Page 1

User Manual

Stratix 8000 and 8300 Ethernet Managed Switches

Page 2

Important User Information

Read this document and the documents listed in the additional resources section about installation, configuration, and

operation of this equipment before you install, configure, operate, or maintain this product. Users are required to

familiarize themselves with installation and wiring instructions in addition to requirements of all applicable codes, laws,

and standards.

Activities including installation, adjustments, putting into service, use, assembly, disassembly, and maintenance are required

to be carried out by suitably trained personnel in accordance with applicable code of practice.

If this equipment is used in a manner not specified by the manufacturer, the protection provided by the equipment may be

impaired.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the

use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or

liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or

software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation,

Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous environment,

which may lead to personal injury or death, property damage, or economic loss.

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death, property

damage, or economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the consequence.

IMPORTANT

Identifies information that is critical for successful application and understanding of the product.

Labels may also be on or inside the equipment to provide specific precautions.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous

voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may

reach dangerous temperatures.

ARC FLASH HAZARD: Labels may be on or inside the equipment, for example, a motor control center, to alert people to

potential Arc Flash. Arc Flash will cause severe injury or death. Wear proper Personal Protective Equipment (PPE). Follow ALL

Regulatory requirements for safe work practices and for Personal Protective Equipment (PPE).

Allen-Bradley, Rockwell Software, Rockwell Automation, Logix5000, RSLinx , RSLogix, RSNetWorx, Stratix 2000, Stratix 5700, Stratix 8000, Stratix 8300, Studio 5000, and Studio 5000 Logix Designer are trademarks of

Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Page 3

Summary of Changes

This manual contains new and updated information. Changes throughout this

revision are marked by change bars, as shown to the right of this paragraph.

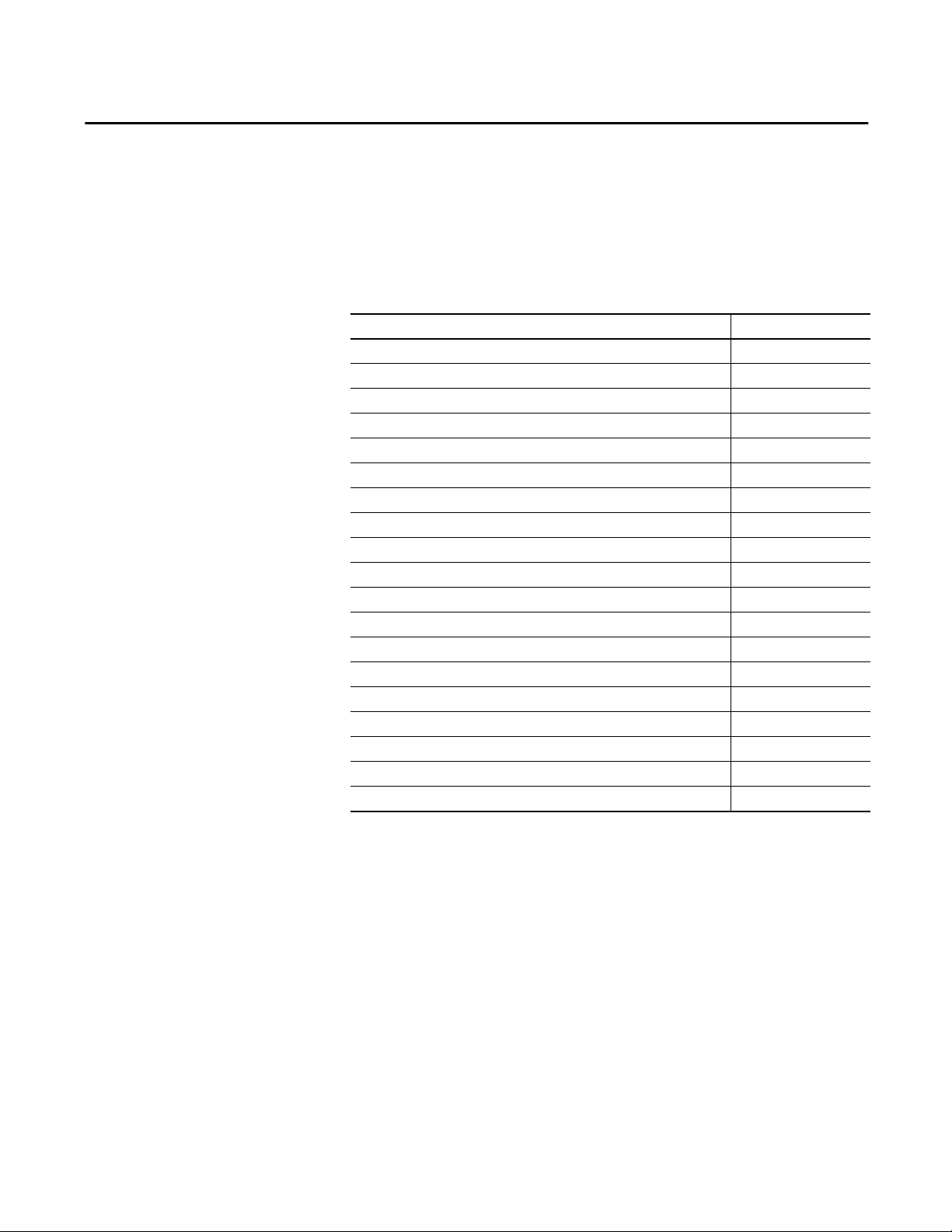

New and Updated Information

This table contains the changes made to this revision.

Topic Page

Updated Device Manager hardware and software requirements 48, 53

New Express Setup window 50, 51

New process for enabling static and connected routing 83, 84

New DeviceManager Web interface 87…139

Rockwell Automation Publication 1783-UM003I-EN-P - March 2014 3

Page 4

Summary of Changes

Notes:

4 Rockwell Automation Publication 1783-UM003I-EN-P - March 2014

Page 5

Table of Contents

Preface

Install the Switch

Studio 5000 Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Access Product Release Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Additional Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Chapter 1

Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Required Tools and Equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Product Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Install the Switch. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Attach Expansion Modules (optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Mount the Switch on a DIN Rail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Mount the Switch on a Wall or Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Install an SFP Module (optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Ground the Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Wire the DC Power Source for the Switch . . . . . . . . . . . . . . . . . . . . . . . . . 29

Wire the DC Power Source for the PoE Expansion Module (optional) . 31

Attach the Power and Relay Connector to the Switch . . . . . . . . . . . . . . . 33

Attach the Power Connector to the PoE Expansion Module (optional). 35

Wire External Alarms (optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Connect to 10/100 Copper Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Connect to a PoE Expansion Module Port . . . . . . . . . . . . . . . . . . . . . . . . . 37

Connect to Dual-purpose Uplink Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Connect to 10/100/1000 Uplink Ports . . . . . . . . . . . . . . . . . . . . . . . . 38

Connect to SFP Fiber Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Connect to 100BaseFX Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Install or Remove the CompactFlash Card . . . . . . . . . . . . . . . . . . . . . . . . . 39

Reset the Switch to Factory Defaults. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Troubleshoot the Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Switch POST Results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

POST Results with a Terminal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Bad or Damaged Cable. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Ethernet and Fiber Cables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Link Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Transceiver Issues . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Port and Interface Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Getting Started

Chapter 2

Switch Front Panel Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Expansion Module Front Panel Descriptions . . . . . . . . . . . . . . . . . . . . . . . 44

Hardware Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

CompactFlash Memory Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Set Up the Switch Initially with Express Setup. . . . . . . . . . . . . . . . . . . . . . 48

Switch Memory Allocation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Device Manager Web Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Rockwell Automation Publication 1783-UM003I-EN-P - March 2014 5

Page 6

Table of Contents

Switch Software Features

Hardware Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Software Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Studio 5000 Environment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Hardware Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Cisco Network Assistant. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Command Line Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Chapter 3

Port Numbering. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Global Macro . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Smartports. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Optimize Ports through Port Roles. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Avoid Smartports Mismatches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Power over Ethernet (PoE) Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Powered Device Detection and Initial Power Allocation . . . . . . . . . 62

Power Management Modes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

VLANs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Isolate Traffic and Users. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Isolate Different Traffic Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Group Users . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

IGMP Snooping with Querier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Spanning Tree Protocol. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Rapid Spanning Tree Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Storm Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Default Storm Control Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . 72

Port Security . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Dynamic Secure MAC Address (MAC ID) . . . . . . . . . . . . . . . . . . . . . 72

Static Secure MAC Address (MAC ID) . . . . . . . . . . . . . . . . . . . . . . . . 73

Security Violations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

EtherChannels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

DHCP Persistence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

CIP Sync Time Synchronization (Precision Time Protocol). . . . . . . . . . 76

Resilient Ethernet Protocol. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

REP Open Segment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

REP Ring Segment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Access Ring Topologies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Link Integrity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

SNMP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Supported MIBs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Port Mirroring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Layer 3 Routing (Stratix 8300 switch only) . . . . . . . . . . . . . . . . . . . . . . . . . 82

Types of Routing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Static and Connected Routing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Cryptographic IOS Software (optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Cable Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Advanced Software Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

6 Rockwell Automation Publication 1783-UM003I-EN-P - March 2014

Page 7

Manage the Switch via the

Device Manager Web Interface

Table of Contents

Chapter 4

Access the Device Manager Web Interface. . . . . . . . . . . . . . . . . . . . . . . . . . 88

Dashboard Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Front Panel View and Status Indicators . . . . . . . . . . . . . . . . . . . . . . . . 89

Switch Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Switch Health. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Port Utilization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Configure Smartports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Customize Smartport Role Attributes. . . . . . . . . . . . . . . . . . . . . . . . . . 96

Configure Port Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Configure Ports to Use QuickConnect Technology . . . . . . . . . . . . . 99

Configure Port Thresholds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Configure EtherChannels. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Configure DHCP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Set up the DHCP Server . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Configure a DHCP IP Address Pool . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Reserve IP Addresses through DHCP Persistence . . . . . . . . . . . . . . 105

Configure VLANs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Assign Ports to VLANs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Configure Power over Ethernet (PoE) Ports . . . . . . . . . . . . . . . . . . . . . . . 108

Configure PTP Time Synchronization. . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Enable Static and Connected Routing . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Enable Connected Routing Only . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Enable Both Static and Connected Routing. . . . . . . . . . . . . . . . . . . . 114

Configure STP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Global Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

PortFast Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Configure REP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Configure Port Security . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Configure IGMP Snooping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Configure SNMP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Use SNMP Management Applications . . . . . . . . . . . . . . . . . . . . . . . . 123

Configure Alarm Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Alarm Relay Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Global Alarms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Port Alarms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Configure Alarm Profiles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Monitor Trends. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Monitor Port Statistics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Monitor REP Topology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Monitor CIP Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Diagnose Cabling Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

View System Log Messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

Use Express Setup to Change Switch Settings. . . . . . . . . . . . . . . . . . . . . . 133

Manage Users. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Reallocate Switch Memory for Routing . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

Restart the Switch. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

Rockwell Automation Publication 1783-UM003I-EN-P - March 2014 7

Page 8

Table of Contents

Manage the Switch via the

Studio 5000 Environment

Upgrade the Switch Firmware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

Upload and Download Configuration Files. . . . . . . . . . . . . . . . . . . . . . . . 139

Chapter 5

EtherNet/IP CIP Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

CIP Network Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

RSLinx Software and Network Who Support . . . . . . . . . . . . . . . . . . 143

Electronic Data Sheet (EDS) Files. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

Data Accessible with CIP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

Add a Switch to the I/O Configuration Tree . . . . . . . . . . . . . . . . . . . . . . 146

Configure Module Properties. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

Connection Properties. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

Switch Configuration Properties. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

Port Configuration Properties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

Advanced Port Properties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

Port Thresholds (storm control) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

Monitor and Reset the Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

Switch Status. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

Port Status. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

Port Diagnostics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

Cable Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

DHCP Pool Display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

DHCP Address Assignment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

Time Sync Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

Time Sync Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

Save and Restore Switch Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . 168

