REMKO RKL 491 DC User Manual

Assembly and operating instructions

Read the instructions prior to performing any task!

REMKO RKL 491 DC

Local inverter room air conditioner in split design

0074-2014-01 Edition 1, en_GB

Installation and operating instructions (translation of the orig-

inal)

Read these operating instructions carefully before commis-

sioning / using this device!

These instructions are an integral part of the system and must

always be kept near or on the device.

Subject to modifications; No liability accepted for errors or mis-

prints!

Table of contents

1 Safety and usage instructions............................................................................................................. 4

1.1 General safety notes....................................................................................................................... 4

1.2 Identification of notes...................................................................................................................... 4

1.3 Personnel qualifications.................................................................................................................. 4

1.4 Dangers of failure to observe the safety notes................................................................................ 4

1.5 Safety-conscious working............................................................................................................... 4

1.6 Safety notes for the operator........................................................................................................... 5

1.7 Safety notes for installation, maintenance and inspection.............................................................. 5

1.8 Unauthorised modification and changes......................................................................................... 5

1.9 Intended use................................................................................................................................... 5

1.10 Warranty........................................................................................................................................ 5

1.11 Transport and packaging.............................................................................................................. 6

1.12 Environmental protection and recycling........................................................................................ 6

2 Technical data....................................................................................................................................... 7

2.1 Technical data................................................................................................................................. 7

3 Structure and function.......................................................................................................................... 8

4

Operation............................................................................................................................................... 9

5 Installation........................................................................................................................................... 11

6 Connecting line................................................................................................................................... 14

7 Electrical connection ......................................................................................................................... 17

8 Troubleshooting and customer service ........................................................................................... 18

9 Care and maintenance ....................................................................................................................... 19

10 Shut-down ........................................................................................................................................... 20

11 Exploded view and spare parts lists................................................................................................. 21

11.1 Exploded view indoor unit........................................................................................................... 21

11.2 Spare parts list - Indoor unit........................................................................................................ 22

11.3 Exploded view outdoor unit......................................................................................................... 24

11.4 Spare parts list - Outdoor unit..................................................................................................... 24

12 Index..................................................................................................................................................... 25

3

1

Safety and

usage instructions

1.1

General safety notes

Carefully read the operating manual before com-

missioning the units for the first time. It contains

useful tips and notes such as hazard warnings to

prevent personal injury and material damage.

Failure to follow the directions in this manual not

only presents a danger to people, the environment

and the system itself, but will void any claims for

liability.

Keep this operating manual and the refrigerant

data sheet near to the units.

1.2

Identification of notes

This section provides an overview of all important

safety aspects for proper protection of people and

safe and fault-free operation.The instructions and

safety notes contained within this manual must be

observed in order to prevent accidents, personal

injury and material damage.

Notes attached directly to the units must be

observed in their entirety and be kept in a fully

legible condition.

Safety notes in this manual are indicated by sym-

bols. Safety notes are introduced with signal words

which help to highlight the magnitude of the danger

in question.

DANGER!

Contact with live parts poses an immediate

danger of death due to electric shock. Damage

to the insulation or individual components may

pose a danger of death.

DANGER!

This combination of symbol and signal word

warns of a situation in which there is immediate

danger, which if not avoided may be fatal or

cause serious injury.

WARNING!

This combination of symbol and signal word

warns of a potentially hazardous situation,

which if not avoided may be fatal or cause

serious injury.

CAUTION!

This combination of symbol and signal word

warns of a potentially hazardous situation,

which if not avoided may cause injury or mate-

rial and environmental damage.

NOTICE!

This combination of symbol and signal word

warns of a potentially hazardous situation,

which if not avoided may cause material and

environmental damage.

This symbol highlights useful tips and recom-

mendations as well as information for efficient

and fault-free operation.

1.3

Personnel qualifications

Personnel responsible for commissioning, opera-

tion, maintenance, inspection and installation must

be able to demonstrate that they hold a qualifica-

tion which proves their ability to undertake the

work.

