Page 1

Installation Instructions

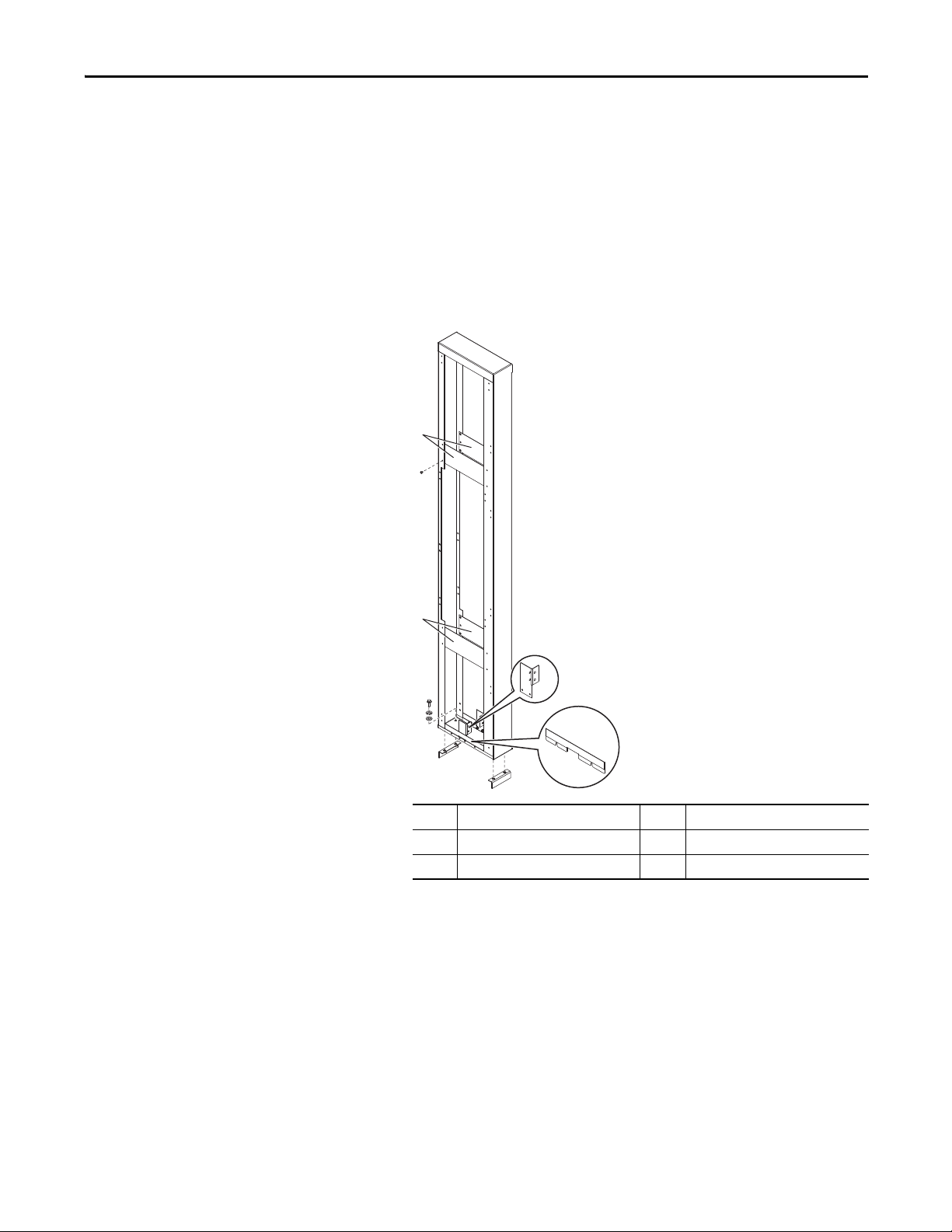

Mounting Channels

PowerFlex 755 Transition Section and Splicing Kit for Floormount Drives and CENTERLINE 2100 Motor Control Centers

Top ic Pa ge

Introduction, Compatibility 1

Additional Resources 2

What the Kits Contain 2

Remove Power from All Equipment 3

Approximate Dimensions 4

Preparing the Transition Section 5

Joining Drive, Transition Section, and MCC 6

Left-side Kit Assembly 7

Right-side Kit Assembly 14

Specifications 25

Introduction

Compatibility

This document explains the recommended procedures that you should use when

joining and splicing a PowerFlex® 755 Floor-mount drive, Frames 8…10, with a

CENTERLINE® 2100 Motor Control Center (MCC).

Before you begin, familiarize yourself with the installation requirements and

recommendations for both the PowerFlex 755 drive and the CENTERLINE

2100 MCC.

The transition section and splicing kit is designed to join together a PowerFlex

755 floor-mount drive and a CENTERLINE 2100 MCC column with or

without 1.5 inch mounting channels.

Diagrams in this publication show the mounting channels installed. Mounting

channels will not be used in all installations.

Page 2

PowerFlex 755 Transition Section and Splicing Kit for Floor-mount Drives and CENTERLINE 2100 Motor Control Centers

Additional Resources

What the Kits Contain

The following table lists publications that provide general PowerFlex 755 drives

and CENTERLINE 2100 MCC related information.

Resource Description

PowerFlex 750-Series AC Drives Installation Instructions,

publication 750-IN001

CENTERLINE 2100 Low Voltage Motor Control Centers

Installation Instructions, publication 2100-IN012

CENTERLINE Motor Control Centers NEMA Type 12 Sealing

Instructions, publication 2100-IN037

Provides detailed information on:

• Installation requirements

• Additional safety requirements

• Drive assembly removal and handling

• Approximate dimensions

Provides detailed information on:

• Installation requirements

• Handling instructions

• Approximate dimensions

Provides detailed information on:

• Sealing NEMA Type 12 structures

You can view or download publications at

http://www.rockwellautomation.com/literature/

.

To order paper copies of technical documentation, contact your local AllenBradley distributor or Rockwell Automation sales representative.

A complete installation requires one transition section and one bus bar splicing

kit. Depending on the catalog number ordered, the kit will be a left-side mount or

a right-side mount relative to the drive. Kits include all joining and splicing

hardware. An IP20, NEMA/UL Type 1 enclosure results when kits are installed

according to these instructions. If a NEMA Type 12 structure is required, follow

the CENTERLINE Motor Control Centers NEMA Type 12 Sealing

Instructions, publication 2100-IN037

.

