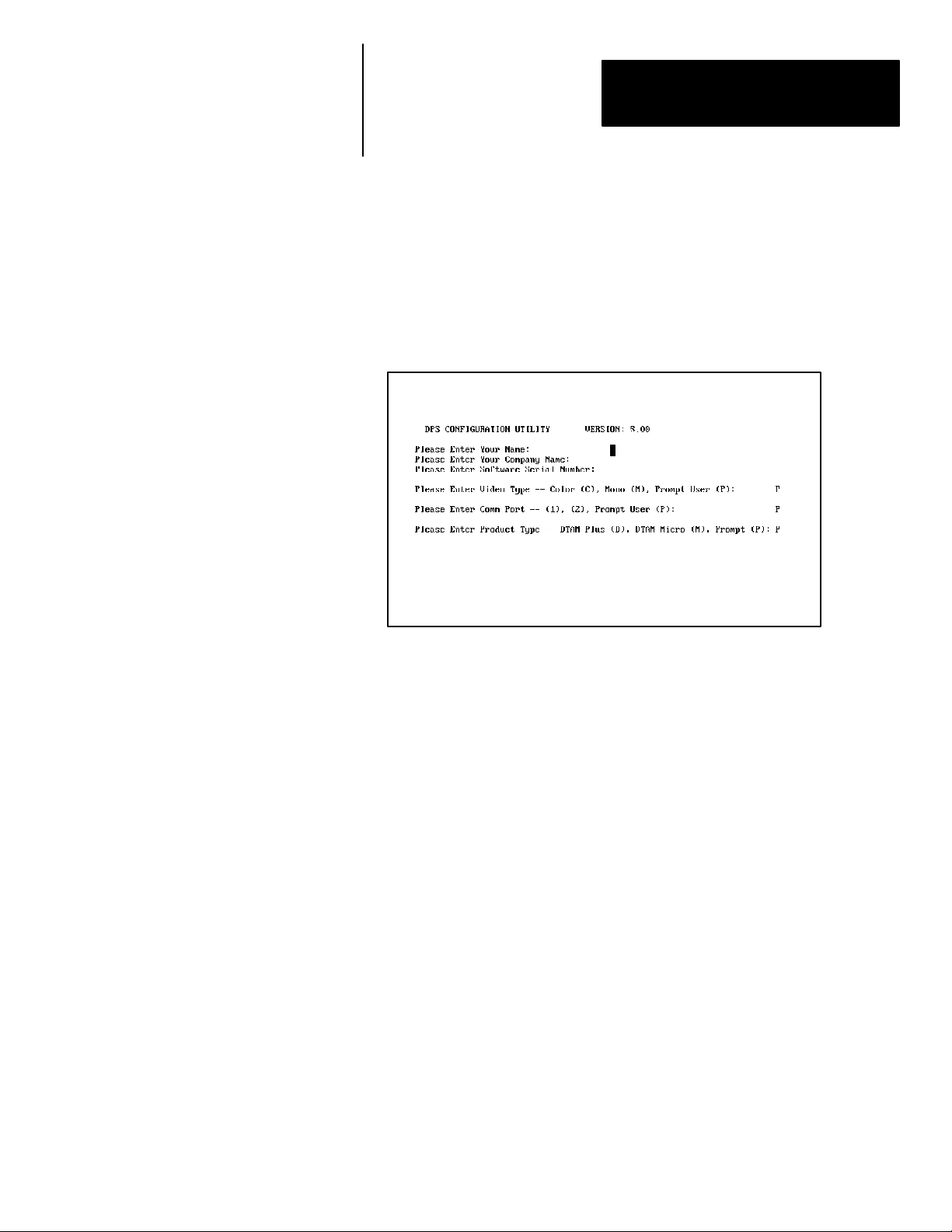

The DPS Configuration Utility screen then appears:

☞ Press [Return] at the Video

Type and Comm Port questions

to prompt the user for this

information during application

development.

8. Enter your name, company name, and software serial number (on

registration card). Also, enter the monitor type and communication port

used by your computer.

The software serial number is required when requesting phone support

(refer to startup screen on next page).

9. After responding to the above questions, you are asked to confirm the

configuration. Press [Return] to accept the configuration.

10. The installation is complete. You are returned to DOS at the new

subdirectory C: \DPS>.

2–5

Page 18

Chapter 2

Installing / Running

DTAM Programming Software

Running DPS

☞ If you installed the software in

another subdirectory, move to

that directory.

To run the DTAM Programming Software:

1. Verify that you are at the \DPS subdirectory where the software resides.

If you are not, enter cd \DPS and press [Return].

C:\DPS>

2. Type DPS and press [Return] to start the program.

C:\DPS> DPS [Return]

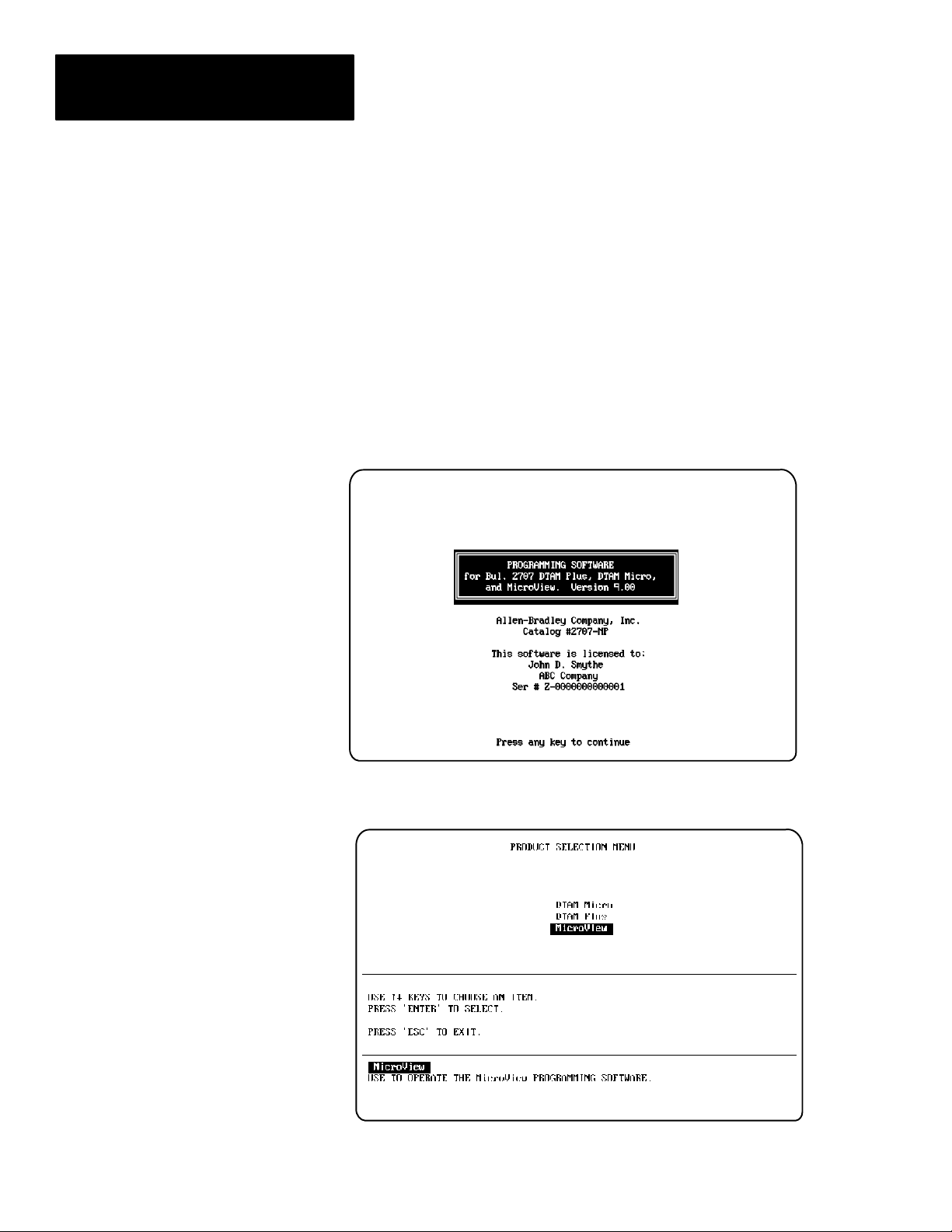

3. Specify whether you are using a color monitor. Enter [Y] or [N].

The startup screen displays. It identifies the DPS version and licensed

owner. A phone support number is provided for your assistance.

Technical Support

Voice: 440–646–6800

FAX: 440–646–6850 or 6890

E–mail: RACLEASKTHEEXPERT@RA.ROCKWELL.COM

Followed by this screen.

2–6

Page 19

Chapter 2

Installing / Running

DTAM Programming Software

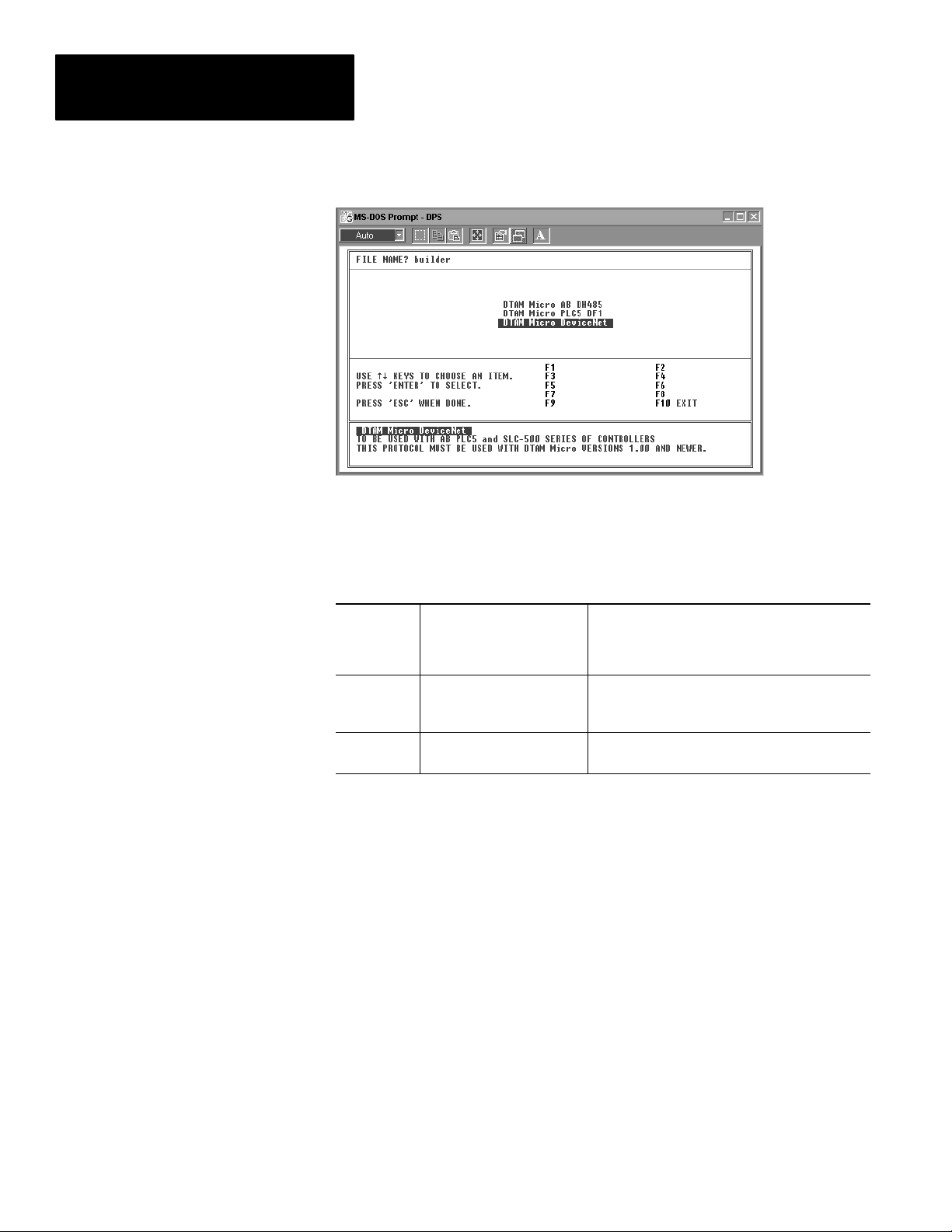

4. Select the product type you are creating an application for (DTAM Micro,

DTAM Plus, or MicroView) and press [Return].

