Page 1

Installation Instructions

IN

Bulletin 1336 PLUS, 1336 IMPACT, and 1336

FORCE

TM

NEMA Type 4/12 Gasket Kit

Installation & Drive Mounting

(Catalog Number 1336–RF2 1336S–RF3

1336–RF4 1336–RF5

1336–RF6 1336–RF7)

What This Option Provides

The NEMA Type 4/12 Gasket Kit provides the information you need

to mount a Bulletin 1336 PLUS, 1336 IMPACT, or 1336 FORCE

drive in an enclosure with the heatsink extended outside the

enclosure. With the heatsink exposed to the ambient air, most of the

heat loss is dissipated into the ambient air instead of into the

enclosure.

The NEMA Type 4/12 Gasket Kit provides the following:

• The materials to mount the drive, the gasket to the cabinet, and

the self tapping screws needed to mount the drive.

• The information needed to lay out the cut out area and drill the

required mounting holes.

Important: You must use screws that have had a thread

sealant applied to prevent water leakage.

Self–tapping screws and the appropriate drilling

pattern are provided. If you choose to use

threaded screws, you must make sure that a

thread sealant has been applied to the screws and

follow the provided tapping pattern when

drilling the holes.

Bulletin 1336–5.87 – November, 1997

Page 2

1–2

Bulletin 1336 PLUS, 1336 IMPACT, and 1336 FORCE NEMA Type 4/12 Gasket Kit

Where These Kits Are

Used

What These Kits Contain

You can use the Gasket Kits in the following ranges:

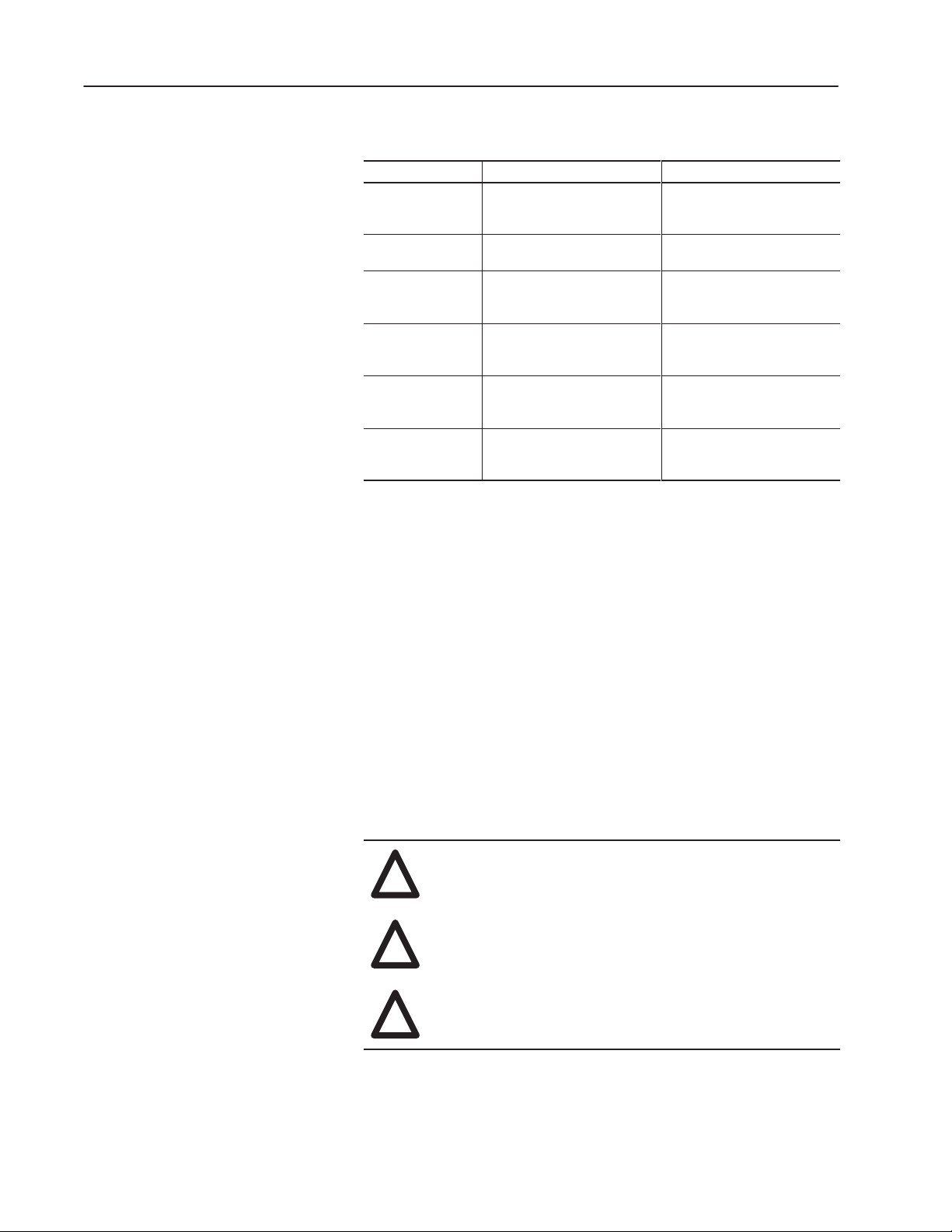

Catalog Number Range Frame Designation

BRF75

RF2

RF3➀

RF4

RF5

RF6

RF7

BRF100

CWF10 – CWF50

AQF05 – AQF50

BRF05 – BRF50

A007 – A015

B007 – B030

C007 – C020

A020 – A030

BX040 – BX060

C025 – C060

A040 – A060

B060 – BX150

C075 – CC125

A075 – A100

B150 – B250

C150 – C250

A4

A1, A2, A3

B

C

D

E

➀ Requires a Series B drive for NEMA Type 4 installations.

Each Gasket Kit contains a NEMA Type 4/12 permanent adhesive

backed gasket.

The self–tapping screws with a thread sealant applied to prevent

water damage have been provided. These screws are sufficient for

mounting the drive in an enclosure with a minimum thickness of 12

gauge––2.67mm (0.1025in).

When properly installed, each Gasket Kit is designed to meet either

NEMA Type 4 (IP65) standards or NEMA Type 12 (IP54) standards.

You must observe the general installation requirements that are

provided in the installation section of your Bulletin 1336 PLUS,

1336 IMPACT, or 1336 FORCE Hardware User Manual.

ATTENTION: Electric shock can cause injury or

!

death. Disconnect all power before working on this

product.

ATTENTION: Hazard of injury exists if you are

!

installing the Gasket Kit on a D or E frame. Refer to

the lifting instructions that were included with this kit.

ATTENTION: Drive heatsink surface temperature

!

may be at or near 100C. To avoid burns, do not

contact with the drive heatsink.

Bulletin 1336–5.87 – November, 1997

Page 3

Bulletin 1336 PLUS, 1336 IMPACT, and 1336 FORCE NEMA Type 4/12 Gasket Kit

1–3

Before Installing the

Gasket Kit

The Bulletin 1336 PLUS, 1336 IMPACT, or 1336 FORCE Hardware

User Manual provides general installation requirements and

connection procedures. In addition to those procedures, you should

note the following before installing the Gasket Kit:

• When locating the drive, allow a minimum clearance from other

components of 101.6mm (4.0in) on the top and bottom, and

50.8mm (2.0in) on either side.

• With the heatsink exposed to the ambient air, the drive dissipates

heat as listed under User/Customer Supplied Enclosures. Refer to

the Drive User Manual, Appendix – Specifications/General.

• When mounting the drive, ensure that the heatsink fins are

vertical.

• Refer to your 1336 PLUS, 1336 IMPACT, or 1336 FORCE User

Manual for internal heat dissipation data.

• For all ratings, you must verify that the selected enclosure

dissipates the total BTUs generated within the enclosure without

letting the internal ambient rise above 50° C. Enclosure

mounting must let the heatsink extend outside the enclosure.

• Refer to Figures 1.1 through 1.6 for information on heatsink

protrusion, cutout, and drilling plans.

Bulletin 1336–5.87 – November, 1997

Page 4

1–4

Bulletin 1336 PLUS, 1336 IMPACT, and 1336 FORCE NEMA Type 4/12 Gasket Kit

Installing the Drive Using

the Gasket Kit

To install the gasket, follow these steps:

1. Cut out the heatsink area.

2. Drill the mounting holes. Before drilling the mounting holes you

should make sure that they follow the appropriate drilling pattern

(Figures 1.1 to 1.6) and carefully read the Important on the first

page of this instruction sheet.

3. Clean and file the surface area to remove any burrs or sharp

edges.

