Page 1

AllenBradley

PLC-3

Communication

Adapter Module

(Cat. No. 1775-KA)

User Manual

Page 2

Table of Contents

Introduction 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

About This Manual 11

Module Description 14

Specifications 16

Applications 16

Installation 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hardware

Programmable Configuration Parameters 219

Backup Configurations 227

Multiple 1775-KA Modules in One PLC-3 233

Installation

Data Highway Communication 31. . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . .

General 31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Some Terminology 31

Levels of Programming 34

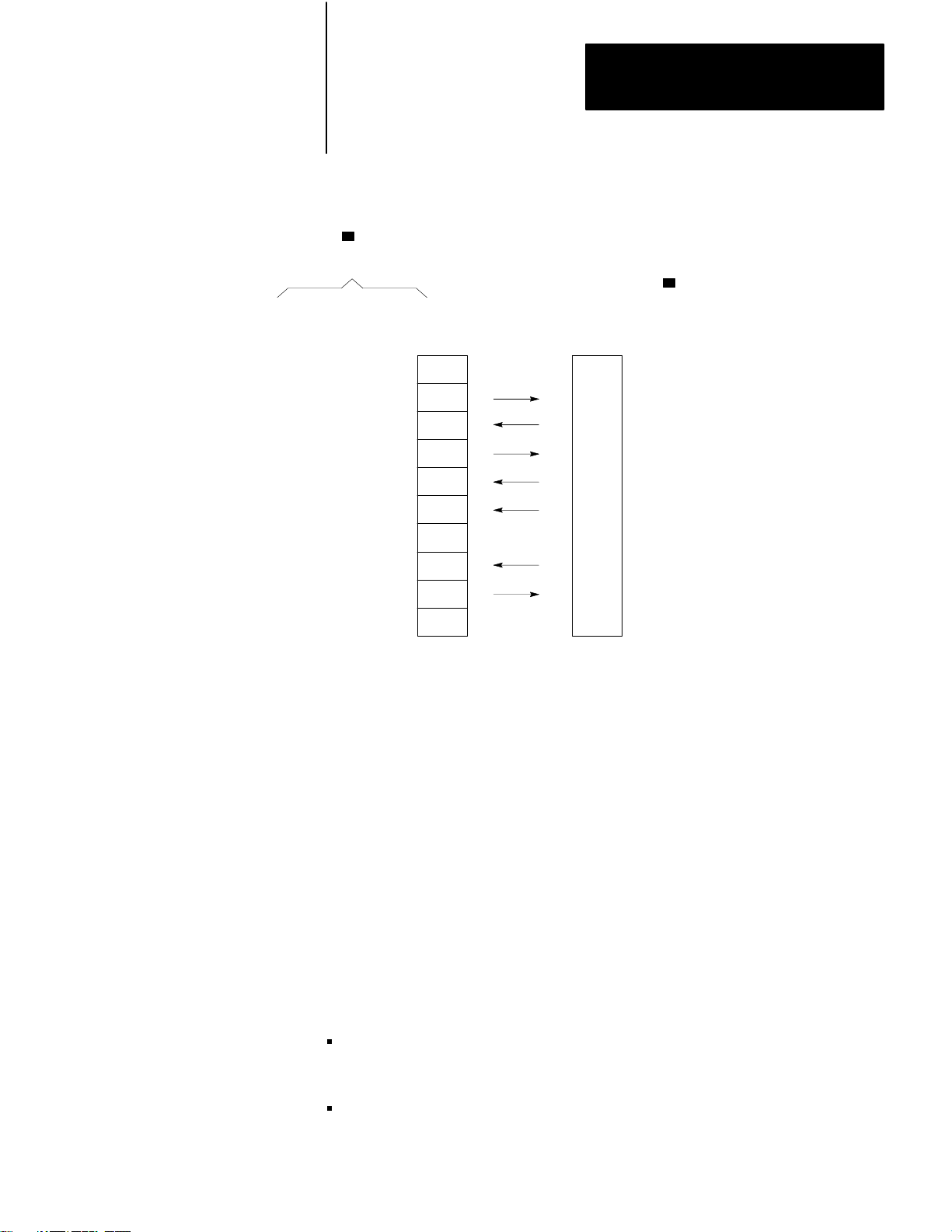

Data Transfers 36

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Addressing Rules and Examples 41. . . . . . . . . . . . . . . . . . . .

General 41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Number Systems 42

Addresses 43

Symbols 44

PLC-3 Address Specifications 47

PLC/PLC-2 Address Specifications 410

Remote Station Address Specifications 412

Expression 413

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Editing 51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General 51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Editing the Message Instruction 51

Allocating Memory 52

Editing Message Procedures 52

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 3

Table of Contentsii

Message Procedure Commands 61. . . . . . . . . . . . . . . . . . . .

General 61. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Assignment Command 62

CREATE Command 65

DELETE Command 65

Execute 66

EXIT Command 66

GOTO Command 67

IF Command 67

ON_ERROR Command 68

STOP Command 69

Functions 69

Comments 611

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Error Reporting 71. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General 71. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reporting Error Codes 71

Recovery from Errors 71

Error

Monitoring

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

72. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Programming Examples 81. . . . . . . . . . . . . . . . . . . . . . . . . . .

General 81. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Individual Commands 81

Message Procedure 84

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Computer to PC Communication 91. . . . . . . . . . . . . . . . . . . .

Introduction to Layered Communication 91. . . . . . . . . . . . . . . . . . . .

Full-Duplex vs Half-Duplex Protocol for the Data Link Layer 95

. . . . .

Full-Duplex Protocol 101. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General 101. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Definition of Link and Protocol 101

Full-Duplex Protocol 102

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

Half-Duplex Protocol 111. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Half-Duplex Protocol 111. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Multidrop Link 111

Transmission Codes 112

Link-Layer Packets 114

Protocol

Half-Duplex Protocol Diagrams 1113

Line

Monitoring

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Environment Definition

. . . . . . . . . . . . . . . . . . . . . . . . . .

117. . . . . . . . . . . . . . . . . . . . . . . . . .

1120. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 4

Table of Contents iii

The Network and Application Layer Protocol 121. . . . . . . . . . .

Network Layer 121. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Application Layer 126

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Message Formats A1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Introduction A1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Basic

Command Set

PLC-3 Commands A13

Privileged Commands A20

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Error Codes B1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General B1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Local Error Codes B1

Reply Error Codes B1

Remote Error Codes B3

Local and Reply Error Codes B4

Remote Error codes received from the 1771-KE/KF

1771-KA, and 1774-KA Modules B14. . . . . . . . . . . . . . . . . . . . . .

Remote Error Codes Received from the 1773-KA Module B15

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

, 1771-KG,

. . . . . . .

Diagnostic Counter Block C1. . . . . . . . . . . . . . . . . . . . . . . . .

Data Highway Port Counters C1. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Modem Port Counters C2

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Detailed Flowcharts D1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Overview D1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

UART Sharing D10

SLEEP and WAKEUP D17

POWERUP D18

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 5

Introduction

Chapter

1

General

About This Manual

The PLC–3 Communication Adapter Module (cat. no. 1775–KA) is an

optional module used in the PLC–3 main chassis or expander chassis. It

serves two purposes:

1. Interfacing the PLC–3 processor with the Allen–Bradley Data

Highway

2. Interfacing the PLC–3 processor with an intelligent RS–232–C

device

This manual describes the installation, programming, and operation of the

1775– KA module. This manual assumes that you are already thoroughly

familiar with the programming and operation of the PLC–3 processor. It

does not assume that you have any prior knowledge of the Allen–Bradley

Data Highway.

Organization

The remaining chapters of this manual are organized as follows:

Chapter 2 – describes installation of the 1775–KA module.

Chapter 3 – presents concepts and terminology for operating the

1775–KA module on the Data Highway.

Chapter 4 – presents general rules for specifying the data addresses you

use in message procedures.

Chapter 5 – explains how you create and edit message procedures and

commands for the 1775–KA module.

Chapter 6 – describes the command language you use in programming

message procedures.

Chapter 7 – describes how the 1775–KA module detects and reports

various types of errors.

Chapter 8 – presents detailed examples of 1775–KA module commands

and message procedures.

Chapter 9 – introduces a layered approach to writing a driver to enable

a computer to communicate to the 1775–K’s RS–232–C channel.

11

Page 6

Chapter 1

Introduction

Chapter 10 – describes how to write a full–duplex line driver to enable

a computer to communicate to the 1775–KA’s RS–232–C channel.

Chapter 11 – describes how to write a half duplex line driver to enable

a computer to communicate to the 1775–KA’s RS–232–C channel.

Chapter 12 – describes the network and application layers of a software

driver to enable a computer to communicate to the 1775–KA’s

RS–232–C channel.

Appendix A – shows detailed message formats.

Appendix B – lists error codes reported by the 1775–KA, 1771–KA,

1771–KG, 1771– KE/KF, 1773–KA, and 1774–KA modules.

Appendix C – lists diagnostic counters stored at the 1775–KA,

1771–KA, 1771–KG, 1771–KE/KF, 1773–KA and 1774–KA modules.

Appendix D – gives detailed flow charts of an example of software

logic for implementing a full–duplex protocol.

Related Documentation

Read this manual in conjunction with the documentation listed in

Table 1.A and Table 1.B. Table 1.A lists related PLC–3 documentation

and Table 1.B lists related Data Highway documentation.

Table 1.A

PLC-3 Documentation

Related

Publication

Number

(Old/New No.)

1775-800/1775-6.7.1

1775-801/1775-6.4.1

1775-806/1775-6.5.3

1775-900/1775-2.1

1775-901/1775-2.2

1775-902/--------

1775-904/1775-2.4

1775-908/1775-2.6

1775-910/1775-2.8

PLC-3 Installation and Operations Manual

PLC-3 Programming Manual

I/O Scanner-Message Handling Module User

Manual

PLC-3 Controller Data Sheet

PLC-3 Main Processor Module Data Sheet

PLC-3 Memory Organization Data Sheet

Power Supply Data Sheet

PLC-3 Memory Modules Data Sheet

PLC-3 Main Chassis Data Sheet

Title

's

12

Page 7

Table 1.B

Related Data Highway Documentation

Publication

Number

(Old/New No.)

Chapter 1

Introduction

Title

1770-810/1770-6.2.1

1771-801/1771-6.5.1

1771-802---------

1771-811/1771-6.5.8

1771/822/1771-6.5.15

1773-801/1773-6.5.2

1774-819/1774-6.5.8

6001-800/6001-6.5.1

6001-802/---------

Data Highway Cable Assembly and Installation Manual

Communication Adapter Module (cat. no. 1771-KA)

User'

s Manual

Communication Controller Module (cat. no.1771-KC/KD)

User'

s Manual

PLC-2 Family/RS-232C Interface Module (cat.no.

1771-KG) User's Manual

Data Highway/RS-232-C Interface Module (cat. no.

1771-KE/KF) User's Manual

PLC-4 Communication Interface Module (cat. no.

1773-KA) User's Manual

Communication Adapter Module (cat. no. 1774-KA)

User'

s Manual

6001 NET (For VMS) Network Communications Software

User'

s Manual

6001 NET (For RSX-1

Software User

1) Network Communication

'

s Manual

Terminology

In this manual you will read about the various commands the 1775–KA

module can send and/or receive. To distinguish between commands, we

use some of the following terms:

a protected command can read or write only specified areas of PC data

table. A switch on the PLC, PLC–2 Family, and PLC–4 Controllers

determines if the PC will accept only protected commands from another

PC or an RS–232–C device. When you use a protected command, you

may have a limited area that you can read or write in the other station’s

memory.

an unprotected command can read or write into any area of PC data

table. A switch on the PC that receives the commands determines if the

PLC, PLC–2 Family, and PLC–4 controller will accept unprotected

commands from another PC or an RS–232–C device.

privileged commands are sent by intelligent RS–232–C devices only.

Such devices include computers and intelligent terminals.

Allen–Bradley PC’s do not send privileged commands, but receive and

reply to them. A privileged command can read or write into any area in

the memory of a PC, whether or not switches on the PC have been set

to allow it to receive only protected commands. The term physical

13

Page 8

Chapter 1

Introduction

command is sometimes used synonymously to mean privileged

command.

non–privileged commands include any command that both PC’s and

RS–232–C device can send. The non–privileged commands include the

protected write and unprotected read and write commands. The

non–privileged commands are also referred to as “PLC/PLC–2 type”

commands.

