Page 1

Installation Instructions

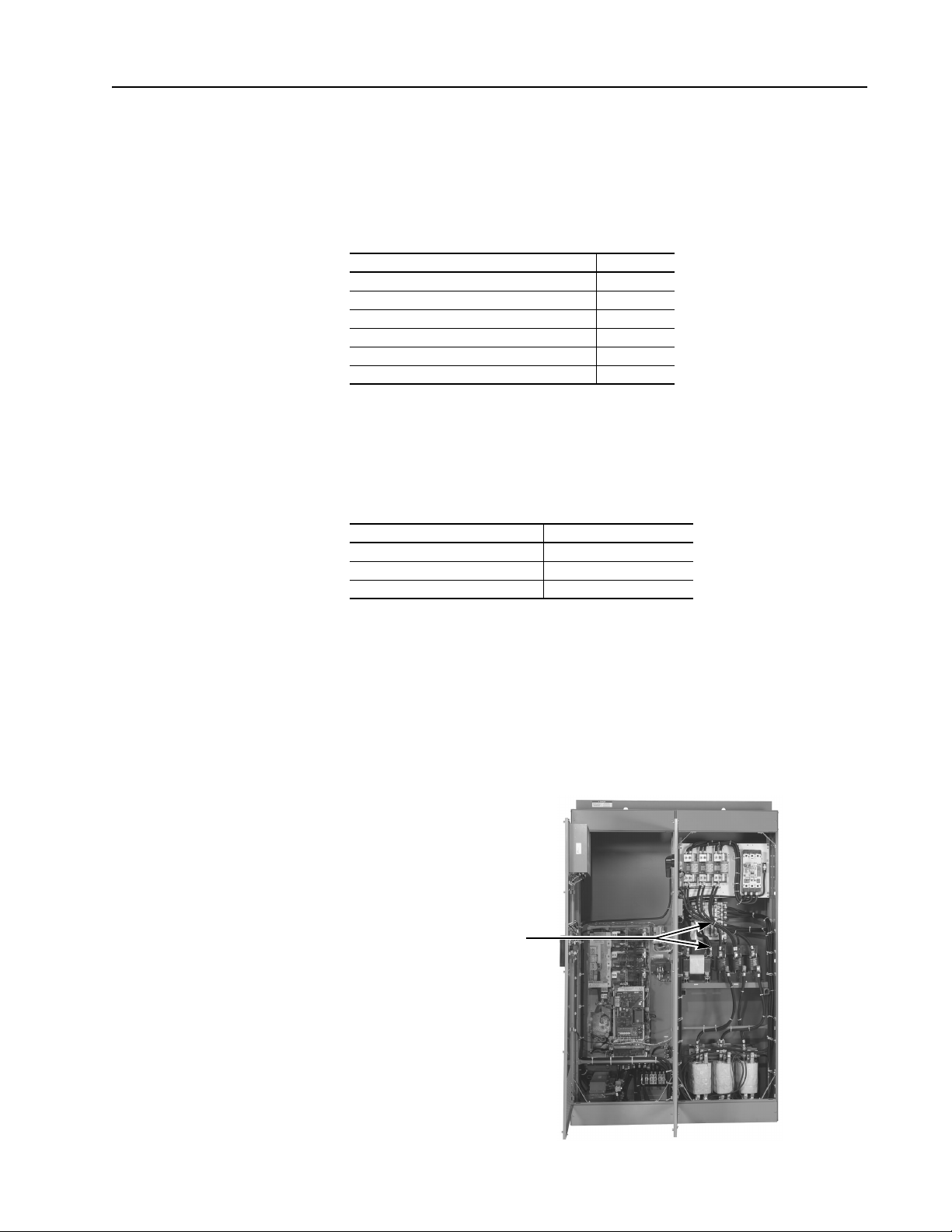

Typical Snubber

Board(s) Location

Inverter Bay Converter Bay

Multipulse Bridge Assembly Parts Kits

These instructions cover front end component replacements on 1336 PLUS

II drives and 1336 IMPACT H frame drives with Multipulse bridge

assemblies.

Description Page

Snubber Board Replacement Kit 1

Converter Diode Replacement Kit 3

Converter Fan Replacement Kit 6

Converter Thermal Switch Replacement Kit 8

Spare Parts 10

Replacement Parts 12

Snubber Board Replacement Kit

Where This Kit Is Used

Snubber Board Replacement Kit (Part Numbers 304470 (AC), 304469,

304468 (DC)) - You can use this kit to replace the snubber boards that are

located on the side of the AC Diode bridge heatsink assembly.

Table 1. Snubber Board Part Numbers

Replacement Kit Number Vendor No.

1336 - SN-SP7B 20849

1336 - SN-SP8B 21032

1336 -SN-SP9B 13960

What This Kit Contains

This kit contains snubber board(s) and these instructions. Note: Number of

snubber boards varies according to kit number.

