Page 1

160-PD1

Profibus-DP

Communication

Module

Catalog Number: 160-PD1

Firmware: 1.00

User Manual

Page 2

Importa nt U ser Information

Solid state equipment has operationa l characteristics differing from those of

electromechanical equipment. “Safety Guidelines for the Application,

Installation and Maintenance of Solid Stat e Contr ols” (Publication SGI-1.1)

describe s s ome important differences be t ween solid state equipment and

hard-wi red el ect ro mechanical d evices . Becau s e of th i s d i fferen ce, and also

because of the wide variety of uses for solid state equipment, all p ers ons

responsible for applyin g t his equipment must sat isf y t hemselves that each

intended application of this equipment is acceptable.

In no event will Rockwell Automation be responsible or liable for indirect

or consequential damages resulting from the use or application of this

equipment.

The examples and diagra m s i n t h i s manual are included solely for

illustrati ve purposes. Because of t he man y v ariables and requirements

associated w ith any particular installation, Rockwell Automation cannot

assume responsibility or liability for actual use based on the examples and

diagrams.

No patent liability is assumed by Rockwell Automation with respect to use

of information, circuits, equi pment, or software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without

written permission of Rockwell Automation is prohibited.

Throughout this manual we use notes to make you aware of safety

considerations.

ATTENTION: Identifies information about practices or

circumstances that can lead to personal injury or death,

!

property damage , or ec onomic loss.

Attentions help you:

• identify a hazard

• avoid the hazard

• recognize the consequences

Important: Identifie s information that is especially important for success ful

application and understanding of the product.

Shock Ha za r d labels may be loca ted on or in side the dri v e

to alert p eo p l e that dan g ero u s vol ta g e m ay b e present.

MicroLogix and SLC are trademarks of Rockwell Automation.

PLC and PLC-5 are registered trademarks of Rockwell Automation.

RSLinx and RSLogix 500 are trademarks of Rockwell Software, Inc.

Windows and Windows NT are registered trademarks of Microsoft Corporation

Profibus is a registered trademark of the Profibus Trade Organisation

Page 3

Using This Manual

Product Overview

Quick Start for Experienced

Users

Ins tallation and Wiring

Table of Contents

Preface

Who Should Use This Manual? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . p-i

Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . p-i

PD1 Compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . p-i

Reference Manuals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . p-ii

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . p-ii

Chapter 1

Module Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Configuration Rotary Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Chapter 2

Required Tools and Equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Chapter 3

EMC Directive 89/336/EEC Compliance. . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Low Voltage Directive 73/23/EEC Compliance . . . . . . . . . . . . . . . . . . . . . 3-1

Profibus-DP Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Module Configuration Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Setting the node address – S1 & S2 . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

Module Installation/Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Keypad or Ready/Fault Panel Removal . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Installing the PD1 Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Removing the PD1 Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Wiring the Drive Terminal Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Wiring the PD1 Ground Terminal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Wiring the Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Connecting the Communication Cable to the Module. . . . . . . . . . . . . . . . 3-8

Profibus Network Termination. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Modes of Operation

Chapter 4

Powering Up the Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

LED Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Operation Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Power-up Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Run Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Error Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Page 4

ii

Profibus Parameter

Descriptions and Data Protocol

Using the 160-PD1 on Profibus

Chapter 5

160 SSC Drive Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Data from Profibus-DP Master to PD1 Slave. . . . . . . . . . . . . . . . . . . . . . . 5-2

Data from PD1 Slave to Profibus-DP Master. . . . . . . . . . . . . . . . . . . . . . 5-2

Control and Status Word PROFIDRIVE. . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

State Transitions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Parameter Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Parameter Access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Parameter attributes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Parameter Access Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Chapter 6

Required Tools. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Create a Profibus Network Configuration Frame . . . . . . . . . . . . . . . . . . . . 6-2

Installing the 160-PD 1 G SD File in the Software Tool Library . . . . . . . . . . 6-2

Configuring the SST-PFB-SLC Scanner. . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Summary of the Example Scanner Con figuration . . . . . . . . . . . . . . . . . . . 6-8

Setting up the SST-PFB-SLC Scanner Card to work in the SLC . . . . . . . . 6-9

SLC Ladder Logic Example. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-11

Controlling the Drive. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-13

The Profibus Telegram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-16

Controlling the Drive

Troubleshooting

Specifications

Chapter 7

Setting the Drive to Enable Network Control . . . . . . . . . . . . . . . . . . . . . . . 7-1

Setting the Node Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Chapter 8

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

LED Indicators and Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

READY LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

COMM LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

FAULT LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

Appendix A

Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Environmental . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Mechanical. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Index

Page 5

Preface

Using This Manual

The purpose of this manual is to provide you with the necessary

informatio n t o apply the Bull et i n 160-P D 1 C ommunication Module.

Described in this manual are methods for installing, configuring, and

troubleshooting the 160-PD1 Profibus Communications Module.

For information on specific drive features, refer to the 160 SSC™

Variable Speed Drive (Series C) User Manual.

Important: Read this manual in its entirety before installing,

operating, servicing, or initializing the PD1 Module.

Who Should Use This Manual?

Conventions

PD1 Compatibility

This manual is intended f or qua lif ied pe rsonnel. To make ef ficient use

of the Communication Module, you must be able to program and

operate Profibus communications devices, as well as have an

understan d ing of the paramete r settings and functions of the 160

Drive.

In this manual we refer to the:

• 160-PD1 Communication Module as Communication Module,

PD1 Module or Module.

• 160 SSC Adjustable Fr equency AC Dri ve as the 160 Drive or

drive.

In addition, parameter numbers and names (both 160 Drive and PD1

Module) are shown in bold typeface and follow the format PXX - [*]

where P denotes parameter, XX denotes the two digit parameter

number, and * represents the parameter name.

For example, P01 - [Output Frequency].

The PD1 Module is compatible only with 160 Drives Series C or

above. When properly connected, the module communicates via a

Profibus-DP network.

Page 6

p–ii Preface

Reference Manuals

For Read This Document

Additional information about networking and the SLC™ 500 SLC 500 Modular Hardware Style Manual 1747-6.2

Information about the AIC+ AIC+ Advanced Interface Converter User Manual 1761-6.4

Instruction set information for the SLC 500 and MicroLogix™ 1000 SLC 500 and MicroLogix 1000 Instru ction Set Reference Manual 1747-6.15

For general MicroLogix 1000 information MicroLogix 1000 User Manual 1761-6.3

For 160 SSC Drive Information: 160 SSC Variable Speed Drive (Series C) User Manual 0160-5.17ML

A complete listing of current Allen-Bradley documentation, including ordering instructions. Also indicates whether the documents

are available on CD-ROM or in multi-languages.

A glossary of industrial automation terms and abbreviations Allen-Bradley Industrial Automation Glossary AG-7.1

Information about the SSC-PFB-SLC™ Scanner Scanner Card User Manual. SST Woodhead documentation can

The following documents contai n addit ional informat ion concernin g

Allen-Br ad ley p r oduc t s. T o obt ain a copy, contac t your local

Allen-Bradle y Sales Off ice or visit the “On-Line Publications” ar ea of

the Allen-Bradley Internet home page at: www.ab.com..manuals.

Publication

Number

Allen-Bradley Publication Index SD499

Version 1.0

be obtained online at http://www.mySST.com/download/

Safet y Precautions

ATTENTION: Only personnel familiar wit h 160 Drives,

Communication Modules and associated machinery should

!

plan or implement the installation, start-up, configuration

and subsequent maintenance of this module. Failure to

comply may result in personal injury and/or equipment

damage.

ATTENTION: This module contains ESD (Electrostatic

Discharge) sensitive parts and assemblies. Static control

!

precautions ar e required when insta lling, testi ng, servicing,

or repairing this ass embly. Component damage may result

if ESD control procedures are not fol lowed. If you are not

familiar with static control procedures, reference

Allen-Bradley Publication 8000-4.5.2, Guarding Against

Electrostatic Damage or any other applicable ESD

protection handbook.

ATTENTION: The driv e contains high volt age capacitors

which take time to di scharge after remov al of AC line po wer.

!

Before instal ling or removing the Communication Module,

ensure isolation of mains supply from line inputs R, S, T

(L1, L2, L3). W ait the r ecommended amount of ti me for the

capacitors to discharge to safe voltage levels (refer to the

160 SSC™ Variable Speed Drive (Series C) User Manual

for recommended time). Failure to do so may result in

personal injury or death.

ATTENTION: When a system is config ured for t he f irst

time, the motor must be disconnected from the machine or

!

process during initia l system testing. Ha zard of injury or

equipment damage may occur due to unintended or

incorrect m achi n e mo tion .

Page 7

Product Overview

This chapter contains the following information:

• The physical layout of the module.

• Location of configuration switches.

• Overview and components.