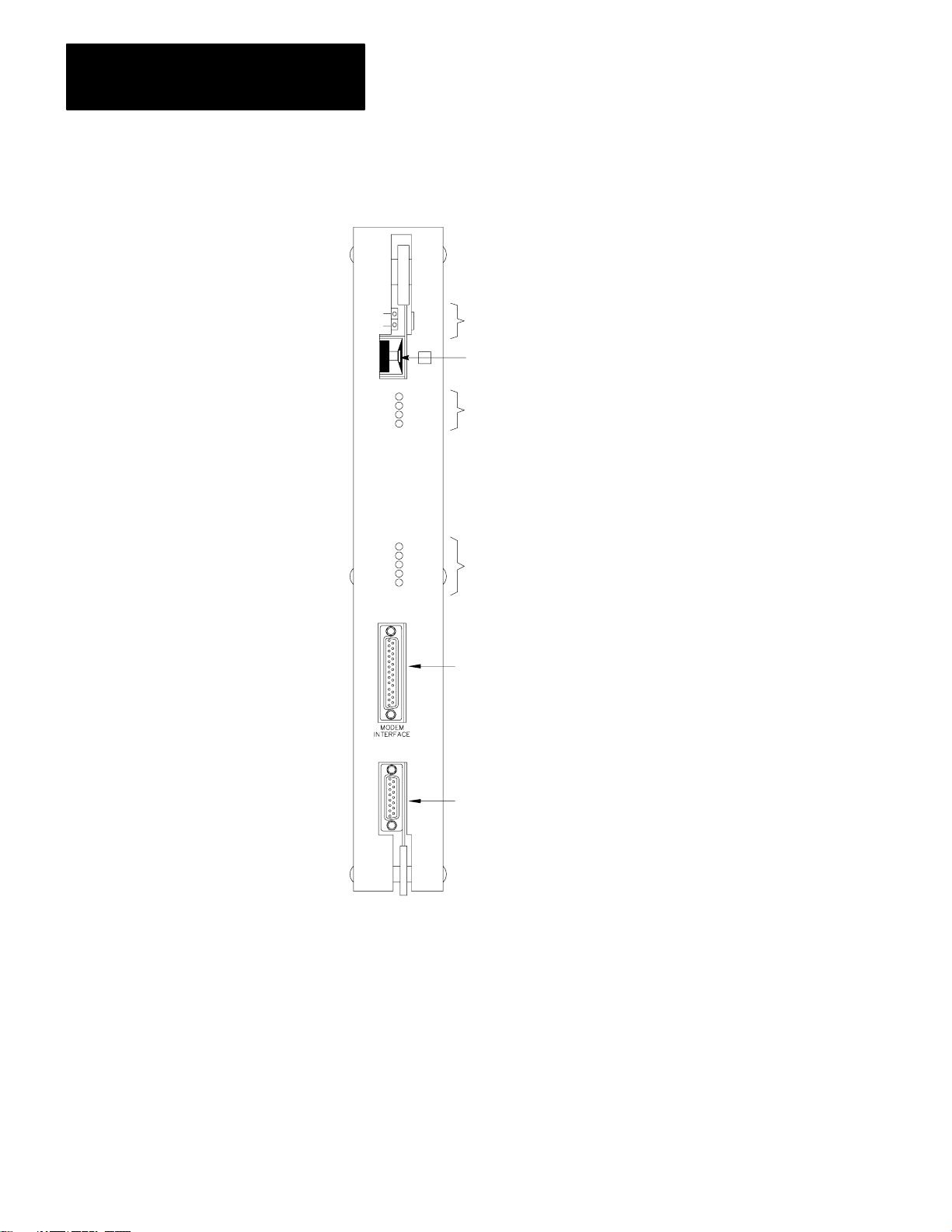

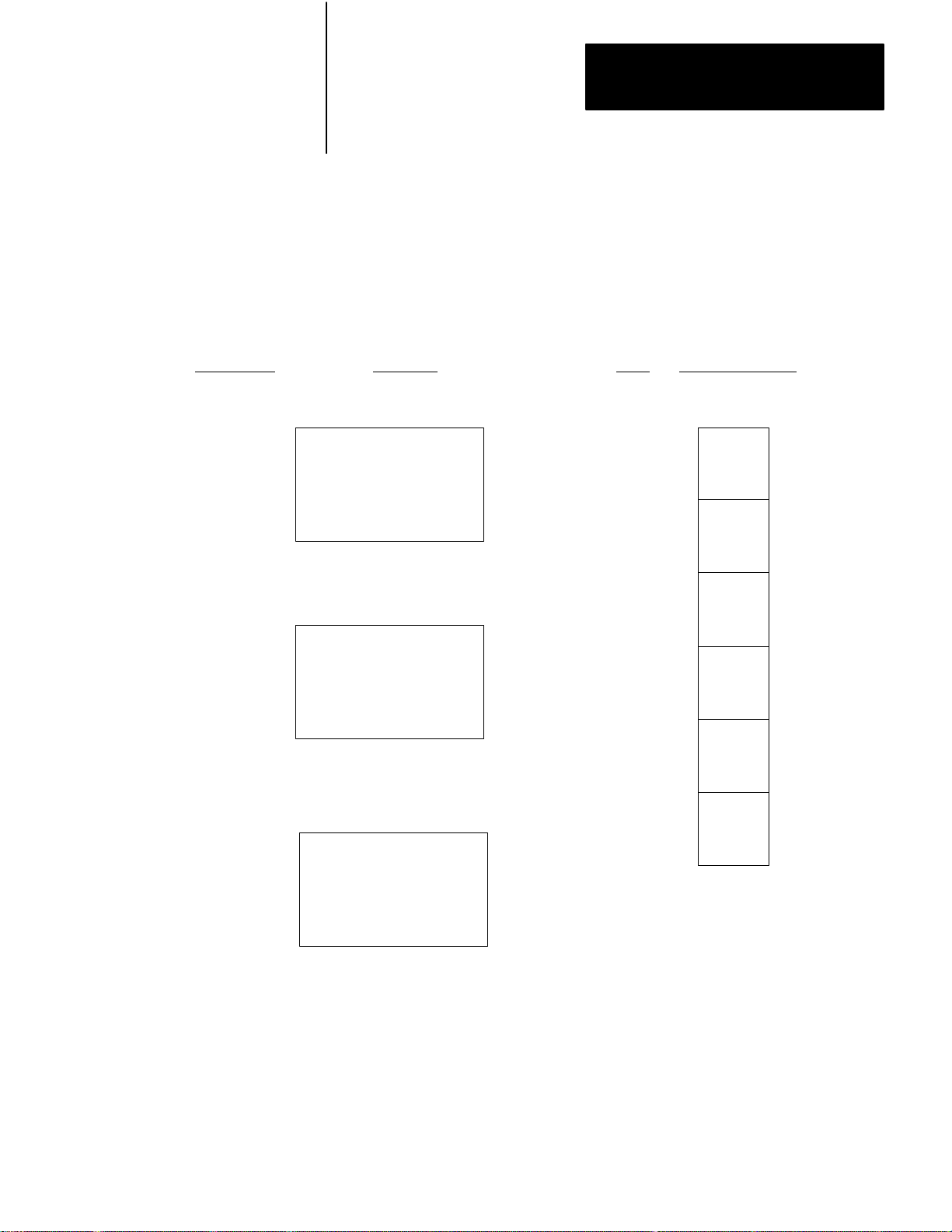

Module Description

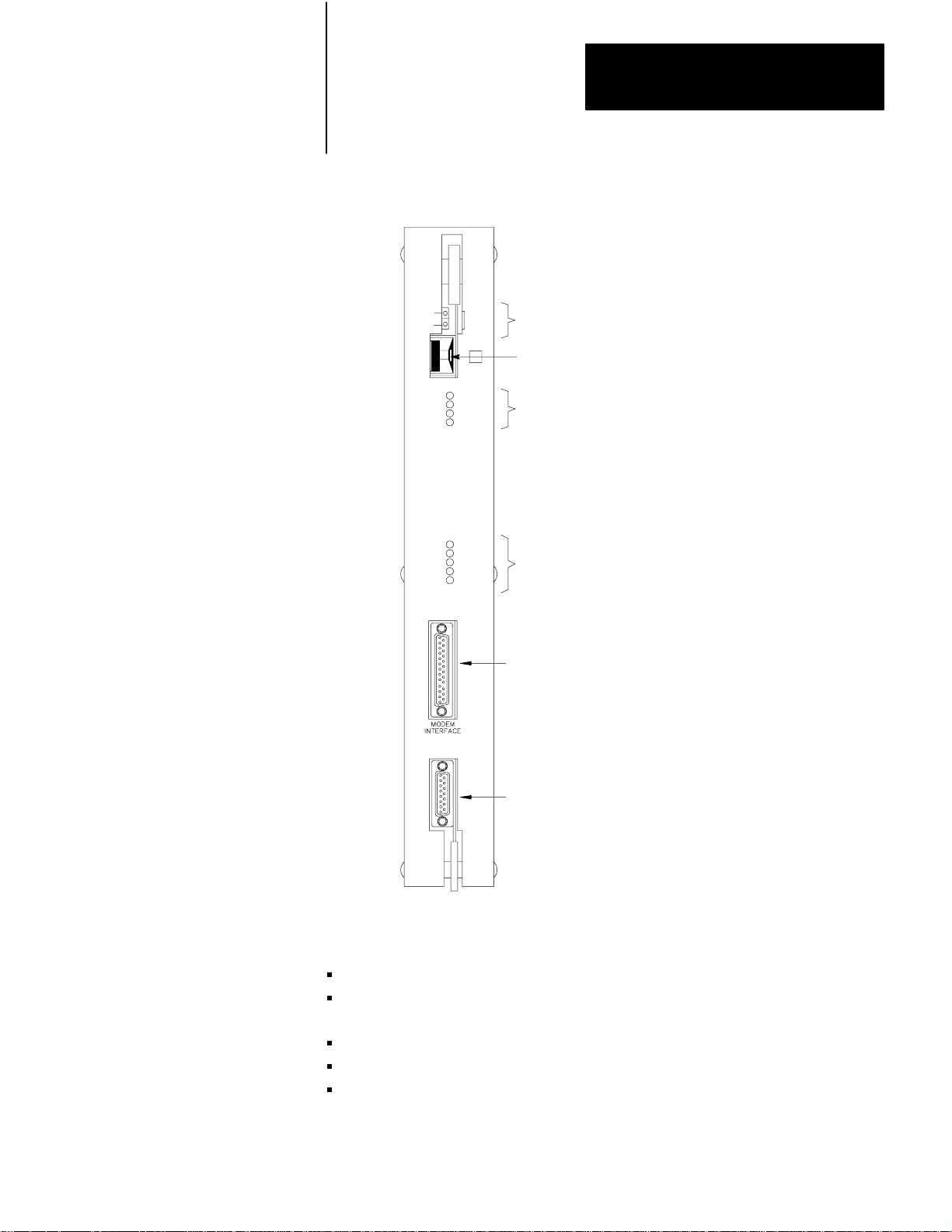

Figure 1.1 illustrates the front of the 1775–KA module. The module has

the following hardware features:

Self–test diagnostic indicators

Thumbwheel switch for setting identification number

Two ports– one for Data Highway and one for RS–232–C

communication

Two sets of indicators – one for each port

Switches for selecting fault responses and communication option

14

Page 9

Chapter 1

Introduction

Figure 1.1

Communication

PASS

FAIL

COMMUNICATION

ADAPTER

Adapter Module (Cat. No. 1775-KA)

KA

XMTG

RCVG

ERR

DIS

MODEM

INTERFACE

XMTG

RCVG

RDY

ERR

DIS

DATA

HWY

SELF

TEST

NO

Self–Test Indicators

Thumbwheel Switch

RS–232–C port Indicators

Data Highway Port Indicators

RS–232–C Port

Data Highway Port

DATA

HWY

10000-I

In addition, the module provides the following software features:

Programmable configuration parameters

Command language that allows for complex logic decisions, looping,

and nesting

Symbolic representation of data and addresses

Embedded arithmetic expressions and logic operations

Decimal, octal, or BCD (binary coded decimal) data entry

15

Page 10

Chapter 1

Introduction

Specifications

Function

Interface the PLC-3 Processor

with the Allen-Bradley Data

Highway and/or with an RS-232-C

device

Location

Single slot in PLC-3 main chassis

or expander chassis

Communication Ports

Data Highway

RS-232-C Modem

Applications

Table 1.C lists the specifications for the 1775–KA module.

Table 1.C

Specifications

Module

Communication Rate

T

o Data Highway - 57.6 kilobaud

recommended

o modem-programmable from 1

T

baud to 19.2 kilobaud

Cabling

o Data Highway-Data Highway

T

dropline cable (Cat.no.1770-CD or

equivalent

T

o modem-Modem interface cable

(cat. no. 1775-CKA or equivalent)

Backplane Power Requirement

2.5A max. @ +5V DC

Ambient T

10

Humidity Rating

emperature Rating

00 o 600C (operational)

0

-40

to

850C (storage)

5% to 95% (without condensation)

As already mentioned, the 1775–KA module serves two main purposes:

Interfacing the PLC–3 processor with the Allen–Bradley Data Highway

Interfacing the PLC–3 processor with an intelligent RS–232–C device

You can use the module for both of these purposes simultaneously.

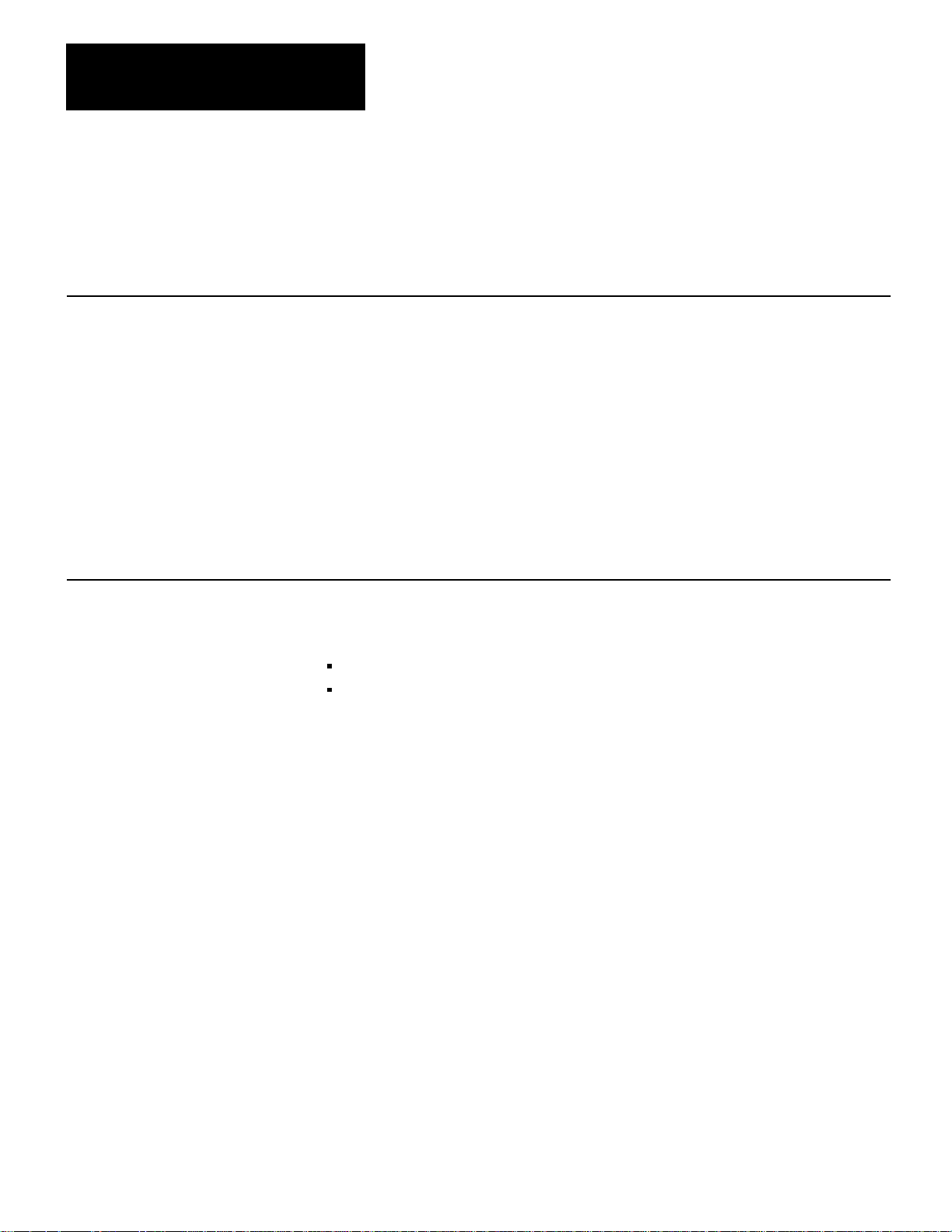

In Data Highway applications, the module serves as an interface between

the PLC–3 programmable controller and the Allen–Bradley Data

Highway. The Data Highway is an industrial communication network

that links together as many as 64 distinct stations. Each station can consist

of a programmable controller (such as the PLC–3), a computer, or an

intelligent RS–232–C device. The central trunkline of the Data Highway

may be up to 10,000 feet long, and each station may be as far as 100 feet

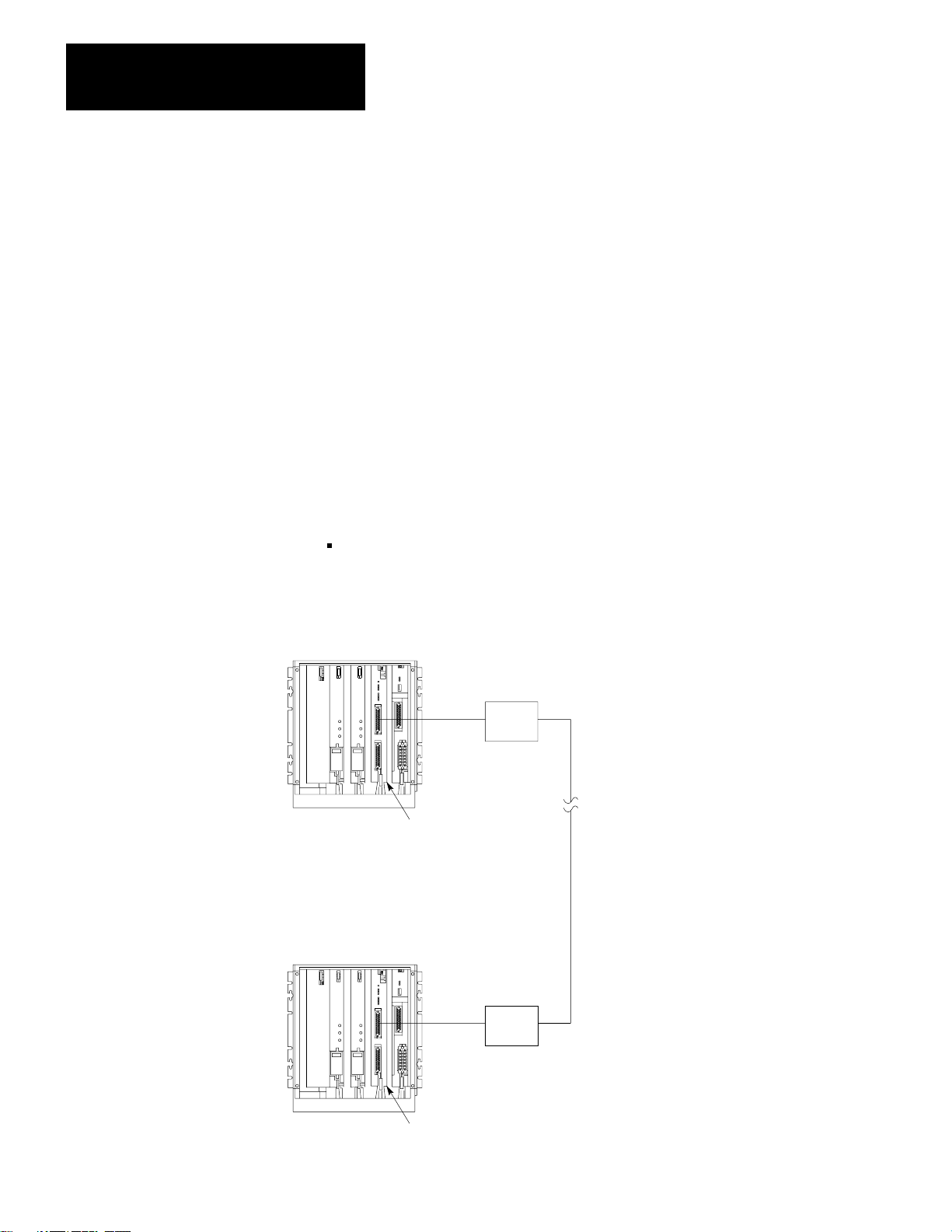

from the trunkline. Figure 1.2 gives an example of a Data Highway

configuration.

16

Page 11

Chapter 1

Introduction

Figure 1.2

Example

PLC-3

Controller

1775-KA

Data Highway Configuration

Allen-Bradley

Data Highway

PC

Module

PC

PC

PC

NOTE: All PCs are Allen-Bradley

PC

Up to 64 Stations

10001–I

17

Page 12

Chapter 1

Introduction

The PLC–3 can support multiple 1775–KA modules in the same PLC–3

chassis. This provides the PLC–3 with concurrent access to several

independent Data Highways.

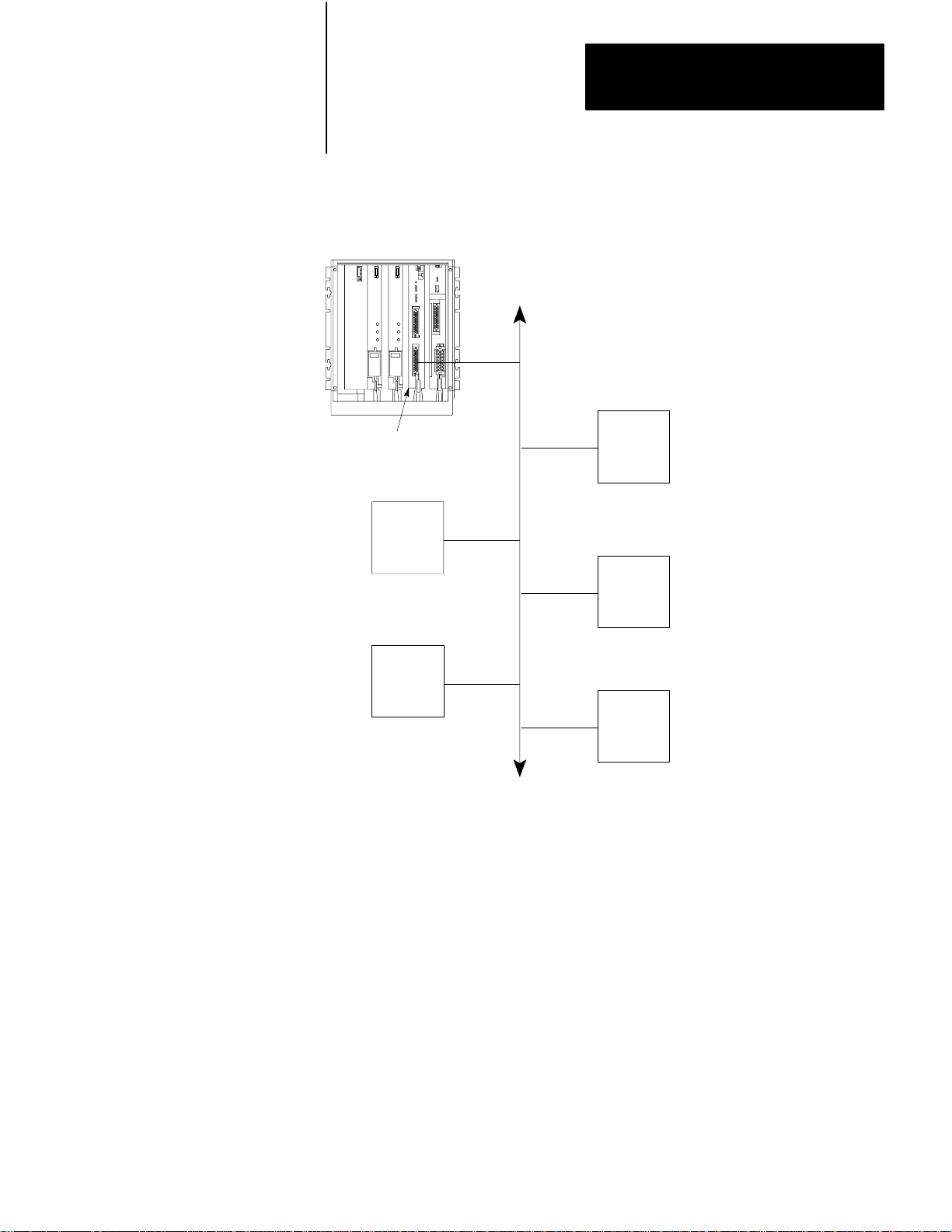

The 1775–KA module can also serve as an interface between the PLC–3

programmable controller and an intelligent RS–232–C compatible device

or any Allen–Bradley PC and its Data Highway module. Some examples

of this application of the module are the following:

Interfacing two PLC–3 controllers through a modem link

Interfacing a PLC–3 controller with a computer (either directly or

through modems)

Interfacing a PLC–3 controller with a remote Data Highway through a

modem link

Interfacing a PLC–3 controller as a slave station on a multipoint

modem link

Interfacing a PLC–3 controller on a point–to–point link with PLC–2

Family processor through a 1771–KG module (The 1772–LR processor

is not supported in this configuration.)

