Page 1

Introduction Chapter 1

Manual Objectives 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1391 Series D 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General Precautions 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Controller Description 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Standard Features 1-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Options/Modifications 1-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Controller Layout 1-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Specifications Chapter 2

Chapter Objectives 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Controller Specifications 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Environmental Specifications 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Controller Power Dissipation 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Transformer Power Dissipation 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table of Contents

1391B-ES Instruction Manual

Receiving, Unpacking and Chapter 3

Inspection

Chapter Objectives 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Receiving 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Unpacking 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Storing 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Description of Operation Chapter 4

Chapter Objectives 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

300V DC Power Bus Supply 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PWM Operation 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Shunt Regulator Operation 4-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Logic Power Supply 4-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Logic Control Boards 4-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fault Monitoring and Detection 4-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Isolated Current Sensing 4-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Integral Circuit Breaker 4-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Line/DB Contactor 4-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Driver Board 4-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A Quad B Board 4-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Starting and Stopping 4-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power-Up/Down Sequence 4-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

i

Page 2

Table of Contents

1391B-ES Instruction Manual

Inputs, Outputs and Adjustments Chapter 5

Chapter Objectives 5-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inputs/Outputs 5-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Potentiometer Adjustments 5-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Switch Settings 5-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation Chapter 6

Chapter Objectives 6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mounting 6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Wiring Recommendations 6-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Wiring 6-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Start-Up Chapter 7

Chapter Objectives 7-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Start-Up Procedure 7-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The 1326AB AC Servomotor Chapter 8

Chapter Objectives 8-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Introduction 8-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Motor Options/Accessories 8-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Transformers and Shunt Regulators Chapter 9

Chapter Objectives 9-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1391 Transformers 9-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Shunt Regulator Operation 9-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Shunt Regulator Installation 9-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting Chapter 10

Chapter Objectives 10-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Troubleshooting 10-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Test Point Descriptions 10-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dimensions Appendix A Interconnect Drawings Appendix B Cable Information Appendix C Controller Options Appendix D

ii

Page 3

Chapter

1

Introduction

Manual Objectives This manual is meant to guide the interface, installation, setup and

troubleshooting of a 1391B-ES AC Servo Controller. The contents are

arranged in order from a general description of the controller to

troubleshooting and maintenance. To ensure successful installation and

operation, the material presented must be thoroughly read and understood

before proceeding. Particular attention must be directed to the Attention

and Important statements contained within.

Important Information about this Manual

This manual has been prepared primarily to support this product in a single

controller application. It is a standard document that is intended to help the

user understand the individual operating characteristics and limitations of

this equipment including hazards associated with installation, setup and

maintenance procedures. Note the following points:

n This equipment has been designed to meet the requirements of a

component controller in an integrated controller system.

n While the potential hazards associated with the controller remain the

same when used in a system environment, it must be noted that special

considerations are to be given to characteristics of other peripheral

solid-state control equipment and the cumulative impact on safety.

n Manufacturers and engineering groups responsible for specification or

design of electrical control equipment must refer to applicable industry

standards and codes for specific safety guidelines and interface

requirements.

n In the actual factory environment, the user is responsible to ensure

compliance with applicable machine and operator safety codes or

regulations which are beyond the scope and purpose of this document.

1391 Series D Allen-Bradley’s commitment to continuing product improvement has led to

the introduction of the 1391 Series D Servo Controller. The catalog

number string for the Series D will be unchanged, however, the controller

nameplate will appear as follows:

CAT 1391B-xxx SER D

This new series incorporates a re-designed Power Driver Board that

increases manufacturing quality and provides a platform for new versions

of the 1391 that are now in development.

This enhancement is totally transparent to the user of this product. The

Control Board and all other components of the controller remain the same.

1-1

Page 4

Chapter 1

Introduction

General Precautions In addition to the precautions listed throughout this manual, the following

statements which are general to the controller must be read and understood.

ATTENTION: Only personnel familiar with the 1391B-ES

!

!

!

Servo Controller and associated machinery should plan or

implement the installation, start-up and subsequent maintenance

of the controller. Failure to comply may result in personal injury

and/or equipment damage.

ATTENTION: An incorrectly applied or installed controller

can result in component damage or a reduction in product life.

Wiring or application errors, such as, undersizing the motor,

incorrect or inadequate AC supply, or excessive ambient

temperatures may result in malfunction of the controller.

ATTENTION: This controller contains ESD (Electrostatic

Discharge) sensitive parts and assemblies. Static control

precautions are required when installing, testing, servicing or

repairing this assembly. Component damage may result if ESD

control procedures are not followed. If you are not familiar with

static control procedures, reference Allen-Bradley publication

8000-4.5.2, Guarding Against Electrostatic Damage or any

other applicable ESD Protection Handbook.

Important: In order to maintain UL listing on Allen-Bradley 1391B-ES

Servo Controllers, the user must

Transformer. Use of any other transformer voids the UL listing.

The user is responsible for providing motor overload protection in

accordance with the National Electrical Code (NEC), and any other local

codes that may apply.

Controller Description The 1391B-ES Pulse Width Modulated Servo Controller is a dedicated,

single axis, AC servo controller. It has been packaged to require a

minimum amount of panel space while containing, as standard, a number

of features required by the machine tool and automated equipment

industries.

The 1391B-ES allows the user to achieve higher operating speeds with

purchased motors or from motors already in use. Depending on the motor,

the 1391B-ES can produce up to 30% more speed without loss of torque.

This can help achieve greater precision, a finer finished product and

increased production from existing machinery.

provide power from a 1391 Isolation

1-2

Page 5

Chapter 1

Introduction

The 1391B-ES is generally used with a computer aided, closed loop

positioning system to control the position and linear or rotary motion of

various machine members on an automated machine.

All components are mounted in an open framed package with a slide-on

front cover. The controller is intended to be panel mounted in an enclosure

and ventilated with filtered and/or cooled air. An internal fan is included to

circulate air over the power heat sink.

The 1391B-ES converts a three-phase, 50/60 Hz input, to a variable AC

voltage with controlled phase, amplitude and frequency. The output which

is proportional to a user supplied analog command, regulates the speed

and/or current (torque) of a 1326 permanent magnet AC servomotor. The

controller is available in ratings of 15, 22.5 and 45A RMS with all package

sizes being identical. A 1391 Transformer, 1326 AC Servomotor and 1326

Cables complete the servo system.

Standard Features The 1391B-ES contains a number of standard features required in a typical

automated machine servo system.

• Input protected against transient voltage.

• A power line/DB contactor which opens the AC line to the controller

and inserts a shunt regulator resistor across the DC bus whenever the

contactor is de-energized.

• An integral circuit breaker which will open all three AC line leads in the

event of a short circuit condition in the power circuitry.

• A standard 300V DC power bus supply that includes an integral shunt

regulator.

• A shunt regulator resistor to dissipate the energy generated by the motor

during regenerative braking.

• Velocity loop components to compensate for a system inertia range

between 0.03 to 1.0 lb.-in.-s

• User selectable mechanical resonance filtering.

• Patented current control implementation.

• Acceleration or torque feedforward differential input.

2

.

• DIP switch configurable.

• Logic Boards that can be quickly removed and easily interchanged for

troubleshooting and diagnostics.

• Three controller ratings that are in the same physical package and have

identical mounting dimensions.

• True vector control.

• Up to 300 feet (91.4 meters) between controller and motor.

1-3

Page 6

Chapter 1

Introduction

Options/Modifications The 1391B-ES contains most functions needed in a servo system.

The following are selectable at the user’s option:

- Contactor Auxiliary Switch

Two N.O. contacts are mounted on the main power contactor and wired

to the power terminal block. These contacts can be used in a motor

brake control circuit or as an indicator that the contactor has closed.

- Current or Torque Amplifier Operation

When the velocity loop is being closed as part of the position control

system, the controller can be configured to operate as a current or torque

amplifier by use of the S2 switch settings.

- External Shunt Regulator Resistor

On 15 and 22.5A controllers an internal power resistor that is part of the

DC bus voltage shunt regulator can dissipate 162 watts continuous

power. Some applications such as an overhauling load have excessive

regenerative energy to dissipate. For these applications, an external

shunt regulator resistor rated at 386 watts continuous can be supplied for

user mounting on 22.5A controllers. This is selectable by removing the

jumper on TB5 and using an external resistor. The shunt has integral

fusing accessible from the outside of 15 and 22.5A controllers. The 45A

controller has an externally mounted resistor and fuse.

Important: An external shunt regulator resistor is included as standard

equipment on 45A units. An additional unit is not required.

