Page 1

AllenBradley

Data Highway II

PLC-3

Communication

Interface

Module

(Cat. No. 1779-KP3,

KP3R)

User Manual

Page 2

Table of Contents

Preface P-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Purpose of This Manual P-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Who Should Read This Manual P-1

Precautionary Notes P-1

What This Package Contains P-1

Frequently Used Terms P-2

Related Products P-2

Related

Publications

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Overview 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

P-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter

Introducing the 1779-KP3 11

A

Data

Data

Allen-Bradley Communication Interface Modules 19

Objectives

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Brief Look at Data Highway II

Highway II Cabling

Highway II Communication

11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12. . . . . . . . . . . . . . . . . . . . . . . . . .

13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14. . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . .

Installing the 1779-KP3 Communication Interface 21. . . . . . .

Chapter

Printed Circuit Boards 21

Set the Switches on the Host Board 21

Set the Thumbwheel Switches 25

Install the KP3 Module 26

Use

Connecting

Connecting

How a PLC-3 Backup System Works on Data Highway II 213

Installing a Back-up PLC-3 System on Data Highway II 214

Creating a Backup System for a PLC-3 Communicating on

Objectives

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

the LIST Option to Select Additional KP3 Parameters

the KP3 to Data Highway II

a PLC-3 to Multiple Data Highway II Links

Multiple Links

21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

27. . . . . . .

212. . . . . . . . . . . . . . . . . . . .

212. . . . . . . . .

. . . . . . .

. . . . . . . .

218. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Programming 31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter

Transferring

Using

Using

Addressing Techniques 38

Addressing Data Highway II Nodes 39

Addressing Memory 310

Programming Examples 314

Objectives

Data

the MOVE Command to T

the TMOVE Command to T

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ransfer Data 33. . . . . . . . . . . . . . . .

ransfer Data 35. . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

Page 3

Table of Contentsii

Operation and Troubleshooting A1. . . . . . . . . . . . . . . . . . . . .

Appendix

KP3 Operation A1

LED Indicators A2

Using

Troubleshooting the KP3 A5

Objectives

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

the Exit Request Switch

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A5. . . . . . . . . . . . . . . . . . . . . . . . . . .

Error Codes B1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix

Error Codes B1

Objectives

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Specifications C1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix

Objectives

C1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 4

Preface

Preface

Purpose of This Manual

Who Should Read This

Manual

This manual describes the Allen–Bradley 1779–KP3, –KP3R

Communication Interface Module and provides information on:

the Data Highway II

Network

other Allen–Bradley communication interface modules

the 1779–KP3, –KP3R hardware and firmware components

installing and configuring the 1779–KP3, –KP3R Module

connecting the 1779–KP3, –KP3R Module to the Data Highway II

network

installing a backup cable system

programming the 1779–KP3, –KP3R Module

You should read this manual before using the 1779–KP3, –KP3R

Communication Interface Module. We assume you have basic knowledge

of:

the Data Highway II network

the Data Highway Plus network

Allen–Bradley PLC Programmable Controllers

programming through Allen–Bradley 6200 software

Precautionary Notes

What This Package Contains

In this manual, you may see:

Important notes that stress information critical to your understanding

and use of the product.

WARNINGs that describe where you may be injured if you do not

follow procedures properly.

CAUTIONs that describe where equipment may be damaged if you do

not follow procedures properly.

If you have ordered the 1779–KP3 or –KP3R communication interface

module, you should have received:

the module itself

this user manual

P–1

Page 5

Preface

Frequently Used Terms

To make this manual easier to read, we occasionally use abbreviated

versions of some terms. You may see:

Term/symbol: Meaning:

DH the Allen–Bradley Data Highway network

DHII

DH+

KP3 module or KP3 the 1779–KP3 communication interface

KP3R module or KP3R the 1779–KP3R communication interface

< >

the Allen–Bradley Data Highway II

network

The Allen–Bradley Data Highway Plus

network.

module. Generally

to both types of modules; we specifically

use KP3R when only referring to it.

module (the redundant–cabling version of

the KP3 module).

(angle brackets) used in text describing

programming. It symbolizes where you

need to add information specific to your

application.

, we use ‘

‘KP3” to refer

Important: In this manual, we use the term ‘‘KP3” to refer to both the

1779–KP3 and 1779–KP3R Modules. When it is necessary to specify the

1779–KP3R Module alone, we do so.

Related Products

P–2

The 1779–KP3 is part of a complete line of Allen–Bradley Data Highway

II product family. The following table lists others:

Product: Catalog Number:

Data Highway II Asynchronous–device

Interface

Data Highway II Synchronous–device

Interface

Data Highway II PLC–2 Communication

Interface Module

Data Highway II/ Data Highway Plus

Interface Module

1779–KFL, –KFLR

1779–KFM, –KFMR

1779–KP2, –KP2R

1779–KP5, –KP5R

Page 6

Preface

Related Publications

The following table shows you where to read more about related

Allen–Bradley products:

Title: Publication Number:

Data Highway II Local Area

Network Overview

Data Highway/Data Highway

Plus/Data Highway II/Data Highway

485 Cable Planning and Installation

Manual

Data Highway II

Asynchronous–device Interface

Data Highway II

Synchronous–device Interface

Data Highway II PLC–2

Communication Interface Module

Data Highway II/ Data Highway

Plus Interface Module

1779–2.10

1770–6.2.2

1779–6.5.1

1779–6.5.2

1779–6.5.3

1779–6.5.6

P–3

Page 7

Overview

Chapter

1

Chapter Objectives

Introducing the 1779-KP3

This chapter serves as an introduction to the Allen–Bradley Data Highway

II PLC–3 Communication Interface Module and contains the following

sections:

Introducing the 1779–KP3

Data Highway II Overview

Data Highway II Communication

Allen–Bradley Communication Interface Modules

This information is meant to provide you with a general overview of these

topics. For further detailed discussions of any of the subjects listed above,

refer to the Preface section titled Related Publications. If you are already

familiar with these subjects, you can proceed to Chapter 2.

The 1779–KP3 is a Data Highway II communication interface module

that allows you to connect your PLC–3

Data Highway II network, providing you with the ability to communicate

to:

other nodes on your Data Highway II link

nodes on another Data Highway II link

Data Highway Plus nodes on a Data Highway Plus sub–network

Programmable Controller to the

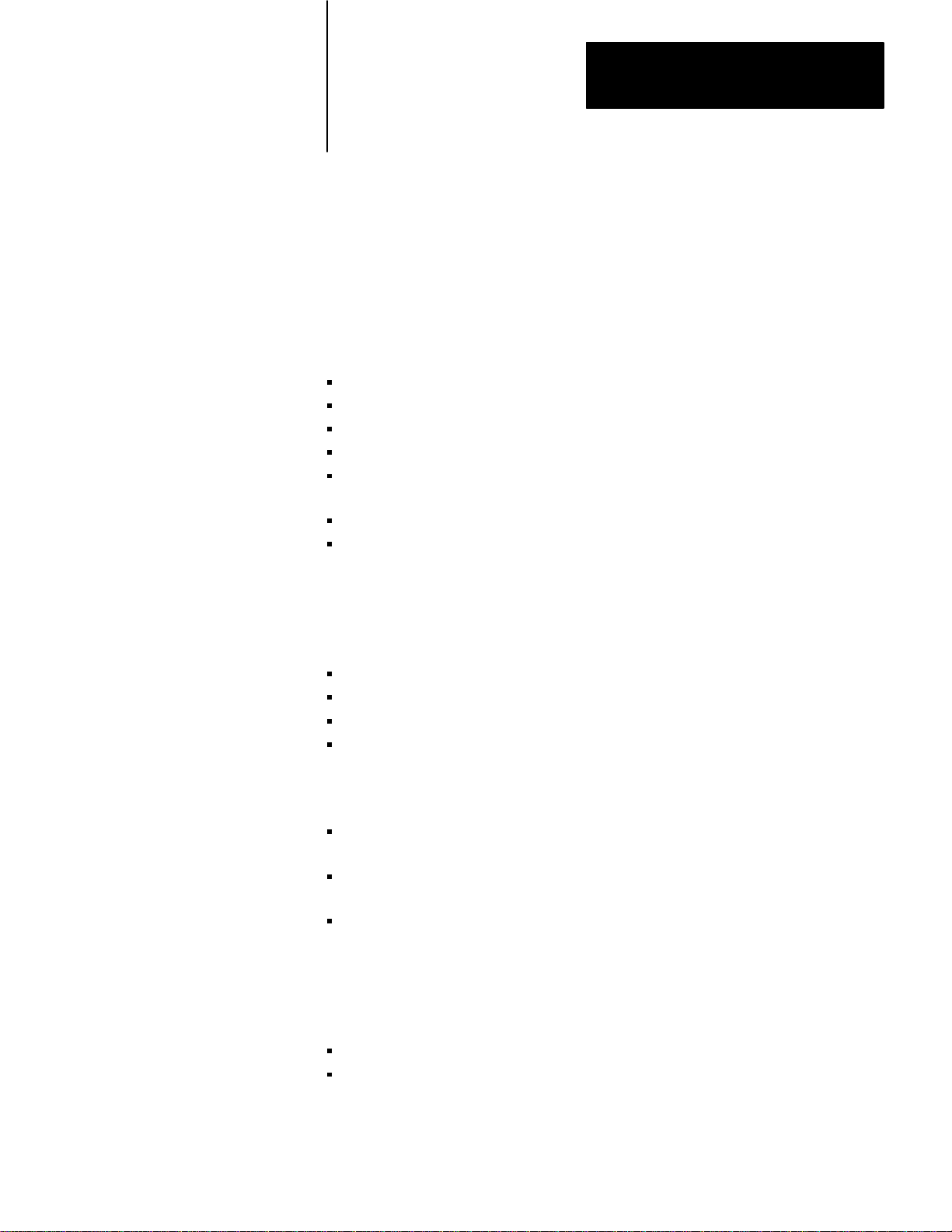

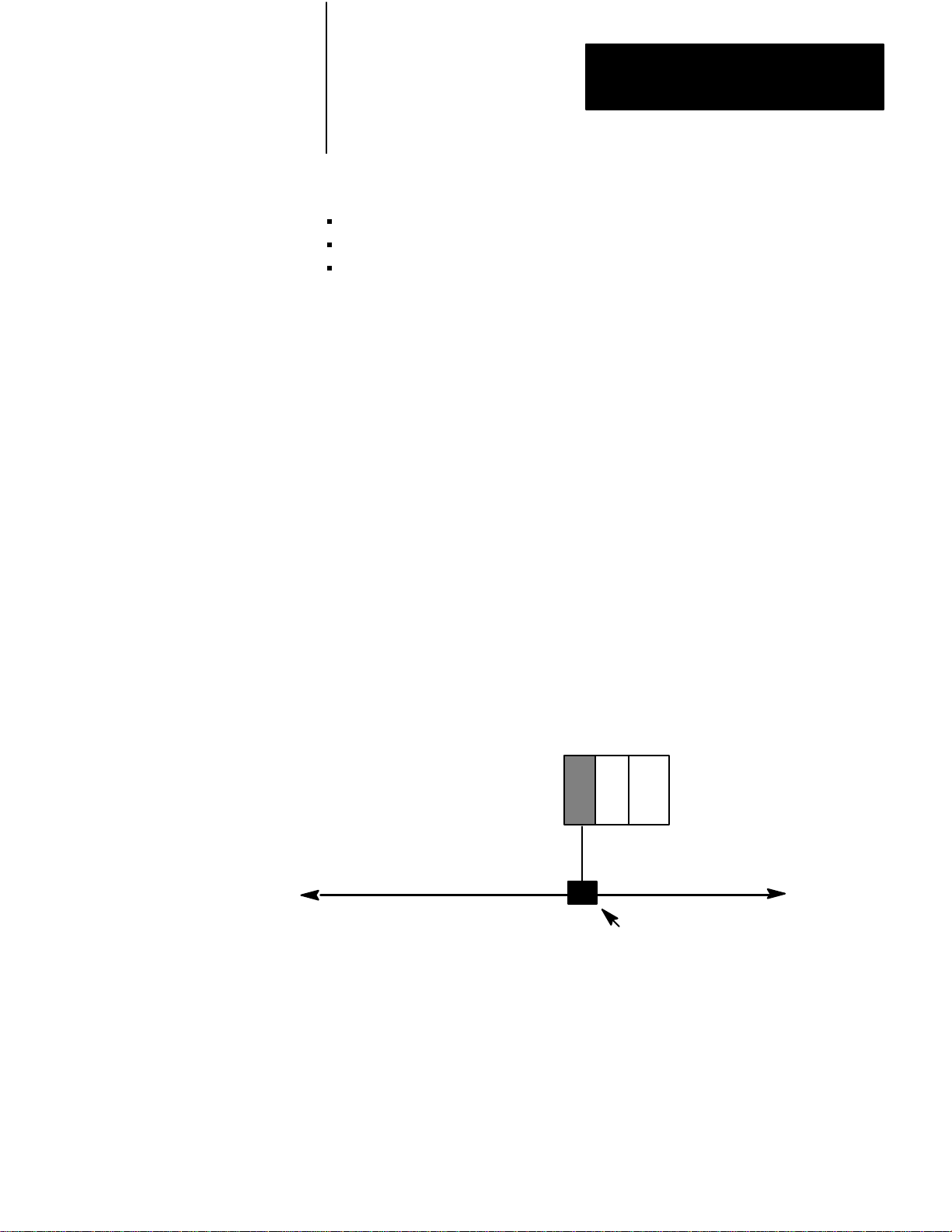

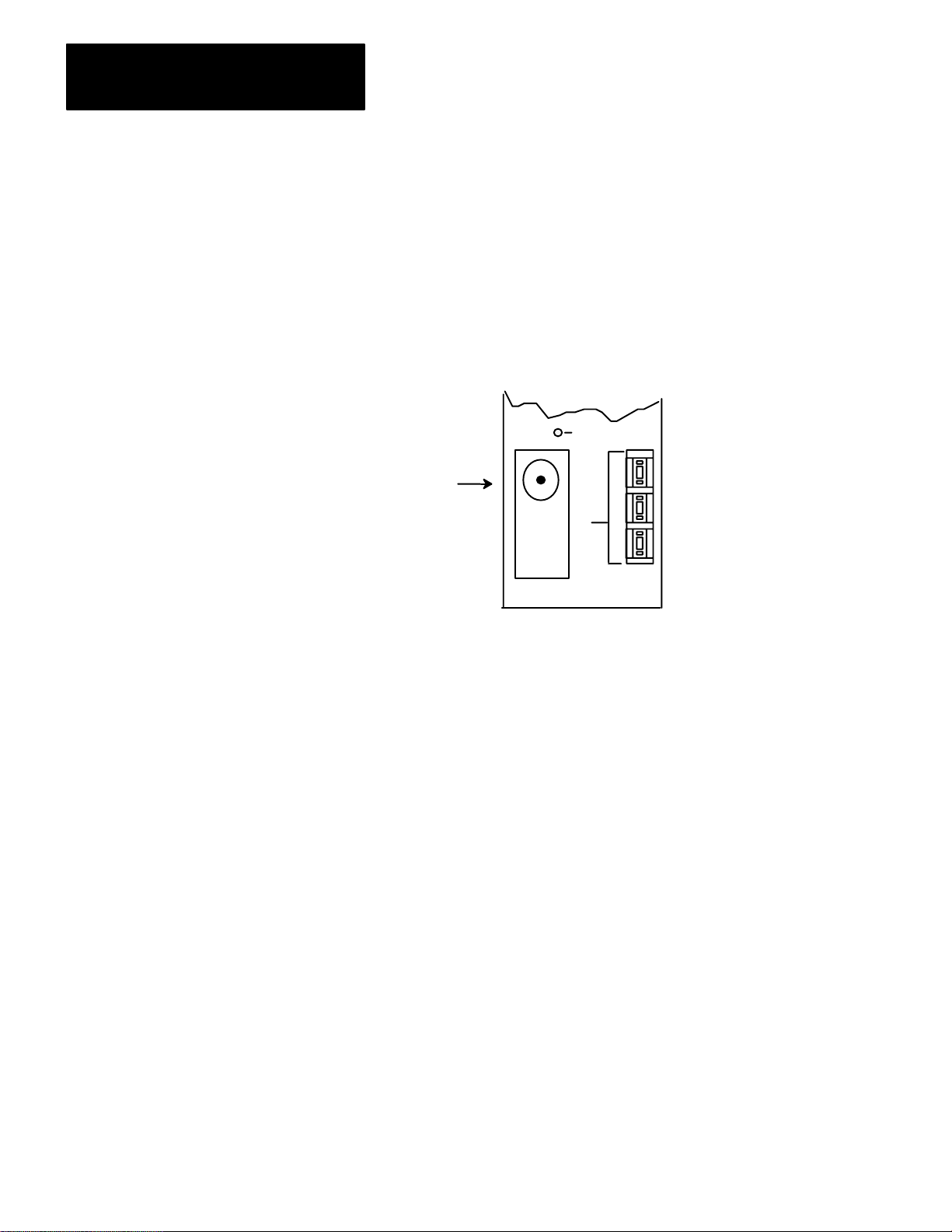

The 1779–KP3 operates in a single slot of an Allen–Bradley PLC–3

chassis. The front of the module (figure 1.1) contains:

LEDs that indicate the state of the module and the state of its

connection to the network

two ports for use in a backed–up system

a single thumbwheel switch that identifies the KP3 interface module

from other KP3 interface modules in the PLC–3 chassis

three thumbwheel switches that determine the node address

a single Data Highway II auxiliary access port that is reserved for

future use

The front panel of the 1779–KP3R Module is shown in Appendix A

(figure A.1) of this manual.