Left-side Kits Right-side Kits Amp

20-750-XBUS-LHNB-1200 20-750-XBUS-RHNB-1200 1200 Standard (15 and 20 in. deep) For use

20-750-XBUS-LHNB-2000 20-750-XBUS-RHNB-2000 2000 Standard (15 and 20 in. deep)

20-750-XBUS-LHNB-3000 20-750-XBUS-RHNB-3000 3000 Standard (15 and 20 in. deep)

20-750-XBUS-LHBB-1200 20-750-XBUS-RHBB-1200 1200 Bumped Back (20 in. deep)

20-750-XBUS-LHBB-2000 20-750-XBUS-RHBB-2000 2000 Bumped Back (20 in. deep)

20-750-XBUS-LHBB-3000 20-750-XBUS-RHBB-3000 3000 Bumped Back (20 in. deep)

20-750-XSEC-LH-20G

20-750-XBUS-LLNB-1200 20-750-XBUS-RLNB-1200 1200 Standard (15 and 20 in. deep) For use

20-750-XBUS-LLNB-2000 20-750-XBUS-RLNB-2000 2000 Standard (15 and 20 in. deep)

20-750-XBUS-LLNB-3000 20-750-XBUS-RLNB-3000 3000 Standard (15 and 20 in. deep)

20-750-XBUS-LLBB-1200 20-750-XBUS-RLBB-1200 1200 Bumped Back (20 in. deep)

20-750-XBUS-LLBB-2000 20-750-XBUS-RLBB-2000 2000 Bumped Back (20 in. deep)

20-750-XBUS-LLBB-3000 20-750-XBUS-RLBB-3000 3000 Bumped Back (20 in. deep)

(1) Hardware is included to install the optional 1.5 mounting channel.

(2) The 15 in. deep transition section can be mounted on the left side or the right side of the PowerFlex 755 drive cabinet.

(1)

20-750-XSEC-RH-20G

20-750-XSEC-BH-15G

(2)

Rating

(1)

N/A 20 in. deep transition section N/A

N/A 15 in. deep transition section N/A

MCC Bus Bar Position Mounting

Channel

with MCCs

that have

1.5 inch

mounting

channels.

with MCCs

that do not

have

mounting

channels.

2 Rockwell Automation Publication 750-IN027C-EN-P - November 2013

Page 3

PowerFlex 755 Transition Section and Splicing Kit for Floor-mount Drives and CENTERLINE 2100 Motor Control Centers

Frame 8 AC Input Drive Shown

Left-side Kits

Follow all steps including the Left-side Kit Assembly sequence for 20 in. deep

left-side-mount transition sections and the 15 in. deep left- or right-side-mount

transition section.

Right-side Kits

Follow all steps including Right-side Kit Assembly sequence for 20 in. deep rightside-mount transition sections and the 15 in. deep left- or right-side-mount

transition section.

Remove Power from All

Equipment

Remove power from all equipment before proceeding with these instructions.

Refer to the product’s installation instructions and review all safety precautions

before performing work on this equipment.

PowerFlex 755 Drive

ATT EN TI ON : To avoid an electric shock hazard, verify that the voltage on the

bus capacitors has discharged completely before servicing. Measure the DC bus

voltage at the -DC and +DC TESTPOINT sockets on the front of the power

module (see Figure 1

Remove power before making or breaking cable connections. When you remove or

insert a cable connector with power applied, an electrical arc may occur. An

electrical arc can cause personal injury or property damage by:

• sending an erroneous signal to your system’s field devices, causing unintended

machine motion

• causing an explosion in a hazardous environment

Electrical arcing causes excessive wear to contacts on both the module and its

mating connector. Worn contacts may create electrical resistance.

1. Turn off and lock out all input power, including any and all external power

sources.

for location).

2. Wait 15 minutes and verify that there is no voltage at the drive’s input

power terminals.

3. Measure the DC bus voltage at the -DC and +DC TESTPOINT sockets

on the front of the power module.

Figure 1 - PowerFlex Drive -DC and +DC Testpoint Sockets

Rockwell Automation Publication 750-IN027C-EN-P - November 2013 3

Page 4

PowerFlex 755 Transition Section and Splicing Kit for Floor-mount Drives and CENTERLINE 2100 Motor Control Centers

