Page 1

1391-DES Digital

AC Servo Drive

User Manual

Page 2

Important User Information Because of the variety of uses for this equipment and because of the

differences between this solid-state equipment and electromechanical

equipment, the user of and those responsible for applying this equipment

must satisfy themselves as to the acceptability of each application and use

of the equipment. In no event will Allen-Bradley Company be responsible

or liable for indirect or consequential damages resulting from the use or

application of this equipment.

The illustrations shown in this manual are intended solely to illustrate the

text of this manual. Because of the many variables and requirements

associated with any particular installation, the Allen-Bradley Company

cannot assume responsibility or liability for actual use based upon the

illustrative uses and applications.

No patent liability is assumed by Allen-Bradley Company with respect to

use of information, circuits or equipment described in this text.

Reproduction of the content of this manual, in whole or in part, without

written permission of the Allen-Bradley Company is prohibited.

This information in this manual is organized in numbered chapters. Read

each chapter in sequence and perform procedures when you are instructed

to do so. Do not proceed to the next chapter until you have completed all

procedures.

ATTENTION: Identifies information about practices or

circumstances that can lead to personal injury or death, property

!

damage or economic loss.

Attentions help you:

• identify a hazard

• avoid the hazard

• recognize the consequences

IMPORTANT: Identifies information that is especially important for

successful application and understanding of the product.

Page 3

Summary of Changes

Summary of Changes

Summary of Manual Changes This release of the 1391-DES User Manual contains some new and updated

information. The new and updated information is summarized in the table

below. For further information, refer to the page numbers provided.

Description of New or Updated Information Page Type

Linear Accel/Decel information added 1-4 New

Speed Regulation specification added 2-1 New

Torque Plus Motor, Gearbox & Cable info 3-4, 7, 8 New

Important statement added to TB1 5-1 New

Bus voltage info added to shunt resistor 5-4 New

Important statement added 5-7 Clarification

Parameter 69 name change 6-14 Update

Parameter 170 maximum value updated 6-18 Update

Parameter 199 updated 6-20 Update

Encoder Wiring 7-5 Clarification

Torque Plus info added to step 11 8-3 New

Torque Plus info added (steps 30, 31) 8-7 New

Figure 8.1 updated 8-10 Update

Linear Accel/Decel information added 8-11 New

Torque Plus data added 9-3 New

#4 added to Auto Tune Fault 11-7 Update

TP50 description updated 11-10 Update

Enclosure items list A-3 New

Interconnect drawings updated & added App. B Update

1-4

Page 4

Chapter

Introduction

Manual Objectives This manual is meant to guide the interface, installation, programming and

troubleshooting of a 1391-DES Digital AC Servo Drive. The contents are

arranged in order from a general description of the drive to troubleshooting

and maintenance. To assure successful installation and operation, the

material presented must be thoroughly read and understood before

proceeding. Particular attention must be directed to the Attention and

Important statements contained within.

Important Information about this Manual

This manual has been prepared primarily to support this product in a single

drive application. It is a standard document that is intended to help the user

understand the individual operating characteristics and limitations of this

equipment including hazards associated with installation, programming and

maintenance procedures. Note the following points:

• This equipment has been designed to meet the requirements of a

component drive in an integrated drive system.

• While the potential hazards associated with the drive remain the same

when used in a system environment, it must be noted that special

considerations are to be given to characteristics of other peripheral

solid-state control equipment and the cumulative impact on safety.

• Manufacturers and engineering groups responsible for specification or

design of electrical control equipment must refer to applicable industry

standards and codes for specific safety guidelines and interface

requirements.

• In the actual factory environment, the user is responsible to ensure

compliance with applicable machine and operator safety codes or

regulations which are beyond the scope and purpose of this document.

1-5

Page 5

Chapter 1

Introduction

General Precautions In addition to the precautions listed throughout this manual, the following

statements which are general to the drive must be read and understood.

ATTENTION: Only personnel familiar with the 1391-DES

!

!

!

Digital Servo Drive and associated machinery should plan or

implement the installation, start-up and subsequent maintenance

of the drive. Failure to comply may result in personal injury

and/or equipment damage.

ATTENTION: An incorrectly applied or installed drive can

result in component damage or a reduction in product life.

Wiring or application errors, such as, undersizing the motor,

incorrect or inadequate AC supply, or excessive ambient

temperatures may result in malfunction of the drive.

ATTENTION: This drive contains ESD (Electrostatic

Discharge) sensitive parts and assemblies. Static control

precautions are required when installing, testing, servicing or

repairing this assembly. Component damage may result if ESD

control procedures are not followed. If you are not familiar with

static control procedures, reference Allen-Bradley publication

8000-4.5.2, Guarding Against Electrostatic Damage or any

other applicable ESD Protection Handbook.

Certification Notice: In order to maintain UL listing on Allen-Bradley

1391-DES Digital Servo Drives, the user must

Isolation Transformer. Use of any other transformer voids the UL listing.

The user is responsible for providing motor overload protection in

accordance with the National Electrical Code (NEC), and any other local

codes that may apply.

provide power from a 1391

Drive Description The 1391-DES Pulse Width Modulated Digital Servo Drive is a digital and

programmable single axis, AC servo drive. It has been packaged to require

a minimum amount of panel space while containing, as standard, a number

of features required by the machine tool and automated equipment

industries.

The 1391-DES allows Allen-Bradley 1326 AC servomotors to be operated

from 33% to 50% over their rated speed. This can help achieve greater

precision, a finer finished product and increased production from existing

machinery.

1-6

Page 6

Chapter 1

Introduction

The 1391-DES is generally used with computer aided, closed loop

positioning systems such as Allen-Bradley “S” Class or IMC products.

These systems control the position and linear or rotary motion of various

machine members on an automated machine. To enhance system reliability,

the 1391-DES has an encoder output (AQB) that produces four channels of

2048, 1024, 512 or 256 lines and two marker pulses per motor revolution

which feeds position information to the position controller.

All components are mounted in an open framed package with a slide-on

front cover. The drive is intended to be panel mounted in an enclosure and

ventilated with filtered and/or cooled air. An internal fan is included to

circulate air over the power heat sink.

The 1391-DES converts a three-phase, 50/60 Hz input, to a variable AC

voltage with controlled phase, amplitude and frequency. The output which

is proportional to a user supplied analog command, regulates the speed

and/or current (torque) of a 1326 permanent magnet AC servomotor. The

drive is available in ratings of 15, 22.5 and 45A RMS with all package

sizes being identical. A 1391 Transformer, 1326 AC Servomotor and 1326

Cables complete the servo system.

Standard Features The 1391-DES contains a number of standard features required in a typical

automated machine servo system.

• Input protected against transient voltage.

• A power line/DB contactor which opens the AC line to the drive and

inserts a shunt regulator resistor across the DC bus whenever the

contactor is de-energized.

• An integral circuit breaker which will open all three AC line leads in the

event of a short circuit condition in the power circuitry.

• A standard 300V DC power bus supply that includes an integral shunt

regulator.

• A shunt regulator resistor to dissipate the energy generated by the motor

during regenerative braking.

• Prompted startup procedure to shorten setup time.

• Two line LCD display and programming panel.

• Patented current control implementation.

• Torque feedforward differential input.

• Microprocessor based logic boards that can be quickly removed and

easily interchanged for troubleshooting and diagnostics.

• Three drive ratings that are in the same physical package and have

identical mounting dimensions.

• True vector control.

• Up to 600 feet (183 meters) between drive and motor.

1-7

Page 7

Chapter 1

Introduction

Options/Modifications The 1391-DES contains most functions needed in a servo system.

The following are selectable at the user’s option:

• Contactor Auxiliary Switch

Two N.O. (normally open) contacts are mounted on the main power

contactor and wired to the power terminal block. These contacts can be

used in a motor brake control circuit or as an indicator that the contactor

has closed.

• Current or Torque Amplifier Operation

When the velocity loop is being closed as part of the position control

system, the drive can be configured to operate as a current or torque

amplifier by selection on the programming panel.

• External Shunt Regulator Resistor

On 15 and 22.5A drives an internal power resistor that is part of the DC

bus voltage shunt regulator can dissipate 162 watts continuous power.

Some applications such as an overhauling load have excessive

regenerative energy to dissipate. For these applications, an external

shunt regulator resistor rated at 386 watts continuous can be supplied for

user mounting on 22.5A drives. This is selectable by removing the

jumper on TB5 and using an external resistor. The shunt has integral

fusing accessible from the outside of 15 and 22.5A drives. The 45A

drive has an externally mounted resistor and fuse.

Important: An external shunt regulator resistor is included as standard

equipment on 45A units. An additional unit is not required.

• Tach Output

A voltage equal to 1.2V DC/1000 RPM is available at TB2.

• Torque or Current Monitor

A voltage equal to 3.0V DC=100% scaled current is available at TB2.

• Anti-Backlash

Anti-backlash control can be implemented with several software

parameters and an additional instruction manual. Contact your local

Allen-Bradley Sales Office for details.

• Linear Accel/Decel

Linear accel/decel can be set using the CR-APG-001 Control Module.

This module provides a manually generated trapezoidal velocity profile

for up to four preset speeds.

Important: The 1391-DES contains one accel/decel rate which can be

used if accel/decel times will be the same.

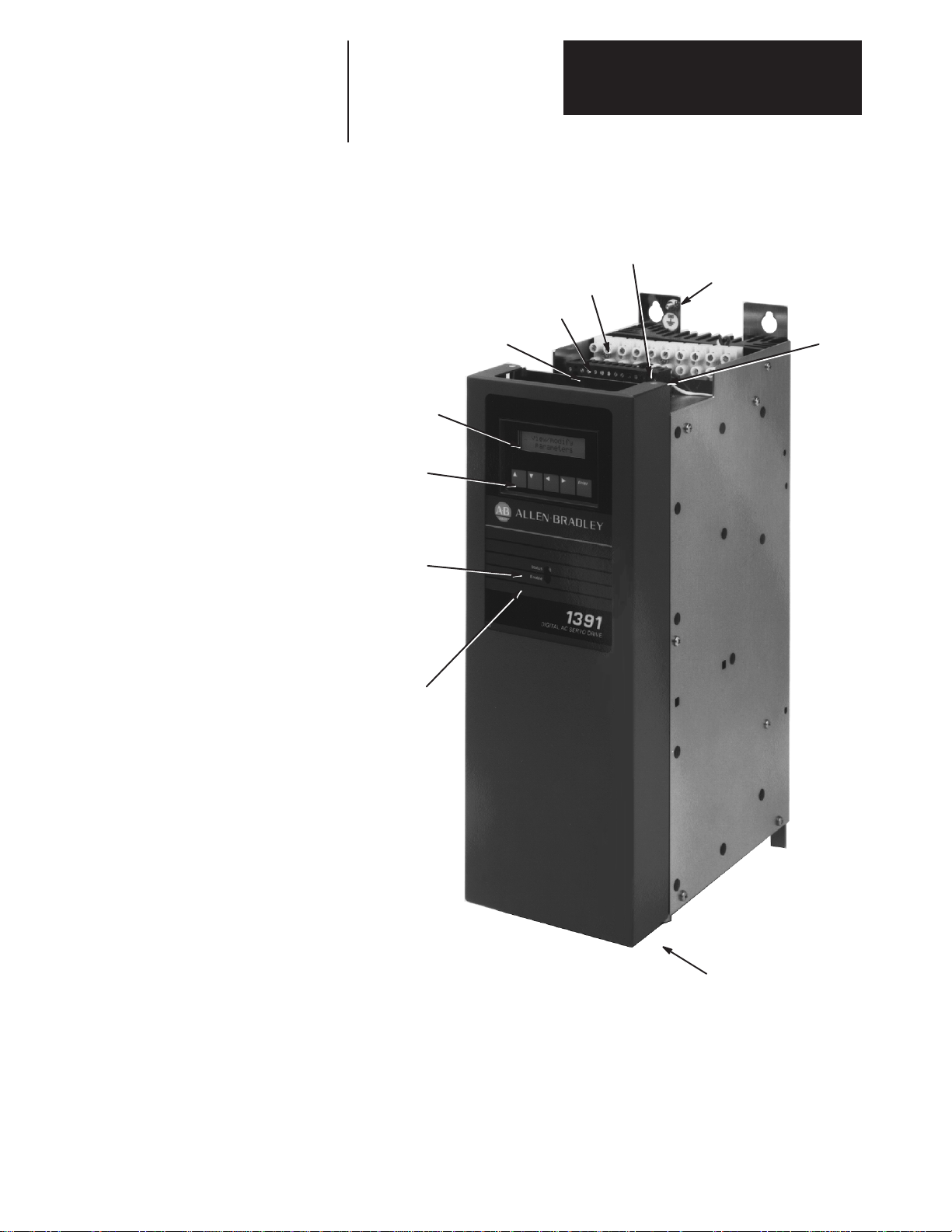

Drive Layout Figure 1.1 provides an exterior view of the 1391-DES AC Servo Drive,

showing accessibility of various components.

