Page 1

User Manual

Stratix 5700 Ethernet Managed Switches

Page 2

Important User Information

Read this document and the documents listed in the additional resources section about installation, configuration, and

operation of this equipment before you install, configure, operate, or maintain this product. Users are required to

familiarize themselves with installation and wiring instructions in addition to requirements of all applicable codes, laws,

and standards.

Activities including installation, adjustments, putting into service, use, assembly, disassembly, and maintenance are required

to be carried out by suitably trained personnel in accordance with applicable code of practice.

If this equipment is used in a manner not specified by the manufacturer, the protection provided by the equipment may be

impaired.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the

use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or

liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or

software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation,

Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous environment,

which may lead to personal injury or death, property damage, or economic loss.

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death, property

damage, or economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the consequence.

IMPORTANT

Identifies information that is critical for successful application and understanding of the product.

Labels may also be on or inside the equipment to provide specific precautions.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous

voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may

reach dangerous temperatures.

ARC FLASH HAZARD: Labels may be on or inside the equipment, for example, a motor control center, to alert people to

potential Arc Flash. Arc Flash will cause severe injury or death. Wear proper Personal Protective Equipment (PPE). Follow ALL

Regulatory requirements for safe work practices and for Personal Protective Equipment (PPE).

Allen-Bradley, ArmorStratix 5700, Logix5000, Rockwell Automation, Rockwell Software, RSLinx, RSLogix , RSNetWorx, Stratix 2000, Stratix 5700, Stratix 8000, Stratix 8300, Studio 5000, Studio 5000 Automation

Engineering & Design Environment, and Studio 5000 Logix Designer are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Page 3

Summary of Changes

This manual contains new and updated information. Changes throughout this

revision are marked by change bars, as shown to the right of this paragraph.

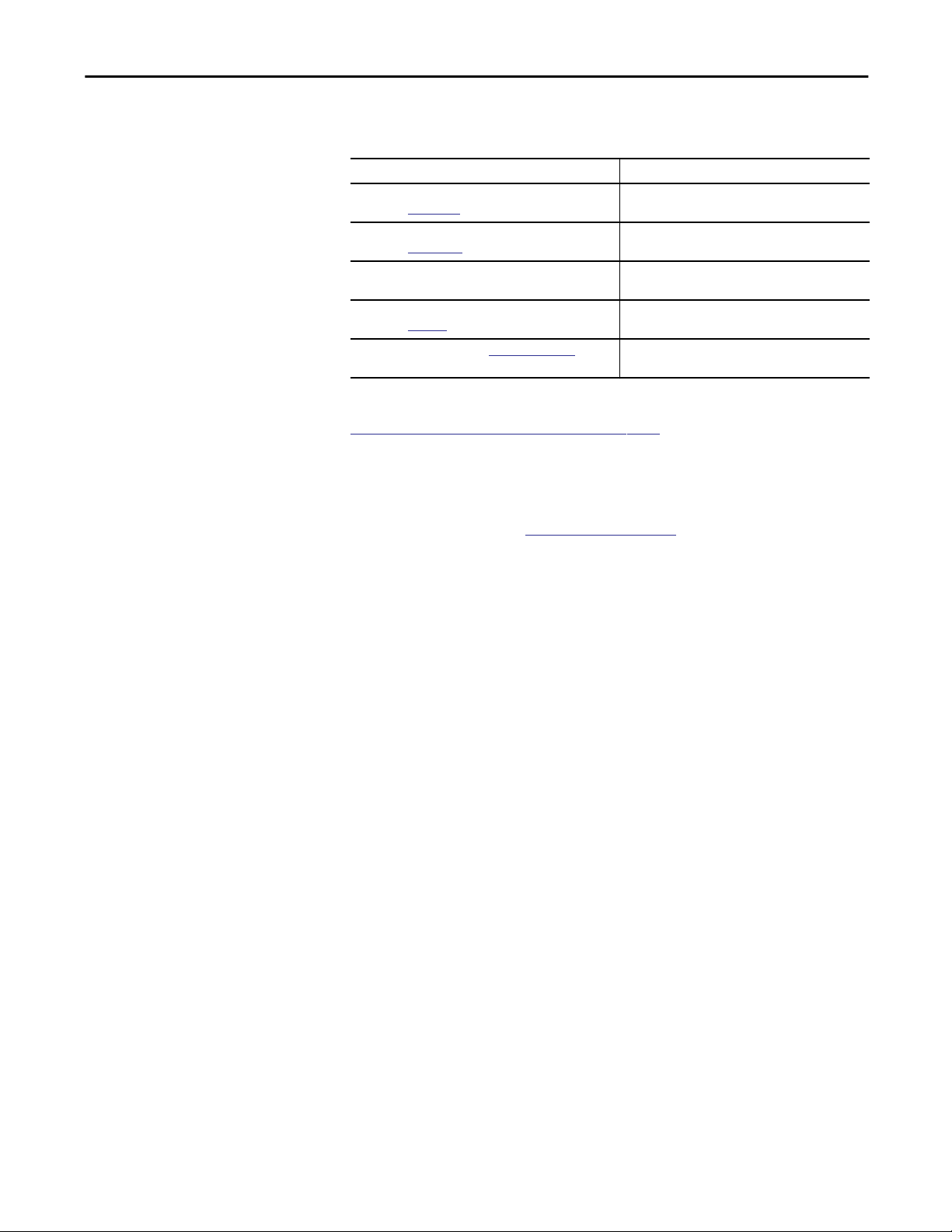

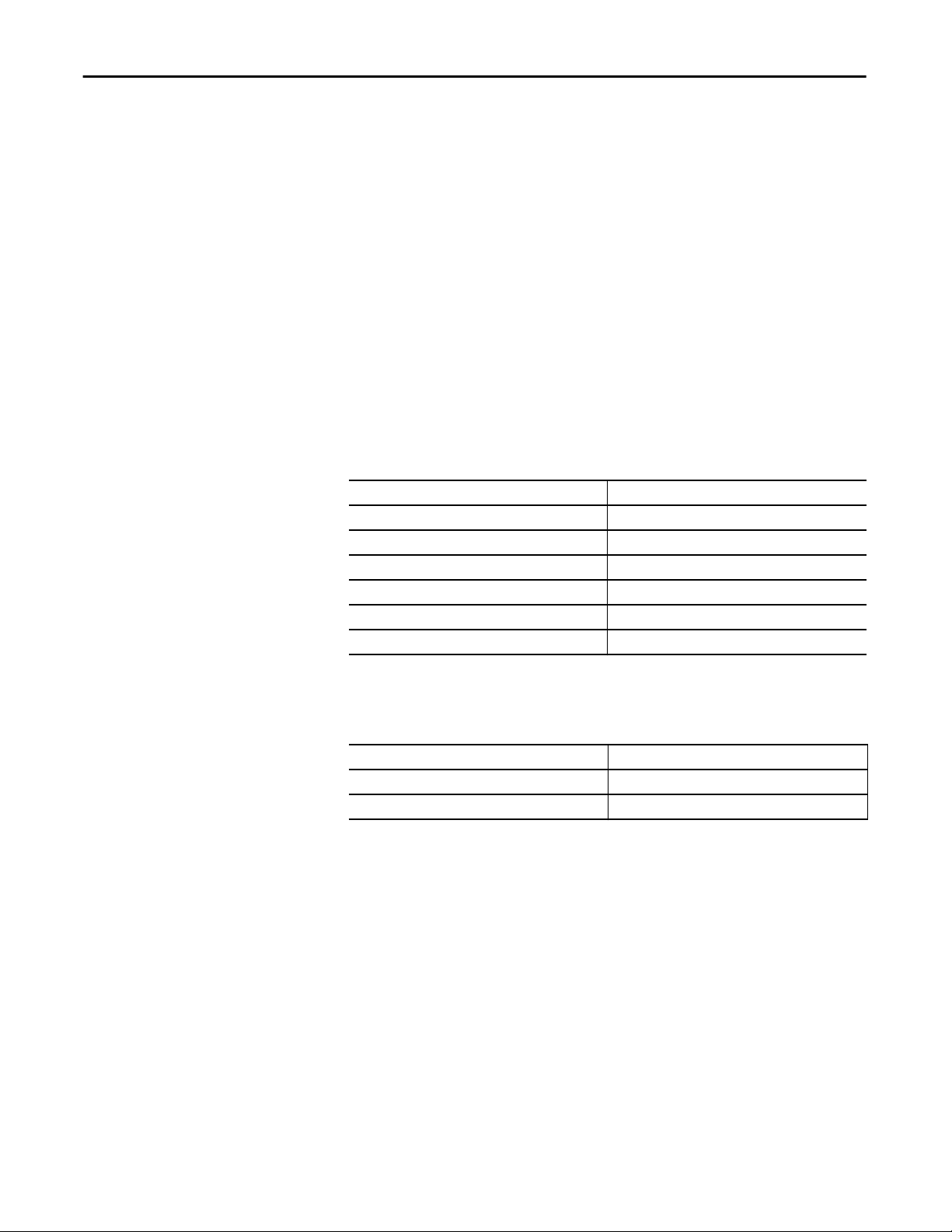

New and Updated Information

This table contains the changes made to this revision.

Topic Page

New switch catalog number descriptions 16

New switch dimensions 18, 21

100BASE-FX/SX and 1000BASE-FX/SX port descriptions 23

ArmorStratix 5700 switch installation 57…66

Express Setup on SFP-port switches 67, 68, 70, 73

Power over Ethernet (PoE) configuration in Studio 5000 environment 201

Module-defined data types for 8-, 16-, and 24-port switches 247, 248, 252, 254, 267, 270

CIP data assignments for 8-, 16-, and 24-port switches 271

ArmorStratix 5700 console port 278

Rockwell Automation Publication 1783-UM004E-EN-P - June 2014 3

Page 4

Summary of Changes

Notes:

4 Rockwell Automation Publication 1783-UM004E-EN-P - June 2014

Page 5

Table of Contents

Preface

About the Switches

Studio 5000 Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Access Product Release Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Additional Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Chapter 1

Switch Catalog Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Switch Software Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Stratix 5700 Switch Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

ArmorStratix 5700 Switch Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Switch Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Switch Hardware Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Configuration Files. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

SD Card. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

SD Card Sync . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Switch Memory Allocation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Device Manager Web Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Hardware Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Software Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Studio 5000 Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Hardware Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Cisco Network Assistant. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Command Line Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Switch Installation

Chapter 2

Stratix 5700 Switch Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Installation Guidelines. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Install or Remove the SD Card (optional) . . . . . . . . . . . . . . . . . . . . . . 33

Verify Switch Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Mount the Switch on a DIN Rail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Remove the Switch from the DIN Rail . . . . . . . . . . . . . . . . . . . . . . . . . 38

Ground the Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Wire the Switch DC Power Source . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Attach the Switch Power Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Wire the Power over Ethernet DC Power Source. . . . . . . . . . . . . . . . 44

Attach the PoE Power Connector. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Install an SFP Module (optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Remove SFP Modules from SFP Module Slots . . . . . . . . . . . . . . . . . . 48

Wire the External Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Attach the Alarm Relay Connector to the Switch . . . . . . . . . . . . . . . 52

Connect to 10/100 and 10/100/1000 Ports . . . . . . . . . . . . . . . . . . . . 52

Connect to 10BASE-T, 100BASE-TX, or 1000BASE-T Ports . . . 53

Connect to PoE Ports. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Connect to SFP Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Connect to a Dual-purpose Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Rockwell Automation Publication 1783-UM004E-EN-P - June 2014 5

Page 6

Table of Contents

Switch Software Features

ArmorStratix 5700 Switch Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Installation Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Install or Remove the SD Card (optional) . . . . . . . . . . . . . . . . . . . . . . 59

Verify Switch Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Mount the Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Ground the Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Connect the Switch to a DC Power Source . . . . . . . . . . . . . . . . . . . . . 64

Wire External Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Connect to 10/100 and 10/100/1000 Ports . . . . . . . . . . . . . . . . . . . . 66

Connect to PoE Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Set Up the Switch Initially with Express Setup . . . . . . . . . . . . . . . . . . . . . . 67

Chapter 3

Port Numbering. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Global Macro . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Smartports. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Optimize Ports through Smartports Port Roles. . . . . . . . . . . . . . . . . . 83

Custom Smartport Roles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Avoid Smartport Mismatches. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Power over Ethernet (PoE). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Powered Device Detection and Initial Power Allocation . . . . . . . . . 86

Power Management Modes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

VLANs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Isolate Traffic and Users. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Isolate Different Traffic Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Group Users . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

IGMP Snooping with Querier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Spanning Tree Protocol. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Port Thresholds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Incoming (storm control) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Outgoing (rate limiting). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Default Port Thresholds Configuration . . . . . . . . . . . . . . . . . . . . . . . . 96

Port Security . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Dynamic Secure MAC Address (MAC ID) . . . . . . . . . . . . . . . . . . . . . 97

Static Secure MAC Address (MAC ID) . . . . . . . . . . . . . . . . . . . . . . . . 98

Security Violations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

EtherChannels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

DHCP Persistence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

CIP Sync Time Synchronization (Precision Time Protocol). . . . . . . . . 100

Network Address Translation (NAT). . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Configuration Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

VLAN Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Configuration Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Traffic Permits and Fixups. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

6 Rockwell Automation Publication 1783-UM004E-EN-P - June 2014

Page 7

Manage the Switch via the

Device Manager Web Interface

Table of Contents

Resilient Ethernet Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

REP Open Segment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

REP Ring Segment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Access Ring Topologies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Link Integrity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

SNMP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Supported MIBs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Port Mirroring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Routing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Configuration Management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

SD Card Synchronization. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Cryptographic IOS Software (optional). . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Cable Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Advanced Software Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Chapter 4

Access the Device Manager Web Interface. . . . . . . . . . . . . . . . . . . . . . . . . 118

