Page 1

I/O ScannerMessage Handling

Module

User’s Manual

Page 2

Table of Contents

Using This Manual 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.0 Important Information for the Reader 11. . . . . . . . . . . . . . . . . . .

1.1

Manual'

1.2 Audience 11

1.3 Terminology 12

1.4 Conventions 12

1.5 Manual Design 13

1.6

Important Information

Introducing the I/O ScannerMessage Handling Module 21. . .

2.0 Chapter Objectives 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 Looking at the 1775S4B Scanner's Front Edge 21

2.1.1 Pass and Fail Indicators 22

2.1.2 Thumbwheel Switch 22

2.1.3

2.1.4 Backup Connector 23

2.1.5 Channel 5 Connector 23

2.1.6 Terminal Swing Arm 23

2.2 1775S4B Scanner Features and Functions 24

2.3

Specifications

2.4 Chapter Summary 25

s Purpose 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

I/O Channel Status Indicators

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

23. . . . . . . . . . . . . . . . . . . . . . .

24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing Your 1775S4B Scanner 31. . . . . . . . . . . . . . . . . . .

3.0 Chapter Objectives 31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 Inserting Your 1775S4B Scanner 31

3.2 Using the 1775S4B Scanner's RS232C Channel 31

3.2.1 Connecting RS232C Devices 31

3.2.2 Connecting an Industrial Terminal 34

3.3 Using the 1775S4B Scanner'

3.4 Chapter Summary 38

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

s I/O T

erminal Swing Arm 35. . . . . .

Operating the LIST Function 41. . . . . . . . . . . . . . . . . . . . . . .

4.0 Chapter Objectives 41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 Entering LIST 41

4.2 Configuring the RS232C Communication Channel 41

4.2.1 TTY (Printer) Defaults 44

4.2.2

CR

T Defaults

4.2.3 Privileges 44

4.2.4 Echo 47

4.2.5 Line Length 47

4.2.6 Pad Characters 47

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

44. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 3

Table of Contentsii

4.2.7 Tabs 48. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.8 Form Feed 48

4.2.9 Mode 48

4.2.10

XON/XOFF

4.2.11

Communication Rate

4.2.12 Parity 410

4.2.13

Stop Bits

4.2.14 Data Bits Per Character 411

4.2.15

ASCII Code Size

4.2.16 Reconfigure 411

4.3

Configuring the I/O Communication Channels

I/O Channel Configuration

4.3.1

4.3.1.1

Communication Rate

4.3.1.2 I/O Chassis Scanning Sequence 412

4.3.2 I/O Rack Group Selection 414

4.3.3 Reconfig and Auto Config 414

4.4 Chapter Summary 416

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

49. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

410. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

410. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

411. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

411. . . . . . . . . . . . .

412. . . . . . . . . . . . . . . . . . . . . . . . . .

412. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Getting Started in Report Generation 51. . . . . . . . . . . . . . . . .

5.0 Chapter Objectives 51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1 Introduction 51

5.2 Command Line Format 51

5.3

Getting Started

5.4 Executing a Simple Procedure 53

5.5 Executing Procedures from the Message Instruction

in the User Program 55

5.6 Control Modes 57

5.7 Chapter Summary 59

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

52. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Logical Addressing for Report Generation 61. . . . . . . . . . . . .

6.0 Chapter Objectives 61. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1 Introduction 61

6.2 Data Table Addressing 61

6.3 Extended Addressing 63

6.4 Chapter Summary 65

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Editing a Procedure 71. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.0 Chapter Objectives 71. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1 Editing a Simple Procedure 71

7.2 Entering the Edit Mode 73

7.3

Editing Commands

7.3.1 Insert Lines 75

7.3.2 Set Line Pointer 76

7.3.3 Advance Line Pointer 77

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

74. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 4

Table of Contents iii

7.3.4 Backup Line Pointer 77. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.3.5 Display Line Number 78

7.3.6 Type Out Lines 78

7.3.7 Searching for Text 79

7.3.8 Change Text Characters 710

7.3.9 Delete Lines 712

7.3.10

Exit Edit Mode

7.4 Editing Messages with a 1775S4A Scanner 713

7.5 Chapter Summary 716

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

713. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using Symbols and Expressions in Report Generation 81. . .

8.0 Chapter Objectives 81. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.1 Creating and Executing a Simple Procedure with a Symbol 81

8.2 Symbols 83

8.3 User Symbols 84

8.3.1

Assignment Statements

8.3.2 Memory Storage for User Symbols 86

8.3.3 User Symbol for Detecting Errors 87

8.4 System Symbols 87

8.4.1 Symbol Table 88

8.4.2 Memory Storage for System Symbols 89

8.5 Expressions 810

8.5.1

Octal/Decimal V

8.5.2 Comparison Operations 812

Complement Operation

8.5.3

8.5.4

Bitwise Operations

8.5.5 Logical Operations 814

8.5.6

Shift Operations

8.5.7

Bit Operation

8.5.8

Arithmetic Operations

8.5.9 Expressions and Logical Addressing 818

8.6 Chapter Summary 820

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

alues 812. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . .

85. . . . . . . . . . . . . . . . . . . . . . . . . . .

813. . . . . . . . . . . . . . . . . . . . . . . . . . . .

814. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

815. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

816. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

817. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Formatting Data in Report Generation 91. . . . . . . . . . . . . . . .

9.0 Chapter Objectives 91. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.1

Formatting Input and Output Data

9.1.1 Specifying a Format 91

9.1.2 Justifying Margins 92

9.1.3

Displaying Data

9.1.4 Specifying a Base Format 95

9.1.4.1 Base Formatting Examples 95

9.1.4.2 String Values 96

9.2 Using Standard Control Characters 97

9.3 Using Carriage and Cursor Control Characters 99

9.4 Using Industrial Terminal Control Characters 912

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . .

. . . . . . . . . . . . . .

91. . . . . . . . . . . . . . . . . . . . . .

93. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 5

Table of Contentsiv

9.5 Using the Conversion Table 913. . . . . . . . . . . . . . . . . . . . . . . . . .

9.6 Chapter Summary 915

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using Commands in Report Generation 101. . . . . . . . . . . . . . .

10.0 Chapter Objectives 101. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.1 Commands 101

10.2 Direct Commands 101

10.2.1

Print

10.2.2 Directory 102

10.2.3 Create 103

10.2.4

Delete

10.2.5 Copy 105

10.2.6 Rename 106

10.2.7 Execute 107

10.3 Indirect Commands 108

10.3.1

Print

10.3.2 Execute 1010

10.3.3 Case 1011

Exit

10.3.4

10.3.5

Stop

10.3.6

If

10.3.7

Goto

10.3.8 On_error 1015

10.3.9 Assignment 1017

10.3.10 Inquire 1020

10.3.11

Delete

10.4 Chapter Summary 1022

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

102. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

104. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

108. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1012. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1013. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1013. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1014. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1021. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using Report Generation Functions 111. . . . . . . . . . . . . . . . . .

11.0 Chapter Objectives 111. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.1 Report Generation Functions 111

11.2 Input Access Functions 112

11.2.1 Getchar 113

11.2.2 Testchar 113

11.2.3 Testline 114

11.3 Format Conversion Functions 115

11.3.1 To_bcd 115

11.3.2 From_bcd 116

11.4 Chapter Summary 116

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

Page 6

Table of Contents v

Execution Time Considerations 121. . . . . . . . . . . . . . . . . . . . .

12.0 Chapter Objectives 121. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.1 Introduction 121

12.2

Active I/O Channels

12.3 Address Complexity 122

12.4 Symbol Order 122

12.5 Assignment Values 122

12.6 Command Line Comments 122

12.7 Chapter Summary 123

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

121. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using a Peripheral

A.0 Appendix Objectives A1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.1 Introduction A1

A.2

Modifying Y

A.2.1 Abbreviating Commands A2

A.2.2 Abbreviating Modifiers A2

A.2.3 Abbreviating Functions A3

A.2.4 Specifying Octal Addresses A3

A.2.5 Using the .EQ. Expression Operator A3

A.2.6

Formatting Data

A.2.7 Suppressing the Line Feed A4

A.3

Bit Shift Operation

A.4 Form Feed Selection in LIST A7

Floating

B.0 Appendix Objectives B1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B.1 Introduction B1

B.2 Program Explanation B2

Point V

Communication Module

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

our Report Generation Procedures A1. . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . .

alues on the 1775S4B Scanner B1. . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A1. . . . . . . . . . . .

A3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Report Generation Quick Reference Guide C1. . . . . . . . . . . .

C.0 Quick Reference C1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Glossary D1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 7

Using This Manual

Chapter

1

1.0

Important Information for

the Reader

1.1

Manual's Purpose

1.2

Audience

Read this chapter before you use the I/O Scanner-Message Handling

Module (cat. no. 1775-S4B). It tells you how to use the Reader this manual

properly and efficiently for the tasks you will have to perform.

This manual shows you how to install and operate your I/O

scanner-message handling module. The operation of this module is divided

into two topics:

Using the I/O scanner-message handling module to communicate with

bulletin 1771 I/O chassis

Using the I/O scanner-message handling module’s report generation

capability

Before you read this manual or attempt to use the I/O scanner-message

handling module, you should be familiar with the basic operation of the

PLC-3 controller. If you are not familiar with the PLC-3 controller, refer to

the following publications:

PLC-3 Programmable Controller Installation and Operations Manual

(publication 1775-6.7.1, formerly 1775-800)

PLC-3 Controller Programming Manual (publication 1775-6.4.1,

formerly 1775-801)

You can also use our Publication Index (publication SD499) as a guide to

further information about products related to our I/O scanner-message

handling module. Consult your local Allen-Bradley distributor or sales

engineer for information regarding this publication or any needed

information.

11

Page 8

Chapter 1

Using this Manual

1.3

Terminology

1.4

Conventions

We refer to certain types of equipment throughout this manual. To make

the manual easier for you to read and understand, we avoid repeating full

product names where possible.

We refer to:

I/O Scanner-Message Handling Module (cat. no. 1775-S4B) as the

1775-S4B scanner

I/O Scanner-Programmer Interface Module (cat. no. 1775-S4A) as the

1775-S4A scanner

Industrial Terminal System (cat. no. 1770-T4) as the industrial

terminal

RS-232-C compatible devices which communicate to the PLC-3

controller through the 1775-S4B scanner, such as the data terminals,

computers, or printers as RS-232-C devices

In this manual, we use certain notational conventions to indicate

keystrokes and items displayed on a CRT or printer:

is used to show keystrokes that you enter from the data

terminal keyboard. The keystrokes appear in blue and may

be enclosed in brackets to indicate a specific key on the

keyboard such as:

[ENTER]

In some cases, rather than specific keystrokes, you may be instructed to

enter a variable. In that case, the variable is printed in blue lower case

letters and enclosed in angle brackets (< >) such as:

<address>

is used to show the 1775-S4B scanner’s response to your

keystrokes such as:

S4B>

We describe any exceptions to these conventions where they occur.

12

Page 9

Chapter 1

Using this Manual

1.5

Manual Design

1.6

Important Information

This manual is designed with as many as three divisions per page. These

divisions include:

Headings in the left margin describe the contents of the text

Text provides explanations, information, and examples

Figures show displays, hardware, and diagrams

In this manual, there are three different types of important information:

WARNING: Informs you where you could injure yourself if

you do not follow the written procedure.

CAUTION: Informs you where you could damage your

equipment if you do not follow the written procedure.

NOTES inform you of exceptions to the general rules or important

information.

13

Page 10

Chapter

2

Introducing the I/O ScannerMessage

Handling Module

2.0 Chapter Objectives

2.1

Looking at the 1775S4B

Scanner's Front Edge

This chapter discusses the functions and features of the 1775-S4B scanner.