Chapter

1

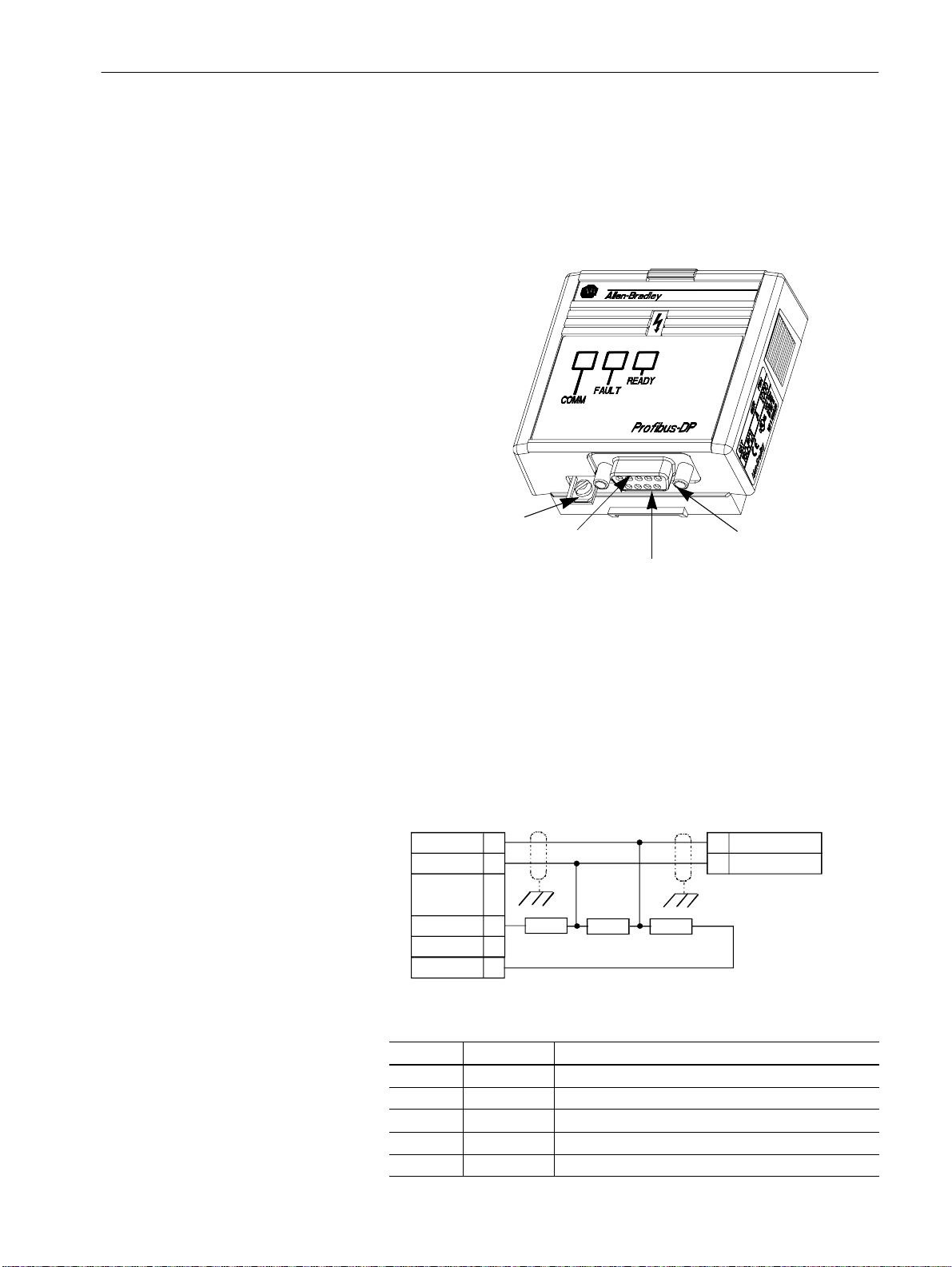

Module Description

The PD1 Module is an optional int erfa ce de v ice design ed to pr ovide a

direct, digital l i nk between a Profibus Master an d th e 160 Drive. The

module connects to the drive through the expansion/keypad port on

the front of the drive. Refer to Fig u res 1 .1 and 1.2 fo r gen eral la yout

of the module and Chapters 4 or 8 for details on t h e LED indicators.

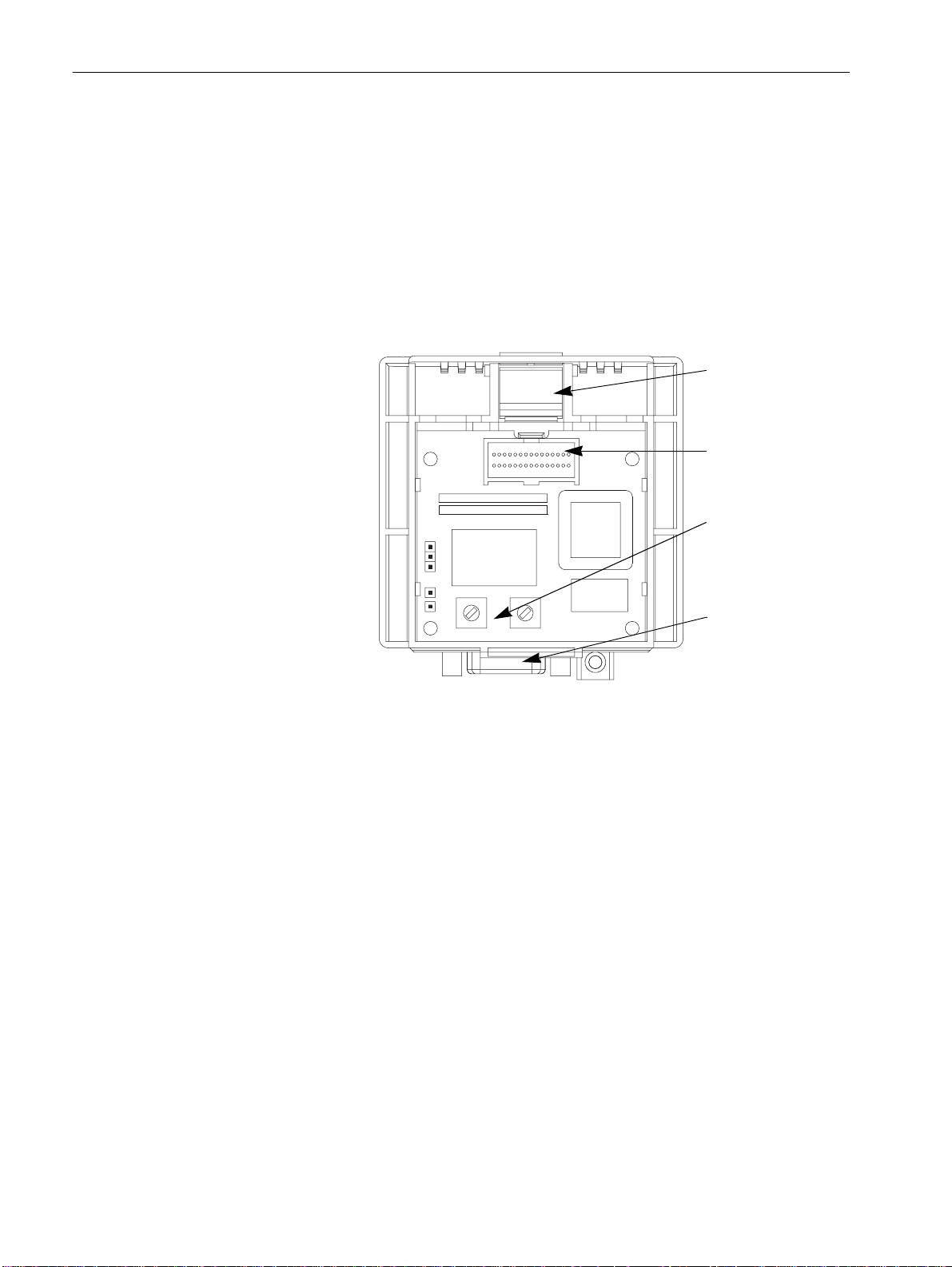

Figure 1.1

Module Front View

Module Installation Latch

Status LEDs

Refer to Chapters 4 & 8

for Further Information

9 Pin, Female D-Shell Connector

Refer to Chapter 3 for Details

Nameplate

Provides Firmware Version

and Series Letter

Page 8

1–2 Product Overview

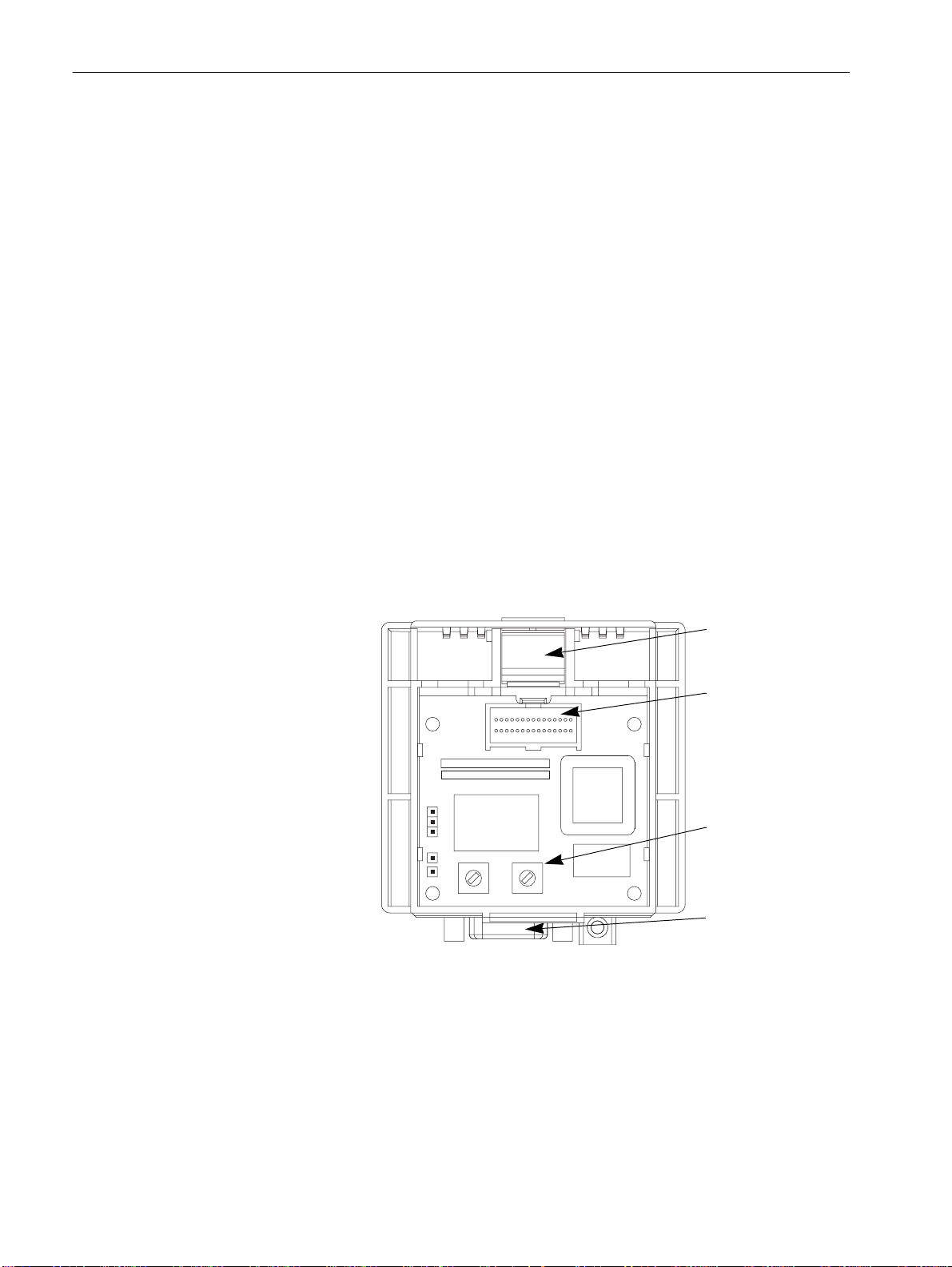

Configuration Rotary Switches

The Communication Module has two ten position rotary switches for

setting the node address. Rotary switches are located on the rear of

the module (see below) and are only accessible when the module is

removed from the 160 Drive. Refer to Chapter 3 for switch

configuration information.