Dashboard Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Front Panel and Status Indicators. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Switch Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Switch Health. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Port Utilization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Configure Smartports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Customize Port Role Attributes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Manage Custom Smartport Macros . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Configure Port Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

Configure Port Thresholds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

Configure EtherChannels. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Configure DHCP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

Set up the DHCP Server . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

Configure a DHCP IP Address Pool . . . . . . . . . . . . . . . . . . . . . . . . . . 138

Reserve IP Addresses through DHCP Persistence . . . . . . . . . . . . . . 139

Configure VLANs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

Assign Ports to VLANs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

Configure Power over Ethernet (PoE) Ports . . . . . . . . . . . . . . . . . . . . . . . 142

Configure PTP Time Synchronization. . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

Enable and Configure Routing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

Enable Connected Routing Only . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

Enable Both Static and Connected Routing. . . . . . . . . . . . . . . . . . . . 148

Configure STP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

Global Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

PortFast Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

Configure REP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

Rockwell Automation Publication 1783-UM004E-EN-P - June 2014 7

Page 8

Table of Contents

Configure NAT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

Create NAT Instances for Traffic Routed

through a Layer 3 Switch or Router . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

Create NAT Instances for Traffic Routed

through a Layer 2 Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

Configure Traffic Permits and Fixups . . . . . . . . . . . . . . . . . . . . . . . . . 161

Configure Port Security. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

Configure IGMP Snooping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

Configure SNMP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

Use SNMP Management Applications . . . . . . . . . . . . . . . . . . . . . . . . 166

Configure Alarm Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

Alarm Relay Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

Global Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

Port Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 168

Configure Alarm Profiles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 168

Monitor Trends. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

Monitor Port Statistics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

Monitor NAT Statistics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

Monitor REP Topology. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

Monitor CIP Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

Diagnose Cabling Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

View System Log Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

Use Express Setup to Change Switch Settings . . . . . . . . . . . . . . . . . . . . . . 178

Manage Users . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

Reallocate Switch Memory for Routing. . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

Restart the Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

Upgrade the Switch Firmware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

Use the SD Card to Synchronize the Configuration or IOS Files . . . . 184

Upload and Download Configuration Files. . . . . . . . . . . . . . . . . . . . . . . . 186

Upgrade License Files. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

Chapter 5

Manage the Switch via the

Studio 5000 Environment

8 Rockwell Automation Publication 1783-UM004E-EN-P - June 2014

EtherNet/IP CIP Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

CIP Network Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

RSLinx Software and Network Who Support . . . . . . . . . . . . . . . . . . 189

Electronic Data Sheet (EDS) Files. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

Data Accessible With CIP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 190

Add a Switch to the I/O Configuration Tree . . . . . . . . . . . . . . . . . . . . . . 191

Configure General Properties. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 192

Connection Properties. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

Module Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 196

Switch Configuration Properties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 197

Switch Status. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 199

Port Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200

Power over Ethernet (PoE). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

Smartports and VLANs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 203

Port Thresholds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 205

Page 9

Table of Contents

Port Security. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 206

Port Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 207

Port Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 208

Cable Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

DHCP Pool Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 210

DHCP Address Assignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 212

Time Sync Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 213

NAT Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 215

Create NAT Instances for Traffic Routed

through a Layer 3 Switch or Router . . . . . . . . . . . . . . . . . . . . . . . . . . . 216

Create NAT Instances for Traffic Routed

through a Layer 2 Switch. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 220

Configure Traffic Permits and Fixups . . . . . . . . . . . . . . . . . . . . . . . . . 228

View Address Translations in RSLinx Software . . . . . . . . . . . . . . . . 229

NAT Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 229

Private-to-Public Translation Diagnostics . . . . . . . . . . . . . . . . . . . . . 231

Public-to-Private Translation Diagnostics . . . . . . . . . . . . . . . . . . . . . 232

SD Flash Sync. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 233

Save and Restore the Switch Configuration. . . . . . . . . . . . . . . . . . . . . . . . 234

Troubleshoot the Switch

Module-defined Data Types

Chapter 6

Verify Boot Fast. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 235

IP Address Issues. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 235

Device Manager Web Interface Issues. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 236

Switch Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 237

Access Direct Managed Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 237

Restart or Reset the Switch. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 239

Restart the Switch from the Device Manager Web Interface. . . . . 239

Restart the Switch from the Logix Designer Application . . . . . . . . 239

Reset the Switch to Factory Defaults . . . . . . . . . . . . . . . . . . . . . . . . . . 240

Recover the Switch Firmware and Restore Factory Defaults. . . . . . . . . 240

Troubleshoot a Firmware Upgrade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 241

Appendix A

Module-defined Input Data Type (6-port Gb switches) . . . . . . . . . . . . 245

Module-defined Output Data Type (6-port Gb switches). . . . . . . . . . . 246

Module-defined Input Data Type (6-port switches) . . . . . . . . . . . . . . . . 246

Module-defined Output Data Type (6-port switches) . . . . . . . . . . . . . . 247

Module-defined Input Data Type (8-port switches) . . . . . . . . . . . . . . . . 247

Module-defined Output Data Type (8-port switches) . . . . . . . . . . . . . . 248

Module-defined Input Data Type (10-port Gb switches) . . . . . . . . . . . 249

Module-defined Output Data Type (10-port Gb switches) . . . . . . . . . 250

Module-defined Input Data Type (10-port switches). . . . . . . . . . . . . . . 250

Module-defined Output Data Type (10-port switches). . . . . . . . . . . . . 252

Module-defined Input Data Type (16-port switches). . . . . . . . . . . . . . . 252

Module-defined Output Data Type (16-port switches). . . . . . . . . . . . . 254

Rockwell Automation Publication 1783-UM004E-EN-P - June 2014 9

Page 10

Table of Contents

Port Assignments for CIP Data

Cables and Connectors

Module-defined Input Data Type (20-port Gb switches) . . . . . . . . . . . 254

Module-defined Input Data Type (18-port Gb switches) . . . . . . . . . . . 257

Module-defined Output Data Type (18-port Gb switches). . . . . . . . . . 260

Module-defined Input Data Type (20-port Gb switches) . . . . . . . . . . . 261

Module-defined Output Data Type (20-port Gb switches). . . . . . . . . . 263

Module-defined Input Data Type (20-port switches) . . . . . . . . . . . . . . . 264

Module-defined Output Data Type (20-port switches) . . . . . . . . . . . . . 266

Module-defined Input Data Type (24-port switches) . . . . . . . . . . . . . . . 267

Module-defined Output Data Type (24-port switches) . . . . . . . . . . . . . 270

Appendix B

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 271

Appendix C

10/100 and 10/100/1000 Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 273

Connect to 10BASE-T- and 100BASE-TX-Compatible Devices 274

Dual-purpose Ports (combo ports) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 276

Console Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 277

Stratix 5700 Console Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 277

ArmorStratix 5700 Console Port. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 278

Alarm Ports. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 279

Cable and Adapter Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 280

SFP Module Cable Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 280

PoE Port Cable Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 280

Adapter Pinouts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 280

History of Changes

Index

Appendix D

1783-UM004D-EN-P, March 2014 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 283

1783-UM004C-EN-P, December 2013 . . . . . . . . . . . . . . . . . . . . . . . . . . . 283

1783-UM004B-EN-P, June 2013 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 285

10 Rockwell Automation Publication 1783-UM004E-EN-P - June 2014

Page 11

Preface

This publication describes the embedded software features and tools for

configuring and managing the Stratix 5700™ Ethernet managed switches. In

addition, this publication provides troubleshooting information to help you

resolve basic switch and network issues.

Use this manual if you configure and monitor Stratix 5700 Ethernet managed

switches. This manual assumes you understand the following:

• Local area network (LAN) switch fundamentals

• Concepts and terminology of the Ethernet protocol and local area

networking

Studio 5000 Environment

The Studio 5000 Automation Engineering & Design Environment™ combines

engineering and design elements into a common environment. The first element

is the Studio 5000 Logix Designer™ application. The Logix Designer application

is the rebranding of RSLogix™ 5000 software and will continue to be the product

to program Logix5000™ controllers for discrete, process, batch, motion, safety,

and drive-based solutions.

The Studio 5000® environment is the foundation for the future of Rockwell

Automation® engineering design tools and capabilities. The Studio 5000

environment is the one place for design engineers to develop all of the elements of

their control system.

Rockwell Automation Publication 1783-UM004E-EN-P - June 2014 11

Page 12

Preface

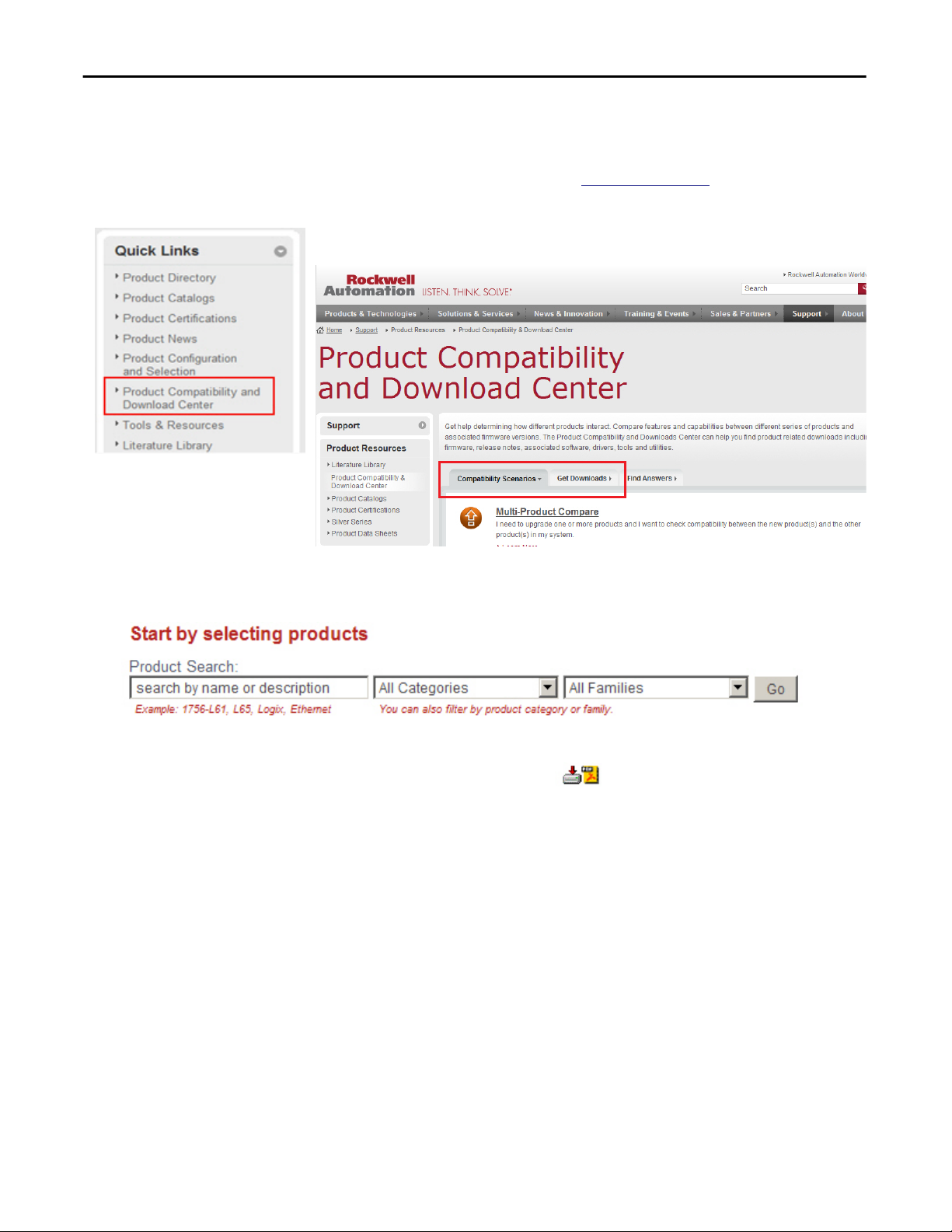

Access Product Release Notes

Product release notes are available online within the Product Compatibility and

Download Center.

1. From the Quick Links list on

Compatibility and Download Center.

