Page 1

Installation Instructions

PCI Bus Card for 1746 Local I/O

(Catalog Numbers 1747-PCIS/PCIS2)

Use this document to in st al l an d configure the Peripheral Comp onen t

Interface (PCI) Bus car d for 1746 Local I/O in your per sonal computer

and connect the card to a Chassis Interface module (1747-PCIL) for

1746 Local I/O. The PCI Bus card works with the Chassis Interface

module and a connec ting cable to make up the 1747 PCI Bus Interface.

To install the card, read:

Compliance to European Union Directives

Verify Package Contents

Installing the Battery and its Connecting Jumper

User SRAM

Setting the Jumper for Battery Back-Up

Setting the Base Memory Address Jumper

Accessing the Computer’s PCI Bus Slots

Installing the Scanner

Selecting the Cable for Your Connections

Connecting the Scanner to the Adapter

General Operation

Calculating Scan Time

Troubleshooting

Specifications

See page:

2

3

3

4

4

5

6

7

7

8

9

9

11

12

For additional information on the installation and use of the Chassis

Interface module, see publication 1747-5.32.

In the instructional text of this doc ument, we refer to the PCI Bus card

as the scanner and the Chassis Interface module as the adapter.

We use these conventions in this document:

Convention Shows

9 pt Courier bold Text you type as shown at the DOS prompt

Publication 1747-5.31–April 1998

Page 2

2 PCI Bus Card for 1746 Local I/O

Compliance to European Union Directives

If this product bears the CE marking, it is approved for installation within

the European Unio n and EEA r egions. It has bee n designe d and te sted to

meet the follow ing directiv es.

EMC Directive

This product is tested to meet Council Directive 89/336/EEC

Electromagnetic Compatibility (EMC) and the following standards, in

whole or in part, documented in a technical construction file:

• EN 50081-2 EMC - Generic Emission S tand ard, Part 2 - I ndustrial

Environment

EN 50082-2 EMC - Gene ric Immunity Standa rd, Part 2 - Indust rial

•

Environment

This product is intended for use in an industrial environment.

Low Voltage Directive

This product is tested t o meet Council Directive 73/23/EEC Low Voltage,

by applying the safety requirements of EN 61131-2 Programmable

Controllers, Part 2 - Equipment Requirements and Tests.

For specific information required by EN 61131-2, see the appropriate

sections in this publication, as well as the following Allen-Bradley

publications:

Industrial Automatio n Wiring and Groundi ng Guidelines For Noise

•

Immunity, publication 1770-4.1

Automation Systems Catal og, publication B111

•

This equipment is classified as open equipment and must be installed

(mounted) in an e nclosure during operation as a means of providing safety

protection.