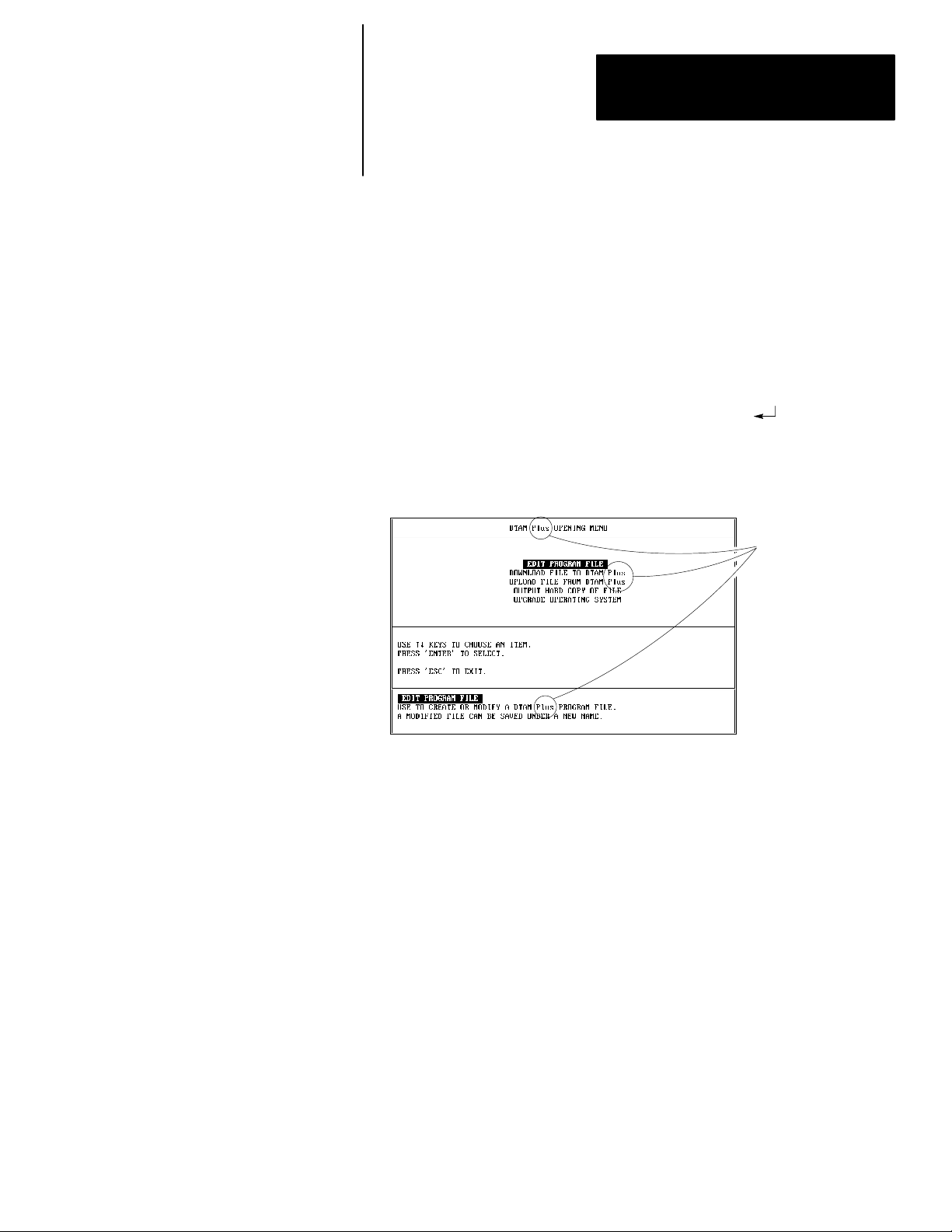

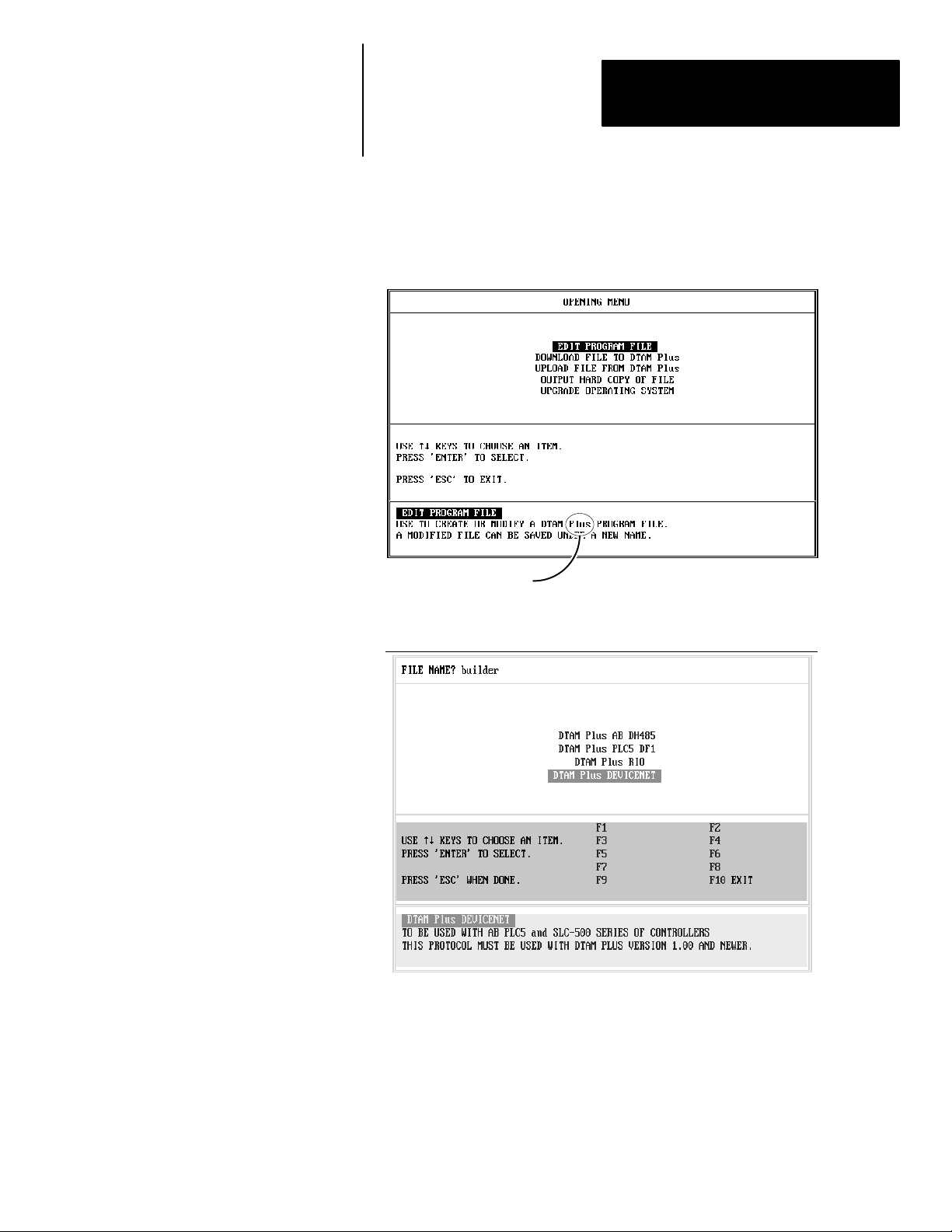

The Opening Menu appears:

Plus, Micro, or MicroView

Depending upon selection.

2–7

Page 20

Chapter 2

Installing / Running

DTAM Programming Software

You are now ready to create a file for your application.

The following chart lists the various protocols and the corresponding

controllers:

DTAM Plus

DTAM Micro

MicroView

AB DH485

PLC5 DF1

PLC5 DF1

RI0

DN

AB DH485

PLC5 DF1

DN

Micro Logix DF1

DN

SLC or Micro Logix (Series C or later)

PLC5 or Micro Logix

PLC5 or Micro Logix

PLC5 or SLC w/1747-SN

PLC or SLC w/★-SDN

SLC or Micro Logix (Series C or later)

PLC5 or Micro Logix

PLC or SLC w/★-SDN

Micro Logix

PLC or SLC w/★-SDN

Note: Once a protocol has been selected and the file has been saved, you

can not change the protocol. A new file must be created when a different

protocol is selected.

2–8

Page 21

Chapter 2

Installing / Running

DTAM Programming Software

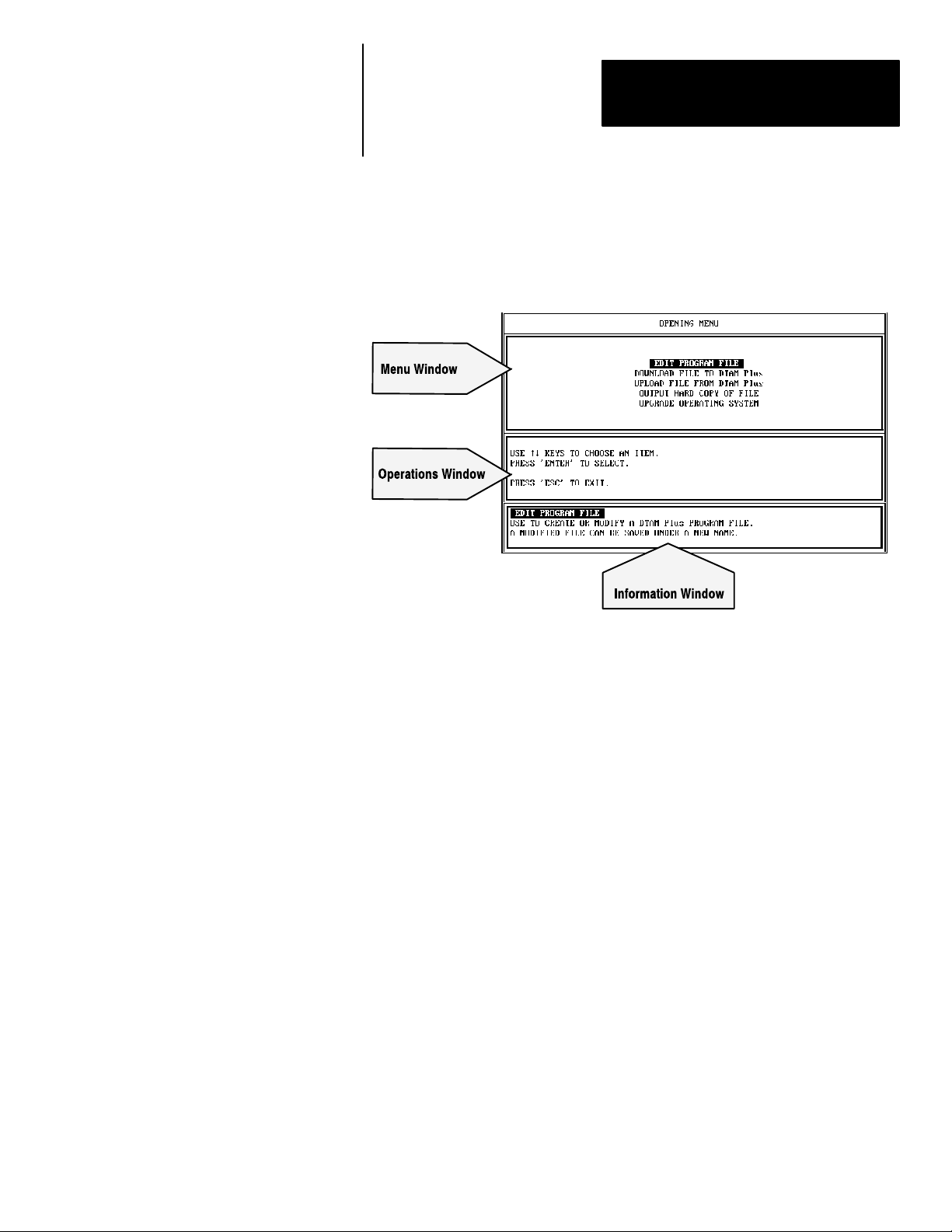

Menu Conventions

Figure 2.1 shows the format of DPS menu screens:

Figure 2.1

DPS Menu Screen Format

Menu Window

The Menu Window lists operations available at the current menu. To

select one of the operations, highlight the operation and press [Return].

