Page 1

AllenBradley

Very HighSpeed

Counter Module

User

(Cat.

No. 1771VHSC Series B)

Manual

Page 2

Important User Information

Because of the variety of uses for the products described in this

publication, those responsible for the application and use of this control

equipment must satisfy themselves that all necessary steps have been taken

to assure that each application and use meets all performance and safety

requirements, including any applicable laws, regulations, codes and

standards.

The illustrations, charts, sample programs and layout examples shown in

this guide are intended solely for example. Since there are many variables

and requirements associated with any particular installation, Allen-Bradley

does not assume responsibility or liability (to include intellectual property

liability) for actual use based upon the examples shown in this publication.

Allen-Bradley publication SGI–1.1, “Safety Guidelines For The

Application, Installation and Maintenance of Solid State Control”

(available from your local Allen-Bradley office) describes some important

differences between solid-state equipment and electromechanical devices

which should be taken into consideration when applying products such as

those described in this publication.

Reproduction of the contents of this copyrighted publication, in whole or

in part, without written permission of Allen–Bradley Company, Inc. is

prohibited.

Throughout this manual we make notes to alert you to possible injury to

people or damage to equipment under specific circumstances.

ATTENTION: Identifies information about practices or

circumstances that can lead to personal injury or death, property

damage or economic loss.

Attention helps you:

Identify a hazard.

Avoid the hazard.

Recognize the consequences.

Important: Identifies information that is especially important for

successful application and understanding of the product.

Important: We recommend you frequently backup your application

programs on appropriate storage medium to avoid possible data loss.

Page 3

Summary of Changes

Summary of Changes

Summary of Changes

This release of the publication contains new and updated information

from the last release.

New Information

This release includes information on the Series B version of the

1771-VHSC module. This includes a new Appendix E on the

differences between period/rate and continuous/rate modes of

operation. This information was not included in the previous version

of this publication.

Updated Information

This release includes updated information in Appendix C,

“application Considerations,” and revised Specifications in

Appendix A.

Change Bars

To help you find new and updated information in this publication, we

have included change bars as shown to the right of this paragraph.

Page 4

Table of Contents

Summary of Changes SOC-1. . . . . . . . . . . . . . . . . . . . . . . .

Summary of Changes SOC-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

New

Information

Updated

Change Bars SOC-1

Information

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using This Manual P-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Purpose of This Manual P-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Audience P-1

Vocabulary P-1

Manual Organization P-1

Related Products P-2

Product

Related

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Compatibility

Publications

SOC-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SOC-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

P-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

P-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Overview of the Very High Speed Counter Module 1-1. . . . . . .

Chapter

Module Description 1-1

Features

Operation in Encoder or Counter Mode 1-2

Counter Mode 1-3

Encoder Mode 1-4

Preset Value 1-6

Rollover Value 1-7

Software Reset 1-7

Gate/Reset

Operation in Period/Rate Mode 1-9

Continuous/Rate Mode 1-12

Operation in Rate Measurement Mode 1-12

Outputs 1-14

Enabling and Forcing Outputs 1-14

Assigning Outputs to Counters 1-14

Operation

Handshaking 1-16

Default

How the Module Communicates with a Programmable Controller 1-17

Chapter Summary 1-18

Objectives

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

of the Module

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Input

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

of Outputs

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuration

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. .

Page 5

Table of Contentsii

Installing the Very HighSpeed Counter Module 2-1. . . . . . . . .

Chapter

European Union Directive Compliance 2-1

Electrostatic Damage 2-2

Power Requirements 2-2

Module

Module Keying 2-3

Setting the Configuration Jumpers 2-4

Connecting Wiring 2-5

Grounding the VHSC Module Wiring 2-6

Installing the Module 2-7

Interpreting the Indicator Lights 2-8

Chapter Summary 2-8

Module

Chapter

Block Transfer Programming 3-1

PLC2 Program Example 3-2

PLC3 Program Example 3-3

PLC5 Program Example 3-4

PLC5/250 Program Example 3-5

Chapter Summary 3-5

Objectives

. . . . . . . . . . . . . . . . . . . . .

EMC Directive 2-1

Low V

oltage Directive

Location in the I/O Chassis

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Programming

Objectives

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2. . . . . . . . . . . . . . . . . . . . . . .

3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuring Your Module 4-1. . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter

Configuring

Configuration Block for a Block Transfer Write 4-2

Bit/Word Descriptions 4-3

Chapter Summary 4-7

Objectives

the VHSC Module

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-1. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Module Status and Input Data 5-1. . . . . . . . . . . . . . . . . . . . . .

Chapter

Reading Data from the Module 5-1

Block Transfer Read for the 1771VHSC Module 5-1

Bit/Word Description for Block Transfer Read 5-3

Chapter Summary 5-4

Objectives

5-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . .

. . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 6

Table of Contents iii

Troubleshooting 6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter

Using the Indicators for Troubleshooting 6-1

Diagnostic Codes Returned by the Module 6-2

Chapter Summary 6-2

Objectives

. . . . . . . . . . . . . . . . . . . .

Troubleshooting Chart 6-1

Diagnostics Reported in Word 1 of BTR 6-2

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Specifications A-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Sample Programs B-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Sample Program for PLC-2 Family Processors B-1. . . . . . . . . . . . . .

Sample Program for PLC-5 Family Processors B-2

Addditional Sample Program for PLC-5 Family Processors B-4

. . . . . . . . . . . . . .

. . . . . .

Application Considerations C-1. . . . . . . . . . . . . . . . . . . . . . . .

Appendix

Types of Input Devices C-1

Examples for Selecting Input Devices C-1

Circuit Overview C-2

Detailed Circuit Analysis C-3

5V

+12 to +24V SingleEnded Driver C-5

Open Collector C-6

Electromechanical

Output

Application Considerations C-8

Input Cable Length C-8

Totempole Output Devices C-8

Cable Impedance C-9

Cable Capacitance C-9

Cable Length and Frequency C-9

Objectives

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dif

ferential Line Driver Example C-4. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Supply Voltage verses Jumper Settings C-6

Limit Switch

Circuits

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . .

C-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C-7. . . . . . . . . . . . . . . . . . . . . . . . . .

C-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Questions and Answers D-1. . . . . . . . . . . . . . . . . . . . . . . . . . .

General D-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Questions and Answers D-1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Period/Rate and Continuous/Rate Examples E-1. . . . . . . . . . .

General E-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Changes made in Revision B E-2

Operation of Outputs in Period/rate Mode

(1771VHSC Revision B Modules) E-3. . . . . . . . . . . . . . . . . . . . .

Operation

of Outputs in Continuous/Rate Mode

. . . . . . . . . . . . . . . . . . . . . . . . . . .

E-4. . . . . . . . . . . . . . .

Page 7

Using This Manual

Preface

Purpose of This Manual

Audience

Vocabulary

This manual shows you how to use the Very High Speed Counter

module with an Allen-Bradley programmable controller. It helps you

install, program, and troubleshoot your module.

You must be able to program and operate an Allen-Bradley

programmable controller (PLC) to make efficient use of this module.

In particular, you must know how to program your PLC for block

transfer-type instructions.

We assume that you know how to do this in this manual. If you do

not, refer to the appropriate programming and operations manual for

the associated programmable controller before you attempt to use

this module.

In this manual, we refer to:

• the Very High Speed Counter module as the “module,” the

“1771-VHSC” or the “VHSC module.”

• the programmable controller as the “controller,” or the “PLC.”

Manual Organization

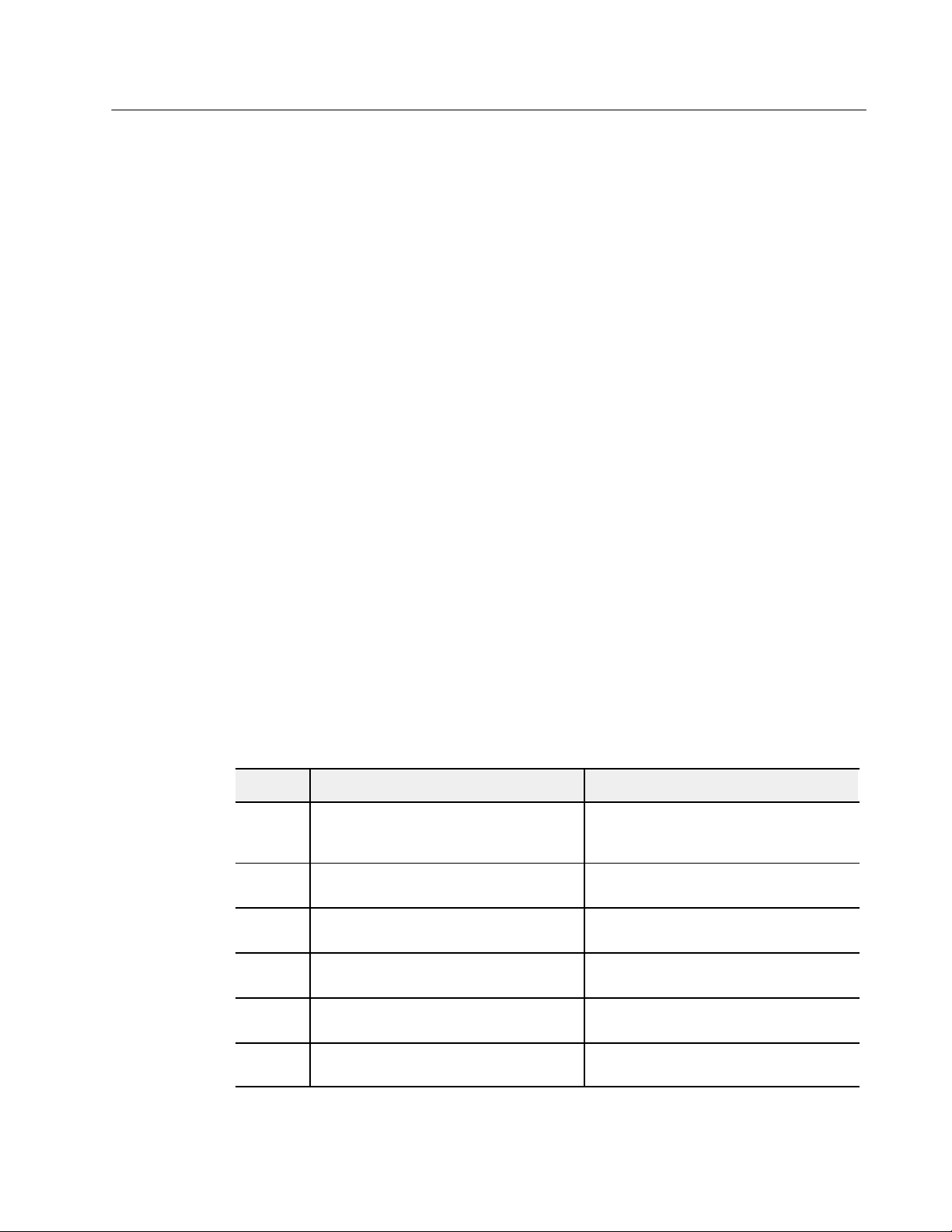

Chapter Title Topics Covered

1 Overview of the Very High Speed Counter Module

2 Installing the Very High Speed Counter Module

3 Module Programming

4 Configuring Your Module

5 Module Status and Input Data

6 Troubleshooting

This manual is divided into six chapters. The following chart shows

each chapter with its corresponding title and a brief description of

the topics covered in that chapter.

Explanation of modes, outputs, default

configuration and how the module communicates

with the processor.

How to install, key, connect wiring, ground and an

explanation of the indicators on the module.

Block transfer programming and programming

examples.

Configuration and description of bit/words for block

transfer write instructions.

Reading data from the module and bit/word

description of the block transfer read.

Using the indicators for troubleshooting and

diagnostic codes.

Page 8

Using This ManualP–2

Appendices

Topics CoveredTitleChapter

A Specifications Specifications for the VHSC module.

B Sample Programs Sample programs for various PLC programs.

C Application Considerations Selection of input devices and circuit descriptions.

D Questions and Answers Helpful answers to the most asked questions.