Publication 1747-5.31–April 1998

Page 3

PCI Bus Card for 1746 Local I/O 3

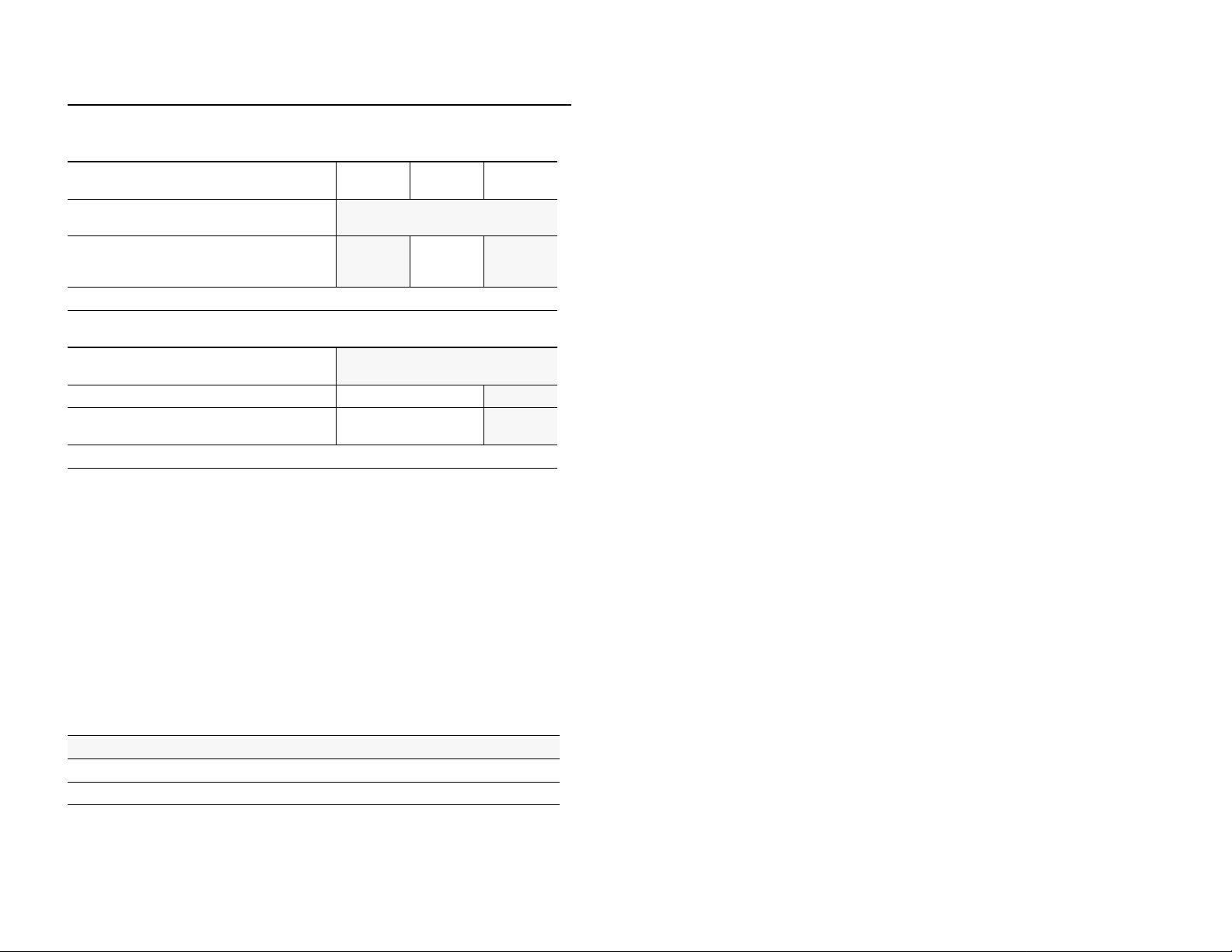

Verify Package Contents

Make sure that you have these items before you discard any packing

material. If an item is missing or incorrect, contact your local sales

representative.

PCI Bus card Installation instructions

(Publication 1747-5.31)

Jumper

for

Battery

Back-up

3.5” Software

Utility disk

PCI Bus card battery

Base Memory

Address Jumper

Battery

30578-M

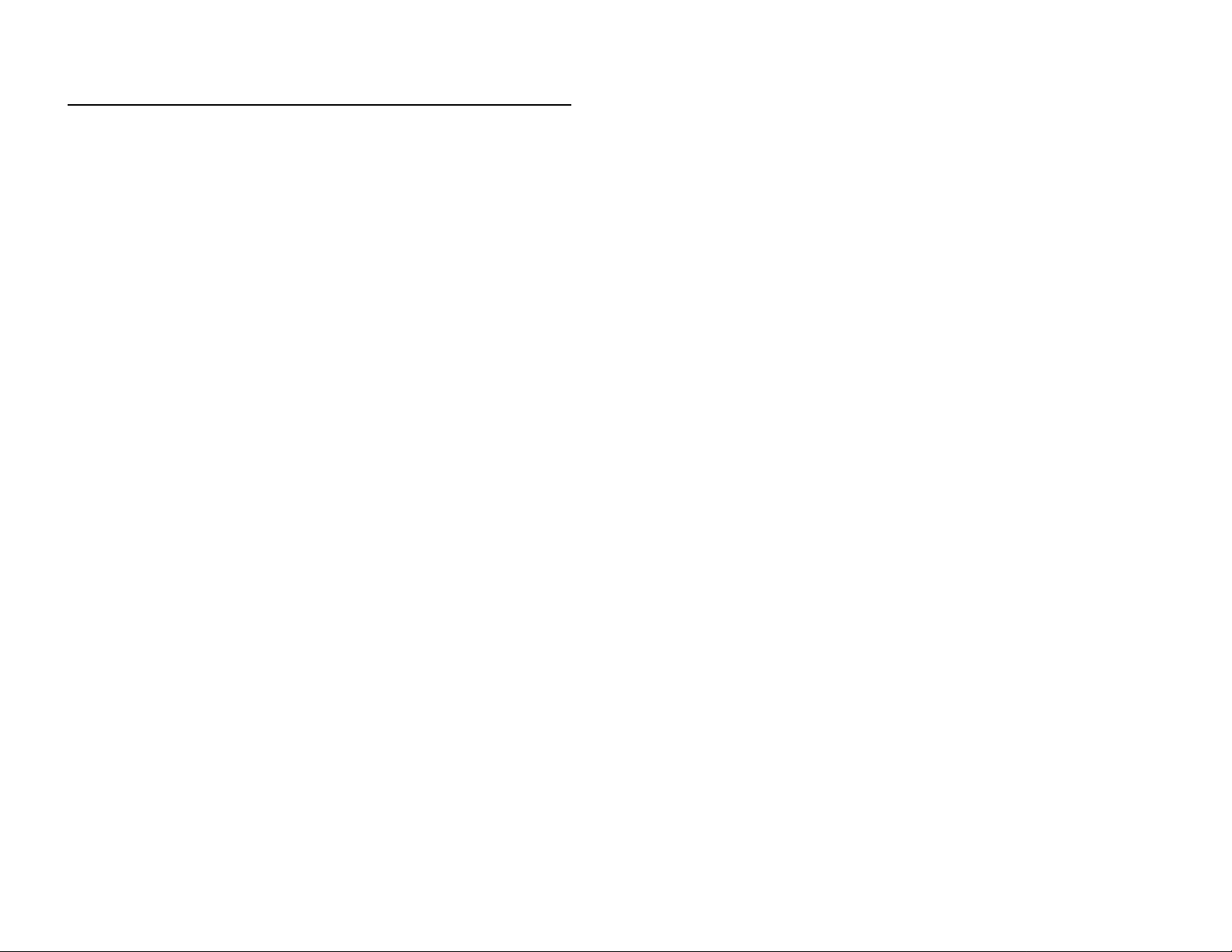

Installing the Battery and its Connecting Jumper

A battery has been incl uded for your scanner . You must install the battery

and jumper on the sc anner before you i nstall the sca nner in the compute r.

