Page 1

Auxiliary Function PROM

(Cat. No. 1772AF4)

for the Mini-PLC-2/15 Controller

User Manual

Page 2

Table of Contents

Introduction 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Functions 12

Applications 12

Manual's Purpose 12

Audience 12

Installation 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation/Removal Handling Instructions 21

Installation 22

Removal 24

Programming 31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General 31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

AF4 Function Sequence 32

AF4 Automatic Checks 33

Programming

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Specific Mathematical Functions

37. . . . . . . . . . . . . . .

Page 3

Introduction

Chapter

1

General

Installation of the Auxiliary Function (AF) PROM (cat. no. 1772-AF4 in your

Mini-PLC-2/15 controller lets you expand its mathematical capabilities.

For simplification, throughout this manual we refer to the Auxiliary Function

PROM (cat. no. 1772-AF4) as the AF4.

The AF4 can only be used with the series A Mini-PLC-2/15 processor module,

firmware revision 11 or later (cat. no. 1772-LV). The AF4 can only be used

with the series B Mini-PLC-2/15 processor module, firmware revision 4 or later.

Programming the AF4 functions with either series Mini-PLC-2/15 processor

module requires the Industrial Terminal (cat. no. 1770-T3).

The AF4 has a 2K (16 bit) word section to which you can transfer your program

(for backup memory) and a 2K word section for higher mathematical functions.

You can only transfer your program into the AF4 with the series B PLC-2/15

controller (Table 1.A). Series A Mini-PLC-2/16 Processor EPROM (publication

1770-91) describes program transfer to PROM. With the series A PLC-2/15

controller, program transfer to the AF4 is not possible.

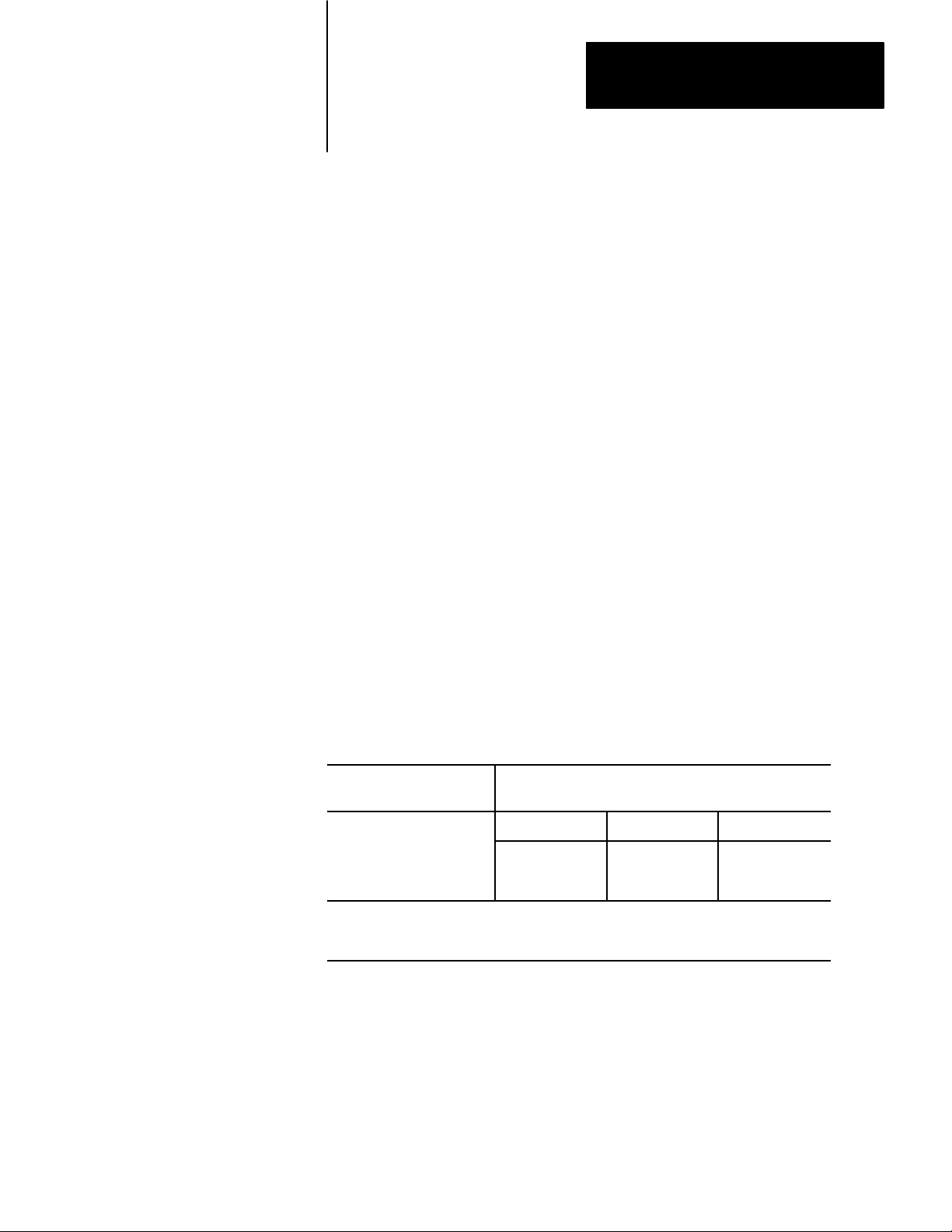

Table 1.A

AF4

PROM Response Controller

MiniPLC2/15 Controller

[1]

2K section for higher mathematical functions would also be erased and all AF1 function

capabilities lost. Once erased, the AF4 functions are irretrievable.

NOTE: The AF4 is sensitive to ultraviolet (UV) light, therefore when exposed

to UV light, both the program and the auxiliary functions are erased. The AF4’s

transparent window is covered with the product label to avoid accidental

alteration of memory from ultraviolet light sources. Do not remove this label.

Series

Read Write Erase [1]

AYesNo No

BYesYes No

You can erase the 2K memory backup portion of the AF4 with ultraviolet light. However, the

User Program 2K Words

11

Page 4

Chapter 1

Introduction

Functions

Applications

The AF4 performs the following arithmetic functions:

Six digit add and subtract

Six digit multiply and divide

BCD to binary conversion

Binary to BCD conversion

Logarithm of a three digit number to the base 10

Logarithm of a three digit number to the base 3

Exponential function -e

Power function -y

+X

+X

Reciprocal of a number - 1

+X

Sine of an angle - sin X

Cosine of an angle - cos X

Square root of a number -x

0.5

These arithmetic functions have applications in various industries such as food

processing, machine tool work, and material handling. Applications in these

industries could be weighing, blending, batch processing, scaling, positioning,

test stands, and heat treating. The square root function is frequently used for

flow measurement and in mining applications.

Manual's Purpose

Audience

This manual shows you how to install and program the AF4 in your

Mini-PLC-2/15 controller.

We assume that you are familiar with programming and operation of the

Mini-PLC- 2/15 and the Industrial Terminal (cat. no. 10770-T3). If this is not

the case, refer to the appropriate publications or see our Publication Index

(publication SD499).

WARNING: : Use only Allen-Bradley authorized programming

devices to program Allen-Bradley programmable controllers.

Using unauthorized programming devices may result in

unexpected operation, possibly causing equipment damage

and/or injury to personnel.

12

Page 5

Installation

Chapter

2

General

Installation/Removal Handling Instructions

During AF4 installation, take special care not to bend or contaminate the pins.

Bent or dirty pins can prevent proper AF4 programming and use. The AF4’s

transparent window is covered with the product label to avoid accidental

alteration of memory from UV light sources. Do not remove this label. Store

the AF4 in its shipping container when not installed in a Mini-PLC-2/15

processor.

The AF4 can be damaged during routine handling if proper precautions are not

taken to reduce static electricity discharges.

Recommended precautions include:

Handle the AF4 by the case without touching its pins.

Use a static free work station.

Wear a conductive wrist strap which has a minimum 200k ohms resistance

and is connected to earth ground.

Ground tools prior to contacting the AF4.

Connect static-free work station to ground through a minimum 200k ohm

resistance.

Control the relative humidity of the installation area - ideal conditions are

40% to 60% relative humidity.

The following is a list of things that should not be done:

Do not handle styrofoam, plastic, or cellophane-covered articles such as

combs, cigarette packages, and candy immediately prior to handling an AF4.

Do not hand the AF4 to someone who is not antistatic protected.

Do not install the AF4 in areas which might contaminate or foul the pins of

the AF4 device.

Do not handle the AF4 by its pins.

Do not slide the AF4 across any surface.

Do not place the AF4 in a non-conductive plastic bag.

21

Page 6

Chapter 2

Installation

When these precautions are followed, the potential difference between the AF4

pins is reduced thereby reducing the problems associated with static discharges.

