Page 1

What This Option Provides

Where This Option Is Used

Installation Instructions

IN

Allen-Bradley

1397

Open Chassis Dynamic Brake

Cat. Nos.1397-DB-AxxxL—240VDC

1397-DB-BxxxL—500VDC

The 1397 Open Chassis Dynamic Brake kit provides a 1397 Dynamic

Brake shipped as loose parts for customer assembly

Each Open Chassis Dynamic Brake kit is sized to a 1397 drive as

detailed below.

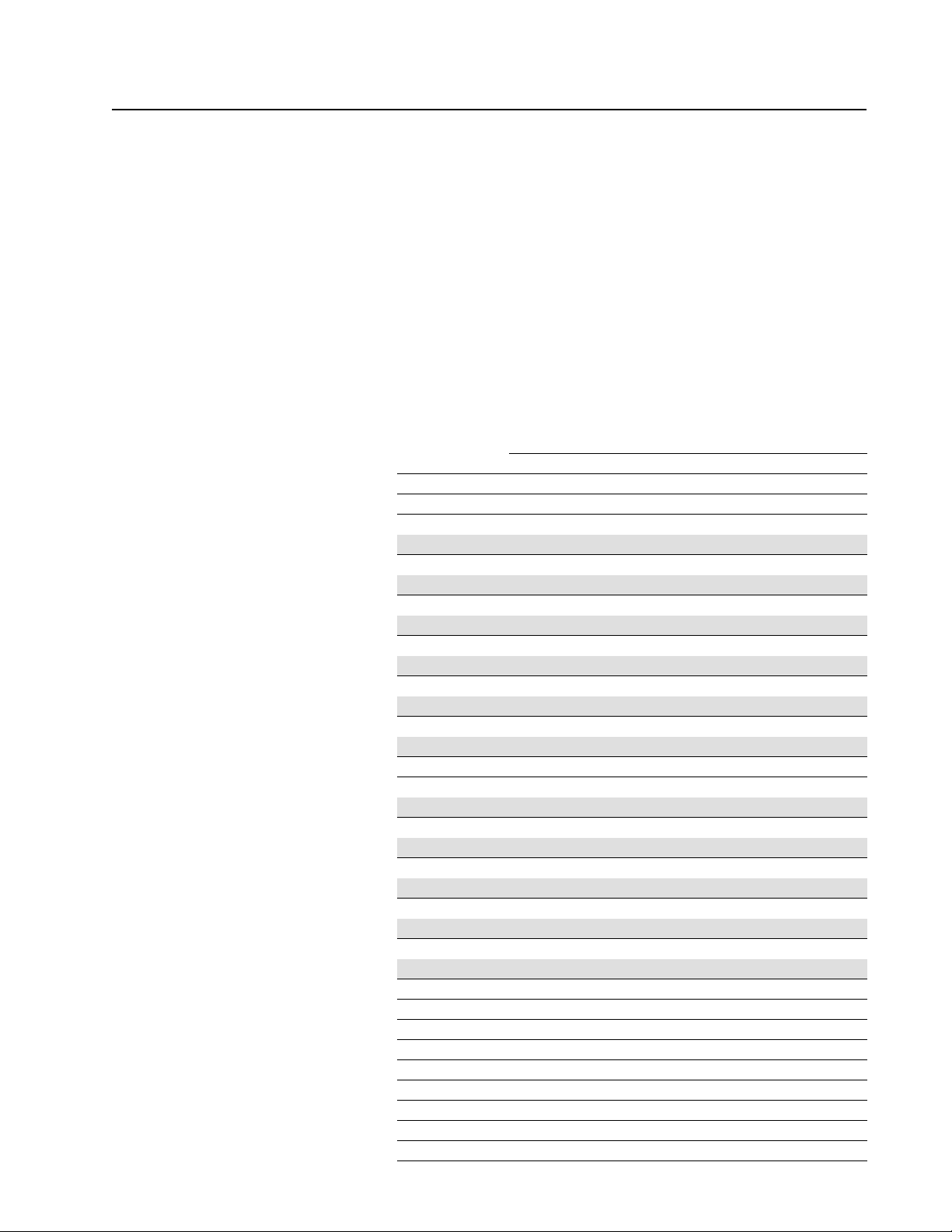

240VAC DB Rating 500VAC DB Rating

Catalog Number

1397-DB-A001L 1.5 (1.2) — —

1397-DB-A002L 2 (1.5) — —

1397-DB-A003L 3 (2.2) — —

1397-DB-B003L — — 3 (2.2)

1397-DB-A005L 5 (3.7) — —

1397-DB-B005L — — 5 (3.7)

1397-DB-A007L 7.5 (5.5) — —

1397-DB-B007L — — 7.5 (5.5)

1397-DB-A010L 10 (7.5) — —

1397-DB-B010L — — 10 (7.5)

1397-DB-A015L 15 (11) — —

1397-DB-B015L — — 15 (11)

1397-DB-A020L 20 (15) — —

1397-DB-B025L — — 20-25 (15-18.5)

1397-DB-A025L 25 (18.5) — —

1397-DB-A030L 30 (22) — —

1397-DB-B030L — — 30 (22)

1397-DB-A040L 40 (30) — —

1397-DB-B040L — — 40 (30)

1397-DB-A060L 50-60 (37-45) — —

1397-DB-B060L — — 50-60 (37-45)

1397-DB-A075L 75 (56) — —

1397-DB-B075L — — 75 (56)

1397-DB-A100L 100 (75) — —

1397-DB-B100L — — 100-125 (75-93)

1397-DB-A125L 125 (93) — —

1397-DB-A150L 150 (112) — —

1397-DB-B150L — — 150 (112)

1397-DB-B200L — — 200 (149)

1397-DB-B250L — — 250 (187)

1397-DB-B300L — — 300 (224)

1397-DB-B400L — — 400 (298)

1397-DB-B500L — — 500 (373)

1397-DB-B600L — — 600 (448)

HP (kW) HP (kW)

&

installation.

1397-5.15 March, 1999

Page 2

1397 Open Chassis Dynamic Brake2

What These Instructions Contain

Specifications

Installation

These instructions and any accompanying instructions contain the

necessary information to assemble

install an Open Chassis 1397

&

Dynamic Brake. Each kit may be used with one or more of the 1397

drive HP ratings described on the previous page. For additional

information on wire recommendations, brake parameters and related

function blocks, refer to the 1397 User Manual.

Duty Cycle

Input Power

Enclosure Type

Altitude Derating 1,000 meters (3,300 feet) maximum without derating.

Mounting Requirements For 1397-DB-A001L-A150L and 1397-B003L-B300L kits, DB

(3) repetitive stops with an average of (1) stop every (10) minutes.

