Page 1

Programming Manual

PowerFlex 750-Series AC Drives

Firmware Versions:1.xxx…10.xxx

Page 2

Important User Information

IMPORTANT

Read this document and the documents listed in the additional resources section about installation, configuration, and

operation of this equipment before you install, configure, operate, or maintain this product. Users are required to

familiarize themselves with installation and wiring instructions in addition to requirements of all applicable codes, laws,

and standards.

Activities including installation, adjustments, putting into service, use, assembly, disassembly, and maintenance are required

to be carried out by suitably trained personnel in accordance with applicable code of practice.

If this equipment is used in a manner not specified by the manufacturer, the protection provided by the equipment may be

impaired.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the

use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or

liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or

software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation,

Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous environment,

which may lead to personal injury or death, property damage, or economic loss.

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death, property

damage, or economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the consequence.

Identifies information that is critical for successful application and understanding of the product.

Labels may also be on or inside the equipment to provide specific precautions.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous

voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may

reach dangerous temperatures.

ARC FLASH HAZARD: Labels may be on or inside the equipment, for example, a motor control center, to alert people to

potential Arc Flash. Arc Flash will cause severe injury or death. Wear proper Personal Protective Equipment (PPE). Follow ALL

Regulatory requirements for safe work practices and for Personal Protective Equipment (PPE).

Allen-Bradley, Rockwell Software, Rockwell Automation, and TechConnect are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Page 3

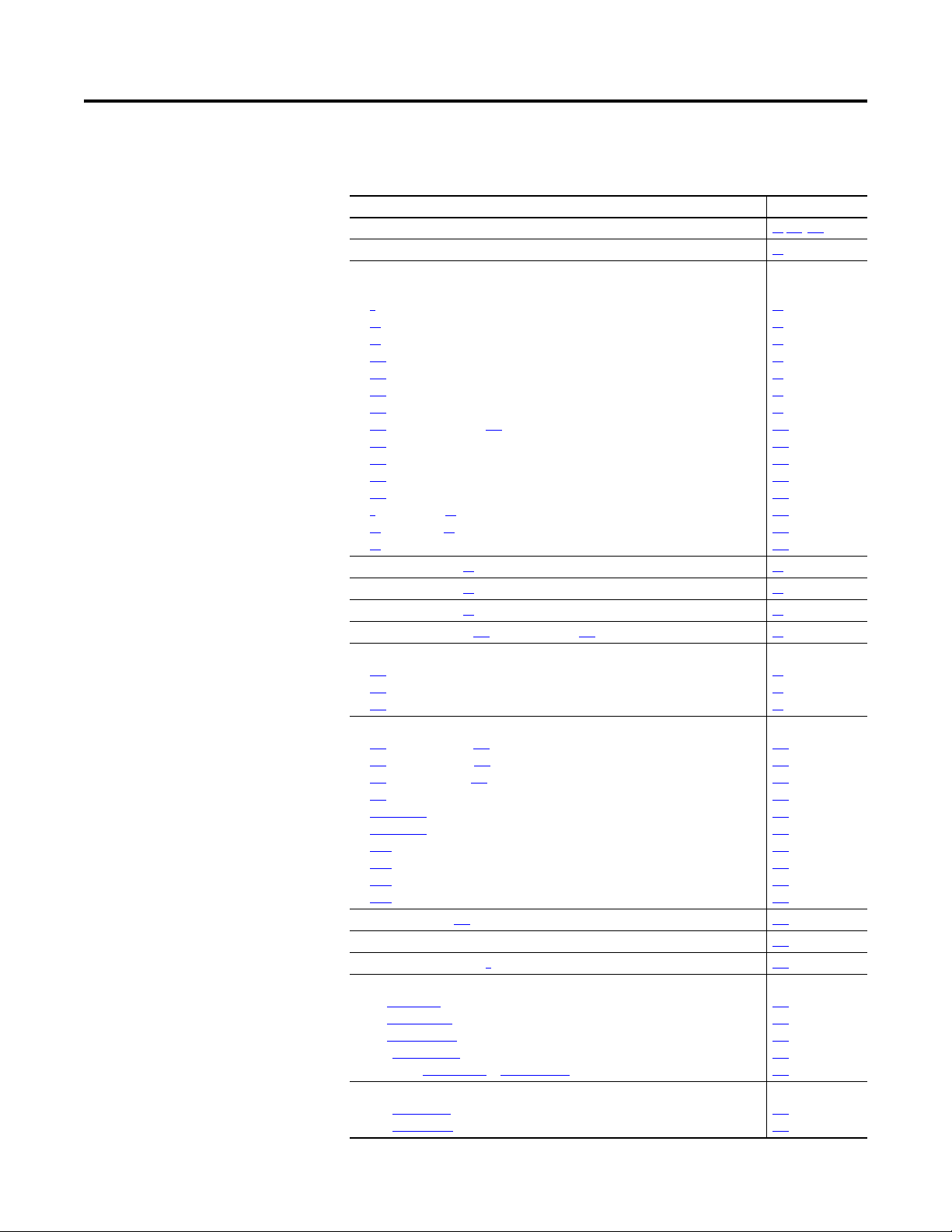

Summary of Changes

New and Updated Information

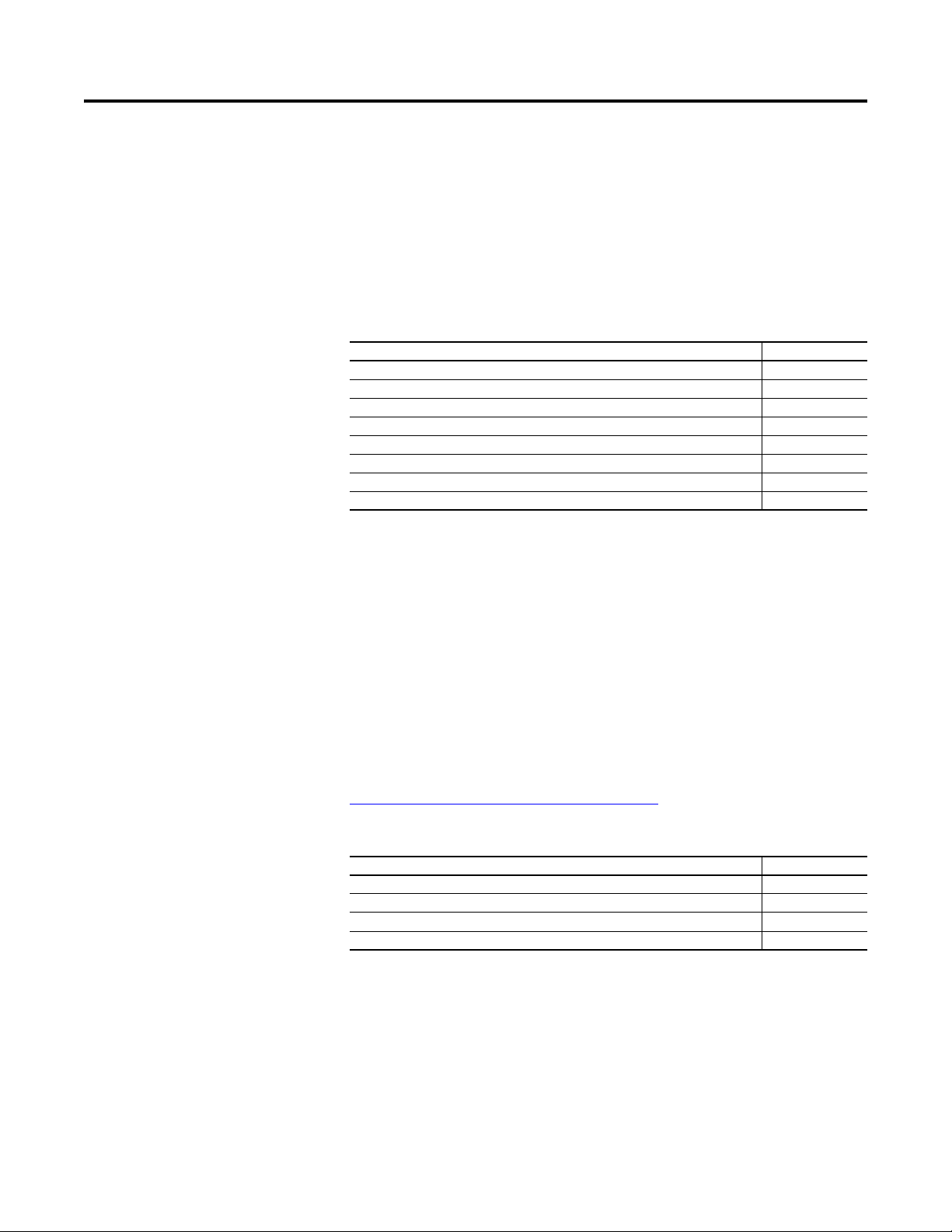

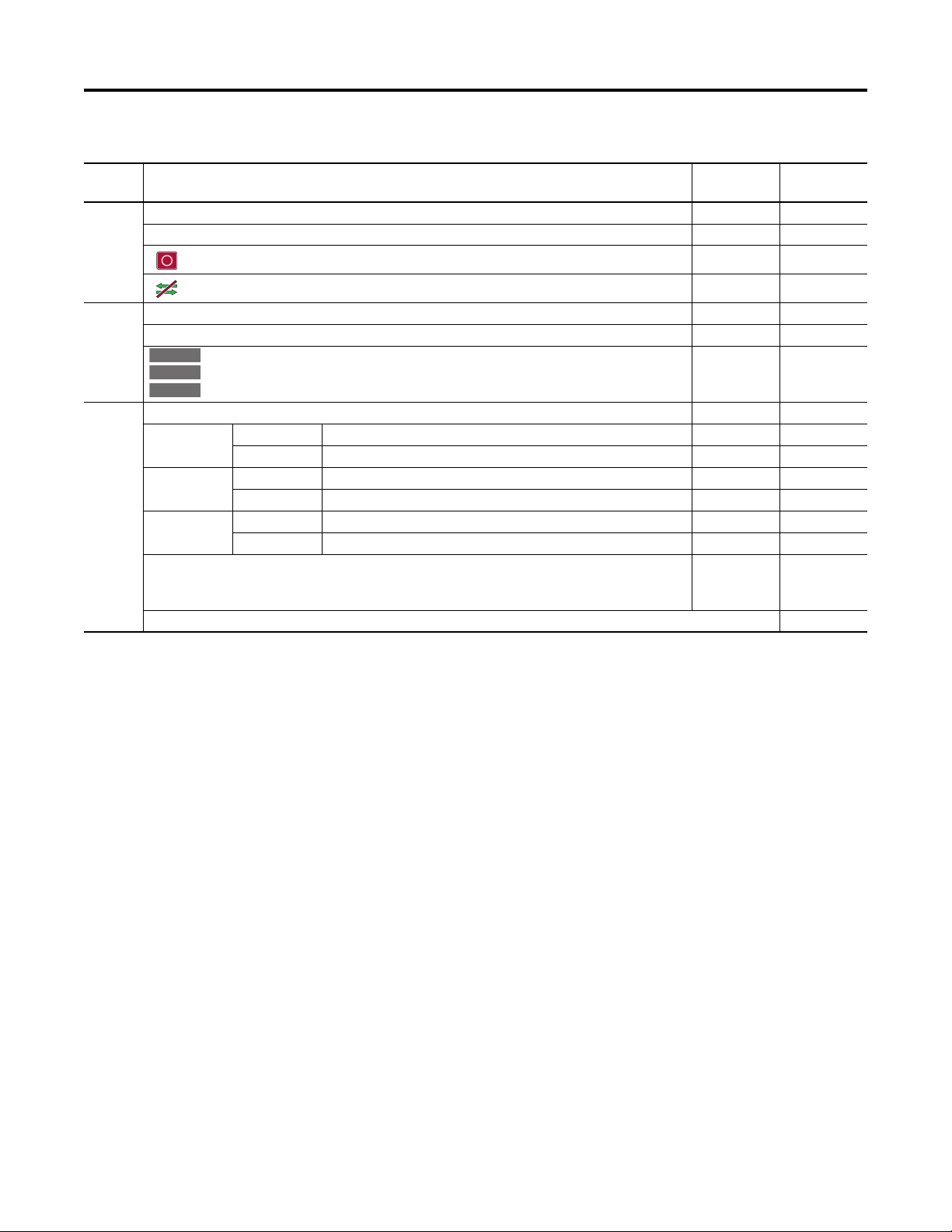

This table contains the changes made to this revision.

Top ic Pag e

The PowerFlex 753 and PowerFlex 755 flashing yellow STS status description changed. 18

Main DC Bus Volt parameter moved to the Metering Group. 42

The following parameters have new descriptions or default, minimum, and/or maximum

values h ave changed.

[Comman ded Trq]

4

35 [Motor Ctrl Mode]

40 [Mtr Options Cfg]

[DI Precharge]

189

312 [SpdTrqPsn Mode D]

326 [Manual Cmd Mask]

[FlyingStart Mode]

356

[Pwr Loss A Level ] and 454 [Pwr Loss B Level]

451

688

[Notch Fltr Atten]

[Psn Reg Ki]

838

839 [Psn Reg Kp]

731 [Homing Control]

[DLX Out 01]…14 [DLX Out 14]

1

17 [DLX In 01]…30 [DLX In 14]

82 [Enc Out FD PPR]

Motor control parameter 40 [Mtr Options Cfg] default setting for Jerk Select changed. 56

Motor control parameter 63 [Break Frequency] has the Voltage to Frequency table added. 60

Motor control parameter 80 [PM Cfg] has a table added. 62

Feedback & I/O parameters 181 [Dl SpTqPs Sel 0 and 182 [Dl SpTqPs Sel 1] has a table added. 73

Units for the following parameters were added.

244 [TO0 On Time]

[TO0 Off Time]

245

276 [Anlg Out0 Stpt]

The following parameters have been added.

[CbFan TotalLife]…484 [CbFan RemainLife]

482

[HSFan TotalLife]…491 [HSFan RemainLife]

489

496

[InFan TotalLife]…498 [InFan RemainLife]

[CRC Fl t Cfg]

964

1700…1731

1800…1831 [UserData Real 00…UserData Real 31]

1900

1901, 1905…1929 [ScaleBlk Scal 00…07]

1902

1903

Diagnostics parameter 935 [Drive Status 1] table changed. 156

Removed “755” icon from parameters 1153 [Dead Time Comp] and 1154 [DC offset Crtl]. 180

Universal feedback parameter 6 [FBO Device Sel] options changed. 275

Descriptions for the following event numbers have changed.

24 “Decel Inhibit

27 “Torq Pro ve C fl ct”

35 “IPM OverCurrent

211 “Safety Brd Fault

901…927 “Machine Check…CIP Motion Error”

The following event numbers were added.