Installation

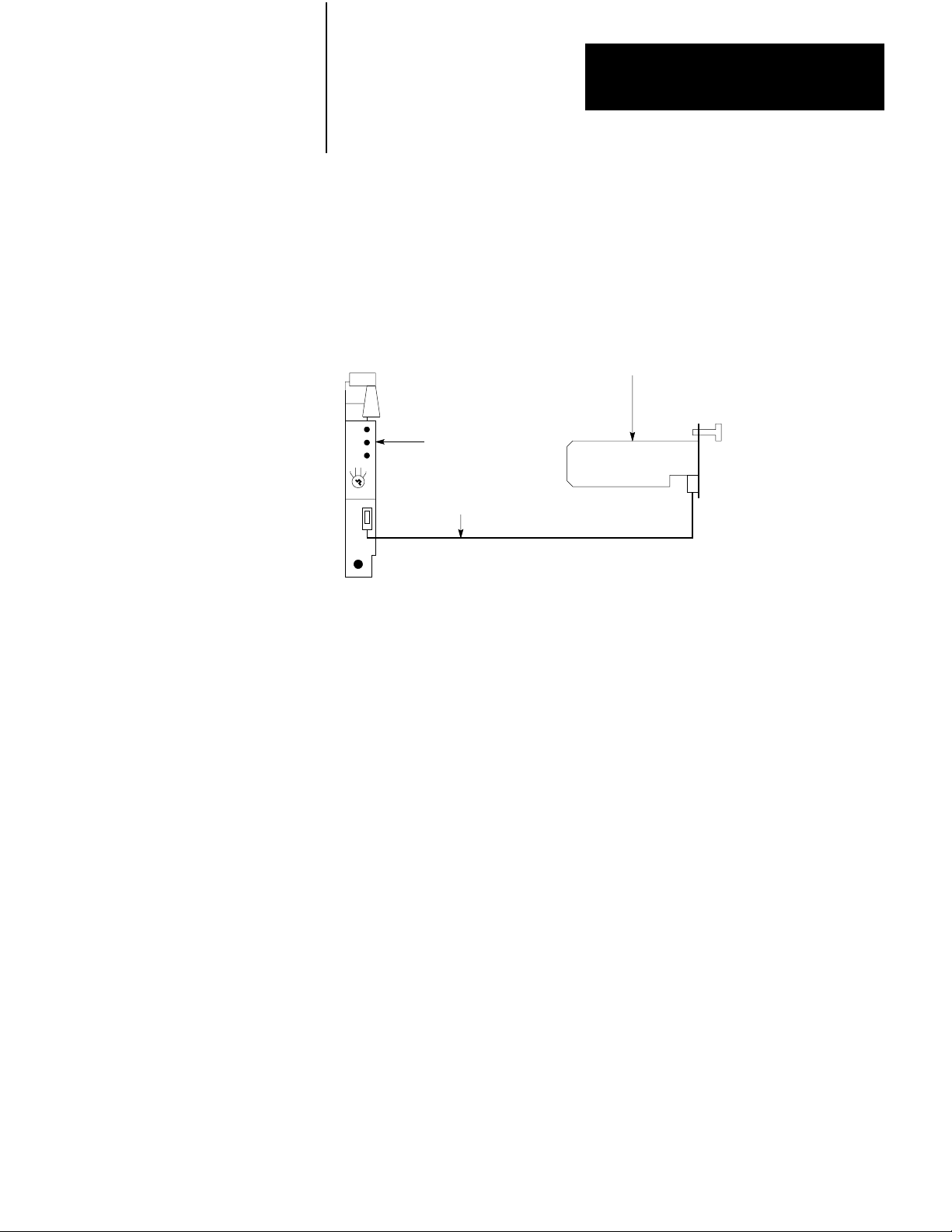

The AF4 fits into a 28-pin ZIF (zero insertion force) socket, which is located

under a hinged door at the lower side of the Mini-PLC-2/15 processor

(Figure 2.1).

Figure 2.1

PROM

Socket

10715I

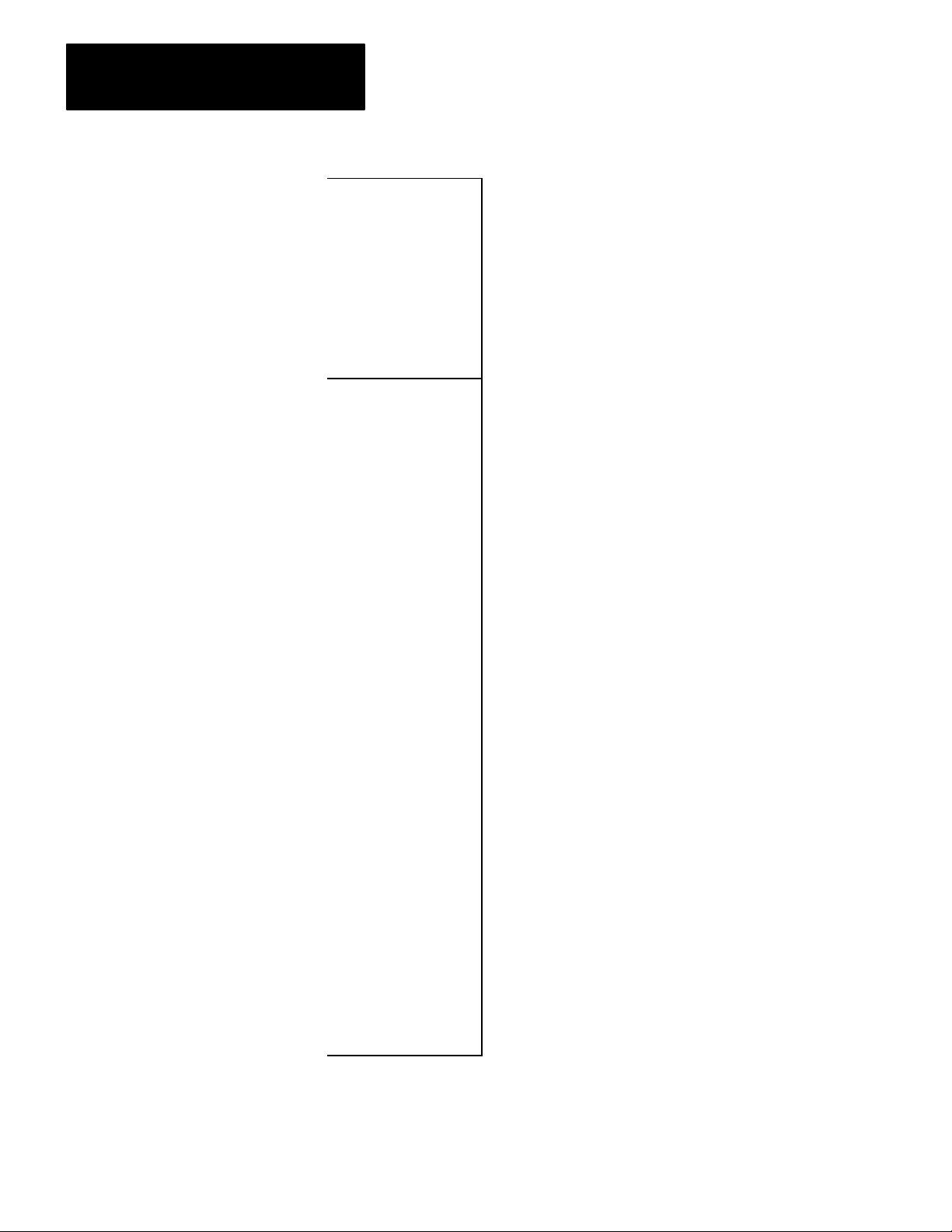

On the underside of the PROM door is a label that illustrates PROM

installation. The notch on the AF4 PROM, when installed, must correspond to

the notch shown on the label. Figure 2.2 shows a properly installed AF4.

22

Figure 2.2

AF4

Installed

PROM

Notch

Lock

OFF

PROM Installation

1772AF4

DO NOT

UP

ERASE

ON

Release

11590

Page 7

Chapter 2

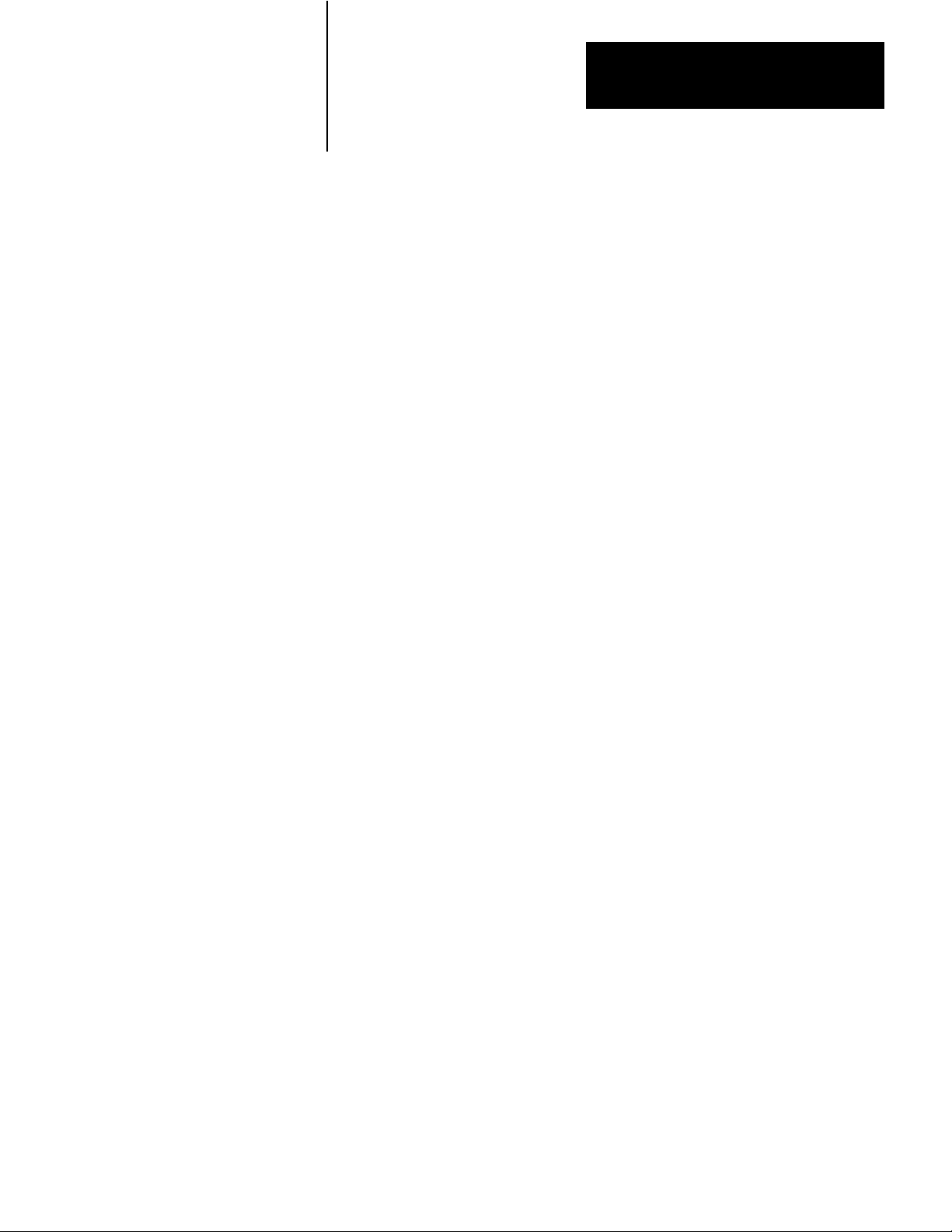

To access the PROM socket, remove the Mini-PLC-2/15 processor module from

the I/O chassis. If you desire to maintain processor memory contents, connect

an external battery pack (Figure 2.3) to the processor with the Mini-Processor

Transport Cable (cat. no. 1772-CD) prior to removing the module from the

chassis.

Figure 2.3

External

Battery Backup

Battery Pack

(Cat. No. 1771BB)

MiniPLC2/15 Processor

(Cat. No. 1772LV)

MiniProcessor

Transport Cable

(Cat. No. 1772CD)

11182

To install the AF4, perform the following steps (Figure 2.2):

1. Turn the mode select switch to PROG.

2. Remove AC power from the I/O chassis power supply.

3. Remove the processor module from the I/O chassis.

4. Check all AF4 pins to ensure they are not bent or dirty.

5. Loosen the screw and lift the PROM door.

6. Push the ON tab in to unlock the socket.

7. Position the AF4 as shown in Figure 2.2. Be sure the notch on your AF4

faces the OFF tab.

8. Line up the AF4 as shown in Figure 2.2 and seat in the socket. Be sure the

pins are aligned as they bend easily.