1-1

Page 8

Chapter 1

Overview

Figure 1.1

Panel of the KP3

Front

A Brief Look at Data Highway II

The following sections provide a brief overview of the Data Highway II

environment and related concepts you should be familiar with before

using the 1779–KP3 module.

Allen–Bradley Data Highway II is local area network designed for the

plant environment that allows your intelligent devices to communicate

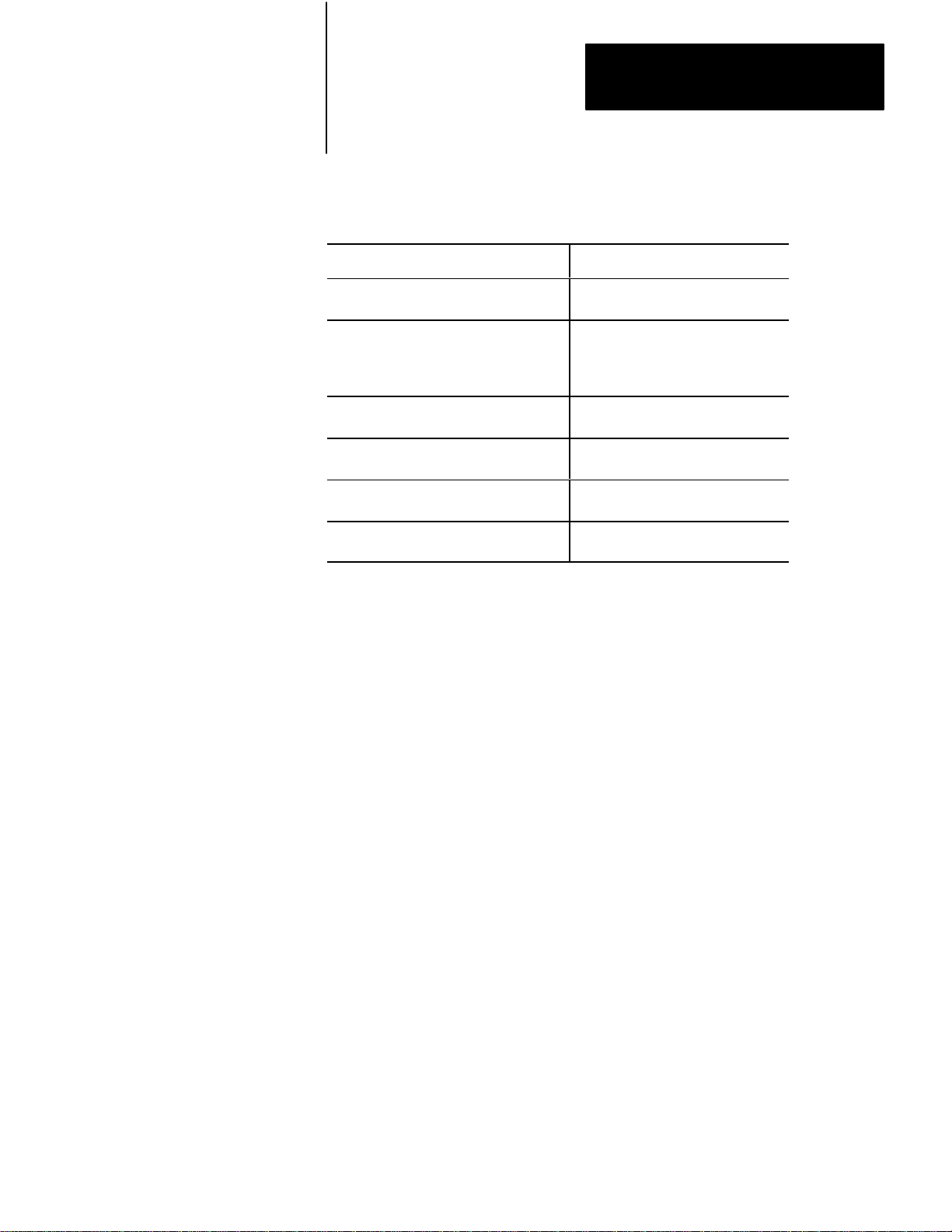

with each other (figure 1.2).

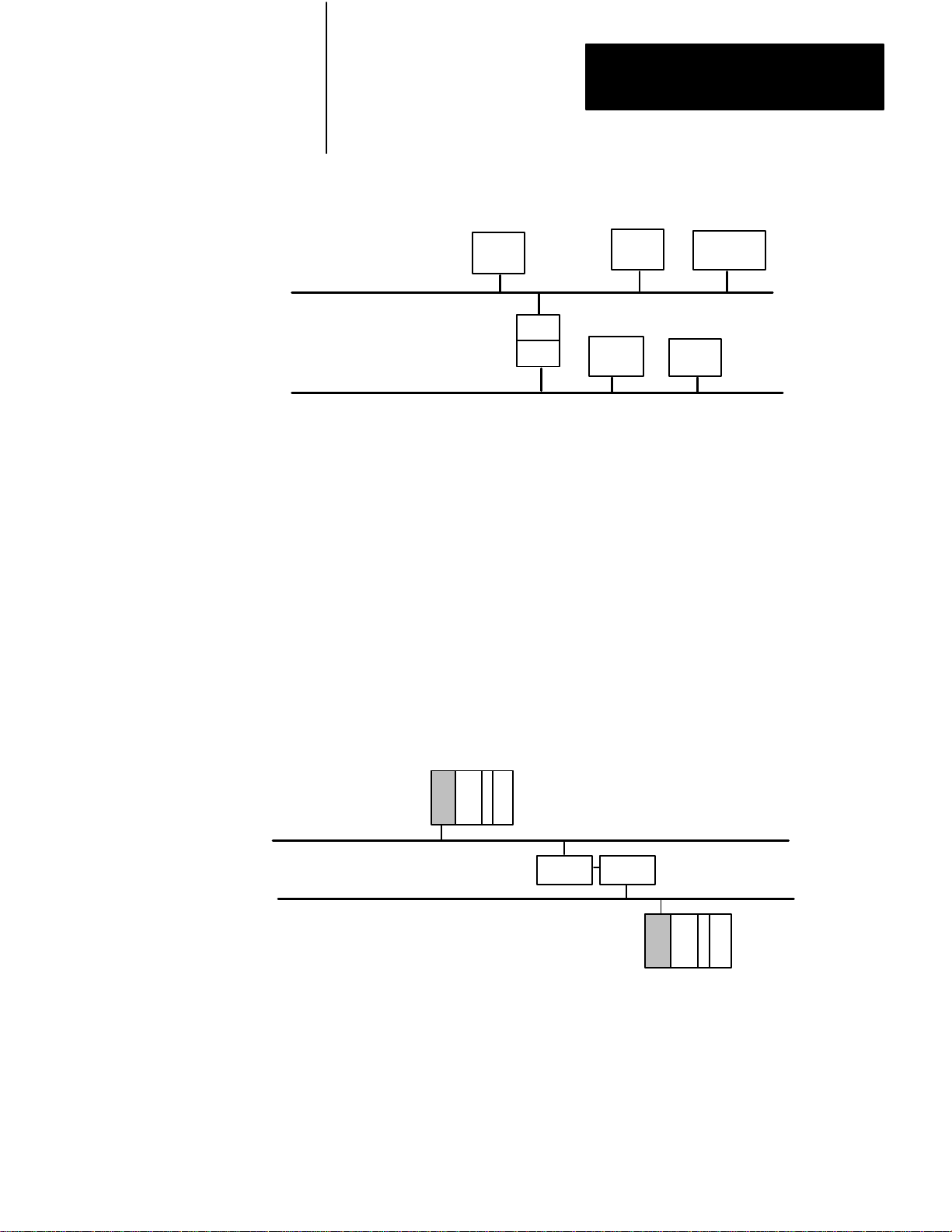

Figure 1.2

Sample

Data Highway II Network

Computer

VAX

1779-KFM Interface

computer

1779-KP3

Interface

Data Highway II

1779-KFL Interface

PLC-3

10992-I

1-2

Page 9

Chapter 1

Overview

The Data Highway II network offers:

a transmission rate of one megabit per second

high immunity to noise

easy connection to control devices

This network is meant for time–critical operations where the status or

position of one device (e.g., PLC Programmable Controller, personal

computer, etc.) may affect another device, or an entire production line.

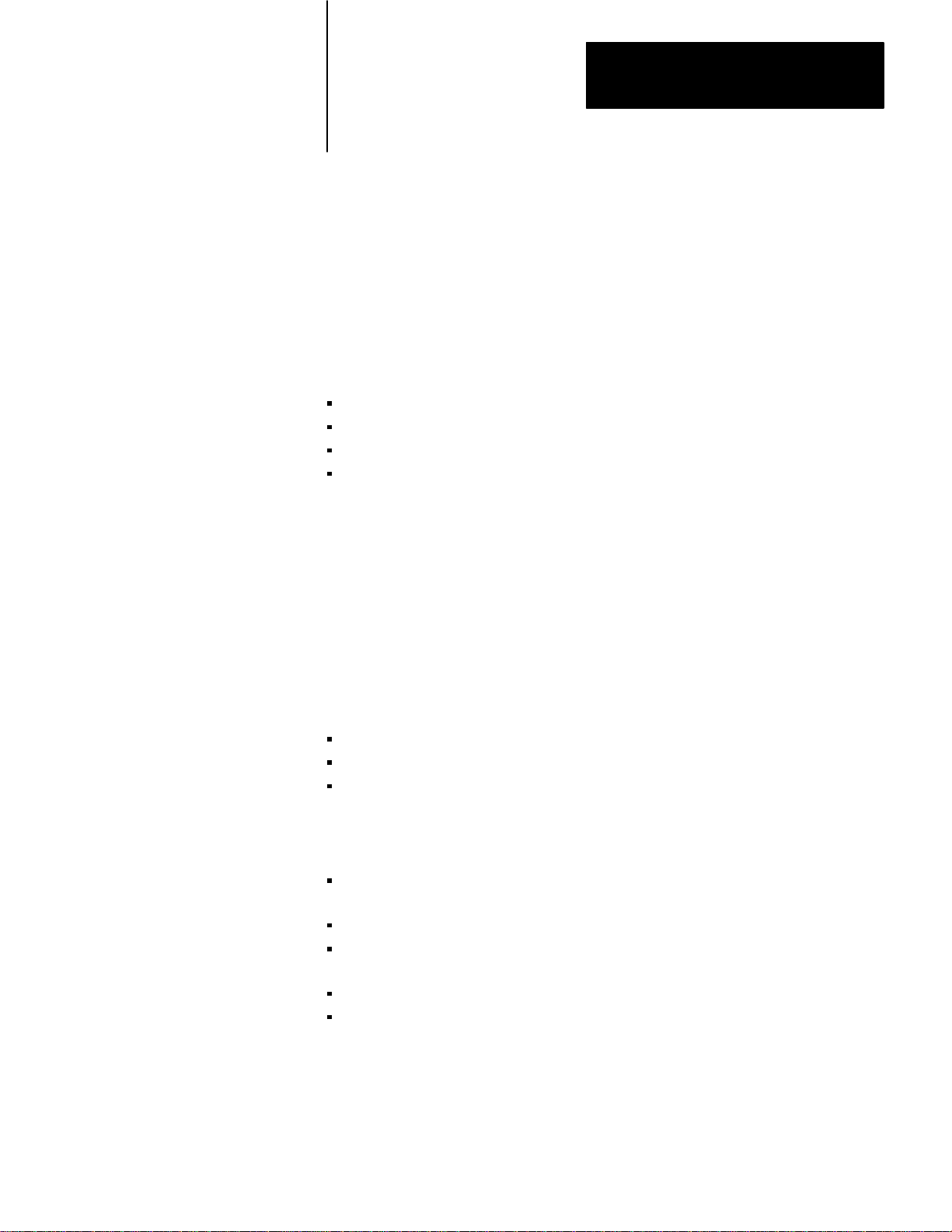

Data Highway II Cabling

All communication on Data Highway II travels from one device to

another through the trunkline (figure 1.3). The trunkline varies in length

depending on the number of nodes and their location. Data Highway II

cabling is compatible with IEEE Specification 802.4 for single channel

phase–continuous FSK (frequency shift keying) systems.

You connect Allen–Bradley PLC Programmable Controllers to the Data

Highway II trunkline via an Allen–Bradley communications interface.

Data Highway II droplines connect the communication interfaces to the

trunkline. The mechanical connection between the dropline and the

trunkline is a local tap (figure 1.3).