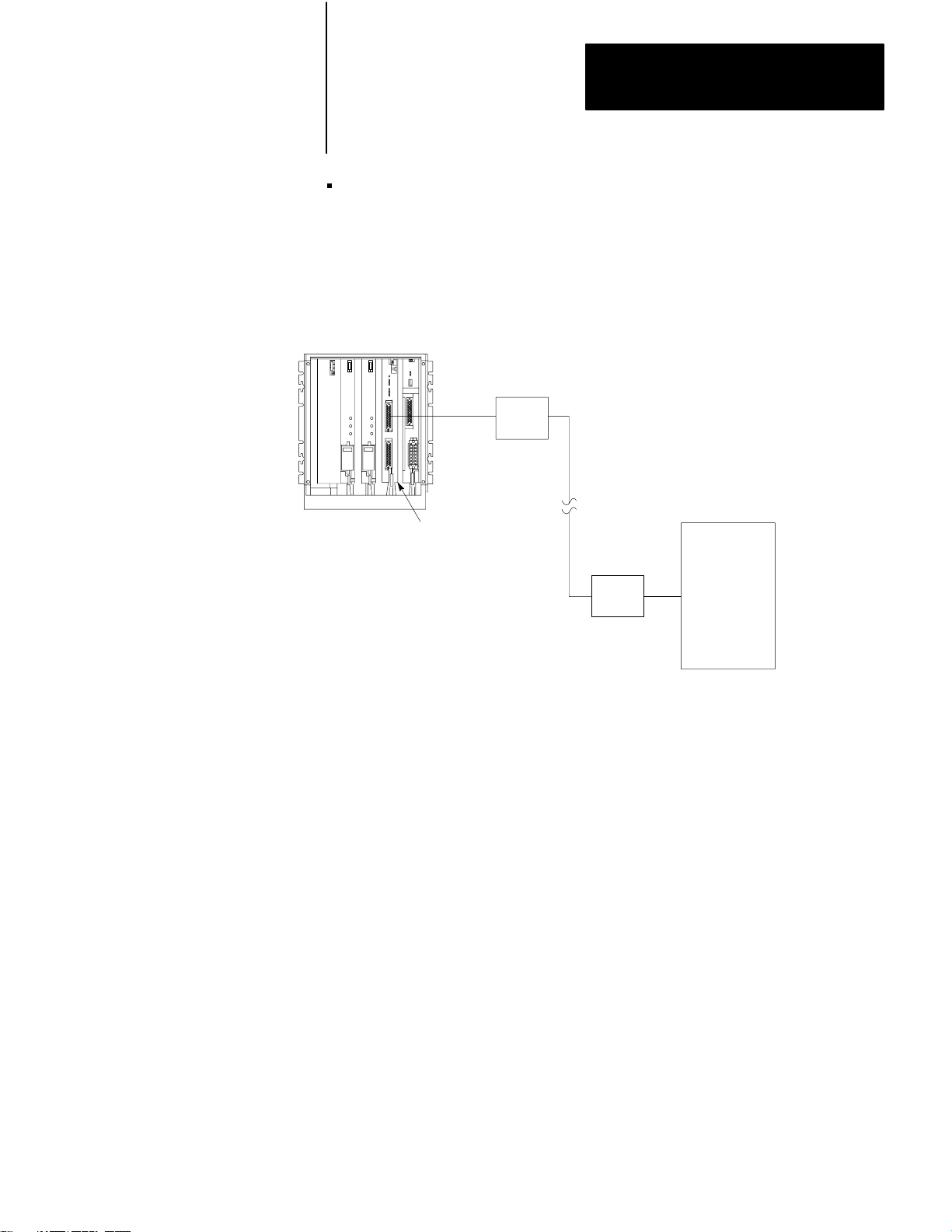

Figure 1.3 shows the 1775–KA module in a typical modem application.

Figure 1.3

Modem Application

Typical

PLC-3

Controller

Modem

Computer

1775-KA

NOTE: Modems required

only

for distances greater

than 50 feet.

Module

Modem

10002–I

18

Page 13

Installation

Chapter

2

General

Hardware Installation

This chapter describes installation of the 1775–KA module in two phases:

Installing hardware

Programming configuration parameters through the PLC–3 LIST

function

Please read the entire manual carefully before attempting to install the

module.

For best results when installing the 1775–KA module, proceed in the

order indicated below.

Switch Settings

The 1775–KA module has a number of hardware switches that must be set

before the module can be installed in the PLC–3 processor. There is a

thumbwheel switch on the front edge of the module and a group of option

switches on the bottom edge.

Thumbwheel Switch

Figure 2.1 shows a thumbwheel switch on the front edge of the 1775–KA

module. This thumbwheel switch designates the number used by the

PLC–3 processor to distinguish one 1775–KA module from another.

Rotate the thumbwheel to select the desired identification number.

21

Page 14

Chapter 2

Installation

Figure 2.1

V

iew of 1775-KA Module

Front

PASS

FAIL

KA

XMTG

RCVG

ERR

DIS

COMMUNICATION

ADAPTER

XMTG

RCVG

RDY

ERR

DIS

MODEM

INTERFACE

DATA

HWY

SELF

TEST

NO

Self–Test Indicators

Thumbwheel Switch

RS–232–C port Indicators

Data Highway Port Indicators

RS–232–C Port

22

Data Highway Port

DATA

HWY

If there is only one 1775–KA module in the PLC–3 chassis, set its

thumbwheel switch to the number 1. If there are multiple 1775–KA

modules in the same PLC–3 chassis, set their thumbwheel switches to

consecutive numbers, starting with the number 1. You may write the

selected number in the space provided beside the thumbwheel switch.

10003-I

Page 15

Chapter 2

Installation

CAUTION: To guard against unpredictable operation of the

PLC–3 processor, do not change the setting on any thumbwheel

switch while the 1775–KA module is powered–up.

Option Switches

Figure 2.2 shows a set of four option switches on the bottom edge of the

1775– KA module. Switches 1 and 2 are used when the PLC–3 controller

is programmed to operate in a backup configuration. Switch number 1

determines whether or not a fault in the 1775–KA module will cause the

primary PLC–3 controller to switch over to the backup PLC–3. Switch

number 2 determines whether or not the 1775–KA module will disable its

Data Highway port when the PLC–3 becomes deactive. Switch 3 is for

RS–232–C communication. Switch 4 is reserved for future use and

should always be left open (up, or off). Use Table 2.A below to determine

the appropriate switch setting:

Figure 2.2

Option

Switches

23

Page 16

Chapter 2

Installation

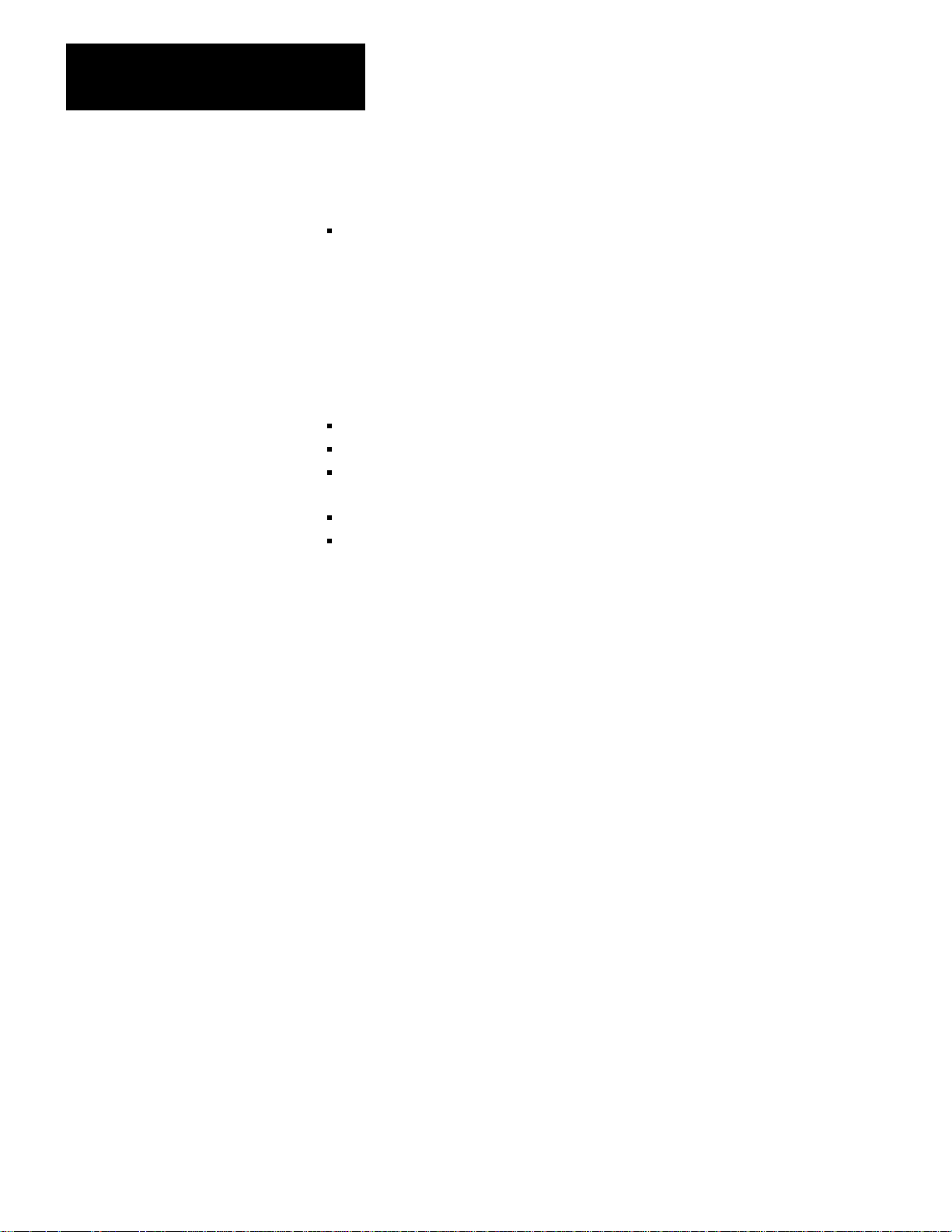

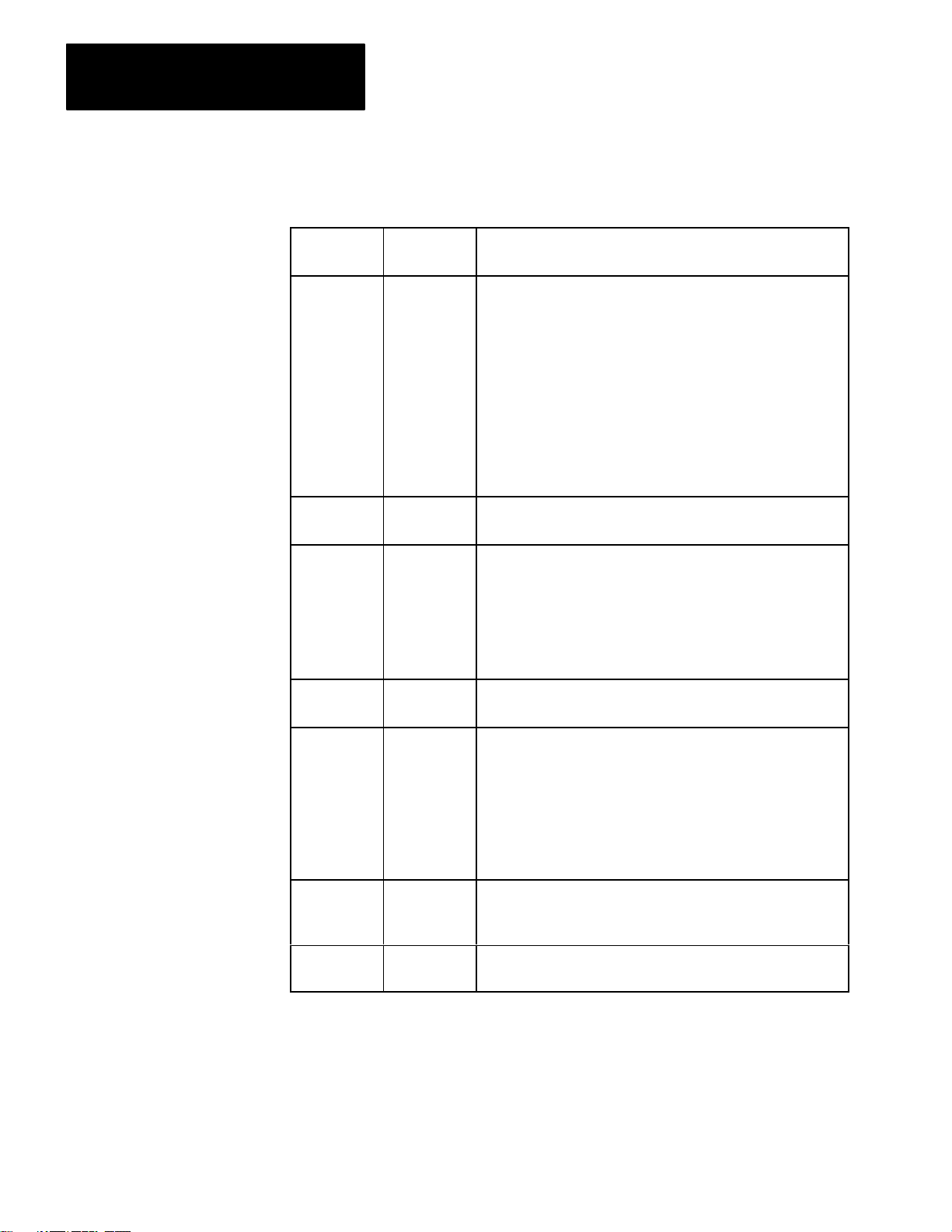

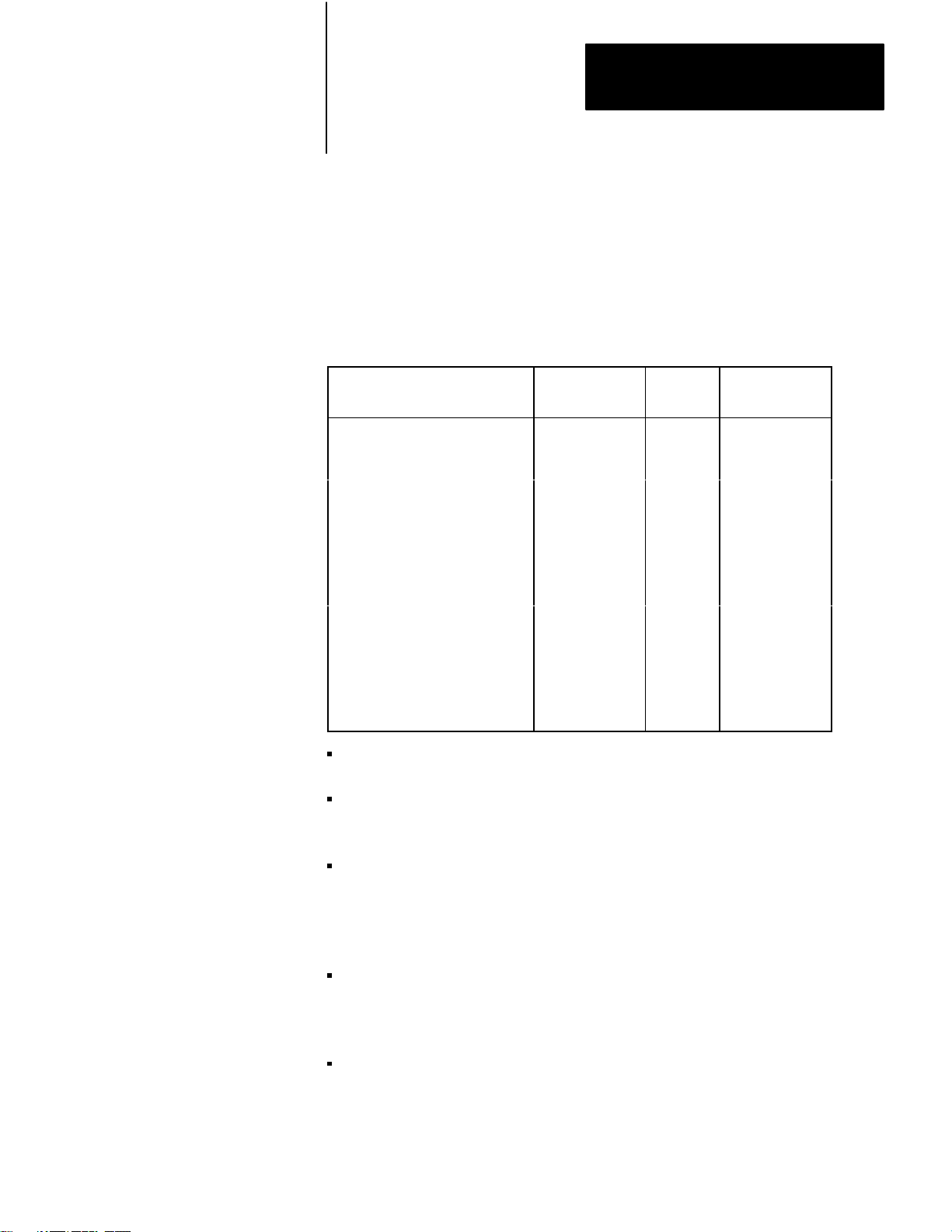

Table 2.A

1775-KA Switch Settings

If this

switch: Is: Then

1 OPEN

1 CLOSED

2 OPEN

2 CLOSED

the PLC will switch over to backup whenever one of the

following fault conditions occurs:

1. The 1775-KA module tries to hold control of the PLC-3

backplane for more than 138 microseconds.