9. Lock the AF4 in place by pushing the OFF tab in.

10.Close the PROM door and tighten the screw.

23

Page 8

Chapter 2

Installation

Removal

To remove the AF4, perform the following steps:

1. Turn the mode select switch to PROG.

2. To maintain processor memory contents connect an external battery pack

to the processor with the mini-processor transport cable (Figure 2.3).

3. Remove AC power from the I/O chassis power supply.

4. Remove the processor module from the I/O chassis.

5. Loosen the screw, lift up the PROM door, and push the ON tab in to

unlock the socket (Figure 2.2).

6. Carefully remove the AF4 and store it in its shipping container.

24

Page 9

Programming

Chapter

3

General

You access the AF4 by pressing [SHIFT][EAF] (execute auxiliary function) or

[SHIFT][SCT] on the keyboard of your Industrial Terminal (cat. no. 1770-T3).

The instruction is an output instruction and may be preceded on a rung by

condition instructions. Once you enter the function, the block diagram of

Figure 3.1 appears on the CRT. To program a specific mathematics functions,

you would enter the appropriate function number (Table 3.A). If you enter a

non-existent function number, the following occurs:

When the processor attempts to execute a function number which does not exist

on the AF4, the response of the processor depends upon whether the keyswitch

is in the RUN or RUN/PROGRAM position.

The responses are:

In the RUN position, the processor stops running and the CRT displays

PROCESSOR FAULT and CHANGE PROCESSOR TO PROGRAM MODE.

The processor and memory LEDs illuminate. After you change processor

operation to program mode the LEDs turn off and the CRT displays MODE

SELECTION menu and PLC-2 RUN TIME ERROR, PRESS 11 TO

CONTINUE. When you press 11 the CRT displays and intensifies the rung

containing the illegal opcode and states ILLEGAL OPCODE INTENSIFIED

INSTRUCTION LINKED WITH CAUSE OF ERROR.

In the RUN/PROGRAM position, the processor stops running and the CRT

displays MODE SELECTION menu and PLC-2 RUN TIME ERROR, PRESS

11 TO CONTINUE. When you press 11 the CRT displays and intensifies the

rung containing the illegal opcode and states ILLEGAL OPCODE

INTENSIFIED INSTRUCTION LINKED WITH CAUSE OF ERROR.

31

Page 10

Chapter 3

Programming

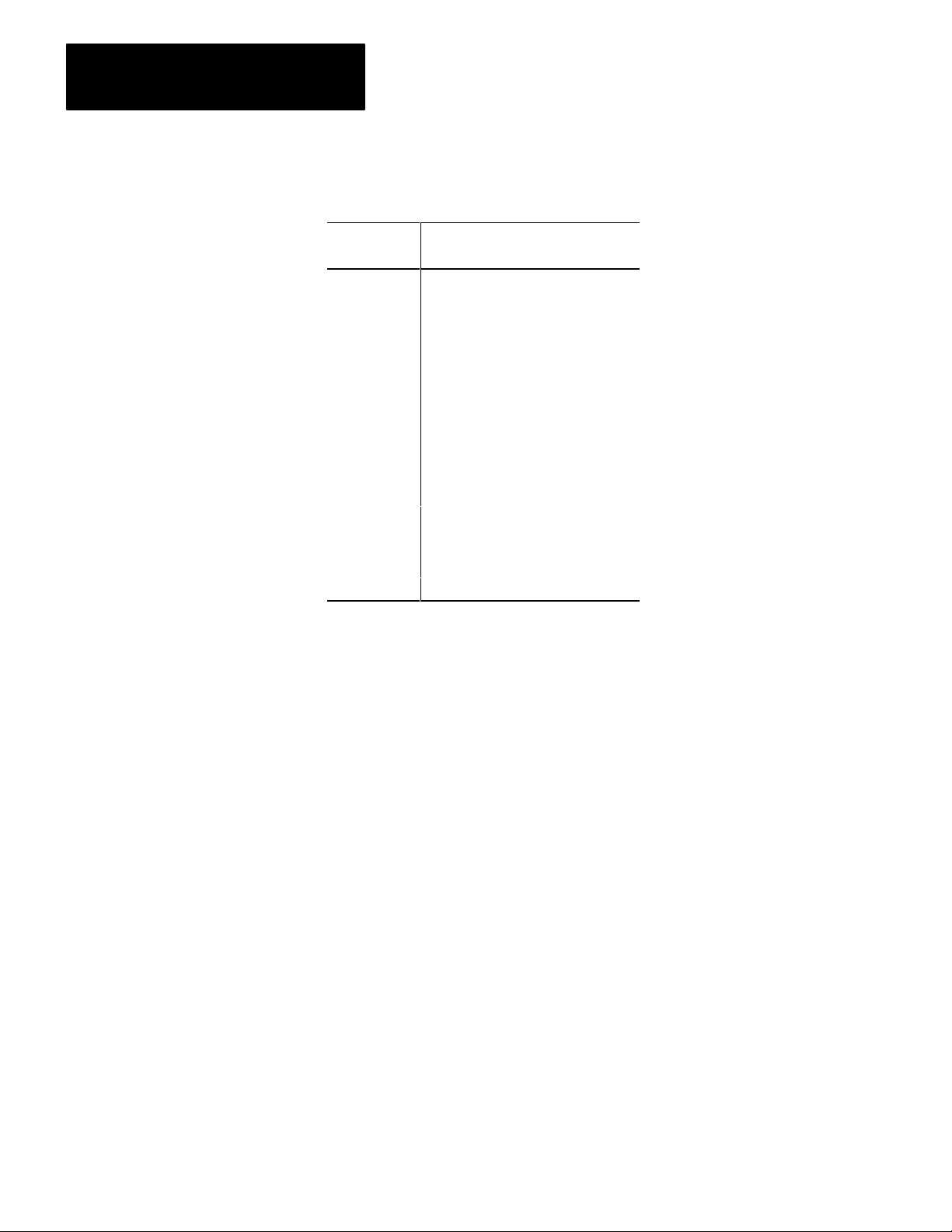

Table 3.A

Function

Numbers for the AF4

Function

Number

01 Add

02 Subtract

03 Multiply

04 Divide

13 BCD to Binary conversion

14 Binary to BCD conversion

30 Log to base 10

31 Natural log (log to base e)

32 Exponential

33 Power

34 Reciprocal

35 Sine

36 Cosine

37 Square Root

Mathematical Operation

You enter an existent function number and then enter data and result addresses

(we will explain this in detail later). The processor then places a number in the

data address.

AF4 Function Sequence

32

When the Mini-PLC-2/15 controller encounters an AF4 function during

program execution and the rung is true, the processor performs the following

steps:

1. Saves its present position in the user program.

2. The interlock system grants access to the AF4 function.

3. Reads the operand’s data stored in the data address that you entered.

4. Reads the result address which you entered.

5. Determines the location of the mathematical routine requested by the

function number.

6. Executes the routine in the AF4 area. (See Avoiding Excessive AF4

Execution Times.)

7. Writes the results at the result address in the data table.

8. Returns program execution to the next instruction in the user program after

the AF4 function is completed. (See Avoiding Excessive AF4 Execution

Times.)

9. Readies itself for the next AF4 operation.

Page 11

Chapter 3

Programming

AF4 Automatic Checks

To guard against improper program execution, automatic check routines are

incorporated in the AF4. The processor uses these routines to prevent the

following:

Executing AF4 functions having invalid function addresses

Spending so much time executing AF4 functions that the controller neglects

its main program and I/O scans

Invalid

Function Addresses

Valid AF4 function addresses include the I/O image table and the data table

(except word 027). Specifically, valid addresses are from 010 to 026, from 030

to 077, and from 110 to the end of the data table. Result addresses must not

reside in the input image table.

When a user programmed function has an invalid address, the response of the

processor depends upon whether the keyswitch is in the RUN or

RUN/PROGRAM position.

The response are:

In the RUN position, the processor stops running and the CRT displays

PROCESSOR FAULT and CHANGE PROCESSOR TO PROGRAM MODE.

The processor and memory LEDs illuminate. After you change processor

operation to program mode the LEDs turn off and the CRT displays MODE

SELECTION menu and PLC-2 RUN TIME ERROR, PRESS 11 TO

CONTINUE. When you press 11 the CRT displays and intensifies the rung

containing the illegal address and states ILLEGAL ADDRESS INTENSIFIED

INSTRUCTION LINKED WITH CAUSE OF ERROR.

In the RUN/PROGRAM position, the processor stops running and the CRT

displays MODE SELECTION menu and PLC-2 RUN TIME ERROR, PRESS

11 TO CONTINUE. When you press 11 the CRT displays and intensifies the

rung containing the illegal address and states ILLEGAL ADDRESS

INTENSIFIED INSTRUCTION LINKED WITH CAUSE OF ERROR.

33

Page 12

Chapter 3

Programming

A

voiding Excessive AF4 Execution T

Table 3.B lists execution times for AF4 functions. To avoid excessive AF4

function execution times, an interlock system is designed into the AF4. This

system automatically checks and does the following:

Permits no AF4 function to run longer than 6ms without returning processor

scan to the processor.

During a program scan each true AF4 function rung which can be completed

in a single scan will be completed as it is encountered. However, upon

encountering a true AF4 function rung which requires multiple program

scans to complete, all other true AF4 function rungs will be “locked out”

until sufficient program scans complete the active AF4 function rung.

Once started, it completes an AF4 function prior to starting the next AF4

function encountered in the user program which has a true rung condition.

imes

Limits the number of enabled AF4 functions in a program to 50. You may

include more functions but you must ensure that no more than 50 are enabled

at one time. This requirement only applies where you have programmed a

function that requires more than one scan to complete.

This time listed in Table 3.B includes:

Overhead for AF4 interlock system

One run through the portion of the AF4 specified by the particular function

To obtain the time required from activation of the input that makes the rung

containing the AF4 function true until the correct answer for the function is in

the data table, you must add the following times to the values in Table 3.B:

Input delay time (from specification for specific input)

One program scan time and one I/O scan time multiplies by the number of

scans specified in Table 3.B

Methods for determining these times are presented in Mini-PLC-2/15, Series B,

Programmable Controller Programming and Operations Manual (publication

1772- 804).