DC Power Supplied from 1397 Drive for all ratings.

For 1.5-300HP drive ratings, 120VAC customer supplied power

required for separate DB contactor operation.

For 400-600HP drive ratings, DB uses drive contactor.

IP00 (Open).

contactor must be mounted in the vertical position.

For 1397-DB-B400L-B600L kits, DB uses drive contactor.

All other DB components may be mounted as required.

ATTENTION: Electric Shock can cause injury or death.

Remove all power before working on this product.

!

The drive is at line voltage when connected to incoming AC

power. Before proceeding with any installation or

troubleshooting activity, disconnect, lockout and tag all

incoming power to the drive. Verify with a voltmeter than no

voltage exists at terminals L1, L2 and L3 on the drive input

power terminal block.

Selection

1397-5.15 March, 1999

ATTENTION: Dynamic braking resistors may be

extremely hot. Install in an enclosure or provide adequate

!

clearance to ensure that nothing can come in direct contact

with, or in proximity to the DB resistors. Failure to observe

this precaution can result in severe burns and damage to, or

destruction of, the equipment.

IMPORTANT : The National Electrical Code (NEC) and local

regulations govern the installation and wiring of the dynamic brake.

AC power wiring, DC power wiring, control wiring and conduit must

be chosen and installed in accordance with these codes and the

information supplied in the 1397 User Manual.

All Open Chassis Dynamic Brake kits include a resistor assembly and

an open cage resistor enclosure. Each resistor assembly consists of a

backplate with one or more pairs of resistors mounted in a series or in

a series/parallel configuration.

Dynamic brake kits 1397-DB-A001L — A150L and

1397-DB-B003L — B300L include a DB contactor with (1) contactor

suppressor that mounts across the contactor coil.

Dynamic brake kits 1397-DB-B400L — B600L use the drive

contactor.

Page 3

1397 Open Chassis Dynamic Brake

What This Option Provides

The DB contactors listed for the following kits require a 120VAC power

supply that will meet the specified continuous and inrush VA values

listed below. To guard against shock hazard, either the open cage

enclosure or an equivalent enclosure must be used to enclose both the

backplate and contactor.

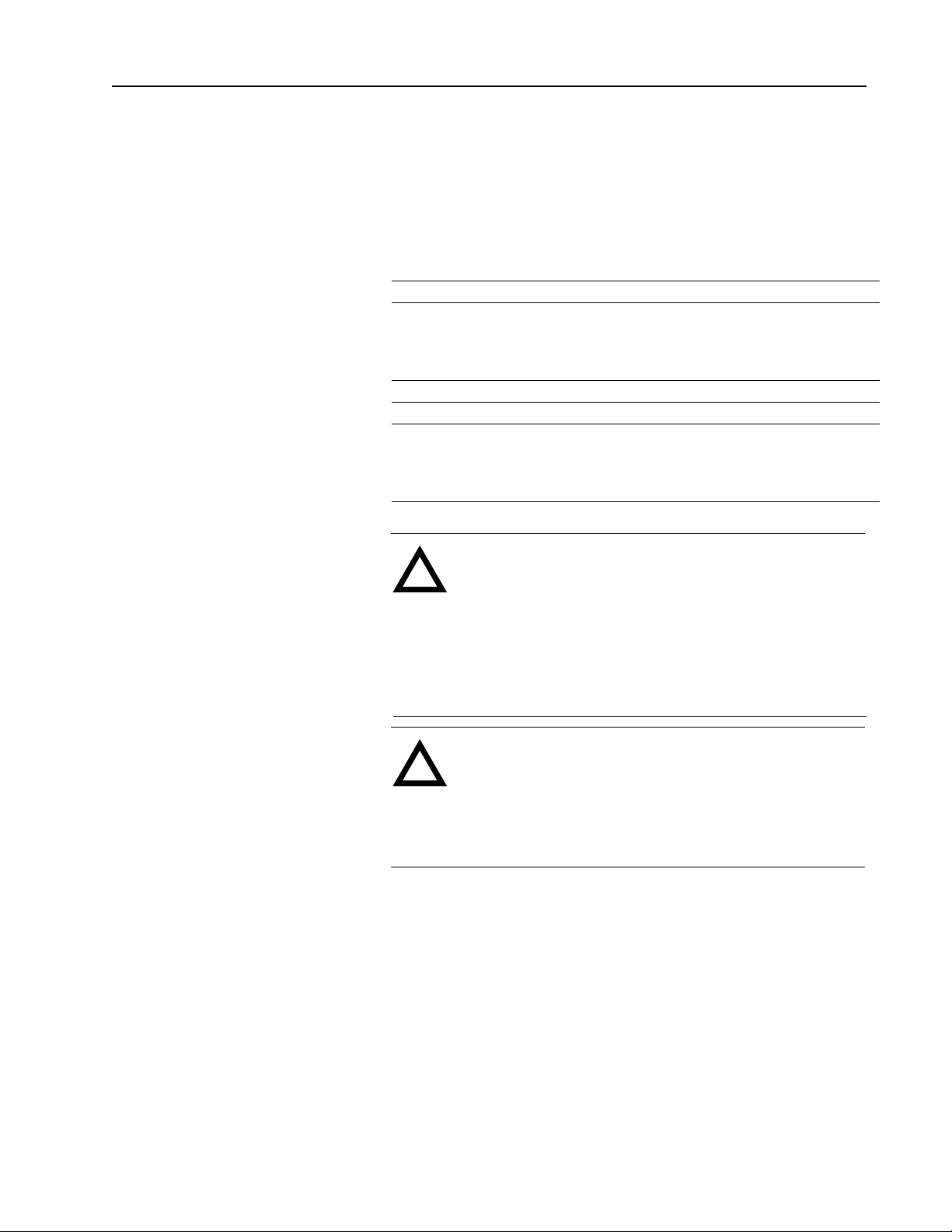

Resistor Assembly Contactor

240VDC

DB Catalog No.