Figure 1.2

Module Rear View

Module Latch

Expansion/Keypad

P ort Connector

Rotary Switches

S1(left) - S2 (right)

D-Shell Connector

Page 9

Chapter

2

Quick Start for Experienced Users

This chapter can help you start using the PD1 Communication

Module. If you have installed or configured a network previously and

are familiar with Allen-Bradley communication modules and drives,

this informat ion c an he lp re d u ce the time o f insta llation. I f you are

uncertain, use the full installation/configuration information

beginning in Chapter 3.

We base the procedures here on the assumption that you understand

the basic concepts, know how to program the 160 Drive and

understand electronic process control.

Because it is a start-up guide for experienced users, this chapter does

not contain detailed explanations about the procedures listed. It does,

however, reference other chapters in this book where you can find

more information.

If you have any questions or are unfamiliar with the terms used or

concepts presented in the procedural steps, always read the

referenced chapters and other recommended do cu mentation b efore

trying to apply the information.

Required Tools and Equipment

This chapter contains the following information:

• What tools and equipment you need.

• When to address the module and program the drive to recognize

the module.

• How to install and wire the Communication Module.

• System power-up procedures.

Have the following tools and equipment ready:

• 3.2 mm (1/8 in.) flat blade screwdriver.

• GSD configuration file (see Page 3-2)

Page 10

2–2 Quick Start for Experienced Users

Procedures

Step Action

10. Check for proper operation.

For Further Info rmation

1. Review Attention statements in the Preface.

Ensure that power to the 160 Drive has been removed. 160 Drive

2.

Verify that the 160 Drive is correctly installed and

3.

wired. Stop Input (TB3-7, TB3-8) must be jumpered

together to start drive.

Configure the 160 Drive for the PD1 Module so the

4.

drive can accept control logic and speed reference via

the network.

Set P46 - [Input Mode] to a value of “2” or “6” as described

in Table 6.A. Th is will co nfigu re the drive to acce pt the logic

commands from the network.

Note: If the value has to be changed, set P56 - [Reset

Functions] to “2” or reboot the drive.

Set P59 - [Frequency Select] to “1.” This will configure the

drive to accept speed commands from the network.

Set P66 - [RPM Scaling] for the RPM/Hz Scaling factor.

This allows theNetwork Reference to be in RPM.

Remove Program Keypad Module or Ready/Fault

5.

Indicati ng Panel from th e dri ve.

6. Set the PD1 Module’s node adress.

7. Install the PD1 Module.

Connect communication cable.

8.

Check correct cable termination (figure 3.7)

9. Power up the drive and the network.

Refer to…

User Manual

160 Drive

User Manual

Chapter 5

(Parameters)

Chapter 3

(Installation)

Chapter 3

(Installation)

Chapter 3

(Installation)

Chapter 3

(Installation)

Chapter 3

(Installation)

Page 11

Chapter

3

Installation and Wi ring

This chapter contains information needed to:

• Meet the requirements of the EMC and Low Voltage directives

for CE compliance.

• Remove a pre-i nstalled Program Keypad Module or Ready/ Fault

Indicating Panel.

• Configure and install the PD1 Module.

• Wire the communication cables.

• Remove the PD1 Module from the drive.

Read this chapter completely before you attempt to install or

configure your module. Before applying power, review the Attention

statements presented throughout this manual. Verify that all

connections are secure and that all selections are correct.

ATTENTION: Unpredictable operation may occur if you

fail to check connections and rotary switch settings for

!

compatibi l ity w i t h your applic a tion. U npre d icta b le

operation may result in personal injury, death, and

equipment damage.

EMC Directive 89/336/EEC Compliance

Low Voltage Directive 73/23/ EEC Compliance

This product complies with Electromagnetic Compatibility (EMC)

Directive 89/336/EEC when conforming with the following

installation requirements:

• The essential requirements for a conf orming EMC inst al lation for

the Bulletin 160 SSC are employed. Refer to the 160 SSC™

Variable Speed Drive (Series C) User Manual.

This produc t complies with Low Voltage Directive 73/23/E E C when

conforming with the following installation requirements:

• The essential requirements for a conforming Low Voltage

Directive installation for the Bulletin 160 SSC are employed.

Refer to the 160 SSC™ Variable Speed Drive (Series C) User

Manual.

• Review the Attention st atements in t h e P reface, and ot her areas

throughout this manual prior to installation o f the module.

Page 12

3–2 Installation and Wiring

Profibus-DP Configuration

Module Configuration Switches

From Profibus-DP point of view the Profibus-DP Slave (PDPS) node

is configured based on a data f ile (*.GSD) which conta ins information

of the size and data-structure of the PDPS.

The Master controls the data exchange to all connected slaves.

The slaves’ I/O data are mapped into memory inside the Master

according to the GSD configuration file.

The Profibus User Organization (PNO) registered the required

Profibus ID as: 0587h.

The GSD file is named: PD1_0587.GSD. It can be downloaded from

the Internet either vi a Allen Bradley Homepage under

http://www/ab.com/drives/Profibus/Index.html or P NO Homepage

under http://www/Profibus.com/downloads.html tha n GSD Libra ry

/ Rockwell Automation AG and Drives.

A micro floppy disk containing this GSD file is also available on

request from stock (RA catalog number: 160-GSD).

The PD1 Module utilizes two ten-position rotary switches (see figure

below) to configure the node address. These switches must be set to

match th e applic ati o n settings. Refer t o t he par ag ra p h s t ha t fo llow.

Figure 3.1

Rotary Switch Location (Back of Module)

Module Latch

Expansion/Keypad

Port Connector

Rotary Switches

S1 (left), S2 (right)

D-Shell Connector

Setting the node address – S1 & S2

Before configuring the PD1 module the node address has to be set.

This is done via two rotary switches (S1, S2) on the PD1, which

enable address settings from 0-99 in decimal format.

The address is calculated in the following way:

Address = (S1 x 10) + (S2 x1)

Important: T wo ident ical node addre sses are not all owed within on e

network section.

Page 13

Module Installation /Re moval

Installation and Wiring 3–3

ATTENTION: The driv e contains high volt age capacitors

which take tim e to discharge after remov al of mains supply .

!

Before installing or removing a keypad/module, ensure

isolation of mains supp ly from line inputs R, S, T (L1, L2,

L3). Wait the recommended amount of time for the

capacitors to discharge to safe voltage levels (refer to the

160 SSC™ Variable Speed Drive (Series C) User Manual

for recommended time). Failure to do so may result in

personal injury or death.

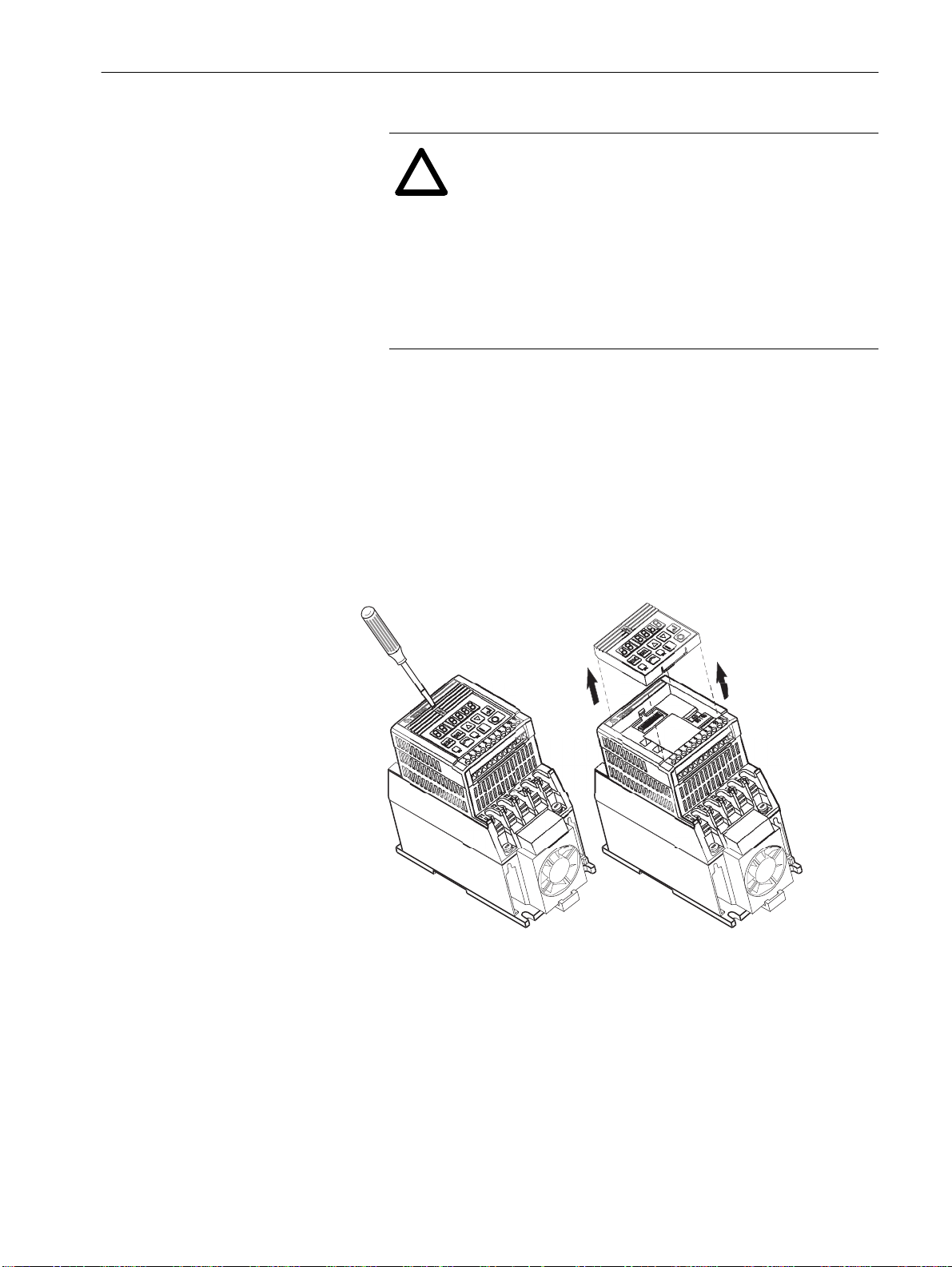

Keypad or Ready/Fault Panel Removal

Before install ing the PD1 Module, i t may be necessary to remove a

previously installed Program Keypad Module or Ready/Fault panel.