1.4

Dangers of failure to observe

the safety notes

Failure to observe the safety notes may pose a risk

to people, the environment and the units. Failure to

observe the safety notes may void any claims for

damages.

In particular, failure to observe the safety notes

may pose the following risks:

n The failure of important unit functions.

n The failure of prescribed methods of mainte-

nance and repair.

n Danger to people on account of electrical and

mechanical effects.

1.5

Safety-conscious working

The safety notes contained in this manual, the

existing national regulations concerning accident

prevention as well as any internal company

working, operating and safety regulations must be

observed.

REMKO RKL

4

1.6

Safety notes for the operator

The operational safety of the units and compo-

nents is only assured providing they are used as

intended and in a fully assembled state.

n The units and components may only be set up,

installed and maintained by qualified per-

sonnel.

n Protective covers (grille) over moving parts

must not be removed from units that are in

operation.

n Do not operate units or components with

obvious defects or signs of damage.

n Contact with certain unit parts or components

may lead to burns or injury.

n The units and components must not be

exposed to any mechanical load, extreme

levels of humidity or extreme temperature.

n Spaces in which refrigerant can leak sufficient

to load and vent. Otherwise there is danger of

suffocation.

n All housing parts and device openings, e.g. air

inlets and outlets, must be free from foreign

objects, fluids or gases.

n The units must be inspected by a service tech-

nician at least once annually. Visual inspec-

tions and cleaning may be performed by the

operator when the units are disconnected from

the mains.

n The local room air conditioner is designed for

flexible use in living and work spaces. Year-

round operation is not recommended.

n Do not leave the appliance running for an

extended period unsupervised.

1.7

Safety notes for installation,

maintenance and inspection

n Appropriate hazard prevention measures must

be taken to prevent risks to people when per-

forming installation, repair, maintenance or

cleaning work on the units.

n The setup, connection and operation of the

units and its components must be undertaken

in accordance with the usage and operating

conditions stipulated in this manual and comply

with all applicable regional regulations.

n Local regulations and laws such as Water

Ecology Act must be observed.

n The power supply should be adapted to the

requirements of the units.

n Units may only be mounted at the points pro-

vided for this purpose at the factory. The units

may only be secured or mounted on stable

structures, walls or floors.

n Mobile units must be set up securely on suit-

able surfaces and in an upright position. Sta-

tionary units must be permanently installed for

operation.

n The units and components should not be oper-

ated in areas where there is a heightened risk

of damage. Observe the minimum clearances.

n The units and components must be kept at an

adequate distance from flammable, explosive,

combustible, abrasive and dirty areas or

atmospheres.

n Safety devices must not be altered or

bypassed.

1.8

Unauthorised modification

and changes

Modifications or changes to units and components

are not permitted and may cause malfunctions.

Safety devices may not be modified or bypassed.

Original replacement parts and accessories

authorised by the manufactured ensure safety. The

use of other parts may invalidate liability for

resulting consequences.

1.9

Intended use

Depending on the model, the equipment and the

additional fittings with which it is equipped is only

intended to be used as an air-conditioner for the

purpose of cooling or heating the air in an

enclosed room..

Different or additional use shall not be classed as

intended use. The manufacturer/supplier assumes

no liability for damages arising from an unintended

use of the equipment. The user bears the sole risk

in such cases.

Using the equipment as intended also includes

working in accordance with the operating manual

and installation instructions and complying with the

maintenance requirements.

Under no circumstances should the threshold

values specified in the technical data be exceeded.

1.10

Warranty

For warranty claims to be considered, it is essential

that the ordering party or its representative com-

plete and return the "certificate of warranty" to

REMKO GmbH & Co. KG at the time when the

units are purchased and commissioned.

