Page 1

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

M035/M036

SERVICE MANUAL

004774MIU

Page 2

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

Page 3

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

SERVICE MANUAL

M035/M036

Page 4

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

Page 5

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

M035/M036

SERVICE MANUAL

004774MIU

Page 6

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

Page 7

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

It is the reader's responsibility when discussing the information contained

within this document to maintain a level of confidentiality that is in the best

interest of Ricoh Americas Corporation and its member companies.

NO PART OF THIS DOCUMENT MAY BE REPRODUCED IN ANY

FASHION AND DISTRIBUTED WITHOUT THE PRIOR

PERMISSION OF RICOH AMERICAS CORPORATION.

All product names, domain names or product illustrations, including

desktop images, used in this document are trademarks, registered

trademarks or the property of their respective companies.

They are used throughout this book in an informational or editorial fashion

only and for the benefit of such companies. No such use, or the use of

any trade name, or web site is intended to convey endorsement or other

affiliation with Ricoh products.

© 2009 RICOH Americas Corporation. All rights reserved.

Page 8

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

Page 9

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

WARNING

The Service Manual contains information

regarding service techniques, procedures,

processes and spare parts of office equipment

distributed by Ricoh Americas Corporation.

Users of this manual should be either service

trained or certified by successfully completing a

Ricoh Technical Training Program.

Untrained and uncertified users utilizing

information contained in this service manual to

repair or modify Ricoh equipment risk personal

injury, damage to property or loss of warranty

protection.

Ricoh Americas Corporation

Page 10

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

Page 11

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

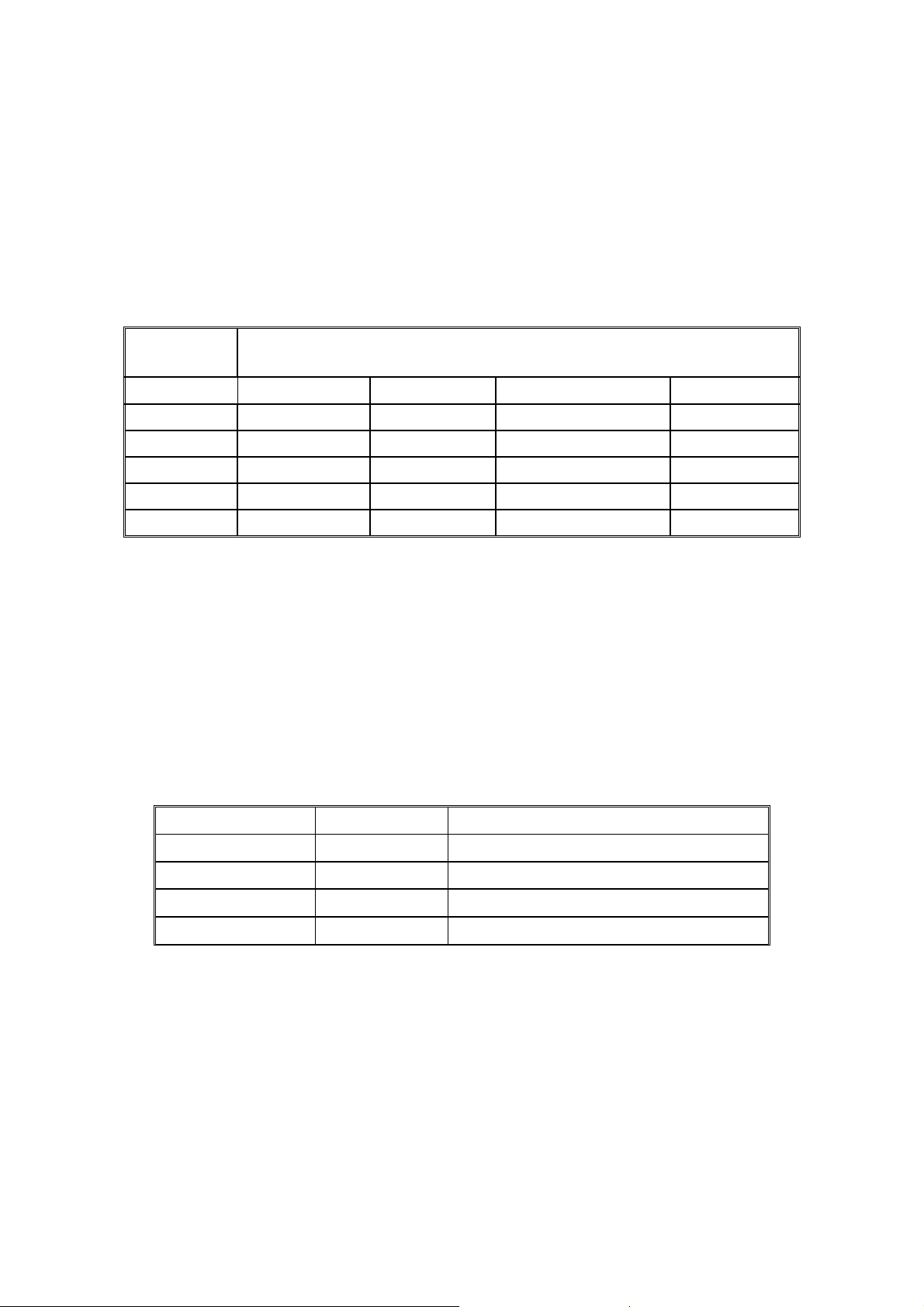

LEGEND

PRODUCT

CODE

M035 -- SP C231N Aficio SP C231N SP C231N

M036 -- SP C232DN Aficio SP C232DN SP C232DN

GESTETNER LANIER RICOH SAVIN

COMPANY

DOCUMENTATION HISTORY

REV. NO. DATE COMMENTS

*

05/2009 Original Printing

Page 12

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

Page 13

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

M035/M036

TABLE OF CONTENTS

PRODUCT INFORMATION

1. PRODUCT INFORMATION.......................................................... 1-1

1.1 SPECIFICATIONS ..................................................................................... 1-1

1.2 MACHINE OVERVIEW .............................................................................. 1-2

1.2.1 COMPONENT LAYOUT ................................................................... 1-2

1.2.2 PAPER PATH ................................................................................... 1-3

1.2.3 DRIVE LAYOUT................................................................................ 1-4

1.3 MACHINE CONFIGURATION ................................................................... 1-6

1.4 GUIDANCE FOR THOSE WHO ARE FAMILIAR WITH

PREDECESSOR PRODUCTS ................................................................. 1-7

INSTALLATION

2. INSTALLATION ........................................................................... 2-1

2.1 INSTALLATION REQUIREMENTS............................................................ 2-1

2.1.1 ENVIRONMENT ............................................................................... 2-1

2.1.2 MACHINE LEVEL ............................................................................. 2-2

2.1.3 MACHINE SPACE REQUIREMENT................................................. 2-2

2.1.4 POWER REQUIREMENTS............................................................... 2-3

2.1.5 INSTALLATION PROCEDURE......................................................... 2-3

PREVENTIVE MAINTENANCE

3. PREVENTIVE MAINTENANCE ................................................... 3-1

3.1 PREVENTIVE MAINTENANCE ................................................................. 3-1

SM i M035/M036

Page 14

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

REPLACEMENT AND ADJUSTMENT

4. REPLACEMENT AND ADJUSTMENT ........................................ 4-1

4.1 BEFORE YOU START............................................................................... 4-1

4.2 SPECIAL TOOLS....................................................................................... 4-2

4.3 EXTERIOR COVERS................................................................................. 4-3

4.3.1 REAR COVER .................................................................................. 4-3

4.3.2 OPERATION PANEL ........................................................................ 4-4

4.3.3 RIGHT COVER ................................................................................. 4-5

4.3.4 LEFT COVER ................................................................................... 4-6

4.3.5 FRONT COVER UNIT ...................................................................... 4-7

4.4 LASER OPTICS ......................................................................................... 4-9

4.4.1 CAUTION DECAL LOCATION.......................................................... 4-9

4.4.2 LASER OPTICS HOUSING UNIT................................................... 4-10

After replacing the laser optics housing unit....................................... 4-12