1-8

Page 8

Figure 1.1

1391-DES Digital AC Servo Drive

Duty Cycle Selector Switch

TB5 – Power Connections

TB4 – Control Signals

Chapter 1

Introduction

Ground Stud

2 Line, 16 Character

LCD Display

5 Button Keypad used

for Programming

Status LED

- Flashes green when no faults are

present and the bus is low.

- Steady green when no faults are

present and bus voltage is OK.

- Flashes red when a fault has

occurred.

Enable LED

- Steady green when Enable input is

closed at TB2-9 & 10.

- Not illuminated when Enable input

is open.

Circuit Breaker

Fuses

TB2 – Interface Signals

TB3 – A Quad B Encoder Output Signals

1-9

Page 9

Chapter 1

Introduction

End of Chapter

1-10

Page 10

Chapter

Specifications

Chapter Objectives Chapter two contains the electrical and environmental specifications for the

1391-DES. Dimensions are provided in Appendix A.

Drive Specifications The general specifications of the 1391-DES are provided in the listing

below. The specifications are divided when necessary for the various drive

ratings.

Specific Drive Ratings 1391-DES15 1391-DES22 1391-DES45

Nominal Bus Voltage 300V DC 300V DC 300V DC

Continuous Current (RMS) 15A 22.5A 45A

Peak Current (RMS) 30A 45A 90A

Continuous Power Output 5.0 kW 7.5 kW 15.0 kW

Peak Power Output 10.0 kW 15.0 kW 30.0 kW

Input Circuit Breaker Rating 17A RMS 26A RMS 38A RMS

Circuit Breaker Interrupt Rating

(Symmetrical Amperes) 1300A 1300A 1300A

Unit Weight in lbs. (kg) 22 (9.97) 28 (12.69) 34 (15.40)

All Drive Ratings

Static Gain (A/RMS) 1.5 x Rated Motor Current / rpm (typical)

Form Factor 1.03 or less

Peak Current Limit Adjust 20 to 300% of Rated Motor Current or 2 x Continuous Rating of

Drive (max.), whichever achieves Drive Peak Current Rating first

Drive Efficiency 85% (Minimum at Rated Load)

Power Factor 95% Minimum

Modulation Frequency 2500 Hz ±10%

Drift (Referred to Tach) 0.07 rpm /Degrees C. Maximum

Speed Regulation 0 to 0.05% of Maximum Motor Speed with 95% Load Change

Ambient Temperature 0 to 60° C (32 to 140° F)

Storage Temperature 0 to 65° C (32 to 149° F)

Input Voltage (from Transformer) Power: 230V AC +10%/–15%, Three-Phase, 50/60 Hz ±3 Hz

Control: 36V AC, Single-Phase

Transformer Input Tolerance +10%, –15%

Relative Humidity 5 to 95% Non-Condensing

Deadband Zero

Altitude 1000 meters (3300 feet)

Integral Fan Output 50 CFM (Unloaded)

Max. RMS Short Circuit Current 1300A (Symmetrical Amperes)

Certifications UL Listed - File No. E59272, CSA Certified - File No. LR32334-548,

Specifications are for reference only and are subject to change without notice.

2-1

Page 11

Chapter 2

Specifications

Environmental Specifications The 1391-DES must be mounted in an enclosure that is clean, dry and

ventilated by filtered or cooled air. Enclosures vented with ambient air

must have appropriate filtering to protect against contamination caused by

oils, coolants, dust, condensation etc. The ambient air temperature must be

kept between 0 to 60° C (32 to 140° F) and the humidity between 5 and

95%, non-condensing.

The 1391-DES is equipped with an integral cooling fan. The general flow

of air through the unit must be maintained by following the recommended

spacing guidelines found in Chapter 7. The 1391-DES can operate at

elevations to 3300 feet (1000 meters) without derating, however, the

current rating must be derated by 3% for each additional 1000 feet (305

meters) up to 10,000 feet (3050 meters). Consult with your local

Allen-Bradley Sales Representative prior to operation over 10,000 feet

(3050 meters).

Drive Power Dissipation The 1391-DES dissipation characteristics are approximated in Table 2.A.

Table 2.A

Drive Power Dissipation

Rated Power Output

(%)

20

40

60

80

100

1391-DES15

(watts)

38

76

114

152

190

1391-DES22

(watts)

55

110

165

220

275

1391-DES45

(watts)

104

208

312

416

520

Transformer Power Dissipation The power dissipation characteristics of the 1391 Isolation Transformer are

shown in Table 2.B.

Table 2.B

1391 Isolation Transformer Power Dissipation

Rated Power Output

(%)

20

40

60

80

100

1.5kVA

(watts)

13

25

38

50

60

3.5kVA

(watts)

35

70

105

140

175

5.0kVA

(watts)

50

100

150

200

250

10.0kVA

(watts)

100

200

300

400

500

12.5kVA

(watts)

125

250

375

500

625

15.0kVA

(watts)

150

300

450

600

750

2-2

Important: Power Dissipation figures shown are for use in calculating

cumulative system heat dissipation to ensure ambient temperature inside

enclosure does not exceed 60° C (140° F).

Page 12

Chapter

Receiving, Unpacking and Inspection

Chapter Objectives Chapter 3 provides the information needed to unpack, properly inspect and

if necessary, store the 1391-DES and related equipment. The section entitled Inspection provides a complete explanation of the 1391-DES catalog numbering system.

Receiving It is the responsibility of the user to thoroughly inspect the equipment

before accepting the shipment from the freight company. Check the item(s)

received against the purchase order. If any items are obviously damaged, it

is the responsibility of the user not to accept delivery until the freight agent

has noted the damage on the freight bill. Should any concealed damage be

found during unpacking, it is again the responsibility of the user to notify

the freight agent. The shipping container must be left intact and the freight

agent should be requested to make a visual inspection of the equipment.

Unpacking Remove all packing material, wedges, or braces from within and around

the drive. Remove all packing material from the cooling fans, heat sink etc.

Important: Before the installation and start-up of the drive, a general

inspection of mechanical integrity (i.e. loose parts, wires, connections,

packing materials, etc.) must be made.

Inspection After unpacking, check the item(s) nameplate catalog number against the

purchase order. An explanation of the catalog numbering system is

included on the following pages as an aid for nameplate interpretation.

Storing The drive should remain in its shipping container prior to installation. If the

equipment is not to be used for a period of time, it must be stored

according to the following instructions:

• Store in a clean, dry location.

• Store within an ambient temperature range of 0 to 65° C (32 to 149° F).

• Store within a relative humidity range of 5% to 95%, non-condensing.

• Do not store equipment where it could be exposed to a corrosive

atmosphere.

• Do not store equipment in a construction area.

3-1

Page 13

Chapter 3

Receiving, Unpacking and Inspection

Isolation Transformer

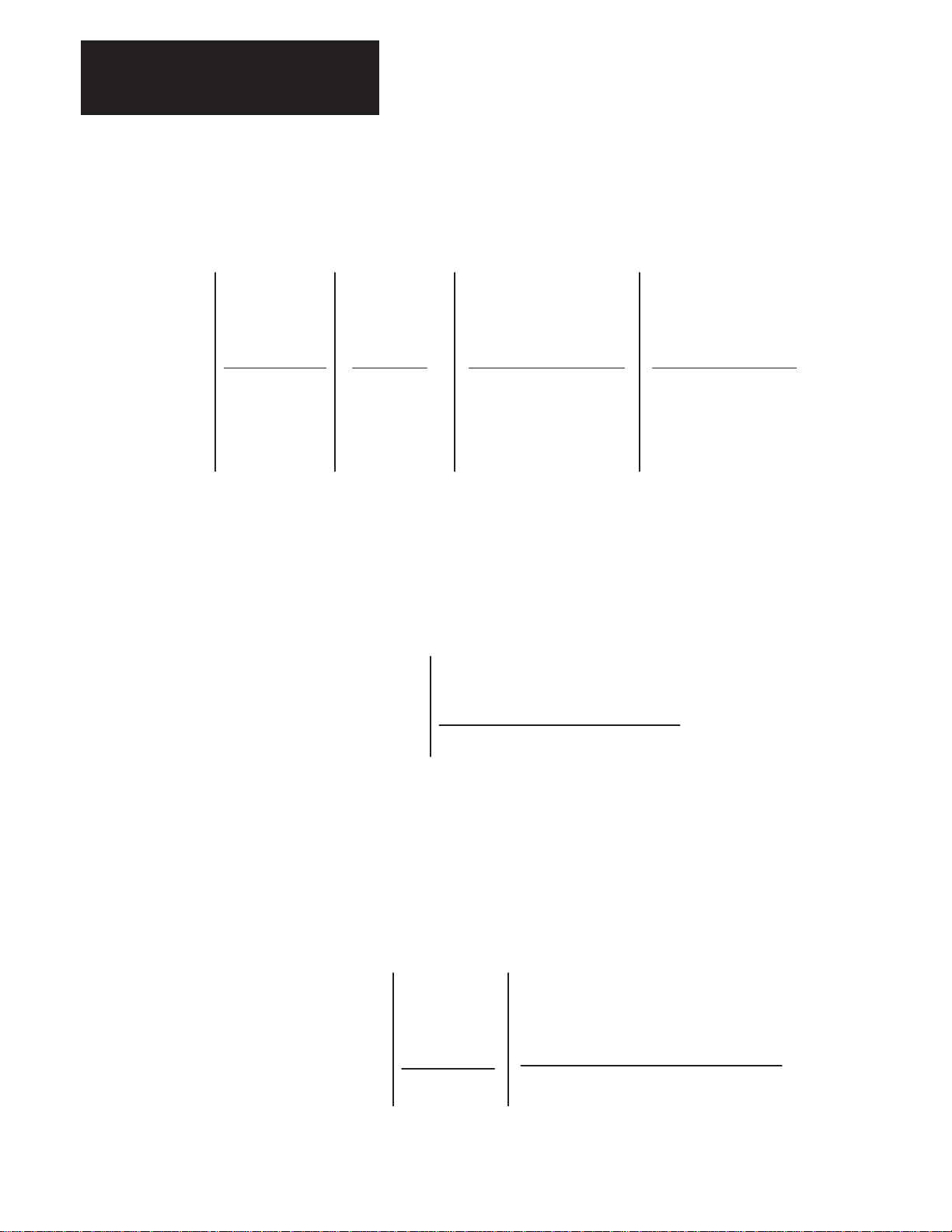

1391 T

First Position Second Position Third Position

Bulletin

Number

–

Type

Description

Letter

Transformer

T

Open Core

and Coil

015

kVA Rating

Number

015

035

050

100

125

150

kVA

1.5

3.5

5.0

10.0

12.5

15.0

NEMA Type 1 Transformer Enclosure Kit

1391

Bulletin

Number

Fourth Position

Primary Voltage

& Frequency

Letter

D

E

N

TA2–

Accessory

Module

D

Description

240/480V AC, ThreePhase, 60 Hz

240/380/415/480V AC,

Three-Phase, 50/60 Hz

208/230/460/575V AC,

Three-Phase, 60 Hz

T

Fifth Position

Secondary

Voltage

Description

Letter

230V AC, three-phase

T

and four 36V AC,

single-phase

C.T.windings

3-2

Description

Letter

Fits all kVA ratings on 1386, 1388,

TA2

1389 and 1391 Isolation Transformers.