- Tach Output

A voltage equal to 2.0V DC/1000 RPM is available at TB2. 1.2V

DC/1000 RPM on units set for 6000 RPM operation.

- Torque or Current Monitor

A voltage equal to 3.0V DC=100% scaled current is available at TB2.

- Anti-Backlash

Provisions to use the 1388 Anti-Backlash module are provided.

Controller Layout Figure 1.1 provides an exterior view of the 1391B-ES AC Servo

Controller, showing accessibility of various components.

1-4

Page 7

Ground Stud

Chapter 1

Introduction

Figure 1.1

1391B-ES AC Servo Controller

TB

TB4

Circuit Breaker

Fuse

5

SW1

TB1

TB2

Diagnostic LED’s

1-5

Page 8

Chapter 1

Introduction

End of Chapter

1-6

Page 9

Chapter

2

Specifications

Chapter Objectives Chapter two contains the electrical and environmental specifications for the

1391B-ES. Dimensions are provided in Appendix A.

Controller Specifications The general specifications of the 1391B-ES are provided in the listing

below. The specifications are divided when necessary for the various

controller ratings.

Specific Controller Ratings 1391B-ESAA15 1391B-ESAA22 1391B-ESAA45

Nominal Bus Output Voltage 300V DC 300V DC 300V DC

Continuous Current (RMS) 15A 22.5A 45A

Peak Current (RMS) 30A 45A 90A

Continuous Power Output 5.0 kW 7.5 kW 15.0 kW

Peak Power Output 10.0 kW 15.0 kW 30.0 kW

Input Circuit Breaker Rating 17A RMS 26A RMS 38A RMS

Circuit Breaker Interrupt Rating

(Symmetrical Amperes) 1300A 1300A 1300A

Unit Weight in lbs. (kg) 22 (9.97) 28 (12.69) 34 (15.40)

All Controller Ratings

Static Gain (A/RMS) 1.5 x Rated Motor Current / rpm

Form Factor 1.03 or less

Peak Current Limit Adjust 20 to 300% of Rated Motor Current (to 2 times continuous

rating of drive, maximum)

Controller Efficiency

(Minimum at Rated Load) 85%

Modulation Frequency 2500 Hz ±10%

Drift (Referred to Tach) 0.07 rpm /Degrees C. Maximum

Ambient Temperature 0 to 60° C (32 to 140° F)

Storage Temperature 0 to 65° C (32 to 149° F)

Input Voltage (from Transformer) Power: 230V AC, Three-Phase, 50/60

Hz ±3 Hz

Control: 36V AC CT, Single-Phase

Relative Humidity 5 to 95% Non-Condensing

Deadband Zero

Altitude 1000 meters (3300 feet)

Integral Fan Output 50 CFM (Unloaded)

Max. RMS Short Circuit Current

(Symmetrical Amperes) 1300A

Transformer Input Tolerance +10%, –15%

2-7

Page 10

Chapter 2

Specifications

Specifications are for reference only and are subject to change without notice.

Environmental Specifications The 1391B-ES must be mounted in an enclosure that is clean, dry and

ventilated by filtered or cooled air. Enclosures vented with ambient air

must have appropriate filtering to protect against contamination caused by

oils, coolants, dust, condensation etc. The ambient air temperature must be

kept between 0 to 60° C (32 to 140° F) and the humidity between 5 and

95%, non-condensing.

The 1391B-ES is equipped with an integral cooling fan. The general flow

of air through the unit must be maintained by following the recommended

spacing guidelines found in Chapter 6. The 1391B-ES can operate at

elevations to 3300 feet (1000 meters) without derating, however, the

current rating must be derated by 3% for each additional 1000 feet (305

meters) up to 10,000 feet (3050 meters). Consult with your local

Allen-Bradley Sales Representative prior to operation over 10,000 feet

(3050 meters).

Controller Power Dissipation The 1391B-ES dissipation characteristics are approximated in Table 2.A.

T able 2.A

Controller Power Dissipation

Rated Power

Output

(%)

20

40

60

80

100

1391B-ESAA

15

(watts)

38

76

114

152

190

1391B-ESAA

22

(watts)

55

110

165

220

275

1391B-ESAA

45

(watts)

104

208

312

416

520

Transformer Power Dissipation The power dissipation characteristics of the 1391 Isolation Transformer are

shown in Table 2.B.

T able 2.B

1391 Isolation Transformer Power Dissipation

Rated Power

Output

(%)

20

40

60

80

100

1.5kV

A

(watts)

13

25

38

50

60

3.5kV

A

(watts)

35

70

105

140

175

5.0kV

A

(watts)

50

100

150

200

250

10.0kV

A

(watts)

100

200

300

400

500

12.5kV

A

(watts)

125

250

375

500

625

15.0kV

A

(watts)

150

300

450

600

750

2-8

Page 11

Important: Power Dissipation figures shown are for use in calculating

cumulative system heat dissipation to ensure ambient temperature inside

enclosure does not exceed 60° C (140° F).

2-9

Page 12

Chapter

3

Receiving, Unpacking and Inspection

Chapter Objectives Chapter 3 provides the information needed to unpack, properly inspect and

if necessary, store the 1391B-ES and related equipment. The section

entitled Inspection provides a complete explanation of the 1391B-ES

catalog numbering system.

Receiving It is the responsibility of the user to thoroughly inspect the equipment

before accepting the shipment from the freight company. Check the item(s)

received against the purchase order. If any items are obviously damaged, it

is the responsibility of the user not to accept delivery until the freight agent

has noted the damage on the freight bill. Should any concealed damage be

found during unpacking, it is again the responsibility of the user to notify

the freight agent. The shipping container must be left intact and the freight

agent should be requested to make a visual inspection of the equipment.

Unpacking Remove all packing material, wedges, or braces from within and around

the controller. Remove all packing material from the cooling fans, heat sink

etc.

Important: Before the installation and start-up of the controller, a general

inspection of mechanical integrity (i.e. loose parts, wires, connections,

packing materials, etc.) must be made.

Inspection After unpacking, check the item(s) nameplate catalog number against the

purchase order. An explanation of the catalog numbering system is

included on the following pages as an aid for nameplate interpretation.

Storing The controller should remain in its shipping container prior to installation.

If the equipment is not to be used for a period of time, it must be stored

according to the following instructions:

• Store in a clean, dry location.

• Store within an ambient temperature range of 0 to 65° C (32 to 149° F).

• Store within a relative humidity range of 5% to 95%, non-condensing.

• Do not store equipment where it could be exposed to a corrosive

atmosphere.

• Do not store equipment in a construction area.

3-10

Page 13

Isolation Transformer

Chapter 3

Receiving, Unpacking and Inspection

1391 T

First Position Second PosiBulletin

Number

–

tion

Type

Description

Letter

Trans-

T

former

Open

Core and

Coil

015

Third Position

kVA Rating

Number

015

035

050

100

125

150

NEMA Type 1 Transformer Enclosure

1391

kVA

1.5

3.5

5.0

10.0

12.5

15.0

TA2–

Primary Voltage

& Frequency

Letter

D

E

N

Kit

D

Fourth Position

Description

240/480V AC,

Three- Phase, 60 Hz

240/380/415/480V

AC, Three-Phase,

50/60 Hz

208/230/460/575V

AC, Three-Phase,

60 Hz

Fifth Position

Secondary

Voltage

Description

Letter

230V AC, three-

T

phase and four

36V AC, singlephase C.T.windings

T

First Position Second PosiBulletin

Number

tion

Accessory

Module

Description

Letter

Fits all kVA ratings on 1388, 1389

TA

and 1391 Isolation Transformers.

2

3-11

Page 14

Chapter 3

Receiving, Unpacking and Inspection

Bulletin 1391B-ES Controller

1391B ES A

First Position Second PosiBulletin

Number

Description

Code

Standard

B

tion

Speed

Capability

Description

Letter

Standard

Blan

1391B

k

Extended

Speed

ES

Range

Third Position

Type and

Construction

Description

Letter

Open

A

Frame,

Internal

Heat Sink

1388 X B

A

Fourth Position

Nominal Output

Voltage

Description

Letter

230V AC,

A

ThreePhase

Accessory Modules

–

Fifth Position

Current

Rating

Description

Number

15A RMS

15

Cont./

30A Peak

22

22.5A RMS

Cont./

45A Peak

45

45A RMS

Cont./

90A Peak

45

–

xxx–

Sixth Position

Options

(if required)

Description

Three character field

assigned to special

modifications.

Contact your local

Allen-Bradley Sales

Representative for

further information.