Install the battery as shown below.

1. Plug the battery in as shown below 2. Plug the jumper in as shown below.

IMPORTANT: When you install the

jumper, the red wire must be on top

and the white wire in the middle.

Red wire

White wire

41176-M

30631-M

Publication 1747-5.31–April 1998

Page 4

4 PCI Bus Card for 1746 Local I/O

User SRAM

256K (1747-PCIS) or 1M (1747-PCIS2) batte ry backed-up SRAM exists

on the scanner to be used by the host CPU. The host applic ation defi nes

the SRAM’s function.

For additional information on access and use of the user SRAM when

using the API software, see 1747 PCI Bus Interface for 1746 Local I/O

API Software user manual, publication 1747-6.5.3. If you are using

another software application, refer to the documentation for that software.

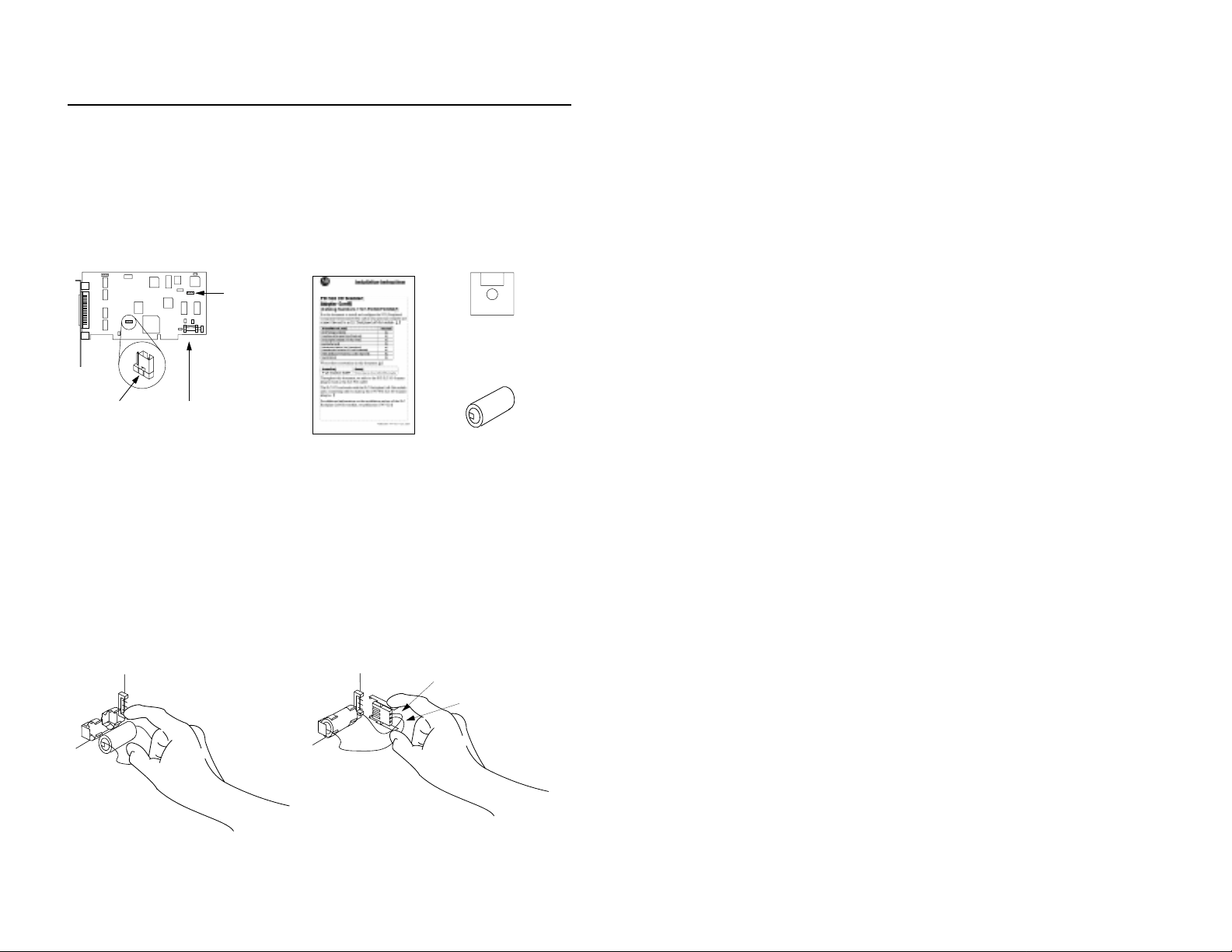

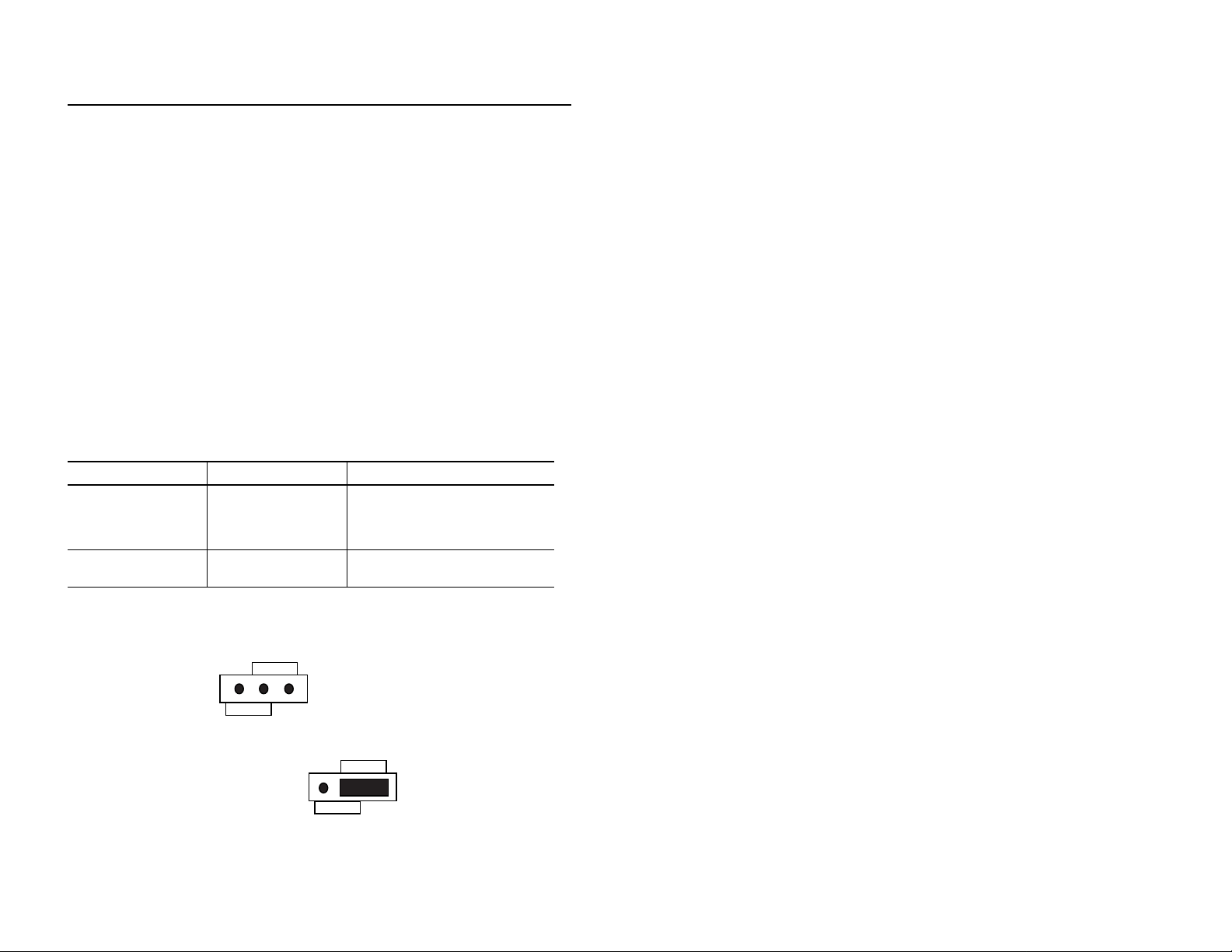

Setting the Jumper for Battery Back-Up

The PCI Bus card uses an o n board jumper that can be set in either of two

positions:

Enabled - This sett ing pr ovides batte ry bac k-up f or bot h Dual P ort

•

RAM and User SRAM. This mode wi ll substantially decrease t he

battery life.

or

Disabled - This setting provides battery back-up for SRAM only

•

The default position on the jumper is to the disabled pos ition. The jumper

for battery back-up looks like this:.

