Page 1

Installation Instructions

PowerFlex 4-Class DSI (Drive Serial Interface)

Network Communication Adapter

This document explains how to install and wire a PowerFlex 4-Class Network

Communication Adapter into a PowerFlex 40 Class or PowerFlex 400 Class drive.

ATTENTION: Risk of injury or death exists. The PowerFlex 40/400

Class drive may contain high voltages that can cause injury or death.

!

Remove power from the drive, and then verify power has been discharged

before removing the drive cover.

ATTENTION: Risk of equipment damage exists. The Network

Communication Adapter contains ESD (Electrostatic Discharge) sensitive

!

parts that can be damaged if you do not follow ESD control procedures.

Static control precautions are required when handling the card. If you are

unfamiliar with static control procedures, refer to Guarding Against

Electrostatic Damage, publication 8000-4.5.2.

If the adapter is being installed in a DSI External Comms Kit, refer to its Installation

Instructions, publication 22-COMM-IN001 before/when installing the adapter. See

“Related Documentation” for details.

Related Documentation

Document Description

DSI External Comms Kit Installation

Instructions, publication 22COMM-IN001

PowerFlex 4-Class Network

Communication Adapter User Manuals,

publications 22COMM-UM

Guarding Against Electrostatic Damage,

publication 8000-4.5.2

Wiring and Grounding Guidelines for PWM

AC Drives, publication DRIVES-IN001

Instructions to install and wire a PowerFlex 4-Class adapter

in a DSI External Comms Kit.

Provides complete installation, wiring, setup, and

communication information for respective PowerFlex

4-Class Network Communication Adapter.

Provides static control procedures for protecting

electrostatic discharge sensitive parts.

Guidelines for proper wiring, grounding, and shielding, and

standard practices for noise protection.

You can view or download publications at www.literature.rockwellautomation.com.

To order paper copies of technical documentation, contact your local Rockwell

Automation distributor or sales representative.

For information such as firmware updates and answers to drive-related questions, go

to the Drives Service & Support web site at www.ab.com/support/abdrives

on the “Downloads” or “Get help with the new Knowledgebase” link.

Step 1

Step 2

and click

Remove power from the drive.

Remove the drive cover.

Page 2

2

Step 3

Step 4

If the adapter has address or data rate switches, and/or an Operating

Mode jumper, set them to appropriate positions. See the adapter User

Manual for complete details.

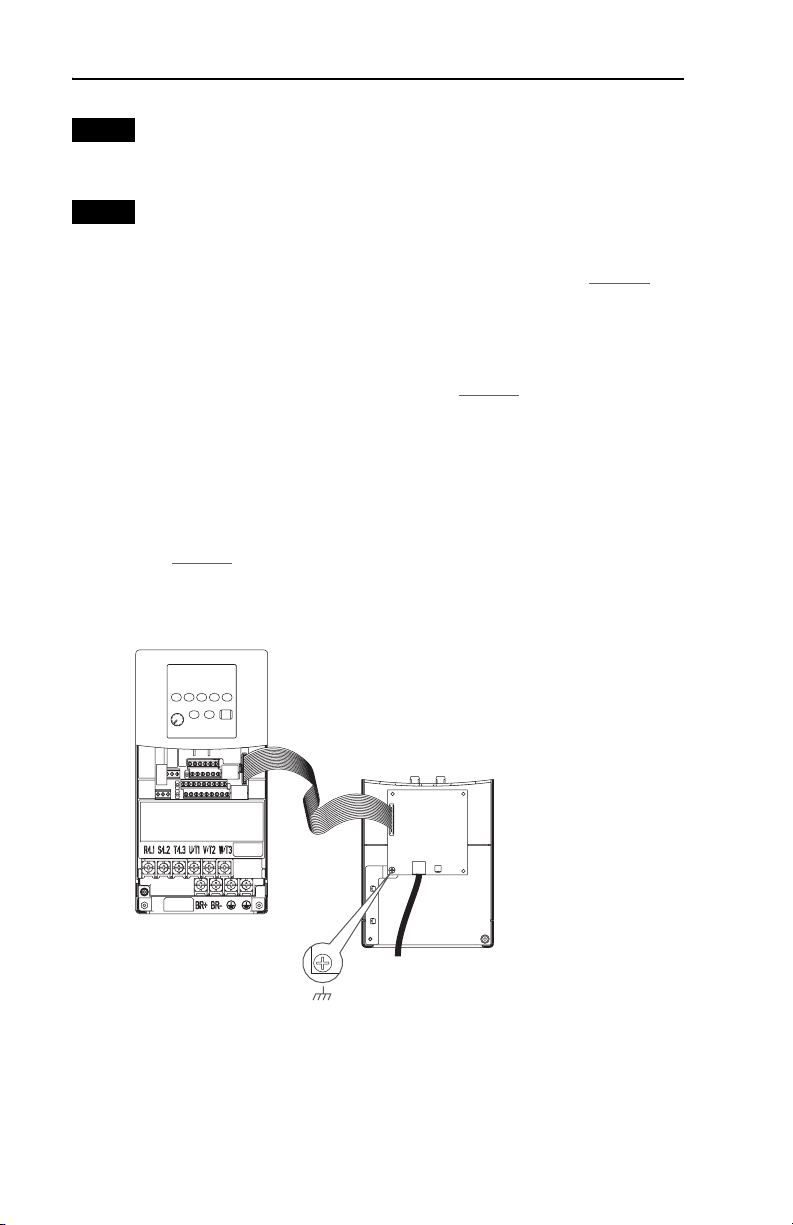

Mount the adapter.

