Page 1

Installation Instructions

Optical Transceiver

1785-TR10BF

The optical transc eiver enabl es a device with a n AUI inte rface to c onnect to

a 10 Mbit/s CSMA/CD LAN (ISO/IEC 8802-3, IEEE 802.3, 10BASE-FL)

via a fiber optic cable.

•

monitoring LEDs for

– link status

– RxData

– collision/jabb er control

– TxData

– power

•

SQE test can be disabled

externally

•

can be plugged directly to the device interface

•

low current consumption

•

compact construction

To the Installer

Topic Pa ge

Description 2

Installation 3

Compliance to European Union Directives 4

Technical Da ta 7

1785-5.19 - January 1999

Page 2

2 Optical Transceiver

Description

The 1785-TR10BF mini optical transceiver can be connected to the AUI

interface of a device either directly or via an AUI cable. It is connected to

the fiber optic cable by a BFOC socket.

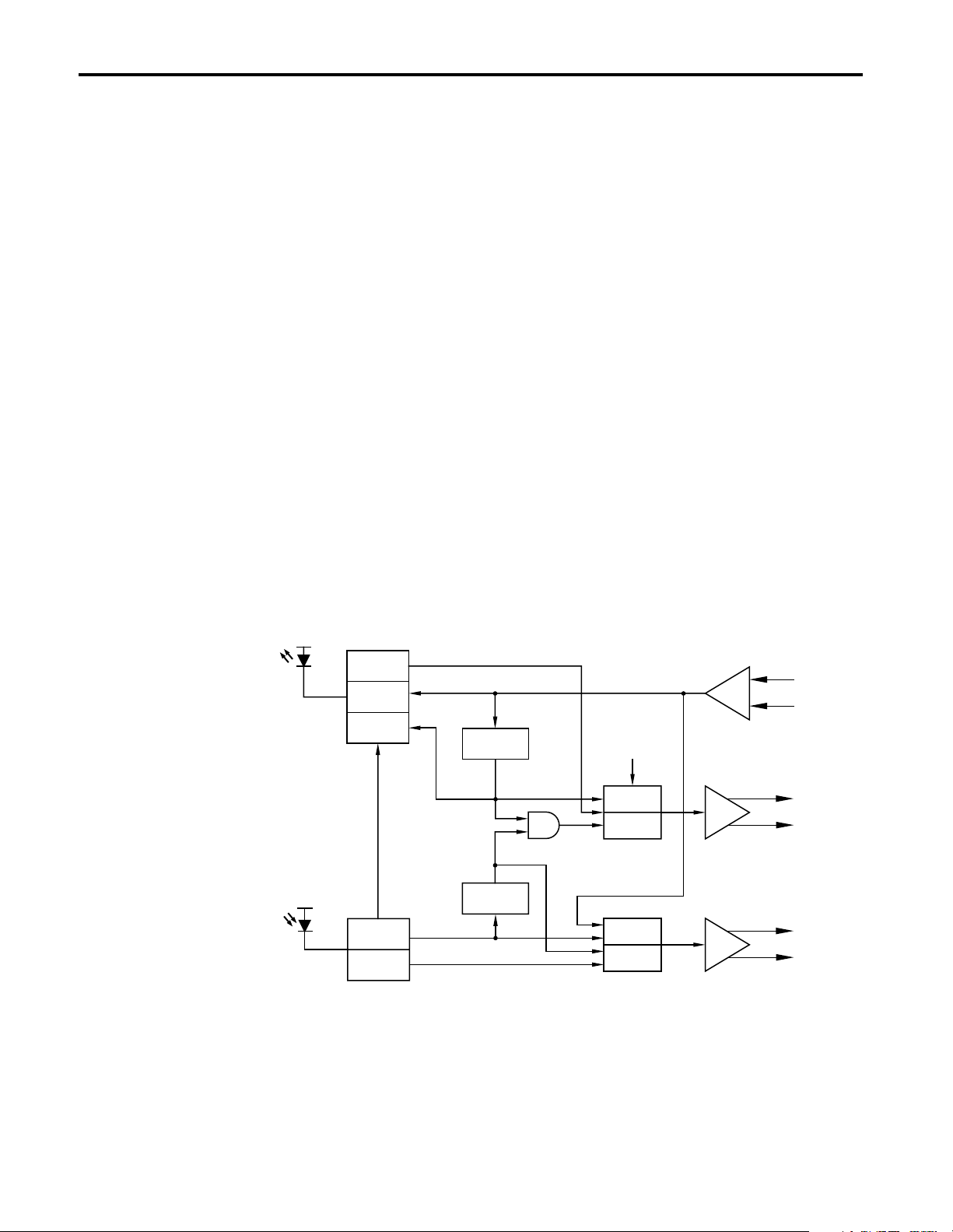

The 1785-TR10BF mini opti cal transc eiver of fer s these func tions ac cording

to IEEE 802.3 10BASE-FL:

•

indication via LEDs of data transmi ssion and reception through th e fiber

optic cable

•

detection of data collisions in the network and reporting them to the

terminal equipment as well as indicating them by an LED

•

ability to enable/disable the SQE test: at the end of every transmit

operation, a short collis ion signal ( heart beat) app rox. 1 µs long is sent to