Locating the Snubber Board(s)

The snubber boards are located on the side of the bridge heatsink in the

converter bay of your drive. The location of the converter bay will vary from

system to system.

Page 2

2 Multipulse Bridge Assembly Parts Kits

!

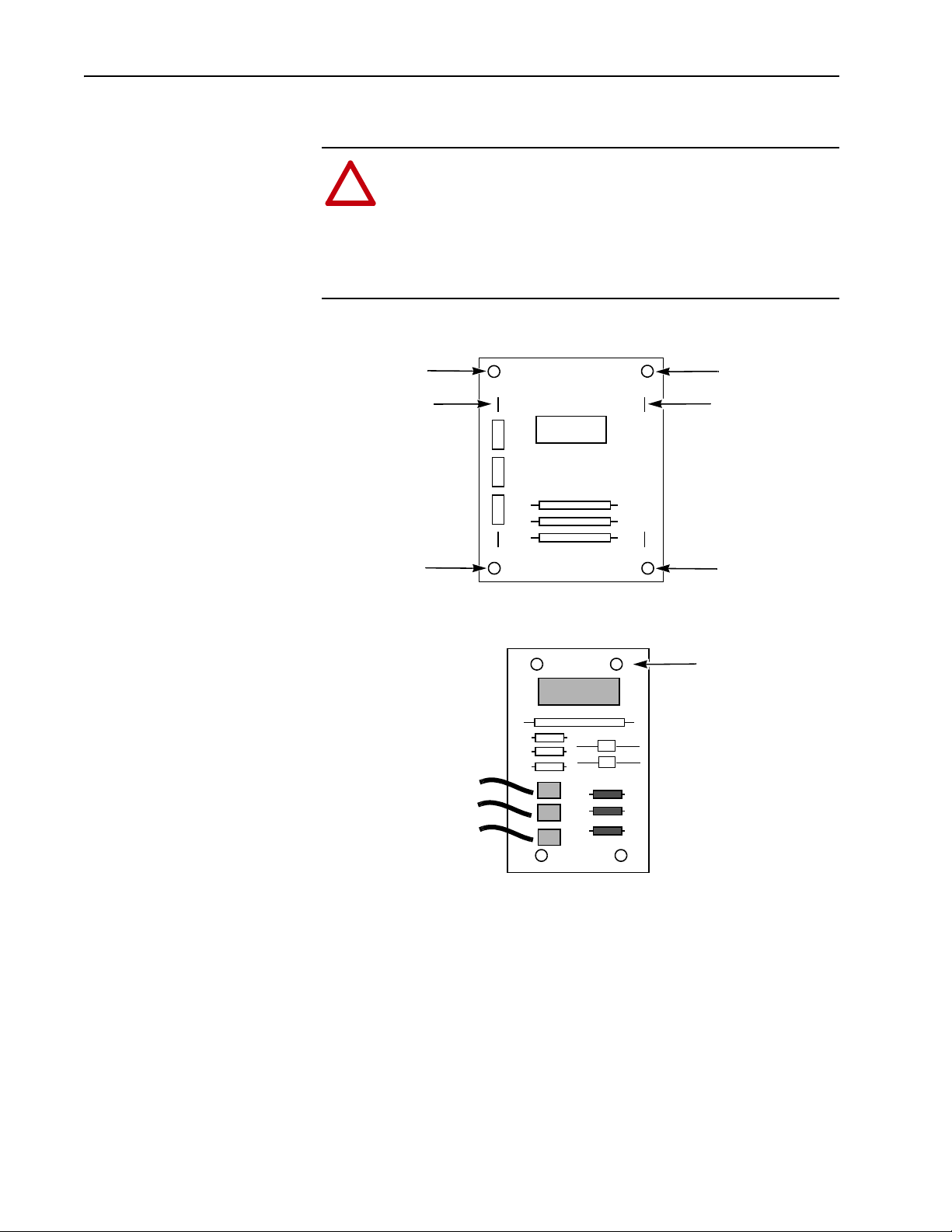

06

16

- Lead

Standoff Hole

Standoff Hole

Standoff Hole

Standoff Hole

+ Lead

DC Snubber Board Front View

AC Snubber Board Front View

Power

Leads

Standoff Hole

(4 Places)

81

82

83

To p

Replacing the Snubber Board(s)

ATTENTION: Disconnect and lock out power from the system

before disassembling the bridge. Failure to disconnect power

may result in death or serious injury. Verify bus voltage by

measuring the voltage between +DC and –DC on terminal block

TB1 located at the bottom of the 1336 Drive in the inverter bay.

Do not attempt to service the drive until the bus voltage has

discharged to zero volts.

