Page 1

Allen-Bradley

ControlNet

Adapter Module

User

(Cat. No. 1771-ACN and

-ACNR Series B)

Manual

Page 2

Important User Information

Because of the variety of uses for the products described in this

publication, those responsible for the application and use of this control

equipment must satisfy themselves that all necessary steps have been taken

to assure that each application and use meets all performance and safety

requirements, including any applicable laws, regulations, codes and

standards.

The illustrations, charts, sample programs and layout examples shown in

this guide are intended solely for purposes of example. Since there are

many variables and requirements associated with any particular

installation, Allen-Bradley does not assume responsibility or liability

(to include intellectual property liability) for actual use based upon the

examples shown in this publication.

Allen-Bradley publication SGI-1.1, Safety Guidelines for the Application,

Installation, and Maintenance of Solid-State Control (available from your

local Allen-Bradley office), describes some important dif

solid-state equipment and electromechanical devices that should be taken

into consideration when applying products such as those described in this

publication.

Reproduction of the contents of this copyrighted publication, in whole or

in part, without written permission of Allen-Bradley Company, Inc., is

prohibited.

ferences between

Throughout this manual we use notes to make you aware of safety

considerations:

A

TTENTION:

circumstances that can lead to personal injury or death, property

damage or economic loss.

Attention statements help you to:

identify a hazard

avoid the hazard

recognize the consequences

Important: Identifies information that is critical for successful application

and understanding of the product.

Identifies information about practices or

Page 3

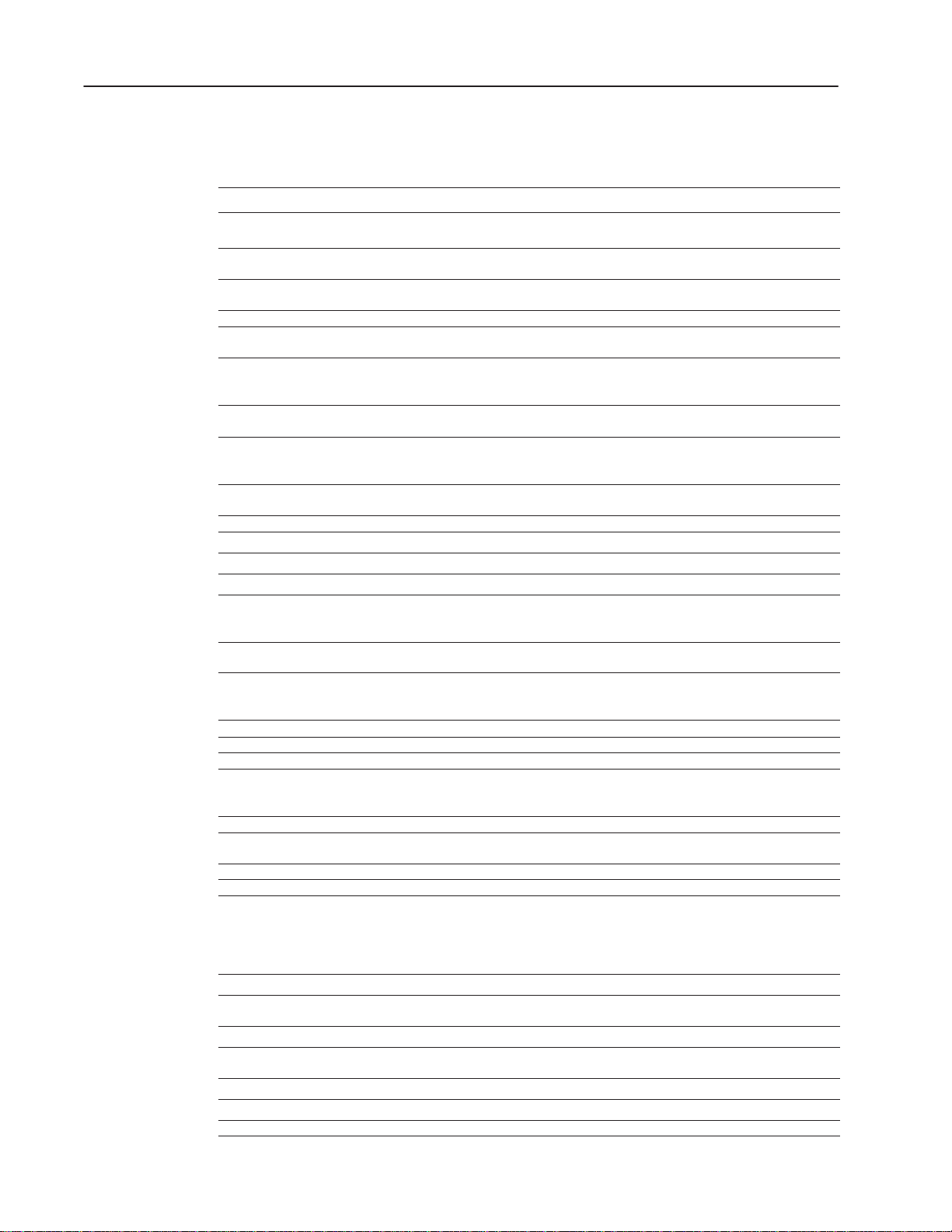

Preface

es

Objectiv

Audience

Vocabulary

What This Manual Contains

Chapter

Read this preface to familiarize yourself with this manual and to

learn how to use it properly and efficiently.

We assume that you have previously used an Allen-Bradley

programmable controller, that you are familiar with its features, and

that you are familiar with the terminology we use. If not, read the

user manual for your processor before reading this manual.

In this manual, we refer to:

• the individual ControlNet adapter module as the “adapter” or

the “module.”

• the programmable controller as the “controller” or the

“processor.”

The contents of this manual are as follows:

What This Manual Contains

Title What’s Covered

Introducing the ControlNet Adapter

1

Modules

Installing Your ControlNet Adapter

2

Module

3 Addressing Modes for Your I/O Hardware addressing and configuration options

Planning to Use Your ControlNet

4

Adapter

5 Troubleshooting

Appendix

A Specifications Module specifications

A Practical Example of ControlNet

B

Concepts

Describes features, capabilities, and hardware

components.

Procedures and guidelines for installing the module;

including power requirements, location, setting

switches, and actual installation.

How the adapter operates on ControlNet and

information to assist in configuring your system.

Troubleshooting aids, including status display, health

indicators and ControlNet status indicators

An example program and description thereof

Publication

1771-6.5.123 – May 1996

Page 4

Using This ManualP–2

Terminology Used in This Manual

Use this term To describe

complementary module

Configuration Manager node node responsible for distributing ControlNet configuration data to all nodes on the

ControlNet network a communication architecture that allows the exchange of messages between

connection an opened communication path between two nodes on a ControlNet network

ControlNet status indicators channel A and channel B indicators on your node indicating status on the ControlNet

DF1 protocol a peer-to-peer link-layer protocol that combines features of ANSI X3.28-1976

DH+ network

(Data Highway Plus)

discrete I/O data transfer type of data transfer in which single units of I/O have discrete relationships with values

drop cable a cable that connects a node to the trunk cable (this is an integral part of

frame single data transfer on a ControlNet link

half–slot addressing a method of addressing where the processor can address its I/O in 1/2–slot I/O groups

high–density i/o module a module that provides 16 input or 16 output terminals

I/O Group an addressing unit that can contain up to 16 input terminals and 16 output terminals

I/O map table table that you configure using the programming software to map data from an I/O

link collection of nodes with unique addresses (in the range of 1-99). Segments

map-table entry one entry in the I/O map table that you configure using the programming software to

maximum scheduled node node with highest network address that can use scheduled time on a ControlNet link

maximum unscheduled node node with highest network address that can use unscheduled time on a ControlNet link

network access port (NAP) port that provides a temporary network connection through an RJ-45 connector

network a series of nodes connected by some type of communication medium. The

network address a node’s address on the network (this replaces MAC ID and node address).

node port of a physical device connecting to the network which requires a network address

network update interval (NUI) single occurrence of the network update time (NUT)

network update time (NUT) repetitive time interval in which data can be sent on the ControlNet network

non-discrete I/O data transfer type of data transfer in which blocks of data transferred to or from I/O modules use

one–slot addressing A method of addressing where the processor can address its I/O in 1–slot I/O groups.

parallel port an input/output port for a device that transmits multiple data and control bits over wires

PC An Allen–Bradley programmable controller, such as the PLC–5

PCCC Programmable Controller Communication Commands, an application-level command

processor a term used to mean an Allen–Bradley programmable controller

quad–density i/o module a module that provides 32 input or 32 output terminals

redundant media dual cable system that allows you to receive the best signal over a network

The following list defines common terms used in this manual.

a module that performs an opposite function; an input module complements an output

module and vice versa

network

Allen-Bradley Company, Inc. products and certified third-party products

link

specification subcategories D1 (data transparency) and F1 (two-way simultaneous

transmission with embedded responses)

an Allen-Bradley local area network made up of one or more token-passing baseband

links

in the processor’s data table; uses the processor’s input- and output-image tables

(I and O files); configured on a per-node basis in the ControlNet I/O map table

1786 taps)

chassis and other devices on the ControlNet network to particular data-table file

addresses

connected by repeaters make up a link; links connected by bridges make up a network

map data from one I/O chassis (or other device on a ControlNet link) to particular

data-table file addresses

connection paths between any pair of nodes can include repeaters, routers, bridges

and gateways

in order to function on the network — a link may contain a maximum of 107 nodes

integer input and output data-table files that you specify; cannot use the processor’s

input- and output-image tables (I and O files); scheduled transfers are configured in

the ControlNet I/O map table, unscheduled transfers make use of ControlNet I/O (CIO)

transfer instructions

connected in parallel

set that Allen-Bradley programmable controllers use to communicate across networks

Publication

1771-6.5.123 – May 1996

Page 5

Using This Manual P–3

Use this term To describe

repeater two-port active physical-layer device that reconstructs and retransmits all traf

hears on one segment to another segment

remote I/O link a serial link for carrying I/O data between a PLC or SLC processor/scanner and

remote I/O adapters

RS-232-C port a serial port that complies with accepted industry standard for serial binary

communication circuits in a point-to-point link

scheduled transfers deterministic and repeatable transfers that are continuous and asynchronous to the

ladder-logic program scan

segment trunk-cable sections connected via taps with terminators at each end;

a segment does not include repeaters

serial port a port that transmits/receives data and control bits sequentially over a single

transmission line (see RS-232-C port)

standard–density i/o module a module that provides up to 8 input terminals or 8 output terminals

tap a component that connects products to the ControlNet trunk cable. A tap is required

for each node and for both sides of each repeater.

terminator a 75-ohm resistor (mounted in a BNC plug) placed on the ends of segments to prevent

reflections from occurring at the ends of cables.

trunk cable bus or central part of a cable system.

trunk-cable section length of trunk cable between any two taps

two–slot addressing a method of addressing where the processor can address its I/O in 2–slot I/O groups

unscheduled transfers non-deterministic data transfers through ladder-initiated communication or

programming devices

fic it

Conventions

We use these conventions in this manual:

In this manual, we show: Like this:

that there is more information about a topic

in another chapter in this manual

that there is more information about the topic

in another manual

More

Publication

1771-6.5.123 – May 1996

Page 6

Using This ManualP–4

Product

Compatibility

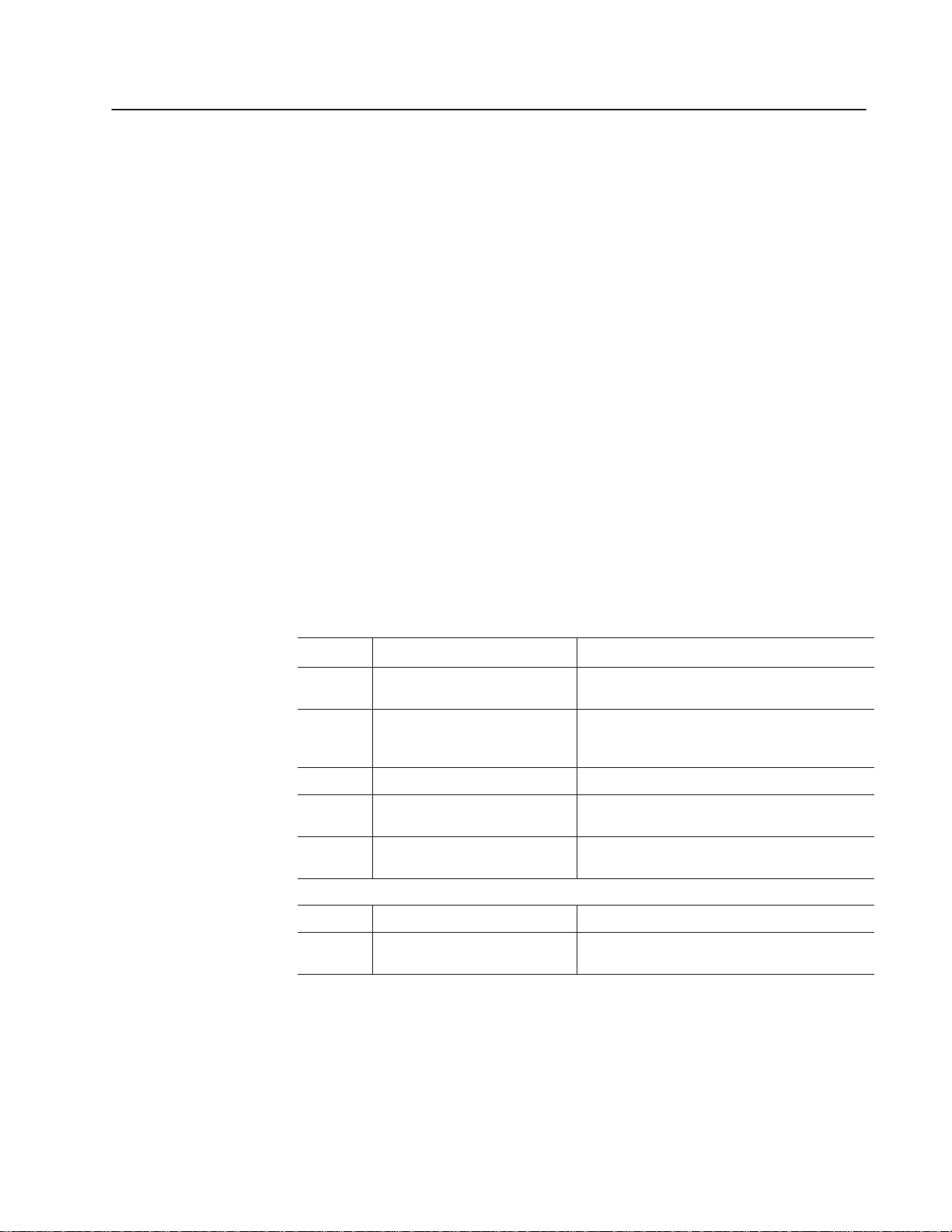

The 1771-ACN and 1771-ACNR adapter modules are two of many

hardware components that make up a programmable controller

system. The table below lists the hardware components and products

with which you can use the adapter module.

Compatible Hardware Products

Product name

Processors PLC–5/20C and PLC-5/40C processors 1785-L20C, 1785-L40C

Communication

Devices

Universal I/O

Chassis

I/O Modules Block transfer modules

Power Supplies System power supply

Description Catalog number

ControlNet KT Communication Card

ControlNet KTx Communication Card

ControlNet Serial/Parallel Communication Interface

Flex I/O ControlNet Adapter

1771 ControlNet Adapter Module

4–slot

8–slot

12–slot

16–slot

8–point I/O Standard density I/O modules

16–point I/O High density I/O modules

32–point I/O Quad–Density I/O modules

Auxiliary power Supply

Auxiliary Power Supply module (120V ac input, 3A)

Auxiliary Power Supply module (120V ac input, 8A)

Redundant Power Supply module

Auxiliary Power Supply module (24V dc input, 8A)

Auxiliary Power Supply module (220/240V ac input, 8A)

Auxiliary Power Supply module (120/220V ac input, 16A)

PLC–2 Power Supply (115V ac input)

PLC–2 Power Supply (24V dc input)

Local Power Supply

Auxiliary Power Supply (24V dc input)

1784-KTC

1784-KTCx

1770-KFC

1794-ACN

1771-ACN, -ACNR

1771–A1, –A1B

1771–A2, –A2B

1771–A3B, A3B1

1771–A4, –A4B

All modules that use the 1771

I/O structure

1771–P1

1771–P2

1771–P3

1771–P4, –P4S, –P4S1

1771–P4R

1771–P5

1771–P6S, –P6S1

1771–PS7

1772–P1

1772–P4

1774–P1

1777–P4

Publication

1771-6.5.123 – May 1996

Page 7

Using This Manual P–5

Related Publications

Summary

For additional information on planning and installing your

ControlNet system, see the following publications:

Publication

ControlNet PLC-5 Programmable Controllers User Manual 1785-6.5.14

ControlNet Cable System Component List AG-2.2

ControlNet Cable System Planning and Installation Manual 1786-6.2.1

ControlNet Coax Tap Installation Instructions 1786-2.3

ControlNet Network Access Cable Installation Instructions 1786-2.6

ControlNet Repeater Installation Instructions 1786-2.7

Industrial Automation Wiring and Grounding Guidelines 1770-4.1

Publication Number

This preface gave you information on how to use this manual

efficiently. Chapter 1 introduces you to the ControlNet remote I/O

adapter module.

Publication

1771-6.5.123 – May 1996

Page 8

Using This ManualP–6

Publication

1771-6.5.123 – May 1996

Page 9

Table

of Contents

Introducing

the ControlNet

Adapter Module

Installing Y

our ControlNet

Adapter Module

Chapter 1

Chapter

Module

Hardware

Chapter Summary

Objectives

Description and Features

Components

Diagnostic

Communication

Network

ControlNet

Network

Indicators

Access Port (NAP)

Connectors

Address Switch Assemblies

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reset Pushbutton

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

Chapter 2

Chapter

Determining

Determining

Setting

Setting

Setting

Installing

Connecting

Powerup

Chapter Summary

Objectives

Power Requirements

the Module Location and Keying the I/O Chassis

the Network

Address Switches

the I/O Chassis Switches

Backplane

Connecting

Switch Assembly

the I/O Chassis Power Supply Configuration Plug

the Adapter Module in the Chassis

Programming T

Sequence

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

Y

our Adapter to the ControlNet Network

erminals to the Network via the NAP

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . .

. . . . . . . .

. . . . . . . . . . . . . . . . .

. . . . . . . . . .

. . .

1–1

1–1

1–1

1–2

1–2

1–3

1–3

1–4

1–4

2–1

2–1

2–1

2–3

2–4

2–4

2–5

2–5

2–6

2–8

2–9

2–10

Addressing Modes for

Your I/O

Chapter 3

Chapter

Addressing

Addressing Summary

Chapter Summary

Objectives

Y

our I/O

Using

2-Slot Addressing

Module Combinations

I/O

Standard-density I/O (8 point) Modules

Using

High-density (16 point) I/O Modules

Using

1-Slot Addressing

Using

Module Combinations

I/O

1/2- Slot Addressing

Using

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . .

. . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Publication 1771-6.5.123 – May 1996

3–1

3–1

3–3

3–3

3–4

3–6

3–7

3–9

3–9

3–1

3–1

1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 10

Table of Contentsii

Planning

to Use Y

our

ControlNet Adapter Module

Troubleshooting

Chapter 4

Chapter

Overview

Discrete

Configuring

Nondiscrete

Configuring

Chapter Summary

Objectives

of Adapter Operation

I/O Data T

Discrete I/O Data T

I/O Data T

ControlNet I/O (CIO) Instructions

Using

Mapping

Example:

Example:

Directly Into Processor Memory

Nondiscrete Input Module Communications

Nondiscrete Output Module Communications

Nondiscrete I/O Data T

Chapter 5

Chapter

Troubleshooting

Chapter Summary

Objectives

Indicators and Display Mnemonics

Health

ControlNet

Status Indicators

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

ransfer

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

With the Status Indicators and Status Display

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ransfers

ransfers

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . .

ransfers

. . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . .

. . . . . . .

. . . . .

. . . .

4–1

4–1

4–2

4–2

4–3

4–3

4–4

4–4

4–5

4–6

4–6

5–1

5–1

5–2

5–3

5–3

Specifications

A Practical Example of

ControlNet Concepts

Appendix A

Specifications

Appendix B

Overview

Example

of Example

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A–1

B–1

B–2

Publication

1771-6.5.123 – May 1996

Page 11

Chapter Objectives

Module Description and Features

Chapter

1

Introducing the ControlNet

Adapter Module

This chapter describes the ControlNet adapter modules’ (cat. no.

1771-ACN and -ACNR):

• features

• hardware components, including

•

diagnostic indicators

•

communication reset pushbutton

• network access port (NAP)

•

ControlNet connectors

•

network address switch assemblies

The 1771-ACN and -ACNR adapters control 1771 remote I/O on the

ControlNet network. The ControlNet network is a communication

architecture that allows the exchange of messages between

Allen-Bradley products and certified third-party products.

Hardware Components

The 1771-ACN and -ACNR Adapters features include:

• high speed data transfer

•

diagnostic messages

• local communication network access through the network access

port (NAP)

• redundant media (1771-ACNR only)

The adapter module consists of the following major components:

•

ControlNet status indicators

•

status display

•

communication reset pushbutton

• network access port (NAP)

• ControlNet connectors (one on 1771-ACN; two on 1771-ACNR)

• module net address switch assemblies (on top of module)

Publication

1771-6.5.123 – May 1996

Page 12

Introducing the ControlNet Adapter Module 1–2

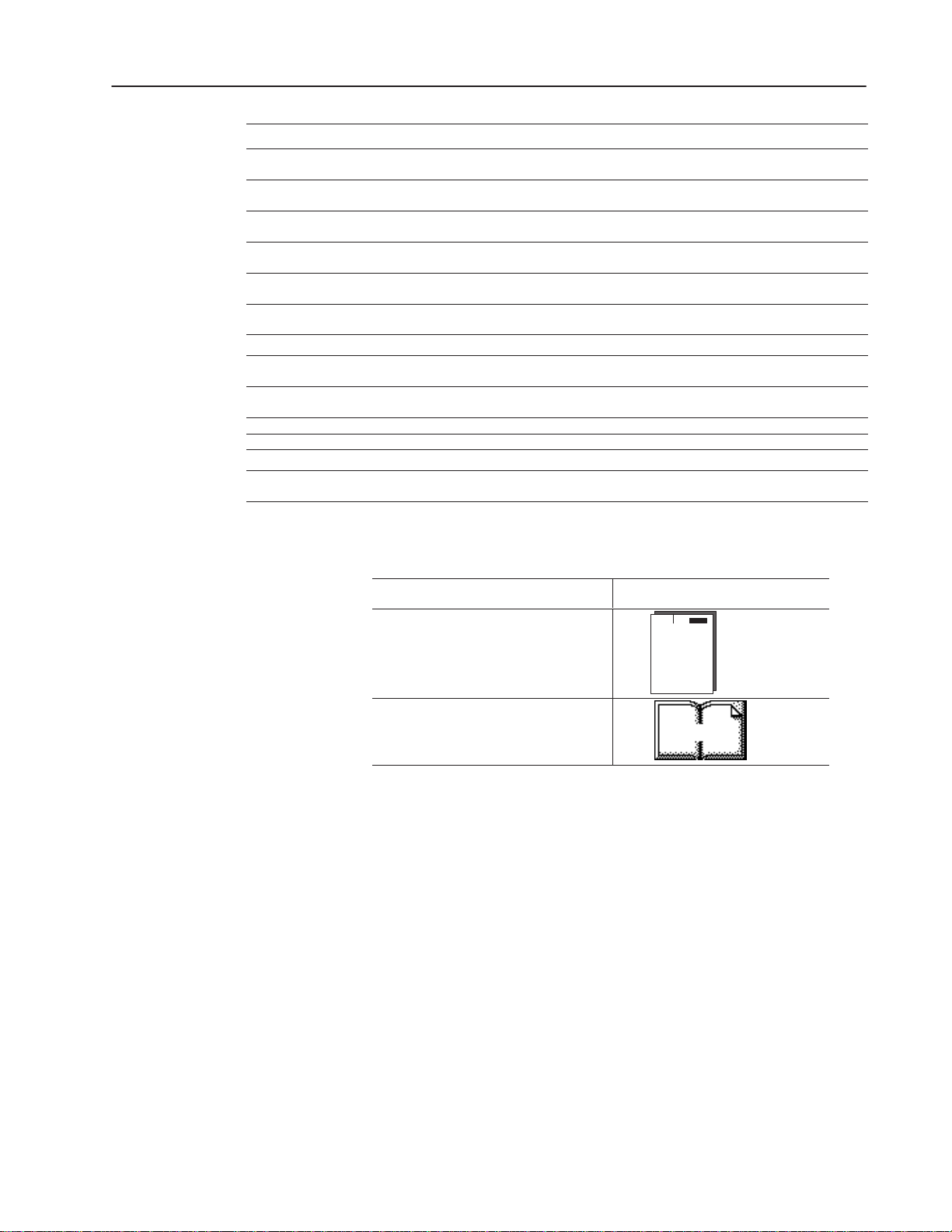

Figure 1.1

ControlNet

Adapter Module

Module Network Address Switches

(accessible thru top of module)