34

Page 13

Chapter 3

Programming

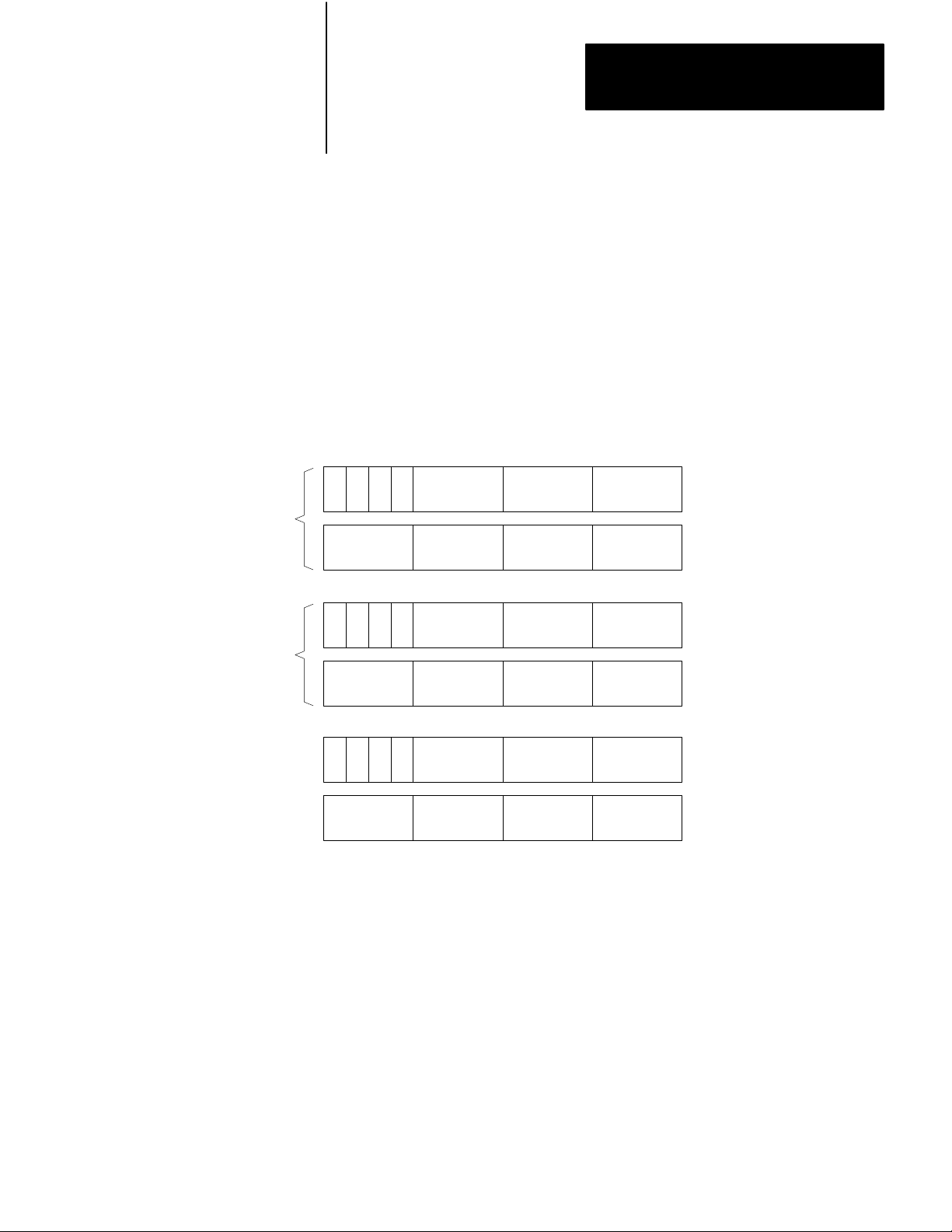

Table 3.B

Execution T

AF4

Log

Natural log

Function

imes

[1]

Reciprocal

Exponential

Powers

35

Page 14

Chapter 3

Programming

Sine

Function

N

A

W

u

v

o

m

g

r

b

.

s

e

T

t

r

i

T

o

m

i

f

e

m

S

e

c

a

n

s

Cosine

Square Root

00.5

(y

)

BCD to Binary

Binary to BCD

36

Page 15

Function

Addition

Chapter 3

Programming

N

A

W

u

v

o

m

g

r

b

.

s

e

T

t

r

i

T

o

m

i

f

e

m

S

e

c

a

n

s

Subtraction

Multiplication

Division

[1]

These times are calculated for a single AF4 function. Overhead for AF4 lock

maintenance and multiple runs through the ladder program to complete some function is

included.

Programming Specific Mathematical Functions

In this section we explain the following for each of the AF4 functions:

What it is

How to enter it in your program

Its format in the data table

a. word arrangement

37

Page 16

Chapter 3

Programming

b. digit location

Sample entry and display rungs. Although there are several techniques to

enter this data, we use get instructions.

Error messages. If an AF4 function has special error message responses to

specific illegal programming procedures, we state these responses.

38

Page 17

Chapter 3

Programming

Status Bits

The most significant four bits of the most significant word of the result data

area are reserved for status bits. These bits have the following meanings:

Enable - bit 17

Sign - bit 16

Done - bit 15

Error bit - bit 14

The enable bit is set at the start of an AF4 function and reset upon completion.

The sign bit, if set, indicates a negative value.

The done bit is reset at the start of an AF4 function and set upon completion.

The error bit is a general error flag that indicates overflow and invalid operand

or result errors. Individual functions determine the actual state of this bit.

Throughout this manual, unused status bits are shown blank for the following

reasons:

Whether the content of an unused status bit is an input word is 0 or 1 is

irrelevant as such bits are ignored in AF4 function execution.

The AF4 reset unused status bits in result words. For simplicity these bits are

left blank.

Accuracy

In the series A, revision A AF4, the typical error is +

1 in the least significant

digit (LSD). However, two functions have errors which exceed this limit.

Function 32, e

+x

, has error limits of +8 and -1 in the least significant digit for a

range of x from 0.00 to -9.99.

Function 33, y

+x

, has error limits of +6 and -1 in the least significant digit when

x is negative.

AF4 Addition Function

An AF4 addition function operates on two 6-digit BCD numbers and presents

the result in a third 6-digit BCD number.

(+

xxx xxx.) + (+xxx xxx.) = +xxx xxx.

39

Page 18

Chapter 3

Programming

How to enter an AF4 Addition Function

To program an AF4 addition function, perform the following steps:

1. Press [SHIFT][EAF] or [SHIFT][SCT] on the keyboard of your industrial

terminal. Figure 3.1 appears on the CRT

Figure 3.1

Execute

Numbers shown are default values and must be replaced

by your values. The number of default address digits

originally displayed, 3 or 4, depends on the size of the

data table.

Auxiliary Function Format

Execute Aux

Function

Function Number:

Data Addr:

Result Addr:

01

010

010

310

Page 19

Chapter 3

Programming

2. Enter 01, the function number for AF4 addition.

This entry identifies that the function entered is to perform an AF4 addition and

that the processor use the data table format shown in Figure 3.2 when executed.

Operands 1 and 2 represent the two 6-digit numbers we wish to add. The six

digits of operand 1 are represented in BCD by the groups of bits labeled digit 1

through 6. Digit 1 and digit 6 are the most significant and the least significant

digits respectively. This digit labeling system also applies to operand 2 and the

result.

Figure 3.2

General

AF4 Addition Function Word and Digit Format

Operand 1

Operand 2

Result

Bit No.

171615141312111076543210

S

S

DERE

S

E = Enable Bit (1 = Function in Progress)

S = Sign Bit (1= Negative)

D = Done Bit (1 = Function Complete)

ER = Error Bit (1 = Overflow)

MSD = Most Significant Digit

LSD = Least Significant Digit

Digit 1

(MSD)

Digit 4

Digit 1

(MSD)

Digit 4

Digit 1

(MSD)

Digit 4

Digit 2 Digit 3

Digit 5

Digit 2 Digit 3

Digit 5

Digit 2 Digit 3

Digit 5

Digit 6

(LSD)

Digit 6

(LSD)

Digit 6

(LSD)

Data Address

m

m + 1

m + 2

m + 3

Result Address

n

n + 1

11481

311

Page 20

Chapter 3

Programming

3. Enter a data address and a result address.

If we select a data address of 201 and a result address of 305, the AF4

establishes the data table format shown in Figure 3.3. Be careful not to select

data and result addresses so close together that the addresses of the operands

following the data address overlap your result address. The data address

eventually contains three digits of operand 1. The AF4 reserves the next three

higher addresses for digits 4 through 6 of operand 1 and digits 1 through 6 of

operand 2. The result address contains the most significant three digits of the

result and the next higher address contains the least significant three digits.

Figure 3.3

AF4

Addition Function Formal After Address Entry

Operand 1

Operand 2

Result

Bit No.

171615141312111076543210

S

S

DERE

S

E = Enable Bit (1 = Function in Progress)

S = Sign Bit (1= Negative)

D = Done Bit (1 = Function Complete)

ER = Error Bit (1 = Overflow)

MSD = Most Significant Digit

LSD = Least Significant Digit

Digit 1

(MSD)

Digit 4

Digit 1

(MSD)

Digit 4

Digit 1

(MSD)

Digit 4

Digit 2 Digit 3

Digit 5

Digit 2 Digit 3

Digit 5

Digit 2 Digit 3

Digit 5

Digit 6

(LSD)

Digit 6

(LSD)

Digit 6

(LSD)

Data Address

201

202

203

204

Result Address

305

306

11482

312

Page 21

Chapter 3

Programming

4. Enter values for operands 1 and 2.

You can enter these values from the keyboard of your industrial terminal or

through ladder diagram functions. Entry of operand 1 - 102746 and operand 2 256384 produces the result 359130 when the addition function executes.

Figure 3.4 shows how the result is stored.

Figure 3.4

Addition Function Format After Execution

AF4

Operand 1

Operand 2

Result

Bit No

171615141312111076543210

S

(0)

S

(0)

S

(0) (0) (1) (0)

E = Enable Bit (1 = Function in Progress)

S = Sign Bit (1= Negative)

D = Done Bit (1 = Function Complete)

ER = Error Bit (1 = Overflow)

DERE

1

02

467

562

843

593

301

Data Address

Word 201

Word 202

Word 203

Word 204

Result Address

Word 305

Word 306

11483

Entry and Display of Input and Result Values

Figure 3.5 shows one method for inserting input values and displaying input

values and results of AF4 addition computations. Although there are several

techniques for accomplishing this, we chose get instructions. The first rung

requests an AF4 addition. The second rung shows the two operands in its top

branch and the resultant sum in its lower branch.

313

Page 22

Chapter 3

Programming

Figure 3.5

Addition Function Input and Result Display Rungs

AF4

Execute Aux

Function

Function Number:

Data Addr:

Result Addr:

01

201

305

201

202

203

204

G

G

G

G

102

746

256

384

305

306

G

G

359

130

Error Message

If the resultant sum has more than six integers, the error bit (bit 14) is set

indicating overflow.

AF4

Subtraction Function

An AF4 subtraction function operates on two 6-digit BCD numbers and

presents the result in a third 6-digit BCD number.

(+

xxx xxx/ - +xxx xxx.) = +xxx xxx.

How to Enter an AF4 Subtraction Function

Storage

Bit

314

To program an AF4 subtraction function, perform the following steps:

1. Press [SHIFT][EAF] or [SHIFT][SCT] on the keyboard of your industrial

terminal. Figure 3.1 appears on the CRT.