333 “I3 Comm Loss

343 “C3 Comm Loss”

[UserData Int 00…UserData Int 31]

, 1904…1928 [ScaleBlk Sel 00…07]

, 1906…1930 [ScaleBlk Int 00…07]

, 1907…1931 [ScaleBlk Real 00…07]

”

”

”

”

,307, 308

52

55

56

73

86

88

92

102

127

147

147

136

243

243

286

79

79

81

105

106

107

212

212

212

212

212

212

213

314

314

314

321

323

323

323

Rockwell Automation Publication 750-PM001J-EN-P - October 2014 3

Page 4

Summary of Changes

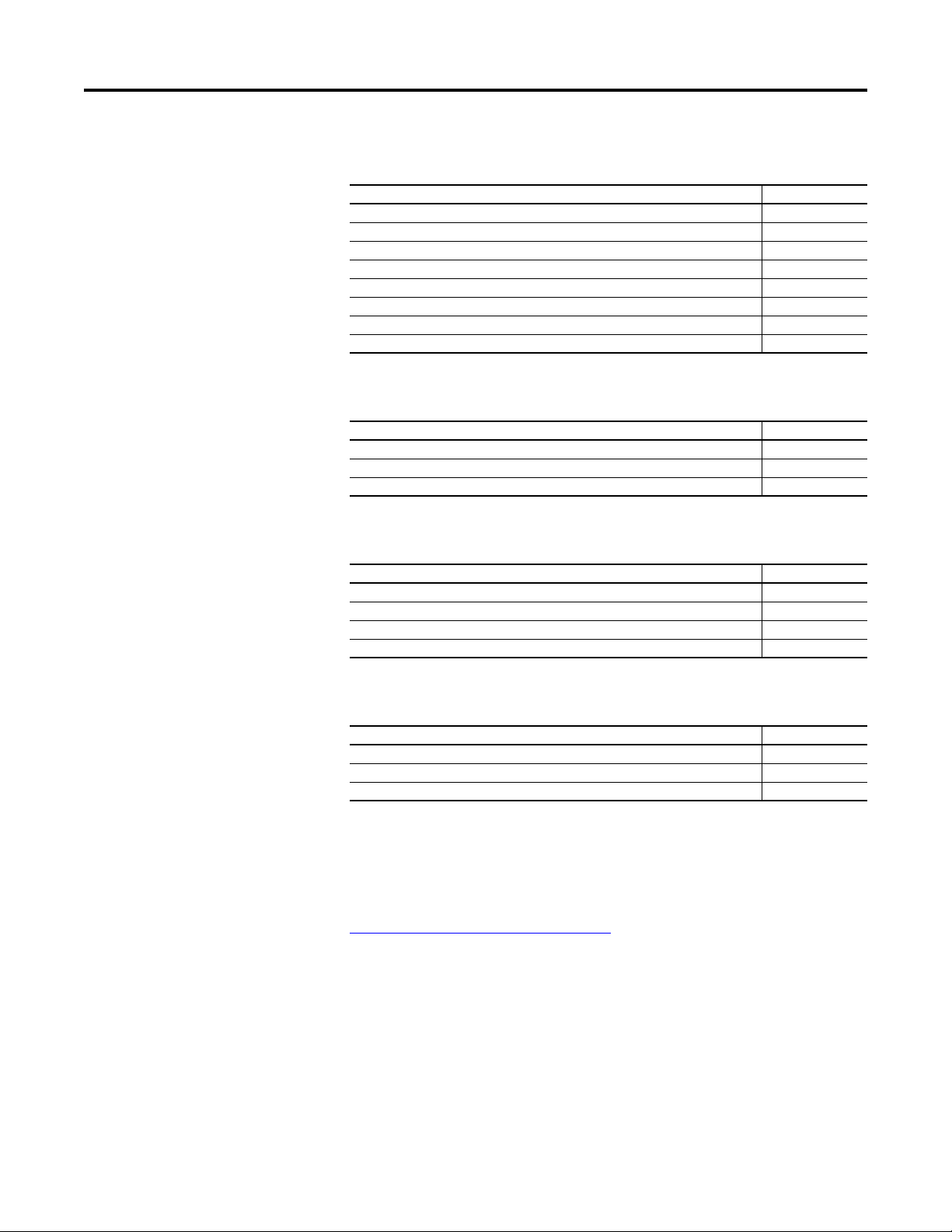

Top ic Pag e

Added Predictive Maintenance with Logix

Remove Table 8 - Integrated Motion on EtherNet/IP Attribute Alphabetical Order from

Appendix E.

Base 10 and Base 16 numbers were added to the attribute mapping tables in Appendix E. 512

information in Appendix B. 475

505

4 Rockwell Automation Publication 750-PM001J-EN-P - October 2014

Page 5

Summary of Changes

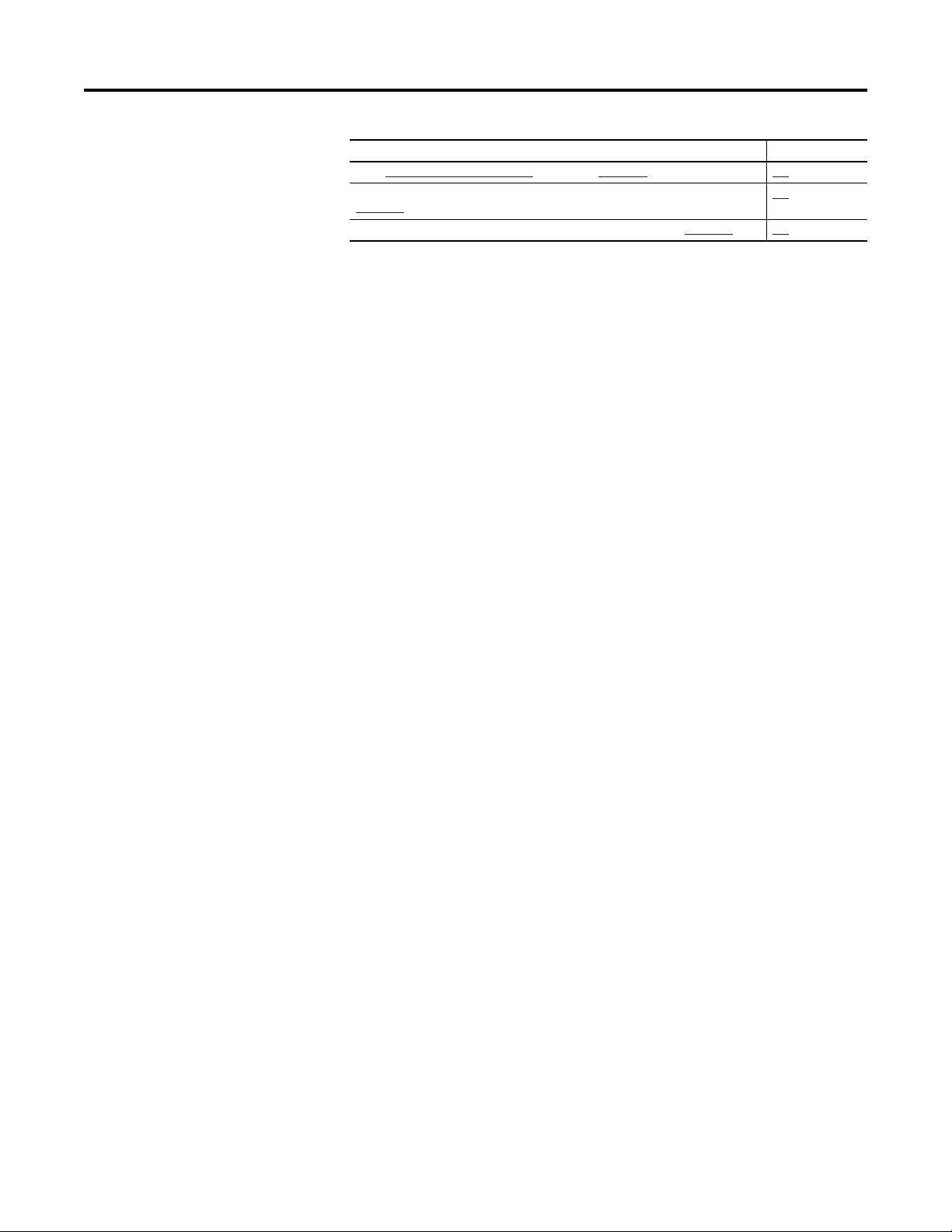

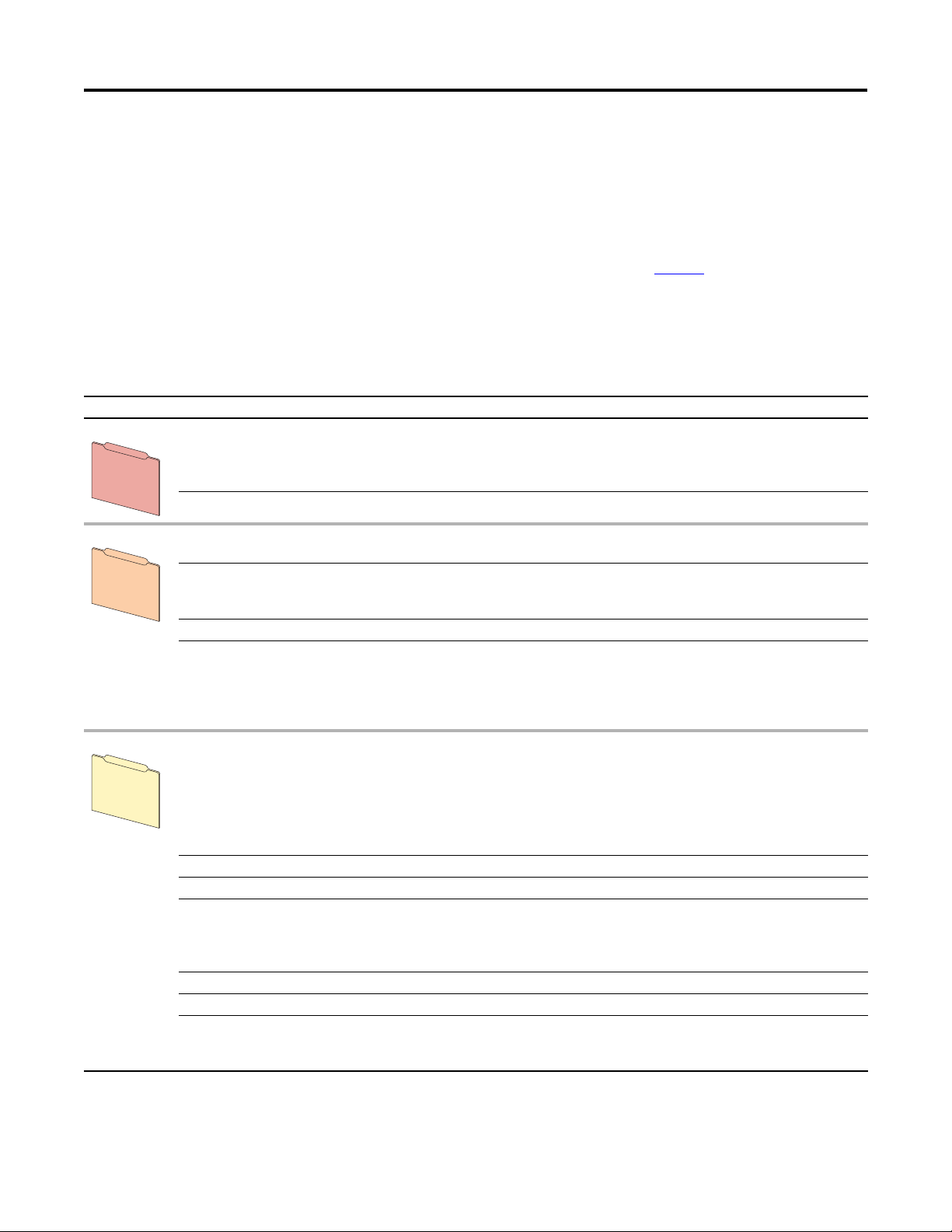

Table of Contents

Preface

Overview

Start Up

Table of Contents

Important User Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

New and Updated Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Who Should Use This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

What Is Not In This Manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Recommended Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Obtaining Manuals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Allen-Bradley Drives Technical Support . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Product Certification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Manual Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

General Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Chapter 1

Start-Up Check List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Start-Up Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Drive Status Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Establishing A Connection With EtherNet/IP . . . . . . . . . . . . . . . . . . . . . 19

Parameter Organization

Drive Port 0 Parameters

Chapter 2

About Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Parameter Access Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

How Drive Parameters are Organized . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

How Option Module Parameters are Organized . . . . . . . . . . . . . . . . . . . . 45

Chapter 3

Drive (Port 0) Monitor File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Drive (Port 0) Motor Control File. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Drive (Port 0) Feedback & I/O File. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Drive (Port 0) Cfg File. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Drive (Port 0) Protection File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Drive (Port 0) Speed Control File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Drive (Port 0) Torque Control File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Drive (Port 0) Position Control File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

Drive (Port 0) Communication File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

Drive (Port 0) Diagnostics File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

Drive (Port 0) Applications File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

Drive (Port 0) General Purpose Parameters. . . . . . . . . . . . . . . . . . . . . . . . 212

Port 10 and Port 11 Parameters

Chapter 4

Inverter (Port 10) Common Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . 216

Inverter n (Port 10) Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 218

Converter (Port 11) Common Parameters . . . . . . . . . . . . . . . . . . . . . . . . 221

Rockwell Automation Publication 750-PM001J-EN-P - October 2014 5

Page 6

Table of Contents

Embedded Feature and Option

Module Parameters

Troubleshooting

Converter n (Port 11) Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 223

Precharge (Port 11) Common Parameters . . . . . . . . . . . . . . . . . . . . . . . . . 227

Precharge n (Port 11) Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 229

Chapter 5

Embedded EtherNet/IP (Port 13) Parameters . . . . . . . . . . . . . . . . . . . . . 234

Communication Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 240

Embedded DeviceLogix (Port 14) Parameters. . . . . . . . . . . . . . . . . . . . . . 243

11-Series I/O Module Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 246

22-Series I/O Module Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 256

Single Incremental Encoder Module Parameters . . . . . . . . . . . . . . . . . . . 267

Dual Incremental Encoder Module Parameters . . . . . . . . . . . . . . . . . . . . 269

Universal Feedback Module Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . 274

Safe Speed Monitor Module Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . 292

Chapter 6

Faults, Alarms and Configurable Conditions . . . . . . . . . . . . . . . . . . . . . . 306

Drive Status Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 307

HIM Indication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 309

Manually Clearing Faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 309

Power Layer Interface (PLI) Board 7-Segment Display . . . . . . . . . . . . . 310

Setting Factory Defaults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 311

System Resource Allocation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 311

Hardware Service Manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 312

Integrated Motion Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 312

Fault and Alarm Display Codes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 312

Parameter Access Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 312

Drive Fault and Alarm Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 313

Inverter (Port 10) Faults and Alarms (Frame 8 and Larger) . . . . . . . . . 328

Converter (Port 11) Faults and Alarms (Frame 8 and Larger) . . . . . . . 333

Precharge (Port 11) Faults and Alarms (Frame 8 and Larger). . . . . . . . 338

N-1 and Re-Rate Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 341

Embedded EtherNet/IP (Port 13) Events . . . . . . . . . . . . . . . . . . . . . . . . . 345

I/O Faults and Alarms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 347

Safe Torque Off Fault . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 347

ATEX Faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 348

Single Incremental Encoder Faults and Alarms. . . . . . . . . . . . . . . . . . . . . 348

Dual Incremental Encoder Faults and Alarms. . . . . . . . . . . . . . . . . . . . . . 349

Universal Feedback Faults and Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . 350

Port Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 357

Common Symptoms and Corrective Actions . . . . . . . . . . . . . . . . . . . . . . 357

PowerFlex 755 Lifting/Torque Proving . . . . . . . . . . . . . . . . . . . . . . . . . . . 360

External Brake Resistor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 360

Technical Support Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 361

6 Rockwell Automation Publication 750-PM001J-EN-P - October 2014

Page 7

Appendix A

Table of Contents

PowerFlex 753 Control Block

Diagrams

PowerFlex 755 Control Block

Diagrams

Application Notes

Using DeviceLogix

List of PowerFlex 753 Control Block Diagrams . . . . . . . . . . . . . . . . . . . . 363

Diagram Conventions and Definitions. . . . . . . . . . . . . . . . . . . . . . . . . . . . 364

List of PowerFlex 755 Control Block Diagrams . . . . . . . . . . . . . . . . . . . . 398

Diagram Conventions and Definitions. . . . . . . . . . . . . . . . . . . . . . . . . . . . 399

Appendix B

Voltage Tolerance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 443

PowerFlex 755 Lifting/Torque Proving . . . . . . . . . . . . . . . . . . . . . . . . . . . 444

Crane Setup with Encoder Feedback. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 446

Crane Setup - Encoderless. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 455

Pump Off Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 463

Predictive Maintenance with Logix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 475

Appendix C

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 483

Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 485

Function Block Elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 485

Bit and Analog I/O Points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 486

Tips. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 488

Program Examples. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 490

Permanent Magnet Motors

Integrated Motion on EtherNet/IP

Index

Appendix D

Compatible Allen-Bradley Servo Motors . . . . . . . . . . . . . . . . . . . . . . . . . . 501

Appendix E

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 505

Feedback Configuration Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 507

Parameter / Instance Attribute Mapping . . . . . . . . . . . . . . . . . . . . . . . . . . 512

Enhanced Attributes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 516

Faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 522

Additional Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 525

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 527

Rockwell Automation Publication 750-PM001J-EN-P - October 2014 7

Page 8

Table of Contents

8 Rockwell Automation Publication 750-PM001J-EN-P - October 2014

Page 9

Preface

Overview

The purpose of this manual is to provide you with the basic information needed

to install, start-up and troubleshoot PowerFlex® 750-Series Adjustable Frequency

AC Drives.

