Page 1

Bulletin 1395

Digital DC Drive

User

in Bulletin 2361

Motor Control Centers for

Drive Systems

1250, 1650, 3000A DC

Series C

Manual

Page 2

Important User Information Solid-State equipment has operational characteristics differing from

those of electromechanical equipment. “Safety Guidelines for the

Application, Installation and Maintenance of Solid-State Cont rols”

(Publication SGI-1.1) describes some important differences between

solid-state equi pment and hard-wired electromechanical devices.

Because of this difference, and also because of the wide variety of

uses for solid-state equipment, all persons responsible for applying

this equipment must satisfy th emse lves that e ach inte nded appl ication

of this equipment is acceptable .

In no event will Rockwell Automation be responsible or liable for

indirect or consequential damages resulting from the use of

application of this equipment.

The examples and diagrams in this manual are included solely for

illustrati ve purpose s. Bec ause of th e many var iable s and requi rements

associated with any partic ular installation, the Rockwell Automation

cannot assume responsibility or liability for actua l use based on the

examples and diagrams.

No patent liability is assumed by Rockwell Automation with respect

use of information, circu its, equipment, or software described in this

manual.

Reproduction of the contents of this manual, in whole or in part,

without written permission of Rockwell Automation is prohibit ed.

Throughout this manual we use notes to make you aware of safety

consideration s:

ATTENTION: Identifies infor mation about practi ces

or circumstances that can lead to personal injury or

!

Attention statements help you to:

• identify a hazard

• avoid a hazard

• recognize the consequences

Datab is a trademark of W . H. Brady Company

CENTERLINE, PLC-5, DriveT ools, and ControlNet are trad emarks of Rockwell International or its

subsidiaries.

death, property damage or economic loss.

Page 3

Table of Contents

Preface Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-1

Who Should Use This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . P-1

Purpose of This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-1

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-2

Contents of this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-3

Related Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-4

Style of this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-5

Terms and Abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-5

Receiving Your Drive System . . . . . . . . . . . . . . . . . . . . . . . . . . . P-5

Rockwell Automation Support . . . . . . . . . . . . . . . . . . . . . . . . . . . P-6

Local Product Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-6

Technical Product Assistance . . . . . . . . . . . . . . . . . . . . . . . . . P-6

Chapter 1 Product Overview

Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Standard Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Standard Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Hardware Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Control Boards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Main Control Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Door-Mounted Programming Terminal . . . . . . . . . . . . . . . . . . 1-6

Adapter Boards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Control/Power Interface Boards . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Power Stage Interface Board . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Unit Power Supply Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Feedback Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

24V DC Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

Gate Interface Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

Power Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

Incoming Power Components . . . . . . . . . . . . . . . . . . . . . . . . 1-12

Incoming Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

AC Input Busbars . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

Main Disconnect (Optional) . . . . . . . . . . . . . . . . . . . . . . . . 1-12

AC Line Fuses (Optional) . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

Control and Field Power . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

AC Line RC Suppressor (Optional) . . . . . . . . . . . . . . . . . . . 1-13

Publicatio n 2361-5.01 July 1998

Page 4

toc–ii Table of Contents

Armature Power Components . . . . . . . . . . . . . . . . . . . . . . . . 1-14

Armature Bridge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14

DC Contactor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-16

Field Power Components . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-17

Field Bridge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-18

Field-Pulse Transformer Board . . . . . . . . . . . . . . . . . . . . . 1-18

Chapter 2 Your 1250A DC Drive

Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

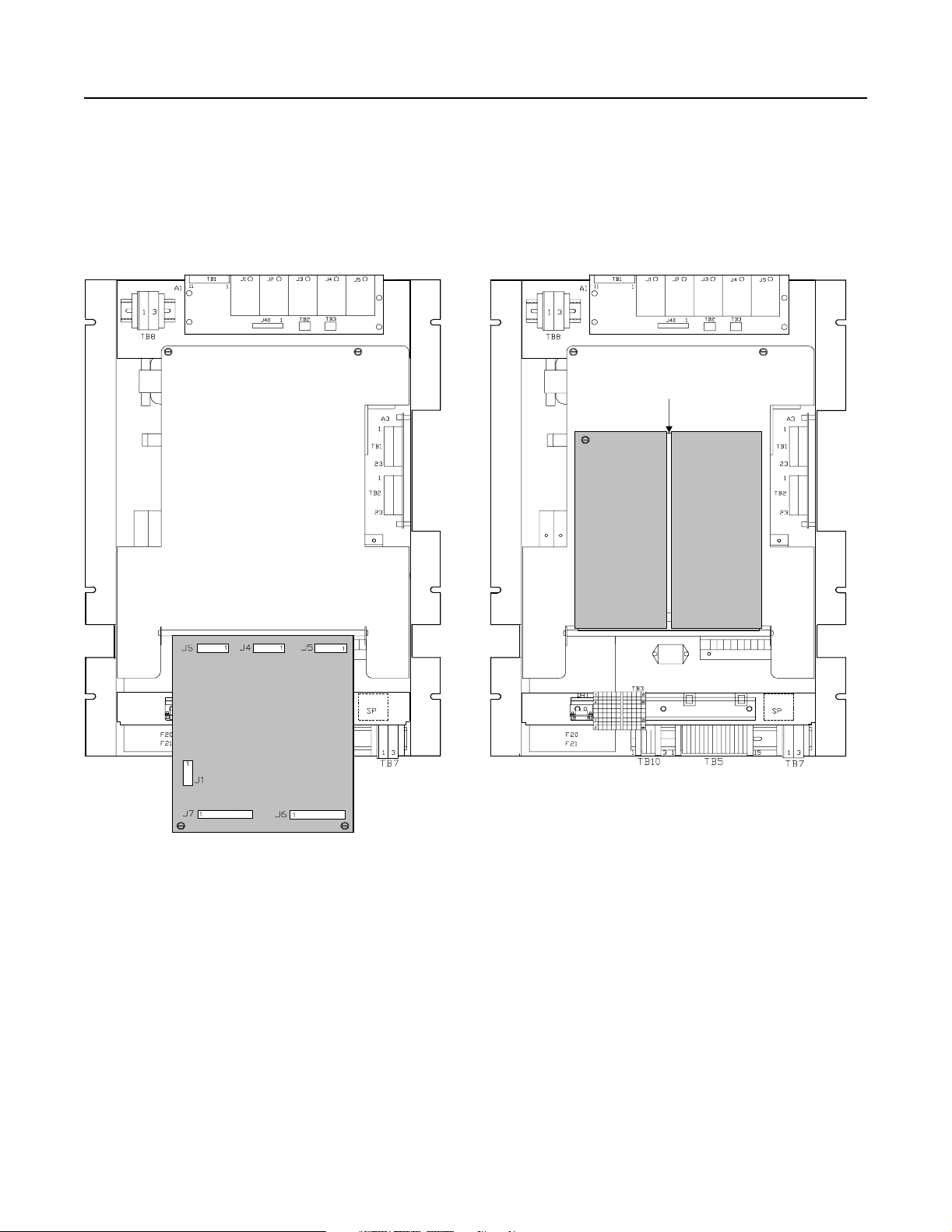

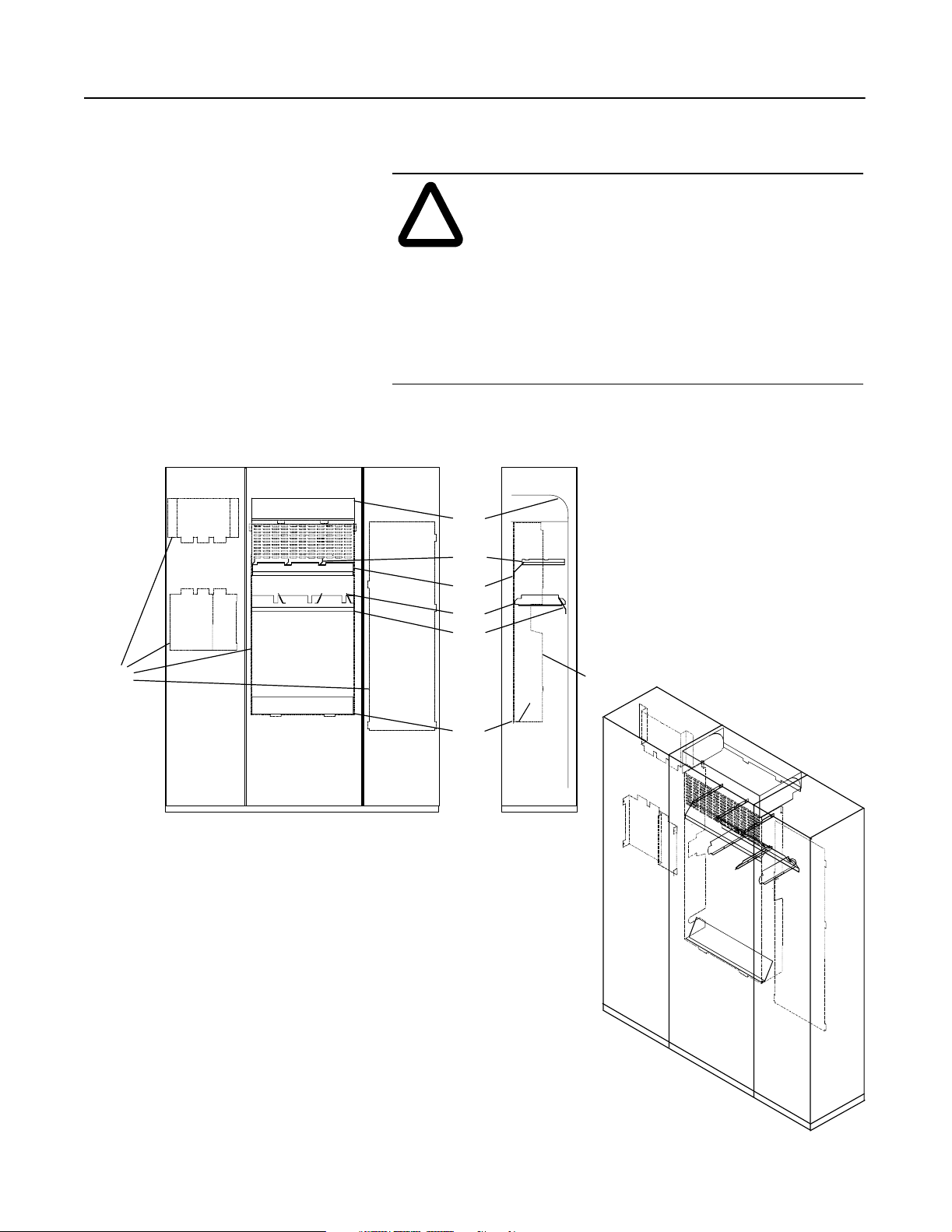

Drive Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Drive Schematics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Symbol Reference Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Drive Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Conclusion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Chapter 3 Your 1650A DC Drive

Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Drive Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Drive Schematics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Symbol Reference Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Drive Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Conclusion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Chapter 4 Your 3000A DC Drive

Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Drive Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Drive Schematics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Symbol Reference Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Drive Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Conclusion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Publicatio n 2361-5.01 July 1998

Page 5

Chapter 5 Installing Your Drive

Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Physically Installing the Drive at Your Site . . . . . . . . . . . . . . . . . 5-2

Inspecting the Air Baffles . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Preparing AC Input Entry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Installing and Configuring Your Drive . . . . . . . . . . . . . . . . . . . . . 5-4

Drive Disconnect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Wiring Recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Drive Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Power Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Field Transformer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Installing the Field Transformer . . . . . . . . . . . . . . . . . . . . . . 5-7

Circuit Board Jumper Connections . . . . . . . . . . . . . . . . . . . . . 5-9

Armature Current Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-12

Chapter 6 Starting Up Your Drive

Table of Contents toc–iii

Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Voltage Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Rated Armature and Field Currents . . . . . . . . . . . . . . . . . . . . . . . 6-2

Appendix A Drive Specifications

Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

General Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Unit Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Electrical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

Power Dissipation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-4

Circuit Breaker Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-5

Circuit Breaker Derating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-6

Input Busbars . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-7

Air Baffle Layouts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-9

Publicatio n 2361-5.01 July 1998

Page 6

toc–iv Table of Contents

Appendix B Catalog Numbers and Spare Parts Kits

Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

Understanding Catalog Numbers . . . . . . . . . . . . . . . . . . . . . . . . B-1

Determining Catalog Numbers . . . . . . . . . . . . . . . . . . . . . . . . B-1

DC Drive Catalog Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-3

DC Drive Spare Parts Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-6

What Does a Spare Parts Kit Include? . . . . . . . . . . . . . . . . . . . B-6

Which Table Do I Use? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-6

Significance of Level Numbers . . . . . . . . . . . . . . . . . . . . . . . . B-6

Definition of Terms Used to Describe "Qty in Kit" . . . . . . . . . . B-7

Catalog Number Description . . . . . . . . . . . . . . . . . . . . . . . . . . B-7

Publicatio n 2361-5.01 July 1998

Page 7

Preface

Preface

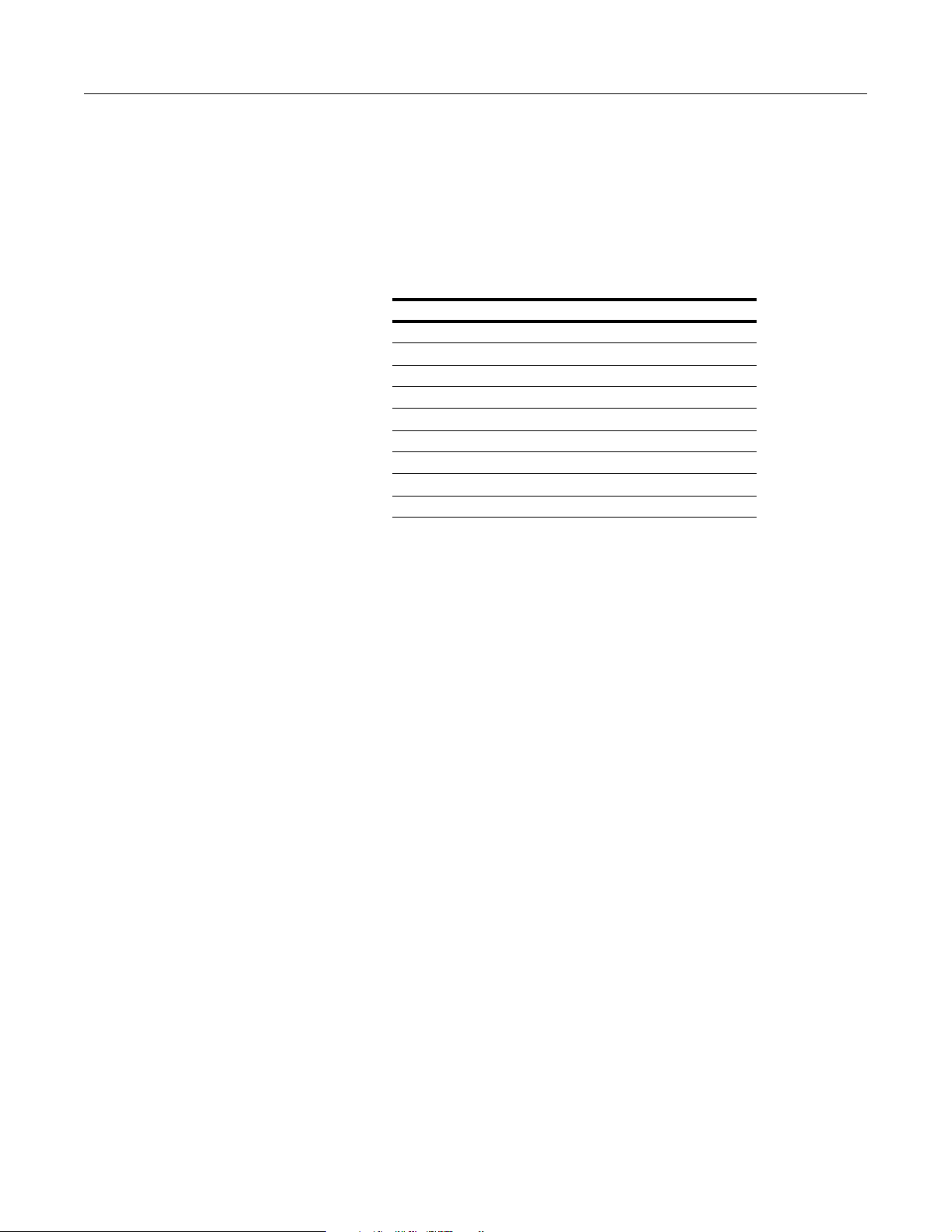

Contents This preface w ill introduce you to the contents and purpose of this

manual. The following topics will be discussed in this preface:

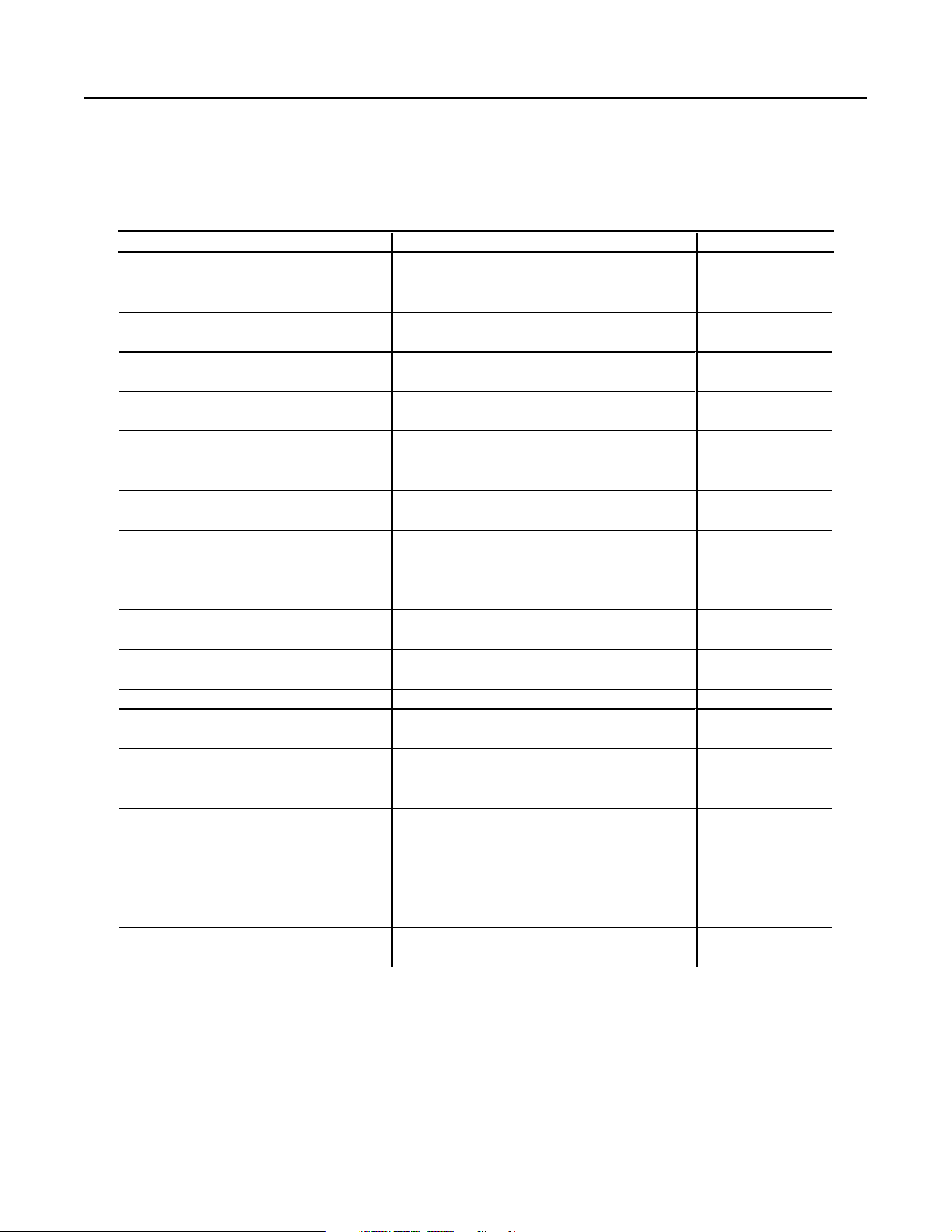

Topic Pa ge

Who Should Use This Manual P-1

Purpose of This Manual P-1

Safety Precautions P-2

Contents of This Manual P-3

Related Documentation P-4

Style of This Manual P-5

Terms and Abbreviations P-5

Receiving Your Drive System P-5

Rockwell Automation Support P-6

Who Should Use This Manual This manual is intende d for those who are re sponsible for instal ling or

operating a Rockwell Automation high-horsepower 1395 drive.