2. From the Compatibility Scenarios tab or the Get Downloads tab, search

for and choose your product.

http://www.ab.com, choose Product

3. Click the download icon to access product release notes.

12 Rockwell Automation Publication 1783-UM004E-EN-P - June 2014

Page 13

Preface

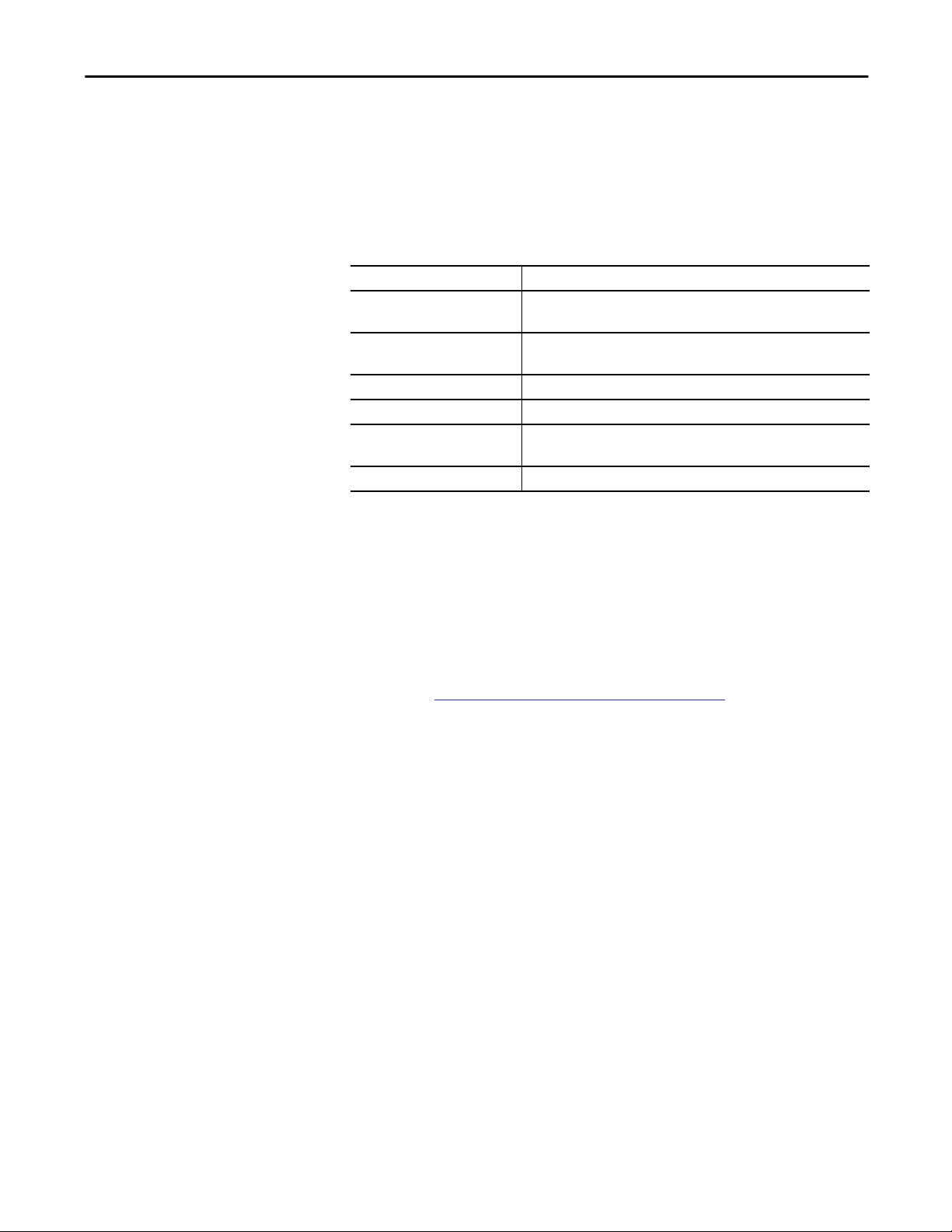

Additional Resources

These documents contain additional information concerning related products

from Rockwell Automation.

Resource Description

Stratix Ethernet Managed Switches Technical Data,

publication

Ethernet Design Considerations Reference Manual,

publication

Device Manager Web interface online help (provided with

the switch)

Industrial Automation Wiring and Grounding Guidelines,

publication

Product Certifications website,

1783-TD001

ENET-RM002

1770-4.1

http://www.ab.com Provides declarations of conformity, certificates, and

Provides specification information for the switches.

Provides information about implementing a system

based on the EtherNet/IP platform.

Provides context-sensitive information on configuring

and using the switch, including system messages.

Provides general guidelines for installing a Rockwell

Automation industrial system.

other certification details.

You can view or download publications at

http:/www.rockwellautomation.com/literature/. To order paper copies of

technical documentation, contact your local Allen-Bradley distributor or

Rockwell Automation sales representative.

For information on additional software features or further configuration, see

these Cisco publications at

http://www.Cisco.com:

• Cisco IE-2000 Command Line Reference Manual

• Cisco IE-2000 Software Configuration Guide

• Cisco IE-2000 Switch System Message Guide

Rockwell Automation Publication 1783-UM004E-EN-P - June 2014 13

Page 14

Preface

Notes:

14 Rockwell Automation Publication 1783-UM004E-EN-P - June 2014

Page 15

About the Switches

Topic Page

Switch Catalog Numbers 16

Switch Software Features 17

Stratix 5700 Switch Dimensions 18

ArmorStratix 5700 Switch Dimensions 21

Switch Front Panel 22

Switch Hardware Features 22

SD Card 23

Switch Memory Allocation 25

Device Manager Web Interface 26

Studio 5000 Environment 27

Cisco Network Assistant 27

Command Line Interface 28

Chapter 1

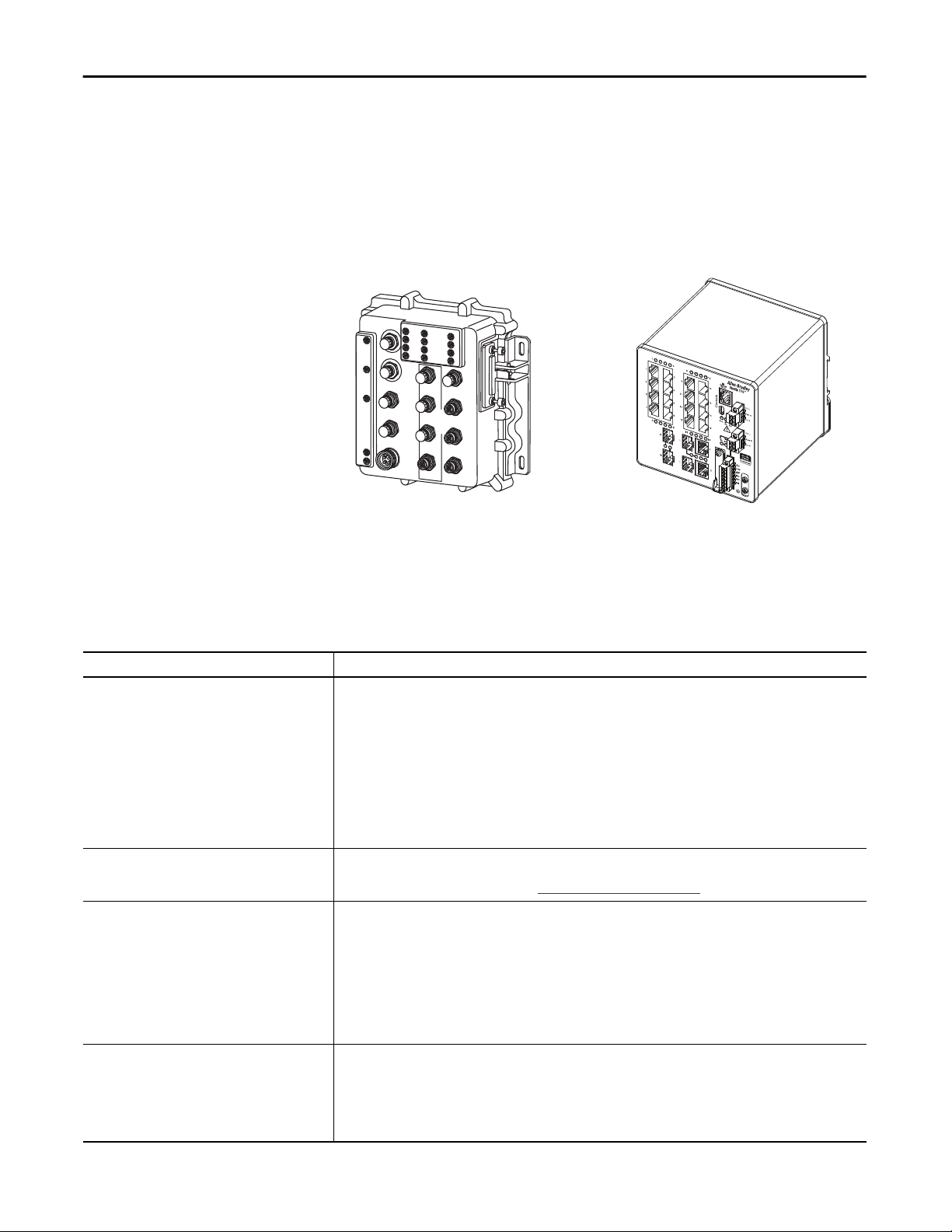

Stratix 5700 Ethernet managed switches provide a secure switching infrastructure

for harsh environments. You can connect these switches to network devices such

as servers, routers, and other switches. In industrial environments, you can

connect Ethernet-enabled industrial communication devices, including

programmable logic controllers (PLCs), human-machine interfaces (HMIs),

drives, sensors, and I/O.

Rockwell Automation Publication 1783-UM004E-EN-P - June 2014 15

Page 16

Chapter 1 About the Switches

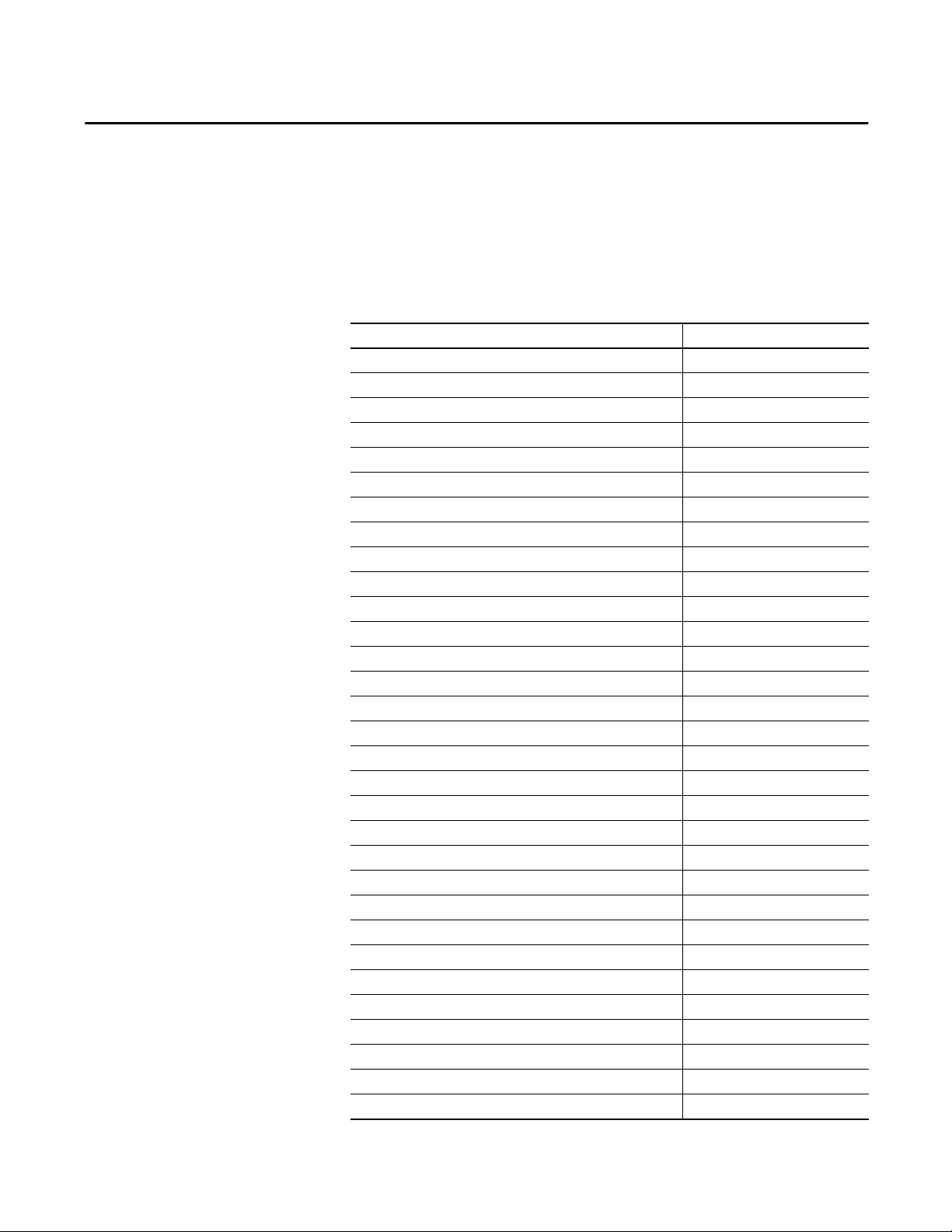

Switch Catalog Numbers

Catalog Number Description

Stratix 5700 Switches

1783-BMS4S2SGL 6 SFP-port (4 Ethernet ports; 2 Gigabit ports) managed switch; lite firmware

1783-BMS4S2SGA 6 SFP-port (4 Ethernet por ts; 2 Gigabit ports) managed switch; full firmware

1783-BMS06SL 6-port (4 Ethernet ports; 2 SFP slots) managed switch; lite firmware

1783-BMS06SA 6-port (4 Ethernet ports; 2 SFP slots) managed switch; full firmware

1783-BMS06TL 6-port (6 Ethernet ports) managed switch; lite firmware

1783-BMS06TA 6-port (6 Ethernet ports) managed switch; full firmware

1783-BMS06SGL 6-port (4 Ethernet ports; 2 SFP Gigabit slots) managed switch; lite firmware

1783-BMS06SGA 6-port (4 Ethernet ports; 2 SFP Gigabit slots) managed switch; full firmware

1783-BMS06TGL 6-port (4 Ethernet ports; 2 Gigabit ports) managed switch; full firmware

1783-BMS06TGA 6-port (4 Ethernet ports; 2 Gigabit ports) managed switch; full firmware

1783-BMS10CL 10-port (8 Ethernet ports; 2 combo ports) managed switch; lite firmware

1783-BMS10CA 10-port (8 Ethernet ports; 2 combo ports) managed switch; full firmware

1783-BMS10CGL 10-port (8 Ethernet ports; 2 combo Gigabit ports) managed switch; lite firmware

1783-BMS10CGA 10-port (8 Ethernet ports; 2 combo Gigabit ports) managed switch; full firmware

1783-BMS10CGN 10-port (8 Ethernet ports; 2 combo Gigabit ports) managed switch; full firmware; network address translation (NAT)

1783-BMS10CGP 10-port (8 Ethernet ports; 2 combo Gigabit por ts) managed switch; full firmware; PTP

1783-BMS12T4E2CGNK 18-port (12 Ethernet ports; 4 PoE/PoE+ ports; 2 combo Gigabit ports) managed switch; full firmware; NAT; conformal coating