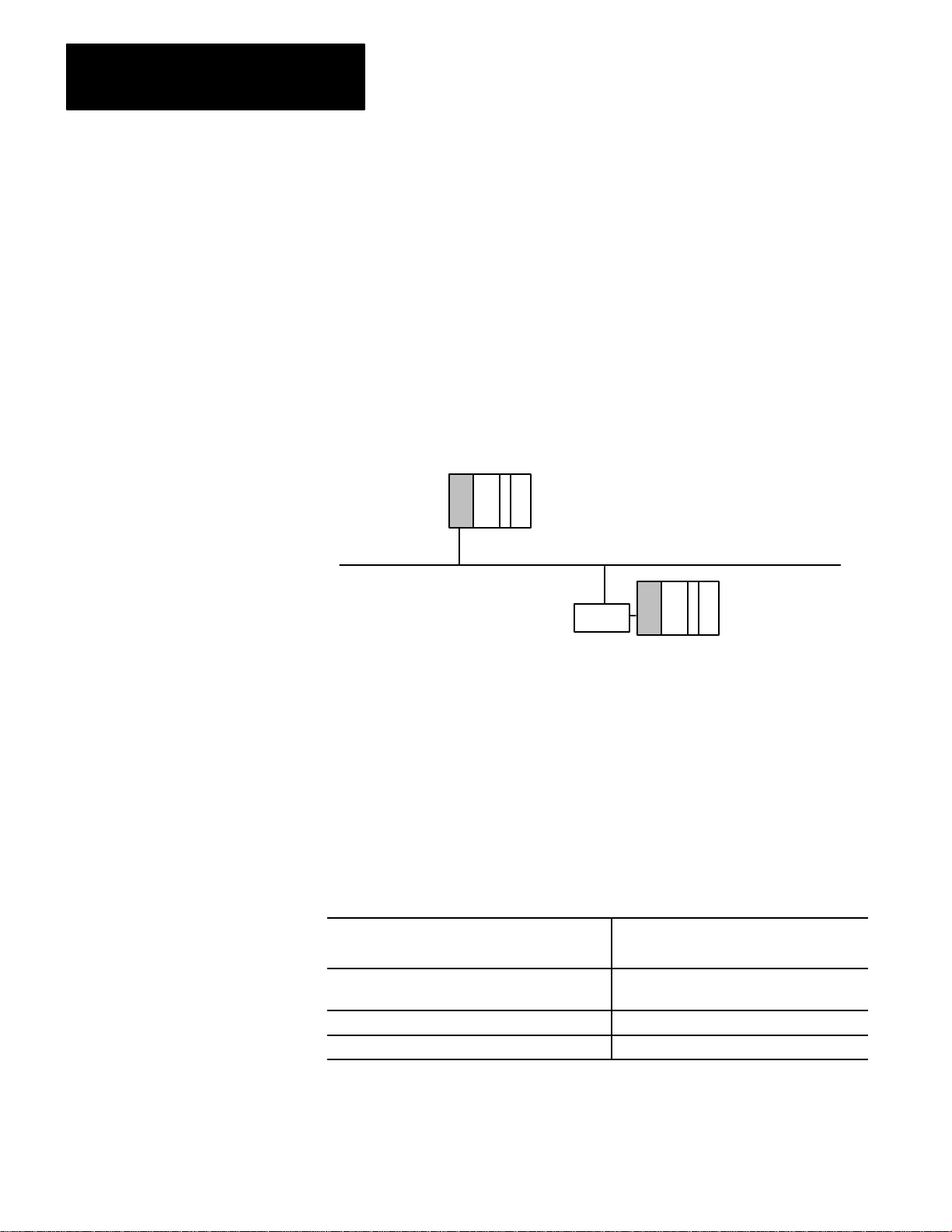

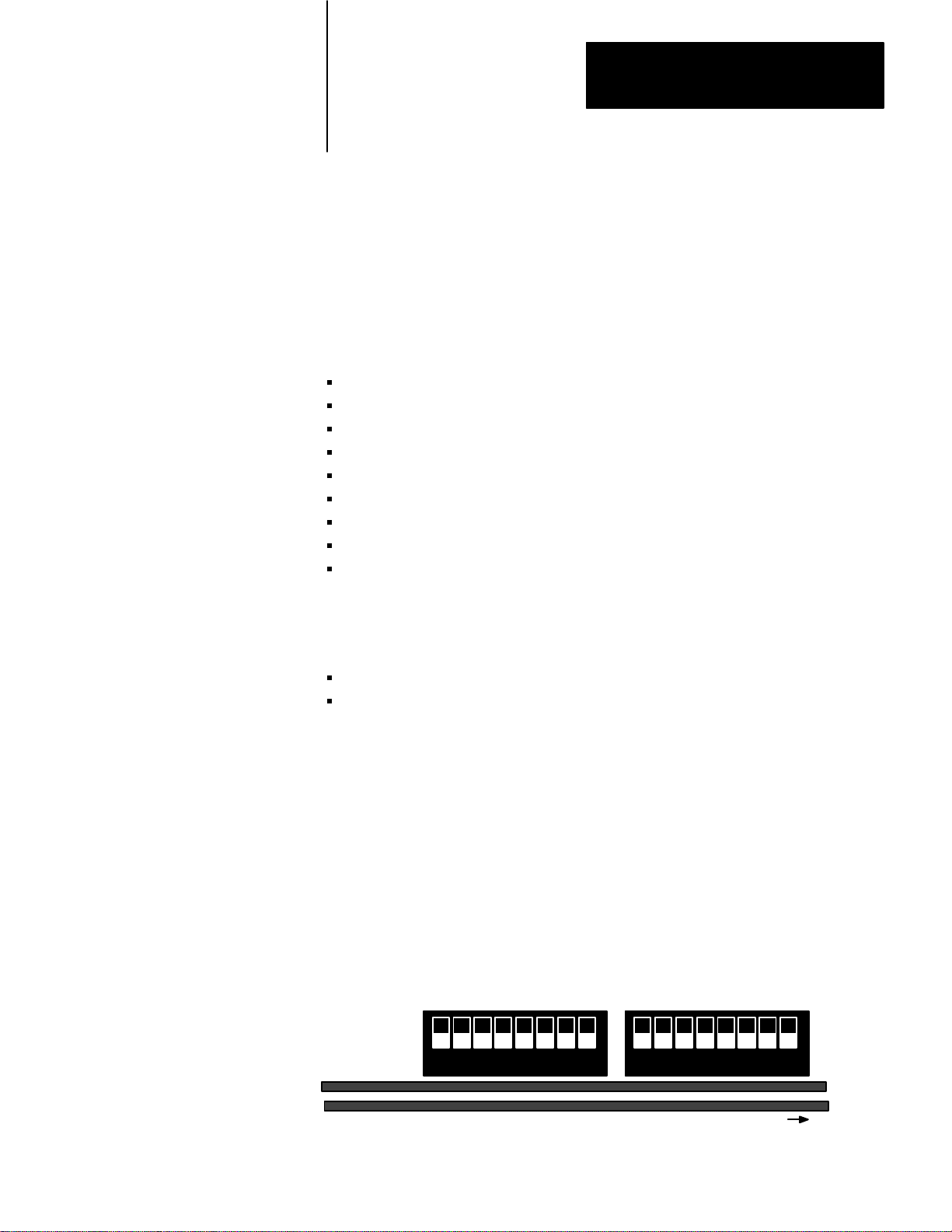

Figure 1.3

KP3

The

Communications

Communication Interface

Interface on Data Highway II

1779-KP3

Allen-Bradley

PLC-3 Programmable

Controller

Dropline

Data Highway II Trunkline

local tap

10993-I

For information on planning and installing Data Highway II refer to the

Allen–Bradley Data Highway/Data Highway Plus/Data Highway II/Data

Highway 485 Cable Planning and Installation Manual, publication

1770–6.2.2.

1-3

Page 10

Chapter 1

Overview

You also have the option of running redundant cabling. You can order

Allen–Bradley Data Highway II interface modules with dual ports, which

allows you to install a back–up cable system. Thus providing more

security for your system if a failure occurs. See Chapter 2 for information

on redundant cabling.

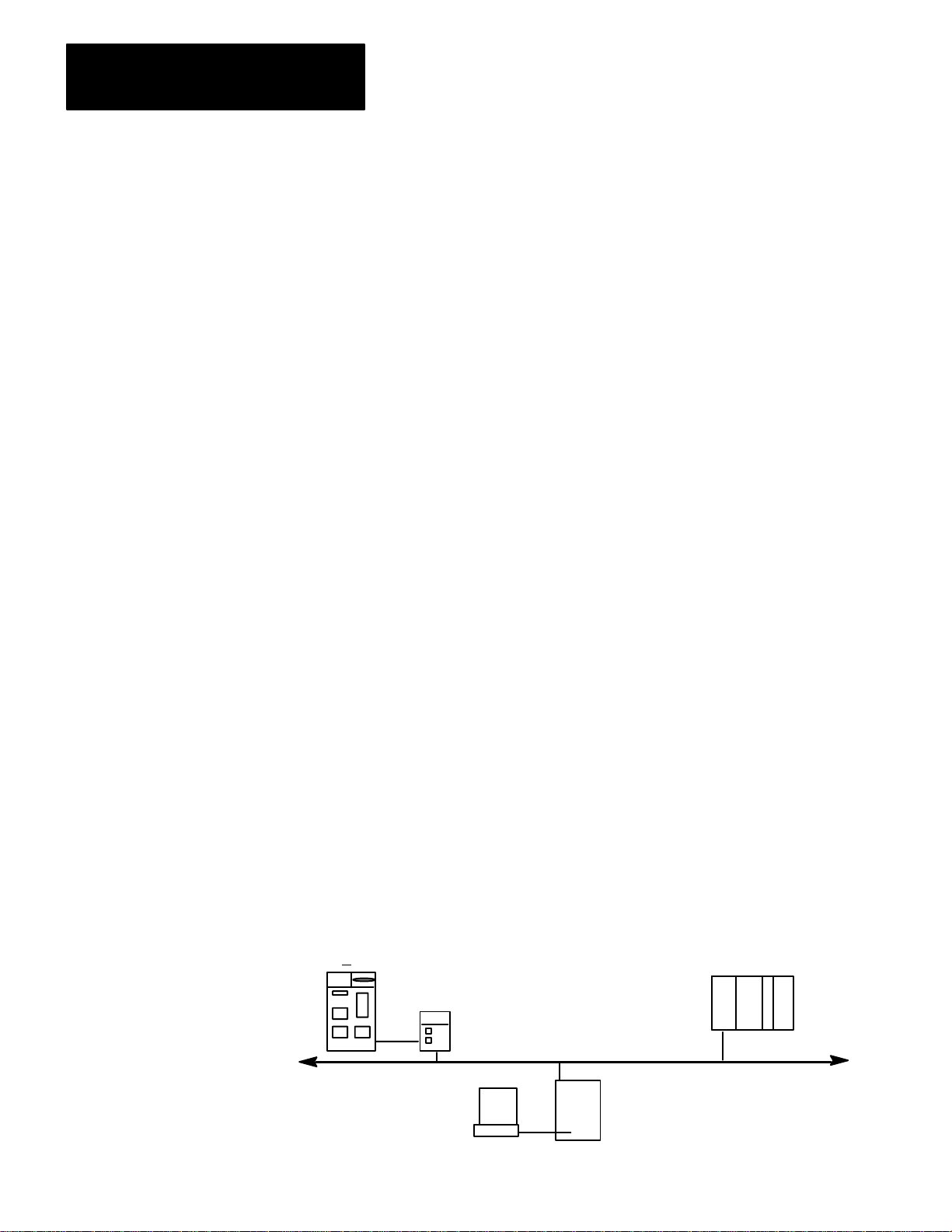

Data Highway II Communication

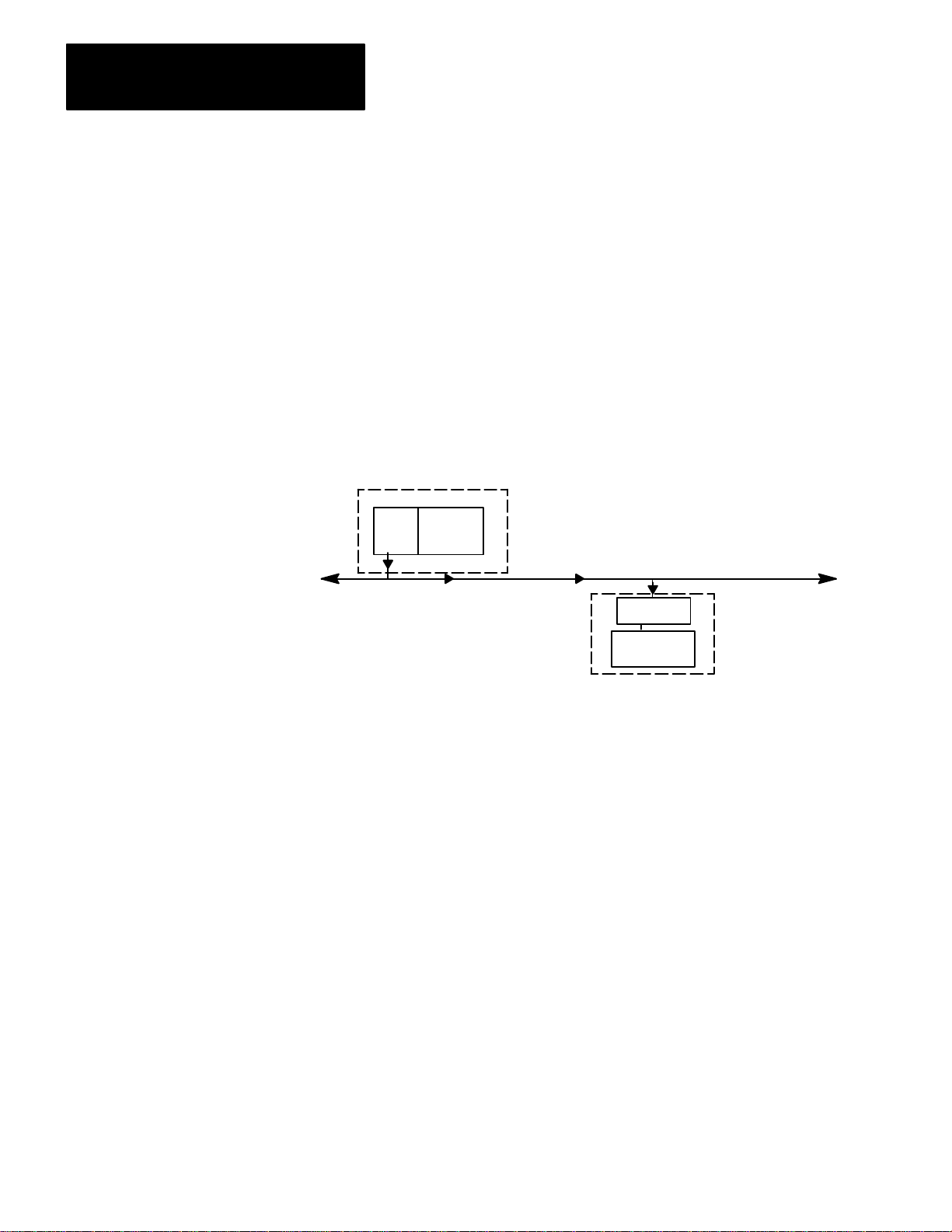

A device and its communication interface make up a node on the Data

Highway II network (figure 1.4). The node sending a message is the

source node; the node receiving a message is the destination node.

Figure 1.4

Data Highway II Nodes

Sample

1779-KP3

PLC-3

Data Highway II

The source node

sends the message.

1779-KFM

Computer

The destination node

receives the message.

10994-I

Allen–Bradley Data Highway II has its own Data Highway II proprietary

communication protocol between the network communication interfaces.

All communication interface modules connected to this network ‘‘talk” to

each other using this protocol. For more information on Data Highway II

protocol, refer to Data Highway II Asynchronous–device Interface User’s

Manual (Publication 1779–6.5.1) or the Data Highway II

Synchronous–device Interface User’s Manual (Publication 1779–6.5.2).