Troubleshoot the Switch

Status Indicators

Chapter 6

IP Address Issues . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

Device Manager Web Interface Issues . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

Switch Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

Access Direct Managed Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

Restart or Reset the Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

Restart the Switch from the Device Manager Web Interface . . . . . 172

Restart the Switch from the Studio 5000 Environment . . . . . . . . . 172

Reset the Switch to Factory Defaults . . . . . . . . . . . . . . . . . . . . . . . . . . 173

Recover the Switch Firmware and Restore Factory Defaults . . . . . . . . . 173

Troubleshoot a Firmware Upgrade. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

Appendix A

Switch Status Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

Dual-purpose Port Status Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

10/100 Copper, 100BaseFX, and SFP Port Status Indicators. . . . . . . . 178

PoE Port Status Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

8 Rockwell Automation Publication 1783-UM003I-EN-P - March 2014

Page 9

I/O Data Types

Table of Contents

Appendix B

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .181

Appendix C

Port Assignments for CIP Data

Cables and Connectors

History of Changes

Index

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .187

Appendix D

10/100 and 10/100/1000 Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

Connect to 10BASE-T- and 100BASE-TX-compatible Devices . 190

100BASE-FX Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 192

SFP Transceiver Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 192

Dual-purpose Ports. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 193

Console Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 193

Cable and Adapter Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

SFP Module Cable Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

PoE Port Cable Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

Adapter Pinouts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

Appendix E

1783-UM003H-EN-P, September 2013 . . . . . . . . . . . . . . . . . . . . . . . . . . 197

1783-UM003G-EN-P, December 2012 . . . . . . . . . . . . . . . . . . . . . . . . . . . 198

1783-UM003F-EN-P, August 2011 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 198

Rockwell Automation Publication 1783-UM003I-EN-P - March 2014 9

Page 10

Table of Contents

Notes:

10 Rockwell Automation Publication 1783-UM003I-EN-P - March 2014

Page 11

Preface

This publication describes the embedded software features and tools for

configuring and managing Stratix 8000™ and Stratix 8300™ Ethernet managed

switches. In addition, this publication provides troubleshooting information to

help you resolve basic switch and network issues.

Use this manual if you configure and monitor Stratix 8000 Ethernet managed

switches. This manual assumes you understand the following:

• Local area network (LAN) switch fundamentals

• Concepts and terminology of the Ethernet protocol and local area

networking

Studio 5000 Environment

The Studio 5000™ Engineering and Design Environment combines engineering

and design elements into a common environment. The first element in the

Studio 5000 environment is the Logix Designer application. The Logix Designer

application is the rebranding of RSLogix™ 5000 software and continues to be the

product to program Logix5000™ controllers for discrete, process, batch, motion,

safety, and drive-based solutions.

The Studio 5000 environment is the foundation for the future of Rockwell

Automation® engineering design tools and capabilities. It is the one place for

design engineers to develop all the elements of their control system.

Rockwell Automation Publication 1783-UM003I-EN-P - March 2014 11

Page 12

Preface

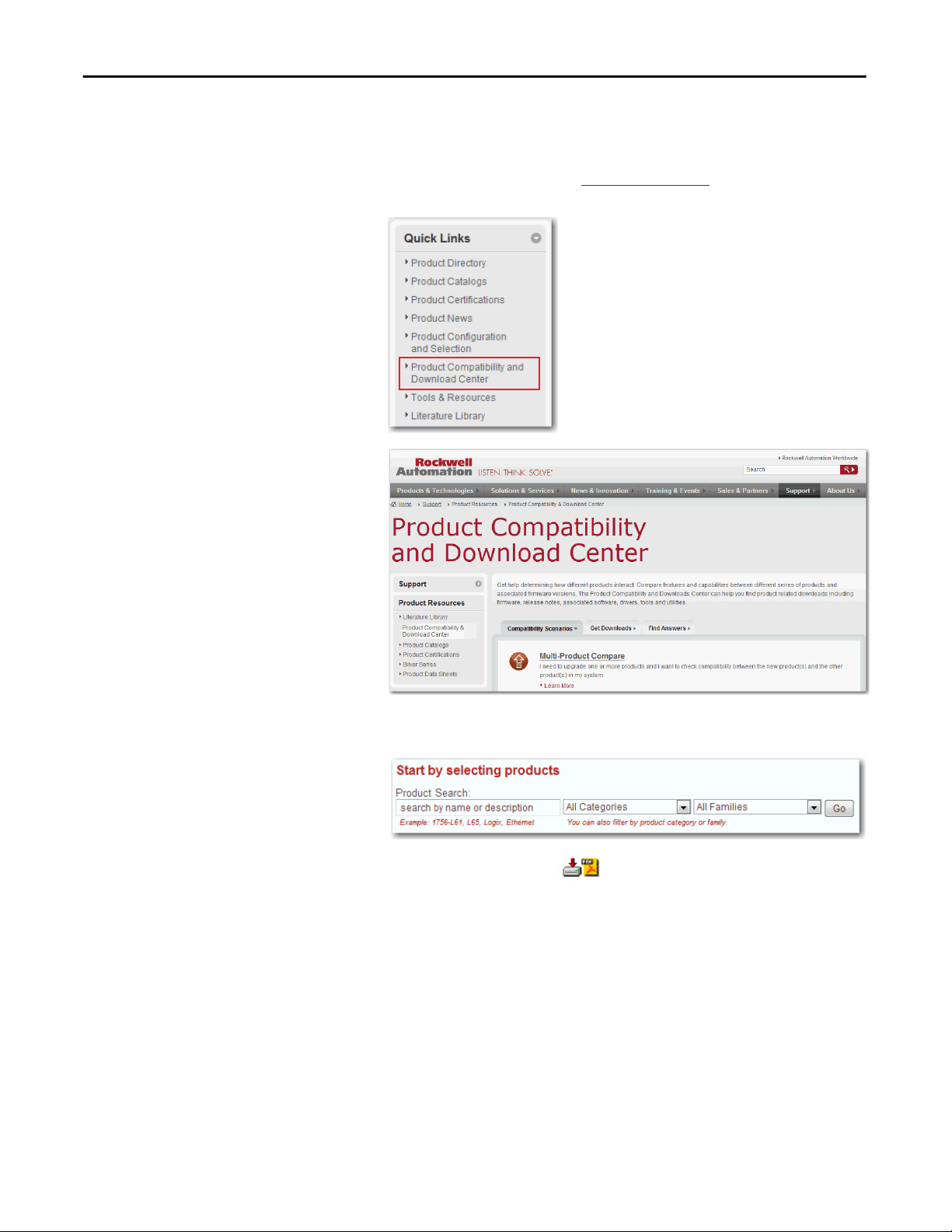

Access Product Release Notes

Product release notes are available online within the Product Compatibility and

Download Center.

1. From the Quick Links list on

Compatibility and Download Center.

http://www.ab.com, choose Product

2. From the Compatibility Scenarios tab or the Get Downloads tab, search

for and choose your product.

3. Click the download icon to access product release notes.

12 Rockwell Automation Publication 1783-UM003I-EN-P - March 2014

Page 13

Preface

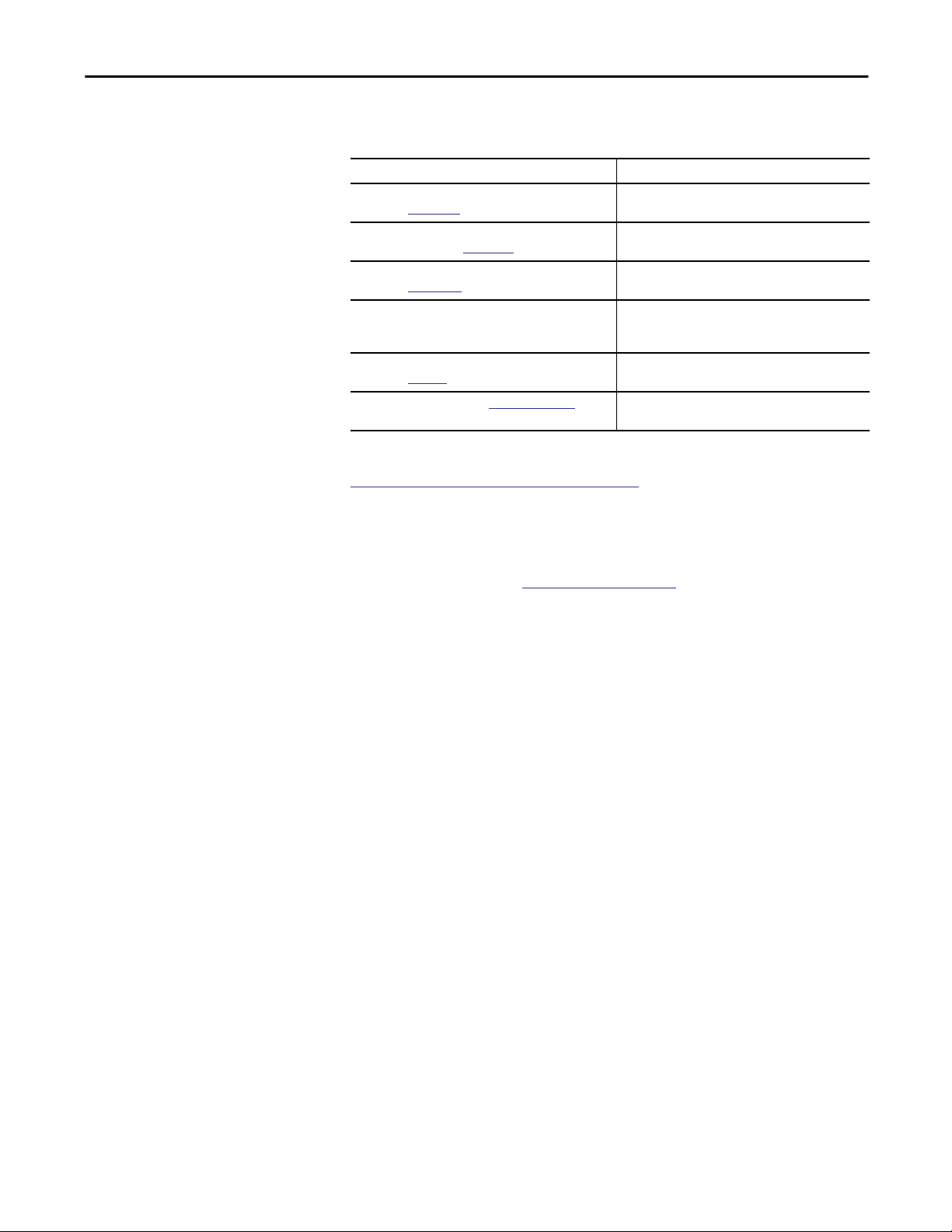

Additional Resources

These documents contain additional information concerning related products

from Rockwell Automation.

Resource Description

Stratix Ethernet Managed Switches Technical Data,

publication

Stratix 8000 Ethernet Managed Switches Installation

Instructions, publication

Stratix 8000 Ethernet Managed Switches Release Notes,

publication

Device Manager Web interface online help (provided with

the switch)

Industrial Automation Wiring and Grounding Guidelines,

publication

Product Certifications website,

1783-TD001

1783-IN005

1783-RN002

1770-4.1

http://www.ab.com Provides declarations of conformity, certificates, and

Provides specification information for the switches.

Describes how to get started installing and configuring

the switch.

Lists enhancements and anomalies associated with the

released software version.

Provides context-sensitive information about

configuring and using the switch, including system

messages.

Provides general guidelines for installing a Rockwell

Automation industrial system.

other certification details.

You can view or download publications at

http://www.rockwellautomation.com/literature. To order paper copies of technical

documentation, contact your local Allen-Bradley distributor or Rockwell

Automation sales representative.