If you do not have a basic understanding of this unit, please refer to

the drive documentation, or contact your local Rockwell Automation

Drive Systems representative for more information before using this

product.

Purpose of This Manual This manual is a supplement to Publication 1395-5.40, titled 1395

Digital DC Drive–User Manual. This manual will cove r:

• hardwa re ove rv ie ws

• specifications

• installation instructions

• configuration and setup information

• spare parts

Publicatio n 2361-5.01 July 1998

Page 8

P-2

Safety Precautions The following general precautions apply to Bulletin 2361 drive

system lineups:

ATTENTION: Only those familiar with the drive

system, the products used in the system, and the

!

associated machinery should plan or implement the

installation, startup, and future maintenance of the

system. Failure to comply can result in personal injury

and/or equipment damage.

ATTENTION: Verify that all sources of AC and DC

power are deenergized and locked out or tagged out in

accordance with the requirements of ANSI/NFPA 70E,

Part II.

ATTENTION: The system may contain stored ener gy

devices. To avoid the hazard of electric al shock, ve rify

that all voltage on capacitors has b een discharge d before

attempting to service, repair, or remove a drive system

or its components. You shou ld only at tempt the

procedures in this manual if you are qualified to do so

and are familiar with solid-state control equipment a nd

the safety procedures in ANSI/NFPA 70E.

ATTENTION: An incorrectly applied o r incorrectly

installed drive sys tem can result in component damage

and/or a reduction in product life . Wiring or applicati on

errors–such as undersizing the motor, incorrect or

inadequate AC supply, and excessive ambient

temperatures–can r esult in the malfunction of hte drive

equipment.

A TTENTION: This dr ive system contains parts and

assemblies that are sensitive to ESD (electrostatic

discharge). Sta tic control precautions are requir ed when

installing, testing, or repairing this assembly.

Component damage can r esult if ESD cont rol procedures

are not followed. If you are not familiar with static

control procedures, refe r to Rockwell Automation

publication 8000-4. 5.2, Guar ding Agains t Electrost atic

Damage, or another adequate handbook on ESD

protection.

Publicatio n 2361-5.01 July 1998

Page 9

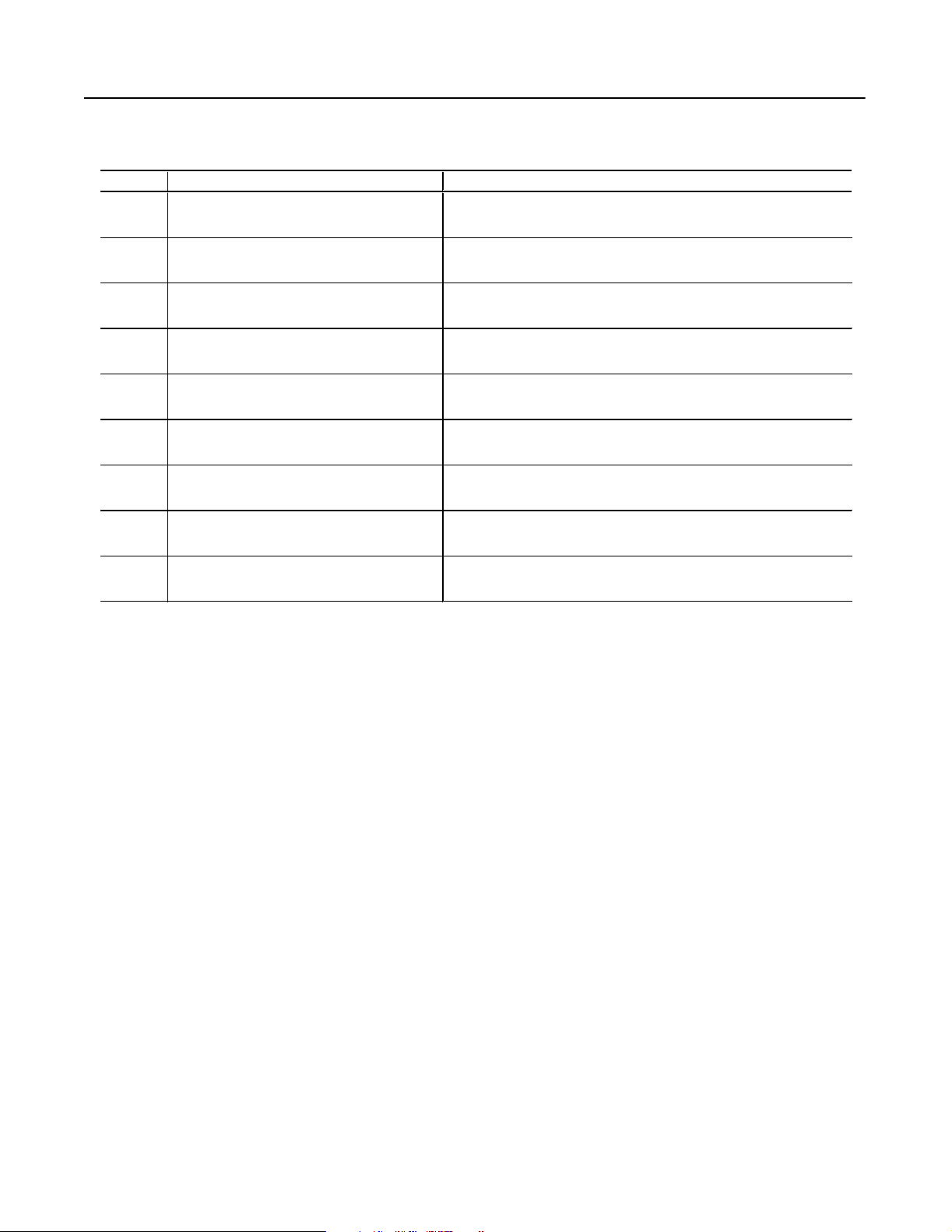

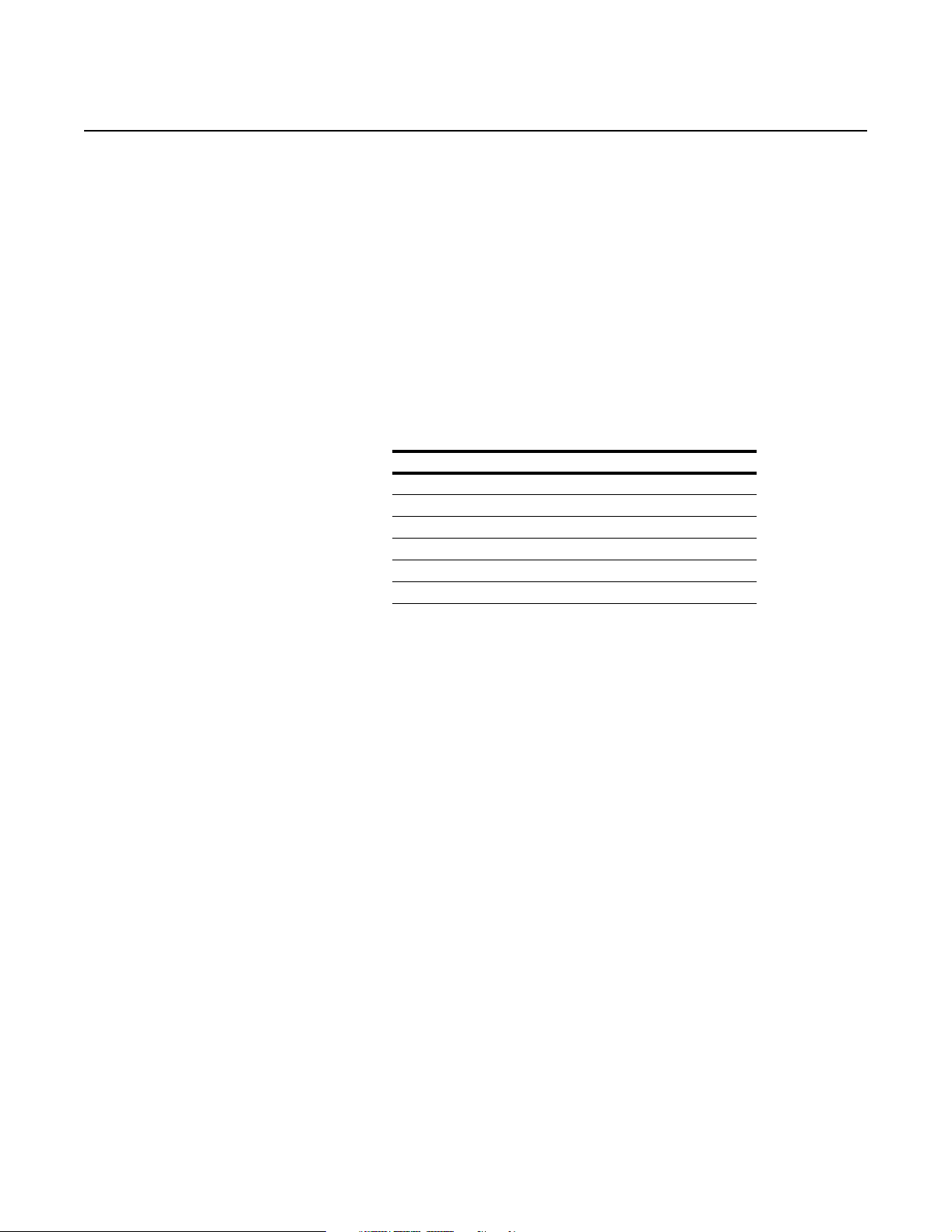

Contents of this Manual

Chapter Title Contents

Preface Purpose, background, and scope of this manual

1 Product Overview Theory of operation, features, and standard options

2 Your 1250A DC Drive Features, components, and schematics of the 1250A drive (R-frame)

3 Your 1650A DC Drive Features, components, and schematics of the 1650A drive (S-frame)

4 Your 3000A DC Drive Features, components, and schematics of the 3000A drive (T-frame)

5 Installing Your Drive Installation procedures and connection details

6 Starting Up Your Drive Information for starting up your drive

A Drive Specifications Electrical, environmental, and operational specifications

P-3

B Catalog Numbers and Spare Parts Kits Explanation of catalog numbers and listings of spare part kits

Publicatio n 2361-5.01 July 1998

Page 10

P-4

Related Documentation Several of the f ollowing documents will be needed to understa nd and

install your drive and its components. To obtain a copy of any

Rockwell Automation publication, please contact your local

Rockwell Automation office or distributor.

For Read This Document Document Number

Information on the 1395 digital DC drives Bulletin 1395 Digital DC Drive–User Manual 1395-5.40

Troubleshooting information for 1395 drives Bulletin 1395 Digital DC Drive–Troubleshooting

Manual

Using the Bulletin 1300 programming terminal Bulletin 1300 Programming Terminal–User Manual 1300-5.5

PLC-5™ information PLC-5 Controllers Brochure 1785-1.2

Additional Information on joining and splicing

together MCCs

Details on receiving, handling, and storing

MCCs

Provides procedures for those tasks that need

to be done at the customer’s site before system

start up

Information and installation instructions for the

1395 Node Adapter Board

Information and installation instructions for the

1395 Discrete Adapter Board

Information and installation instructions for the

1395 ControlNet Communication Board

Information and installation instructions for the

1395 Multi-Communication Board

Information and installation instructions for the

1395 Digital Reference Adapter Board

A description of DriveTools™ software DriveTools Software Brochure 9303-1.0

Information on FD86N enclosures FD86N Drive Systems Enclosure Hardware–

Standards for electrical procedures (wiring

sizes, grounding, etc.)

An article on safety procedures Standard for Electrical Safety Requirements for

A complete listing of current documentation,

including ordering instructions. Also indicates

whether the documents are available on CDROM or in multi-languages

A glossary of industrial automation terms and

abbreviations

Joining and Splicing Vertical Sections–Instructions 2100-5.1

Receiving, Handling, and Storing Motor Control

Centers–Instructions

Bulletin 2300 Installation Manual 2300-5.1

Bulletin 1395 Node Adapter Board–Installation and

Operation Manual

1395 Discrete Adapter Board–Installation and

Operation Manual

Bulletin 1395 ControlNet Communication Board–

User Manual

Bulletin 1395 Multi-Communication

Board–Hardware/Software Reference Manual

Bulletin 1395 Digital Reference Adapter

Board–Hardware/Software Reference Manual

Installation Manual

National Electrical Code

(Published by the National Fire Protection

Association of Boston, MA)

Employee Workplaces

Allen-Bradley Publication Index SD499

Industrial Automation Glossary AG-7.1

1395-5.45

2100-5.5

1395-5.9

1395-5.12

1395-5.37

1395-5.33

1395-5.55

S-3062

ANSI / NFPA 70

ANSI / NFPA 70E

Publicatio n 2361-5.01 July 1998

Page 11

Style of this Manual The following conventio ns are used throughout this m anual:

• ‘ATTENTION’ statements, preceded with the symbol shown,

indicate a circumstanc e that could could lead to personal injury,

!

death, damage to property, or economic loss

• ‘Important’ statements i ndicate key infor matio n for suc cessful ly

performing procedures and understanding the product

P-5

&

• Reference statements, preceded with the symbol shown, lead you

to other resou rces o f info rm ation and instruction

• Horsepower ratings are pr ovided at the start of each drive chapter

• Schematic and layout component abbreviations are explained in

component reference charts in each drive chapter

Terms and Abbreviations The following terms and abbrevia tions are used in this manual:

Term Definition

armature rotating part of a motor

bridge assembly for power (AC/DC) conversion

busbar a large tin-plated copper conductor, used for high-power input and output

feedback status signals/voltages sent from components or external devices

gate an electrical switch

MCC motor control center, an enclosure for drive systems

MOV metal-oxide varistor, used for voltage spike protection

SCR silicon-controlled rectifier, used in power conversion

snubber a resistor/capacitor assembly, used for limiting excess voltage

Receiving Your Drive System You, the Customer, are responsible for thoroughly inspecting the

equipment before accepting the shipment f rom the freight company.

Check the item(s) that you receive against your purchase order. If

any items are obviously damaged, do not accept the delivery until the

freight age nt has noted the damage on the freight bill. Should you

discover any concealed damage during unpacking, you are

responsible for notifying the freight agent. In such a case, leave the

shipping container intact and request that the freight agent make a

visual inspec tion of the equipment.

Publication 2361-5.01 July 1998

Page 12

P-6

Rockwell Automation Support Rockwell Automation offers support services worldwide, with Sales/

Support Office s, a uthorized distributors, and authorized Systems

Integrators loc ated throughout the United States, plus Rockwell

Automation representa tives in every major country in the world.

Local Product Support

Please contac t your local Rockwell Automation representative for:

• sales and order support

• product technical training

• warranty suppor t

• support service agreements

Technical Product Assistance

If you need to contact us for tec hnical assistance, please review the

product and troubleshooting information in this manual first.

For the quickest possible response, please have the catalog num bers

of your products ready when you call.

Publication 2361-5.01 July 1998

Page 13

Chapter

Product Overview

Contents The high-horsepower lin e of 1395 DC drives are Bull etin 1395

regulator product s, with a high-horsepower silicon-controlled

rectifier (S CR) bridge, packaged in a Bulleti n 2361 C ENTERLINE™

motor control center, providing DC power for your high-horsepower

applications.

This first chapter wil l intr oduce you to the high-horsepower Bulletin

1395 drive c overing these topics:

To pi c Pa ge

Standard Features 1-1

Standard Options 1-2

Hardware Overview 1-3

Control Components 1-4

Control/Power Interface Components 1-7

Power Components 1-12

1

Standard Features The high-horsepower Bulletin 1395 drive includes the following

standard features:

• NEMA Class I construction

• High AIC insta ntaneous trip circuit breaker or line fuses for the

AC input, arm ature cell fuses, a nd a DC output contactor

• a six pulse, full-wave rectified armature converter

• 43A single-phase fiel d regula tor

• regenerative (12 50, 1650, and 3000A) or non-regenerative (1250

and 1650A units only)

• 6:1 constant horsepower range

• digital control for cu rre nt, velocity, and configuration

• auto tuning for velocity loop, current loop, field flux table

Publication 2361-5.01 July 1998

Page 14

1-2 Product Overview

• programmable functions ( independent acceleration/deceleration

adjustment, preset speeds, current limit, tapered current limit,

tach loss recovery, system reset)

• protective featur es (instantaneous overc urrent, motor overload ,

feedback loss, field loss, field economy, tach loss recovery,

system reset)

• CENTERLINE Bulletin 2361 Motor Control Center enclosure

Standard Options The following options are available for the high-horsepower 1395

drives:

• 115V AC discret e adapter board

• 24V DC discrete adapter board

• node adapter board

• multi-communications adapter board

• door-mounted DHT or EHT programming terminal

• ‘start/running’ and ‘clear fault/drive faulted’ door- mounted

illuminated pushbuttons

• ‘drive stop’, ‘hardwired stop’, ‘jog forward’, and ‘jog reverse’

door-mounted pushbuttons

• ‘power on’ door-mounte d pilot light

• door-mounted speed potentiometer

• 1-2-3 speed selector

• blower starter (NEMA, IEC)

• 90A single-phase fiel d regula tor

• control circ uit transformer

• top-hat input enclos ure (s tandard for 3000A drive)

• line RC suppressor

• AC power thru bus

Note: Additional options are listed in Appendix B.

