Page 1

160-IB1

InterBus

Communication

Module

Catalog Number: 160-IB1

Firmware: 1.00

User Manual

Page 2

Important User Information

Solid state equipment has operat ional char acteris tics differing from those of

electromechanical equipment. “Safety Guidelines for the Application,

Installation and Maintenance of Solid State Contr ols” ( Publication SGI-1.1)

describes some important differences between solid state equipment and

hard-wired electromechanical devices. Because of this difference, and also

because of the wide variety of uses for solid state equipment, all persons

responsible for applying this equipment must satisfy themselves t hat each

intended application of this equipment is acceptable.

In no event will Rock well Automation be responsible or lia ble for indirect

or consequential damages resulting from the use or application of this

equipment.

The examples and diagrams in this manual are included solely for

illustrative purposes. Because of the many variables and requirements

associated with any particular installation, Rockwell Automation cannot

assume responsibility or liability for actual use based on the examples and

diagrams.

No patent liability is ass umed by Rockwell Automation with respect to use

of information, circuits, equipment, or software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without

written permission of Rockwell Automation is prohibited.

Throughout this manual we use notes to make you aware of safety

considerations.

ATTENTION: Identifies information about practices or

circumstances that can lead to personal injury or death,

!

property damage, or economic loss.

Attentions help you:

• identify a hazard

• avoid the hazard

• recognize the consequences

Important:

Identifies information that is especially important for successful

application and understanding of the product.

Shock Hazard labels may be located on or inside the dri v e

to alert people that dangerous voltage may be present.

MicroLogix and SLC are trademarks of Rockwell Automation.

PLC and PLC-5 are registered trademarks of Rockwell Automation.

RSLinx and RSLogix 500 are trademarks of Rockwell Software, Inc.

Windows and Windows NT are registered trademarks of Microsoft Corporation

InterBus is a registered trademark of the Interbus Club

DRIVECOM is a registered trademark of the DRIVECOM user organization

Page 3

Using This Manual

Product Overview

Quick Start for Experi enced

Users

Ins tallation and Wiring

Table of Contents

Preface

Who Should Use This Manual? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . p-i

Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . p-i

IB1 Compatibility. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . p-i

Reference Manuals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . p-ii

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . p-ii

Chapter 1

Module Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Chapter 2

Required Tools and Equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Chapter 3

DRIVECOM 20 Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

EMC Directive 89/336/EEC Compliance. . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Low Voltage Directive 73/23/EEC Compliance. . . . . . . . . . . . . . . . . . . . . 3-1

Module Installation/Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Keypad or Ready/Fault Panel Removal . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Installing the IB1 Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Removing the IB1 Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

Wiring the Drive Terminal Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Wiring the IB1 Ground Terminal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Wiring the Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Connecting the Communication Cable to the Module. . . . . . . . . . . . . . . . 3-7

Modes of Operation

InterBus Parameter

Descriptions and Data Protocol

Chapter 4

Powering Up the Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

LED Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Operation Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Power-up Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Run Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Error Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Chapter 5

160 SSC Drive Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Data Channels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Data from InterBus Master to IB1 Slave . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Data from IB1 Slave to InterBus Master . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Control and Status Word DRIVECOM 20/21 . . . . . . . . . . . . . . . . . . . . . . 5-3

Drive State Transitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Parameter Access. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Parameter attributes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Parameter Access Fault Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Communication Statistics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Page 4

ii Table of Contents

Using the 160-IB1 on InterBus

Controlling the Drive

Troubleshooting

Specifications

Chapter 6

Required Tools. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Create an InterBus Network Configuration Frame. . . . . . . . . . . . . . . . . . . 6-2

Controlling the Drive with I/O Messaging. . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

The InterBus PCP Telegram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

Reading and Configuring Parameters with the PCP Telegram. . . . . . . . . 6-11

Chapter 7

Setting the Drive to Enable Network Control . . . . . . . . . . . . . . . . . . . . . . . 7-1

Chapter 8

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

LED Indicators and Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Communication Status LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

FLT LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

IB1 Network Error Codes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-4

Appendix A

Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Environmental . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Mechanical. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Index

Page 5

Preface

Using This Manual

The purpose of this manual is to provide you with the necessary

information to apply the Bulletin 160-IB1 Communications Module .

Described in this manual are methods for installing, configuring, and

troubleshooti ng t he 160-IB1 Inter Bus Communications Module.

For information on specific drive features, refer to the 160 SSC™

Variable Speed Drive (Series C) User Manual.

Important: Read this manual in its entirety before installing,

operating, servicing, or initializing the IB1 Module.

Who Should Use This Manual?

Conventions

IB1 Comp atibility

This manual is intended f or qua lif ied pe rsonnel. To make eff icient use

of the Communication Module, you must be able to program and

operate InterBus communications devices, as well as have an

understan d ing of the paramete r settings and functions of the 160

Drive.

In this manual we refer to the:

• 160-IB1 Communication Module as Communication Module ,

IB1 Module or Module.

• 160 SSC Adjustable Fr equency AC Drive as the 160 Drive or

drive .

In addition, parameter numbers and names (both 160 Drive and IB1

Module) are shown in bold typeface and follow the format PXX - [ *]

where P denotes parameter, XX denotes the two digit parameter

number, and * represents the parameter name.

For example, P01 - [Output Frequency].

The IB1 Module is compatible only with 160 Drives Series C or

above. When properly connected, the module communicates via an

InterBus networ k.

Page 6

p–ii Preface

Reference Manuals

For Read This Document

Additional information about networking and the SLC™ 500 SLC 500 Modular Hardware Style Manual 1747-6.2

Information about the AIC+ AIC+ Advanced Interface Converter User Manual 1761-6.4

Instruction set information for the SLC 500 and MicroLogix™

1000

For general MicroLogix 1000 information MicroLogix 1000 User Manual 1761-6.3

For 160 SSC Drive Information 160 SSC™ Variable Speed Drive (Series C) User Manual 0160-5.17ML

A complete listing of current Allen-Bradley documentation,

including ordering instructions. Also indicates whether the

documents are available on CD-ROM or in multi-languages.

A glossary of industrial automation terms and abbreviations Allen-Bradley Industrial Automation Glossary AG-7.1

Information about the SSC-IBS-SLC™ Scanner Scanner Card User Manual. SST Woodhead documentation can

The following documents contain addition al in f ormation c onc erning

Allen-Br ad ley p r oduc t s. To obtain a copy, contac t your loca l A l l e n -

Bradley Sales Office or visit the “On-Line Publications” area of the

Allen-Bradle y Internet home pag e at: www.ab.com.manuals

Publication

Number

SLC 500 and MicroLogix 1000 Instruction Set Reference Manual 1747-6.15

Allen-Bradley Publication Index SD499

Version 1.0

be obtained online at http://www.mySST.com/download/

Safet y Precau ti o n s

ATTENTION: Only personnel familiar with 160 Drives,

Communication Modules and associated machinery should

!

plan or implement the installation, start-up, configuration

and subsequent maintenance of this module. Failure to

comply may result in personal injury and/or equipment

damage.

ATTENTION: This module contains ESD (Electrostatic

Discharge) sensitive parts and assemblies. Static control

!

precautions ar e required when insta lling, testi ng, servicing,

or repairing this ass embly. Component damage may result

if ESD control procedures are not fol lowed. If you are not

familiar with static control procedures, reference

Allen-Bradley Publication 8000-4.5.2, Guarding Against

Electrostatic Damage or any other applicable ESD

protection handbook.

ATTENTION: The dri ve contains high v oltage capacitor s

which take time to di scharge after remov al of AC line po wer.

!

Before instal ling or removing the Communication Module,

ensure isolation of mains supply from line inputs R, S, T

(L1, L2, L3). W ait the r ecommended amount of ti me for the

capacitors to discharge to safe voltage levels (refer to the

160 SSC™ Variable Speed Drive (Series C) User Manual

for recommended time). Failure to do so may result in

personal injury or death.

ATTENTION: When a system is configured for t he first

time, the motor must be disconnected from the machine or

!

process during initia l system testing. Hazard of injury or

equipment damage may occur due to unint ended or

incorrect m achi n e mo tion .

Page 7

Product Overview

This chapter contains the following information:

• The physical layout of the module.

• Overview and components.