For information about additional software features or further configuration, see

these Cisco publications at

http://www.Cisco.com:

• Cisco IE-3000 Command Line Reference Manual

• Cisco IE-3000 Software Configuration Guide

• Cisco IE-3000 Switch System Message Guide

Rockwell Automation Publication 1783-UM003I-EN-P - March 2014 13

Page 14

Preface

Notes:

14 Rockwell Automation Publication 1783-UM003I-EN-P - March 2014

Page 15

Install the Switch

Topic Page

Before You Begin 17

Install the Switch 21

Attach Expansion Modules (optional) 22

Mount the Switch on a DIN Rail 24

Mount the Switch on a Wall or Panel 26

Install an SFP Module (optional) 27

Ground the Switch 28

Wire the DC Power Source for the Switch 29

Wire the DC Power Source for the PoE Expansion Module (optional) 31

Attach the Power and Relay Connector to the Switch to the Switch 33

Attach the Power Connector to the PoE Expansion Module (optional) 35

Wire External Alarms (optional) 35

Connect to 10/100 Copper Ports 37

Connect to a PoE Expansion Module Port 37

Connect to Dual-purpose Uplink Ports 38

Connect to 100BaseFX Ports 39

Install or Remove the CompactFlash Card 39

Reset the Switch to Factory Defaults 40

Troubleshoot the Installation 40

Chapter 1

Rockwell Automation Publication 1783-UM003I-EN-P - March 2014 15

Page 16

Chapter 1 Install the Switch

ATTENTION: Environment and Enclosure

This equipment is intended for use in a Pollution Degree 2 industrial environment, in overvoltage Category II applications (as defined

in IEC 60664-1), at altitudes up to 2000 m (6562 ft) without derating.

This equipment is not intended for use in residential environments and may not provide adequate protection to radio communication

services in such environments.

This equipment is supplied as open-type equipment. It must be mounted within an enclosure that is suitably designed for those

specific environmental conditions that will be present and appropriately designed to prevent personal injury resulting from

accessibility to live parts. The enclosure must have suitable flame-retardant properties to prevent or minimize the spread of flame,

complying with a flame spread rating of 5VA or be approved for the application if nonmetallic. The interior of the enclosure must be

accessible only by the use of a tool. Subsequent sections of this publication may contain additional information regarding specific

enclosure type ratings that are required to comply with certain product safety certifications.

In addition to this publication, see the following:

• Industrial Automation Wiring and Grounding Guidelines, publication

• NEMA Standard 250 and IEC 60529, as applicable, for explanations of the degrees of protection provided by enclosures

North American Hazardous Location Approval

The following information applies when operating this equipment in

hazardous locations.

Products marked "CL I, DIV 2, GP A, B, C, D" are suitable for use in Class I Division 2 Groups

A, B, C, D, Hazardous Locations and nonhazardous locations only. Each product is supplied

with markings on the rating nameplate indicating the hazardous location temperature

code. When combining products within a system, the most adverse temperature code

(lowest "T" number) may be used to help determine the overall temperature code of the

system. Combinations of equipment in your system are subject to investigation by the

local Authority Having Jurisdiction at the time of installation.

1770-4.1, for additional installation requirements

Informations sur l’utilisation de cet équipement en environnements

dangereux.

Les produits marqués "CL I, DIV 2, GP A, B, C, D" ne conviennent qu'à une utilisation en

environnements de Classe I Division 2 Groupes A, B, C, D dangereux et non dangereux.

Chaque produit est livré avec des marquages sur sa plaque d'identification qui indiquent

le code de température pour les environnements dangereux. Lorsque plusieurs produits

sont combinés dans un système, le code de température le plus défavorable (code de

température le plus faible) peut être utilisé pour déterminer le code de température

global du système. Les combinaisons d'équipements dans le système sont sujettes à

inspection par les autorités locales qualifiées au moment de l'installation.

WARNING: EXPLOSION HAZARD

• Do not disconnect equipment unless power has

been removed or the area is known to be

nonhazardous.

• Do not disconnect connections to this

equipment unless power has been removed or

the area is known to be nonhazardous. Secure

any external connections that mate to this

equipment by using screws, sliding latches,

threaded connectors, or other means provided

with this product.

• Substitution of components may impair

suitability for Class I, Division 2.

• If this product contains batteries, they must only

be changed in an area known to be

nonhazardous.

European Hazardous Location Approval

The following applies when the product bears the Ex Marking.

This equipment is intended for use in potentially explosive atmospheres as defined by European Union Directive 94/9/EC and has been found to comply with the Essential Health and

Safety Requirements relating to the design and construction of Category 3 equipment intended for use in Zone 2 potentially explosive atmospheres, given in Annex II to this Directive.

WARNING: RISQUE D’EXPLOSION

• Couper le courant ou s'assurer que

l'environnement est classé non dangereux avant

de débrancher l'équipement.

• Couper le courant ou s'assurer que

l'environnement est classé non dangereux avant

de débrancher les connecteurs. Fixer tous les

connecteurs externes reliés à cet équipement à

l'aide de vis, loquets coulissants, connecteurs

filetés ou autres moyens fournis avec ce produit.

• La substitution de composants peut rendre cet

équipement inadapté à une utilisation en

environnement de Classe I, Division 2.

• S'assurer que l'environnement est classé non

dangereux avant de changer les piles.

16 Rockwell Automation Publication 1783-UM003I-EN-P - March 2014

Page 17

Install the Switch Chapter 1

ATTENTION: This equipment is not resistant to sunlight or other sources of UV radiation.

WARNING:

• This equipment shall be mounted in an ATEX-certified enclosure with a minimum ingress protection rating of at least IP54

(as defined in IEC60529) and used in an environment of not more than Pollution Degree 2 (as defined in IEC 60664-1) when

applied in Zone 2 environments. The enclosure must have a tool-removable cover or door.

• This equipment shall be used within its specified ratings defined by Rockwell Automation.

• Provision shall be made to prevent the rated voltage from being exceeded by transient disturbances of more than 140% of the

rated voltage when applied in Zone 2 environments.

• Secure any external connections that mate to this equipment by using screws, sliding latches, threaded connectors, or other

means provided with this product.

• Do not disconnect equipment unless power has been removed or the area is known to be nonhazardous.

ATTENTION: To comply with the CE Low Voltage Directive (LVD), all connections to this equipment must be powered from a source

compliant with safety extra low voltage (SELV) or protected extra low voltage (PELV).

To comply with UL restrictions, all connections to this equipment must be powered from a source compliant with Class 2 or Limited

Voltage/Current.

Before You Begin

The location where you install the switch must meet these guidelines:

• Operating environment is within the range specified in the technical

specifications. See the Stratix Ethernet Managed Switches Technical Data,

publication

• Clearance to front and rear panels meets these conditions:

– Front-panel status indicators can be easily read.

– Access to ports is sufficient for unrestricted cabling.

– Front-panel direct current (DC) power and relay connector is within

reach of the connection to the DC power source.

• Airflow around the switch and through the vents is unrestricted.

To prevent the switch from overheating, use these minimum clearances:

– Top and bottom: 105 mm (4.13 in.)

– Left and right: 90 mm (3.54 in.)

– Front: 65 mm (2.56 in.)

1783-TD001.

Rockwell Automation Publication 1783-UM003I-EN-P - March 2014 17

Page 18

Chapter 1 Install the Switch

• Temperature surrounding the unit does not exceed 60 °C (140 °F).

IMPORTANT

When the switch is installed in an industrial enclosure, the

temperature within the enclosure is greater than normal room

temperature outside the enclosure.

The temperature inside the enclosure cannot exceed 60 °C (140 °F), the

maximum ambient enclosure temperature of the switch.

• Cabling is away from sources of electrical noise, such as radios, power lines,

and fluorescent lighting fixtures.

• Switch is grounded to a bare metal surface, such as a ground bus or a

grounded DIN rail.

Parts List

Verify that you have these items.

1

2

4

5

31774-M

V

RT

A

V

RT

A

A

1 1783-MS10T switch

3

A

(1)

2 Documentation

3 Power and alarm relay connectors (qty. 2)

4 Console cable

(1) The 1783-MS10T switch is shown as only an example.

If you plan to install a PoE expansion module, verify that you have a PoE power

connector, as shown below.

32437-M

18 Rockwell Automation Publication 1783-UM003I-EN-P - March 2014

Page 19

Required Tools and Equipment

At the end of its life, this equipment should be collected separately from any

unsorted municipal waste.

Obtain these necessary tools and equipment:

Install the Switch Chapter 1

• Ratcheting torque screwdriver that exerts up to 1.69 N

•m (15 in•lbs) of

pressure

• #6 ring terminal lug for 5.3 mm

(10 AWG) wire, such as Thomas & Bett

part number 10RC6 or equivalent

• Crimping tool, such as Thomas & Bett part number WT2000,

ERG-2001, or equivalent

• 5.3 mm

2

(10 AWG) copper ground wire, such as Belden part number 9912

or equivalent

• Wire-stripping tool

• For panel-mounting without a DIN rail, M5 or #10-24 or #10-32 bolts or

screws with 1.27 cm (0.5 in.) O.D. flat washers

For simplified cabling, the automatic medium-dependent interface crossover

(auto-MDIX) feature is enabled by default on the switch. With auto-MDIX

enabled, the switch detects the required cable type for copper Ethernet

connections and configures the interfaces accordingly. Therefore, you can use

either a crossover or a straight-through cable for connections to a switch 10/100

or 10/100/1000 Ethernet port, regardless of the type of device on the other end

of the connection.

For maximum noise immunity, shielded cables must be used on the uplink ports

(Gi1/1 and Gi1/2) on these switches:

• 1783-BMS06TGL

• 1783-BMS06TGA

• 1783-BMS10CGA

• 1783-BMS10CGL

• 1783-BMS10CGN

• 1783-BMS10CGP

• 1783-BMS20CGL

• 1783-BMS20CGN

• 1783-BMS20CGP

• 1783-BMS20CGPK

Rockwell Automation Publication 1783-UM003I-EN-P - March 2014 19

Page 20

Chapter 1 Install the Switch

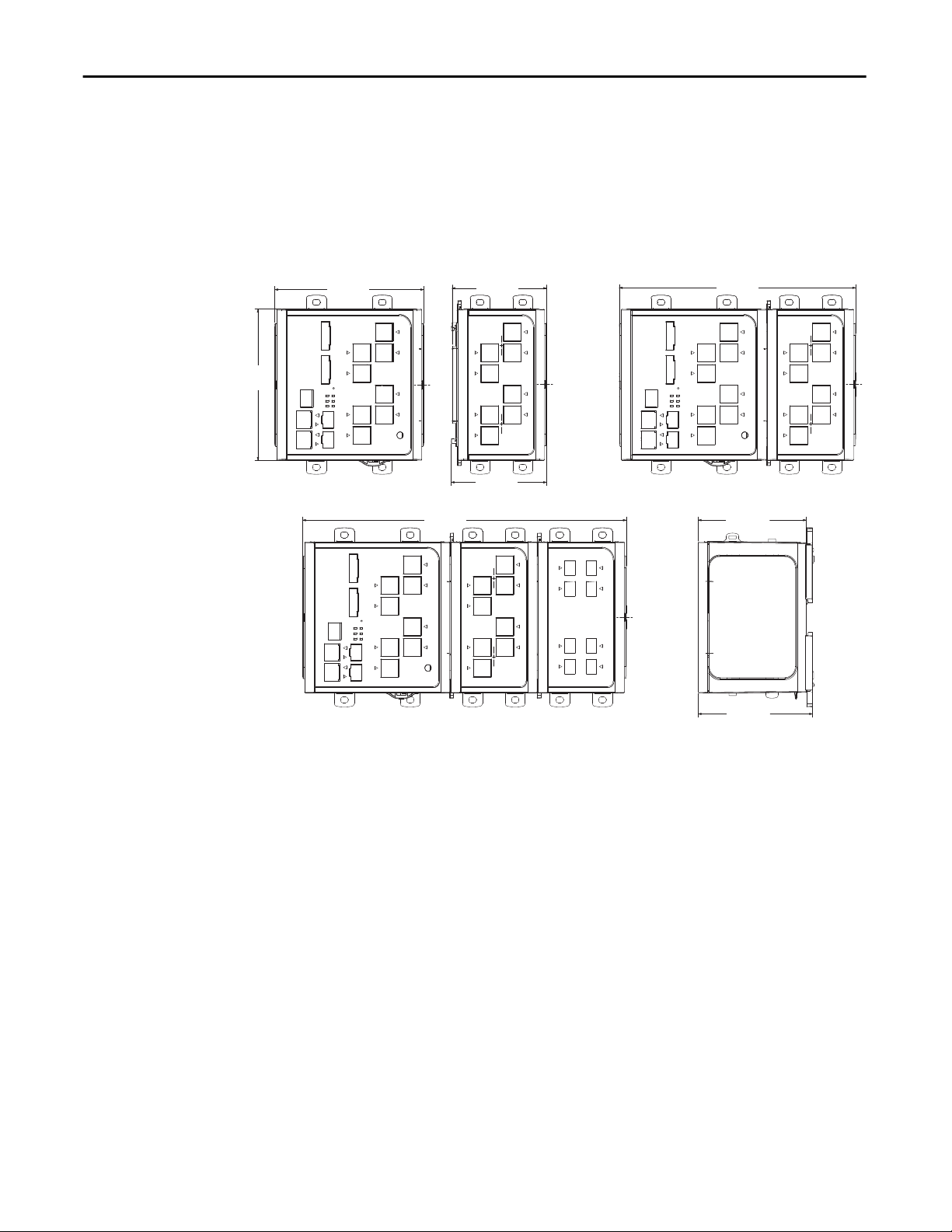

Product Dimensions

The illustrations below show dimensions for the 1783-MS10T switch and the

1783-MX08T expansion module. Dimensions for all other Stratix 8000 and

Stratix 8300 switches and expansion modules are the same as shown below.

14.8 cm

(5.83 in.)

Switch and Expansion Module

15.3 cm

(6.03 in.)

33.27 cm

(13.1 in.)

9.71 cm

(3.82 in.)

9.81 cm

(3.87 in.)

Switch and Expansion Module (mated)

24.3 cm

(9.57 in.)

11.1 cm

(4.38 in.)

Switch

(side view)

11.75 cm

Switch and Expansion Modules (mated)

(4.63 in.)

For panel-mounting, the height of the center of the mounting holes on both the top and bottom latches measures

8.73 mm (0.34 in.) above the top surface (or below the bottom surface) of the switch.

On the switch base unit, the tab hole center-to-center spacing is 6.83 cm (2.69 in.).

For expansion modules, the tab hole center-to-center spacing is 4.36 cm (1.72 in.).

31801-M

20 Rockwell Automation Publication 1783-UM003I-EN-P - March 2014

Page 21

Install the Switch Chapter 1

Install the Switch

Follow these steps to install the switch.

1. (Optional) Attach expansion modules.

2. Mount the switch on one of the following:

• DIN rail

• Wall or panel

3. (Optional) Install an SFP module.

4. Ground the switch.

5. Wire the DC power source for the switch.

6. (Optional) Wire the DC power source for the PoE expansion module.

7. Attach the power and alarm connector.

8. Wire external alarms.

9. Set up the switch initially with Express Setup.

10. Connect to the switch ports:

• 10/100 copper ports

• PoE ports

• Dual-purpose uplink (10/100/1000 and SFP fiber) ports

• 100BaseFX

11. Install or remove the CompactFlash card.

WARNING: If you connect or disconnect the communication cable with power

applied to this module or any device on the network, an electrical arc can occur.

This could cause an explosion in hazardous location installations.

Be sure that power is removed or the area is nonhazardous before proceeding.

WARNING: If you connect or disconnect wiring while the field-side power is on,

an electrical arc can occur. This could cause an explosion in hazardous location

installations.

Be sure that power is removed or the area is nonhazardous before proceeding.

ATTENTION: Prevent Electrostatic Discharge

This equipment is sensitive to electrostatic discharge, which can cause internal

damage and affect normal operation. Follow these guidelines when you handle

this equipment:

• Touch a grounded object to discharge potential static.

• Wear an approved grounding wriststrap.

• Do not touch connectors or pins on component boards.

• Do not touch circuit components inside the equipment.

• Use a static-safe workstation, if available.

• Store the equipment in appropriate static-safe packaging when not in use.

Rockwell Automation Publication 1783-UM003I-EN-P - March 2014 21

Page 22

Chapter 1 Install the Switch

Attach Expansion Modules (optional)

IMPORTANT

If you are adding expansion modules, attach the expansion modules to the

switch before mounting the switch.

The switch can operate as a standalone device with two uplink ports and four or

eight Fast Ethernet ports, or you can increase the number of Fast Ethernet ports

by 8 or 16 by connecting expansion modules.

You can install as many as two expansion modules per base unit. However, only

one of the two modules can be a 1783-MX08F or 1783-MX08S fiber expansion

module.

If you install a 1783-MX08F or 1783-MX08S fiber expansion module, the

module must be in the right-most position, as shown below.

1783-MX08F or

Base Unit

Expansion Module

1783-MX08S

Expansion Module

Depending on the mix of switches and expansion modules, you can have as many

24 Fast Ethernet ports.

22 Rockwell Automation Publication 1783-UM003I-EN-P - March 2014

Page 23

Install the Switch Chapter 1

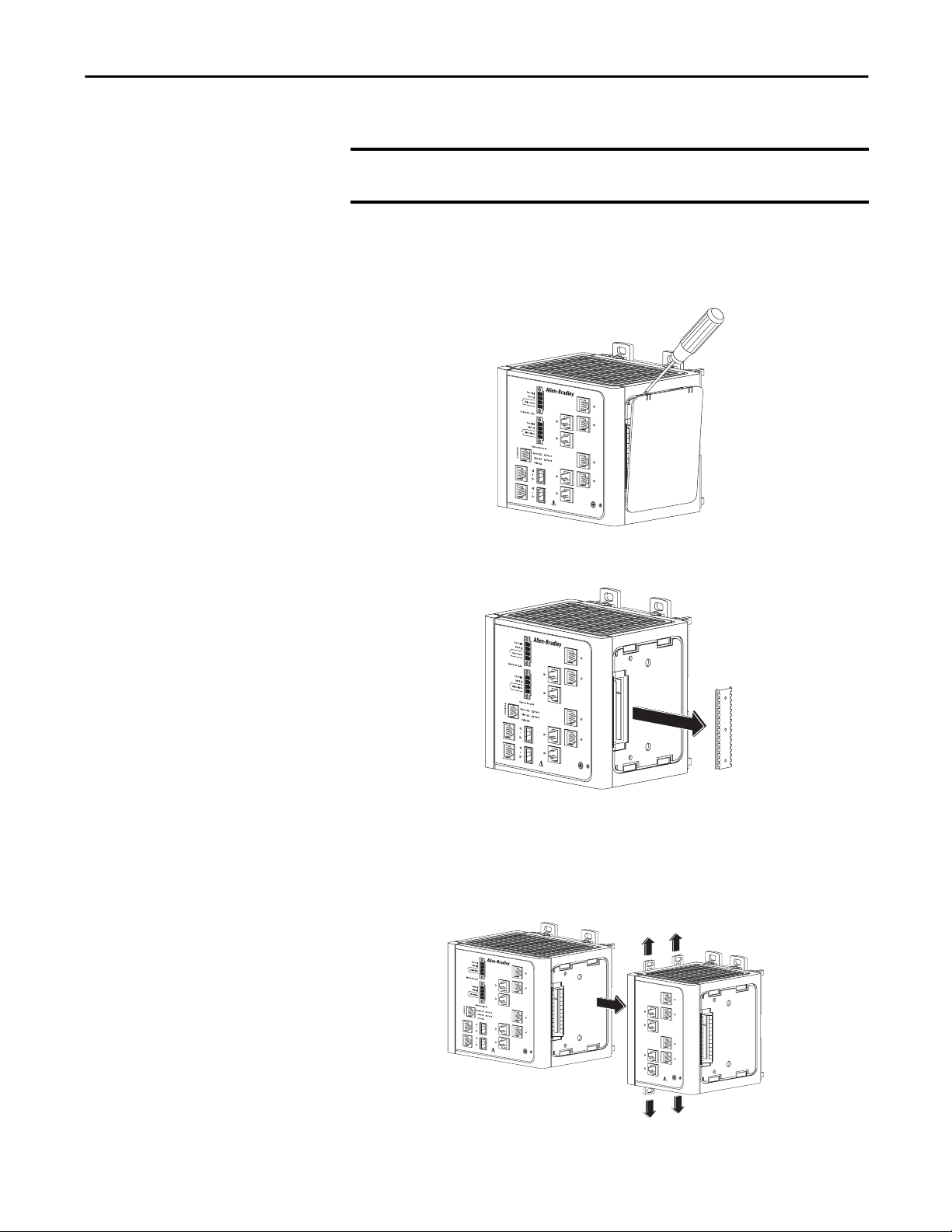

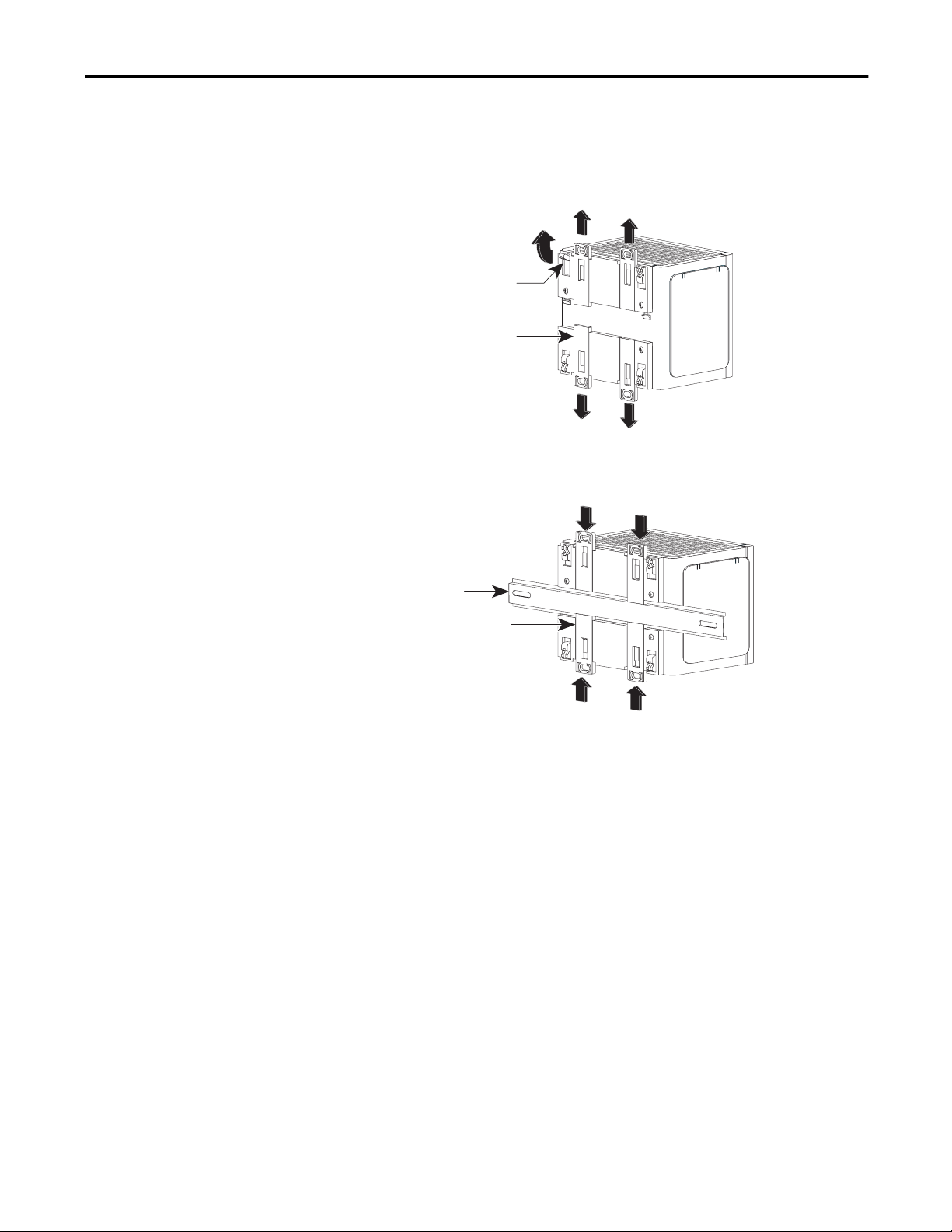

Follow these steps to connect the expansion modules to the switch.

