Page 1

1336 SPIDER

Adjustable

FrequencyACDrive

for the

Fibers Industry

9.9A-60.0A

Firmware Version 2.xxx-5.xxx

User Manual

Page 2

Important User Information

Solid state equipment has operational characteristics differing from those of

electromechanical equipment. “Safety Guidelines for the Application,

Installation and Maintenance of Solid State Controls” (Publication SGI-1.1

available from your local Rockwell Automation Sales Office or online at

http://www.ab.com/manuals/gi) describes some important differences

between solid state equipment and hard-wired electromechanical devices.

Because of this difference, and also because of the wide variety of uses for

solid state equipment, all persons responsible for applying this equipment

must satisfy themselves that each intended application of this equipment is

acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for

indirect or consequential damages resulting from the use or application of

this equipment.

The examples and diagrams in this manual are included solely for

illustrative purposes. Because of the many variables and requirements

associated with any particular installation, Rockwell Automation, Inc.

cannot assume responsibility or liability for actual use based on the

examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to

use of information, circuits, equipment, or software described in this

manual.

Reproduction of the contents of this manual, in whole or in part, without

written permission of Rockwell Automation, Inc. is prohibited.

Throughout this manual we use notes to make you aware of safety

considerations.

ATTENTION: Identifies information about practices or

circumstances that can lead to personal injury or death, property

!

damage, or economic loss.

Attentions help you:

• identify a hazard

• avoid the hazard

• recognize the consequences

Important:Identifies information that is especially important forsuccessful

application and understanding of the product.

Shock Hazard labels may be located on or inside the drive to

alert people that dangerous voltage may be present.

Burn Hazard labels located on the front of the drive alerts

people about a hazard of burns. Do not touch the heatsink

surface during operation of the drive. After disconnecting power

allow time for cooling.

SCANport is a trademark of Rockwell Automation, Inc.

PLC is a registered trademark of Rockwell Automation, Inc.

IBM is a registered trademark of International Business Machines Corporation.

Windows 95 is a registered trademark of Microsoft Corporation.

Page 3

Summary of Changes

Manual Changes The information below summarizes the changes to the 1336 SPIDER

User Manual since the last release. In general, this includes new

information pertaining to Firmware 5.xxx.

Description of Change Page(s)

Step Logic function added

(see New and Updated Parameters below).

Updated Parameters:

[Freq Select 1]

[Current Limit]

[Freq Select 2]

[Language]

[Flying Start En]

[LLoss Restart]

[TB5 Term 2x Sel]

[CRx Out Select]

[Freq Source]

[Break Freq]

New Parameters:

[SLx Logic Step]

[SLx Logic Jump]

[SLx Step Jump]

[SLx Step Setting]

[SLx Time]

[SLx Encoder Cnts]

[Current Step]

Parameter Cross References updated

Parameter Record updated

7–60

7–8, 7–16

7–9

7–16

7–21

7–21

7–22

7–27

7–28

7–38

7–57

7–61

7–62

7–62

7–62

7–63

7–63

7–63

A–4

A–11

Page 4

soc–2 Summary of Changes

Notes

Page 5

Table of Contents

Chapter 1

Information and Precautions Manual Objectives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–1

Catalog Number Explanation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–1

Conventions Used in this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–1

General Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–1

Nameplate Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–3

Chapter 2

General Installation for All

Drives

Mounting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–1

Installation Guidelines. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–2

AC Supply Source. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–3

Input Power Conditioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–3

Input Fuses. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–4

Input Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–5

Electrical Interference - EMI/RFI. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–5

RFI Filtering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–6

CE Conformity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–6

Grounding. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–6

Power Cabling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–9

Output Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–12

Cable Termination. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–13

Adapter Definitions and Communication Option Installation. . . . . . . . . . 2–14

Chapter 3

Installation/Wiring for StandAlone Drives

Control and Signal Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–1

Digital Inputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–2

Pulse Input/Output Option. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–8

Digital Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–8

Analog I/O. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–9

Standard Analog I/O Setup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–10

Optional Analog I/O Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–11

Chapter 4

Installation/Wiring for PLC

Control Drives

Control and Signal Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–1

Digital Inputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–3

Chapter 5

Human Interface Module HIM Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–1

HIM Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–4

Handheld HIM Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–13

Chapter 6

Start-Up Start-Up Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–1

Initial Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–2

Assisted Start-Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–2

Advanced Start-Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–5

Page 6

toc–ii Table of Contents

Chapter 7

Programming Function Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–1

Programming Flow Chart. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–1

Chapter Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–4

Chapter 8

Troubleshooting Fault Descriptions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8–1

Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8–9

Appendix A

Specifications and

Supplemental Information

Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A–1

Derating Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A–3

Parameter Cross Reference - By Number . . . . . . . . . . . . . . . . . . . . . . . . A–4

Parameter Cross Reference - By Name. . . . . . . . . . . . . . . . . . . . . . . . . . A–5

HIM Character Map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A–6

Communications Data Information Format . . . . . . . . . . . . . . . . . . . . . . . A–7

Typical Programmable Controller Communications Configurations. . . . . A–9

Typical Serial Communications Configurations . . . . . . . . . . . . . . . . . . . A–10

Read/Write Parameter Record. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A–11

Initial Parameter Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A–12

Dimensions Appendix B

Appendix C

CE Conformity Requirements for Conforming Installation . . . . . . . . . . . . . . . . . . . . . . . . C–2

Electrical Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C–2

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C–4

Appendix D

Flash Memory What is Flash Memory?. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D–1

Firmware Download Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D–1

Page 7

Chapter 1

Information and Precautions

Chapter 1 provides information on the general intent of this manual,

gives an overall description of the 1336

Frequency AC Drive and provides a listing of key drive features.

Manual Objectives This publication provides planning, installation, wiring and

diagnostic information for the Stand-alone (full I/O) and PLC

control (limited I/O) 1336 SPIDER Drive. To assure successful

installation and operation, the material presented must be thoroughly

read and understood before proceeding. Particular attention must be

directed to the Attention and Important statements contained within.

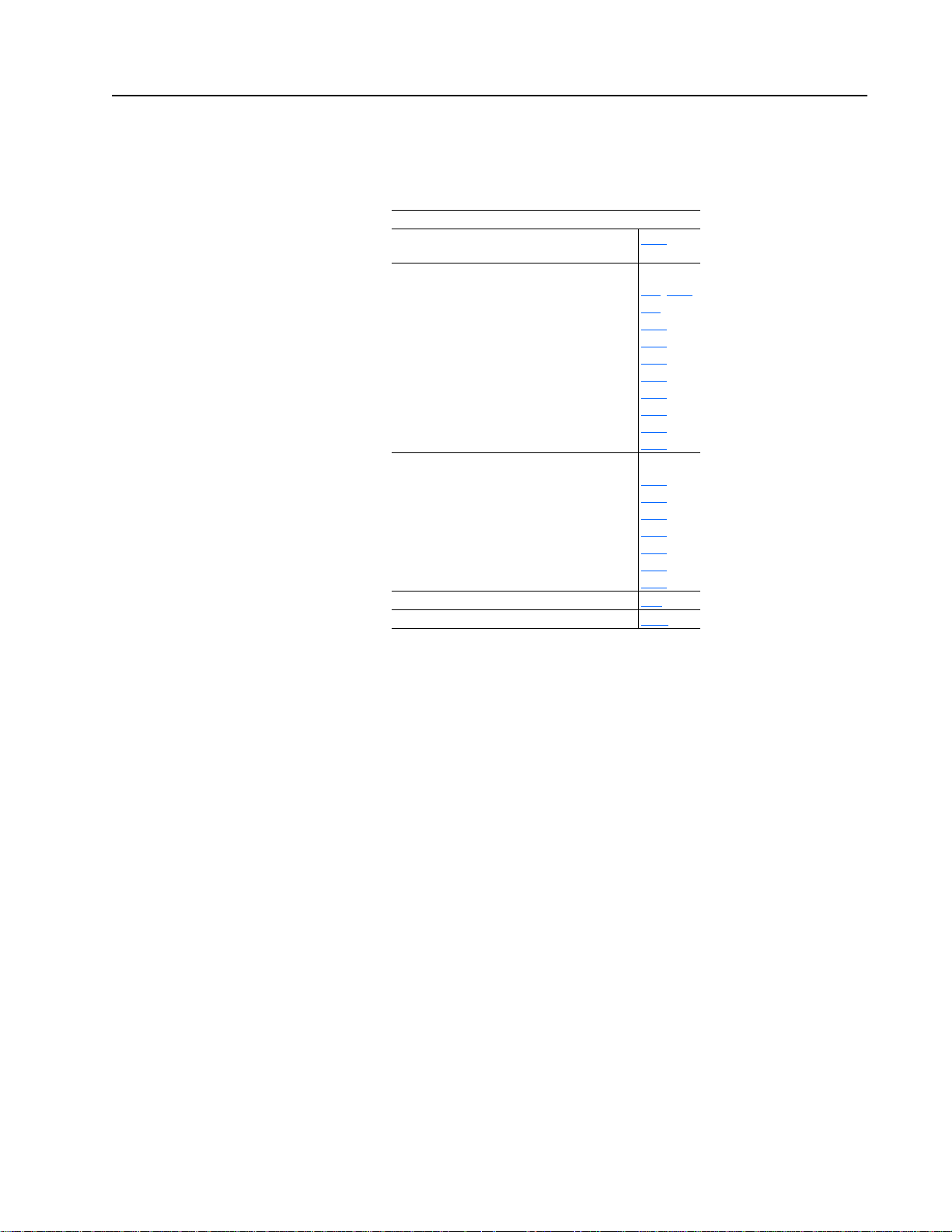

Catalog Number Explanation The diagram below describes the SPIDER catalog numbering system.

SPIDER Adjustable

1336Z

First Position

Bulletin Number

1

P

–

Second Position

Drive Types

Letter Type

P PLC Control

S Stand-Alone

Control

This current is only possible with synchronous motors and for spinning applications. For actual motor current rating, refer to Appendix A.

Conventions Used in this Manual

General Precautions

A

Third Position

Voltage

Letter Voltages

A 200-240V AC or

310V DC

B 380-480VAC or

513-620V DC

022

Fourth Position

Peak Current Rating

Code Peak Current

022 21.6A

036 36.0A

060 60.0A

010 9.9A

017 16.5A

033 33.0

–

N

Fifth Position

1

Enclosure Type

Code Type

N IP 20 (Open Type)

with Line Choke

AE IP 20 (Open Type)

with EMC Filter

–

GM1

Sixth Position

Communication Options

Code Description

GM1 Single Point Remote I/O

GM2 RS-232/422/485, DF1 &

DH485

GM5 DeviceNet™

GM6 Enhanced DeviceNet

To help differentiateparameter names and display text from other text

the following conventions will be used:

• Parameter Names will appear in [brackets]

• Display Text will appear in “quotes”

ATTENTION: Only personnel familiar with the 1336

SPIDER Adjustable Frequency AC Drive and associated

!

machinery should plan or implement the installation, start-up

and subsequent maintenance of the system. Failureto comply

may result in personal injury and/or equipment damage.

ATTENTION: An incorrectly applied or installed drive can

result in component damage or a reduction in product life.

!

Wiring or application errors, such as, undersizing the motor,

incorrect or inadequate ACsupply, or excessive ambient temperatures may result in malfunction of the system.

Page 8

1–2 Information and Precautions

General Precautions (continued)

ATTENTION:Toavoidahazardof electric shock,verifythat

the voltage on the bus capacitors has discharged before

!

performinganyworkon thedrive.MeasuretheDCbusvoltage

atthe + &–terminalsof thePowerTerminalBlock(see Figure

2.1 for location). The voltage must be zero.

ATTENTION: This drive contains ESD (Electrostatic

Discharge) sensitive parts and assemblies. Static control pre-

!

cautions are required when installing, testing, servicing or

repairingthisassembly.Componentdamage may result if ESD

control procedures are not followed. If you are not familiar

with static control procedures, reference A-B publication

8000-4.5.2, “GuardingAgainst Electrostatic Damage” or any

other applicable ESD protection handbook.

ATTENTION: Ground fault detection devices must not be

used on this drive as the sole protection measure against unin-

!

tentionalshockhazard. TheDCcomponentin the groundfault

current may inhibit the correct function of the fault detector.

ATTENTION:ACdrivescancause disturbancestothesupply

network. The basic version of the 1336 SPIDER Drive does

!

not include any harmonic filters and may not fulfill the limits

of the national recommendations. The harmonic voltage disturbances produced by the drive are dependent on the supply

network impedance.

Machinery Directive

ATTENTION: The 1336 SPIDER Drive is a component

intended for implementation in machines or systems for the

!

capital goods industry.

The start-up of the drive in the European market is not

permitted until it has been confirmed that the machine into

which the drives are built is in conformance with the

regulations of the Council Directive Machinery 89/392/EWG.

ATTENTION: The built-in Stop function (control input at

terminal20-25)mustnotbeusedasanemergencystopcircuit.

!

To inhibit uncontrolled machine operation in case of the malfunction of the drive, the user must provide an external

emergency stop circuit, which ensures disconnection of the

power source from the motor. This circuit must be hardwired

with electro-mechanic components and shall not depend on

electronic logic or software. The stopping device (e.g.

mushroom head pushbutton with lock) must be accessible to

the operator. Failure to observe this precaution could result in

bodily injury or loss of life.

