Page 1

1336 IMPACT Quick Start Guide

This Quick Start Guide summarizes the basic steps needed to install, start-up, and program the 1336 IMPACT Adjustable

Frequency AC Drive. The information provided Does Not replace the User Manual and is intended for qualified drive service

personnel only. Refer to the 1336 IMPACT User Manual (publication 1336 IMPACT-5.0) for details on other application

considerations and related precautions.

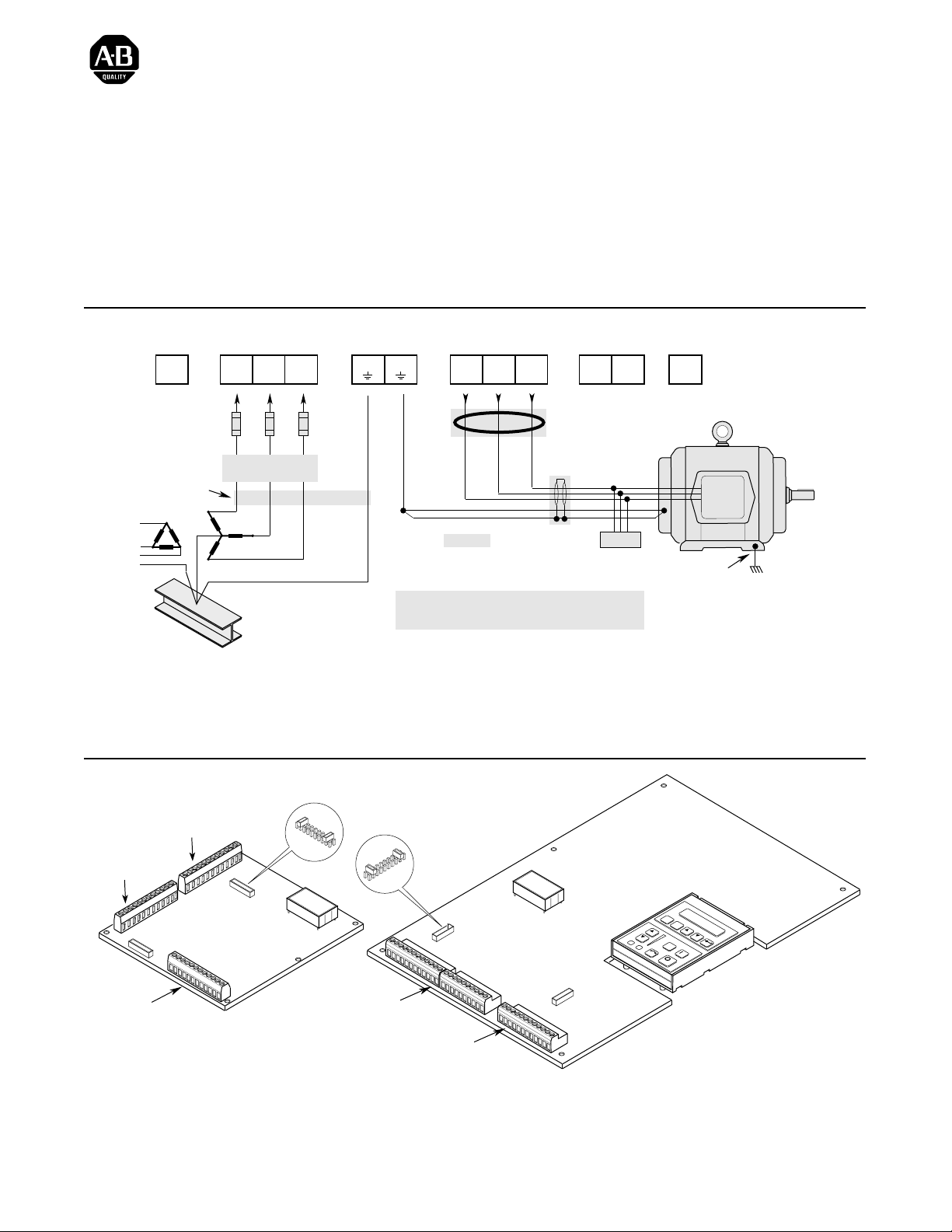

Power Wiring – TB1

TE

Ground

TE

(Not on all drives) (Not on all drives)

Required

Input Fusing

Conduit/4-Wire Cable

Nearest

Building Structure Steel

AC Input

to Drive

R

S

(L1)

(L2)T(L3)

Required Branch

Circuit Disconnect

PE

Ground

PE PE

Important: Verify motor insulation system peak voltage

Diagram shows connections that are common for all drives.

Drive Output

to Motor

U

(T1)V(T2)W(T3)

Common Mode Core*

Shield*

* Optional

rating. For cable lengths greater than 6.1

meters (20 feet), consult the User Manual.

Refer to User Manual for Detailed Information.

Dynamic Brake

DC

+

Motor

Terminator*

Jumper Locations

DC

–

BRK

–

Motor Frame

PE

Ground per

Local Codes

J4 (TB4)

J7 (TB7)

J10 (TB10)