4.5 AIO CARTRIDGE..................................................................................... 4-14

4.5.1 AIO CARTRIDGE (ALL IN ONE CARTRIDGE)............................... 4-14

4.5.2 BLACK AIO MOTOR....................................................................... 4-15

4.5.3 COLOR AIO MOTOR...................................................................... 4-18

4.6 IMAGE TRANSFER ................................................................................. 4-19

4.6.1 IMAGE TRANSFER BELT UNIT..................................................... 4-19

After replacing the image transfer belt unit......................................... 4-20

4.6.2 ITB (IMAGE TRANSFER BELT) CLEANING UNIT......................... 4-21

4.6.3 AGITATOR MOTOR ....................................................................... 4-22

4.6.4 ITB (IMAGE TRANSFER BELT) CONTACT MOTOR..................... 4-23

4.6.5 ITB (IMAGE TRANSFER BELT) CONTACT SENSOR................... 4-24

4.6.6 TM (TONER MARK) SENSOR BASE............................................. 4-25

4.6.7 WASTE TONER BOTTLE SET SENSOR....................................... 4-26

4.6.8 WASTE TONER OVERFLOW SENSOR ........................................ 4-27

4.7 PAPER TRANSFER................................................................................. 4-28

4.7.1 TRANSFER UNIT ........................................................................... 4-28

4.7.2 TRANSFER ROLLER ..................................................................... 4-29

4.7.3 REGISTRATION ROLLER.............................................................. 4-31

Reassembling the registration roller unit ............................................ 4-31

4.7.4 REGISTRATION SENSOR ............................................................. 4-32

M035/M036 ii SM

Page 15

4.7.5 REGISTRATION CLUTCH.............................................................. 4-33

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

4.8 IMAGE FUSING ....................................................................................... 4-34

4.8.1 FUSING UNIT ................................................................................. 4-34

4.8.2 FUSING LAMP................................................................................ 4-36

When Reinstalling the Fusing Lamp................................................... 4-36

4.8.3 TRANSPORT/FUSING MOTOR ..................................................... 4-37

4.9 PAPER FEED .......................................................................................... 4-38

4.9.1 PAPER FEED CLUTCH.................................................................. 4-38

4.9.2 PAPER FEED ROLLER .................................................................. 4-39

4.9.3 SEPARATION PAD ........................................................................ 4-40

4.9.4 PAPER END SENSOR ................................................................... 4-41

4.10 PAPER EXIT ...................................................................................... 4-42

4.10.1 PAPER EXIT ROLLER .............................................................. 4-42

When reinstalling the paper exit roller ................................................ 4-43

4.10.2 PAPER EXIT SENSOR ............................................................. 4-44

4.11 ELECTRICAL COMPONENTS........................................................... 4-45

4.11.1 CONTROLLER BOARD ............................................................ 4-45

4.11.2 EGB (ENGINE BOARD) ............................................................ 4-46

When installing the new EGB ............................................................. 4-47

4.11.3 INTERLOCK SWITCHES .......................................................... 4-48

4.11.4 FUSING FAN MOTOR .............................................................. 4-49

4.11.5 LSU FAN MOTOR..................................................................... 4-50

4.11.6 ID CHIP BOARD ....................................................................... 4-51

4.11.7 PSU ........................................................................................... 4-52

Fuse ................................................................................................... 4-54

4.11.8 HIGH VOLTAGE POWER SUPPLY BOARD ............................ 4-54

4.11.9 TEMPERATURE/HUMIDITY SENSOR ..................................... 4-55

4.11.10 DUPLEX MOTOR (M036 ONLY).............................................. 4-56

4.11.11 EEPROM .................................................................................. 4-57

SYSTEM MAINTENANCE REFERENCE

5. SYSTEM MAINTENANCE REFERENCE .................................... 5-1

5.1 SERVICE PROGRAM................................................................................ 5-1

5.1.1 OVERVIEW....................................................................................... 5-1

5.2 CONFIGURATION AND TEST PAGE INFORMATION ............................. 5-2

SM iii M035/M036

Page 16

5.2.1 OVERVIEW....................................................................................... 5-2

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

To Print the Configuration Page from the Machine............................... 5-2

To Print the Configuration Page from the SOM .................................... 5-2

To Print the Test Page from the Machine............................................. 5-2

To Print the Test Page from the SOM .................................................. 5-2

5.2.2 ERROR LOG .................................................................................... 5-3

5.2.3 COUNTER AND COVERAGE .......................................................... 5-4

Configuration Page............................................................................... 5-4

Test Page............................................................................................. 5-5

5.3 FIRMWARE UPDATING ............................................................................ 5-6

5.3.1 PRINTER MODEL ............................................................................ 5-6

Controller Firmware.............................................................................. 5-6

Engine Firmware .................................................................................. 5-8

5.3.2 BOOT LOADER FIRMWARE............................................................ 5-9

TROUBLESHOOTING

6. TROUBLESHOOTING ................................................................. 6-1

6.1 TROUBLESHOOTING GUIDE................................................................... 6-1

6.2 IMAGE PROBLEMS................................................................................... 6-2

6.2.1 OVERVIEW....................................................................................... 6-2

6.2.2 CHECKING A SAMPLE PRINTOUT................................................. 6-3

Printer Driver Setting for Printing a Sample.......................................... 6-3

M035/M036 SERVICE MANUAL APPENDICES

SEE M035/M036 SERVICE MANUAL APPENDICES SECTION FOR DETAILED TABLE

OF CONTENTS

G849 PAPER FEED UNIT TK1010

SEE SECTION G849 FOR DETAILED TABLE OF CONTENTS

M035/M036 iv SM

Page 17

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

PRODUCT INFORMATION

APPENDIX: SPECIFICATIONS

INSTALLATION

APPENDIX: PREVENTIVE MAINTENANCE

G849 Paper Feed Unit TK1010

PREVENTIVE MAINTENANCE

APPENDIX: TROUBLESHOOTING GUIDE

REPLACEMENT AND ADJUSTMENT

APPENDIX: SP MODE TABLES

TAB

POSITION 1

TAB

POSITION 2

TAB

POSITION 3

TAB

POSITION 4

SYSTEM MAINTENANCE REFERENCE

APPENDIX: MACHINE SWAP

TROUBLESHOOTING

TAB

POSITION 5

TAB

POSITION 6

TAB

POSITION 7

TAB

POSITION 8

Page 18

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

Page 19

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

Read This First

Safety Notices

Important Safety Notices

Prevention of Physical Injury

1. Before disassembling or assembling parts of the printer and peripherals, make sure

that the printer power cord is unplugged.

2. The wall outlet should be near the printer and easily accessible.

3. If any adjustment or operation check has to be made with exterior covers off or open

while the main switch is turned on, keep hands away from electrified or mechanically

driven components.

4. The printer drives some of its components when it completes the warm-up period. Be

careful to keep hands away from the mechanical and electrical components as the

printer starts operation.

5. The inside and the metal parts of the fusing unit become extremely hot while the printer

is operating. Be careful to avoid touching those components with your bare hands.

Health Safety Conditions

Toner is non-toxic, but if you get it in your eyes by accident, it may cause temporary eye

discomfort. Try to remove with eye drops or flush with water as first aid. If unsuccessful, get

medical attention.

Observance of Electrical Safety Standards

The printer and its peripherals must be serviced by a customer service representative who

has completed the training course on those models.

Safety and Ecological Notes for Disposal

1. Do not incinerate toner bottles or used toner. Toner dust may ignite suddenly when

exposed to an open flame.

2. Dispose of used toner, the maintenance unit which includes developer or the organic

photoconductor in accordance with local regulations. (These are non-toxic supplies.)

3. Dispose of replaced parts in accordance with local regulations.

Page 20

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

To prevent a fire or explosion, keep the printer away from flammable liquids, gases,

and aerosols. A fire or an explosion might occur.

Laser Safety

The Center for Devices and Radiological Health (CDRH) prohibits the repair of laser-based

optical units in the field. The optical housing unit can only be repaired in a factory or at a

location with the requisite equipment. The laser subsystem is replaceable in the field by a

qualified Customer Engineer. The laser chassis is not repairable in the field. Customer

engineers are therefore directed to return all chassis and laser subsystems to the factory or

service depot when replacement of the optical subsystem is required.

Use of controls, or adjustment, or performance of procedures other than those

specified in this manual may result in hazardous radiation exposure.