4. Use paint to touch up all raw metal edges.

5. Place the gasket, with the gasket paper still intact, around the

cutout area on the inside of the enclosure and align the mounting

holes. The gasket holes are not equally spaced.

6. Peel away the gasket paper.

7. Firmly press the gasket in place with the adhesive towards the

chassis surface aligning mounting holes.

8. Remove the cover, mounting feet, and four side plates from the

drive.

9. Install the drive in the enclosure using the recommended

mounting screws. You should insert the screws through the drive

chassis to the outside of the enclosure.

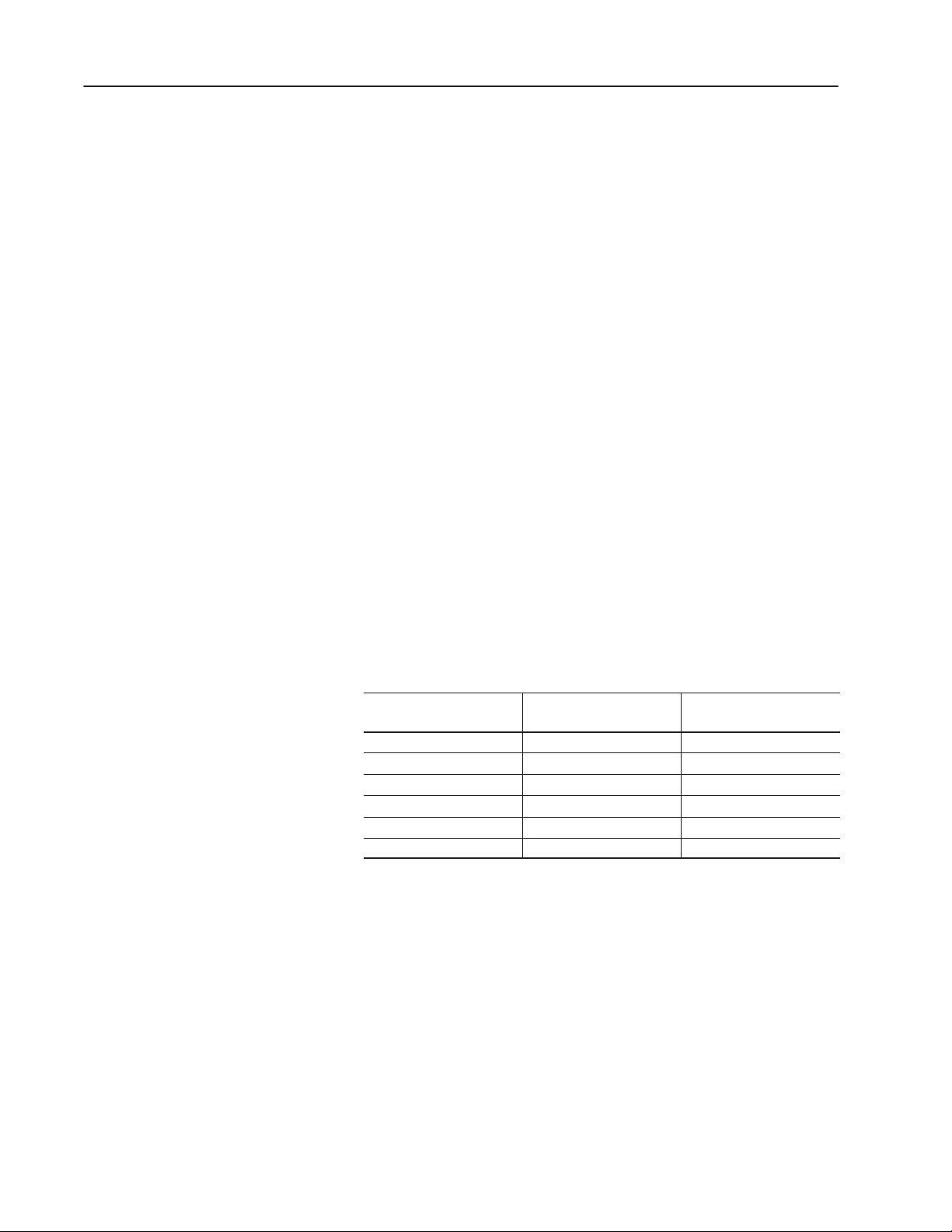

10.Torque all mounting screws to the value shown in the table below.