1. Verify that all power to the drive is removed.

2. Insert a small screwdriv er into slot, pry back and pivot module

out. Avoid bending or twisting the contact pins located under the

module.

Figure 3.2

Removing Program Keypad Module

Program Keypad Module

(or Ready/Fault Panel)

Installing the PD1 Module

After setting the rotary switches, install the PD1 Module in the drive

by following these steps:

1. Verify that all power to the drive is removed.

2. Verify that the latch is up (see Figure 3.3). Insert the modul e,

ensuring that the pins on the back of the module line up with the

drive connector/expansion port.

3. Press the module down until it is full y seated (side s are flush with

the top surface of the drive).

4. Pr ess t h e latc h down u ntil it s naps into place.

Page 14

3–4 Installation and Wiring

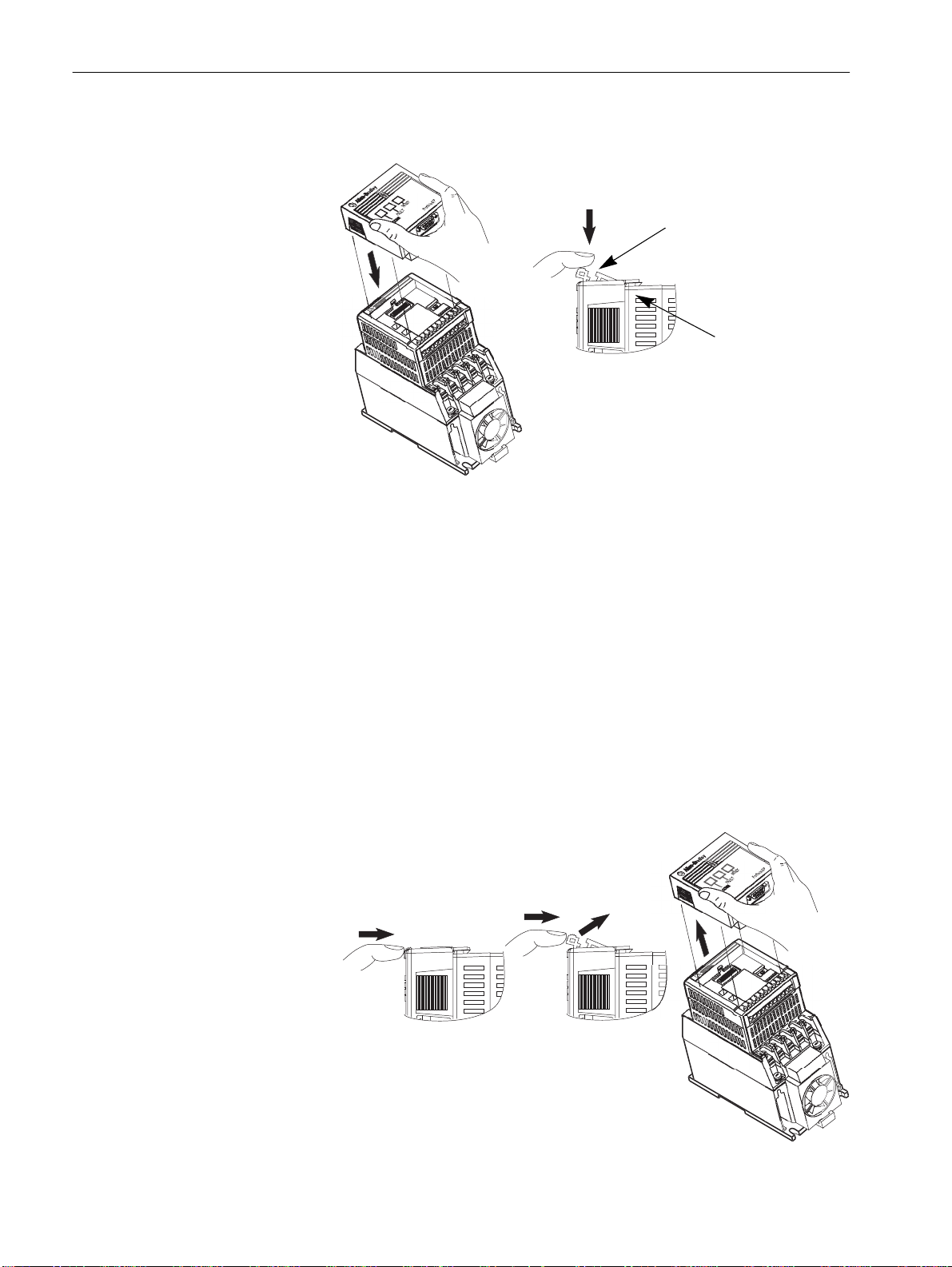

Figure 3.3

Communication Module Installation

Latch must be in this position before

installation. Once installed, push the

latch down until it locks into place.

Module should be flush

with top surface of drive

Removing the PD1 Module

If you need to reconfigure the PD1 Module rotary switches, you must

remove the module from the drive.

1. Verify that all power to the drive is removed. Review Attention

statement on page 3–3.

2. Disconnect the cable/connector from the module (if present).

3. Press in on the module’s latch and then push away and up.

4. Grasp the module and pull straight up. Avoid bending or twisting

the contact p ins loc at ed under neath the cen ter portion of the

module.

Figure 3.4

Removing the Communication Module

Page 15

Installation and Wiring 3–5

Wiring the Drive Terminal Block

The 160 drive and 160-PD1 interface can be controlled on a network

in 2 different mod es.

[Input Mode] = 2

This mode is used where the dr i ve is controlled sol ely by the netw ork.

The 160-SSC drive requires, that a stop signal is present on the

hardware terminals, before the drive can be started.

Control

ether a wire bridge or a normally closed stopping device.

Fitting a stopping device (e.g. pushbutton) in place of the link,

can provide addition al lo ca l st op/emergency stop capability.

Important: Failure to link the stop command input, will result in the

[Input Mode] = 6

This mode is used whereby it is possible to control the drive across

the network or locally, by putting a switch on the Contro l Terminal

Block 3 (TB-3) pins 7 & 8.

When the switch is closed, the Frequency source comes from the

reference as defined by P59 - [Frequency Select]. As we are using

the 160-PD1, the reference is across the Profibus network.

Additionally the start command is active across the network.

Terminal Block 3 (TB-3) pins 7 & 8 need to be linked by

drive generating a fault, and inability to run accross a

network.

When the switch is open, the Frequency source comes from the

terminal block (analogue reference or potmeter), regardless of the

setting of P59 - [ Freque nc y Sel ect]. Additiona ll y the star t command is

controlled by the terminal block or keypad.

Page 16

3–6 Installation and Wiring

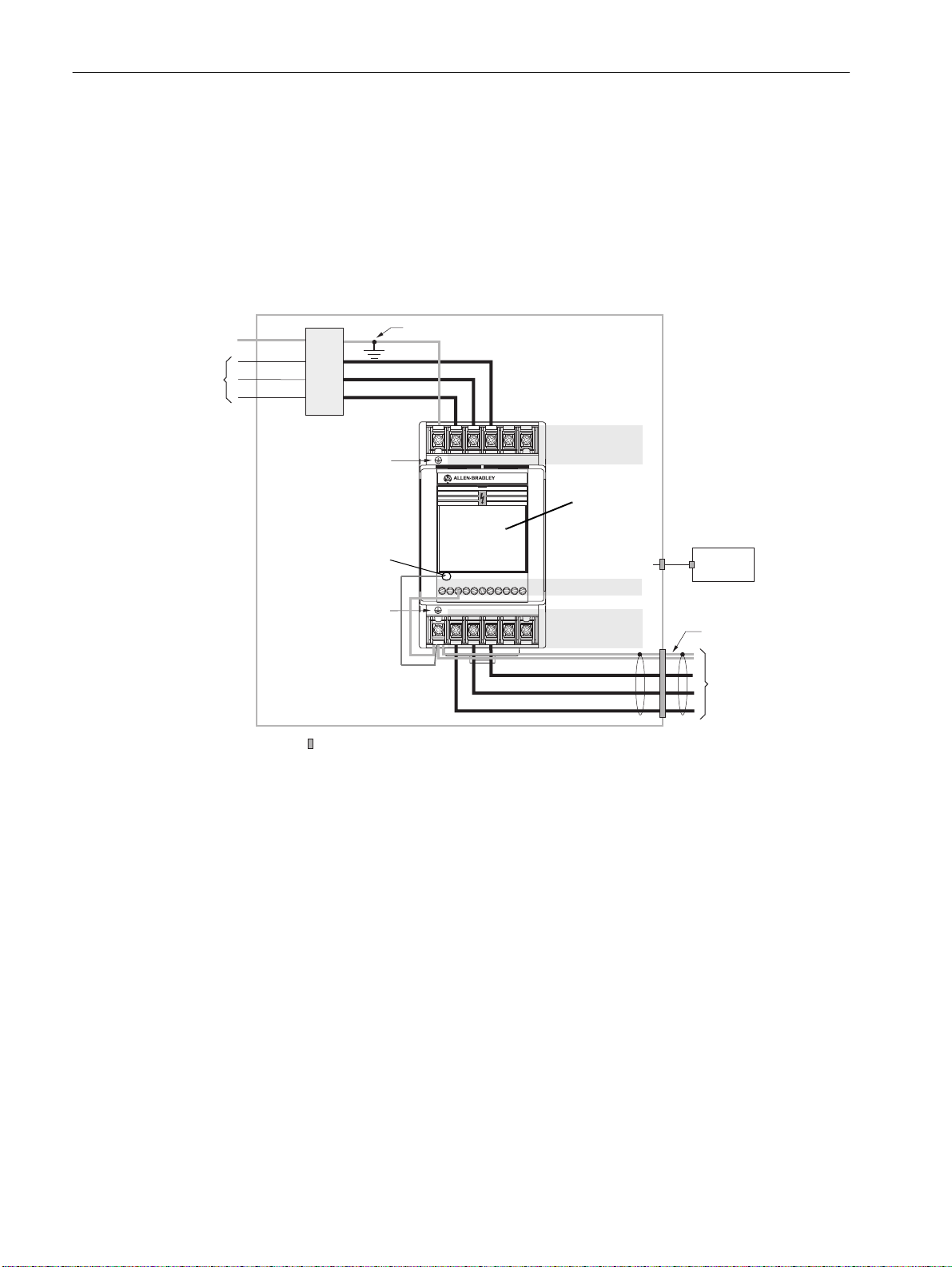

Wiring the PD1 Ground Terminal

AC

nput Line

PE

T (L3)

Line

S (L2)

Filter

R (L1)

Ground T erminal – PE

PD1 Ground Terminal

Ground T erminal – PE

In addition to the ground connections shown in Appendix C of the

160 SSC manual, the ground terminal at the bottom of the PD1

module must be solidly connected (and as short as possible) to the

output ground terminal at TB2 of the 160 SSC drive, as shown in

Figure 3.4:

2

This connection shall have a cross section of 1.5 mm

Figure 3.5

PD1 Module Grounding

Enclosure Ground Connection

T/L3

S/L2

R/L1

BR–

BR+

DC–

DC+

Line Power TB1

PD1 Communi cation

Module

to TB3

Control Wiring TB3

Motor Wiring TB2

S/L2

R/L1

T/L3

FAULT

READY

1

45678910112

3

V/T2

U/T1

W/T3

.