The warranty conditions are detailed in the "Gen-

eral business and delivery conditions". Further-

more, only the parties to a contract can conclude

special agreements beyond these conditions. In

this case, contact your contractual partner in the

first instance.

5

1.11

Transport and packaging

The devices are supplied in a sturdy shipping con-

tainer. Please check the equipment immediately

upon delivery and note any damage or missing

parts on the delivery and inform the shipper and

your contractual partner. For later complaints can

not be guaranteed.

WARNING!

Plastic films and bags etc. are dangerous

toys for children!

Why:

- Leave packaging material are not around.

- Packaging material may not be accessible to

children!

1.12

Environmental protection

and recycling

Disposal of packaging

All products are packed for transport in environ-

mentally friendly materials. Make a valuable contri-

bution to reducing waste and sustaining raw mate-

rials. Only dispose of packaging at approved

collection points.

Disposal of equipment and components

Only recyclable materials are used in the manufac-

ture of the devices and components. Help protect

the environment by ensuring that the devices or

components (for example batteries) are not dis-

posed in household waste, but only in accordance

with local regulations and in an environmentally

safe manner, e.g. using certified firms and recy-

cling specialists or at collection points.

REMKO RKL

6

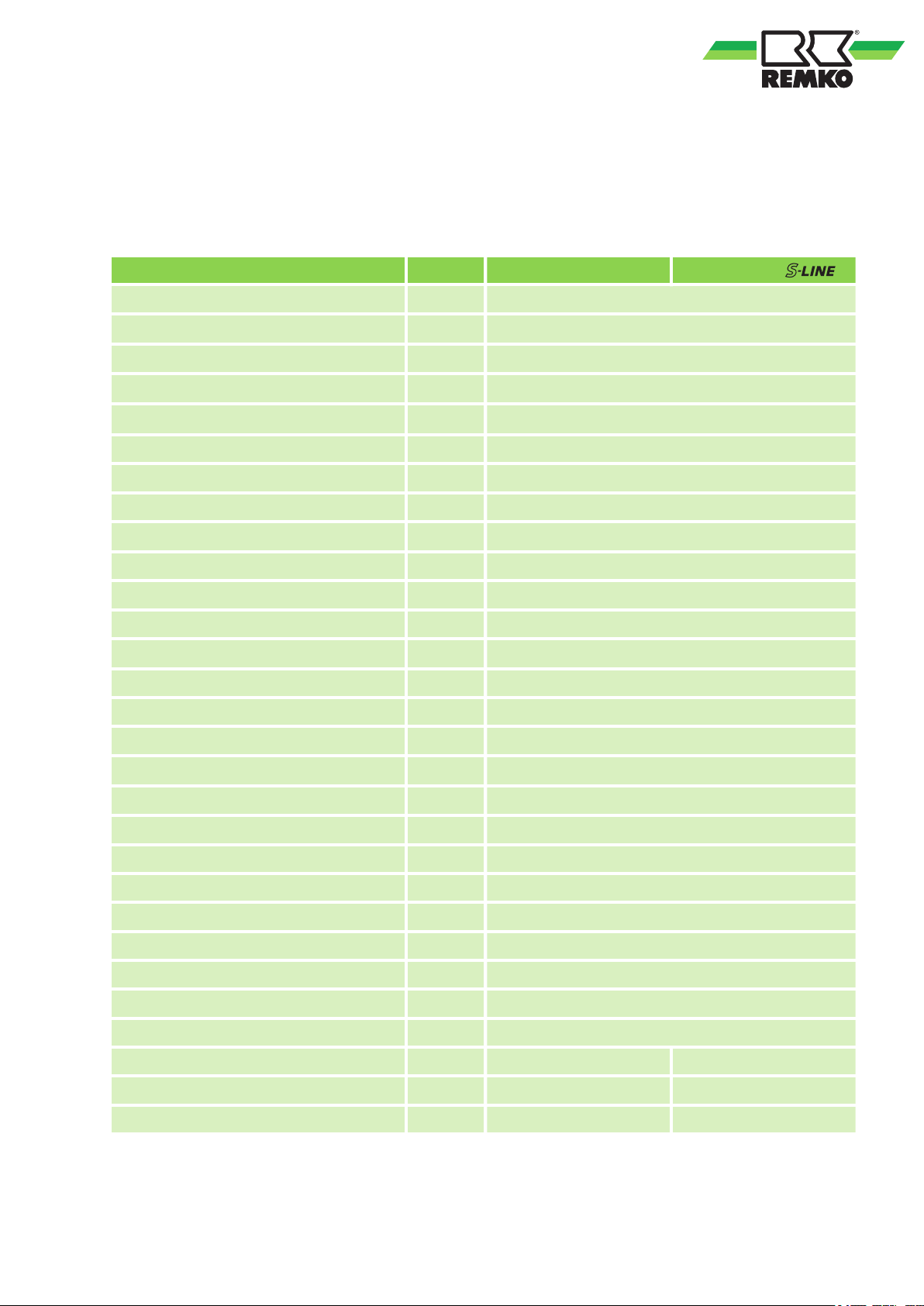

2

Technical data

2.1

Technical data

Unit data

Series RKL 491 DC

RKL 491 DC

Operating mode Local inverter room air conditioner in split design

Nominal cooling output

1)

kW 4.30 (1.80 to 4.60)

Energy efficiency ratio,

1)

B

Energy efficiency size SEER

1)

4.6

Power consumption, annual, Q

CE

kWh 346

Application area (room volume), approx. m³ 120

Adjustment range indoor unit °C/%r.H. +16 to +30 / 35 to 80

Operating range outdoor unit °C/%r.H. +21 to +43 / 35 to 80

Refrigerant

R 410A

3)

Max. operating pressure kPa 4200

Air volume flow per level, indoor unit m³/h 380 / 520 / 600

Max. airflow volume outdoor unit m³/h 1000

Sound pressure level p. stage, ind. unit

2)