Frames A1 – A4

Publication 1336 IMPACT-5.5EN – May, 1999

J5

LANGUAGE MODULE

ALLEN-BRADLEY

L Option Board

Jumpers

J2

TB10

TB11

LANGUAGE MODULE

ALLEN-BRADLEY

ESC

SEL

JOG

All Other Frames

Page 2

1336 IMPACT Quick Start Guide

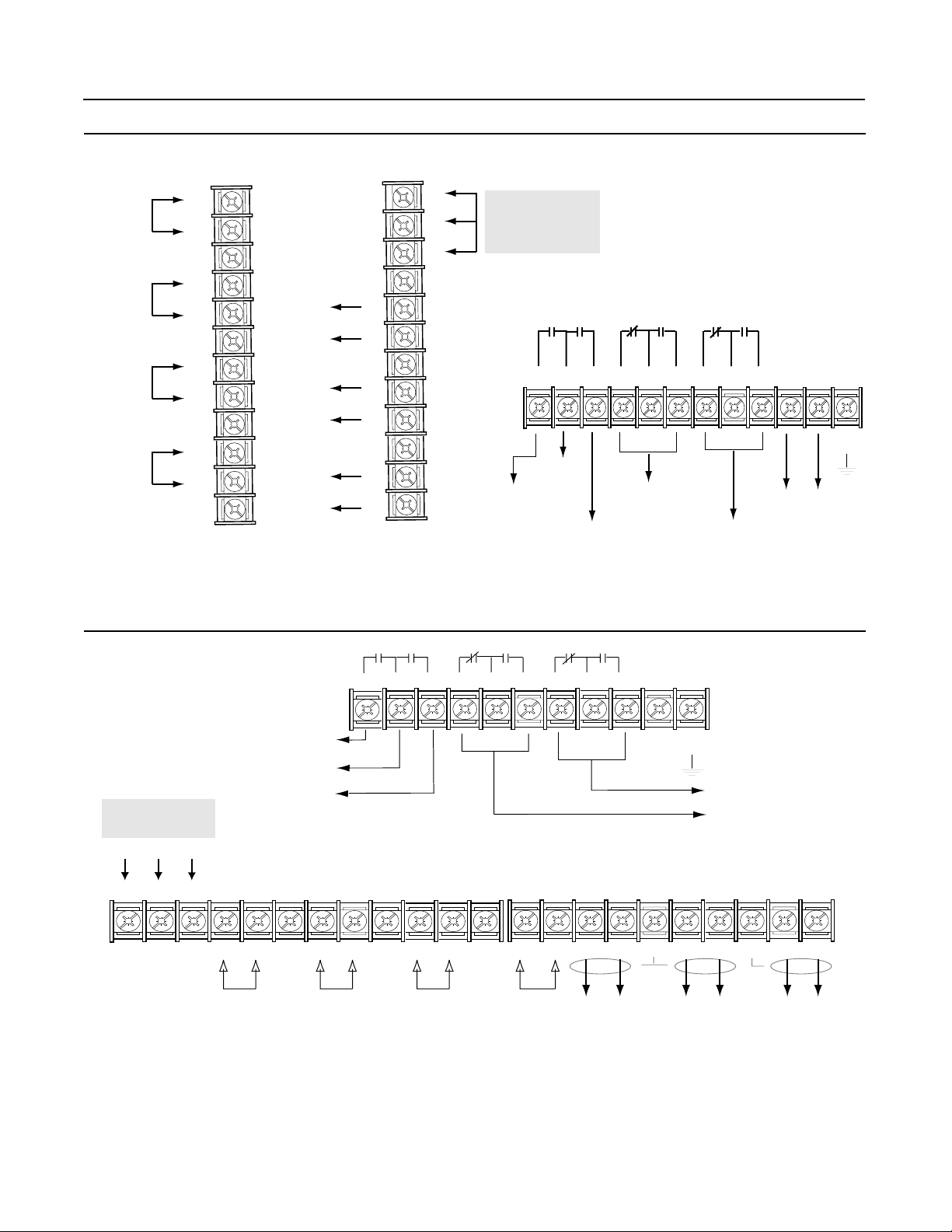

Wiring I/O – A-Frames

Analog

Input 1

Analog

Input 2

4 to 20 mA

Pulse

Source

J7 (TB7)

+

Shield

+

Shield

+

Shield

+

Shield

J4 (TB4)

1

-

-

-

-

2

3

4

5

6

7

8

9

10

11

12

Analog

Output 2

+10V

Com

-10V

Shield

Analog

Output 1

Shield

Shield

4 to 20 mA

+

-

+

-

+

-

1

2

3

4

5

6

7

8

9

10

11

12

DC Power

Supply*

J10 (TB10)

123456789101112

Supply

Relay 1

Default: At Speed

Default: Enable

* The power supply is for drive

input use only.

Relay 3

Default: Not Fault

Relay 2

Default: Not Warning

(Run)

TE

Voltage

Clearance

Relay 4

(Alarm)

Wiring I/O - All Other Frames

TB11

Relay 1

Default:

At Speed

Supply

TB10

DC Power

Supply

+10V Com -10V

1 23456789

+++++++-------

Analog

Input 1

Relay 2

Default:

Enable (Run)

SH SH SH SH SH

Analog

Input 2

123

10 11 12

4-20 mA

Input

4

6

5

789 10

TE

Voltage

Clearance

Relay 4 Default:

Not Warning (Alarm)