Description

Code

Must be or-

A12

dered when

using rareearth motors

3-12

First Position Second PosiBulletin

Number

External Shunt Regulator Resistor

1326 MOD SR22A

First Position Second PosiBulletin

Number

tion

Accessory

Module

–

tion

Type

Code

MO

D

Description

Modification Kit

Third Position

Accessory

Cod

Description

e

Anti-Backlash Module w/mounting

A

assembly

B

Accel/Decel Board w/mounting rack

C

Velocity Reference Board w/mounting

rack

–

Third Position

Description

Code

Description

SR22

Shunt Regulator Resistor for 22.5A

A

Controller

SR45

Shunt Regulator Resistor for 45A

A

Controller

Page 15

1326AB Servomotor

Chapter 3

Receiving, Unpacking and Inspection

1326 A 3

First Position Second PosiBulletin

Number

tion

Type

Letter

A

Description

AC

Servomotor PM

Type

1326A

Third Position

Design

Description

Factory

use only

MO

–

Fourth Position

Series

Description

Sequentially

lettered to

designate

frame diameters.

Description

Code

4.25”

A

(108 mm)

B

5.88”

C

(149 mm)

7.63”

(194 mm)

Shaft Oil Seal Kit

SS V

–

Fifth Position

Motor

Length

Description

Sequentially numbered to

indicate

stack

length within a given

frame size.

E

–

Sixth Position

Max. Op.

Speed

RPM

Letter

200

B

0

C

300

0

E

400

G

0

600

Description

Code

0

72 lb.-in. (8.1 N-m) Holding Brake w/90V DC

A4

Coil.

A5

120 lb.-in. (13.6 N-m) Holding Brake w/90V

A7

DC Coil.

360 lb.-in. (40.7 N-m) Holding Brake w/90V

DC Coil.

A

–

11

Seventh Position

Mounting &

Shaft Description

Description

Cod

e

Inch Combina-

11

tion Face/

Flange with

Keyway

21

NEMA/IEC

Metric Flange

with Keyway

–BA

1–

A4

Eighth Position

Standard

Options

B

First Position Second PosiBulletin

Number

tion

Type

Code

MO

D

D

Description

Modification Kit

Third Position

Shaft

Seal

1

“A” Series motors with brake must use

1326AB-MOD-SSV-A2.

Brake Power Supply Rectifier

1326 MO

–

Fourth Position

Material

Letter

V

D

First Position Second PosiBulletin

Number

tion

Type

Description

Code

Modifica-

MO

tion Kit

D

2

Up to 4 brakes per rectifier can be

used.

Description

Viton

–

Third Position

Description

Code

BP

S

Fifth Position

Motor

Series

for . . .

Letter

-A Series

A

-B Series

B

-C Series

C

Sixth Position

Motor

Mounting

Description

Number

Std. Inch

1

Metric

2

BP

S

Description

Single-phase, full-wave, screw mount

rectifier. 115V AC input, for use with

90V DC brakes.

2

1

3-13

Page 16

Chapter 3

Receiving, Unpacking and Inspection

–

3

RJA

B

Third Position

Code

RJA

B

RJB

C

4

Description

For all AB-A and

AB-B Series Motors

For all AB-B4 and

AB-Cx Series Motors

Motor Junction Box Kit

1326A

B

First Position Second PosiBulletin

Number

3

The motor comes standard with IP65 plug style connectors mounted radially to the motor. This

kit allows the connectors to be brought out axially to the motor without further wiring. Kit

includes Motor Junction Box and Mounting Hardware.

Feedback Mounting Adapter Kit

MO

–

D

tion

Type Description

Description

Code

Modifica-

MO

tion Kit

D

3-14

1326A

B

First Position Second PosiBulletin

Number

4

All kits contain a feedback device mounting adapter and mounting hardware. M4, M5 and M6

include a motor to encoder coupling. M22 and M23 do not include a coupling since it is included

with the resolver feedback device.

–

tion

Type

Code

MO

D

MO

D

Description

Modification Kit

Code

M4

M5

M6

M22

M23

M24

M25

M26

–

M4 C

–

1

Third Position

Mounting Adapter

Kit for . . .

Description

A-B 845H/T Encoder for AB-A series motor

A-B 845H/T Encoder for AB-B series motor

A-B 845H/T Encoder for AB-C series motor

Type VC/VD 4.25” (108 mm) Resolver for AB-B series

motor

Type VC/VD 4.25” (108 mm) Resolver for AB-C series

motor

0.375” (9.5 mm) diameter heavy duty shaft extension

adapter

0.625” (15.9 mm) diameter heavy duty shaft extension

for type VC/VD 4.25” (108 mm) resolver

Foot mounting kit for M25

Fourth Position

Coupling Size

for . . .

Motor Series

Code

A, B, C

C1

For M22,

Blan

M23, M24,

k

M25, M26

Page 17

Feedback Coupling

Chapter 3

Receiving, Unpacking and Inspection

1326 MO

First Position Second PosiBulletin

Number

1326A

–

B

First Position Second PosiBulletin

Number

–

tion

Type

Code

MO

D

Resolver Feedback Package

MO

D

tion

Type

–

D

Description

Modification Kit

–

VC

Third Position

Resolver Feedback

Package

C1

Third Position

Coupling

Size

–

Size

Code

C1

C2

Motor Shaft to Encoder Shaft

3/8” to 3/8” (9.5 mm to

9.5 mm)

3/8” to 1/4” (9.5 mm to

6.3 mm)

Fourth Position

Gear Ratio

Input:Resolver

1:1

Code

Description

VC

4.25” (108 mm) feedback package with cast

housing and single or vernier (dual) format

with receiver (Harowe 11BRW-300-F-58A or

equivalent) type resolver(s) for use with 8200,

IMC 120, IMC 123, Creonics SAM and MAX.

VD

4.25” (108 mm) feedback package with cast

housing and single or vernier (dual) format

with transmitter (Harowe 11BRCX-300-C10/6

or equivalent) type resolver(s) for use with A-B

series 8600 and Creonics.

5

Kit includes Resolver Feedback Package, mounting hardware and 3/8” to 3/8” (9.5 mm to 9.5 mm) resolver to motor mounting

coupling.

Code

MO

D

Description

Modifica-

5

tion Kit

Code

Description

1:1

Single device format – 1 turn of the motor shaft to 1 turn of the

resolver.

1:2

Single device format – 1 turn of the motor shaft to 2 turns of the

1:2.

resolver.

5

Single device format – 1 turn of the motor shaft to 2.5 turns of

1:5

the resolver.

255

Single device format – 1 turn of the motor shaft to 5 turns of the

resolver.

256

Absolute master/vernier format – 1:1 input/master, 255:256

master/vernier for IMC 120, 123 only.

Absolute master/vernier format – 1:1 input/master, 256:255

master/vernier for 8600 series controls and Creonics only.

3-15

Page 18

Chapter 3

Receiving, Unpacking and Inspection

Power and Feedback Cables

1326 C

First Position Second PosiBulletin

Number

–

tion

Type

Letter

C

CC

Description

Connector

& Cable

Assembly

Connector

on both

ends (for

use with

1391CHB)

PA

Third Position

Function

Description

Letter

Power Connection

P

Commutation &

F

Feedback Connection

E

845H Encoder

V

All 4.25”

(108 mm) Resolver

Packages

T

Fourth Position

Power Track

Cable

Description

Letter

All Series

T

Standard

Blan

Cable

k

B

Fifth Position

Motor Size

Used On

Type

Code

Series A & B

AB

(except

1326AB-B4)

C

Series C &

1326AB-B4

All SeriesU

15

Sixth Position

Cable

Length

Code

Description

K

Connector

Kit (No

Cable)

15

15’ (4.6m)

30

30’ (9.1m)

50

50’ (15.2m)

100

100’ (30.4m)

3-16

Blower Mod Kit

1326A

B

First Position Second PosiBulletin

Number

MO

–

D

tion

Type Description

Description

Code

Modifica-

MO

tion Kit

D

–

Third Position

Code

G3

G4

G3

Motor Series

Rear mounted blower for C

series motors

“Saddle” type blower for C

series motors with

encoders

Page 19

End of Chapter

Chapter 3

Receiving, Unpacking and Inspection

3-17

Page 20

Chapter

4

Description of Operation

Chapter Objectives Chapter 4 is intended to familiarize the reader with the circuitry of the

1391B-ES in terms of function and operation.

General The 1391B-ES PWM Servo Controller is made up of the following: 300V

DC power supply, power transistor output modules, shunt regulator circuit,

logic power supply, Logic Control Boards, isolated current sensing, circuit

breaker and line contactor.