External Shunt Regulator Resistor

1391 MOD SR22A

First Position Second Position Third Position

Bulletin

Number

1

Drive comes equipped with this resistor as standard. Catalog number is provided if spare or replacement is required,

–

Type

Code

MOD

Description

Modification Kit

–

Description

Code

SR22A

SR45A

Description

Shunt Regulator Resistor for 22.5A Drive

Shunt Regulator Resistor for 45A Drive

1

Page 14

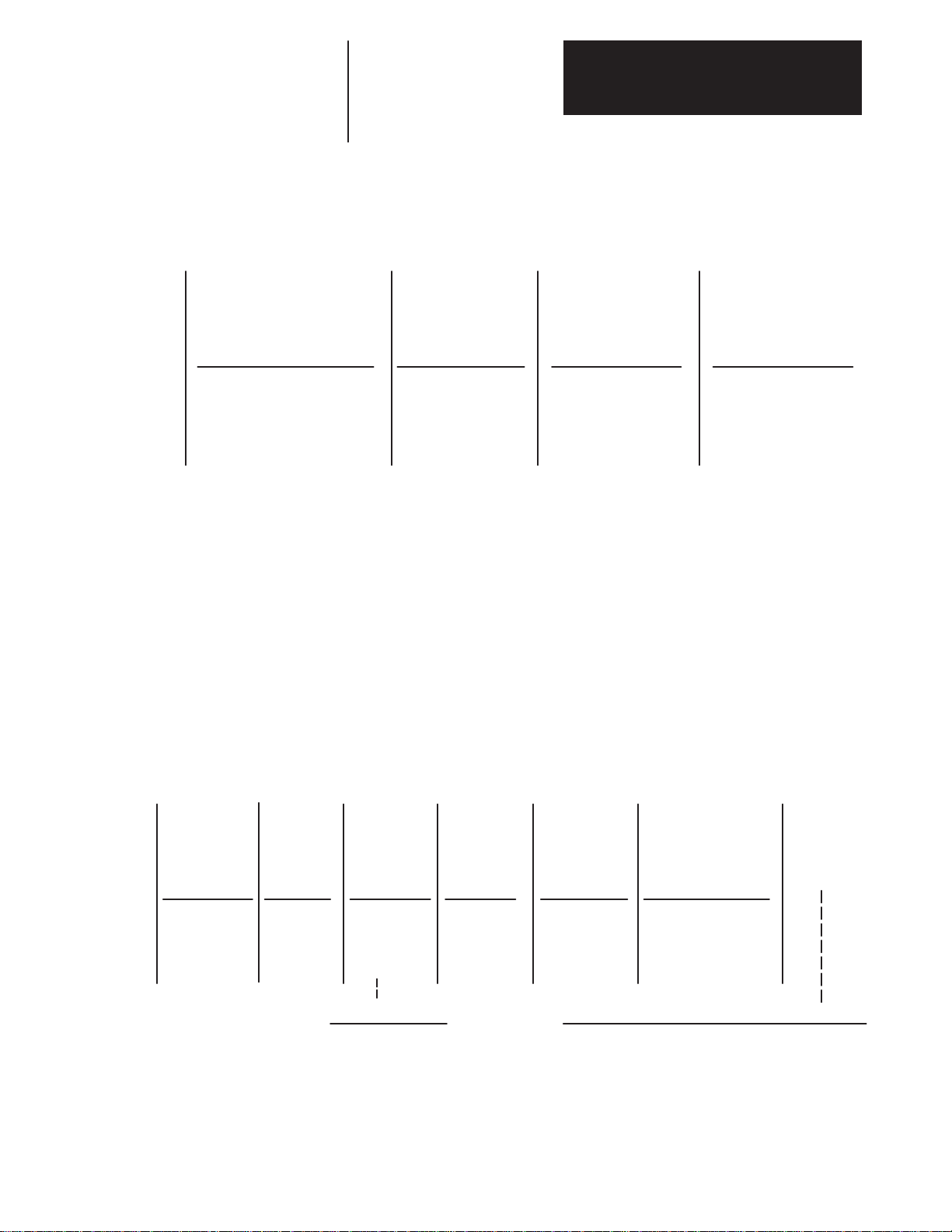

Bulletin 1391-DES Drive

Chapter 3

Receiving, Unpacking and Inspection

1391 DES15

First Position Second Position

Bulletin

Number

Configuration/

Current Rating

Code

DES15

DES22

DES45

Description

15A Continuous Current

22.5A Continuous Current

45A Continuous Current

–

Third Position

User

Interface

Code

DI

DI

Description

Includes Integral

Display

AQB–

Fourth Position

Output

Configuration

Description

Code

Encoder Output –

AQB

2048, 1024, 512,

256 selectable

pulses/motor

revolution

A––

Fifth Position

Options

Description

Letter

24V DC M contactor

A

coil voltage instead of

115V AC (available

on 22A drives only)

Blank

115V AC M contactor

coil voltage

1326AB Servomotor

1326 A 3

First Position Second Position Third Position

Bulletin

Number

Type

Letter

A

Description

AC

Servomotor

PM Type

Design

Description

Factory

use only

–

Fourth Position

Series

Description

Sequentially

lettered to

designate frame

diameters.

Description

Code

4.25” (108 mm)

A

5.88” (149 mm)

B

7.63” (194 mm)

C

Fifth Position

Motor

Length

Description

Sequentially

numbered to

indicate stack

length within a

given frame size.

E

Sixth Position

Max. Op.

2

Speed

RPM

Letter

1600/2000

B

2000/3000

C

3000/4000

E

5000/6000

G

Code

A4

A5

A7

K4

K5

K7

–

Description

72 lb.-in. (8.1 N-m) Holding Brake w/90V DC Coil.

120 lb.-in. (13.6 N-m) Holding Brake w/90V DC Coil.

360 lb.-in. (40.7 N-m) Holding Brake w/90V DC Coil.

72 lb.-in. (8.1 N-m) Holding Brake w/24V DC Coil.

120 lb.-in. (13.6 N-m) Holding Brake w/24V DC Coil.

360 lb.-in. (40.7 N-m) Holding Brake w/24V DC Coil.

11

Seventh Position

Mounting & Shaft

Description

Description

Code

NEMA Inch Combina-

11

tion Face/Flange with

Keyway

21

IEC Metric Flange

with Keyway

–BA

A4

Eighth Position

Standard

Options

2

Ratings shown indicate the rated speed and speed capability of the motor with the 1391-DES (rated/w 1391-DES).

3-3

Page 15

Chapter 3

Receiving, Unpacking and Inspection

1326AB Torque Plus Series Servomotor

1326 AB 30

First Position Second Position Third Position

Bulletin

Number

Type

Letter

AB

Description

Ferrite AC

Servomotor

–

Voltage

Code

A

Rating

230V AC

Fourth Position

Series

Description

Sequentially

lettered to

designate frame

diameters.

Description

Code

115 mm

4

166 mm

5

215 mm

7

Fifth Position

Motor

Length

Description

Sequentially

numbered to

indicate stack

length within a

given frame size.

Shaft Oil Seal Kit

E

Sixth Position

Max. Operating

Speed

Rated/1391-DES

Letter

1600/2000 rpm

B

2000/3000 rpm

C

3000/4000 rpm

E

5000/6000 rpm

G

Code

Description

A4

72 lb.-in. (8.1 N-m) Holding Brake w/90V DC Coil for 1326AB-A4

A5

120 lb.-in. (13.6 N-m) Holding Brake w/90V DC Coil for 1326AB-A5

A7

360 lb.-in. (40.7 N-m) Holding Brake w/90V DC Coil for 1326AB-A7

K4

72 lb.-in. (8.1 N-m) Holding Brake w/24V DC Coil for 1326AB-A4

K5

120 lb.-in. (13.6 N-m) Holding Brake w/24V DC Coil for 1326AB-A5

K7

360 lb.-in. (40.7 N-m) Holding Brake w/24V DC Coil for 1326AB-A7

–

21

Seventh Position

Mounting & Shaft

Description

Description

Code

IEC Metric

21

Flange with

Keyway

–A4

A4

Eighth Position

Standard

Options

3-4

1326AB MOD

First Position Second Position Third Position

Bulletin

Number

Type

Code

MOD

Description

Modification Kit

3

“A” Series motors with brake must use 1326AB-MOD-SSV-A2.

Bulletin

Number

SS V

–

Shaft

Seal

Brake Power Supply Rectifier

1326 MOD BPS

–

4

Up to 4 brakes per rectifier can be used.

Type

Code

MOD

Fourth Position

Material

Description

Letter

Viton

V

–

Description

Modification Kit

–

Description

Code

BPS

A

Fifth Position

Motor

Series

Letter

Standard

A

Series A

B

Series B

C

Series C

Description

Single-phase, full-wave, screw mount

rectifier. 115V AC input, for use with 90V DC

4

brakes.

Torque Plus

-A4

-A5

-A7

Use

Metric

Only

1–

Sixth Position

Motor

Mounting

Number

1

2

3

Description

Std. Inch

Metric

Page 16

Chapter 3

Receiving, Unpacking and Inspection

Motor Junction Box Kit

1326AB MOD RJAB

First Position Second Position Third Position

Bulletin

Number

5

The motor comes standard with IP65 plug style connectors mounted radially to the motor. This kit allows the

connectors to be brought out axially to the motor without further wiring. Kit includes Motor Junction Box and

Mounting Hardware.

–

Type Description

Description

Code

Modifica-

MOD

tion Kit

Feedback Mounting Adapter Kit

5

–

Code

Description

RJAB

For all AB-A & B Series Motors

(A4 & A5 Torque Plus Motors)

RJB

For all AB-B4 & Cx Series Motors

C

(A7 Torque Plus Motors)

6

1326AB MOD

First Position Second Position Third Position

Bulletin

Number

–

Type

Description

Code

Modifica-

MOD

tion Kit

Description

Code

A-B 845H/T Encoder for AB-A series motor (A4 Torque Plus)

M4

A-B 845H/T Encoder for AB-B series motor (A5 Torque Plus)

M5

A-B 845H/T Encoder for AB-C series motor (A7 Torque Plus)

M6

Type VC/VD 4.25” (108mm) Resolver for AB-B series motor (A5 Torque Plus)

M22

Type VC/VD 4.25” (108mm) Resolver for AB-C series motor (A7 Torque Plus)

M23

0.375” (9.5 mm) diameter heavy duty shaft extension adapter

M24

0.625” (15.9 mm) diameter heavy duty shaft extension for type VC/VD 4.25”

M25

(108 mm) resolver

Foot mounting kit for M25

M26

–

M4 C1

Mounting Adapter

Kit for . . .

–

Fourth Position

Coupling Size

for . . .

Code

C1

Blank

Motor Series

A, B, C (A4, A5, A7 Torque Plus)

For M22, M23, M24, M25, M26

6

All kits contain a feedback device mounting adapter and mounting hardware. M4, M5 and M6 include a

motor to encoder coupling. M22 and M23 do not include a coupling since it is included with the resolver

feedback device.

3-5

Page 17

Chapter 3

Receiving, Unpacking and Inspection

–

VC

7

Coupling

Size

–

Size

Code

C1

C2

Motor Shaft to Encoder Shaft

3/8” to 3/8” (9.5 mm to 9.5 mm) –

Standard on all 1326AB Motors

1/4” to 3/8” (6.4 mm to 9.5 mm)

Feedback Coupling

1326 MOD C1

First Position Second Position Third Position

Bulletin

Number

7

The feedback coupling is included as standard with all Feedback Mounting Adapter Kits.

1326AB MOD

First Position Second Position Third Position

–

–

Type

Description

Code

Modifica-

MOD

tion Kit

Resolver Feedback Package

–

1:1

Fourth Position

Bulletin

Number

Code

Description

VC

4.25” (108 mm) feedback package with cast

housing and single or vernier (dual) format with

receiver (Harowe 11BRW-300-F-58A or equivalent)

type resolver(s) for use with A-B series 8200 CNC

]

120, 121, 123.

and IMC

4.25” (108 mm) feedback package with cast

VD

housing and single or vernier (dual) format with

transmitter (Harowe 11BRCX-300-C10/6 or

equivalent) type resolver(s) for use with A-B series

8600, MAX and IMC S Class controllers with a

REC 4096 Board.

Type

Code

MOD

Description

Modification Kit

Resolver Feedback

Package

8

Code

Description

1:1

Single device format – 1 turn of the motor shaft to 1 turn of the resolver.

1:2

Single device format – 1 turn of the motor shaft to 2 turns of the resolver.

1:2.5

Single device format – 1 turn of the motor shaft to 2.5 turns of the resolver.

1:5

Single device format – 1 turn of the motor shaft to 5 turns of the resolver.

255

Absolute master/vernier format – 1:1 input/master, 255:256 master/vernier

for IMC 120, 121, 123 only.

256

Absolute master/vernier format – 1:1 input/master, 256:255 master/vernier

for 8600 series and MAX, IMC S class controls with a REC 4096 Board.

424

Absolute master/vernier format – 1:1 input/master, 424:425 master/vernier

for IMC 120, 121, 123 only.

425

Absolute master/vernier format – 1:1 input/master, 425:424 master/vernier

for 8600 series and MAX, IMC S class controls with a REC 4096 Board.

800

Absolute master/vernier format – 1:1 input/master, 800:801 master/vernier

for IMC 120, 121, 123 only.

801

Absolute master/vernier format – 1:1 input/master, 801:800 master/vernier

for 8600 series controllers (is not applicable for use with MAX and IMC S

Class controls)

Gear Ratio

Input:Resolver

3-6

8

Kit includes Resolver Feedback Package, mounting hardware and 3/8” to 3/8” (9.5 mm to 9.5mm) resolver to motor mounting coupling.