Relay 3 Default: Not Fault

13 14 15 16 17 18 19 20 21 22

Pulse

Source

Analog

Output 1

Analog

Output 2

4-20 mA

Output

2Publication 1336 IMPACT-5.5EN – May, 1999

Page 3

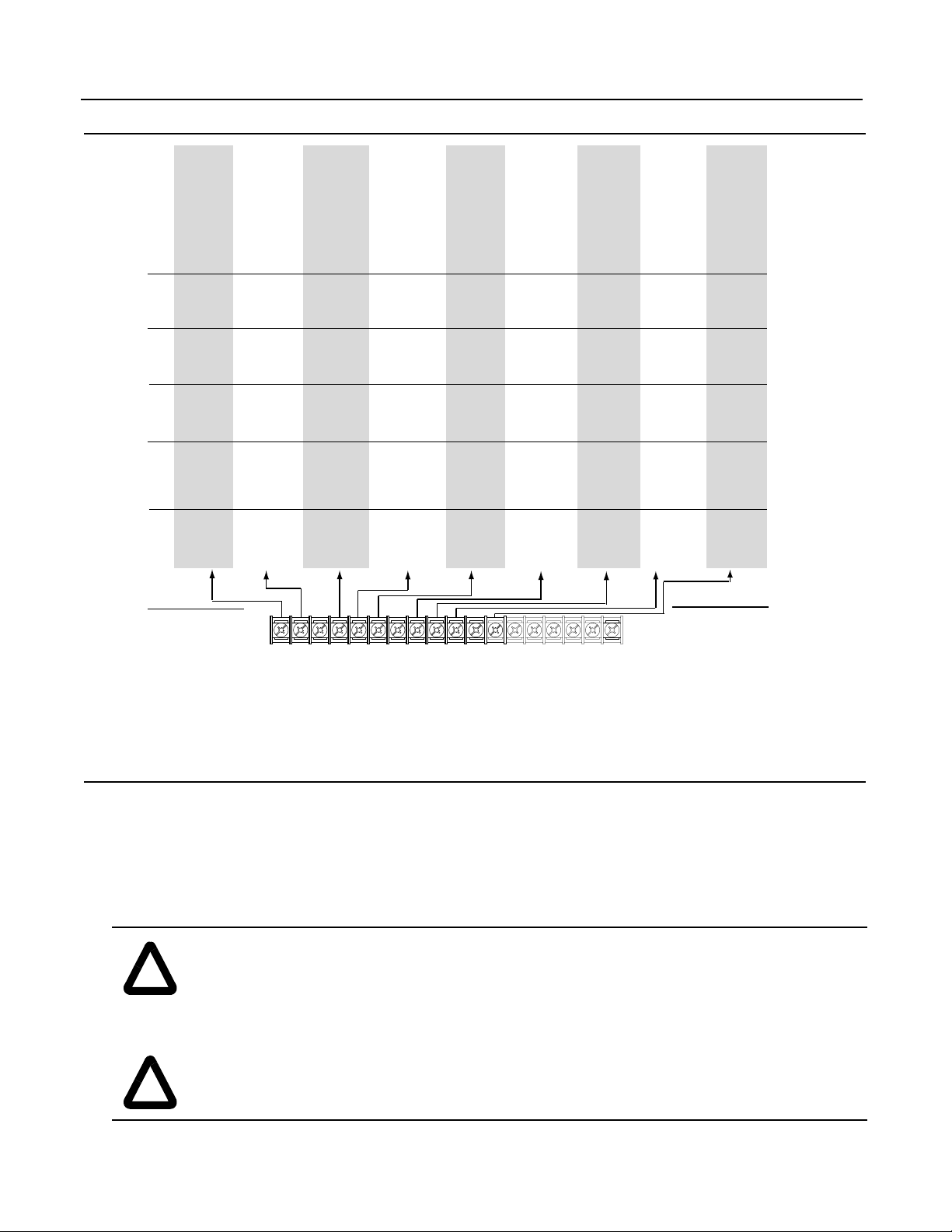

L Option Board

1

Status

2

Start

3

Start

4

Start

5

Start

6

Start

7

Start

8

Start

9

Start

10

Start

11

Start

12

Run Fwd

13

Run Fwd

14

Run Fwd

15

Run Fwd

16

Run Fwd

17

Start

18

Start

19

Start

20

Start

21

Start

22

Start

23

Run Fwd

24

Run Fwd

25

Run Fwd

26

Run Fwd

27

Start

28

Start

29

Start

30

Run Fwd

Spd Select

3

2

1

0

0

0 - Speed Ref 1

0

0

1 - Speed Ref 2

0

1

0 - Speed Ref 3

0

1

1 - Speed Ref 4

1

0

0 - Speed Ref 5

1

0

1 - Speed Ref 6

1

1

0 - Speed Ref 7

1

1

1 - No Change, Last State

Stop/Clr Flt

Stop/Clr Flt

Stop/Clr Flt

Stop/Clr Flt

Stop/Clr Flt

Stop/Clr Flt

Stop/Clr Flt

Stop/Clr Flt

Stop/Clr Flt

Stop/Clr Flt

Stop/Clr Flt

Stop/Clr Flt

Stop/Clr Flt

Stop/Clr Flt

Stop/Clr Flt

Stop/Clr Flt

Stop/Clr Flt

Stop/Clr Flt

Stop/Clr Flt

Stop/Clr Flt

Stop/Clr Flt

Stop/Clr Flt

Stop/Clr Flt

Stop/Clr Flt

Stop/Clr Flt

Stop/Clr Flt

Stop/Clr Flt

Stop/Clr Flt

Stop/Clr Flt

Stop/Clr Flt

19

1336 IMPACT Quick Start Guide

Status

Rev/Fwd

Rev/Fwd

Rev/Fwd

Rev/Fwd

Rev/Fwd

Reverse

Reverse

MOP Incr

Reverse

Accel 1

Run Rev

Run Rev

Run Rev

Run Rev

Run Rev

Rev/Fwd

Rev/Fwd

Spd/Trq 3

Spd/Trq 3

Reverse

Spd/Trq 3

Run Rev

Run Rev

Run Rev

Run Rev

Rev/Fwd

MOP Incr

Reverse

Run Rev

20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36

Common

Status

Jog

Stop Type

Accel 2*/1

MOP Incr

Jog

Forward

Forward

MOP Decr

Forward

Accel 2

Loc/Rem

Stop Type

Accel 2*/1

MOP Incr

Loc/Rem

PTrim En

Flux Enable

Spd/Trq 2

Spd/Trq 2

Forward

Spd/Trq 2

PTrim En

Flux Enable

PTrim En

Jog

MOP Incr

MOP Decr

Forward

MOP Incr

Common

Status

Ext Flt

Ext Flt

Ext Flt

Ext Flt

Ext Flt

Ext Flt

Ext Flt

Ext Flt

Ext Flt

Ext Flt

Ext Flt

Ext Flt

Ext Flt

Ext Flt

Ext Flt

Ext Flt

Ext Flt

Ext Flt

Ext Flt

Ext Flt

Ext Flt

Ext Flt

Ext Flt

Ext Flt

Ext Flt

Ext Flt

Ext Flt

Ext Flt

Ext Flt

Common

Status

Spd Sel 3

Spd Sel 3

Decel 2*/1

MOP Decr

Loc/Rem

Jog

Spd Sel 3

Spd Sel 3

MOP Incr

Decel 1

Spd Sel 3

Spd Sel 3

Decel 2*/1

MOP Decr

Stop Type

Ramp Dis

Reset

Spd/Trq 1

Spd/Trq 1

Ramp Dis

Spd/Trq 1

Reset

Reset

Ramp Dis

Spd Sel 3

MOP Decr

Spd Sel 3

MOP Incr

MOP Decr

Encoder B

Encoder NOT A

Status

Spd Sel 2

Spd Sel 2

Spd Sel 2

Spd Sel 2

Spd Sel 2

Spd Sel 2

Spd Sel 2

Spd Sel 2

MOP Decr

Decel 2

Spd Sel 2

Spd Sel 2

Spd Sel 2

Spd Sel 2

Spd Sel 2

Spd Sel 2

Spd Sel 2

PTrim En

Flux Enable

Reset

Spd Sel 2

Spd Sel 2

Spd Sel 2

Spd Sel 2

Spd Sel 2

Spd Sel 2

Spd Sel 2

MOP Decr

Spd Sel 2

Encoder A

(200mA max.)

