Page 1

M020/M021

SERVICE MANUAL

Page 2

It is the reader's responsibility when discussing the information contained

within this document to maintain a level of confidentiality that is in the best

interest of Ricoh Americas Corporation and its member companies.

NO PART OF THIS DOCUMENT MAY BE REPRODUCED IN ANY

F ASHION AND DISTRIBUTED WITHOUT THE PRIOR

PERMISSION OF RICOH AMERICAS CORPORATION.

All product names, domain names or product illustrations, including

desktop images, used in this document are trademarks, registered

trademarks or the property of their respective companies.

They are used throughout this book in an informational or editorial fashion

only and for the benefit of such companies. No such use, or the use of

any trade name, or web site is intended to convey endorsement or other

affiliation with Ricoh products.

© 2011 RICOH Americas Corporation. All rights reserved.

Page 3

WARNING

The Service Manual contains information

regarding service techniques, procedures,

processes and spare parts of office equipment

distributed by Ricoh Americas Corporation.

Users of this manual should be either service

trained or certified by successfully completing a

Ricoh Technical Training Program.

Untrained and uncertified users utilizing

information contained in this service manual to

repair or modify Ricoh equipment risk personal

injury, damage to property or loss of warranty

protection.

Ricoh Americas Corporation

Page 4

LEGEND

PRODUCT

COMPANY

CODE

M020

M021

LANIER RICOH SAVIN

SP5200DN Aficio SP 5200DN SP5200DN

SP5210DN Aficio SP 5210DN SP5210DN

DOCUMENTATION HISTORY

REV. NO. DATE COMMENTS

*

11/2011 Original Printing

Page 5

M020/M021

TABLE OF CONTENTS

1. PRODUCT INFORMATION .......................................................... 1-1

1.1SPECIFICATIONS ..................................................................................... 1-1

1.2MACHINE CONFIGURATION ................................................................... 1-2

1.2.1 SYSTEM COMPONENTS ................................................................ 1-2

Main ..................................................................................................... 1-2

Options ................................................................................................. 1-2

Internal options ..................................................................................... 1-4

1.3OVERVIEW ................................................................................................ 1-5

1.3.1 MECHANICAL COMPONENT LAYOUT ........................................... 1-5

1.3.2 PAPER PATH ................................................................................... 1-7

2. INSTALLATION ............................................................................ 2-1

2.1MACHINE INSTALLATION ........................................................................ 2-1

2.2INSTALLATION REQUIREMENTS ............................................................ 2-2

2.2.1 ENVIRONMENT ............................................................................... 2-2

2.2.2 MACHINE LEVEL ............................................................................. 2-2

2.2.3 MINIMUM OPERATIONAL SPACE REQUIREMENTS .................... 2-3

2.2.4 POWER SUPPLY ............................................................................. 2-3

2.3CONTROLLER OPTIONS ......................................................................... 2-4

2.3.1 OVERVIEW ...................................................................................... 2-4

I/F Card Slots ....................................................................................... 2-4

SD Card Slots ...................................................................................... 2-4

SDRAM slot .......................................................................................... 2-4

Hard disk connector ............................................................................. 2-4

2.3.2 INSTALLING THE SD MEMORY CARD OPTIONS.......................... 2-5

Installation ............................................................................................ 2-5

2.3.3 SD CARD APPLICATION MOVE ..................................................... 2-7

Overview .............................................................................................. 2-7

Move Exec ........................................................................................... 2-8

Undo Exec ............................................................................................ 2-8

2.3.4 IEEE 802.11 A/G (WIRELESS LAN) ................................................. 2-9

Installation Procedure .......................................................................... 2-9

SM i M020/M021

Page 6

UP Mode Settings for Wireless LAN .................................................. 2-10

SP Mode and UP Mode Settings for IEEE 802.11 a/g Wireless LAN . 2-12

2.3.5 IEEE 1284 INTERFACE BOARD .................................................... 2-13

2.3.6 GIGABIT ETHERNET ..................................................................... 2-15

2.3.7 MEMORY UNIT TYPE G 256MB / I 512MB (ONLY FOR M020) .... 2-17

2.3.8 HARD DISK DRIVE TYPE 2670 (ONLY FOR M020)...................... 2-19

2.3.9 CHECK ALL CONNECTIONS ........................................................ 2-21

2.3.10 IC CARD READER (EXTERNAL OPTIONS) ATTACHING

LOCATION ............................................................................................... 2-21

2.4PAPER FEED UNIT TK1120 (M386) ....................................................... 2-22

2.4.1 ACCESSORY CHECK .................................................................... 2-22

2.4.2 INSTALLATION PROCEDURE ...................................................... 2-22

2.4.3 WHEN STACKING FOUR OPTIONAL PAPER FEED UNITS ........ 2-25

Fixing the units together ..................................................................... 2-26

2.5PAPER FEED UNIT TK1130 (M389) ....................................................... 2-27

2.5.1 ACCESSORY CHECK .................................................................... 2-27

2.5.2 INSTALLATION PROCEDURE ...................................................... 2-27

2.5.3 WHEN STACKING FOUR OPTIONAL PAPER FEED UNITS ........ 2-30

Fixing the units together ..................................................................... 2-31

3. PREVENTIVE MAINTENANCE .................................................... 3-1

3.1MAINTENANCE TABLES .......................................................................... 3-1

3.1.1 USER MAINTENANCE ..................................................................... 3-1

3.1.2 SERVICE MAINTENANCE ............................................................... 3-1

3.2PM PARTS SETTINGS .............................................................................. 3-2

3.2.1 BEFORE REMOVING THE OLD PM PARTS ................................... 3-2

3.2.2 AFTER INSTALLING THE NEW PM PARTS ................................... 3-2

3.2.3 OPERATION CHECK ....................................................................... 3-2

4. REPLACEMENT AND ADJUSTMENT ........................................ 4-1

4.1GENERAL PRECAUTIONS ....................................................................... 4-1

4.1.1 PRECAUTIONS ON DISASSEMBLY ............................................... 4-1

4.1.2 RELEASING PLASTIC LATCHES .................................................... 4-2

4.1.3 AFTER SERVICING THE MACHINE ................................................ 4-2

4.2COVERS .................................................................................................... 4-3

4.2.1 RIGHT COVER ................................................................................. 4-3

4.2.2 LEFT COVER ................................................................................... 4-5

4.2.3 UPPER COVER ................................................................................ 4-6

4.2.4 FRONT COVER ................................................................................ 4-7

M020/M021 ii SM

Page 7

4.2.5 REAR COVER .................................................................................. 4-9

4.2.6 OPERATION PANEL ...................................................................... 4-10

4.3LASER UNIT ............................................................................................ 4-11

4.3.1 CAUTION DECAL LOCATIONS ..................................................... 4-11

4.3.2 LASER UNIT ................................................................................... 4-12

4.3.3 POLYGON MIRROR MOTOR ........................................................ 4-14

4.3.4 LASER SYNCHRONIZATION DETECTOR .................................... 4-15

4.4TRANSFER ROLLER .............................................................................. 4-16

4.5FUSING ................................................................................................... 4-17

4.5.1 FUSING UNIT ................................................................................. 4-17

4.5.2 HOT ROLLER AND PRESSURE ROLLER SECTIONS ................. 4-18

4.5.3 FUSING LAMP ............................................................................... 4-19

4.5.4 HOT ROLLER ................................................................................. 4-20

4.5.5 FUSING THERMISTOR .................................................................. 4-21

4.5.6 THERMOSTATS ............................................................................. 4-21

4.5.7 PRESSURE ROLLER ..................................................................... 4-22

4.5.8 FUSING CLEANING ROLLER ........................................................ 4-23

4.6PAPER FEED .......................................................................................... 4-24

4.6.1 PAPER FEED ROLLER .................................................................. 4-24

4.6.2 FRICTION PAD .............................................................................. 4-24

4.6.3 PAPER END SENSOR ................................................................... 4-27

4.6.4 REMAINING PAPER SENSORS 1 AND 2 ..................................... 4-29

4.6.5 REGISTRATION SENSOR ............................................................. 4-31

4.7BY-PASS TRAY ....................................................................................... 4-32

4.7.1 BY-PASS TRAY UNIT .................................................................... 4-32

4.7.2 BY-PASS FEED ROLLER .............................................................. 4-33

4.7.3 BY-PASS FRICTION PAD .............................................................. 4-34

4.7.4 BY-PASS PAPER SENSOR ........................................................... 4-35

4.8DUPLEX .................................................................................................. 4-36

4.8.1 DUPLEX UNIT ................................................................................ 4-36

4.8.2 DUPLEX ENTRANCE SENSOR ..................................................... 4-37

4.8.3 DUPLEX RELAY SENSOR ............................................................. 4-38

4.9PAPER EXIT ............................................................................................ 4-40

4.9.1 PAPER OVERFLOW SENSOR ...................................................... 4-40

4.9.2 PAPER EXIT SENSOR ................................................................... 4-41

4.10 ELECTRICAL COMPONENTS .......................................................... 4-43

4.10.1 CONTROLLER BOARD ............................................................. 4-43

4.10.2 CONTROLLER BOX ................................................................... 4-44

SM iii M020/M021

Page 8

4.10.3 PSU AND PSU COVER .............................................................. 4-45

4.10.4 ENGINE BOARD ........................................................................ 4-47

When installing a new engine board .................................................. 4-48

4.10.5 ENGINE BOARD BRACKET ...................................................... 4-49

4.10.6 ENGINE BOARD WITH BRACKET ............................................ 4-50

4.10.7 RFID (RADIO FREQUENCY ID) ................................................. 4-51

4.10.8 HVPS (HIGH VOLTAGE POWER SUPPLY) .............................. 4-52

4.10.9 OPERATION PANEL UNIT ......................................................... 4-52

Keyboard Unit .................................................................................... 4-52

Operation panel controller and LCD unit ............................................ 4-54

4.10.10 NVRAM AND EEPROM ............................................................ 4-55

NVRAMs ............................................................................................ 4-55

EEPROM ............................................................................................ 4-56

4.11 SWITCHES ........................................................................................ 4-57

4.11.1 TRAY SET SWITCH AND PAPER SIZE DETECTION SENSOR

BOARD 4-57

4.11.2 REAR-LEFT INTERLOCK SWITCH ........................................... 4-58

4.11.3 REAR-RIGHT INTERLOCK SWITCH ......................................... 4-59

4.11.4 FRONT INTERLOCK SWITCH ................................................... 4-60

4.12 CLUTCHES ........................................................................................ 4-61

4.12.1 OVERVIEW ................................................................................ 4-61

4.12.2 REGISTRATION CLUTCH ......................................................... 4-62

4.12.3 RELAY CLUTCH ........................................................................ 4-62

4.12.4 BY-PASS FEED CLUTCH .......................................................... 4-63

4.12.5 PAPER FEED CLUTCH ............................................................. 4-63

4.13 FANS .................................................................................................. 4-64

4.13.1 OVERVIEW ................................................................................ 4-64

4.13.2 AIO FAN ..................................................................................... 4-65

4.13.3 EXHAUST FAN ........................................................................... 4-65

4.13.4 PSU FAN .................................................................................... 4-66

4.13.5 TRANSFER THERMISTOR ........................................................ 4-66

4.14 OTHER ELECTRICAL COMPONENTS ............................................. 4-67

4.14.1 HDD (OPTION FOR M020) ........................................................ 4-67

4.14.2 DIMM (OPTION FOR M020) ....................................................... 4-68

4.14.3 DUPLEX JUNCTION SOLENOID ............................................... 4-69

4.14.4 TONER END SENSOR .............................................................. 4-70

4.15 DRIVE SECTION ............................................................................... 4-71

4.15.1 OVERVIEW ................................................................................ 4-71

M020/M021 iv SM

Page 9

4.15.2 MAIN MOTOR GEAR ASSY ....................................................... 4-72

4.15.3 MAIN MOTOR ............................................................................ 4-73

4.15.4 PAPER EXIT MOTOR ................................................................ 4-74

4.15.5 DUPLEX MOTOR ....................................................................... 4-75

5. SYSTEM MAINTENANCE REFERENCE ..................................... 5-1

5.1PRINTER SERVICE MODE ....................................................................... 5-1

5.1.1 SP1-XXX (SERVICE MODE) ............................................................ 5-1

5.2ENGINE SERVICE MODE ....................................................................... 5-10

5.2.1 ENGINE MODE TABLE .................................................................. 5-10

SP1-xxx: Feed .................................................................................... 5-10

SP2-xxx: Drum ................................................................................... 5-16

SP3-xxx: Process ............................................................................... 5-18

SP5-xxx: Mode ................................................................................... 5-19

SP7-xxx: Data Log ............................................................................. 5-77

SP8XXX: Data Log 2 .......................................................................... 5-92

5.3FIRMWARE UPDATE ............................................................................ 5-103

5.3.1 TYPE OF FIRMWARE .................................................................. 5-103

5.3.2 PRECAUTIONS ............................................................................ 5-104

Handling SD Cards .......................................................................... 5-104