Page 18

Power and Feedback Cables

Chapter 3

Receiving, Unpacking and Inspection

1326 C

First Position Second Position Third Position

Bulletin

Number

Code

1326

1326ES

Description

Standard

Cable

9

Extended

length cable

used with

1391B-ES

&

1391-DES

Only

9

The extended length option is only available for 1326-CFUxx, CPABxx and CPCxx cables and can only be used with 1391B-ES and 1391-DES drives.

–

Type

Code

C

CC

Description

Connector

& Cable

Assembly

Connector

on both

ends (for

use with

1391C-HB)

PAB

Function

Description

Letter

Power Connection

P

Commutation &

F

Feedback Connection

845H/T Encoder

E

All 4.25” (108 mm)

V

Resolver Packages

Fourth Position

Motor Size

Used On

Type

Code

Series A & B (except

AB

1326AB-B4)

Series C & 1326AB-B4

C

All SeriesU

T

Fifth Position

Power Track

Cable

Description

Letter

All Series,

T

used for

high flex

applications

Blank

Standard

Cable

15

Sixth Position

Cable

Length

Code

Description

K

Connector Kit

(No Cable)

15

15’ (4.6 m)

30

30’ (9.1 m)

50

50’ (15.2 m)

100

100’ (30.4 m)

9

150

150’ (45.7 m)

9

200

200’ (61 m)

9

250

250’ (76.2 m)

9

300

300’ (91.4 m)

Blower Mod Kit

1326AB MOD G3

First Position Second Position Third Position

Bulletin

Number

–

Type Description

Description

Code

Modifica-

MOD

tion Kit

–

Code

G3

G4

Motor Series

Rear mounted blower for C

series motors

“Saddle” type blower for C

series motors with rear

mounted encoders

3-7

Page 19

Chapter 3

Receiving, Unpacking and Inspection

Planetary Gearbox

1326AB PG

–A05

First Position Second Position Third Position

Bulletin

Number

Type

Code

Description

PG

Straight

Planetary Gearbox

RP

Right Angle

Planetary Gearbox

Used on 1326AB

Motor Series

Code

Standard

A

Series A

B

Series B

C

Series C

10

Use only -21 (Metric) style adapter gearboxes for -A4, -A5 Torque Plus Motors.

Torque Plus

10

-A4

10

-A5

10

-A7

–

Fourth Position

Gear Ratio

(Motor Shaft:Output Shaft)

Code

Description

03

3:1

05

5:1

10

10:1

15

15:1

20

20:1

30

30:1

50

50:1

100

100:1

LB 21–

Fifth Position

Options

Code

Description

Blank

No Options

LB

Low Backlash Option

Sixth Position

Adapter

Code

Description

21

Metric

11

English

3-8

Page 20

Introduction Chapter 1

Manual Objectives 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General Precautions 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Drive Description 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Standard Features 1-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Options/Modifications 1-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Drive Layout 1-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Specifications Chapter 2

Chapter Objectives 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Drive Specifications 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Environmental Specifications 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Drive Power Dissipation 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Transformer Power Dissipation 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table of Contents

Receiving, Unpacking & Inspection Chapter 3

Chapter Objectives 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Receiving 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Unpacking 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Storing 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Description of Operation Chapter 4

Chapter Objectives 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

300V DC Power Bus Supply 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PWM Operation 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Shunt Regulator Operation 4-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Logic Power Supply 4-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Logic Control Boards 4-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fault Monitoring and Detection 4-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Microprocessor Control 4-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Isolated Current Sensing 4-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Integral Circuit Breaker 4-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Line/DB Contactor 4-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Driver Board 4-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A Quad B Board 4-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Starting and Stopping 4-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power-Up/Down Sequence 4-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inputs, Outputs and Switch SettingsChapter 5

Chapter Objectives 5-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inputs/Outputs 5-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Switch Settings 5-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

i

Page 21

Table of Contents

Programming Chapter 6

Chapter Objectives 6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Display Description 6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Keypad Description 6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parameter Levels 6-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Accessing Parameter Levels 6-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Programming 6-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parameter Descriptions 6-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation Chapter 7

Chapter Objectives 7-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mounting 7-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Wiring Recommendations 7-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Wiring 7-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Start-Up Chapter 8

Chapter Objectives 8-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Start-Up Procedure 8-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Linear Accel/Decel Control Module 8-11. . . . . . . . . . . . . . . . . . . . . . . . . .

1326AB AC Servomotor Chapter 9

Chapter Objectives 9-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Introduction 9-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Motor Options/Accessories 9-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Transformers and Shunt RegulatorsChapter 10

Chapter Objectives 10-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1391 Transformers 10-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Shunt Regulator Operation 10-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Shunt Regulator Installation 10-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting Chapter 11

Chapter Objectives 11-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Troubleshooting 11-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dimensions Appendix A

Interconnect Drawings Appendix B

Cable Information Appendix C

Block Diagrams Appendix D

Parameter Record Appendix E

ii

Page 22

Chapter

Description of Operation

Chapter Objectives Chapter 4 is intended to familiarize the reader with the circuitry of the

1391-DES in terms of function and operation.

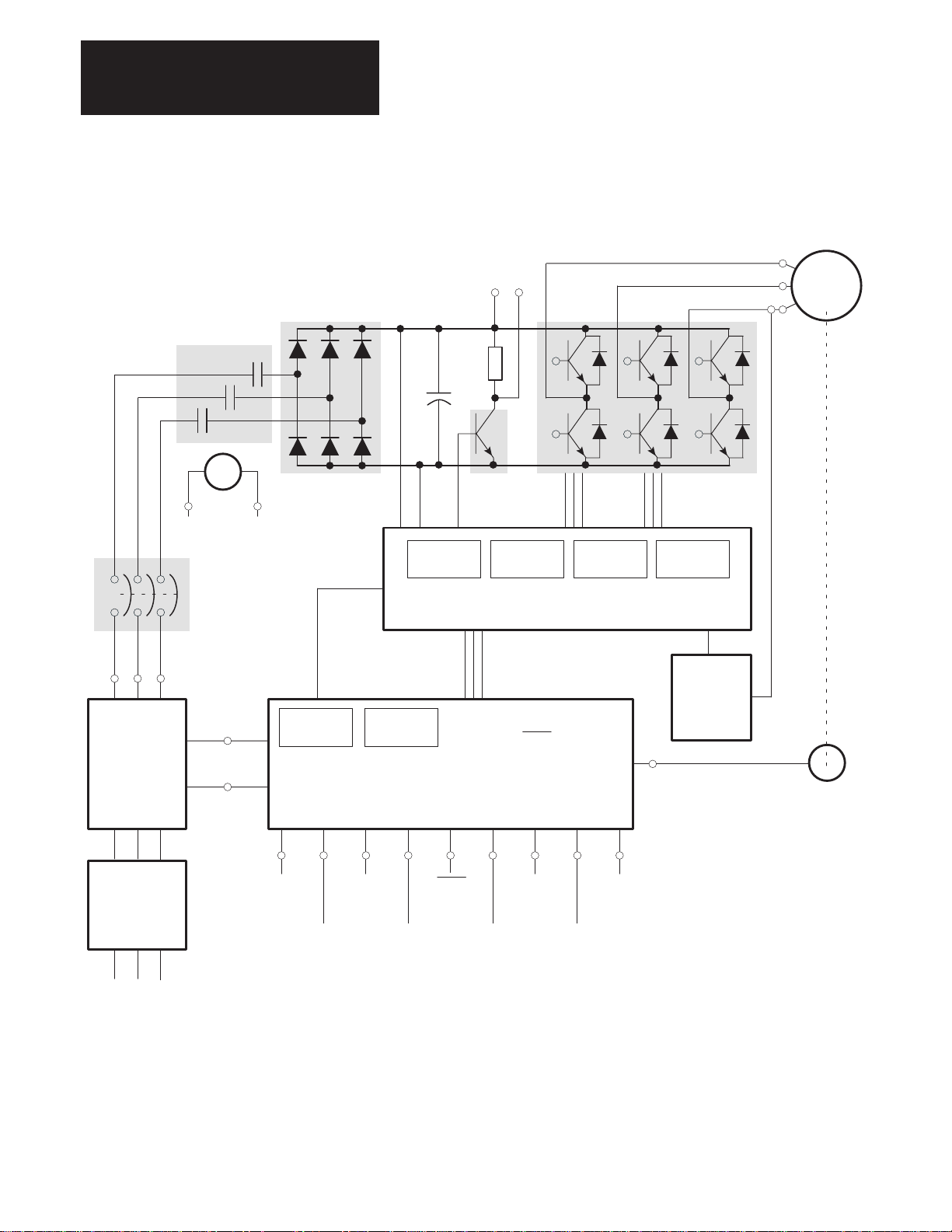

General The intended use of the 1391-DES is to control the speed and torque of an

AC servomotor in a closed loop position system. A complete servo system

can be configured with a 1391-DES Servo Drive, 1326 AC Servomotor

and 1391 Isolation Transformer. Refer to the 1391-DES Block Diagram

presented in Figure 4.4 for general layout.

The 1391-DES PWM Servo Drive is made up of the following: 300V DC

power supply, power transistor output modules, shunt regulator circuit,

logic power supply, microprocessor based logic boards, isolated current

sensing, circuit breaker and line contactor.

300V DC Power Bus Supply The drive contains an integral, unregulated, 300V DC nominal, full load

power supply. It consists of the power transformer input (230V AC,

three-phase, 50 or 60 Hz), a three-phase input bridge rectifier and one

power supply filter capacitor (C1).

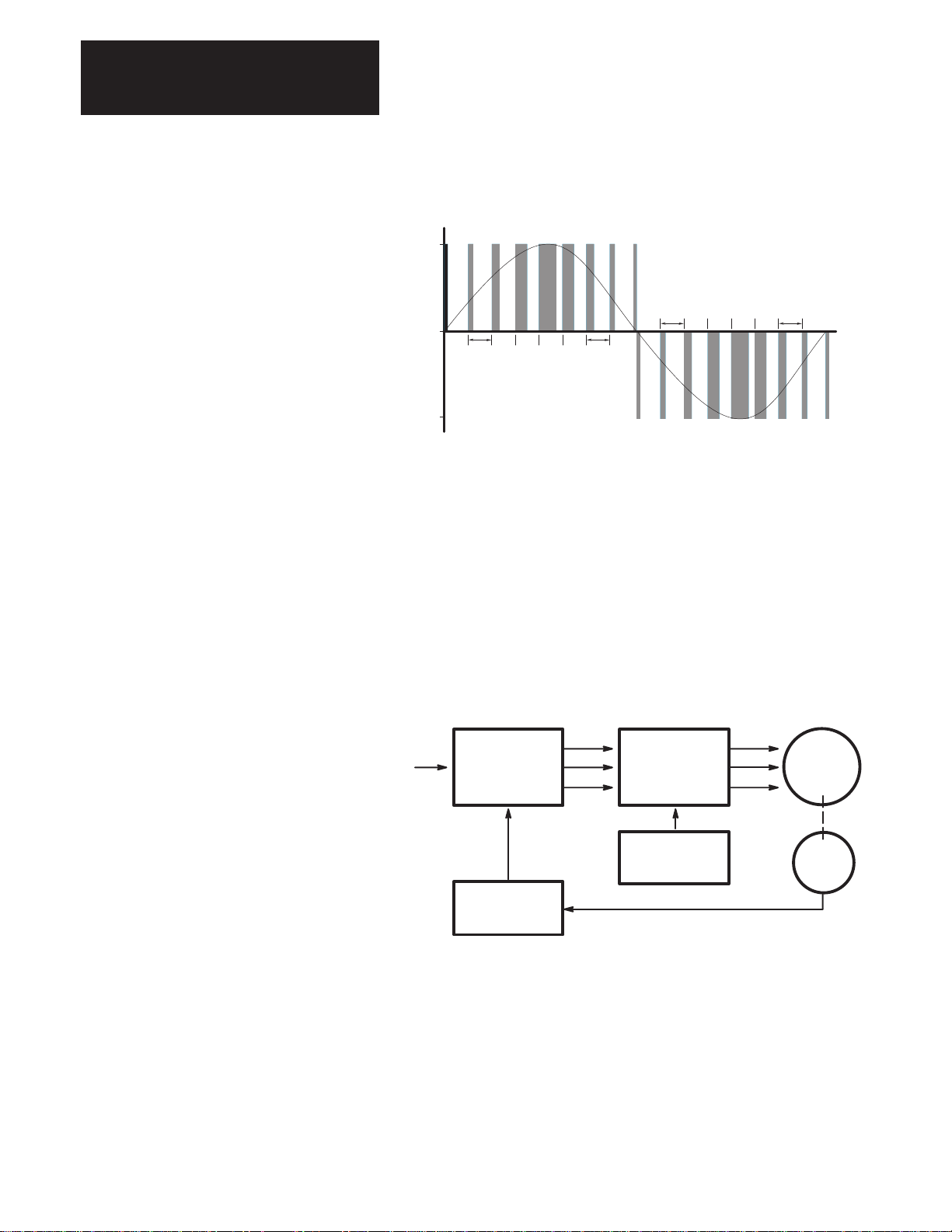

PWM Operation The 1391-DES incorporates a fixed timing wave (V

drive generates a three-phase sine wave by varying the width of the fixed

timing pulses (see Figure 4.1). This frequency corresponds to the velocity

command. The 0 to 10V DC velocity command is scaled to provide an

output frequency (dotted line) that varies from 0 to 200 Hz, depending on

the maximum velocity of the motor. This variable frequency output drives

a permanent magnet AC servomotor whose speed varies as a function of

the frequency.