For information on … See page...

Who Should Use This Manual 9

What Is Not In This Manual 9

Recommended Documentation 9

Obtaining Manuals 10

Allen-Bradley Drives Technical Support 11

Product Certification 11

Manual Conventions 11

General Precautions 12

Who Should Use This Manual

What Is Not In This Manual

Recommended Documentation

This manual is intended for qualified personnel. You must be able to program

and operate Adjustable Frequency AC Drive devices. In addition, you must have

an understanding of the parameter settings and functions.

The PowerFlex 750-Series User Manual is designed to provide only basic start-up

information.

All the recommended documentation listed in this section is available online at

http://www.rockwellautomation.com/literature

.

The following publications provide general drive information.

Title Publication

Wiring and Grounding Guidelines for Pulse Width Modulated (PWM) AC Drives DRIVES-IN001

Safety Guidelines for the Application, Installation and Maintenance of Solid State Control SGI-1.1

A Global Reference Guide for Reading Schematic Diagrams 100-2.10

Guarding Against Electrostatic Damage 8000-4.5.2

Rockwell Automation Publication 750-PM001J-EN-P - October 2014 9

Page 10

Preface

The following publications provide specific PowerFlex 750-Series information on

drive installation, features, specifications, and service:

Title Publication

PowerFlex 750-Series AC Drive Installation Instructions 750-IN001

PowerFlex 750-Series AC Drives Technical Data 750-TD001

Enhanced PowerFlex 7-Class Human Interface Module (HIM) User Manual 20HIM-UM001

PowerFlex 750-Series Safe Torque Off User Manual 750-UM002

Safe Speed Monitor Option Module for PowerFlex 750-Series AC Drives Reference Manual 750-RM001

PowerFlex 750-Series AC Drives Hardware Service Manual (Frame 8 and Larger) 750-TG001

Dynamic Braking Resistor Calculator PFLEX-AT001

DeviceLogix User Manual RA-UM003

The following publications provide specific Network Communications

information:

Title Publication

PowerFlex 755 Drive Embedded EtherNet/IP Adapter 750COM-UM001

PowerFlex 750-Series Drive DeviceNet Option Module 750COM-UM002

PowerFlex 20-750-CNETC Coaxial ControlNet Option Module 750COM-UM003

Obtaining Manuals

The following publications provide necessary information when applying the

Logix Processors:

Title Publication

Logix5000 Controllers Common Procedures 1756-PM001

Logix5000 Controllers General Instructions 1756-RM003

Logix5000 Controllers Process Control and Drives Instructions 1756-RM006

RSLogix 5000 Getting Results 9399-RLD300GR

The following publications provide information that is useful when planning and

installing communication networks:

Title Publication

ContolNet Coax Tap Installation Instructions 1786-5.7

ControlNet Cable System Planning and Installation Manual 1786-6.2.1

ContolNet Fiber Media Planning and Installation Guide CNET-IN001

To order paper copies of technical documentation, contact your local Rockwell

Automation distributor or sales representative.

To find your local Rockwell Automation distributor, visit

www.rockwellautomation.com/locations

10 Rockwell Automation Publication 750-PM001J-EN-P - October 2014

Page 11

Preface

Allen-Bradley Drives Technical Support

Product Certification

Manual Conventions

Online at… By Email at… By Telephone at…

www.ab.com/support/abdrives support@drives.ra.rockwell.com 262-512-8176

For Automation and Control Technical Support:

Title Online at…

Rockwell Automation Technical

Support

http://support.rockwellautomation.com/knowledgebase

Product Certifications and Declarations of Conformity are available on the

internet at: www.rockwellautomation.com/products/certification

• In this manual we refer to PowerFlex 750-Series Adjustable Frequency AC

Drives as: drive, PowerFlex 750, PowerFlex 750 drive or PowerFlex 750

AC drive.

• Specific drives within the PowerFlex 750-Series may be referred to as:

– PowerFlex 753, PowerFlex 753 drive or PowerFlex 753 AC drive

– PowerFlex 755, PowerFlex 755 drive or PowerFlex 755 AC drive

• To help differentiate parameter names and LCD display text from other

text, the following conventions will be used:

– Parameter Names will appear in [brackets] after the Parameter Number.

For example: parameter 308 [Direction Mode].

– Display text will appear in “quotes.” For example: “Enabled.”

• The following words are used throughout the manual to describe an

action:

Word Meani ng

Can Possible, able to do something

Cannot Not possible, not able to do something

May Permitted, allowed

Must Unavoidable, you must do this

Shall Required and necessary

Should Recommended

Should Not Not recommended

Rockwell Automation Publication 750-PM001J-EN-P - October 2014 11

Page 12

Preface

General Precautions

Qualified Personnel

ATTENTION: Only qualified personnel familiar with adjustable frequency AC drives and

associated machinery should plan or implement the installation, start-up and

subsequent maintenance of the system. Failure to comply may result in personal injury

and/or equipment damage.

Personal Safety

ATTENTION: To avoid an electric shock hazard, verify that the voltage on the bus

capacitors has discharged completely before servicing. Check the DC bus voltage at the

Power Terminal Block by measuring between the +DC and -DC terminals, between the

+DC terminal and the chassis, and between the -DC terminal and the chassis. The

voltage must be zero for all three measurements.

ATTENTION: Hazard of personal injury or equipment damage exists when using bipolar

input sources. Noise and drift in sensitive input circuits can cause unpredictable changes

in motor speed and direction. Use speed command parameters to help reduce input

source sensitivity.

ATTENTION: Risk of injury or equipment damage exists. DPI or SCANport host products

must not be directly connected together via 1202 cables. Unpredictable behavior can

result if two or more devices are connected in this manner.

ATTENTION: The drive start/stop/enable control circuitry includes solid state

components. If hazards due to accidental contact with moving machinery or

unintentional flow of liquid, gas or solids exists, an additional hardwired stop circuit

may be required to remove the AC line to the drive. An auxiliary braking method may be

required.

ATTENTION: Hazard of personal injury or equipment damage due to unexpected

machine operation exists if the drive is configured to automatically issue a Start or Run

command. Do not use these functions without considering applicable local, national

and international codes, standards, regulations or industry guidelines.

12 Rockwell Automation Publication 750-PM001J-EN-P - October 2014

Page 13

Product Safety

ATTENTION: An incorrectly applied or installed drive can result in component damage

or a reduction in product life. Wiring or application errors such as under sizing the

motor, incorrect or inadequate AC supply, or excessive surrounding air temperatures

may result in malfunction of the system.

ATTENTION: This drive contains ESD (Electrostatic Discharge) sensitive parts and

assemblies. Static control precautions are required when installing, testing, servicing or

repairing this assembly. Component damage may result if ESD control procedures are

not followed. If you are not familiar with static control procedures, reference Guarding

Against Electrostatic Damage, publication 8000-4.5.2 or any other applicable ESD

protection handbook.

ATTENTION: Configuring an analog input for 0-20 mA operation and driving it from a

voltage source could cause component damage. Verify proper configuration prior to

applying input signals.

ATTENTION: A contactor or other device that routinely disconnects and reapplies the

AC line to the drive to start and stop the motor can cause drive hardware damage. The

drive is designed to use control input signals that will start and stop the motor. If an

input device is used, operation must not exceed one cycle per minute or drive damage

will occur.

Preface

ATTENTION: Drive must not be installed in an area where the ambient atmosphere

contains volatile or corrosive gas, vapors or dust. If the drive is not going to be installed

for a period of time, it must be stored in an area where it will not be exposed to a

corrosive atmosphere.

Class 1 LED Product

ATTENTION: Hazard of permanent eye damage exists when using optical transmission

equipment. This product emits intense light and invisible radiation. Do not look into

module ports or fiber optic cable connectors.

Rockwell Automation Publication 750-PM001J-EN-P - October 2014 13

Page 14

Preface

Notes:

14 Rockwell Automation Publication 750-PM001J-EN-P - October 2014

Page 15

Chapter 1

Start Up

This chapter provides the information needed to start up the PowerFlex

750-Series drive.

Top ic Pag e

Start-Up Check List 15

Start-Up Menu 17

Drive Status Indicators 18

Establishing A Connection With EtherNet/IP 19

Start-Up Check List

• This check list supports the Start-Up menu option.

• A Human Interface Module (HIM) is required to run the Start-Up

routine.

For detailed information on using the HIM, refer to the Enhanced

PowerFlex 7-Class Human Interface Module (HIM) User Manual,

publication 20HIM-UM001.

• The Start-Up routine may modify parameter values for Analog and Digital

I/O.

ATTENTION: Power must be applied to the drive to perform the following start-up

procedure. Some of the voltages present are at incoming line potential. To avoid electric

shock hazard or damage to equipment, only qualified service personnel should perform

the following procedure. Thoroughly read and understand the procedure before

beginning.

Prepare For Initial Drive Start-Up

❏ 1. Confirm that drive has been installed according to the PowerFlex 750-

Series AC Drives Installation Instructions, publication 750-IN001

❏ 2. Confirm that all inputs are connected to the correct terminals and are

secure.

.

❏ 3. Verify that AC line power at the disconnect device is within the rated value

of the drive.

❏ 4. Verify that control power voltage is correct.

Rockwell Automation Publication 750-PM001J-EN-P - October 2014 15

Page 16

Chapter 1 Start Up

❏ 5. The remainder of this procedure requires that a Human Interface Module

(HIM) is connected to DPI Port 1 or 2.

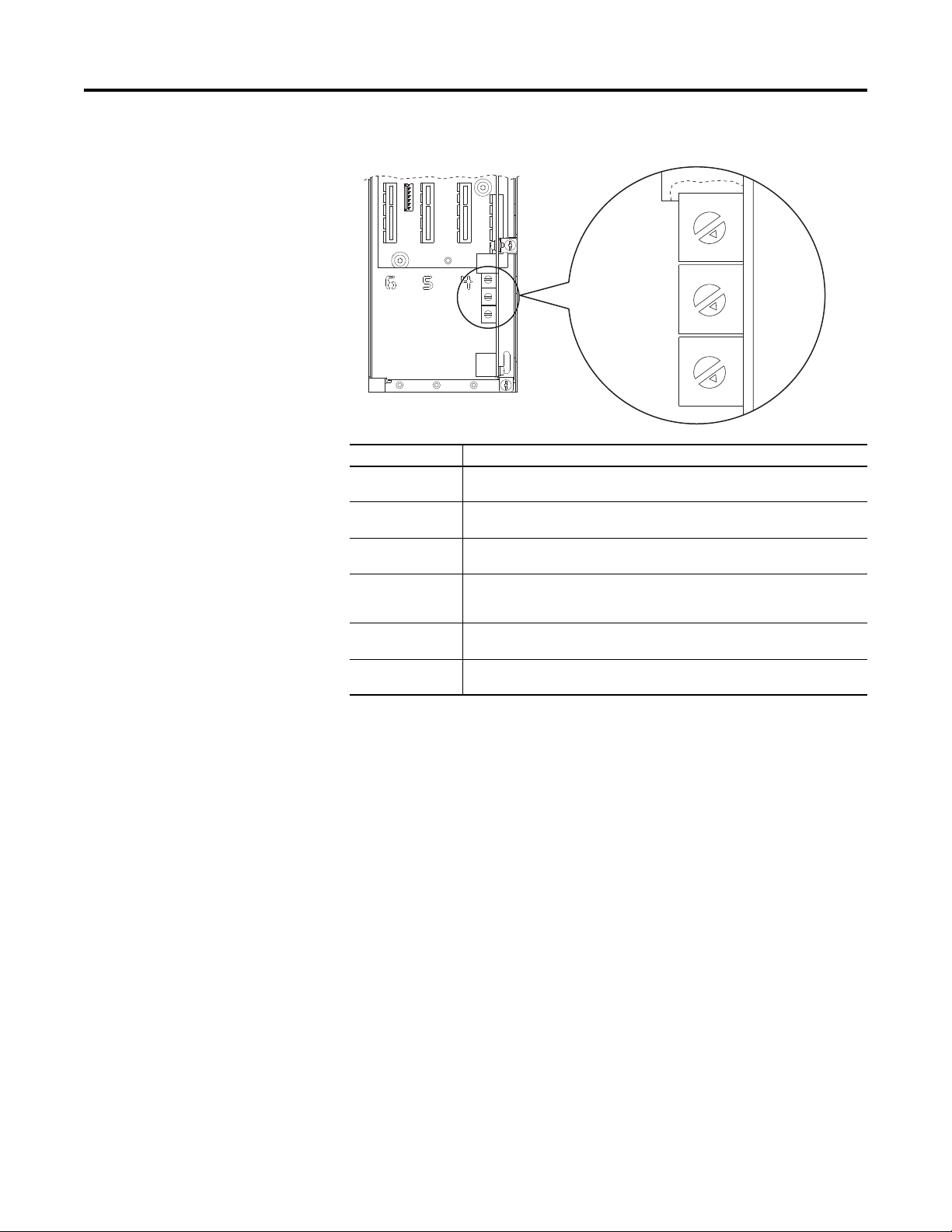

Figure 1 - DPI Ports ➊ and ➋

❏ 6. Apply AC power and control voltages to the drive.

If any digital inputs are configured to Stop – CF, Run, or Enable, verify

that signals are present or the drive will not start. Refer to Chapter

6 for

a list of potential digital input conflicts.

If the STS LED is not flashing green at this point, refer to Drive Status

Indicators on page 18.

❏ 7. When prompted, select a display language. The Start-Up Screen will

automatically display for drives that have not been previously configured.