When you finish reading this chapter, you should:

Be able to identify the hardware components of the 1775-S4B scanner

Know the basic features and functions of the 1775-S4B scanner

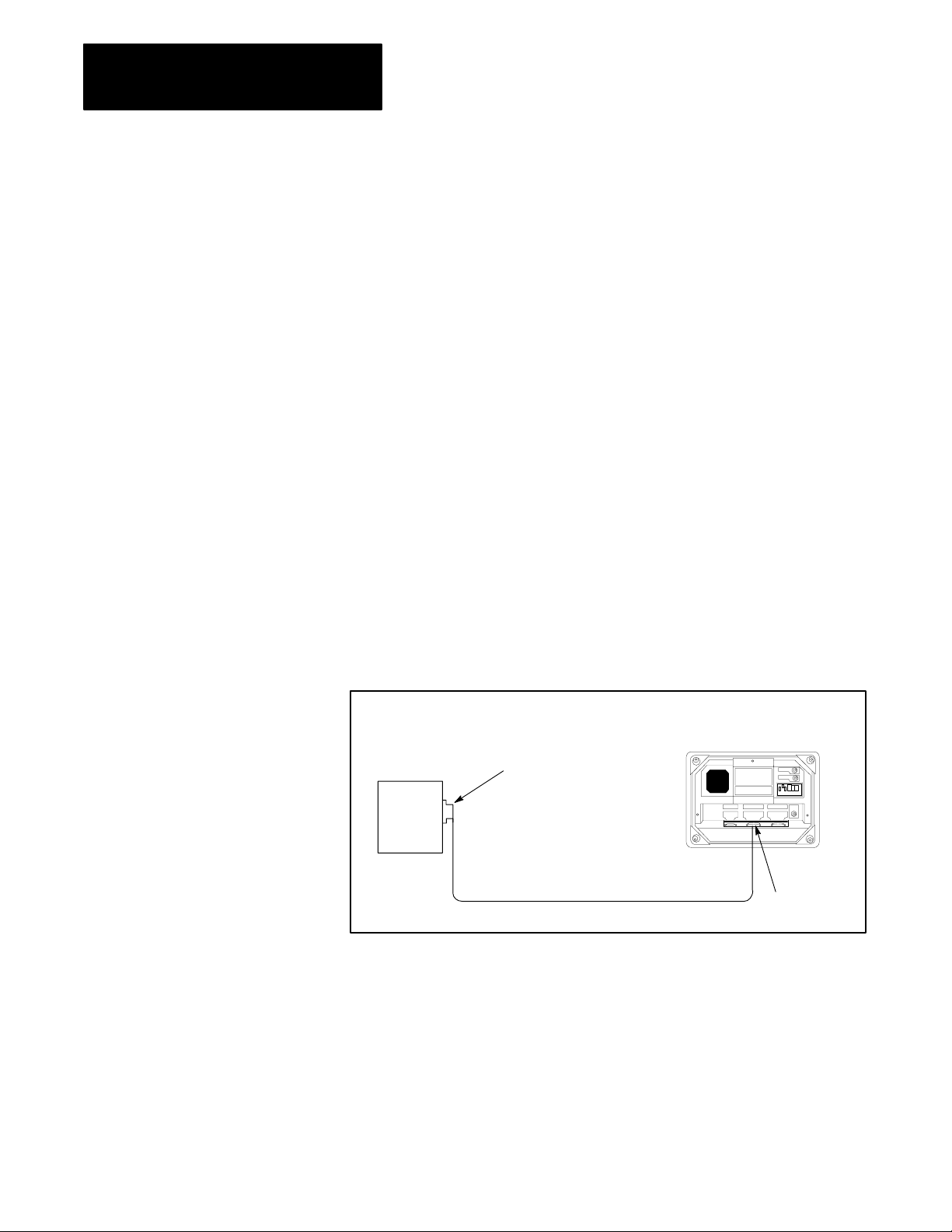

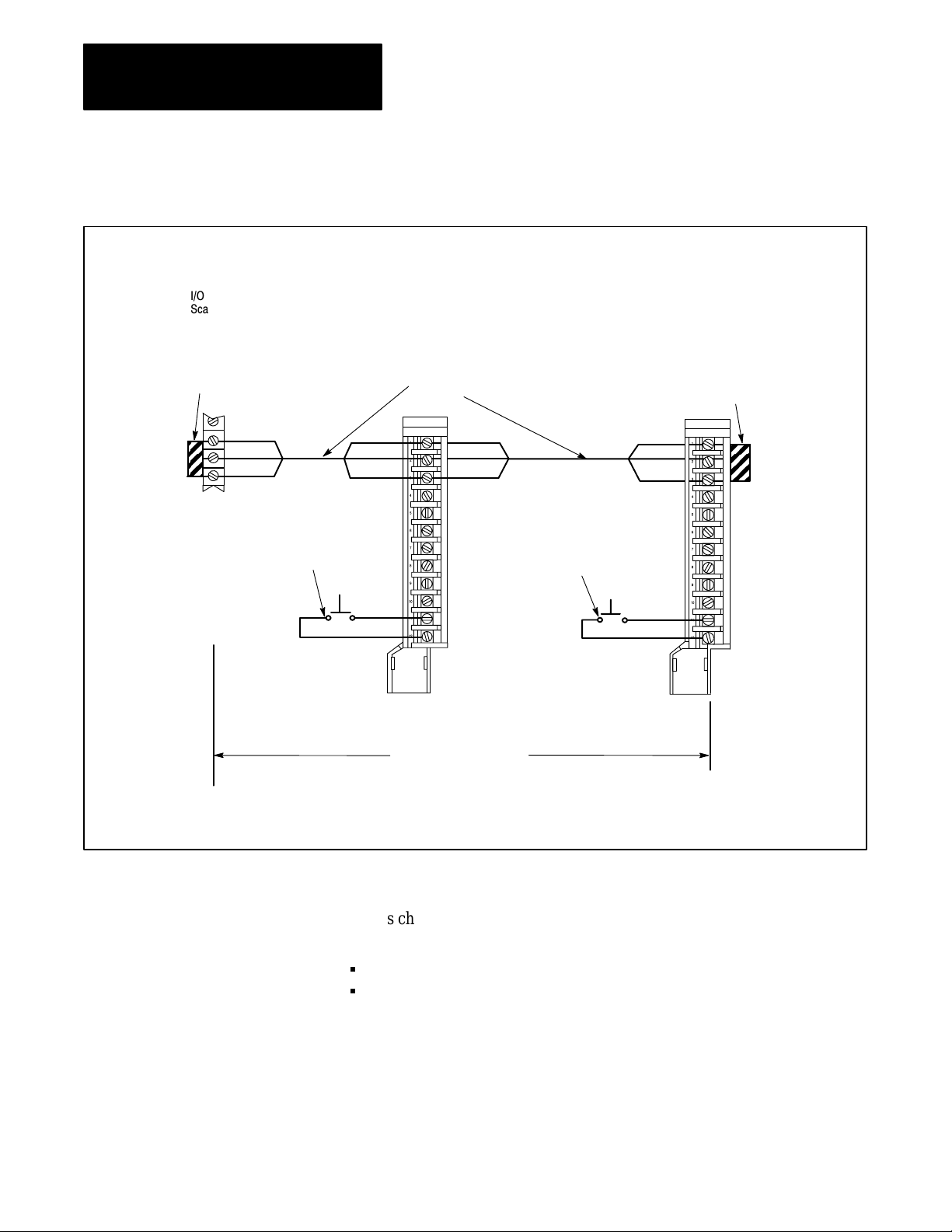

Your 1775-S4B scanner fits into the PLC-3 processor chassis. Looking at

the front edge, you will see the following (figure 2.1):

Pass and Fail indicators

Thumbwheel switch

I/O channel status indicators

Backup connector

Channel 5 connector

Terminal swing arm

These components are described in the following sections.

21

Page 11

Chapter 2

I/O ScannerMessage Handling Module

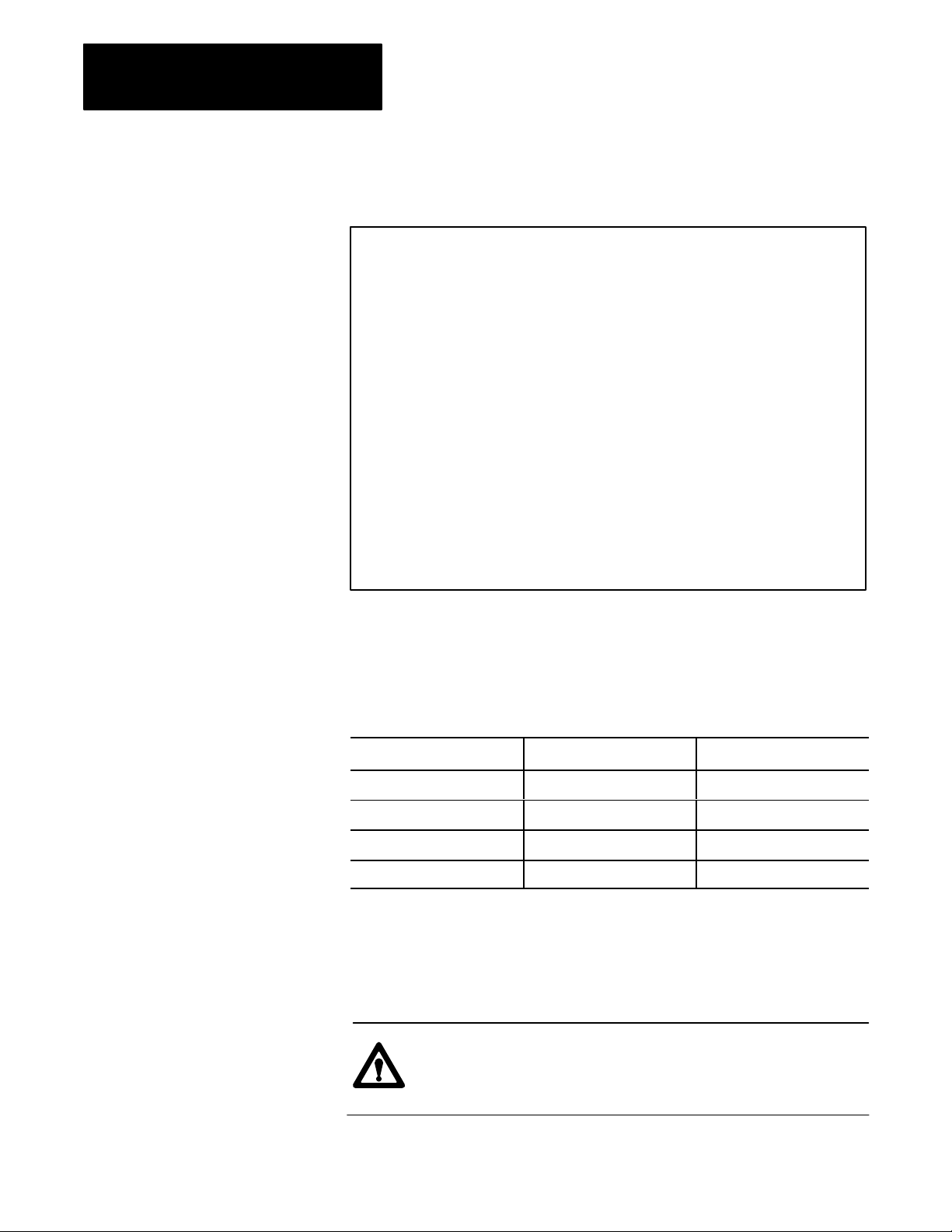

Figure 2.1

ScannerMessage Handling Module

I/O

2.1.1

Pass and Fail Indicators

2.1.2

Thumbwheel Switch

At the top of the 1775-S4B scanner’s front edge, LED indicators labeled

PASS and FAIL keep you informed on the general condition of the

1775-S4B scanner. These indicators have the following meanings:

Pass (green) Fail (red) Meaning

On Off Normal Operation

Off On Module Fault

On On Powerup or system reset

Off Off PLC3 processor is not on

The thumbwheel switch is below the PASS and FAIL indicators. Setting it

at a unique number (1 to 15) enables the PLC-3 processor to differentiate it

from another 1775-S4B scanner.

CAUTION: Do not change the thumbwheel setting on the

1775-S4B scanner while processor power is on. Equipment

damage could result.

22

Page 12

Chapter 2

I/O ScannerMessage Handling Module

2.1.3

I/O Channel Status

Indicators

Below the thumbwheel switch are four green LEDs labeled:

CH1

CH2

CH3

CH4

Each LED corresponds to one of the four I/O communication channels.

Each I/O channel can connect to a bulletin 1771 I/O chassis or a group of

chassis providing direct communication with the 1775-S4B scanner. Each

indicator has the following meanings:

If the LED is: Then:

On Proper communication exists between

1775S4B scanner and the I/O chassis on the

corresponding I/O channel.

Flashing A fault exists on one or more of the I/O chassis

on the corresponding I/O channel.

Off No I/O chassis are connected to the

corresponding I/O channel.

2.1.4

Backup Connector

2.1.5

Channel 5 Connector

2.1.6

Terminal Swing Arm

Below the I/O channel indicators is a connector labeled BACKUP. This

connector is not used.

Below the backup connector is a 25-pin D-shell connector labeled CH5.

This connector provides communication with an RS-232-C device such as

a data terminal, a computer, or a printer. Refer to chapter 3 for installation

information.

Near the bottom of the 1775-S4B scanner is a Terminal Swing Arm (cat.

no. 1775-WA). This swing arm contains the connection terminals for

channels 1 to 4 which scan I/O chassis. We discuss cable connections for

the I/O communication channels in chapter 3.

23

Page 13

Chapter 2

I/O ScannerMessage Handling Module

2.2

1775S4B

Scanner

Features and Functions

Now that you are aware of the 1775-S4B scanner’s hardware components,

this section summarizes the basic features and functions of the I/O

scanner-message handling module:

Features Functions

Four I/O communication

channels

Report generation channel To communicate with an RS232C compatible data terminal for

Status indicators To keep you informed on the 1775S4B scanner's status. These

Thumbwheel switch To distinguish one 1775S4B scanner from another. You can

Terminal swing arm To easily connect bulletin 1771 I/O chassis to the 1775S4B

To communicate with I/O Adapter Modules (cat. no. 1771AS) in

I/O chassis. You can connect up to 16 I/O chassis to one

1775S4B scanner I/O channel. The 1775S4B scanner can

communicate with 2,048 inputs and 2,048 outputs per scanner

total.

report generation. You can execute messages from your data

terminal or from a MSG instruction in the ladder diagram

program.