Jumper for

battery back-up

Publication 1747-5.31–April 1998

Enabled position

Disabled position

41177-M

Page 5

PCI Bus Card for 1746 Local I/O 5

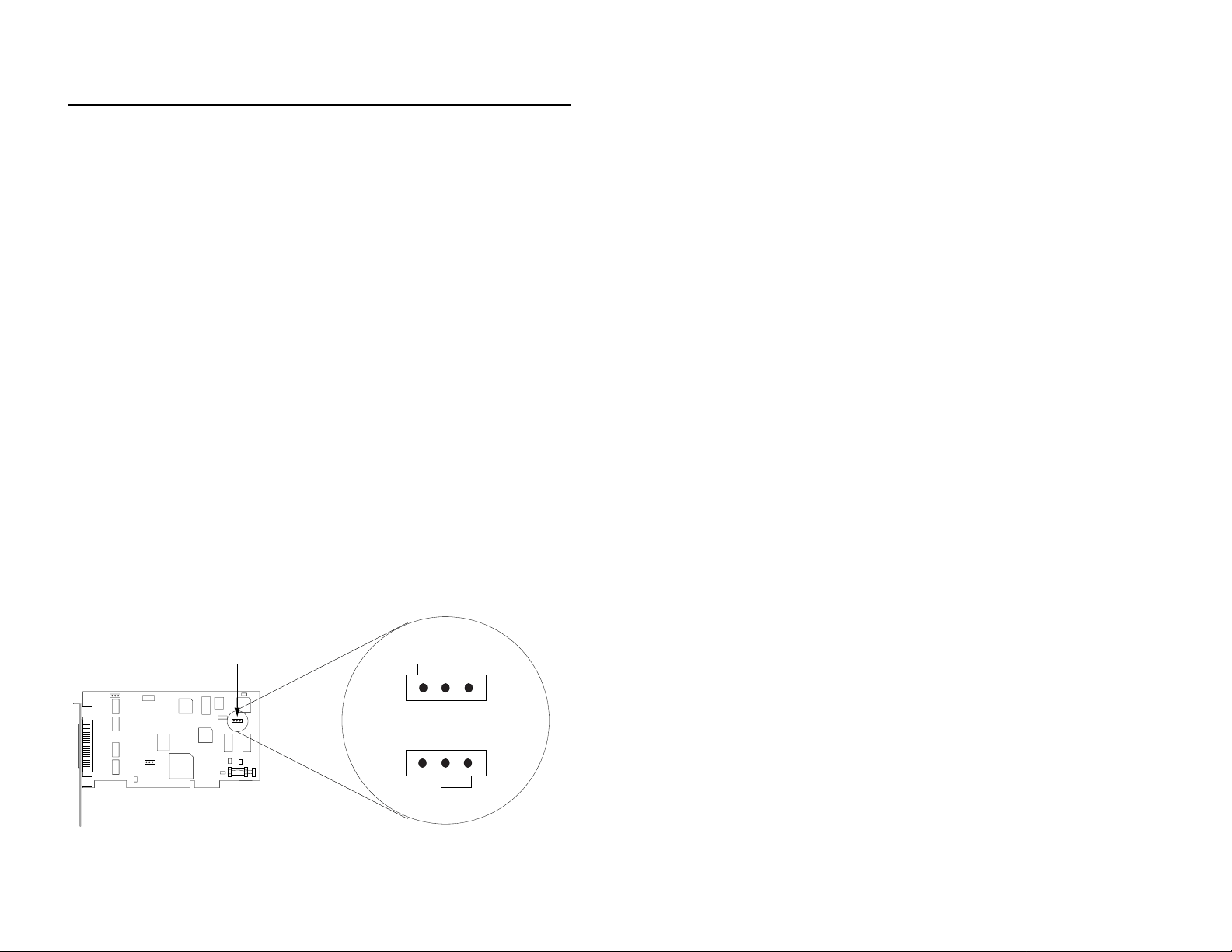

Setting the Base Memory Address Jumper

The host computer and the PCI Bus card exchange data via a dual-port

interface. The dual-por t requires 4 Kbytes of memory . This 4 Kbyte block

of memory begins at the base memor y address assigned to the card by the

PCI BIOS when the computer is started.

Under MS-DOS, Windows 3.1 and Windows for Workgroups, the base

memory address of PC cards should fall within the range of 0 and 1

Megabyte of PC memory. For the newer 32-bit operating systems, this

restriction is n o longer requ ired, and the ba se memory addr ess shoul d be

located anywhere in the PC memory space.

The Base Memory Address j umper (J P2) f orces the PCI BIOS to assign

the base memory address to one of two address ranges, as shown in the

table below . Y ou should s elect the jumper position ba sed on the operating

system running on your PC.

Operating System Jumper Position (JP2) Base Memory Address Range

DOS

Windows 3.1

Windows for Workgroups

Non-Microsoft system

Windows 95

Windows NT

Toward 1Meg position Located in the range between 0 and

1Mb in the PC memory

Toward 32bit position Located anywhere in the available

physical memory of the PC

When looking directly at the 1747-PCIS card, the Base Memory Address

jumper looks like this:

32BIT

This is a jumper that is not covered.

1MEG

32BIT

This is a jumper that has the 32bit

position for Windows 95 covered.

1MEG

Publication 1747-5.31–April 1998

Page 6

6 PCI Bus Card for 1746 Local I/O

Accessing the Computer’s PCI Bus Slots

To install the s ca nner, you must h ave access to the comput er’s PCI bus.

Refer to your comput er’s h ardware manual for inst ructions ab out how to:

1. Shut down the computer’s operating system.

2. Turn off power to the computer.

Important: If y ou disconnect t he ac power fr om the computer , you lose

the chassis ground. El ectrost atic damag e (ESD) protect ion

is lost.

3. Remove the computer’s CP U cover (acc ording to t he manu factu rer’ s

instructions).

4. Select a vacant PCI bus slot.

Important: The scanner will only function in a PCI bus slot.

5. Remove the rear bracket slot’ s expansion cover by loosening the screw

on the back of the computer.

Publication 1747-5.31–April 1998

Page 7

PCI Bus Card for 1746 Local I/O 7

Installing the Scanner

To install the scanner inside the computer:

1. Turn off power to the computer.

Important: If y ou disconnect t he ac power fr om the computer , you lose

the chassis ground. Electros tat ic damage (ESD) protection

is lost.