The intended use of the 1391 ES is to control the speed and torque of an

AC servomotor in a closed loop position system. A complete servo system

can be configured with a 1391B-ES Servo Controller, 1326 AC

Servomotor and 1391 Isolation Transformer. Refer to the 1391B-ES Block

Diagram presented in Figure 4.3.

300V DC Power Bus Supply The controller contains an integral, unregulated, 300V DC nominal, full

load power supply. It consists of the power transformer input (230V AC,

three-phase, 50 or 60 Hz), a three-phase input bridge rectifier and one

power supply filter capacitor (C1).

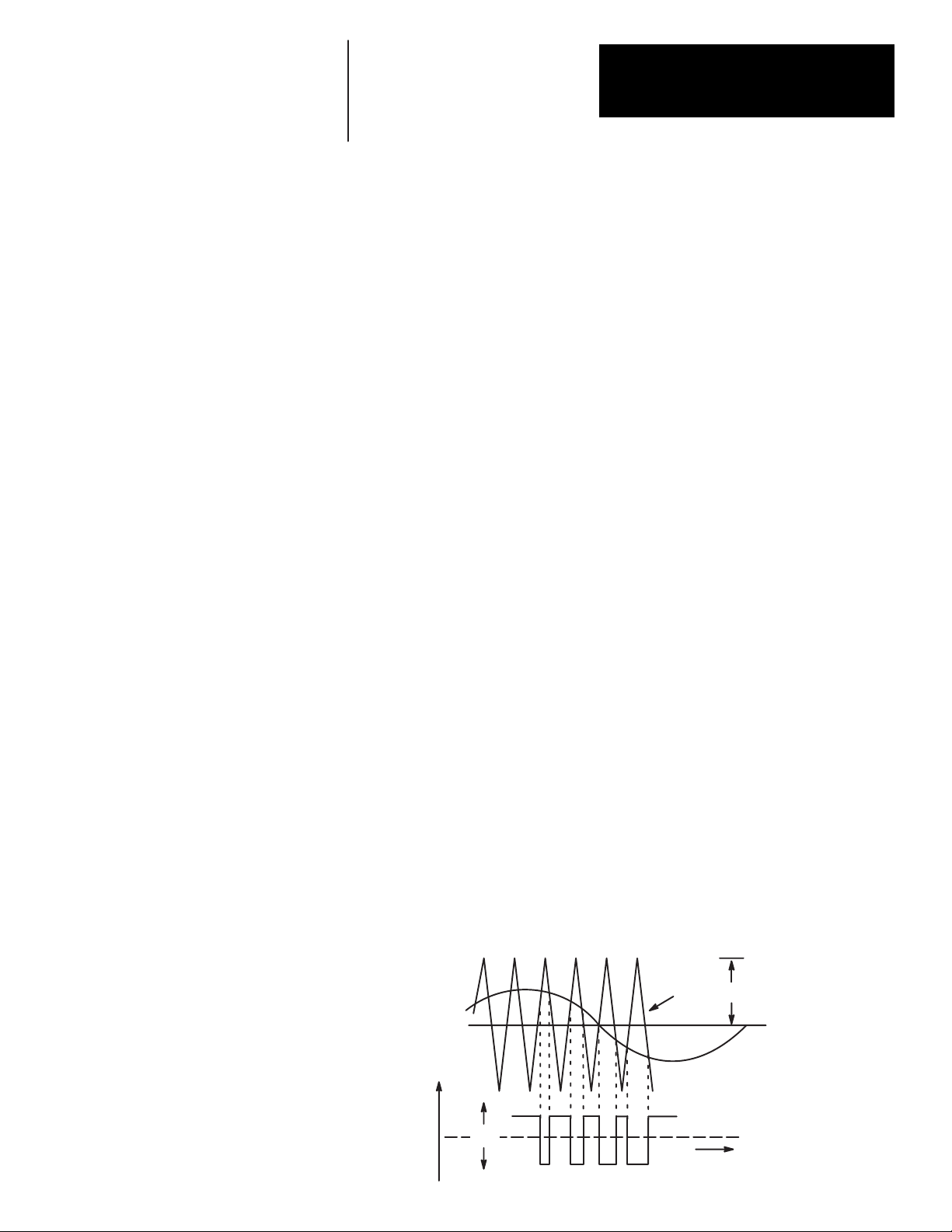

PWM Operation The 1391B-ES incorporates a fixed timing wave (V

controller also generates a three-phase sine wave whose frequency

corresponds to the velocity command. An output voltage signal (V

generated by the intersection of these two curves as shown in Figure 4.1.

Figure 4.1

PWM Waveform

) of 2500 Hz. The

T

) is

O

4-18

V

T

V

O

E

d

E

T

T

Page 21

Chapter 4

Description of Operation

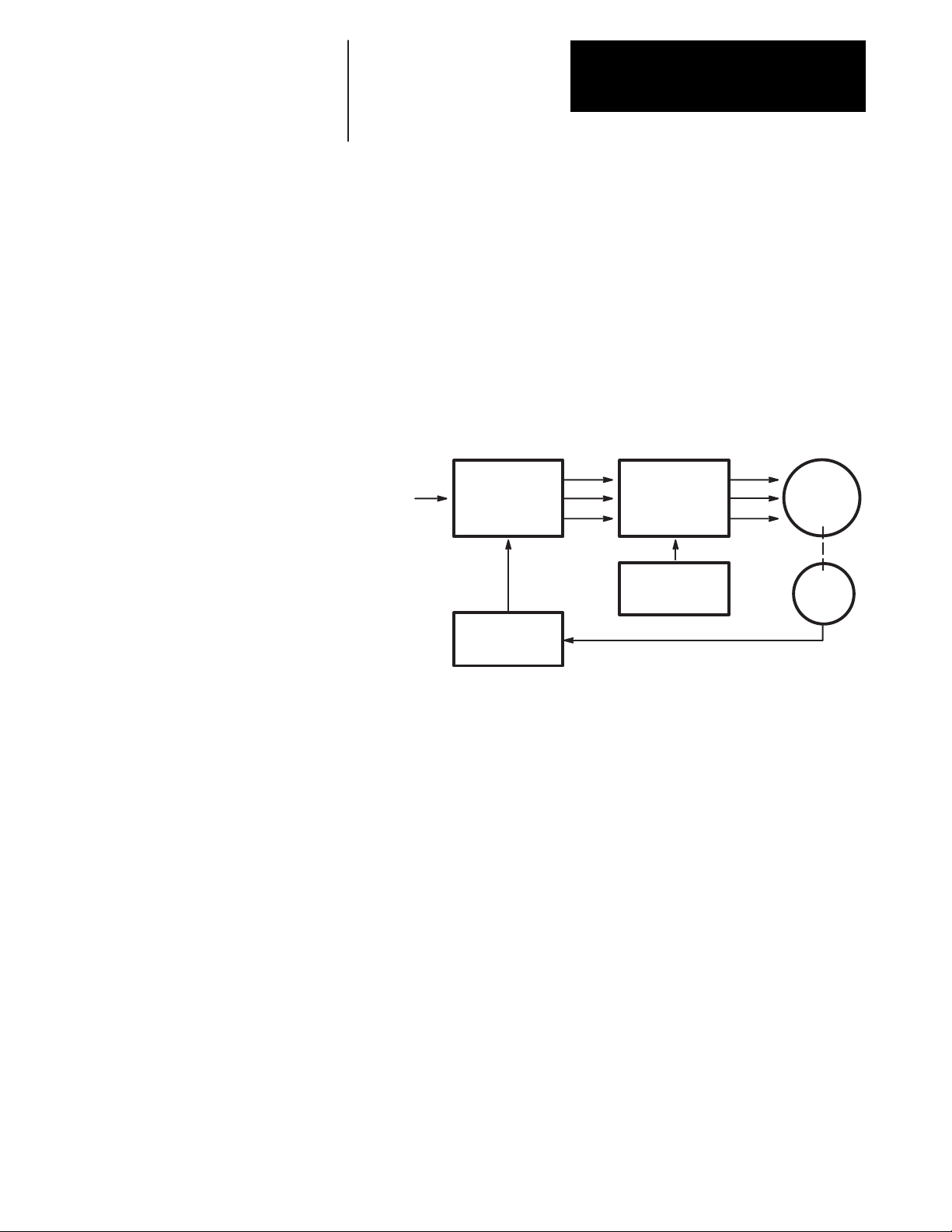

The three-phase relationship between the reference signal and the timing

wave provide a PWM wave to the power transistor base drive. This base

drive switches the power transistors across the 300V DC bus, providing

current to the motor windings, thus causing the motor to turn. A resolver

attached to the motor provides a signal corresponding to the actual rotor

position of the motor. This signal is decoded to a signal representing rotor

position and is fed to the commutation logic along with the torque

command. In this way, the controller combines the desired position signal

and current reference with the decoded resolver signal to produce a

reference signal commanding the controller to speed up or slow down. See

Figure 4.2.