2.

The 1775-KA module experiences a execution timeout of

more than 32 milliseconds

3.

The 1775-KA module experiences an internal stack

overflow

4.

The 1775-KA module experiences severe Data Highway

communication problems.

the primary PLC-3 will not switch to backup when a fault occurs

with the 1775-KA module.

the 1775-KA module will disable is Data Highway port

whenever the primary PLC-3 controller becomes deactive. The

module will no longer be able to transmit or receivemessages

through its Data Highway port.

Also, setting switch 2 to open enables the backup operation

feature.

the Data Highway port on the module will remain active if the

primary PLC-3 becomes deactive.

24

3 OPEN

3 CLOSED

4 OPEN

the module may be connected up to 7,000 cable feet away from

a 1771-KF

In addition to setting switch 3 to the open position, you must

also set switch 2 to closed position. This makes pin 25 on the

RS-232-C port of the 1775-KA module active (refer to figures

2.8 to 2.10). Note that switch 3 must always be closed for

communication with an RS-232-C device other than a

1771-KF

the MODEM INTERF

connected to a standard RS-232-C device that is located within

50 cable feet of the module.

Switch 4 is reserved for future use and should always be left

open.

, a 1771-KG, 1773-KA or another 1775-KA module.

, 1771-KG, 1773-KA, or 1775-KA module.

ACE port of the 1775-KA module may be

Module Placement

After setting the thumbwheel switch, insert the module into any one of the

module slots in the PLC–3 processor chassis. Whenever you power–up

the processor, the module will receive power also.

Page 17

Chapter 2

Installation

Indicators

There are three sets of LED indicators on the front of the 1775–KA

module (Figure 2.1). The first group, labeled SELF–TEST, indicates the

result of internal diagnostic tests that the module continuously performs

on its own hardware and firmware. The second group, labeled MODEM

INTERFACE, indicates the status of communication through the module’s

RS–232–C port. The last group, labeled DATA HWY, indicates the status

of communication through the module’s Data Highway port.

Table 2.B. tells what each indicator means.

Table 2.B

Indicators

LED

Indicator

Group

Self-Test PASS

Modem

Interface

Data

Highway

Indicator

Label

FAIL

XMTG

RCVG

ERR

DIS

XMTG

RCVG

RDY

ERR

DIS

Normal

State

ON

OFF

OFF

OFF

OFF

OFF

OFF

OFF

ON or

OFF

OFF

OFF

Meaning When ON

Module has passed its own internal diagnostic test

Module has failed its own internal diagnostic tests

Module is transmitting a message over the modem interface port

Module is receiving a message over the modem interface port.

User programming error

Module is disabled due to a fault in the PLC-3 processor, or modem interface

port is disabled through the LIST function

Module is transmitting a message over the Data Highway port

Module is receiving a message over the Data Highway port

[1]

Module is ready to transmit a message over the Data Highway port and is

waiting to acquire mastership of the highway

User programming error or communication error on either the Data Highway or

the Modem port

Module is disabled due to a fault in the PLC-3 processor

is disabled through the LIST function

, or Data Highway port

[1]

Depends

on amount of data highway activity

25

Page 18

Chapter 2

Installation

Data Highway Cable Connections

There are two cable connectors, or ports, on the front of the 1775–KA

module (Figure 2.1). The bottom port, labeled DATA HWY., is for

connection to the Allen–Bradley Data Highway. If you are using the

1775–KA module in a Data Highway application, plug the Data Highway

dropline cable into this port. For details on the installation of the Data

Highway cable, refer to the Data Highway Cable Assembly and

Installation Manual (publication 1770–810).

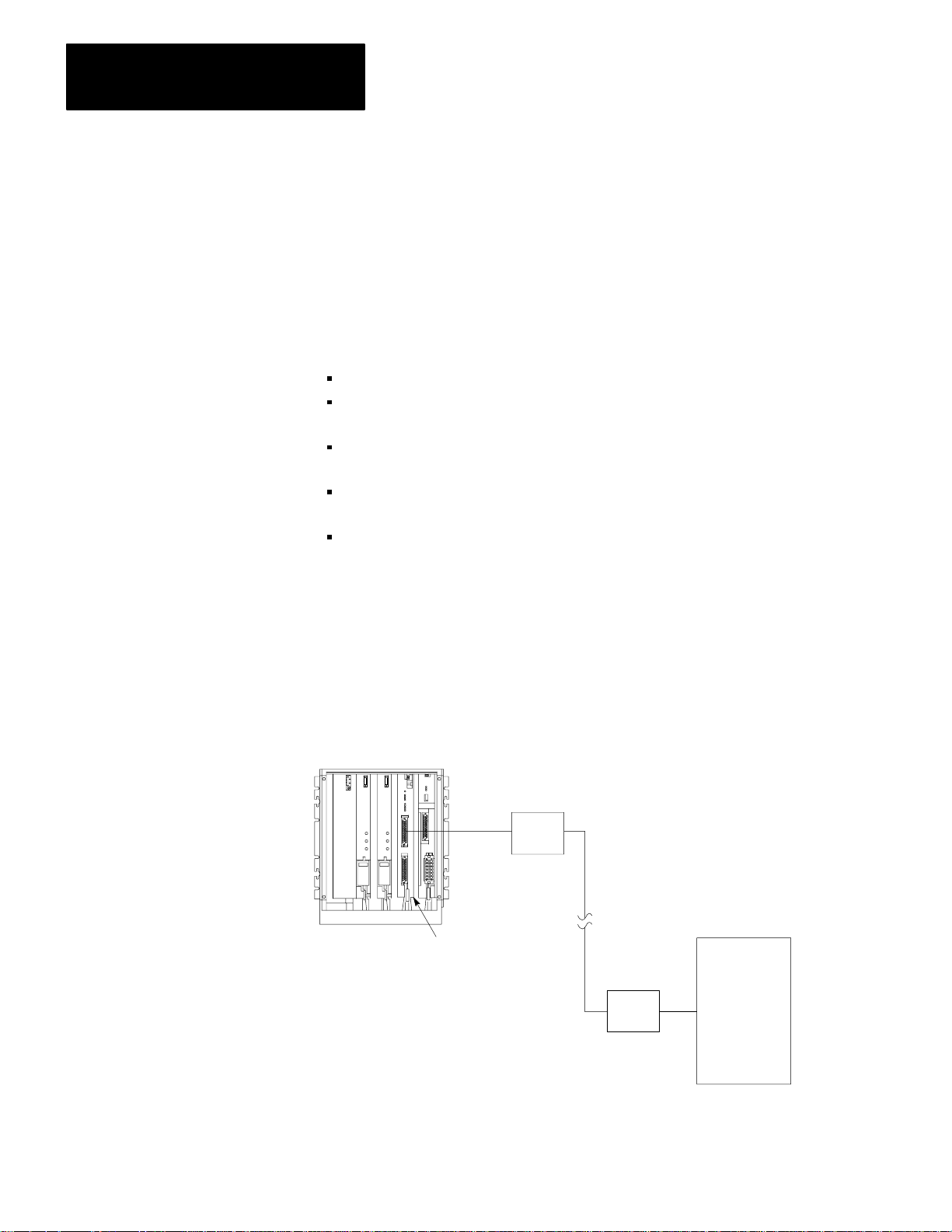

RS-232-C Cable Connections

The RS–232–C port, labeled MODEM INTERFACE on the 1775–KA

module, can interface with any RS–232–C device that is capable of

understanding and generating the communication protocol described in

this chapter. Some typical RS–232–C applications are:

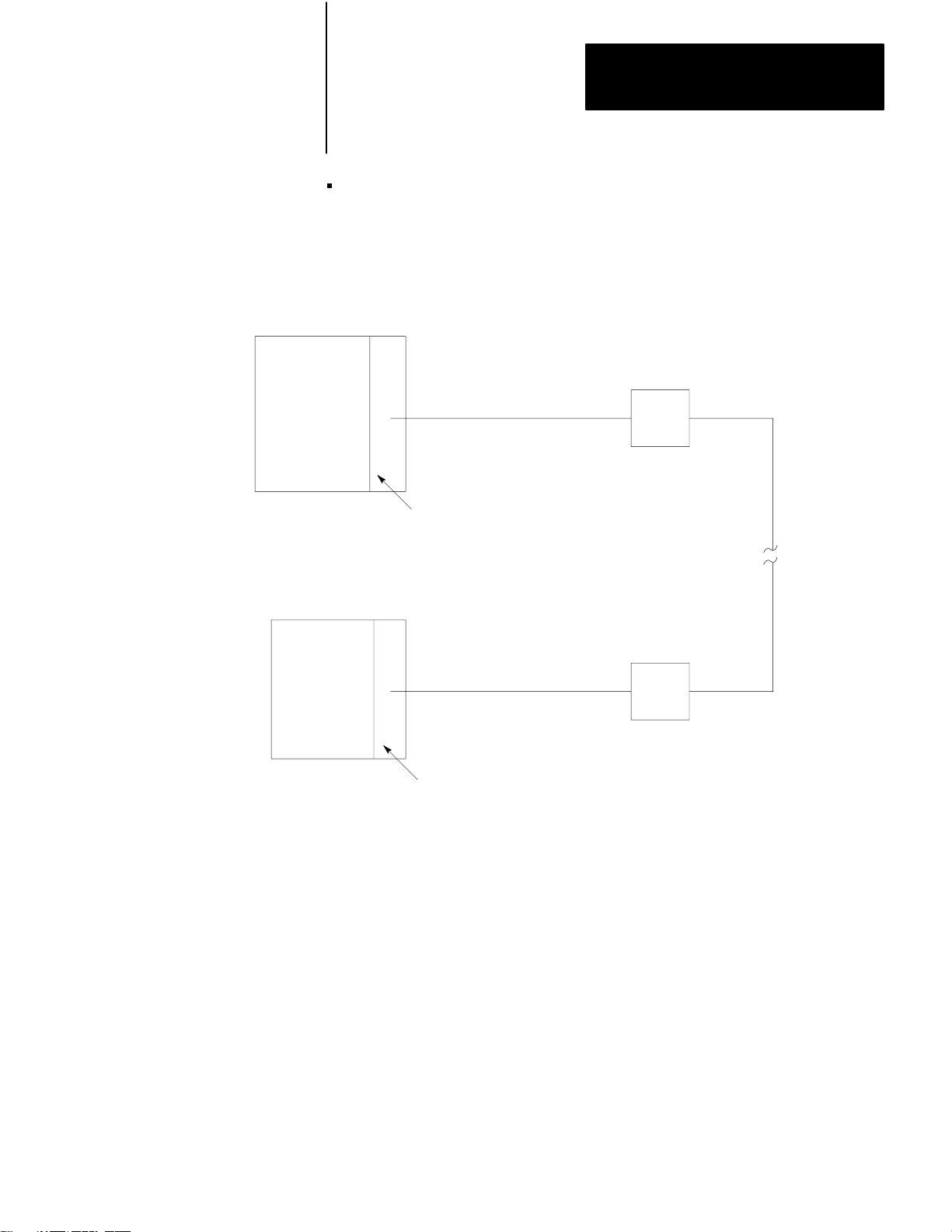

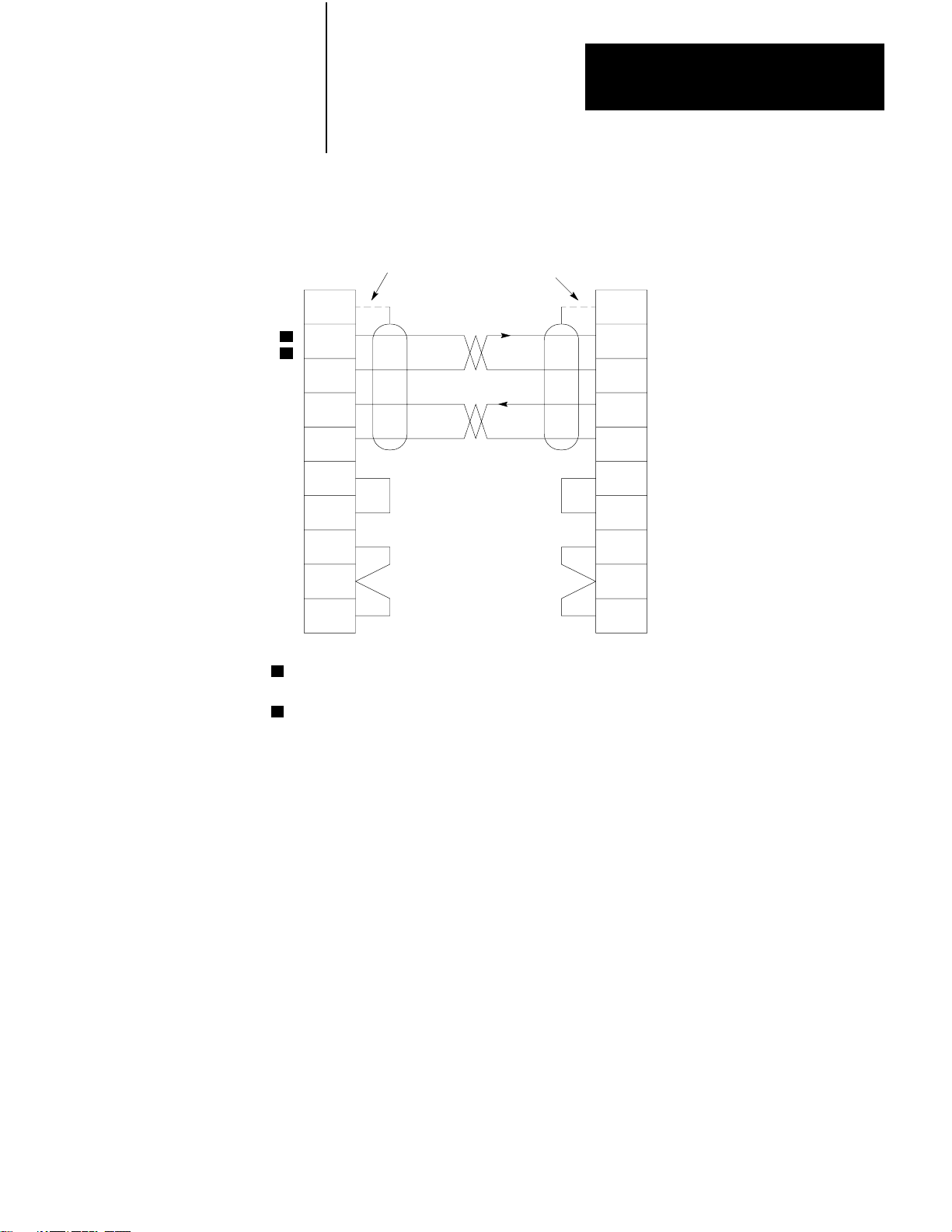

Interfacing two PLC–3 controllers through a modem link (Figure 2.3)

Figure 2.3

Two PLC-3 Controllers

Linking

PLC-3 Controller

Modem

1775-KA

PLC-3 Controller

Module

Modem

26

1775-KA

Module

NOTE: Modems required only

for distances greater

than 50 feet.