E Period/Rate and Continuous/Rate Examples Examples of the differences of these 2 modes

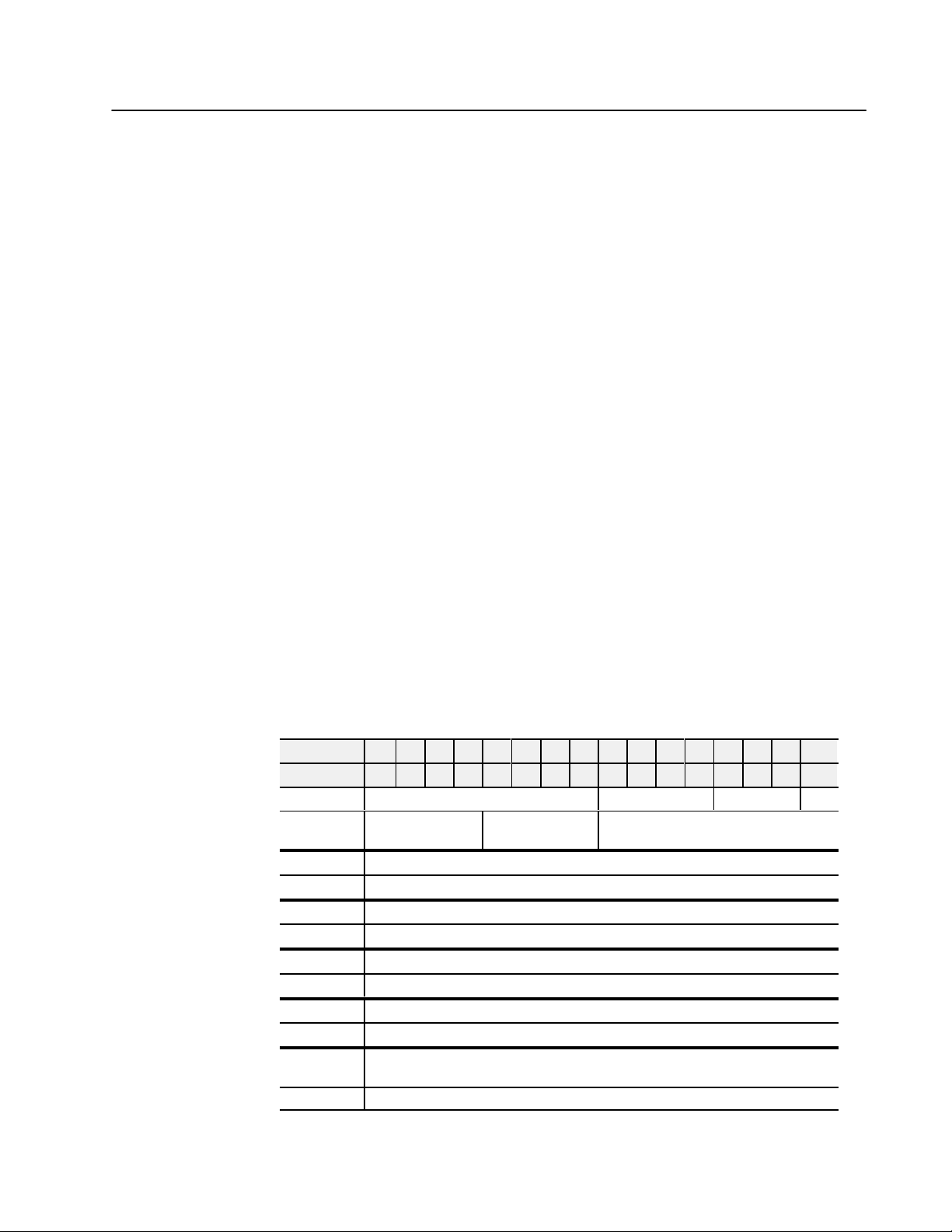

Related Products

Product Compatibility

A

B = Compatible with 1771A1B, A2B, A3B, A4B chassis.

Y

NOTE: Restricted to complementary module placement (refer to chapter 2)

You can install your input module in any system that uses

Allen-Bradley programmable controllers with block transfer

capability and the 1771 I/O structure.

Contact your nearest Allen-Bradley office for more information

about your programmable controllers.

This module can be used with any 1771 I/O chassis. Communication

between the module and the processor is bidirectional. The PLC

sends module information using block transfer write instructions and

the 1771 I/O backplane. The PLC receives module status information

through block transfer read instruction and places it in the data table.

I/O image table use is an important factor in module placement and

addressing selection. The module’s data table use is listed in the

following table.

Table P.A

Compatibility and Use of Data T

Catalog

Number

1771VHSC Rev. A 8 8 18 max 64 max Yes See note See note A and B

1771VHSC Rev. B 8 8 26 max 64 max Yes See note See note A and B

= Compatible with 1771A1, A2, A4 chassis.

es = Compatible without restriction

Input Output Read Write

Image Image Block Block

Bits Bits Words Words

Use of Data T

able

able

Compatibility

Addressing Chassis

1/2 slot 1slot 2slot

Series

Related Publications

For a list of publications with information on Allen-Bradley

programmable controller products, consult our publication index

SD499.

Page 9

Chapter 1

Overview of the Very High

Speed Counter Module

Chapter Objectives

Module Description

This chapter gives you information on:

• features of the VHSC module

• how the module communicates with programmable controllers.

• how the module operates

The VHSC module performs high speed counting for industrial

applications. The module is an intelligent block transfer I/O module

that interfaces signals with any Allen-Bradley programmable

controller that has block transfer capability. Block transfer

programming moves module status data from the module’s memory

to a designated area in the processor data table. It also moves

configuration words from the processor data table to the module

memory.

The VHSC module is a single-slot module that does not require an

external power supply. (Note: The outputs do require a power

supply.) After scanning the inputs and updating the outputs, the input

data is converted to a specified data type in a digital format to be

transferred to the processor’s data table on request. Command and

configuration data is sent from the programmable controller data

table to the module with a BTW instruction.

Features of the Module

The VHSC module counts pulses from encoders (such as

Allen-Bradley Bulletin 845H, K, F, P, E and L), pulse generators or

mechanical limit switches, proximity switches, etc. and returns either

a count or frequency in binary or BCD format.

The module’s features include:

• 4 input channels configurable for encoder mode, counter mode,

period/rate mode and continuous/rate mode

• 8 outputs, isolated in groups of 2

• outputs are current-sourcing at 5 to 24V dc (2A maximum per

output)

• single-ended or differential inputs

• 2-phase encoder inputs up to a frequency of 250KHz

• single-phase counter inputs up to a frequency of 1MHz

• input voltage range of 5 to 24V dc

Page 10

1–2

Overview of the Very High Speed Counter Module

• returns in status either count or frequency in binary or BCD

format

• input counts as high as 999,999

• up to 500KHz in period/rate or rate measurement frequency

modes

• outputs can be tied to any counter

• each output has a user-selectable on-off value

• outputs can be tied back to an input for cascading

• automatic default configuration

• each counter has a user-selectable preset and rollover value

• period/rate w/periodic outputs and period/rate w/dynamic outputs

can be used for totalization

The 1771-VHSC module operates in the following modes:

• counter mode

• encoder X1 mode

• encoder X4 mode

• period/rate mode

• rate measurement frequency mode

• continuous/rate mode

The operation of the module in these modes is described below.

Operation in Encoder or

Counter Mode

The operation of encoder and counter modes is virtually identical.

The only difference between the two modes is in the type of

feedback used.

Use the counter mode if you need the module to read incoming

pulses from a maximum of four encoders (single-ended or

differential), counters, pulse generators, mechanical limit switches,

etc. and return them to the programmable controller as a binary or

BCD number (0-999,999). In counter mode, the module accepts only

one channel feedback.

Use the encoder modes if you need the module to read incoming

quadrature pulses and return them to the programmable controller as

a binary or BCD number (0-999,999). In these modes, the module

accepts two-phase quadrature feedback and counts up or down

depending upon the condition of the phase B input for each counter.

The operation of the module in the encoder/counter modes is as

follows:

Page 11

Overview of the Very High Speed Counter Module

1–3

• counter mode - channel B is tied high or low. Channel A input is

used for pulse. The count is unidirectional with the direction

determined by

channel B.

• encoder X1 - This is a bidirectional count mode; counting up or

down, using quadrature input signals.

• encoder X4 - This is a bidirectional count mode, using quadrature

input signals, with 4 times the resolution of X1.

Each of the counters in encoder/counter mode has values associated

with it. These are:

• preset value

• rollover value

• gate/reset input

• output

Counter Mode

The counter mode allows the module to read incoming pulses and

return them to the programmable controller processor as a binary or

BCD number (0-999,999).

In the counter mode, direction (up counting or down counting) is

determined by the phase B input, which can be a random signal. If

Phase B is high, the counter will count down. If phase B is low or

floating, (that is, not connected), the counter counts up.

If Phase B is: Counter will count (direction):

High Down

Low or floating (not connected) Up

The module reads incoming pulses from a maximum of 4 encoders

(single-ended or differential), counters, pulse generators, mechanical

limit switches, and so forth and returns a count to the programmable

controller processor in a binary or BCD number (0-999,999).

Page 12

1–4

Overview of the Very High Speed Counter Module

The counter mode accepts only one phase feedback. This

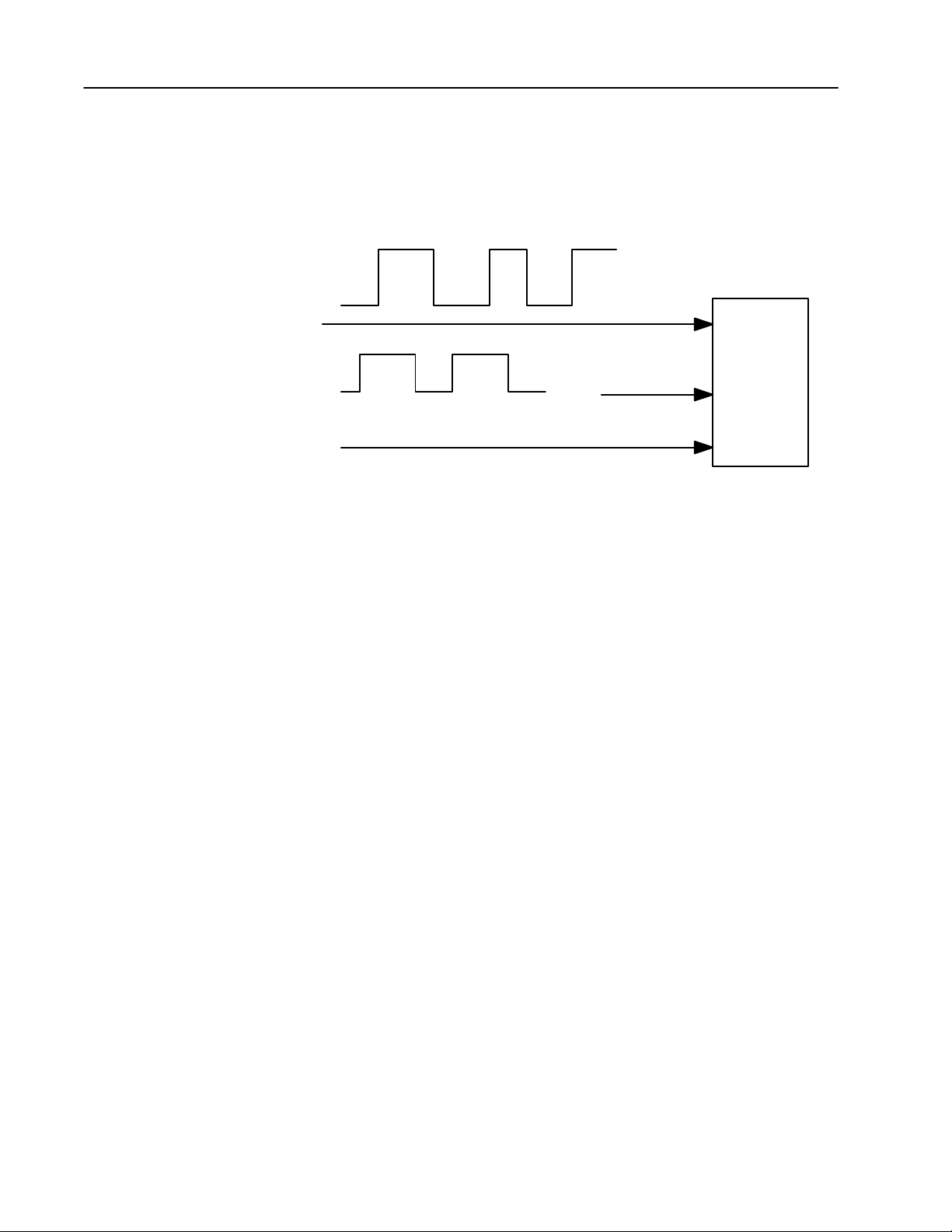

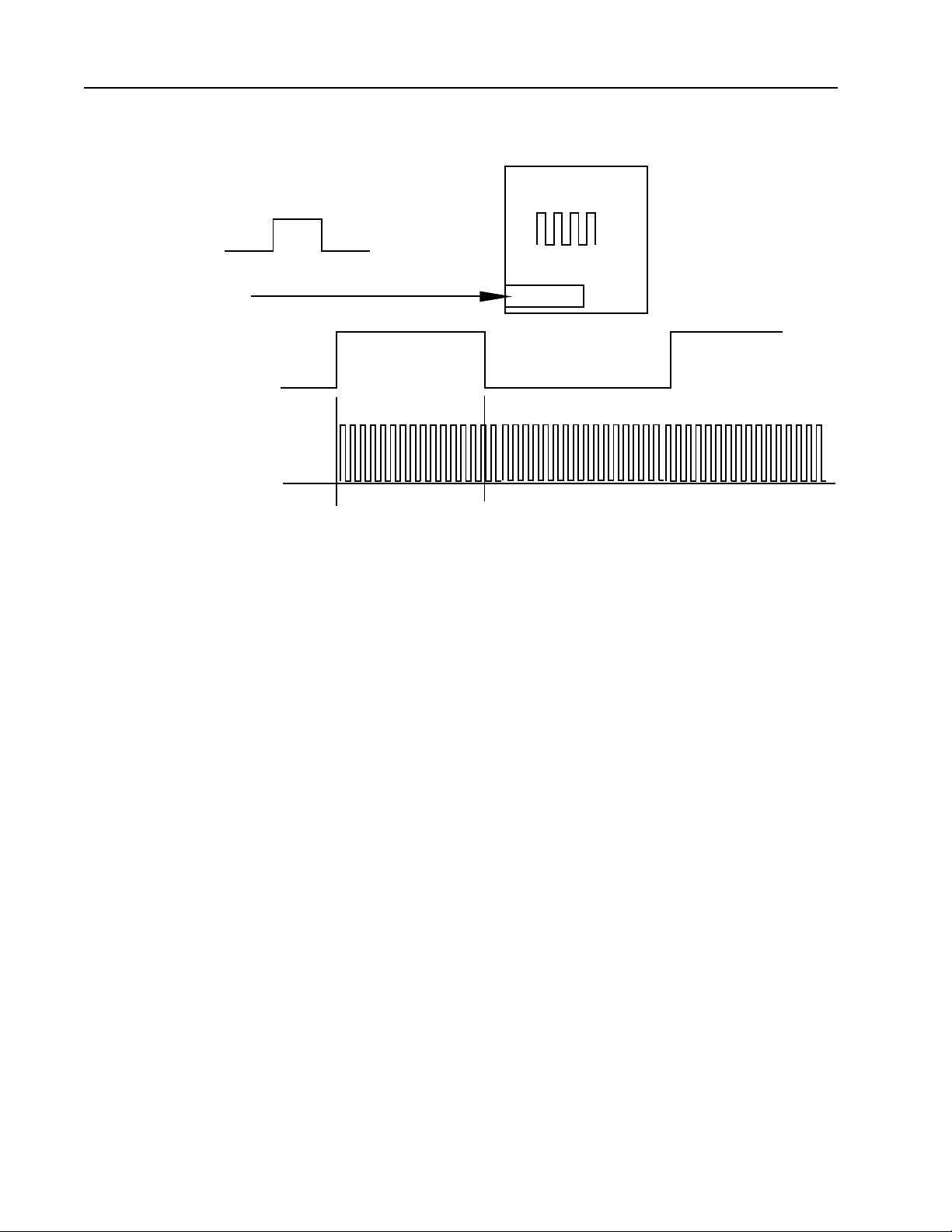

relationship is shown in 1.1.