Operations Windows

The Operations Window displays keyboard operations available at the

current Menu Window.

Information Window

The Information Window displays a brief explanation of each operation

available for the selected menu item.

2–9

Page 22

Chapter 2

Installing / Running

DTAM Programming Software

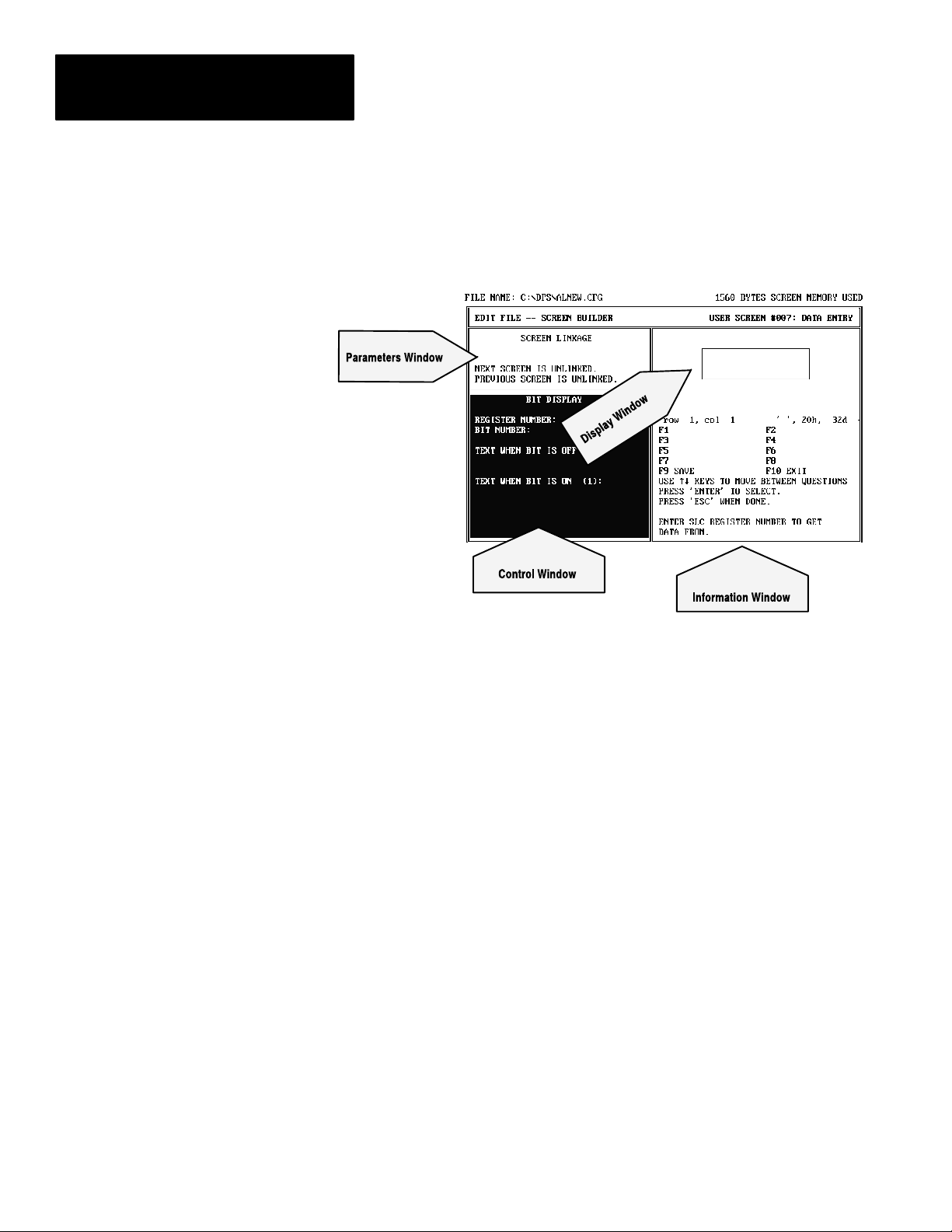

Screen Building Conventions

Figure 2.2 shows the Screen Builder format:

Figure 2.2

Screen Builder Format

There are two information lines at the top of the screen:

• The first line identifies the current program path and file name, as well as

screen memory usage to help you track the size of your program file.

• The second line identifies the current DPS operating area as well as the

current screen number and type.

Screen builder has four windows:

Parameters Window

The Parameters Window displays the linking definitions that have been

established for the current screen.

Display Window

The Display Window simulates the DTAM Plus (4 line display) or DTAM

Micro (2 line display) screen. It displays the formatted data and text as it

would appear to the DTAM operator.

Control Window

The Control Window displays the available data format selection and the

register information which can be defined for the current screen.

Information Window

The Information Window displays information about the function key

operations available at the current screen.

2–10

Page 23

Chapter 2

Installing / Running

DTAM Programming Software

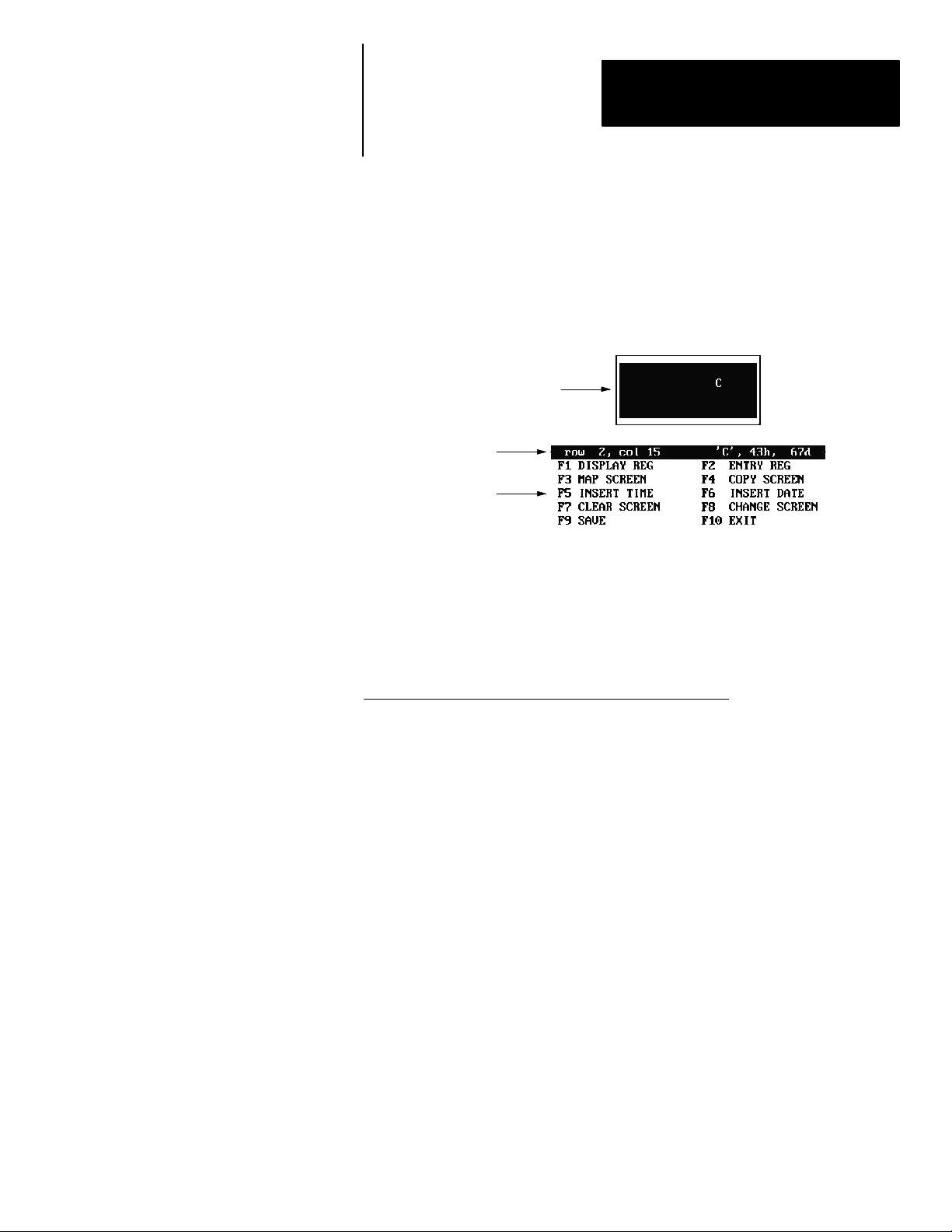

Cursor Status Line

Moving Around Screens

The cursor status line is located between the Display and Information

windows. This line displays the current row and column of the cursor.

Also listed is the character at that position along with the character ASCII

code in hex and decimal formats. Confirm character codes by placing the

cursor under the character and reading the code from the cursor status line.

The following example shows the character C at row 2, column 15.

Display Window

Cursor Status Line

Information Window

DPS uses menus to guide you through the application development process.

Select a menu item and the next menu or screen is displayed. The standard

keyboard operations are:

Linking Application Screens

Use these keys To

[°][±][²][³]

[Return] Select a menu item.

[Esc] Return to the previous menu.

Highlight a menu selection

DTAM application files allow you to present screens in a meaningful

sequence, a hierarchy of possible tasks and operations. To do this, you will

need to specify a link for each screen.

The linking function is the basis of a DTAM operator terminal’s power and

flexibility. When screens are linked, the DTAM becomes an interactive

operator workstation, one that can guide an operator through a hierarchy of

operations. This hierarchy can be as simple or as complicated as your

application requires.

Note: All application screens must be created before they can be linked.

2–11

Page 24

Page 25

Chapter

Objectives

A–B

3

Designing DTAM Plus and

DTAM Micro Applications

This chapter describes the differences between DTAM Micro and DTAM

Plus applications. Also provided are guidelines for creating applications.

Section Page

DTAM Plus / DTAM Micro Comparison 3–2

DTAM Plus / DTAM Micro File Types 3–3

Screen Types and Data Formats 3–4

Data Scaling 3–6

Application Example 3–8

Designing an Application 3–10

3–1

Page 26

Chapter 3

Designing DTAM Plus and

DTAM Micro Applications

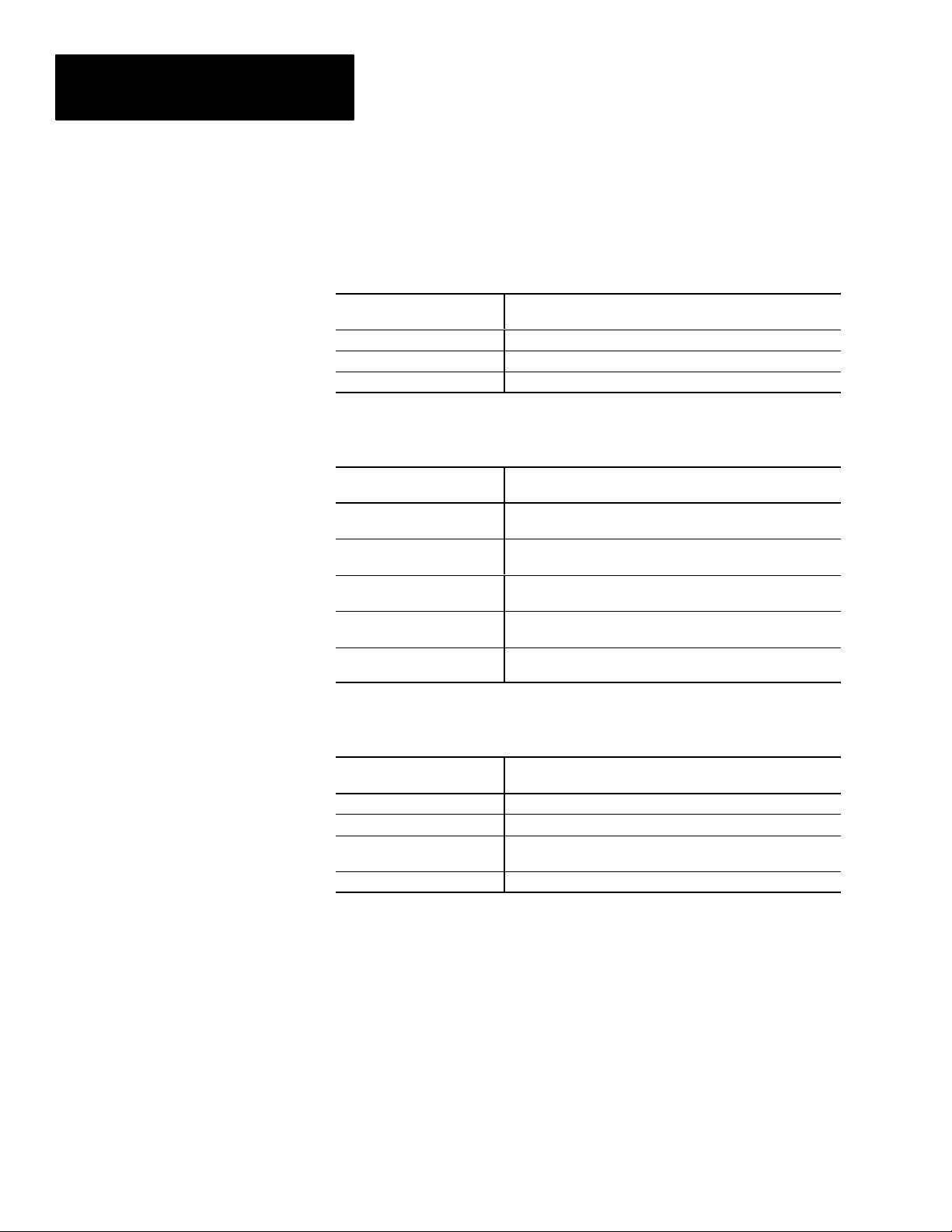

DTAM Plus / DTAM Micro Comparison

Both the applications are created using DPS. The development of

applications for the DTAM Micro and DTAM Plus is very similar. This

manual shows screens for DTAM Plus applications, the DTAM Micro

screens are similar unless noted. The differences in application development

are related to differences in the operator terminals. The following table lists

these differences.