Publication 2361-5.01 July 1998

Page 15

Product Overview 1-3

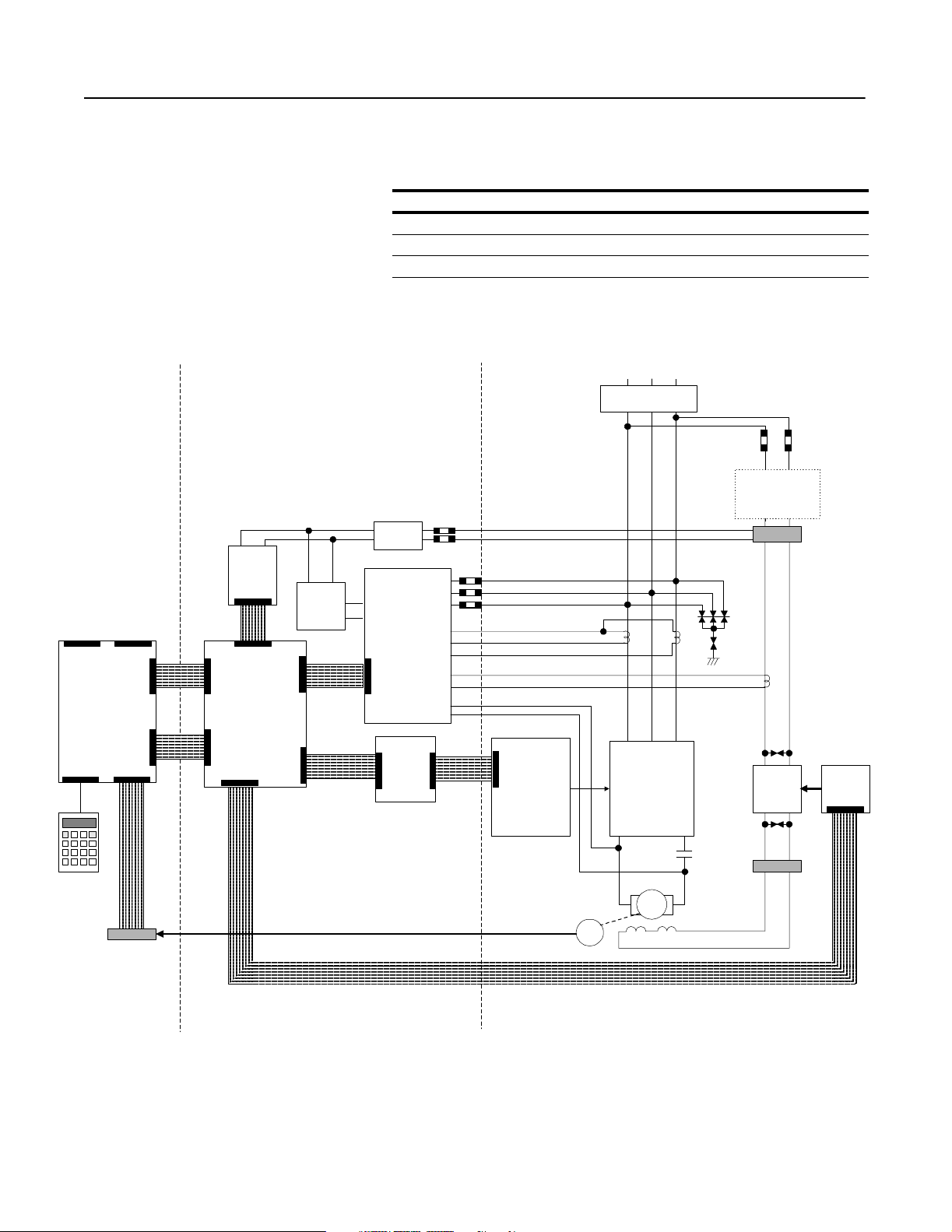

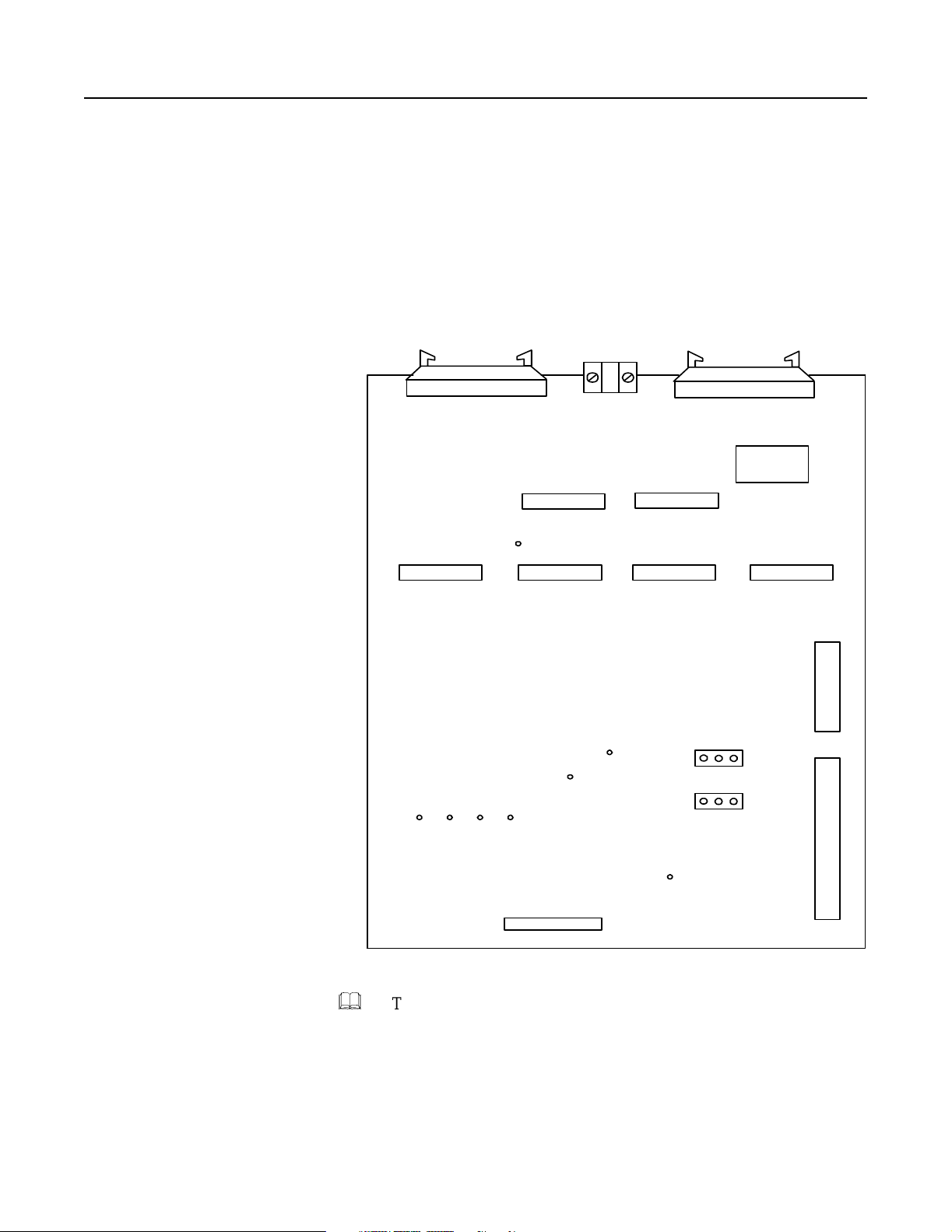

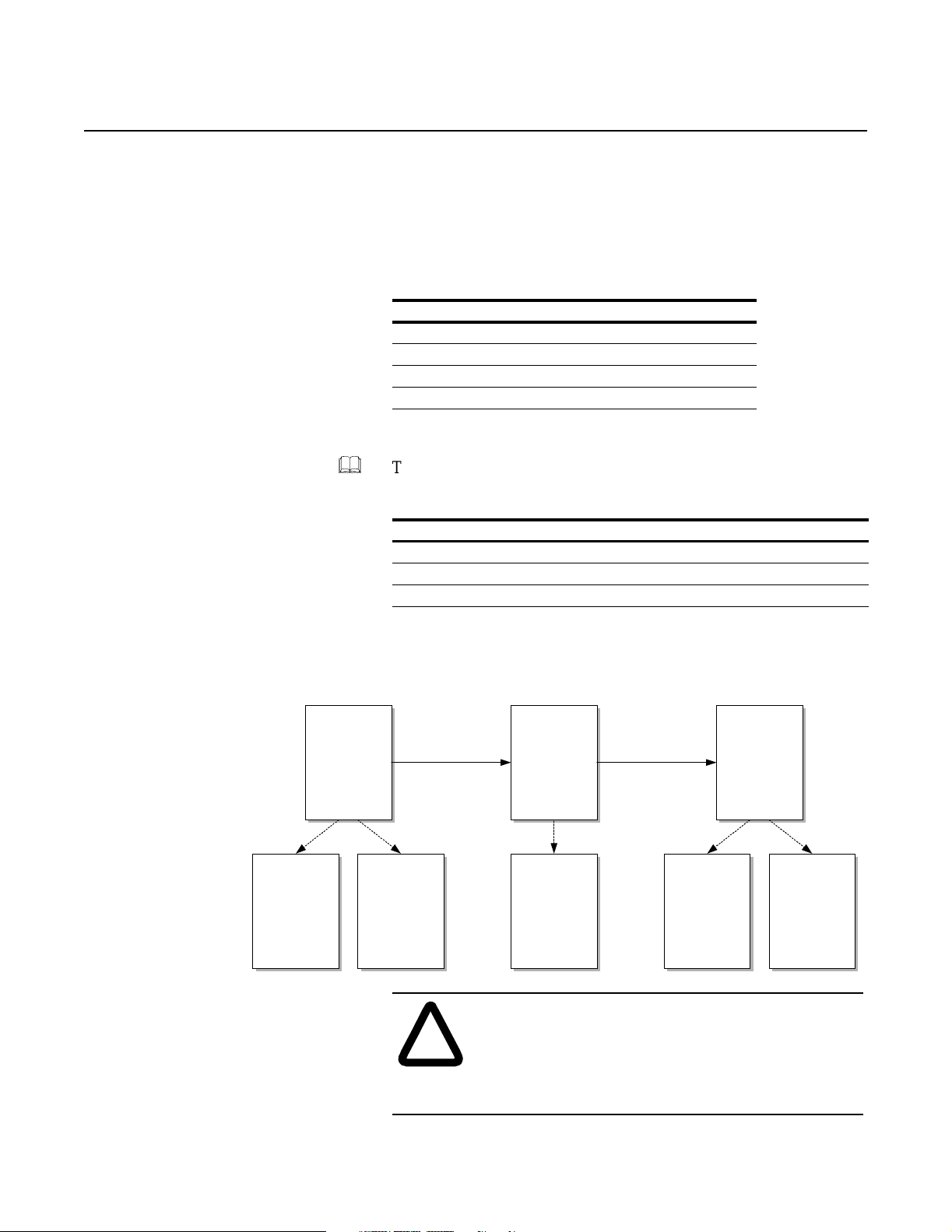

Hardware Overview The hardware components shown in form the high-horsepower 1395

DC drive. These drive components can be broken down into the

following three categor ies:

Hardware Description

Control Controls the drive system and interfaces with external devices

Control/Power Interface Interfaces the control components with the power components

Power Converts AC input to a DC supply for the motor

Figure 1.1

Drive Components

3-Phase AC Power

Circuit Breaker

Field Transformer

(Only Used For AC Inputs of

575 and 660 V AC)

J7 J6

Main Control Board

J4 J1

Programming

Terminal

DHT/DMT

TB3

Control

Transformer

Unit

Power Supply

J1

J7

J5

J8

24V DC

Feedback

Power Supply

J2

Feedback Board

J40

Power Stage

Fuses

AC Line Voltage Feedback

Armature Current Feedback

Field Current Feedback

Armature DC Voltage Feedback

Interface Board

J2

J9

J6

J3A

J3D

-

Gate

Interface

Board

Armature

Pulse

Transformer

Boards

Encoder Feedback

Encoder

3-Phase

SCR Armature

Bridge

-

Motor

Armature

F1 F2 F3 F4

+

M1

A1A2

MOVs

TB8

Single-Phase

SCR Field

Bridge

TB7

Field PT &

Snubber

J1

CONTROL CONTROL/POWER INTERFACE POWER

Publication 2361-5.01 July 1998

Page 16

1-4 Product Overview

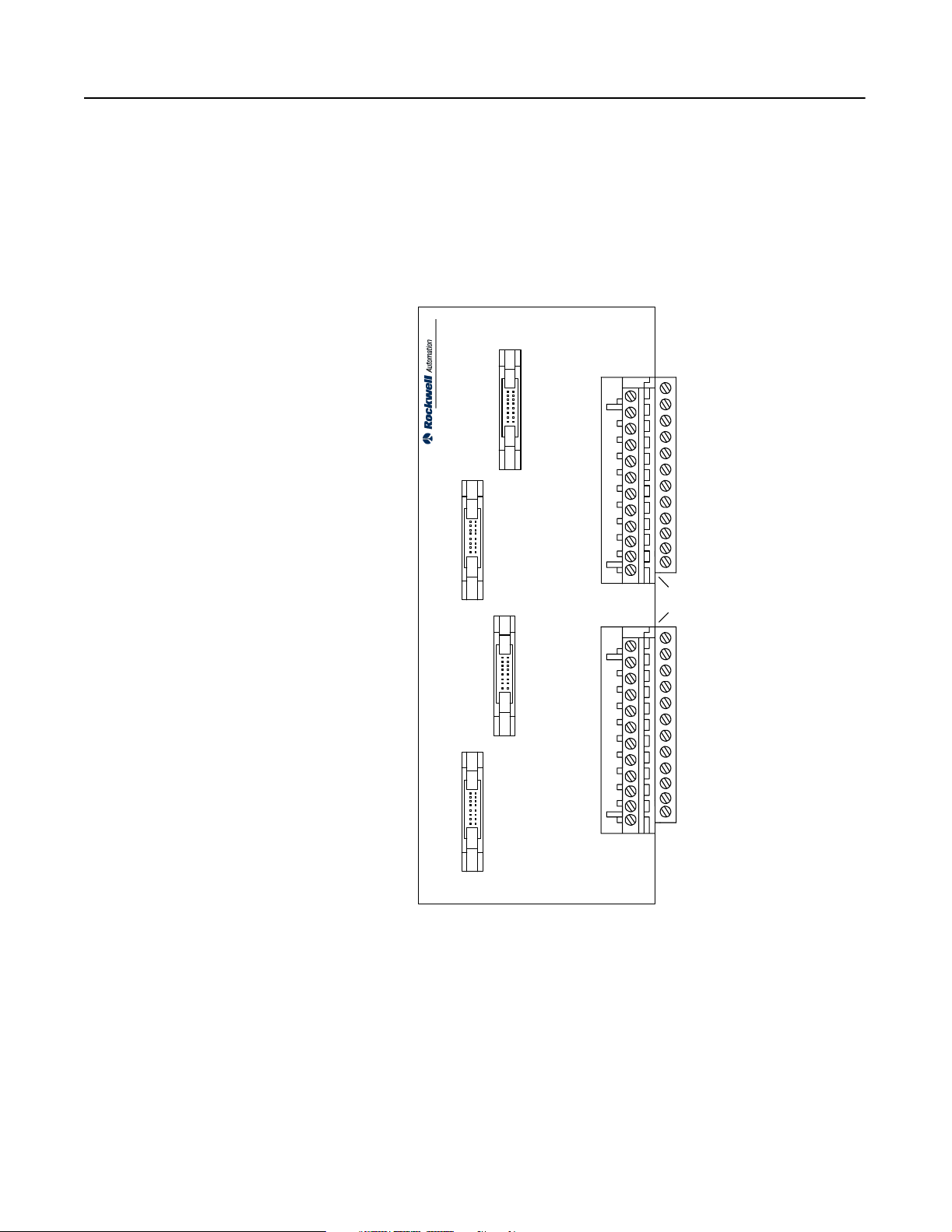

Control Boards The control boards mana ge and control the system, processing status

information from syste m components a nd commanding drive

components and activit ies .

Figure 1.2

Control Boards

Main Control Board Adapter Boards

CH1

FCT

F14 F 15

Feedback Board

Main C ontrol

Board

Feedback Board

Main Control Board

(behind adapter boards)

Discrete or

Digital

Reference

Adapter Board

(Port A )

O

PTIONAL

Communication

Adapter Board

(Port B )

O

PTIONAL

MP

24V DC Supply

Publication 2361-5.01 July 1998

Page 17

Product Overview 1-5

Main Control Board

The main control board is the center of the control pr ocessing. This

board has a number of test points and jumpers that are us ed during

startup and troubleshooting. Refer to the troubleshooting manua l for

more information on test point s and jumpers.

Figure 1.3

Main Control Board

J2 J4 J5

Connection

To

Encoder

TP42

TP50

Connection to Power

Stag e Interface Board

TP2 TP5

TP13

TP12

TP11

TP15

TP23

TP32

TP35

VP

1 2 3

1 2 3

1 2 3

J10

J9

J8

Connection to

Programm ing Terminal

TP9 TP6

TP24

TP8 TP3 9TP17

TP25

TP33

TP21

TP34

TP43

TP1

Connection to Power

Stage Interface Board

TP27 TP26

TP31 TP29

TP30TP38

CP

TP28

TP41

TP20

TP19

TP10

J7

Port A

(To Adapter Board)

SP

TP45

TP46

J6

TP47

TP44

TP20

TP49

1

2

3

TP54

ISO+12V

TP52

TP56

TP51

DGND

-12V

+5V

Port B

(To Adapter Board)

TP58

J14

TP55

+12V

TP53

IGN D

TP58

ISO +5 V

TP57

AGND

Publication 2361-5.01 July 1998

Page 18

1-6 Product Overview

Door-Mounted Programming Terminal

The door-mounted Bul letin 1300 programming terminal is the

interface m odule used to program and control the drive (typically

used in standalone applic ations). This terminal has an LCD screen

and a 24-key environment-sa fe keyp ad.