1. Remove and tag the leads at the + (06) and – (16) stab-on connections on

2. Snap the old board up off the four plastic standoffs and remove.

3. Orient the new board with the stab-on connectors 06 and 16 at the top

4. Reconnect the leads.

the DC snubber board. Remove the leads at stab-on connectors 81, 82

and 83 on AC snubber boards.

(DC boards) or stab-on connectors 81, 82 and 83 in the lower left (AC

boards) and snap into place on the plastic standoffs.

Page 3

Multipulse Bridge Assembly Parts Kits 3

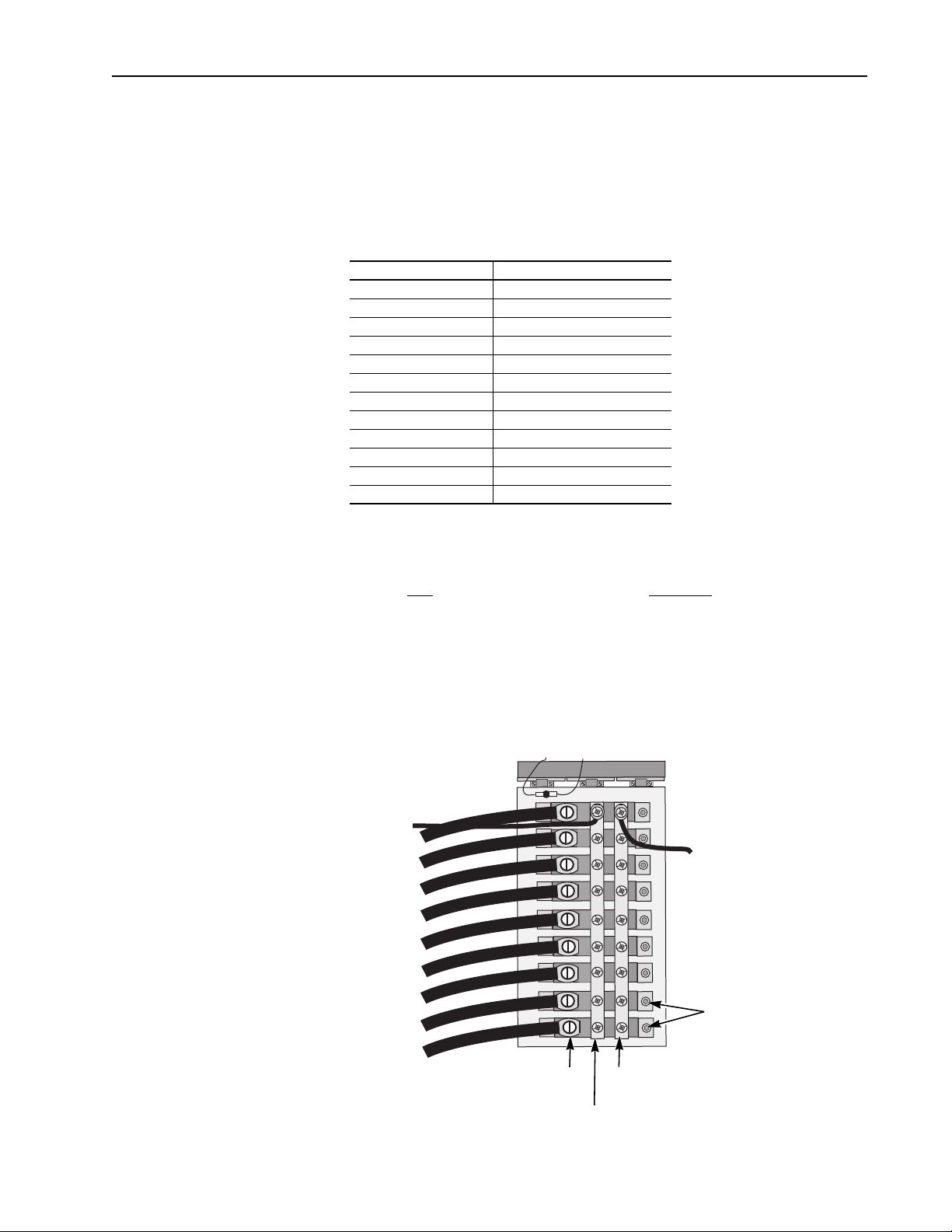

AK

Terminal

K

Terminal

A

Terminal

Converter Diodes

Converter Diode Replacement Kit

Where This Kit Is Used

You can use this kit to replace any of the converter diodes that are located in

the converter bay of your 1336 PLUS II Multipulse or H-Frame 1336

IMPACT drive.

Diodes covered by these instructions are listed in the following table:

Table 2. Converter Diode Part Numbers

Replacement Kit No. Vendor Component Part No.