Chapter

1

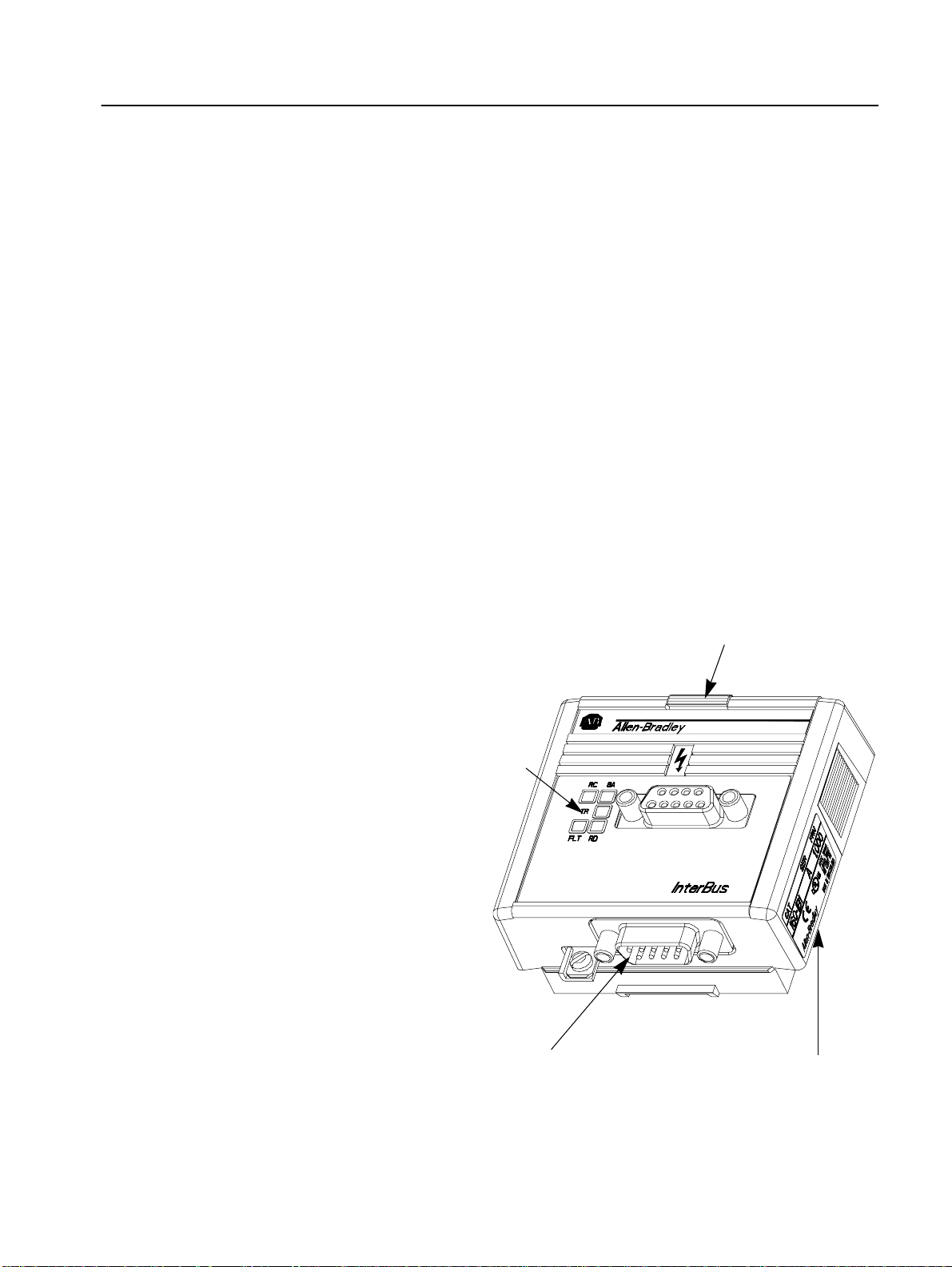

Module Description

The IB1 Module is an optional interface device designed to provide a

direct, digital l ink between a n InterBus M aster and the 1 60 Dri v e. The

module connects to the drive through the expansion/keypad port on

the front of the drive. Refer to the Figure 1.1 for general layout of the

module and Chapters 4 or 8 for details on the LED indicators.

The IB1 Module has the following characteristics:

• 3 word pr ocess data chann el (control, r e f e r ence & diagnostics)

• 1 InterBus PCP telegram for configuration and reading of drive

parameters and error codes

• DRIVECOM 20 (part of 21) profile supp ort.

Figure 1.1

Module Front View

Module Installation Latch

Status LEDs

Refer to Chapt ers 4 & 8

for Further Information

9 Pin, Male D-Shell Connector

Refer to Chapter 3 for Details

Nameplate

Provides Firmware Version

and Series Letter

Page 8

1–2 Product Overview

End of Chapter 1

Page 9

Chapter

2

Quick Start for Ex perie nced Users

This chapter can help you start using the IB1 Communication

Module. If you have installed or configured a network previously and

are familiar with Allen-Bradley communication modules and drives,

this info r mati on can he lp re d u ce the time o f installation . I f you are

uncertain, use the full installation/configuration information

beginning in Chapter 3.

We base the procedures here on the assumption that you understand

the basic concepts, know how to program the 160 Drive and

understand electronic process control.

Because it is a start-up guide for experienced users, this chapter does

not contain detailed explanations about the procedures listed. It does,

however, reference other chapters in this book where you can find

more information.

If you have any questions or are unfamiliar with the terms used or

concepts presented in the procedural steps, always read the

referenced chapters and other recommen d ed documen ta t ion before

trying to apply the information.

Required Tools and Equipment

This chapter contains the following information:

• What tools and equipment you need.

• How to install and wire the Communicati on Module .

• System power-up procedures.

Have the f ollowing tools and equipment r eady:

• 3.2 mm (1/8 in.) flat blade screwdriver.

Page 10

2–2 Quick Start for Experienced Users

Procedures

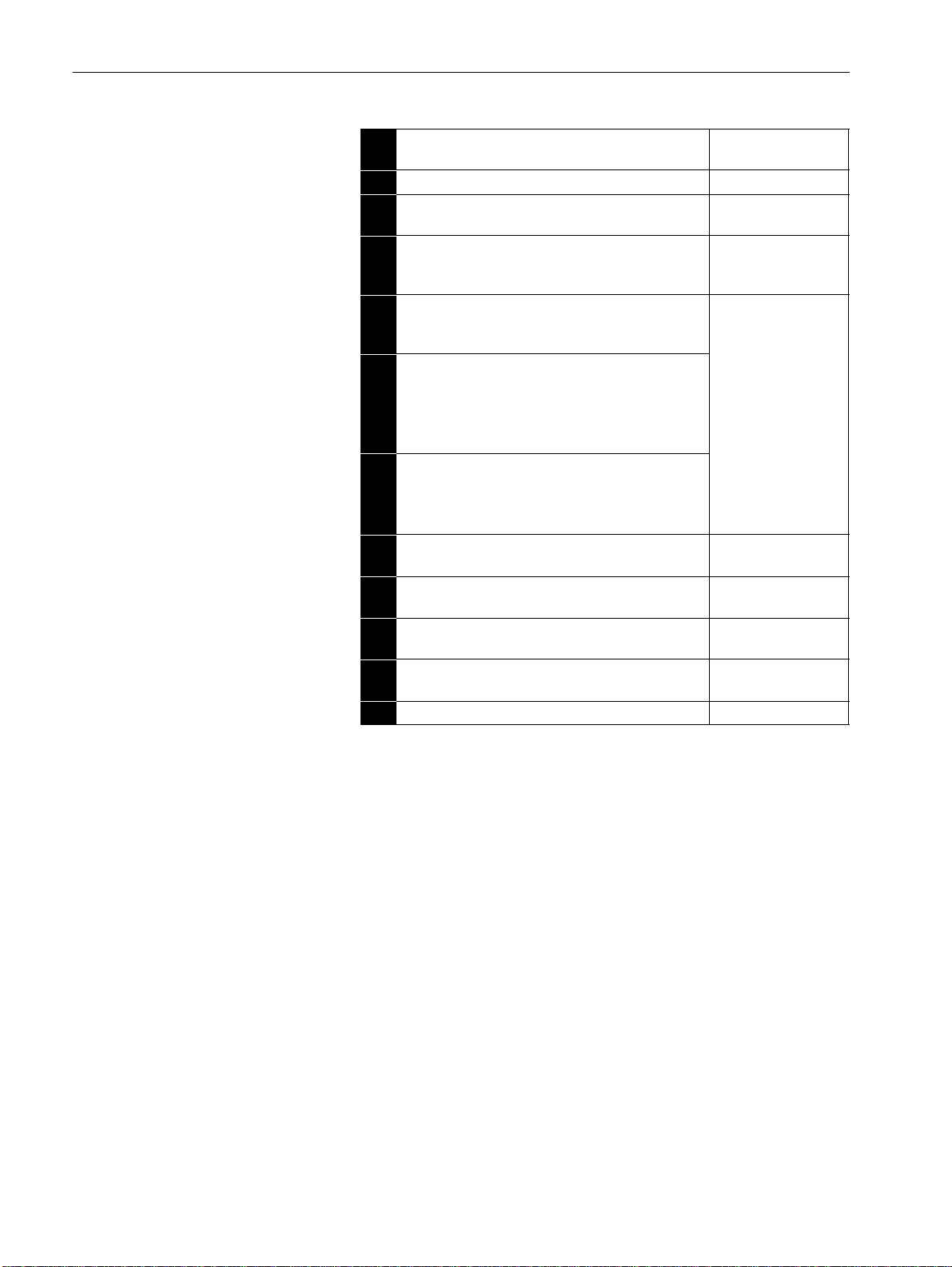

Step Action

For Further Info rmation

1. Review Attention statements in the Preface.

Ensure that power to the 160 Drive has been removed. 160 Drive

2.

Verify that the 160 Drive is correctly installed and

3.

wired. Stop Input (TB3-7, TB3-8) must be jumpered

together to start drive.

Configure the 160 Drive for the IB1 Module so the drive

4.

can accept control logic and speed reference via the

network. *

Set P46 - [Input Mode] to a value of “2” or “6” as described

in Table 6.A. This will configure the d rive to accept the logic

commands from the network.

Note: If the value has to be changed, set P56 - [Reset

Functions] to “2” or reboot the drive.

Set P59 - [Frequency Select] to “1.” This will configure the

drive to accept speed commands from the network.

Set P66 - [RPM Scaling] for the RPM/Hz Scaling factor.

This allows theNetwork Reference to be in RPM.