CENTERLINE 2100 MCC

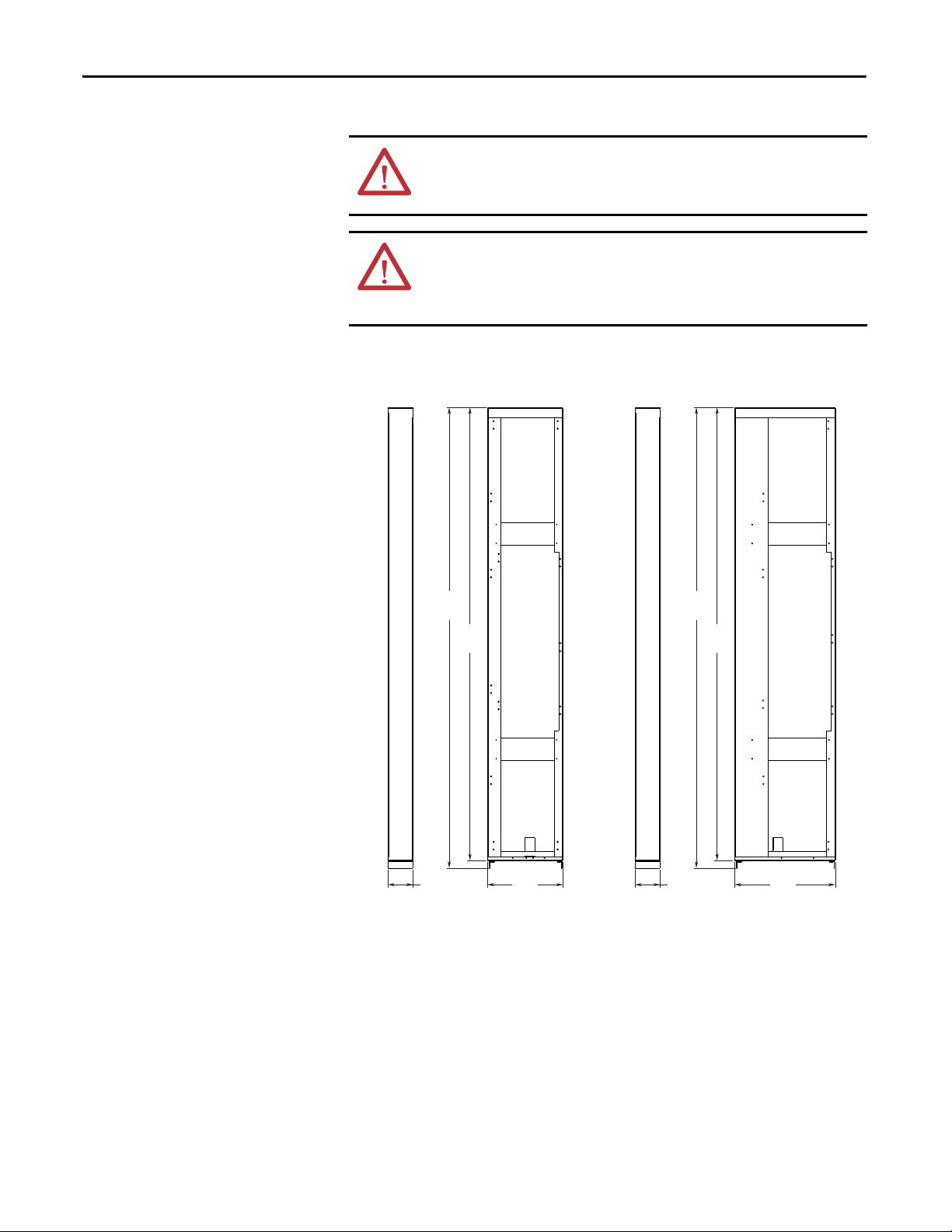

ATT EN TI ON : De-energize all units before installing or removing.

When installing or removing MCC units, when possible, deenergize, lockout, and

tag-out all sources of power to the MCC.

ATT EN TI ON : De-energize all power sources to the motor control center before

joining and splicing with the drive. Failure to de-energize all power sources can

result in severe injury or death. Using a voltmeter, verify that the MCC remote

power sources are disconnected.

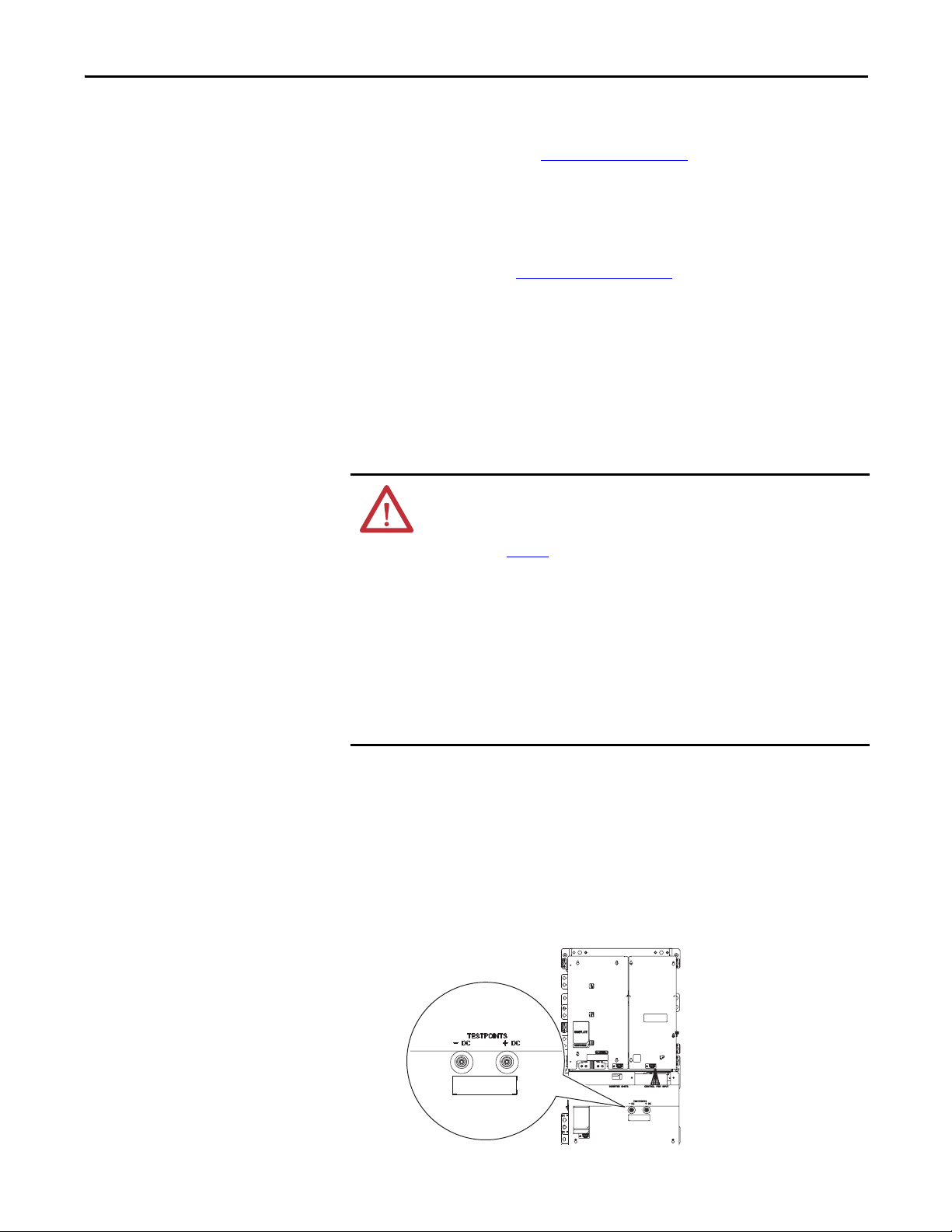

Approximate Dimensions

Dimensions are in millimeters and (inches).

2323

(91.5)

2285

(90.0)

2323

(91.5)

2285

(90.0)

127

(5.0)

20-750-XSEC-BB-20G

4 Rockwell Automation Publication 750-IN027C-EN-P - November 2013

381

(15.0)

127

(5.0)

20-750-XSEC-RH-20G

20-750-XSEC-LH-20G

508

(20.0)

Page 5

PowerFlex 755 Transition Section and Splicing Kit for Floor-mount Drives and CENTERLINE 2100 Motor Control Centers