2. Loosen the expansion slot screw and remove the outside retaining

bracket.

3. Insert the scanner into the edge connector and tighten the expansion

slot screw on the scanner outside retaining bracket.

4. Restore power to the computer.

5. Run PCI diagnostics from the Utility disk to obtain the memory and

interrupt assigned to the scanner by BIOS at power up. Place the

software disk in the PC.

6. Type:

a:\PCISID.EXE.

7. Hit <E nter>.

Selecting the Cable for Your Connections

The scanner must be connec ted to the adapt er. Use one of t he foll owing

cables to make the connection:

3m interconnect cable (Cat. No. 1747-PCIC)

•

10m interconnect cable (Cat. No. 1747-PCIC2)

•

Publication 1747-5.31–April 1998

Page 8

8 PCI Bus Card for 1746 Local I/O

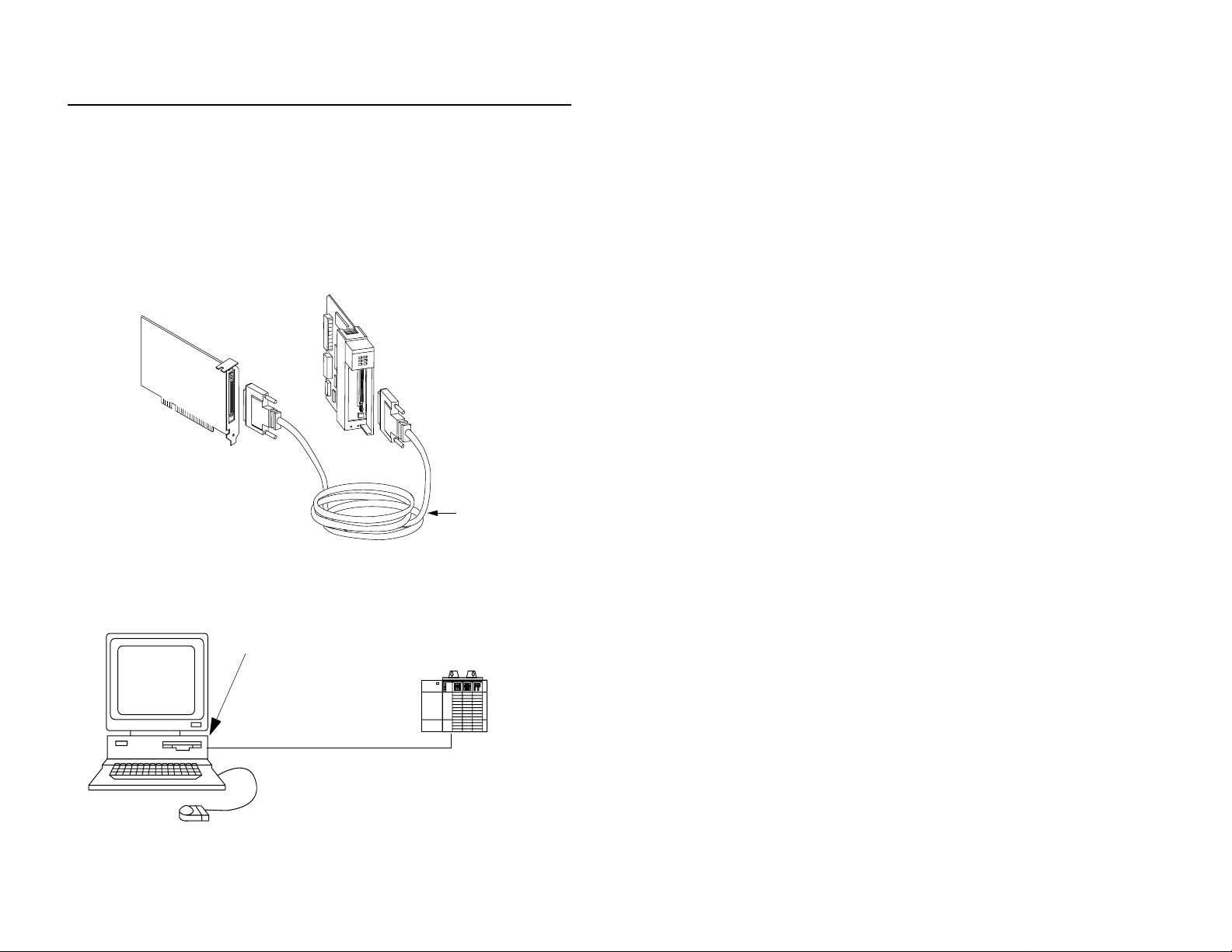

Connecting the Scanner to the Adapter

To connect the scanner to the adapter, you must:

1. Connect one end of the 1747-PCIC cable to the scanner.

2. Connect the other end of the 1747-PCIC cable to the ad apt er. Either

end of cable can connect to either the scanner or adapter.

PCI Bus card

(scanner)

Chassis Interface module

(Adapter)

1747-PCIC cable

30576-M

The figure below shows an example of a c onne ct ion be twee n a PCI Bus

card inside the computer and a Chassis Interface module inside a

local chassis.