Adapter Boards

Optional adapter boards (such as the discrete a dapter board, digital

reference adapter board, node adapter board, and multicommunication adapter boa rd) connect the drive to networks and

provide I/O capabili ties.

&

Adapter board and programming terminal publications are listed in

the preface o f this manual. Please refer to the appropriate manuals for

more information.

Publication 2361-5.01 July 1998

Page 19

Product Overview 1-7

Control/Power Interface Boards Control/power interface boards are used to provide a link between

control boards (which are responsible for managing the drive), and

power components ( which ar e clos ely assoc iated wit h the actua l drive

hardware and operations).

The following items are used to provide this interfacing:

• power stage int erfa ce b o ard

• unit power supply board

• feedback board

These items a re located on the control module in the disconnect bay

of the drive, and are arranged as shown below. Accessibility to the

power stage interface board and the unit powe r supply is gained by

lowering the front panel.

Figure 1.4

Control/Power Interface Boards

Feedback Board

Alternate Field Bridge

Configuration

Field Pulse Transformer

and Snubber Board

CH1

43A Field

FCT

F16

F14

F15

F4

F20

F21

J9

Bridge

FAN 4

24V DC Supply

12345 789

MP

TB1

Power Stage

Interface Board

2MOV

3MOV

Gate Interface

Board

10

CH1

Option 14FX

Field Bridge

FCT

FAN 4

2MOV

3MOV

Unit Power Supply

Board

Publication 2361-5.01 July 1998

Page 20

1-8 Product Overview

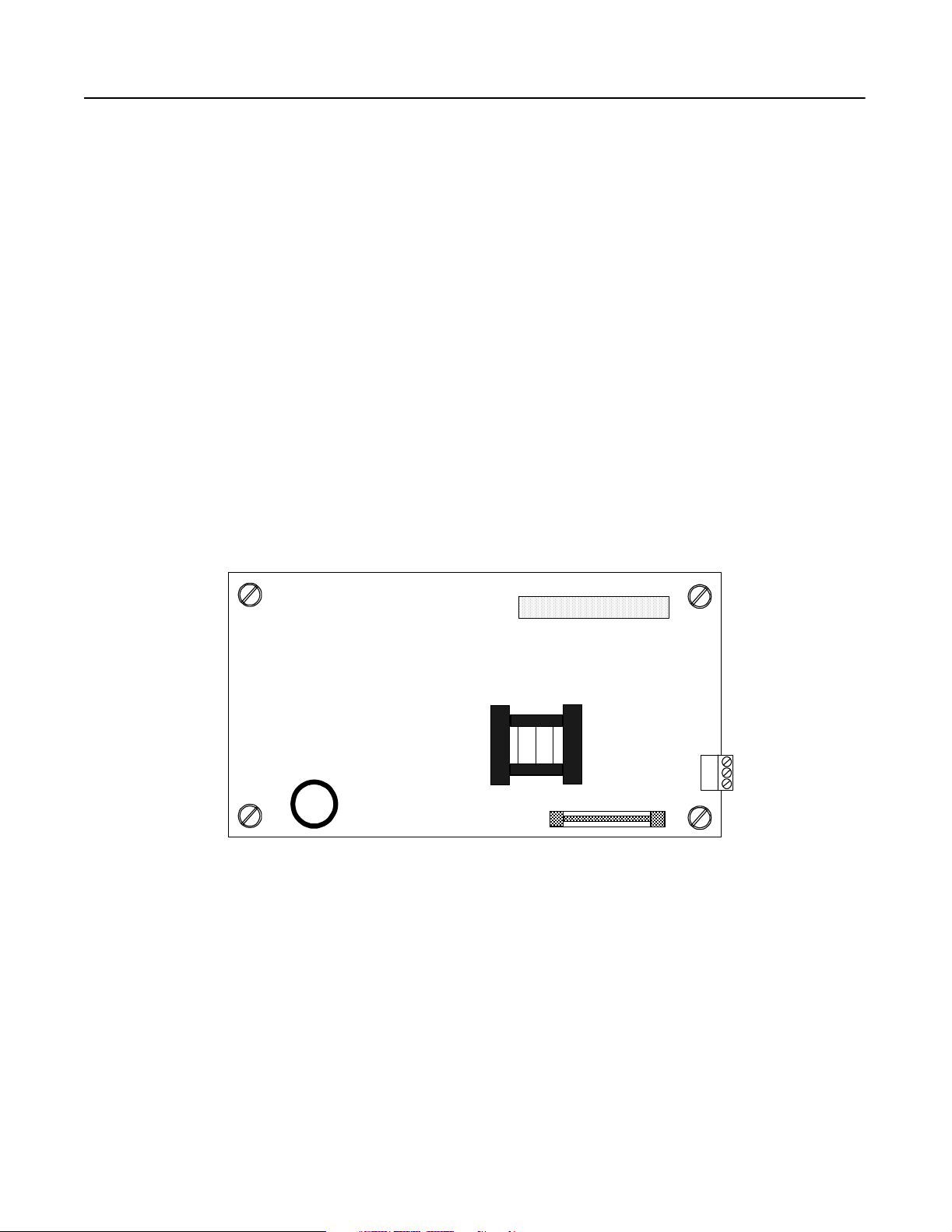

Power Stage Interface Board

The power stage int erface boar d is used as the c hief interfac e between

the main control board and other boards of the system. This board is

responsible f or distributing power and control signals to and from the

main control board, gate interface board, field-pulse transform er

board, feedback board, and unit power supply. Refer to Figure 1.1 to

see how this board is connected in the drive.

Figure 1.5

Power Stage Interface Board

Connection to Unit Power

Supply and TE

J8 J9

Connection to M ain Control Board Connection to M ain Control Board

Connection to

Field Transformer

TP1

(+24V)

J3D

TP8

TP7

TP6

TP5

(-12V)

(Gnd )

(+12V)

(+5V)

TB1

J2J6

Connection to

Feedback Board

J3C J3B J3A

Connections to

Gate Interface Board

Connection to

Main Cont actor , Pilot Re lay,

and Unit Power Supply

TP2

TP3

J1

J11

J12

Publication 2361-5.01 July 1998

&

J7

Connection to

Un it Pow er S upp ly

TP9

Connected to T B3

(Standard Interface)

J10

The test points and jumpers shown in the diagra m are used for startup

and troubleshooting pr ocedures. Refer to the troubles hooti ng manual

for more information on test poin ts and jumpers.

Page 21

Product Overview 1-9

The power stage interface boa rd provide s the following services

between the main control board and othe r boar ds in the system:

• furnishes DC control power to the main cont ro l board (from the

unit power supply)

• provides 3-phas e li ne synchronization signals to the main c ontrol

board

• accepts signals from the main cont r ol board and produces the

logic and drivers for armature and f ield-pulse transformers

• accepts signals f or start/stop logic, protection I/O, and drivers for

operating the main DC contactor

Unit Power Supply Board

The unit power supply board convert s 115V AC input into regulated

+5V DC and ±12V DC control voltages. These control vol tages are

routed through the power stage interfa ce board to provide power to all

the printed circuit boards.

Figure 1.6

Unit Power Supply Board

Connection to Power

Stage Interface Board

(+5V and ±12V)

F1

J1

Connection to Power

1

Stage Interface Board

2

3

(115V AC)

Publication 2361-5.01 July 1998

Page 22

1-10 Product Overview

Feedback Board

The feedback board receives sta tus information from the drive

components, scales it to a signal le vel, and supplies it to the main

control board (through the power stage interface board).

Figure 1.7

Feedback Board

TB1

(1) (2) (3) (4)

Jumper Connection

(Field Current)

150 VAC

TO

300 VAC

AB

576VAC

690VAC

150 VAC

TO

TO

300 VAC

TO

575VAC

690VAC

TO

301VAC

TO

575VAC

576VAC

301VAC

J40

To Pow er Stage

Interface Board

The feedback board has terminals f or the 3-phase AC inputs (A, B,

and C) and for the armature power (VA+ and VA-), a series of jumper

connections to adjust for AC input voltage, jumper connections for

the field current, a bus connection to the power stage interface board,

two terminals blocks for placing burden resistors in parallel to the

circuit, and a Phoenix connection terminal block connect ed to other

drive components.

Note: Jumper settings are defined in the installation chapter of

this manual.

150 VAC

TO

300 VAC

301VAC

TO

575VAC

576VAC

TO

690VAC

C

150 VAC

TO

300 VAC

301VAC

TO

575VAC

VA+

576VAC

690VAC

TO

TB2 TB3

FEEDBACK BURDEN RESISTOR FEEDBACK BURDEN RESISTO R ARMATURE

Not Used

150 VAC

TO

300 VAC

301VAC

TO

575VAC

576VAC

690VAC

VA-

TO

Jumper Connections

(AC In put Voltage )

Publication 2361-5.01 July 1998

24V DC Power Supply

There are three 24V DC power supply units that may be install ed in

the drive. There is a feedback board supply, an optional air flow

sensor supply, and an optional cont rol board supply (us ed to powe r an

optional adapter board) . These supply units are fed from the 1 15V

AC control power circuit.

Page 23

Product Overview 1-11

Gate Interface Board

The gate interface board is the junction between the power stage

interface boar d and the individua l armature-puls e transformer boards.

This board ha s four bus connections to the power stage interface

board and four Phoenix terminal bloc ks distributing signals to the

armature-pulse transformer boards.

Figure 1.8

Gate Interface Board

Connections to Power Stage

Interface Board

TB1

J4

J3

Co nnections to Arm ature-Pulse

Transformer Boards

J2

J1

TB2

Publication 2361-5.01 July 1998

Page 24

1-12 Product Overview

Power Components This section will break down and define the incoming power,

armature power, and field supply components.

Incoming Power Components

Incoming Devices

The 1250 and 1650A DC drives a re intended to be used straight from

the customer- supplied, power controlled incoming lines, without any

additional isolation transformer or line chokes (however, adding

either of these would increa se isolation to other equipment on the

power lines).

The 3000A DC drive does not require an isolation transformer or line

reactors if it is the only eq uipment on the power lines. However, if it

shares power with ot her equipm ent on th e same power lines, it will be

necessary to use eithe r line reactors or an isolation transformer ahead

of the drive.

The system designer needs to provide proper circuit impedence to

limit the sho rt circui t c urrents according t o the break er derat ing cha rts

given in Appendix A.

Some drives may require an output inductor in serie s with the

armature, especially for older machines which do not have enough

internal inductance for a proper armature commutation process.

AC Input Busbars

Tin plated busbars are supplied for all input connections through the

top of the disconnect bay. Busbar dimension dia grams are given in

Appendix A.

Main Disconnect (Optional)

A 3-phase circuit breaker can be supplied on the incoming line for

each high-horsepower drive. Appendix A lists circuit breaker

specifications, and shows diagrams of the circuit breakers settings for

the 1250, 1650, and 3000A DC drives.

AC Line Fuses (Optional)

AC line fuses can be supplied for the 3-phase incoming power.

Note: Units require either a main disconnect or AC line fuses.

Publication 2361-5.01 July 1998

Page 25

Product Overview 1-13

Control and Field Power

The first (L1) an d thir d (L3 ) pha s e of the inco m ing p ow er are t app ed

off and fused to provide single-phase AC power to the primary of

control power t ransformer (115V AC), field supply circuit (460V AC

maximum), and 24V DC power supply.

Note: For drives using a 575 or 660V AC input, a step-down

transformer will be required for the field supply circuit (see

Figur e 1. 12).

AC Line RC Suppressor (Optional)

The optional AC line RC suppressor is a device used for limiting line

voltage spikes in drives when the medium volta ge source to the

primary of the distribution transformer is switched. The option is

offered for a dist ri bution transformer primary voltage of 2300V or

greater.

Publication 2361-5.01 July 1998

Page 26

1-14 Product Overview

Armature Power Components

The armature power components work together to convert the 3phase AC input to a DC output used for powering your motor

armature.

The following items make up the armature power circuitry:

• armature bridge (and its subordinate components)

• cell fuses

• gate board s

• DC contactor

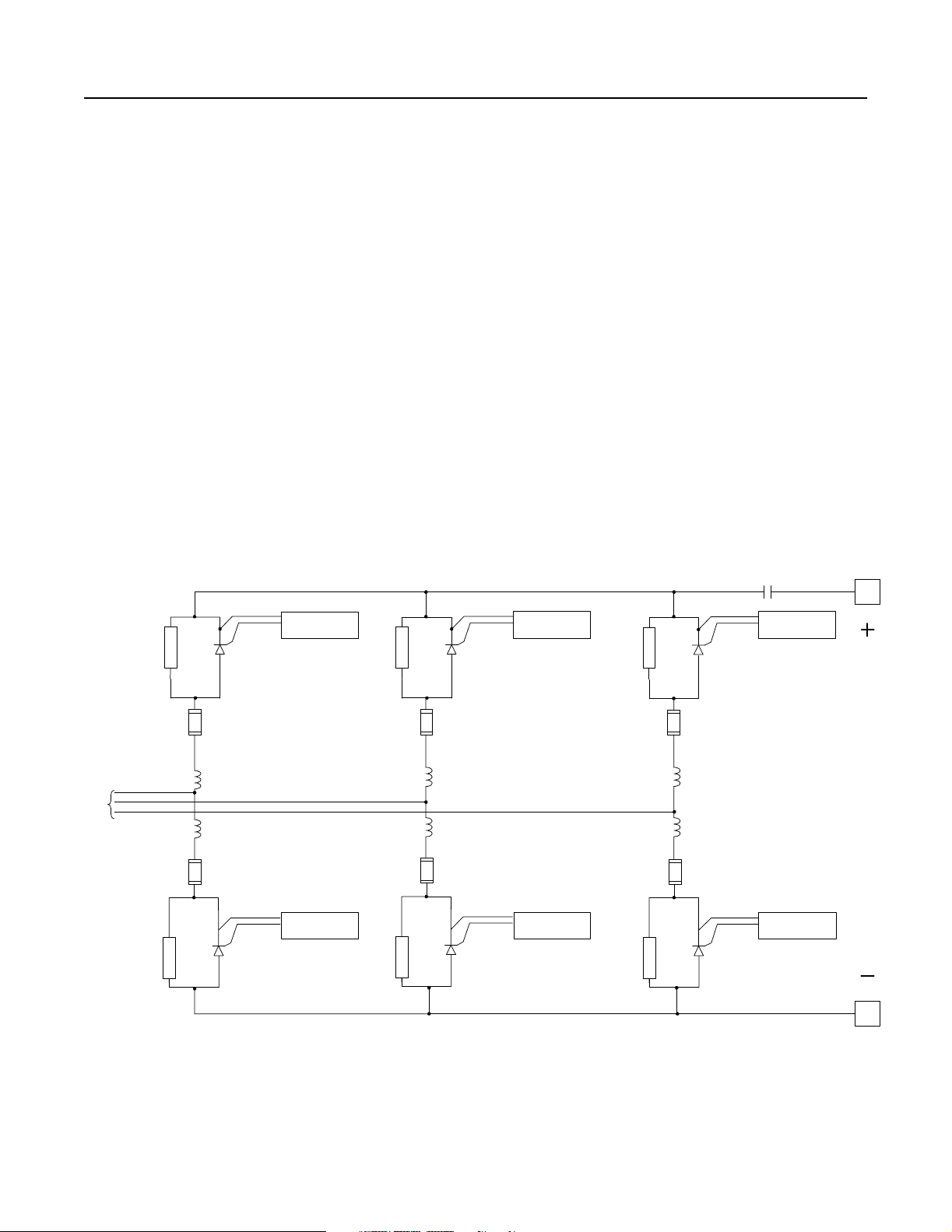

Armature Bridge

The armature bridge is design ed to convert incoming AC power to

DC power. The non-regenerative bridge is shown in Figure 1.9. Cell

fuses protect the thyristors in the event of a bridge failure.

Figure 1.9

Armature Bridge (Non-Regenerative)

3-Phase

AC

Input

Main

Contactor

SNUBBER

Armature-Pulse

Transformer Board

SNUBBER

Armature-Pulse

Transformer Board

SNUBBER

Armature-Pulse

Transformer Board

A1

Armature

Voltage

Armature-Pulse

SNUBBER

Transformer Board

SNUBBER

Armature-Pulse

Transformer Board

SNUBBER

Armature-Pulse

Transformer Board

A2

Publication 2361-5.01 July 1998

Page 27

Product Overview 1-15

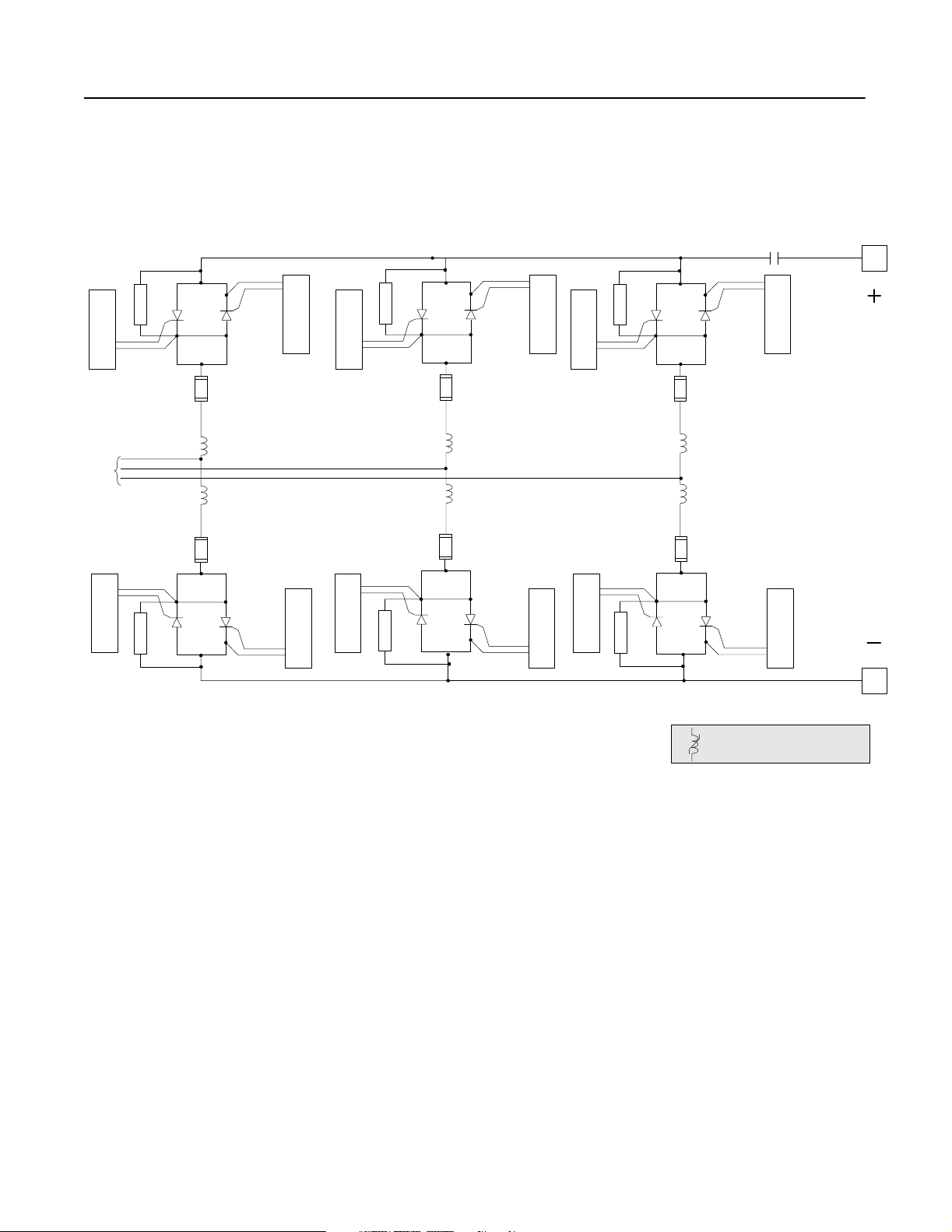

The regenerative bridge , shown in Figure 1.10, allows the bridge to

regenerate, or to di rect p owe r ba ck wards onto the inco ming lines.