NET

ADDRESS

STATUS

OK OK

NET

ADDRESS

STATUS

Status Display and

Net Address

OK Indicator

Diagnostic Indicators

Communication Reset Pushbutton

ControlNet Status Indicators

Network Access Port (NAP)

A

ALLEN-BRADLEY

1771-ACN

A

B

ALLEN-BRADLEY

1771-ACNR

ControlNet Media Port

ControlNet Redundant Media Port

(1771-ACNR only)

1771-ACN 1771-ACNR

Diagnostic Indicators

The OK indicator is located on the front panel of the adapter module

(Figure 1.1). It shows both normal operation and error conditions in

your remote I/O system.

Publication

In addition, an alphanumeric display (net address/status) provides

status code indications when an error occurs during initialization or

operation.

A complete description of the diagnostic indicators and status display

and how to use them for troubleshooting is explained in chapter 5.

Communication Reset Pushbutton

This pushbutton is active whenever the status display shows RSET

or PRL. PRL is active only when the I/O chassis backplane switch is

in the PRL position. If the above conditions are met, you can use the

reset pushbutton (Figure 1.1) to reset the adapter module and resume

communication after a communication error occurs.

1771-6.5.123 – May 1996

Page 13

Introducing the ControlNet Adapter Module 1–3

2

Network Access Port (NAP)

The network access port (Figure 1.1) provides a bidirectional

electrical interface for programming, maintenance, and I/O

monitoring devices in both redundant and non-redundant

connections. Connecting programming terminals to the network

using the NAP is described in Chapter 2.

ControlNet Connectors

Cable connection to the module is through standard BNC connectors

on the module frontplate.

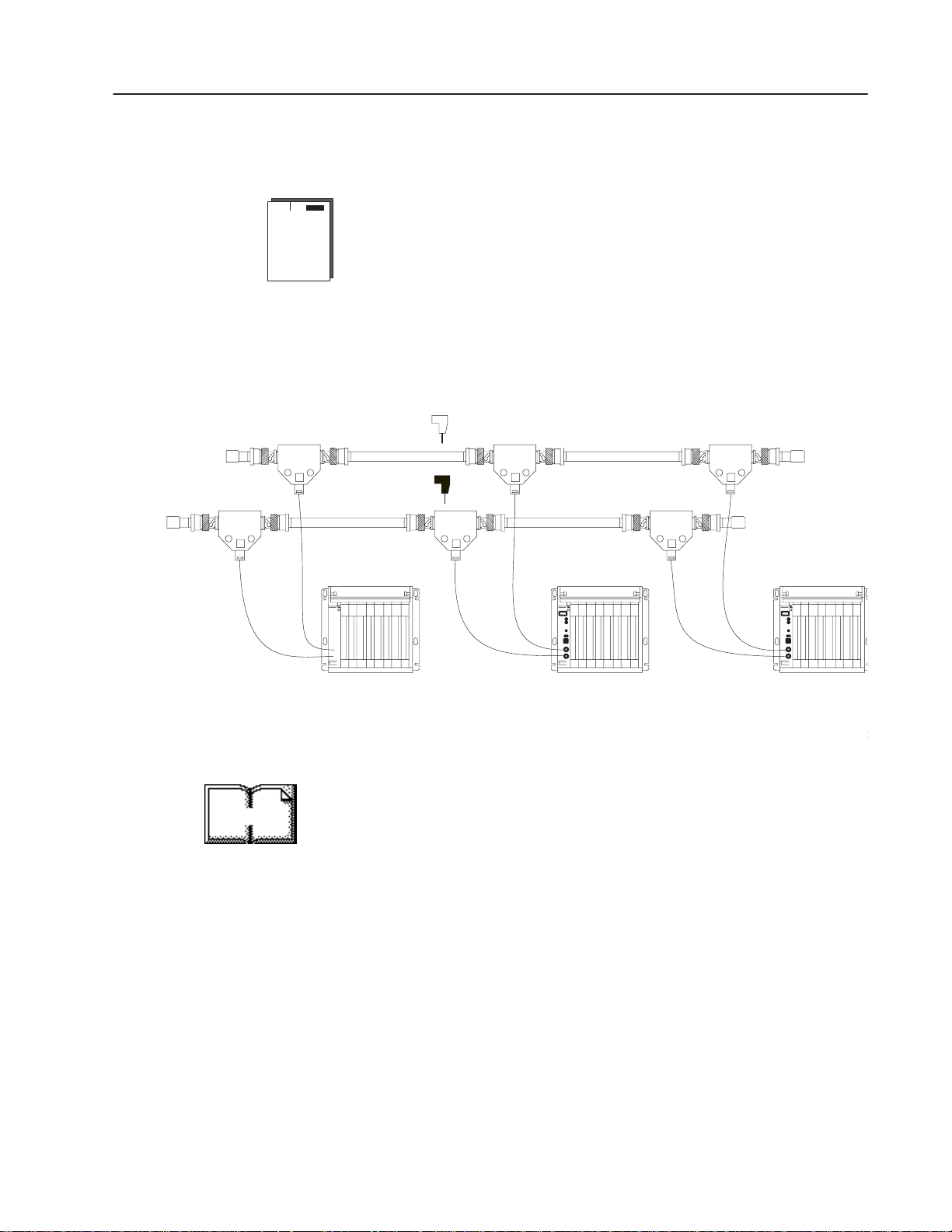

Example

Terminator

of a Redundant System

Terminator

More

trunkline

A =

A

trunkline

B =

B

PLC-5/20C or

PLC-5/40C

➊ End device supporting redundant cabling is a 1771-ACNR.

end device

Refer to the ControlNet Cable System Planning and Installation user

manual, pub. no. 1786-6.2.1 for more information.