LEDs indicate the general module status and the active state of

each I/O communication channel.

insert up to 15 1775S4B scanners in one PLC3 system.

scanner. The terminal swing arm disconnects so you can easily

attach Twinaxial Cable (cat. no. 1770CD). An I/O chassis can

connect to a 1775S4B scanner up to 10,000 cable feet away.

2.3

Specifications

Location

Single slot in a PLC-3 processor chassis

Functions

I/O interface

Report generation

I/O Capacity

2,048 inputs and 2,048 outputs

Channels Per Module

4 I/O communication

1 RS-232-C communication

Communication Rate

57.6 baud or 115.2 kbaud (I/O channel)

110 to 19.2 kbaud (RS-232-C channel)

24

Page 14

I/O Channel Cable Length

10,000 cable feet (max)

Nominal I/O Scan Times

5.5 to 6.5ms for one I/O channel

6ms for two I/O channels

6ms for three I/O channels

6 to 6.5ms for four I/O channels

Backplane Current

2.7A from 5V DC circuit

2mA from +15V DC circuit

2mA from -15V DC circuit

Chapter 2

I/O ScannerMessage Handling Module

2.4

Chapter Summary

Environmental Conditions

Operational Temperature: 0 to 60° C (32 to 140° F)

Storage Temperature: -40 to 85° C (-40 to 185° F)

Relative Humidity: 5 to 95% (without condensation)

In this chapter, you were introduced to the:

Hardware components on the 1775-S4B scanner

Basic features and functions of the 1775-S4B scanner

Specifications of the 1775-S4B scanner

The next chapters describe installation procedures and PLC-3 LIST

selections for the 1775-S4B scanner.

25

Page 15

Chapter

3

Installing Your 1775S4B Scanner

3.0

Chapter Objectives

3.1

Inserting Your 1775S4B

Scanner

3.2

Using the 1775S4B

Scanner's RS232C

Channel

The 1775-S4B scanner provides the PLC-3 processor with an RS-232-C

compatible channel for report generation and a terminal swing arm for I/O

scanning. After reading this chapter, you should be able to:

Insert a 1775-S4B scanner into a PLC-3 system

Connect an RS-232-C device to the channel 5 connector on the

1775-S4B scanner

Connect I/O chassis to the terminal swing arm on the 1775-S4B scanner

The first step is inserting your 1775-S4B scanner. You can slide the

1775-S4B scanner into any slot of a PLC-3 Processor Chassis (cat. no.

1775-Al, 1775-A2). The chassis electromechanically interlocks helping to

guard against inserting or removing modules while power is on.

The channel 5, 25-pin connector provides RS-232-C communication to a

modem, computer, or data terminal for report generation capability. We

discuss report generation in chapter 5. The following two sections discuss

connecting RS-232-C devices to the 1775-S4B scanner.

3.2.1

Connecting RS232C

Devices

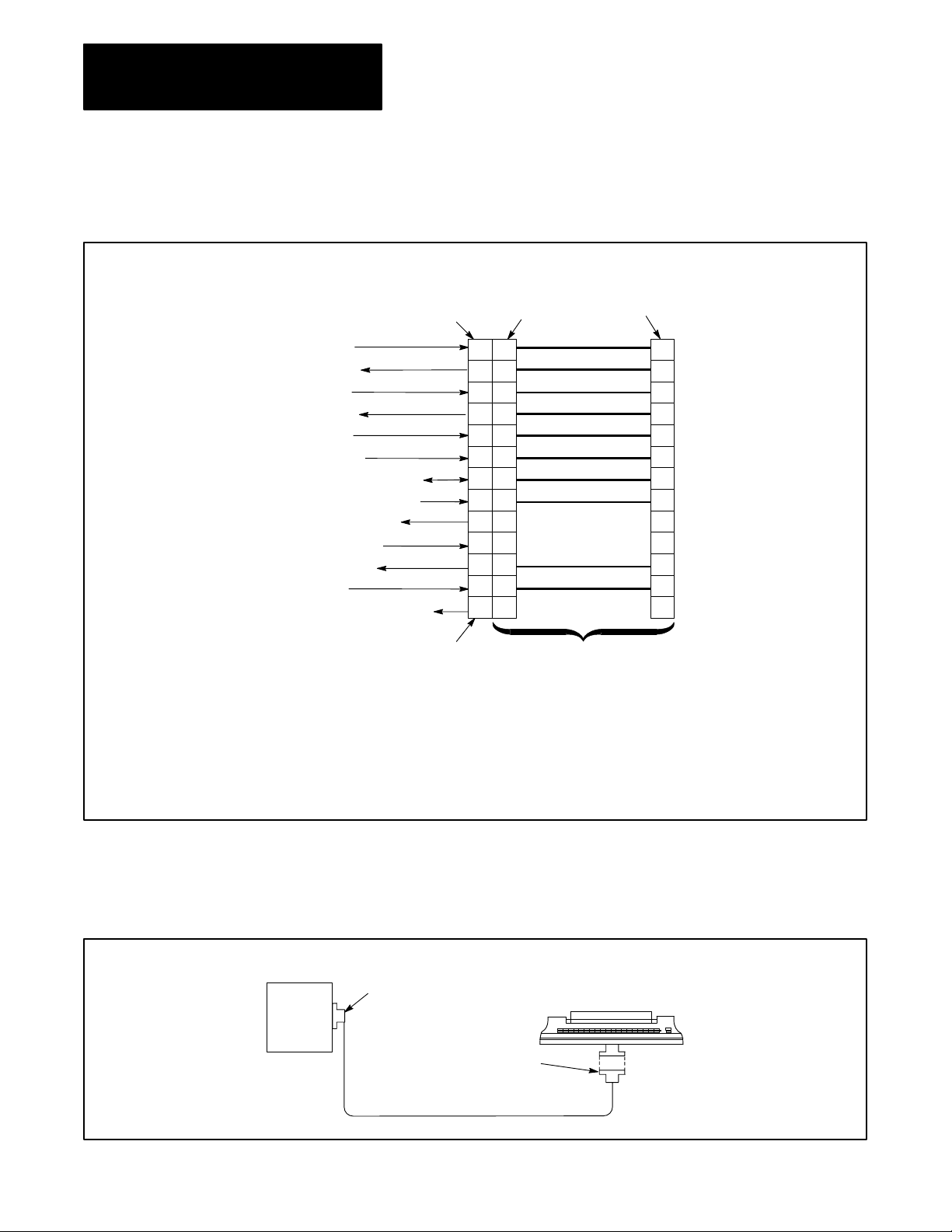

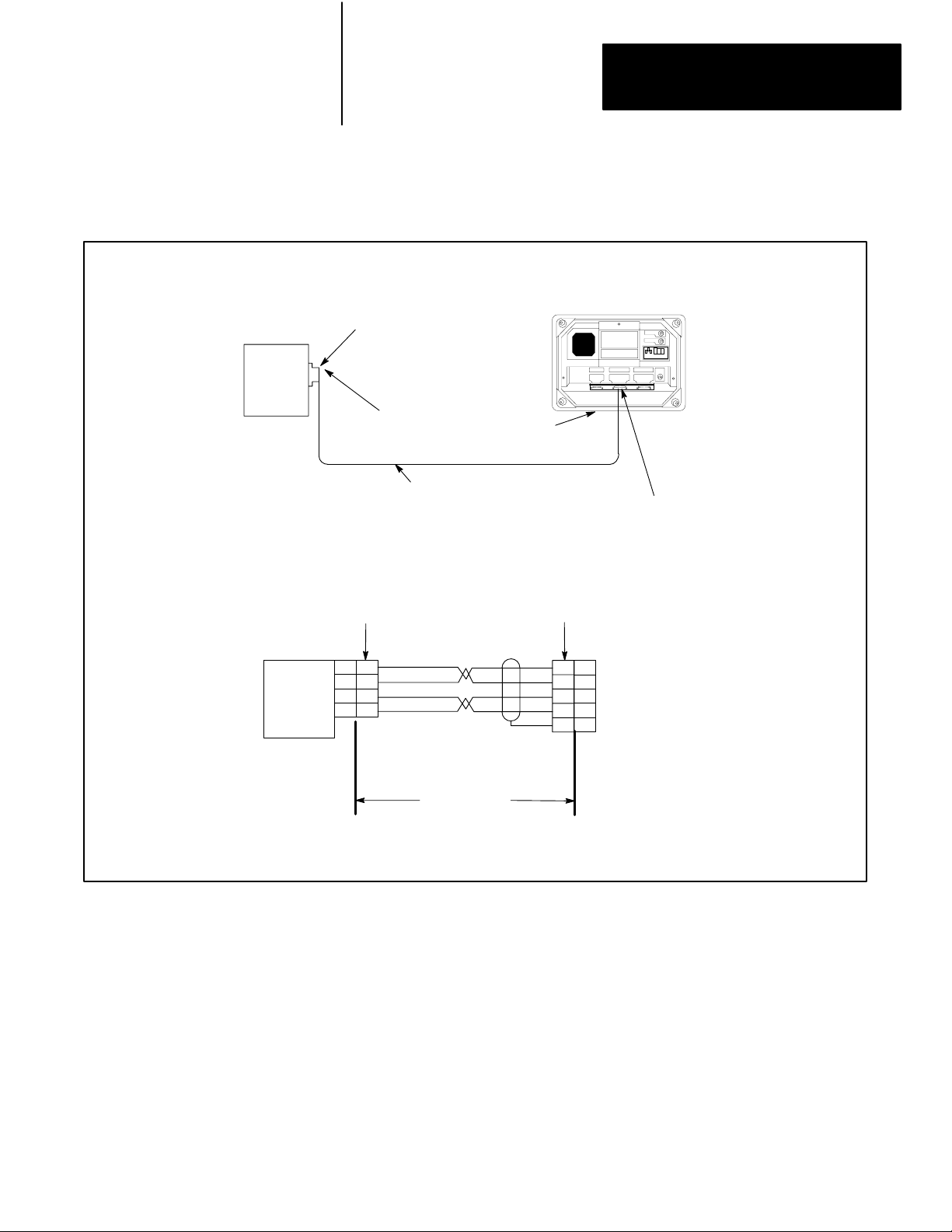

Figure 3.1 shows the pin assignments for the channel 5 connector. You can

use Peripheral Cable (cat. no. 1775-CDC) to connect RS-232-C data

terminals or computers to the 1775-S4B scanner. This peripheral cable is

15 feet or 4.6 meters long (figure 3.2). If you need more distance, you can

connect an RS-232-C device up to 50 feet or 15.2 meters from the

1775-S4B scanner by using Remote I/O Interconnect Cable (cat. no.

1778-CR), or equivalent, and two 25-Pin Connector Kits (cat. no.

1770-XXP). Figure 3.3 shows the appropriate wiring.

If an RS-232-C device must be more than 50 cable feet or 15.2 cable

meters from the 1775-S4B module, use a line driver/receiver or a modem.

You could also use the cable that comes with the RS-232-C device.

However, the connector must have a right angle hood; otherwise, the

PLC-3 processor door will not close.

31

Page 16

Chapter 3

Installing Your 1775S4B Scanner

Figure 3.1

Diagram of Peripheral Cable for Connecting RS232C Device to

Wiring

1775S4B Scanner

Protective

Ground

T

ransmitted Data

1

Received Data

2

Request to send

3

Clear to Send

3

Data Set Ready

Signal Ground (Connom Return)

3

Received Line Signal Detector

4

Isolated T

4

Received Data Return

2

Data T

5

Ring Indicator

4

Isolated T

ransmitted Data

erminal Ready

ransmitted Data Return

CH 5 Connector on

the 1775-S4B Scanner

1

This pin is for both long line and RS-232-C campatible transmission

2

Signals from the data terminal to these input pins have no ef

operation of the module.

3

The module always holds these output pins high (ON).

4

These pins are for long line transmission; they are not RS-232-C compatible.

5

The module always holds this output pin low (OFF).

25-Pin

Female

Connector

1

2

3

4

5

6

7

8

14

18

20

22

25

25-Pin

Male

Connector

(AA)

1

(BA)

2

(BB)

3

(CA)

4

(CB)

5

(CC)

6

(AB)

7

(CF)

8

14

18

(CD)

20

(CE)

22

25

Cat. No. 1775-CDC

Cable (15 ft. 4.6m)

25-Pin

Female

Connector

1

2

3

4

5

6

7

8

14

18

20

22

25

fect on the

32

I/O

Scanner

Message

Handling

Module

(Cat. No.

1775-S4B)

Figure 3.2

Connecting

an RS232C Device to the 1775S4B Scanner Using

Peripheral Cable

25-Pin

Male

Connector

25-Pin

Female

Connector

Cat.

No. 1775-CDC Peripheral Cable (15 ft. 4.6m)

Data T

erminal

(RS-232-C Compatible)

Page 17

Chapter 3

Installing Your 1775S4B Scanner

I/O

Scanner

Message

Handling

Module

(Cat. No.

1775-S4B)

I/O

ScannerMessage

Handling

Module

(Cat. No.