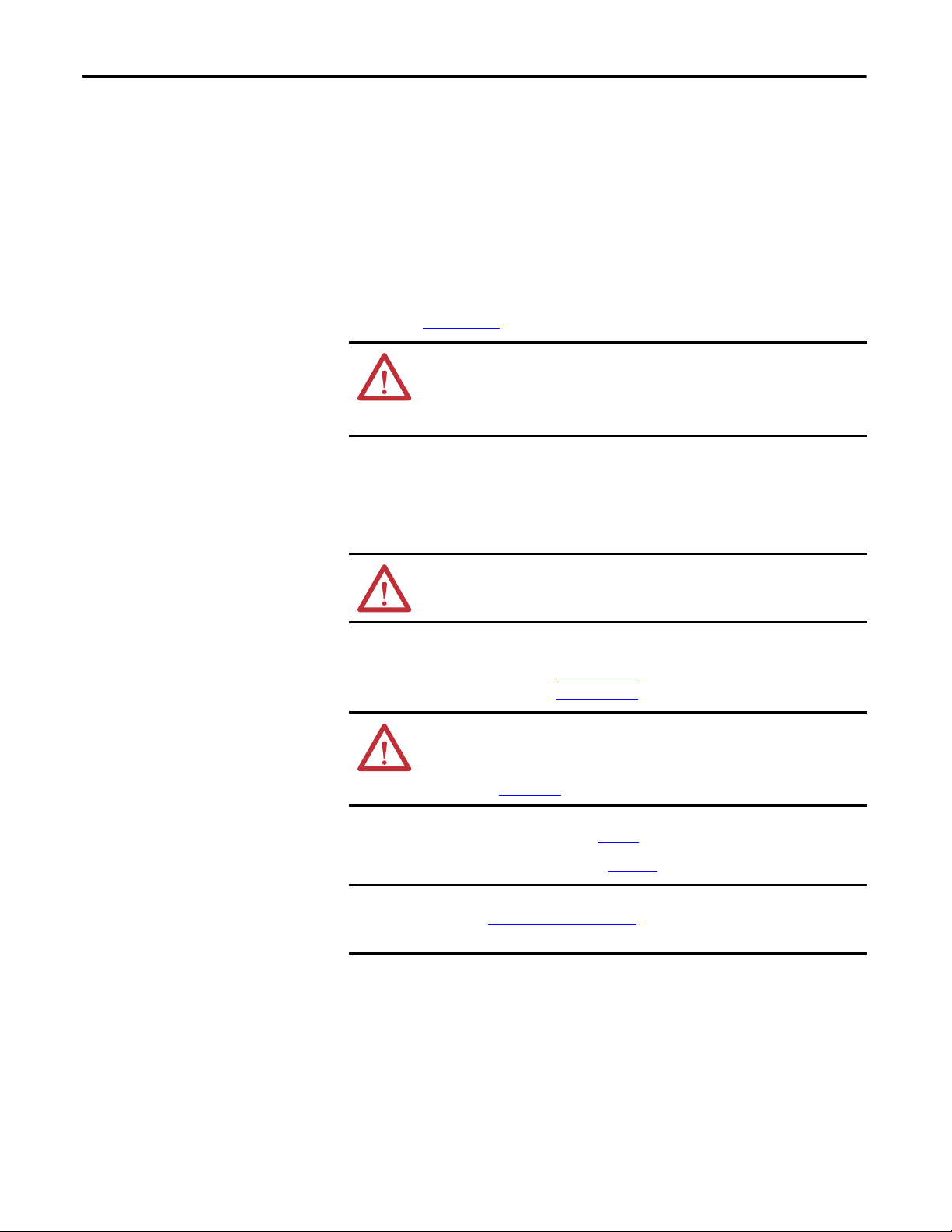

Preparing the Transition

Section

1. Remove and discard the four shipping plates ➊.

2. Remove the masking from the ground terminals

➋.

MCC Columns with Mounting Channels

3. Remove the spacer ➌ on the side of the transition section that will attach to

the MCC column.

MCC Columns without Mounting Channels

3. Remove the mounting channels ➍ from the transition section.

➊

x 4

➊

x 4

➍

No. Description No. Description

➊ Shipping plates ➌ Spacer

➋ Ground Terminal ➍ Mounting Channels

➋

➌

Rockwell Automation Publication 750-IN027C-EN-P - November 2013 5

Page 6

PowerFlex 755 Transition Section and Splicing Kit for Floor-mount Drives and CENTERLINE 2100 Motor Control Centers

IMPORTANT

Joining Drive, Transition

Section, and MCC

Physical restrictions at your installation may not allow the following sequence to

be followed exactly as stated.

Step 1: Remove Drive Assembly

The PowerFlex 755 drive assembly must be removed to access side panels and

horizontal bus bars.

For detailed information on removing and handling the PowerFlex 755 drive

assembly, refer to the PowerFlex 750-Series AC Drives Installation Instructions,

publication 750-IN001

ATT EN TI ON : This drive has a high center of gravity and a tip-over hazard exists.

To guard against death, serious personal injury, and/or equipment damage, do

not subject the drive to high rates of acceleration or deceleration while

transporting. Do not push or pull above the points indicated on the drive.

. Special equipment is required.

Step 2: Remove Plug-in Units, Support Pans, and Access Covers

All plug-in units and support pans must be removed to access side panels and

horizontal bus bars.

ATT EN TI ON : Plug-in MCC units may be heavy or awkward to handle. Use an

assistant or a platform lift device if necessary to help you handle the unit

To complete plug-in unit removal refer to Installing Units with Horizontal

Operating Handles, publication 2100-IN060

Operating Handles, publication 2100-IN014

ATT EN TI ON : MCCs are top and front heavy. To avoid personal injury or

structural damage, never attempt to lift or move the MCC by any means other

than the methods outlined in Receiving and Storing Motor Control Centers,

publication 2100-IN040

If you’re installing a left-mount kit, see page 7

If you’re installing a right-mount kit, see page 14

After completing these instructions, refer to the publications listed on this page and

under Additional Resources

equipment and components.

.

on page 2 for detailed information on reinstalling

, and Installing Units with Vertical

.

.

.

6 Rockwell Automation Publication 750-IN027C-EN-P - November 2013

Page 7

PowerFlex 755 Transition Section and Splicing Kit for Floor-mount Drives and CENTERLINE 2100 Motor Control Centers

➊

➊

➋

➋

➌

Cabinet door and internal components

omitted for clarity.