Remove Program Keypad Module or Ready/Fault

5.

Indicati ng Panel fr om the dri v e.*

6. Install the IB1 Module.

7. Connect communication cable.

8. Power up the drive and the network.

9. Check for proper operation.

* Parameter setting might also be done via the

Keypad Module prior to removal

Refer to…

User Manual

160 Drive

User Manual

Chapter 5

(Parameters)

Chapter 3

(Installation)

Chapter 3

(Installation)

Chapter 3

(Installation)

Chapter 3

(Installation)

Page 11

Chapter

3

Installation and Wiring

This chapter contains inf ormation needed to:

• Check for rotational direction to comply with DRIVECOM 20.

• Meet the requirements of the EMC and Low Voltage direc tives

for CE compliance.

• Remove a pre-installed Program Keypad Module or Ready/Fault

Indicating Panel.

• Install the IB1 Module.

• Wire the communication cables.

• Wire the protection earth connection

• Remove the IB1 Module from the drive.

Read this chapter completely before you attempt to install or

configure your module. Before applying power, revie w the Attention

statements presented throughout this m anual. Verify that all

connections are secure and that all selections are correct.

DRIVECOM 20 Compliance

EMC Directive 89/336/EEC Compliance

Low Voltage Directive 73/23/ EEC Compliance

In order to comply with DRIVECOM 20 forward rotational direction

is def ine d as t urning cloc kwise facing motor shaft with positive speed

reference applied. Refer to the 160 SSC™ (Series C) Variable Speed

Drive User Manual, Start-up procedure, chapter 4.

ATTENTION: Unpredictable operation may occur if you

fail to chec k connections for compatibility with your

!

application. Unpre dictable operation may result i n personal

injury, death, and equipment damage.

This product complies with Ele ctromagnetic Compatibility (EMC)

Directive 89/336/EEC when conforming with the following

installation requirements:

• The essential requi rements for a confor ming EMC inst alla tion for

the Bulletin 160 SSC are employed. Refer to the 160 SSC™

Variable Speed Drive (Series C) User Manual.

This produc t complies with Low Voltag e Di rective 73/23/EEC when

conforming with the following installation requirements:

• The essential requirements for a conforming Low Voltage

Directive installation for the Bulletin 160 SSC are employed.

Refer to the 160 SSC™ Variable Speed Drive User Manual.

• Review the Attention st at ements in t h e P reface, and o t her areas

throughout this manual prior to installatio n o f the module.

Page 12

3–2 Installation and Wiring

Module Installation /Re moval

ATTENTION: The dri ve contains high v oltage capacitor s

which take tim e to discharge after remov al of mains supply .

!

Before installing or removing a keypad/module, ensure

isolation of mains supp ly from line inputs R, S, T (L1, L2,

L3). Wait the recommended amount of time for the

capacitors to discharge to safe voltage levels (refer to the

160 SSC™ Variable Speed Drive (Series C) User Manual

for recommended time). Failure to do so may result in

personal injury or death.

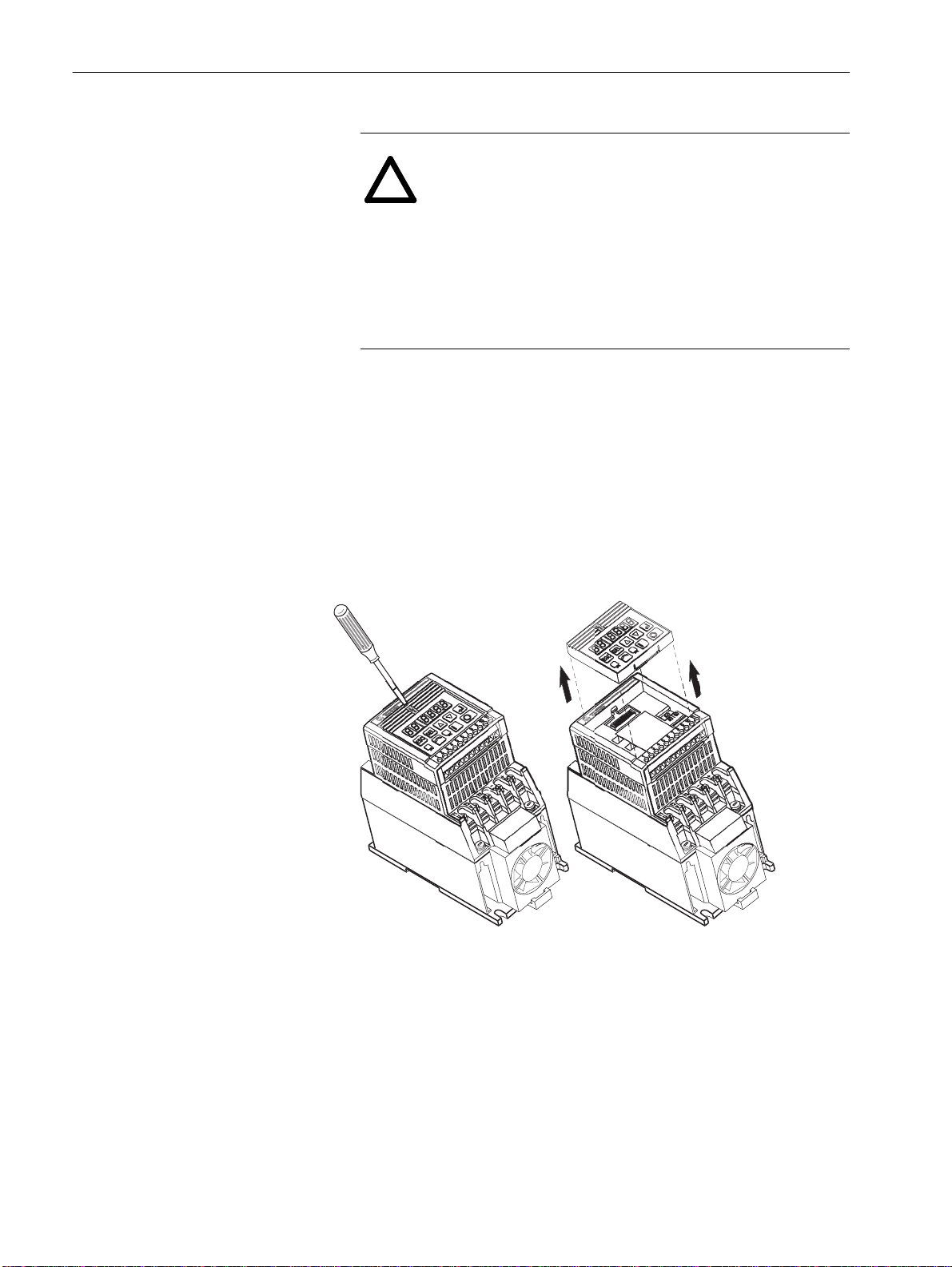

Keypad or Ready/Fault Panel Removal

Before installing the IB1 Module, it may be necessary to remove a

previously installed Program Keypad Module or Ready/Fault panel.

1. Verify that all power to the drive is removed.

2. Insert a small screwdriver into slot, pry back and pivot module

out. Avoid bending or twisting the contact pins located under the

module.

Figure 3.1

Removing Program Keypad Module

Program Keypad Module

(or Ready/Fault Panel)

Installing the IB1 Module

Install the IB1 Module in the drive by following these steps:

1. Verify that all power to the drive is removed.

2. Verify that the latch is up (see Figure 3.2). Insert th e m odule,

ensuring that the pins on the back of the module line up with the

drive connector/expansion port.

3. Pr ess the module do wn unti l it is full y seated (side s are flush with

the top surface of the drive).