dB(A) 45 / 48 / 54

Sound power level max., IT/AT dB(A) 59 / 64

Power supply V/Hz 230 / 1~/ 50

Enclosure class indoor unit / outdoor unit IP 24 / X4

Electr. rated power consumption

1)

kW 1.31

Electr. rated current consumption

1)

A 5.60

Elec. starting current max., LRA A 8.00

Condensate pump, flow rate, max. mm WS 1800

Refrigerant, basic capacity kg 1.08

Refrigerant piping, length mm 3000, 2300 usable

Dimensions indoor unit H/W/D mm 695 / 470 / 335

Dimensions outdoor unit H/W/D mm 490 / 510 / 230

Weight indoor unit kg 35.0

Weight outdoor unit kg 14.0

Standard colour white silver

Serial number 1288... 1289...

EDP no. 1615490 1615491

1)

Air inlet temperature TK 27°C / FK 19°C, outside temperature TK 35 °C, FK 24 °C, max. air flow volume

2)

Distance 1m free field

3)

Contains greenhouse gas per Kyoto protocol (see also information in "Connecting line" chapter)

7

3

Structure and function

Equipment description

The device is particularly suited for flexible opera-

tion, but can also be mounted in a stationary instal-

lation. The local air conditioning unit is comprised

of an indoor unit for setting up on the floor indoors

and an outdoor unit for wall or ground installation

outdoors. In "cooling" mode, the output produced

by the compressor precisely matches itself to

requirements, and thereby regulates the nominal

temperature with minimal temperature deviations.

This "inverter-technology" results in energy savings

over conventional split systems and also reduces

noise emissions to a particularly low level. The

flexible connection pipe serves to transport the

heat outdoors. The outdoor unit discharges the

absorbed heat to the outdoor air by means of a

heat exchanger (condenser). The condensate col-

lected during cooling operation is transported to

the outdoor unit by means of a condensate pump

integrated into the indoor unit and evaporates via

the heat exchanger. The device filters and dehu-

midifies the air and thereby creates a comfortable

room climate. It works fully automatically and offers

numerous additional options thanks to its micro-

processor control system. The device can be con-

veniently operated by means of the infrared remote

control unit included.