1336-BD-SP1A DD89N16K

1336-BD-SP2A DD104N16K

1336-BD-SP3A DD151N16K

1336-BD-SP4A DD260N16K

1336-BD-SP5A DD350N16K

1336-BD-SP6A DD600N18K

1336-BD-SP7A DZ1070N18K

1336-BD-SP8A DD2228N16T

1336-BD-SP9A ND89N16K

1336-BD-SP10A ND171N16K

1336-BD-SP11A ND260N16K

1336-BD-SP12A DZ600N16K

What This Kit Contains

This kit contains a replacement converter diode and these instructions. This

kit does Not

contain the thermal compound Required to mount a new diode.

Locating the Converter Diodes

The converter diodes are located on the Multipulse bridge heatsink

assembly in the converter bay of your drive. A typical heatsink assembly is

shown in the following illustration. Converter diode locations may vary on

some models.

Fan

Page 4

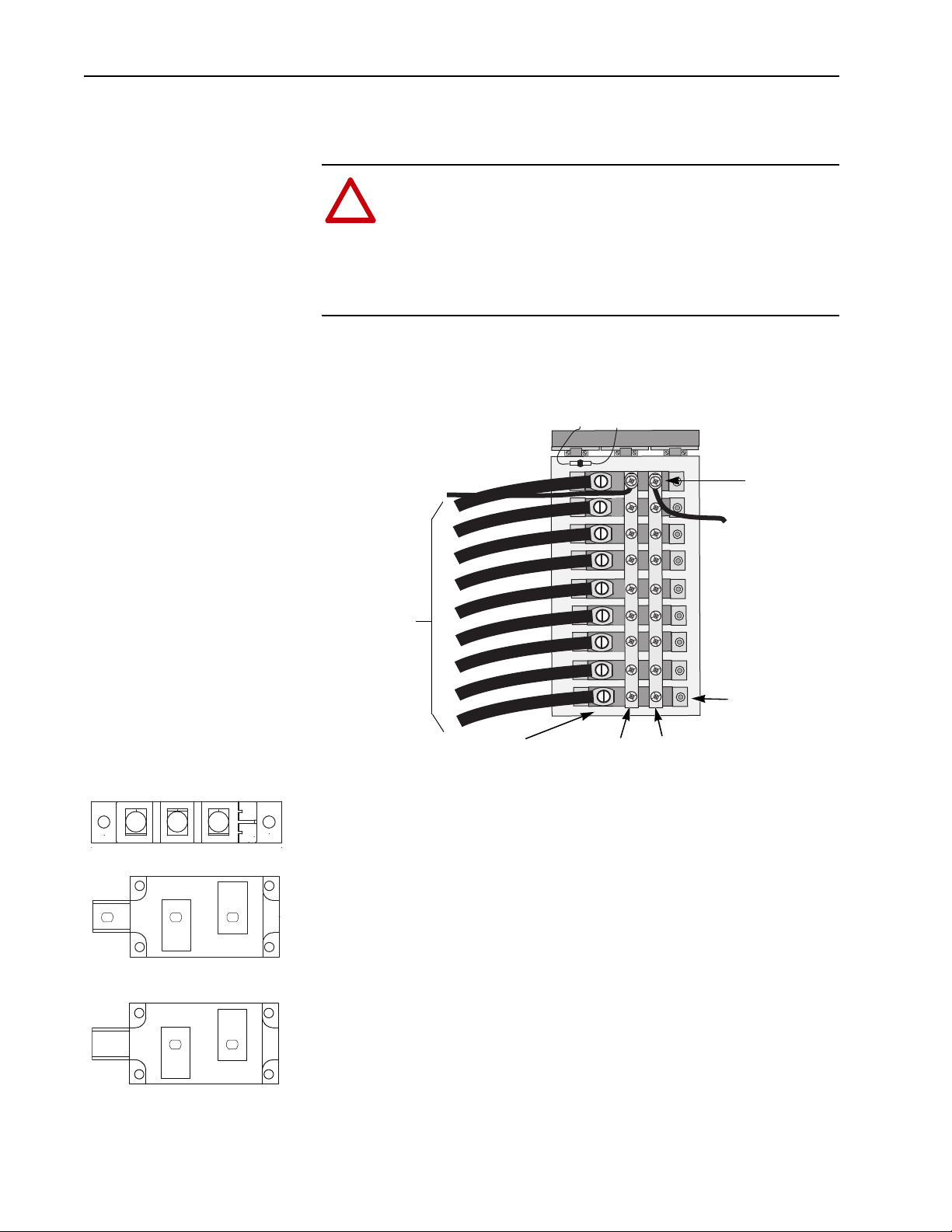

4 Multipulse Bridge Assembly Parts Kits

!