WARNING

WAR NING:

Turn off the main switch before attempting any of the procedures in the Laser Optics

Housing Unit section. Laser beams can seriously damage your eyes.

CAUTION MARKING:

Page 21

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

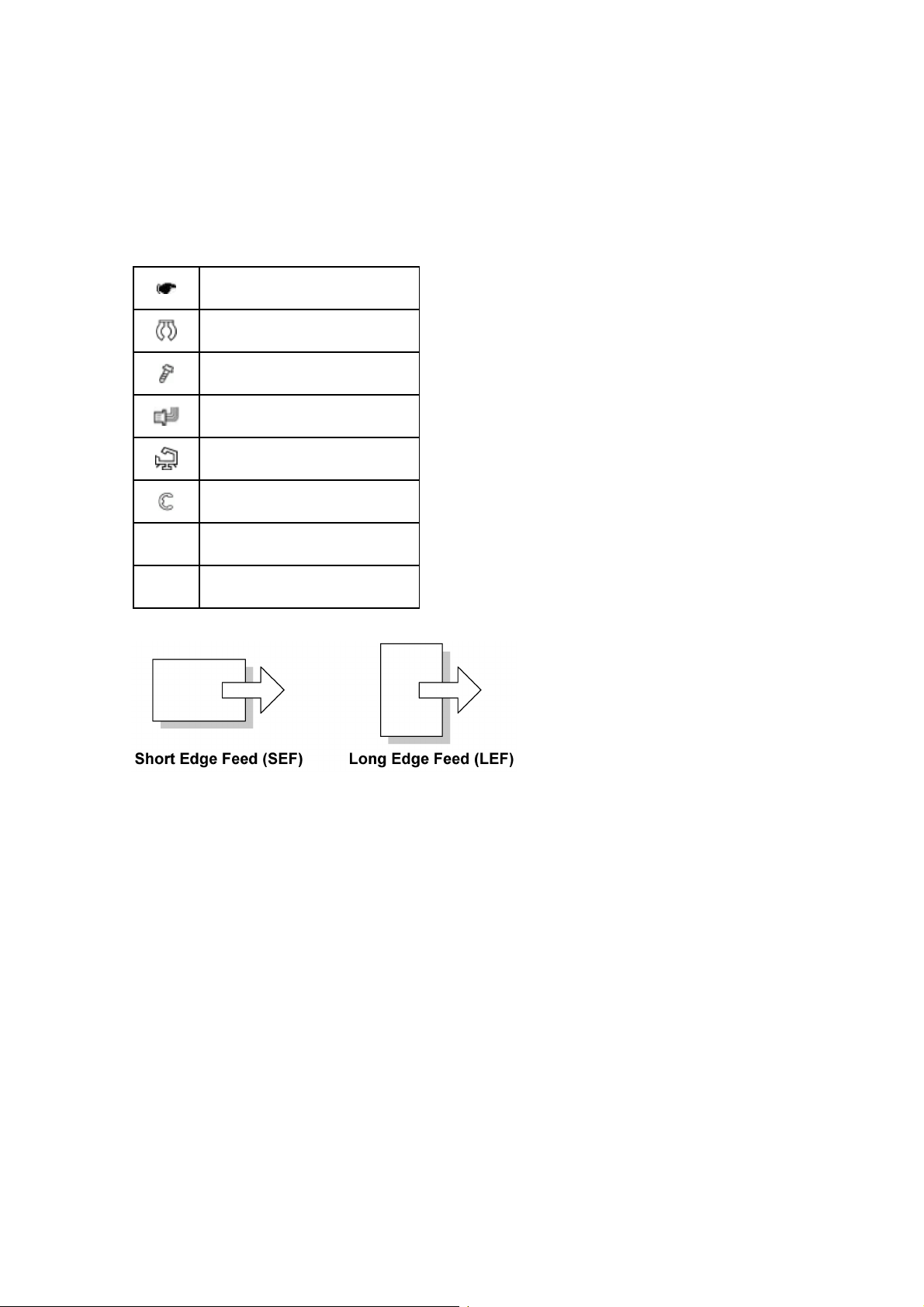

Symbols, Abbreviations and Trademarks

This manual uses several symbols and abbreviations. The meaning of those symbols and

abbreviations are as follows:

See or Refer to

Clip ring

Screw

Connector

Clamp

E-ring

SEF Short Edge Feed

LEF Long Edge Feed

Trademarks

Microsoft®, Windows®, and MS-DOS® are registered trademarks of Microsoft Corporation

in the United States and /or other countries.

PostScript

PCL

Ethernet

PowerPC

Other product names used herein are for identification purposes only and may be

trademarks of their respective companies. We disclaim any and all rights involved with

®

is a registered trademark of Adobe Systems, Incorporated.

®

is a registered trademark of Hewlett-Packard Company.

®

is a registered trademark of Xerox Corporation.

®

is a registered trademark of International Business Machines Corporation.

those marks.

Page 22

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

Page 23

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

PRODUCT INFORMATION

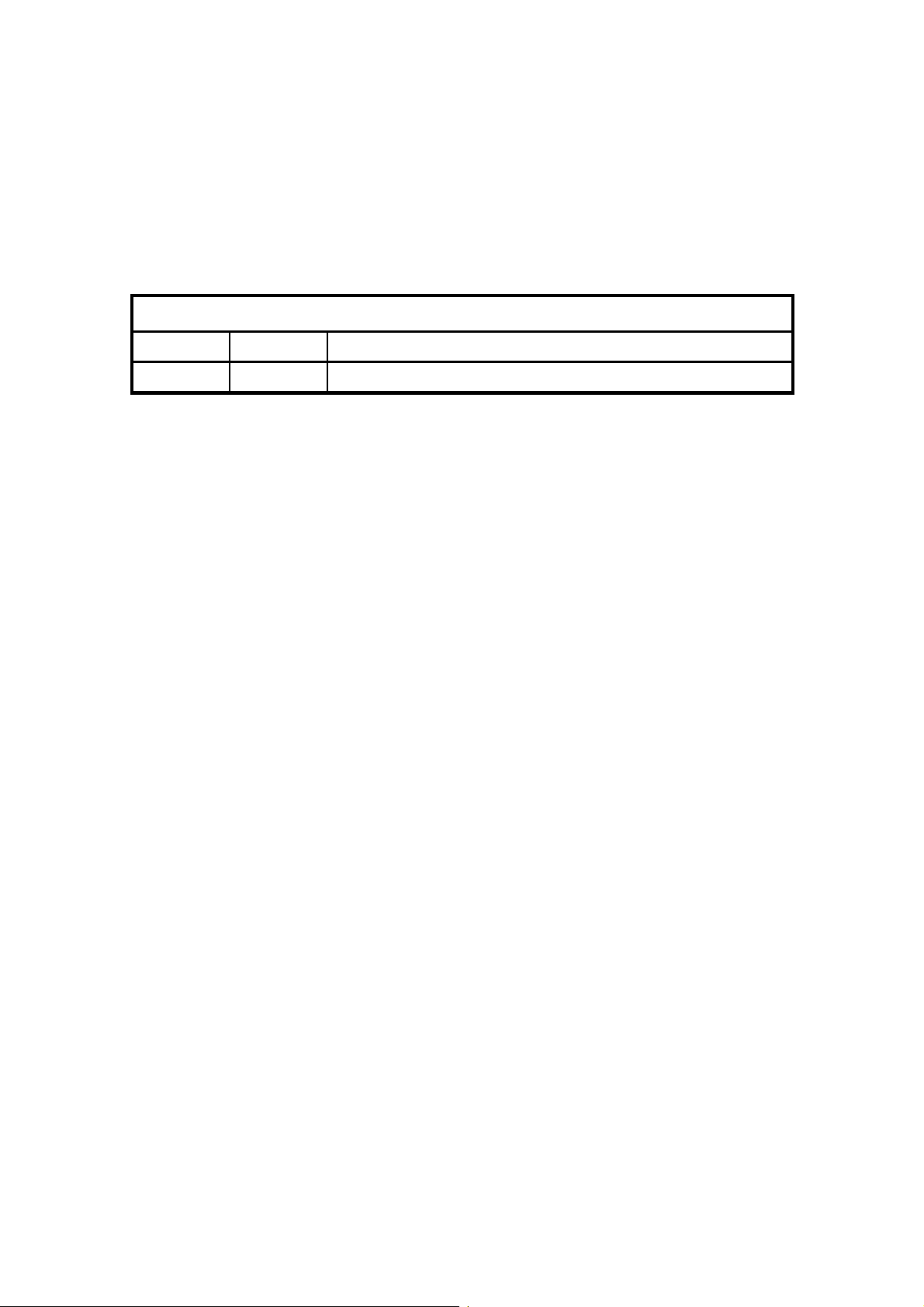

REVISION HISTORY

Page Date Added/Updated/New

None

Page 24

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

Page 25

1. PRODUCT INFORMATION

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

1.1 SPECIFICATIONS

See "Appendices" for the following information:

Specifications

Product

Information

"General Specifications

"Supported Paper Sizes

"

"

SM 1-1 M035/M036

Page 26

Machine Overview

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

1.2 MACHINE OVERVIEW

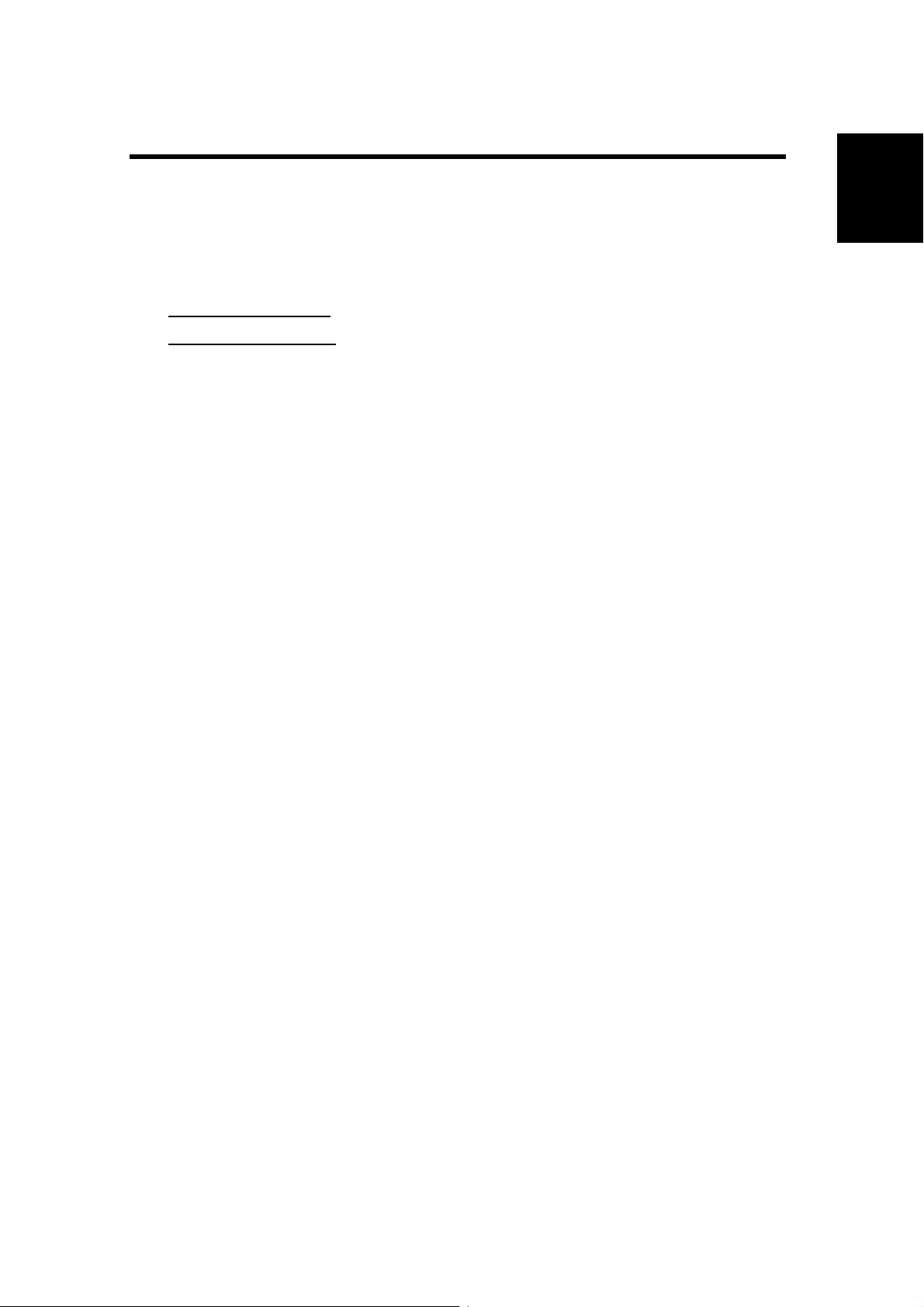

1.2.1 COMPONENT LAYOUT

1. Laser Optics Housing Unit

2. Print Cartridge (AIO)

3. Development Roller (AIO)

4. Paper Exit

5. Fusing Unit

6. Fusing Lamp

7. Duplex Path

8. Transfer Roller

9. Registration Roller

10. By-pass

11. Paper Feed Roller

12. ITB (Image Transfer Belt) Unit

13. OPC (AIO)

14. Tray 1

15 EGB/Controller

M035/M036 1-2 SM

Page 27

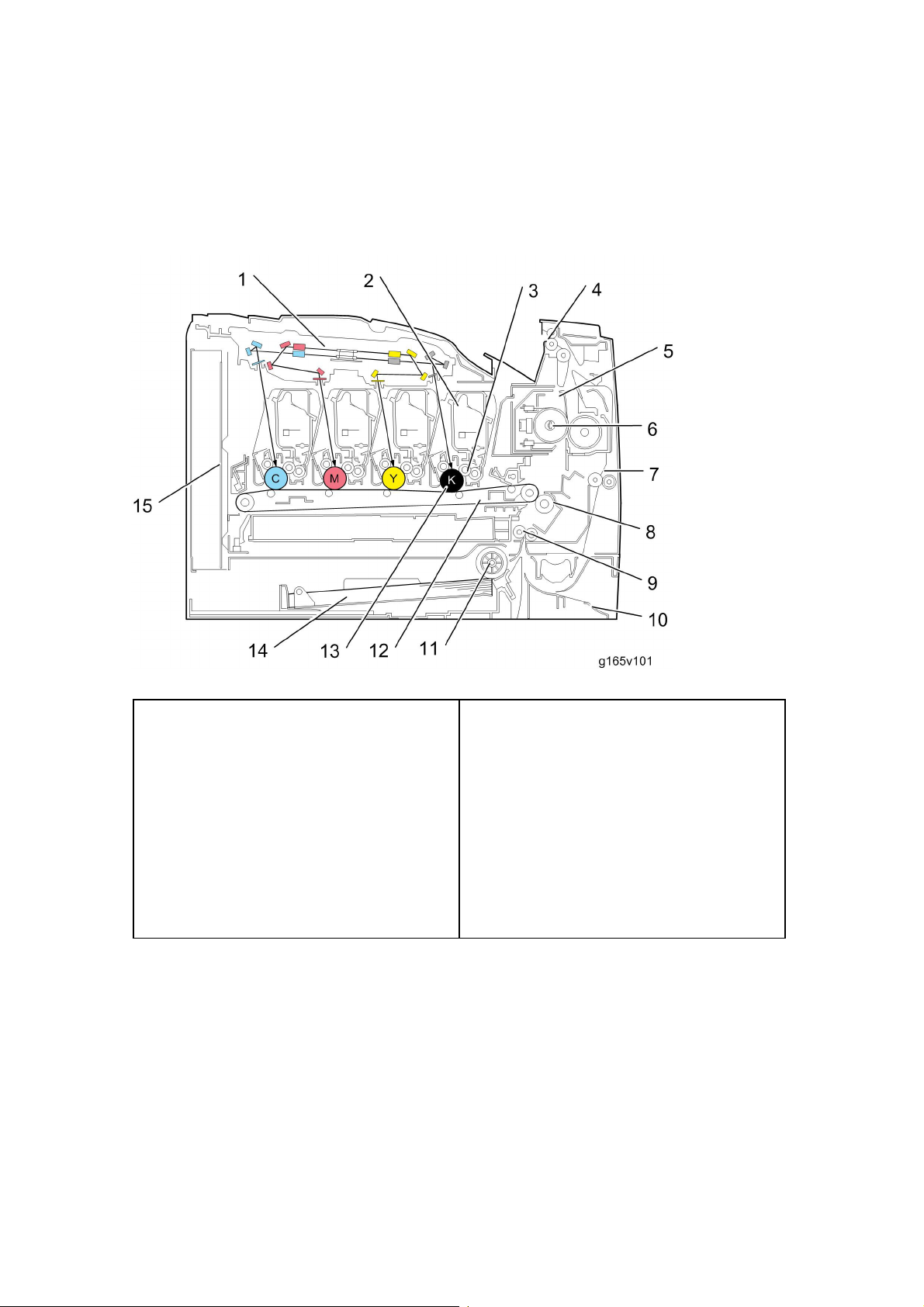

1.2.2 PAPER PATH

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

Machine Overview

Product

Information

1. Paper path from tray 1

2. Duplex path (M036 only)

3. By-pass tray

4. Paper path from tray 2 (optional)

SM 1-3 M035/M036

Page 28

Machine Overview

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

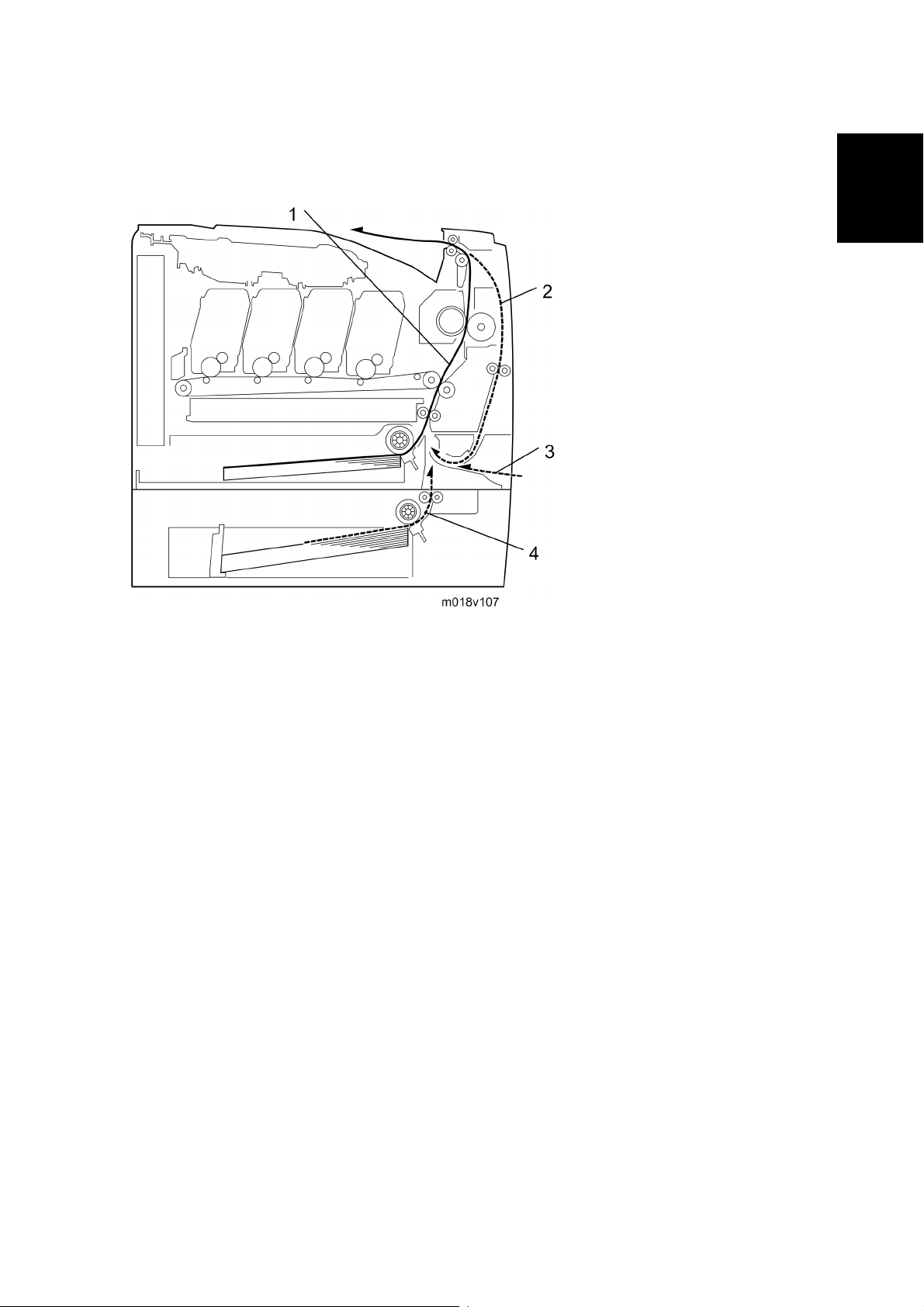

1.2.3 DRIVE LAYOUT

1. Color AIO Motor

2. Black AIO Motor

3. Duplex Motor (M036 only)

4. Transport/Fusing Motor

Color AIO Motor:

This drives the color AIOs (Cyan, Magenta and Yellow)

Black AIO Motor:

This drives the black AIO and the ITB (Image Transfer Belt).

Duplex Motor (M036 only):

This drives the paper exit roller and the duplex roller.

Transport/Fusing Motor:

This drives the fusing unit, paper feed roller, registration roller and paper exit roller via

the paper feed clutch, registration clutch and gears.

5. Registration Clutch

6. Paper Feed Clutch

7. Agitator Motor

8. ITB (Image Transfer Belt) Contact Motor

M035/M036 1-4 SM

Page 29

Machine Overview

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

Registration Clutch:

This transfers drive from the transport/ fusing motor to the registration roller.

Paper Feed Clutch:

This transfers drive from the transport/ fusing motor to the paper feed roller.

Agitator Motor:

This moves the agitators in the waste toner bottle.