1775-S4B)

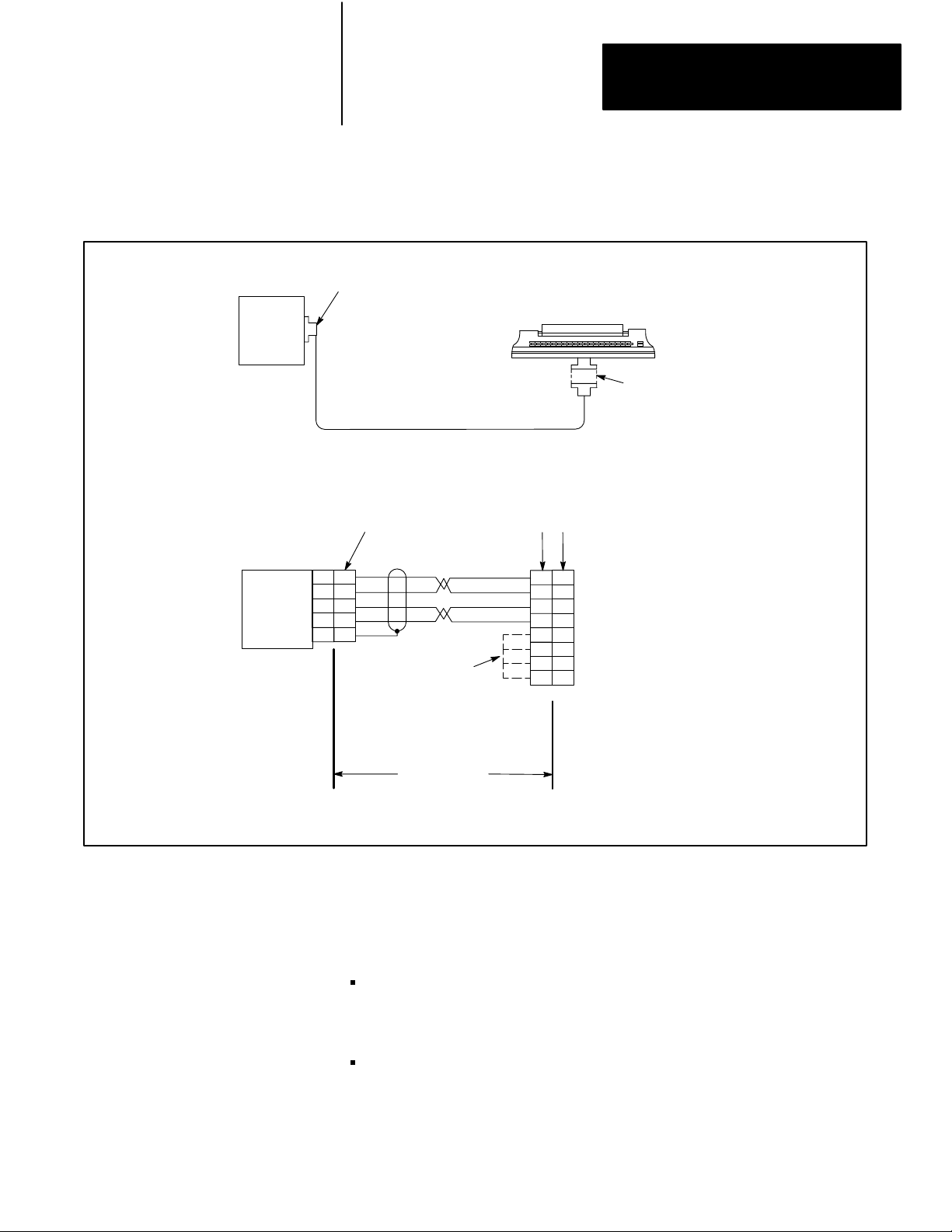

Figure 3.3

Connecting

I/O Interconnect Cable

UserSupplied

Cannon T

7

7

2

2

7

7

3

3

1 1

25Pin Male Connector;

ype DB2505, Male or equivalent

Cat.

No. 1778-CR Cable or equivalent

(50 ft. or 15.2 m maximum)

a)

Connection Diagram

UserSupplied

Connector

UserSupplied

Jumpers refer

to section 3.2

an RS232C Device to the 1775S4B Scanner Using Remote

UserSupplied

Connector,

as Appropriate

UserSupplied Connections

as Appropriate

[AB]

[BA]

[AB]

[BB]

[CB]

[CC]

[CD]

[CF]

7

7

2

2

7

7

3

5

6

20

8

Data T

3

5

6

20

8

erminal

(RS232C Compatible)

Cat. No. 1778-CR Cable

or equivalent

50 ft. or 15.2 m

maximum

b) Wiring Diagram

Some RS-232-C devices may require a high signal for a clear to send (CB)

signal at pin 5, a data set ready (CC) signal at pin 6, or a data carrier detect

(CF) signal at pin 8 for proper operation. Depending on your connections,

note the following:

If you are using the 1775-CDC cable to connect directly between the

1775-S4B scanner and the RS-232-C device or its cable, the 1775-S4B

scanner provides these signals.

If you are constructing a cable for the RS-232-C device, you can jumper

pin 20 to pin 5, 6, or 8 as required by the RS-232-C device.

33

Page 18

Chapter 3

Installing Your 1775S4B Scanner

The RS-232-C device should pull pin 20 high to provide its own signal.

This jumpering is shown by dashed lines in the wiring diagram of

figure 3.3.

3.2.2

Connecting an Industrial

Terminal

You can use the PLC-3 Industrial Terminal Cable (cat. no. 1775-CAT) for

connecting an industrial terminal to the 1775-S4B scanner. Refer to the

steps below for proper connection:

Step 1—Connect the end labeled INDUSTRIAL TERMINAL END to

channel B of the industrial terminal.

Step 2—Connect the end labeled PLC-3 END to the channel 5 connector

on the 1775-S4B scanner.

The 1775-CAT cable is 10 feet or 3 meters long (figure 3.4). If you want to

connect the industrial terminal up to 5,000 cable feet (1,524 cable meters)

away from the 1775-S4B scanner, refer to figure 3.5. Use 1778-CR cable

or equivalent cable and two 25-pin male connector kits (cat. no.

1770-XXP).

Figure 3.4

Connecting

Industrial T

an Industrial T

erminal Cable

erminal to the 1775S4B Scanner Using

Industrial T

(Cat. No. 1770-T1, T2, T3, or T4)

erminal System

34

I/O

Scannermessage

Handling

Module

(Cat. No.

1775-S4B)

25Pin Male

Connector with

Right-Angle Hood

Cat.

No. 1775CA

Industrial T

erminal Cable (10ft. 3 m)

T PLC3

Channel B

Page 19

Chapter 3

Installing Your 1775S4B Scanner

I/O

Scanner

message

Handling

Module

(Cat. No.

1775-S4B)

Figure 3.5

Connecting

an Industrial T

Remote I/O Interconnect Cable

RightAngle Hood

User-Supplied

Cannon T

UserSupplied

Connector

25Pin Male Connector

ype DB2505, Male, or equivalent

Cat. No. 1778CR Cable or equivalent

(5000 ft. or 1524m maximum)

a) Connection Diagram

erminal to the 1775S4B Scanner Using

Industrial T

(Cat. No. 1770T1, T2, T3, or T4)

,

UserSupplied

Connector

erminal System

Channel B

3.3

the 1775S4B

Using

Scanner'

s I/O T

Swing Arm

erminal

I/O

Scanner

Message

Handling

Module

(Cat. No.

1775-S4B)

25

25

14

14

18

18

3

3

25

25

2

18

3

1

Industrial

Terminal

Channel B

2

18

3

1

Cat. No. 1778CR

Cable or equivalent

5000 ft. or 1524 m

maximum

b) Wiring Diagram

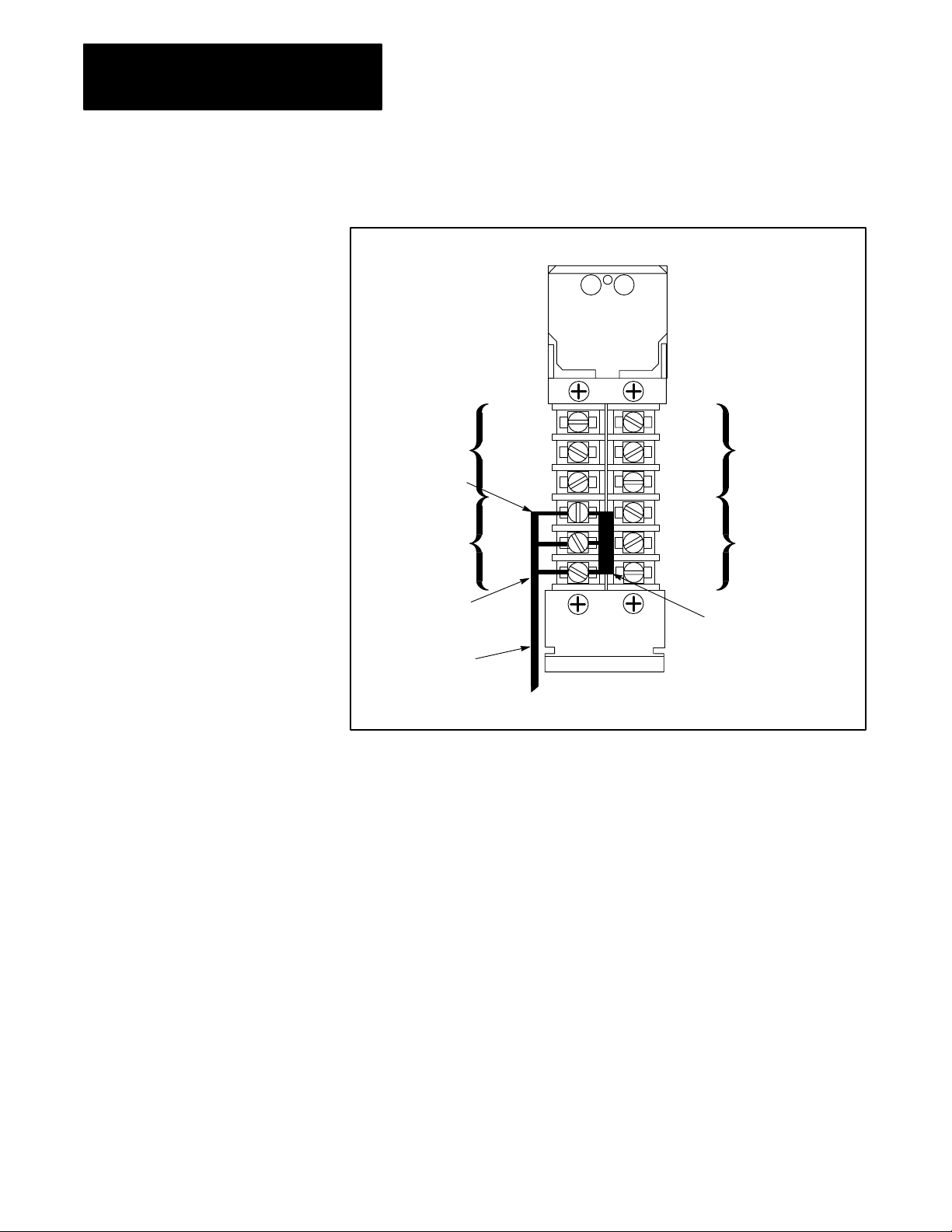

The I/O terminal swing arm provides cable connection for Twinaxial Cable

(cat. no. 1770-CD) which connects to 1771 I/O chassis. This swing arm

contains terminals for I/O channels 1 thru 4. Figure 3.6 shows how to wire

the 1770-CD cable to the terminals on the terminal swing arm.

35

Page 20

Chapter 3

Installing Your 1775S4B Scanner

Figure 3.6

Scanner Module I/O Channel Connections

I/O

Line 1

Shield

Line 2

Line 1

Shield

Line 2

Channel

No. 4

Channel

No. 2

Terminator

(Cat. No. 177)

Channel

No. 3

Blue

Channel

No. 1

Clear

T

winaxial Cable

Cat. No. 1770-CD

Line 1

Shield

Line 2

Line 1

Shield

Line 2

Figure 3.7 shows the terminal identification label which indicates the

proper connections for each I/O adapter module to an I/O channel. This

label is on the side of the module. The connections are made at screw

terminals on a wiring arm in front of each I/O adapter module.

36

Page 21

Figure 3.7

Adapter Module (cat. no. 1771AS) T

I/O

1

2

3

4

5

6

7

8

9

10

11

12

Chapter 3

Installing Your 1775S4B Scanner

erminal Identification Label

Terminal

Identification

Cat. No. 1771AS

Line

1

Shield

Line 2

No connection

No connection

No connection

No connection

No connection

No connection

No connection

IN

RET

Cable

Reset

Perform the following steps to make proper I/O channel connections:

Step 1—Connect the twinaxial cable in a serial (daisy chain) fashion from

the 1775-S4B scanner to each I/O chassis within the I/O channel

(figure 3.8).

Step 2—Connect the signal conductor with blue insulation to the LINE 1

terminal at the 1775-S4B scanner and at each I/O adapter module in the

I/O channel.