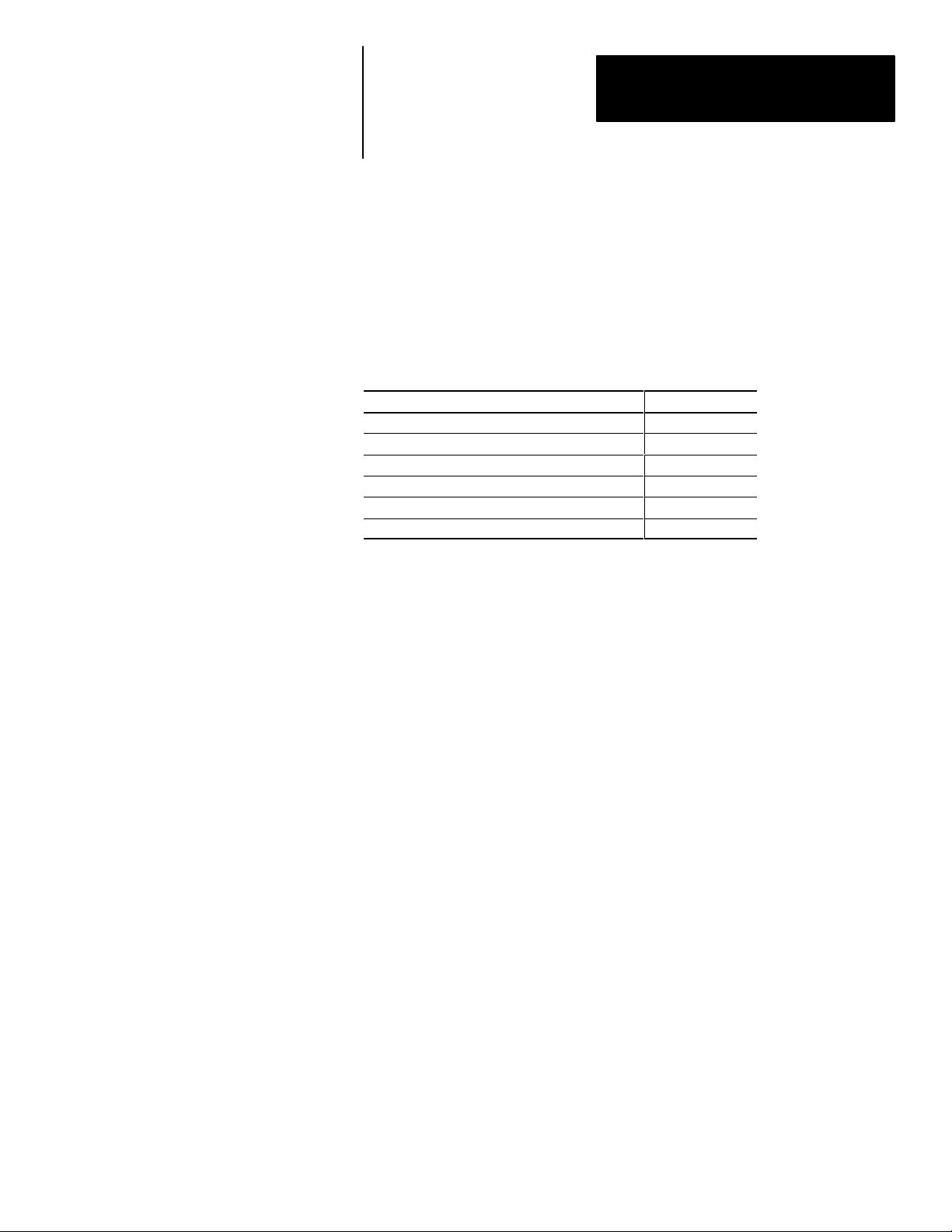

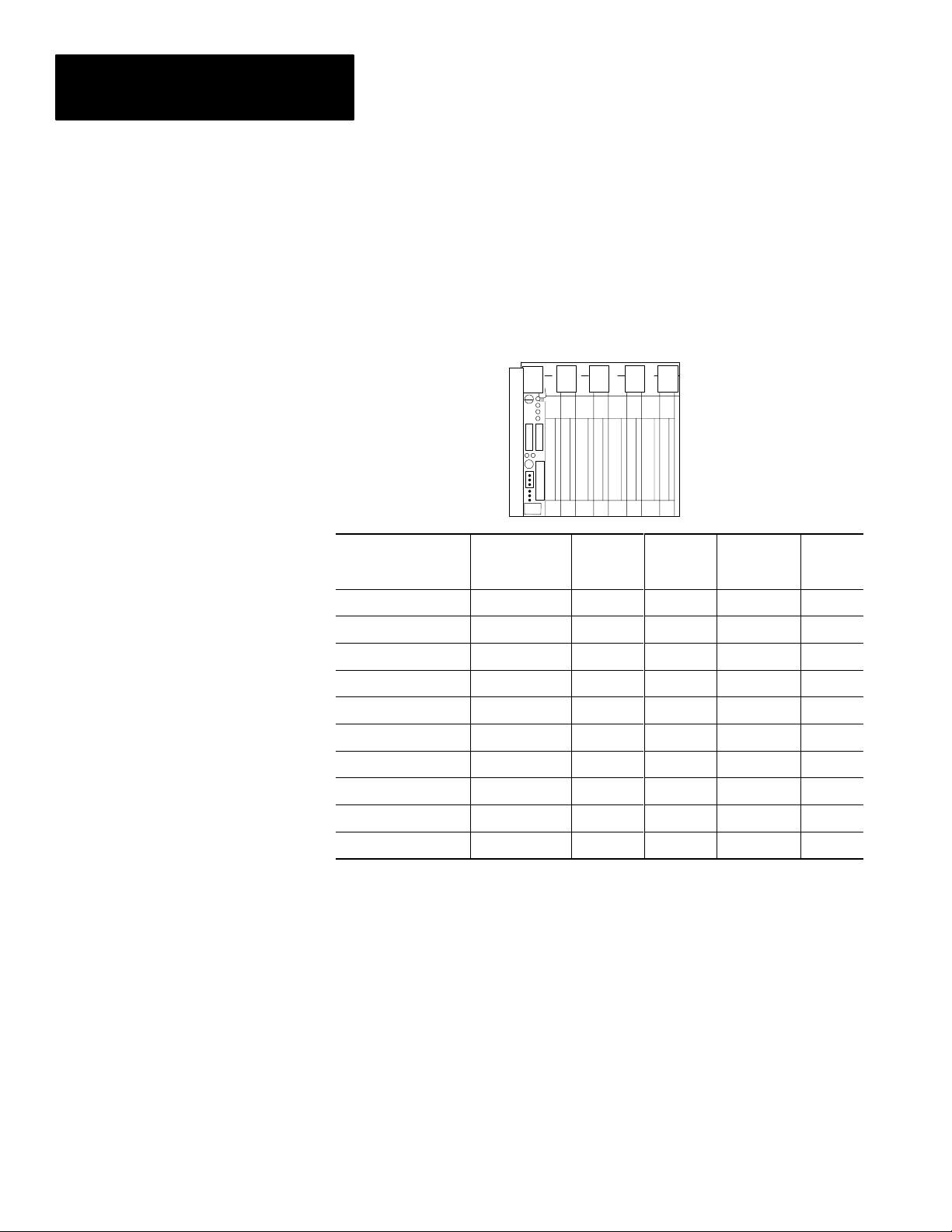

Function DTAM Plus DTAM Micro

Screen Capacity Up to 244 Screens Up to 244 Screens

Terminal Mode Yes No

Function Key Screen Selection No Yes

Alarm LED Yes No

Background Monitor Yes No

Application Upgrade / Downgrade Yes No

Contrast / Backlight Adjustment Yes No

Time / Date Functions Yes No

PID File Operations Yes No

SFC File Operations Yes No

Block Transfer File Operations Yes No

Floating Point File Operation Yes No

Bargraph Display Yes No

[Y], [N], [PREV MENU] keys Yes No

Printer Port Yes No

3–2

The main difference in designing DTAM Micro and DTAM Plus applications

is the screen size.