ITB Contact Motor:

This moves the ITB into contact with and away from the color OPCs.

Product

Information

SM 1-5 M035/M036

Page 30

Machine Configuration

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

1.3 MACHINE CONFIGURATION

M035 M036

Models

Duplex

Unit

M035 Manual Y 500x1 Y

M036 Auto Y 500x1 Y

Optional

Memory

Optional

Tray (G849)

PCL

PS

M035/M036 1-6 SM

Page 31

Guidance for Those Who are Familiar with Predecessor Products

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

1.4 GUIDANCE FOR THOSE WHO ARE FAMILIAR

WITH PREDECESSOR PRODUCTS

The M035/M036 series models are similar to the G165/G166/G167 series. If you have

experience with those products, the following information will be of help when you read this

manual.

Different Points from Previous Products

Print Cartridge (AIO) Longer Life Print Cartridge (AIO) -

Operation Panel 2-line LCD No LCD

M035/M036 G165/G166/G167

Product

Information

SM 1-7 M035/M036

Page 32

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

Page 33

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

INSTALLATION

REVISION HISTORY

Page Date Added/Updated/New

None

Page 34

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

Page 35

2. INSTALLATION

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

2.1 INSTALLATION REQUIREMENTS

2.1.1 ENVIRONMENT

Installation Requirements

Installation

1. Temperature Range: 10°C to 32°C (50°F to 89.6°F)

2. Humidity Range: 15% to 80% RH

3. Ambient Illumination: Less than 2,000 lux (do not expose to direct sunlight)

4. Ventilation: 3 times/hr/person

5. Do not put the machine in areas that get sudden temperature changes. This includes:

Areas directly exposed to cool air from an air conditioner

Areas directly exposed to heat from a heater.

6. Do not put the machine in areas that get exposed to corrosive gas.

7. Do not install the machine at locations over 2,500 m (8,125 ft.) above sea level.

8. Put the machine on a strong, level base. (Inclination on any side must be no more than

5 mm.)