Converter

Diode Mounting

Screw

A

Bus Bar

K

Bus Bar

“AK” Input Terminal

+/- Power Leads

From Snubber

Board

From

Transformer

From

Snubber

Board

AK

K

A

DD350N

1

2

3

4

1

AK

2

K

A

DD104N

K

A

ND260N

1

2

3

4

Replacing the Converter Diode(s)

To replace the converter diode(s), follow these steps:

ATTENTION: Disconnect and lock out power from the system

before disassembling the bridge. Failure to disconnect power

may result in death or serious injury. Verify bus voltage by

measuring the voltage between +DC and –DC on terminal block

TB1 located at the bottom of the 1336 Drive in the Inverter Bay.

Do not attempt to service the drive until the bus voltage has

discharged to zero volts.

1. Remove the power leads to + and -bus bars at the connection points at

the top of the bus bars.

2. Remove the + / - bus bars that are over the converter diode by removing

all the screws at the “A” and “K” mounting points on each diode.

Fan

3. Remove the “AK” input terminal from the converter diode you will be

replacing. Tag leads if you are replacing more than one diode.

4. Remove the mounting screws from the converter diode. The diode will

have two or four mounting screws depending on the model. For

example: the DD104N shown in the accompanying illustration has two

mounting screws, while the DD350N has four.

5. Remove the converter diode.

A. Remove all old heat transfer compound from the heatsink mounting

surface using a tool such as a rubber spatula that will not mar the

heatsink surface. Remove any remaining residue with a soft cloth and

a cleaning fluid such as Essex Cleaning Fluid (Brownell OS-3) by

Dow Corning Co.

B. Use a non-marring cleaning pad such as a Scotchbrite by 3M™ to

remove any oxidation from the heatsink mounting surface and the

face of the diode. DO NOT use steel wool or sandpaper!

C. Follow oxidation removal with a final cleaning with cleaning fluid.

Page 5

Multipulse Bridge Assembly Parts Kits 5

14

32

Important: Thermal Compound must be applied immediately to both

surfaces to prevent oxidation from reoccurring.

6. Apply a thin, even coat of Thermal Compound (not supplied) to the new

diode and the mounting surface. Dow Corning 340 is the recommended

Thermal Compound.

7. Position the new converter diode being careful to match the holes for

the screws.

8. Tighten the screws (2 or 4 depending on model) in the sequence shown

in the illustration, to the Mounting Screw torques in Table 3.

Table 3. Diode Torque Requirements

TORQUE REQUIREMENT

Vendor P/N

DD89N16K 35 in. lb., 4 N–m (+/-15%) 35 in. lb., 4 N–m (+ 5%/-10%)

DD104N16K 35 in. lb., 4 N–m (+/-15%) 35 in. lb., 4 N–m (+ 5%/-10%)

DD151N16K 53 in. lb., 6 N–m (+/-15%) 53 in. lb., 6 N–m (+5%/-10%)

DD260N16K 44 in. lb., 5 N–m (+/-15%) 106 in. lb., 12 N–m (+5%/-10%)

DD350N16K 44 in. lb., 5 N–m (+/-15%) 106 in. lb., 12 N–m (+5%/-10%)

DD600N18K 53 in. lb., 6 N–m (+/-15%) 106 in. lb., 12 N–m (+5%/-10%)

DZ1070N18K 53 in. lb., 6 N–m (+/-15%) 159 in. lb., 18 N–m (+5%/-10%)

DD2228N16T 159 in. lb, 18 N–m (+/-15%) 159 in. lb., 18 N–m (+5%/-10%)

ND89N16K 35 in. lb., 4 N–m (+/-15%) 35 in. lb., 4 N–m (+/-15%)

ND17N16K 35 in. lb., 4 N–m (+/-15%) 35 in. lb., 4 N–m (+/-15%)

ND260N16K 44 in. lb., 5 N–m (+/-15%) 106 in. lb., 12 N–m (+/-15%)

DZ600N16K 44 in. lb., 5 N–m (+/-10%) 106 in. lb., 12 N–m (+/-15%)

Mounting Screw Torque Terminal Connection Torque

9. Bolt down the + and - bus bars, tightening the screws to the Terminal

Connection torque values shown in the previous table.

10. Reattach the power leads at the top of each bus bar and torque the

mounting screws to the value shown under Terminal Connection in the

previous table.

11. Attach the “AK” terminal to the new diode and torque to the specified

Terminal Connection value shown in the Table 3.

Page 6

6 Multipulse Bridge Assembly Parts Kits

Typical Fan

Location

Converter Fan Replacement Kit

Where This Kit Is Used

Converter Fan Replacement (Catalog Number 1336-FAN-SP9A) -You

can use this kit to replace any of the fans that are located on the bridge

heatsink in the converter bay of your1336 PLUS II Multipulse or 1336

IMPACT H-Frame drive. The number of fans varies by model.