Figure 1.1

Block Diagram of Counter Mode

From Encoder/Pulse Generator

Phase A

Terminal

Phase B

Terminal

(direction sense)

Gate/Reset

Terminal

1771VHSC

10677I

Encoder Mode

The encoder mode allows the module to read incoming pulses and

return them to the programmable controller processor as a binary or

BCD number (0-999,999).

In this mode, the module will accept two phase quadrature feedback.

The module senses the relationship between the 2 phases and counts

up or down accordingly.

Encoder X1 mode uses channel A for the pulse input. With B low

(floating), the count direction is up; when B is high, the count

direction is down.

Encoder X4 mode is identical to X1, except it uses quadrature

signals on channel A and channel B, and counts on the leading and

trailing edges of

A and B.

Page 13

Overview of the Very High Speed Counter Module

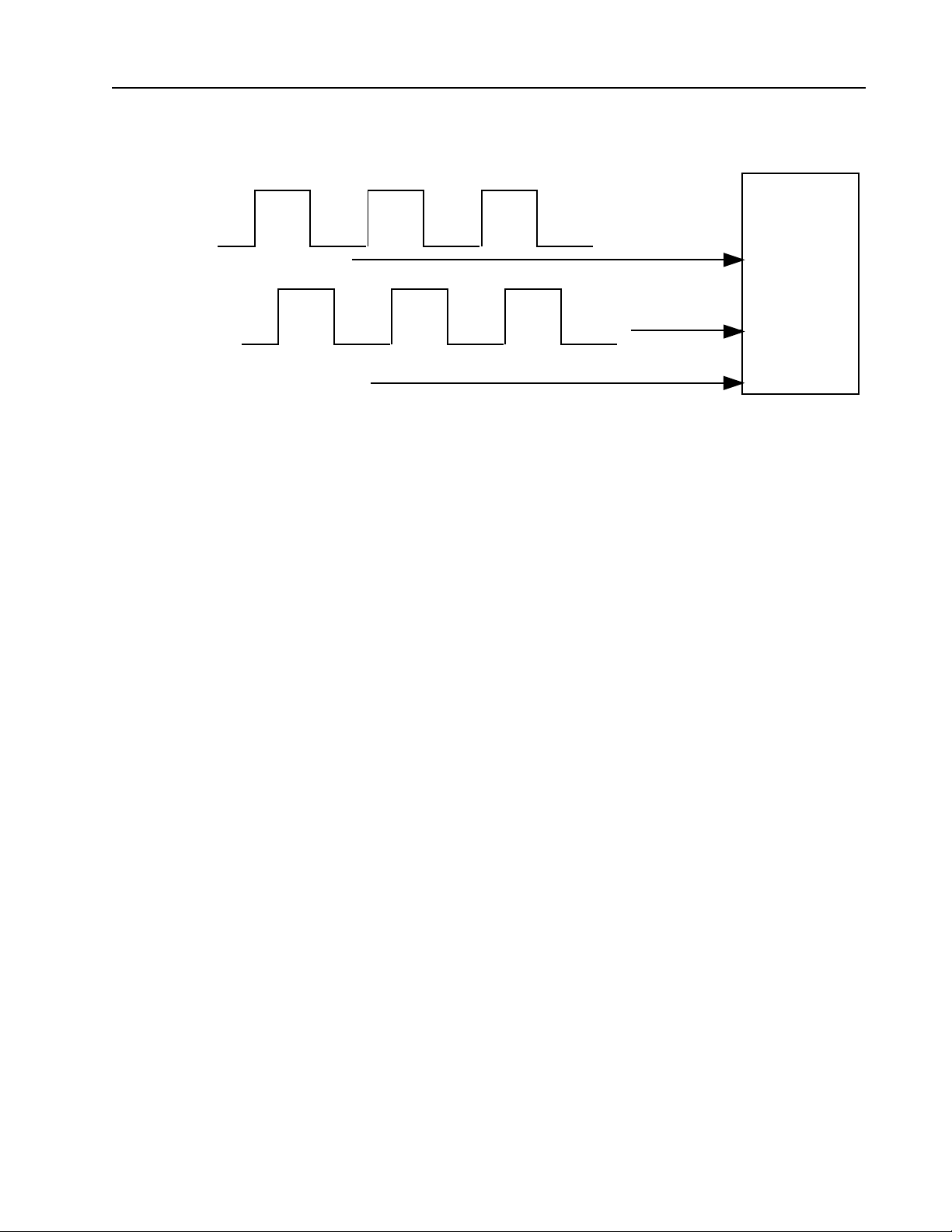

Figure 1.2

Block Diagram of Encoder Mode

From Encoder/Pulse Generator

Phase A

Terminal

Phase B

Terminal

(direction sense)

Gate/Reset

Terminal

1771VHSC

10678I

Direction of Count

The module can count either up or down, depending upon the

condition of the B input for each counter. In encoder applications,

the counter will increment on the leading edge of Phase A, while

phase B determines the direction of the count.

1–5

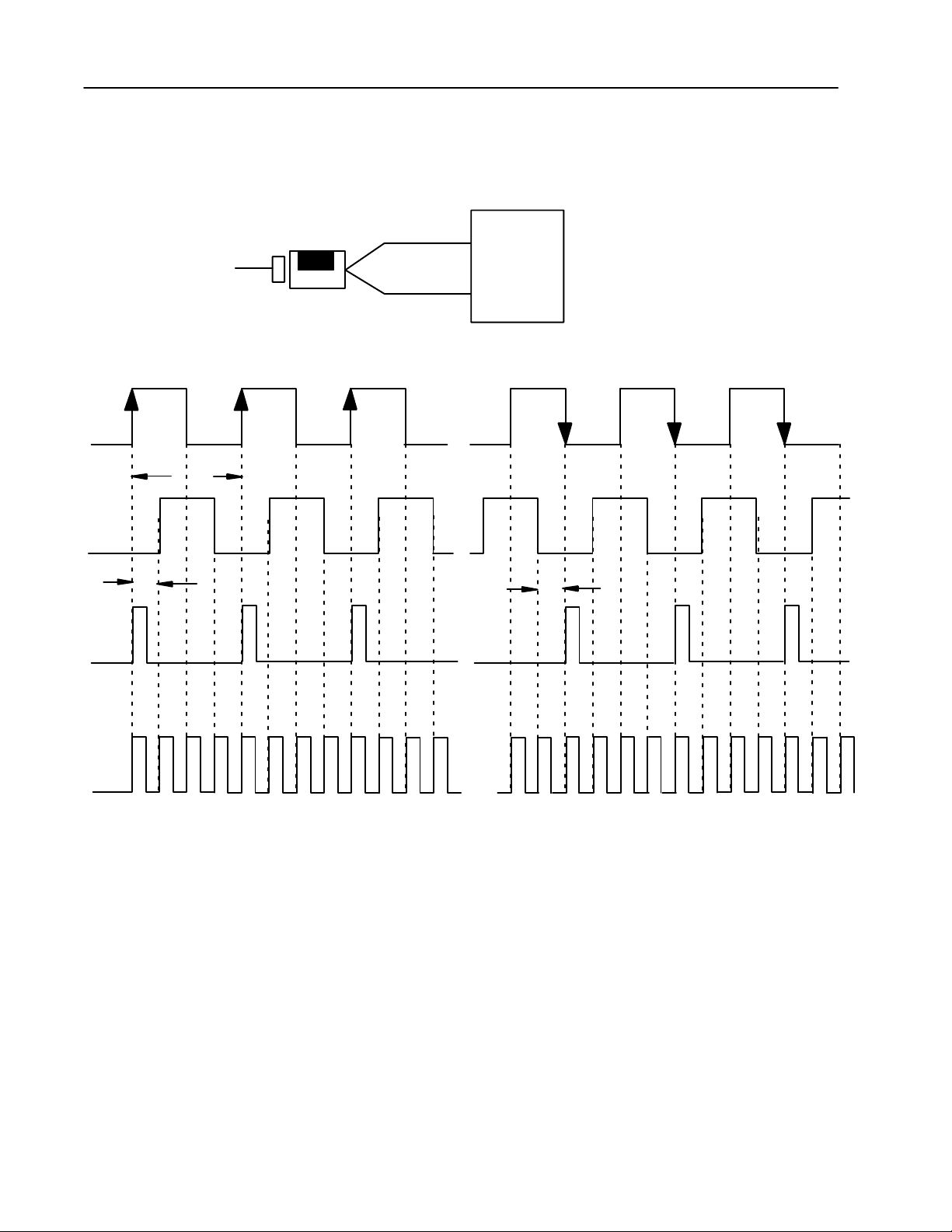

You also have the option of X1 and X4 multiplying of the input

pulses. 1.3 shows the relationships between phases A and B for

forward and reverse directions in encoder applications.

Page 14

1–6

Phase A

Overview of the Very High Speed Counter Module

Figure 1.3

Phase Relationship for Forward or Reverse Directions

Phase A

Forward Rotation

CCW Encoder Rotation

T

4µsec

min

Phase B

Very High Speed

Counter Module

Encoder

Input A

Encoder

Input B

Reverse Rotation

CW Encoder Rotation

Phase B

1µsec

Typical

X1

Multiplying

X4

Multiplying

90

13

1 2 34 56789101112

2

90

The following paragraphs apply to both encoders and counters.

Preset Value

Each of the 4 counters has one preset value associated with it. In the

encoder or counter modes, the preset value represents a reference

point (or count) from which the module begins counting. The

module can count either up or down from the preset value. Preset

values are loaded into the count registers through the preset count

bits. (Refer to word 1, bits 8-11 of the block transfer write

initialization block in chapter 5.) Preset values can range from 0 to

999,999 binary or BCD.

12

123456789101112

10679I

0

0

Page 15

Overview of the Very High Speed Counter Module

1–7

Rollover Value

Each of the 4 counters has one rollover value associated with it.

When the rollover value is reached by the encoder/counter, it resets

to 0 and begins counting again. The rollover values range from 0 to

999,999 binary or BCD (0 represents 1,000,000). The rollover value

is circular (for example: if you program 360, the count will be from

358, 359, 0, 1 etc. in a positive direction and from 1, 0, 359, 358 etc.

in a negative direction).

Software Reset

The counters can also be reset by the Reset Count bits found in Word

1, bits 0-3 of the block transfer write. When one of these bits is set

to 1, the associated counter is reset to zero and begins counting. The

module can also be reset with the gate/reset as explained below.

Refer to chapter 4 for further details.

Gate/Reset Input

There is one gate/reset input for each of the 4 counters. The

gate/reset input, when active, will function in one of the 4 store count

modes outlined below.

Scaling Input Count at the Gate/Reset Terminal

You can scale the incoming count at the gate/reset terminal. Scaling

allows the incoming pulses at gate/reset to be divided by a number in

the range of 1, 2, 4, 8, 16, 32, 64 and 128. Refer to words 21 to 24 in

the BTW file (chapter 4).

Store Count

The store count feature allows the module to store the current count

value of any (or all) of the four counters. The store count feature is

triggered by the state of the gate/reset terminal on the module. The

stored count of each counter is placed in a separate word in the

Block Transfer Read file (words 11-18 respectively). The stored

count value will remain in the block transfer read file until a new

trigger pulse is received at the Gate/Reset terminal. When a new

trigger pulse is received, the old count value will be overwritten by

the new value.

The store count feature is selected by words 3 and 4 of the block

transfer write initialization file. Refer to chapter 4 for further details.