1783-BMS12T4E2CGP 18-port (12 Ethernet ports; 4 PoE/PoE+ ports; 2 combo Gigabit ports) managed switch; full firmware, PTP

1783-BMS12T4E2CGL 18-port (12 Ethernet ports; 4 PoE/PoE+ ports; 2 combo Gigabit ports) managed switch; lite firmware

1783-BMS20CL 20-port (16 Ethernet ports; 2 SFP slots; 2 combo ports) managed switch; lite firmware

1783-BMS20CA 20-port (16 Ethernet ports; 2 SFP slots; 2 combo ports) managed switch; full firmware

1783-BMS20CGL 20-port (16 Ethernet ports; 2 SFP slots; 2 combo Gigabit ports) managed switch; lite firmware

1783-BMS20CGN 20-port (16 Ethernet ports; 2 SFP slots; 2 combo Gigabit ports) managed switch; full firmware; NAT

1783-BMS20CGP 20-port (16 Ethernet ports; 2 SFP slots; 2 combo Gigabit por ts) managed switch; full firmware; PTP

1783-BMS20CGPK 20-port (16 Ethernet por ts; 2 SFP slots; 2 combo Gigabit ports) managed switch; full firmware; PTP; conformal coating

ArmorStratix™ 5700 Switches

1783-ZMS8TA 8-port (8 Ethernet ports) managed switch; full firmware

1783-ZMS16TA 16-por t (16 Ethernet ports) managed switch; full firmware

1783-ZMS24TA 24-por t (24 Ethernet ports) managed switch; full firmware

1783-ZMS4T4E2TGP 10-port (4 Ethernet ports; 4 PoE/PoE+ ports; 2 Gigabit ports) managed switch; full firmware; Precision Time Protocol (PTP)

1783-ZMS8T8E2TGP 18-port (8 Ethernet ports; 8 PoE/PoE+ ports; 2 Gigabit ports) managed switch; full firmware; PTP

SFP Modules

1783-SFP100FX 100BASE-FX multi-mode fiber transceiver

1783-SFP1GSX 1000BASE-SX multi-mode fiber transceiver

1783-SFP100LX 100BASE-LX single-mode fiber transceiver

1783-SFP1GLX 1000BASE-LX single-mode fiber transceiver

These switches are available with either lite or full firmware.

16 Rockwell Automation Publication 1783-UM004E-EN-P - June 2014

Page 17

Catalog Number Description

Power Supply

1606-XL series (recommended)

1606-XLP series (recommended) or equivalent

SD Card

1784-SD1 1 GB Industrial SD card

Class 2, 24V DC output power supplies

About the Switches Chapter 1

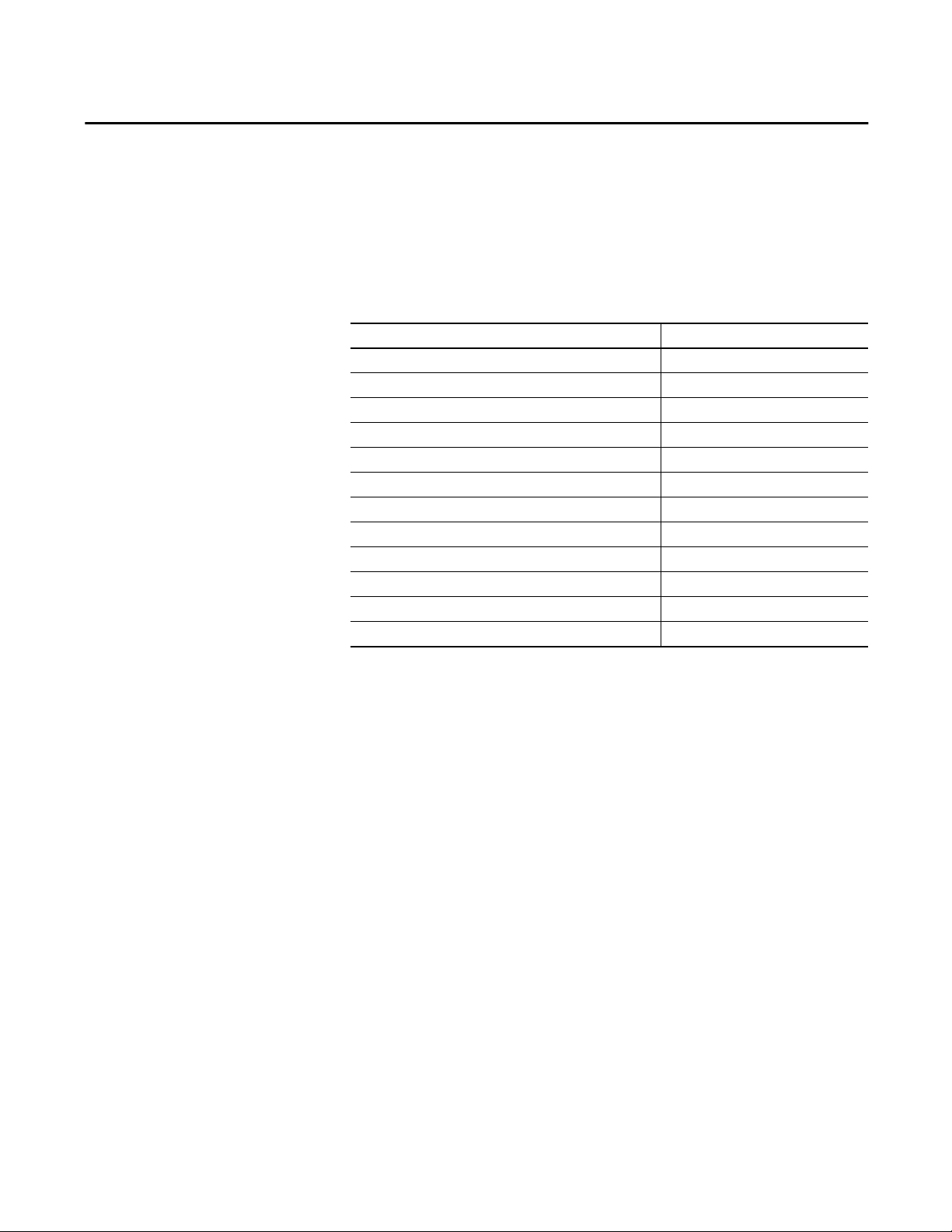

Switch Software Features

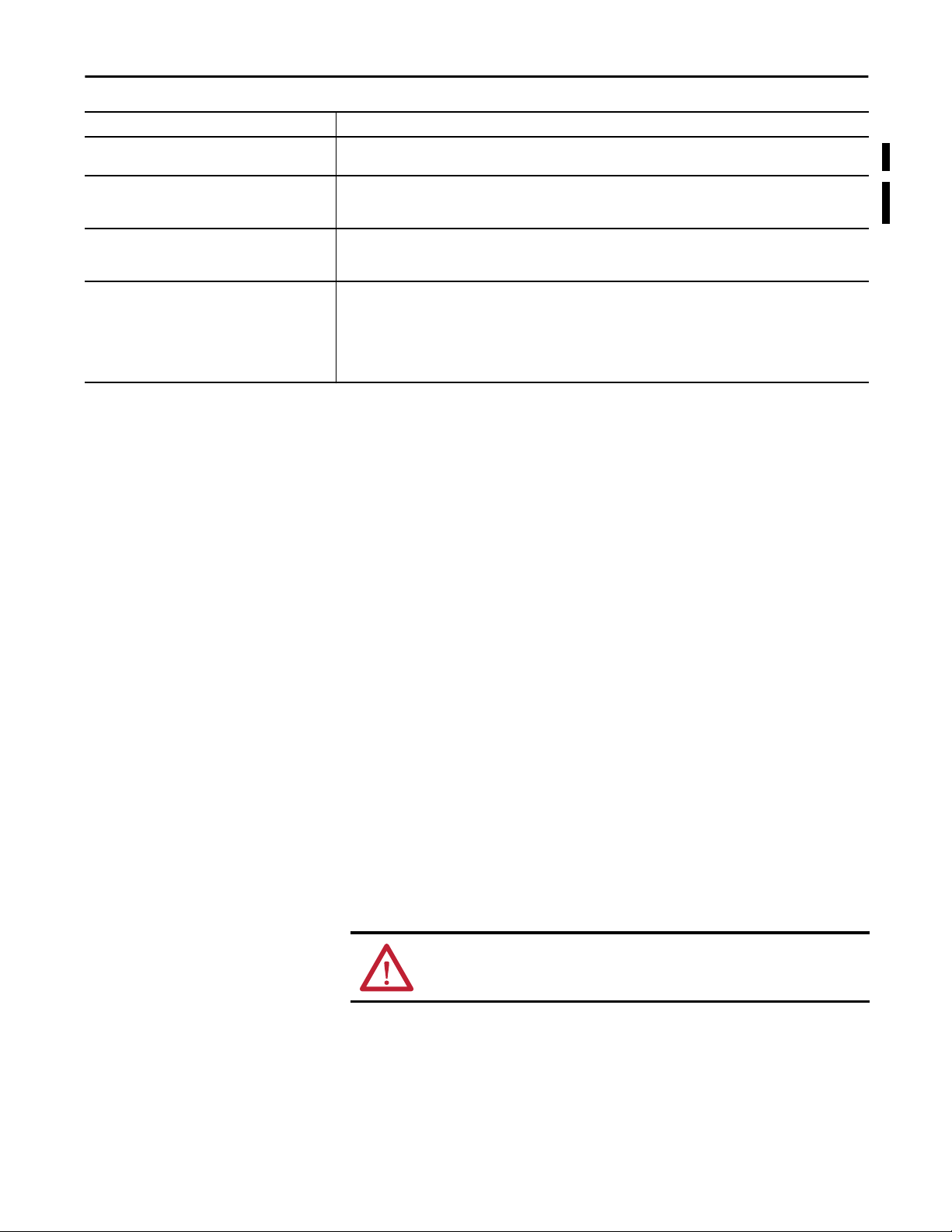

Feature Lite Firmware Full Firmware

CIP Sync (IEEE 1588) Separate option

Resilient Ethernet Protocol (REP)

FlexLinks

Quality of Service (QoS)

STP, RSTP, MST (instances) 64 128

IGMP Snooping with querier

VLANs with trunking 64 255

EtherChannel (link aggregation)

Port Threshold (Storm Control and Traffic Shaping)

IPv6 support

Access Control Lists (ACL)

Static and interVLAN routing

CIP port control and fault detection

MAC ID Port security

IEEE 802.1x security

TACACS+, RADIUS authentication

Encryption (SSH, SNMPv3, HTTPS) Separate IOS firmware available as a separate catalog item

Port mirroring

Syslog

Broken wire detection

Duplicate IP address detection

SNMP

Smartports

DHCP per port

Command line interface (CLI)

These software features are available with the Stratix 5700 switches.

••

•

•

••

•

•

•

•

•

••

•

•

••

••

••

••

•

••

••

••

••

Rockwell Automation Publication 1783-UM004E-EN-P - June 2014 17

Page 18

Chapter 1 About the Switches

Feature Lite Firmware Full Firmware

Compatible with Cisco tools: Cisco Network Assistant

(CNA); CiscoWorks

EtherNet/IP (CIP) interface

••

••

Network address translation (NAT) Separate option

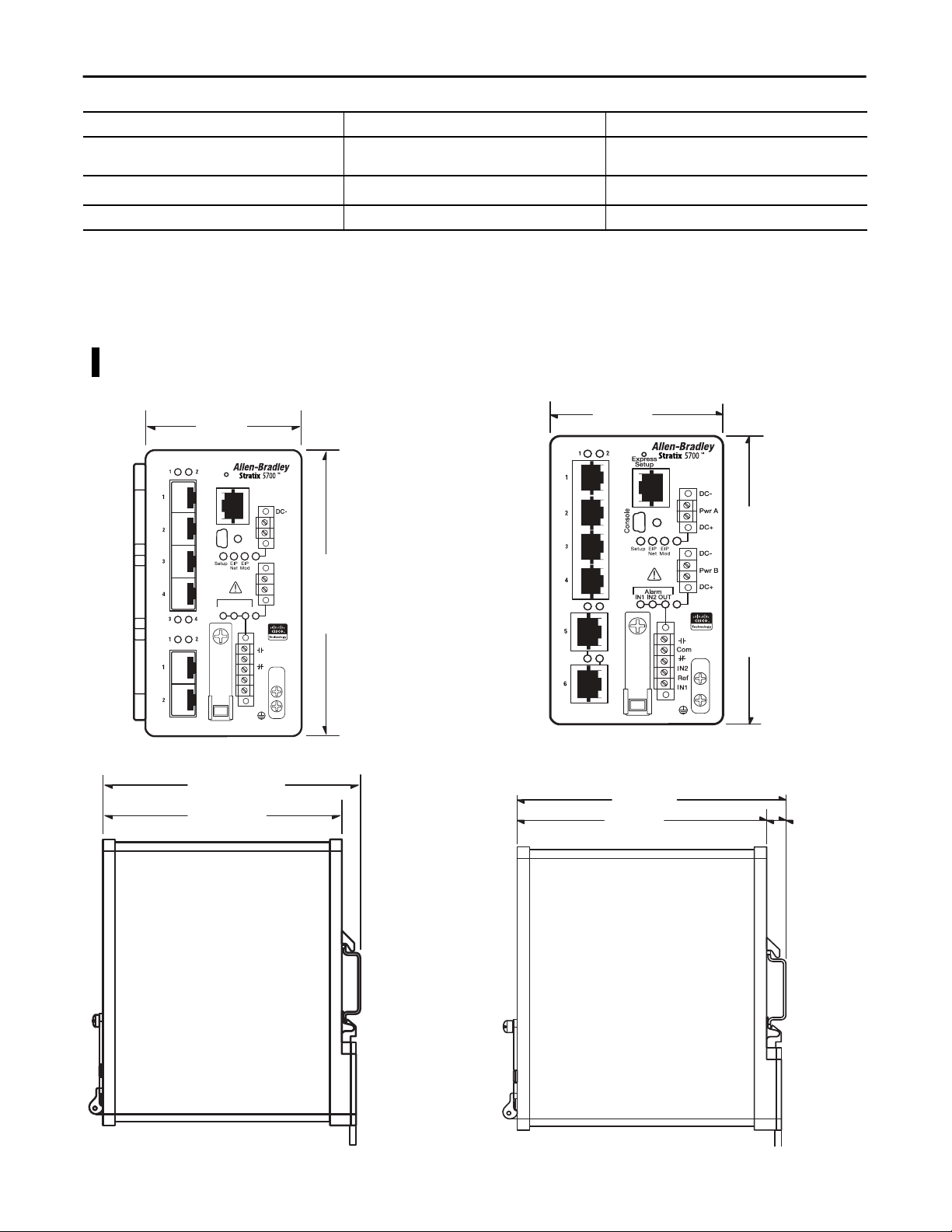

Stratix 5700 Switch Dimensions

6 SFP-port Switches

1783-BMS4S2SGL, 1783-BMS4S2SGA

8.00 cm

(3.15 in.)

