Page 1

Instructions

1336 PLUS, PLUSII, IMPACT, and FORCE

C-Frame Front End Conversion Kit

About This Publication

This publication will guide you through installation of the C-Frame

Conversion Kit for the following drives:

Drive Kit Catalog Part Number

1336S, F, E or T -BX040

1336S, F, E or T -B040

1336S, F, E or T -B050

1336S, F, E or T -BX060

1336S, F, E or T -C025

1336S, F, E or T -C030

1336S, F, E or T -C040

1336S, F, E or T -C050

1336S, F, E or T -CX060

1336-CONVCF-SP1A

1336-CONVCF-SP1A

1336-CONVCF-SP1A

1336-CONVCF-SP1A

1336-CONVCF-SP2A

1336-CONVCF-SP2A

1336-CONVCF-SP2A

1336-CONVCF-SP2A

1336-CONVCF-SP2A

(1)

(2)

Important:This Front-End Conversion Kit is used to service C-frame

drives that require replacement of 1336-SN-SP1A,

1336-SN-SP1B, or 1336-SN-SP2A Snubber Boards and/or

1336-BR-SP5A or 1336-BR-SP6A Bridge Rectifiers which are

all obsolete.

Important:The Snubber Board in this Conversion Kit: 1336-SN-SP1C

(460V) or 1336-SN-SP2B (575V) and the Bridge Rectifier in

this Conversion Kit:1336-BR-SP10A (460V and575V) arenot

backwards-compatible with the components listed in the above

paragraph.

Each Conversion Kit consists of the following components:

• Complete C-Frame drive, less the components listed below.

• Bus Inductor and bus fuse for either BX060

(1)

or CX060

(2)

.

• 1/4 turn screws (qty 2) for the Snubber Board.

• IGBT shorting devices (qty 2) for the J7 and J8 connectors.

• A label to mount next to the nameplate of the converted drive.

The Conversion Kit does not include the following:

• Main Control Board, mounting plate, or option cards.

• Gate Driver Board.

• Precharge Board and mounting brackets.

• Drive enclosure and mounting hardware, etc.

(1)

The Bus Inductor and bus fuse supplied in the CONVCF-SP1A Kit can be used on all C-frame drives (460V).

(2)

The Bus Inductor and bus fuse supplied in the CONVCF-SP2A Kit can be used on all C-frame drives (575V).

Page 2

2 1336 PLUS, PLUSII, IMPACT, and FORCE C-Frame Front End Conversion Kit

ATTENTION: This drive contains ESD (Electrostatic

!

!

!

Discharge) sensitive parts and assemblies. Static control

precautions are required when installing, testing,

servicing or repairing this assembly. Component

damage may result if ESD control procedures are not

followed. If you are not familiar with static control

procedures, reference publication 8000-4.5.2,

“Guarding Against Electrostatic Damage” or any other

applicable ESD protection handbook.

ATTENTION: To avoida shockhazard, assure that all

powerto thedrive has been removed beforeproceeding.

In addition, verify that the DC bus has discharged by

measuring across the “+DC” and “–DC” terminals of

TB1 with a voltmeter. The voltage should be 0.0VDC.

ATTENTION: Wear a wrist-type grounding strap

when servicing/handling all 1336-family drive printed

circuit boards. Failure to protect drive components

against ESD may damage internal drive components.

Refer to Electrostatics Discharge Precautions at the

beginning of Chapter 3 in the C-Frame Troubleshooting

Guide.

Tools

You need the following tools to disassemble and assemble the drive

• C-frame Troubleshooting Guide 1336 PLUS-6.2, 1336 FORCE-6.2, or

1336 IMPACT-6.2.

• Pliers.

• Phillips screwdriver.

• Standard screwdriver.

• Torque wrench, metered in lb-in. or N-m.