1-4

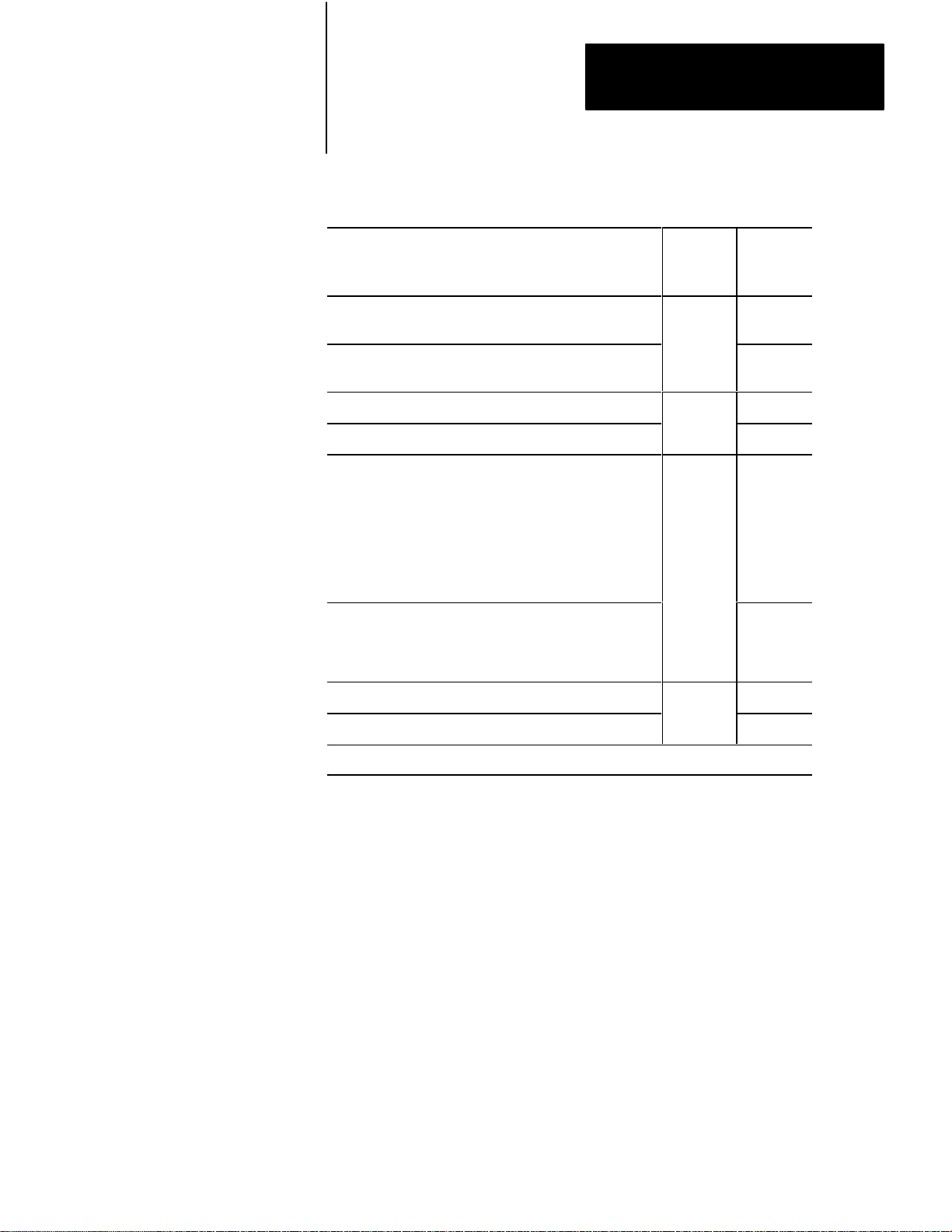

In a Data Highway II configuration, the nodes are situated along a

physical bus (figure 1.5). Communication is sent across the entire length

of the cable to the end nodes. Each node waits and ‘‘listens” for any

message addressed to it, accepts the message, and signals the original

sender that it has received the message.

Page 11

Figure 1.5

Highway II is a Physical Bus Network

Data

Chapter 1

Overview

Node

7

Node

16

10995-I

Node

1

Node

31

While the physical layout of the Data Highway II network is a bus, the

method of access to the network is a logical ring. Nodes are allowed to

communicate on the network while they posses the token. This token is

passed around the ring according to the nodes’ addresses on the Data

Highway II link. While a node possesses the token it is the master, and it

is the only node that can send commands out to the network. When it is

finished, the token passes to the node with the next highest address,

regardless of the node’s physical proximity to the previous node (figure

1.6).

Figure 1.6

Conceptual View of Data Highway II Logical Ring Communication

A

Node

1

Node

31

Node

7

Node

16

10996-I

When a node leaves the ring unexpectedly, the ring performs a recovery

procedure. The node with the next lowest node number attempts to pass

the token to the exiting node, but because it cannot, the ring must undergo

a recovery procedure to rebuild itself. When the message returns to the

inquiring node, the node can then pass the token to the node that has the

next highest number.

1-5

Page 12

Chapter 1

Overview

Data Highway II communication interfaces operate at different modes that

vary according the their relationship with the logical ring. The modes are:

In–ring mode, which is when the interface is a fully operational

member of the ring. It accepts messages, replies to them, and is ready

to send them.

Seeking–membership mode, which is when the interface is trying to

become a member of the ring so that it can send messages.

When we talk of communication on a Data Highway II network, it is

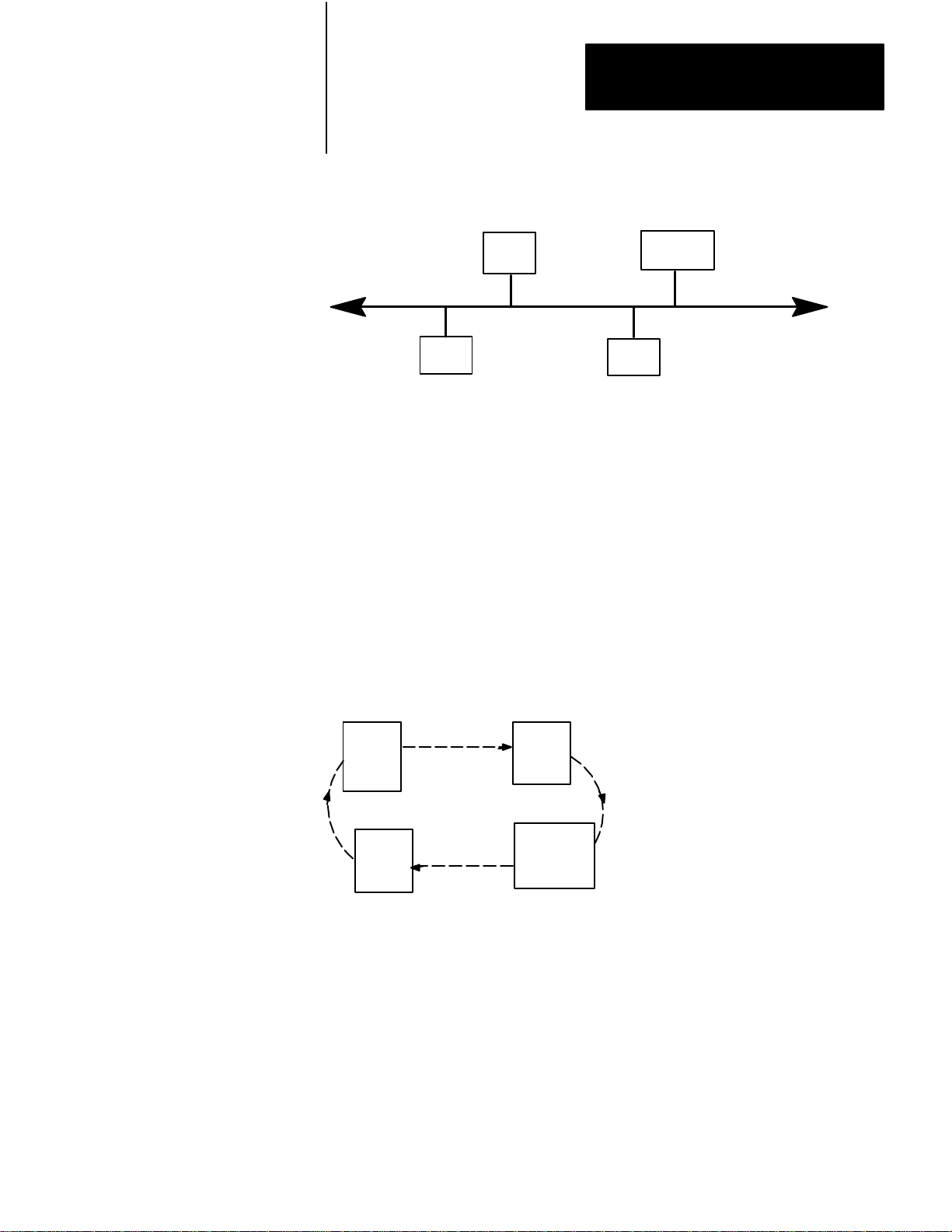

important to keep in mind the concept of a link. A Data Highway II link

is one section of trunkline, including nodes, that makes up a Data

Highway II network (figure 1.7); links are limited by length of the

trunkline. Nodes on different links are ‘‘off–link” with respect to each

other; nodes on the some link are ‘‘on–link” with respect to each other.

Figure 1.7

A

Data Highway II Link

Node

Node

Node Node

Node

10997-I

You can expand your Data Highway II network with the help of two

Allen–Bradley 1779–KP5 communication interface modules configured

as bridges. In this case, you would have two Data Highway II links

(figure 1.8).

1-6

Page 13

Figure 1.8

Data Highway II Links

Two

Chapter 1

Overview

Node

C

Node

Data Highway II Link 1

Data Highway II Link

Node

A

KP5

KP5

2

Node

B

Node

DE

Figure 1.8 shows two Data Highway II links. Notice that to ‘‘Node A”,

‘‘Node B” is on–link, and ‘‘Node D” is off–link. Data Highway II nodes

consider other nodes ‘‘off–link” if, to communicate with them, the Data

Highway II nodes have to cross a bridge.

The link numbers become an important factor when you are addressing

messages. For example, if you have two Data Highway II networks

bridged together via two Allen–Bradley KP5 modules, the two links have

different link numbers (Figure 1.9). You use this link information inside

your message instruction (see Chapter 3 on Programming for more

information).

10998-I

Figure 1.9

Example

Data Highway II Link 1

Data Highway II Link 2

of T

Nodes on the same link (on–link), have the same link number; nodes on

different link (off–link), have different link numbers. Note that your local

link may always be specified as link zero; by default, the link you are

connected to is considered zero with respect to other local nodes you may

be communicating with.

wo Data Highway II Links

PLC-2

Link = 1

KP5

KP5

PLC-3

Link = 2

10999-I

1-7

Page 14

Chapter 1

Overview

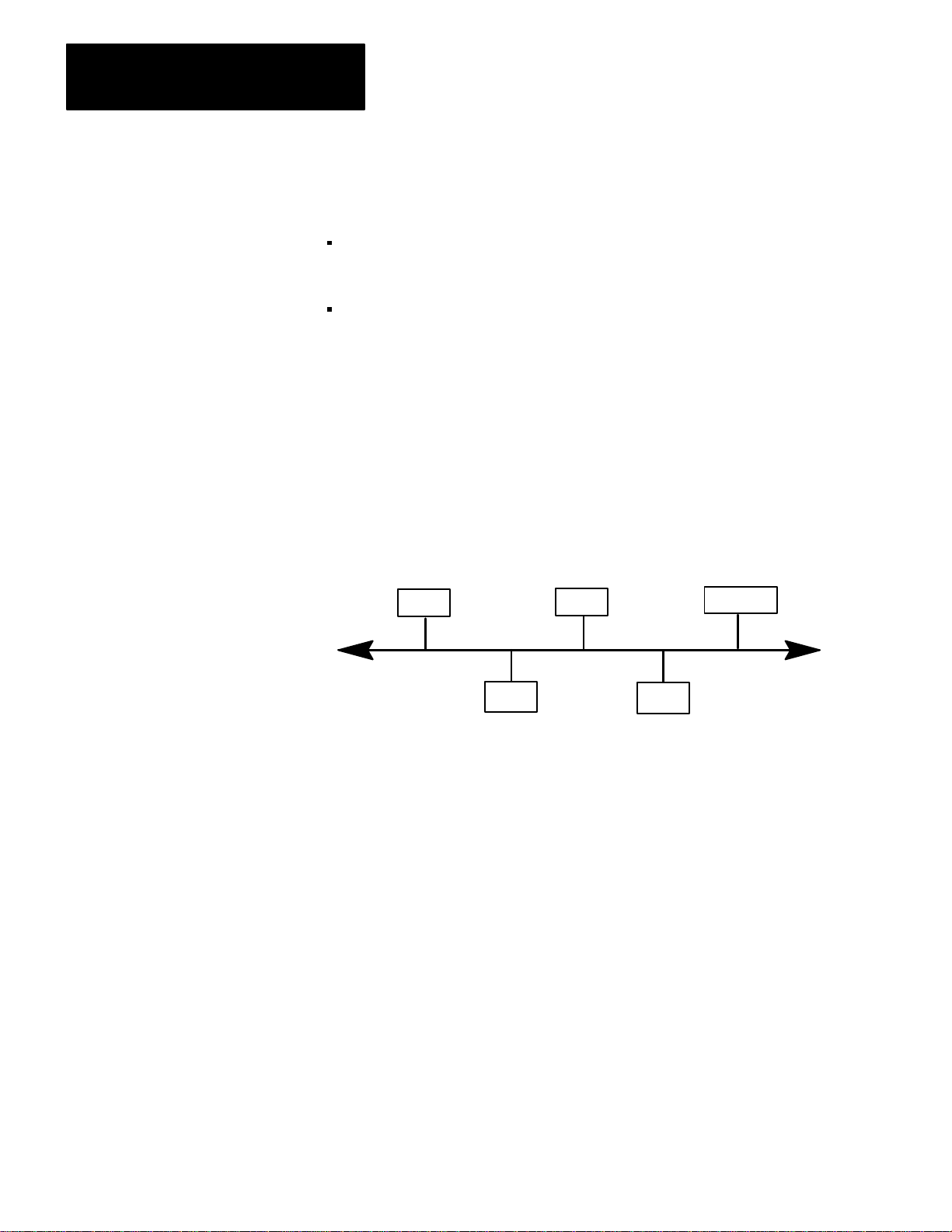

You can also connect a Data Highway Plus subnetwork to your Data

Highway II network via one Allen–Bradley KP5 module. When you have

a Data Highway Plus sub–network attached to your Data Highway II

network, the nodes on Data Highway Plus are considered on–link to the

nodes on Data Highway II.

If you are sending a message instruction from a PLC–3 controller on Data

Highway II to a PLC–5

controller on Data Highway Plus, you would use

the same link number for both (figure 1.10).

Figure 1.10

Example

of Using Link Numbers When Addressing

PLC-3

Link = 0

KP5

Data Highway Plus Sub-link

Data Highway Link 0

PLC-5

Link = 0

11000-I

Note that in the this example, the PLC–5 controller considers the KP3

module a remote station and may refer to the KP3 as offlink. The PLC–5

controller cannot communicate to stations on another Data Highway II

link.

1-8

Note also that when we speak of KP3 communication on the Data

Highway II network, there are different types: communication initiated by

the KP3 and communication initiated via a computer. Refer to the

following table.