Express

Setup

Console

Alarm

IN1 IN2 OUT

These diagrams are representative of the switches. Actual faceplates vary

depending on the catalog number.

6-port Switches

1783-BMS06SL, 1783-BMS06SA, 1783-BMS06TL, 1783-BMS06TA,

1783-BMS06SGL, 1783-BMS06SGA, 1783-BMS06TGL, 1783-BMS06TGA

7.48 cm

(2.94 in.)

Pwr A

DC+

DC-

12.95 cm

Pwr B

(5.1 in.)

DC+

Com

IN2

Ref

IN1

12.95 cm

(5.1 in.)

12.19 cm

(4.8 in.)

11.45 cm

0.75 cm

(0.29 in.)

(4.51 in.)

18 Rockwell Automation Publication 1783-UM004E-EN-P - June 2014

11.67 cm

(4.59 in.)

10.92 cm

(4.3 in.)

0.75 cm

(0.29 in.)

Page 19

About the Switches Chapter 1

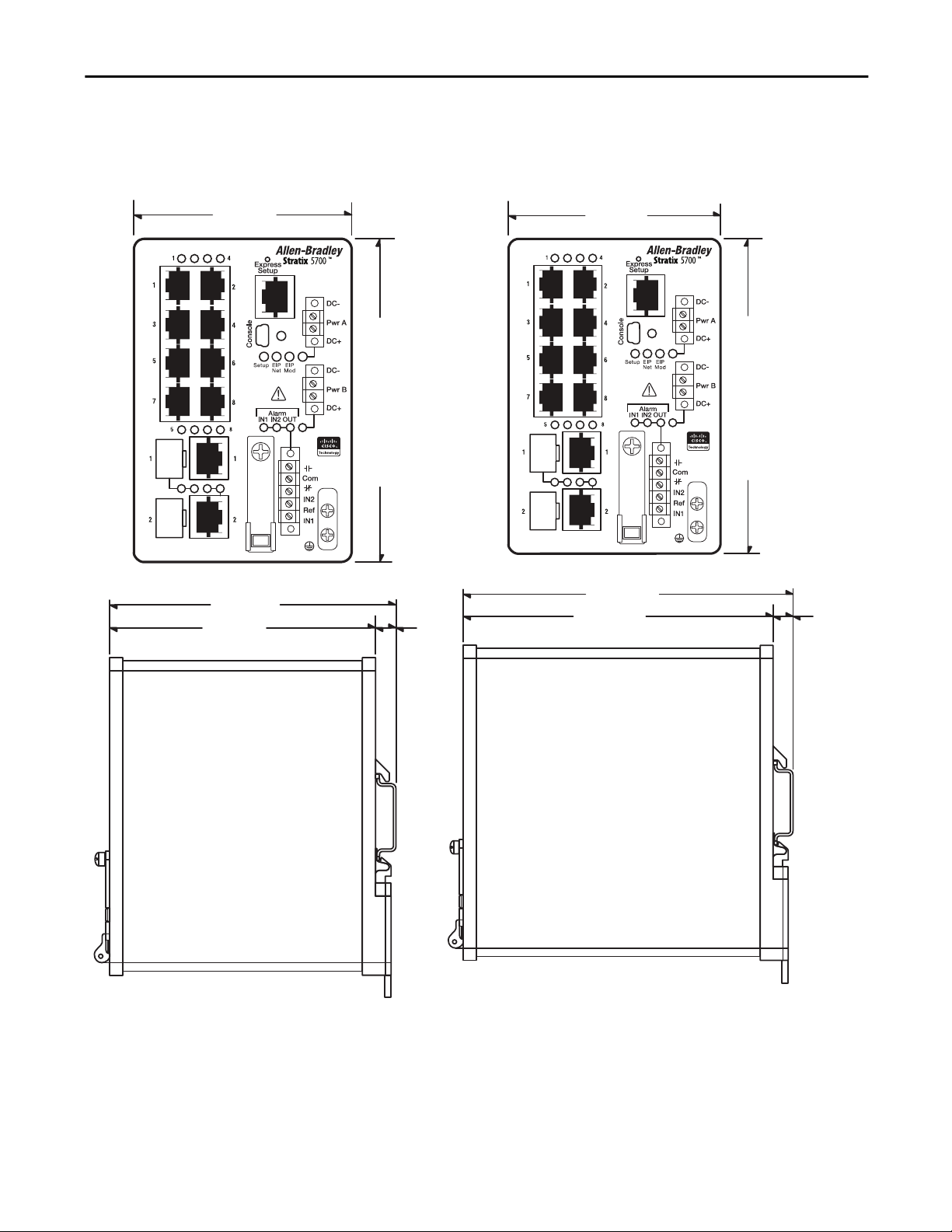

10-port Switches

1783-BMS10CL, 1783-BMS10CA,

1783-BMS10CGL, 1783-BMS10CGA

9.14 cm

(3.6 in.)

11.67 cm

(4.59 in.)

10.92 cm

(4.3 in.)

12.95 cm

(5.1 in.)

0.75 cm

(0.29 in.)

10-port Switch

1783-BMS10CGP, 1783-BMS10CGN

9.14 cm

(3.6 in.)

13.58 cm

(5.345 in.)

12.83 cm

(5.05 in.)

12.95 cm

(5.1 in.)

0.75 cm

(0.29 in.)

Rockwell Automation Publication 1783-UM004E-EN-P - June 2014 19

Page 20

Chapter 1 About the Switches

18- and 20-port Switches

1783-BMS12T4E2CGNK, 1783-BMS12T4E2CGP, 1783-BMS12T4E2CGL,

1783-BMS20CL, 1783-BMS20CA, 1783-BMS20CGL, 1783-BMS20CGP,

1783-BMS20CGN, 1783-BMS20CGPK

12.70 cm

(5.0 in.)

12.95 cm

(5.1 in.)

13.58 cm

(5.345 in.)

12.83 cm

(5.05 in.)

0.75 cm

(0.29 in.)

20 Rockwell Automation Publication 1783-UM004E-EN-P - June 2014

Page 21

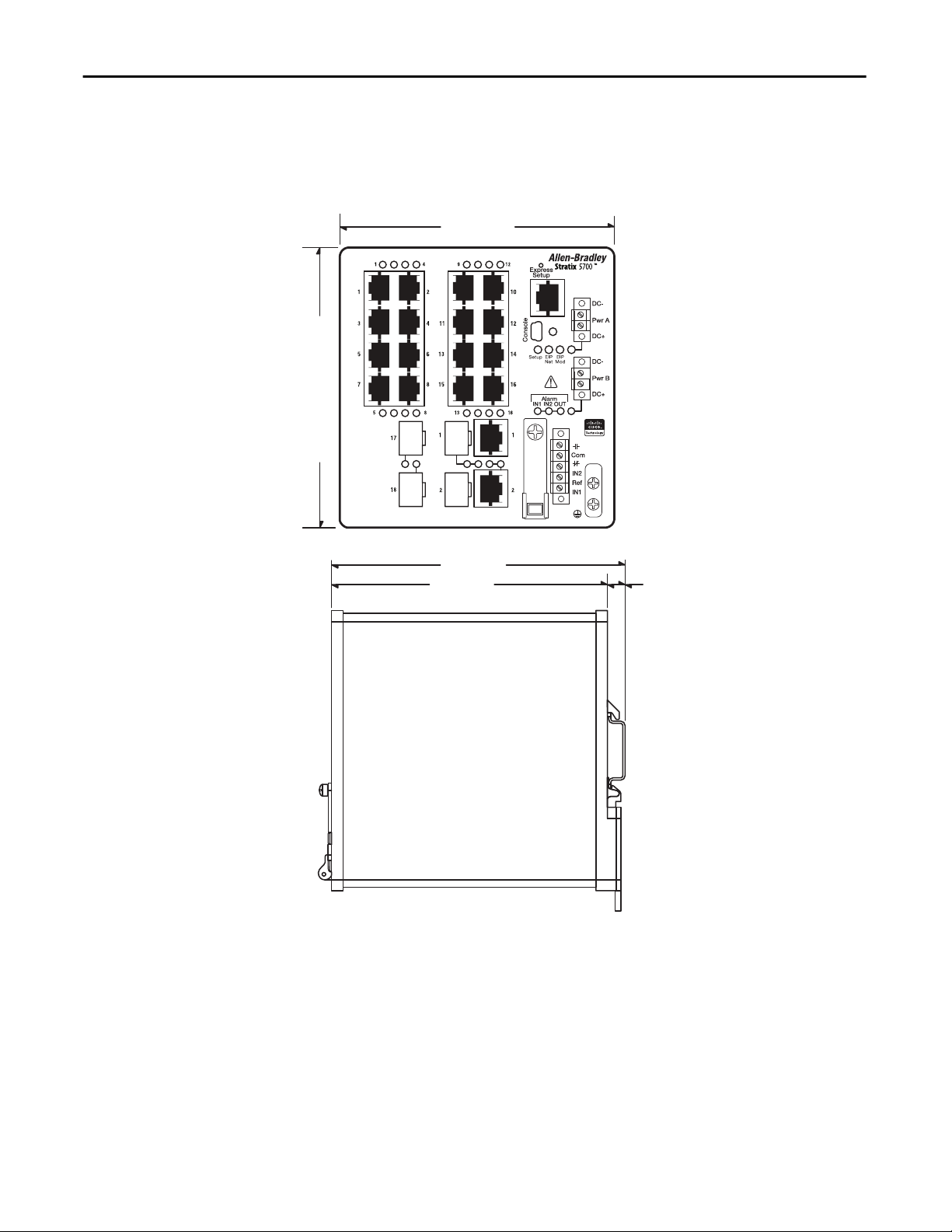

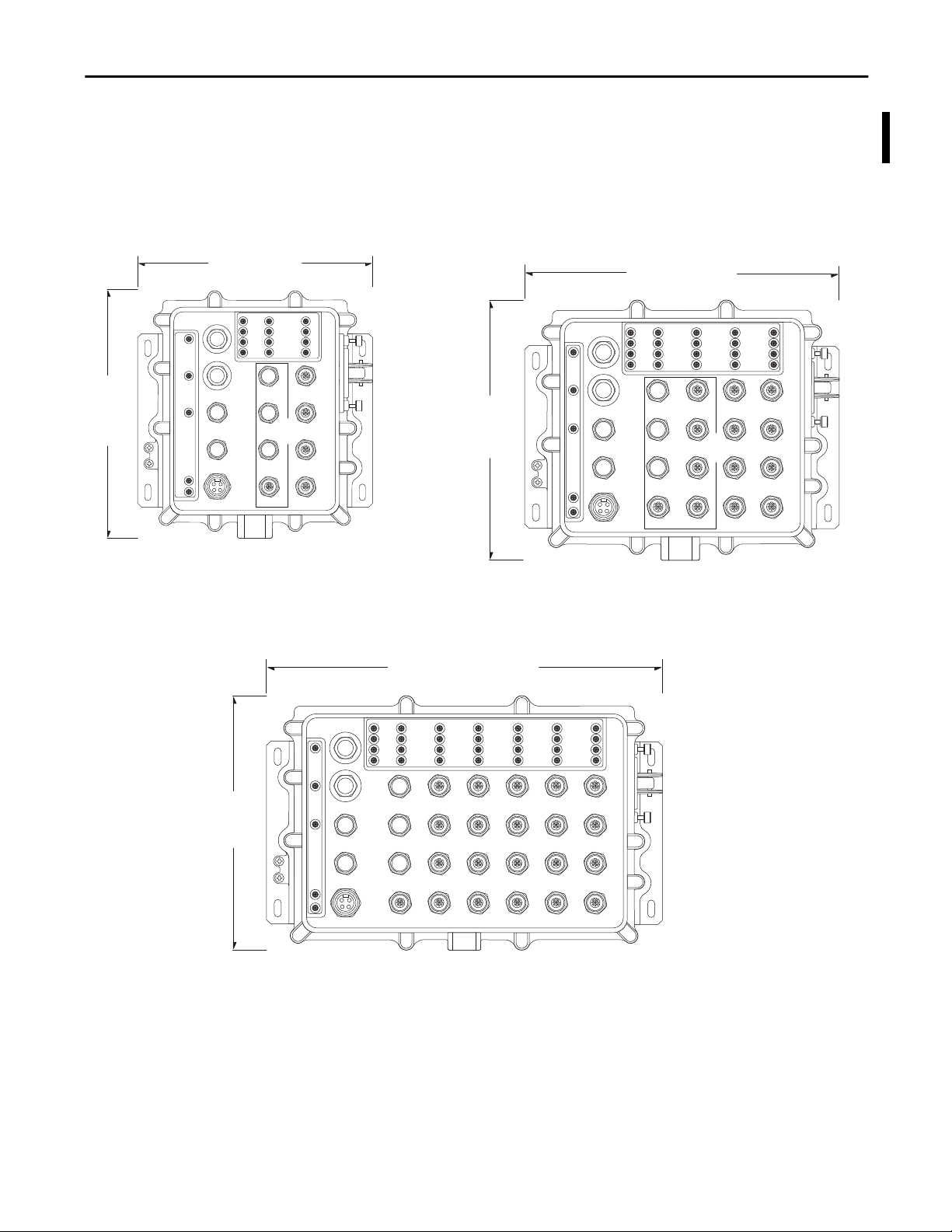

ArmorStratix 5700 Switch Dimensions

About the Switches Chapter 1

24.38 cm

(9.6 in.)