If the Start-Up screen is not displayed press the Enter key.

❏ 8. Press the Enter key to display the Start-Up Menu.

❏ 9. Use the Up/Down Arrow keys to highlight “2. Basic.”

❏ 10. Press the Enter key. Follow the menu using the Enter key which will step

you through the Start-Up routine.

The Start-Up routine asks simple questions and prompts you to input

required information.

16 Rockwell Automation Publication 750-PM001J-EN-P - October 2014

Page 17

Start Up Chapter 1

IMPORTANT

Start-Up Menu

Motor Control Motor Data Feedback Limits Tests Reference I/O Done

Motor Ctrl Motor Data Feedback

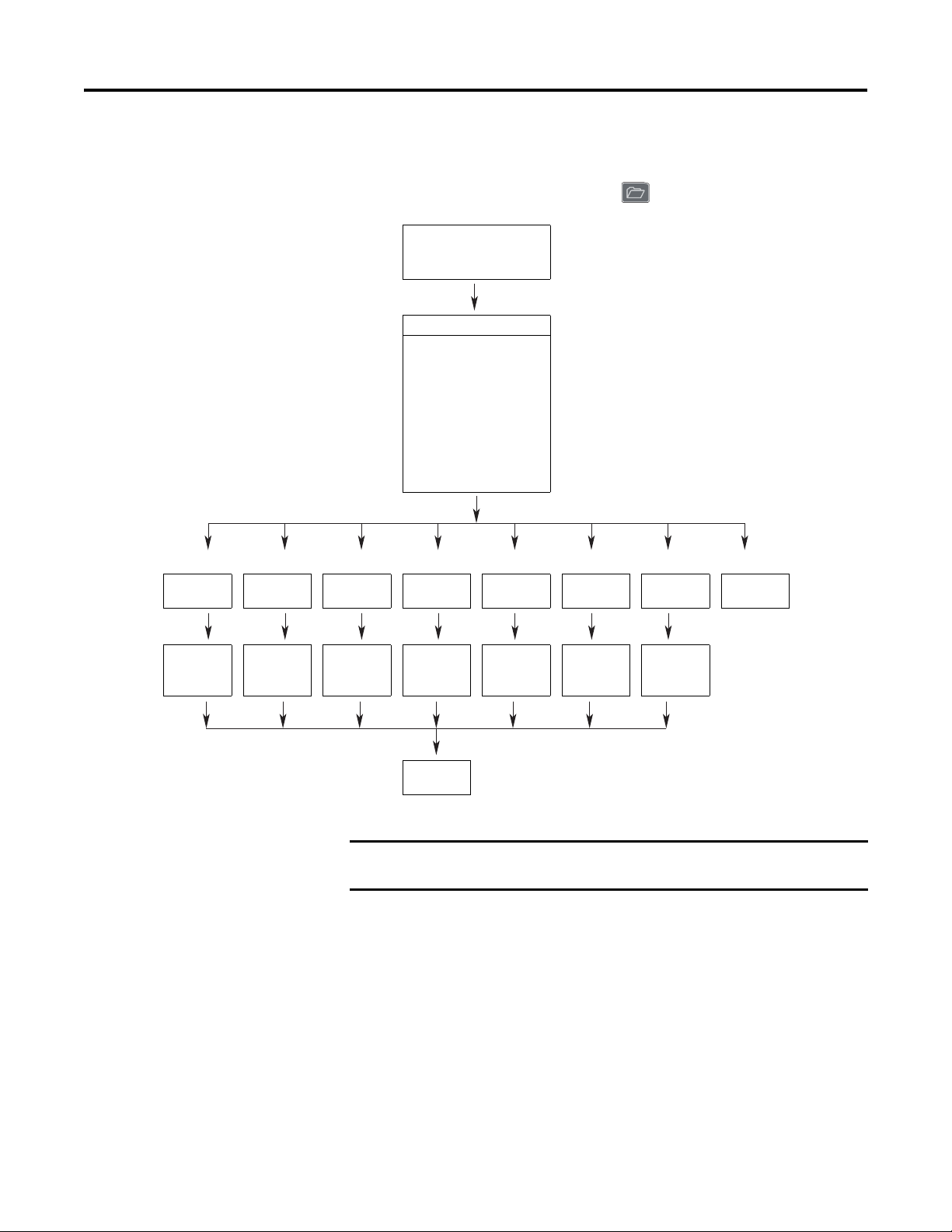

The Human Interface Module (HIM) displays the General Start-Up menu by

default upon initial power up of the drive. To navigate to the Start-Up menu after

the initial power up of the drive, press the (Folders) key.

General Startup

Start-Up Main Menu

Complete these steps in order:

Motor Control

Motor Data

Feedback

Limits

Tes t s

Ref, Ramp, Stop

I/O

Done

Confi g

Limits Tests Ref, Ramp,

Stop

I/O Return to

Main Menu

Motor Ctrl

Return

Motor Data

Return

Fdbk Cnfg

Return

Limits

Return

Return to

Main Menu

Tes t s

Return

Ref, Ramp,

Stop

Return

I/O

Return

If a start up routine is initiated, but must be terminated before the routine is

completed, be sure to press the Abort soft key to completely exit the routine.

Rockwell Automation Publication 750-PM001J-EN-P - October 2014 17

Page 18

Chapter 1 Start Up

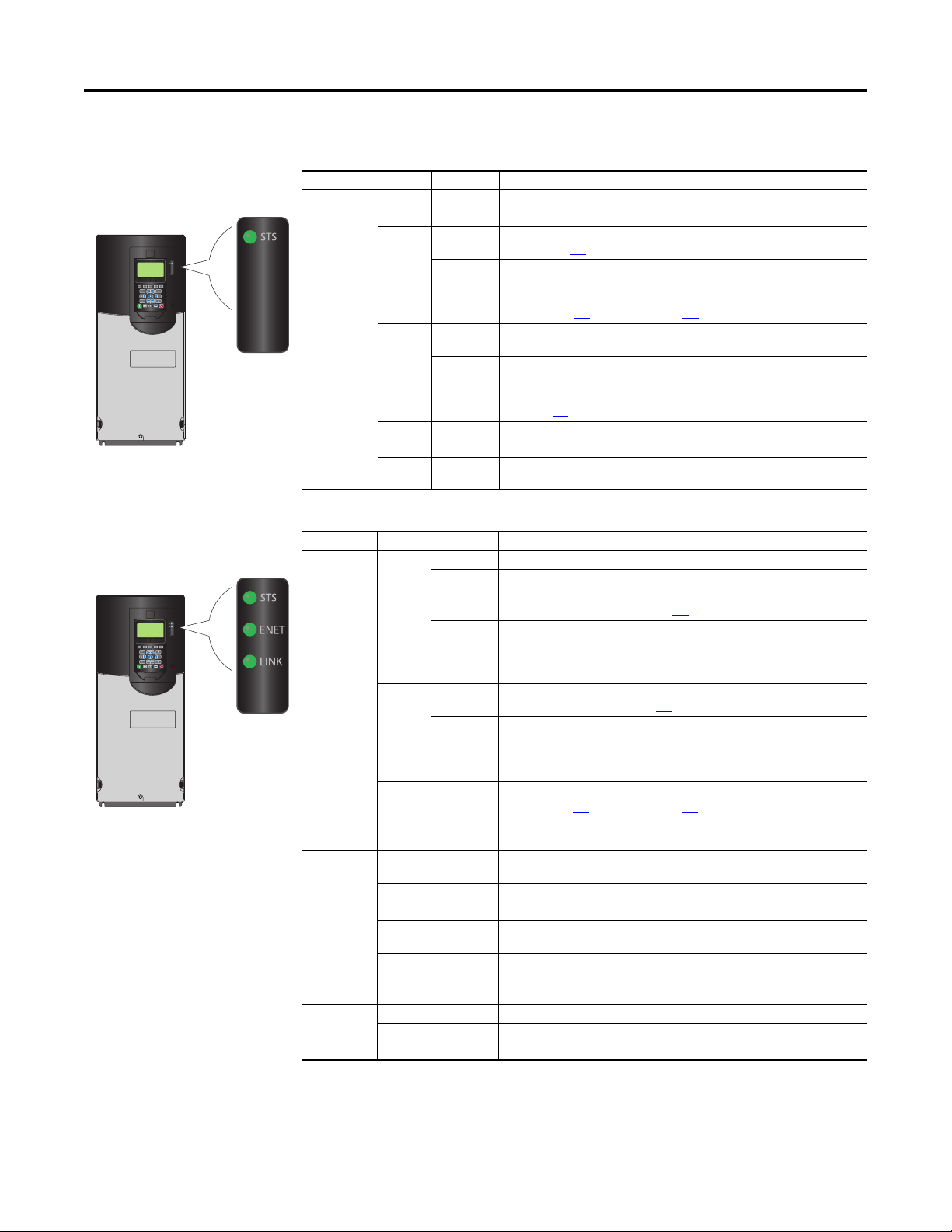

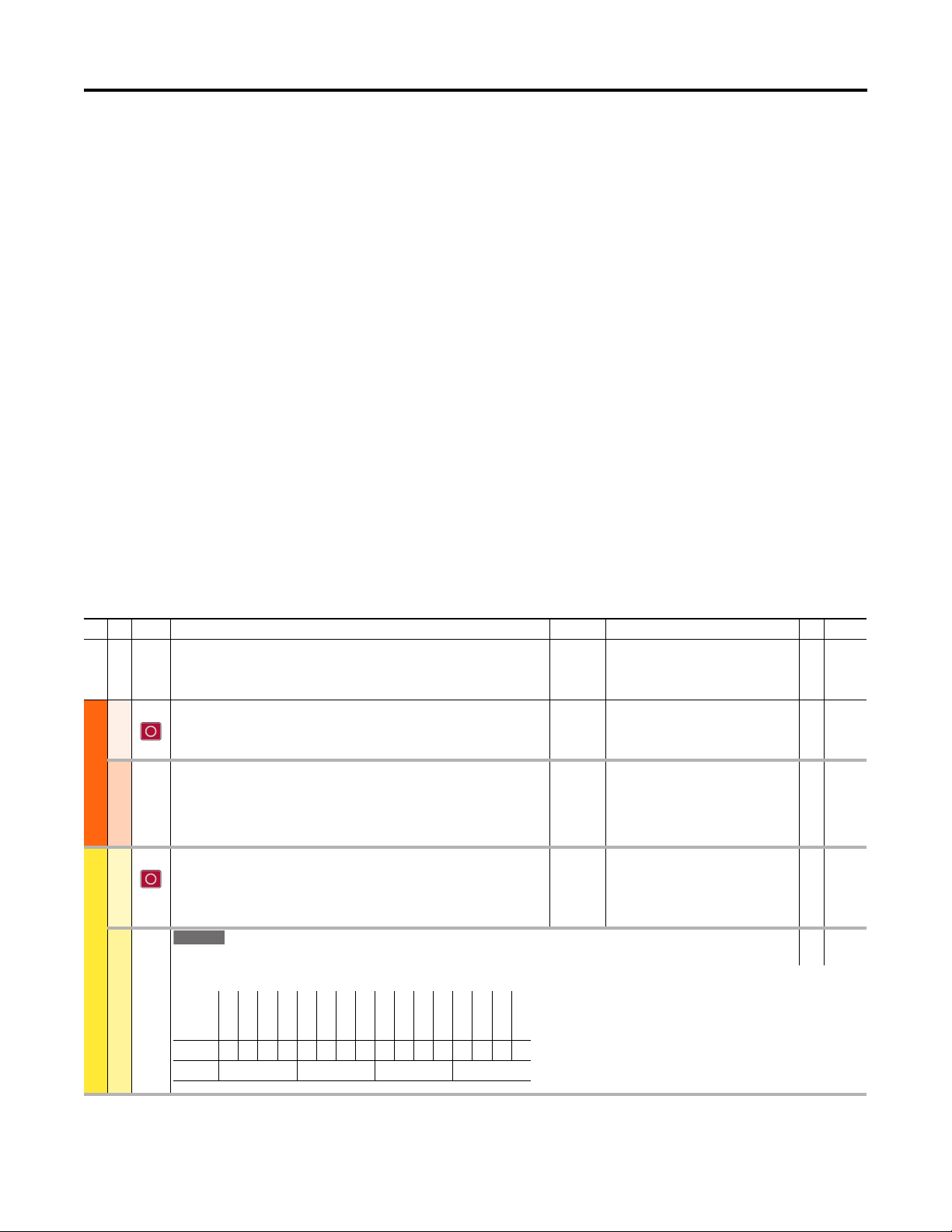

Drive Status Indicators

Table 1 - PowerFlex 753 Status Indicator Descriptions

Name Color State Description

STS

(Status)

Green Flashing Drive ready but not running, and no faults are present.

Steady Drive running, no faults are present.

Yellow Flashing Drive is not running, a start inhibit condition exists and the drive cannot be started.

Steady A t ype 1 (user configurable) alarm exists. If the drive is stopped, it is prevented from

Red Flashing A major fault has occurred. Drive will stop. Drive cannot be started until fault

Steady A non-resettable fault has occurred.

Red /

Yellow

Yellow /

Green

Green /

Red

Flashing

Alternately

Flashing

Alternately

Flashing

Alternately

See parameter 933

starting until the alarm condition is cleared. If the drive is running, it continues to

run but cannot restart until the alarm condition is cleared.

See parameters 959

condition is cleared. See parameter 951

A minor fault has occurred. When running, the drive continues to run. System is

brought to a stop under system control. Fault must be cleared to continue. Use

parameter 950

When running, a type 1 alarm exists.

See parameters 959

Drive is flash updating.

[Start Inhibits].

[Alarm Status A] and 960 [Alarm Status B].

[Last Fault Code].

[Minor Flt Cfg] to enable. If not enabled, acts like a major fault.

[Alarm Status A] and 960 [Alarm Status B].

Table 2 - PowerFlex 755 Status Indicator Descriptions

Name Color State Description

STS

(Status)

ENET Unlit Off Embedded EtherNet/IP is not properly connected to the network or needs an IP

LINK Unlit Off Adapter is not powered or is not transmitting on the network.

Green Flashing Drive ready but not running, and no faults are present.

Steady Drive running, no faults are present.

Yellow Flashing Drive is not running, a type 2 (non-configurable) alarm condition exists and the

Steady A type 1 (user configurable) alarm exists. If the drive is stopped, it is prevented from

Red Flashing A major fault has occurred. Drive will stop. Drive cannot be started until fault

Steady A non-resettable fault has occurred.

Red /

Yellow

Yellow /

Green

Green /

Red

Red Flashing An EtherNet/IP connection has timed out.

Red /

Green

Green Flashing Adapter is properly connected but is not communicating with any devices on the

Green Flashing Adapter is properly connected and transmitting data packets on the network.

Flashing

Alternately

Flashing

Alternately

Flashing

Alternately

Steady Adapter failed the duplicate IP address detection test.

Flashing

Alternately

Steady Adapter is properly connected and communicating on the network.

Steady Adapter is properly connected but is not transmitting on the network.

drive cannot be star ted. See parameter 961

starting until the alarm condition is cleared. If the drive is running, it continues to

run but cannot restart until the alarm condition is cleared.

See parameters 959 [Alar m Status A] and 960 [Alarm Stat us B].

condition is cleared. See parameter 951

A minor fault has occurred. When running, the drive continues to run. System is

brought to a stop under system control. Fault must be cleared to continue. Use

parameter 950 [Minor Flt Cfg] to enable. If not enabled, acts like a major fault.