Terminator

Terminator

➊ end device ➊

Publication

1771-6.5.123 – May 1996

Page 14

Introducing the ControlNet Adapter Module 1–4

’s Selection

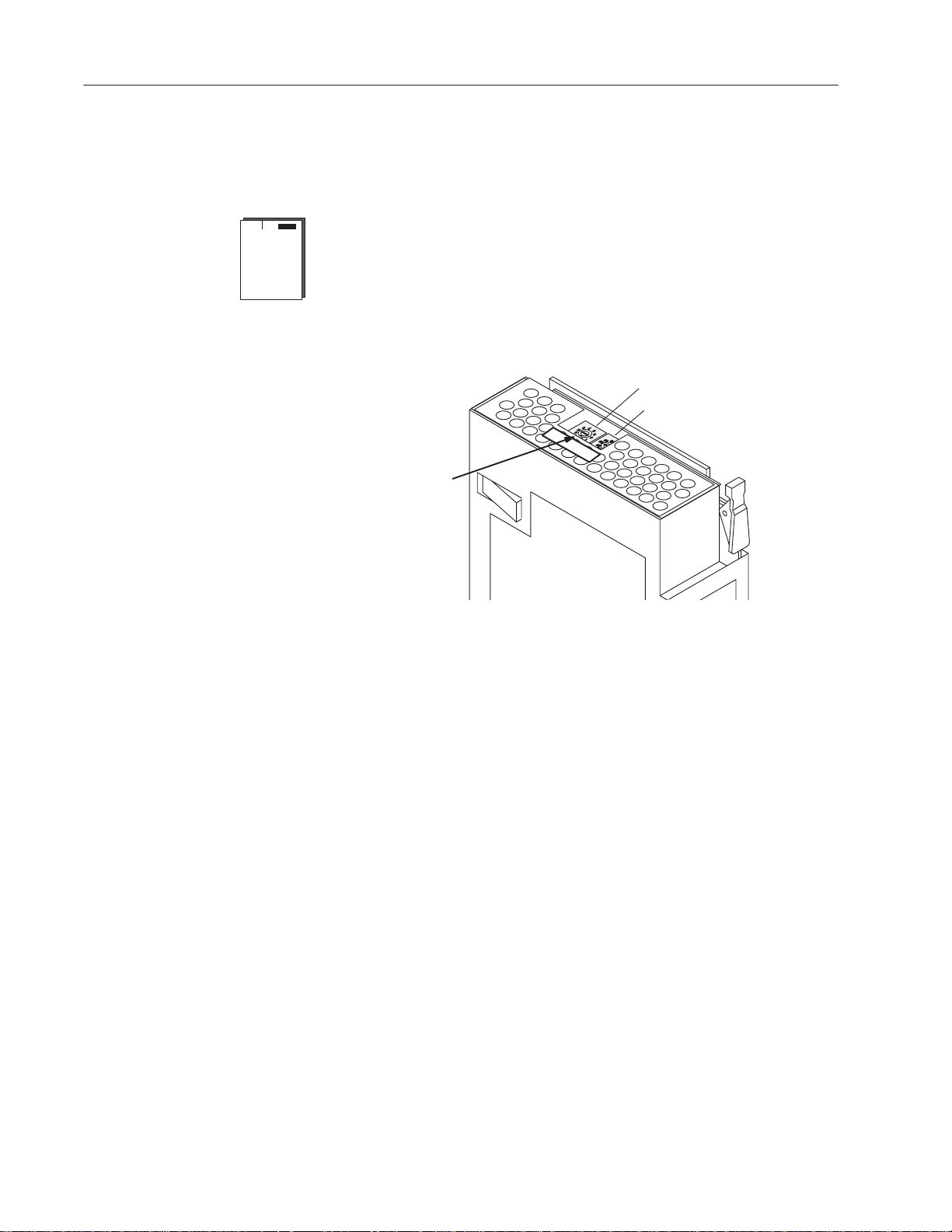

Network Address Switch Assemblies

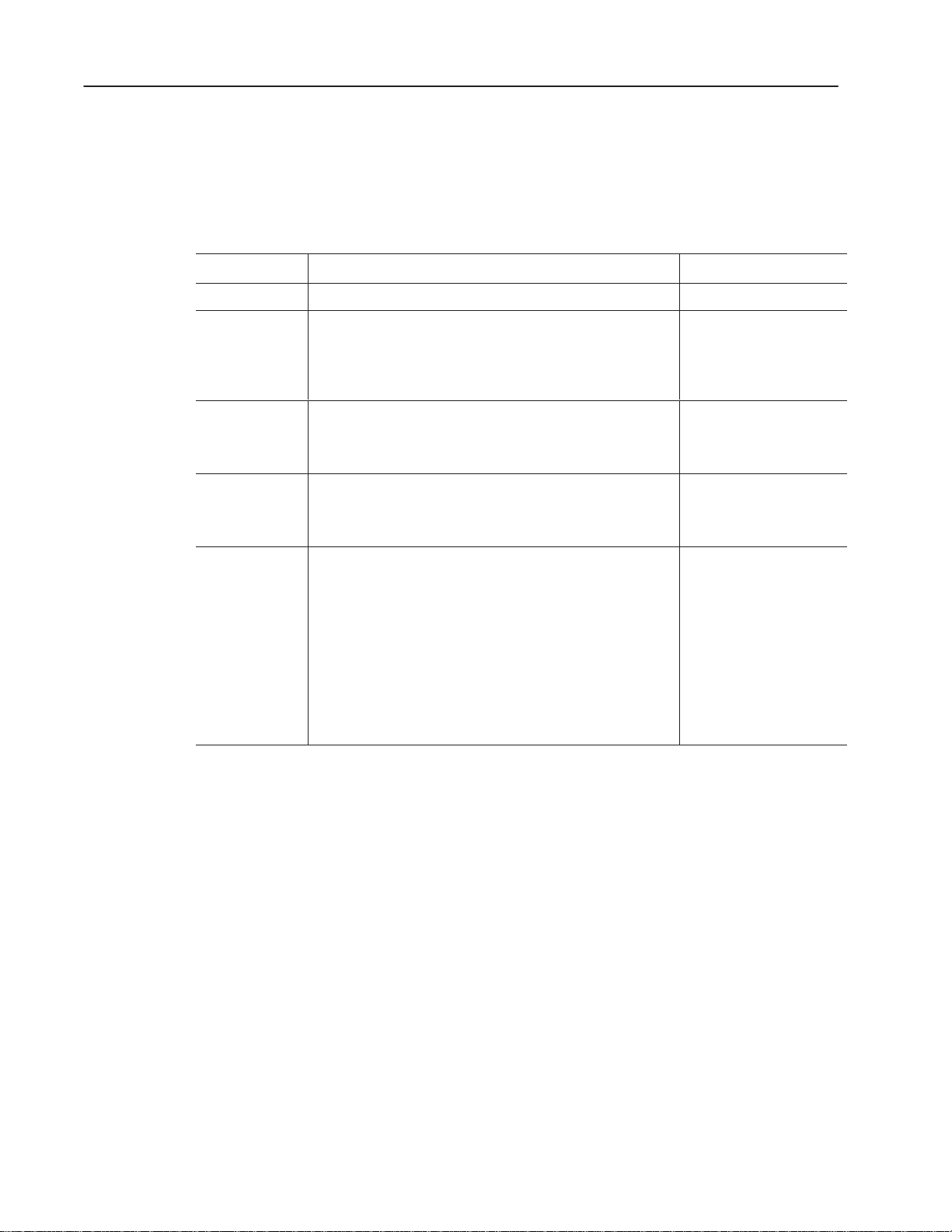

You must set two switch assemblies to configure your adapter

module with its unique network address. Y

through the top of the module. Figure 1.2 shows the location of the

switches. These switches are read on powerup to establish the

network address of the module. Network address switch settings are

described in Chapter 2.

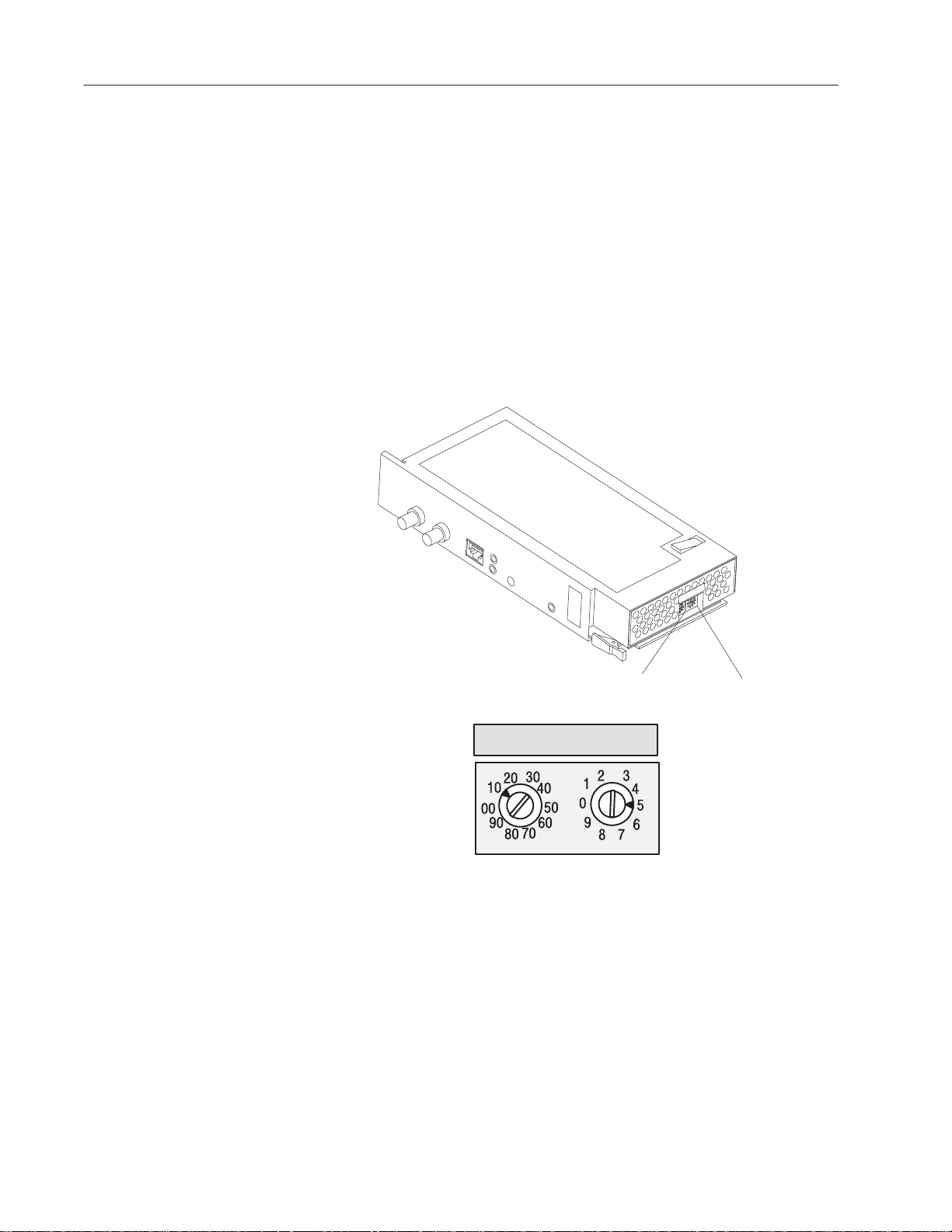

Figure 1.2

Assigning

Address

Switch

Assemblies

the Network Number

ou access these switches

One

Ten’s Selection

Chapter Summary

For optimum throughput, assign addresses to your ControlNet nodes

in a sequential order starting with 02. Address 01 is reserved for the

controlling processor on the network

In this chapter we discussed the functions and hardware components

of the ControlNet Adapter Module.

Publication

1771-6.5.123 – May 1996

Page 15

Chapter Objectives

Chapter

2

This chapter describes the procedures for installing your ControlNet

adapter module. These include:

• CE compliance

• determining power requirements

• determining the module location and keying the I/O chassis

•

setting the network address switches

•

setting the I/O chassis switches

• setting the I/O chassis power supply configuration plug

• installing the adapter module in the chassis

• connecting programming terminals to the network via the

network access port (NAP)

•

powerup sequence

Compliance to European Union Directives

If this product has the CE mark it is approved for installation within

the European Union and EEA regions. It has been designed and

tested to meet the following directives.

EMC Directive

This product is tested to meet Council Directive 89/336/EEC

Electromagnetic Compatibility (EMC) and the following standards,

in whole or in part, documented in a technical construction file:

• EN 50081-2EMC – Generic Emission Standard, Part 2 –

Industrial Environment

• EN 50082-2EMC – Generic Immunity Standard, Part 2 –

Industrial Environment

This product is intended for use in an industrial environment.

Low V

oltage Directive

This product is tested to meet Council Directive 73/23/EEC Low

Voltage, by applying the safety requirements of EN 61131–2

Programmable Controllers, Part 2 – Equipment Requirements and

Tests.

Publication

1771-6.5.123 – May 1996

Page 16

Installing Your ControlNet Adapter Module 2–2

For specific information required by EN 61131-2, see the appropriate

sections in this publication, as well as the following Allen-Bradley

publications:

• Industrial Automation Wiring and Grounding Guidelines For

Noise Immunity, publication 1770-4.1

• Guidelines for Handling Lithium Batteries, publication AG-5.4

• Automation Systems Catalog, publication B111

Determining Power Requirements

Determining the Module Location and Keying the I/O Chassis

The ControlNet adapter module requires a backplane current of 1.0A

at 5V dc. Remember to add this amount to other current

requirements for your I/O chassis.

The ControlNet adapter module must be installed in the leftmost slot

of the I/O chassis.

The I/O chassis backplane connectors are keyed to accept only one

type of module. This prevents accidental insertion of other modules

in the wrong module slot.

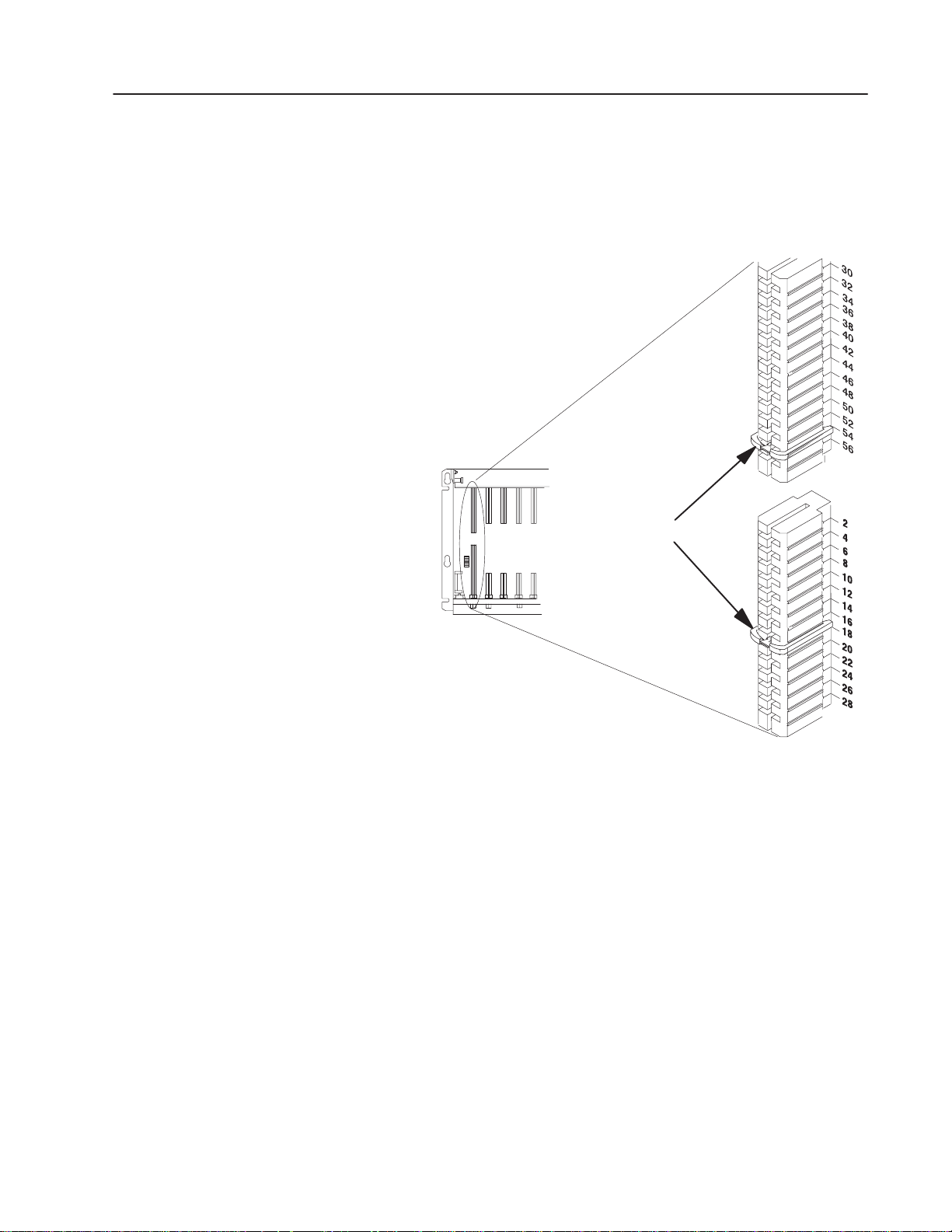

Position the keying bands (Figure 2.1) in the backplane connectors to

correspond to the key slots on the module. This prevents you from

inserting the wrong module in this slot. For the ControlNet adapter

module, position the keying bands:

• between 54 and 56 on the upper connector, and

• between 16 and 18 on the lower connector

ATTENTION: Observe the following precautions

when inserting or removing keys:

!