9. Do not put the machine in areas with strong vibrations.

SM 2-1 M035/M036

Page 36

Installation Requirements

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

2.1.2 MACHINE LEVEL

Front to back: Within 5 mm (0.2") of level

Right to left: Within 5 mm (0.2") of level

2.1.3 MACHINE SPACE REQUIREMENT

Put the printer near the power source with these clearances:

Right side [A]:

Left side [C]:

Front [B]:

Rear [D]:

Over 10 cm (4.0")

Over 70 cm (27.5")

Over 20 cm (7.9")

Over 10 cm (4.0")

M035/M036 2-2 SM

Page 37

2.1.4 POWER REQUIREMENTS

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

Make sure that the plug is tightly in the outlet.

Avoid multi-wiring.

Make sure that you ground the printer.

120 V, 60 Hz: More than 11 A (for North America)

Input voltage level

220 V to 240 V, 50 Hz/60 Hz: More than 6 A (for Europe/ Asia)

Permitted voltage fluctuation: 10%

Do not set anything on the power cord.

Installation Requirements

Installation

2.1.5 INSTALLATION PROCEDURE

Refer to the Quick Installation Guide for details about installing the printer.

SM 2-3 M035/M036

Page 38

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

Page 39

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

PREVENTIVE MAINTENANCE

REVISION HISTORY

Page Date Added/Updated/New

None

Page 40

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

Page 41

3. PREVENTIVE MAINTENANCE

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

3.1 PREVENTIVE MAINTENANCE

See "Appendices" for the "User Replaceable Items.”

Preventive Maintenance

Preventive

Maintenance

SM 3-1 M035/M036

Page 42

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

Page 43

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

REPLACEMENT AND ADJUSTMENT

REVISION HISTORY

Page Date Added/Updated/New

None

Page 44

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

Page 45

4. REPLACEMENT AND ADJUSTMENT

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

4.1 BEFORE YOU START

If there are printer jobs in the printer, print out all jobs in the printer buffer.

Turn off the main power switch and unplug the printer before you do the

procedures in this section.

Before You Start

&

Adjustment

Replacement

SM 4-1 M035/M036

Page 46

Special Tools

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

4.2 SPECIAL TOOLS

PC: Windows 2000/XP/Vista, Windows Server 2003/2003 R2, or Mac OS X.

USB cable or Crossover cable

M035/M036 4-2 SM

Page 47

4.3 EXTERIOR COVERS

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

Turn off the main power switch and unplug the printer before you do the

procedures in this section.

4.3.1 REAR COVER

Exterior Covers

1. Rear tray cover [A] (hooks)

2. Interface cover [B] (hooks)

3. Rear cover [C] (

x 3)

&

Adjustment

Replacement

SM 4-3 M035/M036

Page 48

Exterior Covers

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

4.3.2 OPERATION PANEL

1. Open the top cover [A].

2. Open the front cover [B].

3. Front harness cover [C] (

4. Operation panel [D] ( x 1, x 1)

x 1)

M035/M036 4-4 SM

Page 49

4.3.3 RIGHT COVER

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

1. Rear cover ( p.4-3)

Exterior Covers

2. Operation panel (

3. Right cover [A] (

Top front screw: M3x8, others: M4x10

p.4-4)

x 4)

&

Adjustment

Replacement

SM 4-5 M035/M036

Page 50

Exterior Covers

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

4.3.4 LEFT COVER

1. Rear cover ( p.4-3)

2. Operation panel (

3. Left cover [A] (

Top front screw: M3x8, others: M4x10

p.4-4)

x 3, hook at arrow mark)

M035/M036 4-6 SM

Page 51

4.3.5 FRONT COVER UNIT

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

1. Rear cover ( p.4-3)

Exterior Covers

2. Operation panel (

3. Transfer unit (

4. Right cover (

5. Close the front cover [A].

6. Remove a spring [B] (

Never remove the spring with the front cover open.

When removing the spring when it is extended, it may move in a unexpected

p.4-4)

p.4-29)

p.4-5)

x 1)

&

Adjustment

Replacement

direction and cause a slight injury.

7. Open the front cover.

8. Cover link gear unit [C] (

x 2)

SM 4-7 M035/M036

Page 52

Exterior Covers

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

9. Release the belt [D]

10. Front cover unit [E] (

x 4)

M035/M036 4-8 SM

Page 53

Laser Optics

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

4.4 LASER OPTICS

Turn off the main power switch and unplug the printer before beginning any of the

procedures in this section. Laser beams can cause serious eye injury.

4.4.1 CAUTION DECAL LOCATION

Caution decals are attached as shown below.

Be sure to turn off the main power switch and disconnect the power plug from the

power outlet before beginning any disassembly or adjustment of the laser unit.

This printer uses a class IIIb laser beam with a wavelength of 780 nm and an

output of 7 mW. The laser can cause serious eye injury.

&

Adjustment

Replacement

SM 4-9 M035/M036

Page 54

Laser Optics

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

4.4.2 LASER OPTICS HOUSING UNIT

1. Rear cover ( p.4-3)

2. Controller box cover (

3. Remove the controller bracket (

4. Disconnect the three harnesses from

CN301, 302 and 303 on the EGB (

5. Open the top cover [A].

p.4-46)

p.4-47)

x 3).

6. Lift up the hook [B] of the harness

guide at the rear-left frame and slide the harness guide to the right.

M035/M036 4-10 SM

Page 55

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

7. Remove the springs [D] (left side and right side).

8. Stoppers [C] ( x 2 each; left side and right side)

Laser Optics

9. Remove the laser optics housing unit [E] from the top cover and place it on the main

body.

Always use two hands when carrying the laser optics housing unit. Be sure

not to drop the laser optics housing unit.

&

Adjustment

Replacement

10. Take out the harnesses [F] (

SM 4-11 M035/M036

x 1).

Page 56

Laser Optics

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

11. Pull out the harnesses from the rear side.

12. Remove the laser optics housing unit.

After replacing the laser optics housing unit

Do the following step 4 with the front cover of the printer open.

1. Open the front cover and turn on the printer.

2. Look for the lot number [A] attached to the new laser optics housing unit. Then look for

this lot number on the information sheet (this sheet will be released separately, and will

contain lists of input data for each lot number)

Input the data for this lot number from the information sheets with steps 3 to 7

below.

M035/M036 4-12 SM

Page 57

Laser Optics

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

3. Open the front cover and turn on the printer.

4. Input the settings for the laser optics housing unit.

In the SOM utility, access “LSU Adjustment” inside the “SP Mode 2” tab.

Copy the corresponding LSU data inside the information sheet into the space

provided in the SOM utility.

5. Close the front cover.

6. Execute "Color Registration" in the "SP Mode 2" tab.

7. Adjust the registration settings for each tray and for the front and rear sides of the

paper with the "SP Mode 2" tab if necessary.

&

Adjustment

Replacement

SM 4-13 M035/M036

Page 58

AIO Cartridge

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

4.5 AIO CARTRIDGE

4.5.1 AIO CARTRIDGE (ALL IN ONE CARTRIDGE)

1. Open the top cover.

2. AIO cartridge [A]

M035/M036 4-14 SM

Page 59

AIO Cartridge

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

4.5.2 BLACK AIO MOTOR

1. Left cover ( p.4-6)

2. Disconnect the fusing connector [A] and remove the fusing relay harness [B] (hooks).

3. Fusing harness guide [C] (

x 2)

&

Adjustment

Replacement

SM 4-15 M035/M036

Page 60

AIO Cartridge

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

4. Disconnect the connectors shown by arrows in the above picture and release all

harnesses on the harness guide [D].