4. Press t he latc h down until it sna ps into pl ace.

Page 13

Figure 3.2

Communication Module Installation

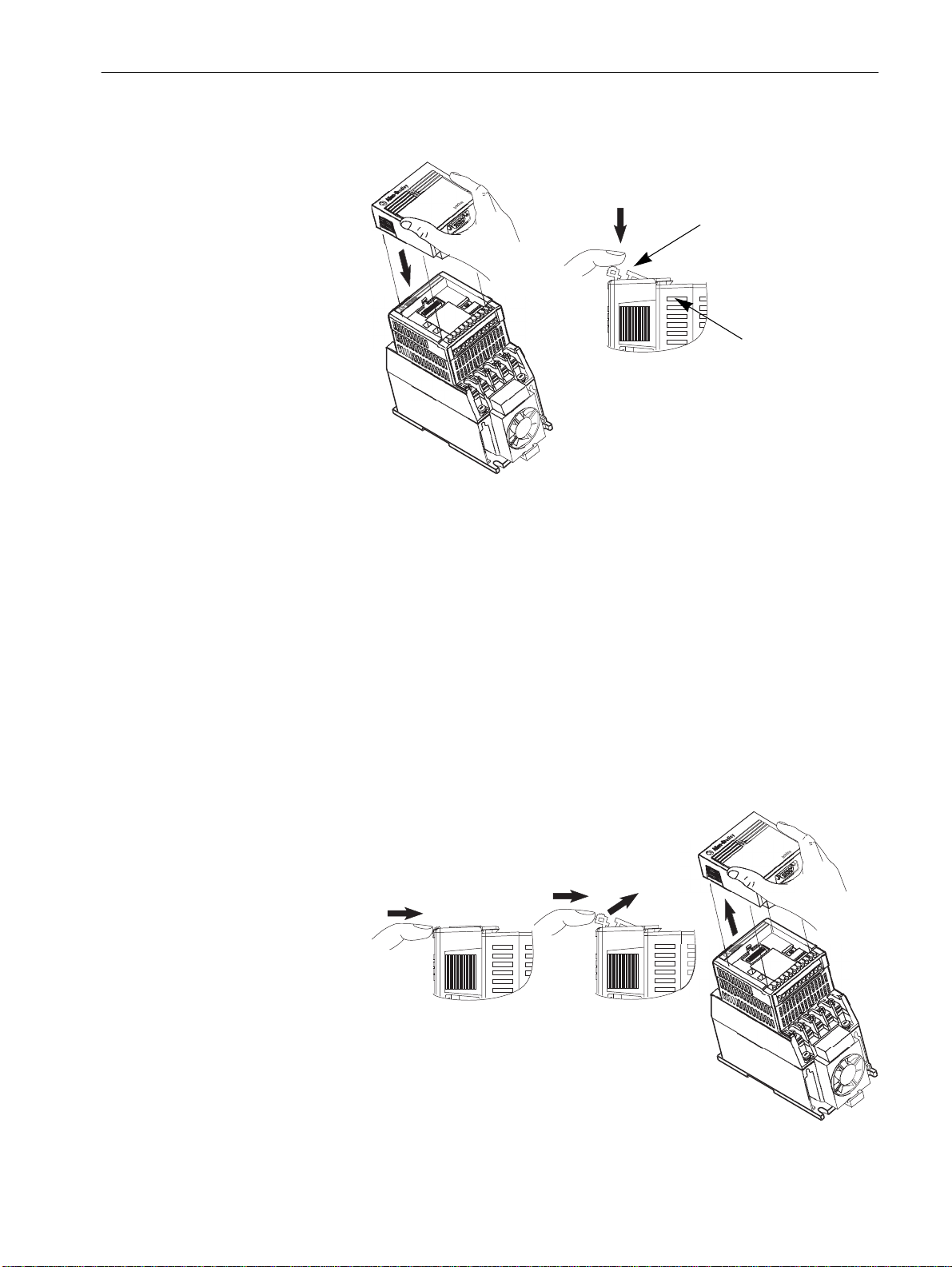

Removing the IB1 Module

Installation and Wiring 3–3

Latch must be in this position before

installation. Once installed, push the

latch down until it locks into place.

Module should be flush

with top surface of drive

If you need to remove the module from the drive, you must

1. Verify that all power to the drive is removed. Review Attention

statement on page 3–2.

2. Disconnect the cable/connector from the module (if present).

3. Press in on the module’s latch and then push away and up.

4. Grasp the module and pull straight up. Avoid bending or twisting

the contact p ins loc at ed under neath the cen ter portion of the

module.

Figure 3.3

Removing the Communication Module

Page 14

3–4 Installation and Wiring

Wiring the Dri ve Terminal Block

The 160 drive and 160-IB1 interface can be controlled on a network

in 2 different mod es.

[Input Mode] = 2

This mode is used where the dr i ve is controlled sol ely by the netw ork.

The 160-SSC drive requires, that a stop signal is present on the

hardware terminals, before the drive can be started.

Control

ether a wire bridge or a normally closed stopping device.

Fitting a stopping device (e.g. pushbutton) in place of the link,

can provide addition al lo c al stop/emergency stop capability.

Important: Failure to link the stop command input, will result in the

[Input Mode] = 6

This mode is used whereby it is possible to cont rol the drive across

the network or locally, by putting a switch on the Control Terminal

Block 3 (TB-3) pins 7 & 8.

When the switch is closed, the Frequency source comes from th e

reference as defined by P59 - [Frequency Select]. As we are using

the 160-IB1, the reference is across t he Interbus network.

Additionally the start command is active across the network.

Terminal Block 3 (TB-3) pins 7 & 8 need to be linked by

drive generating a fault, and inability to run accross a

network.

When the switch is open, the Frequency source comes from the

terminal block (analogue reference or potmeter), regardless of the

setting of f P59 - [Frequency Select]. Additionally the start command

is controlled by the terminal block or keypad.

Page 15

Installation and Wiring 3–5

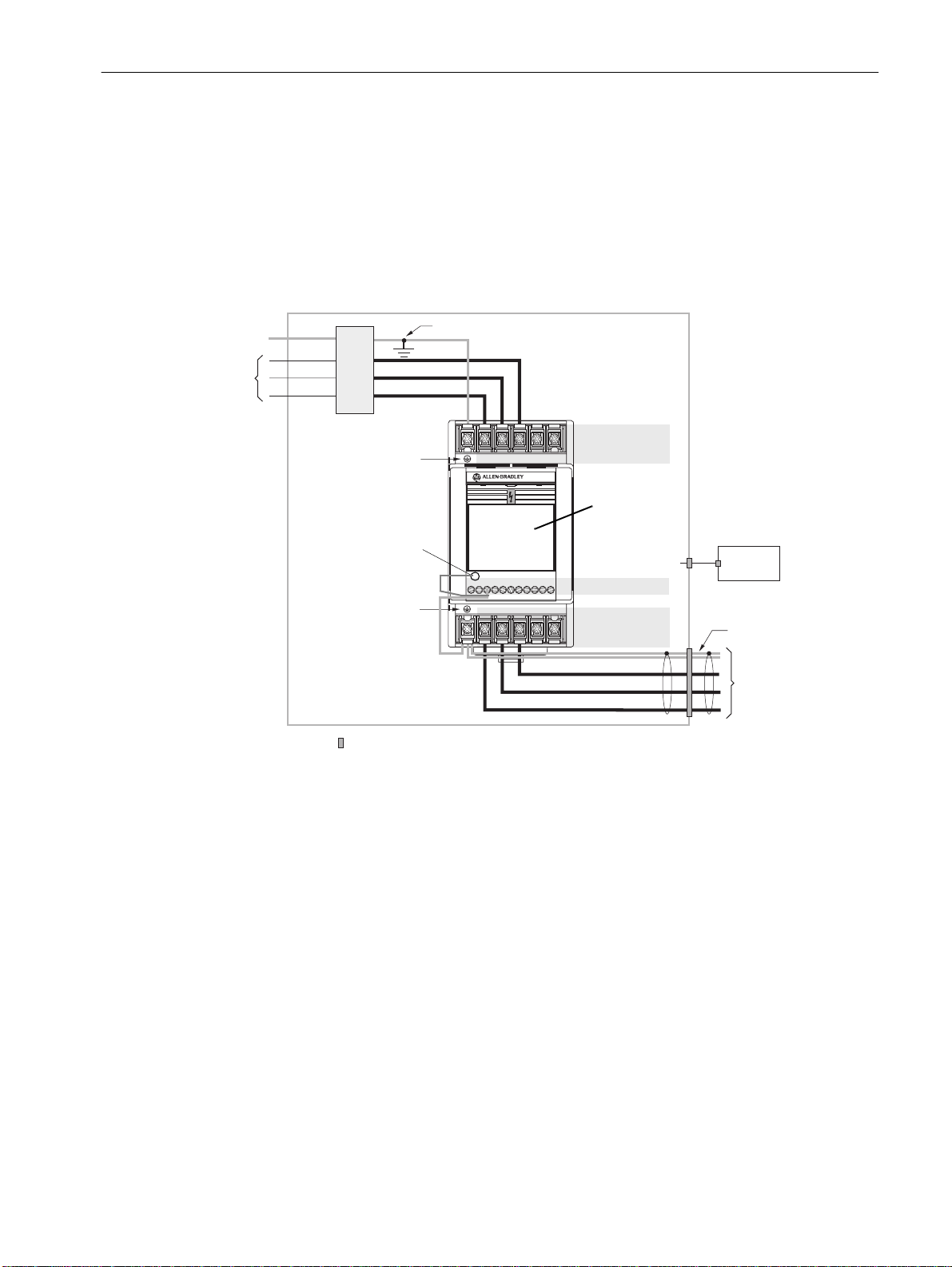

Wiring the IB1 Ground Terminal

PE

T (L3)

AC

nput Line

S (L2)

Filter

R (L1)

Ground T erminal – PE

IB1 Ground Terminal

Ground T erminal – PE

In addition to the ground connections shown in Appendix C of the

160 SSC manual, the ground terminal at the bottom of the IB1

module must be solidly connected (and as short as possible) to the

signal common terminal 3 at TB3 of the 160 SSC drive, as shown in

Figure 3.4:

2

This connection shall have a cross section of 1.5 mm

Figure 3.4

IB1 Module Grounding

Enclosure Ground Connection

Line

T/L3

S/L2

R/L1

R/L1

S/L2

T/L3

BR–

Line Power TB1

BR+

IB1 Communication

FAULT

READY

1

45678910112

3

V/T2

U/T1

W/T3

DC–

DC+

Module

to TB3

Control Wiring TB3

Motor Wiring TB2

.

Control

Cabinet

➊

Shielded Motor Cable

Shielded Enclosure

= EMC Tested Shielded Cable Clamp (or Metal Conduit)

➊

When the control circuitry is located outside of the 160 enclosure.

W/T3

V/T2

U/T1

to Motor

Page 16

3–6 Installation and Wiring

Wiring the Connectors

The example in F igure 3.7 can be use d as a guide when wiring.

Important: Keep communi cat i on w i ring away fro m high noise

sources suc h as motor cab l es .