• insert or remove keys with your fingers

• make sure that key placement is correct

Incorrect keying or the use of a tool can result in

damage to the backplane connector and possible system

faults.

Publication

1771-6.5.123 – May 1996

Page 17

Installing Your ControlNet Adapter Module

You can change the position of these bands if subsequent system

design and rewiring makes insertion of a different type of module

necessary.

Figure 2.1

Keying

Band Positions

2–3

Place keying bands between:

• 54 and 56 on the upper connector

• 16 and 18 on the lower connector

I/O chassis

ATTENTION: Insert or remove

keying bands with your fingers.

Upper Connector

Keying Bands

Lower Connector

11022-I

Publication

1771-6.5.123 – May 1996

Page 18

Installing Your ControlNet Adapter Module 2–4

Setting the Network Address Switches

The switches on the top of the adapter module determine the network

address of the adapter. The two switches are:

• the ten’

• the one’

s switch

s switch

The combination of these switches allows selection of network

addresses from 01 to 99.

Use a small bladed screwdriver to rotate the switches.

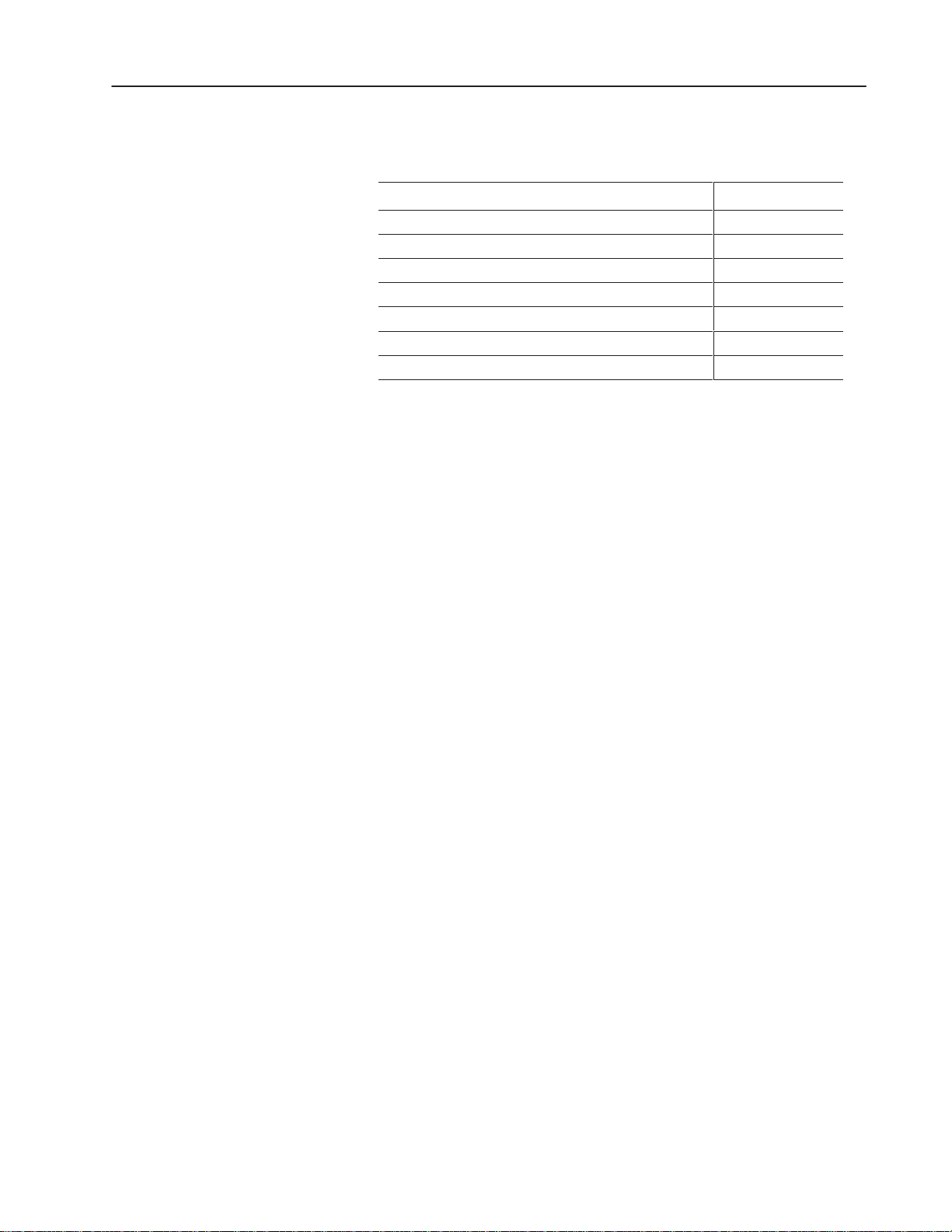

Figure 2.2

Setting

the Network Address

Ten’

s Selection

Ten’

s Selection

NET ADDRESS

One’

For example, the 10’s selection switch is set to 10,

and the 1’s selection switch is set to 5.

10 5

Then,

NOTE:

00 is an invalid number

plus

= 15

.

One’

s Selection

s Selection

Publication

1771-6.5.123 – May 1996

Page 19

Installing Your ControlNet Adapter Module

2–5

Setting the I/O Chassis Switches

Processor Restart Lockout (PRL) –

ON Processor can restart the I/O chassis

after a communication fault. Set this

switch to ON if you plan to use I/O rack

auto-configuration.

OFF The I/O chassis must be restarted at

the chassis.

Always OFF

You must set the I/O chassis backplane switches and power-supply

configuration plug.

Backplane Switch Assembly

This switch assembly is located on the backplane of the I/O chassis.

You use it to select:

• the last state of all outputs

• the processor restart lockout feature

• 1/2-, 1- or 2-slot addressing

Figure 2.3

I/O

Chassis Backplane Switch Assembly Settings for ControlNet

Adapter Module in PLC-5/20C and PLC-5/40C Processor Systems

O

O

N

F

F

12345678

Last State Switch ON Outputs of this chassis remain in last state when a

communication fault is detected by the adapter.

OFF Outputs of this I/O chassis are deenergized when a

communication fault is detected by this adapter

Always OFF

ATTENTION:

connected to this chassis remain in their last state when

a fault occurs and machine motion may continue after

fault detection. We recommend that you set switch 1 to

the OFF position to deenergize outputs wired to this

chassis when a fault is detected.

Addressing Switches

5 6

OFF ON You select 1/2-slot addressing

ON OFF You select 1-slot addressing

OFF OFF You select 2-slot addressing

ON ON Not allowed

If switch 1 is set to the ON position, outputs

10802-I

Publication

1771-6.5.123 – May 1996

Page 20

Installing Your ControlNet Adapter Module 2–6

Setting the I/O Chassis Power Supply Configuration Plug

Set the I/O chassis power-supply configuration plug (Figure 2.4) to

identify the type of power supply you are using with your remote

chassis. This configuration plug is located on the backplane of

1771-A1B through -A4B or later I/O chassis.

Figure 2.4

1771

I/O Chassis Power Supply Configuration Plug Settings

For Use With: Set Chassis Configuration Plug to:

YNN

power supply module installed

in chassis

external power supply in your

remote system

“Y” position

Y

“N” position

I/O Chassis

Power Supply

Configuration

Plug

YN

USING

SUPPL

POWER

MODULE IN

THIS CHASSIS?

Y

Installing the Adapter Module in the Chassis

More

locking-bar pins

front of chassis

12453-I

Once you’ve determined the power requirements and keying for your

adapter module, and have set the appropriate switch assemblies, you

can use the following procedure to install it.

Refer to the Industrial Controller Wiring and Grounding Guidelines

(publication 1770-4.1) for proper grounding and wiring methods to

use when installing your module.

ATTENTION: Remove system power before

removing or installing your module in the I/O chassis.

!

Failure to observe this warning could damage module

circuitry and injure people.

1. Remove power from the I/O chassis before inserting (or

removing) the module.

On chassis equipped with a chassis locking bar

2.

, pull the

locking-bar pins to release the locking bar and swing it up. If

installing in an earlier chassis, lift the module locking latch up.

3. Place the module in the plastic tracks on the top and bottom of the

leftmost slot. These tracks guide the module into position.

Publication

4. Press firmly and evenly to seat the module in its backplane

connectors.

1771-6.5.123 – May 1996

Page 21

Installing Your ControlNet Adapter Module

2–7

ATTENTION: Do not force the module into the

backplane connector

!

with firm pressure, check the alignment and keying.

. If you cannot seat the module

Forcing the module can damage the backplane

connector or the module.

5. Snap the chassis locking bar (or locking latch on earlier chassis)

over the top of the module to secure it. Make sure the locking

pins on the locking bar are fully engaged.

Note: The chassis locking bar will not close if all modules are not

properly seated.

Connecting Your Adapter to the ControlNet Network

You connect your 1771-ACN or -ACNR adapter module to a

ControlNet network via taps. These taps are available:

Straight T-tap Straight Y-tap Right-angle T-tap Right-angle Y-tap

1786-TPS 1786-TPYS 1786-TPR 1786-TPYR

Important: Taps contain passive electronics and must be purchased

from Allen-Bradley for the network to function

properly.

1. Remove the tap’s dust cap (located on the straight or right

angle connector).

If

your node supports: Connect the tap’s straight or right angle connector:

Non-redundant media to the channel A connector on the 1771-ACN or 1771-ACNR

(channel B on the 1771-ACNR is not used)➀

Redundant media

➀ While

both channels are active, Allen-Bradley recommends using channel A for non-redundant media.

• from trunkline A to channel A on the 1771-ACNR

• from trunkline B to

channel B on the 1771-ACNR

Publication

1771-6.5.123 – May 1996

Page 22

Installing Your ControlNet Adapter Module 2–8

segment 1

segment 2

ATTENTION: Do not allow any metal portions of

the tap to contact any conductive material. If you

!

disconnect the tap from the adapter, place the dust cap

back on the straight or right angle connector to prevent

the connector from accidentally contacting a metallic

grounded surface.

tap

dust

cap

20093-I

2. Remove and discard the dust caps from the adapter BNC jacks.

3. Connect this tap’s straight or right angle connector to the

A

BNC connector on the adapter.

segment 1

tap

Important: To prevent inadvertent reversal of

the tap connections (resulting in incorrect LED

displays and troubleshooting), check the tap

drop cable for a label indicating the attached

segment before making your connection.

4. For redundant adapters (1771-ACNR), remove (and save) the

dust cap located on the straight or right angle connector of the

designated tap on the second segment (segment 2).

tap

20093-I

Publication

1771-6.5.123 – May 1996

dust cap

20093-I

Page 23

Installing Your ControlNet Adapter Module

5. Connect this tap’s straight or right angle connector to the B

BNC connector on the adapter.

2–9

Connecting Programming Terminals to the Network via the NAP

segment 1

tap

segment 2

tap

20093-I

After terminating your segments, you connect your node to the

network.