The KP3 has the ability to initiate simple

data transfers to:

another KP3 uploading and downloading of

a KP2 diagnostics

a PLC–5 controller (via a KP5)

You can initiate via a computer

(through a KFM or KFL module):

processor memory

station management

Page 15

Chapter 1

Overview

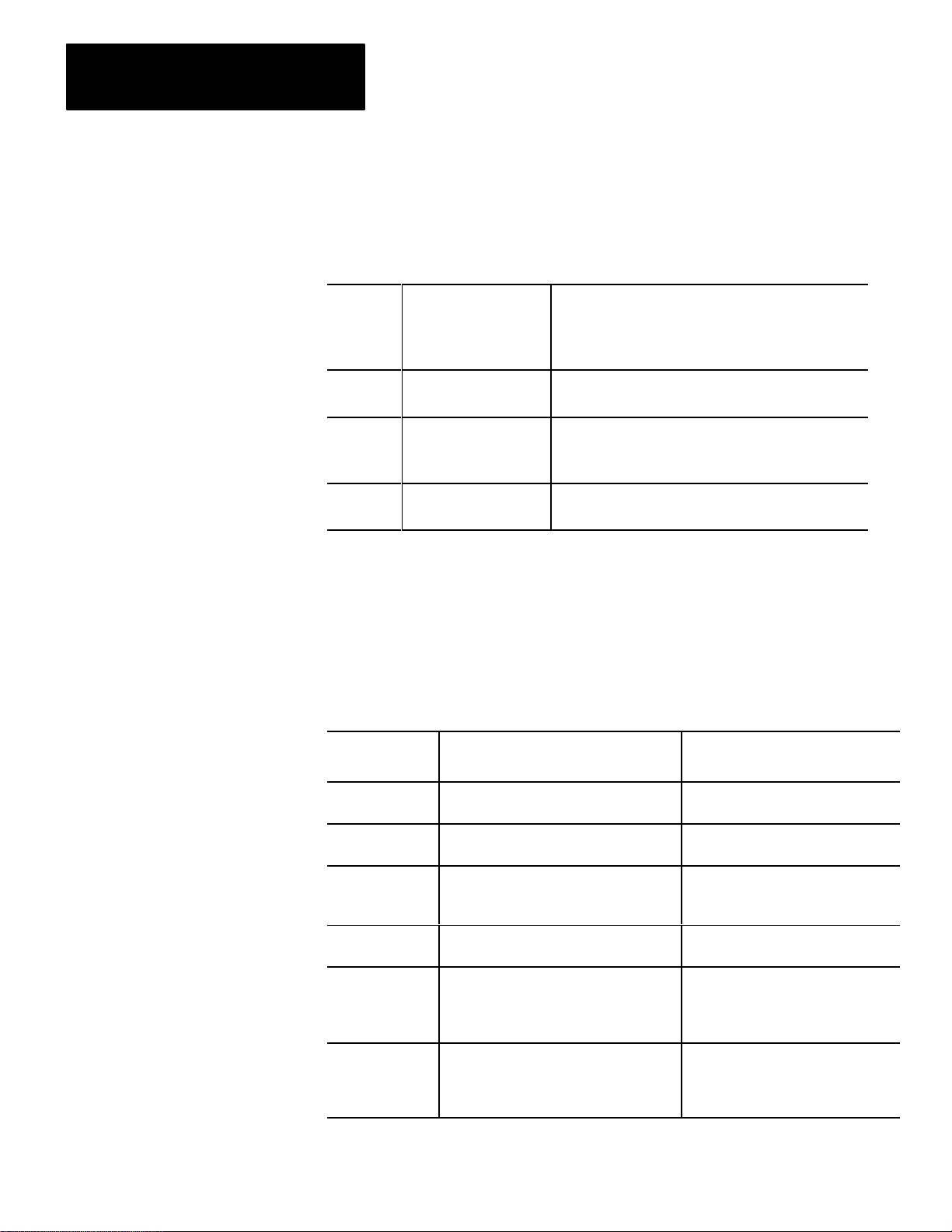

Allen-Bradley Communication Interface Modules

The following tables show the types of on–link and off–link connections

that are possible and the type of Allen–Bradley Communication Interface

Modules you need.

To connect this to a Data Highway

II Link:

an Allen–Bradley PLC–3 Controller 1779–KP3, –KP3R

an Allen–Bradley PLC–2 Controller 1779–KP2, –KP2R

a synchronous interface device

(RS–449 compatible)

an asynchronous interface device

(RS–232, –422 compatible)

another Data Highway II link two 1779–KP5 modules

a Data Highway Plus sub–network

link

1

The 1779–KP2 module does not allow communication to or from

other Data Highway II links.

To connect this to a Data Highway

Plus Sub–network Link:

You must use this

Allen–Bradley communication

interface:

1

1779–KFM, –KFMR

1779–KFL, –KFLR

configured as bridges

one 1779–KP5 Module (see

table below)

You must use this

Allen–Bradley communication

interface:

an Allen–Bradley PLC–3 Controller 1775–S5, –SR5

an Allen–Bradley PLC–2 Controller 1785–KA3

an Allen–Bradley PLC–5 Controller (built–in interface)

personal computer 1784–KT and 6001–F1E

Standard Driver Software or

1785–KE for RS–232

communication

1-9

Page 16

Chapter 1

Overview

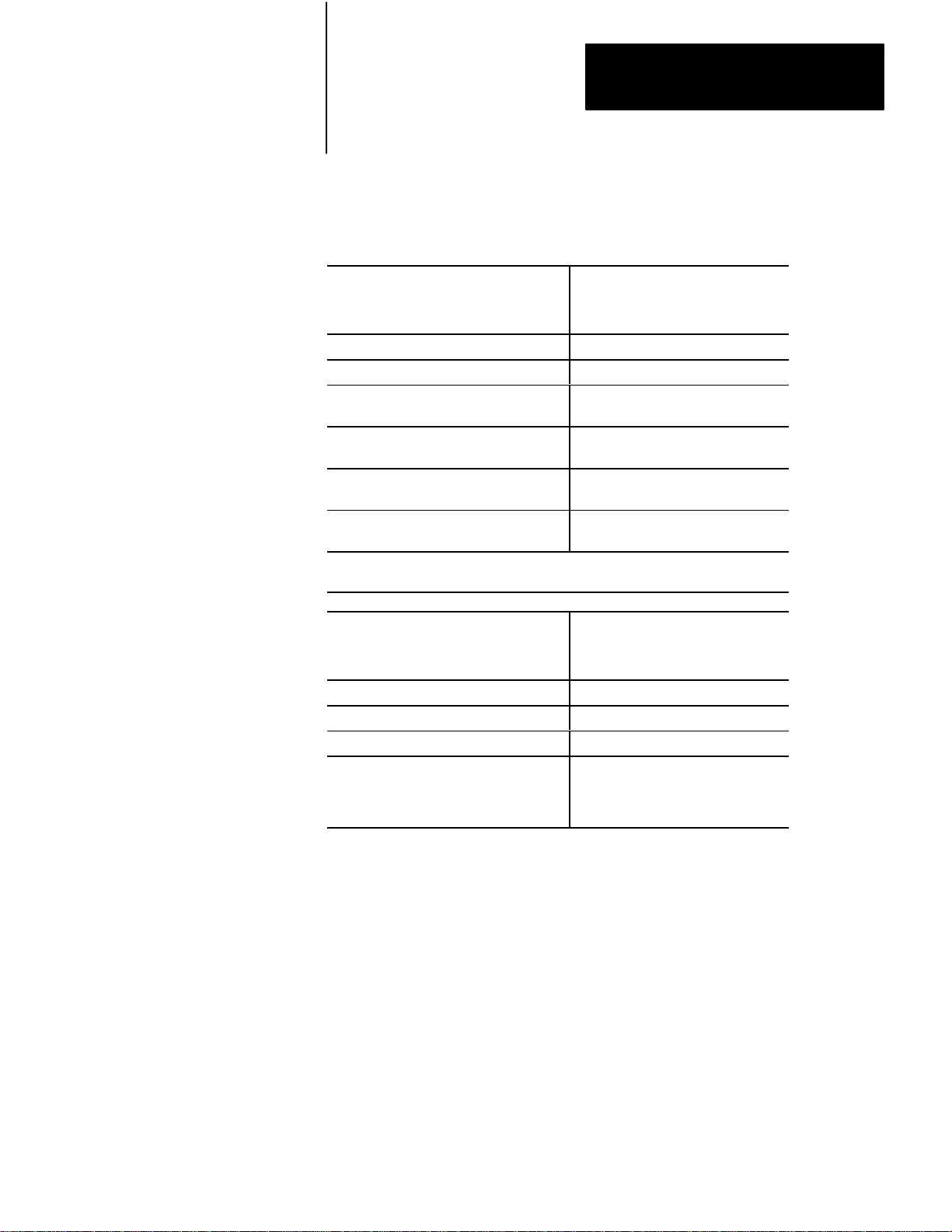

operation LEDs

operation LEDs

PASS–

FAIL–

TEST–

KP3

BACKUP

A

BACKUP

B

1

G. IN–RING

Y. SEEKING

DUP ADDR

Thumbwheel switch that distin

guishes this KP3 from others in

the same chassis.

Two ports for providing optional

PLC-3 backups.

Auxiliary

Data Highway II port

(not used)

operation LEDs

Dropline

connection to the

network.

BACKUP MODE

A

C

T

NORMAL

I

V

I

T

Y

DATA

HWY II

PORT

ERROR

SAT

EXIT

COMP

DHII

AUX

ACCESS

EXIT REQUEST

PORT READY

SIG QUAL

TAP FAIL

EXT TAP CONFIG

L

M

I

S

N

D

K

A

D

D

R

E

S

S

operation LEDs

LED that indicates you have

stopped communication to the net

work.

Optional button you can use to stop

communication to the network.

1

1

Thumbwheel switches that

indicate this node's ad

dress

1-10

Page 17

Chapter

2

Installing the 1779-KP3 Communication Interface

Chapter Objectives

Printed Circuit Boards

This chapter contains the information you need to install your 1779–KP3

Communication Interface module. It covers the following topics:

printed circuit boards

setting the switches on the host board

setting thumbwheel switches

installing the KP3 into the PLC–3 chassis

using the LIST option to select additional KP3 parameters

connecting the KP3 to Data Highway II

connecting a PLC–3 to multiple Data Highway II links

how a PLC–3 backup system works on Data Highway II

installing a backup PLC–3 on Data Highway II

The 1779–KP3 interface is a single module that consists of two printed

circuit boards:

the host board

the media access controller (MAC) board

There are switches associated with each of these boards. Read the

following section before installing your module.

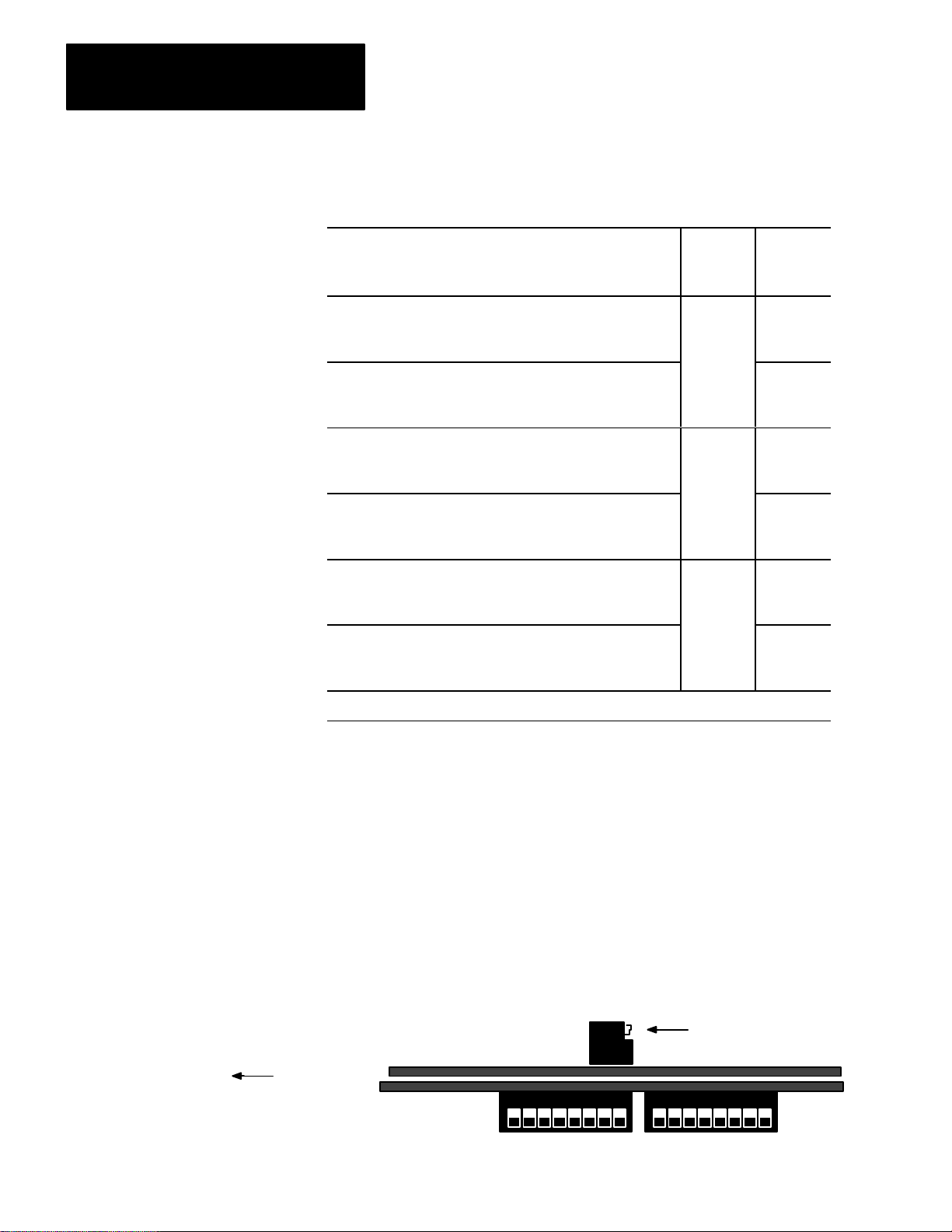

Set the Switches on the Host Board

Host Board

Mac Board

Before you install your KP3 interface, you must set the switches located

inside the module on the host board. There are two groups of switches:

Group 1 and 2. You can view them from the top of the module, looking

inside at the board (figure 2.1).

Figure 2.1

V

iew of Switches on the KP3 Module'

Top

Group 1 Group 2

1 2 3 4 5 6 7 8

s Host Board

1 2 3 4 5 6 7 8

Front of Module

11001-I

21

Page 18

Chapter 2

Installing the 1779-KP3

Communication Interface

You set these switches to select module options and protection/privilege

options. Keep in mind that when the switch is down, it is on (closed);

when it is up, it is off (open). Figure 2.2 shows an example setting; the

white areas correspond to the movable part within each switch.

Figure 2.2

Clarifying

the Switch Positions

Up = OFF

Down = ON

1 2 3 4 5 6 7 8

Switch 3 is OFF, the rest are ON.

11002-I

Setting Switches in Group 1

In Group 1, switches 1 and 2 determine the actions of the KP3 and PLC–3

controller if either should fault for some reason. Switches 3 and 4 are

used if you are using your KP3 in a backup system (see Installing Backup

PLC–3s on Data Highway II later in this chapter for more information).

Switches 5 through 8 are reserved for future Allen–Bradley applications

and you should not set them. Table 2.A lists the Group 1 switches and the

setting indications.

22

Page 19

Table 2.A

Group1

Chapter 2

Installing the 1779-KP3

Communication Interface

Switch Settings

If: Set

switch

number:

you want the KP3 to fault and disable its Data HIghway II

port if the PLC-3 faults

you want the KP3 Data Highway II port to remain

enabled if the PLC-3 faults

you want the PLC-3 to fault if the KP3 faults

you want the PLC-3 to remain enabled if the KP3 faults

the KP3 is part of a backup system

Important:

your primary and backup KP3s to the same link address.

When the backup is in ef

link address of the backup KP3 as one number greater

than the node thumbwheel. If switch 3 is OFF

switch 1

the PLC-3, not the KP3, is in a backup system

Important:

is in a backup PLC-3. It will not react to a switch over

If you select OFF

must

be OFF also.

The KP3 will keep the node address when it

, set the thumbwheels of

fect, Data Highway II sees the

, then

.

To:

1 OFF

ON

2 OFF

ON

3 OFF

ON

you want the backup connector on the KP3 enabled

you want the backup connector on the KP3 disabled

Important:

Do not touch switches 5,6,7, and 8; they are reserved for future use.

4 OFF

ON

Setting Switches in Group 2

The Group 2 switches deal with programming options. Table 2.B lists the

Group 2 switches and the setting indications. Switches 1, 2, 3, 7 and 8

are reserved for future Allen–Bradley applications and you should not set

them.

23

Page 20

Chapter 2

Installing the 1779-KP3

Communication Interface

Table 2.B

2 Switch Settings

Group

If: Set

switch

number:

you want the KP3 to accept write commands to the program

areas of the PLC-3 memory

keyswitch position

you want the PLC-3 keyswitch position checked to

determine if write commands are allowed to the program

areas of PLC-3 memory

you want the KP3 to accept write commands to the data

table areas of the PLC-3 memory

keyswitch position

the PLC-3 keyswitch position checked to determine if write

commands are allowed to the data table areas of PLC-3

memory

you want the KP3 to accept write commands to the status

areas of memory

position

you want the PLC-3 keyswitch position checked to

determine if write commands are allowed to the status areas

of PLC-3 memory

, regardless of the PLC-3 keyswitch

, regardless of the PLC-3

, regardless of the PLC-3

To:

4 ON

OFF

5 ON

OFF

6 ON

OFF

24

Important:

Do not touch switches 1, 2, and 3; they are reserved for future use.