DTAM Plus

4 Lines x 20 Characters

DTAM Micro

2 Lines x 20 Characters

Page 27

Chapter 3

Designing DTAM Plus and

DTAM Micro Applications

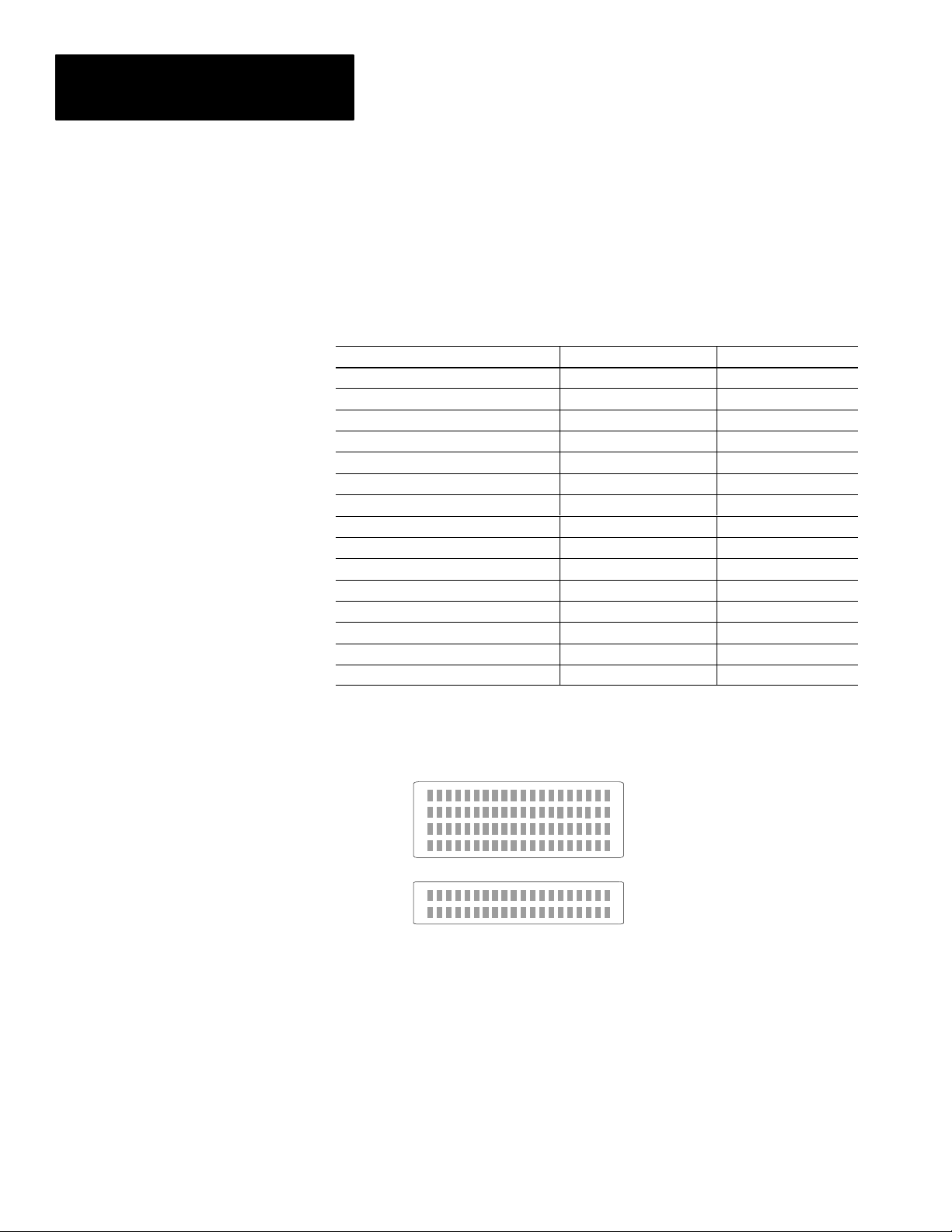

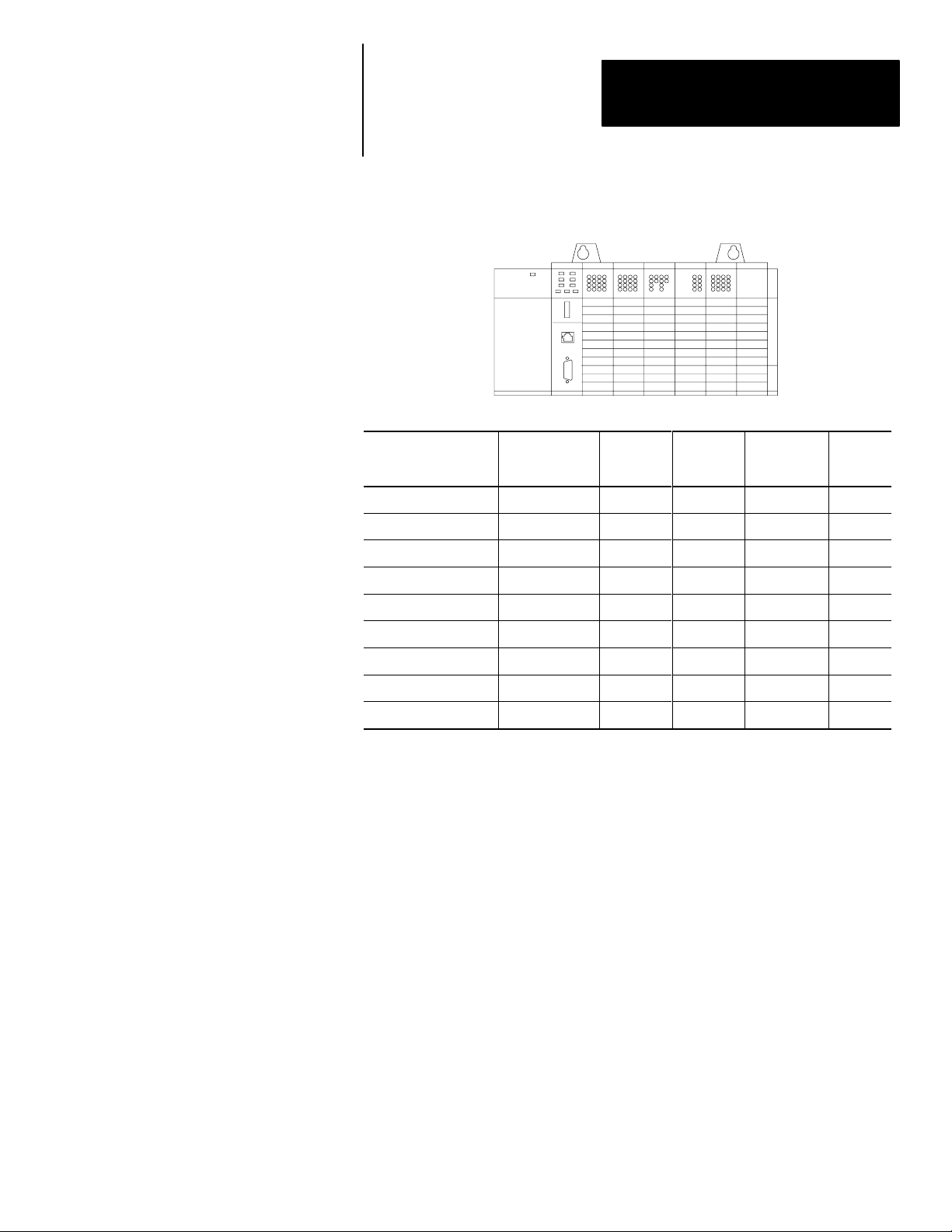

DTAM Plus / DTAM Micro File Types

File Type

Output Yes Yes Read O 0

Input Yes Yes

Status Yes Yes Read / Write S 2 0-127 NA 0-15

Bit (Binary) Yes Yes Read / Write B 3-999 0-999 NA 0-15999

Timer Yes Yes Read / Write T 3-999 0-999 PRE, ACC EN, TT, DN

Counter Yes Yes Read / Write C 3-999 0-99 PRE, ACC

Control Yes Yes Read / Write R 3-999 0-999 LEN, POS

Integer Yes Yes Read / Write N 3-999 0-999 NA 0-15

Floating Point Yes Yes (Limited) Read / Write F 3-999 0-999 NA NA

ASCII Yes Yes Read A 3-999 0-999 NA 0-15

BCD Yes Yes Read / Write D 3-999 0-999 NA 0-15

Block

Transfer

Message Yes Yes Read MG 3-999 0-584

PID Yes No Read / Write PD 3-999 NA NA NA

SFC Yes No Read / Write SC 3-999 NA NA NA

ASCII String Yes Yes Read ST 3-999 0-799 LEN, CHAR 0-15

➀ Octal format, all other values are decimal. ➁ Remote I/O allows the DTAM to write it’s own output words.

File Type Supported By;

DTAM Plus

Yes No Read / Write BT 3-999 0-999 NA NA

DTAM Micro

Both the DTAM Micro and DTAM Plus can read and write PLC and SLC

controller files. Refer to the following when designing applications.

PLC-5 File Types

Integer

Read / Write Identifier File Number Element

0-277➀

Read➁

I 1

0-277➀

Integer

Sub-Element

NA

NA

ERR, RLEN,

DLEN,

DATA 90-51)

Bit Number

0-17➀

0-17➀

CU, CD, DN.

OV, UN

EN, EU,

DN, EM, ER,

UL, IN, FD

NR, TO,

EN, ST, DN,

ER, CO, EW,

SD, SE

SLC File Types

File Type

Output Yes Yes Read O 0 0-255 NA 0-15

Input Yes Yes Read I 1 0-255 NA 0-15

Status Yes Yes Read / Write S 2 0-82 NA 0-15

Bit (Binary) Yes Yes Read / Write B 3, 9-255 0-255 NA 0-4094

Timer Yes Yes Read / Write T 4, 9-255 0-255 PRE, ACC EN, TT, DN

Counter Yes Yes Read / Write C 5, 9-255 0-255 PRE, ACC

Control Yes Yes Read / Write R 6, 9-255 0-255 LEN, POS

Integer Yes Yes Read / Write N 7, 9-255 0-255 NA 0-15

ASCII Yes Yes Read A 3-999 0-999 NA 0-15

ASCII String Yes Yes Read ST 3-999 0-799 LEN, CHAR 0-15

Floating Point Yes

③ Need SLC 5/03 Series C w/OS 301 or SLC 5/04.

File Type Supported By;

DTAM Plus

DTAM Micro

Yes③

(Limited)