2. Enter 02, the function number for AF4 subtraction.

This entry identifies that the function entered is to perform an AF4 subtraction

and that the processor use the data table format shown in Figure 3.6 when

executed. Operands 1 and 2 represent the two 6-digit numbers whose difference

you want to find. The six digits of operand 1 are represented in BCD by the

group of bits labeled digit 1 through 6. Digit 1 and digit 6 are the most

significant and the least significant digits respectively. This digit labeling

system also applies to operand 2 and the result.

Page 23

Figure 3.6

AF4 Subtraction Function Word Digit Format

General

Chapter 3

Programming

Operand 1

Operand 2

Result

Bit No.

171615141312111076543210

S

S

DERE

S

E = Enable Bit (1 = Function in Progress)

S = Sign Bit (1= Negative)

D = Done Bit (1 = Function Complete)

ER = Error Bit (1 = Overflow)

MSD = Most Significant Digit

LSD = Least Significant Digit

Digit 1

(MSD)

Digit 4

Digit 1

(MSD)

Digit 4

Digit 1

(MSD)

Digit 4

Digit 2 Digit 3

Digit 5

Digit 2 Digit 3

Digit 5

Digit 2 Digit 3

Digit 5

Digit 6

(LSD)

Digit 6

(LSD)

Digit 6

(LSD)

Data Address

m

m + 1

m + 2

m + 3

Result Address

n

n + 1

11484

3. Enter a data address and a result address.

If we select a data address of 201 and a result address of 305, the AF4

establishes the data table format shown in Figure 3.7. The data address

eventually contains three digits of operand 2. The AF4 reserves the next three

higher addresses for digits 4 through 6 of operand 1 and digits 1 through 6 of

operand 2. The result address contains the most significant three digits of the

result and the next higher address contains the least significant three digits.

315

Page 24

Chapter 3

Programming

Figure 3.7

Subtraction Function Format After Address Entry

AF4

Operand 1

Operand 2

Result

Bit No.

171615141312111076543210

S

S

DERE

S

E = Enable Bit (1 = Function in Progress)

S = Sign Bit (1= Negative)

D = Done Bit (1 = Function Complete)

ER = Error Bit (1 = Overflow)

MSD = Most Significant Digit

LSD = Least Significant Digit

Digit 1

(MSD)

Digit 4

Digit 1

(MSD)

Digit 4

Digit 1

(MSD)

Digit 4

Digit 2 Digit 3

Digit 5

Digit 2 Digit 3

Digit 5

Digit 2 Digit 3

Digit 5

Digit 6

(LSD)

Digit 6

(LSD)

Digit 6

(LSD)

Data Address

201

202

203

204

Result Address

305

306

11485

316

4. Enter values for operands 1 and 2.

You can enter these values form the keyboard of your industrial terminal or

through ladder diagram functions. Entry of operand 1 = 102746 and operand 2

256384 produces the result -153638 when the subtraction function executes.

Figure 3.8 shows how the result is stored.

Page 25

Operand 1

Bit No

Chapter 3

Programming

Figure 3.8

Subtraction Function Format After Execution

AF4

17 16 15 14 13 12 11 10 7 6 5 4 3 2 1 0

(0)

S

1

02

467

Data Address

201

202

Operand 2

Result

S

(0)

DERE

S

(0) (0) (1) (0)

E = Enable Bit (1 = Function in Progress)

S = Sign Bit (1= Negative)

D = Done Bit (1 = Function Complete)

ER = Error Bit (1 = Overflow)

562

843

531

386

203

204

Result Address

305

306

11486

Entry and Display of Input and Result Values

Figure 3.9 shows one method of inserting input values and displaying input

values and results of AF4 subtraction computations. Although there are several

techniques for accomplishing this, we chose get instructions. The first rung

requests an AF4 subtraction. The second rung shows the two operands in its top

branch and the resultant difference in its lower branch.

Figure 3.9

Af4

Subtraction Function Input and Result Display Rungs

201

202

203

204

G

G

G

G

102

746

256

384

305

306

G

G

153

638

Execute Aux

Function

Function Number:

Data Addr:

Result Addr:

02

201

305

Storage

Bit

317

Page 26

Chapter 3

Programming

Error Message

If the result has more than six integers, the error bit (bit 14) is set indicating

overflow.

AF4

Multiplication Function

An AF4 multiplication function operates on two 6-digit BCD numbers and

presents the results in a 12-digit BCD number.

(+

xxx xxx.) x (+xxx xxx.) = +xxx xxx xxx xxx.

How to Enter an AF4 Multiplication Function

To program an AF4 multiplication function, perform the following steps:

1. Press [SHIFT][EAF] or [SHIFT][SCT] on the keyboard of your industrial

terminal. Figure 3.1 appears on the CRT.

2. Enter 03, the function number for AF4 multiplication.

This entry identifies that the function entered is to perform an AF4

multiplication and that the processor use the data table format shown in

Figure 3.10 when executed. Operands 1 and 2 represent two 6-digit numbers

whose product you want to find. The six digits of operand 1 are represented in

BCD by groups of bits labeled digit 1 through 6. Digit 1 and 6 are the most

significant and least significant digits respectively. Operand 2 and the 12 digits

of the result are labeled similarly.

318

Page 27

Figure 3.10

AF4 Multiplication Function Word and Digit Format

General

Chapter 3

Programming

Bit No.

Operand 1

Operand 2

Result

171615141312111076543210

S

S

S

Digit 1

(MSD)

Digit 4

Digit 1

(MSD)

Digit 4

DE

Digit 1

(MSD)

Digit 7

Digit 2 Digit 3

Digit 5

Digit 2 Digit 3

Digit 5

Digit 2 Digit 3

Digit 5Digit 4

Digit 8 Digit 9

Digit 6

(LSD)

Digit 6

(LSD)

Digit 6

Data Address

m

m + 1

m + 2

m + 3

Result Address

n

n + 1

n + 2

Digit 10

E = Enable Bit (1 = Function in Progress)

S = Sign Bit (1= Negative)

D = Done Bit (1 = Function Complete)

MSD = Most Significant Digit

LSD = Least Significant Digit

Digit 11

Digit 12

(LSD)

n + 3

11487

3. Enter a data address and a result address.

If we enter a data address of 201 and a result address of 305, the AF4

establishes the data table format shown in Figure 3.11. The data address

eventually contains the most significant three digits of operand 1. The AF4

reserves the next three higher addresses for the least significant three digits of

operand 1 and the six digits of operand 2. The result address contains the most

significant three digits of the result. The AF4 reserves the next three higher

addresses for the remaining nine digits of the result.

319

Page 28

Chapter 3

Programming

Figure 3.11

Multiplication Function format After Address Entry

AF4

Bit No.

Operand 1

Operand 2

Result

171615141312111076543210

S

S

S

DE

Digit 1

(MSD)

Digit 4

Digit 1

(MSD)

Digit 4

Digit 1

(MSD)

Digit 7

Digit 2 Digit 3

Digit 5

Digit 2 Digit 3

Digit 5

Digit 2 Digit 3

Digit 5Digit 4

Digit 8 Digit 9

Digit 6

(LSD)

Digit 6

(LSD)

Digit 6

Data Address

201

202

203

204

Result Address

305

306

307

Digit 10

E = Enable Bit (1 = Function in Progress)

S = Sign Bit (1= Negative)

D = Done Bit (1 = Function Complete)

MSD = Most Significant Digit

LSD = Least Significant Digit

Digit 11

Digit 12

(LSD)

310

11488

320

Page 29

Chapter 3

Programming

4. Enter values for operands 1 and 2.

You can enter these values from the keyboard of your industrial terminal or

through ladder diagram functions. Entry of operand 1 - 000400 and operand 2 000200 produces the result 00000080000 (Figure 3.12).

Figure 3.12

AF4

Multiplication Function Format After Execution

Bit No.

Operand 1

Operand 2

Result

171615141312111076 54 3 2 1 0

S

(0)

S

(0)

S

(0)(0)(1)

DE

0

00

004

000

002

000

000

800

000

Data Address

201

202

203

204

Result Address

305

306

307

310

E = Enable Bit (1 = Function in Progress)

S = Sign Bit (1= Negative)

D = Done Bit (1 = Function Complete)

11489

Entry and Display of Input and Result Values

Figure 3.13 shows one method you can use to enter values for operands 1 and 2

and for displaying the results of an AF4 multiplication. Although there are

several techniques for accomplishing this, we chose get instructions. The first

rung requests an AF4 multiplication. The top branch of the second rung shows

the two 6-digit operands while the lower branch shows the 12 digit product.

321

Page 30

Chapter 3

Programming

Figure 3.13

Multiplication Function Input and Result Display Rungs

Af4

Execute Aux

Function

Function Number:

Data Addr:

Result Addr:

03

201

305

201

202

203

204

G

G

G

G

000

400

000

200

305

306

306

306

G

G

G

G

153

638

638

638

AF4 Division Function

An AF4 division function operates on two 6-digit BCD numbers and presents

the results in a 12-digit BCD number.

(+

xxx xxx.) : (+xxx xxx.) = +xxx xxx.xxx xxx

How to Enter an AF4 Division Function

To program an AF4 division function, perform the following steps:

1. Press [SHIFT][EAF] or [SHIFT][SCT] on the keyboard of your industrial

terminal. Figure 3.1 appears on the CRT.

Storage

Bit

322

2. Enter 04, the function number for AF4 division.

This entry identifies that the function entered is to perform an AF4 division and

that the processor use the data table format shown in Figure 3.14 when

executed. Operands 1 and 2 represent two 6-digit numbers whose quotient you

wish to find. The six digits of operand 1 are represented in BCD by groups of

bits labeled digit 1 through 6. Digit 1 and 6 are the most significant and least

significant digits respectively. Operand 2 and the 12 digits of the result are

labeled similarly.

Page 31

Figure 3.14

AF4 Division Function W

General

Chapter 3

Programming

ord and Digit Format

Bit No.

Operand 1

Operand 2

Result

17161514131211107 6 5 4 3 2 1 0

ER

Digit 1

(MSD)

Digit 4

Digit 1

(MSD)

Digit 4

Digit 1

(MSD)

Digit 7

Digit 10

S

S

DE

S

Digit 2 Digit 3

Digit 5

Digit 2 Digit 3

Digit 5

Digit 2 Digit 3

Digit 5Digit 4

Digit 8 Digit 9

Digit 11

Digit 6

(LSD)

Digit 6

(LSD)

Digit 6

Digit 12

(LSD)

Data Address

m

m + 1

m + 2

m + 3

Result Address

n

n + 1

n + 2

n + 3

E = Enable Bit (1 = Function in Progress)

S = Sign Bit (1= Negative)

D = Done Bit (1 = Function Complete)

ER = Illegal Operand (Divide by Zero)

MSD = Most Significant Digit

LSD = Least Significant Digit

11490

3. Enter a data address and a result address.

If we enter a data address of 201 and a result address of 305, the AF4

establishes the data table format shown in Figure 3.15. The data address

eventually contains the most significant three digits of operand 1. The AF4

reserves the next three higher addresses for the least significant three digits of

operand 1 and the six digits of operand 2. The result address contains the most

significant three digits of the result. The AF4 reserves the next three higher

addresses for the remaining nine digits of the result.