Figure 1.10

Armature Bridge (Regenerative)

Main

Contactor

Armature-Pulse

3-Phase

AC

Input

Transformer Board

SNUBBER

Transformer Board

Armature-Pul se

SNUBBER

Armature-Pulse

Transformer Board

Transformer Board

Armature-Pul se

SNUBBER

Armature-Pulse

Transformer Board

Transformer Board

Armature-Pul se

A1

Armature

Voltage

Transformer Board

Armature-Pulse

Armature-Pulse

Transformer Board

SNUBBER

Armature-Pulse

Transformer Board

SNUBBER

Transformer Board

Armature-Pulse

Armature-Pulse

Transformer Board

SNUBBER

Transformer Board

Armature-Pulse

A2

The 3000A unit uses solid core (ferrite)

chokes on the AC line.

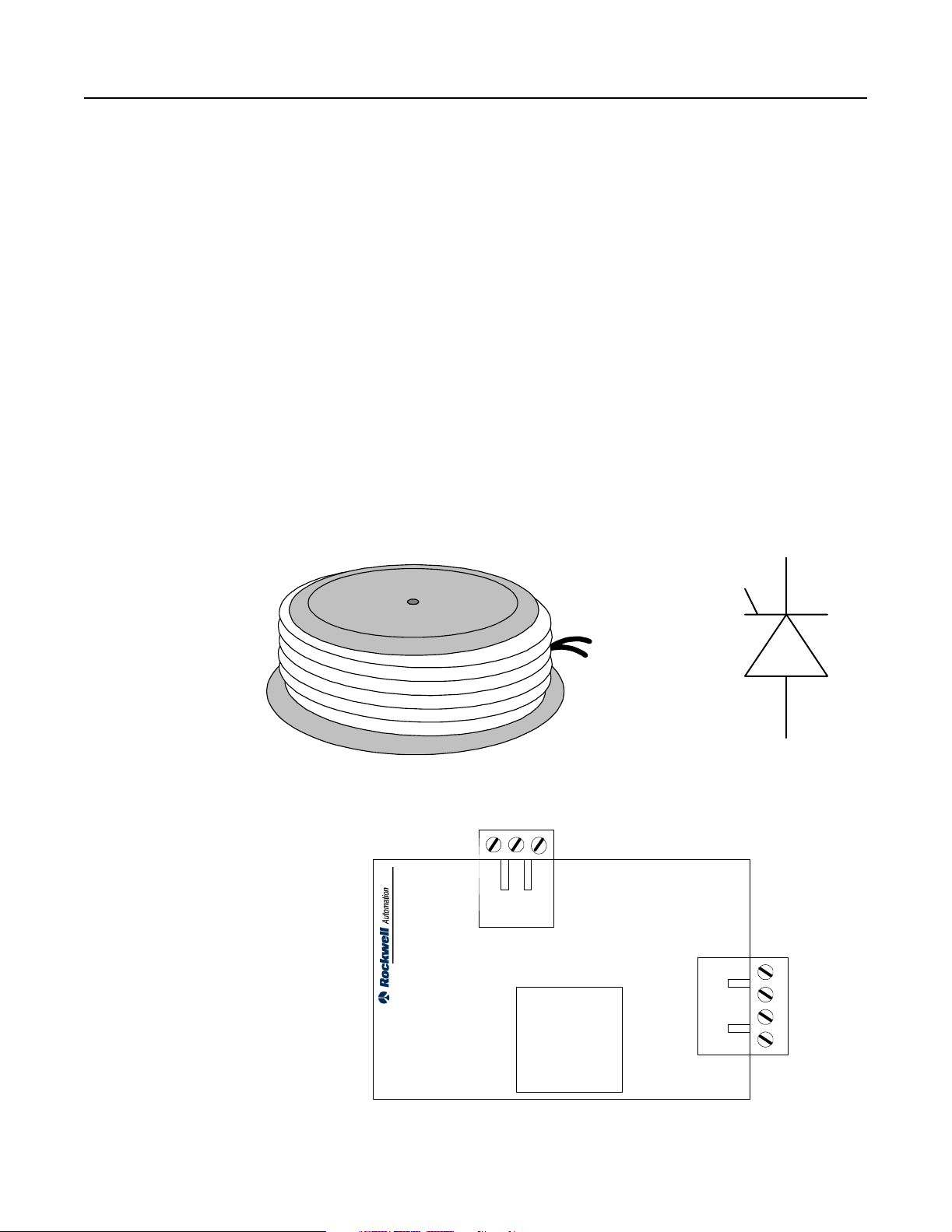

Silicon-Controlled Rectifiers (SCRs)

Each drive uses silicon-c ontrolled rectifiers (SCRs) in the thyristor

bridge to switch the incoming 3-phase AC power to DC output

power.

These SCRs allow current to flow from anode to cathode when two

conditions are met. First, like a diode, it must be forward biased.

Second, an appropriate pulse must be applied to the gate (through the

pulse transformer board).

The current will continue thr ough the SCR until the voltage across it

reverses and the current drops to zero (called line commutation).

Figure 1.11 shows a picture of an SCR, depicting its polarity.

Publication 2361-5.01 July 1998

Page 28

1-16 Product Overview

Silicon-Co ntrolled Rectifier

(SCR )

Snubbers

Snubbers (resistor/capacitor assemblies) are installed in para llel with

the SCRs, working with the cell reactors to provide adequate voltag e

suppression when the SCRs switch off.

Armatur e-Pulse Transformer Boards

Armature-pulse transformer boards provide the appropriate gate

voltage and current to trigger an SC R. In addition, these boards

provide gate driver isolation from the control logic. Figure 1.11

shows an armature-pulse tr ans former board.

DC Contactor

The main DC contactor is used to break the DC current to the motor

armature. Coil voltage to the con tacto r is controll ed by contacts from

the pilot relay.

Figure 1.11

Armature Bridge Hardware

Armature-Pulse Transformer

Board

Anode

Cathode

J2

Gate

Leads

Gate

Anode

Cathode

Publication 2361-5.01 July 1998

J1

Page 29

Product Overview 1-17

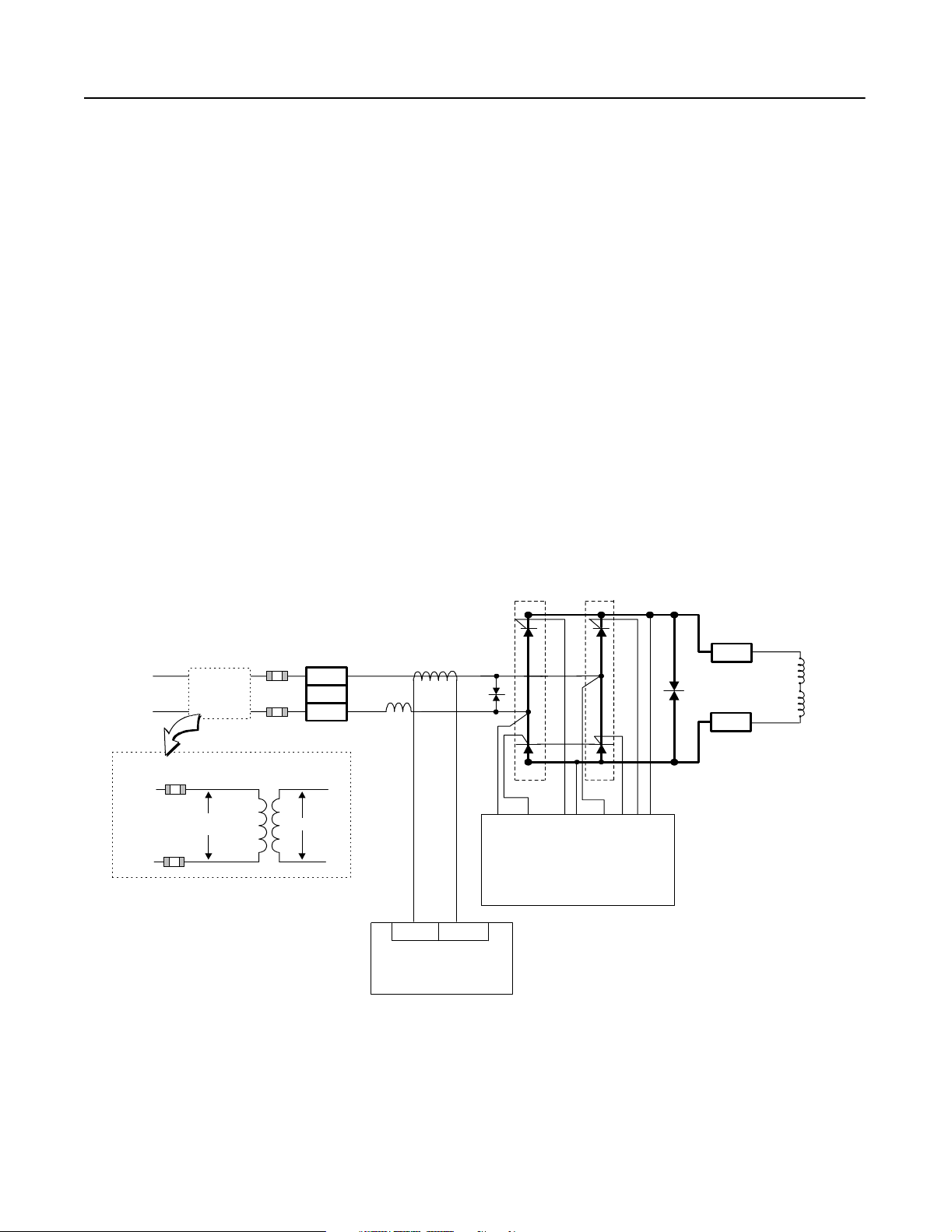

Field Power Components

The field power components work together to convert single-phase

AC power to a DC output used for powering your motor field.

The following items make up the field power circuitry:

• field bridge

• field-pulse tra nsformer board

In addition, fuses, meta l- oxide varistors (MOVs), and an induc tor, as

shown in Figure 1.12, are used to pr otect the field bridge from

extreme curre nt and voltage conditions. The field circuitry is fancooled.

Note: The field power components are rated for voltages up to

460V AC. Drives with input voltages of 575 or 660V AC use a

single-phase fie ld transformer (PT5) to step down the voltage to

460V AC. PT5, shown in Figure 1.12, is connected at the

customer site.

Figure 1.12

Field Bridge

1L1

Field Step-

Downl

Transformer

1L3

Typical Transformer Arrangement

(used for 576 or 660V AC inputs)

1L1

1L3

575 or

660V

(PT5)

H1H2X1

PM1

TB8

1

2

3

460V

X2

FCT

CH1

8

TB1

Feedback Board (A1)

3MOV

Field-Pulse Transformer Board (A5)

9

PM2

G11 F2 L1L3 G12

G21 G22 F1

2MOV

TB7

F +

1

3

F

1

F

2

F

3

F

F -

4

Publication 2361-5.01 July 1998

Page 30

1-18 Product Overview

Standard

Field Bridge

The field bridge uses four SCRs to convert the single-phase AC

power into a DC output. For the SCRs to conduct, they must be

forward biase d and have a pulse applied to the ir gates. The SCR gate

is enabled by the field-pulse tr ansformer board.

Field-Pulse Transformer Board

The field-pulse tranformer board provides the necessary gate volta ge

and current to trigger the SCRs on. This board uses a resistor/

capacitor arrange ment to protect the SCRs from rapid voltage

changes.

Figure 1.13

Field-Pulse Transformer Boards

Connection to Power Stage

Interface (SCR Gate Pulses)

T1

C2

L3

R3

L1

R4

J1

C3

Option 14FX

T3

G11

G12

Connection to SCRs

in PM1 of Field Bridge

F1

D7

F2

G22G21

R13

D8

Connection to SCRs

in PM2 of Field

Connection to Power Stage

Interface (SCR Gate Pulses)

T3

C2

T1

R3

J1

R4

R13

D8

C3

R11

D7

R5

T4

T2

Publication 2361-5.01 July 1998

G11

G12

Connection to SCRs

in PM1 of Field Bridge

F1 F2 L3 L1

G21

G22

Connection to SCRs

in PM2 of Field

Page 31

Chapter

2

Input Voltage (V AC) Nominal Output HP

460 700-750

575 750-900

660 750-1000

Your 1250A DC Drive

Contents This chapter is designed to help you unde rs tand the construction of

your 1250A Bulletin 1395 DC drive. The following topic s will be

covered in this chapter:

Topic Pa ge

Introduction 2-1

Drive Layout 2-2

Drive Schematics 2-3

Symbol Reference Chart 2-6

Drive Structure 2-8

Conclusion 2-8

Introduction Your 1250A DC drive functions with the following features:

• The 1250A drive uses twelve SCRs (regenerative) or six SCRs

(non-regenerative) in the armature bridge to convert the 3-phase

AC input to a DC output. The SCRs are built into a heatsink

assembly and are cooled by the bridge fan.

• The 1250A drive is protected from incoming fault curr ents with a

circuit bre aker. The components of your drive (the armature

bridge, field bridge, and control components) are protected with

fuses, MOVs, snubbers, and/or chokes.

• The 1250A drive is cons tructed and housed in thr ee bays, the f irst

bay containing the AC input and control hardwa re, the second

bay containing the armature bri dge hardware, and the third bay

containing the DC output hardware.

• The 1250A drive has an optional top-hat extension available for

the AC input bay.

• The 1250A drive can be built with an optional through bus

assembly, allowing the 1250A drive and other connected drives

to tap off from the same AC input.

Publication 2361-5.01 July 1998

Page 32

2-2 Your 1250A DC Drive

Drive Layout Figure 2.1

1250A DC Drive Layout

F51 F52 F53

ACT1 ACT3

L1 L2 L3

SP1

SP2

SP3

SP4

F31,

F32, F33

TB1

TB8

CB11

or

J1 J2 J3

J40

EA4

TB2

PP1 PP2

A14R

A11F

S1 S2

F12 F12A F11 F11A

F1, F2,

F3

J4

J5

TB3

F9 F9A F8 F8A

A16R

A13F

PP3

A12R

A15F

S3

F10 F10A

F7 F7A

D1

M1

R1

MP

F17,

F18,

F19

M11

DHT

F20, F 21

1395 Regulator

Control Boards

TB3

TB10

PT2

TB5 TB7

A14F

A11R

TB2 TB1

PP4 PP5 PP6

TB1FAN

SP

FAN1

A16F

A13R

A12F

A15R

A2(-)

Disconnect Bay Bridge Bay Contactor Bay

A1(+)

Publication 2361-5.01 July 1998

Page 33

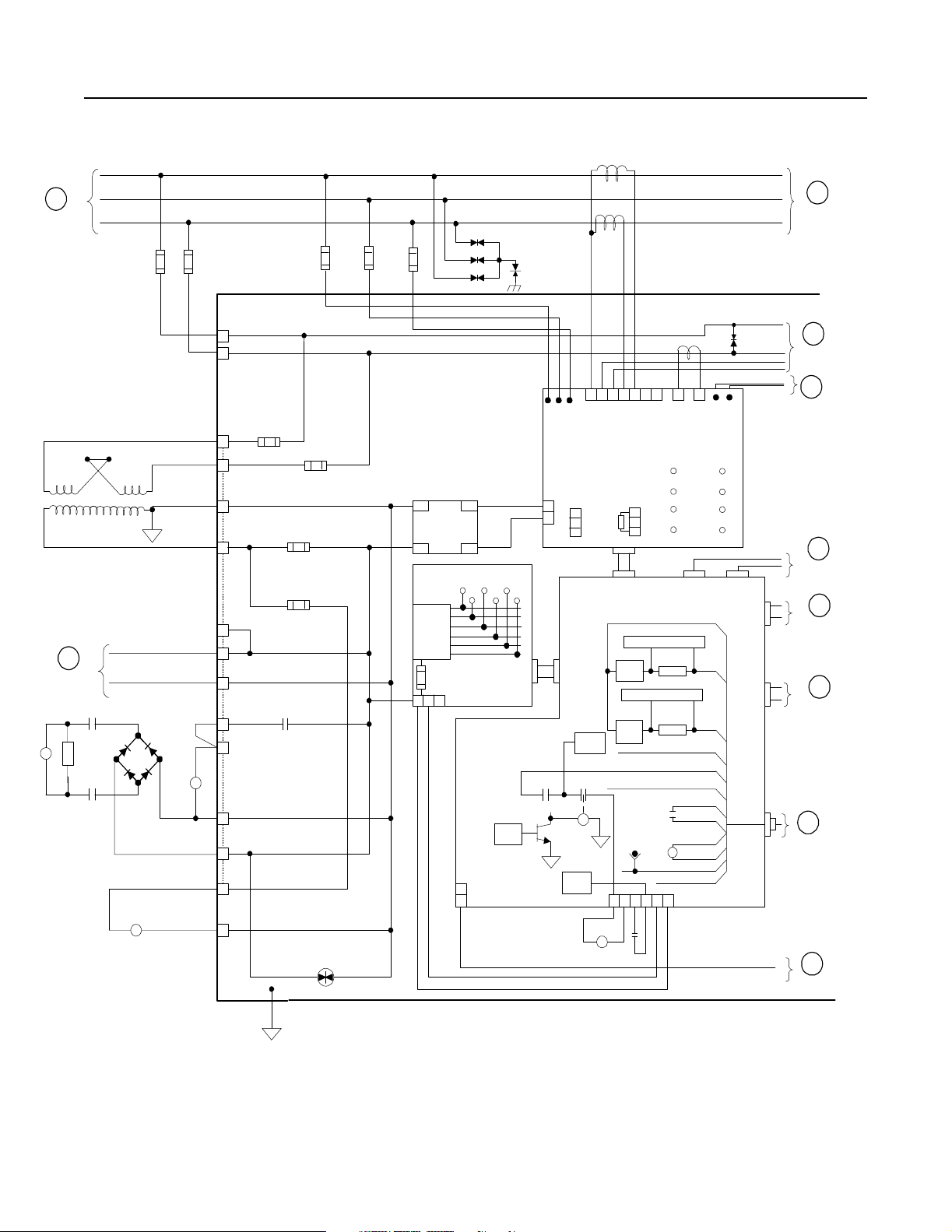

Drive Schematics Figure 2.2

1250A DC Drive Electrical Schematic, Sheet 1

Your 1250A DC Drive 2-3

3-Phase

AC Input

CB11

L1

L2

L3

Circuit Breaker

B

Co ntin ued in

Figure 2.3

Option

F51

F52

F53

Line Fuse

Option

1L1

1L2

1L3

F17

F18

F19

A

Co ntin ued in

Figure 2.3

OL11

M11

DC MOTOR

AC BLOWER

MOTOR

(T1)