Upload/Download ............................................................................. 5-104

Network Connection ......................................................................... 5-104

5.3.3 MACHINE FIRMWARE UPDATE ................................................. 5-105

5.4NVRAM DATA UPLOAD/DOWNLOAD .................................................. 5-107

5.4.1 UPLOADING NVRAM DATA ........................................................ 5-107

5.4.2 DOWNLOADING NVRAM DATA .................................................. 5-108

5.5SD CARD APPLICATION MOVE ........................................................... 5-110

5.5.1 OVERVIEW .................................................................................. 5-110

5.5.2 MOVE EXEC ................................................................................ 5-110

5.5.3 UNDO EXEC ................................................................................ 5-111

5.6MENU MODE ......................................................................................... 5-112

5.7CONTROLLER BOARD DIP SWITCHES .............................................. 5-115

5.8CARD SAVE FUNCTION ....................................................................... 5-116

5.8.1 OVERVIEW .................................................................................. 5-116

Card Save: ....................................................................................... 5-116

5.8.2 PROCEDURE ............................................................................... 5-116

6. TROUBLESHOOTING ................................................................. 6-1

6.1SERVICE CALL CONDITIONS .................................................................. 6-1

SM v M020/M021

Page 10

6.1.1 SUMMARY ....................................................................................... 6-1

6.1.2 SC CODE DESCRIPTIONS .............................................................. 6-2

6.2ERROR MESSAGES ............................................................................... 6-32

6.2.1 COMMON ERROR MESSAGES .................................................... 6-32

6.3JAM DETECTION .................................................................................... 6-37

6.3.1 PAPER JAM DISPLAY ................................................................... 6-37

6.3.2 PAPER JAM SENSORS ................................................................. 6-37

6.3.3 JAM CODES AND DISPLAY CODES ............................................. 6-38

6.3.4 INITIAL JAM RELATIONS .............................................................. 6-40

6.4GENERAL TROUBLESHOOTING ........................................................... 6-41

6.4.1 IMAGE ADJUSTMENT ................................................................... 6-41

Registration Adjustment ..................................................................... 6-41

Parallelogram Image Adjustment ....................................................... 6-41

6.4.2 SKEW ADJUSTMENT .................................................................... 6-42

6.4.3 STREAKS IN THE SUB SCAN DIRECTION .................................. 6-42

7. ENERGY SAVING ........................................................................ 7-1

7.1ENERGY SAVE ......................................................................................... 7-1

7.1.1 ENERGY SAVER MODES ............................................................... 7-1

Timer Settings ...................................................................................... 7-2

Return to Stand-by Mode ..................................................................... 7-2

Recommendation ................................................................................. 7-2

7.1.2 ENERGY SAVE EFFECTIVENESS .................................................. 7-3

7.2PAPER SAVE ............................................................................................ 7-5

7.2.1 EFFECTIVENESS OF DUPLEX/COMBINE FUNCTION .................. 7-5

1. Duplex .............................................................................................. 7-5

2. Combine mode ................................................................................. 7-5

3. Duplex + Combine ............................................................................ 7-6

How to calculate the paper reduction ratio ........................................... 7-6

M020/M021 vi SM

Page 11

Page 12

READ THIS FIRST

Safety, Conventions

Safety

Prevention of Physical Injury

1. Before disassembling or assembling parts of the printer and peripherals, make sure that the

printer power cord is unplugged.

2. The wall outlet should be near the printer and easily accessible.

3. Note that some components of the printer and the paper tray unit are supplied with

electrical voltage even if the main power switch is turned off.

4. If any adjustment or operation check has to be made with exterior covers off or open while

the main switch is turned on, keep hands away from electrified or mechanically driven

components.

5. The inside and the metal parts of the fusing unit become extremely hot while the printer is

operating. Be careful to avoid touching those components with your bare hands.

6. To prevent a fire or explosion, keep the machine away from flammable liquids, gases, and

aerosols.

Health Safety Conditions

Toner and developer are non-toxic, but if you get either of them in your eyes by accident, it may

cause temporary eye discomfort. Try to remove with eye drops or flush with water as first aid. If

unsuccessful, get medical attention.

Observance of Electrical Safety Standards

The printer and its peripherals must be installed and maintained by a customer service

representative who has completed the training course on those models.

Page 13

Safety and Ecological Notes For Disposal

1. Do not incinerate toner bottles or used toner. Toner dust may ignite suddenly when

exposed to an open flame.

2. Dispose of used toner, developer, and organic photoconductors in accordance with local

regulations. (These are non-toxic supplies.)

3. Dispose of replaced parts in accordance with local regulations.

4. When keeping used lithium batteries in order to dispose of them later, do not put more than

100 batteries per sealed box. Storing larger numbers or not sealing them apart may lead to

chemical reactions and heat build-up.

The controller board in this machine contains a lithium battery.

The danger of explosion exists if a battery of this type is incorrectly replaced. Replace

only with the same or an equivalent type of battery recommended by the manufacturer.

Dispose of batteries in accordance with the manufacturer's instructions and local laws

and regulations.

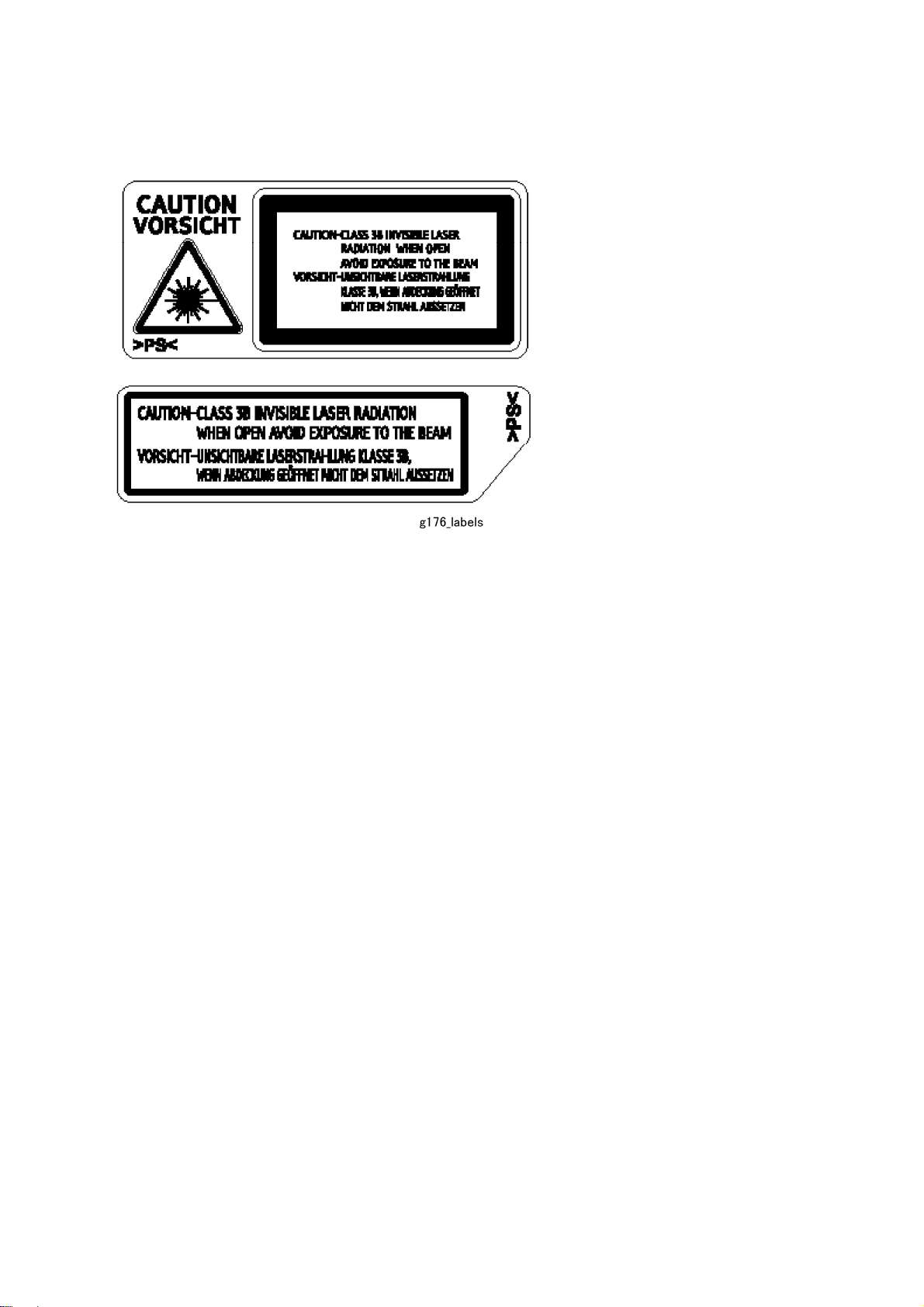

LASER SAFETY

The Center for Devices and Radiological Health (CDRH) prohibits the repair of laser-based

optical units in the field. The optical housing unit can only be repaired in a factory or at a

location with the requisite equipment. The laser subsystem is replaceable in the field by a

qualified Customer Engineer. The laser chassis is not repairable in the field. Customer

engineers are therefore directed to return all chassis and laser subsystems to the factory or

service depot when replacement of the optical subsystem is required.

Use of controls, or adjustment, or performance of procedures other than those

specified in this manual may result in hazardous radiation exposure.

Turn off the main switch before attempting any of the procedures in the Laser Unit

section. Laser beams can seriously damage your eyes.

Page 14

Caution Labels

Page 15

Conventions

Conventions

Symbol What it means

Refer to section number

See Core Tech Manual for details

Screw

Connector

E-ring

C-ring

The following notations are used in text to describe the direction of paper feed: lengthwise and

sideways. The annotations “SEF” and “LEF” denote “Short Edge Feed” and “Long Edge Feed”.

(The arrows indicate the direction of paper feed.)

Page 16

PRODUCT INFORMATION

REVISION HISTORY

Page Date Added/Updated/New

None

Page 17

Page 18

1. PRODUCT INFORMATION

Specifications

1.1 SPECIFICATIONS

See Appendices:

Appendices: Basic Specifications

Appendices: Controller Specifications

Product

Information

SM 1-1 M020/M021

Page 19

1.2 MACHINE CONFIGURATION

1.2.1 SYSTEM COMPONENTS

Main

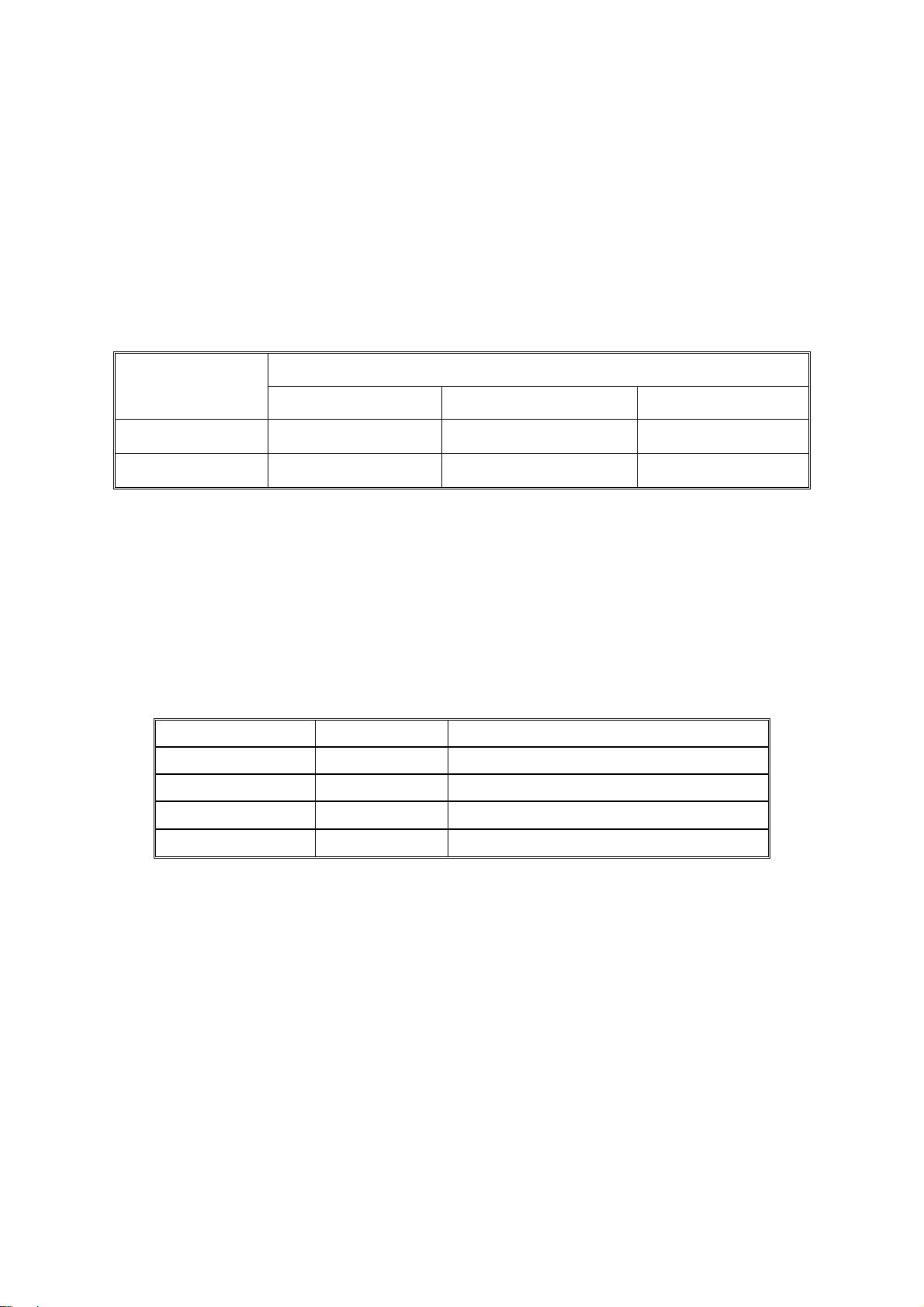

Item Machine code Remarks

Mainframe (45 / 47 ppm) M020

Mainframe (50 / 52 ppm) M021

Options

Item Machine code Remarks

45 ppm (A4 - SEF)