Figure 4.2

Operation

Current

Referenc

e

Commutation

Logic &

Current Loop

Integrator

Position

Decoder

PWM

Generator &

Base Drive

Timing

Signal

Generator

Motor

Resolve

r

Shunt Regulator Operation The 1391B-ES shunt regulator provides power dissipation for regenerative

conditions when the energy returned to the controller by the motor exceeds

that which can be stored in the bus capacitors. The shunt regulator

monitors the bus voltage and at a predetermined “ON” point activates the

shunt regulator transistor, allowing current to flow through the shunt

resistor and dissipating power in the form of heat. A fuse is placed in series

with the resistor to protect it against short circuit conditions. When the

shunt transistor is activated and power is being dissipated at the resistor,

the bus voltage will quickly decrease, turning the transistor off when the

voltage reaches the “OFF” point. This cycle repeats, provided the bus

voltage continues to increase to the “ON” point. If too much regenerative

energy is present, the bus voltage will continue to increase even with the

shunt regulator on. At a predetermined bus voltage level, the 1391B-ES

will determine that an overvoltage condition exists, and trip out on an

Overvoltage Fault.

4-19

Page 22

Chapter 4

Description of Operation

The shunt regulator behavior is further modified by an adjustable duty

cycle timer. The timer is used to model the shunt resistor temperature.

SW1, a selector switch located on the top of the controller (see Figure 1.1)

determines the temperature level and therefore the average power level at

which the controller will trip out. When this level is reached, the controller

will be forced to trip out on an Overvoltage Fault. This action would be

equivalent to turning the shunt regulator off. Refer to Chapter 9 for further

shunt regulator information.

Logic Power Supply The 1391B-ES control logic voltage is ±12V DC and +5V DC. The

voltages are generated on the Power Driver Board, which receives its 36V

AC center-tapped input from a tertiary winding on the isolation

transformer.

Logic Control Boards The Logic Control Boards are the printed circuit boards that are readily

accessible behind the front cover of the controller. They contain all circuits

necessary to control the 1391B-ES. These circuits include: the velocity and

current loop, fault detection and annunciation circuits, power-up/powerdown logic, PWM generation and forward/reverse controlling circuits.

Figure 4.3

1391B-ES Block Diagram

4-20

Page 23

Chapter 4

Description of Operation

Fault Monitoring and Detection A number of Fault Monitor and Detection functions exist on the 1391B-ES

that guard the controller and help to minimize motor and system faults. The

occurrence of a fault will cause the controller to trip out. In this condition,

the Drive OK (DROK) contact will open and remain open until the fault is

cleared. If the DROK contact is wired into the user’s stop circuit, the

line/DB contactor (M) will also de-energize. This will place the shunt

resistor across the bus causing the motor to dynamic brake to a stop.

These fault conditions are annunciated through the front panel LED

indicators. The conditions displayed include:

Overtemperature

The controller contains a thermal switch on the heat sink which indirectly

senses transistor module temperature. If the temperature rating of the

switch is exceeded, the LED illuminates, the DROK contact opens and the

controller is disabled.

Power Fault

A fault related to the power bridge section of the controller will cause the

controller to be disabled, illuminate the LED and open the DROK contact.

Control (Power) Fault

If the control voltage varies more than ±10% of the nominal 12V DC or the

resolver wiring is grounded or missing, this fault will occur. When a fault

is detected, the LED illuminates, the DROK contact opens and the

controller is disabled.

Overvoltage

The DC power bus voltage is continuously monitored. If it exceeds a preset

level of 405V DC, the LED illuminates, the DROK contact opens and the

controller is disabled

Undervoltage

If the DC power bus voltage drops below 50% of its nominal operating

value, the LED illuminates and a signal will be present at TB2-13. A

switch setting on S2 selects the reaction of the DROK contacts to an

undervoltage detection. Two options are possible: 1) DROK opens, but

closes when the bus voltage is restored; 2) DROK is not affected by an

undervoltage.

Important: Regardless of interaction with the DROK contacts, the

transistor bridge is disabled upon an undervoltage condition. This is done

to protect the output transistors against voltage transients.

Current Foldback

The controller contains a fixed time versus current overload circuit which

monitors the current through each leg of the output bridge. If a fixed-time

versus current-product is exceeded, the LED is illuminated and a signal

will be present at TB2-14. This condition will reduce the current limit or

torque available to the motor.

Run/ Enable

The application of an enable signal by the machine position controller will

cause the RUN ENABLE LED to illuminate.

4-21

Page 24

Chapter 4

Description of Operation

Drive Ready

The status of the power supplies and fault conditions are monitored

continuously. If a fault is present, the DRIVE READY LED will not be

illuminated, a fault signal will be present at TB4 and the DROK contact

will be open.

Isolated Current Sensing The Logic Control Boards receive current feedback from the Isolated

Current Sense Board. This circuitry provides the data used for current

limiting and to modify bandwidth.

Integral Circuit Breaker The control logic and power circuitry are protected against overcurrents by

an integral circuit breaker. The DC bus supply and input rectifier utilizes a

three pole magnetic circuit breaker.

Line/DB Contactor The three-phase incoming AC line is opened by the contactor whenever the

Enable signal is removed or a fault occurs. This operation in conjunction

with the shunt regulator reduces the bus voltage when the contactor is

disabled. The Logic Control Board remains energized except when voltage

is removed from the incoming isolation transformer.

Important: The 1391B-ES contains a definite purpose contactor that is not

to be energized/de-energized more than twice an hour on a continuous

basis. The life of the contactor may be reduced considerably if the cycle is

exceeded. Contact your local Allen-Bradley Sales Representative for

additional information.

Power Driver Board The Power Driver Board contains the circuitry needed to switch the power

transistor modules.

A Quad B Board The A Quad B Board changes the resolver signal from a 1326AB or AD

motor into an encoder signal for use by a position controller.

Starting and Stopping

ATTENTION: The Enable control circuitry in the 1391B-ES

!

includes solid-state components. If hazards due to accidental

contact with moving machinery or unintentional flow of liquid,

gas or solids exist, an additional hardwired stop circuit may be

required. Refer to the codes and standards applicable to your

particular system for specific requirements and additional

information. A device that removes AC input power when a

stop is initiated is an integral part of this controller. Refer to the

following individual stop mode explanations.

4-22

Page 25

Chapter 4

Description of Operation

ATTENTION: The user has the ultimate responsibility to

!

determine which stopping method is best suited to the application and will meet applicable standards for operator safety.

Starting and Stopping must be accomplished by hardwired user supplied

elements as shown in Appendix B. Stopping modes for the 1391B-ES are

outlined below. Refer to the paragraphs that follow for detailed

information. The effects described below assume that the 36V AC control

voltage has not been de-energized.

Cause Effect on Motor

De-energize Line/DB Contactor (M) Coil Dynamic Brake

Speed Command brought to Zero Regenerative Brake

Open Enable Input Regenerative Brake

DROK Opens (Fault) Coast to Stop

Dynamic Braking

When the line/DB contactor (M) is de-energized by the control circuitry, an

inherent dynamic braking effect will occur during the DC bus decay,

provided the 36V AC logic voltage is not de-energized. The dynamic

braking effect depends on the value of the shunt regulator resistor and total

load inertia.

Important: Frequent cycling of the line/DB contactor to start/stop the

motor will reduce the life of the contactor. Refer to the paragraph that

follows.

Regenerative Braking

Normal run commands to the controller are performed through the Enable

input and any additional customer supplied control circuitry. Refer to

Appendix B. With input power applied, a mechanical contact closure

between TB2-9 & 10 or solid-state contact closure (open collector, +15 to

+30V DC) between TB2-10 & 12 will cause the controller to run, provided

the line/DB contactor (M) has been energized by the control circuitry.

When the Enable input is de-energized, the maximum available reverse

torque is applied to the motor in a regenerative stopping mode, which will

occur for approximately 450ms.

Coast

An internal controller fault opens the DROK contact. Coasting will only

occur if the DROK contact is not wired to the line/DB contactor coil (M) or

the Enable input circuits.

4-23

Page 26

Chapter 4

Description of Operation

Power-Up/Down Sequence Figure 4.4 describes the various steps involved in the power-up/down

sequence of the 1391B-ES controller.