Step 3—Connect the signal conductor with clear insulation to the LINE 2

terminal. Connect the shield drain wire to the SHIELD terminal.

Step 4—Connect a Terminator (cat. no. 1770-XT) between the terminals at

each end of each I/O channel.

You can optionally connect a normally open, momentary contact switch

between terminals 11 and 12 at each I/O adapter module. You could then

use such a reset switch to reset the I/O adapter module if the PLC-3

processor detects a fault at the I/O chassis. Refer to the PLC-3

Programmable Controller Installation and Operation Manual (publication

1775-6.7.1, formerly 1775-800) for detailed information.

37

Page 22

Chapter 3

Installing Your 1775S4B Scanner

Figure 3.8

Channel Connections

I/O

I/O

Scanner

Module

Arm

Swing

(Car

. No. 1775-W

Terminator

(Cat. No.1770-XT)

Blue

Shield

Clear

A)

Optional

User-supplied

Pushbutton

for I/O Chassis

Restart

I/O Adapter

Module Field

Wiring Arm

(Cat. No. 1771-WB)

Twinaxial

Cable

(Cat. No. 1770-CD)

Blue

Shield

Clear

I/O Adapter

Module Field

Wiring Arm

(Cat. No. 1771-WB)

Terminator

(Cat. No. 1770-XT)

Blue Blue

Shield Shield

Clear Clear

Optional

User-supplied

Pushbutton

for I/O Chassis

Restart

3.4

Chapter Summary

38

10,000 cable ft or

3048 cable m maximum

In this chapter, you read installation procedures for:

Connecting an RS-232-C device to channel 5 for report generation

Connecting I/O chassis to the terminal swing arm for I/O scanning

Before you begin operating the 1775-S4B scanner, we suggest that you

double check all connections.

The next chapter describes LIST selections for the 1775-S4B scanner.

Page 23

Chapter

Operating the LIST Function

4

4.0

Chapter Objectives

4.1

Entering LIST

4.2

Configuring the RS232C

Communication Channel

The LIST function allows you to select parameters to operate the PLC-3

controller. After reading this chapter, you should be able to:

Select operating parameters for the RS-232-C communication channel

on the 1775-S4B scanner

Select operating parameters for the I/O communication channels on the

1775-S4B scanner

You can operate the LIST function for the 1775-S4B scanner through a

1770-T4 terminal or the data access panel on the PLC-3 Main Chassis (cat.

no. 1775-Al). Refer to the PLC-3 Programmable Controller Installation

and Operation Manual (publication 1775-6.7.1, formerly 1775-800) for

detailed information on operating the LIST function.

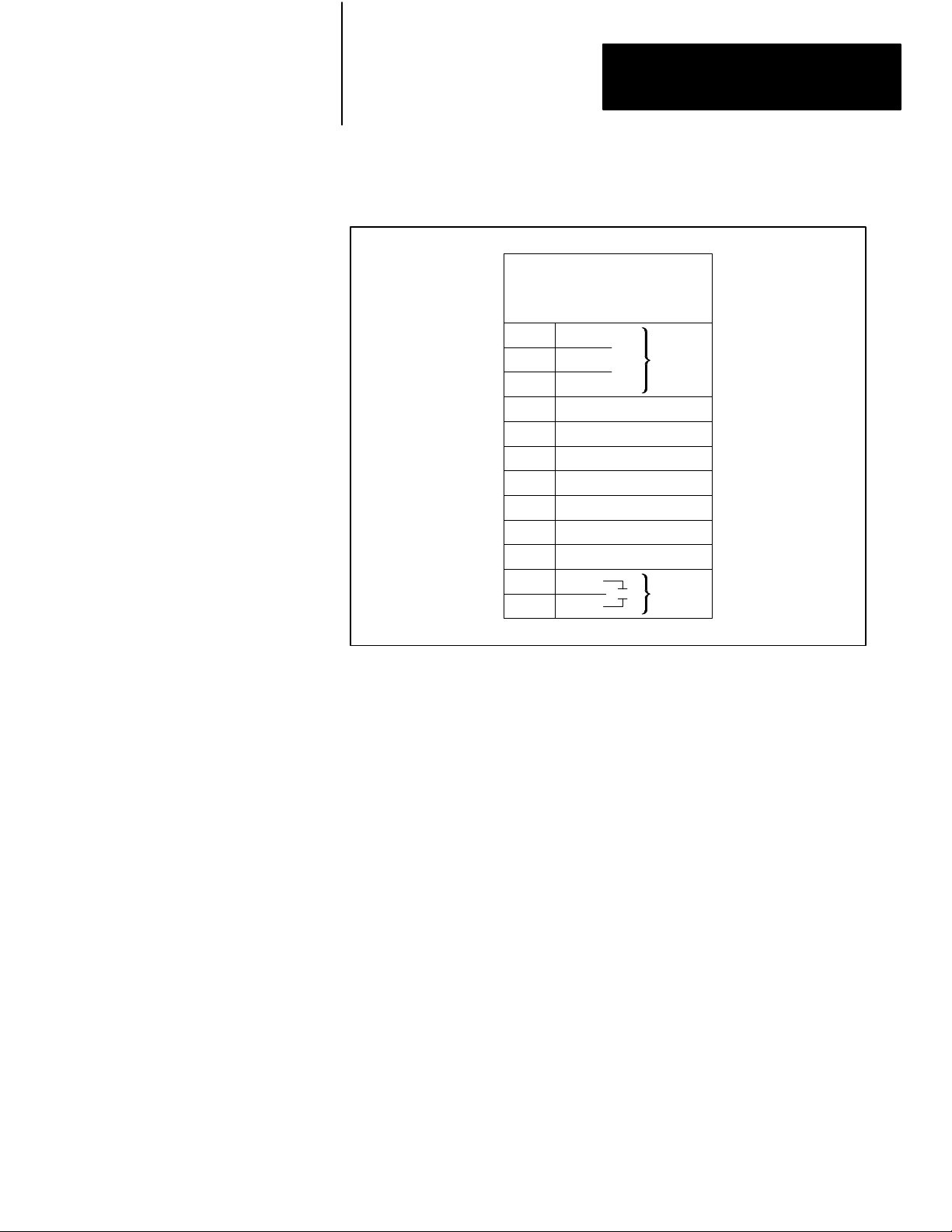

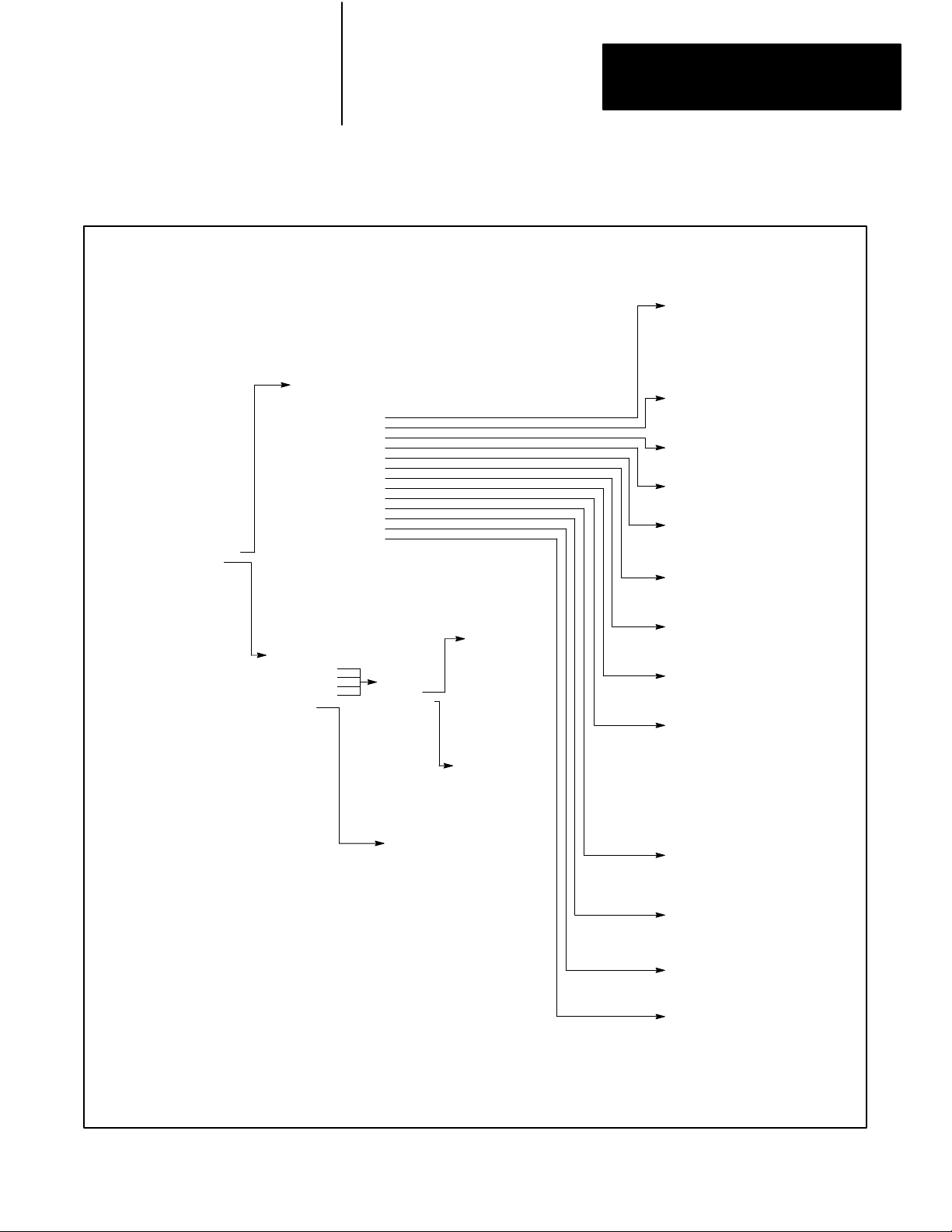

Figure 4.1 shows you the parameters that you can select for each channel.

We explain these parameters in the following sections.

If you select COMM CHAN to configure the RS-232-C communication

channel, you can make the following selections:

TTY (Printer) defaults

CRT defaults

Privileges

Echo

Line length

Pad characters

Tabs

Form feed

Mode

XON/XOFF

Communication rate (baud)

Parity

Stop bits

Data bits/character

ASCII code size

41

Page 24

Chapter 4

Operating the LIST Function

Reconfig

We explain these selections in the following sections.