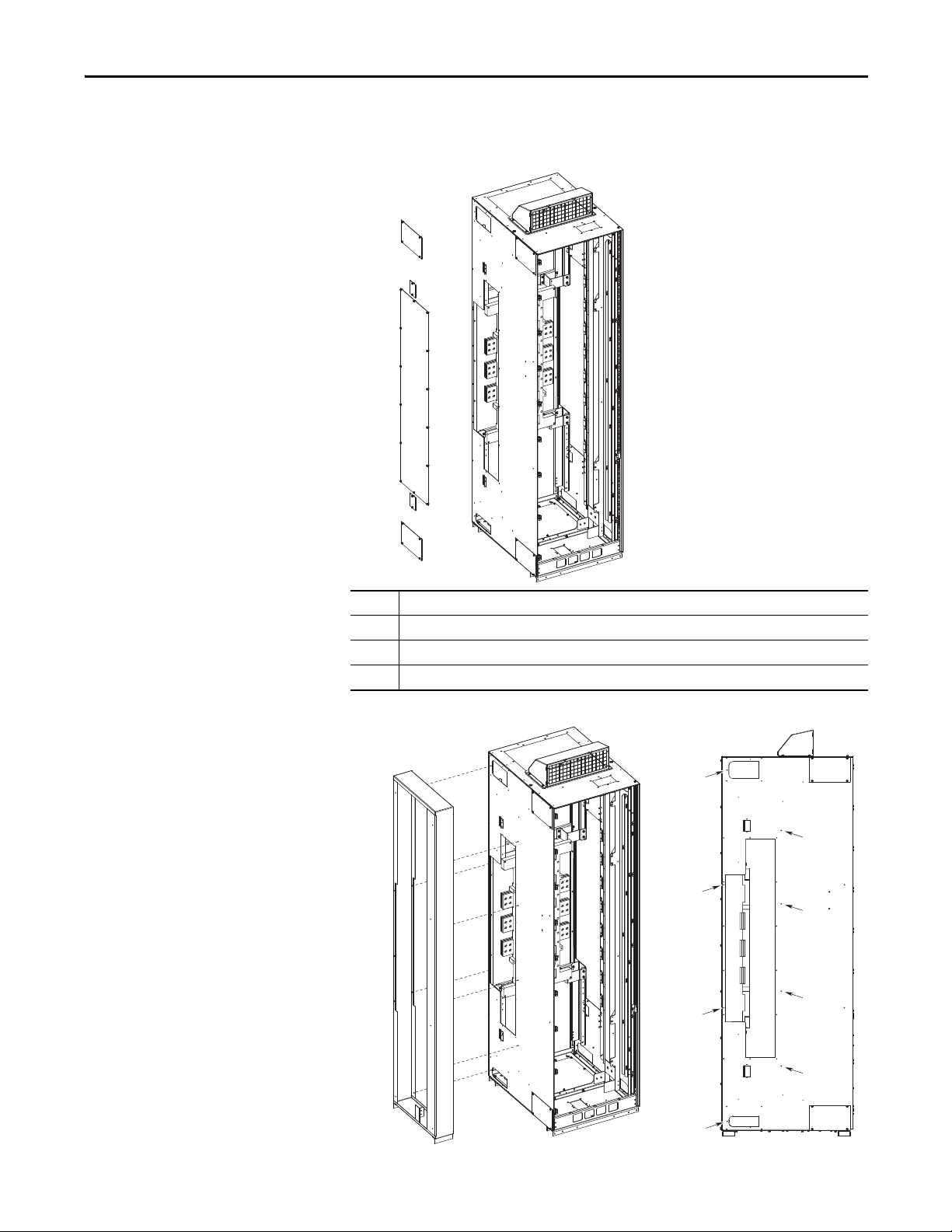

Left-side Kit Assembly

Step 3 (Left): Join Transition Section to Left Side of Drive Cabinet

1. Remove panels from the left side of the PowerFlex 755 drive cabinet.

No. Description

➊ Top and bottom rear-wireway panels.

➋ Top and bottom PE bus-bar access panels.

➌ Main horizontal bus-bar access panel.

2. Align the left transition section with the drive cabinet.

➊

➊

➊

➊

➊

➊

➊

➊

Rockwell Automation Publication 750-IN027C-EN-P - November 2013 7

Page 8

PowerFlex 755 Transition Section and Splicing Kit for Floor-mount Drives and CENTERLINE 2100 Motor Control Centers

IMPORTANT

3. Bring the transition section and drive cabinet together.

4. Pass the M6 x 16 mm hex-head thread-forming screws from inside the

transition section through the joining holes and engage the screws with the

➊ holes in the drive cabinet.

5. Make sure cabinets are level and pushed together tightly.

6. Tighten the screws in a uniform pattern.

Do not use hardware to draw cabinets together.

M6

6.2 N•m (55 lb•in)

10 mm

8 Rockwell Automation Publication 750-IN027C-EN-P - November 2013

Page 9

PowerFlex 755 Transition Section and Splicing Kit for Floor-mount Drives and CENTERLINE 2100 Motor Control Centers

Unit doors, support pans, and access

covers omitted for clarity.

Step 4 (Left): Join MCC Column to Left Side of Transition Section

1. Remove the closing plates from the right side of the MCC column.

➋

➊

➌

➋

➊

No. Description

➊ Top and bottom front-wireway closing plates.

➋ Top and bottom rear-wireway closing plates.

➌ Main horizontal bus-bar closing plates.

Rockwell Automation Publication 750-IN027C-EN-P - November 2013 9

Page 10

PowerFlex 755 Transition Section and Splicing Kit for Floor-mount Drives and CENTERLINE 2100 Motor Control Centers

➋

➊

➊

➊

➊

➊

➊

MCC side of transition section

2. Align the MCC column with the left transition section.

3. Bring the MCC column, transition section, and drive cabinet together.

4. Pass the 1/4-20 x 0.5 in. hex-head thread-forming screws from inside the

MCC column through the joining holes and engage the screws with the

➊

holes in the transition section.

5. Pass the 1/4-20 x 1 in. screw from inside the MCC column through the

transition section joining hole

➋ and secure with the 1/4-20 steel nut.

10 Rockwell Automation Publication 750-IN027C-EN-P - November 2013

Page 11

PowerFlex 755 Transition Section and Splicing Kit for Floor-mount Drives and CENTERLINE 2100 Motor Control Centers

IMPORTANT

6. Make sure cabinets are level and pushed together tightly.

7. Tighten the screws in a uniform pattern.

Do not use hardware to draw cabinets together.

1/4-20

6.2 N•m (55 lb•in)

10 mm

Rockwell Automation Publication 750-IN027C-EN-P - November 2013 11

Page 12

PowerFlex 755 Transition Section and Splicing Kit for Floor-mount Drives and CENTERLINE 2100 Motor Control Centers

IMPORTANT

Step 5 (Left): Join PE Bus Bar and Grounding Bracket

1. Align the protective earth (PE) conductor splicing hardware with the

transition section grounding bracket.

2. Insert and tighten the 1/4-20 x 1 in. screws.

Do not grease or lubricate hardware.