IMPORTANT

You must add expansion modules to the base unit before applying power to

the switch. Remove power from the switch when reconfiguring it.

1. Remove the right side panel by firmly grasping both sides of it in the

middle and pulling it outward.

If necessary, use a screwdriver to pry open the side panel.

31779-M

2. Remove the protective EMI-connector cover from the side panel.

31787-M

3. Push the upper module latches up and the lower module latches down.

Then slide the switch and module together.

The expansion module is shown with the side panel removed. Do not

remove this panel unless you plan to install another module.

31780-M

Rockwell Automation Publication 1783-UM003I-EN-P - March 2014 23

Page 24

Chapter 1 Install the Switch

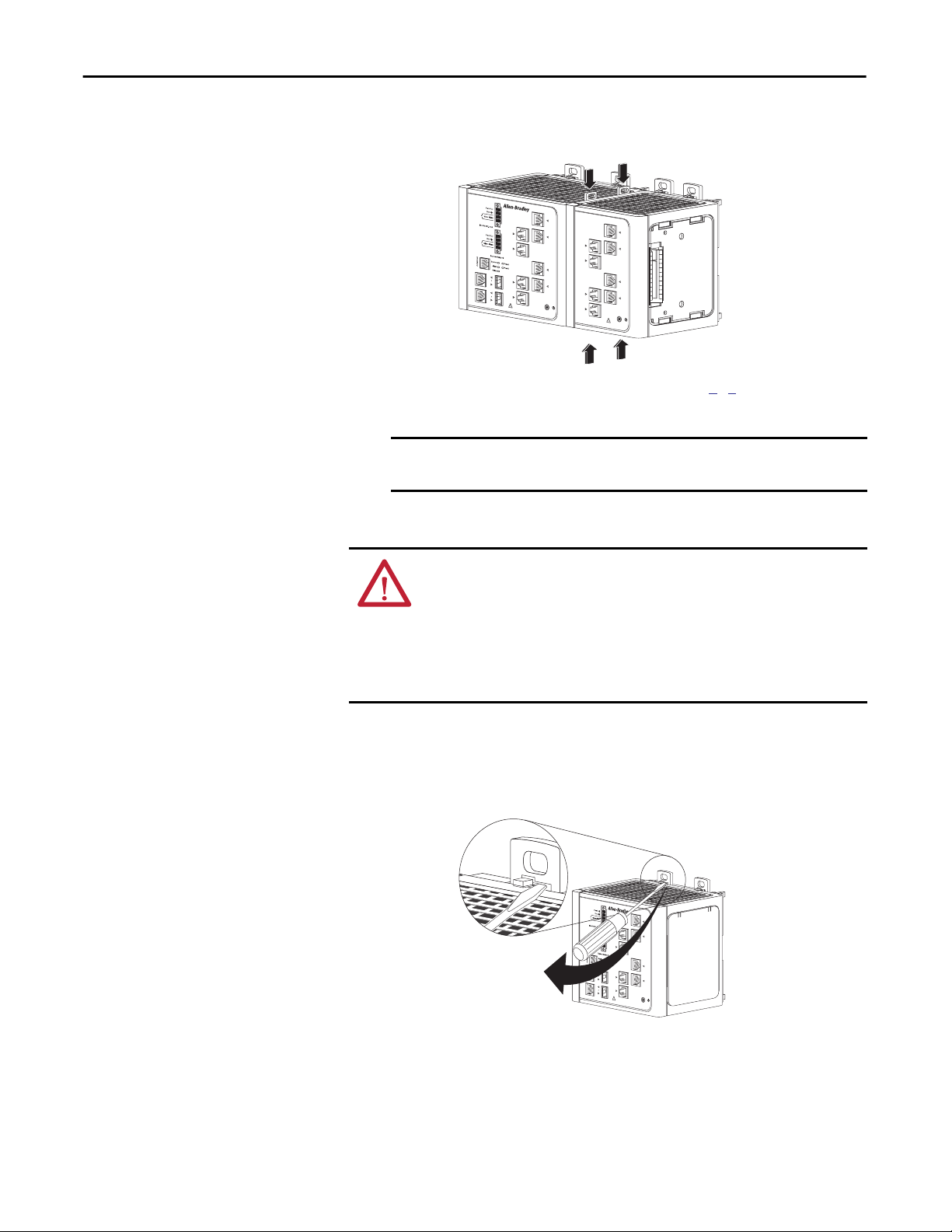

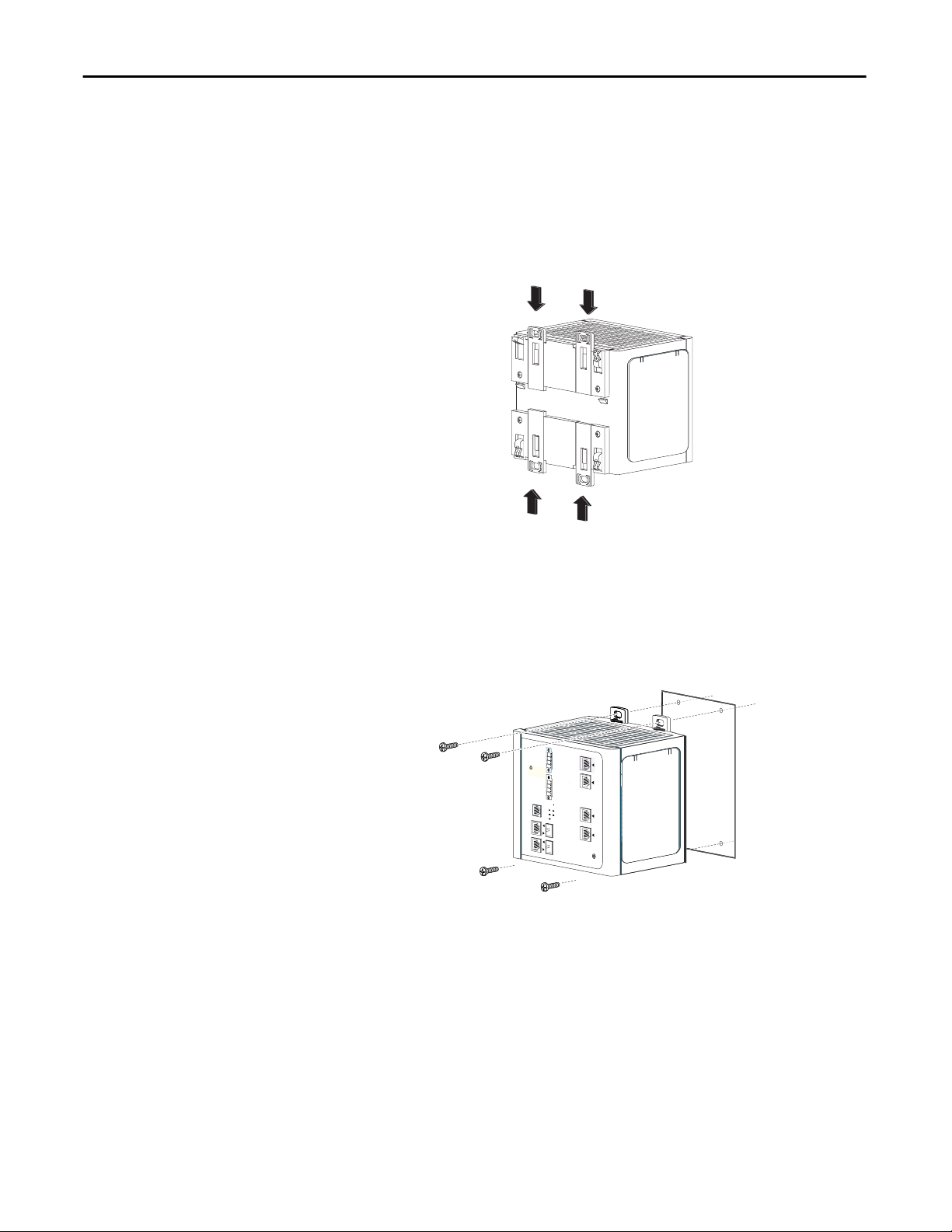

4. Push the upper and lower module latches in to secure the module to the

switch.

31781-M

5. If you are installing a second module, repeat steps 1...4, but secure the

second module to the right side of the first module.

Mount the Switch on a DIN Rail

IMPORTANT

You cannot install an expansion module to the right of the

1783-MX08F or 1783-MX08S fiber expansion module.

WARNING: When using DIN rail mounting, additional grounding is also

accomplished through the DIN rail to chassis ground. Use zinc plated

yellow-chromate steel DIN rail to assist in proper grounding. The use of other

DIN rail materials (for example, aluminum or plastic)) that can corrode, oxidize,

or are poor conductors, can impede proper grounding. Secure DIN rail to

mounting surface approximately every 200 mm (7.8 in.) using end-anchors

appropriately and using a washer plate along the entire length of the DIN rail.

Follow these steps to mount the switch on a DIN rail.

1. Insert a sharp tool, such as a screwdriver, in the space next to the tab, push

gently to release the catch, then turn the screwdriver to push the tab out.

24 Rockwell Automation Publication 1783-UM003I-EN-P - March 2014

31776-M

Page 25

Install the Switch Chapter 1

2. If you are using a heavy-duty 35 mm x 15 mm (1.38 in. x 0.59 in.) DIN rail,

rotate all feet to the extended positions.

Otherwise, if you are using 35 mm x 7.5 mm (1.38 in. x 0.30 in.) DIN rail,

rotate the feet to the recessed positions.

Foot

Latch

31777-M

3. Position the rear panel of the switch directly in front of the DIN rail,

making sure that the DIN rail fits in the space between the two latches.

DIN Rail

Latch

31778-M

4. Push the DIN rail latches in after the switch is over the DIN rail to secure

the switch to the rail.

Rockwell Automation Publication 1783-UM003I-EN-P - March 2014 25

Page 26

Chapter 1 Install the Switch

Mount the Switch on a Wall or Panel

The switch can be mounted on a wall or a panel. You need M5 or #10-24 or

#10-32 bolts or screws with 1.27 cm (0.5 in.) O.D. flat washers. This hardware is

not provided with the switch.

Follow these steps to mount the switch to a wall or a panel.

1. If the DIN rail latches are pushed out, push them in so they are fully

locked in place.

31777-M

2. Rotate all feet to their recessed positions so that the switch can mount flat

on the wall or pane.

If greater air circulation around the switch is required, rotate the feet to

their extended positions before mounting the switch on the wall.

3. Position the rear panel of the switch against the wall or a panel in the

desired location, as shown in this figure.

rwP)CDV

A

2(

4

V

CD

o

r

4

8

RA

t

n

ojaMlA

r

a

r

m

!