1397-DB-A001L 800160-20P 48267-P (1) Resistor 705310-100A 1.5HP/230VAC 7A/240VDC 80 10

1397-DB-A002L 800160-20R 48267-J (2) Series Connected Resistors 2HP/230VAC 9A/240VDC

1397-DB-A003L 800160-20S 48267-H (2) Series Connected Resistors 3HP/230VAC 12A/240VDC

1397-DB-A005L 800160-20T 48267-F (2) Series Connected Resistors 705310-110A 5HP/230VAC 20A/240VDC 100 11

1397-DB-A007L 800160-20V 48267-D (2) Series Connected Resistors 7.5HP/230VAC 29A/240VDC

1397-DB-A010L 800160-20W 48267-C (1) Resistor 705310-130A 10HP/230VAC 38A/240VDC 325 25

1397-DB-A015L 800160-20X 48267-A (2) Series Connected Resistors 15HP/230VAC 55A/240VDC

1397-DB-A020L 800160-20Y 48267-C (4) Series/Parallel Connected Resistors 20HP/230VAC 73A/240VDC

1397-DB-A025L 800160-20RB 48267-B (4) Series/Parallel Connected Resistors705310-140A 25HP/230VAC 93A/240VDC 325 25

1397-DB-A030L 800160-20RC 48267-A (4) Series/Parallel Connected Resistors 30HP/230VAC 110A/240VDC

1397-DB-A040L 800160-20RD 402422-3F (2) Series Connected Resistors 705310-150A 40HP/230VAC 146A/240VDC 900 55

1397-DB-A060L 800160-20RE 402422-3G (2) Series Connected Resistors 50HP/230VAC 180A/240VDC

1397-DB-A075L 800160-20RF 402422-3K (2) Series Connected Resistors 705310-160A 75HP/230VAC 265A/240VDC 900 55

1397-DB-A100L 800160-20RG 402422-3L (2) Series Connected Resistors 705310-170A 100HP/230VAC360A/240VDC 1200 70

1397-DB-A125L 800160-20RH 402422-3P (3) Series Connected Resistors 705310-180A 125HP/230VAC434A/240VDC 2900 105

1397-DB-A150L 800160-20RJ 402422-3Q (3) Series Connected Resistors 150HP/230VAC521A/240VDC

Assembly PNResistor PNDescription PN

Drive

HP/Voltage

60HP/230VAC 218A/240VDC

Motor Armature

Amps/Voltage

VA

INRUSH

VA

3

HOLD

Resistor Assembly Contactor

500VDC

DB Catalog No.

1397-DB-B003L 800160-20SP 48267-N (3) Series Connected Resistors 705310-100A 3HP/460VAC 6A/500VDC 80 10

1397-DB-B005L 800160-20SR 48267-K (3) Series Connected Resistors 5HP/460VAC 10A/500VDC

1397-DB-B007L 800160-20SS 48267-J (3) Series Connected Resistors 7.5HP/460VAC 14A/500VDC

1397-DB-B010L 800160-20ST 48267-H (3) Series Connected Resistors 705310-110A 10HP/460VAC 19A/500VDC 100 11

1397-DB-B015L 800160-20SV 48267-F (3) Series Connected Resistors 15HP/460VAC 27A/500VDC

1397-DB-B020L 800160-20SW48267-C (4) Series Connected Resistors 705310-130A 20HP/460VAC 35A/500VDC 325 25

1397-DB-B025L 25HP/460VAC 45A/500VDC

1397-DB-B030L 800160-20SX 48267-B (4) Series Connected Resistors 30HP/460VAC 52A/500VDC

1397-DB-B040L 800160-20SY 48267-A (4) Series Connected Resistors 40HP/460VAC 73A/500VDC

1397-DB-B060L 800160-20SB 402422-3D (3) Series Connected Resistors 705310-140A 50HP/460VAC 86A/500VDC 325 25

1397-DB-B075L 800160-20SC 402422-3E (3) Series Connected Resistors 705310-150A 75HP/460VAC 129A/500VDC 900 55

1397-DB-B100L 800160-20SD 402422-3F (3) Series Connected Resistors 100HP/460VAC167A/500VDC

1397-DB-B125L 125HP/460VAC207A/500VDC

1397-DB-B150L 800160-20SE 402422-3J (4) Series Connected Resistors 705310-160A 150HP/460VAC250A/500VDC 900 55

1397-DB-B200L 800160-20SF 402422-3K (4) Series Connected Resistors 705310-170A 200HP/460VAC330A/500VDC 1200 70

1397-DB-B250L 802272-53R 402422-7Z (2) Series Connected Resistors 705310-180A 250HP/460VAC412A/500VDC 2900 105

1397-DB-B300L 802272-53S 402422-7AD (2) Series Connected Resistors 300HP/460VAC495A/500VDC