The MAC Board Switch Your Module May Have

If your 1779–KP3 Interface has a series A MAC board, you will also have

a 2–switch group on the MAC board. You can view it from the top of the

module looking down at the MAC board. Figure 2.3 shows the location

of this switch in relation to the host board switches; this is a side view of

this group. Note that this switch does not exist on redundant modules

(1779–KP3R) or 1779–KP3 modules with series B MAC boards.

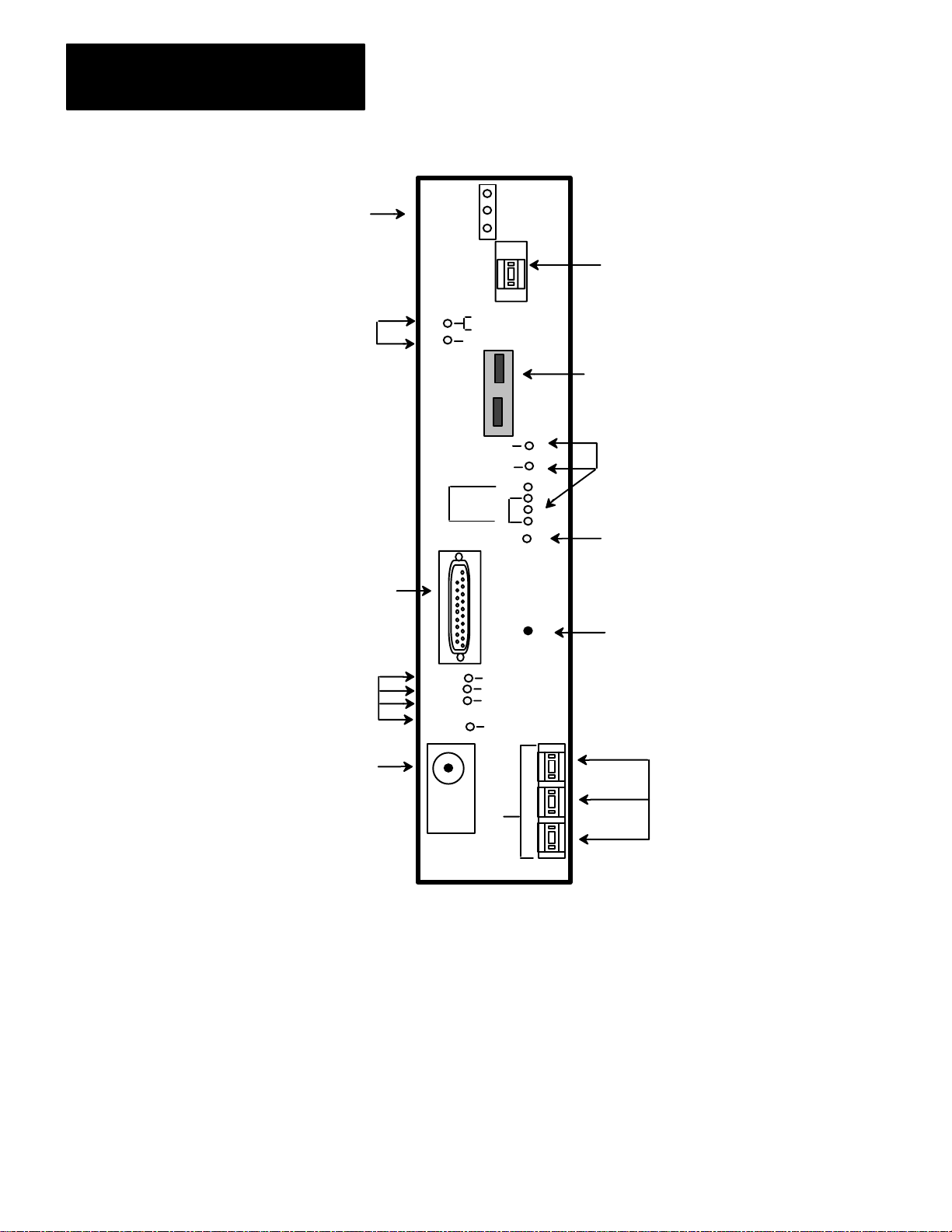

Figure 2.3

The

MAC Board Switch Group

Side view of 2-switch Group

Mac Board

Front of Module

Host Board

1 2 3 4 5 6 7 8

1 2 3 4 5 6 7 8

11003-I

Page 21

Chapter 2

Installing the 1779-KP3

Communication Interface

Verify that both of the switches in this group are set to OFF (open).

Figure 2.4 shows the position they should remain in.

Figure 2.4

Position of the MAC Switches (Front V

Correct

OFF = up

iew)

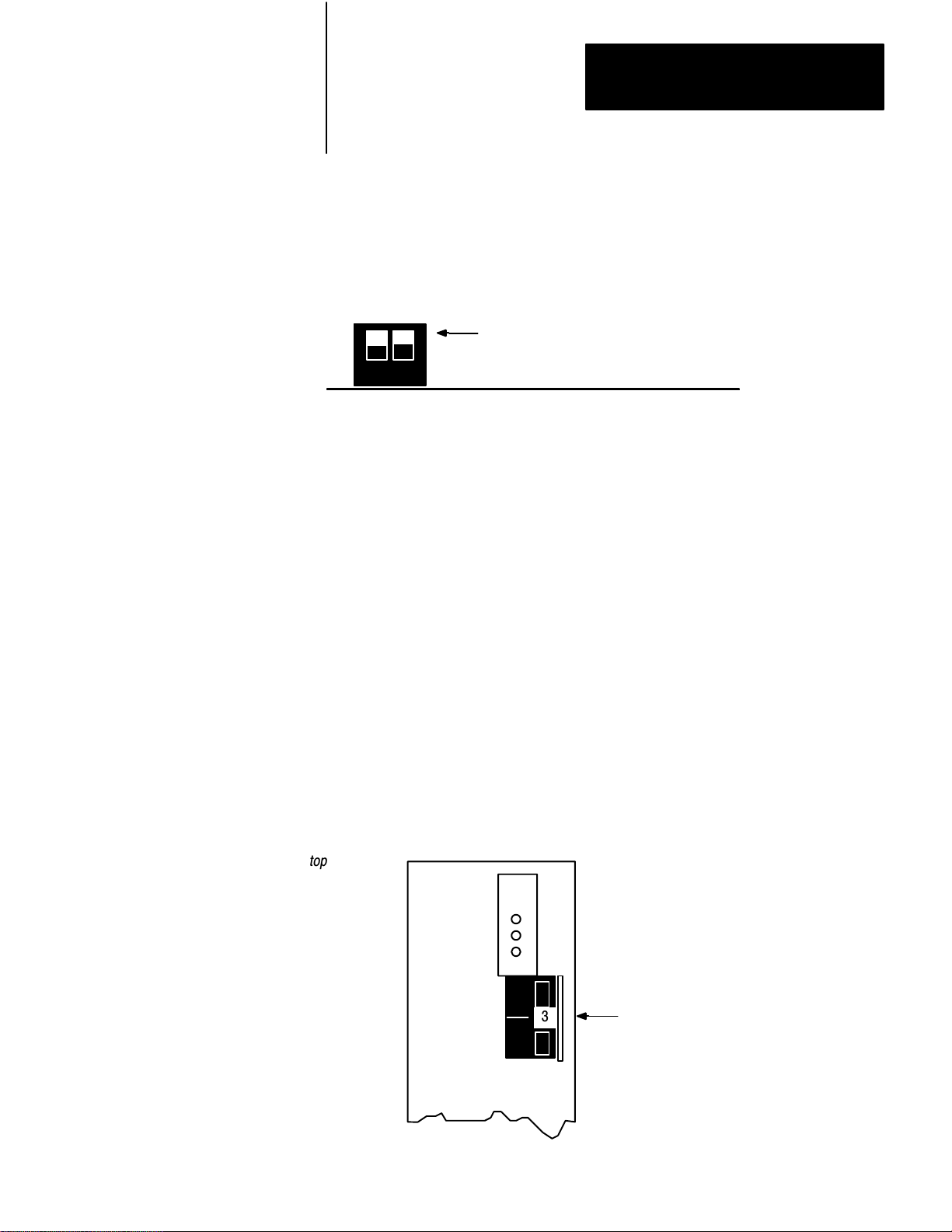

Set the Thumbwheel Switches

1 2

Mac Board

11004-I

Important: Do not to change these switch settings if you have them. In

the later (series B) versions of the KP3 MAC board, changes were made

to the hardware, making the need for this MAC switch unnecessary.

There are four thumbwheel switches on the KP3’s front panel. Use the

one at the top of the module (figure 2.5) to set the KP3’s module number.

This number distinguishes it from other KP3 modules in the chassis. You

should start with the number 1 and as you add KP3 modules to the

chassis, go to the next highest consecutive number.

Important: If you are using the KP3 in a backup system make sure the

module numbers in the primary and backup KP3s are the same.

Figure 2.5

The

Thumbwheel Switch to Set the KP3 Module Number

top of module

PASS

FAIL

TEST

KP3

_

_

_

3

Thumbwheel Switch

25

Page 22

Chapter 2

Installing the 1779-KP3

Communication Interface

Use the three thumbwheel switches at the bottom of the front panel to set

the Data Highway II node address for the KP3. You can use from 1 to

376 octal. For example, to select node address 123, set the thumbwheels

as shown in figure 2.6.

Figure 2.6

Example

Thumbwheel Switch Setting for the Node Address

L

I

N

K

A

D

D

R

E

S

S

1

2

3

Most significant digit

Least significant digit

Install the KP3 Module

Once you have set the switches on the host board and the thumbwheels on

the front panel, you are ready to install the KP3 module into the PLC–3

chassis. The KP3 is a single–slot module that you can place next to any

other PLC–3 module in the chassis.

Important: We assume you have a Data Highway II network up and

running, and a drop line cable ready to attach to the module. If you need

cabling information, refer to the Allen–Bradley Data Highway/Data

Highway Plus/Data Highway II/DH–485 Cable Installation Manual

(publication 1770–6.2.2).

Follow the procedure below to install your KP3 module into your

Allen–Bradley PLC–3 chassis.

1. Remove power from the PLC–3 chassis.

2. Lift the interlock bar that is inside the chassis and secure it to the

brackets that are mounted at the top of the chassis (your chassis may

have a hinged interlock bar attached to the top that flips up away

from the front).

26

Page 23

Chapter 2

Installing the 1779-KP3

Communication Interface

3. Slide the module into the chassis slot, making sure it slides along the

grove at the bottom of the slot. Press firmly until you feel it snap

into the backplane.

4. Pull the interlock bar back into place.

5. Restore power to the chassis.

6. Use LIST to select additional KP3 options (see following section).

Use the LIST Option to Select Additional KP3 Parameters

After you install the KP3 into the chassis, use the LIST option to select

additional operational KP3 parameters. You access the LIST option

through an Allen–Bradley PLC–3 Industrial Terminal (1770–T4) which

has the ability to communicate directly with your Allen–Bradley PLC–3.

Refer to the PLC–3 Controller Installation and Operations manual,

publication 1775–6.7.1, for instructions on accessing the LIST function.

You can also access LIST through Allen–Bradley 6200 Programming

Software (see the PLC–3 Programming Software User Manual for

information, publication 6200–6.5.3).

The following procedure shows you how to use LIST.

1. Connect a T4 Industrial Terminal (1770–T4) to the PLC–3 controller.

2. Turn the T4 terminal ON.

3. Press the shift key and then the mode key. You receive a mode of

operation menu:

SELECT MODE OF OPERATION

1 = PLC3 TERMINAL

2 = ALPHANUMERIC TERMINAL

4. Press 1. You receive a blank screen with a $ sign prompt at the

bottom.

11005-I

27

Page 24

Chapter 2

Installing the 1779-KP3

Communication Interface

5. Enter the LIST function at the $ prompt by pressing the shift key and

then the list key. You receive the SYSTEM–MODE menu:

SYSTEM-MODE SCREEN

1. TEST MONITOR

2. RUN MONITOR

3. *PROGRAM LOAD

4. REMOTE ENABLE

5. SYSTEM STATUS

6. MODULE STATUS

ENTER NEXT>

11006-I

6. Select the MODULE STATUS option by typing 6 <enter>.

The MODULES menu appears, which lists all of the modules in the

PLC–3 system by catalog number, including the KP3.

7. Select 1779–KP3 from the MODULES menu by typing the number

next to it and pressing <enter>. You will receive a DATA HWY II

INTERFACE menu:

Data Hwy II Interface

KP3 1, Node 111

Chassis 0, Slot 6

1 Message Timeouts

2 Token Hold Factor

3 Set Node Mode

4 Input File List

Enter Next>

The menu above shows the 4 different options you have to choose from

within the first menu. When you choose any of these options, you will

receive another menu. The following sections describes each of these

options and the sub–menu options associated with them.

28

Page 25

Chapter 2

Installing the 1779-KP3

Communication Interface

The Message Time-outs Menu

When you choose option 1, you receive the Message Time-outs menu:

KP3 1, MESSAGE TIMEOUTS

1 TIME CRITICAL TIMEOUT

2 SUPERVISORY TIMEOUT

3 THIRD-PARTY TIMEOUT

ENTER NEXT >

This

option:

1

2

3

1

The

default value appears the first time you use this menu.

allows

you to:

set the time-out for

time-critical messages.

set the time-out for

supervisory messages.

Use to send information

that in not time critical,

such as reports.

(Not available with this release.)

Minimum value:

0.01 seconds 10.00 seconds .50 seconds

0.01 seconds 650.00 seconds 1.00 seconds

Maximum

Value:

Default

Value

1

:

Important: You must enter the time–out value for time–critical and

supervisory messages with a decimal point and two digits to the right of it.

The Token Hold Factor Menu

When you select option 2 from the Data Highway Interface menu, you

receive the Token Hold Factor menu:

KP3 1, TOKEN HOLD FACTOR

FACTOR = 1

ENTER FACT

OR >

This menu allows you to set and display the amount of time a node is

allowed to possess the token before passing it to the next node. The menu

allows you to change the link–layer token hold factor.

You can enter a number from 1 to 256, the default factor is 1. With a

factor of 1, the node will hold the token for the standard hold time. The

29

Page 26

Chapter 2

Installing the 1779-KP3

Communication Interface

token hold time is multiplied by the number you enter. For example, if

you enter 2, the token hold time will double. You may want to increase

the token hold time at the node if, for example, that node typically has

more messages to send than other nodes.

The Set Node Mode Menu

When you select option 3 from the Data Highway II Interface menu, you

receive the Set Node Mode menu. This menu allows you to change the

mode of the KP3:

KP3 1, SET NODE MODE

1 INRING

2 ONLINE

3 OFFLINE

The following table shows what each value means.

If

you set the mode to:

INRING

ONLINE

OFFLINE

Then:

the KP3 is fully operational.

the KP3 allows requests for immediate data and `

writes with no reply". The KP3 will not initiate any messages, nor

reply to any

the KP3 will not initiate or respond to any messages.

.

`time-critical

The Input File List Menu

When you select option 4 from the Data Highway II Interface menu, you

receive the Input File List menu:

KP3 1, INPUT FILE LIST

ENTER STATION AND INPUT FILE >

Use this to tell the KP3 which input file to read data from or write data to

when it receives a message from a device using PLC–2–style addressing

(e.g., a 1779–KP2, –KFL, or, –KFM interface module or another KP3

module).