Page 16

1–8

Overview of the Very High Speed Counter Module

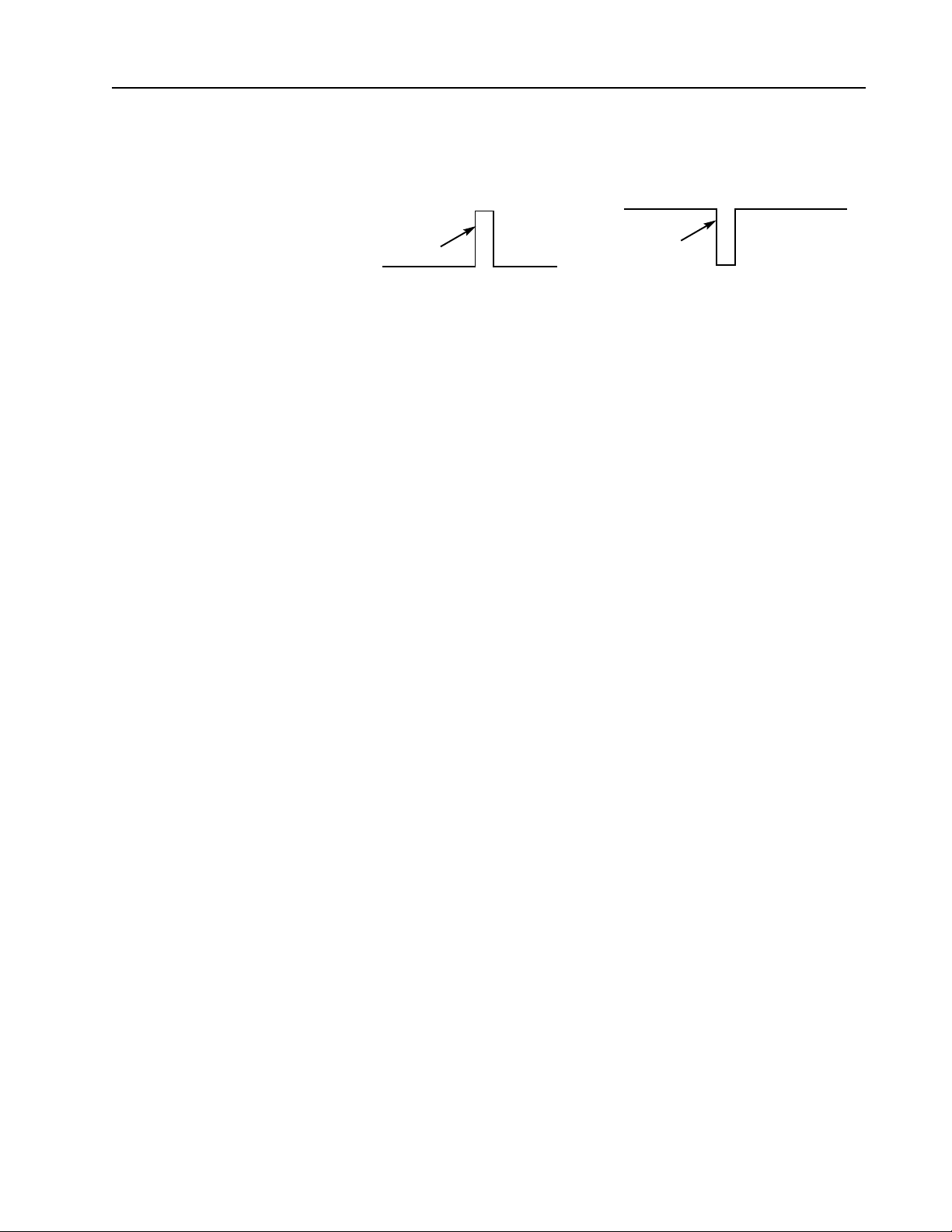

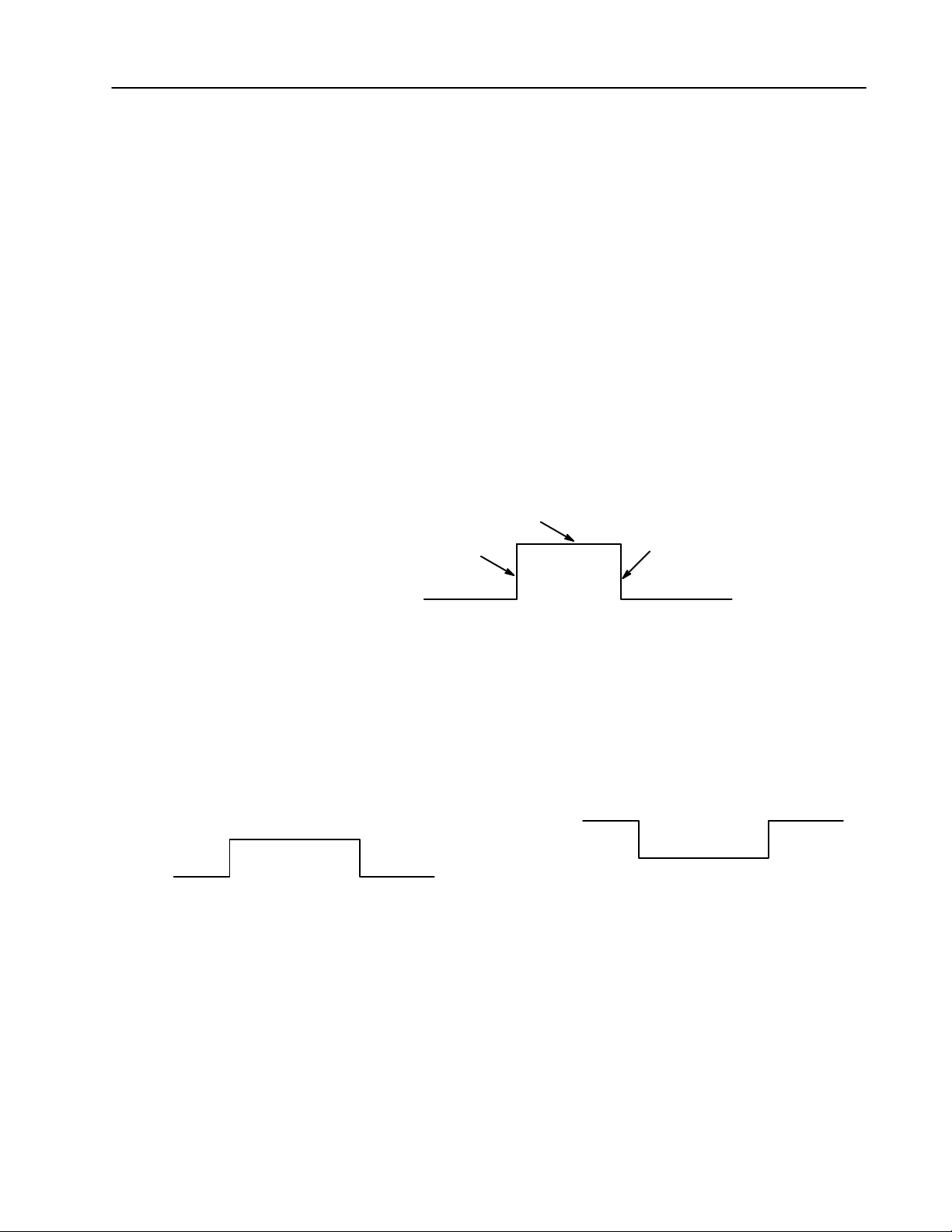

In mode 1, store/continue (1.4), the leading edge of a pulse input on

the gate/reset terminal will cause the current value in the counter to

be read and stored. The counter will continue counting. The stored

count will be available in the block transfer read file. The stored

count information will remain in the block transfer read file until it is

overwritten by new data.

Figure 1.4

Store/Continue

Read, Store Count

and continue counting.

10680I

In mode 2, store/wait/resume (1.5), the gate/reset terminal provides

the capability to inhibit counting when the gate/reset input is high.

Counting resumes when the input goes low. Mode 2 does not reset

the counter, although it does store the count value.

Figure 1.5

Store/Wait/Resume

Stop counting

Store Count

Resume counting

10681I

In mode 3, store-reset/wait/start (1.6), the rising edge of the pulse

on the gate/reset terminal causes the counter to stop counting, store

the current count value in the block transfer read file and reset the

count to zero. The counter does not count while the input pulse on

the gate/reset terminal remains high. Counting resumes from zero on

the falling edge of the pulse at the gate/reset terminal.

Figure 1.6

StoreReset/Wait/Start

Counter has stopped counting

Stop count, store

and reset to zero

Start counting

from zero

10682I

In mode 4, store-reset/start (1.7), on the rising edge of a pulse

input at the gate/reset terminal will cause the counter to store the

accumulated count value and will reset the counter to zero. The

counter continues counting, and the stored count is available in the

block transfer read file.

Page 17

Overview of the Very High Speed Counter Module

Figure 1.7

StoreReset/Start

Rising Edge

1–9

Falling Edge

Operation in

Period/Rate Mode

Store Count,

reset to zero,

start counting.

Store Count,

reset to zero,

start counting.

10683I

Figures 1.4 through 1.7 show the store count feature operating on the

rising edge of the gate/reset pulse. The user has the option of

selecting these same features using the falling edge of the gate/reset

pulse. This selection is made through the gate invert bit as explained

in chapter 4.

The gate invert bit is active in the store count, continuous/rate

and period/rate modes.

The stored count values are saved in words 11 through 18 of the

block transfer read file (chapter 4).

Use the period/rate mode to determine the frequency of input pulses

by counting the number of internal 4MHz clock pulses over a

user-specified number of input signal pulses. At the end of the

specified number of pulses, the module returns the frequency and the

number of internal 4MHz pulses.

A channel configured for period/rate mode acts as a period rate

counter. An internal 4 MHz clock is used as a frequency reference.

This clock is gated by the incoming pulse train at the gate/reset

input. The results of this gating action are the number of pulses or a

frequency. The number of sampled gated 4MHz pulses are returned

in BTR words 3 thru 10, and the frequency in words 11 thru 18.

Select the period/rate mode by setting the appropriate bits in words

3 and 4 of the BTW initialization file (chapter 4). The store count

features are inactive in period/rate mode.

1771-VHSC revision B and later modules count the total number of

pulses occurring at the gate/reset pin. This function is

frequency-limited. This total count is returned when you request

words 19 through 26 in your BTR. You can reset this count by

resetting the reset bit (bits 0-4 in BTW

word 1). Rollover and preset are inactive. Refer to appendix E for

additional information.

1.8 shows a diagram of the module used in the period/rate mode.

Page 18

1–10

Overview of the Very High Speed Counter Module

Figure 1.8

Period/Rate Mode

From user's encoder/pulse generator

Incoming pulse train

at gate/reset terminal

4MHz internal clock

A Not used

B Not used

Gate/Reset Terminal

Sampled pulses

1771VHSC

From internal 4MHz clock

scaler

10684I

In 1.8, the incoming pulse train from the gate/reset terminal is used

to sample pulses from the 4 MHz internal clock. As the frequency of

the incoming pulse train at the gate/reset terminal increases, the

number of sampled pulses from the 4 Mhz clock decreases. This

relationship is shown in Table 1.A. Since accuracy is related to the

number of pulses received over the sample period, the accuracy will

decrease with increasing input frequencies at the Gate/Reset

terminal. To some extent, the decrease in accuracy can be lessened

by scaling the input frequency through the use of a scaler. A scaler

value of 1 will only return an accurate input frequency if incoming

pulses have a 50% duty cycle. If frequency exceeds 500KHz, the

number 999,999 is returned.

