Page 1

Enhanced PLC5 and Ethernet PLC5

Programmable Controller

Memory Module

(Cat. No. 1785-ME16, -ME32, -ME64, and -M100)

Installation Data

To the Installer

Terminology

This document provides you with the following information.

For information about: Go to page:

European Union directive compliance 2

choosing compatible processors and software for the memory module 3

handling the memory module 3

setting backplane switches 4

installing the memory module 5

removing the memory module 5

using the write protection jumper 5

writing to the memory module 6

handling an error while writing to the memory module 8

restoring a program from a memory module 8

specifications 9

These processors are referred to as enhanced PLC-5

programmable controllers:

PLC-5/11

PLC-5/20

PLC-5/30

PLC-5/40, -5/40L

PLC-5/60, -5/60L

PLC-5/80

These processors are referred to as Ethernet PLC-5

programmable controllers:

PLC-5/20E

PLC-5/40E

PLC-5/80E

Page 2

Installation Data

Installation Data

PLC5/11, 5/20, 5/30, 5/40, 5/40L, 5/60

Enhanced PLC5 and Ethernet PLC5

Programmable Controller Memory Module

Programmable Controller Memory Module

European Union Directive Compliance

If this product is installed within the European Union or EEA regions and

the product has a CE mark, the following regulations apply.

EMC Directive

This apparatus is tested to meet Council Directive 89/336 Electromagnetic

Compatibility (EMC):

EN 50081-2 EMC – Generic Emission Standard, Part 2 – Industrial

Environment

EN 50082-2 EMC – Generic Immunity Standard, Part 2 – Industrial

Environment

According to these Standards, the factor which determines, for EMC

purposes, whether an apparatus is deemed to be “Industrial” or “Residential,

commercial and light industrial“, is given in Clause 1 of EN50081-2 as

follows:

Apparatus covered by this standard is not intended for connection

to a public mains network but is intended to be connected to a

power network supplied from a high- or medium-voltage

transformer dedicated for the supply of an installation feeding a

manufacturing or similar plant.

The product described in this manual is intended for use solely in an

industrial environment as defined above. When installed in Europe, any

other application is in contravention of European Union Directives, and a

breach of those laws.

Low Voltage Directive

This apparatus is also designed to meet Council Directive 73/23 Low

Voltage, by applying the safety requirements of EN 61131–2 Programmable

Controllers, Part 2 – Equipment Requirements and Tests.

For specific information that the above norm requires, see the appropriate

sections in this manual, as well as the following Allen-Bradley publications:

Industrial Automation Wiring and Grounding Guidelines, publication

1770-4.1

Guidelines for Handling Lithium Batteries, publication AG-5.4

Automation Systems Catalog, publication B111

2

Page 3

Installation Data

Enhanced PLC5 and Ethernet PLC5

Programmable Controller Memory Module

Choosing Compatible Processors and Software for the Memory Module

Memory Module: Compatible Programmable Controllers: Compatible Software:

1785ME16,

1785ME32 and

1785M100

1785ME64 1785L11B, L20B, L30B

1785L11B, L20B, L30B, L40B, L40L, L60B, L60L,

1785L11B, L20B

1785L20E, 1785L40E

1785L30B

1785L40B, L40L, L60B, L60L

1785L40B, L40L, L60B, L60L

1785L80B

1785L20E, 1785L40E

1785L40B, L60B

1785L40L, L60L

1785L80B

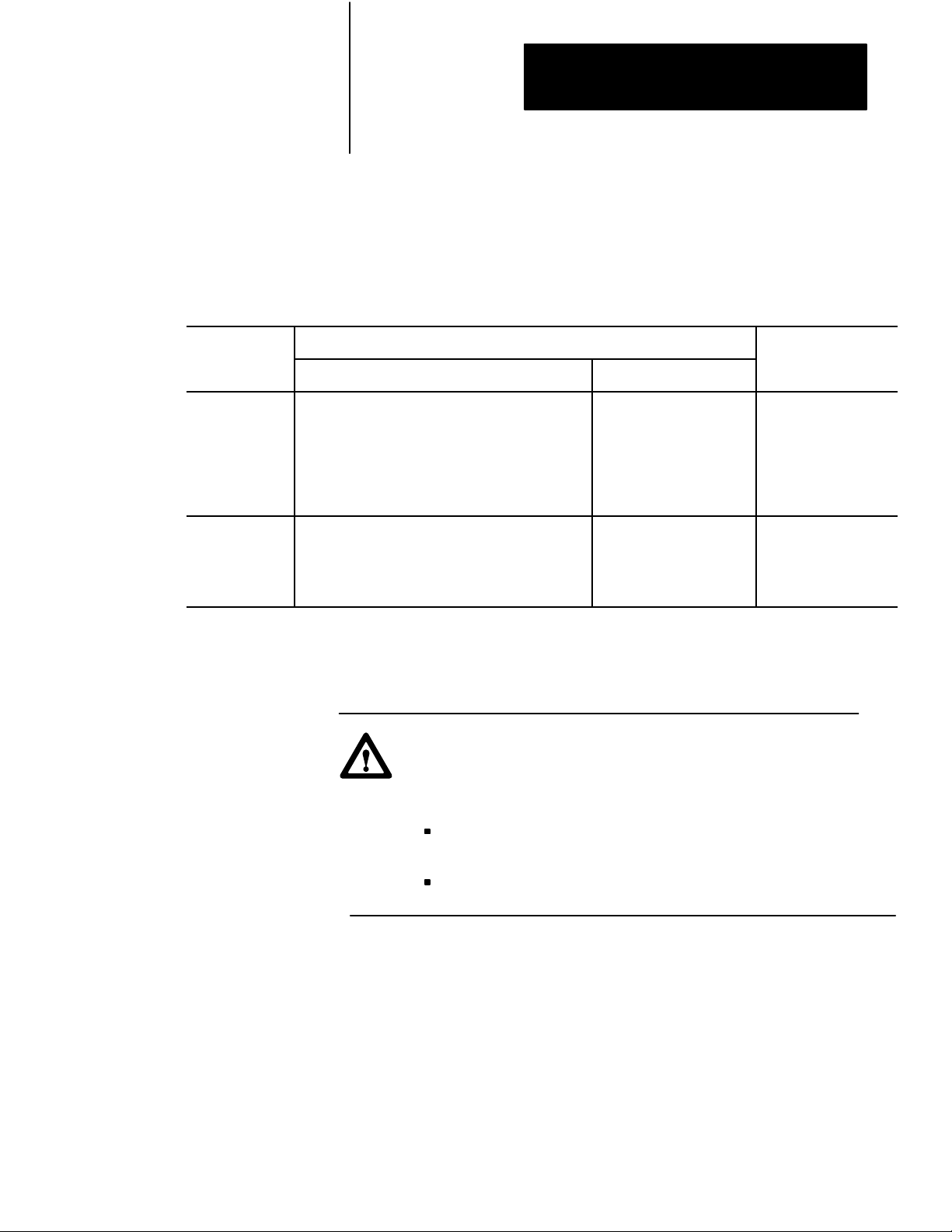

Table 1 shows the the programmable controllers and the software that are

compatible with the 1785-ME16, -ME32, -ME64, -M100

memory modules.

Table 1

1785ME16,

ME32, ME64, M100 Compatibility

Catalog Number: Series and Revision:

series C, revision C and later

series A, revision E and later

series C, revision D and later

series A revision F and later

series B revision F and later

series A, revision J and later

series C, revision C and later

all series, all revisions

series C, revision D and later

series A, revision C and later

series A, revision C and later

series C, revision C and later

6200 PLC5

Programming Software

release 4.4 or later

6200 PLC5

Programming Software

release 4.1 or later

Handling the Memory Module

The memory module is shipped in a static-shielded bag to guard against

electrostatic damage.

ATTENTION: Under some conditions, electrostatic discharge

can degrade performance or damage the memory module.

Observe the following precautions to guard against

electrostatic damage:

Touch a grounded object to rid yourself of static charge

before handling the module.

When not in use, keep the module in its static-shielded bag.

3

Page 4

Installation Data

Installation Data

PLC5/11, 5/20, 5/30, 5/40, 5/40L, 5/60

Enhanced PLC5 and Ethernet PLC5

Programmable Controller Memory Module

Programmable Controller Memory Module

Setting Backplane Switches

If you want the contents of the memory module: Then set switch 6: And set switch 7:

to transfer to processor memory at every powerup OFF OFF

to transfer to processor memory when a defect is detected in existing

processor memory

not to transfer to processor memory at powerup; if the processor

memory is not valid, a processor fault occurs.

Set the I/O chassis backplane switches before you install the PLC-5

processor. Use a ballpoint pen to set each switch (do not use a pencil

because the tip can break off and short the switch).

ON (Closed)

OFF (Open)

Backplane

switches

Backplane

Switches

18594

Use Table 2 to select the mode of memory transfer at power-up.

Table 2

Selecting

Mode of Memory Transfer and Switch Settings

ON ON

ON OFF

4

Page 5

Installation Data

Enhanced PLC5 and Ethernet PLC5

Programmable Controller Memory Module

Installing the Memory Module

Keying pin

Removing the Memory Module

Insert the memory module into the front of the PLC-5 processor by

following these steps:

1. Turn off power to the I/O chassis and processor.

ATTENTION: Do not insert or remove the memory module

under power. Insertion or removal under power can result in

loss of program memory and a processor fault.