10004–I

Page 19

Chapter 2

Installation

Interfacing a PLC–3 controller with a computer, either directly or

through modems (Figure 2.4)

Figure 2.4

a PLC-3 Station to a Computer

Linking

PLC-3

Controller

Modem

Computer

1775-KA

Module

Modem

10005–I

27

Page 20

Chapter 2

Installation

PLC-3

Controller

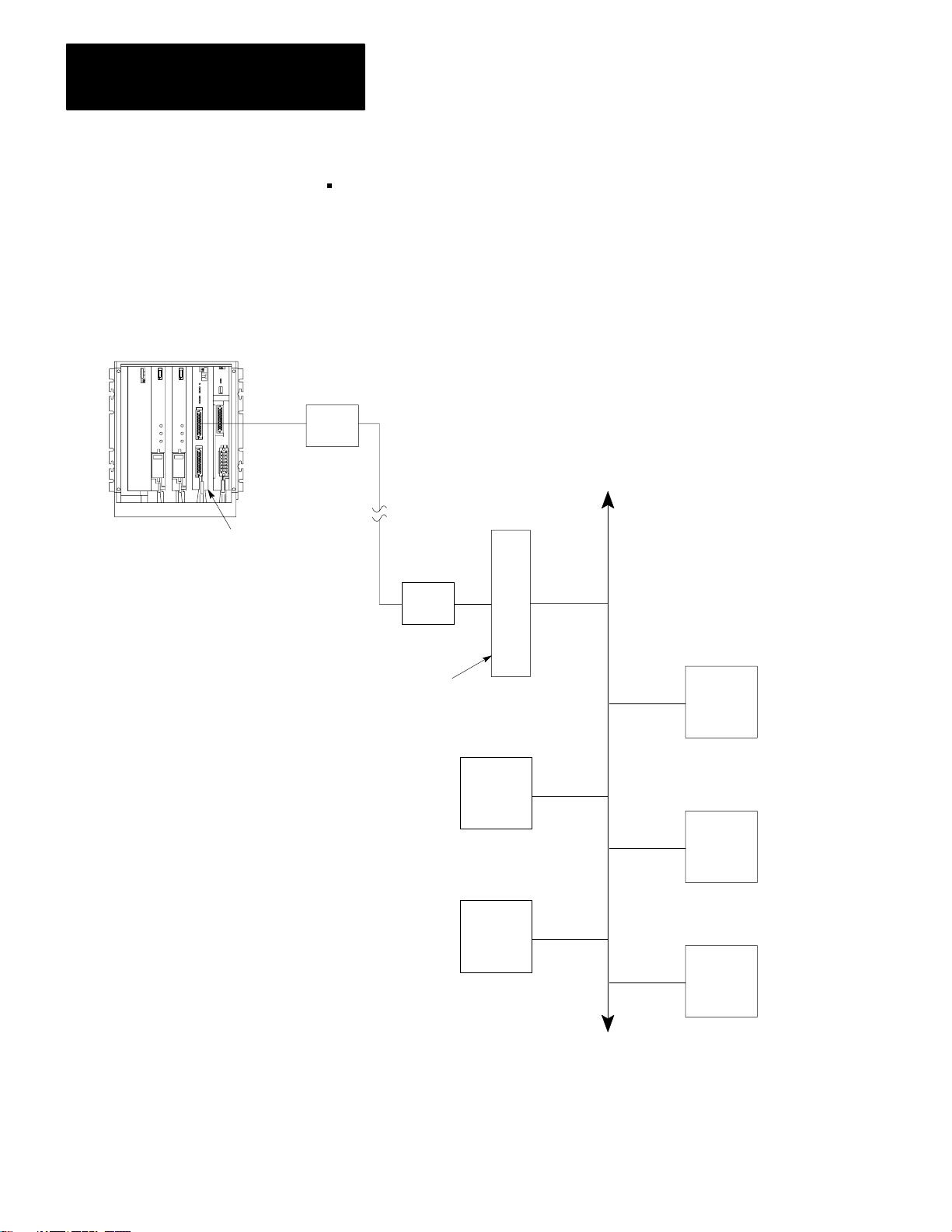

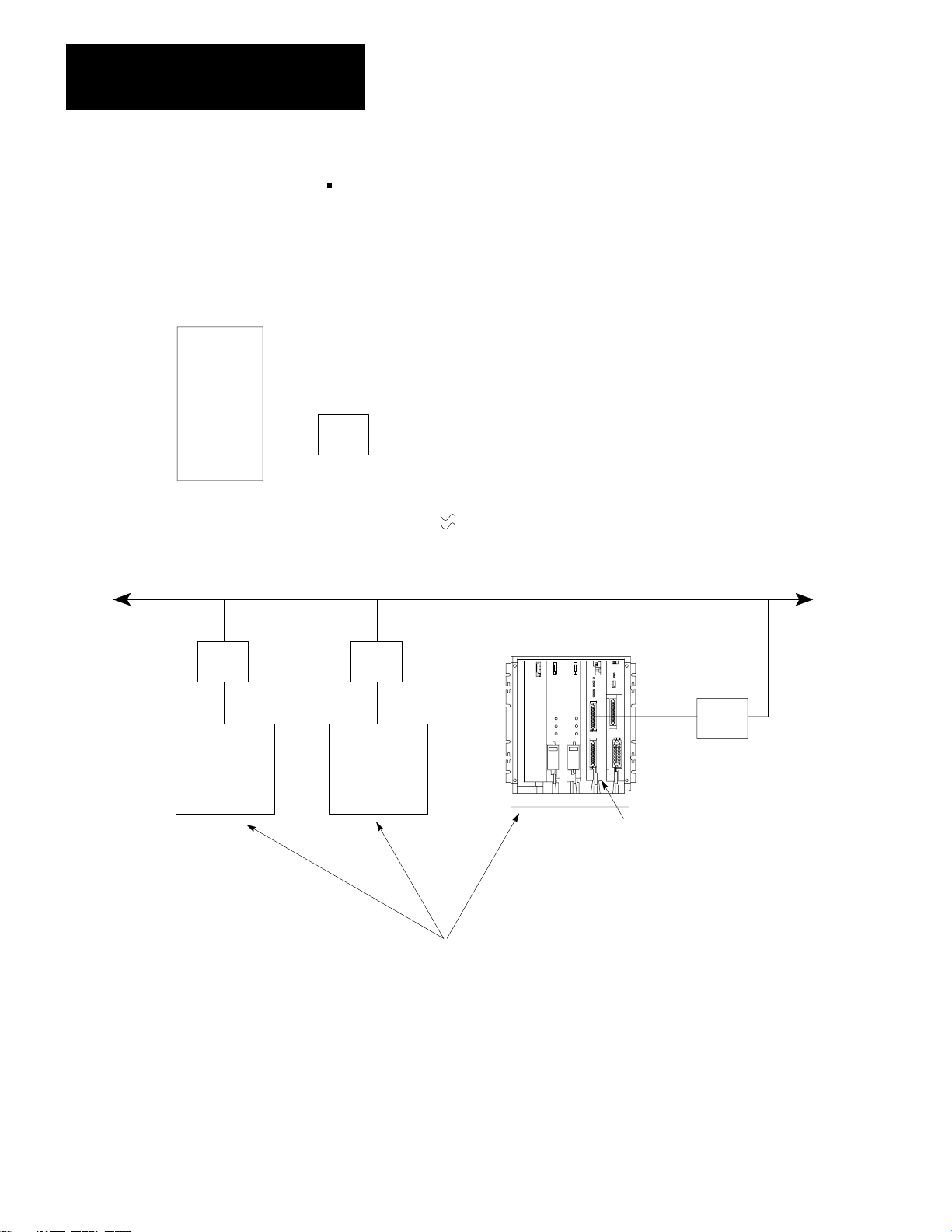

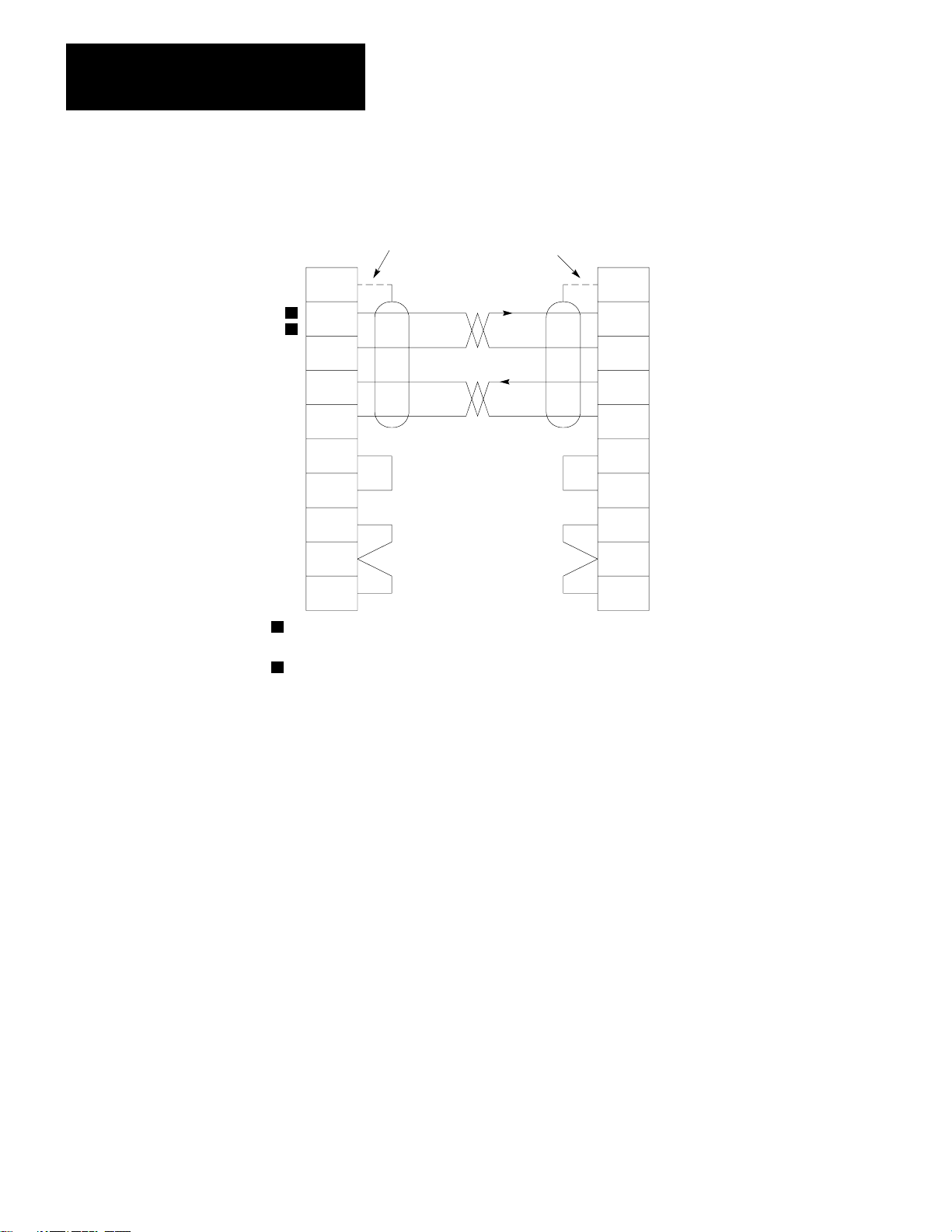

Interfacing a PLC–3 controller with a remote Data Highway through a

modem link (Figure 2.5)

Figure 2.5

a PLC-3 Station to a Remote Data Highway

Linking

Modem

1775-KA

NOTE: All PCs are Allen-Bradley

Module

Modem

1771-KF Module

PC

PC

Allen-Bradley

Data Highway

PC

PC

PC

28

Up to 64 Stations

10006–I

Page 21

Interfacing a PLC–3 controller to a PLC–2 Family processor through a

1771–KG module in a point–to–point link (Figure 2.6)

Figure 2.6

a PLC-3 to PLC-2 Family Controller

Linking

PLC–3 Controller

Chapter 2

Installation

Modem

PLC–2 Controller

1775–KA

1771–KG Module

Module

Modem

NOTE: Modems required only for

distances greater than 50 feet.

10007-I

29

Page 22

Chapter 2

Installation

Computer

Master Station

Interfacing a PLC–3 controller as a slave station on a multipoint

modem link (Figure 2.7)

Figure 2.7

a PLC-3 to a Multi-drop Modem Link

Linking

Multidrop Modem

Multidrop Modem Link

The first four applications above use the module’s RS–232–C port in the

unpolled mode, while the last application uses the polled mode. You can

select the mode of operation and other characteristics of the RS–232–C

port through the LIST function.

Slave Stations

PLC-3 Controller

1775-KA

Modem

Module

10008–I

210

Page 23

Chapter 2

Installation

Each mode of operation requires a different communication protocol. The

unpolled mode uses full–duplex protocol (chapter 10) while the polled

mode uses half–duplex protocol (chapter 11). In general, full–duplex

protocol gives faster data throughput but is more difficult to implement;

half–duplex protocol is easier to implement but gives slow data

throughput.

NOTE: In other Data Highway documentation, full–duplex protocol

might be referred to as DFI protocol, and half–duplex protocol might be

referred to as polled–mode protocol.

Hardware Interface

The modem interface is based on EIA RS–232–C and related standards.

This interface should be compatible with most dedicated and dial–up

network RS–232 modems.

Mechanical

The RS–232 connector on the 1775–KA module is a 25–pin male

connector.

Electrical

Input and output levels on the RS–232 connector conform to the

RS–232–C standard. The transmitter has increased capability to drive a

7,000 foot isolated lines. This number depends on baud rate and refers to

only direct wire connections. (Refer to Table 2.C.)

211

Page 24

Chapter 2

Installation

Table 2.C

Distance

Rate V

ariations

Distance

in feet

1,000 19,200

2,000 9,600

3,000 9,600

4,000 4,800

5,000 4,800

6,000 2,400

7,000 2,400

Maximum

Baud Rate

The receiver is designed to sense the signal generated by a similar

transmitter, and is electrically isolated from all other circuitry on the

module. It consists of an opto–isolater circuit with an input and return

connection at the RS–232 connector. All other signals on the RS–232

connector are driven and received by standard RS–232 interface circuits,

and have a maximum drive capability of 50 feet.

212

Page 25

Chapter 2

Installation

Pinout

The necessary RS–232–C port connections are described in Table 2.D

below:

Table 2.D

RS-232-C

Port Connections

Signal at the

1775-KA Abbreviation Pin Input/Output

chassis/shield drain

transmitted data

received data

request to send

clear to send

data set ready

transmitted data return

data carrier detect

data terminal ready

received data return

1

TXD 2 Output

RXD 3 Input

RTS 4 Output

CTS 5 Input

DSR 6 Input

TXDRET 7/14

DCD 8 Input

DTR 20/11 Output

RXDRET 25/13

TXD (transmitted data) caries serialized data. It is output from the

RS–232 connector.

RXD (received data) is serialized data input to the RS–232 connector.

RXD and RXDRET are isolated from the rest of the circuitry on the

module.

RTS (request to send) is a request from the RS–232 connector to the

modem to prepare to transmit. It typically turns the data carrier on.

When you select the full duplex mode RTS is always asserted. When

you select the half duplex mode RTS is turned on when the module has

permission to transmit; otherwise it is off.

CTS (clear to send) is a signal from the modem to the RS–232

connector that the carrier is stable and the modem is ready to transmit.

The module will not transmit until CTS is true. If CTS is turned off

during transmission, the module will stop sending until CTS is restored.

DTR (data terminal ready) is a signal from the RS–232 connector to the

modem to connect to the phone line (that is, “pick up the phone”). The

module will assert DTR all the time except during the phone hangup

213

Page 26

Chapter 2

Installation

sequence. Some modem will not respond to DTR until the phone rings,

while others will always pick up the phone whether it is ringing or not.

DSR (data set ready) is a signal from the modem to the RS–232

connector that the phone is off–hook. (It is the modem’s answer to

DTR). The module will not transmit or receive unless DSR is true. If

the modem does not properly control DSR, or if no modem is used,

DSR must be jumpered to an RS–232 high signal at the RS–232

connector. (It can be jumpered to DTR).

DCD (data clear ready) is a signal from the modem to the RS–232

connector that the carrier from another modem is being sensed on the

phone line. It will not be asserted unless the phone is off–hook. Data

will not be received at the RS– 232 connector unless DCD is true. In

the full duplex mode the module will not transmit unless DCD is true.

If the modem does not properly control DCD, or if a modem is not

being used, DCD must be jumpered to DTR at the RS–232 connector.

TXDRET (transmitted data return) is the return signal for TXD. It is

connected to module logic ground through a resistor.

RXDRET (received data return) is the return signal for RXD. It is

connected to the isolated receiver, and is isolated from all other

circuitry on the module.

Connections To The RS–232 Port

Connection to the RS–232 port of the 1775–KA can be one of two types:

Short line (50 feet or less)

Isolated long line (between 50 and 7,000 feet)

For short lines, the connection may be either direct or through modems.

You connect an intelligent, RS–232–C compatible device to an interface

module by attaching a cable to both the device and to the module socket

labeled RS– 232–C CHANNEL. The RS–232–C device may be another

Allen–Bradley communication interface module or another

manufacturer’s device. For a standard RS–232–C connection, the cable

should be no longer than 50 feet. If your RS–232–C device has an

Allen–Bradley line driver/receiver, you may use a cable up to 7,000 feet

long.

If you want to connect the 1775–KA module to a 1771–KG or

1771–KE/KF module through the RS–232–C channel, use the cabling

pinout diagram (Figure 2.8) to construct your own cable.

214

Page 27

Chapter 2

Installation

RS–232–C

CHANNEL

Connector

of 1775–KA

Module

1

2

Figure 2.8

Connection

1

2

7

3

25

4

5

6

8

20

to Allen-Bradley 1771-KG or 1771-KE/KF Module

Connect the Shield at One End Only

13

14

11

1

3

RS–232–C

CHANNEL

Connector

2

4

5

6

8

of 1771–KG

or 1771–KE/KF

Module

1

Conductors 2 and 7, 3 and 25 must be twisted pairs for distances longer

than 50 feet.

2

Set switch 3 (on the 1775–KA) OFF when the module is communicating

with another Allen-Bradley device.

If you want to connect the 1775–KA module to a 1775–KA module

through the RS– 232–C channel, use the cabling pinout diagram

(Figure 2.9) to construct your own cable.

10009–I

215

Page 28

Chapter 2

Installation

RS–232–C

CHANNEL

Connector

of 1775–KA

Module

Figure 2.9

Connection

1

1

2

2

7

3

25

4

5

6

8

20

1

Conductors 2 and 7, 3 and 25 must be twisted pairs for distances longer

than 50 feet.

2

Set switch 3 (on the 1775–KA) OFF when the module is communicating

with another Allen-Bradley device.

to Allen-Bradley 1775-KA Module

Connect the Shield at One End Only

25

20

1

3

RS–232–C

CHANNEL

Connector

2

7

4

5

6

8

of 1771–KA

Module

10010–I

216

If you want to connect the 1775–KA module to a modem or computer, use

the cabling pinout diagram (Figure 2.10) to construct your own cable.

Page 29

Chapter 2

Installation

Figure 2.10

Connection

RS–232–C

CHANNEL Connector of

1775–KA

Protective Ground

Transmitted Data

Received Data

Request to Send

Clear to Send

Data Set Ready

Signal Ground

Line Signal Detect

Data Terminal Ready

Received Data

Return

1

Module

to user-Supplied Modem or RS-232-C Device

1

2

3

4

5

6

7

8

20

25

1

Set Switch 3 ON to ground pin 25.

User–supplied

Moderm or

RS–232–C

Device

10011–I

Private lines are permanently connected phone lines used with modems.

Dialup is not needed. Usually the modem hold the handshake lines in the

proper states.