8-port Switches

1783-ZMS8TA, 1783-ZMS4T4E2TGP

23.75 cm

(9.35 in.)

24-port Switch

1783-ZMS24TA

16-port Switches

1783-ZMS16TA, 1783-ZMS8T8E2TGP

30.09 cm

(11.85in.)

24.38 cm

(9.6 in.)

32492

32493

37.46 cm

(14.75in.)

24.38 cm

(9.6 in.)

32494

Rockwell Automation Publication 1783-UM004E-EN-P - June 2014 21

Page 22

Chapter 1 About the Switches

Switch Front Panel

The switch front panel contains the ports, status indicators, and power and relay

connectors.

These diagrams are representative of the switch front panels. Actual front panels

vary depending on the catalog number.

ArmorStratix 5700 Switch

32495

Stratix 5700 Switch

32276-M

Switch Hardware Features

Feature Description

Power and relay connectors You connect the DC power and alarm signals to the switch through two front panel connectors. One connector provides

Console port For configuring, monitoring, and managing the switch, you can connect a switch to a computer through the console port

Dual-purpose uplink ports The two dual-purpose uplink ports available on some models can each be configured for RJ45 (copper) or SFP (fiber) media

10/100 ports You can set the 10/100 ports to operate at 10 or 100 Mbps, full-duplex or half-duplex. You can also set these ports for

These hardware features are available with the switches.

primary DC power (Pwr A) and a second connector (Pwr B) provides secondary power. The two connectors are physically

identical and are on the right side of the front panel.

The 6-pin alarm connector provides an interface for an output alarm relay and two input alarms. The output alarm can be

activated for environmental, power supply, and port status alarm conditions and can be configured to indicate an alarm

with one normally open and one normally closed (form C) contact. From the CLI, you can configure the output alarm to be

normally energized or normally de-energized. The input alarm terminals can be used to activate alarms for any conditions

external to the switch.

The switch can operate with a single power source or with dual power sources. When both power sources are operational,

the switch draws power from the DC source with the higher voltage. If one of the two power sources fail, the other

continues to power the switch.

and a RJ45-to-DB-9 adapter cable or a mini USB cable (neither cables are supplied with the switch). The mini USB driver is

available in the firmware download section at

types. Only one of these connections in each of the dual-purpose ports can be active at a time. If both ports are connected,

the SFP module port has priority.

You can set the copper RJ45 ports to operate at 10, 100, or 1000 Mbps (1000Mbps is not supported on all modules with

combo ports), full-duplex or half-duplex. You can configure them as fixed 10, 100, or 1000 Mbps (Gigabit) Ethernet ports

and can configure the duplex setting.

You can use approved Gigabit (or 100 Mbps) Ethernet SFP modules to establish fiber-optic connections to other switches.

These transceiver modules are field-replaceable, providing the uplink interfaces when inserted in an SFP module slot. You

use fiber-optic cables with LC connectors to connect to a fiber-optic SFP module. These ports operate only in full-duplex.

speed and duplex autonegotiation in compliance with IEEE 802.3-2002. (The default setting is autonegotiate.)

When set for autonegotiation, the port senses the speed and duplex settings of the attached device. If the connected

device also supports autonegotiation, the switch port negotiates the best connection (that is, the fastest line speed that

both devices support and full-duplex transmission if the attached device supports it) and configures itself accordingly. In

all cases, the attached device must be within 100 m (328 ft) of the switch.

http://www.rockwellautomation.com.

22 Rockwell Automation Publication 1783-UM004E-EN-P - June 2014

Page 23

About the Switches Chapter 1

Feature Description

100BASE-FX/SX ports The IEEE 802.3-2002 100BASE-FX ports provide full-duplex, 100 Mbps connectivity over multi-mode fiber (MMF) cables.

1000BASE-FX/SX ports The IEEE 802.3-2002 1000BASE-FX ports on some models provide full-duplex, 1 Gbps connectivity over multi-mode fiber

PoE ports The PoE ports available on some models can be configured for PoE (IEEE 802.3af) or PoE+ (IEEE 802.3at Type 2):

Auto-MDIX When connecting the switch to workstations, servers, and routers, straight-through cables are normally used. However,

These ports use a built-in, small-form-factor fixed (SFF) fiber-optic transceiver module that accepts a dual LC connector.

(MMF) cables. These ports use a built-in, small-form-factor fixed (SFF) fiber-optic transceiver module that accepts a dual LC

connector.

• For PoE configuration, the PoE ports require an external, 2-wire 48V DC input power source.

• For PoE+ configuration, the PoE ports require an external, 2-wire 54V DC input power source.

the automatic medium-dependent interface crossover (auto-MDIX) feature of the switch is enabled by default and

automatically reconfigures the ports to use either a straight-through or crossover cable type.

The Auto-MDIX feature is enabled by default. When the auto-MDIX feature is enabled, the switch detects the required

cable type (straight-through or crossover) for copper Ethernet connections and configures the interfaces accordingly.

You can use the command-line interface (CLI) to disable the auto-MDIX feature. See the online help for more information.

Configuration Files

SD Card

The switch configuration file (config.txt) is in ASCII human-readable format.

This configuration file is stored in nonvolatile memory and is read into the

switches’ Random Access Memory (RAM) as the running configuration when

the switch is powered up. When any changes are made to the configuration, the

changes immediately take effect in the running configuration. The Device

Manager Web interface and the Add-on Profile (AOP) for the Logix Designer

application automatically write changes to flash memory to be retained for the

next power-up cycle. Any changes made via the CLI must be manually written to

flash memory to be retained for the next power-up cycle.

The switch is equipped with a slot for an optional Secure Digital (SD) card, in

addition to the onboard flash memory. The SD card can be used instead of

onboard flash memory to easily restore a switch configuration in case of failure or

to easily duplicate configurations when you are deploying a new network.

If the SD card is installed on the switch, the switch starts the IOS and

configuration present on the SD card. If the SD card is not installed, or files are

not present, the switch reads the on-board boot parameters and restarts from the

specified IOS image on the onboard flash memory.

You must use the SD card available from Rockwell Automation (catalog number

1784-SD1) with the switch.

ATTENTION: Rockwell Automation reserves the right to withhold support if a

non-Rockwell SD card is used in this product.

Rockwell Automation Publication 1783-UM004E-EN-P - June 2014 23

Page 24

Chapter 1 About the Switches

If you start from the SD card and then remove it while the switch is running, the

following conditions apply:

• The Device Manager Web interface is no longer be accessible.

• Changes made by using the CLI or the AOP take effect, but are not saved

when the switch is restarted.

• If the SD card is reinserted into the slot, changes are not saved to the card

unless new changes are made. Then the entire configuration is saved to the

card.

ATTENTION: SD cards commonly have a physical read-only lock switch. If this

switch is engaged, the switch starts from the SD card successfully. Changes

made by using the CLI, AOP, or Device Manager Web interface take effect, but

are not saved when the switch is restarted.

SD Card Sync

You can use the Device Manager Web interface or the AOP for the

Logix Designer application to synchronize the SD card for configuration and

IOS updates. The configuration synchronization process synchronizes

config.text and vlan.dat from the chosen source to the chosen destination.

The IOS image synchronization process synchronizes the existing bootable IOS

image from the chosen source to the chosen destination. This process takes

approximately five minutes to complete.

If other files, such as backup configurations, are present on the SD card, they are

not synchronized.

ATTENTION: When synchronizing, be aware of your start-up source, so that you

know which way to synchronize. Device Manager provides this information on

the SD Card Sync tab. You can overwrite your desired configuration if you

synchronize in the wrong direction.

24 Rockwell Automation Publication 1783-UM004E-EN-P - June 2014

Page 25

About the Switches Chapter 1

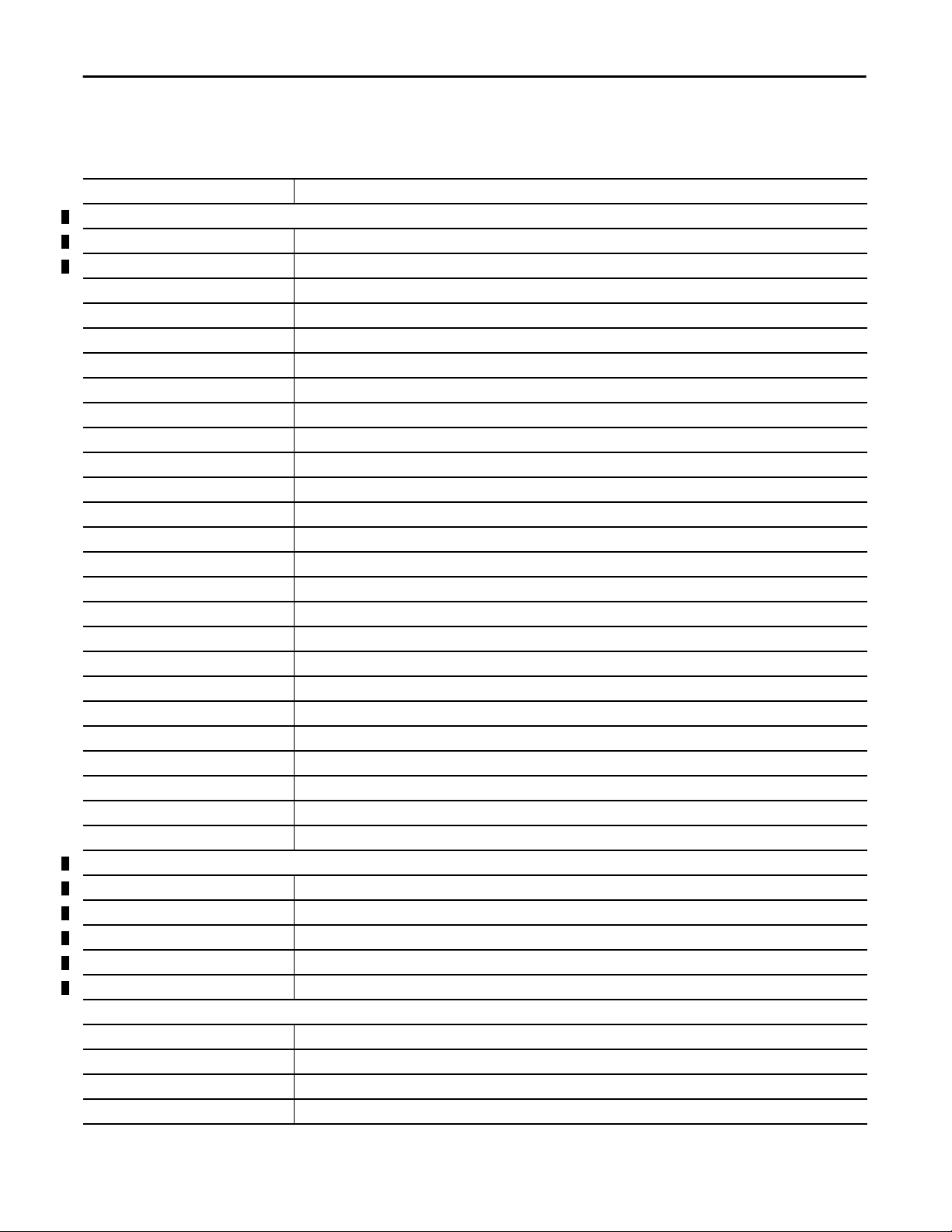

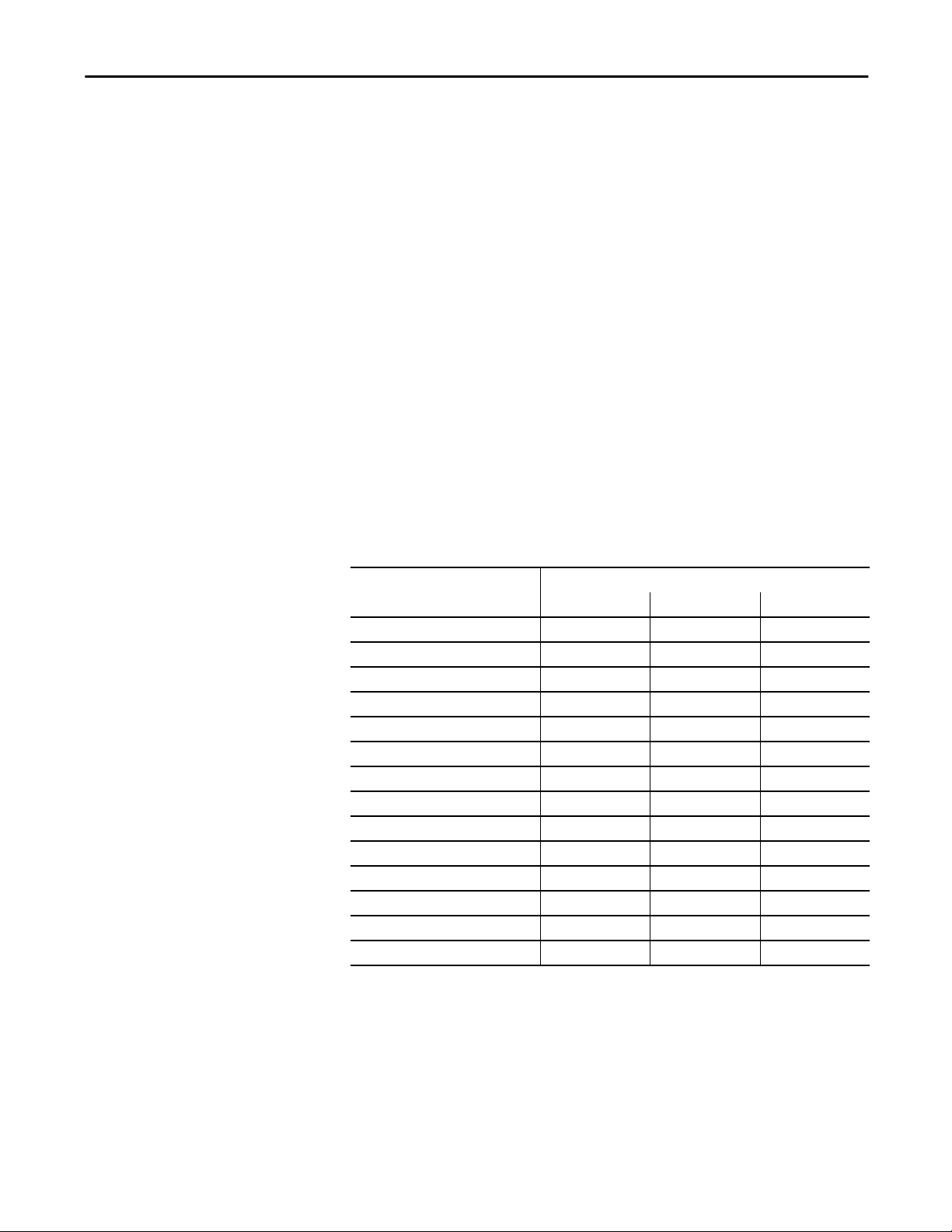

Switch Memory Allocation

The following table provides details on default memory allocation for the

switches.