42

Page 25

I/O Scanner02

Chassis 1 Slot 3

1 Comm Chan

2 I/O Chan

Enter Next>

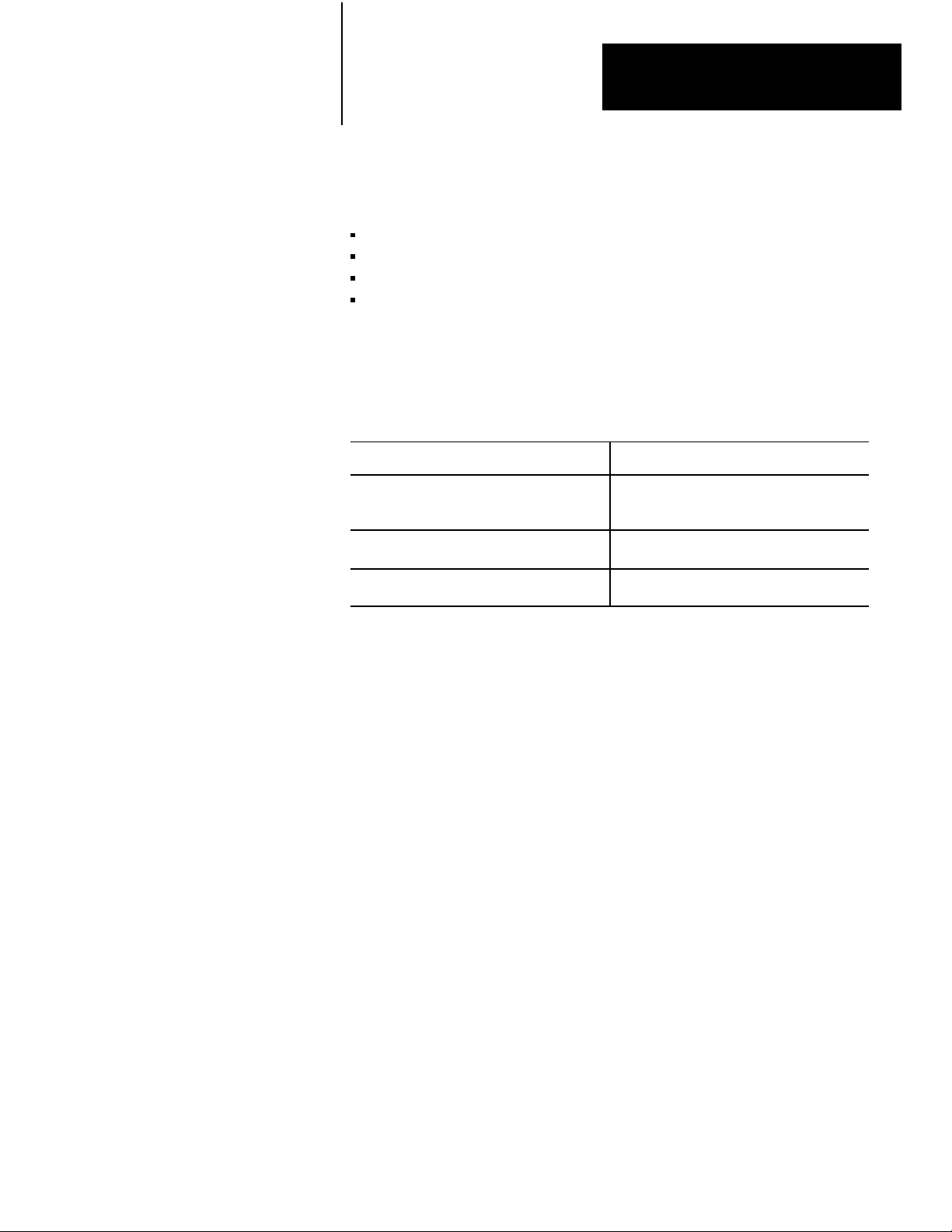

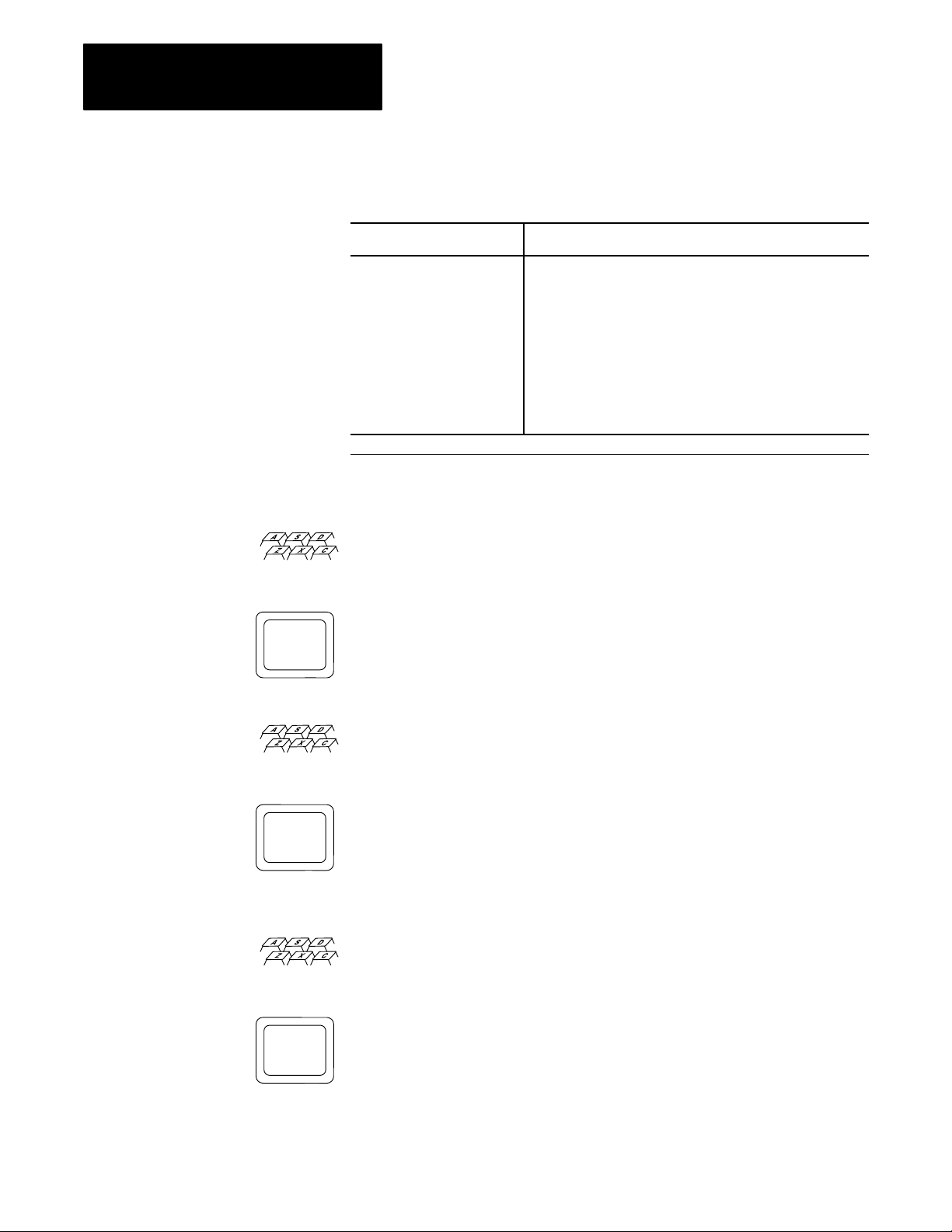

Figure 4.1

Selections for the 1775S48 Scanner

LIST

02Comm Chan 5

1 TTY Defaults

2 CRT Defaults

3 Privileges

4 Echo

5 Line Length

6 Pad Char

7 Tabs

8 FF

9 Mode

10 XON/XOFF

1 Baud

1

12 Parity

13 Stopbits

14 Bits/Char

15 ASCII Code Size

16 Reconfig

Enter Next>

02I/O Chan 4Baud

I/O Scanner02I/O Chan

1 I/O Chan 1

2 I/O Chan 2

3 I/O Chan 3

4 I/O Chan 4

5 Racks

6 Auto Config

7 Reconfig

Enter Next>

02I/O Chan 4

1 Baud

2 * I/O Scan

3 Inactive

Enter Next>

02I/O Racks

1 * 077

2 100177

3 200277

4 300377

Enter Next:

Those selections shown in bold type affect the

operation of the module. The selections not shown

in bold type only cause a movement to another level

of LIST. The LIST display shows an asterisk (*) to

indicate the selection made.

1 57600

2 * 1

15200

3 Inactive

Enter Next>

02I/O Chan 4Chassis

1 003/2/0

2 005/2/2

3 006/2/6/I

4 005/4/4/I/F

5 007/8/0

Enter Next>

Chapter 4

Operating the LIST Function

02Chan

5Privileges

3

5

6

65

73

Enter Next>

02Chan 5Echo

1 * On

2 Off

Enter Next>

02Chan 5Line Length

Line Length 80

Enter Next>

02Chan 5Pad Char

Pad Char 0

Enter Next>

02Chan 5T

abs

1 * Expanded

2 Not Expanded

Enter Next>

02Chan 5FF

1 Expanded

2 * Not Expanded

Enter Next>

02Chan 5Mode

1 * CRT

2 Print

Enter Next>

02Chan 5XON/XOFF

1 * XON/XOFF

2 No XON/XOFF

Enter Next>

02Chan 5Baud Rate

1 110 Baud

2 150 Baud

3 300 Baud

4 600 Baud

1200 Baud

5

6

1800 Baud

7

2400 Baud

8

4800 Baud

9 *

9600 Baud

10

19200 Baud

Enter Next>

02Chan 5Parity

1 Even

2 Odd

3 * None

Enter Next>

02Chan 5Stopbits

1 * 1

2 1.5

3 2

Enter Next>

02Chan 5Bits/Char

1 * 8

2 7

Enter Next>

02Chan 5ASCII Code Size

1 8

2 * 7

Enter Next>

43

Page 26

Chapter 4

Operating the LIST Function

4.2.1

TTY (Printer) Defaults

The TTY defaults selection configures the RS-232-C communication

channel for report generation communication with a printer terminal. Table

4.A lists the parameter selections for TTY defaults. You can use the printer

terminal for report generation functions that we discuss in chapters 5

through 11.

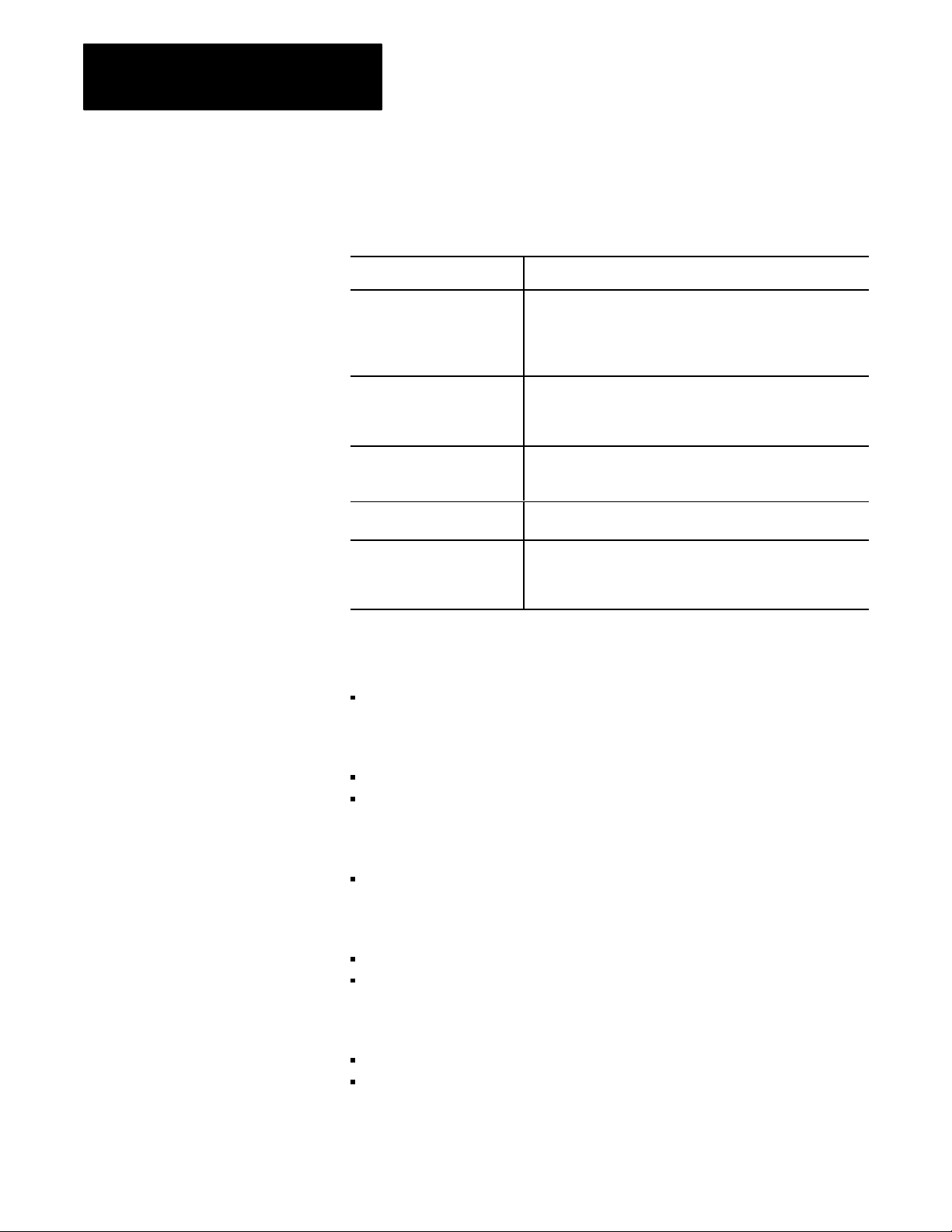

Table 4.A

Channel

5 Default Selections

Parameter TTY Defaults CRT Defaults

Privileges

Echo

Line length

Pad Char

Tabs

Form feed

Mode

XON/XOFF

Baud

Parity

Stop bits

Bits/Character

ASCII Code Size

3, 5, 6, 65, 73

On

80

4

Expanded

Expanded

Print

XON/XOFF

300 Baud

None

1

8

7

3, 5, 6, 65, 73

On

80

0

Not Expanded

Expanded

CRT

XON/XOFF

9600 Baud

None

1

8

7

4.2.2

CRT Defaults

4.2.3

Privileges

44

The CRT defaults selection configures the RS-232-C communication

channel for report generation communication with a CRT terminal. Table

4.A lists the parameter selections for CRT defaults. You can use the CRT

terminal for report generation functions that we discuss in chapters 5

through 11.

You must configure the RS-232-C communication channel for TTY or

CRT defaults. If you make no selection, the channel configures for CRT

defaults.

The LIST function allows you to select operating parameters for the

RS-232-C communication channel on the 1775-S4B scanner. These

operating parameters are called privileges and are primarily a list of PLC-3

memory areas into which channel 5 has access. For example, if a report

generation message is to write into the message area of PLC-3 memory,

you must select privilege 5 which corresponds to the message area after

you select the privileges selection in LIST.

Page 27

Chapter 4

Operating the LIST Function

Some privileges, however, do not deal with PLC-3 memory areas. For

example, privilege 65 allows you to edit or delete report generation

messages. Table 4.B lists the available privileges. We describe all the

privileges below:

Privilege 0—System status area. Allows device on channel 5 to write to

the system status area of PLC-3 memory.

Privilege 1—System pointers area. Allows device on channel 5 to write

to the system pointer area of PLC-3 memory.

Privilege 2—Module status area. Allows device on channel 5 to write to

the module status area of PLC-3 memory.