2

1

4

3

5

6

7

8

LA

LA

LE

IG

AT

LE

Fig. 1: Front view

IG Indoor unit

AT Outdoor unit

LA Air outlet

LE Air intake

1 Recessed grip

2 Infrared receiver

3 Ventilation louvers

4 Control panel

5 Carrying handle

6 Conveyor rollers

7 Connector pipes

8 Condenser fan (back side)

2

1

4

3

5

LE

2

6

Fig. 2: Rear view (indoor unit)

LE Air intake

1 Connector pipes

2 Mount for the outdoor unit

3 Cover

4 Air filter

5 Condensate drain

6 Mains lead with plug

REMKO RKL

8

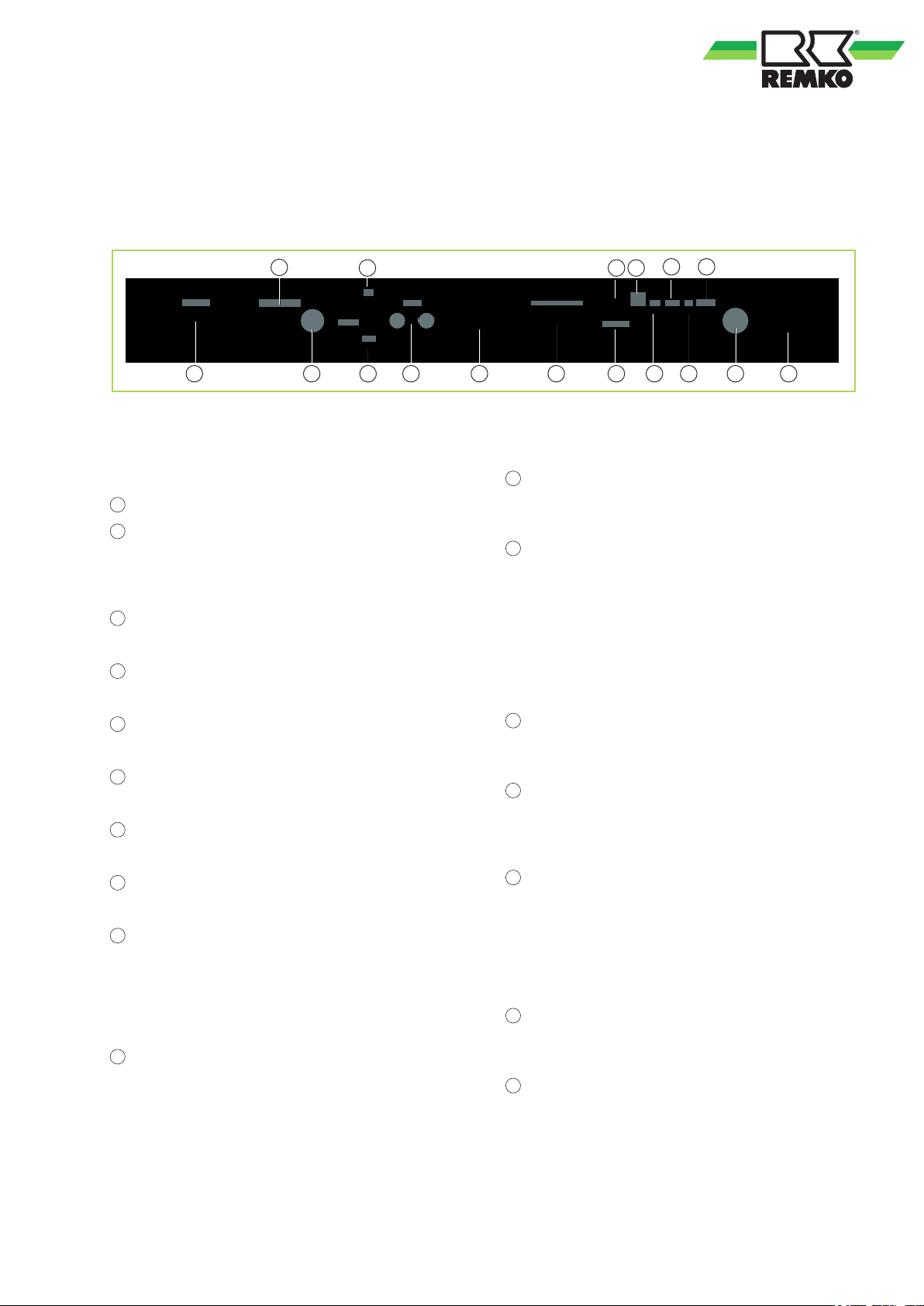

4

Operation

The system can be operated by means of the control panel on the device or via the standard infrared remote

control unit. The functional operation of the buttons among themselves is identical, however, the designation

can vary. The batteries must be correctly inserted before the infrared remote control is used.

9 6

7

5

8

2

1

REMOTE

DRAIN WATER

AUTO

SWING

TIMING

ON

OFF

TIMER

SET

RESET

THERMO CONTROL

COMP. ON

DE-

HUM.

FAN

LO

MED HI AUTO

MODE

3

4

10

11

12

13

14

15

13

16

Fig. 3: Control panel

Legend

1

„ON / OFF“ button

2

„MODE“ button (Fan speed-mode)

The fan speed is indicated by means of LEDs in

the selected modes AUTO-HI-MED-LO or circu-

lated air mode FAN.

3

LED „AUTO“ (Fan mode)

Indication of the automatic fan operation.

4

LED „HI“ (Fan mode)

Indication of the high fan operation.

5

LED „MED“ (Fan mode)

Indication of the average fan operation.

6

LED „LO“ (Fan mode)

Indication of the low fan operation.

7

LED „DE- HUM.“ (Dehumidifying mode)

Indication of the dehumidifying mode.

8

LED „FAN“ (Circulated air )

Indication of the circulated air.

9

LED „COMP. ON“ (Compressor operation)