Page 19

1–1

1Overview of the Very High Speed Counter Module

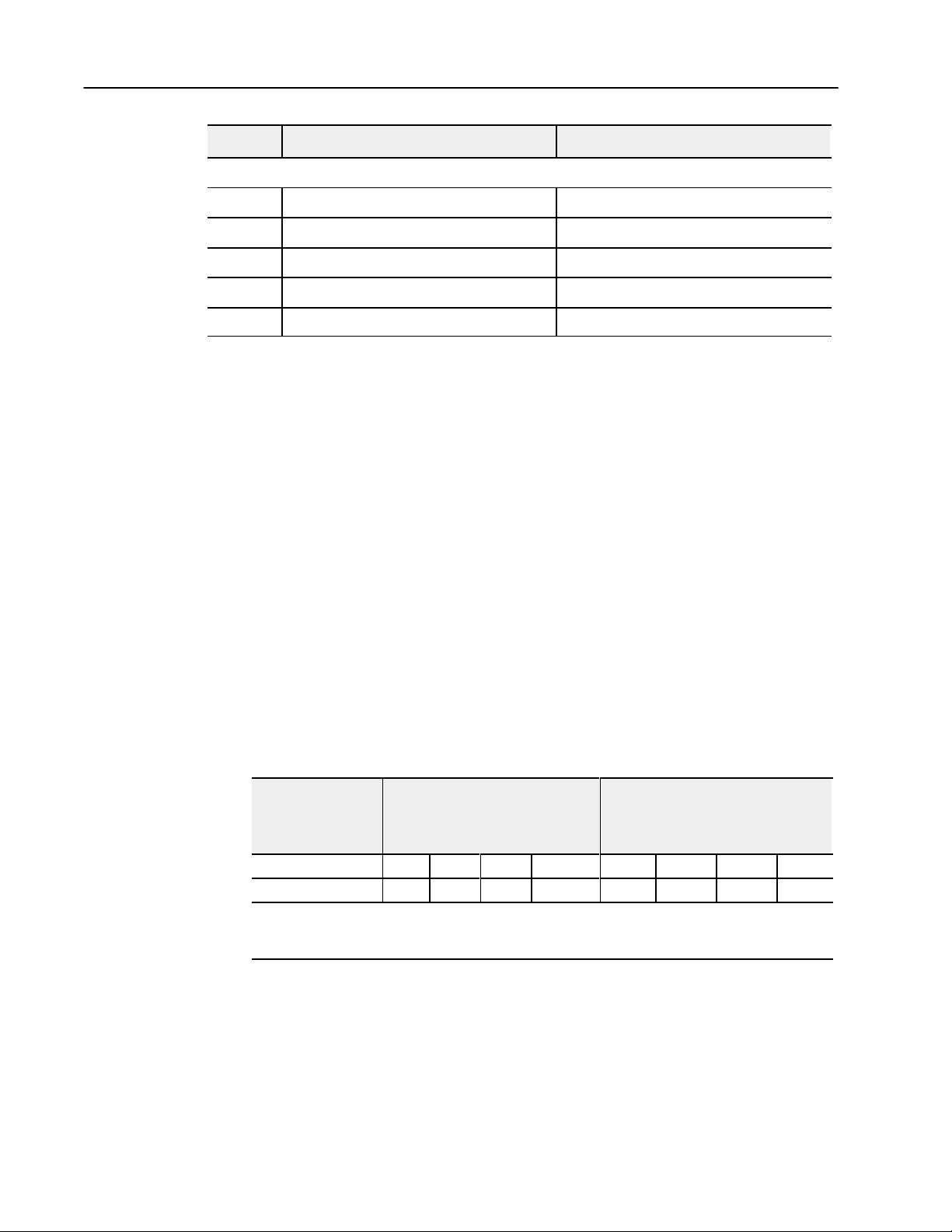

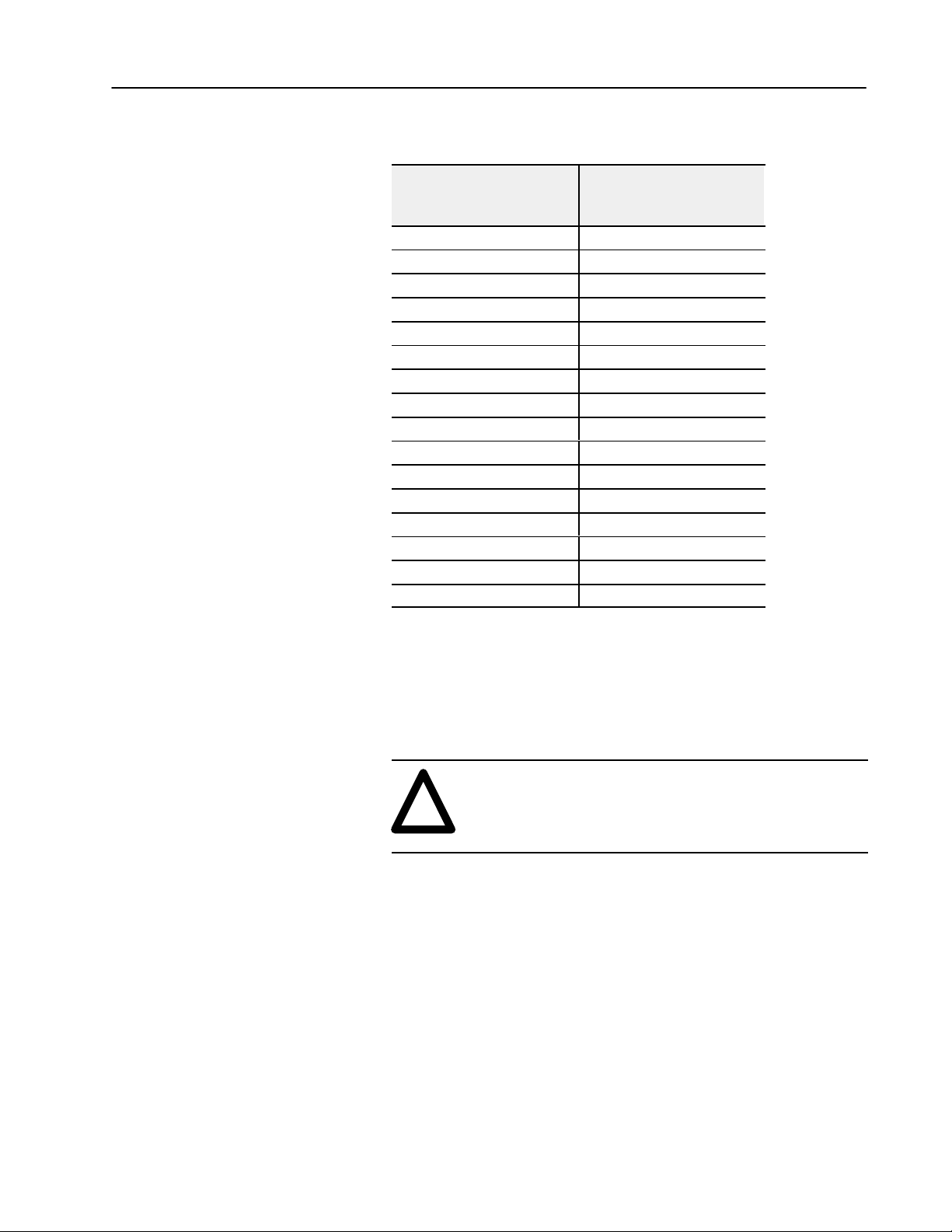

Table 1.A

Relationship

Input Frequency at Gate/Reset

Between Sampled Pulses and Input Frequency

Terminal in Hz

(words 1118 in BTR)

2 1 meg

5 400K

10 200K

20 100K

50 40K

100 20K

200 10K

500 4K

1KHz 2K

2KHz 1K

5KHz 400

10KHz 200

20KHz 100

50KHz 40

100KHz 20

200KHz 10

Sampled Pulses for 1/2 Cycle

of Gate/Reset Pulse

(words 310 in BTR)

Operation of scaler

In period/rate mode, the scaler lets the incoming pulse train at the

gate/reset pin be divided by a user defined number. Acceptable

values for the scaler are 1, 2, 4, 8, 16, 32, 64 and 128. There is one

scaler value for each counter. The default value for each scaler is 1.

Note: A 0 is equivalent to 1.

ATTENTION: Sample period times scaler must be

less than 0.25 seconds or the counter will overflow

!

without providing an overflow indication.

Connection to Counter Inputs

The only input to the module in the period/rate mode is made to the

gate/reset terminal. The counter inputs (channel A and B) are not

used in the period/rate mode.

Page 20

1–12

Overview of the Very High Speed Counter Module

Continuous/Rate Mode

The continuous/rate mode is similar to the period/rate mode

previously described except the outputs in this mode are dynamic

outputs. Use this mode to determine the frequency of input pulses by

counting the number of internal 4MHz clock pulses over a

user-specified number of input signal pulses. Each output is turned

on as soon as the turn-on count is reached, and turned off as soon as

the turn-off count is reached. As the internal 4MHz clock is counted,

the outputs dynamically track the 4MHz count. This allows you to

turn an output on a certain number of 4MHz counts after the

gate/reset pin goes active, and turn it off a certain number of 4MHz

counts later.

1771-VHSC revision B and later modules count the total number of

pulses occurring at the gate/reset pin. This function is

frequency-limited. This total count is returned when you request

words 19 through 26 in your BTR. You can reset this count by

resetting the reset bit (bits 0-4 in BTW

word 1). Rollover and preset are inactive. Refer to appendix E for

additional information.

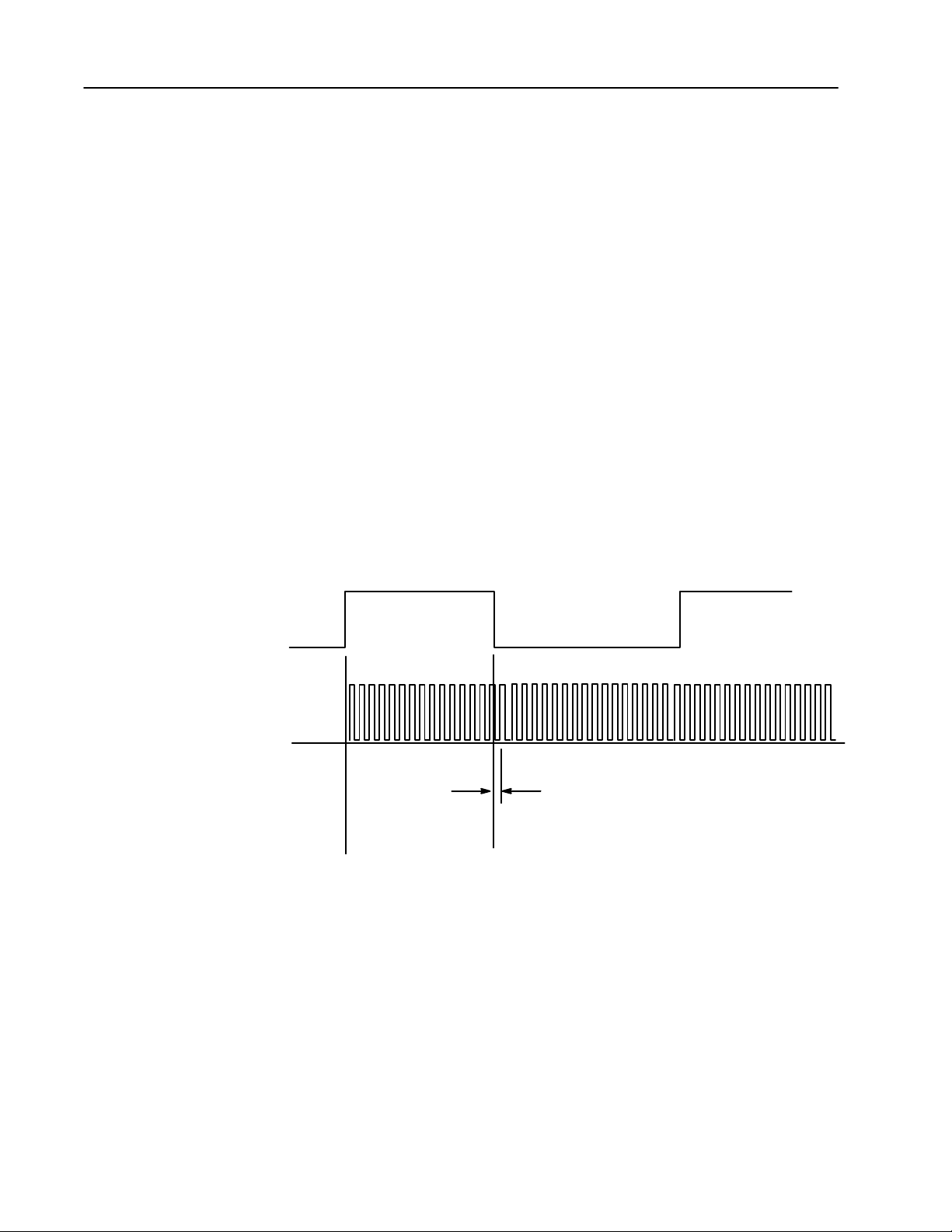

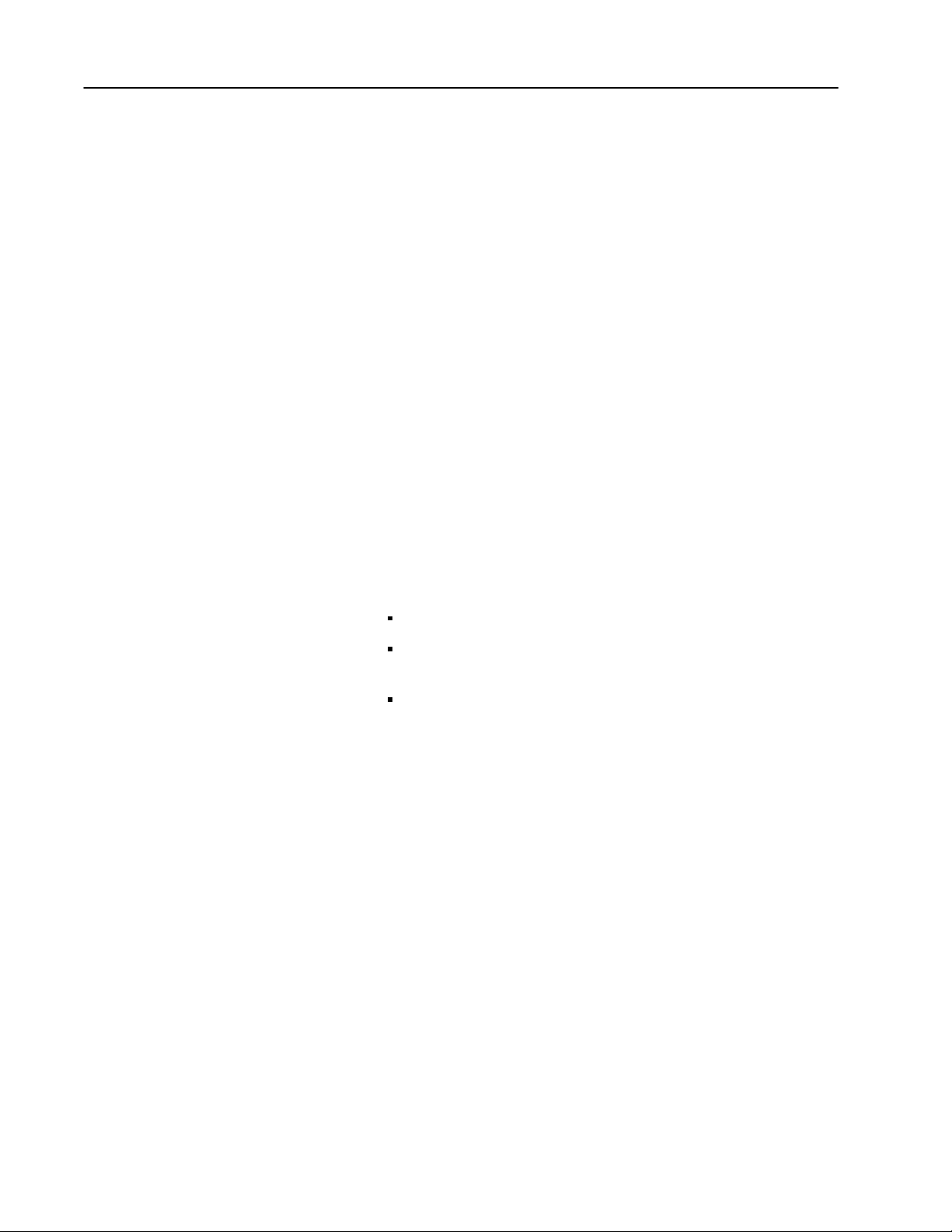

Figure 1.9

Period/Rate and Continuous/Rate Output Operation with

Scaler of 1

Incoming pulse train

at gate/reset terminal

4MHz internal clock

Period/rate

Continuous/rate

Operation in Rate

Measurement Mode

Sampled pulses

Output on/off presets

active only on scaler

number pulse.