Figure 3.5

Wiring the IB1 Connectors

9-Pin, Female D-Shell Co nnector (NEXT)

Ground Connection

Terminal

Pin 1

9-Pin, Male D-Shell Connector (IN)

Pin 9

Note: For better visibility of the status LED's it is recommended to

use a cable inline with connector (180° not 90°).

Figure 3.6

Remote Bus Cable Termination

/DO 6

DO 1

/DI 7

DI 2

COM 3

9

5

green

yellow

pink

gray

brown

6 /DO

1 DO

7 /DI

2 DI

3 COM

Male end via strain relief Female end

(Grounding Clamp)

Note: Wire colors may vary depending on cable manufacturer

Page 17

Installation and Wiring 3–7

Connecting the Communication Cable to the Module

PLC

m

InterBus

Master

Follow these steps to connect your module.

1. Verify that the cable/connector is correctly wired

(See Figure 3.6).

2. Locate the D-shell (IN) connector at the base of the IB 1 Module.

3. Plug cable /connector into the IB1 D-shell connector and secure.

4. Extend the network via the D-shell

(NEXT) connector on the front.

5. Last IB1 of network, D-shell (NEXT) conn ector must be left

empty for the network to be correctly terminated.

Figure 3.7

Remote Bus Connection

Remote Bus

InterBus

SSC160-C

f

Master Interfaces:

mm

ff

InterBus

SSC160-C

InterBus

SSC160-C

f: female connector

m: male connector

Page 18

3–8 Installation and Wiring

End of Chapter 3

Page 19

Chapter

Modes of Operation

Chapter 4 contains the following information:

• Powering up the drive with the IB1 Module installed.

• The modes of operation and LED indications.

4

Powering Up the Drive

LED Indicators

After you ha ve ins talled the IB 1 Module, a pply po wer to the dr i ve and

to the connected device. The READY LED should illuminate.

If it does not, refer to Chapter 8, Troubleshooting.

The IB1 Module has five LEDs (see figure below) which provide

module status.

BA LED

RC LED

TR LED

FAU LT LED

RD LED

The LEDs are defined as follows:

• Four Communication Status LEDs – These LEDs have the

following functions:

RC (yellow): Remote bus Check (Input cable connect ion o.k. )

BA (green): Bus Active

TR (green): Transmit/Receive (PCP Communication active)

RD (red): Remote bus Disable (Output cable connection

missing)

•FLT (red) – This LED tracks the fa ult status of the 160 Drive.

When no faults a re present, the LED will be off. The LED will

illuminate (red) if a drive fault occurs.

For more information refer to Table 8.A.

Page 20

4–2 Modes of Operation

Operation Modes

The IB1 Module has three modes of operation.

• Power- up mode

• Run mode

• Error mode

Power-up Mode

If the power-up sequence is successful, the modul e enters the run

mode (RC LED on) and the TR LED flashes green.

If the power-up sequence fails, the TR LED will go to off and the

module will enter the Error Mode (see below).

Run Mode

After a successful po wer -up, th e IB1 Module enter s the run mode and

operates as a slave device to a master device (BA LED on).

The RC LED i s o n , i n dic at ing the receiving of messages.

In run mode, the module:

• Accepts and responds to messages from the master on the

network.

• Monitors cable integrity an d t ransmission performance.

TR LED is on in case of PCP messages are exchanged. If an error is

detected, the module enters Error Mode (see below).

Error Mode

If the module detects an error, the fault is indicated by the FLT LED.

Refer to Chapter 8 for details on how to recover from an error.

Page 21

160 S S C Dr ive Parameters

Parameter Number

Drive IB1

Index; Subindex

46 0x5FF0; 46

0x5FF9; 46

59 0x5FF0; 59

0x5FF9; 59

66 0x5FF0; 66

0x5FF9; 66

Access [Parameter Name] and Description

Read

Write

Read

Write

Read

Write

Chapter

InterBus Parameter Descriptions

and Data Protocol

This chapter provides a listing and description of the Bulletin 160

Drive parameters related to Networ k Operation, and the IB1 Module

Data Protocol information.

Important: Refer to your 160 S SC™ Varia ble S peed Dri v e (Serie s C)

User Manual for drive parameter descriptions.

[Input Mode]

Configures the TB3 control inputs for various 3-wire or 2-wire control schemes.

Also enables/disables the program keypad module input control.

Settings: must be set to either

2 = Program Keypad Module control or

6 = 2-wire TB3 Control/Keypad or Communication control

A contact closure on TB3 terminals 7 and 8 is required for the drive to respond to a

Run command.

Important: This parameter cannot be programmed while the drive is running.

In addition, power must be cycled or P56 - [Reset Function] must be

set to 2 for the change to take effect.

[Frequency Select]

Selects the source of the frequency command for the drive.

The reference to P58 - [Internal Frequency] is bipolar, so a positive reference gives

forward rotation, and a negative reference gives reverse direction.

Settings:must be set to 1 = internal freq. command from P58 - [Internal Frequency].

[RPM Scaling]

A scaling factor is required to interpret a speed reference in RPM at the [Maximum

Frequency] of the drive. The 160 Drive parameter P 66 - [Preset Frequency 5] is

used by the IB1 Module for this purpose.

P66 = rRPM / rf

rf: required motor frequency to achieve rRPM

rRPM: final RPM at applicat ion output (e.g. speed at gear box output),

which will be displayed at InterBus Master.

Application Speed [rpm] = Drive Output Frequency x P66 [RPM Scaling]

e.g. 1500 rpm = 50 Hz x 30 (4 pole motor) P66 = 30.0 (300)

Gear Box 1:20: 75 rpm = 50 Hz x 1.5 (4 pole motor) P66 = 1.5 (15)

For network operation the P66 values in brackets are valid, which are ten times the

values for key pad operation.

If P66 - [RPM Scaling] is set to 0, speed reference may be sent via the network

directly in 1/10 of Hz.

e.g. SpeedRef [Hz] (InterBus) = 405 results in 40.5 Hz of output frequency.

Speed feedback is considered to be P01 - [Output Frequency],

which reflects the output frequency considering ramp rates.

5

Min./Max.

Values Default

0/9 0

0/1 0

0-240

[0-2400]

50

ATTENTION: Unpr edictable motor speed can cause de ath,

injury or equipment damage. Do not use P66 as the [Preset

!

Frequency 5] function via control terminal wiring.

Note:

P57 [Program lock] may be set to 1 (locked), but parameter programming via network will still be possible.

Page 22

5–2 InterBus Parameter Descriptions and Data Protocol

InterBus Data Protocol

Data Channels

The data transfer in Interbus terminology is called Peripherals

Communications Protocol (PCP).

Process data and parameter data is transmitted in the InterBus system

via two independant transmission chan n els. i.e. the process data

channel and the parameter data channel.

The process data ch annel cyclically transmits process data in the

form of an I/O image. This image contains the logic control word to

start /stop the drive, and the reference to c ontrol the speed, which is

used in the appli catio n progr am to control the dri v e. Ad ditio nally th is

image receives the drive status word, and the speed feedback word,

which is used in the application program to monitor drive operation.

Together with a diagnostics register, this results in three registe rs

being transmitted to and from the drive (see table 5 A & B). This

direct memory access to control the drive is both simple and quick.

The parameter data channel only transm its data if necessary, and is

integrated into the transmission protocol being handled by the

InterBus master. When the parameter data channel is used, the master

inserts a frame of inform ation to send to the dri ve requ esting dif f erent

actions (see table 5E). This frame of informa tion requests a read or

write parameter/attribute which can take several physical cycles of

read/write with handshaking to implement, resulting in much slower

access th an t h e pro ces s da ta cha n n el .

Data from InterBus Master to IB1 S l ave

Thus the combination of the faster process data channel for control,

and the slower parameter data channel, optimises the data

transmission.

A scaling factor is req uired to inte rp ret a speed re ference in RPM .

The 160 Dri ve par amete r P66 - [Preset Frequency 5] is used by the I B1

Module for this purpose. See “160 SSC Drive Parameters” on page1.

ATTENTION: Unpredictable motor speed can cause

death, injury or equipment damage. Do not use P66 as the

!

[Preset Frequency 5] function via contro l t e r mina l wiring.

Table 5.A

Register No. Register (Words) Description

0 Control Word According to DRIVECOM 20

1 Speed Reference Speed reference in RPM

2 Diagnostics reserved

Page 23

InterBus Parameter Descriptions and Data Protocol 5–3

Data from IB1 Slave to InterBus Master

Control and Status Word DRIVECOM 20/21

Speed Feedback, displa yed by Register 1, is scaled in RPM according

to P66 - [RPM Scaling].

Table 5.B

Register No. Register (Words) Description

0 Status Word According to DRIVECOM 20

1 Speed Feedback 160 Drive Output Frequency (motor RPM)

2 Diagnostics reserved

Control an d St at u s w or d b its ar e defined as follo ws (speed control):

Table 5.C

Control Word (Bit definition)

Bit No. DRIVECOM 20 Control SSC160

0 Switch-on 1 = Switch-on

1 Disable voltage 0 = Disable

2 Fast Stop 0 = Stop

3 Enable Operation 1 = Enabled

4 reserved

5 reserved

6 reserved

7 Reset Fault 0 to 1 Transition = Reset

8 to 15 reserved

To start the drive, set the control word (Low Byte) from 6 t o Fh.

To stop the drive, set the control word (Low Byte) to 6.