The RS–232 port can be connected to standard American dial–up modems

and some European modems. Other European standards specify that the

DTR signal will cause the modem to answer the phone whether it is

ringing or not, causing the phone to always be “busy”. Since the modem

port asserts DTR while waiting for a call, it cannot be used with such

modems.

The types of dial–up network modems that can be used are classified into

the following types:

Manual: these are typically acoustically coupled modems. The

connection is established by human operators at both ends, who then

insert the handset into couplers to connect the computers.

DTE–controlled answer: these unattended modems are directly

connected to the phone lines. A module controls the modem via the

217

Page 30

Chapter 2

Installation

DTR, DSR, and DCD signals. It incorporates timeouts and tests to

properly operate these types of modems.

Auto–answer: these modems have self–contained timeouts and tests,

and can answer and hangup the phone automatically.

The modem port has no means to control an auto–dial modem, although it

is possible that it can be used in conjunction with a separate auto–dialer.

Answering

The module continually asserts DTR when it is waiting for a call. Under

this condition the modem will answer a call and assert DSR as soon as

ringing is detected. The module does not monitor the RING indicator in

the RS–232 interface. Once DSR is detected the module starts a timer

(around 10 seconds) and waits for the DCD signal. When DCD is

detected communication can start.

If DCD is not detected within the timeout, the module turns DTR off. This

causes the modem to hangup and break the connection. When the hangup

is complete the modem drops the DSR line. This causes the module to

reassert the DTR line and wait for another call. This feature protects

access to the phone if someone calling a wrong number reaches this

station.

Once DCD is detected the module continues to monitor the DCD line. If

DCD goes false the timeout is restarted. If DCD is not restored within the

timeout, the hangup sequence is initiated. This feature allows the remote

station to re–dial in the event the connection is lost by the phone network.

Note that this handshaking is necessary to guarantee access to the phone

line. If this handshaking protocol is defeated by improper selection of

modem options, or jumpers at the connectors, the modem may answer a

call, but if the connection is lost the modem will not hangup. It will be

impossible for the remote station to reestablish the connection because it

will get a busy signal.

Character Transmission

218

Data is sent serially over the RS–232 interface, one eight–bit byte at a

time. The transmission format conforms to ANSI X3.16, CCITT V.4, and

ISO 1177, with the exception that the parity bit is retained while

extending the data length to eight bits.

Page 31

Chapter 2

Installation

The transmission format may be summarized as follows:

start bit

data bit 0

data bit 1

data bit 2

data bit 3

data bit 4

data bit 5

data bit 6

data bit 7

even parity bit (optional)

one stop bit

The 1775–KA module selects baud and parity through the LIST function

(section titled Programmable Configuration Parameters).

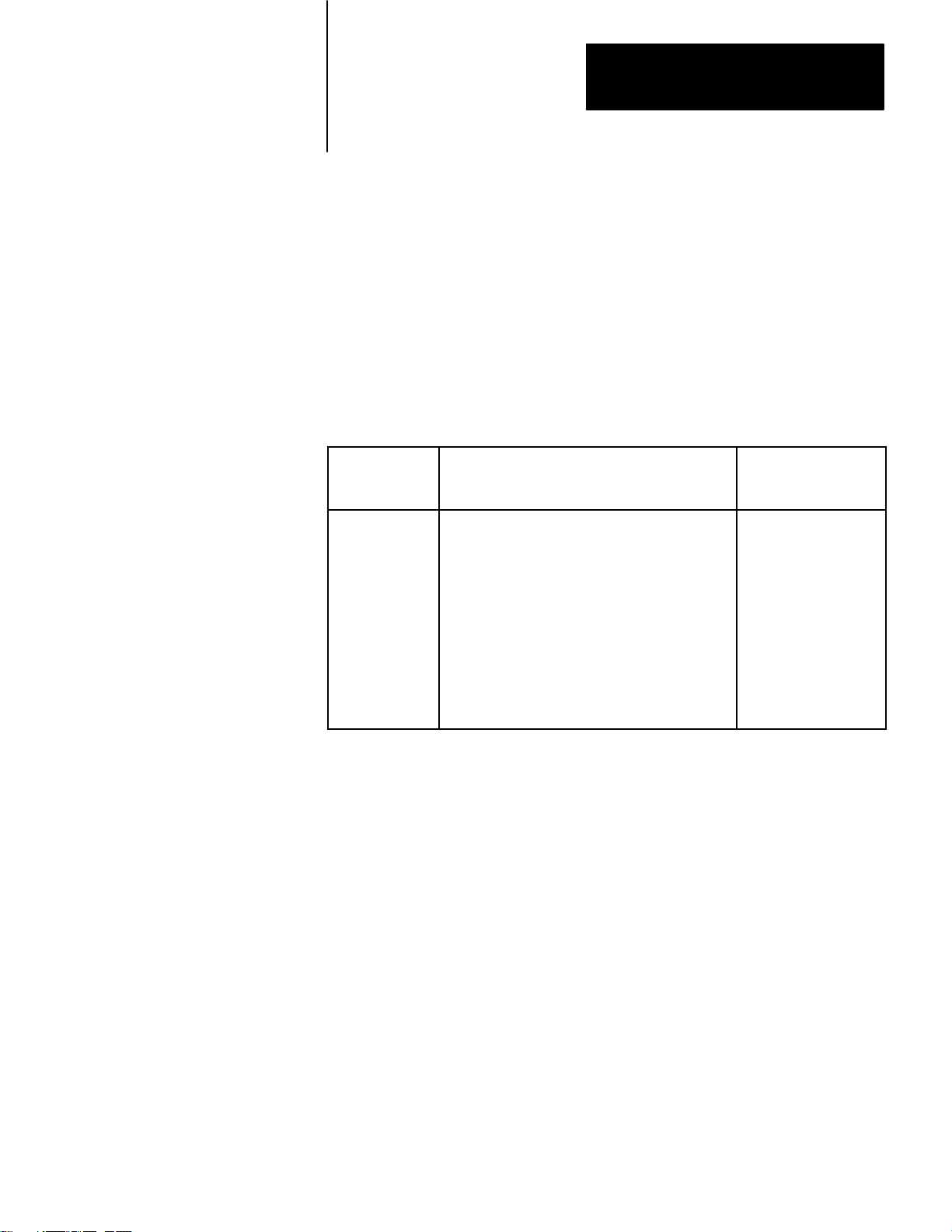

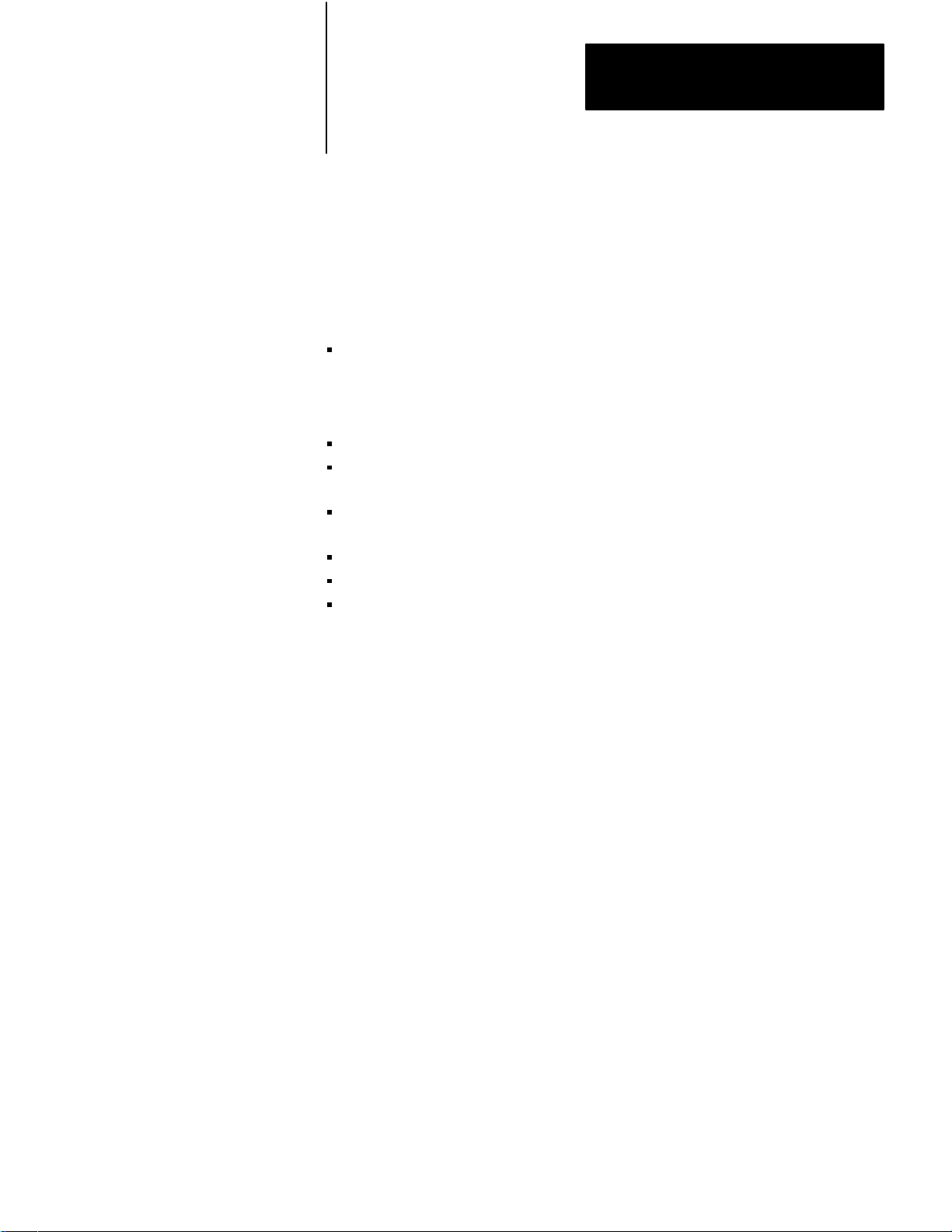

Programmable Configuration Parameters

A number of installation parameters for the 1775–KA module can be

programmed through the PLC–3 LIST function.

The LIST function words by presenting you with a series of lists, or

menus, that allows you to select and establish the module’s operating

parameters. Each option in an upper–level menu represents a submenu of

more detailed options. This process continues until you have selected

enough options to define a single parameter in full detail. Figure 2.11

illustrates the menu structure of LIST. To return to the preceding (next

highest) level of LIST, press the ENTER key without making a new entry.

219

Page 32

Chapter 2

Installation

Figure 2.11

Menu for 1775-KA Module

LIST

System Mode

1

Test–Monitor

2 Run Monitor

3 Program Load

4 Remote Enable

5 System Status

6 *Module Status

Enter Next >

Modules

1 01

1775–ME8

1775–ME8

2 02

3 03

1775–L3

4 04

1775–S4A

5 05

1775–KA A/E

6 06

1775–LX

7 07

1775–LX

8 08

1775–S4B B/A

9 09

1775–S4B B/A

ENTER NEXT

A/A

A/A

A/A

B/A

A/A

A/A

>

Data Hwy Comm

Adapter – 01

Chassis 0 Slot 0

1 Module Options

2 Data Highway Port

3 Modem Port

Enter Next >

KA–01 Module Options

1

Timeout

2 *Send Unprotected

3

Accept Upload/Download

4

Accept W

5 Backup Operation

6 PLC–2 Mask

ENTER NEXT

KA–01 Data Highway Port

1 Enable/Disable Port

2 Station Number

3 Baud Rate

Enter Next >

rites

1

1

1

1

>

KA–01 Module Options

1

Timeout

Enter Timeout >

KA–01 Data Highway Port Enable

1 Enable

2 *Disable

Enter Next >

KA–01 Data Highway Port

Station Number

Enter Station Number >

KA–01 Data Highway Port Baud Rate

1 38400

2 *57600

Enter Next >

= 50/10 sec

= 377

220

KA–01 Modem Port

1 Enable/Disable Port

2 Station Number

3 Baud Rate

4 Communication Mode

5 Even Parity

6 *Send Embedded

Responses

Enter Next >

1

T

oggle selection – select this number to enable

or disable the option.

NOTE: Those selections shown in bold type affect

the operation of the module; the LIST

display

shows an asterisk (*) to indicate when an

option is enabled.

The selections not shown in

bold type only cause a movement to another level

of LIST

.

This selections indicated in this figure are

selected by default at the initial power–up.

KA–01 Modem Port Enable

1 Enable

2 *Disable

1

1

Enter Next >

KA–01 Modem Port

Station – 377

Enter Station Number >

KA–01 Modem Port Baud Rate

1 1

10

2 300

3 600

4 *1200

5 2400

6 4800

7 9600

8 19200

Enter Next >

KA–01 Modem Port Communication Mode

1 *Unpolled Mode

2 Polled – Subscriber Mode

Enter Next >

10012–I

Page 33

Chapter 2

Installation

You access the LIST function by typing the word LIST and press the

ENTER key. After accessing the LIST function, select option 6 MODULE

STATUS from the SYSTEM–MODE MENU. LIST then presents you

with a menu that describes the modules in your system. The menu varies

according to the modules in your PLC–3. A typical menu might be:

MODULES:

1 01 1775–ME8 A/A

2 02 1775–ME8 A/A

3 03 1775–L3 A/A

4 04 1775–S4A B/A

5 05 1775–KA A/E

6 06 1775–LX A/A

7 07 1775–LX A/A

8 08 1775–S4B B/A

9 09 1775–S4B B/A

ENTER NEXT<

Under MODULE STATUS, select the option for 1775–KA. At this point,

LIST presents you with the following menu for the 1775–KA module:

DATA HWY COMM. ADAPTER–nn

CHASSIS cc SLOT ss

1 MODULE OPTIONS

2 DATA HIGHWAY PORT

3 MODEM PORT

ENTER NEXT>

In the above and all following menus, “nn” represents the thumbwheel

setting of the 1775–KA module, “cc” represents the chassis number, and

“ss” represents the number of the chassis slot containing the module. For

more information about the LIST function, refer to Publication 1775–800,

PLC–3 Installation and Operation Manual.

Module Options

Selecting option 1 MODULE OPTIONS from the above menu (section

titled Programmable Configuration Parameters) causes LIST to present

the following menu:

KA – nn MODULE OPTIONS

1 TIMEOUT

2 SEND UNPROTECTED

221

Page 34

Chapter 2

Installation

3 ACCEPT UPLOAD/DOWNLOAD

4 ACCEPT WRITES

5 BACKUP OPERATION

6 PLC–2 MASK

ENTER NEXT>

This menu allows you to select options that apply equally to both the

modem port and the Data Highway port of the 1775–KA module. These

options are described below.

Timeout

The timeout is the maximum amount of time that the 1775–KA module

will wait for another station to reply to one of its messages. The allowed

entries are 0 to 9999, expressed in increments of 1/10 second. LIST

displays the timeout as “xxxx/10 SEC”. Thus, if you enter a timeout

value of 100, the timeout period will be 10 seconds and will be displayed

as 100/10 SEC.

The same timeout setting applies to both the Data Highway and the

modem ports. The default timeout setting is 5 seconds, displayed as 50/10

SEC.

The timeout period applies to each individual transmission. Because of

their size, some messages consist of several packets of data. Each

message packet requires a separate transmission. Therefore, the timeout

is restarted for each packet.

If the 1775–KA module waits longer than the timeout period for a reply to

one of its messages, it generates an error code of 37 (Appendix B). The

module then resumes executing the current message procedure at the line

following the one in which the timeout occurred.

LIST keeps you at this timeout level and allows you to make repeated

changes to the timeout value. To return to the preceding (next highest)

level of LIST, press the ENTER key again without entering a new timeout

value.

222

Page 35

Chapter 2

Installation

Send Unprotected

This option determines whether or not the 1775–KA module will be able

to send unprotected command messages to other stations. If you select

option 2 SEND UNPROTECTED, the 1775–KA module will be able to

send both protected and unprotected commands.

You can use an unprotected command to read or write to any area of a PC

data table. You can use a protected command, however, to write only to

those areas of a PC data table specified by the PC that receives the

command. For more information on protected and unprotected

commands, see section titled Access Privileges, chapter 3.

If you do not select (enable) this option, the module will be able to

transmit only protected commands. At initial power–up, the module

enables the SEND UNPROTECTED option by default.

Accept Upload/Download

This option determines whether or not the 1775–KA module will be able

to execute upload and download commands sent to it by a computer. If

option 3 ACCEPT UPLOAD/DOWNLOAD is selected, the module will

be able to execute both upload and download commands. You send a

sequence of upload and download commands when you want to transfer

the memory of the PLC–3 to another station, or to transfer the memory of

another station to a PLC–3.

If this option is not selected (enabled) the module will not be able to

execute either of these two types of commands. For a description of

upload and download commands, refer to Appendix A. At initial

power–up, the module enables the ACCEPT UPLOAD/DOWNLOAD

option by default.

Accept Writes

This option determines whether or not the 1775–KA module will accept

write–type command messages from a remote Data Highway station when

the local PLC–3 processor’s memory protect keyswitch is on. If option 4

ACCEPT WRITES is selected, the module will accept write commands

regardless of the setting of the PLC–3’s memory protect keyswitch. If

this option is not selected (enabled) the module will accept write

commands when the memory protect keyswitch is off but will reject the

write commands and return an error code of 86 if the memory protect

223

Page 36

Chapter 2

Installation

keyswitch is on. At initial power–up, the module enables the ACCEPT

WRITES option by default.

Backup Operation

This option determines whether or not a pair of 1775–KA modules will

provide backup for each other. Enable option 5 (BACKUP OPERATION)

for both the primary and backup 1775–KA modules to enable backup

operation as described in section 2.3 (backup configurations). If you

make no selection for option 5, backup operation is disabled by default.

The revision C or earlier version of the module does not have the

BACKUP OPERATION option.

PLC–2 Mask

This option determines whether or not the 1775–KA module will mask

out the upper octal digit of the source address when receiving a PLC–2

type command from another station. If you enable option 6

(PLC–2–MASK) the module mask out the upper digit of the address for

selecting the input file. This causes stations with common second and

third digits of their address to access the same input file. For example,

stations 023, 123, 223, and 323 would all access input file 023.