W

RA

N

hTim th

i

s

NI

u

n

i

t

G

g

h

p

a

o

v

e

w

er

m

r

o

c

o

er

th

.d

na

T re t

o

no

e

letri

e

c

ud

c

e

s cc

h

eh

o

ris

k

d

kf

p

ie

o

s

o

c

w

o

e

n

r

n

c

roc

t

d

t

s

b

e

eh

t

f

roi

e

ow

es

r

v

c

gni

nu

i

t

.

rwP

B

(

2

4

V

D

C

ro

DV

4

8

)C

R

t

n

B

M

i

on

r

A

l

a

r

m

E

x

p

r

S

y

s

t

A

l

a

Spu

te

1

2

1

se

s

S

e

t

pu

me

wP

r

A

mr

rwP

B

3

4

ocsiC

C

lata

y

s

t

4. Place M5 or #10-24 or #10-32 bolts or screws with 1.27 cm (0.5 in.) O.D.

flat washers through each DIN rail latch, and screw them into the wall.

26 Rockwell Automation Publication 1783-UM003I-EN-P - March 2014

Page 27

Install the Switch Chapter 1

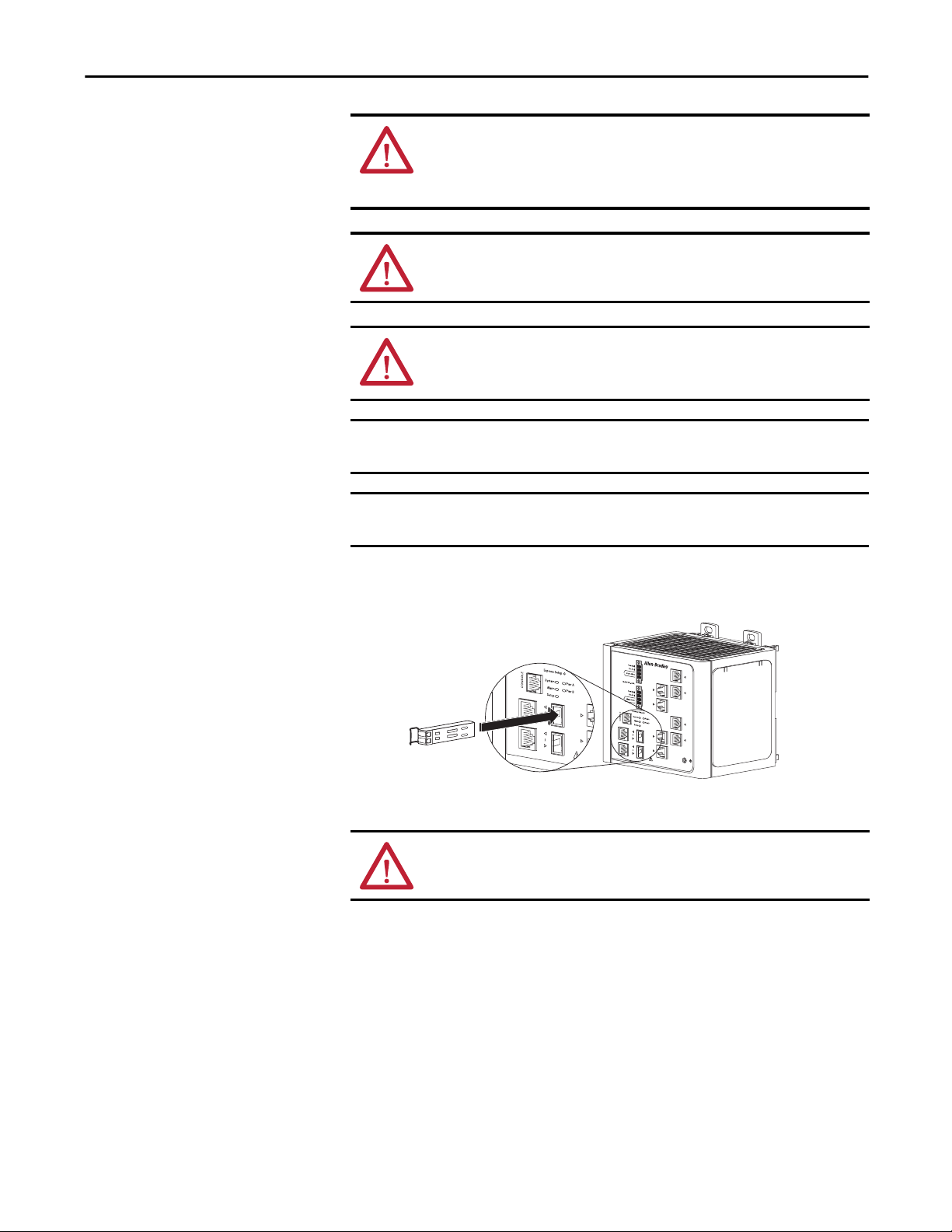

Install an SFP Module (optional)

IMPORTANT

IMPORTANT

ATTENTION: Under certain conditions, viewing the small form-factor

pluggable (SFP) optical transceiver may expose the eye to hazard. When

viewed under some conditions, the optical port may expose the eye beyond the

maximum permissible exposure recommendations.

ATTENTION: SFP modules are static sensitive devices. Always use an ESD wrist

strap or similar individual grounding device when handling SFP modules.

WARNING: When you insert or remove the small form-factor pluggable (SFP)

optical transceiver while power is on, an electrical arc can occur. This could

cause an explosion in hazardous location installations.

Using an SFP module other than those provided by Rockwell Automation will

disable the switch port.

Installing and removing an SFP module can shorten its useful life. Do not

remove and insert SFP modules more often than is absolutely necessary.

Grasp the module on the sides, and insert it into the switch slot until you feel the

connector snap into place.

31782-M

ATTENTION: If the SFP module cannot be fully inserted, stop! Do not force the

module into the slot. Rotate the SFP module 180 degrees and try again.

Rockwell Automation Publication 1783-UM003I-EN-P - March 2014 27

Page 28

Chapter 1 Install the Switch

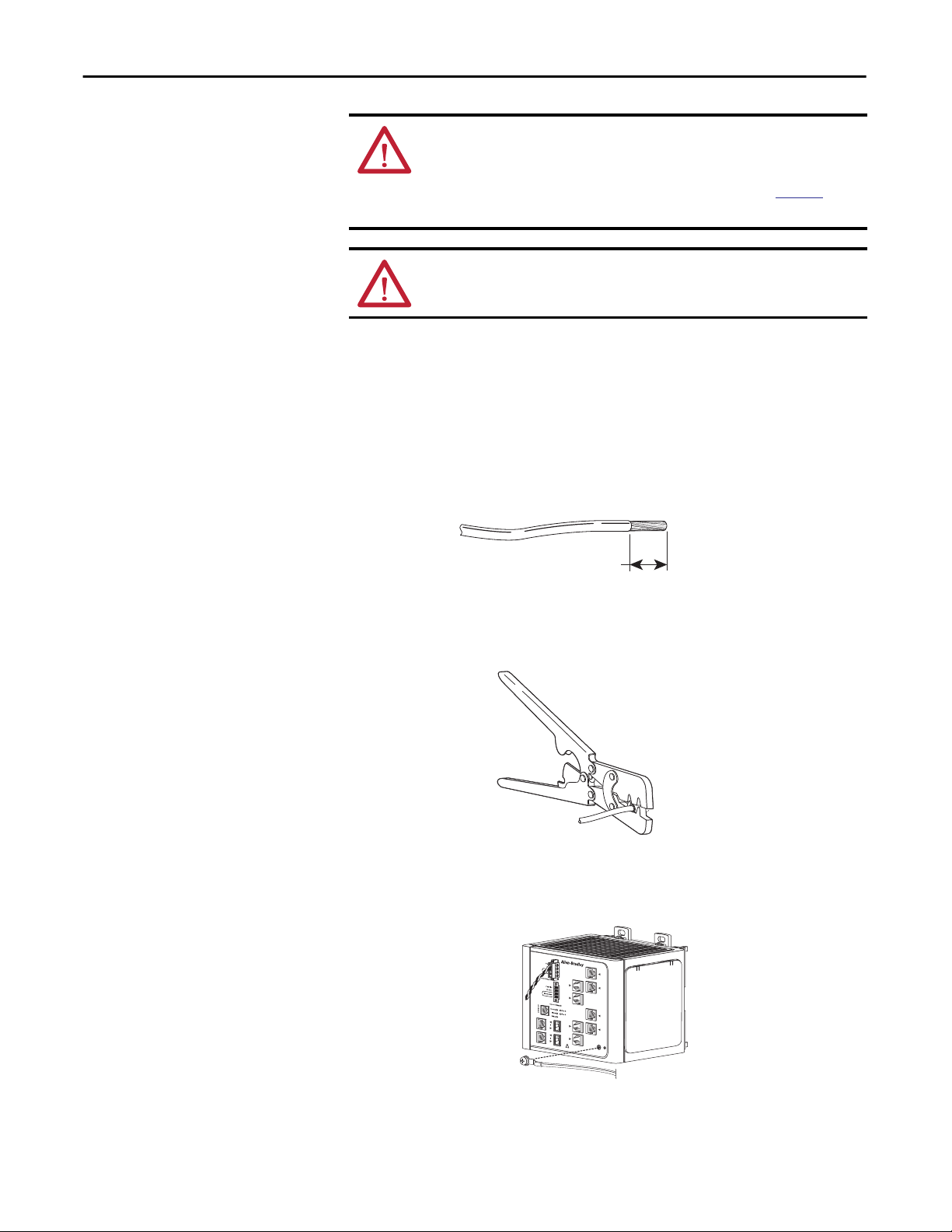

Ground the Switch

ATTENTION: For proper grounding, you must always connect the power supply

functional-ground screw when connecting the power supply. You must provide

an acceptable grounding path for each device in your application. For more

information on proper grounding guidelines, refer to publication

1770-4.1,

Industrial Automation Wiring and Grounding Guidelines.

ATTENTION: You must use the external grounding screw on the front of the

2

switch to ground the switch. Use a 5.3 mm

(10 AWG) ground wire.

Follow these steps to connect the switch to a protective ground.

1. Use a screwdriver to remove the ground screw from the front panel of the

switch.

Store the ground screw for later use.