47 ppm (LT - SEF)

50 ppm (A4 - SEF)

52 ppm (LT - SEF)

Paper Feed Unit TK1120 [A] M386 Without casters

Paper Feed Unit TK1130 [B] M389 With casters

M020/M021 1-2 SM

Page 20

Machine Configuration

Product

Information

SM 1-3 M020/M021

Page 21

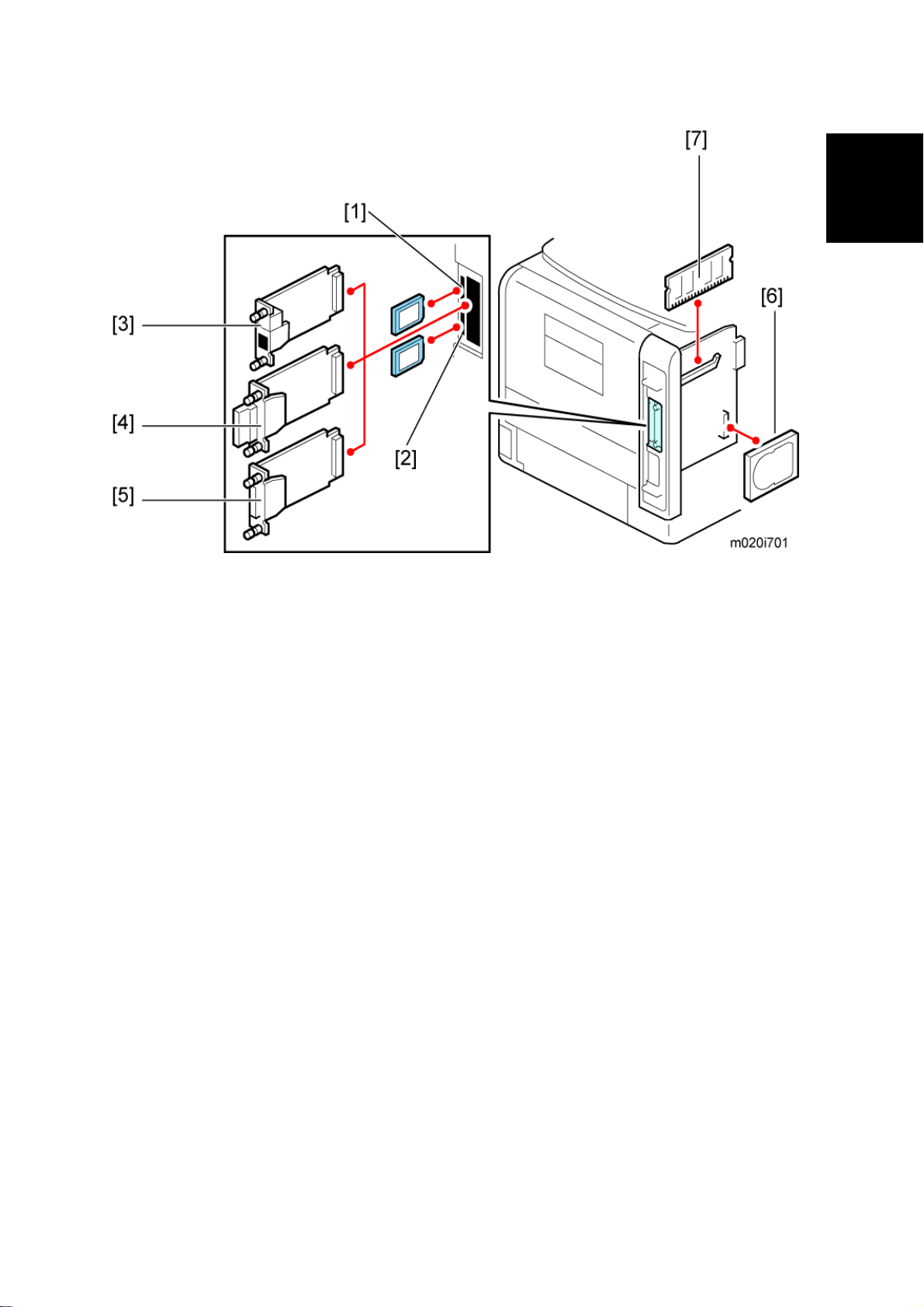

Internal options

Item Machine code Remarks

Memory Unit Type G 256 MB [7] D362 Optional for M020

Memory Unit Type I 512 MB [7] D435 Optional for M020

Hard Disk Drive Type 4310 [6] M394 Optional for M020

IEEE 1284 Interface Board Type A [5] B679

IEEE 802.11a/g interface Unit Type L

[4]

IEEE 802.11a/g Interface Unit Type M

[4]

Gigabit Ethernet Board Type A [3] G874

Gigabit Ethernet Board Type C [3] M397 For NA

SD Card for Netware Printing Type E

[1]