5. Harness guide [D] (

6. Interlock switch base (

7. Controller bracket (

8. Disconnect the connector (CN305) on the EGB.

9. LSU fan motor base [E] (

x 4)

p.4-49 "Interlock Switches")

p.4-46 "Controller Board")

x 2, x 1)

10. Drive unit [F] (

M035/M036 4-16 SM

x 4)

Page 61

11. Drive unit guide [G] (

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

12. Black AIO gear [H] (snap ring x 1)

13. ITB gear [I] (snap ring x 1)

x 3)

AIO Cartridge

14. Black AIO motor [J] (

x 3)

&

Adjustment

Replacement

SM 4-17 M035/M036

Page 62

AIO Cartridge

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

4.5.3 COLOR AIO MOTOR

1. Drive unit ( p.4-15 "Black AIO Motor")

2. Drive unit guide [A] (

x 3)

3. Color AIO gear [B] (ring stopper)

4. Color AIO motor [C] (

x 3)

M035/M036 4-18 SM

Page 63

4.6 IMAGE TRANSFER

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

4.6.1 IMAGE TRANSFER BELT UNIT

1. Remove all the AIO cartridges ( p.4-14).

Image Transfer

2. Transfer unit (

3. Pull out the waste toner bottle [A].

p.4-29)

&

Adjustment

Replacement

4. Release the hook [B] under the guide plate.

5. Move the guide plate [C] underneath the fusing unit to the left, and then remove it.

6. Pull out the image transfer belt unit [D] (

SM 4-19 M035/M036

x 2).

Page 64

Image Transfer

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

After replacing the image transfer belt unit

Do the following step 2 with the front cover of the printer open.

1. Open the front cover and turn on the printer.

2. Execute "Reset Transfer Unit Life Counter" with the "Engine Maintenance" menu.

3. Close the front cover.

4. Execute "Trans. Belt Adjust" with the "Engine Maintenance" menu.

5. Adjust the registration settings for each tray and for the front and rear sides of the

paper with the "Engine Maintenance" menu if necessary.

M035/M036 4-20 SM

Page 65

Image Transfer

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

4.6.2 ITB (IMAGE TRANSFER BELT) CLEANING UNIT

The ITB cleaning unit contains waste toner. When removing the ITB cleaning unit,

put it on a sheet of paper.

1. Image transfer belt unit (

2. Left handle [A] (hook, bushing x 1)

3. Right handle [B] (hook, bushing x 1)

p.4-19)

&

Adjustment

Replacement

4. ITB cleaning unit [C] (

SM 4-21 M035/M036

x 2)

Page 66

Image Transfer

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

4.6.3 AGITATOR MOTOR

1. Right cover ( p.4-3)

2. Motor bracket [A] (

x 2)

3. Agitator motor assembly [B] ( x 1, x 1)

4. Agitator motor [C] (

M035/M036 4-22 SM

x 2)

Page 67

Image Transfer

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

4.6.4 ITB (IMAGE TRANSFER BELT) CONTACT MOTOR

1. Agitator motor ( p.4-22)

2. Release the wire [A].

3. ITB contact motor assembly [B] (

4. ITB contact motor [C] ( x 2)

x 1, x 1)

&

Adjustment

Replacement

SM 4-23 M035/M036

Page 68

Image Transfer

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

4.6.5 ITB (IMAGE TRANSFER BELT) CONTACT SENSOR

1. Right cover ( p.4-5)

2. High voltage power supply board (

3. ITB contact sensor assembly [A] (

p.4-56)

x 1, x 1)

4. ITB contact sensor [B] (hooks)

M035/M036 4-24 SM

Page 69

4.6.6 TM (TONER MARK) SENSOR BASE

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

1. Open the top cover.

Image Transfer

2. Remove all AIO cartridges (

3. Slide the ITB unit to the front side or remove it.

4. Rear cover (

5. Controller box cover (

6. Controller bracket (

7. Disconnect CN306 on the EGB (

p.4-5)

p.4-47)

p.4-14).

p.4-46)

x 1).

&

Adjustment

Replacement

8. Harness cover [A] (hook)

9. TM sensor base [B]

SM 4-25 M035/M036

Page 70

Image Transfer

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

4.6.7 WASTE TONER BOTTLE SET SENSOR

1. Remove all AIO cartridges. ( p.4-14)

2. Image transfer belt unit (

3. EGB (

4. Remove two screws [A] for the waste toner sensor base.

p.4-47)

p.4-19)

5. Waste toner sensor base [B]

6. Remove the mylar fixing three hooks of the waste toner bottle set sensor.

7. Waste toner bottle set sensor [C] (hooks,

M035/M036 4-26 SM

x 1)

Page 71

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

When reinstalling the waste toner bottle set sensor, connect it to the white

connector of the harness.

4.6.8 WASTE TONER OVERFLOW SENSOR

1. Remove all AIO cartridges. ( p.4-14)

Image Transfer

2. Image transfer belt unit (

3. EGB (

4. Waste toner sensor base (

5. Remove the mylar fixing three hooks of the waste toner bottle set sensor.

6. Waste toner overflow sensor [A] (hooks,

When reinstalling the waste toner overflow sensor, connect it to the black

p.4-47)

connector of the harness.

p.4-19)

p.4-26 "Waste Toner Bottle Set Sensor")

x 1)

&

Adjustment

Replacement

SM 4-27 M035/M036

Page 72

Paper Transfer

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

4.7 PAPER TRANSFER

4.7.1 TRANSFER UNIT

1. Open the front cover.

2. Release the locks [A].

3. Transfer unit [B]

M035/M036 4-28 SM

Page 73

4.7.2 TRANSFER ROLLER

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

1. Transfer Unit ( p.4-29)

2. Release the two hooks [A] at both sides of the transfer unit.

Paper Transfer

3. Open the transfer roller unit [B] and remove it.

4. Transfer roller assembly [C] (

x 2)

&

Adjustment

Replacement

SM 4-29 M035/M036

Page 74

Paper Transfer

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

5. Release the holder [D] at the left side of the transfer roller unit (hook).

6. Transfer roller [E]

M035/M036 4-30 SM

Page 75

4.7.3 REGISTRATION ROLLER

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

1. Transfer unit ( p.4-29)

Paper Transfer

2. Transfer roller unit (

3. Tension springs [A] (both sides)

4. Registration idle roller [B] ( x 2, gear x 1, bushing x 2)

5. Registration roller [C] (

p.4-30)

x 2, gear x 2, bushing x 2)

Reassembling the registration roller unit

&

Adjustment

Replacement

When installing the tension spring, make sure that the tension spring correctly hooks onto

the bushing of the registration idle roller as shown above [A].

SM 4-31 M035/M036

Page 76

Paper Transfer

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

4.7.4 REGISTRATION SENSOR

1. Rear cover ( p.4-3)

2. Right Cover (

3. Registration sensor assembly [A] (

p.4-5)

x 1, x 1)

4. Registration sensor [B] (hooks)

M035/M036 4-32 SM

Page 77

4.7.5 REGISTRATION CLUTCH

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

1. Rear cover ( p.4-3)

Paper Transfer

2. Left cover (

3. Transport/Fusing motor (

4. Registration clutch [A] (

p.4-6)

p.4-38)

x 1)

&

Adjustment

Replacement

SM 4-33 M035/M036

Page 78

Image Fusing

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

4.8 IMAGE FUSING

Make sure that the fusing unit is cool before you touch it. The fusing unit can be

very hot.

Make sure to restore the insulators, shields, etc after you service the fusing unit.

4.8.1 FUSING UNIT

1. Open the front cover.

2. Rear cover (

3. Right cover (

4. Left cover (

5. Disconnect the connectors [A] [B] (hook).

p.4-3)

p.4-5)

p.4-6)

M035/M036 4-34 SM

Page 79

Image Fusing

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

The sponge [C] clamps the harness. Install this sponge in the same position

after reinstalling the fusing unit.

6. Fusing unit [D] ( x 2)

&

Adjustment

Replacement

SM 4-35 M035/M036

Page 80

Image Fusing

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

4.8.2 FUSING LAMP

1. Fusing unit ( p.4-35)

2. Fusing front cover [A] (

x 4)

3. Fusing lamp [B] (

x 2, ground cable x 1)

When Reinstalling the Fusing Lamp

The terminal [A], which shows the voltage and power ratings, must be placed at the left

side of the fusing unit (fusing cable side).