Page 9

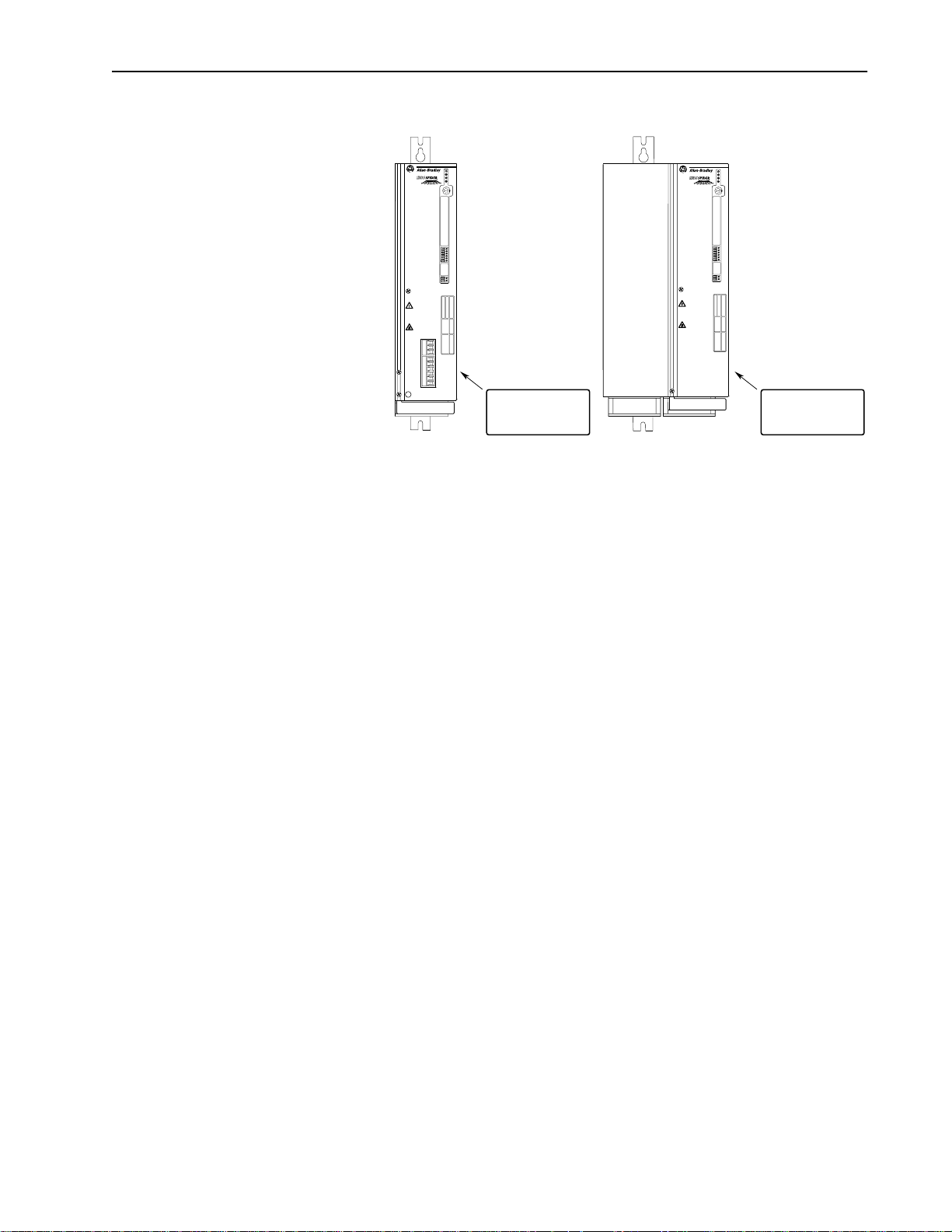

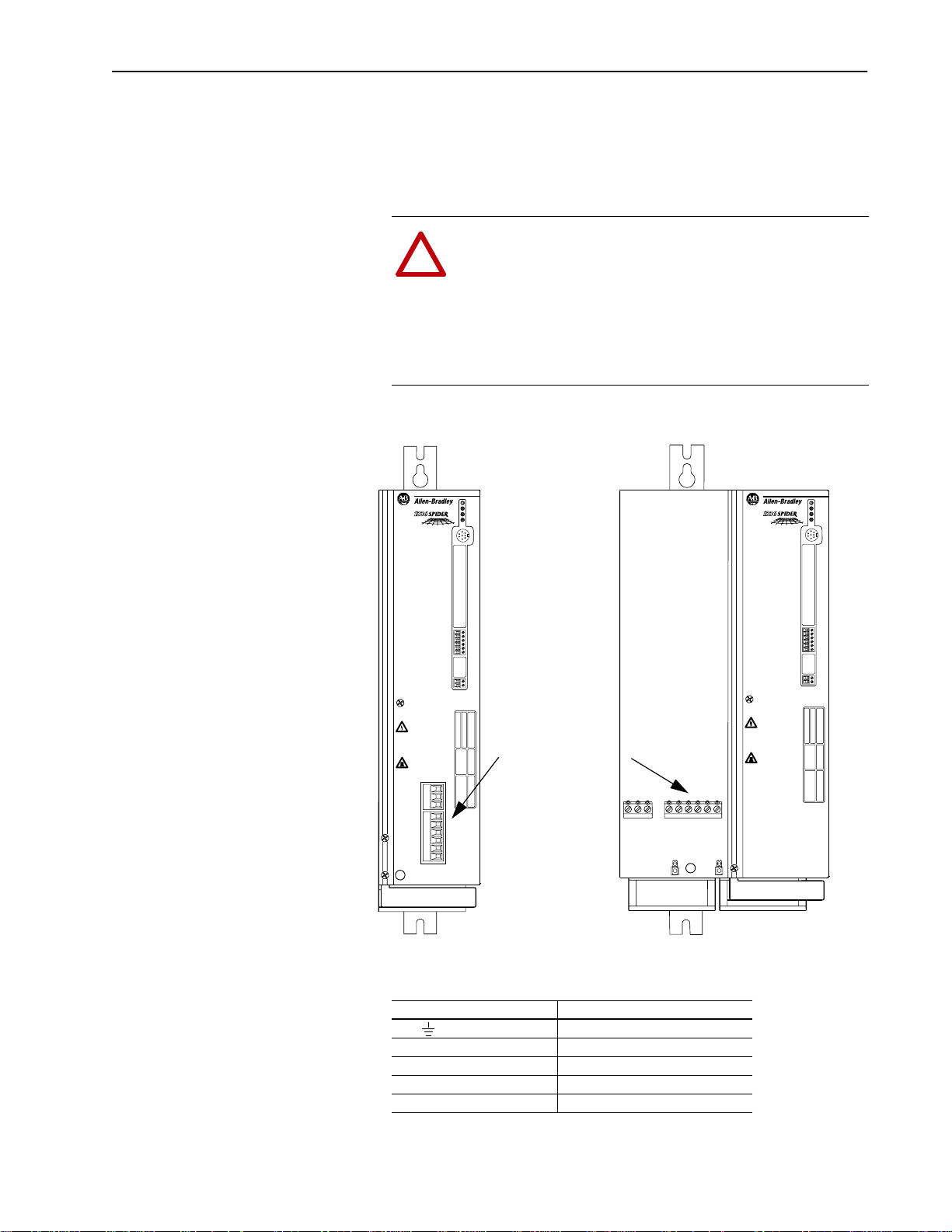

Nameplate Location

Information and Precautions 1–3

PWR

RUN

STOP

FAULT

TB1

TB2

TB3

TB4

TB5

TB6

TB7

DEVICE IS LIVE UP TO

180SEC AFTER REMOVING

MAINS VOLTAGE.

GERÄT FÜHRT BIS

180SEK NACH DEM

AUSSCHALTEN SPANNUNG.

L'APPAREIL RESTE SOUS

TENSION JUSQU'A 180 S

APRES LA MISE HORS SERVICE.

L1

L2

L3

45 (–)

47 (+)

48

U

V

W

PE

Nameplate Located on

Side Panel

9.9A through 36A Drives

PWR

RUN

STOP

FAULT

TB1

TB2

TB3

TB4

TB5

TB6

TB7

DEVICE IS LIVE UP TO

180SEC AFTER REMOVING

MAINS VOLTAGE.

GERÄT FÜHRT BIS

180SEK NACH DEM

AUSSCHALTEN SPANNUNG.

L'APPAREIL RESTE SOUS

TENSION JUSQU'A 180 S

APRES LA MISE HORS SERVICE.

Nameplate Located on

33A and 60A Drives

Side Panel

Page 10

1–4 Information and Precautions

End of Chapter 1

Page 11

Chapter 2

General Installation for All Drives

Chapter 2 provides the information you need to properly mount and

wire the main power connections of 1336 SPIDER Drives. In

addition, installation instructions are provided for the communication

options (GM1, GM2, etc.). Detailed control and signal wiring for the

Stand-alone or PLC control version is presented in Chapter 3 or 4,

respectively. Since most start-up difficulties are the result of incorrect

wiring, every precaution must be taken to assure that the wiring is

done as instructed. All items must be read and understood before the

actual installation begins.

ATTENTION: Thefollowinginformationismerely a

guide for proper installation. The Allen-Bradley

!

Company cannot assume responsibility for the

complianceorthenoncompliancetoanycode,national,

localorotherwisefortheproperinstallationofthisdrive

or associated equipment. A hazard of personal injury

and/or equipment damage exists if codes are ignored

during installation.

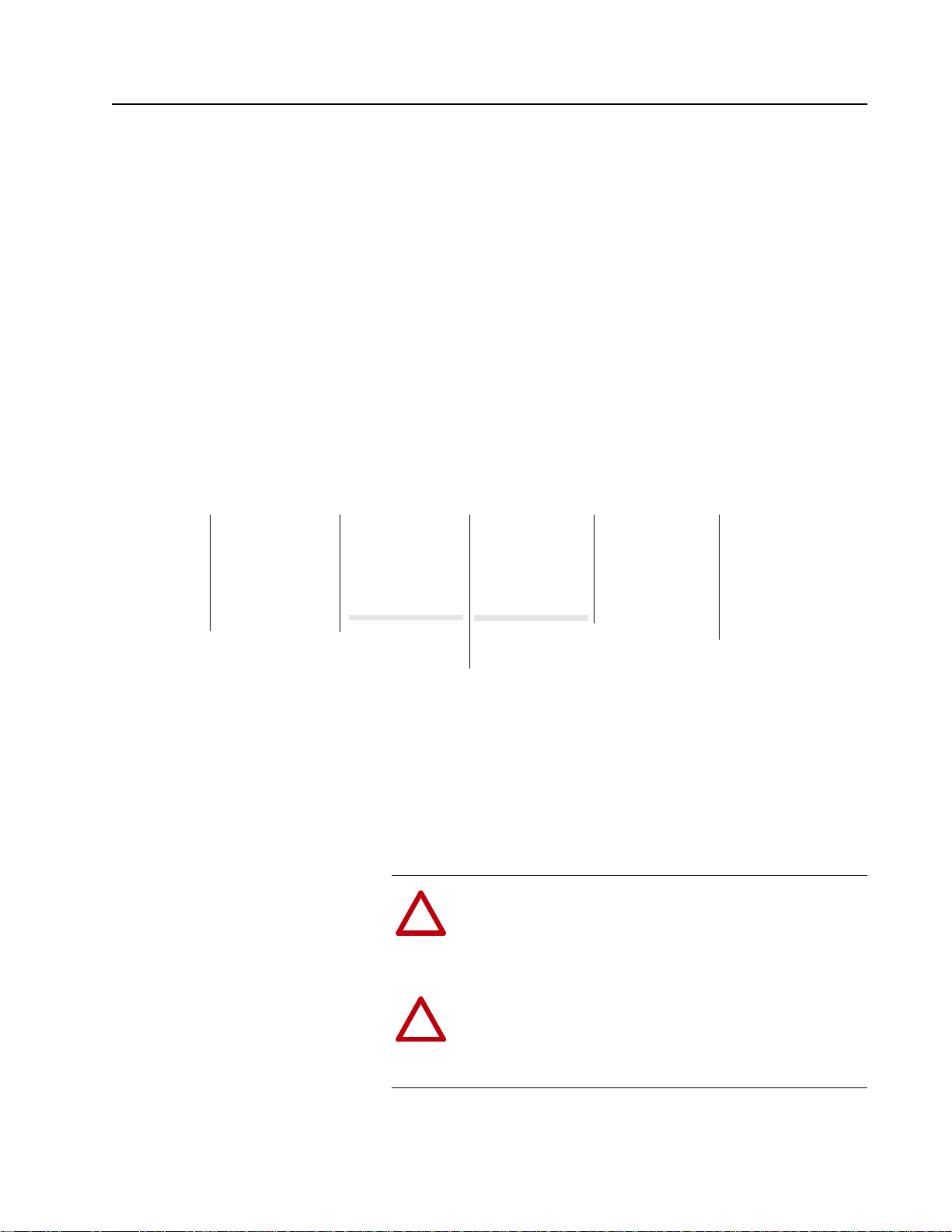

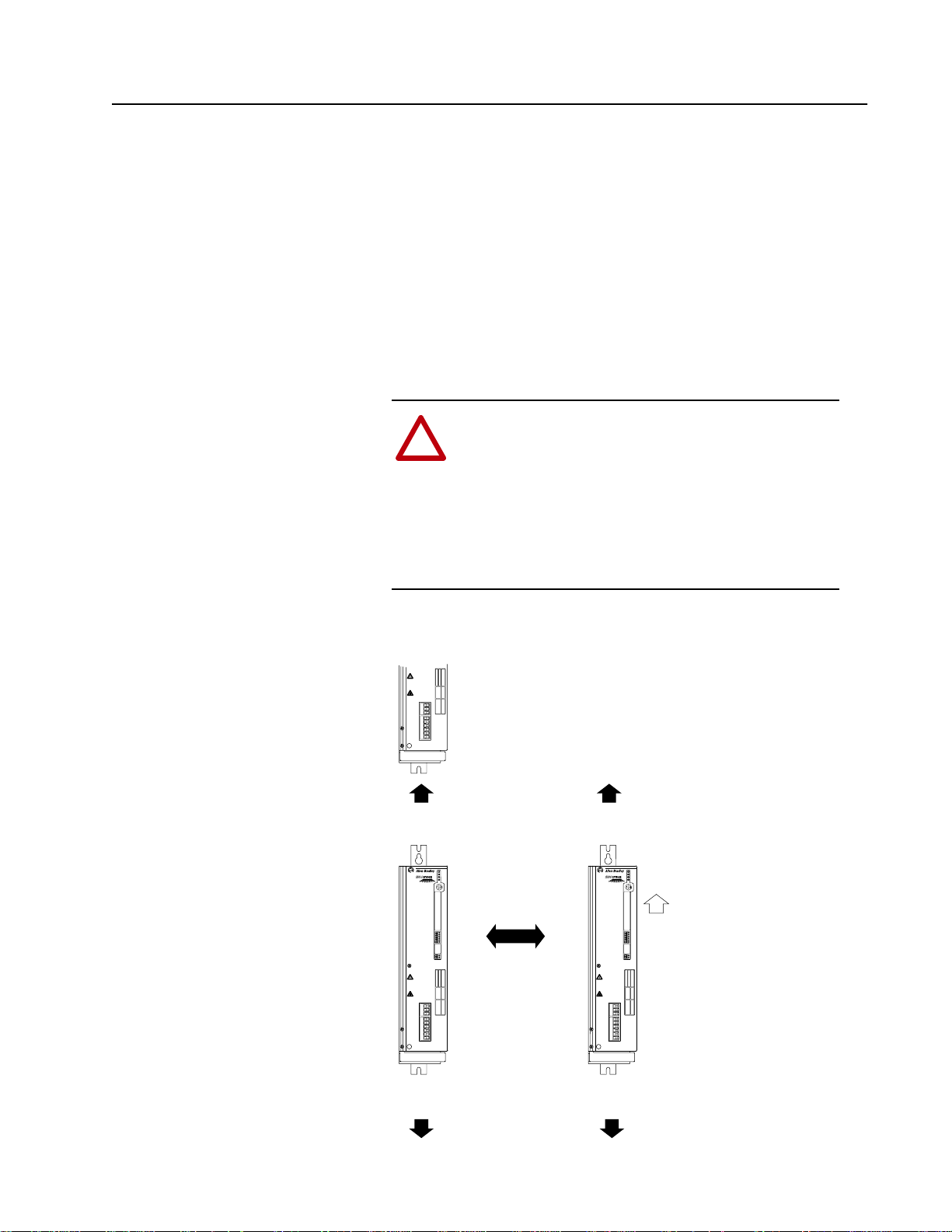

Mounting Minimum Mounting Requirements for Proper Heat Dissipation

(Dimensions shown are between drives or other devices)

DEVICE IS LIVE UP TO

180SEC AFTER REMOVING

MAINS VOLTAGE.

GERÄT FÜHRT BIS

180SEK NACH DEM

AUSSCHALTEN SPANNUNG.

L'APPAREIL RESTE SOUS

TENSION JUSQU'A 180 S

APRES LA MISE HORS SERVICE.

PE

101.6 mm

(4.0 in.)

PWR

RUN

STOP

FAULT

TB1

TB2

TB3

TB4

TB5

TB6

TB7

DEVICE IS LIVE UP TO

180SEC AFTER REMOVING

MAINS VOLTAGE.

GERÄT FÜHRT BIS

180SEK NACH DEM

AUSSCHALTEN SPANNUNG.

L'APPAREIL RESTE SOUS

TENSION JUSQU'A 180 S

APRES LA MISE HORS SERVICE.

PE

Normal Spacing

5.1 mm (0.2 in.)

15.2 mm (0.6 in.)

Required to

Remove Cover

101.6 mm

(4.0 in.)

PWR

RUN

STOP

FAULT

TB1

TB2

TB3

TB4

TB5

TB6

TB7

DEVICE IS LIVE UP TO

180SEC AFTER REMOVING

MAINS VOLTAGE.

GERÄT FÜHRT BIS

180SEK NACH DEM

AUSSCHALTEN SPANNUNG.

L'APPAREIL RESTE SOUS

TENSION JUSQU'A 180 S

APRES LA MISE HORS SERVICE.

PE

UP

101.6 mm

(4.0 in.)

101.6 mm

(4.0 in.)