T o c ont rol the dr i ve via Terminal Block (T B3), the Control Word Low

Byte must be set to 06h (state READY TO SWITCH ON).

Table 5.D

Status Word (Bit definition)

Bit No. DRIVECOM 20 Status SSC160

0 Ready to switch-on 1 = Ready

1 Switched-on 1 = Switched-on

2 Operation enabled 1 = Enabled

3 Fault 1 = Fault

4 Voltage-disabled 0 = Disabled

5 Fast stop 0 = Stop

6 Switch-on-disabled 1 = Disabled

7 reserved

8 reserved

9 Remote 0 = Local

10 Speed Ref. Reached 1 = Speed Ref. Reached *

11 Speed limited 1 = Speed limited *

12 reserved

13 reserved

14 Reverse Disabled 1 = Reverse Disabled

15 Direction 1 = Reverse (running)

* Internal speed reference/feedback is computed in 0.1Hz increments.

Due to rounding issues speeds in RPM may differ.

Resolution error in RPM = P66 * 0.05.

Example: for P66 = 16.6 the possible error is 1 RPM.

Page 24

5–4 InterBus Parameter Descriptions and Data Protocol

Drive State Transitions

SWITCH ON DISABLED

(Power-up and diagnostics o.k.)

9

Disable voltage

xxxx xx0x

8

Shutdown

xxxx x110

2

xxxx x110

READY TO SWITCH ON

(No interlock)

Switch on

3

xxxx x111

SWITCHED ON

(Driv e enable inter l o ck)

The following Figure 5.1 shows the most important state transitions

Figure 5.1

State Diagram

DRIVE FAULT

00x1'1000

1

01x0'0000

Disable voltage

7

xxxx xx0x

Fast stop

xxxx x01x

Disable voltage

xxxx xx0x

10

Fast stop

xxxx x01x

0011'0001

Shutdown

6

xxxx x110

0011' 001 1

15

12

Reset fault

0xxx xxxx

to

1xxx xxxx

Disable voltage

xxxx xx0x

Enable operation

4

xxxx 1111

OPERATION ENABLED

(RUN commanded)

State Transition Names

Dri ve S ta t e Names

with associated

and

Numbers

Shutdown

5

xxxx 011x

0011' 011 1

with associated

Status Words

11

FAST STOP ACTIVE

Fast stop

xxxx x01x

(Low Byte) appear inside the boxes

(Decel erate to 0 frequ.)

Control Words

(Low Byte) appear outside the boxes

0001' 011 1

State Transition Description

Triggered State

Transi tion Name

Disable voltage

Transit ion

7, 9, 10, 12 xxxx xx0x Stop operation (current loop off) from any STATE and after FAST STOP ACTIVE.

(High priority stop)

Shutdown

2, 5, 6, 8 xxxx x110 Command to get to READY TO SWITCH ON after SWITCH ON DISABLED or fault

(Stop command)

Switch on * 3 xxxx x111 Command to get (from READY TO SWITCH ON) to SWITCHED ON state can be

Fast stop 7, 10, 11 xxxx x01x Stop as fast as possible (with current )

Power-up successfull * 1 Needs no command as it is done inside the module itself

Enable operation 4 xxxx 1111 Start the drive if previous states are SWITCHED ON or READY TO SWITCH ON.

Reset f ault 15 0xxx xxxx t o

Control Word

Bit 7..... Bit 0 Description

reset. Command to stop the drive if it is running.

replaced by Enable operation for running

Comand to clear a present fault

1xxx xxxx

* These transitions are not needed for operation.

Note: The state SWITCHED ON is like power on to the drive, but this is a virtual state because the power to

the drive is applied all the time in our case.

Page 25

InterBus Parameter Descriptions and Data Protocol 5–5

P arameter Access

Parameter acces s i s establish ed b y object indices and parameter

related sub- ind i ces to be sent via the PCP telegram.

Table 5.E

Parameter

Type

Display P01 – P20,

Program P30 – P84 0x5FF1 1 – 86 (84) Read Parameter Default

Program P30 – P84 0x5FF2 1 – 86 (84) Read Parameter Low Limit

Program P30 – P84 0x5FF3 1 – 86 (84) Read Parameter High Limit

Program P30 – P84 0x5FF4 1 – 86 (84) Read Parameter Attribute

Program P30 – P84 0x5FF9 30 – 86 (84) Write

Fault Code 0x603F Active Fault according to Table 8B

Parameter

Numbers Index Sub-Index (decimal)

0x5FF0 1 to 99(1-20, 30-84) Read

P30 – P84

Parameter attributes

Each parameter is described by an attribute to be read according to

table 5.F. The attribute consists of one word with 2 bytes which are

defined as follows:

High Byte stores the Unit (scaling) according to the ta ble 5.G,

Low Byte stores the parameter number.

Table 5. F

High Byte Units

0 Decimal 1

1 Decimal 0.1

2 Decimal 0.01

3 Hexadecimal 1

4 Binary 1

5 Decimal (signed) 1

6 Decimal (signed) 0.1

7 Decimal (signed) 0.01

Parameter Access Fault Codes

("Additional Error Codes")

The error messages listed in the table 5.G indicated problems when

attempting to access parameters via PCP.

The drive will NOT fault but indicate to the user that a specific

parameter access failed.

Table 5.G

Error Code Error

1 Parameter size is too small (e.g. byte instead of word)

4 Parameter value is out of limits

10 Parameter write attempt while drive is running

11 Parameter number too small

12 Pa rameter size is too large (e.g. 3 bytes instead of two bytes)

20 Parameter number not valid

22 Parameter number is too high

30 No valid response from drive

Page 26

5–6 InterBus Parameter Descriptions and Data Protocol

Communication Statistics

The following communication statistics can be read via the InterBus

Register 3 from the Networ k opt ion.

Table 5.H

Write Read

Decimal Hex Statistics

0 0 Background task counter

14 E Total PCP messages received

15 F Total PCP message errors received

16 10 Total PCP messages sent

17 11 Total PCP message errors sent

18 12 Total PCP protocol aborts

Others Diagnostics

Page 27

Chapter

6

Using the 160-IB1 on InterBus

The purpose of this chapter is to provide an example of the steps

necessary to use the 160-IB1 on an InterBus network. As InterBus is a

3rd party network, we will be usi ng a n SST-IBS-SLC scanner to act as

a master for InterBus, residing in an A-B SLC500 rack.

The SST scanner sends I/O messages periodically to a Bulletin

160-IB1 to start and stop the drive and control its speed. Additionally

the Bulletin 160-IB1 responds to these I/O messa ges by sending

status messages and speed feedback back to the scanner. In this way

the ladder logic program in the A-B SLC500 PLC can control the

drive .

The Bulle tin 160-IB1 also s uppor t s an Inter B u s t e legr am w hi c h c a n

be used to configure or read parameters from the drive.

This chapter contains the following information:

• How to create an InterBus network configuration frame.

• A sample ladder logic program to control the Bulletin 160 SSC

using I/O messaging

• A description of the InterBus PCP telegram.

• A sample ladder logic program to execute the PCP telegram

Required Tools

The SST-IBS-SLC scanner for the SLC500 is used in the exampl es in

this manual. However the concepts demonstrated in the examples

apply to any InterBus master.

The following too l s are needed to comp l et e this chapter.

• Bulletin 160 series C equipped with a 160-IB1 InterBus

communication module

• SLC500 processor with a digital input card to issue start & stop

commands

• Phoenix IBS CMD SWT G4 software to configure the scanner

and a null modem RS232 serial cable.

Page 28

6–2 Using the 160- IB1 on InterBus

Creat e an Inte rBus Network Configuration Frame

This example assumes that the SLC 500 rack has been configured

correctly with the SST-IBS-SLC card in slot 3. If configuration is

required an example of configuration is shown further in this chapter

– The InterBus PCP Telegram. Additionally it is a ssumed that a

160 drive with an 160-IB1 interface is connected on the Int erBus

remote bus with a relevant 9 way D shell connector (see chapter 3).

Invoke Phoenix IBS CMD software and create a new proj ect with

”File Menu” and ”New”.

Go to extended mode,.

then to the ”Settings” mode. On the ”Settings” dialogue box select the

Drivers tab and select the ”co mmunication path” button.

In this example, the connection to the SST scanner is via a null

modem cable from the serial port on C O M 1 at 9600 baud.

Adjust the path accordingly and click OK twice.

Page 29

Using the 160-IB1 on InterBus 6–3

Click (select) the controlle r board and right mouse click ”type” to

select the type of scanner.

Click IBS USC(4K) as the controller type and click ok.

With the ”controller board” selected, hit F3 on your PC (the state

button). Select Configuration (on-line) and click ok. If the processor

is faulted, you will not be able to go on-line. So p u t the processor int o

program mode with the keyswitch., then select Configuration

(on-line).

Now select ”configuration” and ” configuration frame” and ”read in ”

the network that is attached to the scanner.

You will probably get the message that the paramet eris a tio n o f the

controller board will be lost. This is ok because it was not valid

anyway. Select Yes.

Also you may get the message that the software is unable to read the

parameter channel settings. Select OK to continue.

In this case you see one module has been identified as a DRIVECOM

assembly with InterBus library identifier 227.

Page 30

6–4 Using the 160- IB1 on InterBus

.

Look at the LED’s on the 160-IB1 module, BA is flashing, indicating

that the module is not being controlled by anything.

Now with the controller still selected, right click and choose

”Parameterization” and ”Edit” to specify how we want the scanner to

start up.