(T2)

(T3)

1

PS1

ACL

FG

24VDC

161689

0.5A

ACN

TB230HI

TB120LO

PL1

M11

OL11

2

To 115V AC Discrete Adapter Board

To 24V DC Discrete Adapter Board

or 24V DC Digital Reference Board

FOOTNOTES :

Par t of 2 4V DC D isc rete Ad apter Op tion

1

or 24V DC Digital Referenc e Option

2

Part of 115VAC Discete Adapter Option

Publication 2361-5.01 July 1998

Page 34

2-4 Your 1250A DC Drive

Figure 2.3

1250A DC Drive Schematic, Sheet 2

A

Continued

fro m Fig ure

2.2

(X1 )

Continued

Figure 2.2

M1

(H3) (H2)

(H1 )

B

fro m

MP

R1

1K

25W

MP

120V

1L3

1L1

1L2

(H4)

FAN 1

ACT-1

E

ACT-3

F21

F20

TB8

1

2

TB5 F14

1

2

PT2

MP

12

GND

STUD

F16

F4

PR

3

5

4

15

9

10

14

6

11

13

(X2)

PE

D1

F1

L1A

F15

FAN 4

F2

L3A

F3

AC2 +

PWR SUPPLY

+12

-12

+5

COM

+ 12 IS O

+12 ICOM

1 2 5

SP3

SP2

SP1 SP4

(A9)

24VDC

(137825)

-AC1

UNIT PWR SU PPLY (A6)

TP1 TP2

TP3

TP6

F1

J2

TB1

1

(TE)

2

TP4

1395

LOGIC

TP5

3MOV

FCT

11 6

5 10 7 1 2 9 8

A B C

FEEDBACK PCB

(A1)

FDBK

RES.

J40

J2

POWER STAGE

INTERFAC E PCB (A7)

1395

LOGIC

1395

LOGIC

1395

TE

J1

1 2 3

TB3

FDBK

B URD EN

RES.

ARM.

115V 24V

O1 O2 O3

115V 24V

O1 O2 O3

ESR-COAST

DRIVE

READY

K 2

TP5

24VDC

E SR

24V COMM 12

4 5 6

M1

TB2

4

3

B URD EN

J1

E-COAST

K2

+24 V

TE

J7

LOGIC

K3

SYST EM

TRIP

1395

LOGIC

P R

PILOT RELAY

FIELD RANGE

(43A Field)

J44

J43

J42

J41

J3A-J3D

R

R

115V HI

115V LO

K1

24V+ 11

J11

MOTOR

TEMP.

J12

RESET

4

5

6

7

8

9

10

VA+ V A-

J39

J38

J37

J36

J6

1

2

3

J10

Continued on

Next Page

G

Continued on

Next Page

A1

A2

H

Continued on

Next Page

J

Continued on

Next Page

J9

J8

K

Continued on

Next Page

L

Continued on

Next Page

M

Continued on

Next Page

N

Continued on

Next Page

Publication 2361-5.01 July 1998

PE

Page 35

E

Continued fr om

Previous Page

SNUBBER

4R

1F

F12A

F12B

CH11

CH14

F9A F9B

SNUBBER

1R

4F

SNUBBER

6R

F11A

F8A

SNUBBER

3R

SNUBBER

2R

3F

F10A

F11B

CH12 CH13

CH15 CH16

F8B

F7A F7B

SNUBBER

5R

6F

5F

F10B

2F

M1

Your 1250A DC Drive 2-5

H

Continued from

Previous Page

+

A1

DC MOT OR

-

A2

(A2)

ARM

(A1)

G

Continued from

Previous Page

J

Continued from

Previous Page

K

Continued from

Previous Page

L

Continued from

Previous Page

Gate

Interface

PCB

S1 S2 S3

WHT

3

1

ARMATURE PULSE

TFMR

(12 TOTA L)

J1

4

J2

J5

RED

123

SYS

PROC

"SP"

J7 J6

MAIN

CONTROL

PCB(AB)

CURR

PROC

"CP"

PM 1 PM 2

L3

HEATSINK

G1

G2

L1

F2

FIELD PULSE

TFMR AND SNUBBER

PCB(A5)

(1 TOTAL)

J1

VEL

PROC

"VP"

J4

1024PPR

COMMON

V+ 12-15V

SIGNAL B

SIGNAL B

SIGNAL A

SIGNAL A

SHIELD

MOUNTE D

TERMINAL

SHUNT FIELD

DOOR

+

1

2 MOV

TB7

TB7

-

3

G2

G1

F1

+12 COM

+ 12 V

Z

A

A

J1

DHT

2S

TB3

13

14

15

16

Z

17

B

B

18

19

20

TE

1024PPR

COMMON

V+ 12-15V

SIGNAL B

SIGNAL B

SIGNAL A

SIGNAL A

SHIELD

(F1 ) (F 2) (F3 ) (F 4)

Encode r

(Du al Out Ex am ple)

PROGRAMMING

M

Continued from

Previous Page

N

Continued fr om

Previous Page

TB10

1

2345

TE

P ORT " A" POR T ’B ’

6

+24V Out

-24V ECOAST

+24V ECOAST

Ready 2

Ready 1

115V Common Out

115V ECOAST2

115V ECOAST1

Reset In

Motor Temp In

Common In

TB3

12

11

10

9

8

7

6

5

4

3

2

1

24V DC

ECOAST

Drive Ready Output

115V AC Common

115V AC ECOA ST

Reset

Mo tor Therm ostat

No te: Mo re co nfig uratio n d eta ils for T B3 ar e gi ven in the

installation chapter of publication 1395-5.40.

24V DC or 115V AC

Voltage Source

Publication 2361-5.01 July 1998

Page 36

2-6 Your 1250A DC Drive

Symbol Reference Chart

Table 2.A: 1250A DC Drive Symbol-to-Component Reference

Symbol Description Option 460V AC 575V AC 660V AC

(A1.RES) A1 PCB feedback scaling resistor 3.65 ohm, 2 W, 1%

2 - 3MOV Field suppressors

A1 Feedback PCB

A11F-A16F Armature pulse transformer PCB

A11R-A16R Armature pulse transformer PCB

A3 Gate interface PCB

A5 Field pulse transformer PCB

A6 Unit power supply PCB

A7 Power stage interface PCB

A8 Main contr ol PCB

A9 Feedback PCB power supply

ACT1, 3 Line current transducer 2000:1

C1 Armature snubber capacitors 2µF, 2000V

CB11 Circuit breaker

CH1 Field choke

CH11 - 16 Cell chokes Air-core, 3.5uH, 1017A

D1 M1 bridge diode

DHT/DMT Configuration terminal

EA2 Tachometer adap ter scaling PCB

EA3 DHT/EHT configuration terminal

EA4 Line RC suppressor

EA5 Air flow sensor PCB

F1 - 3 Control branch / feedback PCB fuses 1A KTK 1A KTK 10A A70P

F14 - 15 PT2 control transformer primary fuses

F16 PT2 control transformer secondary fuses 5A KLDR

F17 - 19 Motor blower fuses 30A 3P (size 1) or 60A 3P (size 2)

F20 - 21 Field fusing for 460V AC configuration 45A, FRS

Field transformer primary fusing for 575V AC

configuration with 10kVA transformer

Field transformer primary fusing for 575V AC

configuration with 15kVA transformer

Field transformer primary fusing for 575V AC

configuration with 20kVA transformer

Field transformer primary fusing for 575V AC

configuration with 50kVA transformer

Field transformer primary fusing for 660V AC

configuration with 10kVA transformer

Field transformer primary fusing for 660V AC

configuration with 15kVA transformer

Field transformer primary fusing for 660V AC

configuration with 20kVA transformer

Field transformer primary fusing for 660V AC

configuration with 50kVA transformer

F31 - 33 Line RC snubber fuses

F4 Terminal block control power fuse 7A KLDR

F7 - 12, F7A - 12 A Armature bridge fu ses 630A, 1250V, 170M

F51 - 53 AC line fuses

FAN1-C1 Armature fan capacitor 25µF

FAN1 Armature bridge fan 2800CFM

FAN4 Field h eatsink fan 145 CFM

FCT Field current transducer 1000:1

J10 DHT/EHT configuration terminal D-shell

ä

1200A, N-frame

ä

ä

ä

ä

ä

ä

8A KLDR

25A, FRS

ä

30A, FRS

ä

45A, FRS

ä

100A, FRS

25A, 150X

ä

40A, 150X

ä

40A, 150X

ä

100A, 150X

ä

25A KTK 25A KTK 25A A70P

ä

1200A, KRPC

ä

Publication 2361-5.01 July 1998

Page 37

Your 1250A DC Drive 2-7

Symbol Description Option 460V AC 575V AC 660V AC

M1 DC armature contactor 1800A

M11 Motor blower starter 27A (size 1) / 45A (size 2)

MP Main p ilot for pilot relay

OL11, OL12 Motor blower overload

ä

PB1 Stop pushbutton

PB3 E-stop pushbutton

PB4 Jog forward pushbutton

PB5 Jog reverse pushbutton

PBL2 Start / running illuminated pushbutton

PBL6 Fault / clear faults illuminated pushbutton

Red EH,1NO/1NC

ä

Red MH P-P, 2NC

ä

Black FH, 1 NO/1NC

ä

Black FH, 1 NO/1NC

ä

Amber, 1NO/1NC

ä

Clear, 1N0/1NC

PE Power ground bus

ä

PL1 Power on pilot lig ht

Red, 115VAC XF-type

PM1 - 2 Field SCRs 90A, 1200V

PP1 - 6 Arm ature power poles

PR M1 contactor pilot relay

PS1 24V DC power supply 24V DC, 0.5A

ä

ä

24V DC, 0.5A

1.5 kVA

PS2 Air flow sensor p ower supply

PT2 Control transformer

PT5 Field transformer, 18A 10 kV A

Field tran sfor m er , 28A

Field tran sfor m er , 40A

Field tran sfor m er , 70A

ä

ä

ä

15 kVA

20 kVA

50 kVA

R1 M1, suppressor resistor 1k-ohm, 50 W

R1 - 2 Armature snubber resistors 40 ohm 240 W

R11 - 12 Multi-communication channels A & B terminal resistors 150 ohm, 2 W

ä

RH1 Speed potentiometer

5k-ohm, 2 W

S1 - 3 Heatsink thermoswitches 165°F

ä

S5 Air flow sensor

1000FPM

SCR SCR 1200A, 1800V

SCR-R SCR, (regeneration) 1200A, 1800V

SP PR suppressor

SP1 - 3 Line-to-line MOVs 460J, 320V AC 550J, 385V AC 600J, 420V AC

SP4 Y-to-ground 760J, 680V AC 760J, 680V AC 1050J, 750V AC

ä

SS3 Speed 1 - 2 - 3 selector switch

Std op, 2 NO/ 2 NC

TAS1 Motor thermoguard

TB1-FAN Bridge fan & capacitor terminal block

TB10 TE shield terminal block

TB3 Option PCB I/O terminal block

TB5 Branch power & 115 control terminal block

TB7 Field DC output terminal block

TB8 Field AC in put terminal block

TB11 O ptional miscellaneous control terminal block

TE Zero potential bus

Publication 2361-5.01 July 1998

Page 38

2-8 Your 1250A DC Drive

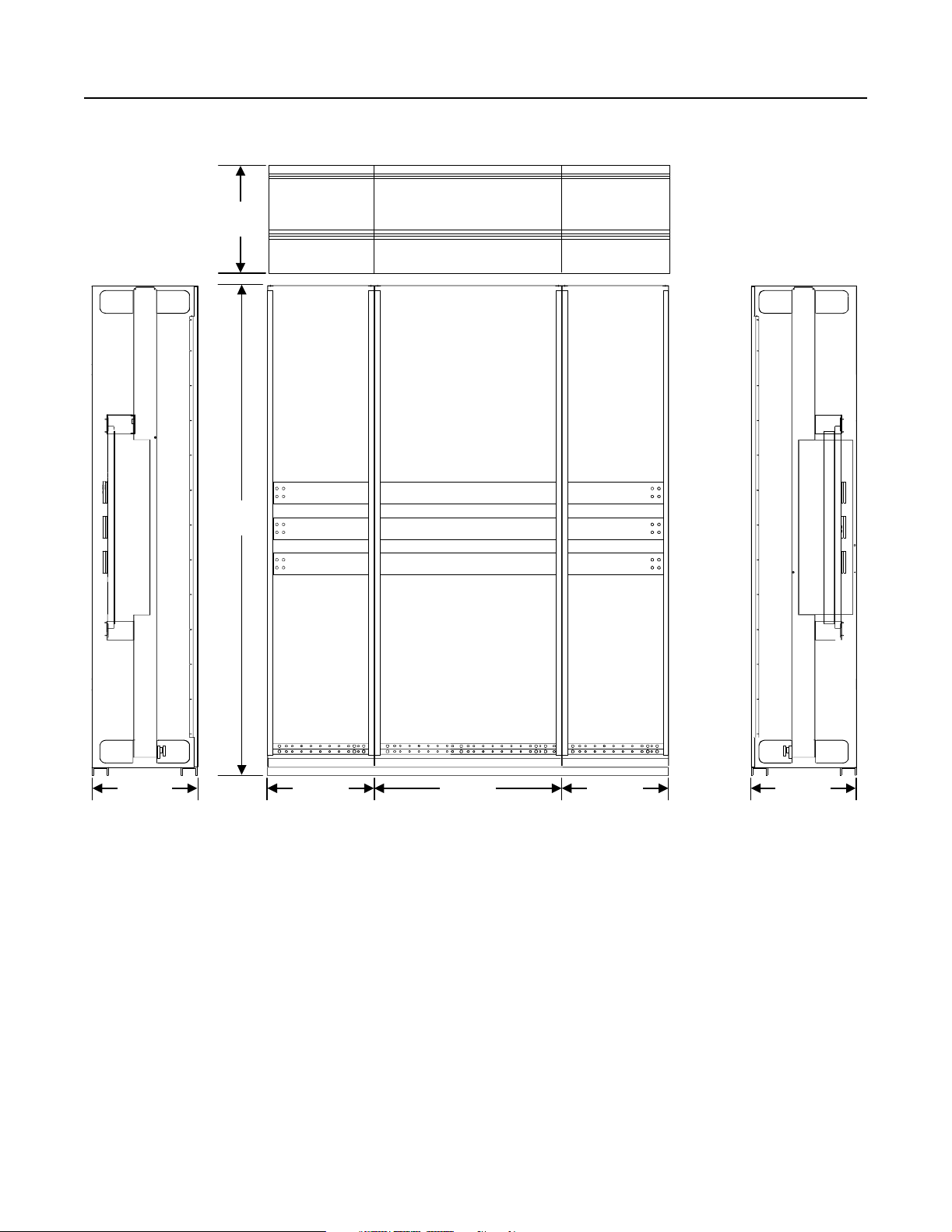

Drive Structure Figure 2.4

1250A DC Drive Structure

20 inches

(508 mm)

91.5 inches

(2324 mm)

20 inches

(508 mm)

20 inches

(508 mm)

35 inches

(889 mm)

20 inches

(508 mm)

20 inches

(508 mm)

Conclusion This chapter covered the components, sc hematics, and structure of

your 1250A DC drive. Unit specifications, derating charts, a power

dissipation chart, a circuit breaker illustration, an air baffle diagram,

and an input busbar diagram for the 1250A DC drive are all given in

Appendix A.

Publication 2361-5.01 July 1998

Page 39

Chapter

3

Input Voltage (V AC) Nominal Output HP

460 800-1000

575 1000-1250

660 1250

Your 1650A DC Drive

Contents This chapter is designed to help you unde rs tand the construction of

your 1650A Bulletin 1395 DC drive. The following topic s will be

covered in this chapter:

Topic Pa ge

Introduction 3-1

Drive Layout 3-2

Drive Schematics 3-3

Symbol Reference Chart 3-6

Drive Structure 3-8

Conclusion 3-8

Introduction Your 1650A DC drive functions with the following features:

• The 1650A drive uses twelve SCRs (regenerative) or six SCRs

(non-regenerative) in the armature bridge to convert the 3-phase

AC input to a DC output. The SCRs are built into a heatsink

assembly and are cooled by the bridge fan.

• The 1650A drive is protected from incoming fault curr ents with a

circuit breaker, and the DC output is protected from faul t currents

with a DC contactor. The components of your drive (the

armature bridge, field bridge, and control components) are

guarded with fuses, MOVs, snubbers, and/or chokes.

• The 1650A drive is cons tructed and housed in thr ee bays, the f irst

bay containing the AC input and control hardwa re, the second

bay containing the armature bri dge hardware, and the third bay

containing the DC output hardware.