monitor the electronics

•

jabber control and displa y: protect the network from data packet s that are

too long (> 70 ms)

•

link status: an IDLE signal continuously monitors the fiber optic cable

segment for breakage

Fiber Optic Interface

Jabber

Protect

Tx-Data

Idle

Generator

(acc. to 10BASE-FL)

Lowlight

Detection

Rx-Data

Tx-Packet

Detect

Rx-Packet

Detect

Collision

Detector

DISABLE

ENABLE

ENABLE/

DISABLE

SQE-Test

Generator

Collision

Osc.

Loopback

Data

Rx-Data

DO

CI

AUI Interface

(15-pin sub-D connector)

DI

1785-5.19 - January 1999

Page 3

Optical Transceiver 3

Installation

Fiber Optic Connection

Two BFOC sockets are available for connecting the 1785-TR10BF

transceiver to a fib er op tic segment. One conne ction is u sed f or t ransmitti ng

and one for receiving data over the fiber optic cable.

The maximum length of the fiber optic segment is

•

2000 m for 50/125 fiber

•

3000 m for 62.5/125 fiber

Power Supply

The operating voltage (+12 V) is taken from the connected device via the

15-pin sub-D socket of the AUI interface.

SQE Test Setting

The slide switch on the top of the transceiver case is used to activate and

deactivate the SQE test. Before placing the transceiver in ope ration, you

should check to see whether the connected device requires the SQE test to

be on or off. As deli vered from the factory, the SQE test is on.