Select ”S t art u p w i t h out PDP” and uncheck ”star t data transmi s si o n ”

(action 23) an d click ok.

Page 31

Using the 160-IB1 on InterBus 6–5

Now save the file wit h a filename. Choose ”File” and ”Save”

commands.

The network should now be configured with the 160-IB1 BA LED

now steady green. If not , check that the processor is in Run mode.

InterBus assigns a communication reference (CR) dynamically when

the network(frame) is read in. It starts with the first module it sees on

the network, assigns a CR=2 and specifies memory alloc ation for the

I/O messaging. Then the CR and memory allocation increments for

each module it sees. Therefore any new nodes added to a network

should ALWAYS be added to the end of the network.

In order to view t h e memory allocation, select ”Monitor” and

”Controller Board” and ”Address Monitor”.

The 160-IB1 with the DRIVECOM 20/21 implementation is mapped

3 words input and 3 words output, mapped to the start of the memory

of the scanner card. In this case as the IBS scanner is in slot 3 of the

SLC rack, then address 0 is the first output address of the card i.e.

O:3.0.

Outputs

Address 0 C ommand word

Address 1 Speed reference

Address 2 Diagnostics

Address 512 (Inputs) are the first input addresses of the scanner card :

I:3.0

Address 0 Status word

Address 1 Speed feedback

Address 2 Diagnostics.

Page 32

6–6 Using the 160- IB1 on InterBus

Controlling the Drive with I/O Messaging

Now adjust the drive parameters as defined in chapter 5 of this

manual in order to test the driv e with the following program example:

Figure 6.1

Drive Test Program Ladder Logic Example.

Ladder diagram continued on next page

Page 33

Using the 160-IB1 on InterBus 6–7

Drive Test Program Ladder Logic Example (continued)

Page 34

6–8 Using the 160- IB1 on InterBus

The InterBus PCP Telegram

The Peripherals Communication Protocol (PCP) of InterBus supports

2 different type s of independent data transmission.

The 3 words tha t were mapped previously in this chapter, is the

process data channel which is the cyclic transmitted I/O data to start/

stop the drive and provide reference and feedback. The parameter

data channel is mu c h slower, working a r ound the process data

channel, to read/write parameters to the drive.

The param et er dat a channel i s handl ed b y th e In ter B us master and

transmits a frame of infor ma tion only when required.

This form of me ssaging i s per formed by cop ying data to and fr om the

SST-IBS-SLC card M0 and M 1 files . Therefore the SS T-IBS-SLC

card needs to be setup to support the PCP telegram.

If starting from scratch create a new project using RSLogix500

software and select the I/O Configuration to specify the processor,

Digital Input card and SST-IBS-SLC. If you are using an existing

configuration you will need to modify to suit.

Note that the example configur ation below has an additi onal SST card

in slot 2. This is not used in the following example.

The Scanner is configured for the rack with generic ID = 13635.

Page 35

Using the 160-IB1 on InterBus 6–9

Select the Advanced Config button, to setup the card as shown. This

means th at t here are 32 words reserved for pro cess data (I/O) and the

M files are set to 384 words. To make PC P functi on we need to setup

the G files with data . So the G files length = 7.

Select the Edit G file data button, to setup the data for the In t erB us

telegram. (see SST-IBS-SLC user manual for details)

Word 0 is fi xe d by the SL C

Word 1 bit 12=1 (4096)

Word 5 defines where M files stop for I/O and where M files start for

PCP (22 5)

Wo rd 6 Com mand buffer size for PCP

These values are just an ex ample of setup and t h e SS T-IBS-SLC user

manual should be consulted to optimise the PCP s etup.

Download this I/O conf iguration to the SLC. The card is now setup to

communicate with the InterBus telegram.

How it works

The number of words to be setup in the M files, varies as the type of

message to be transmitted. In the sa m pl e program follow ing , t he M

files are being copied to integer files so we can easily send/receive

data.

N7:70 is M0:3.225 onwards – the output data to the drive

N7:80 is M1:3.225 onwards – the input data fr om the drive

Page 36

6–10 Using the 160- IB1 on InterBus

This is an example of a read drive parameter (all values in hex)

The first node on the networ k is a communication r efer ence (CR) = 2,

with the para meter read access index of 5FF0 (see table 5E) and th e

sub-index s p eci fyi n g parameter 8 [H eatsink Temperature].

Once transmitted, the response in

N7:80 provid es an echo of the command word

N7:81 number of words following

N7:82 CR

N7:83 result of comms 0=success

N7:84 number of bytes read (in this case 1 word)

N7:85 data read 45 hex = 69 decimal which is the normal value

registered on the heatsink, when temperature is below it.

This is an example of a read attribute drive parameter

(all values in hex)

The first node on the networ k is a communication r efer ence (CR) = 2,

with the parameter read attribute access index of 5FF4 (see table 5E),

and the sub- ind ex sp eci fy i n g parameter 30 [Accel Time 1].

Once transmitted, the response is similar to above:

N7:85 LSB of 1E is parameter 30, MSB of 1 is multiplier

(see table 5F).

This is an example of a write attribute drive parameter

(all values in hex)

In this example the w rite access index is 5FF9 (see table 5E) and the

sub-index s p eci fy in g parameter 30 [ Acce l T ime 1].

N7:73 specifies the number of bytes to write

N7:7 4 is the data to writ e

N7:80 provid es an echo of the command word

N7:81 number of words following

N7:82 CR

N7:83 result of comms 0=success

N7:84 & N7:85 are not valid, being values that were updated on the

read at tr ibute exercise.

Page 37

Using the 160-IB1 on InterBus 6–11

Reading and Configuring Parameters wi th the PCP Telegram

Figure 6.2

PCP Telegram Ladder Logic Example

This program example can be made to operate by first setti ng I:1.4 to

request a read or write ope ration, t he set ting B3:20 b it 0 t o 1 to upd ate

the data in N7:70 onwards into the M0 files, the n setting B3:20 bit 1

to 1 to send the data.

Ladder diagram continued on next page

Page 38

6–12 Using the 160- IB1 on InterBus

PCP Telegram Ladder Logic Example (continued)

Page 39

Chapter

7

Controlling the Drive

Controlling the 160 Drive from a programmable controller is

accomplished using Message Commands to communicate through

the IB1 Module to the drive . To send a Start or Stop command to the

drive, the corresponding control bits in the DRIVECOM Control

Word must be set.

Setting the Drive to Enab le Network Control

The 160 Drive must be configured to accept logic and speed

commands from the network. This is done by configuring three

parameters:

1. Set P46 - [Input Mode] to a value of “2” or “6” as described in the

following Table. This will configure the drive to accept the logic

commands from the network.

Important: The d rive may be op e r a t ed in other mo des as long as

the InterBus Master provides an Enable command

(control w o rd = 0x6)

2. Set P59 - [Frequency Select] to “1.” This will configure the drive

to accept speed comman ds from the network .

3. Set P66 - [RPM Scaling] according to rated nameplate s peed.

(See chapter 5 for details).

Changing the above parameters can be done with the 160 Keypad

Module or configuration software such as DriveExplorer.

Important: For a new Input Mode to take af fect, dr i ve pow er must be

cycl ed o r para mete r P56 - [Reset Functions] must be set to

“2” instead.

Page 40

7–2 Controlling the Drive

End of Chapter 7

Page 41

Chapter

Troubleshooting

The purpose of this chapter is to help you troubleshoot your IB1

Module.

ATTENTION: Servicing energized industrial control

equipment can be hazar dous. Electrical shock, burns, or un-

!

intentional actuation of controll ed industrial equipment

may cause death or serious injury . Follow th e safety-rel ated

practices of NPFA 70E, Electrical Safe ty for Employee

Workplaces, when working on or near ener gized equipment.

Do not work alone on energized equipment.

ATTENTION: Do not attempt to defeat or override fault

circuits. T he cause of a fault indicati on must be determined

!

and corrected before attempting operation. Failure to

correct a dri ve or system malfunct ion may result in personal

injury and/or equipment damage due to uncontrolled

machine system operation.

8

Setup

LED Indicators and Troubleshooting

Make sure parameters P46, P59 and P66 have been set accord i ng to

chapter 5.

The IB1 Statu s LEDs can hel p you troubleshoot the modul e in the

event that problems occur. Refer to t he paragraphs that fo llow for

details.

Status LEDs

Refer to Chapter 4 for

detailed LED descriptions

Page 42

8–2 Troubleshooti ng

Communication Status LEDs

In case no LED i s o n , chec k t h e op t i o ns co n n ect ed t o the S SC160.

The four Communication Status LEDs provide status information on

module operations. Table 8.A shows how to use the LED to detect and

correct common operating problems.

Table 8.A

Communication Status LEDs Indications

Name

(Function) State What It Means: What To Do:

RC

(Remote Bus

Check)

BA

(Bus Active)

TR (Transmit/

Receive)

RD

(Remote Bus

Disable)

Off No power, processor reset,

InterBus reset or network link to

predecessor in line interrupted

yellow Input cable connection o.k. No action require d.

Off Bus inactive Check InterBus Master setup.

green Bus Active / Data exchange No action required.

Off No PCP Communication If PCP operation is desired, check

green PCP Communication active No action required.

Off Outgoing InterBus enabled No action required.

red InterBus Reset or outgoing Bus

disable

Check Power Supply, Network

Cable and InterBus Master

operation.