323

Page 32

Chapter 3

Programming

Figure 3.15

Division Function Format After Address Entry

AF4

Bit No.

Operand 1

Operand 2

Result

171615141312111076543210

ER

Digit 1

(MSD)

Digit 4

Digit 1

(MSD)

Digit 4

Digit 1

(MSD)

Digit 7

Digit 10

Digit 2 Digit 3

Digit 5

Digit 2 Digit 3

Digit 5

Digit 2 Digit 3

Digit 5Digit 4

Digit 8 Digit 9

Digit 11

Digit 6

(LSD)

Digit 6

(LSD)

Digit 6

Digit 12

(LSD)

S

S

S

DE

Data Address

201

202

203

204

Result Address

305

306

307

310

E = Enable Bit (1 = Function in Progress)

S = Sign Bit (1= Negative)

D = Done Bit (1 = Function Complete)

ER = Illegal Operand (Divide by Zero)

MSD = Most Significant Digit

LSD = Least Significant Digit

11491

324

Page 33

Chapter 3

Programming

4. Enter values for operands 1 and 2.

You can enter these numbers from the keyboard of your industrial terminal or

through ladder diagram functions. Entry of operand 1 = 000400 and operand 2

- 000200 produces the result 000002.000000 (Figure 3.16).

Figure 3.16

AF4

Division Function Format After Execution

Bit No.

Operand 1

Operand 2

Result

171615141312111076 54 3 2 1 0

S

(0)

S

(0)

DE

S

(0)(0)(1)ER(0)

0

00

004

000

002

000

020

000

000

Data Address

201

202

203

204

Result Address

305

306

307

310

E = Enable Bit (1 = Function in Progress)

S = Sign Bit (1= Negative)

D = Done Bit (1 = Function Complete)

ER = Illegal Operand (Divide by Zero)

11492

Entry and Display of Input and Result Values

Figure 3.17 shows one method you can use to enter values for operands 1 and 2

and for displaying the results of an AF4 division. Although there are several

techniques for accomplishing this, we chose get instructions. The first rung

requests an AF4 division function. The top branch of the second rung shows

the two 6-digit operands while the lower branch shows the 12 digit quotient.

325

Page 34

Chapter 3

Programming

Figure 3.17

Division Function Input and Result Display Rungs

AF4

Execute Aux

Function

Function Number:

Data Addr:

Result Addr:

04

201

305

201

202

203

204

G

G

G

G

000

400

000

200

305

306

306

306

G

G

G

G

000

002

000

000

Error Message

If you divide by zero, the error bit (bit 14) is set and the result reads zero.

AF4 BCD to Binary Conversion Function

The AF4 BCD (binary coded decimal) to binary conversion function converts a

BCD number (from 0 to 4095) into a 12-bit binary number.

How to Enter an AF4 BCD to Binary Conversion Function

To program an AF4 BCD to binary conversion function, perform the following

steps:

Storage

Bit

326

1. Press [SHIFT][EAF] or [SHIFT][SCT] on the industrial terminal

keyboard. Figure 3.1 appears on the CRT.

Page 35

Chapter 3

Programming

2. Enter 13, the function number for AF4 BCD to binary conversion.

This entry identifies that the function entered is to perform an AF4 BCD to

binary conversion and that the processor use the data table format shown in

Figure 3.18 when executed.

Figure 3.18

General

AF4 BCD to Binary Conversion Function Word and Digit Format

Bit No.

Operand

Result

171615141312111076543210

DE

Digit 1 (MSD)

(Always = 0)

Digit 4

ER

S

S

E = Enable Bit (1 = Function in Progress)

S = Sign Bit (1= Negative)

D = Done Bit (1 = Function Complete)

ER = Error Bit (1 = BCD Number > 4095 Entered)

MSD = Most Significant Digit

LSD = Least Significant Digit

Digit 2

(Always = 0)

Digit 5

Digit 3

(Must be 3 4)

Digit 6

(LSD)

Data Address

m

m + 1

Result Address

n

11493

3. Enter a data address and a result address.

If we choose a data address of 200 and a result address of 300, the data table

format is as shown in Figure 3.19. The most significant three digits of the

operand (the BCD number we want to convert to binary) reside in the data

address word 200 and the least significant three digits reside in the next higher

address, 201. The first two digits are always zero and the third digit must not

exceed four. The number, converted to binary format, is stored in bits 0 through

13 in the result address, word 300.

Figure 3.19

AF4

BCD to Binary Conversion Function Format After Address Only

Bit No.

Operand

Result

17 16 15 14 13 12 11 10 7 6 5 4 3 2 1 0

Digit 2

(Always = 0)

Digit 5

(Must be

DE

Digit 1 (MSD)

(Always = 0)

Digit 4

ER

S

S

E = Enable Bit (1 = Function in Progress)

S = Sign Bit (1= Negative)

D = Done Bit (1 = Function Complete)

ER = Error Bit (1 = BCD Number > 4095 Entered)

MSD = Most Significant Digit

LSD = Least Significant Digit

Digit 3

Digit 6

(LSD)

3 4)

Data Address

200

201

Result Address

300

11494

327

Page 36

Chapter 3

Programming

Bit No.

Operand

4. Enter the operand.

You can enter the operand from the keyboard of your industrial terminal or

through ladder diagram functions. If we choose to enter 4095, the largest BCD

number that we can convert to a 12 bit binary number, we obtain the data table

configuration shown in Figure 3.20.

Figure 3.20

Af4

BCD to Binary Conversion Function Format After Execution

17 16 15 14 13 12 11 10 7 6 5 4 3 2 1 0

Data Address

200

(0)

S

004

201

Result Address

300

11495

Result

095

S

ER

DE

(0) (0) (1) (0)

E = Enable Bit (1 = Function in Progress)

S = Sign Bit (1= Negative)

D = Done Bit (1 = Function Complete)

ER = Error Bit (1 = BCD Number > 4095 Entered)

111111111111

Entry and Display of Input and Result Values

Figure 3.21 shows one method for inserting input values and displaying inputs

and results of an AF4 BCD to binary conversion. Although there are other

methods for accomplishing this, we chose get instructions. The first rung

requests an AF4 BCD to binary conversion. The top branch of the second rung

shows the BCD number we want to convert (004095) in words 200 and 201.

The bottom branch shows in the hexadecimal notation FFF (bits 0 through 13 in

word 300 have the states shown in Figure 3.20).

Figure 3.21

AF4

BCD to Binary Conversion Function Input and Display Rungs

Execute Aux

Function

200

004

300

FFF

Function Number:

Data Addr:

Result Addr:

201

G

G

G

095

13

200

300

Storage

Bit

328

Page 37

Chapter 3

Programming

Error Message

If you enter a BCD number larger than 4095, the error bit (bit 14) is set and the

result reads zero.

AF4 Binary to BCD Conversion Function

The AF4 binary to BCD conversion function converts a 12-bit binary number to

a BCD number (from 0 to 4095).

How to Enter an AF4 Binary to BCD Conversion Function

To program an AF4 binary to BCD conversion function, perform the following

steps:

1. Press [SHIFT][EAF]or [SHIFT][SCT] on the keyboard of your industrial

terminal. Figure 3.1 appears on the CRT.

Bit No.

Operand

2. Enter 14, the function number for the AF4 binary to BCD conversion.

This entry identifies that the function entered is to perform an AF4 binary to

BCD conversion and that the processor use the data table format shown in

Figure 3.22 when executed.

Figure 3.22

General

AF4 Binary to BCD Conversion Function Word and Digit Format

171615141312111076543210

S

Digit 1 (MSD)

DE

S

E = Enable Bit (1 = Function in Progress)

S = Sign Bit (1= Negative)

D = Done Bit (1 = Function Complete)

MSD = Most Significant Digit

LSD = Least Significant Digit

(Always = 0)

Digit 4

12 Bit Binary Number

Digit 2

(Always = 0)

Digit 5

Digit 3

Digit 6

(LSD)

Data Address

m

Result AddressResult

n

n + 1

11496

3. Enter a data address and a result address.

If we choose a data address of 200 and a result address of 300, the data table

format is as shown in Figure 3.23. Bits 0 through 13 or word 200 are reserved

for the operand (the 12-bit binary number we want to convert to BDD). The

result address, 300, contains the most significant three digits of the resulting

BCD number and the least significant three digits reside in the next higher

address, 301. The first two digits of the BCD number are always zero and the

third digit can not exceed four.

329

Page 38

Chapter 3

Programming

Figure 3.23

Binary to BCD Conversion Function Format After Address Entry

AF4

Bit No.

Operand

171615141312111076543210

Data Address

S

Digit 1 (MSD)

DE

S

E = Enable Bit (1 = Function in Progress)

S = Sign Bit (1= Negative)

D = Done Bit (1 = Function Complete)

MSD = Most Significant Digit

LSD = Least Significant Digit

(Always = 0)

Digit 4

12 Bit Binary Number

(Always = 0)

Digit 2

Digit 5

Digit 3

Digit 6

(LSD)

200

Result AddressResult

300

301

11497

4. Enter the operand.

You can enter the operand from the keyboard of your industrial terminal or

through ladder diagram functions. If we choose to set bits 0 through 13 in word

200, that is, insert the largest possible binary number in 12 bits, we obtain 4095

for the corresponding BCD number (Figure 3.24). The ones in bits 0 through

13 of word 200 indicate that each bit is set.

330

Bit No.

Operand

Result

Figure 3.24

AF4

Binary to BCD Conversion Function Format After Execution

17 16 15 14 13 12 11 10 7 6 5 4 3 2 1 0

S

S

(0) (0) (1)

E = Enable Bit (1 = Function in Progress)

S = Sign Bit (1= Negative)

D = Done Bit (1 = Function Complete)

11 11 11 11 11 11

DE

004

095

Data Address

200

Result Address

300

301

11498

Page 39

Chapter 3

Programming

Entry and Display of Input and Result Values

Figure 3.25 shows one method for inserting input values and displaying inputs

and results of an AF4 binary to BCD conversion function. Although there are

other methods for accomplishing this, we chose get instructions. The first rung

requests an AF4 binary to BCD conversion function. The top branch of the

second rung shows the binary number (in the hexadecimal notation FFF) that

we want converted to BCD. In this example, the binary number is the largest

possible, with bits 0 through 13 of word 200 set as shown in figure 3.24. The

lower branch shows the resulting BCD number, 004095, in words 300 and 301.