Table 4. Fan Part Numbers

Replacement Kit # Vendor #

1336 - FAN - SP9A 21087

What This Kit Contains

This kit contains a replacement fan and these instructions.

Locating the Fan(s)

The fans are located on the multi-pulse bridge heatsink in the converter bay

of your drive. Fans are oriented to draw air up through the heatsink

assembly.

Page 7

Multipulse Bridge Assembly Parts Kits 7

!

Fan Spacer

Air Flow

Fan Wires

Replacing the Fan(s)

To replace the fan(s), follow these steps:

ATTENTION: Disconnect and lock out power from the system

before disassembling the drive. Failure to disconnect power may

result in death or serious injury. Verify bus voltage by measuring

the voltage between +DC and –DC on terminal block TB1 which

is located at the bottom of the 1336 Drive in the Inverter Bay. Do

not attempt to service the drive until the bus voltage has

discharged to zero volts.

1. Remove the red 115V power supply and white neutral wires from the

stab-on connectors on the fan.

Fan

2. Using a thin, standard screwdriver, remove the screws and lockwashers

that secure the fan.

3. Remove the fan and fan spacer.

4. Put the new fan in place, making sure that you align the holes in the

bridge with the holes in the four corners of the fan and fan spacer.

Important:Make sure that the arrows on the fan are pointing towards

the top of the cabinet.

5. Start the screws and lockwashers in the four corners.

6. Tighten the screws to 1.36 N–m (12 lbs.–in.).

7. Attach the red power supply and white neutral wires to the stab-on

connectors on the fan.

Page 8

8 Multipulse Bridge Assembly Parts Kits

Fan

Remote

Thermal

Switch(es)

Location

Internal Mount

Thermal

Switch(es)

Location

Converter Thermal Switch Replacement Kit

Where This Kit Is Used

Converter Thermal Switch Replacement (Catalog Number

1336-TR-SP8A) - You can use this kit to replace the thermal switch(es) that

are located on the multipulse bridge assembly in the converter bay of your

1336 PLUS II Multipulse or H-Frame IMPACT drive.

Table 5. Thermal Switch Part Numbers

Replacement Kit # Vendor #

1336 - TR- SP8A 16283

What This Kit Contains

This kit contains a replacement thermal switch and these instructions.

Locating the Thermal Switches

The thermal switches are mounted on the bridge heatsink located in the

converter bay of your drive.

Important: On some drive models the thermal switch may be located

remotely at the top of the heatsink above the bus bars as shown in the

following illustration. In cases where the thermal switch is mounted

remotely it will not be necessary to remove the “AK” input terminals or bus

bars for access to the switch.

Page 9

Multipulse Bridge Assembly Parts Kits 9

!

“AK”

Bus Bar

Thermal

Switch

600 HP and higher Thermal Bridge shown

Location

Thermal

Switch

Replacing the Thermal Switch(es)

To replace the thermal switch(es), follow these steps:

ATTENTION: Disconnect and lock out power from the system

before disassembling the drive. Failure to disconnect power may

result in death or serious injury. Verify bus voltage by measuring

the voltage between +DC and –DC on terminal block TB1 which

is located at the bottom of the 1336 Drive located in the Inverter

Bay of the cabinet. Do not attempt to service the drive until the

bus voltage has discharged to zero volts.

Important: If your thermal switch is NOT located under a bus bar, it will

not be necessary to perform steps 1, 2, 7 or 9.

1. Remove the flex bus or wire connected to the “AK” input terminal bus

bar or diode that is located over the thermal switch you need to replace.

2. If your unit is equipped with a bus bar, remove it.

3. Remove the red power wires from the thermal switch.

4. Remove the thermal switch.

5. Thread in the new thermal switch by hand until it is snug.

6. Tighten the screw on the thermal switch to 1.81 N–m (16 lbs.–in.).

7. Bolt the “AK” input terminal bus bar or wire terminal to the diode and

see Table 8 for kit reference numbers.

Page 10

10 Multipulse Bridge Assembly Parts Kits

Spare Parts

To determine spare parts for your Bridge Assembly, follow these steps:

A. Determine Drive Size (HP) using Table 6 for CT or Table 7 for VT and

then the type of multi-pulse transformer used in the drive package.

B. Find drive size and move to the right until you are under the column

which describes the transformer. That number is the bridge assembly

number (Table 8).