Encoder NOT B

+12V

Status

Spd Sel 1

Spd Sel 1

Spd Sel 1

Spd Sel 1

Spd Sel 1

Spd Sel 1

Spd Sel 1

Spd Sel 1

Spd Sel 1

Spd Sel 1

Spd Sel 1

Spd Sel 1

Spd Sel 1

Spd Sel 1

Spd Sel 1

Spd Sel 1

Spd Sel 1

Spd Sel 1

Spd Sel 1

Spd Sel 1

Spd Sel 1

Spd Sel 1

Spd Sel 1

Spd Sel 1

Spd Sel 1

Spd Sel 1

Spd Sel 1

Spd Sel 1

Spd Sel 1

3

0

0

0

0

1

1

1

1

Encoder Common

Enable

Enable

Enable

Enable

Enable

Enable

Enable

Enable

Enable

Enable

Enable

Enable

Enable

Enable

Enable

Enable

Enable

Enable

Enable

Enable

Enable

Enable

Enable

Enable

Enable

Enable

Enable

Enable

Enable

Enable

Spd/Trq Select

2

1

0

0 - Zero Torque

0

1 - Speed Reg

1

0 - Torque Reg

1

1 - Min Trq/Spd

0

0 - Max Trq/Spd

0

1 - Sum Trq/Spd

1

0 - Zero Torque

1

1 - Zero Torque

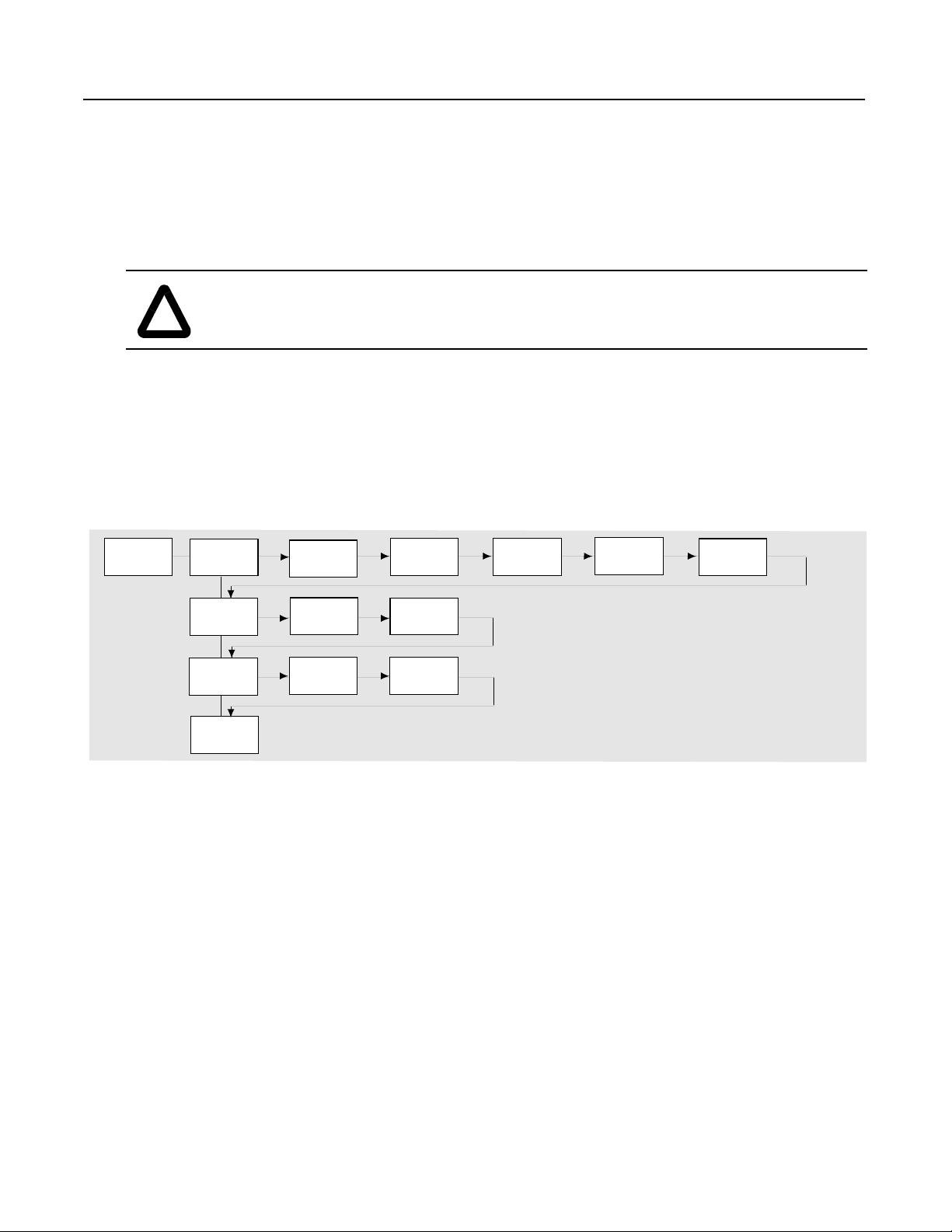

Start-Up

This start-up procedure co vers only the most commonly adjusted values using the 1 336 IMPACT “Startup” mode. Refer to the

User Manual for detailed information.

The following procedure is written for users who have a Human Interface Module (HIM) installed. For users without a HIM,

respective external commands and signals must be supplied. It is also assumed that all parameters are at factory default

settings.

ATTENTION: Power must be applied to the drive to perform the following. Some of the voltages present

are at incoming line potential. T o avoid a shock hazard or damage to equipment, only qualified driv e service

!

!

Publication 1336 IMPACT-5.5EN – May, 19993

personnel should perfo rm the fo l lowing procedure. Thoroughly read and under sta n d th e pro cedure before

beginning. If an e ven t does not occur while perfor ming this procedure, Do Not Proceed. Remo ve po wer b y

opening the branch circuit disconnect device and correct the malfunction before continuing.

ATTENTION: To avoid a hazard of electric shock when wiring or servicing the drive, verify that the

voltage on the bus capacitors has discharged. Measure the DC bus v oltage at the + and - terminals of TB1.

The voltage must be zero.

Page 4

1336 IMPACT Quick Start Guide

1. Verify that AC line power and control power match the drive rating.

2. If an L option is installed, verify that the Stop and Enable interlock inputs are present. If this option is not installed, verify

that jumpers are installed at pins 3 and 4 and 17 and 18 on J5 on A Frame drives or J2 on B Frame and up drives. Ref er to

Jumper Locations.

3. If standard I/O is being used, verify that jumpers are wired correctly.

4. If Analog Option is installed, verify that parameters are properly configured (refer to the User Manual).

ATTENTION: In all of the following steps, rotation of the motor may occur. To guard against injury ,

incorrect rotation, and possible equipment damage, read each step carefully and perform with caution.

!

5. Apply AC power and control voltages to the drive. The LCD display should light and display a drive status of “Stopped”