Read / Write Identifier File Number Element

Read / Write F 3-999 0-999 NA NA

Integer

Integer

Sub-Element

Bit Number

CU, CD, DN,

OV, UN

EN, EU,

DN, EM, ER,

UL, IN, FD

3–3

Page 28

Chapter 3

Designing DTAM Plus and

DTAM Micro Applications

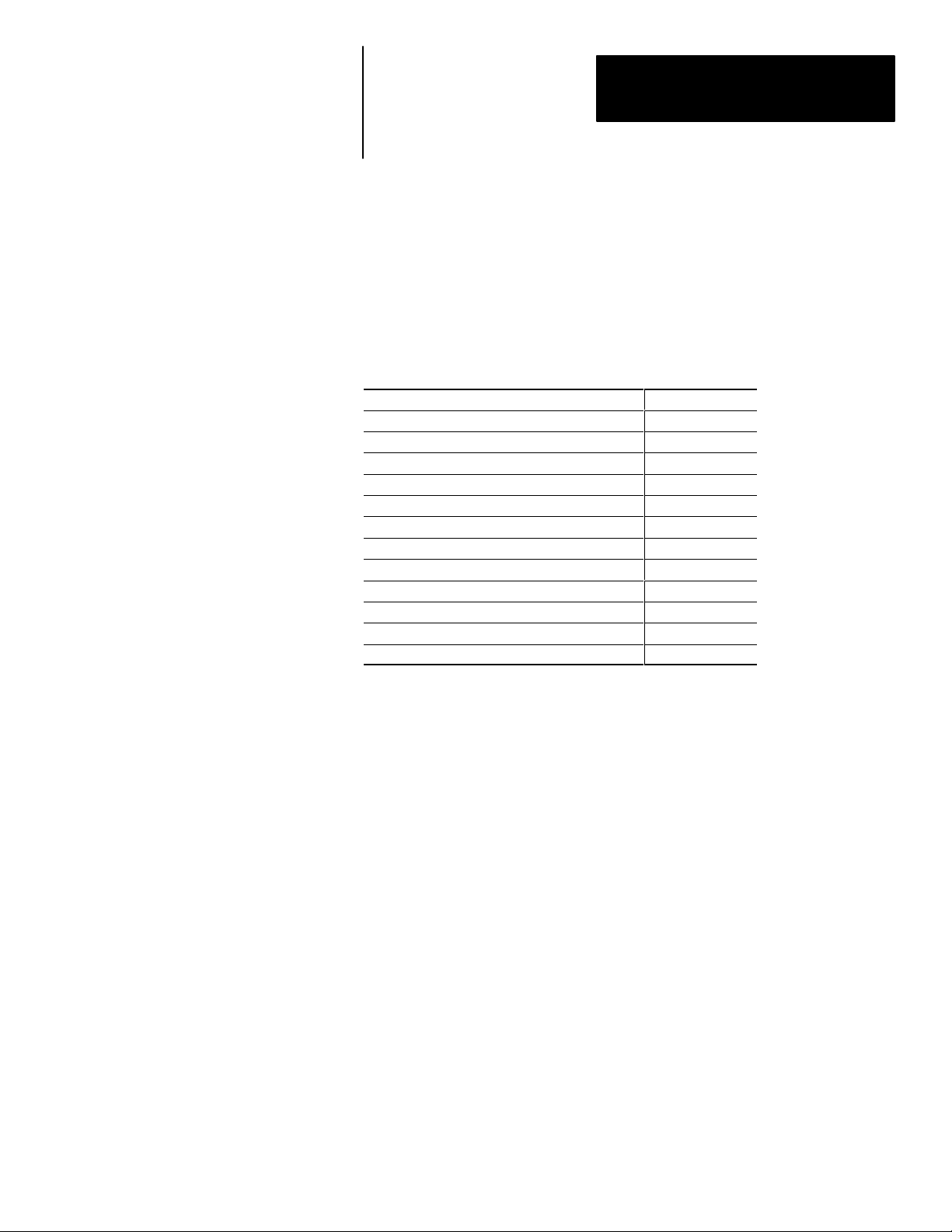

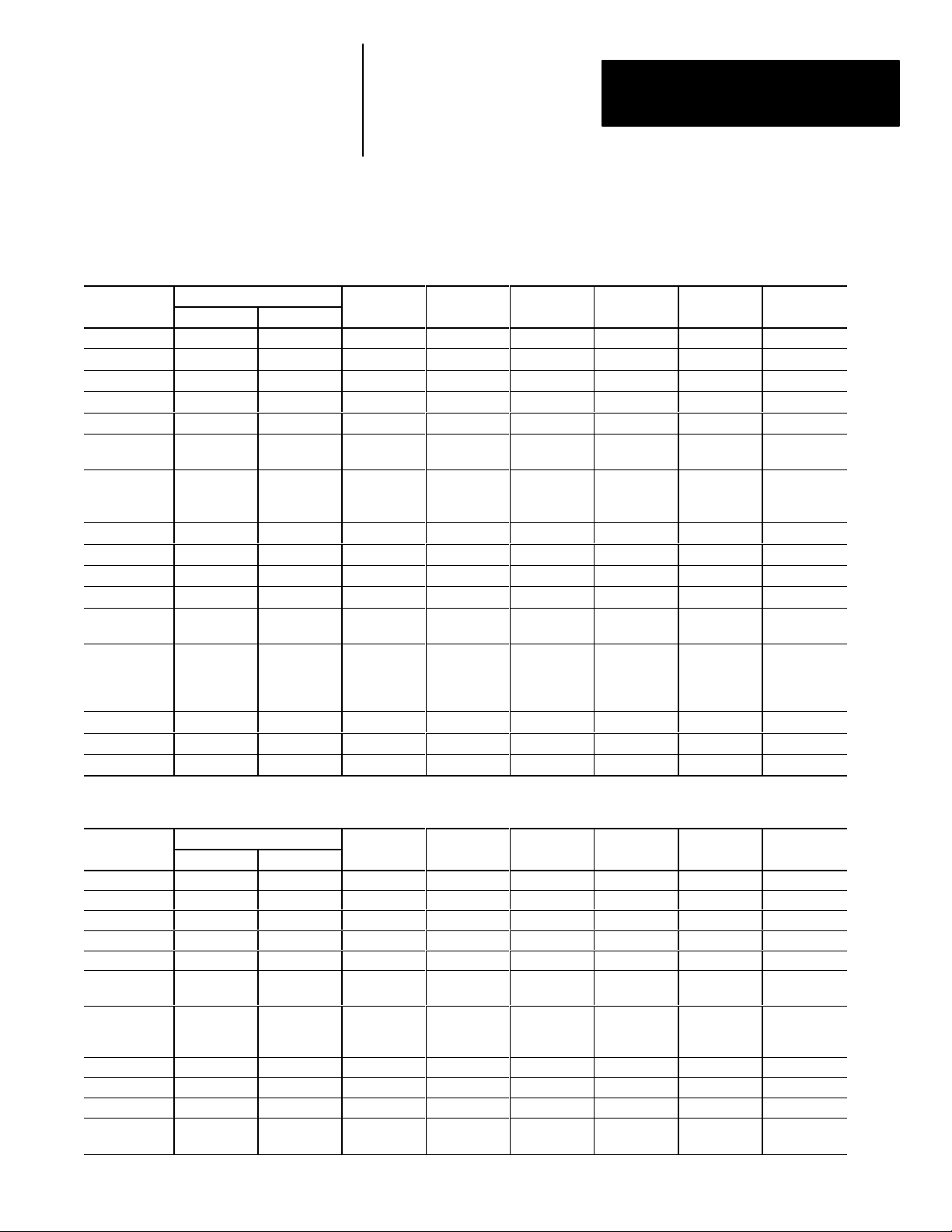

Screen Types and Data Formats

Some application screens require that you specify register information.

Each DTAM screen type supports different data formats. The following table

lists each screen type and the data formats supported.

PLC Data Formats

Display, Alarm,

Format

Bit

16 Bit Signed Integer

16 Bit Unsigned Integer

16 Bit BCD

16 Bit Hex

32 Bit Floating Point

32 Bit Unsigned Integer

32 Bit BCD

32 Bit Hex

ASCII

➀ Bar Graph, Printer Form, and Background Monitor are only available on DTAM Plus Operator

Modules.

Printer Form ➀

Screens

n

n

n

n

n

n n n

n n n

n n n

n

n

Data Entry

Screens

n n

n n n n

n n

n n n n

Bar Graph

Screens ➀

Background

Monitor ➀

Recipe

Screens

3–4

Page 29

Chapter 3

Designing DTAM Plus and

DTAM Micro Applications

SLC Data Formats

Display, Alarm,

Format

Bit

16 Bit Signed Integer

16 Bit Unsigned Integer

16 Bit BCD

16 Bit Hex

32 Bit Unsigned Integer

32 Bit BCD

32 Bit Hex

ASCII

➀ Bar Graph, Printer Form, and Background Monitor are only available on DTAM Plus Operator

Modules.

Printer Form ➀

Screens

n n n

n n n n n

n n n

n n n n n

n

n n n

n n n

n

n

Data Entry

Screens

Bar Graph

Screens ➀

Background

Monitor ➀

Recipe

Screens

3–5

Page 30

Chapter 3

Designing DTAM Plus and

DTAM Micro Applications

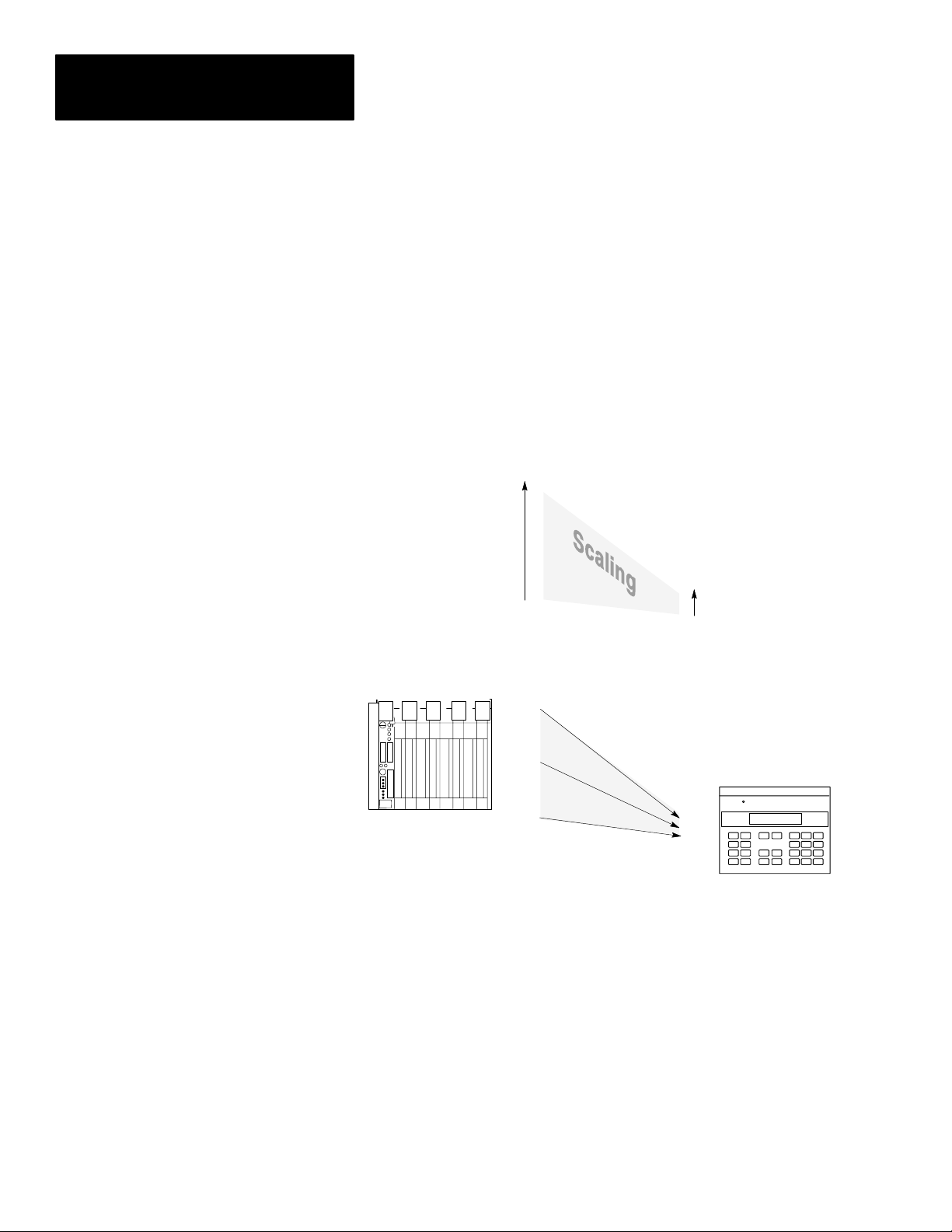

Data Scaling

Data entered by an operator can be scaled from engineering units such as

gallons or PSI to machine control values. Likewise, data displays can

take raw numeric values and scale them so they are displayed in

engineering units.

Scaling of data is accomplished by defining a proportional ratio between the

register value range and the display or entry value range. If a 1:1 ratio exists,

the DTAM displayed or entered value equals the controller register value.

Here is an example of scaling using a data display to scale a register data

range of 0 to 4,095 to a DTAM display range of -100 to +300.

Controller

Register Limits

4,095

4,095

DTAM

Display Limits

+300

0

-100

If the Display

Register Contains:

4,095

2,047

This Value

Is Displayed:

0

+300

+100

-100

When the ratio between the controller register values and DTAM display or

entry values is not a multiple of 2, the value is rounded. Rounding may

result in a 1 count error. Depending upon the direction of the scaling, this

means that:

• The DTAM display value may be off by 1 when the controller register

value is scaled

• The controller register value may be off by one when a DTAM data entry

is scaled.

An error screen appears if a rounding error occurs at the end points of a data

range. You must either increase the minimum or decrease the maximum

range of either the controller register or display ranges.

3–6

Page 31

Chapter 3

Designing DTAM Plus and

DTAM Micro Applications

Scaling Formulas

The scaling formula for a DTAM display value is:

Displayed Value= m x Register Value + b

Where:

Display Maximum Value – Display Minimum Value

m =

Register Maximum Value – Register Minimum Value

Display Minimum Value – ( m x Register Minimum Value )

b =

The scaling formula for an entered valued is:

Register Value = m x Entered Value + b

Where:

Register Maximum Value – Register Minimum Value

m =

b =

Entry Maximum Value – Entry Minimum Value

Register Minimum Value – ( m x Entry Minimum Value )

Scaling example: Register Range = 0 ! 4,095

Display Range = -100 ! +300

Actual Register Value = 2,047

300 - (-100)

m =

4,095 - 0

b =

-100 - (0.0977 x 0) = -100

= 0.0977

Displayed Value = 0.0977 x 2,047 + (-100)

= 99.9919

= 100

3–7

Page 32

Chapter 3

Designing DTAM Plus and

DTAM Micro Applications

Application Example

Sub Menu

1. East Pump/Tank

2. West Pump/Tank

The following example shows typical menus and screens of a DTAM Plus

application. The same application could be created on a DTAM Micro with

the following exceptions:

• DTAM Micro screen is 2 lines by 20 characters. Large screens would

have to be shortened or broken down into separate screens.

• The DTAM Micro cannot support a bar graph screen.

DTAM Plus Application Outline

Main Menu

1. Pump/Tank Levels

2. Pump Control

3. Flow/Level Status

4. Controller Status

Security

* Restricted Access *

Enter Your Security

Code: * * * * * * * *

Data Display

East Pump: 280 CFM

West Pump: 0 CFM

North Pump: 207 CFM

South Pump: 70 CFM

Data Display

Controller Status

Scan Time is: 7 ms

Controller is: Online

Battery Power: OK

Data Display

East Feed Pump

Main Pump is: On

Fill Rate: 280 CFM

Tank is 38% Full

Data Display

East Feed Pump

Efficiency: 77%

Run Time:693 Hrs.

Next Serv:307 Hrs.

3–8

Data Display

West Feed Pump

Main Pump is: Off

Fill Rate: 8 CFM

Tank is 72% Full

Data Display

West Feed Pump

Efficiency: 83%

Run Time:22 Hrs.

Next Serv:978 Hrs.

Data Entry

East Tank: 38% Full

Setpoint is 280 CFM

Please Enter New

Setpoint: 145

Data Entry

West Tank: 72% Full

Setpoint is 170 CFM

Please Enter New

Setpoint:

Data Display

East Tank: 38% Full

West Tank: 72% Full

North Tank: 16% Full

South Tank: 5% full

Bar Graph

Tank Total Pumping

Rate is: 557 CFM

Page 33

Chapter 3

Designing DTAM Plus and

DTAM Micro Applications

Example Application Description

Pump/Tank Levels

When Pump/Tank Levels is selected from the Main Menu, a Sub-Menu

displays two new choices (East Pump/Tank and West Pump/Tank). Selecting

either of these Sub-Menu items allows you to display pump and tank

information for the East or West systems.