Example: Bridge 304246 =1336-BD-SP5A diode kit#

1336-SN-SP9B snubber board kit #

1336-FAN-SP9A fan kit

1336-TR-SP8A thermo switch kit

Table 6. CT Bridge Assemblies

1336 Constant Torque Used with 12P ISO. XFMR Used with 12P Auto XFMR Used with 18P ISO. XFMR Used with 18P Auto XFMR

Drive Size (HP)

AB Part Numbers Bridge # Bridge # Bridge # Bridge #

BX040C 301746 304976 301749 301743

B050C 301746 304976 301750 301743

BX060C 301746 304976 301750 301743

B060C 301746 304976 301750 301743

B075C 301746 304976 304247 301743

B100C 304250 304976 304247 301744

B125C 301747 304976 301751 301744

BX150C 301747 304976 301751 301744

B150C 301747 304976 304248 301744

B200C 301747 304652 304249 301745

B250C 304245 304652 301752 301745

BP250C 304245 304652 301752 301745

BP300C 304245 304652 301752 301745

BP350C 304246 304652 301753 301745

BP400C 304248 304652 301753 304348

BP450C 304248 304977 301235 304348

B300C 304245 304652 301752 301745

B350C 304246 304652 301753 301745

B400C 301748 304652 301753 304348

B450C 301748 304977 301753 304348

B500C 301233 304977 301235 304348

B600C 301233 304977 301236 304348

B700C 301234 304978 301236 301231

B800C 301234 304978 301236 301231

Page 11

Multipulse Bridge Assembly Parts Kits 11

Table 7. VT Bridge Assemblies

1336 Variable Torque Used with 12P ISO. XFMR Used with 12P Auto XFMR Used with 18P ISO. XFMR Used with 18P Auto XFMR

Drive Size (HP)