When running, a type 1 alarm exists.

See parameters 959

Drive is flash updating.

address.

Adapter is performing a self-test.

network.

[Alarm Stat us A] and 960 [Alarm Status B].

[Type 2 Alarms].

[Last Fault Code].

18 Rockwell Automation Publication 750-PM001J-EN-P - October 2014

Page 19

Start Up Chapter 1

IMPORTANT

IMPORTANT

IMPORTANT

The Status Indicator LEDs on the HIM cradle do not indicate the current status of an

installed Communication Adapter option. If an optional Communication Adapter is

installed, refer to that option’s user manual for a description of LED location and

indication.

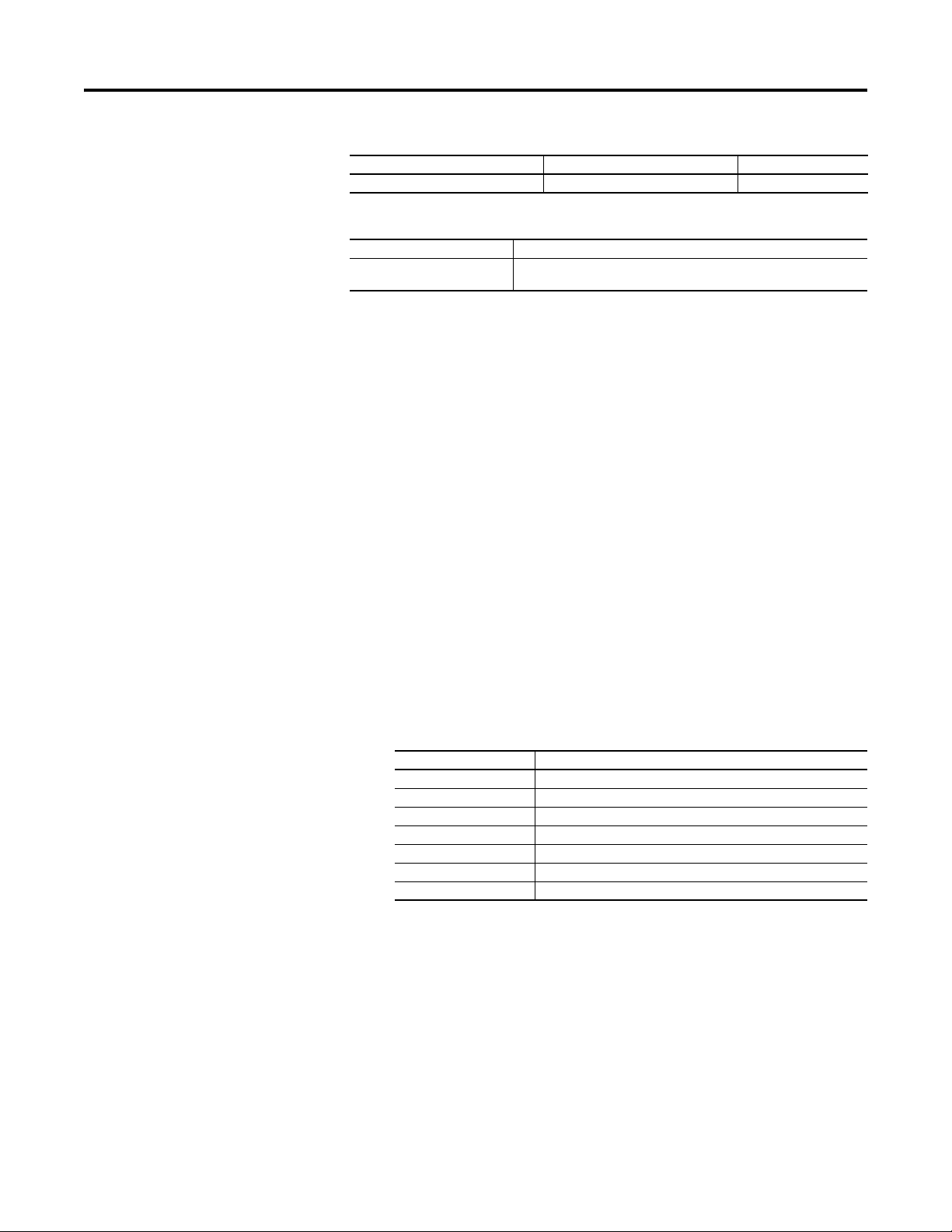

Establishing A Connection With EtherNet/IP

There are three methods for configuring the embedded EtherNet/IP adapter’s IP

address:

• Adapter Rotary Switches – Use the switches when working on a simple,

isolated network (for example, 192.168.1.xxx) that has other products

with switches to set their IP addresses, does not need to be accessed from

outside the network, and you prefer a simplified node addressing method.

The three adapter switches are read when the drive powers up, and

represent three decimal digits from top to bottom (see Figure 2

). If set to a

valid address (001-254), the adapter will use that value as the lower octet of

its IP address (192.168.1.xxx, where xxx = rotary switch settings), along

with a subnet mask of 255.255.255.0 and there will be no gateway

configured. Also, the setting for adapter P36 [BOOTP] is automatically

ignored.

See Figure 2

and its accompanying table for all possible switch settings and

their related descriptions.

When using the adapter rotary switches, set the IP address before power is applied

because the adapter uses the IP address it detects when it first receives power.

•BOOTP Server – Use BOOTP if you prefer to control the IP addresses of

devices using a server. The IP address, subnet mask, and gateway addresses

will then be provided by the BOOTP server.

•Adapter Parameters – Use adapter parameters when you want more

flexibility in setting up the IP address, or need to communicate outside the

control network using a gateway. The IP address, subnet mask, and

gateway addresses will then come from the adapter parameters you set.

Regardless of the method used to set the adapter’s IP address, each node on the

EtherNet/IP network must have a unique IP address. To change an IP address, you

must set the new value and then remove and reapply power to (or reset) the adapter.

Rockwell Automation Publication 750-PM001J-EN-P - October 2014 19

Page 20

Chapter 1 Start Up

Ones

Posi tion

Hundreds

Posi tion

Ten s Po si tio n

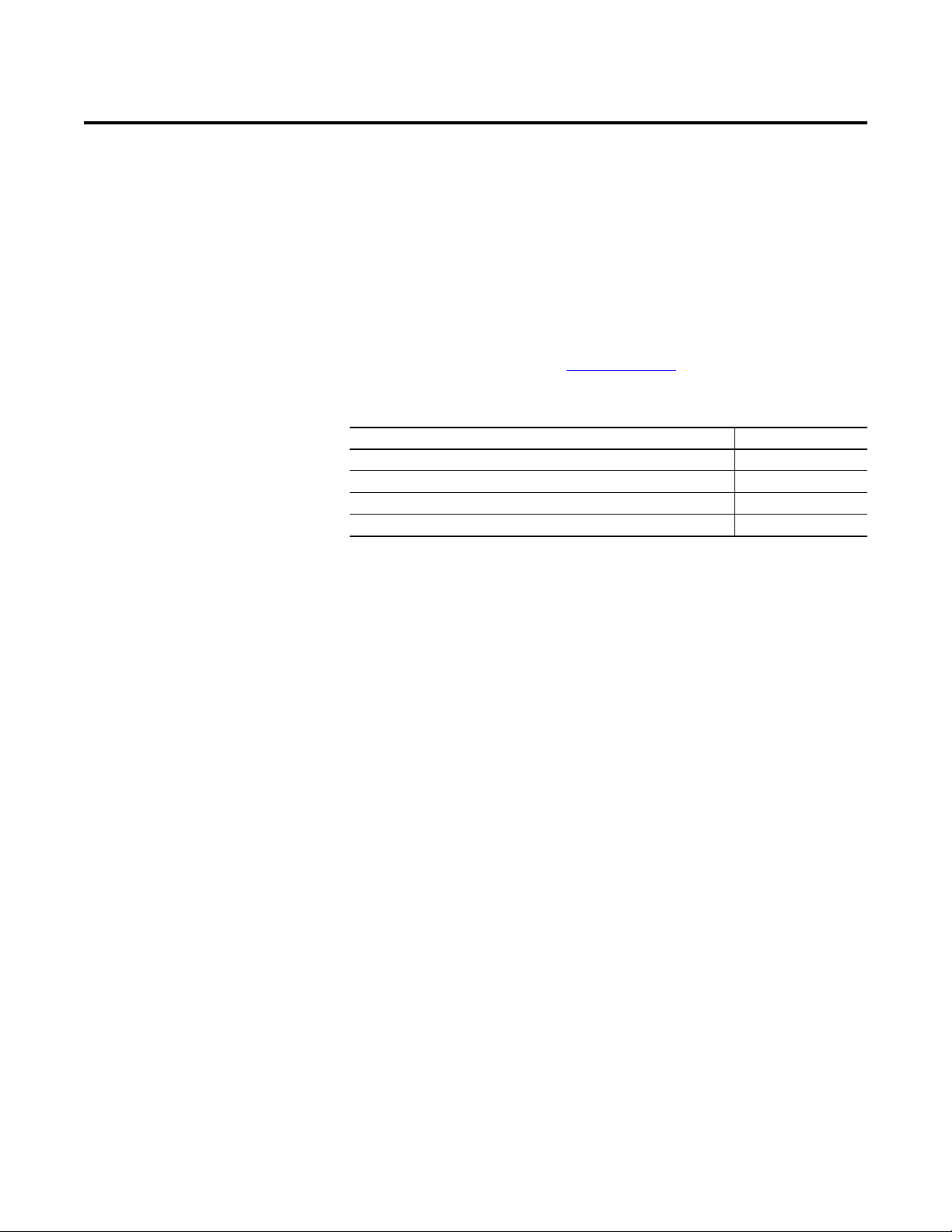

Figure 2 - Setting the IP Address Switches

5

6

4

7

3

8

2

9

1

0

5

6

4

7

3

8

2

9

1

0

5

6

4

7

3

8

2

9

1

0

Possible Settings Description

000 Adapter will use, depending on P36 [BOOTP], the BOOTP setting or the adapter parameter

001…254 Adapter will use the rotary switch settings for the IP address (192.168.1.xxx, where xxx =

255…887 Adapter will use, depending on P36 [BOOTP], the BOOTP setting or the adapter parameter

888 Resets the adapter IP address function to factory defaults. Thereafter, the drive must be

889…998 Adapter will use, depending on P36 [BOOTP], the BOOTP setting or the adapter parameter

999

(default settings)

settings for the IP address.

rotary switch settings).

settings for the IP address.

powered down, the switches set to a setting other than 888, and then the drive must be

powered up again to accept the new address.

settings for the IP address.

Disables the rotary switches. Adapter will use, depending on P36 [BOOTP], the BOOTP

setting or the adapter parameter settings for the IP address.

20 Rockwell Automation Publication 750-PM001J-EN-P - October 2014

Page 21

Chapter 2

Parameter Organization

This chapter lists and describes the PowerFlex 750-Series Port 0 drive parameters.

The parameters can be programmed (viewed/edited) using a Human Interface

Module (HIM). Refer to Enhanced PowerFlex 7-Class Human Interface Module

(HIM) User Manual, publication 20HIM-UM001

HIM to view and edit parameters. As an alternative, programming can also be

performed using DriveTools™ software and a personal computer.

Top ic Pag e

About Parameters 22

Parameter Access Level 23

How Drive Parameters are Organized 24

How Option Module Parameters are Organized 45

, for information on using the

Rockwell Automation Publication 750-PM001J-EN-P - October 2014 21

Page 22

Chapter 2 Paramete r Organ ization

753

Options

Reserved

Reserved

Reserved

Reserved

Reserved

Reserved

Reserved

Reserved

Reserved

Reserved

Reserved

Reserved

Reserved

Digital In 2

Digital In 1

Digital In 0

Default0000000000000000

Bit 1514131211109876543210

0 = Condition False

1 = Condition True

About Parameters

To configure a drive module to operate in a specific way, certain drive parameters

may have to be configured appropriately. Three types of parameters exist:

•Numeric Parameters

These parameters have a single numeric value (such as 1750.0 RPM).

•ENUM Parameters

These parameters allow a selection from 2 or more items. The LCD HIM

will display a text message for each item.

•Indirect Parameters

These parameters, represented by a maximum value of 159999 or

159999.15, are used to create assignments or to select either a data source

or destination. The first two digits are used to select a port. The next four

digits select a parameter number. If applicable, the two digits following the

decimal point select a bit. For example, to assign an I/O option module in

port 4 using a run contact on digital input 0, parameter 163 [DI Run] is set

to 040001.00.

•Bit Parameters

These parameters have individual bits associated with features or

conditions. If the bit is 0, the feature is off or the condition is false. If the

bit is 1, the feature is on or the condition is true.

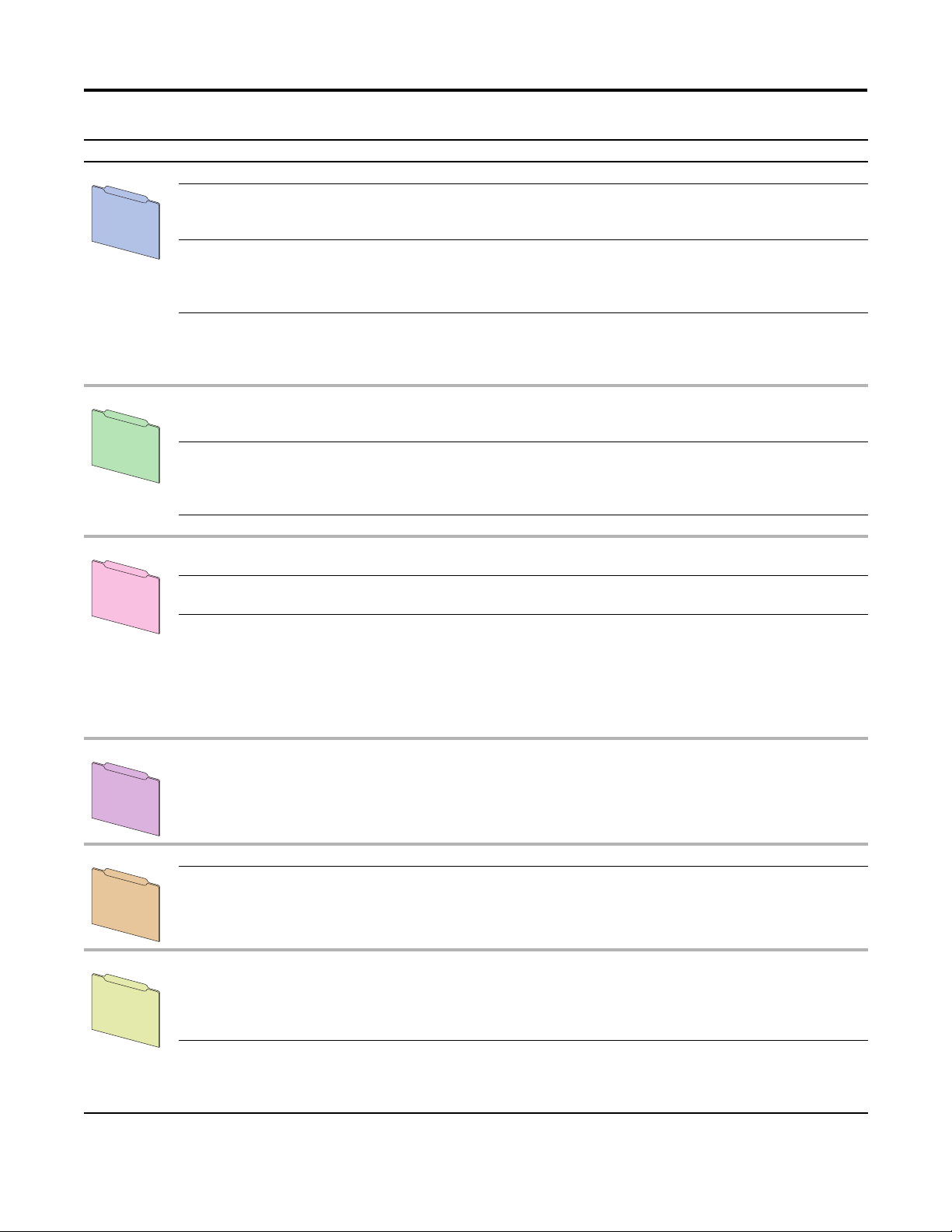

The following table shows how each parameter type is presented in this manual.