) of 2500 Hz. The

T

4-1

Page 23

Chapter 4

Description of Operation

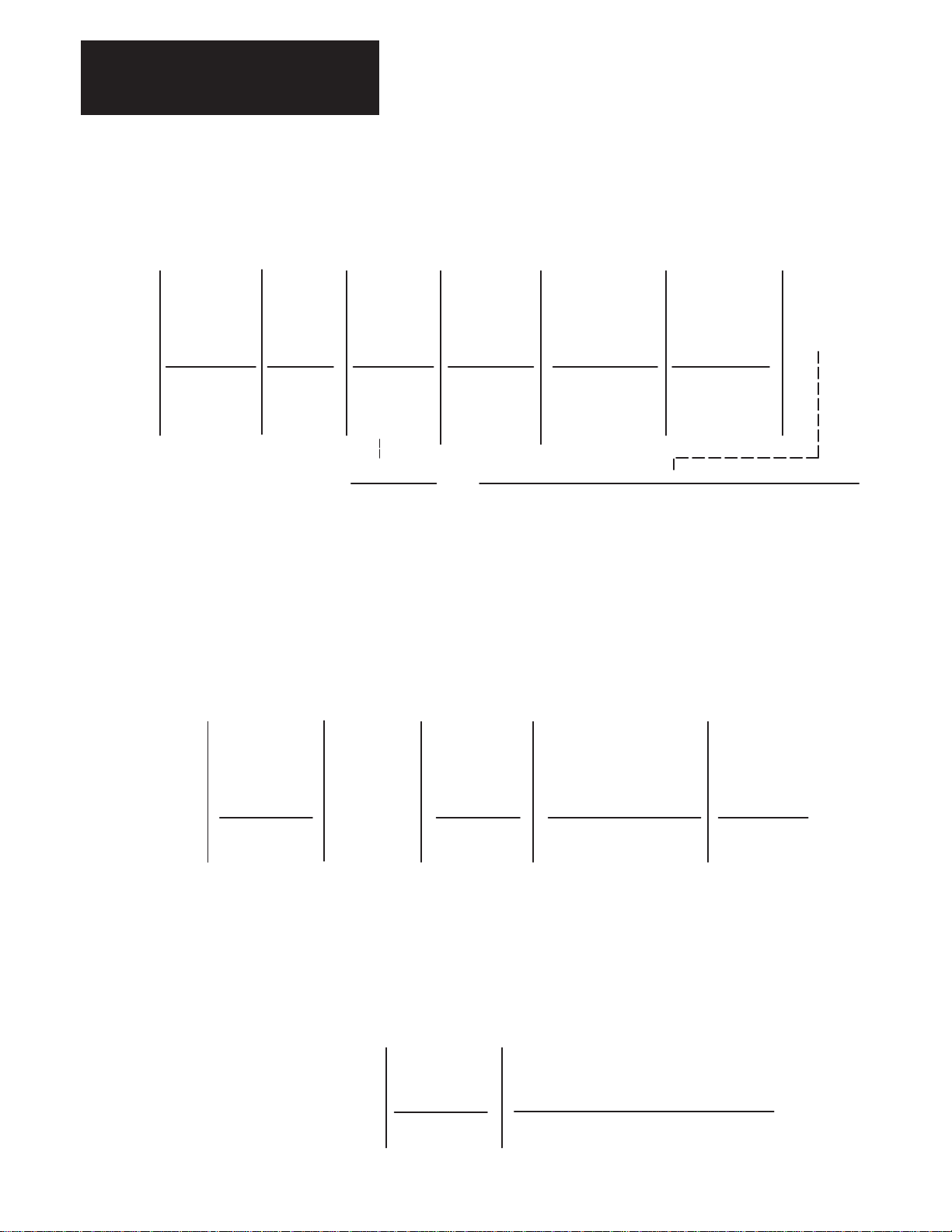

Figure 4.1

PWM Waveform

300V DC

Bus

400µs

Typical

0

400µs

Typical

400µs

Typical

400µs

Typical

Time

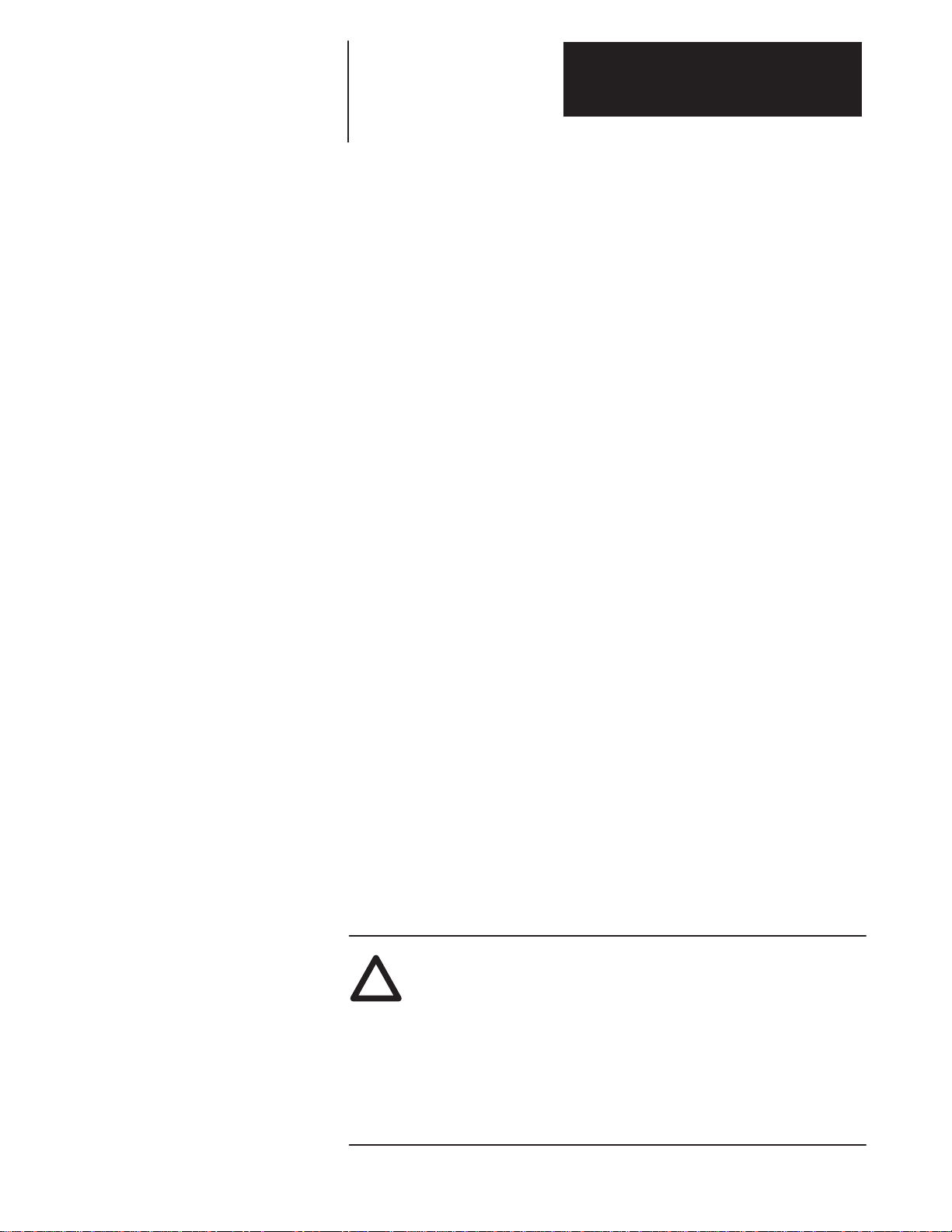

The three-phase relationship between the reference signal and the timing

wave provide PWM pulses to the power transistor base drive. This base

drive switches the power transistors across the 300V DC bus, providing

current to the motor windings, thus causing the motor to turn. A resolver

attached to the motor provides a signal corresponding to the actual rotor

position of the motor. This signal is decoded to a signal representing rotor

position and is fed to the commutation logic along with the torque

command. In this way, the drive combines the desired position signal and

current reference with the decoded resolver signal to produce a reference

signal commanding the motor to speed up or slow down. See Figure 4.2.

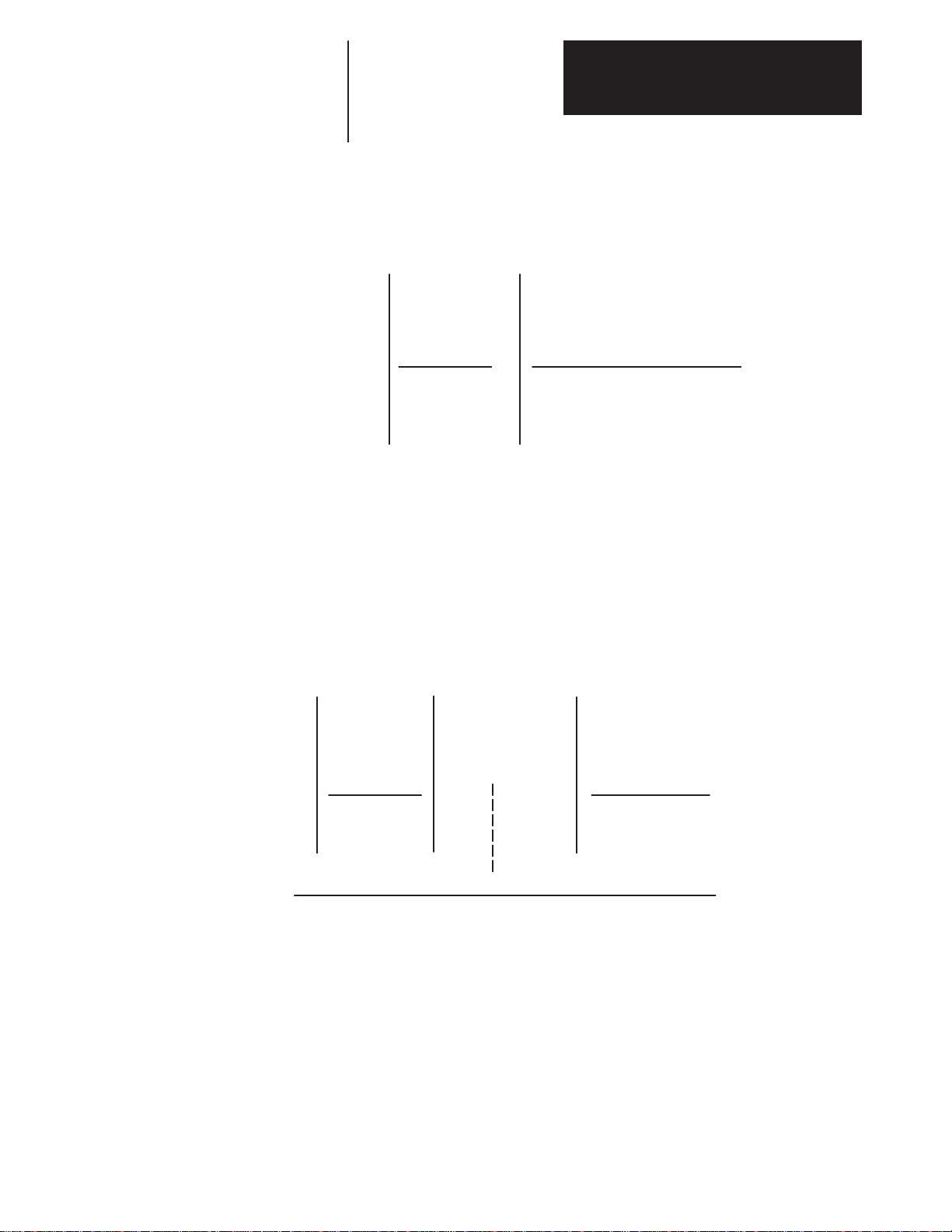

Figure 4.2

Operation

4-2

Current

Reference

Commutation

Logic & Current

Loop Integrator

Position Decoder

PWM Generator

& Base Drive

Timing Signal

Generator

Motor

Resolver

Page 24

Chapter 4

Description of Operation

Shunt Regulator Operation The 1391-DES shunt regulator provides power dissipation for regenerative

conditions when the energy returned to the drive by the motor exceeds that

which can be stored in the bus capacitors. The shunt regulator monitors the

bus voltage and at a predetermined “ON” point activates the shunt

regulator transistor, allowing current to flow through the shunt resistor and

dissipating power in the form of heat. A fuse is placed in series with the

resistor to protect it against short circuit conditions. When the shunt

transistor is activated and power is being dissipated at the resistor, the bus

voltage will quickly decrease, turning the transistor off when the voltage

reaches the “OFF” point. This cycle repeats, provided the bus voltage

continues to increase to the “ON” point. If too much regenerative energy is

present, the bus voltage will continue to increase even with the shunt

regulator on. At a predetermined bus voltage level, the 1391-DES will

determine that an overvoltage condition exists, and trip out on an

Overvoltage Fault.