PowerFlex 40 Class Frames B and C, and PowerFlex 400 Class Frame C

A. Mount the adapter on the required special drive cover (see Figure 1 for

part numbers).

– Frame C: Use the adapter screw to secure the adapter to the cover.

Important: Tighten the adapter’s lower left screw to properly

ground the adapter (see Figure 1).

– Frame B: Disregard the screw and snap the adapter in place.

Important: Install the drive cover onto the drive using both cover

fasteners to properly ground the adapter.

B. Connect one end of the Internal Interface cable to the DSI port on the

drive and the other end to the mating DSI connector on the adapter

(Figure 2

Figure 1 Mounting and Grounding the Adapter – PowerFlex 40 Class Frames B and C,

).

and PowerFlex 400 Class Frame C

PowerFlex 40 Drive

(Frame C shown as

example with cover removed)

0.9 N-m

(8.0 lb.-in.)

1 Place

Adapter Mounted on Back of

Required Special Drive Cover

(Frame C cover shown)

PowerFlex 40 Class Frame B: Part No. 22B-CCB

PowerFlex 40 Class Frame C: Part No. 22B-CCC

PowerFlex 400 Class Frame C: Part No. 22C-CCC

Ground for Frame C Drives

NOTE: For Frame B drives, the lower

left adapter screw does not ground the

adapter. To ground the adapter, install

the special drive cover onto the drive

using both cover fasteners.

Page 3

Figure 2 Connecting DSI Ports with Internal Interface Cable

(22-COMM-E EtherNet/IP

Adapter shown as example)

➊

➋

3

PowerFlex 40 Drive

(Frame C shown as

example with cover removed)

PowerFlex 400 Class Frame D and Higher

C. With the adapter board right side up, remove its mounting screw from

the lower left hole. Save the screw for mounting in step F.

D. Connect the Internal Interface cable to the DSI port on the drive (see

Figure 3

E. With the adapter board oriented bottom side up, route the Internal

Interface cable under the adapter, and then to the mating DSI connector

on the adapter.

F. Install the adapter, bottom side up, to the right side of the display board

by snapping it into place. Then insert the adapter mounting screw into

the lower left hole on the board.

Important: Tighten the mounting screw in the adapter’s lower left hole

➌

Back of Required

Special Drive Cover

Item Description

DSI Connector

➊

15.24 cm (6 in.) Internal Interface cable

➋

Network cable

➌

).

to ground the adapter to the drive.

Page 4

Figure 3 Mounting and Connecting the Adapter – PowerFlex 400 Class Frame D and

A

A

Higher

Adapter Installation

Bottom of

Adapter Board

(Side View)

LEDs

Step 5

Step 6

Step 7

Internal Interface

Ribbon Cable

0.9 N-m

(8.0 lb.-in.)

1 Place

PowerFlex 400 Drive (Frame D shown

as example with cover removed)

Connect one end of the network cable to the network. Make sure to use

the proper cable for the network. See the adapter User Manual’s “Related

Documentation” section for appropriate publication(s).

Route the other end of the network cable through the bottom of the

PowerFlex 40/400 Class drive, and connect the cable to the adapter using

the adapter’s mating socket or terminal block. For complete wiring details,

see the adapter User Manual.

Important: Make sure to properly route, wire, and ground the cable.

Always separate the communications wiring from the power

and motor wiring. For more information, see Wiring and

Grounding Guidelines for PWM AC Drives.

Read the adapter User Manual for information to configure and

determine how to apply the network to the host product.

Connector

U.S. Allen-Bradley Drives Technical Support

Tel: (1) 262.512.8176, Fax: (1) 262.512.2222, Email: support@drives.ra.rockwell.com, Online: www.ab.com/support/abdrives

www.rockwellautomation.com

Power, Control and Information Solutions Headquarters

mericas: Rockwell Automation, 1201 South Second Street, Milwaukee, WI 53204-2496 USA, Tel: (1) 414.382.2000, Fax: (1) 414.382.4444

Europe/Middle East/Africa: Rockwell Automation, Vorstlaan/Boulevard du Souverain 36, 1170 Brussels, Belgium, Tel: (32) 2 663 0600, Fax: (32) 2 663 0640

sia Pacific: Rockwell Automation, Level 14, Core F, Cyberport 3, 100 Cyberport Road, Hong Kong, Tel: (852) 2887 4788, Fax: (852) 2508 1846

Publication 22COMM-IN002A-EN-P – January, 2008 P/N 376924-P01

Copyright © 2008 Rockwell Automation, Inc. All rights reserved. Printed in USA.

Loading...

Loading...