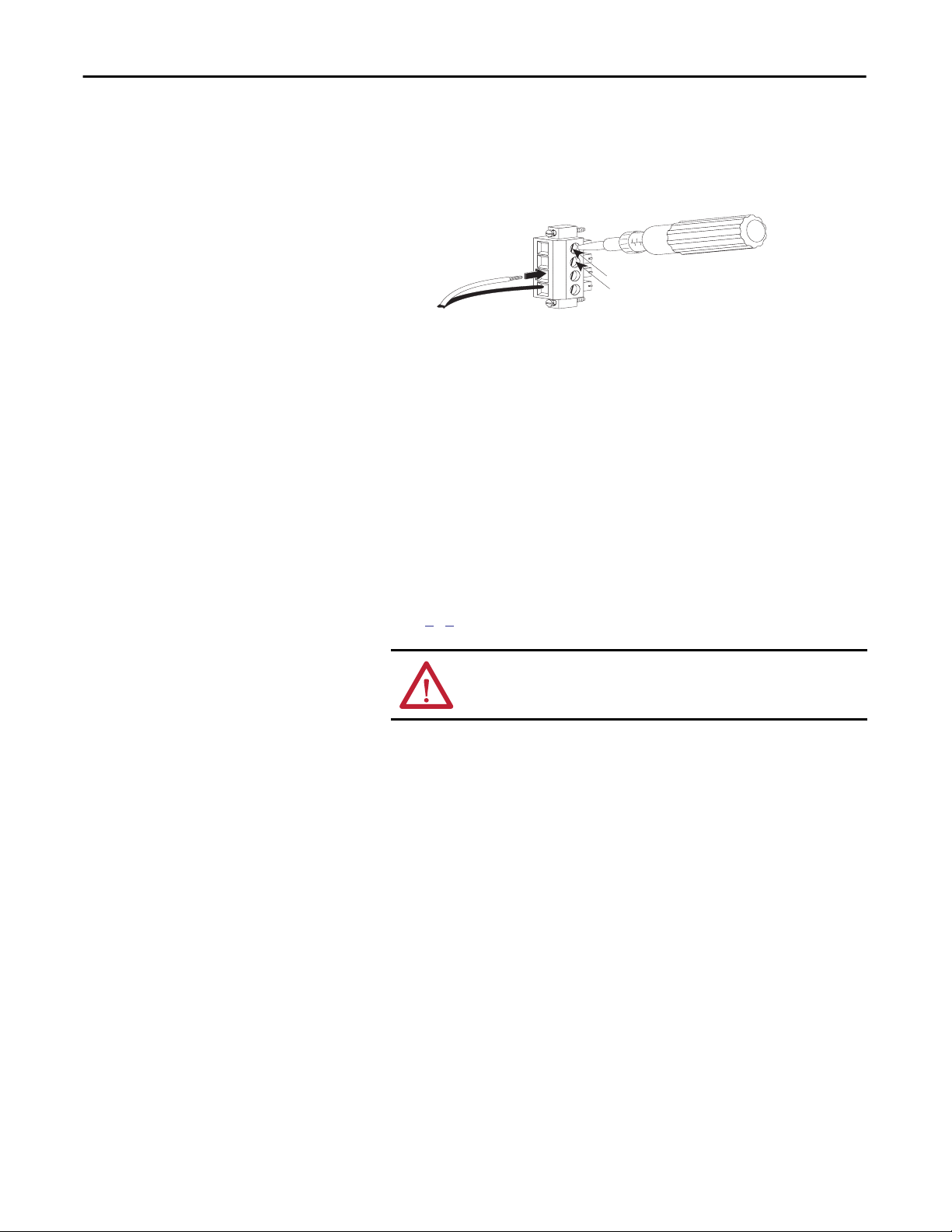

2. If your ground wire is insulated, use a wire stripping tool to strip the

2

5.3 mm

(10 AWG) ground wire to 12.7 mm (0.5 in.) ± 0.5 mm (0.02 in.).

12.7 mm (0.5 in.)

31789-M

3. Insert the ground wire into the ring terminal lug.

4. Use a crimping tool to crimp the ring terminal to the wire.

31790-M

5. Slide the ground screw through the ring terminal.

6. Insert the ground screw into the ground-screw opening on the front panel.

VRTAA

28 Rockwell Automation Publication 1783-UM003I-EN-P - March 2014

31791-M

Page 29

Install the Switch Chapter 1

7. Use a ratcheting torque screwdriver to tighten the ground screw and ring

terminal lug to the switch front panel to 0.96 N•m (8.5 lb•in).

8. Attach the other end of the ground wire to a grounded bare-metal surface,

such as a ground bus, or a grounded DIN rail.

Wire the DC Power Source for the Switch

WARNING: Before performing any of the following procedures, make sure that

power is removed from the DC circuit or the area is nonhazardous before

proceeding.

WARNING: To comply with the CE Low Voltage Directive (LVD), this equipment

must be powered from a source compliant with the safety extra low voltage

(SELV) or protected extra low voltage (PELV).

To comply with UL restrictions, this equipment must be powered from a source

compliant with Class 2 or Limited Voltage/Current.

Follow these steps to wire DC power to the switch.

1. Locate the power and alarm relay connector and identify the positive and

return DC power connections.

The positive DC power connection is labeled V, and the negative DC

power connection is the adjacent connection labeled RT. Connections

labeled A are used for the alarm relay connectors.

V

RT

A

A

31783-M

2. Measure a length of 0.82…0.52 mm

2

(18…20 AWG) copper wire long

enough to connect to the DC power source.

3. Using an 18-gauge wire-stripping tool, strip each of the two wires to

6.3 mm (0.25 in.) ± 0.5 mm (0.02 in.).

Do not strip more than 6.8 mm (0.27 in.) of insulation from the wire.

Stripping more than the recommended amount of wire can leave exposed

wire from the connector after installation.

6.8 mm (0.27 in.)

31784-M

Rockwell Automation Publication 1783-UM003I-EN-P - March 2014 29

Page 30

Chapter 1 Install the Switch

4. Insert the exposed part of the positive wire into the connection labeled V

and the exposed part of the return wire into the connection labeled RT.

Make sure that you cannot see any wire lead. Only wire with insulation can

extend from the connector.

VRTA A

V

RT

31785-M

5. Use a ratcheting-torque screwdriver to torque the power and relay

connector captive screws above the installed wire leads to 0.23 N•m

(2.0 lb•in).

6. Connect the other end of the positive wire (the one connected to V) to the

positive terminal on the DC power source, and connect the other end of

the return wire (the one connected to RT) to the return terminal on the

DC power source.

You can use a second power source to provide redundant power. The alarm

relays on the switch can be used to warn you if one of the power supplies

fails. The switch operates properly with only one power source connected

at either Pwr A or Pwr B.

7. If you are installing the switch and are using a second power source, repeat

steps

2…6 with a second power and relay connector.

ATTENTION: If multiple power sources are used, do not exceed the

specified isolation voltage.

30 Rockwell Automation Publication 1783-UM003I-EN-P - March 2014

Page 31

Install the Switch Chapter 1

Wire the DC Power Source for the PoE Expansion Module (optional)

WARNING: Before performing any of the following procedures, make sure that

power is removed from the DC circuit or the area is nonhazardous before

proceeding.

WARNING: To comply with the CE Low Voltage Directive (LVD), this equipment

must be powered from a source compliant with the safety extra low voltage

(SELV) or protected extra low voltage (PELV).

To comply with UL restrictions, this equipment must be powered from a source

compliant with Class 2 or Limited Voltage/Current.

Power supply requirements for a PoE expansion module depend on your

application.

Application Power Consumption Power Supply per Port Allen-Bradley Products

PoE only

IEEE 802.3af

PoE and PoE +

IEEE 802.3at Type 2

44…57V DC (48V DC nom) 15.4 W, max Switched mode power supplies:

50…57V DC (54V DC nom) 15.4 W, max for PoE

30 W, max for PoE+

• 1606-XL Standard

• 1606-XLE Essential

• 1606-XLP Compact

• 1606-XLS Performance

Follow these steps to wire DC power to the PoE expansion module.

1. Locate the power connector and identify the positive and return DC

power connections.

DC -

DC +

2. Measure a length of 0.82…0.52 mm

32437-M

2

(18…20 AWG) copper wire long

enough to connect to the DC power source.

3. Use an 18-gauge wire-stripping tool to strip each of the two wires to

6.3 mm (0.25 in.) ± 0.5 mm (0.02 in.).

Do not strip more than 6.8 mm (0.27 in.) of insulation from the wire.

Stripping more than the recommended amount of wire can leave exposed

wire from the connector after installation.

6.8 mm (0.27 in.)

31784-M

Rockwell Automation Publication 1783-UM003I-EN-P - March 2014 31

Page 32

Chapter 1 Install the Switch

4. Insert the exposed part of the positive wire into the DC + connection and

the exposed part of the return wire into the DC - connection.

5. Make sure that you cannot see any wire lead; only wire with insulation can

extend from the connector.

DC +

DC -

32436-M

6. Use a ratcheting-torque screwdriver to torque the power connector captive

screws above the installed wire leads to 0.23 N•m (2.0 lb•in).

7. Connect the other end of the positive wire (the one connected to DC +)

to the positive terminal on the DC power source, and connect the other

end of the return wire (the one connected to DC -) to the return terminal

on the DC power source.

32 Rockwell Automation Publication 1783-UM003I-EN-P - March 2014

Page 33

Install the Switch Chapter 1

Attach the Power and Relay Connector to the Switch

ATTENTION: The input voltage source of the alarm circuits must be an isolated

source and limited to less than or equal to 24 V DC, 1 A.

ATTENTION: Exposure to some chemicals can degrade the sealing properties of

materials used in the relay. Periodically inspect the relay and check for any

degradation. If the relay appears damaged in any way, replace the switch.

Sealed Device: Relay Model AGN200A03, manufactured by Matsushita Electric

Works

Relay Cover: Manufacture of Plastic Material—Nippon Oil Corp.

Designation of Plastic Material—Type FC-100

Generic Name of Plastic Material —Liquid crystal polymer

Relay Body: Manufacture of Plastic Material—Ueno Fine Chemicals Industry Ltd.

Designation of Plastic Material— Type 2125G

Generic Name of Plastic Materialv—Liquid crystal polymer

Relay Epoxy: Manufacture of Material—Resinous Kasei Co. Ltd.

Designation of Material – Type A-2500BK

Generic Name of Plastic Material—Epoxy Resin

Sealed Device: Relay Model B4GA003Z, manufactured by Fujitsu Takamisawa

Electric Co. Ltd.

Relay Cover: Manufacture of Plastic Material —Sumitomo Chemical Co. Ltd.

Designation of Plastic Material—Type E4009

Generic Name of Plastic Material—Liquid crystal polymer

Relay Body: Manufacture of Plastic Material—Sumitomo Chemical Co. Ltd.

Designation of Plastic Material—Type E6807LHF

Generic Name of Plastic Material—Liquid crystal polymer

Relay Epoxy: Manufacture of Material—Sumitomo Bakelite Co. Ltd.

Designation of Material—Type ‘SUMIMAC’ ECR-9750K2

Generic Name of Plastic Material—Epoxy Resin

Rockwell Automation Publication 1783-UM003I-EN-P - March 2014 33

Page 34

Chapter 1 Install the Switch

Follow these steps to connect the DC power source and relay connector to the

switch.

1. Insert the power and relay connector into the Pwr A receptacle on the

switch front panel.

VRTA A

31786-M

2. Use a screwdriver to tighten the captive screws on the sides of the power

and relay connector.

3. If a second power source is required, insert a second power and relay

connector into the Pwr B receptacle on the switch front panel.

ATTENTION: If multiple power sources are used, do not exceed the

specified isolation voltage

.

VRTAA

VRTA A

31788-M

4. Use a screwdriver to tighten the captive screws on the sides of the second

power and relay connector.

34 Rockwell Automation Publication 1783-UM003I-EN-P - March 2014

Page 35

Install the Switch Chapter 1

Attach the Power Connector to the PoE Expansion Module (optional)

Follow these steps to connect the DC power source to the PoE expansion

module.

1. Insert the power connector into the DC input terminal block on the PoE

expansion module.

2. Use a screwdriver to tighten the captive screws on the sides of the power

connector.

Wire External Alarms (optional)

The alarm relays on the switch are normally open. To connect an external alarm

device to the relays, you must connect two relay contact wires to complete an

electrical circuit. Because each external alarm device requires two connections to

a relay, the switch supports a maximum of two external alarm devices.

ATTENTION: The input voltage source of the alarm circuits must be an isolated

source and limited to less than or equal to 24 V DC, 1 A.

For wire connections to the power and relay connector, you must use UL and CSA

rated, style 1007 or 1569 twisted-pair copper appliance wiring material (AWM)

wire (such as Belden part number 9318).

Follow these steps to wire alarms.

1. Measure two strands of twisted-pair wire (18...20 AWG) long enough to

connect to the external alarm device.

2. Use a wire stripper to remove the casing from both ends of each wire to

6.3 mm (0.25 in.) ± 0.5 mm (0.02 in.).

IMPORTANT

Do not strip more than 6.8 mm (0.27 in.) of insulation from the wires.

Stripping more than the recommended amount of wire can leave

exposed wire from the power and relay connector after installation.

Rockwell Automation Publication 1783-UM003I-EN-P - March 2014 35

Page 36

Chapter 1 Install the Switch

3. Insert the exposed wires for the external alarm device into the two

connections labeled A, as shown in the following figure.

1

2

6

24

!

!

-

1 External device, relay wire A connection 1 2 External device, relay wire A connection 2

4. Use a screwdriver to torque the power and relay connector captive screw

(above the installed wire leads) to 0.23 N•m (2.0 lb•in).