Rating Number of Screws

RF2 14 2.9 (26)

RF3 10 2.9 (26)

RF4 8 2.9 (26)

RF5 12 2.9 (26)

RF6 16 2.9 (26)

RF7 26 2.9 (26)

Torque

N*m (in–lbs)

Bulletin 1336–5.87 – November, 1997

Page 5

Bulletin 1336 PLUS, 1336 IMPACT, and 1336 FORCE NEMA Type 4/12 Gasket Kit

Figure1.1

Heat Sink Through-the-Back Mounting – Frames A1, A2, A3

1

210.0

(8.25)

98.0

(3.86)

196.0

(7.72)

1–5

249.7

(9.83)

234.2

(9.2204)

1

78.1

(3.076)

78.2

(3.080)

182.1

(7.17)

220.0

(8.66)

All Dimensions in Millimeters and (Inches)

Cutout

10 Required

4.3 (0.171) Dia. for 10-32 x 12.7 (0.5) Self-Tap – 4.0 (0.159) for 10-32 x 12.7 (0.5) Threaded

Customer-supplied hardware should have thread sealant applied before installation.

Drive

1

Shading indicates approximate size

of drive inside enclosure.

Back of Enclosure

A1 = 50.8 (2.00)

A2 = 71.4 (2.81)

A3 = 98.8 (3.85)

Bulletin 1336–5.87 – November, 1997

Page 6

1–6

Bulletin 1336 PLUS, 1336 IMPACT, and 1336 FORCE NEMA Type 4/12 Gasket Kit

Figure 1.2

Heat Sink Through-the-Back Mounting – Frames A4

1

257.0

80.4

(3.17)

120.7

(4.75)

(10.12)

160.9

(6.33)

241.3

(9.50)

317.0

(12.48)

301.2

(11.86)

1

225.9

(8.89)

150.6

(5.93)

75.3

(2.96)

225.0

(8.86)

285.0

(11.22)

Cutout

All Dimensions in Millimeters and (Inches)

14 Required

4.3 (0.171) Dia. for 10-32 x 12.7 (0.5) Self-Tap – 4.0 (0.159) for 10-32 x 12.7 (0.5) Threaded

Customer-supplied hardware should have thread sealant applied before installation.

Bulletin 1336–5.87 – November, 1997

Drive

1

Shading indicates approximate size

of drive inside enclosure.

Back of Enclosure

90.0 (3.54)

Page 7

Bulletin 1336 PLUS, 1336 IMPACT, and 1336 FORCE NEMA Type 4/12 Gasket Kit

Figure 1.3

Heat Sink Through-the-Back Mounting – Frame B

1

267.2

(10.52)

6.35

(0.25)

257.1

(10.12)

1–7

435.4

(17.14)

1

410.2

(16.15)

308.6

(12.15)

283.2

(11.15)

2.54

(0.10)

127.0

(5.00)

244.4

(9.62)

415.3

(16.35)

Cutout as Viewed

from INSIDE Enclosure

All Dimensions in Millimeters and (Inches)

8 Required

4.3 (0.171) Dia. for 10-32 x 12.7 (0.5) Self-Tap – 4.0 (0.159) for 10-32 x 12.7 (0.5) Threaded

Customer-supplied hardware should have thread sealant applied before installation.

Drive

Back of Enclosure

129.3 (5.09)

1

Shading indicates approximate size

of drive inside enclosure.

Bulletin 1336–5.87 – November, 1997

Page 8

1–8

Bulletin 1336 PLUS, 1336 IMPACT, and 1336 FORCE NEMA Type 4/12 Gasket Kit

Figure 1.4

Heat Sink Through-the-Back Mounting – Frame C

1

303.8

(11.96)

4.8

(0.19)

282.5

(11.12)

660.4

(26.00)

635.0

(25.00)

1

508.0

(20.00)

381.0

(15.00)

254.0

(10.00)

4.8

(0.19)

273.1

(10.75)

Cutout

644.7

(25.38)

1

Shading indicates approximate size

of drive inside enclosure.

127.0

(5.00)

All Dimensions in Millimeters and (Inches)

Drive

12 Required

4.3 (0.171) Dia. for 10-32 x 12.7 (0.5) Self-Tap

4.0 (0.159) for 10-32 x 12.7 (0.5) Threaded

Customer-supplied hardware should have

thread sealant applied before installation.