and an output frequency of “+0.00 Hz.” If the drive detects a fault, a statement relating to the fault will be shown on the

display. Record the information, remove power, and correct the fault source before proceeding.

6. From the Status Display, press the Enter key (or any key). “Choose Mode” will be displayed . Pres s the Increment (or

Decrement) key until “Startup is displayed. Press Enter.

Important: All questions can be answered Yes or No. Pressing Enter will select the default (“Y” or “N”). Pressing the

Increment (or Decrement) key will change the selection. Press Enter to select. Choosing “Y” allows you to proceed

through the step, and choosing “No” will advance you to th e next step . The figure below shows the steps involved.

Startup

Quick Motor

Tune?

No

Configure

Digital?

No

Configure

Analog?

No

Done

Yes

Enter Motor

Data?

Relay

Yes Yes

Output

Inputs

Yes Yes

Yes Yes Yes Yes

Encoder?

L Option

Outputs

Regen/

Brake?

Phase

Rotation?

Autotune?

Important: Pleas e note the following:

• The “Startup” mode can be e xit ed at an y time by pressing ESCape until the Status Display i s shown. If you wish

to re-enter the “Startup” mode, simply select “Reset Sequence” to start from the beginning. Selecting “Continue”

allows you to resume from the point where you left off.

• Completing the last action in any step will automatically take you to th e next step.

• Pressing SELect will activate line 2 of the display. This must be done for all values.

• Press the Increment (or Decrement) key to adjust a value (skip if value is correct). Press Enter to store the value

or retain existing value. Pressing Enter again will cause you to move to the next step (parameter)

7. Cycle power to acti v ate changes. This completes the “Assisted Startup” procedure. Depending o n your application, furt her

parameter programming and/or “Advanced Startup” may be required. Refer to the User Manual for details.

4Publication 1336 IMPACT-5.5EN – May, 1999

Page 5

1336 IMPACT Quick Start Guide

Drive Dimensions

To determine the size of your drive, refer to the following illustration and table.

Depth

HIM Operation

Width

Height

Frame

A1

A2

A3

A4

B

C

D

E-Enclosed

E-Open

F

G

H

➀

Fan height (635.0 (25.00)) not included.

Width x Height x Depth

Millimeters (inches)

215.9 (8.50) x 290.0 (11.42) x 160.0 (6.30)

215.9 (8.50) x 290.0 (11.42) x 180.5 (7.10)

215.9 (8.50) x 290.0 (11.42) x 207.0 (8.15)

260.0 (10.24) x 350.0 (13.78) x 212.0 (8.35)

276.4 (10.88) x 476.3 (18.75) x 225.0 (8.86)

301.8 (11.88) x 701.0 (27.60) x 225.0 (8.86)

381.5 (15.02) x 1240.0 (48.82) x 270.8 (10.66)

511.0 (20.12) x 1498.6 (59.00) x 477.5 (18.80)

511.0 (20.12) x 1498.6 (59.00) x 372.6 (14.67)

762.0 (30.00) x 2286.0 (90.00) x 635.0 (25.00)

762.0 (30.00) x 2387.6 (94.0) x 635.0 (25.00)

1270.0 (50) x 2324.1 (91.50)➀ x 635.0 (25)

Parameter programming or viewing is accomplished through the Program or Display modes shown below.