IPDS Unit Type 5200 [1] M388-04 For NA

IPDS Unit Type 5200 [1] M388-05 For EU

SD Card for Fonts Type C [1] M352 For EU

M344 For NA

M344 For EU

M388-03

M020/M021 1-4 SM

Page 22

1.3 OVERVIEW

Overview

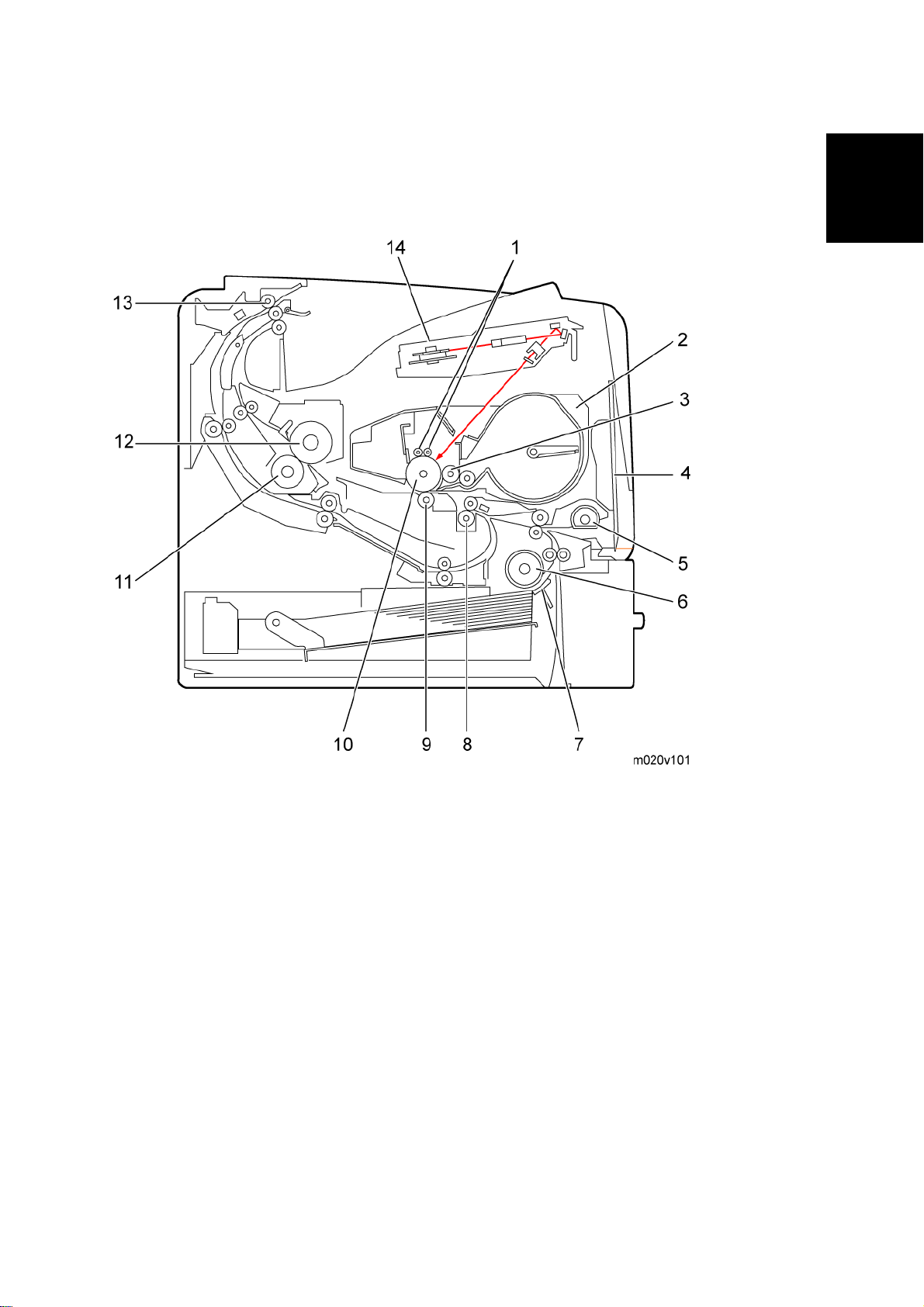

1.3.1 MECHANICAL COMPONENT LAYOUT

Product

Information

1. Charge roller 8. Registration roller

2. Cartridge (AIO-type) 9. Transfer roller

3. Development roller 10. Drum

4. By-pass feed tray 11. Pressure roller

5. By-pass feed roller 12. Hot roller

6. Paper feed roller 13. Paper exit roller

7. Friction pad 14. Laser unit

SM 1-5 M020/M021

Page 23

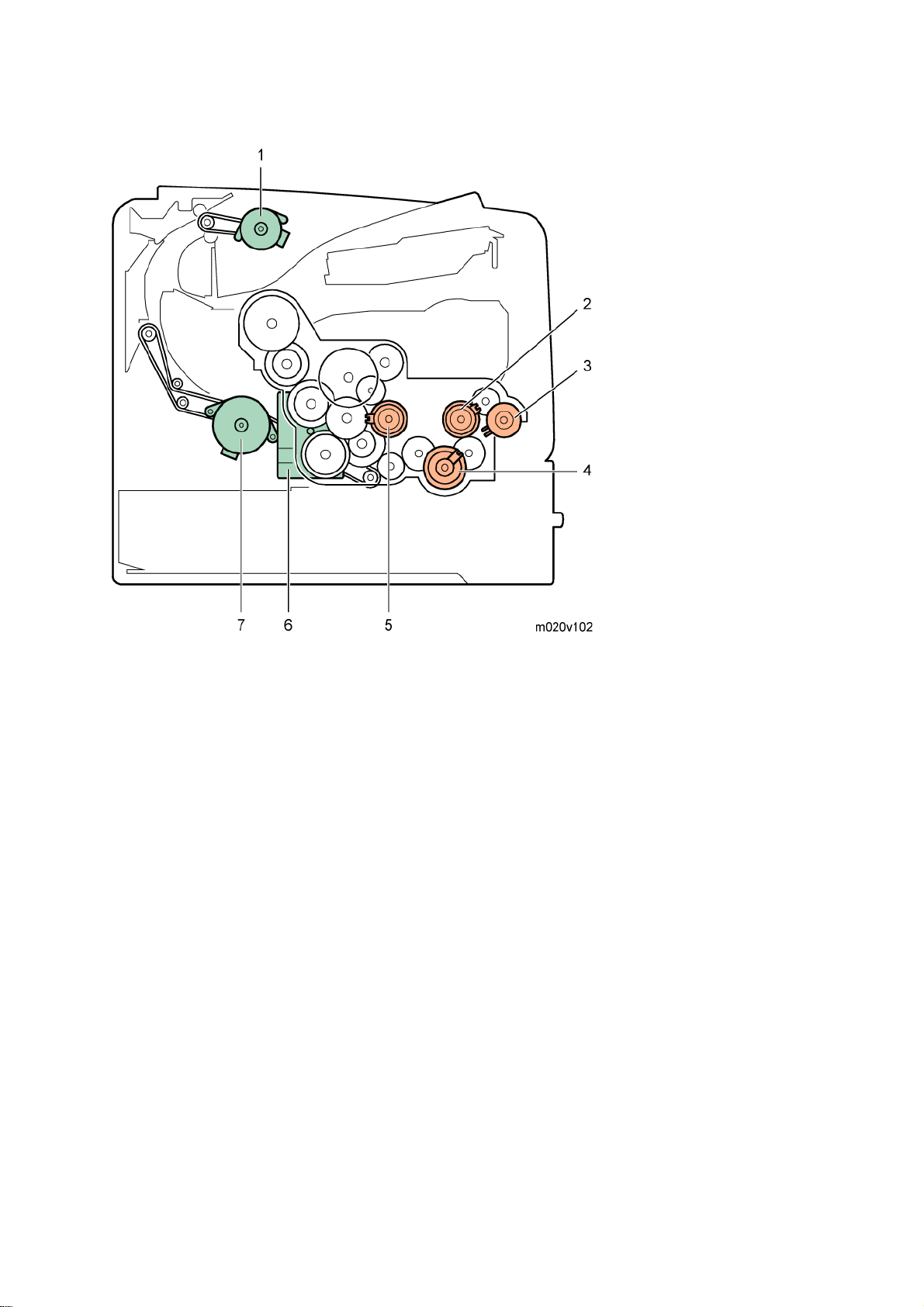

Drive Layout

1. Paper exit motor

2. Relay clutch

3. By-pass feed clutch

4. Paper feed clutch

5. Registration clutch

6. Main motor

7. Duplex motor

M020/M021 1-6 SM

Page 24

1.3.2 PAPER PATH

Overview

Product

Information

1. Paper feed through duplex unit

2. Paper exit to the paper stack

3. Paper feed from tray 1

4. Paper feed from by-pass tray

5. Paper feed from optional PFU (tray 2)

6. Paper feed from optional PFU (tray 3)

7. Paper feed from optional PFU (tray 4)

8. Paper feed from optional PFU (tray 5)

SM 1-7 M020/M021

Page 25

Page 26

INSTALLATION

REVISION HISTORY

Page Date Added/Updated/New

None

Page 27

Page 28

2. INSTALLATION

2.1 MACHINE INSTALLATION

Refer to the following sections for installation details for all models.

Category Item Machine code References

Machine Installation

Main unit -

Paper Feed Unit TK1120 M386 p.2-22

Paper Feed Unit TK1130 M389 p.2-27

Memory Unit Type G 256 MB D362

Memory Unit Type I 512 MB D435

Hard Disk Drive Type 4310 M394

IEEE 802.11a/g interface Unit

Type L (NA) *1

IEEE 802.11a/g interface Unit

Options

Type M (EU) *1

IEEE 1284 Interface Board

Type A

M020/

M021

M344

M344

B679

Quick Installation Guide

p.2-4, p.2-5

Installation

Gigabit Ethernet Board Type A

*1

Gigabit Ethernet Board Type C

*1

IPDS Unit Type 5200 D571

SD Card for Netware Printing

Type E

Drivers -

*1: These units cannot be installed at the same time.

SM 2-1 M020/M021

G874

M397

Software Guide,

M388-03

Section 6

Software Guide,

Section 1

Page 29

Installation Requirements

2.2 INSTALLATION REQUIREMENTS

2.2.1 ENVIRONMENT

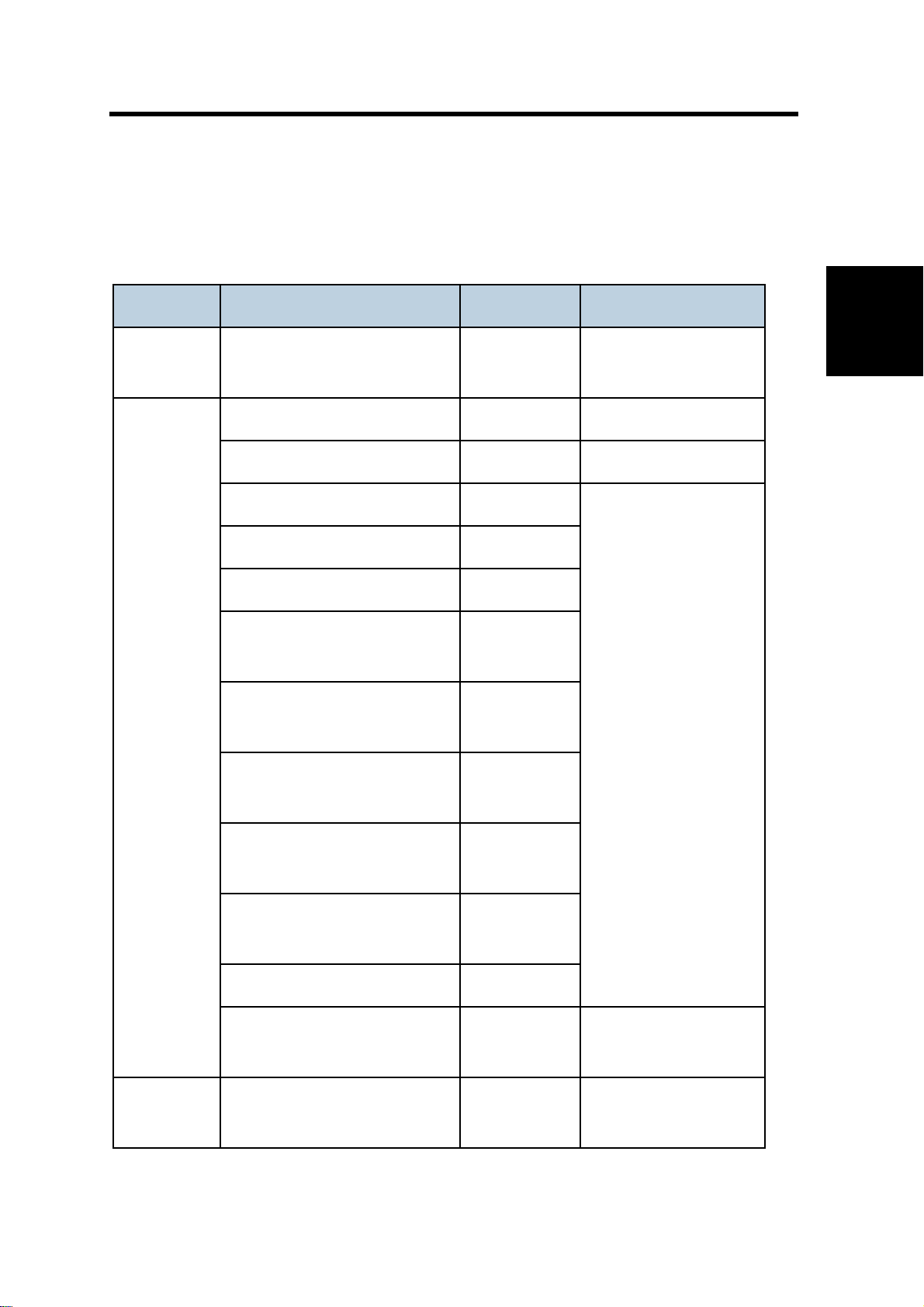

–Temperature and Humidity Chart–

Temperature Range: 10°C to 32°C (50°F to 89.6°F)

Humidity Range: 15% to 80% RH

Ambient Illumination: Less than 1,500 lux (Do not expose to direct sunlight.)

Ventilation: Room air should turn over at least 3 times/hr/person

3

Ambient Dust: Less than 0.1 mg/m

Do not install the machine where it will be exposed to direct sunlight or to direct airflow

(from a fan, air conditioner, air cleaner, etc.).

Do not install the machine where it will be exposed to corrosive gas.

Install the machine at a location lower than 2,000 m (6,560 ft.) above sea level.

Place the machine on a firm and level base.

Do not install the machine where it may be subjected to strong vibration.

2.2.2 MACHINE LEVEL

Front to back: Within 5 mm (0.2") of level

Right to left: Within 5 mm (0.2") of level

M020/M021 2-2 SM

Page 30

Installation Requirements

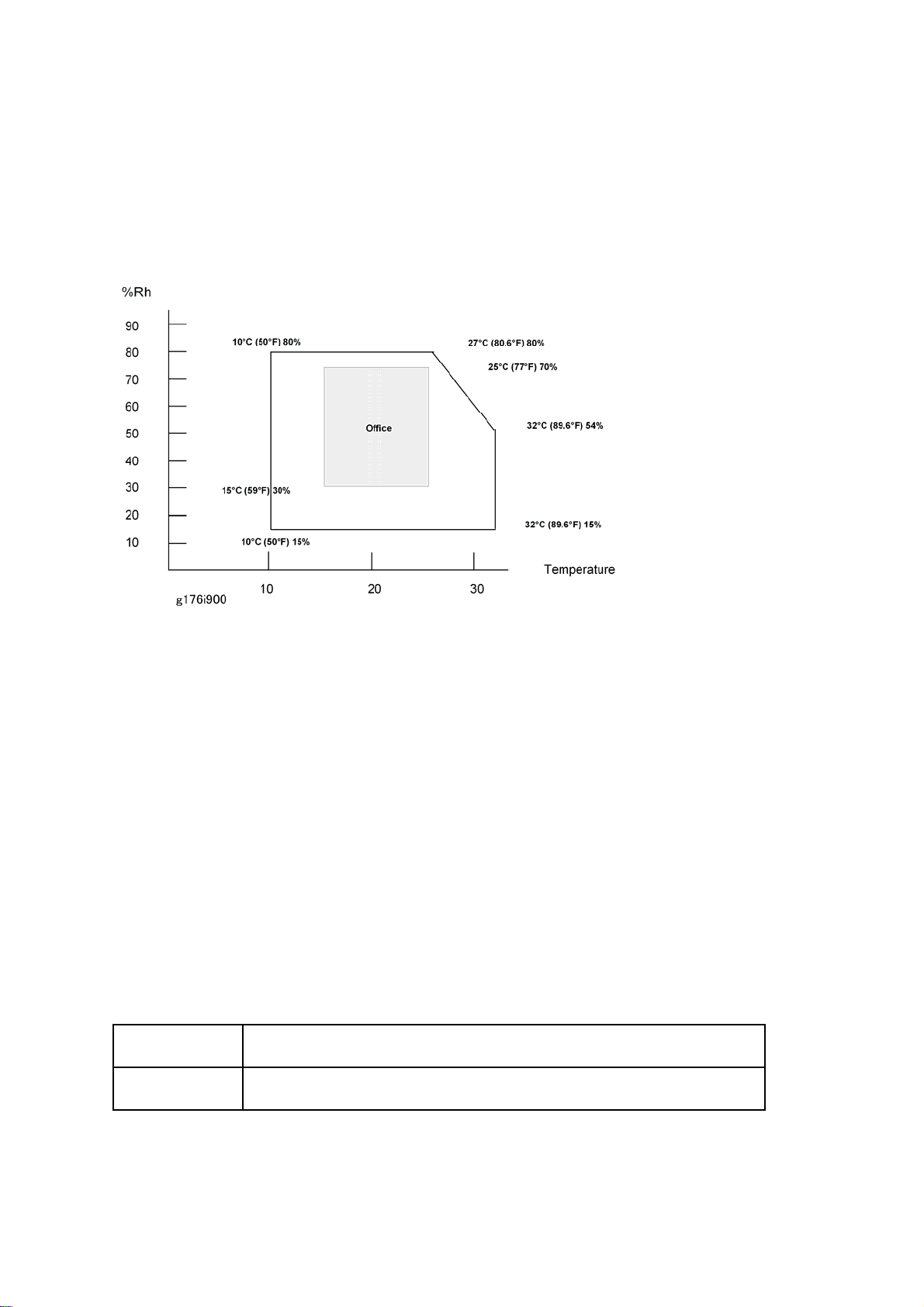

2.2.3 MINIMUM OPERATIONAL SPACE REQUIREMENTS

Place the machine near the power source, providing clearance as shown.

Installation

A: Rear – 200 mm (7.9")

B: Right – 100 mm (4.0")

C: Front – 350 mm (13.8")

D: Left – 100 mm (4.0")

2.2.4 POWER SUPPLY

Make sure that the wall outlet is near the machine and easily accessible. After

completing installation, make sure the plug fits firmly into the outlet.

Avoid multiple connections to the same power outlet.

Be sure to ground the machine.

Input voltage:

North America: 120 – 127 V, 60 Hz, 12 A

Europe/Asia: 220 – 240 V, 50/60 Hz, 8 A

Image quality guaranteed at rated voltage ± 10%.

Operation guaranteed at rated voltage ± 15%.

SM 2-3 M020/M021

Page 31

Controller Options

2.3 CONTROLLER OPTIONS

2.3.1 OVERVIEW

This machine has an I/F card slot for optional I/F connections and SD card slots.