Pump Control

Allows you to enter new pump setpoints to be entered. A security code is

required to access the Data Entry screens.

Data Entry screens use data from the SLC or PLC (% Full & CFM) to

display this information along with a prompt to enter a new setpoint. When a

new setpoint is entered, the value is checked to verify that it is within the

programmed limits. If the value is within the entry limits, the number is then

scaled to engineering units and sent to the SLC or PLC. If the value is

outside the limits, an error message informs you of the valid range. You can

then enter another value.

Flow/Level Status

Allows access to three Data Display screens identifying the flow rates for the

four pumps. All values are updated in real time and are scaled to engineering

units by the DTAM. Using the [NEXT] key on the DTAM keypad, an

operator can display the sequence of Data Display screens. The Bar Graph

screen (DTAM Plus only), lets you view the data in a graphic format.

Controller Status

Shows the status of the controller (SLC or PLC).

3–9

Page 34

Chapter 3

Designing DTAM Plus and

DTAM Micro Applications

Designing an Application

Appendix B contains worksheets for designing both DTAM Micro and

DTAM Plus applications. Both application layout and screen design

worksheets are provided.

Use the application design worksheets to layout a logical sequence of

screens. Make copies of the worksheets as needed. On each worksheet, list

the screen numbers, type of screens, register numbers, etc.

DTAM Application Worksheet

Use the screen worksheets to define screen text and layout. Make copies of

the screen worksheets and write out each application screen.

DTAM Plus

Screen Worksheet

Screen #

DTAM Micro

Screen Worksheet

Screen #

Before you design an application, become familiar with the types of screens

and how they function. To assist you, a sample application is provided in

this chapter. In addition, you should become familiar with the controller files

and data types supported for each operator module type and selected protocol

(see previous section). When register information is required, this manual

lists the applicable data formats (such as ASCII or 16 Bit Hex) for each

controller file type.

3–10

Page 35

Chapter 3

Designing DTAM Plus and

DTAM Micro Applications

Recommended sequence for creating an application:

Step 1 On paper, design all the operator screens with the associated register

numbers, and produce a map of how all screens are linked together.

Step 2 Construct all screens using DPS. Save the program file without

linking.

Step 3 Link the application screens. Use the design from step 1.

When you have established all links, save the program file.

An error display will warn you of any unlinked screens.

Step 4 Download the application file.

Step 5 Use the Simulate function (described in the DTAM Micro or DTAM

Plus user manuals) to verify operations such as screen links, text, and

screen types.

Step 6 Run the application.

3–11

Page 36

Page 37

Chapter

Chapter Objectives

Opening Menu

A–B

4

Creating or Editing

an Application File

This chapter describes how to open, edit and save an application file.

Section Page

Opening Menu 4–1

Edit Application File 4–2

Save Application File 4–4

The Opening Menu is the first menu displayed each time you run

the software.

Note: If you specified prompts for monitor type and product type during

installation, these prompts will appear before the opening menu.

The Opening Menu displays the following operations:

• Edit Program File

• Download File to DTAM Plus or Micro

• Upload File from DTAM Plus or Micro

• Output Hard Copy of File

• Upgrade Operating System

4–1

Page 38

Chapter 4

Creating or Editing an Application File

Edit Application File

The directory only lists files compatible

with the currently specified hardware type.

For example, if DTAM Micro is specified

only DTAM Micro applications are listed.

To create or edit an application:

1. Select Edit Program File to create or edit a DTAM application file.

You are prompted for the file name to edit or create. All DTAM

application files in the current directory are listed.

If files already exist, each file name is followed by the type of Operating

System the file was created for:

• AB DH485 for point to point or 32 node operation with SLC

controllers.

• PLC5 DF1 for DF1 connection to PLC-5 serial port (channel 0).

• AB BASIC only applies to DTAM Plus programming when

communicating with an SLC BASIC module (Catalog No.

1746-BAS).

• RIO only applies to DTAM Plus programming when communicating

with an a PLC-5 or SLC 5/03 / 5/04 over a remote I/O link.

4–2

2. Select the name of an existing application file or enter a new file name.

If you entered a new file name, you must select an operating system:

Page 39

Chapter 4

Creating or Editing an Application File

After you select an existing file or enter the operating system (for new

files), the Edit File - Option Selection menu is displayed.

DTAM Micro or

MicroView or

DTAM Plus

3. Access the following functions from the Edit File - Option Selection

menu to create your application screens and enter configuration data.

4–3

Page 40

Chapter 4

Creating or Editing an Application File

Save Application File

Select this

Menu Option:

DTAM Configuration Data

Screen Builder

Alarm Screen Builder

Background Monitor

Print Form Builder

Function Key Builder

Applies to:

DTAM-

Plus

Micro-

View

✓

✓ ✓ ✓

✓ ✓

✓

✓

✓

DTAM-

Micro

✓

✓

Set configuration and operating

parameters.

Create or modify application

screens.

Create or modify alarm screens.

Assign background registers and

limits for the DTAM Plus to monitor.

Create or modify DTAM Plus

Printer Forms.

Assign application specific

operations to the DTAM Micro

function keys.

To

Save the application periodically while you are working on the application

screens and save the file again before you exit the software.

To save an application periodically during editing:

1. Press [F9].

You are prompted to save the application under the current file name or

you can enter a new file name.

Note: If the same file name currently exists under a different product

type, you are prompted if you want to overwrite the existing file.

4–4

Page 41

Chapter 4

Creating or Editing an Application File

2. Press [Return] to save the application under the file name entered when

the application file was opened.

Or enter a new file name:

If you were creating a new file, the new file name replaces the file

name entered when the application was opened.

If you are editing an existing file, the original file is unchanged.

The file and all edits made prior to the last save are stored under the

new file name.

3. After saving the file, you can continue with your editing of the application

To save an application before exiting:

1. Exit the software by pressing [F10].

You are prompted save the application under the current file name or you

can enter a new file name.

2. If you enter a new file name, the original file is unchanged. All edits are

stored under the new file name.

After saving the file, you are returned to a DOS prompt.

4–5

Page 42

Page 43

Chapter

Chapter Objectives

A–B

5

Using Screen Builder

This chapter describes options common to all of the Screen Builder types.

Section Page

Screen Builder 5–1

Accessing Screen Types 5–2

Editing Screen Displays 5–4

Copying Screens 5–5

Selecting Other Screens 5–6

Clearing Screens 5–7

Inserting Time or Date 5–8

Exiting Screen Builder 5–9

Screen Builder

Screen Builder is one of the menu items available when you select Edit

Program File from the Opening menu. Use Screen Builder to create:

• Menus and Sub-menus

• Data Entry screens

• Data Display screens

• Security screens

• Recipe screens

• Bar Graph screens (DTAM Plus only)

Alarm and Special menu security screens are not created within Screen

Builder. These screens are created using other DPS functions:

• For alarm screens, refer to Chapter 13.

• For the Special menu security screen, see Chapter 14.

5–1

Page 44

Chapter 5

Using Screen Builder

Accessing Screen Types

To access Screen Builder screens:

1. Select Screen Builder from the Edit File - Option Selection menu.

The Screen Builder for the main menu screen (screen #1) displays:

5–2

2. If you have designed your main menu screen, you can create it now as

described in Chapter 6. Each application must have a main menu screen.

If you want to create another screen type, proceed to the next step.

Page 45

Chapter 5

Using Screen Builder

3. Press [F8] on any screen to access the other screen types. You are

prompted for a screen number:

Press [F6] to go to the next available unused screen or [F8] to view the

contents of the next programmed screen.

4. If you enter any screen number other than screen #1 (main menu screen),

you are prompted for a screen type:

5. Select a screen type. A Screen Builder for the selected screen type is

then displayed. Refer to Chapters 6 through 11.

Screen Type Chapter

Menus and Sub-Menus 6

Data Displays 7

Data Entry 8

Security 9

Recipe 10

Bar Graph ➀

➀ DTAM Plus only.

11

5–3

Page 46

Chapter 5

Using Screen Builder

Editing Screen Displays

5–4

When you are editing screen text, the following editing operations are

available:

Screen Text Edit Functions

Screen Edit Key Function

Arrow keys

[°] [±] [²] [³]

[Del] Deletes the character at the cursor position.

[Back Space] Deletes the character to the left of the cursor position. The

[Ins] Toggles the insert mode on or off. Characters entered in the

Move the screen cursor.

cursor is moved to the left one space.

insert mode are shifted to the right. A block shaped cursor

indicates the insert mode is on. An underline cursor indicates

that insert mode is off.

The extended DTAM character set can be used, refer to Appendix A for

additional information.

Screen Builder Function keys

The following function keys are available on most screen types.

Function

Key

[F3] LINK

[F4] COPY

[F5] INSERT TIME

[F6] INSERT DATE

[F7] CLEAR

[F8] CHANGE

[F9] SAVE

[F10] EXIT

Designation

SCREENS

SCREEN

SCREEN

SCREEN

Applies to:

DTAM Plus DTAM Micro

✓ ✓

✓ ✓

✓

✓

✓ ✓

✓ ✓

✓ ✓

✓ ✓

Function

Accesses screen mapping functions

that link application screens in a

logical sequence.

Link screens only after all of the

screens have been created.

Copies an existing screen to or from

the current display window. Both the

source and destination screens must

be of the same type (such as Data

Display screens).

Inserts the time into the display.

Only available with a DTAM Plus

having the Calendar/Clock option.

Inserts the date into the display.

Only available with a DTAM Plus

having the Calendar/Clock option.

Clears the current screen. You have

the option of clearing only the screen

text or deleting the entire screen

including any linking you may have

established.

Displays menu for selecting another

screen type.

Saves the application without exiting

the Screen Builder function.

Prompts you to save the application

to the current file and exits the DPS

software

Page 47

Chapter 5

Using Screen Builder

Copying Screens

Use the copy function [F4] to save time when creating similar screens. Both

the source screen and the destination screen must be of the same type. For

example, you can’t copy Data Entry screen text into a Data Display screen.

When you copy a screen, all register data and display text is also copied.

Edit the screen as needed after copying.

To copy a screen:

1. Open the screen you want to copy the screen to or from. In this example

a Data Display screen:

2. Press [F4].

You are prompted for the screen to copy to or from:

3. Press [F1] to copy the current screen to another screen. Press [F2] to

copy another screen to the current screen.

You are prompted for a screen number.

4. Enter the screen number and press [Return].

The screen is copied.

5. Edit the copied screen text and/or register data, refer to descriptions of

individual screen types (Chapters 6 through 11).

5–5

Page 48

Chapter 5

Using Screen Builder

Selecting Other Screens

After you have completed an application screen, use [F8] Change Screen to

edit another screen. You can change to any screen except an alarm screen.

Use the Alarm Builder function (Chapter 13) to access alarm screens.

To change screens:

1. Select [F8] Change Screen.

You are prompted for a screen number.

8

2. Enter the screen number you want to change to or select one of the

function keys:

Function Key Designation Function

[F1] FIRST

SCREEN

[F6] NEXT

UNUSED

[F7] LAST

SCREEN

[F8] NEXT PROG Selects the next programmed screen.

Returns to screen #1, the main menu.

Selects the next unused screen.

Selects the last programmed screen.

The selected screen is displayed.

5–6

Page 49

Chapter 5

Using Screen Builder

Clearing Screens

Use the [F7] Clear Screen function to clear all or part of the currently

displayed screen.

To clear a screen:

1. Open the screen you want to clear.

2. Select [F7] Clear Screen.

You are prompted for a clear screen option:

8

3. Select the Clear Screen option.

Press: To:

ENTER

[Return]

DELETE

[Del]

ESCAPE

[Esc]

Clear the display text only. Screen linking and register data for the screen

are not deleted.

Clears the entire screen including screen display text, register data, and

screen links.

Cancels the clear screen function.

The screen is cleared.

4. Continue programming or change to another screen.

5–7

Page 50

Chapter 5

Using Screen Builder

Inserting the Time or Date

If you are programming a DTAM Plus with a clock/calendar option, you can

insert the time or date into any application screen. Time and date functions

are not available on the DTAM Micro.