M035/M036 4-36 SM

Page 81

4.8.3 TRANSPORT/FUSING MOTOR

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

1. Rear cover ( p.4-3)

Image Fusing

2. Left cover (

3. Disconnect the fusing connector [A] (hook).

4. Fusing harness guide [B] (

5. Duplex timing belt [C]

p.4-6)

x 2)

&

Adjustment

Replacement

6. Transport/Fusing motor assembly [D] (

7. Transport/Fusing motor [E] (

SM 4-37 M035/M036

x 3, x 3, ground plate x 1)

x 3)

Page 82

Paper Feed

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

4.9 PAPER FEED

4.9.1 PAPER FEED CLUTCH

1. Rear cover ( p.4-3)

2. Left cover (

3. Disconnect the fusing relay harness [A] (hook).

4. Paper feed clutch [B] (

p.4-6)

x 1, x 1)

M035/M036 4-38 SM

Page 83

4.9.2 PAPER FEED ROLLER

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

1. Remove all the AIO cartridges.

2. Remove the waste toner bottle.

Paper Feed

3. Rear cover (

4. Left cover (

5. Paper feed clutch (

6. Close the top cover and front cover.

7. Pull out the tray.

8. Stand the printer with the rear side facing

the table.

9. Slide the paper feed shaft [A] to the left side ( x 2).

p.4-3)

p.4-6)

p.4-39)

&

Adjustment

Replacement

10. Paper feed roller [B] (hook)

SM 4-39 M035/M036

Page 84

Paper Feed

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

4.9.3 SEPARATION PAD

1. Pull out the tray.

2. Push down the bottom plate [A].

3. Separation pad [B] (hooks, spring x 1)

When reinstalling the separation pad, make sure that the mylar [C] is not placed

under the separation pad. The right side image above shows incorrect installation.

M035/M036 4-40 SM

Page 85

4.9.4 PAPER END SENSOR

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

1. Rear cover ( p.4-3)

Paper Feed

2. Right cover (

3. High voltage power supply board (

4. Paper end sensor assembly [A] (

p.4-5)

p.4-56)

x 1)

&

Adjustment

Replacement

5. Paper end sensor [B] (hooks)

SM 4-41 M035/M036

Page 86

Paper Exit

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

4.10 PAPER EXIT

4.10.1 PAPER EXIT ROLLER

1. Operation panel ( p.4-4)

2. Remove the bushing [A] (

x 1)

3. Move the bushing [B] to the left side (

4. Paper exit roller [C]

5. Remove the four exit guides [D], gear [E] (

x 1).

x 1) and bushing [F].

M035/M036 4-42 SM

Page 87

Paper Exit

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

When reinstalling the paper exit roller

Make sure that the ground wire [A] from the discharge sheet touches the ground plate [B]

on the printer after reinstalling the paper exit roller.

&

Adjustment

Replacement

SM 4-43 M035/M036

Page 88

Paper Exit

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

4.10.2 PAPER EXIT SENSOR

1. Rear cover ( p.4-3)

2. Right cover (

3. Right bracket [A] (

p.4-5)

x 3: M3x8, x 1 [B]: M4x10)

4. Mylar [C]

This mylar is necessary for reinstalling the paper exit sensor.

5. Paper exit sensor [D] (hooks,

M035/M036 4-44 SM

x 1)

Page 89

4.11 ELECTRICAL COMPONENTS

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

4.11.1 CONTROLLER BOARD

1. Rear cover ( p.4-3)

2. Controller box cover [A] (

x 7)

Electrical Components

3. Interface bracket [B] (

x 2)

&

Adjustment

Replacement

4. Controller board [C] (

SM 4-45 M035/M036

x 6)

Page 90

Electrical Components

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

4.11.2 EGB (ENGINE BOARD)

1. Rear cover ( p.4-3)

2. Controller board (

3. EGB [A] (

x 6, all s)

p.4-46)

4. EEPROM [B]

M035/M036 4-46 SM

Page 91

Electrical Components

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

When installing the new EGB

1. Remove the EEPROM from the old EGB.

2. Install it on the new EGB with the mark [A] pointing to the left side of the board after

you replace the EGB.

3. Replace the EEPROM if the EEPROM on the old EGB is defective.

Keep the EEPROM away from objects that can cause static electricity. Static

electricity can damage EEPROM data.

Make sure that the EEPROM is correctly installed on the EGB.

&

Adjustment

Replacement

SM 4-47 M035/M036

Page 92

Electrical Components

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

4.11.3 INTERLOCK SWITCHES

1. Operation panel ( p.4-4)

2. Rear cover (

3. Left cover (

4. Interlock switch base [A] (

Removing the spring [B] first makes this procedure easier.

Remove all the connectors after the interlock switch base has been removed.

p.4-3)

p.4-6)

x 4, all s)

5. Two interlock switches [C] at the outside of the base and one interlock switch [D] at the

inside of the base (hooks)

M035/M036 4-48 SM

Page 93

4.11.4 FUSING FAN MOTOR

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

1. Operation panel ( p.4-4)

Electrical Components

2. Rear cover (

3. Left cover (

4. Interlock switch base (

5. Fusing fan base [A] (

p.4-3)

p.4-6)

p.4-49)

x 2, x 1)

&

Adjustment

Replacement

6. Fusing fan motor [B] (hooks,

Install the fusing fan motor with its decal facing the outside of the machine.

SM 4-49 M035/M036

x 1)

Page 94

Electrical Components

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

4.11.5 LSU FAN MOTOR

1. Operation panel ( p.4-4)

2. Rear cover (

3. Left cover (

4. LSU fan motor [A] (hooks,

Install the LSU fan motor with its decal facing the outside of the machine.

p.4-3)

p.4-6)

x 1)

M035/M036 4-50 SM

Page 95

4.11.6 ID CHIP BOARD

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

1. Operation panel ( p.4-4)

Electrical Components

2. Rear cover (

3. Left cover (

4. Controller box cover (

5. Disconnect the connector (CN305) on the EGB.

6. Interlock switch base (

7. Fusing fan base (

8. Drive unit (

9. Take the harnesses aside around the LSU fan base [A].

p.4-3)

p.4-6)

p.4-46)

p.4-49)

p.4-50)

p.4-15)

&

Adjustment

Replacement

10. LSU fan base [A] (

11. ID Chip Board [B] ( x 3)

x 2, x 1)

SM 4-51 M035/M036

Page 96

Electrical Components

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

4.11.7 PSU

1. Operation panel ( p.4-4)

2. Rear cover (

3. Left cover (

4. Drive unit (

5. LSU fan base (

6. PSU guide [A] (

7. Power cord bracket [B] (

8. Ground cable [C] (

p.4-3)

p.4-6)

p.4-15)

p.4-51 "LSU Fan Motor")

x 3)

x 1)

x 2)

9. Power switch assembly [D] (

M035/M036 4-52 SM

x 3, x 2)

Page 97

10. PSU assembly [E] ( x 4, all s)

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

Electrical Components

11. PSU [F] ( x 4)

There are two types of PSUs for this model. Do not install a wrong PSU in the

machine.

PSU has yellow [a] on the transistor is for NA models and PSU has green [b] on

the transistor is for EU models.

&

Adjustment

Replacement

SM 4-53 M035/M036

Page 98

Electrical Components

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

Fuse

There is the removable fuse on the PSU.

Fuse No. Rating

FU101: NA 15 A, 125V

FU101: EU, ASIA 6.3A, 250V

Use a correct rating fuse for the fuse replacement. Never use a wrong rating fuse.

If do so, the machine may be damaged.

Never try direct connection of PSU circuit without a fuse.

4.11.8 HIGH VOLTAGE POWER SUPPLY BOARD

1. Remove all AIO cartridges.

2. Operation panel (

3. Rear cover (

4. Right cover (

p.4-4)

p.4-3)

p.4-5)

5. High Voltage Power Supply Board [A] (

M035/M036 4-54 SM

x 7, ground cable x 1, x 1)

Page 99

4.11.9 TEMPERATURE/HUMIDITY SENSOR

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

1. Operation panel ( p.4-4)

Electrical Components

2. Rear cover (

3. Right cover (

4. Temperature/Humidity sensor [A] (

p.4-3)

p.4-5)

x 1, x 1)

&

Adjustment

Replacement

SM 4-55 M035/M036

Page 100

Electrical Components

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

4.11.10 DUPLEX MOTOR (M036 ONLY)

1. Operation panel ( p.4-4)

2. Rear cover (

3. Left cover (

4. Disconnect the fusing connector [A]

5. Duplex timing belt [B]

6. Left bracket [C] (

p.4-3)

p.4-6)

x 4)

7. Duplex motor [D] (

M035/M036 4-56 SM

x 2, x 1)

Loading...

Loading...