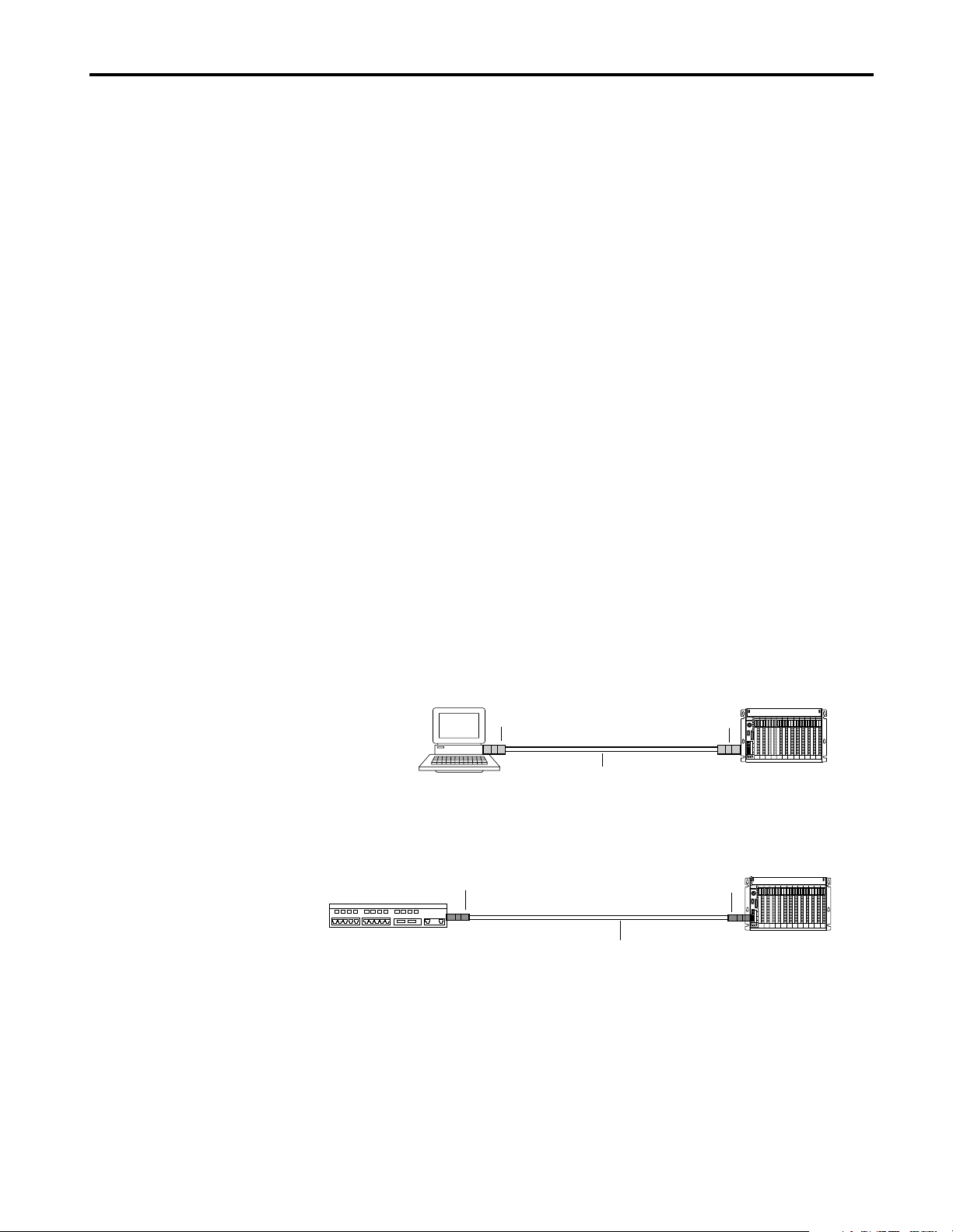

Connecting two devices

Connecting to

a fiber optic interface hub

Connecting Devices

1785-TR10BF 1785-TR10BF

Fiber optic cable 2000 meters (50/125 microns)

3000 meters (62.5/125 microns) max.

Fiber optic cable 2000 meters (50/125 microns)

3000 meters (62.5/125 microns) max.

Hub

PC

1785-TR10BF 1785-TR10BF

For Additional Information

For standards information, go to

copy of this publication, go to

PLC5E

PLC5E

http://www.ieee.or g/. To download a .PDF

http://www.theautomationbookstore.com/.

1785-5.19 - January 1999

Page 4

4 Optical Transceiver

Compliance to European Union Directives

If this product has the marking, it is approved for installation within the

European Union and EEA regions. It has been designed and tested to meet

the following directives.

EMC Directive

This product is tested to meet Council Directive 89/336/EEC

Electromagnetic Compatibility (EMC) and the following standards, in

whole or in part, documented in a technical construction file:

•

EN 50081-2 EMC - Generic Emission Standard,

Part 2 - Industrial Environment

•

EN 50082-2 EMC - Generic Immunity Standard,

Part 2 - Industrial Environment

This product is intended for use in an industrial environment.

Low Voltage Directive

This product is tested to meet Council Directive 73/23/EEC Low Voltage,

by applying the safe ty req uir ements of EN 609 50 - In form ation Technology

Equipment.