Figure 3.25

AF4 Binary to BCD Conversion Function Input and Result Display Rungs

Execute Aux

Function

200

G

004

300

FFF

Function Number:

Data Addr:

Result Addr:

201

G

G

095

14

200

300

Storage

Bit

Sign Bits

If you encounter any binary data where the sign bit is not in bit 16, you must

move the sign bit into bit 16 of an auxiliary data table word prior to doing a

binary to BCD conversion. If, for example, the sign bit of your module is bit 15

in word 200, the rungs in Figure 3.26 permit you to make a binary to BCD

conversion. The first rung puts word 200 data into word 201. Rung two sets bit

16 in word 201 if bit 15 in word 200 is set. The AF4 binary to BCD conversion

function in rung three then uses word 201 as its data address.

331

Page 40

Chapter 3

Programming

Figure 3.26

Transfer

200

G

200

15

of Sign Bit

Execute Aux

Function

Function Number:

Data Addr:

Result Addr:

14

201

AF4 Log to Base 10 Function

The AF4 log to the base 10 function finds the log of a 3-digit BCD integer. The

result is a 6-digit BCD number with an implied decimal point after the most

significant digit.

201

PUT

201

PUT

16

log (xxx.) - x.xx xxx

How to Enter an AF4 Log to Base 10 Function

To program an AF4 log to base 10 function perform the following steps:

1. Press [SHIFT][EAF] or [SHIFT][SCT] on the keyboard of your industrial

terminal. Figure 3.1 appears in the CRT.

2. Enter 30, the function number for an AF4 log to base 10 function.

This entry identifies that the function entered is to perform an AF4 log to base

10 calculation and that the processor use the data table format shown in

Figure 3.27 when executed. The three digits of the number whose log you want

are represented in BCD by the digits labeled 1 through 3 in the operand. The

6-digit result is represented by digits labeled 1 through 6. The most significant

digit (MSD) and least significant digit (LSD) are labeled.

332

Page 41

Figure 3.27

AF4 Log to Base 10 Function W

General

Chapter 3

Programming

ord and Digit Format

Bit No.

Operand

Result

171615141312111076543210

Digit 1

(MSD)

ER

Digit 1

(MSD)

Digit 4

DE

E = Enable Bit (1 = Function in Progress)

D = Done Bit (1 = Function Complete)

ER = Error Bit (1 = Input is 0)

MSD = Most Significant Digit

LSD = Least Significant Digit

Digit 2

Digit 2

Digit 5

Digit 3

(LSD)

Digit 3

Digit 6

(LSD)

Data Address

m

Result Address

n

n + 1

11499

3. Enter a data address and a result address.

If we select a data address of 201 and a result address of 305, the AF4

establishes the data table format shown in Figure 3.28. The data address is

reserved for the three digits of the number whose log you want. The result

address, 305, is reserved for the first three digits of the resultant log; the next

higher address, 306, is reserved for the last three digits. The implied decimal

point in the result is after the MSD.

Bit No.

Operand

Result

Figure 3.28

AF4

Log to Base 10 Function Format After Address Entry

171615141312111076543210

Digit 1

(MSD)

DE

ER

E = Enable Bit (1 = Function in Progress)

D = Done Bit (1 = Function Complete)

ER = Error Bit (1 = Input is 0)

MSD = Most Significant Digit

LSD = Least Significant Digit

Digit 1

(MSD)

Digit 4

Digit 2

Digit 2

Digit 5

Digit 3

(LSD)

Digit 3

Digit 6

(LSD)

Data Address

201

Result Address

305

306

11500

333

Page 42

Chapter 3

Programming

Operand

4. Enter the operand.

You can enter the operand from the keyboard of your industrial terminal or

through ladder diagram functions. Entry of operand - 648 produces the result

2.81157 when the log function executes. Figure 3.29 shows how the result is

stored.

Figure 3.29

AF4 Log to Base 10 Function Format After Execution

171615141312111076543210Bit No.

648

Data Address

201

Result Address

305

306

Result

ER

(0) (1)

E = Enable Bit (1 = Function in Progress)

D = Done Bit (1 = Function Complete)

ER = Error Bit (1 = Input is 0)

DE

(0)

281

157

Entry and Display of Input and Result Values

Figure 3.30 shows one method for inserting the operand and displaying the

input value and result of an AF4 log to base 10 function. Although there are

several techniques for accomplishing this, we chose get instructions. The first

rung requests an AF4 log to base 10 function. The second rung shows the

operand 648 in word 201 in the upper branch and the desired log 2.81157 in

words 305 and 306 in the lower branch.

Figure 3.30

AF4 Log to Base 10 Function Input and Result Display Rungs

Execute Aux

Function

Function Number:

Data Addr:

Result Addr:

201

305

11507

30

334

201

G

648

305

G

281

Storage

Bit

306

G

157

Page 43

Chapter 3

Programming

Error Messages

If you try to find the log of zero, the error bit is set and the result is zero.

AF4 Natural Log Functions

The AF4 natural log function finds the natural log of a 3-digit BCD integer to

the base e. The result is a 6-digit BCD value with an implied decimal point after

the most significant digit.

In (xxx.) - x.xx xxx

How to Enter an AF4 Natural Log Function

To program an AF4 natural log function, perform the following steps:

1. Press [SHIFT][EAF] or [SHIFT][SCT] on the keyboard of your industrial

terminal. Figure 3.1 appears on the CRT.

Bit No.

Operand

Result

2. Enter 31, the function number for the AF4 natural log function.

This entry identifies that the function entered is to perform an AF4 natural log

calculation and that the processor use the data table format shown in

Figure 3.31 when executed. The three digits of the operand (the number whose

natural log you want) and represented in BCD by the groups of bits labeled digit

1 through 3. The six digits of the result are labeled digit 1 through 6. A decimal

point is implied after the MSD.

Figure 3.31

General

AF4 Natural Log Function Word and Digit Format

171615141312111076543210

Digit 1

(MSD)

ER

Digit 1

(MSD)

Digit 4

DE

E = Enable Bit (1 = Function in Progress)

D = Done Bit (1 = Function Complete)

ER = Error Bit (1 = Input is 0)

MSD = Most Significant Digit

LSD = Least Significant Digit

Digit 2

Digit 2

Digit 5

Digit 3

(LSD)

Digit 3

Digit 6

(LSD)

Data Address

m

Result Address

n

n + 1

11501

3. Enter a data address and a result address.

335

Page 44

Chapter 3

Programming

If we enter a data address of 201 and a result address of 305, the AF4

establishes the data table format shown in Figure 3.32. The data address

eventually contains the operand. The result address (word 305) contains the first

three digits of the result and word 306 contains the last three digits.

Figure 3.32

AF4 Natural Log Function Format After Address Entry

Bit No.

Operand

Result

171615141312111076543210

Digit 1

(MSD)

ER

Digit 1

(MSD)

Digit 4

DE

E = Enable Bit (1 = Function in Progress)

D = Done Bit (1 = Function Complete)

ER = Error Bit (1 = Input is 0)

MSD = Most Significant Digit

LSD = Least Significant Digit

Digit 2

Digit 2

Digit 5

Digit 3

(LSD)

Digit 3

Digit 6

(LSD)

Data Address

201

Result Address

305

306

11502

4. Enter the number for the operand.

You can enter this number from the keyboard of your industrial terminal or

through ladder diagram functions. Entry of operand = 648 produces the result

6.47389 when the natural log function executes. Figure 3.33 shows how the

result is stored.

336

Operand

Result

Figure 3.33

AF4

Natural Log Function Format After Execution

171615141312111076543210Bit No.

64 8

DE

(0) (1) (0)

ER

E = Enable Bit (1 = Function in Progress)

D = Done Bit (1 = Function Complete)

ER = Illegal Operand (1 = Input is 0)

64 7

38 9

Data Address

201

Result Address

305

306

11503

Page 45

Chapter 3

Programming

Entry and Display of Input and Result Values

Figure 3.34 shows one method for inserting the operand and displaying the

input value and result of an AF4 natural log function. Although there are

several techniques for accomplishing this, we chose get instructions. The first

rung requests an AF4 natural log function. The second rung shows the operand

648 in word 201 in the upper branch and the desired natural log 6.47389 in

words 305 and 306 in the lower branch.

Figure 3.34

AF4 Natural Log Function Input and Result Display Rungs

Execute Aux

Function

Function Number:

Data Addr:

Result Addr:

31

201

305

201

G

648

305

G

647

306

G

389

Storage

Error Messages

If you try to find the natural log of zero, the error bit is set and the result is zero.

AF4 Exponential Function

The AF4 exponential function finds the value of the exponential function ex.

The result is in terms of a base number r and a power of 10, s, by which the base

number is multiplied to obtain the exponential function value. The equation is:

+x

e

=r(10)

s

where:

x= +

X.XX

r = resultant base number = X.XX

Bit

s = the exponent of 10 = +

X.

How to Enter an AF4 Exponential Function

To program an AF4 exponential perform the following steps:

1. Press [SHIFT][EAF] or [SHIFT][SCT] on the keyboard of your industrial

terminal. Figure 3.1 appears on the CRT.

337

Page 46

Chapter 3

Programming

2. Enter 32, the function number for an AF4 exponential function.

This entry identifies that the function entered is to perform an AF4 exponential

calculation and that the processor use the data table format shown in

Figure 3.35 when executed.

Figure 3.35

General AF4 Exponential Function W

ord and Digit Format

Bit No.

Operand

Result Base r

s (Power of 10)

171615141312111076543210

S

DE

S

E = Enable Bit (1 = Function in Progress)

S = Sign Bit (1 = Negative)

D = Done Bit (1 = Function Complete)

MSD = Most Significant Digit

LSD = Least Significant Digit

Digit 1

(MSD)

Digit 1

(MSD)

Digit 1 (MSD) Digit 3

(Always = 0) (Always = 0)

Digit 2

Digit 2

Digit 2

Digit 3

(LSD)

Digit 3

(LSD)

(LSD)

Data Address

m

Result Address

n

n + 1

11504

3. Enter a data address and a result address.

If we choose a data address of 200 and a result address of 305, the AF4

establishes the data table format shown in Figure 3.36. The three digits of the

word 200 are reserved for the operand (the power to which e is being raised).

The result address is reserved for the three digits of 4, the base number of the

answer with an implied decimal after the MSD. The next higher address, word

306, is reserved for s, the power of 10. The implied decimal point of exponent s

is after the LSD; the MSD and digit 2 are always zero. The base number r is

accurate to +

.01.

338

Figure 3.36

AF4 Exponential Function Format After Address Entry

Bit No.