After you install an option, check that the machine can recognize it (see "Check All

Connections" at the end of this section).

I/F Card Slots

The I/F slot is used for one of the optional I/F connections (only one can be installed):

Gigabit Ethernet [3], IEEE802.11a/g (Wireless LAN) [4] or IEEE 1284 interface board [5].

SD Card Slots

Slot 1 [1] (Upper) is used for the Security Card (standard) and IPDS Unit.

If IPDS Unit is to be installed, first merge IPDS application into the Security Card with SP

mode

Slot 2 [2] (Lower) is used for the VM card and service (for example, updating the firmware).

SDRAM slot

The SDRAM slot is used for the SDRAM memory [7] (Standard for type M021, optional for

type M020).

Hard disk connector

Hard disk connector is used for the hard disk [6] (Standard for type M021, optional for type

M020) installation.

M020/M021 2-4 SM

Page 32

Controller Options

2.3.2 INSTALLING THE SD MEMORY CARD OPTIONS

Installation

Keep SD memory cards out of reach of children. If a child swallows an SD memory

card, consult a doctor immediately.

Do not subject the card to physical shocks.

The VM card is optional for M020 models only. To use it, the optional 512 MB SDRAM

module must be installed.

1. Check the contents of the package.

2. Turn off the power, and then unplug the power cord.

Installation

3. Remove the screw, and then carefully remove the cover of the SD card slot.

4. Carefully push in the SD card (notched corner downward and leading), until it clicks into

place.

Insert the SD card in the appropriate slot as follows:

Upper slot: SD font card, NetWare card, Security SD card (Standard for M020), IPDS

card.

Lower slot: For service only (Firmware update, application move, etc.)

The SD card supplied with the optional hard disk (M020 model only) can be used in either

of the two slots.

SM 2-5 M020/M021

Page 33

Controller Options

5. Reattach the cover over the SD card. Fasten the screw to secure the cover.

Do not touch the card while the printer is in use. It may come loose, even if pushed only

slightly. The slot cover must be reattached.

You can confirm that the SD card was installed correctly by checking the control panel

menu. Depending on the SD card, certain menu items appear on the display.

SD card supplied with the optional hard disk (M020 model only): Make sure [Machine

Data Encryption] appears in [Security Options]. Depending on settings, [Machine Data

Encryption] might not appear. For details about how to confirm this setting, consult your

administrator.

NetWare card: Make sure [NetWare] appears in [Effective Protocol] under [Network].

M020/M021 2-6 SM

Page 34

Controller Options

2.3.3 SD CARD APPLICATION MOVE

The PostScript3 application and fonts cannot be moved to another SD card. However,

other applications can be moved onto the PostScript3 SD card.

Overview

The service program "SD Card Appli Move" (SP5-873) lets you copy application programs from

one SD card to another SD card.

Slot 1 (Upper) is used to store application programs. But there are 3 possible applications

(PostScript 3, DOS (DataOverwriteSecurity) unit, PictBridge). You cannot run application

programs from Slot 2 (Lower). However you can move application programs from Slot 2 (Lower)

to Slot 1 (Upper) with the following procedure.

Make sure that the target SD card has enough space.

1. Enter SP5873 "SD Card Appli Move".

2. Then move the application from the SD Card in Slot 2 (Lower) to the SD Card in Slot 1

(Upper).

Do steps 1 - 2 again if you want to move another application program.

3. Exit the SP mode.

Be very careful when you do the SD Card Appli Move procedure:

The data necessary for authentication is transferred with the application program from an

SD card to another SD card. Authentication fails if you try to use the SD card af ter you copy

the application program from one card to another card.

Do not use the SD card if it has been used before for other purposes. Normal operation is

Installation

not guaranteed when such an SD card is used.

Keep the SD card in a safe place after you copy the application program from one card to

another card. This is done for the following reasons:

1) The SD card can be the only proof that the user is licensed to use the application

program.

2) You may need to check the SD card and its data to solve a problem in the future.

SM 2-7 M020/M021

Page 35

Controller Options

Move Exec

The menu "Move Exec" (SP5873-001) lets you copy application programs from the original SD

card to another SD card.

Do not set ON (Lock) the write-protect switch of the system SD card or application SD

card on the machine. If the write-protect switch is ON, a download error (e.g. Error

Code 44) occurs during a firmware upgrade or application merge.

1. Turn the main switch off.

2. Make sure that an SD card is in SD Card Slot 1 (Upper). The application program is copied

to this SD card.

3. Insert the SD card with the application program in SD Card Slot 2 (Lower).The application

program is copied from this SD card.

4. Turn the main switch on.

5. Start the SP mode.

6. Select SP5873-001 "Move Exec."

7. Follow the messages shown on the operation panel.

8. Turn the main switch off.

9. Remove the SD card from SD Card Slot 2 (Lower).

10. Turn the main switch on.

11. Check that the application programs run normally.

Undo Exec

"Undo Exec" (SP5873-002) lets you copy back application programs from an SD card to the

original SD card. You can use this program when, for example, you have mistakenly copied

some programs by using Move Exec (SP5873-001).

Do not set ON (Lock) the write protect switch of the system SD card or application SD

card on the machine. If the write protect switch is ON, a download error (e.g. Error

Code 44) occurs during a firmware upgrade or application merge.

1. Turn the main switch off.

2. Insert the original SD card in SD Card Slot 2 (Lower). The application program is copied

back into this card.

3. Insert the SD card with the application program in SD Card Slot 1 (Upper).The application

program is copied back from this SD card.

4. Turn the main switch on.

5. Start the SP mode.

6. Select SP5873-002 "Undo Exec."

M020/M021 2-8 SM

Page 36

7. Follow the messages shown on the operation panel.

8. Turn the main switch off.

9. Remove the SD card from SD Card Slot 2 (Lower).

This step assumes that the application programs in the SD card are used by the

machine.

10. Turn the main switch on.

11. Check that the application programs run normally.

Controller Options

12. Make sure that the machine can recognize the option (see "p.2-21" at the end of this

section).

2.3.4 IEEE 802.11 A/G (WIRELESS LAN)

Installation Procedure

Unplug the main machine power cord before you do the following procedure.

You can only install one of the network interfaces or printer enhanced option at one time: IEEE

802.11 a/g (Wireless LAN), Gigabit Ethernet, or File Format Converter.

Installation

1. Remove the two screws and remove the cover of the slot in which the Wireless LAN

interface board is to be installed.

2. Fully insert the Wireless LAN interface board.

SM 2-9 M020/M021

Page 37

Controller Options

3. Tighten the two screws to secure the interface board.

Check the Wireless LAN interface board is connected firmly to the interface board slot.

You may have to move the machine if the reception is not clear.

Make sure that the machine is not located near an appliance or any type of equipment

that generates strong magnetic fields.

Put the machine as close as possible to the access point.

UP Mode Settings for Wireless LAN

Enter the UP mode. Then do the procedure below to perform the initial interface settings for

IEEE 802.11 a/g. These settings take effect every time the machine is powered on.

You cannot use the wireless LAN if you use Ethernet.

1. Press the "User Tools/Counter" key.

2. On the touch panel, press "System Settings".

The Network I/F (default: Ethernet) must be set for either Ethernet or wireless LAN.

3. Select "Interface Settings".

4. Press "Wireless LAN". Only the wireless LAN options show.

5. Communication Mode. Select either "802.11 Ad hoc" or "Infrastructure".

6. SSID Setting. Enter the SSID setting. (The setting is case sensitive.)

7. Channel. You need this setting when Ad Hoc Mode is selected.

Region A (mainly Europe and Asia)

Range: 1-13, 36, 40, 44 and 48 channels (default: 11)

Region B (mainly North America)

Range: 1-11, 36, 40, 44 and 48 channels (default: 11)

M020/M021 2-10 SM

Page 38

Controller Options

The allowed range for the channel settings may vary for different countries.

In some countries, only the following channels are available: Range: 1-1 1 channels

(default: 11)

8. WEP (Encryption) Setting. The WEP (Wired Equivalent Privacy) setting is designed to

protect wireless data transmission. The same WEP key is required on the receiving side in

order to unlock encoded data. There are 64 bit and 128 bit WEP keys.

WEP:

Selects "Active" or "Inactive" ("Inactive" is default.).

Range of Allowed Settings:

64 bit: 10 characters

128 bit: 26 characters

9. Press "Return to Default" to initialize the wireless LAN settings.

Press "Yes" to initialize the following settings:

Transmission mode

Channel

Transmission Speed

WEP

SSID

WEP Key

Installation

SM 2-11 M020/M021

Page 39

Controller Options

SP Mode and UP Mode Settings for IEEE 802.11 a/g Wireless LAN

The following SP commands and UP modes can be set for IEEE 802.11 a/g.

SP No. Name Function

5840-006 Channel MAX

5840-007 Channel MIN

Transmission

5840-008

Speed

5840-011 WEP Key Select Used to select the WEP key (Default: 00).

UP mode Name Function

SSID Used to confirm the current SSID setting.

WEP Key Used to confirm the current WEP key setting.

WEP Mode

Sets the maximum range of the channel settings for the

country.

Sets the minimum range of the channel settings

allowed for the country.

Sets the transmission speed.

Auto, 54 Mbps, 48 Mbps, 36 Mbps, 24 Mbps, 18 Mbps,

12 Mbps, 9 Mbps, 6 Mbps, 11 Mbps, 5.5 Mbps, 2 Mbps,

1 Mbps (Default: Auto).

Used to show the maximum length of the string that

can be used for the WEP Key entry.

M020/M021 2-12 SM

Page 40

Controller Options

2.3.5 IEEE 1284 INTERFACE BOARD

Unplug the main machine power cord before you do the following procedure.

Before beginning work, ground yourself by touching something metal to discharge any

static electricity. Static electricity can damage the IEEE 1284 interface board.

Do not subject the IEEE 1284 interface board to physical shocks.

For connection to the IEEE 1284 interface board, use a half pitch 36-pin interface

cable.

1. Check the contents of the package.

Installation

2. Remove the two screws and remove the cover of the slot in which the 1284 interface board

is installed.

3. Fully insert the IEEE 1284 interface board.

SM 2-13 M020/M021

Page 41

Controller Options

4. Tighten the two screws to secure the interface board.

Confirm that the IEEE 1284 interface board was correctly installed by printing the

configuration page. If it is correctly installed, "Parallel Interface" will appear for "Device

Connection" on the configuration page.

If the board was not installed properly, repeat the p rocedure from step 3.

For details on printing the configuration, see "p.2-21" at the end of this section.

M020/M021 2-14 SM

Page 42

2.3.6 GIGABIT ETHERNET

Unplug the main machine power cord before you do the following procedure.

1: Gigabit Ethernet Board

2: Protective caps (one each for the Ethernet port and the USB port)

Controller Options

Installation

3: Ferrite core (Design of the ferrite core varies according to printer model.)

1. Check the contents of the package.

2. Disconnect the cables from the Ethernet port and USB port of the printer, and cover each

port with its protective cap.

3. Remove the two screws and remove the cover of the slot in which the Gigabit Ethernet

board is installed.

SM 2-15 M020/M021

Page 43

Controller Options

4. Fully insert the Gigabit Ethernet board.

5. Tighten the two screws to secure the Gigabit Ethernet board.

Check the Gigabit Ethernet board is connected firmly to the interface board slot.

6. Attach the ferrite core [3] to the LAN cable, and connect the LAN cable to the machine.

7. Make sure that the machine can recognize this option (see ‘p.2-21’ at the end of this

section).

M020/M021 2-16 SM

Page 44

Controller Options

2.3.7 MEMORY UNIT TYPE G 256MB / I 512MB (ONLY FOR M020)

Unplug the main machine power cord before you do the following procedure.

1. Controller unit (

2. Place the controller board on a flat surface. The SDRAM module is installed in the slot

shown in the illustration above.

p.4-43)

Installation

3. To install the recommended memory, align the notch of the memory module with the

protruding part of the vacant slot, and then carefully insert the module at an angle.

4. Keeping the module at an angle, press it down until it clicks into place.

SM 2-17 M020/M021

Page 45

Controller Options

5. Align the controller board with the top and bottom rails, and then push it carefully in, until it

stops.

6. Fasten the controller board to the printer with the two screws.

After finishing the installation, you can check the SDRAM module is properly installed:

Print the configuration page from the [List/Test Print] menu. If it is installed properly , the

memory capacity will appear under "Total Memory" on the configuration page.

The table below shows the total SDRAM module capacities.

Standard Extended Total

256 MB 256MB 512 MB

256 MB 512 MB 768MB

M020/M021 2-18 SM

Page 46

2.3.8 HARD DISK DRIVE TYPE 2670 (ONLY FOR M020)

Unplug the main machine power cord before you do the following procedure.

1: Hard disk

2: Screws (Knob screws x 3)

1. Check the package contains the above.

Controller Options

Installation

2. Controller unit (

3. Place the controller board on a flat surface. The hard disk is installed in the slot shown in

the illustration above.

p.4-43)

4. Insert the protrusion on the front end of the hard disk board into the notch on the back panel

of the controller board.