You can connect programming terminals to the ControlNet network

by connecting to the network access port (NAP). Two methods are

shown below

.

Using 1784-KTC or -KTCx communication card and NAP Using 1770-KFC communication interface and NAP

Programming Terminal

OK

Programming Terminal

1784-KTC or

-KTCx

1786-CP

➀

A

B

ALLEN-BRADLEY

1771-ACNR

Serial or Parallel

Connection

1770-KFC

1786-CP

ControlNet

product

ControlNet Network

➀

The

1786-CP cable can be plugged into any ControlNet product’

programming capability on the ControlNet network. A programming terminal connected

through this cable is counted as a node and must have a unique address.

ControlNet Network

s NAP to provide

ATTENTION: Use the 1786-CP cable when

connecting a programming terminal to the network

!

through NAPs. Using a commercially available

RJ-style cable could result in possible network failures.

➀

ALLEN-BRADLEY

ControlNet

product

OK

A

B

1771-ACNR

Publication

1771-6.5.123 – May 1996

Page 24

Installing Your ControlNet Adapter Module 2–10

Powerup Sequence

NET

ADDRESS

STATUS

Status

OK

OK Indicator

Reset pushbutton

Channel A and B

indicators

Look carefully at the status display and OK indicator when powering

up the module. These indicators provide meaningful information on

proper module operation.

1. Apply power to the chassis – the OK indicator should not light.

2. The module runs a power on self test (POST). During this test,

the status displays 0000 through 8888.

3. If the OK indicator is red, and the display shows POST-RSET,

then POST has failed.

a. Press the reset pushbutton to reset.

The module reruns the POST program. If POST-RPLC

appears on the status display again, POST has failed again.

b. Replace the module.

4. If:

a. the OK indicator begins to blink green, and

b. the series/revision level of the module is displayed in the

status window (e.g. A/A, A/B, etc.), and

c. the channel A and B indicators blink alternately, the module

has passed POST

.

INIT

A#nn

IDLE

A#nn

If the indications are neither of those indicated in 3 or 4, refer to

chapter 5, “Troubleshooting.”

5. The module status displays INIT-A#nn (where nn is the node

number of module).

6. The channel indicators indicate network condition as shown in

the indicator table in chapter 5.

7. Then the display shows IDLE-A#nn (where nn is the node

number of module), indicating a successful configuration by the

ControlNet Configuration Manager.

For detailed information on planning and installing your ControlNet

system, see the following publications:

More

Publication Publication Number

ControlNet Cable System Component List AG-2.2

ControlNet Cable System Planning and Installation Manual 1786-6.2.1

ControlNet Coax Tap Installation Instructions 1786-2.3

ControlNet Network Access Cable Installation Instructions 1786-2.6

ControlNet Repeater Installation Instructions 1786-2.7

Industrial Automation Wiring and Grounding Guidelines 1770-4.1

Chapter Summary

Publication

1771-6.5.123 – May 1996

In this chapter you learned how to install your adapter module.

Chapter 3 tells you how to address your I/O.

Page 25

ЙЙЙЙЙЙ

Chapter Objectives

Addressing Your I/O

Chapter

3

In this chapter, you will learn:

• addressing your I/O

• using 2-slot addressing, including:

• I/O module combinations

• using standard-density I/O (8 point) modules

• using high-density (16 point) I/O modules

• using 1-slot addressing, including:

• I/O module combinations

• using 1/2- slot addressing

•

addressing summary

Programmable controllers that use the ControlNet adapter module

can address their I/O in 2-slot, 1-slot or 1/2 slot I/O groups. These

three addressing methods are referred to as 2-slot addressing, 1-slot

addressing and 1/2-slot addressing.

You select the addressing method with switch 5 and 6 in the I/O

chassis backplane switch assembly

chassis independently with only one method of addressing for each

chassis.

For each I/O chassis in your system, you must define how many I/O

chassis slots make up an I/O group (1 word each in the input image

table and output image table); this choice is the chassis’ addressing

mode. Choose from among these available modes:

• 2-slot addressing

2

I/O chassis slots = 1 I/O group = 1 input

image word and 1 output image word = 16 input

bits and 16 output bits.

• 1-slot addressing

1

I/O chassis slot = 1 I/O group = 1 input image

word and 1 output image word = 16 input bits and

16 output bits.

• 1/2-slot addressing

1/2

of an I/O chassis slot = 1 I/O group = 1 input

image word and 1 output image word = 16 input bits

and 16 output bits.

16

bits input

16 bits input and 16 bits output

16 bits input and 16 bits output

16 bits output

. You make this selection for each

Processor Memory

Rack #

Output Image Table

Word #

x

x

x

x

x

x

x

x

Input Image Table

Word #

x

x

x

x

x

x

x

x

Publication

1771-6.5.123 – May 1996

Page 26

Addressing Modes for Your I/O 3–2

I/O groups are made up of I/O terminals (NO TAG). An I/O group is

an addressing unit that can contain up to 16 input terminals and 16

output terminals. You select an I/O chassis to have either 2-slot,

1-slot or 1/2-slot I/O groups.

Figure 3.1

An

I/O Group - Up to 16 Input T

Input

Terminals

00

01

02

03

04

05

06

07

10

11

12

13

14

15

16

17

erminals and 16 Output T

Output or

00

01

02

03

04

05

06

07

10

11

12

13

14

15

16

17

Input

Terminals

00

01

02

03

04

05

06

07

10

11

12

13

14

15

16

17

Output

Terminals

erminals

2-slot

I/O Group

1-slot I/O Group

13073

I/O racks are made up of I/O groups (NO TAG). An I/O rack is an

addressing unit that can contain up to eight I/O groups.

Figure 3.2

An

I/O Rack - Up to Eight I/O Groups

01234567

Power

Source Not Indicated

13074

Publication

1771-6.5.123 – May 1996

Page 27

Addressing Modes for Your I/O 3–3

Using 2-Slot Addressing

Definition: The processor addresses two I/O module slots as one I/O

group.

Concept: Each physical 2-slot I/O group is represented by a word in

the input image table and a word in the output image table. Each

input terminal corresponds to a bit in the input image table word and

each output terminal corresponds to a bit in the output image table

word.

The maximum number of bits available for one 2-slot I/O group is

32: 16 bits in the input image table and 16 bits in the output image

table. The type of module you install (either 8 or 16-point I/O)

determines the number of bits in the words that are used.

You select 2-slot addressing by setting switches 5 and 6 of the I/O

chassis backplane switch assembly to the OFF position as shown in

Chapter 2.

I/O Module Combinations

The combination of I/O modules you can use depends on the

addressing method and I/O chassis you select.

NO TAG lists acceptable I/O module combinations with 2-slot

addressing.

T

able 3.A

I/O

Module Combinations W

I/O Chassis

Series

A, B

B or later only 1 16-point input and output module 16 16

I/O Module Combinations Per I/O Group

2 8-point input modules 16 0

2 8-point output modules 0 16

1 8-point input and output module 8 8

1 8-point input and 1 nondiscrete module 16 8

1 nondiscrete and 1 8-point output module 8 16

2 nondiscrete modules 16 16

1 16-point input and 1 8-point output module 16 8

1 8-point input and 1 16-point output module 8 16

ith 2-slot Addressing

Data T

Input Image Table Output Image Table

able Bits Used

Publication

1771-6.5.123 – May 1996

Page 28

Addressing Modes for Your I/O 3–4

Using Standard-density I/O (8 point) Modules

Standard-density I/O modules provide eight input terminals or eight

output terminals. NO TAG illustrates the 2-slot I/O group concept

with two 8-point input modules. NO TAG shows an 8-point input

module and an 8-point output module in a 2-slot I/O group.

Figure 3.3

Two

8-point Input Modules Using One Word of the Input Image

Table

2-slot I/O Group

Input

Terminals

00

01

02

03

04

05

06

07

Output image table w ord corresponding

to the I/O group.

17 16 15 14 12

Input image table word corresponding

to the I/O group.

17 16 15 14 12

13

13

11

unused

11

10

10

07

07

06

06

Input

Terminals

10

11

12

13

14

15

16

17

04

05 03

04

05 03

02 01

00

02 01 00

Publication

11867

1771-6.5.123 – May 1996

Page 29

Addressing Modes for Your I/O 3–5

Figure 3.4

8-point

Input and Output Modules Using Eight Bits of the Input

Image Table W

ord and Eight Bits of the Output Image T

2-slot I/O Group

able W

ord

Input

Terminals

00

01

02

03

04

05

06

07

Output image table word corresponding

17 16 15 14 12

Output bits used

Input image table word corresponding

17 16 15 14 12

13

13

11

11

10

10

Output

Terminals

06

07

06

07

10

11

12

13

14

15

16

17

05 03

04

unused

04

05 03

to the I/O group.

02 01 00

to the I/O group.

02 01

00

Always 0

Input bits used

Publication

14965

1771-6.5.123 – May 1996

Page 30

Addressing Modes for Your I/O 3–6

Using High-density (16 point) I/O Modules

16-point I/O modules provide 16 input terminals or 16 output

terminals. 16-point I/O modules use a full word in the input or

output image table when they are addressed as a 2-slot I/O group

(NO TAG). Two 16-point modules (one input and one output) can

be used in a 2-slot I/O group.

Figure 3.5

16-point

Input and Output Modules Using T

wo W

ords of the Image T

2-slot I/O Group

able

Inp ut

Terminals

00

01

02

03

04

05

06

07

10

11

12

13

14

15

16

17

Output image table word corresponding

to the I/O g r ou p .

06

07

17

16 15 14 12

Input image table word corresponding

to the I/O g ro u p .

17 16 15 14 12

13

13

11

11

10

10

07

06

Output

Terminals

05 03

04

04

05 03

00

01

02

03

04

05

06

07

10

11

12

13

14

15

16

17

02 01 00

02 01

00

15559

Publication

Because these modules use a full word in the image table, the only

type of module you can use in a 2-slot I/O group with a 16-point

module is one that performs the opposite (complementary) function;

an input module complements an output module and vice-versa.

You can use an 8-point module with a 16-point module in a 2-slot

group; it must perform the opposite function. However, eight bits in

the I/O image table are unused.

1771-6.5.123 – May 1996

Page 31

Addressing Modes for Your I/O 3–7

Using 1-Slot Addressing

Definition: The processor addresses one I/O module slot as one I/O

group.

Concept: The physical address of each I/O group corresponds to an

input and output image table word. The type of module you install

(8, 16, or 32-point) determines the number of bits in these words that

are used.

You select 1-slot addressing by setting switches 5 and 6 of the I/O

chassis backplane switch assembly as shown in Chapter 2:

• switch 5 to the ON position

• switch 6 to the OFF position

With 1-slot addressing, because 16 input AND 16 output bits are

available in the processor’s image table for each I/O slot, you can use

any mix of 8-point, 16-point or nondiscrete I/O modules in the I/O

chassis.

To use 32-point I/O modules with 1-slot addressing, you must install,

as a pair, an input module and an output module in 2 adjacent slots of

the I/O chassis beginning with I/O slot 0 (NO TAG). If you cannot

pair the modules in this way, one of the two slots of the pair must be

empty. For example, if I/O slot 0 holds a 32-point input module, I/O

slot 1 can hold an 8, 16, or 32-point output module (or a module that

uses the backplane for power only); otherwise, it must be empty.

Figure 3.6

Using

32-point I/O Modules with 1-slot Addressing

Input/Output Pairs

I/O

I/O

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

I/O I/O

I/O Chassis Slot Number

I/O I/O

I/O

I/O

14973

Thirty-two-point I/O modules need 32 input or 32 output bits in the

processor’s image table. Because only 16 input and 16 output bits

are available for each I/O group, to address a 32-point I/O module,

the ControlNet adapter module uses the unused input or output word

associated with the adjacent I/O slot.

Publication

1771-6.5.123 – May 1996

Page 32

Addressing Modes for Your I/O 3–8

When the 1771-ACN/ACNR ControlNet adapter module addresses a

1-slot I/O group containing a 32-point I/O module, the adapter

module uses the unused word assigned to the adjacent I/O module

slot. For example, the adapter module uses the unused input word

associated with I/O slot 1 (because that slot must hold an output

module and does not use its input word).