Output on/off presets

active during entire

pulse.

10684I

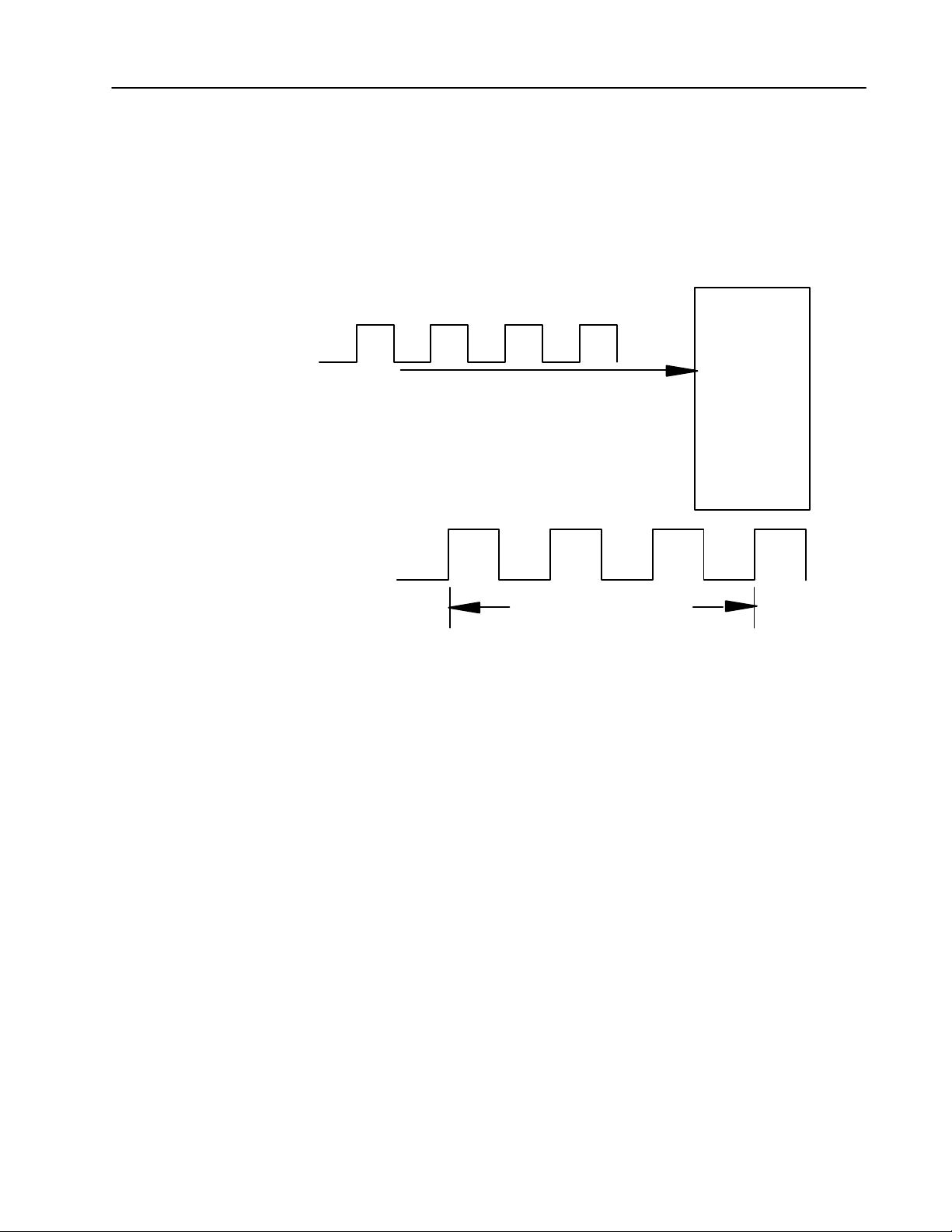

Use the rate measurement mode to count incoming pulses for a

user-specified time interval. At the end of the interval, the module

returns a value representing the sampled number of pulses and a

value indicating the incoming frequency. When the count and

frequency are updated, any associated outputs are checked against

their associated presets.

Page 21

Overview of the Very High Speed Counter Module

The value representing the sampled number of pulses is returned in

BTR words 3 thru 10, and the value indicating the incoming

frequency is returned in words 11-18. The total count equals the

number of pulses received during the sample period. The operation

of rate measurement mode is shown below in 1.10.

Figure 1.10

Operation of the Rate Measurement Mode

From user's encoder/pulse generator

1–13

From user's encoder/pulse generator

Example:

In 1.10, three counts have been accumulated during the user-selected

time period. If you had selected 50 milliseconds as the sample

period, the frequency returned to the programmable controller

processor in words 11-12 would be:

Channel A

Channel B

(not used)

Gate/Reset terminal

(not used)

Userselectable sample time

1771VHSC

Module

10685I

Frequency = Counts/Sample period = 3 counts/50 milliseconds = 60

Hz

You would read 60 Hz as the frequency in the Block Transfer Read

file (words 11 and 12). Words 3 and 4 would contain the value 3.

Since the default configuration for the VHSC module is the Counter

mode, the user must select the rate measurement mode through the

block transfer write initialization file. This is done by setting the

appropriate bits in words 3 and 4 of the block transfer write

initialization file (chapter 4). If frequency exceeds 500KHz, the

number 999,999 is returned.

Page 22

1–14

Overview of the Very High Speed Counter Module

Sample Period

You can set the sample period used in the frequency calculation in

the rate measurement mode. Allowable values are 10 milliseconds to

2 seconds in 10 millisecond increments. The default value is 1

second. (Note: A 0 in the BTW initialization word is equivalent to

the default value of 1 second.)

The sample period is set in words 21 through 24 of the BTW

initialization file (chapter 4).

Connection to Counter Inputs

The only user connections used in the rate measurement mode are to

phase A of the module. The gate/reset and channel B terminals are

not used in this mode.

Outputs

The VHSC module has 8 outputs, isolated in groups of 2. Each of

the outputs is capable of sourcing current and will operate between 5

and 24 volts dc. You must connect an external power supply to each

of the outputs. The outputs can source 2 amps dc. The outputs are

hardware-driven and will turn on in less than 10µsec when the

appropriate count value has been reached.

Enabling and Forcing Outputs

Outputs may be forced on or off independent of count or frequency

value. To force the outputs, they must first be enabled. Enabling the

outputs is done through a data table word 2, bits 0-7 in the BTW

initialization file (chapter 4). Once the outputs have been enabled,

they may be forced on by setting bits 8-15 in word 2 of the BTW

initialization file. The outputs can be forced off by setting the enable

bit to 0.

Assigning Outputs to Counters

By setting bits in the block transfer write initialization file, you can

assign the outputs on the module to any of the various counters. You

can assign as many as 8 outputs to a given counter. However, an

output may be assigned only once to a counter--it is not possible to

use the same output with 2 different counters. Refer to words 25, 30,

35, 40, 45, 50, 55, 60 of the BTW initialization file in chapter 4.

Page 23

Overview of the Very High Speed Counter Module

1–15

Operation of Outputs

When the outputs for the VHSC module are enabled and assigned to

a counter they operate in an ON-OFF fashion. For example, assume

that the module were programmed to turn ON an output when a

count value of 2000 was reached. Further, assume that the user

desired to have the output remain energized for a period of 3000

counts and then turn OFF. The end result would be that the outputs

would turn ON at count of 2000, would remain energized for 3000

additional counts, and would turn OFF at 5000 counts. The ON and

OFF values are circular around zero. In the rate measurement mode,

the On and Off values associated with each output represent a

frequency value instead of a count value. The maximum frequency

value which may be entered in an On or Off value is 500,000Hz.

Refer to 1.11.

Figure 1.11

OnOff Operation of Output

Output remains energized for 3000 additional counts

Output turns on at count value of 2000

Output remains energized

for 3000 additional counts.

Output turns ON

at count of 2000.

When values in words 2627 are less than

values in words 2829.

Output turns off at count value of 5000

Refer to 1.12. Using output 0 as an example, when the value in

words 26 and 27 is less than the value in words 28 and 29, the output

turns on at 2000 and off at 5000. If the value in words 26 and 27 is

greater than the value in words 28 and 29, the output turns off at

2000 and on at 5000.

Figure 1.12

Effect of Values in Words 26 through 29

Output turns OFF

at count of 5000.

Output turns OFF

at count of 2000.

When values in words 2627 are greater than

values in words 2829.

Output turns ON

at count of 5000.

Refer to words 26-29, 31-34, 36-39, 41-44, 46-49, 51-54, 56-59,

61-64 of the block transfer write initialization file in chapter 5.

10686I

10687I

Isolation of Outputs

The module provides 1500V ac forced rms isolation between each of

the counters and the backplane of the I/O rack.

Page 24

1–16

Overview of the Very High Speed Counter Module

Tying Outputs to Counters

You can jumper any of the outputs to any of the counter inputs on the

module field wiring arm. In this way, it is possible to use the outputs

to reset a counter or to cascade counters. If using the outputs this

way, make certain that the input voltage jumpers are set to interface

with the appropriate output voltage.

Handshaking

A pair of handshaking bits are provided for each counter. These bits

are called New Data (ND) bits in the BTR instruction, and New Data

Acknowledge (NDA) bits in the BTW instruction. They indicate

when a stored data value has been most recently updated. These bits

are provided for count/accumulate applications, but can be used

whenever the stored data is updated at a rate slower than the block

transfer time.

The New Data bit (BTR status word 1, bits 4-7 for counters 0-3

respectively) can be used by the ladder program to indicate that a

store register (BTR words 11-18) has been updated by one of the

following events:

Default Configuration

An active gate transition in any of the store count modes

The end of the gate sample period in either the period/rate or

continuous/rate modes

The end of the programmed sample period in rate

measurement mode

The ND bit is reset in the ladder program by a 0 to 1 transition of the

corresponding NDA bit, and then performing a BTW. A BTW length

of 1 word can be use for this handshaking procedure.

Note: A BTW length of 1 has no effect on the preset or reset bits in

BTW word 1, and does not qualify as a configuration BTW. (For

example, if the BTW valid bit is set, it will remain set after the BTW

with a length of 1 is sent.)

A default configuration is built into the module. The default

configuration is automatically selected on power-up if the user has

not configured the module through a Block Transfer Write

Initialization file. The module can be placed in the default

configuration by writing a block transfer write initialization file with

all zeroes to the module.

Page 25

Overview of the Very High Speed Counter Module

1–17

The default mode for the VHSC module is the counter mode for all 4

of the counters. In the default configuration, the module will

continuously return counts (0-999,999 binary) to the programmable

controller processor. The presets and rollovers associated with each

of the 4 counters will not be active, nor will any of the outputs be

active.

How the Module Communicates with a Programmable Controller

The processor transfers data to and from the module using block

transfer write (BTW) and block transfer read (BTR) instructions in

your ladder diagram program. These instructions let the processor

obtain input values and status from the module, and let you establish

the module’s mode of operation (1.13).

Figure 1.13

How the Module Communicates with a Programmable

Controller

3

1

BTW

2

VHSC Module

1771VHSC

BTR

4

PC Processor

(PLC5/15 Shown)

5

6

Data Table

User Program

12933I

1. The processor transfers your configuration data and commands to

the module using a BTW instruction.

2. External devices generate input signals that are transmitted to the

module.

3. The module converts these signals into binary or BCD format,

and stores these values and controls their output until the

processor requests their transfer.

4. When instructed by your ladder program, the processor performs

a BTR of the values and stores them in a data table.

5. The processor and module determine that the transfer was made

without error, and that input values are within a specified range.

Page 26

1–18

Overview of the Very High Speed Counter Module

6. Your ladder program can use/or move the data (if valid) before it

is written over by the transfer of new data in a subsequent

transfer.

Chapter Summary

In this chapter you learned how your module operates, and how your

module communicates with the programmable controller.

Page 27

Chapter 2

Installing the Very HighSpeed

Counter Module

Chapter Objectives

Before You Install Your Module

Calculate the power requirements of all modules in each chassis. Power Requirements

Determine where to place the module in the I/O chassis. Module Location in the I/O Chassis

Key the backplane connector in the I/O chassis. Module Keying

Make connections to the wiring arm. Connecting Wiring and Grounding

European Union Directive Compliance

This chapter gives you information on:

• calculating the chassis power requirement

• keying a chassis slot for your module

• setting the voltage and filter jumpers

• wiring the input module’s field wiring arm

• installing the input module

Before installing your module in the I/O chassis you must:

Action required: Refer to:

If this product is installed within the European Union or EEA

regions and has the CE mark, the following regulations apply.