Page 12

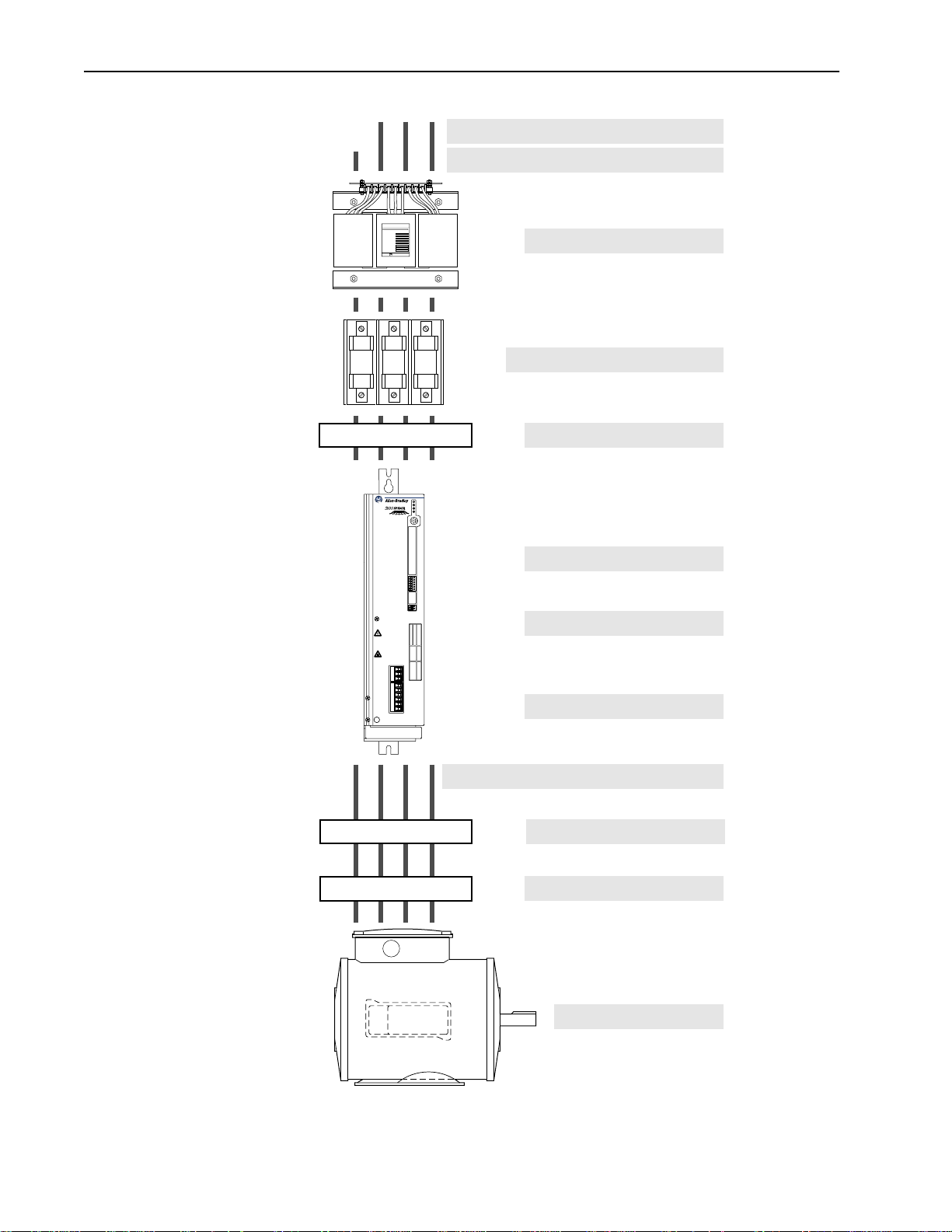

2–2 General Installation for All Drives

Installation Guidelines

GND

CAT. NO.

FREQUENCY

POWER RATING

PRIMARY VOLTAGE

SECONDARY VOLTAGE

INSULATION CLASS

NO. OF PHASES

VENDOR PART NO.

DEVICE IS LIVE UP TO

180SEC AFTER REMOVING

MAINS VOLTAGE.

GERÄT FÜHRT BIS

180SEK NACH DEM

AUSSCHALTEN SPANNUNG.

L'APPAREIL RESTE SOUS

TENSION JUSQU'A 180 S

APRES LA MISE HORS SERVICE.

AC Supply Source

Harmonics/RFI/EMC

Page 2–3

Page 2–5 &

Appendix C

ALLEN-BRADLEY

Input Power Conditioning

Input Fusing & Circuit Breakers

Input Devices

PWR

RUN

STOP

FAULT

TB1

TB2

TB3

TB4

TB5

TB6

TB7

Electrical Interference

Grounding

Page 2–3

Page 2–4

Page 2–5

Page 2–5

Page 2–6

PE

Power Cabling

Control & Signal Cabling

Output Devices

Cable Termination

Page 2–9

Chapters 3 & 4

Page 2–12

Page 2–13

Motor

Page 13

General Installation for All Drives 2–3

AC Supply Source 1336 SPIDER drives are suitable for use on a circuit capable of

delivering up to a maximum of 200,000 rms symmetrical amperes,

600 volts.

ATTENTION: To guard against personal injury and/or

equipmentdamage causedby improperfusing, useonly the

!

recommended line fuses specified in Table 2.A.

Unbalanced Distribution Systems

This drive is designed to operate on earthed-neutral, three-phase

supply systems whose line voltages are symmetrical. 240V ACdrives

may be operated with one phase referenced to ground.

Ungrounded Distribution Systems

1336 SPIDER drives are not designed to operate in ungrounded

systems.

Input Power Conditioning In general, the 1336 SPIDER is suitable for direct connection to an

AC line of the correct voltage. Certain conditions can exist, however,

that prompt consideration of a line reactor or isolation transformer

ahead of the drive.

The basic rules to aid in determining whether a line reactor or

isolation transformer should be considered are as follows:

1. If the AC source experiences frequent power outages or

significant voltage transients, users should calculate the source

transformer VA. If thesource transformer VA exceeds the VAmax

(1MVA) and the drive is installed close to the source, it is an

indication that there may be enough energy behind these voltage

transients to cause nuisance input fuse blowing, overvoltage

faults or drive power structure damage. In these cases, a line

reactor or isolation transformer should be considered.

2. If the AC source does not have a neutral or one phase referenced

to ground (see Unbalanced Distribution Systems), an isolation

transformer with the neutral of the secondary grounded is required. If

the line-to-ground voltages on any phase can exceed 125% of the

nominal line-to-line voltage, an isolation transformer with the neutral

of the secondary grounded, is

3. If the AC line supplying the drive has power factor correction

capacitors that are switched in and out, an isolation transformer

or 5% line reactor is recommended between the drive and

capacitors. If the capacitors are permanently connected and not

switched, the general rules above apply.

highly recommended.

Page 14

2–4 General Installation for All Drives

Input Fuses The 1336 SPIDER should be installed with input fuses. However,

local/national electrical codes may determine additional requirements

for these installations.

Installations per U.S. NEC/UL/CSA

In general, the specified fuses are suitable for branch short circuit

protection and provide excellent short circuit protection for the drive.

The fuses offer a high interrupting capacity and are fast acting. Refer

to the North American selections in Table 2.A.

IEC Installations

For those installations that are not required to meet the U.S. NEC/

UL/CSA, the specified fuses are suitable for branch short circuit

protection and provide excellent short circuit protection for the drive.

The fuses offer a high interrupting capacity and are fast acting. Refer

to the selections in Tables 2.A and 2.B.

ATTENTION: The 1336 SPIDER does not provide input

powershort circuit protection.Specifications forthe recom-

!

mendedfusetoprovidedriveinputpowerprotectionagainst

short circuits is provided.

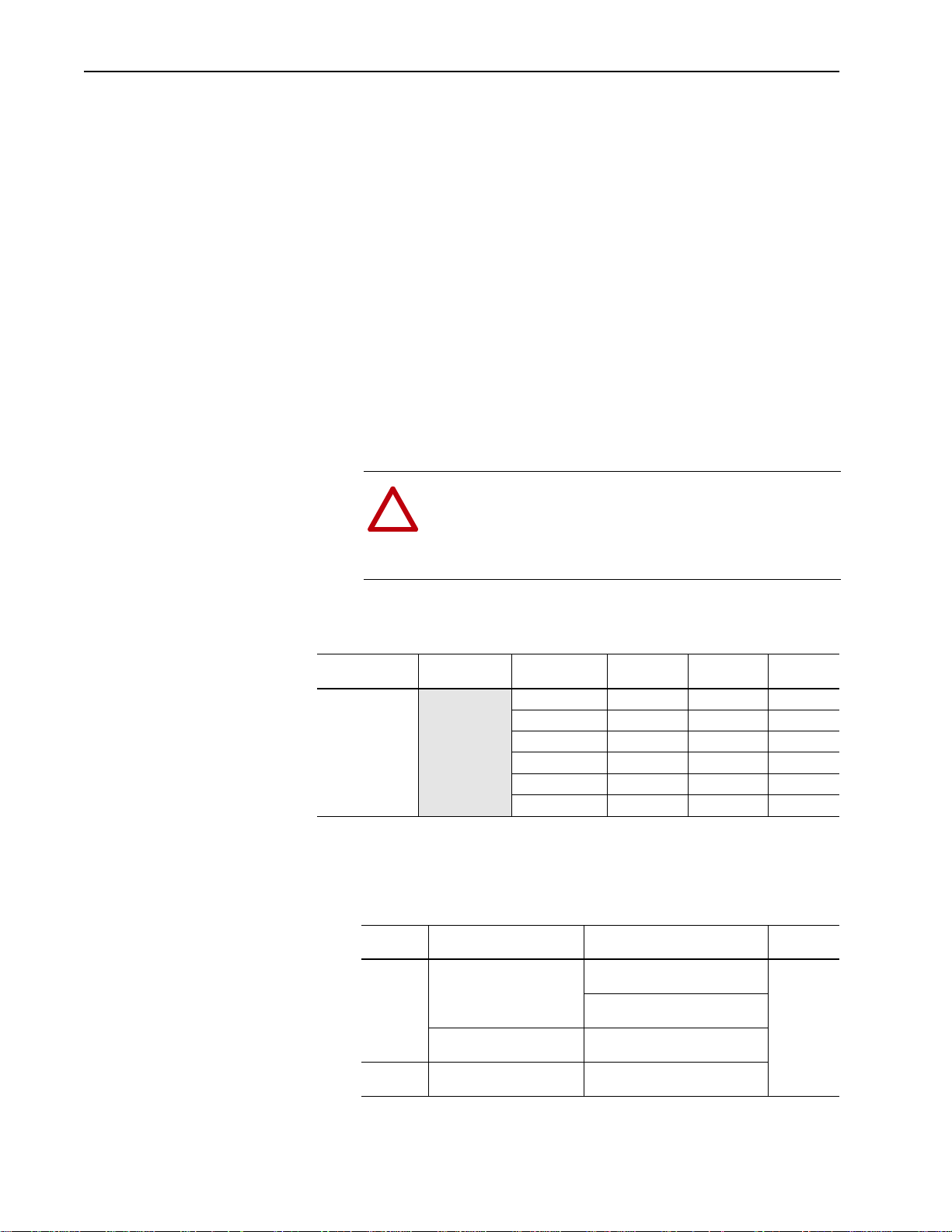

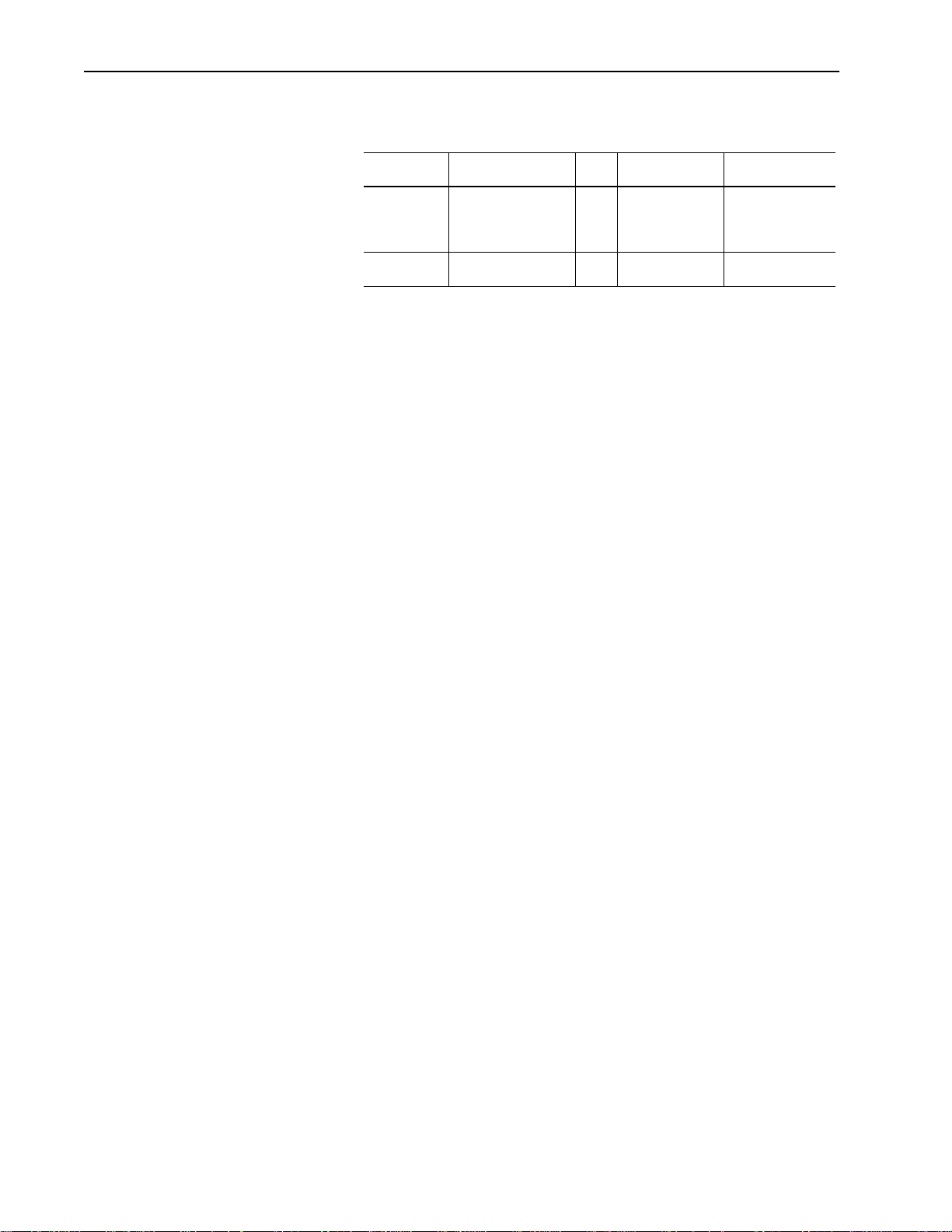

Table 2.A

Maximum Recommended AC InputLine Fuse Ratings (fuses are user supplied)

European

Installations

The recommended fuse is

Class gG, general

industrial applications.

NorthAmerican

Installations

The recommended fuse is

UL Class CC, T

or J.