You can use SDM templates to configure system resources in the switch to

optimize support for specific features, depending on how the switch is used in the

network. You can select a template to provide maximum system usage for some

functions; for example, use the default template to balance resources, and use

access template to obtain maximum ACL usage. To allocate hardware resources

for different usages, the switch SDM templates prioritize system resources to

optimize support for certain features.

The following SDM Templates are available:

• Default

• Routing

• Dual IPv4 and IPv6

Consider using the routing template if you enable static routing, or if you have

more than 180 IGMP groups or multicast routes. Consider using the Dual IPv4

and IPv6 template if you are using IPv6.

You can select SDM templates for IP version 4 (IPv4) to optimize these features.

Feature Memory Alloc ation

Default Routing Dual IPv4 and IPv6

Unicast MAC addresses 8 K 4 K 7.5 K

IPv4 IGMP groups + multicast routes 0.25 K 0.25 K 0.25 K

IPv4 unicast routes 0 4.25 K 0

IPv6 multicast groups 0 0 0.375 K

Directly connected IPv4 hosts 0 4 K

Directly connected IPv6 addresses 0 0 o

Indirect IPv4 routes 0 0.25 K

Indirect IPv6 routes 0 0 0

IPv4 policy based routing aces 0 0

IPv4/MAC QoS aces 0.375 K 0.375 K 0.375 K

IPv4/MAC security aces 0.375 K 0.375 K 0.375 K

IPv6 policy based routing aces 0 0 0

IPv6 QOS aces 0 0 0

IPv6 security aces 0 0 0.125 K

Rockwell Automation Publication 1783-UM004E-EN-P - June 2014 25

Page 26

Chapter 1 About the Switches

Device Manager Web Interface

You can manage the switch by using the Device Manager Web interface to

configure and monitor the switch. The Device Manager Web interface is a

graphical device management tool for configuring, monitoring, and

troubleshooting individual switches.

The Device Manager Web interface displays real-time views of switch

configuration and performance. It simplifies configuration tasks with features

such as Smartports to quickly set up the switch and its ports. It uses graphical,

color-coded displays, such as the Front Panel view, graphs, and animated

indicators to simplify monitoring tasks. It provides alert tools to help you to

identify and to solve networking problems.

You can display the Device Manager Web interface from anywhere in your

network through a Web browser such as Microsoft Internet Explorer.

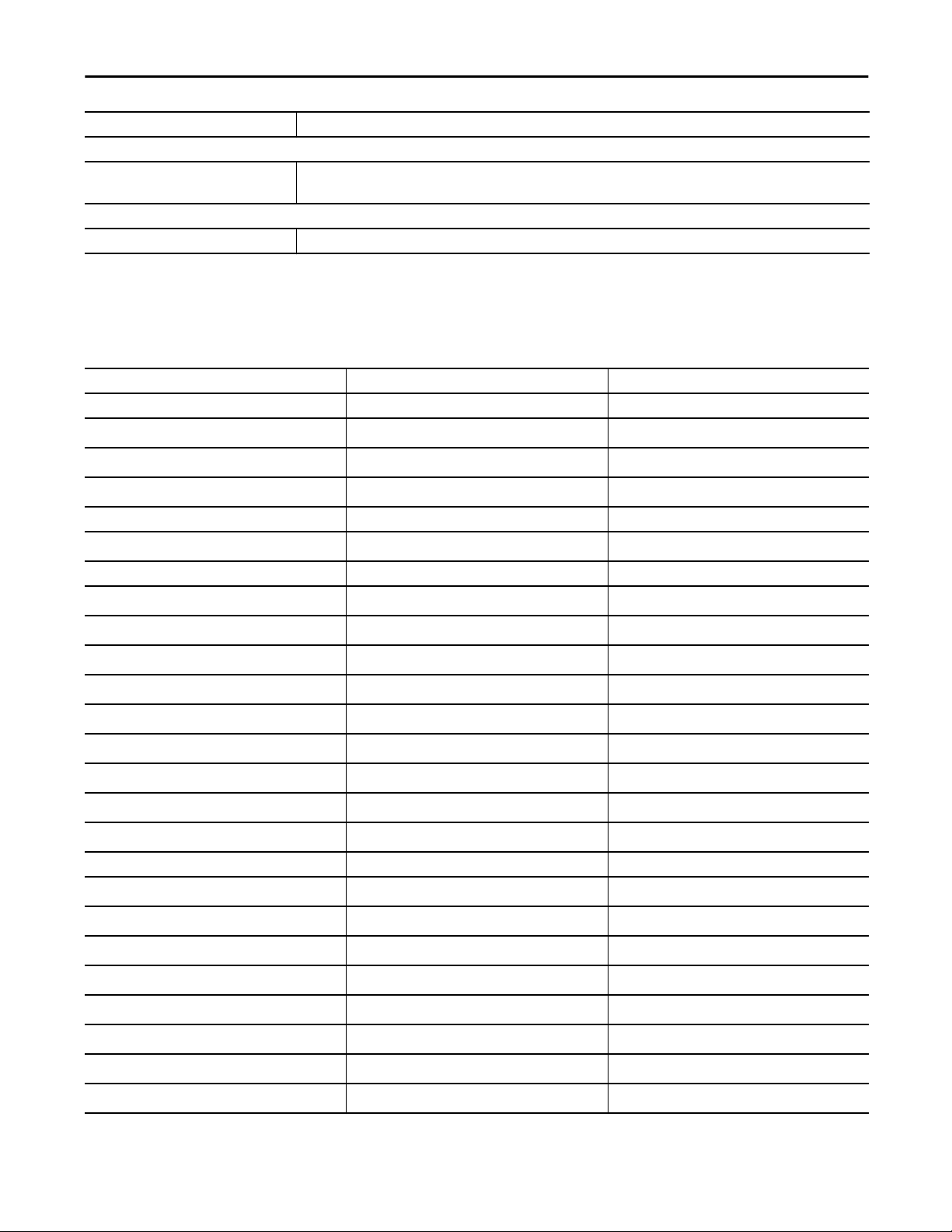

Hardware Requirements

Attribute Requirement

Processor speed 1 GHz or faster (32-bit or 64-bit)

RAM 1 GB (32-bit) or 2 GB (64-bit)

Available hard drive space 16 GB (32-bit) or 20 GB (64-bit)

Number of colors 256

Resolution 1024 x 768

Font size Small

Software Requirements

Web Browser Version

Microsoft Internet Explorer 9.0, 10.0, or 11.0 with JavaScript enabled

Mozilla Firefox 25 or 26 with JavaScript enabled

The Device Manager Web interface verifies the browser version when starting a

session to be sure that the browser is supported.

TIP

So that the Device Manager Web interface runs properly, disable any

pop-up blockers or proxy settings in your browser software and any

wireless clients running on your computer or laptop.

26 Rockwell Automation Publication 1783-UM004E-EN-P - June 2014

Page 27

About the Switches Chapter 1

Studio 5000 Environment

Cisco Network Assistant

You can manage the switch by using the Logix Designer application in the

Studio 5000 environment. The Logix Designer application is IEC 61131-3

compliant and offers relay ladder, structured text, function block diagram, and

sequential function chart editors for you to develop application programs.

Hardware Requirements

Attribute Requirement

Processor speed Pentium II 450 MHz min

Pentium III 733 MHz (or better) recommended

RAM 128 MB min

256 MB recommended

Free hard drive space 3 GB

Optical drives DVD

Video requirements 256-color VGA graphics adapter

800 x 600 min resolution (True Color 1024 x 768 recommended)

Resolution 800 x 600 min resolution (True Color 1024 x 768 recommended)

Cisco Network Assistant is a Web interface that you download from Cisco’s

website and run on your computer. It offers advanced options for configuring and

monitoring multiple devices, including switches, switch clusters, switch stacks,

routers, and access points.

To use the software, follow these steps.

1. Go to

http://www.cisco.com/go/NetworkAssistant.

You must be a registered user, but you need no other access privileges.

2. Find the Network Assistant installer.

3. Download the Network Assistant installer, and run it.

You can run it directly from the Web if your browser offers this choice.

4. When you run the installer, follow the displayed instructions.

5. In the final panel, click Finish to complete the Network Assistant

installation.

6. See the Network Assistant online help for more information.

Rockwell Automation Publication 1783-UM004E-EN-P - June 2014 27

Page 28

Chapter 1 About the Switches

Command Line Interface

You can manage the switch from the command line interface (CLI) by

connecting your personal computer directly to the switch console port or

through the network by using Telnet.

To access the CLI through the console port, follow these steps.

1. Connect to the console port in one of these ways:

• Use a RJ45-to-DB-9 adapter cable (not supplied with the switch) to

connect to the standard 9-pin serial port on a personal computer.

• Use a standard mini-USB cable (not supplied with the switch) to

connect to the mini-USB port on a personal computer.

• If you are using the USB cable, download the drivers for your

Microsoft Windows computer from

http://www.rockwellautomation.com.

2. Connect the other end of the cable to the console port on the switch.

WARNING: The console port is intended only for temporary local

programming purposes and not intended for permanent connection. If

you connect or disconnect the console cable with power applied to this

module or the programming device on the other end of the cable, an

electrical arc can occur. This could cause an explosion in hazardous

location installations. Be sure that power is removed or the area is

nonhazardous before proceeding.

3. Start a terminal-emulation program on the personal computer.

4. Configure the personal computer terminal emulation software for

9600 bps, 8 data bits, no parity, 1 stop bit, and no flow control.

28 Rockwell Automation Publication 1783-UM004E-EN-P - June 2014

Page 29

Switch Installation

Topic Page

Stratix 5700 Switch Installation 30

Installation Guidelines 31

Install or Remove the SD Card (optional) 33

Verify Switch Operation 34

Mount the Switch on a DIN Rail 36

Remove the Switch from the DIN Rail 38

Ground the Switch 38

Wire the Switch DC Power Source 40

Attach the Switch Power Connectors 43

Wire the Power over Ethernet DC Power Source 44

Attach the PoE Power Connector 46

Install an SFP Module (optional) 46

Remove SFP Modules from SFP Module Slots 48

Wire the External Alarms 49

Attach the Alarm Relay Connector to the Switch 52

Connect to 10/100 and 10/100/1000 Ports 52

Connect to 10BASE-T, 100BASE-TX, or 1000BASE-T Ports 53

Connect to PoE Ports 54

Connect to SFP Modules 55

Connect to a Dual-purpose Port 56

ArmorStratix 5700 Switch Installation 57

Installation Guidelines 57

Install or Remove the SD Card (optional) 59

Verify Switch Operation 60

Mount the Switch 61

Ground the Switch 62

Connect the Switch to a DC Power Source 64

Wire External Alarms 65

Connect to 10/100 and 10/100/1000 Ports 66

Connect to PoE Ports 66

Set Up the Switch Initially with Express Setup 67

Chapter 2

Rockwell Automation Publication 1783-UM004E-EN-P - June 2014 29

Page 30

Chapter 2 Switch Installation

Stratix 5700 Switch Installation

ATTENTION: Environment and Enclosure

This equipment is intended for use in a Pollution Degree 2 industrial environment, in overvoltage Category II applications (as defined

in IEC 60664-1), at altitudes up to 2000 m (6562 ft) without derating.

This equipment is not intended for use in residential environments and may not provide adequate protection to radio communication

services in such environments.

This equipment is supplied as open-type equipment. It must be mounted within an enclosure that is suitably designed for those

specific environmental conditions that will be present and appropriately designed to prevent personal injury resulting from

accessibility to live parts. The enclosure must have suitable flame-retardant properties to prevent or minimize the spread of flame,

complying with a flame spread rating of 5VA or be approved for the application if nonmetallic. The interior of the enclosure must be

accessible only by the use of a tool. Subsequent sections of this publication may contain additional information regarding specific

enclosure type ratings that are required to comply with certain product safety certifications.