1/4-20 x 1 in.

7.3 N•m (65 lb•in)

10 mm

12 Rockwell Automation Publication 750-IN027C-EN-P - November 2013

Page 13

PowerFlex 755 Transition Section and Splicing Kit for Floor-mount Drives and CENTERLINE 2100 Motor Control Centers

1/4-20

7.3 N•m (65 lb•in)

10 mm

➊

➌

➋

1/4-20 x 1 in.

1/4-20 x 1 in.

1/4-20 x 1.25 in.

Step 6 (Left): Connect PE Splicing Cables

1. Pass the cables through the bottom wireway openings.

2. Connect the PE splicing cables between the MCC and drive PE bus bars.

No. Description Hardware

➊ 1200A with 25.4 mm (1 in.) bus bar. Requires two splice cables.

➋ 2000A with 25.4 mm (1 in.) bus bar. Requires two splice cables.

2000A with 50.8 mm (2 in.) bus bar. Requires three splice cables.

➌ 3000A with 50.8 mm (2 in.) bus bar. Requires three splice cables.

See Tab le 3

required hardware.

for a list of

Rockwell Automation Publication 750-IN027C-EN-P - November 2013 13

Page 14

PowerFlex 755 Transition Section and Splicing Kit for Floor-mount Drives and CENTERLINE 2100 Motor Control Centers

Unit doors, support pans, and access

covers omitted for clarity.

➊

➋

➊

➊

➊

➊

➊

MCC column

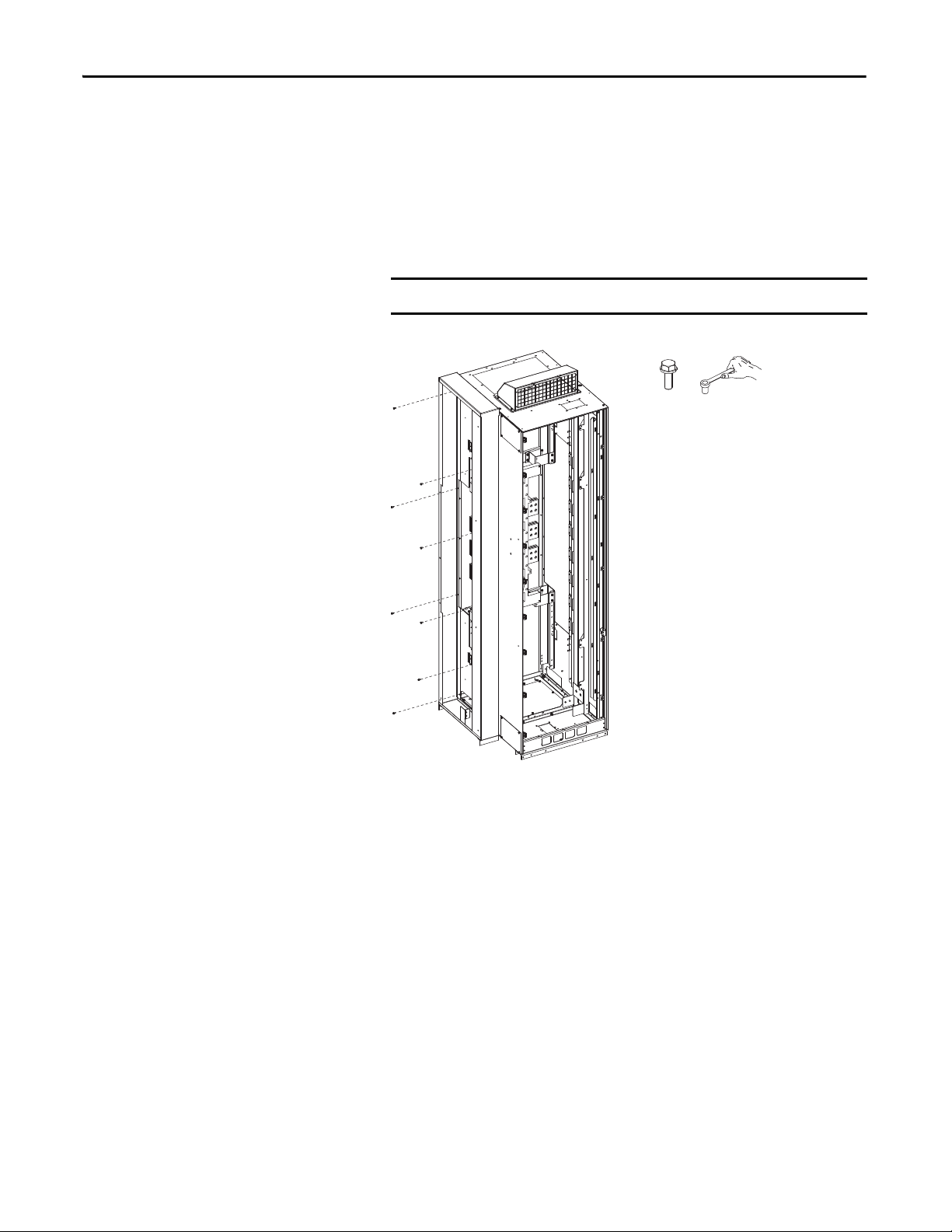

Right-side Kit Assembly

Step 3 (Right): Join Transition Section to Left Side of MCC Column

1. Remove the closing plates from the left side of the MCC column.

➋

➊

➌

➋

➊

No. Description

➊ Top and bottom front-wireway closing plates.

➋ Top and bottom rear-wireway closing plates.

➌ Main horizontal bus-bar closing plates.

2. Align the right transition section with the MCC column

14 Rockwell Automation Publication 750-IN027C-EN-P - November 2013

Page 15

PowerFlex 755 Transition Section and Splicing Kit for Floor-mount Drives and CENTERLINE 2100 Motor Control Centers

IMPORTANT

1/4-20

6.2 N•m (55 lb•in)

10 mm

3. Bring the transition section and MCC column together.

4. Pass the 1/4-20 x 0.5 in. hex-head thread-forming screws from inside the

transition section through the joining holes and engage the screws with the

➊ holes in the MCC column.

5. Pass the 1/4-20 x 1 in. screw from inside the MCC column through the

transition section joining hole

➋ and secure with the 1/4-20 steel nut.

6. Make sure cabinets are level and pushed together tightly.

7. Tighten the screws in a uniform pattern.

Do not use hardware to draw cabinets together.