1397-DB-B400L 802272-53T 402422-7AH (2) Series Connected Resistors

1397-DB-B500L 802272-53V 402422-7AL (2) Series Connected Resistors

1397-DB-B600L 802272-53W 402422-7AN (2) Series Connected Resistors

Assembly PNResistor PNDescription PN

Drive

HP/Voltage

60HP/460VAC 100A/500VDC

Motor Armature

Amps/Voltage

Not Applicable

VA

INRUSH

VA

HOLD

1397-5.15 March, 1999

Page 4

4

1397 Open Chassis Dynamic Brake

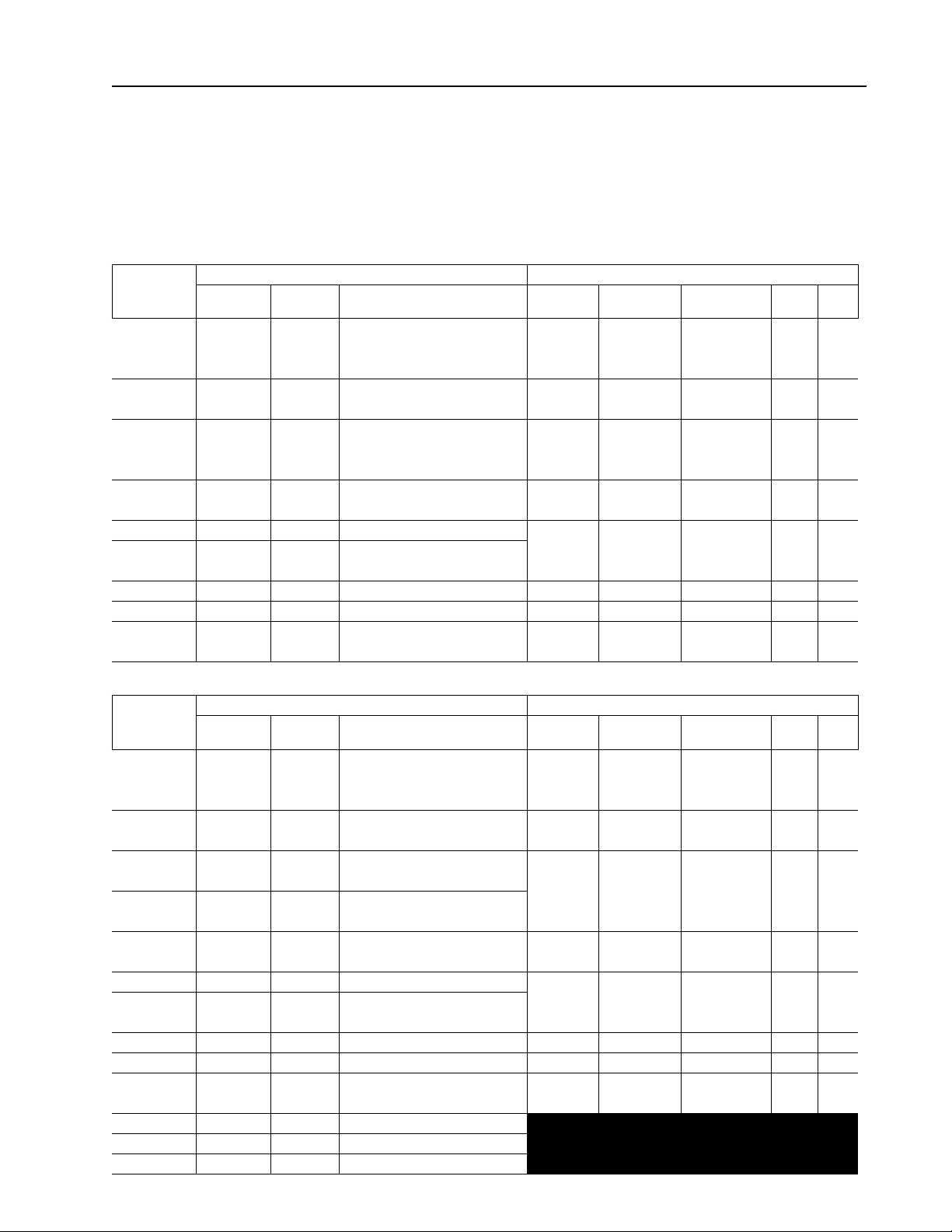

Resistor Assembly Dimensions

Side — Single Resistor — Cat. No. 1397-DB-A001L

9.65 (0.38)

Maximum Projection

45.2 (1.78)

Side — Two/Four Resistors — Cat. Nos. 1397-DB-A002L - A150L

9.65 (0.38)

Maximum Projection

90.4 (3.56)

Side — Three/Four Resistors — Cat. Nos. 1397-DB-B003L - B040L

Maximum Projection

169.9 (6.69)

9.65 (0.38)

12.7

(0.50)

508.0 (20.0)

482.6 (19.0)

12.7

(0.50)

41.4 (1.63)

508.0

(20.0)

203.2

(8.0)

177.8

(7.0)

Bottom — Mounting Panel

Cat. Nos. 1397-DB-A001L - A150L

Cat. Nos. 1397-DB-B003L - B200L

Side — Two Resistors — Cat. Nos. 1397-DB-B250L - B600L

787.4 (31.0)

749.3 (29.5)

63.5

(2.5)

Grommet Hole

47.8 (1.88) Dia.

7.92 (0.312) Dia.

— 4 Places —

Maximum Projection

397.0 (15.63)

19.05

(0.75)

1397-5.15 March, 1999

469.9

(18.5)

368.3

(14.5)

438.2 (17.25)

Bottom — Mounting Panel

Cat. Nos. 1397-DB-B250L - B600L

8.76 (0.345) Sq.

— 4 Places —

31.75

(1.25)

All Dimensions in Millimeters and (Inches)