210

Page 27

Chapter 2

Installing the 1779-KP3

Communication Interface

When the KP3 receives a message containing PLC–2–style addressing, it

searches the input file list and reads to or writes from the input file

specified for the node that sent the message. If the sending node is not in

the list, the KP3 uses the octal address of the source node as the decimal

input–file number.

You can enter any given node only once into the input file list, for

example:

KP3 1, INPUT FILE LIST

ENTER STATION AND INPUT FILE > :5 2

The example above sets up node ‘‘5” to read from or write to input file

‘‘2”.

If the station is on another Data Highway II link, specify the link number

before the : sign. If the station is not user 1 (e.g., channel 2 of a

1779–KFL module), put a period (.) and after the node number, and

followed by the user number.

To delete an input file entry, enter the node, followed by ‘‘/D”, for

example:

KP3 1, INPUT FILE LIST

ENTER STATION AND INPUT FILE > :5 /D

211

Page 28

Chapter 2

Installing the 1779-KP3

Communication Interface

Connecting the KP3 to Data Highway II

Once you have installed and configured the KP3 module, follow the

procedure below to connect it to the highway.

Important: If you are connecting a backup PLC–3 system to Data

Highway II, remember that you must run at least 30 feet of trunkline cable

between droplines to the primary and backup KP3 modules.

1. Locate the Data Highway II Port on the KP3 front panel.

EXT TAP CONFIG

L

M

Dropline

connection to the

network.

DATA

HWY II

PORT

KP3

I

S

N

D

K

A

D

D

R

E

S

Front Panel

S

1

1

Connecting a PLC-3 to Multiple Data Highway II Links

2. Connect a Data Highway II dropline to the connector by sliding the

dropline connector over the port and twisting the collar clockwise.

If you have a KP3R module, repeat steps 1 and 2 for the port labeled Data

Highway II PORT 2.

You can connect a PLC–3 to multiple Data Highway II links. The PLC–3

requires one KP3 for each Data Highway II link it communicates over.

Follow the procedure below to connect a PLC–3 to multiple Data

Highway II links.

1. Install one KP3 in the PLC–3 chassis for each link the PLC–3 will

communicate over.

2. Select a unique module number on the thumbwheel of each KP3 in

the same chassis.

3. Connect each KP3 module to separate links via separate droplines.

212

Page 29

Chapter 2

Installing the 1779-KP3

Communication Interface

You can assign the same node address to more than one KP3 in the same

PLC–3 chassis as long as the KP3s are communicating over different

links.

Important: You are not required to connect these separate links by Data

Highway II bridges.

How a PLC-3 Backup System Works on Data Highway II

When we talk about a ‘‘backup” system, we a talking about having a

primary PLC–3 on the network and a backup PLC–3. The pairs need to

be connected in such a way that one ‘‘takes over” if something should

happen to the other (switchover).

When you configure a backup system on Data Highway II, the primary

and backup KP3s must have their thumbwheels set to the same link

address. As far as the Data Highway II is concerned, however, the backup

KP3 will assume a link address that is one number higher than the

primary KP3.

For example, if you have set the link address on both KP3s to 176 octal,

Data Highway II will list the backup KP3 as having a link address of 177

octal. This enables you to send messages to the backup KP3 from other

nodes on the link. When a switchover occurs, the backup KP3 will

become node 176 as far as the link is concerned. Node 177, the link

address of the backup KP3, will then disappear from the link.

What You Should to Monitor Possible Switchover

At the time a switchover happens and the backup KP3 becomes the

primary KP3, the new primary KP3 has no way of knowing which

messages were initiated by the former primary KP3. For this reason, you

should monitor the run/backup bit (data table status section, file 0, word

3, bit 7) in your PLC–3 ladder diagram program. In the event of a

switchover, set the done bit of each message instruction. This allows any

message being initiated during a switchover to be sent again.

Important: Alert the proper personnel when a switchover occurs. One

way you can provide this indication is by having your program monitor

the run/backup bit, and turn on alarms or lights when the status changes

from backup to run. This bit is set in the primary processor and reset in

the backup processor.

213

Page 30

Chapter 2

Installing the 1779-KP3

Communication Interface

Installing a Back-up PLC-3 System on Data Highway II

You can set up a PLC–3 backup system in three ways, using an:

I/O Scanner–programmer Interface Module (1775–S4A), a PLC–3 I/O

Scanner Communication Adapter Module (1775–S5) or a Memory

Communication Module (1775–MX) without the KP3

S4A, S5, or MX with the KP3

S4A or S5 with an MX, and the KP3

The following sections discuss each of these possibilities.

Using an S4A, S5 or MX Without the KP3

You can connect the primary and backup PLC–3s by connecting the

1775–S4A (1775–S5, or 1775–MX) in each PLC–3 processor (figure 2.7).

Figure 2.7

Backup

Cabling W

Primary PLC-3

ithout the KP3

S4A KP3

Backup

Backup PLC-3

S4A KP3

Backup

214

11007-I

This method is recommended when the application process requires that

the Data Highway II switchover of communication happens after the

backup PLC–3 has taken control of the live I/O. Use this method when

the KP3 is involved in primarily supervisory transactions. This method is

fully explained in the PLC–3 Backup Concepts Manual (publication

1775–6.3.1).

You can also directly connect the S5 or MX modules in the primary and

backup PLC–3s.

Using the S4A, S5, or MX With the KP3

You can connect the S4A (S5 or MX) module to the KP3 module in both

the primary and backup PLC–3s. Then connect the KP3 in the primary

PLC–3 to the KP3 in the backup PLC–3 (figure 2.8).

Page 31

Figure 2.8

Cabling W

Backup

Chapter 2

Installing the 1779-KP3

Communication Interface

ith the KP3

Primary PLC-3

S4A KP3

Backup Backup

Backup

Important: Because of the various options for this cable, refer to

the backup cable configuration information in the PLC–3 Backup

Concepts Manual (publication 1775–6.3.1).

1775-CBB

Cable

A

B

1775-CBB or

1779-CBC Cable

KP3

A

Backup

B

Backup PLC-3

S4A

11008-I

This method provides faster switchover of communications between

primary and backup PLC–3s. Use this method when:

the application process requires that switchover occur as fast as

possible and that the backup KP3 switches to primary operation without

waiting for the backup PLC–3 to take control of the I/O.

the KP3 module is involved in many time–critical transactions.

you plan to send time–critical messages to the PLC–3 processor.

Because of the various options for this cable, refer to the backup cable

configuration information in the PLC–3 Backup Concepts Manual

(publication 1775–6.3.1).

Important: The 1775–CBB cable assembly has one end that you can

configure. When making cables, note the location of the locking

connector tab on the module to be certain of the correct connector

position. The S4A and MX modules both have the locking tab on the

opposite side in comparison to the KP3. The connection between the S4A

and the KP3 module is a straight through cable in relation to pin 1 of the

connectors (figure 2.9).

The 1779–CBC cable is shipped assembled at both ends.

215

Page 32

Chapter 2

Installing the 1779-KP3

Communication Interface

Figure 2.9

Cabling Using the SA4 and KP3 Modules in Detail

Backup

1775-CBB

1779-CBC Cable

or

S4A

Backup

KP3

Backup A

Backup B

Backup A

Backup B

1775-CBB Cable

Using an S4A or S5, an MX, and a KP3

KP3 S4A

Pin 1

1775-CBB or

1779-CBC Cable

11009-I

You can provide backup PLC–3s by connecting the S4A (or S5) module

to the KP3 module in both the primary and backup PLC–3s. Then

connect each KP3 to the MX modules. Then connect the primary MX

module to the MX in the backup (figure 2.10). This method provides

faster switchover of communications between the primary and backup

PLC–3 processors.

216

Page 33

Chapter 2

Installing the 1779-KP3

Communication Interface

Figure 2.10

an S4A, MX, and a KP3 for Running Backup Cabling

Using

1775-CM Cable (2 feet)

1775-CBB or

1779-CBC Cable

S4A

Backup

1775-CM Cable (2 feet)

Backup A

Backup B

Pin 1

KP3

Pin 1

MX MX

Pin 1

XMT

REC

1775-CM Cable Assembly

Pin 1

XMT

REC

KP3 S4A

Backup A

Pin 1

Backup B

Pin 1

1775-CBB or

1779-CBC Cable

Backup

Pin

1

11010-I

Important: The 1775–CBB cable assembly has one end that you can

configure. When making cables, note the location of the locking

connector tab on the module to be certain of the correct connector

position. The S4A and MX modules both have the locking tab on the

opposite side in comparison to the KP3. The connection between the S4A

and the KP3 module is a straight through cable in relation to pin 1 of the

connectors.

The 1779–CBC cable is shipped assembled at both ends.

The 1775–CM cable assembly includes four cables: two for

transmit/receive connections for the MX modules, and two interconnect

cables that you can use to connect the KP3 modules to the MX modules.

217

Page 34

Chapter 2

Installing the 1779-KP3

Communication Interface

Backup Cable Wiring for Linking a KP3 to an S4A, S5, or MX

The following diagram shows the recommended wiring for a backup cable

linking a KP3 module to an S4A or MX module.

Figure 2.11

Recommended

W

iring for Backup Cable Linking a KP3 to an S4A, S5, or MX Module

Creating a Backup System for

a PLC-3 Communicating on

Multiple Links

S4A

Pin 1

1

2

3

4

1

2

3

4

11011-I

If the PLC–3 processor is communicating on more than one link, connect

the KP3s in each chassis by routing a 1775–CBB cable from backup port

A on the first KP3 to backup port B on the next KP3 (figure 2.12).

Figure 2.12

Backup

Cable W

KP3

Backup A

ith More Than One Data Highway II Link

KP3 KP3

Backup A

1775-CBB or

1779-CBC Cable

Backup

KP3 S4A

A

Backup A

Pin

1

1775-CBB

1779-CBC Cable

or

218

Pin 1

Backup B

Pin 1

Pin 1

Backup B

Pin 1

Pin 1

Backup

Pin 1

B

Important: Because of the various options for this cable, refer to the

backup cable configuration information in the PLC–3 Backup

Concepts Manual (publication 1775–6.3.1).

Pin 1

Backup B

Pin 1

1775-CBB or

1779-CBC Cable

11012-I

Page 35

Chapter 2

Installing the 1779-KP3

Communication Interface

Important: The 1775–CBB cable assembly has one end that you can

configure. When making cables, note the location of the locking

connector tab on the module to be certain of the correct connector

position. The S4A and MX modules both have the locking tab on the

opposite side in comparison to the KP3. The connection between the S4A

and the KP3 module is a straight through cable in relation to pin 1 of the

connectors.

The 1779–CBC cable is shipped assembled at both ends.

219

Page 36

Programming

Chapter

3

Chapter Objectives

Transferring Data

This chapter contains information on programming your PLC–3 to

communicate on the Data Highway II network. We will discuss the

information you place in a PLC–3 message send instruction. The PLC–3

Message Send instruction itself is covered in greater detail in the PLC–3

Programmable Controller Programming Manual (publication 1775–6.4.1).

This chapter covers the following topics:

transferring data

the TO and FROM qualifiers

the format for addressing Data Highway II nodes

the format for addressing the memory in Allen–Bradley PLC

Programmable Controllers

The terms onlink and offlink are used extensively throughout this chapter

and we assume that you are familiar with them. For an overview of these

concepts, refer to Chapter 1.

This section covers the commands and qualifiers you can use to transfer

data using the KP3 module.

The commands you can use are listed in the table below:

Command:Use

MOVE

TMOVE

A qualifier is a word used to specify the details of the data transfer. The

qualifiers you can use with the commands above are listed in the

following table.

to:

tell the KP3 to move a bit, a word, or a contiguous block of words. This is usually

used to move data to or from a remote node on Data Highway II, but you can

also use it to move data to and from a node on Data Highway Plus or within the

PLC-3.

tell the KP3 to move a bit, a word, or a contiguous block of words. This can be

used to transfer data to and from an onlink Data Highway II node. It is usually

used to transfer small amounts of time-critical data in a small amount of time.

31

Page 37

Chapter 3

Programming

Qualifier: Use:

TO to

FROM

NOSTATUS only

specify the destination of the data transfer

either command and it must be followed an address (which must include a

data table address and can include a remote node address). You can

abbreviate as T

to specify where you want to transfer data from. You can use FROM with either com

mand, but if omitted, you must replace it with an integer constant. FROM is always

followed by an address (which must include a data table address and can include a

remote node address). You can abbreviate as F.

with a TMOVE command designed to transfer data to some remote

node. Use when error reporting is not necessary and you want to eliminate

the time spent receiving information about the success or failure of the

command (see the TMOVE Command section for usage). You can

abbreviate as N.

.

. Y

ou must use T

O when using

You can specify an integer constant in a MOVE or TMOVE command in

place of the FROM qualifier and its associated address. The correct

format for an integer constant is:

#digit

Where digit is either the integer 0 or 1. You can use integer constants only

when moving bits.

I0:10

You enter the commands and qualifiers in a command line to create a

PLC–3 message instruction. The following is an example of a typical

command line containing a command and qualifiers:

MOVE FROM 1:50$B222:2 TO $B111:1, 1000

Figure 3.1 shows an example message instruction display of the data from

the command above.

Figure 3.1

Example

02

of a Message Instruction Display

MSG

MESSAGE TYPE 1

CTL=FB010:0000= XXX

CH:E2.9.1

MOVE FROM 1:50$B222:2

TO $B111:1,1000

STAT

( EN )

12

STAT

( DN )

15

STAT

( ER )

13

11013-I

32

Page 38

Chapter 3

Programming

Refer to the PLC–3 Programming manual (publication 1775–6.4.1) for

more information on the PLC–3 Message Send Instruction. The

following sections cover each command in more detail and give examples

for usage. In the syntax examples that follow, we use angle brackets < >

to indicate information that you will enter that is specific to your

application. For example <address> in a command line indicates where

you would add an address specific to your application.

Using the MOVE Command to Transfer Data

Use the MOVE command to instruct the KP3 to transfer a:

bit

word

contiguous block of information

Usually this data is transferred to or from a remote node on Data Highway

II. You can, however, use the MOVE command to transfer data within the

local PLC–3 simply by omitting the ‘‘remote” node address (the node you

are transferring the data to).

You must specify the TO qualifier when using the MOVE command; you

can specify the FROM qualifier (optional). If you do not use FROM, you

must replace it with an integer constant (see preceding section for

description).

Syntax for the MOVE Command With the FROM Qualifier

The syntax for this command when using the FROM qualifier is:

MOVE FROM <address> TO <address> or

MOVE TO <address> FROM <address>

Where: is:

MOVE the

FROM

<address>

the qualifier that specifies where you want to transfer data from; you

can abbreviate as F

must include a data table address and can include a remote node

address). The FROM qualifier is optional, but if you omit it, you must

replace if with an

the address where the data that you are moving resides. This is either

a Data Highway II node address or programmable controller memory

address (see section titled

information).

command that tells the KP3 to transfer data.

. FROM is always followed by an address (which

integer constant (

see page 3-2).

Addressing T

echniques

for addressing style

33

Page 39

Chapter 3

Programming

Where: is:

TO the

<address>

qualifier that specifies the destination of the data transfer; you can

abbreviate as T

followed by an address (which must include a data table address and

can include a remote node address).

the destination address for the data you are moving. This is either a

Data Highway II node address or programmable controller memory

address (see section titled

information).

. Y

ou must specify the T

Addressing T

O qualifier and it must be

echniques

for addressing style

These are examples of using the MOVE command with the FROM

qualifier:

MOVE FROM $B2:3/4 TO :76$B40:50/2

M F :66$010/1 T $B2:3/4

Syntax for the MOVE Command With an Integer Constant

The syntax for this command when using an integer constant is:

MOVE <integer constant> TO <address> or

MOVE TO <address> <integer constant>

Where: is:

MOVE the

<integer constant>

TO

<address>

command that tells the KP3 to transfer data.

what you use in place of the FROM qualifier

#digit, where digit is either 0 or 1.

the qualifier that specifies the destination of the data transfer; you

can abbreviate as T

be followed by an address (which must include a data table

address and can include a remote node address.

the address where the data resides that you are moving. This is

either a Data Highway II node address or programmable controller

memory address (see section titled

addressing style information).