Control

Cabinet

➊

Shielded Motor Cable

Shielded Enclosure

= EMC Tested Shielded Cable Clamp (or Metal Conduit)

➊

When the control circuitry is located outside of the 160 enclosure.

W/T3

V/T2

U/T1

to Motor

Page 17

Installation and Wiring 3–7

Wiring the Connector

The examples below can be used as a guide when wiring.

Important: Keep communicatio n wiring awa y from high noise sources

such as mot o r cabl es . Use terminated cabl e on ly fo r th e

last node (end of chain)

Figure 3.6

Wiring the PD1 Connector

Ground Connection

Terminal

Pin 1

9-Pin, Female D-Shell Connector

Pin 9

The PDP network cables are connected to the PD1 module using a

9-pole D-Shell connector with a suitable opening facing downwards.

The pin layout of the connector follows the Profib us s tandard.

The Vcc (pin 6) and GND signal (pin 5) can be used for external bus

termination.

Important: Only use cable that c onforms to Pro fi Bus cable standards .

Belden type 3079A ProfiBus cable or equivalent is

recommended.

Figure 3.7

Cable Termination

RxD/TxD-N 8

RxD/TxD-P 3

Vcc 6

GND 5

A

B

390 220 390 Ohm

8 RxD/TxD-N

3 RxD/TxD-P

Termination resistors are only required at both ends of the network

Pin Name Function

Case Shield Bus cable shield. Connected to PE internally on the PD1

3 B-Line Positive

5 GND BUS Isolated GND

6 +5V BUS Isolated +5V Vcc*

8 A-Line Negative

Page 18

3–8 Installation and Wiring

Connecting the Communication Cable to the Module

Network

Termination

Resistor *

PLC

Profibus

Master

Follow these steps to connect your module.

1. Verify that the cable/connector i s corr e ctly wired (see Figure 3.6

and Figure 3.7).

2. Locate the D-shell connector at the base of the PD1 Module.

3. Plug cable/connector into the PD1 D-shell connector and secure.

Figure 3.8

Profibus Connection

Internal

Network

Termination

Resistor

Profibus-DP

SSC160-C

Profibus-DP

SSC160-C

Profibus-DP

SSC160-C

Profibus Network Termi nation

* Termination is required at both ends of the network.

The Profibus master might offer on-board termination.

Make sure that other Profib us slav es with on-board term ination are set

up correct l y.

The network must be terminated at the first (network master) and the

last PD1 module. A bus cable connector with an internal resistor

network must be used as no internal termination is provied on the

PD1 module. (Refer to Figure 3.7).

Page 19

Chapter

Modes of Operation

Chapter 4 contains the following information:

• Powering up the drive with the PD1 Module installed

• LED Indicators

• Operation Modes

4

Powering Up the Drive

LED Indicators

After you have installed the PD1 Module, apply power to the drive

and to th e connected d ev ice. The R EADY LED should illuminate.

If it does not, refer to Chapter 8, Troubleshooting.

The PD1 Module has three LEDs (see figure below) which provide

module status.

READY LED

FAU LT LED

COMM LED

The LEDs are defined as follows:

•COMM – The COMM LED has four possible states:

Green (steady) Communication ok, data is exchanged.

Red (steady) Diagnostics failed at power-up

or fatal error.

Red (flashing) Profibus configuration fault (5 to 6 flashes).

Off No communication takes place / No power

For more details refer to Troubleshooting, Table 8.A

•FAULT – This LED tracks the fault status of the 160 Drive.

When no faults are present, the LED will be off. The LED will

illuminate (red) if a drive or an option board fault occurs.

•READY – The Ready LED will illuminate (green) whenever the

module is connected to the drive and power is applied.

Page 20

4–2 Modes of Operation

Operation Modes

The PD1 Module has three modes of operation.

• Power-up mode

• Run mode

• Error mode

Power-up Mode

The following sequence of operation occurs:

1. During power-up, the READY LED illuminates green and the

FAULT and READY LED’s light up for a short periode.

2. The module reads and stores the rotary switch settings.

If the power-up sequence is successful, the module enters the run

mode and the COMM LED turns solid green as soon as data is

exchanged.

If the powe r -up sequ ence f ails, the COMM and FA ULT LED will stay

solid red and the module will enter the Error Mode (see below).

Run Mode

After a successful power-up, the PD1 Module enters the run mode

and operates as a slave device to a master d e v ice. In run mode, the

module:

• Accepts and responds to messages from the master on the

network.

• Monitors cable integrity an d t ransmissio n performance.

• COMM LED green if communication with the master is ok.

If an error is detected, the module enters Error Mode (see below).

Error Mode

Errors are indicated either by the COMM LED:

• Flashing red (5 to 6 flashs) signals a Profibus configuration fault

• Flashing red (other than 5 to 6 flashs) signals a fatal error

• Solid red signals that the power-up sequence failed

or the FAULT LED, which illuminates solid red at any 160 drive fault

or option board fault.

SSC160 drive faults are also indicated by the FAULT LED.

(See table 8.B).

Refer to Chapter 8 for details on how to recover from an error.

Page 21

160 S S C Dr ive Parameters

Chapter

5

Profibus Parameter Descriptions

and Data Protocol

This chapter provides a listing and description of the Bulletin 160

Drive parameters related to Network Operation, and the PD1 Module

Data Protocol information.

Important: Refer to your 160 S SC™ Variable Speed Dri v e (Ser ies C )

User Manual for drive parameter descriptions.

Drive PD1 (Tab. 5E)

46 4

5

59 4

5

66 4

5

Access [Parameter Name] and Description

Read

write

Read

Write

Read

Write

[Input Mode]

Configures the TB3 control inputs for various 3-wire or 2-wire control schemes.

Also enables/disables the program keypad module input control.

Settings: must be set to either

2 = Program Keypad Module control or

6 = 2-wire TB3 Control/Keypad or Communication control

A contact closure on TB3 terminals 7 and 8 is required for the drive to respond to a

Run command.

Important: This parameter cannot be program med while the drive is running.

In addition, power must be cycled or P56 - [Reset Function] must be

set to 2 for the change to take effect.

[Frequenc y Sele c t]

Selects the source of the frequency command for the drive.

The reference to P58 - [Internal Frequency] is bipolar, so a positive reference gives

forward rotation, and a negative reference gives reverse direction.

Settings:must be set to 1 = internal freq. command from P58 - [Internal Frequency].

[RPM Scaling]

A scaling factor is required to interpret a speed reference in RPM at the [Maximum

Frequency] of the dri ve . The 160 Drive parameter P66 - [Preset Frequency 5] is

used by the PB1 Module for this purpose.

P66 = rRPM / rf

rf: required motor frequency to achieve rRPM

rRPM: final RPM at application output (e.g. speed at gear box output),

which will be displayed at Profibus Master

Application Speed [rpm] = Drive Output Frequency x P66 [RPM Scaling]

e.g. 1500 rpm = 50 Hz x 30 (4 pole motor) P66 = 30.0 (300)

900 rpm = 60 Hz x 15 (8 pole motor) P66 = 15.0 (150)

Gear Box 1:20: 75 rpm = 50 Hz x 1.5 (4 pole motor) P66 = 1.5 (15)

For network operation the P66 values in brackets are valid, which are ten times the

values for keypad operation.

If P66 - [RPM Scaling] is set to 0, speed reference may be sent via the network

directly in 1/10 of Hz.

e.g. SpeedRef [Hz] (Profibus) = 405 results in 40.5 Hz of output frequency.

Speed feedback is considered to be P01 - [Output Frequency],

which reflects the output frequency considering ramp rates.

Min./Max.

Values DefaultParam. No Param. Oper.

0/9 0

0/1 0

0-240

[0-2400]

50

ATTENTION: Unpredictable motor speed can cause deat h,

injury or equipment damage. Do not use P66 as the [Preset

!

Frequency 5] function via control terminal wiring.

Page 22

5–2 Profibus Parameter Descriptions and Data Protocol

Drive PD1 (Tab. 5E)

Access [Parameter Name] and Description

116 4 Read only [PD1 SW Version]

This parameter indicates the software version of the PD1 option.

The number is in the form of xx.yy where xx indicates the major revision level and yy

indicates the minor revision level.

Min./Max.

Values DefaultParam. No Param. Oper.

0.00 to 10.0 1.0

Note: P57 [Program lock] may be set to 1 (locked), b ut parameter prog ra m m in g vi a network w ill st ill be

possible.

Profib us -DP Data Protocol

This chapter provides you with the PD1 Module Data Protocol

information.