AB Part Numbers Bridge # Bridge# Bridge # Bridge #

BX040V 301746 304976 301749 301743

B040V 301746 304976 301750 301743

BX060V 301746 304976 301750 301743

B060V 301746 304976 304247 301743

B075V 301746 304976 304247 301744

B100V 304250 304976 304247 301744

B125V 301747 304976 301751 301744

B150V 301747 304976 304249 301744

B200V 304245 304652 304249 301745

B250V 304245 304652 301752 301745

BP250V 304245 304652 301752 301745

BP300V 304246 304652 301753 301745

BP350V 301748 304652 301753 301745

BP400V 301748 304977 301235 304348

BX250V 304245 304652 301752 301745

B300V 304246 304652 301753 301745

B350V 301748 304652 301753 304348

B400V 301748 304977 301235 304348

B450V 301233 304977 301235 304348

B500V 301233 304977 301236 304348

B700V 301234 304978 301236 301231

B800V 301234 304978 301236 301231

Page 12

12 Multipulse Bridge Assembly Parts Kits

Replacement Parts

Bridge # Diode Snubber Fan Thermal Switch

301229 1336-BD-SP5A 1336-SN-SP8B 1336-FAN-SP9A 1336-TR-SP8A

301230 1336-BD-SP6A 1336-SN-SP8B 1336-FAN-SP9A 1336-TR-SP8A

301231 1336-BD-SP5A 1336-SN-SP8B 1336-FAN-SP9A 1336-TR-SP8A

301232 1336-BD-SP5A 1336-SN-SP8B 1336-FAN-SP9A 1336-TR-SP8A

301233 1336-BD-SP6A 1336-SN-SP9B 1336-FAN-SP9A 1336-TR-SP8A

301234 1336-BD-SP7A 1336-SN-SP9B 1336-FAN-SP9A 1336-TR-SP8A

301235 1336-BD-SP6A 1336-SN-SP9B 1336-FAN-SP9A 1336-TR-SP8A

301236 1336-BD-SP7A 1336-SN-SP9B 1336-FAN-SP9A 1336-TR-SP8A

301738 1336-BD-SP1A 1336-SN-SP7B N/A 1336-TR-SP8A

301739 1336-BD-SP3A 1336-SN-SP7B N/A 1336-TR-SP8A

301740 1336-BD-SP2A 1336-SN-SP8B 1336-FAN-SP9A 1336-TR-SP8A

301741 1336-BD-SP3A 1336-SN-SP8B 1336-FAN-SP9A 1336-TR-SP8A

301742 1336-BD-SP4A 1336-SN-SP8B 1336-FAN-SP9A 1336-TR-SP8A

301743 1336-BD-SP1A 1336-SN-SP7B N/A 1336-TR-SP8A

301744 1336-BD-SP1A 1336-SN-SP8B 1336-FAN-SP9A 1336-TR-SP8A

301745 1336-BD-SP3A 1336-SN-SP8B 1336-FAN-SP9A 1336-TR-SP8A

301746 1336-BD-SP2A 1336-SN-SP9B 1336-FAN-SP9A 1336-TR-SP8A

301747 1336-BD-SP4A 1336-SN-SP9B 1336-FAN-SP9A 1336-TR-SP8A

301748 1336-BD-SP6A 1336-SN-SP9B 1336-FAN-SP9A 1336-TR-SP8A

301749 1336-BD-SP3A 1336-SN-SP9B N/A 1336-TR-SP8A

301750 1336-BD-SP2A 1336-SN-SP9B 1336-FAN-SP9A 1336-TR-SP8A

301751 1336-BD-SP4A 1336-SN-SP9B 1336-FAN-SP9A 1336-TR-SP8A

301752 1336-BD-SP5A 1336-SN-SP9B 1336-FAN-SP9A 1336-TR-SP8A

301753 1336-BD-SP6A 1336-SN-SP9B 1336-FAN-SP9A 1336-TR-SP8A

303680 1336-BD-SP8A 1336-SN-SP9B 1336-FAN-SP9A 1336-TR-SP8A

304243 1336-BD-SP5A 1336-SN-SP8B 1336-FAN-SP9A 1336-TR-SP8A

304244 1336-BD-SP6A 1336-SN-SP8B 1336-FAN-SP9A 1336-TR-SP8A

304245 1336-BD-SP5A 1336-SN-SP9B 1336-FAN-SP9A 1336-TR-SP8A

304246 1336-BD-SP5A 1336-SN-SP9B 1336-FAN-SP9A 1336-TR-SP8A

304247 1336-BD-SP3A 1336-SN-SP9B 1336-FAN-SP9A 1336-TR-SP8A

304248 1336-BD-SP5A 1336-SN-SP9B 1336-FAN-SP9A 1336-TR-SP8A

304249 1336-BD-SP5A 1336-SN-SP9B 1336-FAN-SP9A 1336-TR-SP8A

304250 1336-BD-SP3A 1336-SN-SP9B 1336-FAN-SP9A 1336-TR-SP8A

304348 1336-BD-SP5A 1336-SN-SP8B 1336-FAN-SP9A 1336-TR-SP8A

304742 1336-BD-SP5A 1336-SN-SP8B 1336-FAN-SP9A 1336-TR-SP8A

304976 1336-BD-SP9A 1336-SN-SP7B 1336-FAN-SP9A 1336-TR-SP8A

304652 1336-BD-SP10A 1336-SN-SP8B 1336-FAN-SP9A 1336-TR-SP8A

304977 1336-BD-SP11A 1336-SN-SP8B 1336-FAN-SP9A 1336-TR-SP8A

304978 1336-BD-SP12A 1336-SN-SP8B 1336-FAN-SP9A 1336-TR-SP8A

To order replacement kits:

A. Find the bridge part number on the actual order related schematics or the

Bridge Assembly data nameplate.

B. Reference that number to this page for replacement kit numbers.

Table 8. Bridge Parts List

Note: All kits are qty (1) pcs.

Page 13

Notes:

Multipulse Bridge Assembly Parts Kits 13

Page 14

Rockwell Automation Support

Rockwell Otomasyon Ticaret A.Ş., Kar Plaza İş Merkezi E Blok Kat:6 34752 İçerenköy, İstanbul, Tel: +90 (216) 5698400

Rockwell Automation provides technical information on the Web to assist you in using its products.

At http://www.rockwellautomation.com/support

sample code and links to software service packs, and a MySupport feature that you can customize to make the best

use of these tools. You can also visit our Knowledgebase at http://www.rockwellautomation.com/knowledgebase

for FAQs, technical information, support chat and forums, software updates, and to sign up for product notification

updates.

, you can find technical manuals, technical and application notes,

For an additional level of technical phone support for installation, configuration, and troubleshooting, we offer

TechConnect

representative, or visit http://www.rockwellautomation.com/support/

SM

support programs. For more information, contact your local distributor or Rockwell Automation

.

Installation Assistance

If you experience a problem within the first 24 hours of installation, review the information that is contained in this

manual. You can contact Customer Support for initial help in getting your product up and running.

United States or Canada 1.440.646.3434

Outside United States or Canada Use the Worl dwide Loca tor

Rockwell Automation representative.

at http://www.rockwellautomation.com/rockwellautomation/support/overview.page, or contact your local

New Product Satisfaction Return

Rockwell Automation tests all of its products to help ensure that they are fully operational when shipped from the

manufacturing facility. However, if your product is not functioning and needs to be returned, follow these

procedures.

United States Contac t your distributor. You must provide a Customer Support case number (call the phone number above to obtain one) to your

Outside United States Please contact your local Rockwell Automation representative for the return procedure.

distributor to complete the return process.

Documentation Feedback

Your comments will help us serve your documentation needs better. If you have any suggestions on how to improve

this document, complete this form, publication RA-DU002

, available at http://www.rockwellautomation.com/

literature/.

Publication 1336-5.91 - May 2013 PN-206339

Supersedes Publication 1336-5.91 - March 2002 Copyright © 2013 Rockwell Auto mation, Inc. All rights reserved. Pr inted in the U.S.A.

Loading...

Loading...