Figure 4.4

Controller Power-Up / Down Sequence

POWER-UP

SEQUENCE

Application of 240V AC to Isolation

Transformer

a) Logic power supplies and base drive circuits

power-up.

b) Apply 115V AC to contactor.

c) Power bus charges.

d) If no faults are encountered, the DROK relay

energizes. Controller is ready to receive

customer enable signal.

Enable Signal Applied

Minimum of 100 ms after Contactor is Closed

a) Base drive enabled and will respond to

customer command inputs.

Enable Signal is Applied Prior to 36V AC

Power

a) When 36V AC power is applied, fault circuits

detect that the enable signal is already applied.

Random fault conditions occur.

b) Re-application of enable after resetting the

controller and with 36V AC power still

present, will energize the controller.

Fault

Fault

Fault

Fault

Fault

POWER-DOWN

SEQUENCE

Enable Signal Removed

a) Motor will regenerate to a stop.

b) Output power stage is disabled.

c) DROK relay maintains a no fault status.

240V AC Power Removed

a) Logic and DC link power supplies begin

decaying to zero volts.

b) Undervoltage (fault) condition occurs.

4-24

Fault Condition Occurs

a) Controller output stage disabled.

b) DROK relay is de-energized and a fault is

latched.

c) If contactor is wired to the DROK relay in a

stop string, contactor will open and the shunt

regulator will discharge the power bus

supply.

Page 27

End of Chapter

Chapter 4

Description of Operation

4-25

Page 28

Chapter

5

Inputs, Outputs and Adjustments

Chapter Objectives Chapter 5 contains descriptions of the various inputs and outputs available

on the 1391B-ES Servo Controller. Additionally, a comprehensive listing

and description of the potentiometer and switch adjustments is provided. In

some cases adjustment methods are provided for use during start-up. This

information is provided to help you understand some of the important

aspects about the controller prior to the actual installation and start-up. For

information on shunt regulator adjustments, refer to Chapter 9.

Inputs/Outputs The following paragraphs provide detailed descriptions of the various

inputs and outputs available for the 1391B-ES. See Figure 5.2 for terminal

block locations.

Terminal Block - TB1

Resolver Signals (TB1, Terminals 1-10)

These terminals are used for connection to the resolver. Refer to Appendix

B for connection details.

Terminal Block - TB2

Velocity Command Input (TB2, Terminals 1, 2)

The controller will accept up to a ±10V DC velocity command signal to

achieve maximum motor speed. The plus (+) and minus (–) reference are at

terminals 2 and 1, respectively. Shield must be terminated at source end

only. The differential impedance of the velocity command input is 40k

ohms (20k ohms for single ended inputs).

Signal Common (TB2, Terminals 3, 6, 12, 17)

Signal input reference point.

5-26

Buffered Output (TB2, Terminal 4)

This output is the differentially isolated velocity or torque command

applied at terminals 1 and 2 of TB2. It can be wired to the torque command

input (TB2-15 and 16) for torque block operation.

Page 29

Chapter 5

Inputs, Outputs and Adjustments

Adjustable Current Limit (TB2, Terminal 5)

The current limit of the controller is set to 300% or twice the continuous

rating of the controller, whichever is lower. Connecting this terminal to

Signal Common will enable potentiometer R148. The range of this pot is

20 to 300% or twice the continuous rating of the controller, whichever is

lower. This is used for feed to hard stop applications. When the workpiece

activates this condition through a limit switch or other user supplied

device, the current will be limited to the value set by R148, protecting the

motor against possible overheating.

Tachometer Output (TB2, Terminal 7)

A voltage corresponding to the motor velocity and direction of rotation will

be present between this terminal and Signal Common. With switch S2-1

(see the section entitled Switch Settings) set to “ON,” a voltage of ±1.2V

DC/1000 rpm will be present. With the switch in the “OFF” position, a

voltage of ±2.0V DC/1000 rpm will be present.

I Command Output (TB2, Terminal 8)

The voltage present between this terminal and Signal Common

corresponds to the motor current. A voltage of ±3.0V DC equals the rated

motor current as set by switch S1.

Enable Input (TB2, Terminals 9, 10)

Normal Run commands to the controller are performed through the Enable

input and any additional user supplied run control circuitry. With input

power applied and the line contactor energized, a solid-state contact closure

(rated +15 to +30V DC, 30 mA) between TB2-10 & 12 or a mechanical

contact closure between TB2-9 & 10 will cause the controller to run. When

this input is de-energized, the control will cause a regenerative braking

action in the motor.

Reset (TB2, Terminal 11)

Removing the Enable signal and momentarily connecting this terminal to

Signal Common will reset the controller after a controller fault occurs.

Important: A Reset must

not be initiated until the cause is determined and

corrected.

Low Bus (TB2, Terminal 13)

This terminal provides an open collector output rated at 12V DC, 5mA to

indicate a low bus voltage condition. Reference to Signal Common.

Current Foldback (TB2, Terminal 14)

This terminal provides an open collector output rated at 12V DC, 5mA to

indicate that current foldback is in operation. Reference to Signal

Common.

5-27

Page 30

Chapter 5

Inputs, Outputs and Adjustments

Torque Command Input (TB2, Terminals 15, 16)

Terminals 15 and 16 provide a small amount of input filtering for operating

the controller in a torque block or velocity feedforward mode. A ±3V DC

command equals 100% of the S1 current setting (i.e. motor rated current).

The buffered output of the command at terminal 4 of TB2 can be

connected to terminal 16 if more filtering is desired.

Spares (TB2, Terminals 18-20)

Reserved for future use and are not to be used.

Terminal Block - TB3 (A Quad B Board)

Figure 5.1 provides interconnect information between the position

controller and TB3 on the A Quad B Board.

ATTENTION: To guard against possible damage to the A

!

Quad B Board, assure that wiring between TB3 and the position

controller is correct. Refer to Figure 5.1.

Figure 5.1

A Quad B Board Wiring

A Quad B Board

1 TB2 20

21S3

987654321

Power

Supply

Input

Important: Note terminal orientation prior to wiring.

1

Recommended Wire – Belden #9728 or equivalent. Maximum distance between the A Quad B

Board and the position controller is 40 feet (12.2 meters) using a 5 volt signal. For distances up

to 300 feet (91 meters), 18 AWG (0.8 mm

2

For proper operation when interconnecting to IMC products, the B and B (NOT) signals must be

reversed.

When interfacing to IMC 121 or 123 controllers, use the 1391-CAQB cable.

Top Logic Control Board

10 TB3 1

To Position

1

Controller

2

) wire and an 8 to 15V DC power supply must be used.

1

TB3

Number

1

2

3

4

5

6

7

8

9

10

Description

A

A (NOT)

2

B

B (NOT)

Z

Z (NOT)

+5V DC (

Signal Common

+8 to +15V DC

In

No Connection

2

± 5%)

The A Quad B option operates in the same manner as the Allen-Bradley

845H Line Driver Encoder (26LS31 line driver output). The option

requires either a regulated +5V DC at terminal 7 or an unregulated +8 to

+15V DC input at terminal 9 (board draws 125mA maximum). The pulse

train output is selectable to 256, 512, 1024 or 2048 lines per revolution via

the Encoder Output switch, S3 (see page 5-36).

5-28

Page 31

Chapter 5

Inputs, Outputs and Adjustments

Terminal Block - TB4

Drive OK (DROK) Contacts (TB4, Terminals 17, 18)

Application of power to the transformer energizes the logic supply of the

controller. When 90% of rated DC Bus voltage is achieved and no

controller faults are detected, this relay contact is closed. The contact

remains closed until a controller fault occurs or power is removed from the

transformer. Contact rating: 115V AC, 1A or 24V DC, 0.3A. Refer to

Switch Settings – Drive OK/Drive Ready on page 5-35 for further

information.

36V AC Logic Supply Voltage (TB4, Terminals 19, 20, 21)

The isolation transformer contains four separate windings. Each winding

supplies 36V AC with a center tap. The 36V AC leads are brought out to

terminals 19 and 21 of TB4. The center tap must be connected to terminal

20 of TB4. See Chapter 9 for transformer details.

Terminal Block - TB5

Motor Power Terminals (TB5, Terminals 1, 2, 3)

Motor power is provided at these terminals. Refer to Chapter 6 and

Appendix B for connection details.

Input Power Terminals (TB5, Terminals 4, 5, 6)

The controller requires a 230V AC, three-phase, 50 or 60 Hz input supplied

by the transformer secondary. Refer to Chapters 6, 9 and Appendix B for

wiring and transformer information.