The shunt regulator behavior is further modified by an adjustable duty

cycle timer. The timer is used to model the shunt resistor temperature.

SW1, a selector switch located on the top of the drive (see Figure 1.1)

determines the temperature level and therefore the average power level at

which the drive will trip out. When this level is reached, the drive will be

forced to trip out on an Overvoltage Fault. This action would be equivalent

to turning the shunt regulator off. Refer to Chapter 10 for further shunt

regulator information.

Logic Power Supply The 1391-DES control logic voltage is ±12V DC and +5V DC. The

voltages are generated on the Power Driver Board, which receives its 36V

AC input from a tertiary winding on the isolation transformer.

Logic Control Boards The Logic Control Boards are the printed circuit boards that are readily

accessible behind the front cover of the drive. They contain all circuits

necessary to control the 1391-DES. These circuits include: the velocity and

current loop, programming panel, A Quad B Board, fault detection and

annunciation circuits, power-up/power-down logic, PWM generation and

forward/reverse controlling circuits.

Fault Monitoring and Detection A number of fault monitor and detection functions exist on the 1391-DES

that guard the drive and help to minimize motor and system faults. The

occurrence of a fault will cause the drive to trip out. In this condition, the

Drive OK (DROK) contact will open and remain open until the fault is

cleared. If the DROK contact is wired into the user’s stop circuit, the

line/DB contactor (M) will also de-energize. This will place the shunt

resistor across the bus causing the motor to dynamic brake to a stop.

These fault conditions are annunciated through the front panel display. The

conditions displayed include:

4-3

Page 25

Chapter 4

Description of Operation

Overtemperature

The drive contains a thermal switch on the heat sink which indirectly

senses transistor module temperature. If the temperature rating of the

switch is exceeded, the DROK contact opens and the drive is disabled.

Power Fault

A fault related to the power bridge section of the drive will cause the drive

to be disabled and open the DROK contact.

Control Voltage Fault

If the control voltage varies more than ±10% of the nominal 12V DC, this

fault will occur. When a fault is detected, the DROK contact opens and the

drive is disabled.

Resolver Loss Fault

If the resolver wiring is grounded or missing, this fault will occur. When a

fault is detected, the DROK contact opens and the drive is disabled.

Overvoltage

The DC power bus voltage is continuously monitored. If it exceeds a preset

level of 405V DC, the DROK contact opens and the drive is disabled

Undervoltage

If the DC power bus voltage drops below 50% of its nominal operating

value an undervoltage fault occurs. Parameter 130 selects the reaction of

the DROK contacts to an undervoltage detection. Two options are possible:

1) DROK opens, but closes when the bus voltage is restored; 2) DROK is

not affected by an undervoltage.

Important: Regardless of interaction with the DROK contacts, the

transistor bridge is disabled upon an undervoltage condition. This is done

to protect the output transistors against voltage transients.

Current Foldback

The drive contains a fixed time versus current overload circuit which

monitors the current through each leg of the output bridge. If the overload

is sustained for a period, resulting in the drive rating being exceeded, the

circuitry will reduce (foldback) the peak output current of the drive. A

continuous overload will fold the available peak current down to its

continuous rating. This condition will reduce the current limit or torque

available to the motor.

Enable LED

The application of an enable signal by the machine position drive will

cause the front panel ENABLE LED to illuminate.

Status LED

The status of the power supplies and fault conditions are monitored

continuously. If a fault is present, the front panel FAULT/DRIVE READY

LED will flash red and the DROK contact will be open. If the drive is

operational, this LED will be green.

4-4

Page 26

Chapter 4

Description of Operation

Microprocessor Control The 1391-DES is controlled by an 80C196KB microprocessor. Velocity

control, sequencing, fault logic, programming and option control is

performed by the processor. Current control is analog, as is the input

velocity command. The input command is fed through a 14 bit digital to

analog converter (13 bits/8192 resolution and a +/– sign bit).

Isolated Current Sensing The Logic Control Boards receive current feedback from the Isolated

Current Sense Board. This circuitry provides the data used for current loop

closure.

Integral Circuit Breaker The DC bus supply, input rectifier and power circuitry are protected against

overcurrents by an integral three pole magnetic circuit breaker. This is not

designed nor intended to meet NEC branch circuit requirements.

Line/DB Contactor The three-phase incoming AC line is opened by the contactor whenever the

voltage on the contactor coil is removed. This operation in conjunction

with the shunt regulator reduces the bus voltage when the contactor is

disabled. The Logic Control Board remains energized except when voltage

is removed from the incoming isolation transformer.

Important: The 1391-DES contains a definite purpose contactor that is not

to be energized/de-energized more than twice an hour on a continuous

basis. The life of the contactor may be reduced considerably if the cycle is

exceeded. Contact your local Allen-Bradley Sales Representative for

additional information.

Power Driver Board The Power Driver Board contains the circuitry needed to switch the power

transistor modules.

A Quad B Board The A Quad B Board changes the resolver signal from a 1326AB or AD

motor into an encoder signal for use by a position controller (such as an

IMC S Class or 12x family controller).

Starting and Stopping

ATTENTION: The Enable control circuitry in the 1391-DES

!

includes solid-state components. If hazards due to accidental

contact with moving machinery or unintentional flow of liquid,

gas or solids exist, an additional hardwired stop circuit may be

required. Refer to the codes and standards applicable to your

particular system for specific requirements and additional

information. A device that removes AC input power when a

stop is initiated is an integral part of this drive. Refer to the

following individual stop mode explanations.

4-5

Page 27

Chapter 4

Description of Operation

ATTENTION: The user has the ultimate responsibility to

!

determine which stopping method is best suited to the application and will meet applicable standards for operator safety.

Starting and Stopping must be accomplished by hardwired user supplied

elements as shown in Appendix B. Stopping modes for the 1391-DES are

outlined below. Refer to the paragraphs that follow for detailed

information. The effects described below assume that the 36V AC control

voltage has not been de-energized.

Cause Effect on Motor

De-energize Line/DB Contactor (M) Coil Dynamic Brake

Speed Command brought to Zero Regenerative Brake

Open Enable Input Regenerative Brake

DROK Opens (Fault) Coast to Stop

Dynamic Braking

When the line/DB contactor (M) is de-energized by the control circuitry, an

inherent dynamic braking effect will occur during the DC bus decay,

provided the 36V AC logic voltage is not de-energized. The dynamic

braking effect depends on the value of the shunt regulator resistor and total

load inertia.

Important: Frequent cycling of the line/DB contactor to start/stop the

motor will reduce the life of the contactor.

Regenerative Braking

Normal run commands to the drive are performed through the Enable input

and any additional customer supplied control circuitry. Refer to Appendix

B. With input power applied, a mechanical contact closure (or solid-state

contact closure rated +15 to +30V DC, 30 mA) between TB2-9 & 10 will

cause the drive to run, provided the line/DB contactor (M) has been

energized by the control circuitry. When the Enable input is de-energized,

the maximum available reverse torque is applied to the motor in a

regenerative stopping mode, which will occur for approximately 450ms.

Coast

4-6

An internal drive fault opens the DROK contact. Coasting will only occur

if the DROK contact is not wired to the line/DB contactor coil (M) or the

Enable input circuits.