Drive Catalog

Number

1336Z- _ A022 3.0 1.8 30A

1336Z- _ A036 5.0 3.0 30A

1336Z- _ A060 8.3 5.0 50A

1336Z- _ B010 2.7 1.6 20A

1336Z- _ B017 4.6 2.7 20A

1336Z- _ B033 9.1 5.5 40A

Drive Output

kVA Rating

Drive Output

kW Rating

Table 2.B

Recommended Fuses for Shared DC Bus Applications

(Fuses must be mounted between the drive and the shared DC bus)

AC Line

Rating Description Fuse Type

240V AC with Earthed Transformer

Star Point

with B Phase Grounded AJT (Gould or equivalent),

480V AC with Earthed Transformer

Star Point

LP-CC (Bussmann or equivalent),

300V DC rating

AJT (Gould or equivalent),

500V DC rating

500V DC rating

AJT (Gould or equivalent),

500V DC rating

Maximum

Fuse Rating

Maximum

Fuse Rating

See Table

2.A

Page 15

General Installation for All Drives 2–5

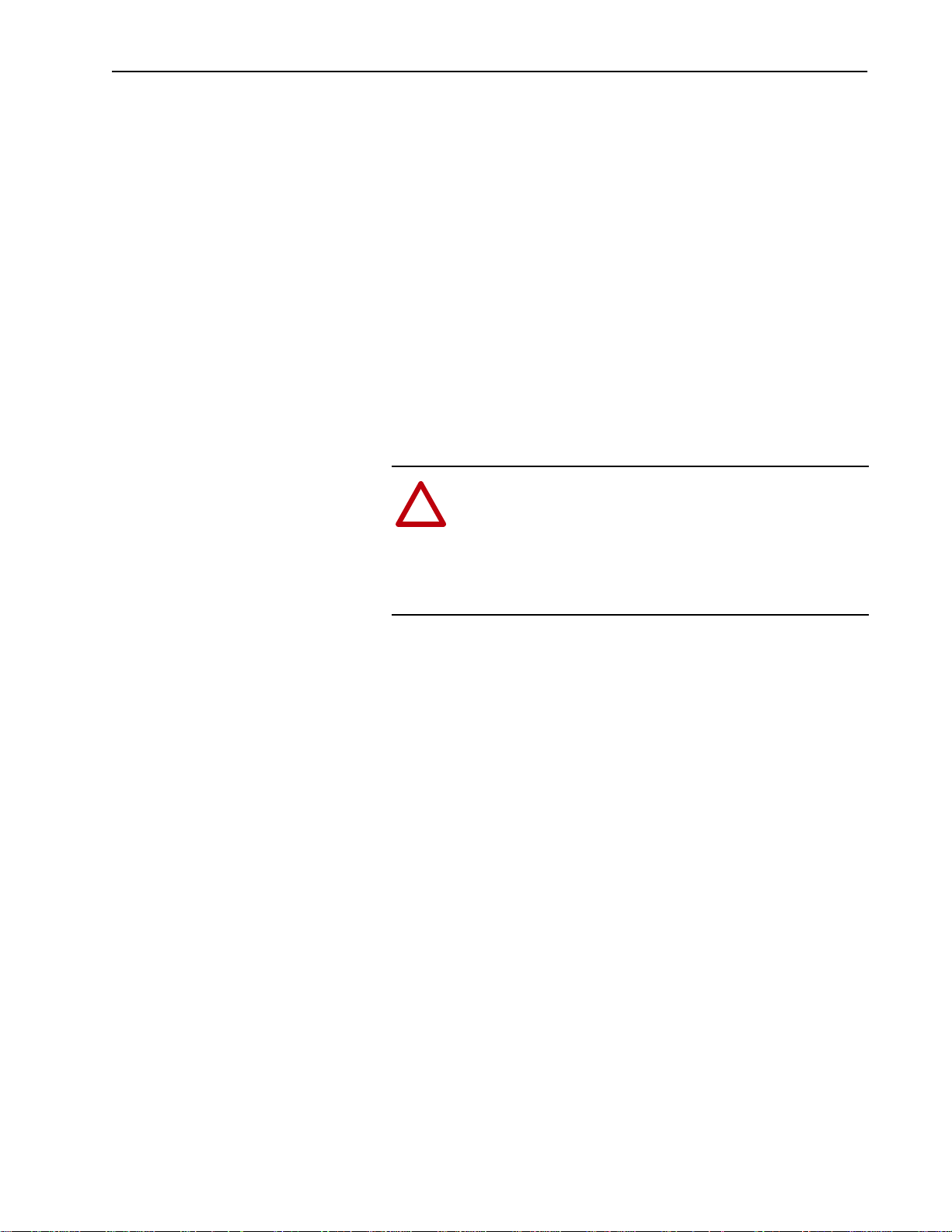

Input Devices Starting and Stopping the Motor

ATTENTION: The drive start/stop control circuitry includes solid-statecomponents. If hazards due to accidental

!

contact with moving machinery or unintentional flow of

liquid, gas or solids exist, an additional hardwired stop circuit may be required to remove ACline power to thedrive.

WhenAC power isremoved, there will be a lossof inherent

regenerativebrakingeffect &the motor will coast toa stop.

An auxiliary braking method may be required.

Repeated Application/Removal of Input Power

ATTENTION: The drive is intended to be controlled by

control input signals that will start and stop the motor. A

!

device that routinely disconnects then reapplies line power

to the drive for the purpose of starting and stopping the

motor is not recommended.

Electrical Interference - EMI/RFI Immunity

The immunity of 1336 SPIDER drives to externally generated

interference is good. Usually, no special precautions are required

beyond the installation practices provided in this publication.

Since coils can generate severe electrical transients, it is

recommended that the coils of DC energized contactors associated

with drives be suppressed with a diode or similar device. AC supplied

coils should utilize an R-C suppressor.

Emission

Careful attention must be given to the arrangement of power and

ground connections to the drive to avoid interference with nearby

sensitive equipment. The cable to the motor carries switched voltages

and should be routed well away from sensitive equipment.

The ground conductor of the motor cable must be connected to the

drive ground (PE) terminal directly. Connecting this ground

conductor to a cabinet ground point or ground bus bar may cause high

frequency current to circulate in the ground system of the enclosure.

The motor end of this ground conductor must be solidly connected to

the motor case ground.

Shielded cable must be used to guard against radiated emissions from

the motor cable. The shield must be connected to the drive ground

(PE) terminal and the motor ground as outlined above. Armored cable

can be used if radiation is not a concern.

Page 16

2–6 General Installation for All Drives

The drive has a smallcommon mode choke in the power output (U, V

& W). On installations that do not use shielded cable, additional

common mode chokes can help reduce common mode noise at the

drive output. Common mode chokes can also be used on analog or

communication cables. Refer to page 2–13 for further information.

An RFI filter can be used and in most situations provides an effective

reduction of RFI emissions that may be conducted into the main

supply lines.

If the installation combines a drive with sensitive devices or circuits,

it is recommended that the lowest possible drive PWM carrier

frequency be programmed.

RFI Filtering 1336 SPIDER drives can be ordered with an integral RFI filter, which

controls radio-frequency conducted emissions into the main supply

lines and ground wiring.

If the cabling and installation recommendation precautions described

in this manual are adhered to, it is unlikely that interference problems

will occur when the drive is used with conventional industrial

electronic circuits and systems. However, a filter may be required if

there is a likelihood of sensitive devices or circuits being installed on

the same AC supply.

Where it is essential that very lowemission levelsmust be achievedor

if conformity with standards is required the optional RFI filter must

be used. Refer to Appendix C for installation and grounding information.

CE Conformity Refer to Appendix C.

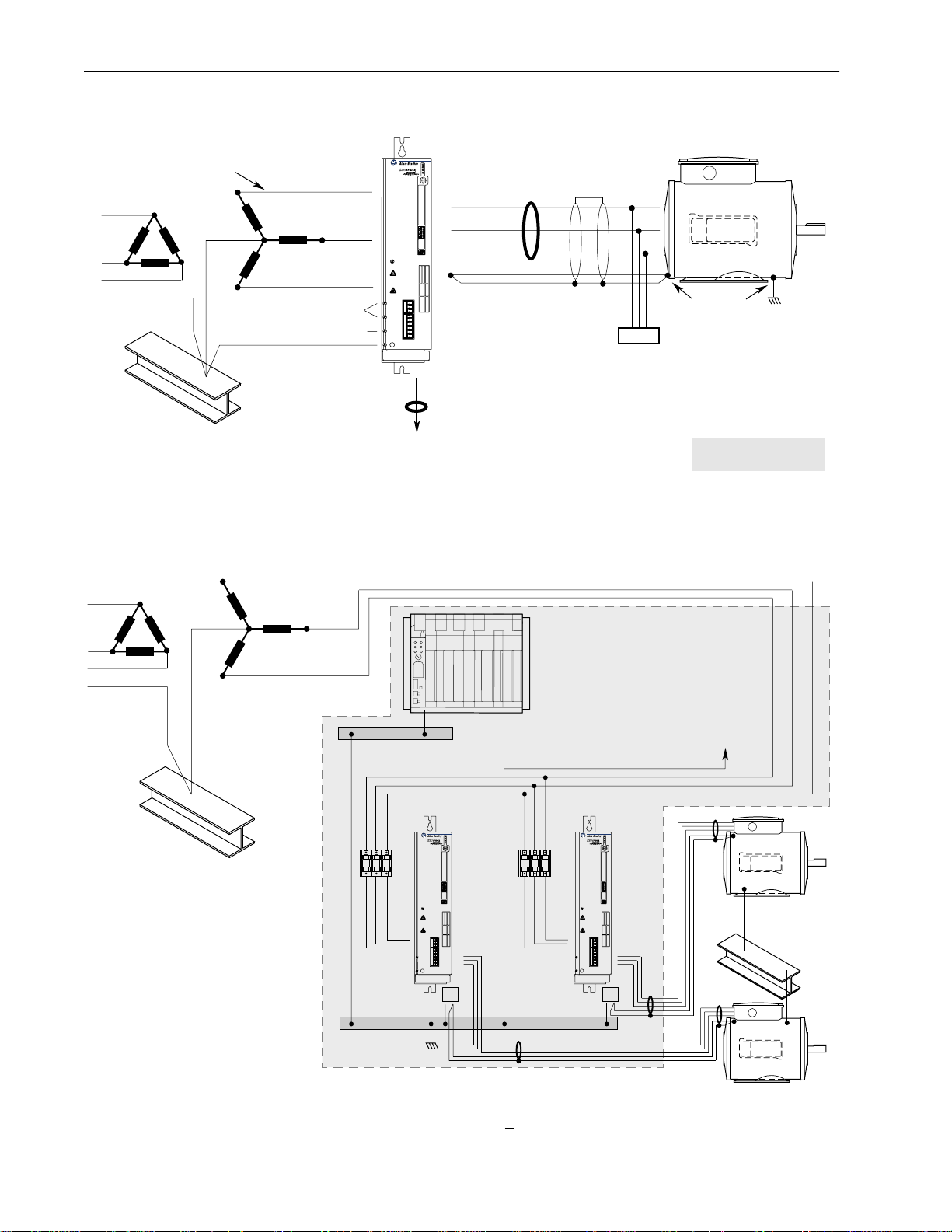

Grounding Refer to the grounding diagram on page 2–8. The drive must be

connected to system ground at the power ground (PE) terminal.

Ground impedance must conform to the requirements of national and

local industrial safety regulations (NEC, VDE 0160, BSI, etc.) and

should be inspected and tested at appropriate and regular intervals.

In any cabinet, a single, low-impedance ground point or ground bus

bar should be used. All circuits should be grounded independently

and directly. The AC supply ground conductor should also be

connected directly to this ground point or bus bar.

Sensitive Circuits

It is essential to define the paths through which the high frequency

ground currents flow. This will assure that sensitive circuits do not

share a path with such current. Control and signal conductors should

not be run near or parallel to power conductors.

Page 17

General Installation for All Drives 2–7

Motor Cable

The ground conductor of the motor cable (drive end) must be

connected directly to the drive ground (PE) terminal (see General

Grounding on page 2–8), not to the enclosure bus bar. Grounding

directly to the drive (and filter, if installed) can provide a direct route

for high frequency current returning from the motor frame and ground

conductor. At the motor end, the ground conductor should also be

connected to the motor case ground.

If shielded or armored cables are used, the shield/armor should also

be grounded at both ends as described above.

Discrete Control and Signal Wiring

The control and signal wiring must be grounded at the drive (see

General Grounding on page 2–8). If shielded control and signal wires

are used, the shield must also be grounded at the drive end only.

If the control and signal wires are short, and contained within a

cabinet which hasno sensitive circuits, the use of shielded control and

signal wiring may not be necessary, but is always recommended.

Safety Ground - PE (Potential Earth)

This is the safety ground required by code. This point must be

connected to adjacent building steel (girder, joist) or a floor ground

rod, provided grounding points comply with national or local electric

code regulations. The line input PE wire must be connected to the

bottom PE terminal (see General Grounding on page 2–8). If a

cabinet ground bus is used, refer to Grounding on page 2–6.

RFI Filter

Important: Using the integral RFI filter may result in relatively high

ground leakage currents. Surge suppression devices are

incorporated in the drive. The filter must be solidly

grounded. Grounding must not rely on flexiblecables and

should not include any form of plug or socket that would

permit inadvertent disconnection. The integrity of this

connection should be periodically checked.

Page 18

2–8 General Installation for All Drives

General Grounding

Conduit/4-Wire Cable

to Motor & Signal PE Ground

Nearest

Building Structure Steel

(for further grounding info, see "

PWR

RUN

STOP

FAULT

PE

DEVICE IS LIVE UP TO

180SEC AFTER REMOVING

MAINS VOLTAGE.

GERÄT FÜHRT BIS

180SEK NACH DEM

AUSSCHALTEN SPANNUNG.

L'APPAREIL RESTE SOUS

TENSION JUSQU'A 180 S

APRES LA MISE HORS SERVICE.

TB1

TB2

TB3

TB4

TB5

TB6

TB7

L1 (R)

L2 (S)

L3 (T)

Do Not Use

PE

RIO/DH+

Common

or Analog

Mode Core*

To Computer/Position Controller

Control and Signal Wiring" in Chapter 3 or 4

Single-Point Grounding/Panel Layout

L1 (R)

U (T1)

V (T2)

W (T3)

PE/Gnd.

Common

Mode

Core*

Shield*

Shield

Motor

Terminator*

)

Motor Frame

PE

Ground per

Local Codes

* Options that can be

installed as needed.

Nearest

Building Structure Steel

L2 (S)

L3 (T)

Zero Volt Potential Bus

(Isolated from Panel)

PE Ground Bus

(Grounded to Panel)

For Programmable Controller

grounding recommendations,

refer to publication 1770-4.1

1336 SPIDER 1336 SPIDER

PWR

RUN

STOP

FAULT

TB1

TB2

TB3

TB4

TB5

TB6

TB7

DEVICE IS LIVE UP TO

180SEC AFTER REMOVING

MAINS VOLTAGE.

GERÄT FÜHRT BIS

180SEK NACH DEM

AUSSCHALTEN SPANNUNG.

L'APPAREIL RESTE SOUS

TENSION JUSQU'A 180 S

APRES LA MISE HORS SERVICE.

PE

PE PE

PWR

RUN

STOP

FAULT

TB1

TB2

TB3

TB4

TB5

TB6

TB7

DEVICE IS LIVE UP TO

180SEC AFTER REMOVING

MAINS VOLTAGE.

GERÄT FÜHRT BIS

180SEK NACH DEM

AUSSCHALTEN SPANNUNG.

L'APPAREIL RESTE SOUS

TENSION JUSQU'A 180 S

APRES LA MISE HORS SERVICE.

PE

To Nearest Building

Structure Steel

Nearest Building

Structure Steel

Important:Grounding requirementswillvarywith the drivesbeingused. Other driveswithTrueEarth (TE)terminalsmusthave azeropotentialbus, separate frompotential

earth(PE) ground bus. Notethat busescanbe tied together atonepoint in the control cabinetorbrought back separately tothebuilding ground grid (tied within3meters

(10 feet)).

Page 19

General Installation for All Drives 2–9

Power Cabling Input and output power connections are performed through the power

terminal blocks (see Figure 2.1 for location).

Important: For maintenance and setup procedures, the drive may be

operated without a motor connected.

ATTENTION: The National Codes and standards (NEC,

VDE,BSI etc.) andlocalcodes outlineprovisionsfor safely

!

installing electrical equipment. Installation must comply

with specifications regarding wire types, conductor sizes,

branch circuit protection anddisconnect devices.Failure to

do so may result in personal injury and/or equipment damage.

Figure 2.1

Power Terminal Block Locations

DEVICE IS LIVE UP TO

180SEC AFTER REMOVING

MAINS VOLTA GE.

GERÄT FÜHRT BIS

180SEK NACH DEM

AUSSCHALTEN SPANNUNG.