Page 5

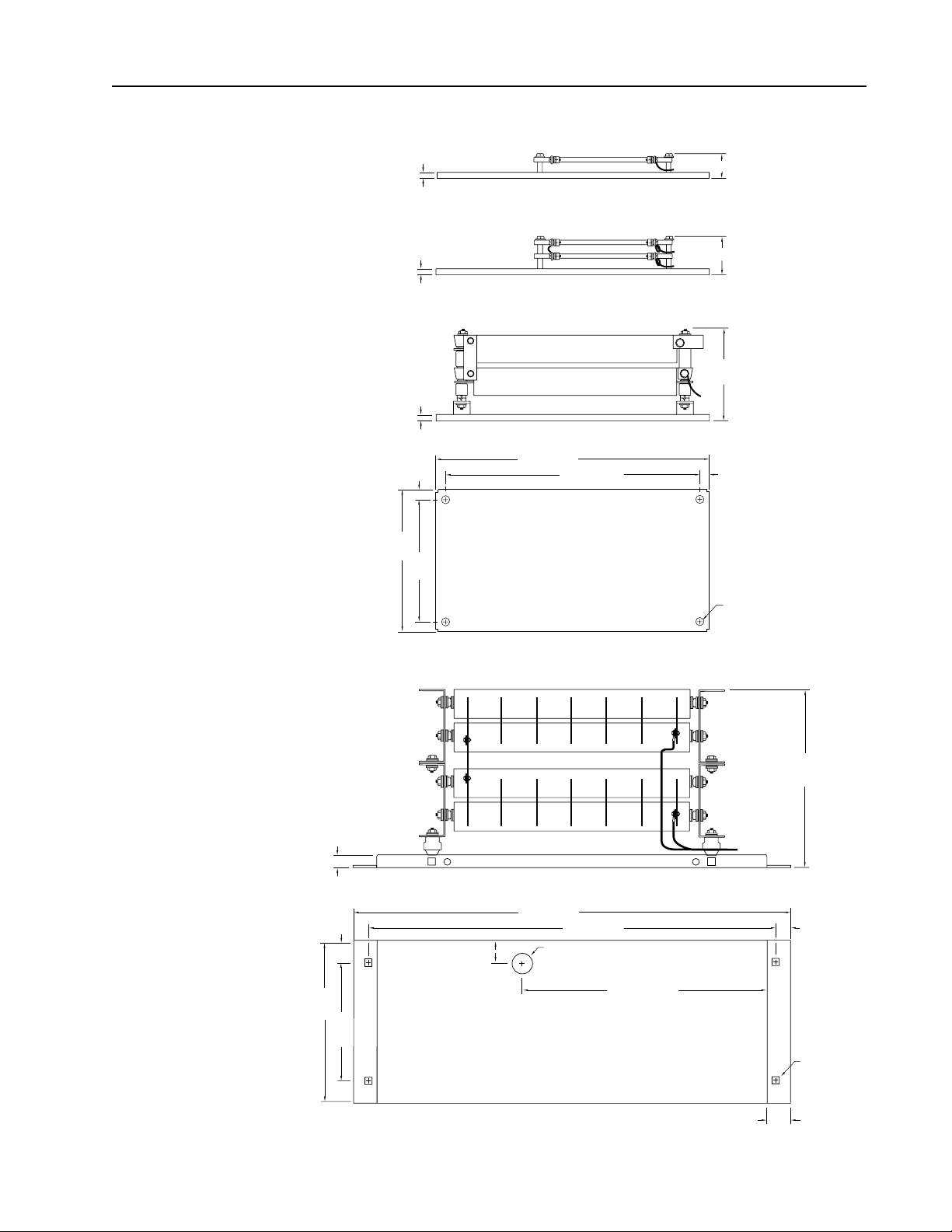

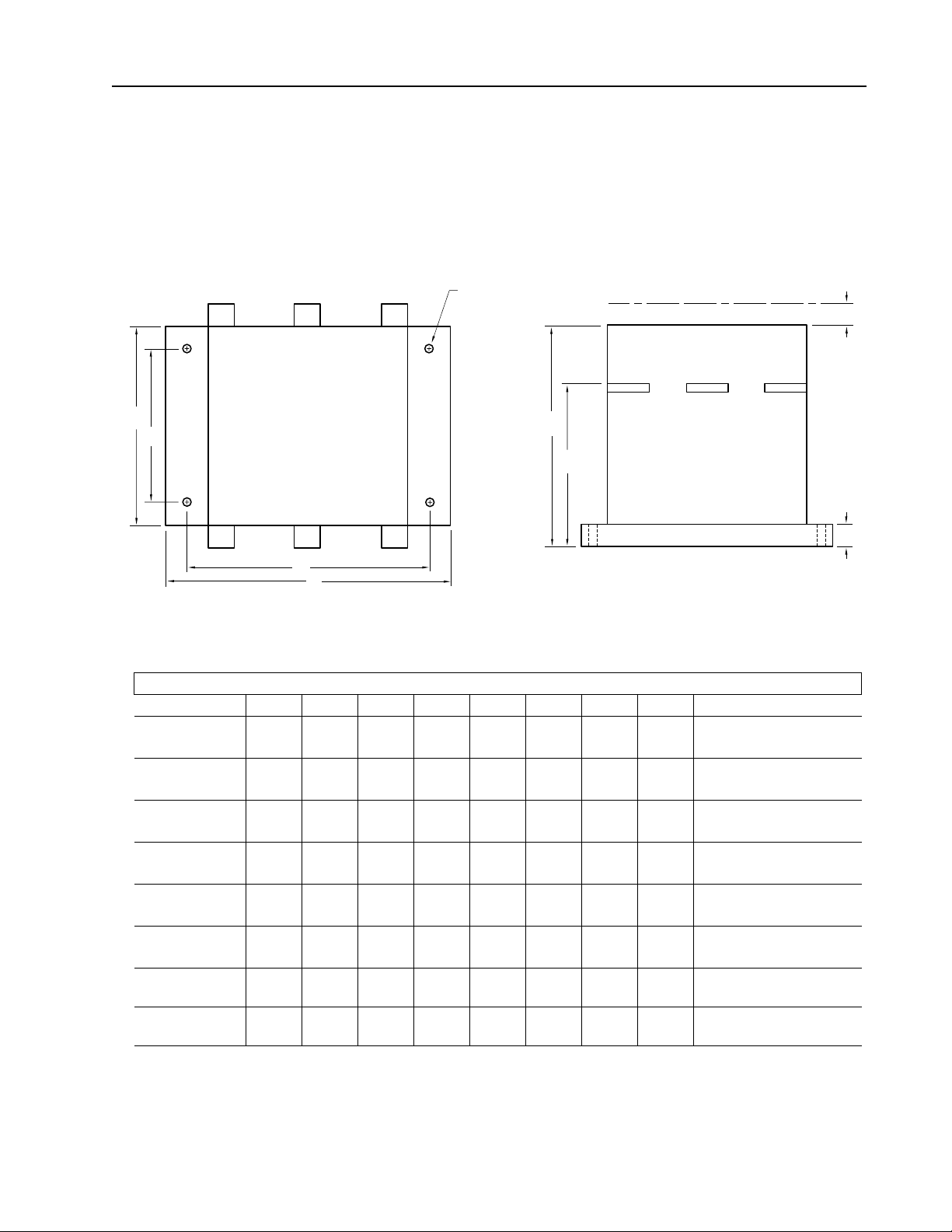

Contactor Dimensions

A

B

Mounting Hole Dia.

— 4 Places —

1397 Open Chassis Dynamic Brake

Uninsulated Wall

E

F

5

H

C

D

Top

Contactor Dimensions—All Dimensions in Millimeters and (Inches)

PN ABCDEFGHMounting Hole Dia.

705310-100A 69.1

(2.72)

705310-110A 81.0

(3.19)

705310-130A 130.0

(5.12)

705310-140A 130.0

(5.12)

705310-150A 198.0

(7.80)

705310-160A 198.0

(7.80)

705310-170A 207

(8.2)

705310-180A 272

(10.71)

59.9

(2.36)

69.4

(2.74)

100.0

(3.94)

100.0

(3.94)

140.0

(5.52)

140.0

(5.52)

140

(5.52)

200

(7.88)

35.0

(1.38)

45.0

(1.78)

90.0

(3.55)

90.0

(3.55)

120.0

(4.73)

120.0

(4.73)

160

(6.3)

170

(6.7)

43.9

(1.73)

54.0

(2.13)

102.0

(4.02)

102.0

(4.02)

136.0

(5.36)

136.0

(5.36)

182

(7.17)

198

(7.8)

118.9

(4.68)

121.5

(4.79)

137.0

(5.40)

137.0

(5.40)

168.0

(6.62)

168.0

(6.62)

178

(7.01)

226

(8.9)

76.0

(3.00)

80.0

(3.15)

95.0

(3.75)

95.0

(3.75)

103.0

(4.1)

103.0

(4.1)

107

(4.22)19(0.75)30(1.20)

140

(5.52)23(0.91)45(1.78)

0.35

(8.89)

8.9

(0.35)

21.5

(0.85)

21.5

(0.85)30(1.19)

10.5

(0.42)

10.5

(0.42)

— 4.5

— 4.5

30.0

(1.19)

15,0

(0.60)

15.0

(0.60)

Side

(0.18)

(0.18)

5.7

(0.23)

5.7

(0.23)

6.8

(0.27)

6.8

(0.27)

6.8

(0.27)

6.8

(0.27)

G

1397-5.15 March, 1999

Page 6

6

1397 Open Chassis Dynamic Brake

Open Cage Resistor Enclosure Dimensions

C

B

E

D

F

G

16.0

(.62)

7.87

(.31)

Mounting Hole

Dimension

1.52

(.06)

8.89

(.35)

1.52

(.06)

9.45

(.37)

9.65

(.38)

19.1

(.75)

19.1

(.75)

A

Mounting Tab

Dimension

H

Top/Bottom Side

Open Cage Resistor Enclosure Dimensions—All Dimensions in Millimeters and (Inches)