2. Insert the memory module firmly but gently into the processor with

the keying pin in the down position. When the memory module is

inserted correctly you will hear the connector pins on the back of the

memory module snap together with the mating connector in

the processor.

18590

Remove the memory module by following these steps:

1. Turn off power to the I/O chassis and processor.

Keying pin

Using the Write Protection Jumper

Write protection

jumper

18592

ATTENTION: Do not insert or remove the memory module

under power. Insertion or removal under power can result in

loss of program memory and a processor fault.

2. Grasp the finger grip tabs and firmly pull the memory module out of

the processor.

18591

The write protection jumper allows you to program the memory module.

The memory module is packaged with the jumper in the correct position to

write to the memory module.

After writing to the memory module, remove the write protection jumper

using a pair of needle nose pliers. Store the jumper in a safe place for

future use. Once you remove the jumper, you cannot write to the

memory module.

5

Page 6

Installation Data

Installation Data

PLC5/11, 5/20, 5/30, 5/40, 5/40L, 5/60

Enhanced PLC5 and Ethernet PLC5

Programmable Controller Memory Module

Programmable Controller Memory Module

Writing to the Memory Module

Card Guides

Locking

Bar

Ejector

Ta b

PLC5

processor

19632

Use the following steps to store a program on your memory module.

Important: If you are using a 1785-L40B series A, revision B or a

1785-L60B series A, revision B processor, you must have the Global

Status Flag file set to zero. Access this file through the channel

configuration screen for channels configured for DH+ communications. If

the Global Status Flag file is set to any number except zero and you try to

write to a memory module, you will lose processor memory and a

processor fault occurs.

1. Insert the memory module into the processor using the installation

procedure in this document (see page 5).

2. On the I/O chassis backplane, set backplane switch 6 to the ON

position and switch 7 to the OFF position (see page 4).

3. Install the processor into the I/O chassis.

4. Turn on power to the processor and I/O chassis.

5. Put the processor in Program or Rem Program mode.

18593

If you try to write to a memory module when the processor is in any

other mode, you receive a

NO ACCESS OR PRIVILEGE

VIOLATION message.

6. Develop or download your program online (make sure you initialize

your data table values).

6

Page 7

Ladder Editor

Main Menu

General Utilities

F7

General

Utility screen

W

rite EEPROM

F7

Installation Data

Enhanced PLC5 and Ethernet PLC5

Programmable Controller Memory Module

7. Transfer a duplicate of your program to the memory module. You

must be programming online to write to a memory module (use the

figure below).

| I:001 O:005 |

+––]/[––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––( )––+

| 14 10 |

| +TON–––––––––––––––+ |

+––––––––––––––––––––––––––––––––––––––––––––––––––+TIMER ON DELAY +–(EN)–+

| |Timer T4:0| |

| |Time base 0.01+–(DN) |

| |Preset 12| |

| |Accum 0| |

| +––––––––––––––––––+ |

| +MSG––––––––––––––––––––+ |

+–––––––––––––––––––––––––––––––––––––––––––––+SEND/REC MESSAGE +–(EN)–+

| |Control Block N7:10+–(DN) |

| | +–(ER) |

| +–––––––––––––––––––––––+

+––––––––––––––––––––––––––––––[END OF FILE]–––––––––––––––––––––––––––––––––+

Press a function key.

(file 2, rung 3)

Rem Prog Forces:None Edits:None 5/40 Addr 25 LIMIT

Change Config Return Program Documnt Search General Data Force Edit

Mode Display to Menu Dirctry Utility Monitor

F1 F2 F3 F4 F5 F6 F7 F8 F9 F10

[Y] [Enter] or [F8] - Yes

[N] [Enter] or [F10] - No

If you confirm the procedure, the memory module write begins.

During this procedure, the “PROC” LED on the processor

flashes green and the programming terminal beeps until the

write procedure is completed.

If no error occurs during the write to the memory module, you

see the following message displayed: EEPROM

SUCCESSFULLY

BURNED

8. Remove the memory module from the processor using the removal

procedure in this document (see page 5).

9. Label the memory module with a ballpoint pen. Use the space

provided to label the program transferred to the memory module.

18595

7

Page 8

Installation Data

Installation Data

PLC5/11, 5/20, 5/30, 5/40, 5/40L, 5/60

Enhanced PLC5 and Ethernet PLC5

Programmable Controller Memory Module

Programmable Controller Memory Module

Handling an Error while Writing to the Memory Module

Restoring a Program from a Memory Module

If an error occurs during a write to the memory module, you see this

message displayed: EEPROM

NOT BURNED

If you get this message, do the following:

check that you inserted the write protect jumper

check minor fault bit (S:10/8) in the status file. If this bit is set, then

there is not enough memory on your memory module to upload the

program from the processor.

review the “Writing to the Memory Module” procedure (see page 6)

and repeat it from the beginning

You can restore a program from a memory module to the processor

memory using the following procedure.