Page 28

Chapter 4

Description of Operation

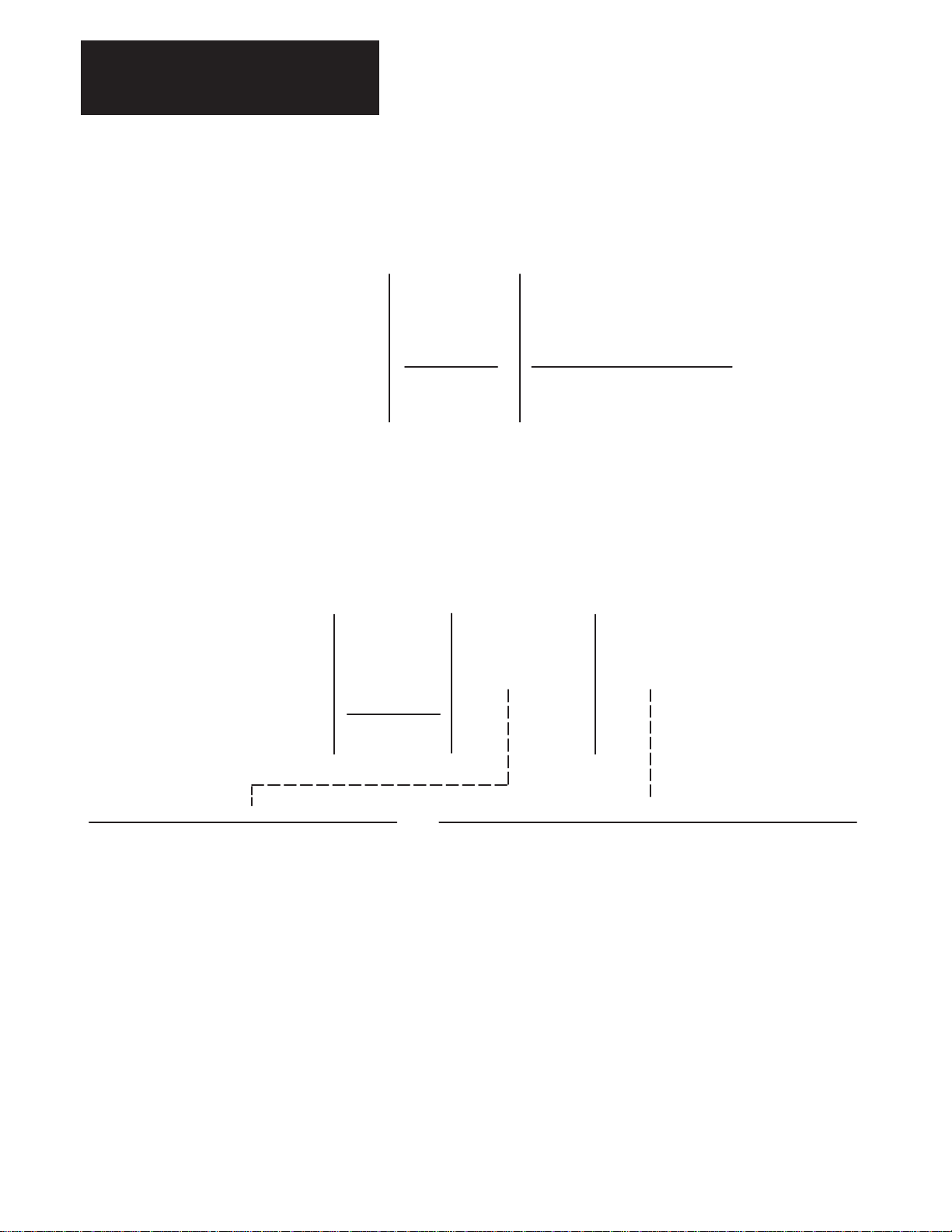

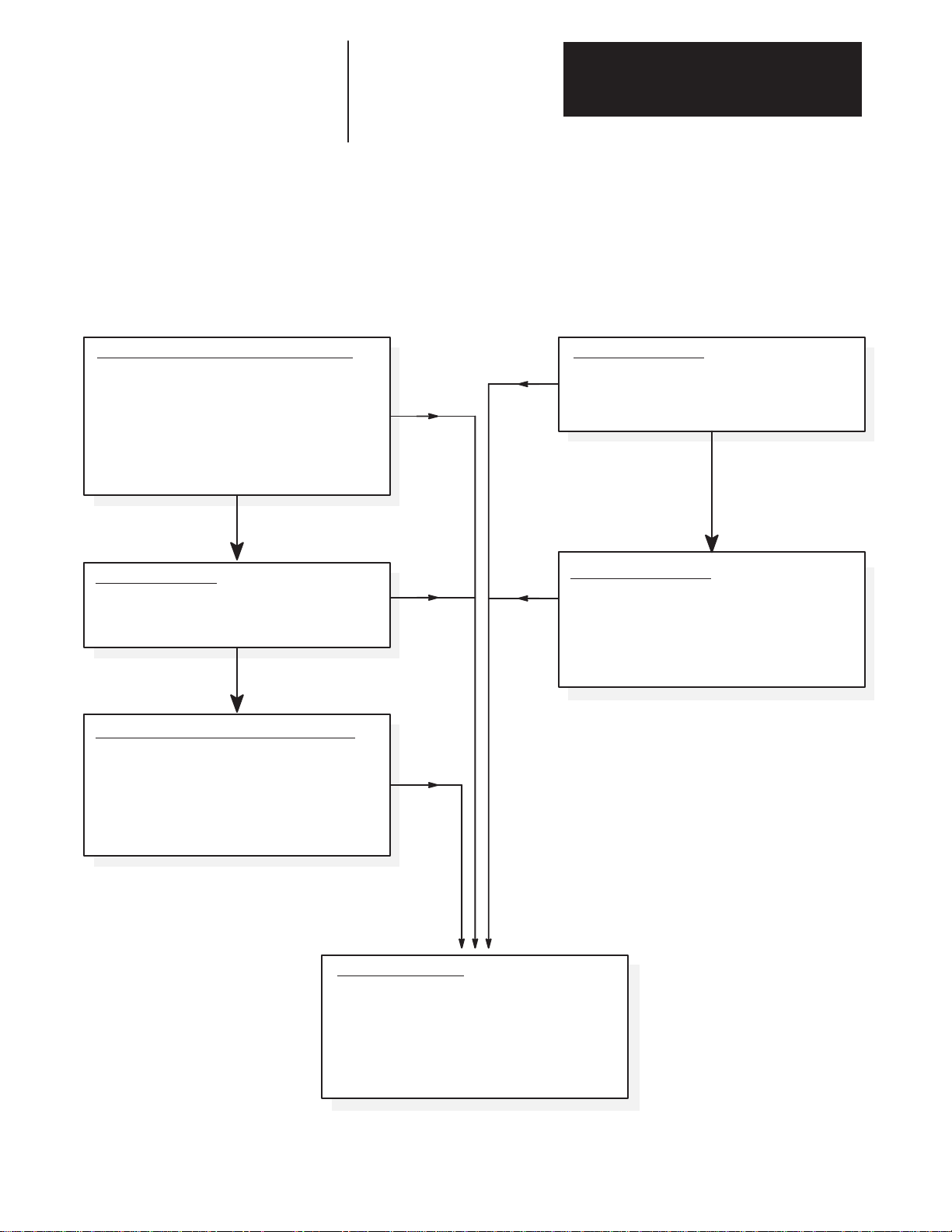

Power-Up/Down Sequence Figure 4.3 describes the various steps involved in the power-up/down

sequence of the 1391-DES Drive.

Figure 4.3

Drive Power-Up / Down Sequence

POWER-UP SEQUENCE

Apply AC Input Power to Isolation Transformer

a) Logic power supplies and base drive circuits

power-up.

b) Apply 115V AC to contactor.

c) Power bus charges.

d) If no faults are encountered, the DROK relay

energizes. Drive is ready to receive customer

enable signal.

Enable Signal Applied

Minimum of 100 ms after Contactor is Closed

a) Base drive enabled and will respond to velocity

command inputs.

Enable Signal is Applied Prior to 36V AC Power

a) When 36V AC power is applied, fault circuits detect

that the enable signal is already applied. Random

fault conditions occur.

b) Re-application of enable after resetting the drive

and with 36V AC power still present, will energize

the drive.

Fault

Fault

Fault

Fault

Fault

POWER-DOWN SEQUENCE

Enable Signal Removed

a) Motor will regenerate to a stop.

b) Output power stage is disabled.

c) DROK relay maintains a no fault status.

AC Input Power Removed

a) Logic and DC link power supplies begin decaying to

zero volts.

b) Undervoltage (fault) condition occurs.

c) DROK relay de-energizes based on setting of

parameter 130.

Fault Condition Occurs

a) Drive output stage disabled.

b) DROK relay is de-energized and a fault is

displayed.

c) If contactor (M) is wired to the DROK relay in a

stop string, contactor will open and the shunt

regulator will discharge the power bus supply.

4-7

Page 29

Chapter 4

Description of Operation

Contactor

Rectifier D1

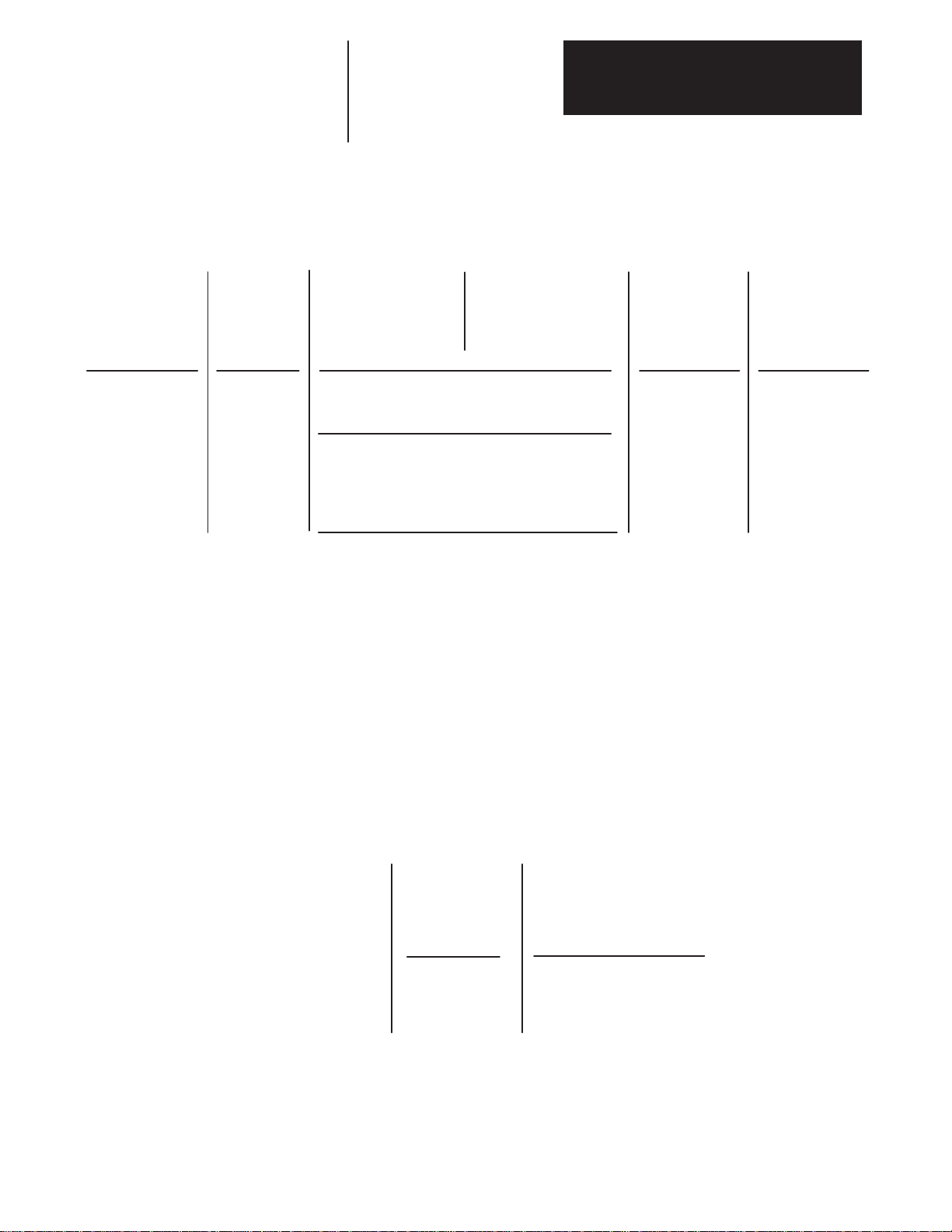

Figure 4.4

1391-DES Block Diagram

External Shunt

Regulator

Resistor

TB5–1

TB5–2

TB5–3

1326A AC

Servomotor

Isolation

Transformer

(MPT)

M

M

M

TB4–11

Contactor Coil

Circuit Breaker

(MCB)

TB5–4

TB5–5

TB5–6

TB4–19

TB4–21

36V AC

1–Phase

M

TB4–12

Protection

Circuitry

Digital Control Boards

Shunt

Regulator

Power Driver Board

Control

Logic

R1

C1

Shunt

Regulator

Transistor

Transistor

Base Drive

LEDs

Status

Enable

Logic

Suppy

Power Transistor

Output Modules

Power Fault

Protection

TB1–1

through

TB1–10

Isolated

Current

Sense

Board

Brushless

Resolver

User Supplied

Branch Circuit

Protection &

Disconnect

AC Line Input

4-8

TB2–1

TB2–2

TB2–3

Velocity

Command

TB2–4

TB2–5

Velocity

Output

TB2–6

TB2–7

Current

Output

TB2–9

TB2–10

Reset Torque

Enable

TB2–11

TB2–12

Adjustable

Current

Limit

TB2–13

TB2–14

Command

Input

TB2–15

TB2–16

Encoder

Output

TB3–1

through

TB3–10

TB4–17

TB4–18

DROK

Contact

Page 30

Chapter

Inputs, Outputs and Switch Settings

Chapter Objectives Chapter 5 contains descriptions of the various inputs and outputs available

on the 1391-DES Digital Servo Drive. Additionally, information for

properly setting the drive switches is provided for reference when you

perform start-up. For information on shunt regulator adjustments, refer to

Chapter 10.

Inputs/Outputs The following paragraphs provide detailed descriptions of the various

inputs and outputs available for the 1391-DES. See Figure 5.2 for terminal

block locations.

Terminal Block - TB1

Resolver Signals (TB1, Terminals 1-10)

These terminals are used for connecting the commutation resolver from the

motor to the drive. Refer to Appendix B for connection details.

Important: Terminal 1 of TB1 must be connected to chassis ground at the

Ground Stud (see Figure 5.2 for Ground Stud location).

Terminal Block - TB2

Please note that there are no connections to TB2-18, 19 & 20.

Velocity Command Input (TB2, Terminals 1, 2)

The drive will accept up to a ±10V DC velocity command signal to achieve

maximum motor speed. Voltages lower than ±10V DC can be used by

reprogramming parameter 211 (Analog Velocity Gain). The plus (+) and

minus (–) reference are at terminals 2 and 1, respectively. Shield must be

terminated at one end only. The differential impedance of the velocity

command input is 80k ohms (40k ohms for single ended inputs).

Signal Common (TB2, Terminals 3, 5, 7, 8, 12, 17)

Signal input reference point.

Analog Out 1 (Velocity) (TB2, Terminal 4)

A voltage corresponding to the motor velocity and direction of rotation will

be present between this terminal and signal common (Terminal 5). +1.2V

DC for each 1000 rpm is available. Minimum impedance that can be

placed across this output is 10k ohm.

5-1

Page 31

Chapter 5

Inputs, Outputs and Switch Settings

Analog Out 2 (Current) (TB2, Terminal 6)

A voltage corresponding to positive and negative current will be present at

this terminal and signal common (Terminal 7). +3V DC equals 100% of the

continuous rating of the motor with +6V DC equaling 200%. Minimum

impedance that can be placed across this output is 10k ohm.

Enable Input (TB2, Terminals 9, 10)

Normal Run commands to the drive are performed through the Enable

input and any additional user supplied run control circuitry. With input

power applied and the line contactor energized, a mechanical contact

closure (or a solid-state contact closure rated +15 to +30V DC, 30 mA)

between TB2-9 & 10 will cause the drive to run. When this input is

de-energized, the control will cause a regenerative braking action in the

motor.

Reset (TB2, Terminal 11)

Removing the Enable signal and momentarily connecting this terminal to

signal common (TB2-12) will reset the drive after a drive fault occurs.

Important: A Reset must

not be initiated until the cause is determined and

corrected.

Adjustable Current Limit (TB2, Terminal 13, 14)

The current limit of the drive is set to 300% of motor continuous rating or

twice the continuous rating of the drive, whichever is lower. Applying a

voltage between 0 and +10V DC to terminals 13 & 14 will limit the peak

current of the drive. The range of this input is the lower of the following:

- Value set by parameters 156 and 157,

- Twice the continuous rating of the drive.

For each volt applied, 30% reduction of current limit is achieved, based on

300% of motor rating being available. If only 200% current (drive peak) is

available, a voltage of less than 3.33 volts will have no effect on current

limit. On TB2, pin 14 must be positive with respect to pin 13 for this input

to operate. Refer to the following information.