1. From the Status Display, press to display “Choose Mode.”

2. Press or to display “Program” (or “Display”).

3. Press .

4. Press or until the desired file is displayed.

5. Press .

6. Press or until the desired group is displayed.

7. Press .

8. Press or to scroll to the desired pa rameter.

Publication 1336 IMPACT-5.5EN – May, 19995

Page 6

HIM Structure

1336 IMPACT Quick Start Guide

Power-Up and

Status Display

or or or or

Choose Mode

EEProm Search Password Display Process

Save Values

Recall Values

Reset Defaults

Drive to HIM

HIM to Drive

Parameters

Links

Control

Status

Control Logic

Reset Drive1

Fault Queue

Warning Queue

Login

Logout

Modify

Process Display

Program

Operator Level

Mode Level

Link Start Up

Set Links

Clear All Links

Monitor

Motor Status

Drive/Inv Status

SCANport Status

Fault Status

Testpoints

Control

Drive Logic Select

Control Limits

Speed/Torq Mode

Speed Reference

Accel/Decel

Torque Reference

Feedback Device

Speed Feedback

Speed Regulator

Fault Setup

Fault Config

Fault Limits

Test Points

Interface/

Comm

Digital Config

Analog Inputs

Analog Outputs

SCANport Config

SCANport Status

SCANport Analog

Gateway Data In

Gateway Data Out

Parameters

(See Next Page)