Rockwell Automation Publication 750-IN027C-EN-P - November 2013 15

Page 16

PowerFlex 755 Transition Section and Splicing Kit for Floor-mount Drives and CENTERLINE 2100 Motor Control Centers

IMPORTANT

Step 4 (Right): Join PE Bus Bar and Grounding Bracket

1. Align the protective earth (PE) conductor splicing hardware with the

transition section grounding bracket.

2. Insert and tighten the 1/4-20 x 1 in. screws.

Do not grease or lubricate hardware.

1/4-20 x 1 in.

7.3 N•m (65 lb•in)

10 mm

16 Rockwell Automation Publication 750-IN027C-EN-P - November 2013

Page 17

PowerFlex 755 Transition Section and Splicing Kit for Floor-mount Drives and CENTERLINE 2100 Motor Control Centers

Cabinet door and internal components

omitted for clarity.

Step 5 (Right): Join Drive Cabinet to Left Side of Transition Section

1. Remove panels from the right side of the PowerFlex 755 drive cabinet.

➊

➋

➌

➋

No. Description

➊ Top and bottom rear-wireway panels.

➋ Top and bottom PE bus-bar access panels.

➌ Main horizontal bus-bar access panel.

➊

Rockwell Automation Publication 750-IN027C-EN-P - November 2013 17

Page 18

PowerFlex 755 Transition Section and Splicing Kit for Floor-mount Drives and CENTERLINE 2100 Motor Control Centers

2. Align the right transition section with the drive cabinet.

➊

➊

➊

➊

➊

➊

➊

➊

3. Bring the transition section, MCC column, and drive cabinet together.

4. Pass the M6 x 16 mm hex-head thread-forming screws from inside the

drive cabinet through the joining holes and engage the screws with the

holes in the transition section.

➊

18 Rockwell Automation Publication 750-IN027C-EN-P - November 2013

Page 19

PowerFlex 755 Transition Section and Splicing Kit for Floor-mount Drives and CENTERLINE 2100 Motor Control Centers

IMPORTANT

1/4-20

7.3 N•m (65 lb•in)

10 mm

➊

➌

➋

1/4-20 x 1 in.

1/4-20 x 1 in.

1/4-20 x 1.25 in.

5. Make sure cabinets are level and pushed together tightly.

6. Tighten the screws in a uniform pattern.

Do not use hardware to draw cabinets together.

M6

6.2 N•m (55 lb•in)

10 mm

Step 6 (Right): Connect PE Splicing Cables

1. Pass the cables through the bottom wireway openings.

2. Connect the PE splicing cables between the MCC and drive PE bus bars.

No. Description Hardware

➊ 1200A with 25.4 mm (1 in.) bus bar. Requires two splice cables.

➋ 2000A with 25.4 mm (1 in.) bus bar. Requires two splice cables.

2000A with 50.8 mm (2 in.) bus bar. Requires three splice cables.

➌ 3000A with 50.8 mm (2 in.) bus bar. Requires three splice cables.

Rockwell Automation Publication 750-IN027C-EN-P - November 2013 19

See Tab le 3

required hardware.

for a list of

Page 20

PowerFlex 755 Transition Section and Splicing Kit for Floor-mount Drives and CENTERLINE 2100 Motor Control Centers

IMPORTANT

Main Horizontal Bus -bar

Main Horizontal

Bus-bar Splicing Bars

Flat Washers

One-Piece Nut and Conical Spring Washer

Bus Clamps

Front

Step 7: Join Horizontal Bus and Splicing Bars

Splicing kits will contain either two or four sets of hardware per splice bar,

depending on the current rating of the horizontal bus. Assemble hardware as

depicted in Figure 2

listed in Ta bl e 1

Figure 2 - Splicing Hardware Configuration Detail

and uniformly tighten splice kit hardware to the final torque

.

Note for NO-OX-ID: If you’re using corrosion inhibitor on bus bars, do not get

any on the bus splicing hardware. It will prevent the hardware from being

properly torqued. Damage may occur.

20 Rockwell Automation Publication 750-IN027C-EN-P - November 2013

See Tab le 3 for main horizontal bus-bar splicing bar dimensions.

Page 21

PowerFlex 755 Transition Section and Splicing Kit for Floor-mount Drives and CENTERLINE 2100 Motor Control Centers

Standard Bus-bar Position

MCC Horizontal Bus

PowerFlex Drive

Horizontal Bus

Front

MCC Horizontal Bus

PowerFlex Drive

Horizontal Bus

Front

MCC Horizontal Bus

PowerFlex Drive

Horizontal Bus

Front

Left-side Standard Bus-bar Splice Kits

Figure 3 - 1200A (Kit No. 20-750-XBUS-LHNB/LLNB-1200) - Standard Bus-bar Position

3/8-16 x 1.38 in.

Figure 4 - 2000A (Kit No. 20-750-XBUS-LHNB/LLNB-2000) - Standard Bus-bar Position

3/8-16 x 2.25 in.

Figure 5 - 3000A (Kit No. 20-750-XBUS-LHNB/LLNB-3000) - Standard Bus-bar Position

3/8-16 x 2.75 in.

3/8-16 x 2.25 in.

Rockwell Automation Publication 750-IN027C-EN-P - November 2013 21

Page 22

PowerFlex 755 Transition Section and Splicing Kit for Floor-mount Drives and CENTERLINE 2100 Motor Control Centers

Bumped-Back Bus-bar Position

3/8-16 x 1.38 in.

MCC Horizontal Bus

PowerFlex Drive

Horizontal Bus

Front

3/8-16 x 2.25 in.

MCC Horizontal Bus

Power Flex Dri ve

Horizontal Bus

Front

MCC Horizontal Bus

Power Flex Dri ve

Horizontal Bus

Front

Left-side Bumped-Back Bus-bar Splice Kits

Figure 6 - 1200A (Kit No. 20-750-XBUS-LHBB/LLBB-1200) - Bumped-Back Bus-bar Position

Figure 7 - 2000A (Kit No. 20-750-XBUS-LHBB/LLBB-2000) - Bumped-Back Bus-bar Position

Figure 8 - 3000A (Kit No. 20-750-XBUS-LHBB/LLBB-3000) - Bumped-Back Bus-bar Position

3/8-16 x 2.25 in.

3/8-16 x 2.75 in.

22 Rockwell Automation Publication 750-IN027C-EN-P - November 2013

Page 23

PowerFlex 755 Transition Section and Splicing Kit for Floor-mount Drives and CENTERLINE 2100 Motor Control Centers

Standard Bus-bar Position

3/8-16 x 1.38 in.