Be sure to set the hard disk board parallel with the controller board.

SM 2-19 M020/M021

Page 47

Controller Options

5. Fit the hard disk on the connector of the controller board carefully until it stops.

6. Tighten the two screws by turning them clockwise with a coin, and then secure the hard

disk board by tightening the third screw from the under side of the controller board.

7. Align the controller board with the top and bottom rails, and then push it carefully in, until it

stops.

8. Fasten the controller board to the printer with the two screws.

M020/M021 2-20 SM

Page 48

Controller Options

After finishing installation, you can check whether the hard disk is properly installed:

Print the configuration page from the [List/Test Print] menu. If it is installed properly , you

will see "Hard Disk" will appear for "Device Connection" on the configuration page.

If the Hard disk is not properly installed, repeat this procedure.

For details on printing the configuration, see "p.2-21" at the end of this section.

2.3.9 CHECK ALL CONNECTIONS

1. Plug in the power cord. Then turn on the main switch.

2. Enter the printer user mode. Then print the configuration page.

User Tools > Printer Settings > List Test Print > Config. Page

All installed options are shown in the "System Reference" column.

2.3.10 IC CARD READER (EXTERNAL OPTIONS) ATTACHING

LOCATION

Installation

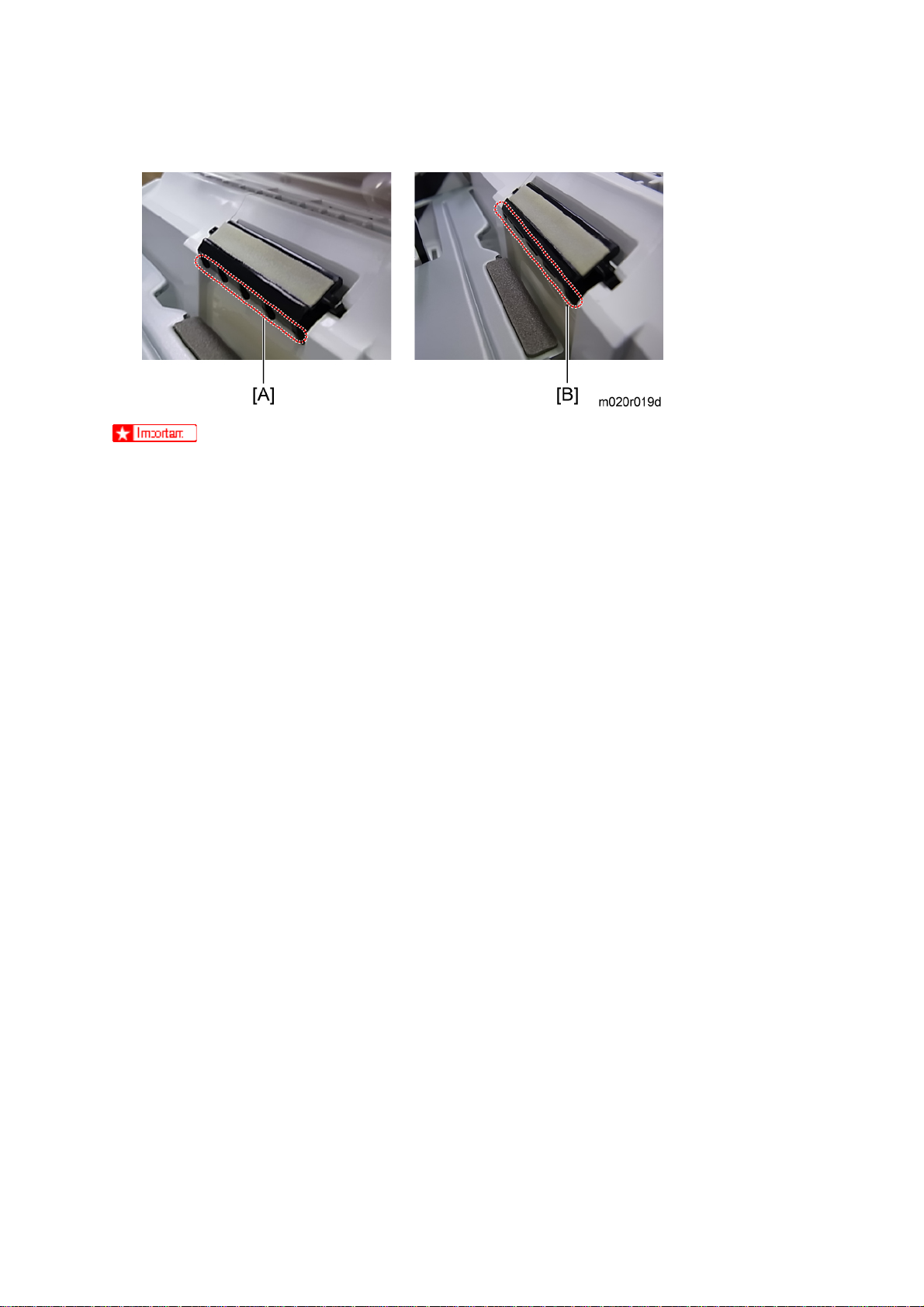

To enable good communication between the IC card reader and the IC card, install the IC card

reader at the position above [A].

Position the IC card reader with the upper edge 10 mm (0.4 in.) below the air inlet [B].

Align the front edge of the IC card reader with the front line of the air inlet [C].

The USB cable of the IC card reader should be fixed with clamps to prevent it from

sagging.

SM 2-21 M020/M021

Page 49

Paper Feed Unit TK1120 (M386)

2.4 PAPER FEED UNIT TK1120 (M386)

2.4.1 ACCESSORY CHECK

Confirm that you have these accessories.

Description Q'ty

Installation instructions 1

EMC sheet 1

Fixation screws 2

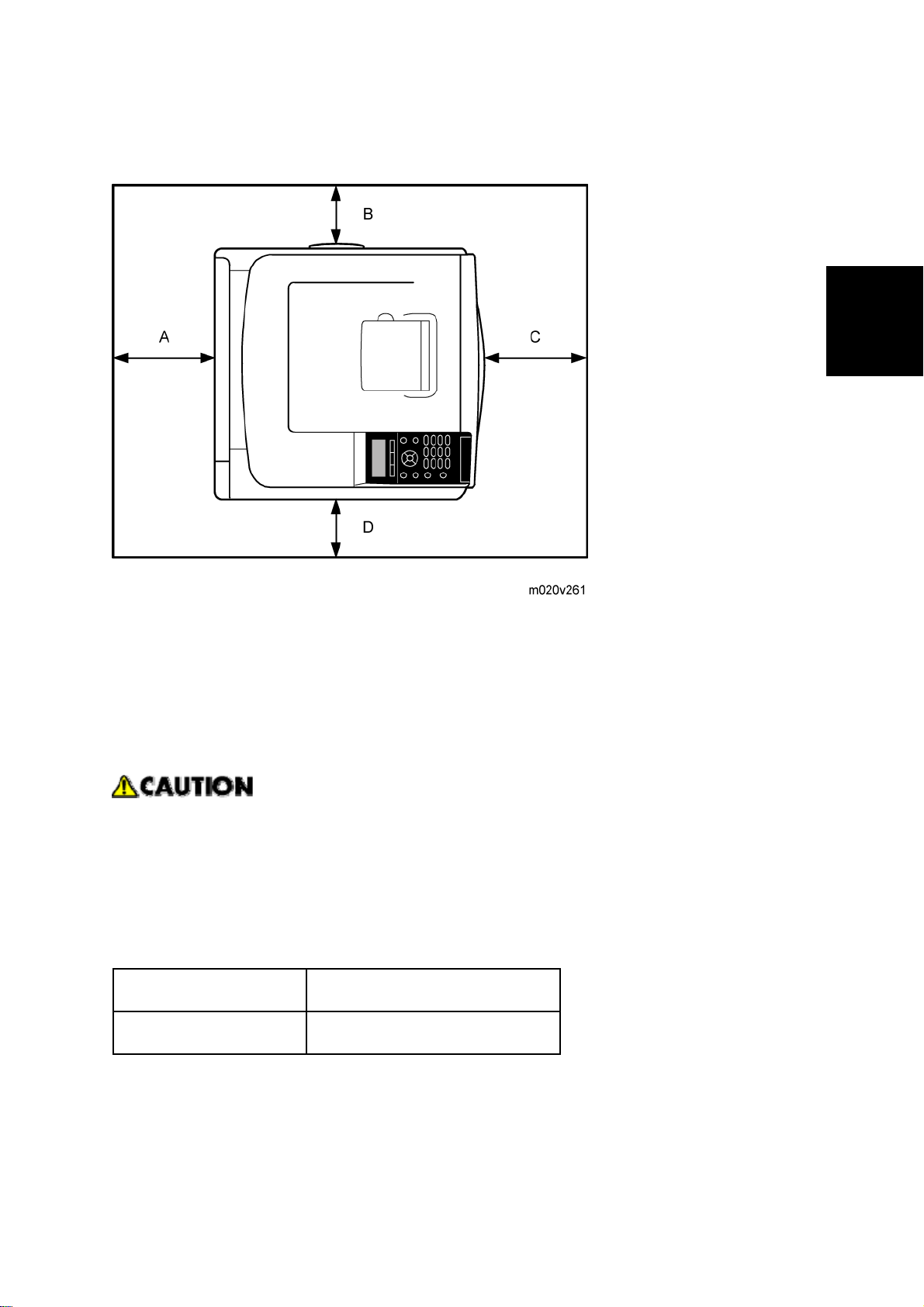

2.4.2 INSTALLATION PROCEDURE

Unplug the main machine's power cord before starting the following procedure.

The number of optional paper feed units that can be attached depends on the location where

the machine is installed.

[A]: Up to three paper feed units (M386 [D]) can be installed on a desk.

[B]: Up to three paper feed units (M386 [D]) and one paper feed unit (M389 [E]) can be

installed on the floor.

[C]: Attach the optional paper feed unit with casters (M389 [E]) to the bottom of the machine

to install the machine directly on the floor.

M020/M021 2-22 SM

Page 50

Paper Feed Unit TK1120 (M386)

1. Remove all tape and cardboard from the optional paper feed unit [A].

2. Pull the paper tray of the main unit part way out; then, remove the tape and cardboard in

the paper tray, and push the tray back in.

Installation

3. Lift the printer using the inset grips on both sides of the printer.

When moving the printer, do not hold on the following parts as doing so could

cause a malfunction:

The handle of the standard paper tray.

The underside of the by-pass tray.

SM 2-23 M020/M021

Page 51

Paper Feed Unit TK1120 (M386)

4. Set the machine [A] on the paper feed unit [B].

Two people are required to lift the machine.

When installing a second paper feed unit, place it on the first paper feed unit

before placing the printer onto the pair of paper feed units

5. Remove the paper(s) tray from the paper tray unit(s).

6. Load paper into the paper tray(s). Adjust the side and end fences as necessary. If loading

1

/2"x 14" paper, remove the end fence and set it in the special compartment.