Table 3 - Table Explan ation

➊➋ ➌

No. Display Name

Full Na me

Description

28 Motor NP RPM

Motor Nameplate Revolutions Per Minute

Motor Data

MOTOR CONTROL

Vector Regulator

Digin Functions

FEEDBACK & I/O

Digital Inputs

Rated RPM shown on the motor nameplate.

107 Trq Adapt En

Tor que Ad apt io n En ab le

Enables or disables the adaptive torque calculation. This selec tion is active only in motor

control mode flux vector induction (P35 [Motor Ctrl Mode] = 3 “Induction FV”).

164 DI Run Forward

Digital Input Run Forward

Assigns a digital input used to run the drive (2 wire control) and command forward

direction.

220 Digital In Sts

Digital Input Status

Status of the digital inputs resident on the main control board (Port 0).

Values

Units:

Default:

Min/Max:

Default:

Options:

Default:

Min/Max:

RPM

1750.0

1.0 / 40000.0

1 = “Enabled”

0 = “Disabled”

1 = “Enabled”

0.00

0.00 / 159999.15

Read-Write

Data Type

RW Real

RW 32-bit

Integer

RW 32-bit

Integer

RO 16-bit

Integer

22 Rockwell Automation Publication 750-PM001J-EN-P - October 2014

Page 23

Param eter Organizat ion Chapter 2

753

755

755 (8+)

No. Name

Description

➊ File and Group organization

No. - Parameter Number

Parameter value cannot be changed until the drive is stopped.

Parameter cannot be set to DataLink In.

➋ Name - Parameter name as it appears in the DriveExecutive software.

Description - Brief description of parameter function. The first line is the full text parameter name.

= Parameter or option is specific to PowerFlex 753 drives only.

= Parameter or option is specific to PowerFlex 755 drives only.

= Parameter or option is specific to PowerFlex 755 Frame 8 drives and larger only.

➌ Value s - Define the various operating characteristics of the parameter. There are 3 types of Values.

ENUM Default: Lists the value assigned at the factory.

Options: Displays the selections available.

Bit Default: Lists the value assigned at the factory.

Options: Displays the selections available.

Numeric Default Lists the value assigned at the factory.

Min/Max. Displays lowest possible setting/Displays highest possible setting.

Indicates if parameter is read-write or read-only.

RW = Read-Write

RO = Read Only

Indicates parameter data type (i.e. integer, floating point, boolean). 32-bit Integer

Read-Write Data Type

RW

RO

Parameter Access Level

Three parameter access level options are selectable by P301 [Access Level].

• Option 0 “Basic” is the most limited view that only displays commonly

utilized parameters and options.

• Option 1 “Advanced” is an expanded view that may be required to access

more advanced drive features.

• Option 2 “Expert” provides a comprehensive view of the drive’s entire

parameter set.

Rockwell Automation Publication 750-PM001J-EN-P - October 2014 23

Page 24

Chapter 2 Paramete r Organ ization

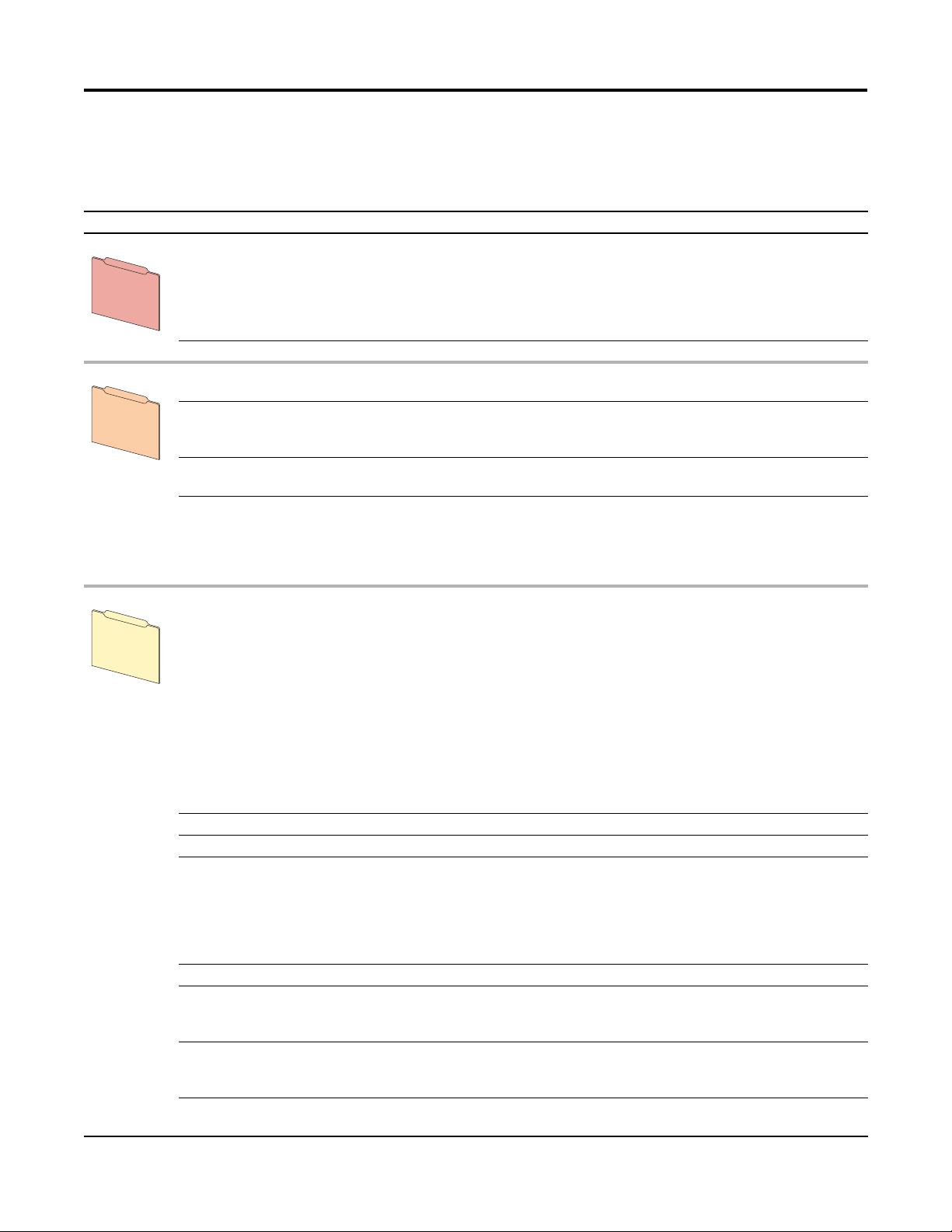

How Drive Parameters are Organized

DriveExecutive programming software displays parameters in “Linear List” or

“File Group Parameter” format. Viewing the parameters in “File Group

Parameter” format simplifies programming by grouping parameters that are used

for similar functions. There are eleven files. Each file is divided into multiple

groups of parameters.

Drive (Port 0) parameter descriptions begin on page 51

Basic Parameter View (Port 0)

Parameter 301 [Access Level] set to option 0 “Basic.”

File Group Parameters

Monitor Metering O utput Frequency 1

Monitor

Drive Data Rated Volts 20 Rated Amps 21 Rated kW 22

Motor Control Motor Data Motor NP Volts 25

Motor Control

Mtr Ctrl Options Motor Ctrl Mode 35 Maximum Voltage 36

Volt s per Hert z VHz Curv e 65

Autotune Autot une 70 Autotun e Torque 71 IPM_Lg_25_pc t 1630

Feedback & I/O Digin Functions Digital In Cfg 150

Feedback and IO

Control Board IO

Digital Inputs

753

Digital Outputs

753

Motor PTC

Analog Inputs

753

Analog Outputs

Commanded SpdRef 2

Mtr Vel Fdbk 3

Commanded Trq 4

Motor NP Amps 26

DI Enable 155

DI Clear Fault 156

DI Aux Fault 157

DI Stop 158

DI Cur Lmt Stop 159

DI Coast Stop 160

755

Digital In Sts 220

Digital In Sts 220 Dig In Filt Mask 222 Dig In Filt 223

753

Dig Out Sts 225

Dig Out Invert 226

PTC Cfg 250 PTC Status 251

Anlg In Type 255 Anlg In0 Value 260 Anlg In0 Hi 261 Anlg In0 Lo 262

753

Anlg Out Type 270 Anlg Out0 Sel 275 Anlg Out0 Data 277

Tor que C ur F dbk 5

Flux Cur Fdbk 6

Output Current 7

Output Voltage 8

Motor NP Hertz 27

Motor NP RPM 28

Maximum Freq 37

DI Start 161

DI Fwd Reverse 162

DI Run 163

DI Run Forward 164

DI Run Reverse 165

RO0 Sel 230

RO0 Level Sel 231

RO0 Level 232

RO0 Level CmpSts 233

.

Output Power 9

DC Bus Volts 11

Mtr NP Pwr Units 29

Motor NP Power 30

PWM Frequency 38 IPM Stc OfsTst K

IPM_Lg_50_pct 1631

IPM_Lg_75_pct 1632

IPM_Lg_100_pct 1633

IPM_Lg_125_pct 1634

DI Jog 1 166

DI Jog 1 Forward 167

DI Jog 1 Reverse 168

DI Jog 2 169

DI Jog 2 Forward 170

DI Jog 2 Reverse 171

TO0 S el 240

TO0 Leve l Sel 241

TO0 Leve l 242

TO0 Level CmpSts 243

Anlg Out0 DataHi 278

Anlg Out0 DataLo 279

Motor Poles 31

(1) Frames 1…7 Only

IPM_Ld_0_pct 1635

IPM_Ld_100_pct 1636

DI Manual Ctrl 172

DI Speed Sel 0 173

DI Speed Sel 1 174

DI Speed Sel 2 175

DI HOA Start 176

DI Accel 2 179

DI Decel 2 180

Anlg Out0 Hi 280

Anlg Out0 Lo 281

Anlg Out0 Val 282

(1)

1660

24 Rockwell Automation Publication 750-PM001J-EN-P - October 2014

Page 25

File Group Parameters

Drive Cfg Preferences Speed Units 300 Access Level 301 Language 302

Drive Cong

Control Cfg Voltage Class 305

SpdTrqPsn Mode A 309

Duty Rating 306

Direction Mode 308

Auto Manual Ctrl Logic Mask 324

Auto Mask 325

Manual Cmd Mask 326

Alt Man Ref Sel 328

Alt Man Ref AnHi 329

Alt Man Ref AnLo 330

Manual Preload 331

Manual Ref Mask 327

Braking Features Stop Mode A 370

Stop Mode B 371

Bus Reg Mode A 372

Bus Reg Mode B 373

Protection Motor Overload Motor OL Actn 410

Protection

Mtr OL at Pwr Up 411

DB Resistor Type 382

DB Ext Ohms 383

DB Ext Watts 384

DB ExtPulseWatts 385

Mtr OL Factor 413

Mtr OL Hertz 414

Stop Dwell Time 392

Dec Inhibit Actn 409

Mtr OL Reset Lvl 415

MtrOL Reset Time 416

Mtr OL Alarm Lvl 412

Load Limits Current Lmt Sel 421

Current Limit 1 422

Shear Pin Cfg 434

Shear Pin 1 Actn 435

Shear Pin1 Level 436

Shear Pin 1 Time 437

Power Loss Power Loss Actn 449 Pwr Loss Mode A 450

Speed Control Speed Limits Max Fwd Speed 520

Speed Control

Max Rev Speed 521

Speed Ramp Rates Accel Time 1 535

Accel Time 2 536

Speed Reference Spd Ref A Sel 545

Spd Ref A Stpt 546

Spd Ref A AnlgHi 547

Spd Ref A AnlgLo 548

Torque Control Torque Reference Trq Ref A Sel 675

Torq ue Con tro l

Trq Ref A Stpt 676

Trq Ref A AnlgHi 677

Trq Ref A AnlgLo 678

Trq Ref A Mult 679

Min Fwd Speed 522

Min Rev Speed 523

Decel Time 1 537

Decel Time 2 538

Spd Ref B Sel 550

Spd Ref B Stpt 551

Spd Ref B AnlgHi 552

Spd Ref B AnlgLo 553

Trq Ref B Se l 68 0

Trq Ref B Stpt 681

Trq Ref B An lgH i 682

Trq Ref B An lgL o 68 3

Trq Ref B Mult 684

Jog Acc Dec Time 539

Jog Speed 1 556

Jog Speed 2 557

MOP Init Select 566

MOP Init Stpt 567

Selected Trq Ref 685

Param eter Organizat ion Chapter 2

Preset Speed 1 571

Preset Speed 2 572

Preset Speed 3 573

Preset Speed 4 574

Preset Speed 5 575

Preset Speed 6 576

Preset Speed 7 577

Communication Comm Control Port 1 Reference 871

Communication

DPI Datalinks Data In A1 895

Data In A2 896

Data In B1 897

Data In B2 898

Diagnostics Status Speed Ref Source 930

Diagnostics

Last StartSource 931

Last Stop Source 932

Start Inhibits 933

Last StrtInhibit 934

Fault/Alarm Info Minor Flt Cfg 950

Last Fault Code 951

Fault Status A 952

Fault Status B 953

Rockwell Automation Publication 750-PM001J-EN-P - October 2014 25

Data In C1 899

Data In C2 900

Data In D1 901

Data In D2 902

Drive Status 1 935

Drive Status 2 936

Condition Sts 1 937

Data Out A1 905

Data Out A2 906

Data Out B1 907

Data Out B2 908

Data Out C1 909

Data Out C2 910

Data Out D1 911

Data Out D2 912

Page 26

Chapter 2 Paramete r Organ ization

Advanced Parameter View (Port 0)

Parameter 301 [Access Level] set to option 1 “Advanced.”