The time field takes up 5 character positions and is displayed in the

format HH:MM. AM/PM and seconds are not displayed to conserve space.

However AM/PM and the seconds are shown on print forms in the format

HH:MM:SS AM.

The date field takes up 9 character positions and is displayed in the format

MMM/DD/YY.

To insert the time or date:

1. Use the arrow keys to position the cursor where you want to insert the

date or time.

2. Press [F5] to insert the time or [F6] to insert the date.

The current date or time is inserted on the display:

Time

Date

3. Continue programming the remainder of the screen.

5–8

Page 51

Chapter 5

Using Screen Builder

Exiting Screen Builder

You can exit Screen Builder at any time during the design of an application.

Screen edits are not lost when you exit Screen Builder, however, we

recommend that you press [F9] SAVE before exiting.

To exit Screen Builder:

1. Press [Esc].

If you haven’t established screen linking, you are provided a reminder:

2. Press [Y] to acknowledge the reminder (if displayed).

After exiting Screen Builder, the Edit File - Option Selection menu

is displayed.

You can re-enter Screen Builder later for additional edits or to establish

screen linking.

5–9

Page 52

Page 53

Chapter

Chapter Objectives

Menu Screens

A–B

6

Creating Menu and

Sub-Menu Screens

This chapter describes how to create the main menu and sub-menu screens.

Section Page

Menu Screens 6–1

Building a Menu 6–2

Main Menu and Sub-Menu Screen Builder 6–3

Creating a Menu Screen 6–4

Menu Screens provide easy access to different parts of an application.

Menus structure an application on the basis of specific tasks and

responsibilities.

Each menu screen may consist of up to 8 different menu items. When

selected (by pressing a corresponding numeric key), a menu item displays

the linked screen or sub-menu.

A typical menu screen might look like this:

1. Temp Set 3. Level

2. Monitor

Main Menu Screens

The Main Menu is always operator screen #1. This menu lists the primary

components of your application. All other menus and data screens are

accessed from this screen.

There are two differences between the main menu and sub-menus:

• The DTAM Plus [MAIN MENU] or DTAM Micro [MENU] key displays

the Main Menu. This key is active at all times, unless an alarm is

detected.

• The Main Menu is the first screen that appears after a restart or reset,

unless an alarm is detected.

Sub-Menu Screens

Sub-menu screens are identical in appearance to the main menu screen.

Sub-menu screens enable you to expand the scope of an application by

providing directed choices through linked menus. This allows you to

construct a large application and maintain efficient access to specific areas.

6–1

Page 54

Chapter 6

Creating Menu and

Sub-Menu Screens

Building a Menu

When you build a menu, you are directing the operator to more specific

screens. A menu is a numbered list of components available at the current

stage of a process. Number each successive menu entry sequentially. The

number tells the operator which DTAM keypad key ([1] through [8]) to press

for each menu item (1 through 8).

The following example shows the menu structure of a DTAM Plus

application. The operator uses the DTAM numeric keypad keys to select a

menu item. Pressing [1] on the keypad selects the Pump Application screen.

Screen #11 is linked to keypad key [1] on the DTAM while this menu is

displayed. Pressing keypad key [2] on the DTAM Plus displays another

menu which has different links assigned to keypad keys [1],[2] and [3].

Screen 11 Screen 20 Screen 39 Screen 40

Main Menu

Items 1 through 8 correspond

to DTAM keypad keys

1 through 8. Each key can

be linked to a screen number.

To assign menu text, position the cursor at the location you want the list to

begin and enter text.

Enter Menu

Text here.

Screens can’t be linked to DTAM keypad keys ([1] - [8]) until you have first

created the screens. After creating your application screens, you can return

to the menu screens and assign the links, refer to Chapter 12.

6–2

Page 55

Chapter 6

Creating Menu and

Sub-Menu Screens

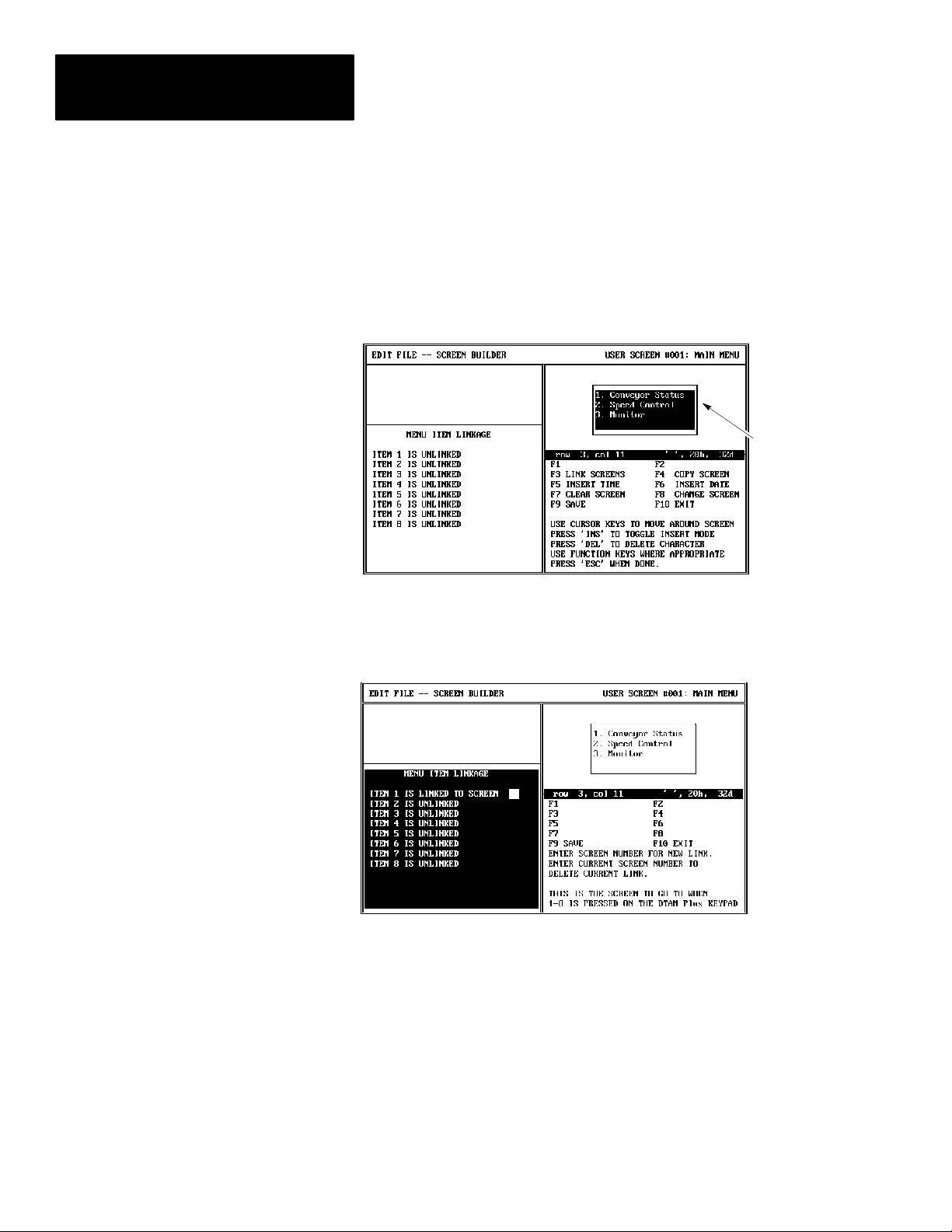

Main Menu and Sub-Menu Screen Builder

The screen for creating the main menu and sub-menu screens is the same for

the DTAM Plus and DTAM Micro. The only difference is the DTAM Micro

has a 2 line display and the DTAM Plus can display 4 lines.

Menu Screen Builder Function keys

Applies to:

Function

Key

[F2] CHANGE

[F3] LINK

[F4] COPY

[F5] INSERT TIME

[F6] INSERT DATE

[F7] CLEAR

[F8] CHANGE

[F9] SAVE

[F10] EXIT

Designation

PREV

SCREENS

SCREEN

SCREEN

SCREEN

DTAM

Plus

DTAM

Micro

✓

✓ ✓

✓ ✓

✓

✓

✓ ✓

✓ ✓

✓ ✓

✓ ✓

Function

Only applies to DTAM Plus sub-menu screens.

Displays linking prompt used to designate the

screen displayed when the operator presses the

[PREV MENU] key (DTAM Plus only).

Accesses screen mapping functions that link

application screens in a logical sequence.

Link screens only after all of the screens have

been created. Refer to Chapter 12.

Copies an existing screen to or from the current

display window. Both the source and destination

screens must be of the same type (Menu

screens).

Inserts the time into the menu. Only available

with a DTAM Plus having the Calendar/Clock

option.

Inserts the date into the menu. Only available

with a DTAM Plus having the Calendar/Clock

option.

Clears the current screen. You have the option

of clearing only the screen text or deleting the

entire screen including any linking you may have

established.

Selects another operator screen.

Saves the application without exiting the Screen

Builder function.

Prompts you to save the application to the

current file and exits the DPS software.

6–3

Page 56

Chapter 6

Creating Menu and

Sub-Menu Screens

Creating a Menu Screen

To create a menu screen:

1. Select Screen Builder from the Edit File - Option Selection menu.

The screen builder for the main menu (screen #1) is displayed.

2. If you are creating a sub-menu, press [F8], enter the screen number, and

select a sub-menu screen type.

The screen builder for a sub-menu is displayed. The sub-menu screen

builder is the same as the main screen (shown above).

3. Enter the screen text. The sequence, length and location of the text does

not matter but make sure you number each menu item (1 through 8).

Enter menu

text.

4. Press [F9] to save the screen.

Note: You can’t link screens to a menu until all of the application screens

have been created. Chapter 12 describes how to link screens to a menu.

6–4

Page 57

Chapter

Chapter Objectives

Data Displays

A–B

7

Creating Data Display Screens

This chapter describes how to create data display screens.

Section Page

Data Displays 7–1

Scaling 7–1

Data Display Screen Builder 7–2

Inserting Display Data 7–3

Display Register Format Selections 7–5

Data display screens allow you to monitor the value of registers in the SLC

or PLC. The DTAM continuously reads the registers to update (at a userdefined rate) the displayed values.

Scaling

This is how a data display screen may appear:

Tank Level = 33 Gallons

10% Full Press NEXT

To construct data display screens, you need to specify:

• The type of screen as data display

• The type of data stored in the PLC or SLC register

• The register to access (address)

• Any data format and display information

• The display position for the data

• Any additional text information that you want to display

Data in controller data files can be scaled to standard engineering units such

as gallons, pounds, feet, etc. Data is scaled by setting up a proportion

between the controller register data limits and the DTAM data display limits.

Refer to the description of scaling in Chapter 3.

Note: The 32 bit BCD data format cannot be scaled.

7–1

Page 58

Chapter 7

Creating Data Display Screens

Data Display Screen Builder

The screen for creating data display screens is the same for the DTAM Plus

and DTAM Micro. The only exceptions are the DTAM Micro display does

not show the time and date function keys and has a smaller display size (2

lines of 20 characters).

Data Display Screen Builder Function Keys

Applies to:

Function

Key

[F1] DISPLAY REG

[F3] MAP SCREEN

[F4] COPY

[F5] INSERT TIME

[F6] INSERT DATE

[F7] CLEAR

[F8] CHANGE

[F9] SAVE

[F10] EXIT

Designation

SCREEN

SCREEN

SCREEN

DTAM

Plus

✓ ✓

✓ ✓

✓ ✓

✓

✓

✓ ✓

✓ ✓

✓ ✓

✓ ✓

DTAM

Micro

Function

Inserts data display field at the cursor point.

Accesses the display register information.

Accesses screen mapping functions that link

application screens in a logical sequence.

Link screens only after all of the screens have

been created.

Copies an existing screen to or from the current

display window. Both the source and destination

screens must be of the same type (Data Display

screens).

Inserts the time into the display. Only available

on a DTAM Plus having the Calendar/Clock

option.

Inserts the date into the display. Only available

on a DTAM Plus having the Calendar/Clock

option.

Clears the current screen. You have the option of

clearing only the screen text or deleting the

entire screen including any linking you may have

established.

Selects another operator screen.

Saves the application without exiting the Screen

Builder function.

Prompts you to save the application to the

current file and exits the DPS software.

7–2

Page 59

Chapter 7

Creating Data Display Screens

Creating a Display Screen