If the restore fails, the old program remains in memory and the EEPROM

transfer bit (minor fault bit S:10/3) is cleared.

Important: When restoring a program from a memory module using a

1785-L40B series A, revision B or a 1785-L60B series A, revision B

processor, the memory module overwrites the DH+ station address for

channel 1A.

Card Guides

Locking

Bar

19633

Ejector

Ta b

PLC5

processor

1. Turn off power to I/O chassis and processor.

2. Remove the processor from the I/O chassis.

3. Set backplane switch 6 and 7 of the switch assembly group to the

OFF position (see page 4). This allows the memory module

memory to transfer to processor memory at power-up.

4. Install the processor into the I/O chassis.

5. Install the memory module containing the program to be restored into

the processor using the installation procedure in this document (see

page 5).

6. Turn on power to the processor. Program transfer and execution

begin immediately with the processor keyswitch in Run or

Rem position.

8

Page 9

Locking

Bar

Ejector

Ta b

Installation Data

Enhanced PLC5 and Ethernet PLC5

Programmable Controller Memory Module

Important: You can have continuous processor memory backup after

restoring a program from a memory module to a processor by following

these instructions:

1. Turn off power to the processor and I/O chassis.

2. Remove the memory module by following the removal procedure in

this document (see page 5).

3. Remove the write protection jumper with needle nose pliers to guard

against unauthorized changes. Store the jumper in a safe place for

future use.

4. Re-install the memory module into the processor by following the

installation procedure in this document (see page 5).

5. Remove the processor from the I/O chassis.

Card Guides

Specifications

PLC5

processor

19633

6. Set switch 6 and 7 of the assembly backplane switches to the ON

position (see page 4).

7. Re-install the processor into the I/O chassis.

The following table shows the specifications for the memory modules.

Memory Module 1785ME16 1785ME32 1785ME64 1785M100

Capacity 16K words 32K words 64K words 100K words

Type Nonvolatile

Write Protection By removing the jumper

Weight 85.05 g

3 oz

Environment

Shock Testing

Operating Temperature

Storage Temperature

Relative Humidity 5 to 95% (without condensation)

Operating 15 g peak acceleration at 11 ms duration

0° to 60° C (32° to 140° F)

40° to 85° C (40° to 185° F)

70.875 g

2.5 oz

70.875 g

2.5 oz

70.875 g

2.5 oz

Nonoperating 3 g peak acceleration at 11 ms duration

Vibration Testing 2 g peak acceleration at 10500 Hz

Agency Certification

(when product or package is marked)

• CSA certified

• CSA Class I, Division 2

Groups A, B, C, D

• UL listed

• CE marked for all applicable directives

9

Page 10

Installation Data

Installation Data

PLC5/11, 5/20, 5/30, 5/40, 5/40L, 5/60

Enhanced PLC5 and Ethernet PLC5

Programmable Controller Memory Module

Programmable Controller Memory Module

AllenBradley, a Rockwell Automation Business, has been helping its customers improve

productivity and quality for more than 90 years. We design, manufacture and support a broad

range of automation products worldwide. They include logic processors, power and motion

control devices, operator interfaces, sensors and a variety of software. Rockwell is one of the

worlds leading technology companies.

Worldwide representation.

Argentina •

Denmark • Ecuador

Ireland

Philippines •

Sweden

AllenBradley Headquarters, 1201 South Second Street, Milwaukee, WI 53204 USA, Tel: (1) 414 3822000 Fax: (1) 414 3824444

Publication

Supercedes

10

Australia • Austria • Bahrain

• Israel • Italy • Jamaica •

• Switzerland • T

17855.10 September 1995

Publication 17852.1

• Egypt • El Salvador • Finland • France •

Poland • Portugal • Puerto Rico • Qatar • Romania • Russia-CIS • Saudi Arabia • Singapore

aiwan

1 Septemebr 1993

• Belgium • Brazil •

Japan • Jordan • Korea • Kuwait • Lebanon

• Thailand • T

urkey • United Arab Emirates • United Kingdom • United States • Uruguay

Bulgaria • Canada

Germany • Greece • Guatemala • Honduras • Hong Kong • Hungary

• Chile •

• Malaysia • Mexico •

China, PRC • Colombia

Netherlands

• Slovakia • Slovenia •

• Costa Rica •

• New Zealand •

• V

enezuela

Croatia • Cyprus

• Iceland •

Norway

South Africa, Republic

• Yugoslavia

Copyright

• Czech Republic •

India • Indonesia

• Pakistan •

1995 AllenBradley Company

Peru

•

• Spain •

PN

95512330

, Inc. Printed in USA

•

Loading...

Loading...