• The 1650A drive has an optional top-hat extension available for

the AC input bay.

• The 1650A drive can be built with an optional through bus

assembly, allowing the 1650A drive and other connected drives

to tap off from the same AC input.

Publication 2361-5.01 July 1998

Page 40

3-2 Your 1650A DC Drive

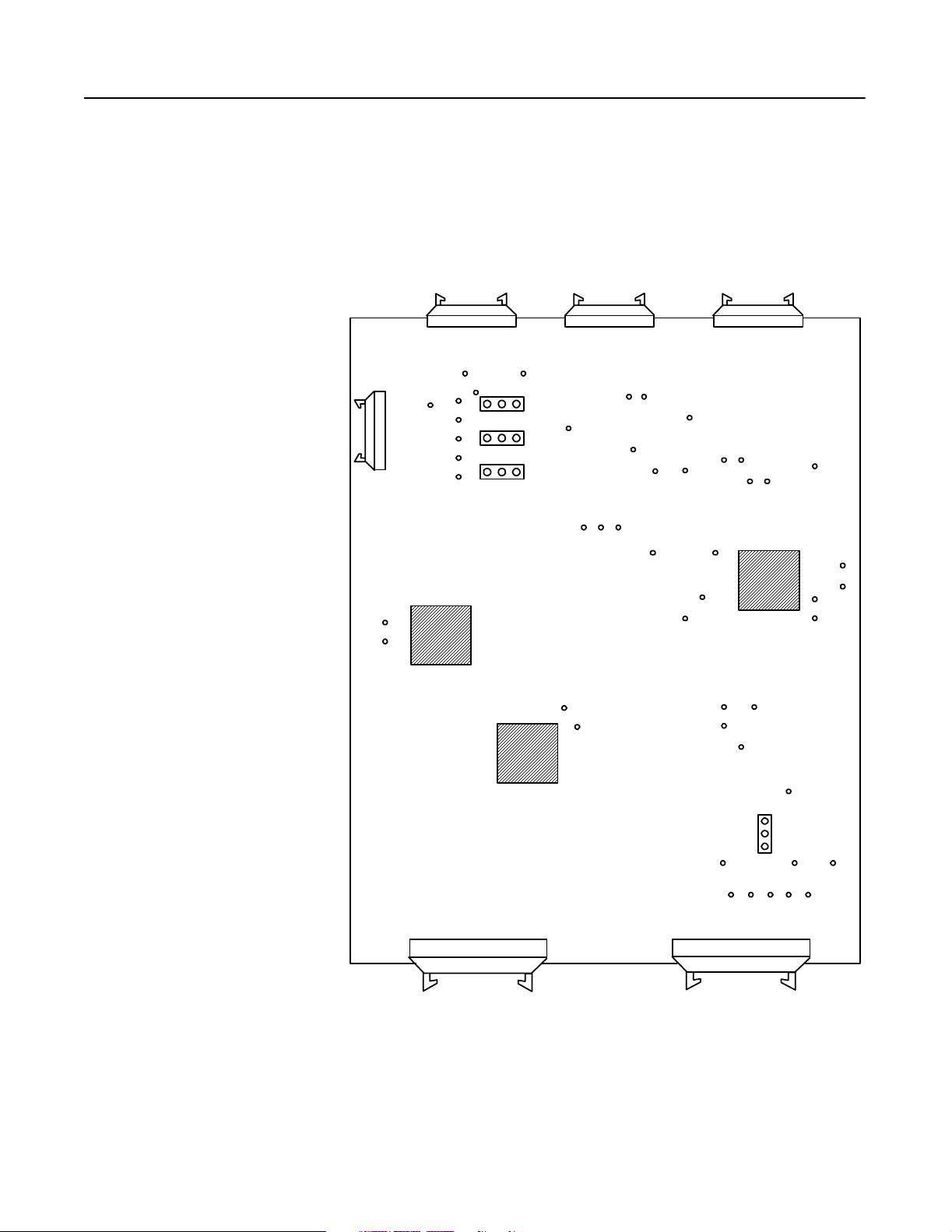

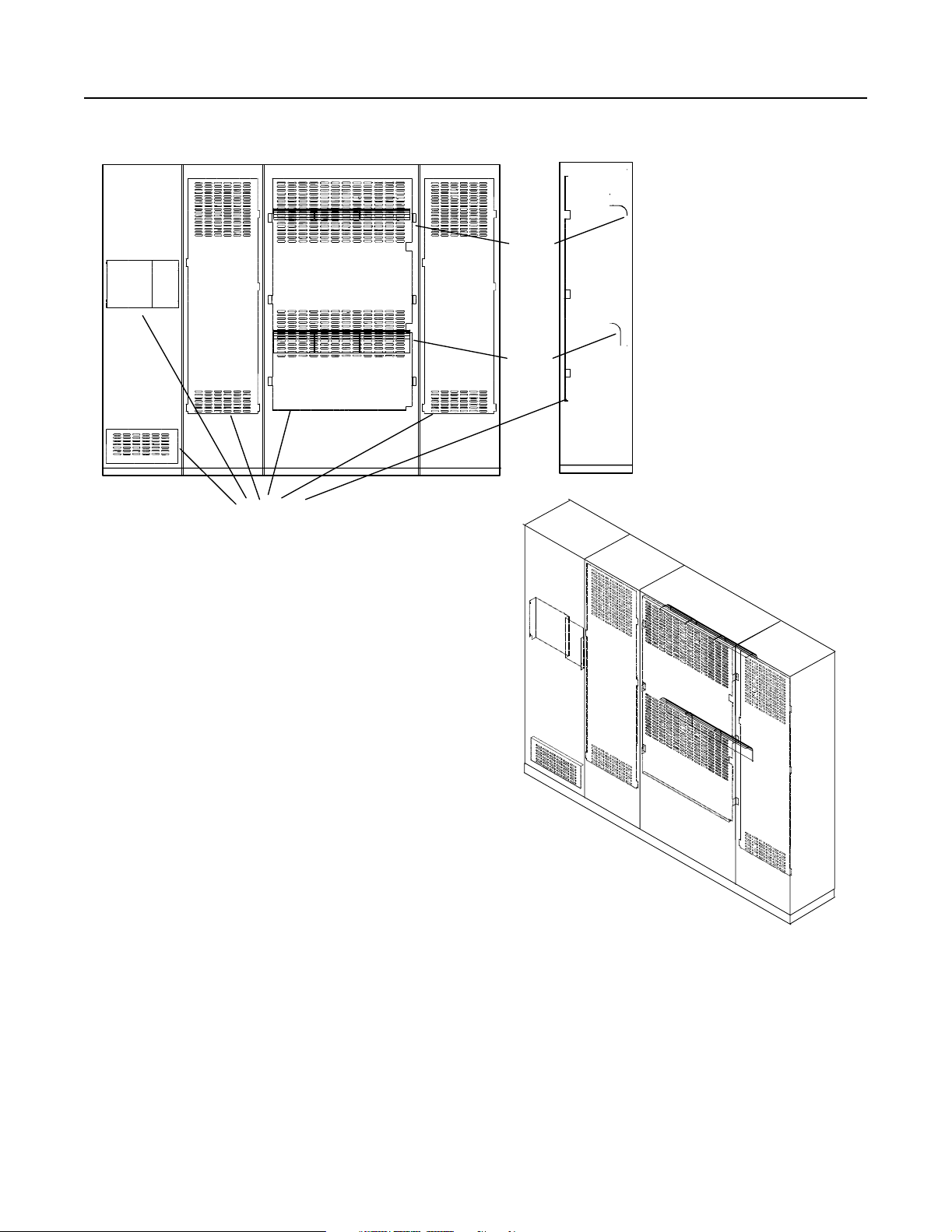

Drive Layout Figure 3.1

1650A DC Drive Layout

F51 F52 F53

ACT1 ACT3

L1 L2 L3

SP1

SP2

SP3

SP4

F31,

F32, F33

TB1

TB8

CB11

or

J1 J2 J3

J40

EA4

TB2

PP1 PP2

A14R

A11F

S1 S2

F12 F12A F11 F11A F10

F1, F2,

F3

J4

J5

TB3

F9 F9A F 8 F8A F 7 F7A

A16R

A13F

PP3

A12R

A15F

S3

F10A

D1

MP

R1

M1

F17,

F18,

F19

M11

F27,

F28,

F29

M12

DHT

F20, F 21

1395 Regulator

Control Boards

TB3

TB10

PT2

TB5 TB7

A14F

A11R

TB2 TB1

PP4 PP5 PP6

TB1FAN

SP

FAN1

A16F

A13R

A12F

A15R

A2(-)

Disconnect Bay Bridge Bay Contactor Bay

A1(+)

Publication 2361-5.01 July 1998

Page 41

Drive Schematics Figure 3.2

1650A DC Drive Electrical Schematic, Sheet 1

Your 1650A DC Drive 3-3

3-Phase

AC Input

CB11

L1

L2

L3

Circuit Breaker

B

Co ntinu ed in

Figure 4.3

Option

F51

F52

F53

Line Fuse

Option

1L1

1L2

1L3

F17

F18

F19

F27

F28

F29

A

Con tinu ed in

Figure 4.3

OL11

M11

M12

OL12

DC MOTOR

AC BLOWER

MOTOR

(T1)

(T2 )

(T3)

DC MOTOR

AC BLOWER

MOTOR

(T1)

(T2)

(T3)

1

PS1

ACL

FG

24VDC

161689

0.5A

ACN

TB230HI

TB120LO

PL1

M11

M12

OL11

OL12

2

To 115V AC Discrete Adapter Board

To 24V DC Discrete Adapter Board

or 24V DC Digital Reference Board

FOOTNOTES :

Part of 24V D C Discrete Adapter Option

1

or 24V DC Digital Reference Option

2

Part of 115V AC Discete Adapter Option

Publication 2361-5.01 July 1998

Page 42

3-4 Your 1650A DC Drive

Figure 3.3

1650A DC Drive Schematic, Sheet 2

A

Continued

from Figure

3.2

(X1)

Continued

Figu re 3.2

M1

(H3) (H2)

(H1)

B

from

MP

R1

1K

25W

MP

120V

1L1

1L2

1L3

(H4)

FAN 1

ACT-1

E

ACT-3

F21

F20

TB8

1

2

TB5 F14

1

2

PT2

MP

12

GND

STUD

F16

F4

PR

3

5

4

15

9

10

14

6

11

13

(X2)

PE

D1

F1

L1A

F15

FAN 4

F2

L3A

F3

AC2 +

PWR SUPP LY

+12

-12

+5

COM

+12 IS O

+12 ICOM

1 2 5

SP3

SP2

SP1 SP4

(A9 )

24VDC

(137825)

-AC1

UNIT PWR SUPP LY (A6 )

TP 1 TP 2

TP3

TP6

F1

J2

TB1

1

(TE)

2

TP4

1395

LOGIC

TP5

3MOV

FCT

5 10 7 1 2 9 8

11 6

A B C

FEEDBACK PCB

(A1)

FDB K

RES.

J40

J2

POWE R STAGE

INTERFACE PCB (A7)

1395

LOGIC

1395

LOGIC

1395

TE

J1

1 2 3

TB3

FDBK

B URD EN

RES.

ARM.

115V 24V

O1 O2 O3

11 5V 24 V

O1 O2 O3

ESR-COAST

DRIVE

READY

K 2

TP5

24VDC

E SR

24V COMM 12

4 5 6

M1

TB2

4

3

B URD EN

J1

E-COAST

K2

+24 V

TE

J7

LOGIC

K3

SYSTEM

TRIP

1395

LOGIC

P R

PILOT RELAY

FIELD R ANG E

(43A Field)

J44

J43

J42

J41

J3A-J3D

R

R

115V HI

115V LO

K1

24V+ 11

VA+ VA-

J11

MOTOR

TEMP.

J12

RESET

4

5

6

7

8

9

10

J39

J38

J37

J36

J6

J9

1

2

J8

3

J10

Continued on

Next Page

G

Continued on

Next Page

A1

A2

H

Continued on

Next Page

J

Continued on

Next Page

K

Continued on

Next Page

L

Continued on

Next Page

M

Continued on

Next Page

N

Continued on

Next Page

Publication 2361-5.01 July 1998

PE

Page 43

E

Continued from

Previous P age

SNUBBER

4R

1F

F12A

F12B

CH11

CH14

F9A F9B

SNUBBER

1R

4F

SNUBBER

6R

F11A

F8A

SNUBBER

3R

SNUBBER

2R

3F

5F

F10A

F11B

CH12 CH13

CH15 CH16

F8B

F7A F7B

SNUBBER

5R

6F

F10B

2F

M1

Your 1650A DC Drive 3-5

H

Contin ued from

Previous Page

+

A1

DC MOT OR

-

A2

(A2)

ARM

(A1)

G

Continued from

Previous Page

J

Continued from

Previo us Page

K

Continued from

Previo us Page

L

Contin ued from

Previous Page

Gate

Inte rface

PCB

S1 S2 S 3

WHT

3

1

ARMATURE PULSE

TFMR AND SNUBBER

(12 TOTAL)

J1

4

J2

J5

RED

123

SYS

PROC

"SP"

J7 J6

MAIN

CONTROL

PCB(AB)

CURR

PROC

"CP"

PM1 PM2

HEATSINK

L3

G1

G2

L1

F2

G1

FIELD PULSE

TFMR AND SNUBBER

PCB(A5)

(1 T OTAL)

J1

VEL

PROC

"VP"

J4

1024PP R

COMMON

SIGNAL B

SIGNAL B

SIGNAL A

SHIELD

MOUNTED

TERMINAL

SHUNT FIELD

DOOR

+

1

2 MOV

TB7

TB7

-

3

G2

F1

+12 COM

+12 V

Z

A

A

J1

DHT

2S

TB3

13

14

15

16

Z

17

B

B

18

19

20

TE

1024PP R

COMMON

V+ 12-15V

SIGNAL B

SIGNAL B

SIGNAL A

SIGNAL A

SHIELD

(F1) (F2) (F3) (F4)

Encoder

(Dua l Out Exam ple)

V+ 12-15V

SIGNAL A

PROGRAMMING

M

Contin ued from

Previous Page

N

Contin ued from

Previous Page

TB10

1

2345

TE

PORT "A" PORT ’B’

6

+24V O ut

-24V ECOAST

+24V ECOAST

Ready 2

Ready 1

115V Com mon Out

115V ECO AST2

115V ECO AST1

Reset In

Motor Temp In

Common In

TB3

12

11

10

9

8

7

6

5

4

3

2

1

24V DC

ECOAST

Drive Ready Output

115V AC Com mon

115V AC ECOAST

Reset

Motor Thermostat

Note: M ore configu ration details fo r T B3 are given in the

installation c hapter of pu blication 139 5-5.40.

24V DC or 115V AC

Voltage Source

Publication 2361-5.01 July 1998

Page 44

3-6 Your 1650A DC Drive

Symbol Reference Chart

Table 3.A: 1650A DC Drive Symbol-to-Component Reference

Symbol Description Option 460V AC 575V AC 660V AC

(A1.RES) A1 PCB feedback scaling resistor 4.22 ohm, 2 W, 1%

2 - 3MOV Field suppressors

A1 Feedback PCB

A11F-A16F Armature pulse transformer PCB

A11R-A16R Armature pulse transformer PCB

A3 Gate interface PCB

A5 Field pulse transformer PCB

A6 Unit power supply PCB

A7 Power stage interface PCB

A8 Main control PCB

A9 Feedback PCB power supply

ACT1 - 3 Line current transducer 3000:1

C1 Armature snubber capacitors 2µF, 2000V

ä

CB11 Circuit breaker

CH1 Field choke

CH11 - 16 Cell chokes Air-core, 3.5uH, 1017A

D1 M1 bridge diode

DHT/DMT Configuration terminal

EA2 Tachometer adapter scaling PCB

EA3 DHT/EHT configuration terminal

EA4 Line RC suppressor

EA5 Air flow sensor PCB

F1 - 3 Control branch / feedback PCB fuses 1A KTK 1A KTK 10A A70P

F14 - 15 PT2 control transformer primary fuses 8A KLDR

F16 PT2 control transformer secondary fuses 5A KLDR

F17 - 19, F27 - 29 Motor blower fuses

F20 - 21 Field fusing for 460V AC configuration 45A, FRS

Field transformer primary fusing for 575V AC

configuration with 10kVA transformer

Field transformer primary fusing for 575V AC

configuration with 15kVA transformer

Field transformer primary fusing for 575V AC

configuration with 20kVA transformer

Field transformer primary fusing for 575V AC

configuration with 50kVA transformer

Field transformer primary fusing for 660V AC

configuration with 10kVA transformer

Field transformer primary fusing for 660V AC

configuration with 15kVA transformer

Field transformer primary fusing for 660V AC

configuration with 20kVA transformer

Field transformer primary fusing for 660V AC

configuration with 50kVA transformer

F31 - 33 Line RC snubber fuses

F4 Terminal block control power fuse 7A KLDR

F7 - 12, F7A - 12A Bridge fuses 800A, 1250V, 170M

F51 - 53 AC line fuses

FAN1-C1 Armature fan capacitor 25µF

FAN1 Armature bridge fans 2800CFM

FAN 4 Field heatsink fan 1 45 CFM

FCT Field current transducer 1000:1

1600A, R-frame

ä

ä

ä

ä

ä

30A 3P (size 1) / 60A 3P (size 2)

25A, FRS

ä

30A, FRS

ä

45A, FRS

ä

100A, FRS

25A, 150X

ä

40A, 150X

ä

40A, 150X

ä

100A, 150X

ä

25A KTK 25A KTK 25A A70P

ä

1600, KRPC

Publication 2361-5.01 July 1998

Page 45

Your 1650A DC Drive 3-7

Symbol

J10 DHT/EHT configuration terminal D-shell

Description

Option 460V AC 575V AC 660V AC

ä

M1 DC armature contactor 3000A

M11, M12 Motor blower starter

ä

27A (size 1) / 45A (size 2)