VRTA A

V

RT

31785-M

5. Repeat steps 1…4 to insert the input and output wires of an additional

external alarm device into the second power and relay connector.

The following figure shows the completed wiring for two power supplies

and two external alarm devices.

1

2

3

6

4

24

!

!

1 Power source A positive connection 5 Power source B positive connection

2 Power source A return connection 6 Power source B return connection

3 External device 1, relay wire major alarm connection 7 External device 2, relay wire minor alarm

4 External device 1, relay wire major alarm connection 8 External device 2, relay wire minor alarm

5

6

7

6

8

24

!

!

-

connection

connection

36 Rockwell Automation Publication 1783-UM003I-EN-P - March 2014

Page 37

Install the Switch Chapter 1

Connect to 10/100 Copper Ports

Connect to a PoE Expansion Module Port

1. Insert a straight-through, twisted four-pair, Category 5e or better cable

with an RJ45 connector into the port.

VRTA A

To 10/100 ports

31795-M

2. Insert the other cable end into an RJ45 connector on the other device.

Two expansion modules provide PoE capability:

• The 1783-MX04E PoE expansion module provides four PoE ports. You

can configure as many as four ports in any combination of PoE and PoE+.

• The 1783-MX04T04E PoE expansion module provides four PoE ports

and four non-PoE ports. You can configure as many as four ports in any

combination of PoE and PoE+.

The PoE expansion modules each require a separate power supply. For power

supply requirements based on your application, refer to

page 31.

1. Insert a straight-through, twisted four-pair, Category 5e or better cable

with an RJ45 connector into the port.

To 10/100 PoE Ports

2. Insert the other cable end into an RJ45 connector on the other PoE

powered device.

Rockwell Automation Publication 1783-UM003I-EN-P - March 2014 37

Page 38

Chapter 1 Install the Switch

Connect to Dual-purpose Uplink Ports

The switches have two dual-purpose uplink ports. Each dual-purpose uplink port

has a 10/100/1000 RJ45 connector for a copper interface and a slot for an SFP

module. Only one port of the dual-purpose port can be active at a time. If an SFP

module port is connected, the SFP module port has priority.

Connect to 10/100/1000 Uplink Ports

1. Insert a straight-through, twisted four-pair, Category 5e or better cable

with an RJ45 connector into the port.

VRTAA

To 10/100/1000 Ports

31795-M

2. Insert the other cable end into an RJ45 connector on the other device.

Connect to SFP Fiber Ports

ATTENTION: Class 1 laser product. Laser radiation is present when the small

form-factor pluggable (SFP) optical transceiver is open and interlocks bypassed.

Only trained and qualified personnel should be allowed to install, replace, or

service this equipment.

Follow these steps if you installed an SFP module. For instructions on installing,

removing, and connecting to SFP modules, see the documentation that shipped

with the SFP module.

1. Insert a fiber-optic cable with an LC connector into the SFP fiber port.

VRTAA

2. Insert the other cable end into the other device.

38 Rockwell Automation Publication 1783-UM003I-EN-P - March 2014

31796-M

Page 39

Install the Switch Chapter 1

Connect to 100BaseFX Ports

Install or Remove the CompactFlash Card

ATTENTION: Class 1 laser product. Laser radiation is present when the system is

open and interlocks bypassed. Only trained and qualified personnel are allowed

to install, replace, or service this equipment.

1. Insert a fiber-optic cable with an LC connector into the 100BASE-FX

port of the 1783-MX08F expansion module.

31797-M

2. Insert the other cable end into the other device.

The switches ship with the CompactFlash card installed. Follow this procedure

when you need to install or remove it from the switch.

WARNING: When you insert or remove the CompactFlash Card while power is

on, an electrical arc can occur. This could cause an explosion in hazardous

location installations. Be sure that power is removed or the area is

nonhazardous before proceeding.

Install or remove the CompactFlash card by grasping the tab on the card and

either inserting it or removing it from the slot at the bottom of the switch.

VRTAA

31792-M

IMPORTANT

You can install and remove the CompactFlash card while the switch is powered.

However, if you do not have a CompactFlash card installed in the switch, you

are unable to do the following:

• Start the Device Manager Web interface when you apply power to the

switch.

• Save configuration changes you made with the AOP via software.

• Start up the switch.

Rockwell Automation Publication 1783-UM003I-EN-P - March 2014 39

Page 40

Chapter 1 Install the Switch

Reset the Switch to Factory Defaults

Troubleshoot the Installation

Follow this procedure if you need to restore the switch to its factory default

settings. This procedure resets the switch to its original factory settings. Any

configuration changes you have made are lost.

1. Remove power from the switch.

2. Reapply power to the switch.

3. While the switch is powering up, press and hold the Express Setup button.

4. When the EIP Mod, EIP Net and Setup status indictors turn red, release

the Express Setup button.

The switch continues powering up in its factory default state.

5. To reconfigure the switch, see

Setup on page 48.

The status indicators on the front panel provide troubleshooting information

about the switch. They show power-on self-test (POST) failures, portconnectivity problems, and overall switch performance. You can also get statistics

from the browser interface, the command-line interface (CLI), or a Simple

Network Management Protocol (SNMP) workstation.

Set Up the Switch Initially with Express

Switch POST Results

As power is applied to the switch, it begins the POST, a series of tests that runs

automatically to ensure that the switch functions properly. It can take several

minutes for the switch to complete POST.

POST starts with status indicator tests that cycle once through the EIP Mod, EIP

Net, Setup, Pwr A, and Pwr B status indicators. While POST proceeds, the EIP

Mod status indicator blinks green, and all the other status indicators remain off.

If POST completes successfully, the System status indicator changes to solid

green, and the other status indicators display their normal operating status. If the

switch fails POST, the System status indicator turns red.

ATTENTION: POST failures are usually fatal. Contact your Rockwell Automation

technical support representative if your switch does not pass POST.

POST Results with a Terminal

If you have a terminal connected to the console port, you can also view POST

status and test results on the terminal. If the terminal displays unclear characters,

try resetting the terminal-emulation software to 9600 bits per second.

40 Rockwell Automation Publication 1783-UM003I-EN-P - March 2014

Page 41

Install the Switch Chapter 1

Bad or Damaged Cable

Always make sure that the cable does not have marginal damage or failure. Even if

a cable is capable of connecting at the physical layer, subtle damage to the wiring

or connectors can corrupt packets.

This situation is likely when the port has many packet errors or the port

constantly loses and regains the link. To troubleshoot, try the following:

• Swap the copper or fiber-optic cable with a known, undamaged cable.

• Look for broken, bent, or missing pins on cable connectors.

• Rule out any bad patch panel connections or media convertors between

the source and destination.

If possible, bypass the patch panel, or eliminate faulty media convertors

(fiber-optic-to-copper).

• Try the cable in another port or interface to determine if the problem

follows the cable.

Ethernet and Fiber Cables

Make sure that you have the correct cable type for the connection:

• Use Category 3 copper cable for 10 Mb/s UTP connections.

• You can use Category 5, 5e, or 6 UTP or STP cable for 10/100 Mbps

connections.

• For 1000 Mbps (1 gigabit per second) connections, use Category 5e or

Category 6 UTP or STP cable.

• For fiber-optic connectors, verify that you have the correct cable for the

distance and the port type.

• Make sure that the connected device ports both match and use the same

type of encoding, optical frequency, and fiber type.

Rockwell Automation Publication 1783-UM003I-EN-P - March 2014 41

Page 42

Chapter 1 Install the Switch

Link Status

Verify that both sides have a network link. A single broken wire or one shut down

port can cause one side to show a link, but not the other side. A Link status

indicator does not guarantee that the cable is fully functional. The cable can

encounter physical stress that causes it to function at a marginal level. If the Link

status indicator for the port is not lit, do the following:

• Connect the cable from the switch to a known good device.

• Make sure that both ends of the cable are connected to the correct ports.

• Verify that both devices have power.

• Verify that you are using the correct cable type.

• Rule out loose connections. Sometimes a cable appears to be seated, but is

not. Disconnect the cable, and then reconnect it.

Transceiver Issues

Use only Rockwell Automation SFP modules on the switch. Each SFP module

has an internal serial EEPROM that is encoded with security information. This

encoding identifies and validates that the module meets the requirements for the

switch. Other manufacturers’ SFP modules do not function correctly.

Check these items:

• Verify that the SFP module is valid and functional. Exchange a suspect

module with a known good module. Verify that the module is supported

on this platform.

• Use the CLI show interfaces command or the CLI show int status

command to verify the error-disabled or shutdown status of the port or

module. Re-enable the port if needed.

• Make sure that all fiber connections are properly cleaned and securely

connected.

Port and Interface Settings

A cause of port connectivity failure can be a disabled port. Verify that the port or

interface is not disabled or powered down for some reason. If a port or interface is

manually shut down on one side of the link or the other side, the link does not

come up until you re-enable the port. Use the CLI show interfaces privileged

EXEC command to verify the port or interface error-disabled, disabled, or

shutdown status on both sides of the connection. If needed, re-enable the port or

the interface.

42 Rockwell Automation Publication 1783-UM003I-EN-P - March 2014

Page 43

Getting Started

Topic Page

Switch Front Panel Description 44

Expansion Module Front Panel Descriptions 44

Hardware Features 47

CompactFlash Memory Card 48

Set Up the Switch Initially with Express Setup 48

Switch Memory Allocation 52

Device Manager Web Interface 53

Studio 5000 Environment 54

Cisco Network Assistant 54

Command Line Interface 55

Chapter 2

The Stratix 8000 and Stratix 8300 Ethernet managed switches provide a secure

switching infrastructure for harsh environments. You can connect these switches

to network devices, such as servers, routers, and other switches. In industrial

environments, you can connect Ethernet-enabled industrial communication

devices, including programmable logic controllers (PLCs), human-machine

interfaces (HMIs), drives, sensors, and I/O.

The Stratix 8000 Ethernet managed switch is a Layer 2 switch. The Stratix 8300

Ethernet managed switch adds Layer 3 routing to the Stratix 8000 switch. The

Stratix 8300 switch contains all the features of the Stratix 8000 switch, plus a

number of IP routing protocols, along with enhanced security and quality of

service (QoS) features.

Rockwell Automation Publication 1783-UM003I-EN-P - March 2014 43

Page 44

Chapter 2 Getting Started

Switch Front Panel Description

The switch front panel contains the ports, the status indicators, and the power

and relay connectors.

Figure 1 - 1783-MS10T Switch

1

2

3

1 Power and relay connectors

2 Console port

3 Dual-purpose ports

4 10/100 ports

5 Protective ground connection

4

5

31826-M

Expansion Module Front Panel Descriptions

Figure 2…Figure 7 show the expansion module front panels.

Figure 2 - 1783-MX08T Switch Copper Expansion Module (side cover removed)

1

31827-M

1 10/100 ports

44 Rockwell Automation Publication 1783-UM003I-EN-P - March 2014

Page 45

Figure 3 - 1783-MX08F Switch Fiber Expansion Module

1

1 100BASE-FX ports

Figure 4 - 1783-MX04S SFP Expansion Module

Getting Started Chapter 2

31797-M

1

1 100BASE-FX SFP ports

Figure 5 - 1783-MX08S SFP Expansion Module

1

32439-M

32440-M

1 100BASE-FX SFP ports

Rockwell Automation Publication 1783-UM003I-EN-P - March 2014 45

Page 46

Chapter 2 Getting Started

Figure 6 - 1783-MX04E PoE Expansion Module

1

2

3

32444-M

1 DC input terminal block

2 PoE status indicator

3 PoE ports

Figure 7 - 1783-MX04T04E PoE Expansion Module

1

4

1 10/100 non-PoE ports

2 DC-Input terminal block

3 PoE status indicator

4 PoE ports

2

3

32386-M