Data from Profibus-DP Master to PD1 Slave

The Profibus Telegram consists of several bytes (words) according to

the follo wing table :

Table 5. A

Byte Byte No. Description

Control Word (LSB) 1 Control Word according to PROFIDRIVE and SSC160

Control Word (MSB) 2 Includes bits for parameter access control

(see table 5.E)

Speed Reference (LSB) 3 Speed reference in 0.1 Hz

Speed Reference (MSB) 4 0 to 2400 = 0 to 240 Hz

Parameter Value (LSB) 5 Parameter value

Parameter Value (MSB) 6

Par. Number 7 Parameter number to access (refer to SSC160 manual)

Reserved 8 not used

Data from PD1 Slave to Profibus-DP Master

Table 5. B

Byte Byte No. Description

Status Word (LSB) 1 Status Word according to PROFIDRIVE and SSC160

Status Word (MSB) 2 Includes bits for par ameter access control

(see table 5.E)

Speed Feedback (LSB) 3 Output Frequency

Speed Feedback (MSB) 4 Speed feedback corresponds to P01 [Ou tput

Frequency], w hich re flects the output frequency

considering ramp rates. (scaling as above)

Parameter Value (LSB) 5 Parameter value

Parameter Value (MSB) 6

Parameter Number 7 Parameter number to access (refer to SSC160 manual)

Parameter Access Status 8 Parameter Access Status=0x01 indicates a valid

access cycle (see table 5.G)

Page 23

Profibus Parameter Descriptions and Data Protocol 5–3

Control and Status Word PROFIDRIVE

Control an d St at u s w or d b its ar e defined as follo ws (speed control):

Table 5. C

Control Word (Bit definition)

Bit No. PROFIDR IVE (Control) Function

0 On / Off 1 1 = Enable op., 0 = Stop drive according to P34

1 Operating condition / Off 2 1 = Enable operation according to P34

2 Operating condition / Off 3 1 = Enable operation, 0 = Fast Stop

3 Enable / Inhibit operation 1 = Run / Start operation,

4 Operating Condition /

Inhibit ramp

5 Reserved

6 Enable / Inhibit Setpoint 1 = Speed Ref Enable

7 Acknowledge Fault Reset at 0 to 1 transition

8 to 12 Reserved

13 Parameter Operation 0

14 Parameter Operation 1 Parameter access according to Table 5.E

15 Parameter Operation 2

1 = Enable,

0 = Ramp to zero

To start the drive, set the control word (Low Byte) from 6 t o 5Fh.

To stop the drive, set the control word (Low Byte) to 57h.

T o c ont rol the dr i ve via Terminal Block (TB3), the Control Word Lo w

Byte must be set to 06h (state READY TO SWITCH ON).

Table 5. D

Status Word (Bit definition)

Bit No. PROFIDRIVE (Status) Function

0 Ready / Not for switch on 1 = Ready (Diagnostics o.k.)

1 Ready / Not for operation 1 = Ready (Diagnostics o.k.)

2 Operation enabled / inhibited 1 = Drive operating (Bit 3 of Control Word)

3 Fault / no Fault 1 = Faulted

4 No Off 2 / Off 2 1 = Enabled (Bit 1 of Control Word)

5 No Off 3 / Off 3 1 = Enabled (Bit 2 of Control Word)

6 Switch On Inhibit / not inhibit 1 = Inhibited (Bit 1,2 of Control Word not set)

7 Reserved

8 Ref. Within Limits / not 1 = Speed Reference within range (P32, P 33)

9 Control requested /

operation on site

10 Ref. reached 1 = Speed Reference reached

11 Direction 1 = Reverse, 0 = Forward

12 Reverse Request 1 = Reverse Request at TB input

13 Parameter Operation 0

14 Parameter Operation 1 Parameter access according to Table 5.E

15 Parameter Operation 2

1 = Master is requested to take control

* Internal speed reference/feedback is computed in 0.1Hz increments.

Due to rounding issues speeds in RPM may differ.

Resolution error in RPM = P66 * 0.05.

Example: for P66 = 16.6 the possible error is 1 RPM.

Page 24

5–4 Profibus Parameter Descriptions and Data Protocol

Stat e Transitio ns

RUNNING

0011' 0111 0011'0001

Control Words

Status Words

The following Figure 5.1 shows the most important state transitions

Figure 5.1

State Diagram

NOT READY TO

SWITCH ON

0FF2

or

0FF3

x1x1'1111

01xx'0000

xxxx'x110

READY TO

0FF1

(Low Byte) appear outside the boxes

(Low Byte) appear inside the boxes

SWITCH ON

Acknowledge Bit

1

—>

0

FAULT

0xxx'1000

Parameter Operation

Acco rdin g to Table 5.E, t hree p a rame ter op e r a tion bits in t he cont rol/

status word allow access t o certain p arameter values:

Table 5.E

Bit

Parameter Operation

0 0 0 0 No operation

1 0 0 1 Read Attr ibutes

2 0 1 0 Read minimum

3 0 1 1 Read maximum

4 1 0 0 Read value

5 1 0 1 Write value

6 1 1 0 Read default

7 111Unused

15 14 13 Description

Page 25

Profibus Parameter Descriptions and Data Protocol 5–5

P arameter Access

Parameter Attributes

Each parameter is described by an attribute to be read according to

table 5.F. The attribute consists of one word with 2 bytes which are

defined as follows:

High Byte stores the Unit (scaling) according to the table 5.G,

Low Byte stores the parameter number.

Table 5.F

High Byte Units

0 Decimal 1

1 Decimal 0.1

2 Decimal 0.01

3 Hexadecimal 1

4 Binary 1

5 Decimal (signed) 1

6 Decimal (signed) 0.1

7 Decimal (signed) 0.01

Parameter Access Status

The following access codes are returned i n t h e Parameter Access

Status Byte:

Table 5. G

Fault Code Fault Description Parameter Access Status

.

Bit 7Bit 6Bit 5Bit 0

- Network option is processing access

request

0 No fault, access successfull 0001

1 Parameter value is out of limits 0011

2 Parameter write attempt while drive is

running

3Parameter number is too small 0111

4 Parameter number is too high 1001

5Parameter number not valid 1011

6 No valid response from drive 1101

7Incorrect Parameter Operation code1111

xxx0

0101

A successful access is indicated by Access Status Byte 000’0001.

Page 26

5–6 Profibus Parameter Descriptions and Data Protocol

End of Chapter 5

Page 27

Chapter

6

Using the 160-PD1 on Profibus

The purpose of this chapter is to provide an example of the steps

necessary to use the 160-PD1 on a Profibus network. As Profibus is a

3rd party network, we will be using the SST-PFB-SLC scanner to act

as a master for Profibus, residing in an A-B SLC500 rack.

The SST scanner sends I/O messages periodically to a Bulletin

160-PD1 to start and stop the dri v e and co ntrol i ts spee d. Additio nally

the Bulletin 160-PD1 responds to these I/O message s b y sending

status messages and speed feedback back to the scanner. In this way

the ladder logic program in the A-B SLC500 PLC can control the

drive.

The Bulletin 160-PD1 a lso suppor ts a Prof ib us t ele gram which c an be

used to configure or read parameters from the drive .

This chapter contains the following information:

• How to create a Profibus network configuration frame.

Required Tools

• How to configure the SST-PFB-SLC scanner for use in a SLC

rack.

• A sample ladder logic program to control the Bulletin 160 SSC

using I/O messaging.

• A description of the Profibus te l egram.

• A sample ladder logic program to execute the telegram.

The SST-PFB-SLC scanner for the SLC500 is used in the examples

in this manual. However the concepts demonstrated in the examples

apply to any Profibus master.

The following too l s are needed to comp l et e this chapter.

• Bulletin 160 series C or higher, equipped with a 160-PD1

Profibus communication module

• SLC500 processor with a digital input card to issue start & stop

commands.

• SST-PFB-SLC scanner card, SST Configuration Tool and null

modem cable.

Page 28

6–2 Using the 160-PD1 on Profibus

Create a Profibus Network Configuration Frame

The SST Profibus scanners come with a software tool for configuring

the scanner. If you activate this program in your computer the

following screen should appear.

Network

Configuration

window

Device

Library

window

Installing the 160-PD1 GSD File in the Software Tool Library

Online

Browse

window

Follow the steps outlined below only when a new GSD file needs to

be added to the SST PROFIBUS Configuration Software Tool.

Typically this is only done once, after the software tool is initially

installed or before configuring the scanner for the network.

The software tool comes with standard data files. Additional data

files, such as the 160-PD1 GSD file, will need to be added to

configure the 160-PD1 in the scanner.

Click on the ”New Devic e” icon to add GSD files to the softw are

library tool.

An ”Add PROFIBUS devices” Applet window will appear.

Prompts for the location of the PROFIBUS data files to be added to

the library will follow.

Page 29

Using the 160-PD1 on Profibus 6–3

Find the dire ct o ry l o cation of the data file(s) you wish to add

(typically, the source location is a floppy disk in drive A: ).

”PD1_0587.gsd” is the GSD file for the 160-PD1 as shown below.

Select ”PD1_0587.gsd” for the 160-PD1 and click Open.

Click on the (+) sign of the Slaves folder as shown below.

The software tool will automatically create a Rockwell Automation

sub-folder (in the Slaves folder) if it does not already exist. The

160-PD1 is now shown in the library and the software tool is now

ready to configure a 160-PD1 on a PROFIBUS network.

Page 30

6–4 Using the 160-PD1 on Profibus

Configuring the SST-PFB-SLC Scanner

The following steps are performed to configure the SST-PFB-SLC

scanner using the SST PR OFIBUS configuration softw are tool.

Click on the (+) sign of the Masters folder in the Library window to

open the SST sub-folder. Ava ilable DP masters are displayed in this

sub-folder.

Then, double-click the SST-PFB-SLC MASTER in the Masters

folder in the Library window to add the scanner to the network.

A user-defined Name and Description can be given to t he scanner.

In our example the scanner will be Station 0 on the network.

The Paramet er tab i s n o t s h own here a s th e defa ult s ett i ngs are used.

Connection and Baud Rate settings configure how the software tool

will communicate with t h e CON FIG RS232 port on the scanner.

Click on the COM Port tab.

Accept the settings in our example (COM1 on the PC at 115200 bps

baud rate), as shown below.

When you click OK to accept these settings, the scanner will appear

in the Network window.

Page 31

Using the 160-PD1 on Profibus 6–5

Double-click on the scanner in the Network window.

Double-click on PROFIBUS_DP will open the Network window.

Specify the Baud Rate 1.5 M Baud and click OK to accept the setting.

Click on the (+) sign of the Slaves folder in the Library window and

the Rockwell Automation sub-folder to display the available DP

slaves or the 160-PD1 slave

Double-click on the 160-PD1 listed in the Device Library and the

Rockwell Automation library folder. A user-defined Name and

Description can be given to this 160-PD1.

In our example, this device will be Station 3 on the network. Other

stations may be chosen by using the arrow to display a drop-down list

in the Station window.

Page 32

6–6 Using the 160-PD1 on Profibus

Click OK and the GSD file previously loaded, creates a fixed format

I/O structure of 8 bytes in and 8 bytes out. Click on the Modules tab

to view.

Now the 160-PD1 address starting point needs to be specified.

Click on the SLC Address tab.

In our SLC example code, the 160-PD1 has been mapped at:

Inputs I:2.14

Outputs O:2.14

This is 14 words offset from the start address of the card.

Select the ” Out 8byt es” from the available options, and specify an

offset of 14.