MP Main pilot for pilot relay

OL11, OL12 Motor blower overload

PB1 Stop pushbutton

PB3 E-stop pushbutton

PB4 Jog forward pushbutton

PB5 Jog reverse pushbutton

PBL2 Start / running illuminated pushbutton

PBL6 Fault / clear fau lts illuminated p u shbutton

ä

ä

Red EH,1NO/1NC

ä

Red MH P-P, 2NC

ä

Black FH, 1NO/1NC

ä

Black FH, 1NO/1NC

ä

Amber, 1NO/1NC

ä

Clear, 1NO/1NC

PE Power ground bus

PL1 Power on pilot lig h t

ä

Red, 115VAC XF-type

PM1 - 2 Field SCRs 90A, 1200V

PP1 - 6 Armature power poles

PR M1 contactor pilot relay

PS1 24V DC power supply 24V DC, 0.5A

PS2 Air flow sensor power supply

PT2 Control transformer

ä

ä

24V DC, 0.5A

1.5 kVA

PT5 Field transformer, 18A 10 kVA

Field transformer, 28A

Field transformer, 40A

Field transformer, 70A

ä

ä

ä

15 kVA

20 kVA

50 kVA

R1 M1, suppressor resistor 1k-ohm, 50 W

R1 - 2 Armature snubber resistors 40 ohm 240 W

R11 - 12 Multi-communication channels A & B terminal resistors 150 ohm, 2 W

RH1 Speed potentiometer

ä

5k-ohm, 2W

S1 - 3 Heatsink thermoswitches 170°F

S5 Air flow sensor

ä

1000FPM

SCR SCR 1800A, 1800V

SCR-R SCR, (regeneration) 1800A, 1800V

SP PR suppressor

SP1 - 3 Line-to-line MOVs 460J, 320V AC 550J, 385V AC 600J, 420V AC

SP4 Y-to-ground 760J, 680V AC 760J, 680V AC 1050J, 750V AC

SS3 Speed 1 - 2 - 3 selector switch

ä

Std op, 2 NO/2 NC

TAS1 Motor thermoguard

TB1-FAN Bridge fan & capacitor terminal block

TB10 TE shield terminal block

TB3 Option PCB I/O terminal block

TB5 Branch power & 115 control terminal block

TB7 Field DC output terminal block

TB8 Field AC input terminal block

TB11 Op tional m iscellaneous con trol terminal block

TE Zero potential bus

Publication 2361-5.01 July 1998

Page 46

3-8 Your 1650A DC Drive

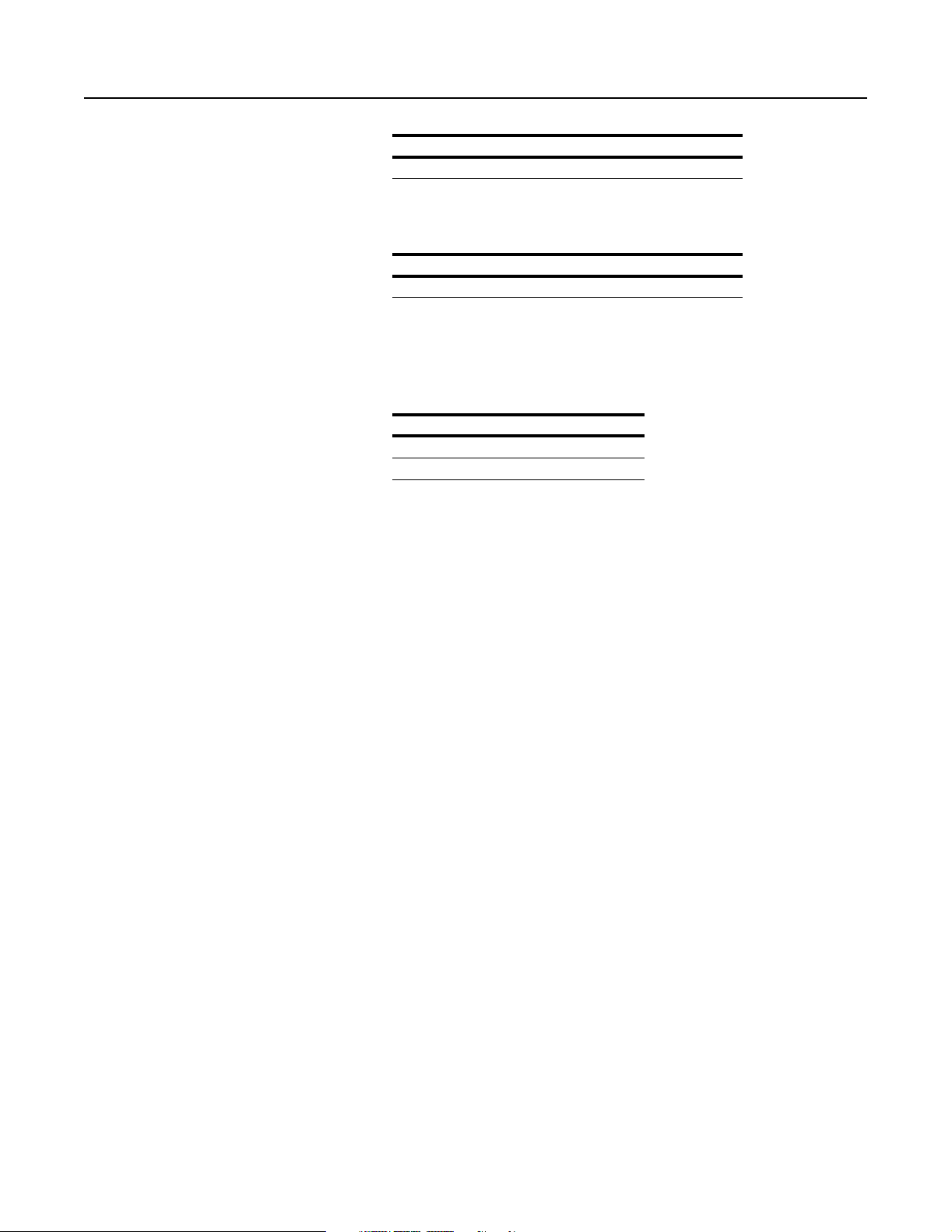

Drive Structure Figure 3.4

1650A DC Drive Structure

20 inches

(508 mm)

91.5 in ches

(2324 mm)

20 inches

(508 mm)

20 inches

(508 mm)

35 inches

(889 mm)

20 inches

(508 mm)

20 inches

(508 mm)

Conclusion This chapter covered the components, sc hematics, and structure of

your 1650A DC drive. Unit specifications, derating charts, a power

dissipation chart, a circuit breaker illustration, an air baffle diagram,

and an input busbar diagram for the 1650A DC drive are all given in

Appendix A.

Publication 2361-5.01 July 1998

Page 47

Chapter

4

Input Voltage (V AC) Nominal Output HP

460 1250-1750

575 1500-2250

660 1500-2500

Your 3000A DC Drive

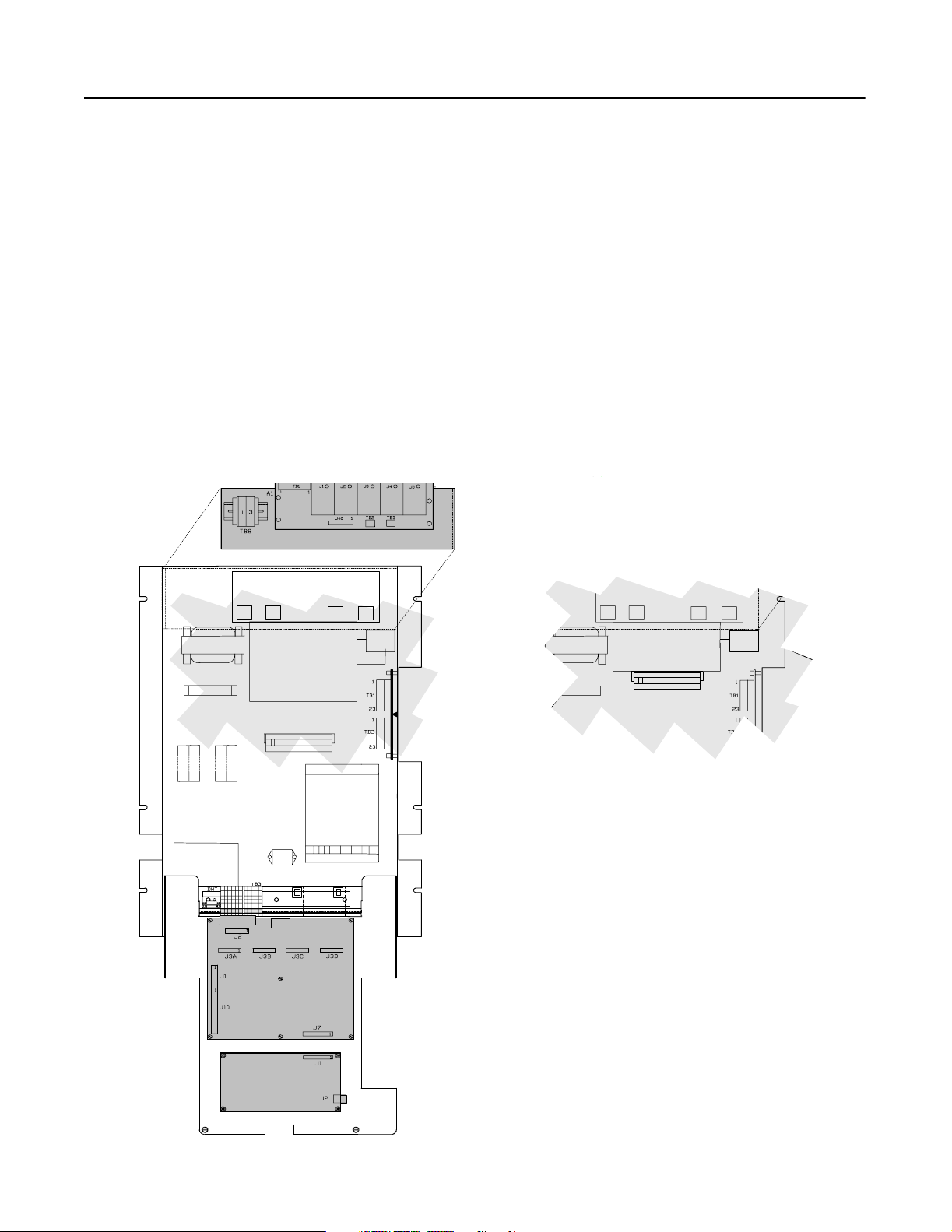

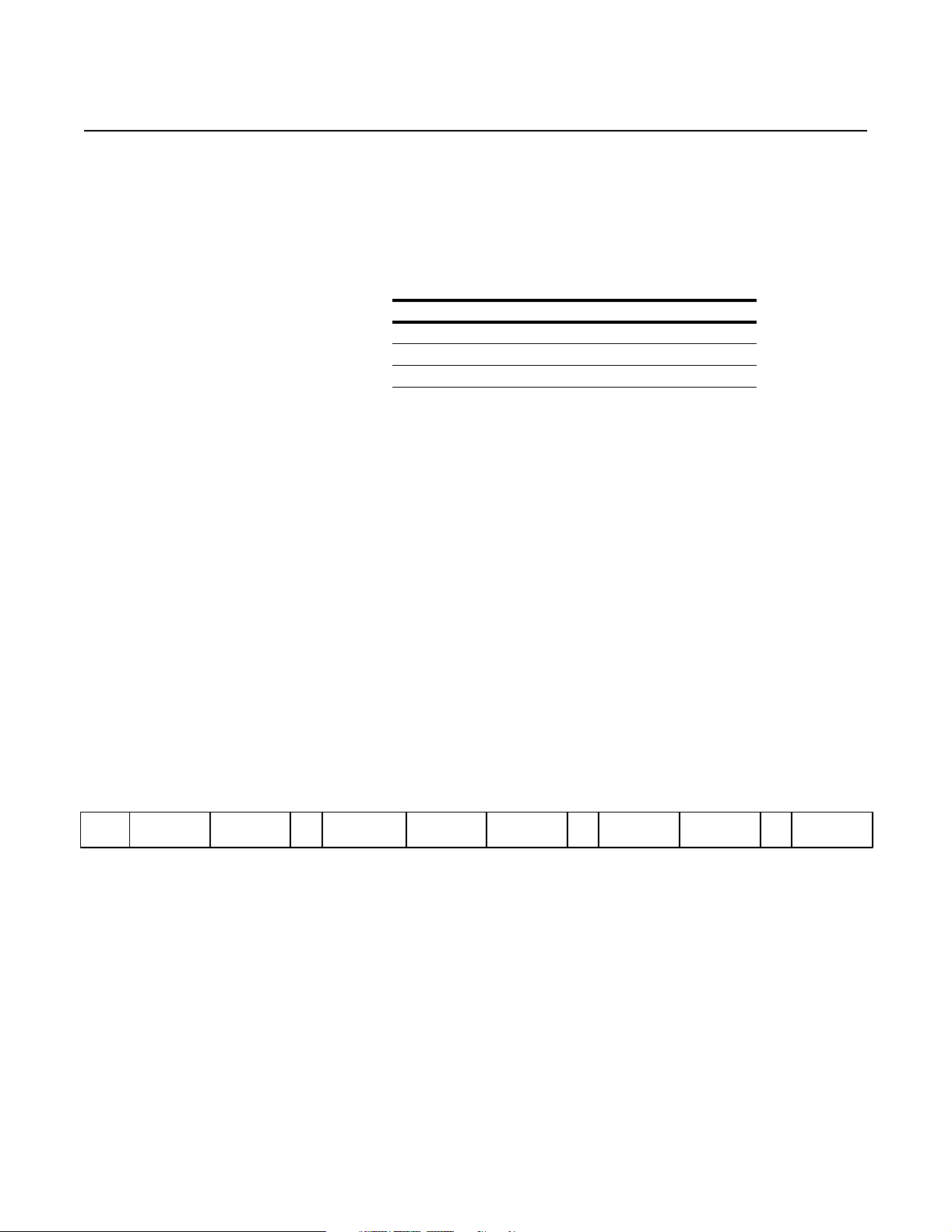

Contents This chapter is designed to help you unde rs tand the construction of

your 3000A Bulletin 1395 DC drive. The following topic s will be

covered in this chapter:

Topic Pa ge

Introduction 4-1

Drive Layout 4-2

Drive Schematics 4-3

Symbol Reference Chart 4-6

Drive Structure 4-8

Conclusion 4-8

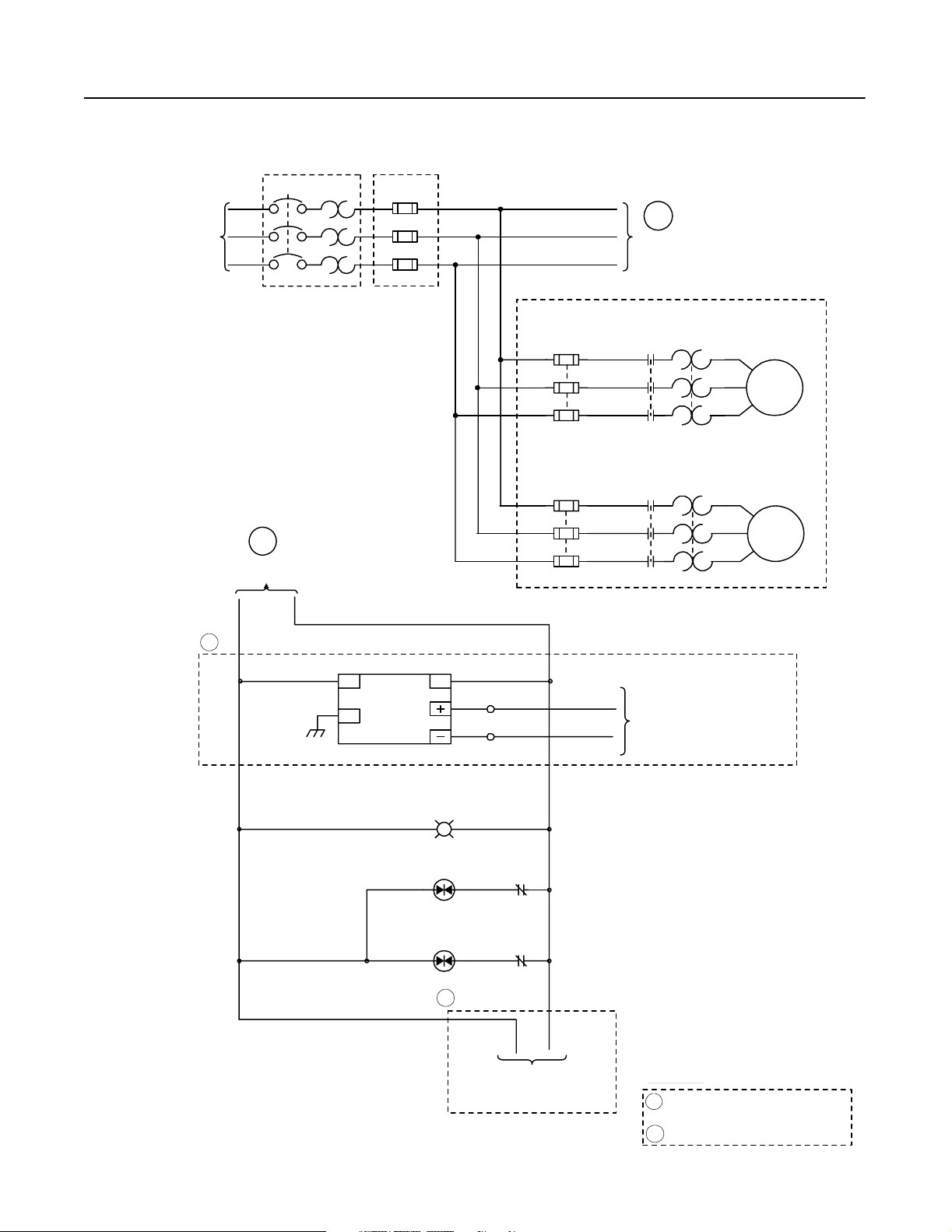

Introduction Your 3000A DC drive functions with the following features:

• The 3000A drive uses twelve SCRs in the armature bridge to

convert the 3-phase AC input to a DC output, six for the posi tive

DC output and six for the negative. The SCRs are built into a

heatpipe asse mbly and are cooled by the bridge fan.

• The 3000A drive is protected from incoming fault curr ents with a

circuit breaker, and the DC output is protected from faul t currents

with a DC contactor. The components of your drive (the

armature bridge, field bridge, and control components) are

protected with fuses, MOVs, snubbers, and/or chokes.

• The 3000A drive is construct ed and house d in four bays, the first

bay containing the AC input and control hardwa re, the second

bay containing the fuses, the third bay containing the armatu re

bridge hardware, and the fourth bay containing the DC output

hardware.

• The 3000A drive has a standard top-hat extension over the

disconnect bay for the AC input.

Publication 2361-5.01 July 1998

Page 48

4-2 Your 3000A DC Drive

Drive Layout Figure 4.1

3000A DC Drive Layout