External Shunt Regulator Resistor (TB5, Terminals 8, 9, 10)

The 22.5A controllers have provisions to accept an external shunt resistor

to supplement the integral unit. This is available for applications that

require the dissipation of more regenerative energy to the DC Bus. To use

an external shunt resistor, first remove the jumper at terminals 8 and 10 of

TB5. Consult the Allen-Bradley sales office for application assistance.

The shunt regulator resistor supplied with the 1391B-ESAA45 must be

externally mounted and connected to terminals 8 and 9 of TB5 prior to

operation. Refer to Chapter 9 and Appendix B for details.

5-29

Page 32

Chapter 5

Inputs, Outputs and Adjustments

Figure 5.2

Terminal Block, Potentiometer and Switch Locations

Resolver Signals

TB1

110

Adjustable Current Limit

Gain

Scale

R132

R148

R144

S1

S2

ON

OFF

112

R1

DS1

DS2

DS3

DS4

DS5

DS6

DS7

DS8

Current Feedback

Scaling Switch

Configuration Switch

Offset

Overtemperature (red)

Power Factor (red)

Control Power (red)

Overvoltage (red)

Undervoltage (yellow)

Current Foldback (yellow)

Run Enable (green)

Drive Ready (green)

5-30

120

TB2

I/O Signals

Page 33

Chapter 5

Inputs, Outputs and Adjustments

Potentiometer Adjustments Preliminary adjustment of the Logic Control Board potentiometers is

required as explained below. Descriptions of the potentiometers follow.

Initially the potentiometers shall be set as shown in Table 5.A. See

Figure 5.2 for potentiometer locations.

T able 5.A

Initial Potentiometer Settings

Potentiometer

Current Limit (R148)

Velocity Gain (R144)

Offset (R1) and Scale

(R132)

Setting

10

4

Leave at the present setting until adjustment

becomes necessary in the Start-Up Procedure.

Current Limit (R148)

This single turn potentiometer adjusts the maximum current available to

the servomotor when TB2-5 is grounded. The maximum setting is 300% of

the motor rating or twice the continuous rating of the controller, whichever

is lower. The pot can be calibrated (fine tuned) using TP21 and the

proportion: 3V DC=100% continuous motor current.

Velocity Gain (R144)

This potentiometer is used to fine tune the response characteristics of the

system. Clockwise rotation increases the dynamic gain of the servo

amplifier, while counterclockwise rotation decreases gain. When used in

conjunction with the integral gain switch, the system response can be

adjusted over a wide range.

Offset (R1)

Adjustment for the system offset voltages is provided by this multi-turn

pot.

Velocity Command Scale (R132)

This adjustment is a multi-turn pot that scales the command signal with the

velocity feedback signal.

5-31

Page 34

Chapter 5

Inputs, Outputs and Adjustments

Switch Settings This section provides information on setting the Duty Cycle Selector

switch (SW1), Current Scaling switch (S1), configuration switches (S2)

and the A Quad B Encoder Output switch (S3). Refer to Figure 5.2 for

switch locations. Note that the settings for 1326AP motors are the same as

1326AB motors.

Duty Cycle Selector Switch - SW1

The Duty Cycle Selector Switch (SW1) which is located on top of the

controller, modifies the behavior of the shunt regulator. The switch

determines the temperature level and therefore the average power level at

which the controller will fault. Refer to Chapter 9 for detailed switch

setting information.

Current Feedback Scaling Switch - S1

The 1391B-ES employs a current feedback scaling circuit which allows a

controller to be used with 1326 AC Servomotors having lower current

ratings.

Tables 5.B and C provide the information necessary to correctly set the

current feedback scaling using switch S1. Table 5.B provides general

information on switch settings for typical motor / controller combinations.

Table 5.C provides examples of switch settings for specific 1326 AC

Servomotors. Refer to the motor nameplate for actual rated current (I

is

C

continuous current rating in amperes).

Important: The motor and controller rated current (as listed on their

respective nameplates) should be noted and the correct adjustment of

switch S1 made prior to applying power to the system.

Set S1 to a position equal or nearest to the rated motor current. One setting

higher must be used if the motor current is between current ratings. Once

the current feedback scaling is set, the current limit and peak current

capabilities will be a function of the motor current rating and not the

controller current rating.

5-32

Page 35

T able 5.B

T ypical Current Feedback Scaling

Motor Rated

1391B-ESAA1

5

15.0

14.1

13.1

12.2

11.3

10.3

9.4

8.4

7.5

6.6

5.6

4.7

3.8

2.8

1.9

0.9

Current

1391B-ESAA2

2

22.5

21.1

19.7

18.3

16.9

15.5

14.0

12.6

11.3

9.8

8.5

7.0

5.7

4.2

2.8

1.4

Chapter 5

Inputs, Outputs and Adjustments

1391B-ESAA4

5

45.0

42.2

39.4

36.6

33.8

30.9

28.1

25.3

22.5

19.7

16.9

14.1

11.3

8.4

5.6

2.8

S1 Switch Setting

F

E

D

C

B

A

9

8

7

6

5

4

3

2

1

0

T able 5.C

T ypical Scaling for 1326 AC Servomotors

Motor Catalog

Number

1326AB-A1E

1326AB-A2E

1326AB-A3E

1326AB-B1C

1326AB-B1E

1326AB-B2C

1326AB-B2E

1326AB-B3C

1326AB-B3E

1326AB-B4E

1326AB-C1C

1326AB-C1E

1326AB-C2C

1326AB-C2E

1326AB-C3C

1326AB-C3E

1326AB-C4B

1326AB-C4C

1326AD-K2G

1326AD-K3G

1326AD-K4F

1326AD-K5E

2

I

C

2.6

5.2

7.8

5.7

8.2

11.4

16.4

(A)

1391B-ESAA1

5

2

5

8

6

8

C

17.0

24.6

35.7

11.7

16.6

C

23.3

33.2

34.4

49.1

38.2

46.6

4.8

4.9

4.9

4.8

5

5

5

5

1

For reference only. Refer to motor nameplate for rated current value.

2

Settings for 1326AP and 1326AB AC motors are identical. If using blower, increase the motor

rated current by 35% and set S1 accordingly.

S1 Switch Setting

1391B-ESAA2

2

1

3

5

4

5

8

B

C

8

B

3

3

3

3

1

1391B-ESAA4

5

5

6

8

C

5

8

B

C

F

D

F

5-33

Page 36

Chapter 5

Inputs, Outputs and Adjustments

Configuration Switch - S2

Prior to start-up, the switch positions of S2 must be checked against the

listing in Table 5.D to ensure proper setting. Refer to the paragraphs

following the table for switch descriptions.

ATTENTION: Only personnel familiar with the 1391B-ES

!

controller and its associated machinery should plan or

implement the adjustment, calibration, start-up and subsequent

maintenance of the controller. Failure to comply may result in

personal injury and/or equipment damage.

ATTENTION: An incorrectly applied or calibrated controller

!

can result in component damage or a reduction in product life.

Wiring or application errors, such as, undersizing the motor,

incorrect or inadequate AC supply, or excessive ambient

temperatures may result in malfunction of the controller.

Switch

S2-1

S2-2

S2-3

S2-4

S2-5

S2-6

S2-7, 8

S2-9, 10

S2-11, 12

Function

Tachometer Scaling

Cut In

I

D

Magnitude

I

D

Drive OK / Drive

Ready

Torque Block / Velocity Loop Operation

Velocity Loop

Compensation

Error Amp Gain

Tachometer Filter

Staircase Filtering

T able 5.D

S2 Switch Descriptions (* Denotes factory setting for 1326AB motors)

Description/Setting

ON 1.2V / krpm 1326AB-Axx and 1326AD motors

OFF 2.0 / krpm 1326AB-Bxx & 1326AB-Cxx motors up to 4000 rpm*

See Table 5.E

ON 1326AB motors*

OFF 1326AD motors

ON DROK closes if no faults are detected and the bus voltage is up*

OFF DROK closes if no faults are detected, with or without bus voltage

ON Torque block operation

OFF Velocity loop operation*

ON Reduces integral gain (bandwidth) for high inertia systems

OFF Normal gain*

Reduces velocity loop gain when running 1326AD motors

S2-7

OFF OFF None*

OFF ON 33%

ON OFF 33%

ON ON 50%

Additional filtering in tach feedback circuit for mechanical resonances, etc.