Drive Cat. Nos. PN ABCDEFGH

1397-DB-A001L - A150L

1397-DB-B003L - B200L

800798-54R 131.8

(5.19)

142.8

(5.62)

187.5

(7.38)

266.7

(10.50)

25.4

(1.00)

Back

46.0

(1.81)

25.4

(1.00)

241.30

(9.50)

1397-5.15 March, 1999

Page 7

Open Cage Resistor

Enclosure Dimensions

1397 Open Chassis Dynamic Brake

A

7

B

Side

Slotted Mounting Holes

Slotted Mounting Holes

C

End

Bottom

Approximate Open Cage Resistor Enclosure Dimensions—All Dimensions in Millimeters and (Inches)

Drive Cat. Nos. PN A B C

1397-DB-B 250L -B600L 802272-52S 454.0

(17.9)

752.5

(29.6)

468.3

(18.4)

1397-5.15 March, 1999

Page 8

8

1397 Open Chassis Dynamic Brake

1397-DB-A001L — A150L

B003L — B300L

Dynamic Brake Kit Operation

Dynamic braking slows down a rotating DC motor and its load. It is an uncontrolled process. During dynamic

braking, the motor armature is disconnected from the drive. A resistor is placed across the motor’s rotating

armature (now acting as a generator), and the resulting current causes braking torque in the motor. The motor

will decelerate, even with a drive malfunction, as long as motor shunt field excitation is maintained.

The drive must have the DC contactor open for dynamic braking to occur. Dynamic Braking is typically initiated

with a Coast/DB stop command or a drive fault. Under drive fault conditions, the DC contactor opens and applies

the dynamic braking grid across the armature for a dynamic braking stop.

DYNAMIC BRAKE

45

RESISTORS

DB

1

2

5

6

A1

DBR

DB RESISTOR

3

A1

MOTOR ARMATURE

A2

AC

INPUT

1397 DRIVE

181/L1

81

182/L2

82

182/L3

83

1FU

2FU

3FU

281

282

283

A1 (+)

ARMATURE

SUPPLY

45 (–)

120V AC

CUSTOMER SUPPLY

DYNAMIC BRAKE TERMINAL BLOCK

6

A1

A2

DB

2SS R

DYNAMIC BRAKE

P5-6

(34)

4

5

13

CONTACTOR

14

MOTOR SHUNT FIELD

F1

4

14

FAN

AUX

FROM

FIELD

P5-5

SUPPLY

F2

35-F237-F1

2

1

P6-5

DBCR

(33)

13

3

P6-2

DB AUX

1397-DB-A001L — A150L

B003L — B300L

Wiring

Remove and lockout all power to the drive and follow the wiring diagram above.

➊

Connect user supplied leads between drive terminals A1

If the motor has a series field, connect the motor series leads between drive terminal 45 and DB resistor

➋

terminal DBR.

➌

Connect the suppressor included with the kit between DB contactor terminals A1 and A2 and place the label

included with the kit near the contactor.

Use auxiliary contacts 33

➍

➎

Remove the jumper between terminals 3

between drive terminals 2, 3

Connect the user supplied 120VAC DB contactor power supply as shown.

➏

34 when available.

&

&

4 at the drive terminal block and connect user supplied leads

&

4 and DB contactor terminals A1, 13

&

45 and DB resistor assembly terminals 3

&

14.

&

DBR.

Refer to 1397-DB-A001L—A150L/B003L—B300L Dynamic Brake Kit Operation

above and proceed to Setup on the last page.

1397-5.15 March, 1999

Page 9

1397 Open Chassis Dynamic Brake

1397-DB-B400L — B600L

Dynamic Brake Kit Operation

Dynamic braking slows down a rotating DC motor and its load. It is an uncontrolled process. During dynamic

braking, the motor armature is disconnected from the drive. A resistor is placed across the motor’s rotating

armature (now acting as a generator), and the resulting current causes braking torque in the motor. The motor

will decelerate, even with a drive malfunction, as long as motor shunt field excitation is maintained.

When the motor is running normally, the drive’s normally-open M contacts are closed and the normally-closed

M contact is open. When the drive is connected to the motor, the dynamic braking resistor assembly is

disconnected.

For 1397-DB-B400L — B600L Kits

If You are Using the Basic Configuration . . .

1397 DRIVE

AC

INPUT

181/L1

81

82

83

182/L2

182/L3

1FU

2FU

3FU

281

282

283

47 (+)

ARMATURE

SUPPLY

45 (–)

M

M

A1

DBR

1

1

A2/S1

2

S2

DB RESISTORS

A1

MOTOR ARMATURE

A2

M

9

DYNAMIC BRAKE

TERMINAL BLOCK

2

1

P6-5

DBCR

3

3

P6-2

4

13

M AUX

RRB1-5RRB1-6

MOTOR SHUNT FIELD

F1

F2

14

FROM

FIELD

SUPPLY

35-F237-F1

Remove and lockout all power to the drive and follow the wiring diagram above.

Route the DB resistor cables through the grommeted hole in the resistor mounting panel. Connect to connection

➊

bars DBR

A2/S1 at the top of the 1397 drive using the (2) M10 hex bolts, washers and KEP nuts supplied

&

with the kit. Torque to 23.00 N-m (200 lb.-in.).

Verify that the removable connector bar link at A2/S1 is installed.

➋

➌

Verify that the jumper between terminals 3

&

4 at the drive terminal block is installed.

Remove the lockout and reapply power. Refer to 1397-DB-B400L—B600L Dynamic Brake Kit

Operation above and proceed to Setup on the last page.

1397-5.15 March, 1999

Page 10

10

1397 Open Chassis Dynamic Brake

For 1397-DB-B400L — B600L Kits

If You are Using DB with an Inverting Fault Circuit Breaker . . .

1397 DRIVE

AC

INPUT

181/L1

81

182/L2

82

182/L3

83

DYNAMIC BRAKE

TERMINAL BLOCK

1FU

281

2FU

282

3FU

283

2

1

P6-5

DBCR

P6-2

47 (+)

ARMATURE

SUPPLY

45 (–)

4

13

M AUX

RRB1-5RRB1-6

MOTOR SHUNT FIELD

F1

14

8

3

FROM

FIELD

SUPPLY

M

M

F2

35-F237-F1

A1

DBR

7

7

A2/S1

2

S2

DB RESISTORS

6

5

DRV

MOT

A1

MOTOR ARMATURE

A2

M

IFP Kit

A1

S2

1397 DRIVE

DBR

1

A2/S1

4

2

3

Remove and lockout all power to the drive and follow the wiring diagram above.

Follow the wiring diagram above to connect the motor armature to the drive and Inverting Fault Circuit Breaker.