Motor/

Inverter

Motor Nameplate

Encoder Data

Inverter

Motor Constants

File Level

Application Autotune

Group Level

Flux Braking

DC Braking/Hold

Max Mtr Current

Fast Flux Up

Start Dwell

Prog Function

Bus Reg/Control

Process Trim

Flying Start

Autotune Setup

Autotune Status

Autotune Results

Drive to HIM

HIM to Drive

Element Level

Publication 1336 IMPACT-5.5EN – May, 19996

Page 7

1336 IMPACT Quick Start Guide

Parameters - Files, Groups, and Elements

Name No. Min./Max. Value Name No. Min./Max. Value

Monitor Neg Mtr Cur Lim 73 Calc/0.0%

Motor Status Pos Torque Lim 74 0.0%/Calc

Motor Speed 81 -8 x BMS/+8 x BMS Neg Power Lim 75 Calc/0.0%

Motor Frequency 89 -250.000/+250.000 Hz Regen Power Lim 76 -800.0%/0.0%

Motor Current 83 0.0/6553.5 amps Current Rate Lim 77 Calc/200.0%

Motor Voltage 85 0/+3000 volts Max Mtr Current 195 0/1

Motor Voltage % 234 0/800% Min Speed Limit 215 0.0

Motor Torque % 86 -800.0/+800.0%

Speed/Torq Mode

Motor Flux % 88 12.5/100.0% Spd/Trq Mode Sel 68 0/5

Motor Power% 90 -800.0/+800.0%

Speed Reference

Enc Pos Fdbk Low 227 0/65535 Speed Ref 1 29 -8x/+8xBMS rpm

Enc Pos Fdbk Hi 228 0/65535 Speed Scale 1 30 -3.9999/+3.9999

Int Torque Ref 229 -800/+800% Speed Ref 2 31 -8x/+8xBMS rpm

Drive/Inv Status Speed Ref 3 32 -8x/+8xBMS rpm

DC Bus Voltage 84 0/1000V Speed Ref 4 33 -8x/+8xBMS rpm

Logic Input Sts 14 Bit selection Speed Ref 5 34 -8x/+8xBMS rpm

Drive/Inv Status 15 Bit selection Speed Ref 6 35 -8x/+8xBMS rpm

Drive/Inv Sts 2 196 Bit selection Speed Ref 7 36 -8x/+8xBMS rpm

Run Inhibit Sts 16 Bit selection Speed Scale 7 37 -3.9999/+3.9999

Command Spd Sts 82 -8 x BMS/+8 x BMS Jog Speed 1 38 -8x/+8xBMS rpm

Torque Limit Sts 87 Bit selection Jog Speed 2 39 -8x/+8xBMS rpm

Spd Reg Output 225 -300.0/+300.0%

Accel/Decel

Spd Error 226 -8 x BMS/+8 x BMS Accel Time 1 42 0.0/6553.5 sec

SCANport Status Accel Time 2 43 0.0/6553.5 sec

Dir/Ref Owner 128 Bit selection Decel Time 1 44 0.0/6553.5 sec

Start/Stop Owner 129 Bit selection Decel Time 2 45 0.0/6553.5 sec

Jog1/Jog2 Owner 130 Bit selection S-Curve Percent 47 0.0/100.0%

Ramp/ClFlt Owner 131 Bit selection

Torque Reference

Flux/Trim Owner 132 Bit selection Torque Ref 1 69 -800.0/+800.0%

Fault Status Slave Torque % 70 -200.00/+200.00%

PwrUp Flt Status 219 Bit selection

Feedback Device

Ncfg Flt Status 220 Bit selection Fdbk Device Type 64 1/3

Fault Status 1 221 Bit selection Encoder PPR 8 Calc/20000 ppr

Fault Status 2 222 Bit selection

Speed Feedback

Warning Status 1 223 Bit selection Scaled Spd Fdbk 63 -32767/+32767

Warning Status 2 224 Bit selection Fdbk Filter Sel 65 0/4

Testpoints Fdbk Filter Gain 66 -5.00/+5.00

Test Data 1 92 -32768/+32767 Fdbk Filter BW 67 0.2/900.0 rad/sec

Test Select 1 93 0/65535 Notch Filtr Freq 185 5.0/135.0 Hz

Test Data 2 94 -32768/+32767 Notch Filtr Q 186 2/500

Test Select 2 95 0/65535

Speed Regulator

Control Total Inertia 157 0.01 sec/655.00 sec

Drive Logic Select Spd Desired BW 161 0.00 rad/sec/Calc

Logic Options 17 Bit selections Ki Speed Loop 158 0.0/4095.9

Stop Dwell Time 18 0.0/10.0 sec Kp Speed Loop 159 0.0/200.0

Zero Speed Tol 19 0.0 rpm/8xBMS rpm Kf Speed Loop 160 0.500/1.000

Start Dwell Spd 193 -0.1/+0.1 x BMS Error Filtr BW 162 Calc/1500.0 rad/sec

Start Dwell Time 194 0.0/10.0 sec Droop Percent 146 0.0/25.5%

Control Limits Fault Setup

Rev Speed Limit 40 -6xBMS rpm/0.0 rpm

Fault Config

Fwd Speed Limit 41 0.0 rpm/+6xBMS rpm Fault Select 1 20 Bit selection

Pos Mtr Cur Lim 72 0.0%/Calc Warning Select 1 21 Bit selection

/BMS rpm

7Publication 1336 IMPACT-5.5EN – May, 1999

Page 8

1336 IMPACT Quick Start Guide

Name No. Min./Max. Value Name No. Min./Max. Value

Fault Config cont. SCANport Config

Fault Select 2 22 Bit Selection SP2 Wire Enable 181 Bit Selection

Warning Select 2 23 Bit Selection SP Enable Mask 124 Bit Selection

Fault Limits Dir/Ref Mask 125 Bit Selection

Absolute Overspd 24 0.0 rpm/BMS rpm Start/Jog Mask 126 Bit Selection

Motor Stall Time 25 0.1/3276.7 sec Clr Flt/Res Mask 127 Bit Selection

Motor Overload % 26 110.0/400.0%

SCANport Status

Line Undervolts 27 10.0/90.0% Dir/Ref Owner 128 Bit selection

Testpoints Start/Stop Owner 129 Bit selection

Test Data 1 92 -32768/+32768 Jog1/Jog2 130 Bit selection

Test Select 1 93 0/65535 Ramp/CIFlt Owner 131 Bit selection

Test Data 2 94 -32768/+32767 Flux/Trim Owner 132 Bit selection

Test Select 2 95 0/65535

SCANport Analog

Interface/Comm SP An In1 Select 133 1/16

Digital Config SP An In1 Value 134 -32767/+32767

Relay Config 114 0/38 SP An In1 Scale 135 -1.000/+1.000

Relay Config 1 115 -800.0/+800.0% Sp An In2 Select 136 1/16

Relay Config 2 187 0/36 Sp An In2 Value 137 -32767/+32767

Relay Setpoint 2 188 800.0/+800.0 Sp An In2 Scale 138 -1.000/+1.000

Relay Config 3 189 0/36 Sp An Output 139 -32767/+32767

Relay Setpoint 3 190 -800.0/+800.0

Gateway Data In

Relay Config 4 191 0/36 Data In A1 140 -32767/+32767

Relay Setpoint 4 192 -800/+800.0% Data In A2 141 -32767/+32767

L Option Mode 116 1/25 Data In B1 142 -32767/+32767

L Option In Sts 117 Bit Selection Data In B2 143 -32767/+32767

Mop Increment 118 0.0/BMS Data In C1 144 -32767/+32767

Mop Value 119 0.0/BSMNA Data In C2 145 -32767/+3276

Pulse In PPR 120 500/2000 Data In D1 146 -32767/+32767

Pulse In Scale 121 0.01/10.00 Data In D2 147 -32767/+32767

Pulse In Offset 122 -BMS/+BMS

Gateway Data Out

Pulse In Value 123 0.0/+8xBMS Data Out A1 148 -32767/+32767