EMC Directive

This apparatus is tested to meet Council Directive 89/336/EEC

Electromagnetic Compatibility (EMC) using a technical construction

file and the following standards, in whole or in part:

• EN 50081-2 EMC – Generic Emission Standard, Part 2 –

Industrial Environment

• EN 50082-2 EMC – Generic Immunity Standard, Part 2 –

Industrial Environment

The product described in this manual is intended for use in an

industrial environment.

Low Voltage Directive

This apparatus is also designed to meet Council Directive 73/23/EEC

Low Voltage, by applying the safety requirements of EN 61131–2

Programmable Controllers, Part 2 – Equipment Requirements and

Tests.

For specific information that the above norm requires, see the

appropriate sections in this manual, as well as the following

Allen-Bradley publications:

Page 28

2–2

Installing the Very High-Speed Counter Module

• Industrial Automation Wiring and Grounding Guidelines,

publication 1770-4.1

• Guidelines for Handling Lithium Batteries, publication AG-5.4

• Automation Systems Catalog, publication B111

Electrostatic Damage

Power Requirements

Electrostatic discharge can damage semiconductor devices inside this

module if you touch backplane connector pins. Guard against

electrostatic damage by observing the following warning:

ATTENTION: Electrostatic discharge can degrade

performance or cause permanent damage. Handle the

!

module as stated below.

• Wear an approved wrist strap grounding device when handling

the module.

• Touch a grounded object to rid yourself of electrostatic charge

before handling the module.

• Handle the module from the front, away from the backplane

connector. Do not touch backplane connector pins.

• Keep the module in its static-shield bag when not in use, or

during shipment.

Your module receives its power through the 1771 I/O chassis

backplane from the chassis power supply. The maximum current

drawn by the module from this supply is 650mA (3.25 Watts).

Module Location in the I/O Chassis

Add this value to the requirements of all other modules in the I/O

chassis to prevent overloading the chassis backplane and/or

backplane power supply.

Place your module in any slot of the I/O chassis except for the

extreme left slot. This slot is reserved for processors or adapter

modules.

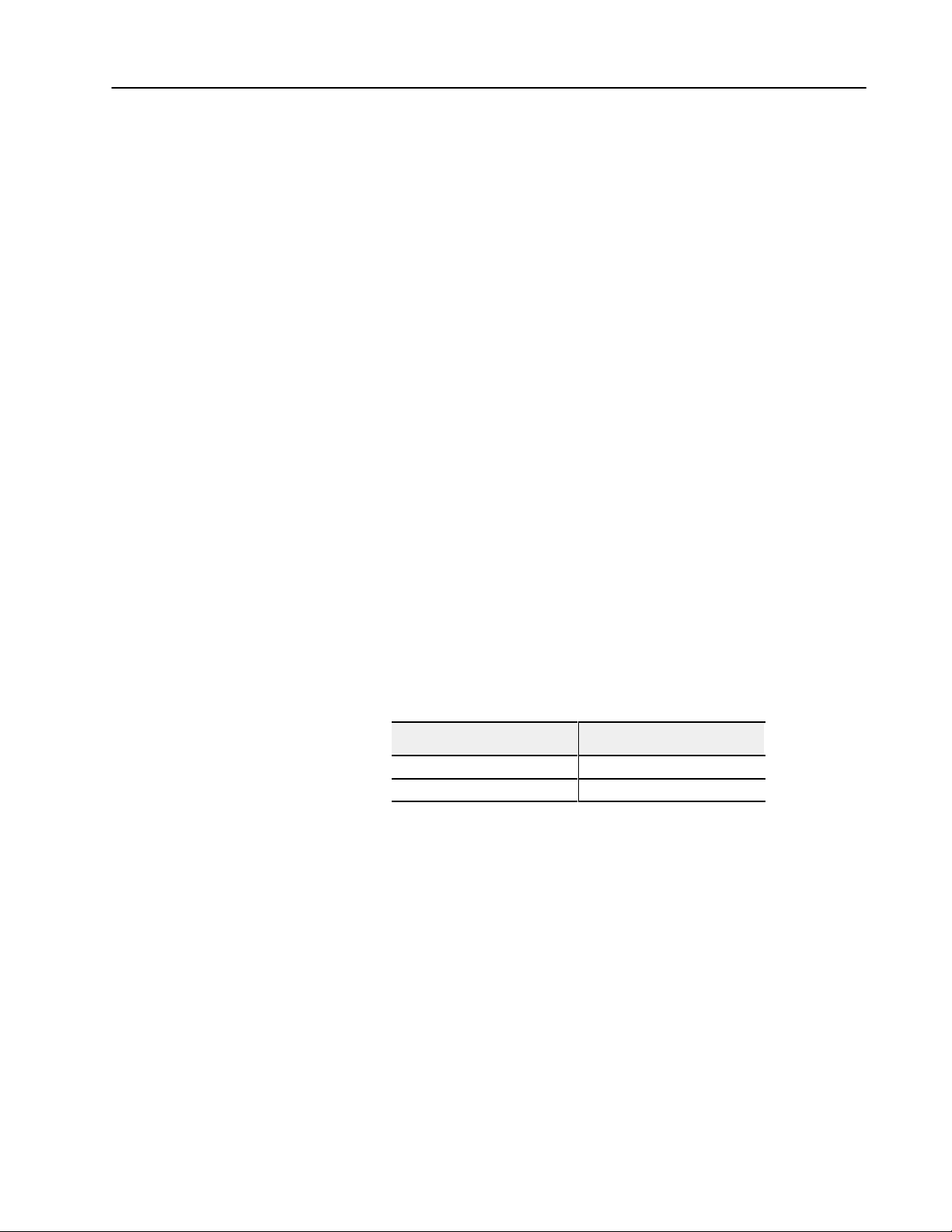

When using: You can:

2slot addressing place your module in any module group with any 8bit or block

transfer module.

1slot addressing place your module in any module group with any 8bit, 16bit or block

transfer module.

1/2slot addressing, no restrictions on module location.

After determining the module’s location in the I/O chassis, connect

the wiring arm to the pivot bar at the module’s location.

Page 29

Installing the Very High-Speed Counter Module

2–3

Module Keying

Use the plastic keying bands, shipped with each I/O chassis, for

keying the I/O slot to accept only this type of module.

The module is slotted in two places on the rear edge of the circuit

board. The position of the keying bands on the backplane connector

must correspond to these slots to allow insertion of the module. You

can key any connector in an I/O chassis to receive these modules

except for the leftmost connector reserved for adapter or processor

modules. Place keying bands between the following numbers

labeled on the backplane connector (Figure 2.1):

• Between 24 and 26

• Between 28 and 30

You can change the position of these bands if subsequent system

design and rewiring makes insertion of a different type of module

necessary. Use needlenose pliers to insert or remove keying bands.

Figure 2.1

Keying Positions

2

4

6

8

10

12

14

16

18

20

22

24

26

Keying Bands

Upper Connector

28

30

32

34

36

14288

Page 30

2–4

Installing the Very High-Speed Counter Module

Setting the Configuration Jumpers

The VHSC module has user-selectable jumpers for each input

channel. These jumpers consist of one each:

•filter or high speed operation jumper

•+5V or +12-24V operation jumper

Each counter has a total of 6 jumpers associated with it:

•Channel A filter/high speed jumper

•Channel A voltage jumper

•Channel B filter/high speed jumper

•Channel B voltage jumper

•Gate/reset filter/high speed jumper

•Gate/reset voltage jumper

These jumpers can be set independent of each other. You can select

the filter action and voltage for each channel and for the gate/reset

input independently.

The high speed operation is the preferred mode of operation for the

1771-VHSC module. Use this mode when the inputs are driven by

devices such as encoders or line drivers.

Use the filter mode on the inputs when a mechanical switch is

providing the input. The filter provides de-bouncing for the

mechanical switch. The frequency of counting must be less than

100Hz when the filter mode is selected.

Use these jumpers to match the operation of the module with the

input supplied. Settings are shown in Figure 2.2.

To set the jumpers, proceed as follows:

1.Remove the four screws securing the side cover to the module

and remove the covers.

2.Using your fingers, reposition the jumpers associated with each

input channel according to your requirements. Refer to

Figure 2.2.

Page 31

Installing the Very High-Speed Counter Module

Figure 2.2

Setting the Configuration Jumpers

2–5

Filter Jumper

Position

Down Down 1224V High Speed (factory default setting)

Down Up 5V High Speed

Up Down 1224V with low speed filter

Up Up 5V with low speed filter

Voltage Jumper

Position

FILTER

SPEED

HI

A0

B0

G0

Description of Operation

*

5V

1224V

Connecting Wiring

10688I

In the filter position, the module will not see frequencies above 100Hz.

*

3.Reposition the cover and secure with the 4 screws removed in

step 1.

Connect your I/O devices to the 40-terminal field wiring arm (cat.

no. 1771-WN) shipped with the module (Figure 2.3). Attach the

field wiring arm to the pivot bar at the bottom of the I/O chassis.

The field wiring arm pivots upward and connects with the module so

you can install or remove the module without disconnecting the

wires.

Page 32

2–6

Installing the Very High-Speed Counter Module

Figure 2.3

Connection Diagram for Very High Speed Counter Module (1771VHSC)

(See

applicable codes and laws.)

Channel A

Channel B

Gate Not input

Gate Not input

Channel B

Channel A

Channel A

Channel B

Gate Not Input

Gate Not Input

Channel B

Channel A

Output

Customer Common 01

Output 2

Customer Common 23

Output 4

Customer Common 45

Output 6

Customer Common 67

/Channel A Return

/Channel B Return

/Channel B Return

/Channel A Return

/Channel A Return

/Channel B Return

/Channel B Return

/Channel A Return

0

2

4

6

8

10

12

14

16

18

20

22

24

26

28

30

32

34

36

38

40

Channel A Input

Channel B Input

Gate Input

Gate Input

Channel B Input

Channel A Input

Channel A Input

Channel B Input

Gate Input

Gate Input

Channel B Input

Channel A Input

Customer V

Output

Customer V

Output 3

Customer V

Output

Customer V

Output

CC

1

CC

CC

5

CC

7

01

23

45

67

Counter 0

Counter 1

Counter 2

Counter 3

Note: Terminals on the left are

even numbered (2 thru 40), and

terminals on the right are odd

numbered (1 thru 39).

The sensor cable must be shielded. The

shield must:

•extend the length of the cable, but be

connected only at the 1771 I/O chassis

•extend up to the point of termination

Important:The shield should extend to the

termination point, exposing just

enough cable to adequately

terminate the inner conductors.

Use heat shrink or another

suitable insulation where the wire

exits the cable jacket.

(Actual wiring runs in this direction.)

Grounding the VHSC

Module Wiring

10689I

When using shielded cable, ground the foil shield and drain wire

only at one end of the cable. We recommend that you wrap the foil

shield and drain wire together and connect them to a chassis

mounting bolt (Figure 2.4). At the opposite end of the cable, tape

exposed shield and drain wire with electrical tape to insulate it from

electrical contact.

Page 33

Installing the Very High-Speed Counter Module

Figure 2.4

Cable Grounding

2–7

Ground Shield at

I/O chassis

mounting bolt

Shield and drain

twisted into single

strand

Installing the Module

Field

Wiring Arm

17798

Refer to Wiring and Grounding Guidelines, publication 1770-4.1 for

additional information.

When installing your module in an I/O chassis:

1. First, turn off power to the I/O chassis:

ATTENTION: Remove power from the 1771 I/O

chassis backplane and wiring arm before removing or

!

installing an I/O module.

Failure to remove power from the backplane could

cause injury or equipment damage due to possible

unexpected operation.

Failure to remove power from the backplane or wiring

arm could cause module damage, degradation of

performance, or injury.

2. Place the module in the plastic tracks on the top and bottom of the

slot that guides the module into position.

3. Do not force the module into its backplane connector. Apply firm

even pressure on the module to seat it properly.

Page 34

2–8

Installing the Very High-Speed Counter Module

4. Snap the chassis latch over the top of the module to secure it.

5. Connect the wiring arm to the module.

Interpreting the Indicator Lights

The front panel of the input module contains 12 input indicators, 8

output indicators, an active indicator and a fault indicator

(Figure 2.5). At power-up, the active and fault indicators are on. An

initial module self-check occurs. If there is no fault, the red indicator

turns off. If a fault is found initially or occurs later, the fault indicator

lights and the active indicator is forced off.

When an input LED (A, B) is on, it indicates that the input is high.

When the output LED is on, it indicates that the module has

commanded the output to be on. When a gate/reset indicator (G) is

on, its input is high. Since that signal can be inverted, it does not

indicate whether the signal on that terminal is necessarily logically

true.

Possible module fault causes and corrective action are discussed in

the chapter titled “Troubleshooting.”

Figure 2.5

Diagnostic Indicators

Chapter Summary

ACTIVE

INPUTS

A0 A1 A2 A3

B0 B1 B2 B3

G0 G1 G2 G3

OUTPUTS

00 02 04 06

01 03 05 07

FAULT

Active Indicator

Input Indicators

Output Indicators

Fault Indicator

10690I

In this chapter you learned how to install your input module in an

existing programmable controller system and how to wire to the field

wiring arm.

Page 35

Module Programming

Chapter 3

Chapter Objectives

Block Transfer

Programming

In this chapter we describe:

block transfer programming

sample programs in the PLC-2, PLC-3 and PLC-5 processors

Your module communicates with the processor through bidirectional

block transfers. This is the sequential operation of both read and

write block transfer instructions.

The following example programs accomplish this handshaking

routine. These are minimum programs; all rungs and conditioning

must be included in your application program. You can disable

BTRs, or add interlocks to prevent writes if desired. Do not eliminate

any storage bits or interlocks included in the sample programs. If

interlocks are removed, the program may not work properly.