NO TAG illustrates the concept of 1-slot addressing with two

32-point I/O modules.

Figure 3.7

1-slot

I/O Group Concept With 32-point I/O Modules

32–point I/O M odules

Image Table

Wor ds Allo c ated

for I/O Gro u p 0

Inp u t Wo rd 0

Slot 0

Input Module

I/O G ro u p 0

Slot 1

Output M odule

I/O G ro u p 1

Output W ord 0

Image Table

Wor ds Allo c ated

for I/O Gro u p 1

Inp u t Wo rd 1

Output W ord 1

14258

Publication

1771-6.5.123 – May 1996

Page 33

Addressing Modes for Your I/O 3–9

I/O Module Combinations

The combination of I/O modules you can use depends on the

addressing method and I/O chassis you select.

The table below lists acceptable I/O module combinations with 1-slot

addressing.

T

able 3.B

I/O

Module Combinations W

ith 1-slot Addressing

I/O Chassis

Series

A, B

B or later only

I/O Module Combinations Per I/O Group

1 8-point input module 8 0

1 8-point output module 0 8

1 8-point input and output module 8 8

1 8-point input and 1 nondiscrete output module 16 8

1 nondiscrete input and 1 8-point output module 8 16

1 nondiscrete module 8 8

any mix of 8, 16 and 32-point input and output

modules (when using 32 point modules, install in

pairs – input and output in each group)

any mix of 8 and 16-point modules, and

nondiscrete or intelligent modules

Data T

Input Image Table Output Image Table

16 16

16 16

able Bits Used

Using 1/2- Slot Addressing

Definition: The processor addresses one-half of an I/O module slot as

one I/O group.

Concept: The physical address of each I/O slot corresponds to two

input and two output image table words. The type of module you

install (8-, 16-, or 32-point) determines the number of bits in these

words that are used.

You select 1/2-slot addressing by setting switches 5 and 6 of the I/O

chassis backplane switch assembly as shown in Chapter 2:

• switch 5 to the OFF position

• switch 6 to the ON position

With 1/2-slot addressing, since 32 inputs bits AND 32 output bits are

available in the processor’s image table for each I/O group, you can

mix 8-point, 16-point, 32-point and nondiscrete modules in any order

in the I/O chassis.

Publication

1771-6.5.123 – May 1996

Page 34

Addressing Modes for Your I/O 3–10

32–pointInput Modul

NO TAG illustrates the 1/2-slot addressing concept with a 32-point

I/O module. A 32-point I/O module (with 1/2-slot I/O groups) uses

two words of the image table. When you use 8 and 16-point I/O

modules with 1/2-slot addressing, you get fewer total I/O points.

Figure 3.8

1/2-slot

Addressing Concept

e

Input

#

00

02

04

06

–

10

12

14

16

–

00

02

04

06

–

10

12

14

16

–

1/2–slot

I/O G ro up

0

1/2–slot

I/O G ro up

1

Input Word 0

17 010 7

Output W ord 0

17 10 07

Unused

Input Word 1

17 10 07

Output W ord 1

17 10

Unused

Image T able

W ords A llocated

for I/O G r o up 0

Image T able

W ords A llocated

for I/O G roup 1

07

1/2–slot

I/O Group

0

1/2–slot

I/O Group

1

Input

#

01

03

05

07

–

11

13

15

17

–

01

03

05

07

–

11

13

15

17

–

T

able 3.C

I/O Chassis

Series

A, B

I/O Module Combinations W

I/O Module Combinations Per I/O Group

1 8-point input module 8 0

ith 1/2-slot Addressing

1 8-point output module 0 8

1 8-point input and output module 8 8

1 8-point input and 1 nondiscrete output module 16 8

1 nondiscrete input and 1 8-point output module 8 16

1 nondiscrete module 8 8

B or later only any mix of 8, 16 and 32-point input and output modules,

nondiscrete modules, and intelligent modules

14259

Data T

able Bits Used

Input Image Table Output Image Table

16 16

Publication

1771-6.5.123 – May 1996

Page 35

Addressing Modes for Your I/O 3–11

Addressing Summary

Use this table as a quick reference for addressing.

Addressing

Mode

2-slot

1-slot

1/2-slot

• Two I/O module slots = 1 group

• Each physical 2-slot I/O group corresponds to one word (16 bits) in the

input image table and one word (16 bits) in the output image table

• When you use 16-point I/O modules, you must install as a pair an input

module and an output module in an I/O group; if you use an input module

in slot 0, you must use an output module in slot 1 (or it must be empty).

This configuration gives you the maximum use of I/O.

• You cannot use a nondiscrete module and a 16-point module in the same

I/O group because nondiscrete modules use 8 bits in both the input and

output table. Therefore, 8 bits of the 16-point module would conflict with

the nondiscrete module.

• You cannot use 32-point I/O modules.

• One I/O module slot = 1 group

• Each physical slot in the chassis corresponds to one word (16 bits) in the

input image table and one word (16 bits) in the output image table

• When you use 32-point I/O modules, you must install as a pair an input

module and an output module in an even/odd pair of adjacent I/O group; if

you use an input module in slot 0, you must use an output module in slot 1

(or it must be empty). This configuration gives you the maximum usage of

I/O.

• Use any mix of 8- and 16-point I/O modules, nondiscrete or intelligent

modules in a single I/O chassis. Using 8-point modules results in fewer

total I/O.

• One half of an I/O module slot = 1 group

• Each physical slot in the chassis corresponds to two words (32 bits) in the

input image table and two words (32 bits) in the output image table

• Use any mix of 8-, 16-, and 32-point I/O or nondiscrete and intelligent

modules. Using 8-point and 16-point I/O modules results in fewer total I/O.

• With the processor-resident local rack set for 1/2-slot addressing, you

cannot force the input bits for the upper word of any slot that is empty or

that has an 8-point or 16-point I/O module. For example, if your have an

8-point or a 16-point I/O module in the first slot of your local rack (words 0

and 1 of the I/O image table, 1/2-slot addressing), you cannot force the

input bits for word 1 (I:001) on or of

However, in a remote chassis using a 1771-ACN or -ACNR adapter, all

points can be forced, including those not physically present. In the

example above, chassis word I:001 can be forced on or off.

Guidelines

f.

Chapter Summary

In this chapter we discussed how to address your hardware and the

various remote I/O configurations and options you can use in your

remote system.

Publication

1771-6.5.123 – May 1996

Page 36

Addressing Modes for Your I/O 3–12

Publication

1771-6.5.123 – May 1996

Page 37

es

er

Chapter Objectiv

Chapter

4

Planning to Use Your

ControlNet Adapter Module

This chapter explains how the adapter operates on ControlNet and

provides information to assist in configuring your system. This

includes:

• overview of adapter operation

• discrete I/O data transfer

• configuring discrete I/O data transfers

• nondiscrete I/O data transfers

• using ControlNet I/O (CIO) instructions

• mapping directly into processor memory, including examples of

nondiscrete input module and output module communication

• configuring nondiscrete I/O data transfers

Overview of Adapt

Operation

The controlling processor (network address 01) on ControlNet

contains an I/O map table. This map table stores the information

necessary for communications to be established. Each map table

entry corresponds to 1 transfer of data between the processor and an

I/O rack, or between the processor and another ControlNet processor.

The information in each map table is used to open a logical

“connection” between 2 devices.

Connections are established between the processor and each adapter

to exchange input and output data on the network. Status information

is transferred along with the I/O data and is stored in a separate

status file in the specified processor. Refer to the ControlNet PLC–5

ogrammable Contr

Pr

more on status information available.

Important: The processor compares the specified module type (in

the map table) with the device with which

communication is being attempted. Therefore, when

changing from a 1771-ACN to a 1771-ACNR, or vice

versa, you must specify the new module type in the map

table.

oller Use Manual, publication 1784-6.5.14, for

Publication

1771-6.5.123 – May 1996

Page 38

4–2

Discrete

ransfer

Planning to Use Your ControlNet Adapter Module

I/O Data T

Configuring Discrete I/O Data Transfers

All 1771 discrete I/O data is mapped into the processor’s I/O image

table according to the user-configurable I/O map table stored in the

processor. This image table location is specified on the ControlNet

configuration screen.

ControlNet provides significant flexibility when configuring discrete

I/O data transfers. The following are important factors to consider as

you plan and configure your system.

• I/O is not automatically mapped into the processor’s I/O image

file based on the network address of the adapter. If you manually

configure your system, I/O from an adapter is mapped into the

I/O image file based on the I/O image file address that you enter

into your configuration. If you automap your system, I/O is

mapped into the first available I/O image space outside of the

local rack image space.

For

example, if your local chassis is 12 slots and is using 1-slot

addressing mode, it will use rack numbers 0 and 1. ControlNet I/O

mapping would then start with rack 2. Note that even though the local

chassis only used 1/2 of rack 1, ControlNet I/O cannot map into any rack

number used by the local chassis.

• Always configure your remote I/O system first. Remote I/O

devices must use the I/O image space which corresponds to their

rack number and size. A conflict could occur if you automap

ControlNet first, and it uses I/O image space which matches a

rack number on the remote I/O. Automap remote I/O first, and

then automap ControlNet, since ControlNet can use any unused

I/O image space.

• I/O image space for a given ControlNet connection must be

contiguous. ControlNet software cannot break up a map entry

into multiple I/O image file locations.

For

example, if you automap a device which requires 4 words of I/O

image table, it will map into the first available 4 word block in the I/O

image table, even if there are several 2 word blocks available prior to the

4 block area.

• All 1771 I/O placement rules for discrete I/O module (8, 16 and

32 point) addressing still apply.

• You can configure the adapter to scan a minimum of 0 input

words to a maximum of 32 input words in the physical rack. Data

from input modules in the chassis beyond the configured rack

size will not be sent to the processor.

• You can configure the adapter to write to a minimum of 0 output

words to the maximum number of words in the the physical rack

(up to 32 maximum). Modules in the chassis beyond the

configured rack size will not receive outputs from the processor,

and will respond as if they were receiving all zeroes.

Publication

1771-6.5.123 – May 1996

Page 39

More

screte

a

Planning to Use Your ControlNet Adapter Module

4–3

• The number of input words and output words do not have be the

same for an adapter.

• Update times (Expected Network Packet Times) are not required

to be the same for all remote racks in the system. Update times

can be selected based on your application requirements.

Refer to the PLC-5 ControlNet programmable controller manual or

6200 Software manuals for more information on the ControlNet

configuration screens.

Nondi

Transfers

I/O Dat

More

There are 2 methods for data transfer to and from 1771 nondiscrete

I/O modules on ControlNet:

• ControlNet I/O (CIO) instructions

• mapping directly into the processor’s memory

Using ControlNet I/O (CIO) Instructions

By programming CIO instructions into your ladder logic, you can

either read or write data to or from a module. The CIO instruction is

only active when the processor is in the RUN mode. This method

uses the unscheduled portion of the Network Update Interval (NUI)

to complete the transfers.

Refer to the ControlNet PLC–5 Pr

Manual, publication 1784-6.5.14, for more information on CIO

instructions.

ogrammable Contr

oller Use

Publication

1771-6.5.123 – May 1996

Page 40

4–4

Planning to Use Your ControlNet Adapter Module

Mapping Directly Into Pr

ocessor Memory

ControlNet also allows mapping 1771 nondiscrete I/O modules

directly into processor memory. This eliminates the need for

programming CIO or other transfer instructions in your ladder

program. When you map a nondiscrete I/O module, the processor

opens a connection to the adapter. Data is produced and/or consumed

over the network, continuously and asynchronous to the ladder logic

program scan. At the adapter, nondiscrete transfers are initiated to

the module in its resident chassis asynchronous to the network

activity. Once configured, these data transfers are active in all

processor modes (RUN, PROG, and TEST).