For specific informat ion requi red by EN 60950 , see the ap propriat e section s

in this publication, as well as the followin g Allen-Bradley publication s:

•

Industrial Automation Wiring and Grounding Guidelines for Noise

Immunity, publication 1770-4.1

•

Automation Systems Catalog, publication B111

1785-5.19 - January 1999

Page 5

Optical Transceiver 5

Hazardous Location Approval

This product may be certified for general use as well as for use in hazardous locations. Actual agency

certification is indicated by the product label as shown below, and not by statements in any user

documentation.

Example of the certification product label:

CL I, DIV 2

GP A,B,C,D

TEMP

To comply with certification for use in hazardous locations, the following information becomes a part of the

product literature for this certified industrial control product.

• This equipment is suitable for use in Class I, Division 2, Groups A, B, C, D, or non-hazardous locations only.

• The products having the appropriate markings (that is, Class I, Division 2, Groups A, B, C, D) are certified for

use in other equipment where the suitability of combination (that is, application or use) is determined by the

local authority having jurisdiction.

Important: Due to the modular nature of a programmable control system, the product with the highest

temperature rating determines the overall temperature code rating of a programmable control system in a Class I,

Division 2, location. The temperature code rating is marked on the product label as shown.

Temperature code rating:

CL I, DIV 2

GP A,B,C,D

TEMP

/RRNIRUWHPSHUDWXUH

FRGHUDWLQJKHUH

The following warnings apply to products having certification for use in hazardous locations.

ATTENTION: Explosion hazard -

• Substitution of components may impair suitability for Class I, Division 2.

!

• Do not replace components unless power has been switched off or the area is known to be

non-hazardous.

• Do not disconnect equipment unless power has been switched off or the area is known to be

non-hazardous.

• Do not disconnect connectors unless power has been switched off or the area is known to be

non-hazardous. Secure any user-supplied connectors that mate to external circuits on this

equipment by using screws, sliding latches, threaded connectors, or other means such that

any connection can withstand a 15 Newton (3.4 lb.) separating force applied for a minimum of

one minute.

1785-5.19 - January 1999

Page 6

6 Optical Transceiver

Approbation d’utilisation en environnements dangereux

Ce produit est certifié pour une utilisation générale aussi bien que pour une utilisation en environnements

dangereux. La certification en vigueur est indiquée par l'étiquette produit et non par des indications dans la

documentation utilisateur.

Exemple d'étiquette de certification d'un produit :

Pour satisfaire à la certification en environnements dangereux, les informations suivantes font partie intégrante de

la documentation des produits de commande industrielle certifiés.

• Cet équipement ne convient qu’à une utilisation en environnements de Classe 1, Division 2, Groupes A, B, C, D,

• Les produits portant le marquage approprié (c'est-à-dire, Classe 1, Division 2, Groupes A, B, C, D) sont

CL I, DIV 2

GP A,B,C,D

TEMP

ou non dangereux.

certifiés pour une utilisation avec d'autres équipements, les combinaisons d’applications et d’utilisation étant

déterminées par le bureau local d'inspection qualifié.

Important : De par la nature modulaire des systèmes de commande programmables, le produit ayant le code de

température le plus élevé détermine le code de température global du système dans un environnement de

Classe 1, Division 2. Le code de température est indiqué sur l'étiquette produit.

Code de température

:

CL I, DIV 2

GP A,B,C,D

TEMP

Le code de température

est indiqué ici

Les avertissements suivants s'appliquent aux produits certifiés pour une utilisation en environnements dangereux.

DANGER : Risque d’explosion

• La substitution de composants peut rendre cet équipement inadapté à une utilisation en

!

environnement de Classe 1, Division 2.

• Couper le courant ou s’assurer que l’environnement est classé non dangereux avant de

remplacer des composants.

• Couper le courant ou s’assurer que l’environnement est classé non dangereux avant de

débrancher l’équipement.