The controller controls the cooling output by

means of switching the compressor on or off. Com-

pressor operation is indicated by means of the

LED. If the LED flashes, the compressor will be

activated in max. 3 mins.

10

Button „▼ ▲“ Temperature setting

The desired nominal temperature can be set with

the „▼ ▲“ buttons in steps of 1°C between 16 and

30°C.

11

Display

The display shows the set nominal temperature or

the residual time of a programmed timer.

12

"ON" and "OFF" timer

The timer function can be used to switch the

device on or off automatically in hourly intervals

( „▼▲“ buttons) by means of pressing the "SET"

button. The function can be used to program the

switch-on timer when the device is off and the

switch-off timer when the device is on, for up to 24

hours. Both timers can be deleted by means of

pressing the "RESET" button.

13

LED „TIMING ON and OFF“

Indicator of activation (LED ON) or deactivation

(LED OFF) of the timing on and off

14

„AUTO SWING“ button

The direction of the discharged air via the oscil-

lating fins can be adjusted to fixed or oscillating by

pressing the "AUTO SWING" button.

15

LED „DRAIN WATER“

If the pump is unable to transport the collected

condensate then this is signalised via an acoustic

alarm in combination with the flashing "DRAIN

WATER" LED. The device will be operational again

after the container is emptied by means of the con-

densate drain.

16

Infrared receiver

The device receives the signals from the infrared

remote control via the sensor.

17

„FAN“ button(only on the infrared remote con-

trol)

The ventilator speed can be adjusted by means of

pressing the "FAN" button.

9

Loading...

Loading...