File Group Parameters

Monitor Metering O utput Frequency 1

Monitor

Drive Data R ated Volts 20 Rated Amps 21 Rated kW 22

Motor Control Motor Data Motor NP Volts 25

Motor Control

Mtr Ctrl Options Motor Ctrl Mode 35 Maximum Voltage 36

Volts per Hertz Start Acc Boost 60

Autotune Au totune 70

Feedback & I/O Digin Functions Digital In Cfg 150

Feedback and IO

Control Board IO

Digital Inputs

753

Digital Outputs

753

Motor PTC

Analog Inputs

753

Analog Outputs

R0 Predict Main

Commanded SpdRef 2

Mtr Vel Fdbk 3

Commanded Trq 4

Motor NP Amps 26

Run Boost 61

Autotune Torque 71

IR Voltage Drop 73

Ixo Voltage Drop 74

Flux Current Ref 75

DI Enable 155

DI Clear Fault 156

DI Aux Fault 157

DI Stop 158

DI Cur Lmt Stop 159

DI Coast Stop 160

DI Start 161

DI Fwd Reverse 162

DI Run 163

DI Run Forward 164

DI Run Reverse 165

755

Digital In Sts 220

Digital In Sts 220 Dig In Filt Mask 222 Dig In Filt 223

753

Dig Out Sts 225

Dig Out Invert 226

Dig Out Setpoint 227

PTC Cfg 250 PTC Status 251

Anlg In Type 255

Anlg In Sqrt 256

Anlg In Loss Sts 257

753

Anlg Out Type 270

Anlg Out Abs 271

753

RO PredMaint Sts 285

RO0 Load Type 286

Torque Cur Fdbk 5

Flux Cur Fdbk 6

Output Current 7

Output Voltage 8

Output Power 9

Output Powr Fctr 10

Motor NP Hertz 27

Motor NP RPM 28

Maximum Freq 37

PWM Frequency 38

Break Voltage 62

Break Frequency 63

Total Inertia 76

Inertia Test Lmt 77

DI Jog 1 166

DI Jog 1 Forward 167

DI Jog 1 Reverse 168

DI Jog 2 169

DI Jog 2 Forward 170

DI Jog 2 Reverse 171

DI Manual Ctrl 172

DI Speed Sel 0 173

DI Speed Sel 1 174

DI Speed Sel 2 175

DI HOA Start 176

DI MOP Inc 177

DI MOP Dec 178

RO0 Sel 230

RO0 Level Sel 231

RO0 Level 232

RO0 Level CmpSts 233

RO0 On Time 234

RO0 Off Time 235

Anlg In0 Value 260

Anlg In0 Hi 261

Anlg In0 Lo 262

Anlg Out0 Sel 275

Anlg Out0 Stpt 276

RO0 Load Amps 287

RO0 TotalLife 288

DC Bus Volts 11

DC Bus Memory 12

Elapsed MWH 13

Elapsed kWH 14

Elapsed Run Time 15

Mtr NP Pwr Units 29

Motor NP Power 30

Mtr Options Cfg 40

Flux Up Enable 43

Flux Up Time 44

VHz Curve 65

IPM_Lg_25_pct 1630

IPM_Lg_50_pct 1631

IPM_Lg_75_pct 1632

IPM_Lg_100_pct 1633

IPM_Lg_125_pct 1634

DI Accel 2 179

DI Decel 2 180

DI SpTqPs Sel 0 181

DI SpTqPs Sel 1 182

DI Stop Mode B 185

DI BusReg Mode B 186

DI PwrLoss ModeB 187

DI Pwr Loss 188

DI Precharge 189

DI Prchrg Seal 190

DI PID Enable 191

DI PID Hold 192

TO0 Sel 240

TO0 Level Sel 241

TO0 Level 242

TO0 Level CmpSts 243

TO0 On Time 244

TO0 Off Time 245

Anlg In0 LssActn 263

Anlg In0 Raw Val 264

Anlg Out0 Data 277

Anlg Out0 DataHi 278

Anlg Out0 DataLo 279

RO0 ElapsedLife 289

RO0 RemainLife 290

Elpsd Mtr MWHrs 16

Elpsd Rgn MWHrs 17

Elpsd Mtr kWHrs 18

Elpsd Rgn kWHrs 19

Motor Poles 31

(1)

IPM Stc OfsTst K

1660

(1) Frames 1…7 Only

IPM_Ld_0_pct 1635

IPM_Ld_100_pct 1636

DI PID Reset 193

DI PID Invert 194

DI Torque StptA 195

DI Fwd End Limit 196

DI Fwd Dec Limit 197

DI Rev End Limit 198

DI Rev Dec Limit 199

DI PHdwr OvrTrvl 200

DI NHdwr OvrTrvl 201

Anlg In0 Filt Gn 265

Anlg In0 Filt BW 266

Anlg Out0 Hi 280

Anlg Out0 Lo 281

Anlg Out0 Val 282

RO0 LifeEvntLvl 291

RO0 LifeEvntActn 292

26 Rockwell Automation Publication 750-PM001J-EN-P - October 2014

Page 27

File Group Parameters

Drive Cfg Preferences Speed Units 300 Access Level 301 Language 302

Drive Cong

Control Cfg Voltage Class 305

Duty Rating 306

Direction Mode 308

SpdTrqPsn Mode A 309

SpdTrqPsn Mode B 310

SpdTrqPsn Mode C 311

Actv SpTqPs Mode 313

SLAT Err Stpt 314

SLAT Dwell Time 315

SpdTrqPsn Mode D 312

Auto Manual Ctrl Logic Mask 324

Auto Mask 325

Manual Cmd Mask 326

Alt Man Ref Sel 328

Alt Man Ref AnHi 329

Alt Man Ref AnLo 330

Manual Preload 331

Manual Ref Mask 327

Drive Memory Reset Meters 336

Start Features Start At PowerUp 345

PowerUp Delay 346

Auto Retry Fault 347

Auto Rstrt Tries 348

Auto Rstrt Delay 349

Sleep Wake Mode 350

SleepWake RefSel 351

Sleep Level 352

Sleep Time 353

Wake Level 354

FlyingStart Mode 356

Wake Time 355

Braking Features Stop Mode A 370

Stop Mode B 371

Bus Reg Mode A 372

Bus Reg Mode B 373

Bus Reg Lvl Cfg 374

Bus Reg Level 375

Protection Motor Overload Motor OL Actn 410

Protection

Mtr OL at Pwr Up 411

DB Resistor Type 382

DB Ext Ohms 383

DB Ext Watts 384

DB ExtPulseWatts 385

Flux Braking En 388

Flux Braking Lmt 389

Mtr OL Factor 413

Mtr OL Hertz 414

Stop Dwell Time 392

DC Brake Lvl Sel 393

DC Brake Level 394

DC Brake Time 395

Mtr OL Reset Lvl 415

MtrOL Reset Time 416

Mtr OL Alarm Lvl 412

Load Limits Drive OL Mode 420

Current Lmt Sel 421

Current Limit 1 422

Current Limit 2 423

Active Cur Lmt 424

Current Rate Lmt 425

Regen Power Lmt 426

Power Loss Power Loss Actn 449 Pwr Loss Mode A 450

Motor Power Lmt 427 Shear Pin Cfg 434

Shear Pin 1 Actn 435

Shear Pin1 Level 436

Shear Pin 1 Time 437

Shear Pin 2 Actn 438

Shear Pin2 Level 439

Shear Pin 2 Time 440

Pwr Loss Mode B 453

Pwr Loss A Level 451

Pwr Loss A Time 452

Pwr Loss B Leve l 454

Pwr Loss B Time 455

Ground Fault Ground Warn Actn 466

Ground Warn Lvl 467

Predictive Main PredMaint Sts 469

PredMaintAmbTemp 470

PredMaint Rst En 471

PredMaint Reset 472

CbFan Derate

755 (8+)

CbFan TotalLife

CbFan ElpsdLife

CbFan RemainLife

CbFan EventLevel

CbFan EventActn

755 (8+)

755 (8+)

755 (8+)

755 (8+)

755 (8+)

481

482

483

484

485

486

HSFan Derate 488

HSFan TotalLife 489

HSFan ElpsdLife 490

HSFan RemainLife 491

HSFan EventLevel 492

HSFan EventActn 493

HSFan ResetLog

(1)

InFan Derate 495

InFan TotalLife 496

InFan ElpsdLife 497

MtrBrngTotalLife 502

MtrBrngElpsdLife 503

MtrBrngRemainLif 504

MtrBrngEventLvl 505

MtrBrngEventActn 506

MtrBrng ResetLog 507

494

MtrLubeElpsdHrs 508

MtrLubeEventLvl 509

MtrLubeEventActn 510

InFan RemainLife 498

InFan EventLevel 499

InFan EventActn 500

InFan ResetLog 501

(1) 755 Frames 1…7 only.