Page 3

1336 PLUS, PLUSII, IMPACT, and FORCE C-Frame Front End Conversion Kit 3

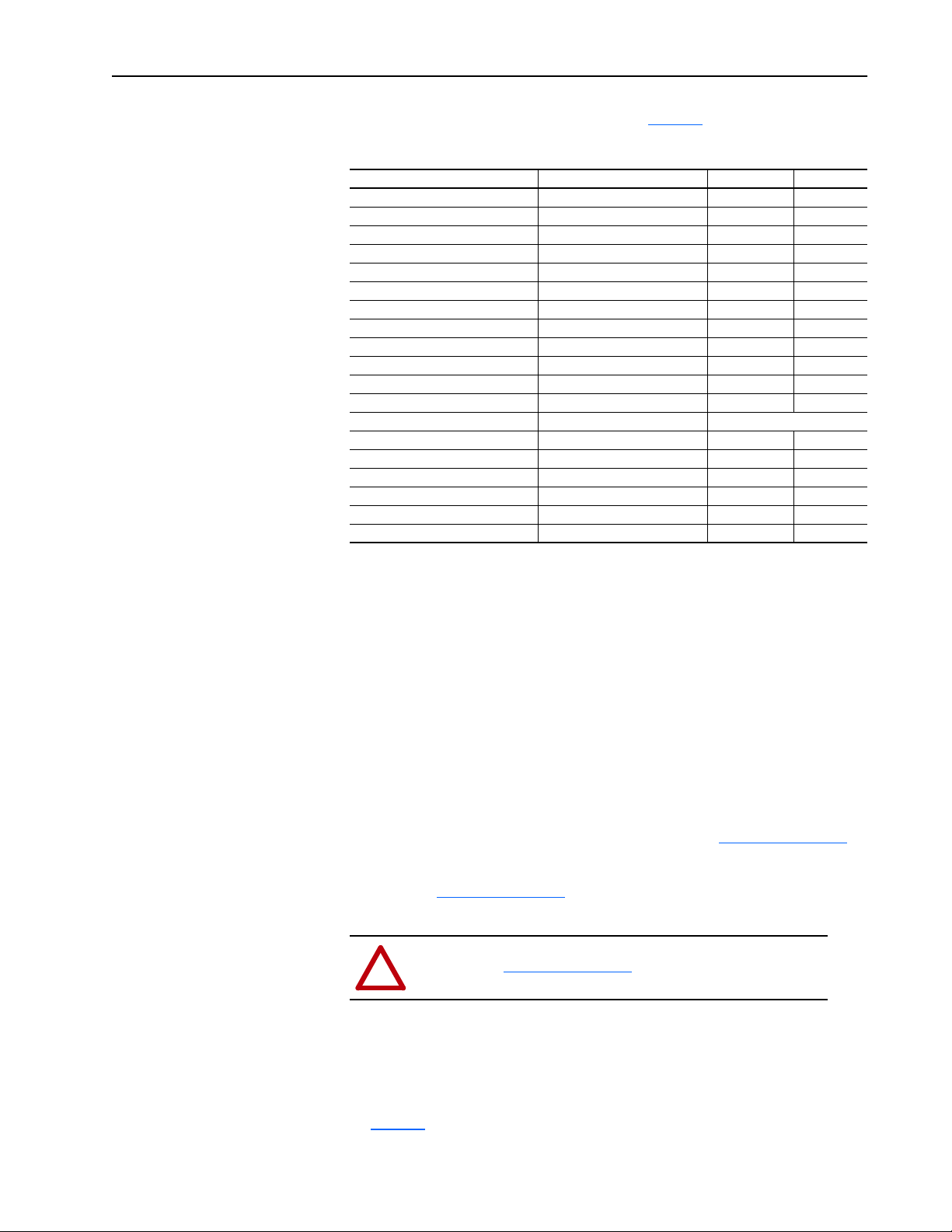

Fastener Torque

Specifications

Fastener Torque Specifications are listed in Table A.

Table A Fastener Torque Specifications

Component Fastener Application Torque lb-in. Torque N-m

Main Control Board Mounting Plate 8 – 10 0.9 – 1.1

Gate Driver Board Mounting Plate 8 – 10 0.9 – 1.1

Precharge Board Mounting Plate 8 – 10 0.9 – 1.1

Bus Capacitor Bank Bank to chassis 25 – 31 2.8 – 3.5

DC Bus Inductor Wires to bus bars 25 – 31 2.8 – 3.5

DC Bus Inductor TB1 mounting plate to chassis 25 – 31 2.8 – 3.5

Snubber Board Bus bars to capacitor bank 25 – 31 2.8 – 3.5

Snubber Board Board to SCR1 25 – 31 2.8 – 3.5

Snubber Board Board to PM1 – PM3 30 – 39 3.4 – 4.4

Power Modules PM1 – PM3 Module to heat sink 25 – 31 2.8 – 3.5

Input Rectifier Rectifier to heat sink 25 – 31 2.8 – 3.5

Bus Fuse F1 Fuse to chassis 200 – 220 22.6 – 24.8

Thermistor Thermistor to heat sink Hand tighten only

TB1 Wires to terminals 25 – 31 2.8 – 3.5

TB2 Wires to terminals 8 0.9

TB3 Wires to terminals 8 0.9

Ground Sense CT Bracket to chassis 25 – 31 2.8 – 3.5

Ground Sense CT Positive bus bar junction 25 – 31 2.8 – 3.5

Ground Sense CT Bus bars to capacitor bank 25 – 31 2.8 – 3.5

Instructions

1. Back-up the programming of the drive being converted before

proceeding:

– Store the programming of the drive in the HIM (if applicable to your

HIM) or

– Use Drive Tools, Drive Explorer, or Drive Explorer Light to back-up

the programming of the drive.

2. Remove andlock out the line power from the existing C-frame drive that

will be converted.

3. For disassembly instructions, refer to Chapter 3 in the Troubleshooting

Guide. The 1336-CONVCF-SPxA Kit is shown in

Figure 1 on page 5.

4. An illustration of the CONVCF Kit with numbered cables and wires is

shown in

Figure 2 on page 6. The cables have the destination connector

number on them.

ATTENTION: Make sure the two shorting devices

!

shown in

connecting into J7 and J8 of the Gate Driver Board.

Figure 3 on page 6 are removed before

5. For assembly instructions refer to Chapter 3 in the Troubleshooting

Guide.

6. Re-connect the power and control wiring. Torque specs are listed in

Table A.

Page 4

4 1336 PLUS, PLUSII, IMPACT, and FORCE C-Frame Front End Conversion Kit

7. Install the CONVCFlabel on the Main ControlBoard Mounting Plate as

shown in

Figure 1 on page 5. This indicates the conversion has been

done on your drive.

8. Refer to the Plus/PlusII/Impact/Force User Manual for Start-Up

instructions.

9. Reinstall the Main Control Board, Gate Driver Board and Precharge

Board from the old drive. Refer to

of the converted drive will be necessary.

10.Re-install the shorting devices into the same cable connectors on the old

drive. This will prevent any damage to the IGBT’s from static electricity

while handling and shipping the old drive.

11.Return the old drive core to Allen-Bradley if the drive is in warranty.

Figure 1 on page 5. No programming

Page 5

1336 PLUS, PLUSII, IMPACT, and FORCE C-Frame Front End Conversion Kit 5

Figure 1 Drive Components for 1336-CONVCF Kit

Heat Sink and

Fan Assembly

New Label

Factory Installed

1336-CONVCF-SPxA

Load Sharing

Resistor

Bus Fuse

Snubber Board

460V has 1

575V has 2

and LEMs

These components

are included in the

1336-CONVCF-SPxA Kit.

End user will remove all of these components from the existing

drive and install on the 1336-CONVCF-SPxA Kit.

Remove the shorting devices before attaching

cables to the Gate Driver Board. Refer to Figure 3.

Ground Sense

CT Connector

Snubber Board

Connector

ATTENTION:

Power Module

Connectors

SCR

Connector

Gate Driver Board

Ribbon Cable

Connector

Thermistor

Connector

Bus Capacitor

Bank

Bus Inductor

(Behind Ground

Sense CT)

Bus Cap

Connectors

Snubber Board/SCR

Connector

Add New Label Here,

Customer Installed

1336-CONVCF-SPxA

Existing Label

Nameplate

Factory Installed

Main

Control

Board

Interface Board

Connectors

HIM

Connector

(Optional)

Control

Interface

Board

ab1006a

Page 6

6 1336 PLUS, PLUSII, IMPACT, and FORCE C-Frame Front End Conversion Kit

Figure 2 1336-CONVCF-SPxA Conversion Kit.

J6

J2

J10

J7

J15

J8

J4

J1

J2

ab1008a

Figure 3 1336-CONVCF-SPxA Conversion Kit showing the shorting devices.

J7

Shorting

Devices

J8

ab1009a

Page 7

Notes:

1336 PLUS, PLUSII, IMPACT, and FORCE C-Frame Front End Conversion Kit 7

Page 8

Netscape Navigator is a registered trademark of Netscape Communications Corporation

IBM is a registered trademark of International Business Machines Corporation

Microsoft, MS-DOS and Windows are registered trademarks of Microsoft Corporation

Publication 1336 FREST-5.15 Ð May, 2001 P/N 196517-P01

Copyright © 2001 Rockwell Automation. All rights reserved. Printed in USA.

Loading...

Loading...