L'APPAREIL RESTE SOUS

TENSION JUSQU'A 180 S

APRES LA MISE HORS SERVICE.

45 (–)

47 (+)

PE

PWR

RUN

STOP

FAULT

TB1

TB2

TB3

TB4

TB5

TB6

TB7

Power Terminal Blocks

L1

L2

L3

48

U

V

W

Cover Removed to

Show Terminal

Blocks

L1 L2 L3 45

M4

(–)47(+)

48 U V W

PE

M4

DEVICE IS LIVE UP TO

180SEC AFTER REMOVING

MAINS VOLTA GE.

GERÄT FÜHRT BIS

180SEK NACH DEM

AUSSCHALTEN SPANNUNG.

L'APPAREIL RESTE SOUS

TENSION JUSQU'A 180 S

APRES LA MISE HORS SERVICE.

PWR

RUN

STOP

FAULT

TB1

TB2

TB3

TB4

TB5

TB6

TB7

Table 2.C

Power Terminal Block Signals

Terminal Description

PE Potential Earth Ground

L1 (R), L2 (S), L3 (T) AC Line Input Terminals

(+) 47 & (–) 45 DC Bus Terminals

(+) 47 & 48 Braking Resistor

U (T1), V (T2), W (T3) Motor Connection

Page 20

2–10 General Installation for All Drives

Table 2.D

Power Terminal Block Specifications

Drive Catalog

Number

1336Z-_ A022

1336Z-_ A036

1336Z-_ B010

1336Z-_ B017

1336Z-_ A060

1336Z-_ B033

1

Motor Cables

A variety of cable types are acceptable for drive installations. For

many installations, unshielded cable is adequate, provided it can be

separated from sensitive circuits. As an approximate guide, allow a

spacing of 0.3 meters (1 foot) for every 10 meters (32.8 feet) of

length. In all cases, long parallel runs mustbe avoided. Usecable with

the appropriate insulation class.

Max./Min. Wire Size

mm2 (AWG)

0.2/4 (24/10) M3 0.5-0.6 (4.4-5.3) 7 (0.28)

0.5/10 (20/6) M4 1.2-1.5 (10.6-13.3) 10 (0.39)

Wire sizes given are maximum/minimum sizes that terminal block will accept - these are not

recommendations. Use Copper wire only. Wire gauge requirements and recommendations are based

on 75 degree C. Do not reduce wire gauge when using higher temperature wire.

1

Screw

Size

Torque Range

N-m (lb.-in.)

Remove Insulation

mm (in.)

The cable should be 4-conductor with the ground lead being

connected directly to the drive ground terminal (PE) and the motor

frame ground terminal.

Shielded Cable

Shielded cable is recommended if sensitive circuits or devices are

connected or mounted to the machinery driven by the motor. The

shield must be connected to both the drive ground (drive end) and

motor frame ground (motor end). The connection must be made at

both ends to minimize interference.

If cable trays or large conduits are to be used to distribute the motor

leads for multiple drives, shielded cable is recommended to reduce or

capture the noise from the motor leads and minimize “cross coupling”

of noise between the leads of different drives. The shield should be

connected to the ground connections at both the motor and drive end.

Armored cable also provides effective shielding. Ideally it should be

grounded only at the drive (PE) and motor frame. Some armored

cable has a PVC coating over the armor to prevent incidental contact

with grounded structure. If, due to the type of connector, the armor is

grounded at the cabinet entrance, shielded cable should be used

within the cabinet if power leads will be run close to control signals.

In some hazardous environments it is not permissible to ground both

ends of the cable armor because of the possibility of high current

circulating at the input frequency if the ground loop is cut by a strong

magnetic field. This only applies in the proximity of powerful

electrical machines. In such cases, consult factory for specific

guidelines.

Page 21

General Installation for All Drives 2–11

Conduit

If metal conduit is preferred for cable distribution, the following

guidelines should be followed.

• Drives are normally mounted in cabinets and ground connections

are made at a common ground point in the cabinet. Normal

installation of conduit provides grounded connections to both the

motor frame ground (junction box) and drive cabinet ground.

These ground connections help minimize interference. This is a

noise reduction recommendation only, and does not affect the

requirements for safety grounding (refer to pages 2–6 and 2–7).

• No more than three sets of motor leads can be routed through a

single conduit. This will minimize “cross talk” that could reduce

the effectiveness of the noise reduction methods described. If

more than threedrive/motor connections per conduit are required,

shielded cable as described above must be used. If practical, each

conduit should contain only one set of motor leads.

ATTENTION: Toavoidapossible shockhazardcaused by

induced voltages, unused wires in the conduit must be

!

grounded at both ends. For the same reason, if a drive sharing a conduit is being serviced or installed, all drives using

this conduit should be disabled. This will eliminate the possible shock hazard from “cross coupled” drive motor leads.

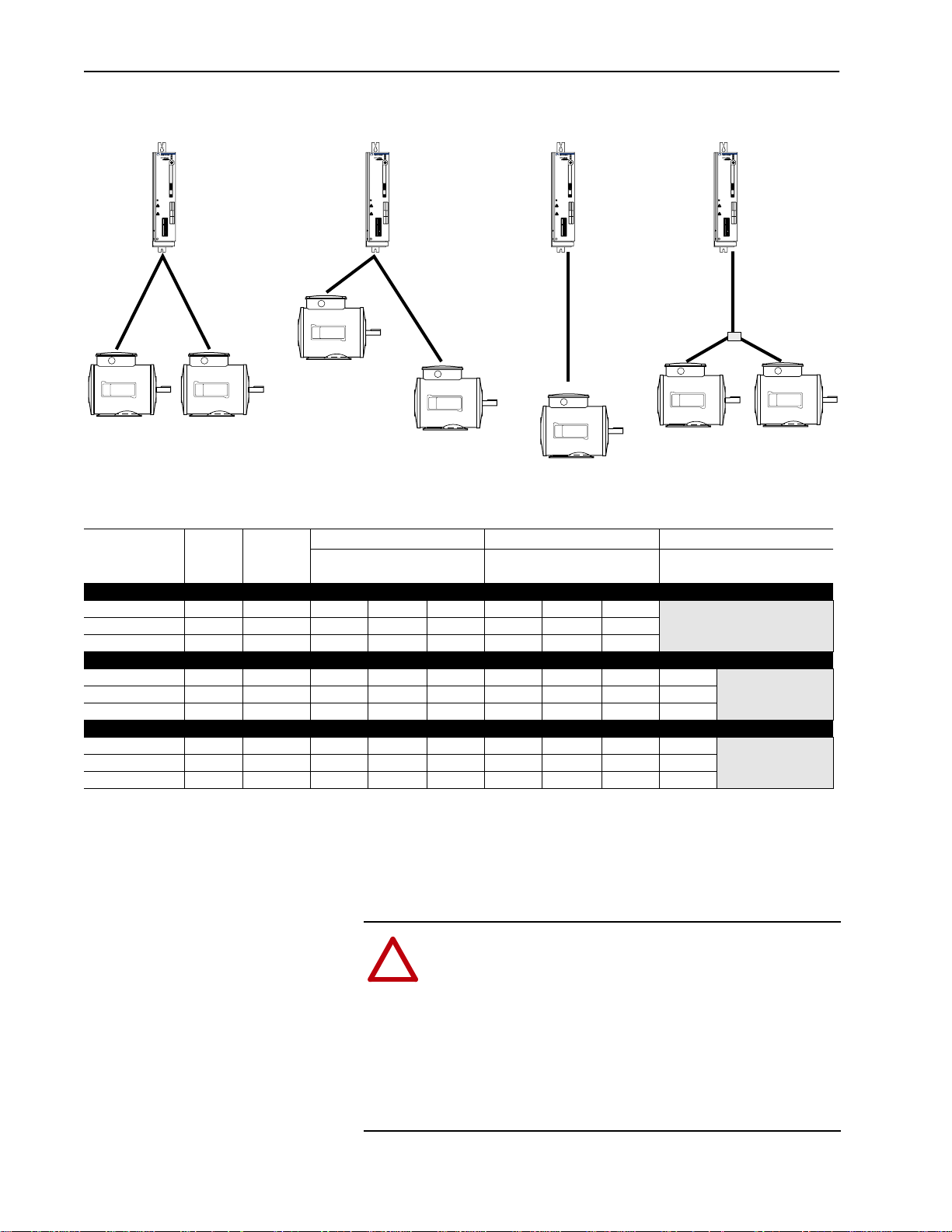

Motor Lead Lengths

Installations with long cables to the motor may require the addition of

output reactors or cable terminators to limit voltage reflections at the

motor. Excessive cable charging current can also reduce the amount

of current available to produce rated motor torque. Refer to Table 2.E

for the maximum cable length allowed for various installation

techniques. Shaded distances are restricted by cable capacitance

charging current. The figure on the next page illustrates how total

cable length iscalculated. Failure to followthese guidelines can result

in poor motor performance and nuisance drive overcurrent or

overload tripping. For installations that exceed the recommended

maximum lengths listed, contact the factory.

Please note that the cable lengths shown are guidelines. Your

application may be restricted to a shorter cable length due to wire

type, wire placement, line reactor and type of motor.

Dynamic Brake Resistor Wiring

All brake resistor wiring must be twisted wire run in conduit separate

from control wiring. Maximum cable length is 2.5 meters (8.2 feet).

Size wire according to the “Brake Current” provided on page A–3.

Brake resistor dimensions and specifications can be found in

Appendix B.

Page 22

2–12 General Installation for All Drives

How to Measure Motor Cable Lengths Limited by Capacitance

PWR

RUN

STOP

FAULT

TB1

TB2

TB3

TB4

TB5

TB6

TB7

DEVICE IS LIVE UP TO

180SEC AFTER REMOVING

MAINS VOLTAGE.

GERÄT FÜHRT BIS

180SEK NACH DEM

AUSSCHALTEN SPANNUNG.

L'APPAREIL RESTE SOUS

TENSION JUSQU'A 180 S

APRES LA MISE HORS SERVICE.

PE

PWR

RUN

STOP

FAULT

TB1

TB2

TB3

TB4

TB5

TB6

TB7

DEVICE IS LIVE UP TO

180SEC AFTER REMOVING

MAINS VOLTAGE.

GERÄT FÜHRT BIS

180SEK NACH DEM

AUSSCHALTEN SPANNUNG.

L'APPAREIL RESTE SOUS

TENSION JUSQU'A 180 S

APRES LA MISE HORS SERVICE.

PE

PWR

RUN

STOP

FAULT

TB1

TB2

TB3

TB4

TB5

TB6

TB7

DEVICE IS LIVE UP TO

180SEC AFTER REMOVING

MAINS VOLTAGE.

GERÄT FÜHRT BIS

180SEK NACH DEM

AUSSCHALTEN SPANNUNG.

L'APPAREIL RESTE SOUS

TENSION JUSQU'A 180 S

APRES LA MISE HORS SERVICE.

PE

PWR

RUN

STOP

FAULT

TB1

TB2

TB3

TB4

TB5

TB6

TB7

DEVICE IS LIVE UP TO

180SEC AFTER REMOVING

MAINS VOLTAGE.

GERÄT FÜHRT BIS

180SEK NACH DEM

AUSSCHALTEN SPANNUNG.

L'APPAREIL RESTE SOUS

TENSION JUSQU'A 180 S

APRES LA MISE HORS SERVICE.

PE

15 (50)

90 (295)

90 (295)

165 (540)

180 (590)

150 (490)

15 (50) 15 (50)

All examples represent motor cable length of 180 meters (590 feet).

Table 2.E

Maximum Motor Cable Length Restrictions in meters (feet) - 380V-480V Drives

No External Devices 1321-3R55-A Reactor at Drive 1321-3R25-A Reactor at Drive

Motor Insulation Class

not less than . . .

Motor Insulation Class

not less than . . .

Motor Insulation Class

not less than . . .

Drive Catalog

Number

Peak

Current

Rating

1

Cable

Diameter

mm2 (AWG)

220-240V AC 800V 1000V 1200V 800V 1000V 1200V

1336Z- _ A022 21.6A 2.5 (12) 120 (394) 120 (394) 120 (394) 180 (590) 180 (590) 180 (590)

1336Z- _ A036 36.0A 2.5 (12) 180 (590) 180 (590) 180 (590) 180 (590) 180 (590) 180 (590)

1336Z- _ A060 60.0A 6.0 (8) 180 (590) 180 (590) 180 (590) 180 (590) 180 (590) 180 (590)

380-400V AC 1000V 1200V 1400V 1000V 1200V 1400V 1000V 1200V 1400V

1336Z- _ B010 9.9A 2.5 (12) 15 (50) 105 (344) 105 (344) 30 (98) 180 (590) 180 (590) 60 (197)

1336Z- _ B017 16.5A 2.5 (12) 15 (50) 115 (377) 115 (377) 30 (98) 180 (590) 180 (590) 60 (197)

1336Z- _ B033 33.0A 6.0 (8) 15 (50) 155 (509) 180 (590) 30 (98) 180 (590) 180 (590) 60 (197)

460-480V AC 1200V 1400V 1600V 1200V 1400V 1600V 1200V 1400V 1600V

1336Z- _ B010 9.9A 2.5 (12) 15 (50) 105 (344) 105 (344) 30 (98) 180 (590) 180 (590) 60 (197)

1336Z- _ B017 16.5A 2.5 (12) 15 (50) 115 (377) 115 (377) 30 (98) 180 (590) 180 (590) 60 (197)

1336Z- _ B033 33.0A 6.0 (8) 15 (50) 120 (394) 180 (590) 30 (98) 180 (590) 180 (590) 60 (197)

1

This current is only possible with synchronous motors and for spinning applications. For actual motor current rating, refer to Appendix A.

Output Devices Drive Output Disconnection

ATTENTION: Toguard againstdrive damage, always disablethedrivebefore disconnecting themotorfrom the drive

!

output terminals. Any disconnecting means wired to the

drive output terminals U, V and W must be capable of disabling the driveif opened duringdrive operation.If opened

(motor disconnected) during drive operation, the drive will

continue to produce output voltage between U, V, & W

(drive damage could occur). An auxiliary contact must be

used to simultaneously disable the drive.

Page 23

General Installation for All Drives 2–13

Common Mode Cores

The 1336 SPIDER includes an integral output common mode core.

This will help reduce the common mode noise at the drive output and

guard against interference with other electrical equipment (programmable controllers, sensors, analog circuits, etc.). In addition, reducing

the PWM carrier frequency will reduce the effects and lower the risk

of common mode noise interference. Refer to the table below for

additional information.

Table 2.F

1336 SPIDER Common Mode Chokes

Catalog Number Used with . . . Description

1321-M001 Communications Cables, Analog

Signal Cables, etc.

Cable Termination Optional Cable Terminator

Voltage doubling at motor terminals, known as reflected wave phenomenon, standing wave or transmission line effect, can occur when

using drives with long motor cables.

Open Style - Signal Level

Inverter duty motors with phase-to-phase insulation ratings of 1200

volts or higher should be used to minimize effects of reflected wave

on motor insulation life.

Applications with non-inverter duty motors or any motor with exceptionally long leads may require an output filter or cable terminator. A

filter or terminator will help limit reflection to the motor, to levels

which are less than the motor insulation rating.

Table 2.D lists the maximum recommended cable length for unterminated cables, since the voltage doubling phenomenon occurs at different lengths for different drive ratings. If your installation requires

longer motor cable lengths, a reactor or cable terminator is recommended.

Optional Input/Output Reactor Specifications

Bulletin 1321 Reactors listed in the 1336 PLUS-3.0 Price Sheet can

be used for drive input and output. These reactors are specifically

constructed to accommodate IGBT inverter applications with switching frequencies up to 20 kHz. They have a UL approved dielectric

strength of 4000 volts, opposed to a normal rating of 2500 volts. The

first two and last two turns of each coil are triple insulated to guard

against insulation breakdown resulting from high dv/dt. When using

motor line reactors, it is recommended that the drive PWM frequency

be set to its lowest value to minimize losses in the reactors.