Operand

s (Power of 10)

17 16 15 14 13 12 11 10 7 6 5 4 3 2 1 0

S

DE

S

E = Enable Bit (1 = Function in Progress)

S = Sign Bit (1 = Negative)

D = Done Bit (1 = Function Complete)

MSD = Most Significant Digit

LSD = Least Significant Digit

Digit 1

(MSD)

Digit 1

(MSD)

Digit 1 (MSD) Digit 3

(Always = 0) (Always = 0)

Digit 2

Digit 2

Digit 2

Digit 3

(LSD)

Digit 3

(LSD)

(LSD)

Data Address

200

Result AddressResult Base r

305

306

11505

Page 47

Operand

Chapter 3

Programming

4. Enter the operand.

You can enter the operand from the keyboard of your industrial terminal or

through ladder diagram functions. Entry of an operand (exponent) of e) of 9.42

yields an exponential function value of 1.23(10)

305 and the exponent of ten resides in word 306 as shown in Figure 3.37.

Figure 3.37

AF4 Exponential Function Format After Execution

171615141312111076543210Bit No.

S

(0)

942

004

. The base r resides in word

Data Address

200

s (Power of 10)

(0) (1)

DE

S

(0)

E = Enable Bit (1 = Function in Progress)

S = Sign Bit (1 = Negative)

D = Done Bit (1 = Function Complete)

123

004

Result AddressResult Base r

305

306

11506

Entry and Display of Input and Result Values

Figure 3.38 shows one method for inserting input values and displaying input

values and results of an AF4 exponential function. Although there are several

techniques for accomplishing this, we chose get instructions. The first rung

requests execution of an AF4 exponential function. The second rung contains

9.42, the exponent of e in word 200 with an implied decimal point after the first

digit. It also shows the result, (1.23)(10)

004

, in the form of 123 in word 305 and

004 in word 206. The decimal points are implied.

Figure 3.38

AF4

Exponential Function Input and Result Display Rungs

201

G

648

305

G

647

306

G

389

Execute Aux

Function

Function Number:

Data Addr:

Result Addr: 305

32

Storage

Bit

339

Page 48

Chapter 3

Programming

AF4 Power Function

The AF4 power function evaluates y+

x and gives the result in terms of a base

number r and a power of 10, s, by which you multiply this base number to

obtain the power function value. The equation is:

y+

x = r(10)

+s

where:

y = input base = XXX.

x = input exponent = XX.X

r = result base = X.XX

s = resultant exponent = +

XX. (The first digit is always zero)

A request for zero to the zero power will result in plus one.

How to Enter an AF4 Power Function

To program an AF4 power function perform the following steps:

1. Press [SHIFT][EAF] or [SHIFT][SCT] on the keyboard of your industrial

terminal. Figure 3.1 appears on the CRT.

2. Enter 33, the function number for an AF4 power function.

This entry identifies that the function entered is to perform an AF4 power

function calculation and that the processor use the data table format shown in

Figure 3.39 when executed. The data address is reserved for the three digits of

the base number y. Digits 1 and 3 are the most significant digit (MSD) and least

significant digit (LSD) respectively. The implied decimal point is after the

LSD. The three digits in the next higher address are reserved for the exponent,

x, with an implied decimal point after digit 2. The three digits of the result

address are reserved for the result base, r, with the decimal point after the MSD.

The next higher address is reserved for the resultant exponent s. Digit one of

the exponent s is always zero; the implied decimal point is after digit 3.

340

Page 49

Figure 3.39

General

Bit No.

Base y

Chapter 3

Programming

AF4 Power Function W

171615141312111076543210

S

ord and Digit Format

Digit 1

(MSD)

Digit 2

Digit 3

(LSD)

Data Address

m

Exponent x

Result Base, r

s (Power of 10)

3. Enter a data address and a result address.

If we enter a data address of 200 and a result address of 300, the AF4

establishes the data table format shown in Figure 3.40. Word 200 is reserved

for the base y and word 201 is reserved for the exponent x. The result address,

word 300, is reserved for the result base r; word 301 contains the resultant

exponent s.

Figure 3.40

AF4 Power Function Format After Address Entry

S

DE

S

E = Enable Bit (1 = Function in Progress)

S = Sign Bit (1 = Negative)

D = Done Bit (1 = Function Complete)

ER = Error Bit (1 = Overflow when y > 9.99(10) )

MSD = Most Significant Digit

LSD = Least Significant Digit

Digit 1

(MSD)

Digit 1

ER

(MSD)

Digit 1 (MSD) Digit 3

(Always = 0)

Digit 2

Digit 2

Digit 2

x 099.

Digit 3

(LSD)

Digit 3

(LSD)

(LSD)

m + 1

Result Address

n

n + 1

11508

Bit No.

Base y

Exponent x

Result Base, r

s (Power of 10)

171615141312111076543210

S

S

DE

S

E = Enable Bit (1 = Function in Progress)

S = Sign Bit (1 = Negative)

D = Done Bit (1 = Function Complete)

ER = Error Bit (1 = Overflow when y > 9.99(10) )

MSD = Most Significant Digit

LSD = Least Significant Digit

Digit 1

(MSD)

ER

Digit 1

(MSD)

Digit 1 (MSD) Digit 3

(Always = 0)

Digit 2

Digit 1

(MSD)

Digit 2

Digit 2

x 099.

Digit 3

(LSD)

Digit 2

(LSD)

Digit 3

(LSD)

(LSD)

Data Address

200

201

Result Address

300

301

11509

341

Page 50

Chapter 3

Programming

4. You can enter base y and exponent x values from the keyboard of the

industrial terminal or through ladder diagram functions. Entry of y - 124

in word 200 and 2 - 02.0 in word 201 produces the result 15376 when the

power function executes. Figure 3.41 shows how the result is stored as

1.53(10)

Figure 3.41

AF4 Power Function Format After Execution

171615141312111076543210Bit No.

Base y

4

. The result is truncated.

S

(0)

124

Data Address

200

Exponent x

Result Base, r

s (Power of 10)

S

(0)

DE

(0) (1) (0)

E = Enable Bit (1 = Function in Progress)

S = Sign Bit (1 = Negative)

D = Done Bit (1 = Function Complete)

ER = Error Bit (1 = Overflow when y > 9.99(10) )

ER

S

(0)

020

153

004

x 099.

201

Result Address

300

301

11510

342

Page 51

Chapter 3

Programming

Entry and Display of Input and Result Values

Figure 3.42 shows one method for inserting the input values and displaying

input values and result of an AF4 power function. Although there are several

techniques for accomplishing this, we chose get instructions.

The first rung requests the AF4 to evaluate a power function. The top branch of

the second rung contains the input base, 124, in word 200 and the input

exponent 02.0 in word 201. The lower branch of rung 2 contains the result,

1.53(10

in word 301. The implied decimal points in the result base and result exponent

are after digits 1 and 3 respectively.

Figure 3.42

AF4

4

) in the form of result base (153) in word 300 and result exponent (004)

Power Function Input and Result Rungs

Execute Aux

Function

200

G

124

300

G

153

Function Number:

Data Addr:

Result Addr: 300

201

G

020

301

G

004

33

200

Error Message

If you input a negative number for the input base y, the absolute value of y is

used and the error bit is set.

If yx >

9.99(10)

099

, the error bit is set, and a result of zero is returned.

AF4 Reciprocal Function

Storage

Bit

The AF4 reciprocal function finds the value of the reciprocal of a 6-digit BCD

number and presents the result in a 6-digit BCD number.

1

+

xxx xxx.

If you try to find the reciprocal of +

= +.xxx xxx

1, the result will read .999 999 with the

appropriate sign.

343

Page 52

Chapter 3

Programming

How to Enter an AF4 Reciprocal Function

To program an AF4 reciprocal function, perform the following steps:

1. Press [SHIFT][EAF] or [SHIFT][SCT] on the keyboard of your industrial

terminal. Figure 3.1 appears on the CRT.

2. Enter 34, the function number for an AF4 reciprocal function.

This entry identifies that the function entered is to perform an AF4 reciprocal

calculation and that the processor use the data table format shown in

Figure 3.43 when executed.

Figure 3.43

General AF4 Reciprocal Function W

ord and Digit Format

Bit No.

Operand

Result

171615141312111076543210

S

DE

SER

E = Enable Bit (1 = Function in Progress)

S = Sign Bit (1 = Negative)

D = Done Bit (1 = Function Complete)

ER = Error Bit (Illegal Operand, 1 = Input is 0)

MSD = Most Significant Digit

LSD = Least Significant Digit

Digit 1

(MSD)

Digit 4 Digit 5

Digit 1

(MSD)

Digit 4

Digit 2

Digit 2

Digit 5

Digit 3

Digit 6

(LSD)

Digit 3

Digit 6

(LSD)

Data Address

m

m + 1

Result Address

n

n + 1

11511

344

Page 53

Chapter 3

Programming

3. Enter a data address and a result address.

If we choose a data address of 200 and a result address of 305, the AF4

establishes the data table format shown in Figure 3.44. The data address

eventually contains the most significant three digits of the operand (the number

whose reciprocal we seek). The next higher address, word 201, is reserved for

the three least significant digits of the operand. The result address contains the

most significant three digits of the result; the next address word 306, contains

the least significant three digits of the result. The implied decimal points in the

operand and the result are after the LSD and before the MSD respectively.

Figure 3.44

AF4

Reciprocal Function Format After Address Entry

Bit No.

Operand

Result

171615141312111076543210

S

DE

SER

E = Enable Bit (1 = Function in Progress)

S = Sign Bit (1 = Negative)

D = Done Bit (1 = Function Complete)

ER = Error Bit (Illegal Operand, 1 = Input is 0)

MSD = Most Significant Digit

LSD = Least Significant Digit

Digit 1

(MSD)

Digit 4 Digit 5

Digit 1

(MSD)

Digit 4

Digit 2

Digit 2

Digit 5

Digit 3

Digit 6

(LSD)

Digit 3

Digit 6

(LSD)

Data Address

200

201

Result Address

305

306

11512

4. Enter the operand.

You can enter the operand from the keyboard of your industrial terminal or

through ladder diagram functions. Entry of operand 124 yields as its reciprocal

the value .008064 as shown in Figure 3.45.

345

Page 54

Chapter 3

Programming

Operand

Figure 3.45

Reciprocal Function Format After Execution

AF4

171615141312111076543210Bit No.

S

(0)

00 0

12 4

Data Address

Result

200

G

000

305

008

DE

SER

(0) (0) (0) (0)

E = Enable Bit (1 = Function in Progress)

S = Sign Bit (1 = Negative)

D = Done Bit (1 = Function Complete)

ER = Error Bit (Illegal Operand, 1 = Input is 0)

00 8

06 4

Result Address

Entry and Display of Input and Result Values

Figure 3.45 shows one method of inserting input values and displaying input

values and results of an AF4 reciprocal function. Although there are several