➊

➋

Remove the connector bar link at A2/S1, but retain the A2/S1 connection bar and all (4) mounting bolts.

➌

Replace the (2) lower bar bolts removed previously. Torque to 23.00 N-m (200 lb.-in.).

➍

Replace the upper A2/S1 terminal bar using the (2) upper bar bolts removed previously. Torque to 23.00 N-m

(200 lb.-in.).

Connect the Inverting Fault Circuit Breaker kit to the DRV and MOT terminals as shown. Refer to the Inverting

➎

Fault Circuit Breaker Installation Instructions for additional information.

➏

Route customer supplied cable between A2/S1 and MOT. Cable should be sized to the same guage as the DB

resistor cables.

➐

Route the DB resistor cables through the grommeted hole in the resistor mounting panel. Connect to connection

bars DBR

&

A2/S1 at the top of the 1397 drive using the (2) M10 hex bolts, washers and KEP nuts supplied

with the kit. Torque to 23.00 N-m (200 lb.-in.).

Verify that the jumper between terminals 3

➑

4 at the drive terminal block is installed.

&

Remove the lockout and reapply power. Refer to 1397-DB-B400L—B600L Dynamic Brake Kit

Operation above and proceed to Setup on the last page.

1397-5.15 March, 1999

Page 11

1397 Open Chassis Dynamic Brake

11

For 1397-DB-B400L — B600L Kits

If You are Using DB with a Motor Series Field

—S1 connected to A2—with an Inverting Fault CIrcuit Breaker . . .

1397 DRIVE

AC

INPUT

181/L1

81

182/L2

82

182/L3

83

DYNAMIC BRAKE

TERMINAL BLOCK

1FU

281

2FU

282

3FU

283

2

1

P6-5

DBCR

P6-2

47 (+)

ARMATURE

SUPPLY

45 (–)

4

13

M AUX

RRB1-5RRB1-6

MOTOR SHUNT FIELD

F1

14

9

3

FROM

FIELD

SUPPLY

M

M

F2

35-F237-F1

A1

DBR

7

7

A2/S1

2

S2

DB RESISTORS

6

5

DRV

MOT

A1

MOTOR ARMATURE

A2

S1

MOTOR SERIES FIELD

S2

1

8

M

IFP Kit

A1

S2

DBR

A2/S1

1397 DRIVE

4

2

3

Remove and lockout all power to the drive and follow the wiring diagram above.

Follow the wiring diagram above to connect the motor armature to the drive and Inverting Fault Circuit Breaker.

➊

➋

Remove the connector bar link at A2/S1, but retain the A2/S1 connection bar and all (4) mounting bolts.

➌

Replace the (2) lower bar bolts removed previously. Torque to 23.00 N-m (200 lb.-in.).

➍

Replace the upper A2/S1 terminal bar using the (2) upper bar bolts removed previously. Torque to 23.00 N-m

(200 lb.-in.).

Connect the Inverting Fault Circuit Breaker kit to the DRV and MOT terminals as shown. Refer to the Inverting

➎

Fault Circuit Breaker Installation Instructions for additional information.

➏

Route customer supplied cable between A2/S1 and motor connection A2 or S1. Cable should be sized to the

same guage as the DB resistor cables.

➐

Route the DB resistor cables through the grommeted hole in the resistor mounting panel. Connect to connection

bars DBR

&

A2/S1 at the top of the 1397 drive using the (2) M10 hex bolts, washers and KEP nuts supplied

with the kit. Torque to 23.00 N-m (200 lb.-in.).

Connect the motor series field between S1

➑

➒

Verify that the jumper between terminals 3

S2.

&

&

4 at the drive terminal block is installed.

Remove the lockout and reapply power. Refer to 1397-DB-B400L—B600L Dynamic Brake Kit

Operation above and proceed to Setup on the last page.

1397-5.15 March, 1999

Page 12

1397 Open Chassis Dynamic Brake12

For 1397-DB-B400L — B600L Kits

If You are Using DB with a Motor Series Field

—S1 connected to A2—without an Inverting Fault CIrcuit Breaker . . .

1397 DRIVE

AC

INPUT

181/L1

81

182/L2

82

182/L3

83

1FU

2FU

3FU

281

282

283

47 (+)

ARMATURE

SUPPLY

45 (–)

M

M

A1

DBR

6

6

A2/S1

2

S2

DB RESISTORS

5

A1

MOTOR ARMATURE

A2

S1

MOTOR SERIES FIELD

S2

1

7

M

DYNAMIC BRAKE

TERMINAL BLOCK

2

1

P6-5

DBCR

P6-2

4

13

M AUX

RRB1-5RRB1-6

MOTOR SHUNT FIELD

F1

F2

14

FROM

FIELD

SUPPLY

35-F237-F1

A1

S2

8

3

1397 DRIVE

DBR

A2/S1

3

Remove and lockout all power to the drive and follow the wiring diagram above.

➊Follow the wiring diagram above to connect the motor armature to the drive and Inverting Fault Circuit Breaker.

➋Remove the connector bar link at A2/S1, but retain the A2/S1 connection bar and all (4) mounting bolts.

➌Replace the (2) lower bar bolts removed previously. Torque to 23.00 N-m (200 lb.-in.).

➍Replace the upper A2/S1 terminal bar using the (2) upper bar bolts removed previously. Torque to 23.00 N-m

(200 lb.-in.).

➎Route customer supplied cable between A2/S1 and motor connection A2 or S1. Cable should be sized to the

same guage as the DB resistor cables.

➏Route the DB resistor cables through the grommeted hole in the resistor mounting panel. Connect to connection

bars DBR

& A2/S1 at the top of the 1397 drive using the (2) M10 hex bolts, washers and KEP nuts supplied

with the kit. Torque to 23.00 N-m (200 lb.-in.).

➐Connect the motor series field between S1 & S2.

➑Verify that the jumper between terminals 3 & 4 at the drive terminal block is installed.

4

2

Remove the lockout and reapply power. Refer to 1397-DB-B400L—B600L Dynamic Brake Kit

Operation above and proceed to Setup on the last page.

1397-5.15 March, 1999

Page 13

1397 Open Chassis Dynamic Brake 13

For 1397-DB-B400L — B600L Kits

If You are Using DB with a Motor Series Field

—S1 connected to A2/S1—with an Inverting Fault CIrcuit Breaker . . .