8

7. Insert the paper tray(s) back in the paper tray unit(s).

M020/M021 2-24 SM

Page 52

Paper Feed Unit TK1120 (M386)

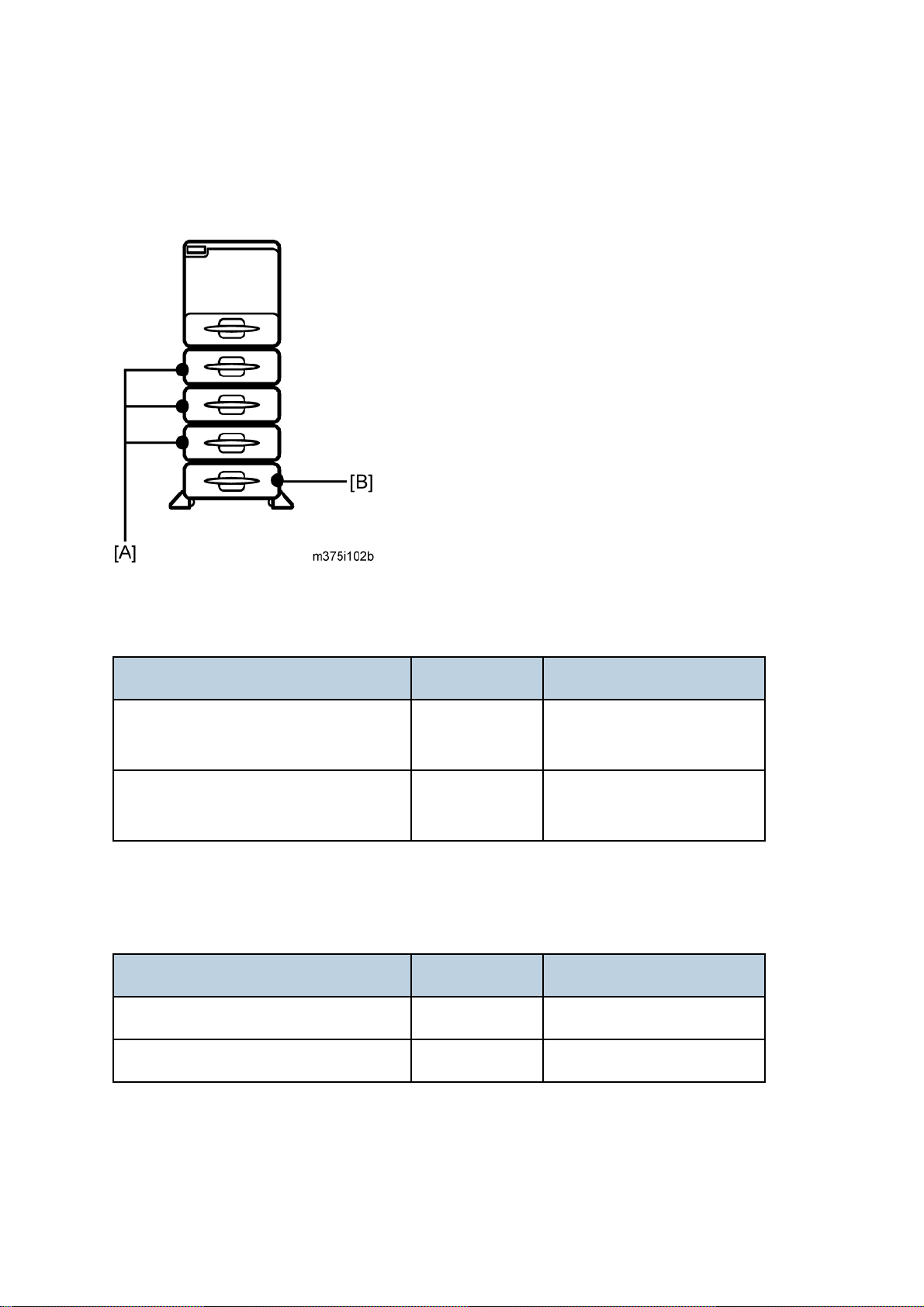

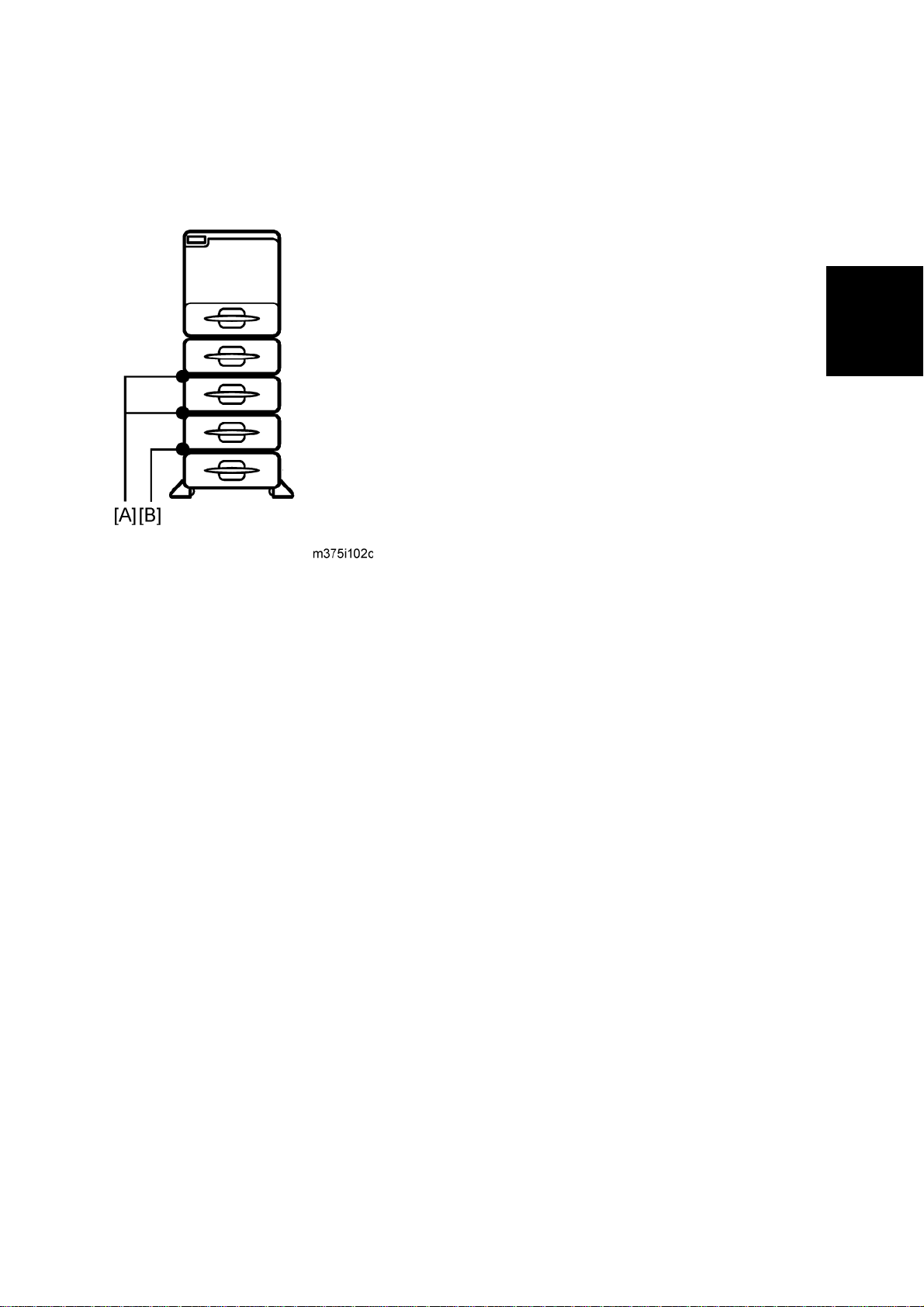

2.4.3 WHEN STACKING FOUR OPTIONAL PAPER FEED UNITS

Paper feed units should be fixed to each other with screws when stacking four optional paper

feed units. Fix the paper feed units to each other as described below.

Installation

1. Between top three optional units [A]

2. Between the unit with casters (forth optional) and the third optional unit [B]

SM 2-25 M020/M021

Page 53

Paper Feed Unit TK1120 (M386)

Fixing the units together

1. Pull out the paper trays of the paper feed units to be fixed.

2. Fix the paper feed unit at the rear side [A] with the two screws that come with the paper

feed unit.

Never detach the stabilizers of the paper feed unit with casters (M389).

M020/M021 2-26 SM

Page 54

2.5 PAPER FEED UNIT TK1130 (M389)

2.5.1 ACCESSORY CHECK

Confirm that you have these accessories.

Description Q'ty

Paper Feed Unit TK1130 (M389)

Installation instructions 1

EMC sheet 1

2.5.2 INSTALLATION PROCEDURE

Unplug the main machine's power cord before starting the following procedure.

Installation

The number of optional paper feed units that can be attached depends on the location where

the machine is installed.

[A]: Up to three paper feed units (M386 [D]) can be installed on a desk.

[B]: Up to three paper feed units (M386 [D]) and one paper feed unit (M389

[E]) can be installed on the floor.

[C]: Attach the optional paper feed unit with casters (M389 [E]) to the bottom of the machine

to install the machine directly on the floor.

SM 2-27 M020/M021

Page 55

Paper Feed Unit TK1130 (M389)

1. Remove all tape and cardboard from the optional paper feed unit [A].

2. Pull the paper tray of the main unit part way out; then, remove the tape and cardboard in

the paper tray, and push the tray back in.

3. Lift the printer using the inset grips on both sides of the printer.

When moving the printer, do not hold on the following parts as doing so could

cause a malfunction:

The handle of the standard paper tray.

The underside of the by-pass tray.

M020/M021 2-28 SM

Page 56

4. Set the machine [A] on the paper feed unit [B].

Paper Feed Unit TK1130 (M389)

Installation

Two people are required to lift the machine.

When installing a second paper feed unit, place it on the first paper feed unit

before placing the printer onto the pair of paper feed units

5. Remove the paper(s) tray from the paper tray unit(s).

6. Load paper in the paper tray(s). Adjust the side and end fences as necessary. If loading

1

/2"x 14" paper, remove the end fence and set it in the special compartment.

8

7. Insert the paper tray(s) back in the paper tray unit(s).

SM 2-29 M020/M021

Page 57

Paper Feed Unit TK1130 (M389)

2.5.3 WHEN STACKING FOUR OPTIONAL PAPER FEED UNITS

Paper feed units should be fixed each other with screws when stacking four optional paper feed

units. Fix the paper feed units to each other as described below.

1. Between top three optional units [A]

2. Between the unit with casters (forth optional) and third optional unit [B].

M020/M021 2-30 SM

Page 58

Fixing the units together

1. Pull out the paper trays of the paper feed units to be fixed.

Paper Feed Unit TK1130 (M389)

Installation

2. Fix the paper feed unit at the rear side [A] with the two screws that come with the paper

feed unit.

Never detach the stabilizers of the paper feed unit with casters (M389).

SM 2-31 M020/M021

Page 59

Page 60

PREVENTIVE MAINTENANCE

REVISION HISTORY

Page Date Added/Updated/New

None

Page 61

Page 62

Maintenance Tables

3. PREVENTIVE MAINTENANCE

3.1 MAINTENANCE TABLES

3.1.1 USER MAINTENANCE

The customer can replace all PM items with the Maintenance Kit.

The user can maintain this machine. For more see "Printer Engine Service Mode".

The operation panel shows “Replace Maintenance Kit” when the PM counter reaches 120 k.

After the user replaces the fusing unit in the maintenance kit, the machine automatically resets

the PM counter.

Item Quantity Remarks

Fusing unit 1 -

Transfer roller 1 -

Paper feed roller 5 For standard and optional tray(s)

Friction pad 5 For standard and optional tray(s)

3.1.2 SERVICE MAINTENANCE

See "Appendices" for the following information:

Preventive Maintenance Items

Other Yield Parts

Preventive

Maintenance

SM 3-1 M020/M021

Page 63

PM Parts Settings

3.2 PM PARTS SETTINGS

3.2.1 BEFORE REMOVING THE OLD PM PARTS

1. Enter the SP mode.

2. Output the SMC logging data with SP5-990-004.

3. Clear the PM counters with SP7-804.

4. Exit the SP mode.

Item SP

All Units 7-804-002

Fusing Unit 7-804-003

Transfer Roller 7-804-004

Paper Feed Roller 7-804-005

For the fusing unit, there is a new unit detection mechanism. It is not necessary to reset the PM

counter.

3.2.2 AFTER INSTALLING THE NEW PM PARTS

1. Turn on the main power switch.

2. Output the SMC logging data with SP5-990-004 and check the counter values.

3. Make sure that the PM counters for the replaced units are “0” with SP7-803. If the PM

counter for a unit was not reset, then reset that counter with SP 7-804.

3.2.3 OPERATION CHECK

Check if the sample image has been printed normally.

M020/M021 3-2 SM

Page 64

REPLACEMENT AND ADJUSTMENT

REVISION HISTORY

Page Date Added/Updated/New

None

Page 65

Page 66

General Precautions

4. REPLACEMENT AND ADJUSTMENT

4.1 GENERAL PRECAUTIONS

4.1.1 PRECAUTIONS ON DISASSEMBLY

Always turn off the main power switch and unplug the machine before attempting any

of the procedures in this section.

Use extreme caution when removing and replacing components. The cables in the machine are

located very close to moving parts; proper routing is a must.

After components have been removed, any cables that have been displaced during the

procedure must be restored as close as possible to their original positions. Before removing any

component from the machine, note any cable routings that may be affected.

Before servicing the machine:

1. Verify that documents are not stored in memory.

2. Remove the print cartridge before you remove parts.

3. Unplug the power cord.

4. Work on a flat and clean surface.

5. Replace with authorized components only.

6. Do not force plastic material components.

Make sure all components are returned to their original positions.

Laser Unit

1. Do not loosen or adjust the screws securing the LD drive board on the LD unit. Doing so will

throw the LD unit out of adjustment.

2. Do not adjust the variable resistors on the LD unit, as these are permanently adjusted at

the factory. If replacement of the LD drive board is necessary, replace the entire LD unit.

3. Keep the polygon mirror and toroidal lens free of dust. Laser performance is very sensitive

to dust on these components.

4. Do not touch the shield glass or the surface of the polygon mirror with bare hands.

5. Do not adjust the Laser Synchronization detector on the LD unit, as these are permanently

Replacement

and

Adjustment

adjusted at the factory.

Transfer Roller

1. Never touch the surface of the transfer roller with bare hands.

2. Be careful not to scratch the transfer roller, as the surface is easily damaged.

SM 4-1 M020/M021

Page 67

General Precautions

Fusing

1. After installing the fusing thermistor, make sure that it is in contact with the hot roller and

that the roller can rotate freely.