If you disable option 6, each station accesses a unique input file with the

same number as the station number. For example, station 123 would

access input file 123; station 223 would access input file 223. If you

make no selection for option 6, the PLC–2 MASK option is disabled by

default. The revision D or earlier version of the module does not have the

PLC–2 MASK option.

Data Highway Port

Selecting option 2 DATA HIGHWAY PORT from the above menu

(section titled Programmable Configuration Parameters) causes LIST to

present the following menu:

224

KA – nn DATA HIGHWAY PORT

1 ENABLE/DISABLE PORT

2 STATION NUMBER

3 BAUD RATE

ENTER NEXT>

Page 37

Chapter 2

Installation

This menu allows you to select options that apply to only the Data

Highway port of the 1775–KA module. These options are described

below.

Enable/Disable Port

This option determines whether or not the 1775–KA module can

communicate over the Data Highway. you must select the ENABLE

option in order to allow communication to take place. If you make no

selection, the PLC–3 disables this port by default.

Note, however, that you cannot use LIST to change any other parameters

of the Data Highway port unless you first DISABLE the port. After you

are done entering parameters through LIST, don’t forget to ENABLE the

Data Highway port again.

Station Number

This option selects the number by which the PLC–3 station is identified

on the Data Highway. Allowable station numbers are 1 to 376 octal. In

particular, note that the number 377 is illegal. Entering 377 as the station

number will automatically disable the 1775–KA module, and you will not

be able to ENABLE it again through LIST until you select a different

station number. If you make no selection, the PLC–3 assumes the illegal

address 377 by default.

Baud Rate

This option specifies the communication rate over the Data Highway. A

communication rate of 57,600 baud is recommended.

Modem Port

Selecting option 3 MODEM PORT from the above menu (section titled

Programmable Configuration Parameters) causes LIST to present the

following menu:

KA–NN modem port

1 ENABLE/DISABLE PORT

2 STATION NUMBER

3 BAUD RATE

4 COMMUNICATION MODE

225

Page 38

Chapter 2

Installation

5 EVEN PARITY

6 SEND EMBEDDED RESPONSES

ENTER NEXT>

This menu allows you to select options that apply to only the modem port

of the 1775–KA module. These options are described below.

Enable/Disable Port

This option determines whether or not the 1775–KA module can

communicate through its RS–232–C port. You must select the ENABLE

option in order to allow this communication to take place. If you make no

selection, the PLC–3 disables the RS–232–C port by default.

Note, however, that you cannot use LIST to change any other parameters

of the RS–232–C port unless you first disable the port. After you are

done entering parameters through LIST, don’t forget to enable the

RS–232–C port again

Station Number

This option selects the number by which the PLC–3 station is identified

on an RS–232–C communication link. In particular, note that the number

377 is illegal. Entering 377 as the station number will automatically

disable the RS– 232–C port of the 1775–KA module, and you will not be

able to enable it again through LIST until you select a different station

number. If you make no selection, the station number will be 377 by

default.

Baud Rate

This option specifies the communication rate over the RS–232–C port.

The choices are:

110 baud 2400 baud

300 baud 4800 baud

600 baud 9600 baud

1200 baud 19200 baud

226

For long–line communication, the maximum allowed rate is 4800 baud.

The default baud rate is 1200 baud (see Table 2.D).

Page 39

Chapter 2

Installation

Communication Mode

This option determines whether the RS–232–C port of the 1775–KA

module can operate in a half–duplex (polled) or full–duplex (unpolled)

mode. Select full– duplex for point–to–point communication through the

RS–232–C port. Select half–duplex if the 1775–KA module is installed

as a slave station on a multipoint modem link. If you make no selection,

the 1775–KA selects the full– duplex (unpolled) mode by default.

Even Parity

This option determines what kind of parity check is used for all

communications through the RS–232–C port. If option 5 EVEN PARITY

is selected, the 1775–KA module will test for even parity in all

communications through its RS–232–C port. If this option is not

selected, the module will not perform any parity checking. At power–up,

the PLC–3 disables the even parity option by default.

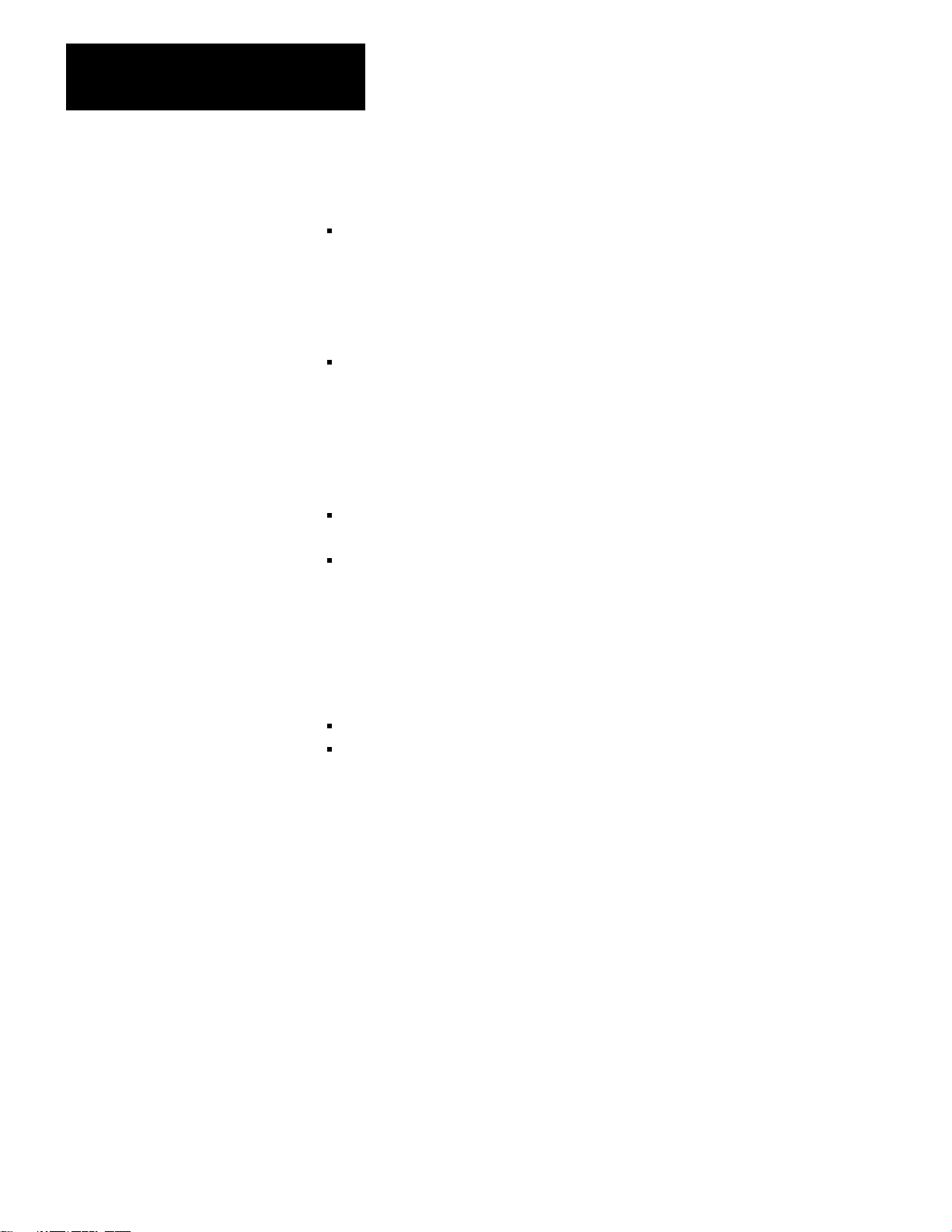

Backup Configurations

Send Embedded Responses

This option determines whether or not the 1775–KA module will be able

to send embedded responses through its RS–232–C port. Responses are

acknowledgments (ACKs or NAKs) to messages received from other

stations. An embedded response is one whose characters are transmitted

between the bytes of a regular message. In this way, the response to a

previously received message is transmitted along with a new message. At

power–up, the PLC–3 disables the embedded responses option by default.

The 1775–KA module can combine with the PLC–3 processor to form a

backup system. System backup is described in greater detail in the

PLC–3 Programmable Controller Backup Concepts Manual (pub. no.

1775–6.3.1). The following discussion is an overview of system backup

and the role of the 1775–KA in various backup procedures.

There are two possible backup configurations for the 1775–KA module:

Two 1775–KA modules in the same PLC–3 controller

One 1775–KA module in a primary PLC–3 controller and another

1775–KA in a backup PLC–3 controller

The first configuration provides backup for the 1775–KA module itself.

Here, both 1775–KA modules are always active, and both are independent

stations on their communication network. Therefore, each 1775–KA

227

Page 40

Chapter 2

Installation

module must have its own unique station number. If you want to send the

same message through both 1775– KA modules, you must program the

two separate message instructions.

The second configuration provides system backup for the PLC–3

controller.

If the 1775–KA modules are Rev. C or earlier, you:

1. Assign different station addresses to each communication adapter

module.

2. If the programs in the primary and backup processors are identical:

you must be sure that all information sent to the primary processor is

also sent to the backup processor.

you must examine the run/backup bit (data table status section, file 0,

word 3, bit 17) on every rung used to transmit data. This bit is set in

the primary processor and reset in the backup processor. Examining it

helps to prevent sending duplicate messages over the Data Highway.

If the 1775–KA modules are Rev. D or later, you can:

follow the two steps described above

or

select BACKUP OPERATION with the PLC–3 LIST function.

To implement backup operation, follow these steps:

1. Using the option switches on both 1775–KA modules, set switch 2 to

the OPEN position. Recall (section titled Option Switches) that this

causes the module to disable its Data Highway port if the PLC–3

becomes deactivated.

WARNING: If you do not set these switches OPEN on both

1775–KA modules, these modules will assume the same station

address when the primary PLC–3 becomes deactive. This may

shut down communication on the Data Highway, and

unexpected machine motion may result.

228

Page 41

Chapter 2

Installation

2. Use the LIST function to disable the modem and Data Highway

ports.

3. Use the LIST function to select BACKUP OPERATION for both the

primary and backup 1775–KA modules. For more information, see

the PLC–3 Installation and Operation manual (publication

1775–6.7.1). Thus, when you select BACKUP OPERATION, the

condition appears like this:

5*BACKUP OPERATION

4. Use the LIST function to assign the same station address to the

modules for the primary PLC–3 and the backup PLC–3 processor.

You can never give the 1775–KA module a station address of 3778,

and when you select the BACKUP OPERATION, you can not give

the module an address of 2778.

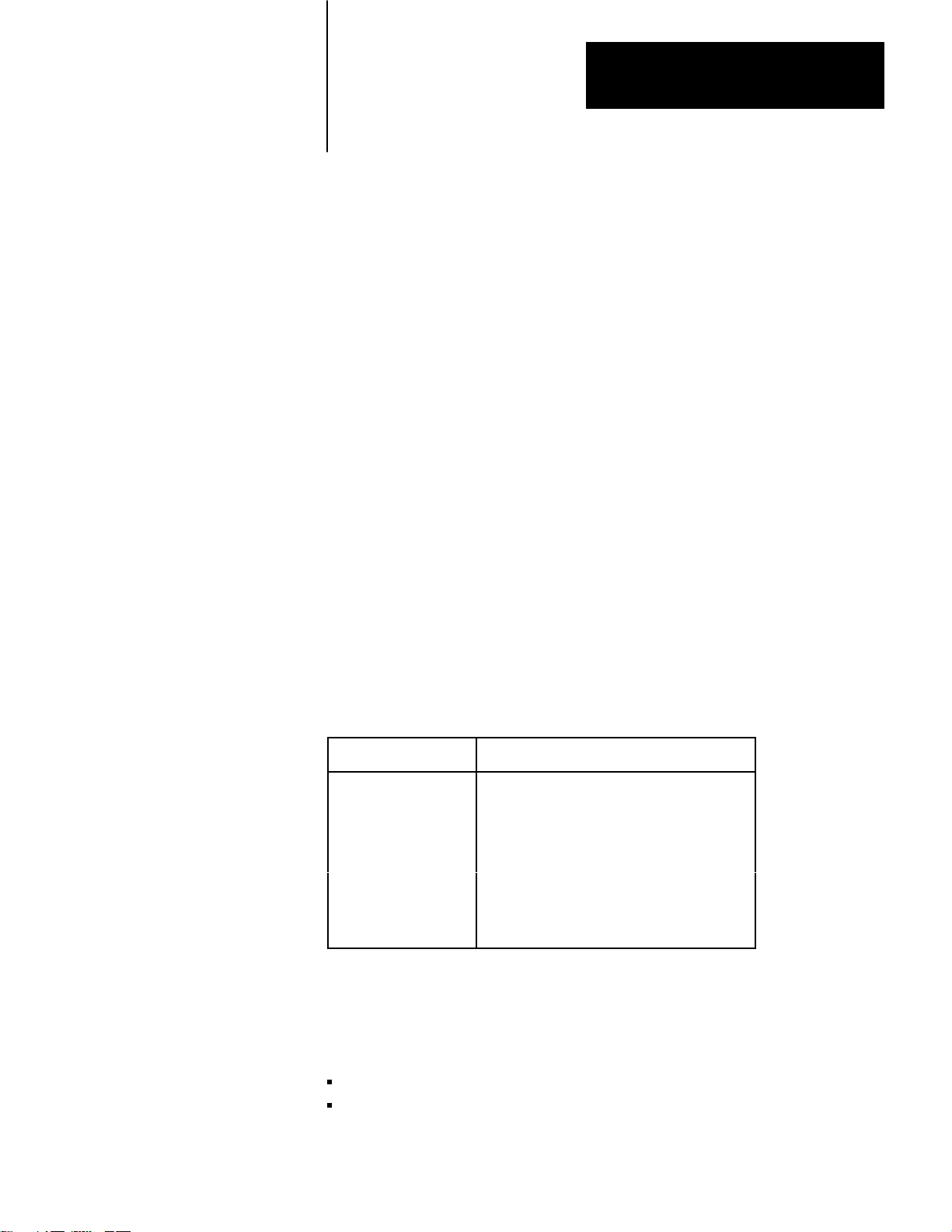

Because you have chosen BACKUP OPERATION, the module in the

backup PLC–3 will assume an address other than the address you

assign it with the LIST function (Figure 2.12).

You assign both modules an identical address.

If

the address

is between:

0018 and 276

3008 and 376

8

8

The backup module assumes

an address that is:

1008 higher than the primary module

2008 lower than the primary module

At switchover, the address for the backup module returns to the

station address you assigned to it with the LIST function.

5. Use the LIST function to enable whichever (Data Highway or

Modem) port you are using to connect primary to backup.

229

Page 42

Chapter 2

Installation

Figure 2.12

addresses of the primary and backup PLC-3 controllers change during switchover

How

Before switchover: Primary PCL–3 Backup PLC–3

You set these

station addresses: 010

The module assume

the station addresses:

010

010

110

.

After switchover:

You previously set

these station addresses: 010

The module assume

the station addresses:

Backup PLC–3

110

Primary PCL–3

010

010

10013–I

230

Page 43

Chapter 2

Installation

Using Manual Switchover

After you select the BACKUP OPERATION for a rev. D. (or later)

1775–KA module, you may choose to use your PLC–3 backup system for

manual switchover. In manual switchover, you must initiate the

switchover by changing the position of a switch in a backup cable. (Refer

to the PLC–3 Programmable Controller Backup Concepts Manual, pub.

1775–803, for more details.) You must be sure to turn off the faulted

PLC–3 processor before you begin the switchover, however.

If

a manual switchover occurs:

And: Then:

the PLC-3 processor is waiting for a

response

another station on the Data Highway is

initiating a message

you are only communicating with the

primary PLC-3

the response is ignored

you may not receive a response from

either PLC-3 processor

program other stations on the Data

Highway to recover from this condition

the other stations on the Data Highway

will receive time-out errors for

messages they send after the primary

goes deactive and before switchover

occurs.

. Y

ou must

You can program the MSG instruction to execute a message upon

switchover or you can send commands to the backup PLC–3 processor

(Figure 2.13). As long as you get responses from the backup processor,

switchover has not yet occurred.

231

Page 44

Chapter 2

Installation

E0000

00

E0000

01

E0000

00

S0003

17

S0003

17

NOTE:

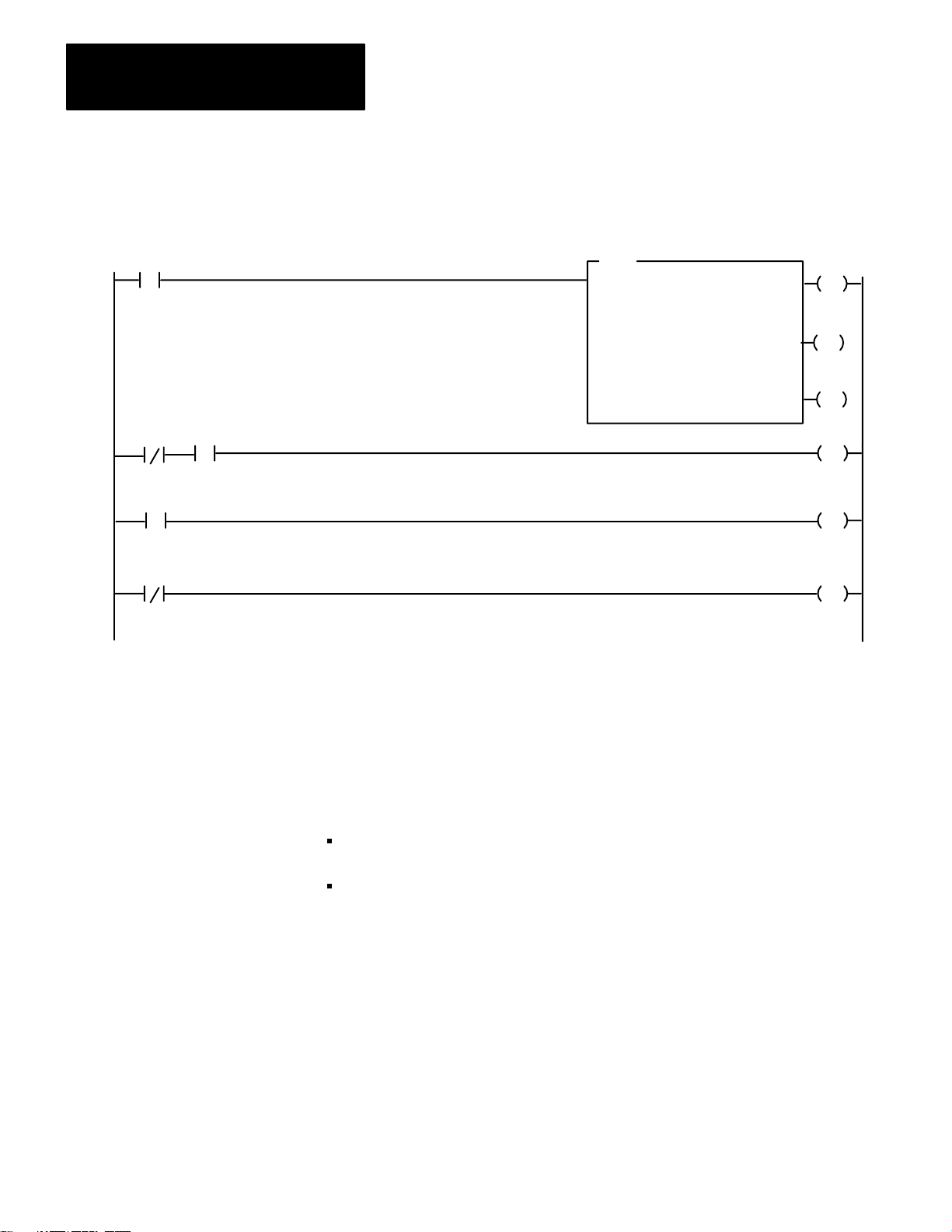

Figure 2.13

Example

PLC-3.