Important: By usingan outputreactor theeffectivemotor voltage will

be lower because of the voltage drop across the reactor this may also mean a reduction of motor torque.

Page 24

2–14 General Installation for All Drives

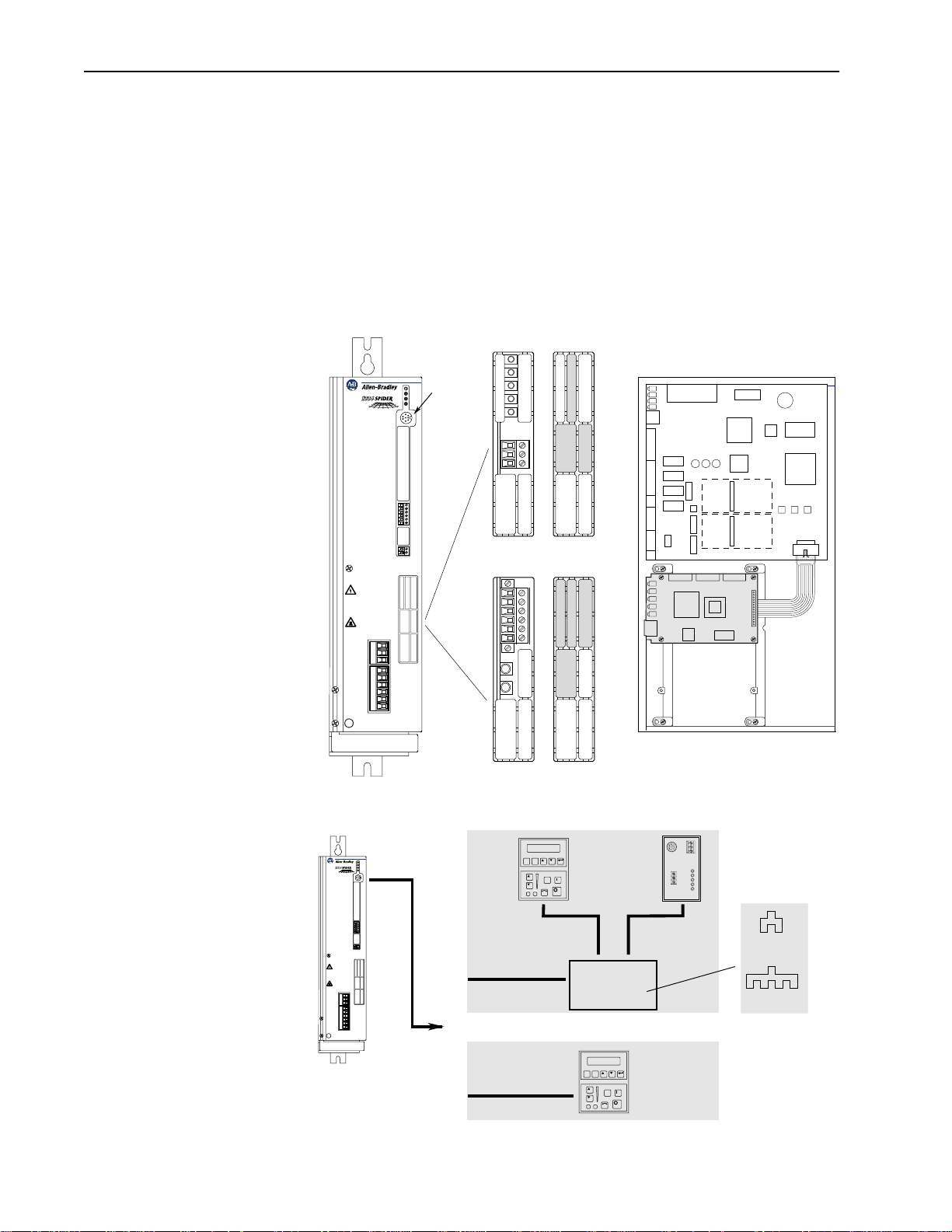

Adapter Definitions and

Communication Option

Installation

Serial communication devices such as the Human Interface Module

that are connected to the drive are identified by SCANport as

Adapters. Depending on the drive and options ordered, different

adapters are available. The communication options available for the

1336 SPIDER can be mounted as shown in Figure 2.2. Access to the

communication ports and LEDs is gained by removing the knockouts

shown. Figure 2.3 shows the maximum distance allowed between

external devices.

Figure 2.2

Adapter Locations

Remote I/O

Adapter 2

DEVICE IS LIVE UP TO

180SEC AFTER REMOVING

MAINS VOLTAGE.

GERÄT FÜHRT BIS

180SEK NACH DEM

AUSSCHALTEN SPANNUNG.

L'APPAREIL RESTE SOUS

TENSION JUSQU'A 180 S

APRES LA MISE HORS SERVICE.

45 (–)

47 (+)

PE

PWR

RUN

STOP

FAULT

TB1

TB2

TB3

TB4

TB5

TB6

TB7

(Remove Shaded Areas)(Installed)

DeviceNet

Adapter 1

L1

L2

L3

48

U

V

W

J1

J3

TB1

Slot A

Slot B

(Communication Board Installed)

J11

J8

J13

J2

(Remove Shaded Areas)

(Installed)

Figure 2.3

Remote Device Distances

RIO

PWR

RUN

STOP

FAULT

TB1

TB2

TB3

TB4

TB5

TB6

TB7

DEVICE IS LIVE UP TO

180SEC AFTER REMOVING

MAINS VOLTAGE.

GERÄT FÜHRT BIS

180SEK NACH DEM

AUSSCHALTEN SPANNUNG.

L'APPAREIL RESTE SOUS

TENSION JUSQU'A 180 S

APRES LA MISE HORS SERVICE.

L1

L2

L3

45 (–)

47 (+)

48

U

V

W

PE

Total cable distance between

each device and drive must

Length = X Meters

ESC SEL

JOG

Cable Length in

Meters = 10 – X

Maximum Cable

Length = 10 Meters

HIM or Other

Remote Device

Port Expansion

Option

(1203-SG2)

or

ESC SEL

JOG

be 10 meters (33 feet) or less.

1

Communications Port for remote HIM/communication options (Adapter 2) or Expansion Options (Adapters 2, 3, 4, 5) is located at TB1.

SCANport

Comm

Status

120/240V AC

Input

Communication Module

Cable Length in

Meters = 10 – X

HIM or Other

Remote Device

23

1203-SG2

2345

1203-SG4

Expansion Options

1

Page 25

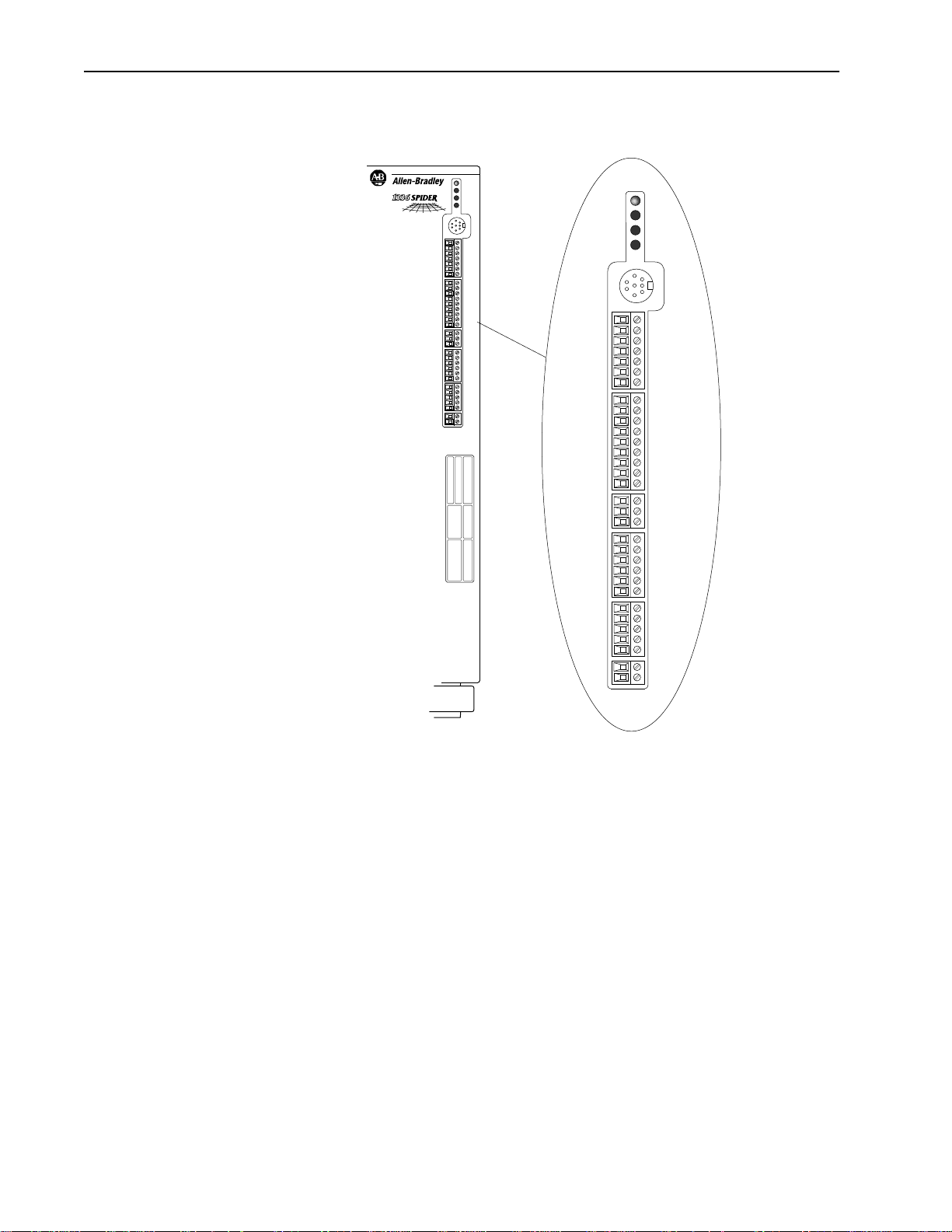

Installation/Wiring for Stand-Alone Drives

Chapter 3 provides the information you need to perform the control

and signal wiring for Stand-alone 1336 SPIDER Drives. In addition,

installation information is provided for the Analog Option Boards.

Refer to Chapter 2 for general installation and wiring.

Control and Signal Wiring General Wiring Information

General requirements for analog and digital signal wire include:

stranded copper 0.750-0.283 mm

shield, 300V minimum insulation rating and a temperature rating

suitable for the application (not less than 60 degrees C.). Refer to

Table 3.A for terminal block specifications and Figure 3.1 for

locations.

Chapter 3

2

(18-22 AWG), twisted-pair, 100%

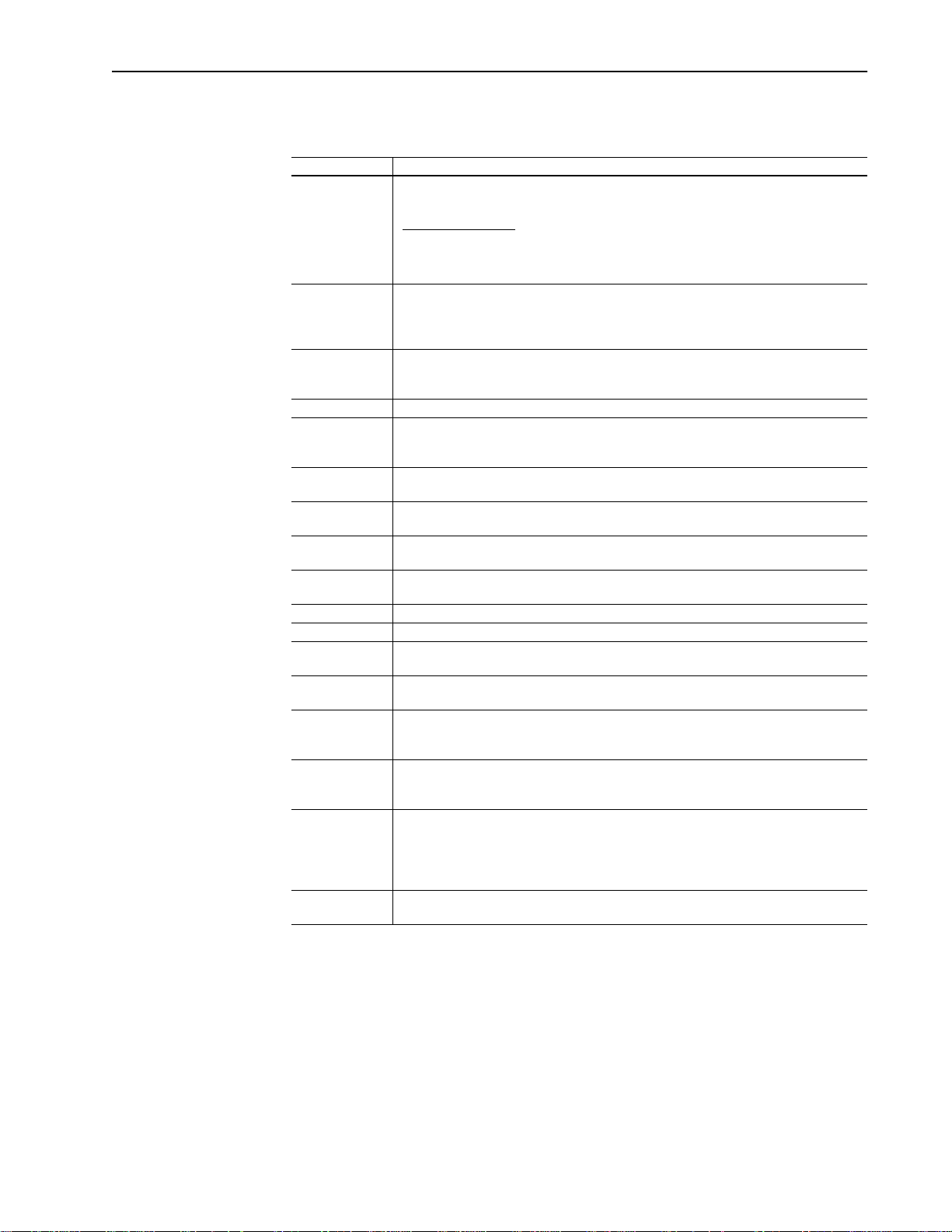

Table 3.A

Control and Signal Terminal Block Specifications

Drive Catalog

Number

All 0.14-1.5 (28-16) M2 0.22-0.25 (1.9-2.2) 9 (0.35)

1

Wire sizes given are maximum/minimum sizes that terminal block will accept - these are not

recommendations. Use Copper wire only. Wire gauge requirements and recommendations are based

on 75 degree C. Do not reduce wire gauge when using higher temperature wire.

Max./Min. Wire Size

mm2 (AWG)

1

Screw

Size

Torque Range

N-m (lb.-in.)

Remove Insulation

mm (in.)

Signal Connections

If the drive control connections are to be linked to an electronic

circuit or device, the common or 0V line should, if possible, be

grounded at the device (source) end only.

Important: The signal common (0V) of the drive is internally

connected to PE. User speed reference signals are

terminated to logiccommon at TB2, terminal 5. This puts

the negative (or common) side of these signals at earth

ground potential. Control schemes must be examined for

possible conflicts with this type of grounding scheme.

Cable Routing

If unshielded cable is used, signal circuits should not run parallel to

motor cables or unfiltered supply cables with a spacing less than 0.3

meters (1 foot). Cable tray metal dividers or separate conduit should

be used.

Important: When user installed control and signal wiring with an

insulationratingofless than 600Vis used,thiswiringmust

be routed inside the drive enclosure and separated from

any other wiring and/or uninsulated live parts.