PCI Bus card (inside

the computer)

Personal Computer

Publication 1747-5.31–April 1998

1747-PCIC Cable

Chassis Interface

module (insid e t h e

local chassis)

30173

Page 9

PCI Bus Card for 1746 Local I/O 9

General Operation

The scanner is a PCI Bus ca rd that i s instal led in a PC. I t scans 17 46 I/O

modules via the 1747-PCIC cable and adapter. The scanner can

communicate to any 1746 I/O module.

The application program on the PC will provide the software driver to

initialize and control the scanner. Once the scanner is running, it

continuously retrieves all the input data from the 1746 I/O modul es and

places the data in dual po rt memory on board the scanner. Output data is

constantly sent fr om the same dual port memory to the 1746 I/O mod ules.

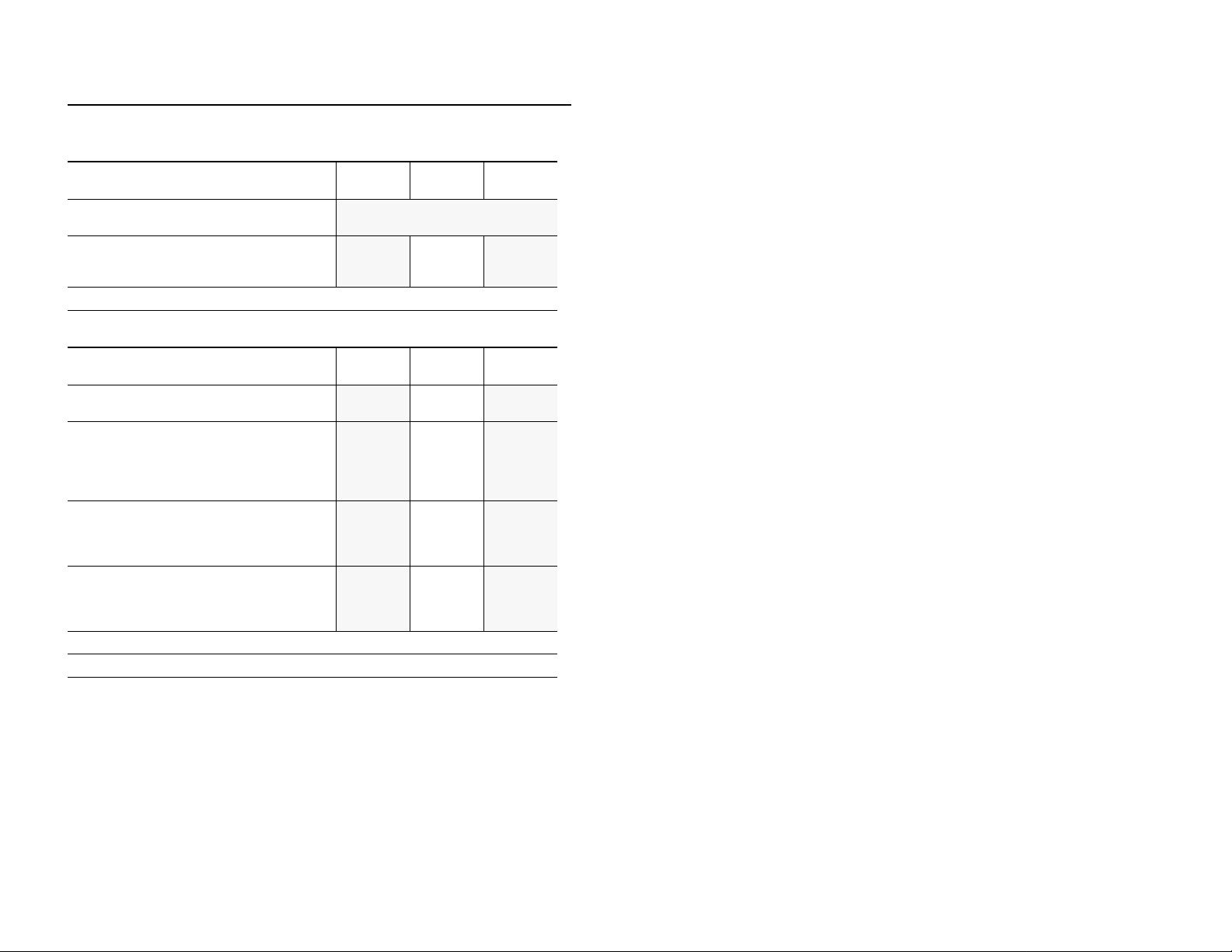

Calculating Scan Time

Scan time represents the elapsed time it takes your scanner to retrieve

input data from all I/O modules and place it in dua l por t memor y on the

scanner one time.

Add the rows in the following tables to calculate input and output scan

times. Fill in the shaded boxes. All times are in microseconds.