MCC Horizontal Bus

PowerFlex Drive

Horizontal Bus

Front

MCC Horizontal Bus

PowerFlex Drive

Horizontal Bus

Front

MCC Horizontal Bus

PowerFlex Drive

Horizontal Bus

Front

Right-side Standard Bus-bar Splice Kits

Figure 9 - 1200A (Kit No. 20-750-XBUS-RHNB/RLNB-1200) - Standard Bus-bar Position

Figure 10 - 2000A (Kit No. 20-750-XBUS-RHNB/RLNB-2000) - Standard Bus-bar Position

3/8-16 x 2.25 in.

Figure 11 - 3000A (Kit No. 20-750-XBUS-RHNB/RLNB-3000) - Standard Bus-bar Position

3/8-16 x 2.25 in.

3/8-16 x 2.75 in.

Rockwell Automation Publication 750-IN027C-EN-P - November 2013 23

Page 24

PowerFlex 755 Transition Section and Splicing Kit for Floor-mount Drives and CENTERLINE 2100 Motor Control Centers

Bumped-Back Bus-bar Position

3/8-16 x 1.38 in.

MCC Horizontal Bus

PowerFlex Drive

Horizontal Bus

Front

MCC Horizontal Bus

PowerFlex Drive

Horizontal Bus

Front

MCC Horizontal Bus

PowerFlex Drive

Horizontal Bus

Front

Right-side Bumped-Back Bus-bar Splice Kits

Figure 12 - 1200A (Kit No. 20-750-XBUS-RHBB/RLBB-1200) - Bumped-Back Bus-bar Position

Figure 13 - 2000A (Kit No. 20-750-XBUS-RHBB/RLBB-2000) - Bumped-Back Bus-bar Position

3/8-16 x 2.25 in.

Figure 14 - 3000A (Kit No. 20-750-XBUS-RHBB/RLBB-3000) - Bumped-Back Bus-bar Position

3/8-16 x 2.25 in.

3/8-16 x 2.75 in.

24 Rockwell Automation Publication 750-IN027C-EN-P - November 2013

Page 25

PowerFlex 755 Transition Section and Splicing Kit for Floor-mount Drives and CENTERLINE 2100 Motor Control Centers

Specifications

Tighten all bus connections with a torque wrench and socket according to

intervals established by your maintenance policy. If a torque wrench is not

available, tighten until the conical spring washer is flat. Do not grease or lubricate

the hardware.

Table 1 - Torque Requirements

Description Hardware Torque

Transition section to drive cabinet joining screws M6 6.2 N•m (55 lb•in)

Transition section to MCC column joining screws 1/4-20 6.2 N•m (55 lb•in)

Protective earth (PE) conductor splice connection 1/4-20 7.3 N•m (65 lb•in)

Main horizontal bus-bar splice connection 3/8-16 38 N•m (336 lb•in)

Table 2 - Horizontal Bus Required Splice Hardware

Amp Rating Description Quantity

1200 3/8-16 x 1.38 in. bus clamp assembly 12

3/8 flat washer 24

3/8-16 one-piece nut and conical spring washer 24

2000 3/8-16 x 2.25 in. bus clamp assembly 12

3/8 flat washer 24

3/8-16 one-piece nut and conical spring washer 24

3000 3/8-16 x 2.25 in. bus clamp assembly 6

3/8-16 x 2.75 in. bus clamp assembly 6

3/8 flat washer 24

3/8-16 one-piece nut and conical spring washer 24

Table 3 - PE Bus Required Splice Hardware

PE Bus Bar Width Amp Rating Description Quantity

25.4 mm (1.0 in.) 1200 and 2000 762 mm (30 in.) 250 MCM cable 2

1/4-20 x 1.25 in. hex-head cap screw 1

1/4-20 x 1.0 in. hex-head cap screw 3

1/4 flat washer 7

1/4 conical spring washer 4

1/4-20 G5 hex nut 3

50.8 mm (2.0 in.) 2000 and 3000 762 mm (30 in.) 250 MCM cable 2

914 mm (36 in.) 250 MCM cable 1

1/4-20 x 1.25 in. hex-head cap screw 1

1/4-20 x 1.0 in. hex-head cap screw 6

1/4 flat washer 10

1/4 conical spring washer 7

1/4-20 G5 hex nut 5

Rockwell Automation Publication 750-IN027C-EN-P - November 2013 25

Page 26

Rockwell Automation Support

Rockwell Automation provides technical information on the Web to assist you in using its products.

At http://www.rockwellautomation.com/support

code and links to software service packs, and a MySupport feature that you can customize to make the best use of these

tools. You can also visit our Knowledgebase at http://www.rockwellautomation.com/knowledgebase

information, support chat and forums, software updates, and to sign up for product notification updates.

, you can find technical manuals, technical and application notes, sample

for FAQs, technical

For an additional level of technical phone support for installation, configuration, and troubleshooting, we offer

Te c h C o n n e c t

representative, or visit http://www.rockwellautomation.com/support/

SM

support programs. For more information, contact your local distributor or Rockwell Automation

.

Installation Assistance

If you experience a problem within the first 24 hours of installation, review the information that is contained in this

manual. You can contact Customer Support for initial help in getting your product up and running.

United States or Canada 1.440.646.3434

Outside United States or Canada Use the Worldwi de Lo cator

local Rockwell Automation representative.

at http://www.rockwellautomation.com/rockwellautomation/support/overview.page, or contact your

New Product Satisfaction Return

Rockwell Automation tests all of its products to help ensure that they are fully operational when shipped from the

manufacturing facility. However, if your product is not functioning and needs to be returned, follow these procedures.

United States Contact your distributor. You must provide a Customer Support case number (call the phone number above to obtain one) to your

distributor to complete the return process.

Outside United States Please contact your local Rockwell Automation representative for the return procedure.

Documentation Feedback

Your comments will help us serve your documentation needs better. If you have any suggestions on how to improve this

document, complete this form, publication RA-DU002

U.S. Allen-Bradley Drives Technical Support - Tel: (1) 262.512.8176, Fax: (1) 262.512.2222, E-mail: support@drives.ra.rockwell.com

Online: www.ab.com/support/abdrives

Allen-Bradley, Rockwell Software, Rockwell Automation, PowerFlex, RSLinx, DriveExplorer, DriveExecutive, ControlFLASH, and TechConnect are trade marks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Publication 750-IN027C-EN-P - November 2013

Supersedes Publication 750-IN027B-EN-P - February 2013 Copyright © 2013 Rockwell Auto mation, Inc. All rights reserved. Pr inted in the U.S.A.

, available at http://www.rockwellautomation.com/literature/.

Loading...

Loading...