Analog Inputs Data Out A2 149 -32767/+32767

An In 1 Value 96 -32767/+32767 Data Out B1 150 -32767/+32767

An In 1 Offset 97 -19.980/+19.980 volts Data Out B2 151 -32767/+32767

An In 1 Scale 98 -16.000/+16.000 Data Out C1 152 -32767/+32767

An In 1 Filter BW 182 0.0/200.0 rad/sec Data Out C2 153 -32767/+32767

An In 2 Value 99 -32767/+32767 Data Out D1 154 -32767/+32767

An In 2 Offset 100 -19.980/+19.980 volts Data Out D2 155 -32767/+32767

An In 2 Scale 101 -16.000/+16.000

An In2 Filter BW 183 0.0/200.0 rad/sec

mA Input Value 102 -32767/+32767

mA In Offset 103 -32.000/+32.000 mA

mA In Scale 104 -16.00

mA In Filter BW 184 0.0/200.0 rad/sec

Analog Outputs

An Out 1 Value +0 105 -32767/+32767

An Out 1 Offset 106 -20.000/+20.000

An Out 1 Scale 107 -1.000/+1.000

An Out 2 Value 108 -32767/+32767

An Out 2 Offset 109 -19.980/+19.980 volts

An Out 2 Scale 110 -1.000/+1.000

mA Out Value 111 -32767/+32767

mA Out Offset 112 -32.000/+32.000 mA

mA Out Scale 113 -1.000/+1.000

8Publication 1336 IMPACT-5.5EN – May, 1999

Page 9

1336 IMPACT Quick Start Guide

Name No. Min./Max. Value Name No. Min./Max. Value

Motor Inverter Function Sel 212 0/27

Motor Nameplate Function Output1 213 Varies

Nameplate HP 2 0.2 hp/2000.0 hp Function Output2 214 0/65535

Nameplate RPM 3 1 rpm/1500 rpm Function In9 232 -32767/+32767

Nameplate Amps 4 0.1 amps/Calc Function In 10 233 -32767/+32767

Nameplate Volts 5 75 volts/575 volts

Bus Reg Control

Namplate Hz 6 1.0/250.0 Hz Bus/Brake Option 13 Bit selection

Motor Poles 7 2/40 poles

Process Trim

Service Factor 9 1.00/2.00 PTrim Output 48 -800.0/+800.0%

Encoder Data PTrim Reference 49 -800.0/+800.0%

Encoder PPR 8 Calc/2000 ppr PTrim Feedback 50 -800.0/+800.0%

Inverter PTrim Select 51 Bit selection

PWM Frequency 10 1000 Hz/From drive PTrim Filter BW 52 0.0/240.0 rad/sec

Inverter Amps 11 0.1 amps/From drive PTrim Preload 53 -800.0/+800.0%

Inverter Volts 12 75/575 volts PTrim Ki 54 0.000/16.000

Motor Constants PTrim Kp 55 0.000/16.000

Stator Resistance 166 0.00/100.00% PTrim Lo Limit 58 -800.0/+800.0%

Leak Inductance 167 0.00/100.00% PTrim Hi Limit 59 -800.0/+800.0%

Flux Current 168 0.00/75.00% PTrim Out Gain 60 -8.000/+8.000

Slip Gain 169 0.0/400.0% Max Rev Spd Trim 61 -6 x /0.0 BMS rpm

Motor Poles 7 2/40 poles Max Fwd Spd Trim 62 0.0 rpm/+6xBMS rpm

Application Flying Start

Flux Braking FStart Select 216 0/2

Bus/Brake Option 13 Bit selection FStart Speed 217 P40/P41

DC Braking/Hold Autotune

Bus/Brake Option 13 Bit selection Autotune Setup

DC Brake Current 79 0.0%/Calc Autotune/Dgn Sel 173 Bit selection

DC Brake Time 80 0.0/6553.5 sec Trans Dgn Config 172 Bit selection

400% Mtr Current Autotune Torque 64 250%/100.0%

Max Mtr Current 195 0/1 Autotune Speed 165 0.3 x BMS/BMS

Fast Flux Up Autotune Status

Bus/Brake Option 13 Bit selection Autotune Status 156 Bit selection

Fast Flux Level 78 100.0%/Calc Inverter Dgn 1 174 Bit selection

Start Dwell Inverter Dgn 2 175 Bit selection

Start Dwell Spd 193 -0.1 x / +0.1 x BMS Autotune Errors 176 Bit selection

Start Dwell Time 194 0.0/10.0 sec

Autotune Results

Prog Function Stator Resistance 166 0.00/100.00%

Function In1 198 Varies Leak Inductance 167 0.00/100.00%

Func 1 Mask/Val 199 Varies Flux Current 168 0.00/75.00%

Func 1 Eval Sel 200 0/17 Slip Gain 169 0.0/400%

Function In2 201 Varies Total Inertia 157 0.0/655.00 sec

Func 2 Mask/Val 202 Varies Spd Desired BW 161 0.00/Calc rad/sec

Func 2 Eval Sel 203 0/17

Function In3 204 Varies

Func 3 Mask/Val 205 Varies

Func 3 Eval Sel 206 0/17

Function In4 207 Varies

Function In5 208 Varies

Function In6 209 Varies

Function In7 210 Varies

Function In8 211 Bit selection

Publication 1336 IMPACT-5.5EN – May, 19999

Page 10

1336 IMPACT Quick Start Guide

This Page Intentionally Blank

10Publication 1336 IMPACT-5.5EN – May, 1999

Page 11

1336 IMPACT Quick Start Guide

Publication 1336 IMPACT-5.5EN – May, 199911

Page 12

Allen-Bradley, a Rockwell Automation Business, has been helping its customers improve

productivity and quality for more than 90 years. We design, manufacture and support a broad range

of automation products worldwide. They include logic processors, power and motion control devices,

operator interfaces, sensors and a variety of software. Rockwell is one of the world’s leading

technology companies.

Worldwide representation.

Argentina • Australia • Austria • Bahr ain • Belgium • Brazil • Bulgaria • Canada • Chile • China, PRC • Colombia • Costa Rica • Croatia • Cyprus • Czech Republic • Denmark •

Ecuador • Egypt • El Salvador • Finland • France • Germany • Greece • Guatemala • Honduras • Hong Kong • Hungary • Iceland • India • Indonesi a • Ireland • Israel • Italy •

Jamaica • Japan • Jordan • Korea • Kuwait • Lebanon • Malaysia • Mexico • Netherlands • New Zealand • Norway • Pakistan • Peru • Philippines • Poland • Portugal • Puerto Rico •

Qatar • Romania • Russia-CIS • Saudi Arabia • Singapore • Slovakia • Slovenia • South Africa, Republic • Spain • Sweden • Switzerland • Taiwan • Thailand • Turkey • United Arab

Emirates • United Kingdom • United States • Uruguay • Venezuela • Yugoslavia

Allen-Bradley Headquarters, 1201 South Second Street, Milwaukee, WI 53204 USA, Tel: (1) 414 382-2000 Fax: (1) 414 382-4444

Publication 1336 IMPACT-5.5EN – May, 1999

Copyright 1997 Rockwell Automat ion. Printed in USA

Loading...

Loading...