Page 26

3–2 Installation/Wiring for Stand-Alone Drives

Figure 3.1

Control and Signal Terminal Blocks

PWR

RUN

STOP

FAULT

TB1

1

2

3

TB2

4

5

6

7

8

9

10

11

12

TB3

13

14

15

16

17

TB4

18

19

20

21

22

TB5

23

24

25

26

27

TB6

28

29

30

24VC

TB7

24V

TB1

TB2

TB3

TB4

TB5

TB6

TB7

PWR

RUN

STOP

FAULT

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

24VC

24V

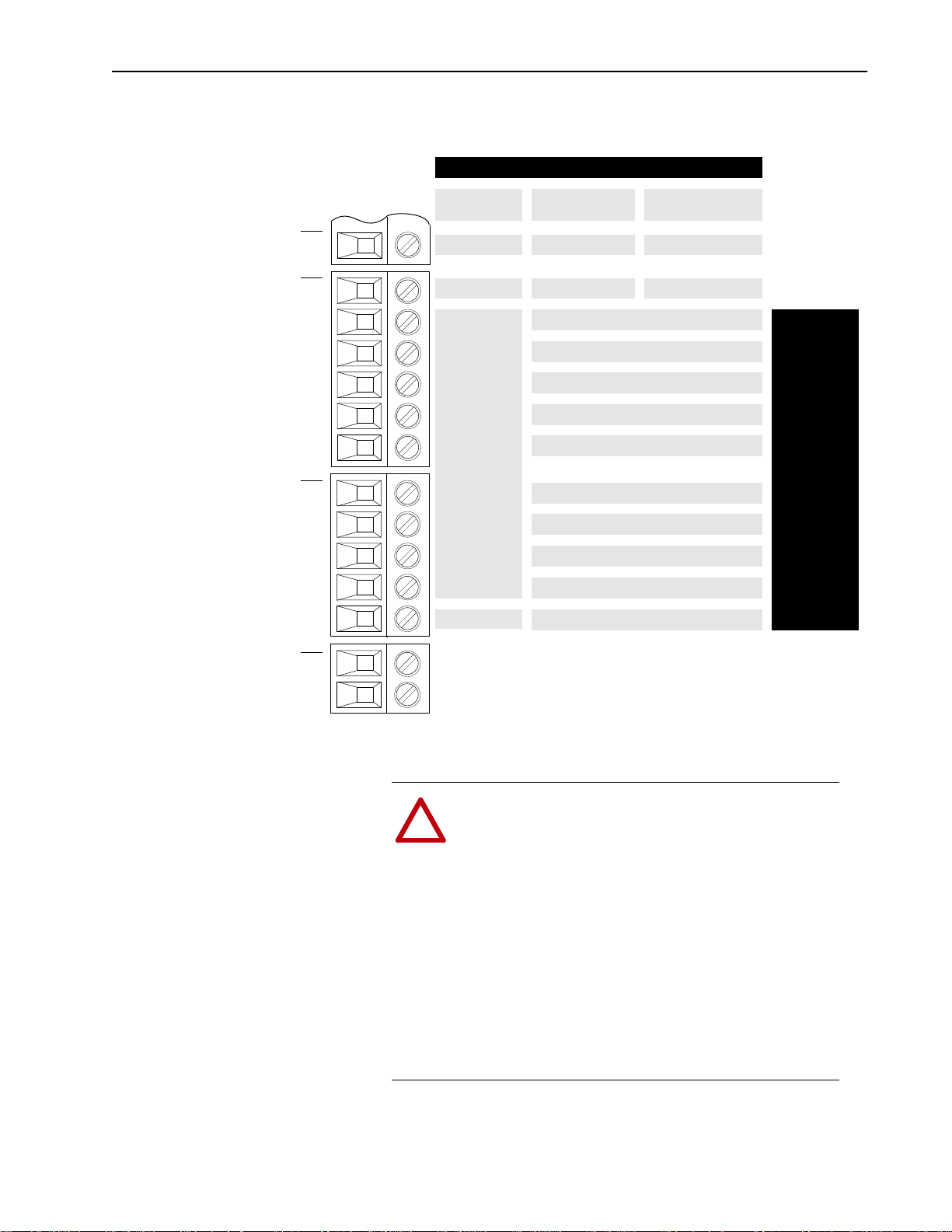

Digital Inputs Digital inputs are connected at TB4-TB6.

Input Mode Select

A number of combinations are available by first programming

[Input Mode] to the desired control scheme (i.e. 2 wire, 3 wire or

Status). The remaining inputs can then be configured by

programming parameters 242-247 ([TB5 Term 22 Sel] - [TB6 Term

28 Sel]). Refer to the table on page 3–5 and the Digital I/O parameter

group in Chapter 7 for programming information.

Page 27

Input 1

Input 2

TB4

19

TB5

20

Installation/Wiring for Stand-Alone Drives 3–3

Figure 3.2

Digital I/O Default Settings

Input Mode (Start/Stop Functions Only)

2

Status

(Factory Default)

Status Run Forward Start

Stop/Fault Reset

2-Wire Control

Single-Source Control

3

Stop/Fault Reset3Stop/Fault Reset

3-Wire Control

Single-Source Reversing

3

Common

Input 3

Input 4

Input 5

Common

Input 6

Input 7

Input 8

Common

Input 9

24V Common

21

22

23

24

25

TB6

26

27

28

29

30

TB7

24V

Common

Rev/For4 (Programmable)

Status Only

Default Mode

shown at right

is not active

when

[Input Mode]

is set to "Status"

3

Enable

1

See

Speed Select

2

If this mode is selected, the status of all inputs can be read at the [Input Status] parameter.

However, only “Stop/Fault Reset” and “Enable” will have control function.

3

These inputs must be present (reprogram if necessary) before drive will start.

4

Bit 0 of [Direction Mask] must = 1 to allow TB5 direction change/bipolar operation.

Jog (Programmable)

Auxiliary3 (Programmable)

Common

1

Speed Select 3

Speed Select 21 (Programmable)

Speed Select 11 (Programmable)

Common

Enable

Table.

(Programmable)

3

(Not Programmable)

Factory

Default Inputs

ATTENTION: A hazard of personal injury from

automatic restart exists with 2-wire control. 2-wire

!

control uses maintained Run contacts that act as both

Run(closed)andStop (open) devices.OpeningtheStop

contact (terminal 20) will stop the drive.If this contact

is reclosed, any fault will be reset. If a valid Start

commandisstill present,thedrivewillrestart.Only use

2-wire control for applications outlined in NFPA79,

“Under Voltage Protection.”

If a 3-wire device (i.e. HIM) is also used, pressing the

HIM Stop key will also stop the drive. Releasing the

Stop key will clear any faults that are present, but the

drive will not restart without cycling the Start contact.

Page 28

3–4 Installation/Wiring for Stand-Alone Drives

Circuits must be capable of operating with high = true logic.

DC external circuits in the low state must generate a voltage of no

more than 8V DC. Leakage current must be less than 1.5 mA into a

2.5k ohm load.

DC external circuits in the high state must generate a voltage of +20

to +26 volts and source a current of approximately 10 mA for each

input. The stand-alone version is compatible with these

Allen-Bradley PLC modules:

• 1771-OB • 1771-OQ16 • 1771-OB16

• 1771-OBD • 1771-OYL

• 1771-OBN • 1771-OZL

• 1771-OQ • 1771-OBB

The 24 volt power supply is capable of supplying a total of 16 digital

inputs.

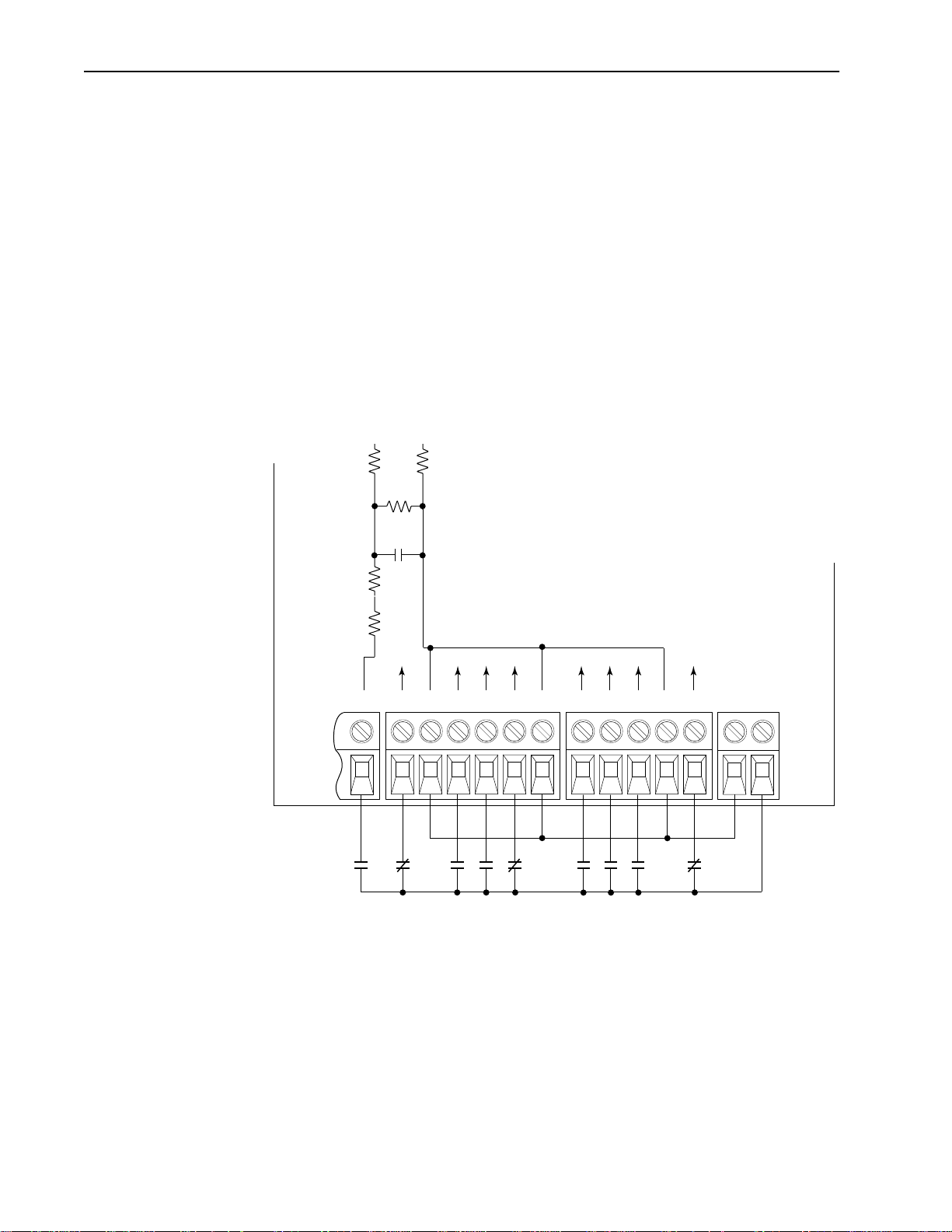

510 510

20k

Typical

0.22µf

510

1k

2019 21 22 23 24 25

TB4 TB5 TB6 TB7

Contacts shown are general, refer to Input Mode Select and information presented above.

26 27 28 29 30

24V Common

24V

Page 29

Installation/Wiring for Stand-Alone Drives 3–5

Available Functions for Inputs 3 through 8

A variety of combinations made up of the following inputs are a v ailable.

Input Description

“2 Acc/1 Acc”

“2 Dec/1 Dec”

“1st Accel”

“2nd Accel”

“1st Decel”

“2nd Decel”

“Aux Fault” Faultsthe drivevia externaldevices (i.e. motor thermoswitch,O.L. relays, etc.).Opening this

“Clear Fault” If drive has faulted, closing this input will clear the fault.

“Dig Pot Up”

“Dig Pot Dn”

“Forward” Closing these inputs (Forward or Reverse) commands the corresponding direction. If both

“Rev/For” Available only with three-wire control - Closing this input commands reverse direction and

“Jog” Closingthis inputstarts thedrive and causesit torun at programmedjog frequency.Opening

“Local Ctrl” Closing this input gives exclusive control of drive logic to the inputs at terminals 19-30. No

“Reverse” See “Forward” above.

“PI Enable” Enables the output of the process PI loop.

“PI Reset” Opening this input clamps the process PI integrator value at zero. Closing this input allows

“Run Reverse” Available Only with two-wire control - Closing this input issues both a start command and a

“Speed Sel 1”

“Speed Sel 2”

“Speed Sel 3”

“Stop Type” Closing thisinput selectsthe stopmode in [Stop Select 2] as the method ofstopping whena

“Sync” Normally wired to multiple drives – When the Sync input is low, the drive operates normally.

“Traverse” Settingthis inputlow disablesthe traverse function. When the input is high,the traversefunc-

Closing these inputs will command the corresponding accel or decel rate. If both inputs are

open or both are closed, the current rate is maintained.

Input 1st2

No Command 0 0

Accel/Decel 1 0 1

Accel/Decel 2 1 0

Allows selection of the accel or decel time used by the drive. 1=2nd, 0=1st

contact will fault(F02 -Aux Fault) thedrive andshut theoutput off,ignoring theprogrammed

stop mode.

These inputs increase (up) or decrease (down) the drive commanded frequency when MOP

(Motor Operated Potentiometer) is chosen as the frequency command source. The rate of

increase/decrease is programmable.

inputs are open or both are closed, the current direction is maintained.

opening this input commands forward direction.

this input stops the drive using the programmed stop mode.

other devices may issue logic commands (excluding Stop) to the drive.

the integrator to continue to operate.

reverse command to the drive. Opening the input issues a stop command to the drive.

These inputs choose the frequency command source for the drive. See following pages for

details.

stop command is issued. Opening this input selects the stop mode in [Stop Select 1] as the

method of stopping.

When the input ishigh, the speed of the drive willbe held constant and the speed command

willhave no effect.During thisperiod thespeed input ofthe drivewill normally be changedto

a different source and/or value. Allows synchronizedchange of frequency command tomultiple drives.

tion will be active. [Speed Control] must also be set to “P Jump” for the function to be active.

nd

Important: The [Input Mode] parameter can be changed at any time,

but the change will not affect drive operation until power

tothe drivehas beenremovedand busvoltagehas decayed

completely. When changing thisparameter,it is important

to note that the functions of the Start and Stop inputs will

change when power is reapplied to the drive.

The programming options allowyou to select an input combination to

meet the needs of a specific installation. The firmware will verify

programming, to assure selection of an appropriate combination.

Page 30

3–6 Installation/Wiring for Stand-Alone Drives

Speed Select/Frequency Reference

The drivespeed command can be obtained from a number of different

sources. The source is determined by drive programming and the

condition of the Speed Select Inputs on TB6 (or reference select bits

of command word if PLC controlled - see Appendix A).

The default source for a command reference (all speed select inputs

open) is the selection programmed in [Freq Select 1]. If any of the

speed select inputs are closed, the drive will use other parameters as

the speed command source. See Table 3.B and the examples that

follow.

Table 3.B

Speed Select Input State vs. Frequency Source

Speed Select 3 Speed Select 2 Speed Select 1 Frequency Source

Open Open Open [Freq Select 1]

Open Open Closed [Freq Select 2]

Accessed through [Freq Select 2] parameter [Preset Freq 1]

Open Closed Open [Preset Freq 2]

Open Closed Closed [Preset Freq 3]

Closed Open Open [Preset Freq 4]

Closed Open Closed [Preset Freq 5]

Closed Closed Open [Preset Freq 6]

Closed Closed Closed [Preset Freq 7]

Important: The final speed command may be affected by the type of

modulation selected with [Speed Control], parameter 77.

See [Speed Control] in Chapter 7 for further information.

Important: If a bi-polar input option (LA6 or LA7) is installed, the

signal is designated “AnalogInput 0.”Note thefollowing:

3 Wire Control – If [Input Mode] is set to “3 Wire”

and the bi-polar input is selected as the active

frequency reference [Freq Select 1 or 2], it is

assumed that direction control is desired via analog

polarity. If another source has control of direction, a

“Bipolar Direction” fault (F16) will occur. If

direction control via polarity is not required, bit 7 of

[Direction Mask] should be set to “0.” This causes

the input to be treated as a 0-10V frequency

reference only. Negative analog signals are treated

as zero and direction control must come from

another source.