Page 33

Using the 160-PD1 on Profibus 6–7

Select the ”In8bytes” f ro m the available options and specify an offset

of 14.

Now click OK to accept these addresses.

Use the null modem cable that came with the scanner to connect

COM1 on the PC and the CONFIG RS232 port on the scanner.

Downloading the configuaration to the scanner is protected by the

processor keyswitch. Turn the keyswitch to "Program".

Right-click on the scanner in the network window and select ”Load

Configuration”. If a minimum cycle time attention window pops up,

click OK to continue. After the configuration has been loaded into the

scanner ”Configured Program” will be displayed in the message

window. Turn the processor keyswitch to "Run".

Page 34

6–8 Using the 160-PD1 on Profibus

Click File and Save As from the tool bar, as an unique File Name.

The configuration of the scanner is now complete.

Note that cycl i ng power t o t he scanne r is recommended.

Summary of the Example Scanner Configuration

Table 6. A

Scanner to 160-PD1 Control words Byte SLC Add

Control Word (LSB) 1 O:2.14

Control Word (MSB) 2

Speed Feedback (LSB) 3 O:2.15

Speed Feedback (MSB) 4

Parameter Value (LSB) 5 O:2.16

Parameter Value (MSB) 6

Parameter Index 7 O:2.17 (LSB)

Parameter Handshake

8

O:2. 17 (MSB)

Table 6. B

160-PD1 to scanner Status words Byte SLC Add

Status Word (LSB) 1 I:2.14

Status Word (MSB) 2

Speed Feedback (LSB) 3 I:2.15

Speed Feedback (MSB) 4

Parameter Value (LSB) 5 I:2.16

Parameter Value (MSB) 6

Parameter Index 7 I:2.17 (LSB)

Parameter Handshake

8

I:2.1 7 (MSB)

Page 35

Using the 160-PD1 on Profibus 6–9

Setting up the SST-PFB-SLC Scanner Card to work in the SLC

In order t ha t the scanner can operate i n the SLC rack, first the SLC

rack configur ation needs to be set up. Using RSLogix500 in an offline

state, create a new program and setup the I/O configurat ion as sho wn.

The I/O configuration utilizes a digital input card in slot 1 to provide

com m ands to star t & stop the drive et c.

The SST-PFB-SLC scanner card i s d ropped into slo t 2 u s i ng ”O t her”

from the cards available column. You are require d t o specify the card

with an ID Code = 13635.

Please note tha t the ex ample c onf igura tion con tains a n addi tional card

in slot 3 which is not used in the following example.

With the card in slot 2 selected, click on Adv Config to specify the

number of words used in the card.

Page 36

6–10 Using the 160-PD1 on Profibus

Specify values as shown in the following window.

Click OK when finished and download the configuration to the SLC.

Page 37

Using the 160-PD1 on Profibus 6–11

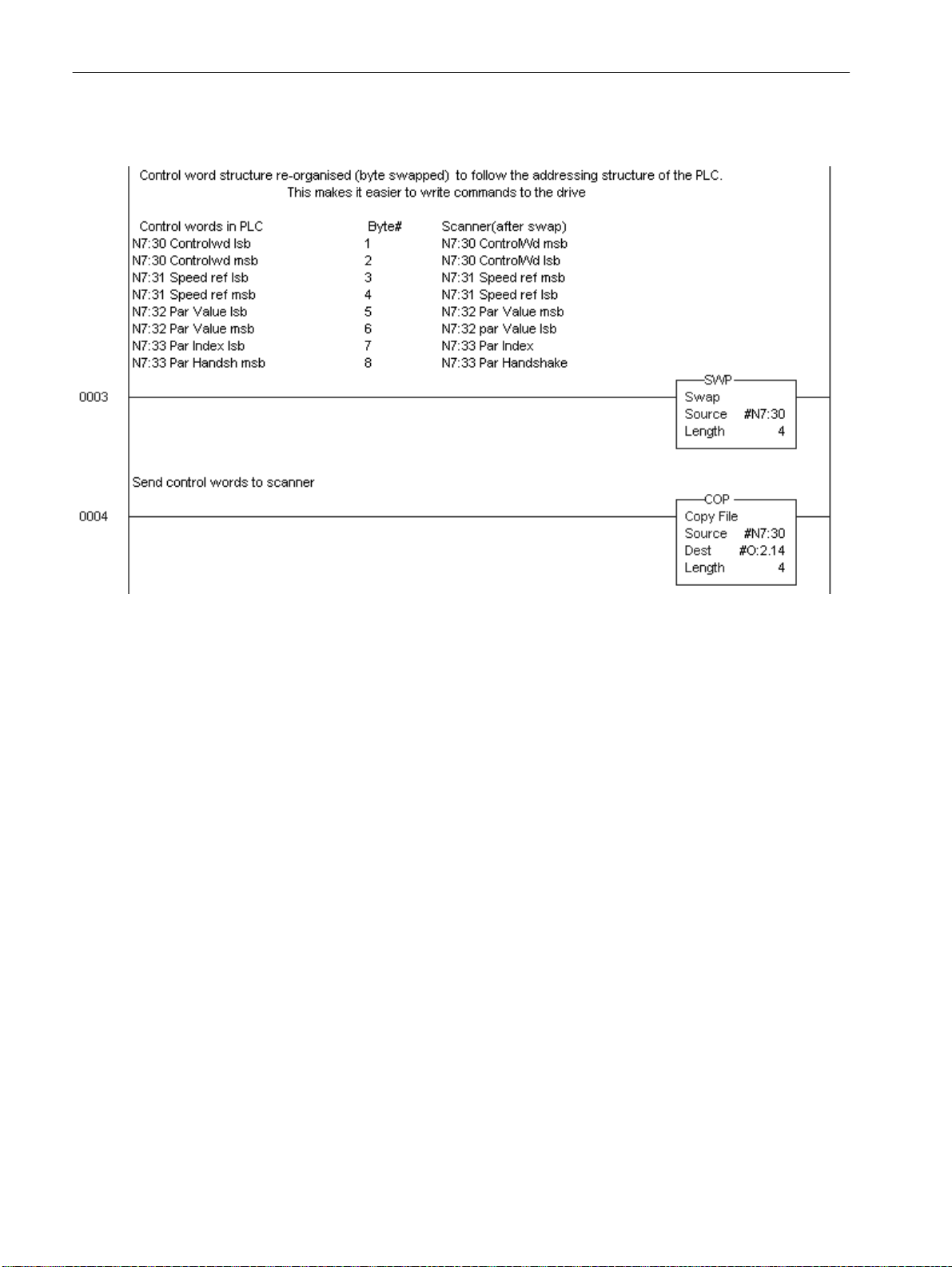

SLC Ladder Logic Example

Profib us scanners v ary from manufacturer to manuf acturer , in how the

bytes are or de re d i n a w o rd . T he SST-PFB-S LC s c ann er ca r d rec eives

/ transmit data with the Most Significant Byte (MSB) first and the

Least Significant Byte (LSB) second. This is opposite to ho w we read

/ write information in the SLC. This section of program below

reverses the high / low byte order using the SWP instruction.

Figure 6.1

SLC Ladder Logic Example.

SLC Ladder diagram continued on next page

Page 38

6–12 Using the 160-PD1 on Profibus

SLC Ladder Logic Example (continued)

Once the bytes have been swapped, the control and status words can

be manipulated as per normal.

Note: If your scanner does not order the MSB first, LSB second, but

the other way around, then the program above can be omitted.

Page 39

Using the 160-PD1 on Profibus 6–13

Controlling the Drive

Adjust the drive parameters as specified at the start of chapter 5

in order to test the drive with the following program example.

Figure 6.2

Drive Test Program Ladder Logic Example.

Ladder diagram continued on next page

Page 40

6–14 Using the 160-PD1 on Profibus

Drive Test Program Ladder Logic Example (continued)

Ladder diagram continued on next page

Page 41

Using the 160-PD1 on Profibus 6–15

Drive Test Program Ladder Logic Example (continued.

Page 42

6–16 Using the 160-PD1 on Profibus

The Profibus Telegram

The Profibus implementation of the 160-PD1 (as specified by the

GSD file) suppor ts 2 diff erent types of indepe ndent data tr ansmis sion.

The 2 words of control and status utilized above is the process data

cyclically transmitted / received, to start / stop the drive, provide a

reference, and get dr i v e feedb ack. This da ta trans mission pr ovide s th e

quickest means of communicating with the drive.

An additional parameter data channel is provided which is much

slower , w orking around the proc ess data cha nnels abov e, to r ead/write

parameters to a drive. This handles one parameter at a time, specified

by an index (parameter number) and a data channel.

In the example below, N7:41 contains the parameter number (Index),

and N7:4 2 contains a ny data that is to be written to the parameter

specified. These are copied to the Control words of the scanner for

action (N7:32 & 3). The command to read (80h) or write (A0h) is

copied from N7:43 & N7:44 and is shown on Rungs 4 & 5 on the

ladder above, as it forms the MSB part of the Logic Control Word.

This is an example of a read drive p arameter (all values in hex)

N7:40 is the Logic Control Word, where LSB = 5F (Drive running),

MSB = 80 (read operation).

N7:41 is the parameter number 2 = [Output Voltage].

N7:50 is the data from the drive on N7:22.

The value of D4h represents 212 Volts decimal.

N7:51 is a copy of the parameter number (Index) in the LSB

and the handshake if read operation was successful (MSB = 1).

This is another example of a read drive parameter

(all values in hex)

N7:40 is the Logic Control Word, where LSB = 5F (Drive running),

MSB = 80 (read operation).

N7:41 is the parameter number 8 = [Heatsink Temperature].

N7:50 is the data from the drive on N7:22.

The value of 45h represents 69 degrees C decimal.

N7:51 is a copy of the parameter number (Index) in the LSB

and the handshake if read operation was successful (MSB = 1).

Page 43

Using the 160-PD1 on Profibus 6–17

This is an example of a write drive parameter (all values in hex)

N7:40 is the Logic Control Word, where LSB = 5F (Drive running),

MSB = A0 (write operation).

N7:41 is the parameter number 1Eh (30 decimal) = [Accel Time 1].

N7:42 is the data to be sent to the drive 14h (20 decimal),

which represents an Accel = 2.0 seconds.

N7:50 is not relevant when a write operation i s i n progress.

However it will provide 14h when revert to a read operation.

N7:51 is a copy of the parameter number (Index) in the LSB

and the handshake if read operation was successful (MSB = 1).