S2-9

OFF OFF 430 Hz*

OFF ON 284 Hz

ON OFF 204 Hz

ON ON 165 Hz

Introduces additional filtering to the velocity command from positioning controller to

minimize staircasing effects from the DAC output

S2-11

OFF OFF – *

OFF ON 159 Hz

ON OFF 159 Hz

ON ON 79 Hz

S2-8 Gain Reduction

S2-10 Filter Bandwidth

S2-12 Filter Bandwidth

5-34

Page 37

Chapter 5

Inputs, Outputs and Adjustments

Tachometer Scaling (S2-1)

Switch S2-1 is used to configure the 1391B-ES tachometer synthesis

circuitry to a range appropriate for the applied motors. Select the “ON”

position for 1326AD and 1326AB-Axx motors and speeds to 6000 rpm.

“OFF” is used for 1326AB-Bxx and Cxx motors to 4000 rpm.

ID Cut In (S2-2)

This switch sets the ID cut in speed. ID is a phase specific current added to

the torque producing current at higher speeds to extend the performance

range of the controller. The ID point differs with the motor used. Refer to

Table 5.E for switch settings. For motors not listed, consult your

Allen-Bradley Sales Representative.

T able 5.E

S2-2 Switch Positions

Motor Catalog

Number

1326AB-A1E

1326AB-A2E

1326AB-A3E

1326AB-B1C

1326AB-B1E

1326AB-B2C

1326AB-B2E

1326AB-B3C

1326AB-B3E

1326AB-B4E

1326AB-C1C

1326AB-C1E

1

1

Settings for 1326AP and 1326AB AC motors are identical. If using blower, increase the motor

rated current by 35% and set S1 accordingly.

S2-2 Switch

Setting

ON

ON

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

Motor Catalog

Number

1326AB-C2C

1326AB-C2E

1326AB-C3C

1326AB-C3E

1326AB-C4B

1326AB-C4C

1326AD-K2G

1326AD-K3G

1326AD-K4F

1326AD-K5E

1

S2-2 Switch

Setting

OFF

ON

OFF

ON

OFF

OFF

OFF

OFF

OFF

OFF

ID Magnitude (S2-3)

This switch is used to identify the type of motor being used. Set the switch

to “ON” to signify a 1326AB motor and “OFF” for a 1326AD motor.

Drive OK/Drive Ready (S2-4)

This switch causes the DROK contacts to close under different

circumstances.

If the switch is set to “ON,” the contact will close if no faults are detected

and the bus voltage is nominal. An undervoltage condition will cause the

DROK contacts to open.

If the switch is placed to the “OFF” position, the contacts will close once

the undervoltage condition clears. Bus undervoltage will not effect the

DROK contacts.

5-35

Page 38

Chapter 5

Inputs, Outputs and Adjustments

Torque Block/Velocity Loop Operation (S2-5)

Switch S2-5 is used to disable the velocity error amplifier to configure the

controller for torque block operation. In torque block mode the controller

acts as a current amplifier producing current (torque) proportional to the

command present at terminals 15 and 16 of TB2. Note that the Command

Scale and Velocity Loop Gain potentiometers (R132 & R144) have no

effect in the torque block mode. Scaling for torque block is ±3V

Command=100% of the S1 Current Setting (i.e. motor rated current). Place

switch S2-5 to the “ON” position for torque block operation and “OFF” for

velocity loop operation.

Velocity Loop Compensation (S2-6)

This switch is used to compensate the velocity loop for applications with

higher load inertia. Position the switch to “ON” for high inertia

compensation. High inertia compensation will generally improve

performance on systems with load inertias greater than three times motor

rotor inertia, although the user may wish to evaluate the impact of this

compensation at slightly lower inertias.

Error Amp Gain (S2-7, 8)

1326AD motors require less gain on the velocity loop. Switches S2-7 and 8

reduce the gain by a fixed percentage. If both switches are “OFF,” there is

no gain reduction. If either switch is ON, the gain will be reduced by 33%.

If further gain reduction is required, both switches should be placed to

“ON,” which provides a 50% reduction.

Tachometer Filter (S2-9, 10)

If the motor/tach is operating in a mechanically noisy system, additional

tach filtering may be necessary. These switches offer four levels of

filtering. Filter bandwidth can be decreased from 430 Hz. to 165 Hz. using

the switch settings described in Table 5.D.

Staircase Filtering (S2-11, 12)

These switches provide additional filtering to minimize “staircasing” of the

DAC output from the position loop controller. Three levels of velocity

command filtering are available as shown in Table 5.D.

A Quad B Encoder Output Switch - S3

S3 selects the line count that will be output from the A Quad B Board.

5-36

ATTENTION: Incorrect setting of S3 can cause erratic and/or

!

improper machine motion which may result in personal injury

or equipment damage. Assure that switch S3 has been properly

set as shown in Figure 5.3.

Page 39

Figure 5.3

A Quad B Board Switch (S3) Settings

Chapter 5

Inputs, Outputs and Adjustments

– ON –

S3

21

2 Marker Pulses per

Revolution

CCW Rotation of Motor Shaft

(similar to Allen-Bradley

845H)

Line

Count/

Revolution

2048

1024

512

256

A (NOT)

B (NOT)

Z (NOT)

S3-2

Switch Setting

OFF

OFF

ON

ON

A

B

Z

S3-1

Switch Setting

OFF

ON

OFF

ON

When using the A Quad B option with Allen-Bradley IMC motion

controllers, the AMP parameters will be set according to the line count

selected. In general, one parameter must be justified when using this

device. The normal line counts per cycle of the encoder must be divided

by two since the controller will see two markers per cycle.

Example (using an IMC 120 Controller)

With switch S3 set to 1024 lines per revolution (S3-2 OFF, S3-1 ON), the

lines per cycle of the position feedback device (located in the Feedback

Parameters File) must be 2048.

1024 x 4 = 4096 / 2 = 2048

Lines/Revolutio

n

(Quadrature)

2

Markers/Revolution

5-37

Page 40

Chapter

6

Installation

Chapter Objectives Chapter 6 provides the information needed to mount and wire the

1391B-ES Servo Controller for operation. Since most start-up difficulties

are the result of incorrect wiring, every precaution must be taken to assure

that the wiring is done as instructed. All items must be read and

thoroughly understood before the actual installation begins.

ATTENTION: The following information is merely a guide for

!

proper installation. The National Electrical Code and any other

governing regional or local code will overrule this information.

The Allen-Bradley Company cannot assume responsibility for

the compliance or the noncompliance to any code, national,

local or otherwise for the proper installation of this controller or

associated equipment. A hazard of personal injury and/or

equipment damage exists if codes are ignored during

installation.

Mounting Mounting dimensions for the 1391B-ES Servo Controller can be found in

Appendix A. Chapter 2 provides information on power dissipation and

environmental specifications. The controller must be located on a flat,

rigid, vertical surface and must not be subjected to shock, vibration,

moisture, oil mist, dust, corrosive vapors, etc. or temperatures that exceed

60° C (140° F) ambient.

Controllers can be mounted adjacent to each other with a minimum

clearance of 0.312” (7.9mm) between units and/or surrounding cabinetry

and non-current carrying surfaces. However, it is recommended that a

space of approximately 1.0” (25.4mm) be left between adjacent units to

allow easy access and removal of the front cover. To allow for proper

airflow, a minimum clearance of 3.0” (76.2mm) is required along the top

and bottom of the unit and any adjacent components.

The transformer that supplies 230V AC, three-phase and 36V AC to each

servo controller must have 3” (76.2mm) of clearance around it and any

adjacent components. This will allow for proper airflow and wiring access.

The transformer can be mounted in either a horizontal or vertical position.

6-38

Page 41

ATTENTION: The installation of the controller must be

!

Wiring Recommendations General Information

The information supplied in this manual on wire sizes, practices, layouts,

system configurations and grounding/shielding techniques for the

1391B-ES Servo Controller are presented as guidelines. Due to the

diversity of applications and systems, no single method of wiring is

completely applicable.

planned such that all cutting, drilling, tapping and welding can

be accomplished with the controller removed from the

enclosure. The controller is of the open type construction and

any metal debris must be kept from falling into it. Metal debris

or other foreign matter may become lodged in the circuitry

resulting in component damage.

Chapter 6

Installation

Important: This information represents common PWM servo system

wiring configurations, size and practices that have proven satisfactory in a

majority of applications. The National Electrical Code, local electrical

codes, special operating temperatures, duty cycles or system configurations

will take precedence over the values and methods listed.

Wire Sizes

Unless noted, the wire sizes in this manual are recommended minimums

and assume type MTW wire (machine tool wire, 75° C, minimum) per

NFPA 79. Since ambient conditions vary widely, on certain applications, a

derating factor has to be taken into account. Also, wiring to controllers or

motors exceeding 50 feet (15.2 meters) in length (total includes to and