IB Master setup (initiate PCP).

No action required on last device

in line (emty top plug). Otherwise

check cabling and reset Master.

FLT LED

When the FLT LED is red, a drive fault is present.

Table 8.B

)

InterBus Faults (DRIVECOM 20

Fault No.

[Hex]

0 no fault 0

1000 General Malfunction nn

2200 Internal Current 13

2300 Current on Device Output Side 12

2320 Current on Device Output Side: Short Circuit/ Eart h Leakage 46

2331 Current on Device Output Side: Earth Leakage Phase U 38

2332 Current on Device Output Side: Earth Leakage Phase V 39

2333 Current on Device Output Side: Earth Leakage Phase W 40

2341 Current on Device Output Side: Short Circuit Phases U-V 41

2342 Current on Device Output Side: Short Circuit Phases V-W 42

2343 Current on Device Output Side: Short Circuit Phases W-U 43

3210 Internal Over Voltage 5

3221 Internal Under Volta ge No. 1 3

3222 Internal Under Volta ge No. 2 4

4210 Excess Temperature Device 8

4310 Excess Temperature Drive 20

5000 Model of drive not valid

5300 Device Hardware: Operating Unit 11

5310 Device Hardware: Data Storage RAM

5320 Device Hardware: Data Storage EPROM

6100 Device: Internal Software 32

6200 Device: User Software 33

6320 Device Software/ Data Record: Parameter Error 48

7500 IBS fatal protocol error

Fault Name Fault Code

in Object 603F

SSC160 [Dec]

Page 43

Troubleshooting 8–3

Fault No.

[Hex]

7510 Serial interface to drive timeout

7520 Serial interface IBS bus not active

8100 Monitoring: Communication 36

8311 Monitoring/ Torque Control: Excess Torque 7

8313 Monitoring/ Torque Control: Standstill Torque 6

Fault Name Fault Code

SSC160 [Dec]

Drive faults can be re ad via index 0x603F. Refer to Table 8.C Table

8.D for fault n u m ber rel a tion.

Drive fault codes can be read by accessing drive parameter P07 - [Last

Fault]. Refer to Table 8.C and Table 8.D for f ault descriptions/actions.

Table 8.C

160 Drive

Fault Code Fault Indication Description Corrective Action

00 No Fault The d r ive is currently not faulted. No action required.

03 Power Loss Fault DC Bus voltage remains below 85% nominal on

power up for longer than 5 seconds.

04 Undervoltage Fault DC Bus voltage fell below the minimum value while

05 Overvoltage Fault DC Bus maximum voltage exceeded. Bus overvoltage caused by motor regeneration. Extend

06 Motor Stall Fault Motor has stalled. Motor load is exce ssive. Longer accel time or reduced load required.

07 Motor Overload Fault Internal electronic overload trip. Excessive motor

08 Overtemperature Fault Excessive heat detected. Clear blocked or dirty heat sink fins. Check ambient

11 Operator Fault The keypad has been removed while the drive is

12 Overcurrent Fault Overcurrent detected in hardware trip circuit. Check short circuit at the drive output or excessive load

13 Software Over

Current Fault

20 Drive Overload Fault An internal electronic overload trip has occurred.

22 Drive Reset Stop input not present. Check stop input at TB3 terminal 8.

32 EPROM Fault EPROM has invalid data. Reset EPROM using P56 - [Reset Functions].

33 Max Retries Fault Drive did not reset fault within the specified retries. Repa ir system fault.

36 Incompatible Fault Incompatible communication module installed. Verify compatibility of communication module.

38 Phase U Fault Phase to ground fault detected between drive and

39 Phase V Fault Phase to ground fault detected between drive and

40 Phase W Fault Phase to ground fault detected between drive and

41 UV Short Fault Excessive current has been detected between

42 UW Short Fault Excessive current has been detected between

43 VW Short Fault Excessive current has been detected between

46 Intermittent Phase

Fault

48 Reprogramming Fault Occurs when reset defaults is performed. Clear fault.

the motor was running.

load exists.

powered.

Motor current exceeded value set in parameter 79. A longer acceleration time, reduced load, or removal of

The drive is overheating.

motor phase U.

motor phase V.

motor phase W.

these two drive output terminals.

these two drive output terminals.

these two drive output terminals.

An external short occurred while running

diagnostics.

1

1

Fault Codes

Monitor incoming AC line for low voltage or line power

interruption.

Monitor incoming AC line for low voltage or line power

interruption.

the decel time, or install dynamic brake option or external

capacitor module.

Reduce motor load.

temperature. Check for blocked or non-operating fan.

Clear the fault. Do not remove the keypad underpower.

conditions at the motor.

motor shaft blockage is required

Clear blocked or dirty heat sink fins. Check ambient

temperature. Check for blocked or non-operating fan.

Check wiring between dr ive and motor. Check motor for

grounded phase.

Check wiring between dr ive and motor. Check motor for

grounded phase.

Check wiring between dr ive and motor. Check motor for

grounded phase.

Check the motor and external wiring to the drive output

terminals for a shorted condition.

Check the motor and external wiring to the drive output

terminals for a shorted condition.

Check the motor and external wiring to the drive output

terminals for a shorted condition.

Check wiring between the drive and the motor. Check for

more than one shorted output.

Refer to the 160 SSC™ V S D (Series C) User Manual for the most current fault code information.

Page 44

8–4 Troubleshooti ng

IB1 Network Error Codes

The following error codes could be returned when accessing the IB1

Module.

Table 8.D

Network Fault Codes

Fault Code Fault Indicati on Description Corre ctive Action

7510

7520 Unit lost Connection Timeout on serial link Check units plugs to SSC160 and IBS cable.

7500 Unit unrecov erable Fault Unexpected Network Fault

5000 Model of Drive not valid Use 160 Drive with version ’C’ or higher Replace Drive

Serial Fault

No serial Connection established Check if SSC160 of version ‘C’ or higher has been

installed. (Refer to drives nameplate).

Check 30 pin connector on the options back.

Check Parameter setting according to Section 6.

restart IBS master or d rive

Page 45

Specifications

Appendix

A

Electrical

Environmental

Communications

Mechanical

Supply Voltage Supplied by Drive

Power Consumption 1.4 Watts (280 mA) maximum

Ambient Temperature

Operating 0 to 65° C (32 to 149° F)

Storage –40 to 85° C (–40 to 185° F)

Relative Humidity 0 to 95% non-condensing

Vibrati on 1.0 G Operational

2.0 G Non-operational

Shock 15.0 G Oper a tional

30.0 G Non-operat ional

Altitude 1,000 m (3,300 ft.) without derating

Baud Rate 500 kBaud

Protocol Drivecom 20 (21)

Dimensions are in Millimeters and (inches)

(1)

17.34

(0.68)

(2)

21.4

(0.85)

(1)

Required for module removal.

(2)

Module adds this dimension to the overall drive depth.

(3)

Required for connecting cable

(3)

60

(15)

Page 46

A–2 Speci fications

End of Appendix A

Page 47

Index

B

Baud Rate

, A–1

C

Cabling

CE Complian ce

Communication Cable

Communication Statistic s

Configuration

Control W o rd

Controlling, Drive

, 3–6

, 3–1

Parameters

SST-IBS-SLC

, 6–11

, 5–3

, 3–7

, 6–8

, 6–6, 7–1

D

Data Channels

Data Protocol

Dimensions

, 5–2

, 5–2

, A–1

E

Error Mode

, 4–2

F

Fault Codes

, 8–3

Drive

Network

Parameter Access

, 8–4

, 5–5

, 5–6

M

Manuals, related

Modes of Operation

Error Mode

Power-up

Run Mode

Module Installation

, p–ii

, 4–2

, 4–2

, 4–2

, 3–2

N

Network Control, Enable

, 7–1

P

Parameter

Access

Attributes

Data channel

Descriptions

PCP Tel egram

Peripherals Communic. Protocol

(PCP)

Power-up Mode

Publications

On-line

Related

, 5–5

, 5–5

, 5–2

, 5–1

, 6–8, 6–11

, 5–2, 6–8

, 4–2

, p–ii

, p–ii

Q

Quick Start

, 2–1

I

I/O Messaging

Installation

InterBus Net wo rk

Configuration Frame

Error Codes

, 6–6

, 3–1

, 8–4

K

Keypad Removal

, 3–2

L

Ladder Logic Example

PCP Telegram

Test Program

LEDs

Communic. Status

Fault Status

, 6–11

, 6–6

, 4–1, 8–2

, 6–2

, 4–1, 8–2

R

Remot e Bus

Cable Termination

Connection

Removal, Module

Required Tools

Run Mode

, 3–7

, 3–3

, 2–1, 6–1

, 4–2

S

Scanner SST-IBS-SLC

Configuration

Description

Settings

Specifications

Communications

Electrical

Environmental

Mechanical

, 6–8

, 6–1

, 6–2

, A–1

, A–1

, A–1

, A–1

, 3–6

Page 48

Index–2

State Transitions

Status Wo rd

, 5–3

T

Troubleshooting

, 5–4

, 8–1

W

Web Sites

Wiring

, p–ii

Connectors

Drive Terminal Block

Ground Terminal

, 3–6

, 3–4

, 3–5

Page 49

Page 50

Publication 160IB1-UM010A-EN – October, 2001 P/N 899.02.91

Copyright © 2001 Rock well Automation. All rights reserved. Printed in Sw itzerland.

Loading...

Loading...