Param eter Organizat ion Chapter 2

Prchrg Control 321

Prchrg Delay 322

Prchrg Err Cfg 323

Brake Off Adj 1 402

Brake Off Adj 2 403

Dec Inhibit Actn 409

Mtr OL Counts 418

Mtr OL Trip Time 419

Load Loss Action 441

Load Loss Level 442

Load Loss Time 443

OutPhaseLossActn 444

Out PhaseLossLvl 445

UnderVltg Action 460

UnderVltg Level 461

InPhase LossActn 462

InPhase Loss Lvl 463

DC Bus Mem Reset 464

MchBrngTotalLife 511

MchBrngElpsdLife 512

MchBrngRemainLif 513

MchBrngEventLvl 514

MchBrngEventActn 515

MchBrngResetLog 516

MchLubeElpsdHrs 517

MchLube EventLvl 518

MchLubeEventActn 519

Rockwell Automation Publication 750-PM001J-EN-P - October 2014 27

Page 28

Chapter 2 Paramete r Organ ization

File Group Parameters

Speed Control Speed Limits Max Fwd Speed 520

Speed Control

Max Rev Speed 521

Speed Ramp Rates Accel Time 1 535

Accel Time 2 536

Speed Reference Spd Ref A Sel 545

Spd Ref A Stpt 546

Spd Ref A AnlgHi 547

Spd Ref A AnlgLo 548

Spd Ref A Mult 549

Spd Ref B Sel 550

Spd Ref B Stpt 551

Spd Ref B AnlgHi 552

Spd Ref B AnlgLo 553

Spd Ref B Mult 554

Sp eed Trim Tr im R ef A Sel 6 00

Trim Ref A Stpt 601

Trim RefA AnlgHi 602

Trim RefA AnlgLo 603

Slip/Droop Comp Droop RPM at FLA 620

Slip RPM at FLA 621

Slip Comp BW 622

Speed Regulator Spd Options Ctrl 635

Speed Reg BW 636

Filtered SpdFdbk 640

Speed Error 641

Speed Comp Speed Comp Sel 665

Speed Comp Gain 666

Speed Comp Out 667

Torque Control Torq ue Li mit s Pos Torqu e Lim it 670

Torq ue Con tro l

Neg Torque Limit 671

Torque Reference Trq Ref A Sel 675

Trq Ref A Stpt 676

Trq Ref A AnlgHi 677

Trq Ref A AnlgLo 678

Trq Ref A Mult 679

Inertia Comp

755

Inertia Adaption

Inertia CompMode 695 Inertia Acc Gain 696

755

InAdp LdObs Mode 704

Inertia Adapt BW 705

InertiaAdaptGain 706

Frictio n Comp

755

FrctnComp Mode 1560

FrctnComp Trig 1561

Min Fwd Speed 522

Min Rev Speed 523

Decel Time 1 537

Decel Time 2 538

Spd Ref Scale 555

Jog Speed 1 556

Jog Speed 2 557

MOP Reference 558

Save MOP Ref 559

MOP Rate 560

MOP High Limit 561

MOP Low Limit 562

MOP Init Select 566

MOP Init Stpt 567

Trim Ref B Sel 604

Trim Ref B Stpt 605

Trim RefB AnlgHi 606

Trim RefB AnlgLo 607

Speed Reg Kp 645

Speed Reg Max Kp 646

Speed Reg Ki 647

Trq Ref B Sel 680

Trq Ref B Stpt 681

Trq Ref B AnlgHi 682

Trq Ref B AnlgLo 683

Trq Ref B Mult 684

Inertia Dec Gain 697

Load Estimate 707

InertiaTrqAdd 708

FrctnComp Hyst 1562

FrctnComp Time 1563

Overspeed Limit 524

Zero Speed Limit 525

Skip Speed 1 526

Skip Speed 2 527

Skip Speed 3 528

Skip Speed Band 529

Jog Acc Dec Time 539 S Curve Accel 540

S Curve Decel 541

DI ManRef Sel 563

DI ManRef AnlgHi 564

DI ManRef AnlgLo 565

Preset Speed 1 571

Preset Speed 2 572

Preset Speed 3 573

Preset Speed 4 574

Preset Speed 5 575

Preset Speed 6 576

Preset Speed 7 577

TrmPct RefA Sel 608

TrmPct RefA Stpt 609

TrmPct RefA AnHi 610

TrmPct RefA AnLo 611

Spd Loop Damping 653

Spd Reg Int Out 654

TrmPct RefB Sel 612

TrmPct RefB Stpt 613

TrmPct RefB AnHi 614

TrmPct RefB AnLo 615

VHzSV Spd Reg Kp 663

VHzSV Spd Reg Ki 664

Spd Reg Pos Lmt 655

Spd Reg Neg Lmt 656

SReg Output 660

Selected Trq Ref 685 Torque Step 686

Filtered Trq Ref 689

Limited Trq Ref 690

Inert Comp LPFBW 698

Ext Ramped Ref 700

Inertia Comp Out 699

IA LdObs Delay 709

Load Observer BW 711

InertAdptFltrBW 710

FrctnComp Stick 1564

FrctnComp Slip 1565

FrctnComp Rated 1566

FrctnComp Out 1567

28 Rockwell Automation Publication 750-PM001J-EN-P - October 2014

Page 29

File Group Parameters

Posit ion Cont rol Position Cfg/Sts PTP PsnRefStatus 720

Position Control

Position Control 721

Position Homing Homing Status 730

Homing Control 731

755

Position Watch

PsnWatch1 Select 745

PsnWatch1 DtctIn 746

PsnWatch1 Stpt 747

Interpolator

755

Interp Control 755 Interp Psn Input 756

Direct Psn Ref Select 765 Psn Direct Stpt 766

Point to Point PTP Control 770

PTP Mode 771

DI Indx Step 772

DI Indx StepRev 773

DI Indx StepPrst 774

755

Phase Lock Loop

PLL Control 795

PLL Ext Spd Sel 796

PLL Ext Spd Stpt 797

PLL Ext SpdScale 798

Electronic Gear Psn Ref EGR Out 815 Psn EGR Mult 816

Position Offset Psn Offset 1 Sel 820

Psn Offset 1 821

Ld Psn Fdbk Scal

755

LdPsn Fdbk Mult 825 LdPsn Fdbk Div 826

Position Reg Psn Error 835

Communication Comm Control Port 1 Reference 871

Communication

Port 2 Reference 872

Port 3 Reference 873

Security Port Mask Act 885

Logic Mask Act 886

DPI Datalinks Data In A1 895

Data In A2 896

Data In B1 897

Data In B2 898

Owners Stop Owner 919

Start Owner 920

Psn Selected Ref 722

Psn Command 723

DI Find Home 732

DI Redefine Psn 733

DI OL Home Limit 734

PsnWatch2 Select 748

PsnWatch2 DtctIn 749

PsnWatch2 Stpt 750

Interp Vel Input 757

Interp Trq Input 758

Psn Direct Ref 767

PTP Ref Sel 775

PTP Reference 776

PTP Feedback 777

PTP Ref Scale 778

PTP Index Preset 779

PLL Psn Ref Sel 799

PLL Psn Stpt 800

PLL BW 801

PLL LPFilter BW 802

PLL Virt Enc RPM 803

Psn EGR Div 817

Psn Offset 2 Sel 822

Psn Offset 2 823

Psn Actual 836

Psn Load Actual

755

837

Psn Reg Ki 838

Psn Reg Kp 839

Port 4 Reference 874

Port 5 Reference 875

Port 6 Reference 876

Write Mask Act 887

Write Mask Cfg 888

Data In C1 899

Data In C2 900

Data In D1 901

Data In D2 902

Jog Owner 921

Dir Owner 922

Param eter Organizat ion Chapter 2

Psn Reg Status 724

Zero Position 725

Find Home Speed 735

Find Home Ramp 736

Interp Psn Out 759

Interp Vel Out 760

Interp Trq Out 761

PTP Setpoint 780

PTP Accel Time 781

PTP Decel Time 782

PTP Speed FwdRef 783

PTP Command 784

PLL EPR Input 804

PLL Rvls Input 805

PLL Psn Out Fltr 806

PLL Speed Out 807

PLL Speed OutAdv 808

Psn Offset Vel 824

PReg Pos Int Lmt 840

PReg Neg Int Lmt 841

PsnReg IntgrlOut 842

PsnReg Spd Out 843

Port13 Reference

755

877

Port14 Reference 878

Data Out A1 905

Data Out A2 906

Data Out B1 907

Data Out B2 908

Clear Flt Owner 923

Manual Owner 924

In Pos Psn Band 726

In Pos Psn Dwell 727

Actual Home Psn 737

User Home Psn 738

PTP Fwd Vel Lmt 785

PTP Rev Vel Lmt 786

PTP S Curve 787

PTP Vel Override 788

PTP EGR Mult 789

PTP EGR Div 790

PLL Enc Out 809

PLL Enc Out Adv 810

PLL EPR Output 811

PLL Rvls Output 812

PReg Pos Spd Lmt 844

PReg Neg Spd Lmt 845

Psn Reg Droop 846

Psn Fdbk 847

Psn Gear Ratio 848

Drive Logic Rslt 879

DPI Ref Rslt 880

DPI Ramp Rslt 881

DPI Logic Rslt 882

Drive Ref Rslt 883

Drive Ramp Rslt 884

Data Out C1 909

Data Out C2 910

Data Out D1 911

Data Out D2 912

Ref Select Owner 925

Rockwell Automation Publication 750-PM001J-EN-P - October 2014 29

Page 30

Chapter 2 Paramete r Organ ization

File Group Parameters

Diagnostics Status Speed Ref Source 930

Diagnostics

Last StartSource 931

Last Stop Source 932

Start Inhibits 933

Last StrtInhibit 934

Fault/Alarm Info Minor Flt Cfg 950

Last Fault Code 951

Fault Status A 952

Fault Status B 953

755

Peak Detection

PkDtct Stpt Real 1035

PkDtct Stpt DInt 1036

PkDtct1 In Sel 1037

Applications Process PID PID Cfg 1065

Applications

PID Control 1066

PID Ref Sel 1067

PID Ref AnlgHi 1068

PID Ref AnlgLo 1069

PID Setpoint 1070

PID Ref Mult 1071

Tor que Pro ve

755

Trq Prove Cfg 1100

Trq Prove Setup 1101

DI FloatMicroPsn 1102

Trq Prove Status 1103

Fibers Function Fiber Control 1120

Fiber Status 1121

Sync Time 1122

Adjustable Vltg Adj Vltg Config 1131

Adj Vltg Selec t 1133

Adj Vltg Ref Hi 1134

Adj Vltg Ref Lo 1135

Pump Jack Rod Speed 1165

Rod Torque 1166

Rod Speed Cmd 1167

Pump Off Pump Off Config 1187

Pump Off Setup 1188

Pump Off Action 1189

Pump Off Control 1190

Pump Off Status 1191

Drive Status 1 935

Drive Status 2 936

Condition Sts 1 937

Drive OL Count 940

Status1 at Fault 954

Status2 at Fault 955

Fault Frequency 956

Fault Amps 957

Fault Bus Volts 958

PkDtct1PresetSel 1038

Peak1 Cfg 1039

Peak 1 Change 1040

PID Fdbk Sel 1072

PID Fdbk AnlgHi 1073

PID Fdbk AnlgLo 1074

PID FBLoss SpSel 1075

PID FBLoss TqSel 1076

PID Fdbk 1077

PID Fdbk Mult 1078

Trq Lmt SlewRate 1104

Speed Dev Band 1105

SpdBand Intgrtr 1106

Traverse Inc 1123

Traverse Dec 1124

Max Traverse 1125

Adj Vltg TrimSel 1136

Adj Vltg Trim Hi 1137

Adj Vltg Trim Lo 1138

Adj Vltg Command 1139

Adj Vltg AccTime 1140

Adj Vltg DecTime 1141

TorqAlarm Action 1168

TorqAlarm Config 1169

TorqAlarm Dwell 1170

TorqAlarm Level 1171

TorqAlm Timeout 1172

TorqAlarm TOActn 1173

Pump Cycle Store 1192

Set Top ofStroke 1193

Torque Setpoint 1194

Pump Off Level 1195

Pump Off Speed 1196

Pump Off Time 1197

IGBT Temp Pct 941

IGBT Temp C 942

At Limit Status 945

Safety Port Sts 946

Drive Temp Pct 943

Drive Temp C 944

Alarm Status A 959

Alarm Status B 960

AlarmA at Fault 962

AlarmB at Fault 963

Type 2 Alarms 961

PeakDetect1 Out 1041

PkDtct2 In Sel 1042

PkDtct2PresetSel 1043

PID Output Sel 1079

PID Output Mult 1080

PID Upper Limit 1081

PID Lower Limit 1082

PID Deadband 1083

PID LP Filter BW 1084

PID Preload 1085

Peak2 Cfg 1044

Peak 2 Change 1045

PeakDetect2 Out 1046

PID Prop Gain 1086

PID Int Time 1087

PID Deriv Time 1088

PID Status 1089

PID Ref Meter 1090

PID Fdbk Meter 1091

PID Error Meter 1092

PID Output Meter 1093

Brk Release Time 1107

Brk Set Time 1108

Brk Alarm Travel 1109

Brk Slip Count 1110

Float Tolerance 1111

MicroPsnScalePct 1112

ZeroSpdFloatTime 1113

755

Br ake Test To rq

1114

P Jump 1126 DI Fiber SyncEna 1129

DI Fiber TravDis 1130

Adj Vltg Preset1 1142

Adj Vltg Preset2 1143

Adj Vltg Preset3 1144

Adj Vltg Preset4 1145

Adj Vltg Preset5 1146

Adj Vltg Preset6 1147

Adj Vltg RefMult 1149

Adj Vltg Scurve 1150

Adj Vltg TrimPct 1151

Min Adj Voltage 1152

Dead Time Comp 1153

DC Offset Ctrl 1154

Adj Vltg Preset7 1148

Total Gear Ratio 1174

Max Rod Speed 1175

Max Rod Torque 1176

Min Rod Speed 1177

Motor Sheave 1178

PCP Pump Sheave 1180

Gearbox Limit 1181

Gearbox Rating 1182

Gearbox Ratio 1183

Gearbox Sheave 1184

OilWell Pump Cfg 1179

Pct Cycle Torque 1198

Pct Lift Torque 1199

Pct Drop Torque 1200

Stroke Pos Count 1201

Stroke Per Min 1202

Pump Off Count 1203

PumpOff SleepCnt 1204

Day Stroke Count 1205

DI PumpOff Disbl 1206

Pump OffSleepLvl 1207

30 Rockwell Automation Publication 750-PM001J-EN-P - October 2014

Page 31

File Group Parameters

Applications Profiling

Applications

755

Profile Status 1210

Units Traveled 1212

Profile Command 1213

Counts Per Unit 1215

ProfVel Override 1216

Prof DI Invert 1217

DI Hold Step 1218

DI Abort Step 1219

DI Abort Profile 1220

Camming

755

PCAM Control 1390

PCAM Mode 1391

PCAM Psn Select 1392

PCAM Psn Stpt 1393

PCAM Psn Ofst 1394

PCAM PsnOfst Eps 1395

Roll Position

755

Roll Psn Config 1500

Roll Psn Status 1501

RP Psn Fdbk Stpt 1502

RP Psn Fdbk Sel 1503

Tor que Bo ost

755

PsnTrqBst Ctrl 1515

PsnTrqBst Sts 1516

PsnTrqBst RefSel 1517

PsnTrqBstPsnOfst 1518

PsnTrqBst UNWCnt 1519

Variable Boost VB Config 1535

VB Status 1536

VB Voltage 1537

VB Time 1538

755

Spindle Orient

SO Config 1580

SO Status 1581

SO Setpoint 1582

SO Offset 1583

Id Compensation

755

Id Comp Enbl 1600

Id Comp Mtrng 1 1601

IdCompMtrng 1 Iq 1602

Id Comp Mtrng 2 1603

IdCompMtrng 2 Iq 1604

Id Comp Mtrng 3 1605

IdCompMtrng 3 Iq 1606

DI Vel Override 1221

DI StrtStep Sel0 1222

DI StrtStep Sel1 1223

DI StrtStep Sel2 1224

DI StrtStep Sel3 1225

DI StrtStep Sel4 1226

PCAM Span X 1396

PCAM Scale X 1397

PCAM Span Y 1398

PCAM ScaleY Sel 1399

PCAM ScaleYSetPt 1400

PCAM VelScaleSel 1401

PCAM VelScaleSP 1402

PCAM Slope Begin 1403

PCAM Slope End 1404

PCAM Main EndPnt 1405

PCAM Main Types 1406

Roll Psn Preset 1504

Roll Psn Offset 1505

RP EPR Input 1506

PsnTrqBst Ps X1 1520

PsnTrqBst Ps X2 1521

PsnTrqBst Ps X3 1522

PsnTrqBst Ps X4 1523

PsnTrqBst Ps X5 1524

VB Minimum 1539

VB Maximum 1540

VB Accel Rate 1541

VB Decel Rate 1542

SO EPR Input 1584

SO Rvls Input 1585

SO Rvls Output 1586

SO Cnts per Rvls 1587

Id Comp Mtrng 4 1607

IdCompMtrng 4 Iq 1608

Id Comp Mtrng 5 1609

IdCompMtrng 5 Iq 1610

Id Comp Mtrng 6 1611

IdCompMtrng 6 Iq 1612

Param eter Organizat ion Chapter 2

Step 1, 2, 3…16 Type 1230, 1240, 1250…1380

Step 1, 2, 3…16 Velocity 1231, 1241, 1251…1381

Step 1, 2, 3…16 Accel 1232, 1242, 1252…1382

Step 1, 2, 3…16 Decel 1233, 1243, 1253…1383

Step 1, 2, 3…16 Value 1234, 1244, 1254…1384

Step 1, 2, 3…16 Dwell 1235, 1245, 1255…1385

Step 1, 2, 3…16 Batch 1236, 1246, 1256…1386

Step 1, 2, 3…16 Next 1237, 1247, 1257…1387

Step 1, 2, 3…16 Action 1238, 1248, 1258…1388

Step 1, 2, 3…16 Dig In 1239, 1249, 1259…1389

PCAM Main Pt X 0, 1, 2…15 1407, 1409, 1411…1437

PCAM Main Pt Y 0, 1, 2…15 1408, 1410, 1412…1438

PCAM Aux EndPnt 1439

PCAM Aux Types 1440

PCAM Aux Pt X 1, 2, 3…15 1441, 1443, 1445…1469

PCAM Aux Pt Y 1, 2, 3…15 1442, 1444, 1446…1470

PCAM Status 1471

PCAM Vel Out 1472

PCAM Psn Out 1473

DI PCAM Start 1474

RP Rvls Input 1507

RP Rvls Output 1508

RP Unwind 1509

PsnTrqBst Trq Y2 1525

RP Unit Scale 1510

RP Psn Output 1511

RP Unit Out 1512

PsnTrqBst TrqOut 1528

PsnTrqBst Trq Y3 1526

PsnTrqBst Trq Y4 1527

VB Frequency 1543

VB Min Freq 1544

VB Flux Thresh 1545

VB Flux Lag Freq 154 6

VB Current Rate 1548

VB Current Hyst 1549

VB Cur Thresh 1550

VB Rate Lag Freq 1551

VB Filt Flux Cur 1547

SO Unit Scale 1588

SO Position Out 1589

SO Unit Out 1590

SO Accel Time 1591

SO Decel Time 1592

SO Fwd Vel Lmt 1593

SO Rev Vel Lmt 1594

Id Comp Regen 1 1613

IdCompRegen 1 Iq 1614

Id Comp Regen 2 1615

IdCompRegen 2 Iq 1616

Id Comp Regen 3 1617

IdCompRegen 3 Iq 1618

Id Comp Regen 4 1619

IdCompRegen 4 Iq 1620

Id Comp Regen 5 1621

IdCompRegen 5 Iq 1622

Id Comp Regen 6 1623

IdCompRegen 6 Iq 1624

Rockwell Automation Publication 750-PM001J-EN-P - October 2014 31

Page 32

Chapter 2 Paramete r Organ ization

Expert Parameter View (Port 0)

Parameter 301 [Access Level] set to option 2 “Expert.”

File Group Parameters

Monitor Metering O utput Frequency 1

Monitor

Drive Data R ated Volts 20 Rated Amps 21 Rated kW 22

Motor Control Motor Data Motor NP Volts 25

Motor Control

Mtr Ctrl Options Motor Ctrl Mode 35

Commanded SpdRef 2

Mtr Vel Fdbk 3

Commanded Trq 4

Motor NP Amps 26

Maximum Voltage 36

Maximum Freq 37

PWM Frequency 38

Mtr Options Cfg 40

Torque Cur Fdbk 5

Flux Cur Fdbk 6

Output Current 7

Output Voltage 8

Motor NP Hertz 27

Motor NP RPM 28

Bus Utilization 42

Flux Up Enable 43

Flux Up Time 44

Flux Down Ki 4 5

Flux Down Kp 4 6

Output Power 9

Output Powr Fctr 10

DC Bus Volts 11

DC Bus Memory 12

Mtr NP Pwr Units 29

Motor NP Power 30

Econ At Ref Ki 47

Econ AccD ec Ki 48

Econ AccD ec Kp 49

Stability Filter 50

Stab Volt Gain 51

Stab Angle Gain 52

Elapsed MWH 13

Elapsed kWH 14

Elapsed Run Time 15

Elpsd Mtr MWHrs 16

Elpsd Rgn MWHrs 17

Elpsd Mtr kWHrs 18

Elpsd Rgn kWHrs 19

Motor Poles 31

IPM V FB HP Filt 1648

IPM SpdEst Filt 1649

IPM SpdEst Kp 1650

IPM SpdEst Ki 1651

IPM SpdEst KiAdj 1652

IPM Tran PWM 1653

IPMTran PWM Hyst 1654

IPM Tran Mode 1655

IPM TranMod Hyst 1656

IPM Tran Filt Lo 1657

IPM Tran Filt Hi 1658

IPM Tran Angle 1659

IPM Stc OfsTst K 1660

IPM Lq Cmd BW 1661

Volts per Hertz Start Acc Boost 60

Run Boost 61

Autotune Au totune 70

Autotune Torque 71

IR Voltage Drop 73

Ixo Voltage Drop 74

Flux Current Ref 75

Vector Regulator VCL Cur Reg BW 95