Example: Nondiscrete Input Module Communications

1

2

PLC-5/40C

01234567

4

3

Empty

1771 8 Point In

01234567

1771-IXHR

1771-P4S

Nondiscrete

Input Module

1. The processor opens a connection to the adapter for consuming

the data from the nondiscrete module. The processor requests the

adapter to produce the module’s data at the Actual Network

Packet Time shown in the configuration.

2. Upon receiving the request, the adapter starts initiating

continuous read requests to the module. This occurs

asynchronous to any activity on the network.

3. The module processes the read requests and responds to the

adapter as fast as it can.

4. The adapter produces the most recently received copy of the

module’s data on the network at the Actual Network Packet Time.

Note: If the nondiscrete input module can only respond to read

requests every 50ms, and you set your update time to 10ms, the

adapter will be sending 5 copies of each data block.

Publication

1771-6.5.123 – May 1996

Page 41

Planning to Use Your ControlNet Adapter Module

Example: Nondiscrete Output Module Communications

1

PLC-5/40C

2

3

1771 8 Point In

Empty

1771-OFE

1771-P4S

4–5

01234567

01234567

Nondiscrete

Output Module

1. The processor opens a connection to the adapter for producing the

data for the nondiscrete module.

2. The processor produces the most recent copy of the designated

data table value you specified in your configuration onto the

network at the Actual Network Packet Time.

3. The adapter consumes the packet from the processor, and initiates

a nondiscrete write transfer to the output module. Only 1

nondiscrete write transfer is active to any module at a time.

Nondiscrete I/O data is stored in integer files that you specify in your

ControlNet configuration screen. Each map entry for a nondiscrete

I/O data transfer defines an offset into the Data Input File (DIF) or

Data Output File (DOF) where data is stored.

Using separate data table files for nondiscrete I/O data transfer

allows the processor to present nondiscrete I/O data in the same

manner as discrete I/O data – continuously transmitted and

asynchronous to the ladder logic program scan.

Publication

1771-6.5.123 – May 1996

Page 42

4–6

hapter Su

ary

Planning to Use Your ControlNet Adapter Module

Configuring Nondiscrete

I/O Data T

ransfers

The following are important factors to consider when planning and

configuring nondiscrete I/O modules:

• You can communicate with nondiscrete I/O modules anywhere in

the rack, including slots that are not mapped into the discrete I/O

image files. Note that nondiscrete I/O modules can be placed so

no I/O image space is used.

For

example, in an 8-slot chassis with 1-slot addressing, you can place

discrete modules in the first 4 slots and only map 4 words of I/O image

table. Y

ou could then place nondiscrete modules in the last 4 slots

without using more I/O image space.

• Slots in the adapter are physically referenced starting at 0 and

continuing by 1 up to a maximum of 15 (depending on the size of

your chassis) regardless of the addressing mode (2, 1, or 1/2) used

within the chassis.

• The explicit ControlNet I/O transfer instruction (CIO) can also be

included in your ladder logic program to communicate with

nondiscrete I/O modules.

• One or more connections are required per module, depending on

the type of module. A separate connection is used for a read or

write.

•

Modules accommodated by the processor

transfer mechanism are typically those that require a one-time

configuration and are continuously read from or written to.

’s nondiscrete I/O data

C

mm

More

Refer to the ControlNet PLC–5 Pr

Manual, publication 1784-6.5.14, chapter 2 for more information on

supported nondiscrete I/O modules.

In this chapter, you learned about adapter operation, discrete I/O data

transfer, configuring discrete I/O data transfer, nondiscrete I/O data

transfer, and configuring nondiscrete I/O data transfer. In addition,

you learned some important factors about nondiscrete I/O data

transfers.

Appendix B is an example of some of the concepts learned in this

chapter.

ogrammable Contr

oller Use

Publication

1771-6.5.123 – May 1996

Page 43

Chapter Objectives

Troubleshooting W

ith the

Status Indicators and

Status Display

Chapter

5

In this chapter, you will learn how to use the indicators on the

module frontplate for troubleshooting the module. This includes:

• troubleshooting with the status indicators and status display,

including:

• OK indicator and display mnemonics

•

ControlNet status indicators

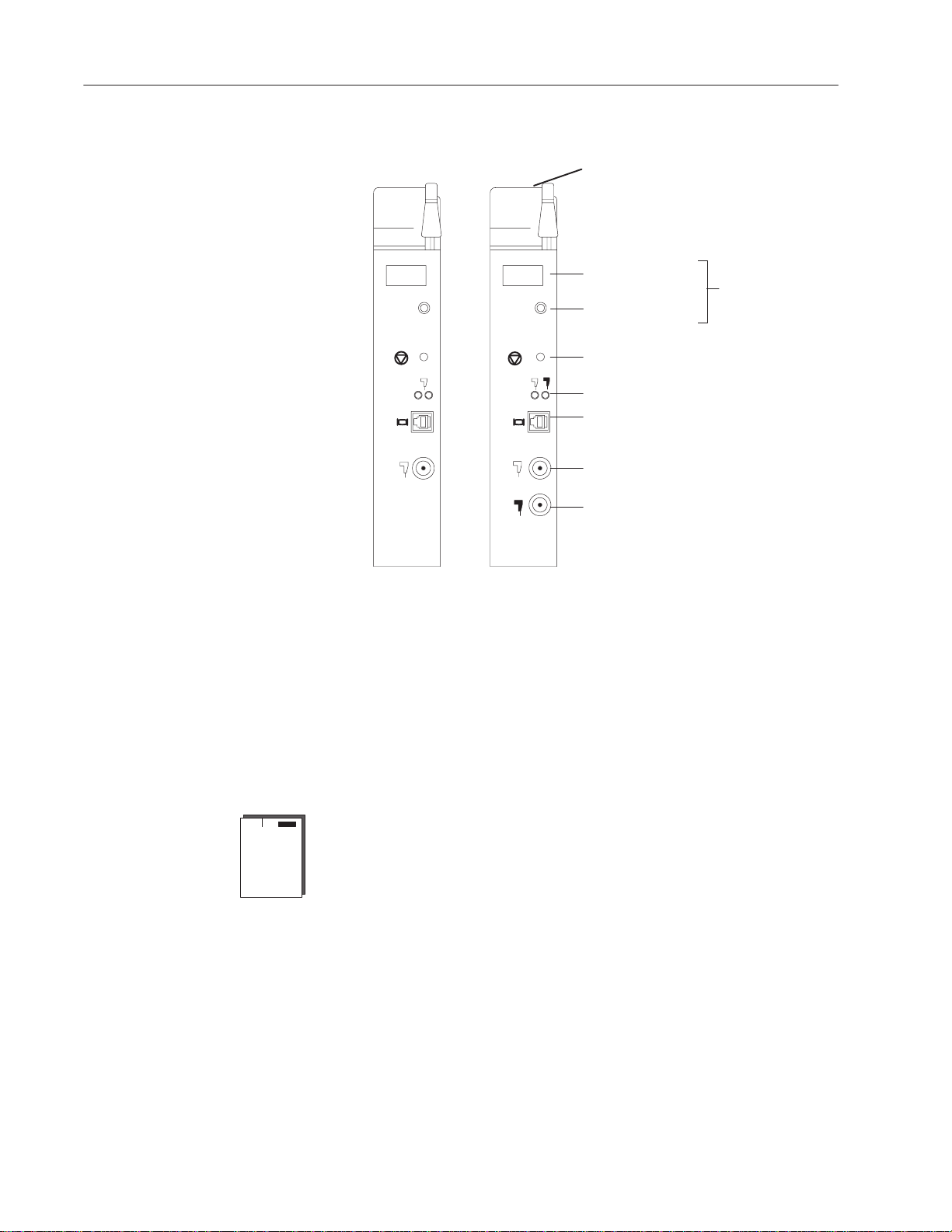

The module has indicators on the front plate, as shown below. These

indicators consist of:

• OK indicator

•

status indicators

•

display of status and address

Use these indicators for troubleshooting the module.

NET

ADDRESS

STATUS

OK

1771-ACN 1771-ACNR

The following tables describe problems that may occur, probable

causes, and recommended courses of action.

NET

ADDRESS

STATUS

Status Display and Net Address

OK

OK Indicator

ControlNet Status Indicators

Publication

1771-6.5.123 – May 1996

Page 44

5–2

T

Descr

n

Probable Cause

Rec

n

Troubleshooting

OK Indicator and Display Mnemonics

Display

OK

Indicator

OK

Red/

Green

Mnemonic

NET

ADDRESS

STATUS

iptio

ommended Actio

Off

Of

f

Blinking Red

Red

Blinking Green

Check power supply, cable

None Module not communicating

Power supply fault

connectors, and seat adapter firmly

in chassis.

Defective adapter Contact Allen-Bradley service.

POST Adapter is running Power On Self Test None None

CODE

UPDT

POST

RSET

A#00

ERR

MOD

ERR

RACK

ERR

PRL

SHRT

BP

DUPL

NODE

SW

ERR

Firmware update mode.

Module failed Power On Self Test

Illegal ControlNet address. Network address set to 00.

I/O module placement error.

Illegal backplane switch settings. Illegal addressing mode selected.

Adapter in processor restart lockout

mode. (Adapter to processor link is

normal.)

Communication on link. Excessive

noise on backplane or possible shorted

backplane

Duplicate node.

Switch error.

Adapter firmware is being

updated via A-B Flash Update

Utility.

RAM or FLASH test failed.

Processor fault or watchdog

timeout.

Incorrect I/O module density for

addressing mode used.

Processor restart lockout switch

on chassis backplane in on

position.

I/O module or chassis backplane

bad.

Another adapter with the same

ControlNet address is on the link.

Network address switches have

been changed since module

powerup.

None

Push the reset pushbutton on the

front of the module.

Power down the adapter and change

the network address switches.

Place I/O module in correct slot in

chassis.

Power down the adapter and change

the backplane switches.

Depress reset button on module to

clear lockout feature, or cycle power.

Replace module or chassis as

necessary.

Power down the adapter and change

the network address switches to

correct node.

Set network address switches to

correct address and cycle power to

the adapter.

RAM or FLASH test failed.

RPLC Fatal Power On Self Test failure.

Processor fault or watchdog

timeout.

Contact Allen-Bradley service.

None Hardware fault. Defective hardware.

No communication with

INIT Requires ControlNet configuration.

ControlNet Configuration

Manager node.

IDLE Processor not actively controlling I/O. Adapter not mapped.

NET

ERR

Nework error.

Cable error or no other nodes on

network.

Verify Configuration Manager node is

operating.

Verify mapping of adapter in

processor.

Verify network cabling.

Publication

1771-6.5.123 – May 1996

Page 45

OK Indicator

las in n o

OK Indicator

Red/

Red/

OK

OK

Green

Green

Display

Display

Mnemonic

Mnemonic

NET

NET

ADDRESS

ADDRESS

STATUS

STATUS

Description

Description

Troubleshooting

Probable Cause

Probable Cause

5–3

Recommended

Recommended Action

Action

Green

RUN

PRGM

Normal indication – processor is in

RUN mode.

Normal indication – processor is in

program or test mode.

Blinking

alternately red

BOOT Running boot code. Adapter has corrupted firmware.

and green

ControlNet Status Indicators

A

and

Off No power None or power up

Steady red Faulted unit Cycle power or reset unit

Alternating red/green Self-test None

Alternating red/off Incorrect node configuration Check network address and other ControlNet configuration

None None

None None

Update adapter firmware with A-B

Flash Update Utility.

• steady

–

indicator is on continuously in the defined state.

• alternating – the two indicators alternate between the two defined states at the

same time (applies to both indicators viewed together). The two indicators are

always in opposite states, out of phase.

• flashing – the indicator alternates between the two defined states (applies to

each indicator viewed independent of the other). If both indicators are

flashing, they must flash together, in phase.

B

Cause Action

If fault persists, contact A-B representative or distributor.

parameters

A

Off Channel disabled Program network for redundant media, if required

Steady green Normal operation None

Flashing green/off Temporary errors None; unit will self-correct

Flashing red/off Media fault Check media for broken cables, loose connectors, missing

Flashing red/green Incorrect network configuration Cycle power or reset unit