Bits E0000/00 and E0000/01 are internal storage bits. You can use any unused data

table section to reference these bits. Bit S0003/17 is the run/backup bit.

of a Rung that Sends a Message during switchover from primary PLC-3 to backup

MSG

MESSAGE TYPE

CTL = FB200:00001 = 0

CHANNEL: E2.5.

#H045$N4:17= $B3:5

STAT

1

EN

12

STAT

DN

15

STAT

ER

13

E0000

00

E0000

L

01

E0000

U

01

Using Automatic Switchover

After you select the BACKUP OPERATION for a rev. D. (or later)

1775–KA module, you may want to use automatic switchover for your

PLC–3 backup system. During automatic switchover:

the 1775–KA module for the primary PLC–3 processor disables its

Data Highway port.

the 1775–KA module for the backup PLC–3 processor becomes the

address that you selected with the LIST function (rather than the

corresponding address it received during the BACKUP OPERATION).

NOTE: You cannot select the BACKUP OPERATION for a multidrop

modem applications because the modem port will not become disabled

after a PLC–3 processor fault regardless of the switch settings on the

module.

232

Page 45

If

an automatic switchover occurs:

And: Then:

Chapter 2

Installation

the PLC-3 processor is waiting for a

response

another station on the Data Highway is

initiating a message

another station is communicating with

the primary PCL-3 processor

the response is ignored

possibly neither of the PLC-3 processors will

respond to the message. Y

other stations on the Data Highway to recover

from this condition

the other station will receive no indication that

a switchover has occurred. Y

however

execute a message upon switchover (fig.

2.13) or send commands to the backup

PLC-3 processor

communicate with the backup, you know that

no switchover has occurred

, program a MSG instruction to

. If you are able to

ou must program

ou can,

Run/Backup Bit

It is important to alert the proper personnel when a switchover occurs.

One way you can provide such indication is by having your program

monitor the run/backup bit (data table status section, file 0, word 3, bit 17)

and turn on alarms or lights when the status changes from backup to run.

This bit is set in the primary processor and reset in the backup processor.

Multiple 1775-KA Modules in

One PLC-3

It is also possible to link a single PLC–3 controller to more than one Data

Highway by installing multiple 1775–KA modules in the same PLC–3. In

this configuration, each 1775–KA module connects to a different Data

Highway, and each has a unique station number on its associated highway.

However, all the 1775–KA modules in the same PLC–3 controller can

have either the same or different station numbers.

CAUTION: If such a PLC–3 station is communicating through

a PLC/PLC–2 buffer file and all of the stations’ 1775–KA

modules have the same station number, then all of these

modules will transfer data through the same buffer file. This

can cause unpredictable results if several 1775–KA modules try

to read or write to the buffer file at the same time.

When such a PLC–3 station transmits a command message to a remote

Data Highway station, the thumbwheel number specified in the PLC–3

message instruction (section titled PLC–3 Stations) determines which

1775–KA module actually transmits the command.

233

Page 46

Chapter

Data Highway Communication

3

General

Some Terminology

This chapter introduces some of the concepts and terminology involved

with operating the 1775–KA module of the Data Highway.

The Allen Bradley Data Highway is a communication network for

industrial control applications. The Data Highway consists of a central

trunkline cable that may be up to 10,000 feet long. This cable can link

together as many as 64 distinct communication points (or nodes) called

stations.

Each station consists of some type of processor and a station interface

module. The station interface module enables the processor to

communicate with other stations on the Data Highway. The 1775–KA

module is the station interface module for the PLC–3 processor. Table 3.A

lists all possible combinations of station interface modules and processors.

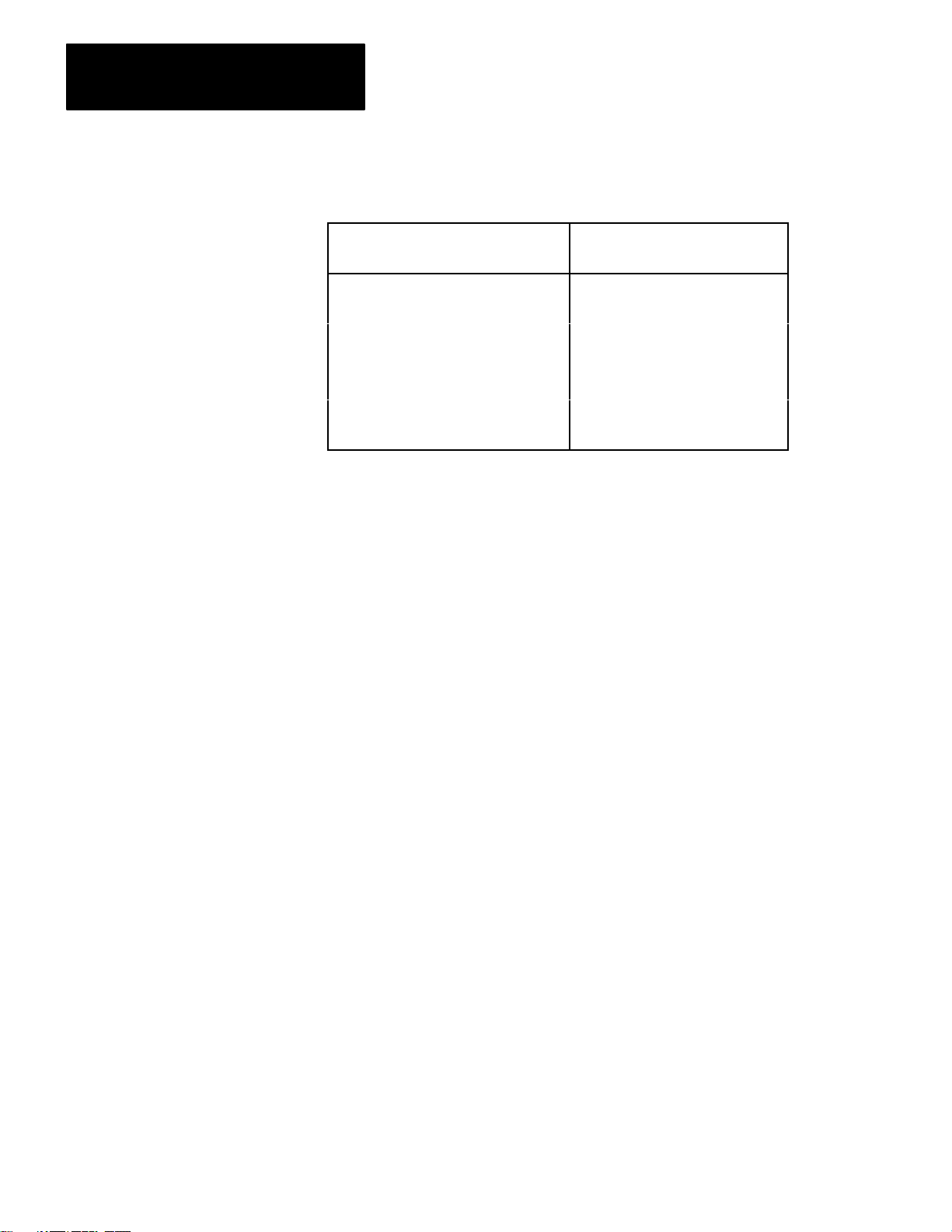

Table 3.A

Components

Station

Processor

Station Interface Module

PLC-4 Microtrol

PLC-3

PLC-2 Family

PLC

Computer or other

programmable

RS-232-C compatible

device

Communication Terminology

Stations communicate with each other by sending messages over the Data

Highway. There are two types of messages:

Command messages

Reply messages

1773-KA Communication Interface Module

1775-KA Communication Adapter Module

1771-KA Communication Adapter Module

1774-KA Communication Adapter Module

1771-KC/KD/KE/KF Communication Controller

Module

31

Page 47

Chapter 3

Data Highway Communication

A command message either gives (writes) data to, or requests (reads)

data from, one station to another. A reply message is a station’s response

to a command message.

Command messages are generated by message procedures that you

program into the 1775–KA module. Execution of a message procedure is

controlled by the message (MSG) instruction in the PLC–3 ladder

diagram program. When a 1775–KA module receives a command

message from another station, the module automatically generates the

appropriate reply message.

As points of reference, we can talk about local and remote stations. The

local station is the one currently initiating some action, or the one we are

currently doing something with. All other stations are then remote.

We can also describe stations in terms of their relationship to a message.

The transmitting station is the one sending the message, and the

receiving station is the one that gets the message. A station that transmits

a command message is called a command station, and a station that

transmits a reply message is called a reply station.

You can send either:

a single message procedure command (Chapter 6) that may be up to 76

characters long.

the name of a Data Highway message procedure which contains a

group of commands and is stored in the 1775–KA module

You specify the station that will receive the command with a PLC–3

extended address. This address always takes the form:

E2.5.nn

where

E2 specifies that this command addresses the module status

area of PLC–3 memory

32

5 specifies that you are sending the message instruction

through the 1775–KA module

nn is replaced with the thumbwheel setting on your particular

1775–Ka module

Page 48

Chapter 3

Data Highway Communication

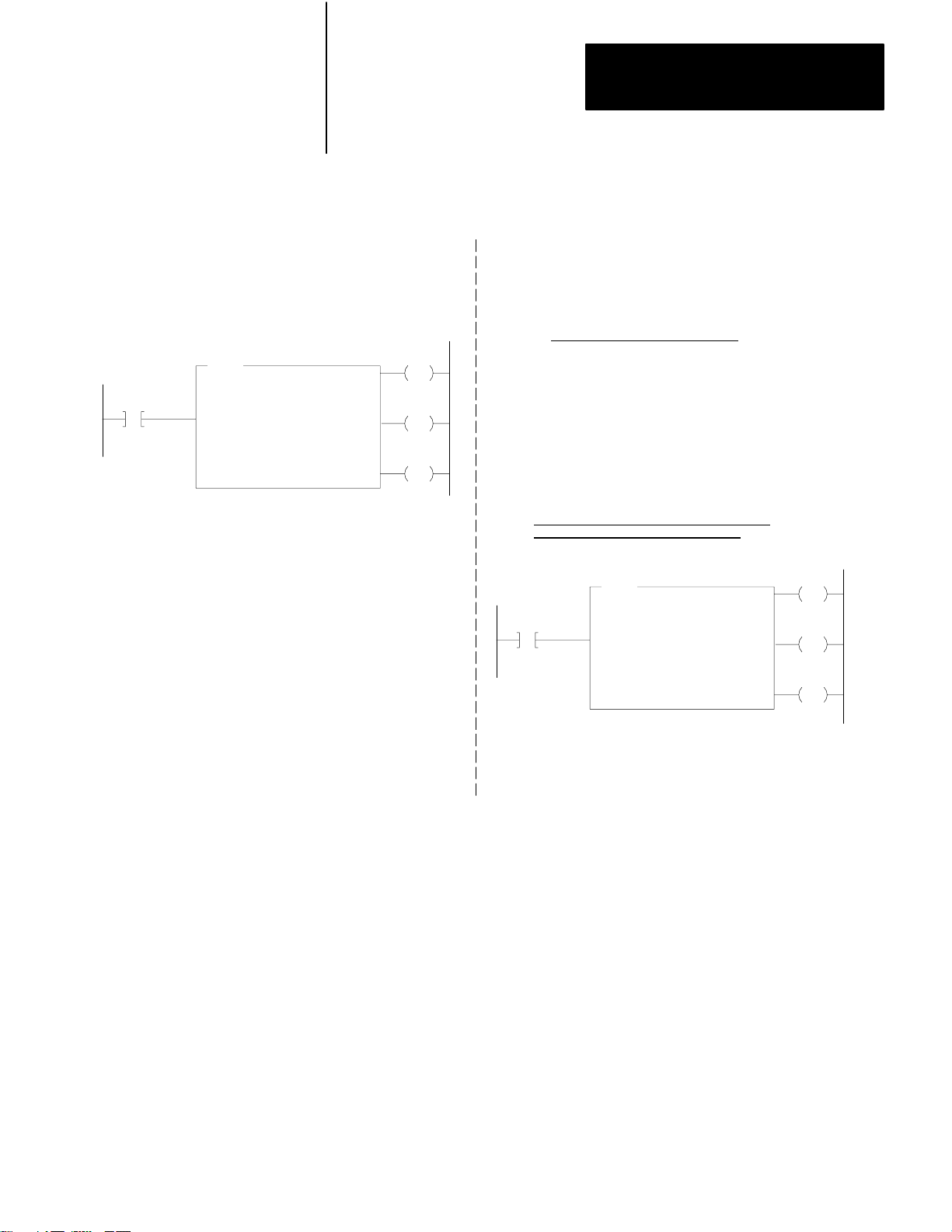

To enter a message instruction, complete the steps below:

1. Enter a condition that, when true, will activate the message

instruction. In Figure 3.1, we used an examine–on for input word

0012

, bit 01.

8

Figure 3.1

of Programming in Data Highway Communication

Levels

1) PLC–3 Processor

Ladder Diagram Program

MSG

10012

01

Message instruction to

execute message procedure

PROC_A

3) Data Highway

DLE STX DST SRC CMD STS TNSW ADDR SIZE

MESSAGE TYPE 1

CTL = FB200:0000=200

CHANNEL: E2.5.1

@PROC_A

STAT

EN

12

STAT

DN

15

STAT

ER

13

2) 1775–KA Module

Data Highway Message Procedure

PROC_A

#H024$B12:37 = 15

Message procedure command

to transmit a message to data

highway station number 24

DATA

(OPTIONAL)

DLE EXT BCC

Command message

transmitted to

station 24

10014–I

33

Page 49

Chapter 3

Data Highway Communication

2. Press the message instruction key.

3. Specify message type 1.

4. Choose a control file word where status information about the

message command can be stored. In our Figure 3.1, we used binary

file 200, word 200.

Data transfers can be either solicited or unsolicited, depending on whether

they are initiated by the local or a remote station, respectively. Either type

of station initiates the data transfer by issuing a command message. If the

local station issues the command message, the corresponding reply

message is said to be solicited because the local station has solicited, or

requested, the data contained in the reply message. If a remote station

issues the command message, that message is said to be unsolicited.

Levels of Programming

For solicited messages, a local station receives data from a remote station

during a read operation. The local station sends data to a remote station

during a write operation.

For unsolicited messages, a local station receives data from a remote

station during a write operation. A local station sends data to a remote

station during a read operation.

In read operations, the command message requests the data transfer, but

the corresponding reply message actually contains the data being

transferred. In write operations, the command message contains the data

being transferred, and the reply message merely reports the status (receipt

or non–receipt) of the transfer.

The PLC–3 processor must be free to control its own processes at the

same time that the 1775–KA module is communicating over the Data

Highway. For this reason, both the processor and the module have their

own programs and programming languages. Figure 3.1 illustrates how

these two programming levels (processor and module) interrelate.

34

PLC-3 Program

The first link in the communication process is your PLC–3 ladder diagram

program. You send a Data Highway command message by means of the

message (MSG) instruction. Figure 3.1 shows a typical MSG instruction.

Page 50

Chapter 3

Data Highway Communication

When the rung becomes true, the message instruction begins sending

command(s) across the Data Highway. At the same time, bits in a control

file word change their state (Table 3.B) to reflect the status of the

command. Even if the rung becomes false, the message command will

continue to send commands across the highway.

Table 3.B

Status of Bits in a Control File W

The

WHEN:

the message instruction is true

the enable bit (16) is set

the latched enable bit (12) is set

the remote Data Highway module has received the message instruction

the request bit (17) is set

the 1775-KA module begins operation

the busy bit (14) is set

the operation is complete

the busy bit (14) is set

either the done bit (15) or the error bit (13) is set

the rung becomes false

the request bit (17) is reset

the busy bit (14) is reset

the enable bit (16) is reset

the latched enable bit (12) is reset

the rung becomes true a second time

either the done bit (15) or the error bit (13) is reset

ord

5. Enter an extended address for the channel. In our Figure 3.1, we

address the module status area of memory, specify the 1775–KA

module, and a thumbwheel setting of 1.

6. Enter either a command or a command procedure. In Figure 3.1, we

entered the command procedure, PROC_A.

Data Highway Message Procedure

As already stated, the 1775–KA module has its own programming

language that consists of commands (Chapter 8). A group of related

commands make up a Data Highway message procedure. These

commands and message procedures determine what messages are

transmitted over the Data Highway.

35

Page 51

Chapter 3

Data Highway Communication