2 Wire Control – If [Input Mode] is set to “2 Wire,”

it is assumed that direction control is provided via

the 2 wire inputs (Run Forward and Run Reverse).

Bit 7 of [Direction Mask] must be set to “0.” This

causes the input to be treated as a 0-10V frequency

reference only. Negative analog signals are treated

as zero. Failure to set the Mask will generate a

“Bipolar Direction” (F16) fault.

Page 31

Installation/Wiring for Stand-Alone Drives 3–7

Example 1

3 Wire Control - Application calls for a local Human Interface

Module (HIM) speed command or remote 4-20mA from a PLC. The

drive is programmed as follows:

• [Freq Select 1] = Adapter 1

• [Freq Select 2] = Analog Input 0

With Speed Select inputs 2 & 3 open and the selector switch set to

“Remote” (Speed Select 1 closed), the drive will follow [Freq Select

2] (Analog Input 0). With the switch set to “Local” (Speed Select 1

open) all speed select inputs are open and the drive will follow the

local HIM (Adapter 1) as selected with [Freq Select 1].

Speed Select 3 (Open)

Speed Select 2 (Open)

Speed Select 1

Remote

Local

26

27

28

Example 2

Application is to follow a local HIM unless a preset speed is selected.

The drive is programmed as follows:

• [Freq Select 1] = Adapter 1

• [Freq Select 2] = Preset Freq 1

• [Preset Freq 1] = 10 Hz.

• [Preset Freq 2] = 20 Hz.

• [Preset Freq 3] = 30 Hz.

Contact operation for the speed select switch is described in the table

below. If the user does not select an input as Speed Select 3, [Preset

Freq 4-7] would not be available.

Local

See Table

1

26

2

3

27

28

Speed Select 2

Speed Select 1

Switch

Position

Local Open Open [Freq Select 1] Adapter 1

1 Closed Open [Freq Select 2] Preset Freq 1

2 Open Closed [Preset Freq 2] 20 Hz.

3 Closed Closed [Preset Freq 3] 30 Hz.

Speed Select Input

Parameter Used for

Speed Ref.

Programmed

Setting1 (#28) 2 (#27)

Page 32

3–8 Installation/Wiring for Stand-Alone Drives

Pulse Input/Output Option Pulse Input

!

The pulse input signal must be an externally powered square-wave

pulse at a 5V TTL logic level. As measured at the terminal block,

circuits in the high state must generate a voltage between 3.6 and

5.5V DC at 8 mA. Circuits in the low state must generate a voltage

between 0.0 and 0.8V DC. Maximum input frequency is 250kHz.

Scale factor [Pulse/Enc Scale] must be set.

Pulse Output

Provides a TTL pulse train suitable for driving up to three

1336 SPIDER pulse inputs or a separate 125 ohm load at TTL levels

(4V at 32 mA source, 0.8V at 3.2 mA sink).

Important: An LA5 Analog Option must be installed to use the pulse

ATTENTION: If input voltages are maintained at levels

above ±15V DC, signals may be degraded and component

damage may result.

input/output options. See Figure 3.4 for terminal

designations.

Digital Outputs The digital outputs are at terminals 10 through 18 of TB3-TB4.

Figure 3.3

Digital Outputs

TB3

Contacts Shown

in Unpowered State

(or powered state with

fault/alarm present)

Terminal

10, 11

11, 12

13, 14

14, 15

16, 17

17, 18

Signal

CR1 Programmable Contact

CR2 Programmable Contact

CR3 Programmable Contact

CR4 Programmable Contact

CR1

CR2

CR3

CR3

CR4

CR4

10

11

12

13

14

15

16

17

18

Resistive Rating = 115V AC/30V DC, 5.0A

Inductive Rating = 115V AC/30V DC, 2.0A

Output 1

Common

Output 2

Output 3

Common

Output 4

Output 5

TB4

Common

Output 6

Important: The power supply used for relay contact outputs requires a field installation

of transient voltage surge suppression with maximum clamping voltage of

2.5 kV on all control boards.

Page 33

Installation/Wiring for Stand-Alone Drives 3–9

Analog I/O The 1336 SPIDERanalog I/O configuration provides a standard set of

inputs and outputs with the capability to install up to 2 option boards,

thus replacing the standard I/O with a variety of options. All

connections are performed at TB2 and TB3. Installing an option

board in the slot A or B location will change the function of those

terminals on TB2-TB3 from standard. Only one option board can be

installed in each slot. Figure 3.4 shows the standard and optional I/O

configurations.

Figure 3.4

Analog I/O – TB2 and TB3

TB2 TB3

123 4567 8 9

Standard

Analog I/O

Pot.

Std.

Reference

1

+5V

Isolated

Input 0 (+)

LA2

10V or 20mA

Isolated

Input 0 (+)

LA6

±

10V, ±20mA

Isolated

Input 0 (+)

LA7

±

10V, ±20mA

1

If an Option Board is installed in Slot A, the +5V pot. reference will not be

available. If a 5V source is required, it must be user supplied.

Standard Analog Input 2

(Non-Isolated)

56

++––

0-10V

Jumper J11 Set to "0-10V"

Single-Ended

Input 0

Pot., 10V or 20mA

Isolated

Input 0 (–)

10V or 20mA

Isolated

Input 0 (–)

±

10V, ±20mA

Isolated

Input 0 (–)

±

10V, ±20mA

Single-Ended

Input 1

Pot., 10V or 20mA

or (select 1) or (select 1)

Isolated

Input 1 (+)

10V or 20mA

Thermistor

Isolated

Input (+)

Isolated

Input 1 (+)

10V or 20mA

Signal

Common

Isolated

Input 1 (–)

10V or 20mA

Thermistor

Isolated

Input (–)

Isolated

Input 1 (–)

10V or 20mA

Single Ended

Output 1

0-10V Only

Single-Ended

Output 1

20mA Only

Isolated

Output 1 (+)

10V or 20mA

Isolated

Output 1 (+)

10V or 20mA

Isolated

250 kHz

Pulse In (+)

2

Single Ended

Output 0

0-10V Only

Single-Ended

Output 0

10V or 20mA

Isolated

Output 0 (–)

10V or 20mA

Isolated

Input 2 (–)

10V or 20mA

Non-Isolated

250 kHz

Pulse Output

Single-Ended

Std.

Input 2

Pot., 10V or 20mA

S

i

g

n

a

l

C

o

m

m

o

n

Single-Ended

Input 2

LA1

Pot., 10V or 20mA

Isolated

Output 0 (+)

LA3

10V or 20mA

Isolated

Input 2 (+)

LA4

10V or 20mA

Single-Ended

Output 0

LA5

10V or 20mA

Analog I/O Option Slot A Analog I/O Option Slot B

2

Standard Analog Input 2 is maintained at this terminal – configure with J11.

Analog I/O Examples

Standard Analog Output 0

(0-10V Non-Isolated)

879

Isolated Pulse Train Input

to LA5 Option Board

Optional

Pulse I/O

89

+ –

Pulse Train Output from LA5

Option Board (Non-Isolated)

567

Common

Pulse

Source

Signal

Common

0-20mA

Output

Return

Isolated

Output 1 (–)

10V or 20mA

Isolated

Output 1 (–)

10V or 20mA

Isolated

250 kHz

Pulse In (–)

Standard Remote

Potentiometer

Remote Potentiometer

to Standard Analog Input 0

12345

5V Ref.

Jumper J8 Set to "Pot"

Optional

Analog I/O

Isolated Input to

LA2 Option Board

12

+ –

Isolated Output from

LA3 Option Board

89

+ –

Page 34

3–10 Installation/Wiring for Stand-Alone Drives

Standard Analog I/O Setup The 1336 SPIDER has a series of jumpers to connect the standard I/O

to TB2-TB3 when no analog options (LA1, LA2, etc.) are present.

The connectors at Slot A and Slot B (see below) each have four

jumpers connecting pins 1-2, 3-4, 5-6 and 7-8. These jumpers must be

in place for the inputs and outputs to be active at TB2-TB3.

Figure 3.5

Analog Option Installation

Slot A

Jumpers

TB2-4 Common

TB2-3 Input 1

TB2-2 Input 0

TB2-1 Pot Ref. (5V)

Text Does Not Appear on Board

(for explanation purposes only)

Remaining Pins

Not Shown

Analog Option Board

(Slot B)

TB3-2 Common

TB1-2 Output 1

TB2-7 Output 0

TB2-6 Input 2

Text Does Not Appear on Board

(for explanation purposes only)

Remaining Pins

Not Shown

In addition, each input can be configured for 0-10V, 0-20 mA or

potentiometer. Placing a jumper across the top of the connector (J8,

J11, J13) configures that input for 0-10V operation (see below). The

bottom provides 0-20 mA and the right-side provides potentiometer

operation. Please note that all three are factory set at 0-10V.

Slot B

Slot B

Jumpers

Slot A

J2

J8

J13

J11

0-10V

0-20 mA

0-10V

0-20 mA

0-10V

0-20 mA

J11 (TB2-6, Input 2)

(0-20 mA Configuration Shown)

Pot PotPot

J13 (TB2-3, Input 1)

(Pot Configuration Shown)

J8 (TB2-2, Input 0)

(0-10V Configuration Shown)

Page 35

Installation/Wiring for Stand-Alone Drives 3–11

Optional Analog I/O

Configurations

Option Board Installation/Removal

The desired analog option boards can be user installed. Prior to

installation, the jumpers at Slot A and/or Slot B must be removed.If a

board is removed at a later time, the jumpers must be reinstalled.

Refer to the detailed instructions supplied with the option boards.

ATTENTION: Drivepowermustbe removedprior to

jumper installation/removal.

!

Option Board Setup

Before operation, each installed option board must configured. The

board will have one or two DIP switches depending on the option

selected. The first function (input or output) is configured with the S1

DIP switch – the second function (if present) is configured with S51.

Using the table below, set the switch(es) for correct operation.

Important: Due to different switch manufacturers, the individual

switches will be designated “A or 1” and “B or 2.” In

addition, switch positions will be indicated as “Off or 0”

and “On or 1.”

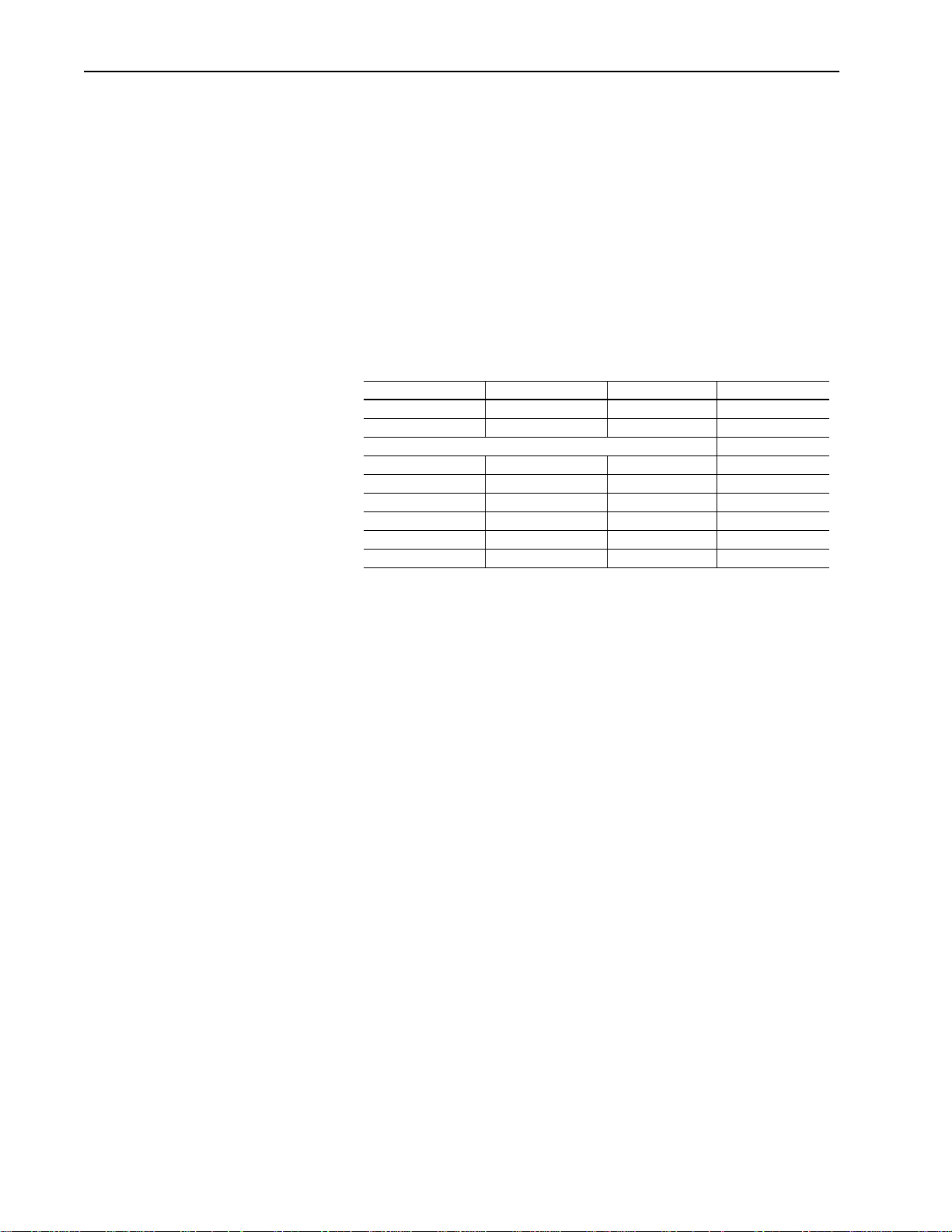

S1 and S51 Configuration Settings

2

1

DIP Switch S1 DIP Switch S51

Option

Function Mode

LA1 Output 0 10V Off/“0” Off/“0”

20mA On/“1” On/“1”

LA2 Input 0 10V Off/“0” On/“1” Input 1 10V Off/“0” On/“1”

20mA On/“1” Off/“0” 20mA On/“1” Off/“0”

LA3 Output 0 10V Off/“0” Off/“0” Output 1 10V Off/“0” Off/“0”

20mA On/“1” On/“1” 20mA On/“1” On/“1”

LA4 Input 2 10V Off/“0” On/“1” Output 1 10V Off/“0” Off/“0”

20mA On/“1” Off/“0” 20mA On/“1” On/“1”

LA5 Output 0 10V Off/“0” Off/“0”

20mA On/“1” On/“1”

LA6 Input 0 10V Off/“0” On/“1”

20mA On/“1” Off/“0”

LA7 Input 0 10V Off/“0” On/“1” Input 1 10V Off/“0” On/“1”

20mA On/“1” Off/“0” 20mA On/“1” Off/“0”

Switches S1 and S51

On / 1 =Off / 0 =

Switch Setting

A/1 B/2 A/1 B/2

Function Mode

Configure Standard Analog Input 2 with J11.

See page 3–10 for further information.

Switch Setting

Page 36

3–12 Installation/Wiring for Stand-Alone Drives

All isolated I/O is designed with full galvanic (greater than 10 meg

ohms, less than 50 pf) isolation. This results in an insulation

withstand capability of 200VAC from each channel to PE ground and

between channels. The Analog I/O Option Boards are summarized

below.

Option Board Type Slot Description

LA1 Dual Analog Output B This option replaces both standard analog outputs

LA2 Dual Isolated Input A This option replaces the two standard analog inputs

LA3 Dual Isolated Output B Replaces Analog Input 2 and both standard analog

LA4 Isolated Input/

LA5 Analog Output/Pulse

LA6

LA7

1

Isolated Output

Output/Pulse Input

1

Isolated Bipolar/

Isolated Thermistor

Input

1

Isolated Bipolar

Input/Isolated Input