Percent of Percent of

Voltage

10V 10% 4V 180%

9V 30% 3V 210%

8V 60% 2V 240%

7V 90% 1V 270%

6V 120% 0V (open) 300%

5V 150%

Peak Rating Voltage Peak Rating

5-2

Torque Command Input (TB2, Terminals 15, 16)

Terminals 15 and 16 provide a small amount of input filtering for operating

the drive as a torque block (with IMC S Class, MAX, IMC 121 and 123) or

velocity feedforward mode. A ±3V DC command equals 100% of the

motor current setting (as set by parameter 155).

Page 32

Chapter 5

Inputs, Outputs and Switch Settings

Terminal Block - TB3 (A Quad B Board)

Figure 5.1 provides interconnect information between the position

controller and TB3 on the A Quad B Board.

ATTENTION: To guard against possible damage to the A

!

Figure 5.1

A Quad B Board Wiring

Quad B Board, assure that wiring between TB3 and the position

controller is correct. Refer to Figure 5.1.

A Quad B Board

1 TB2 20

1 TB3 10

To Position

Controller

Important: Note terminal orientation prior to wiring.

1

Recommended Wire – Belden #9728 or equivalent. Maximum distance between the A Quad B Board and

the position controller is 40 feet (12.2 meters) using a 5 volt signal. For distances up to 300 feet (91 meters),

18 AWG (0.8 mm

2

For proper operation when interconnecting to IMC classic products (IMC 110, 12x), the B and B (NOT)

signals must be reversed.

3

When interfacing to IMC 121 or 123 controllers, use the 1391-CAQB cable. When interfacing to the

integrated packages of the MAX or S Class controls, use the 1391-SAQB or 1391 SAQBK cable.

1

2

) wire (Belden 9388 or equivalent) and an 8 to 15V DC power supply must be used.

Top Logic Control Board

21S1

987654321

Power Supply

1

Input

TB3

Number

1

2

3

4

5

6

7

8

9

10

Description

A

A (NOT)

2

B

2

B (NOT)

Z

Z (NOT)

+5V DC (

Signal Common

+8 to +15V DC In

No Connection

±5%)

The A Quad B option operates in the same manner as the Allen-Bradley

845H Line Driver Encoder (26LS31 line driver output). The option

requires either a regulated +5V DC at terminal 7 or an unregulated +8 to

+15V DC input at terminal 9 (board draws 125mA maximum). The pulse

train output is selectable to 256, 512, 1024 or 2048 lines per revolution via

the Encoder Output switch, S1 (see page 5-6).

Terminal Block - TB4

Please note that there are no connections to TB4-20 & 22.

Contactor Coil (TB4, Terminals 11, 12)

Connections to the coil of the integral contactor are performed at these

terminals. The coil voltage is 115V AC, 50/60 Hz.

Important: Drives with a catalog number of 1391-DESxx-DI-AQB-A will

have a 24V DC coil. Drives with a catalog number of 1391-DESxx-DIAQB-B will have a 240V AC coil.

5-3

Page 33

Chapter 5

Inputs, Outputs and Switch Settings

“M” Contactor Auxiliary Contacts (TB4, Terminals 13, 14, 15, 16)

The auxiliary contacts of the integral contactor are accessed through these

terminals. Refer to Table 5.A for contact ratings.

Table 5.A

“M” Contact Ratings (minimum 50 mA at all voltages)

AC Ratings

Volts

)

(U

e

12-120

220-240

380-480

500-600

Amperes

)

(I

e

6

3

1.5

1.2

DC Ratings

Volts

)

(U

e

28

110

220

440

660

Amperes

)

(I

e

5.0

1.25

0.62

0.27

0.20

Drive OK (DROK) Contacts (TB4, Terminals 17, 18)

Application of power to the transformer energizes the logic supply of the

drive. When 50% of rated DC Bus voltage is achieved and no drive faults

are detected, this relay contact is closed. The contact remains closed until a

drive fault occurs or power is removed from the transformer. Contact

rating: 115V AC, 1A or 24V DC, 0.3A.

36V AC Logic Supply Voltage (TB4, Terminals 19, 21)

The isolation transformer contains four separate windings. Each winding

supplies 36V AC. The 36V AC leads are brought out to terminals 19 and

21 of TB4. See Chapter 10 for transformer details.

Terminal Block - TB5

Motor Power Terminals (TB5, Terminals 1, 2, 3)

Motor power is provided at these terminals. Refer to Chapter 7 and

Appendix B for connection details.

5-4

Input Power Terminals (TB5, Terminals 4, 5, 6)

The drive requires a 230V AC, three-phase, 50 or 60 Hz input supplied by

the transformer secondary. Refer to Chapters 7, 10 and Appendix B for

wiring and transformer information.

External Shunt Regulator Resistor (TB5, Terminals 8, 9, 10)

The 22.5A drives have provisions to accept an external shunt resistor to

supplement the integral unit. This is available for applications that require

the dissipation of more regenerative energy to the DC Bus. To use an

external shunt resistor, first remove the jumper at terminals 8 and 10 of

TB5. Consult your Allen-Bradley sales office for application assistance.

Additionally, the bus voltage can be monitored at terminals 9 (+) and 7 (–)

of TB5.

The shunt regulator resistor supplied with the 1391-DES45 must be

externally mounted and connected to terminals 8 and 9 of TB5 prior to

operation. Refer to Chapter 10 and Appendix B for details.

Page 34

Chapter 5

Inputs, Outputs and Switch Settings

Figure 5.2

Terminal Block, Circuit Board and Switch Locations

TB1

1

A Quad B Board

1

TB3

Ground Stud

Top View of Controller

Main Logic Control Board

Display Board

Memory Board

1

2

S1

1

TB2

1

1

TB5

10

SW1

MCB

22

F3

1

F2

11

TB4

F3 provided on 15 & 22.5A units only

15A = Bussmann KLM10 or equivalent

22.5A = Bussmann FNQ6 1/4 or equivalent

F1

A Quad B Board

Main Logic Control Board

Display, Memory and Adapter Boards

5-5

Page 35

Chapter 5

Inputs, Outputs and Switch Settings

Switch Settings This section provides information on setting the Duty Cycle Selector

switch (SW1) and the A Quad B Encoder Output switch (S1). Note that the

settings for 1326AP motors are the same as 1326AB motors. Refer to

Figure 5.2 for switch locations.

Duty Cycle Selector Switch - SW1

The Duty Cycle Selector Switch (SW1) which is located on top of the

drive, modifies the behavior of the shunt regulator. The switch determines

the temperature level and therefore the average power level at which the

drive will fault. Refer to Chapter 10 for detailed switch setting information.

A Quad B Encoder Output Switch - S1

S1 selects the line count that will be output from the A Quad B Board.

ATTENTION: Incorrect setting of S1 can cause erratic and/or

!

improper machine motion which may result in personal injury

or equipment damage. Assure that switch S1 has been properly

set as shown in Figure 5.3.

Figure 5.3

A Quad B Board Switch (S1) Settings

– ON –

S1

12

2 Marker Pulses per Revolution

CCW Rotation of Motor Shaft

(similar to Allen-Bradley 845H)

Line Count/

Revolution

2048

1024

512

256

A (NOT)

B (NOT)

Z (NOT)

S1-1

Switch Setting

OFF

ON

OFF

ON

A

B

Z

S1-2

Switch Setting

OFF

OFF

ON

ON

5-6

Page 36

Chapter 5

Inputs, Outputs and Switch Settings

When using the A Quad B option with Allen-Bradley IMC motion

controllers, the AMP parameters will be set according to the line count

selected. In general, one parameter must be justified when using this

device.

Important: For all IMC classic products (IMC 110, 12x) the normal line

counts per cycle of the encoder must be divided by two since the drive will

see two markers per cycle.

Example (using an IMC 12x Controller)

With switch S1 set to 1024 lines per revolution (S1-2 OFF, S1-1 ON), the

lines per cycle of the position feedback device (located in the Feedback

Parameters File) must be 2048.

1024 x 4 = 4096 / 2 = 2048

(Quadrature)

Lines/Revolution 2 Markers/Revolution

5-7

Page 37

Chapter 5

Inputs, Outputs and Switch Settings

End of Chapter

5-8

Page 38

Chapter

Programming

Chapter Objectives This chapter explains the programming/setup system of the 1391-DES

Digital AC Servo Drive. Included is an explanation of the display, general

programming procedure and description of the programmable parameters.

You will need to read this chapter before performing the start-up procedure

provided in Chapter 8.

Display Description The 1391-DES display is used for programming, as well as status and

diagnostic messages. The display consists of a 16 character, 2 line,

“Super-Twist” LCD (Liquid Crystal Display) that allows a wide viewing

area. The display can be divided into several different sections as shown in

Figure 6.1.

Figure 6.1

LCD Display

Level Indicator

Parameter Number

Parameter Name

Parameter Value

When power is applied to the 1391-DES the Basic Display (see Figure 6.4)

will be shown. The Basic Display alternates (every 2 seconds) between the

two displays shown. The alternating display indicates that the drive is

functioning normally.

Keypad Description The 1391-DES display panel utilizes five keys (pushbuttons) which allow

the various parameters to be accessed. Once a parameter is accessed, status

information of the drive can be viewed. In addition, certain parameters can

also be modified.

Each of the keys has several functions depending on the view/modify

mode. Refer Figure 6.2 and the paragraphs that follow for a description of

the display panel controls.

6-1

Page 39

Chapter 6

Programming

Figure 6.2

1391-DES Display Panel

Display

Keypad

Up Arrow Key

This key is used to increase values when modifying

parameters. Other uses will be described when applicable.

Down Arrow Key

The Down Arrow key is used to activate modifiable

parameters or decrease values. Other uses will be described

as required.

Left Arrow Key

This key is used to scroll through parameters or move the

cursor when modifying parameters. Other key functions will

be described as needed.

Right Arrow Key

The Right Arrow key can be used to scroll through

parameters or move the cursor when modifying. Other key

functions will be described when required.

6-2

Enter

Enter Key

The Enter key is used to make a selection or store a changed

parameter value in memory. Other key functions will be

described as needed.

Page 40

Chapter 6

Programming

Parameter Levels For ease of use, the various parameters of the 1391-DES are numbered and

arranged in three different levels. The levels range from viewing simple

drive status parameters to more complex setup information. The three

levels are as follows:

View Level

The View level allows viewing only of the drive operating conditions (see

below). The View level is denoted on the display by a single dot (

the upper left corner (see Figure 6.1).

03 Drive Size

19 Final Velocity Command

20 Velocity Feedback

45 Iq (Torque) Current Reference

50 Current Feedback Rated

51 Current Limit

57 Analog Velocity Command

154 Motor Type

253 Display Software Version

254 Drive Software Version

) in

Modify Level

The Modify level allows access to the View level parameters in addition to

the system configuration parameters listed below. This level of

programming allows parameter modification to some of the View level

parameters and the other parameters listed. The Modify level is denoted by

two dots (

68 Bandwidth Maximum

69 Auto Tune Friction Compensation

128 EEprom Functions

130 Drive OK Mode

131 Language Select

132 Velocity Mode Select

133 Torque Mode Select

144 Clockwise Velocity Limit

145 Counterclockwise Velocity Limit

146 Accel/Decel Ramp

156 Positive Current Limit

157 Negative Current Limit

159 Current Preload

168 Kp Velocity Loop

169 Ki Velocity Loop

170 Feed Forward Gain

171 Static Gain

182 Desired Velocity Bandwidth

183 Velocity Damping Selection

184 Velocity Low Pass Filter Bandwidth

185 Lead/Lag Velocity Feedback Filter Gain

186 Lead/Lag Velocity Feedback Filter Bandwidth

187 Auto Tune Velocity

188 Auto Tune Current Limit

189 Auto Tune Inertia

190 Auto Tune Select

210 A/D Converter Offset

211 Analog Velocity Gain

) in the upper left corner of the display (see Figure 6.1).

6-3

Page 41

Chapter 6

Programming

212 D/A #1 Gain

233 Cable Compensation

Maintenance Level

The Maintenance level allows access to all of the parameters listed in the

View and Modify levels in addition to the parameters listed below. Two

squares (

denote that this level is active (see Figure 6.1).

04 Adapter Type

05 Logic Command

06 Drive Faults

07 Drive Status

08 Auto Tune Status

17 Velocity Reference Whole

18 Velocity Reference Fraction

21 Filtered Velocity Feedback

22 Average Motor Velocity

23 Resolver Turns

24 Resolver Position Feedback

25 Pre Ramp Velocity

33 Proportional Velocity Error

34 Velocity Loop PI Output

35 Integral Velocity Error

44 External Torque Reference

46 Id (Flux) Current Reference

47 IT Protection Limit