Privilege 3—Data table area. Allows device on channel 5 to write to the

data table area of PLC-3 memory.

Privilege 4—Program area. Allows device on channel 5 to write to the

program area of PLC-3 memory.

Privilege 5—Message area. Allows device on channel 5 to write to the

message area of PLC-3 memory.

Privilege 6—System symbol area. Allows device on channel 5 to write

to system symbol area of PLC-3 memory.

Privilege 7—User symbol area. Allows device on channel 5 to write to

user symbol area of PLC-3 memory.

Privilege 10—Force table area. Allows device on channel 5 to write to

force table area of PLC-3 memory.

Privilege 65—Edit report generation messages. Allows device on

channel 5 to edit or delete report generation messages.

Privilege 73—Accept keyboard input. Allows device on channel 5 to

input data for report generation.

45

Page 28

Chapter 4

Operating the LIST Function

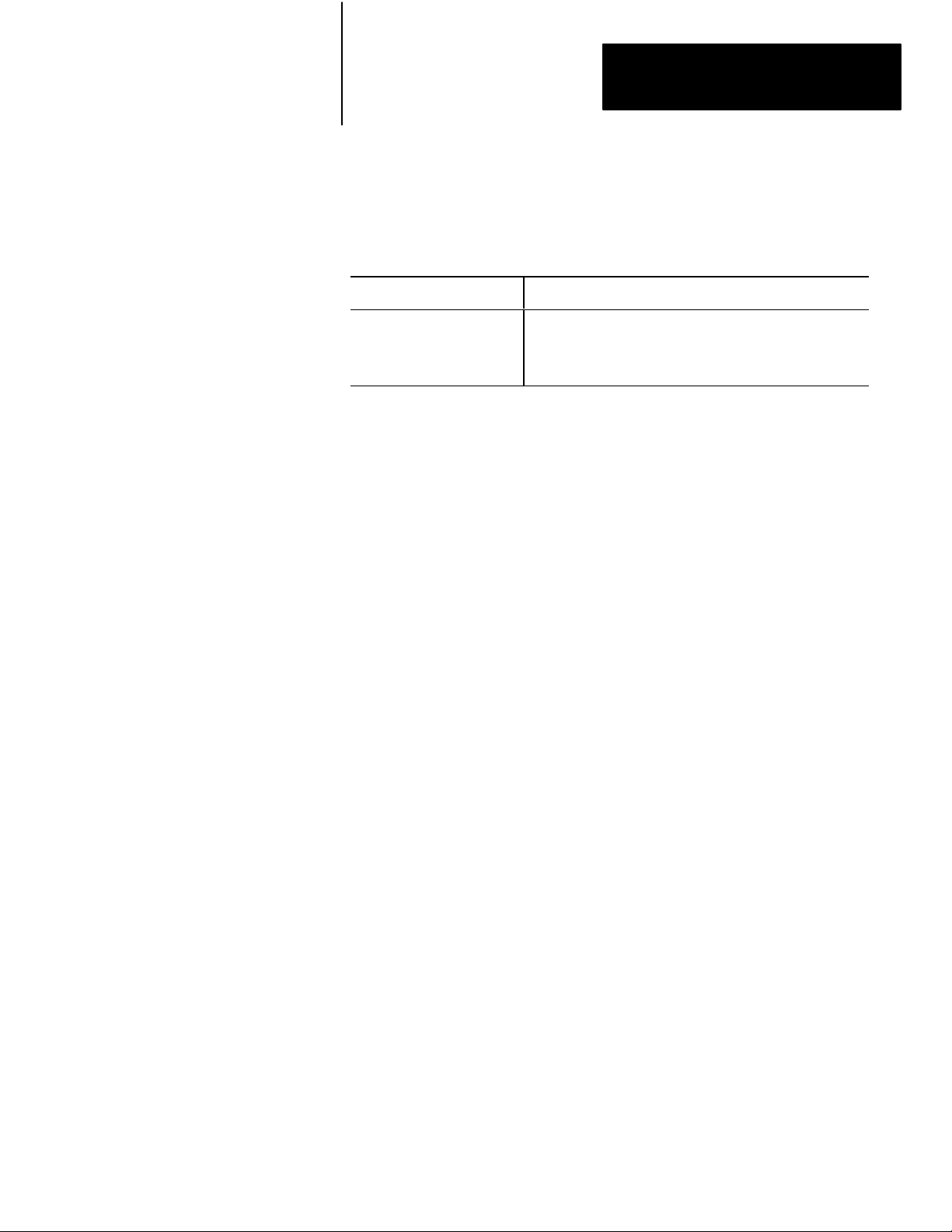

Table 4.B

Privileges

Privilege Number Description

0

1

2

3

4

5

6

7

10

65

73

1

indicates the default privileges.

Write access to system status area

Write access to system pointers area

Write access to module status area

Write access to data table area

Write access to program area

Write access to messages area

Write access to systems symbols area

Write access to user symbols area

Write access to force tables area

Edit or delete report generation messages

Accept keyboard input for report generation

1

1

1

1

1

To add a privilege to channel 5, type the number of the privilege. For

example:

At the privileges menu if you enter:

ENTER NEXT > 10

The PLC-3 processor adds privilege 10 (write access to force table area)

and redisplays the privileges list.

You can make a privilege independent of the memory protect keyswitch

position by typing /I after the privilege number. For example:

46

If you enter:

ENTER NEXT >3/I

The PLC-3 processor places /1 after privilege 3 (write access to data table

area) and redisplays the privileges list. Then the PLC-3 processor updates

the data table regardless of the memory protect keyswitch position.

To delete a privilege from a local channel, type /D after the privilege

number. For example:

If you enter:

ENTER NEXT > 4/D

The PLC-3 processor deletes privilege 4 (write access to the user program

area) and redisplays the privileges list.

If you do not specify privileges, the default privileges are 3, 5, 6, 65,

and 73.

Page 29

Chapter 4

Operating the LIST Function

4.2.4

Echo

4.2.5

Line Length

The echo selection determines whether channel 5 immediately transmits

back to the data terminal a copy of each character received from the data

terminal. To enable the echo selection, your RS-232-C device must be set

for full-duplex. Note the following:

If you: Then:

Select echo

Do not select echo

Each keystroke from the data terminal prints out or displays after

being echoed by the channel.

The keystrokes do not display, unless you can configure the data

terminal to do so directly.

The echo selection defaults to on.

You can select a line length value of 0 to 255 characters. If you select a

value of 1 to 255, a new line starts automatically whenever the line length

of a message exceeds the line length value selected.

As an example, consider message text stored with the intention of printing

on a 132-column printer. If an 80-column printer is used, selecting a line

length value of 80 automatically causes a new line to start after 80

characters. This prevents the end of each line from being lost. The default

line length is 80 characters.

4.2.6

Pad Characters

If you select value 0, a new line does not automatically start. You can use

the value 0 for many applications involving graphic displays.

After CR and LF characters are sent to an unbuffered printer to start a new

line, the printer needs some time to position the print head at the start of

the new line. NUL characters follow CR and LF characters to give the

printer this time. Pad characters (1 to 255) provide the number of needed

NUL characters. If no NUL characters are needed, enter a pad characters

value of 0. If you do not specify a pad character, this selection defaults

to 0.

47

Page 30

Chapter 4

Operating the LIST Function

4.2.7

Tabs

4.2.8

Form Feed

The tabs selection determines what the channel transmits for a tab

function:

If you select: Then:

Not expanded

Expanded

The channel sends an HT (tab) character in the message

transmission for each HT character in the stored message text.

Sending tab characters is only appropriate when transmitting to a

data terminal which supports a hardware tab function.

The channel considers a tab position to exist every 8 columns.

Each time a HT character is reached in the stored message, the

channel sends the number of SP characters to move the cursor

to the next tab position.

The default selection is not expanded.

The form feed selection determines what character or characters the

channel transmits to accomplish the form feed function:

If you select: Then:

Not expanded

Expanded

The channel sends a FF character in the transmission for each

FF character in the message text. Sending FF characters is only

appropriate when transmitting to a data which supports a

hardware form feed function.

The channel sends seven LF characters in the message

transmission for each FF character in the stored message text.

This selection does not provide a true form feed function, but it

can provide a separation between messages.

48

4.2.9

Mode

The default selection is expanded.

The mode selection determines what the 1775-S4B scanner does when you

enter a DEL (delete character) from your keyboard. You can make the

following selections:

If you select: Then:

CRT

Print

A DEL character causes the 1775S4B scanner to send back the

characters BS, SP, BS to erase the character from the screen.

A DEL character causes the 1775S4B scanner to send back the

character being deleted so that it prints again with a slash (/)

character on each side. For example, if you type an E, you would

see it printed as:

E

If you then delete it, you would see:

E/E/

Page 31

Chapter 4

Operating the LIST Function

With either selection, a DEL character deletes the previous character

entered. The default selection is CRT.

4.2.10

XON/XOFF

The XON/XOFF selection determines whether the 1775-S4B scanner

responds to XON and XOFF characters received from the data terminal.

Some data terminals can receive data transmissions at a faster rate than

they can print. They hold the received data in a buffer until the printing can

catch up during the time between transmissions from the module.

However, when a long message is transmitting, this buffer can become full.

Therefore, the 1775- S4B scanner provides an XON/XOFF hand-shaking

function which temporarily inhibits data transmissions until the buffer has

room. To use this hand-shaking function, you can generate the following

characters:

DC3 (XOFF) character generates automatically when the buffer is full

or if you enter [CTRL] S from the keyboard.

DC l (XON) character generates automatically when the buffer is full or

if you enter [CTRL] Q from the keyboard.

CAN (cancel) character generates if you enter [CTRL] X or [BREAK]

from the keyboard.

This selection operates as follows:

If you select: Then:

XON/XOFF

NO XON/XOFF

When the data terminal sends the ASCII character DC3 (XOFF),

the 1775S4B scanner is inhibited from transmitting until it

receives the ASCII character DC1 (XON).

You can use the ASCII character CAN (cancel) to abort the

suspended transmission. The 1775S4B scanner ignores any

other character.

The 1775S4B scanner does not respond to any DC3 (XOFF)

character received from the data terminal.

The default selection is XON/XOFF.

49

Page 32

Chapter 4

Operating the LIST Function

4.2.11

Communication Rate

4.2.12

Parity

The rate at which the 1775-S4B scanner communicates with RS-232-C

devices connected on its channel 5 connector is the communication or baud

rate. You can select one of the following communication rates:

110 Baud

150 Baud

300 Baud

600 Baud

1200 Baud

1800 Baud

2400 Baud

4800 Baud

9600 Baud

19200 Baud

Select the communication rate by typing the number corresponding to the

desired rate. The 1775-S4B scanner displays an asterisk next to the current

communication rate. The default selection is 9600 Baud.

The 1775-S4B scanner can communicate through channel 5 using the

following parity selections:

4.2.13

Stop Bits

If you select: Then:

Even

Odd

None

The channel transmits an even parity bit with each character and

checks for an even parity bit in each character received.

The channel transmits an odd parity bit with each character and

checks for an odd parity bit in each character received.

The channel does not transmit a parity bit and does not check for

a parity bit in each character received.

The 1775-S4B scanner displays an asterisk next to the current parity state.

The default parity selection is none.

You can specify the number of stop bits that the 1775-S4B uses to

communicate with its RS-232-C communication channel. The stop bit

selections are 1, 1.5, or 2. The 1775-S4B scanner displays an asterisk next

to the current stop bit selection. To change the number of stop bits, type the

number corresponding to the desired selection. The default stop bits

selection is 1.

410

Page 33

Chapter 4

Operating the LIST Function

4.2.14

Data Bits Per Character

4.2.15

ASCII Code Size

4.2.16

Reconfigure

The bits/char selections are 7 or 8. The channel transmits the selected

number of data bits per character. The channel only accepts characters

received with the selected number of data bits per character. The default

selection is 8 data bits per character.

The ASCII code size selections are 7 or 8. You use this selection when 8

data bits per character is selected. Then select one of the following:

If you select: Then:

7

8

The RS232C communication channel uses the first 7 bits only

in decoding the character transmitted.

The RS232C communication channel uses all 8 bits in

decoding the character transmitted.

The default ASCII code size is 7.

The reconfigure selection implements the channel 5 selections. For

example, if you select CRT defaults, the 1775-S4B scanner does not

implement the change until you select reconfigure. In response to selecting

reconfig:

4.3

Configuring the I/O

Communication Channels

If channel 5: Then:

Is not currently executing

Is currently executing

The 1775S4B scanner reconfigures the channel immediately.

The 1775S4B scanner waits until the task completes executing

before it reconfigures the channel.

When the 1775-S4B scanner reconfigures the channel, the asterisk beside

the reconfiguration selection disappears.

If you select I/O CHAN to configure an I/O communication channel, you

can select the following parameters:

I/O Chan 1

I/O Chan 2

I/O Chan 3

I/O Chan 4

Racks

Auto Config

Reconfig

We explain these parameters in the following sections.