This i s an exampl e of a read after a write drive parameter

(all values in hex)

Page 44

6–18 Using the 160-PD1 on Profibus

Figure 6.3

Profibus T elegram Ladder Logic Example.

Page 45

Chapter

Controlling the Drive

Controlling the 160 Drive from a programmable controller is

accomplished using the Telegram described in Chapter 5 to

communicate through the PD1 Module to the drive.

7

Setting the Drive to Enab le Network Control

The 160 driv e must be configured to accept logic and speed

commands from the network. This can be done by configurin g two of

the 160 parameters:

1. Set P46 - [Input Mode] to a value of “2” or “6” as described in the

following Table. This will configure the drive to accept the logic

commands from the network.

Important: The d rive may be ope r a ted i n other mo des as long as

the Profib us Master provides an Enable command

(control w o rd = 0x6)

2. Set P59 - [Frequency Select] to “1.” This will configure the drive

to accept speed commands fro m the network .

3. Set P66 - [RPM Scaling] according to rated namepla te s peed.

Changing the above parameters can be done with the 160 Keypad

Module or configuration software such as DriveExplorer.

Important: For a new Input Mode to take af fect, dr i ve pow er must be

cycl ed o r para mete r P56 - [Reset Functions] must be set to

“2” instead.

Setting the Node Address

The node address on the PD1 Module should be configured to the

desired setting for the network. After configuration, install the PD1

Module into the 160 Drive as explained in Chapter 3.

Page 46

7–2 Controlling the Drive

End of Chapter 7

Page 47

Chapter

Troubleshooting

The purpose of this chapter is to help you troubleshoot your P D1

Module.

ATTENTION: Servicing energized industrial control

equipment can be hazardous. Electrical shock, burns, or

!

unin tent ional a c tuation o f controlled industrial equ ipment

may cause death or serious injury . Follow th e safety-rel ated

practices of NPFA 70E, Electrical Safety for Employee

Workplaces, when working on or near energiz ed equipment.

Do not work alone on energized equipment.

ATTENTION: Do not attempt to defeat or override fault

circuits. T he cause of a fault indicati on must be determined

!

and corrected before attempting operation. Failure to

correct a dri ve or system malfunct ion may result in personal

injury and/or equipment damage due to uncontrolled

machine system operation.

8

Setup

LED Indicators and Troubleshooting

Make sure parameters P46, P59, P66 and P116 have been set

according to chapter 5.

The PD1 Status LEDs can help you troubleshoot the module in the

event that problems occur. Refer to t he paragraphs that follow for

details.

Status LEDs

READY LED

The green READY LED will illuminat e whene ver the PD1 Module is

connected t o the drive and power is applied.

Page 48

8–2 Troubleshooting

COMM LED

The COMM LED provides status information on module operations.

Table 8.A shows how to use the LED to detect and correct common

operating problems.

Table 8. A

COMM LED Indications

Color State What It Means: What To Do:

Green Off No communication takes place,

No power.

steady Communication ok,

data is exchanged

Red steady Diagnostics failed at power-up

or Fatal Error

flashing A cascade of 5 or 6 flashs means

Profibus configuration fault.

Any other flashs indicate Fatal Error

Check Po wer Supply,

Network Configuration

No action required.

Cycle power to the drive. If problem

persists, exchange PD1 Module

Check Network Configuration,

Profibus Master Setup and

SSC160 Setting (Section 5)

Exchange PD1 Module

FAULT LED

When the FAULT LED lights red, a drive fault (including

Fatal Er r o r

or an option board fault is present. Drive fault codes can be read by

accessing drive parameter P07 - [L a s t Fau l t].

Refer to Tables 8.B and 8.C for fault descriptions/actions.

Table 8. B

160 Drive

Fault Code Fault Indication Description Corrective Action

00 No Fault The drive is currently not faulted. No action required.

03 Power Loss F ault DC Bus voltage remains below 85% nominal on

power up for longer than 5 seconds.

04 Undervoltage Fault DC Bus voltage fell below the minimum value

while the motor was running.

05 O vervoltage Fault DC Bus maximum voltage exceeded. Bus overvoltage caused by motor regeneration.

06 Motor Stall Fault Motor has stalled. Motor load is excessive. Longer accel time or reduced load required.

07 Motor Overload Fault Internal electronic overload trip. Excessive

motor load exists.

08 Overtemperature Fault Excessive heat detected. Clear blocked or dirty heat sink fins. Check ambient

11 Operator Fault The keypad has been removed while the drive

is powered.

12 Overcurrent Fault Overcurrent detected in hardware trip circuit. Check short circuit at the drive output or excessive

20 Drive Overload Fault An internal electronic overload trip has

occurred. The drive is overheating.

22 Drive Reset Stop input not present. Check stop input at TB3 terminal 8.

32 EPROM Fault EPROM has invalid data. Reset EPROM using P56 - [Reset Func tions].

33 Max Retries Fault Drive did not reset fault within the max retries

specified.

38 Phase U Fault Phase to ground fault detected between drive

and motor phase U.

1

1

Fault Codes

Monitor incoming AC line for low voltage or line power

interruption.

Monitor incoming AC line for low voltage or line power

interruption.

Extend the decel time, or install dynamic brake option

or external capacitor module.

Reduce motor load.

temperature. Check for blocked or non-operating fan.

Clear the fault. Do not remove the keypad

underpower.

load conditions at the motor.

Clear blocked or dirt y heat sink fins. Check ambient

temperature. Check for blocked or non-operating fan.

Repair system fault.

Check wiring between drive and motor. Check motor

for grounded phase.

Refer to the 160 SSC™ Variable Speed Drive (Series C) User Manual for the most cur rent faul t code

information.

),

Page 49

Troubleshooting 8–3

Table 8.B (continued)

160 Drive

Fault Code Fault Indication Description Corrective Action

39 Phase V Fault Phase to ground fault detected between drive

and motor phase V.

40 Phase W Fault Phase to ground fault detected between drive

and motor phase W.

41 UV Short Fault Excessive current has been detected between

these two drive output terminals.

42 UW Short Fault Excessive current has been detected between

these two drive output terminals.

43 VW Short F ault Excessive current has been detected between

these two drive output terminals.

48 Reprogramming Fault Occurs when reset defaults is performed. Clear fault.

49 Zero Overload Fault Occurs when load requires excessive current at

zero hertz.

1

1

Fault Codes

Check wiring between drive and motor.

Check motor for grounded phase.

Check wiring between drive and motor.

Check motor for grounded phase.

Check the motor and external wiring to the drive

output terminals for a shorted condition.

Check the motor and external wiring to the drive

output terminals for a shorted condition.

Check the motor and external wiring to the drive

output terminals for a shorted condition.

Reduce motor load and/or motor dwell time at zero

hertz.

Refer to the 160 SSC™ Variable Speed Drive (Series C) User Manual for the most cur rent faul t code

information.

Table 8. C

Network Fault Codes

Fault Code Fault Indication Description Corrective Action

51 Serial Fault No serial Connection established Check if SSC160 of version ‘C’ or higher has been

52 Network lost connection Timeout on Network Check connection between Master and Slave

53 False Drive Type Drive Type is not compatible to option board Check if SSC160 of version > ‘C’ has been installed.

installed. (Refer to drives nameplate)

Check 30 pin connector on the options back.

Check parameter setting according to Section 5.

Page 50

8–4 Troubleshooting

End of Chapter 8

Page 51

Specifications

Appendix

A

Electrical

Environmental

Communications

Mechanical

Supply Voltage Supplied by Drive

Power Cons u m ptio n 0.75 Watt s (150 m A ) maximum

Ambient Temperature

Operating 0 to 65° C (32 to 149° F)

Storage –40 to 85° C (–40 to 185° F)

Relative Humidity 0 to 95% non-condensing

Vibrati on 1.0 G Opera tional

2.0 G Non-operational

Shock 15.0 G Oper a tional

30.0 G Non-operational

Altitude 1,000 m (3,300 ft.) without derating

Baud Rate 9.6k - 12M BPS

Protocol PROFIDRIVE

Dimensions are in Millimeters and (inches)

(1)

17.34

(0.68)

(2)

21.4

(0.85)

(1)

Required for module removal.

(2)

Module adds this dimension to the overall drive depth.

Page 52

A–2 Specifications

End of Appendix A

Page 53

Index

B

Baud Rate

, 6–5, A–1

C

Cable Termination

Cabling

CE Complian ce

Communication Cable

Configuration

Control W o rd

Controlling, Drive

, 3–7

Profibus-DP

Rotary Switch

SST-PFB-SLC

, 3–7

, 3–1

, 3–2

, 3–2

, 6–4

, 5–3

, 6–13, 7–1

D

Data Protocol

Dimensions

, 5–2

, A–1

E

Error Mode

, 4–2

F

Fault Codes

, 8–2

Drive

Network

, 8–3

, 3–8

M

Manuals, related

Modes of Operation

Error Mode

Power-up

Run Mode

Module Installation

, p–ii

, 4–1

, 4–2

, 4–2

, 4–2

, 3–3

N

Node Address, Setting

P

Parameter

Access

attributes

Descriptions

Power-up Mode

Profibus

Telegram

Profibus Net work

Configuration Frame

Termination

Publications

On-Line

Related

, 5–5

, 5–5

, 5–1

, 4–2

, 5–2, 6–16

, 3–8

, p–ii

, p–ii

Q

, 3–2

, 6–2

G

GSD file

, 3–2, 6–2

I

Installation

, 3–1

K

Keypad Removal

, 3–3

L

Ladder Logic Example

Profibus Telegram

, 6–11

SLC

Test Program

LEDs

COMM

FAULT

READY

, 6–13

, 4–1, 8–2

, 4–1, 8–2

, 4–1, 8–1

, 6–18

Quick Start

, 2–1

R

Removal, Module

Required Tools

Run Mode

, 2–1, 6–1

, 4–2

S

Scanner

Configuration

Setting up

SST-PFB-SLC

Specifications

Communications

Electrical

Environmental

Mechanical

Status Wo rd

, 6–9

, A–1

, A–1

, 5–3

, 3–4

, 6–8

, 6–1

, A–1

, A–1

Page 54

Index–2

T

Troubleshooting

W

Web Sites

Wiring

, p–ii, 3–2

Drive Terminal Block

Ground Terminal

PD1 Connector

, 8–1

, 3–5

, 3–6

, 3–7

Page 55

Page 56

Publication 160PD1-UM011B-EN – June, 2003 P/N 899.02.86

Copyright © 2003 Rockwell Automation. All rights reserved. Printed in Switzerland.

Loading...

Loading...