. Y

ou must specify the T

. The correct format is

O qualifier and it must

Addressing T

echniques

for

These are examples of using the MOVE command with an integer

constant:

MOVE #1 TO :76$222/3

M #0 T :76$B2:3/4

See the section titled Programming Examples, at the end of this chapter,

for more command examples.

34

Page 40

Chapter 3

Programming

Using the TMOVE Command to Transfer Data

Like the MOVE command, you use the TMOVE command to tell the KP3

to transfer a:

bit

word

contiguous block of information

Unlike the MOVE command, the TMOVE command can only be used to

transfer data to and from a remote node. This data bypasses some

message processing for faster communication between nodes, therefore

you should use TMOVE for transferring small amounts of time–critical

data. The maximum amount of data that you can transfer with TMOVE

depends on the memory address involved (see section titled Addressing

Techniques for information on addressing a block of words.)

The following sections show examples and syntax of the TMOVE

command line that include:

the FROM qualifier

an integer constant

the FROM and NOSTATUS qualifiers

NOSTATUS qualifier and an integer constant

Remember, the TO qualifier is always specified.

Syntax for the TMOVE Command With the FROM Qualifier

The syntax for the TMOVE command when using the FROM qualifier is:

TMOVE FROM <address> TO <address> or

TMOVE TO <address> FROM <address>

Where: is:

TMOVE the

FROM

<address>

command that tells the KP3 to transfer data to or from a remote

node.

the qualifier that specifies where you want to transfer data from;

you can abbreviate as F

(which must include a data table address and can include a remote

node address).

the address where the data that you are moving resides. This is

either a Data Highway II node address or programmable controller

memory address (see section titled

addressing style information).

. FROM is always followed by an address

Addressing T

echniques

for

35

Page 41

Chapter 3

Programming

Where: is:

TO the

<address>

qualifier that specifies the destination of the data transfer; you

can abbreviate as T

be followed an address (which must include a data table address

and can include a remote node address).

the destination address for the data you are moving. This is either

a Data Highway II node address or programmable controller

memory address (see section titled

addressing style information).

. Y

ou must specify the T

Addressing T

O qualifier and it must

echniques

for

These are examples of using the TMOVE command with the FROM

qualifier:

TMOVE FROM :66$010 TO $B2:3

TM F $B2:3 T :66$010

Syntax for the TMOVE Command With an Integer Constant

The syntax for the TMOVE command when using an integer constant is:

TMOVE <integer constant> TO <address> or

TMOVE TO <address> <integer constant>

Where: is:

TMOVE the

<integer constant>

TO

<address>

command that tells the KP3 to transfer data to or from a remote

node.

what you use in place of the FROM qualifier

#digit, where digit is either 0 or 1.

the qualifier that specifies the destination of the data transfer; you

can abbreviate as T

be followed an address (which must include a data table address

and can include a remote node address).

the destination address for the data you are moving. This is either

a Data Highway II node address or programmable controller

memory address (see section titled

addressing style information).

. Y

ou must specify the T

. The correct format is

O qualifier and it must

Addressing T

echniques

for

These are examples of using the TMOVE command with an integer

constant:

TMOVE #1 TO :76$222/3

TM #0 T :76$B2:3/4

36

Page 42

Chapter 3

Programming

See the section titled Programming Examples, at the end of this chapter,

for more command examples.

Syntax for the TMOVE Command With the FROM and NOSTATUS Qualifiers

The syntax for the TMOVE command when using the FROM and

NOSTATUS qualifiers is:

TMOVE FROM <address> TO <address> NOSTATUS or

TMOVE TO <address> FROM <address> NOSTATUS

Where: is:

TMOVE the

node.

FROM

<address>

TO

<address>

NOSTATUS

the qualifier that specifies where you want to transfer data from;

you can abbreviate as F

(which must include a data table address and can include a remote

node address).

the address where the data that you are moving resides. This is

either a Data Highway II node address or programmable controller

memory address (see section titled

addressing style information).

the qualifier that specifies the destination of the data transfer; you

can abbreviate as T

be followed an address (which must include a data table address

and can include a remote node address).

the destination address for the data you are moving. This is either

a Data Highway II node address or programmable controller

memory address (see section titled

addressing style information).

the qualifier used only with a TMOVE command designed to

transfer data to some remote node. Use when error reporting is not

necessary and you want to eliminate the time spent receiving

information about the success or failure of the command. You can

abbreviate as N.

command that tells the KP3 to transfer data to or from a remote

. FROM is always followed by an address

Addressing T

. Y

ou must specify the T

Addressing T

echniques

O qualifier and it must

echniques

for

for

These are examples of using the TMOVE command with the FROM and

NOSTATUS qualifiers:

TMOVE FROM :66$010 TO $B2:3 NOSTATUS

TM T $B2:3 F :66$010 N

37

Page 43

Chapter 3

Programming

Syntax for the TMOVE Command With an Integer Constant and the

NOSTATUS Qualifier

The syntax for the TMOVE command when using an integer constant

and the NOSTATUS qualifier is:

TMOVE <integer constant> TO <address> NOSTATUS or

TMOVE TO <address> <integer constant> NOSTATUS

Where: is:

TMOVE the

<integer constant>

TO

<address>

NOSTATUS

command that tells the KP3 to transfer data to or from a remote

node.

what you use in place of the FROM qualifier

#digit, where digit is either 0 or 1.

the qualifier that specifies the destination of the data transfer; you

can abbreviate as T

be followed an address (which must include a data table address

and can include a remote node address).

the destination address for the data you are moving. This is either

a Data Highway II node address or programmable controller

memory address (see section titled

addressing style information).

the qualifier used only with a TMOVE command designed to

transfer data to some remote node. Use when error reporting is not

necessary and you want to eliminate the time spent receiving

information about the success or failure of the command. You can

abbreviate as N.

. Y

ou must specify the T

. The correct format is

O qualifier and it must

Addressing T

echniques

for

These are examples of using the TMOVE command with an integer

constant:

TMOVE #1 TO :76$222/3

TM #0 T :76$B2:3/4

Addressing Techniques

38

See the section titled Programming Examples, at the end of this chapter,

for more command examples.

In the previous sections, we used many examples with <address> as part

of the PLC–3 command line. This describes what type of information you

place into your command line to designate an address. There are two

types of addressing we cover:

Data Highway II node addresses

programmable controller memory addresses

Page 44

Chapter 3

Programming

You need to specify both of these to create a complete address. The

general format is:

<link> : <node> . <user> <&> <addr> <, or / > <size>

Information on specifying link, node and user numbers is covered in the

following section. Information on specifying addr (addresses) is covered

in the section titled Addressing Memory.

Addressing Data Highway II Nodes

The order of the addressing Data Highway II nodes is:

<link number> :<node number> .<user number>

This is an example of a node address:

1 :50.1

Where: is:

1 the

:

50

.

1

link number

a delimiter; must precede the node number

the node number; must be preceded by a colon delimiter

a delimiter; must precede the user number

the user number; must be preceded by a decimal point delimiter

You must assign Data Highway II nodes addresses that include each of the

following:

link number, which is the number of the link you are communicating

from. Note that you can omit this parameter, or use zero in its place, if

the remote node is on the local link.

node number, which is the address for the communication interface on

the link. Enter a number from 1 to 376 (octal). Node addresses 0 and

377 are reserved on Data Highway II and cannot be used.

user number, which identifies the particular device attached to the

communications interface. It is optional; the default is user 1. You do

not need to specify the user number when you are transferring data to

or from a KP2, KFM, or another KP3 (you do not need to specify a user

number if you are transferring an immediate read command to a KP2 or

KP3). The KFL can have more than one device connected to it. Use

device number 1 to address KFL channel 1, and 2 to address KFL

channel 2.

39

Page 45

Chapter 3

Programming

The KP5 can also have more than one user. When using the KP5 as a

Data Highway II/Data Highway Plus interface, you can use user

numbers from 2 to 20 to identify Data Highway Plus devices.

For example, the address of a PLC–5 (that has its node address

switches set to 4) connected to a KP5 (with a node #20) that is

connected to a Data Highway Link might look like: :20.04 (figure 3.2).

Figure 3.2

Addressing

Address :20.04

a Node When the Interface Has More Than One Device Attached

Data Highway II Link

Node #20

KP5

Addressing Memory

User #4 User #5

PLC-5

PLC-5

11014-I

In addition to addressing a node, you need to address the PLC controller

memory at your node or the memory of the device connected to another

node. Data is referenced by its address in memory. In a command line,

you must precede a memory address with a dollar sign ($), which acts as a

delimiter to tell the KP3 module that it has encountered a data address.

A memory address is made up of one or more of the following parts:

This: is:

wordaddr the

fileaddr

size

bit

extraddr

imblock

numerical address of a word.

the alphanumeric address of a PLC-2, PLC-3 or PLC-5 controller file.

the number of words of data you are transferring; this is always preceded

by a comma (,).

the number of a particular bit within the addressed word; this is always

preceded by a back-slash mark (/).

PLC-3 extended address format. Y

memory section, not just a data table section. Refer to the PLC-3

Programmable Controller Programming Manual (publication 1775-6.4.1)

for more information on extended addressing.

immediate block number at some remote KP3.

ou can use this to address any

310

Page 46

Chapter 3

Programming

The following list shows the possible ways you form memory addresses:

$ wordaddr

$ wordaddr/bit

$ wordaddr,size

$ fileaddr:wordaddr

$ fileaddr:wordaddr/bit

$ fileaddr:wordaddr,size

$ extaddr

& imblock

Important: The numbers you enter into the fields when addressing

memory are interrupted as decimal (base 10) unless you indicate that they

are octal (base 8). You can specify an octal number by starting it with a

zero. For example, 17 is interpreted as decimal 17, but 017 is interpreted

as octal 17 (or decimal 15). In all of the examples that follow, we will use

a leading zero to indicate octal addresses. Some addresses, however, are

always interrupted as octal.

Addressing a Word

This section provides examples of addressing a word in each PLC–2,

PLC–3, and PLC–5 memory.

To

address a

single word in:

PLC-2 memory

PLC-3 memory

PLC-5 memory

Use this format:

$wordaddr

$fileaddr:wordaddr

or

$extaddr

$extaddr

Examples:

$010 (specifies the word at address 010)

$B11

1:1 (specifies word 1 of binary file 1

$E3.1.8.11

$E0.10.2.0 (specifies word 2 or integer file 10)

1.0.1 (extended addressing)

11)

311

Page 47

Chapter 3

Programming

Addressing a Block of Words

This section provides examples of addressing a block of words in each

PLC–2, PLC–3, and PLC–5 memory.

To

address

block of

words in:

PLC-2

memory

PLC-3

memory

Use this format:

a

$wordaddr,size

$fileaddr:wordaddr,size

or

$extaddr,size

Examples:

$010,22 (specifies 22 words beginning with the

address 010).

The maximum number of words you can specify with

the size parameter is 65,535 for MOVE command.

For TMOVE, the maximum is 18 (if wordaddr is

127) and 17 (if wordaddr is

than

$A1:0,1024 (specifies 1024 words starting at word 0

of ASCII file 1)

$E3.1.9.1.0.0, 1024 ( specifies 1024 words starting at

word 0 to ASCII file 1).

The maximum number of words you can specify with

the size parameter is 65,535 for MOVE command.

For TMOVE, the maximum is based on the following

chart (all values in decimal).

File: Word: Maximum:

0 0 18

0

0

0 < word

0 < word

greater than

≤254

≤254

less

127).

17

16

312

17

16

16

15

PLC-5

memory

$extraddr,size

0 < file

≤254

file > 254

0 < file ≤ 254

file > 254

$E0.10.1.0,10 specifies 10 words beginning with word

1 of file 10.

word ≤ 254

word ≤ 254

word > 254

word > 254

Addressing Immediate-access Block Numbers

There are 16 immediate–access blocks of 42 bytes in length in every KP3

or KP2 module. To address them you ‘‘specify & digit”, where digit can

be from 0 to 15. When you define an immediate–access block, you are

setting aside an area in the KP3 that will be updated (via the TMOVE

command) with data from a specified area in the PLC–3 memory.

Page 48

Chapter 3

Programming

When another node reads the immediate–access block, it does not have to

wait as long to receive a reply. Usually, the node that receives a command

must wait to receive the token before it can reply to a command. With the

immediate–access block, the node that receives the command can transmit

a reply without having to wait to receive the token first. Thus the node

that sent the command, receives a reply sooner.

To transfer data using the immediate blocks, use the TMOVE command to

update the data in the local node’s immediate blocks and/or to read data

from some remote node’s immediate blocks.

Based on the nature of data, the user program must update the local node’s

immediate blocks at the selected time interval. In the following example,

we show a user program that updates the immediate block in the local

KP3 at 5–second intervals (figure 3.3), then one that reads it (figure 3.4).

Figure 3.3

User

Program to Initiate and Update Immediate Blocks at Five-Second Intervals

T0005

15

WB020:0000 WB020:0000

15

WB020:0000

12

Figure 3.4

User

Program to Read Immediate Blocks

I0:10

02

13

MSG

MESSAGE TYPE 1

CTL=FB020:0000= 0

CH:E2.9.1

TMOVE FROM $A1:0,5

TO &1

TON

0.1 SECOND

TP = 50

TA = 0

MSG

MESSAGE TYPE 1

CTL=FB001:0000= 0

CH:E2.9.1

TMOVE FROM :17&1 TO

$N0:0,5

STAT

( EN )

12

STAT

( DN )

15

STAT

( ER )

T0005

T0005TIMER ON

( TE )

17

T0005

( TD)

15

11015-I

STAT

( EN )

12

STAT

( DN )

15

STAT

( ER )

11016-I

313

Page 49

Chapter 3

Programming

Addressing a Bit Within a Word

This section provides examples of addressing a bit within a word in each

PLC–2, PLC–3, and PLC–5 memory.

Programming Examples

To

address

bit within

a word in:

PLC-2

memory

PLC-3

memory

PLC-5

memory

use this format:

a

$wordaddr/bit

$fileaddr:wordaddr/bit

or

$extaddr/bit

$extaddr/bit $E0.10.2.0/01

Examples:

$010/5 (specifies bit 5 of address 010)

$B11

$E3.1.8.11

1:2/3 (specifies bit 3 of word 2 of binary file 1

1.0.2/3 (extended addressing)

1 (specifies bit 1

1 of word 2 of file 10)

11)

This section contains examples of programming PLC–2, PLC–3, and

PLC–5 programmable controllers using the MOVE and TMOVE

commands.

The following table contains examples of using the MOVE command to

move a word:

To

move data

from:

Command line example:

Explanation:

314

PLC-3 to PLC-2

PLC-3 to PLC-2

PLC-3 to PLC-3

PLC-3 to PLC-3

PLC-3 to PLC-5

PLC-3 to PLC-5 MOVE FROM :40.2$E0.10.2.0 TO $B2:3

MOVE FROM :66$010 T

M F :66$010 T $B2:3

MOVE FROM $B2:3 TO :66$010 or

M F $B2:3 T :66$010

MOVE FROM :76$I4:50 T

M F :76$I4:50 T $B2:3

MOVE FROM $B2:3 TO :76$I4:50 or

M F $B2:3 T :76$I4:50

MOVE FROM $B2:3 T

or M F $B2:3 T :40.2$E.0.10.2.0

or M F :40.2$E.0.10.2.0 T $B2:3

O $B2:3 or

O $B2:3 or

O :40.2$E0.10.2.0

T

ransfers word 010 from node 66 to

word 3 of binary file 2.

T

ransfers word 3 of binary file 2 to

word address 010 at node 66.

T