1397 DRIVE

AC

INPUT

181/L1

81

182/L2

82

182/L3

83

1FU

2FU

3FU

281

282

283

47 (+)

ARMATURE

SUPPLY

45 (–)

M

M

A1

DBR

8

8

A2/S1

2

S2

DB RESISTORS

7

IFP Kit

5

DRV

MOT

A1

A2

6

S1

S2

MOTOR ARMATURE

MOTOR SERIES FIELD

1

9

M

DYNAMIC BRAKE

TERMINAL BLOCK

2

1

P6-5

DBCR

10

3

P6-2

4

13

M AUX

RRB1-5RRB1-6

MOTOR SHUNT FIELD

F1

F2

14

FROM

FIELD

SUPPLY

35-F237-F1

A1

1397 DRIVE

S2

DBR

A2/S1

3

Remove and lockout all power to the drive and follow the wiring diagram above.

➊Follow the wiring diagram above to connect the motor armature to the drive and Inverting Fault Circuit Breaker.

➋Remove the connector bar link at A2/S1, but retain the A2/S1 connection bar and all (4) mounting bolts.

➌Replace the (2) lower bar bolts removed previously. Torque to 23.00 N-m (200 lb.-in.).

➍Replace the upper A2/S1 terminal bar using the (2) upper bar bolts removed previously. Torque to 23.00 N-m

(200 lb.-in.).

➎Connect the Inverting Fault Circuit Breaker kit to the DRV and MOT terminals as shown. Refer to the Inverting

Fault Circuit Breaker Installation Instructions for additional information.

➏Route and connect the A2 motor cable to drive connection bar A2/S1.

➐Route customer supplied cable between A2/S1 and motor connection S1. Cable should be sized to the same

guage as the DB resistor cables.

➑Route the DB resistor cables through the grommeted hole in the resistor mounting panel. Connect to connection

bars DBR

& A2/S1 at the top of the 1397 drive using the (2) M10 hex bolts, washers and KEP nuts supplied

with the kit. Torque to 23.00 N-m (200 lb.-in.).

➒Connect the motor series field between S1 & S2.

➓Verify that the jumper between terminals 3 & 4 at the drive terminal block is installed.

4

2

Remove the lockout and reapply power. Refer to 1397-DB-B400L—B600L Dynamic Brake Kit

Operation above and proceed to Setup on the last page.

1397-5.15 March, 1999

Page 14

1397 Open Chassis Dynamic Brake14

For 1397-DB-B400L — B600L Kits

If You are Using DB with a Motor Series Field

—S1 connected to A2/S1—without an Inverting Fault CIrcuit Breaker . . .

1397 DRIVE

AC

INPUT

181/L1

81

182/L2

82

182/L3

83

1FU

2FU

3FU

281

282

283

A1 (+)

ARMATURE

SUPPLY

45 (–)

M

M

A1

DBR

8

8

A2/S1

2

S2

DB RESISTORS

6

7

A1

A2

5

S1

S2

MOTOR ARMATURE

MOTOR SERIES FIELD

1

9

M

DYNAMIC BRAKE

TERMINAL BLOCK

2

1

P6-5

DBCR

10

3

P6-2

4

13

M AUX

FAN

RRB1-5RRB1-5

MOTOR SHUNT FIELD

F1

F2

14

FROM

FIELD

SUPPLY

35-F237-F1

A1

1397 DRIVE

S2

DBR

A2/S1

3

Remove and lockout all power to the drive and follow the wiring diagram above.

➊Follow the wiring diagram above to connect the motor armature to the drive and Inverting Fault Circuit Breaker.

➋Remove the connector bar link at A2/S1, but retain the A2/S1 connection bar and all (4) mounting bolts.

➌Replace the (2) lower bar bolts removed previously. Torque to 23.00 N-m (200 lb.-in.).

➍Replace the upper A2/S1 terminal bar using the (2) upper bar bolts removed previously. Torque to 23.00 N-m

(200 lb.-in.).

➎Route and connect the A2 motor cable to drive connection bar A2/S1.

➏Route customer supplied cable between A2/S1 and motor connection S1. Cable should be sized to the same

guage as the DB resistor cables.

➐Route and connect the S2 motor cable to drive connection S2.

➑Route the DB resistor cables through the grommeted hole in the resistor mounting panel. Connect to connection

bars DBR

& A2/S1 at the top of the 1397 drive using the (2) M10 hex bolts, washers and KEP nuts supplied

with the kit. Torque to 23.00 N-m (200 lb.-in.).

➒Connect the motor series field between S1 & S2.

➓Verify that the jumper between terminals 3 & 4 at the drive terminal block is installed.

4

2

Remove the lockout and reapply power. Refer to 1397-DB-B400L—B600L Dynamic Brake Kit

Operation above and proceed to Setup on the last page.

1397-5.15 March, 1999

Page 15

1397 Open Chassis Dynamic Brake 15

Setup

Important: Depending upon the application, additional parameter

adjustments may be required. If additional options are installed,

different parameter settings may be required. Perform the Start-Up

and Adjustment procedure in the 1397 User Manual to verify all

parameter settings

Stop Mode

P.115 [Stop Mode Type]

Reset to 2 Coast/DB for dynamic braking.

1397-5.15 March, 1999

Page 16

Rockwell Automation helps its customers receive a superior return on their investment by bringing

together leading brands in industrial automation, creating a broad spectrum of easy-to-integrate

products. These are supported by local technical resources available worldwide, a global network

of system solutions providers, and the advanced technology resources of Rockwell.

Worldwide representation.

Argentina • Australia • Austria • Bahrain • Belgium • Bolivia • Brazil • Bulgaria • Canada • Chile • China, People’s Republic of • Colombia • Costa Rica • Croatia • Cyprus

Czech Republic • Denmark • Dominican Republic • Ecuador • Egypt • El Salvador • Finland • France • Germany • Ghana • Greece • Guatemala • Honduras • Hong Kong

Hungary • Iceland • India • Indonesia • Iran • Ireland • Israel • Italy • Jamaica • Japan • Jordan • Korea • Kuwait • Lebanon • Macau • Malaysia • Malta • Mexico

Morocco • The Netherlands • New Zealand • Nigeria • Norway • Oman • Pakistan • Panama • Peru • Philippines • Poland • Portugal • Puerto Rico • Qatar • Romania • Russia

Saudi Arabia • Singapore • Slovakia • Slovenia • South Africa, Republic of • Spain • Sweden • Switzerland • Taiwan • Thailand • Trinidad • Tunisia • Turkey • United Arab Emirates

United Kingdom • United States • Uruguay • Venezuela

Rockwell Automation Headquarters, 1201 South Second Street, Milwaukee, WI 53204-2496 USA, Tel: (1) 414 382-2000, Fax: (1) 414 382-4444

Publication 1397-5.15 — March, 1999 P/N 179213 (01)

Supersedes June, 1998 Copyright 1998 Rockwell International Corporation Printed in USA

Loading...

Loading...