Estimate Minimum Input Scan Time

Quantity Fixed Scan

Digital I/O Modules:

number of class 0 input words:

Specialty I/O Modules (Class 1)

number of 1746-BAS modules (class 1):

number of 1746-NIO4V modules:

number of 1746-FIO4V modules:

number of 1746-NI4V modules:

Specialty I/O Modules (Class 3 and 4)

number of 1746-HSCE modules:

number of 1747-SN modules:

number of 1746-BAS modules (class 4):

Forced Input Overhead

number of class 0 input words:

number of specialty input words:

number of specialty I/O modules:

Input Scan Overhead (Add this time to the total from the I/O modules) 36

Minimum Input Scan Time (total)

Time

X 48 =

X 490 =

X 265 =

X 265 =

X 325 =

X 712 =

X 1185 =

X 650 =

X 6 =

X 9=

X 30 =

Total

Publication 1747-5.31–April 1998

Page 10

10 PCI Bus Card for 1746 Local I/O

Estimate Maximum Input Scan Time

Minimum Input Scan Time

(from previous table)

Maximum Specialty I/O Input Scan Time

number of class 1 specialty I/O modules:

number of class 3 and 4 specialty I/O modules:

Quantity Fixed Scan

Time

X 50 =

X 200 =

Maximum Input Scan Time (total)

Total

Estimate Minimum Output Scan Time

Quantity Fixed Scan

Digital I/O Modules:

number of class 0 input words:

Specialty I/O Modules (Class 1)

number of 1746-BAS modules (class 1):

number of 1746-NIO4V modules:

number of 1746-FIO4V modules:

number of 1746-NO4V modules:

Specialty I/O Modules (Class 3 and 4)

number of 1746-HSCE modules:

number of 1747-SN modules:

number of 1746-BAS modules (class 4):

Forced Output Overhead

number of class 0 output words:

number of specialty output words:

number of specialty I/O modules:

Output Scan Overhead (Add this time to the total from the I/O modules) 36

Minimum Input Scan Time (total)

Time

X 46 =

X 500 =

X 277 =

X 277 =

X 330 =

X 608 =

X 1208 =

X 655 =

X 6 =

X 9=

X 30 =

Total

Publication 1747-5.31–April 1998

Page 11

PCI Bus Card for 1746 Local I/O 11

Estimate Maximum Output Scan Time

Minimum Input Scan Time

(from above table)

Maximum Specialty I/O Output Scan Time

number of class 1 specialty I/O modules:

number of class 3 and 4 specialty I/O modules:

Quantity Fixed Scan

Time

X 50 =

X 200 =

Maximum Output Scan Time (total)

Total

Estimate Output Scan Time Plus Processor Overhead

Minimum or Maximum Output Scan Time

(from previous tables)

Overhead if DII Enabled 60

Processor Overhead minimum = 140

Output Scan Time Plus Processor Overhead (total)

maximum = 200

Troubleshooting

Use the utilit es disk that came in this packa ge for troubleshooting.

The diagnostic/util ity disk ha s a readme.tx t file that e xplains t he utilit ies

on the disk and directions on how to execute them.

We recommend that you make the diagnostic/utility disk bootable (use

the DOS

SYS command) so you can run diagnos tic utilit ies dire ctly fro m

a floppy drive in the PC. The PCI bus card must have the base memory

address jumper set for DOS (1 Meg position).

The diagnostic utility disk contains these utilities:

This utility selection: Uses this executable:

scanner diagnostics ocdiag.exe

PCI backplane/card utility pcisid.exe

Publication 1747-5.31–April 1998

Page 12

12 PCI Bus Card for 1746 Local I/O

•

Specifications

Operational Slot Temperature 0 to 60

Non-operational Slot Temperature -40 to 85

Relative Humidity 5-95% without condensation

Vibration

10-60Hz

60-150Hz

Operational Shock 30G peak for 11 +/-1ms

Non-operational Shock 50G peak for 11 +/-1ms

Power Dissipation 600mA @ 5V dc

Agency Certification

(when product or packaging is marked)

o

o

Constant 0.012 in displacement

Constant 2.0G acceleration

3W

U

listed

R

USC

L

marked for all applicable directives

Worldwide representation.

Argentina • Australia • Austria • Bahrain • Belgium • Brazil • Bulgaria • Canada • Chile • China, PRC •

Colombia • Costa Rica • Croatia • Cyprus • Czech Republic • Denmark • Ecuador • Egypt • El Salvador • Finland •

France • Germany • Greece • Guatemala • Honduras • Hong Kong • Hungary • Iceland • India • Indonesia •

Ireland • Israel • Italy • Jamaica • Japan • Jordan • Korea • Kuwait • Lebanon • Malaysia • Mexico • Netherlands

New Zealand • Norway • Pakistan • Peru • Philippines • Poland • Portugal • Puerto Rico • Qatar • Romania •

Russia-CIS • Saudi Arabia • Singapore • Slovakia • Slovenia • South Africa, Republic • Spain • Sweden •

Switzerland • Tai wan • Thailand • Turke y • United Arab Emirates • United Kingdom • United States • Uruguay •

Venezuela • Yugoslavia

Allen-Bradley Headquarters, 1201 South Second Street, Milwaukee, WI 53204 USA,

Tel: (1) 414 382-2000 Fax: (1) 414 382-4444

Publication 1747-5.31-April 1998 PN 955131-20

Copyright 1997 Allen-Bradley, Inc. Printed in USA

Loading...

Loading...