• Couper le courant ou s’assurer que l’environnement est classé non dangereux avant de

débrancher les connecteurs. Fixer tous les connecteurs fournis par l’utilisateur pour se

brancher aux circuits externes de cet équipement à l’aide de vis, loquets coulissants,

connecteurs filetés ou autres, de sorte que les connexions résistent à une force de séparation

de 15 newtons (1,5 kg - 3,4 lb) appliquée pendant au moins une minute.

1785-5.19 - January 1999

Page 7

Optical Transceiver 7

Technical Data

Transceiver interface (AUI)

Operating voltage +12 V

Current consumption (no signal) 200 mA

Bit rate (Manchester Code) 10 Mbit/s

Dimensions W x H x D 44 mm x 22 mm x 91 mm (1.8 in. x .83 in. x 3.6 in.)

Weight 130 g

Ambient temperature 0° C to +50° C

Storage temperature –20° C to +80° C

Relative humidity 10 % to 90 % (non-condensing)

Fiber optic interface: Transmitter

Light source LED

Wave length 820 nm

Minimum peak optical power [in dBm/µW] fed

into the fiber optic cable

50/125

62.5/125

Fiber type gradient

IDLE-Signal 1 MHz ± 10%

Preamble loss transmit typ. 1 bit; max. 2 bit

Steady state delay 20 ns

Jabber protect time out 70 ms

Jabber reset 450 ms

Fiber optic interface: Receiver

Photo detector PIN diode

Optical input power > –31 dBm (0.8 µW)

Bit error rate (1µW)

Low light threshold –30 dBm (1 µW)

Saturation limit ≥ –9 dBm

Preamble loss receive typ. 1 bit; max. 3 bit

Steady state delay 20 ns

Collision detection time (Data in → SQE out) max. 350 ns

Input:

Termination resistor

Sensitivity

Maximum DC component

Output:

Output voltage

(data and CD signal)

CD signal frequency

SQE Test (heartbeat)

delay time

length

AUI cable length

–19/ 12.6

–16/ 25

9

–

< 10

78 Ω ±1%

500 mVPP

± 50 V

1,6 VPP

10 MHz ± 10%

can be disabled

1100 ns

1000 ns

0 to 50 m max.

1785-5.19 - January 1999

Page 8

Connection capabilities

LINK

RX

CD

TX

P

Transceiver interface

Fiber optic interface

Connections with pin assignments

Transceiver interface

(15-pin sub-D plug)

Fiber optic interface

Displays

Conductors/Wire Size/Category

Agency Certification

(when product is marked)

plugged directly on to the AUI interface of connected device

or connected by an AUI cable (50 m max. length)

Fiber optic cable segment maximum

2000 m (50/125 microns) or 3000 m (62.5/125 microns) long

Input:DO-A: pin 3; DO-B: pin 10

Output:DI-A: pin 5; DI-B: pin 12

Collision detect:CI-A: pin 2; CI-B: pin 9

Power:GND: pin 6; +12 V: pin 13

Shielding:pin 1, 4, 8, 11, 14

2 x IEC 874-10 BFOC/2.5 sockets

* green LED: LINK (link status)

on - fiber optic connection OK

* yellow LED: RX (Rx data)

on - data being received over fiber optic cable link

* red LED: CD (collision detect)

brief flash – data collision

continuously on – jabber control active

* yellow LED: TX (Tx data)

on - data being transmitted through fiber optic cable link

* green LED: P (power)

on – supply voltage present

Category 1

CUS

1

• Information Technology Equipment

• Industrial Control Equipment

• Class I, Div. 2, Groups A, B. C, D

Hazardous Location

• EN 50082-1, 2

• EN 55022, Radiated Emission Class B

• EN 60950

FCC Part 15, SubPart B

1

Refer to the Industrial Automation Wiring and Grounding Guidelines for Noise Immunity, publication 1770-4.1.

Publication 1785-5.19 - January 1999 PN 955134-73

Copyright 1999 of Rockwell International Corporation. Printed in the U.S.A.

Loading...

Loading...