Optionally, the block transfer write (BTW) instruction is initiated

when the module is first powered up, and subsequently only when

the programmer wants to write a new configuration to the module.

At all other times the module is basically in a repetitive block

transfer read (BTR) mode.

Your module will work with a default configuration of all zeroes

entered in the configuration block. See the configuration default

section to understand what this configuration looks like. Also, refer

to Appendix B for example configuration blocks and instruction

addresses to get started.

The following example programs illustrate the minimum

programming required for communication to take place.

Page 36

3–2

Module Programming

PLC2 Program Example

Figure 3.1 below shows a sample PLC-2 program.

Figure 3.1

Family Sample Program Structure

PLC2

The

VHSC module is located in rack 1, module group 0, slot 0. The data address 030 is among the first available timer/counters used for block transfer

The default block length of 0 results in a 18 word block transfer read. The module status data is returned to the processor starting at address 301.

If a block length other than 0 is specified for the BTR or BTW the BTR and BTW cannot be enabled during the scan.

VHSC BTR Data Address

VHSC BTR

Done Bit

1

The

VHSC module is located in rack 1, module group 0, slot 0. The data address 031 is among the first available

The

default block length of 0 results in a 64 word block transfer write. The module configuration

could also include the configuration bit (word 1, bit 0) to limit the block transfer write.

2

110

07

VHSC BTW

Done Bit

110

06

VHSC BTW

Enable Bit

010

06

VHSC BTR

Enable Bit

010

07

BTR

BLOCK TRANSFER READ

DATA ADDRESS:

MODULE ADDRESS:

BLOCK LENGTH:

FILE: 301-400

timer/counters used for block transfer

data is stored starting at address 201. The preconditions

BTW

BLOCK TRANSFER WRITE

DATA ADDRESS:

MODULE ADDRESS:

BLOCK LENGTH:

FILE: 201-300

030

100

00

031

100

00

010

EN

07

110

DN

07

010

EN

06

110

DN

06

.

.

This rung is used to place a zero between the first available timer counters used for all block transfers and those used throughout the rest of

the program.

3

This rung uses a BTR done bit to trigger a move of the count data stored at 301 to a buffered location at 331. The program should access all data

from the buffered file (count 0 MSD would be located in word 333 and the LSD in word 334.)

032

G

0

VHSC BTR

Done Bit

4

110

07

FFM

FILE TO FILE MOVE

COUNTER ADDR:

POSITION:

FILE LENGTH:

FILE A:

FILE R:

RATE PER SCAN:

301-322

331-352

033

18

18

032

PUT

0

033

EN

17

1

033

DN

15

Page 37

Module Programming

3–3

PLC3 Program Example

Block transfer instructions with the PLC-3 processor use one binary

file in a data table section for module location and other related data.

This is the block transfer control file. The block transfer data file

stores data that you want transferred to the module (when

programming a block transfer write) or from the module (when

programming a block transfer read). The address of the block

transfer data files are stored in the block transfer control file.

The industrial terminal prompts you to create a control file when a

block transfer instruction is being programmed. The same block

transfer control file is used for both the read and write

instructions for your module. A different block transfer control file

is required for every module.

A sample program is shown in Figure 3.2 below.

Figure 3.2

Family Sample Program Structure

PLC3

The VHSC module is located in rack 1, module group 0, slot 0. The control file is a 10 word file, shared by the BTR and BTW, starting at B12:0.

The data obtained by the processor from the VHSC is placed in memory starting at location N13:101, and with the default length of 0 is 18 words

long. The MSD of counter 0 is stored in N13:103 and the LSD of counter 0 is stored in N13:104.

VHSC BTR/BTW

Control Block

BTR

VHSC BTR

Done Bit

B12:0

15

VHSC BTR

Error Bit

B12:0

13

The VHSC module is located in rack 1, module group 0, slot 0. The control file is a 10 word file, shared by the BTR and BTW, starting at B12:0.

The

data sent by the processor to the VHSC is placed in memory starting at location N13:1, and with the default length of 0 is 64 words long. If the

default mode of VHSC operation is desired (rollover at 999,999 outputs disabled), this rung can be optional. The module configured bit can also

be used as a precondition to increase BTR throughput.

VHSC BTW

Done Bit

B12:0

5

VHSC BTW

Error Bit

B12:0

3

BLOCK XFER READ

RACK:

GROUP:

MODULE:

CNTL:

DATA:

LENGTH:

VHSC BTR/BTW

Control Block

BTW

BLOCK XFER WRITE

RACK:

GROUP:

,MODULE:

CNTL:

DATA:

LENGTH:

B12:0

N13:101

B12:0

N13:1

1

0

0

0

VHSC BTR

Error Bit

B12:0

EN

1

0

DN

0

0

VHSC BTW

Error Bit

B12:0

EN

DN

ER

U

13

ER

U

3

Page 38

3–4

Module Programming

PLC5 Program Example

Block transfer instructions with the PLC-5 processor use one binary

file in a data table section for module location and other related data.

This is the block transfer control file. The block transfer data file

stores data that you want transferred to the module (when

programming a block transfer write) or from the module (when

programming a block transfer read). The address of the block

transfer data files are stored in the block transfer control file.

The industrial terminal prompts you to create a control file when a

block transfer instruction is being programmed. A different block

transfer control file is used for the read and write instructions

for your module.

Figure 3.3

Family Sample Program Structure

PLC5

The

VHSC module is located in rack 0, module group 0, slot 0. The BTR control file starts at N21:0 and is 5 words long. The data obtained by the

processor from the VHSC is placed in memory starting at location N22:101, and with the default length of 0 is 18 words

0 is stored in N22:103 and the LSD of counter 0 is stored in N22:104.

VHSC BTR

Enable Bit

N21:0

1

15

VHSC BTW

Enable Bit

N21:5

15

VHSC BTR

Control File

BTR

BLOCK XFER READ

RACK:

GROUP:

MODULE:

CONTROL:

DATA FILE:

LENGTH:

CONTINUOUS:

long. The MSD of counter

EN

0

0

DN

0

N21:0

N22:101

ER

0

N

The VHSC module is located in rack 0, module group 0, slot 0. The BTWcontrol file starts at N21:5 and is a 5 words long.

The data sent by the processor to the VHSC is stored in memory starting at location N22:1, and with the default length of 0 is 64 words long.

VHSC BTR

Enable Bit

N21:0

2

15

VHSC BTW

Enable Bit

N21:5

15

VHSC BTW

Control File

BTW

BLOCK XFER WRITE

RACK:

GROUP:

MODULE:

CONTROL:

DATA FILE:

LENGTH:

CONTINUOUS:

N21:5

N22:1

EN

0

0

DN

0

ER

0

N

Page 39

Module Programming

3–5

PLC5/250 Program

Example

Block transfer instructions with the PLC-5/250 processor use one

binary file in a data table section for module location and other

related data. This is the block transfer control file. The block transfer

data file stores data that you want transferred to the module (when

programming a block transfer write) or from the module (when

programming a block transfer read). The address of the block

transfer data files are stored in the block transfer control file.

The industrial terminal will automatically select the control file

based on rack, group, and slot, and whether it is a read or write. A

different block transfer control file is used for the read and write

instructions for your module. A different block transfer control file

is required for every module.

Figure 3.4

PLC5/250

The VHSC module is located in rack 0, module group 0, slot 0. The data obtained by the processor from the VHSC is placed in memory starting

at location 1BTD0:101, and with the default length of 0 is 18 words long. The MSD of counter 0 is stored in 1BTD0:103 and the LSD of counter 0

is stored in 1BTD0:104.

VHSC BTR

Enable Bit

BR000:0

1

EN

Family Sample Program Structure

VHSC BTW

Enable Bit

BW000:0

EN

BTR

BLOCK XFER READ

RACK:

GROUP:

MODULE:

CONTROL BLOCK

DATA FILE:

BT LENGTH:

CONTINUOUS:

BT TIMEOUT 4

VHSC BTR

Control File

BR000:0

1BTD0:101

NO

EN

0

0

DN

0

ER

0

The

VHSC module is located in rack 0, module group 0, slot 0. The data sent by the

1BTD0:1, and with the default length of 0 is 64 words long.

VHSC BTW

Enable Bit

BW000:0

EN

Chapter Summary

VHSC BTR

Enable Bit

BR000:0

2

EN

In this chapter, you learned how to program your programmable

controller and you were given sample programs for each family of

controllers. For additional programs, refer to Appendix B.

processor to the VHSC is stored in memory starting at location

VHSC BTW

Control File

BTW

BLOCK XFER WRITE

RACK:

GROUP:

MODULE:

CONTROL BLOCK

DATA FILE:

BT LENGTH:

CONTINUOUS:

BT TIMEOUT: 4

BW000:0

1BTD0:1

NO

EN

0

0

DN

0

ER

0

Page 40

Chapter 4

Configuring Your Module

Chapter Objectives

Configuring the VHSC

Module

In this chapter you will read how to configure your module’s

hardware, condition your inputs and enter your data.

You must configure your module to conform to the input device and

specific application that you have chosen. Data is conditioned

through a group of data table words that are transferred to the

module using a block transfer write (BTW) instruction.

You can configure the following features for the 1771-VHSC

module:

• type of input

• data format

• preset values

• rollover values

Configure your module for its intended operation by means of your

programming terminal and write block transfers.

Note: Programmable controllers that use 6200 software (release 4.2

or higher) programming tools can take advantage of the IOCONFIG

Addendum utility to configure this module. IOCONFIG Addendum

uses menu–based screens for configuration without having to set

individual bits in particular locations. Refer to your 6200 software

literature for details.

Important: It is strongly recommended that you use IOCONFIG

Addendum to configure this module. The IOCONFIG

Addendum utility greatly simplifies configuration. If

the IOCONFIG Addendum is not available, you must

enter data directly into the data table. Use this chapter

as a reference when performing this task.

During normal operation, the processor transfers from 1 to 64 words

to the module when you program a BTW instruction to the module’s

address.

Page 41

4–2

Configuring Your Module

Configuration Block for a Block Transfer Write

Word 15 14 13 12 11 10 09 08 07 06 05 04 03 02 01 00

1 Format Preset New Data Acknowledge Reset

2 Force Outputs Enable Outputs

Gate/

3

Reset

Gate/

4

Reset

5 Rollover Counter 0 MSD

6 Rollover Counter 0 LSD

7 Rollover Counter 1 MSD

8 Rollover Counter 1 LSD

9 Rollover Counter 2 MSD

10 Rollover Counter 2 LSD

11 Rollover Counter 3 MSD

12 Rollover Counter 3 LSD

The complete configuration block for the block transfer write to the

module is defined in Table 4.A below.

Table 4.A

Configuration Block for the VHSC Module Block T

Counter 1 configuration

Counter 3 configuration

Gate/

Reset

Gate/

Reset

ransfer W

Counter 0 configuration

Counter 2 configuration

rite

13 Preset Counter 0 MSD

14 Preset Counter 0 LSD

15 Preset Counter 1 MSD

16 Preset Counter 1 LSD

17 Preset Counter 2 MSD

18 Preset Counter 2 LSD

19 Preset Counter 3 MSD

20 Preset Counter 3 LSD

21 Scaler 1, Counter 0

22 Scaler 2, Counter 1

23 Scaler 3, Counter 2

24 Scaler 4, Counter 3

25 Not used Tie Output 0 to Counter

26 Output 0 On MSD

27 Output 0 On LSD

28 Output 0 Off MSD

29 Output 0 Off LSD

30 Not used Tie Output 1 to Counter

31 Output 1 On MSD

32 Output 1 On LSD

33 Output 1 Off MSD

Page 42

Configuring Your Module

34 Output 1 Off LSD

Words repeat for each additional output: 3539 output 2, 4044 output 3, 4549 output 4, 5054 output 5, 5559 output 6

60 Not used Tie Output 7 to Counter

61 Output 7 On MSD

62 Output 7 On LSD

63 Output 7 Off MSD

64 Output 7 Off LSD

4–3

00010203040506070809101112131415Word

Bit/Word Descriptions

Bit/word descriptions of BTW file words are presented in Table 4.B.

Enter data into the BTW instruction after entering the instruction into

your ladder diagram program.

Table 4.B

ord Definitions for the VHSC Module

Bit/W

Word Bits Description

These bits control the reset function. When one of these bits

Word 1 bits 0003

bits 0407

bits 0811

bits 1214 Not used

bit 15

Word 2 bits 0007

bits 0815

transitions from 0 to 1, the counter is reset to 0 and begins counting.

The bits correspond to the 4 counters: bit 00 = counter 0; bit 01 =

counter 1; bit 02 = counter 2; bit 03 = counter 3.

New data acknowledge bits. When one of these bits transitions from 0

to 1 the corresponding new data bit in BTR word 1, bits 47 will be

reset. Bit 04 corresponds to counter 0, bit 05 to counter 1, etc.

These bits control the preset function. When one of these bits is set to

1, the preset count value is automatically loaded into the counter and

the counter begins counting. (Note: The preset count values are

loaded into words 13 through 20.) The bits correspond to the counters

as follows: Bit 08 = counter 0; bit 09 = counter 1; bit 10 = counter 2; bit

11 = counter 3.

This bit determines whether BCD or binary format is used.

Bit 15 = 0 Indicates all values in the BTW file and the BTR file will be

in binary. (Diagnostic byte (word 1) is always BCD.)

Bit 15 = 1 Indicates all values in the BTW file and the BTR file will be

in BCD.

Enables outputs. Bit 00 corresponds to output 0, bit 01 to output 1,