2. Be careful to avoid damage to the hot roller stripper pawls and their tension springs.

3. Do not touch the fusing lamp and rollers with bare hands.

4. Make sure that the fusing lamp is positioned correctly and that it does not touch the inner

surface of the hot roller.

Paper Feed

1. Do not touch the surface of paper feed rollers.

2. To avoid misfeeds, the side and end fences in each paper tray must be positioned correctly

so as to align with loaded paper size.

4.1.2 RELEASING PLASTIC LATCHES

Many of the parts are held in place with plastic latches. The latches break easily, so release

them carefully. To release a latch, press the hook end of the latch away from the part to which it

is latched.

4.1.3 AFTER SERVICING THE MACHINE

1. Make sure all parts that require grounding are properly grounded.

2. Make sure the interlock switch is functioning.

3. Do not leave unused solder or parts inside the machine.

4. Do not leave any tools inside the machine.

5. Make sure all wires are properly connected and routed.

6. Make sure wires are not jammed between parts of the machine.

M020/M021 4-2 SM

Page 68

4.2 COVERS

4.2.1 RIGHT COVER

1. Pull the standard tray [A] out.

Covers

2. Gently push the front cover release button [B], and open the front cover [C].

3. Open the rear cover [D].

and

Adjustment

Replacement

SM 4-3 M020/M021

Page 69

Covers

4. Right cover [C] ( x 3 [A], hook [B] x 1)

To remove the right cover safely, release it from the power switch by pulling the cover

forward and outward slightly, and then release it from the Inlet socket by pushing the

cover backward slightly.

M020/M021 4-4 SM

Page 70

4.2.2 LEFT COVER

1. Pull the standard paper tray out ( p.4-3).

Covers

2. Open the front cover (

3. Slide the control board unit [B] out (Knob screw [A] x 2).

4. Open the rear cover (

p.4-3).

p.4-3).

and

Adjustment

Replacement

5. Left cover [A] (

SM 4-5 M020/M021

[B] x 4, hooks [C] x 2).

Page 71

Covers

4.2.3 UPPER COVER

1. Right cover ( p.4-3)

2. Left cover (

3. Open the front cover and the rear cover.

4. 4 screws [A].

5. Operation panel (

p.4-5)

p.4-10)

6. Part [A] of upper cover.

7. Part [B] of upper cover (Hooks [C] x 2).

M020/M021 4-6 SM

Page 72

4.2.4 FRONT COVER

1. Pull out the standard paper tray.

Covers

2. By-pass tray (

3. Open the front cover [B].

4. Right cover (

5. Left cover (

p.4-32)

p.4-3)

p.4-5)

Replacement

and

Adjustment

6. Close the front cover [B].

7. Release the tension spring [A].

8. Reopen the front cover [B].

SM 4-7 M020/M021

Page 73

Covers

9. Front cover [A] (Hooks x 2).

Remove the by-pass tray unit before removing the front cover.

Close the front cover before releasing the tension spring.

M020/M021 4-8 SM

Page 74

4.2.5 REAR COVER

1. Open the rear cover.

Covers

2. Rear cover [A](Hooks x 2).

To remove the rear cover easily, release the right hook by pushing the cover against

the left side of mainframe lightly, and then pull out the right corner.

and

Adjustment

Replacement

SM 4-9 M020/M021

Page 75

Covers

4.2.6 OPERATION PANEL

1. Left cover ( p.4-5)

2. Open the front cover.

3. Operation panel [A] ( [B] x 1, hooks x 2).

M020/M021 4-10 SM

Page 76

4.3 LASER UNIT

Turn off the main power switch and unplug the machine before attempting any of the

procedures in this section. Laser beams can seriously damage your eyes.

4.3.1 CAUTION DECAL LOCATIONS

Laser Unit

and

Adjustment

Replacement

SM 4-11 M020/M021

Page 77

Laser Unit

4.3.2 LASER UNIT

Turn off the main switch and unplug the machine before attempting any of the

procedures in this section. Laser beams can seriously damage your eyes.

1. Right cover (

2. Left cover (

3. Upper cover (

4. Grounding wire [A] and 2 connectors [B], [C] ( x 2, grounding screw x 1).

p.4-3)

p.4-5)

p.4-6)

5. Laser unit [A] (

Never touch the surface of the mirror with bare hands.

M020/M021 4-12 SM

x 4).

Page 78

When reinstalling the laser unit.

Use the scanner positioning pins (P/N: A0069104) to reinstall the unit.

Laser Unit

Set the positioning pins as shown above. Then secure the laser unit.

Replacement

and

Adjustment

SM 4-13 M020/M021

Page 79

Laser Unit

4.3.3 POLYGON MIRROR MOTOR

Turn off the main switch and unplug the machine before attempting any of the

procedures in this section. Laser beams can seriously damage your eyes.

1. Upper cover (

2. Laser unit (

3. Polygon mirror cover [A] (Grounding screw x 1, x 1, x 2, tape x 1)

Keep the tape [B] above. The tape is necessary when reassembling the laser unit.

p.4-6)

p.4-12)

4. Polygon mirror motor [A] (

M020/M021 4-14 SM

x 4, x 1)

Page 80

4.3.4 LASER SYNCHRONIZATION DETECTOR

1. Laser unit ( p.4-12)

2. Laser synchronization detector [A] (

x 1)

Laser Unit

Replacement

and

Adjustment

SM 4-15 M020/M021

Page 81

Transfer Roller

4.4 TRANSFER ROLLER

1. Open the front cover.

2. Remove the AIO unit.

3. Remove the transfer roller [A] as shown above.

Do not touch the transfer roller surface.

Set the transfer roller with its green end (indicated by the arrow in the upper-right

photo) on the right side.

Make sure that the transfer roller is set securely.

M020/M021 4-16 SM

Page 82

4.5 FUSING

4.5.1 FUSING UNIT

Before handling the fusing unit, make sure that the unit is cool enough. The fusing unit

can be very hot.

Fusing

1. Open the rear cover [A].

2. Release the lock levers [B].

3. Pull the fusing unit [C] out.

and

Adjustment

Replacement

SM 4-17 M020/M021

Page 83

Fusing

4.5.2 HOT ROLLER AND PRESSURE ROLLER SECTIONS

1. Fusing unit ( p.4-17)

2. Fusing left cover [A] (

3. Fusing right cover [B] (

4. Separate the fusing unit [A] into the hot roller section [B] and the pressure roller section [C]

(

x 4).

x 1)

x 1)

M020/M021 4-18 SM

Page 84

4.5.3 FUSING LAMP

1. Fusing unit ( p.4-17)

Fusing

2. Fusing left and right covers (

3. Lamp left stay [A] (

4. Remove the screw [B] on the left terminal of the fusing unit.

5. Lamp right stay [C] (

6. Remove the screw [D] on the right terminal of the fusing unit.

x 1)

x 1)

p.4-18)

and

Adjustment

Replacement

7. Fusing lamp [A]

SM 4-19 M020/M021

Page 85

Fusing

4.5.4 HOT ROLLER

Do not touch the fusing lamp and rollers with your bare hands.

1. Hot roller section (

2. Fusing lamp (

3. Hot roller gear [A] ( x 1)

4. Hot roller left stay [B] (

5. Hot roller right stay [C] (

6. Remove the c-ring [D].

p.4-18)

p.4-19)

x 1)

x 1)

7. Hot roller [A] (bearing x 2, insulator x 2)

Slowly pull out the hot roller from the hot roller section, making sure not to damage the

hot roller on the stripper pawls.

M020/M021 4-20 SM

Page 86

4.5.5 FUSING THERMISTOR

1. Fusing unit ( p.4-17)

2. Fusing drawer connector [A] (

x 1)

Fusing

3. Fusing thermistor [B] (

x 1, x 1)

4.5.6 THERMOSTATS

1. Hot roller ( p.4-20)

2. Thermostats [A] (

Do not reuse thermostats that are already opened. Safety is not guaranteed if you do

x 2)

Replacement

and

Adjustment

this.

SM 4-21 M020/M021

Page 87

Fusing

4.5.7 PRESSURE ROLLER

1. Pressure roller section ( p.4-18)

2. Fusing entrance guide [A] (

x 3)

3. Pressure roller [A] (bearing x 2)

M020/M021 4-22 SM

Page 88

4.5.8 FUSING CLEANING ROLLER

1. Pressure roller section ( p.4-18)

Fusing

2. Pressure roller (

3. Fusing cleaning roller [A]

p.4-22)

and

Adjustment

Replacement

SM 4-23 M020/M021

Page 89

Paper Feed

4.6 PAPER FEED

4.6.1 PAPER FEED ROLLER

1. Pull out the paper tray before removing the paper feed roller.

2. Press the paper feed roller [A] to the left side and remove it.

4.6.2 FRICTION PAD

1. Remove the paper tray from the machine before removing the friction pad.

2. Friction pad [A] (Hooks x 2, spring x 1).

M020/M021 4-24 SM

Page 90

When reinstalling the friction pad follow this order:

1. Place the spring [A].

Paper Feed

and

Adjustment

Replacement

SM 4-25 M020/M021

Page 91

Paper Feed

2. Gently push the friction pad [A] down into the slot while bending the Mylar sheet [B] slightly

outward.

A: No Good -- The friction pad catches the Mylar sheet.

B: Good -- Mylar sheet located at outside of the friction pad.

To prevent the friction pad from catching on the Mylar sheet, place the friction pad while

bending the Mylar sheet slightly outward.

M020/M021 4-26 SM

Page 92

4.6.3 PAPER END SENSOR

1. All optional paper tray units.

2. Pull the standard paper tray out.

3. AIO unit.

Paper Feed

4. Fusing unit (

5. Transfer roller (

6. Lay down the machine face up.

p.4-17)

p.4-16)

and

Adjustment

Replacement

7. Feeler cover [A] (

Confirm that all paper trays are detached from the machine before lying it down.

Take care when handling this machine because of its weight. (Approximately 23

kg/51 lb)

8. Remove the feeler [A] by bending the bushing slightly in the direction indicated by the arrow

in the left photo.

x 1).

SM 4-27 M020/M021

Page 93

Paper Feed

9. Paper end sensor [A] (Hooks x 3,

x 1) .

M020/M021 4-28 SM

Page 94

4.6.4 REMAINING PAPER SENSORS 1 AND 2

1. All optional paper tray units

2. Pull the standard paper tray out.

3. AIO unit.

Paper Feed

4. Fusing unit (

5. Transfer roller (

6. Lay down the machine face up.

p.4-17)

p.4-16)

and

Adjustment

Replacement

7. Feeler cover [A] (

Confirm that all paper trays are detached from the machine before lying it down.

Take care when handling this machine because of its weight. (Approximately 23

kg/51 lb)

8. Remove the feeler [A] by bending the bushing slightly in the direction indicated by the arrow

in the left photo.

x 1).

SM 4-29 M020/M021

Page 95

Paper Feed

9. Remaining paper sensor 1 [A] and remaining paper sensor 2 [B] (Hooks x 3 (For each

sensor), x 1 (For each sensor)).

M020/M021 4-30 SM

Page 96

4.6.5 REGISTRATION SENSOR

1. Open the Front cover.

2. AIO unit.

3. Sensor cover [A] (Hooks x 4).

Paper Feed

4. Registration sensor [A] (

x 1).

and

Adjustment

Replacement

SM 4-31 M020/M021

Page 97

By-pass Tray

4.7 BY-PASS TRAY

4.7.1 BY-PASS TRAY UNIT

1. Pull the standard paper tray out.

2. Open the by-pass tray.

3. Bend two hooks [A] inward slightly and release them.

4. Pull the by-pass tray [A] obliquely down and remove it.

M020/M021 4-32 SM

Page 98

4.7.2 BY-PASS FEED ROLLER

1. Left cover ( p.4-5)

By-pass Tray

2. Right cover (

3. Front cover (

4. Remove the AIO unit.

5. Engine board with bracket (

6. Paper guide [A] ( x 2).

p.4-3)

p.4-7)

p.4-50)

Replacement

and

Adjustment

7. Actuator [A].

8. By-pass feed clutch (

SM 4-33 M020/M021

p.4-63)

Page 99

By-pass Tray

9. By-pass feed roller [A] (

Before attaching the paper guide, confirm that the actuator and the by-pass feed roller

are installed securely and that they move smoothly.

[B] x 2, bushing x 2 [C]).

4.7.3 BY-PASS FRICTION PAD

1. By-pass feed roller ( p.4-33)

2. By-pass friction pad [A] (hooks x 2).

M020/M021 4-34 SM

Page 100

4.7.4 BY-PASS PAPER SENSOR

1. Left cover ( p.4-5)

By-pass Tray

2. Engine board with bracket (

3. By-pass feed clutch (

4. By-pass paper sensor [A] (Hooks x 3, x 1).

p.4-63)

p.4-50)

and

Adjustment

Replacement

SM 4-35 M020/M021

Loading...

Loading...