411

Page 34

Chapter 4

Operating the LIST Function

4.3.1

I/O Channel Configuration

4.3.1.1

Communication Rate

4.3.1.2

I/O Chassis Scanning

Sequence

If you select an I/O channel, you can make the following selections for the

corresponding I/O communication channel:

Communication rate (baud)

I/O scan

We explain these selections in the following sections.

You can select one of the following communication rates for the

corresponding I/O communication channel:

If you select: Then:

57.6 kbaud

115.2 kbaud

You can change the order of execution for an I/O scan of the corresponding

I/O communication channel by selecting the I/O scan selection in LIST.

When you configure an I/O channel for I/O scan, list the I/O chassis in the

order that you want the 1775-S4B scanner to communicate with them. This

allows you to assign a higher priority to some I/O chassis than to others by

listing the higher priority chassis more than once.

The maximum I/O channel cable length can be 10,000 feet.

The maximum I/O channel cable length can be 5,000 feet.

412

As an example, if there are six entries in the I/O chassis list, and entries 1

and 4 are the same, then the chassis listed under entries 1 and 4 will be

updated twice as often as the other chassis. You can list a chassis as often

as you desire, provided that the list contains no more than 32 entries.

Each I/O chassis is listed once in the default configuration at initial

powerup or after an autoconfigure.

When forming the I/O chassis list, remember the following considerations:

Rack numbers which are not assigned consecutively cause greater

memory requirements by allocating memory for unused racks.

No more than 16 I/O adapters can connect to one I/O communication

channel on the 1775-S4B scanner.

No more than 16 different rack numbers can be assigned to one

1775-S4B scanner.

When using complementary or duplicate I/O, two chassis with the same

rack and starting module group numbers must be on different channels

Page 35

Chapter 4

Operating the LIST Function

of the same 1775-S4B scanner. Refer to the PLC-3 Programmable

Controller Installation and Operations Manual (publication 1775-6.7.1,

formerly 1775-800) for detailed information on complimentary and

duplicate I/O.

Rack number 778, is used for internal PLC-3 communication. Do not

assign this number to an I/O rack (although you can use the associated

addresses for internal storage).

Use the following format to enter chassis in the chassis list:

<entry number>/<rack number>/<chassis size>/

<starting module group number>/<attributes >

Entry number defines the position of the entry in the chassis list. For

example, to insert an entry between the third and fourth entries, use entry

number 4. The new entry becomes the fourth entry, and all entries

numbered 4 or greater have their numbers incremented by one.

Rack number is the I/O chassis’ I/O rack number, in octal. The rack

number must be within the range of the rack group selected for the

1775-S4B scanner (refer to section 3.2). The last two digits of the rack

number must correspond to the switch settings on the I/O adapter module

in the I/O chassis.

Chassis size is the number of module groups in the chassis. You can enter:

2 for a 32 I/O chassis

4 for a 64 I/O chassis

8 for a 128 I/O chassis

Starting module group is the lowest numbered module group in the chassis.

It can be 0, 2, 4, or 6.

Attributes can be:

I if the chassis is for inputs only

F if a fault in the chassis is to be considered a major fault

You can have 0, 1, or 2 attributes associated with the chassis.

You can delete entries from the rack list by typing the entry number and

pressing [ENTER]. For example:

To delete the third entry in the rack list, type:

3 [ENTER]

413

Page 36

Chapter 4

Operating the LIST Function

The 1775-S4B scanner removes the third entry in the rack list and

redisplays the rack list.

An asterisk (*) appearing before an entry in the rack list indicates that the

corresponding I/O chassis or I/O adapter module is faulted.

4.3.2

I/O Rack Group Selection

4.3.3

Reconfig and Auto Config

The I/O rack group selection in LIST selects the range of I/O rack numbers

that the I/O scanner module can address. Presently, the PLC-3 controller

uses only rack number 0 to 76

, and the first rack group is selected by

8

default, so you do not have to make a selection here.

The subscript (

If you plan to use rack numbers greater than 37

) indicates that the value is expressed in an octal format.

8

, consider the following:

8

Racks numbered greater than 378 increase the I/O scan time.

The amount of memory required for the input and output sections

depends on the highest rack number containing inputs or outputs,

respectively. Therefore, skipping rack numbers is an inefficient use of

memory.

The I/O channel portion of LIST includes selections for reconfig and auto

config. A reconfig implements other changes which you made in LIST. For

example, if you list an I/O chassis three times in the rack list, and you

change the rack list to include that chassis 6 times, the 1775-S4B scanner

does not change its polling sequence until you select reconfig. Reconfig

works for the all the I/O communication channels. Therefore, you can

reconfigure the I/O communication channels once, after making all I/O

channel selections, instead of making separate reconfigure selections for

each I/O channel.

414

If an asterisk is displayed next to the reconfig selection, change(s) have

been requested but not implemented. Upon selecting reconfig, the

1775-S4B scanner implements the changes and removes the asterisk.

CAUTION: If the PLC-3 processor is in the run mode and

executing block transfers, selecting reconfig could cause a bad

address fault to occur.

Page 37

Chapter 4

Operating the LIST Function

If this situation occurs you should:

Clear the bad fault address in a fault routine

Clear the block transfer bit

Restart the block transfer in the ladder diagram program

Auto config first creates a new I/O chassis list in which each I/O chassis

has equal priority with no attributes assigned. Then a reconfiguration

executes.

The 1775-S4B scanner performs an auto configure at powerup under the

following conditions:

No I/O channel configured for I/O scan has entries in the rack list.

Neither auto configure nor reconfigure has been selected during a

previous powerup (at least since the last time you cleared memory).

When forming the I/O chassis list during an auto configuration, the

1775-S4B scanner polls all valid addresses (rack 0 to 768). If the

1775-S4B scanner receives response to an address, it adds that I/O rack

address to the list. To assign attributes or priorities to the I/O chassis, add

them manually through LIST and reconfigure the I/O channel.

You can only perform an auto configuration when:

PLC-3 processor is in program load mode.

Power is applied to the I/O chassis.

Switch 2 of each I/O chassis is set to “on” to allow the I/O chassis to be

restarted from the PLC-3 processor.

If power is not applied to the I/O chassis, the PLC-3 processor attempts to

perform an auto configuration, and since the I/O chassis does not respond,

the 1775-S4B scanner does not enter it in the I/O chassis list. For an entry

to get into the I/O chassis list in auto config, a valid communication path

must exist between the 1775-S4B scanner and the I/O adapter module for

the I/O chassis.

415

Page 38

Chapter 4

Operating the LIST Function

4.4

Chapter Summary

In this chapter, you read about PLC-3 LIST selections for the 1775-S4B

scanner. You can access LIST from the PLC-3 front panel or the RS-232-C

channel (channel 5) on the 1775-S4A scanner. Upon selecting the

1775-S4B scanner:

Select COMM CHAN to configure channel 5

Select I/O CHAN to configure an I/O channel

The remainder of this publication describes the 1775-S4B scanner’s report

generation capability. If you do not use this capability, you do not need to

read the remaining chapters.

416

Page 39

Chapter

5

Getting Started in Report Generation

5.0

Chapter Objectives

5.1

Introduction

The 1775-S4B scanner uses a programming language for report generation

to print or display formatted text and data. After reading this chapter, you

should be able to:

Understand the command line structure

Write and execute a simple procedure

Execute a procedure using the message instruction in a ladder diagram

program

Before you start generating reports with your 1775-S4B scanner, you need

to understand certain key concepts:

Report generation—A programming language that the 1775-S4B

scanner uses to print or display formatted text and data.

Procedure—A collection of report generation command lines that the

1775-S4B scanner uses to generate formatted text and data.

Report—The output generated when a procedure is executed. For

example, shift report, machine status report, or downtime report.

5.2

Command Line Format

We refer to these terms throughout the discussion of report generation for

the 1775-S4B scanner.

The general format for a command line that you will use to generate

reports is:

<command> </modifier> <parameters> <;comment>

The command tells the 1775-S4B scanner what to do. The 1775- S4B

scanner only recognizes one command per command line.

The optional modifier tells the 1775-S4B scanner which way to execute the

command.

The parameters tell the 1775-S4B scanner what data to change.

51

Page 40

Chapter 5

Getting Started in Report Generation

The optional comment tells someone reading the procedure what the

command line does. The 1775-S4B scanner accepts the semicolon (;)

delimiter as an instruction to ignore the rest of the line. So, you can use the

semicolon to document command lines in a procedure.

As an example, suppose you enter the line:

P ‘FIRST SHIFT PRODUCTION’;TITLE OF REPORT

P is the abbreviation for the print command which tells the 1775-S4B

scanner to print out the data FIRST SHIFT PRODUCTION. TITLE OF

REPORT is the comment which tells what the command line prints out.

5.3

Getting Started

Now that you have been introduced to report generation, let’s do some

programming. In describing report generation programming, we use the

following icons to indicate your action and the 1775-GA module’s

response:

shows your input. The actual input characters are shown in

blue.

shows the 1775-GA module’s response to your input.

Before you program your 1775-S4B, you need to perform the following

steps:

Step 1—Configure the RS-232-C channel through LIST (chapter 4).

Step 2—Connect the data terminal to the channel 5 connector on the

1775-S4B scanner. These connections are described in chapter 3.

Step 3—If you are using an industrial terminal, select alphanumeric mode.

This selection makes the industrial terminal function as a data terminal.

Then make sure you select the same communication options for the

industrial terminal that you selected in LIST for channel 5 on the

1775-S4B scanner.

52

Step 4—Press [ENTER] or [RETURN]. The terminal displays the prompt:

S4B>

You are now ready to use your 1775-S4B scanner for report generation.

Page 41

Chapter 5

Getting Started in Report Generation

5.4

Executing

Procedure

a Simple

If you have the S4B> prompt on your CRT, you can create and execute

report generation procedures. The first step is to create the procedure by

entering the edit mode.

Simply type:

Ed @TEST1 [ENTER]

ED is the abbreviation for the edit command. The edit command is a report

generation command that enables you to create and store a new procedure

or edit an existing procedure. Also, you may notice that an (@) sign

precedes the first character in the procedure name. The 1775-S4B scanner

interprets an @ sign as a system symbol delimiter and accepts the

characters that follow as the procedure name. Following the @ sign, you

can use up to eight characters to name your procedure. Report generation

accepts any alphanumeric character(s) and the underscore character(s) (_)

for procedure names. Procedures names must start with a letter following

the @ sign.

NOTE: If you are using an industrial terminal to execute report generation

procedures, you cannot use lower case letters to name a procedure as the

industrial terminal does not recognize lower case letters. However, the

1775-S4B scanner does recognize lower case letters.

After you enter the command line above, the 1775-S4B scanner enters the

edit mode by displaying the following lines on the CRT:

<EOB>

*

<EOB> means end of block and signifies that the file, or the memory area

for the procedure is currently empty.

Next, you have to tell the 1775-S4B scanner that you want to insert some

text. So type:

I [ENTER]

When the cursor moves to the line after the asterisk, the 1775-S4B scanner

is ready for you to enter a line.

Type:

P ‘PRINTING ON THE’[ENTER]

P ‘SCREEN’[ENTER]

53

Page 42

Chapter 5

Getting Started in Report Generation

The 1775-S4B scanner’s line pointer or cursor moves to the next line.

Now exit the insert mode by pressing [ENTER].

The 1775-S4B scanner returns the * signifying the edit mode.

Then press E followed by [ENTER] to exit the edit mode.

The 1775-S4B scanner returns the S4B> prompt. You can now execute

your procedure.

Just type:

S4B> @TEST1

If you followed the instructions, the CRT displays the lines:

PRINTING ON THE

SCREEN

S4B>

Figure 5.1 summarizes the instructions presented in this section.

Figure 5.1

Creating

and Executing a Simple Procedure

S4B> ED @ TEST1

<EOB>

*I

P `PRINTING ON THE'

P `SCREEN'

S4B> @ TEST1

PRINTING ON THE

SCREEN

S4B>

54

Page 43

Chapter 5

Getting Started in Report Generation

Now type:

S4B> DI [ENTER]

DI is the abbreviation for the directory command. The directory command

returns:

All stored procedure names

Extended address of all procedures

Number of words used by each procedure

If you made a mistake while entering the procedure, you can edit your

procedure. Editing instructions are discussed in chapter 7 of this manual.

5.5

Executing Procedures from

the Message Instruction in

the User Program

In addition to commanding the execution of a procedure from the terminal,

you can use the message send instruction to execute a report generation

procedure from a ladder diagram program. You simply specify an extended

address of the 1775-S4B scanner which enables it to execute the procedure.

When the logic of the rung in the ladder diagram program is true, the Main

Processor Module (cat. no. 1775-LI, L2), or the (CPU), alerts the

1775-S4B scanner to execute the specified procedure. The CPU continues

to scan the rest of the program after alerting the 1775-S4B scanner. The

1775-S4B scanner then executes the procedures and turns on the done bit if

the procedure executes properly. If a problem occurs during procedure

execution, the 1775-S4B scanner turns on the error bit, and an error code

displays in the MSG instruction block.

The message instruction requires the following parameters:

Control file address

Channel address

Message type

Procedure name

The control file address is the data table file address that the PLC-3

processor uses to store the message status bits, error code, channel address,

and procedure name. The control file should be a binary file and can have a