In addition to this publication, see the following:

• Industrial Automation Wiring and Grounding Guidelines, publication

• NEMA Standard 250 and IEC 60529, as applicable, for explanations of the degrees of protection provided by enclosures

1770-4.1, for additional installation requirements

North American Hazardous Location Approval

The following information applies when operating this equipment in

hazardous locations.

Products marked "CL I, DIV 2, GP A, B, C, D" are suitable for use in Class I Division 2 Groups

A, B, C, D, Hazardous Locations and nonhazardous locations only. Each product is supplied

with markings on the rating nameplate indicating the hazardous location temperature

code. When combining products within a system, the most adverse temperature code

(lowest "T" number) may be used to help determine the overall temperature code of the

system. Combinations of equipment in your system are subject to investigation by the

local Authority Having Jurisdiction at the time of installation.

WARNING: EXPLOSION HAZARD

• Do not disconnect equipment unless power has

been removed or the area is known to be

nonhazardous.

• Do not disconnect connections to this

equipment unless power has been removed or

the area is known to be nonhazardous. Secure

any external connections that mate to this

equipment by using screws, sliding latches,

threaded connectors, or other means provided

with this product.

• Substitution of components may impair

suitability for Class I, Division 2.

• If this product contains batteries, they must only

be changed in an area known to be

nonhazardous.

Informations sur l’utilisation de cet équipement en environnements

dangereux.

Les produits marqués "CL I, DIV 2, GP A, B, C, D" ne conviennent qu'à une utilisation en

environnements de Classe I Division 2 Groupes A, B, C, D dangereux et non dangereux.

Chaque produit est livré avec des marquages sur sa plaque d'identification qui indiquent

le code de température pour les environnements dangereux. Lorsque plusieurs produits

sont combinés dans un système, le code de température le plus défavorable (code de

température le plus faible) peut être utilisé pour déterminer le code de température

global du système. Les combinaisons d'équipements dans le système sont sujettes à

inspection par les autorités locales qualifiées au moment de l'installation.

WARNING: RISQUE D’EXPLOSION

• Couper le courant ou s'assurer que

l'environnement est classé non dangereux avant

de débrancher l'équipement.

• Couper le courant ou s'assurer que

l'environnement est classé non dangereux avant

de débrancher les connecteurs. Fixer tous les

connecteurs externes reliés à cet équipement à

l'aide de vis, loquets coulissants, connecteurs

filetés ou autres moyens fournis avec ce produit.

• La substitution de composants peut rendre cet

équipement inadapté à une utilisation en

environnement de Classe I, Division 2.

• S'assurer que l'environnement est classé non

dangereux avant de changer les piles.

30 Rockwell Automation Publication 1783-UM004E-EN-P - June 2014

Page 31

Switch Installation Chapter 2

European Hazardous Location Approval

The following applies when the product bears the Ex Marking.

This equipment is intended for use in potentially explosive atmospheres as defined by European Union Directive 94/9/EC and has been found to comply with the Essential Health and

Safety Requirements relating to the design and construction of Category 3 equipment intended for use in Zone 2 potentially explosive atmospheres, given in Annex II to this Directive.

Compliance with the Essential Health and Safety Requirements has been assured by compliance with EN 60079-15 and EN 60079-0.

ATTENTION: This equipment is not resistant to sunlight or other sources of UV radiation.

WARNING:

• This equipment shall be mounted in an ATEX-certified enclosure with a minimum ingress protection rating of at least IP54 (as

defined in IEC60529) and used in an environment of not more than Pollution Degree 2 (as defined in IEC 60664-1) when applied in

Zone 2 environments. The enclosure must have a tool-removable cover or door.

• This equipment shall be used within its specified ratings defined by Rockwell Automation.

• Provision shall be made to prevent the rated voltage from being exceeded by transient disturbances of more than 140% of the

rated voltage when applied in Zone 2 environments.

• Secure any external connections that mate to this equipment by using screws, sliding latches, threaded connectors, or other

means provided with this product.

• Do not disconnect equipment unless power has been removed or the area is known to be nonhazardous.

Installation Guidelines

WARNING: If you connect or disconnect Ethernet cables with power applied to

this module or any device on the network, an electrical arc can occur. This could

cause an explosion in hazardous location installations.

Be sure that power is removed or the area is nonhazardous before proceeding.

ATTENTION: The alarm port cables are not to exceed 10.0 m (32.81 ft).

At the end of its life, this equipment should be collected separately from any

unsorted municipal waste.

When determining where to place the switch, observe these guidelines:

• Airflow around the switch is unrestricted. To prevent the switch from

overheating, observe the following minimum clearances:

– Top and bottom: 50.8 mm (2.0 in.)

– Sides: 50.8 mm (2.0 in.)

– Front: 50.8 mm (2.0 in.)

Rockwell Automation Publication 1783-UM004E-EN-P - June 2014 31

Page 32

Chapter 2 Switch Installation

• For 10/100 ports and 10/100/1000 ports, the cable length from a switch

to an attached device cannot exceed 100 m (328 ft).

• The fiber-optic cable length from a switch to an attached device cannot

exceed the distance specified in

Appendix C.

• For maximum noise immunity, shielded cables must be used on the RJ45

uplink ports (Gi1/1 and Gi1/2) on these switches:

– 1783-BMS06TGL

– 1783-BMS06TGA

– 1783-BMS10CGL

– 1783-BMS10CGA

– 1783-BMS10CGN

– 1783-BMS10CGP

– 1783-BMS12T4E2CGNK

– 1783-BMS12T4E2CGP

– 1783-BMS12T4E2CGL

– 1783-BMS20CGL

– 1783-BMS20CGN

– 1783-BMS20CGP

– 1783-BMS20CGPK

• Temperature surrounding the unit does not exceed 60 °C (140 °F).

IMPORTANT

When the switch is installed in an industrial enclosure, the

temperature within the enclosure is greater than normal room

temperature outside the enclosure.

The temperature inside the enclosure cannot exceed 140 °F (60 °C), the

maximum ambient enclosure temperature of the switch.

• Clearance to front and rear panels meets these conditions:

– Front-panel status indicators can be easily read.

– Access to ports is sufficient for unrestricted cabling.

– Front-panel direct current (DC) power connectors and the alarm relay

connector are within reach of the connection to the DC power source.

• Cabling is away from sources of electrical noise, such as radios, power lines,

and fluorescent lighting fixtures.

• Connect the unit to only a Class 2 DC power source.

ATTENTION: Do not wire more than 1 conductor on any single terminal.

32 Rockwell Automation Publication 1783-UM004E-EN-P - June 2014

Page 33

Switch Installation Chapter 2

Install or Remove the SD Card (optional)

WARNING: When you insert or remove the CompactFlash/SD memory card

while power is on, an electrical arc can occur. This can cause an explosion in

hazardous location installations.

Be sure that power is removed or the area is nonhazardous before proceeding.

To install or replace the SD card, follow these steps.

1. On the front of the switch, locate the door that protects the SD card slot.

2. Loosen the captive thumb screw at the top of the door by using a

screwdriver to open the door.

3. Install or remove the card:

• To install the card, slide it into the slot, and press it firmly in place until

it latches in the spring loaded mechanism. The card is keyed so that you

cannot fully insert it the wrong way.

•

32271-M

Rockwell Automation Publication 1783-UM004E-EN-P - June 2014 33

Page 34

Chapter 2 Switch Installation

• To remove the card, push it in and let it pop out via the spring-loaded

mechanism. Grasp the card top and pull it out. Place it in an antistatic

bag to protect it from static discharge.

Setup

EIP

EIP

Net

Mod

Alarm

IN1

IN2

OUT

32272-M

4. Close the guard door and fasten the captive screw by using a screwdriver to

keep the door in place.

Verify Switch Operation

Before installing the switch in its final location, power on the switch, and verify

that the switch powers up.

The time required for the switch to start up is directly related to your switch

configuration. Start time is negatively affected by such things as the following:

• Spanning Tree Learning mode

• Number of files or images in onboard flash memory

34 Rockwell Automation Publication 1783-UM004E-EN-P - June 2014

Page 35

Switch Installation Chapter 2

To test the switch, follow these steps.

1. Apply power to the switch.

To apply power to a switch that is directly connected to a DC power

source, locate the circuit breaker on the panel board that services the DC

circuit, and switch the circuit breaker to the ON position.

2. Verify the start-up sequence.

When you power on the switch, it automatically begins a start-up routine.

The System status indicator blinks green as the IOS software image loads.

If the routine fails, the System status indicator turns red.

IMPORTANT

Start-up failures are usually fatal to the switch. Contact your

Rockwell Automation representative immediately if your switch does

not complete the start sequence successfully.

IMPORTANT

You can disable boot fast and run the Power-on Self Test (POST) by

using the IOS CLI. See the appropriate documentation at

http://www.Cisco.com for more information.

3. After successfully running this test, do the following:

a. Turn off power to the switch.

b. Disconnect the cables.

c. Decide where you want to install the switch

Rockwell Automation Publication 1783-UM004E-EN-P - June 2014 35

Page 36

Chapter 2 Switch Installation

Mount the Switch on a DIN Rail

The switch ships with a spring-loaded latch on the rear panel for mounting on a

DIN rail.

WARNING: If you connect or disconnect console port cables with power

applied to this module or any device on the network, an electrical arc can occur.

This could cause an explosion in hazardous location installations.

Be sure that power is removed or the area is nonhazardous before proceeding.

WARNING: Do not use the USB-mini console port in hazardous locations.

ATTENTION: Prevent Electrostatic Discharge

This equipment is sensitive to electrostatic discharge, which can cause internal

damage and affect normal operation. Follow these guidelines when you handle

this equipment:

• Touch a grounded object to discharge potential static.

• Wear an approved grounding wriststrap.

• Do not touch connectors or pins on component boards.

• Do not touch circuit components inside the equipment.

• Use a static-safe workstation, if available.

• Store the equipment in appropriate static-safe packaging when not in use.

ATTENTION: This equipment is supplied as open type equipment. It must be

mounted within an enclosure suitably designed for those specific

environmental conditions and appropriately designed to prevent personal

injury resulting from accessibility to live parts. The interior of the enclosure

must be accessible only by using a tool.

The enclosure must meet IP 54 or NEMA type 4 minimum enclosure rating

standards.

ATTENTION: To prevent the switch from overheating, make sure these

minimum clearances:

• Top and bottom: 50.8 mm (2.0 in.)

• Exposed side (not connected to the module): 50.8 mm (2.0 in.)

• Front: 50.8 mm (2.0 in.)

ATTENTION: The console ports are intended for temporary local programming

purposes only and not intended for permanent connection.

The console port cables are not to exceed 3.0 m (9.84 ft) and must not contain

hubs.

36 Rockwell Automation Publication 1783-UM004E-EN-P - June 2014

Page 37

Switch Installation Chapter 2

ATTENTION: Under certain conditions, viewing the optical port may expose the

eye to hazard. When viewed under some conditions, the optical port may

expose the eye beyond the maximum permissible exposure recommendations.

ATTENTION: Class 1 laser product. Laser radiation is present when the system is

open and interlocks bypassed. Only trained and qualified personnel should be

allowed to install, replace, or service thisequipment.

ATTENTION: This product is grounded through the DIN rail to chassis ground.

Use zinc plated yellow-chromate steel DIN rail to assure proper grounding. The

use of other DIN rail materials (for example, aluminum or plastic) that can

corrode, oxidize, or are poor conductors, can result in improper or intermittent

grounding. Secure DIN rail to mounting surface approximately every 200 mm

(7.8 in.) and use end-anchors appropriately.

To attach the switch to a DIN rail, follow these steps.

1. Position the rear panel of the switch directly in front of the DIN rail,

making sure that the DIN rail fits in the space between the two hooks near

the top of the switch and the spring-loaded latch near the bottom.

2. Holding the bottom of the switch away from the DIN rail, place the two

hooks on the back of the switch over the top of the DIN rail.

32285-M

3. Push the switch toward the DIN rail to cause the spring loaded latch at the

bottom rear of the switch to move down and snap into place.

Rockwell Automation Publication 1783-UM004E-EN-P - June 2014 37

Page 38

Chapter 2 Switch Installation

Remove the Switch from the DIN Rail

To remove the switch from a DIN rail or a rack, follow these steps.

1. Remove power from the switch, and disconnect all cables and connectors

from the front panel of the switch.

2. Insert a tool, such as a flat-head screwdriver, in the slot at the bottom of the

spring-loaded latch and use it to release the latch from the DIN rail.

32286-M

Ground the Switch

For DC power connections, use UL- and CSA-rated, style 1007 or 1569

twisted-pair copper appliance wiring material (AWM) wire.

WARNING: If you connect or disconnect power or alarm wiring while the

field-side power is on, an electrical arc can occur. This could cause an explosion

in hazardous location installations. Be sure that power is removed or the area is

nonhazardous before proceeding.

ATTENTION: This equipment must be grounded. Never defeat the ground

conductor or operate the equipment in the absence of a suitably installed

ground conductor. Contact the appropriate electrical inspection authority or an

electrician if you are uncertain that suitable grounding is available.

This equipment is intended to be grounded to comply with emission and immunity

requirements. Make sure that the switch functional ground lug is connected to

earth ground during normal use.

ATTENTION: To make sure that the equipment is reliably connected to earth

ground, follow the grounding procedure instructions and use a suitable ring

terminal lug, such as Thomas & Betts part number 10RCR or equivalent.

38 Rockwell Automation Publication 1783-UM004E-EN-P - June 2014

Page 39

Switch Installation Chapter 2

ATTENTION: For proper grounding, you must always connect the power supply

functional-ground screw when connecting the power supply. You must provide

an acceptable grounding path for each device in your application. For more

information on proper grounding guidelines, refer to publication

1770-4.1,

Industrial Automation Wiring and Grounding Guidelines.

Use at least 4 mm2 (12 AWG) wire to connect to the external grounding screw.

The ground lug is not supplied with the switch. You can use one of the these

options:

• Single ring terminal

• Two single ring terminals