Back of Enclosure

129.3 (5.09)

Bulletin 1336–5.87 – November, 1997

Page 9

Bulletin 1336 PLUS, 1336 IMPACT, and 1336 FORCE NEMA Type 4/12 Gasket Kit

Figure 1.5

Heat Sink Through-the-Back Mounting – Frame D

Detail

4.6 (0.18)

9.9 (0.39)

356.1

(14.02)

362.2

(14.26)

375.2

(14.77)

1

6.1

(0.24)

1–9

1178.1

(46.38)

1118.6

(44.04)

1

962.7

(37.90)

806.7

(31.76)

650.8

(25.62)

494.5

(19.47)

338.6

(13.33)

26.7

(1.05)

1145.3

(45.09)

Cutout as Viewed

from INSIDE Enclosure

587.0

(23.11)

See Detail

(30.47)

680.5

(26.79)

773.9

867.4

(34.15)

1054.4

(41.51)

(7.19)

26.7

(1.05)

1

Shading indicates approximate size

of drive inside enclosure.

* Minimum dimension allowed – More space will

improve fan effectiveness and heat dissipation.

182.6

All Dimensions in Millimeters

and (Inches)

Drive

Back of Enclosure

84.1 (3.31) *

16 Required

4.3 (0.171) Dia. for 10-32 x 9.7 (0.38) Self-Tap

4.0 (0.159) for 10-32 x 9.7 (0.38) Threaded

Customer-supplied hardware should have

thread sealant applied before installation.

Bulletin 1336–5.87 – November, 1997

Page 10

1–10

Bulletin 1336 PLUS, 1336 IMPACT, and 1336 FORCE NEMA Type 4/12 Gasket Kit

Figure 1.6

Heat Sink Through-the-Back Mounting – Frame E

1

508.0

1422.4

(56.00)

1

1095.8

(43.14)

(20.00)

5.8

(0.23)

1084.1

(42.68)

Cutout

489.0

(19.25)

477.3

(18.79)

127.0

(5.00)

54.1

(2.13)

127.0

(5.00)

75.4

(2.97)

1

Shading indicates approximate size

of drive inside enclosure.

* Minimum dimension allowed – More space will

improve fan effectiveness and heat dissipation.

5.8

(0.23)

All Dimensions in Millimeters and (Inches)

Drive

26 Required

4.3 (0.171) Dia. for 10-32 x 9.7 (0.38) Self-Tap

4.0 (0.159) for 10-32 x 9.7 (0.38) Threaded

Customer-supplied hardware should have

thread sealant applied before installation.

Back of Enclosure

132.33 (5.21) *

Bulletin 1336–5.87 – November, 1997

Page 11

Notes

Bulletin 1336 PLUS, 1336 IMPACT, and 1336 FORCE NEMA Type 4/12 Gasket Kit

1–11

Bulletin 1336–5.87 – November, 1997

Page 12

Allen-Bradley, a Rockwell Automation Business, has been helping its customers improve

productivity and quality for more than 90 years. We design, manufacture and support a broad

range of automation products worldwide. They include logic processors, power and motion

control devices, operator interfaces, sensors and a variety of software. Rockwell is one of the

worlds leading technology companies.

Worldwide representation.

Argentina • Australia • Austria • Bahrain • Belgium • Brazil • Bulgaria • Canada • Chile • China, PRC • Colombia • Costa Rica • Croatia • Cyprus • Czech Republic •

Denmark • Ecuador • Egypt • El Salvador • Finland • France • Germany • Greece • Guatemala • Honduras • Hong Kong • Hungary • Iceland • India • Indonesia •

Ireland • Israel • Italy • Jamaica • Japan • Jordan • Korea • Kuwait • Lebanon • Malaysia • Mexico • Netherlands • New Zealand • Norway • Pakistan • Peru •

Philippines • Poland • Portugal • Puerto Rico • Qatar • Romania • Russia–CIS • Saudi Arabia • Singapore • Slovakia • Slovenia • South Africa, Republic • Spain •

Sweden • Switzerland • Taiwan • Thailand • Turkey • United Arab Emirates • United Kingdom • United States • Uruguay • Venezuela • Yugoslavia

Allen-Bradley Headquarters, 1201 South Second Street, Milwaukee, WI 53204 USA, Tel: (1) 414 382-2000 Fax: (1) 414 382-4444

Bulletin 1336–5.87 – November, 1997

Supersedes August, 1997

1–1

Copyright 1997 Rockwell International Corporation Printed in USA

P/N 74002–109–01(D)

Loading...

Loading...